Patents

Literature

81results about How to "Reduce exhaust pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

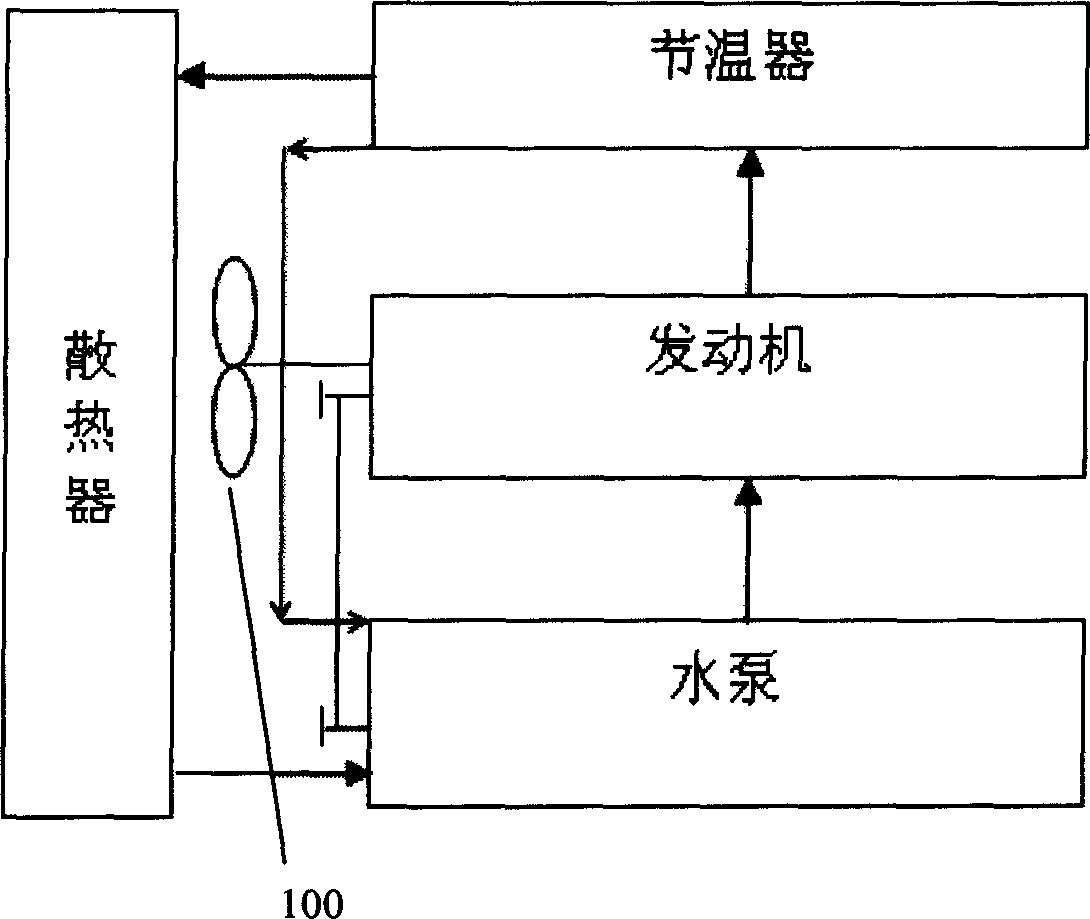

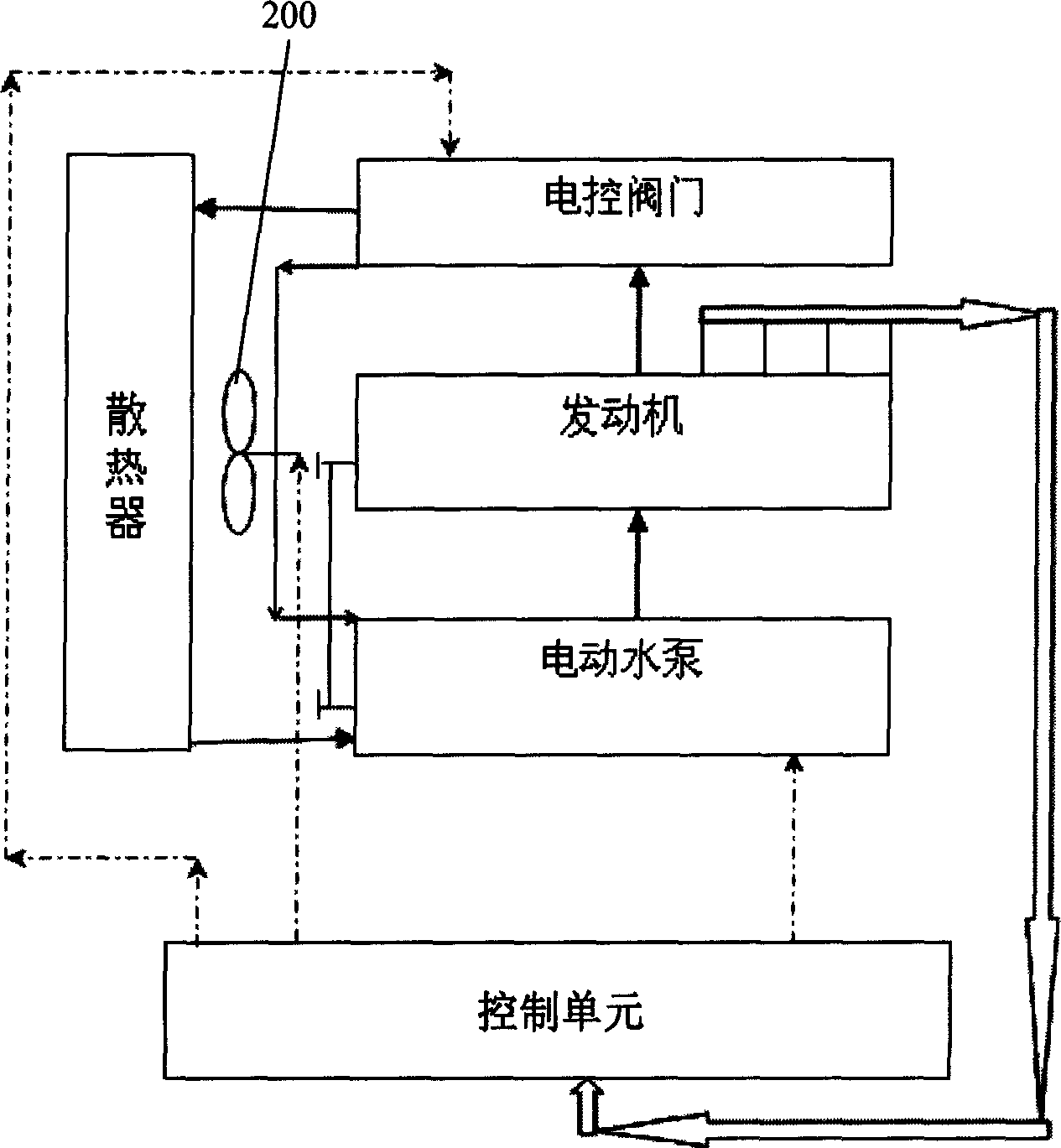

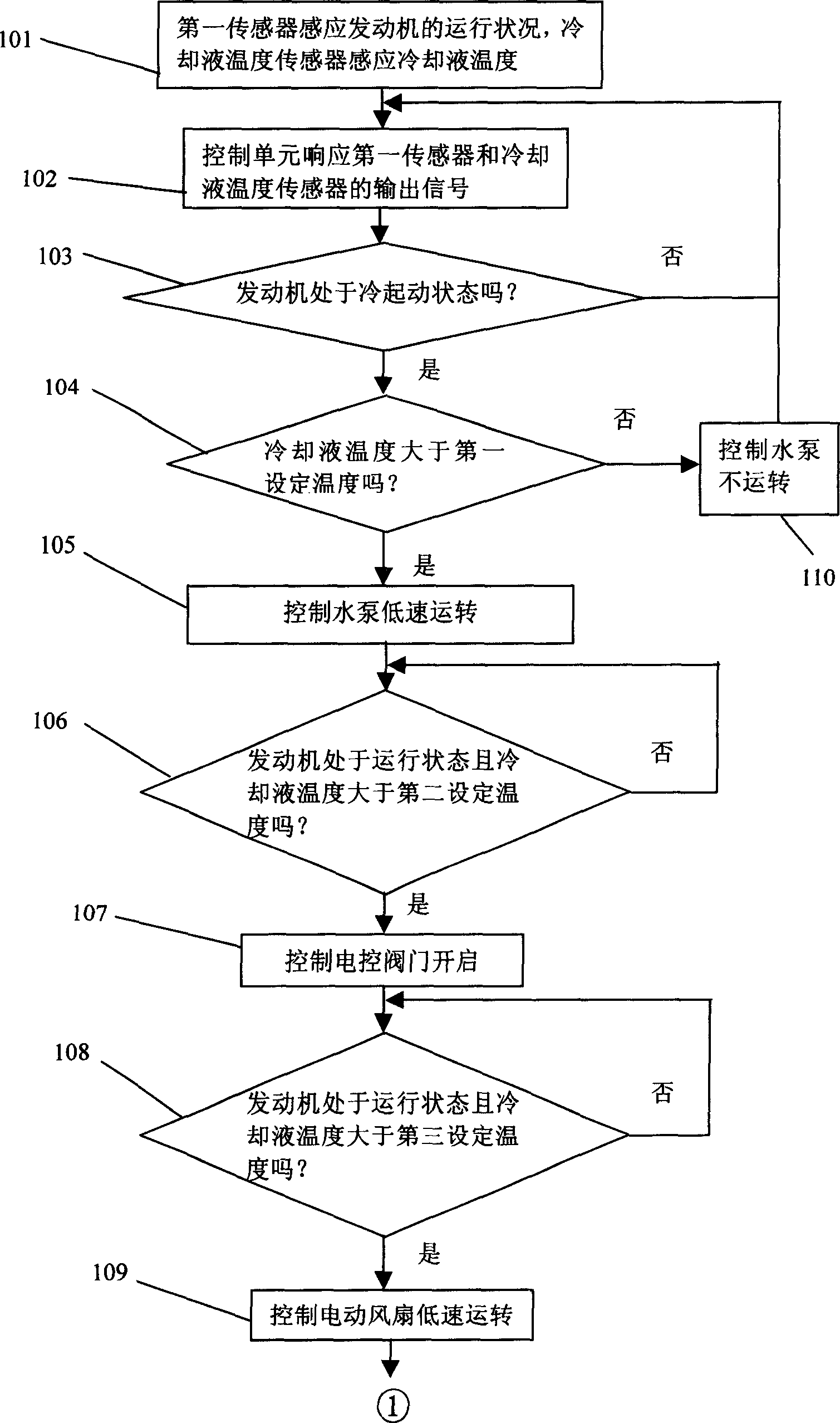

Water cooling system of engine and cooling method thereof

InactiveCN1884804AIncrease starting speedReduce exhaust pollutionLiquid coolingCoolant flow controlLiquid temperatureEngineering

The invention relates to an engine water cooling system and relative cooling method, wherein the first sensor senses the working condition of engine; the cooling liquid temperature sensor senses the temperature of cooling liquid inside the engine; the control unit responds the signals of first sensor and the cooling liquid temperature sensor, to control the electric water pump to operate when the temperature of cooling liquid is higher than the first preset temperature when the engine starts, to drive the cooling liquid to cool the engine, to improve the starting property of engine and the discharging property of heating machine; and the electric controller based on the operation parameter of engine and the temperature of cooling liquid, controls the switch of electric valve, the electric water pump and the rotation speed of electric fan, to control the circulation and the flux of cooling liquid, and the cooling ability of cooling fan, to improve the property of engine.

Owner:BYD CO LTD

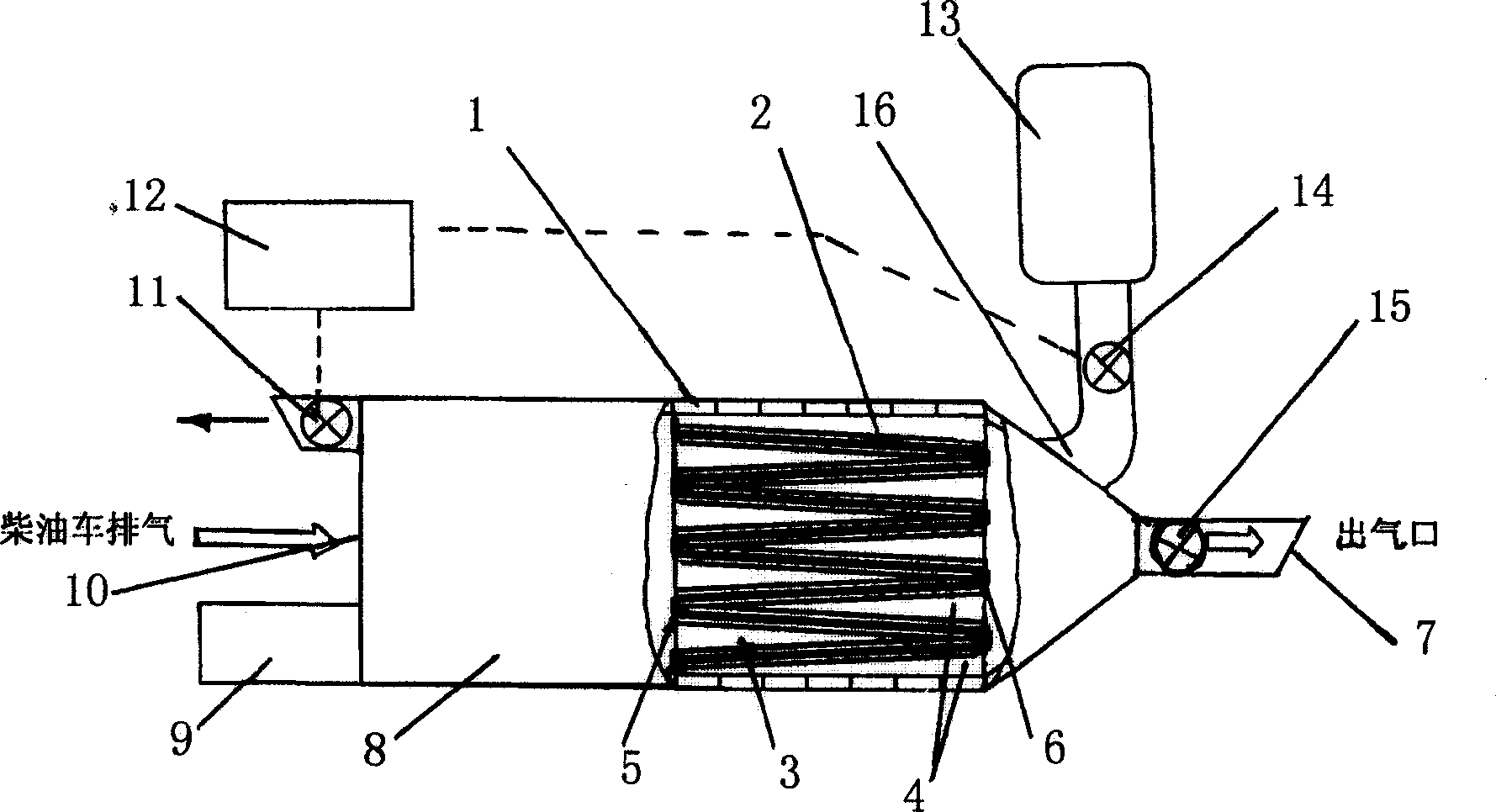

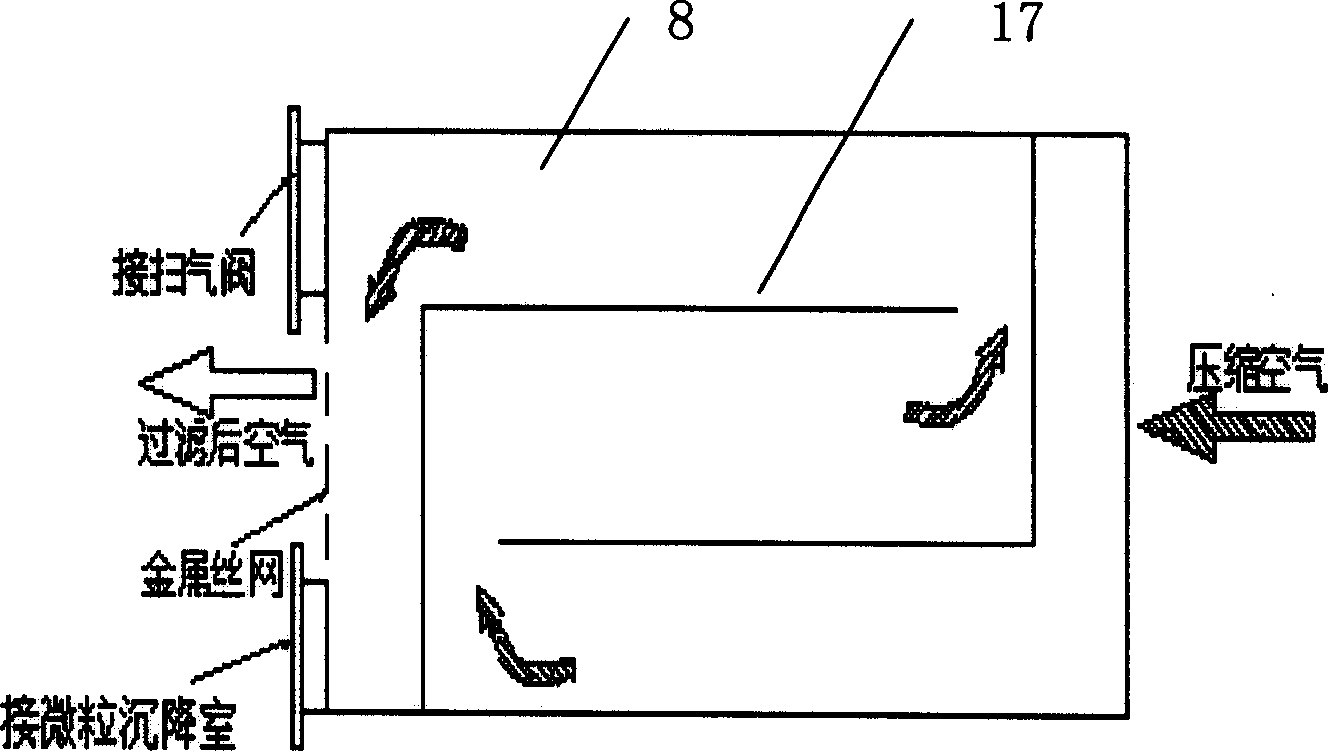

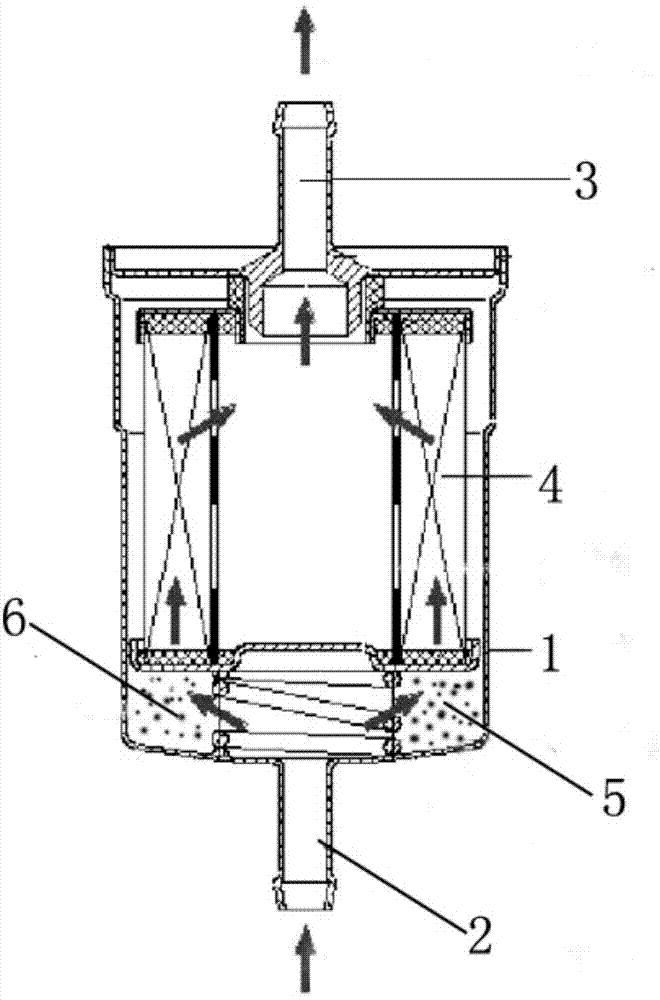

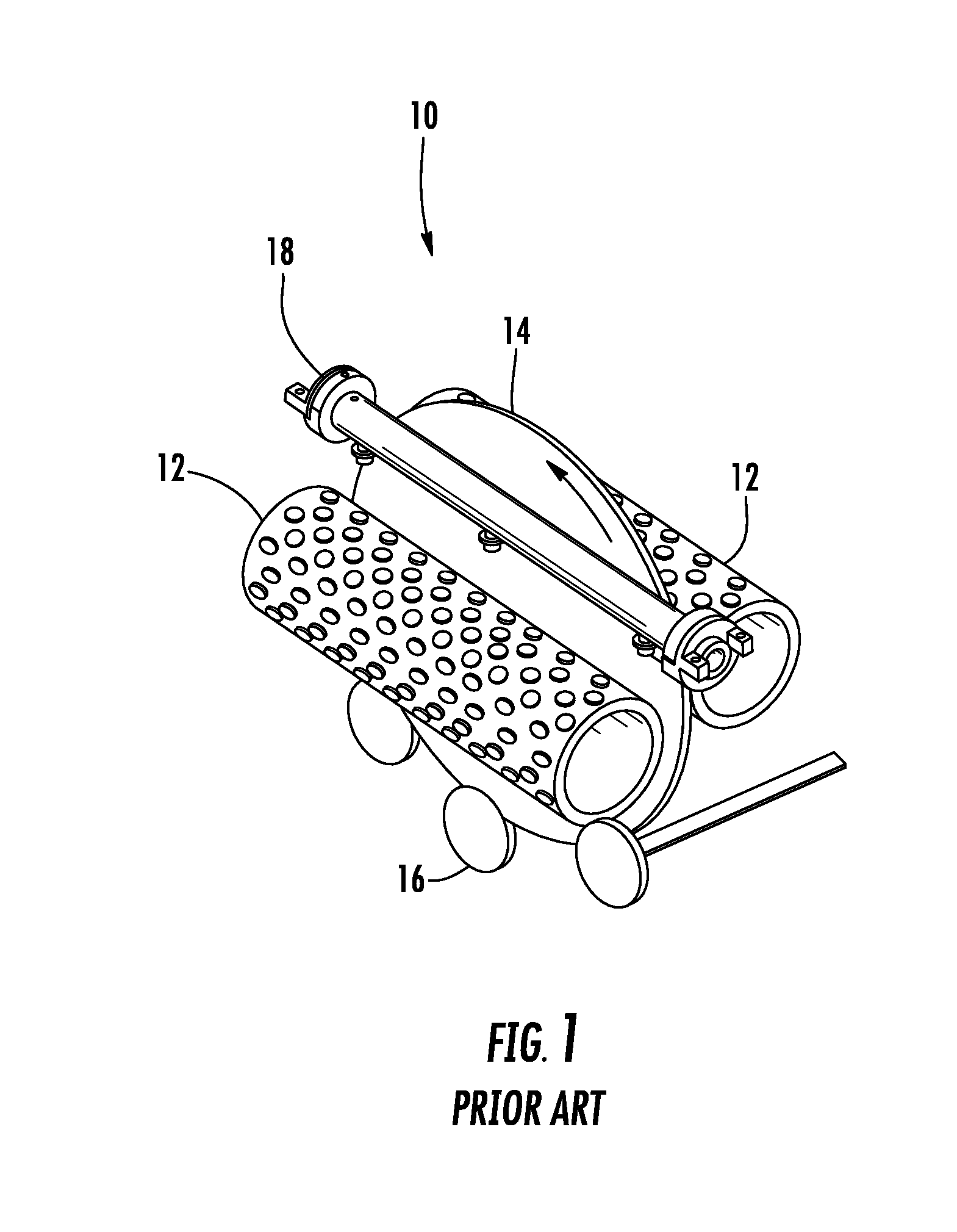

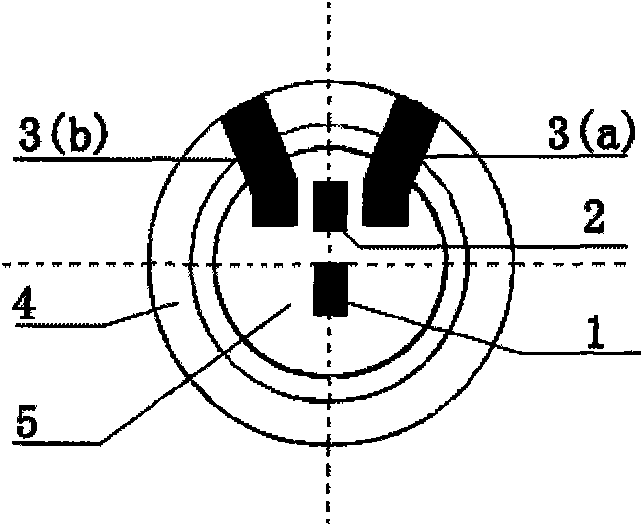

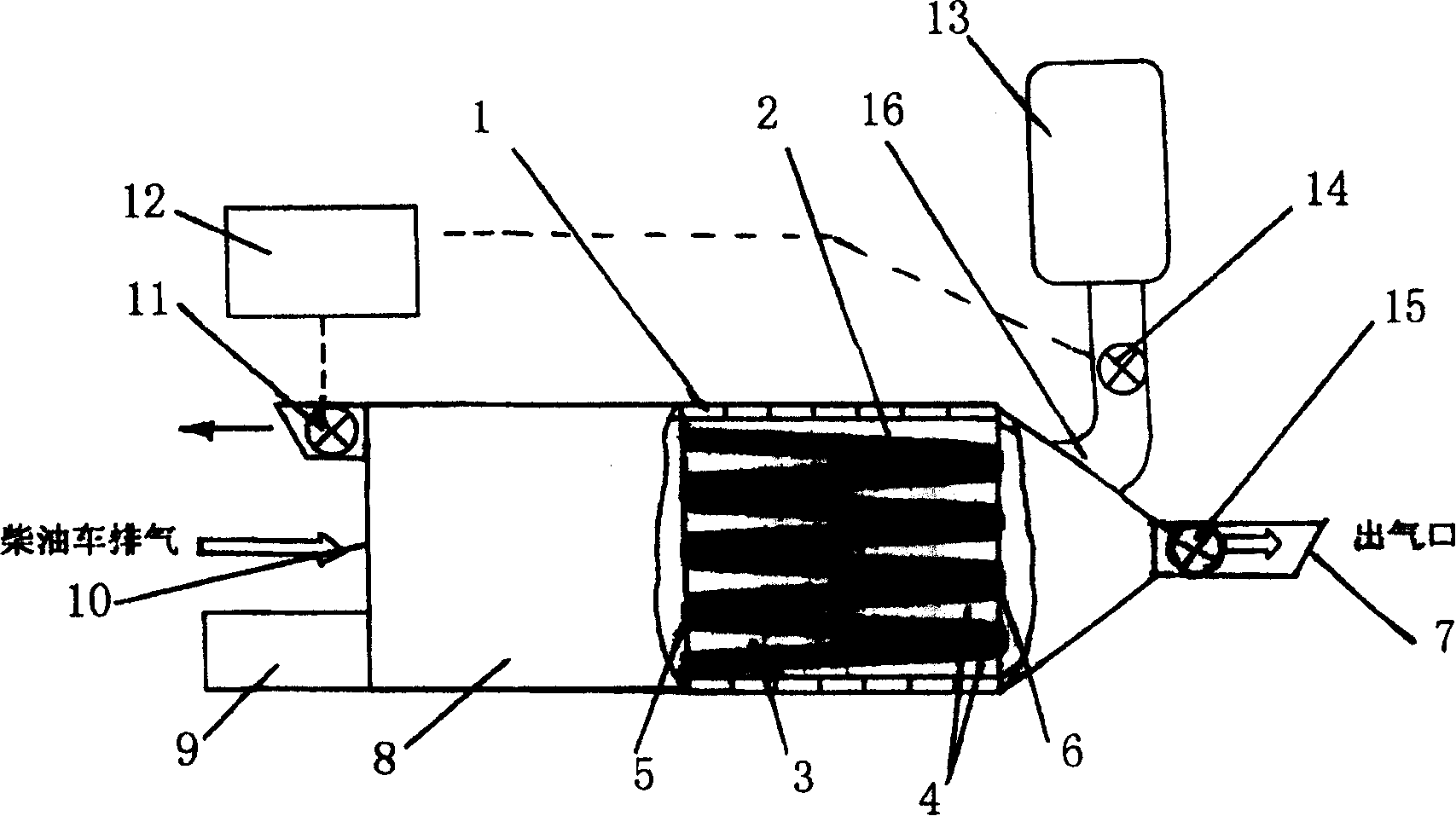

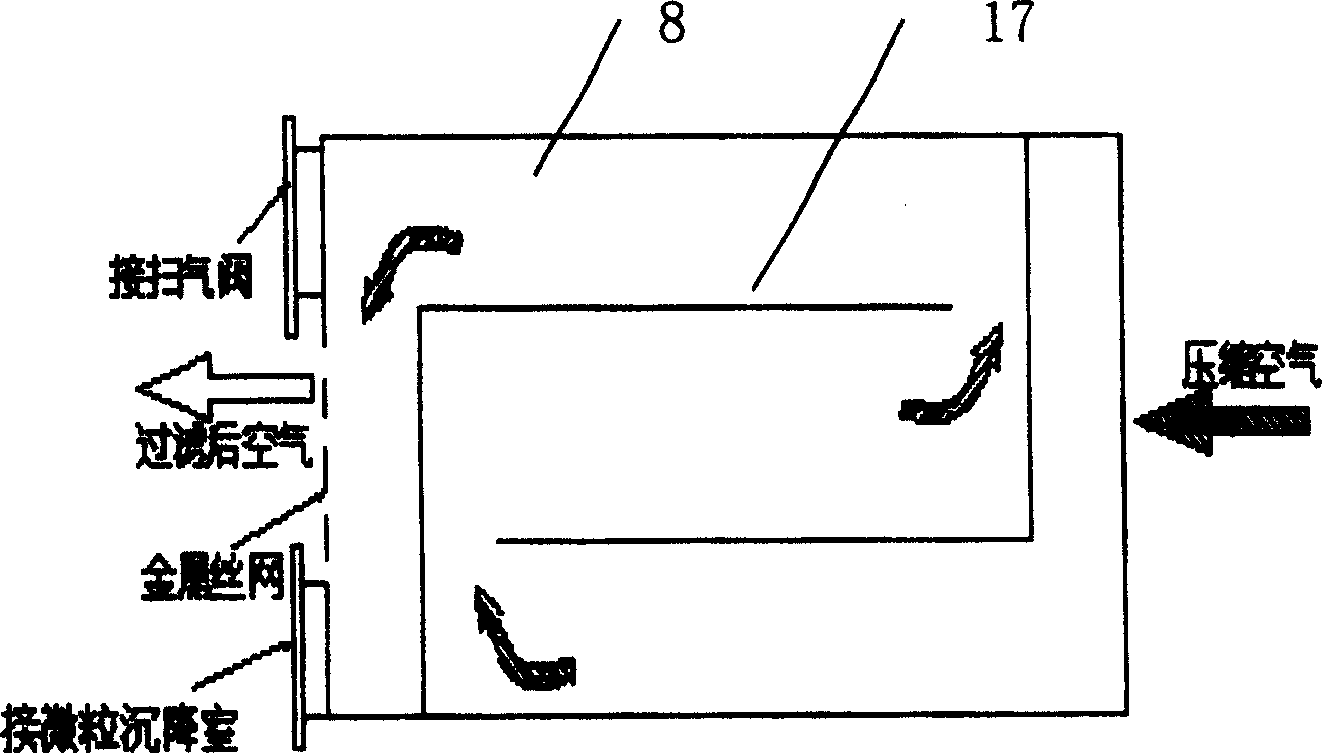

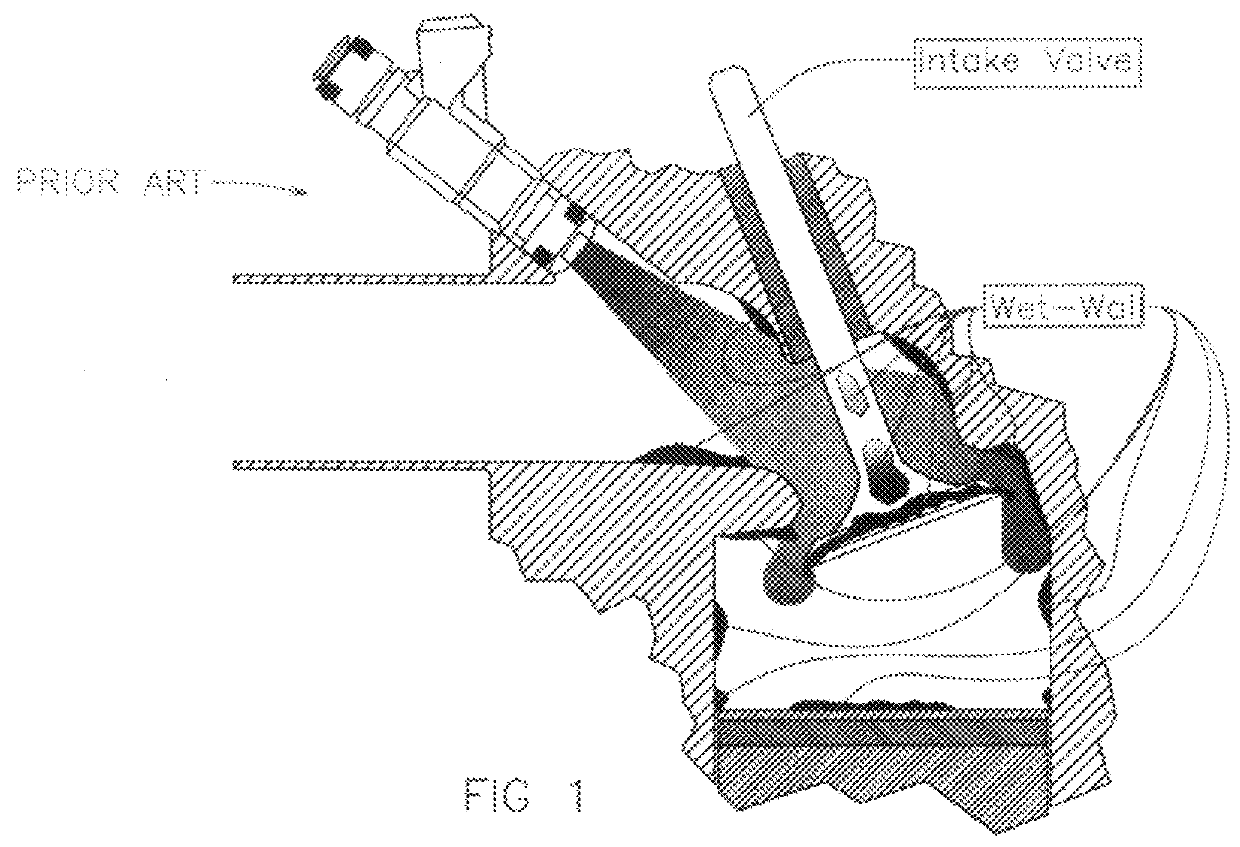

Wall flow type net plate apparatus with reverse jet regenerating unit for collecting microparicle discharged by diesel vehicle

InactiveCN1693682AReduce exhaust pollutionReduce manufacturing costExhaust apparatusSilencing apparatusParticulatesMicroparticle

This invention discloses a converse regenerating wall flow type metal net plate apparatus for collecting microparticle discharged by diesel vehicle. The composite metal plate masking filter layer inclined certain angles in outer shell, 'WW' type is formed through baffle. Extension room is set between air intake and the filter layer, the room is connected to scavenging valve and carbon smoke second collecting device. Pneumatic disc valve, blowback cavity and air compress air tank at one side of the gas outlet are connected to the shell. Waste gas discharged by the engine enters from collector intake, and particles in the waste gas are entrapped when it flows through 'WW' type composite metal shadow masking. Discharging back pressure ascends when the particles deposit to certain quantity, and the regenerating equipment starts to blow out the accumulative particles from filter, and the particles are second collected and burned in collector. The structure is simple, cost is low, purification effect and regeneration effect is good, life is long and a good product for generalization.

Owner:TSINGHUA UNIV +1

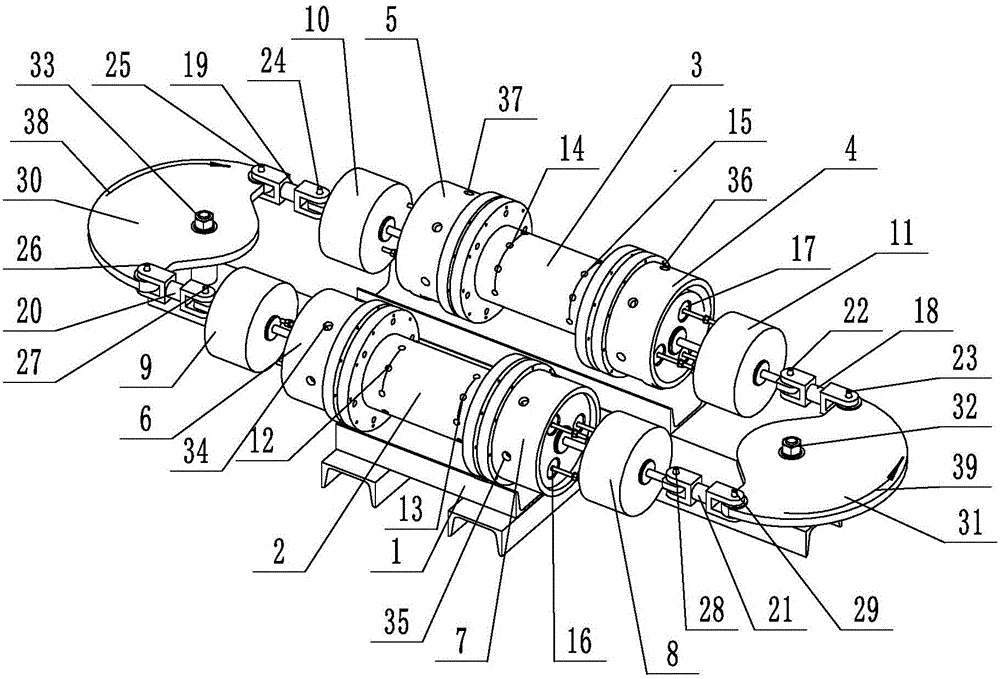

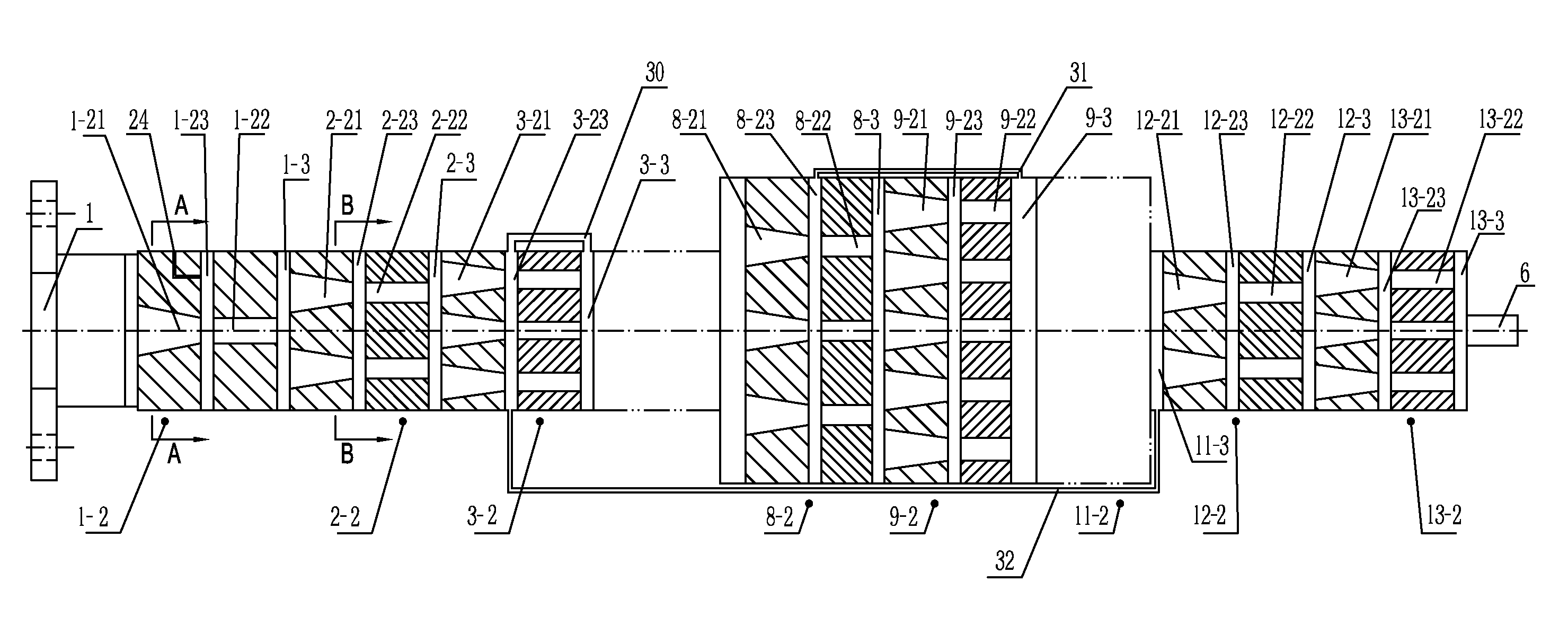

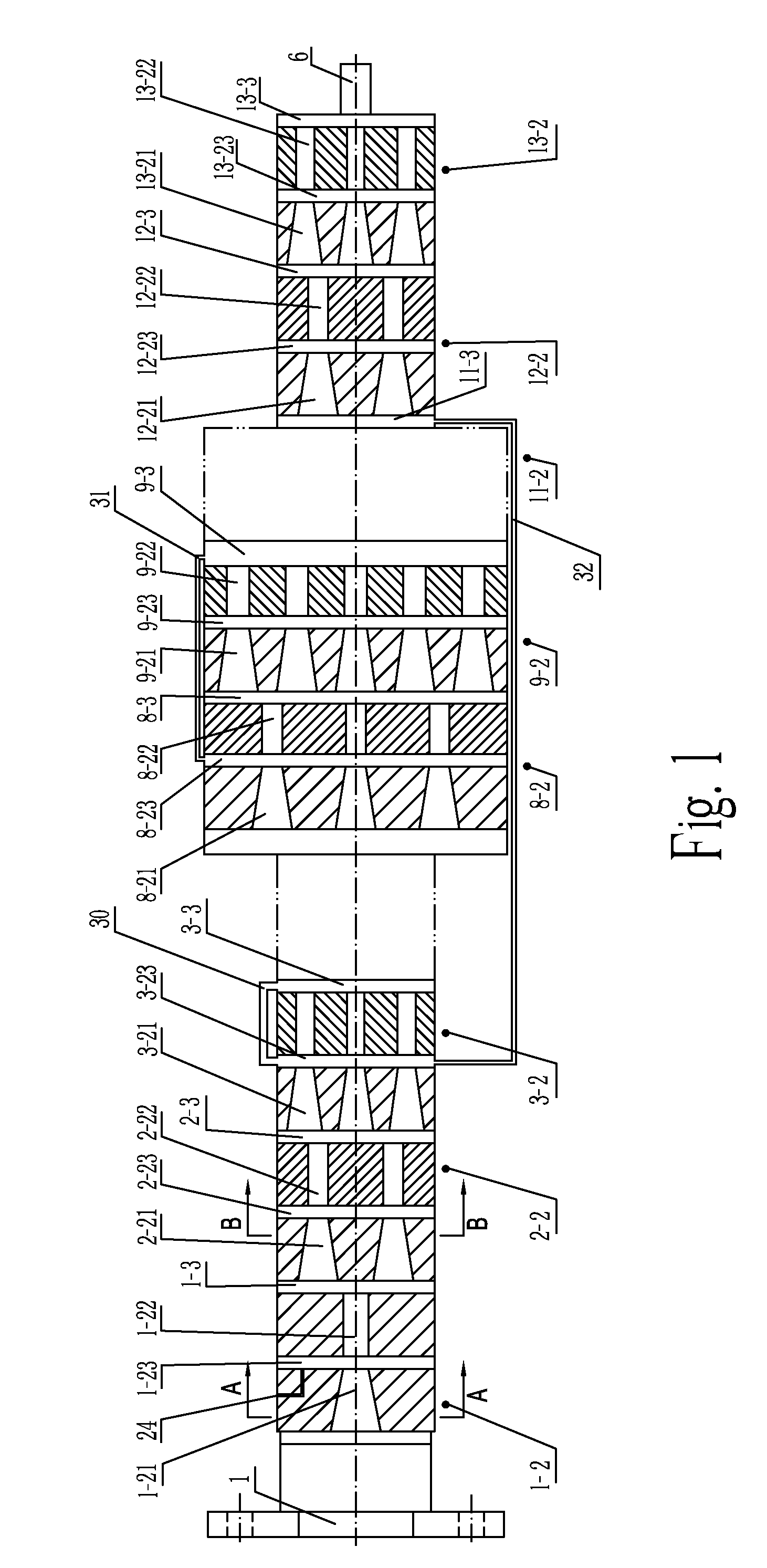

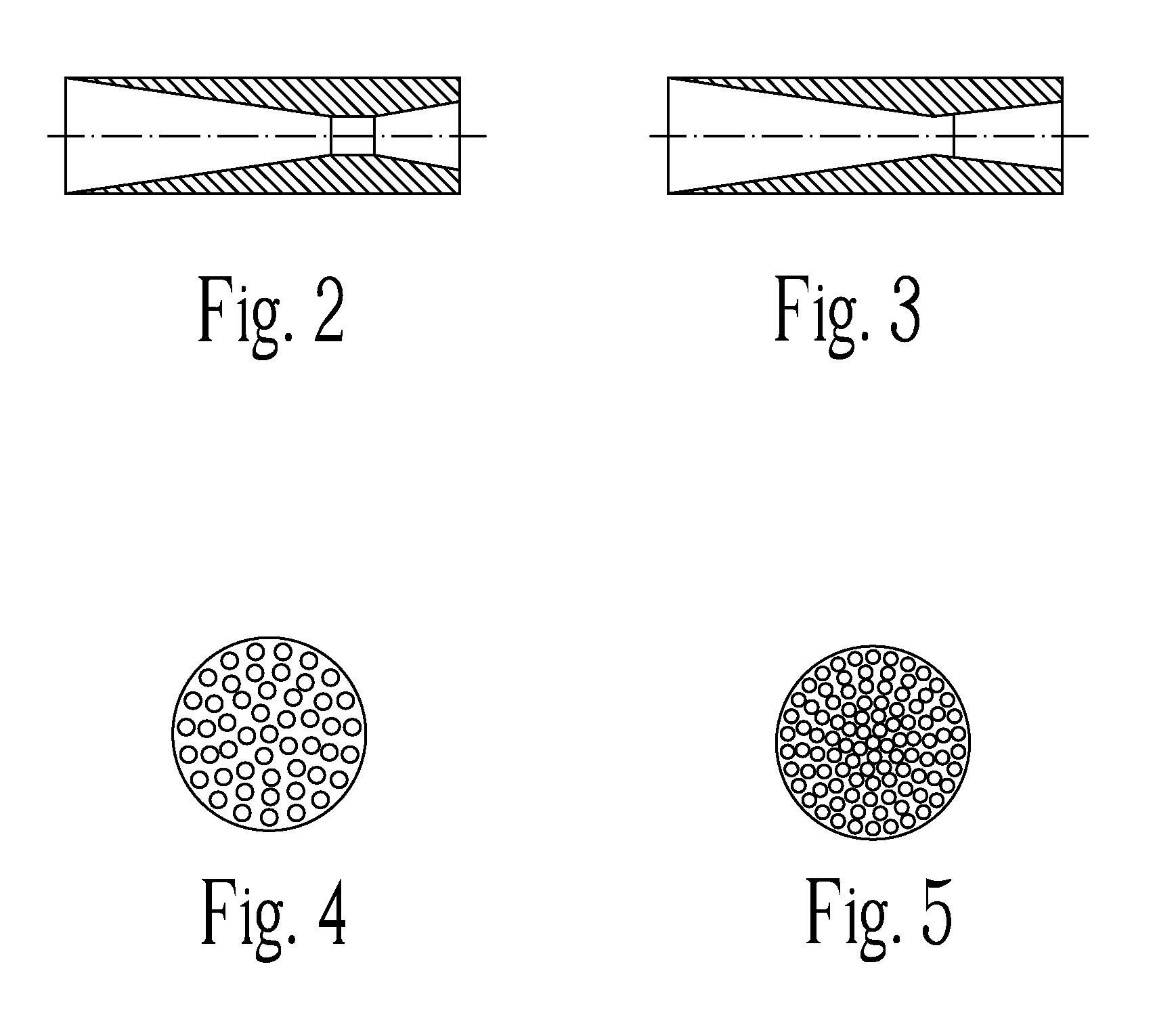

Electromechanical hybrid power mobile automatic transmission drive system

ActiveCN102069703ACompact structureReduce manufacturing costGas pressure propulsion mountingToothed gearingsElectricitySystems design

An electromechanical hybrid power mobile automatic transmission drive system is designed as an integral, which only comprises 29 main parts and can generate 6 forward gears and 1 reverse gear. Since a motor is arranged on an input shaft integrally, the whole motor has a synchronous speed with the input shaft. The motor has the functions of a generator and can drive a vehicle to travel by utilizing counterforce generated by the generator field, so as to generate electricity when an automobile travels, the automobile engine power is not additionally consumed due to the load of the generator when electricity is generated while the automobile travels, thereby reaching the energy-saving purpose. When a hybrid power driving pattern is used, a clutch and a brake are not required for gear changing during the vehicle is started or driven, thus realizing stepless speed changing and large torque transmission.

Owner:GUANGZHOU HUADU WORLDWIDE AUTOMATIC TRANSMISSION

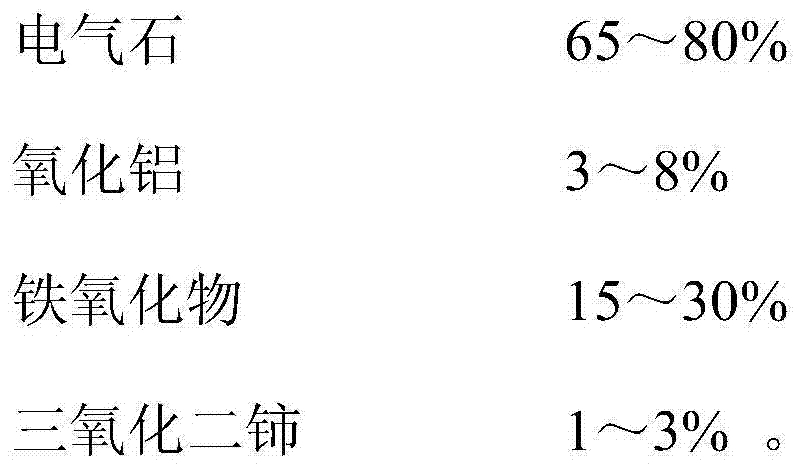

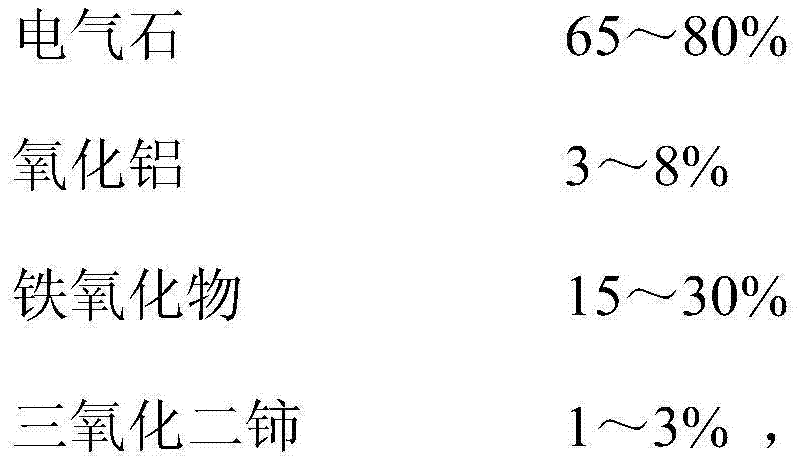

Vehicular internal combustion engine fuel-borne catalyst and application thereof

InactiveCN104845682AImprove combustion efficiencyHigh calorific valueInternal combustion piston enginesCombustion-air/fuel-air treatmentGasolineInternal combustion engine

The invention discloses a vehicular internal combustion engine fuel-borne catalyst and application thereof. The vehicular internal combustion engine fuel-borne catalyst comprises, by mass percent, 65-80% of tourmaline, 3-8% of aluminum oxide, 15-30% of iron oxide and 1-3% of dicerium trioxide. The vehicular internal combustion engine fuel-borne catalyst has the advantages of safety, reliability, simplicity in application, no physicochemical damage to an engine, no influence on a vehicular structure, a circuit, an oil circuit and mechanical properties, capability of achieving remarkable energy-saving and emission-reducing effects, lower vehicular maintenance cost, higher power, low use cost and long service life and can be applied to various diesel vehicles, gasoline vehicles, LPG (liquefied petroleum gas) vehicles and the like.

Owner:余任文

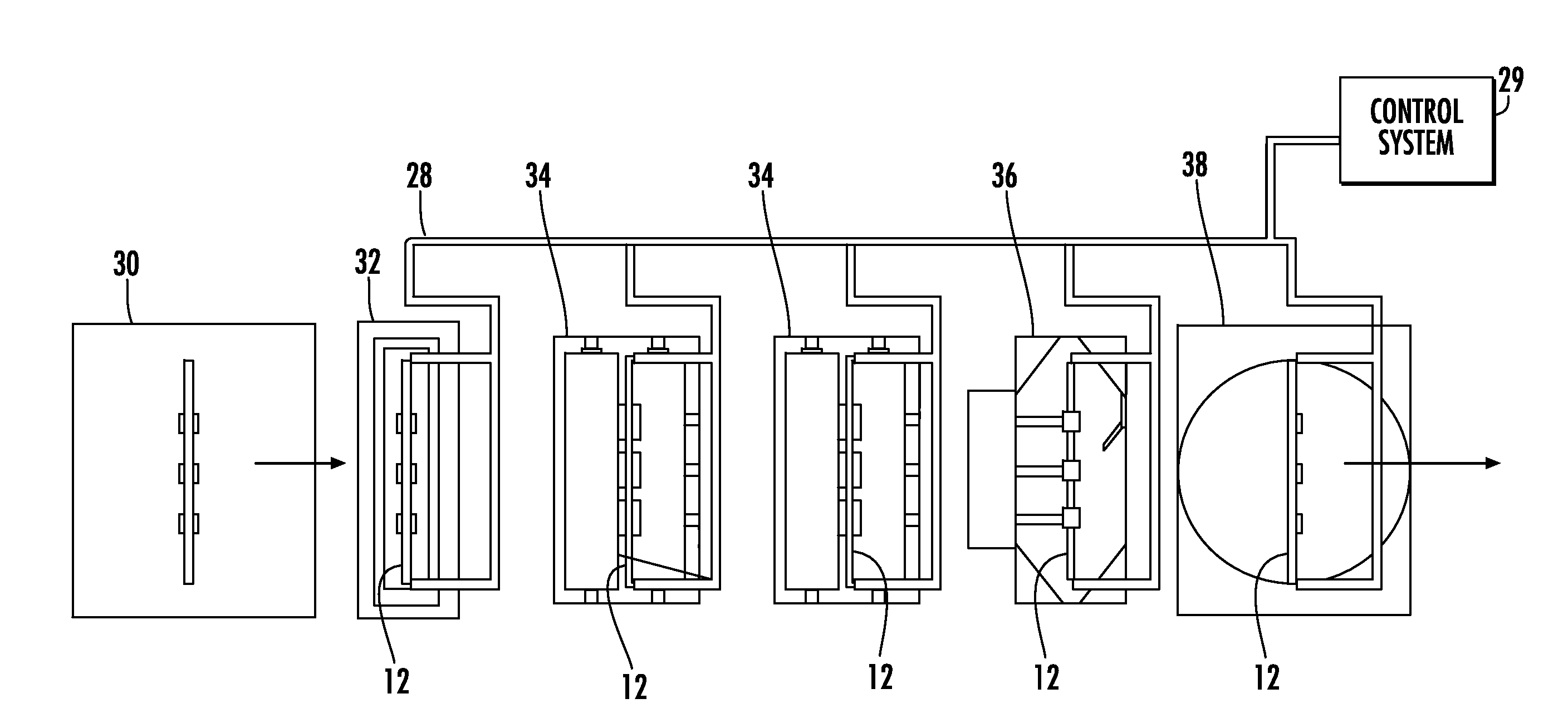

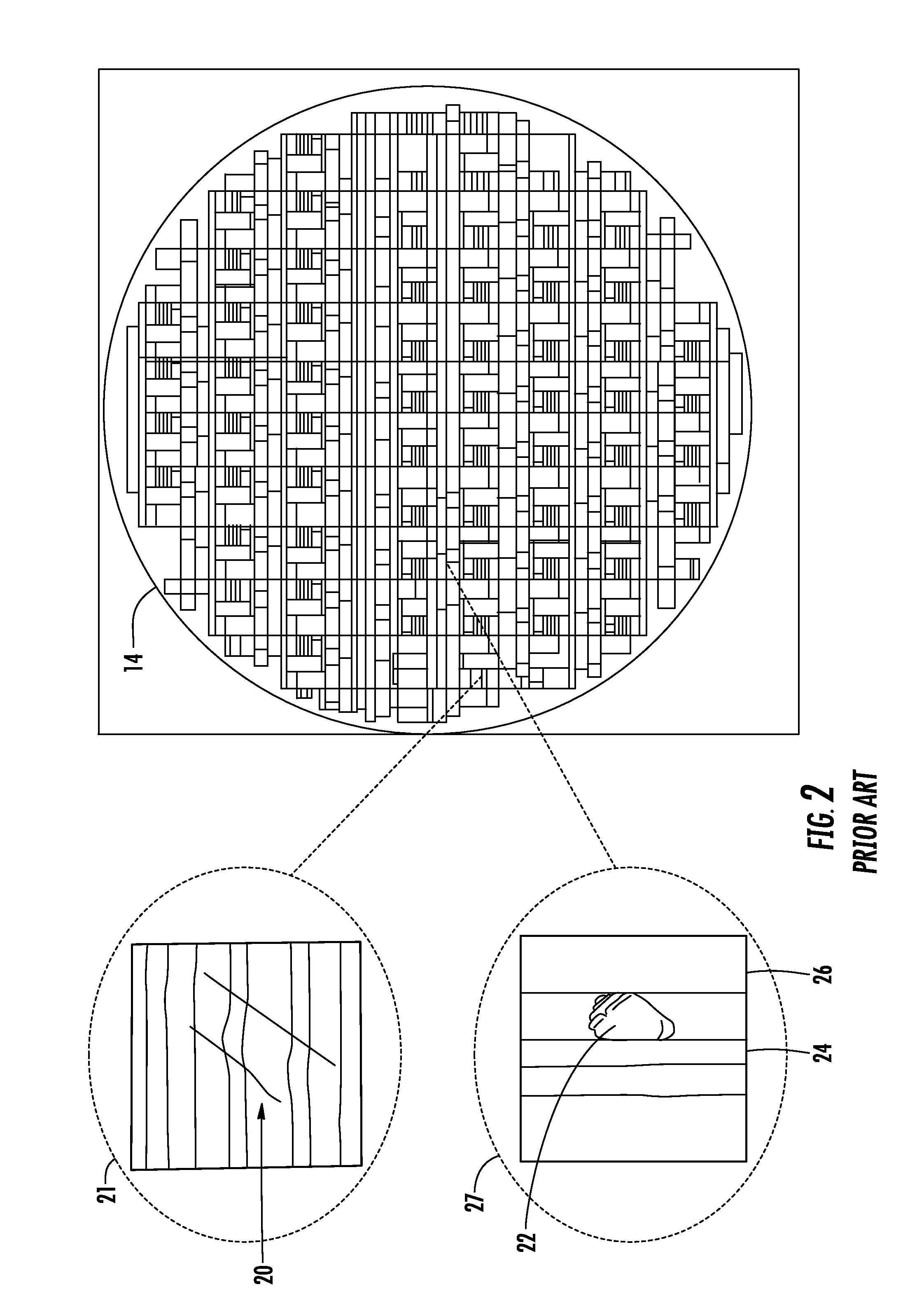

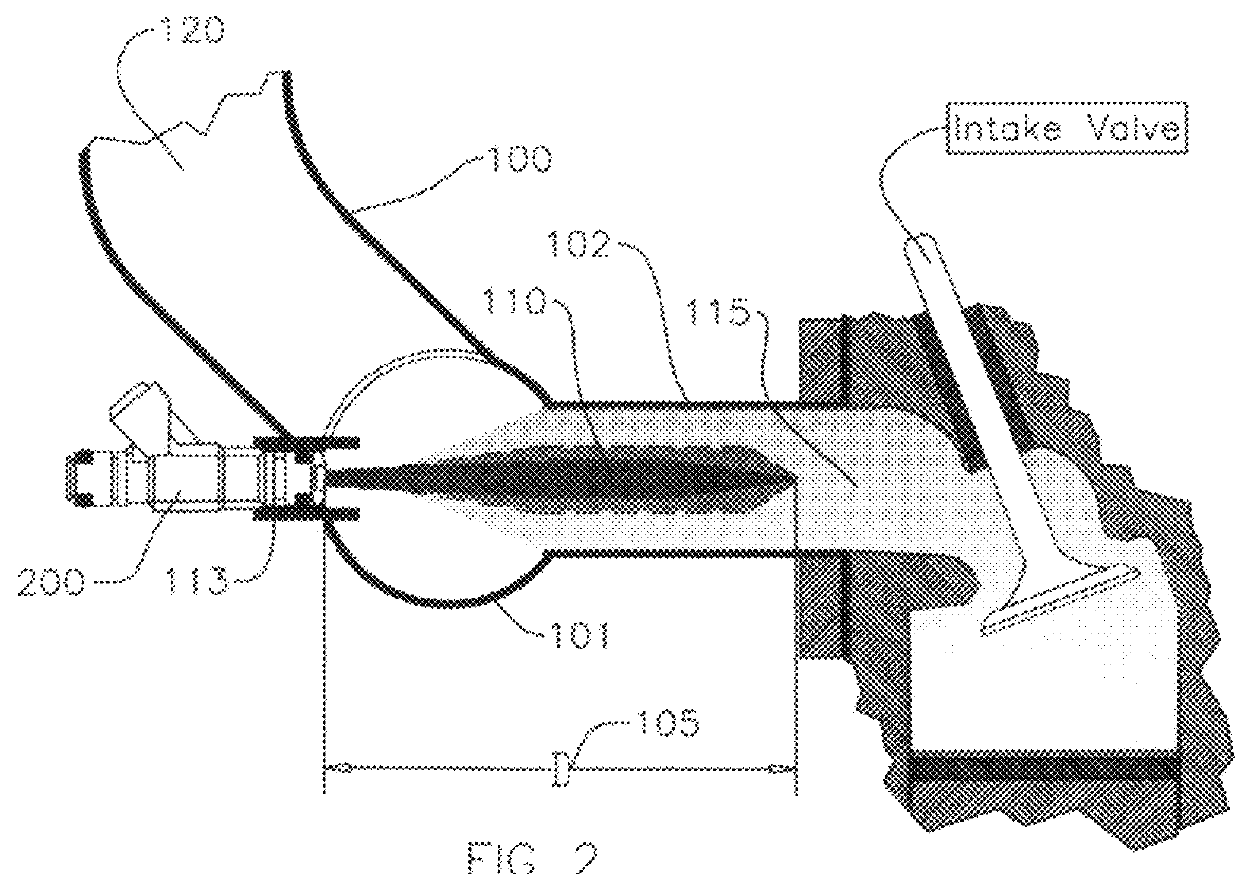

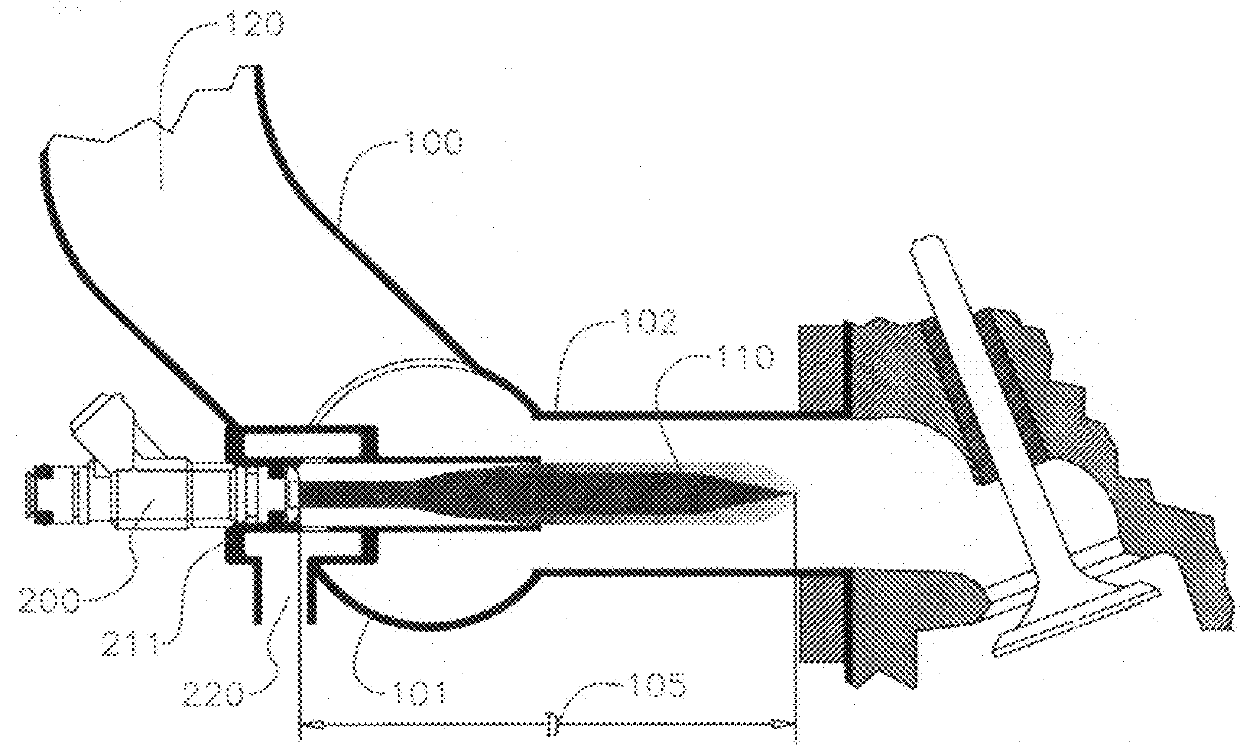

Drying apparatus with exhaust control cap for semiconductor wafers and associated methods

ActiveUS20130199580A1Increase the sectionHow to improvePipe supportsServomotor componentsMechanical engineeringSemiconductor

A drying apparatus for drying a semiconductor wafer includes a processing chamber including a rinsing section and a drying section adjacent thereto. The rinsing section has a chamber loading slot associated therewith for receiving the semiconductor wafer. The drying section has a chamber unloading slot associated therewith for outputting the semiconductor wafer. An exhaust control cap is carried by the processing chamber and includes a bottom wall, a top wall, at least one intermediate wall between the bottom and top walls, and a side wall coupled to the top, bottom and the at least one intermediate wall to define stacked exhaust sections. The exhaust control cap has a cap loading slot aligned with the chamber loading slot, a cap unloading slot aligned with the chamber unloading slot, and at least one exhaust port configured to be coupled to a vacuum source.

Owner:STMICROELECTRONICS SRL

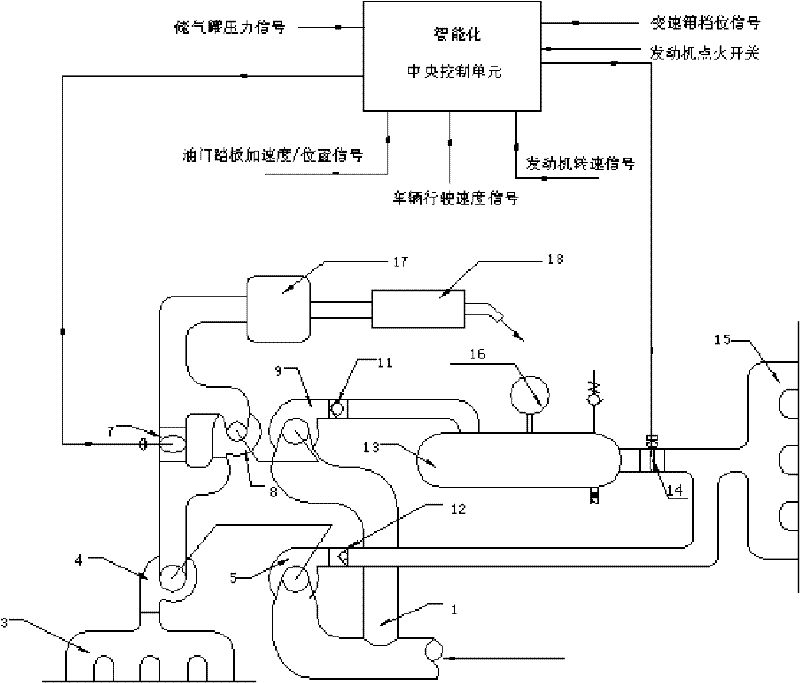

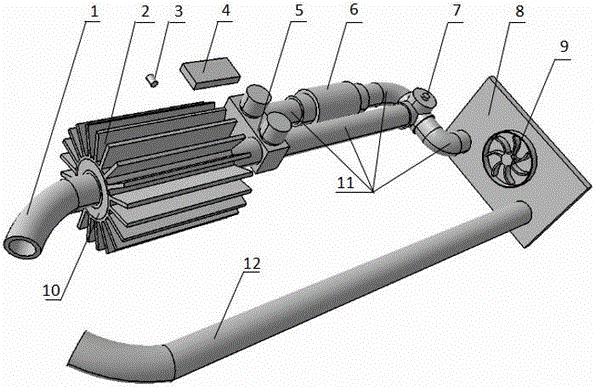

Dynamic air supplying device of turbocharged diesel engine

InactiveCN102242668AReduce exhaust pollutionReduce fuel consumptionInternal combustion piston enginesForced inductionAir–fuel ratio

The invention relates to a dynamic air supplying device of a turbocharged diesel engine. The device comprises a main turbocharger connected with a waste gas exhaust pipe of the engine. An auxiliary turbocharger connected with the main turbocharger in series is also arranged on the waste gas exhaust pipe of the engine. The auxiliary turbocharger comprises an auxiliary turbine and an auxiliary booster, which are connected coaxially. An air outlet pipe of the auxiliary booster is connected with an air inlet manifold of the engine through an air storage tank. An electric by-pass valve is installed on the auxiliary turbine in parallel. An electric air supplying valve is arranged between the air storage tank and the air inlet manifold of the engine. By adopting the dynamic air supplying device disclosed by the invention, air can be supplied in time before the air-fuel ratio of the engine is out of balance; after the engine enters a normal working state, the dynamic air supplying device exits timely; power and electric resources of vehicles are not used; and adverse effects on the vehicles cannot be resulted.

Owner:常州天大龙成节能环保科技有限公司

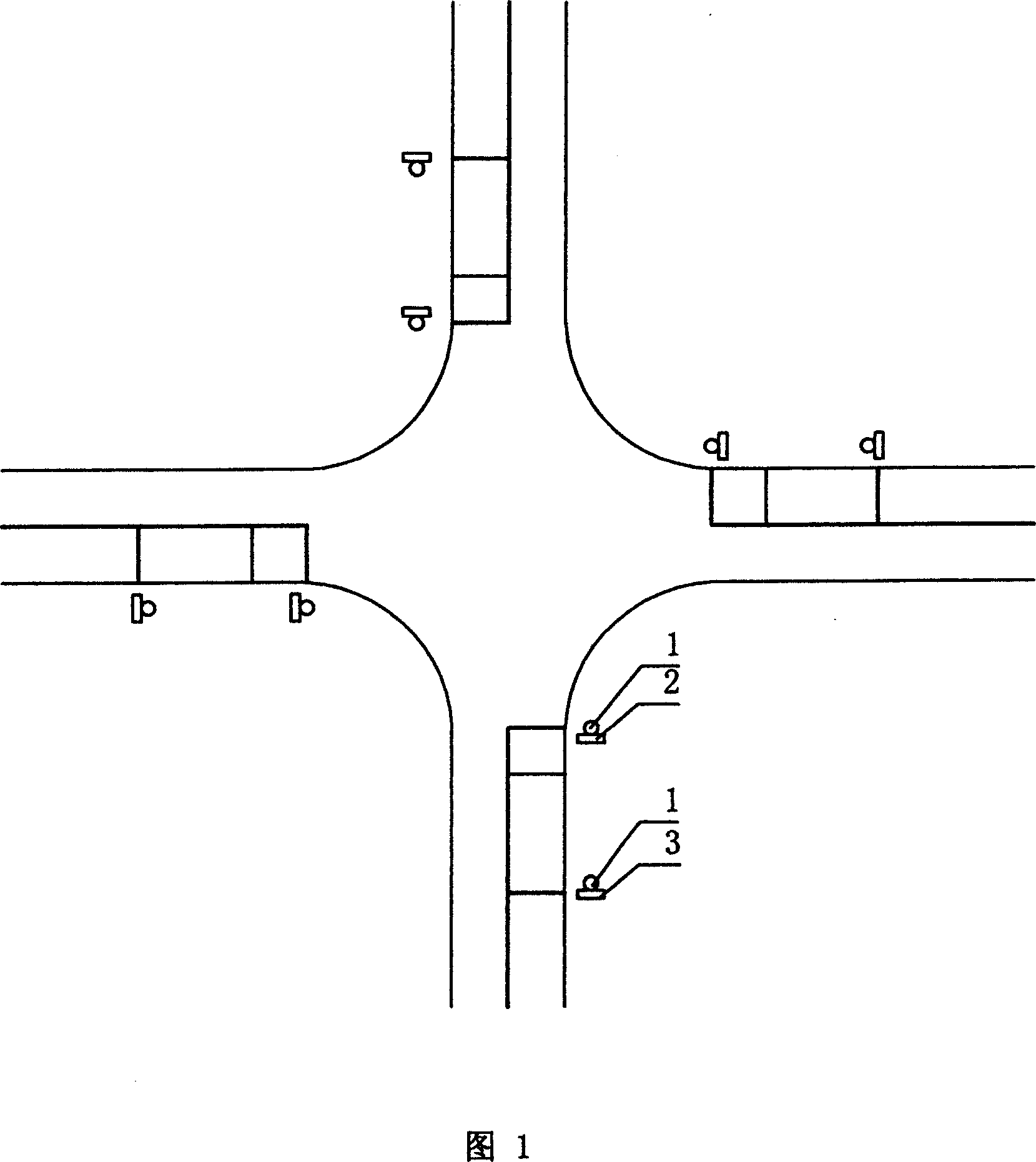

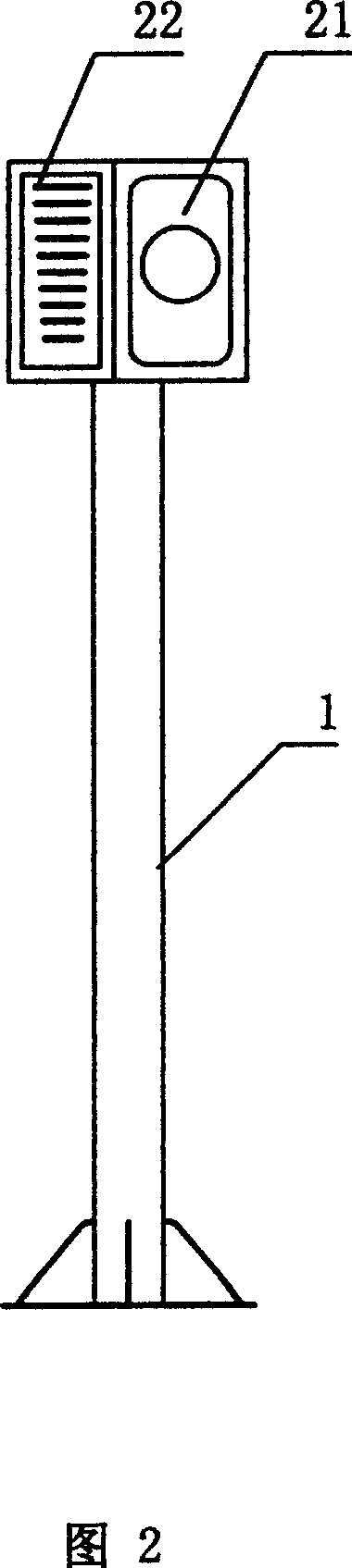

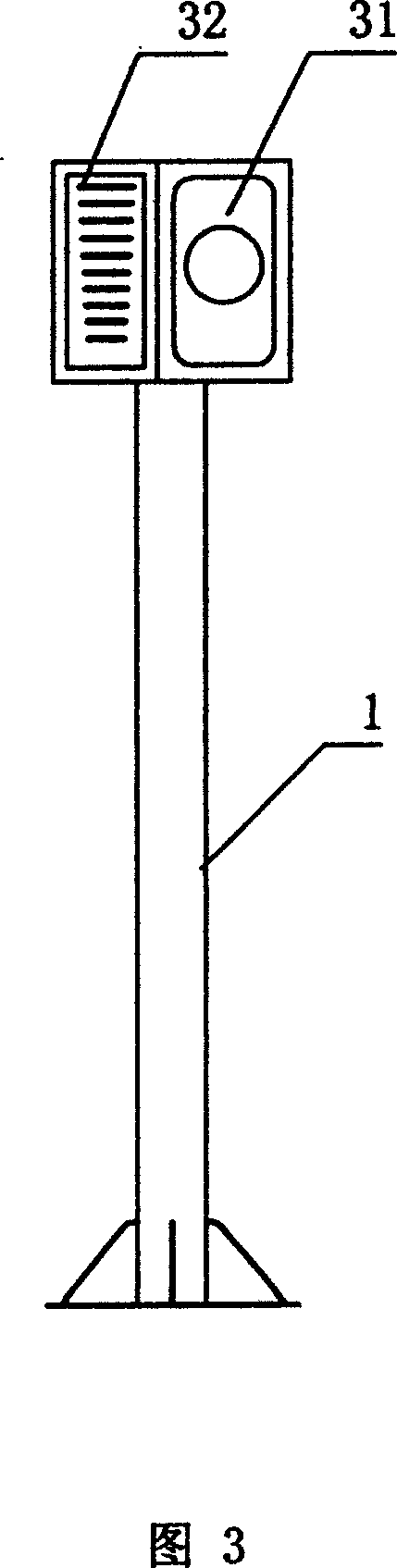

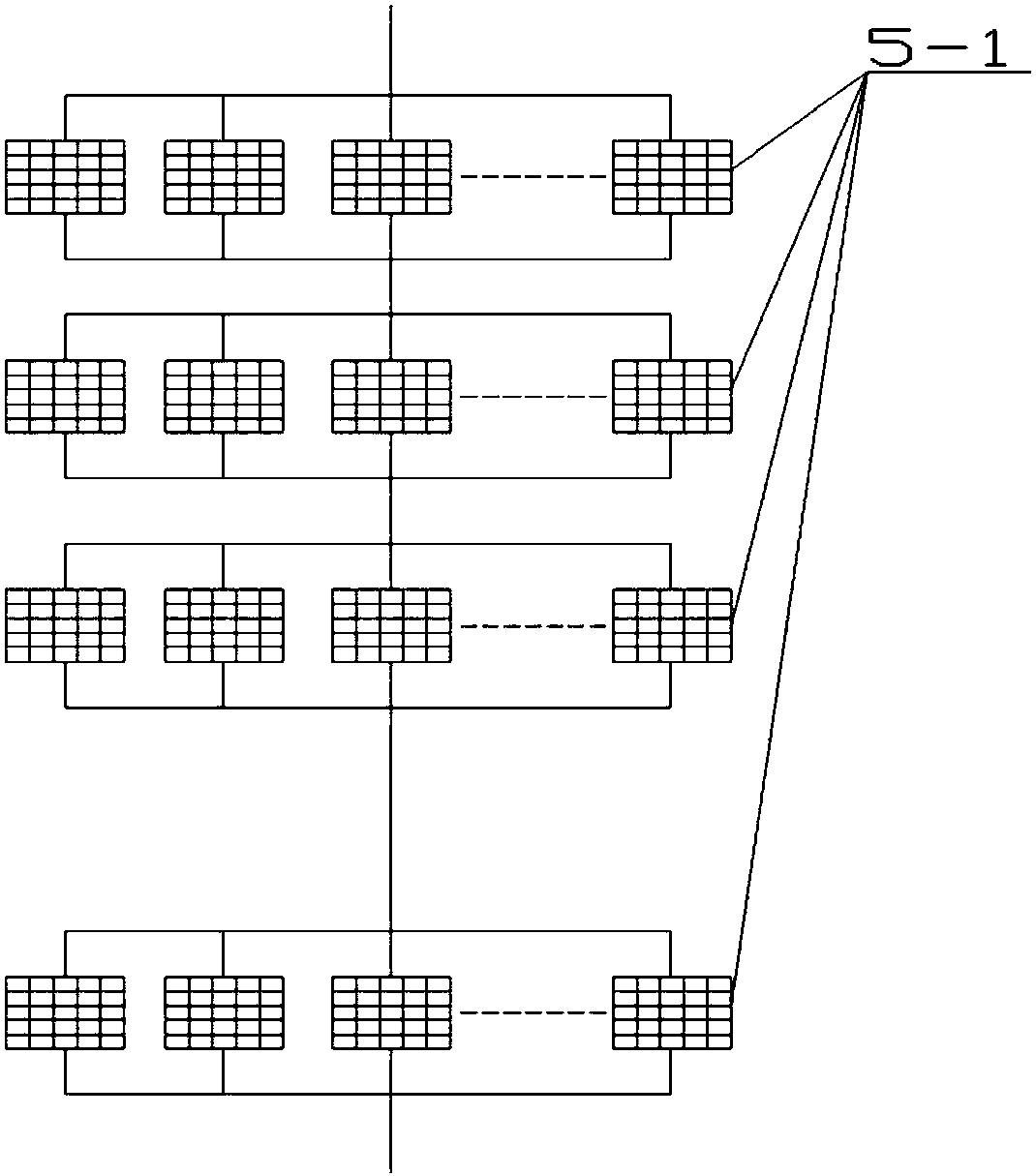

Traffic signal apparatus

InactiveCN101064064ASpeed up smoothlyConducive to speed upArrangements for variable traffic instructionsEngineeringSignal lamp

This invention discloses one traffic signal machine, which comprises one signal device set on one side of road under control traffic signal, wherein the signal device comprises indication lamp device set in road entrance; the indication lamp device is set with reverse timing device for stop, direct left and right turning; the said signal device also comprises one indication signal device at interval with indication lamp for car orderly forward or turning to wait road lamp.

Owner:许学光

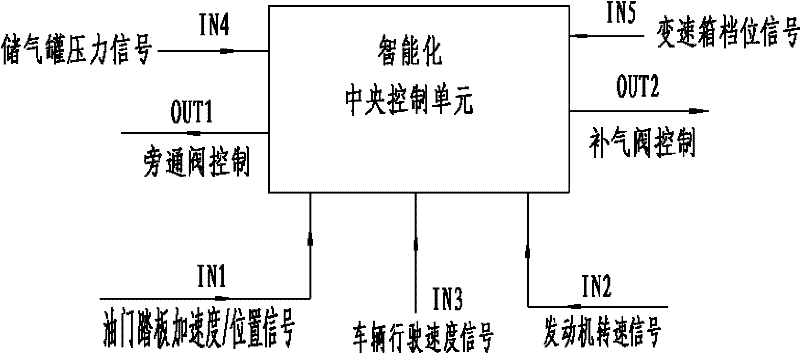

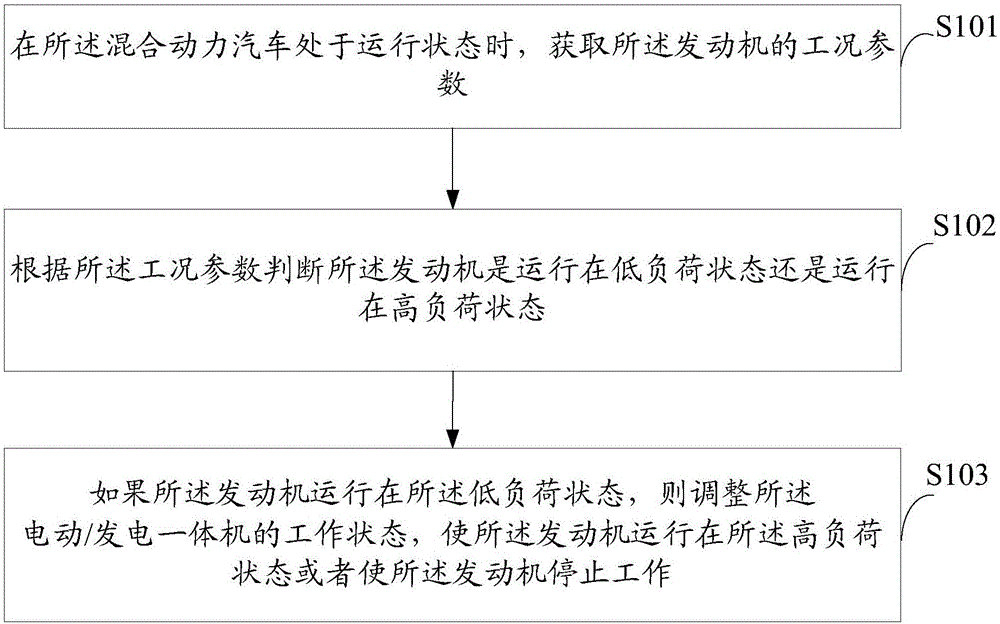

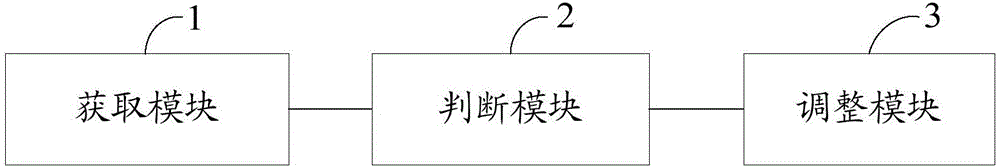

Power control method and system of hybrid electric vehicle

The invention discloses a power control method and system of a hybrid electric vehicle. The power control method and system of the hybrid electric vehicle are applied to the hybrid electric vehicle which comprises an engine and an electric / generation all-in-one machine. The working condition parameters of the engine are obtained when the hybrid electric vehicle is in a running state; whether the engine runs in a low load condition or in a high load condition is judged according to the working condition parameters; the load of the engine in the high load condition is higher than that in the low load condition; and the working condition of the electric / generation all-in-one machine is adjusted if the engine runs in the low load condition to make the engine to run in the high load condition or make the engine stop working. By applying the power control method and system of the hybrid electric vehicle, the engine can be made to run in the high load condition or stop working through adjusting the working condition of the electric / generation all-in-one machine, the engine is avoided working in the low load condition, so that the temperature of exhaust gas can be increased, nitric oxide in exhaust gas can be fully decomposed by an exhaust gas aftertreatment system, and the exhaust gas pollution is decreased.

Owner:WEICHAI POWER CO LTD

Saver and cleanser for gasoline

InactiveCN1445341AImprove atomization qualityLower activation energyLiquid carbonaceous fuelsAlcoholCombustion

An oil-saving cleaner of gasoline for car contains cleaning disperser (the mixture of dichloroethane and N-methyl-2-pyrrolidone), combustion promoter (alcohol-in-benzene), anti-explosion agent (the mixture of ferrocene and isopropanol), polar solvent (methanol or ethanol) and non-polar solvent (benzene, toluene, xylene, or their mixture). It can improve performance of gasoline, clean gasoline, making gasoline fully burn, and decrease pollution of tail gas.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Tail gas purifying device capable of generating electricity through automobile tail gas waste heat temperature difference

InactiveCN107605579AImprove utilization efficiencyPlay the role of energy saving and emission reductionInternal combustion piston enginesExhaust apparatusPressure riseElectricity

The invention discloses a tail gas purifying device capable of generating electricity through automobile tail gas waste heat temperature difference. The tail gas purifying device comprises a purifierbox body, a three-way catalyst, a temperature difference electricity generating device, a filter device, an electric precipitation device, a pressure rising and releasing converter and a storage battery. The three-way catalyst is arranged inside the front end of the purifier box body. The temperature difference electricity generating device is arranged outside the purifier box body, is close to the three-way catalyst end and is connected with the storage battery through the pressure rising and releasing converter. The filter device is arranged in the purifier box body and located at the rear end of the temperature difference electricity generating device. The electric precipitation device is located at the rear end inside the purifier box body and connected with the storage battery. The tail gas purifier utilizes the automobile tail gas temperature difference to generate the electricity, the effects of energy saving and emission reduction are achieved, the tail gas utilization efficiency can be effectively improved, meanwhile, exhaust pollution can be reduced, and the environment can be improved.

Owner:NANJING UNIV OF SCI & TECH

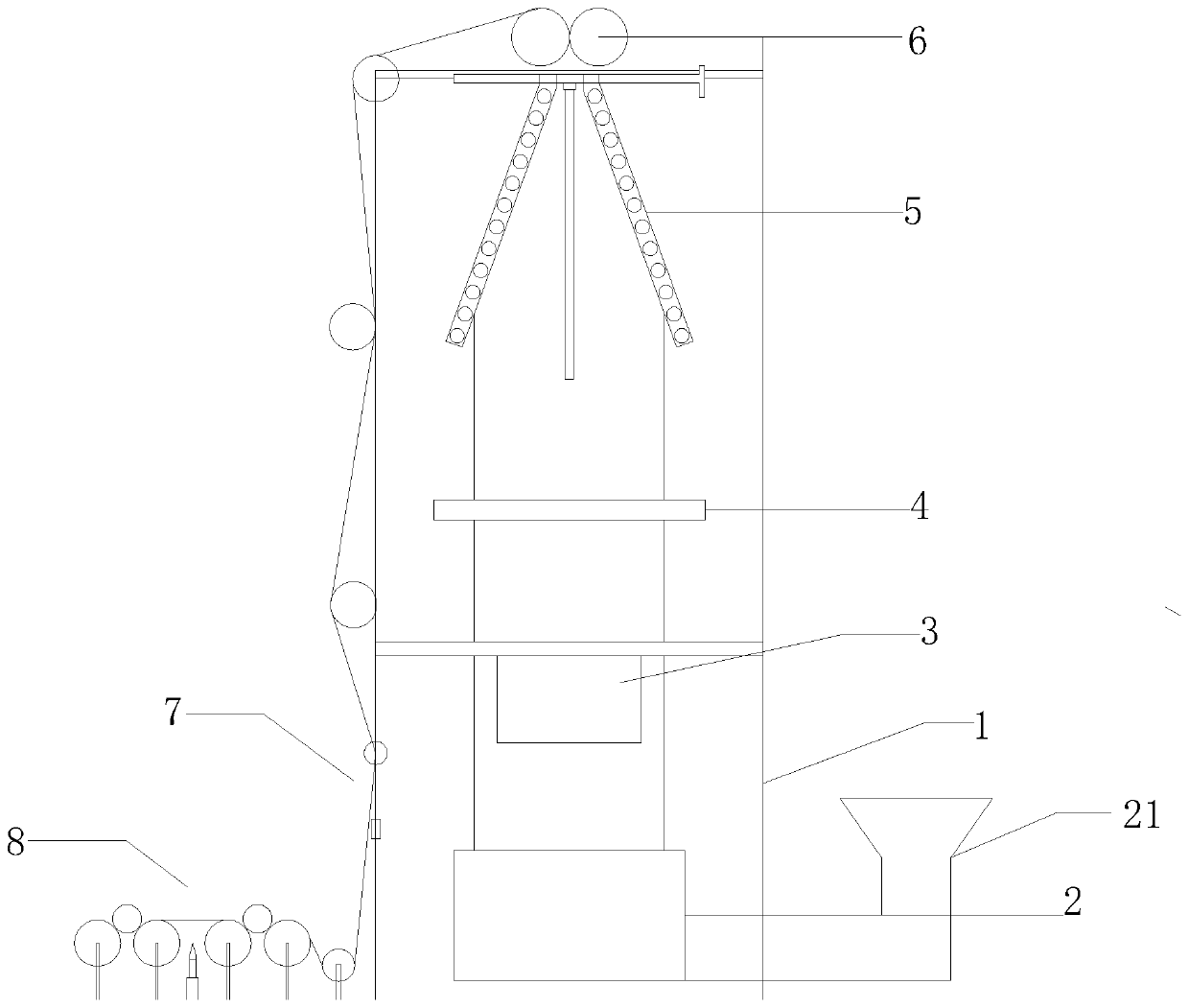

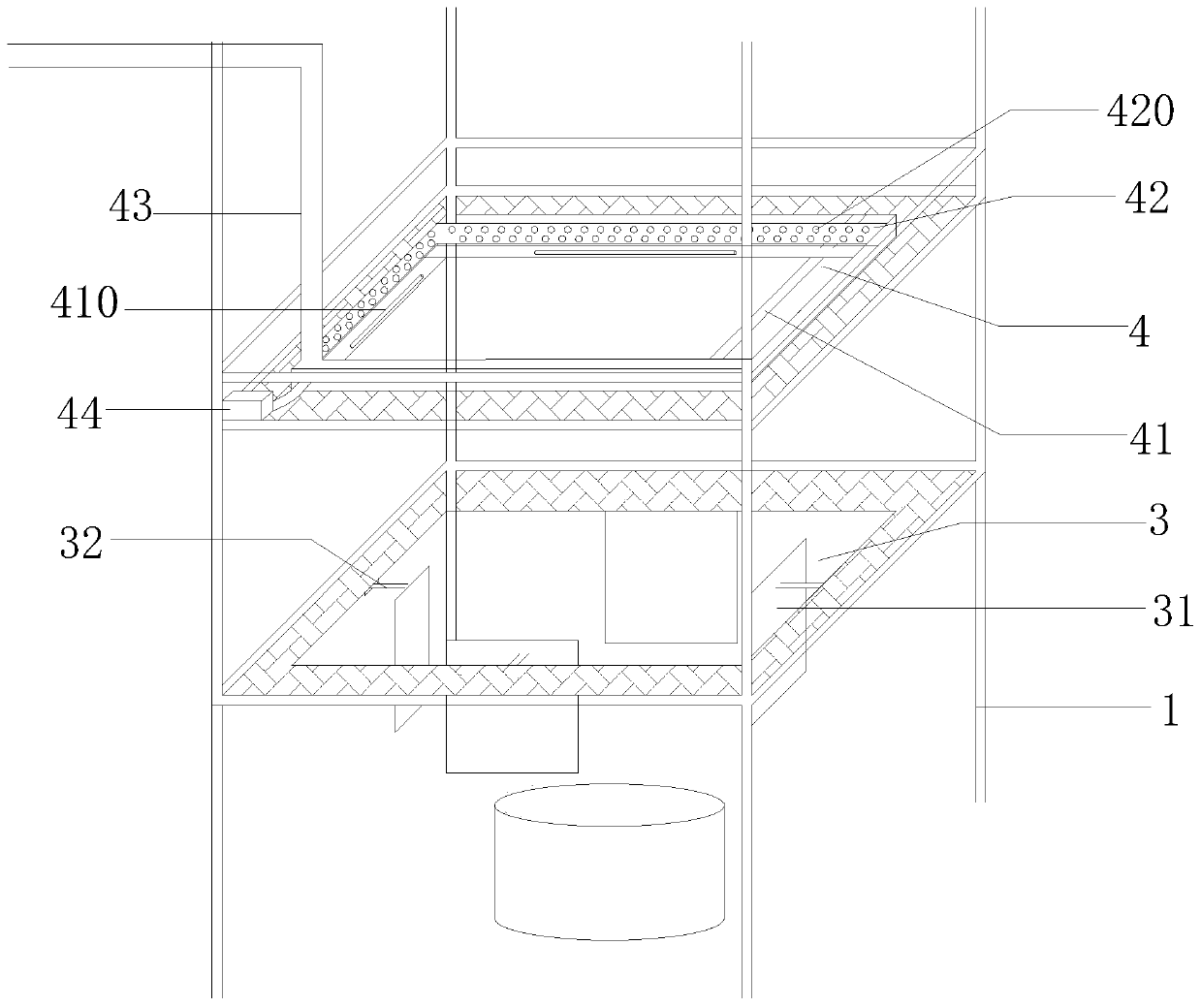

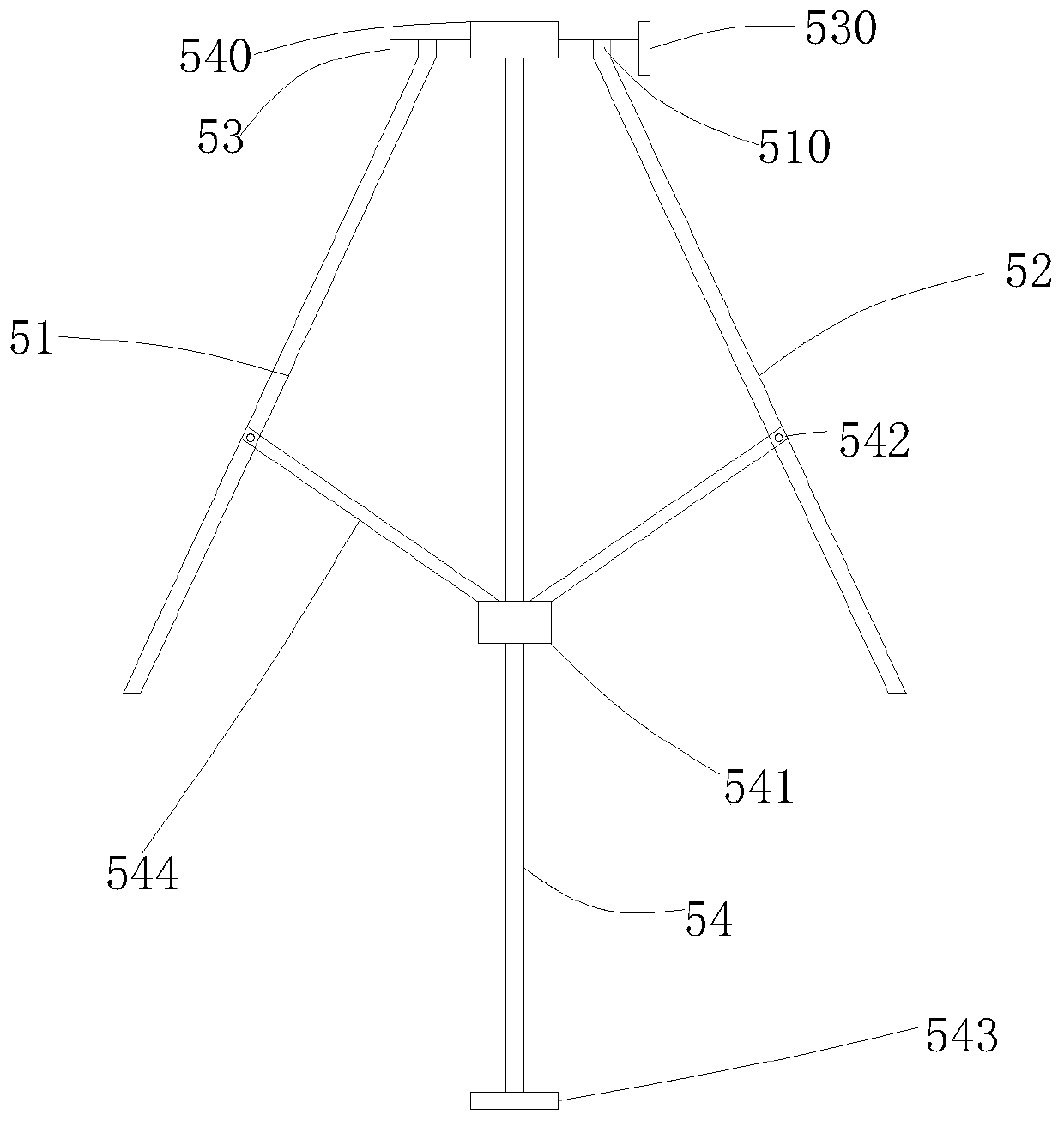

Plastic film production device and process thereof

ActiveCN111113854AReduce exhaust pollutionGuaranteed trimmingTubular articlesPlastic filmManufacturing engineering

The invention discloses a plastic film production device and a process thereof. The production device comprises a machine frame with a hollow structure, a blow molding machine head is installed at theinner center of the frame, a limiting mechanism, an air extraction device, a herringbone plate and a traction device are sequentially arranged on the machine frame above the blow molding machine headaccording to the process of plastic film forming, a movable and adjustable counting device is arranged on the traction device, a cutting device and a winding device are sequentially arranged on the outer side ground of the machine frame at the output end of the traction device, and the winding device further comprises a film breaking device. The process comprises the following steps of (1) extruding molding of a plastic film; (2) setting and exhausting; (3) clamping flattening and pressing; (4) cutting and layering; and (5) winding and packing. According to the plastic film production deviceand the process thereof, through the improvement of the process equipment, in the production process, limiting is conducted on the plastic film protect the plastic film from being scratched, the volatile waste gas of the production plastic film is exhausted, the environment is protected, the length of the plastic film is accurately measured, accurate cutting and breaking of the plastic film are achieved, the plastic film production device is suitable for the production of plastic films of various specifications, and the production efficiency and product quality are improved.

Owner:GUIZHOU TIANXING PLASTIC PRODS

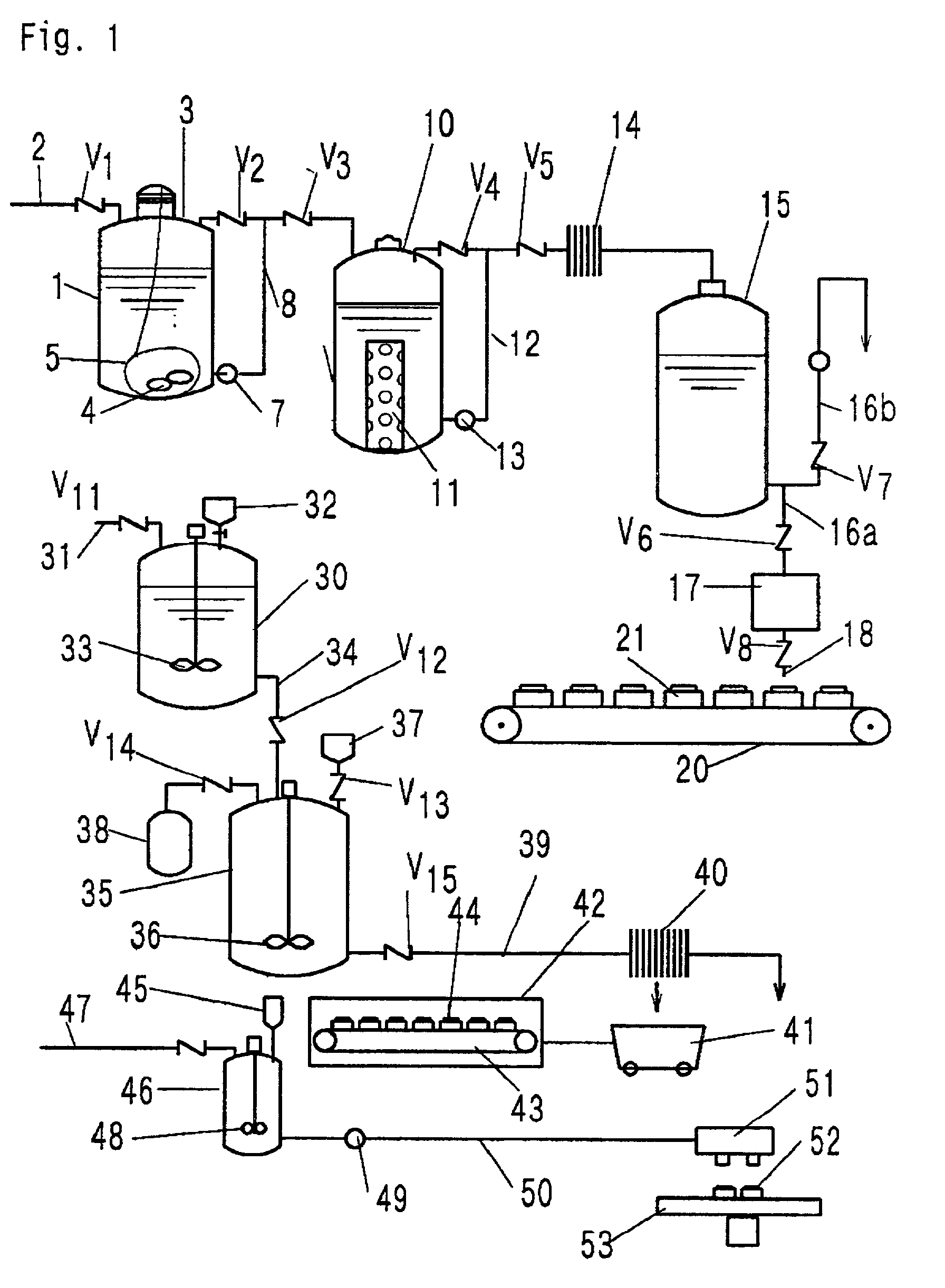

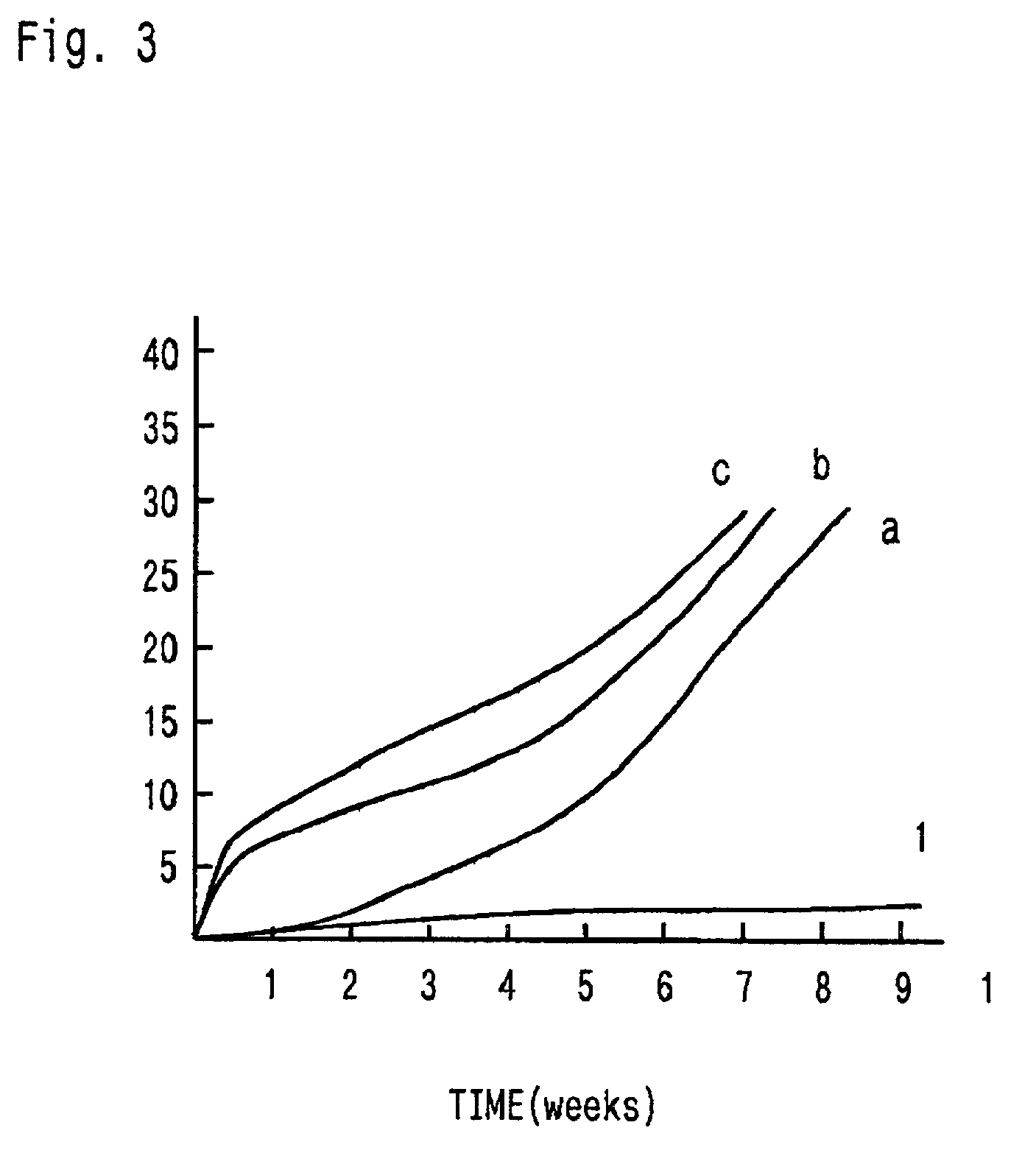

Liquid fuel-reforming process

InactiveUS20020155585A1Increase heightReduce exhaust pollutionFungiEnzymologyAfter treatmentLiquid fuel

A process for reforming oil fuel comprises the steps of contacting oil fuel with activated aspergillus fungi for a certain period and then mixing the resulting oil fuel with unreformed oil fuel. The reformed oil fuel may be treated with a magnetic catalyst after treatment by the activated aspergillus fungi.

Owner:OKADA MASAO

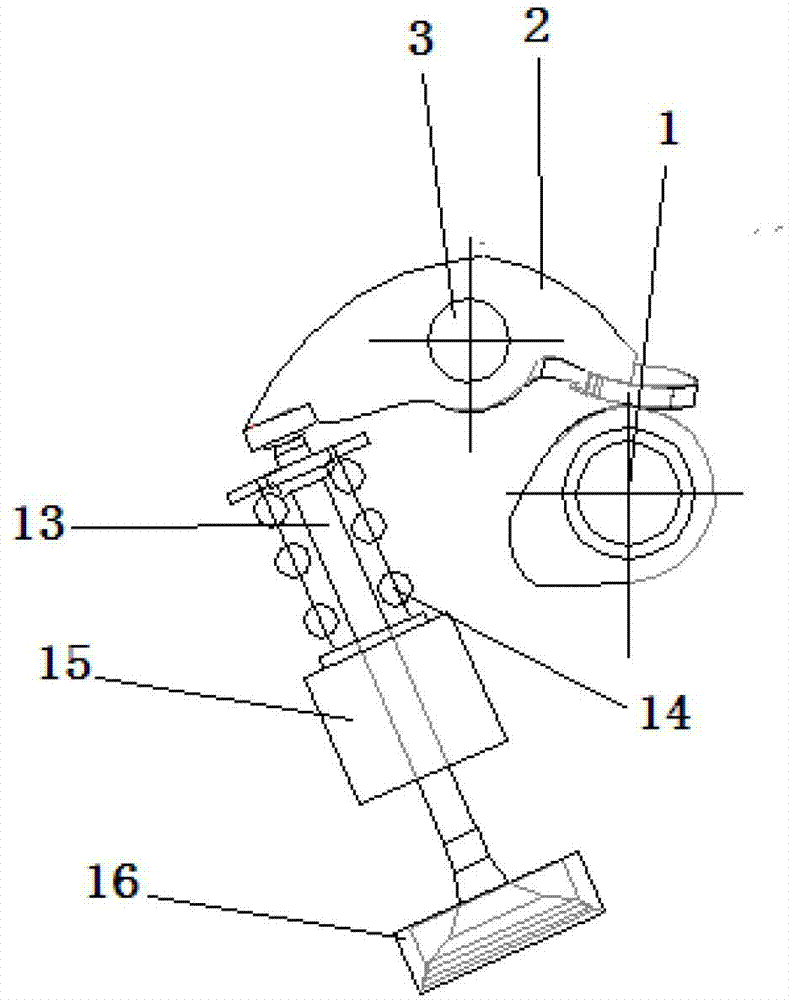

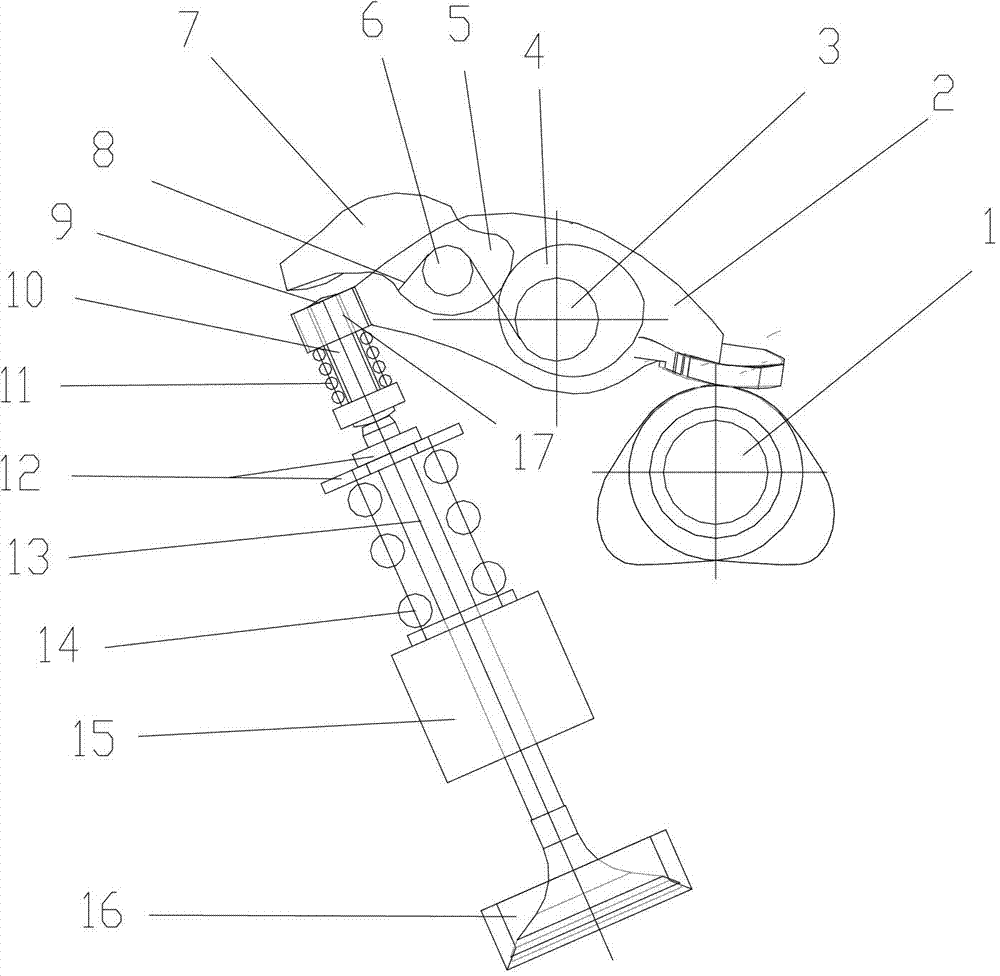

Swinging arm mechanism controlled by using double cams

InactiveCN102966391AImprove performanceReduce air lossValve arrangementsMachines/enginesCombustionExternal combustion engine

The invention discloses a swinging arm mechanism controlled by using double cams. The swinging arm mechanism comprises a main swinging arm which is rotationally connected to a main swinging arm shaft, wherein one end of the main swinging arm is tightly contacted with a camshaft; a pressure ring is arranged at the other end of the main swinging arm; a tappet mechanism is arranged at the top end of a valve rod of an internal combustion engine; the pressure ring is connected with the tappet mechanism in a sliding way; a secondary swinging arm shaft is fixedly arranged at one end of the main swinging arm where the pressure ring is arranged; a secondary swinging arm is rotationally hinged on the secondary swinging arm shaft; a second cam is formed on the end part of one end of the secondary swinging arm which is positioned on the secondary swinging arm shaft; a control cam is fixedly arranged on the main swinging arm shaft; the cam is tightly contacted and connected with the second cam through a tension spring; a convex part is formed at one end of the second swinging arm which is far away from the second cam; and the convex part is contacted tightly or in interval contact with the tappet mechanism which is arranged at the top end of the valve rod of the internal combustion and is used for compressing the valve rod. Due to the adoption of the swinging arm mechanism, the lift of a transmission mechanism can be adjusted easily in the running processes of a mechanical system and the internal combustion engine, and the performance of the mechanical system and the internal combustion engine can be improved.

Owner:TIANJIN UNIV

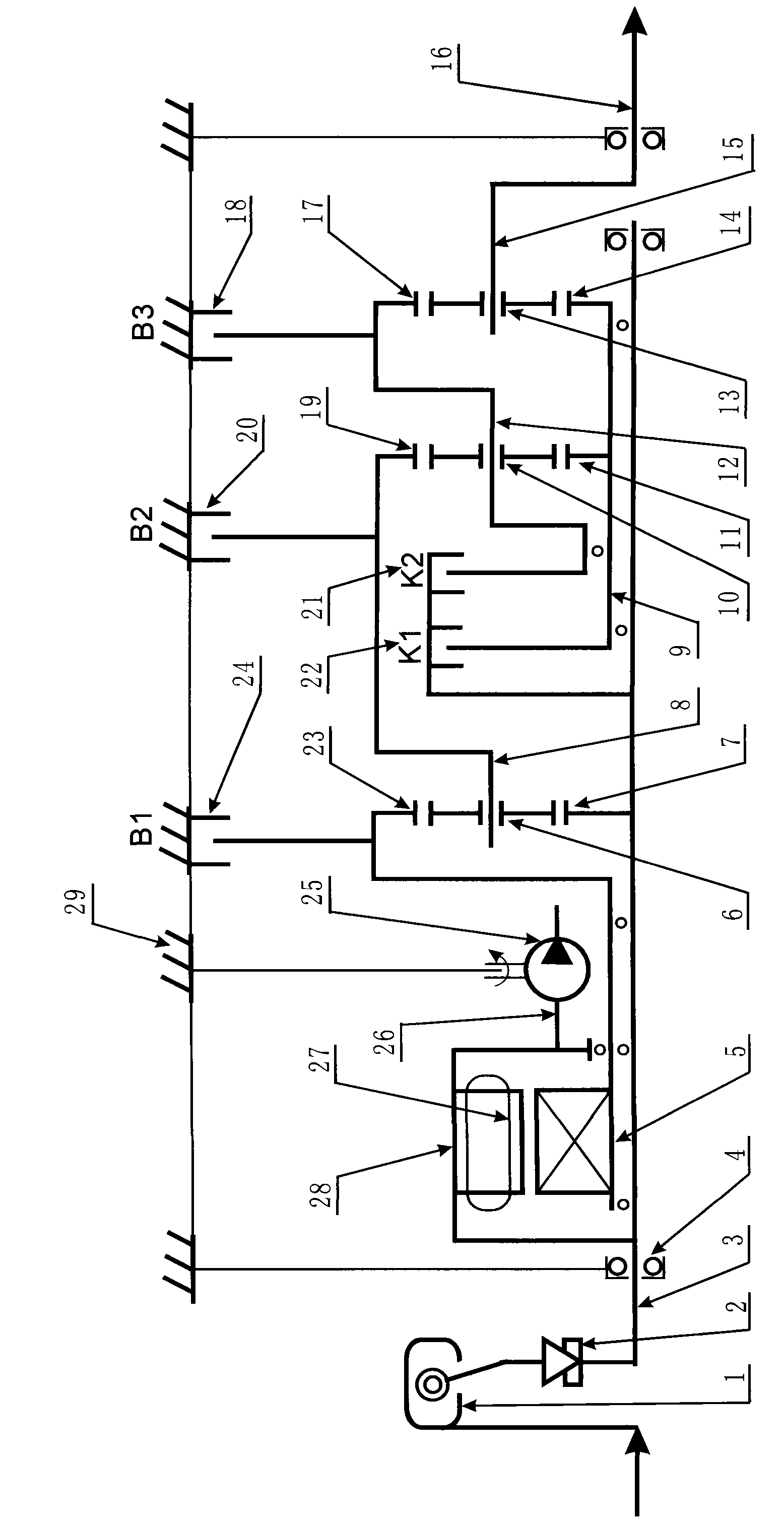

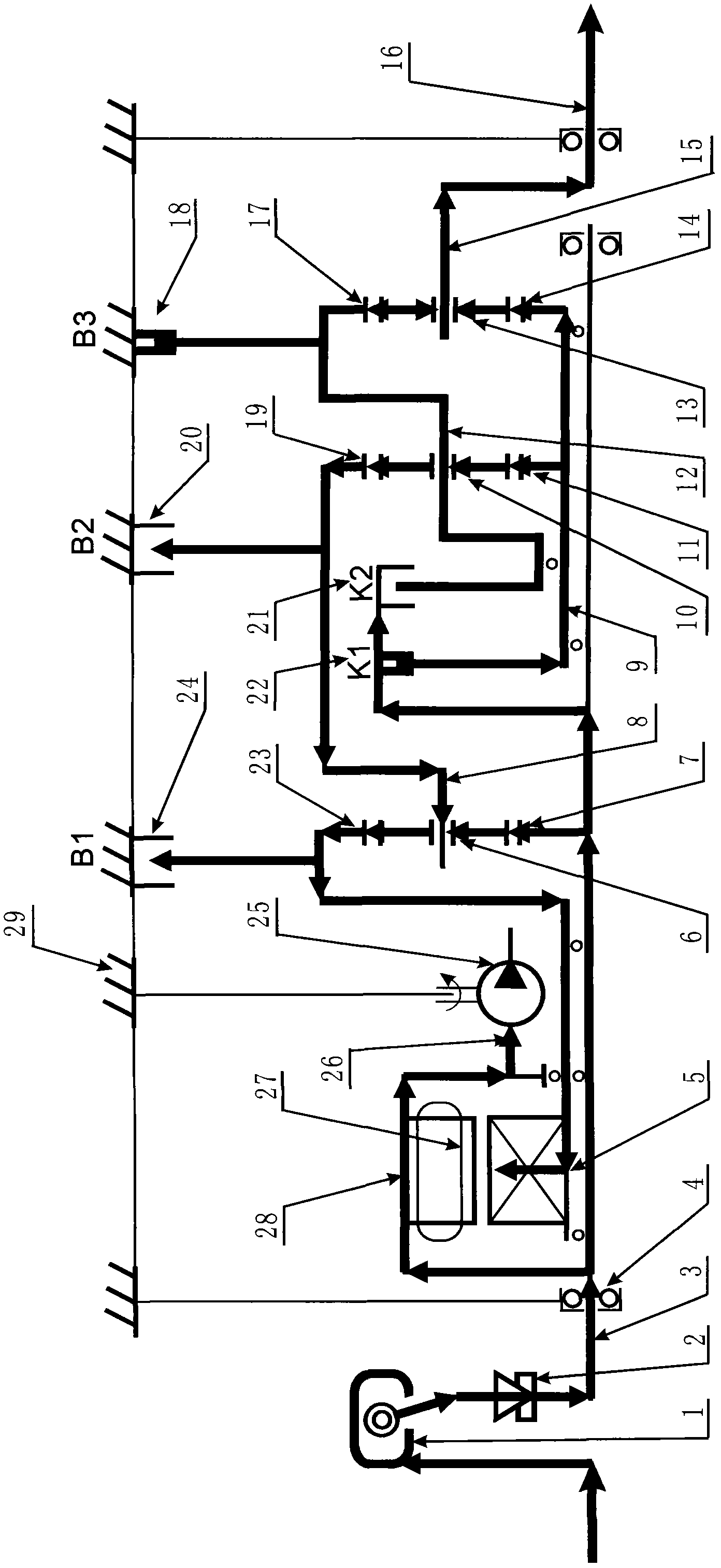

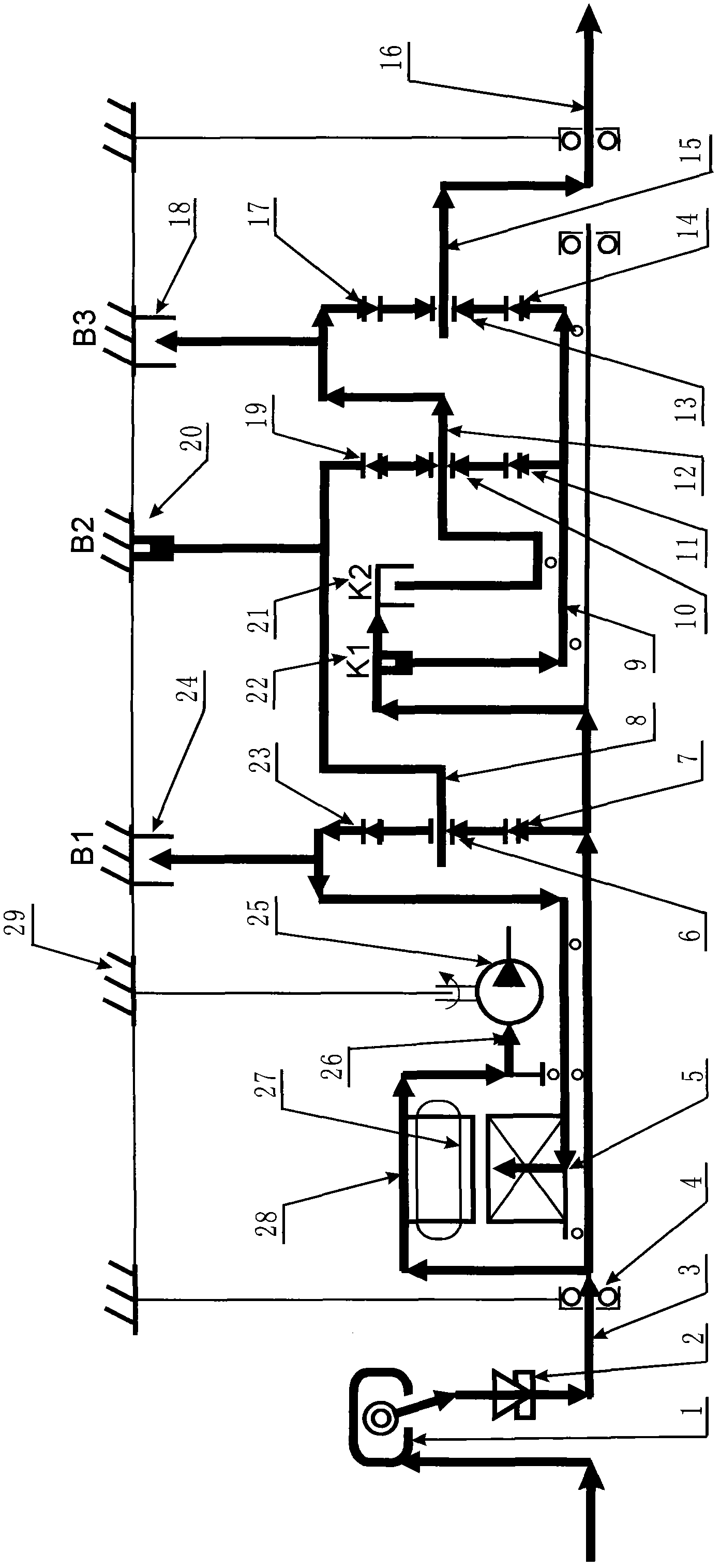

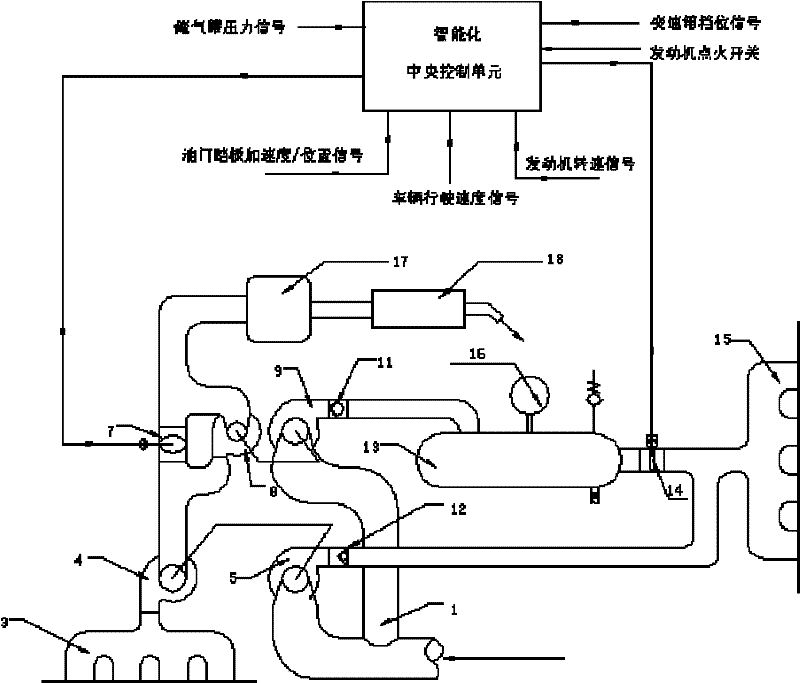

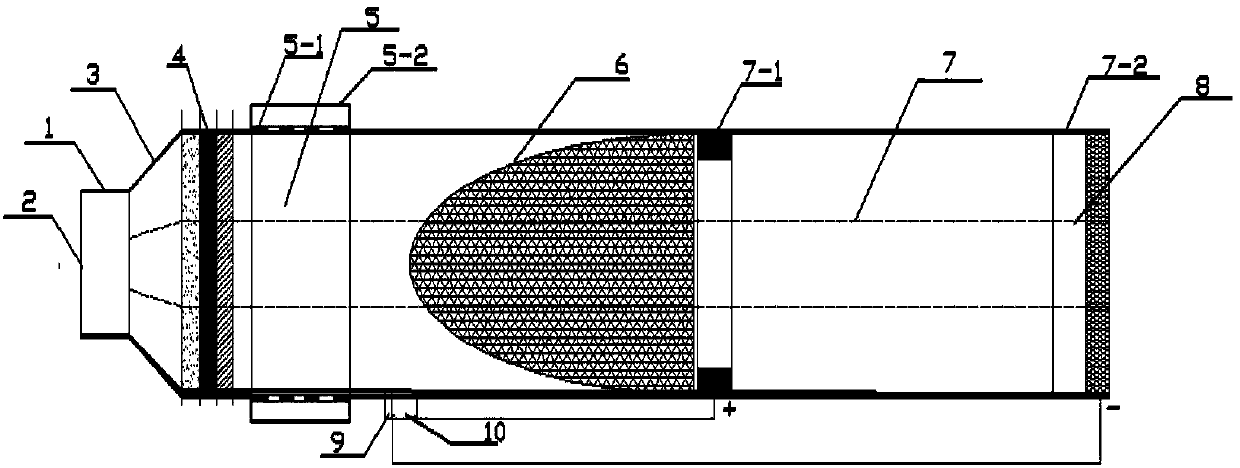

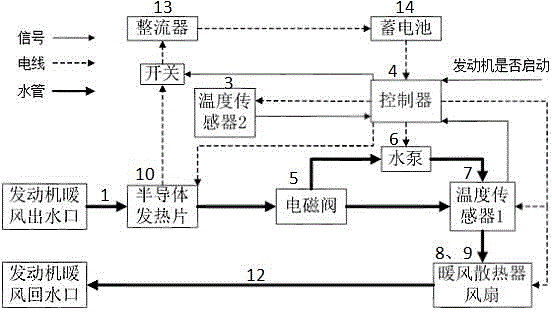

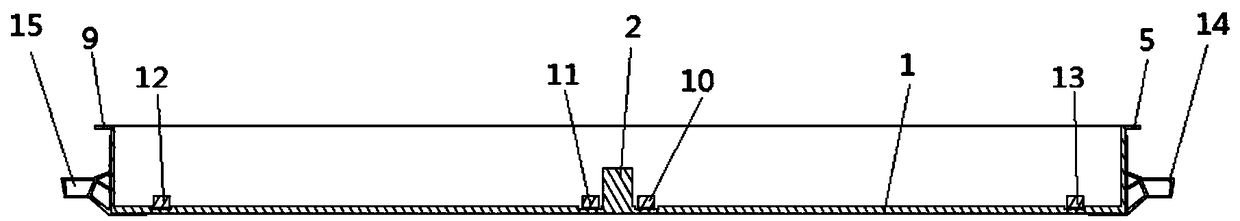

Semiconductor parking heater capable of achieving thermoelectric power generation

InactiveCN106286070AReduce fuel consumptionReduce exhaust pollutionAir-treating devicesVehicle heating/cooling devicesHeating efficiencyThermal efficiency

The invention provides an efficient semiconductor parking heater capable of achieving thermoelectric power generation. The semiconductor parking heater capable of achieving thermoelectric power generation comprises a parking heater body and a thermoelectric power generation device. The parking heater body comprises an engine warm air water outlet connecting water inlet pipe (1), an engine warm air water return opening connecting water return pipe (12), other pipelines (11), a pipeline heat insulation material, a cylindrical semiconductor heating piece (10), a two-position three-way electromagnetic reversing valve (5), a water pump (6), temperature sensors (3) and (7), an automobile warm air system, a storage battery (14) and a parking heater controller. The thermoelectric power generation device comprises a semiconductor power generation piece, namely a semiconductor heating piece (10), semiconductor heating piece cold face radiating plates (2), a thermoelectric power generation controller and a rectifier (13). According to the semiconductor parking heater capable of achieving thermoelectric power generation, when an automobile engine is not started, the electric quantity of the storage battery of the automobile is used for preheating engine cooling liquid and a cab, and therefore the problems that a traditional fuel parking heater is large in size, low in heat efficiency, excessively large in oil consumption, insufficient in combustion and likely to pollute the environment are solved; and when the engine is started, the cylindrical semiconductor heating piece stops the heating function, the power generation effect starts to be played, thermoelectric power generation can be conducted through the temperature difference between the cooling liquid and an engine compartment, and energy is sufficiently utilized.

Owner:徐嘉浩

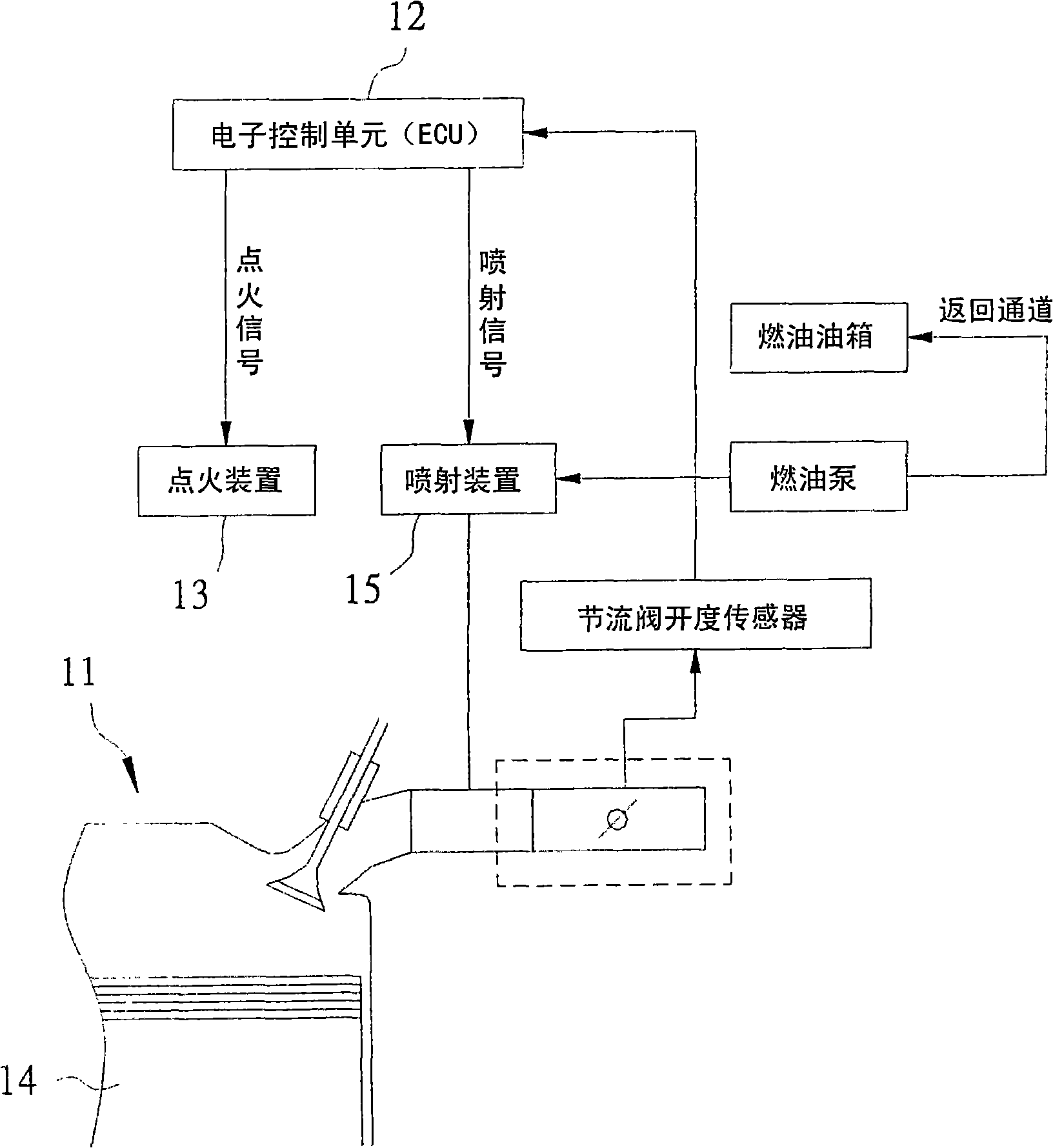

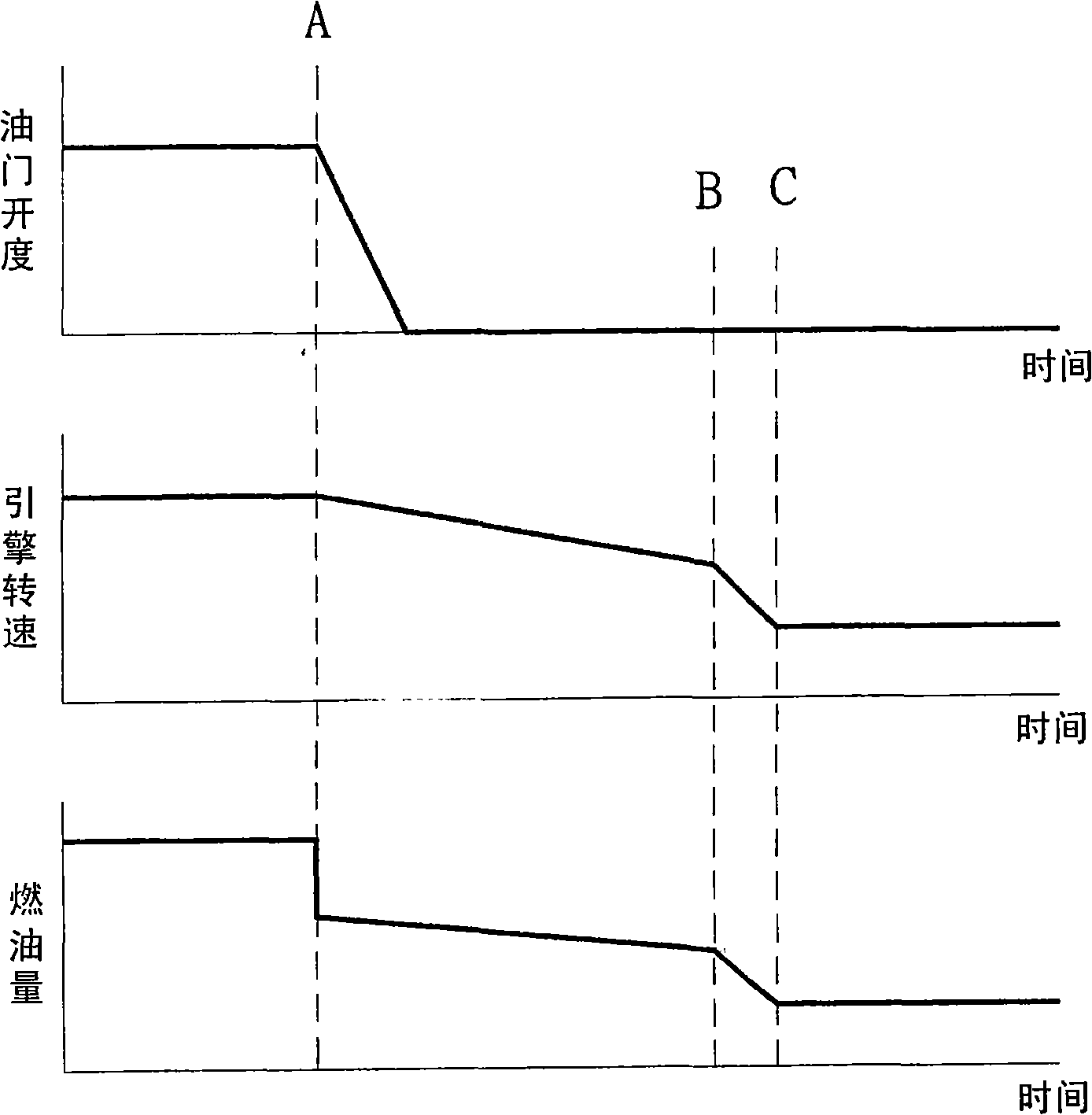

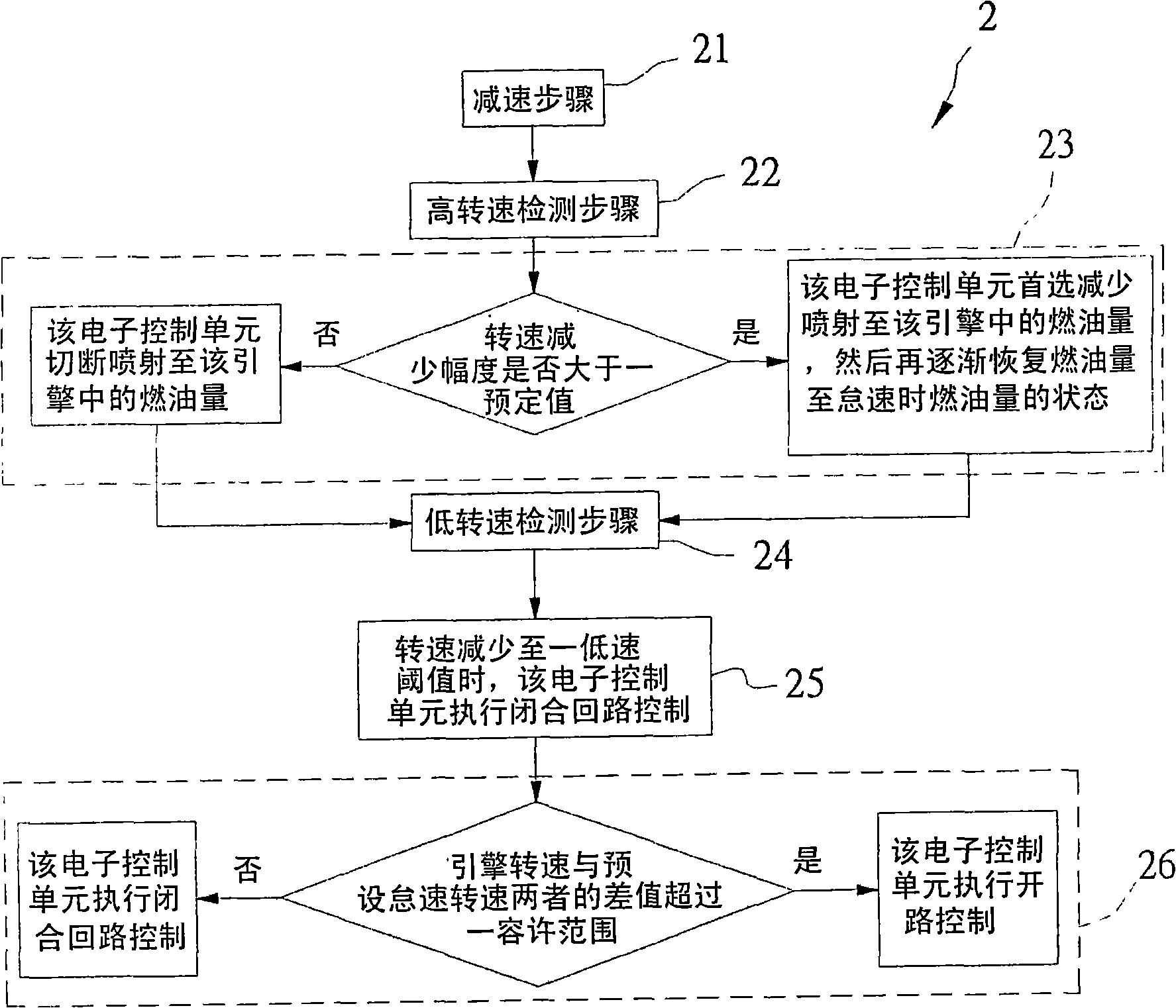

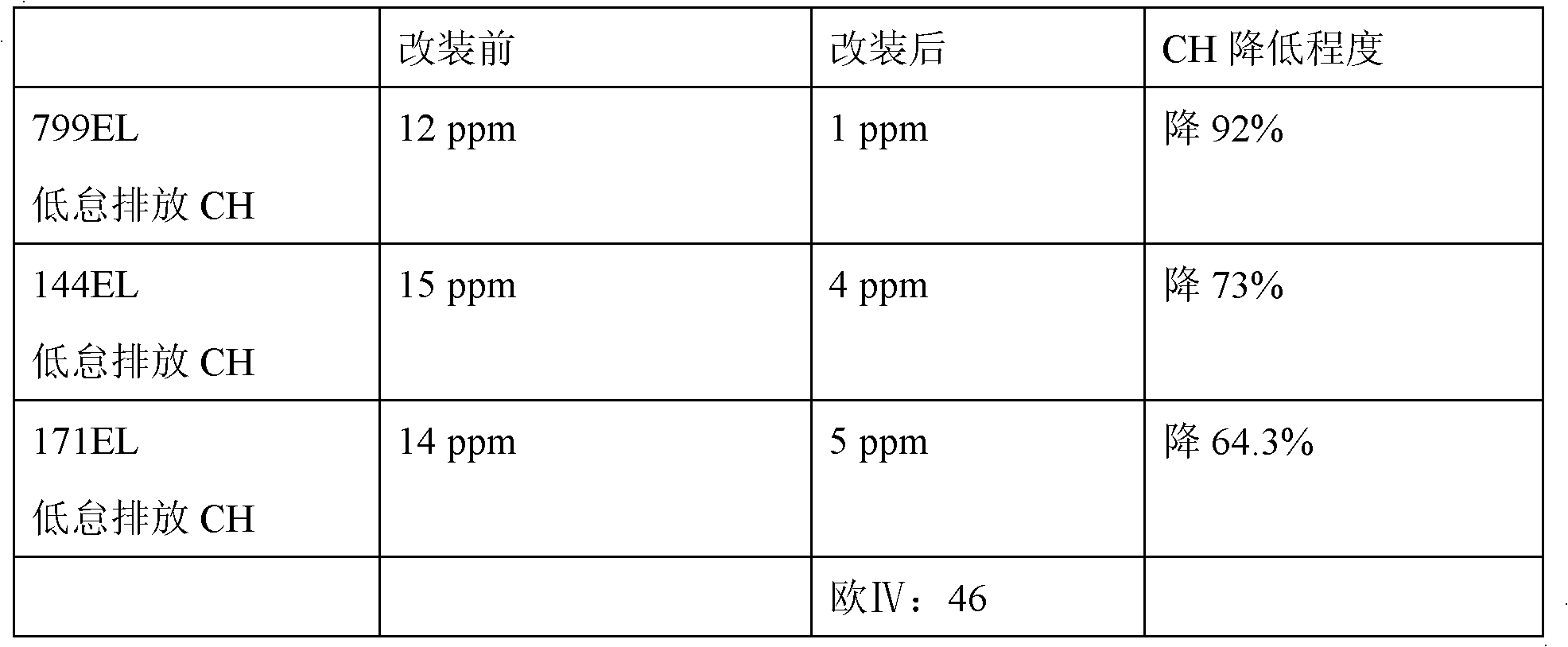

Reduced speed method of motorcycle injection type engines

InactiveCN101275493AReduce fuel wasteReduce exhaust pollutionElectrical controlMachines/enginesElectronic control unitFuel oil

The invention relates to a speed reduction method for a jet engine of a motorcycle, comprising the steps of speed reducing, high rotating speed detecting, first controlling, low rotating speed detecting, second controlling and idle speed controlling. The reduction amplitude of the rotating speed of the engine is judged in the first controlling step, and then the fuel oil injection strategy for an electronic control unit is determined, so that when the motorcycle slows down, no excessive fuel oil is injected into the engine, the fuel oil waste is effectively reduced, the exhaust pollution is lowered, and the oil sediment on an exhaust pipe is avoided; in addition, in the second controlling step and the idle speed controlling step, the amount of fuel oil injected to the engine is controlled, the case that engine flameout caused by lack of fuel oil in the process of speed reducing and speed idling is prevented, thus to effectively improve the ride marketability of the motorcycle.

Owner:KYMCO

Aqueous alcohol fuel and production thereof

An aqueous alcohol fuel and its production are disclosed. The fuel consists of 94~96% alcohol 70~85%, isobutyl alcohol 7.5~15%, isopropyl alcohol 5.25~10.5% and isoamyl alcohol 2.25~4.5%. The process is carried out by proportioning, delivering various raw materials into synthesizing pot, agitating at normal temperature and pressure for 20~60mins and mixing to obtain the aqueous alcohol fuel. It is simple and cheap, has various raw material, better combustion and chemical stabilities, and less environmental pollution.

Owner:夏源河 +1

Front multi-element catalyst and preparation method thereof

ActiveCN102133536ASolution to short lifeIncrease powerPhysical/chemical process catalystsDispersed particle separationPollutionEnergy conservation

The invention discloses a front multi-element catalyst and a preparation method thereof, and belongs to the field of automobile exhaust purification. The catalyst solves the technical problems of short life and high oil consumption of the conventional ternary catalyst. The front multi-element catalyst is prepared from heavy calcium carbonate, water glass, alumina, iron oxide, Ce2O3 and the balance of water, and is spherical. The catalyst is prepared by adopting a sintering method. The front multi-element catalyst has the advantages of long life (3 to 5 years), energy conservation, emission reduction, no secondary pollution and power increment; and the catalyst is mainly used for treating exhaust of vehicles. The method has simple process, is convenient for operation, and has mild reaction conditions.

Owner:兰嘉铭

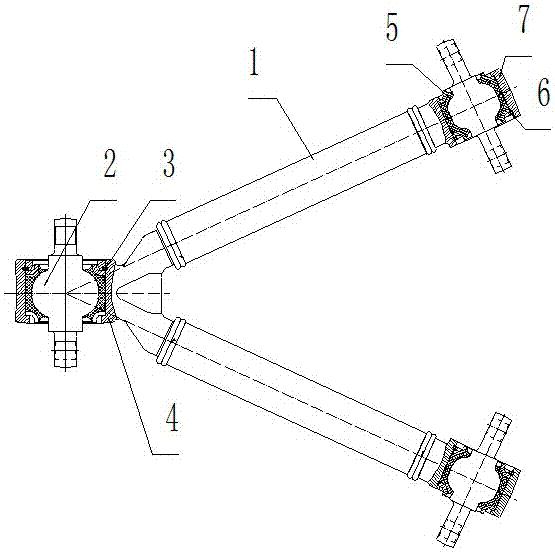

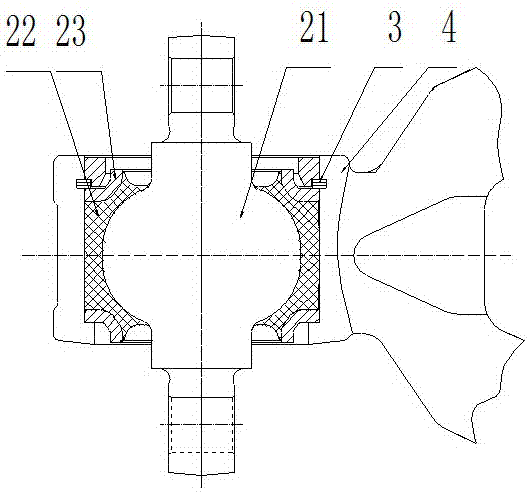

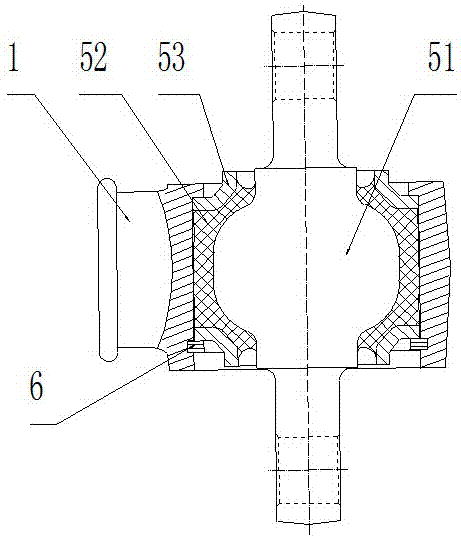

Heavy type commercial vehicle V-shaped thrust rod assembly and assembly method thereof

ActiveCN107415615AIncrease stiffnessImprove carrying capacityPivoted suspension armsMetal working apparatusFriction weldingStructural engineering

The invention discloses a heavy type commercial vehicle V-shaped thrust rod assembly and an assembly method thereof. The V-shaped thrust rod assembly comprises a V-shaped end socket assembly, a small end socket assembly and a connecting rod; the V-shaped end socket assembly comprises a V end reinforcing type spherical hinge, a V end spring collar and a V-shaped end socket; and the small end socket assembly comprises a small end spherical hinge, a small end spring collar and a small end socket. The assembly method of the heavy type commercial vehicle V-shaped thrust rod assembly includes the steps that firstly the V-shaped end socket and the small end socket are connected with each other through the connecting rod in a frictional welding mode, then the V-shaped end socket assembly and the small end socket assembly are assembled, and the heavy type commercial vehicle V-shaped thrust rod assembly is formed. In the assembly method of the heavy type commercial vehicle V-shaped thrust rod assembly, both the V end spring collar and the small end spring collar are pressed into a clamping groove of the V-shaped end socket or the small end socket through a specialized pressing device, and the specialized pressing device is composed of a guide mechanism, an upper pressing plate, a pressing head, a transition taper sleeve and a positioning seat. According to the technical scheme of the heavy type commercial vehicle V-shaped thrust rod assembly and the assembly method thereof, the weight of a V-shaped thrust rod can be reduced by 10-15%, the fatigue resistant strength of the heavy type commercial vehicle V-shaped thrust rod assembly and the power of a heavy type commercial vehicle are improved, the service life of the thrust rod assembly is prolonged, the fuel consumption is reduced, and the exhaust pollution is lowered.

Owner:ANQING HUITONG AUTOMOTIVE PARTS

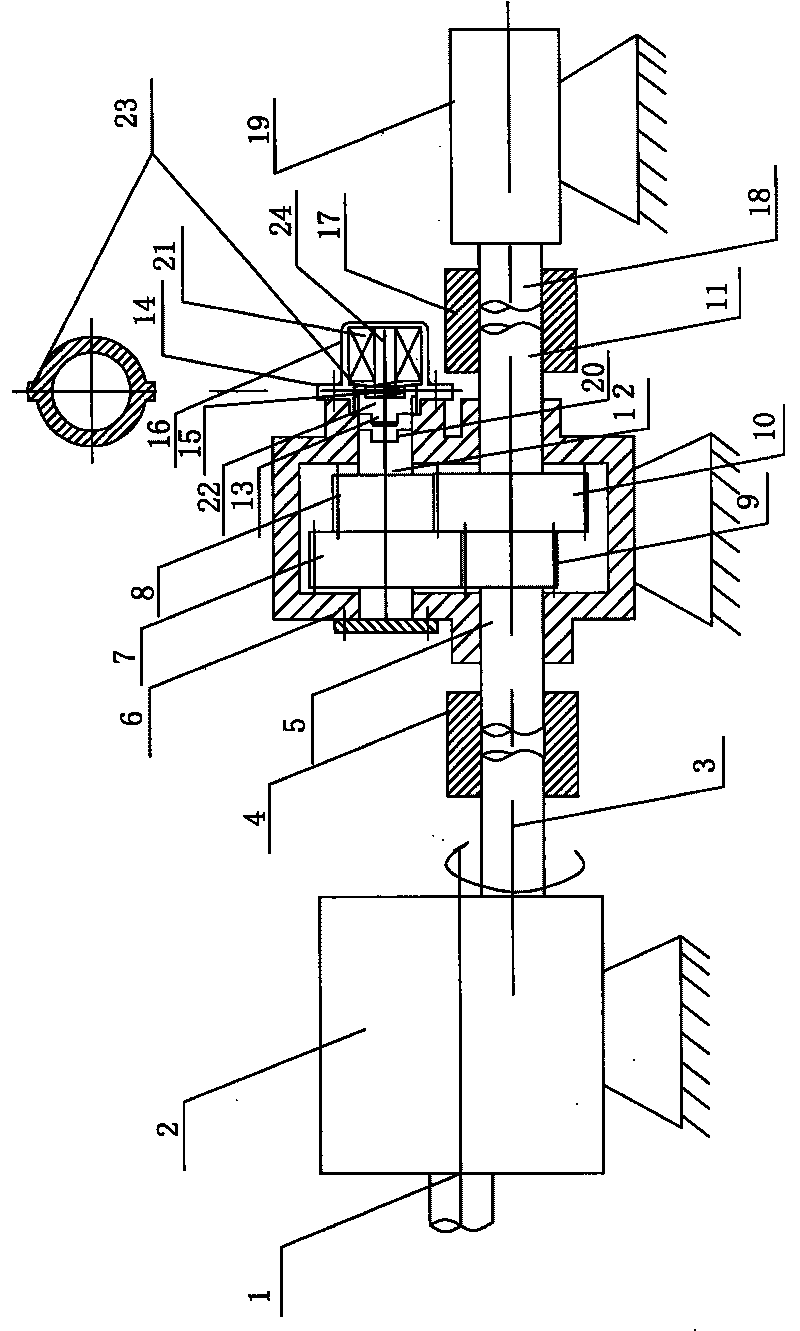

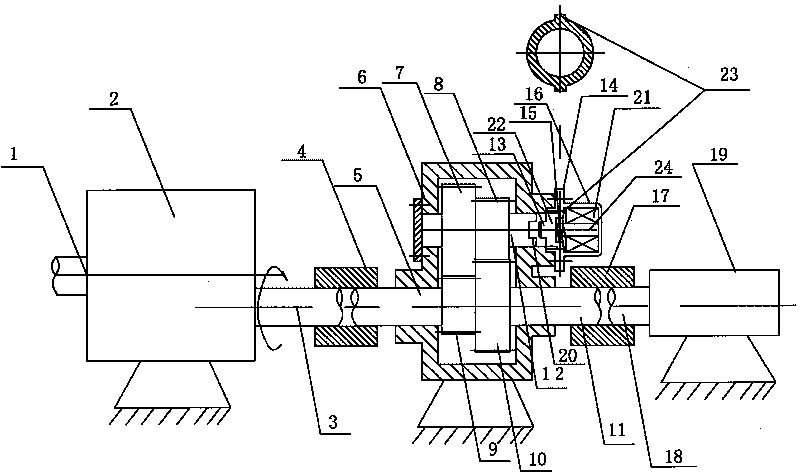

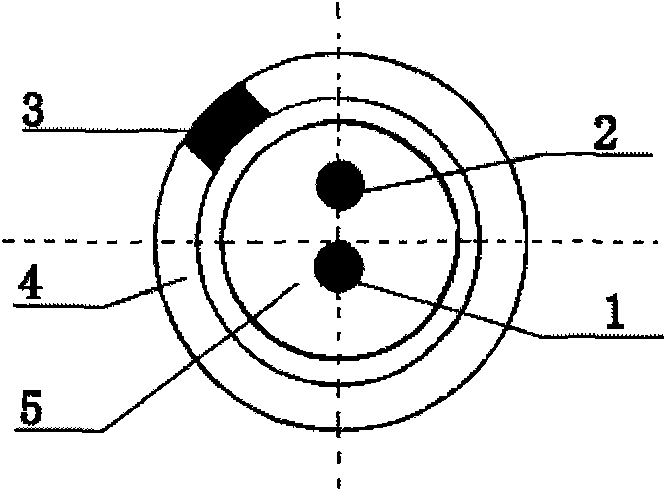

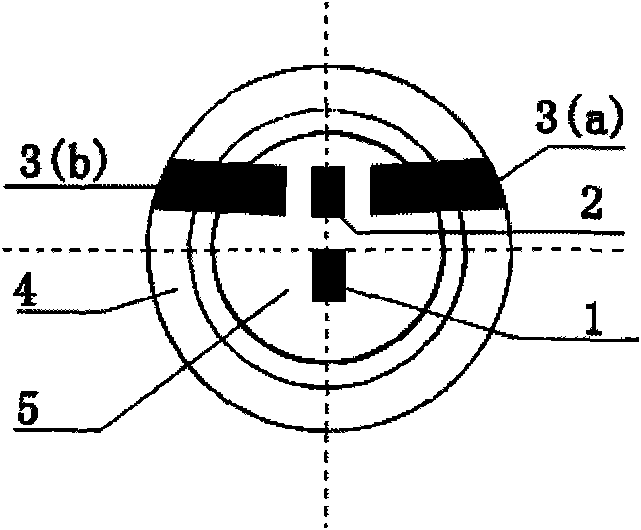

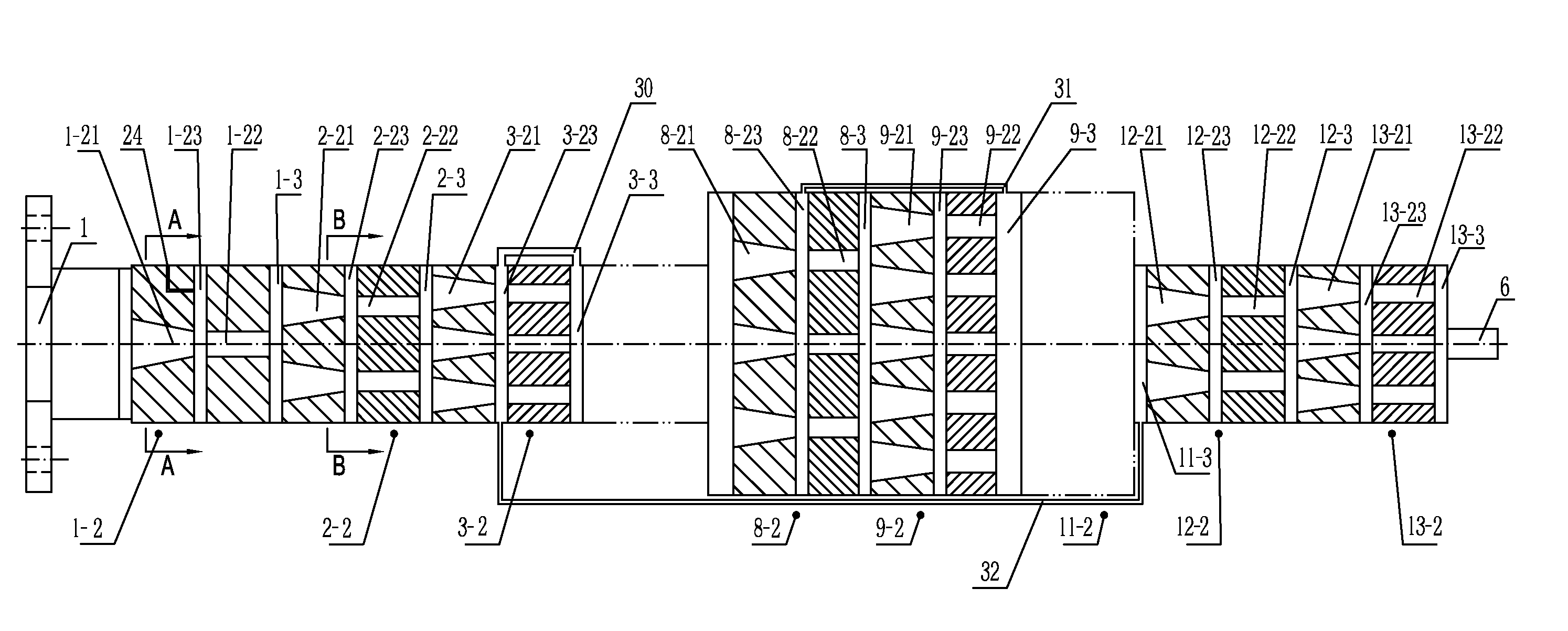

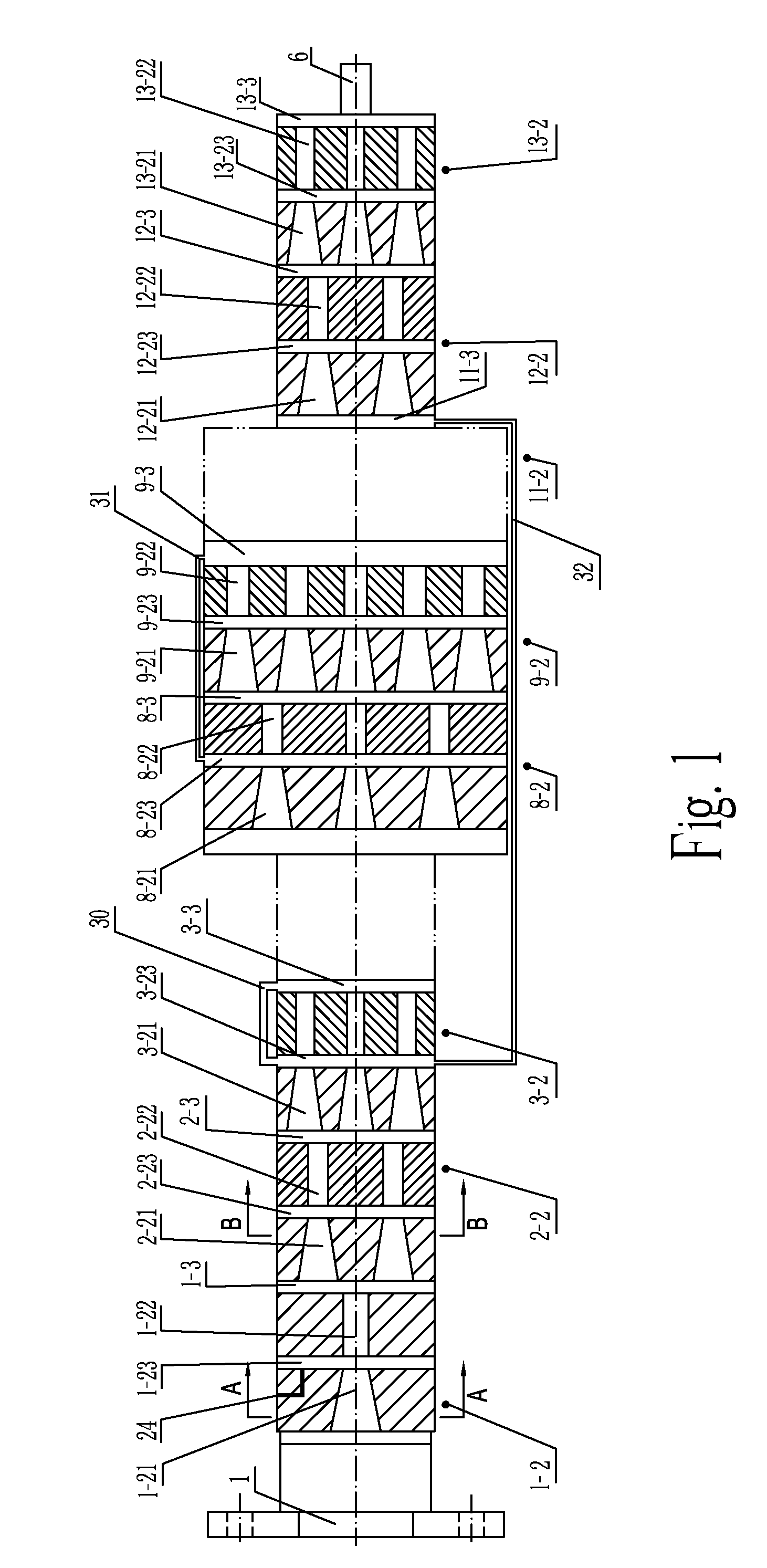

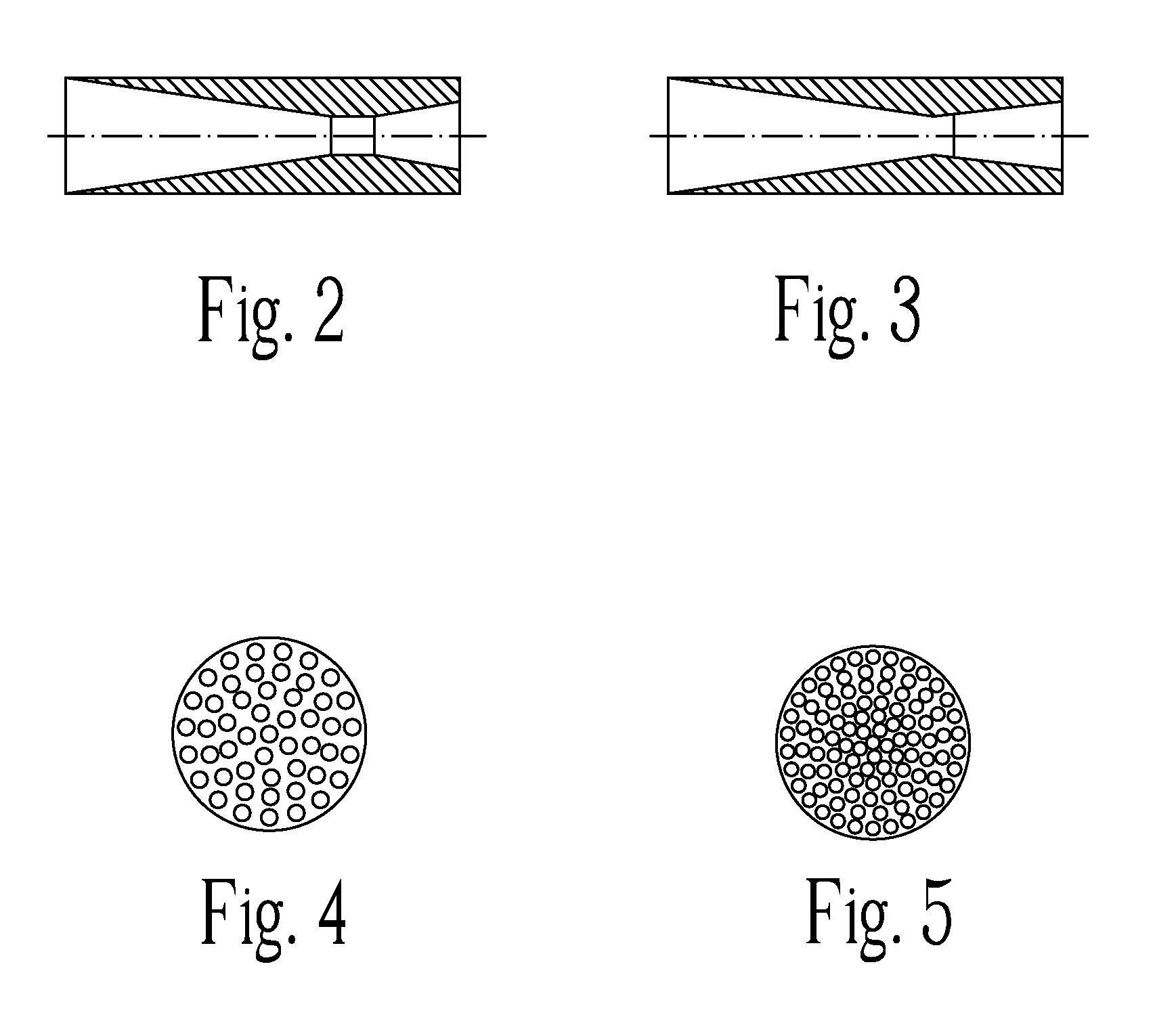

Large angular displacement controlling device for mechanical system

InactiveCN101701551AImprove performanceSimple structureEngine controllersMachines/enginesCombustionElectric machine

The invention relates to a large angular displacement controlling device for a mechanical system, which comprises a variable-speed motor, a first input shaft, a first transmission gear, a second input shaft, a second transmission gear, a third transmission gear and a fourth transmission gear, wherein the input end of the variable-speed motor is connected with a control shaft of a control motor, the output end of the variable-speed motor is connected with a control shaft of a prime motor, and the variable-speed motor is provided with a second-level or multi-level gear; the first input shaft is connected with the control shaft of the control motor; the first transmission gear is fixed on the first input shaft; the second transmission gear and the third transmission gear are fixed on the second input shaft; the second transmission gear is meshed with the first transmission gear; the fourth transmission gear is positioned at one side of the first transmission gear and is meshed with the third transmission gear, and the fourth transmission gear is fixedly connected with an output shaft of the variable-speed motor connected with the control shaft of the prime motor; and one end of the second input shaft is supported on the shell of the variable-speed motor, and the other end of the second input shaft is supported at the other side of the shell of the variable-speed motor and is connected with a phase angle locking device through a locking groove formed on the end of the other side. The invention has simple structure and can improve the performance of the mechanical system, improve the combustion efficiency and reduce the exhaust pollution.

Owner:TIANJIN UNIV

Parallel-series electrode multigap energy-saving environmental-friendly spark plug

The invention relates to a parallel-series electrode multigap energy-saving environmental-friendly spark plug. An iron shell is welded with two parallel type side electrodes keeping a proper spacing; a porcelain core is respectively provided with one central electrode and one bridging type central electrode, and the upper ends of the central electrode and the bridging type central electrode are both exposed out of a porcelain surface; and gaps among electrodes are all in a series structure. By adopting the technical scheme and especially after the central electrodes are changed into square flat shapes and have edge type marginal discharge, the invention enhances the arc-through capability, reduces the load of an ignition system, improves the burning velocity of a mixed gas, and prolongs the service life of related parts; sparks generated among the electrodes are all directly exposed in the mixed gas, therefore, the ignition energy loss is reduced, and the burning efficiency of the mixed gas is enhanced; jump-spark gaps are increased, therefore, the gap free adjustment is realized; and the two central electrodes are in the square flat shapes and are relatively enlarged in cross sectional areas, therefore, the service life of the spark plug is prolonged. Thus, the invention more enables the mixed gas to be sufficiently burned, saves fuel, reduces cost and pollution, and enhances the power of a motor.

Owner:席其红

Device with trace emission for treatment of exhaust gas

InactiveUS7857095B2Reduce exhaust emissionsReduce exhaust pollutionGas treatmentExhaust apparatusAtmospheric airEngineering

This invention relates to a kind of devices with trace emission resulted for treatment of exhaust gas. The device comprises a vessel having only one opening that serves as inlet. At least two gas exchange sections in sequence are provided inside the vessel after inlet of exhaust gas, between two gas exchange sections there is a gas mixture chamber at their connection part. The gas exchange chamber at first gas exchange section has a through opening leading to outside atmosphere area. With this configuration, on entering into the gas exchange section, exhaust gas will be ejected inwards and causes very strong entrainment, which makes the gas chamber become vacuum and sucks air with oxygen from atmosphere into gas chamber via the through opening to atmosphere. Formed high-pressure gas is burned furiously with combustible gas in the gas chamber at next stage, and the remaining exhaust gas is transferred into next gas exchange section with very high-speed revolution occurring on exhaust gas and momentum transfer. The higher negative pressure is, the more gas is consumed. In this way, the exhaust gas will be treated and only trace emission, even no emission, will be resulted.

Owner:ZHANG YUGUANG +1

Horizontally-opposed-cylinder, horizontally-opposed-piston and two-stroke homogeneous compression-ignition engine and generators

ActiveCN106285934ACompact structureHigh failure rateMachines/enginesElectricityHomogeneous charge compression ignition

The invention discloses a horizontally-opposed-cylinder, opposed-piston and two-stroke homogeneous compression-ignition reciprocating engine and linear generators. Two pistons are arranged inside each of two parallel cylinders for doing work oppositely; four blast pump pistons, of which the effective area is 2-3 times greater than that of the work-doing pistons, are arranged behind the four pistons, and are used for supplying pressurized mixed fuel gas to the cylinders; four coaxial linear generators are arranged behind four blast pumps; shaft heads behind the four generators are connected with two interconnecting fulcrums of two semicircular rocker mechanisms fixed to central vertical shafts at the two ends of the two cylinders; when the two pistons in one cylinder move towards a combustion chamber, which is shared by the two pistons, in the center of the cylinder, the two pistons in the other cylinder move oppositely to the two ends of the cylinder; when the two pistons in one cylinder move up to 5-10 degrees in front of an upper stopping point, mixed fuel catches fire and bursts out through compression ignition to force the two pistons to rapidly move towards a lower stopping point, push the coaxial blast pumps to blast air, push the generators to generate electricity and push the two semicircular rocker mechanisms to rotate in the reverse direction so as to push the two pistons in the other cylinder to do compression work on the upper stopping point at the center of the cylinder.

Owner:高阳

Saver and cleanser for gasoline

InactiveCN1204235CImprove atomization qualityLower activation energyLiquid carbonaceous fuelsGasoline fuelEthylene Dichloride

A gasoline fuel-saving purifying agent, relating to an automobile gasoline fuel-saving purifying agent using gasoline as fuel, the invention includes a detergent dispersant, a combustion aid, an antiknock agent, a polar solvent, and a non-polar solvent. The dispersant is a mixture of dichloroethane and N-methyl-2-pyrrolidone, wherein the content of dichloroethane is 5-20%, and the content of N-methyl-2-pyrrolidone is 5-20%; It is benzene alcohol with a content of 2-10%; the antiknock agent is a mixture of ferrocene and isopropanol, wherein the content of ferrocene is 3-5%, and the content of isopropanol is 5-15%; polarity The solvent is methanol or ethanol with a content of 20-40%; the non-polar solvent is benzene, toluene, xylene or their mixtures with a content of 20-40%. It has the advantages of improving the performance of gasoline, improving the cleanliness of fuel, promoting the full combustion of fuel, reducing automobile exhaust pollution, and keeping the car in good working condition.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

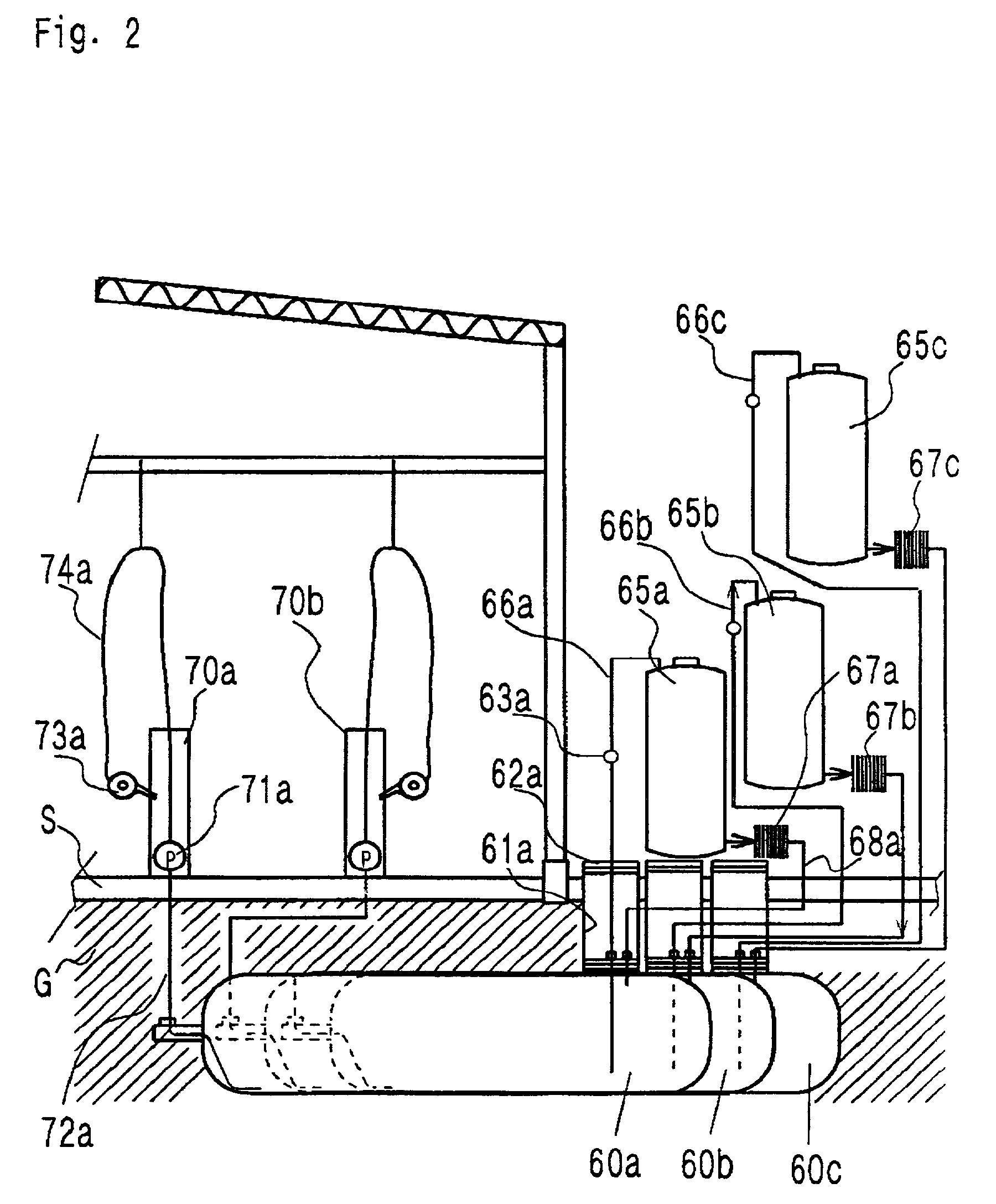

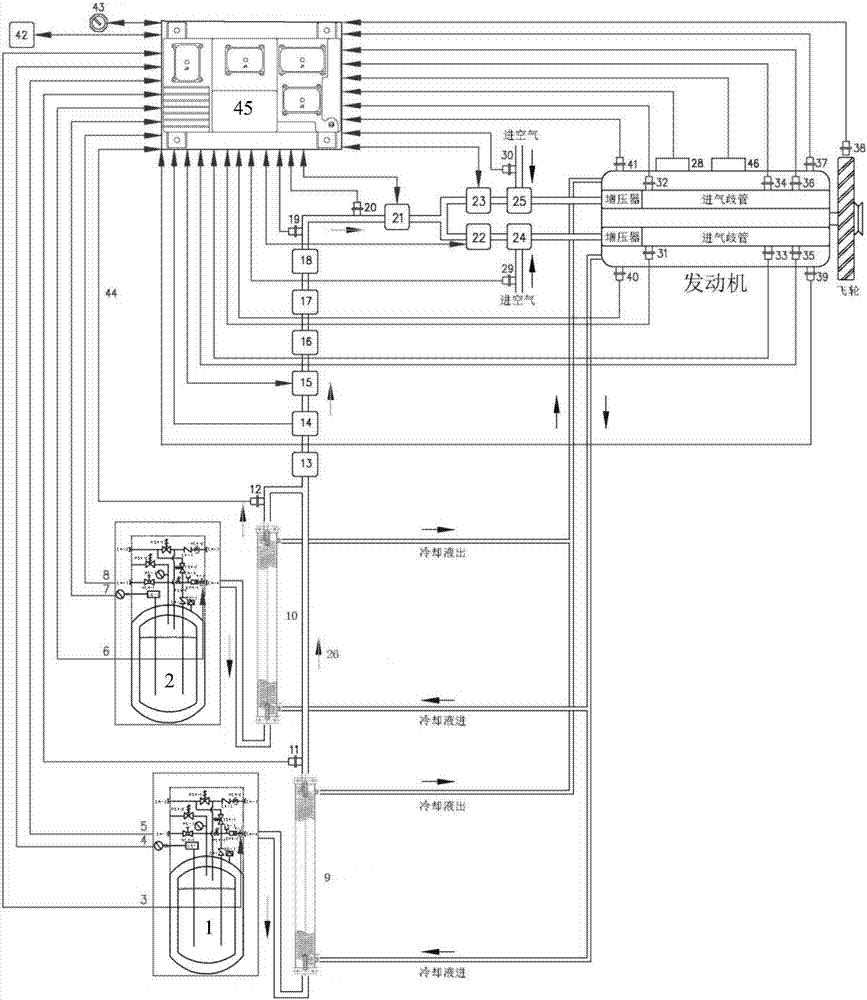

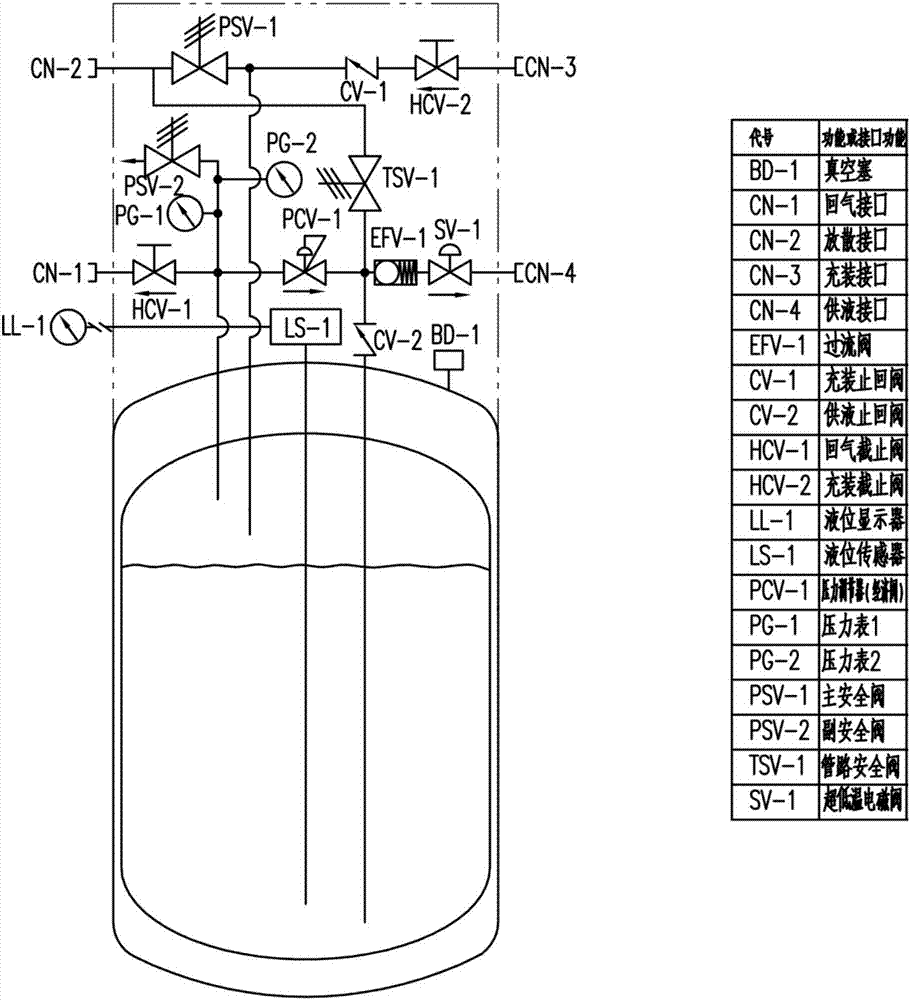

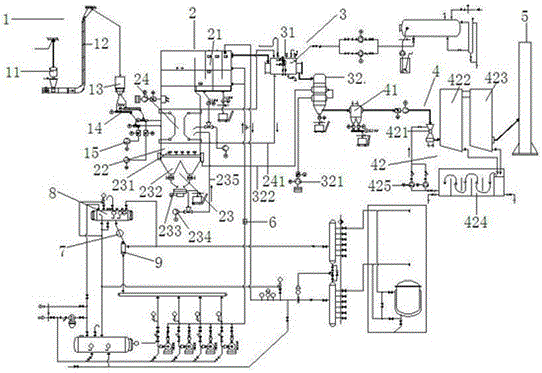

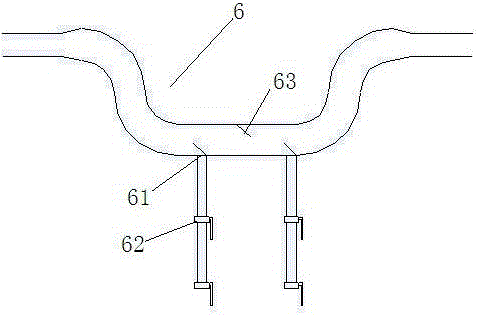

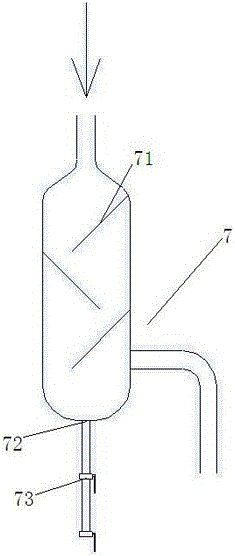

LNG supply system

InactiveCN107061052AEasy to modifyLow initial investmentInternal combustion piston enginesFuel supply apparatusSocial benefitsControl system

The invention discloses a natural gas supply system for a high-power LNG-diesel oil dual-fuel engine. The natural gas supply system comprises a storage system, a supply system and a control system, wherein the storage system is connected with the supply system; the supply system is simultaneously connected with the storage system and the engine; and the control system communicates with the storage system, the supply system and the engine respectively. The natural gas supply system disclosed by the invention has obvious economical and social benefits, can save a lot of fuel cost for an enterprise and also can greatly reduce the exhaust pollution of the engine.

Owner:JIANGSU FOLAIYIN ENG TECH CO LTD

Wall flow type net plate apparatus with reverse jet regenerating unit for collecting microparicle discharged by diesel vehicle

InactiveCN100395435CReduce exhaust pollutionReduce manufacturing costExhaust apparatusSilencing apparatusParticulatesMicroparticle

This invention discloses a converse regenerating wall flow type metal net plate apparatus for collecting microparticle discharged by diesel vehicle. The composite metal plate masking filter layer inclined certain angles in outer shell, 'WW' type is formed through baffle. Extension room is set between air intake and the filter layer, the room is connected to scavenging valve and carbon smoke second collecting device. Pneumatic disc valve, blowback cavity and air compress air tank at one side of the gas outlet are connected to the shell. Waste gas discharged by the engine enters from collector intake, and particles in the waste gas are entrapped when it flows through 'WW' type composite metal shadow masking. Discharging back pressure ascends when the particles deposit to certain quantity, and the regenerating equipment starts to blow out the accumulative particles from filter, and the particles are second collected and burned in collector. The structure is simple, cost is low, purification effect and regeneration effect is good, life is long and a good product for generalization.

Owner:TSINGHUA UNIV +1

Device with Trace Emission for Treatment of Exhaust Gas

InactiveUS20080178583A1Reduce exhaust pollutionIncrease speedGas treatmentExhaust apparatusAtmospheric airEngineering

This invention relates to a kind of devices with trace emission resulted for treatment of exhaust gas. The device comprises a vessel having only one opening that serves as inlet. At least two gas exchange sections in sequence are provided inside the vessel after inlet of exhaust gas, between two gas exchange sections there is a gas mixture chamber at their connection part. The gas exchange chamber at first gas exchange section has a through opening leading to outside atmosphere area. With this configuration, on entering into the gas exchange section, exhaust gas will be ejected inwards and causes very strong entrainment, which makes the gas chamber become vacuum and sucks air with oxygen from atmosphere into gas chamber via the through opening to atmosphere. Formed high-pressure gas is burned furiously with combustible gas in the gas chamber at next stage, and the remaining exhaust gas is transferred into next gas exchange section with very high-speed revolution occurring on exhaust gas and momentum transfer. The higher negative pressure is, the more gas is consumed. In this way, the exhaust gas will be treated and only trace emission, even no emission, will be resulted.

Owner:ZHANG YUGUANG +1

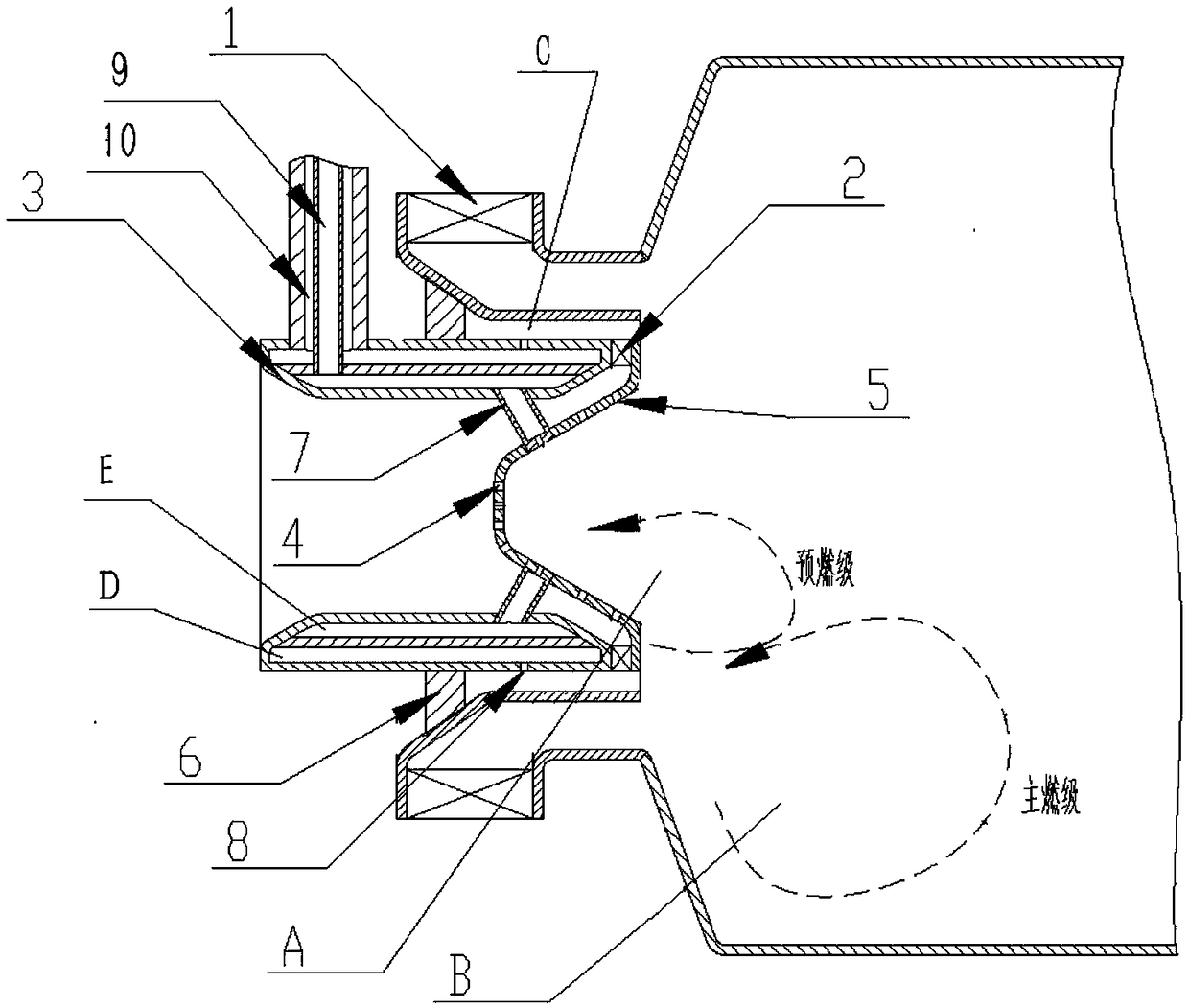

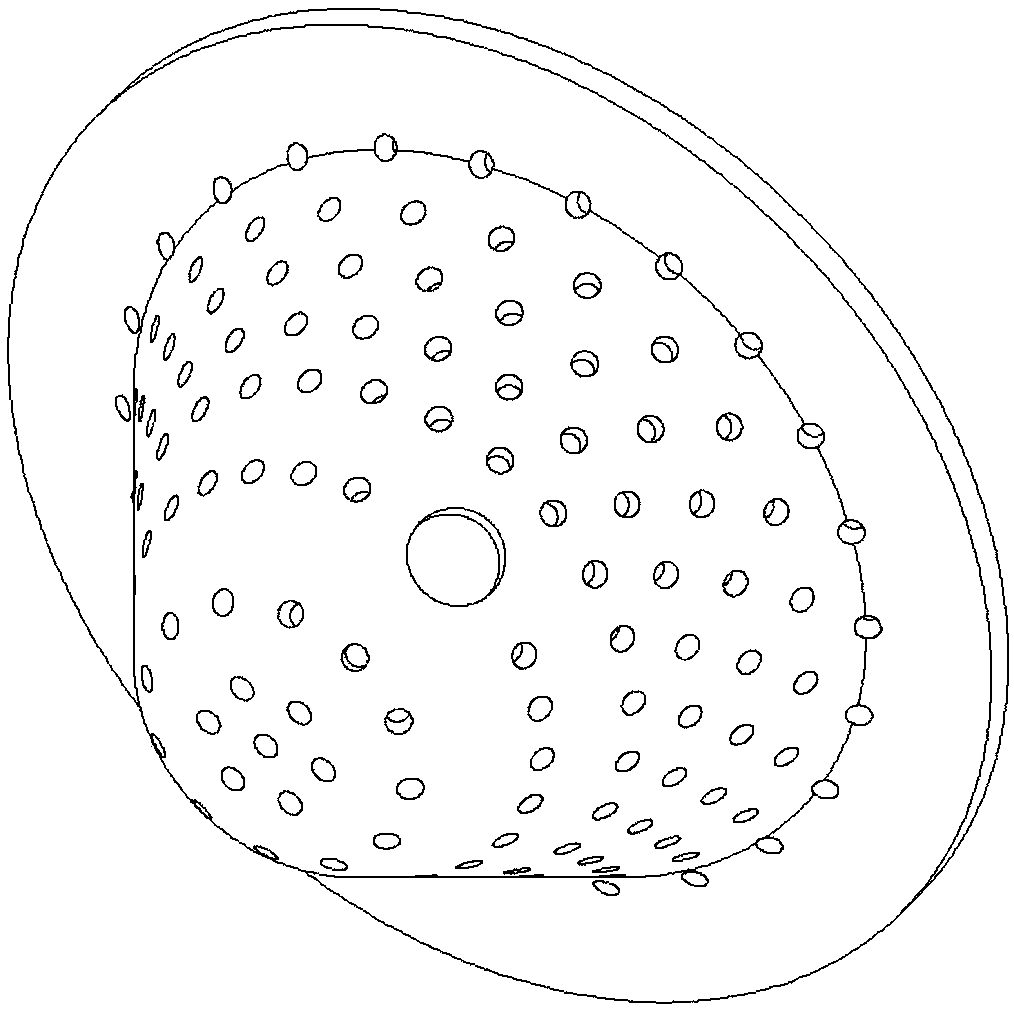

Standing vortex cavity rotational flow atomization device for head of flame tube

ActiveCN109282307ASimple structureAchieve staged combustionContinuous combustion chamberCombustion chamberInlet channel

The invention relates to the field of main combustion chamber design of an aero-engine, in particular to a standing vortex cavity rotational flow atomization device for a head of a flame tube. The standing vortex cavity rotational flow atomization device comprises an outer swirler, a nozzle shell body, a supporting rod, a standing vortex cavity, an inner swirler, a main oil pipe, an auxiliary oilpipe and a fuel pipe, wherein the nozzle shell body comprises an outer cylinder, a middle cylinder body and an inner cylinder, a main nozzle is formed in the wall surface of the outer cylinder, a cooling through hole is formed in the wall surface of the standing vortex cavity, a middle air flow channel is formed between the outer cylinder and the outer swirler, a main oil cavity is formed betweenthe outer cylinder and the middle cylinder body, an auxiliary oil cavity is formed between the middle cylinder body and the inner cylinder, and an air inlet channel is formed between the inner cylinder and the standing vortex cavity. The device has the advantages that the structure is simple, staged combustion of an main combustion chamber of the aero-engine, and the defects in the prior art are solved.

Owner:AECC SHENYANG ENGINE RES INST

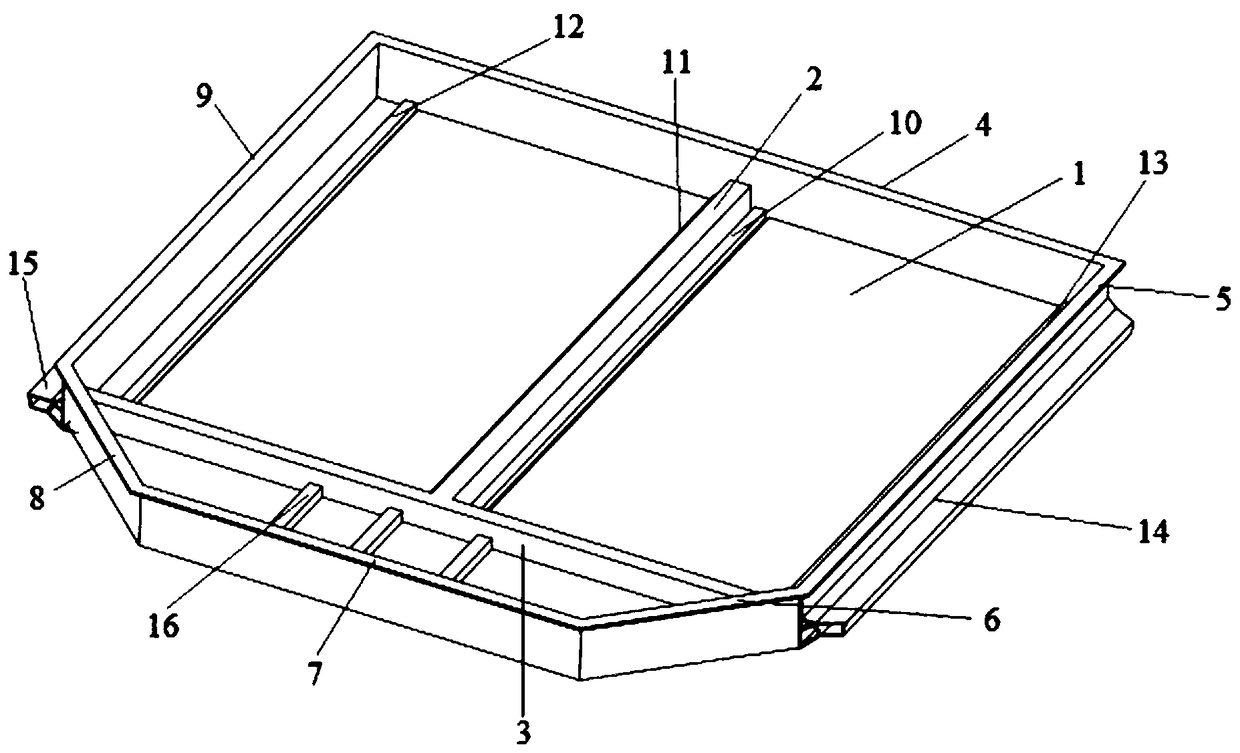

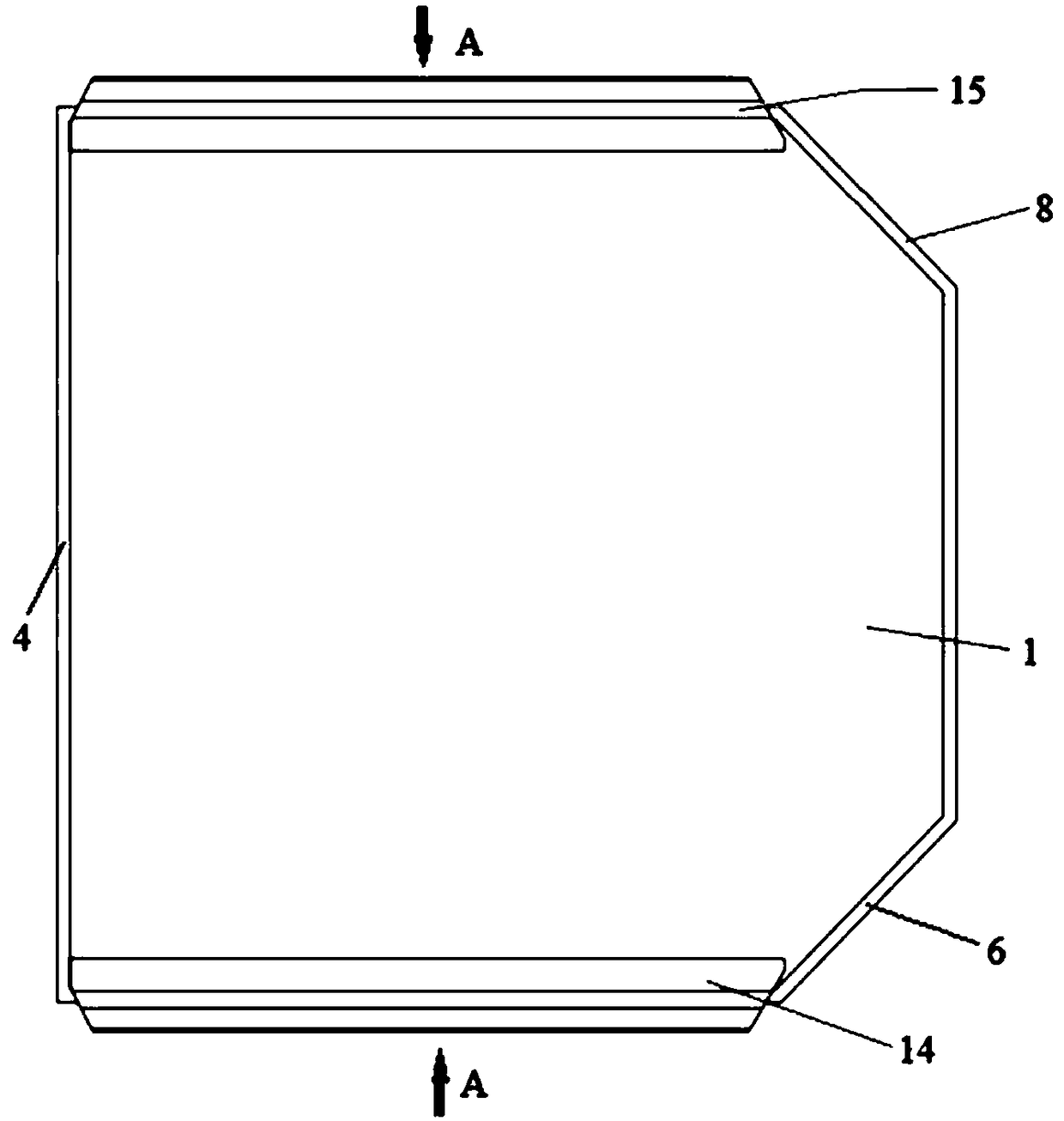

Battery box lower box body of new energy electric automobile

The invention discloses a battery box lower box body of a new energy electric automobile. The battery box lower box body comprises a lower surface plate and a lower box body frame which are connectedwith each other fixedly; the materials of the lower surface plate and the lower box body frame are non-metallic composite materials; the lower box body frame comprises a first connecting frame, a second connecting frame, and a third connecting frame, a fourth connecting frame, a fifth connecting frame, a sixth connecting frame, a seventh connecting frame and an eighth connecting frame which are orderly connected with each other; one end of the first connecting frame is fixedly connected to the middle position of the second connecting frame, and the other end of the first connecting frame is fixedly connected to the middle position of the third connecting frame; and one end of the second connecting frame is fixedly connected to the joint of the fourth connecting frame and the fifth connecting frame, and the other end of the second connecting frame is fixedly connected to the joint of the seventh connecting frame and the eighth connecting frame. According to the battery box lower box body of the new energy electric vehicle provided by the invention, the composite materials are adopted, so that the lightweight requirement is met, the power performance of the automobile is improved, the fuel consumption is reduced, and the exhaust pollution is reduced, thus the battery box lower box body is suitable for being applied to the field of new energy electric automobiles.

Owner:广东亚太轻量化技术研究有限公司

Small and medium size boiling type ready-packaged organic carrier heating furnace

ActiveCN106642092ABurn fullyImprove thermal efficiencyCombination devicesFluidized bed combustionAir preheaterProtection system

The invention discloses equipment comprising a feeding device, a hearth, a waste heat device, a tail gas treatment device and a chimney connected in sequence, wherein the lower portion in the hearth is a fuel combustion area connected with a quartz sand circulating system; a hot oil heater is arranged at the upper portion in the hearth, and connected with an oil feeding and draining device via an oil pipe; the outlet of the hot oil heater is connected with a steam generator of the waste heat device, and the outlet of the steam generator is connected with the inlet of an air preheater; the steam generator and a steam pipe forms a fluidized bed circular protection system arranged between the hot oil heater and the fuel combustion area; and the tail gas treatment device comprises a multi-pipe dust remover and circular cleaning equipment connected in sequence. The hearth, the waste heat device, the tail gas treatment device and the chimney are connected in sequence, so that ash generated during a combustion process in the hearth can be effectively deposited under the effect of the waste heat device and the tail gas treatment device, the thermal discharge temperature of the chimney can also be further reduced, and emission pollution generated by the heating furnace is reduced, and environment protection is facilitated.

Owner:JIANGSU JINCHENZHEN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com