Patents

Literature

1587 results about "Liquid temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water is a liquid at the temperatures and pressures that are most adequate for life. Specifically, at a standard pressure of 1 atm, water is a liquid between 0 and 100 °C (32 and 212 °F). Increasing the pressure slightly lowers the melting point, which is about −5 °C (23 °F) at 600 atm and −22 °C (−8 °F) at 2100 atm.

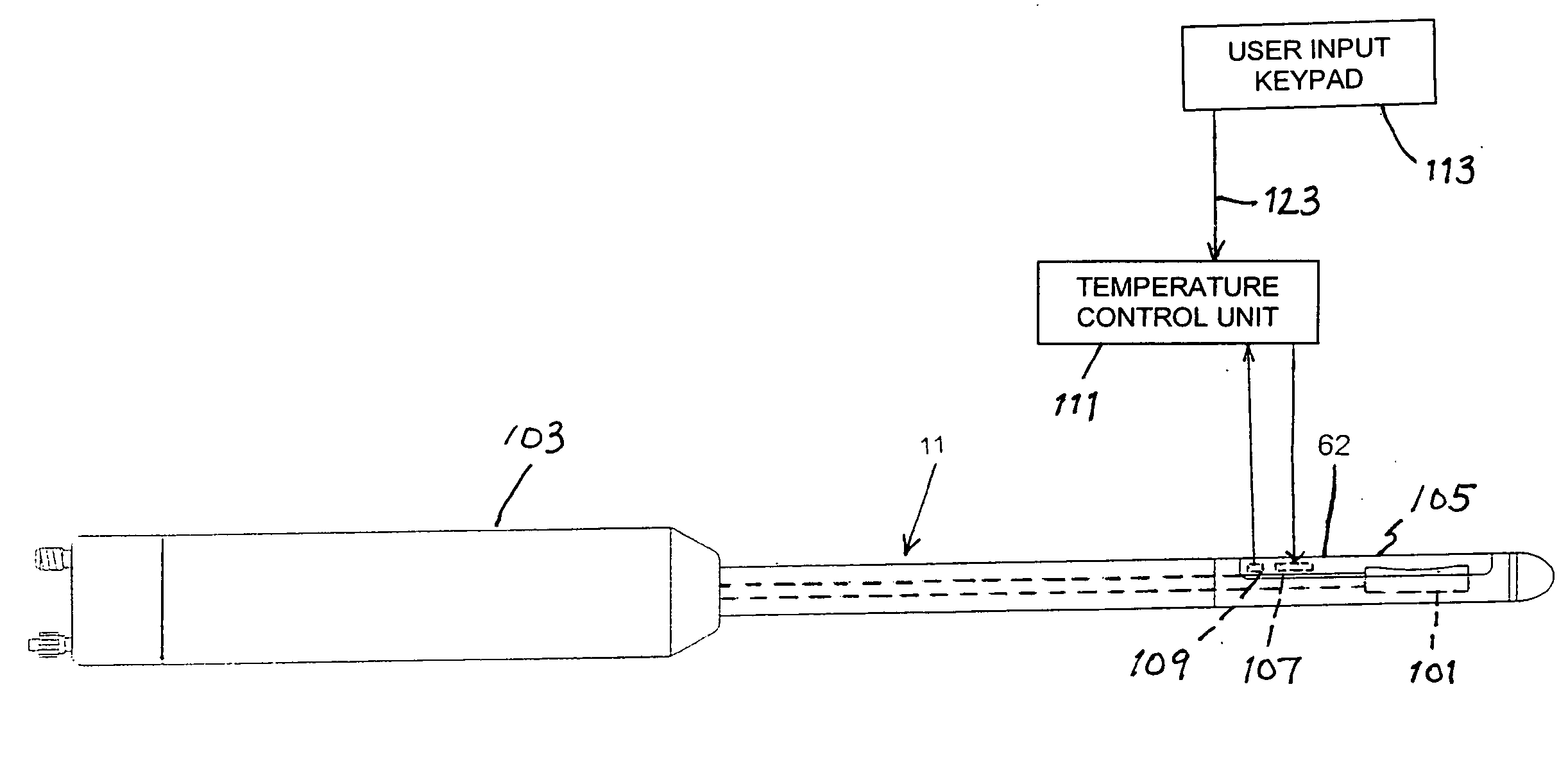

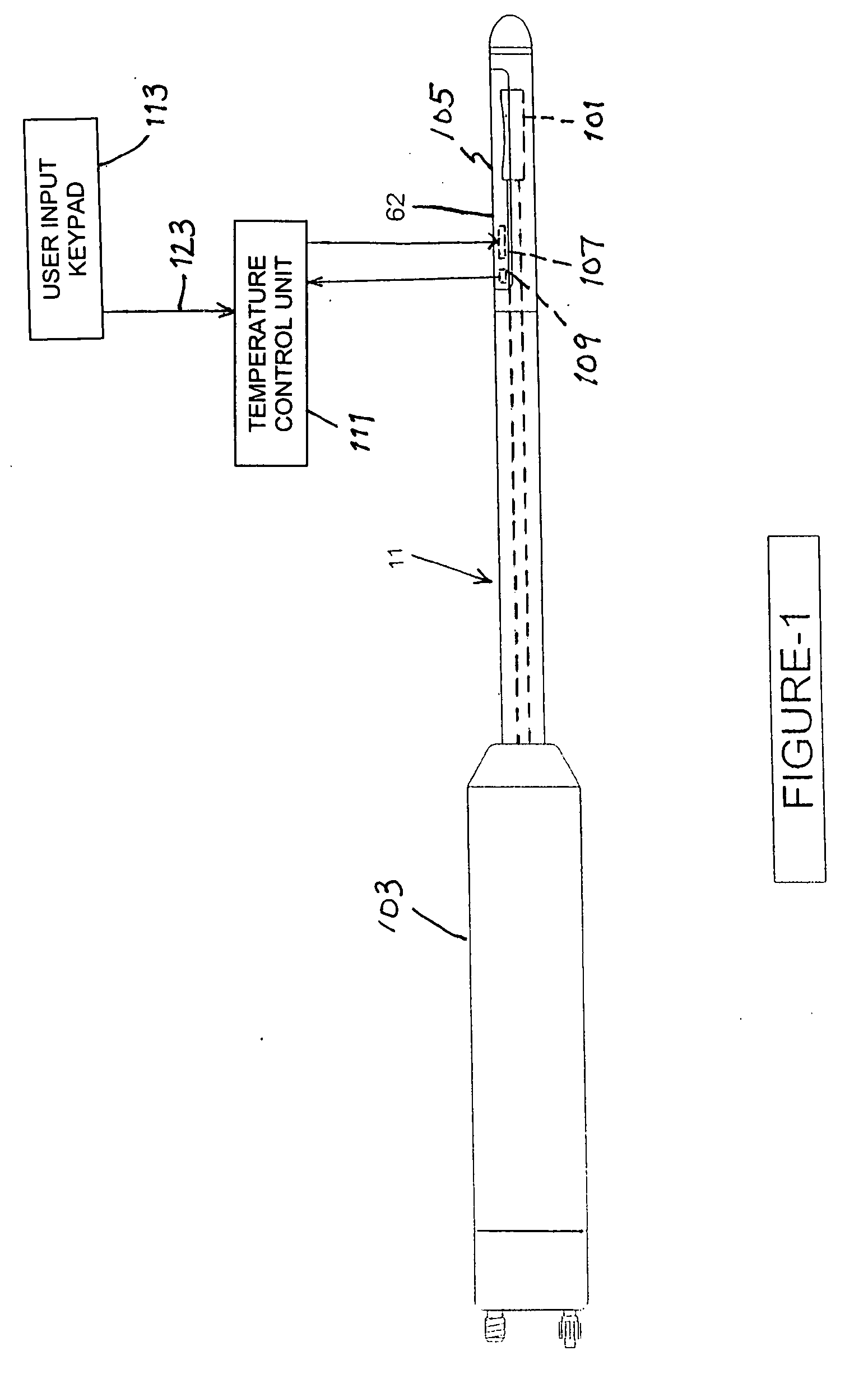

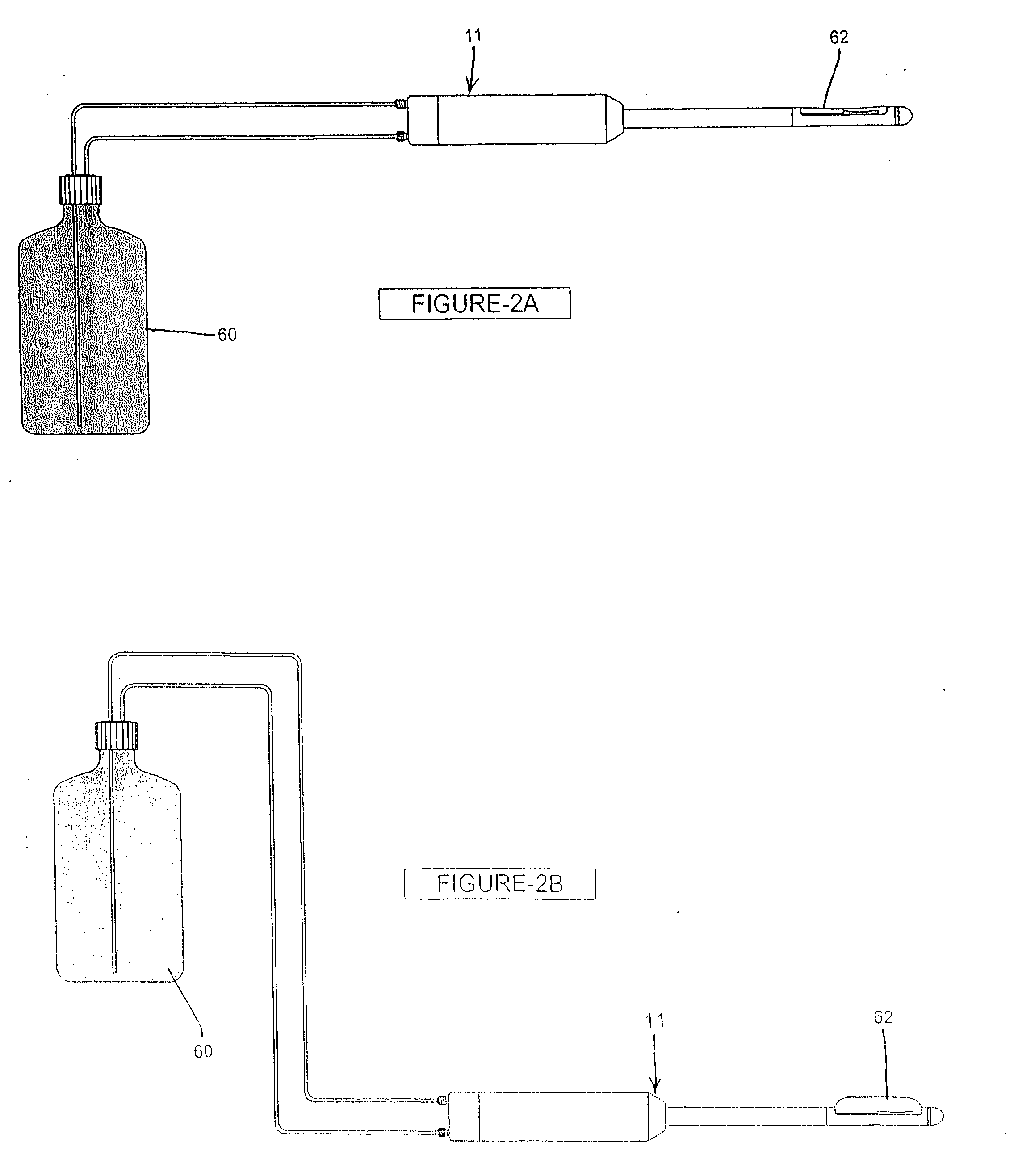

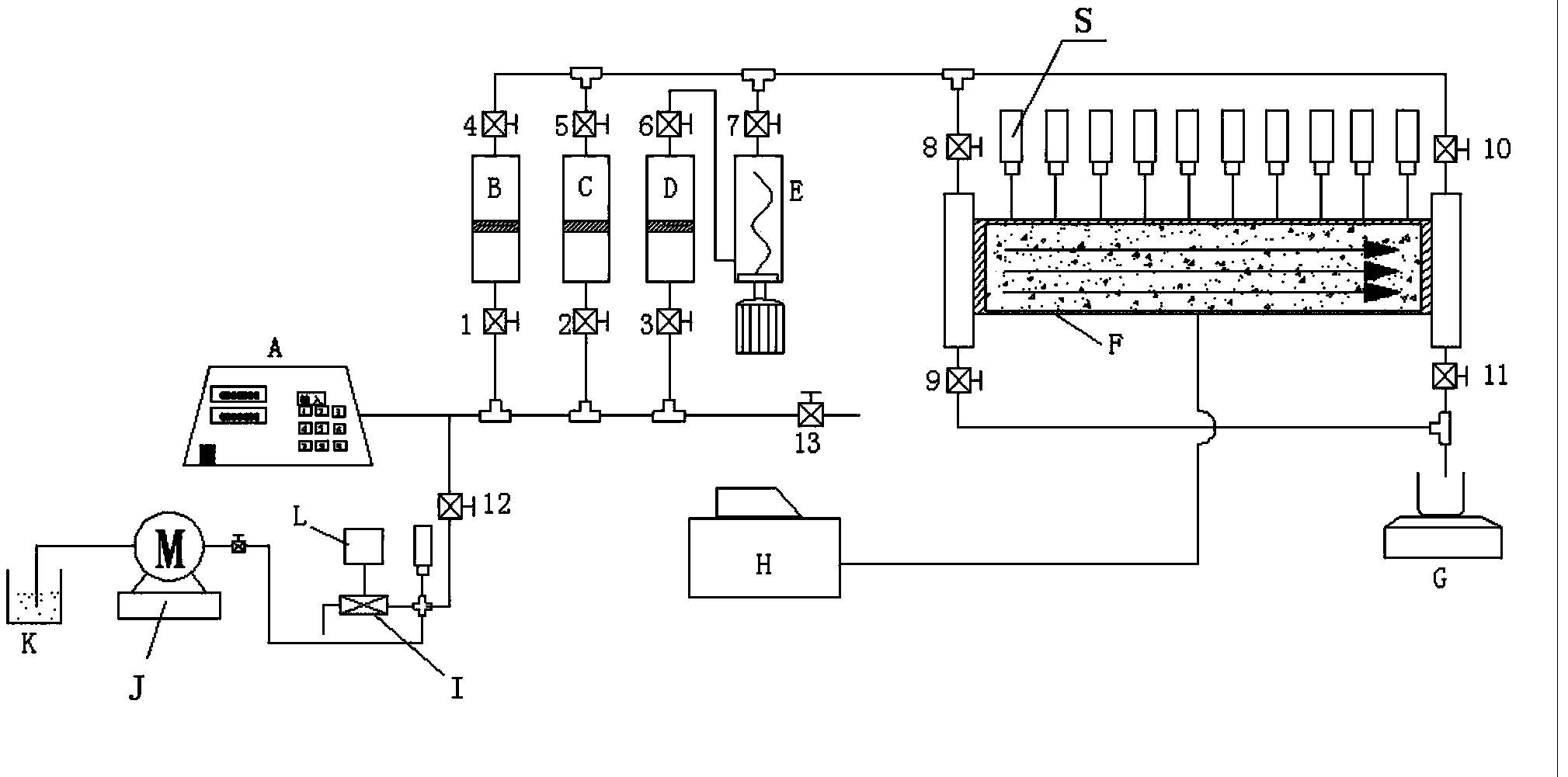

Elevated coupling liquid temperature during HIFU treatment method and hardware

InactiveUS20080281200A1Avoid necrosisEnhanced couplingUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyLiquid temperatureUltrasonic vibration

A medical procedure utilizes a high-intensity focused ultrasound instrument having an applicator surface, a liquid-containing bolus or expandable chamber acting as a heat sink, and a source of ultrasonic vibrations, the applicator surface being a surface of a flexible wall of the bolus, the source of ultrasonic vibrations being in operative contact with the bolus. The applicator surface is placed in contact with an organ surface of a patient, the source is energized to produce ultrasonic vibrations focused at a predetermined focal region inside the organ, and a temperature of liquid in the bolus is controlled while the applicator surface is in contact with the organ surface to control temperature elevation in tissues of the organ between the focal region and the organ surface to necrose the tissues to within a desired distance from the organ surface.

Owner:US HIFU

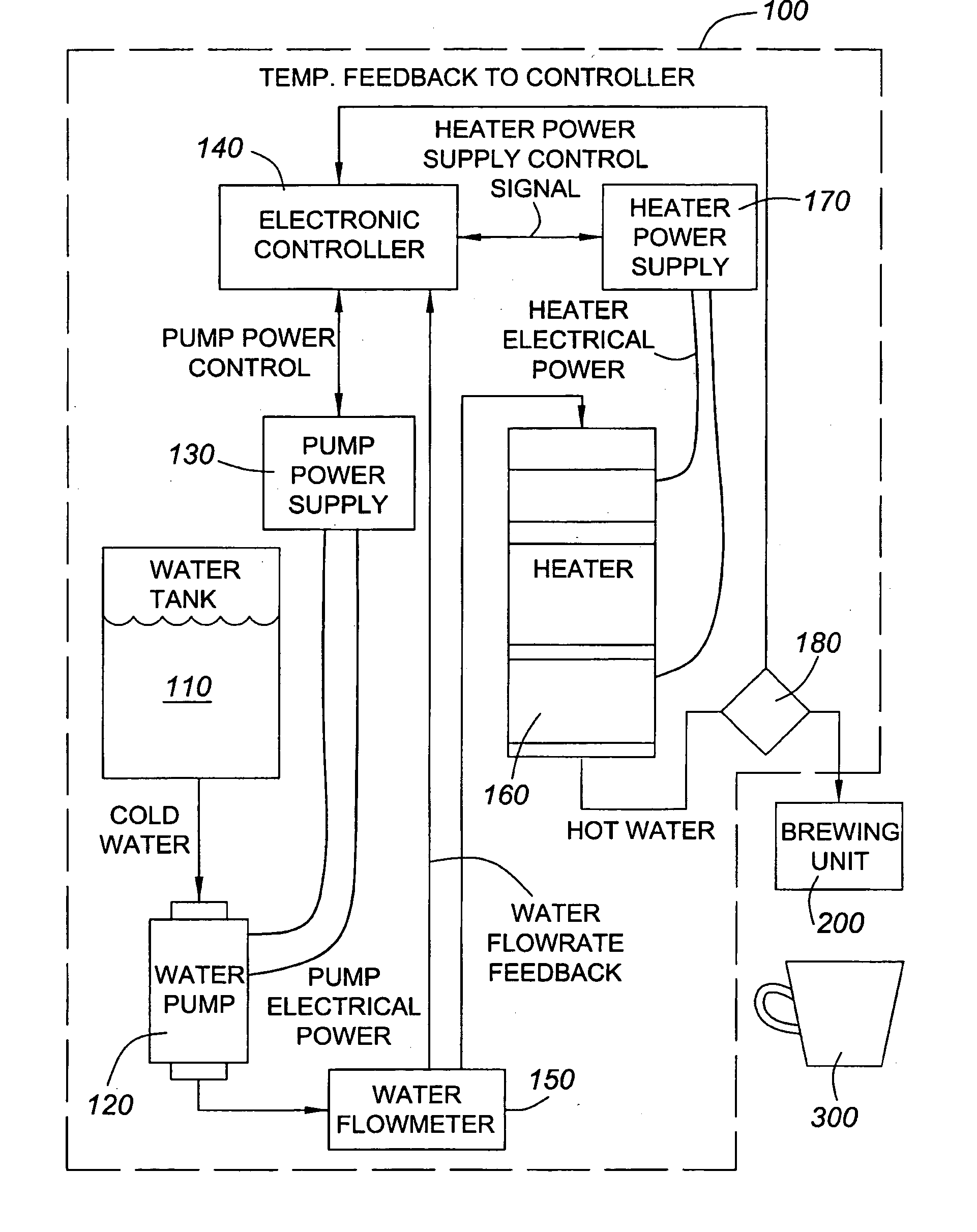

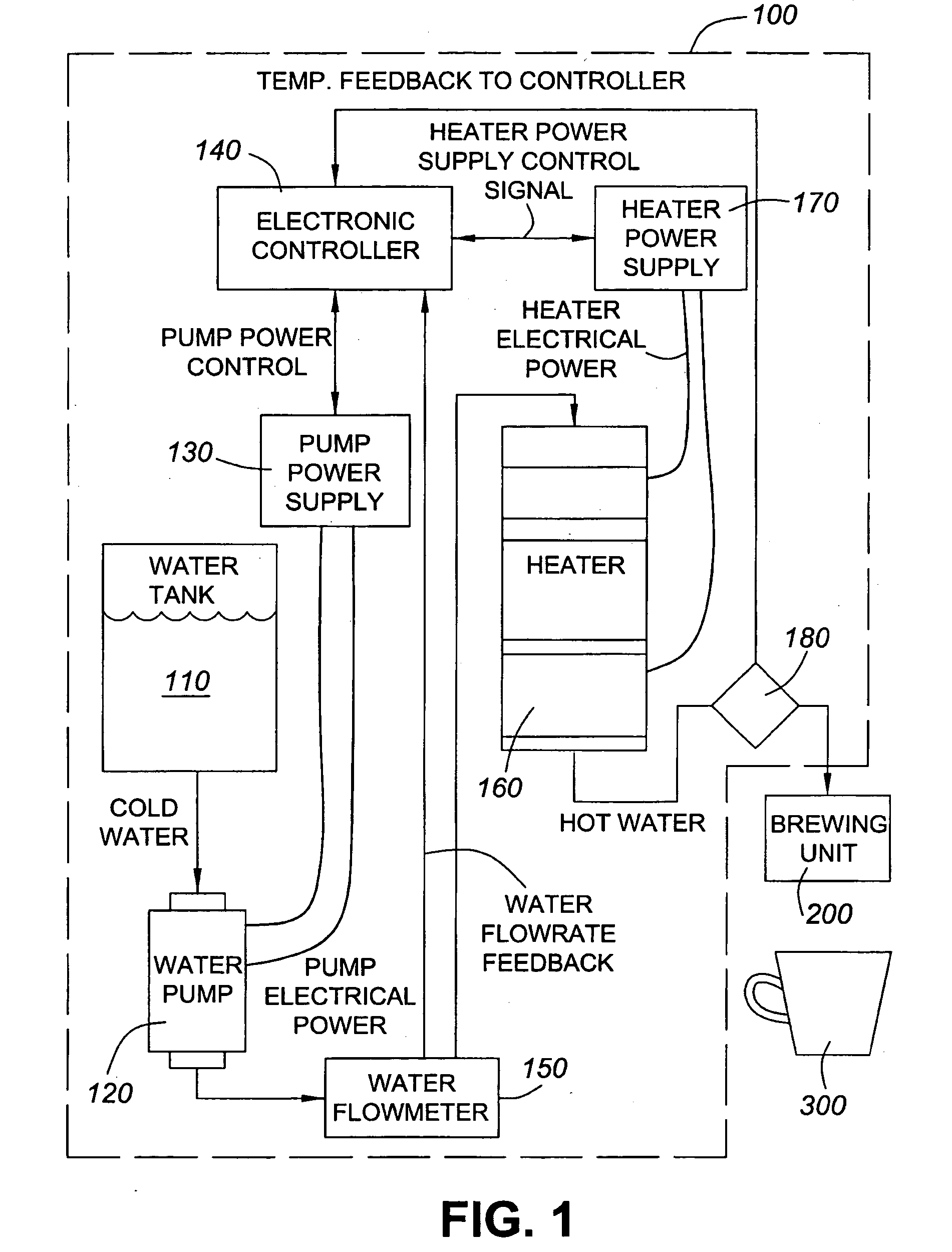

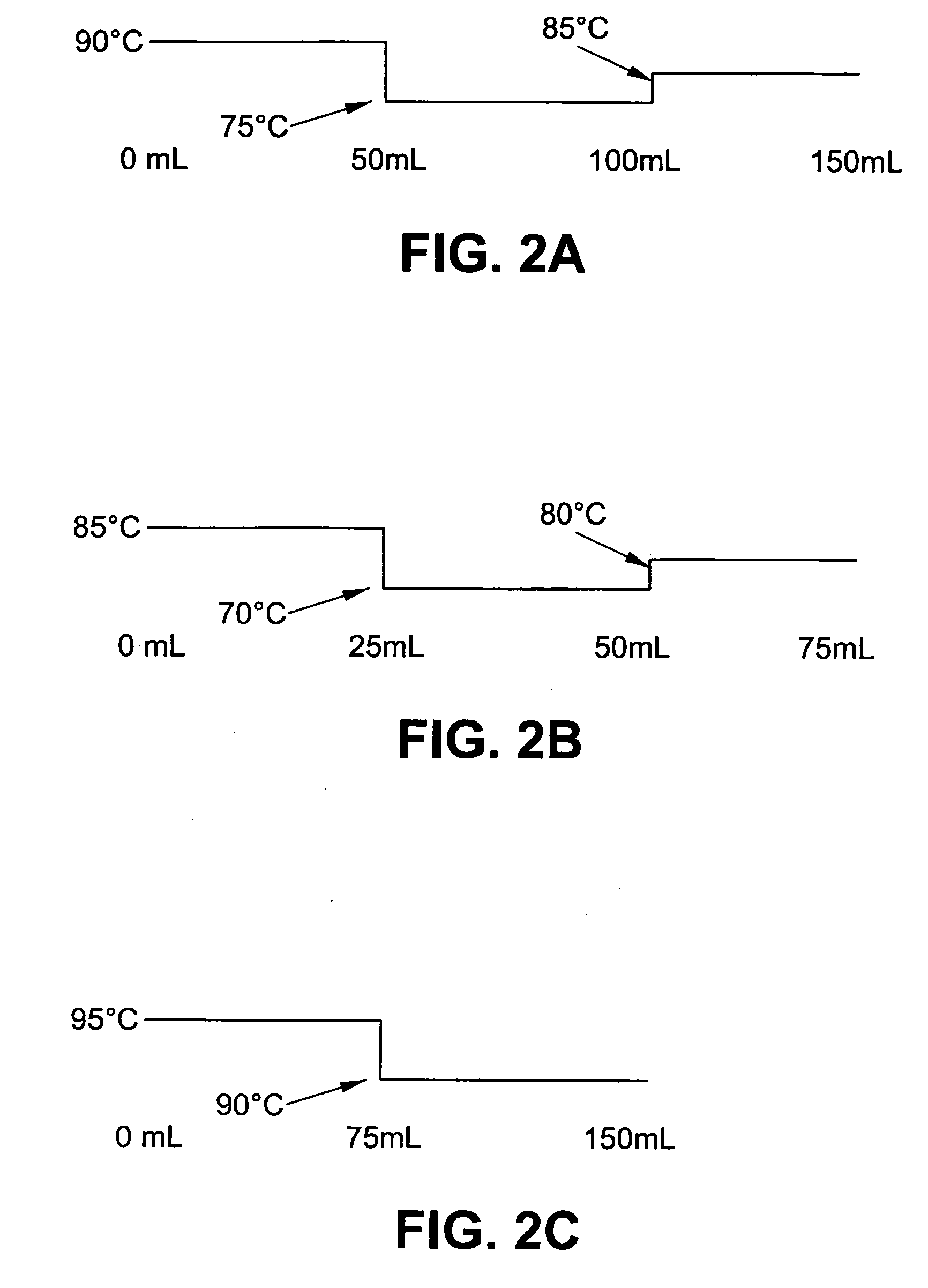

Method and apparatus for optimizing variable liquid temperatures

A method, apparatus, and related beverage profiles for on-demand heating of liquid used for beverage dispensing where such heating is dynamically variable according to the applicable profile. The apparatus includes a heating unit, electronic controller, and sensing devices. A water tank supplies the heating unit via a water pump controlled by the controller that also controls the heating unit. Feedback control loops provide control data to the controller to optimize liquid temperatures for a given beverage type in accordance with predetermined profiles.

Owner:NESTEC SA

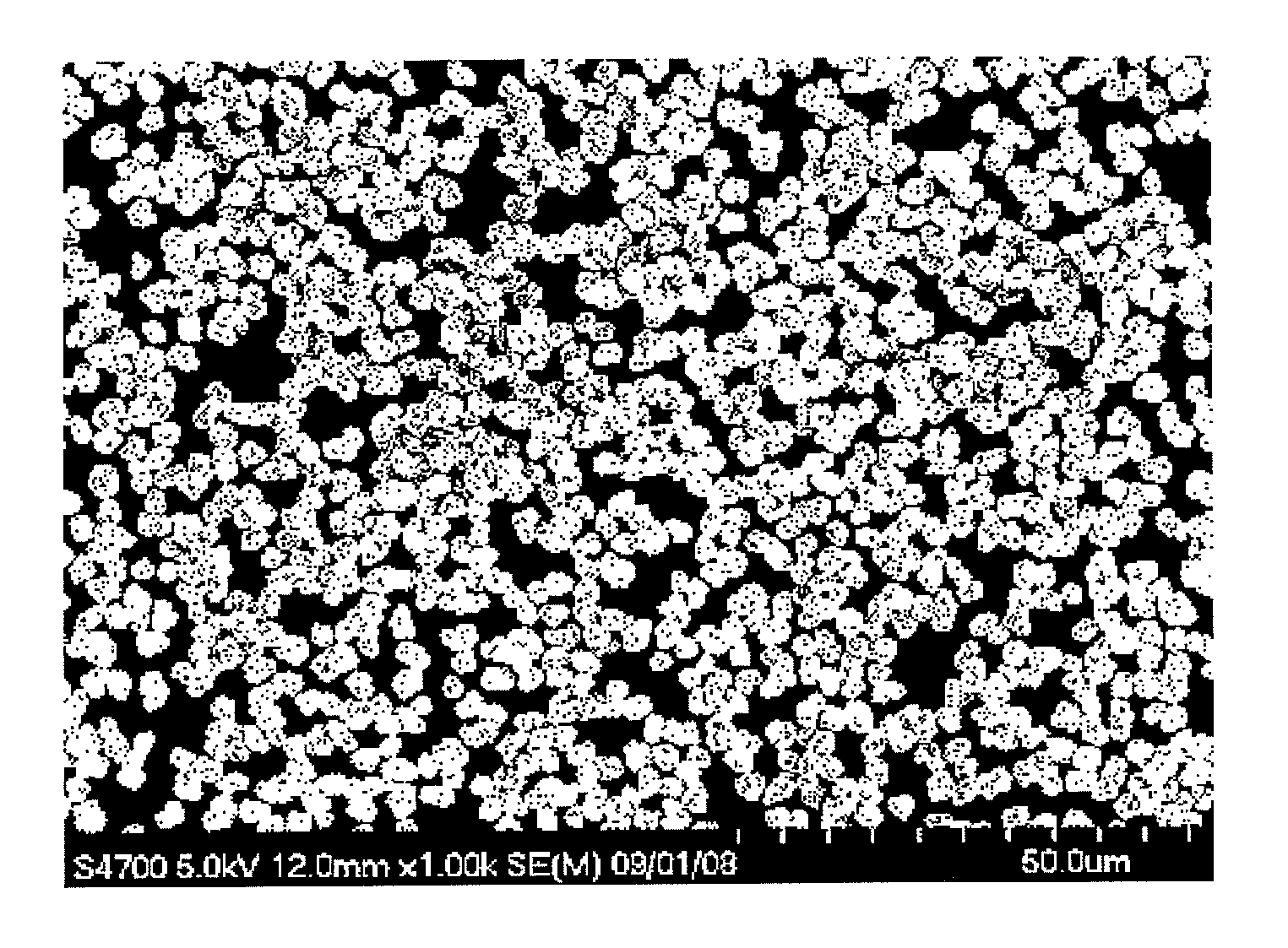

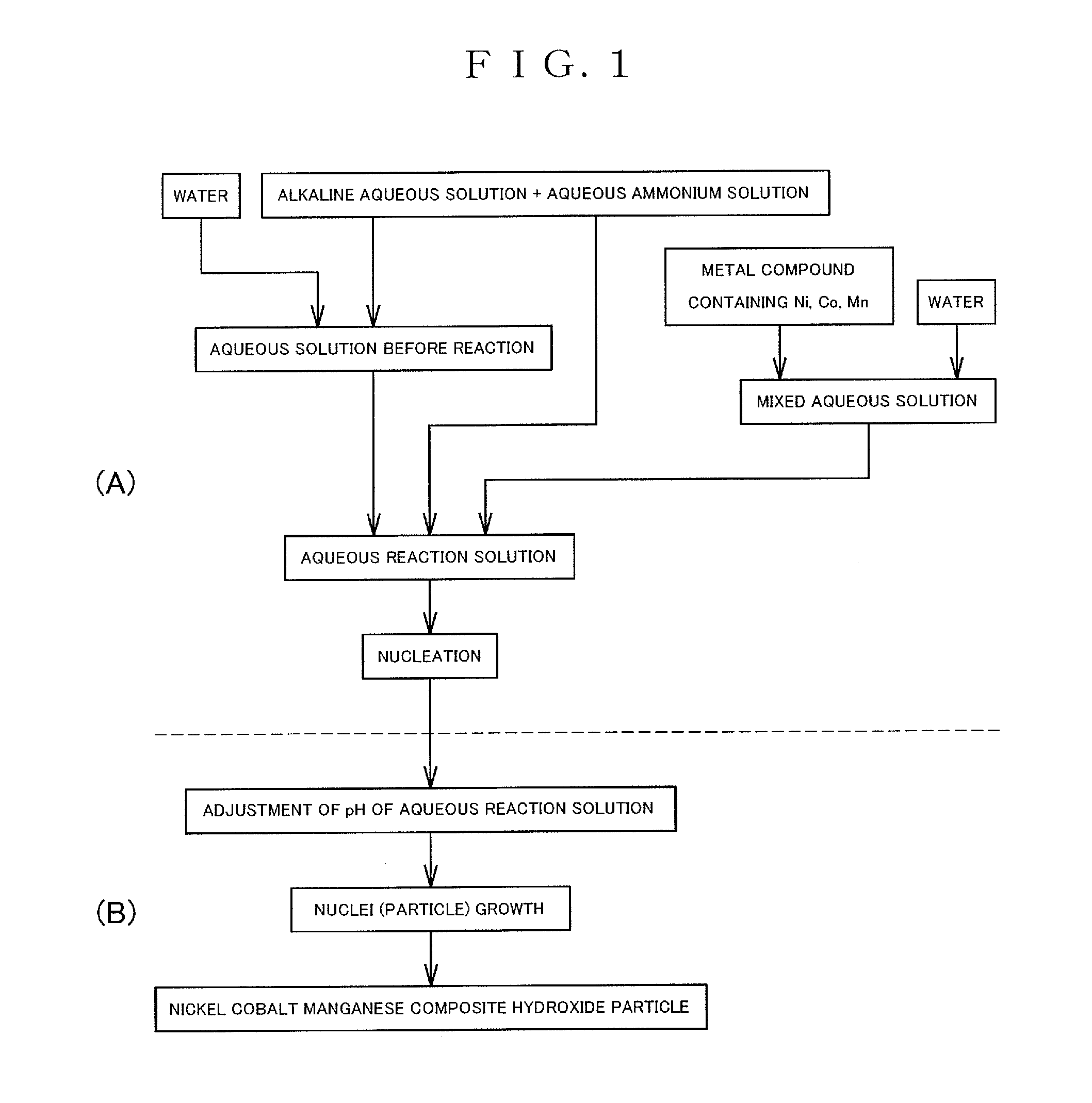

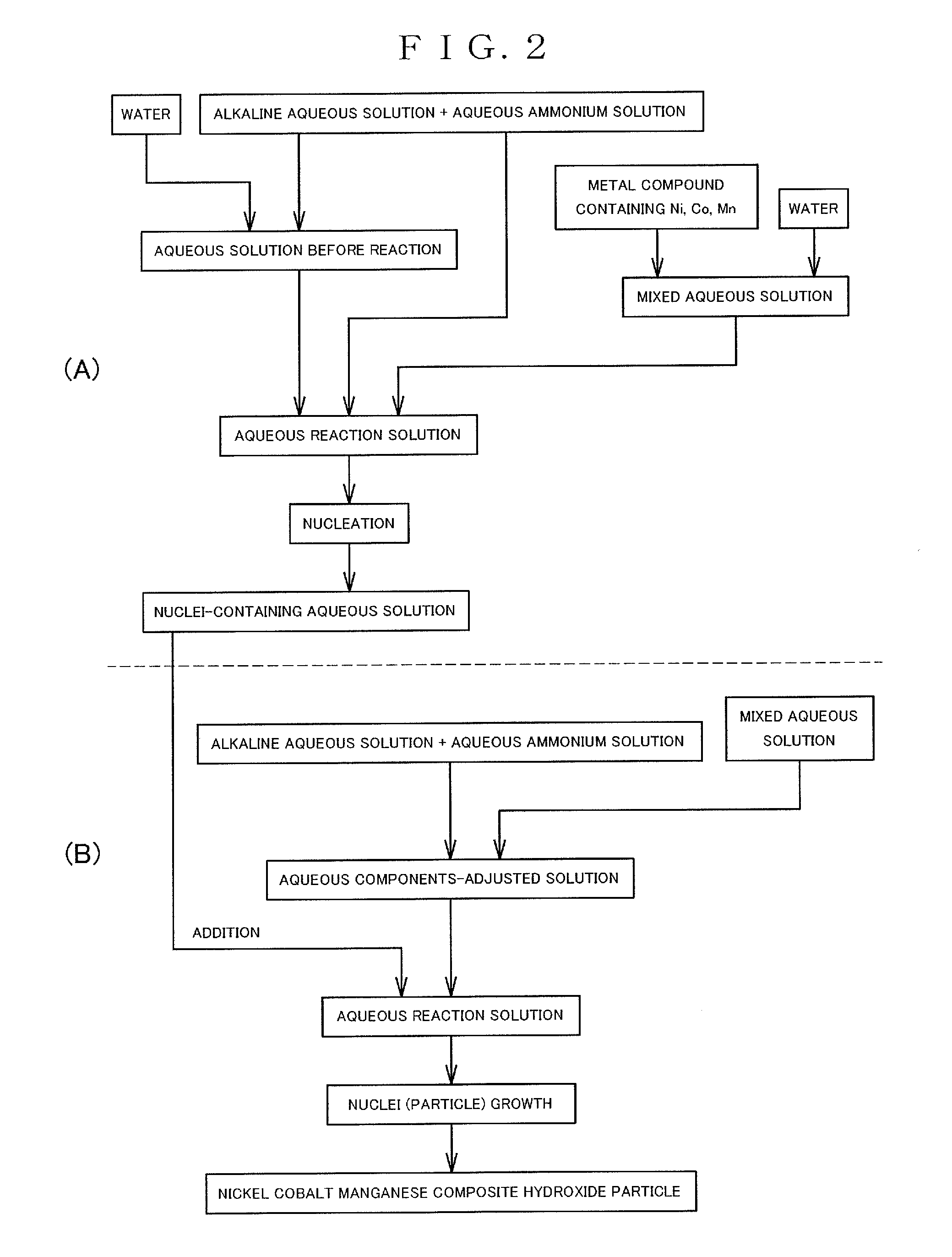

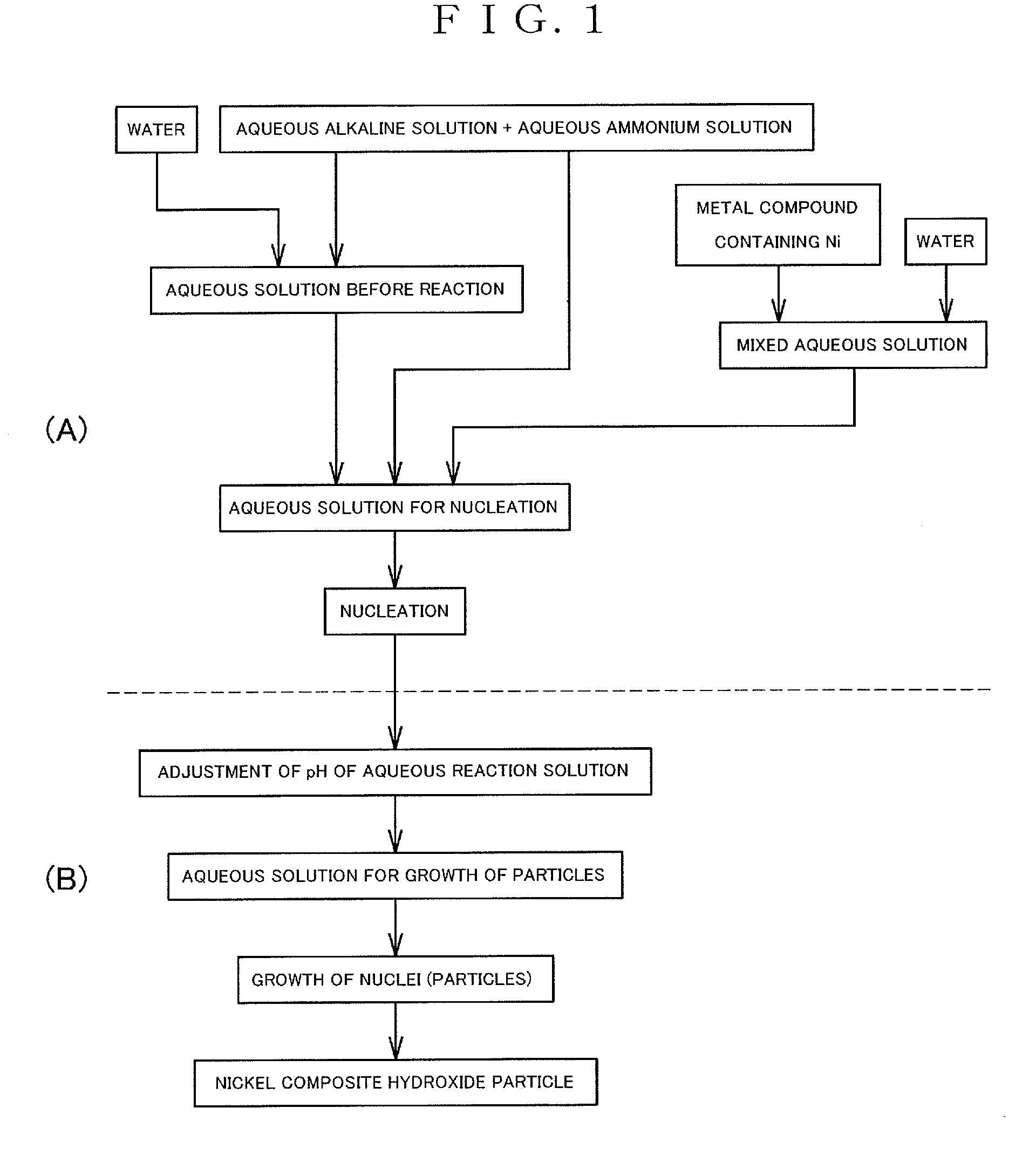

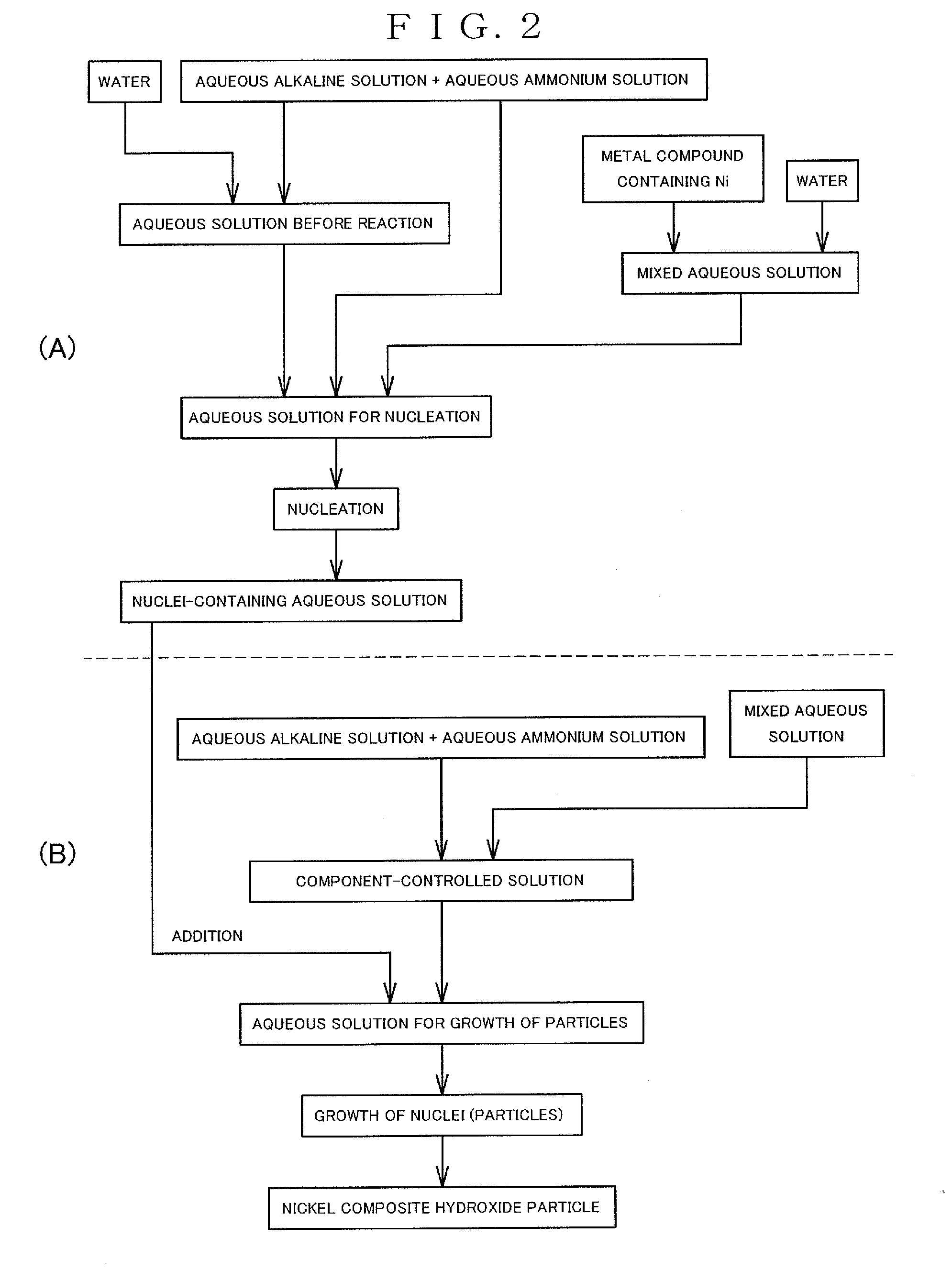

Nickel-cobalt-manganese complex hydroxide particles and method for producing same, positive electrode active material for nonaqueous electrolyte secondary battery and method for producing same, and nonaqueous electrolyte secondary battery

ActiveUS20120270107A1Growth inhibitionFast executionNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLiquid temperatureManganese

An object of the present invention is to provide nickel cobalt manganese composite hydroxide particles having a small particle diameter and a uniform particle size distribution, and a method for producing the same.[Solution]A method for producing a nickel cobalt manganese composite hydroxide by a crystallization reaction is provided. The method includes: a nucleation step of performing nucleation by controlling a pH of an aqueous solution for nucleation including metal compounds containing nickel, cobalt and manganese, and an ammonium ion donor to 12.0 to 14.0 in terms of the pH as measured at a liquid temperature of 25° C. as a standard; and a particle growth step of growing nuclei by controlling a pH of an aqueous solution for particle growth containing nuclei formed in the nucleation step to 10.5 to 12.0 in terms of the pH as measured at a liquid temperature of 25° C. as a standard.

Owner:SUMITOMO METAL MINING CO LTD +1

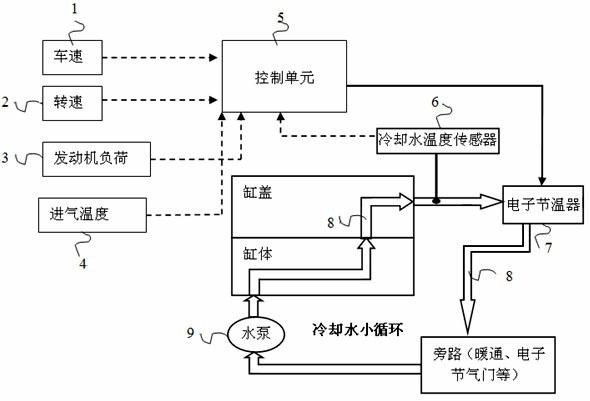

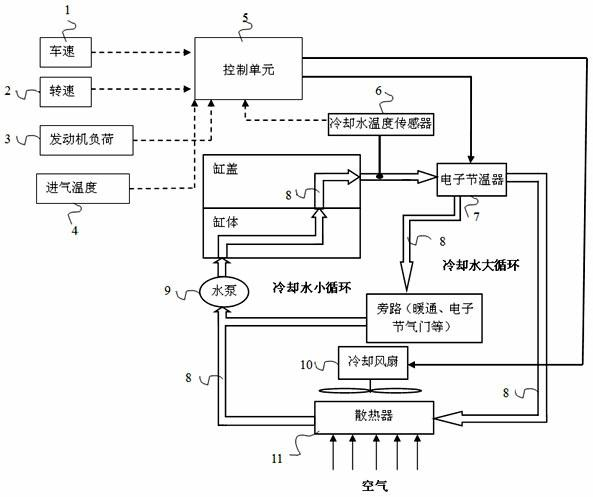

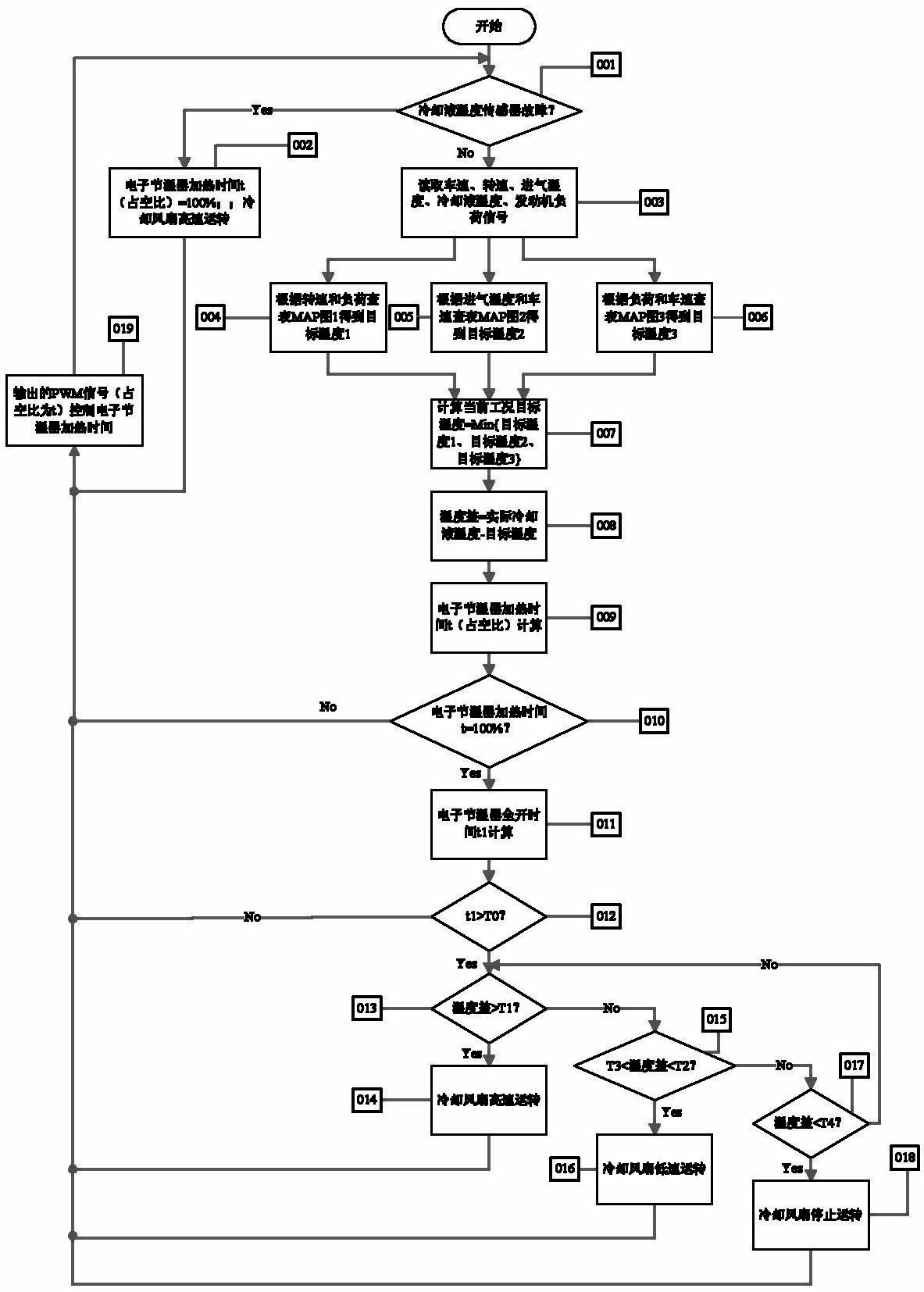

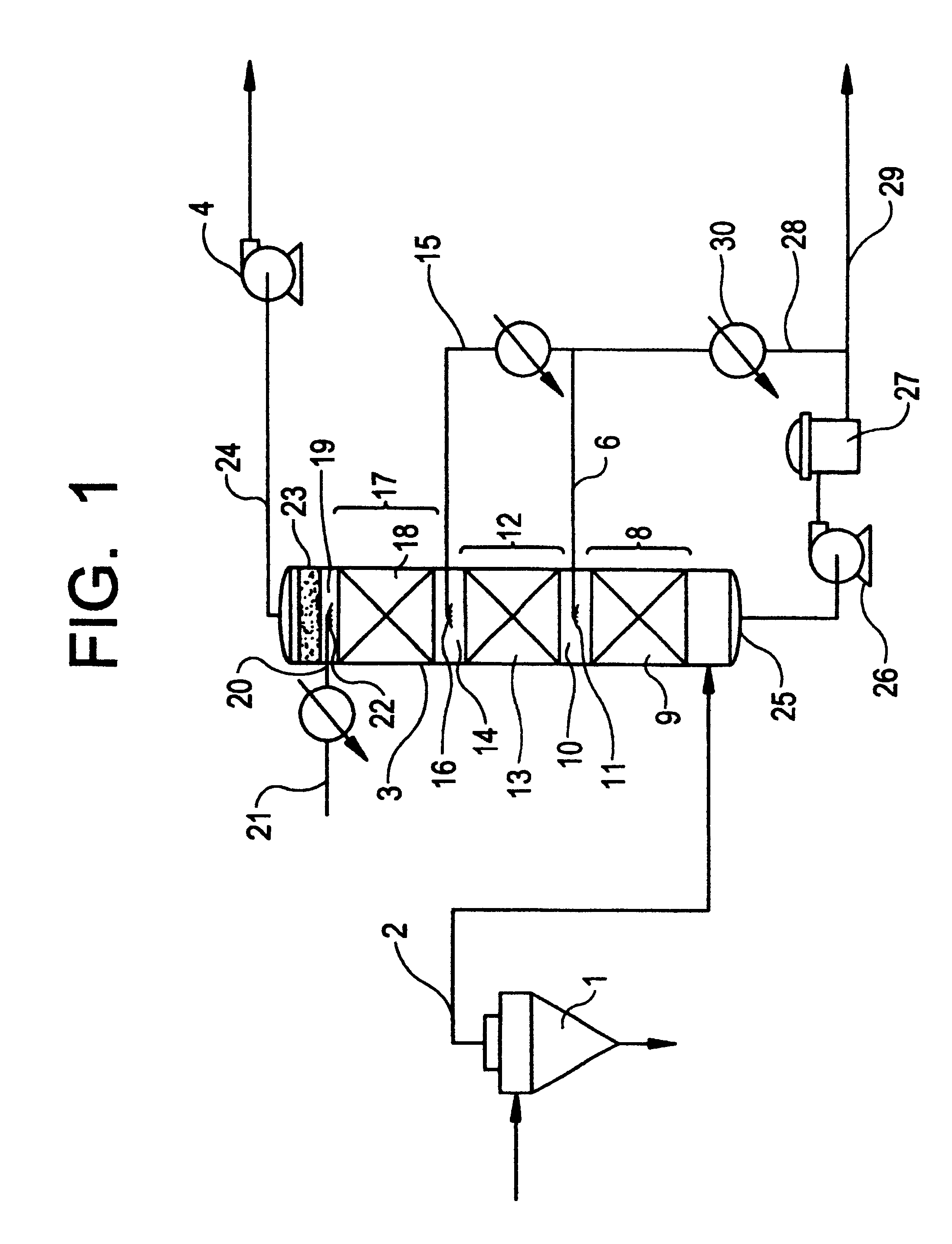

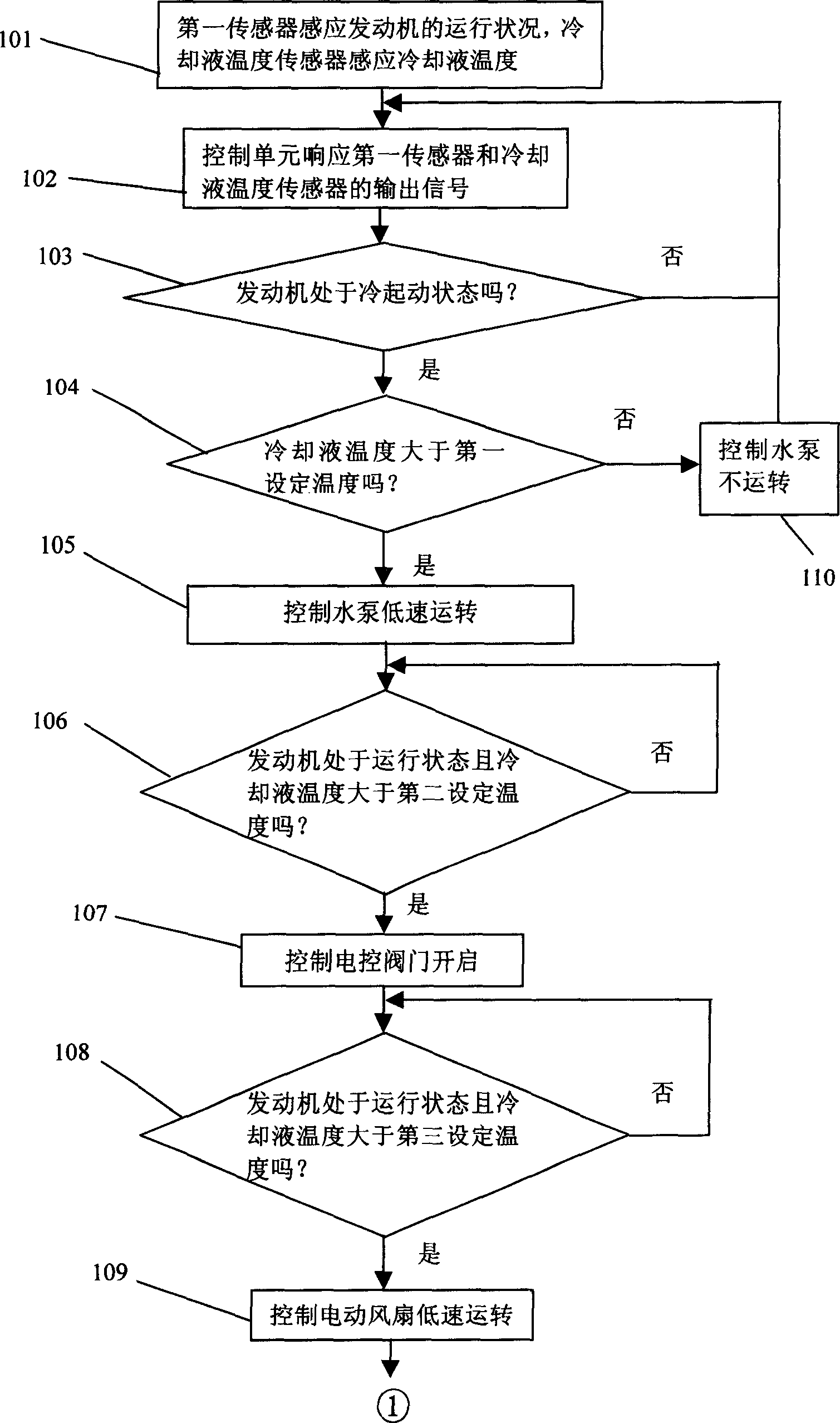

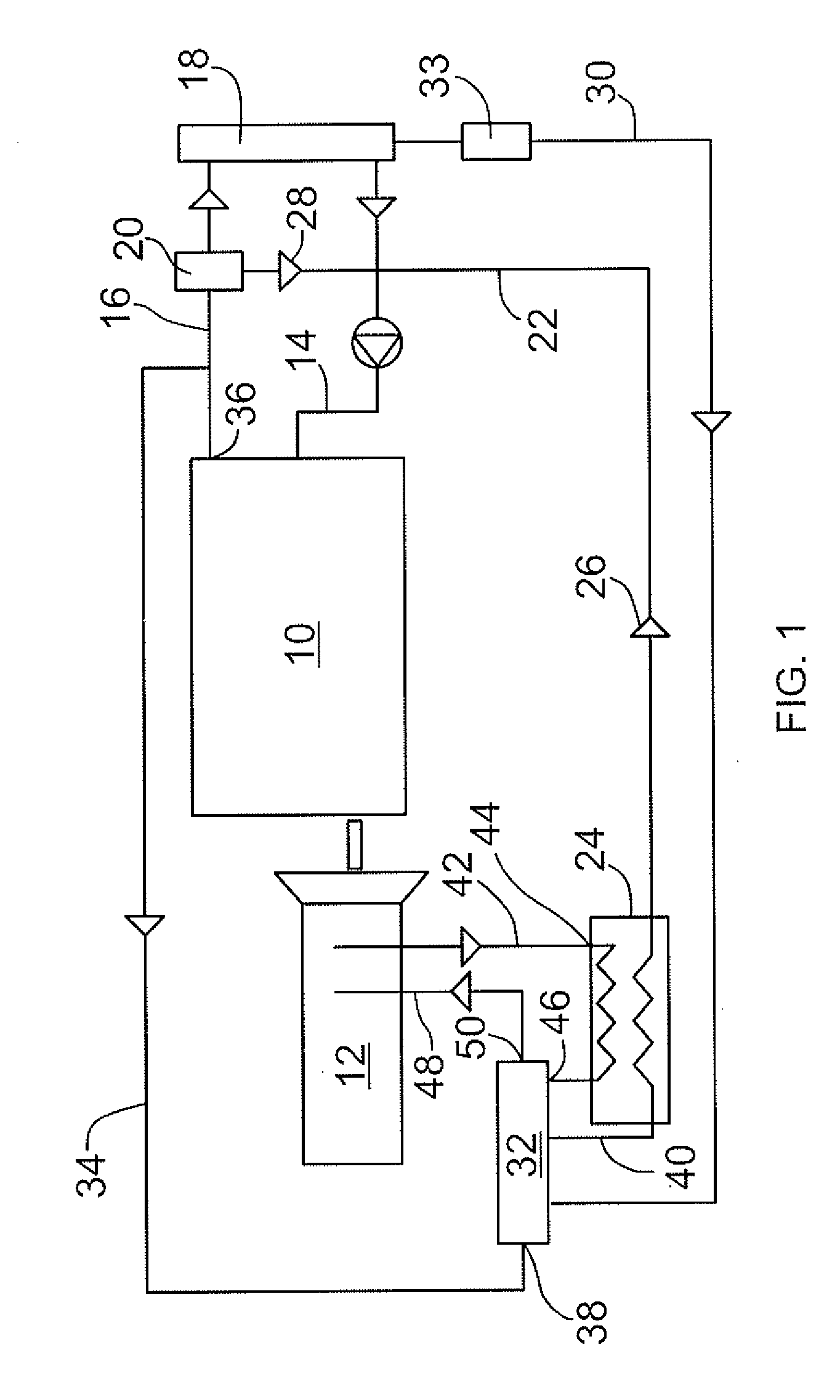

Engine cooling system and temperature control method of cooling liquid thereof

ActiveCN102182540AEmission reductionReduce turn-on timeCoolant flow controlMachines/enginesLow speedLiquid temperature

The invention discloses an engine cooling system and a temperature control method of cooling liquid thereof. The engine cooling system comprises a heat radiator, a water pump, a circulating water jacket, an electronic thermostat, a cooling fan, a cooling liquid temperature sensor and an engine control unit, wherein the control unit determines the cooling liquid target temperature of an engine under the current operation working condition according to acquired signals, such as engine rotating speed, load, speed, air inlet temperature, and the like and ensures that the engine works under the optimal cooling liquid temperature condition by controlling the heating time of the electronic thermostat and the high and low speed running of the cooling fan.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Liquid sensor and ice detector

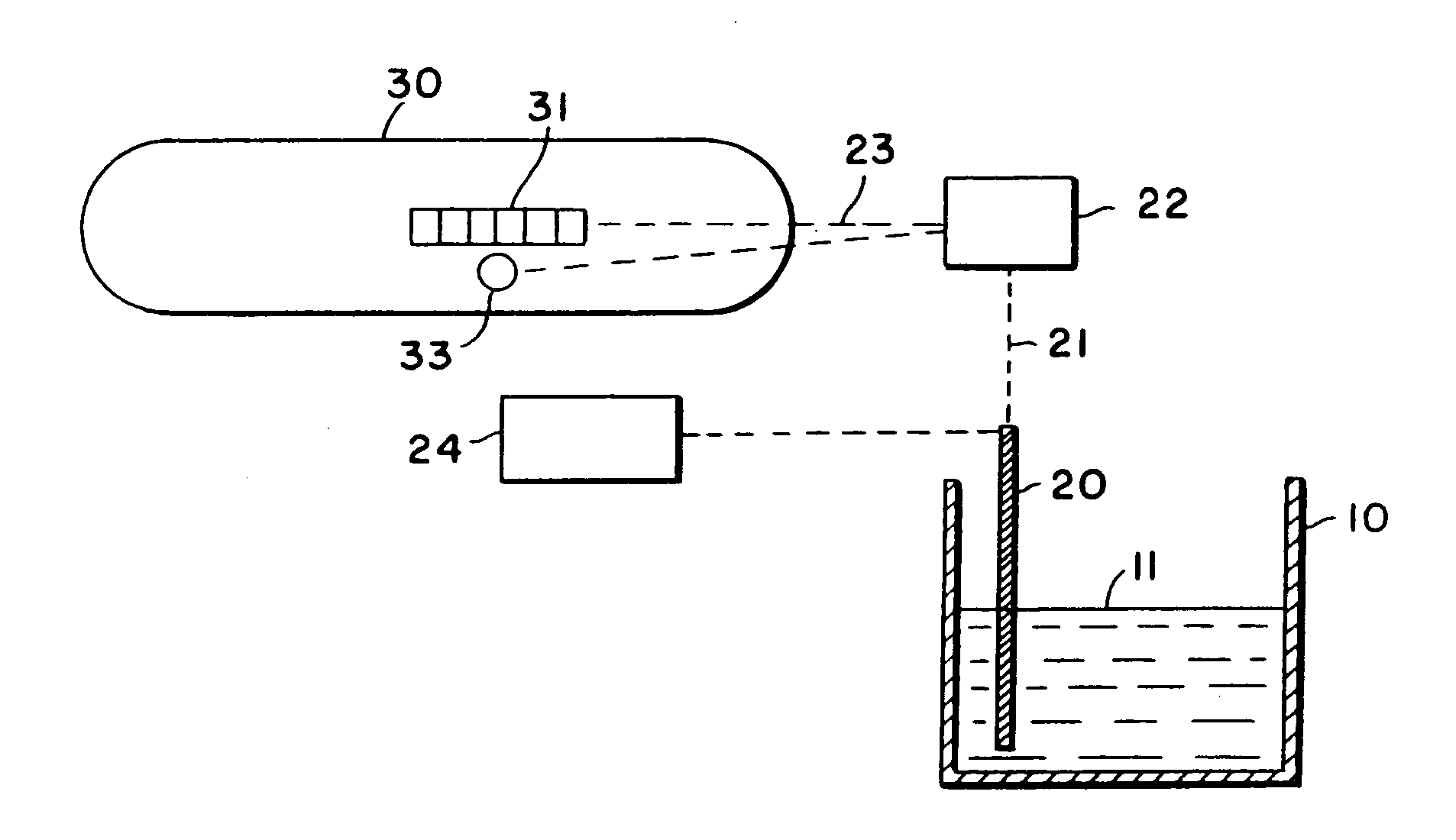

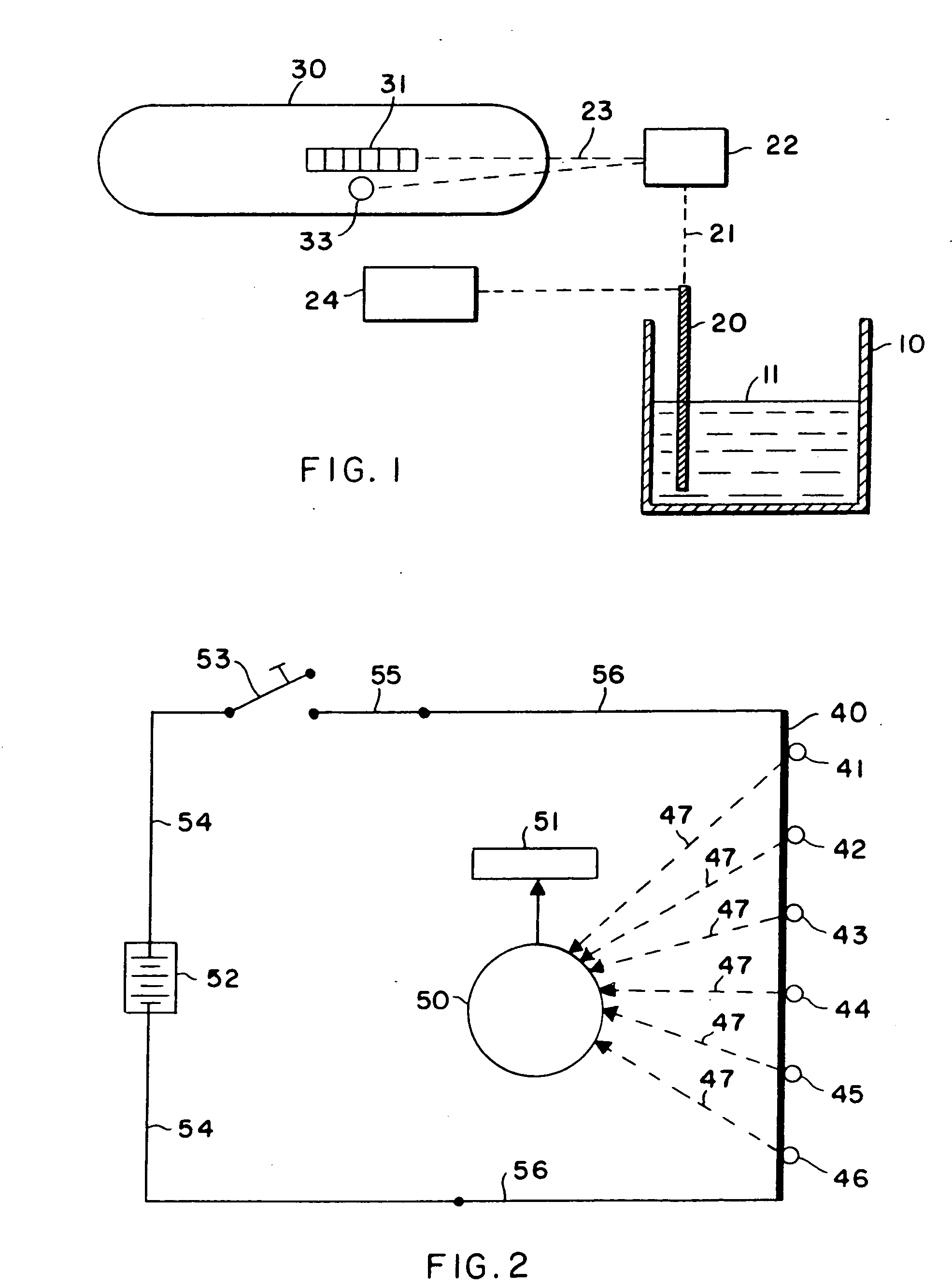

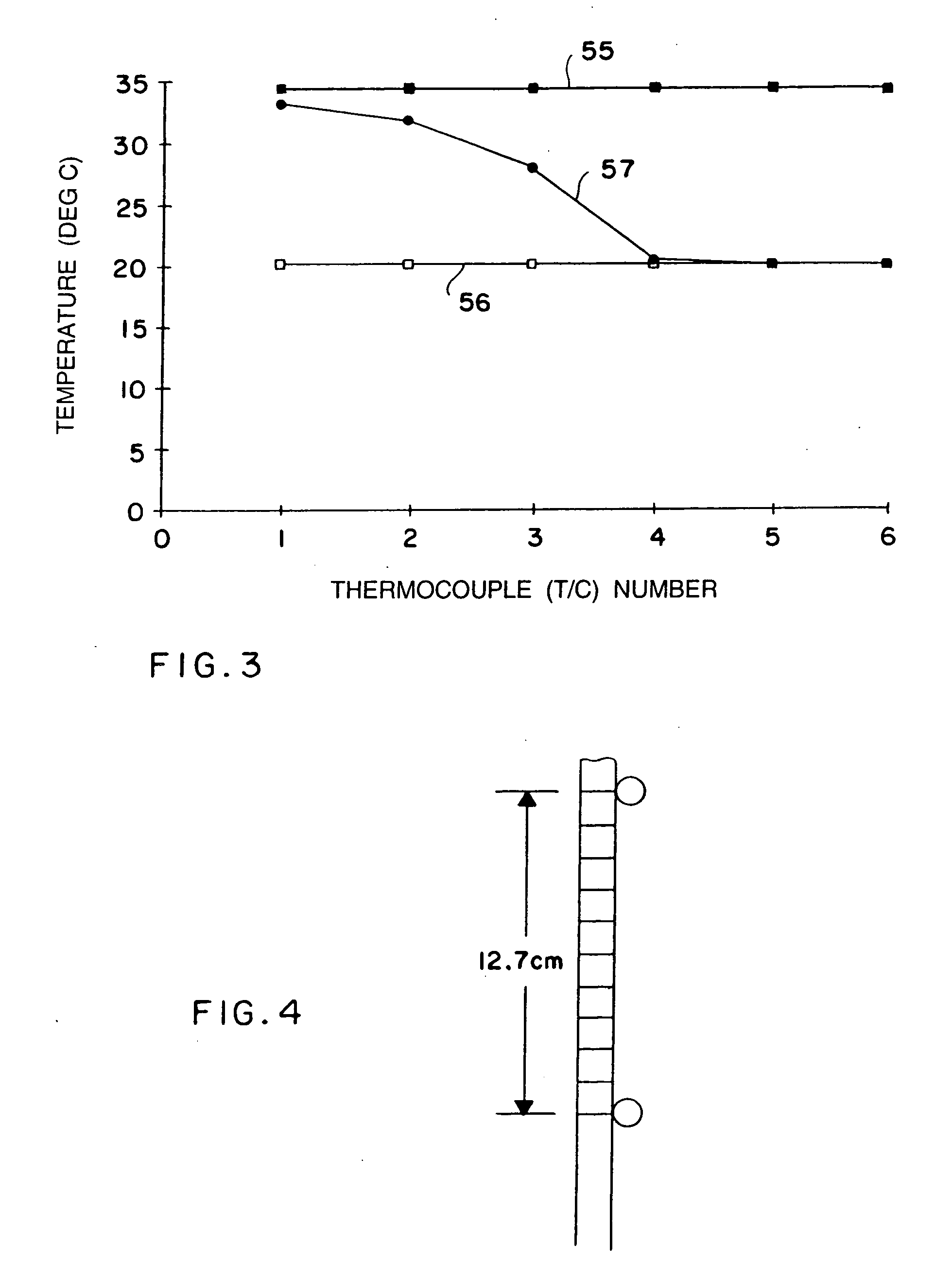

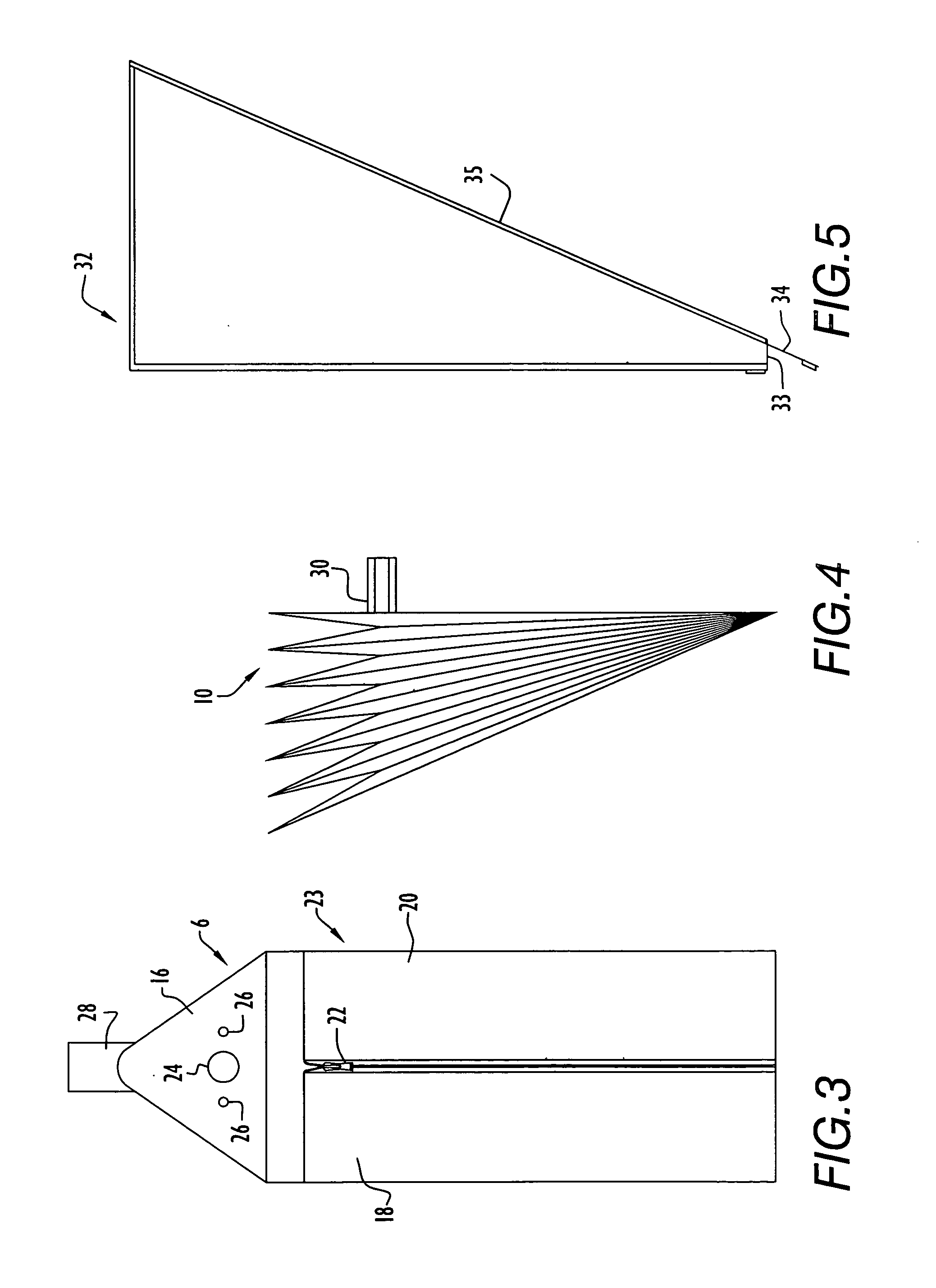

InactiveUS20050126282A1Difference in efficiencyRemove heat moreMachines/enginesLubrication indication devicesScreen printingLiquid temperature

An improved apparatus and a method of measuring and interpreting reliably, simply and accurately the information on continuous liquid level, liquid temperature and other liquid properties within a vessel. The apparatus could be made of a powered heater element and temperature sensors can be screen-printed, vacuum deposited, etched, welded, soldered or plated on one or both sides of a single rigid or a flexible substrate. The geometry of the heater determines the curve shape, such as steepness or shallowness of a temperature profile along a heater. Various parallel and serial configurations of thermocouples or temperature sensors can be used to measure the temperature along a heater. Simultaneous measurements from all the temperature sensors, before and after heat is applied, are used to generate accurate temperature profiles for the entire heater. Different features of the temperature profiles will determine accurately the liquid level, liquid temperature and other liquid properties. Apparatus of the invention may also be used to detect ice formation.

Owner:MAATUK JOSEF

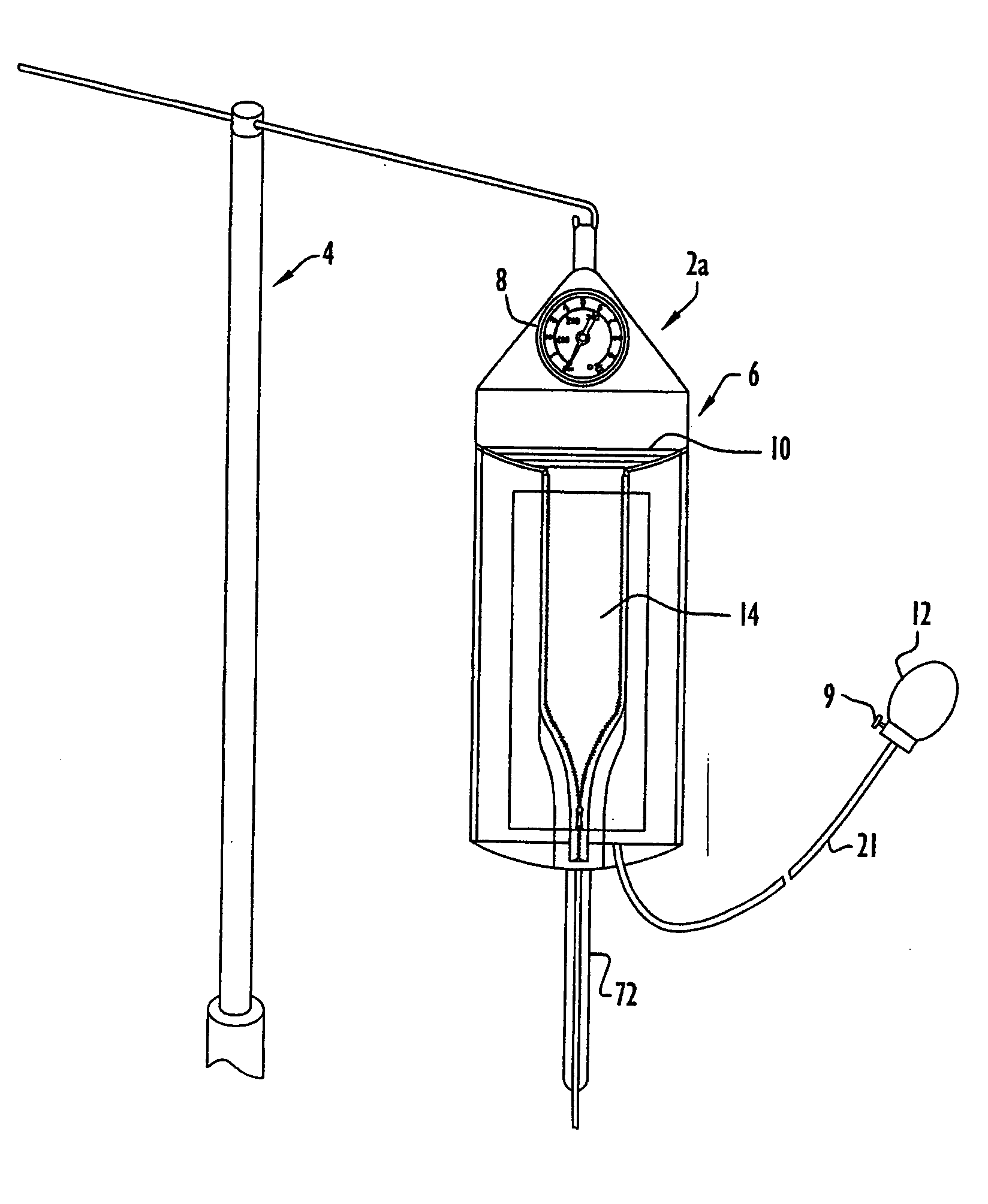

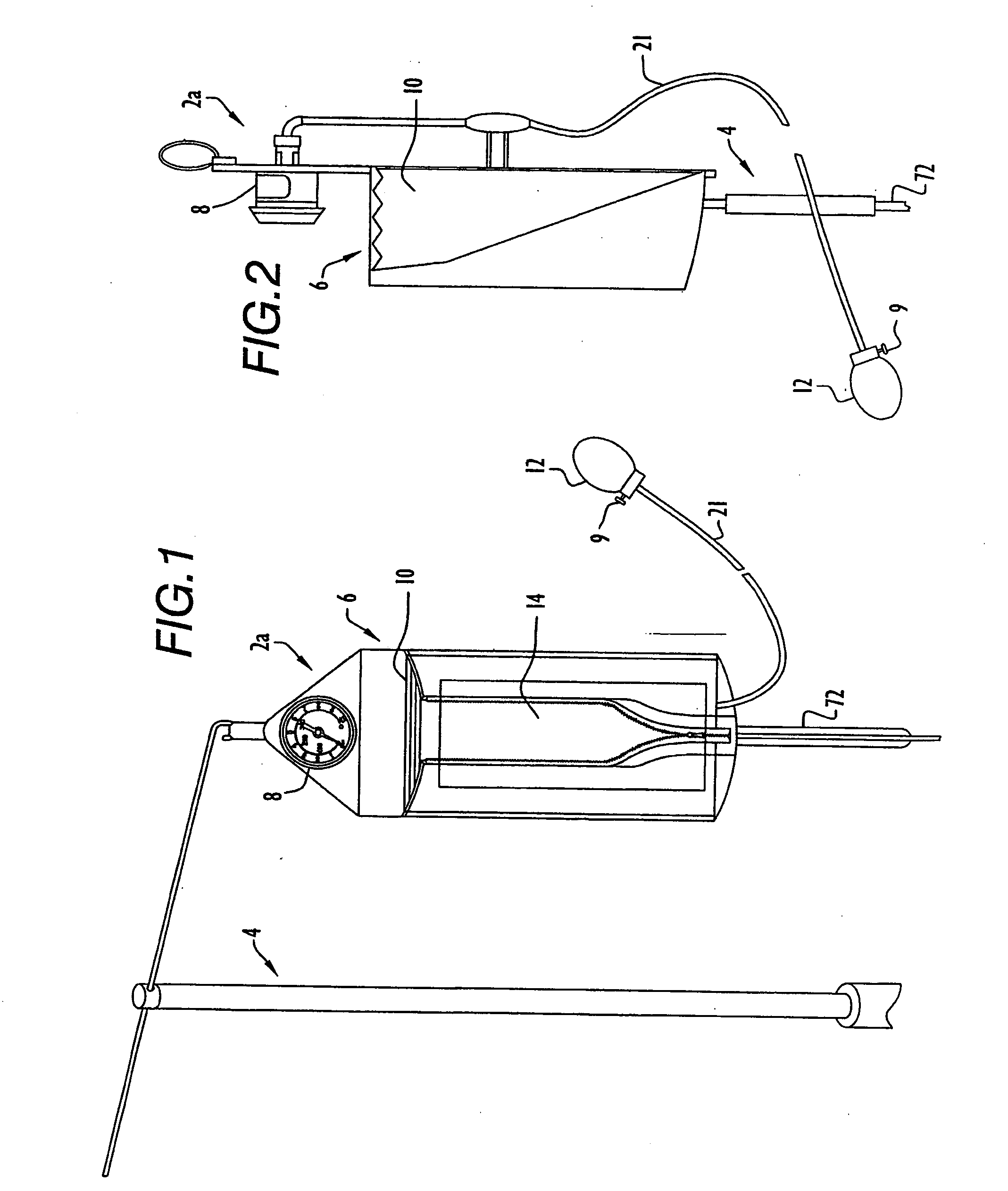

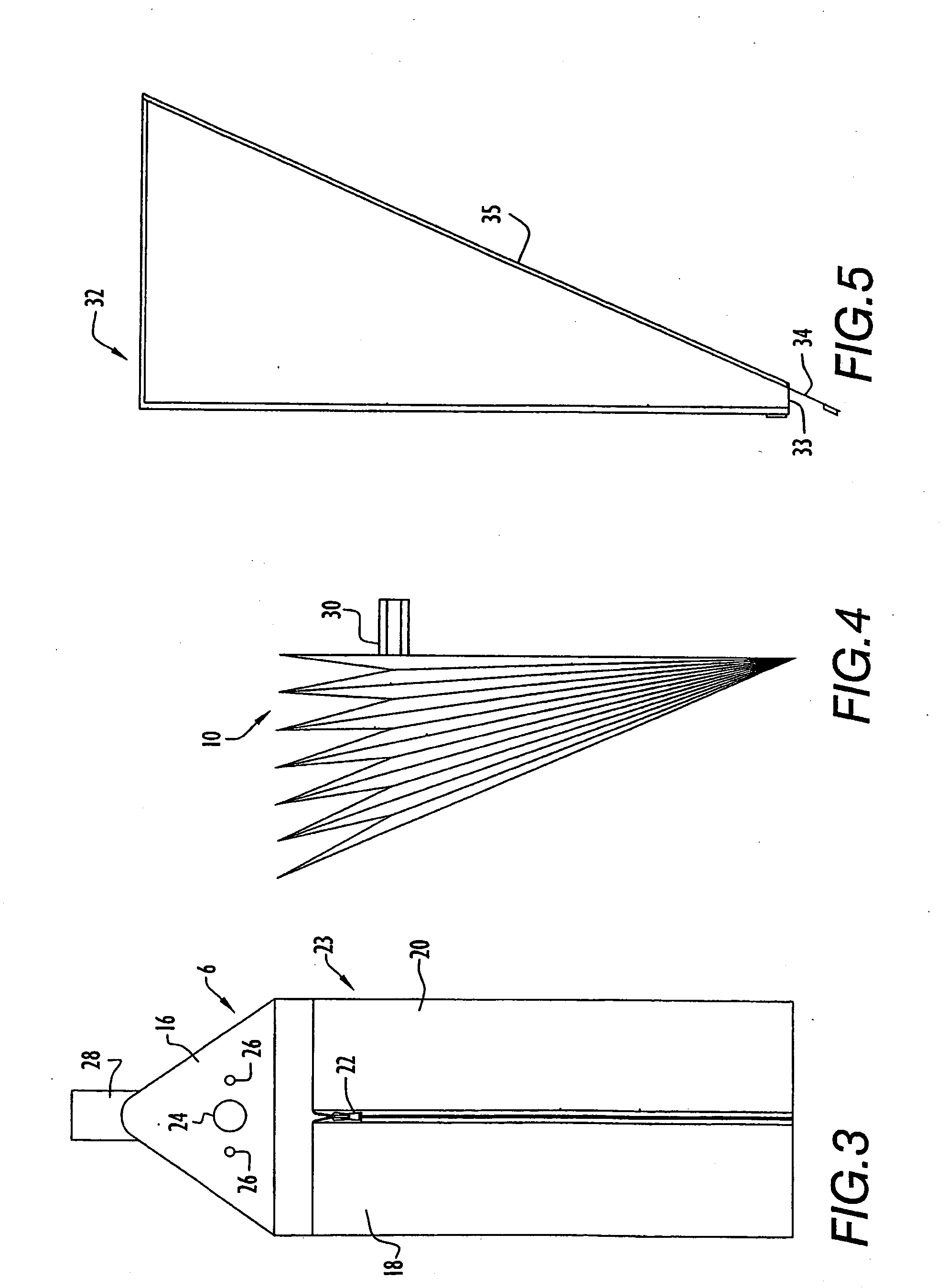

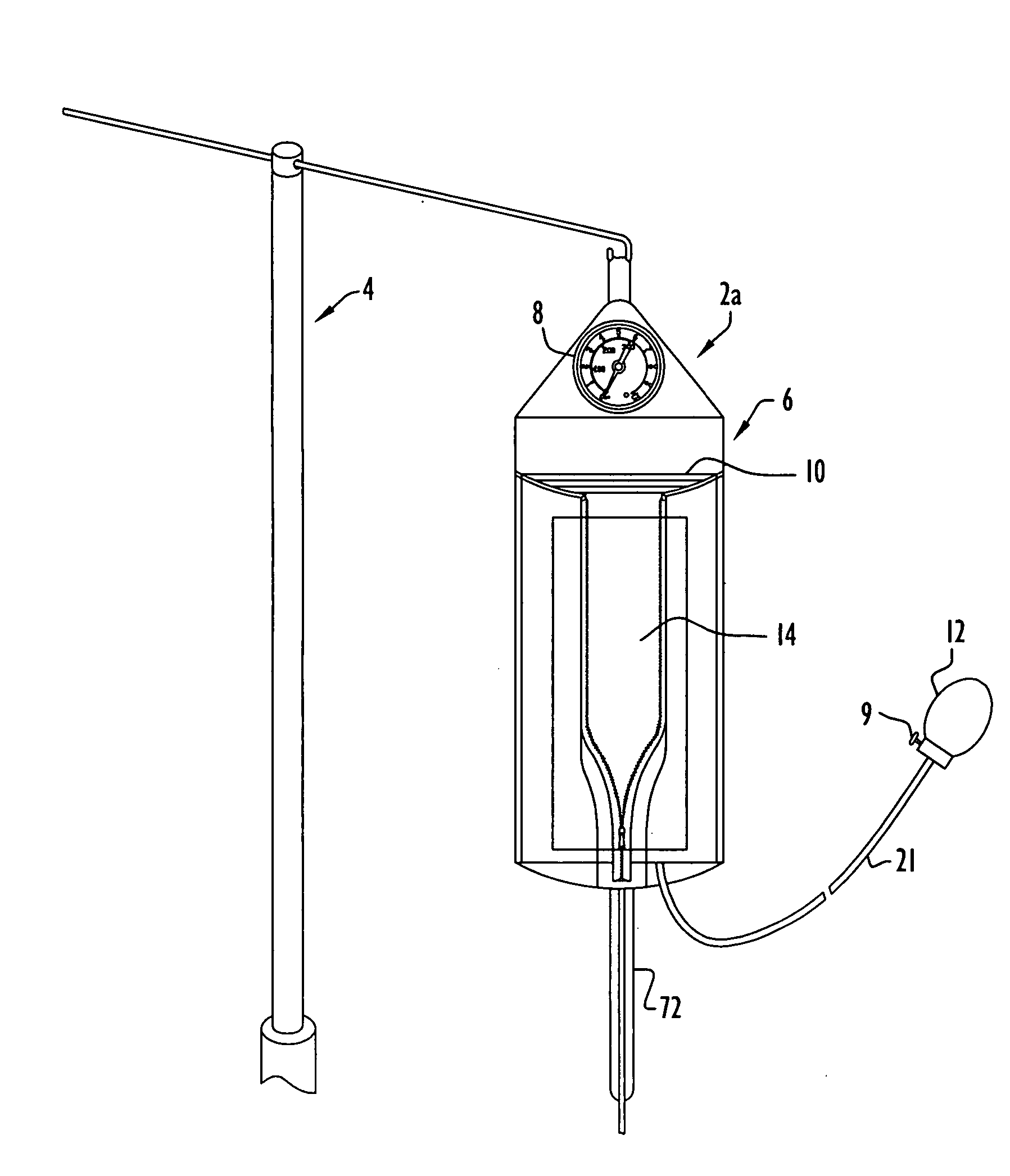

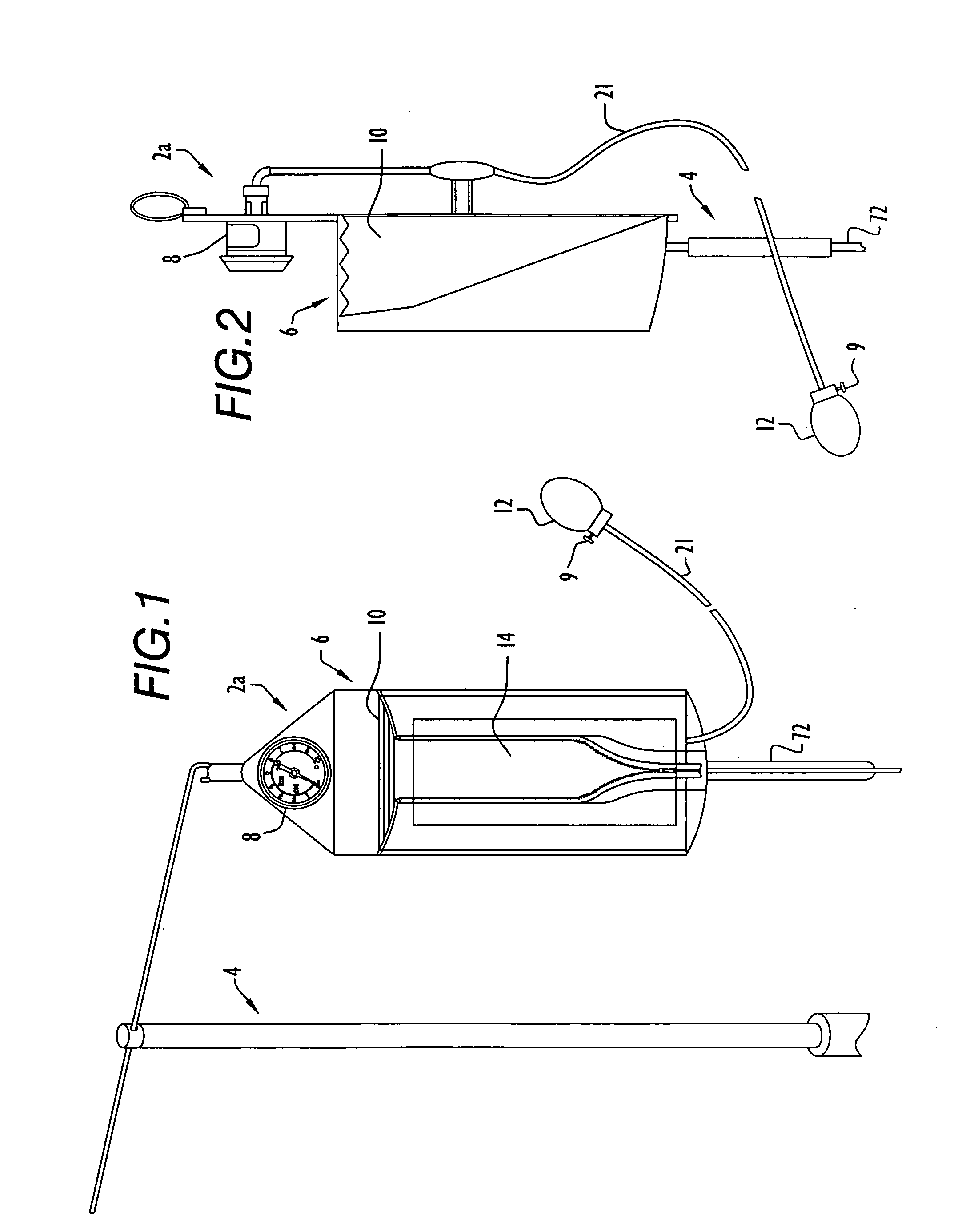

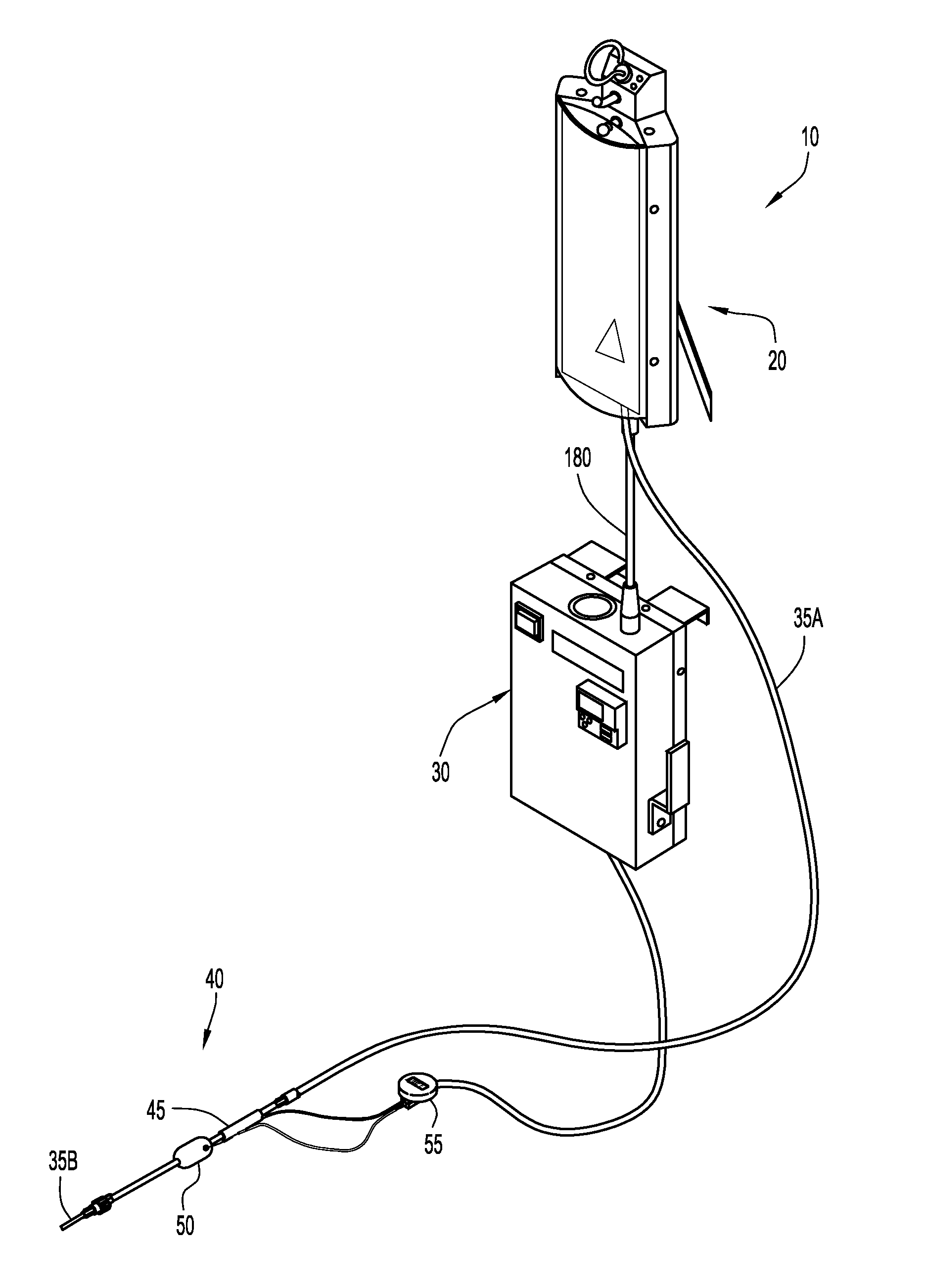

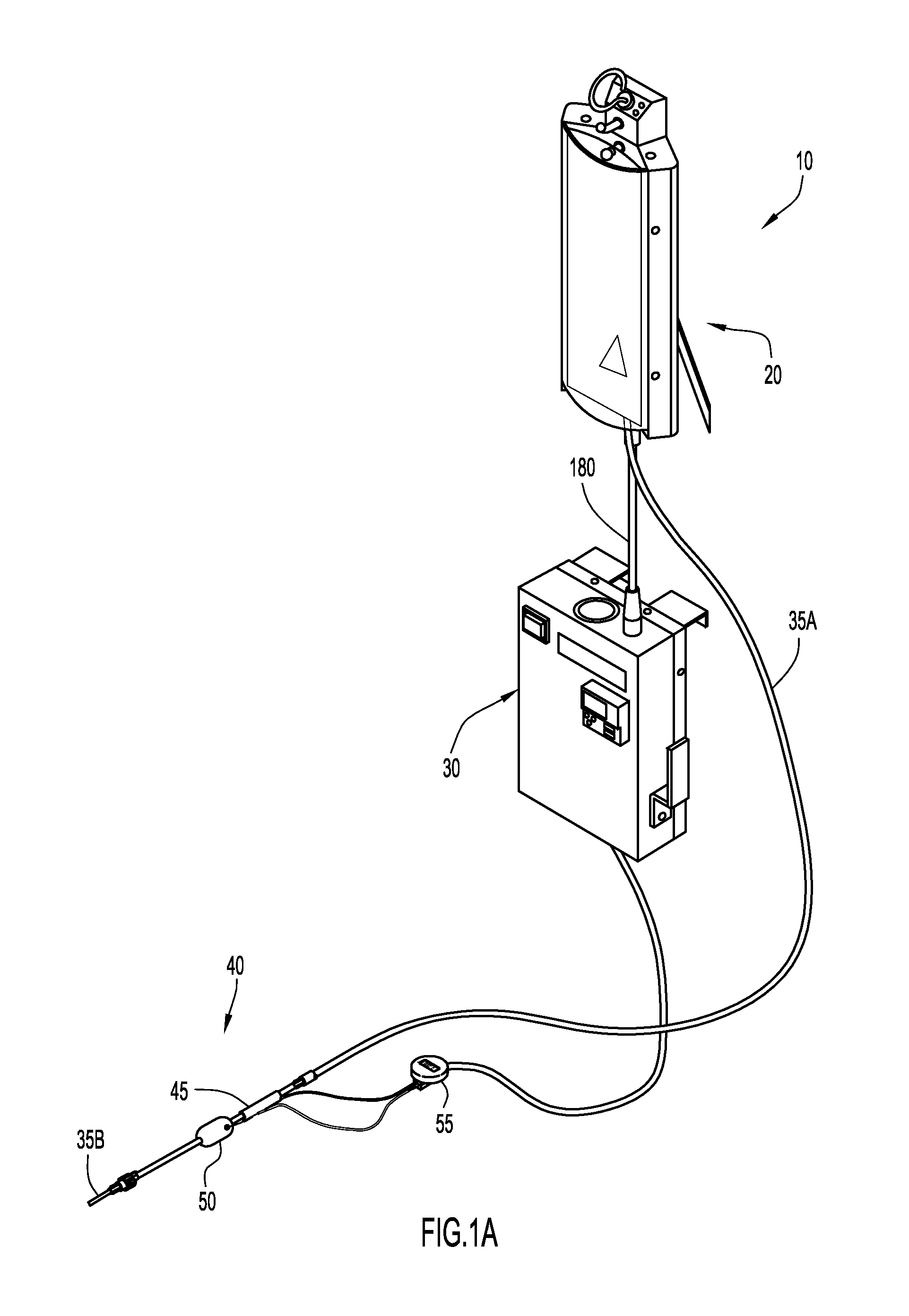

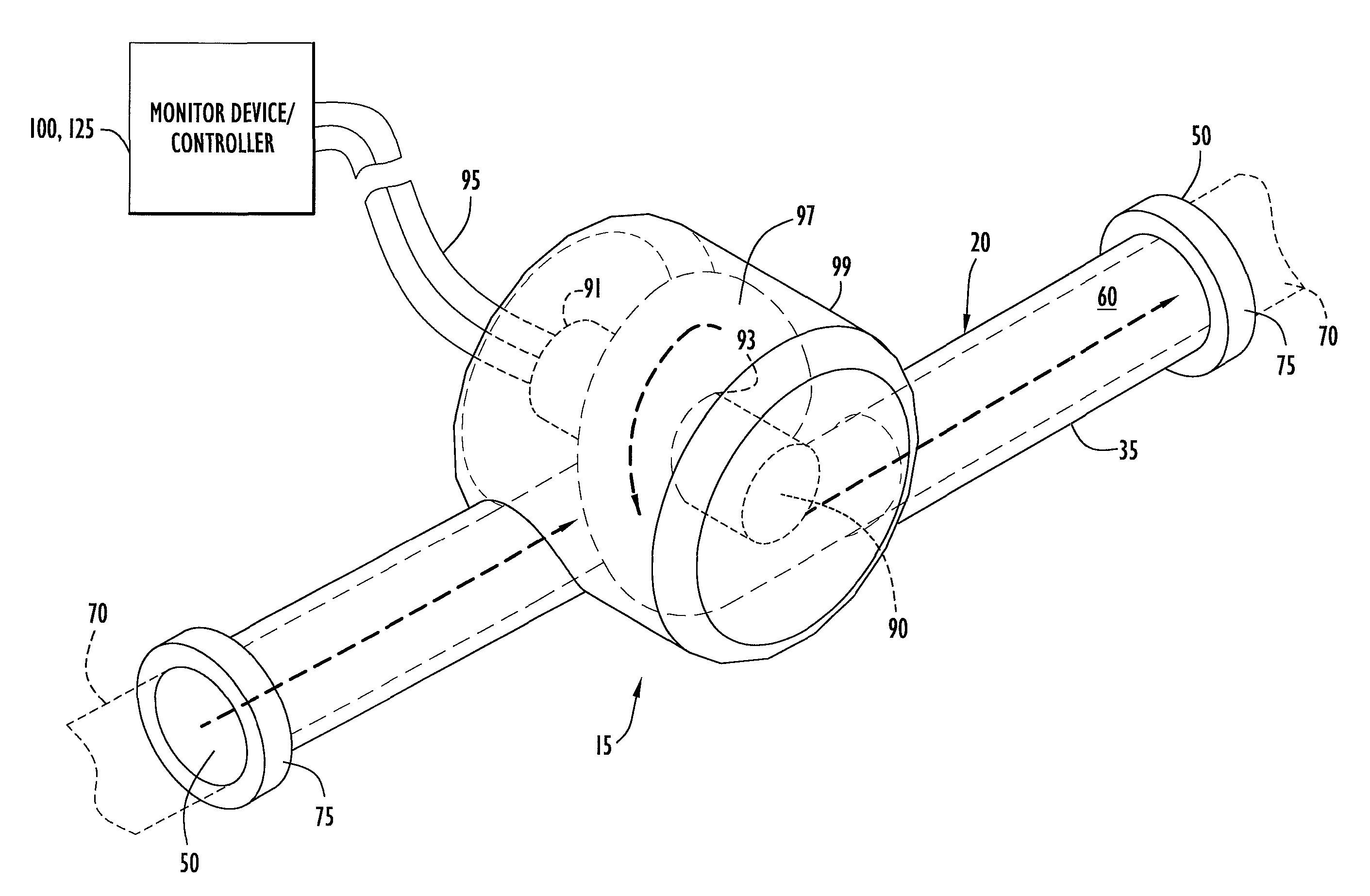

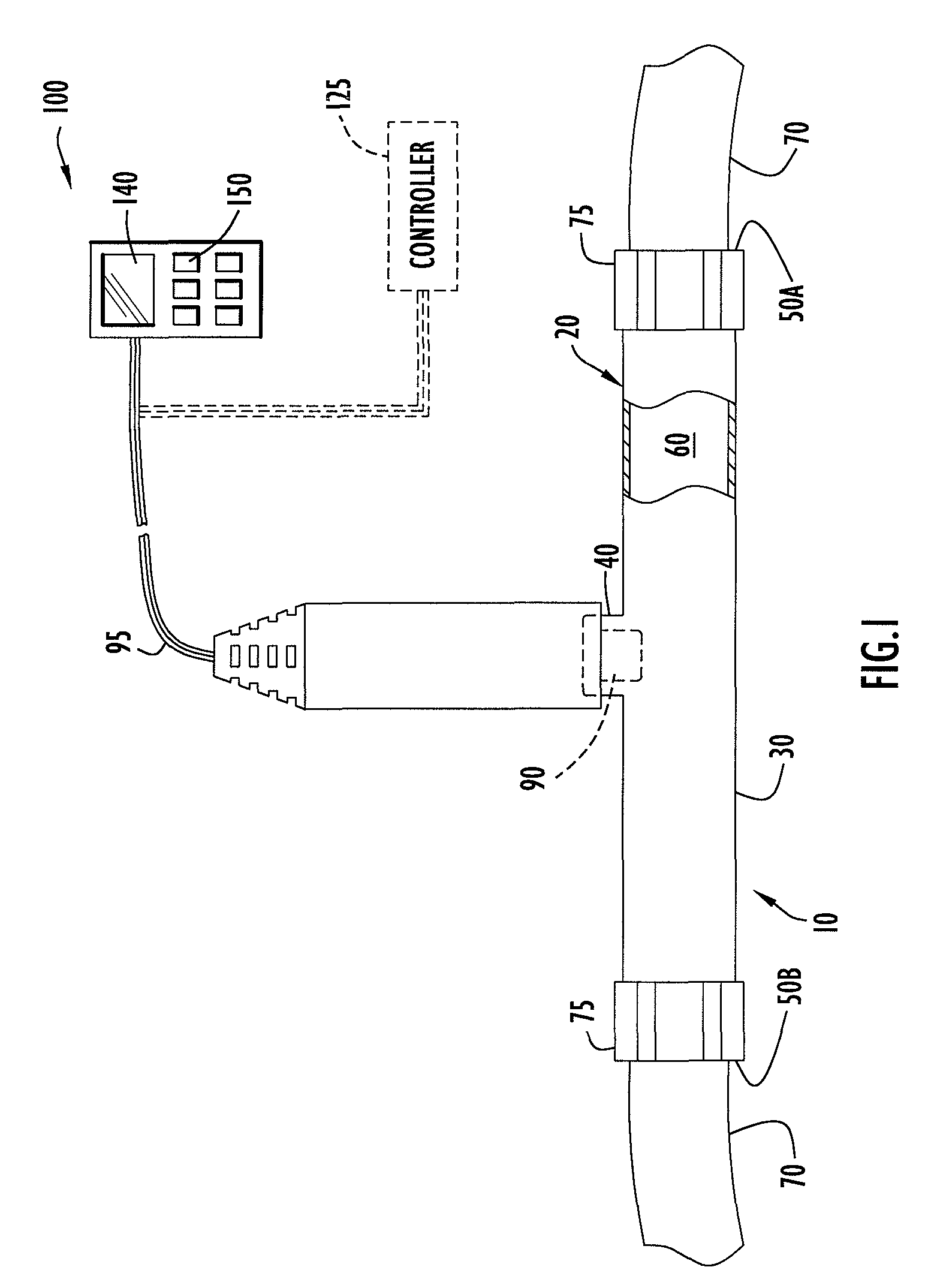

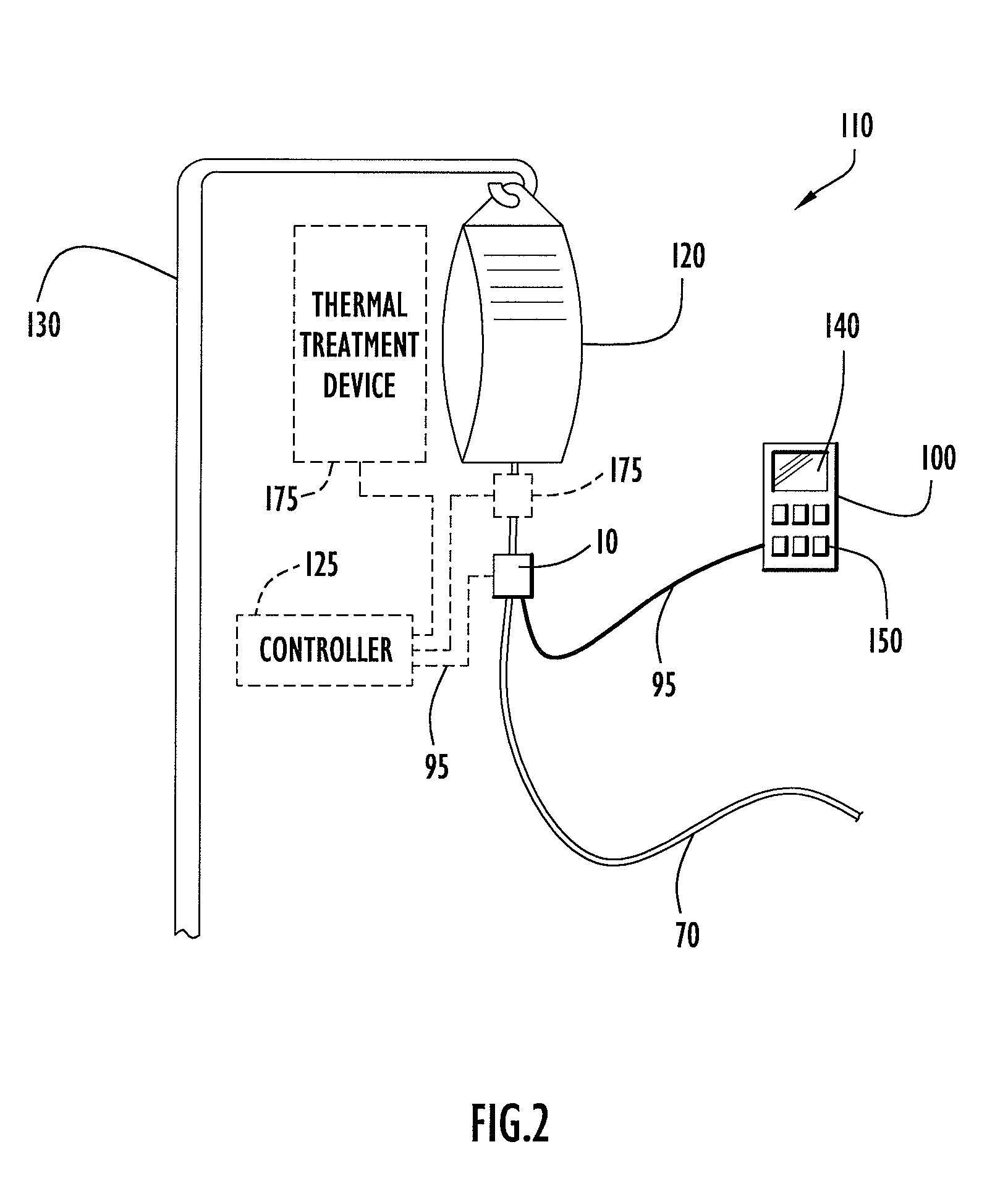

Method and Apparatus for Pressure Infusion and Temperature Control of Infused Liquids

A method and apparatus for pressure infusion and temperature control of infused liquids includes a receptacle for receiving a liquid-filled bag containing intravenous solution or other liquid and an inflatable pressure device. The inflatable pressure device is disposed within a pressure device bag and is positioned proximate the liquid-filled bag in the receptacle. The inflatable pressure device expands within the pressure device bag upon inflation and exerts pressure on the liquid-filled bag. A heating element may be disposed on the inflatable pressure device bag to heat the liquid-filled bag to a desired temperature. The liquid may alternatively be maintained at a desired temperature, while flowing to a patient via a heating assembly disposed along a tube. The heating assembly includes a sleeve having a slot for receiving the tube and a plurality of individually controlled heaters. An infrared sensing device is mounted proximate a drip chamber to ascertain a drip count, while a temperature sensor is disposed within a holder that is positioned toward the entry site on a patient. A heat controller controls the heaters based on a drip count, while a safety controller disables heater operation in response to liquid temperature exceeding the desired temperature. Thus, the safety controller and heat controller, in combination, control the heating assembly heaters based on liquid temperature and flow rate, respectively. Alternatively, the liquid-filled bag may be heated to a desired temperature whereby the heating assembly includes a single heater controlled by a controller to maintain the liquid at the desired temperature during infusion of the liquid into a patient.

Owner:MEDICAL SOLUTIONS INC

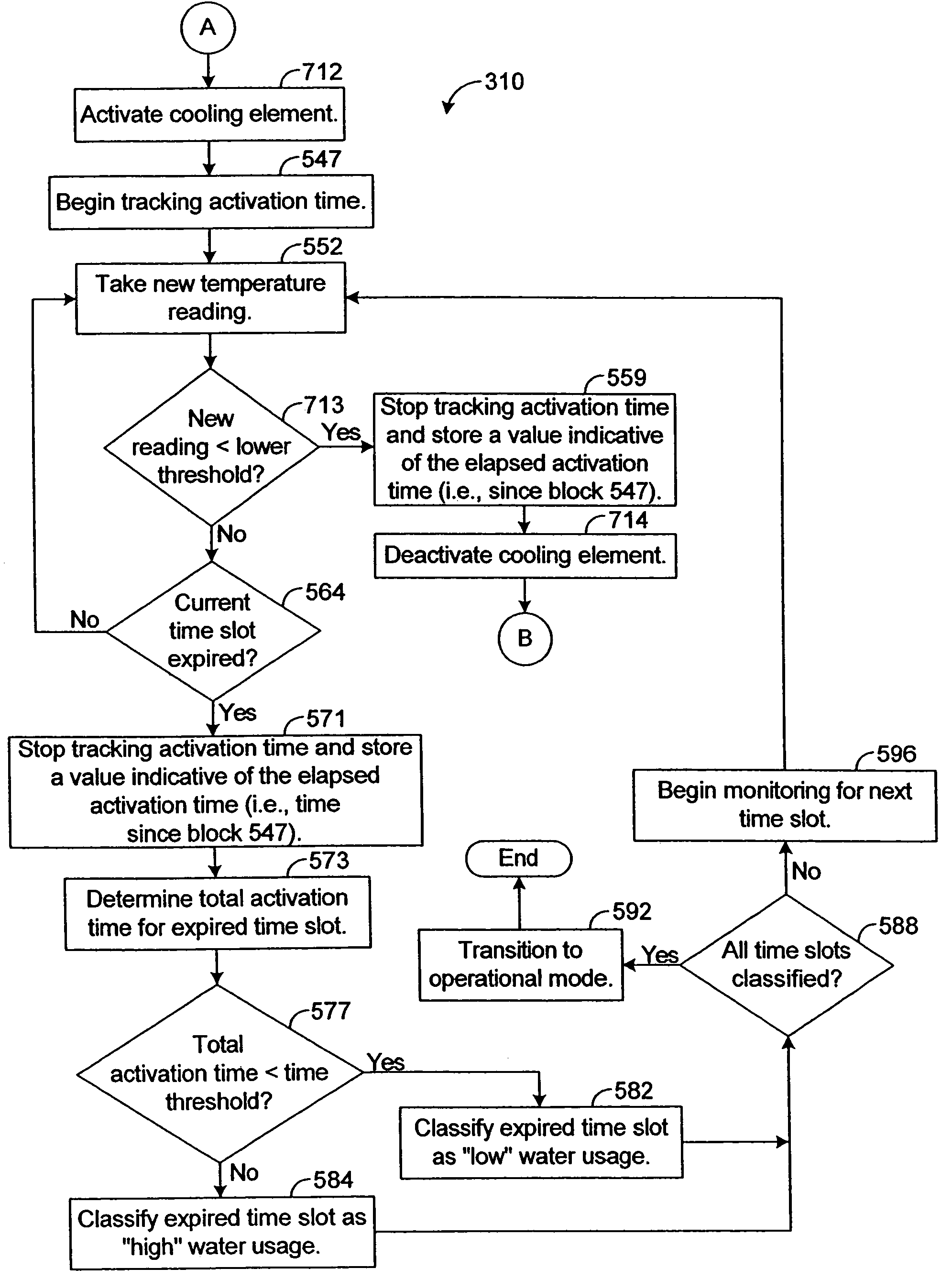

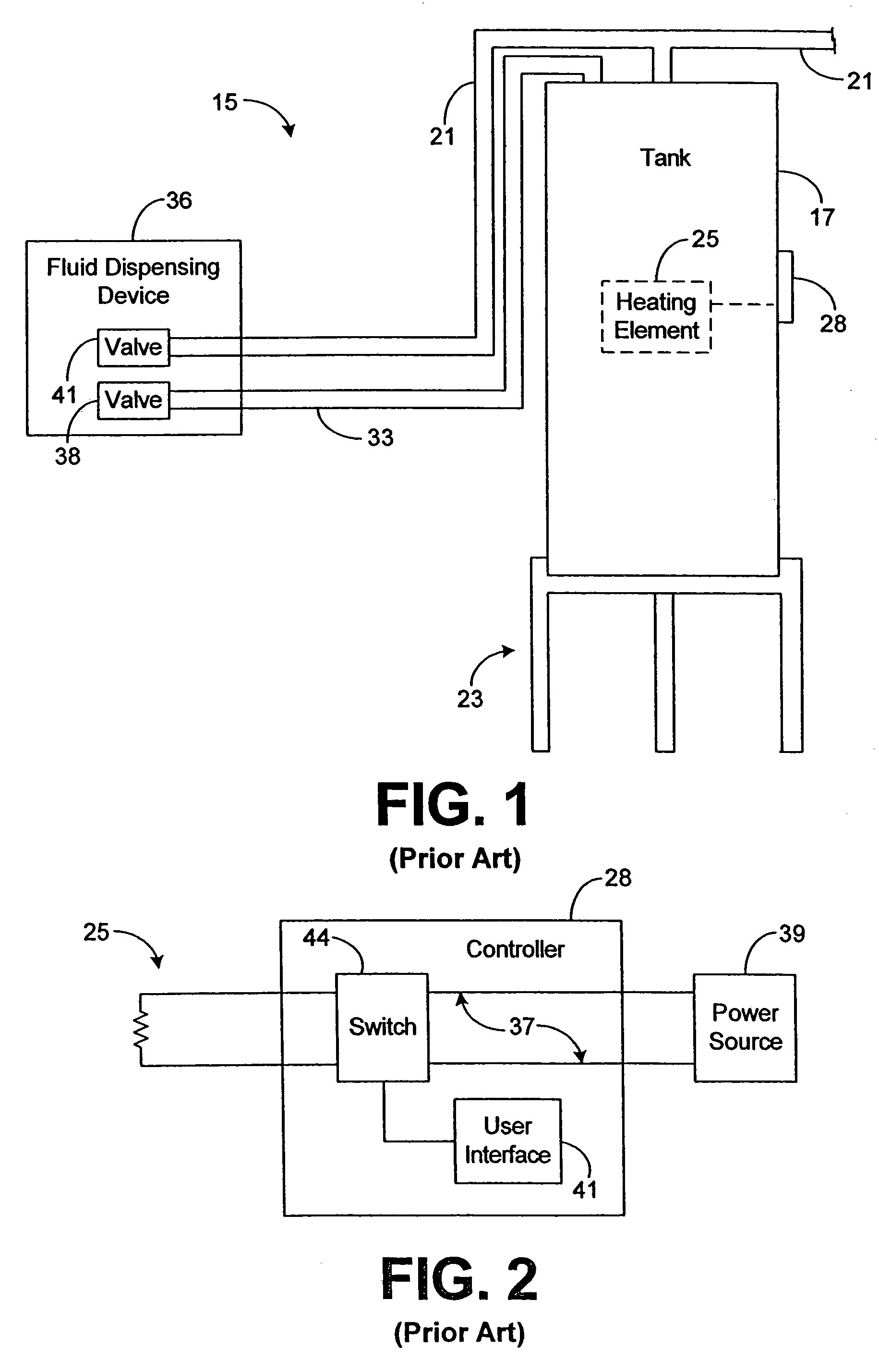

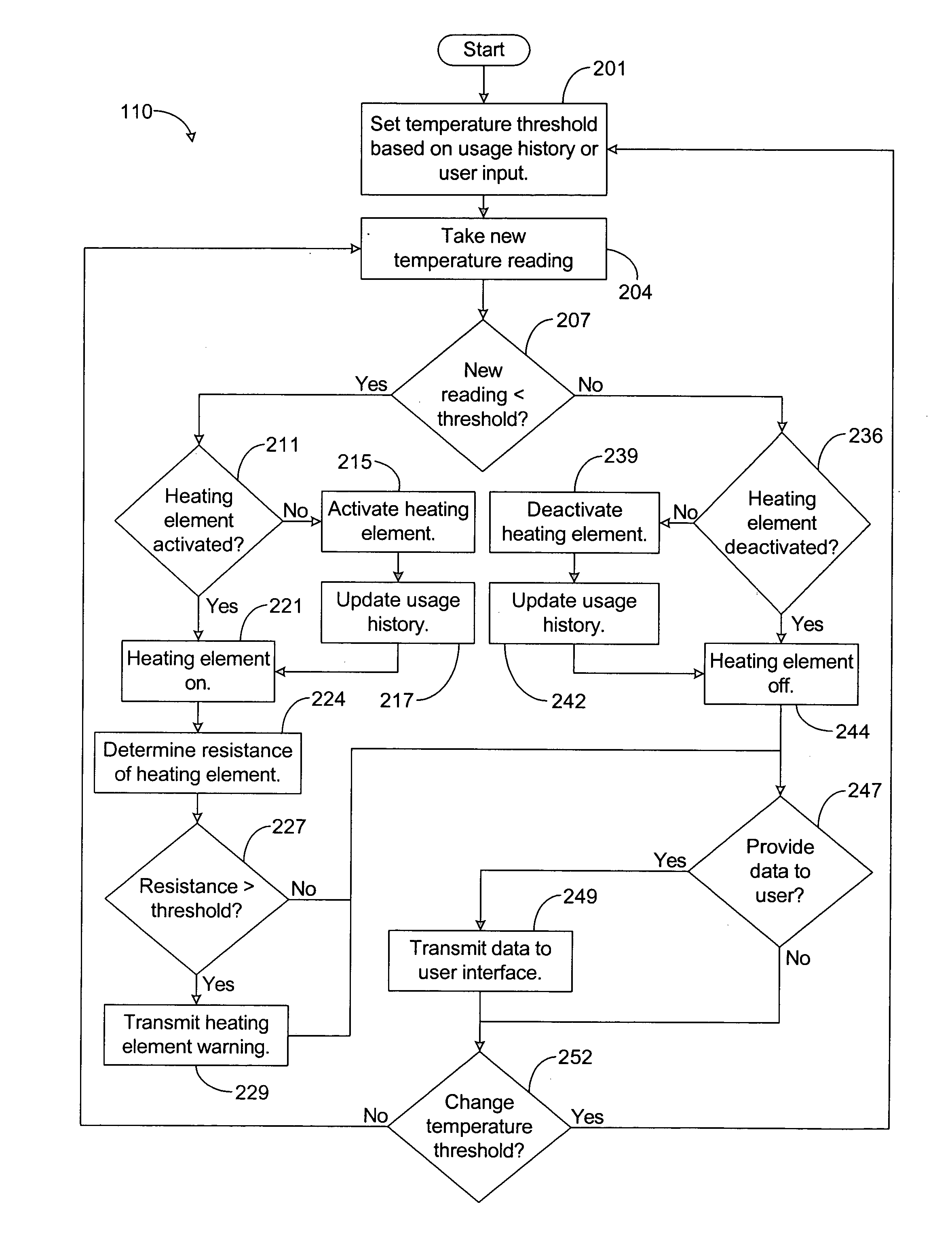

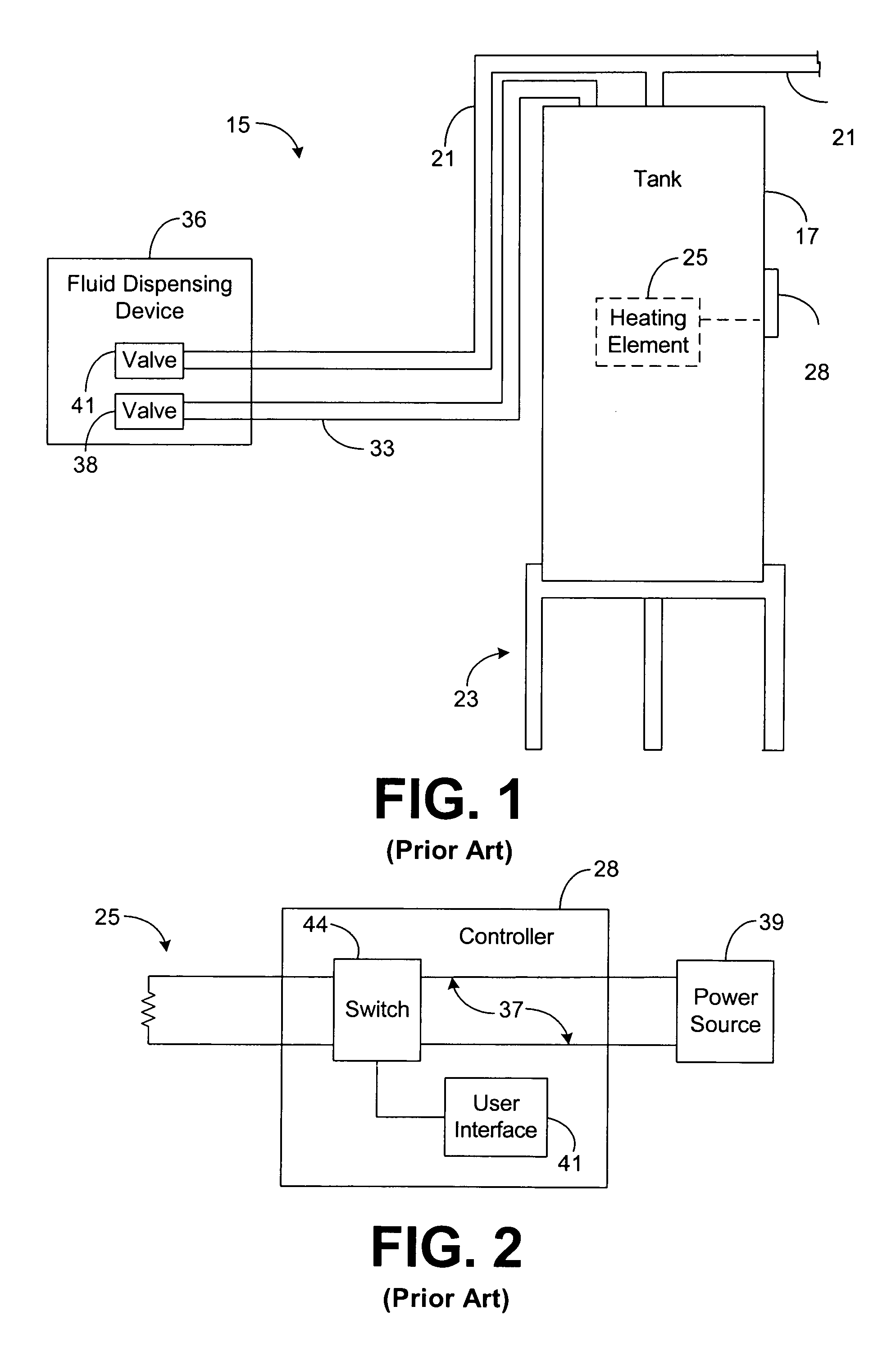

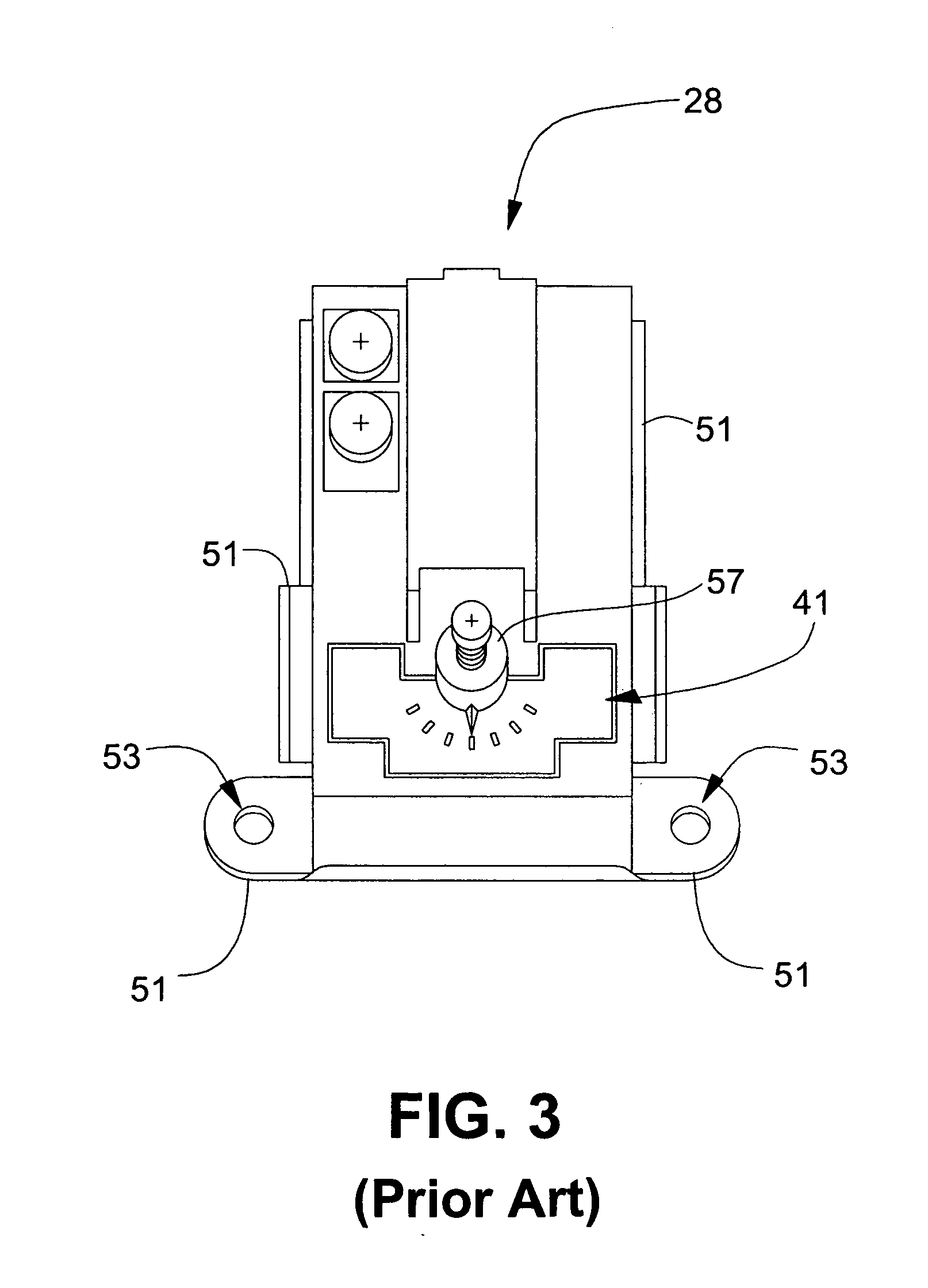

System and method for controlling temperature of a liquid residing within a tank

InactiveUS7065431B2Temperature control using digital meansThermometers using electric/magnetic elementsTemperature controlLiquid temperature

A system for controlling a temperature of a liquid residing within a tank comprises a temperature sensor, a temperature control element, memory, and logic. The temperature sensor is configured to detect the temperature of the liquid residing within the tank, and the temperature control element is coupled to the tank. The memory stores data indicative of a usage history of the tank, and the logic is configured to automatically control the temperature control element based on the data.

Owner:A O SMITH

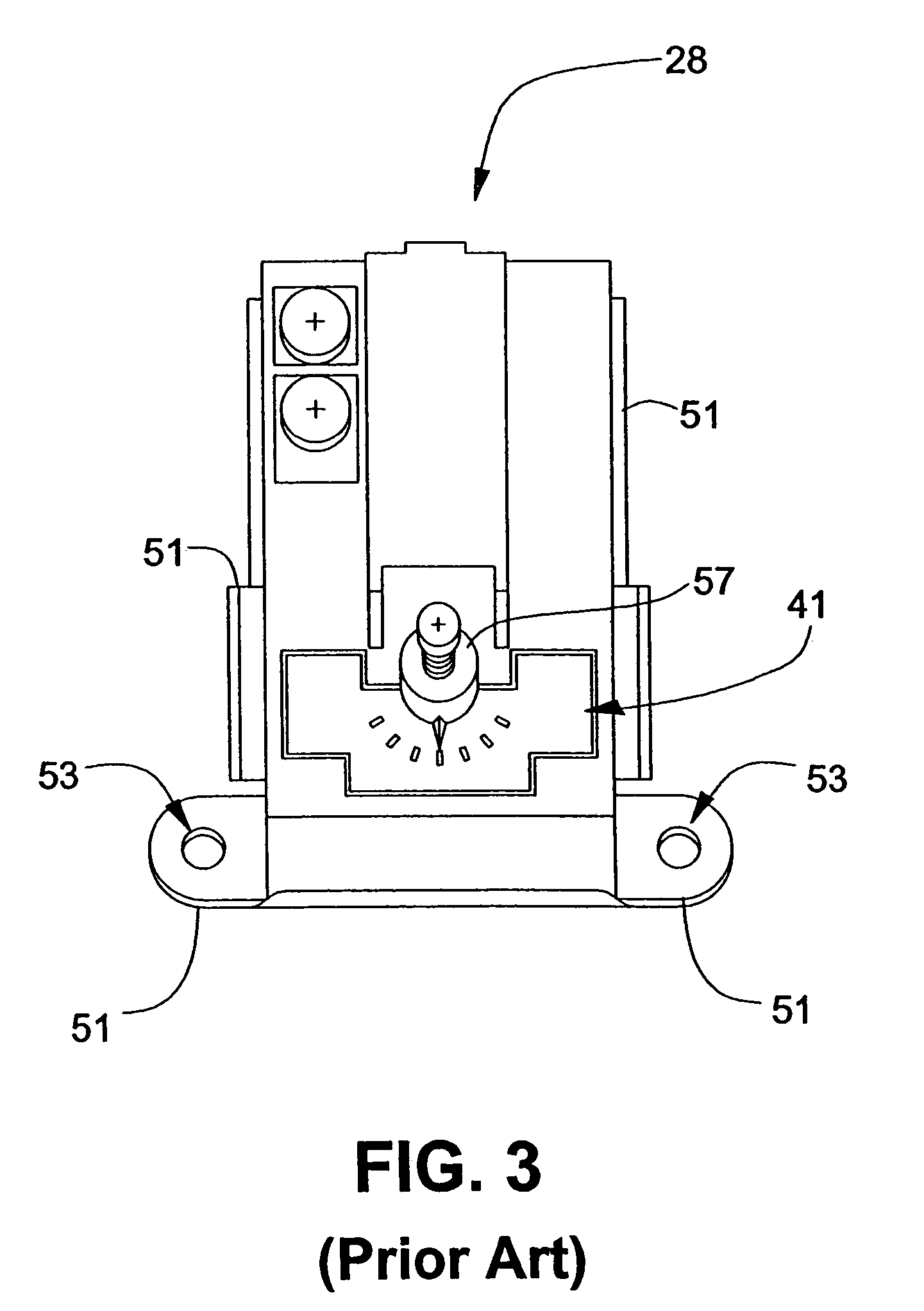

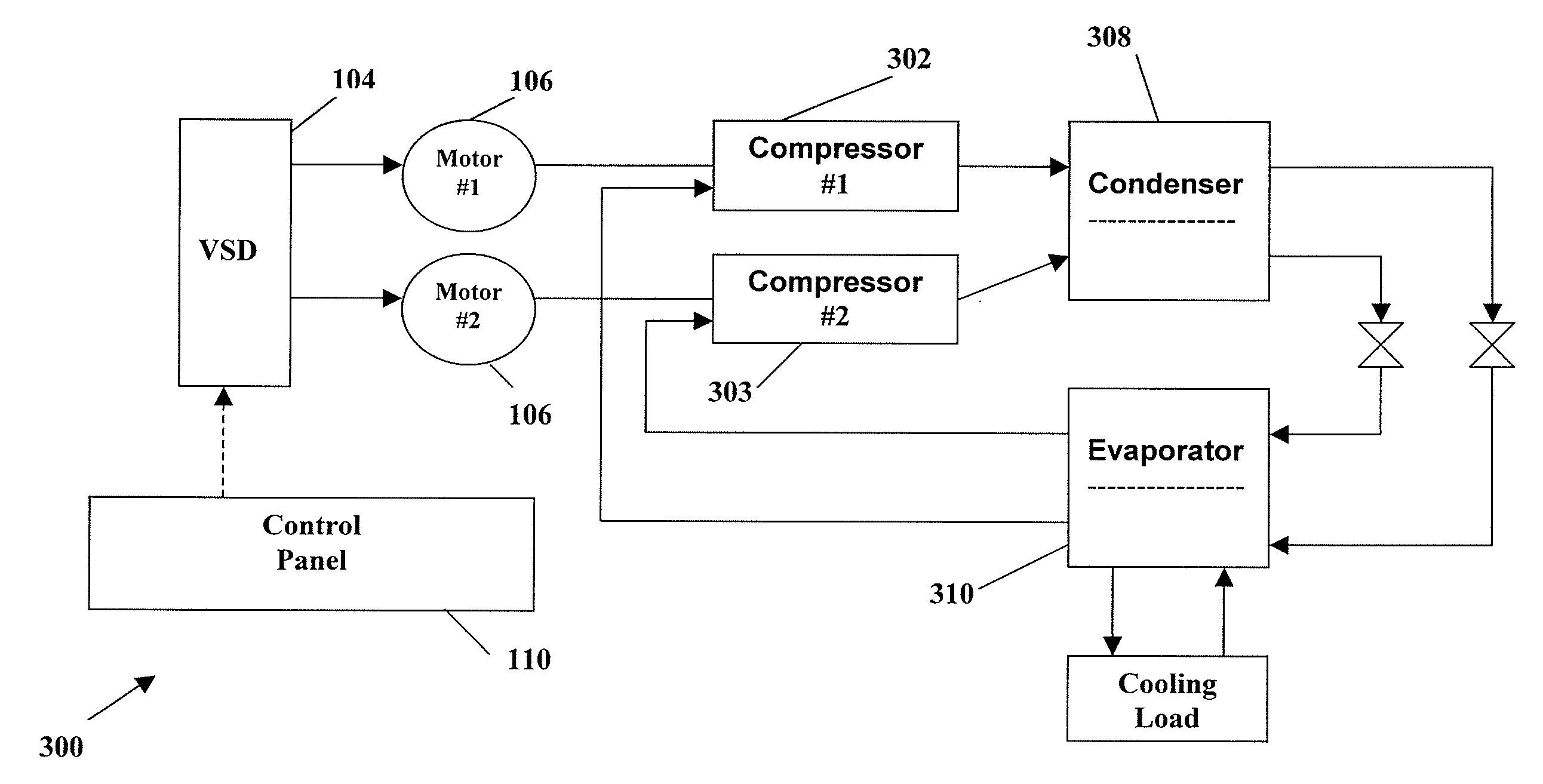

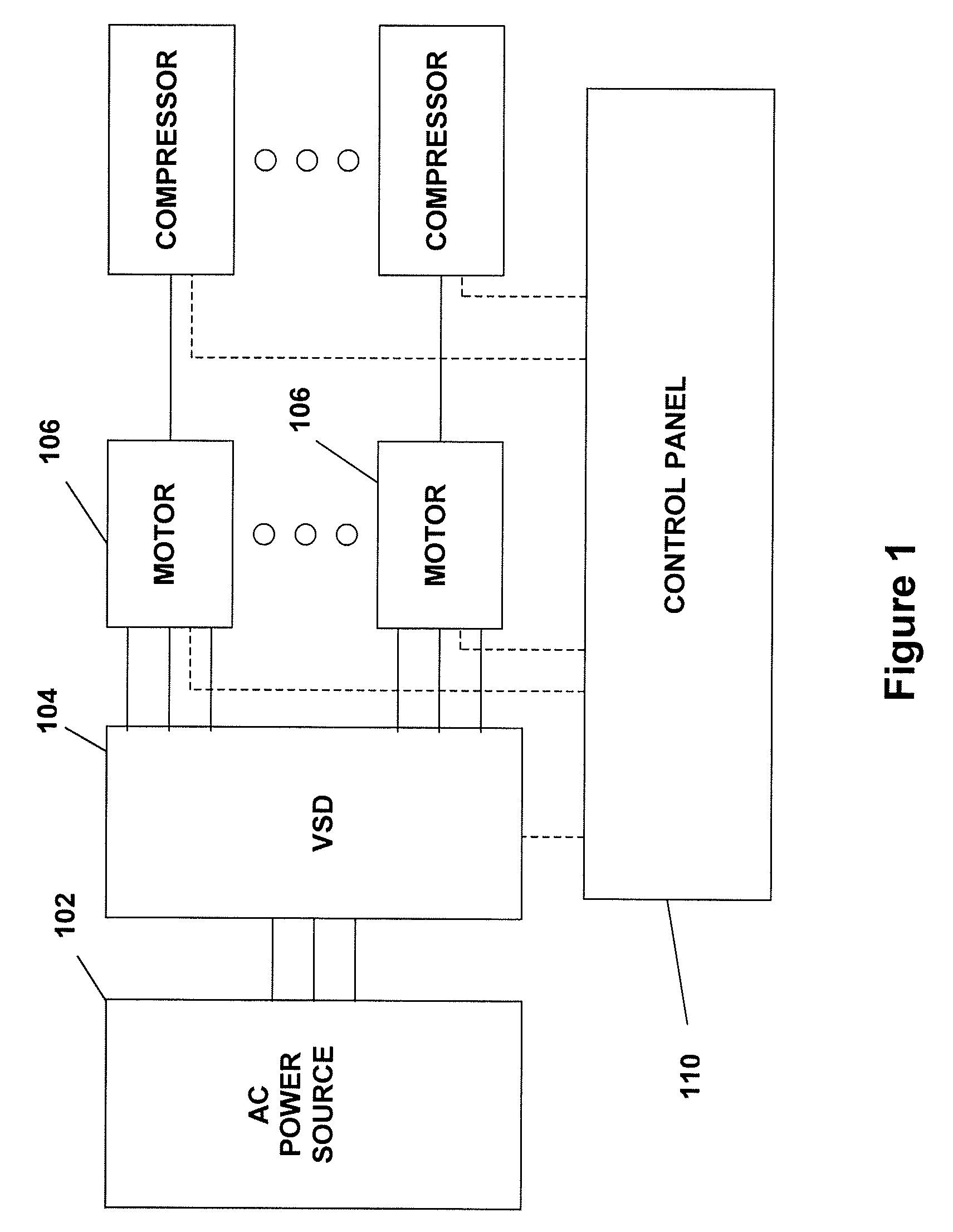

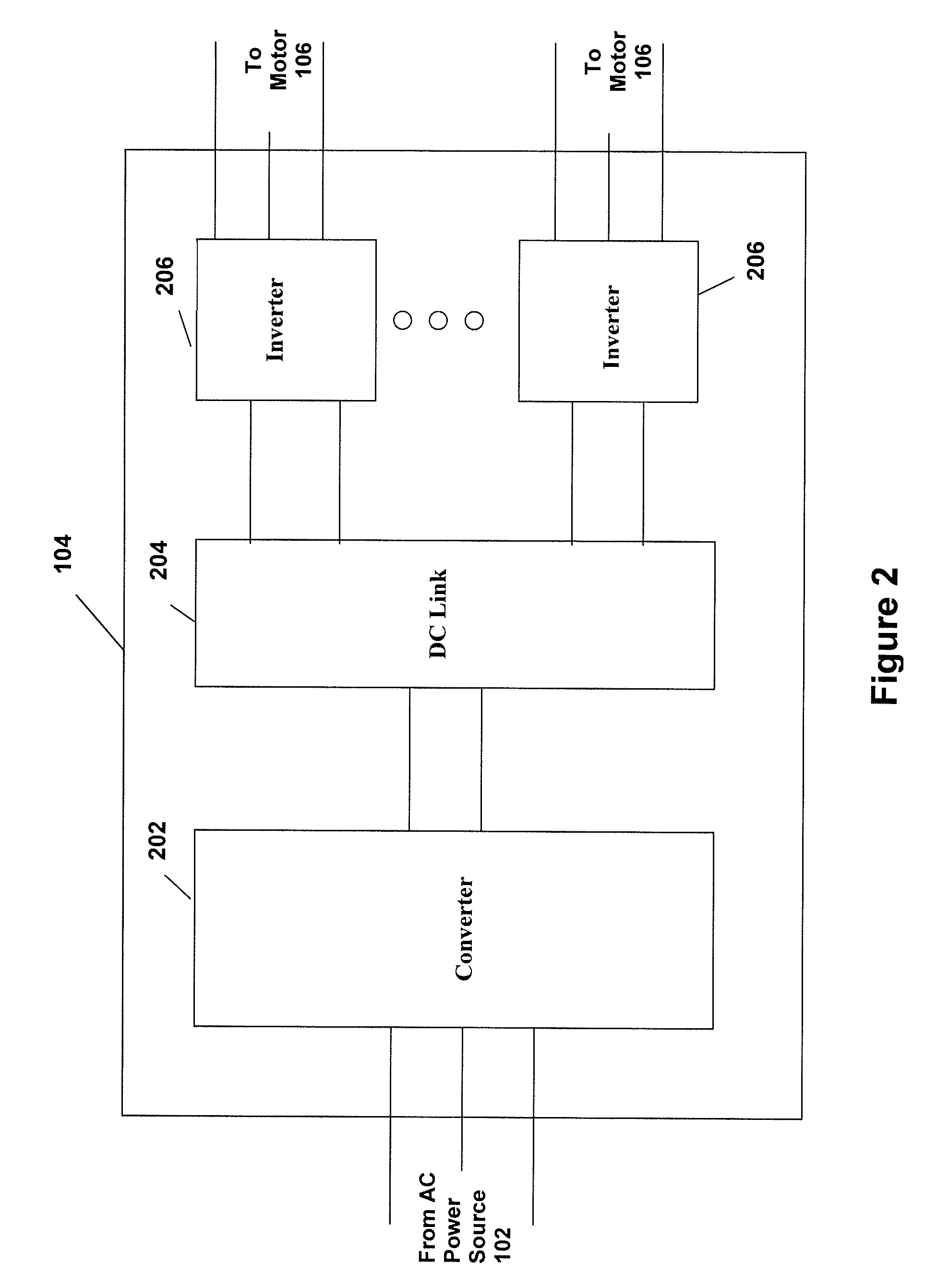

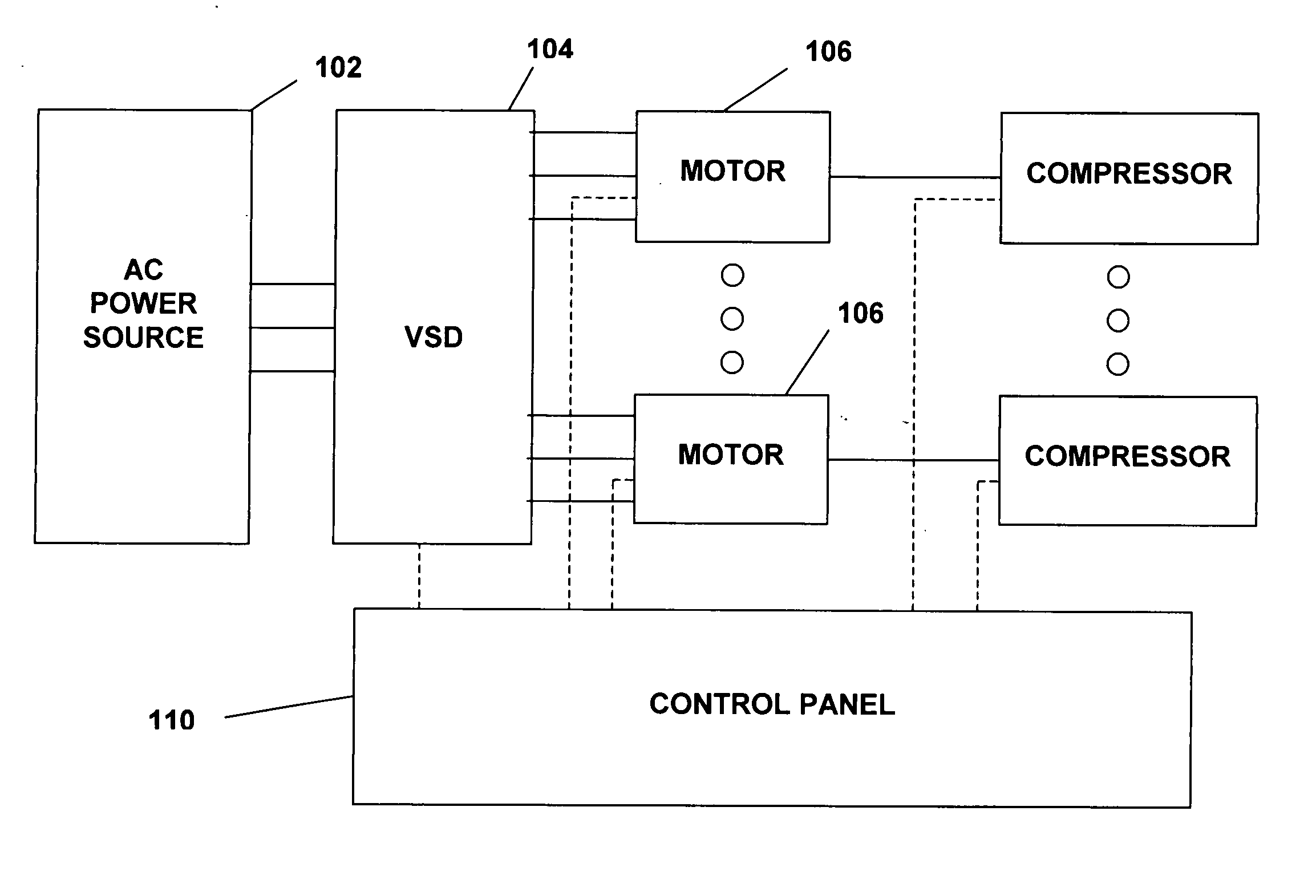

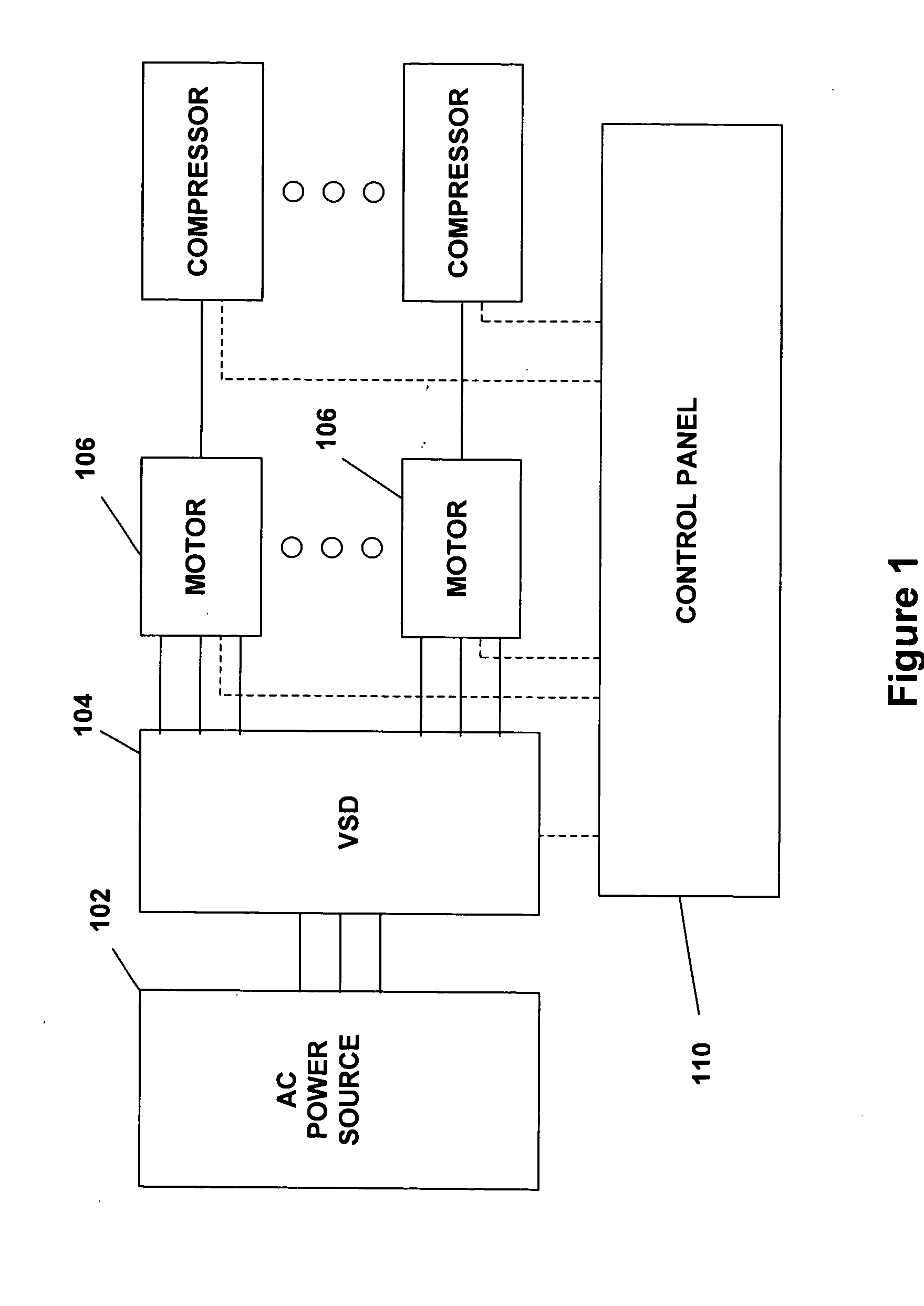

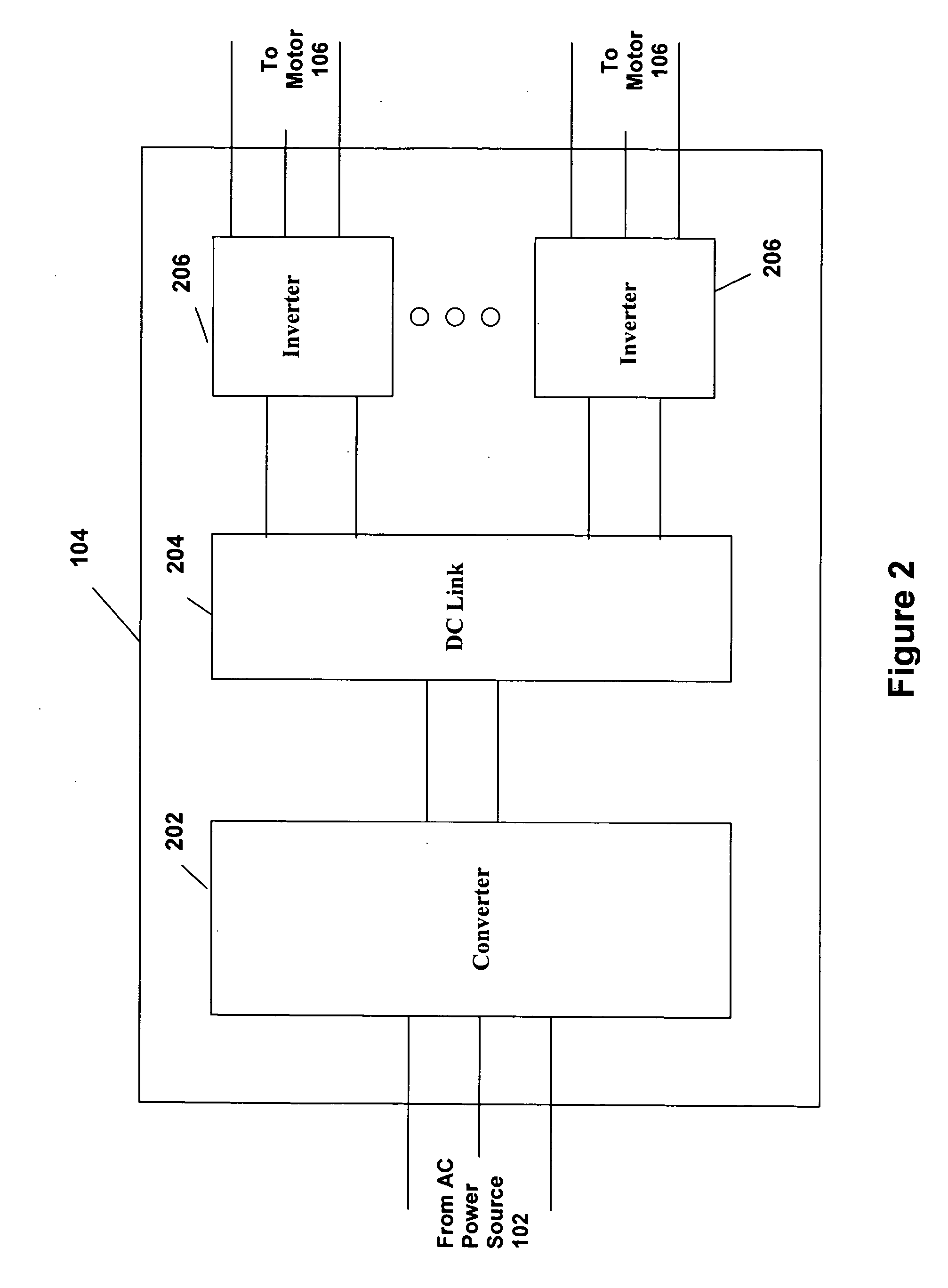

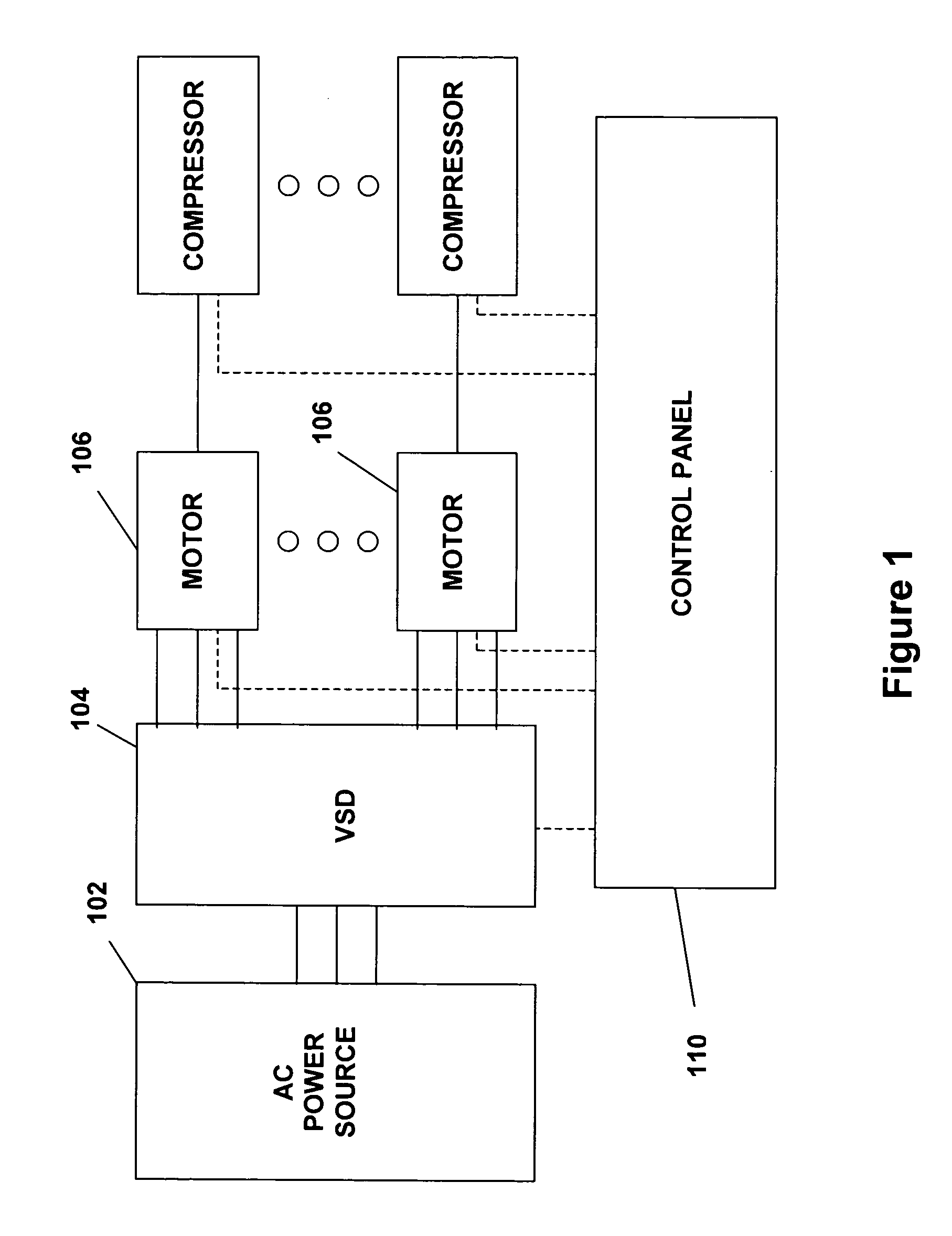

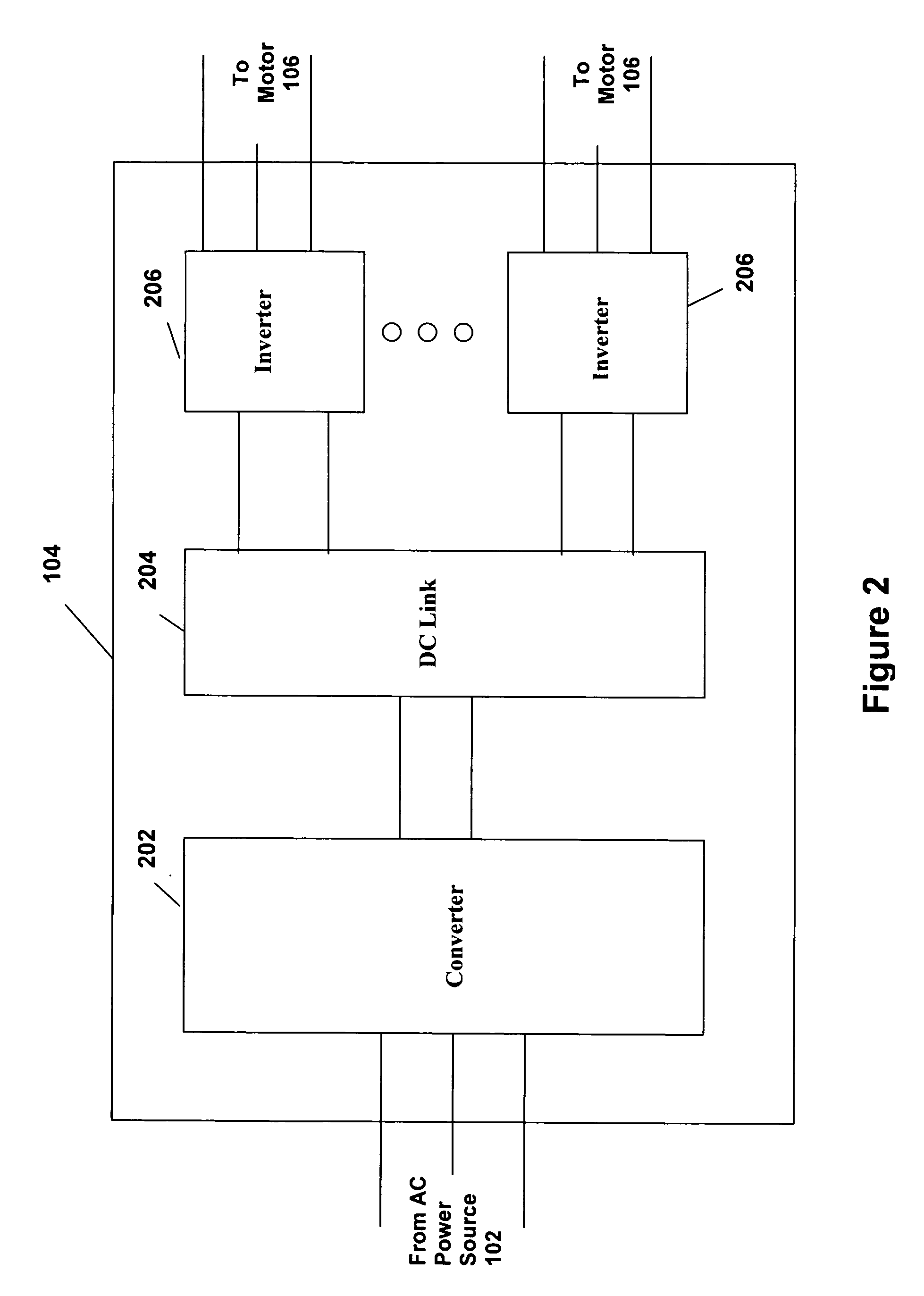

System and method for capacity control in a multiple compressor chiller system

ActiveUS20070056300A1Easy to controlImprove system efficiencyCompression machines with non-reversible cycleCompression machines with cascade operationLiquid temperatureEngineering

A capacity control algorithm for a multiple compressor liquid chiller system is provided wherein the speed and number of compressors in operation are controlled in order to obtain a leaving liquid temperature setpoint. In response to an increase in the load in the chiller system, the algorithm determines if a compressor should be started and adjusts the operating speed of all operating compressors when an additional compressor is started. In response to a decrease in the load in the chiller system with multiple compressors operating, the algorithm determines if a compressor should be de-energized and adjusts the operating speed of all remaining operating compressors when a compressor is de-energized.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

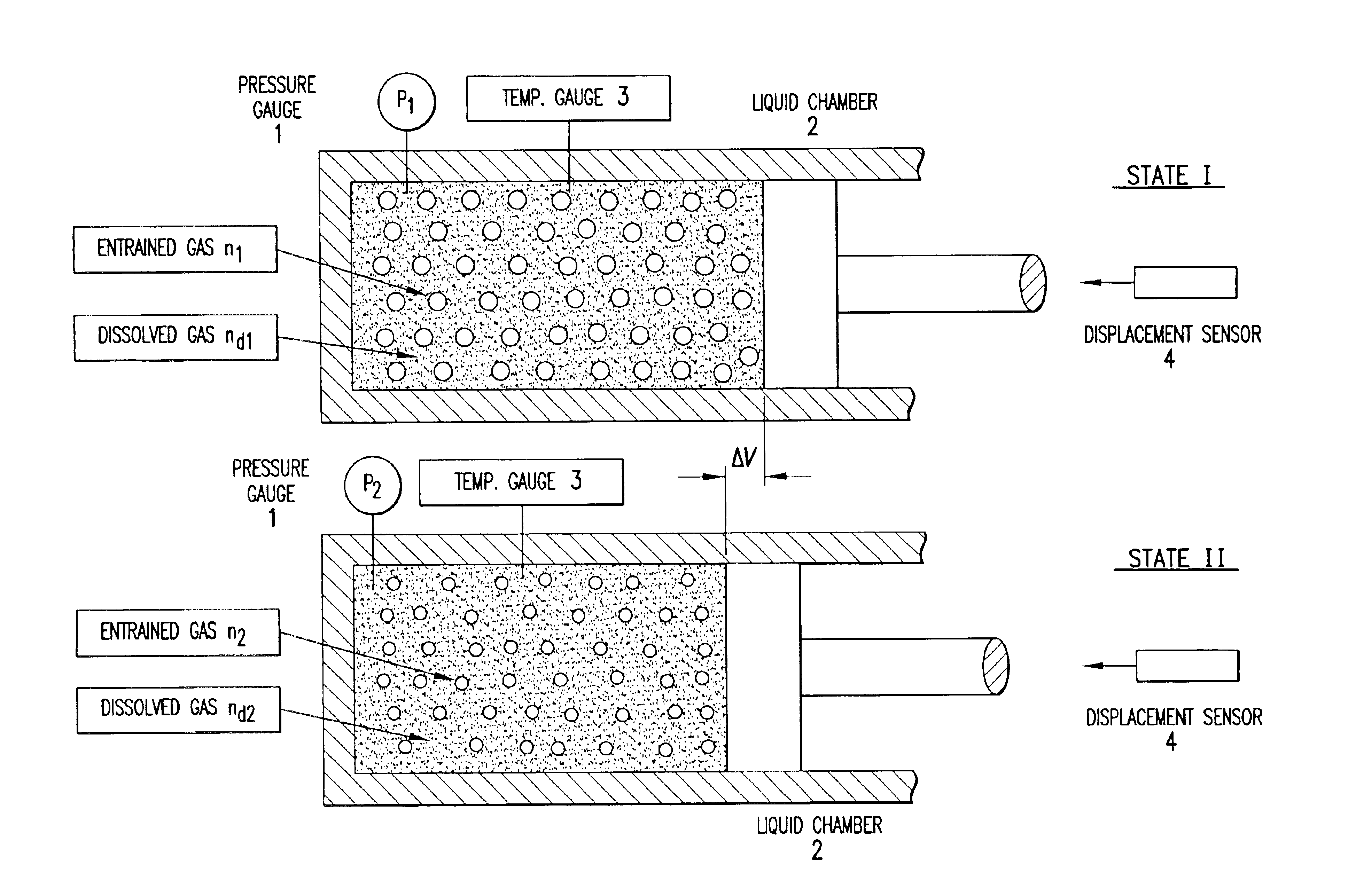

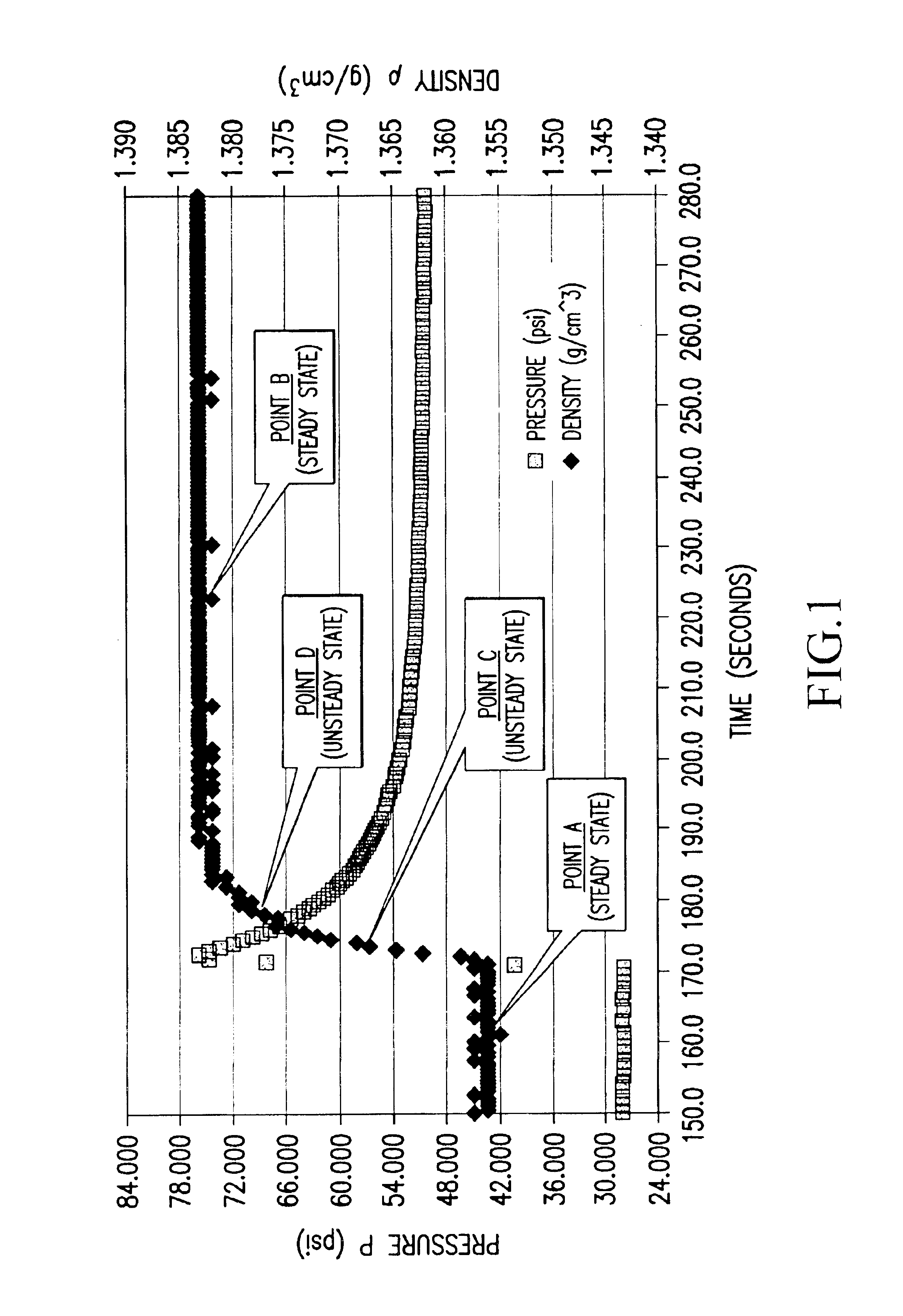

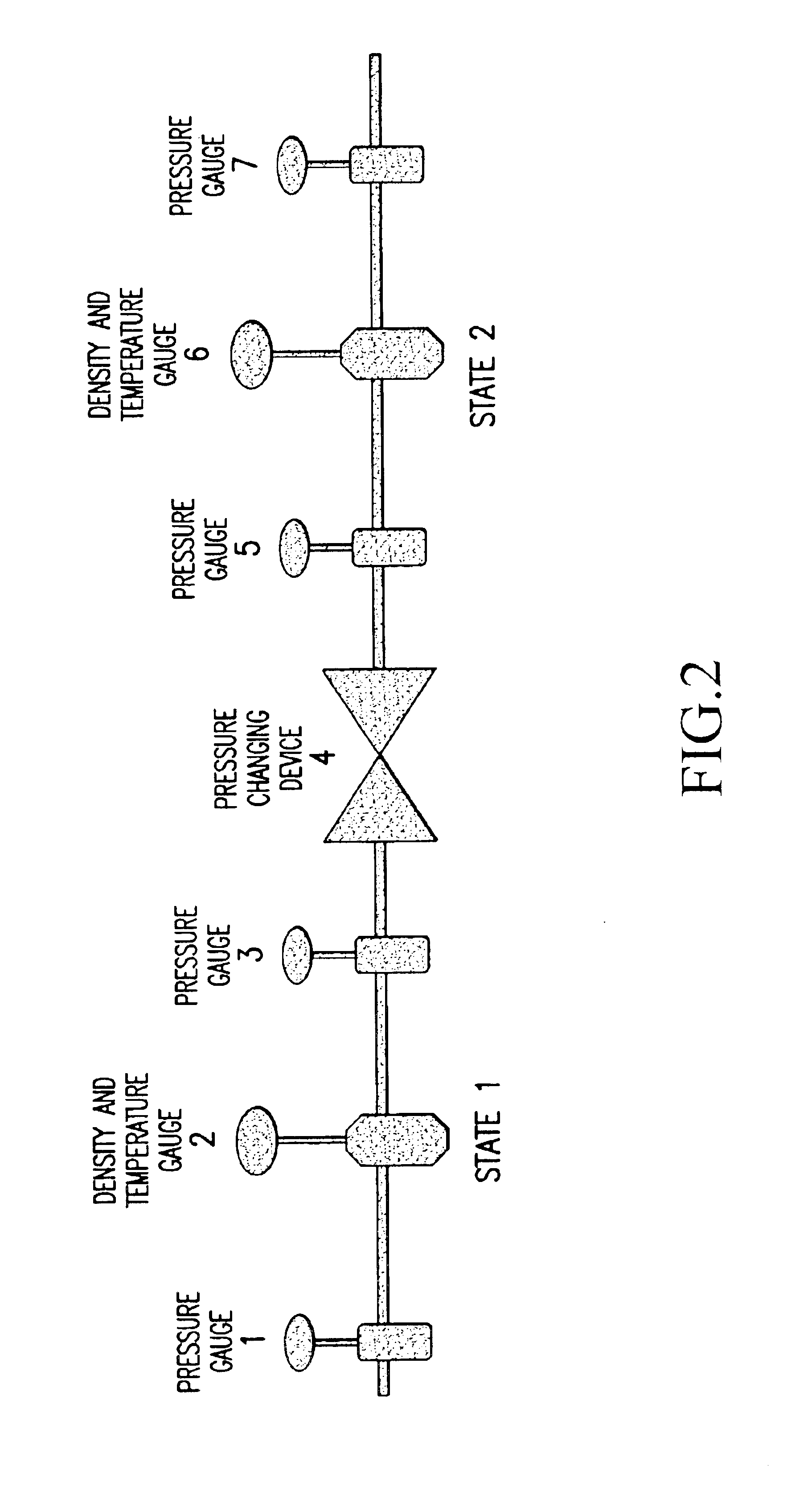

Real time determination of gas solubility and related parameters in manufacturing processes

InactiveUS6847898B1Easy to controlEasy to handleTesting beveragesSpecific gravity by measuring pressure differencesSolubilityApparent density

Methods and apparatuses for determining entrained and / or dissolved gas content of gas-liquid mixtures. Data generated is used to control the True (air-free) or Apparent (air-containing) Density or Entrained Air content of liquids within optimum ranges, e.g. in paper coating processes and in the manufacture of food products, personal care products, pharmaceutical products, paints, petroleum blends, etc. For example, an indirect method of continuously determining the amount of gas entrained in a liquid, by: continuously measuring the temperature, flow rate, and apparent density of the mixture at two different pressure states, and calculating the volume percentage of the gas in the liquid by using equation (28) x%=VsVs+V(28)wherein V is the volume of the gas-free liquid calculated by equation (23) V=1ρ1-[P2P2-P1(1ρ1-1ρ2)-RTP2-P1g(Δ PQa)](23)in which P1 and P2 are two different ambient pressures and ΔP=P2−P1, ρ1 and ρ2 are apparent densities of the liquid sample measured at P1 and P2, respectively, R is the constant of the Ideal Gas Law, T is the liquid temperature, Q is the flow rate, g(ΔP / Qa) is a function for determining the amount of gas being dissolved between P2 and P1, and Vs is determined by equation (27) Vs=TsTP1P2Ps(P2-P1)(1ρ1-1ρ2)-RTsPs(P1P2-P1g(Δ PQa)-g(P1-PsQa)).(27)

Owner:APPVION INC

Method and apparatus for pressure infusion and temperature control of infused liquids

A method and apparatus for pressure infusion and temperature control of infused liquids includes a receptacle for receiving a liquid-filled bag containing intravenous solution or other liquid and an inflatable pressure device. The inflatable pressure device is disposed within a pressure device bag and is positioned proximate the liquid-filled bag in the receptacle. The inflatable pressure device expands within the pressure device bag upon inflation and exerts pressure on the liquid-filled bag. A heating element may be disposed on the inflatable pressure device bag to heat the liquid-filled bag to a desired temperature. The liquid may alternatively be maintained at a desired temperature, while flowing to a patient via a heating assembly disposed along a tube. The heating assembly includes a sleeve having a slot for receiving the tube and a plurality of individually controlled heaters. An infrared sensing device is mounted proximate a drip chamber to ascertain a drip count, while a temperature sensor is disposed within a holder that is positioned toward the entry site on a patient. A heat controller controls the heaters based on a drip count, while a safety controller disables heater operation in response to liquid temperature exceeding the desired temperature. Thus, the safety controller and heat controller, in combination, control the heating assembly heaters based on liquid temperature and flow rate, respectively. Alternatively, the liquid-filled bag may be heated to a desired temperature whereby the heating assembly includes a single heater controlled by a controller to maintain the liquid at the desired temperature during infusion of the liquid into a patient.

Owner:MEDICAL SOLUTIONS INC

Fluid Identification Device and Fluid Identification Method

InactiveUS20100294021A1Solution to short lifeHigh measurement accuracyMeasurement of fluid loss/gain rateMaterial thermal conductivityLiquid temperatureIdentification device

A fluid identification device of long life for identification of a target fluid. The device uses at least two liquid type detection parts each of which is equipped with both of a temperature detector and a heating element, selects electrical conduction to any one of the heating elements, and identifies the target fluid based on a fluid temperature detection signal of the temperature detector in the fluid detection part not including the heating element whose electrical conduction has been selected and an output of the fluid type detection circuit.

Owner:MITSUI MINING & SMELTING CO LTD

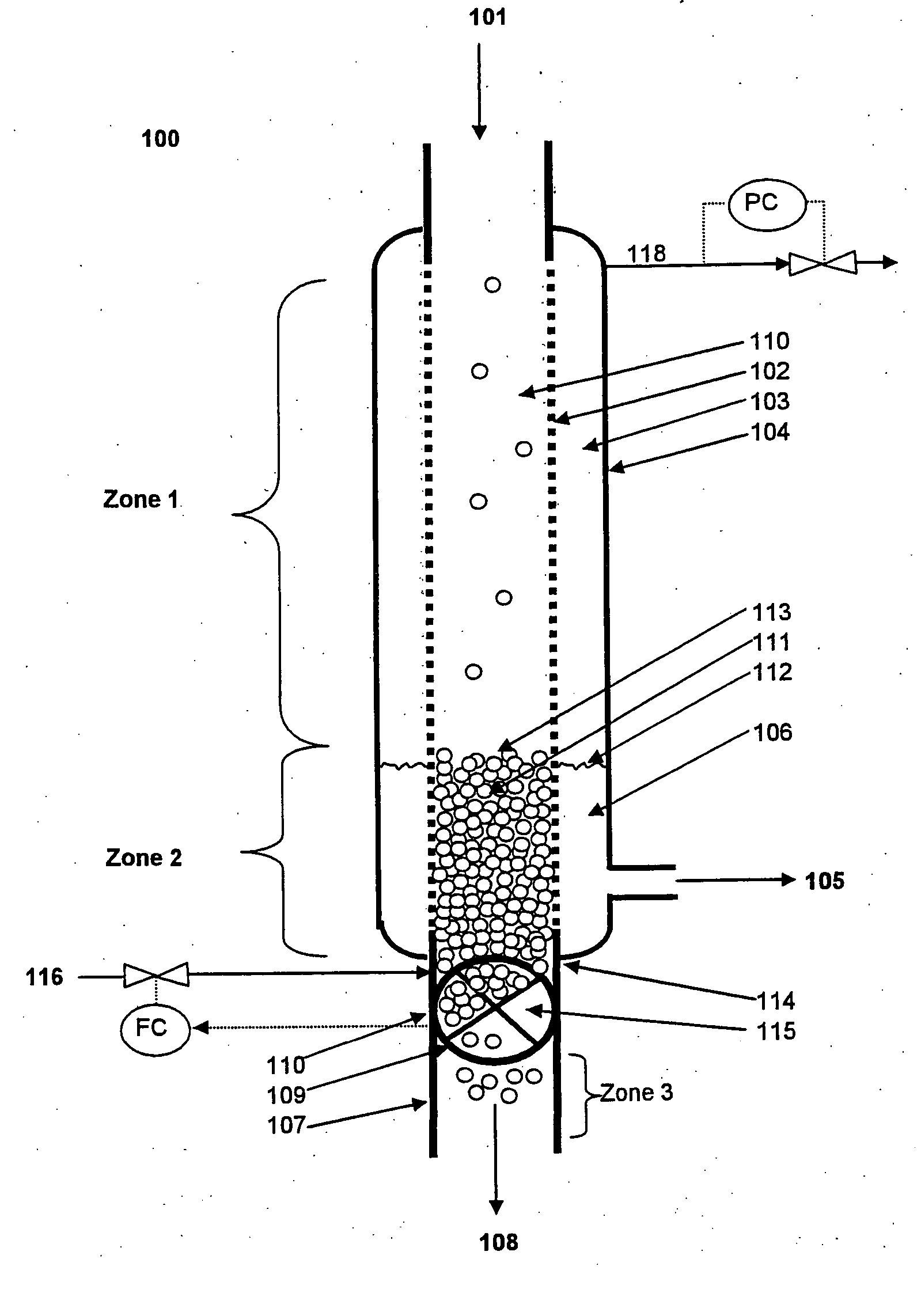

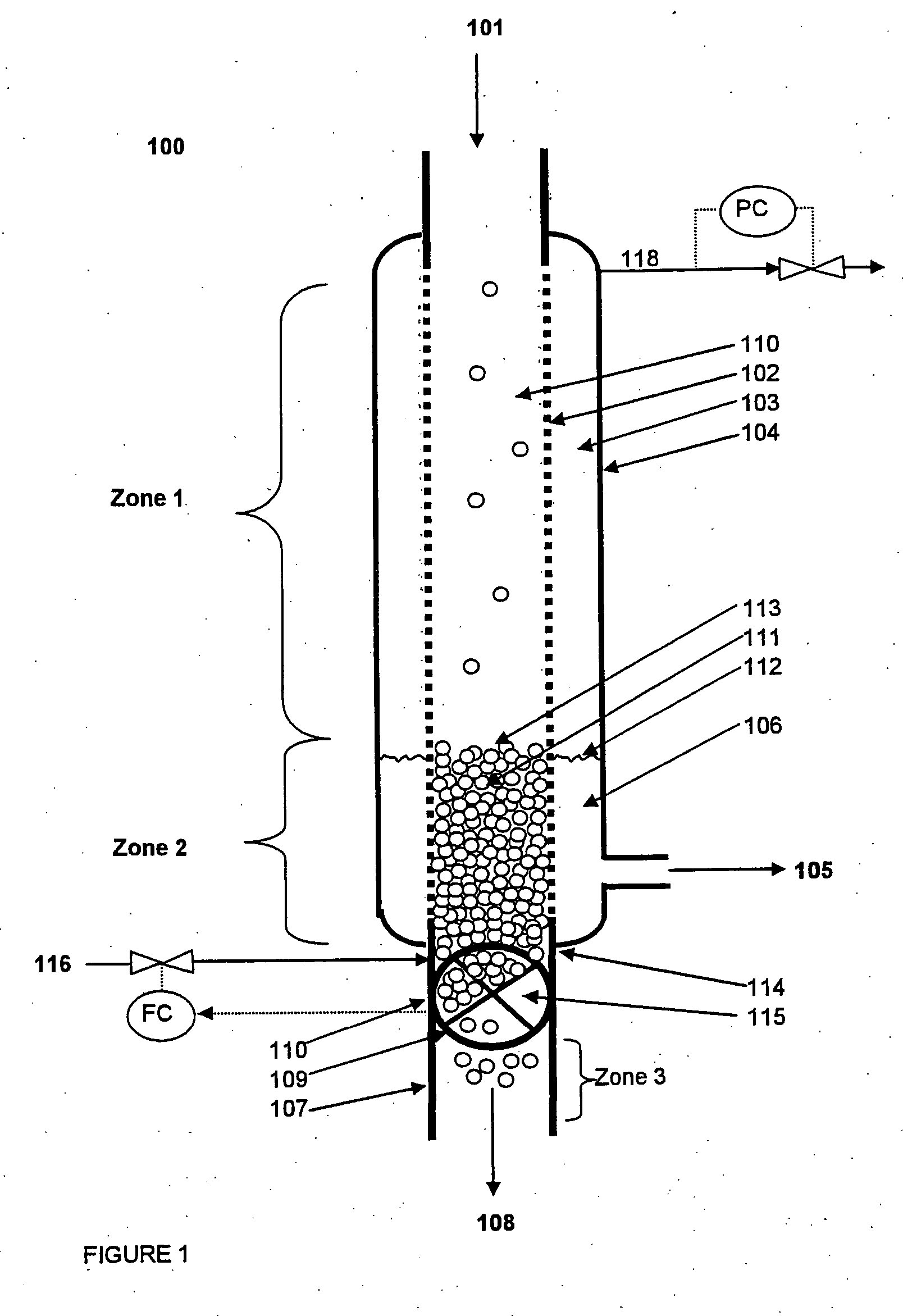

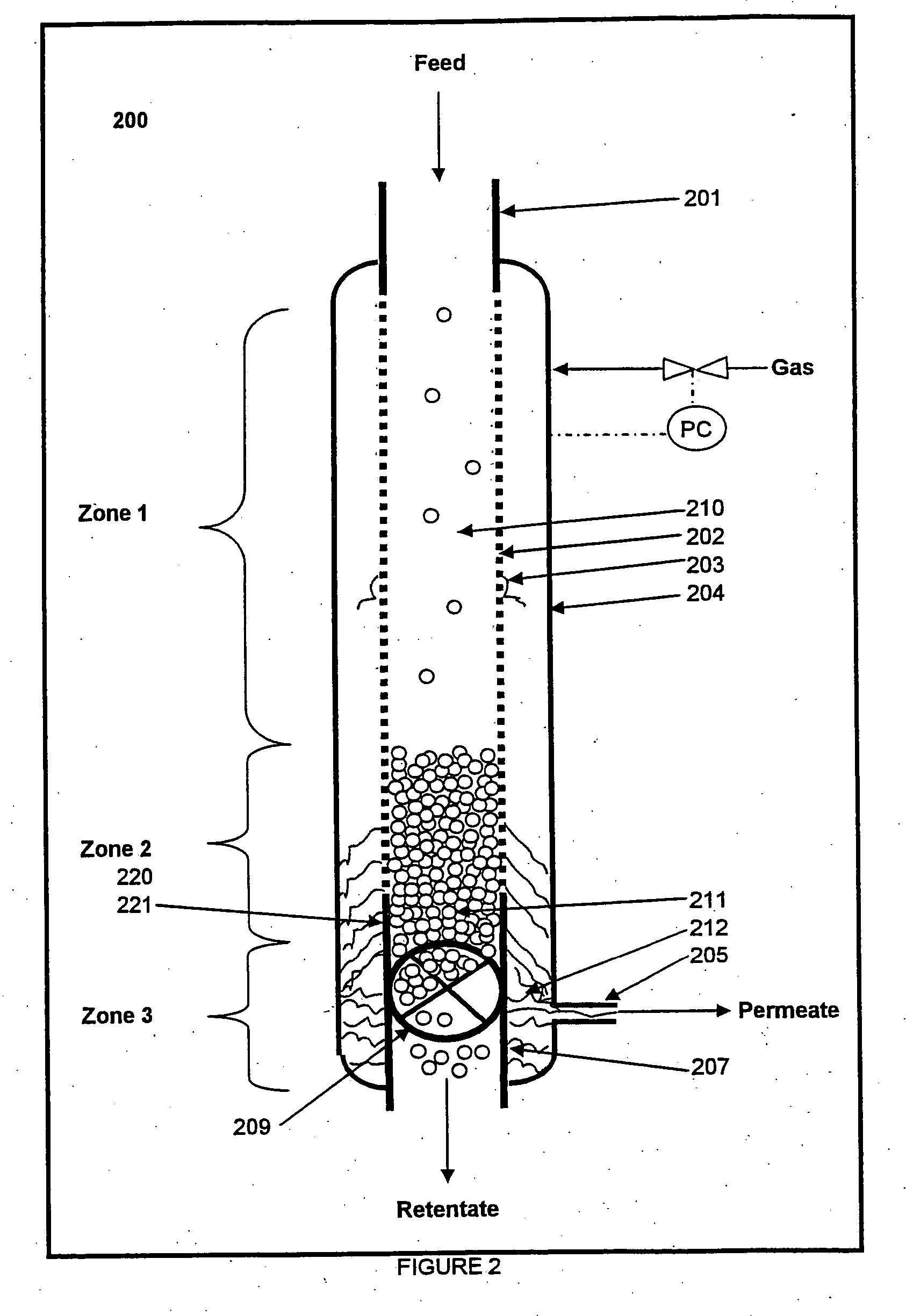

Crystallized pellet/liquid separator

ActiveUS20070062872A1Keep the pressureLow solidsWater/sewage treatment by centrifugal separationUltrafiltrationLiquid temperatureReverse osmosis

A process and apparatus which reduces the fines in a liquid discharge stream and / or increases the dryness of a solids discharge stream while under a pressure equal to or greater than the vapor pressure of the liquid. There is provided a process for separating particles such as polyethylene terephthalate or polyethylene naphthalate from a liquid in a slurry comprising: a. feeding a slurry comprising solid particles and a liquid into a within a separation zone maintained at a pressure equal to or greater than the vapor pressure of the liquid; b. contacting the slurry in the separation zone with a porous filter, optionally a microfilter, nanofilter, reverse osmosis filter, or ultrafilter, and separating liquid from the particles, wherein the liquid flows through the filter into an outer annulus defined as a space between the wall of the separation device and the filter, and said porous filter optionally having a terminal point beyond which the separated liquid does not pass from the outer annulus back through the filter; c. accumulating no liquid in the outer annulus or accumulating liquid in the outer annulus at a level below or in front of the terminal point, and continuously discharging the separated liquid from the outer annulus through a liquid outlet; d. decoupling the particles from the separation zone through the solids outlet to a low pressure below the vapor pressure of the liquid at the liquid temperature within the separation zone while maintaining a pressure on the particles prior to decoupling at or above the vapor pressure of the liquid within the separation zone.

Owner:ALPEK POLYESTER SA DE CV

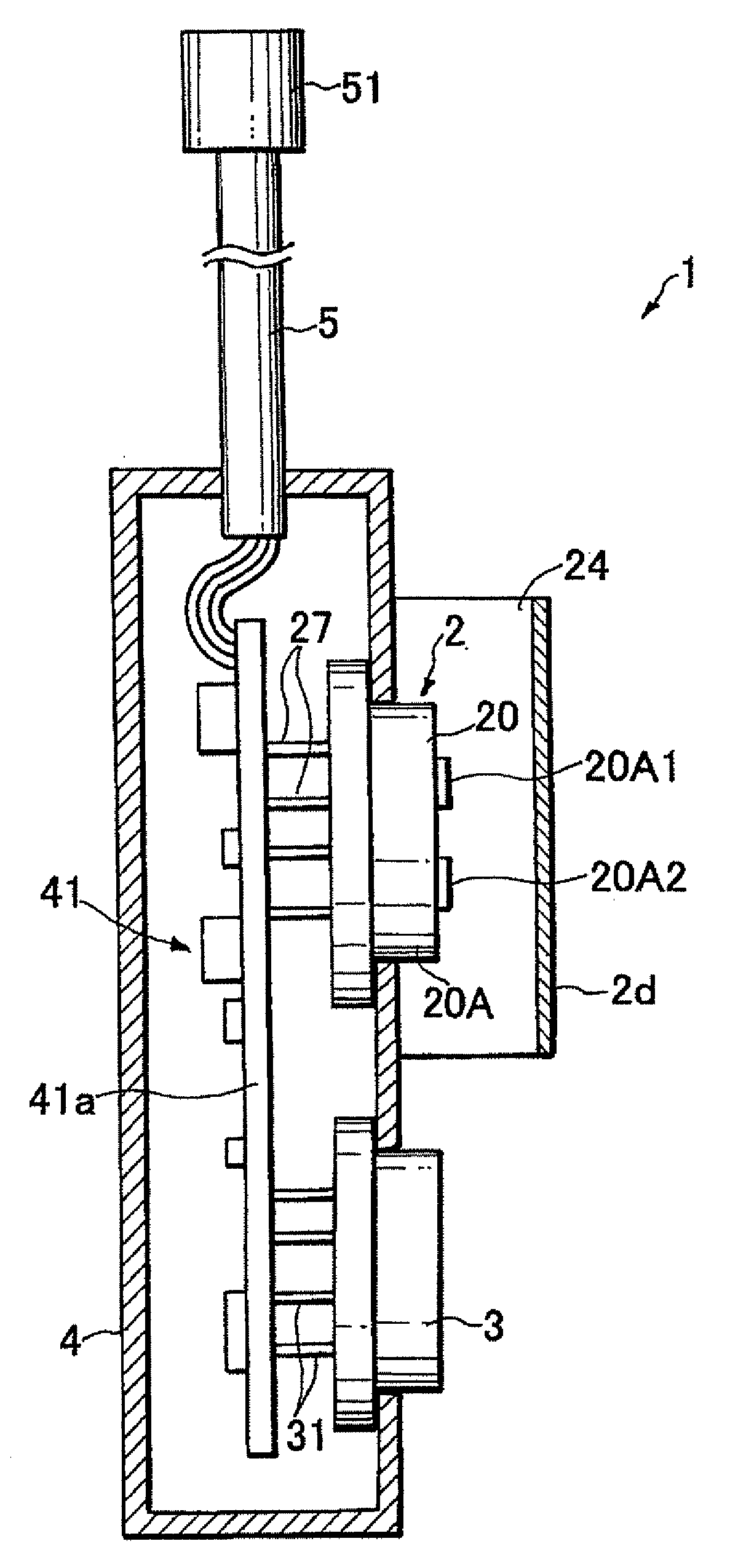

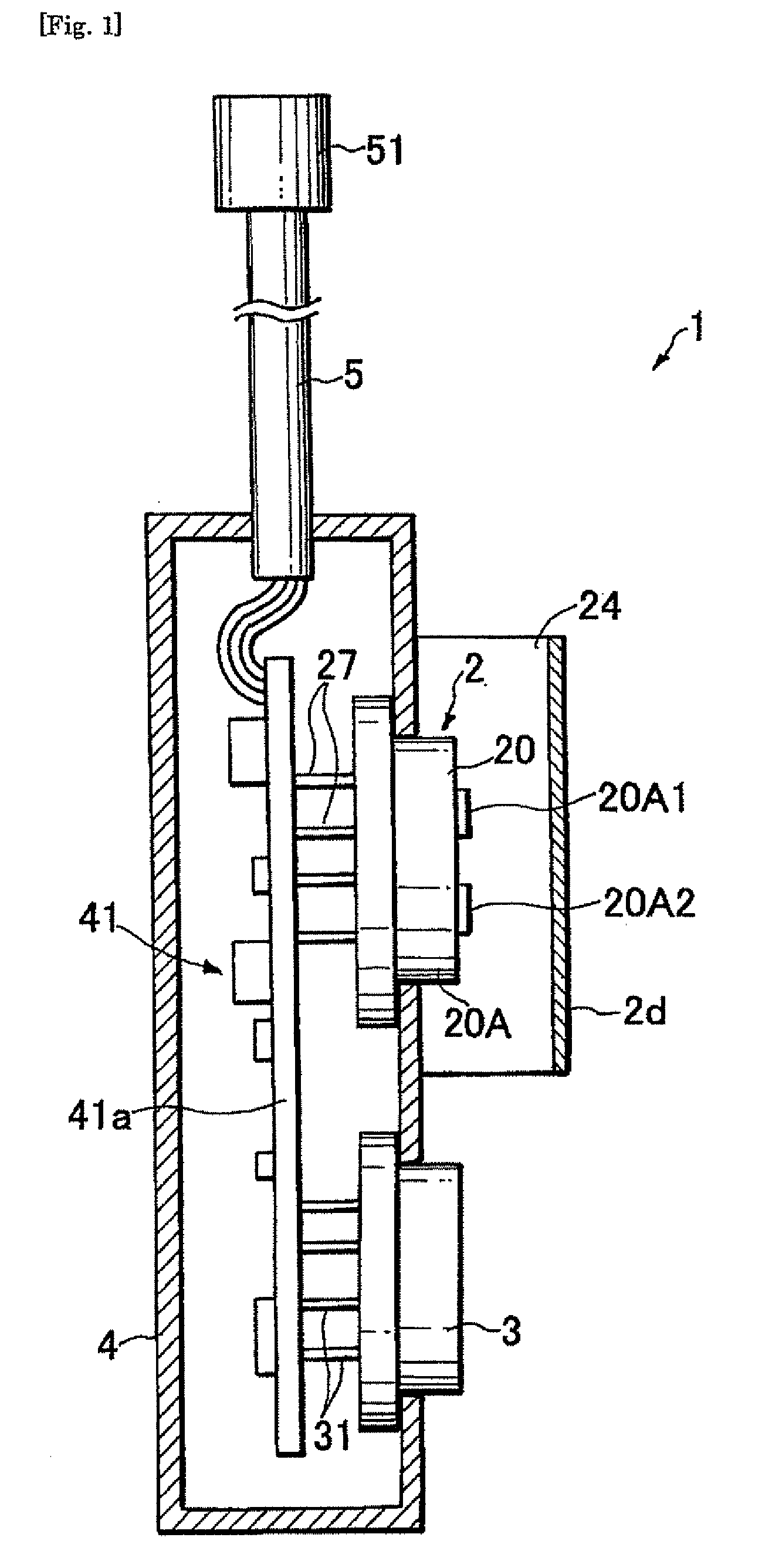

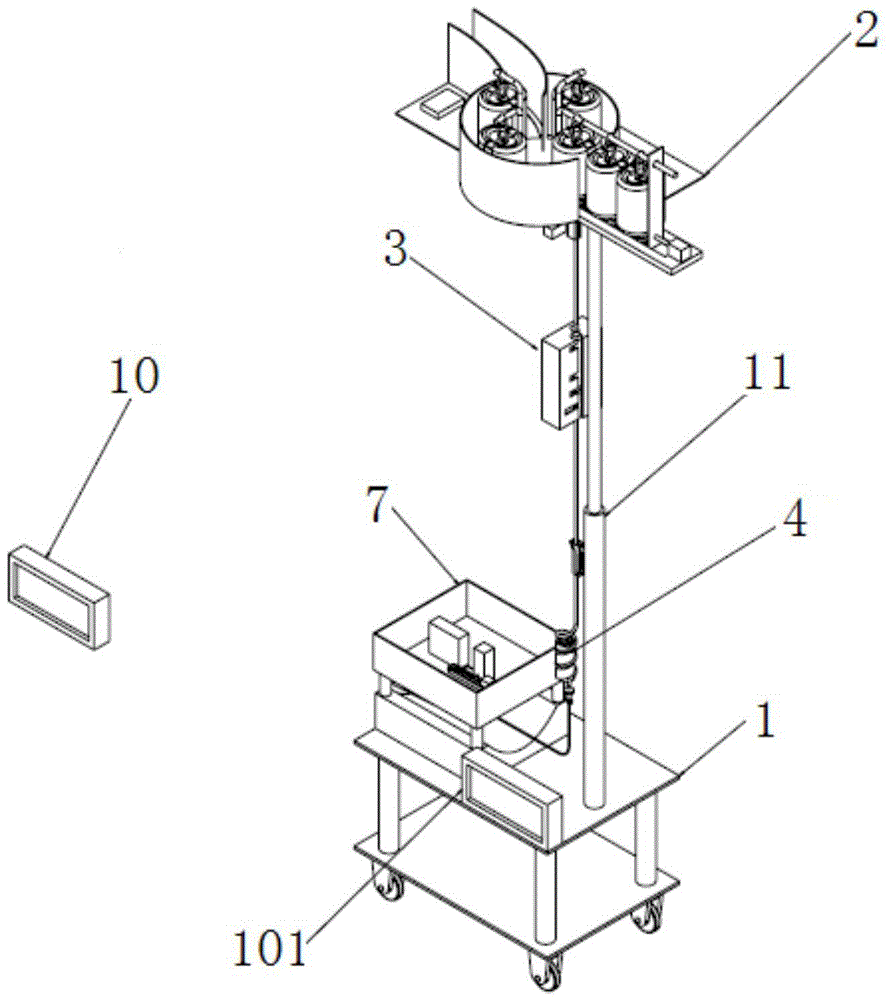

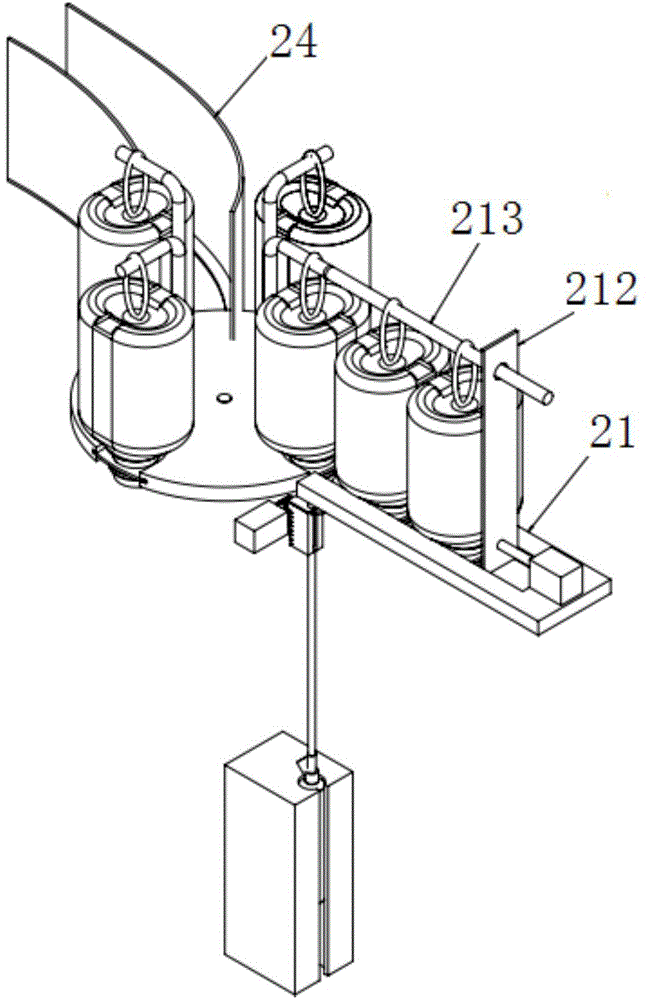

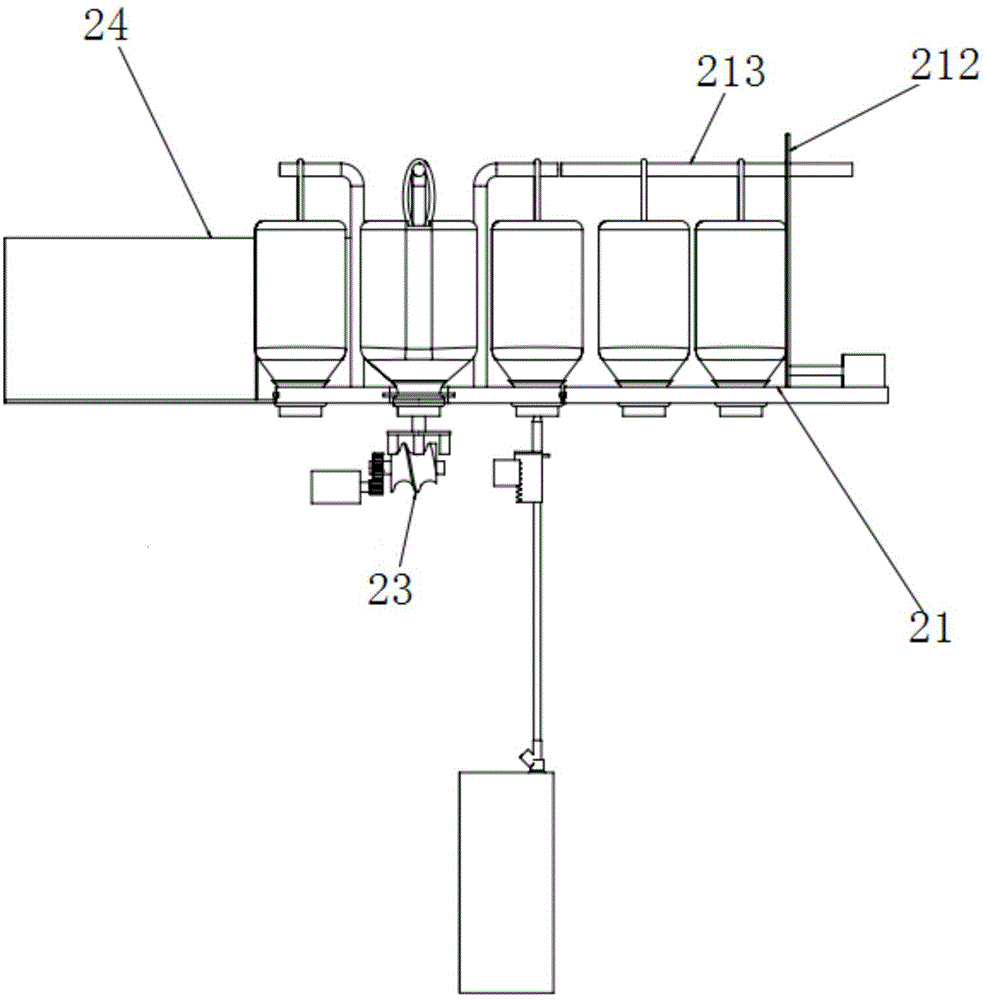

Intelligent infusion device

ActiveCN104784771AMonitor drop rateRealize automatic integrationFlow monitorsLiquid temperatureAutomatic control

The invention discloses an intelligent infusion device. The intelligent infusion device comprises an infusion bottle control mechanism, a puncture outfit mechanical arm mechanism, an infusion liquid dynamic monitoring mechanism, an infusion liquid temperature control mechanism, an automatic needle plugging and unplugging mechanism, a central control station and a central control unit. The central control unit corresponds to the puncture outfit mechanical arm mechanism, the liquid dynamic monitoring mechanism, the liquid temperature control mechanism and the automatic needle plugging and unplugging mechanism. The intelligent infusion device has the advantage that automatic integration in the infusion process can be achieved, which is concretely embodied in that an infusion bottle can be automatically changed; infusion dripping speed, flowing speed and liquid bubbles are monitored, the infusion dripping speed and flowing speed are controlled, and the bubbles are eliminated in time; in the infusion process, an infusion tube is heated, and heating temperature is automatically controlled; through control of mechanical arms, automatic needle plugging and unplugging are achieved; the central receiver controls controllers of all units, so that control over all stages in the infusion process is achieved.

Owner:深圳文健医疗科技有限公司

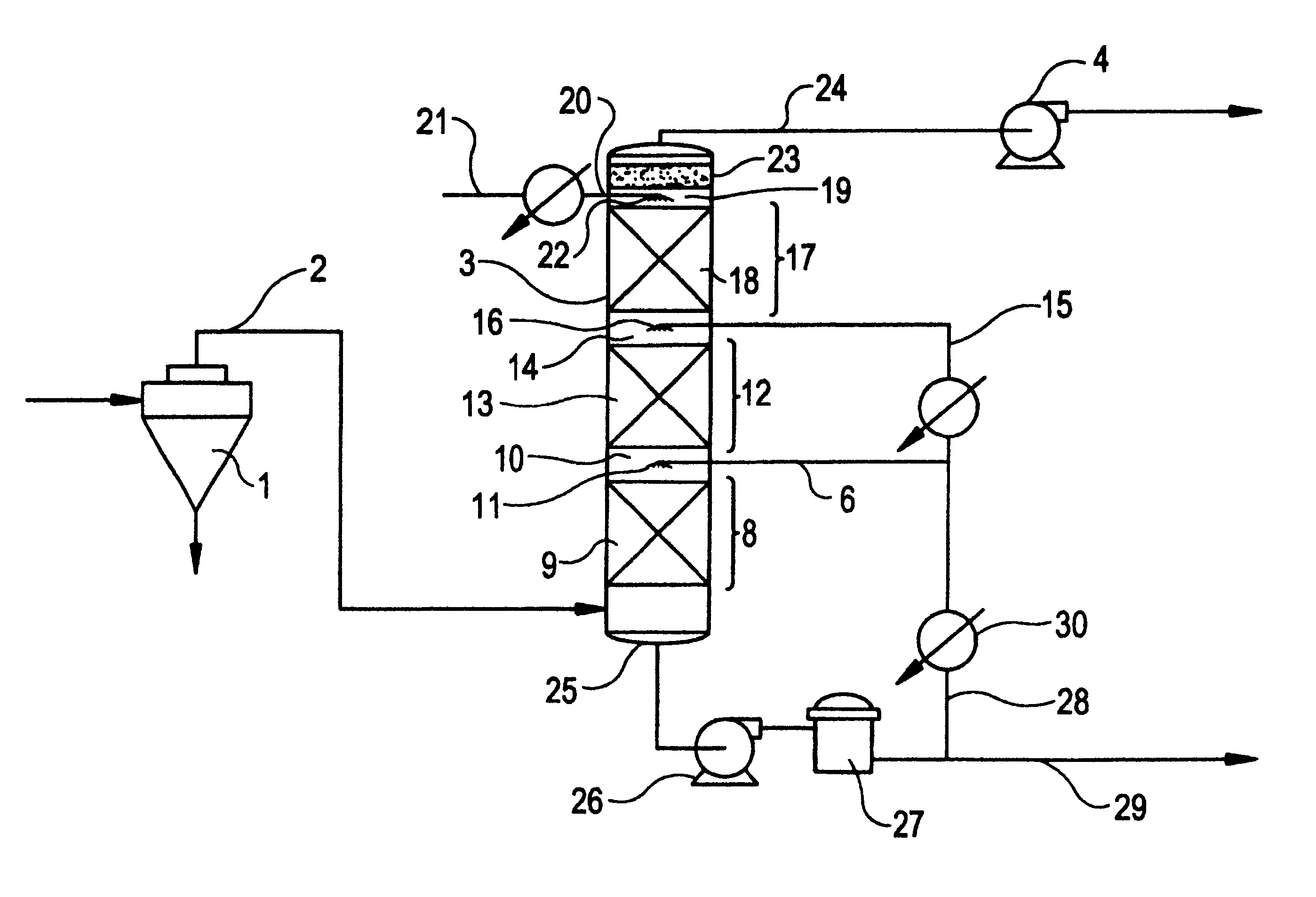

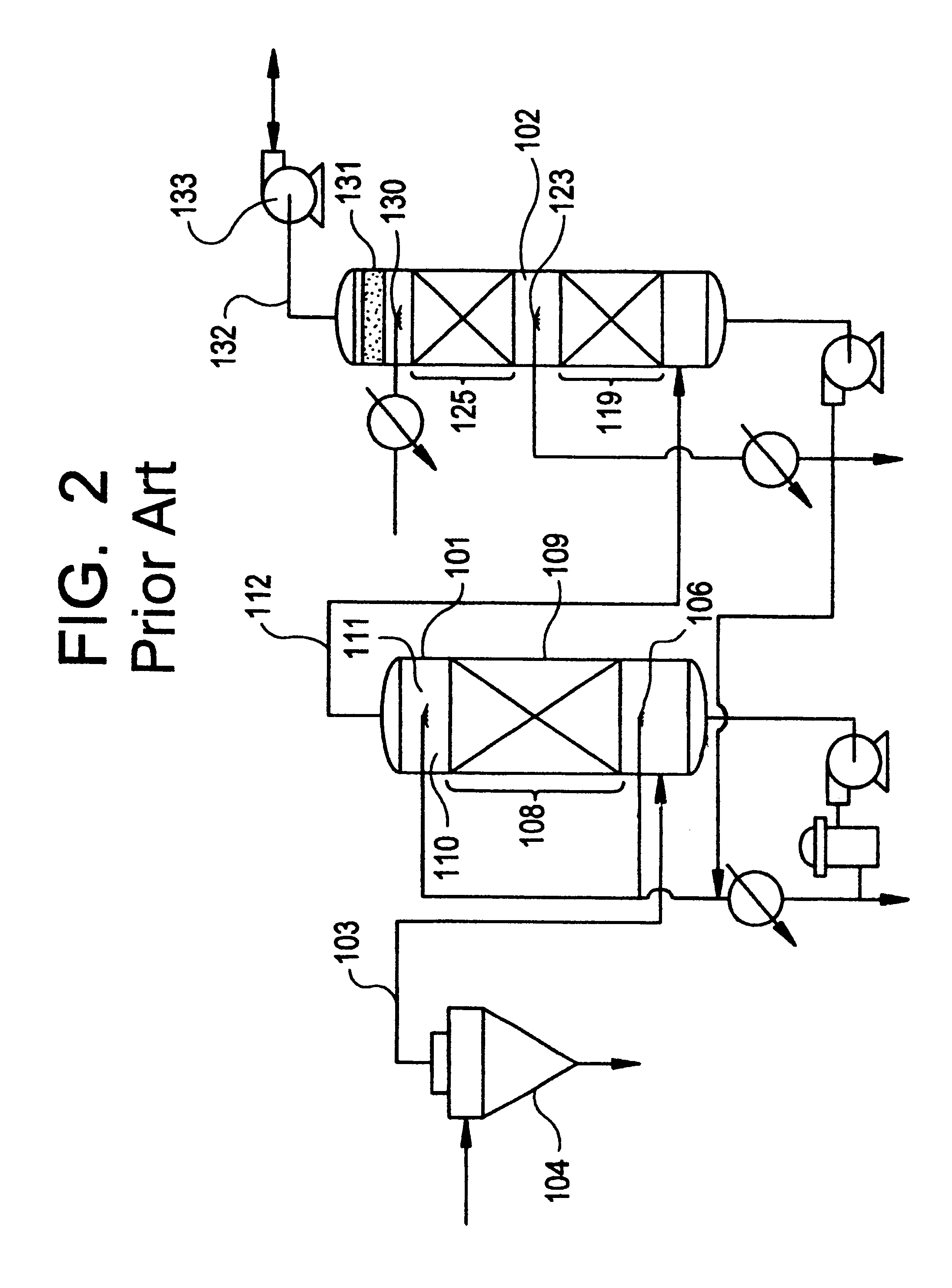

System to quench gasses and remove condensables

A method and apparatus for quenching and scrubbing a hot gas using a liquid in a single packed column while controlling mist formation. Hot gas is introduced at the bottom of the column and drawn upward countercurrent to the scrubbing liquid. The column has three stages, each packed and fed liquid from above. The first stage is a quench region wherein the gas flow rate, liquid flow rate and liquid temperature are controlled such that the quench rate does not exceed 5.4° C. / ft2 of packing to prevent formation of an aerosol mist. The second and third stages for scrubbing employ packed regions separately supplied with increasingly cooler and purer liquid.

Owner:INVISTA NORTH AMERICA R L

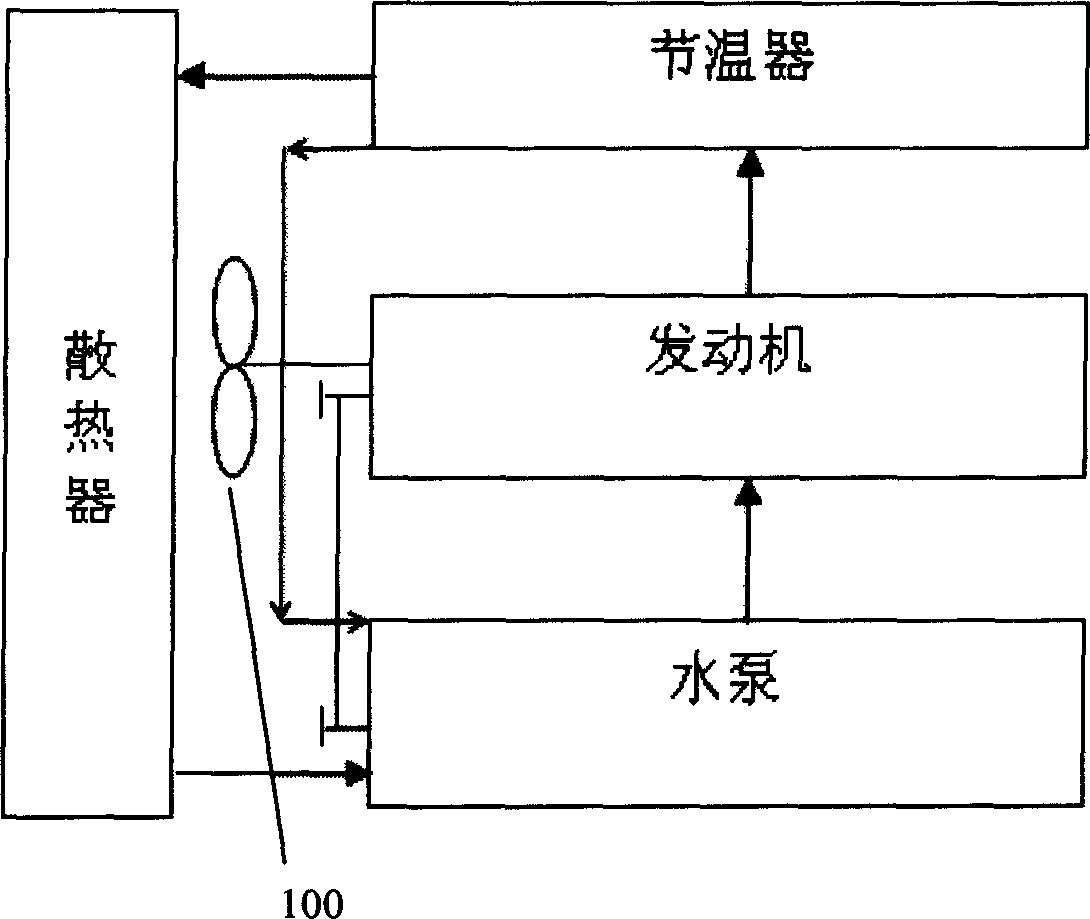

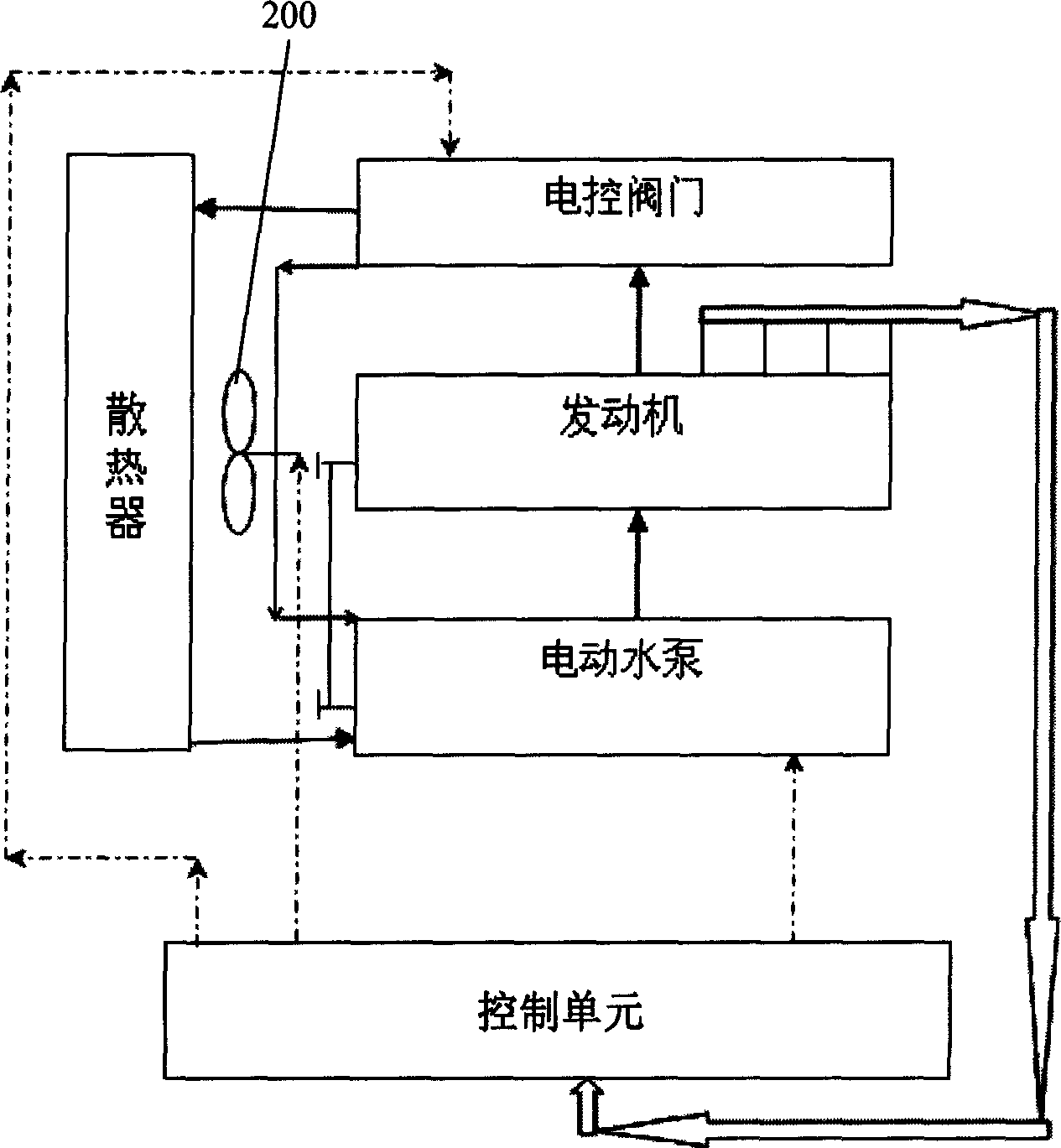

Water cooling system of engine and cooling method thereof

InactiveCN1884804AIncrease starting speedReduce exhaust pollutionLiquid coolingCoolant flow controlLiquid temperatureEngineering

The invention relates to an engine water cooling system and relative cooling method, wherein the first sensor senses the working condition of engine; the cooling liquid temperature sensor senses the temperature of cooling liquid inside the engine; the control unit responds the signals of first sensor and the cooling liquid temperature sensor, to control the electric water pump to operate when the temperature of cooling liquid is higher than the first preset temperature when the engine starts, to drive the cooling liquid to cool the engine, to improve the starting property of engine and the discharging property of heating machine; and the electric controller based on the operation parameter of engine and the temperature of cooling liquid, controls the switch of electric valve, the electric water pump and the rotation speed of electric fan, to control the circulation and the flux of cooling liquid, and the cooling ability of cooling fan, to improve the property of engine.

Owner:BYD CO LTD

Nickel complex hydroxide particles and nonaqueous electrolyte secondary battery

ActiveUS20120276454A1Formation of new can be suppressedGrowth inhibitionOther chemical processesSynthetic resin layered productsLiquid temperatureParticle growth

Disclosed are: nickel complex hydroxide particles that have small and uniform particle diameters; and a method by which the nickel complex hydroxide particles can be produced. Specifically disclosed is a method for producing a nickel complex hydroxide by a crystallization reaction, which comprises: a nucleation step in which nucleation is carried out, while controlling an aqueous solution for nucleation containing an ammonium ion supplying material and a metal compound that contains nickel to have a pH of 12.0-13.4 at a liquid temperature of 25° C.; and a particle growth step in which nuclei are grown, while controlling an aqueous solution for particle growth containing the nuclei, which have been formed in the nucleation step, to have a pH of 10.5-12.0 at a liquid temperature of 25° C. In this connection, the pH in the particle growth step is controlled to be less than the pH in the nucleation step.

Owner:SUMITOMO METAL MINING CO LTD

Method and Apparatus for Controlling Temperature of Medical Liquids

A system for controlling temperature of intravenous fluids includes a thermal treatment device and a temperature sensing device to measure a temperature of the fluid flowing through the sensor. The temperature sensing device may simultaneously collect two temperature measurements. For example, the sensing device may include sensors that measure the temperature of the fluid at two disparate locations along the medical fluid line. Additionally, the sensors may measure the temperature of the fluid within the medical fluid line, as well as the ambient temperature outside of the line. The thermal treatment device includes a conduit configured to have a nonlinear flow path through the device. The thermal treatment device thermally treats fluid within the conduit to a desired temperature or range.

Owner:MEDICAL SOLUTIONS

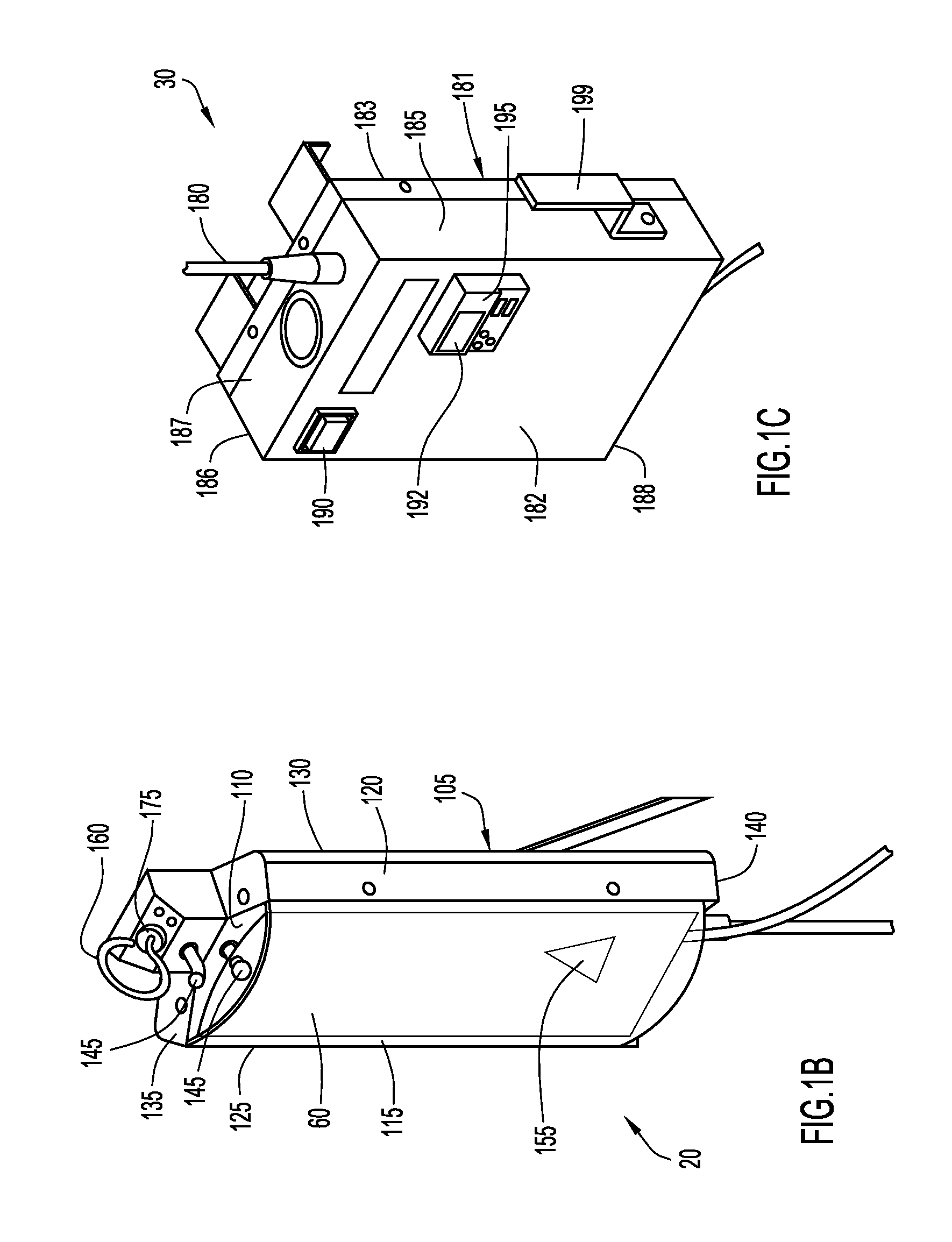

High-temperature and high-pressure plugging / sticking preventing simulation evaluation device and method

The invention relates to a high-temperature and high-pressure plugging / sticking preventing simulation evaluation device and method. The device comprises a well drilling liquid pressure control unit, a liquid storage unit, a stratum model, a plugging liquid temperature control unit and a confining pressure unit. The stratum model is provided with a crack simulating stratum forms, and a pressure sensor is distributed on the crack. The pressure and the temperature of plugging liquid entering the stratum model and pressure applied to the stratum model are controlled, pressure values of different depths of the crack are measured through the pressure sensor, and flow of the plugging liquid is measured according to a weighing method. The high-temperature and high-pressure plugging / sticking preventing simulation evaluation device and method can evaluate the plugging effect of different plugging materials and plugging slurry under the same condition and provide scientific research methods for the research of plugging well leakage and extrusion theories, the preparation of plugging agents which are strong in staying performance, forming of process technologies of preventing the plugging agents from sticking backwards, the building of laboratory plugging simulation evaluation method standards and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

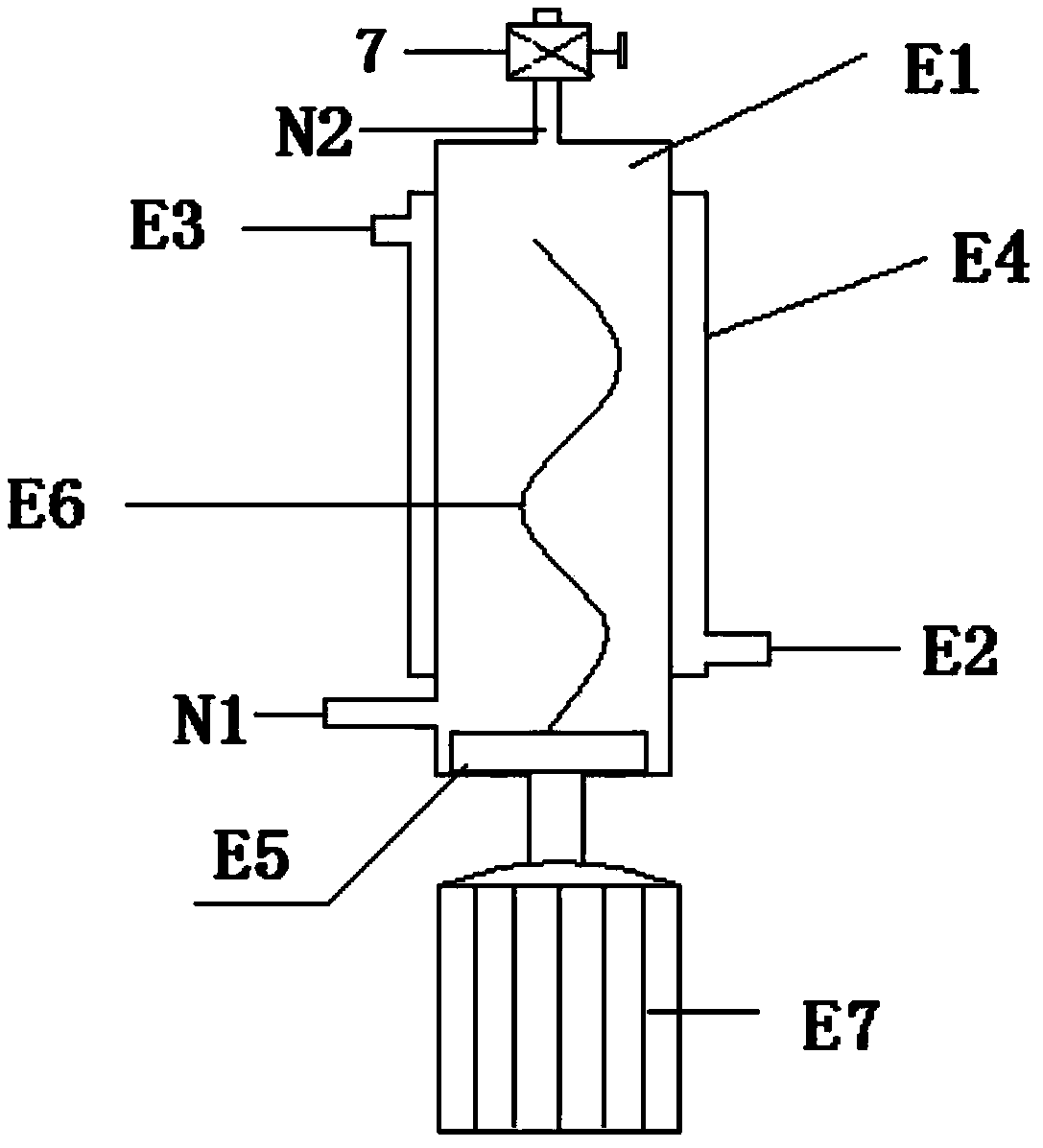

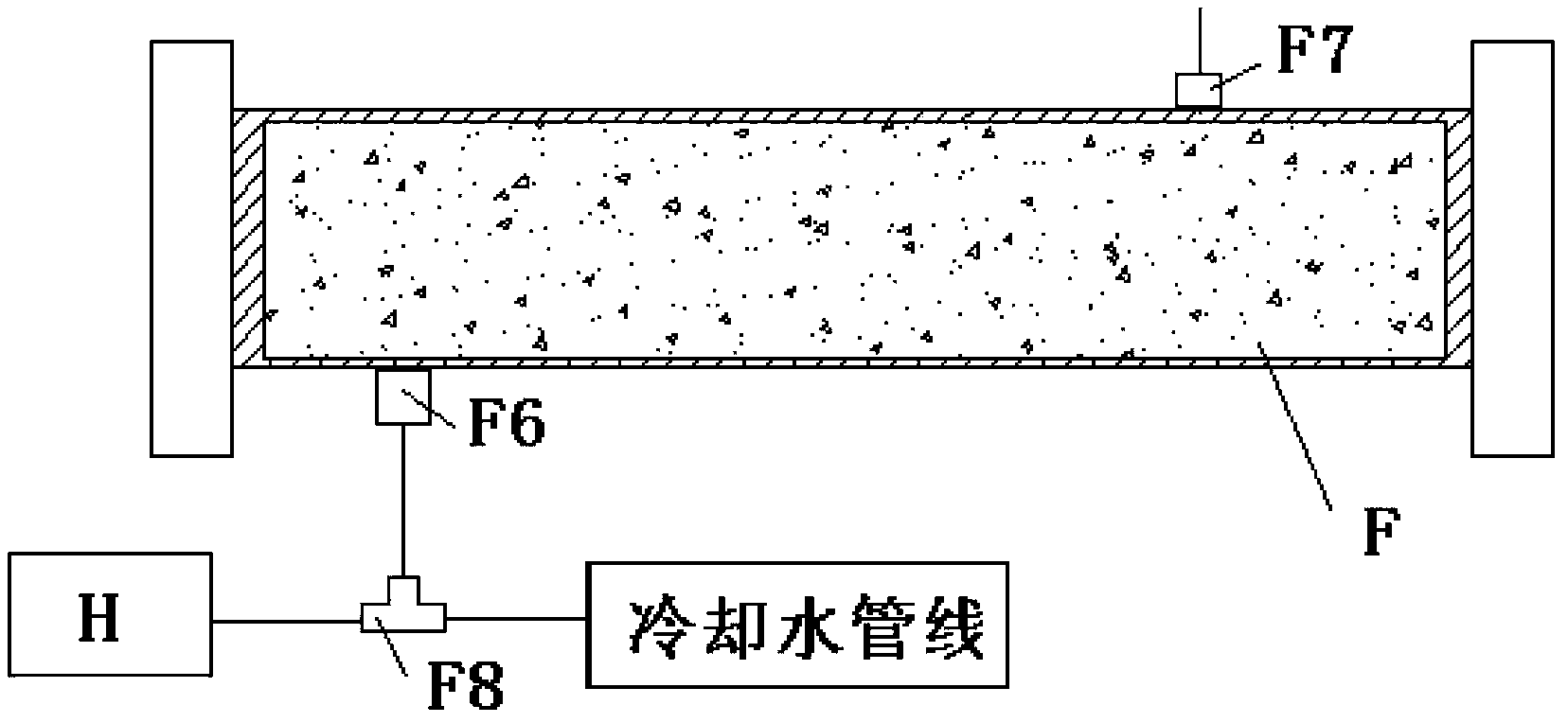

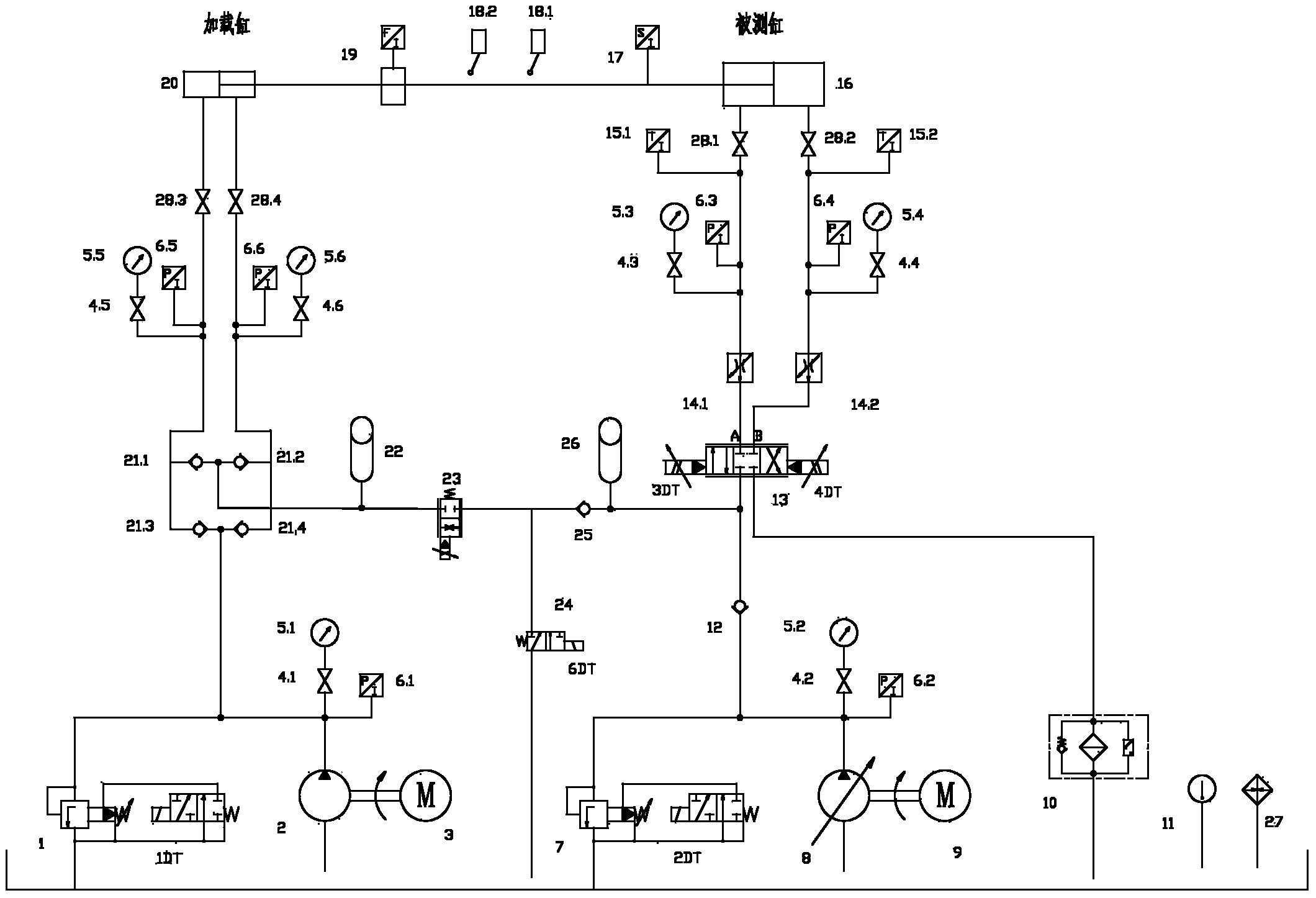

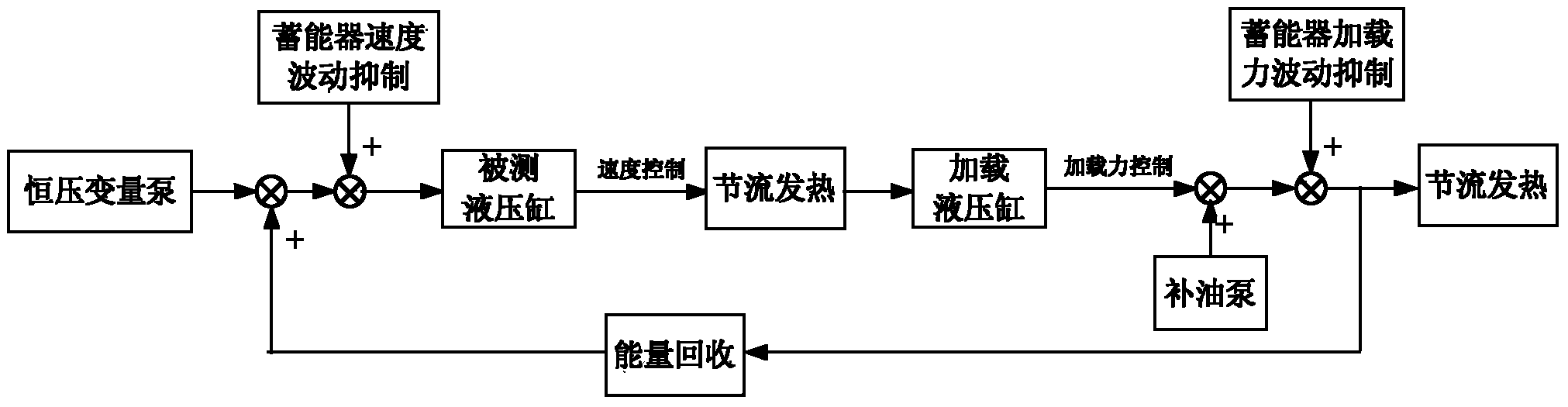

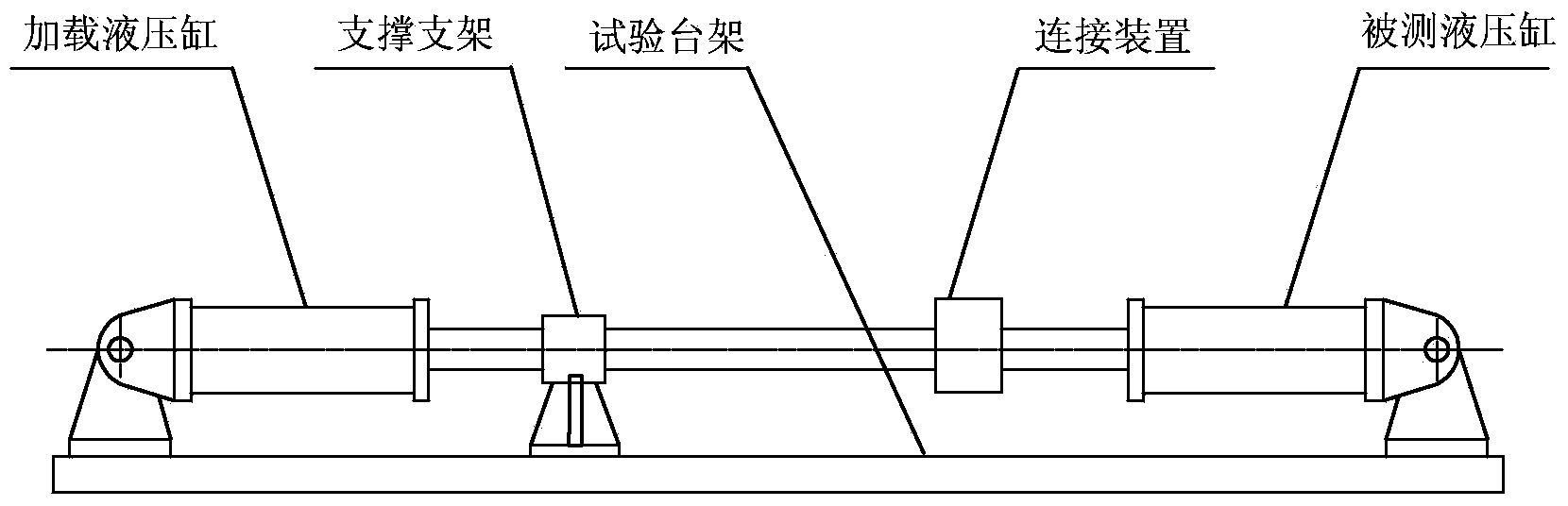

Energy-conservation and low-impact hydraulic cylinder test testbed hydraulic control system

InactiveCN103644151AStable energyRealize full working condition simulationFluid-pressure actuator testingLiquid temperatureFuel tank

The invention discloses an energy-conservation and low-impact hydraulic cylinder test testbed hydraulic control system. The system comprises a constant pressure variable pump, two electromotors, two electromagnetic unloading overflow valves, six check valves, two energy accumulators, an electrohydraulic proportional direction valve, two speed regulating valves, four ball valves, an oil supplementing pump, a proportional throttle valve, an electromagnetic reversing valve, a loading hydraulic cylinder, six pressure sensors, two temperature sensors, a displacement sensor, a force sensor, two travel switches, six pressure measuring connectors, six pressure gages, a heater, a liquid level liquid temperature gage, a filter and an oil tank. The energy-conservation and low-impact hydraulic cylinder test testbed hydraulic control system has the advantages that stable energy is provided for low-impact control over the speed of a tested hydraulic cylinder while energy is conserved, low-impact stable control over the loading force is achieved, meanwhile, the actual work condition that loads of the hydraulic cylinder probably change continuously in work can be simulated, all the work conditions of the loads of the hydraulic cylinder can be simulated, and power input is reduced.

Owner:YANSHAN UNIV

System and method for controlling temperature control elements that are used to alter liquid temperature

InactiveUS6989514B2Dc network circuit arrangementsThermometers using electric/magnetic elementsTemperature controlLiquid temperature

A system for controlling temperature control elements used to alter temperatures of a liquid comprises a temperature sensor, a first temperature control element, a second temperature control element, and logic. The temperature sensor is configured to sense temperatures of the liquid, and the first and second temperature control elements are each configured to alter a temperature of the liquid. The logic is configured to selectively control, based on the sensed temperatures, activation states of the first and second temperature control elements such that a total activation time associated with the first temperature control element is substantially equal to a total activation time associated with the second temperature control element.

Owner:A O SMITH

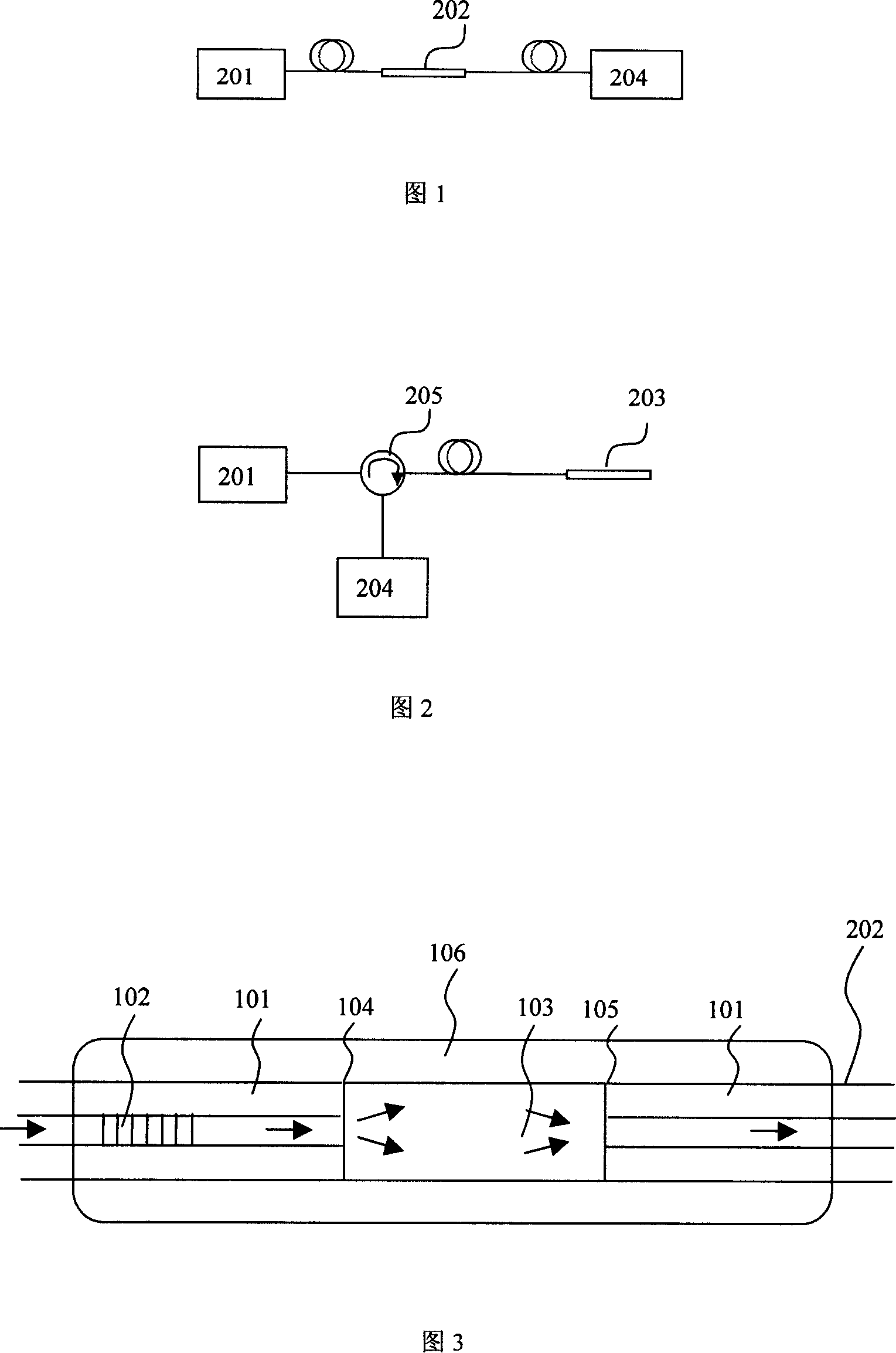

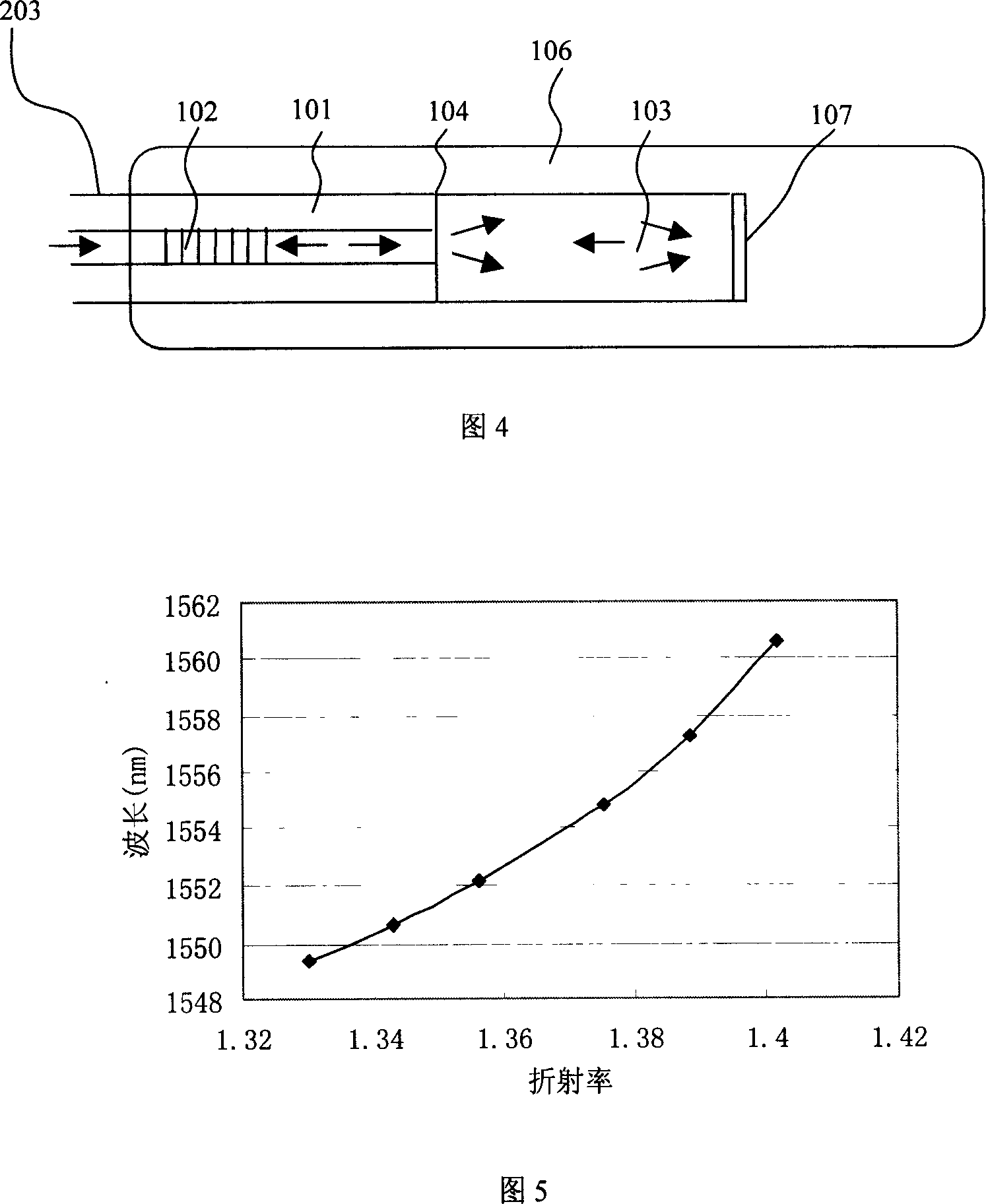

Fibre optic sensor for measuring temperature and refractive index of liquid contemporarily

InactiveCN1963400ASimple structureEasy to manufacturePhase-affecting property measurementsThermometers using physical/chemical changesGratingLiquid temperature

This invention discloses one fiber sensor to measure liquid temperature and reflection rate, wherein, the device comprises transparent and reflection types; the transparent device comprises wide band light source with out end connected to the sensor of temperature ad reflection rate with output end connected to the wave length modulation device; the transparent fiber temperature and reflection rate sensor comprises fiber Brag grating, single mode input fiber and fiber without fiber and output fiber; the reflection device comprises fiber ring device connected to wide band source, wave length demodulator and reflection temperature and reflection rate sensor.

Owner:CHINA NAT ACAD NANOTECH & ENG

System and method for capacity control in a multiple compressor chiller system

ActiveUS20050223724A1Easy to controlImprove system efficiencyCompression machines with non-reversible cycleEfficient regulation technologiesLiquid temperatureControl theory

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

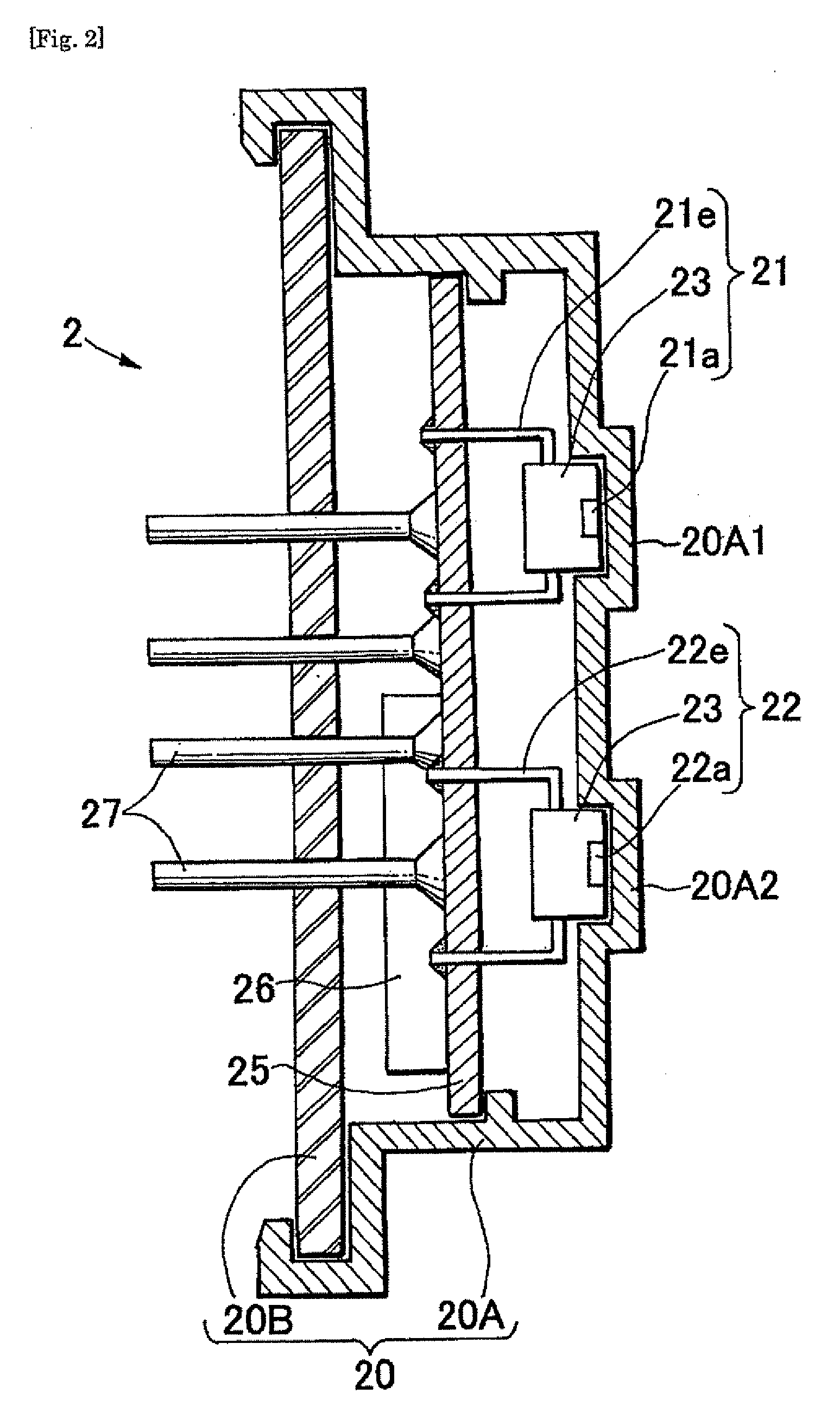

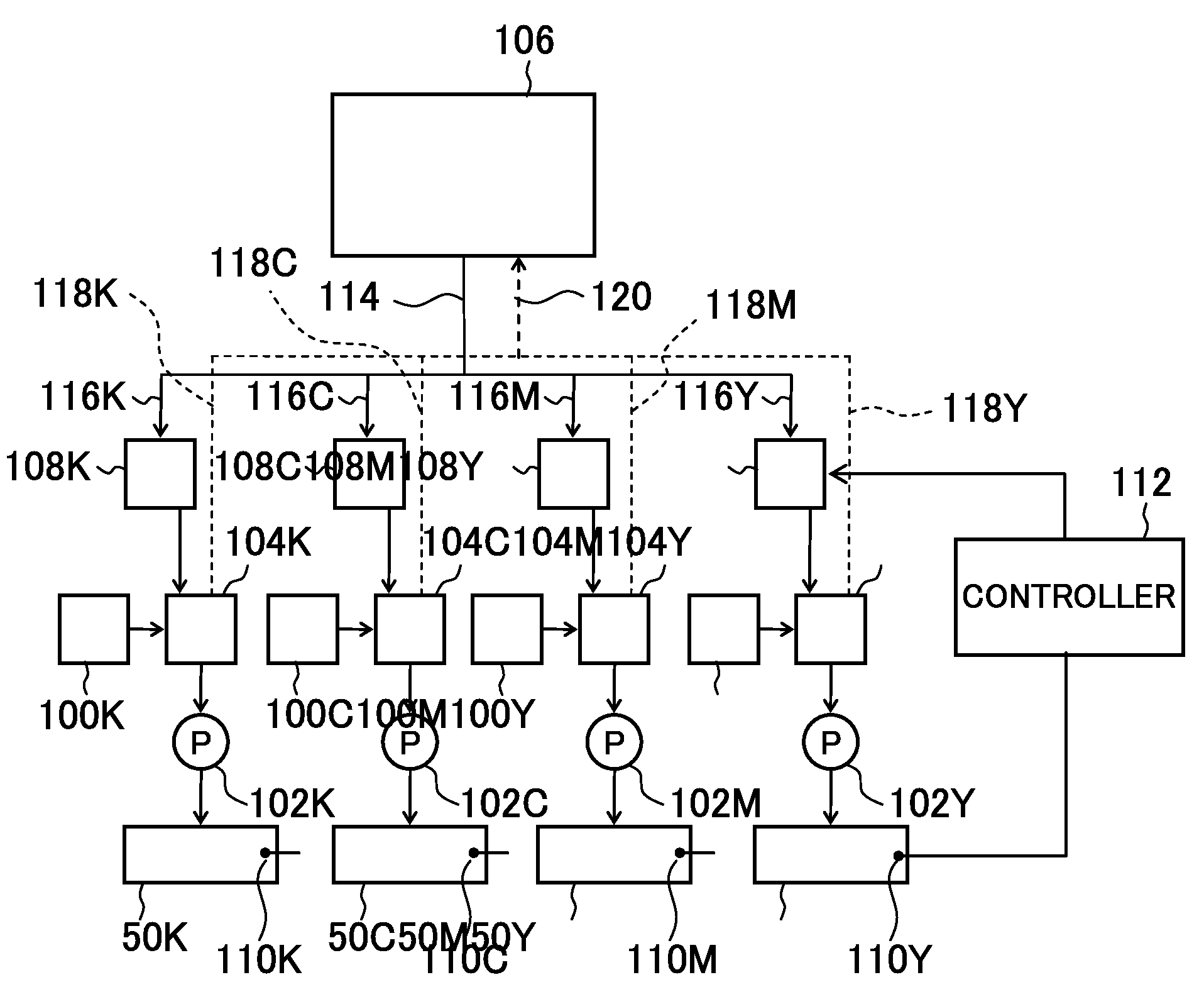

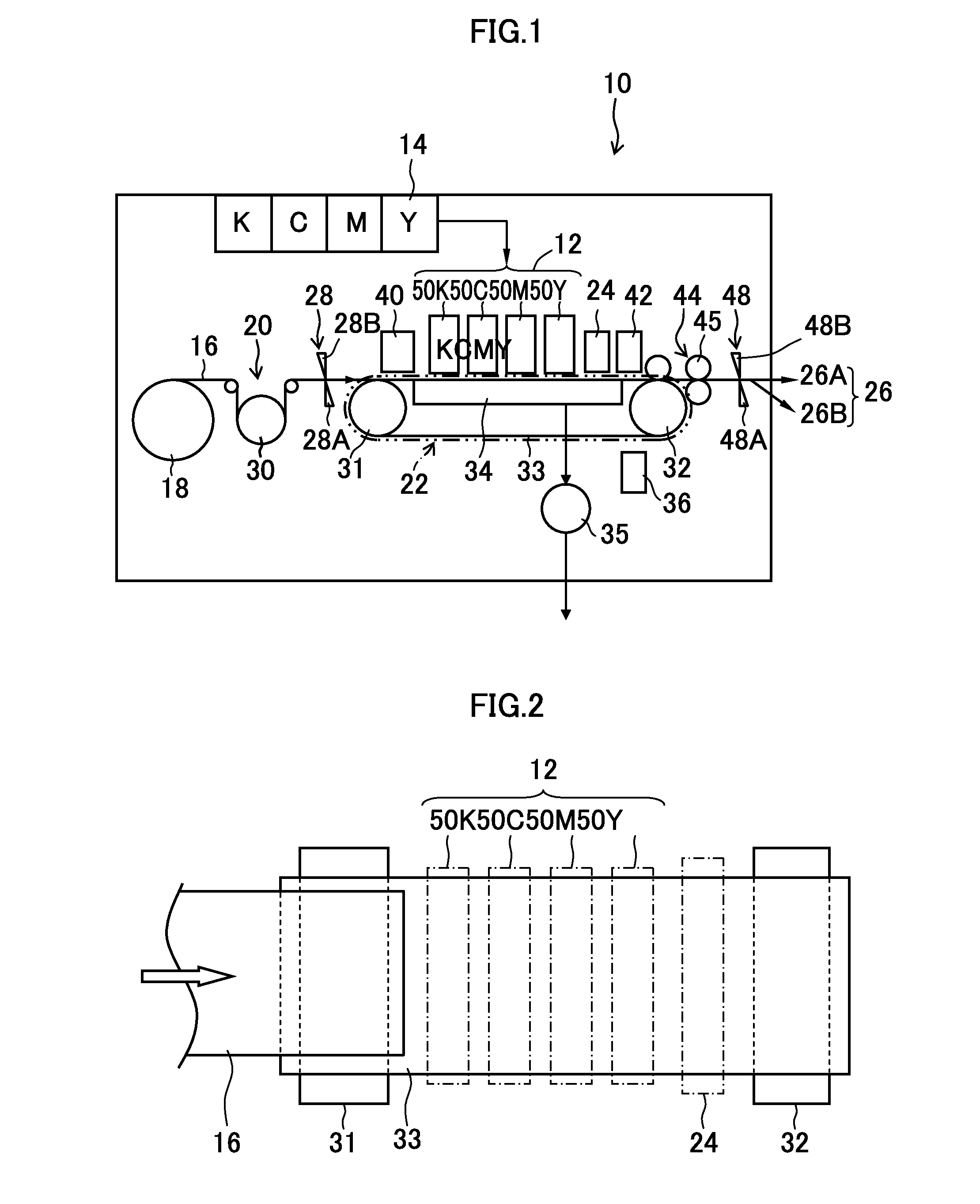

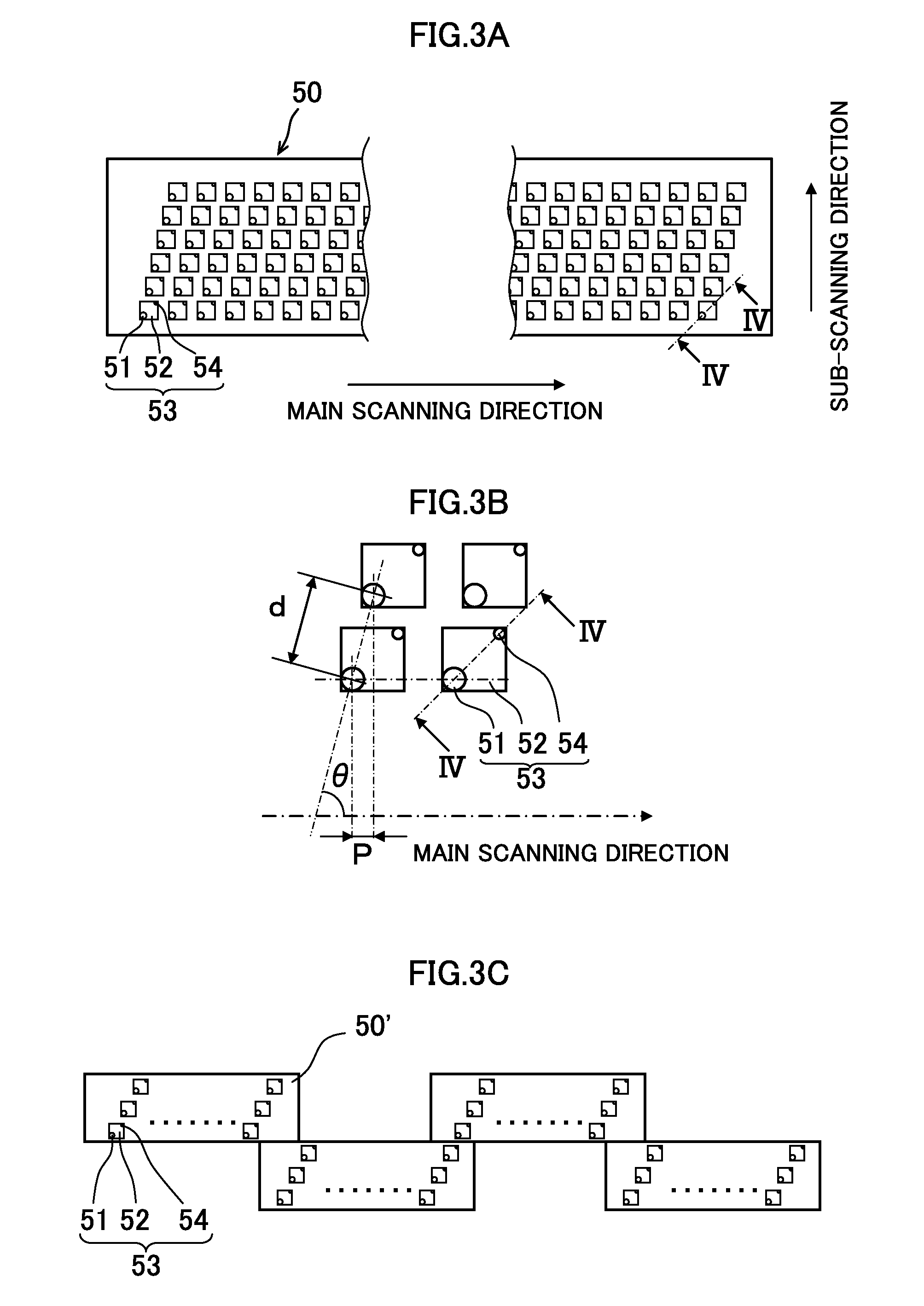

Liquid supply apparatus and image forming apparatus

ActiveUS8303072B2Ejection stability of each liquid ejection head can be stabilizedDensity unevenness caused by the difference in liquid temperature can be eliminatedOther printing apparatusLiquid temperatureLiquid medium

A liquid supply apparatus includes: a plurality of heat exchange devices which are respectively provided in a plurality of supply paths for supplying liquids to a plurality of liquid ejection heads respectively, are supplied with a liquid medium adjusted to a predetermined temperature from a liquid temperature adjusting device, and conduct heat exchange between the liquids flowing in the plurality of supply paths and the liquid medium supplied from the liquid temperature adjusting device; a plurality of flow rate adjusting devices which are respectively provided correspondingly to the plurality of heat exchange devices and adjust a flow rate of the liquid medium supplied to each of the plurality of heat exchange devices from the liquid temperature adjusting device; and a controller which controls each of the plurality of flow rate adjusting devices to individually change the flow rate of the liquid medium supplied from the liquid temperature adjusting device to the plurality of heat exchange devices.

Owner:FUJIFILM CORP

Method for manufacturing tobacco cut stems

InactiveCN102440433AGood colorIncrease fill valueTobacco preparationTobacco treatmentLiquid temperatureManufacturing technology

The patent of the invention relates to the field of reproduced tobacco product manufacturing technology, in particular to a method for manufacturing tobacco cut stems. The method comprises the following steps: the cut stems after being cut enter a continuous extraction device, and are extracted with solvent, wherein the proportion of materials to the solvent is 1:20, the time lasts 20-60 minutes, and the temperature of the solvent is 20-50 DEG C; an extraction mode is as follows: forward flow is conducted, the extracted cut stems are subjected to solid-liquid separation through extrusion and centrifugation, and then subjected to feed liquid backfill, wherein the feed liquid concentration is 30%-40%, the feed liquid temperature is 20-40 DEG C, the application proportion is 40-120%; and the backfill mode is as follows: the spraying is conducted. After being subjected to liquid feed backfill, the cut stems have higher water content which is about 65%, so that the water content of the cut stems after the water pretreatment is reduced to about 35% from 65%, and then the cut stems are subjected to tower type expansion or air flow drying. The cut stems prepared by the process has better color and luster and good filling value, the cigarette quality is improved obviously, the harmful contents such as tar and carbon monoxide in the cigarette are reduced greatly, the utilization ratio of stem raw materials is improved greatly, and the cost for a single box is lowered greatly.

Owner:SHANGHAI JUHUA TECH

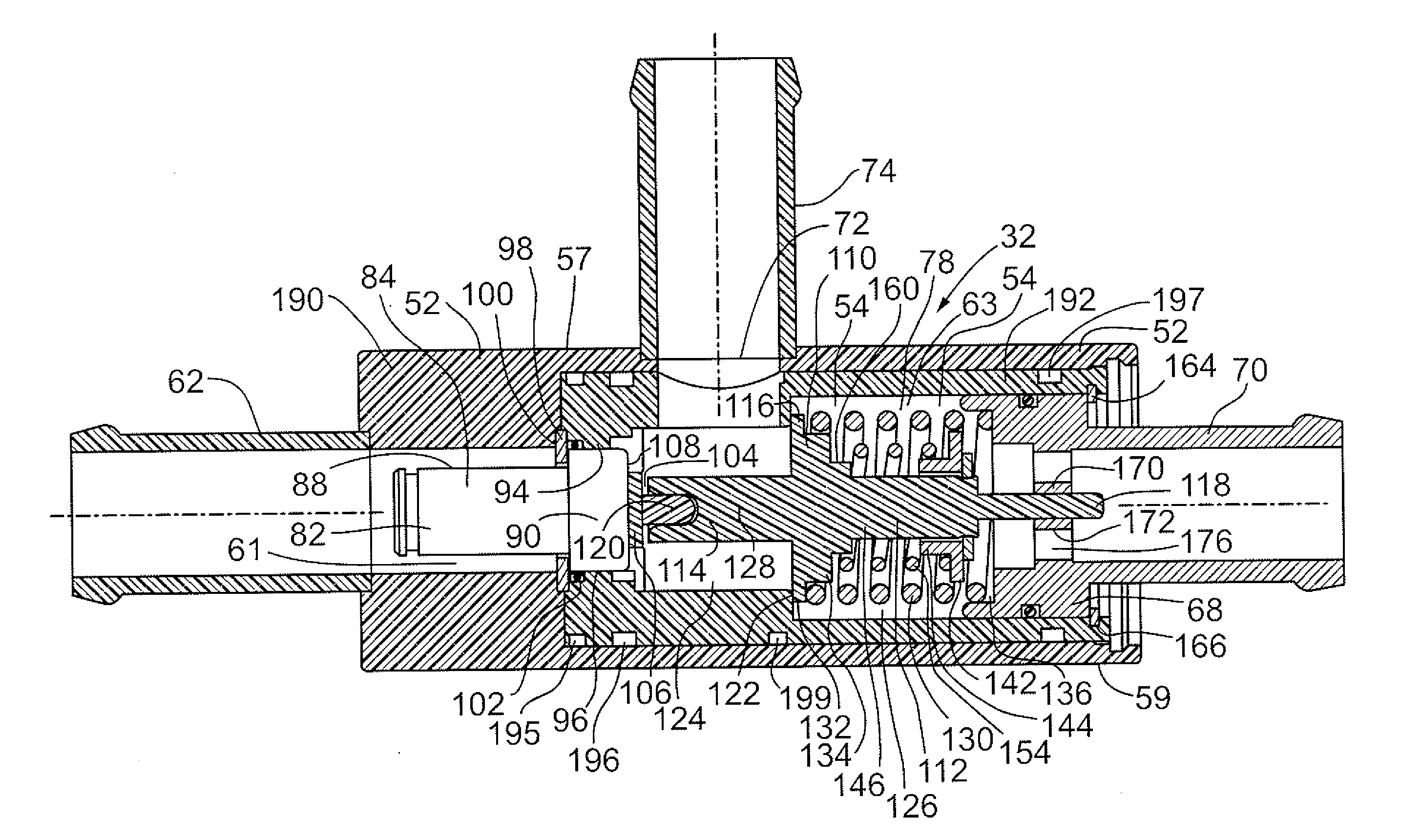

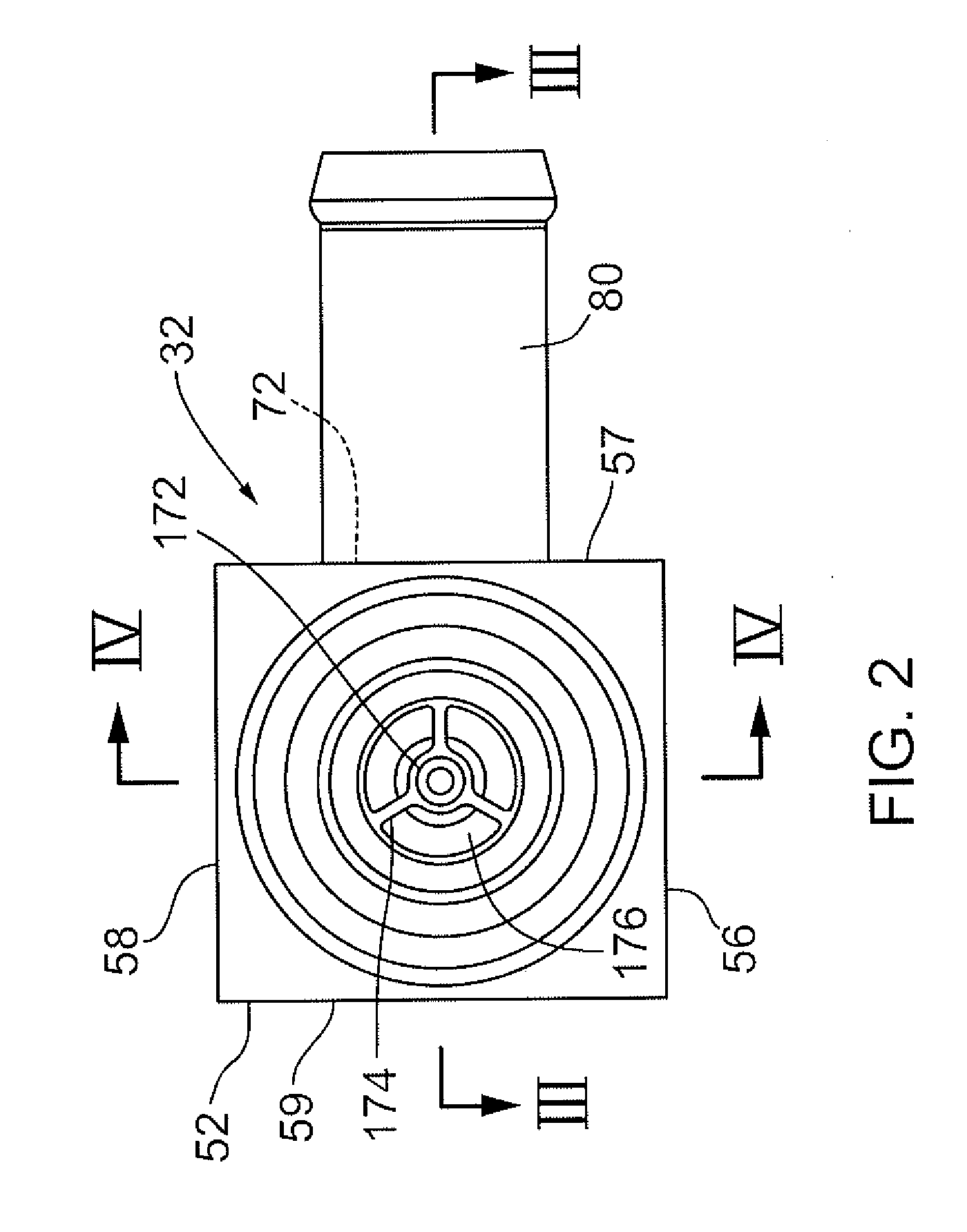

Valve apparatus for regulating a heat exchange liquid

ActiveUS20100181516A1Temperature control without auxillary powerCoolant flow controlWaxLiquid temperature

A valve apparatus can be used to select between a cold or a hot coolant for heat exchange, this selection depending on whether an attached heat exchanger is to operate as a cooler or a heater. The apparatus includes a valve housing with first and second chambers formed therein, first inlet and outlet ports for flow of a primary liquid into and out of the first chamber and further ports for flow of coolant at different temperatures through the second chamber. A linear actuator in the housing has a body containing wax and a plastic piston that is movable to an extended position by expansion of the wax. The actuator body is located in the first chamber so the temperature of the wax is dependent on the liquid's temperature in the first chamber. An end portion of the actuator adjacent to the second chamber is made of plastic. A valve mechanism for controlling coolant flow is operably connected to the piston and located in the second chamber. This mechanism includes a spool movable by the actuator.

Owner:DANA CANADA CORP

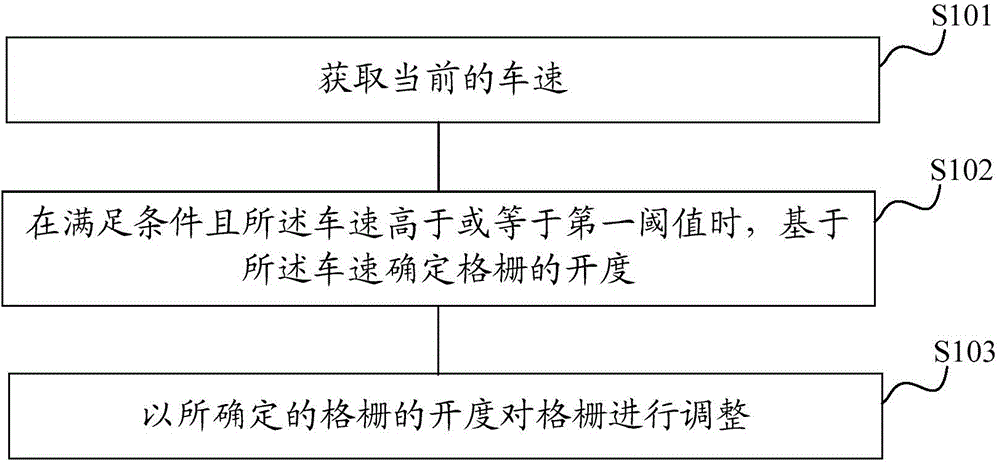

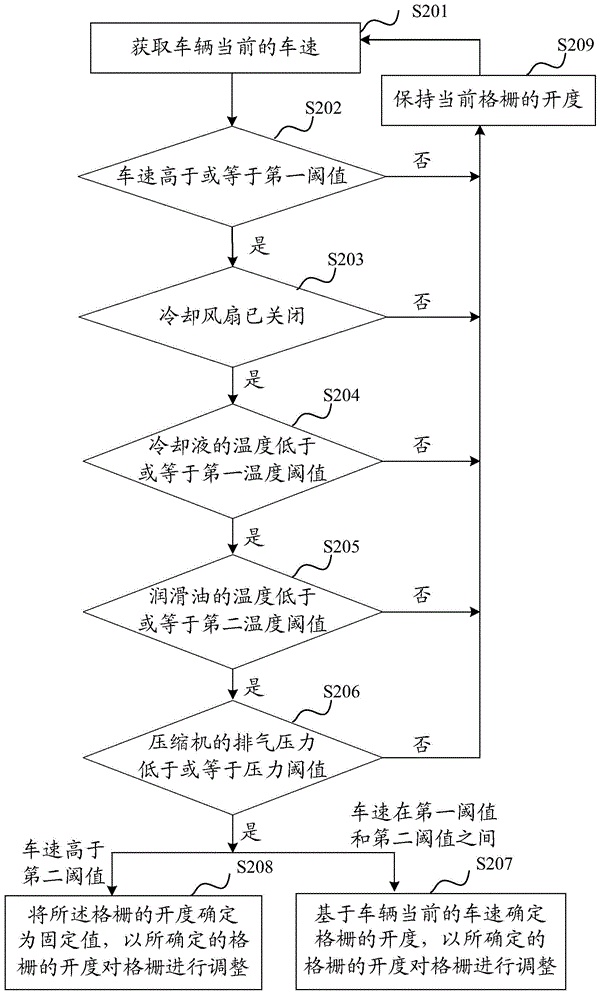

Grating control method and device

ActiveCN104972894AReduce drag coefficientReduce fuel consumptionPropulsion coolingGratingLiquid temperature

A grating control method and device is provided; the method comprises the following steps: obtaining present vehicle speed; determining grating opening degree according to the vehicle speed when conditions are satisfied and the vehicle speed is higher than or equal to a first threshold value; adjusting the grating according to the determined grating opening degree. The conditions comprise: a cooling fan is closed; the temperature of a cooling liquid of an engine is lower than or equal to a first temperature threshold; the temperature of lubricating oil of the engine is lower than or equal to a second temperature threshold; an exhaust pressure of an air-conditioning compressor is lower than or equal to a pressure threshold. The method allows air inlet of grating of passing vehicle to meet the demand of a cooling system, fully considers vehicle speed and cooling fan on / off condition, engine cooling liquid temperature, engine lubricating oil temperature and air-conditioning compressor exhaust pressure, thus determining grating opening degree, and adjusting the grating according to the determined grating opening degree; the method can control the grating opening degree according to the vehicle speed, thus effectively reducing wind resistance coefficient, and reducing system oil consumption.

Owner:SAIC MOTOR

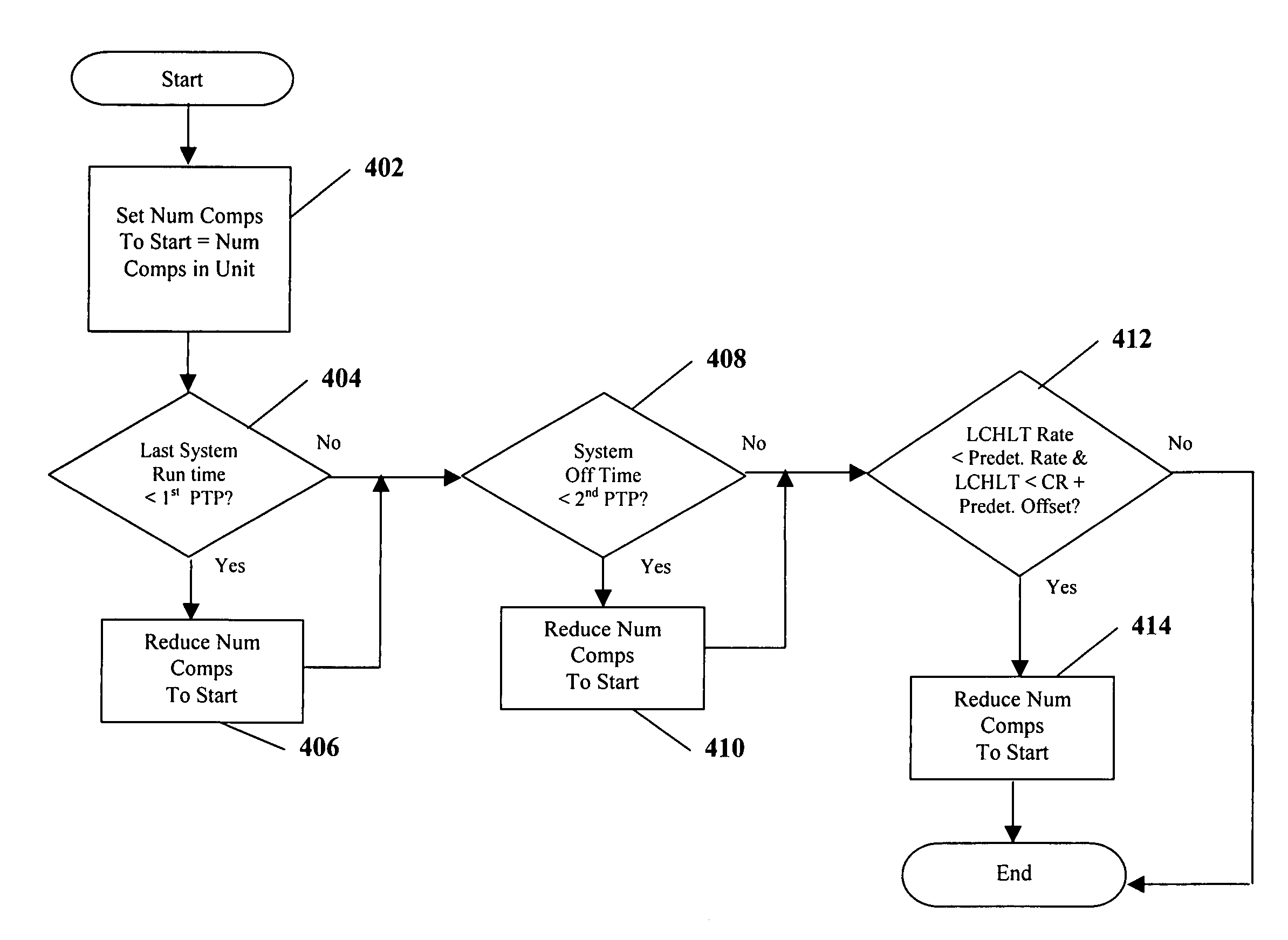

Startup control system and method for a multiple compressor chiller system

ActiveUS7231773B2Improve system efficiencyQuickly and easily determineCompression machines with non-reversible cycleCompression machines with cascade operationLiquid temperatureControl system

A startup control algorithm for a multiple compressor liquid chiller system is provided wherein the maximum number of compressors to be started to satisfy system load conditions is provided. The control algorithm designates all of the compressors of the multiple compressor system for starting and reduces the number to be started in response to the satisfaction of several predetermined criteria. The predetermined criteria are related to the leaving chilled liquid temperature, the shutdown time for the chiller system and the last operating time period for the chiller system.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

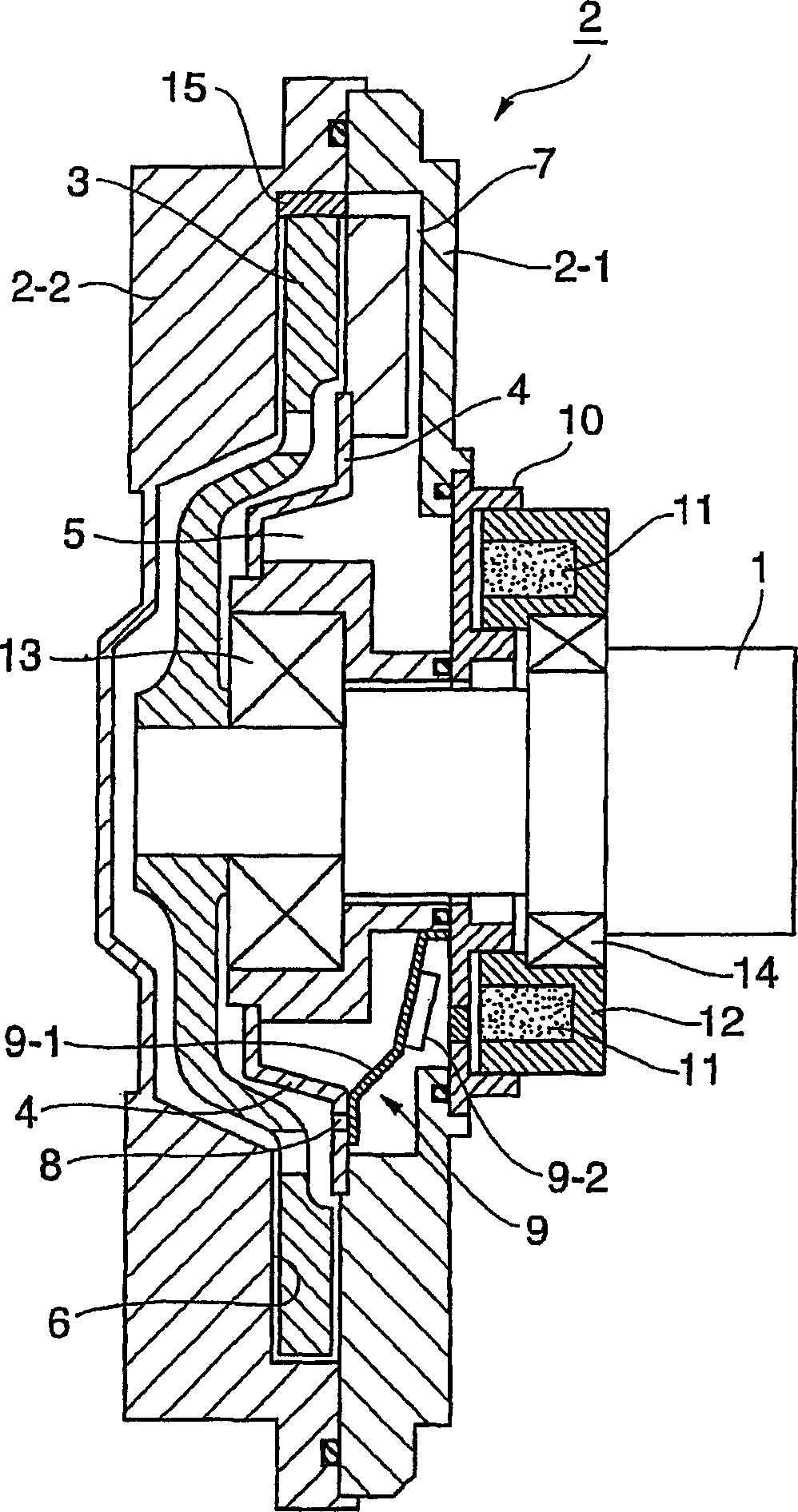

Method and apparatus for measurement and control of temperature for infused liquids

ActiveUS8226293B2Accurate and reliable temperature indicationEasy to measureThermometer detailsMedical devicesLiquid temperatureDisplay device

A device according to present invention embodiments measures the temperature of fluid within an IV line at selected locations. The device may be in the form of a fitting including a projection in fluid communication with a fluid channel to receive a temperature sensor. A thermally conductive receptacle may be disposed in the projection to receive the temperature sensor and partially extends into the fluid channel for contact with the fluid. The temperature sensor may be coupled to a temperature display device and / or controller to display the measured temperature and / or control a thermal element to regulate fluid temperature. The fitting may further include a looped configuration and / or a control valve that controls the flow of fluid through the fluid channel. In addition, the device may further be connected to, or be in the form of, a needle hub to measure fluid temperature proximate the entry site on a patient.

Owner:MEDICAL SOLUTIONS INC

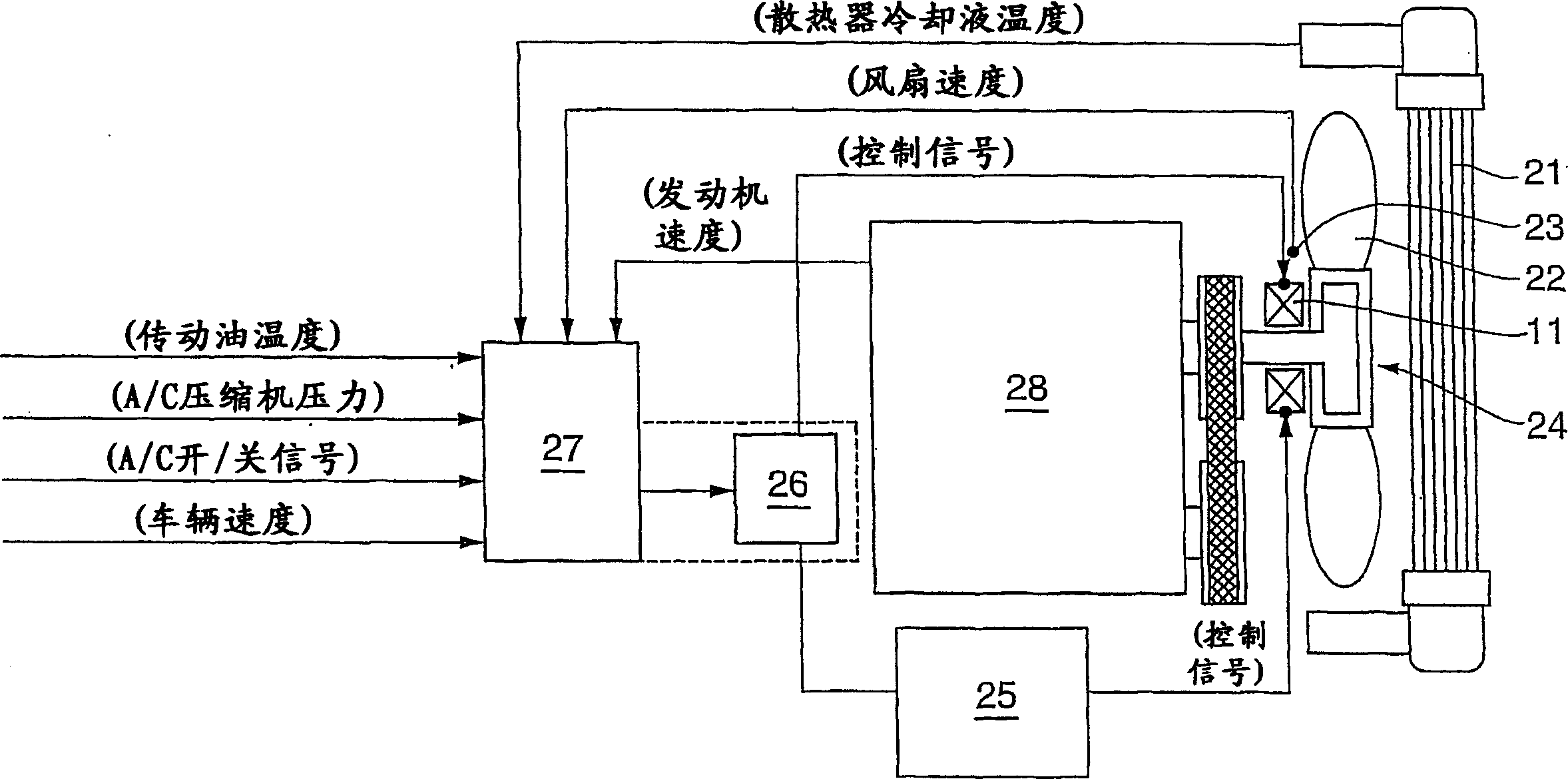

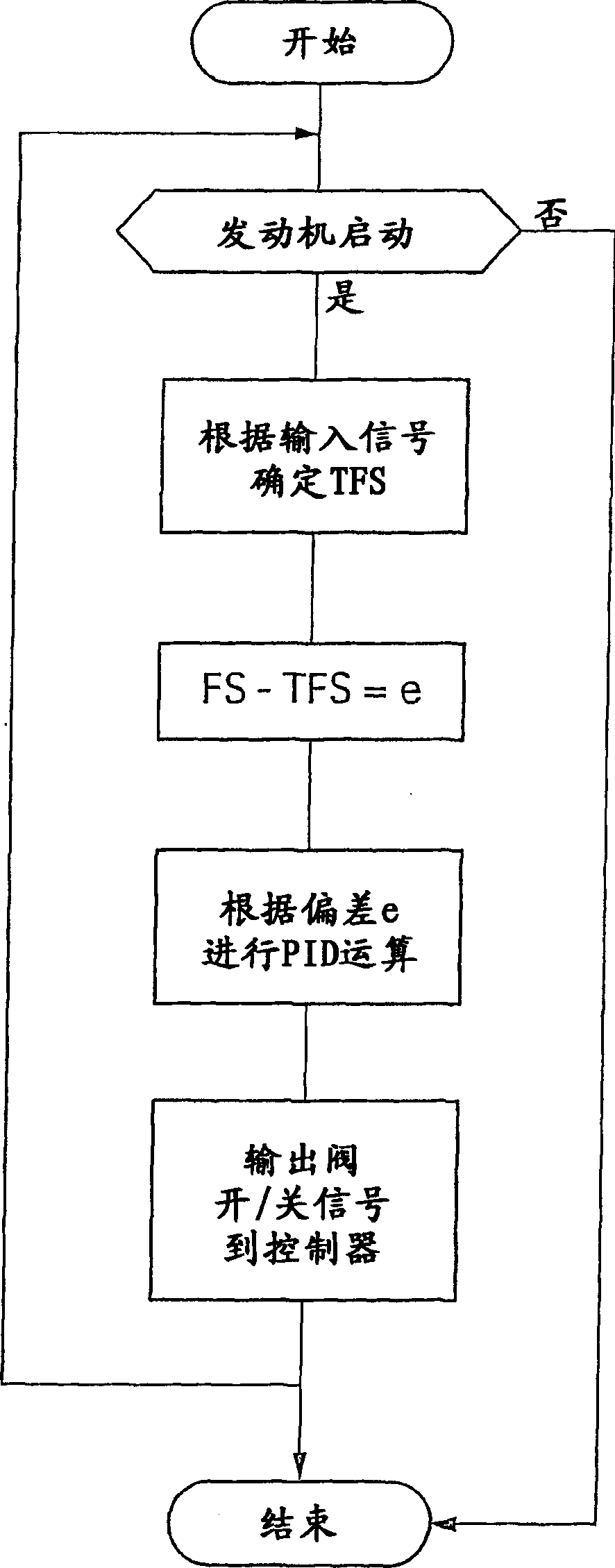

Control method for external control type fan clutch

ActiveCN1807917AImprove cooling effectSuppress noiseElectrical controlCoolant flow controlLiquid temperatureControl signal

A method is provided for controlling an external control type fan clutch. The method controls the On / Off of an electromagnet-activated valve for an oil feed adjusting hole. The method uses a PID control on the basis of radiator cooling liquid temperature, fan speed, transmission oil temperature, vehicle speed, engine speed, compressor pressure of an air conditioner, and an On / Off signal of the air conditioner. Individual gains of the PID control are determined by a gain matrix containing the optimum fan speed demanded by the engine, the actual metered fan speed, and the engine speed. The PID control is made on the basis of the gains to that a control signal is outputted. The control method can improve mileage, raise the cooling efficiency of an air conditioner and suppress fan noise.

Owner:USUI CO LTD

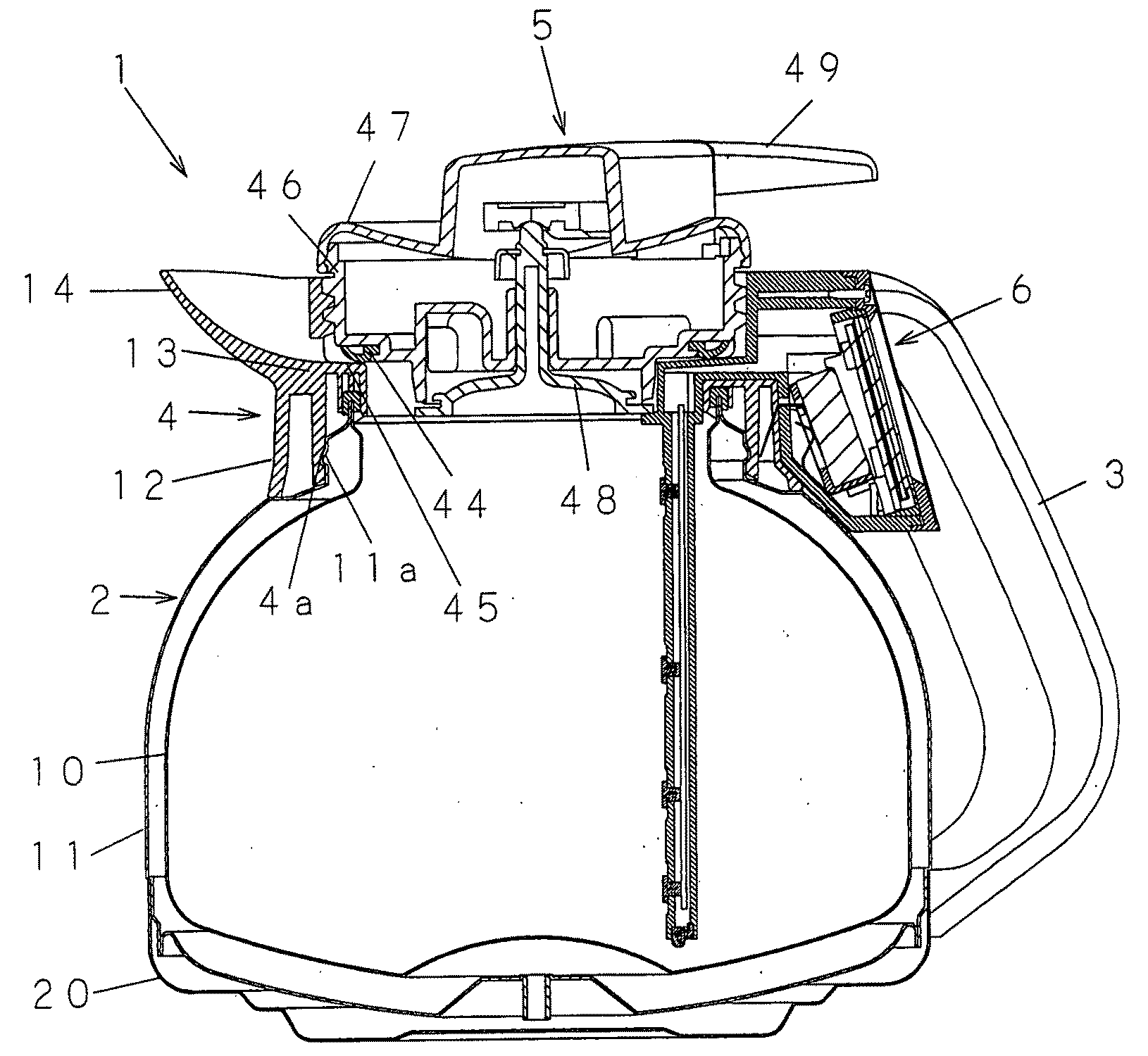

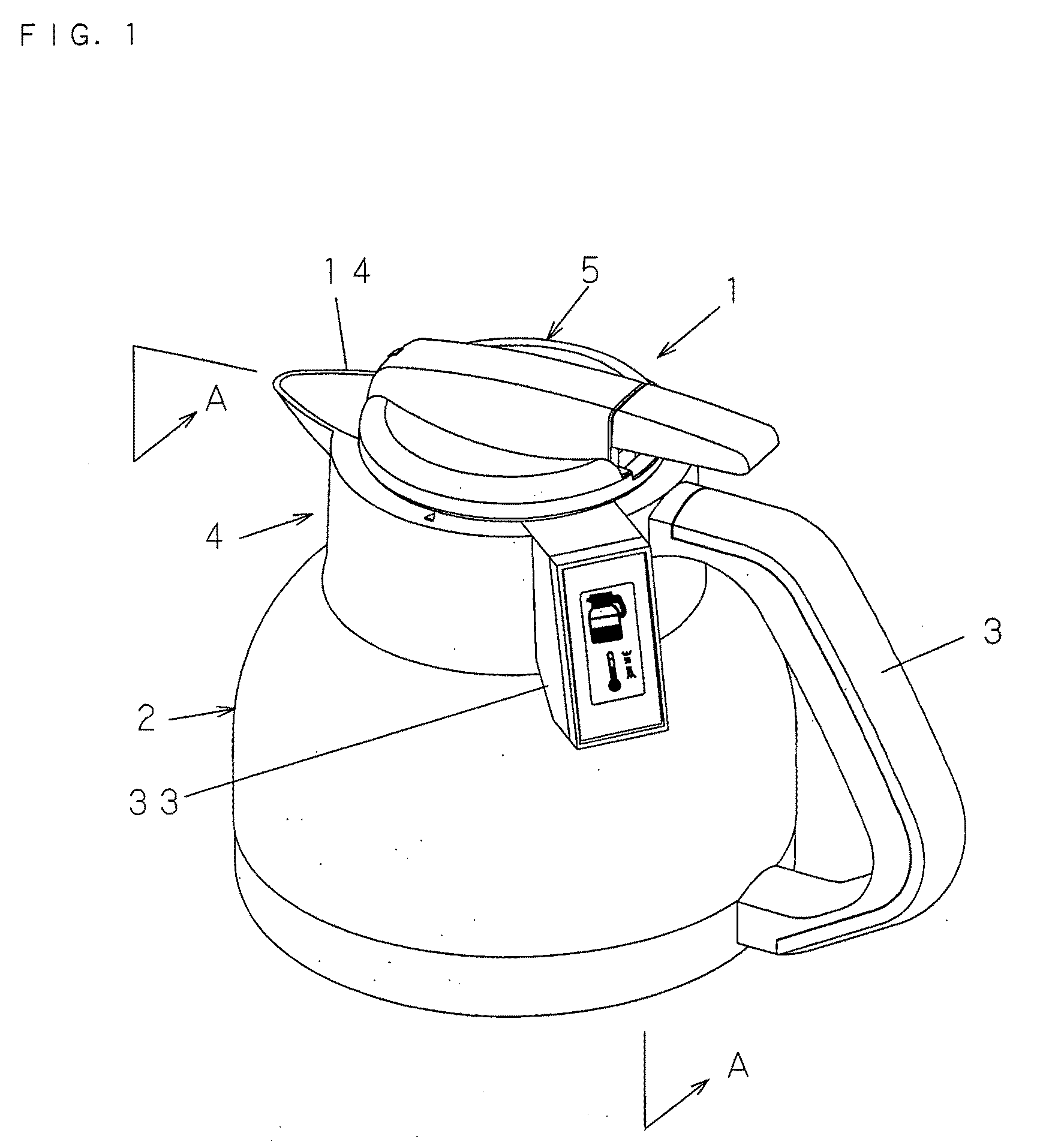

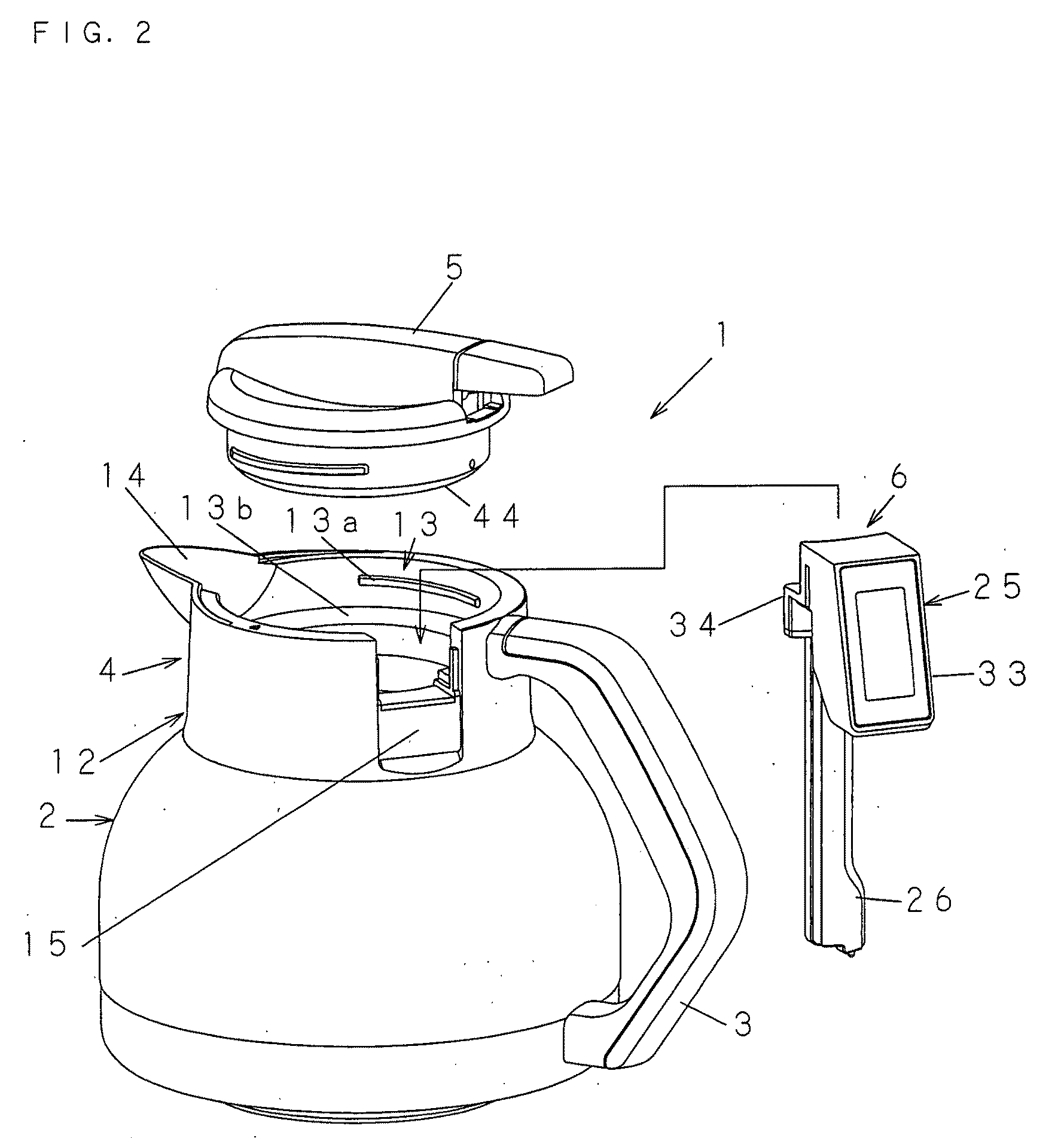

Liquid container

InactiveUS20090139324A1Simple structureThermometer detailsTemperature measurement in household appliancesLiquid temperatureEngineering

There is provided a liquid container that has solved the problem of the impossibility to easily see a liquid surface within an inner bottle, namely a remaining liquid amount within a container, and the problem of the impossibility to easily check whether a liquid temperature inside the inner bottle being a vacuum double bottle is held at a desired temperature. A liquid container, including: an inner container which houses a liquid; a shoulder member which is a member mounted on the upper portion of this inner container and has a handle and a spout on the opposite side thereto; and a lid which is removably placed at the top of this shoulder member and opens / closes a top opening of the inner container, wherein the liquid container where a liquid amount inside the inner container is invisible from the outside is provided with a detecting unit having a liquid amount detecting means and a liquid temperature detecting means which are inserted into the inner container and detect a liquid amount and a liquid temperature, and a unit outer package which displays the liquid amount and the liquid temperature detected by the detecting means on the outer surface of the liquid container.

Owner:ALLGO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com