Patents

Literature

574 results about "Capacity control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Capacity control. A revenue management component used to modify risk factors. Used in passenger travel, accommodation and tourism-related industries, a control is implemented to manage risks associated with overbooking.

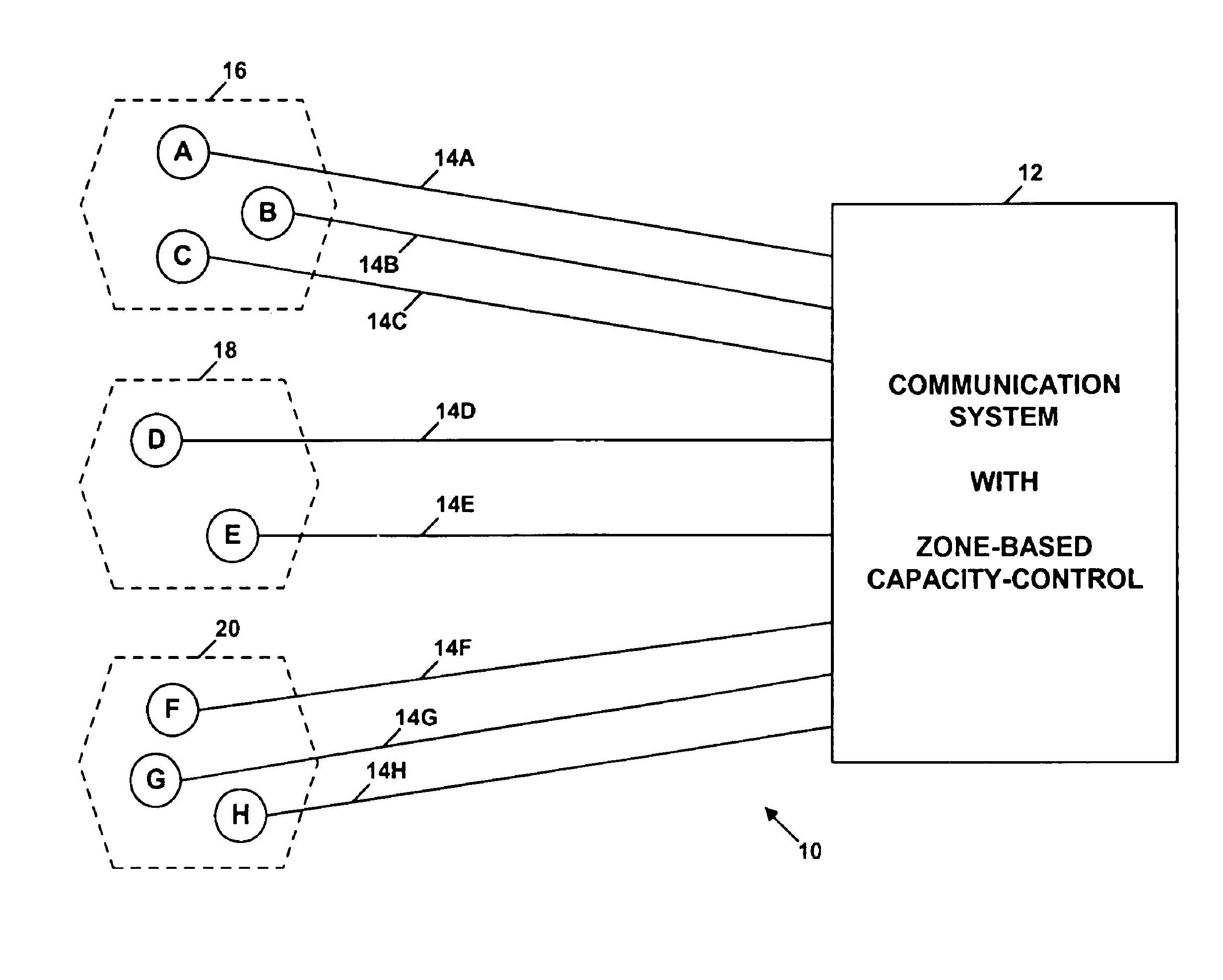

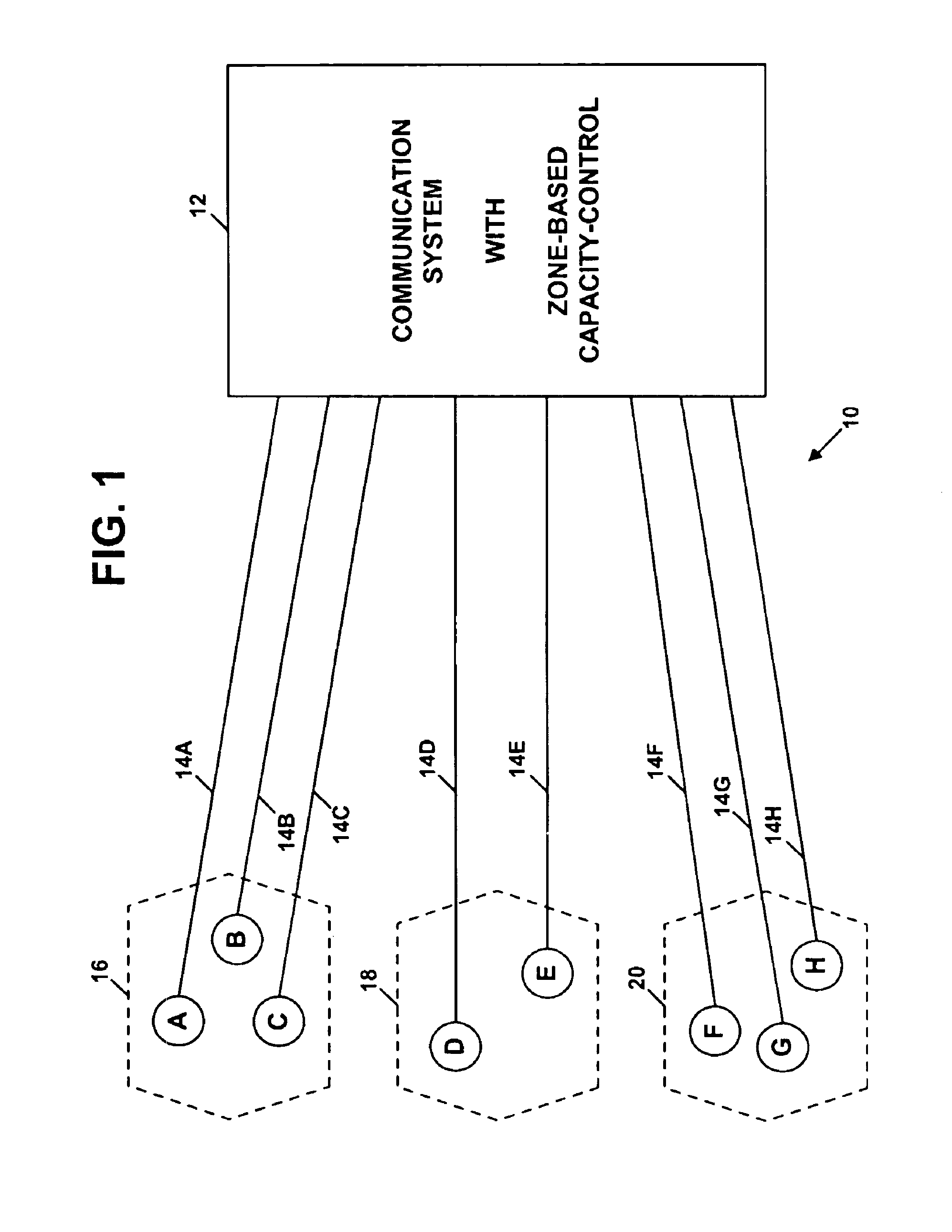

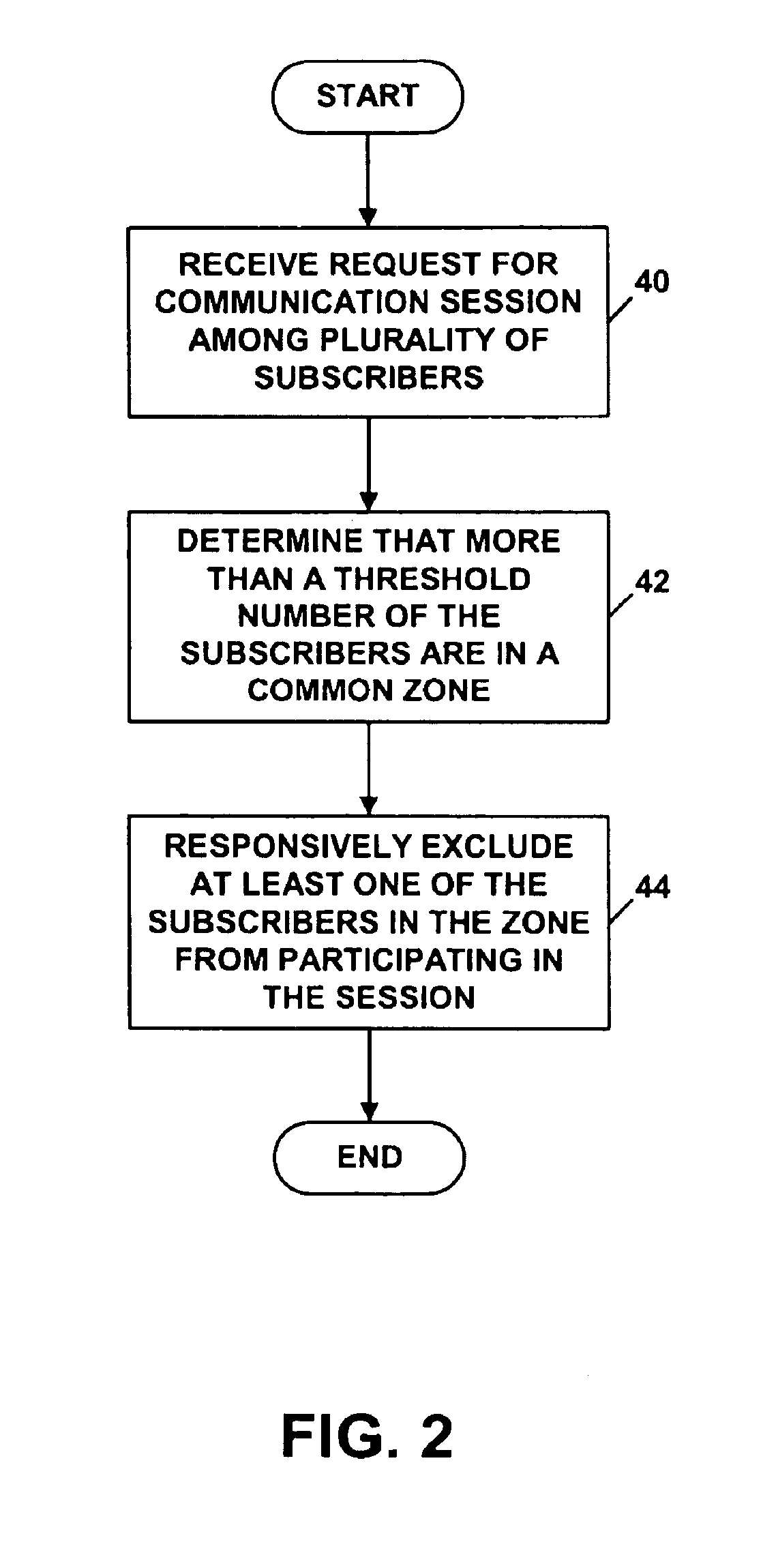

Method and system for zone-based capacity control

InactiveUS6882850B2Avoid accessPreventing situationSpecial service provision for substationMultiplex system selection arrangementsControl communicationsDistributed computing

A mechanism is disclosed for controlling capacity in a communication system, based on zones in which subscribers are located. When a subscriber seeks to establish a communication session among multiple subscribers, a determination is made as to whether more than a threshold number of the subscribers are located in a common zone. If so, the excess subscribers in that zone are excluded from participating in the session.

Owner:SPRINT SPECTRUM LLC

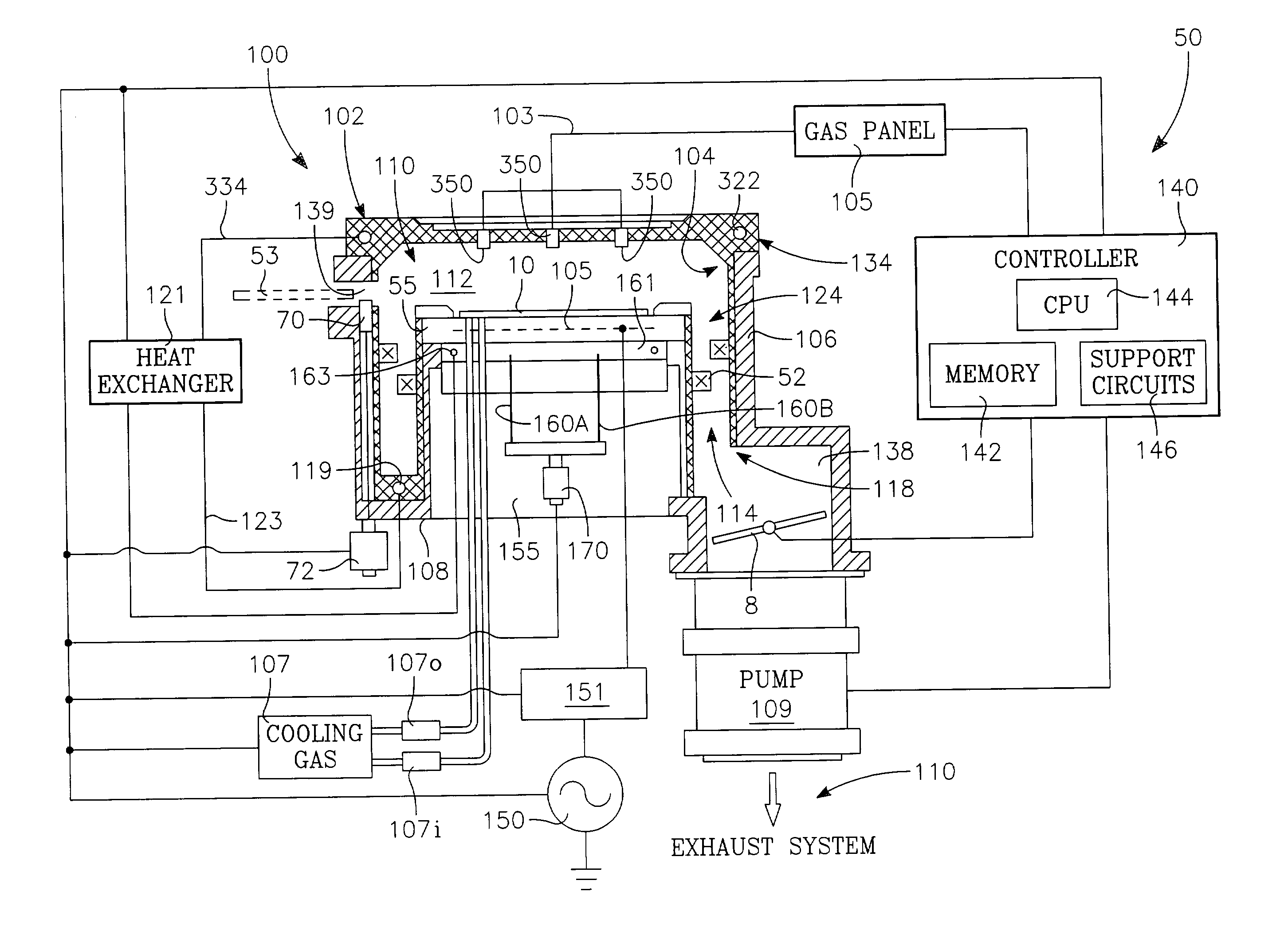

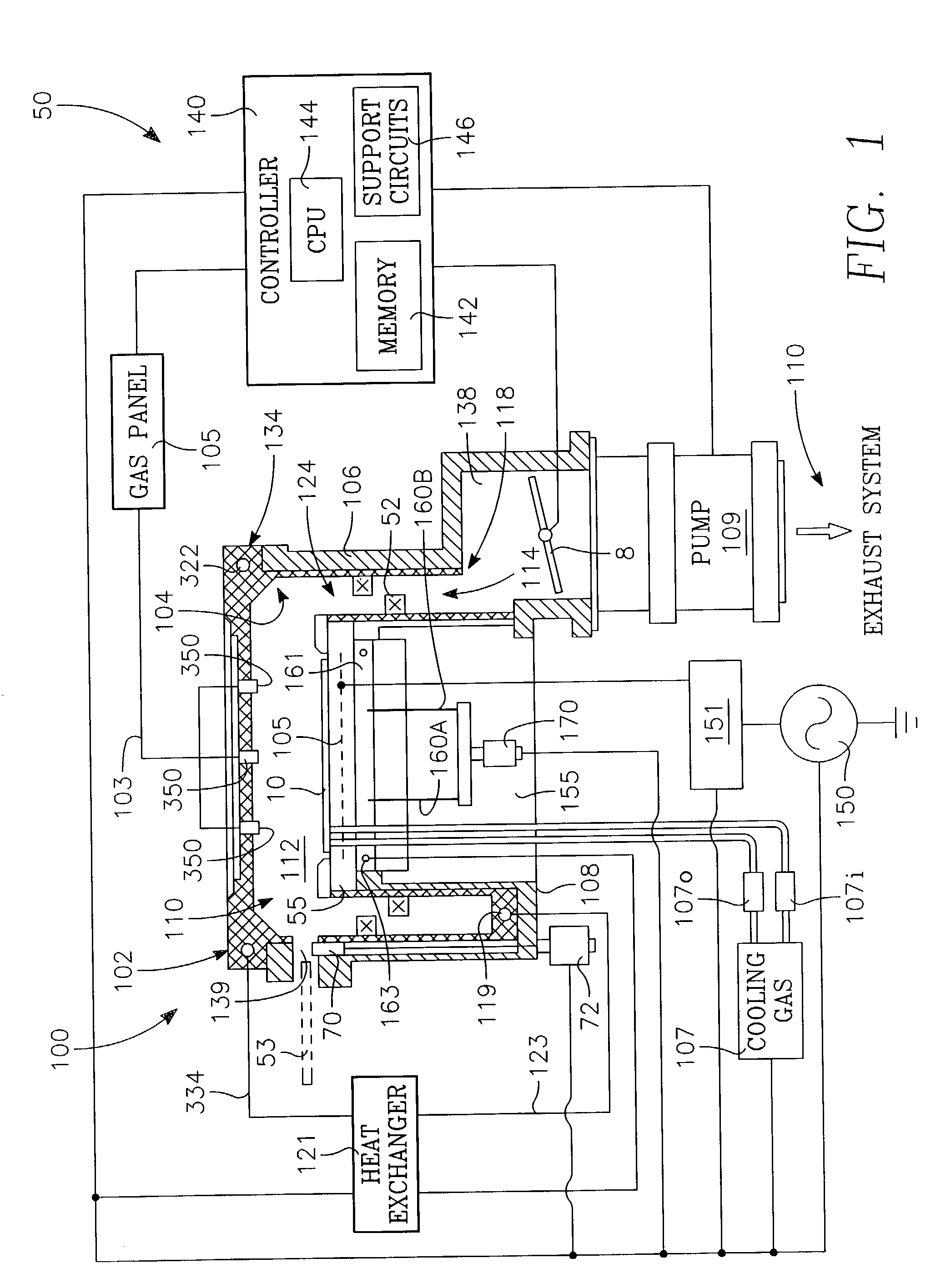

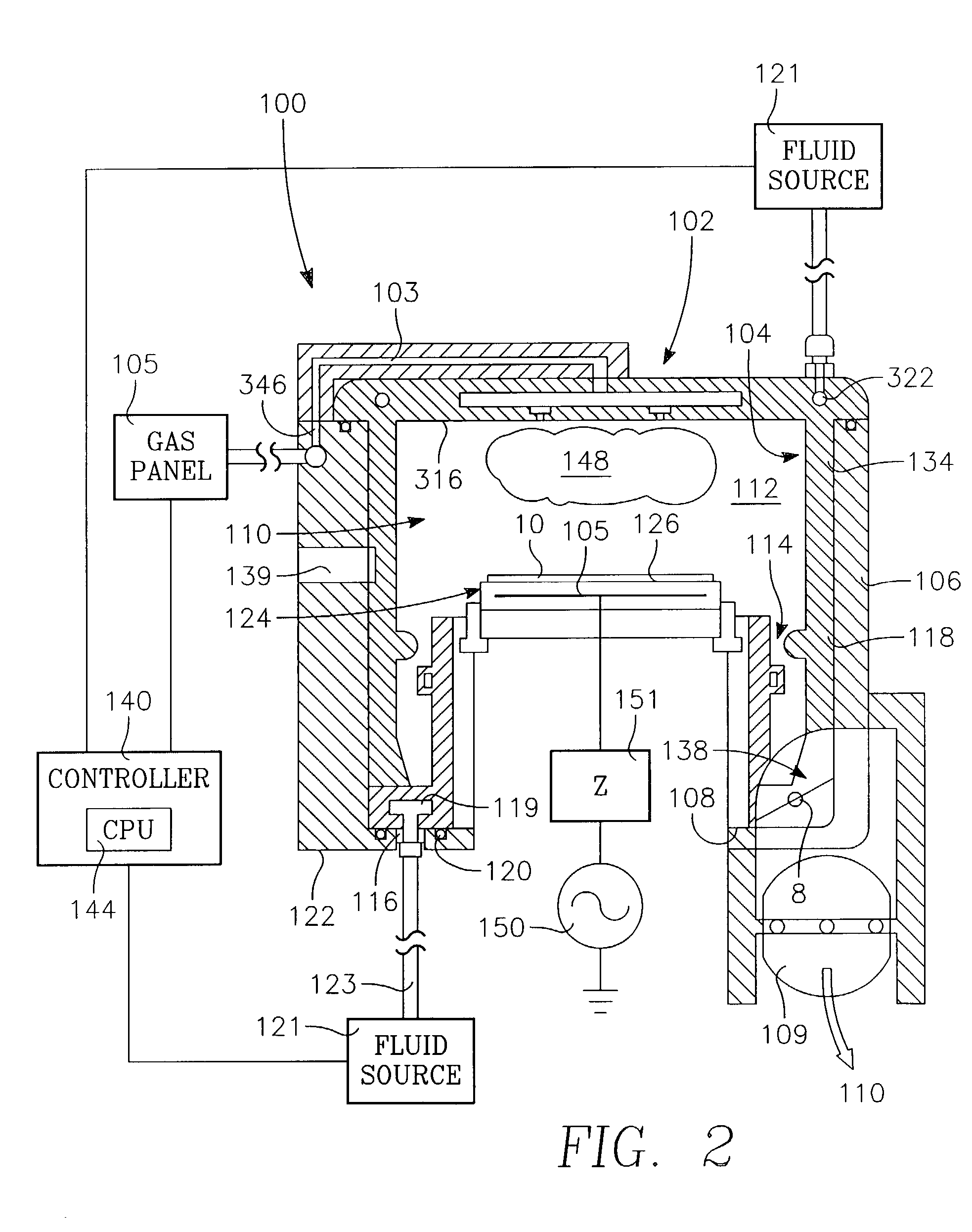

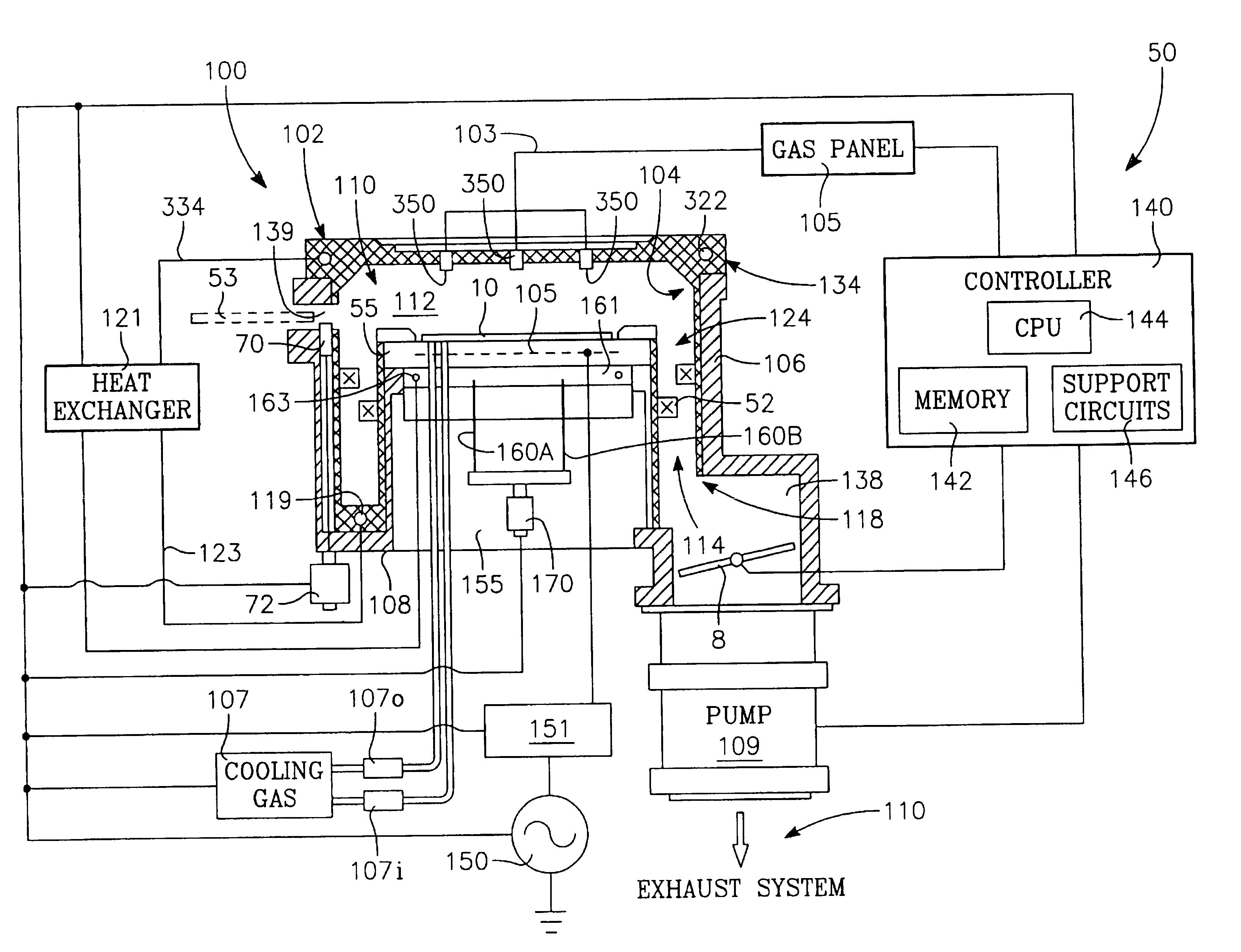

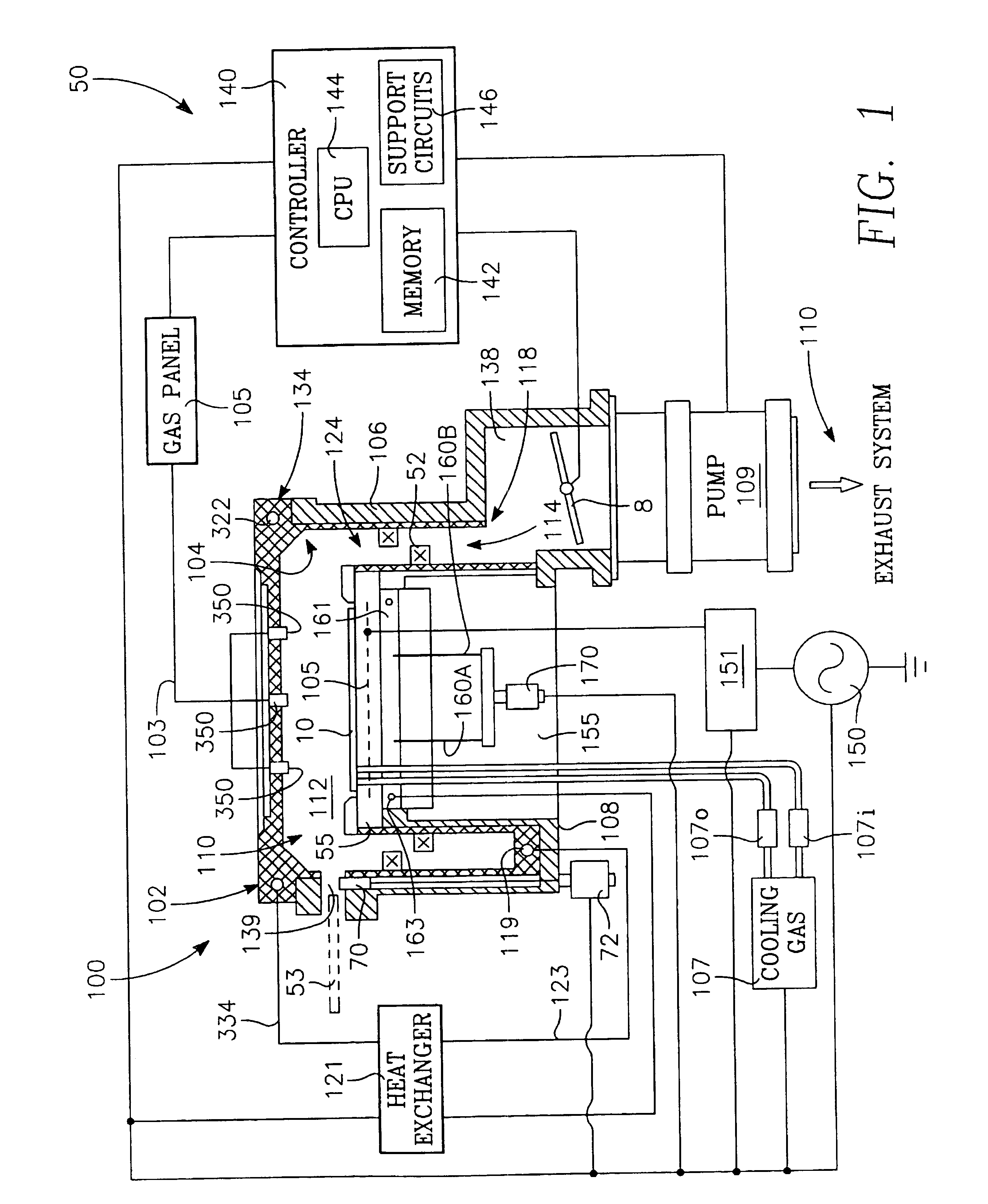

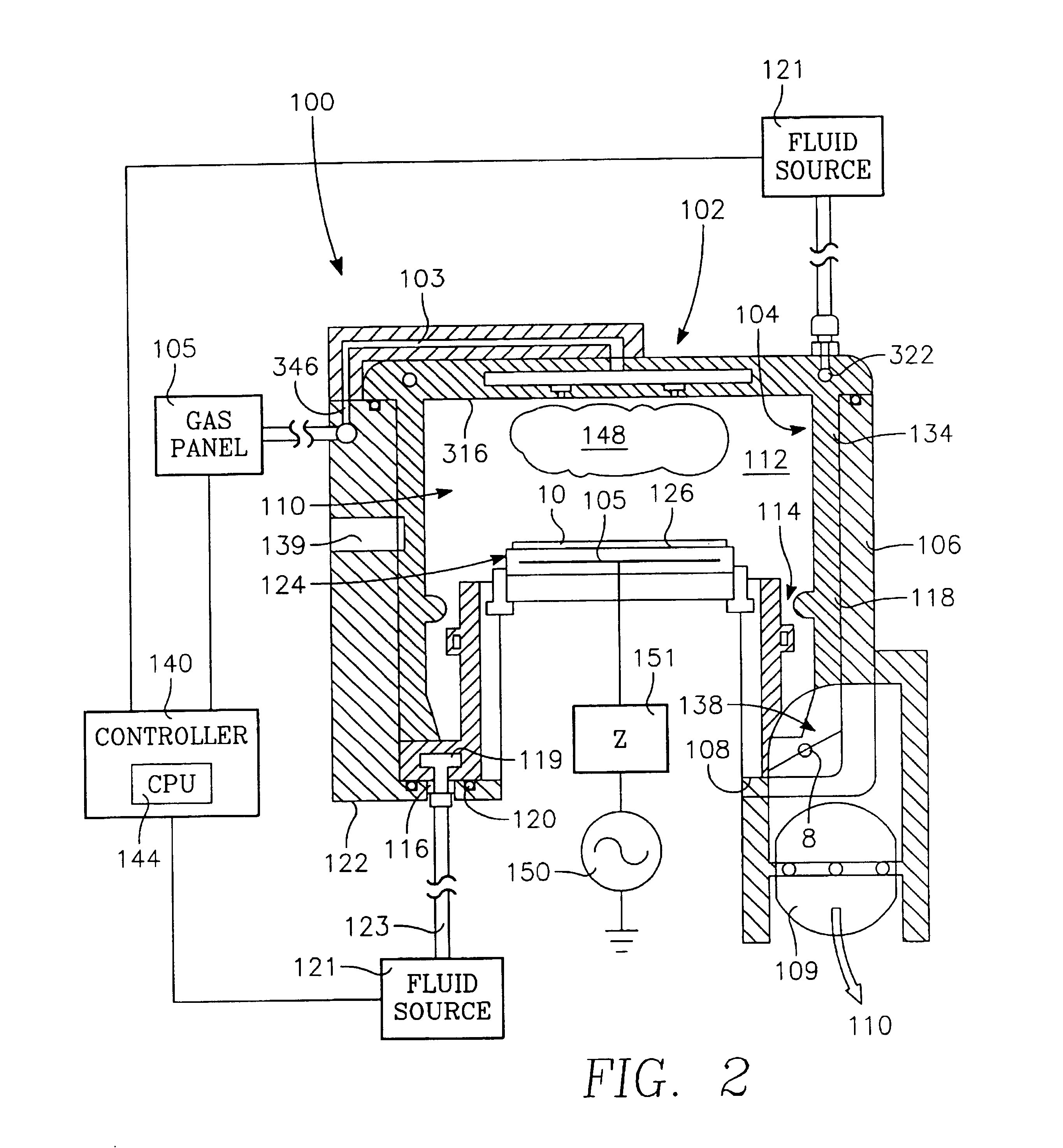

Dielectric etch chamber with expanded process window

InactiveUS20030037880A1Improve adhesionIncrease chanceElectric discharge tubesDecorative surface effectsDielectricCapacitive coupling

A capacitively coupled reactor for plasma etch processing of substrates at subatmospheric pressures includes a chamber body defining a processing volume, a lid provided upon the chamber body, the lid being a first electrode, a substrate support provided in the processing volume and comprising a second electrode, a radio frequency source coupled at least to one of the first and second electrodes, a process gas inlet configured to deliver process gas into the processing volume, and an evacuation pump system having pumping capacity of at least 1600 liters / minute. The greater pumping capacity controls residency time of the process gases so as to regulate the degree of dissociation into more reactive species.

Owner:APPLIED MATERIALS INC

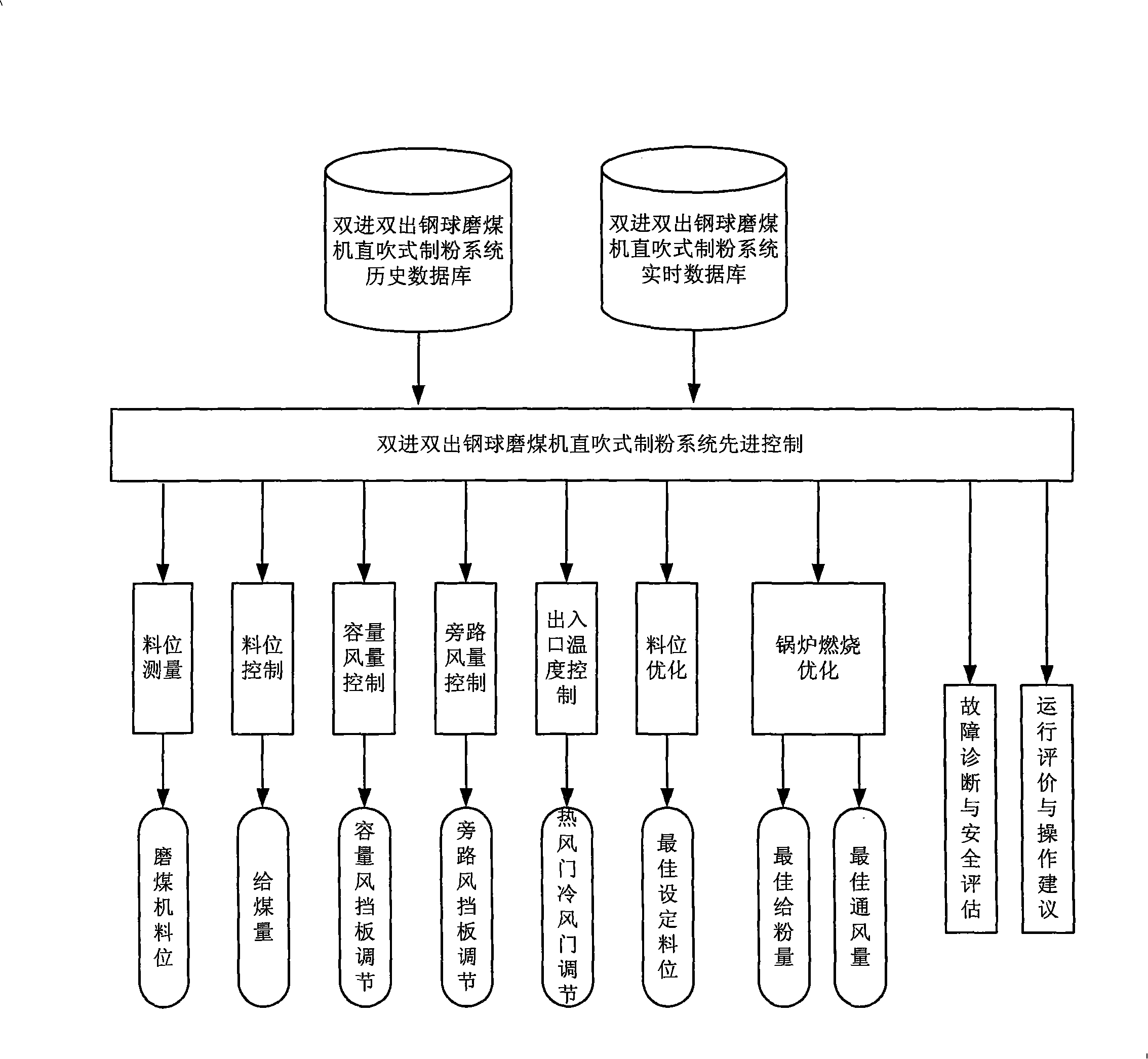

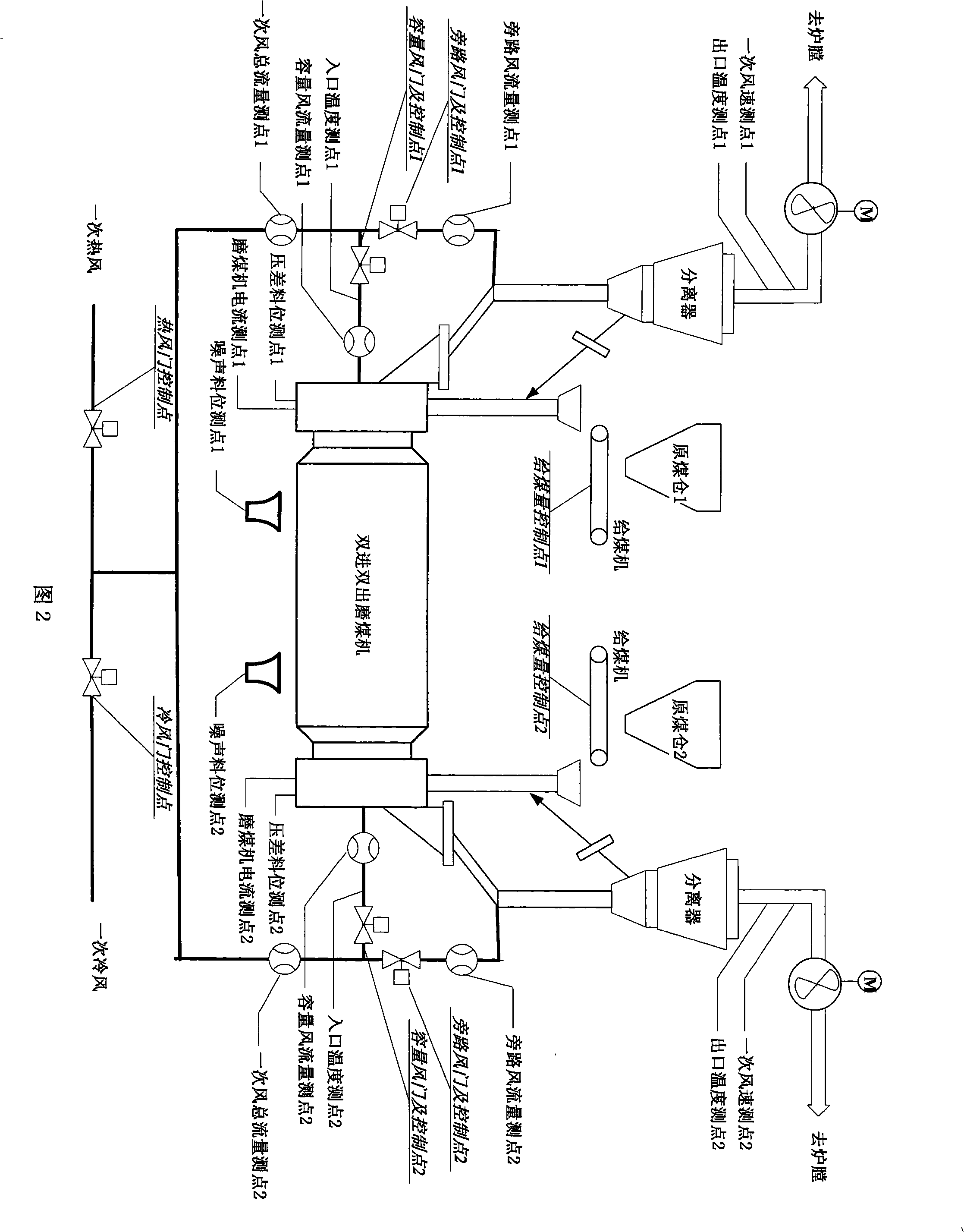

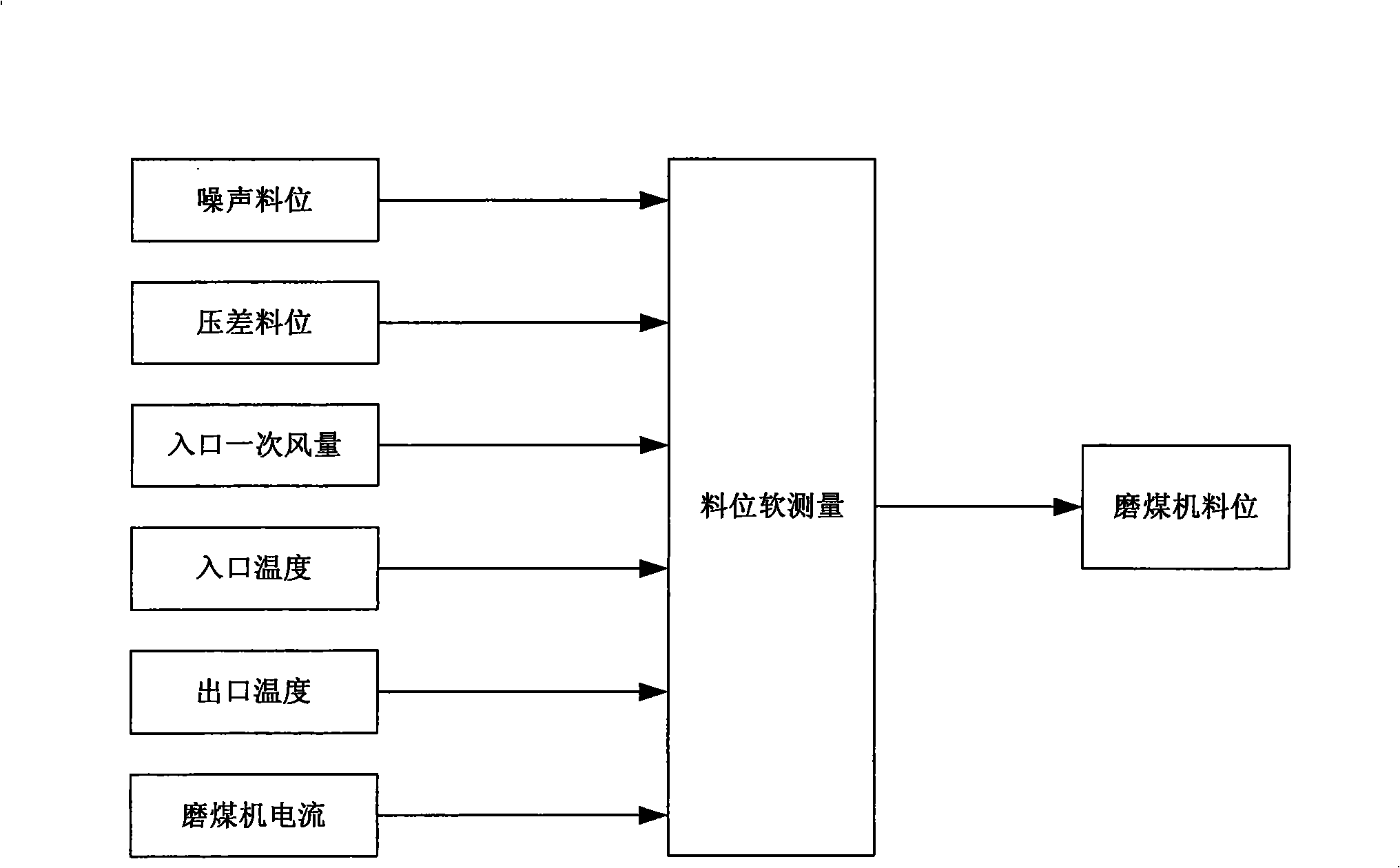

Double-inlet double-outlet steel ball coal mill straight blowing type milling system optimized control method

ActiveCN101334666AImprove combustion efficiencyGuaranteed uniformityGrain treatmentsProgramme total factory controlTemperature controlCombustion

The invention discloses an optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method. The method obtains the material position of the coal grinding machine after carrying out soft-measurement processing by collecting the noise material position of the coal grinding machine, the material position of pressure difference, the current of the coal grinding machine, one-time air quantity, one-time opening of the hot wind door and the cold wind door of an inlet, inlet temperature and outlet temperature; the control comprises material position control, air quantity capacity control, bypass air quantity control and the temperature control of the inlet and the outlet; the material position is optimized and the best material position of the coal grinding machine is searched online so as to ensure the combustion safety of the boiler and coal powder supply quantity when the load of the boiler is adjusted. The boiler combustion is optimized: according to the boiler technology, the load and the running working conditions, the powder supply quantity and the ventilation quantity of each coal grinding machine are optimized and the combustion efficiency of the boiler is improved. Malfunction diagnosis, running evaluation and analysis are carried out to the system and reasonable suggestions are provided so as to ensure the system to run continuously, stably, safely and economically; the optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method is widely applied to the dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation system or industrial similar systems in other industries.

Owner:西安蓝海机械仪表成套有限责任公司

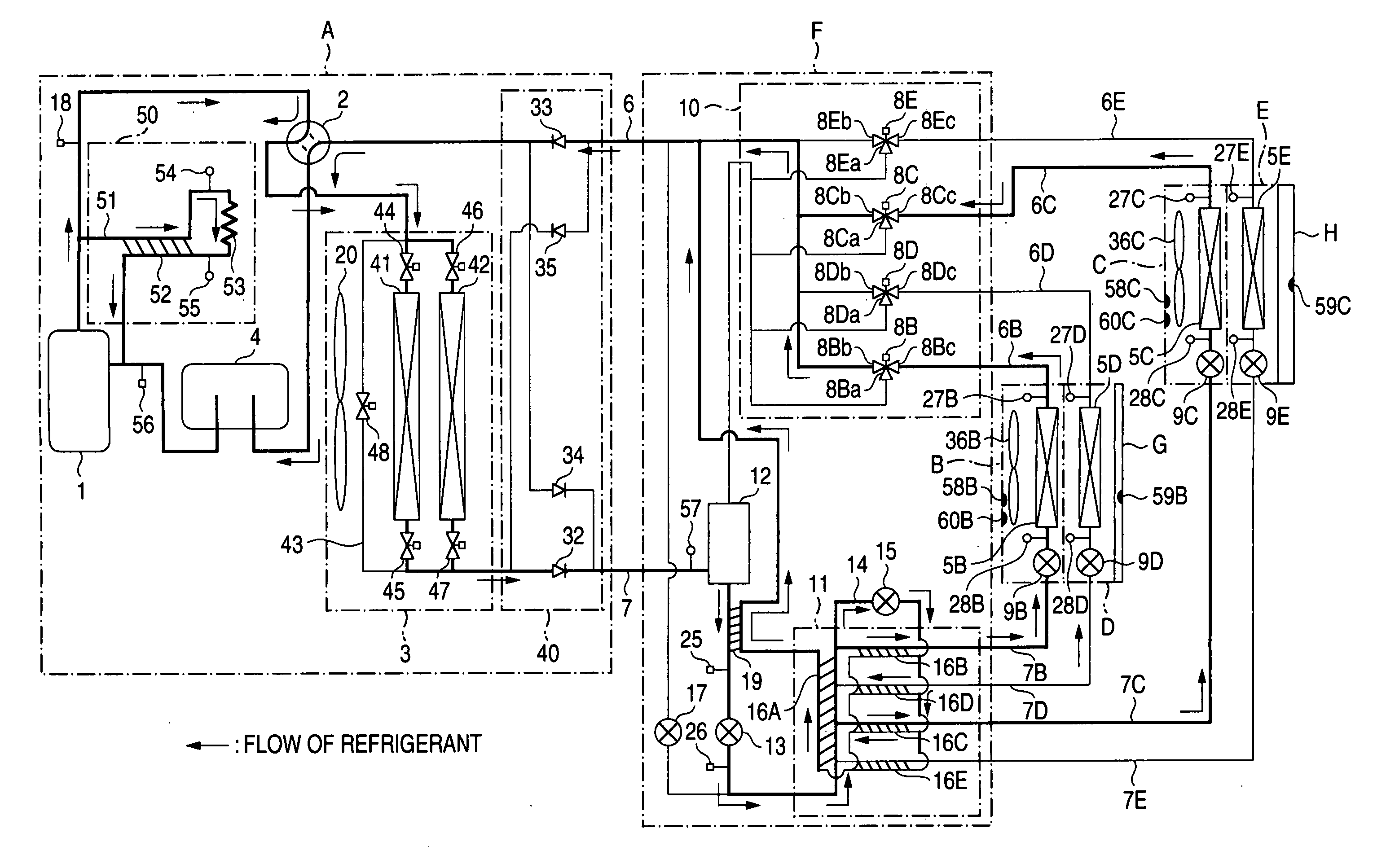

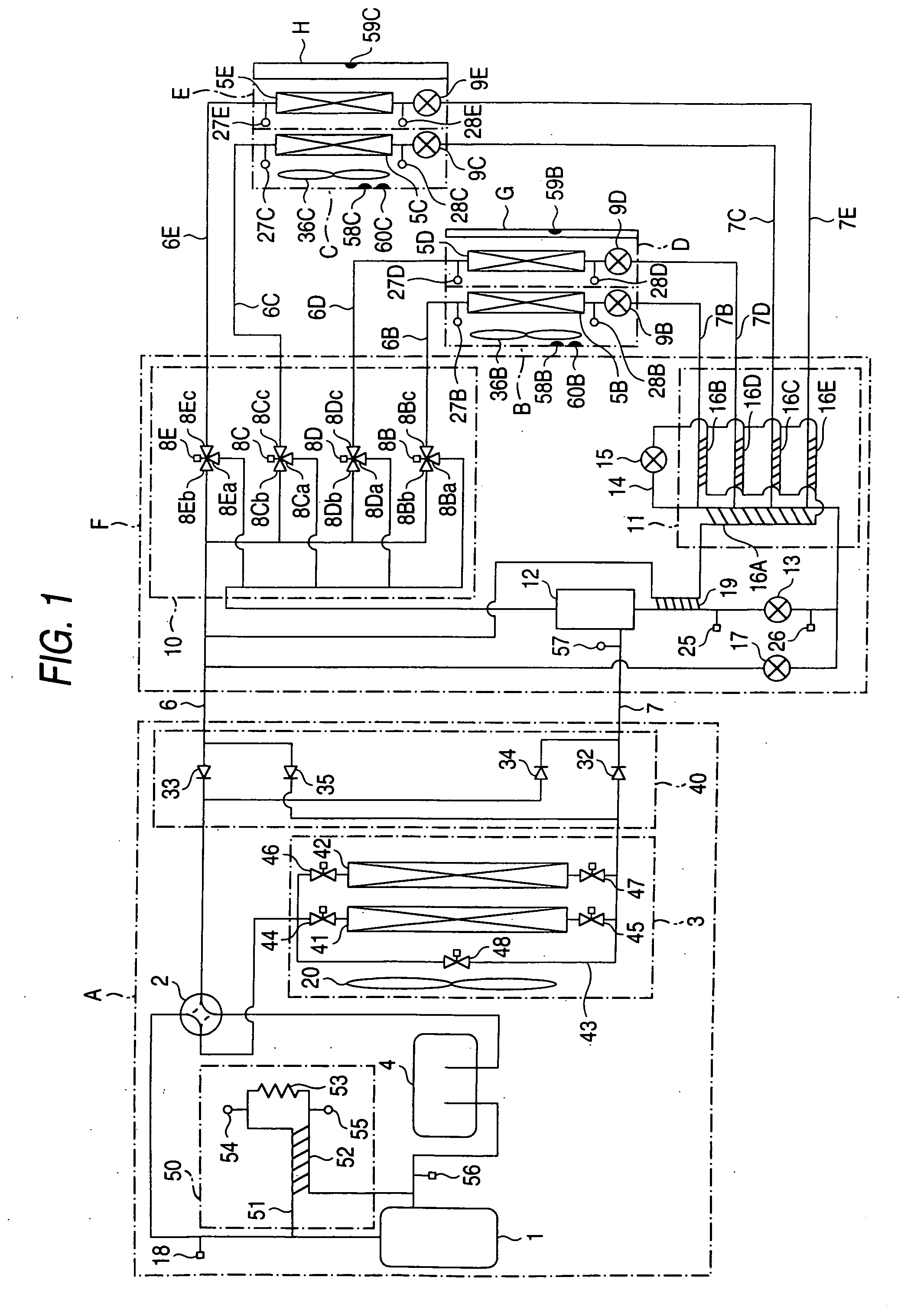

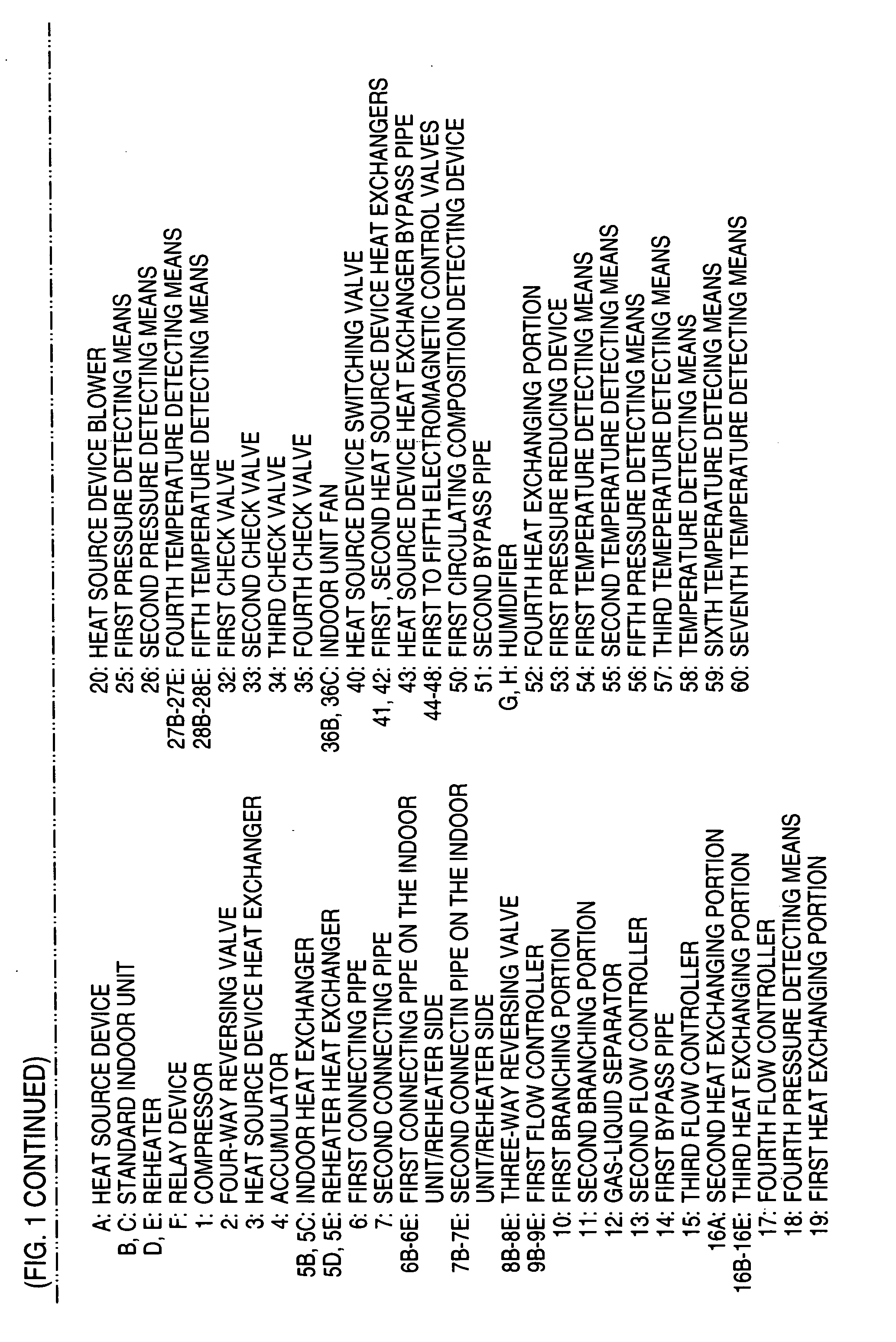

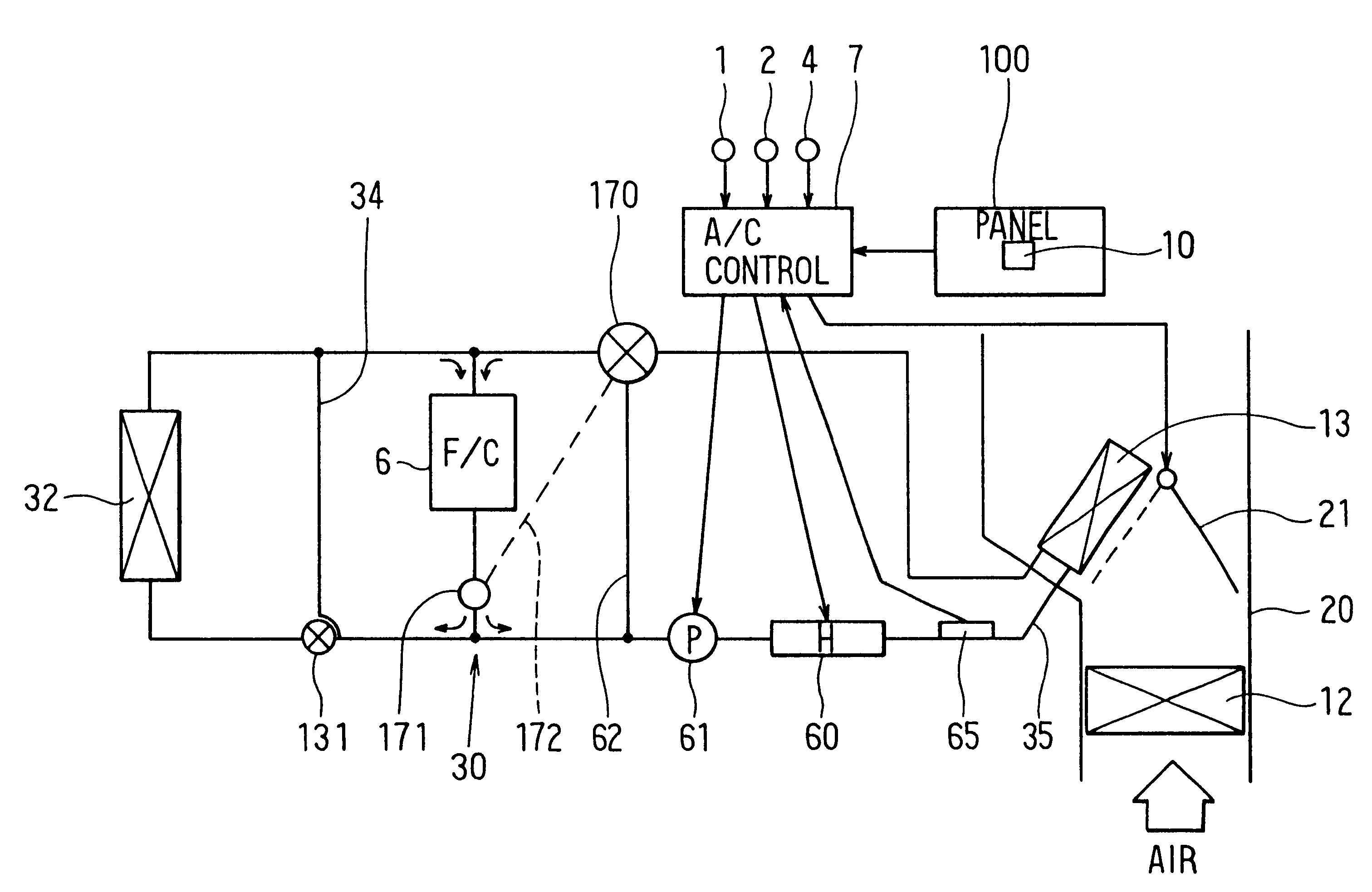

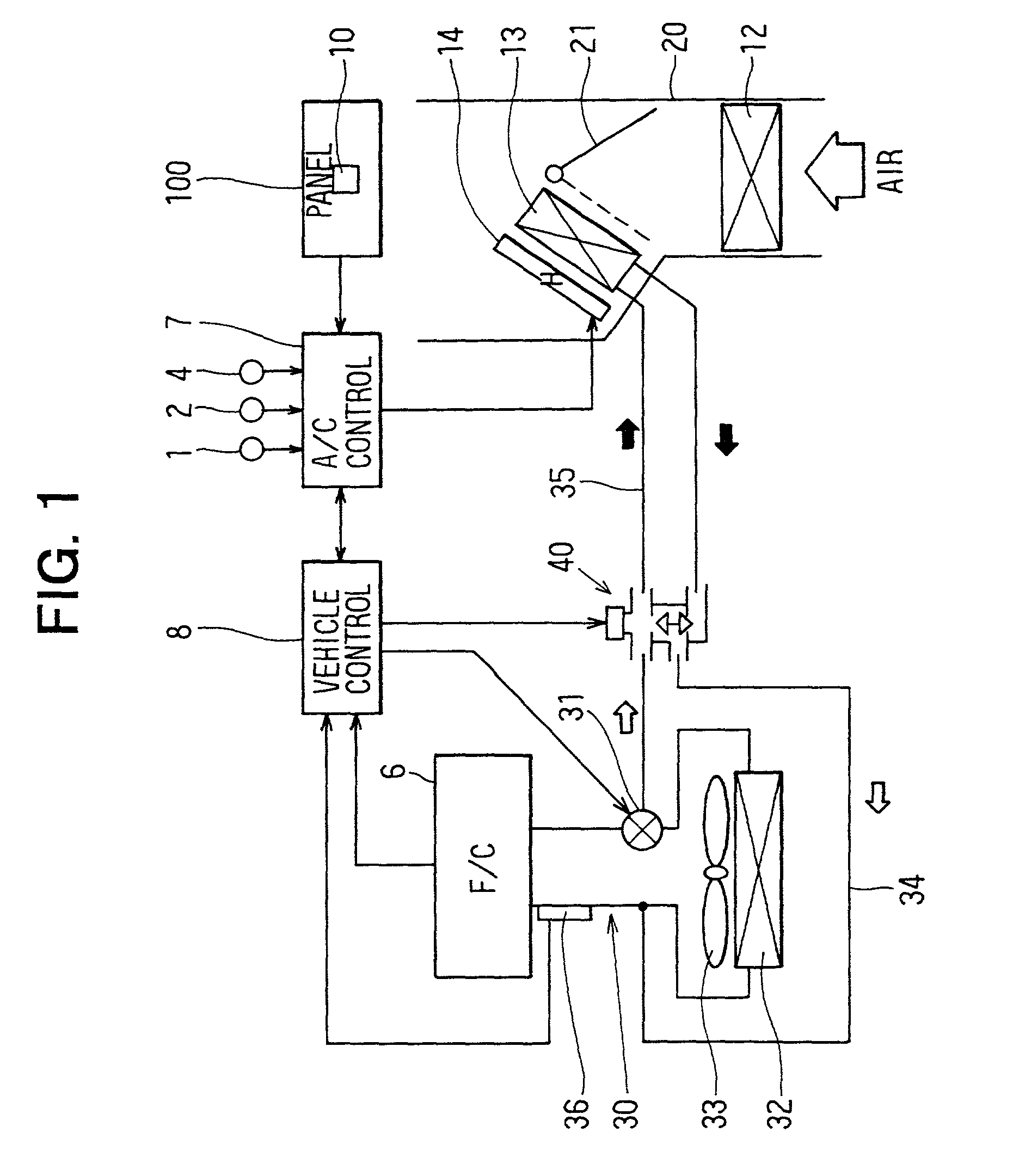

Air conditioner

InactiveUS20060254294A1Compression machines with several evaporatorsCompression machines with reversible cycleEngineeringAir conditioning

An air conditioning apparatus has plural indoor units having: plural heat exchangers; and flow controllers respectively corresponding to the heat exchangers. In each of the indoor units, one heat exchanger is used as a condenser, and another heat exchanger is used as an evaporator, thereby causing the indoor unit to perform a temperature and humidity controlling operation. An indoor unit(s) which is not set to perform the temperature and humidity controlling operation may be caused to perform a heating operation or a cooling operation. Capacity controls on the condensers and the evaporators are performed by corresponding flow controllers. Gas refrigerants ejected from plural heat exchangers serving as evaporators are joined together, and then distributed to plural heat exchangers serving as condensers.

Owner:MITSUBISHI ELECTRIC CORP

Dielectric etch chamber with expanded process window

InactiveUS6716302B2Improve adhesionIncrease chanceElectric discharge tubesDecorative surface effectsDielectricCapacitive coupling

A capacitively coupled reactor for plasma etch processing of substrates at subatmospheric pressures includes a chamber body defining a processing volume, a lid provided upon the chamber body, the lid being a first electrode, a substrate support provided in the processing volume and comprising a second electrode, a radio frequency source coupled at least to one of the first and second electrodes, a process gas inlet configured to deliver process gas into the processing volume, and an evacuation pump system having pumping capacity of at least 1600 liters / minute. The greater pumping capacity controls residency time of the process gases so as to regulate the degree of dissociation into more reactive species.

Owner:APPLIED MATERIALS INC

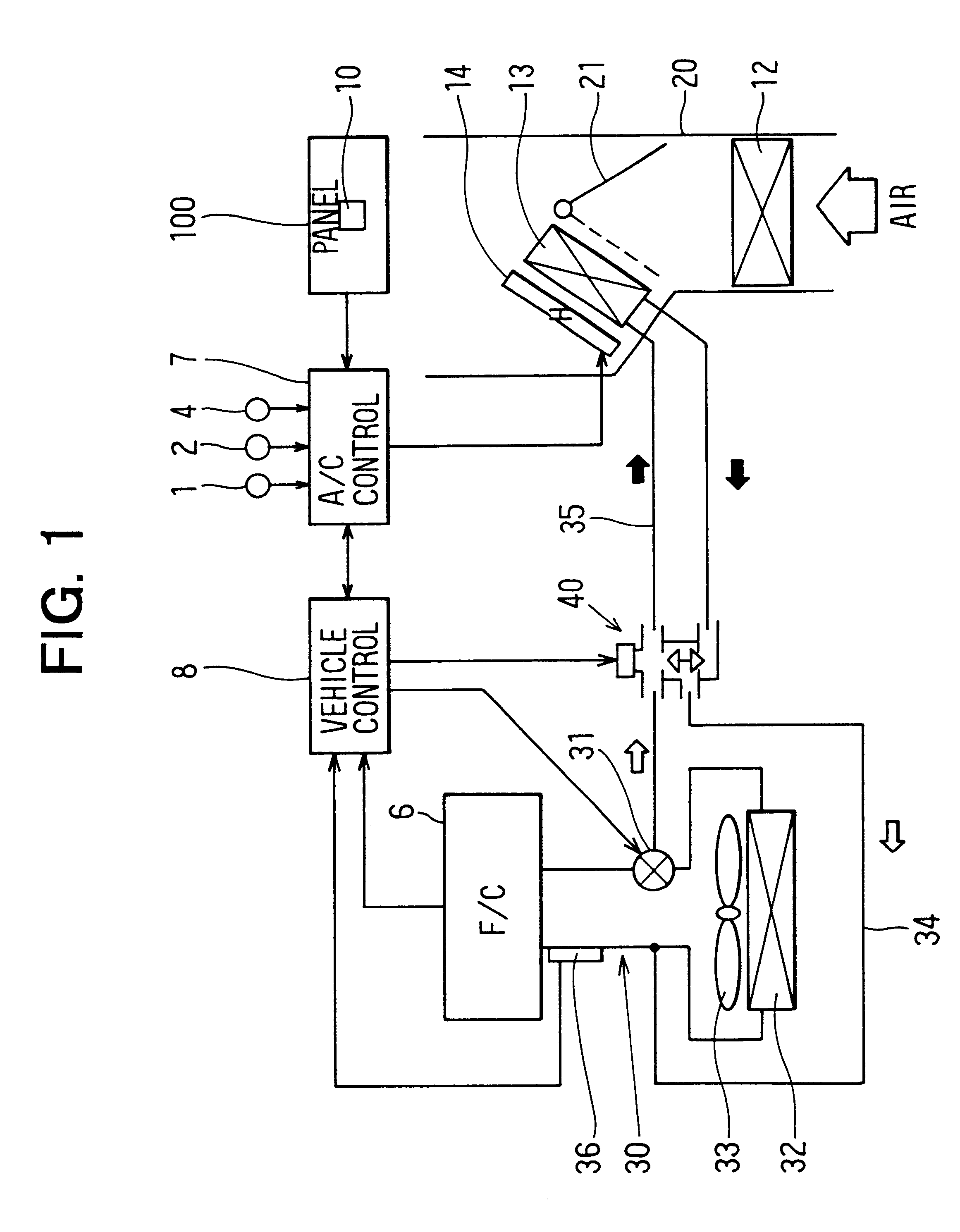

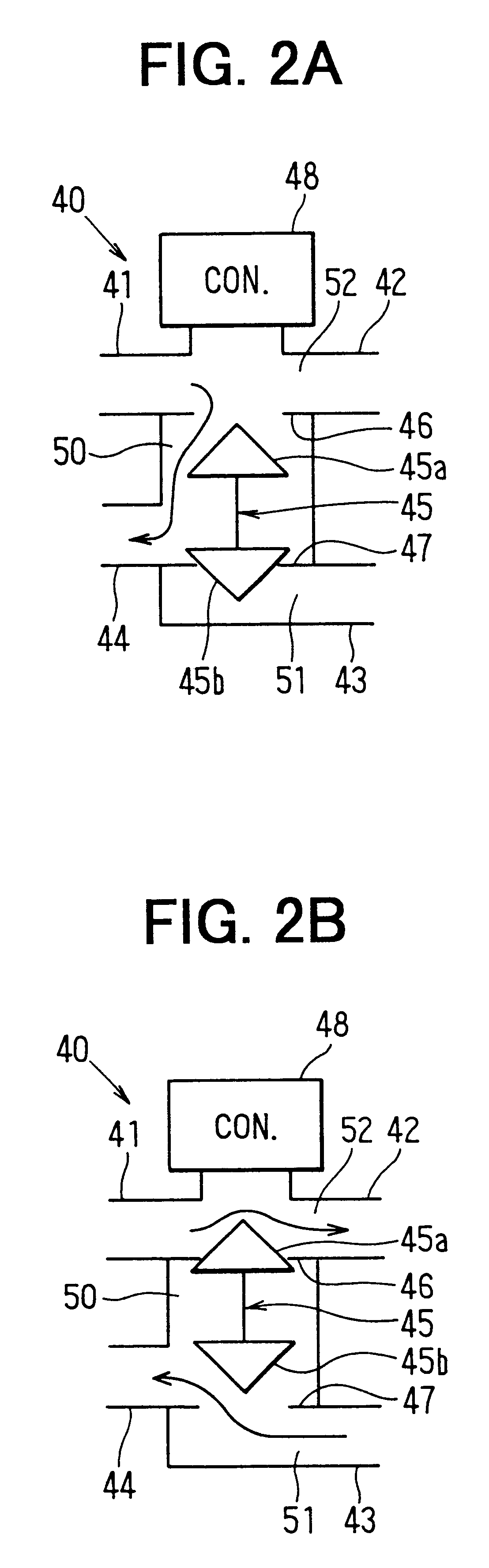

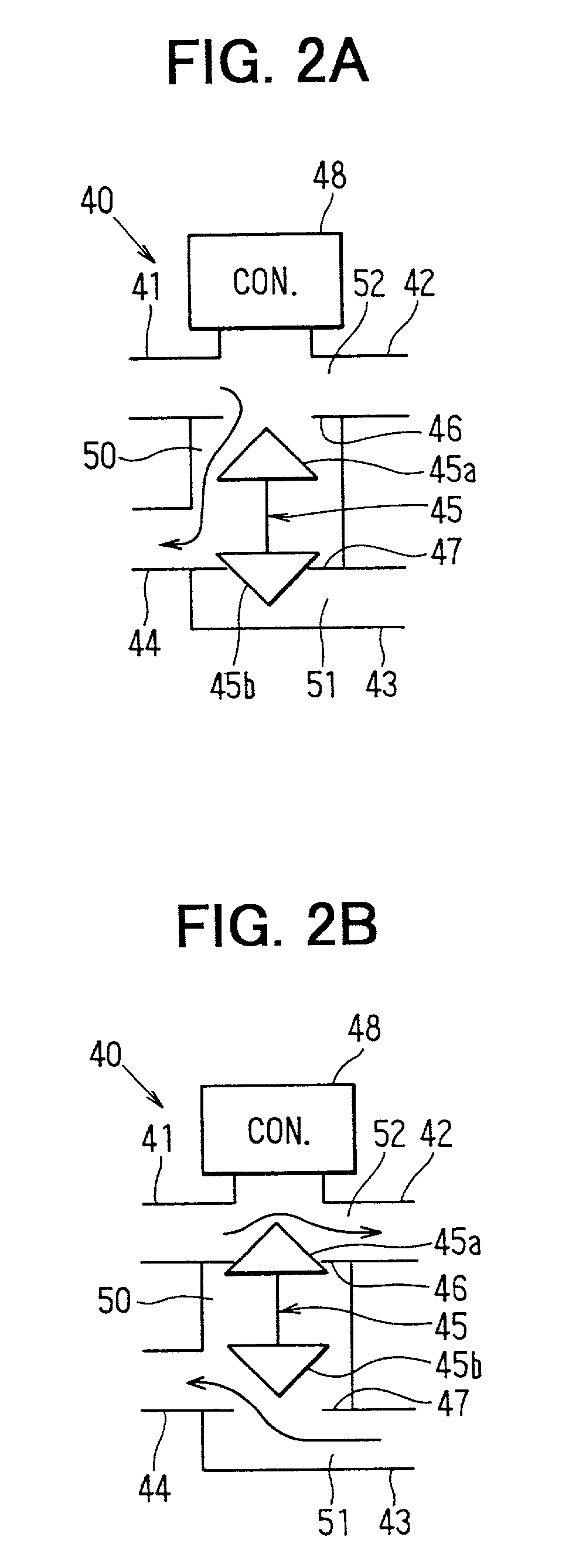

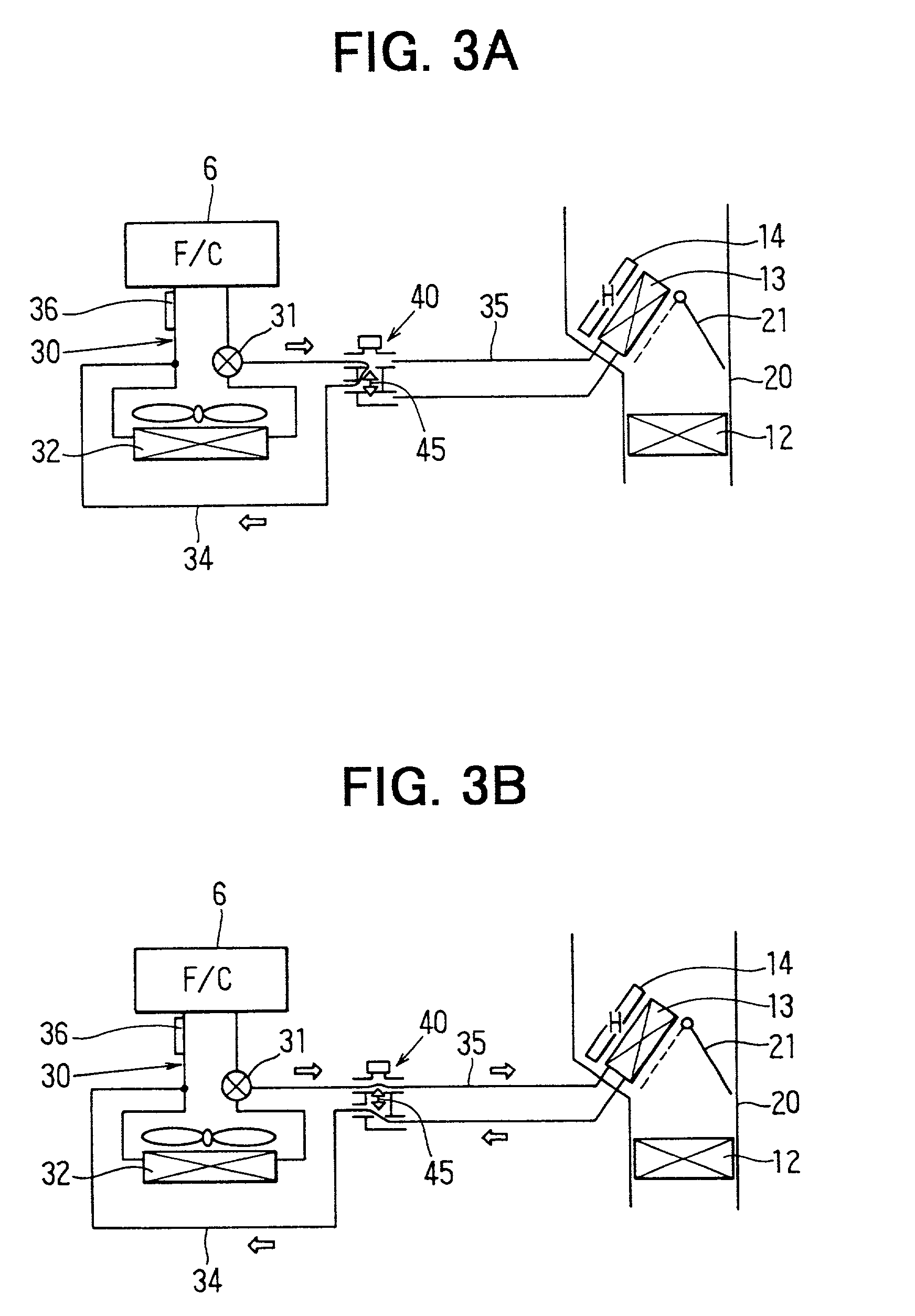

Vehicle air conditioner with heating capacity control of cooling water circuit

InactiveUS6454180B2Easy to useIncrease temperatureAir-treating devicesVehicle heating/cooling devicesFuel cellsWater flow

In a vehicle air conditioner where air blown into a passenger compartment is heated in a heater core using cooling water for cooling a fuel cell system as a heating source, a flow amount of cooling water flowing into the heat core is controlled by a control valve based on a surplus heat quantity of the fuel cell system and a necessary heat quantity of the passenger compartment. Further, when the surplus heat quantity of the fuel cell system is smaller than the necessary heat quantity, an insufficient heat quantity is supplemented by a supplementary heater.

Owner:DENSO CORP

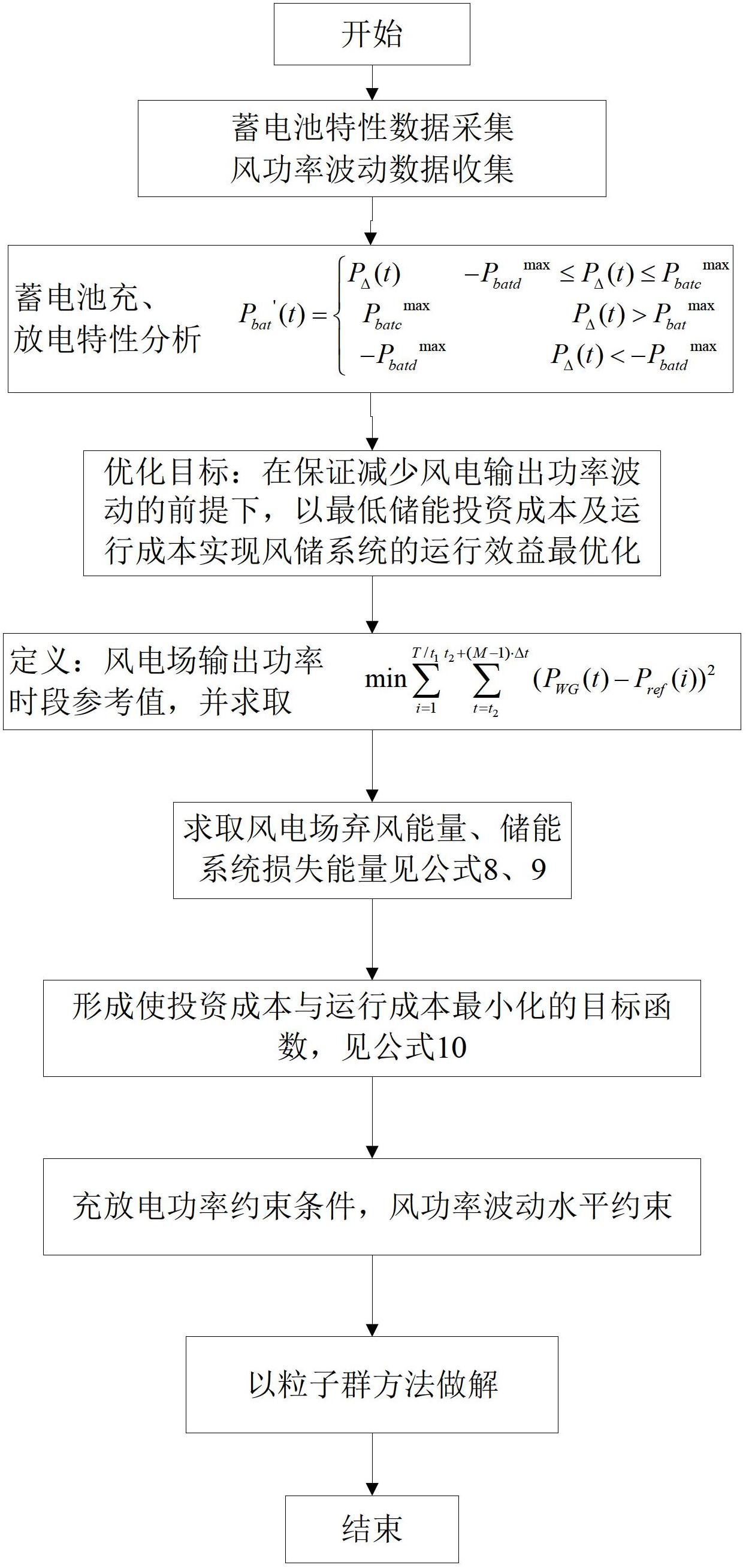

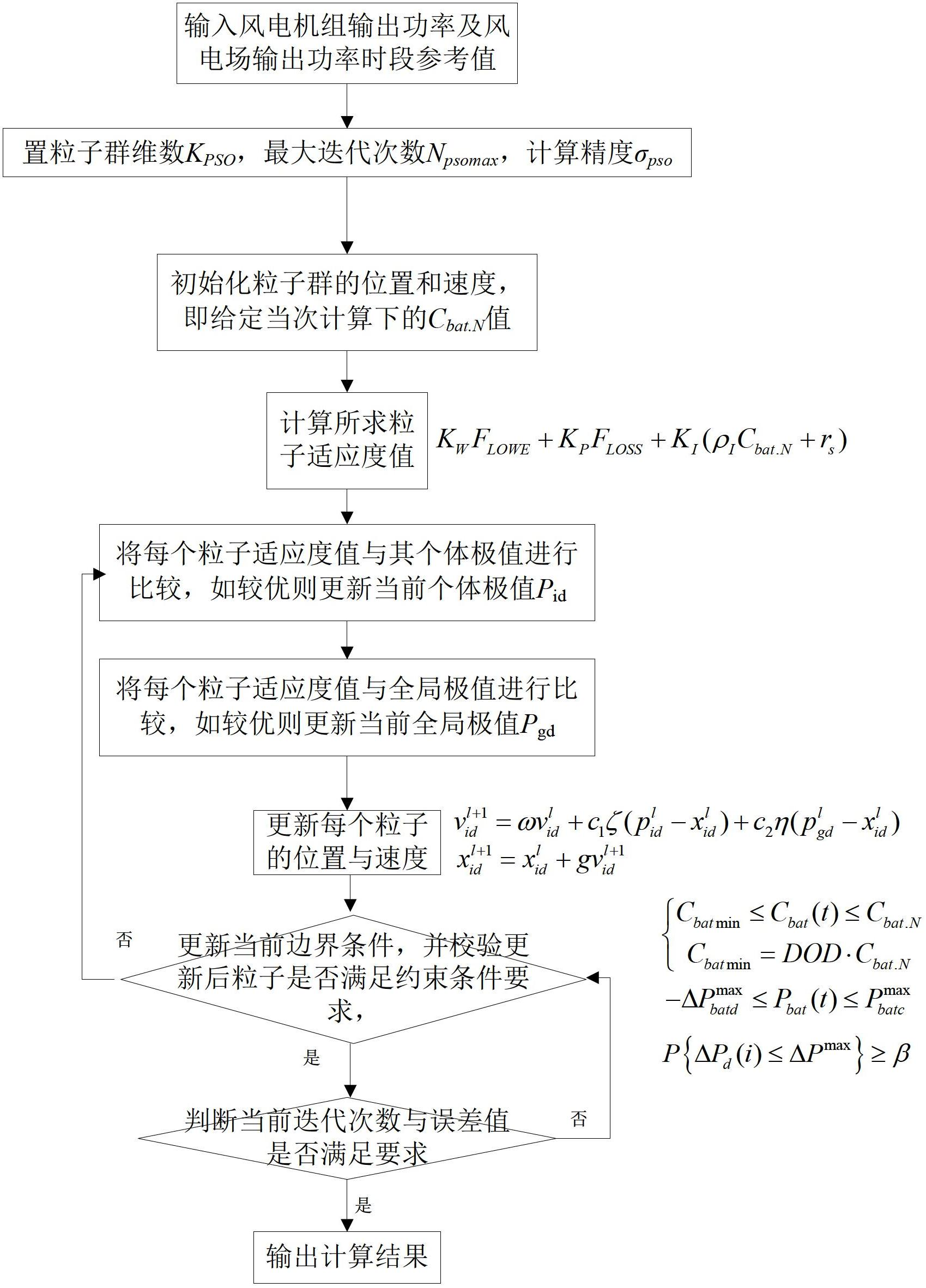

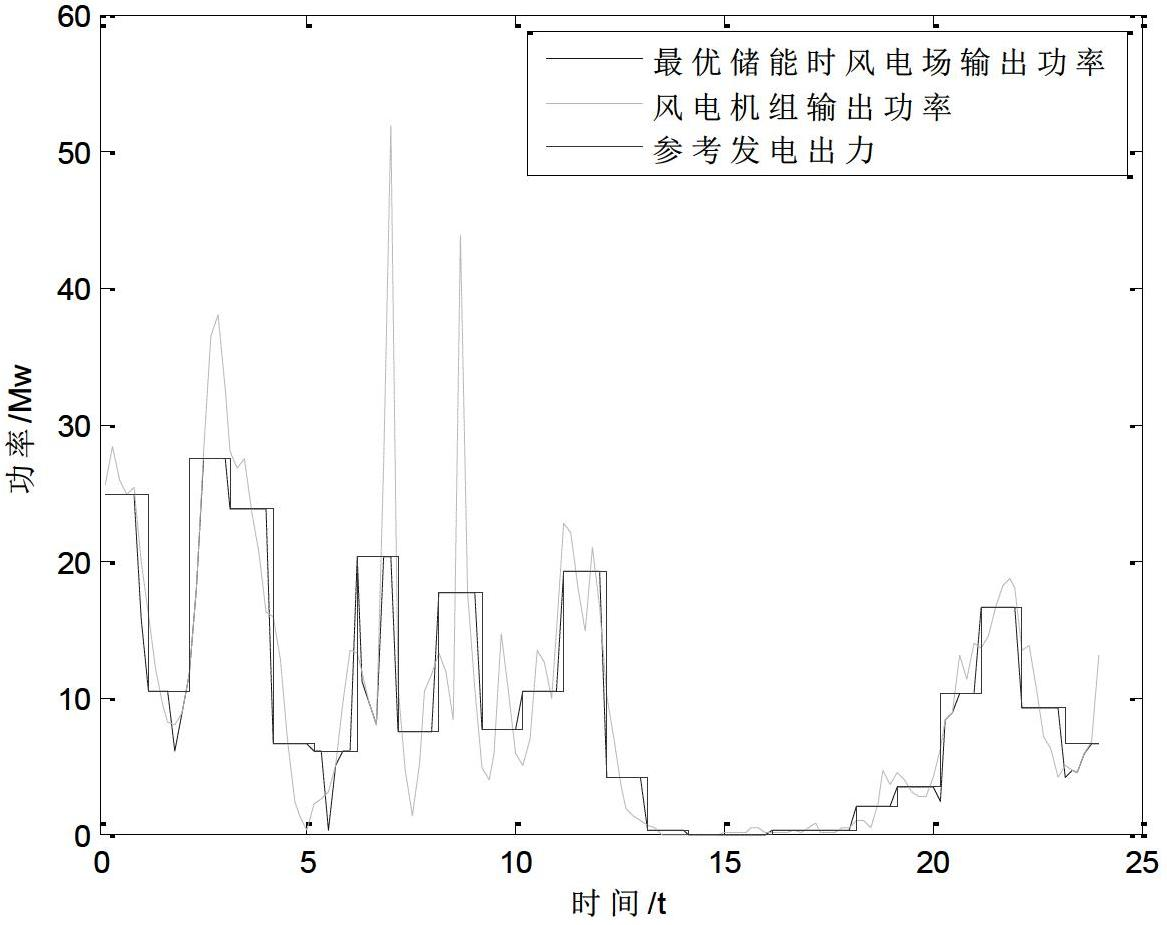

Wind power station energy storage capacity control method based on particle swarm optimization

InactiveCN102664423AEffective connection scheduling operation modeImprove receptivityEnergy storageBiological modelsParticle swarm algorithmEnergy analysis

The invention relates to a wind power station energy storage capacity control method based on particle swarm optimization. The wind power station energy storage capacity control method includes the steps of taking the interval reference value of the wind power station output power which is adapted to the dispatching cycle of a power grid as a foundation, taking the influence of the wind-abandoning energy of a wind power station and the lost energy of an energy storage system into consideration, taking the lowest costs of the energy storage investment and a wind and power operation system as target functions, establishing a policy model for energy storage capacity optimizing based on a storage battery energy storage system, and then applying the improved particle swarm optimization to solve the functions. By the aid of the wind power station energy storage capacity control method based on the particle swarm optimization, the wind power which is output under effect of the energy storage system can be output smoothly at intervals, so that effective connection between the energy storage system and the existing dispatching operation manner can be realized, and the best economic benefit can be achieved simultaneously.

Owner:SHANDONG UNIV

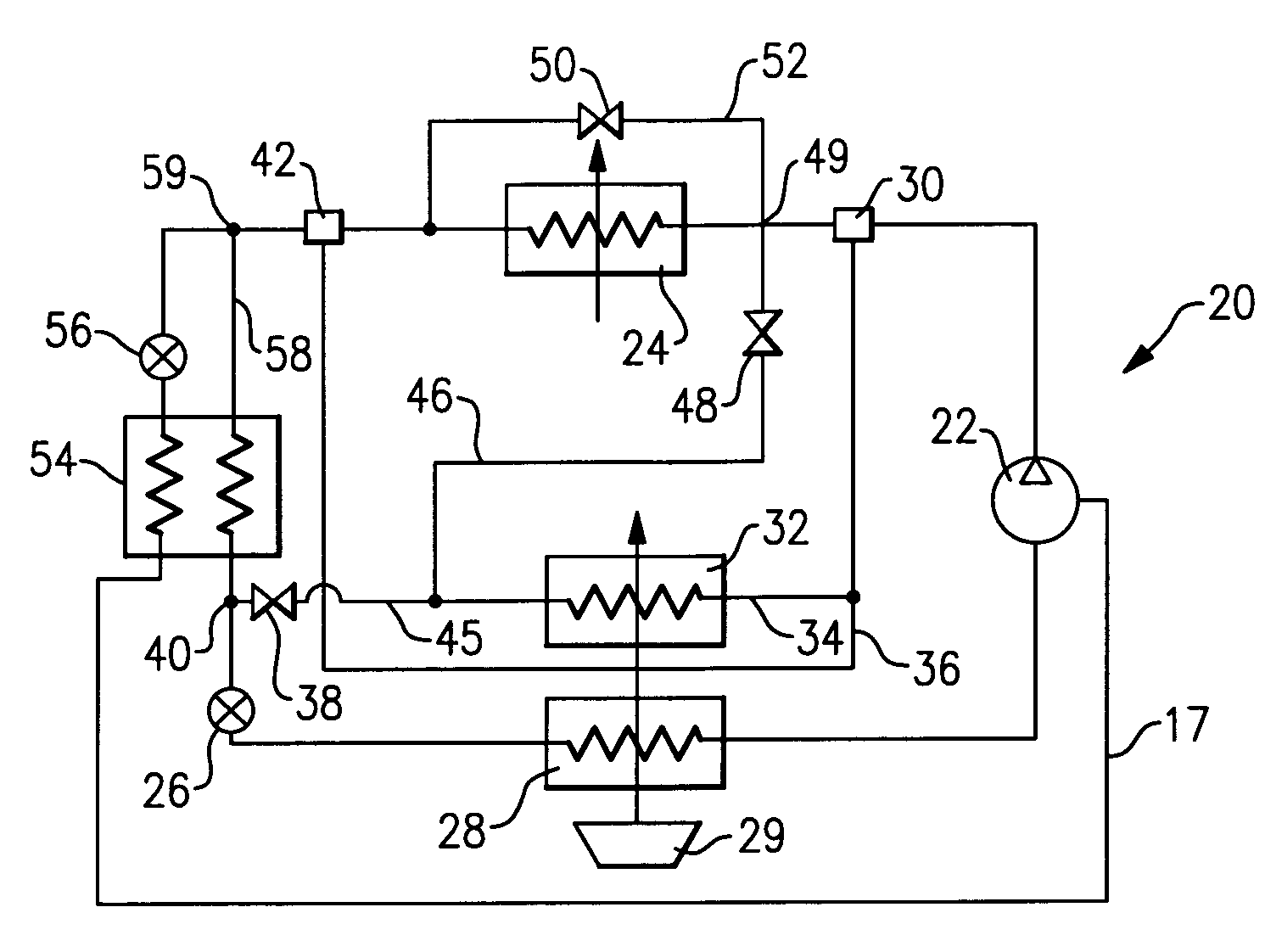

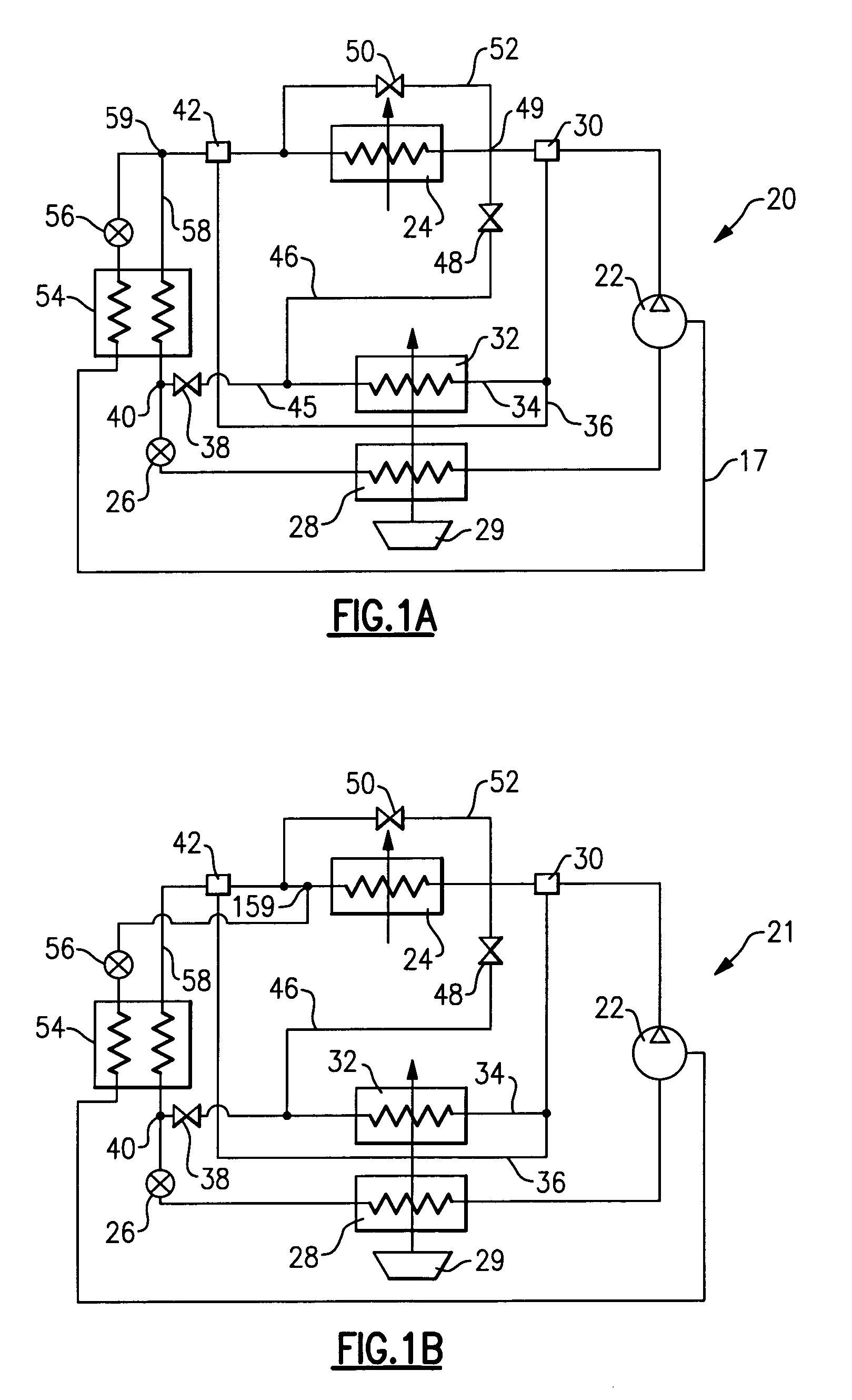

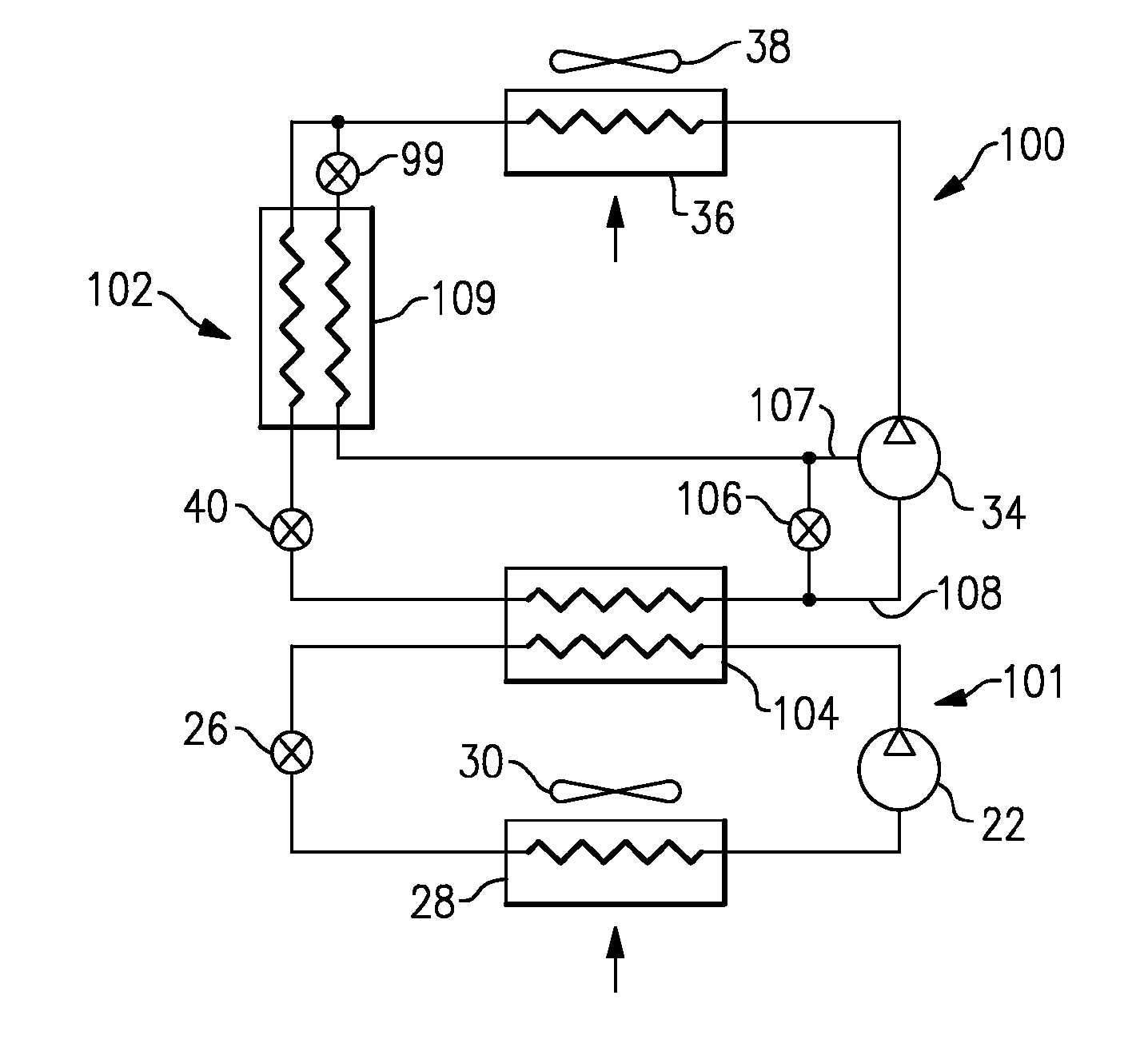

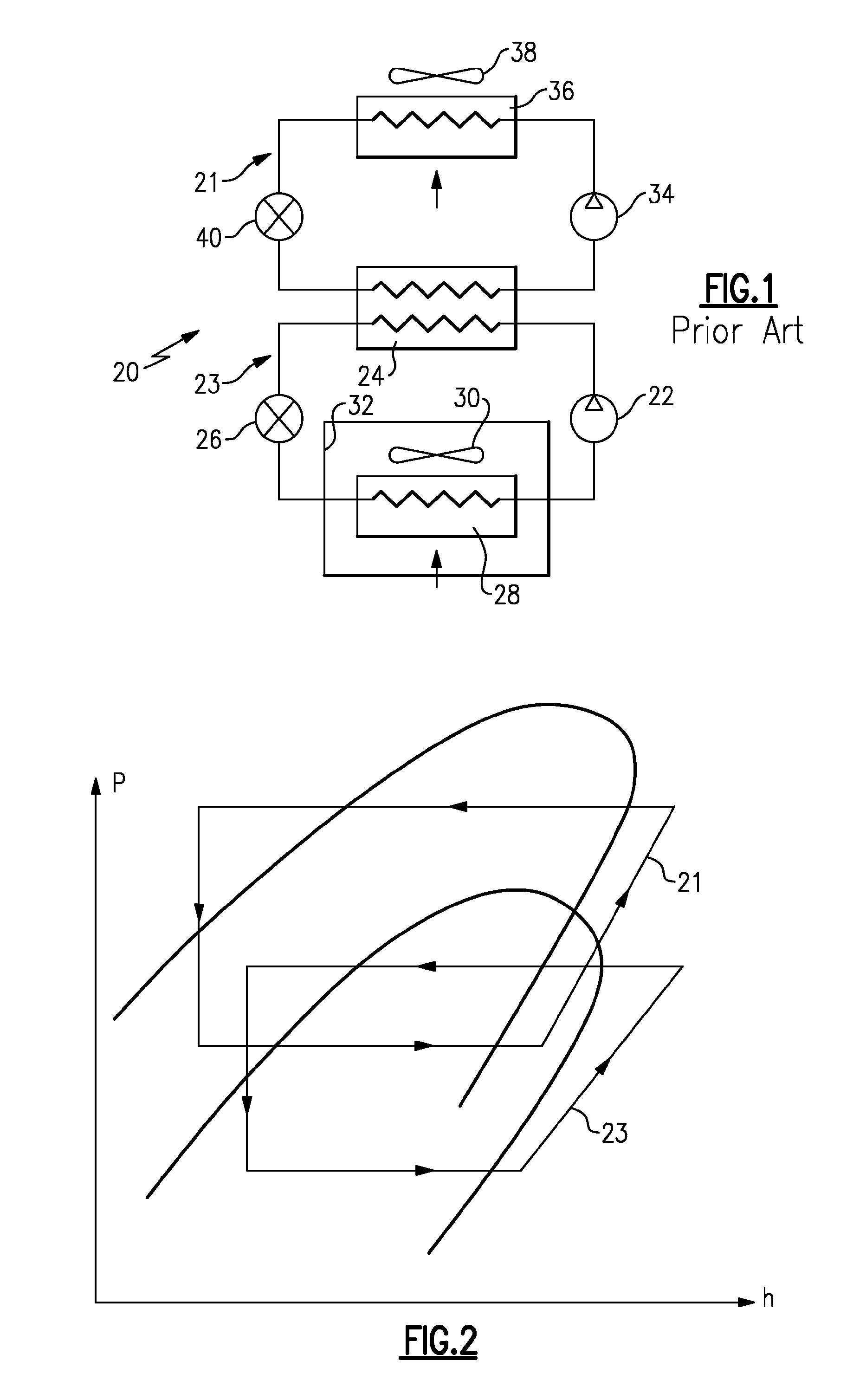

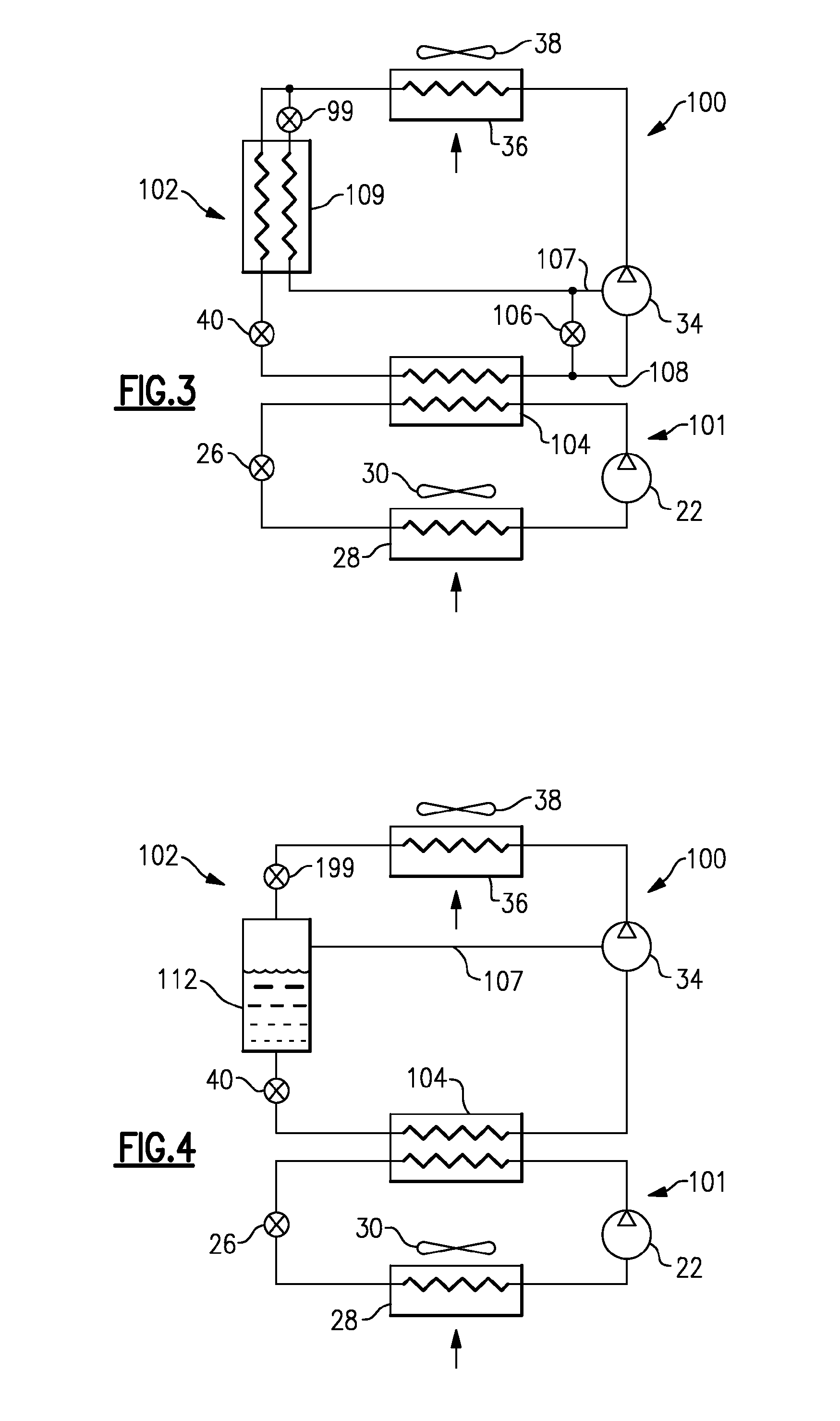

Hybrid reheat system with performance enhancement

ActiveUS6941770B1Reduce the temperatureMechanical apparatusFluid circulation arrangementPerformance enhancementOperation mode

An economizer loop is incorporated into the refrigerant system, which in conjunction with any selected reheat mode of operation, provides augmented performance, improved reliability, and enhanced control in meeting external heat load demands. A refrigerant system includes several features that can be selectively utilized alone or in combination with each other to provide an enhanced control over system cooling and dehumidification capability. In particular, a reheat coil is incorporated into the refrigerant system, and has alternative connection points to the main circuit, positioned both upstream and downstream of a condenser. Also, a flow control device allows a selective bypass around a condenser. In this manner, the refrigerant flowing through the reheat coil can be controlled to provide a desired level of temperature and humidity. Finally, the compressor may include an unloader feature such that additional steps in capacity control can be provided.

Owner:CARRIER CORP

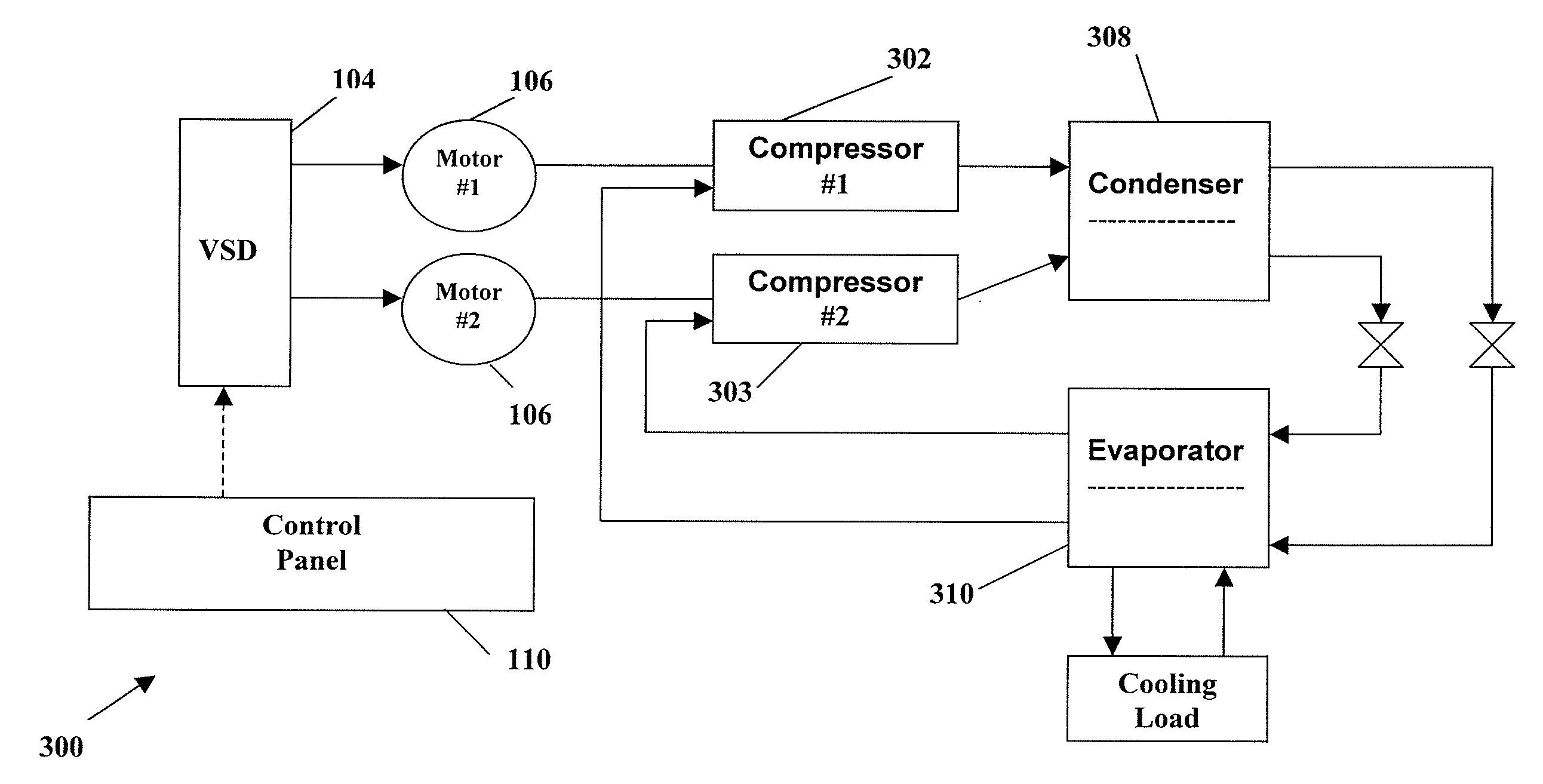

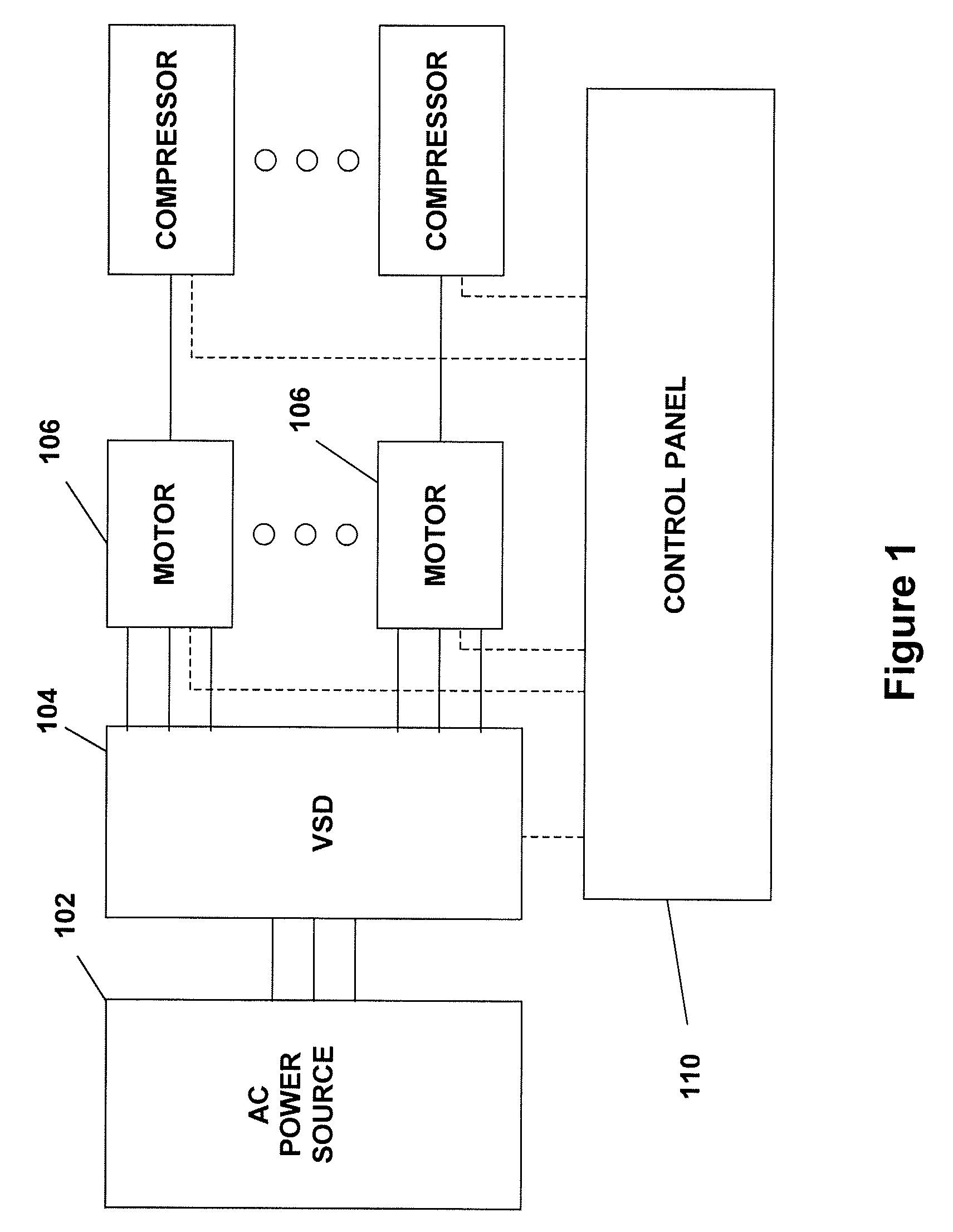

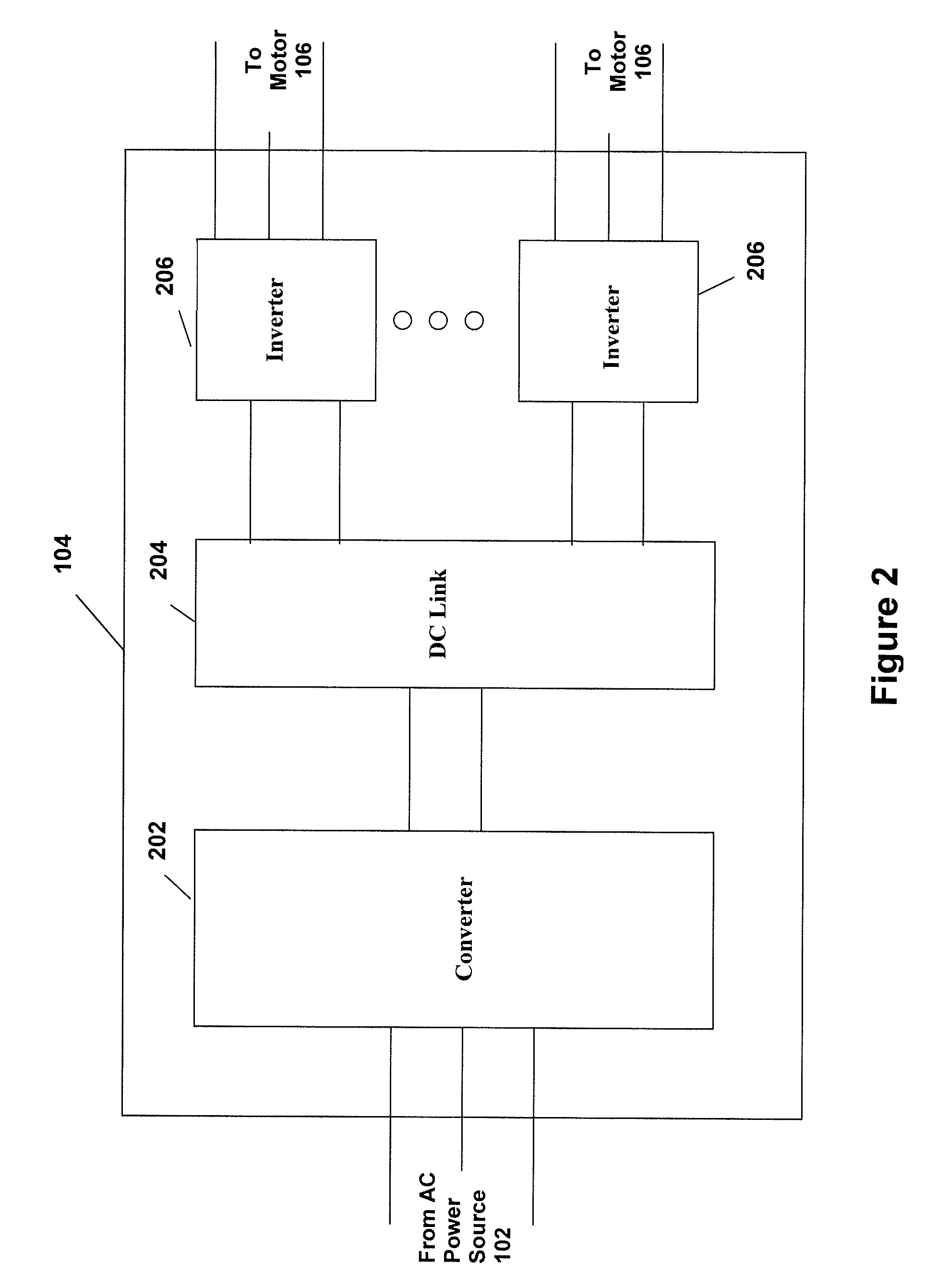

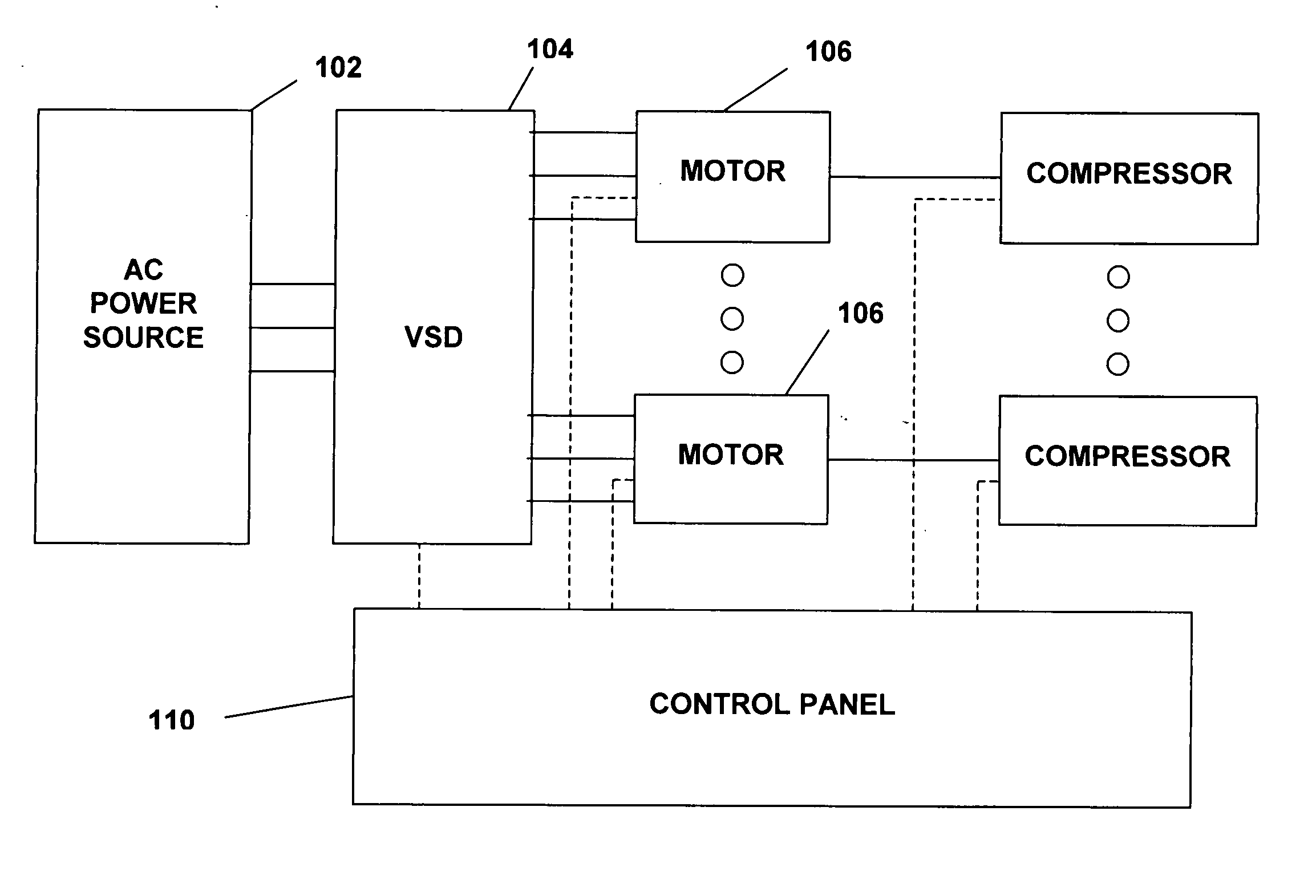

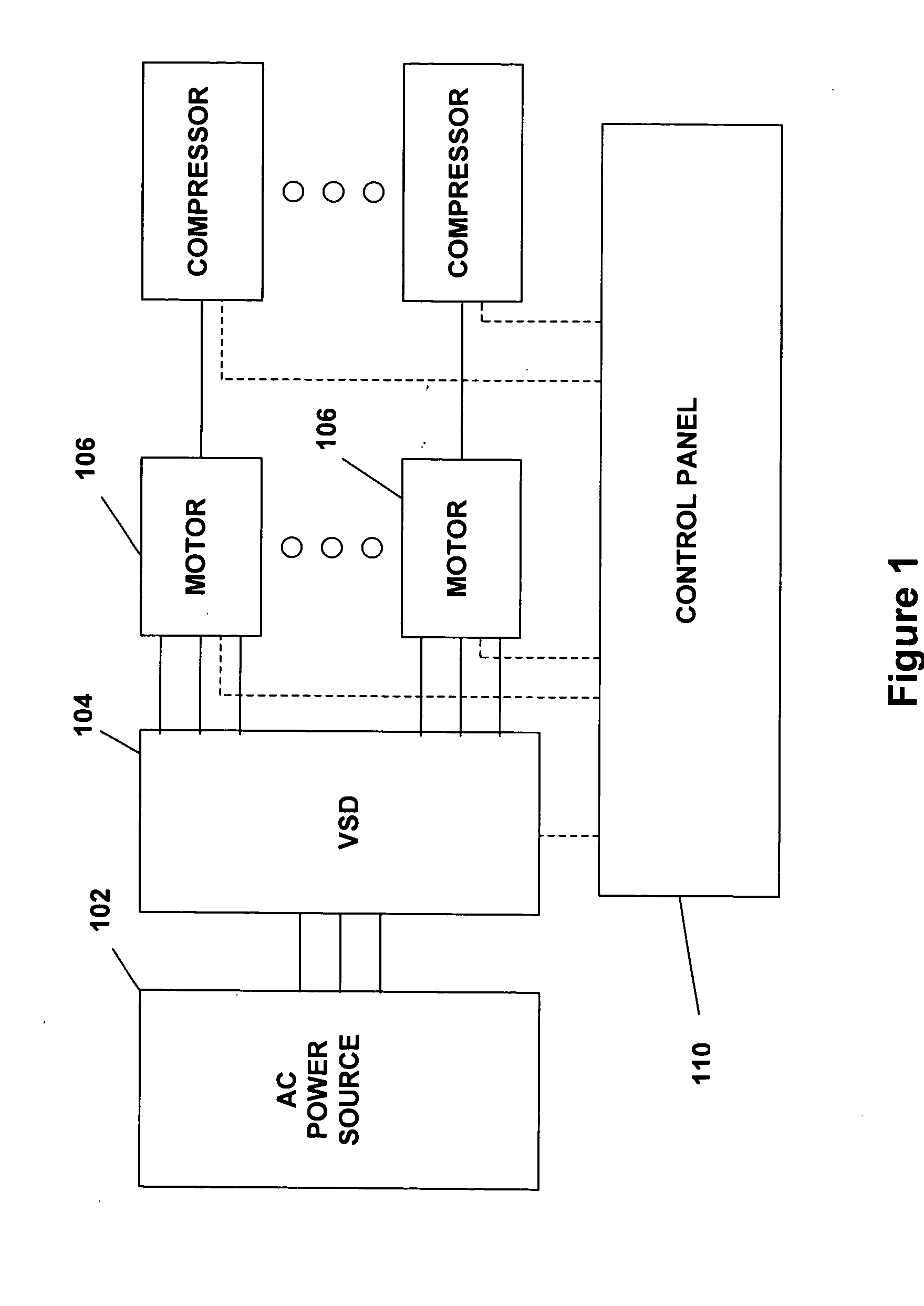

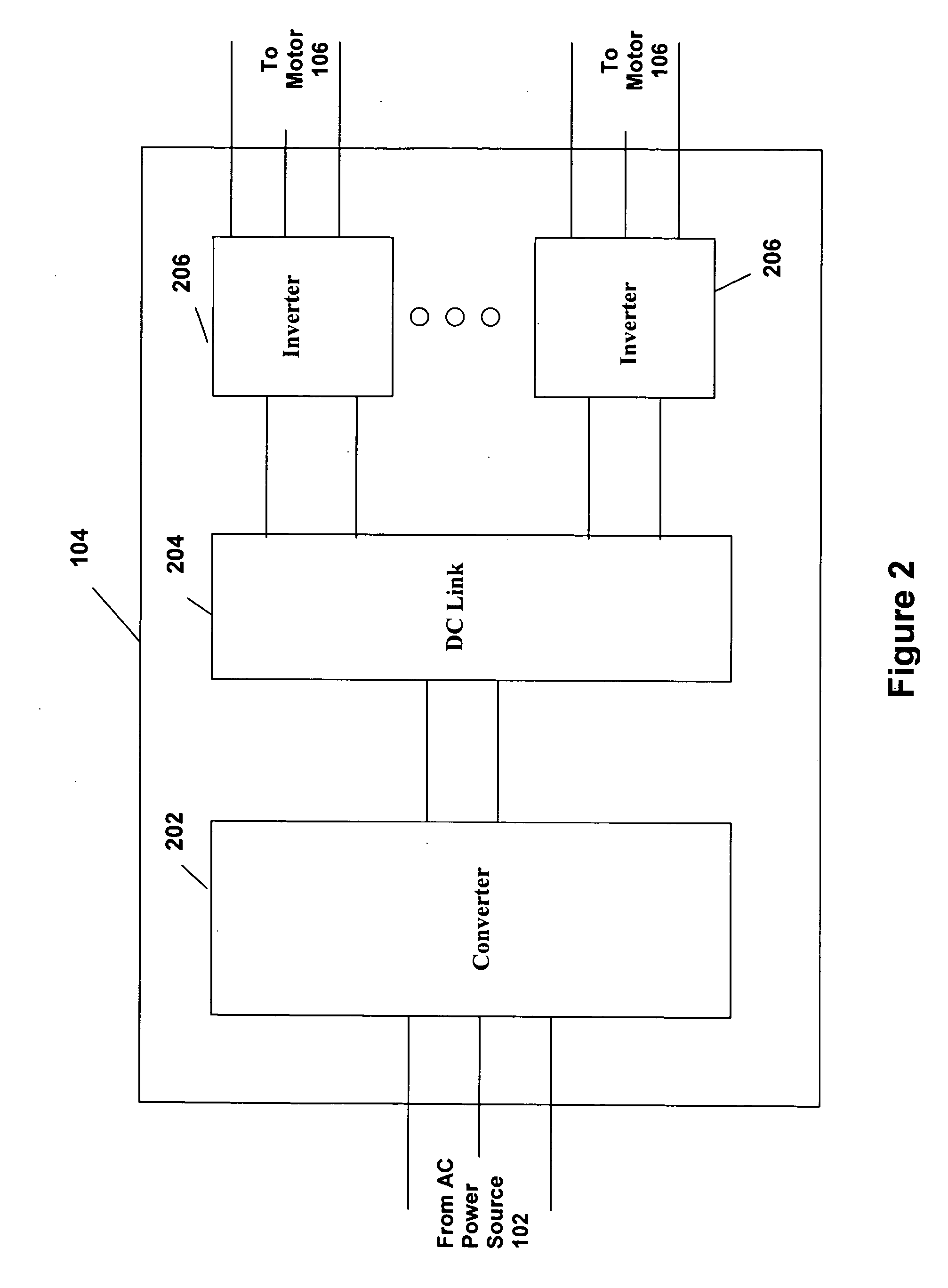

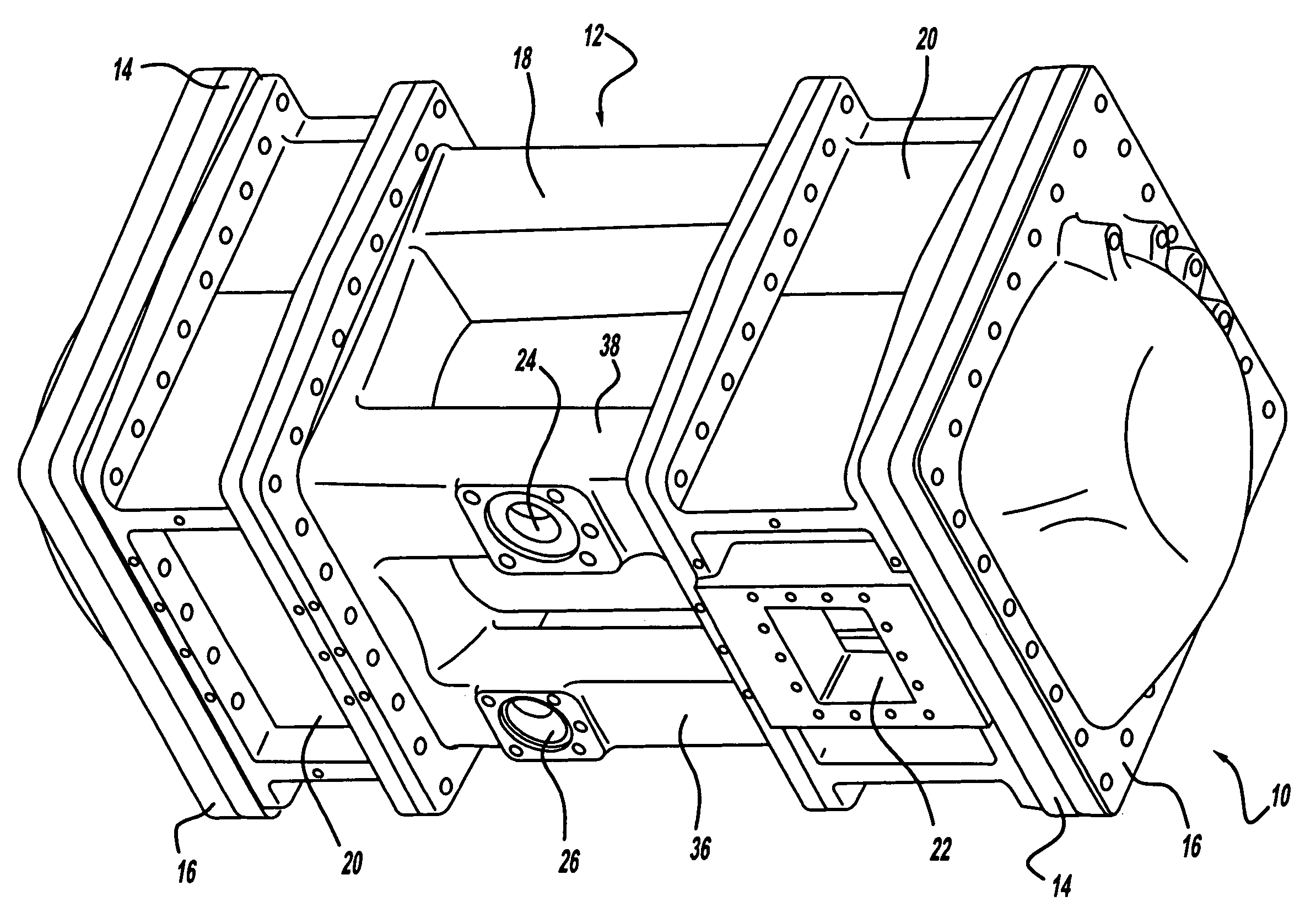

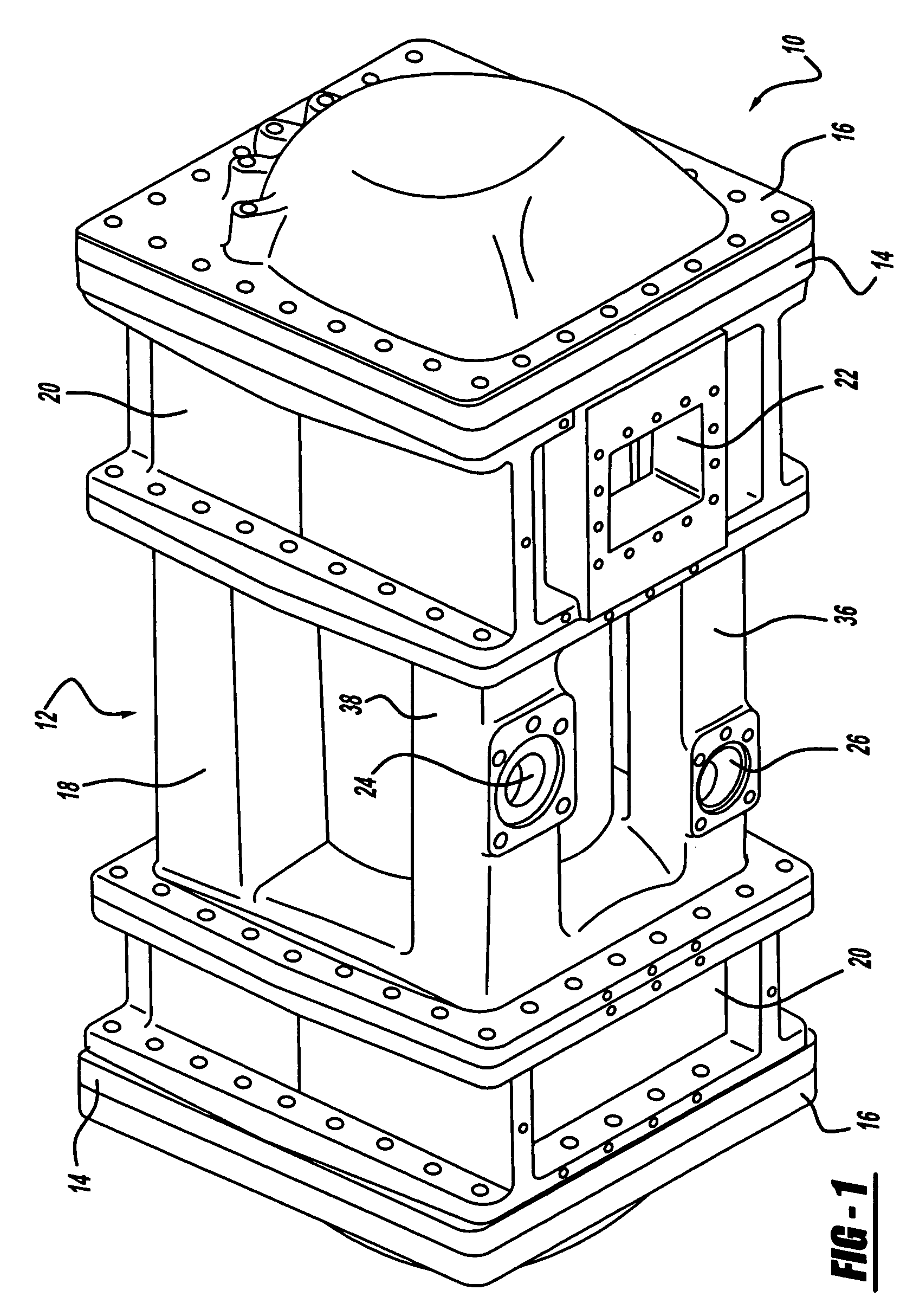

System and method for capacity control in a multiple compressor chiller system

ActiveUS20070056300A1Easy to controlImprove system efficiencyCompression machines with non-reversible cycleCompression machines with cascade operationLiquid temperatureEngineering

A capacity control algorithm for a multiple compressor liquid chiller system is provided wherein the speed and number of compressors in operation are controlled in order to obtain a leaving liquid temperature setpoint. In response to an increase in the load in the chiller system, the algorithm determines if a compressor should be started and adjusts the operating speed of all operating compressors when an additional compressor is started. In response to a decrease in the load in the chiller system with multiple compressors operating, the algorithm determines if a compressor should be de-energized and adjusts the operating speed of all remaining operating compressors when a compressor is de-energized.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

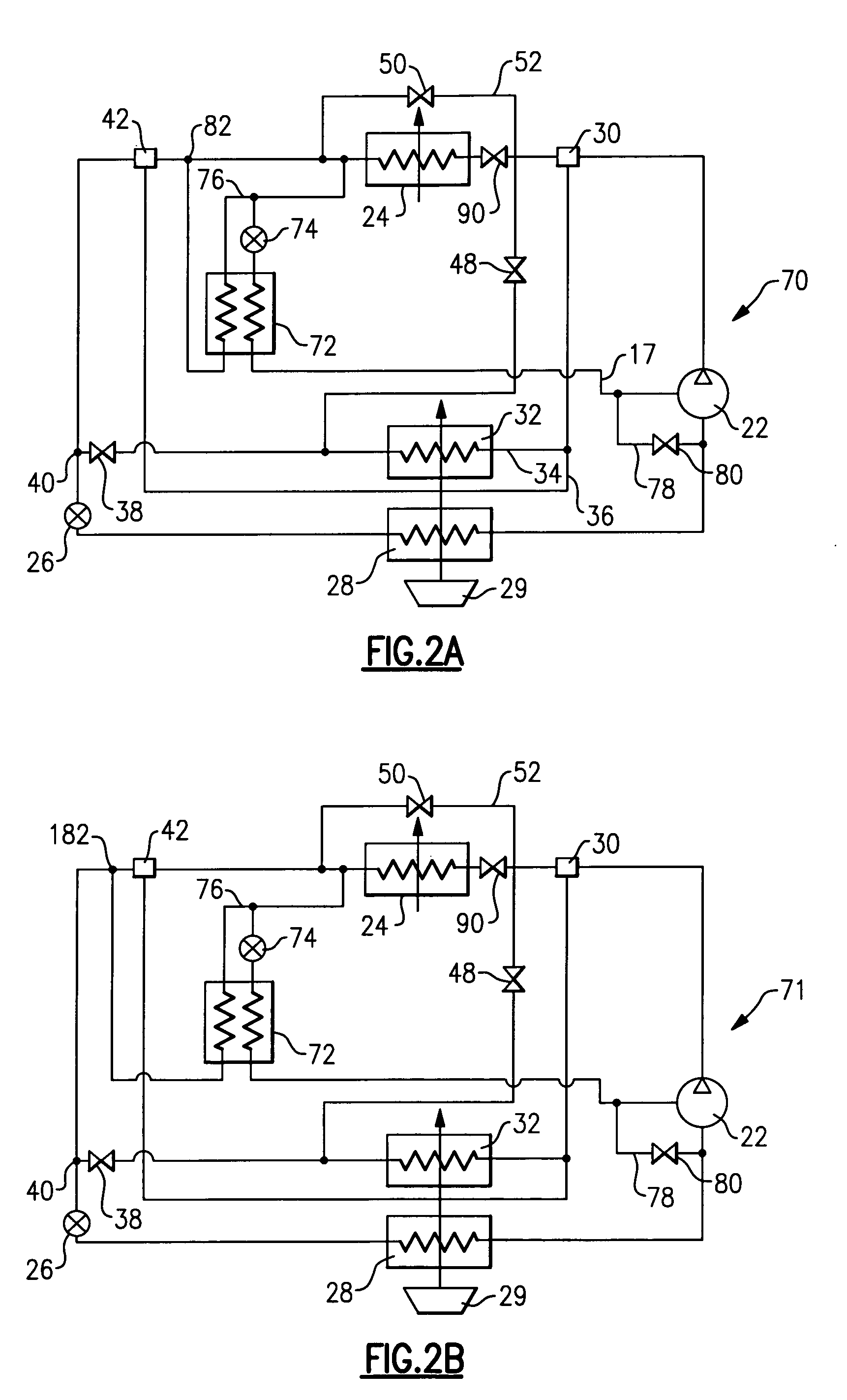

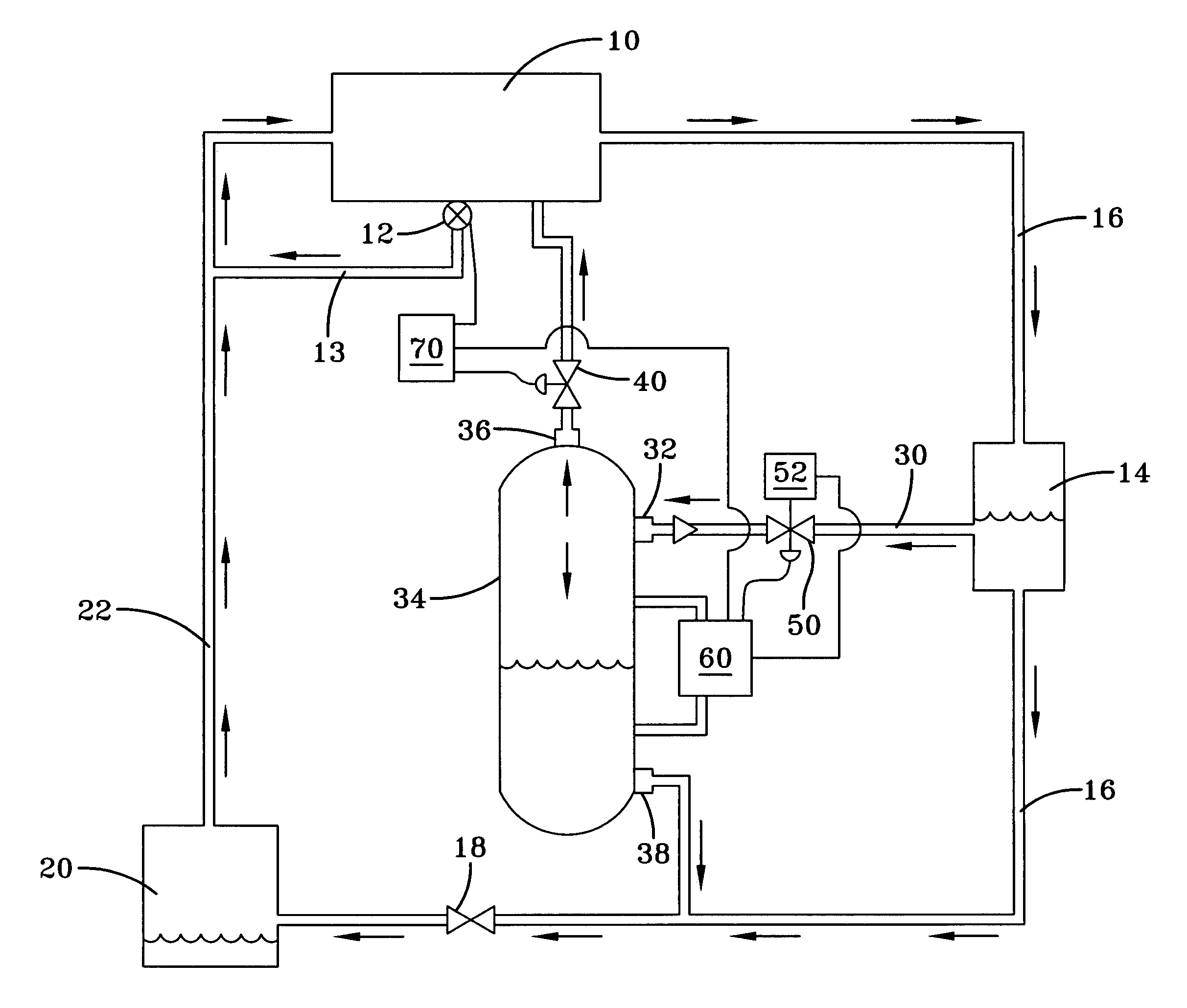

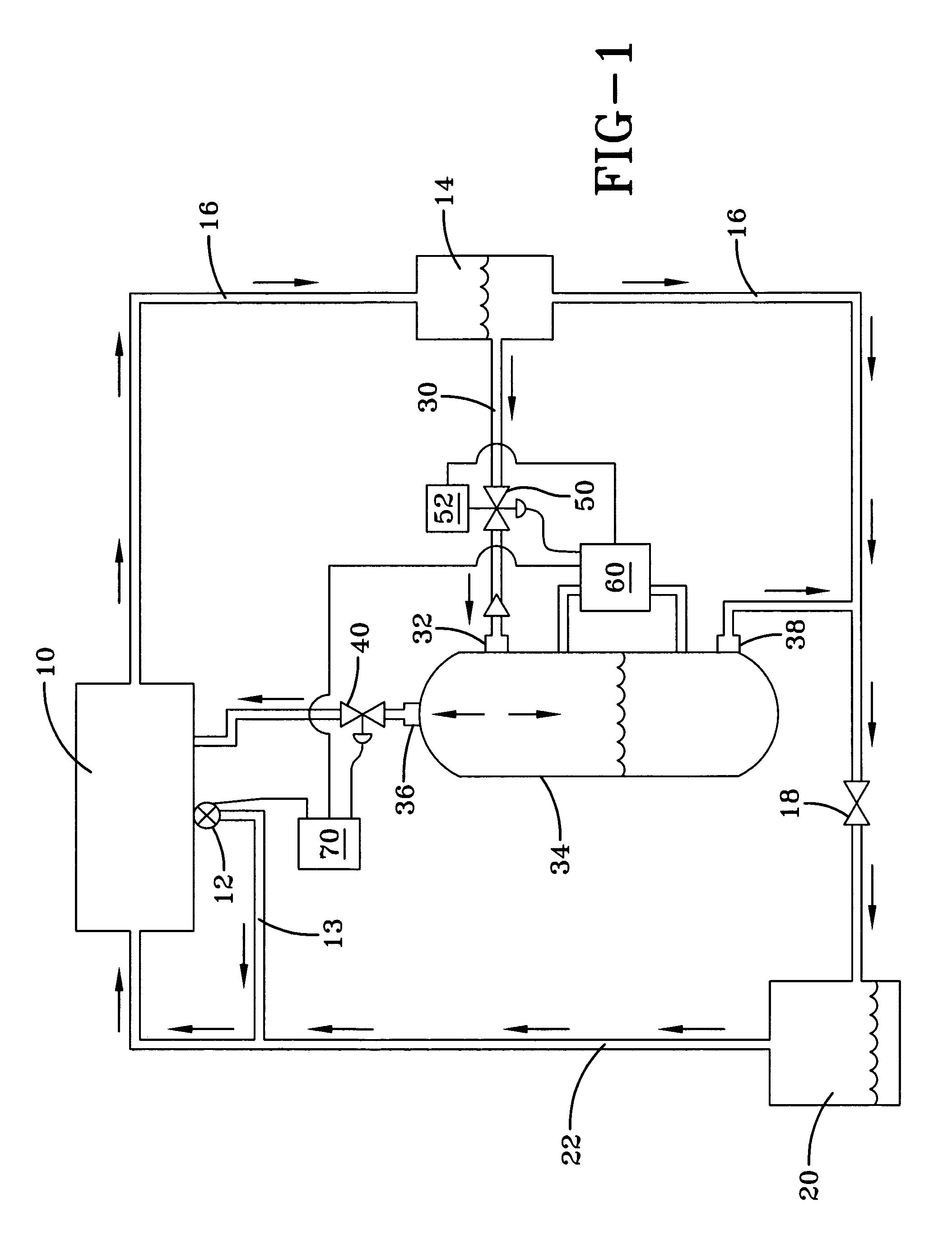

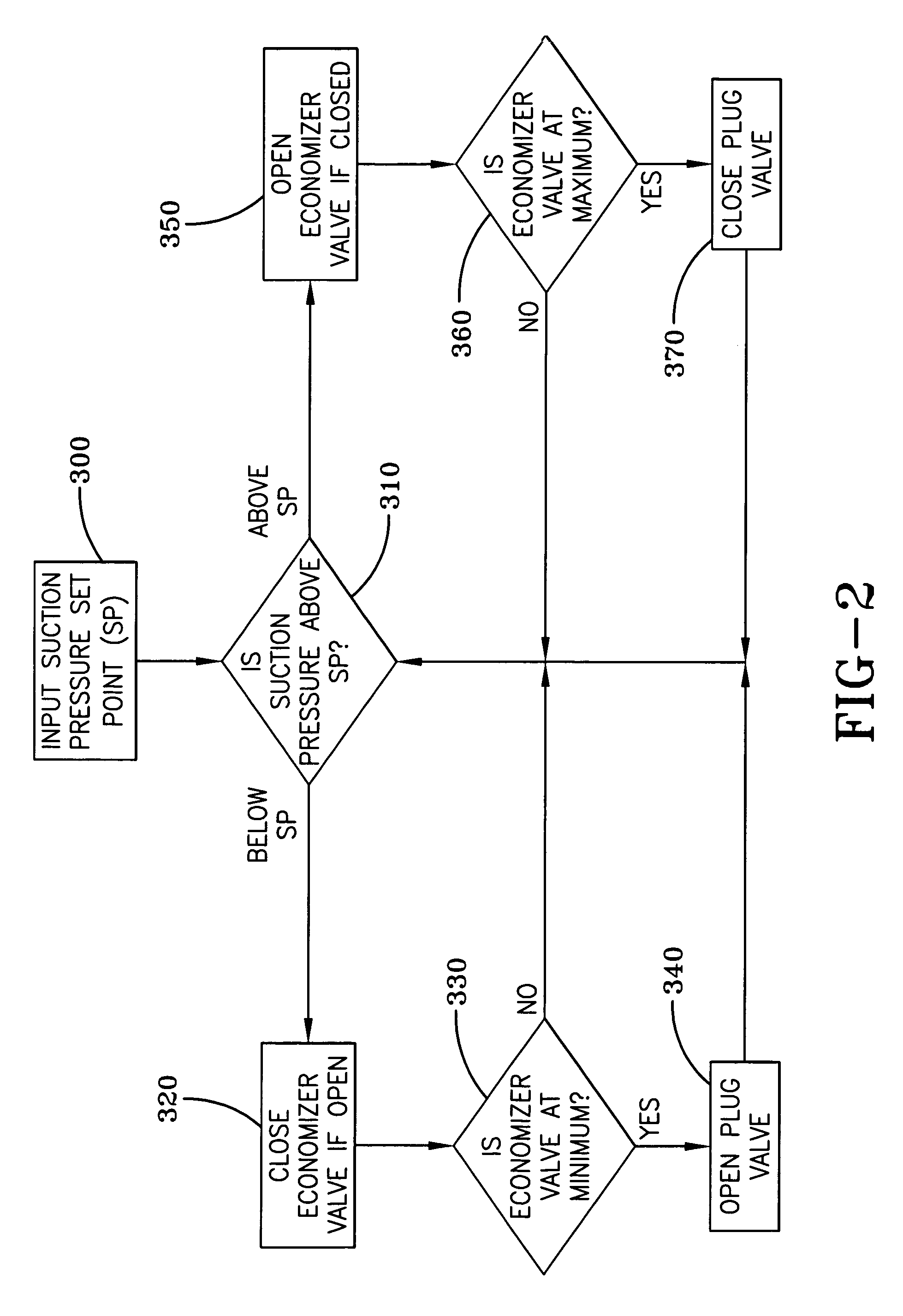

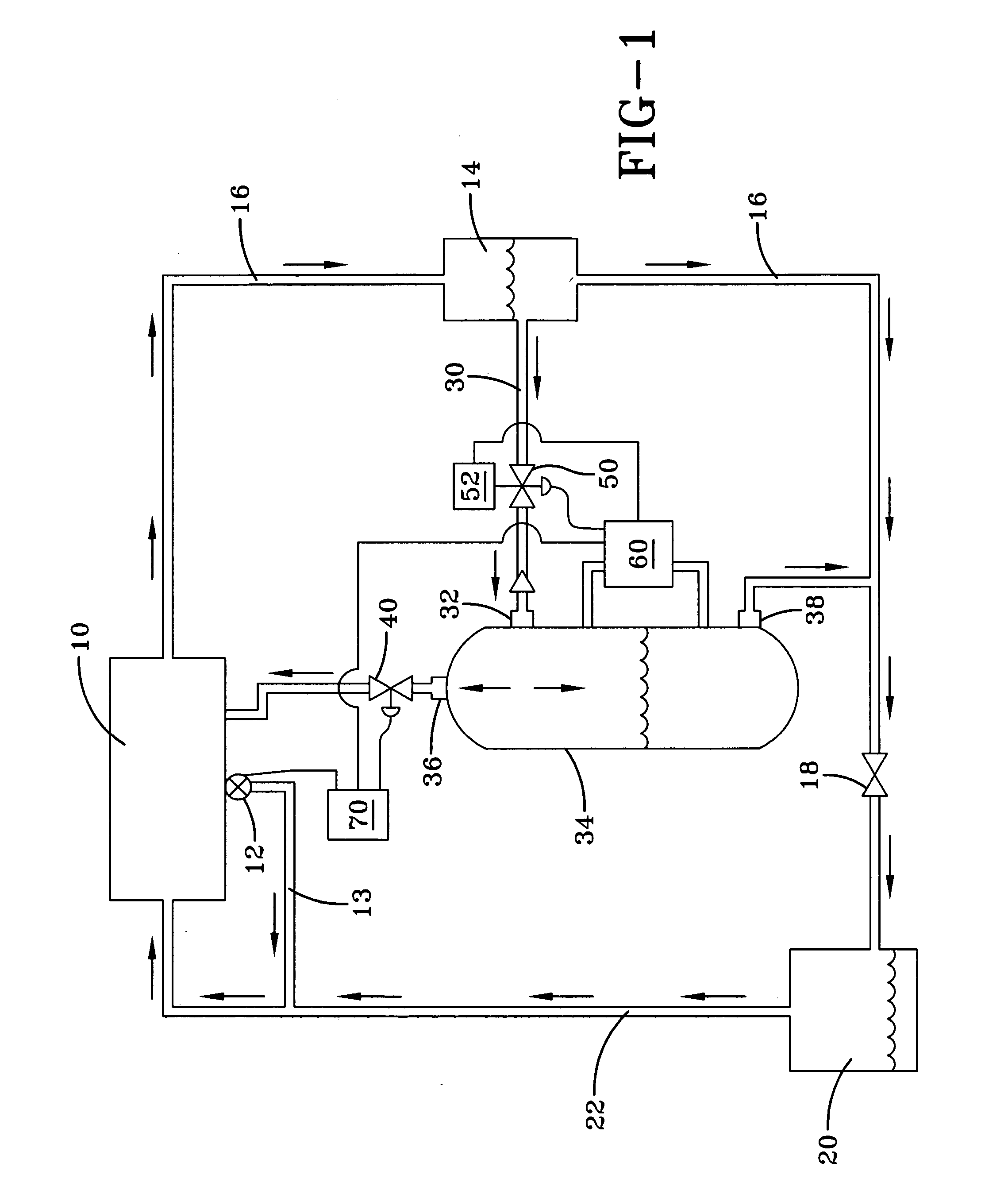

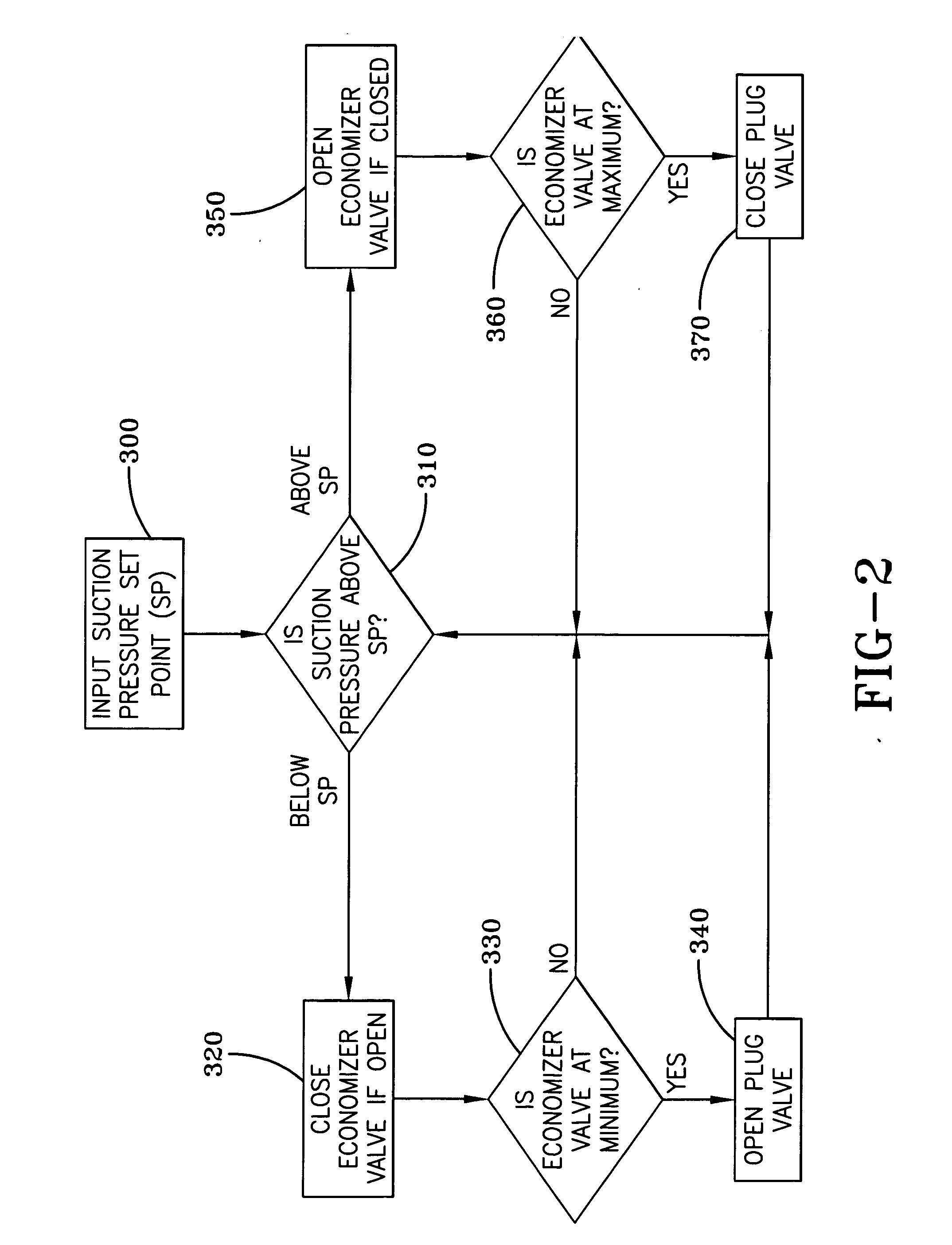

Capacity control for economizer refrigeration systems

ActiveUS6973797B2Efficient and flexible and reliable and variable capacity controlMechanical apparatusCompression machines with non-reversible cycleSystem capacityControl valves

An economizer-equipped refrigeration system and method is provided for simultaneous operation of at least one capacity control valve controlling an independent bypass circuit with operation and variable control of the economizer circuit to permit efficient, flexible, and reliable variable system capacity control, without leakage that sacrifices system peak capacity.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

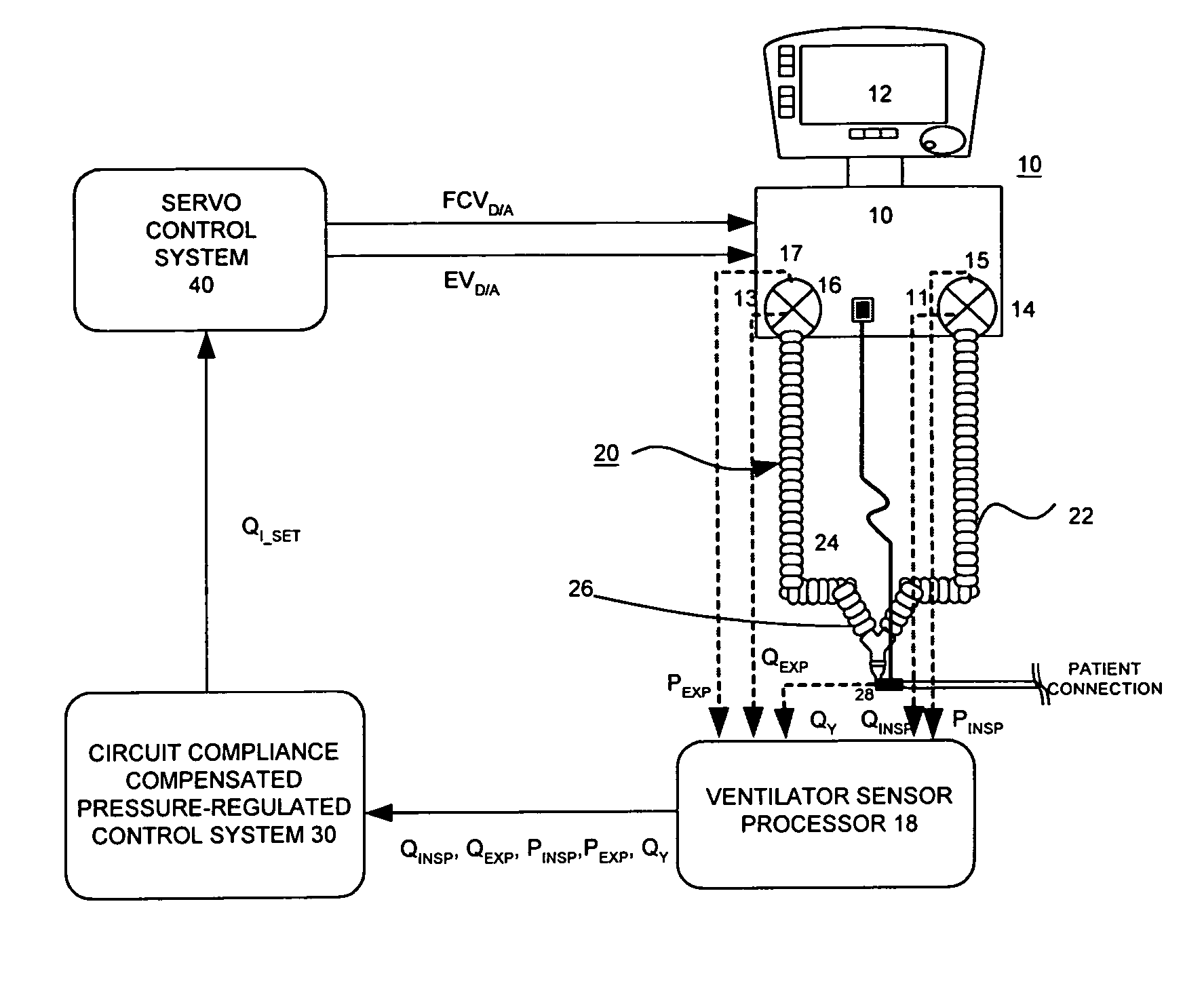

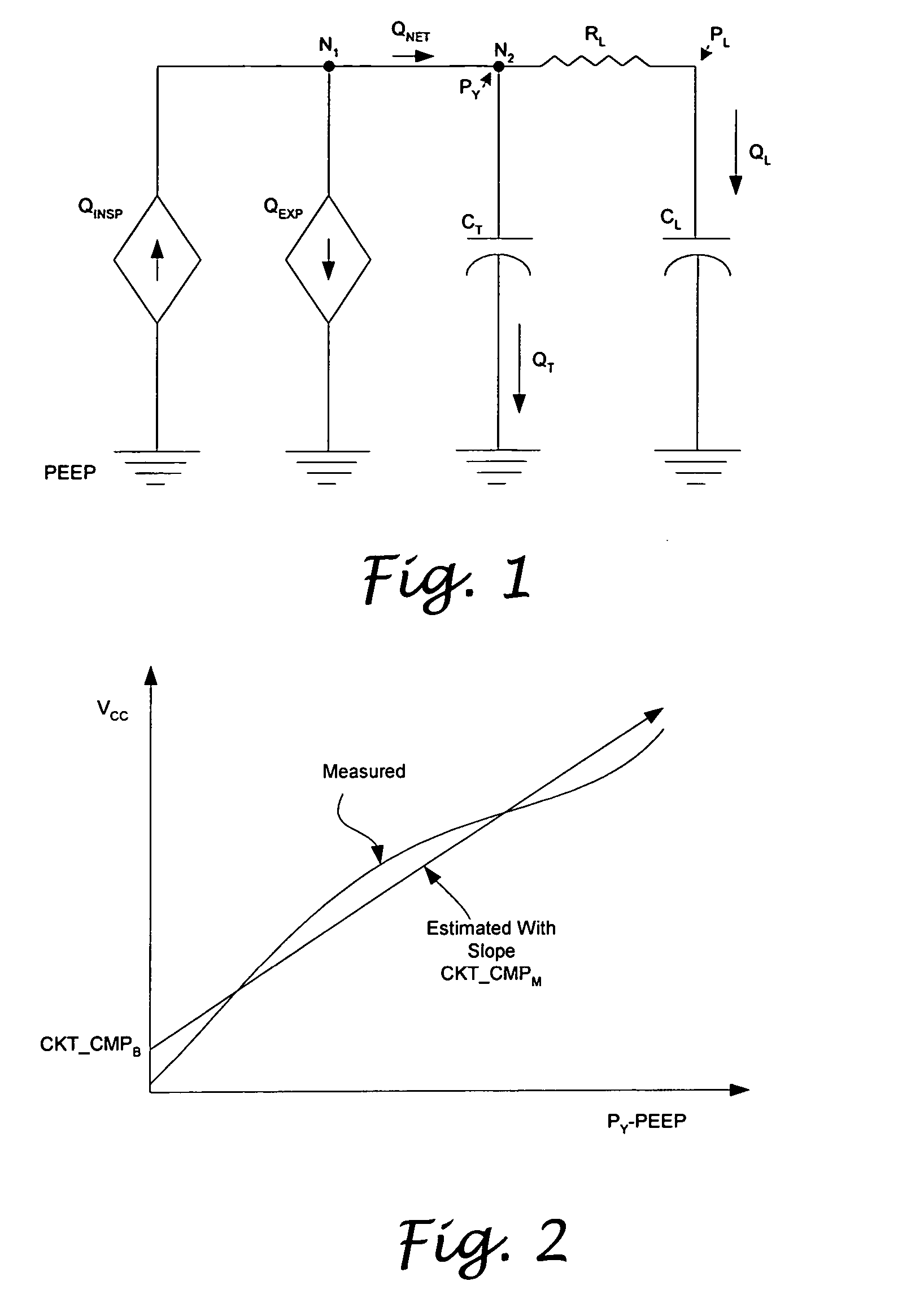

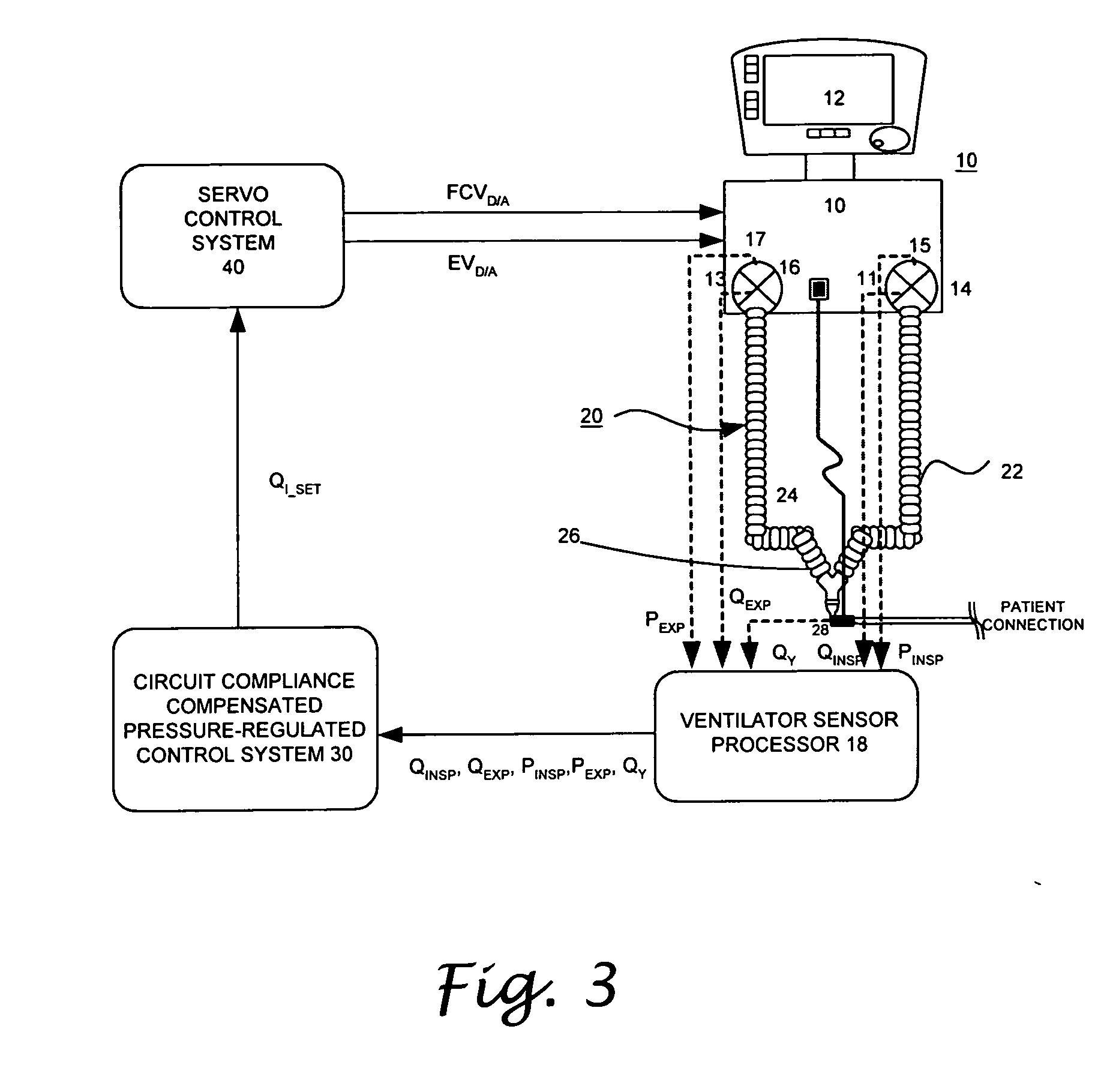

System and method for circuit compliance compensated pressure-regulated volume control in a patient respiratory ventilator

ActiveUS20070101992A1Prolonging inspiratory timeAccurate pressureRespiratorsOperating means/releasing devices for valvesPeak valueAirway pressures

A system and a method for circuit compliance compensated pressure control in a patient respiratory ventilation system, having a pressure regulated feedback servo control loop, a pressure-regulated volume controller, and a patient volume observer. The patient volume observer is operative to estimate a patient volume, that is, the volume actually delivered to the patient by accounting for volume deviation or loss caused by patient circuit leakage and valve dynamics. Based on the difference between the estimated patient volume and a set tidal volume, the pressure-regulated volume controller is operative to generate and update a circuit compliance pressure compensation factor. The pressure regulated feedback servo control loop is operative to modulate the peak airway pressure based on the circuit compliance pressure compensation factor, so as to achieve the set tidal volume while maintaining a constant inspiratory time and a constant I:E ratio.

Owner:VYAIRE MEDICAL 211 INC

Vehicle air conditioner with heating capacity control of cooling water circuit

InactiveUS20010018832A1Easy to useIncrease temperatureAir-treating devicesVehicle heating/cooling devicesFuel cellsWater flow

In a vehicle air conditioner where air blown into a passenger compartment is heated in a heater core using cooling water for cooling a fuel cell system as a heating source, a flow amount of cooling water flowing into the heat core is controlled by a control valve based on a surplus heat quantity of the fuel cell system and a necessary heat quantity of the passenger compartment. Further, when the surplus heat quantity of the fuel cell system is smaller than the necessary heat quantity, an insufficient heat quantity is supplemented by a supplementary heater.

Owner:DENSO CORP

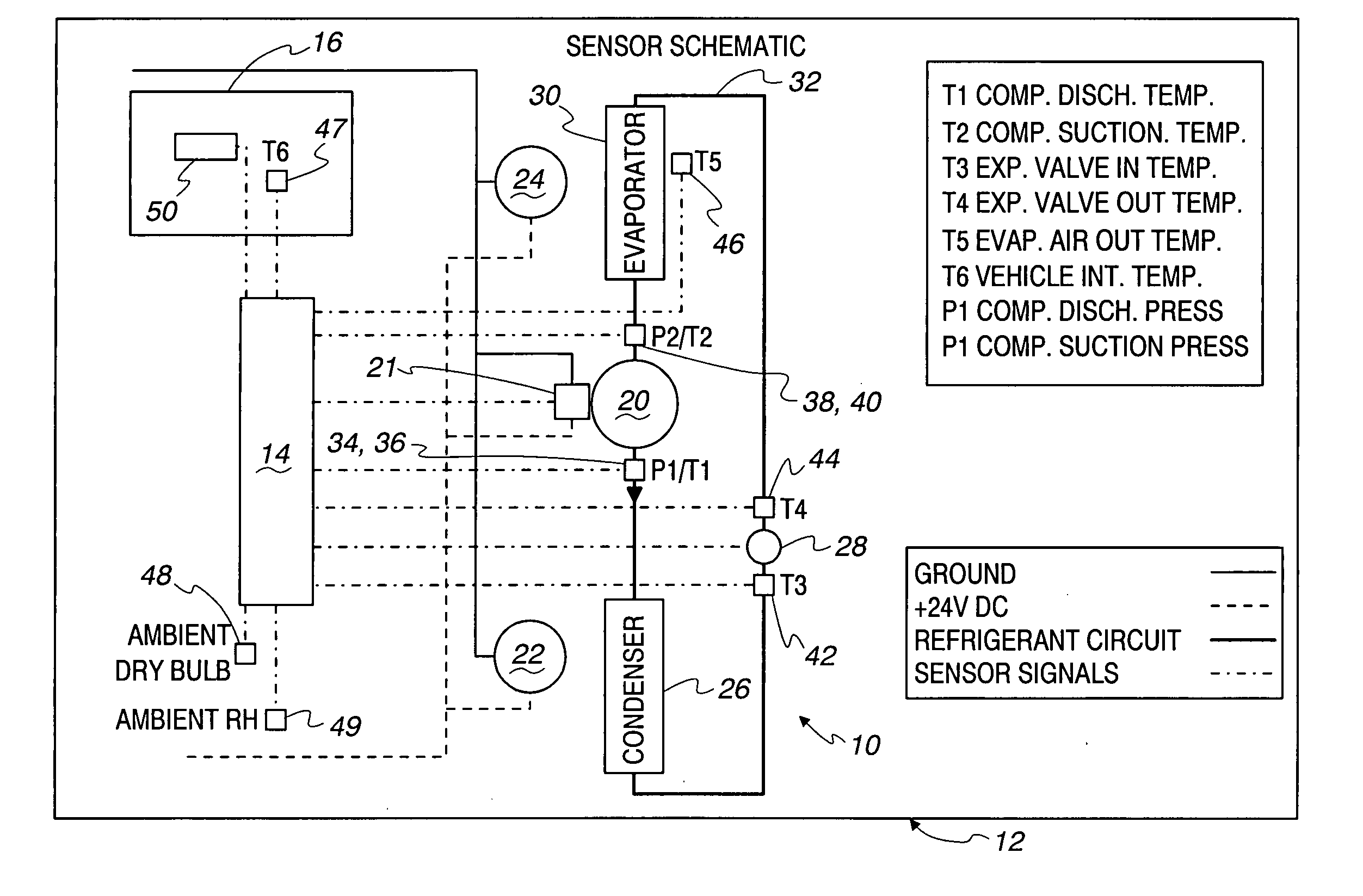

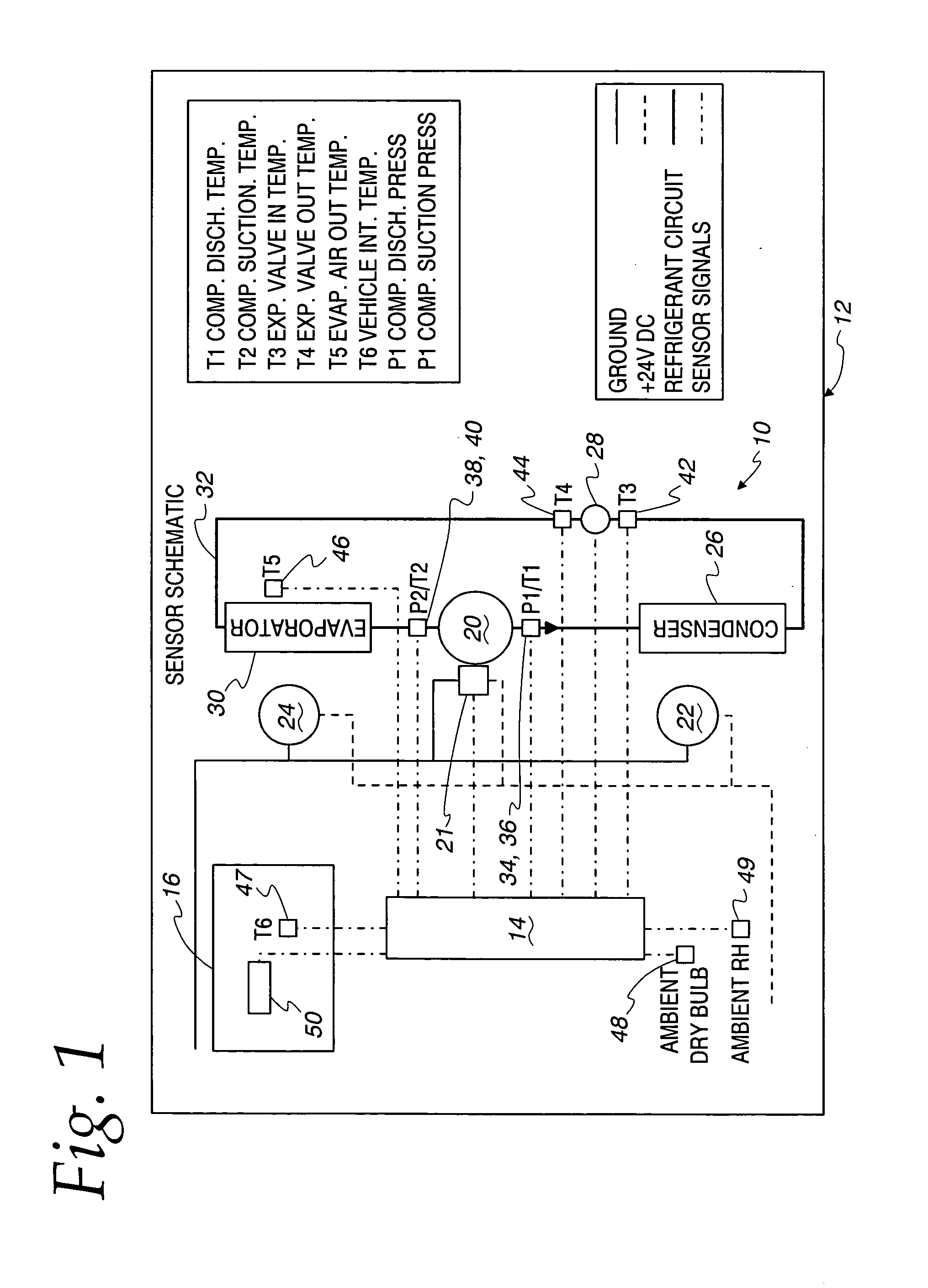

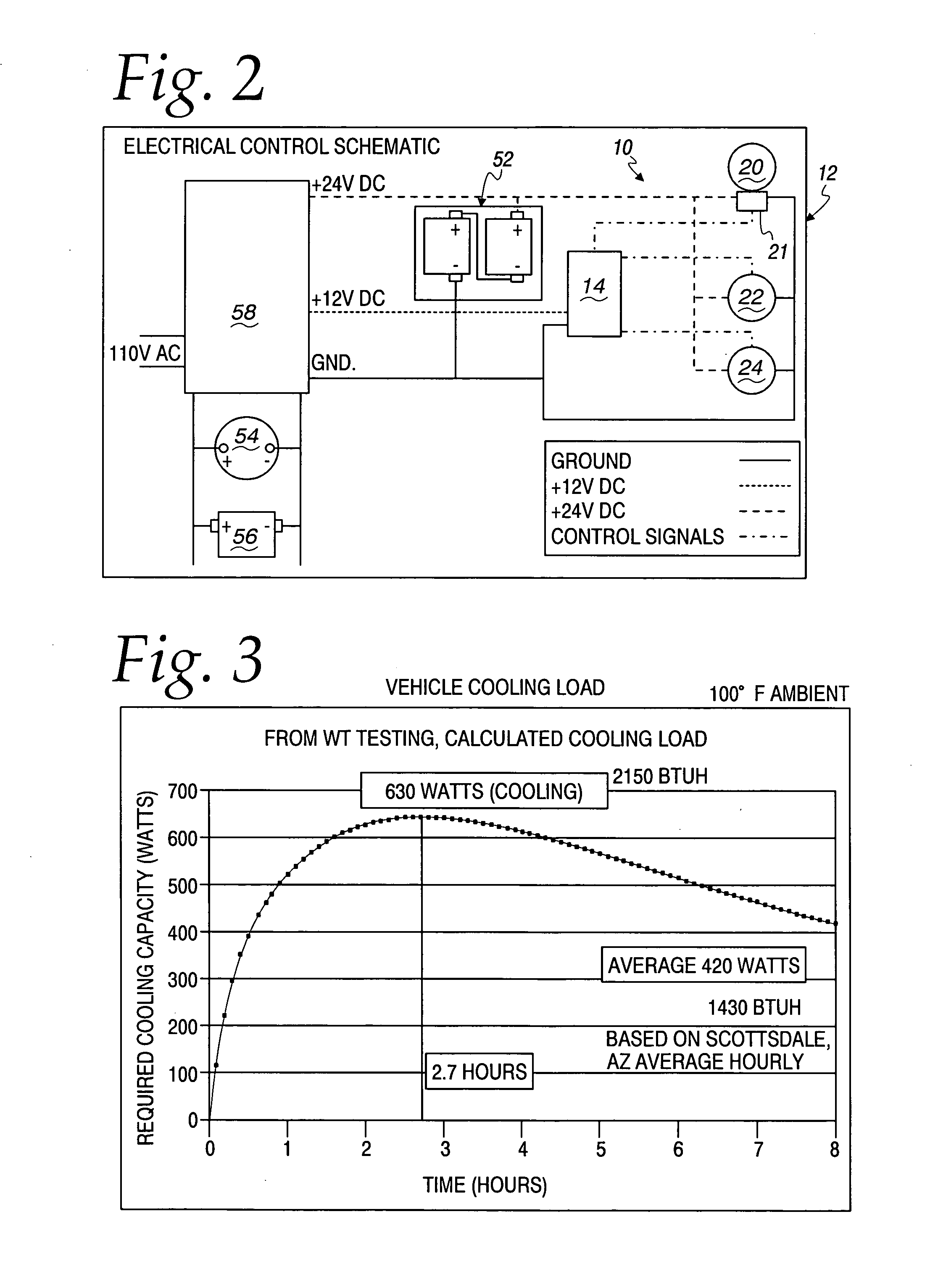

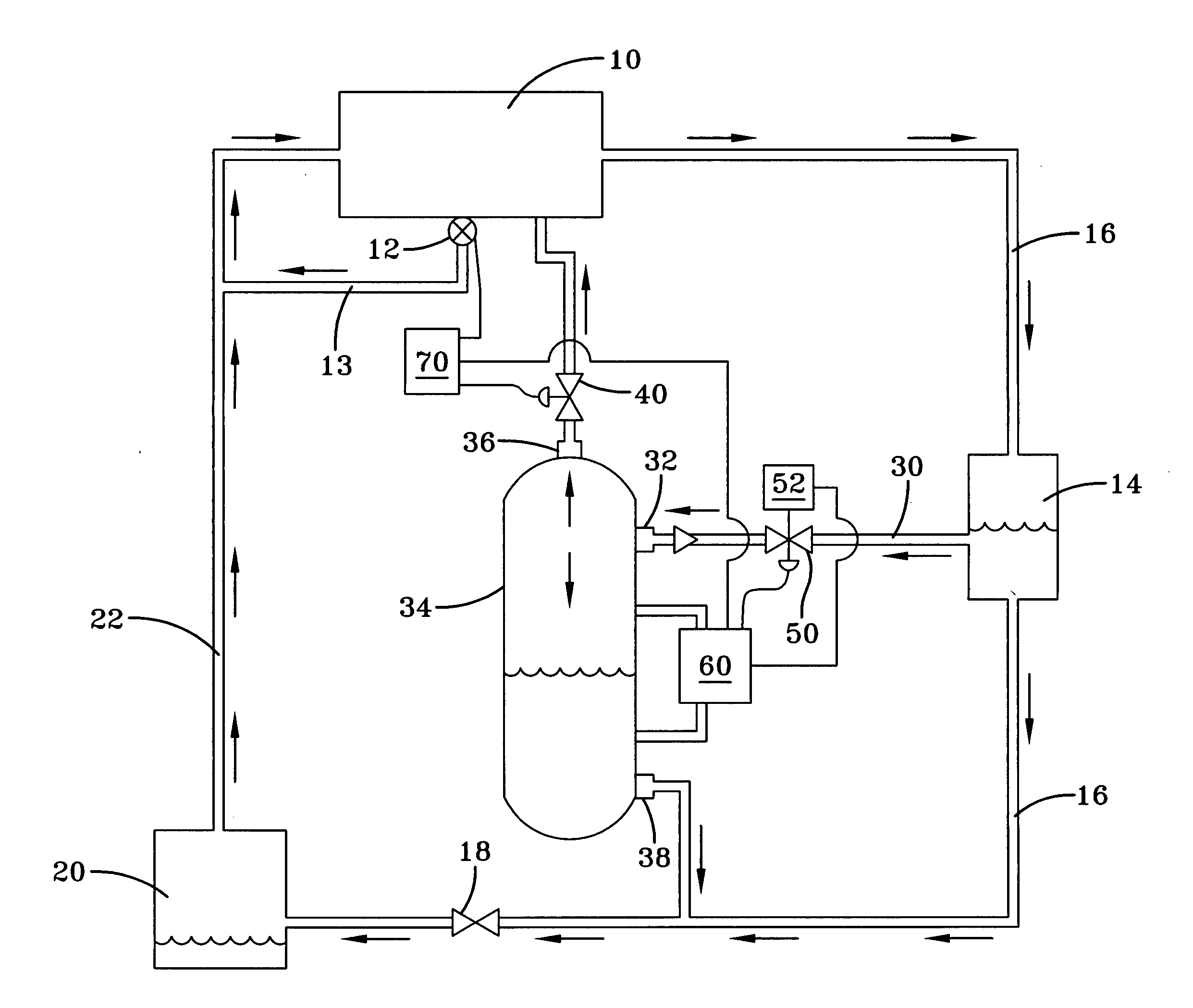

Energy efficient capacity control for an air conditioning system

InactiveUS20060112702A1Air-treating devicesCompression machines with non-reversible cycleAir conditioningControl theory

An air conditioning system (10) is provided for cooling a compartment (16) of a truck when the main engine is not running. The system (10) includes a variable speed compressor (20), a variable speed condenser fan (22), a variable speed evaporator blower (24), and a controller (14) configured to optimize the cooling capacity of the system (10) to the cooling requirements of the compartment (16) by selectively adjusting the speeds of the variable speed components (20,22,24).

Owner:MODINE MFG CO

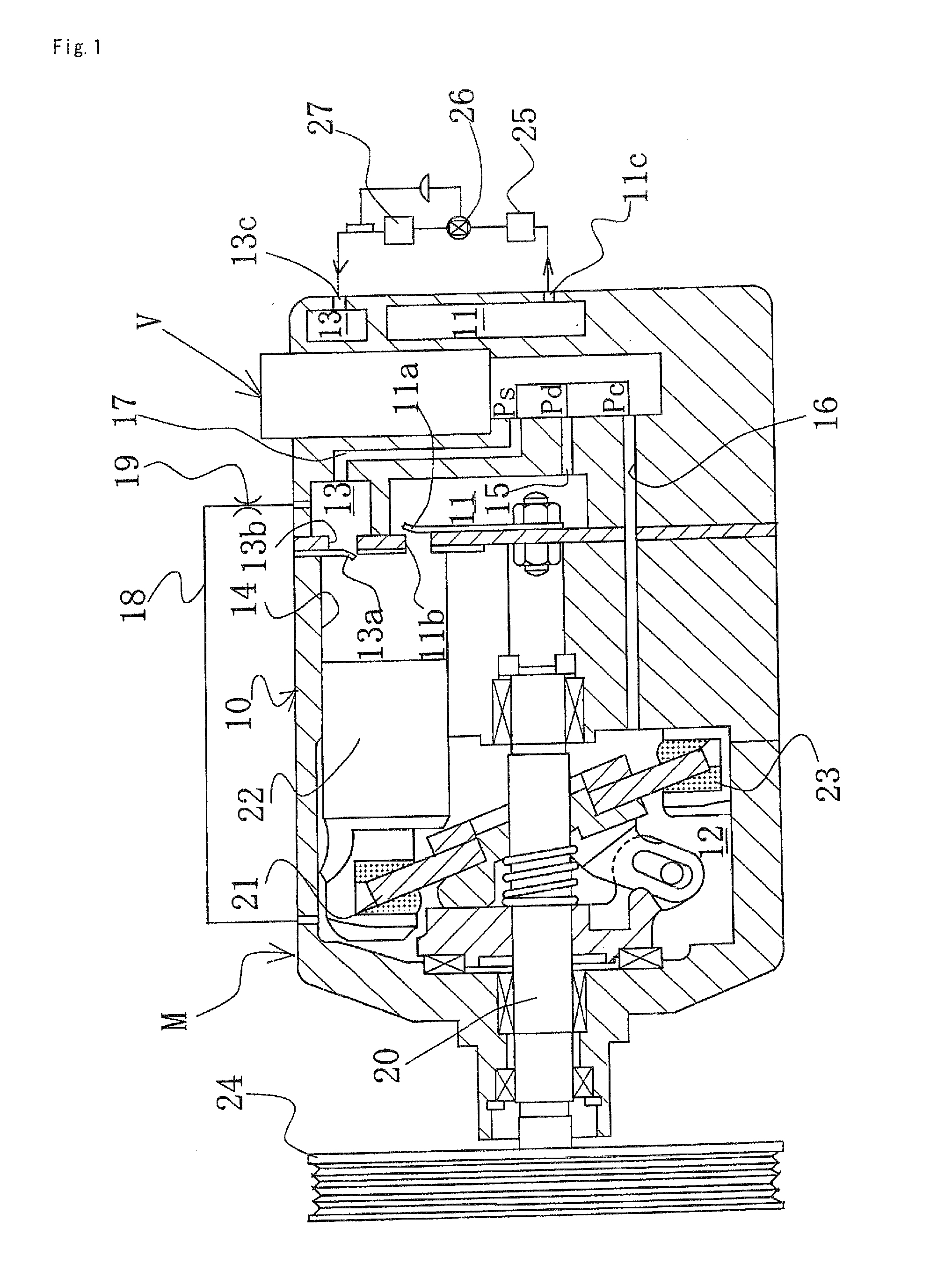

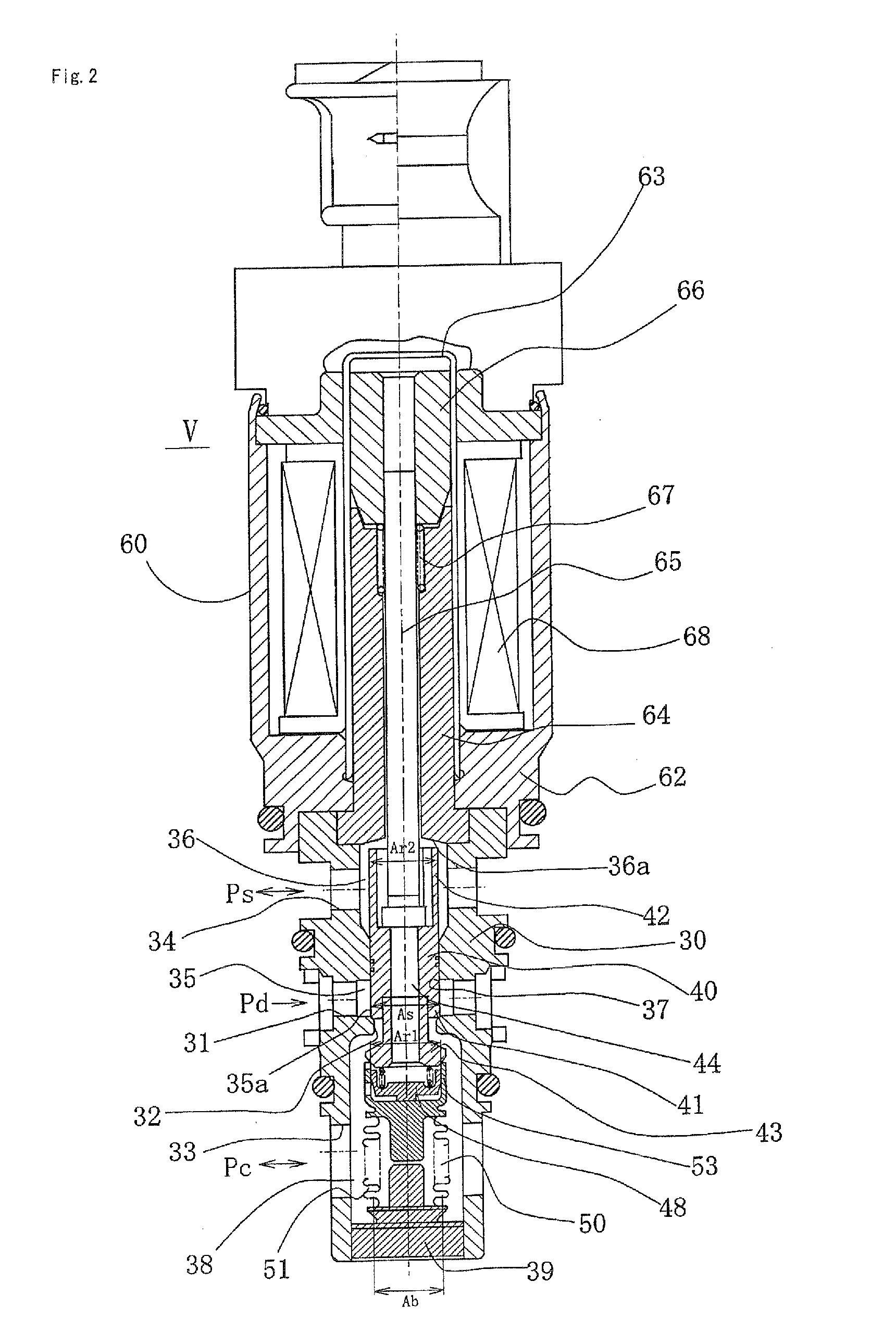

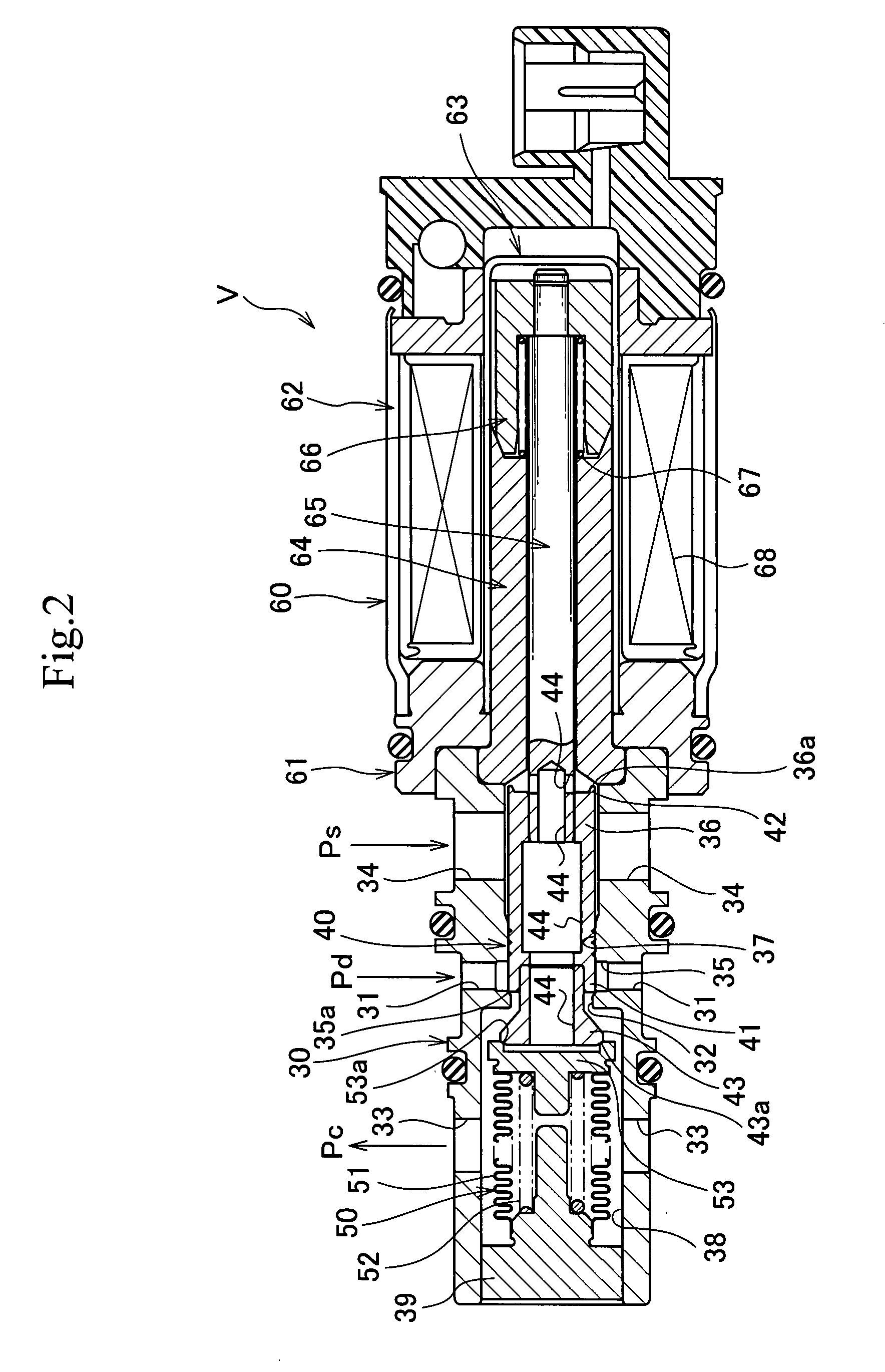

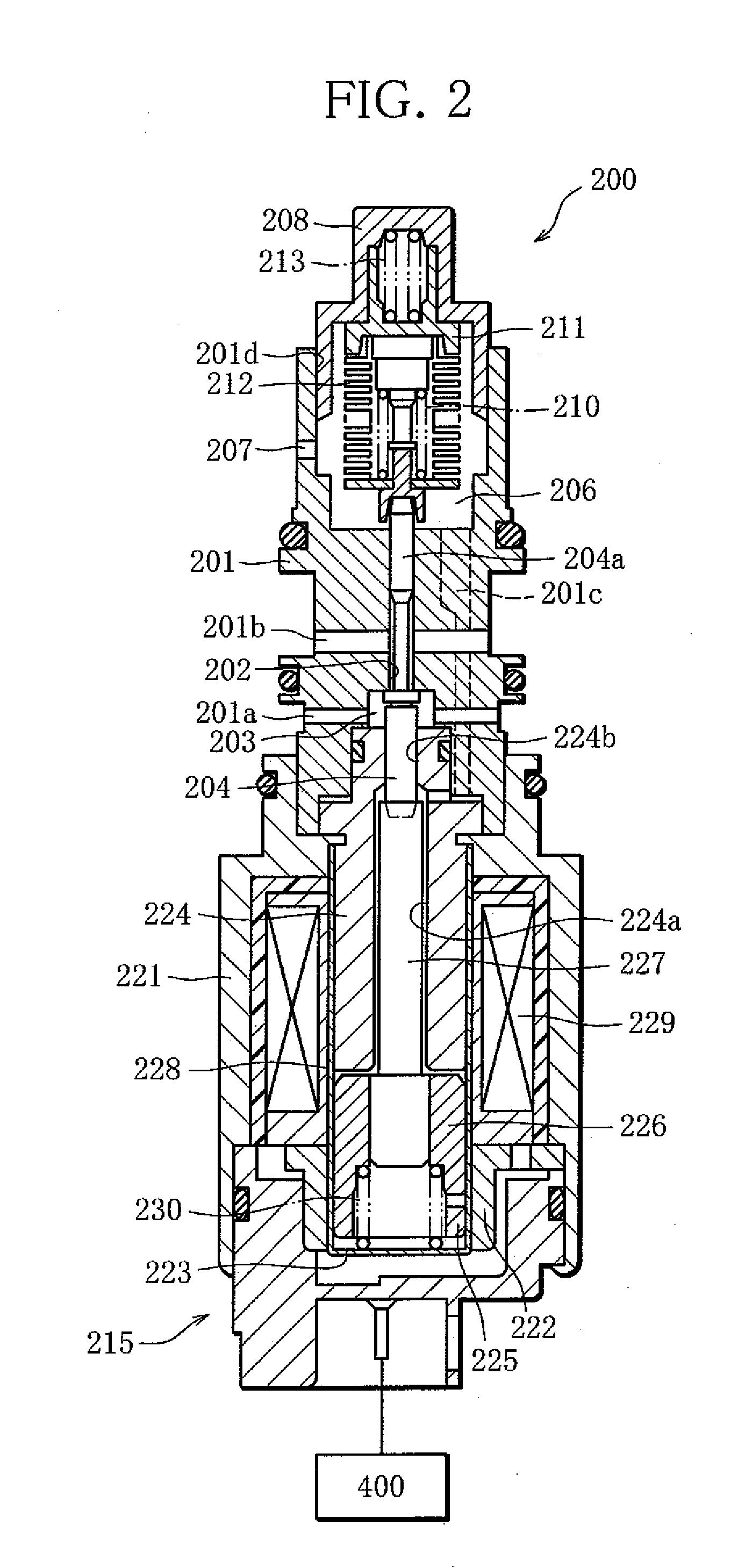

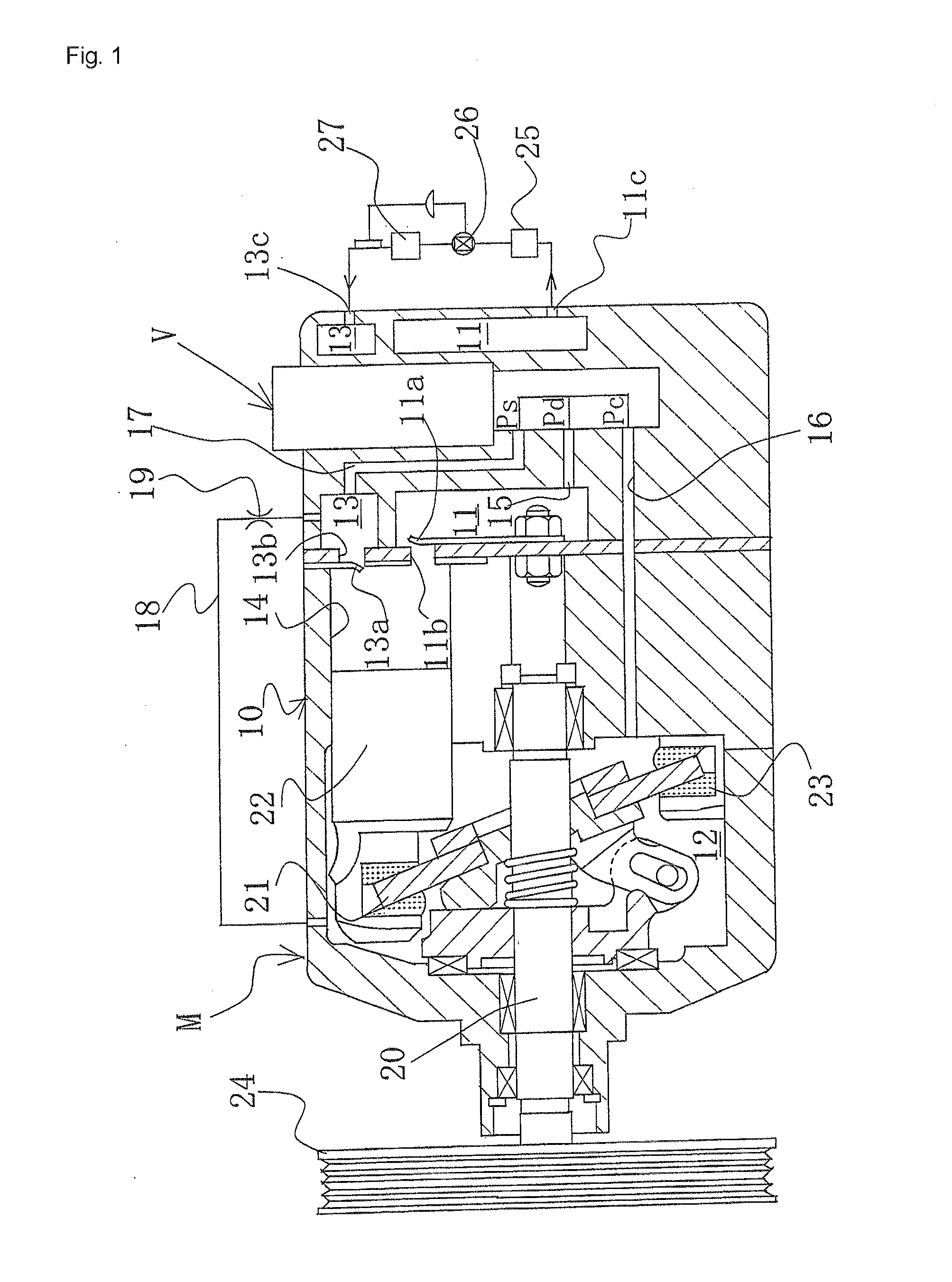

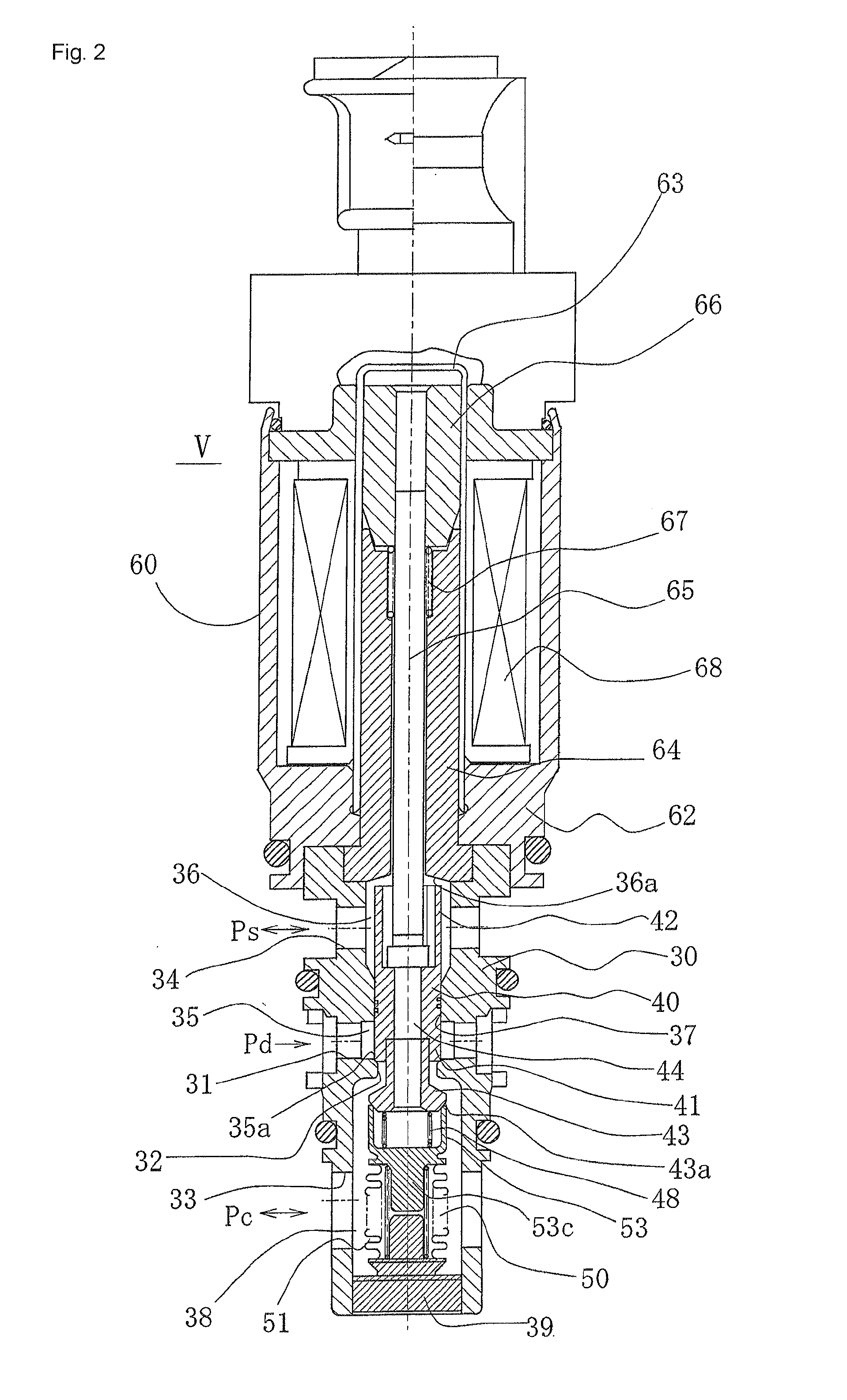

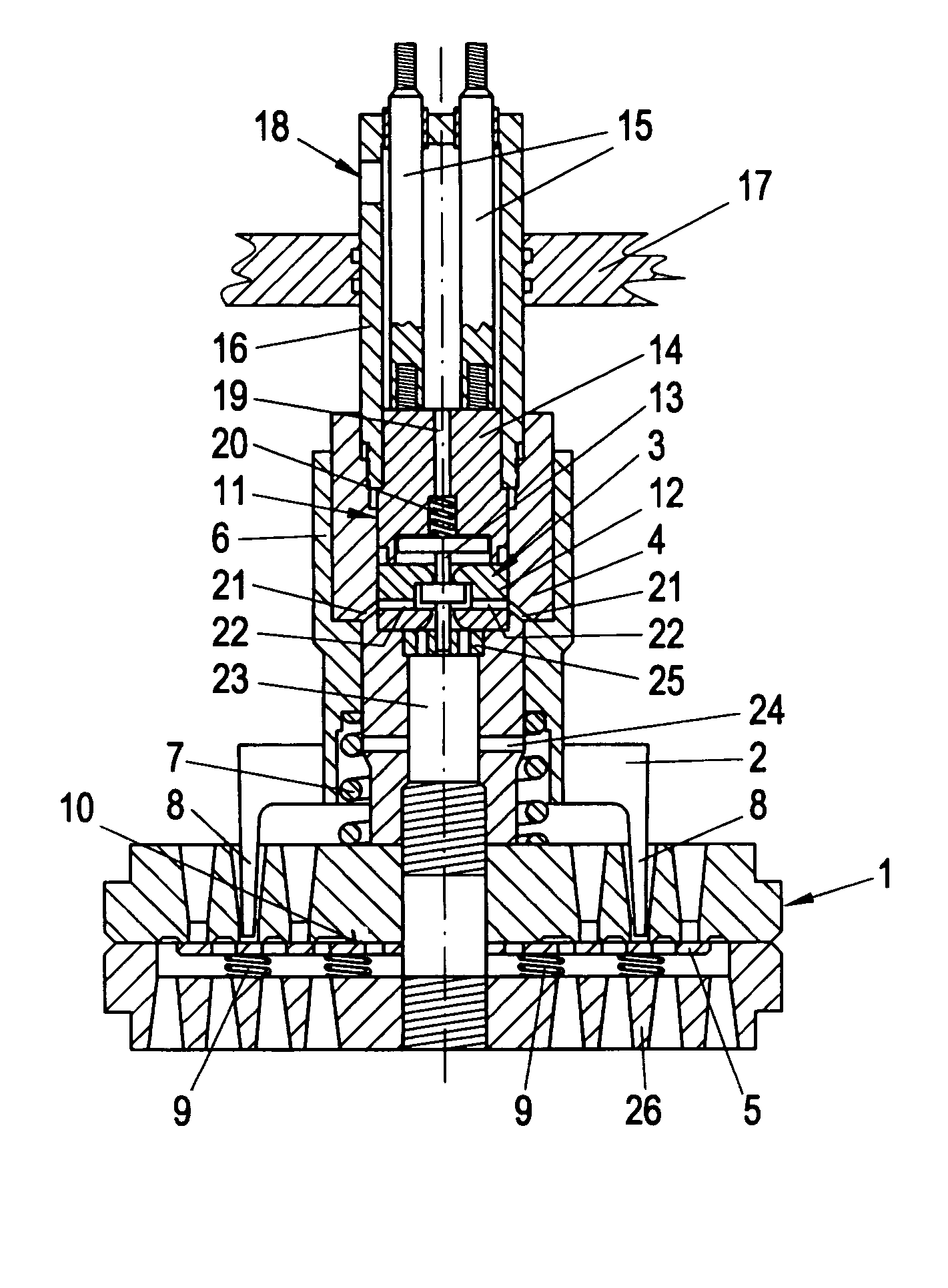

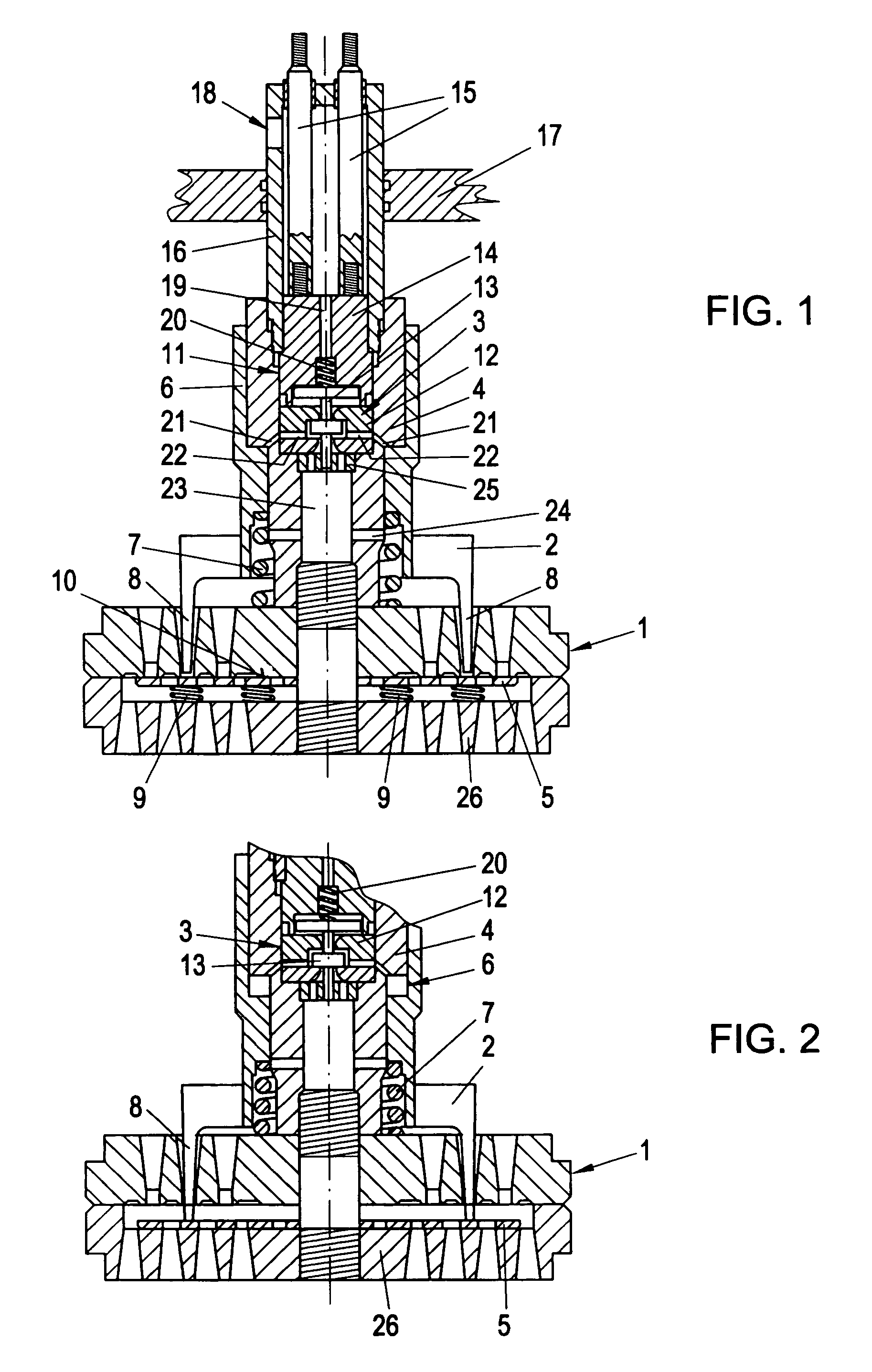

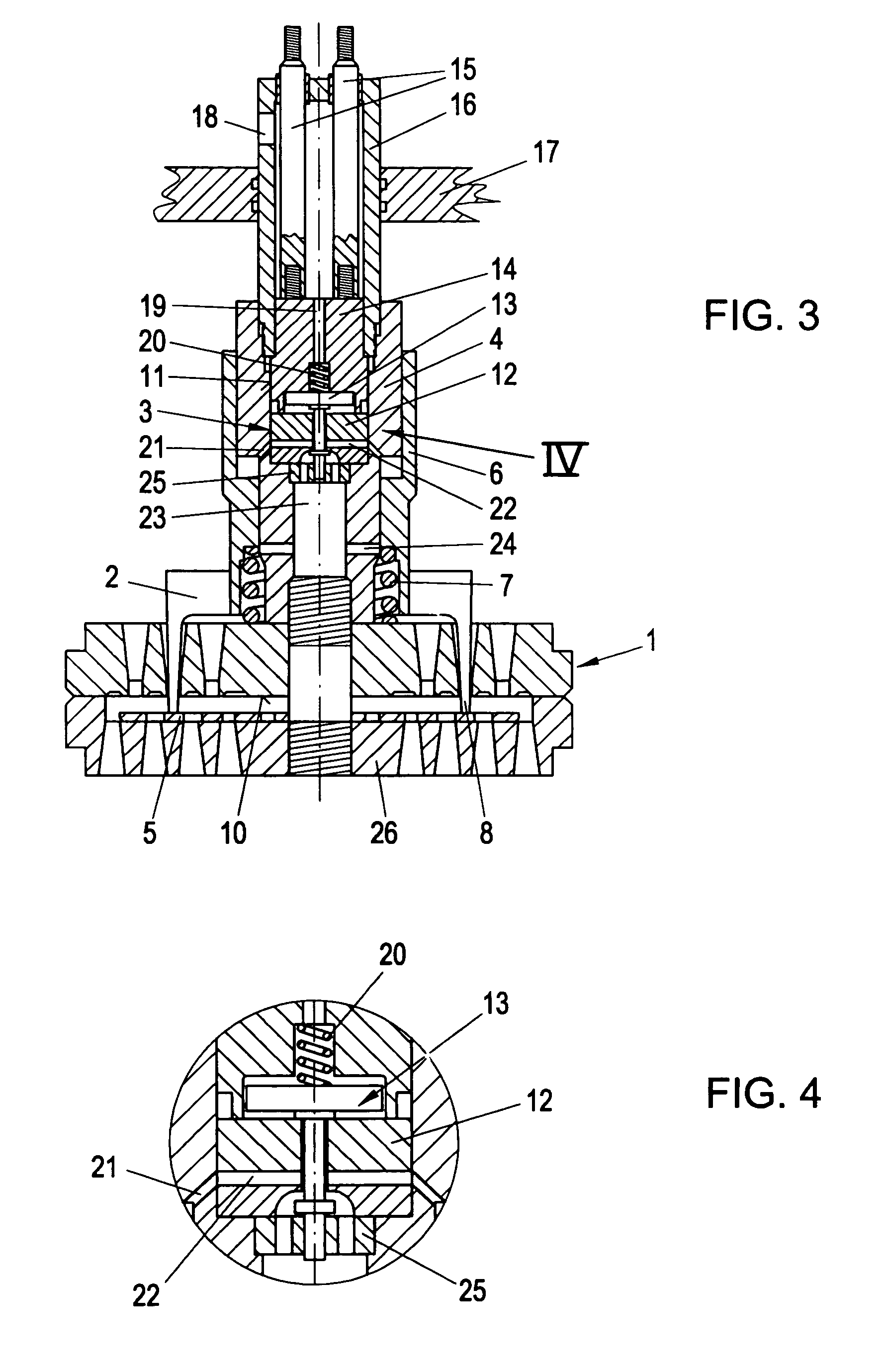

Volume control valve

ActiveUS20120198992A1Minimum capacityGood conditionMulti-stage pumpsPositive-displacement liquid enginesControl valvesBearing surface

A capacity control valve capable of enhancing the function of discharging liquid refrigerant in a control chamber during startup of a variable capacity compressor, and improving the control speed of a swash plate during control is provided. The valve has an adapter that has an annular bearing surface and is provided to a free end of a pressure-sensitive body in the elongation and constriction direction, and a valve body for discharging liquid refrigerant, moveably provided inside the adapter. A slit is provided to an engaging part of the adapter with a third valve part, and an introduction hole for causing the control chamber pressure to act on a bottom surface of the valve body for discharging the liquid refrigerant is provided to the base part side, and an urging force is provided whereby the valve body for discharging the liquid refrigerant is urged in a valve-opening direction away from the third valve part.

Owner:EAGLE INDS

Refrigerant system with cascaded circuits and performance enhancement features

InactiveUS20100147006A1Easy to operateImprove performanceCompression machines with non-reversible cycleCompression machines with cascade operationPerformance enhancementEngineering

An improved refrigerant system incorporates at least two circuits arranged in a cascaded relationship. Preferably, the upper circuit utilizes a hydrocarbon refrigerant and preferably the lower circuit utilizes CO2 refrigerant. Preferably, the CO2 circuit mainly operates in a subcritical region. To improve the efficiency and capacity control of the cascaded refrigerant system, at least one of the circuits is equipped with performance enhancement features such as, for example, an economized function provided by a flash tank or economizer heat exchanger. Additional enhancement features can also include a liquid-suction heat exchanger and bypass function.

Owner:CARRIER CORP

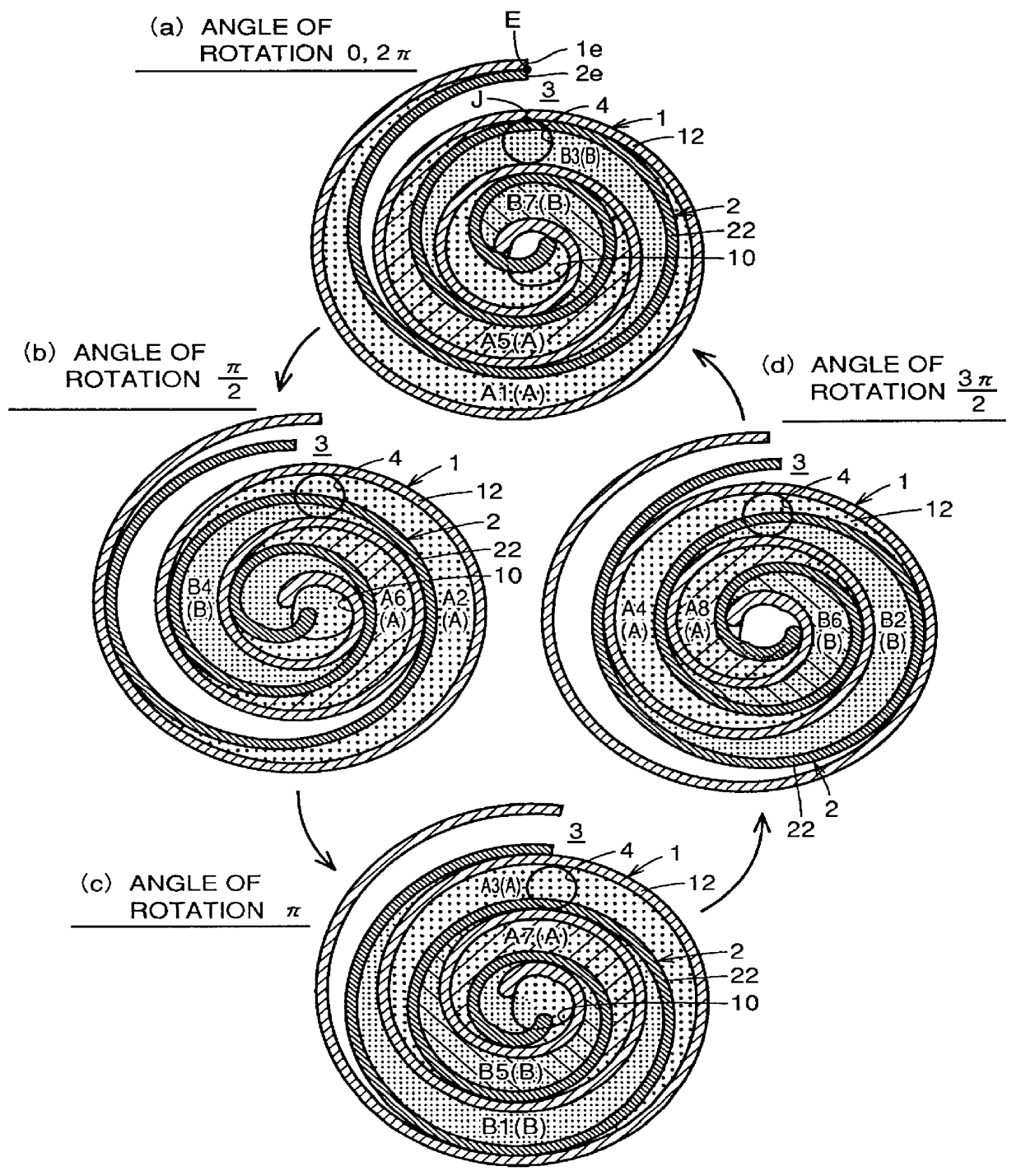

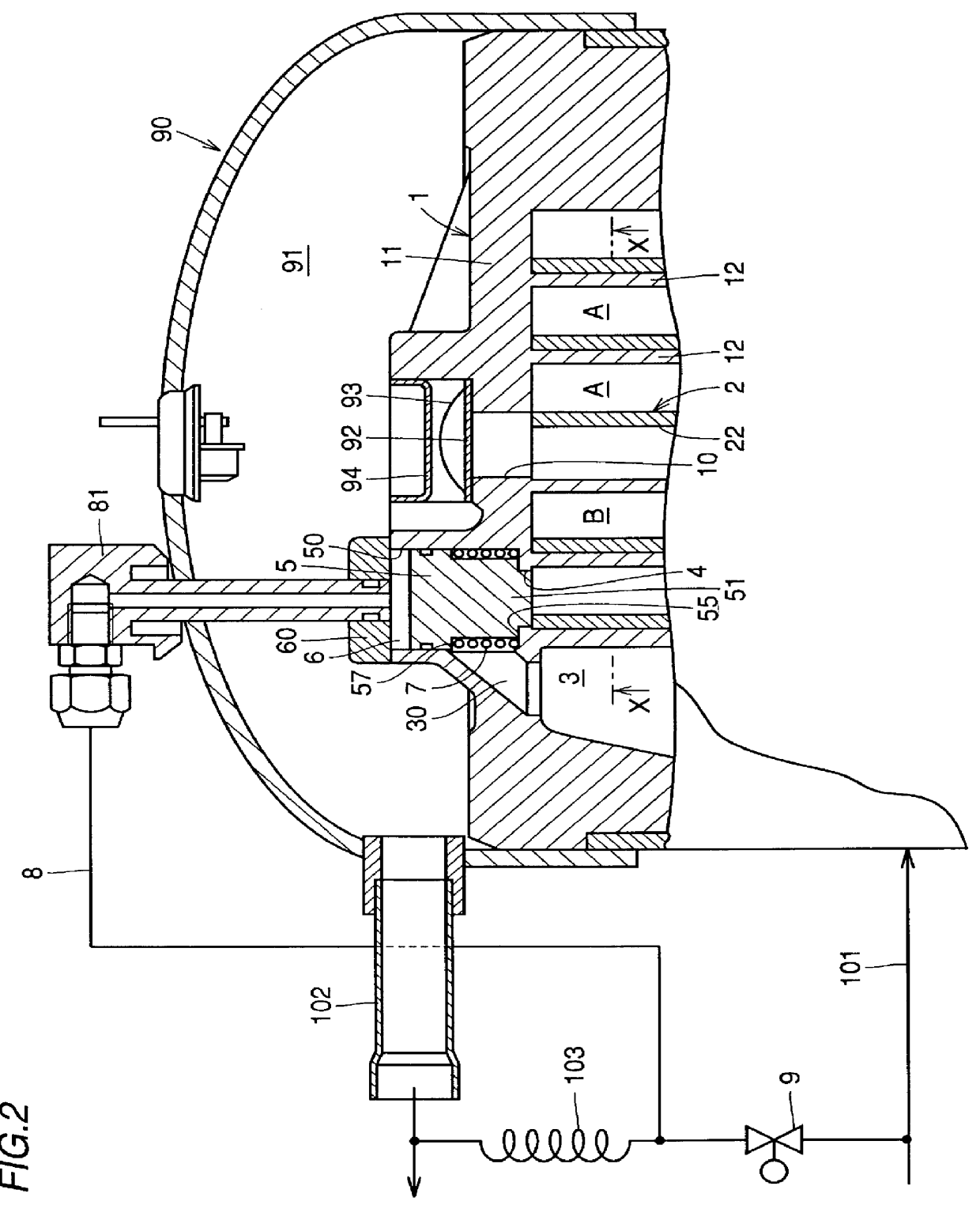

Scroll type fluid machine

InactiveUS6139287AOperating means/releasing devices for valvesEngine of arcuate-engagement typeSpiral bladeEngineering

PCT No. PCT / JP97 / 02013 Sec. 371 Date Nov. 3, 1998 Sec. 102(e) Date Nov. 3, 1998 PCT Filed Jun. 11, 1997 PCT Pub. No. WO98 / 57066 PCT Pub. Date Dec. 17, 1998A scroll type fluid machine having a bypass hole structure for capacity control is disclosed. The scroll type fluid machine comprises a first scroll having a first spiral blade, and a second scroll having a second spiral blade. A first fluid working chamber is formed between an inner surface of the first spiral blade, and a second scroll having a second spiral blade. A first fluid working chamber is formed between an inner surface of the first spiral blade and an outer surface of the second spiral blade, and a second fluid working chamber is formed between an outer surface of the first spiral blade and an inner surface of the second spiral blade. A winding end of the first spiral blade is extended so that the first fluid working chamber and the second fluid working chamber open and close with respect to a single low-pressure port. A common bypass hole making the first and second fluid working chambers communicate with the low-pressure port in common is provided.

Owner:DAIKIN IND LTD

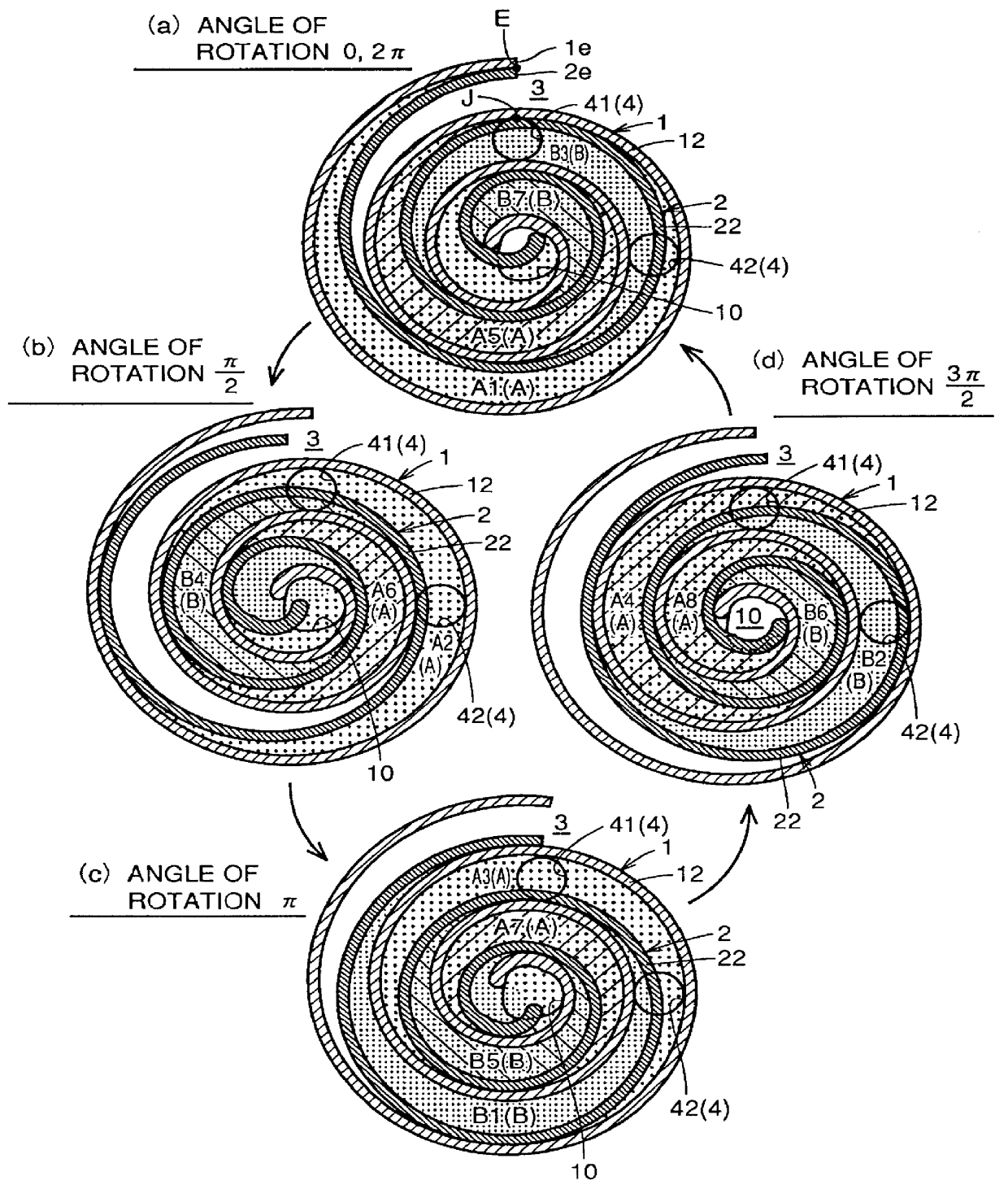

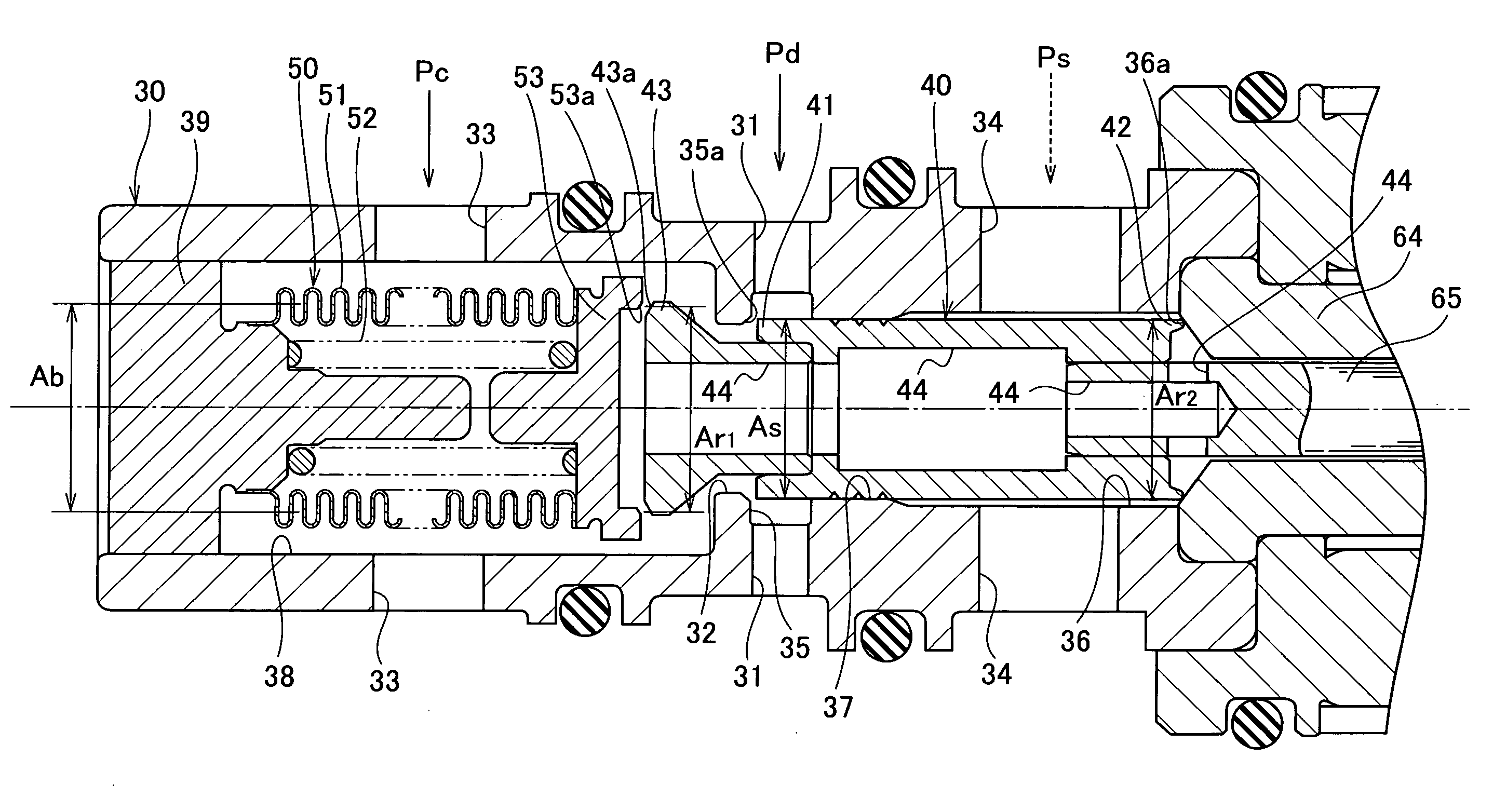

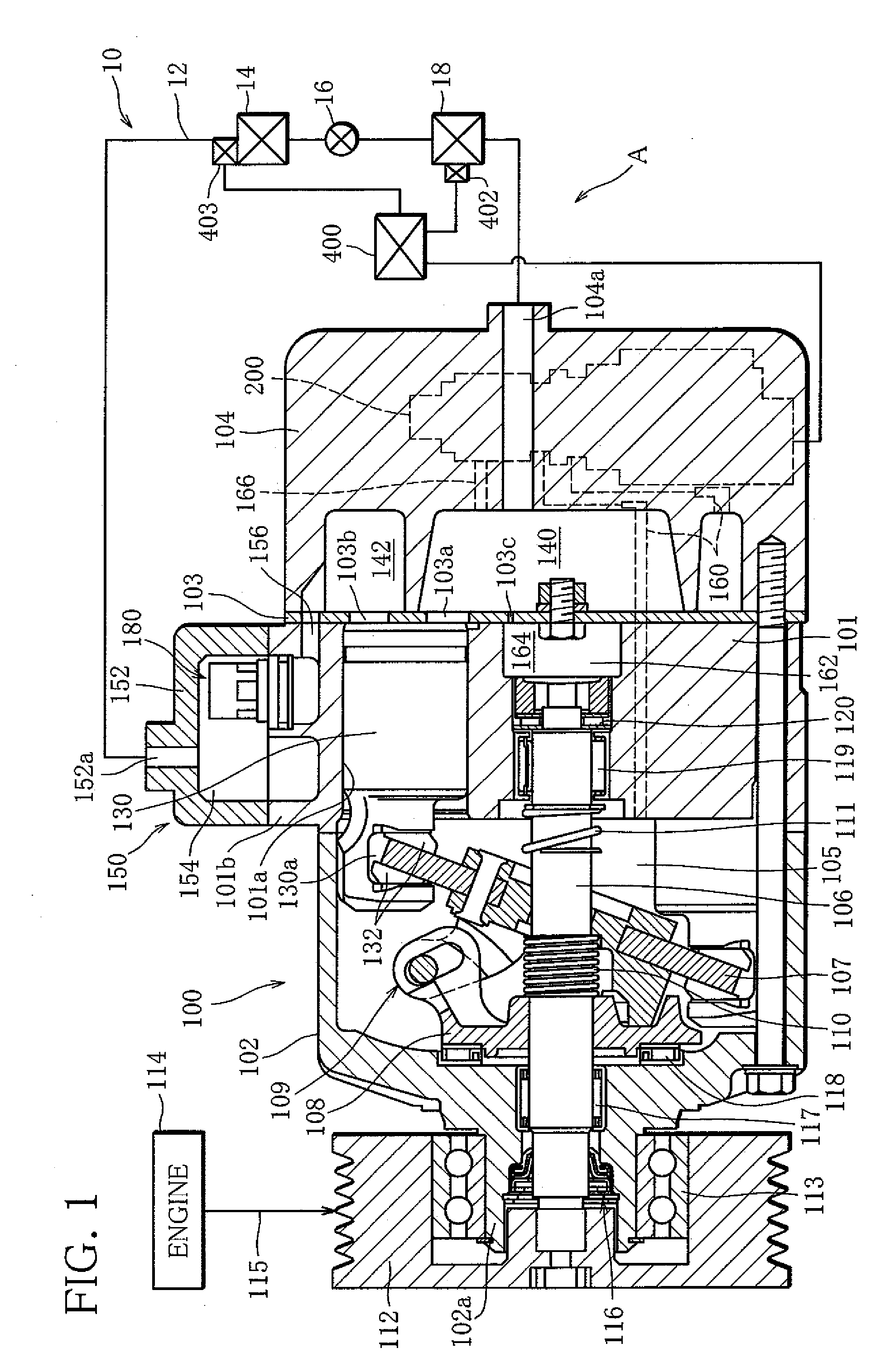

Capacity Control Valve

ActiveUS20080138213A1Stable controlLow costOperating means/releasing devices for valvesWorking fluid for enginesEngineeringControl room

A capacity control valve of the present invention includes a valve body (40) integrally having a first valve portion (41) for opening / closing a discharge-side path for having a discharge chamber (11) communicate with a control chamber (12) and a second valve portion (42) for opening / closing a suction-side path for having a suction chamber (13) communicate with the control chamber (12), a pressure sensitive body (50) arranged in a third valve chamber (38) in the middle of the suction-side path, a valve seat body (53) provided at the pressure sensitive body (50), a third valve portion (43) connected to the valve body (40) for opening / closing the suction-side path by engagement and disengagement with the valve seat body (53) and the like. One of an engagement face 43a of the third valve portion and a seat face 53a of the valve seat body is formed into a spherical shape with a radius of curvature R satisfying 9 mm<R<11 mm and the other of the engagement face 43a of the third valve portion and the seat face 53a of the valve seat body is formed into a tapered surface shape having a center angle α satisfying 120°<α<160°. By this, a liquid refrigerant or the like accumulating in the control chamber can be discharged efficiently, and predetermined capacity control can be carried out rapidly.

Owner:EAGLE INDS +1

Processes for producing nano-space controlled polymer ion-exchange membranes

InactiveUS20050049320A1Increase resistanceHigh film stabilitySolid electrolytesIon-exchanger regenerationPolymer scienceFunctional monomer

A polymer film substrate is irradiated with ions to make a large number of nano-sized through-holes and the substrate is further irradiated with an ionizing radiation so that a functional monomer is grafted or co-grafted onto a surface of the film and within the holes; in addition, the sulfonic acid group is introduced into the graft chains, thereby producing a polymer ion-exchange membrane that has high oxidation resistance, dimensional stability, electrical conductivity and methanol resistance, as well as an ion-exchange capacity controlled over a wide range.

Owner:JAPAN ATOM ENERGY RES INST

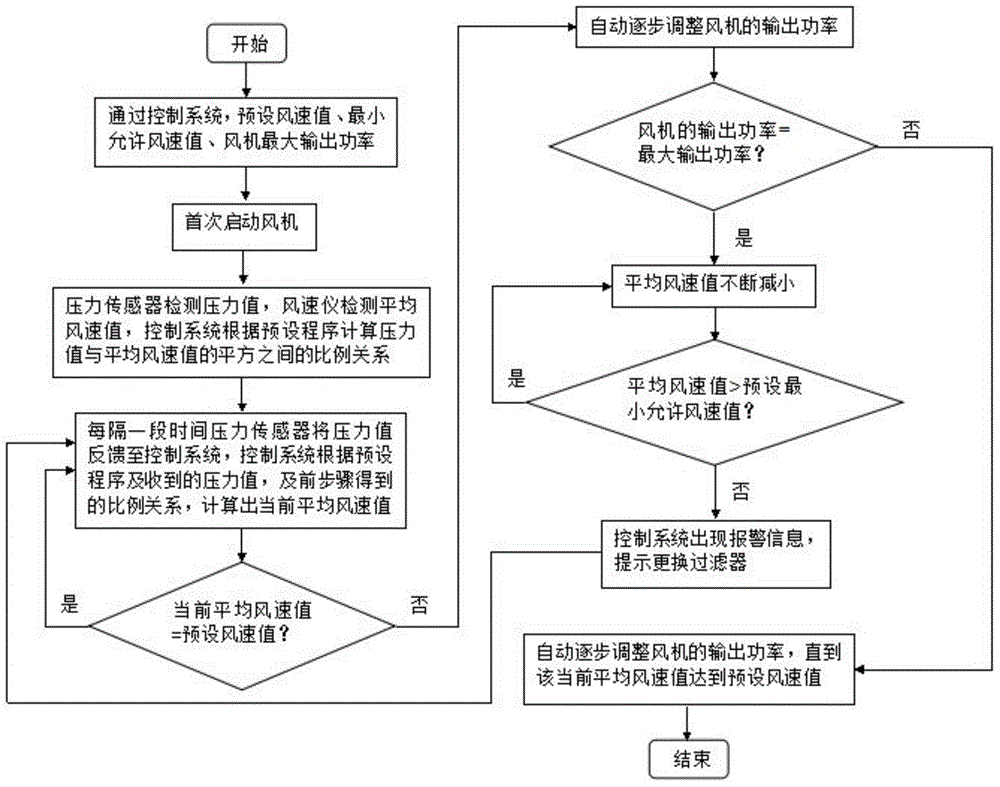

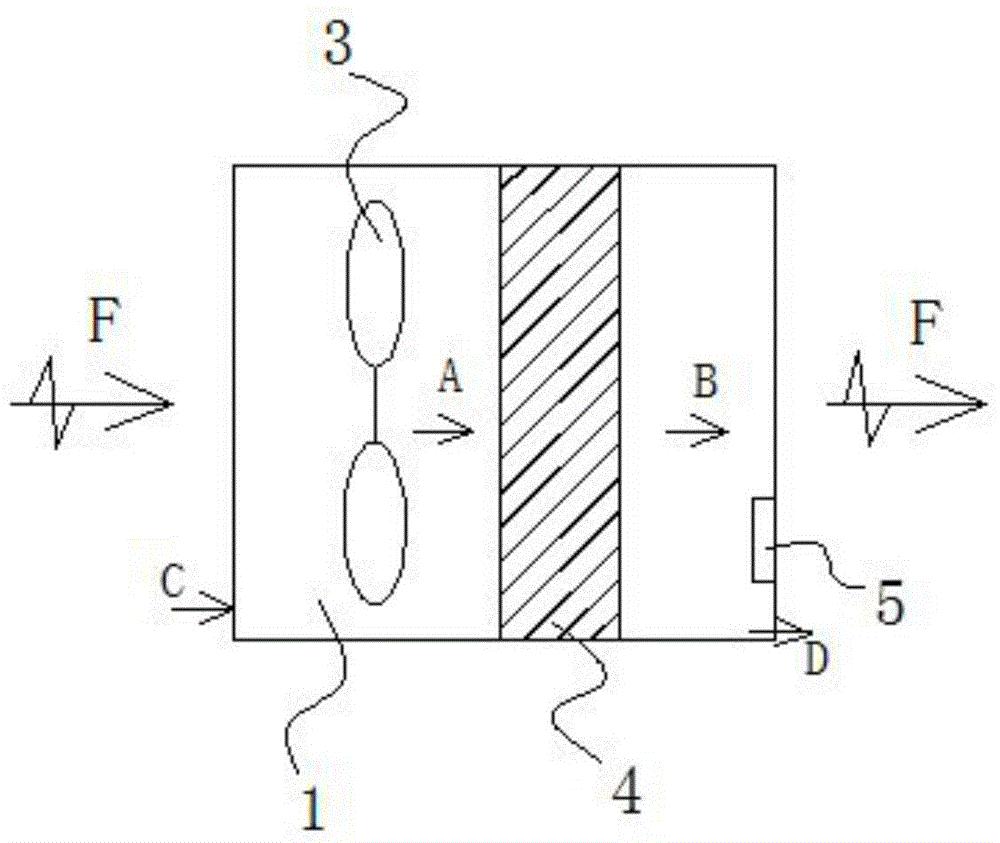

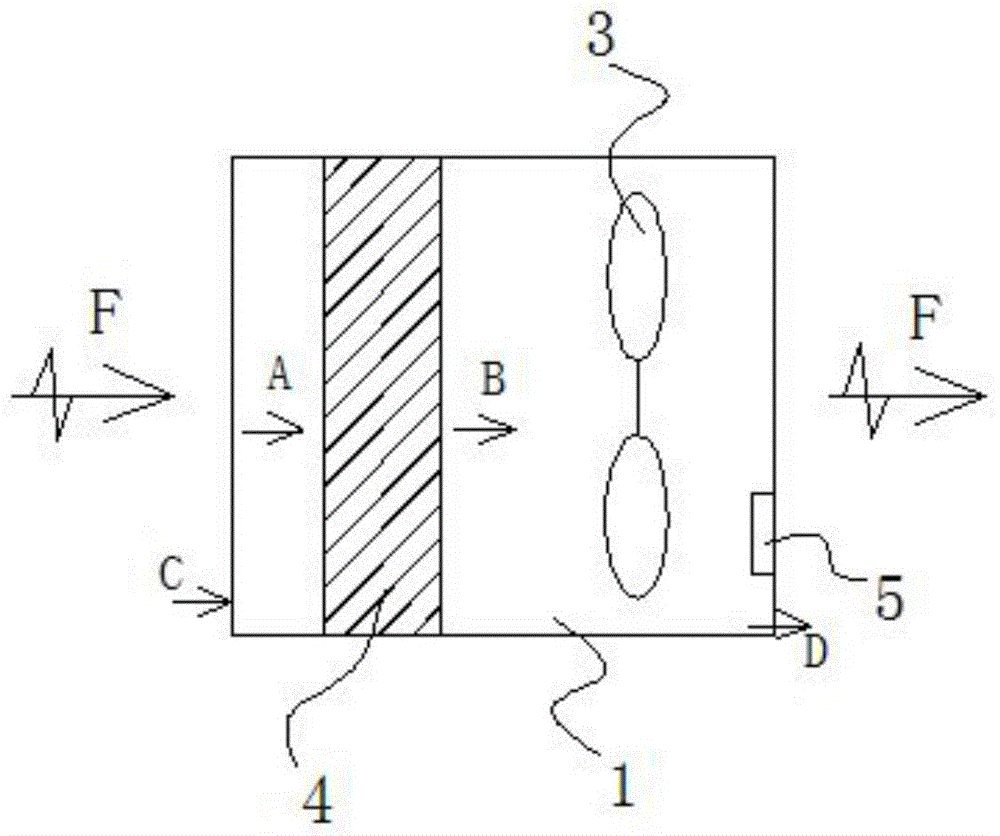

Air capacity control method of air purifying device and air purifying device

InactiveCN104913457AAchieve a constant outputNo false positivesMechanical apparatusSpace heating and ventilation safety systemsControl systemEngineering

The invention discloses an air capacity control method of an air purifying device. The air capacity control method includes the following steps: 1, the air purifying device is arranged, and a pressure sensor is arranged at the leeward position of a filter; 2, an air speed value is preset; 3, the pressure sensor detects pressure values, an anemoscope detects average air speed values, and a control system calculates scale values between the pressure values and squares of the average air speed values according to a preset program; 4, the pressure sensor feeds the pressure values back to the control system at set intervals, and the control system calculates current average air speed values according to the preset program, the received pressure values and the scale values in the previous step; 5, if the current average air speed values are smaller than the preset air speed value, the output power of a draught fan is automatically and gradually adjusted till the current average air speed values reach the preset air speed value, and therefore the air capacity is controlled to be stably output. The invention further discloses the air purifying device. The air capacity control method and the air purifying device have the functions of high-accuracy air capacity control and accurate filter-replacement reminding.

Owner:杨志荣 +1

System and method for capacity control in a multiple compressor chiller system

ActiveUS20050223724A1Easy to controlImprove system efficiencyCompression machines with non-reversible cycleEfficient regulation technologiesLiquid temperatureControl theory

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

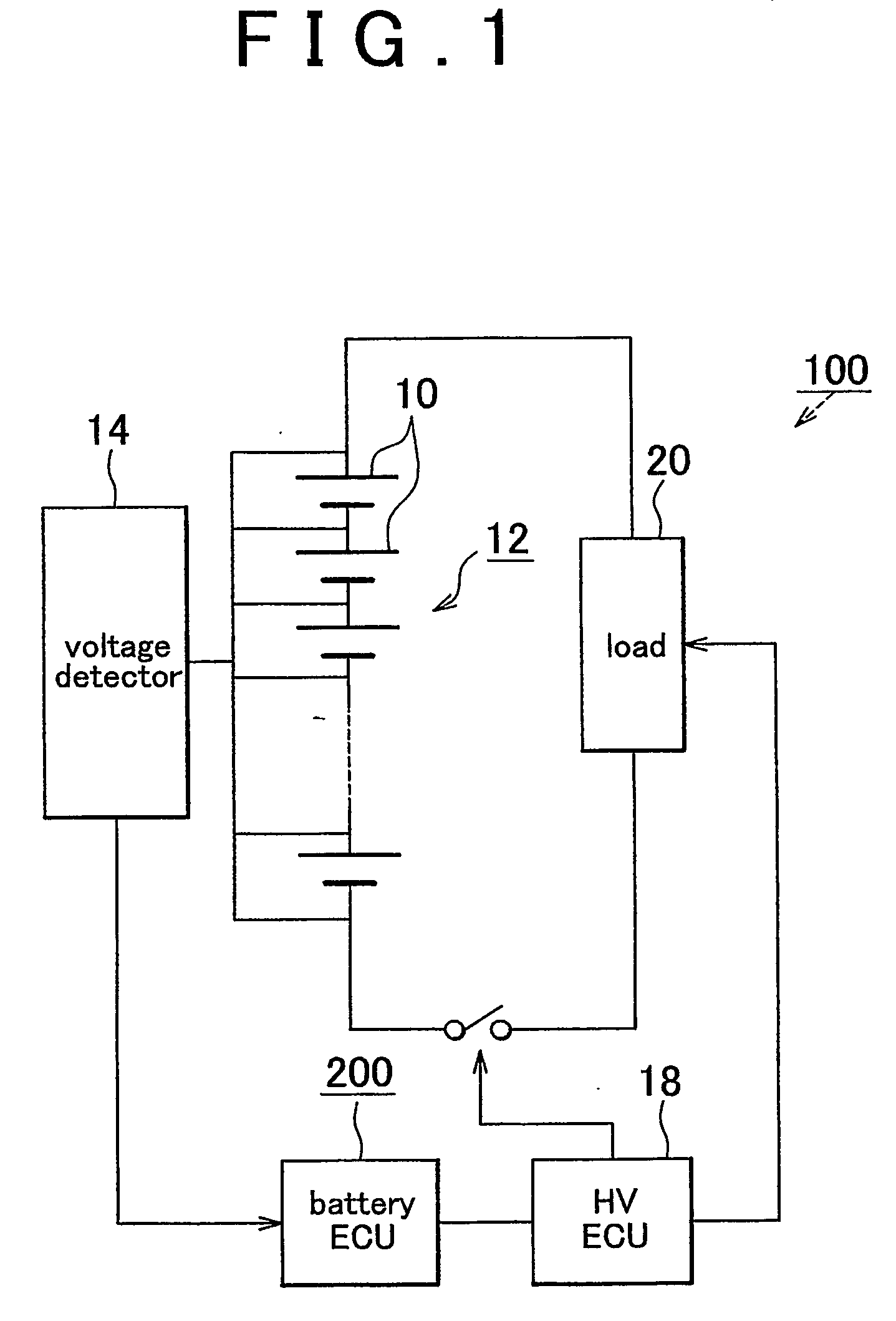

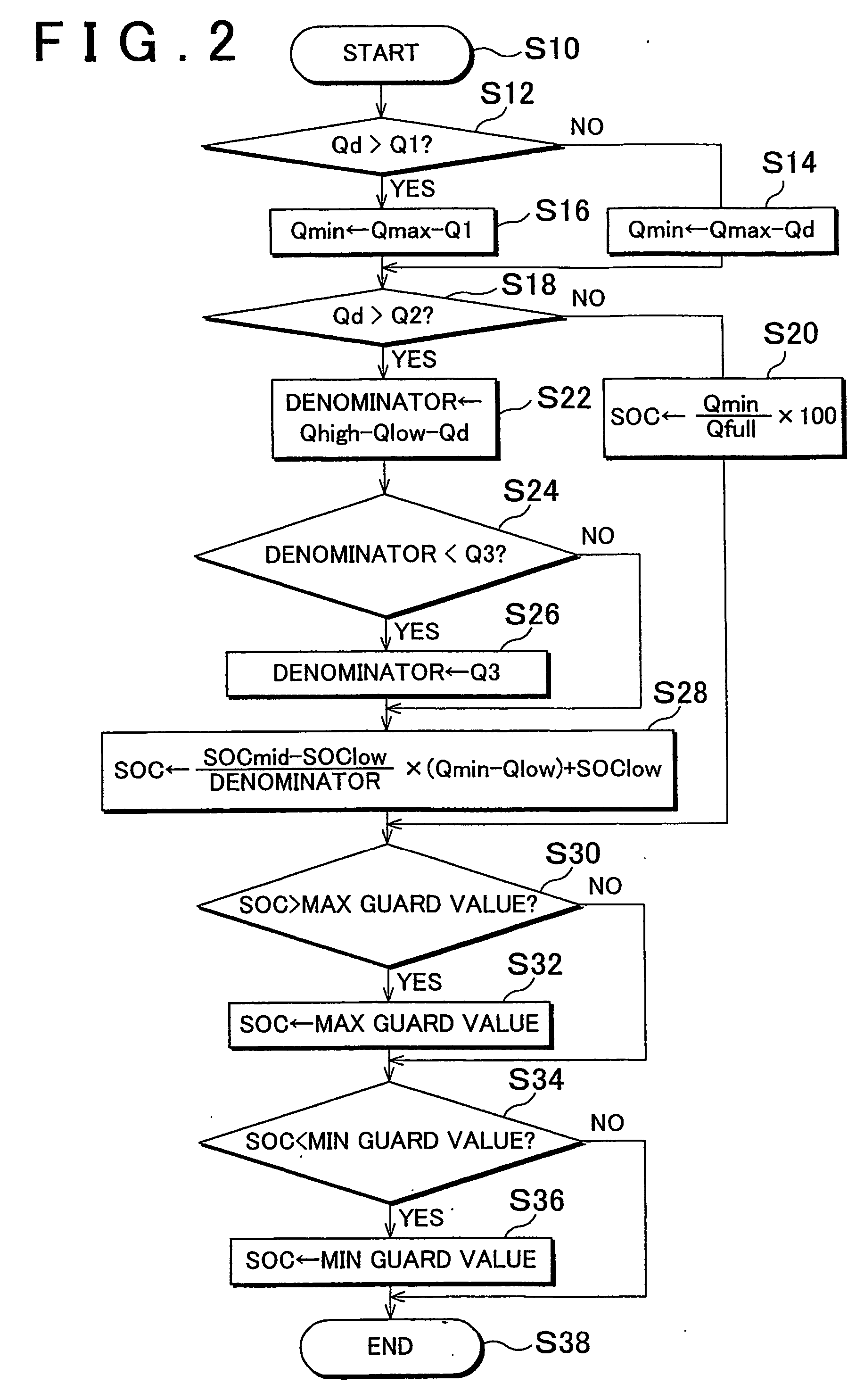

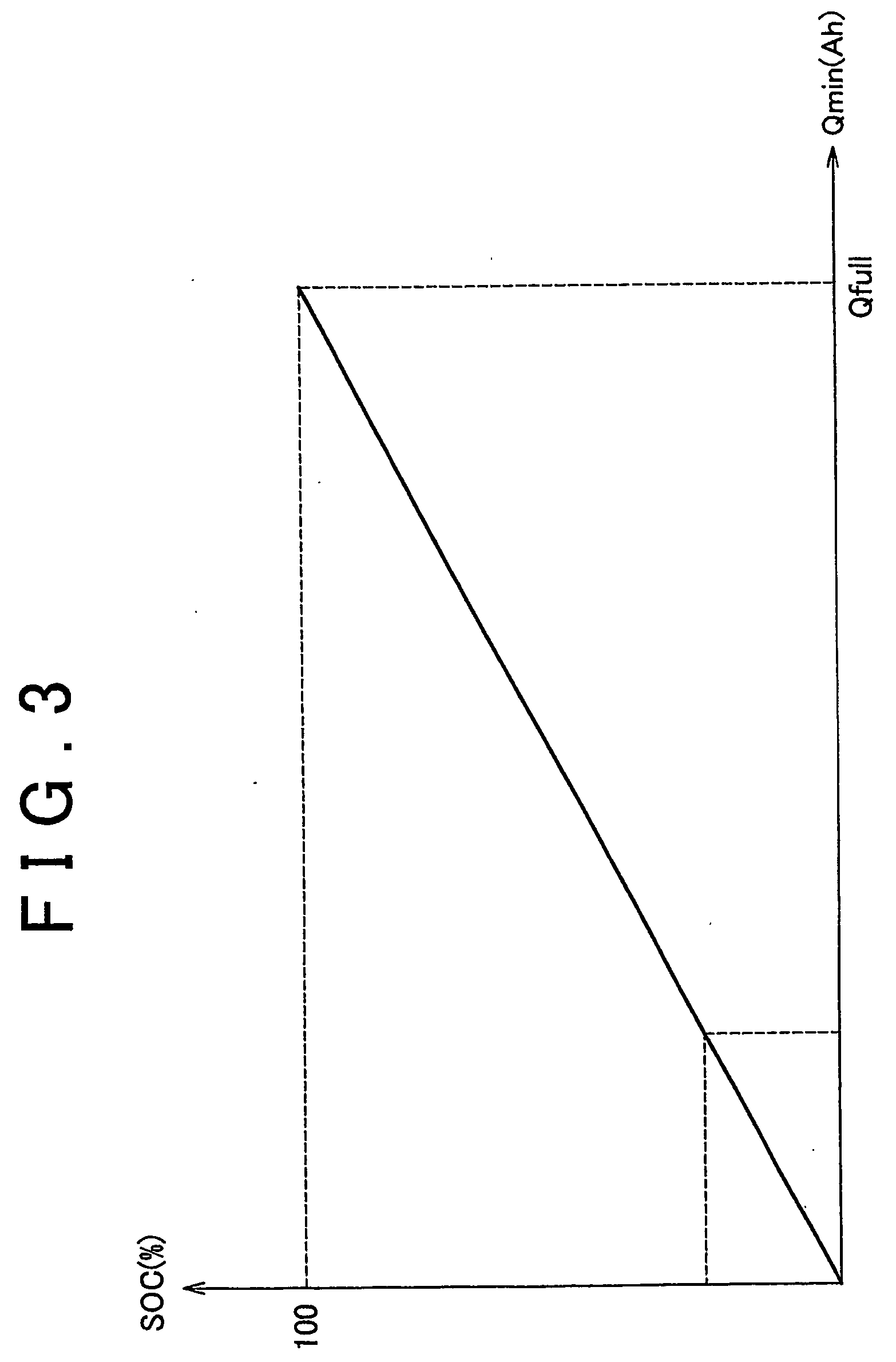

Battery pack capacity control system

ActiveUS20060152195A1High precisionImprove accuracyCircuit monitoring/indicationCharge equalisation circuitContinuationControl system

If the capacity variation is greater than a pre-stored value, the SOC converted from Qmin sometimes cannot recover to a control center value. In such a case, inconveniences including the continuation of an event where the HVECU cannot output a command to stop the charging are prevented by computing an apparatus SOC and reporting the SOC to the HVECU. The apparent SOC is computed by increasing the value of SOC in accordance with the magnitude of the capacity variation. The thus-computed apparent SOC is reported to the HVECU by the battery ECU, so that it can be determined that the control center value has been exceeded. Thus, it becomes possible to provide battery control apparatus, method and program and a battery control system for a battery pack which are capable of controlling the charging / discharging of the battery pack with an improved accuracy despite capacity variation.

Owner:TOYOTA JIDOSHA KK

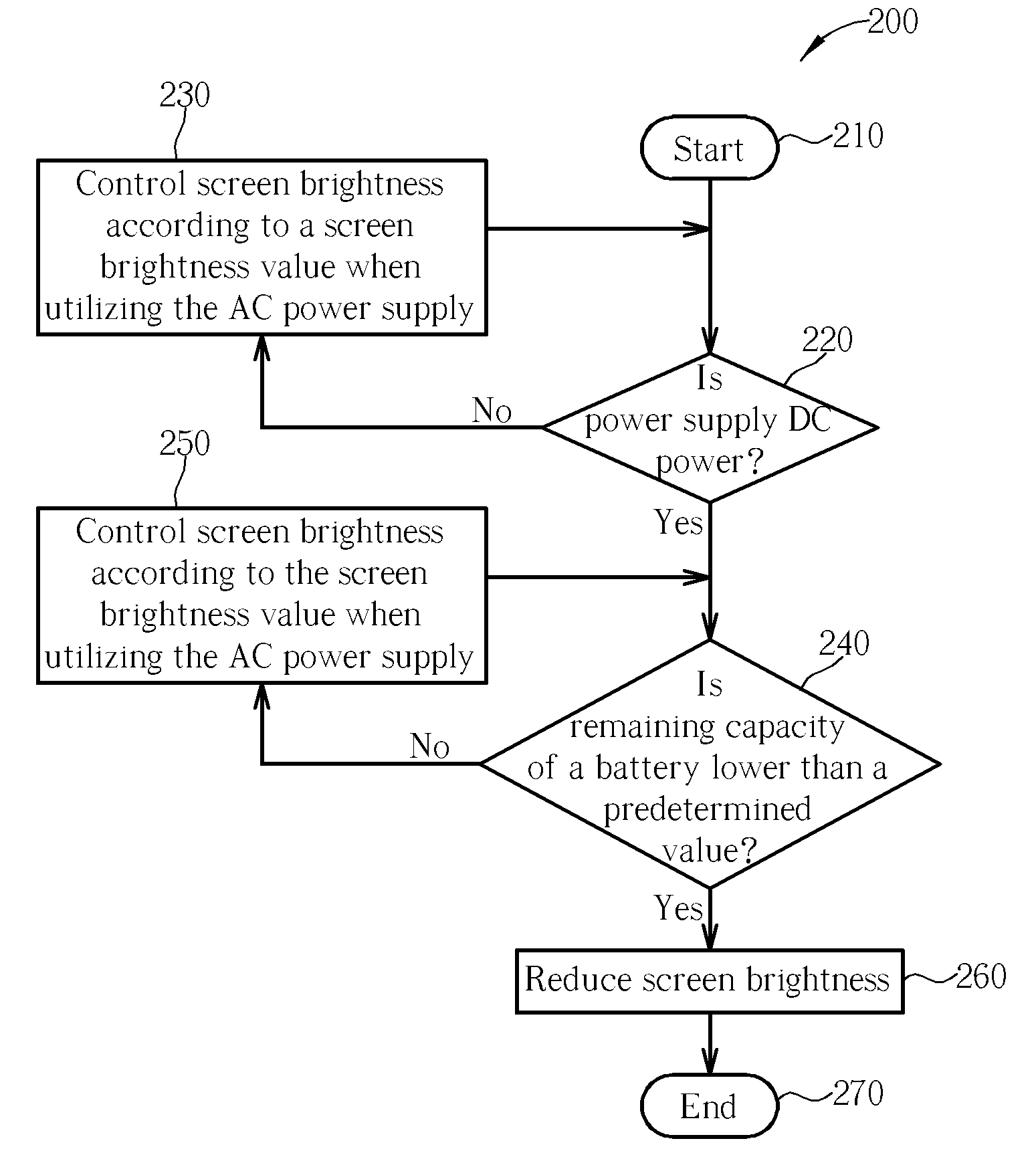

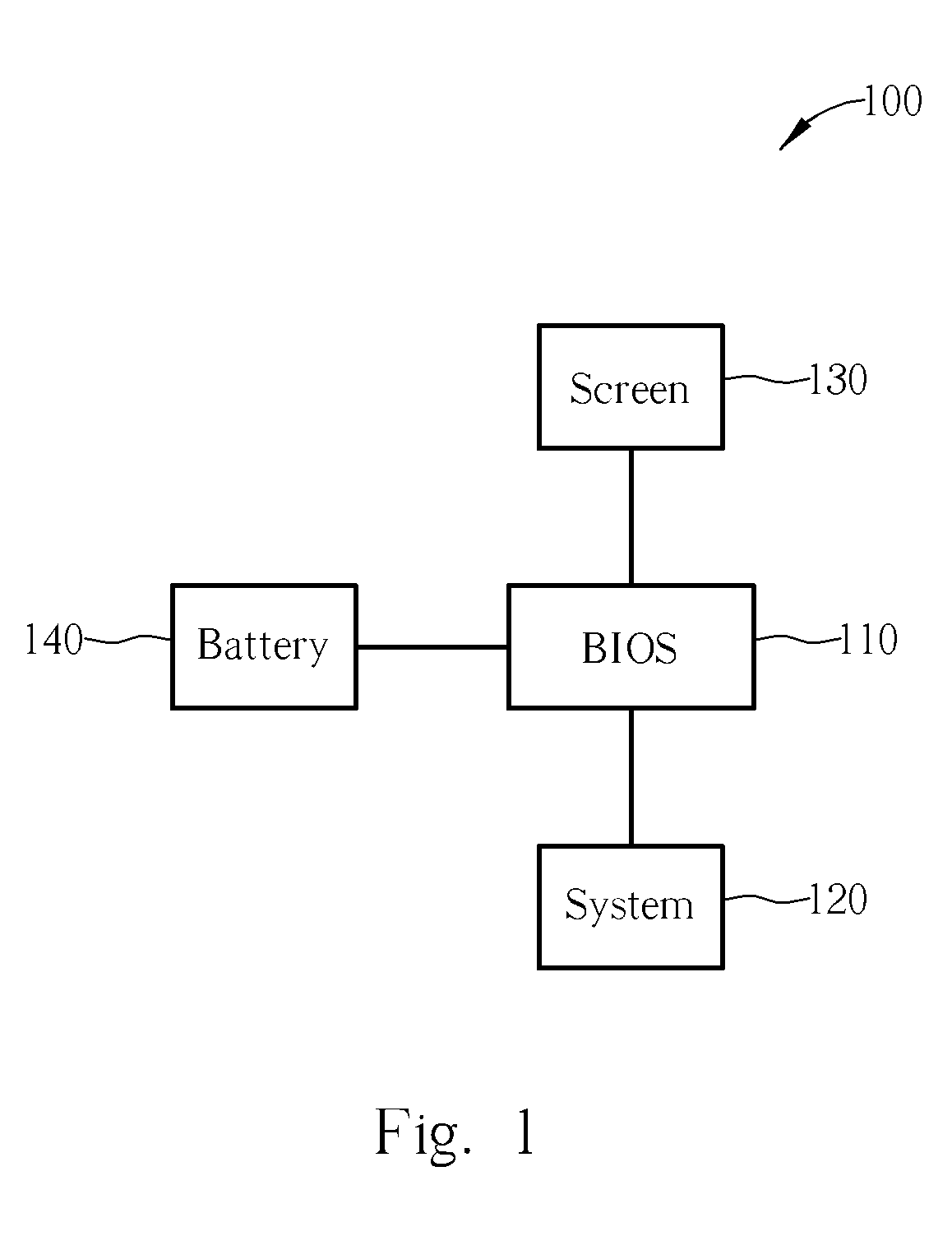

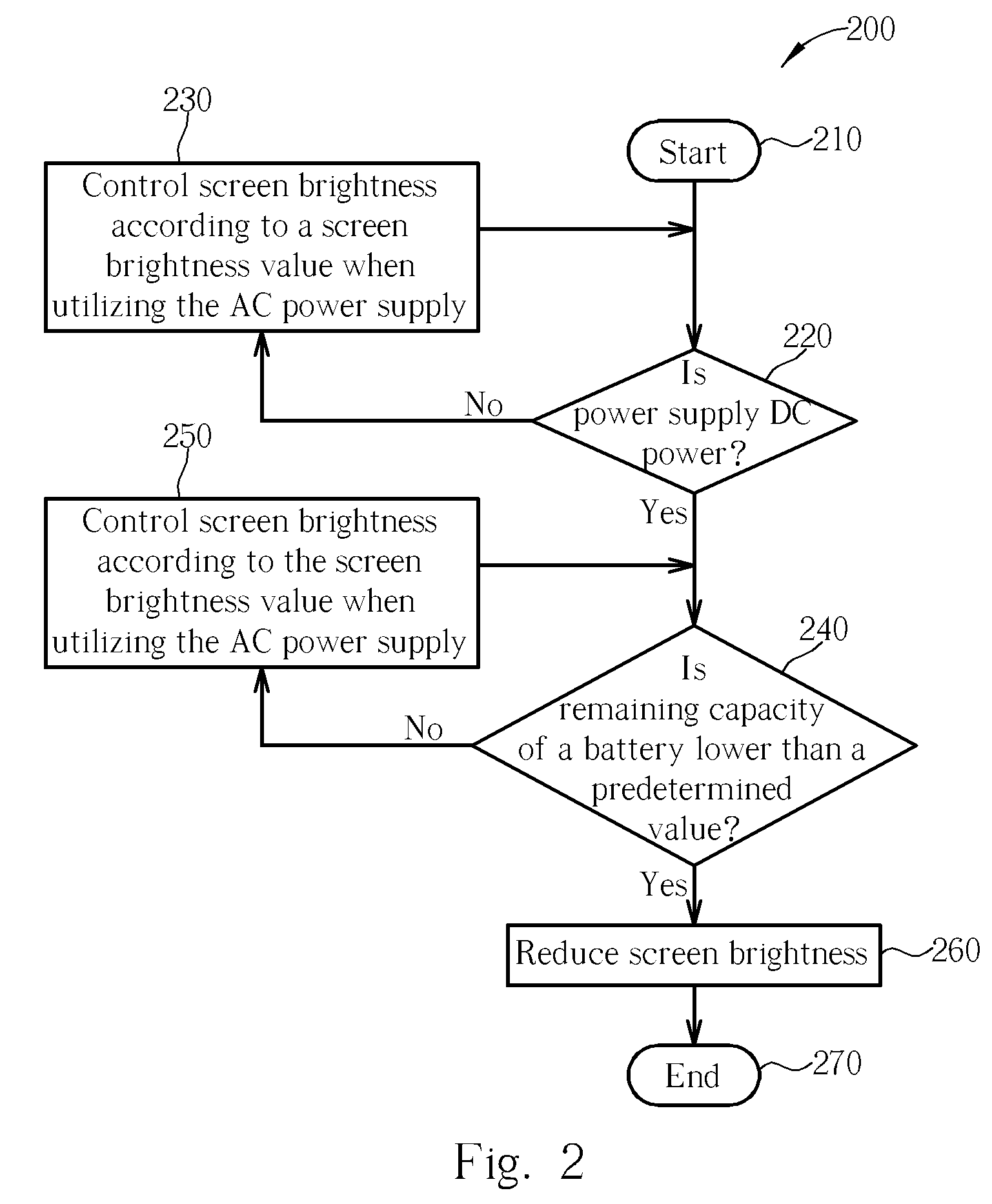

Method of Controlling Screen Brightness of an Electronic Device

InactiveUS20060238531A1Cathode-ray tube indicatorsInput/output processes for data processingControl electronicsElectrical battery

A method of controlling screen brightness of an electronic device includes detecting the remaining capacity of a battery installed on an electronic device, and controlling screen brightness of the electronic device according to the remaining capacity of the battery. Power consumption of the electronic device can be reduced according to the remaining capacity of the battery; therefore, battery run time of the electronic device can be increased.

Owner:WISTRON CORP

Capacity control for economizer refrigeration systems

ActiveUS20050247071A1Efficient and flexible and reliable and variable system capacity controlEfficient and flexible and reliable and variable capacity controlMechanical apparatusCompression machines with non-reversible cycleSystem capacityEngineering

An economizer-equipped refrigeration system and method is provided for simultaneous operation of at least one capacity control valve controlling an independent bypass circuit with operation and variable control of the economizer circuit to permit efficient, flexible, and reliable variable system capacity control, without leakage that sacrifices system peak capacity.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

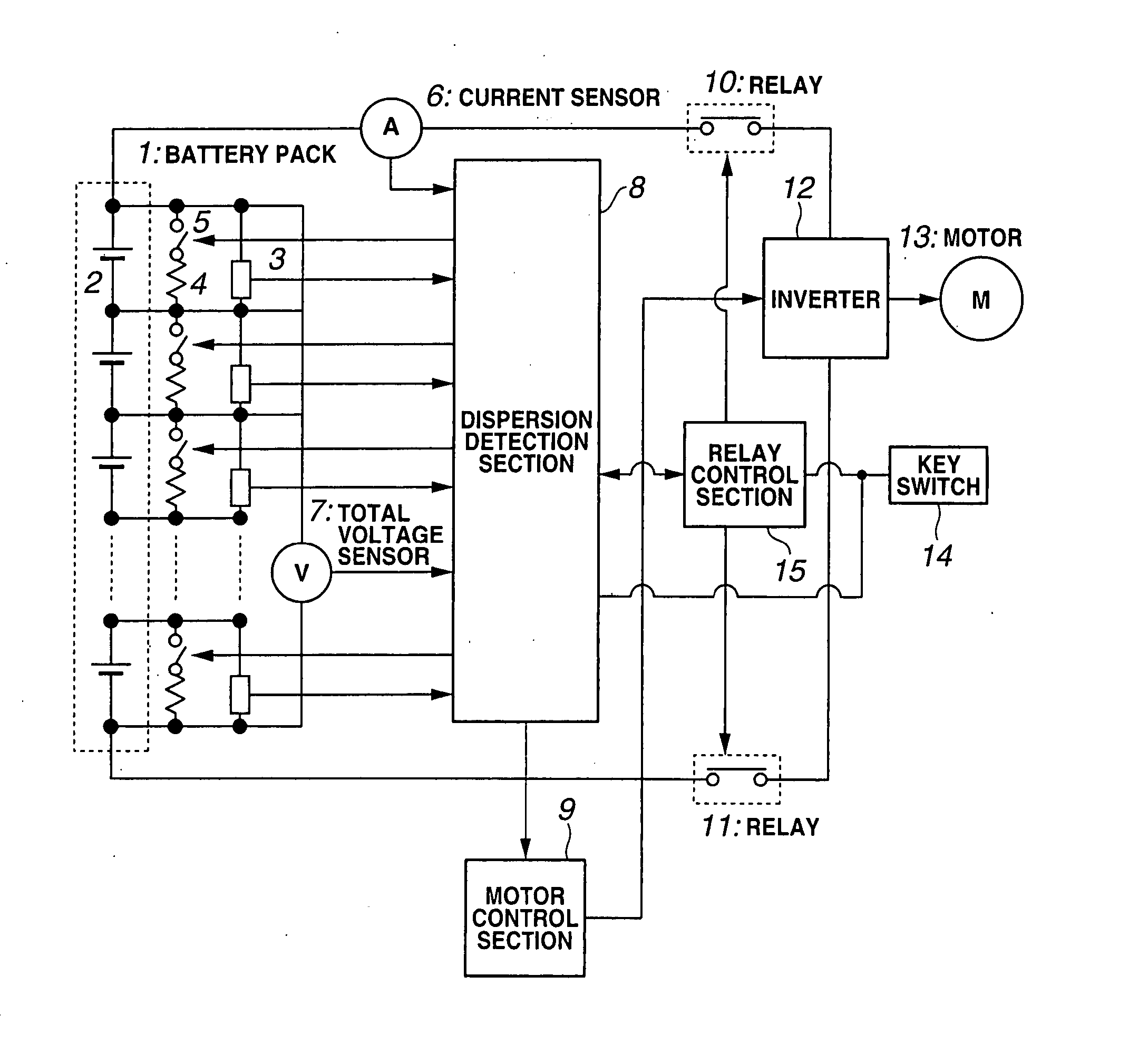

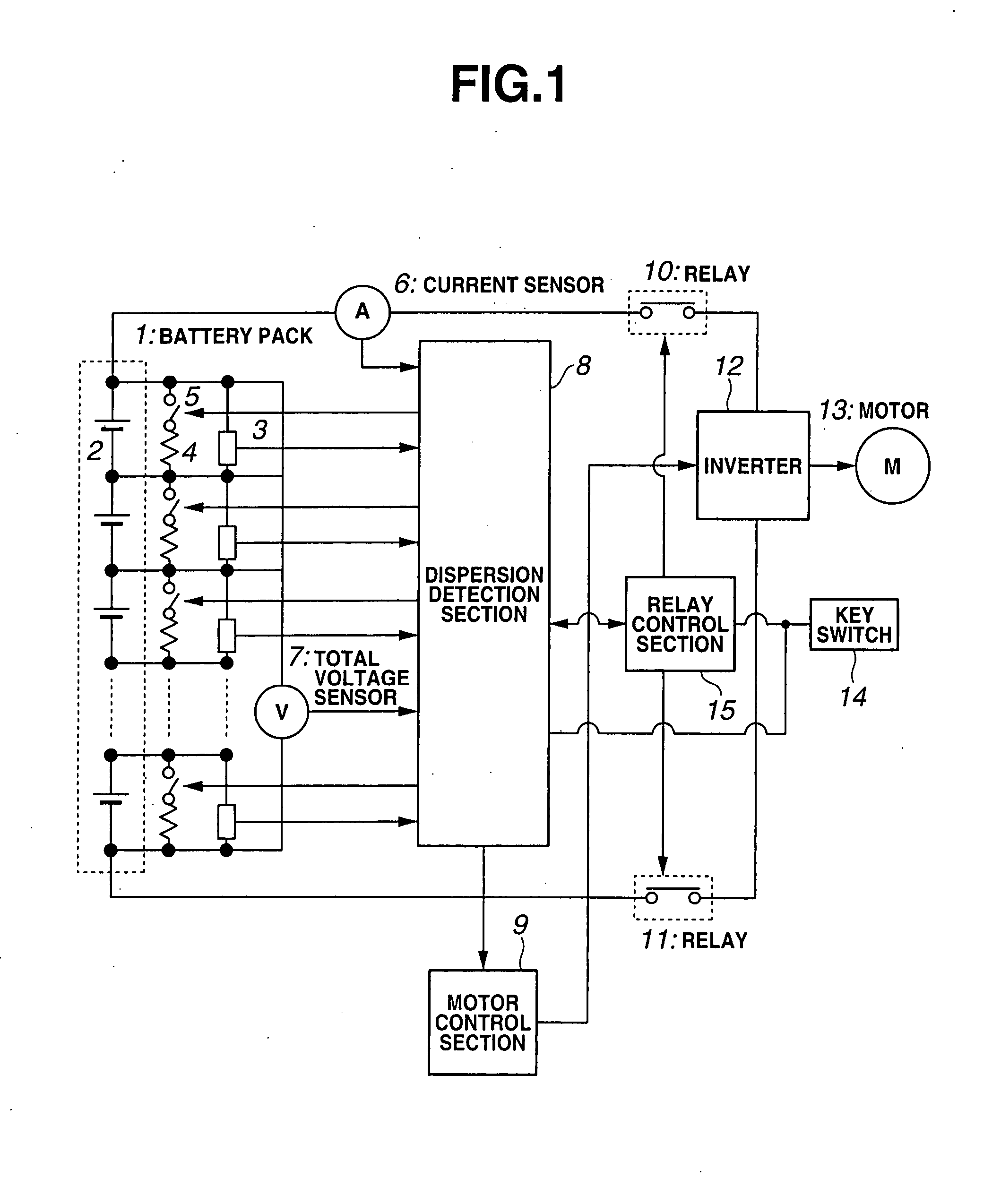

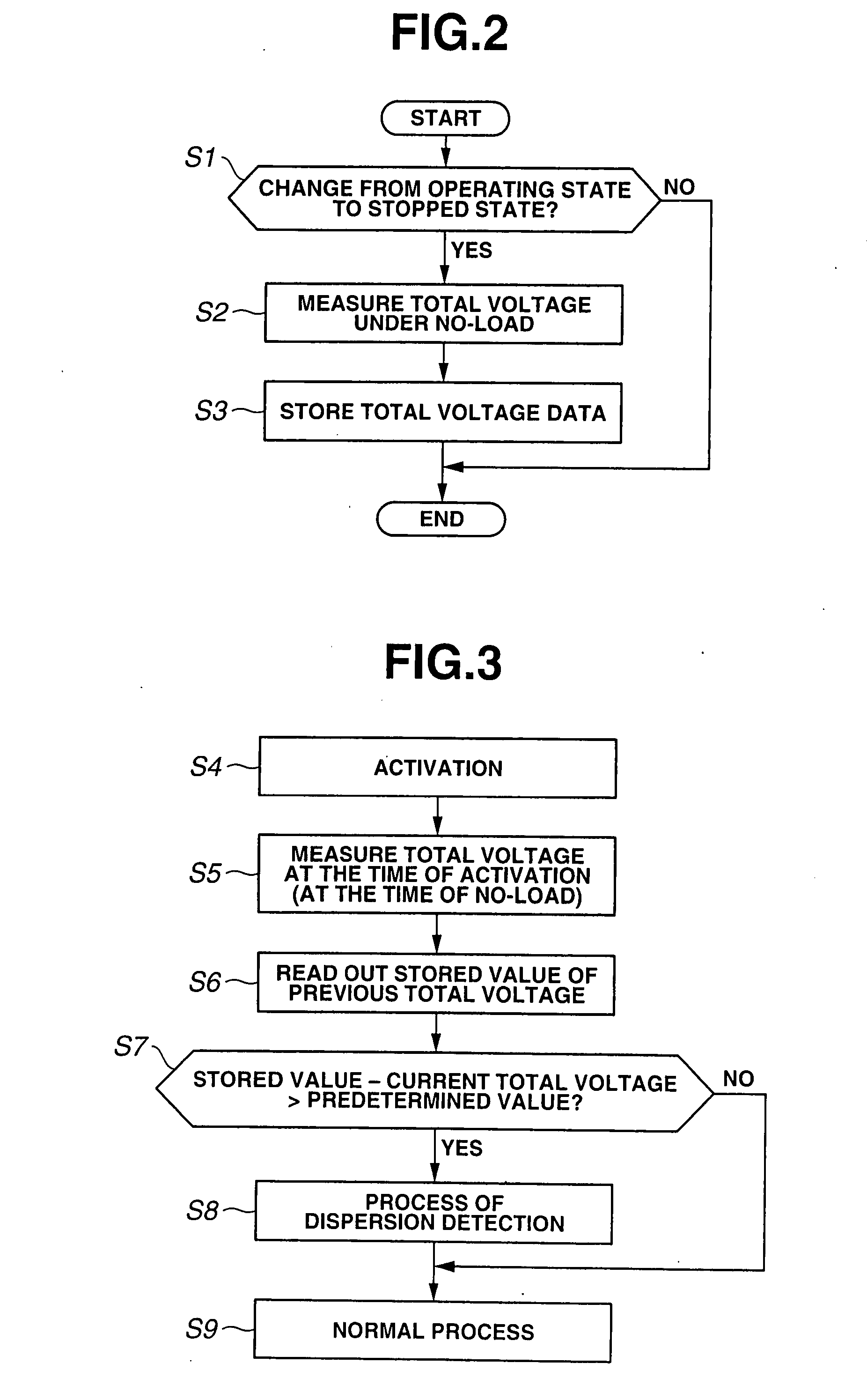

Remaining-capacity dispersion detecting apparatus and remaining-capacity control apparatus for battery pack

ActiveUS20080048617A1Batteries circuit arrangementsCurrent/voltage measurementTerminal voltageBias detection

A remaining-capacity dispersion detecting apparatus for a battery pack having a plurality of cells includes a total voltage sensing section adapted to sense a total voltage which is a terminal voltage of the whole of battery pack; a storing section adapted to store a value of the total voltage when the battery pack becomes under unloaded condition from loaded condition; and a dispersion detecting section. The dispersion detecting section is adapted to detect a value of the total voltage at a time of activation before the battery pack becomes under the loaded condition from the unloaded condition, to compare the currently-detected total voltage value with the total voltage value previously stored by the storing section, and to detect a dispersion in respective remaining capacities of the plurality of cells in the case where a difference between the currently-detected total voltage value and the previously-stored total voltage value is greater than or equal to a predetermined value.

Owner:NISSAN MOTOR CO LTD

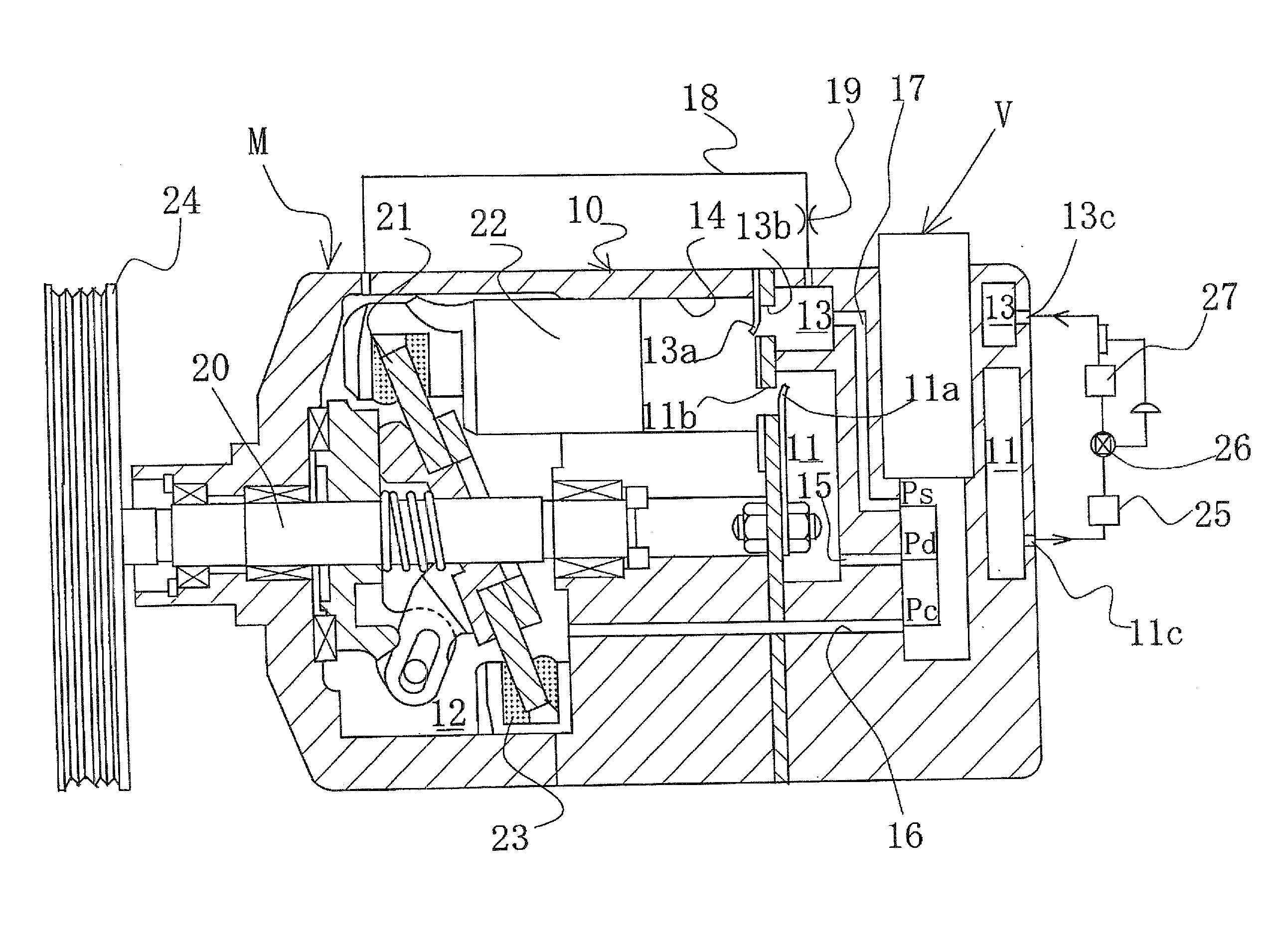

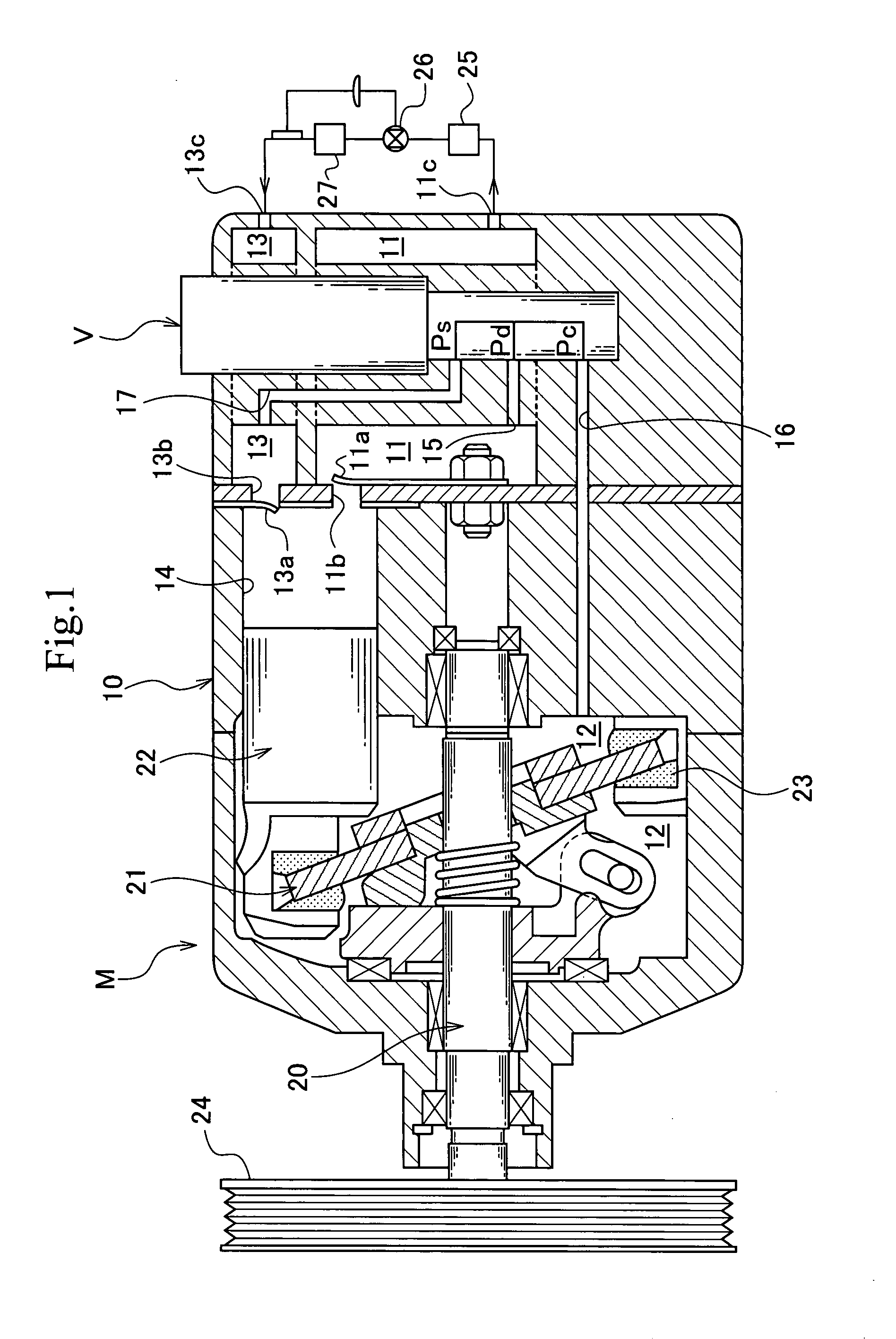

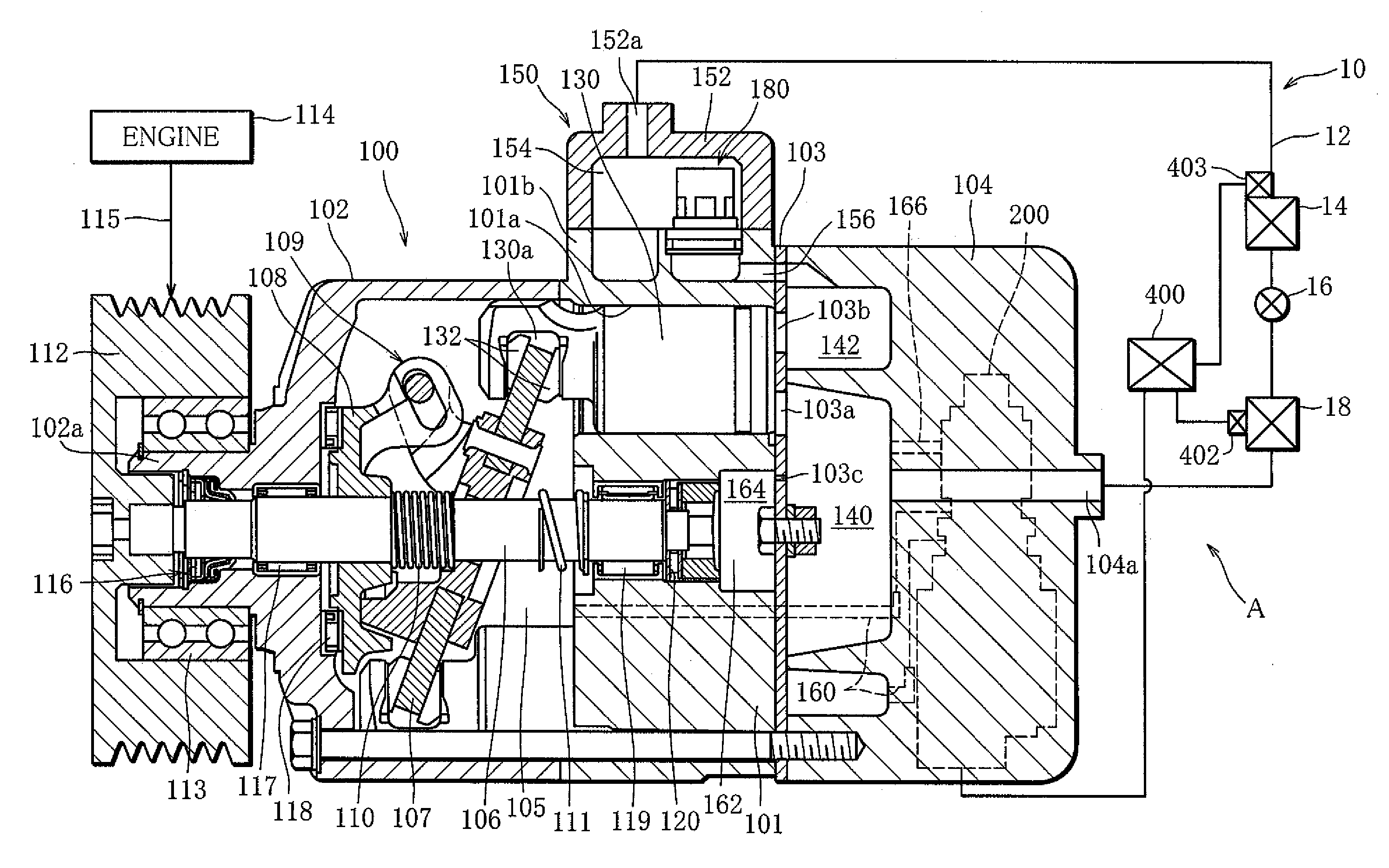

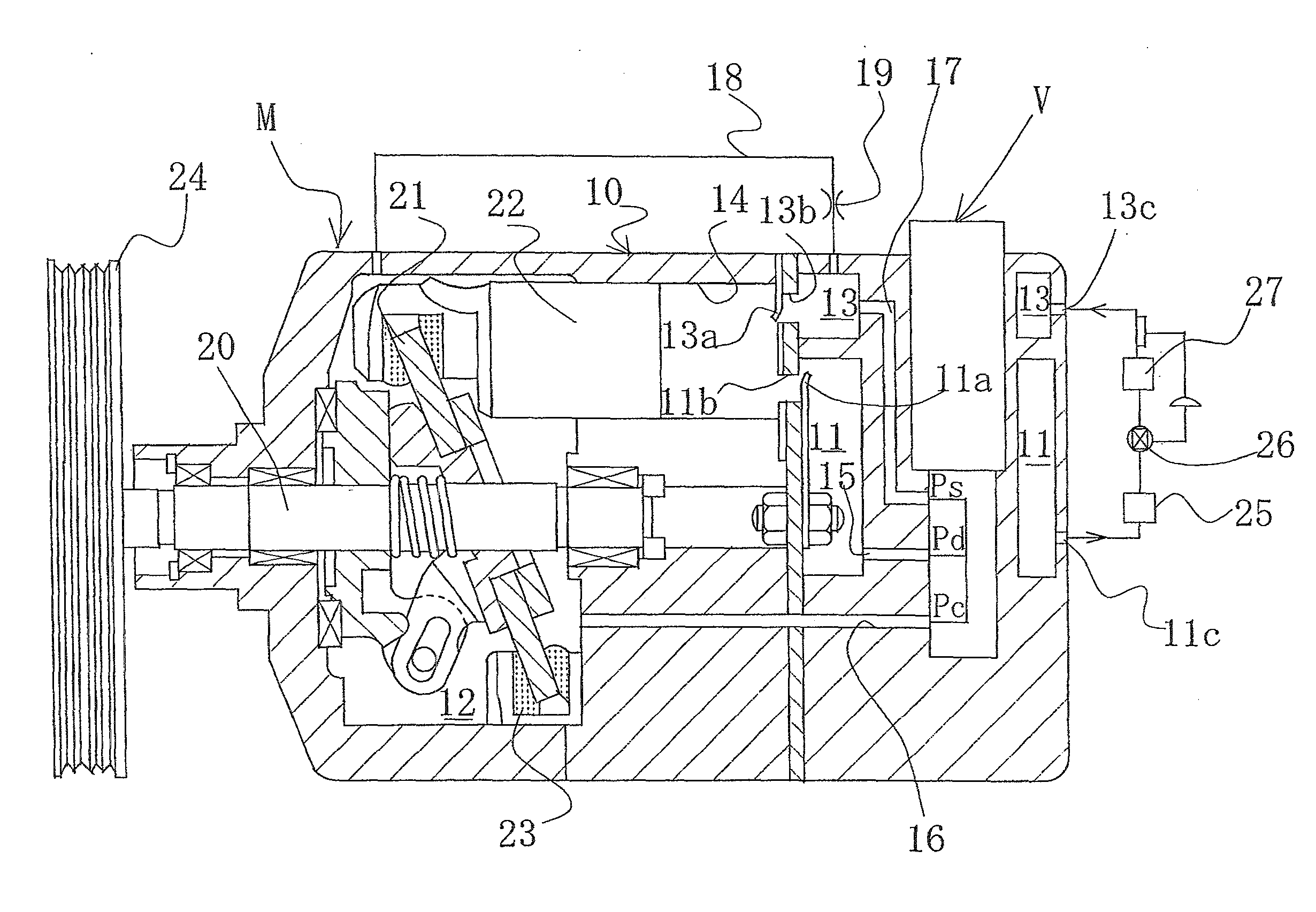

Capacity Control System for Variable Capacity Compressor and Display Device for the System

InactiveUS20110219797A1Accurately calculating drive loadEasy to saveCompression machines with non-reversible cycleVehicle heating/cooling devicesControl systemDisplay device

A capacity control system for a variable capacity compressor includes target suction pressure setting means for setting, based on external information input from external information detection means, a target suction pressure for controlling the pressure in a suction pressure region as a control target, suction pressure estimation means for estimating, based on the external information, a pressure that is estimated to prevail in the suction pressure region if the variable capacity compressor is operated with a maximum discharge capacity, and discharge capacity determination means for determining, based on the suction pressure estimated by the suction pressure estimation means and the target suction pressure set by the target suction pressure setting means, whether the variable capacity compressor is operating with the maximum discharge capacity or with a controlled discharge capacity.

Owner:SANDEN CORP

Capacity control valve

ActiveUS20130291963A1Easy to control speedEasy to manufactureAir-treating devicesOperating means/releasing devices for valvesEngineeringControl valves

A capacity control valve for increasing the ability to drain liquid refrigerant from a control chamber during startup of a variable-capacity compressor without changing the control valve characteristics has a spring acting in the direction of valve opening provided between an adapter and a free end of a pressure-sensitive body in the extension and contraction direction thereof and having an annular seat surface, and a third valve part having an annular engaging surface for opening and closing a suction-side passage by engaging and disengaging with the seat surface of the adapter.

Owner:EAGLE INDS

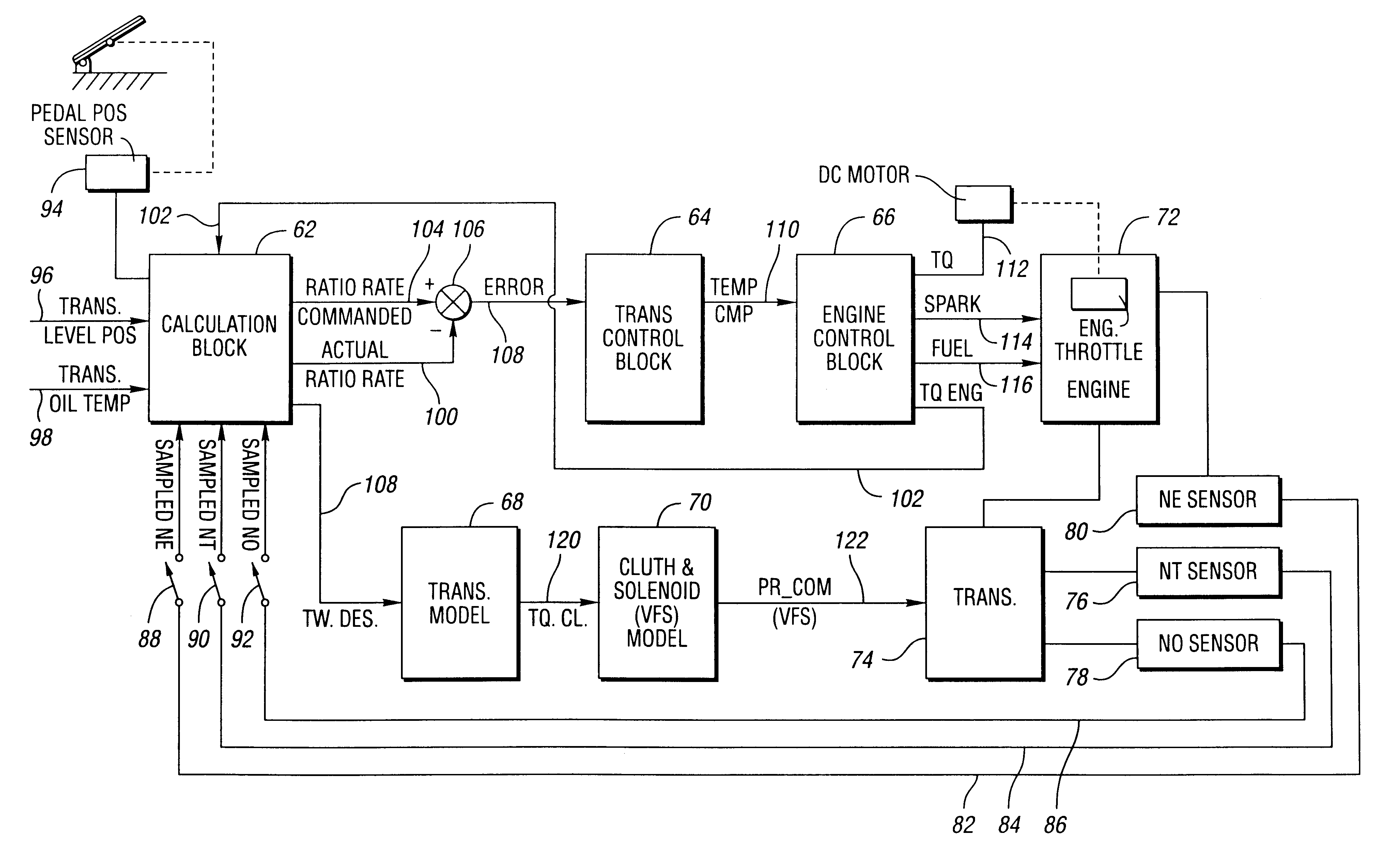

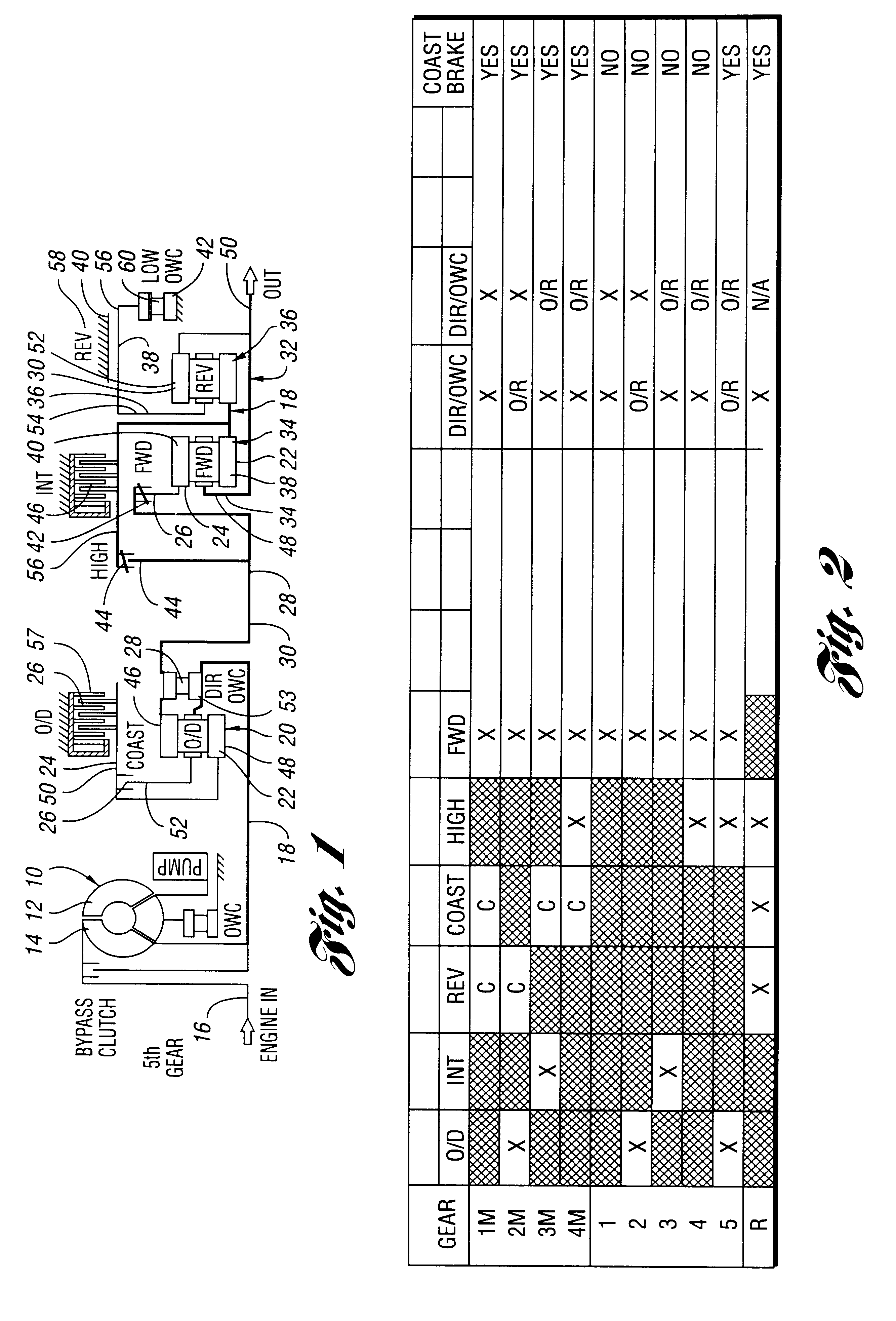

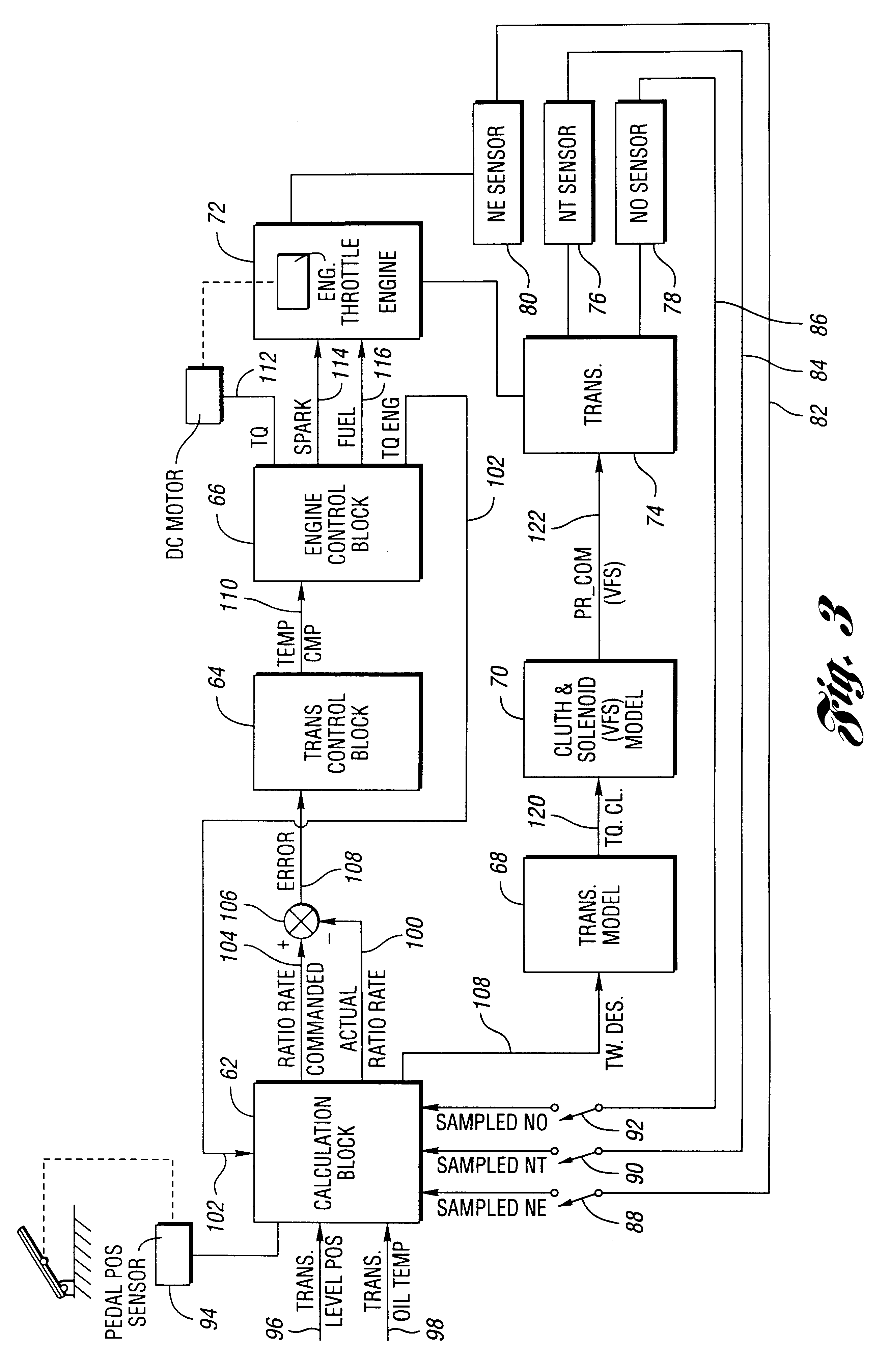

Automatic transmission shift control

InactiveUS6449548B1Digital data processing detailsGearing controlThrottle controlElectronic controller

An automatic transmission ratio shift control system and method for a powertrain having a throttle-controlled engine and multiple-ratio gearing, torque flow paths through the gearing being established and disestablished by pressure-operated friction elements, an electronic controller for establishing torque transitions between the friction elements as ratio changes occur in the multiple-ratio gearing, the engine throttle being controlled by an electronic throttle control that is decoupled from the driver-controlled accelerator pedal, the transmission torque output being controlled by means of a friction element capacity control strategy including a feed-forward torque term determined by changes in commanded torque, the slip duration during a ratio change being controlled by means of closed-loop engine torque control.

Owner:FORD GLOBAL TECH LLC

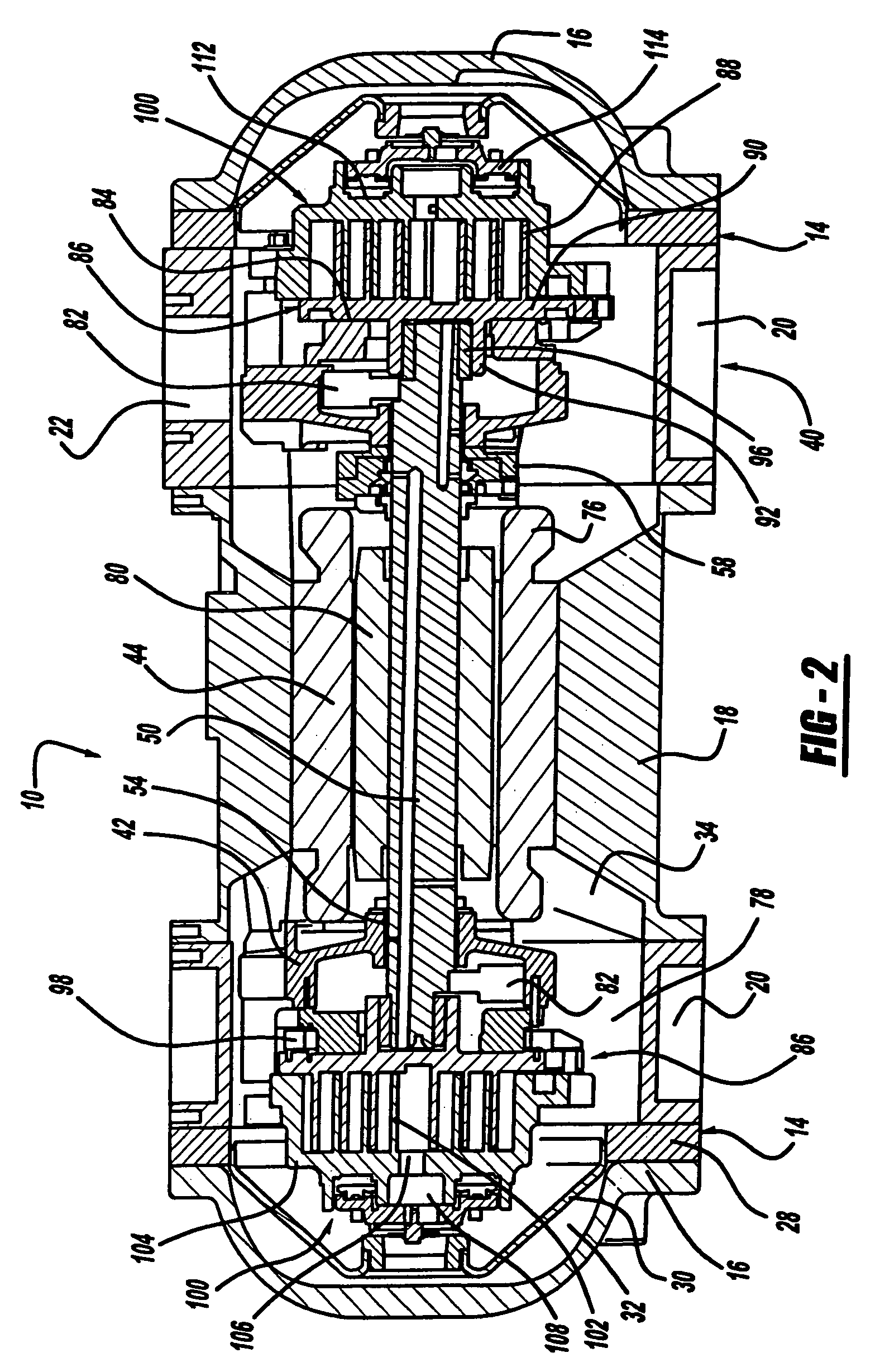

Method of stepless capacity control of a reciprocating piston compressor and piston compressor with such control

InactiveUS7331767B2Minimal clearance volumeSimple and compact mannerPositive displacement pump componentsFlexible member pumpsWork cycleEngineering

For stepless capacity control of a reciprocating piston compressor, an unloader (2) arranged on a suction valve (1) keeps open said suction valve (1) over a thereby controllable portion of the working cycle of the compressor by means of an unloading piston (4) biased by gas pressure via a control valve (3). The gas pressure biasing the unloading piston (4) is always above the gas pressure required to overcome the maximum possible reverse flow force, whereby a controllable partial discharge of the unloading cylinder (6) is performed in each phase of the working cycle up to the closing of the suction valve (1) by means of the control valve (3), which is designed to switch rapidly. The theoretical discharge time of the entire discharging volume for the partial discharge is preferably maximal nearly equal or even less than twice the duration of the working cycle.

Owner:HOERBIGER VENTILWERKE AKTIENGES

Plural compressors

ActiveUS7201567B2Maximize compactnessMean for controlling systemRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeElectric machineControl system

A compressor system includes a pair of compressors located in a common shell. A common drive shaft drives both compressors and the drive shaft is powered by a single motor. One or both of the compressors can be equipped with a pulse width modulated capacity control system and a vapor injection system. When one compressor is equipped with these systems, the capacity can be varied between 50% and 110%. When both compressors are equipped with these systems, the capacity can be varied between 0% and 120%.

Owner:COPELAND LP

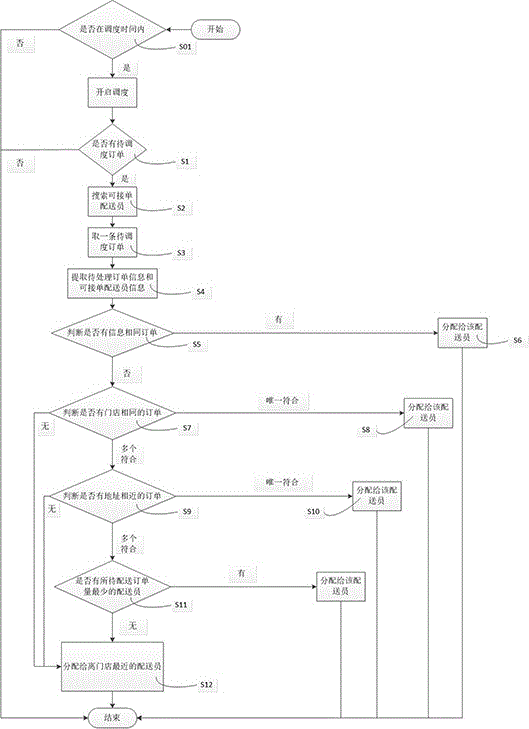

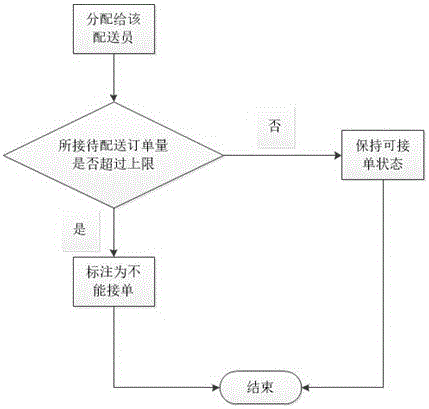

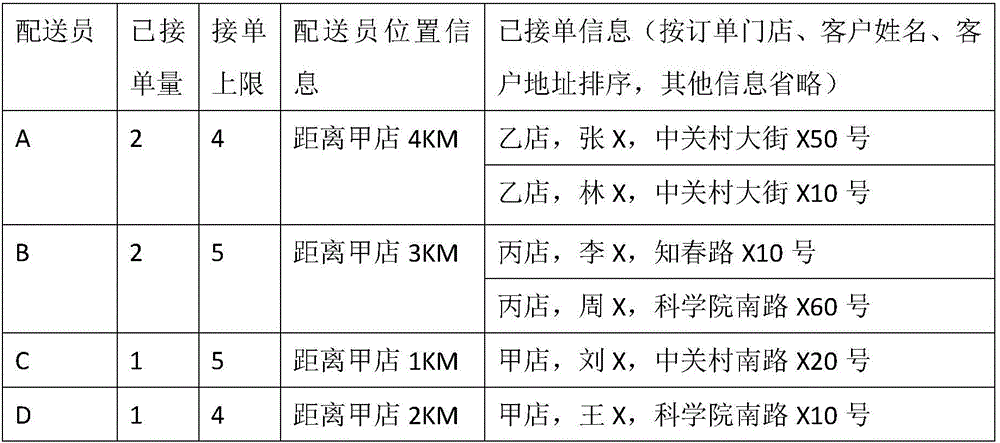

Order intelligent scheduling method

The invention discloses an order intelligent scheduling method. According to the method, a lot of manual labor and operation cost of the company can be saved through control of scheduling time and the state of delivery personnel, and order processing of the same information, order processing of the same store, order processing of similar addresses, delivery capacity control of the delivery personnel and cooperative work of shortest path control so that the reasonability of scheduling can be guaranteed, and powerful support is provided for enhancing the delivery efficiency.

Owner:多点生活(中国)网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com