Bending torsion test loading device for steel tube concrete pile

A technology of steel tube concrete column and loading device, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc. It can solve the problems of affecting rotation, not being able to guide engineering practice well, and large friction, etc., to achieve assembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

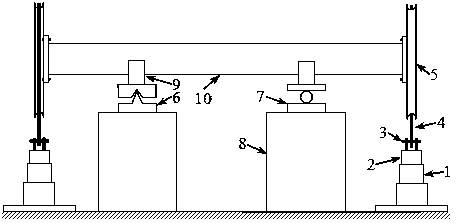

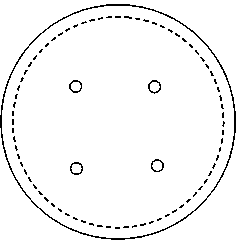

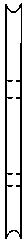

[0013] During the actual application of the present invention, at first two reaction piers 8 are fixed on the ground according to the distance required for the test, and the fixed hinge support 6 and the sliding hinge support 7 equipped with the rotating support 9 are fixed on the reaction piers 8 Above, the fixed hinge support 6 and the sliding hinge support 7 can ensure the boundary conditions of the concrete-filled steel tube column 10 being bent, and realize an ideal simply-supported state, and the rotating support 9 can ensure the flexible rotation of the steel-filled steel tube concrete column 10 . Both ends of the concrete-filled steel pipe column 10 are connected together with the grooved disc 5 by bolts and placed on two rotating supports 9. The tension jack 1 for applying bending moment and torque is installed on the outside of the reaction pier 8, located on the concrete-filled steel pipe column. On the opposite side of the grooved disc 5 at both ends of the column 1...

Embodiment 2

[0015] The present invention can replace the arc-shaped seat bracket 11 with the rectangular seat bracket 12 when carrying out the bending and torsion test of the rectangular steel tube concrete column, and the same is true for columns with other cross-sectional shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com