Control system

A system pressure, compression system technology, applied in variable speed drives to improve performance at part loads, background art

The application generally relates to being used for having a first-level field, to achieve the effect of reducing complexity and improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

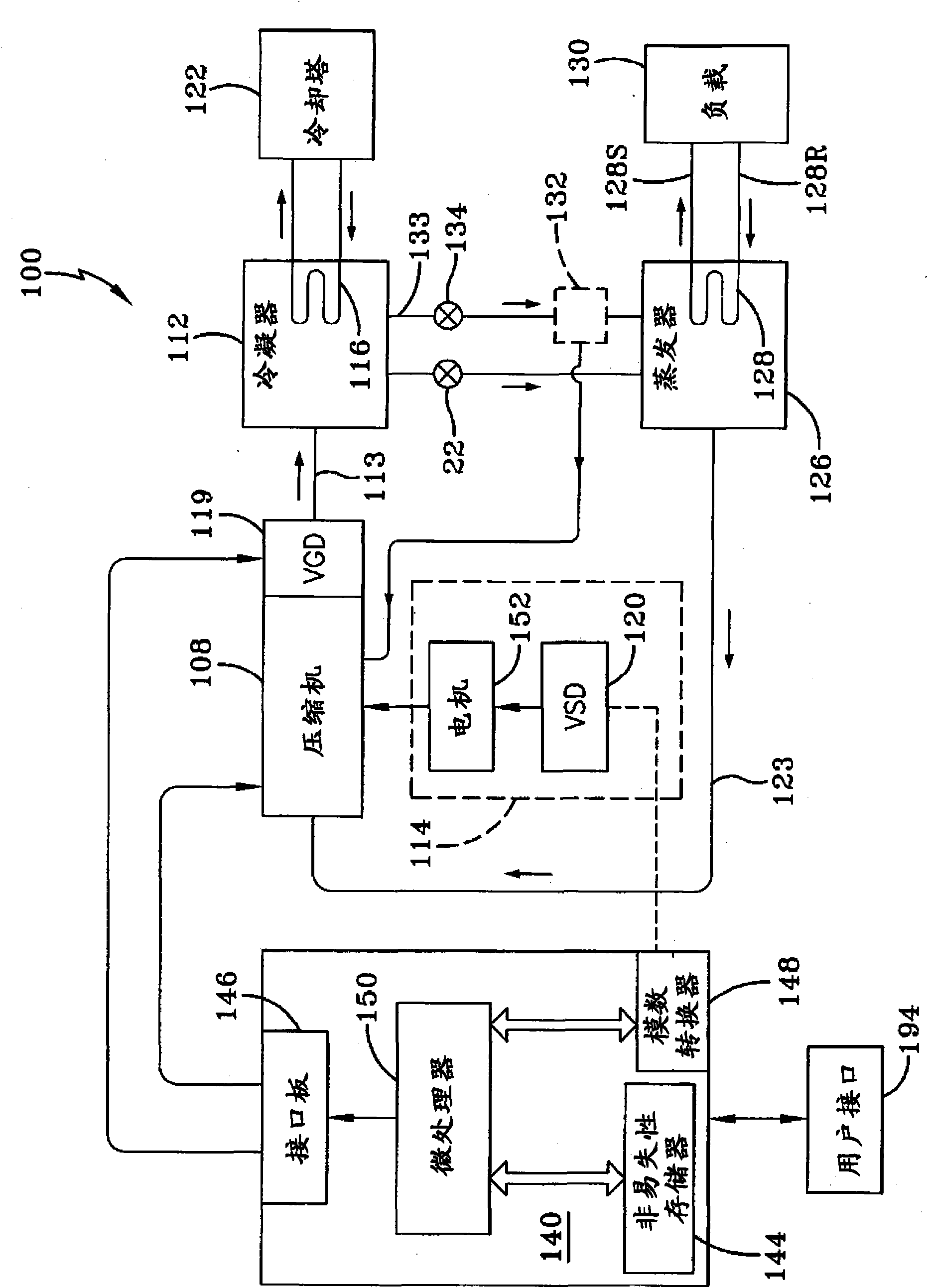

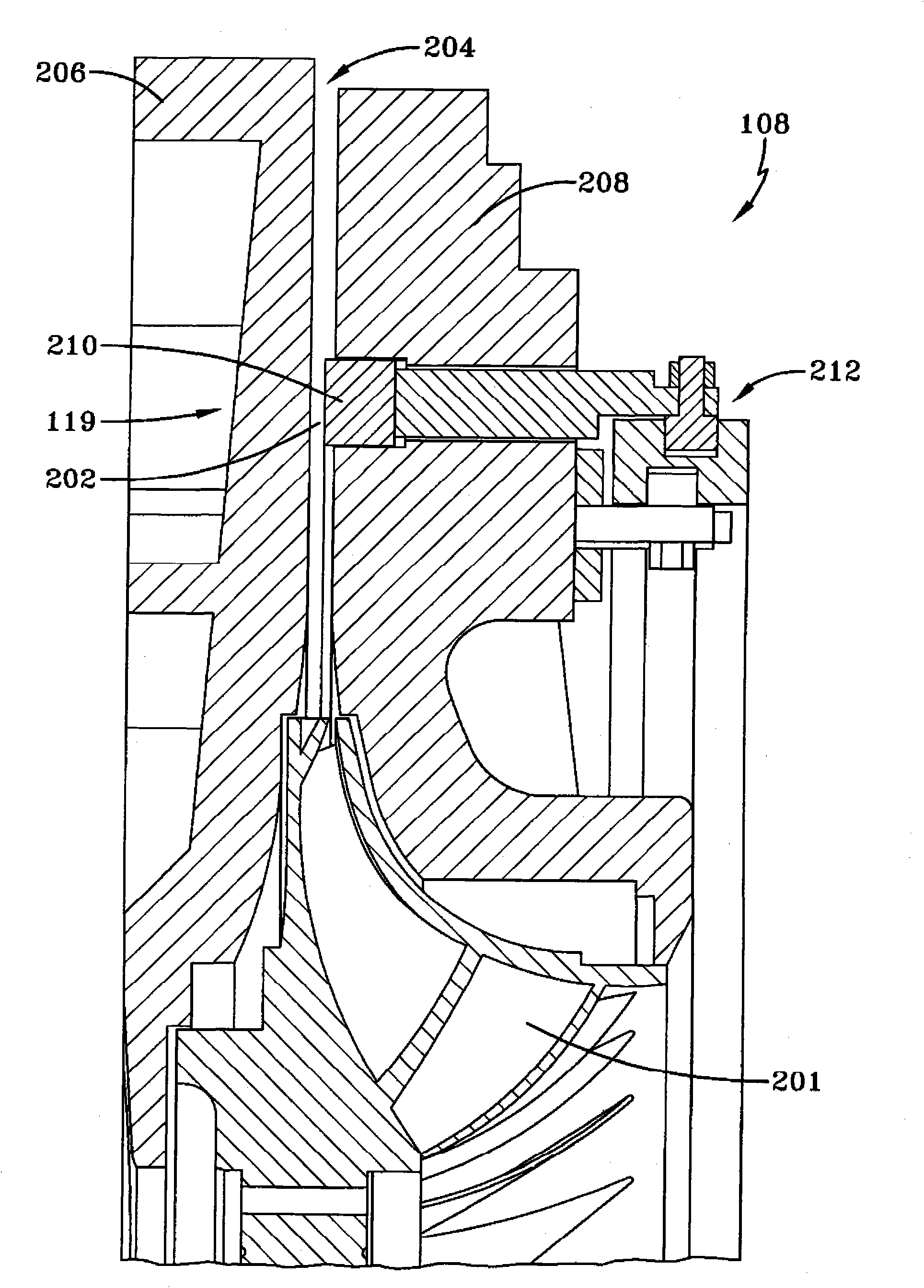

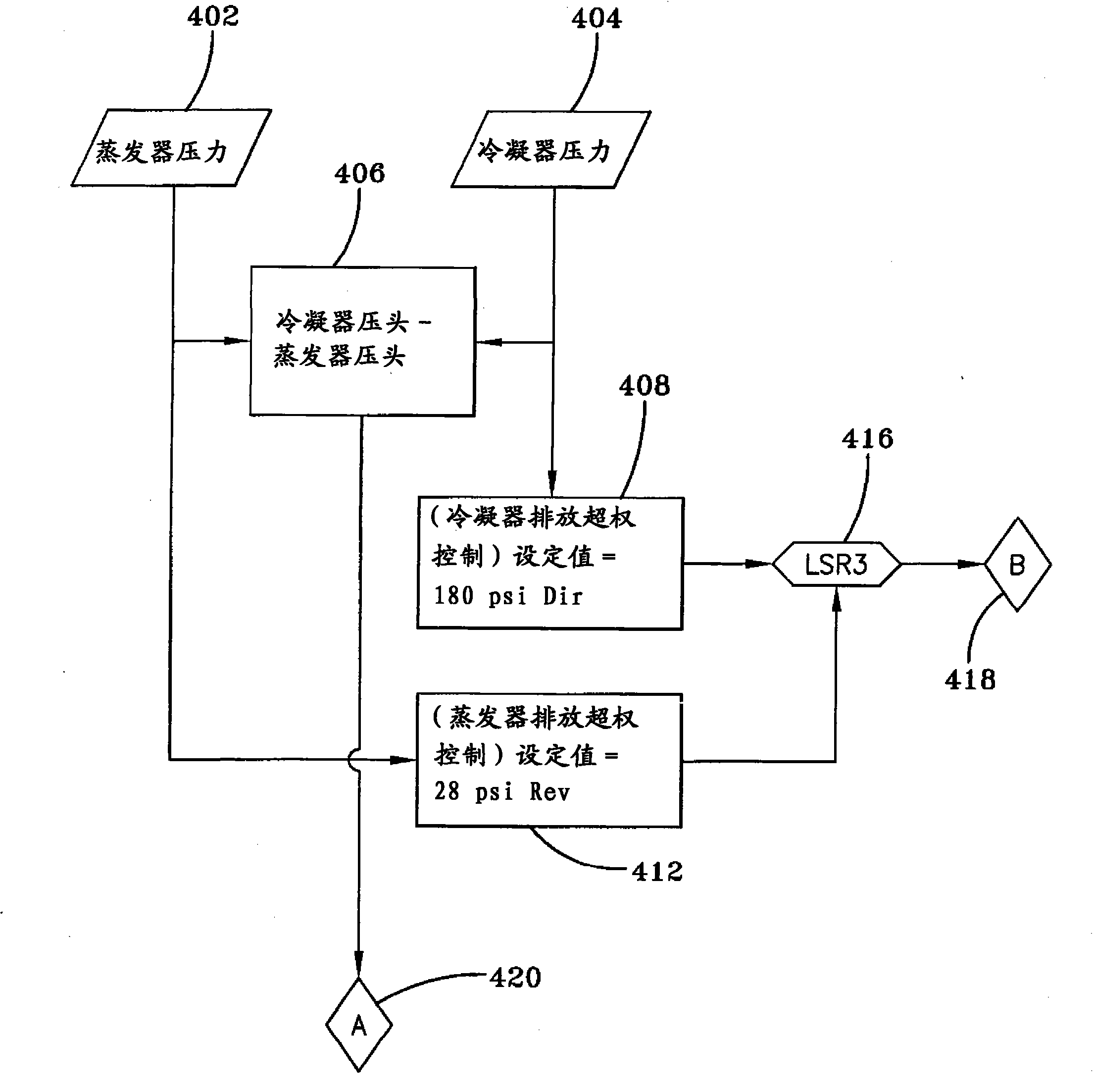

[0024] exist figure 1 In, a general HVAC & R chiller system 100 is shown by way of example, to which the present invention is applicable. An HVAC & R system 100 for controlling, for example, a centrifugal gas compressor 108 in an HVAC & R or liquid cooler system 100 is described below. Compressor 108 may be a single-stage or multi-stage centrifugal compressor. The flow of refrigerant gas through compressor 108 is automatically controlled to maintain desired parameters within predetermined ranges and prevent stall and surge conditions within system 100 . The VGD 119 in each stage of the compressor 108 controls the impeller 201 of the compressor (see figure 2 ) refrigerant flow at the outlet. The VGD 119 arrangement reduces mass flow, reduces or eliminates flow reduction stall, and improves the operating efficiency of compressor 108 when operating at part load conditions. Capacity control through the use of a variable geometry diffuser in conjunction with a variable speed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com