Equipment for transfer and/or handling and transport of workpieces

A workpiece and equipment technology, applied in the field of equipment for taking out injection molded articles from injection molding machines, can solve problems such as difficulty in grasping workpieces, production interruptions, production defects, etc., to save cable connections, improve resolution, The effect of simplifying replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

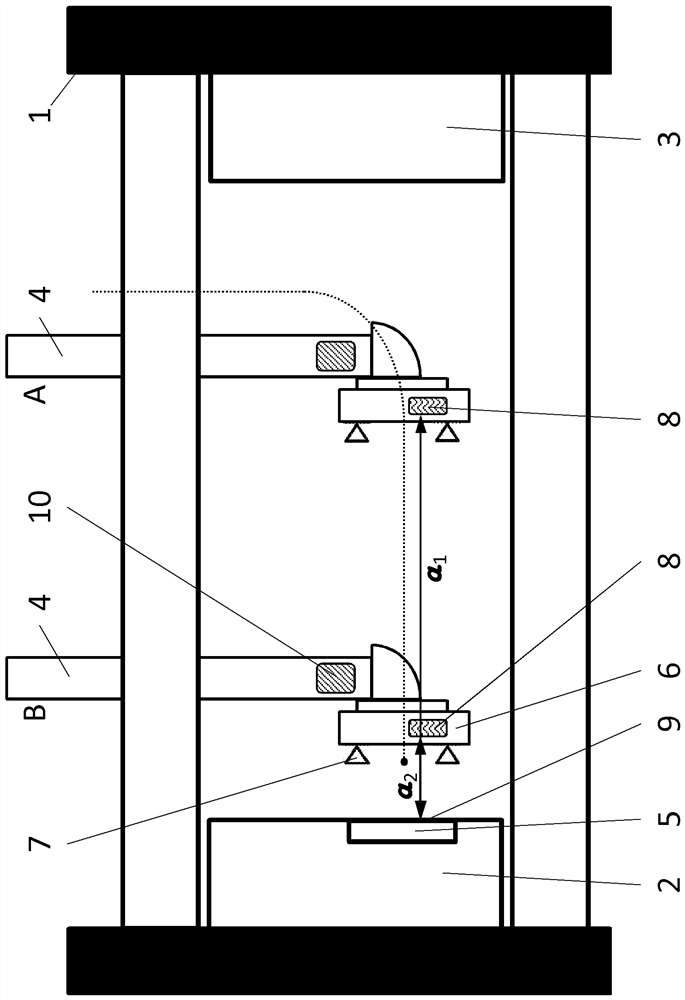

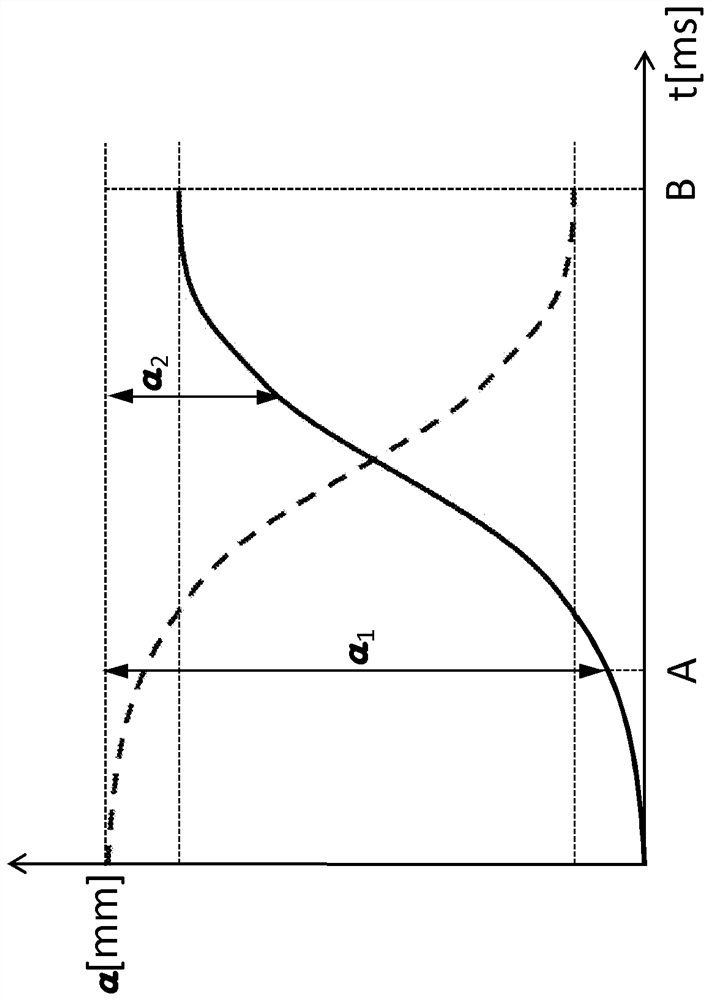

[0027] according to figure 1 The injection molding machine 1 is shown with the mold halves 2 , 3 open. The robot 4 enters the opened tool halves 2 , 3 for removal of the workpiece 5 . Position A of the robot 4 is entry into the open mold, wherein in position A the robot 4 has reached the point for releasing the measurement of the reference plane 9 .

[0028] In position B, the robot 4 is located in the region of the workpiece 5 .

[0029] The automatic manipulator 4 can be moved by means of a drive which can be acted upon by a programmable control and regulating unit. The robot 4 is provided with a gripper 6 and has at least one suction nozzle 7 . A programmable control and regulation unit 10 is provided in the robot 4 , which optionally has a separate sensor evaluation unit.

[0030] A distance measuring device 8, such as a TOF sensor, is arranged in the gripper 6 of the automatic manipulator 4, and the distance measuring device is used to detect the distance a from the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com