Water cooling system of engine and cooling method thereof

A technology of a water cooling system and a cooling method, which is applied in the cooling of the engine, engine components, machines/engines, etc., can solve the problems of poor engine, low control accuracy, and lowering the crankshaft starting speed of the engine driven engine, and achieves the starting success rate and Beneficial start-up time, reduced exhaust pollution, improved economy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

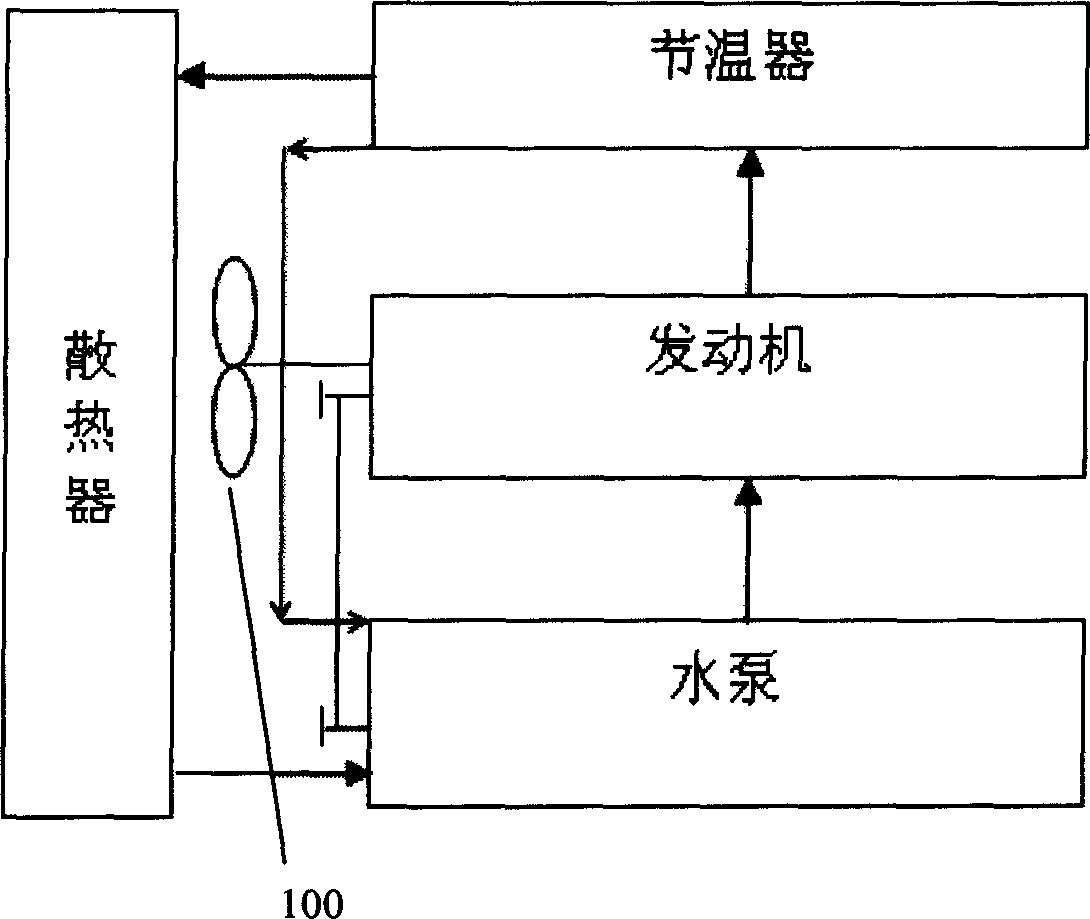

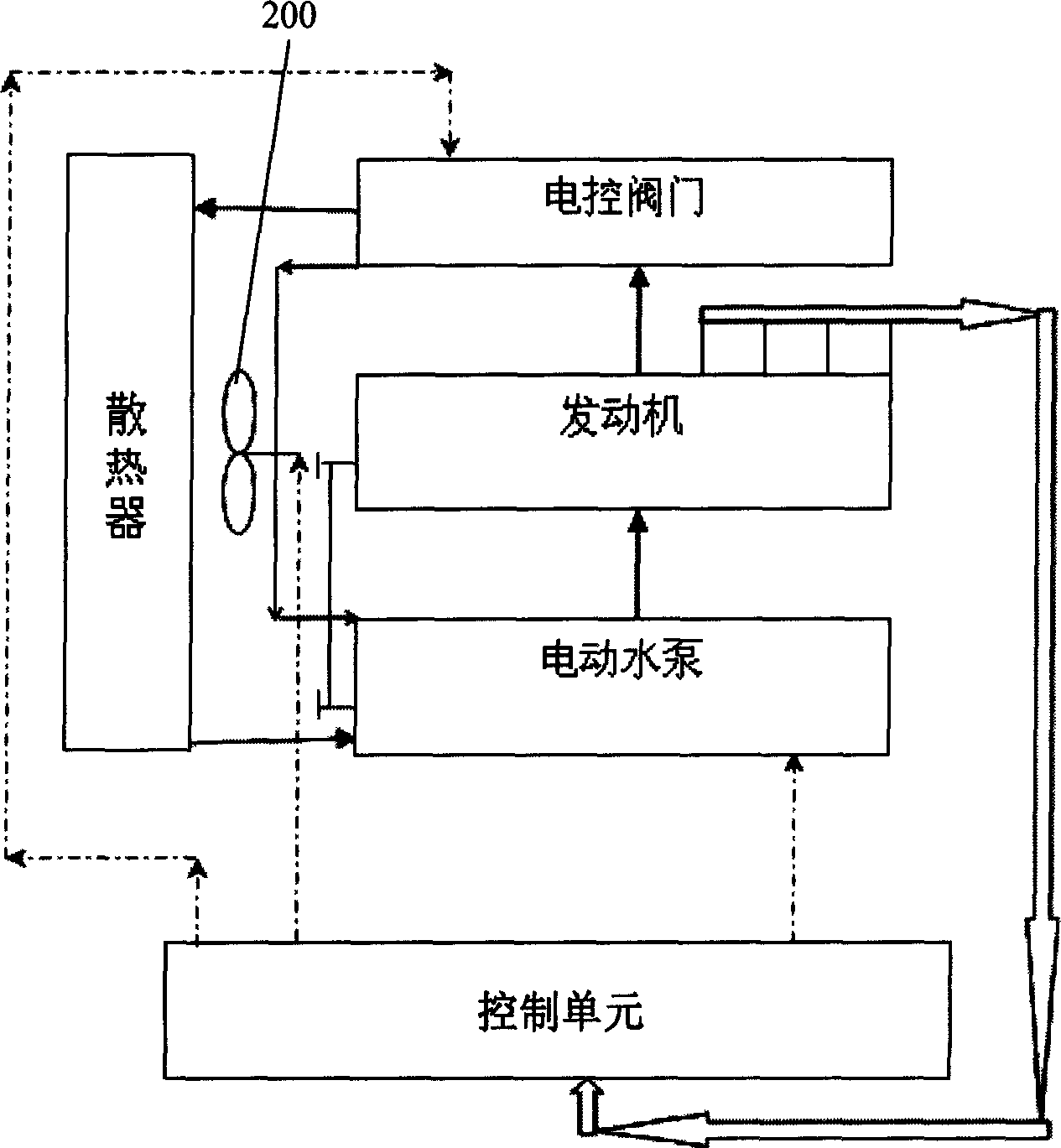

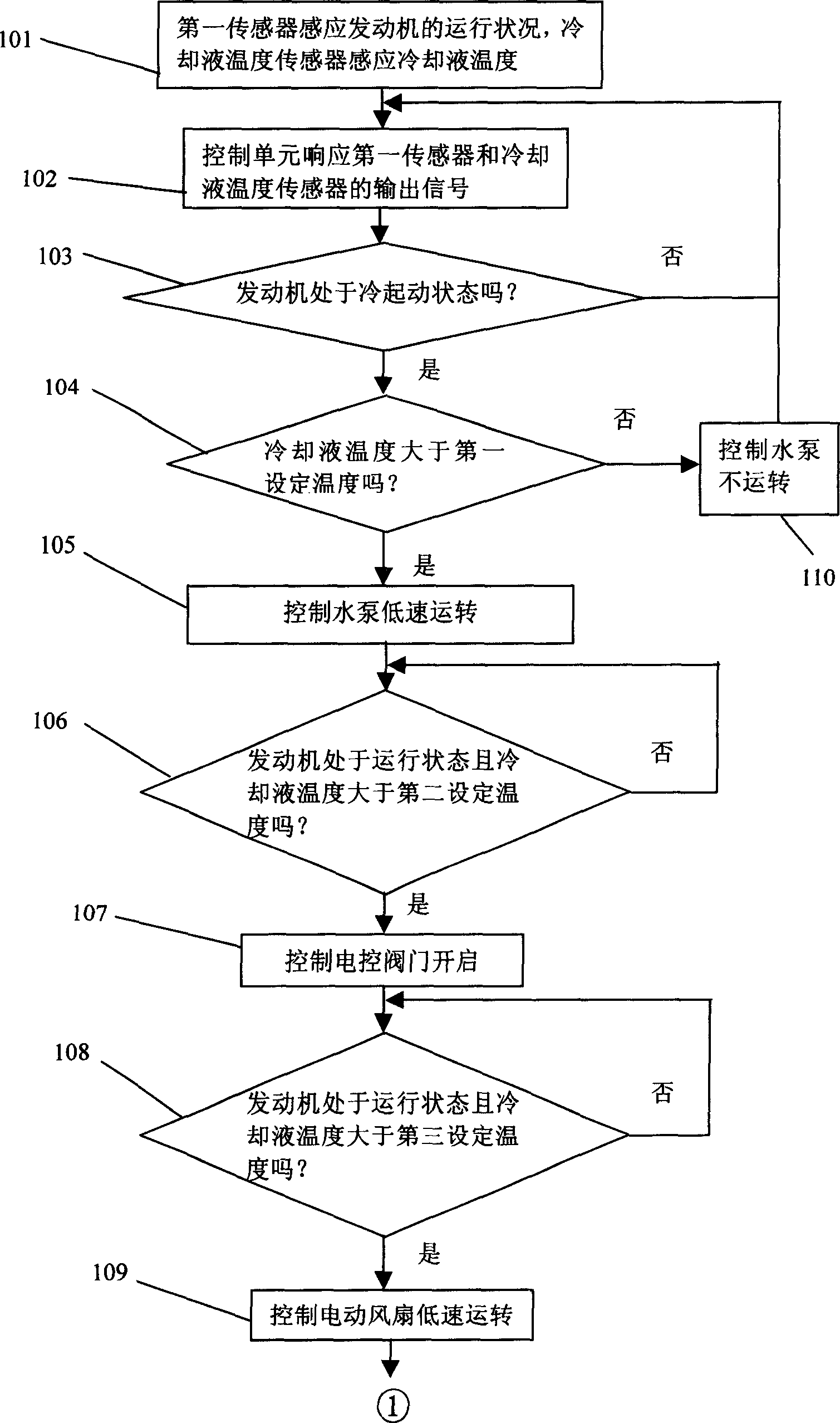

[0040] Such as figure 2 As shown, the water cooling system includes an engine, a first sensor, a coolant temperature sensor, an electric water pump, a circulating water channel, and an electronic control unit. The first sensor is used to sense the operating conditions of the engine, which can be an engine speed sensor, and can also include an engine section. Valve position sensor and engine load sensor. The coolant temperature sensor is used to sense the temperature of the coolant in the engine. It can further include electronically controlled valves, a radiator and an electric fan 200 . The control unit responds to the signals of the engine speed sensor, engine throttle position sensor, engine load sensor and coolant temperature sensor, and controls the electric water pump, electric control valve and electric fan respectively after processing. The circulating water channel can include small circulation and large circulation. The coolant in the small circulation can be driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com