Patents

Literature

1292 results about "Counterforce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In nuclear strategy, a counterforce target is one that has a military value, such as a launch silo for intercontinental ballistic missiles, an airbase at which nuclear-armed bombers are stationed, a homeport for ballistic missile submarines, or a command and control installation.

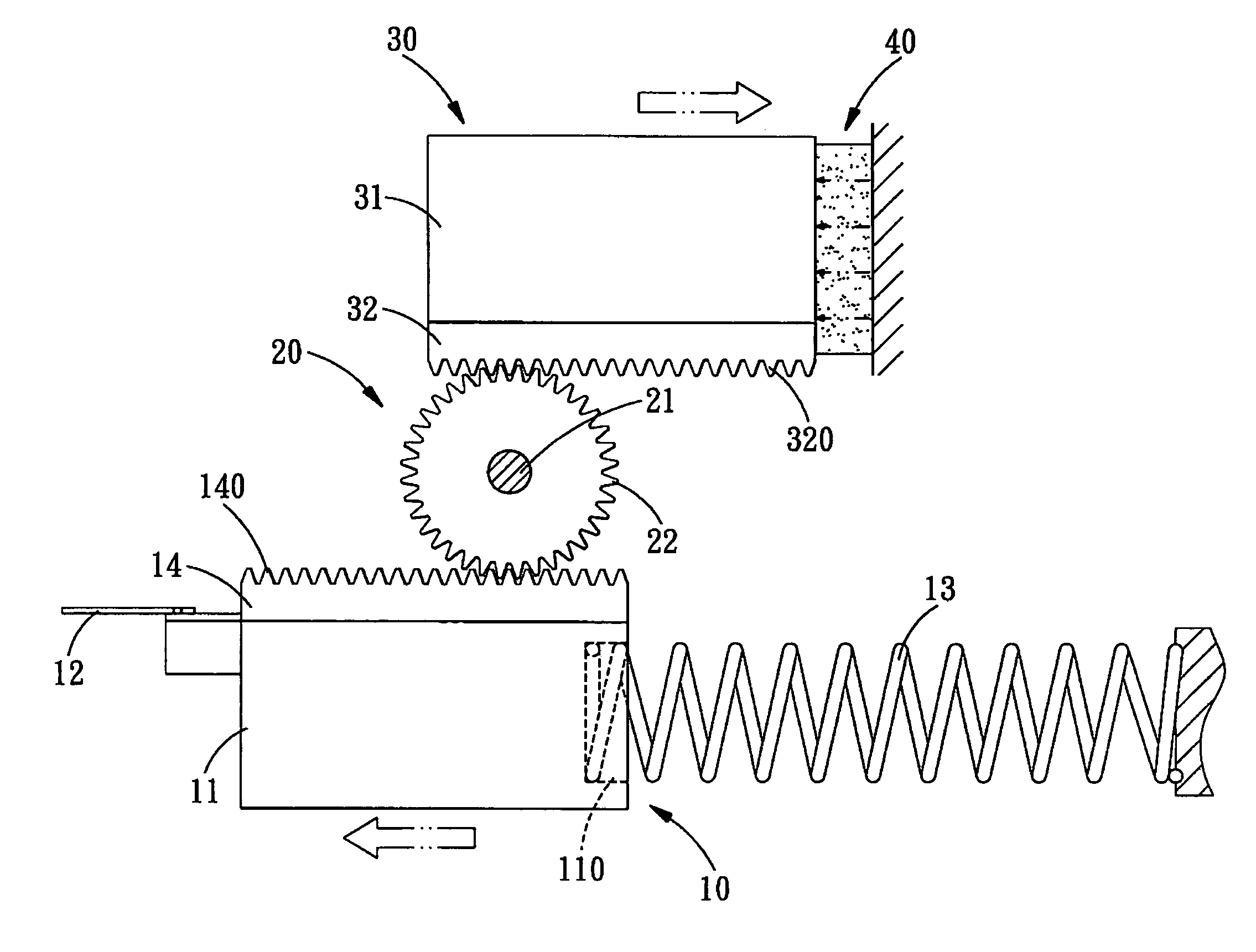

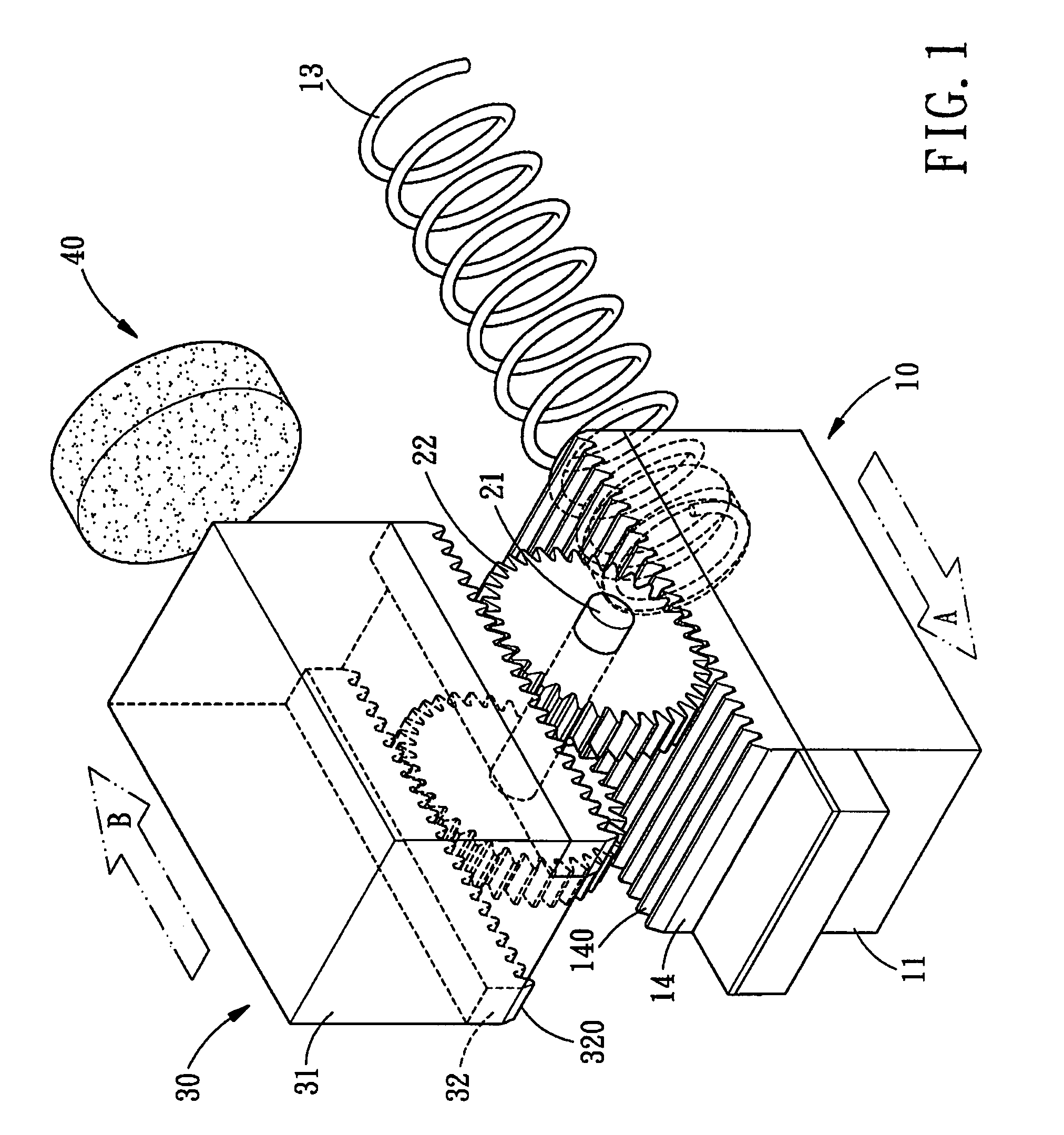

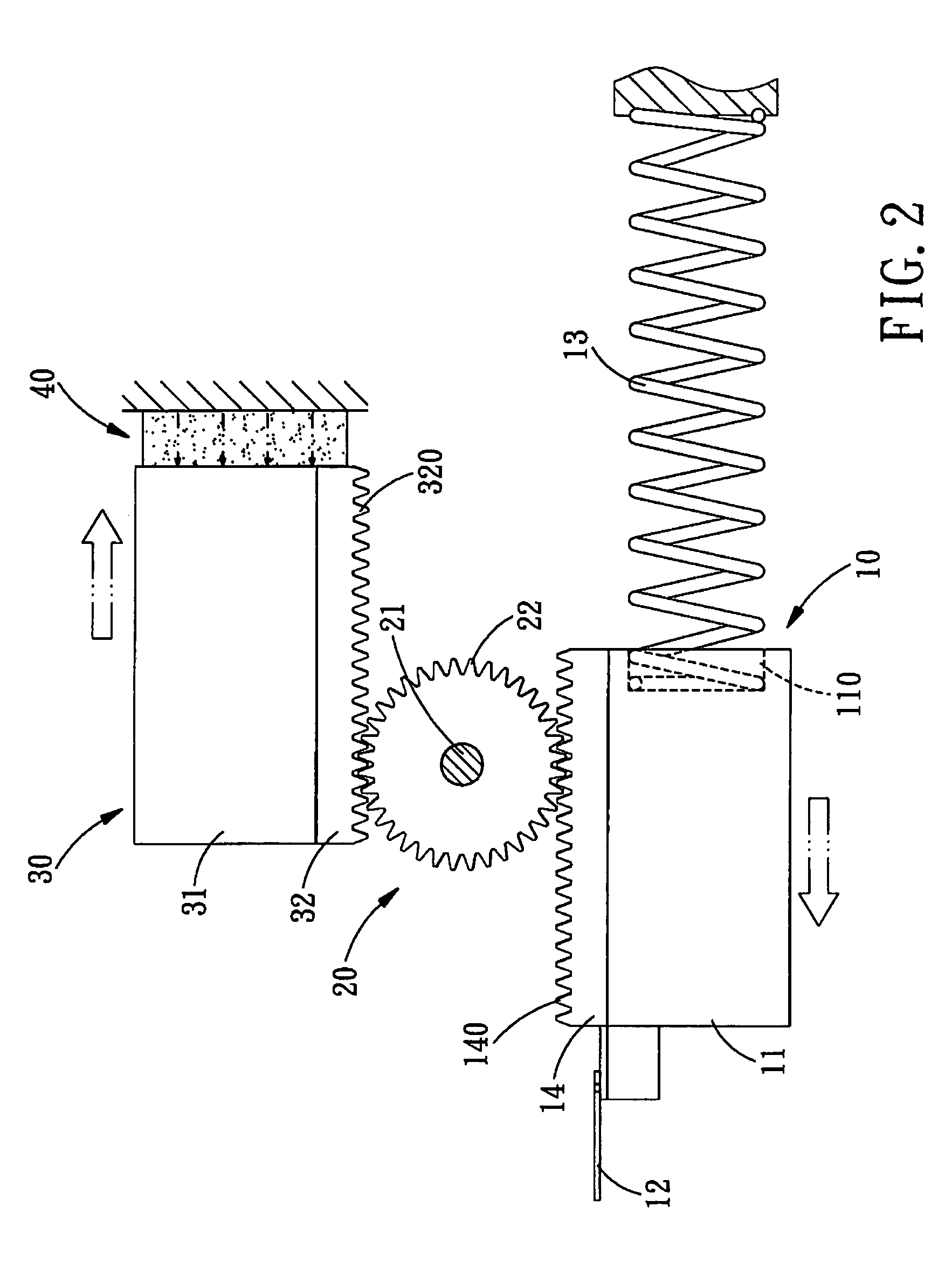

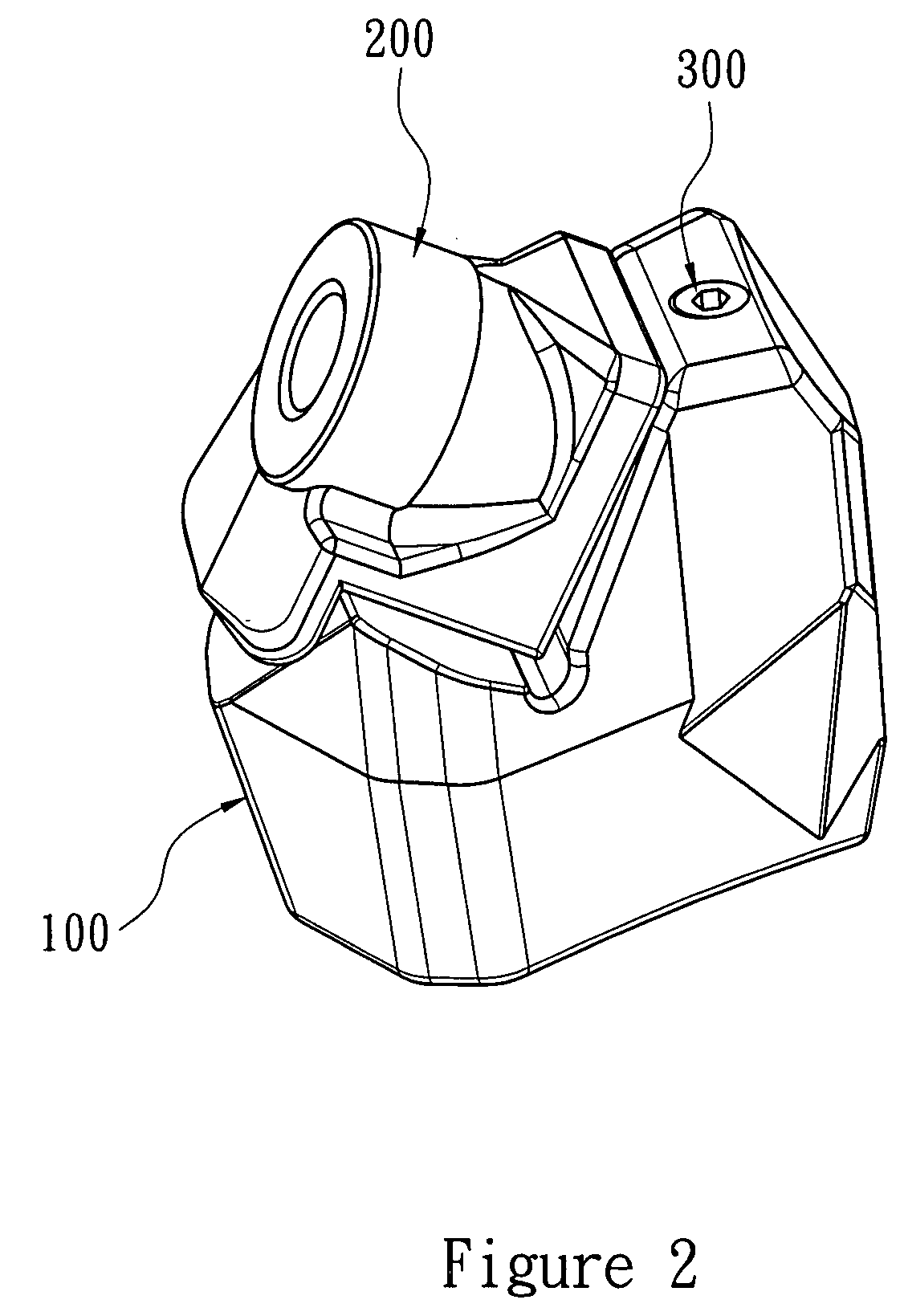

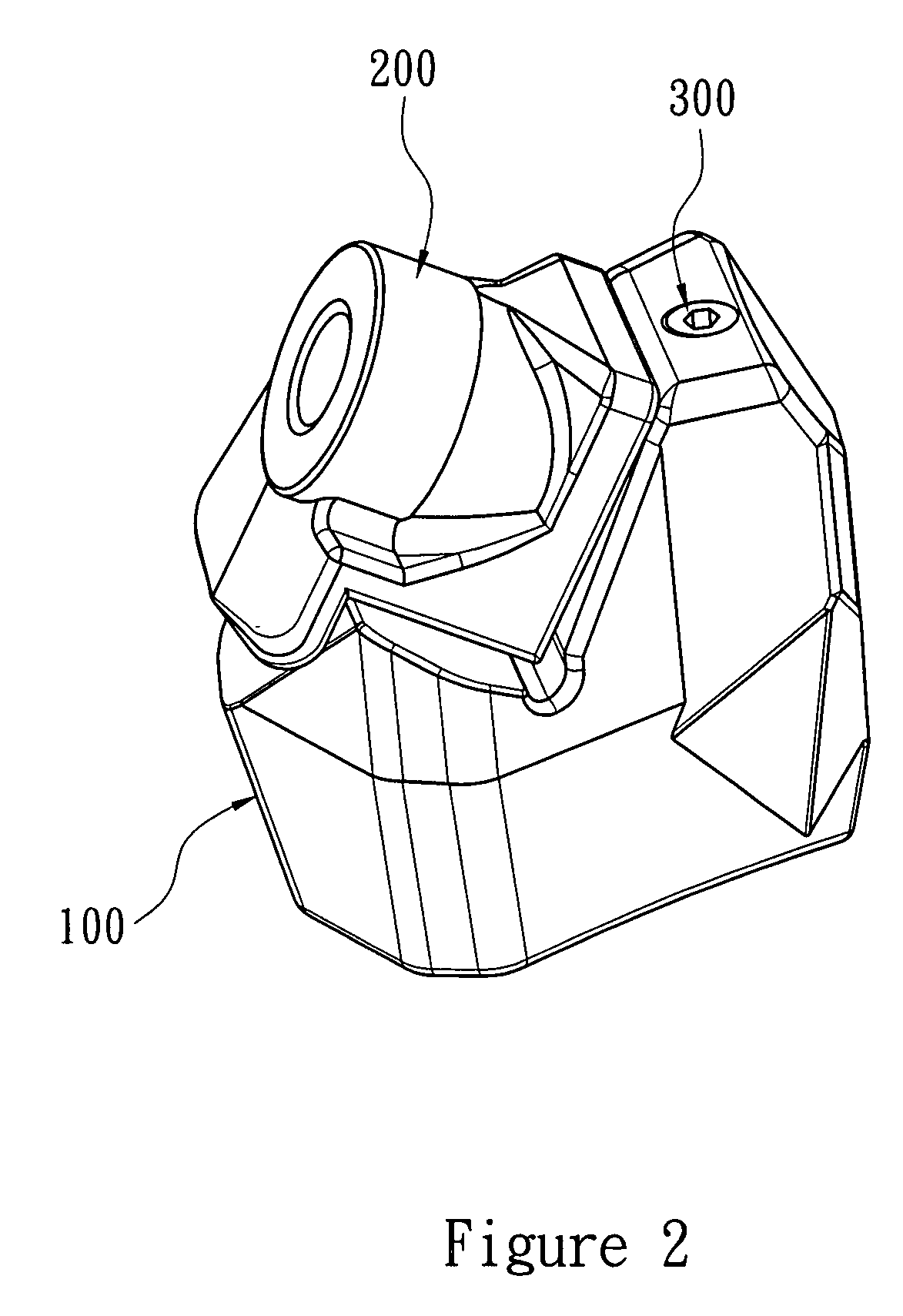

Counterforce-counteracting device for a nailer

A counterforce-counteracting device for a nailer comprises an active device, a rotating member, and a weight device. The active device drives the rotating member and the weight device to move. After the active device moves, the weight device is driven by the rotating member to produce a counterforce, so as to counteract the counterforce of the nailer. Thereby, such a device is secure and is easy to assemble.

Owner:ORGAN TECH CORP CO LTD

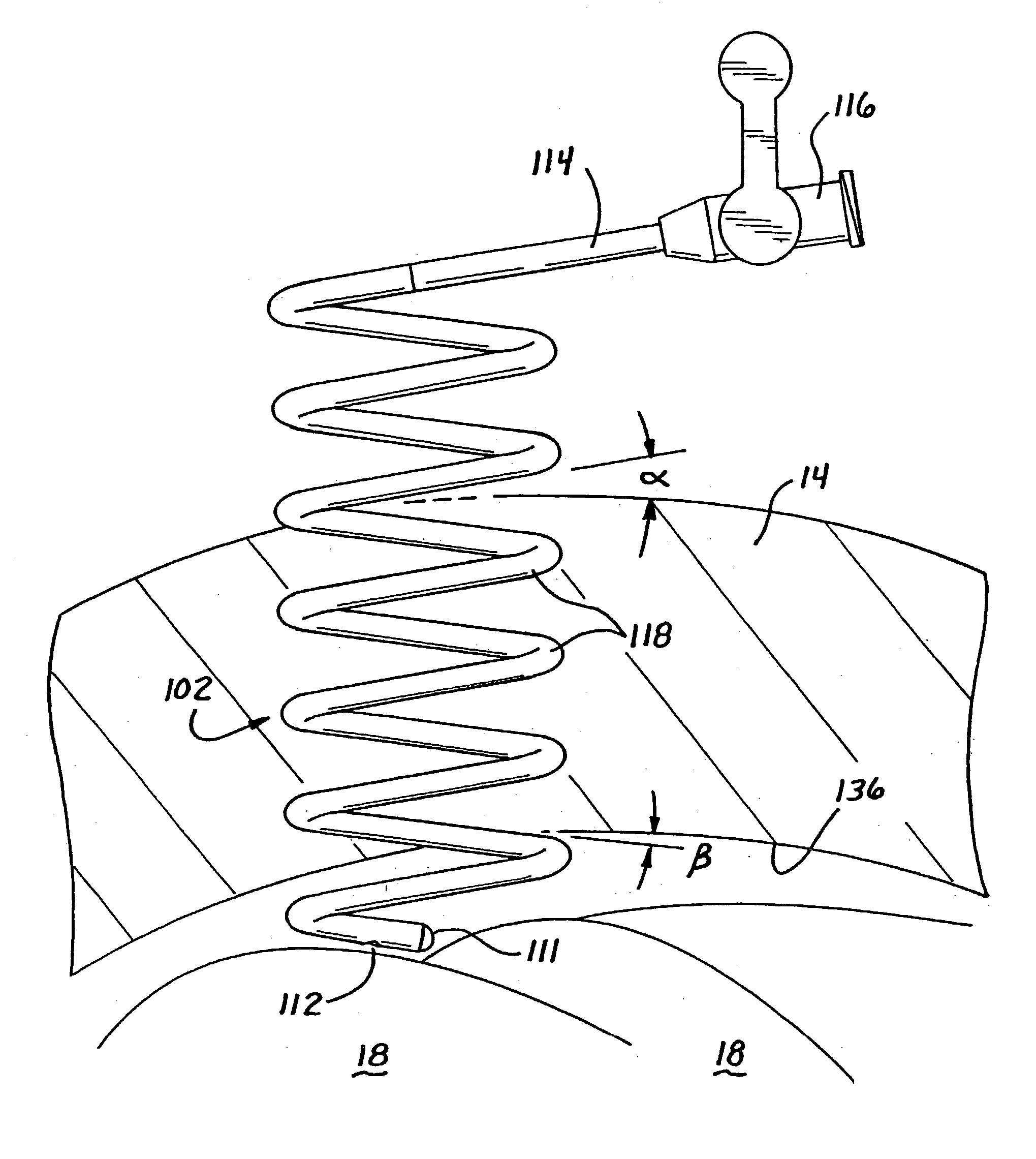

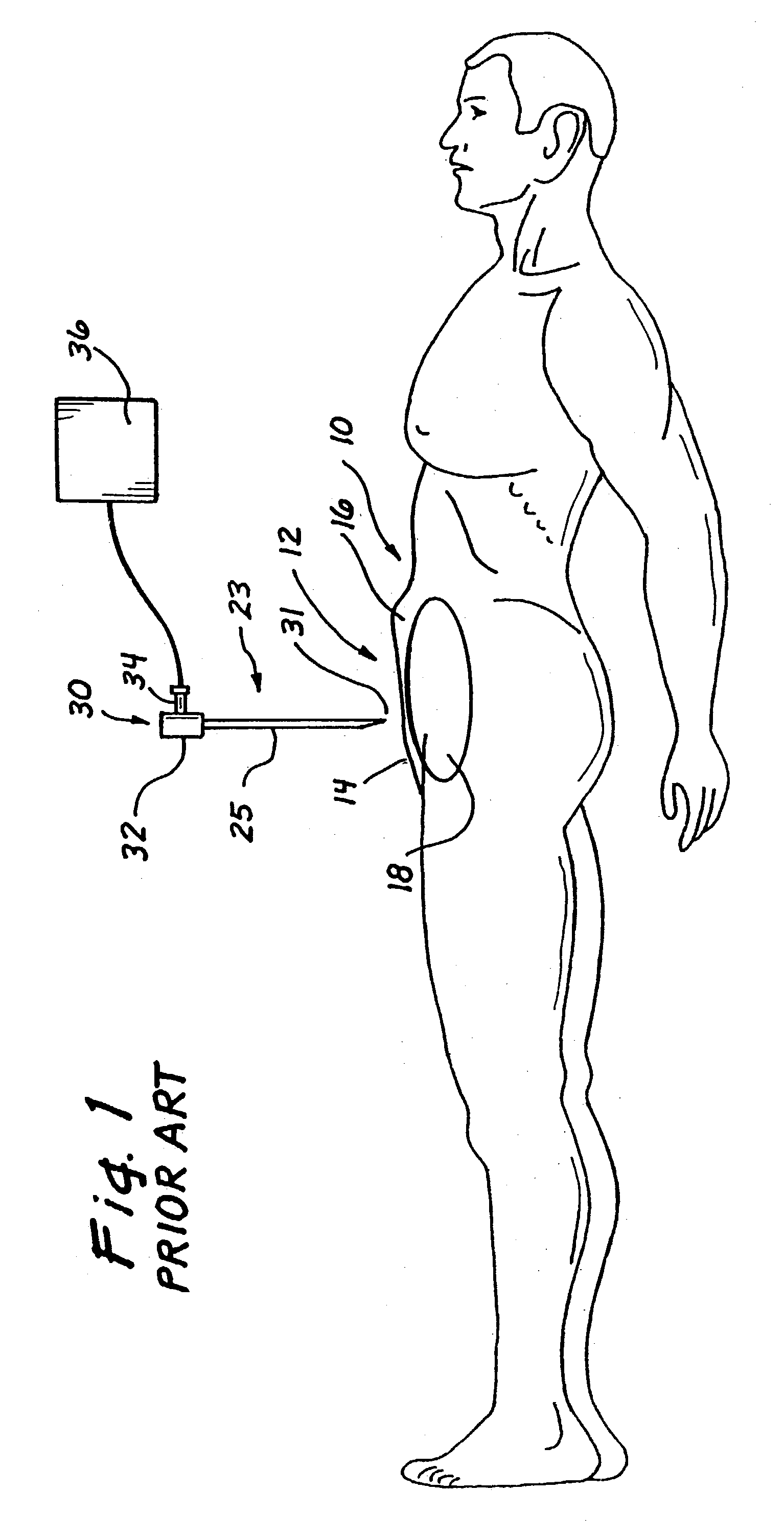

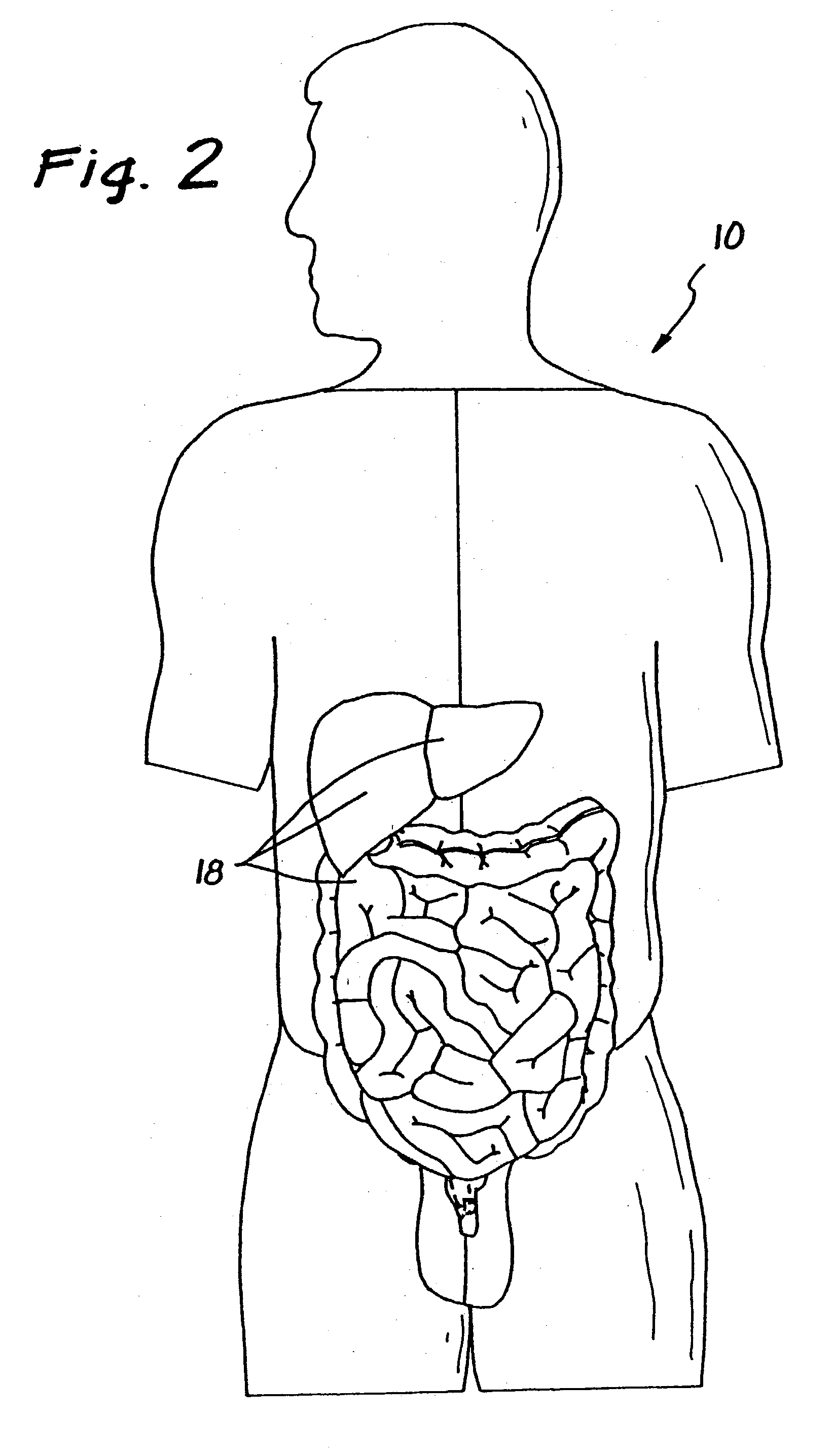

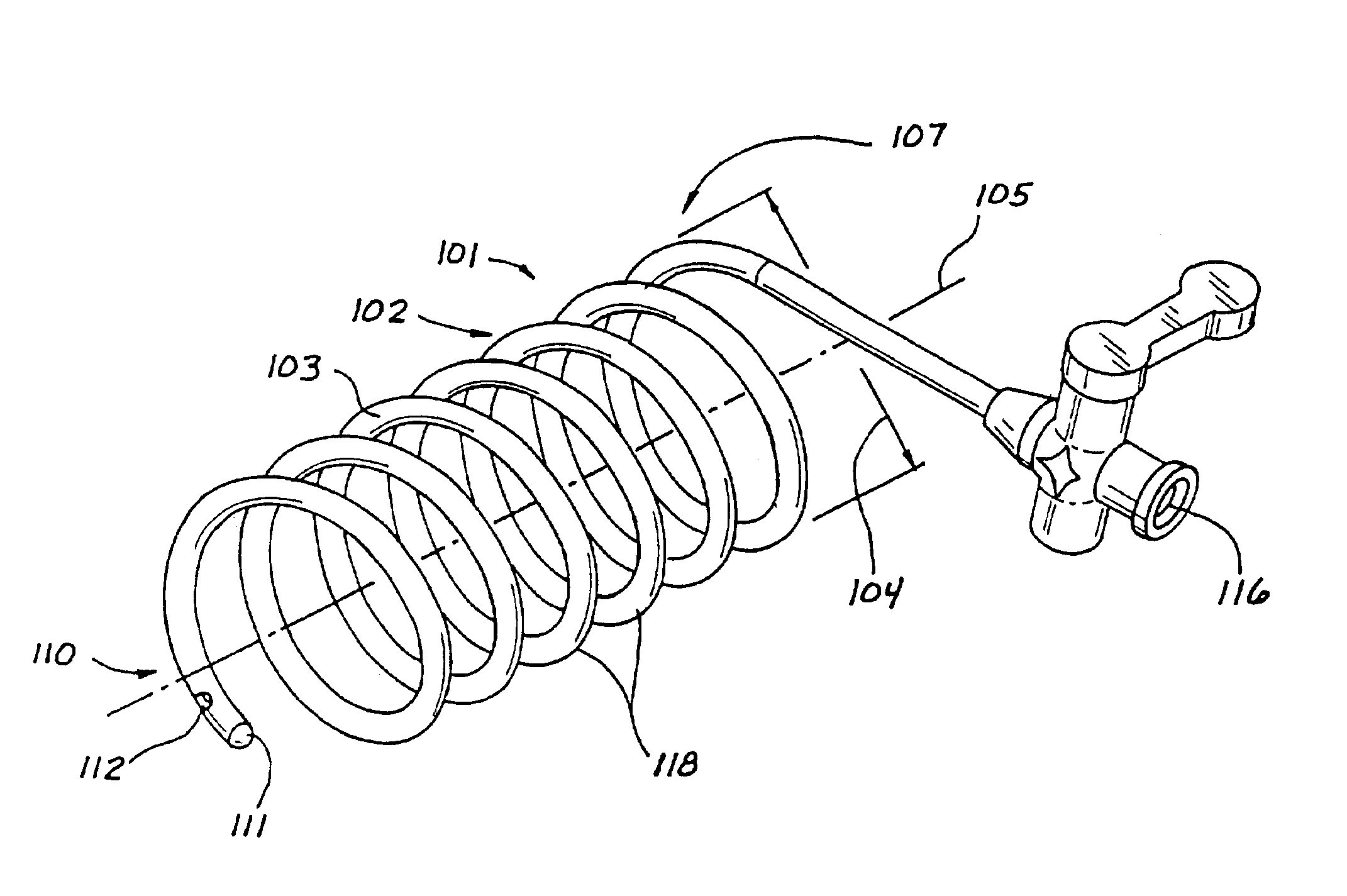

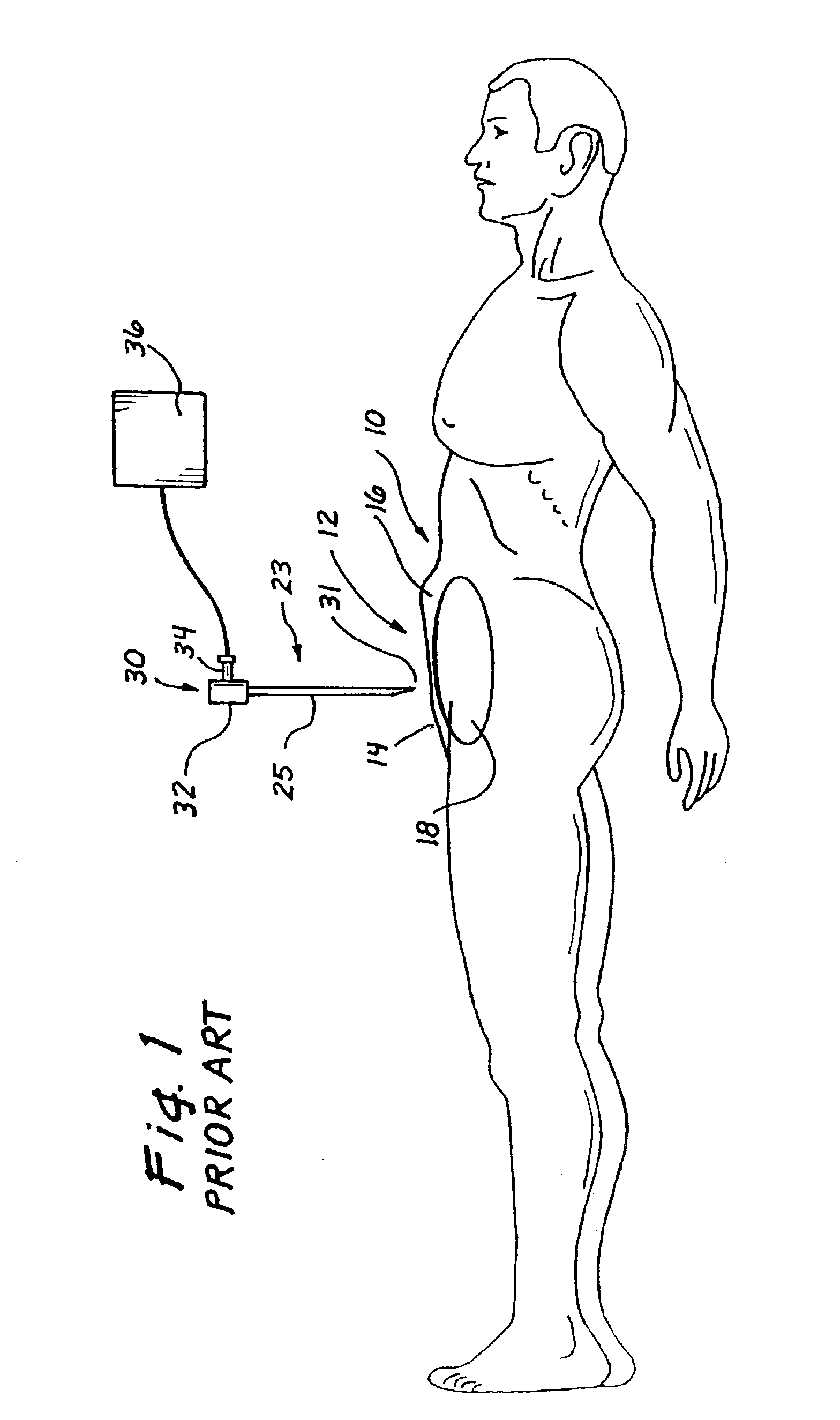

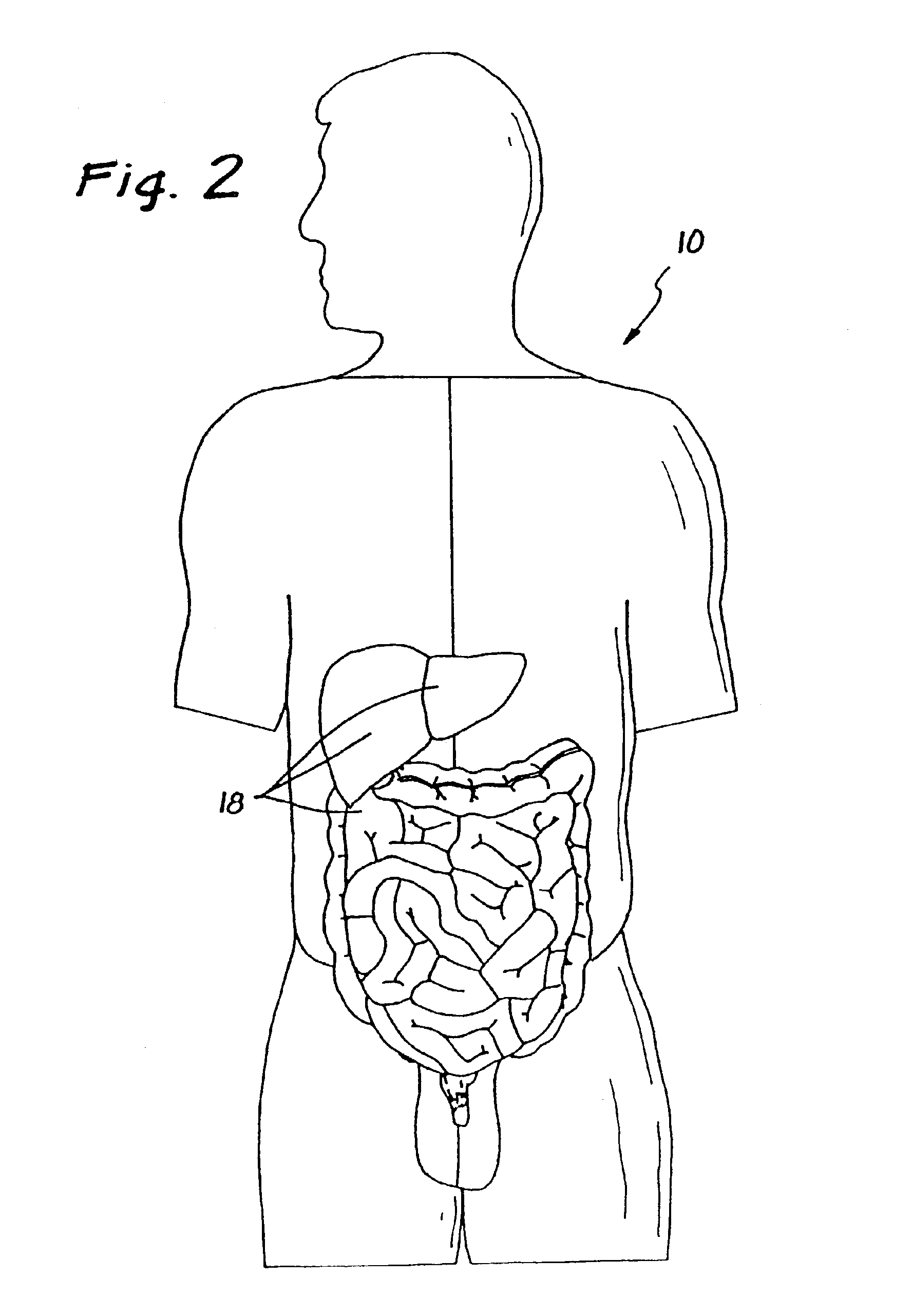

Surgical access apparatus and method

A laparoscopic insufflation device is provided in the configuration of a coil with a blunt tip. The device is capable of passing through the abdominal wall without cutting tissue, and exiting the abdominal wall substantially parallel to the inner surface. While rotation of the coiled device results in forward movement through the abdominal wall, a counter force can be applied to the device to create a safety space between the wall and the interior organs. With the blunt distal tip, parallel exit angle, and safety space, there is substantially no threat to the interior organs during placement of the device. Further space can be generated with the use of pressured gas to produce an abdominal cavity for the subsequent placement of trocars. By rotatably attaching the coiled insufflation device to a trocar, the advantage of a counter force can be used not only to establish the safety space but also to pull the trocar into the abdominal wall with a counterforce which resists tenting.

Owner:APPL MEDICAL RESOURCES CORP

Surgical access apparatus and method

InactiveUS6887194B2Improve visualizationAvoid attenuationSurgical needlesBlunt dissectorsAbdominal cavityExit angle

A laparoscopic insufflation device is provided in the configuration of a coil with a blunt tip. The device is capable of passing through the abdominal wall without cutting tissue, and exiting the abdominal wall substantially parallel to the inner surface. While rotation of the coiled device results in forward movement through the abdominal wall, a counter force can be applied to the device to create a safety space between the wall and the interior organs. With the blunt distal tip, parallel exit angle, and safety space, there is substantially no threat to the interior organs during placement of the device. Further space can be generated with the use of pressured gas to produce an abdominal cavity for the subsequent placement of trocars. By rotatably attaching the coiled insufflation device to a trocar, the advantage of a counter force can be used not only to establish the safety space but also to pull the trocar into the abdominal wall with a counterforce which resists tenting.

Owner:APPL MEDICAL RESOURCES CORP

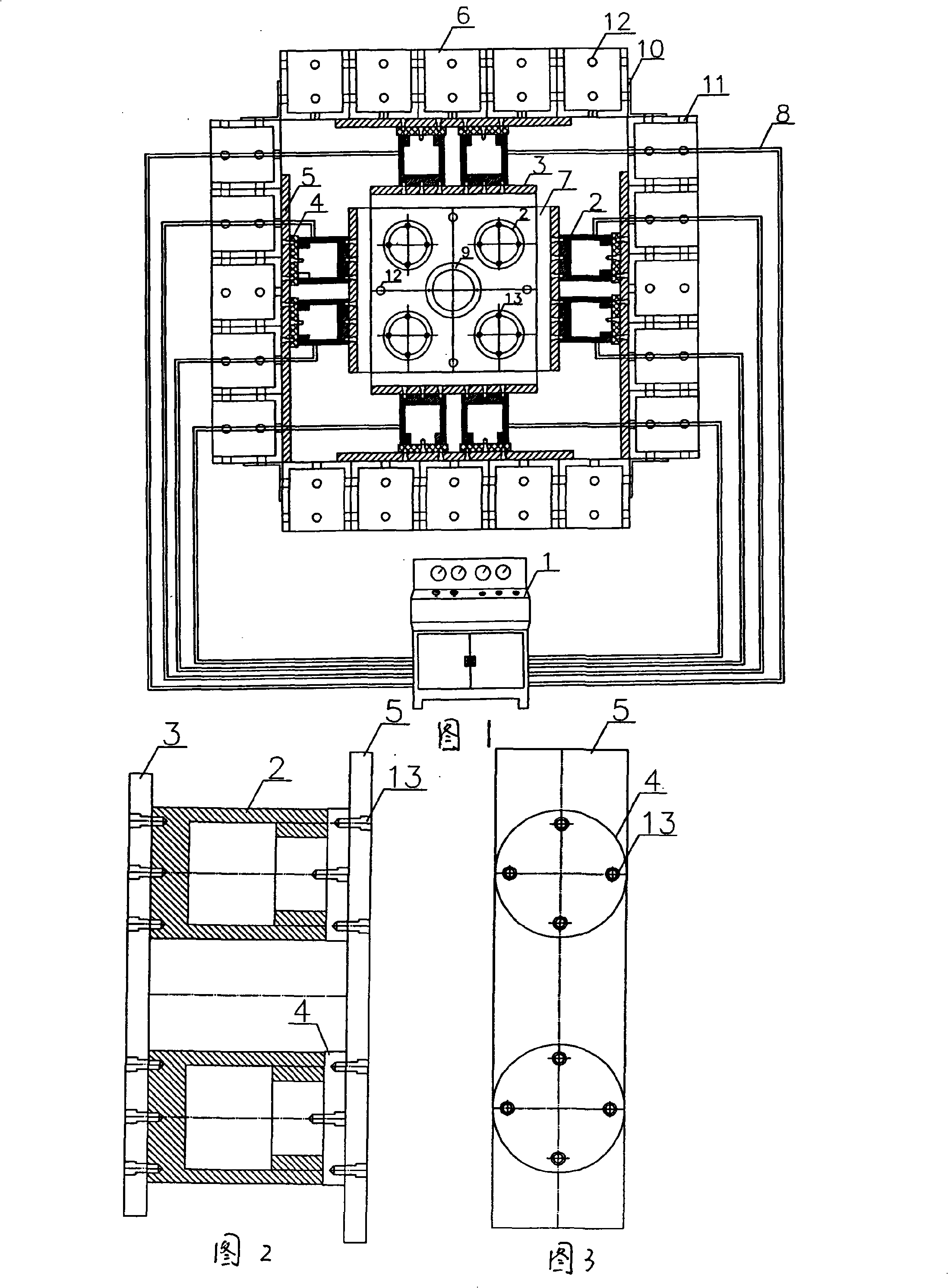

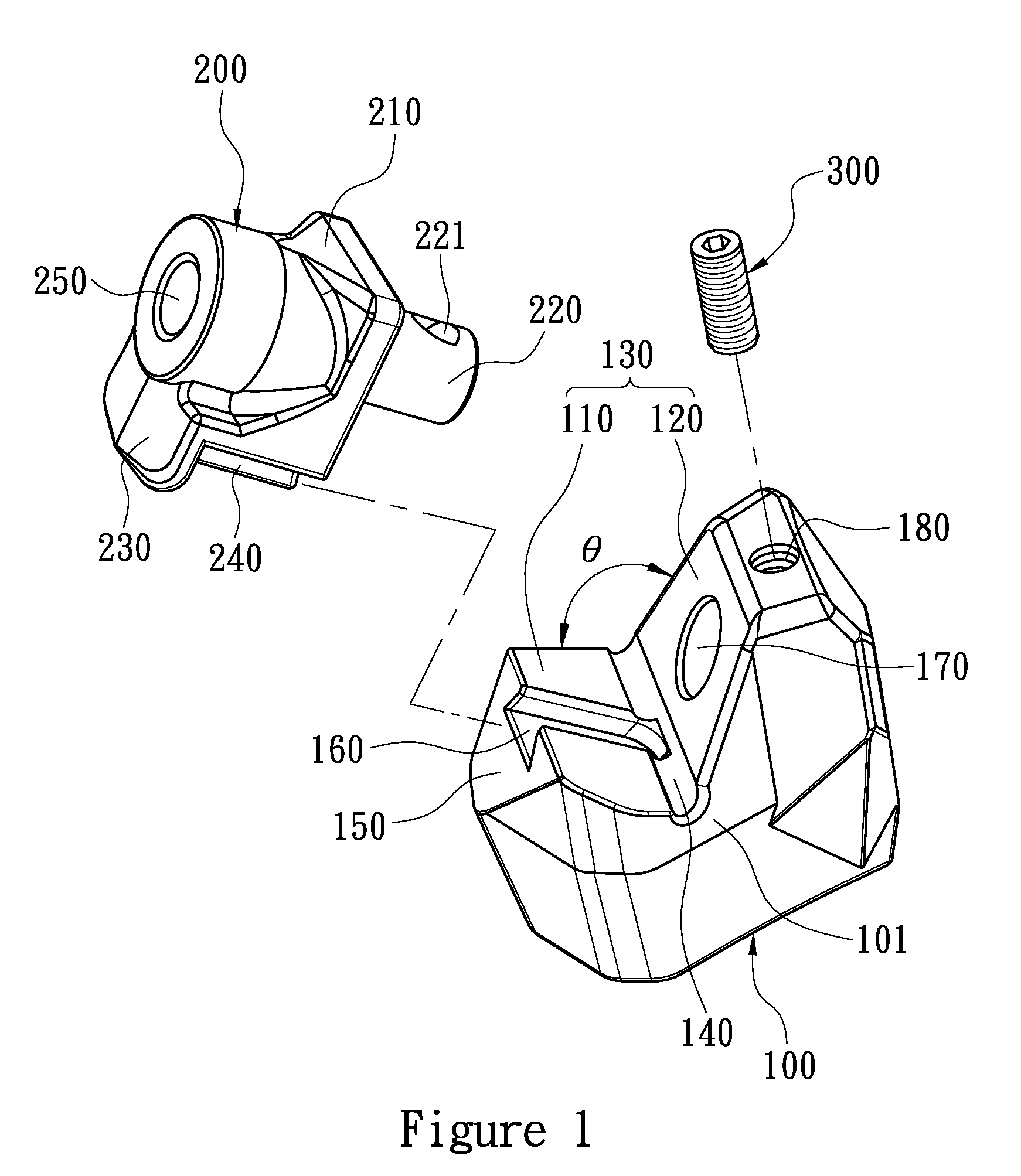

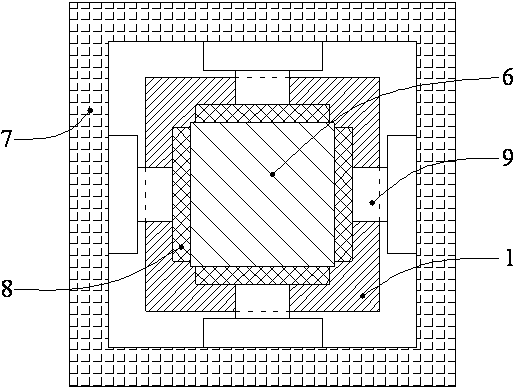

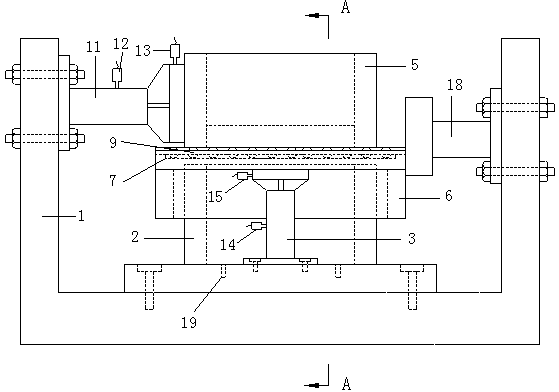

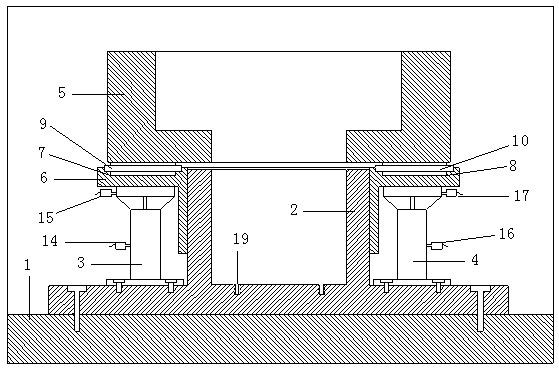

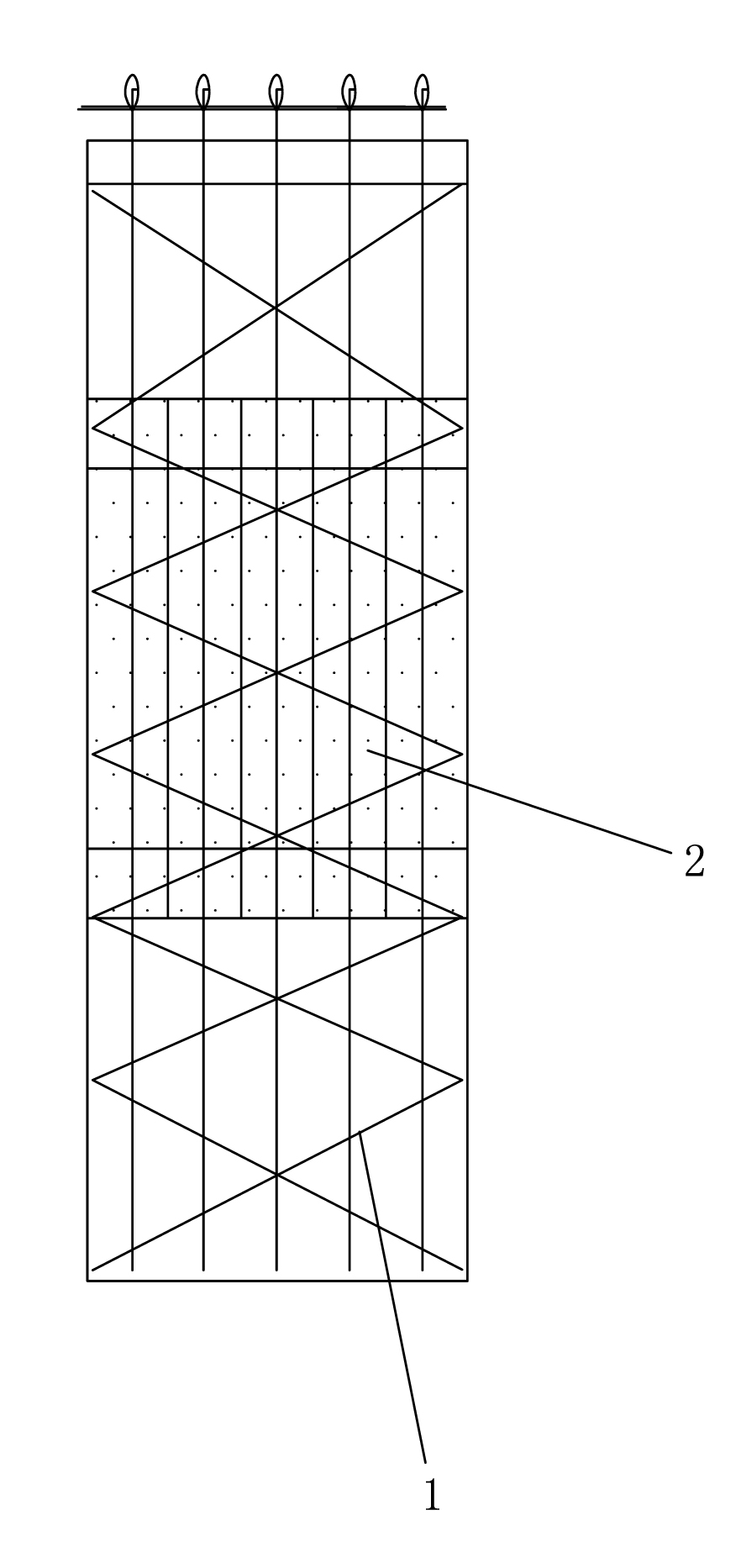

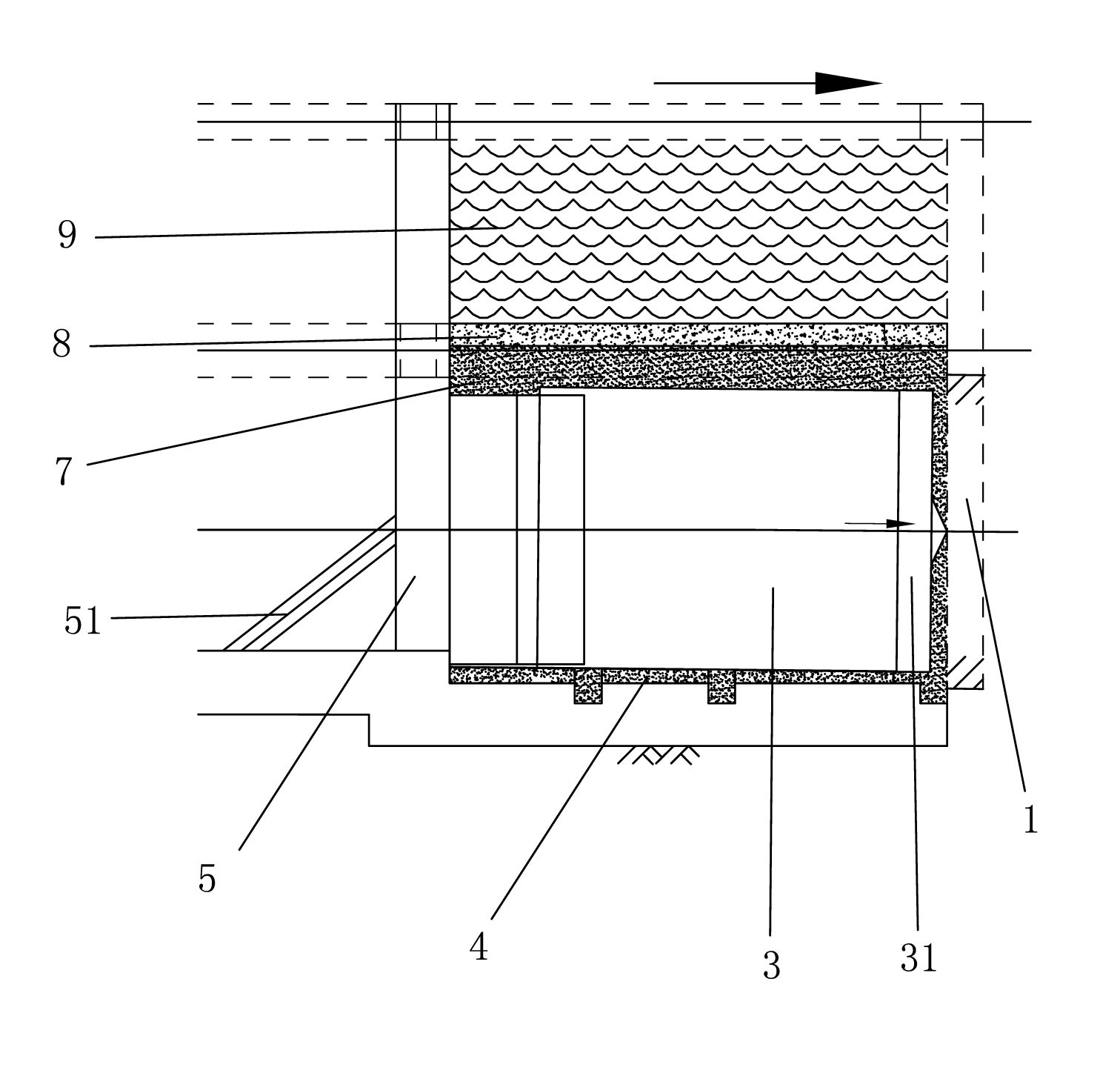

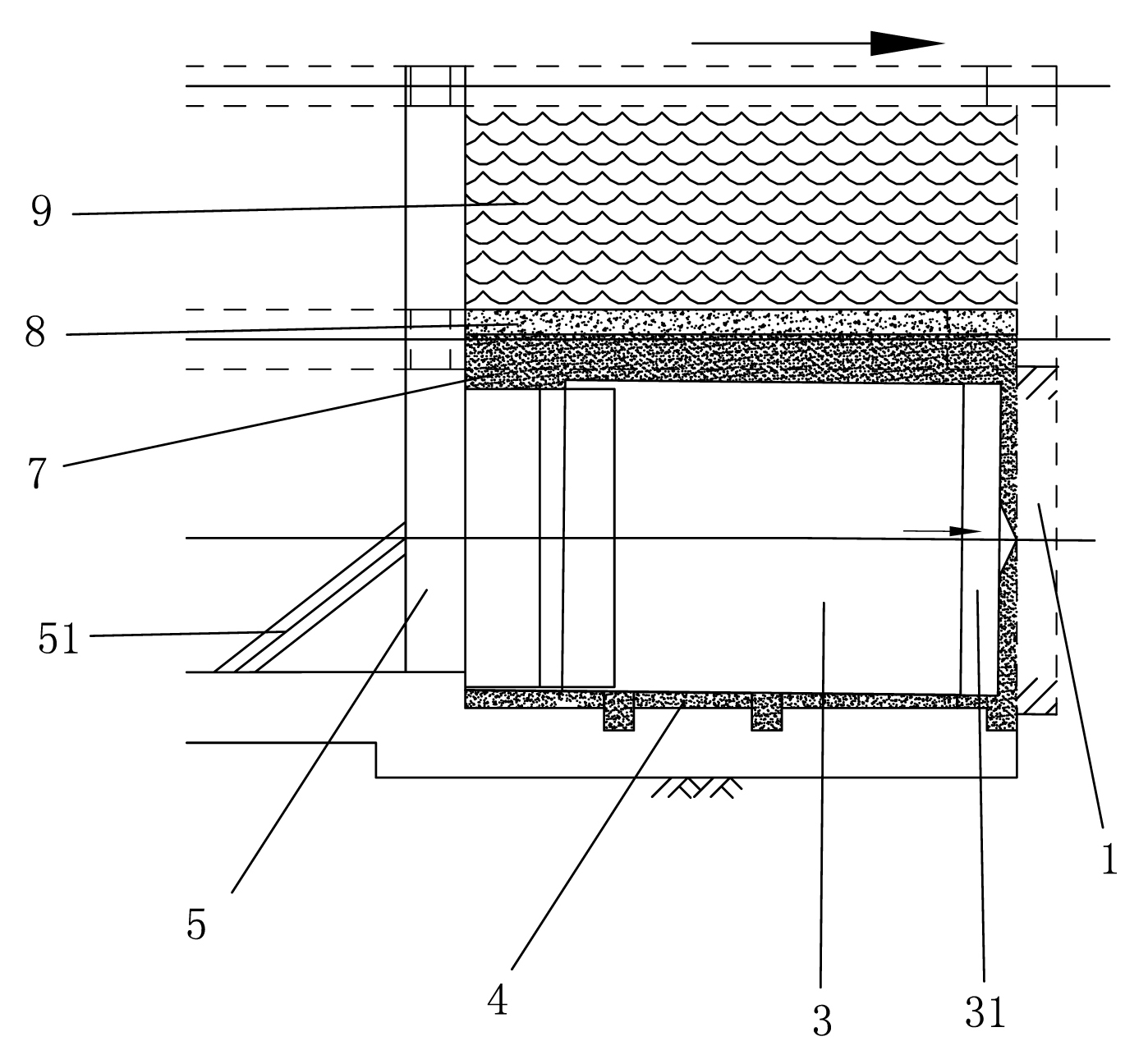

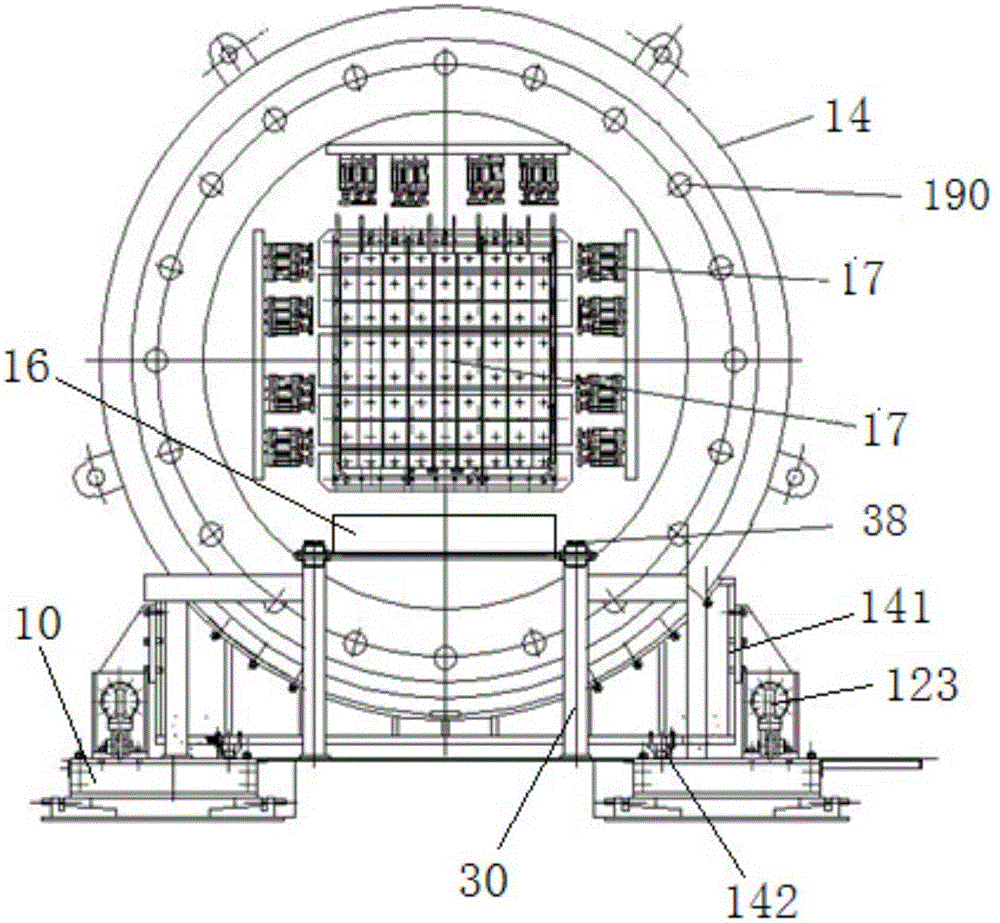

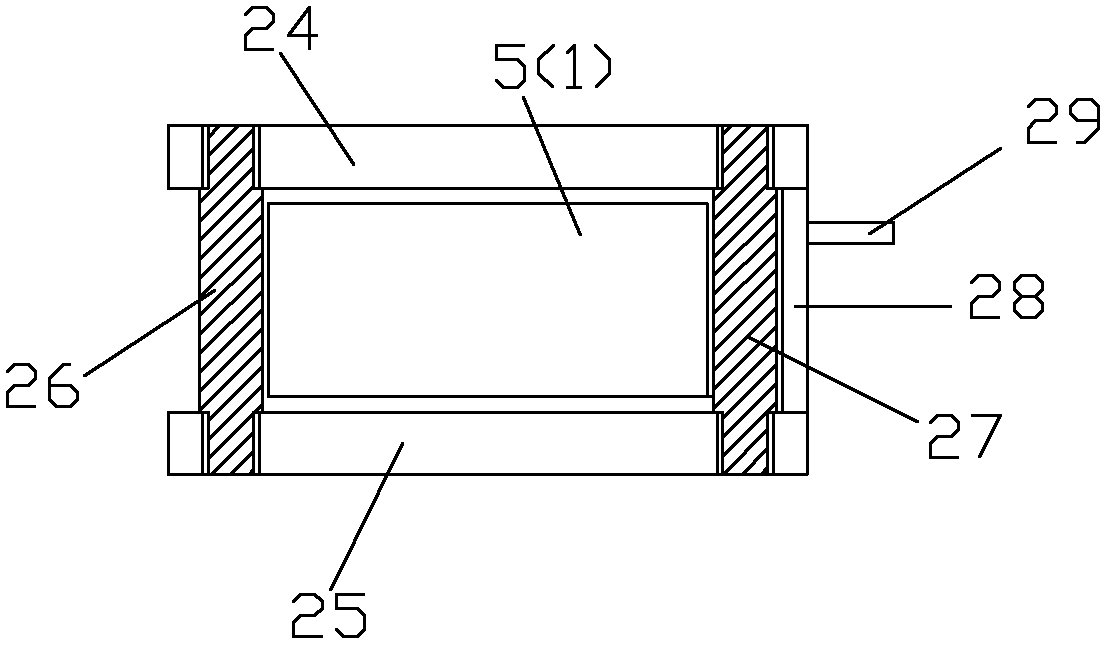

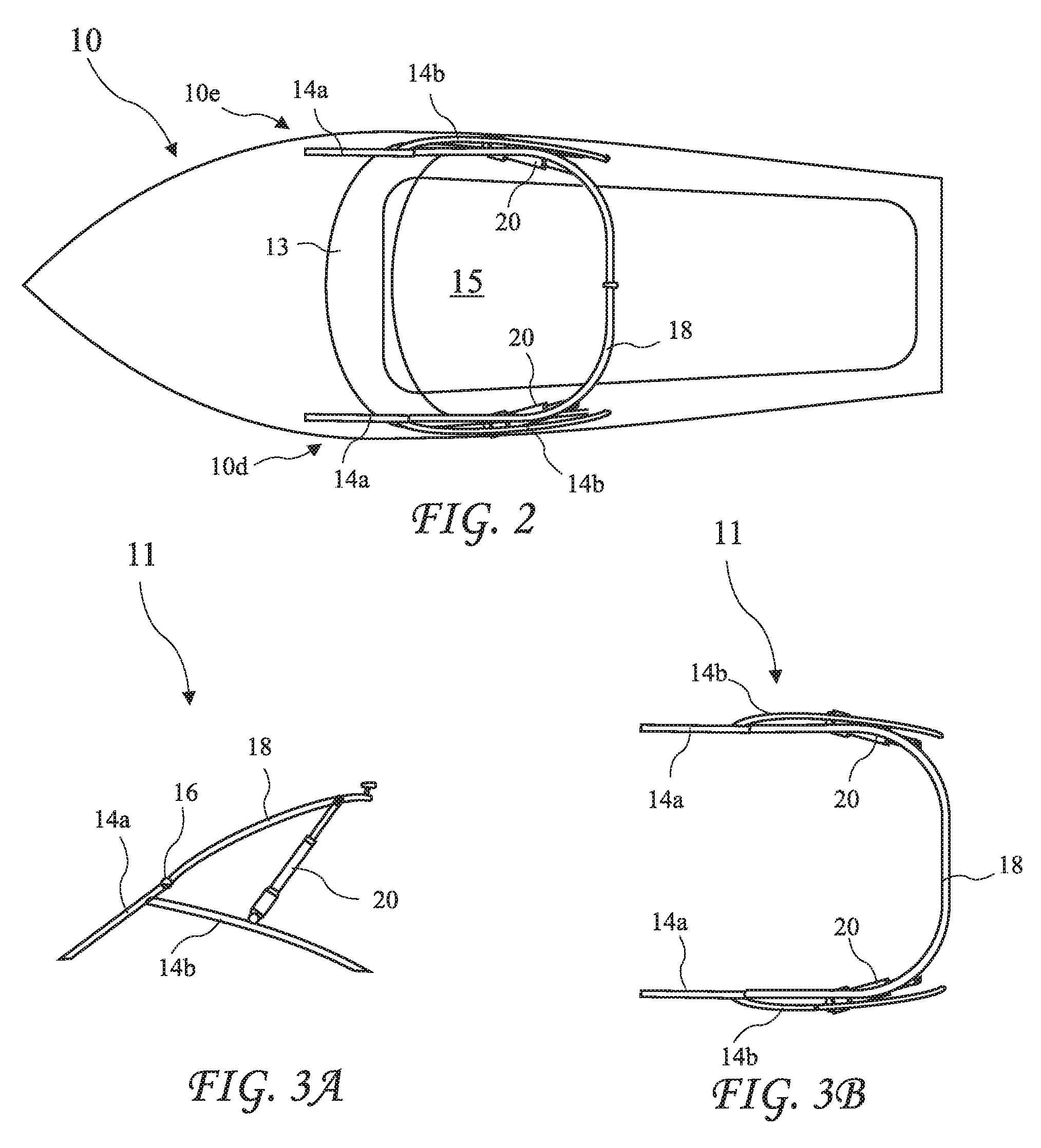

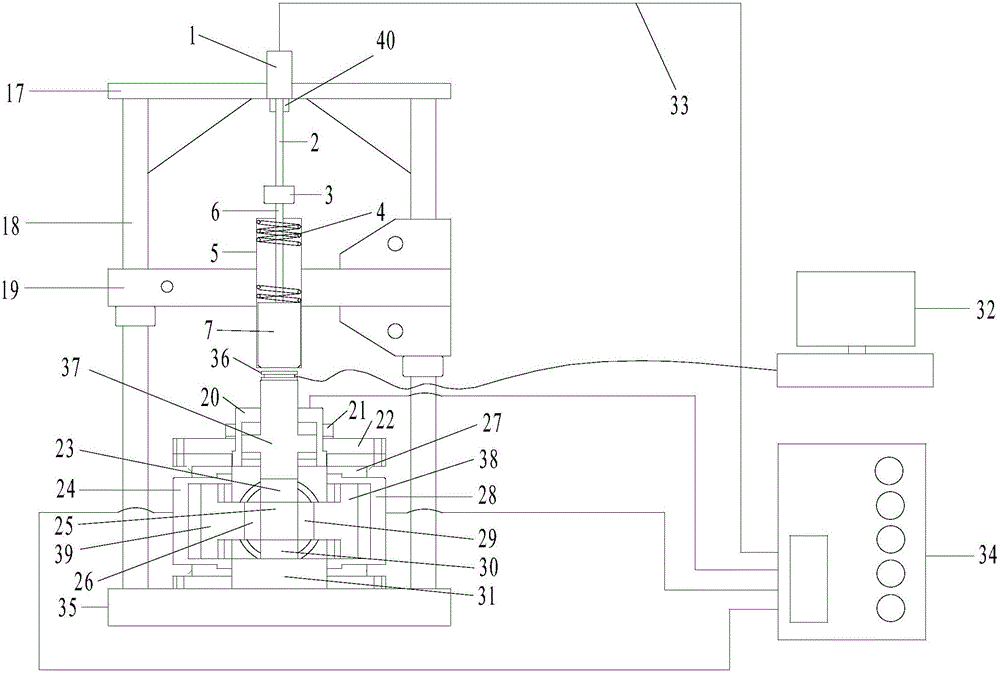

High crustal stress genuine three-dimensional load model trial system

The invention relates to a true three-dimensional loading model experiment system for highland stress, comprising an intelligent hydraulic control system, a high-pressure loading system and a counterforce device system, wherein, the high-pressure loading system is arranged in the counterforce device system; an intelligent hydraulic control test bed of the intelligent hydraulic control system is connected with the high-pressure loading system through a high-pressure oil pipe; the high-pressure loading system comprises a jack and loading plates; one end of the jack is connected with the loading plates; the other end of the jack is connected with the counterforce device system; and six loading plates connected with the jack respectively cling to front, rear, left, right, upper, lower side surfaces of a trial model. The system has the advantages of synchronous and independent highland stress loading, high loading automation degree and loading accuracy, more loading functions, the realization of the axial loading opening of a cavity, high rigidity of the loading system, good integral stability, simple and convenient operation and so on. The system can be widely used in deep underground cavity model experiment and research in engineering fields such as hydroelectric power, transportation, energy, mine, national defense and so on.

Owner:SHANDONG UNIV

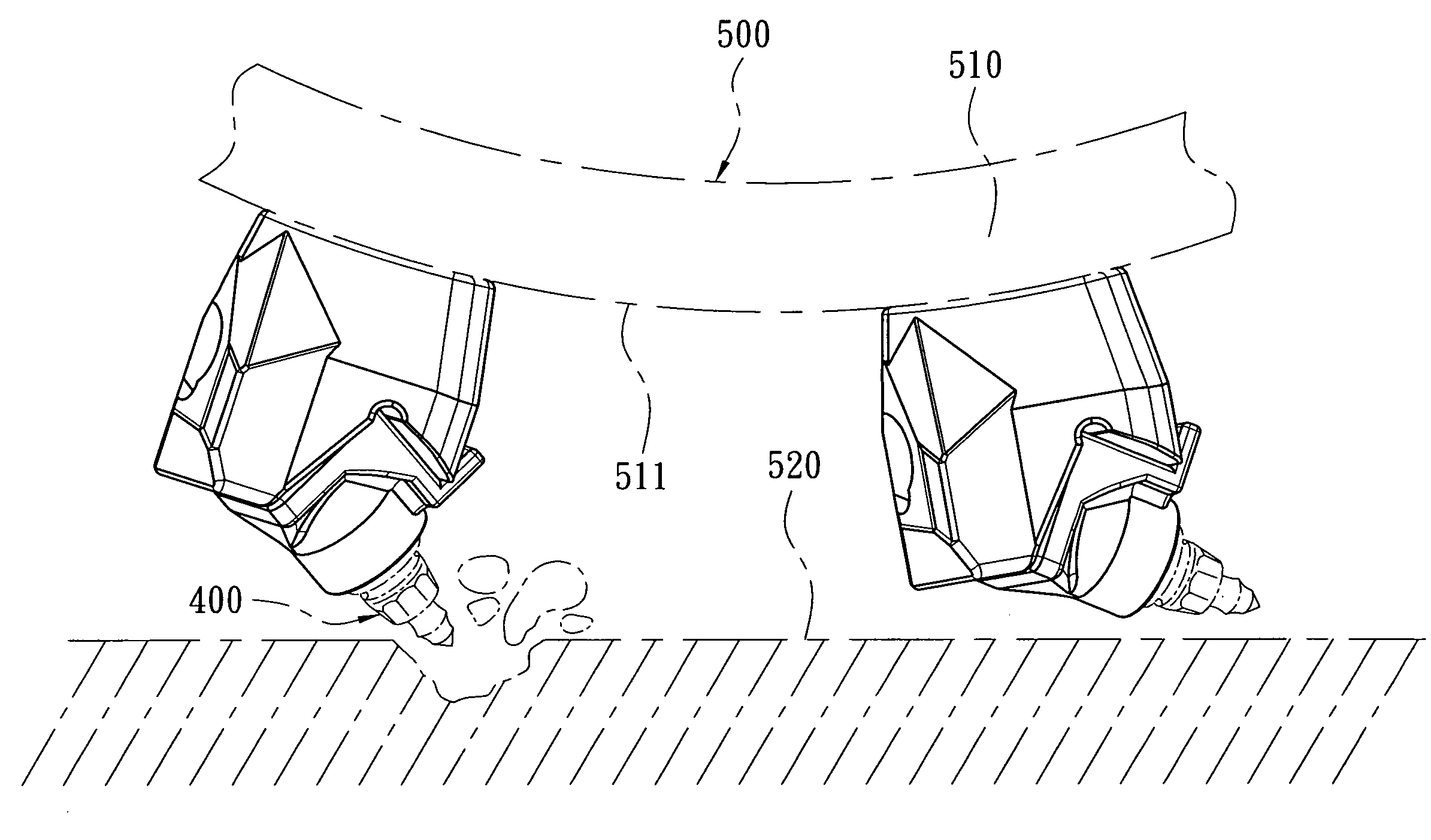

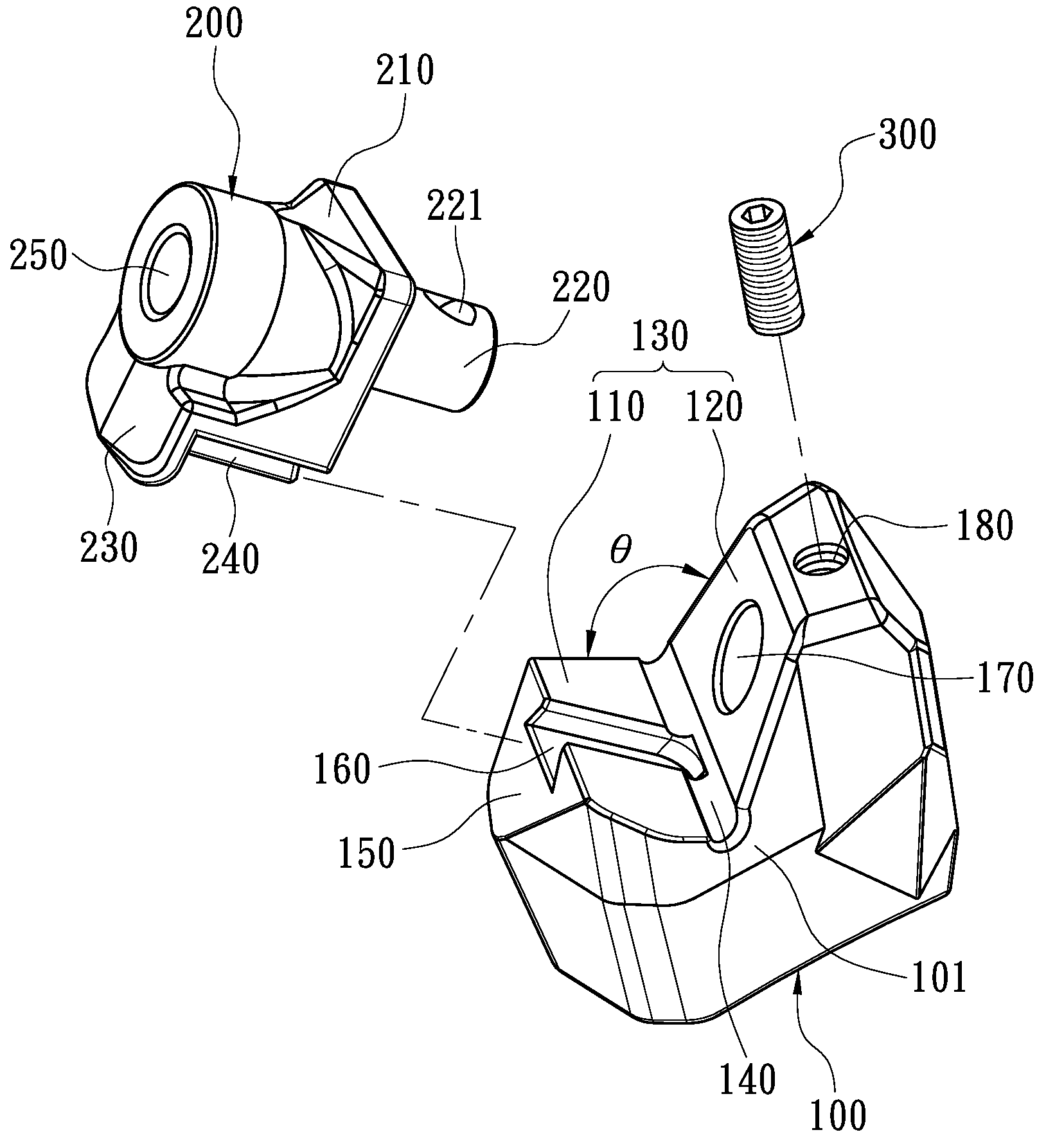

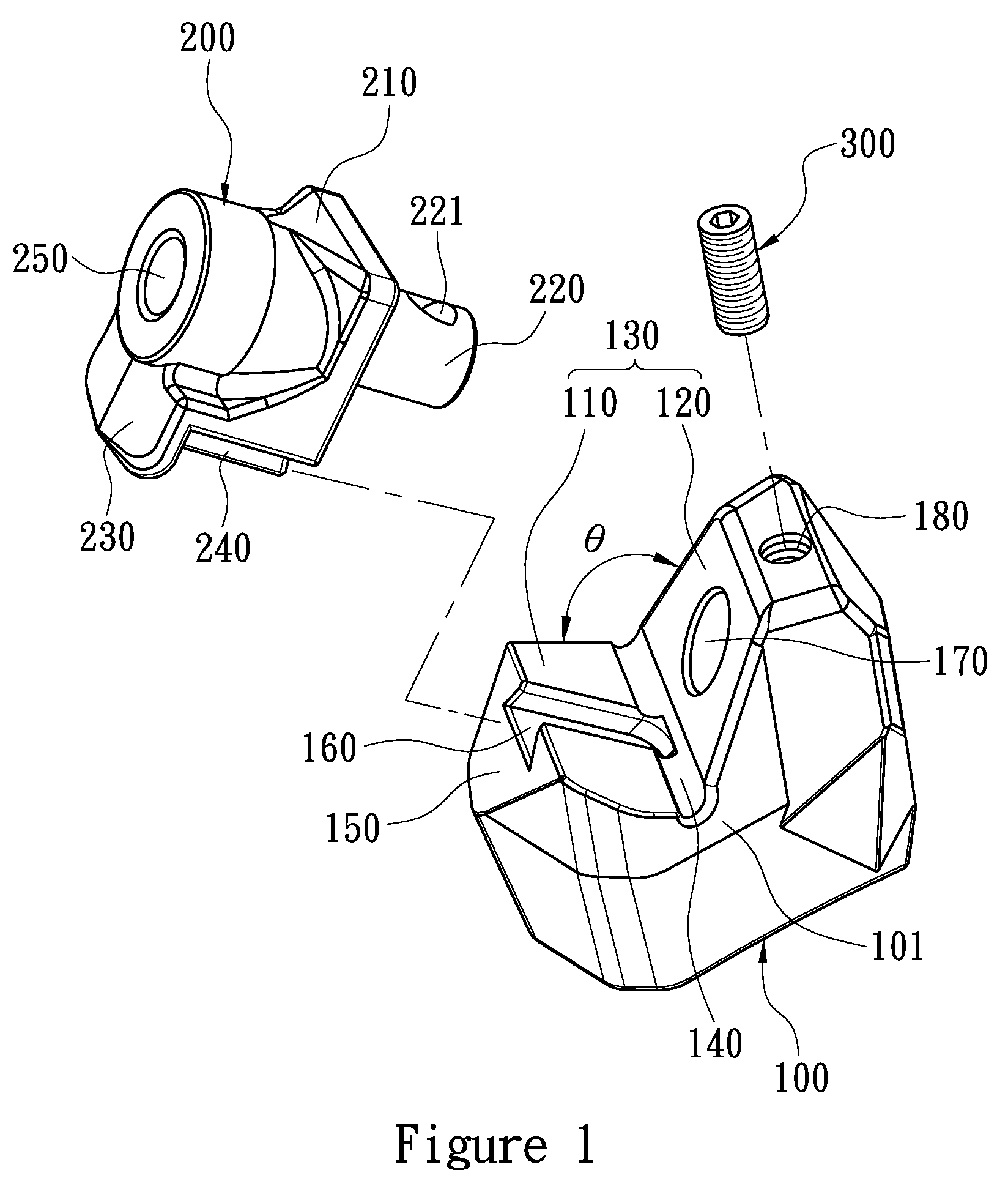

Tool holding device

ActiveUS20090085396A1High mechanical strengthConnection strengthSlitting machinesStone-like material working toolsEngineeringUltimate tensile strength

A tool holding device is disclosed, and the tool holding device includes a base, a block, and a fastening member for securing the block. The base includes a receiving portion defined between a countering wall and a shoulder wall, a surface defined adjacent to the shoulder wall perpendicularly and away from the countering wall, a penetrated hole defined on the countering wall, and a positioning hole communicating with the penetrated hole. The block includes a holding portion held in the receiving portion, a handle received in the penetrated hole, and a holding hole for holding a chisel. The countering wall and the shoulder wall define an angle less than or equal to 90 degrees. Therefore, the counterforce bearing of the base and block are both enhanced to raise the strength of the tool holding device.

Owner:EVERPADS

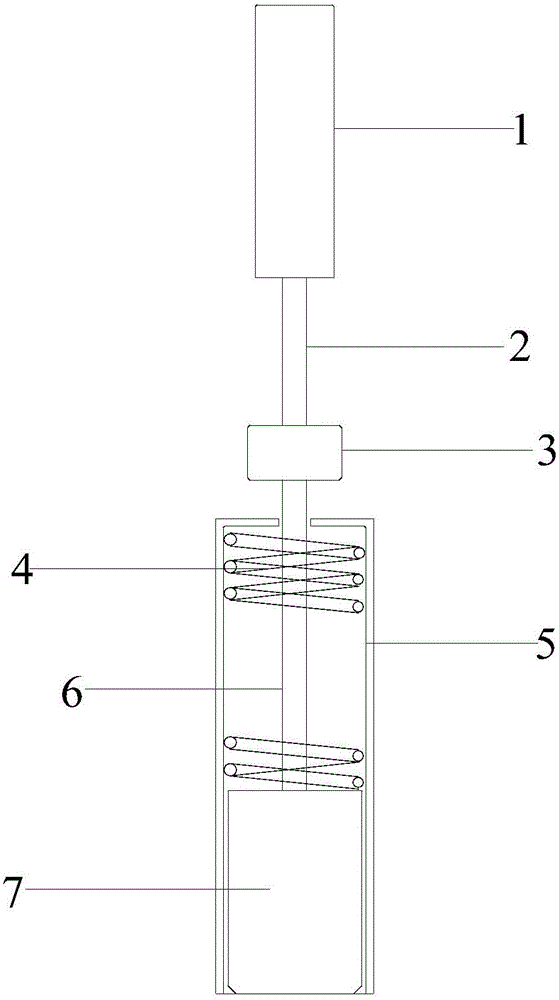

Triaxial impact ground pressure true simulation test system

InactiveCN103471914AReduce intensityMaterial strength using tensile/compressive forcesMaterial strength using single impulsive forceEngineeringHigh stress

The invention discloses a triaxial impact ground pressure true simulation test system. The triaxial impact ground pressure true simulation test system is characterized by comprising a flexible loading unit, a confining pressure loading unit and an impact loading unit, wherein the flexible loading unit is used for applying vertical pressure on a test piece through a loading oil cylinder and a counterforce steel strand, the confining pressure loading unit is used for enabling the test piece to be under the condition of triaxial stress, the impact loading system is used for applying impact load on the test piece, the test piece is destroyed under the conditions of high stress and impact disturbance, the strength of the test piece is reduced, the test piece generates a certain displacement, in the process, the counterforce steel strand in the flexible loading unit is used for quickly supplementing load to the test piece, and further the extrusion and the action of external surrounding rocks to coal and rock masses are simulated. The triaxial impact ground pressure true simulation test system can be used for well simulating the occurring conditions of impact ground pressure, and the triaxial loading conditions are especially applicable to the simulation of gravity type impact ground pressure in a mining roadway.

Owner:SHANDONG UNIV OF SCI & TECH

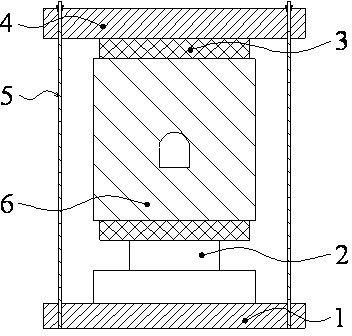

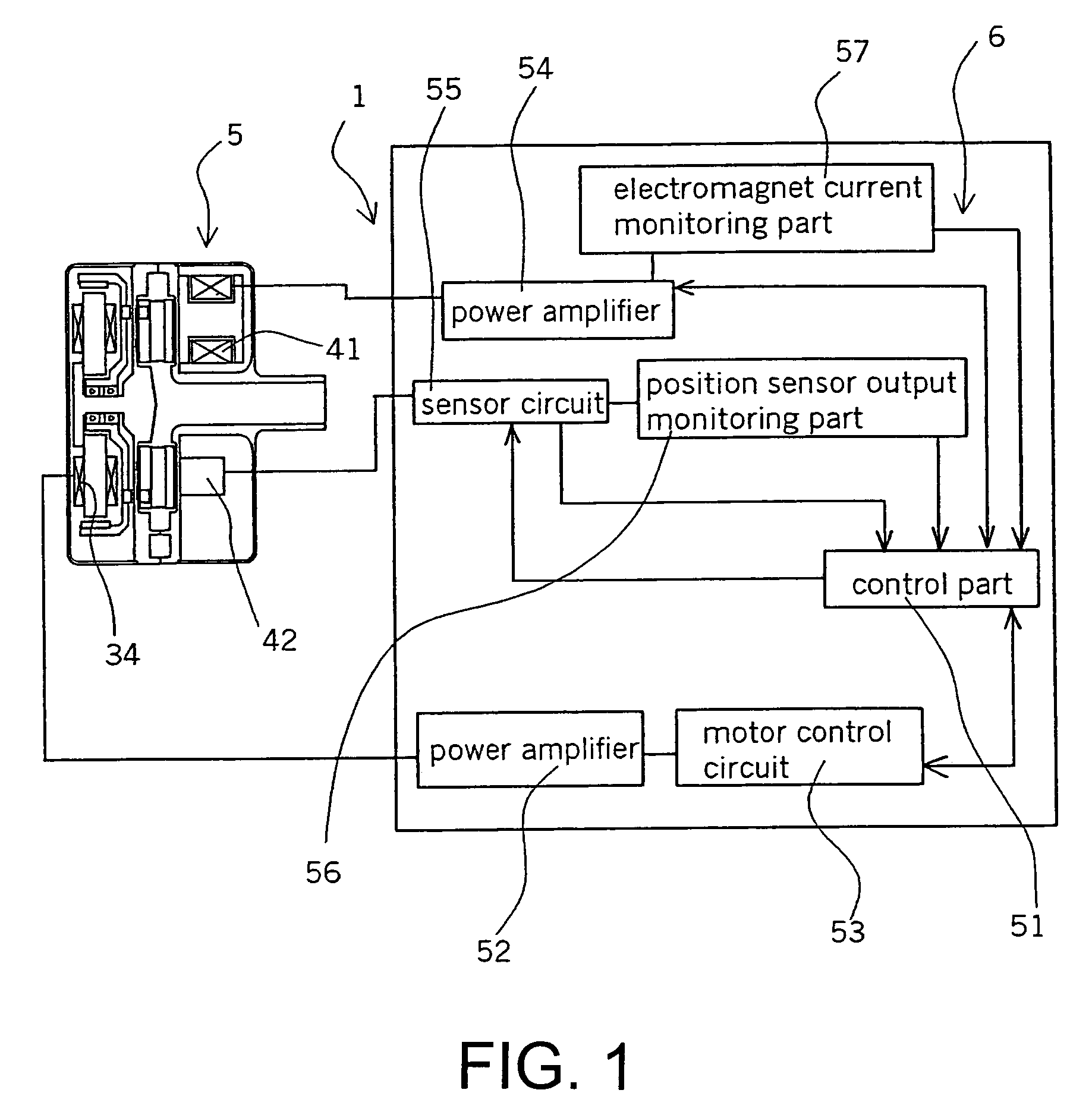

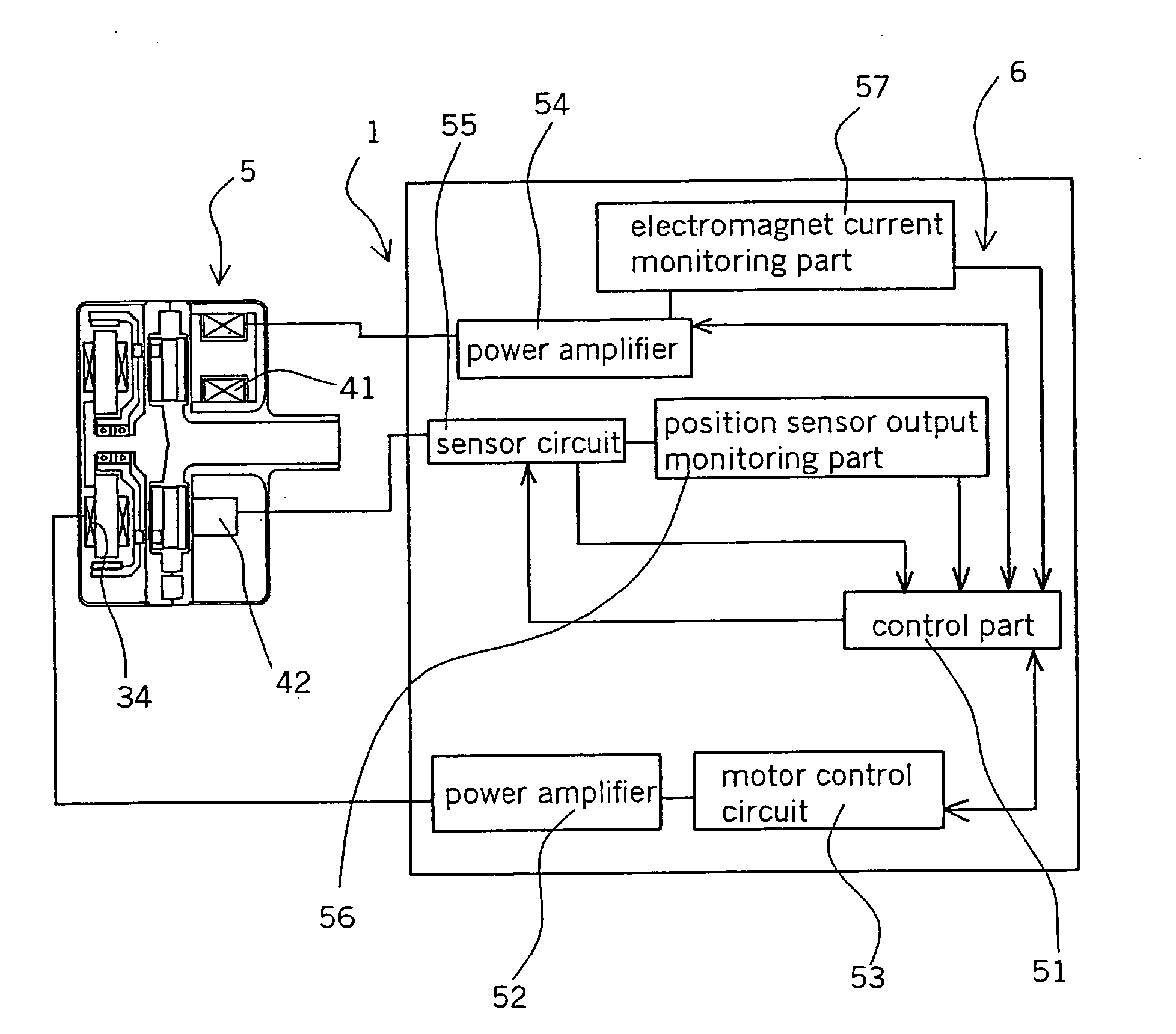

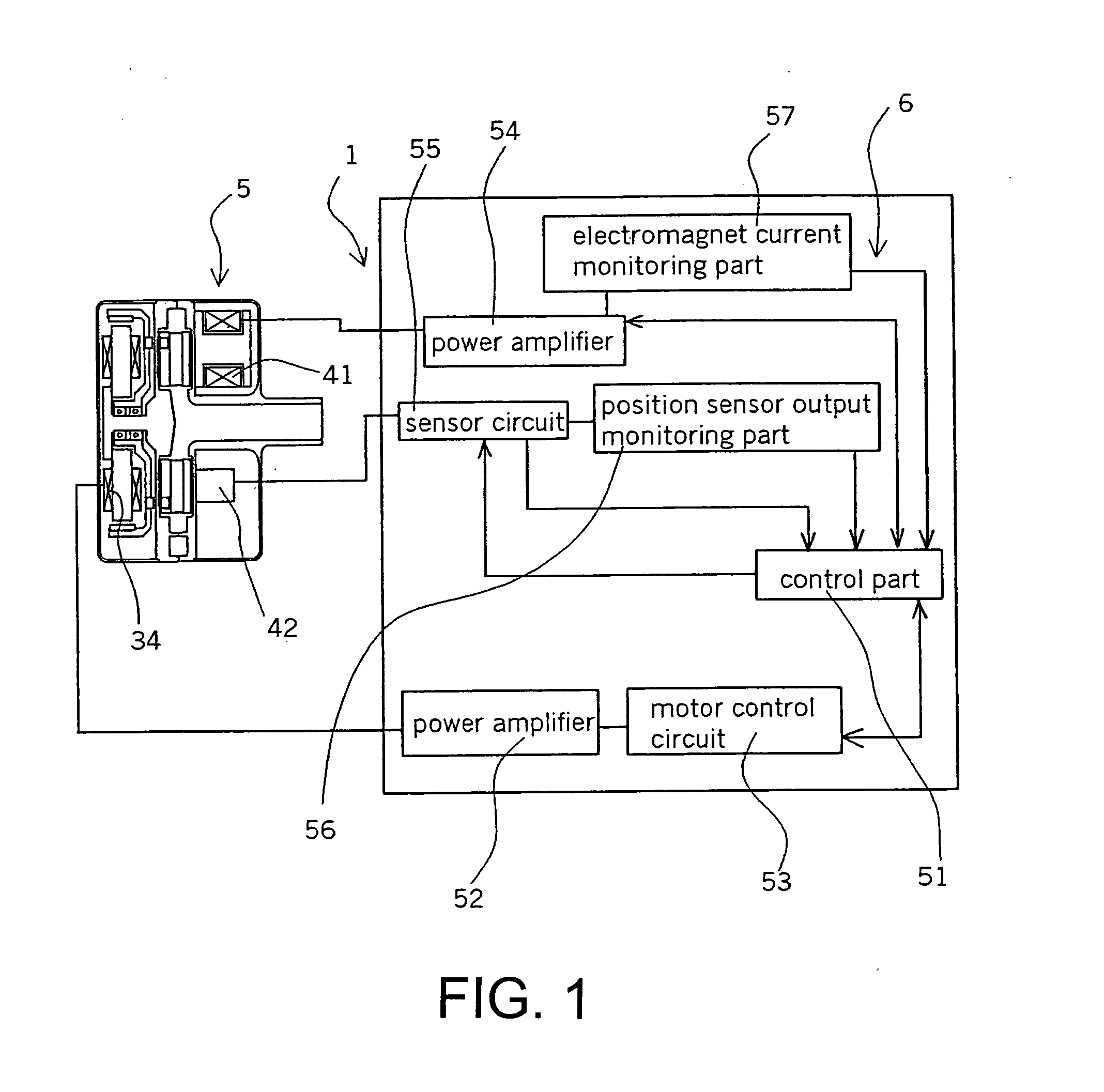

Centrifugal fluid pump apparatus

A centrifugal fluid pump apparatus includes a control mechanism including an emergency impeller rotation function. The emergency impeller rotation function includes a rotation termination function when the failure detection function detects a failure; impeller magnetic counterforce application function to apply a current to the electromagnet sufficient to overcome the magnetic attraction force of the rotor to the impeller caused by the magnet; hydrodynamic levitation control detection function to detect rotation of the impeller and the rotor by using a motor current monitored by the motor current monitoring function; motor speed control function for increasing the motor speed up to a predetermined value after the hydrodynamic levitation control detection function detects that the hydraulic bearing coupling between the impeller and the rotor has been made; and impeller magnetic counterforce termination function to terminate current to the electromagnet once the predetermined impeller rotation speed is reached.

Owner:TERUMO KK

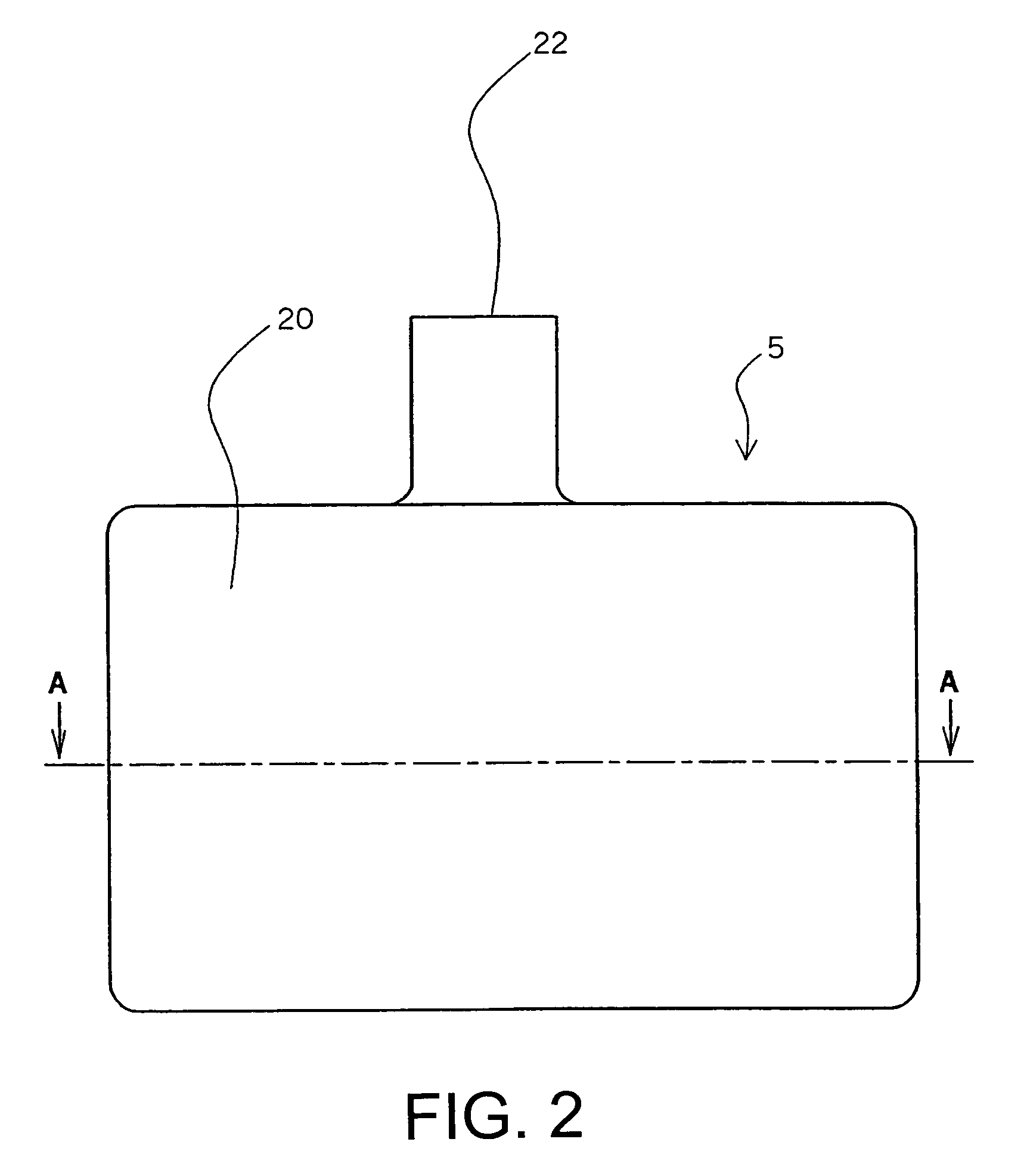

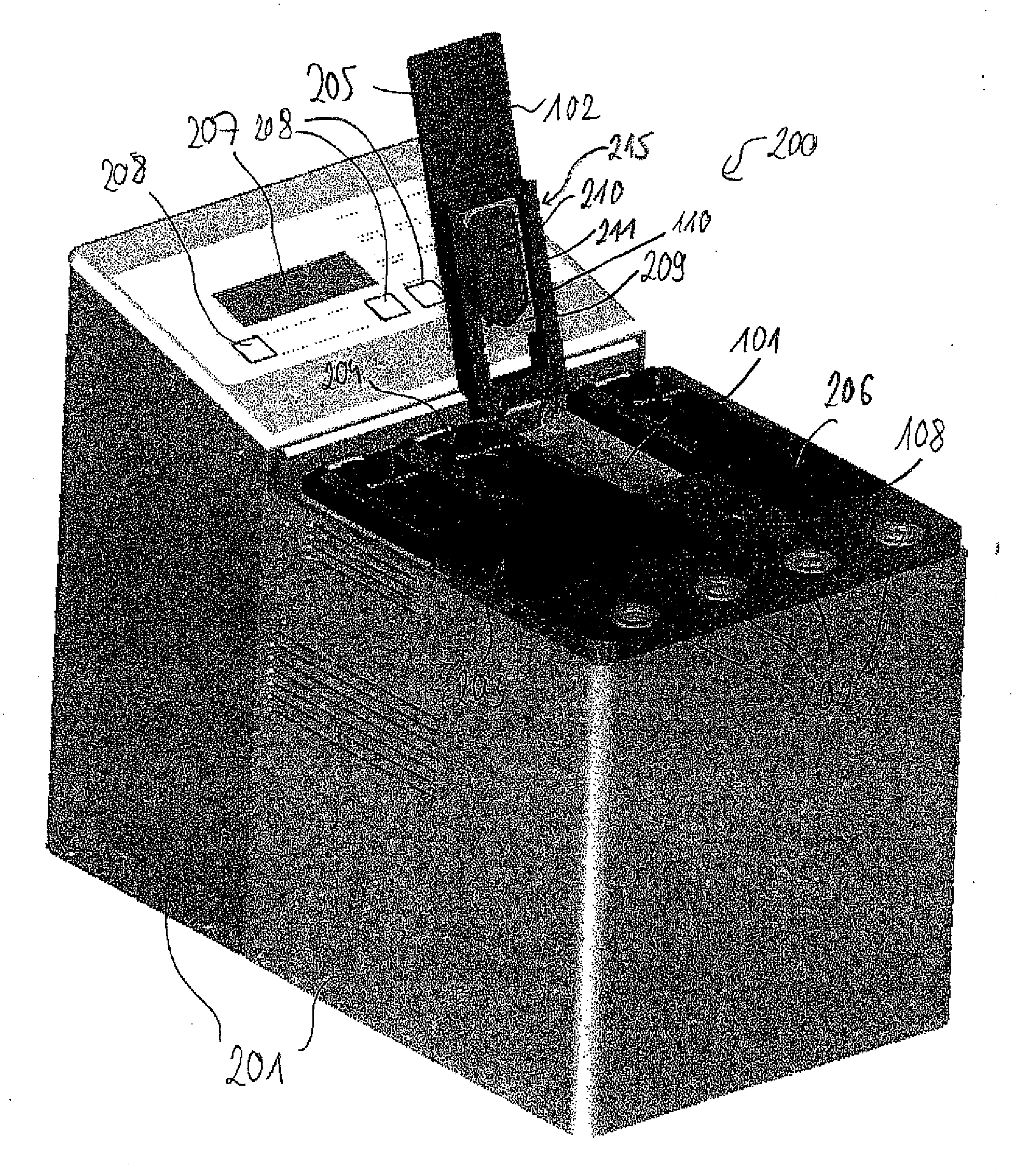

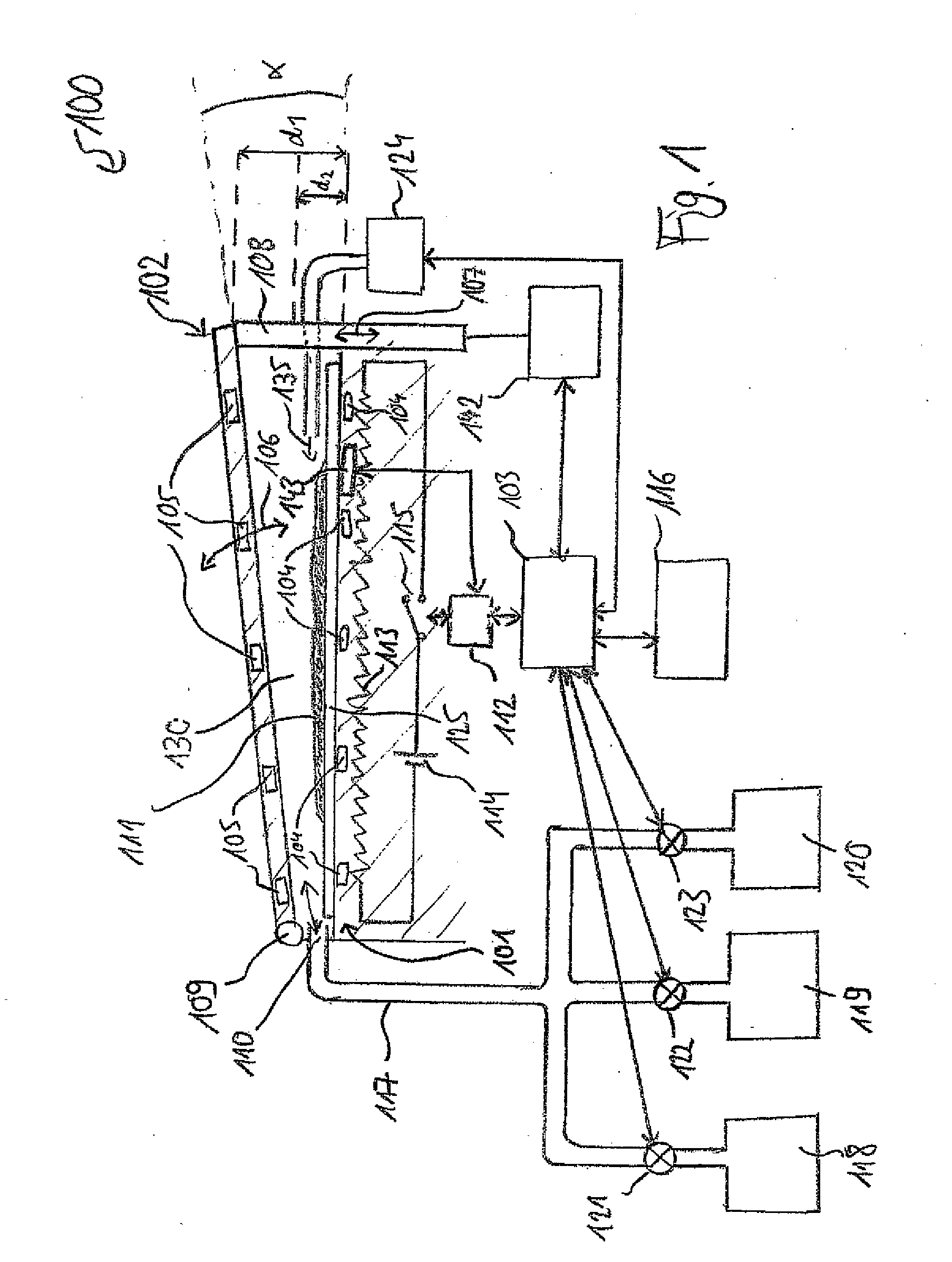

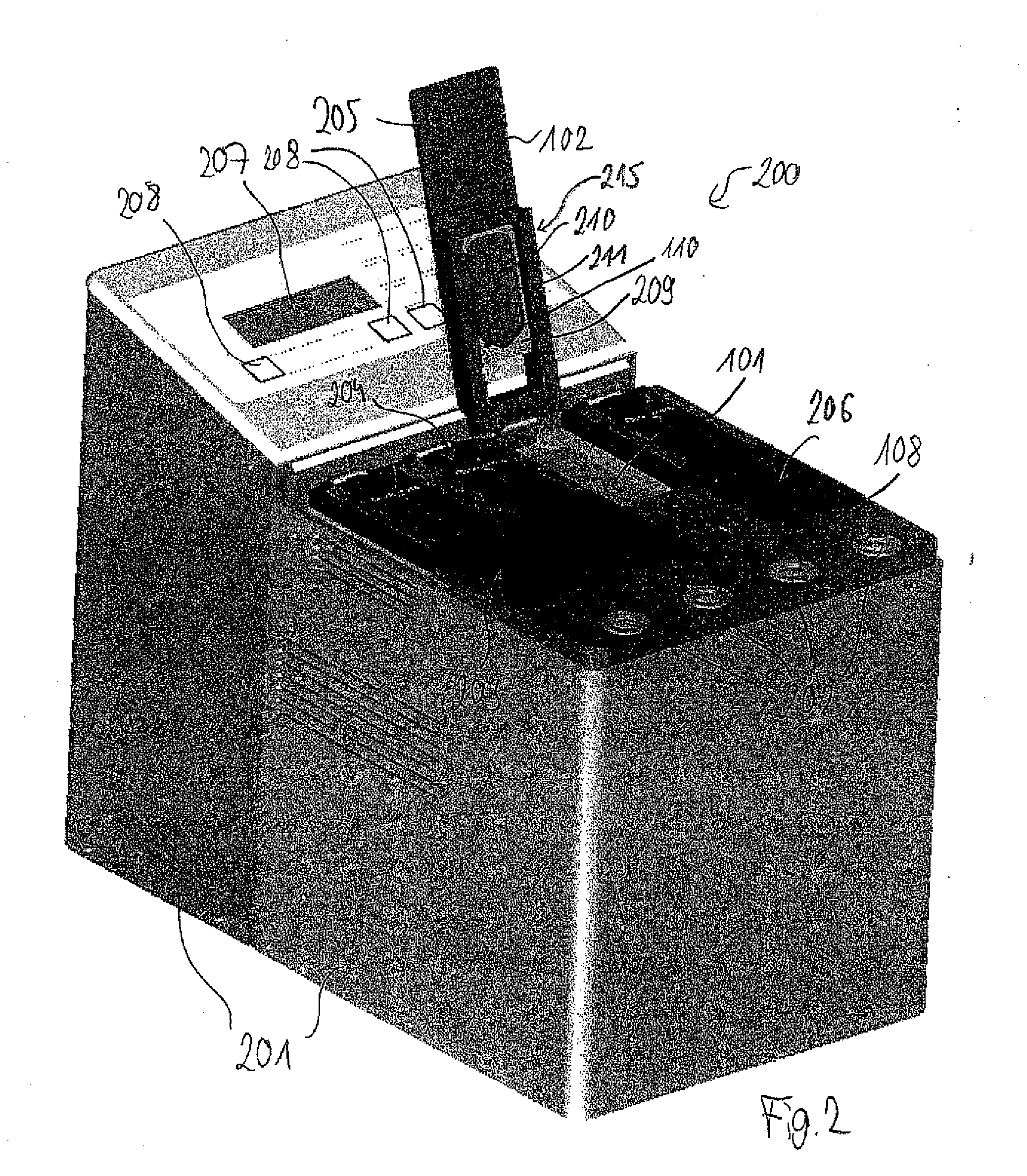

Sample handling device for and a method of handling a sample

InactiveUS20100031757A1More effective or relevantImprove throughputWithdrawing sample devicesPreparing sample for investigationEngineeringCounterforce

A sample handling device (100) for handling a sample, the sample handling device (100) comprising a base part (101), a cover part (102), a first force generating unit (104, 105) adapted to generate an attracting force promoting attraction between the base part (101) and the cover part (102), a second force generating unit (108, 142) adapted to generate a counterforce having at least a component being oriented opposite to the attracting force to promote a motion of the base part (101) and the cover part (102) relative to each other, and a control unit (103) adapted for controlling the second force generating unit (108, 142) for moving the base part (101) and the cover part (102) relative to each other for influencing a sample space (130) between the base part (101) and the cover part (102) for accommodating the sample.

Owner:QINSTRUMENTS GMBH

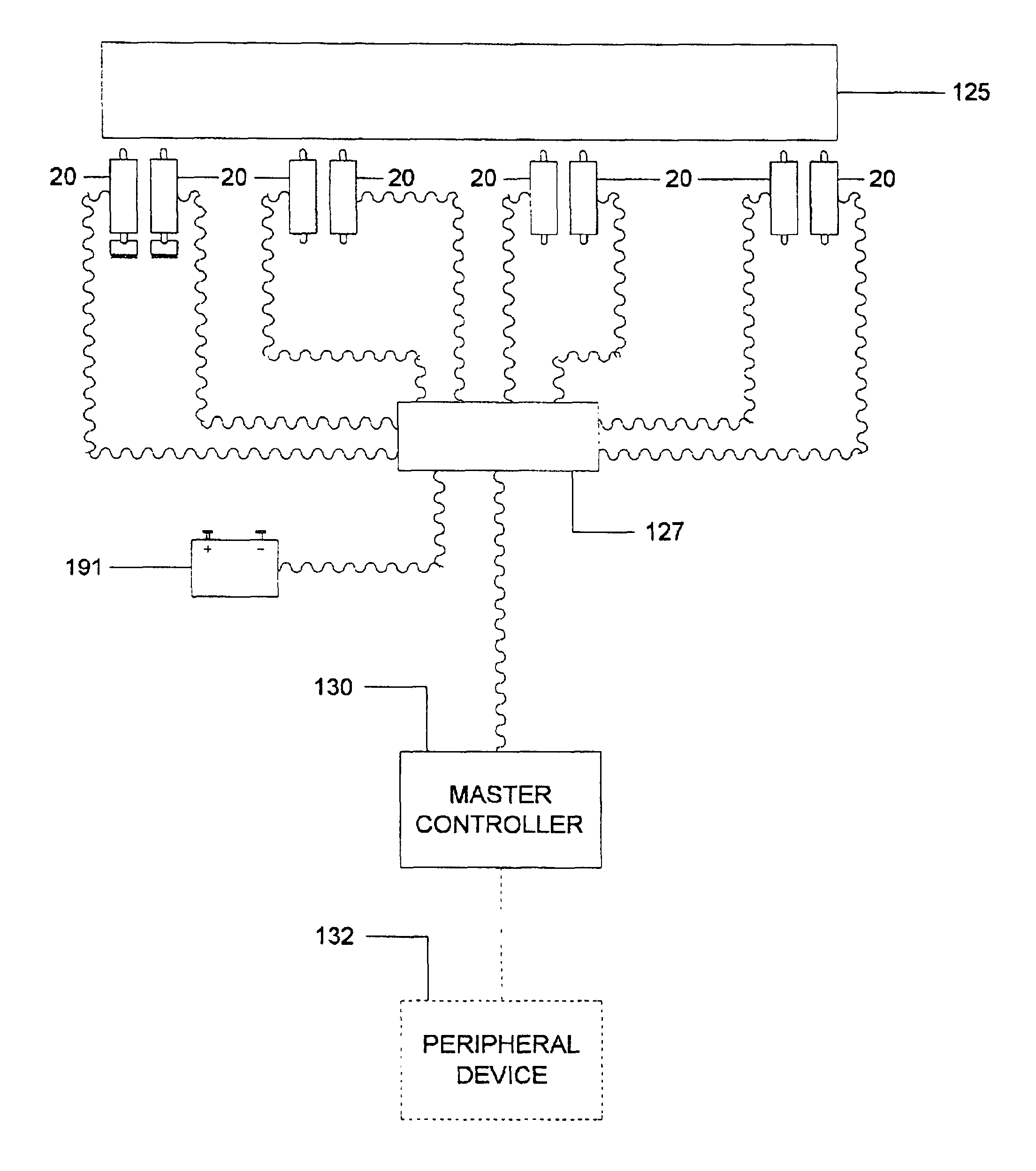

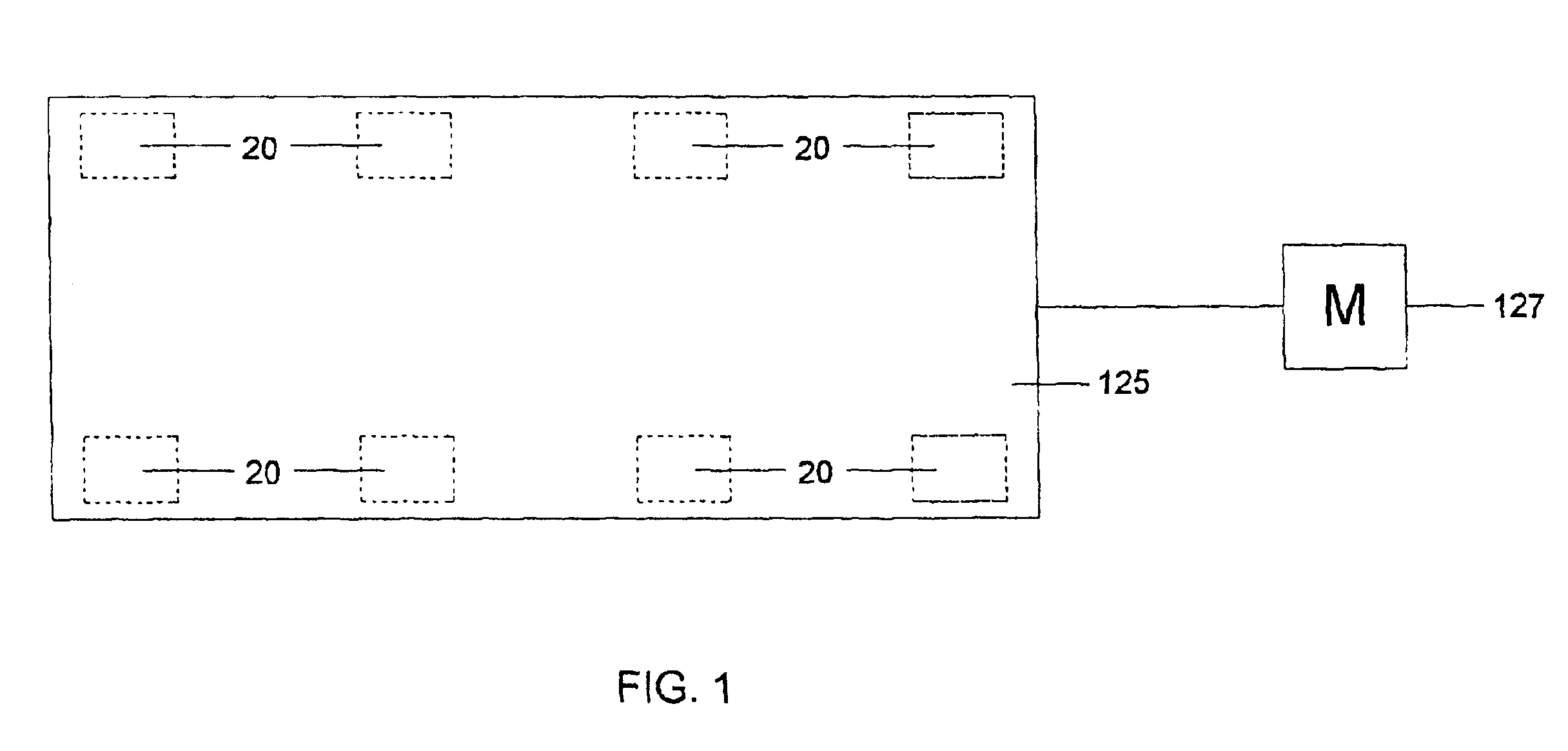

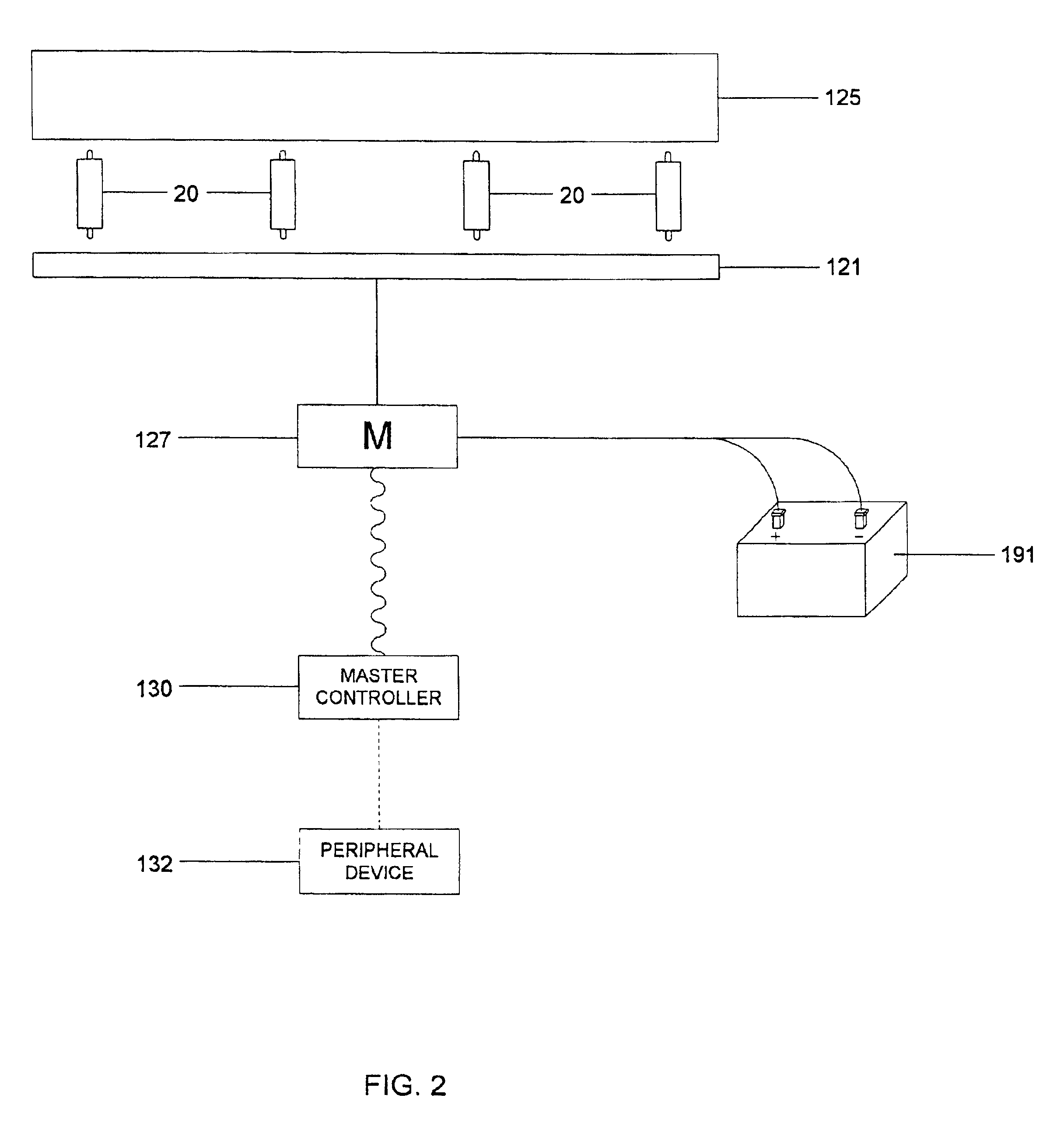

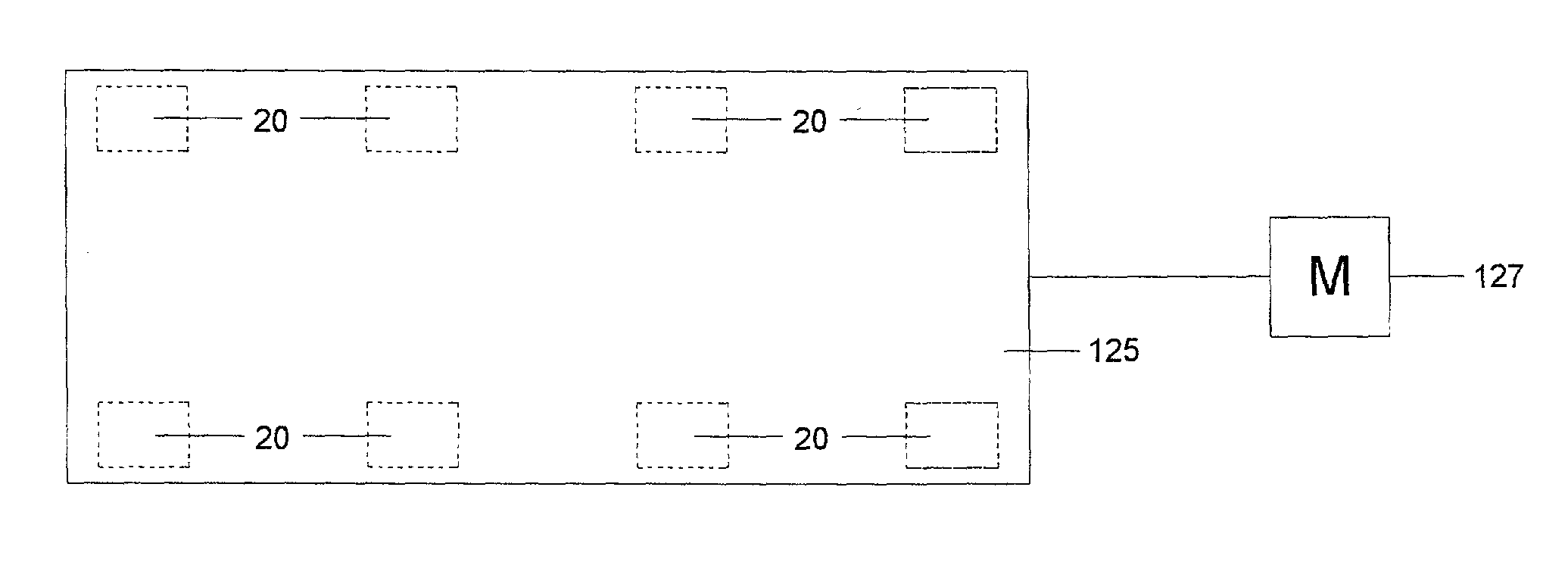

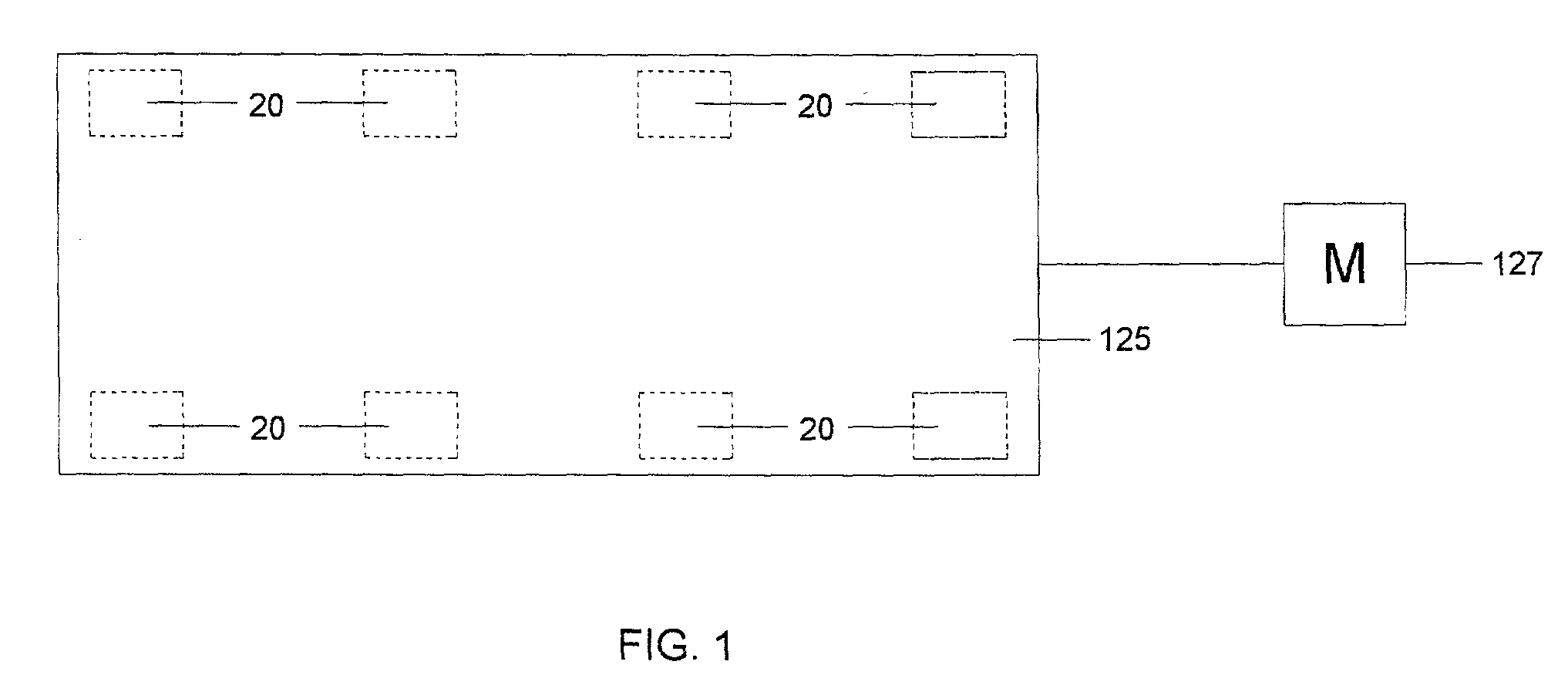

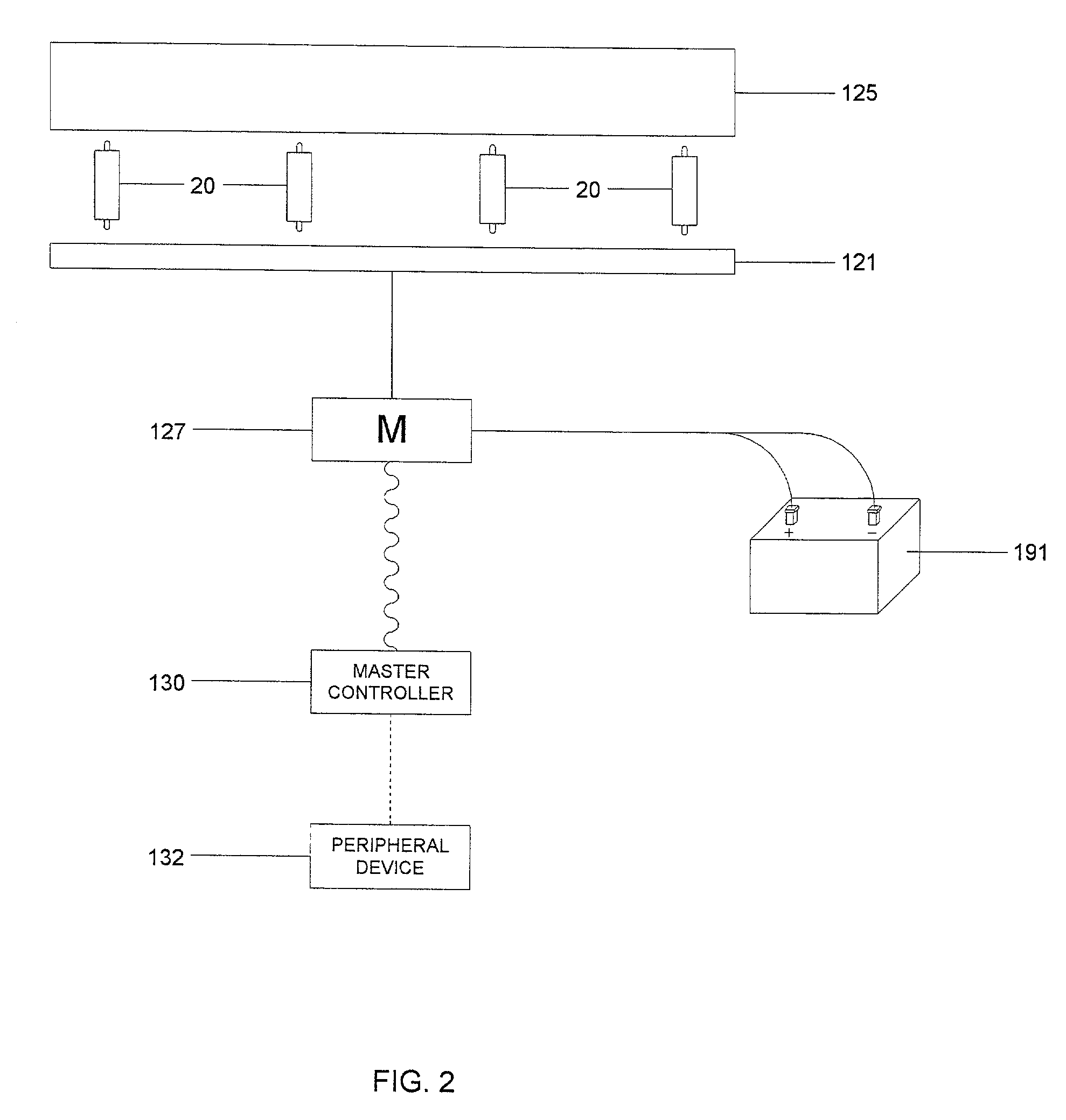

RF multiple load cell scale

InactiveUS6919516B2Eliminate needEnergy efficient ICTWeighing apparatus using elastically-deformable membersMicrocomputerTransceiver

Load cells forming one or more weighing scales are connected to each other and to a common concentrator which communicates to a master controller in the control house via RF wireless communication. The load cells are polled by and provide weight reading to concentrator to the master controller. A digital load cell is used which includes a rocker pin, guided beam, torsion ring or other counterforce, a circuit board mounted on the counterforce and an enclosure sealing the circuit board and all but the load bearing surfaces of the counterforce and a mounded antenna. The circuit board includes a microcomputer and a transceiver. RF communication is provided with the circuit board through a antenna mounted on the enclosure. One or a number of load cells may be connected to a computer or controller to form one or more weighing scales with one or more weighing scales connect to a control house through wireless RF communication. The preferred embodiment uses passive receivers for receiving the signals and waveguide to minimize power requirements.

Owner:METTLER TOLEDO INC

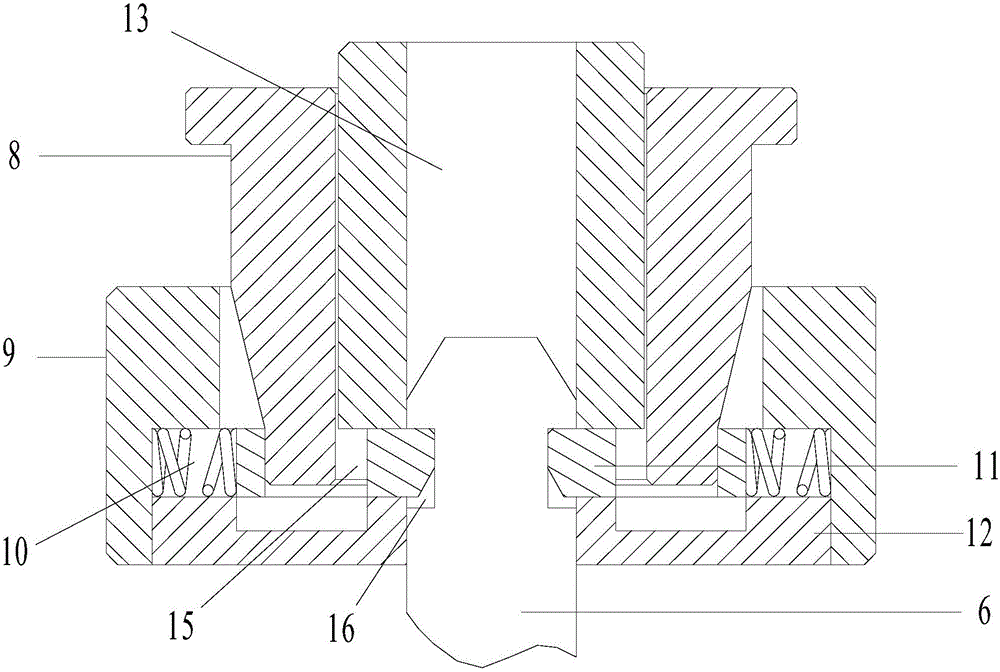

Indoor stretching-shearing testing device for anchor rod

InactiveCN103543069AImplement vertical loadingAchieve axial stretching effectMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesJackscrewCounterforce

The invention relates to an indoor stretching-shearing testing device for an anchor rod, belonging to the technical field of geotechnical engineering. The device comprises a counterforce frame, a horizontal loading system, a lower shearing box, a vertical loading system, a horizontal guide rail system, an upper shearing box and a limit device. Due to the structure design of the horizontal guide rail system, the shearing movement of the upper shearing box along the horizontal loading direction is realized and a friction resistance in a shearing process can be effectively reduced. A first vertical loading jack and a second vertical loading jack in the vertical loading system are connected with the same hydraulic control system, thus a test anchor rod can always bear a vertically upward axial stretching force in the vertical loading process. By the indoor stretching-shearing testing device for an anchor rod, a shearing damage test of the anchor rod under different axial drawing forces can be realized and the defect that a conventional indoor stretching-shearing testing device for an anchor rod is only capable of performing a pure-stretching test is overcome; and the indoor stretching-shearing testing device for an anchor rod is of great importance in acquiring stretching-shearing damage test data of the anchor rod and understanding a damage mechanism of the anchor rod under a stretching and shearing comprehensive function.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Centrifugal fluid pump apparatus

A centrifugal fluid pump apparatus includes a control mechanism; and a body including a pump section having an impeller rotating inside a housing; a rotor having an impeller attraction magnet; a motor for rotating the rotor; an impeller attraction electromagnet for attracting the impeller thereto; an impeller-position detection sensor; and hydrodynamic bearing means provided on an inner surface of the housing. The control mechanism has a position sensor output monitoring function or an electromagnet current monitoring function, a motor current monitoring function; and an emergency impeller rotation function. The emergency impeller rotation function includes a rotation termination function of terminating current to the motor and the electromagnet when the failure detection function detects a failure to thereby terminate rotation of the rotor and the impeller; impeller magnetic counterforce application function to apply a current to the electromagnet sufficient to overcome the magnetic attraction force of the rotor to the impeller caused by the magnet; hydrodynamic levitation control detection function to detect rotation of the impeller and the rotor by using a motor current monitored by the motor current monitoring function; motor speed control function for increasing the motor speed and hence the impeller rotation speed up to a predetermined value after the hydrodynamic levitation control detection function detects that the hydraulic bearing coupling between the impeller and the rotor has been made; and impeller magnetic counterforce termination function to terminate current to the electromagnet once the predetermined impeller rotation speed is reached.

Owner:TERUMO KK

Tool holding device

ActiveUS7537288B2Enhance counterforce bearingImprove connection strengthSlitting machinesStone-like material working toolsEngineeringUltimate tensile strength

A tool holding device is disclosed, and the tool holding device includes a base, a block, and a fastening member for securing the block. The base includes a receiving portion defined between a countering wall and a shoulder wall, a surface defined adjacent to the shoulder wall perpendicularly and away from the countering wall, a penetrated hole defined on the countering wall, and a positioning hole communicating with the penetrated hole. The block includes a holding portion held in the receiving portion, a handle received in the penetrated hole, and a holding hole for holding a chisel. The countering wall and the shoulder wall define an angle less than or equal to 90 degrees. Therefore, the counterforce bearing of the base and block are both enhanced to raise the strength of the tool holding device.

Owner:EVERPADS

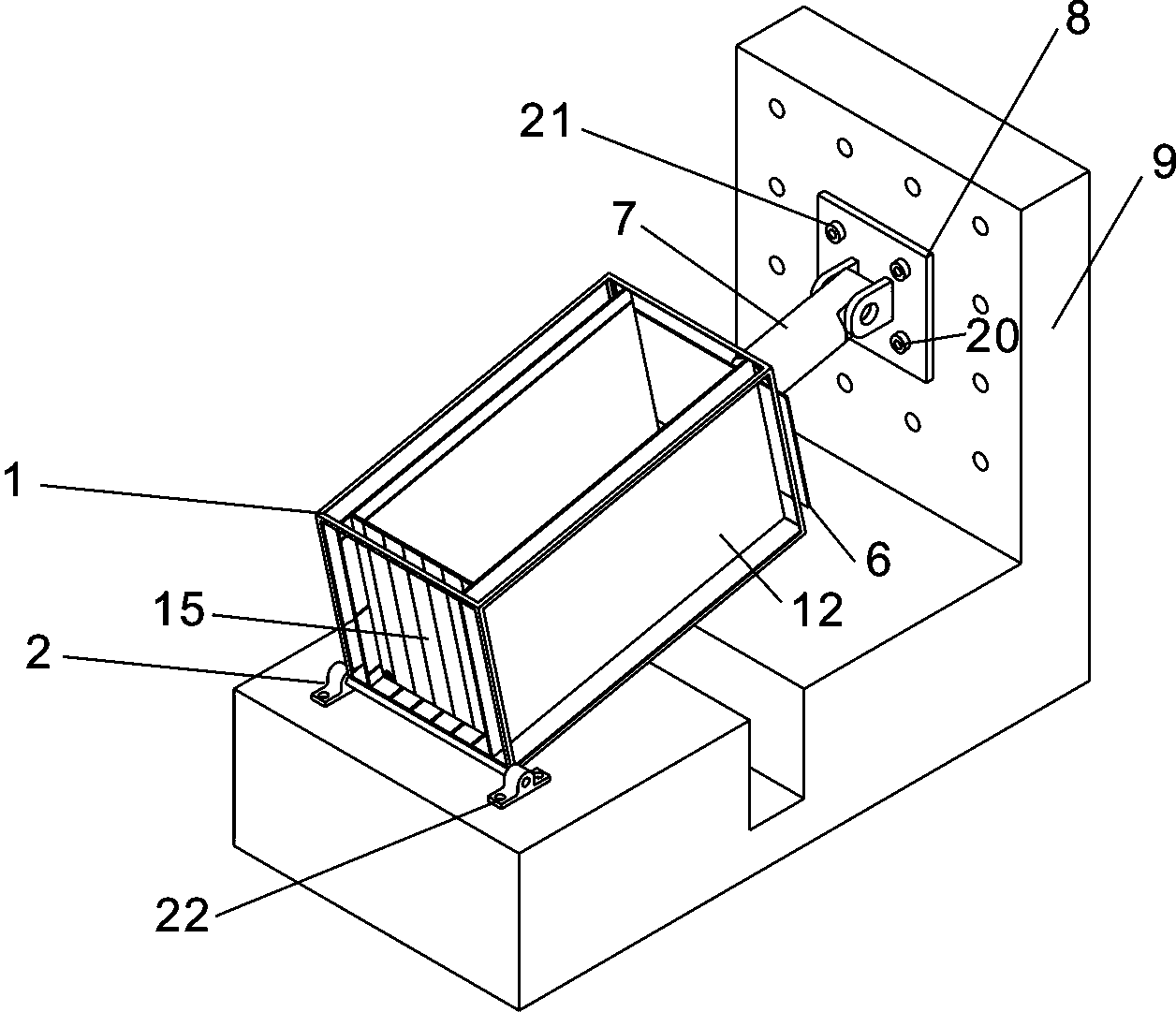

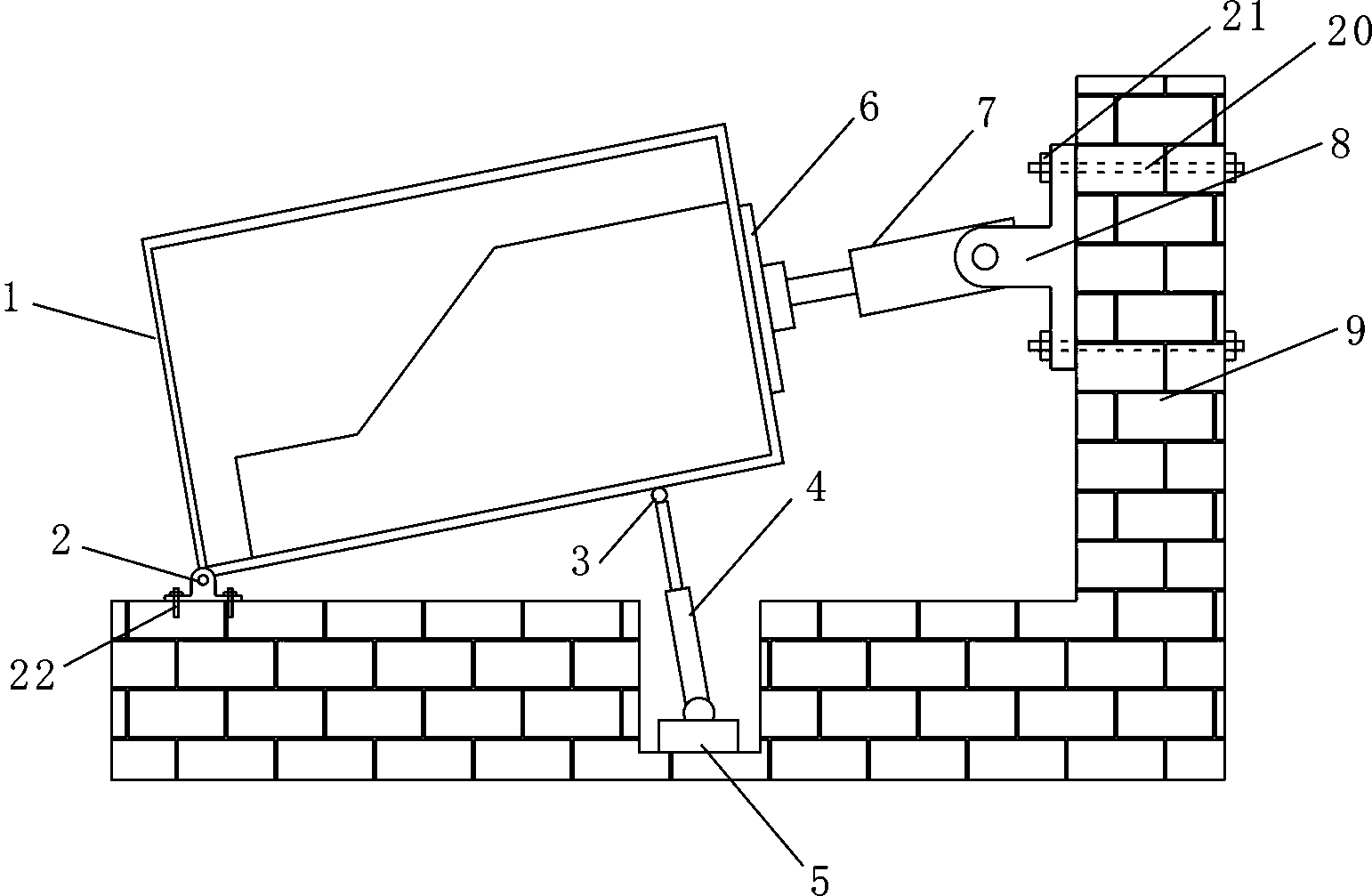

Large movable lateral uplifting composite lading slope physical model test apparatus

InactiveCN103353516AMeet the test requirementsAvoid sizeEarth material testingPhysical modelEngineering

A large movable lateral uplifting composite lading slope physical model test apparatus comprises a test framework, a bottom uplifting mechanism, a rear portion loading mechanism and a water level elevating simulation mechanism; the bottom of the front portion of the test frame is hinged to the test site ground surface, the test frame is formed by mutually splicing a front panel at the front portion, at least two vertically-arranged guard boards and a frame baseboard at the bottom portion, and the spacing between adjacent guard boards is adjustable; the bottom uplifting mechanism is arranged below the test frame and is used for driving the rotation of the test frame around the hinge pint at the front portion; and the rear portion loading mechanism comprises a loading steel board, an electro-hydraulic servo loading machine and a counterforce wall, the counterforce wall is arranged behind the test frame, the rear end of the electro-hydraulic servo loading machine is hinged to the counterforce wall, the front end of the electro-hydraulic servo loading machine is connected with the loading steel board, and the rear portion loading mechanism is used for applying action force to a slope physical model in the test frame from the rear end of the test frame. The apparatus is suitable for large-size slope physical models, and can realize the establishment of three-dimensional models better satisfying geometric similarity conditions than real slopes.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

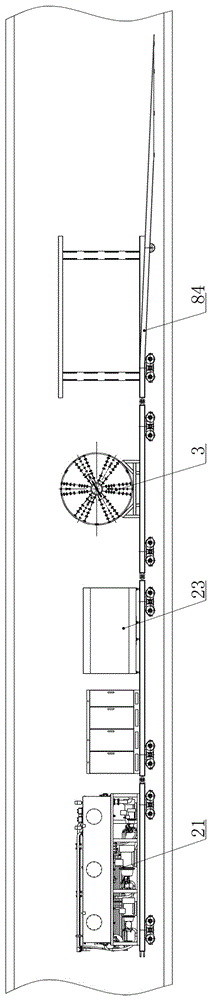

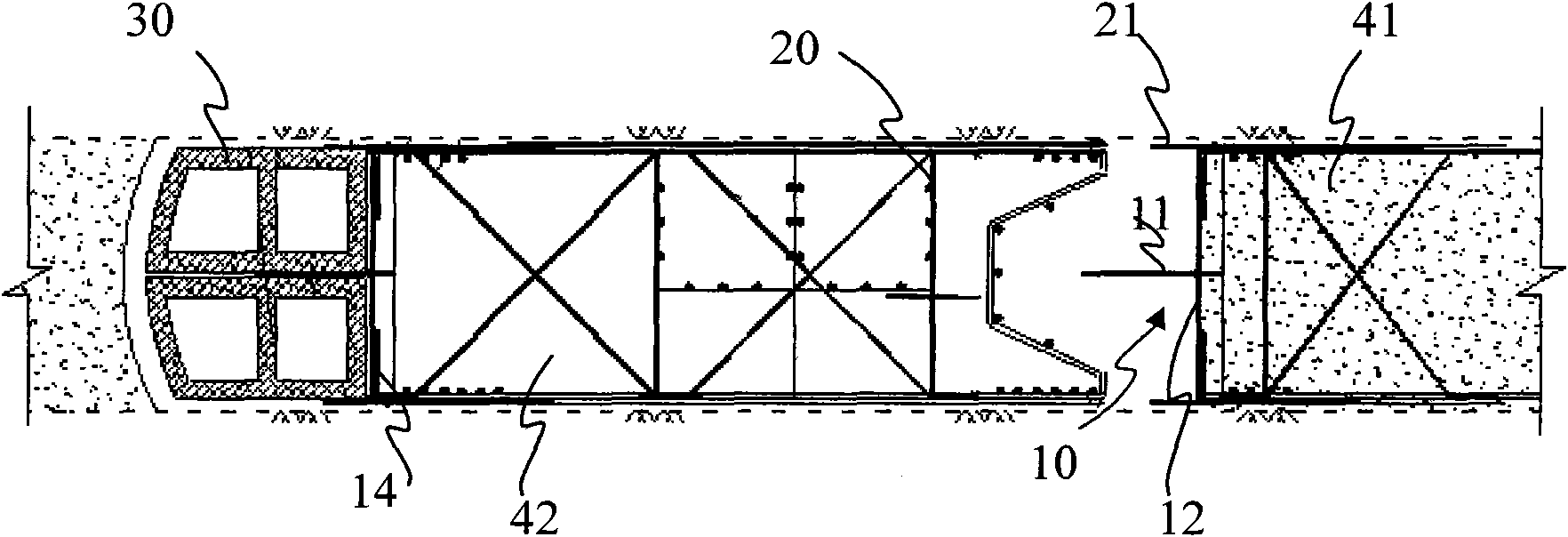

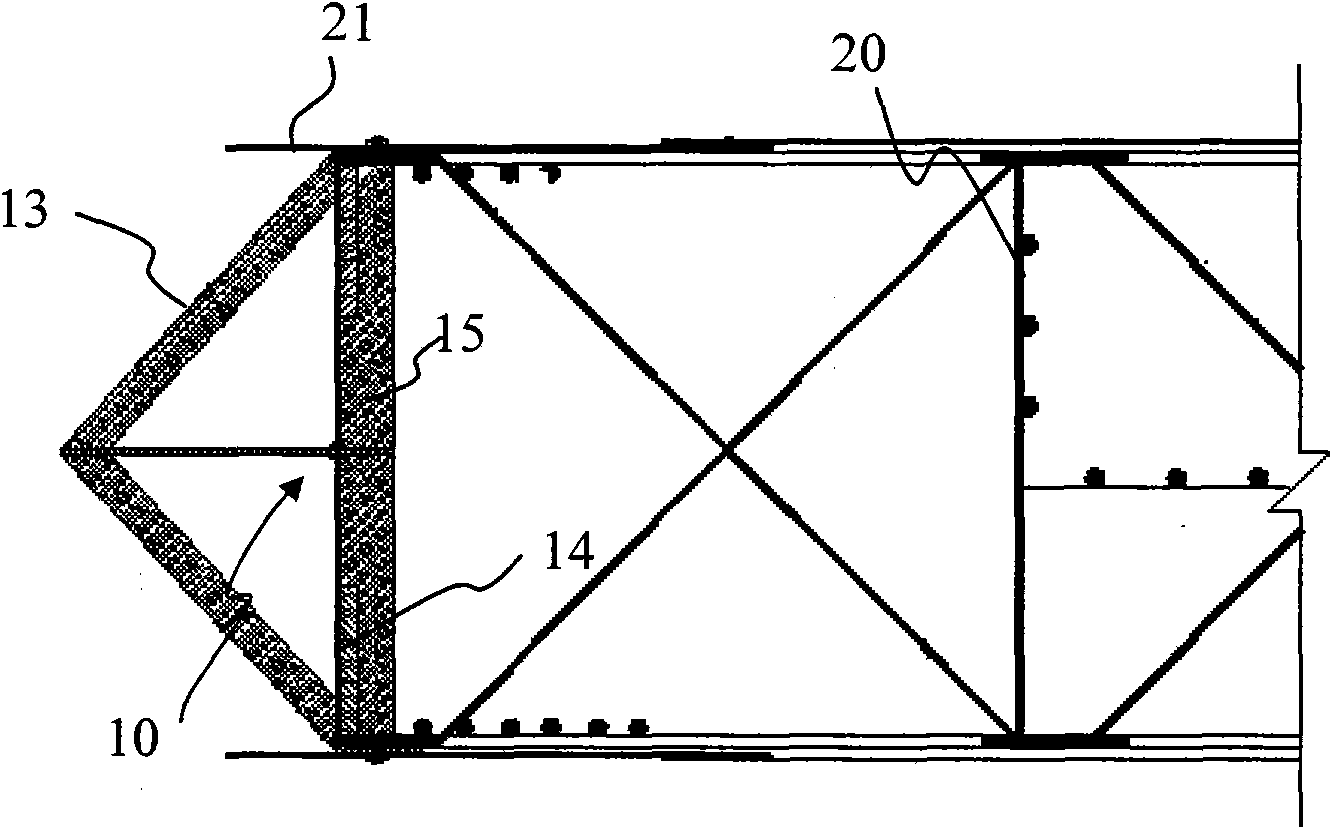

Shield machine balance originating method

ActiveCN102022119AEnsure safetyThere will be no water gushing and sand gushingTunnelsEngineeringCounterforce

The invention discloses a shield machine balance originating method, which comprises the following steps of: constructing a continuous wall envelope structure in a foundation pit; pouring a guide table in an originating well of the foundation pit; pouring a concrete counterforce wall in the originating well; assembling and debugging a shield machine in the originating well; arranging a first negative ring duct piece in the debugged shield machine, pushing the duct piece out of a shield tail to connect the counterforce wall, and sealing the duct piece; jacking a cutter head of the shield machine to the continuous wall, and backfilling the originating well with a sand layer, a concrete layer and a water layer from bottom to top; grouting in back of the duct piece wall; and performing advancement by the shield machine. Because the shield is backfilled in the well before the shield machine originates advancement, the pressure of water and soil inside and outside the foundation pit is balanced, water and sand are not burst when the shield machine originates advancement, and the safety of the foundation pit and the shield machine can be effectively ensured.

Owner:CHINA TUNNEL CONSTR GUANGDONG

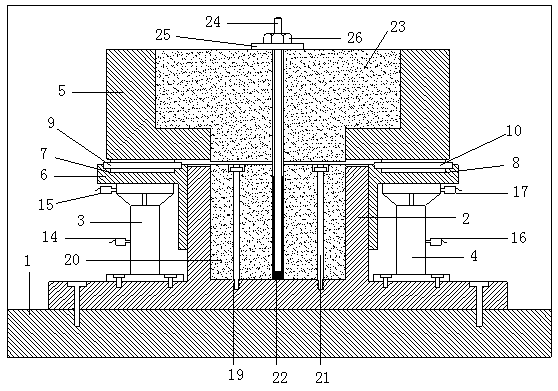

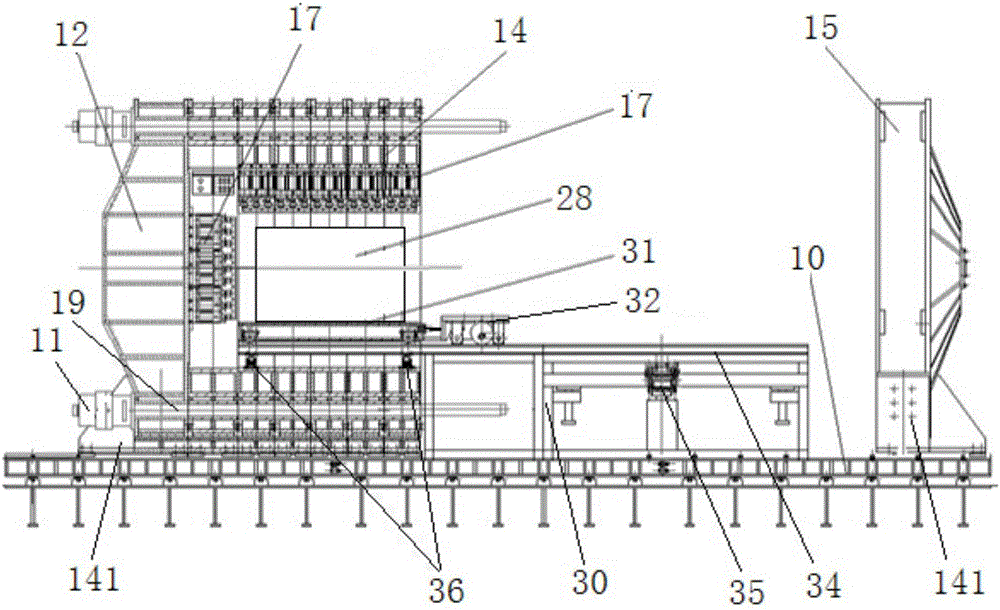

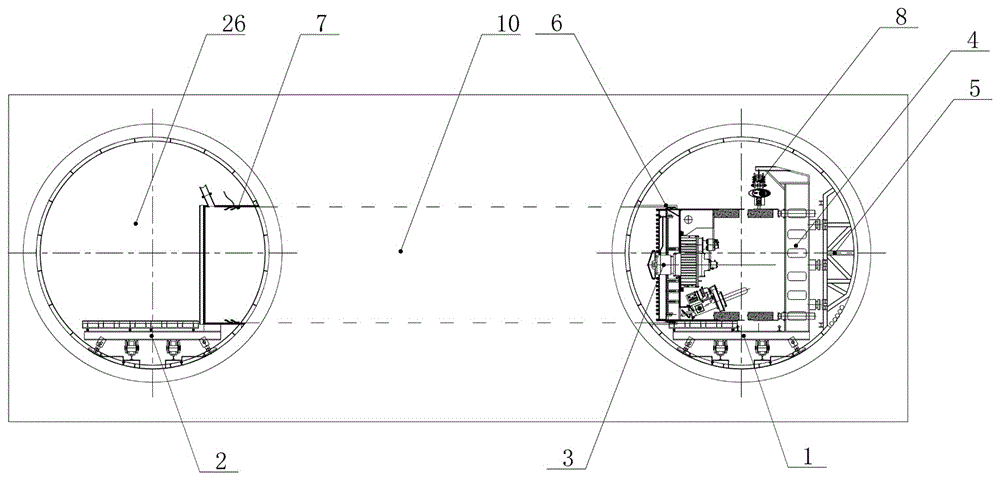

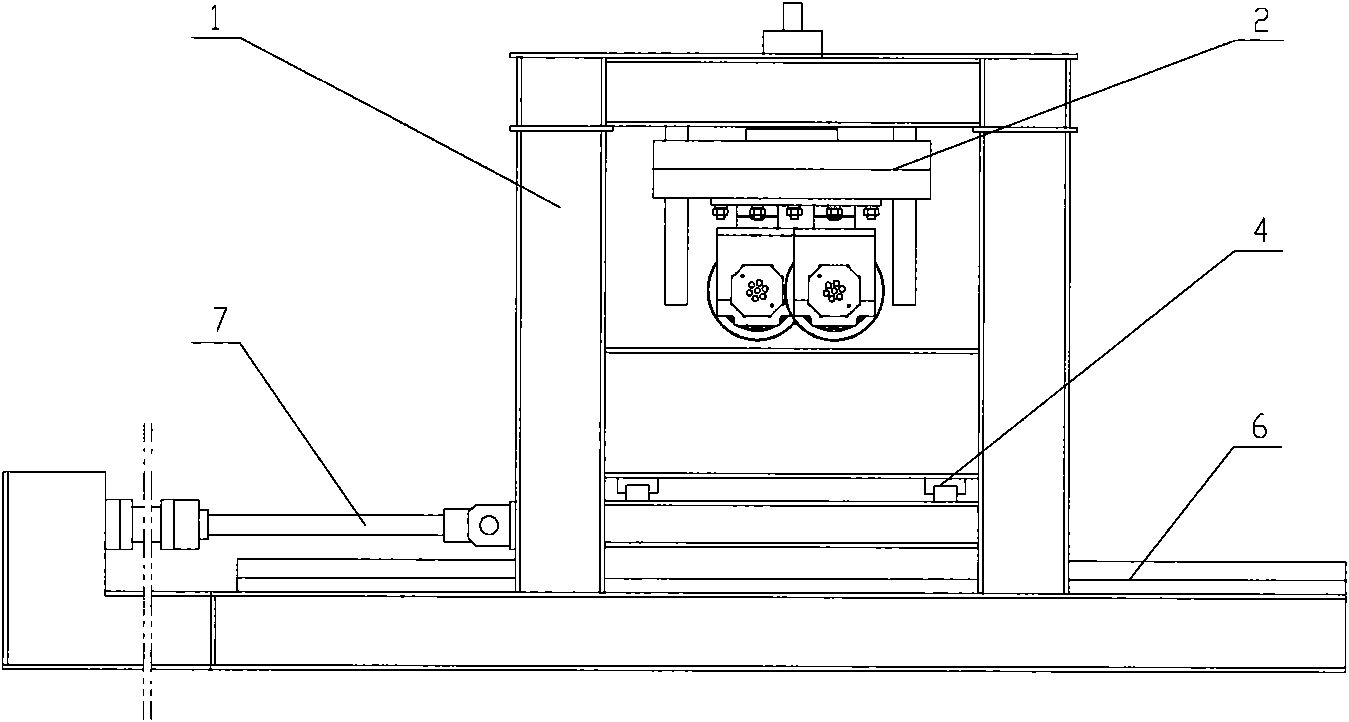

Multifunctional physical simulation test system for coal engineering and coal model test method

ActiveCN106018105AHigh loading tonnageLarge model sizeMaterial strength using tensile/compressive forcesPermeability/surface area analysisTest chamberModel test

The invention relates to a multifunctional physical simulation test system for coal engineering. The system comprises a test chamber, a model forming subsystem, a hydraulic loading control subsystem, a test subsystem and a gas pumping and injecting subsystem, wherein the test chamber comprises a loading frame and a counterforce cover detachably connected to one end of the loading frame; the loading frame and the counterforce cover are coaxially mounted on a base; a guide rail is arranged on the base in an axial direction of the loading frame; and support seats capable of sliding along the guide rail are mounted on the guide rail and are mounted at bottoms of the loading frame and the counterforce cover respectively; a track conveying subsystem for conveying models is detachably connected between the model forming subsystem and the test chamber. The invention further provides a coal model test method. According to the multifunctional physical simulation test system for coal engineering and the coal model test method, operation such as drilling, joint forming, fracturing, coal and gas outburst, excavation and support of underground construction and the like under actions of crustal stress, gas pressure and comprehensive multiple factors can be simulated, and an experimental verification means is provided for coal and gas outburst related occurrence mechanism, prediction and control.

Owner:CHONGQING UNIV

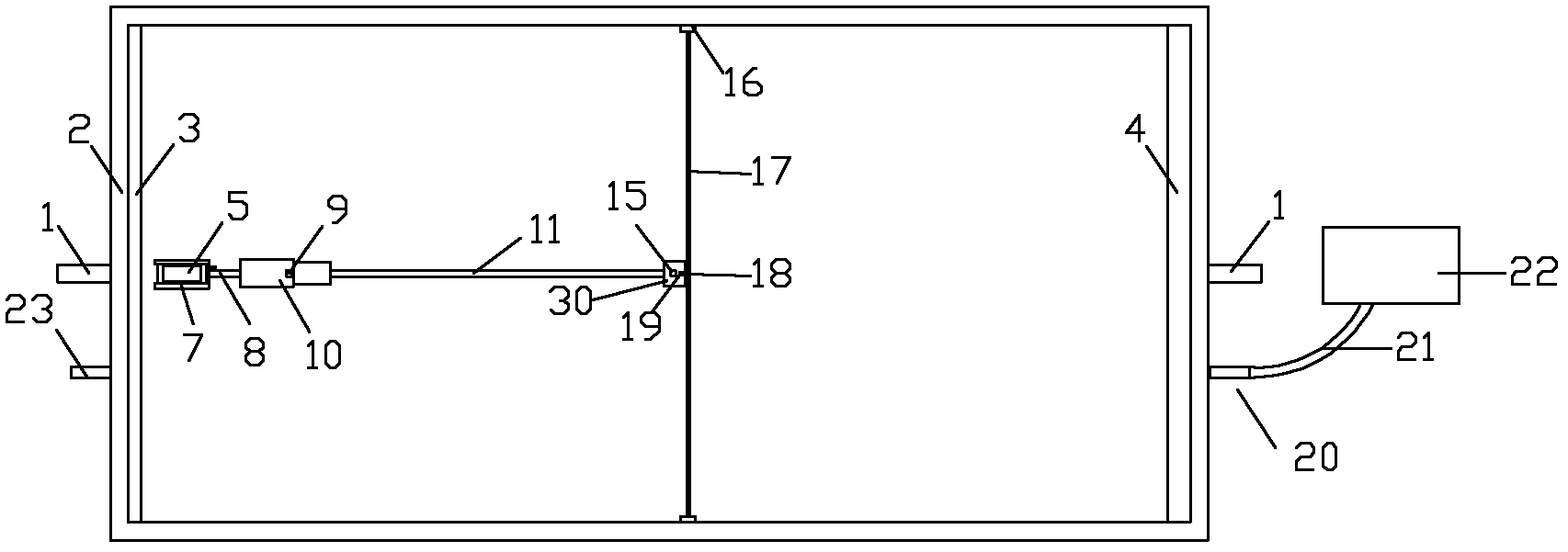

Foundation base model test device capable of bidirectional loading

The invention discloses a foundation base model test device capable of bidirectional loading. A force-bearing framework is a rectangular steel frame, a model slot is of a rectangular steel structure, is provided with an upper opening and is formed by welding of a box template, the force-bearing framework is sleeved at the periphery of the model slot, a horizontal actuator counterforce column is vertically erected on the left end part of the model slot, the left end of the horizontal actuator is connected with the horizontal actuator counterforce column, the right end of the horizontal actuator is connected with the top of a pile, the upper end of a vertical actuator is connected with a cross beam at the upper part of the force-bearing framework, the lower end of the vertical actuator is connected with the top of the pile through a vertical dowel steel, a row of drain valves are arranged at the lower part of the left side wall of the model slot, an inlet valve is arranged at the lower part of the right side wall of the model slot, and a water supply pipe of the inlet valve is connected with a constant-pressure water tank. Monitoring is systematic and comprehensive, embedding of monitoring instruments is relatively easy, and automatic and real-time monitoring on multiple physical quantities can be realized. The foundation base model test device disclosed by the invention can be used in conducting model tests like slope foundation, composite foundation and pile foundation.

Owner:HUBEI ELECTRIC ENG CORP +1

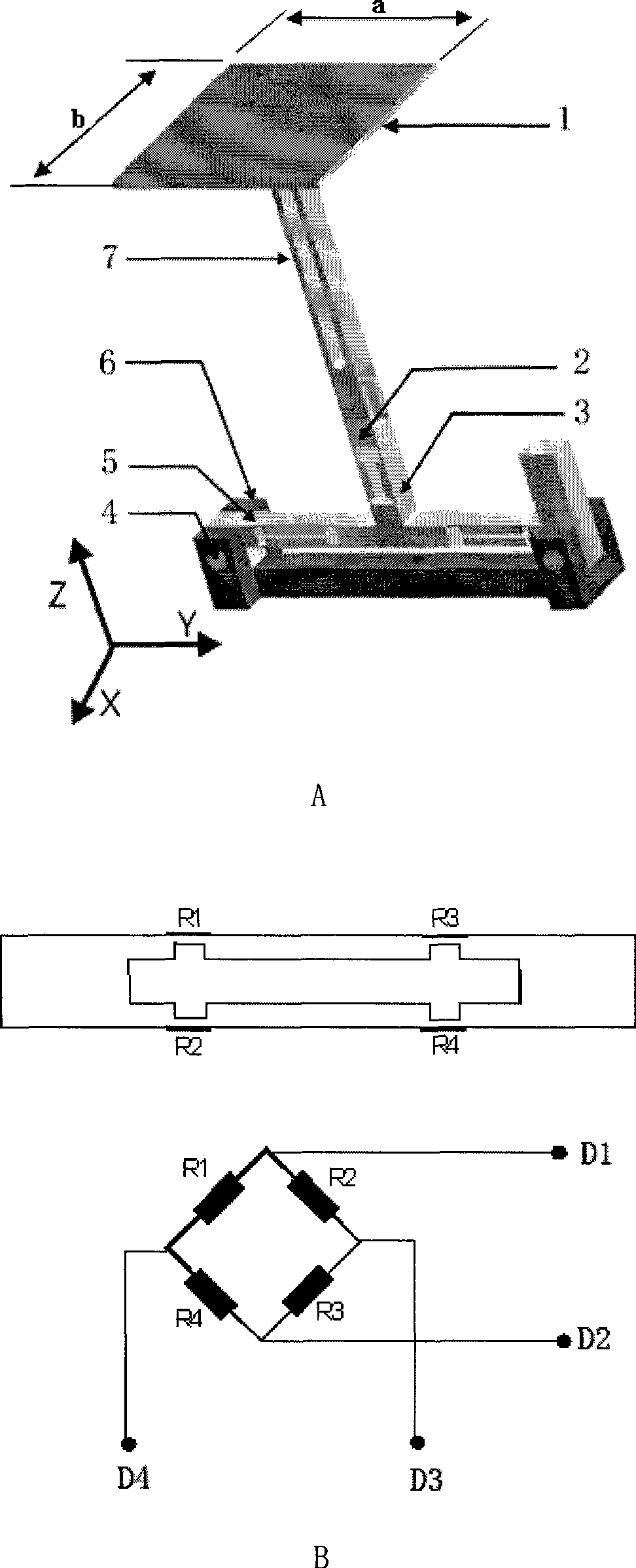

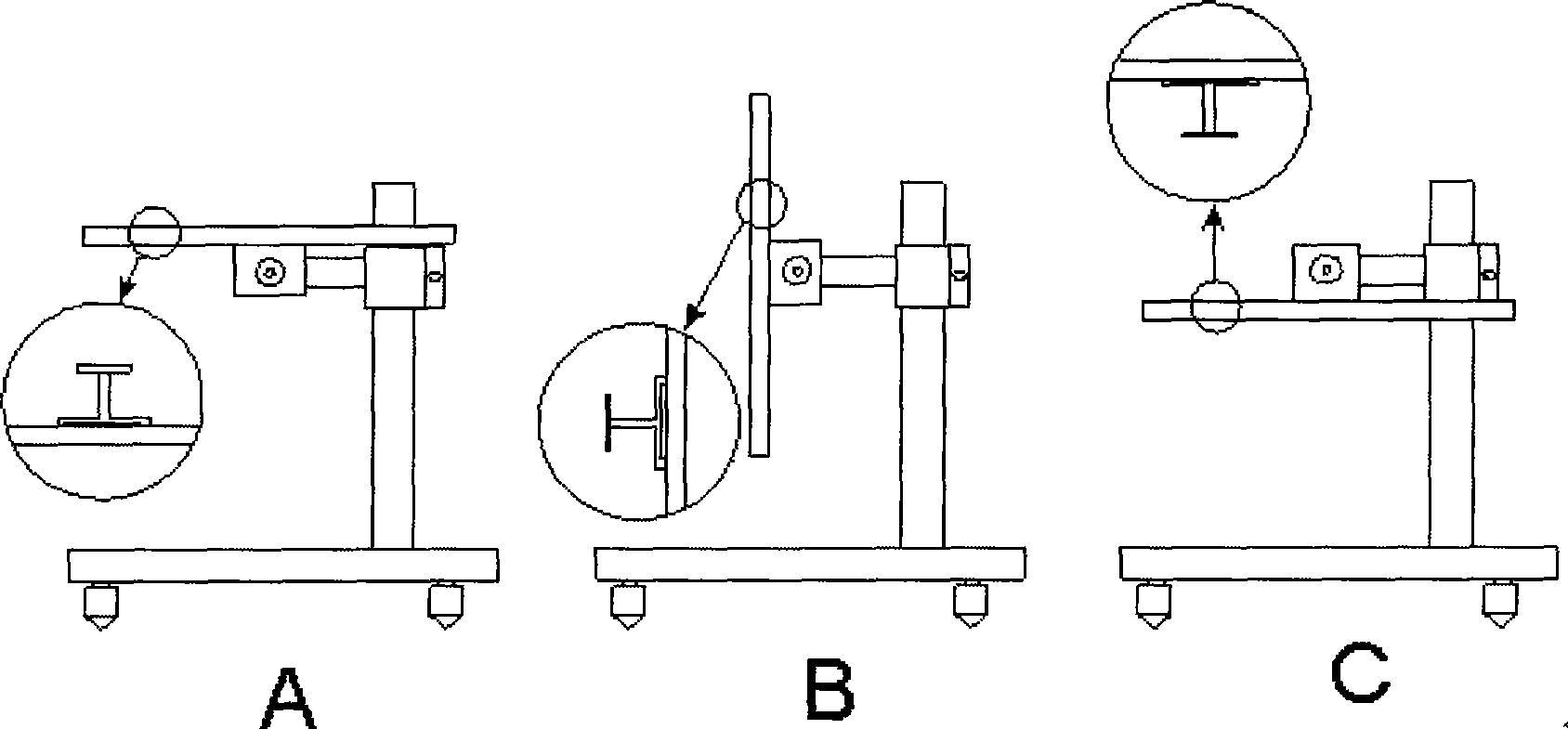

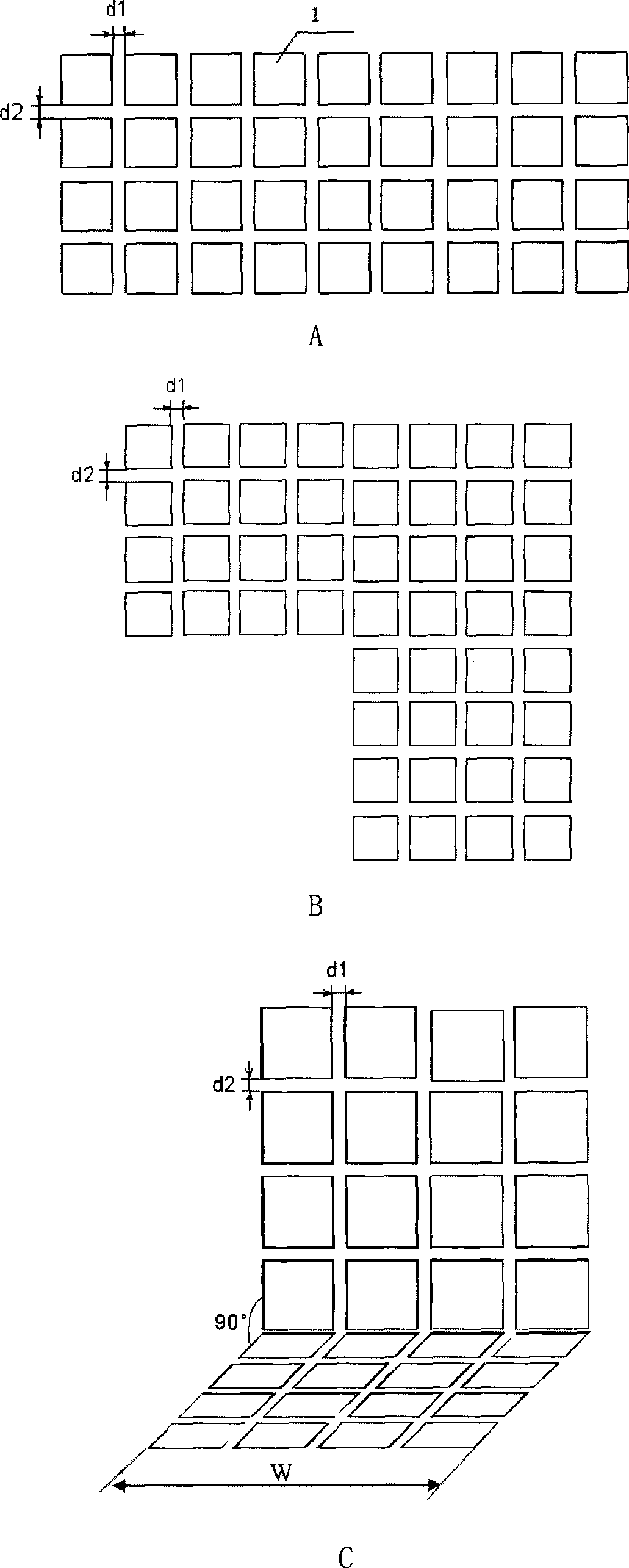

Test method and system of animal foot-face contact counter force

The invention relates to a testing method and a system for the surface-contact counterforce of the foot and surface of an animal. The invention belongs to the technology of force measuring. The method includes the following steps: confirming a sensor, the rate capacity and resolving capability of which meet requirements; demarcating the sensor; designing the arrangement form of a force measuring array; designing an animal movement channel formed by the sensor; conducting the animal to pass through a force measuring sensor channel; using a video image and the counterforce data collected in a sensor system for screening the data of the whole sole of the animal acted on the sensor as the effective data. The system includes a sensor array bracket, the force measuring sensor array arranged on the sensor array bracket; the strain signal of the sensor on the array is connected on a computer by a conditioning amplifier. The system also includes a high speed vidicon which realizes synchronous collection with the force measuring data. The system can simultaneously measure the information like the contact counterforce, the contact time and the moving action between each sole of a large gecko and a spider and an attachment surface when the large gecko and the spider move on a horizontal plane, on a vertical plane and on a ceiling.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

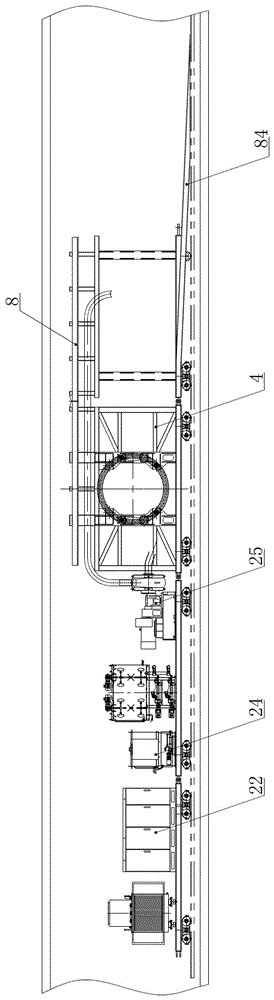

Shield tunneling machine for tunnel connecting passageway and connecting passageway tunneling method of shield tunneling machine

ActiveCN106437735AReaction support enoughCompact and reasonable structure designTunnelsShield tunnelingUltimate tensile strength

The invention belongs to the technical field of tunnel construction equipment, and relates to a shield tunneling machine for a tunnel connecting passageway and a connecting passageway tunneling method of the shield tunneling machine. The shield tunneling machine comprises a start end supporting walking platform and a receiving end supporting walking platform which are respectively arranged on material transportation rails in two main tunnels, a shield tunneling machine main unit, a counterforce supporting frame and a main tunnel supporting assembly which are respectively arranged on the start end supporting walking platform and a corresponding main tunnel duct piece, and a start end socket sealing assembly and a receiving end socket sealing assembly which are respectively arranged at the start end and the receiving end of the connecting passageway, wherein a duct piece hanging assembly is arranged on the start end supporting walking platform; a jacking tunneling assembly is arranged between the counterforce supporting frame and the shield tunneling machine main unit. The shield tunneling machine can realize automatically mechanical excavation; the labor intensity is greatly reduced, the energy consumption is reduced, and the cost is reduced; meanwhile, equipment construction is stable, and the efficiency is high; settling of the ground is effectively controlled, and the construction risk is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

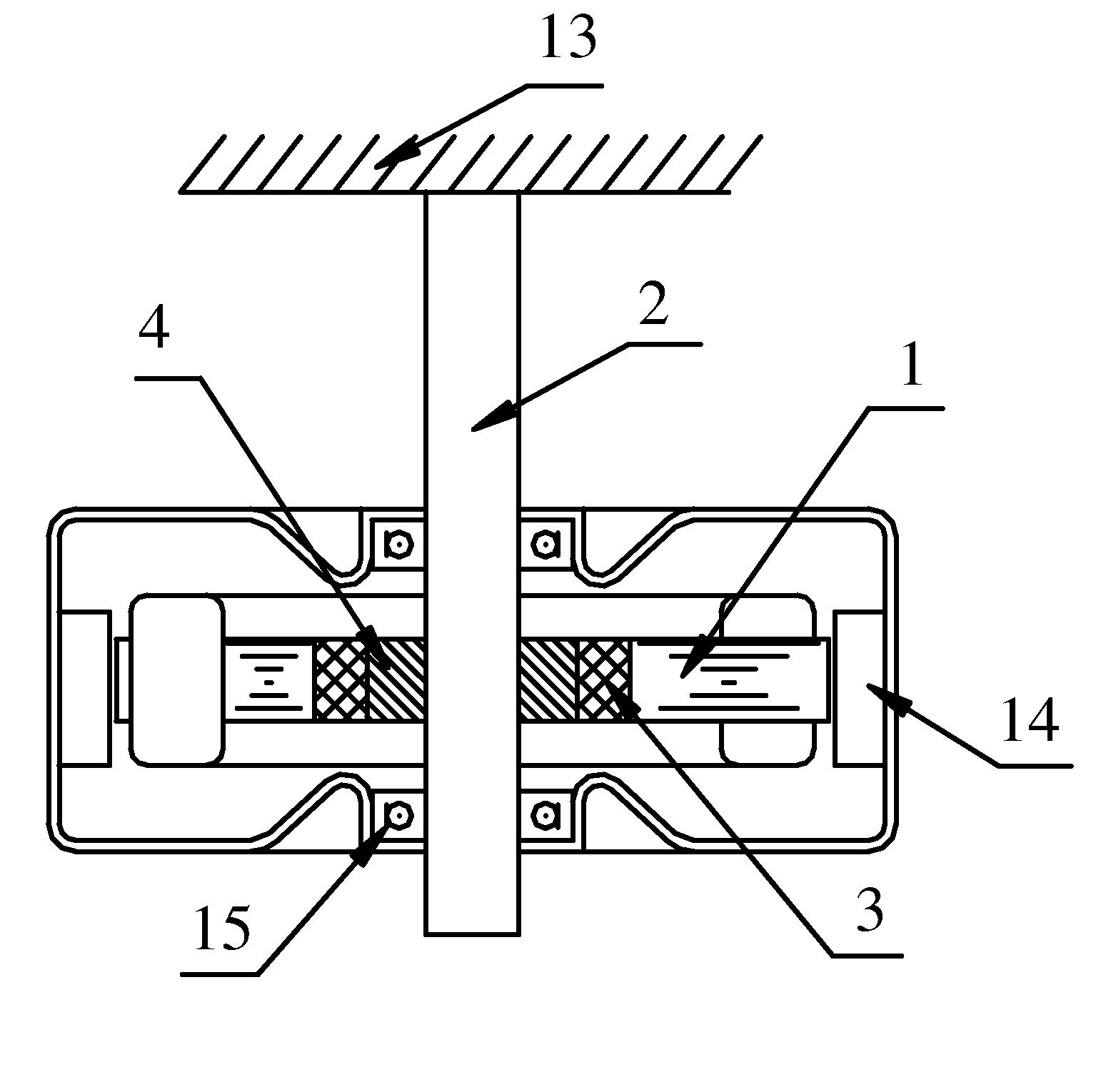

Shock absorbing connector

ActiveUS20080143198A1Reduce noiseReduce vibrationMagnetic circuit rotating partsSupports/enclosures/casingsEngineeringCounterforce

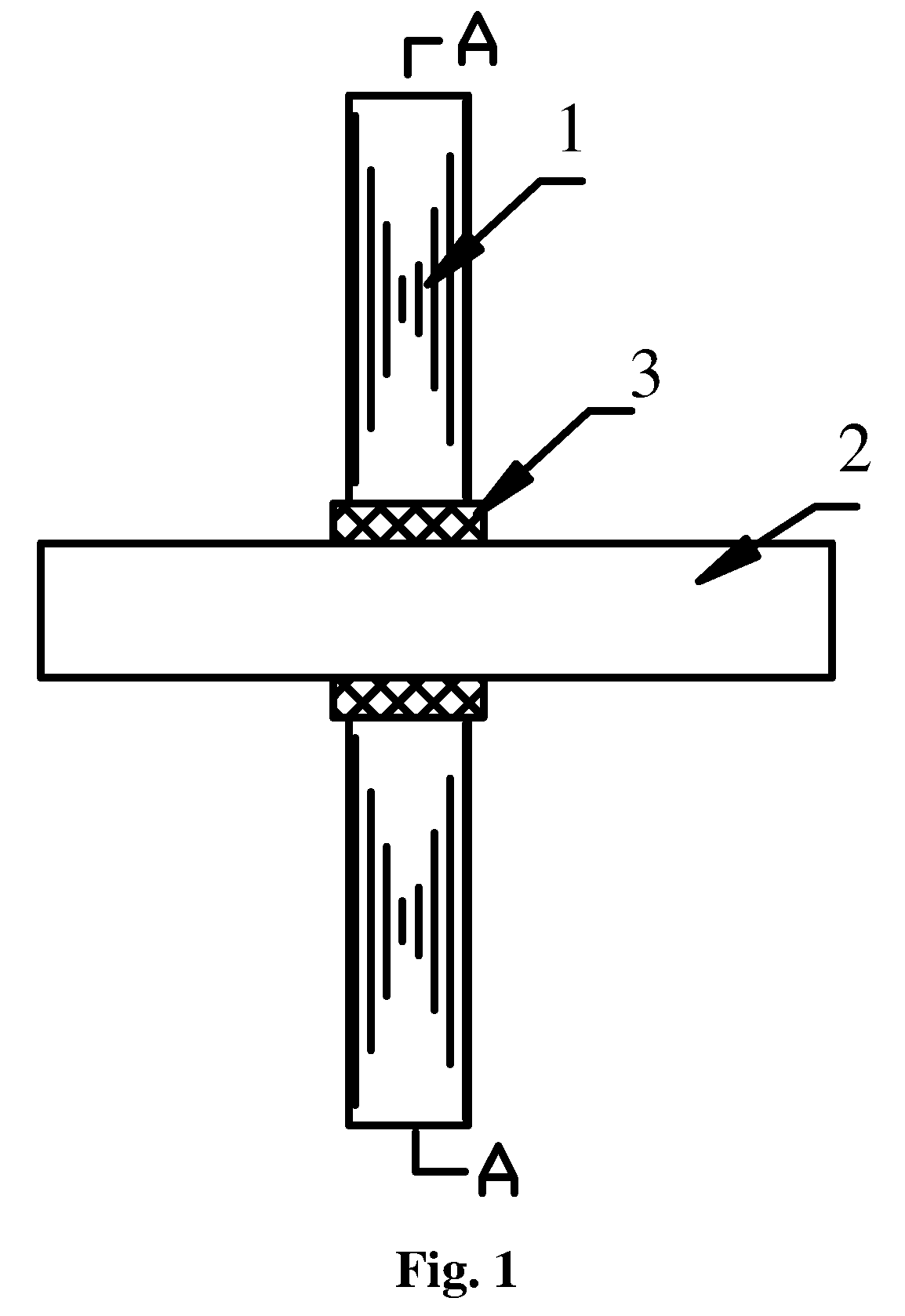

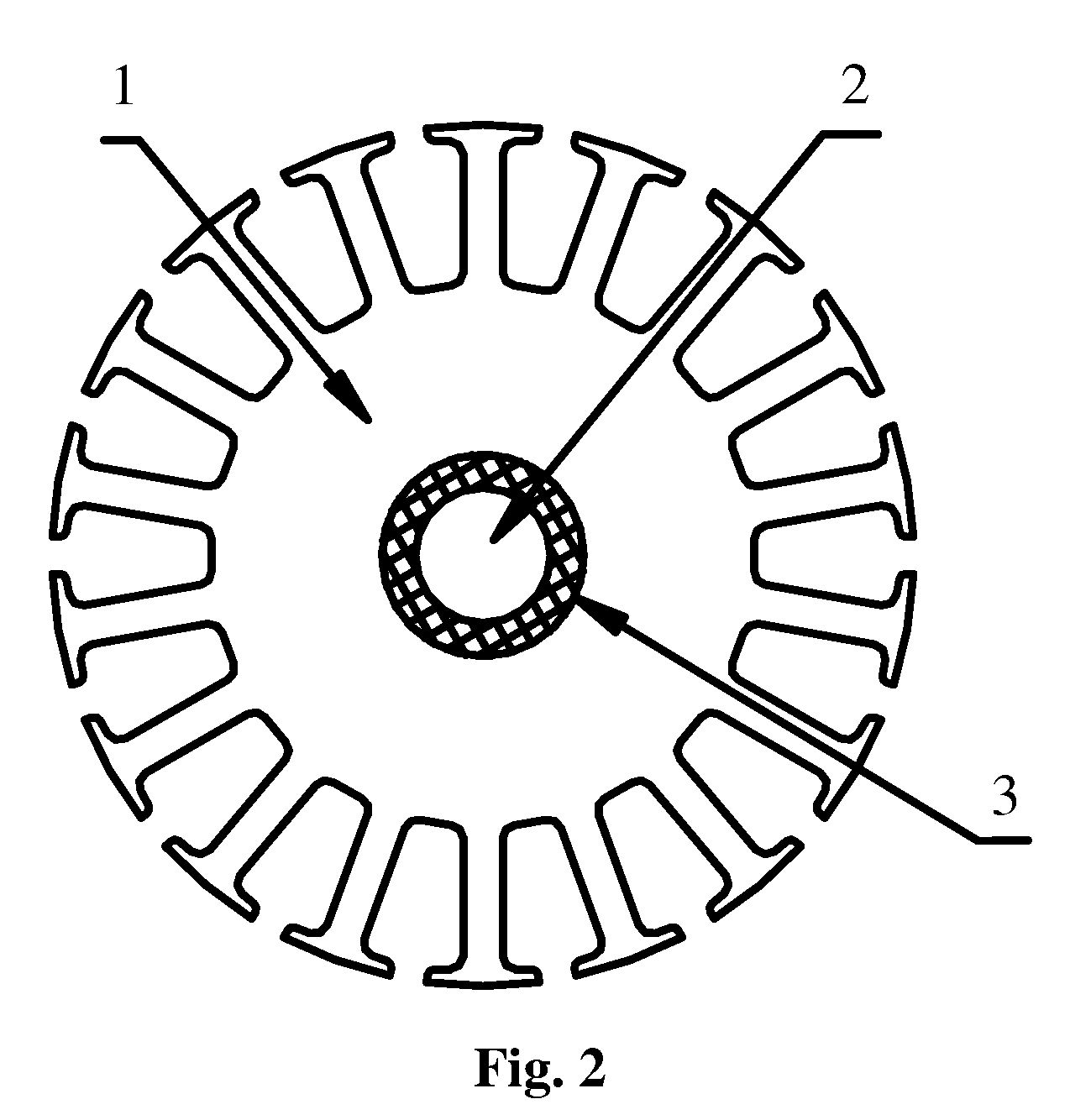

Taught herein is a motor, comprising a stator core (1), a shaft (2) nested around the stator core (1), and shock-absorbing connector, wherein the shock-absorbing connector is disposed between the stator core (1) and the shaft (2) so as to absorb and buffer unbalanced counterforces acting on the stator core (1) and to dampen the shocks experienced by the shaft (2) and reduce the overall noise generated by the motor.

Owner:ZHONGSHAN BROAD OCEAN

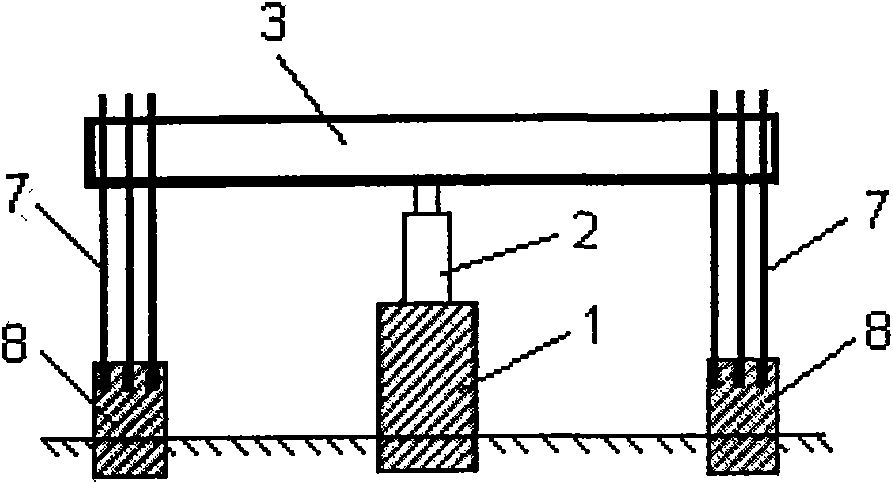

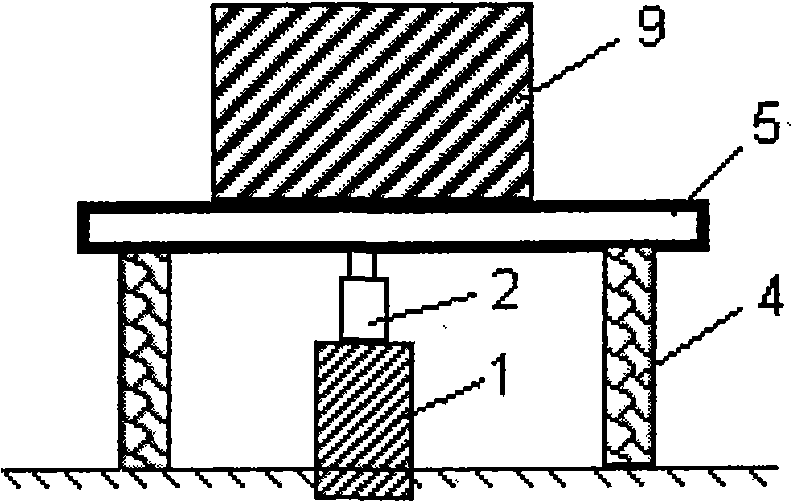

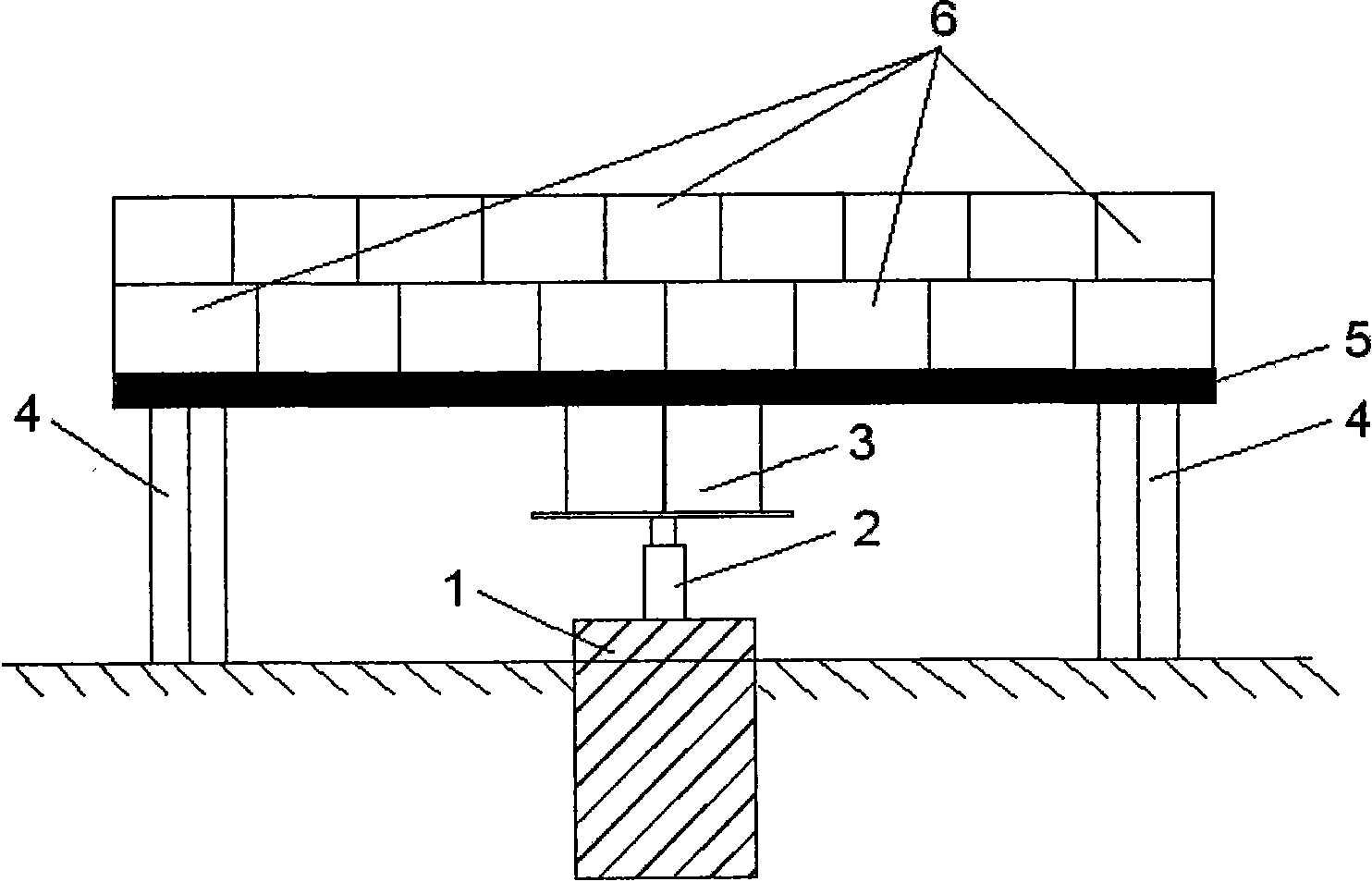

Foundation pile static test loading counterforce test method and weight boxes used by same

InactiveCN101560779AEasy and fast shippingFast transferFoundation testingMaterial strength using tensile/compressive forcesEngineeringCounterforce

The invention relates to a foundation pile static test loading counterforce test method and weight boxes used by the same. The test method comprises the following steps: arranging a jack in fit connection with a test apparatus on the top of a foundation pile to be tested; stacking and loading balances on a bearing platform under the cooperation of an auxiliary support structure; and testing the loading bearing capacity of the foundation pile to be tested through the test apparatus in fit connection with the jack when the jack gradually jacks up the bearing platform, wherein the balances stacked and loaded on the bearing platform is the piled balance material loaded in a plurality of the weight boxes. The weight boxes which are used in the test method for loading the balance material are particularly detachable combined type weight boxes. After assembly on the site, the weight boxes can be put into use when a loading machine is used to load the local balance material such as sandstone into the boxes. The test method is simple, convenient and quick, greatly reduces the construction cost, and has high safety. In addition, the test method can be used in a random sampling test of the static test for a large-tonnage filling pile.

Owner:CHINA MCC5 GROUP CORP

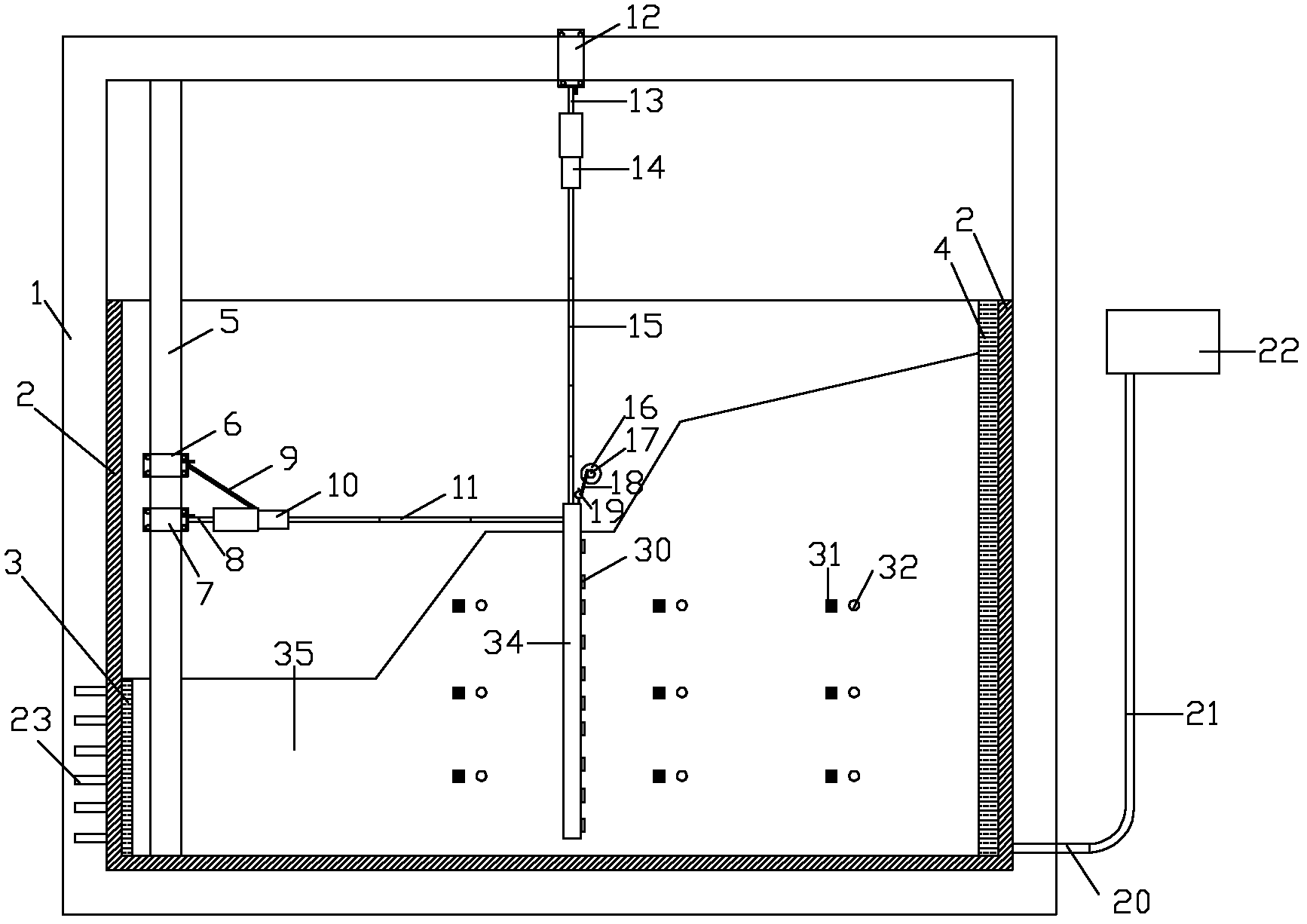

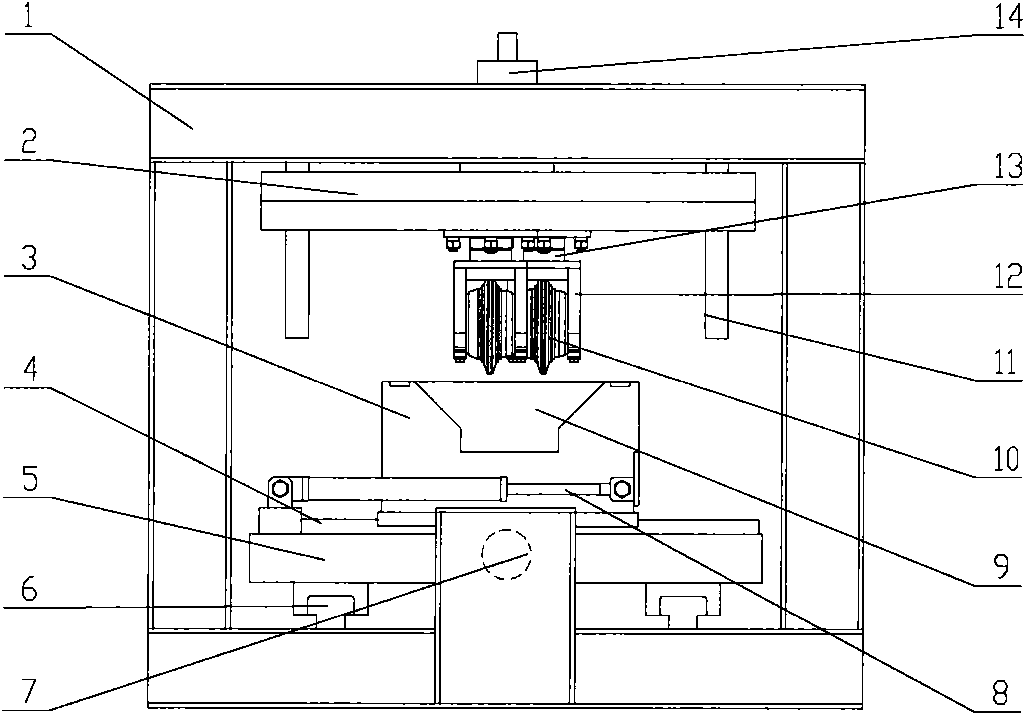

Synchronous detection test device for multi-item parameters of linear TBM hobs

InactiveCN101592533ARock breaking test data is accurateShorten the development and design cycleForce measurementMechanical clearance measurementsHydraulic cylinderPhase difference

The invention provides a synchronous detection test device for multi-item parameters of linear TBM hobs applied in the full-section hard-rock tunneling machine industry. The whole device consists of a self-counterforce frame, a regulate tool rest, an X-direction moving worktable, an X-direction linear guide rail, a Y-direction moving worktable, a Y-direction linear guide rail, an X-direction hydraulic cylinder, a rock sample, a hob, a four-rod guide mechanism, three-direction pressure sensors, a Z-direction hydraulic cylinder and the like, wherein the lateral movement direction of the rock sample is set as an X axis; the axial direction of the hob is set as a Y axis; the direction perpendicular to the surface of the rock sample is set as a Z axis; the rock sample is fixed on a trolley; the regulate tool rest is arranged on the four-rod guide mechanism; the X-direction moving worktable and the Y-direction moving worktable are arranged on a horizontal linear guide rail; the hob is arranged in a hob seat and is connected with the regulate tool rest through the three-direction pressure sensors; the rock sample is arranged and clamped on the X-direction moving worktable; and the three direction hydraulic cylinders are fixed with the fixed self-counterforce frame respectively. The device has the advantage of more precise function of simulating the process of breaking rocks through the hob, and is used for the synchronous detection of three-direction force, tool interval, penetration degree, wear degree, phase difference and other parameters of the hob in the states of linear paths and high-speed rotation of a plurality of hobs.

Owner:SHENYANG HEAVY MACHINERY GROUP

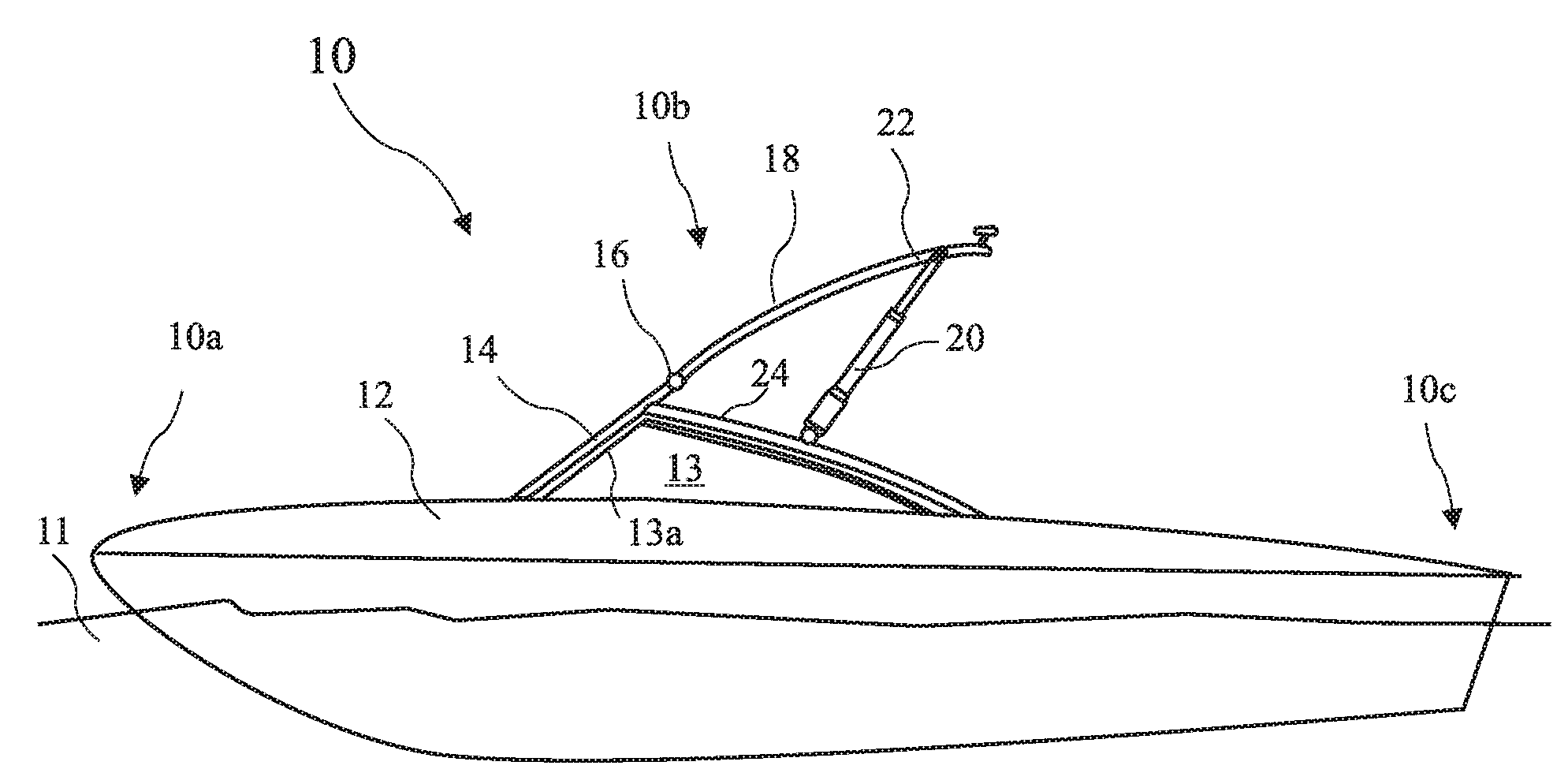

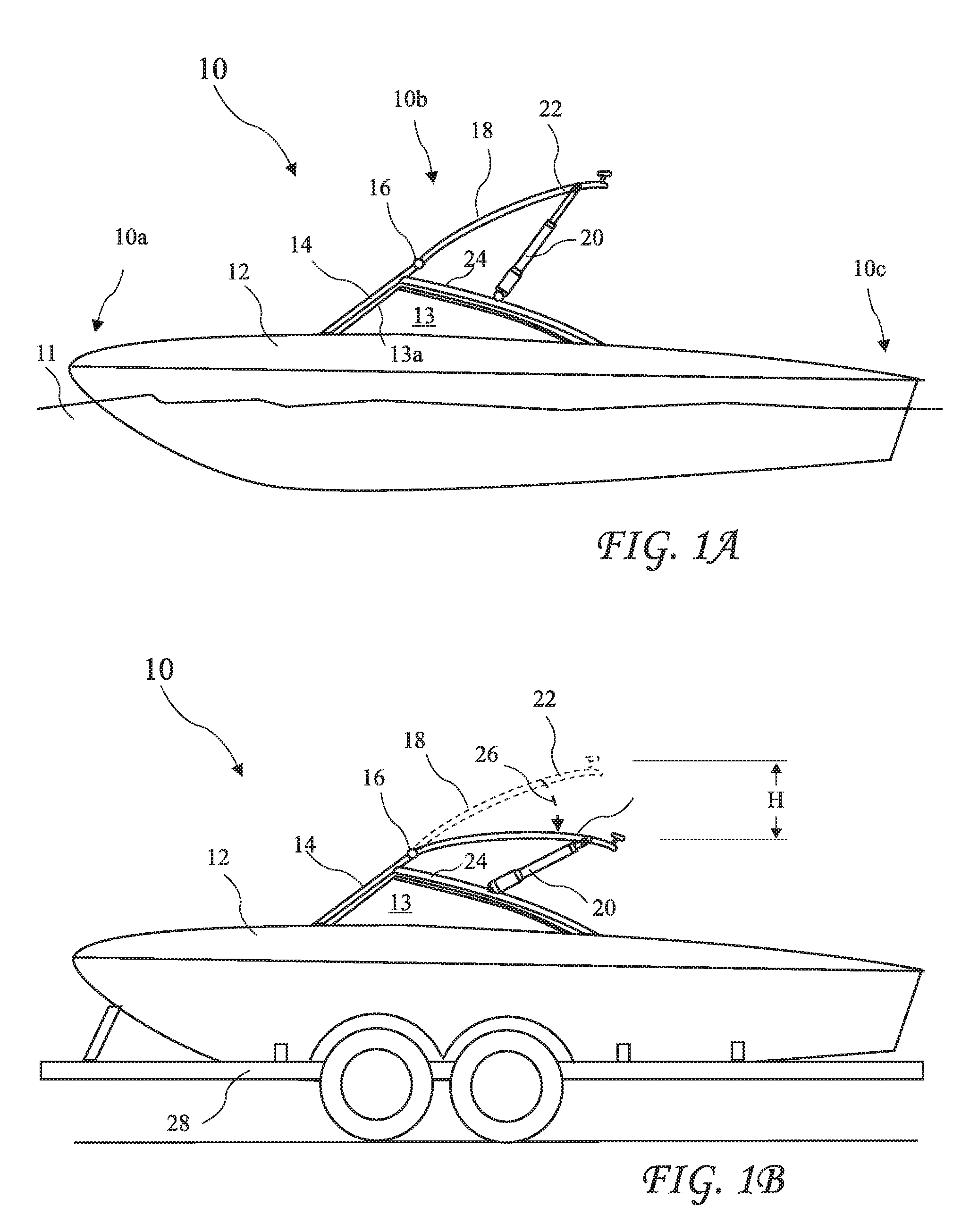

Lowerable water sport tow attachment

InactiveUS7536971B1Effectively jam-lockPrevent back creepVessel partsRecreational vesselsEngineeringTower

A water craft includes a tow tower including a tower loop raised and lowered by two linear actuators. The tower loop is firmly supported in the raised position by the linear actuators to provide a proper attachment for towing enthusiasts, and is lowered to allow the water craft to be stored in a normal height garage structure. The linear actuators are unique designs with large shaft diameter, short stroke, and high overlap between the shaft and actuator body, and in particular include novel compressible bumpers to create a compressive jam-lock counterforce at full extension to effectively jam-lock the linear actuator and prevent back creep.

Owner:FRY JOHN

Bending torsion test loading device for steel tube concrete pile

InactiveCN103558099ASolution conditionsSolve the two major problems of non-ideal rotation of CFST columns when torque is appliedMachine part testingStrength propertiesCircular discPull force

The invention discloses a bending torsion test loading device for a steel tube concrete pile. According to the bending torsion test loading device for the steel tube concrete pile, two problems that the bending moment condition is not ideal and simple, and the rotation of the steel tube concrete pile is not ideal when the torque is applied in a previous bending torsion test are solved. The bending torsion test loading device comprises two tension jacks, tension sensors, a connection joint, steel wire ropes, round groove discs, a fixed hinge support, a sliding hinge support, two counterforce pillars and rotation supports, wherein the rotation supports are mounted on the fixed hinge support and the sliding hinge support respectively; the two tension jacks are mounted on the outer sides of the two counterforce pillars respectively and located on different sides of the round groove discs on two ends of the steel tube concrete pile; the top ends of the tension jacks are provided with the tension sensors; the tension sensors are connected with the steel wire ropes which are wound on the round groove discs through connection joints. Due to the adoption of the bending torsion test loading device for the steel tube concrete pile, bending torsion test results of the steel tube concrete pile fit with finite element analysis results well. Meanwhile, the bending torsion test loading device for the steel tube concrete pile also has the characteristics of convenience in assembly and recyclability.

Owner:SHENYANG JIANZHU UNIVERSITY

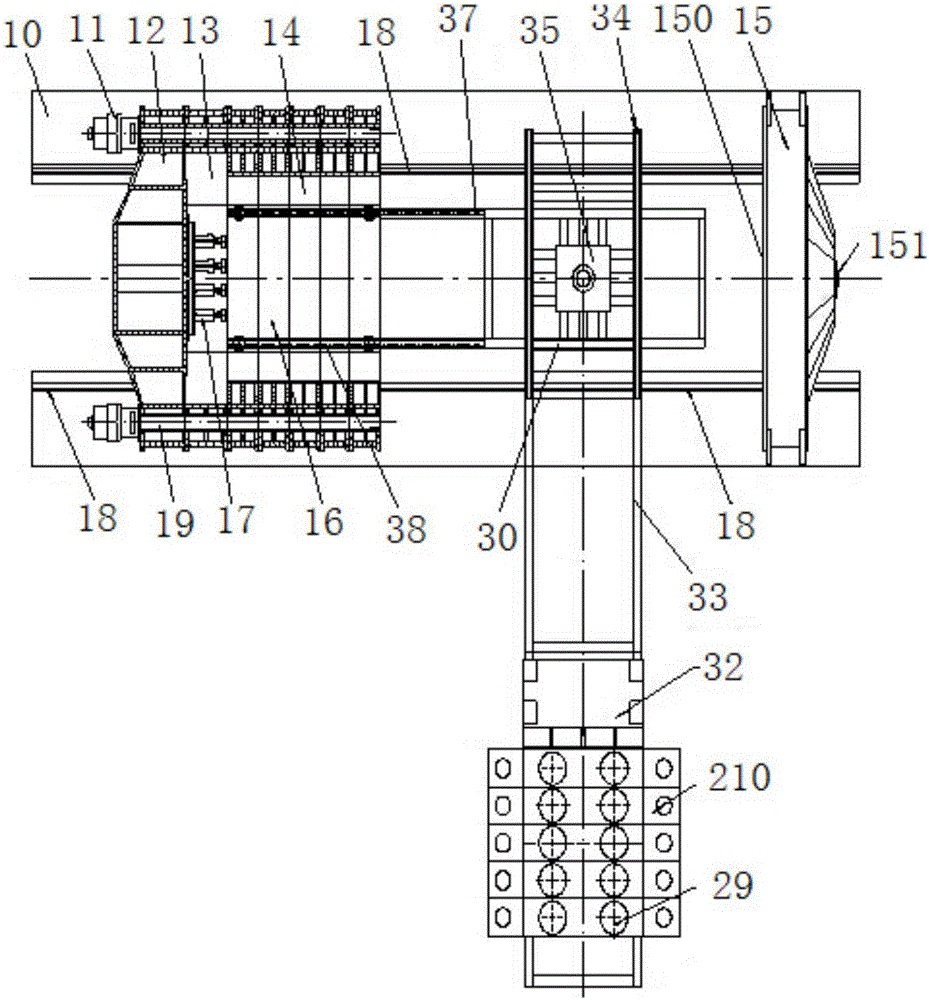

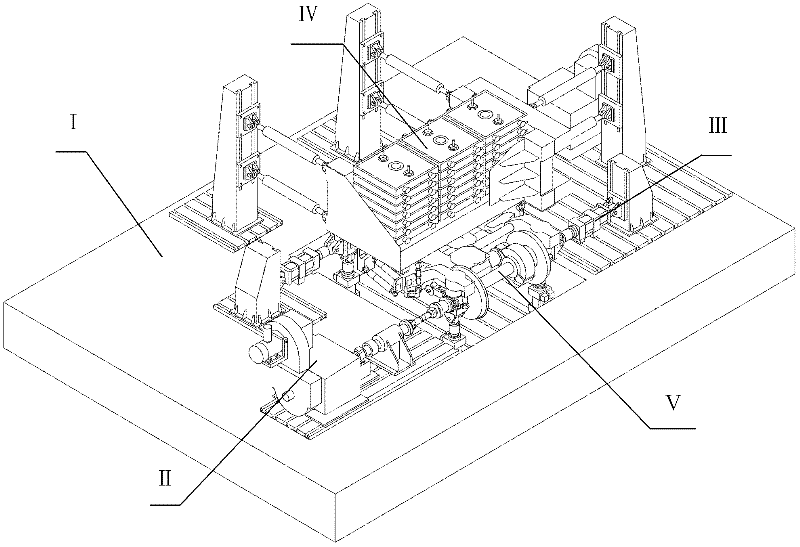

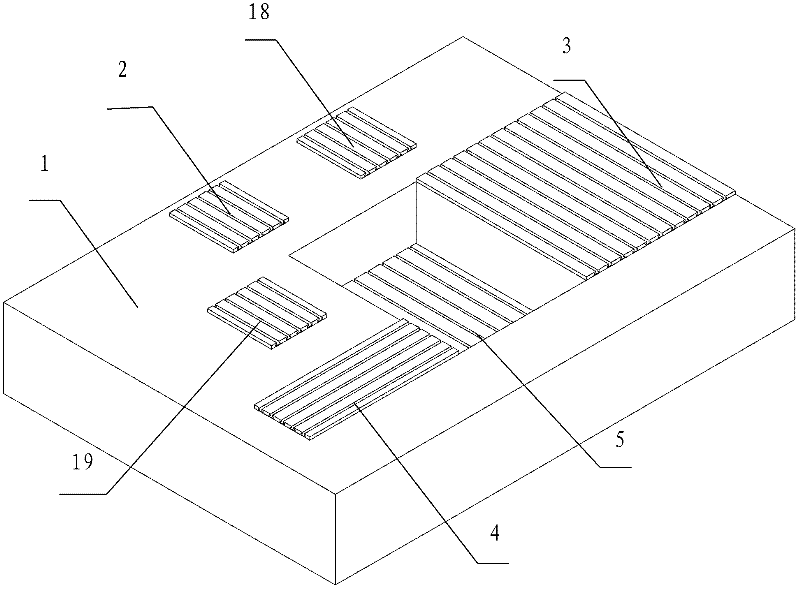

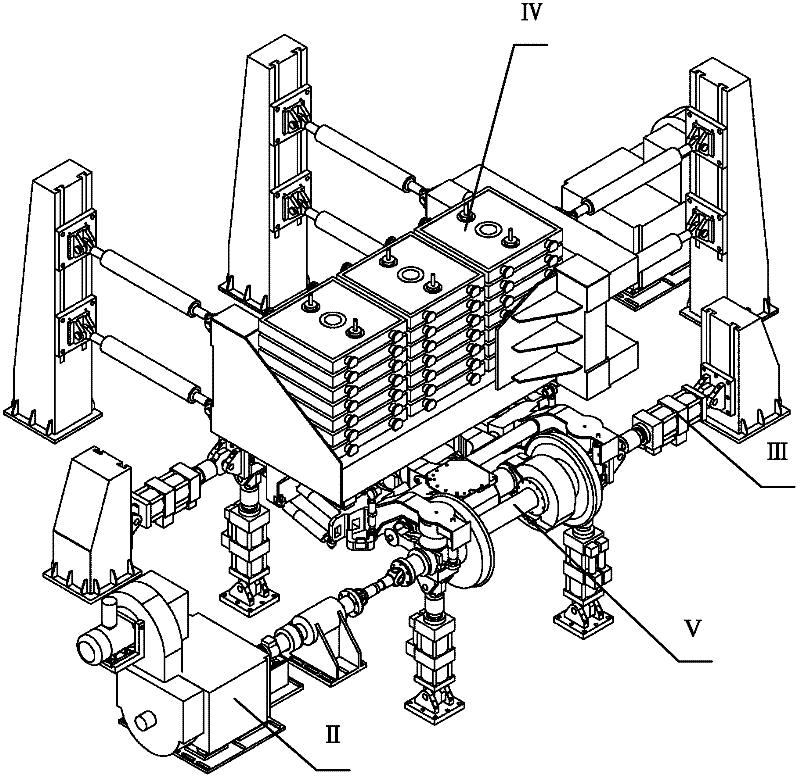

Reliability test platform for frame and traction transmission system of bogie of bullet train

The invention discloses a reliability test platform for a frame and a traction transmission system of a bogie of a bullet train. The platform comprises a mechanical assembly part, a test platform base and a hydraulic pump station, wherein the test platform base consists of a concrete base of a rectangular pit, and a No.1 counterforce seat base platform, a No.2 counterforce seat base platform, a large-range adjustable platform, a base pit platform, a driving device base platform and a No.3 counterforce seat base platform which are poured in the concrete base and are positioned in the same horizontal plane; the mechanism assembly part comprises loading devices, an excitation system assembly and a semi-vehicle quality simulation device; the loading devices are fixed on the driving device base platform and the large-range adjustable platform; the excitation system assembly is provided with four vertical actuators and two horizontal excitation assemblies; the bottom ends of the four vertical actuators are fixedly connected with the base pit platform; one end of one horizontal excitation assembly and one end of the other horizontal excitation assembly are fixedly connected with the large-range adjustable platform and the No.3 counterforce seat base platform; and the bottom end of the semi-vehicle quality simulation device is fixed on the test platform base.

Owner:JILIN UNIV

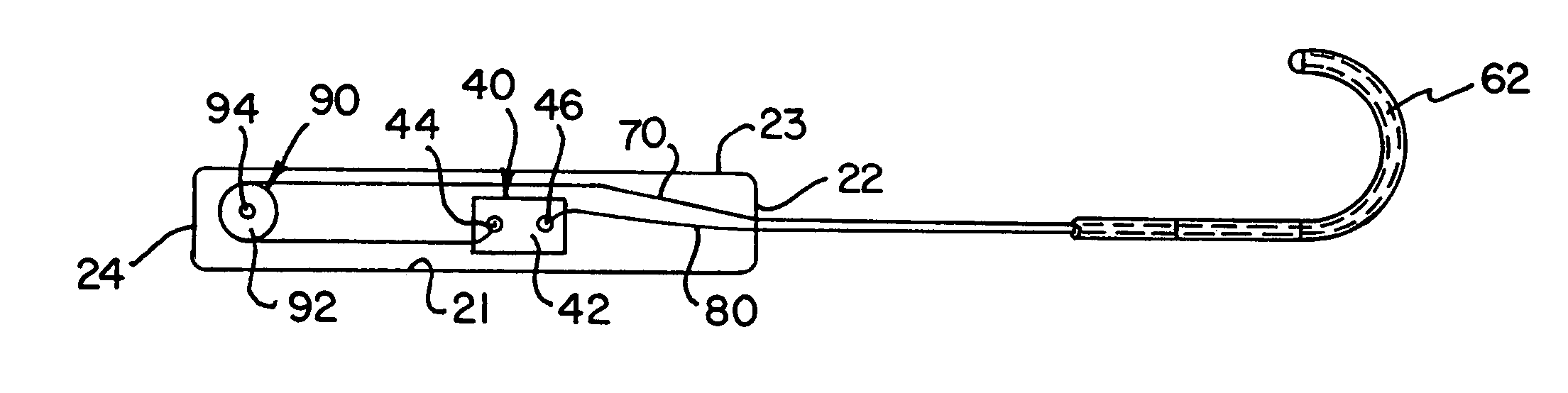

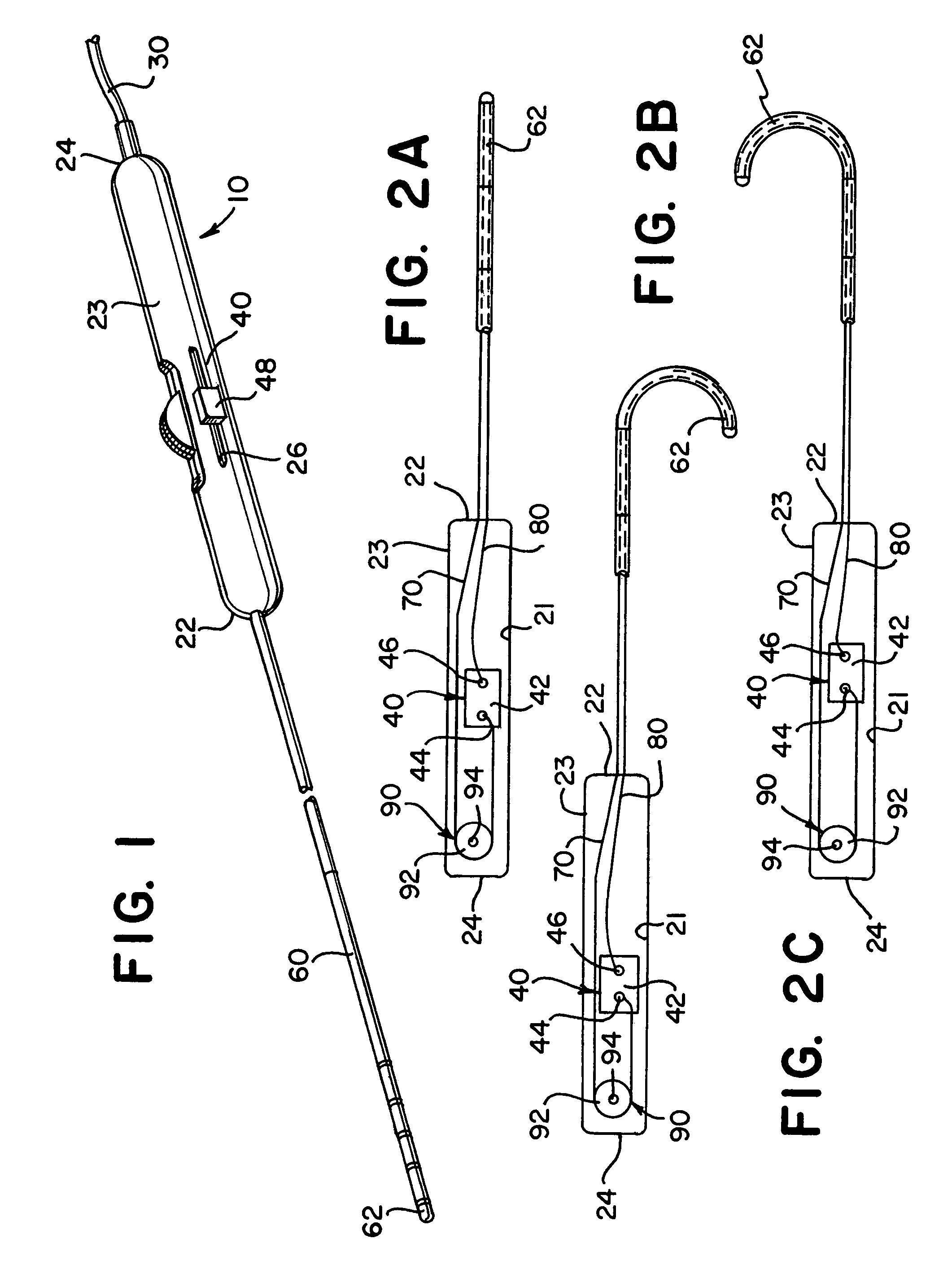

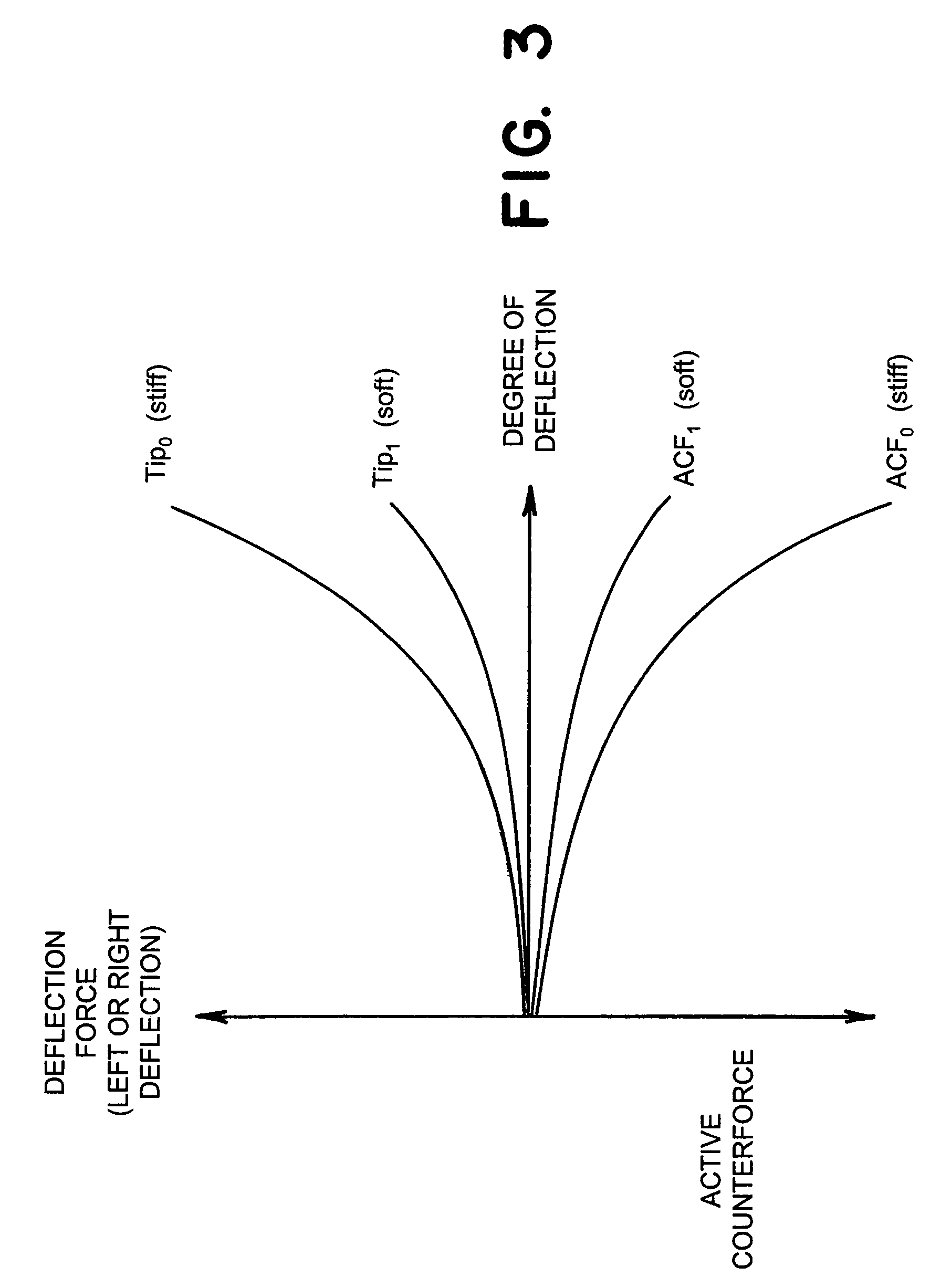

Active counterforce handle for use in bidirectional deflectable tip instruments

InactiveUS7524301B2Little if any resistanceReduce forceMedical devicesCatheterCombined useEngineering

The present invention is directed to an active handle assembly for use in a bidirectional steerable surgical instrument having a deflectable distal end. Typically, the surgical instrument includes a handle component which the user manipulates to cause a distal end of the instrument to deflect. The distal end comprises an end tip portion of a shaft which extends outwardly from the handle. A control mechanism is disposed within the handle and extends through the shaft for selectively controlling the direction and degree of deflection at the distal end. For example, one exemplary control mechanism uses control or steering wires to deflect the distal end. The active counterforce mechanism according to the present invention is designed to be used in combination with the control mechanism and provides a force which counters the return to center force generated by the deflection of the shaft at the distal end thereof. Optimally, the active counterforce mechanism balances the return to center force across the instrument's deflection range in distal and proximal directions. This results in the user experiencing minimal, if any, resistance during the manual manipulation of the control mechanism.

Owner:BOSTON SCI SCIMED INC

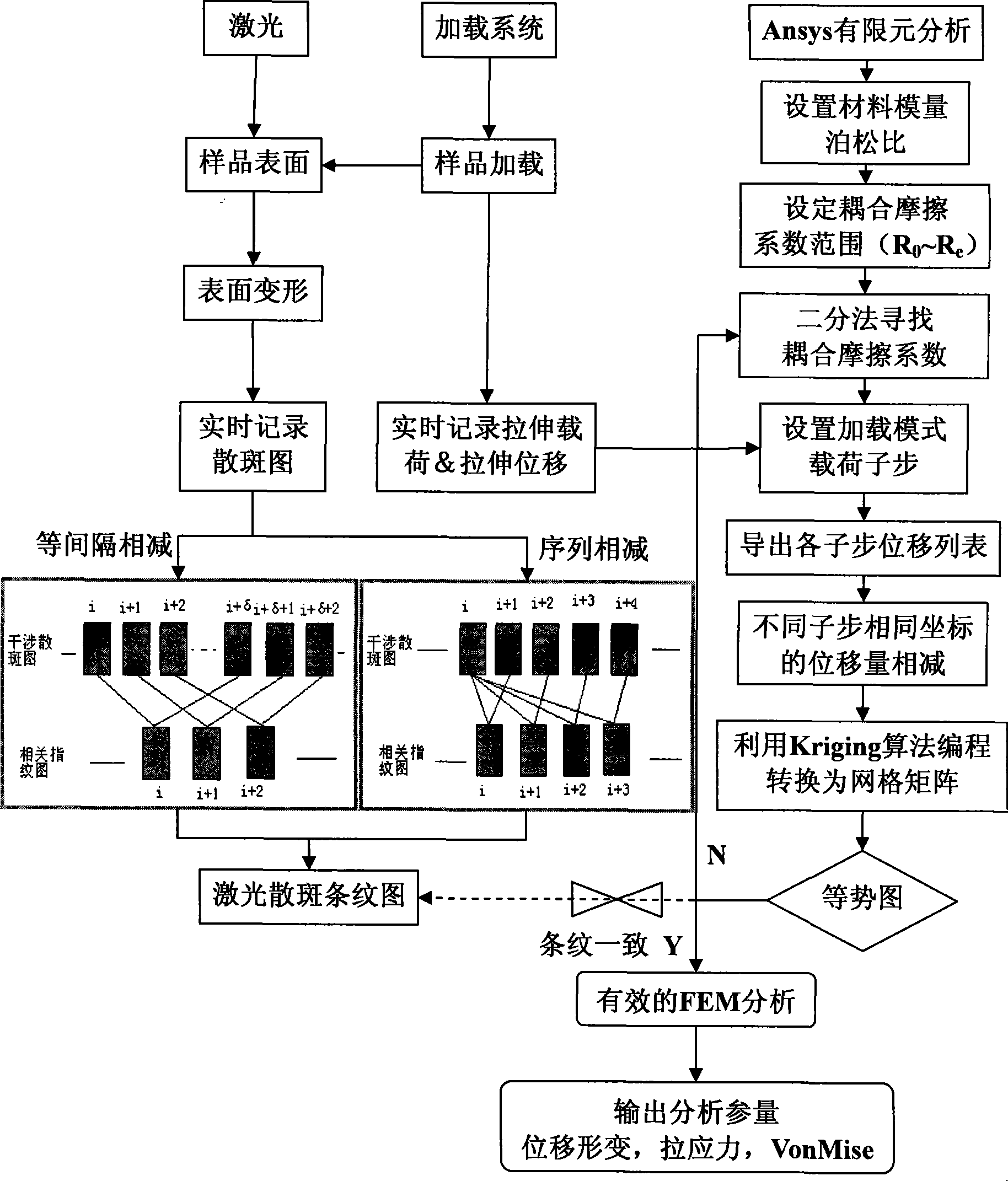

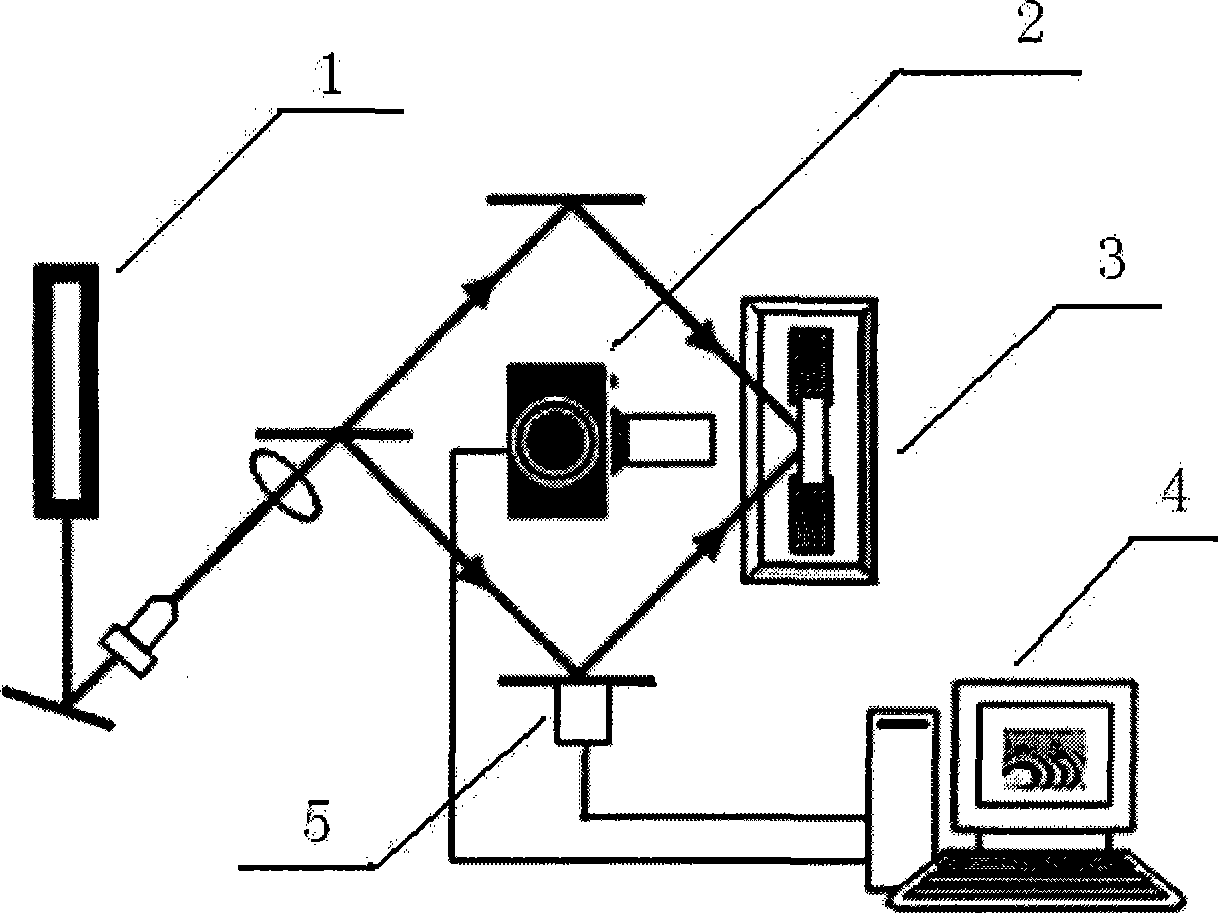

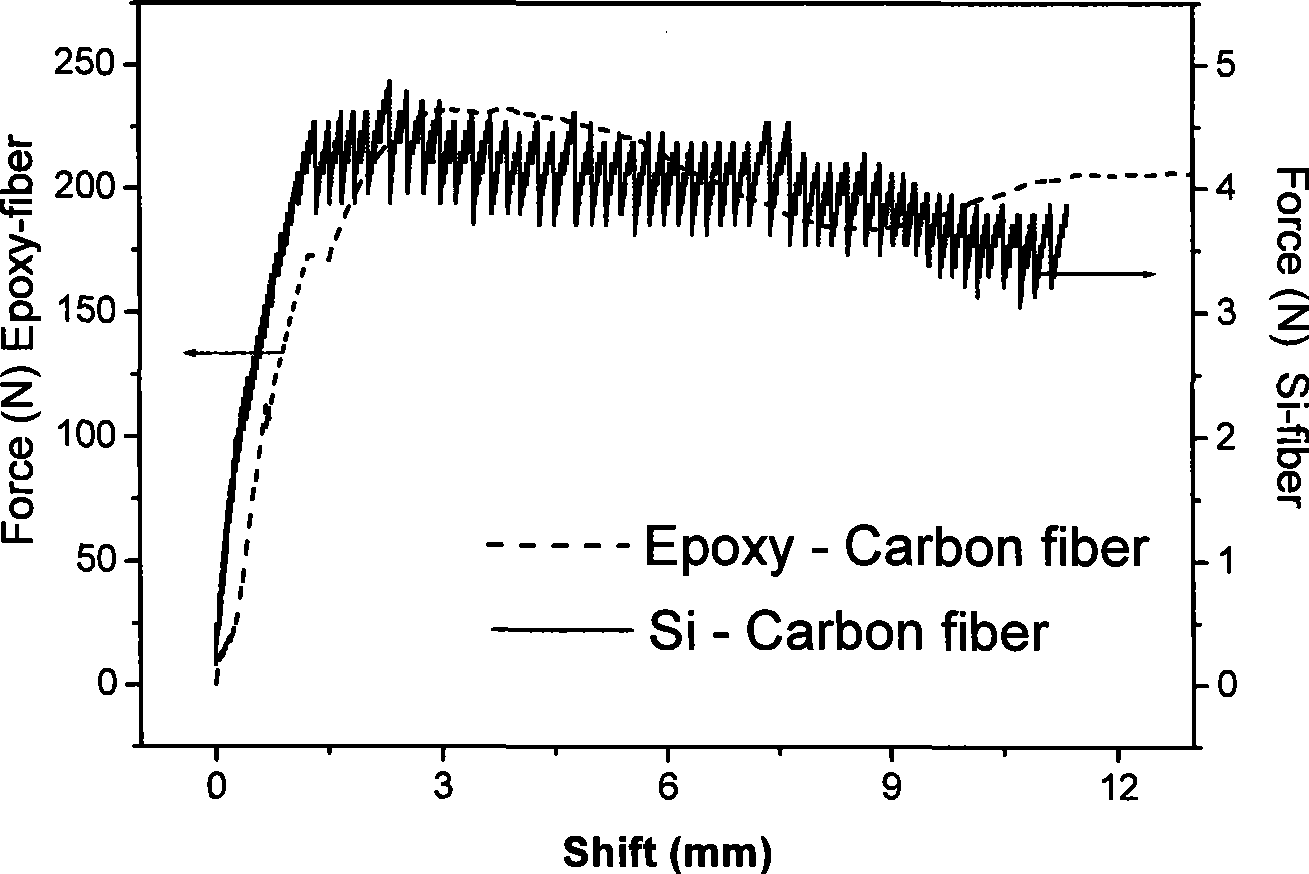

Method for quantitatively analyzing material interface properties by combining non-destructive testing and definite element modelling

InactiveCN101545849AImprove stressReal-time observation of mesoscopic damage behaviorMaterial analysis by optical meansUsing optical meansNon destructiveFiber

The invention relates to a method for quantitatively analyzing material interface properties by combining non-destructive testing and definite element modelling. In the method, by loading a composite material, a non-destructive testing system records a loading variable; and at the same time, a finite element method correspondingly simulates the whole loading process of a test piece according to intrinsic properties, modulus, tensile strength, Poisson ratio and the like of the material so as to find a simulation state corresponding to the non-destructive testing variable and further obtain comprehensive analysis results, including various physical quantities reflecting the material interface properties such as friction coefficient between fibers and a matrix, stress, straining, counterforce and the like, in the simulation state. The non-destructive testing high-precision method verifies partial parameters of finite element analysis, and the finite element analysis provides more comprehensive analysis results. The method has the advantages of high sensitivity, credible quantitative values and no need of damaging an adhesive layer.

Owner:INST OF CHEM CHINESE ACAD OF SCI

RF multiple load cell scale

InactiveUS20040026135A1Eliminate needEnergy efficient ICTWeighing apparatus using elastically-deformable membersMicrocomputerTransceiver

Load cells forming one or more weighing scales are connected to each other and to a common concentrator which communicates to a master controller in the control house via RF wireless communication. The load cells are polled by and provide weight reading to concentrator to the master controller. A digital load cell is used which includes a rocker pin, guided beam, torsion ring or other counterforce, a circuit board mounted on the counterforce and an enclosure sealing the circuit board and all but the load bearing surfaces of the counterforce and a mounded antenna. The circuit board includes a microcomputer and a transceiver. RF communication is provided with the circuit board through a antenna mounted on the enclosure. One or a number of load cells may be connected to a computer or controller to form one or more weighing scales with one or more weighing scales connect to a control house through wireless RF communication. The preferred embodiment uses passive receivers for receiving the signals and waveguide to minimize power requirements.

Owner:METTLER TOLEDO INC

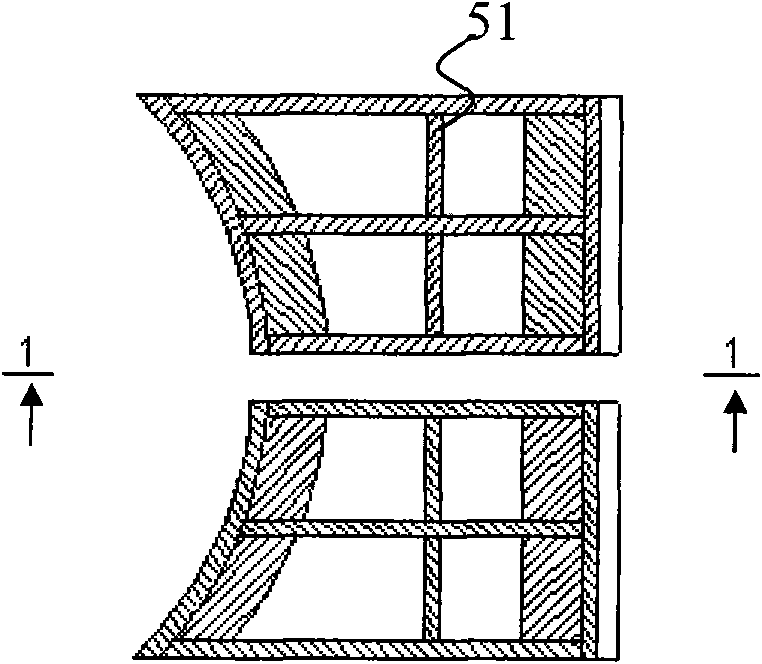

Cross steel plate water-stopping joint continuous concrete wall and joint construction method thereof

InactiveCN101608447AIncreased shear strengthImprove integrityArtificial islandsUnderwater structuresSlurry wallCement slurry

The invention provides a cross steel plate water-stopping joint of a continuous concrete wall and a joint construction method thereof. The cross steel plate joint comprises a longitudinal water-stopping steel plate and a horizontal head steel plate, wherein the longitudinal water-stopping steel plate is about 35-50 cm long, a detouring flow line of cement slurry is lengthened, the impermeability of the joint of the continuous concrete wall is enhanced, the bottom of the horizontal head steel plate extends to the tank bottom level or is inserted into the soil by 20 cm, and the detouring flow line of concrete and sand pulp along the bottom of the head steel plate is blocked; during constructing, a cross steel plate and a steel reinforcement cage are welded into a whole which is then deposited into a tank section so that the joint and a wall body have better integrity; a counterforce box is deposited at the back of the cross steel plate and is impacted to enter soil by over + / -30 cm, and then carpolite or clay are backfilled at the back for sealing; the concrete is cast in the tank section; the counterforce box is pulled out, then a flushing or shoveling tool corresponding to the cross steel plate in structure is adopted to remove the attachment at the part so as to ensure the water-stopping effect and the joint intensity of the cross steel plate.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

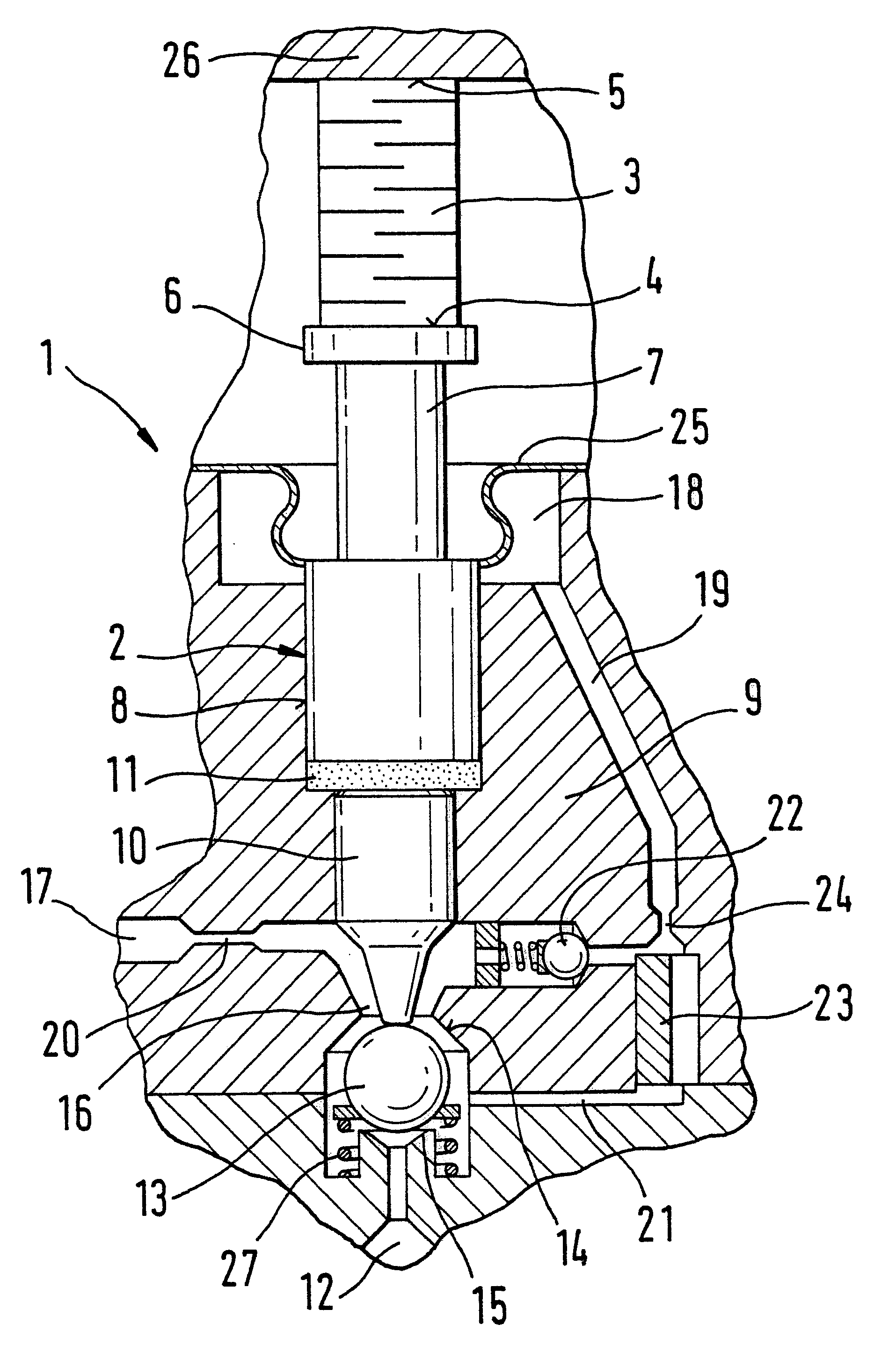

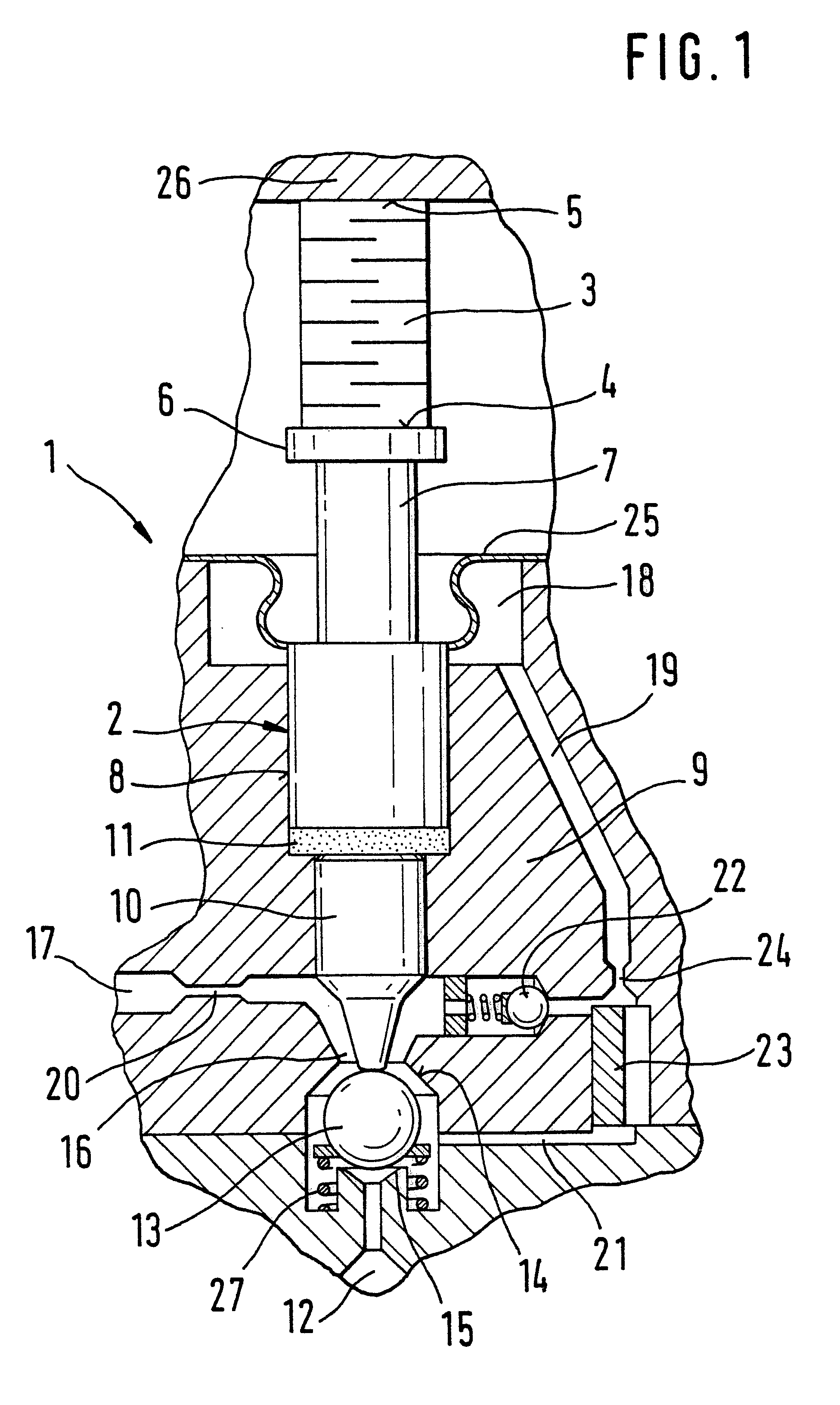

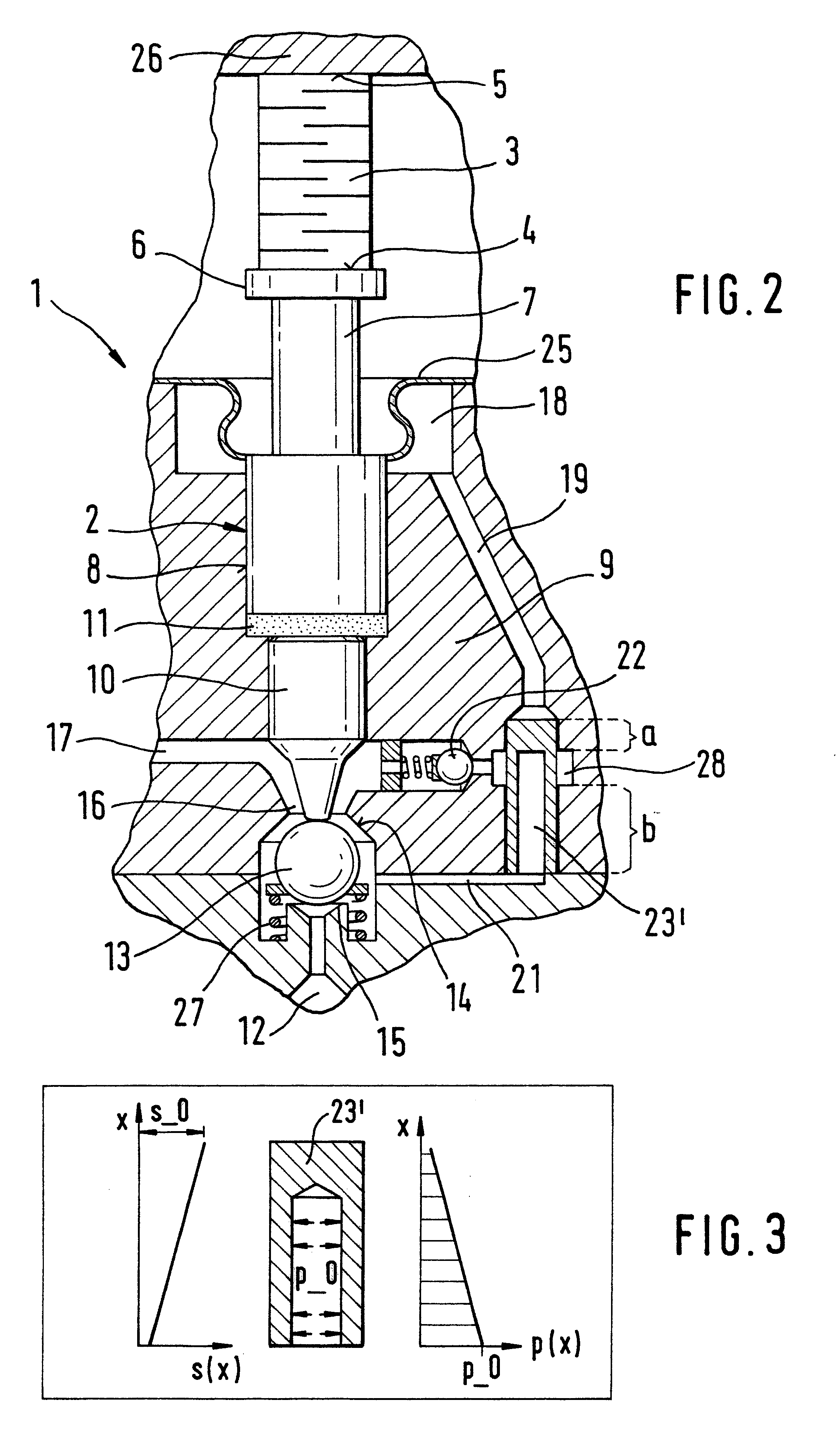

Valve for controlling fluids

InactiveUS6427968B1Low production costOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesSystem pressureEngineering

A valve (1) for controlling liquids is embodied with a piezoelectric unit (3) for actuating a valve member (2) that is axially displaceable in a bore (8) of a valve body (9). One end of the bore (8) adjoins a valve system pressure chamber (18) defined by a sealing element (25), and its other end adjoins a valve low-pressure chamber (16), which has a leak drainage conduit (17) and which communicates with the valve system pressure chamber (18) via a compensation conduit (19), which has a pressure limiting device (20, 23') and a filling device (23, 23'). The valve member (2) is assigned a valve closing member (13), which cooperates in such a way with at least two valve seats (14, 15), disposed in the valve low-pressure chamber (16), for opening and closing the valve (1) that in a closing position it separates the valve low-pressure chamber (16) from a valve control chamber (12), which is at high pressure, and in an intermediate position between the valve seats (14, 15) it fluidically connects the valve low-pressure chamber (16) to the valve control chamber (12); at least one damping device (20, 23', 24) for damping the control motions of the valve member (2) is provided and briefly generates hydraulic counterforces (Fig.).

Owner:ROBERT BOSCH GMBH

Energy storage drop hammer type dynamic-static coupling loading testing device

ActiveCN106198227AReasonable structural designEasy to operateMaterial strength using tensile/compressive forcesControl systemHydraulic pump

The invention provides an energy storage drop hammer type dynamic-static coupling loading testing device and belongs to the technical field of prevention and control of mine disasters. The energy storage drop hammer type dynamic-static coupling loading testing device comprises a framework, an impact force loading system, a static load loading system, a load control system and a high-speed data signal acquisition system; the impact force loading system comprises a third hydraulic oil cylinder, a retractable limiting sleeve, a drop hammer releasing device, a sleeve and a drop hammer; the retractable limiting sleeve is fixed on the framework above the drop hammer releasing device; a piston rod of the third hydraulic oil cylinder penetrates through the retractable limiting sleeve and then is fixedly connected with a positioning sleeve; the static load loading system comprises a counterforce box body; the counterforce box body is internally provided with an upper pressing head, a lower pressing head, a left pressing head and a right pressing head; the left pressing head is connected with a first static load piston; the right pressing head is connected with a second static load piston; the upper pressing head is connected with a dynamic load piston; the dynamic load piston is arranged below the drop hammer; the load control system comprises a hydraulic pump station; the hydraulic pump station is connected with each hydraulic oil cylinder; an impact force sensor is arranged at the top of the dynamic load piston and is connected with a computer.

Owner:LIAONING TECHNICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com