Patents

Literature

8631results about "Biological sludge treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

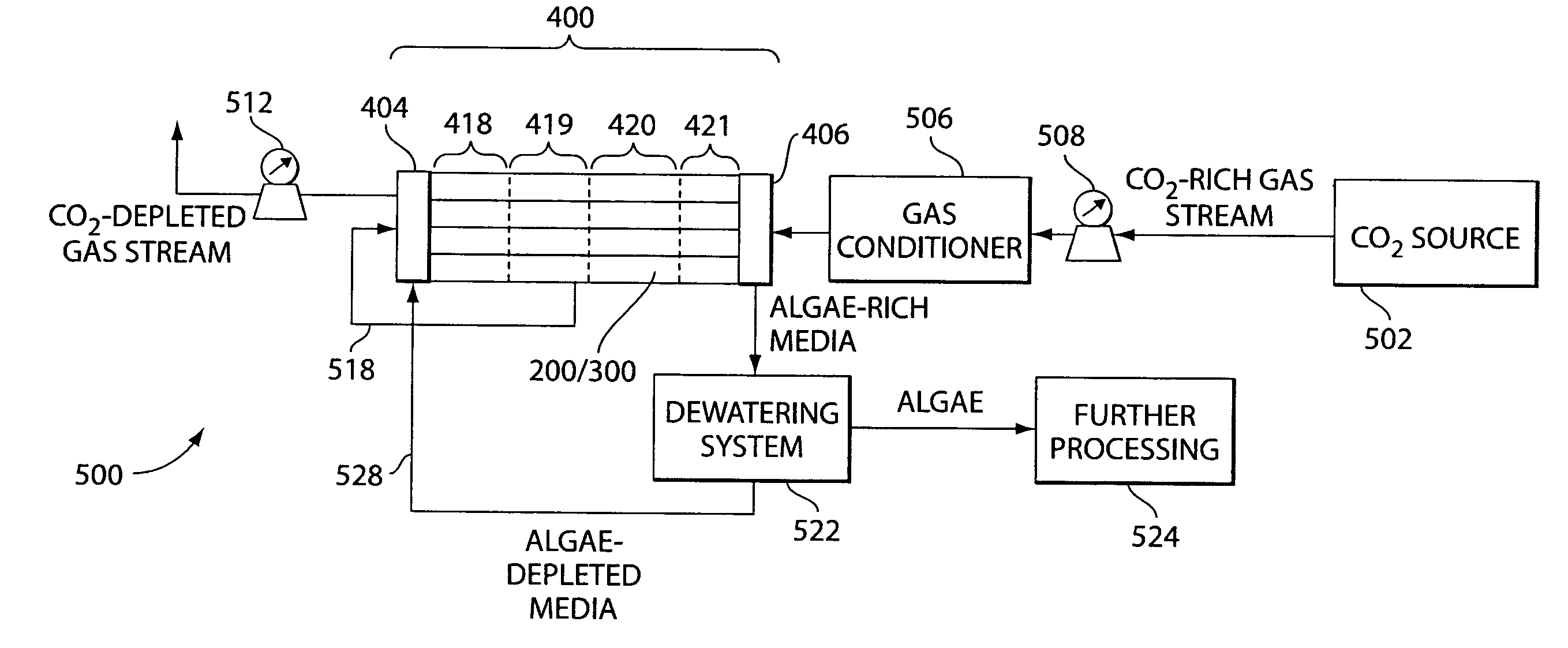

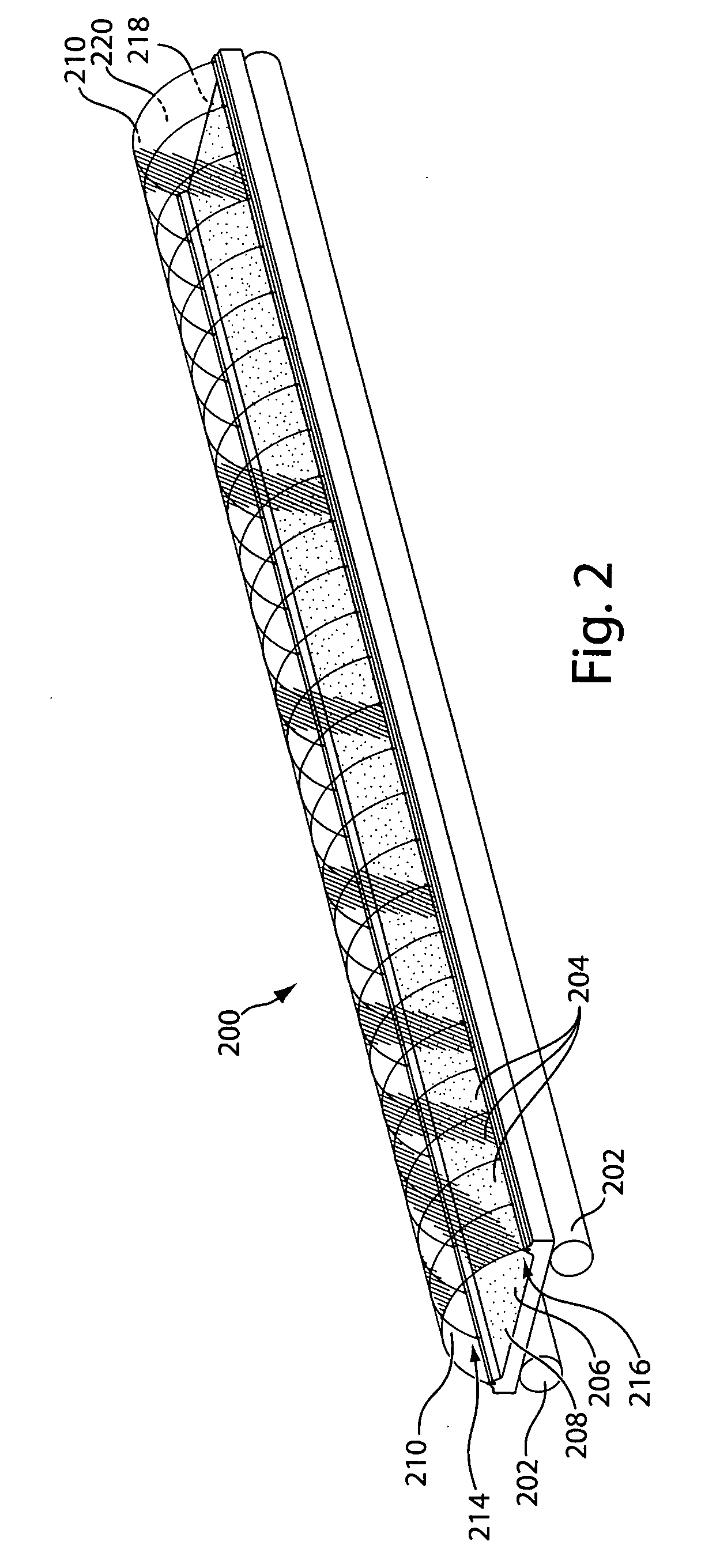

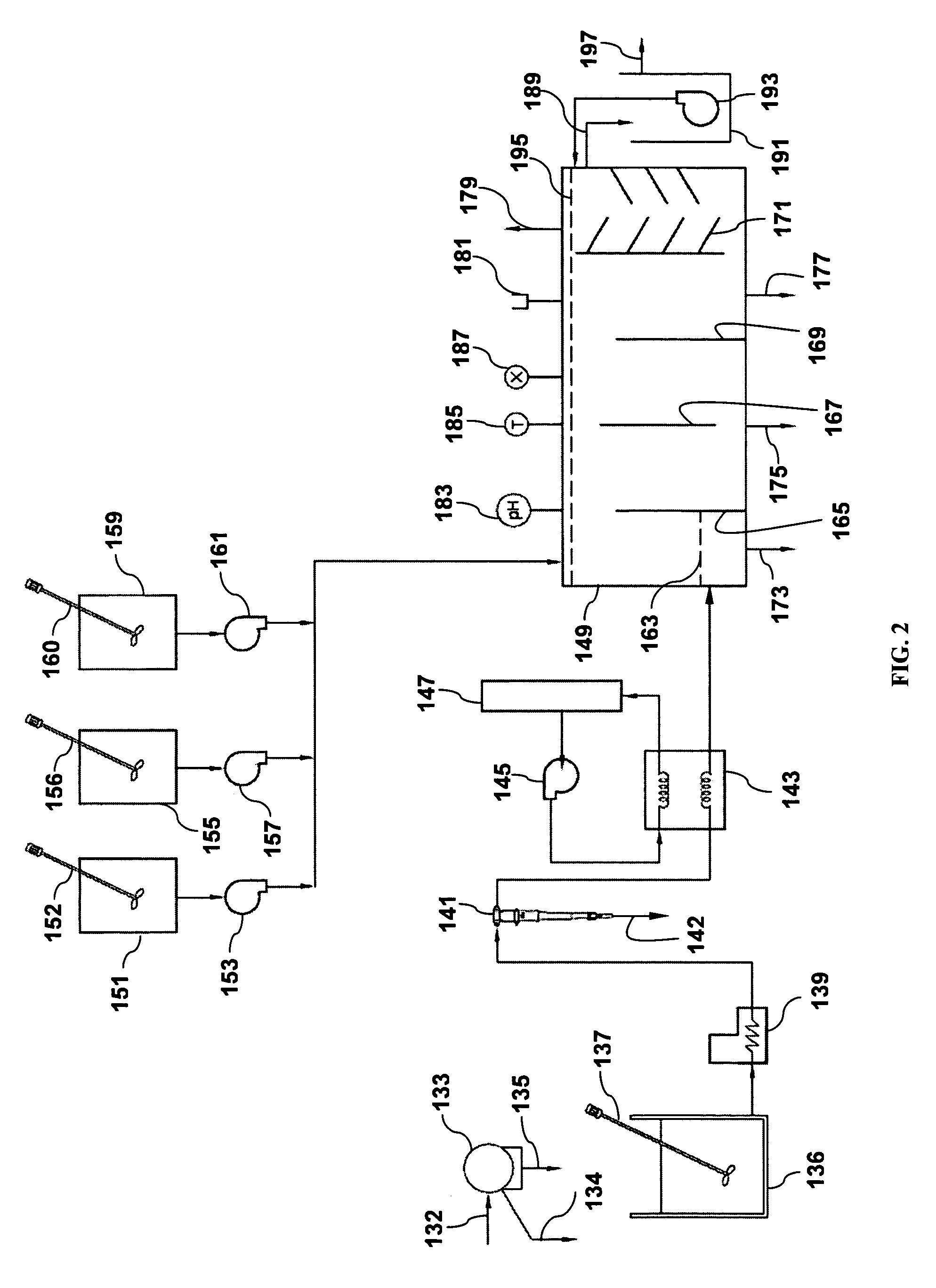

Integrated photobioreactor-based pollution mitigation and oil extraction processes and systems

InactiveUS20080009055A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselLiquid medium

Integrated systems including a photobioreactor system designed to contain a liquid medium comprising at least one species of phototrophic organism therein, and a facility associated with extracting and / or processing oil extracted from mixtures of oil and solid material, such as an oil sands facility, are described. Processes for using a photobioreactor system as part of a gas-treatment process and system able to at least partially remove certain undesirable pollutants from a byproduct gas stream produced by an oil sands facility are also described. Examples of such pollutants that may be removed include compounds contained within combustion gases, e.g., CO2 and / or NOx. These pollutants processed with the photobioreactor system, and, in some embodiments, biomass produced with the photobioreactor system may be utilized to produce a fuel source (e.g., biodiesel) and cutting stock for further operation of or use in the oil sands facility. Such uses of certain embodiments can provide an efficient means for recycling carbon, thereby reducing CO2 emissions, fuel, and / or cutting stock requirements for a given quantum of energy produced. In addition, in some cases the photobioreactor can be integrated with a holding pond and waste heat from the oil extraction process can be used to maintain the photobioreactor temperature and / or provide energy for other processes. Accordingly, embodiments described herein can improve the overall environmental and economic profile of the oil sands facility.

Owner:GREENFUEL TECHNOLOGIES CORPORATION

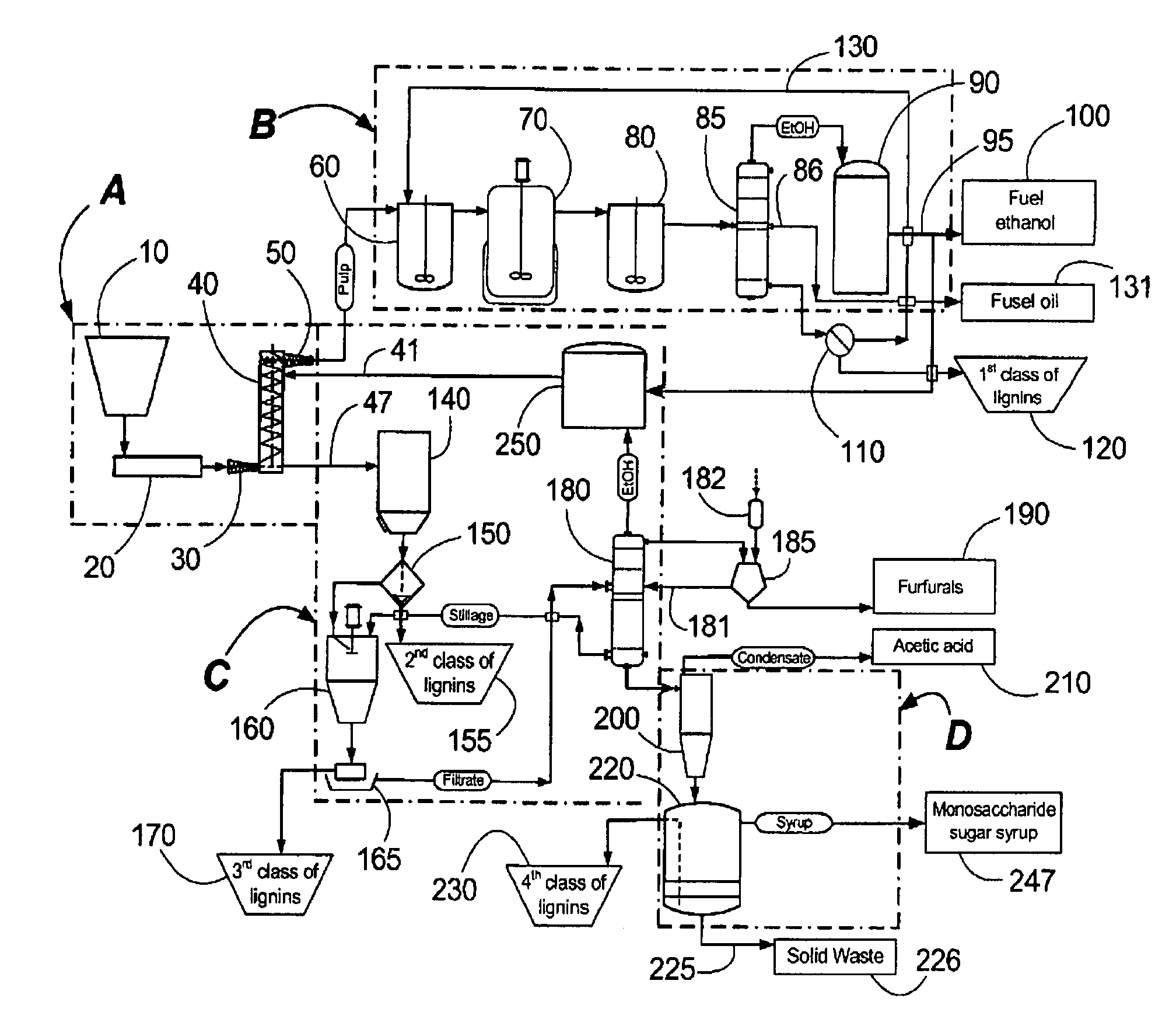

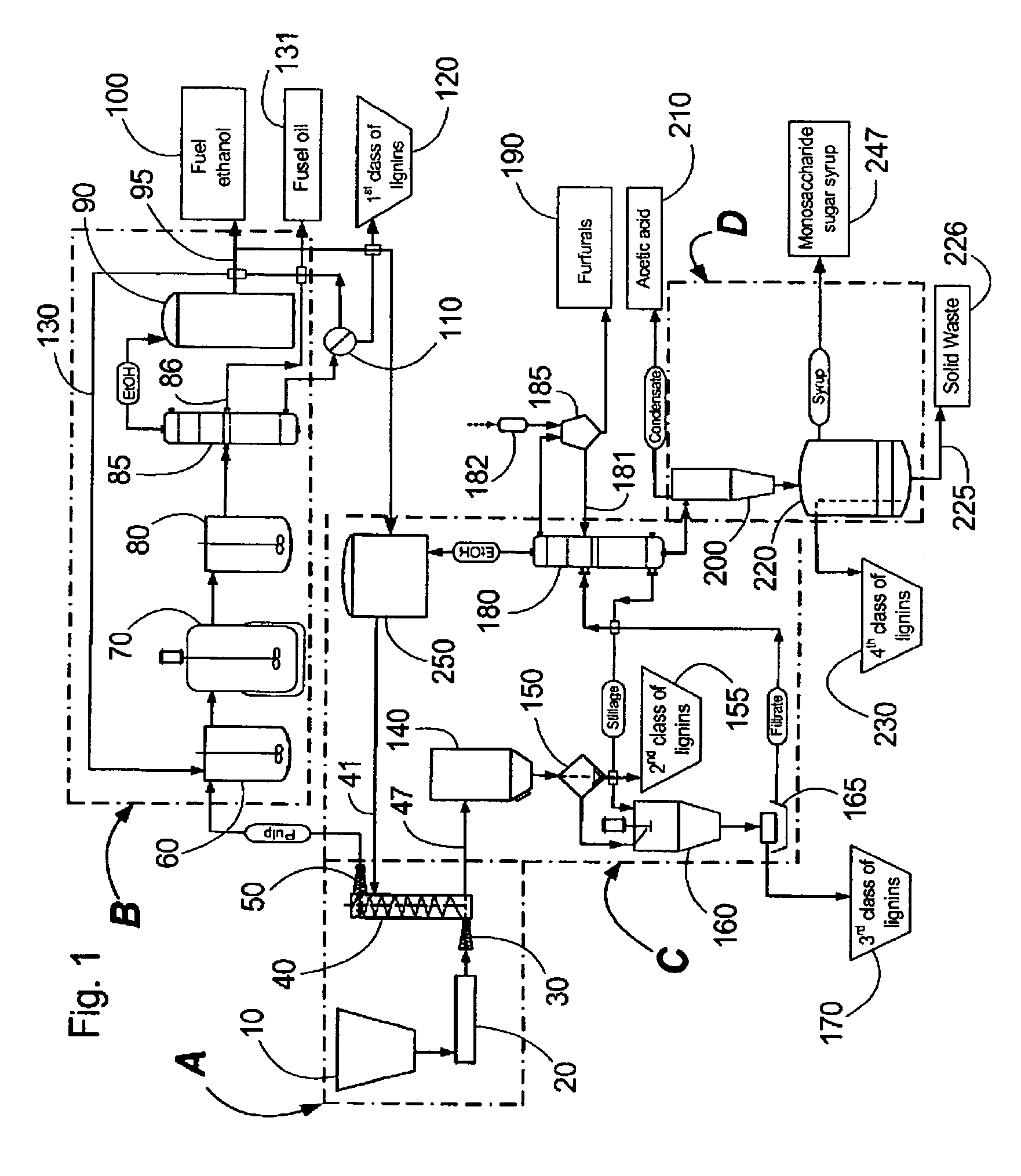

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

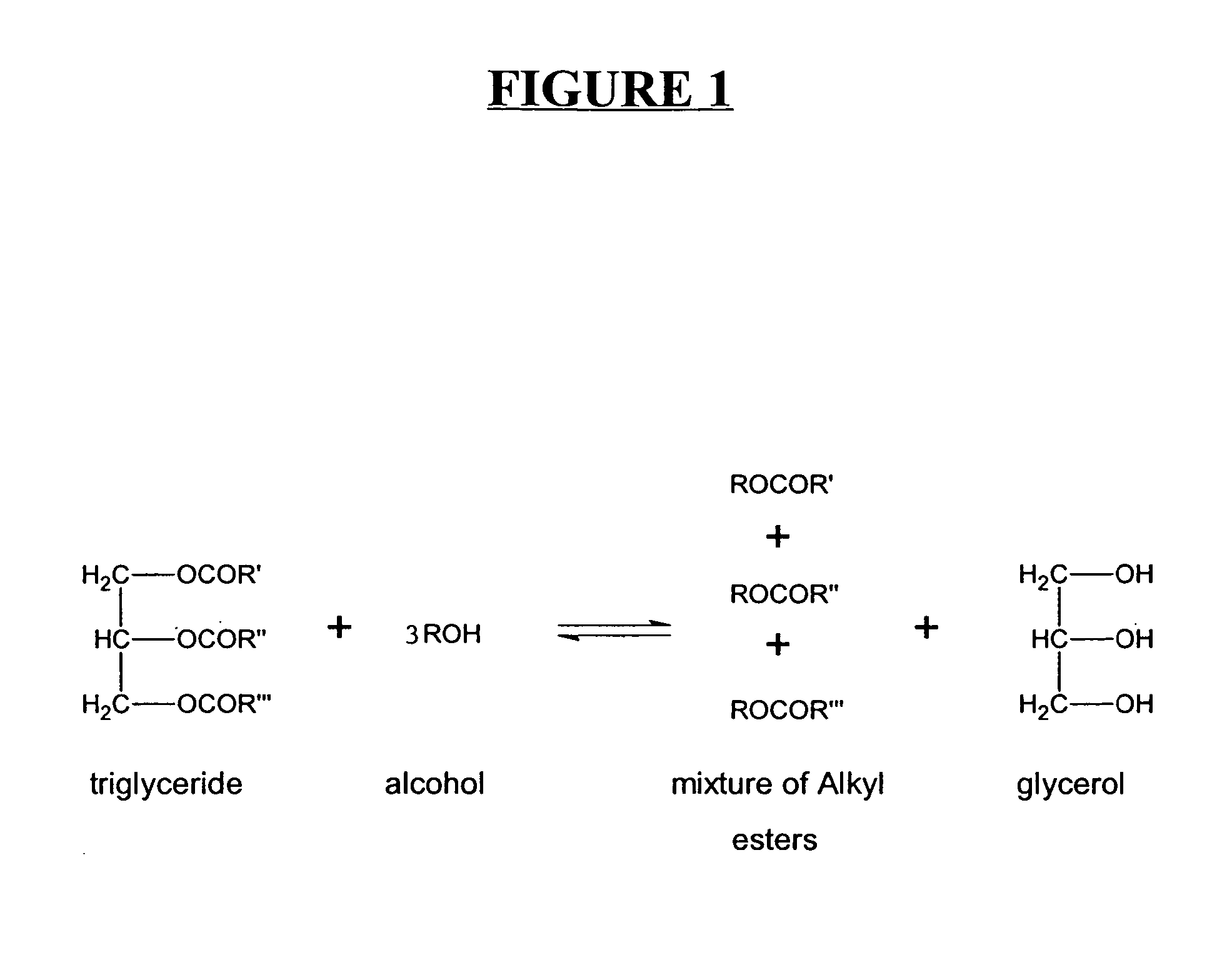

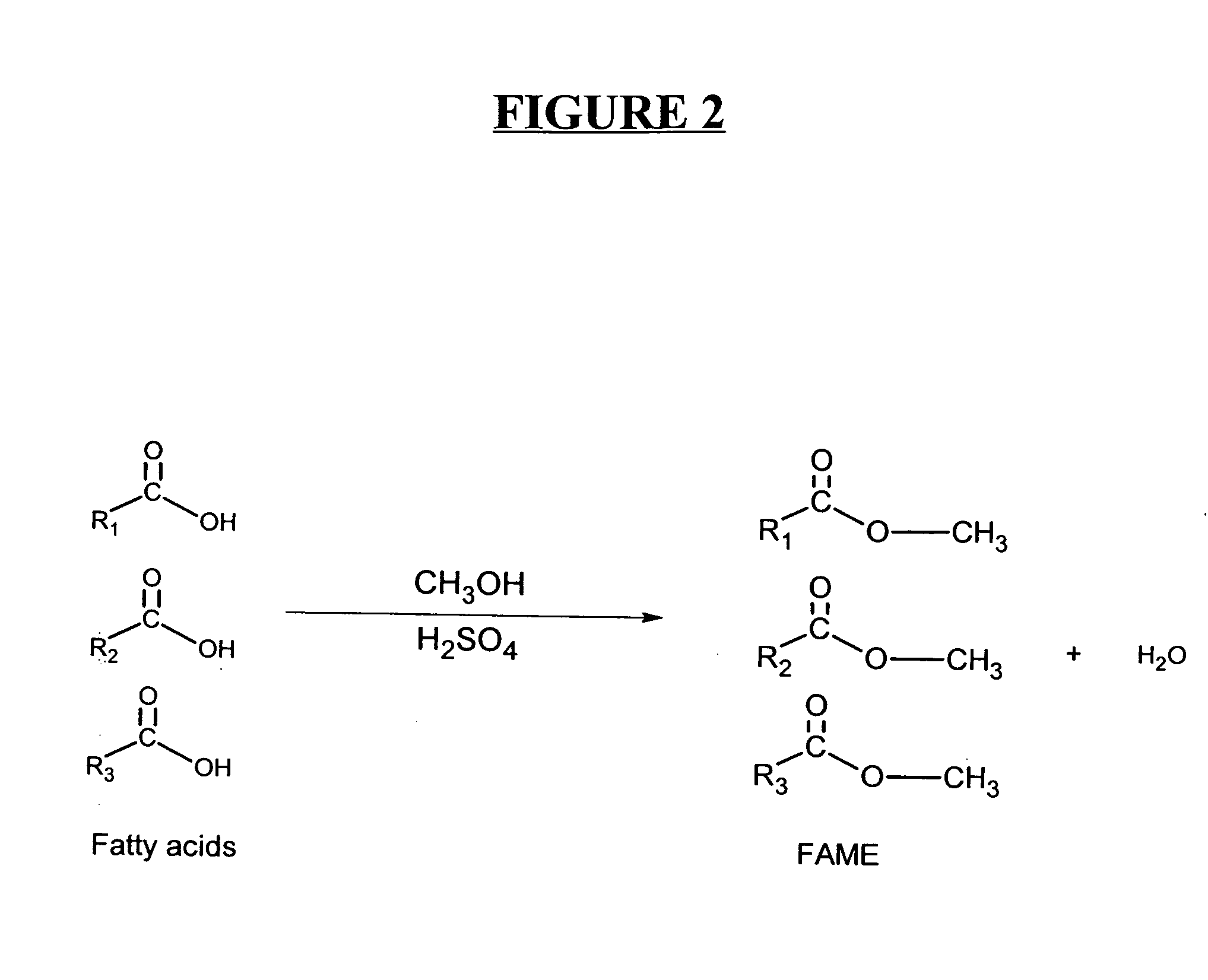

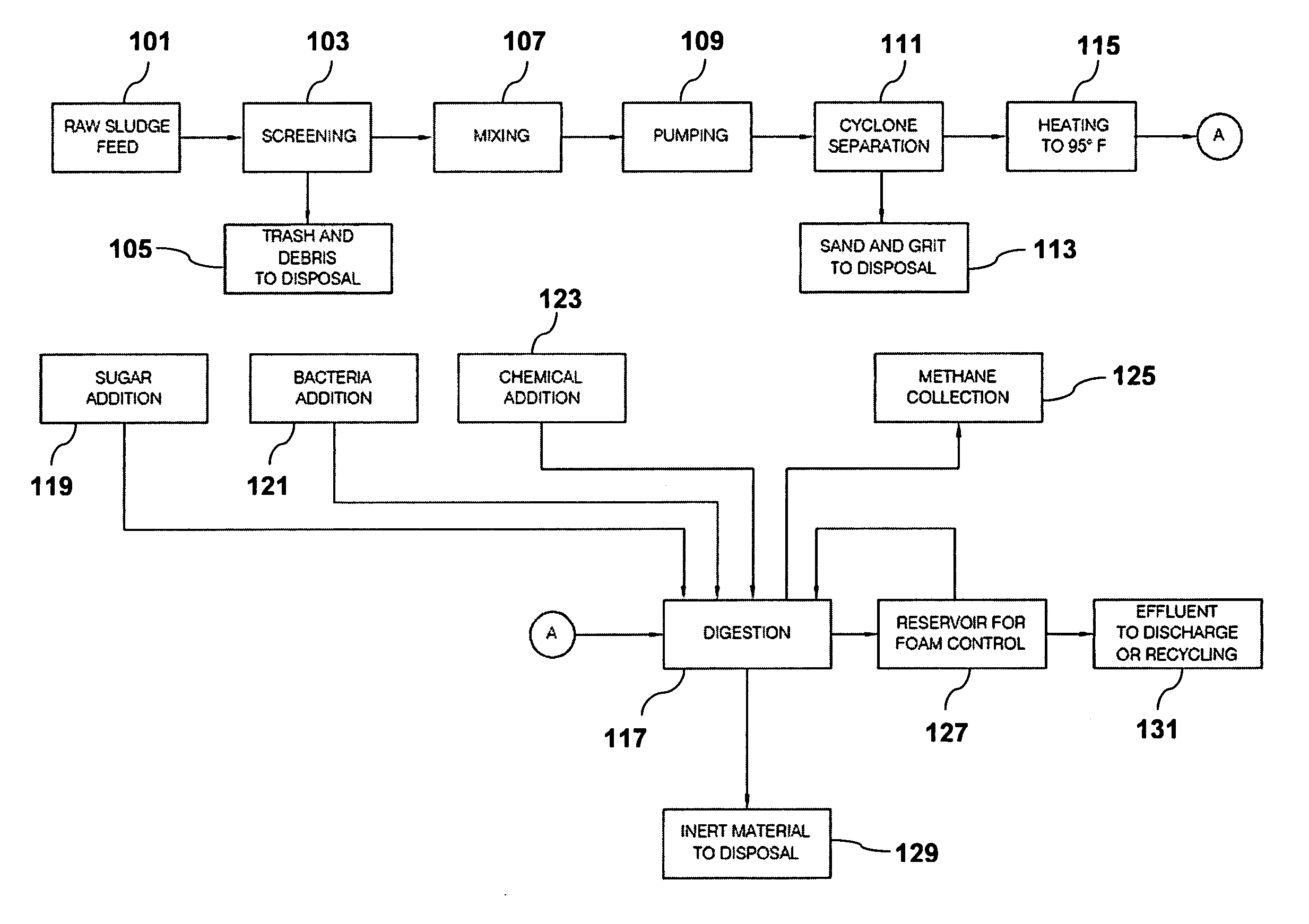

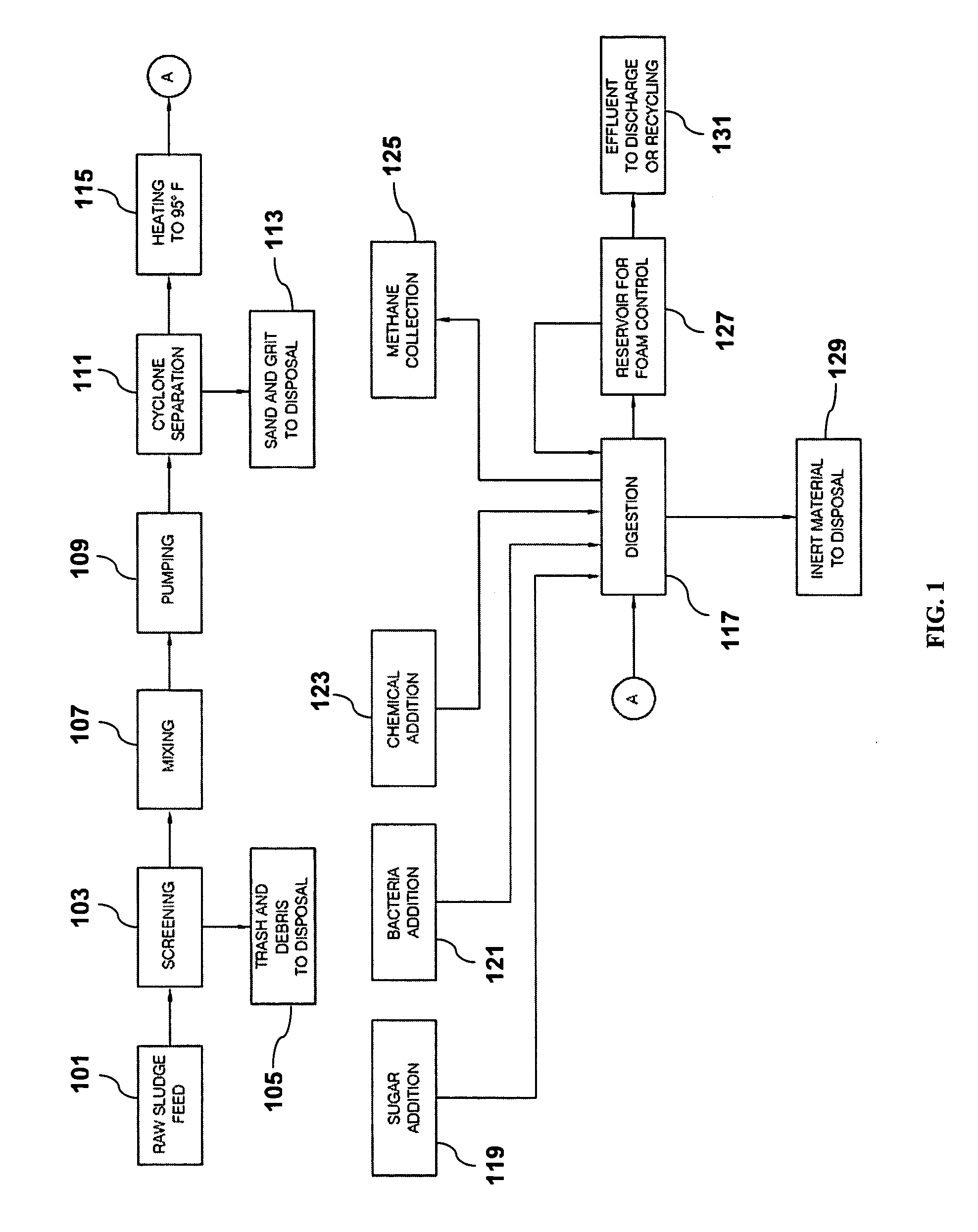

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

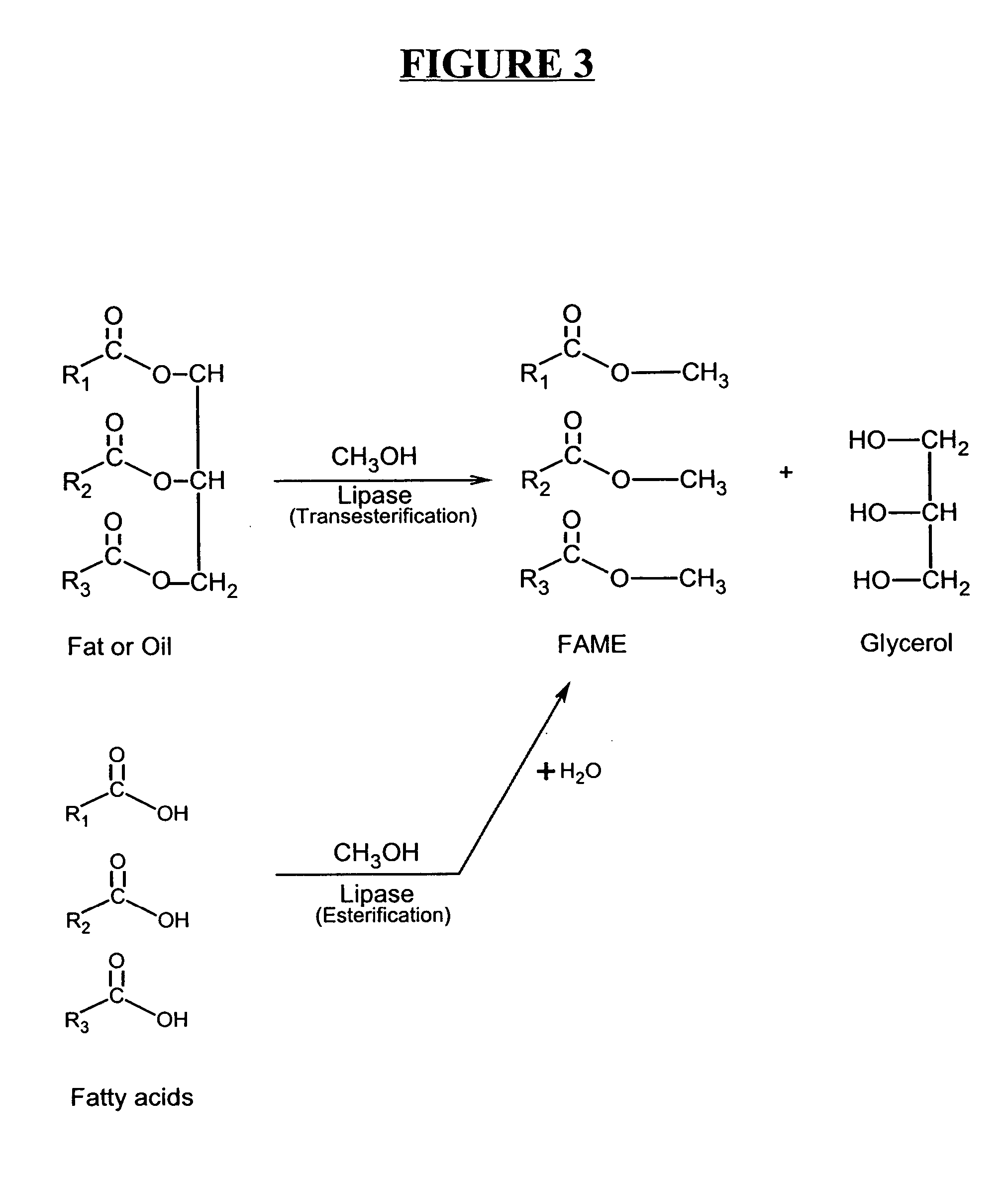

ActiveUS20050112735A1Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationLipid formationSludge

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

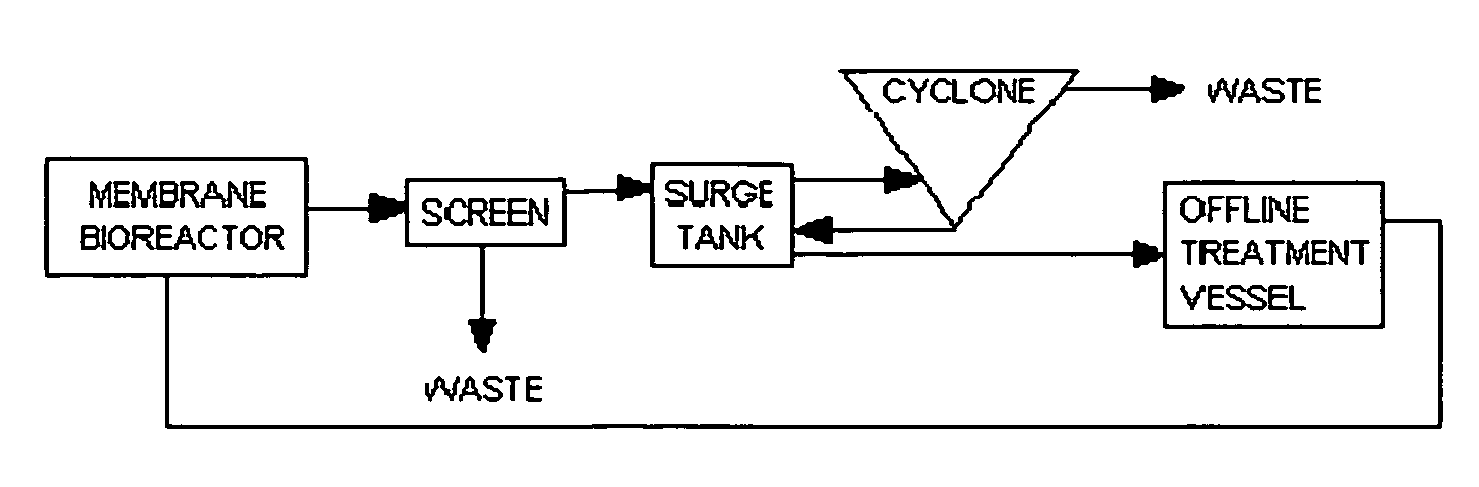

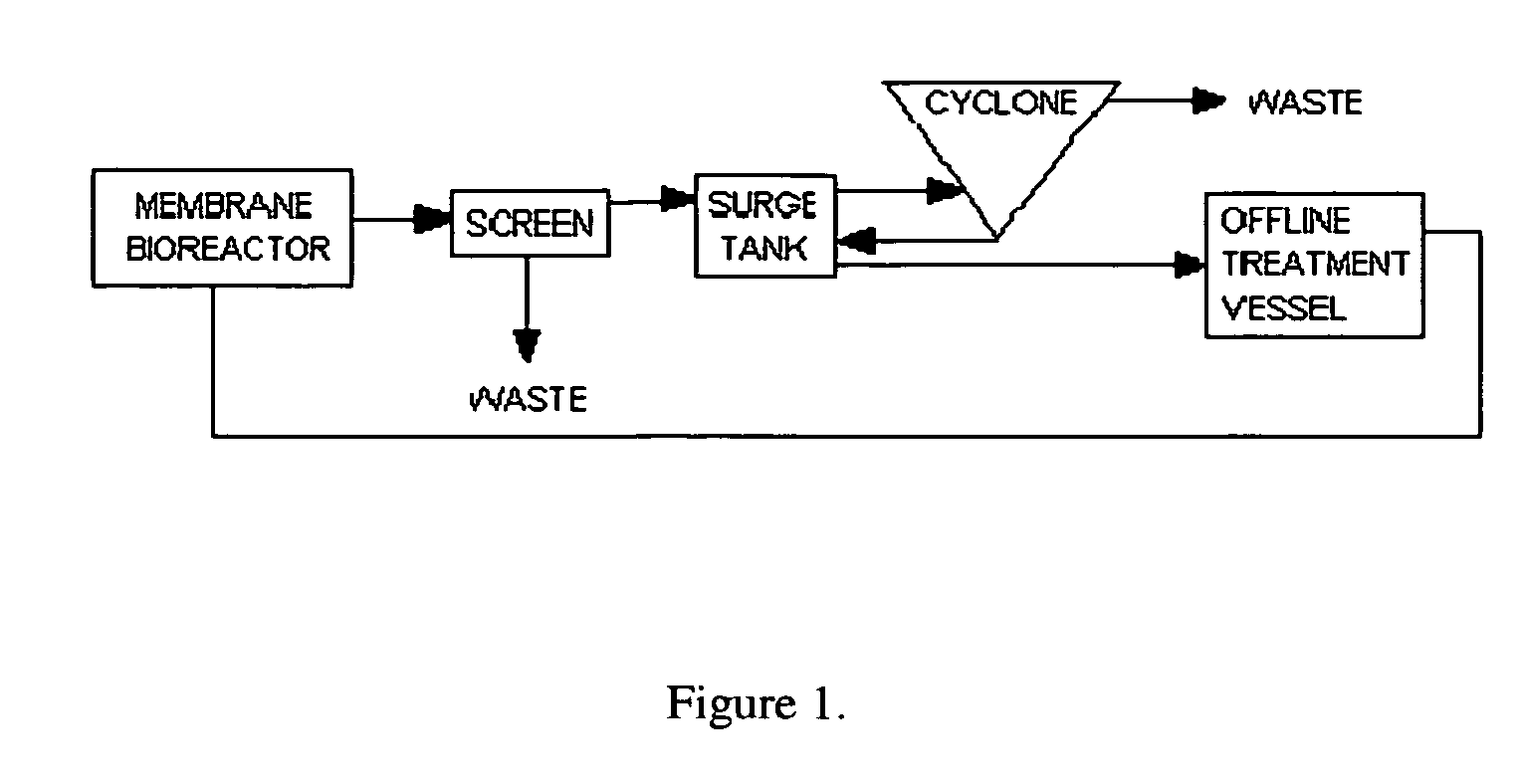

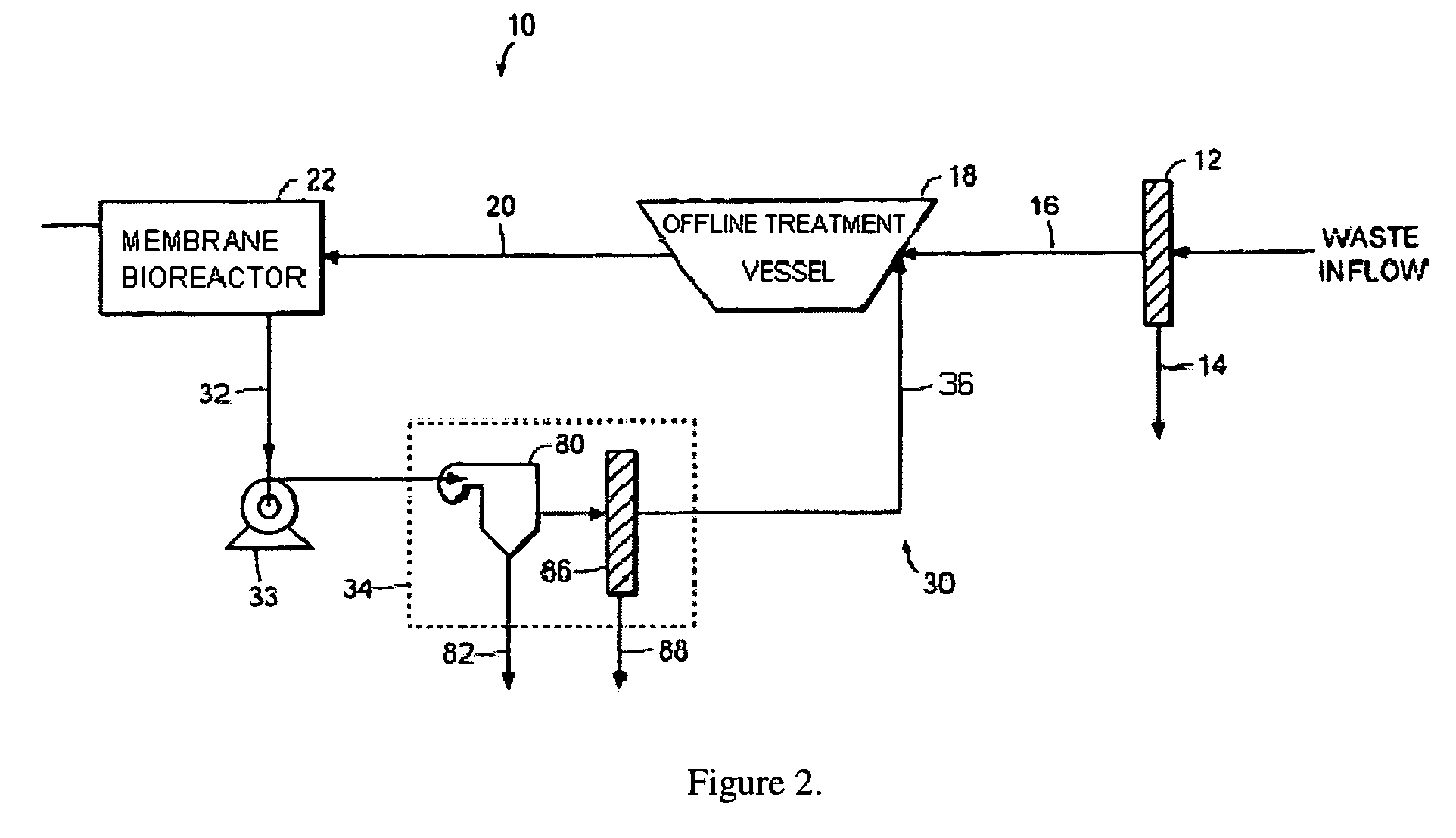

Filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS20060201876A1Low costReducing resourceWater/sewage treatment by centrifugal separationWater treatment parameter controlFiltrationMembrane bioreactor

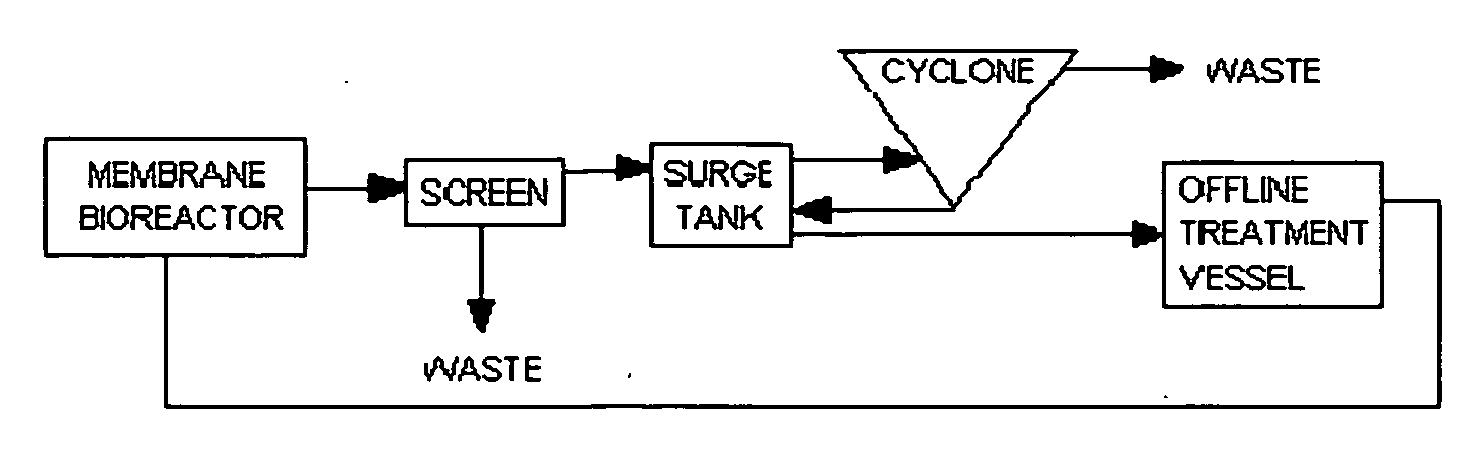

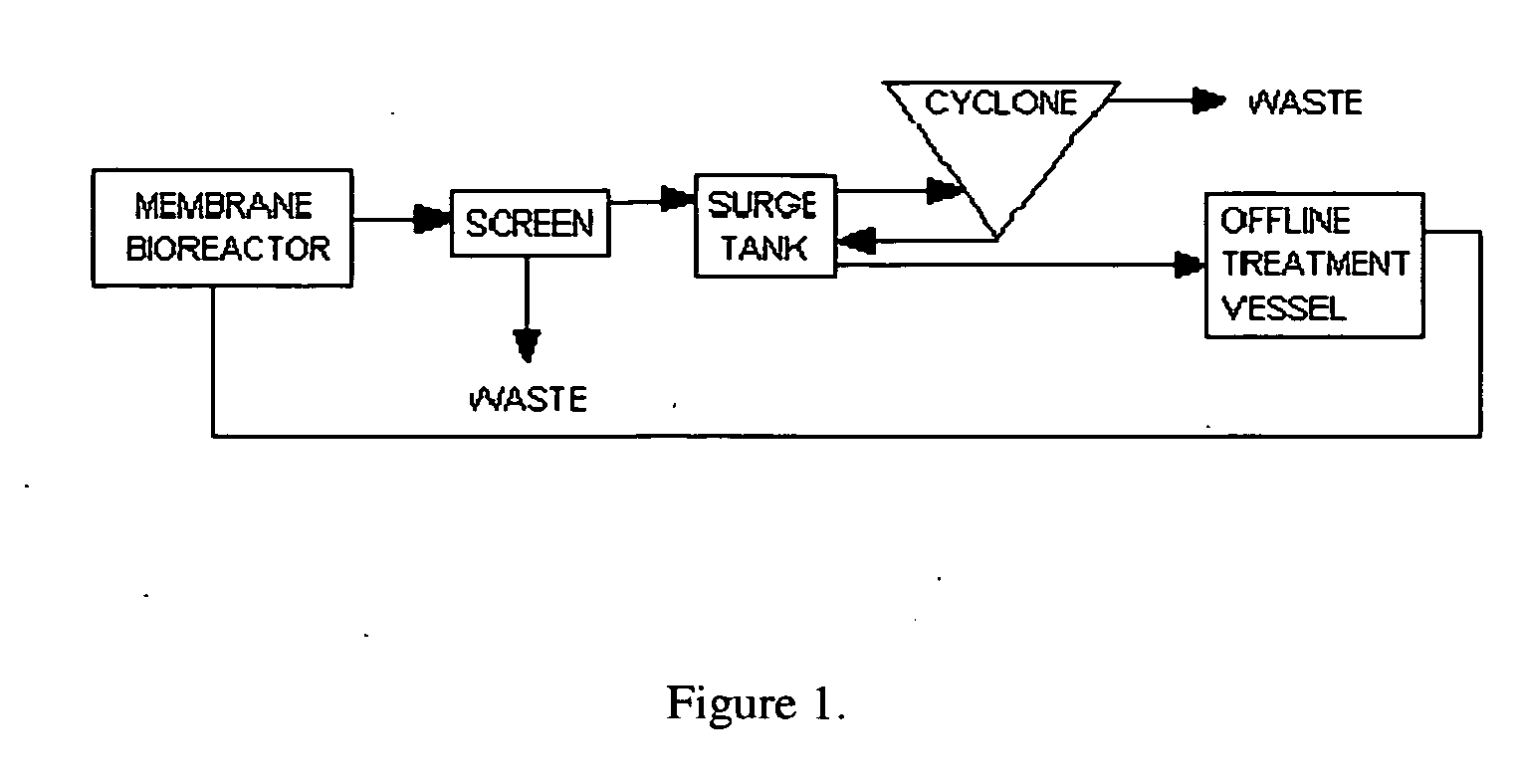

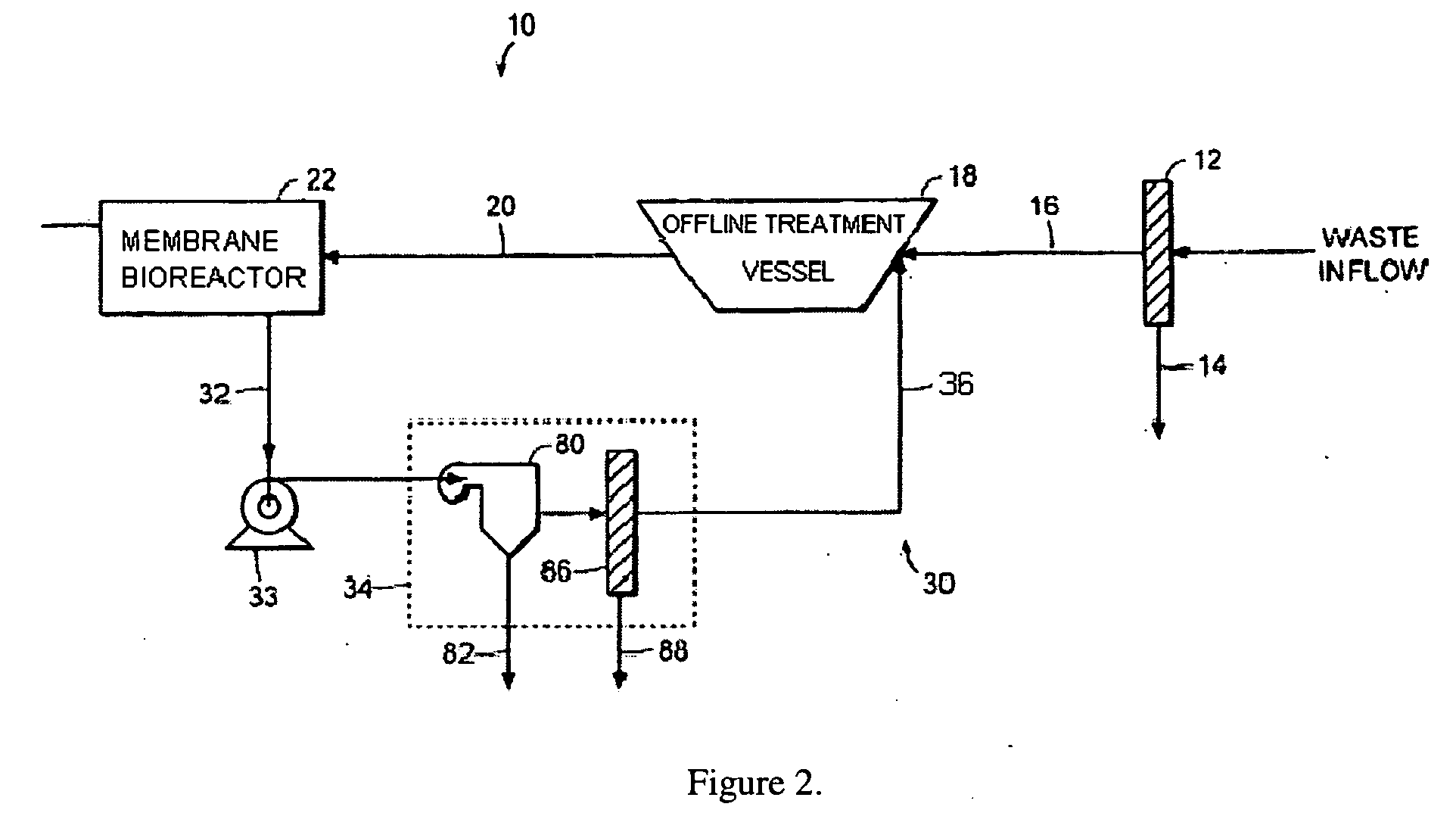

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge.

Owner:EVOQUA WATER TECH LLC

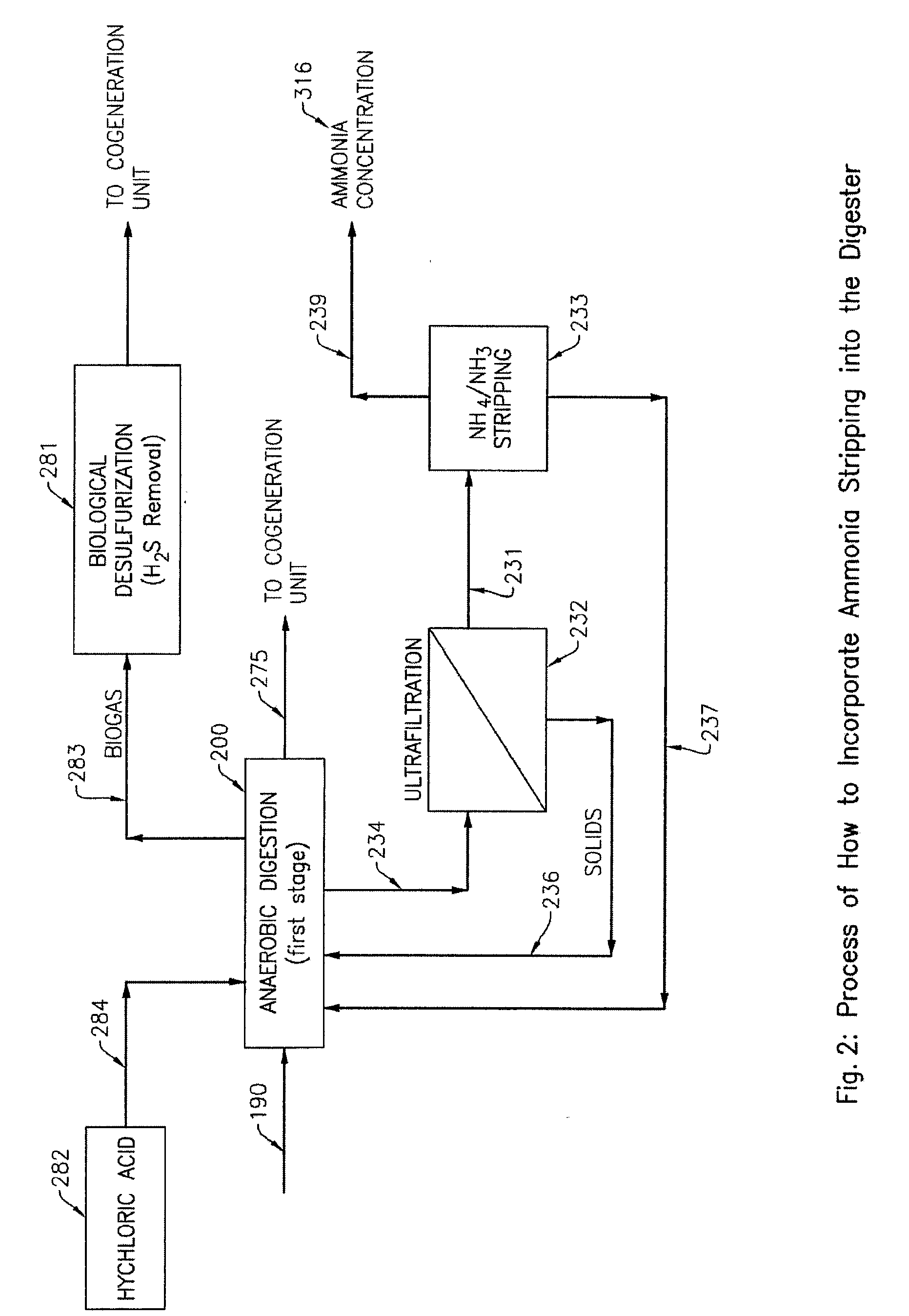

Method and plant for the treatment of liquid organic waste

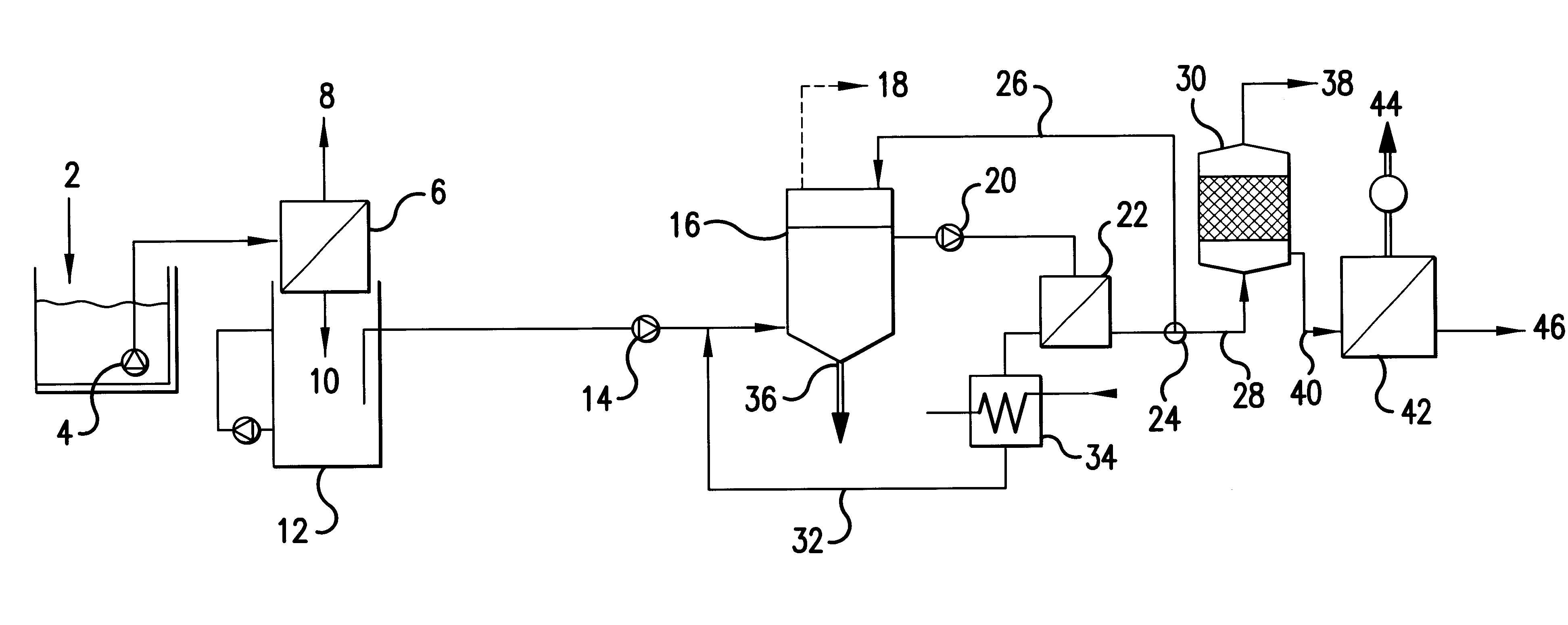

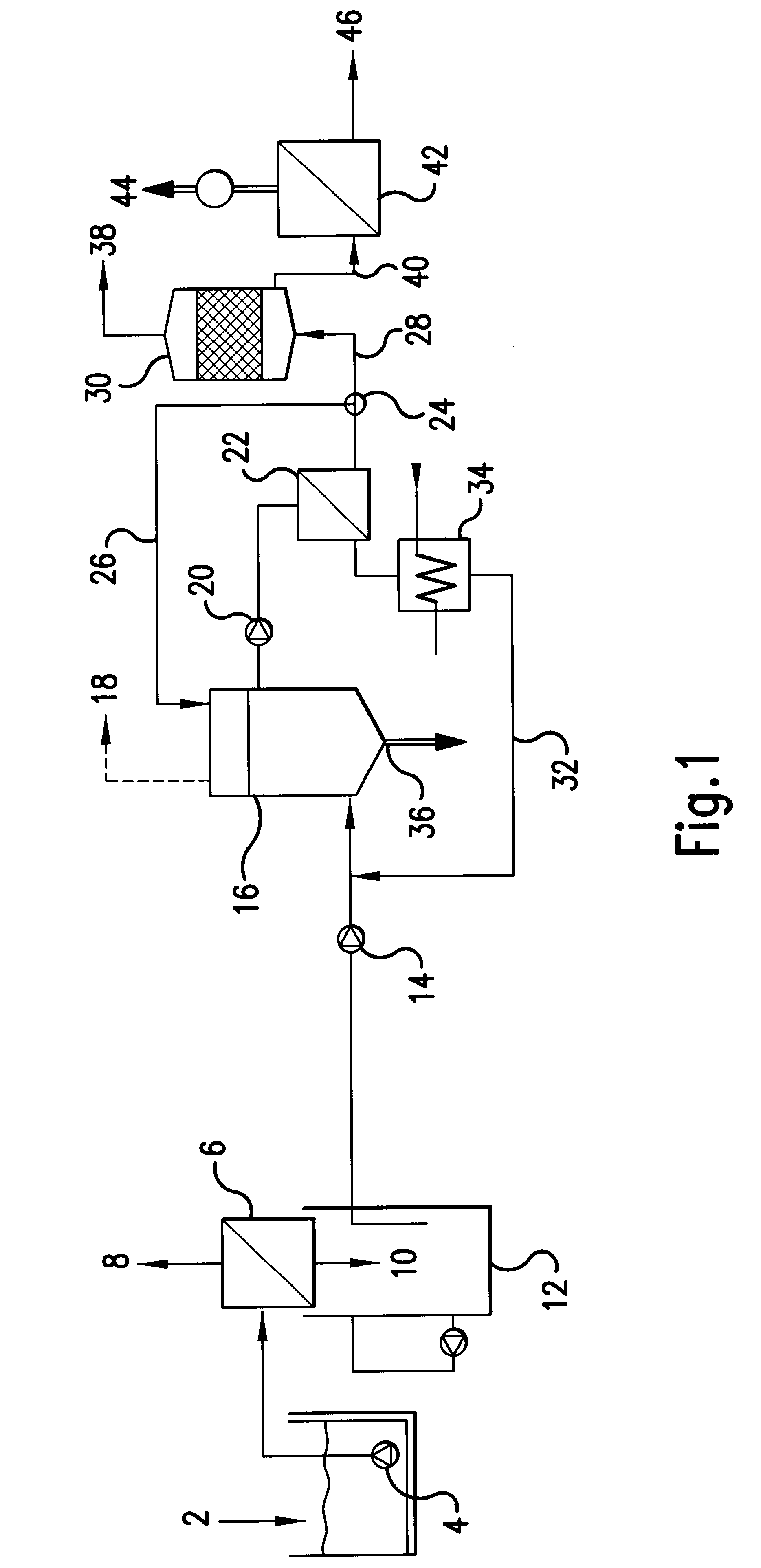

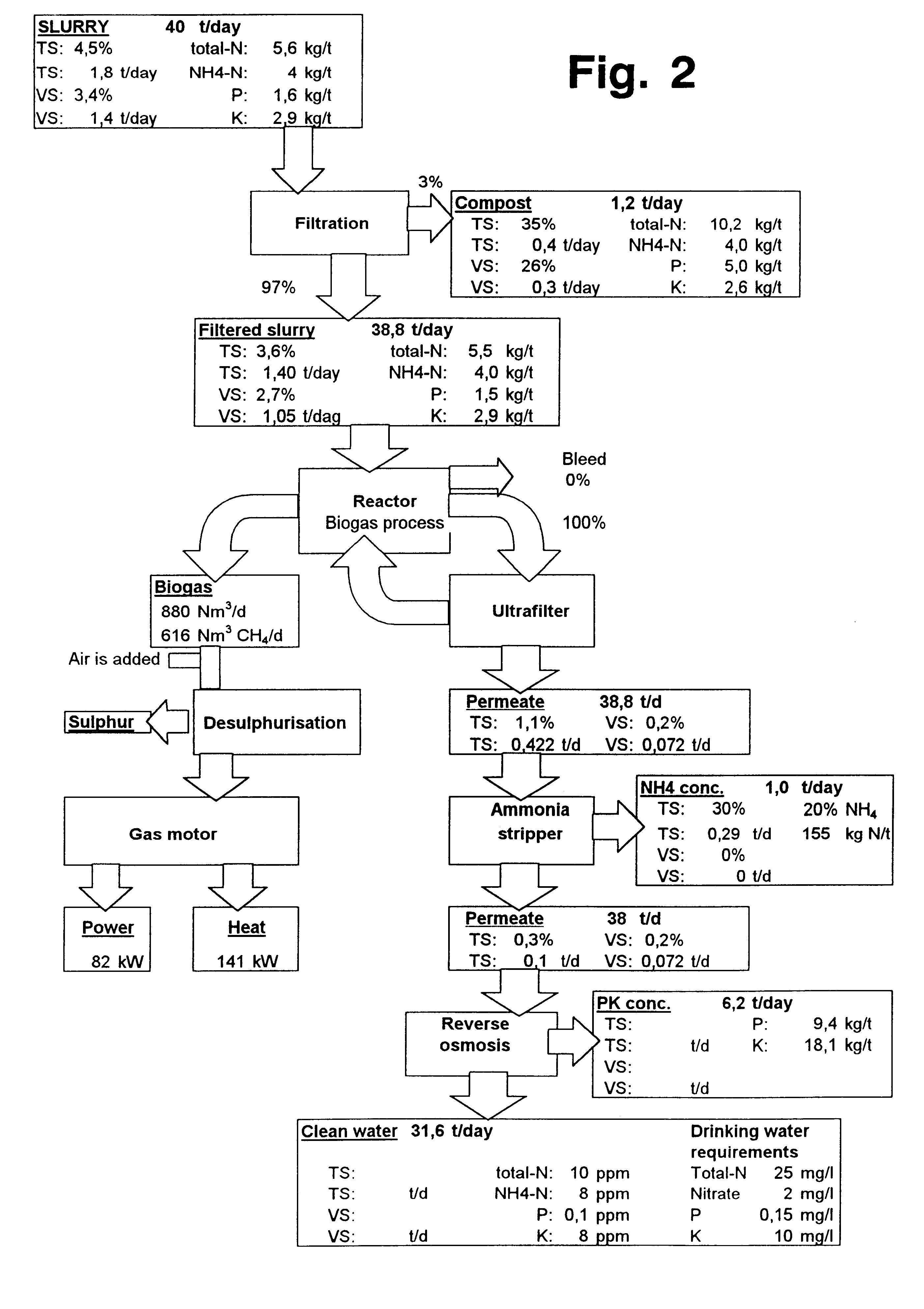

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

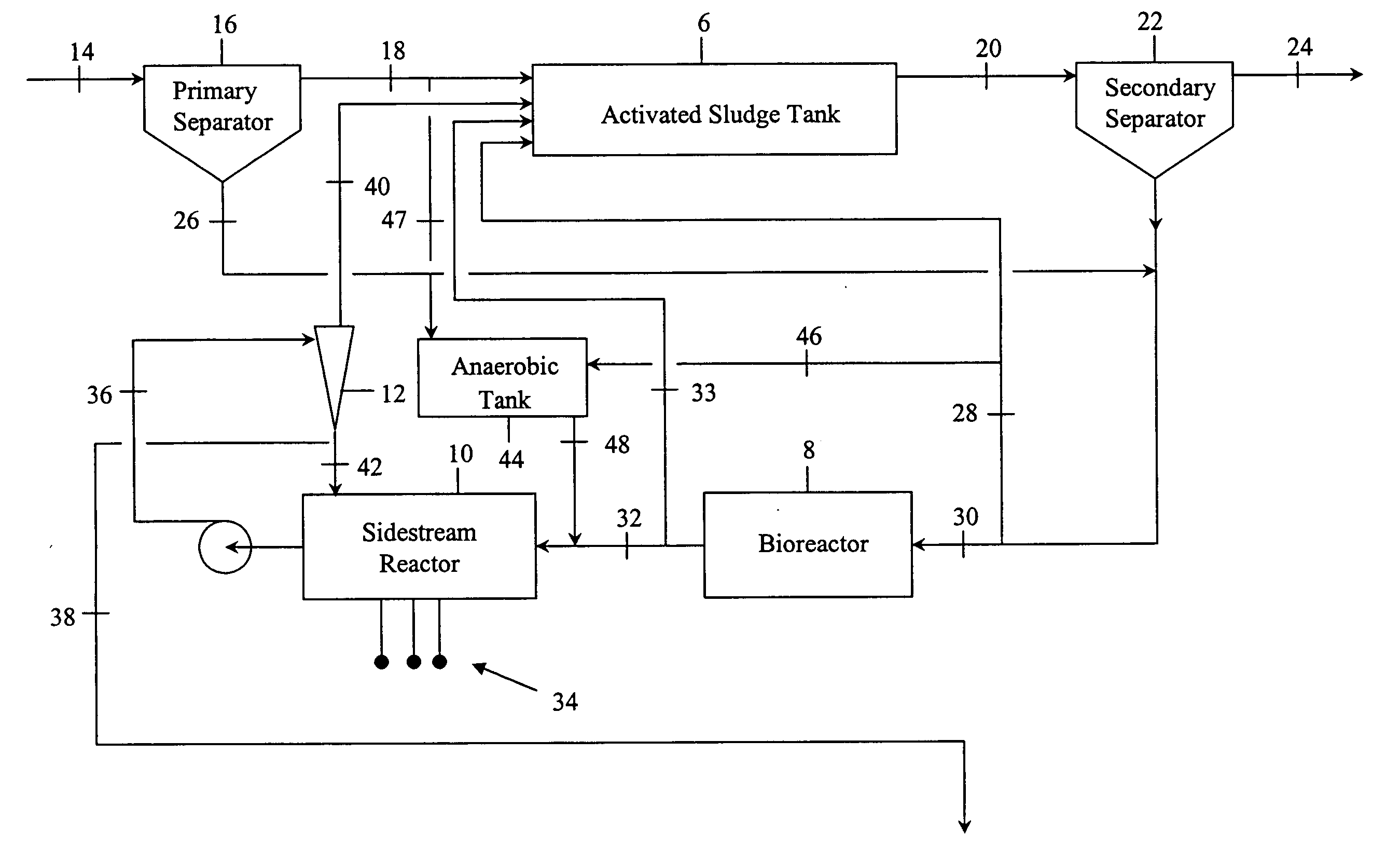

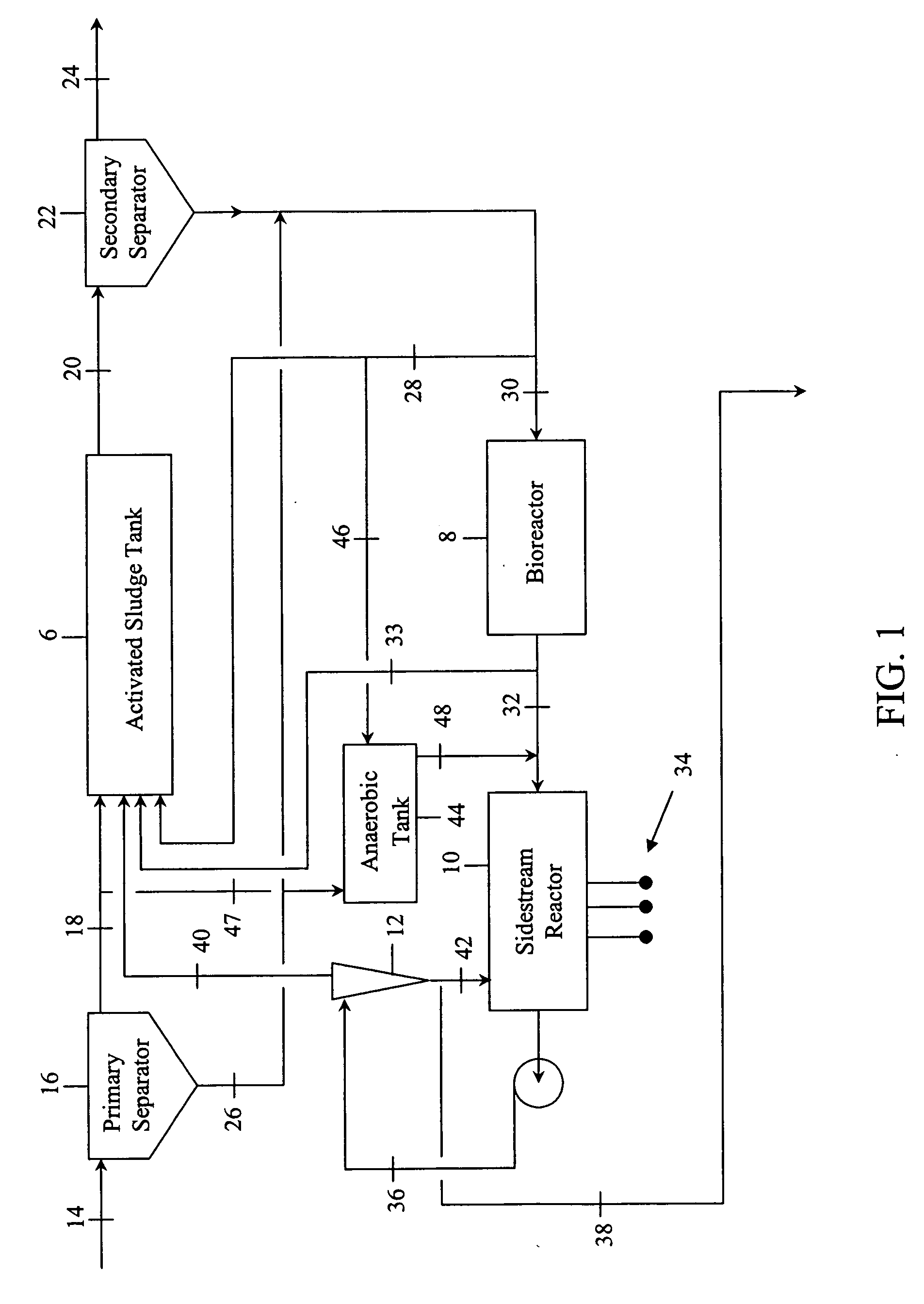

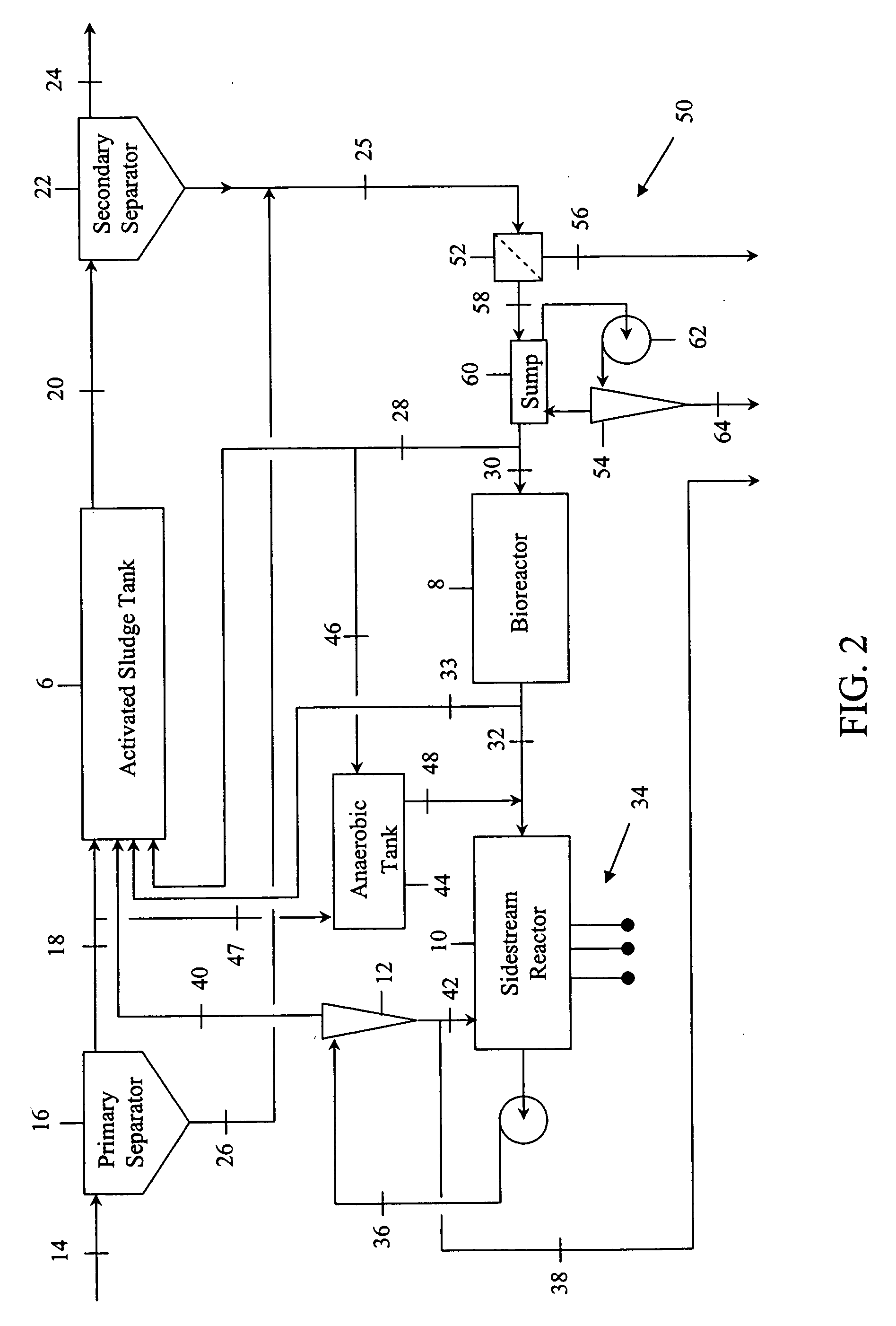

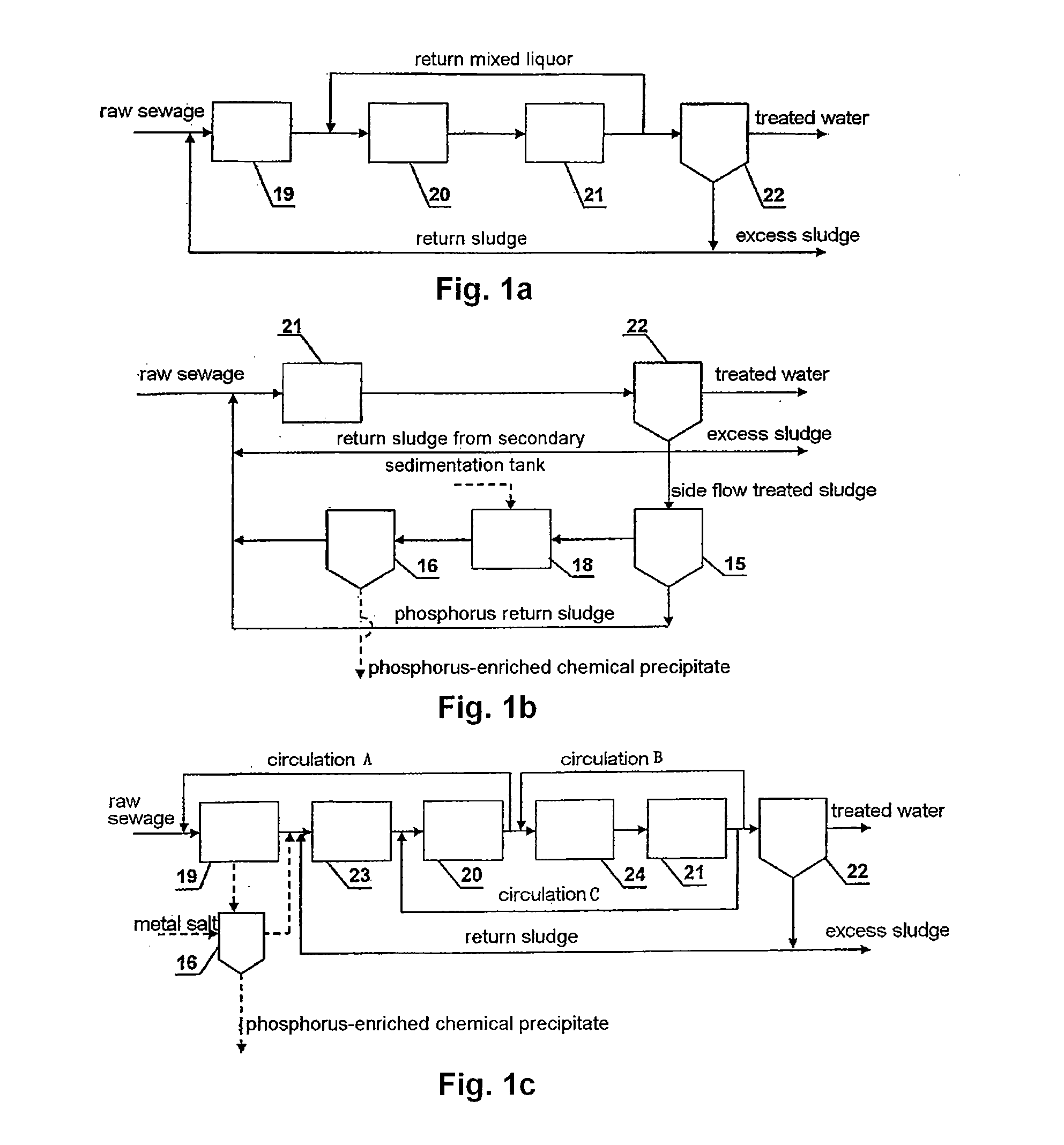

Process to enhance phosphorus removal for activated sludge wastewater treatment systems

InactiveUS20070000836A1Water/sewage treatment by centrifugal separationWater treatment parameter controlActivated sludgePhosphate

Contaminated wastewaters comprising biochemical oxygen demand (BOD), nitrogen and phosphorus are treated by an activated sludge process. The process utilizes an activated sludge tank, a solid-liquid separator, and a bioreactor to significantly reduce, or eliminate, waste activated sludge (WAS) within a sludge stream. A sidestream reactor is employed downstream from the bioreactor to remove soluble phosphates left in the sludge stream by the low WAS process. Within the sidestream reactor, a source of multivalent metal ions is added to a slightly alkaline sludge stream to precipitate the phosphates. The solid phosphates have a specific gravity higher than that of the organic matter in the sludge stream and may be separated from the sludge stream based upon differential settling velocity.

Owner:EVOQUA WATER TECH LLC

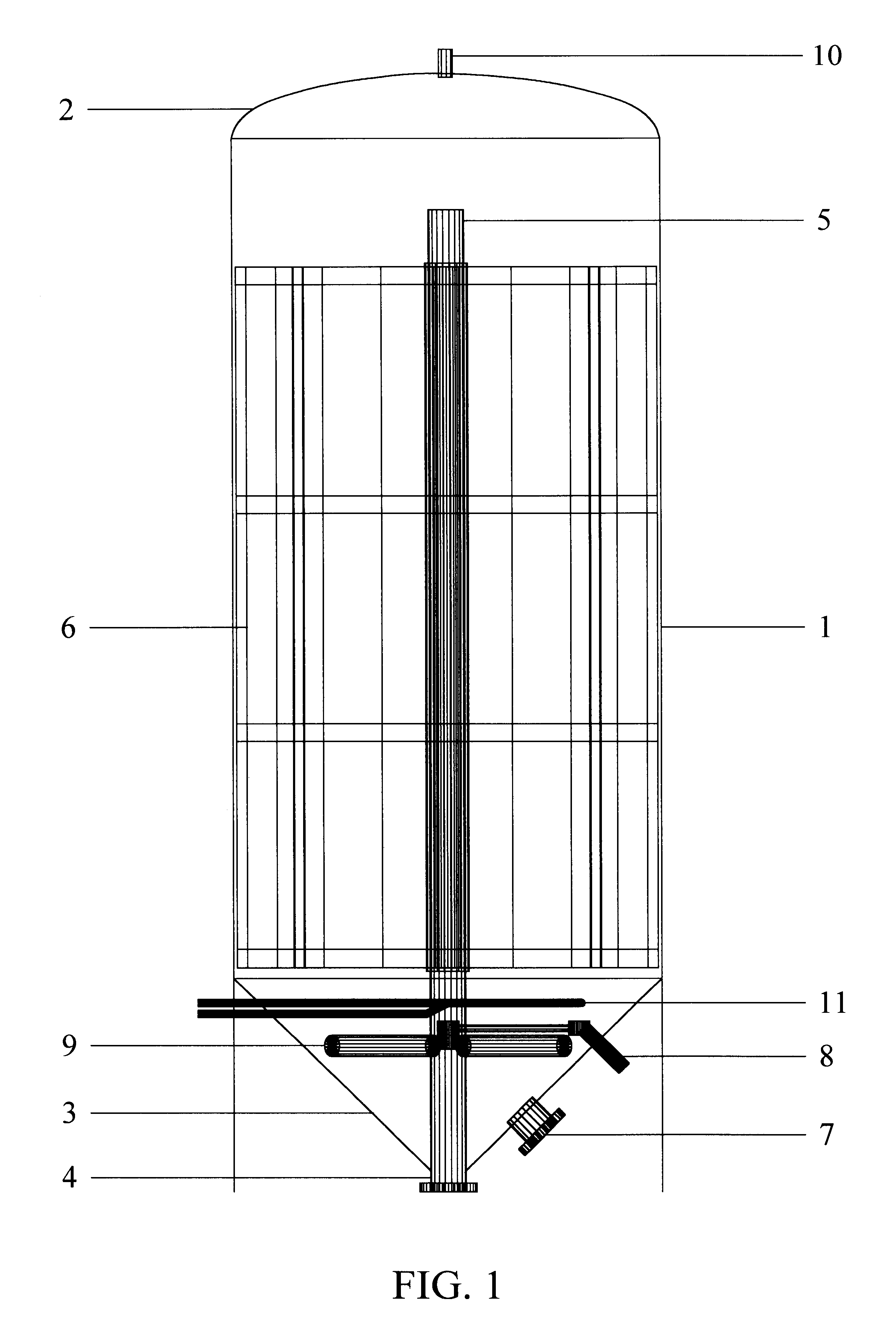

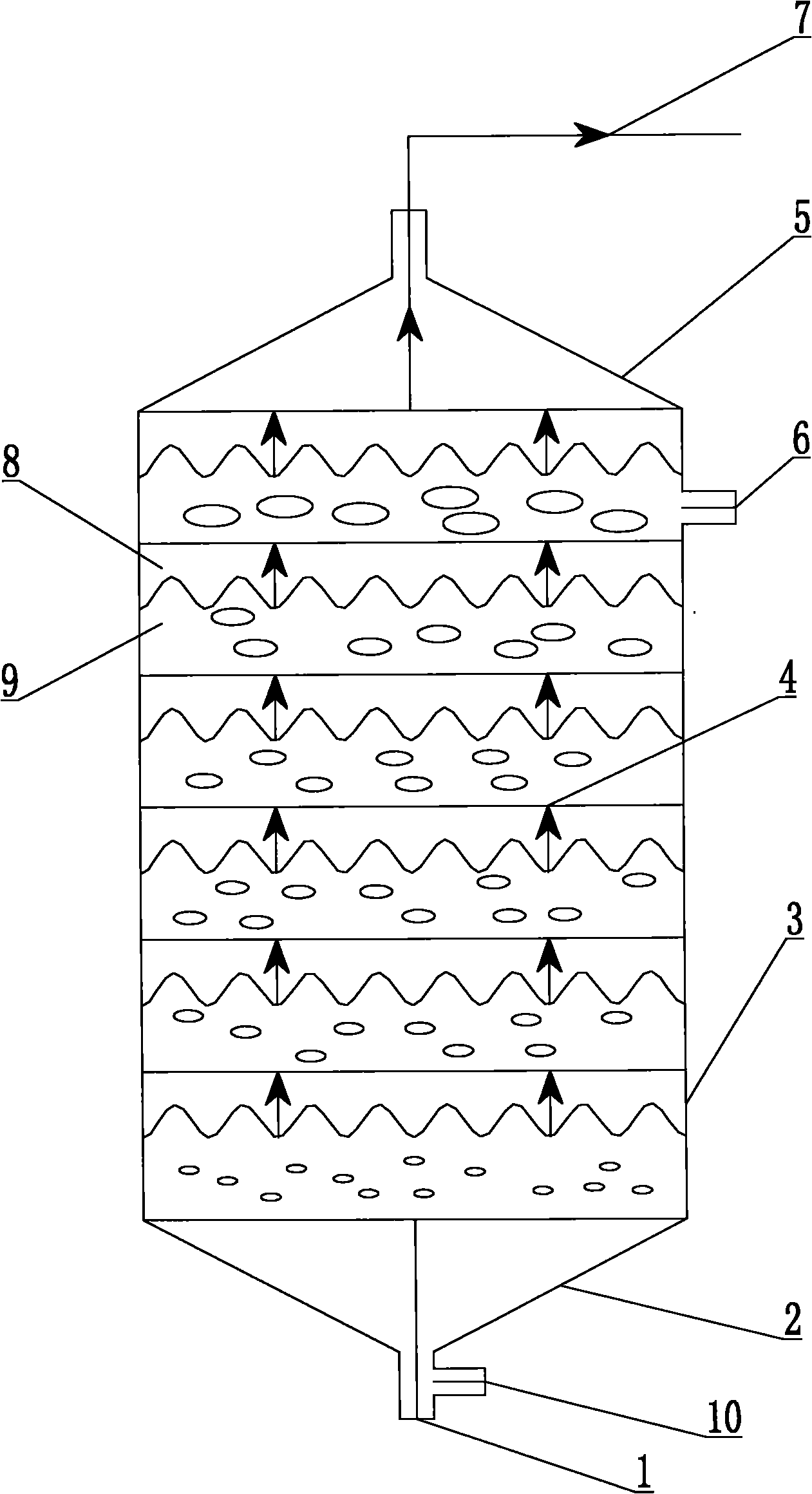

Anaerobic digester system and method

InactiveUS6254775B1High densityIncrease alkalinityGas production bioreactorsTreatment with aerobic and anaerobic processesSlurryMethane gas

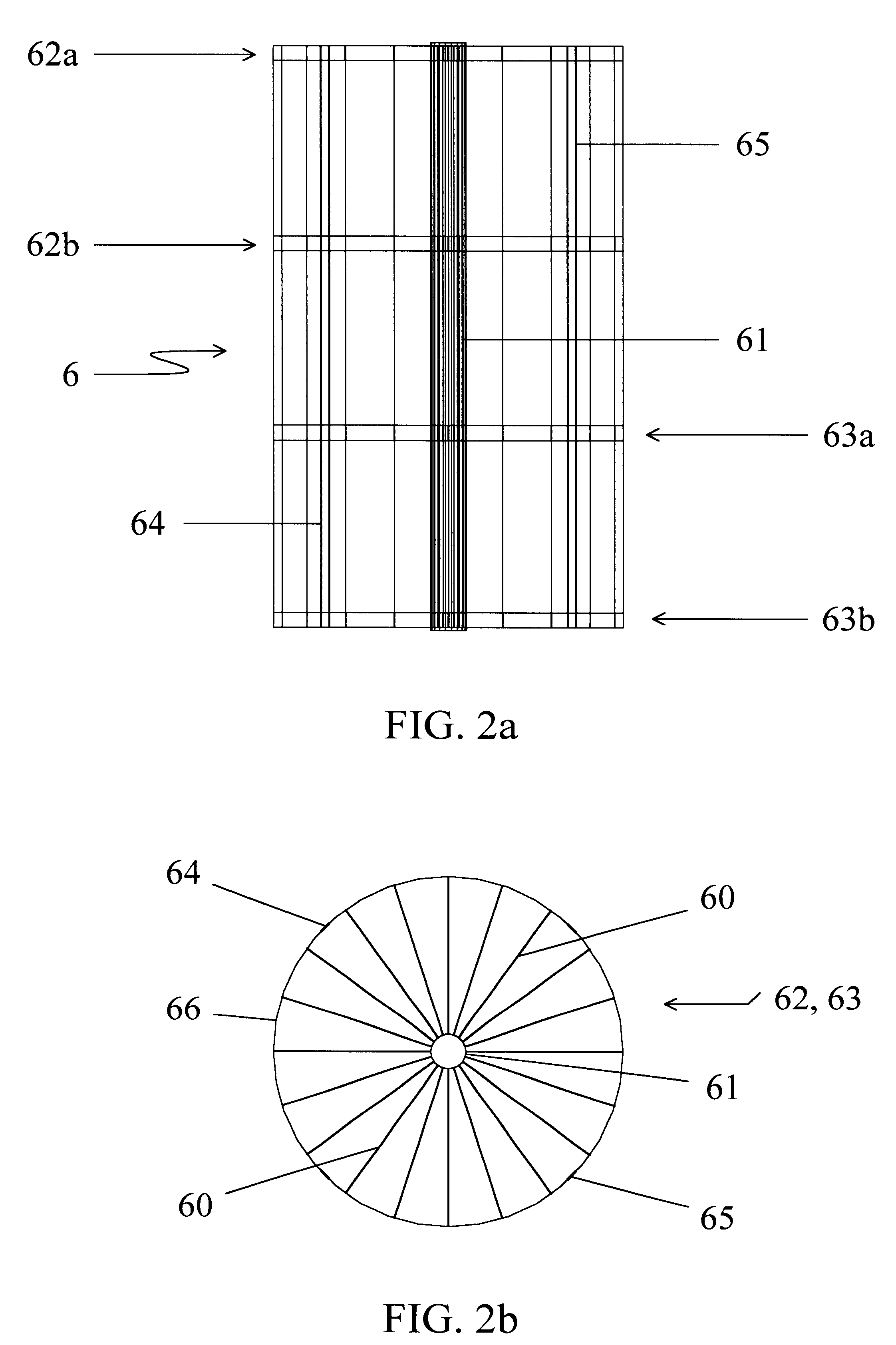

An anaerobic digester system has a vertically upright vessel, a matrix arranged in the vessel supporting a microorganism biomass thereon, an input for supplying an input slurry of liquid and suspended solids at an upper portion of the vessel above the matrix, a gas output at the top of the vessel for withdrawing gas generated by anaerobic digestion of solids, and an effluent output at the bottom of the vessel for withdrawing liquid and remaining solids. The vessel has a preferred liquid height to diameter ratio of 2 to 1, and is constructed of inert fiberglass-reinforced plastic coated with a translucent blue gel pigment layer for filtering light at wavelengths that promote biomass cultivation. The matrix is formed as an array of panels mounted to a spindle with wheels fixed at spaced intervals along its vertical height, and the panel are made of a polyethylene grass matting providing a high surface area to volume ratio of at least 20 to 1. Gas from the top of the vessel is recycled to the bottom to generate bubbles for mixing the feedstock. The related method of anaerobic digestion includes comminuting input wastes with a slurry grinder into a pumpable slurry 8-10 % by weight solids, and providing as the biomass hydrolytic bacteria, and fermentative bacteria including acetogenic and methanogenic bacteria to produce a methane gas product. Other products include an organic soil additive, bacterial solids plant food, and a filtrate used as plant tonic.

Owner:RENERGY

Black-odor river pollution treatment method

InactiveCN101417840AEfficient removalControl and reduce the total amount receivedTreatment using aerobic processesWater aerationMicrobial agentSelf purification

The invention discloses a method for managing town black and olid river pollution in situ by utilizing biological repair technology, which takes the steps and measures of aerating and oxygenizing in riverway, adding a complex microbial agent, biologically repairing bottom sediment, arranging a bio-nest system and the like, so as to control and eliminate the exogenous and endogenous pollution of the river, purify the water quality of the river, improve the self-purification ability of the water body and achieve the purpose of eliminating black and olid. The method does not need to build structures in the riverway or lead the river water out of the riverway to be treated, or dredge the bottom sediment in the river, therefore the method is generally applicable to incomplete sewage interception and dredging or the rivers which can not be intercepted sewage or dredged temporarily, and the in situ treatment to the riverway which is affected by tide and has complicated fluid variation. Therefore, the method which can lead the water body to recover normal ecological function provides the practical, economic and convenient treatment method for various town black and olid rivers.

Owner:黎赓桓 +1

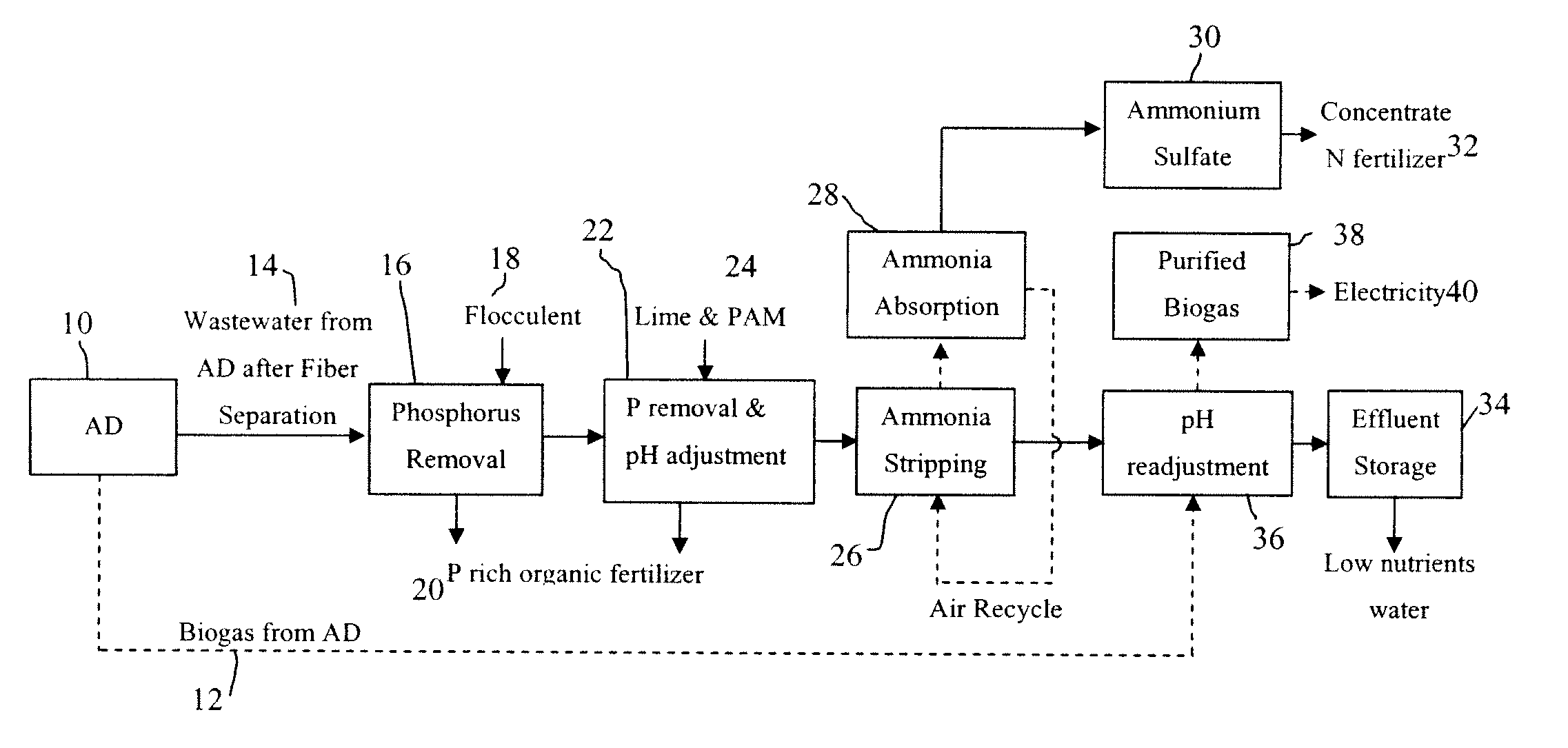

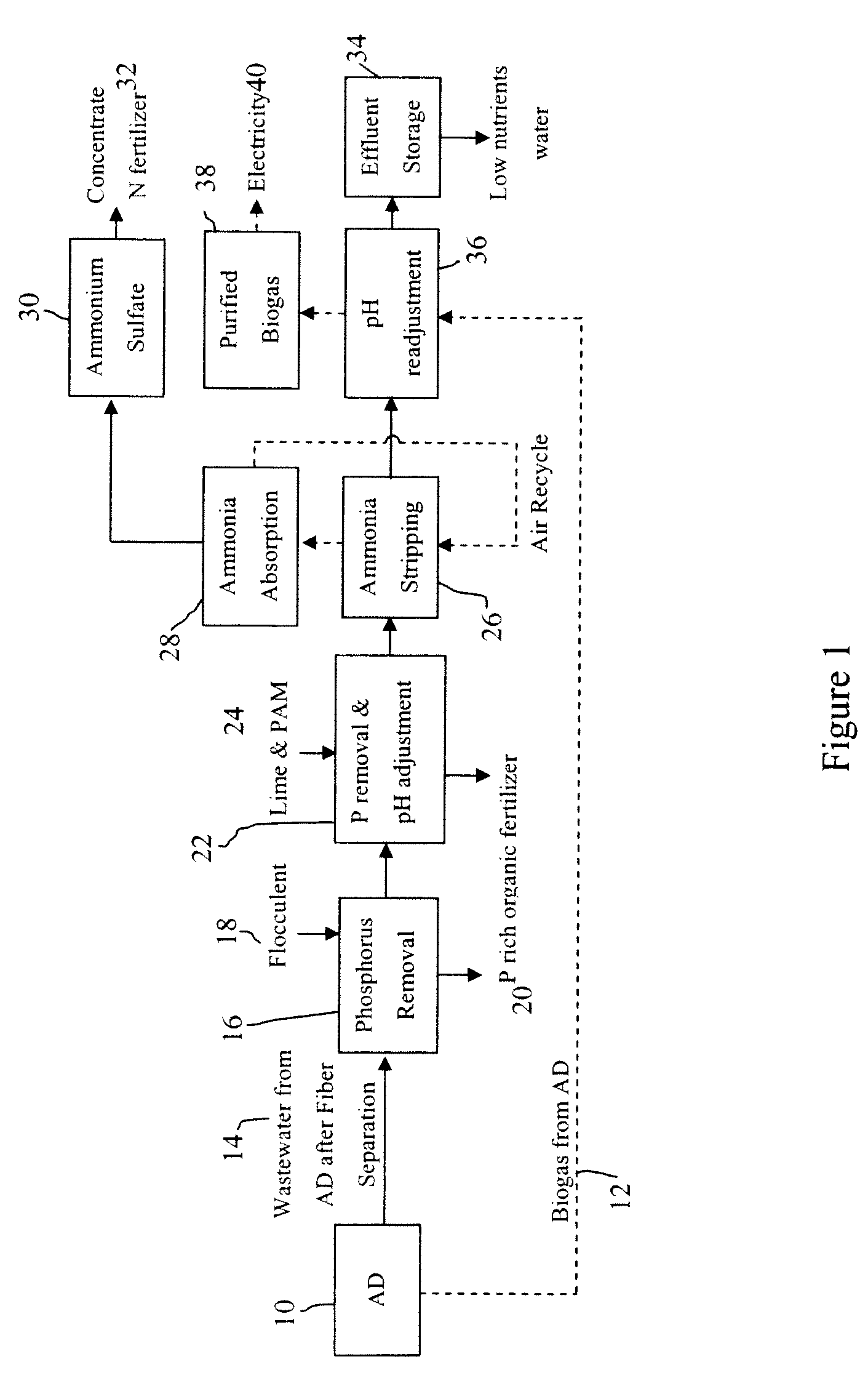

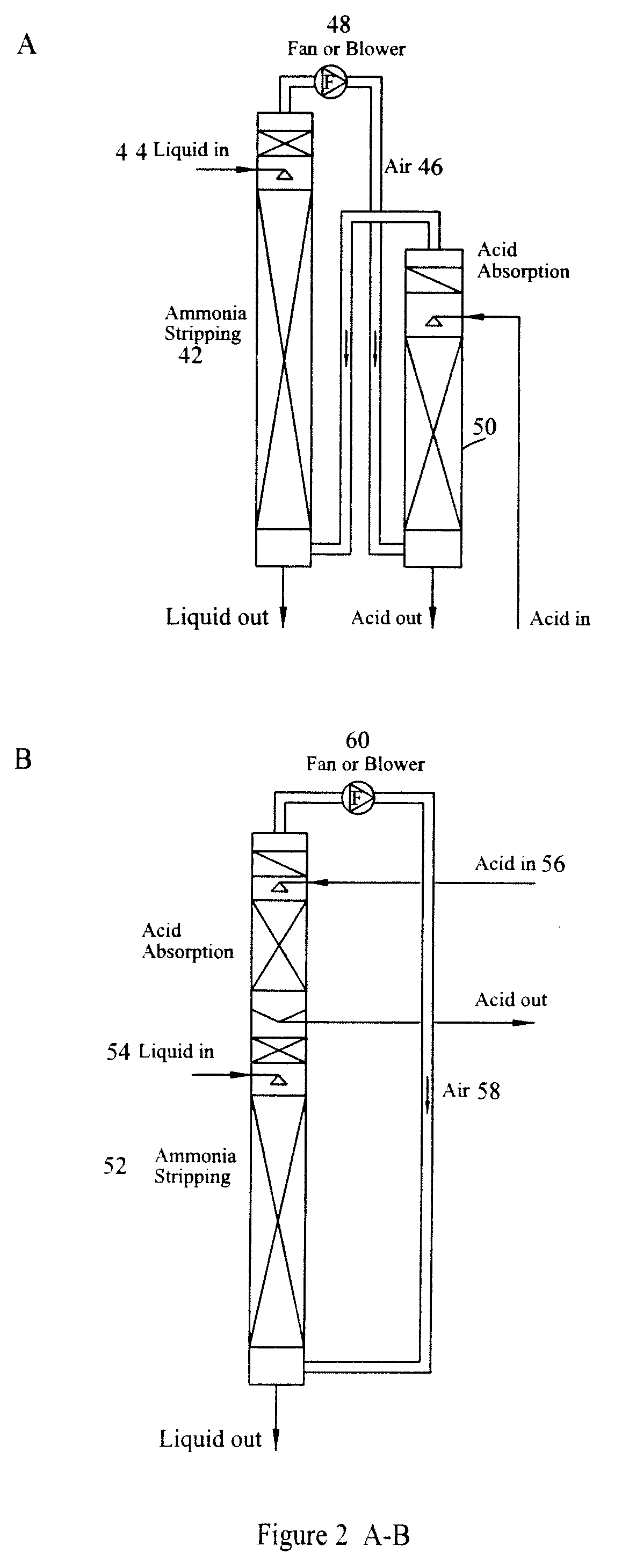

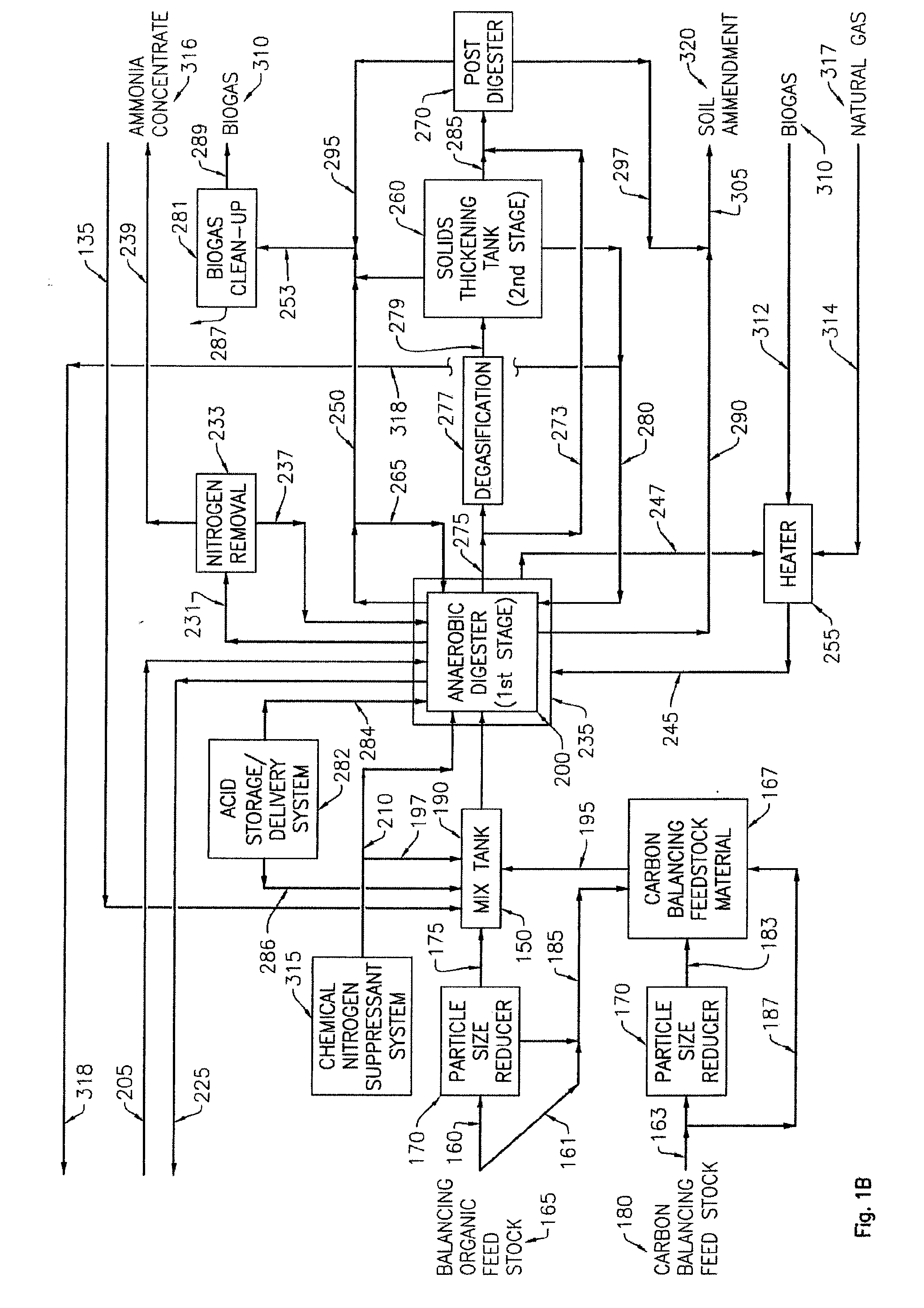

Combined nutrient recovery and biogas scrubbing system integrated in series with animal manure anaerobic digester

InactiveUS20090206028A1Inherent flexibilityIncrease flexibilityBio-organic fraction processingBiological substance pretreatmentsFecesNitrogen

An economical, integrated system works in series with anaerobic digestion of animal waste to recover nitrogen and phosphorous, while also scrubbing the produced biogas.

Owner:WASHINGTON STATE UNIV RES FOUND INC

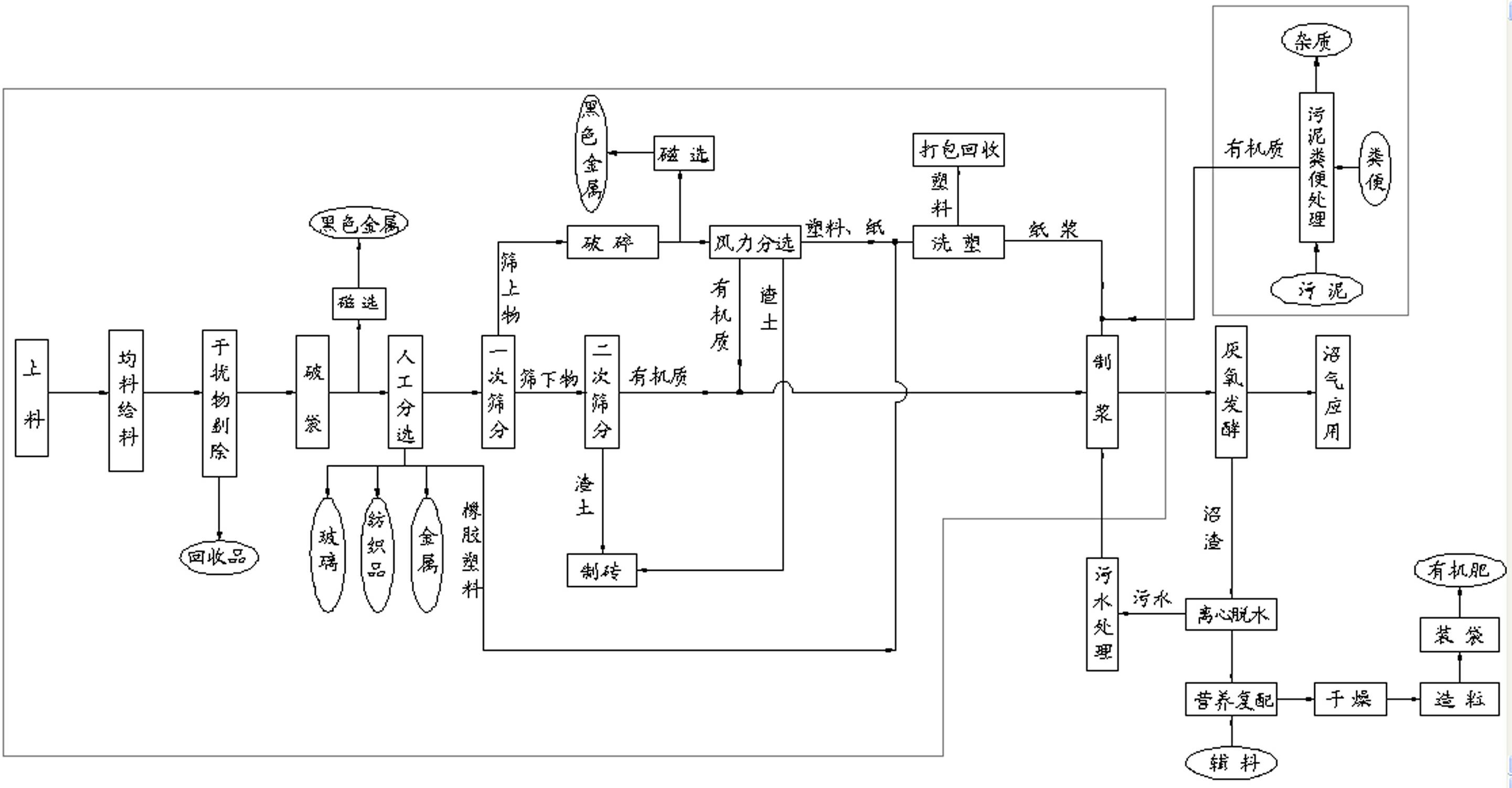

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

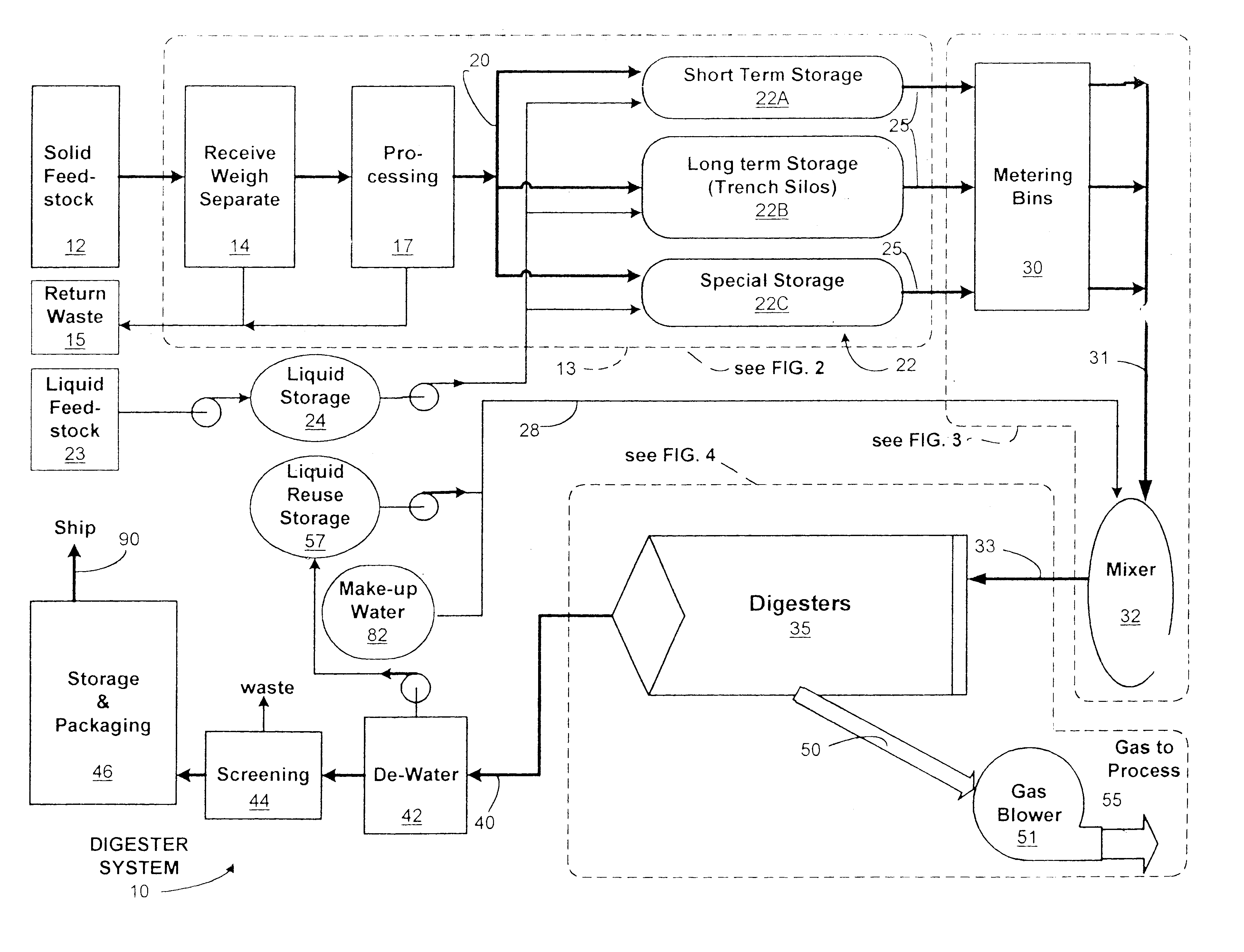

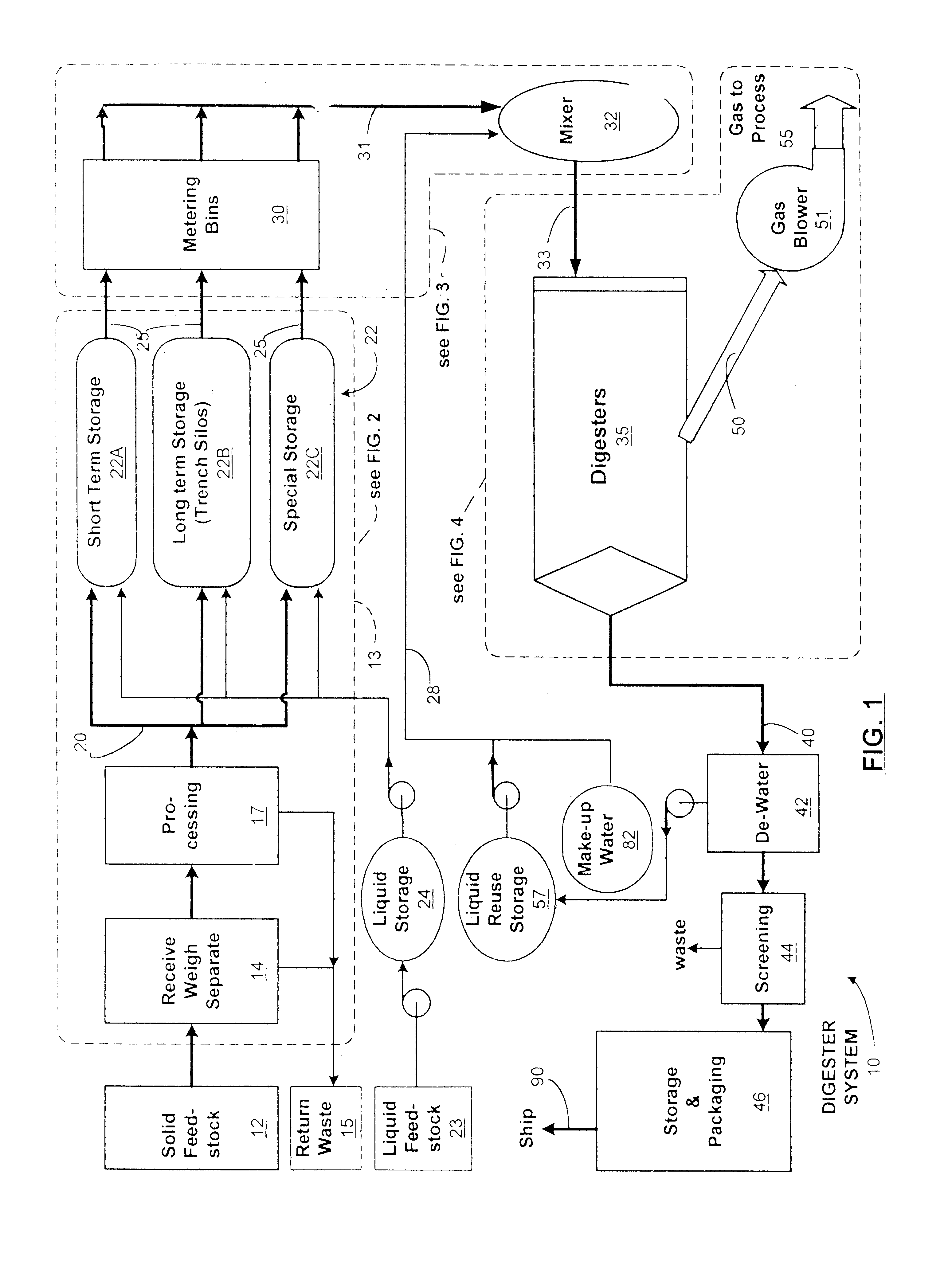

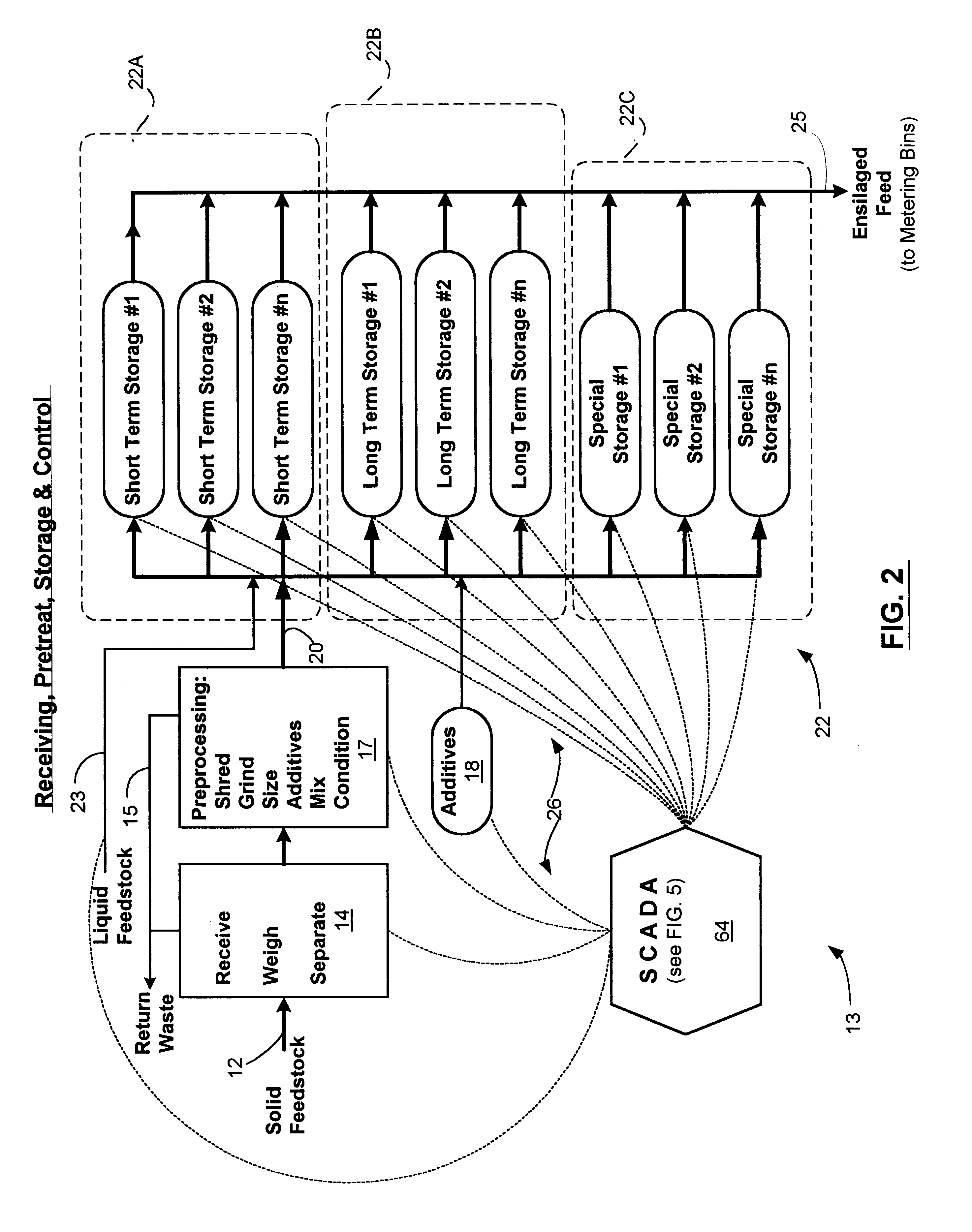

Anaerobic digester system

InactiveUS6296766B1Easy to monitorEasy to controlData processing applicationsBiological treatment regulationGrowth plantEnvironmental engineering

A method for an anaerobic digester system is provided that employs a cumulative data base to better monitor and control the anaerobic process, as compared with conventional anaerobic digester systems. The method includes the storing and ensiling of a feedstock, preferably a biomass, to form a digester feed material, which then processed by a digester. The process evolves a biogas and forms a digested material. The process is monitored, to collect a plurality of digester data from all stages of the process. These individual points or elements of the data are telemetered to a cumulative data base for storage and eventual retrieval and the cumulative data base is mined to compile predictive, feed forward controls and construct feedstock correlations between the metabolic activity within the digesters and an analysis of the feedstocks into the digesters. The method further includes the production of a high quality plant growth media from the digested mash, and recovery of the biogas generated within the digester. The biogas is collected with the aid of a biogas recovery system. The biogas is predominantly methane, and the anaerobic digester system is preferably operated to maximize the quantity and quality of methane generated.

Owner:TECHN INFORMATION

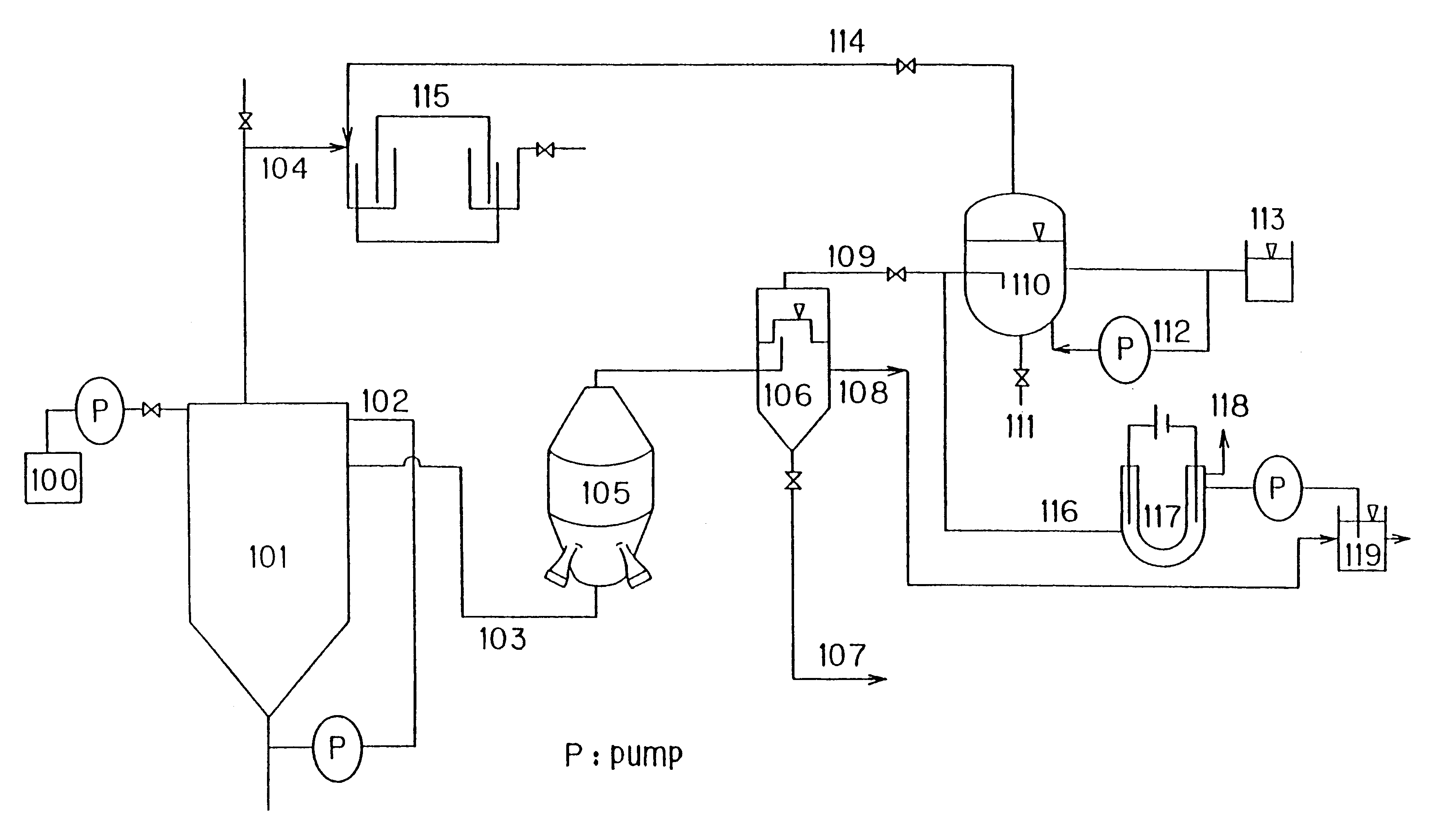

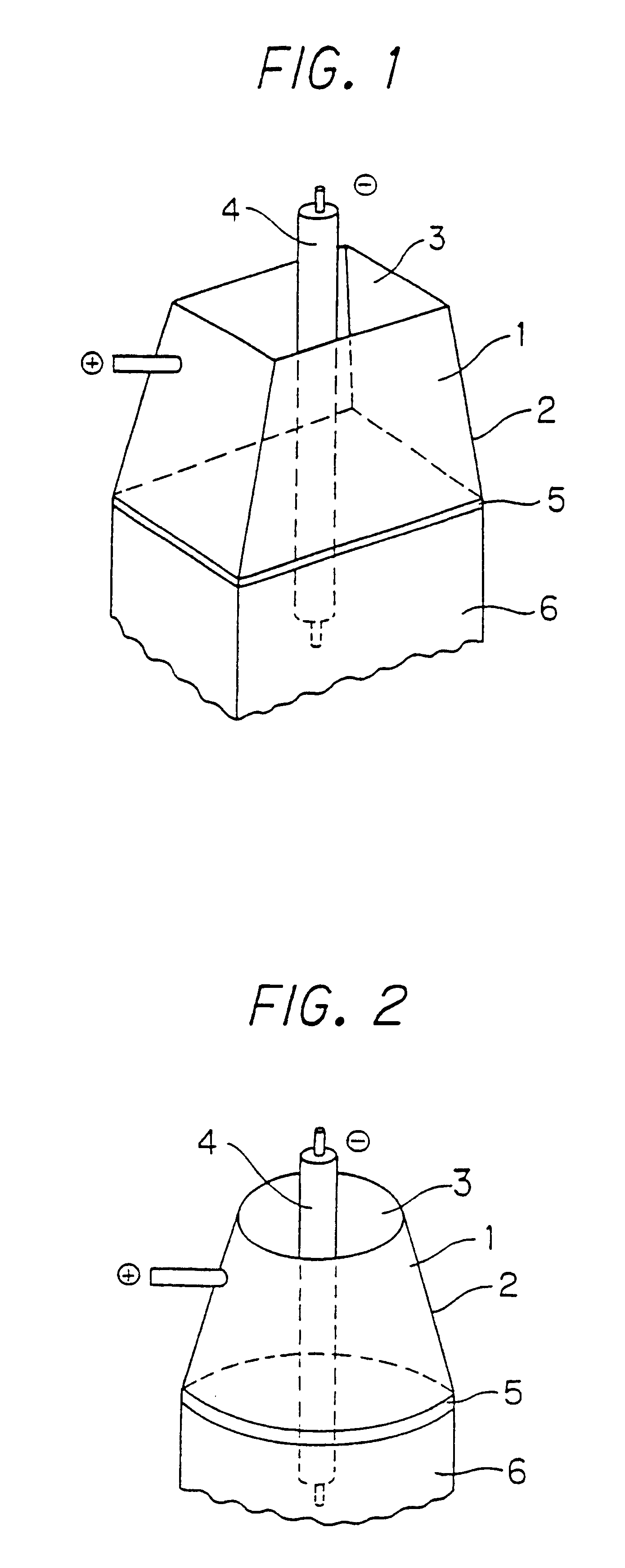

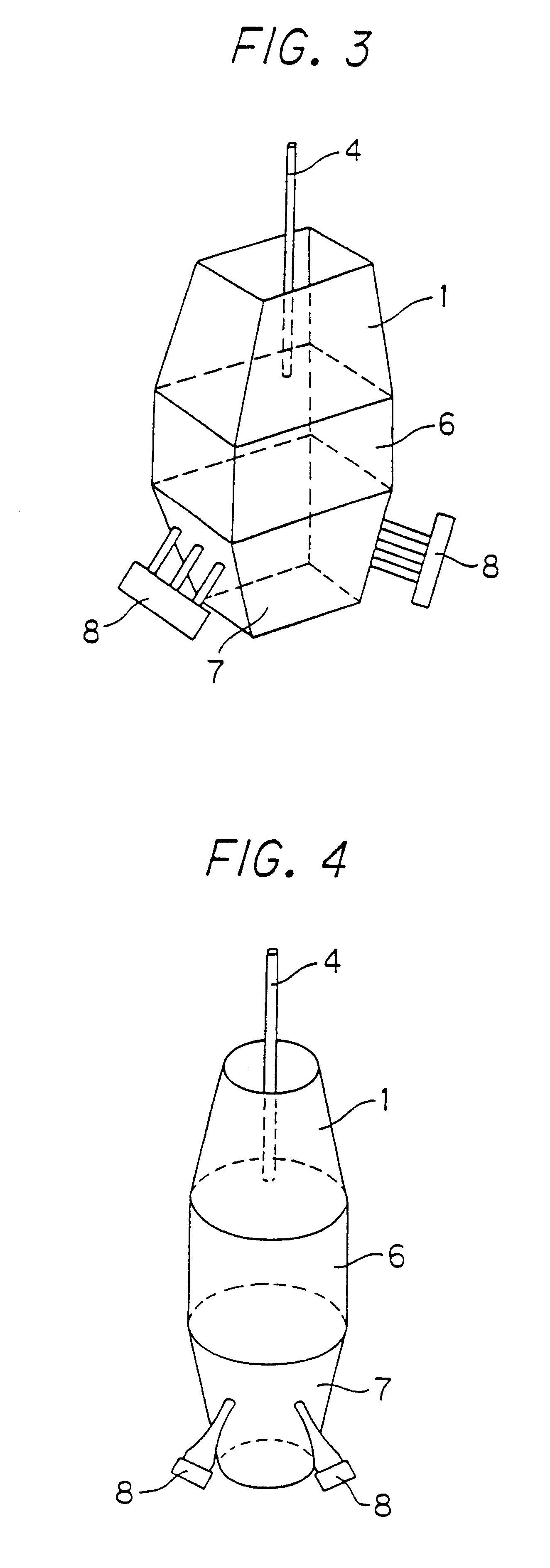

Method and apparatus for treatment of organic matter-containing wastewater

InactiveUS6547951B1Improve efficiencyImprove abilitiesCellsLiquid separation by electricitySurface layerWave form

Disclosed is a novel method for treatment of wastewater containing organic contaminant materials by oxidatively decomposing the contaminant materials by a radical reaction involving hydroxyl radicals. The method comprises passing the wastewater through a wastewater treatment conduit (6) comprising a straightly tubular member (6) and a radical generating part consisting of a truncated pyramidal or conical tubular member (1) having an inner surface layer of titanium dioxide to serve as a positive electrode and connected to the upstream end of the straightly tubular member and a negative electrode rod (4) coaxially held relative to the truncated tubular member and applying a pulsed DC voltage having a rectangular wave form at a specified frequency. The efficiency of wastewater treatment can be improved by providing an ultrasonic part consisting of a truncated tubular member similar (7) to the above and connected to the downstream end of the straightly tubular member and an ultrasonic vibrator (8) mounted thereon to emit pulsed ultrasonic waves.

Owner:DAISHIN DESIGN CORP

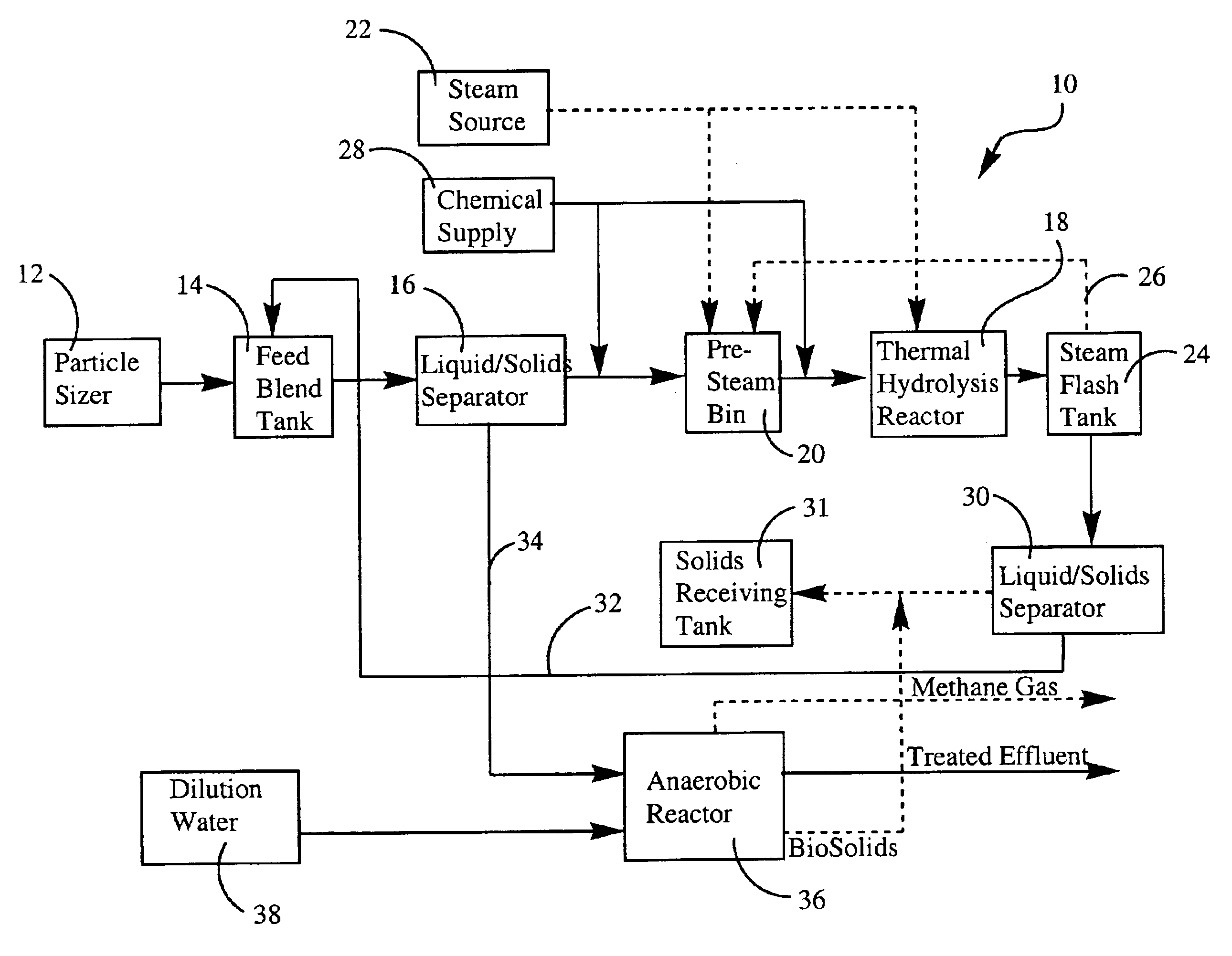

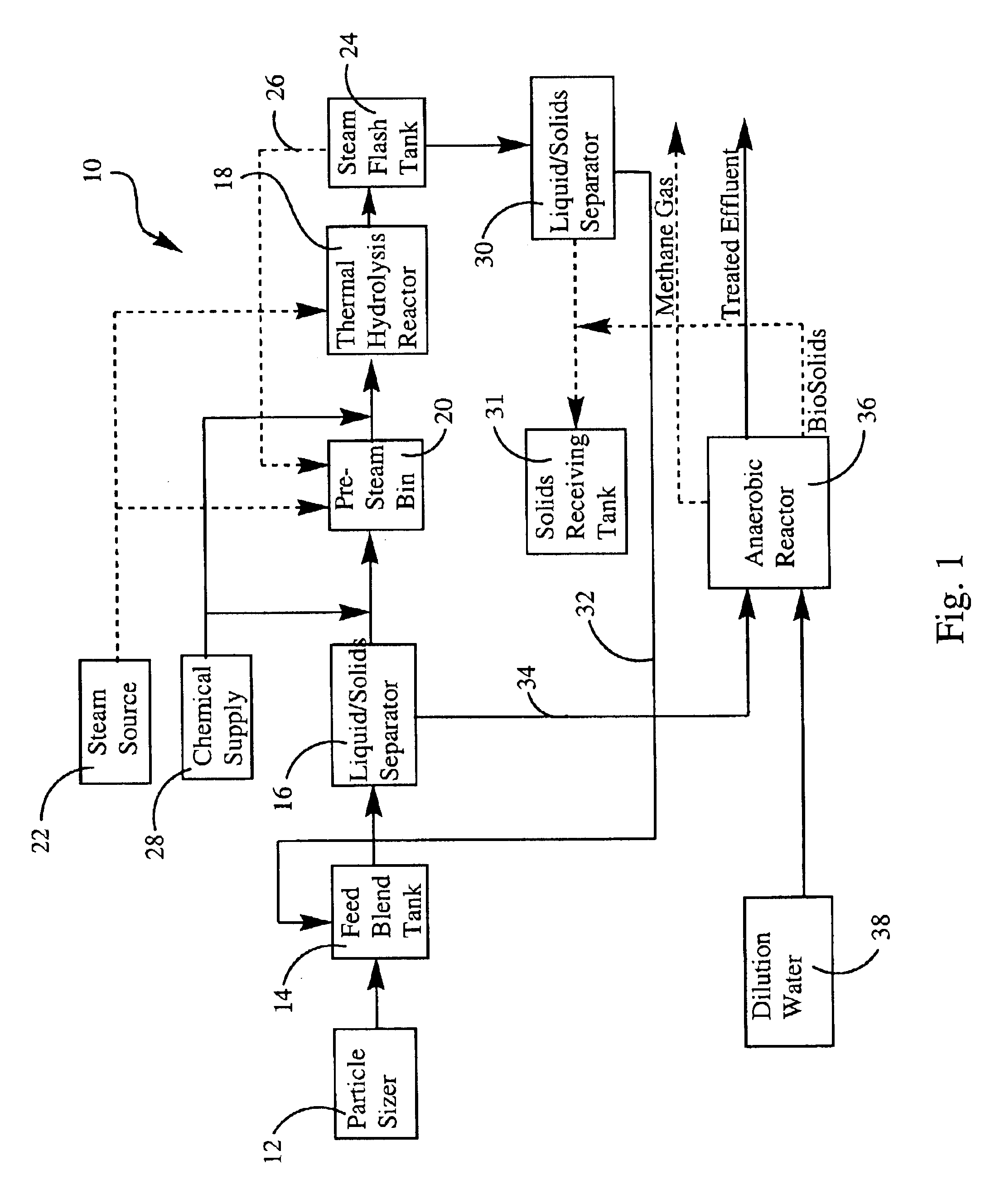

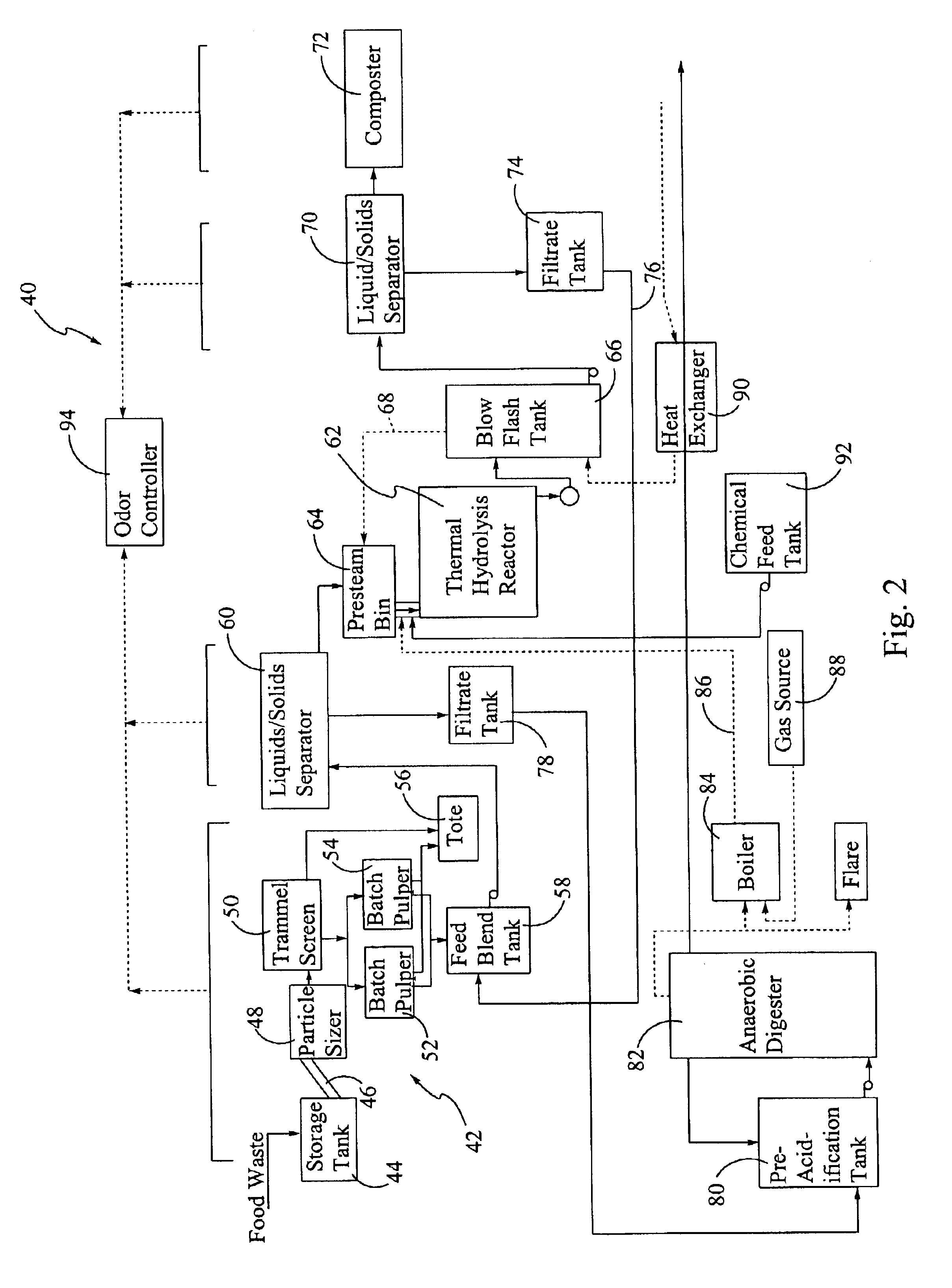

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

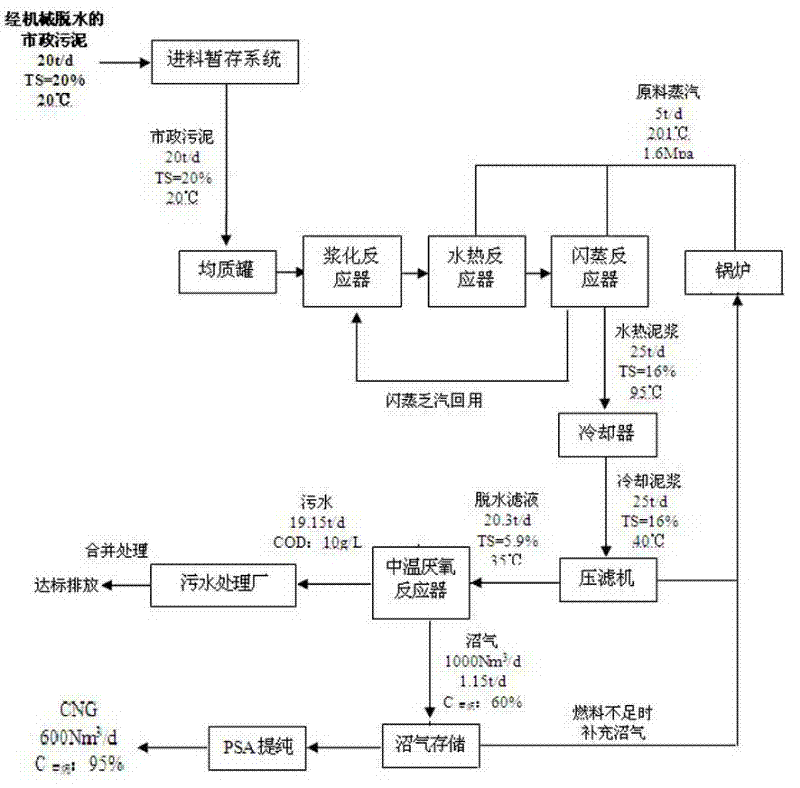

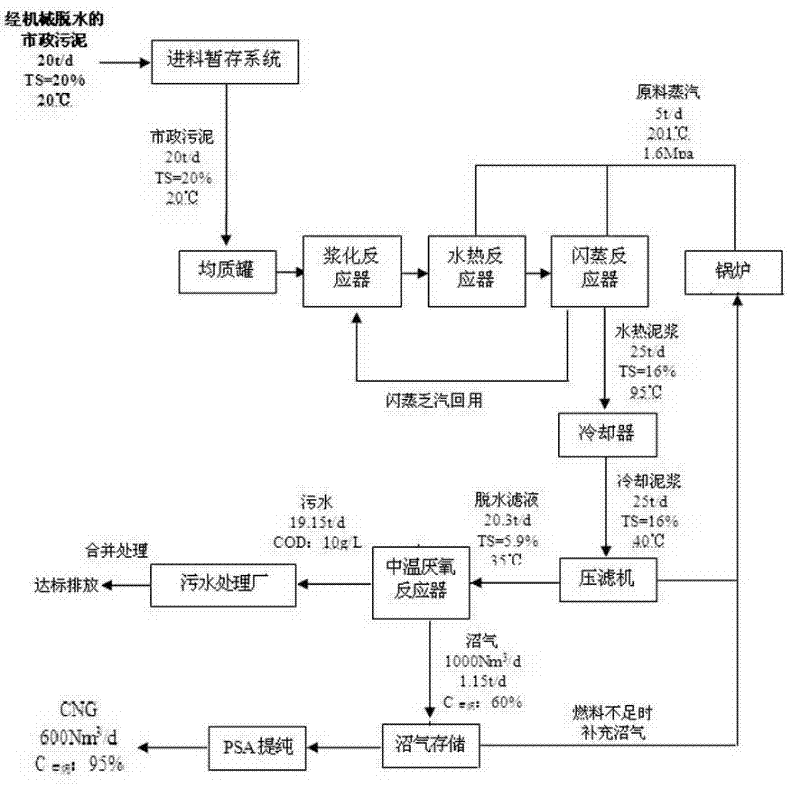

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820AAdvanced technologyHighlight energy savingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

Methods and Systems for Biomass Recycling and Energy Production

InactiveUS20090227003A1Reduce the amount requiredPromote growthBioreactor/fermenter combinationsBiological substance pretreatmentsAlgaeBiology

The present invention comprises methods and systems for treating biomass wastes to result in usable byproducts. Biomass is treated to remove debris, transferred to microbial digester units, such as anaerobic and aerobic digesters, and the resultant solids and liquids are provided to an algae production unit. Algae are harvested and beneficial byproducts are retained. Gases, heat and energy produced by energy conversion units are used in units of the system or provided to external sources. Water is cleaned and when separated from the algae and other solids in the algae harvesting unit may be provided to external sources, or may be used in other units of the system. The methods and systems disclosed herein provide for an efficient and substantially complete use of the components of the input biomass.

Owner:CORE INTPROP HLDG

Novel method for innocent treatment and utilization of dead livestock and poultry

InactiveCN101182247ASave energyNo secondary pollutionBio-organic fraction processingInternal combustion piston enginesSlagSludge

The invention discloses a novel method of the harmless treatment and utilization of livestock and poultry which died of disease according to the steps as follows: firstly, various kinds of the animal bodies of the livestock and the poultry which died of disease are collected; secondly, the animal bodies are crushed; thirdly, the crushed animal bodies are sterilized under high temperature and highpressure and separated for filtering, the material of oil and fat flows into a cooling pool, and the material of hair and bone is dried; fourthly, the material of hair and bone after drying is carbonized; fifthly, the material of oil and fat after cooling is added with catalyst, high-efficiency compound microorganism, trash, organic wastewater and sludge; sixthly, the mixed organic material is put into an anaerobic tower to be fermented, and then biogas, biogas slurry and biogas slag are processed for three-phase separation; seventhly, the biogas is used for burning and generating electricity; eighthly, the biogas slurry inside a fertilizer storing pool is used as farmland fertilizer; ninthly, the biogas slag is added with the high-efficiency compound microorganism and the catalyst for secondary ferment; tenthly, the material after the secondary ferment is made into agricultural high-efficiency organic fertilizer. The invention solves the problem of the environmental pollution caused by the livestock and poultry which died of disease and change the waste livestock and poultry which died of disease into valuables.

Owner:浙江威尔斯生物能源开发有限公司

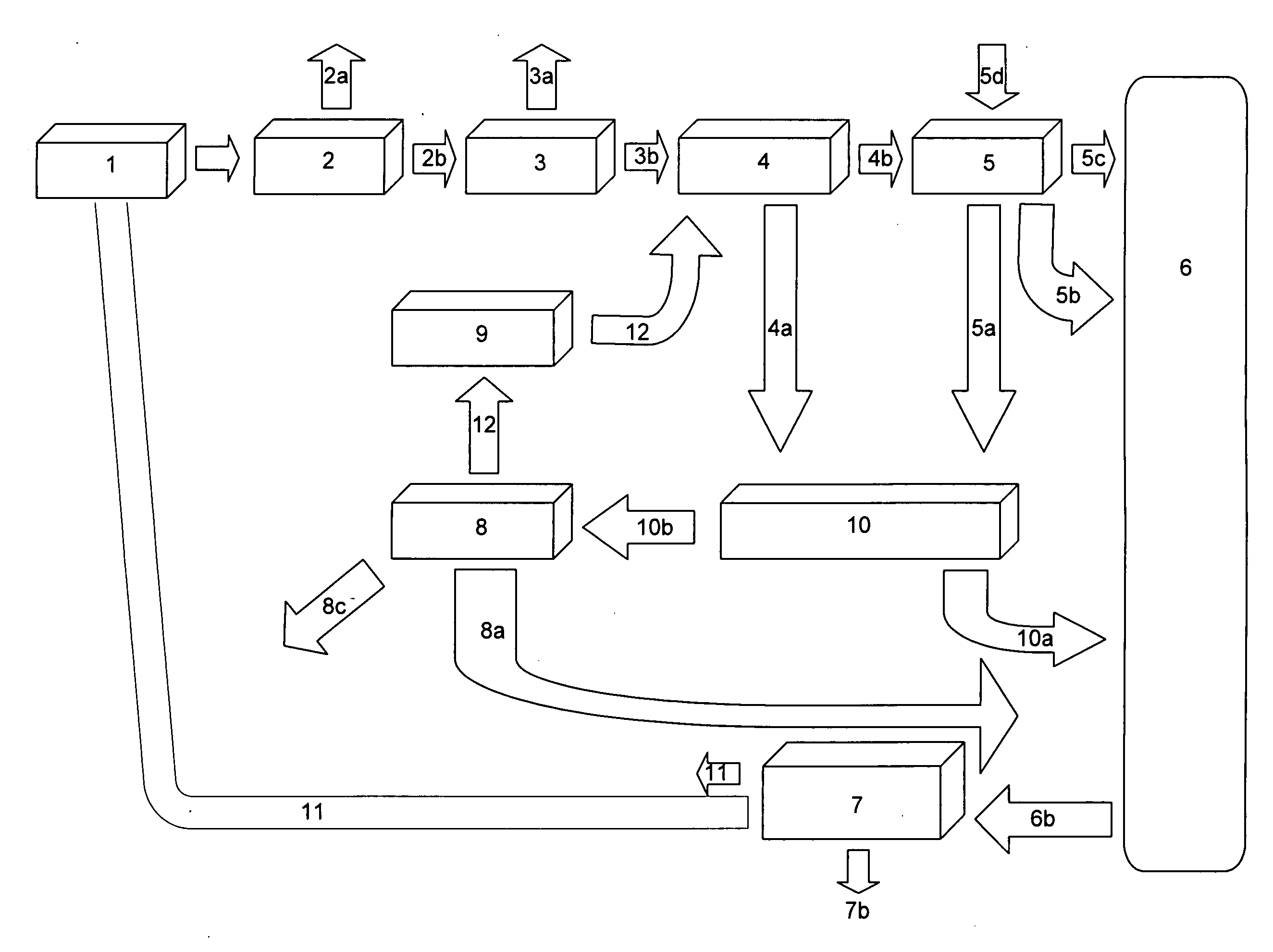

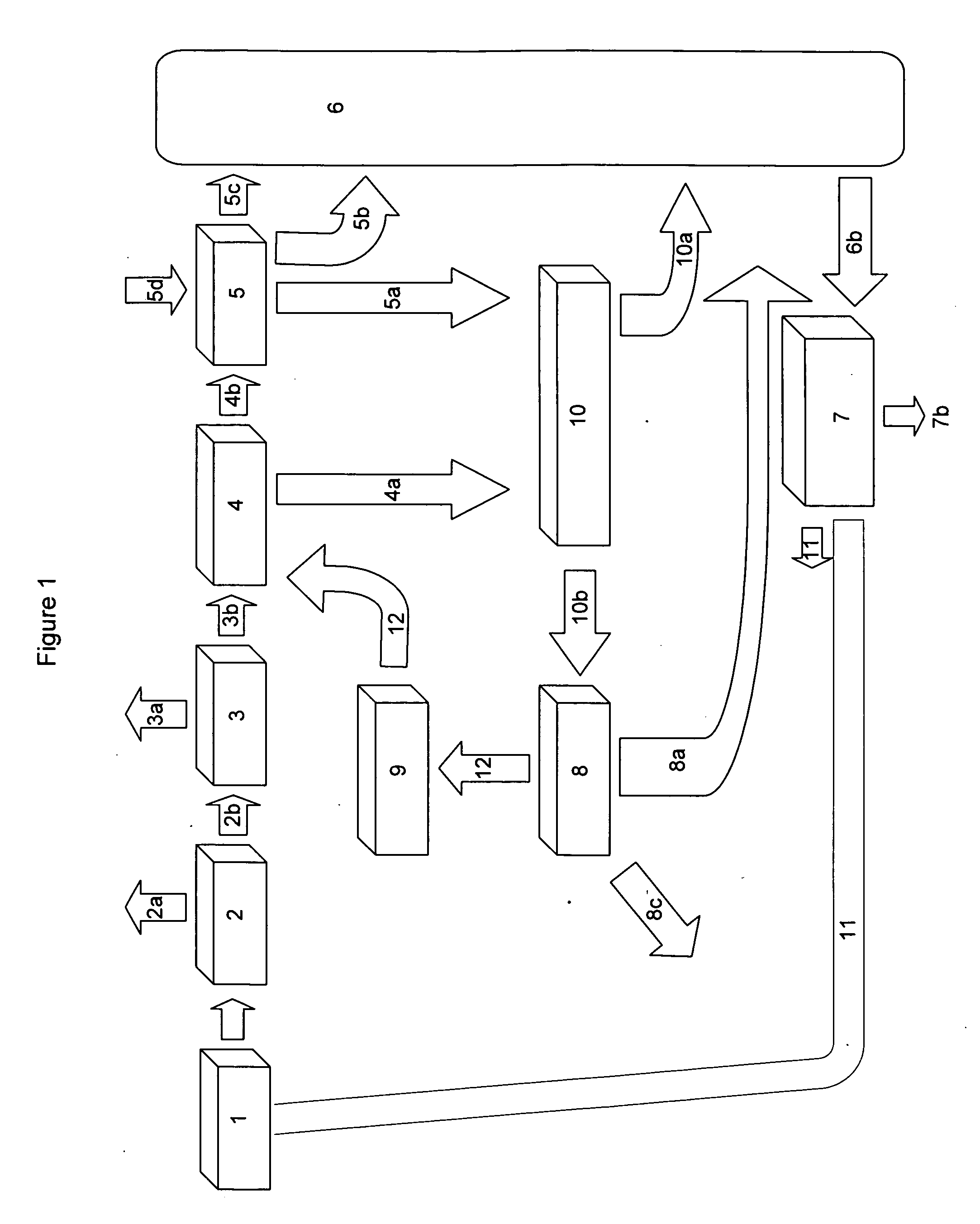

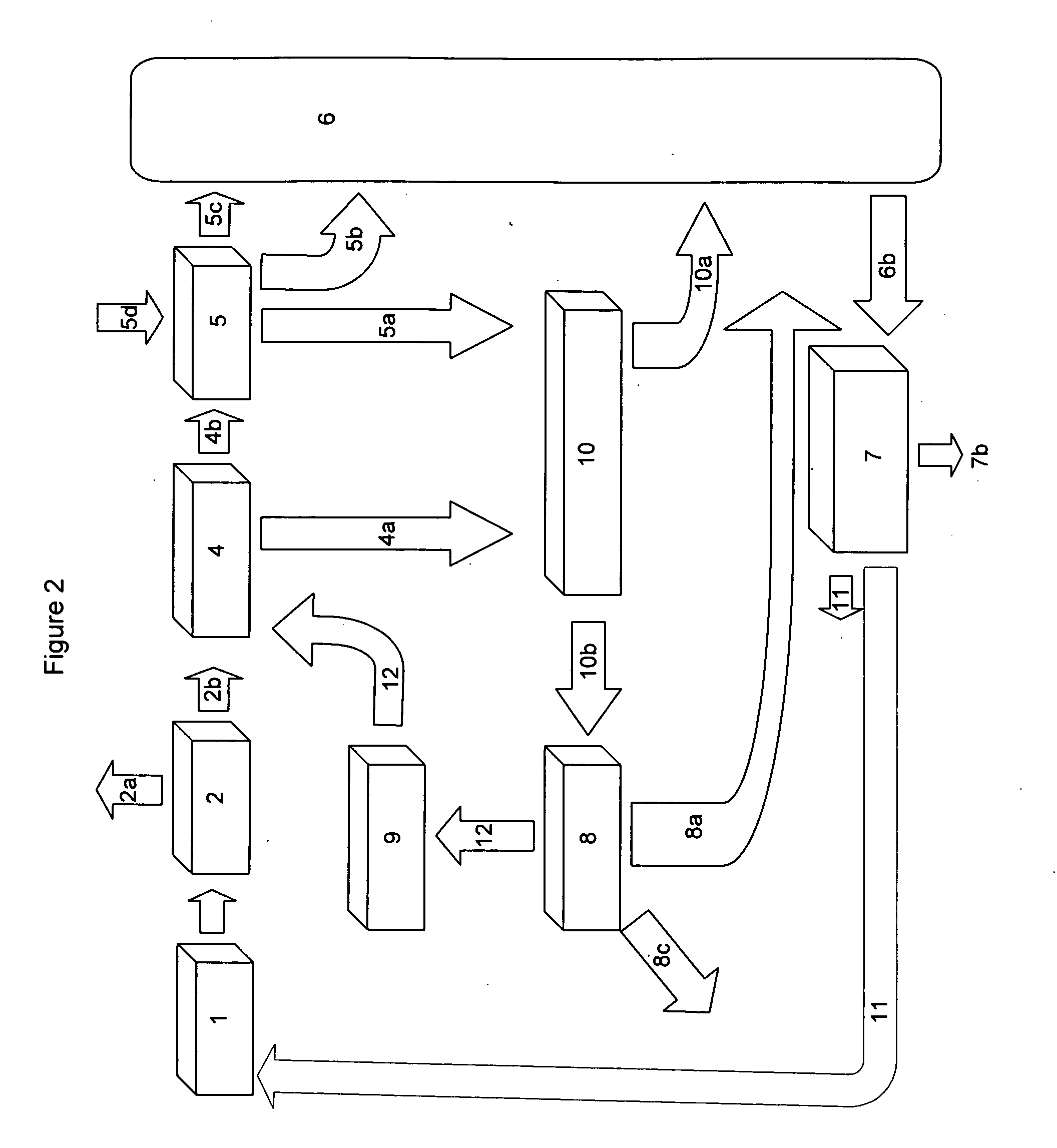

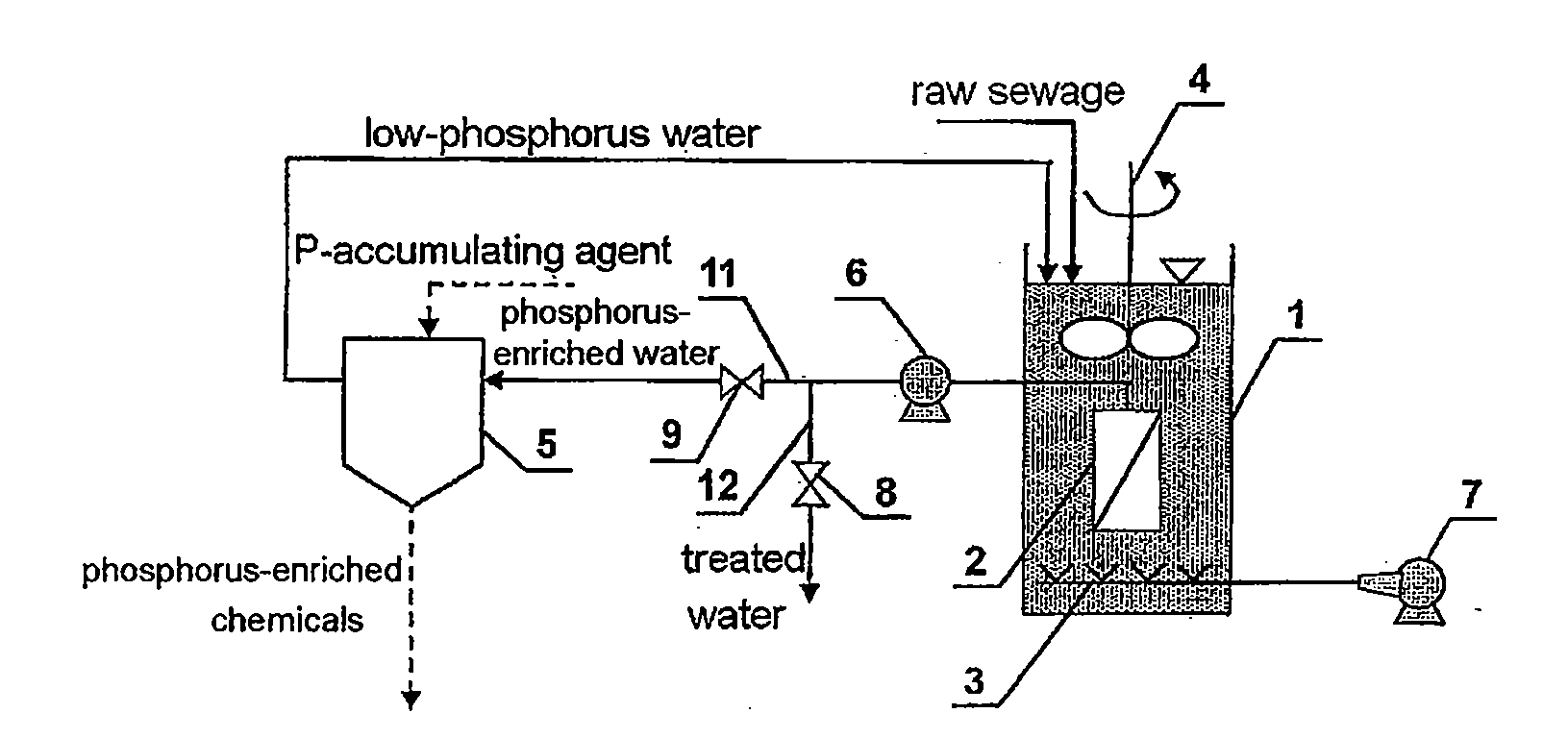

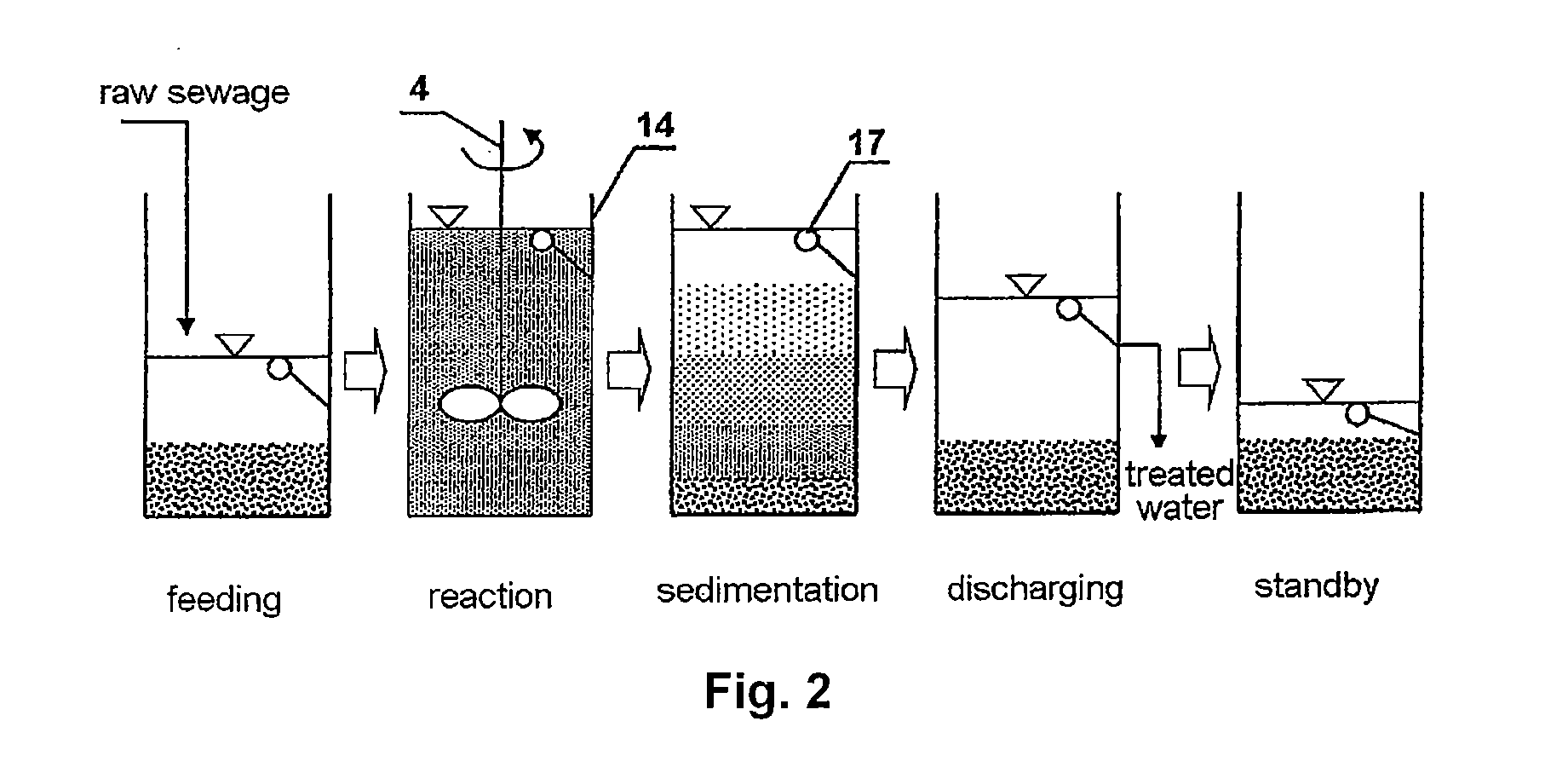

Sewage Treatment Process and System

InactiveUS20120018374A1Reduce space utilizationEfficient removalDialysis systemsTreatment with aerobic and anaerobic processesWater flowSewage

A sewage treatment process is provided, which includes the following steps: a) sewage feeding step, comprising introducing raw sewage into a biological reaction tank (1) to a predetermined time or liquid level; b) reaction step comprising performing aeration and stirring intermittently in the biological reaction tank (1); c) treated water discharging step, comprising performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a first permeate, which is taken as the final treated water; d) standby step comprising stopping aeration in the biological reaction tank (1); and e) phosphorus-enriched water discharging step, comprising keeping anaerobic condition in the biological reaction tank (1) and performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a second permeate, the second permeate entering inside a phosphorus recycling unit (5) which is set independent from the biological reaction tank (1), the phosphorus recycling unit (5) removing phosphorus from water, the second permeate becoming low-phosphorus water, and the low-phosphorous water flowing back to the biological reaction tank (1); the sewage treatment process runs in cycle by repeating above steps. A corresponding treatment system is also provided.

Owner:SUN YOUFENG

Digesters

Methods and devices are disclosed for converting predominantly organic waste materials, such as sludge, into useful byproducts.

Owner:TOLBERT & ASSOCS

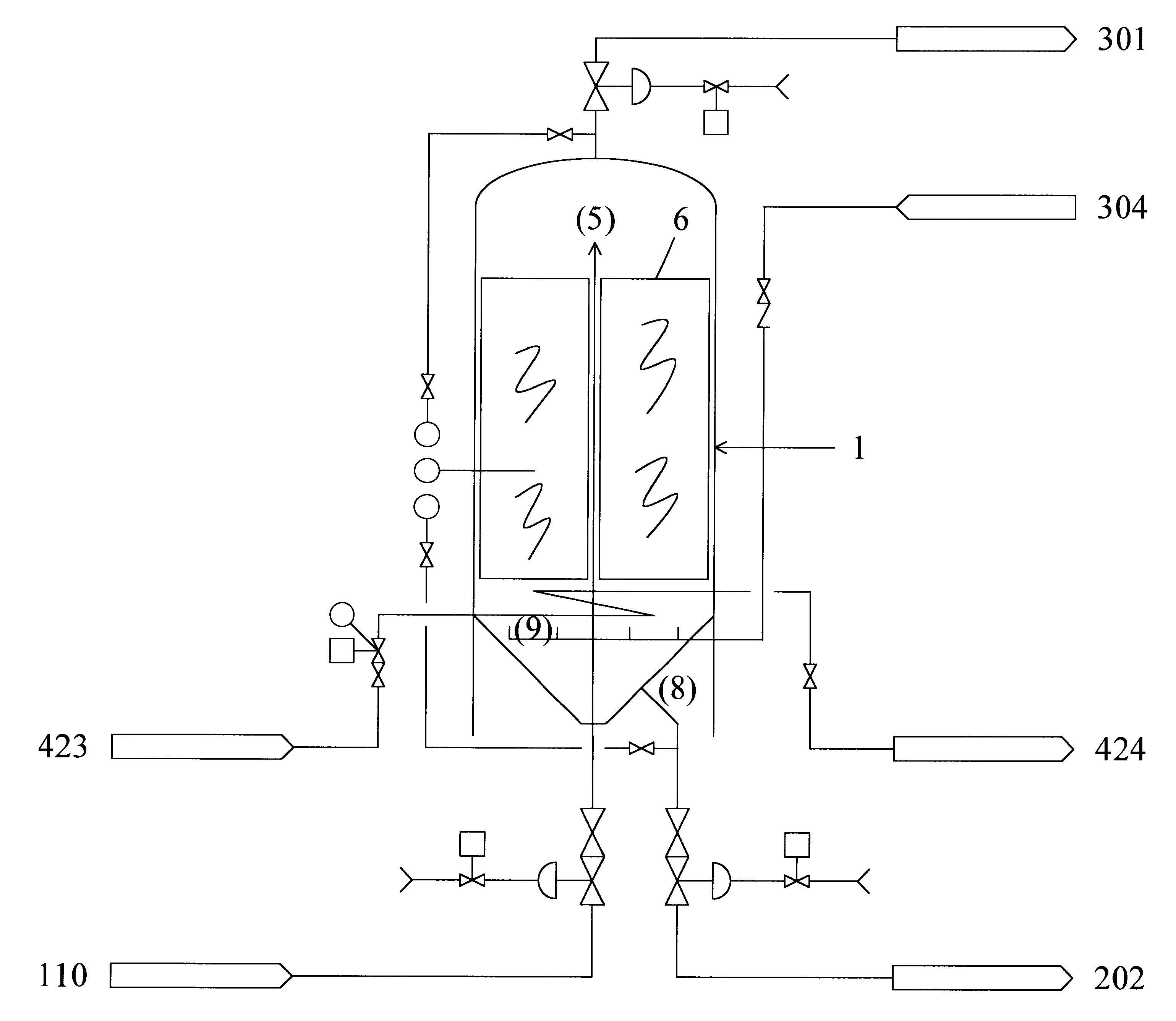

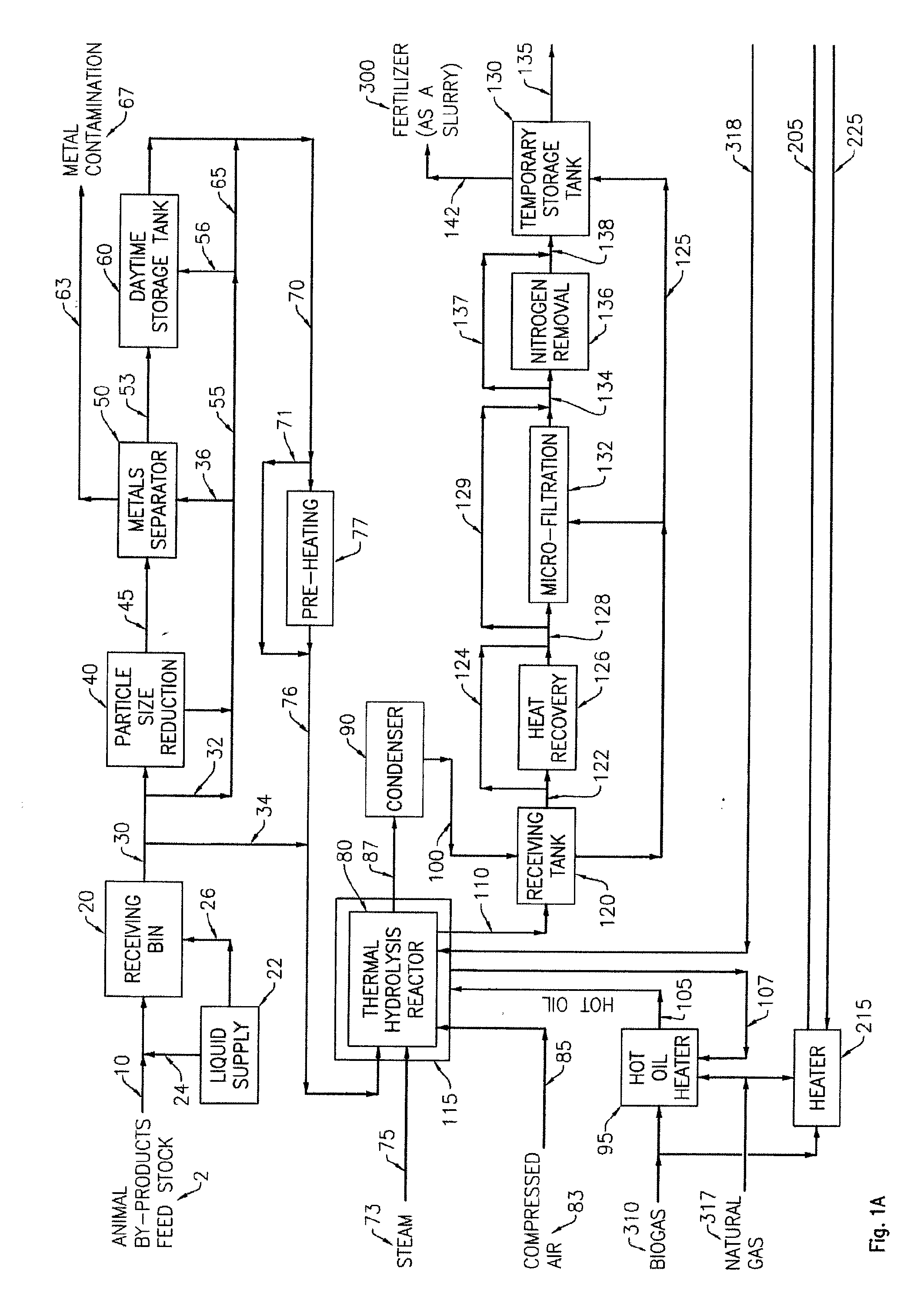

Apparatus and Process for Production of Biogas

ActiveUS20100021979A1Quick conversionDigesting retention timeBioreactor/fermenter combinationsBiological substance pretreatmentsHydrolysateSolid fraction

A process and an apparatus for the manufacture of biogas and a solids fraction from an organic waste feedstock is provided. The process involves thermal hydrolysis of the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours, to produce a hydrolysate. The hydrolysate undergoes anaerobic digestion at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce a biogas stream and a digestate. The digestate is separated into a solids fraction and a liquid fraction, and a portion of the solids fraction is recycled for further anaerobic digestion. The biogas stream, characterized as having a methane content from between 55 to 80% by volume, and the solids fraction, are recovered. The apparatus includes a receiving bin for receiving and supplying organic waste feedstock to a thermal hydrolysis reactor. The thermal hydrolysis reactor for processing the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours to produce a hydrolysate. An anaerobic digester for processing the hydrolysate at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce the biogas and a digestate, and a solids thickening tank for separating the digestate into the solid fraction, a liquid fraction and a secondary biogas fraction.

Owner:GEMINI CORP

Filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS7387723B2Significant comprehensive benefitsLow costWater/sewage treatment by centrifugal separationMembranesFiltrationMembrane bioreactor

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge.

Owner:EVOQUA WATER TECH LLC

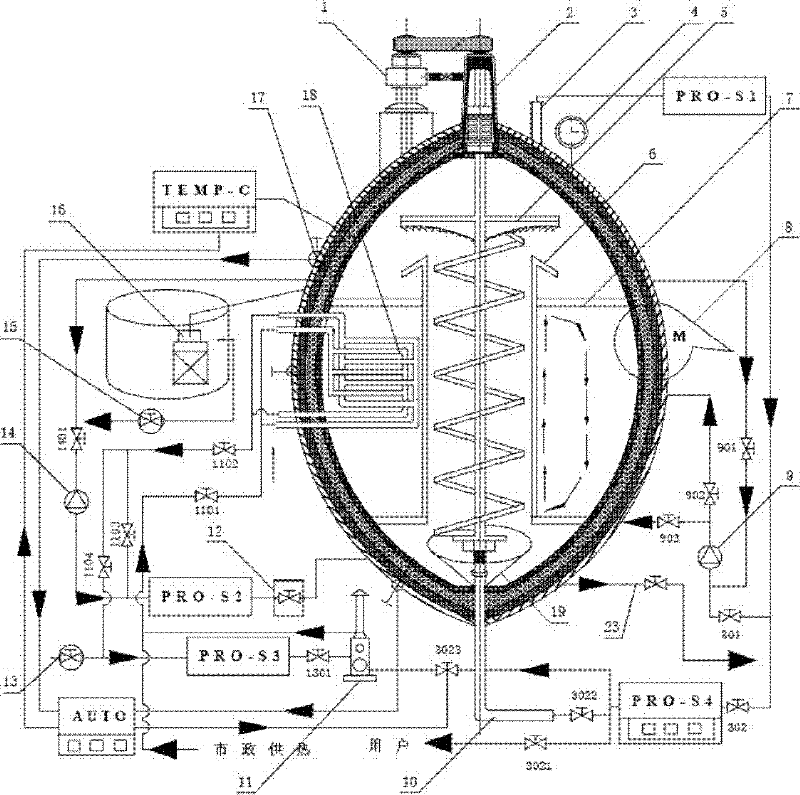

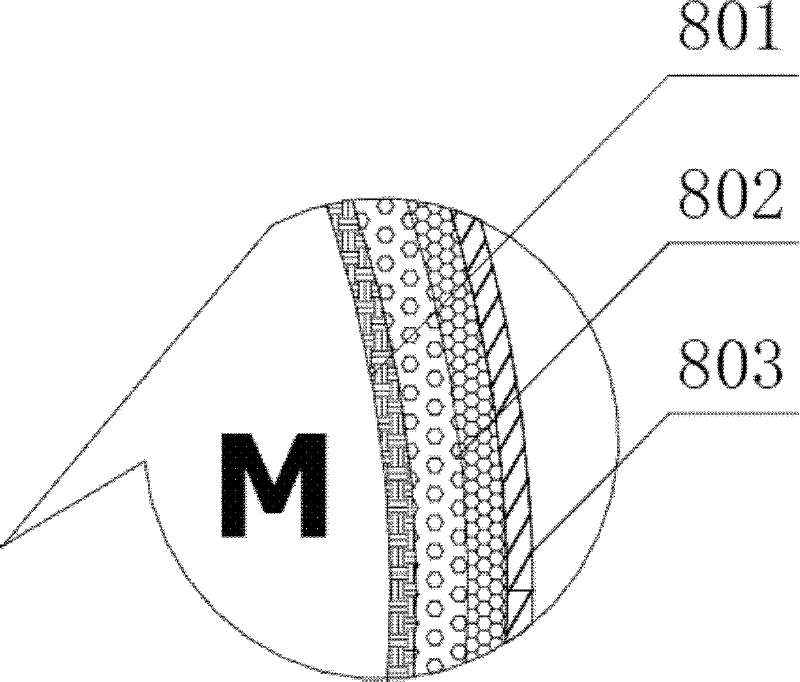

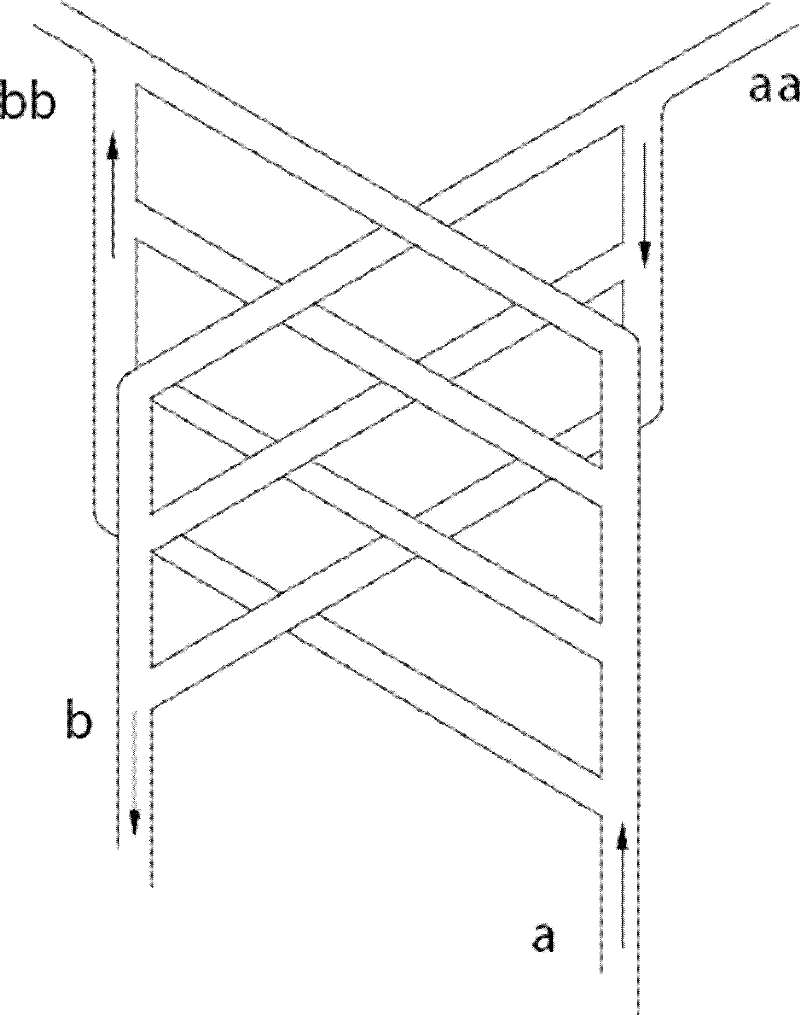

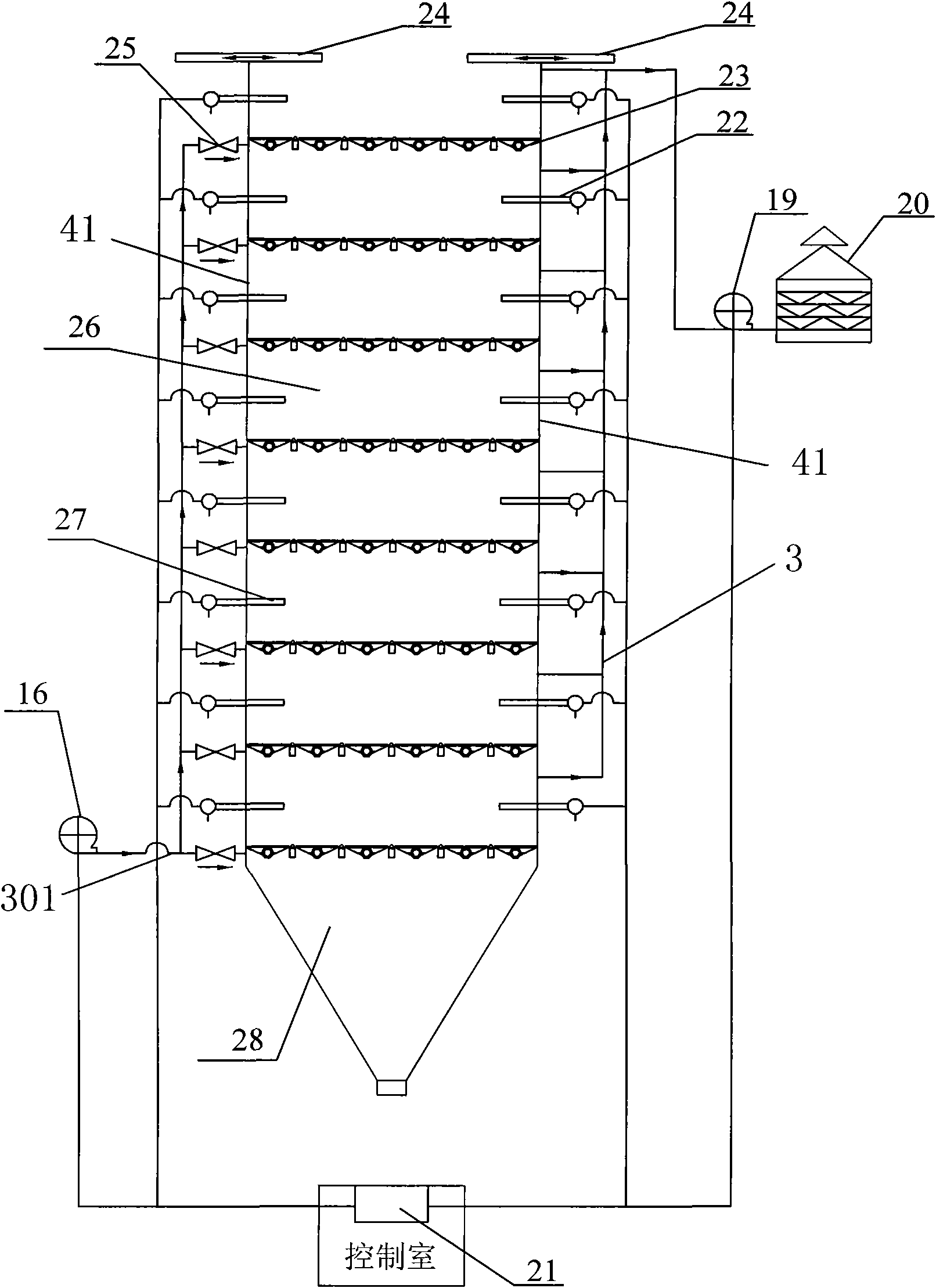

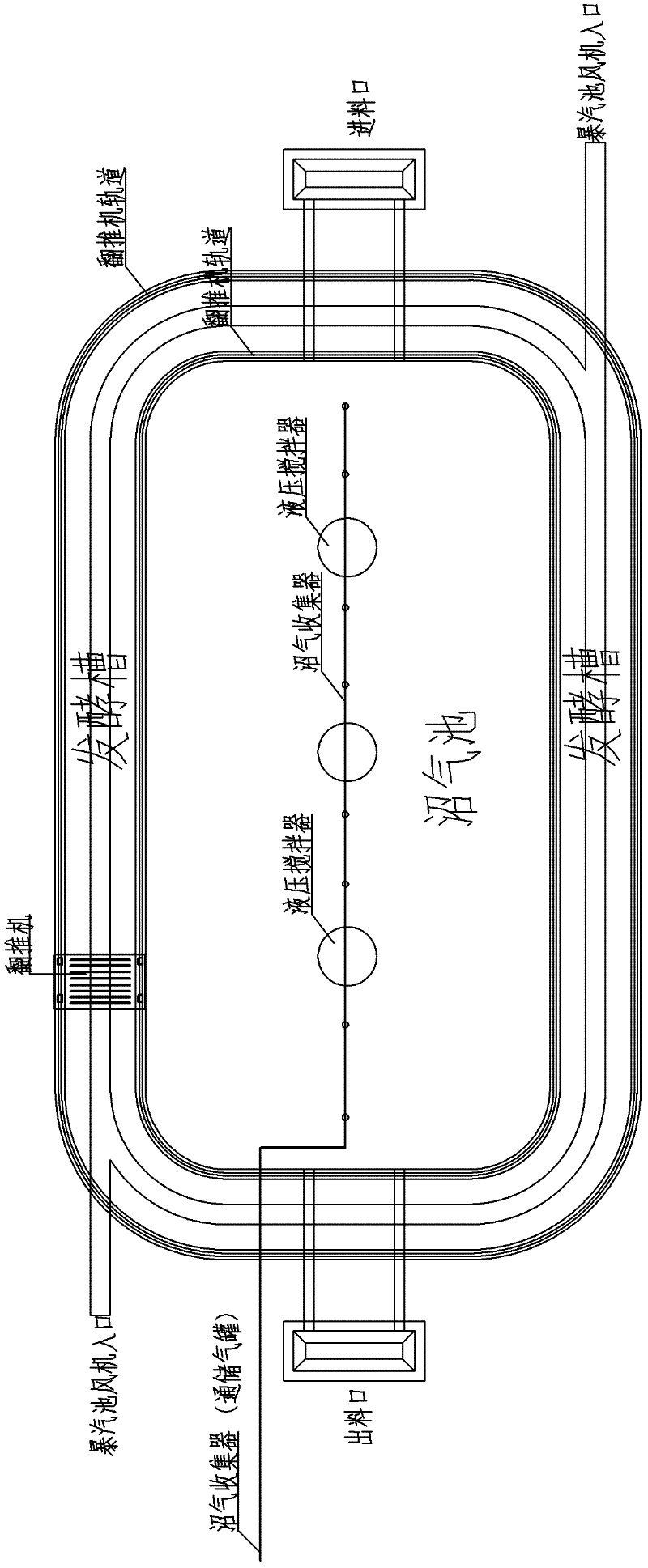

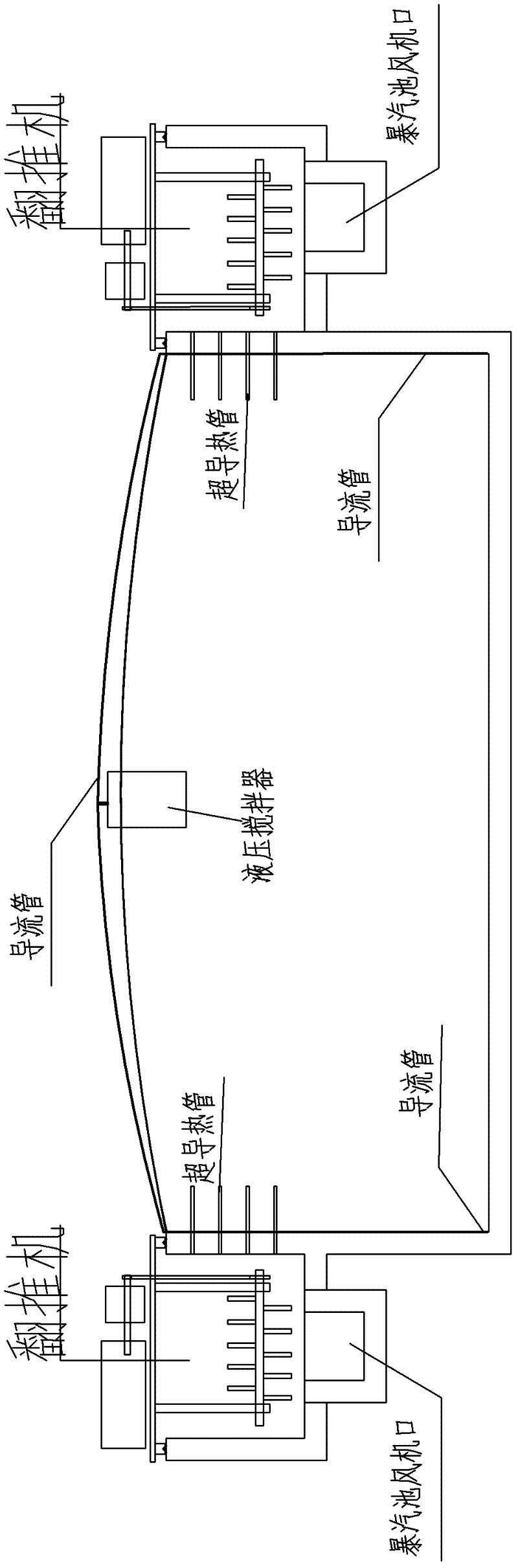

Multi-cycle stirring egg-shaped anaerobic fermentation system

ActiveCN102517199ASimple structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSlurry

The invention discloses a multi-cycle stirring egg-shaped anaerobic fermentation system. The system comprises a fermentation tank body and a driving device arranged on the fermentation tank body, wherein the fermentation tank body is egg-shaped, the center of the inner cavity of the fermentation tank body is provided with an inner barrel type spiral stirrer, the outside of the inner barrel type spiral stirrer is provided with a stirrer inner barrel, a temperature heating device is arranged between the wall of the fermentation tank body and the stirrer inner barrel, the bottom of the inside ofthe tank is provided with an umbrella-shaped gas flow distribution device; the upper part of the fermentation tank body is provided with a vent pipe and a pressure control device, the bottom of the fermentation tank body is provided with an umbrella-shaped gas flow distribution device gas inlet pipe and a mud-discharging and sand-discharging outlet; and the side wall of the fermentation tank bodyis communicated with a biogas circulation system, a biogas slurry circulation system, a gas-liquid circulation system, a heating system, a temperature control system and a biogas residue and biogas slurry storage pool respectively. The multi-cycle stirring egg-shaped anaerobic fermentation system adopts multi-cycle stirring to increase the stirring efficiency of the system; and the anaerobic fermentation environment is improved, the fluid is mixed evenly, the temperature difference slightly fluctuates, the energy consumption of the system is low, the fermentation rate is high and the system is suitable for popularization and application.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

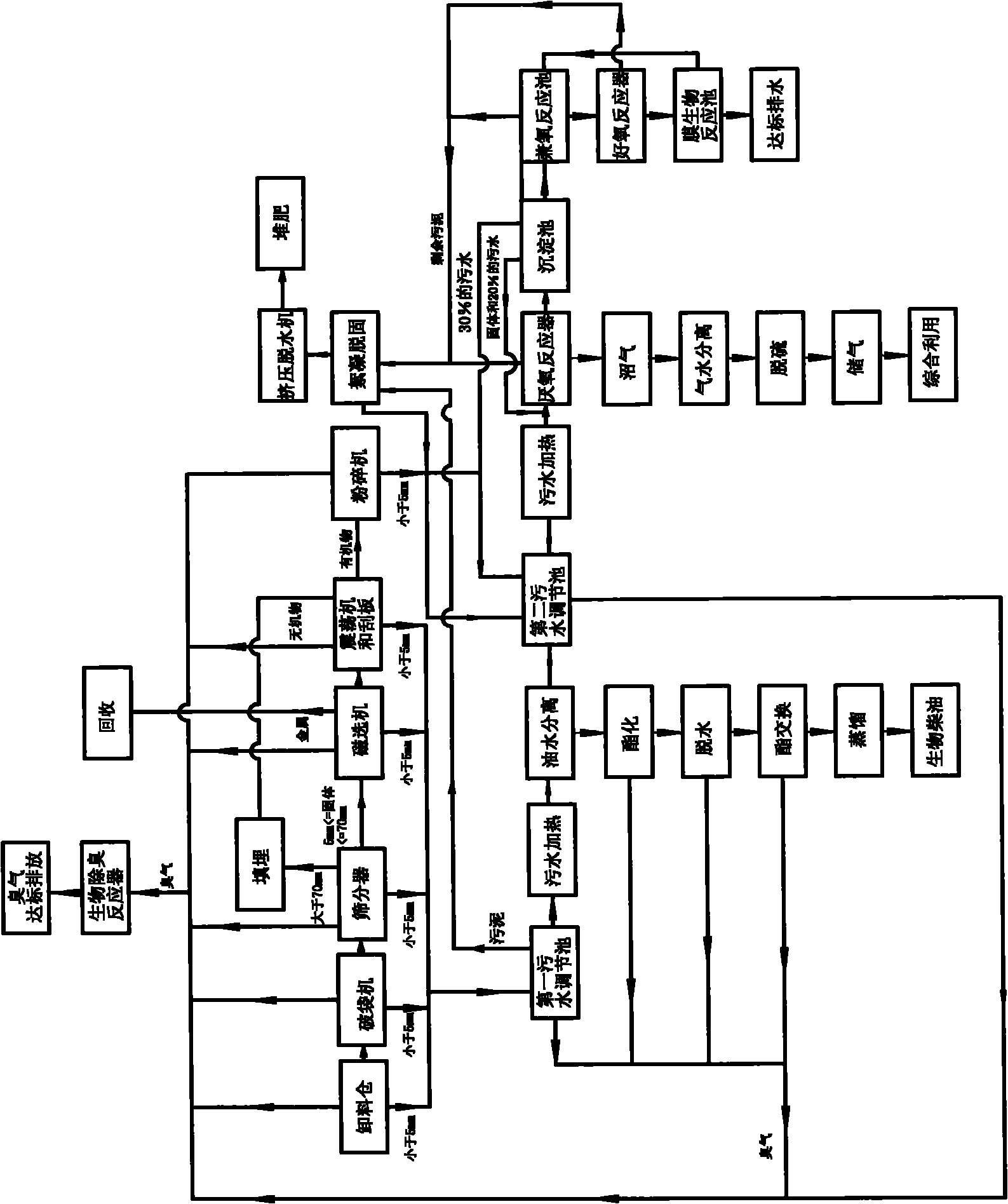

Centralized kitchen waste treatment method

ActiveCN101837366ARealize harmless treatmentRecycling is possibleFatty oils/acids recovery from wasteBio-organic fraction processingResource utilizationOil water

The invention relates to a centralized kitchen waste treatment method which comprises the following steps of: (A) sorting kitchen waste; (B) separating oil from water; (C) treating oil; (D) treating sewage; and (E) treating odor. Compared with a traditional kitchen waste burying method, by using the centralized kitchen waste treatment method, a great amount of soil is saved and an available methane resource is generated, kitchen waste reaches 100 percent of harmlessness, more than 95 percent of resource utilization and more than 95 percent of quantitative reduction, and the harmless treatmentof waste and the recycle of resources are truly realized.

Owner:北京昊业怡生科技有限公司

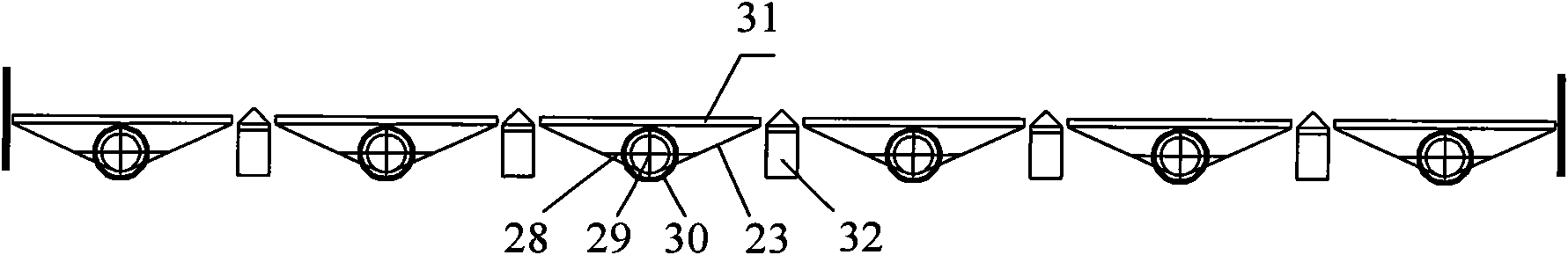

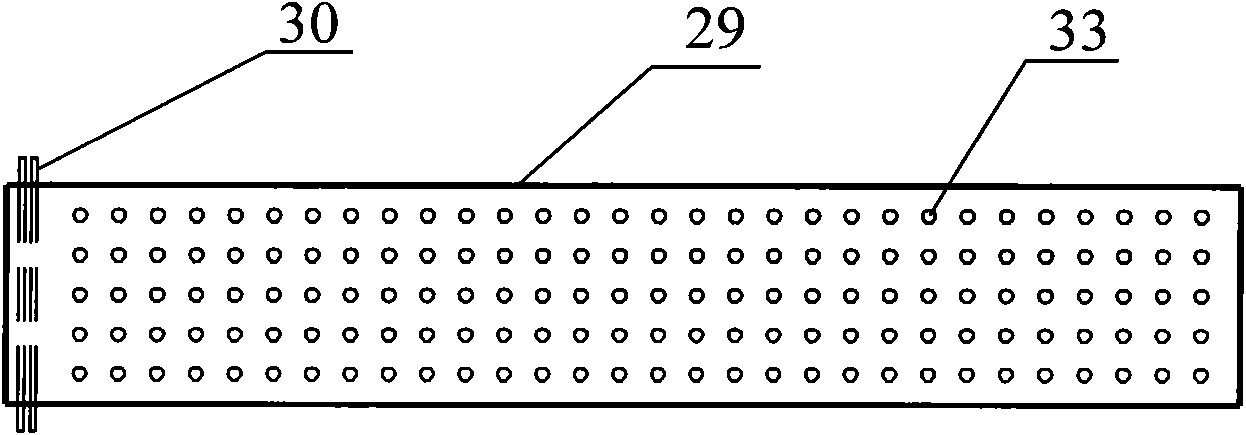

Circulating sludge biological fermentation tank, processing system and processing method

ActiveCN102153388AReduce wind pressureReduce air volumeBio-organic fraction processingSludge treatment by de-watering/drying/thickeningSludgeControl room

The invention discloses a circulating sludge biological fermentation tower which comprises a tower body, an openable tower cover, a storage tank and a plurality of rotatable fermentation devices, wherein the openable tower cover is arranged on the top of the tower body; the storage tank is arranged at the bottom of the tower body; the rotatable fermentation devices are arranged in the tower body in parallel; the fermentation devices divide an inner cavity of the tower body into a plurality of layers of fermentation bins along the axial direction; the lower part of each layer of fermentation device is provided with a ventilating oxygen supply pipeline communicated with a blower; the upper part of each layer of fermentation device is provided with an air outlet pipeline communicated with aninduced draft fan and a monitoring device; the monitoring device is controlled by a control room; and a mechanism for driving the fermentation devices and the tower cover to move, the blower and the induced draft fan are all controlled by the control room. The invention also discloses a circulating sludge biological processing system and a processing method. By the circulating sludge biological fermentation tower, the circulating sludge biological processing system and the processing method, industrial biological fermentation desiccation treatment can be continuously and stably carried out onsludge under the conditions of high efficiency and low energy consumption.

Owner:深圳市如茵生态环境建设有限公司

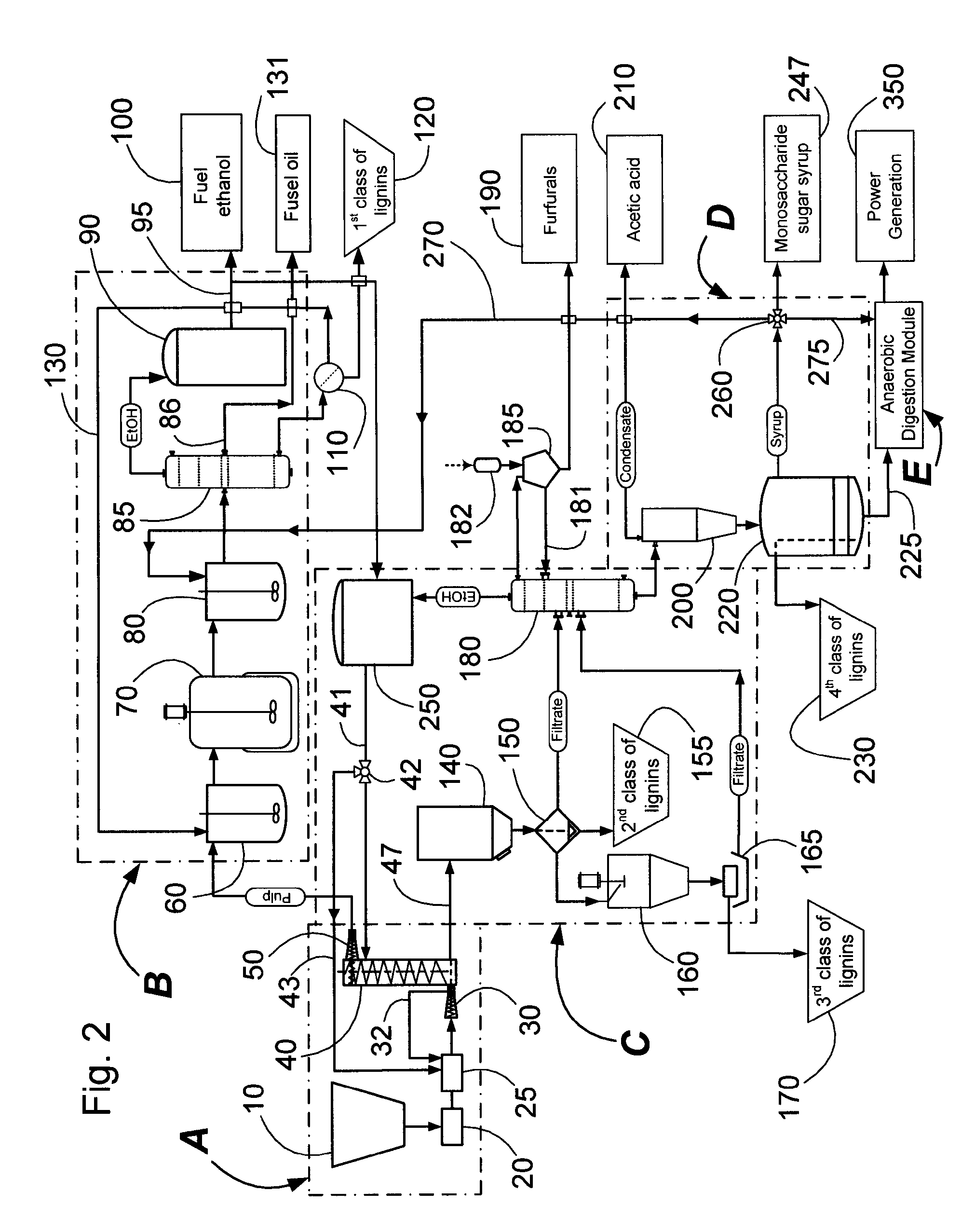

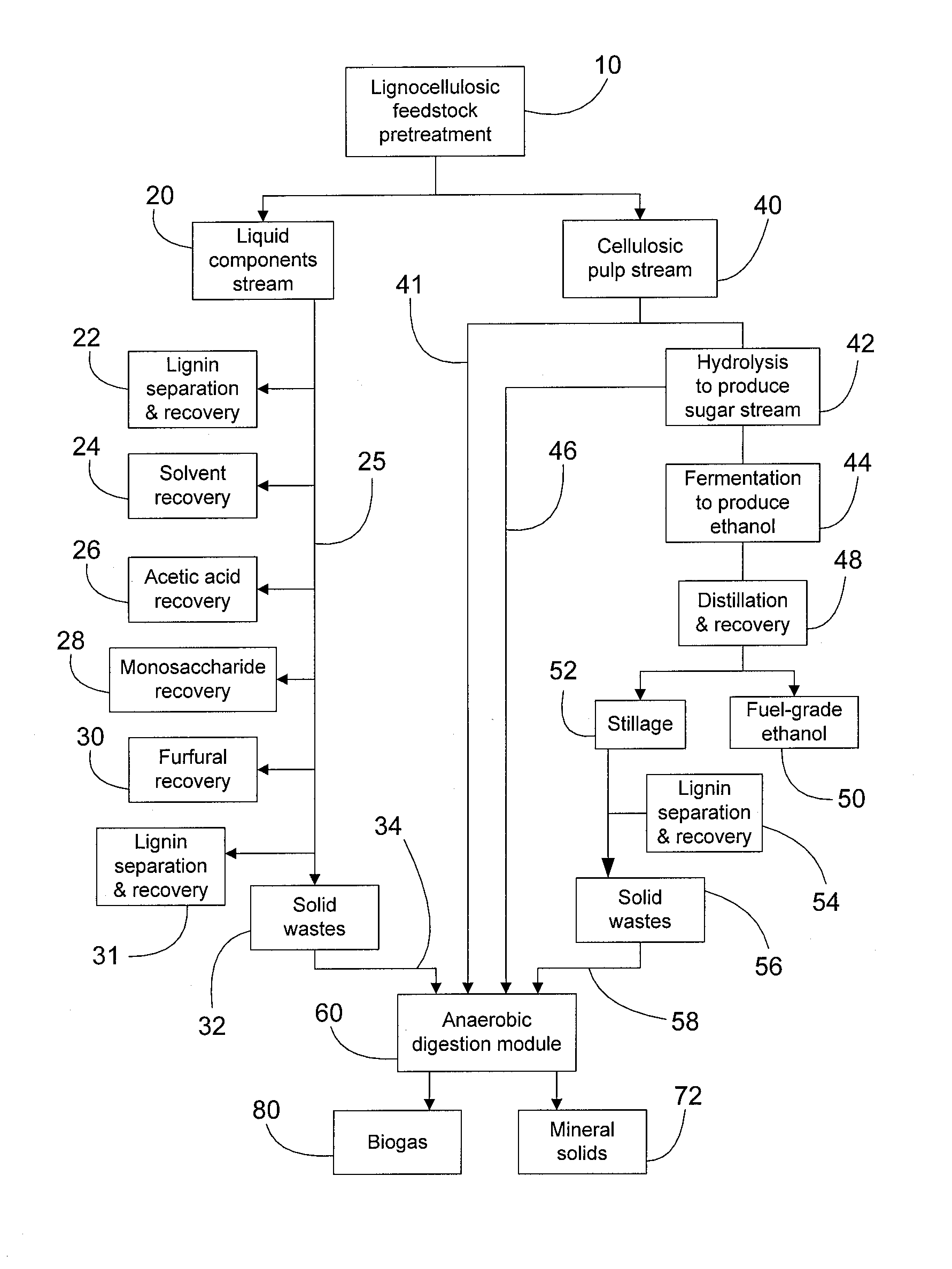

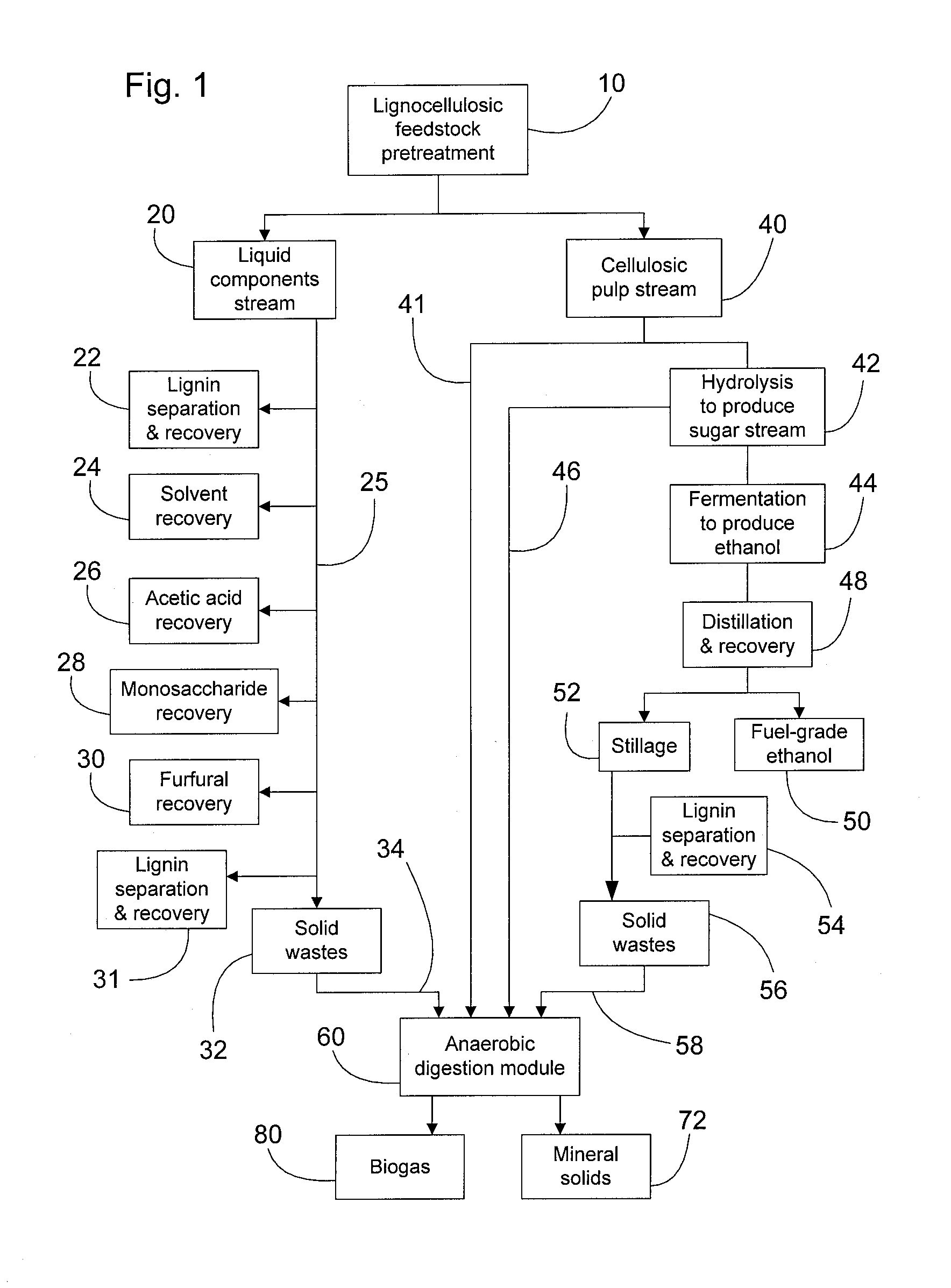

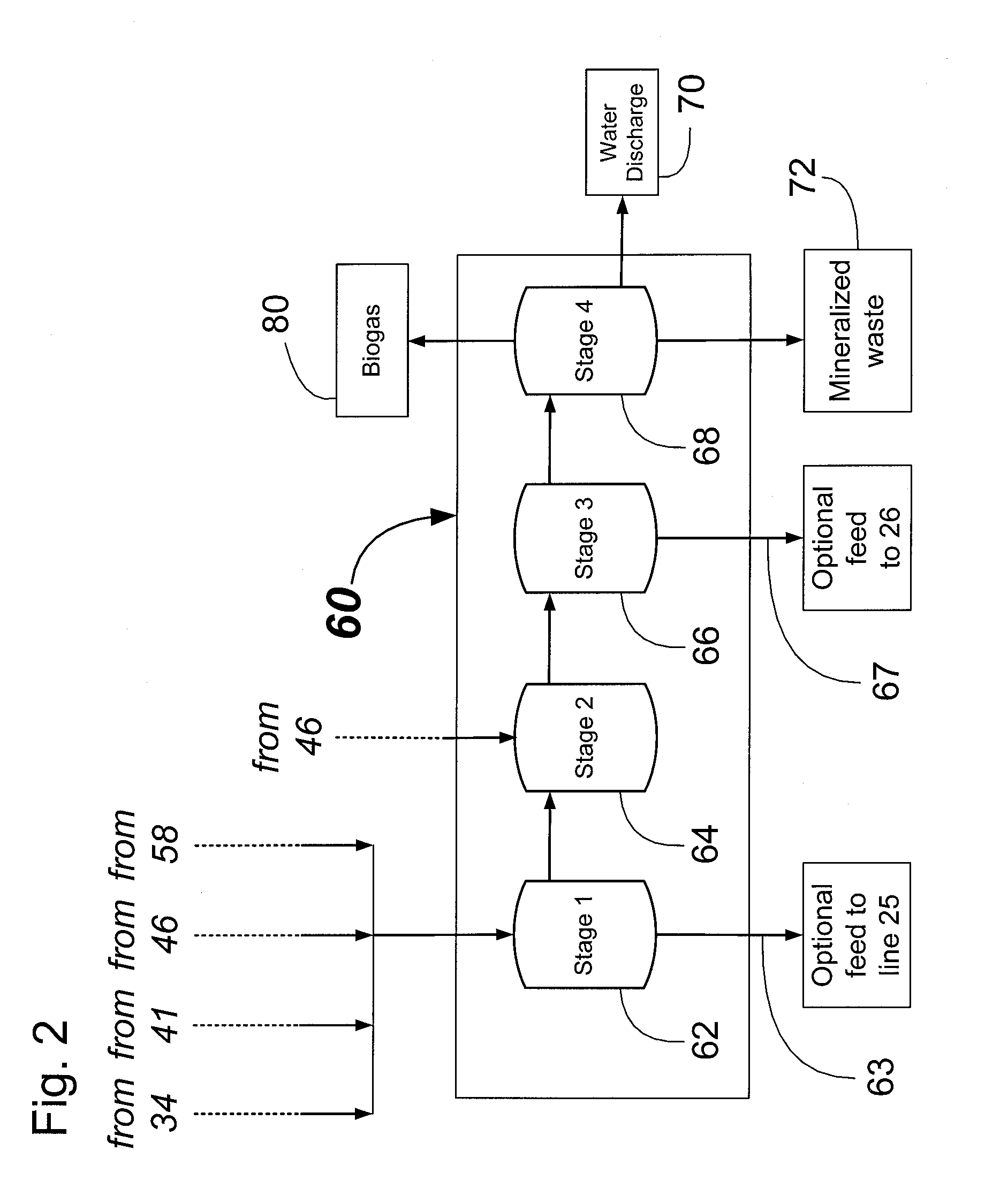

Concurrent Anaerobic Digestion and Fermentation of Lignocellulosic Feedstocks

InactiveUS20110236946A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholSemi solid

A process for concurrent production of lignins, fuel alcohol, and biogas from lignocellulosic feedstocks. The process comprises: (1) pretreating a lignocellulosic feedstock to produce a solubilised liquid components stream comprising lignins, lignin-derived compounds, and a cellulosic pulp stream, (2) separating the liquid stream from the cellulosic pulp stream, (3) processing the liquid stream to separate and recover at least lignins, lignin-derived compounds, and semi-solid waste material, (b) processing the cellulosic pulp stream to saccharify and ferment the cellulose pulp to produce a beer which is then separated into fuel-grade alcohol and a waste stillage material, (4) anaerobically digesting the semi-solid waste material from the liquid stream and the waste stillage material to produce a biogas. The rate of anaerobic digestion can be manipulated by controllably supplying a portion of the monosaccharides produced from the cellulosic pulp. The cellulosic pulp stream may also be anaerobically digested.

Owner:LIGNOL INNOVATIONS

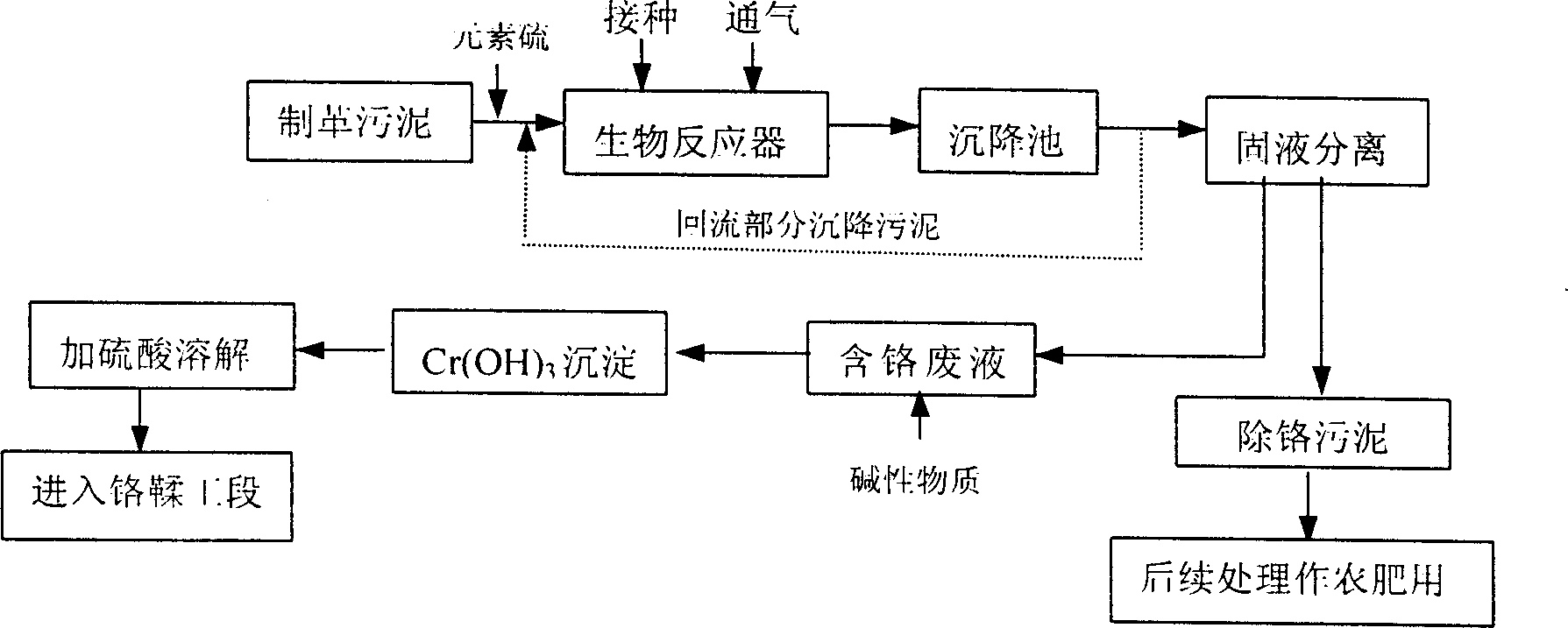

Thiobacillus thiooxidans and biological eliminating method of chromium in tanning sludge

InactiveCN1389564ALess value lossAchieve recyclingBacteriaSludge processingThiobacillus ferrooxidansSludge

The invention relates to sulfur oxide sulfur bacilli and biological eliminating method of chromium in tanning mud. Bacterial strain is named as TS6, preserve mark is CGMCCNO.0759. The method of eliminate chromium in tanning mud by above mentioned sulfur oxide sulfur bacilli is adding 1-3 g / L sulfur into tanning mud in biology reactor, inocualting 10-15% (v / v, the same below) TS6 bacteria strain, stirring, ventilating and subsiding; that 10-20% of subsiding mud backflow to reactor; dehydrating suprplus subsiding mud; adding basic material into liquid part to turn Cr3+ into Cr(OH)3 and subside, sediment is dissolved by sulfuric acid, then there is the tannage stage; solid part is neutralized to agriculture. The elimianting rate of Cr in mud is 95%-100%, reserving rate of nutrient in mud is above 80%.

Owner:周立祥 +1

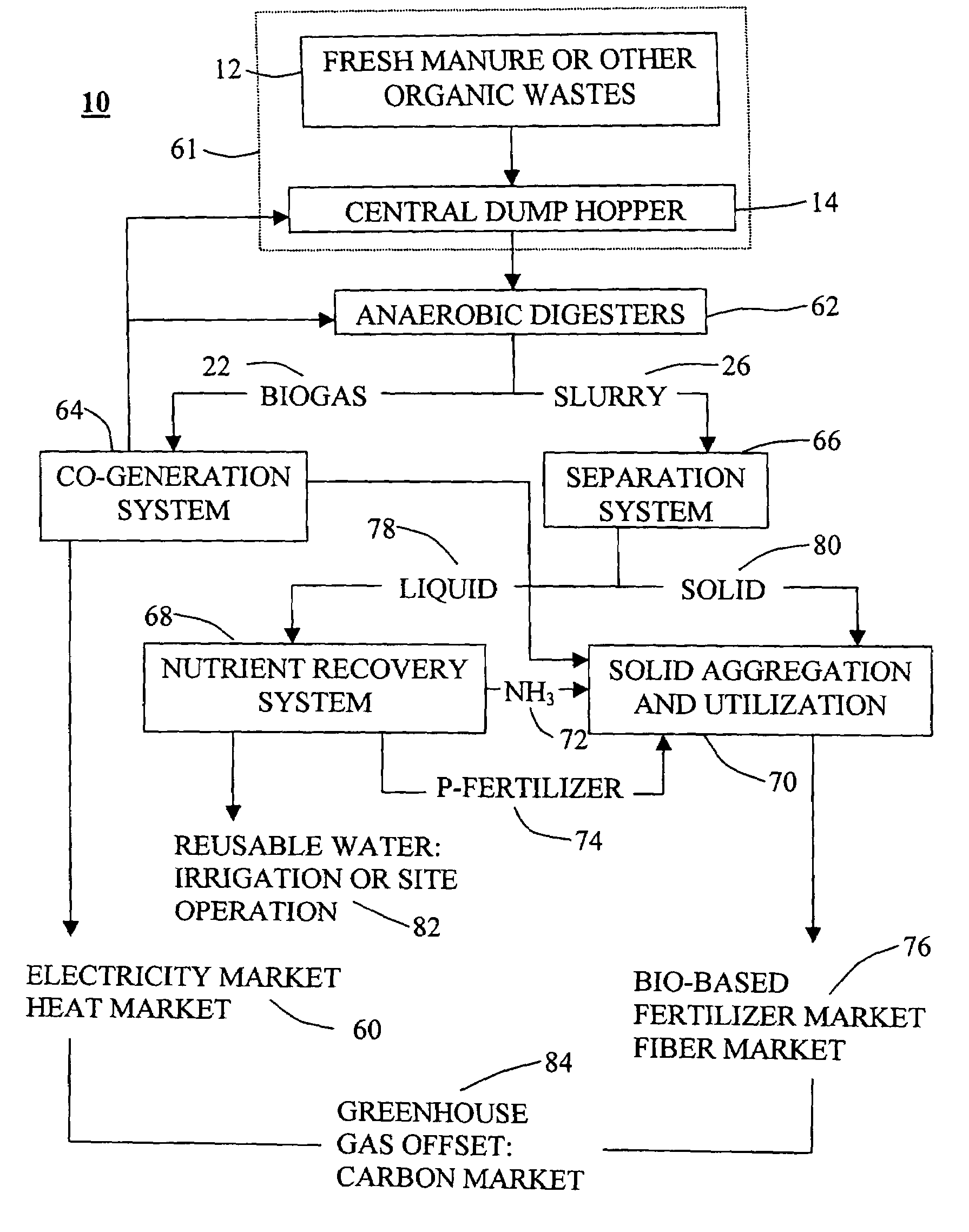

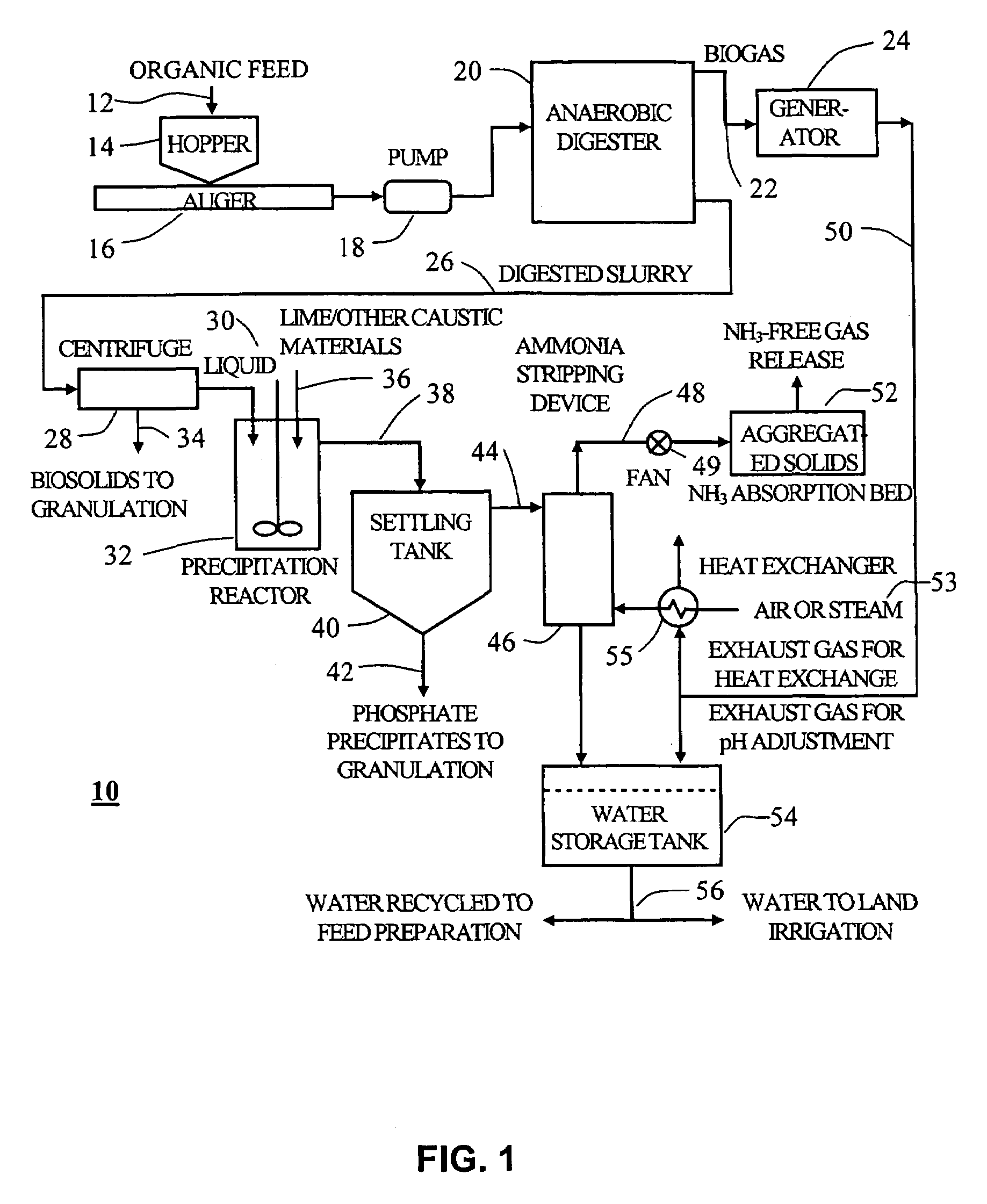

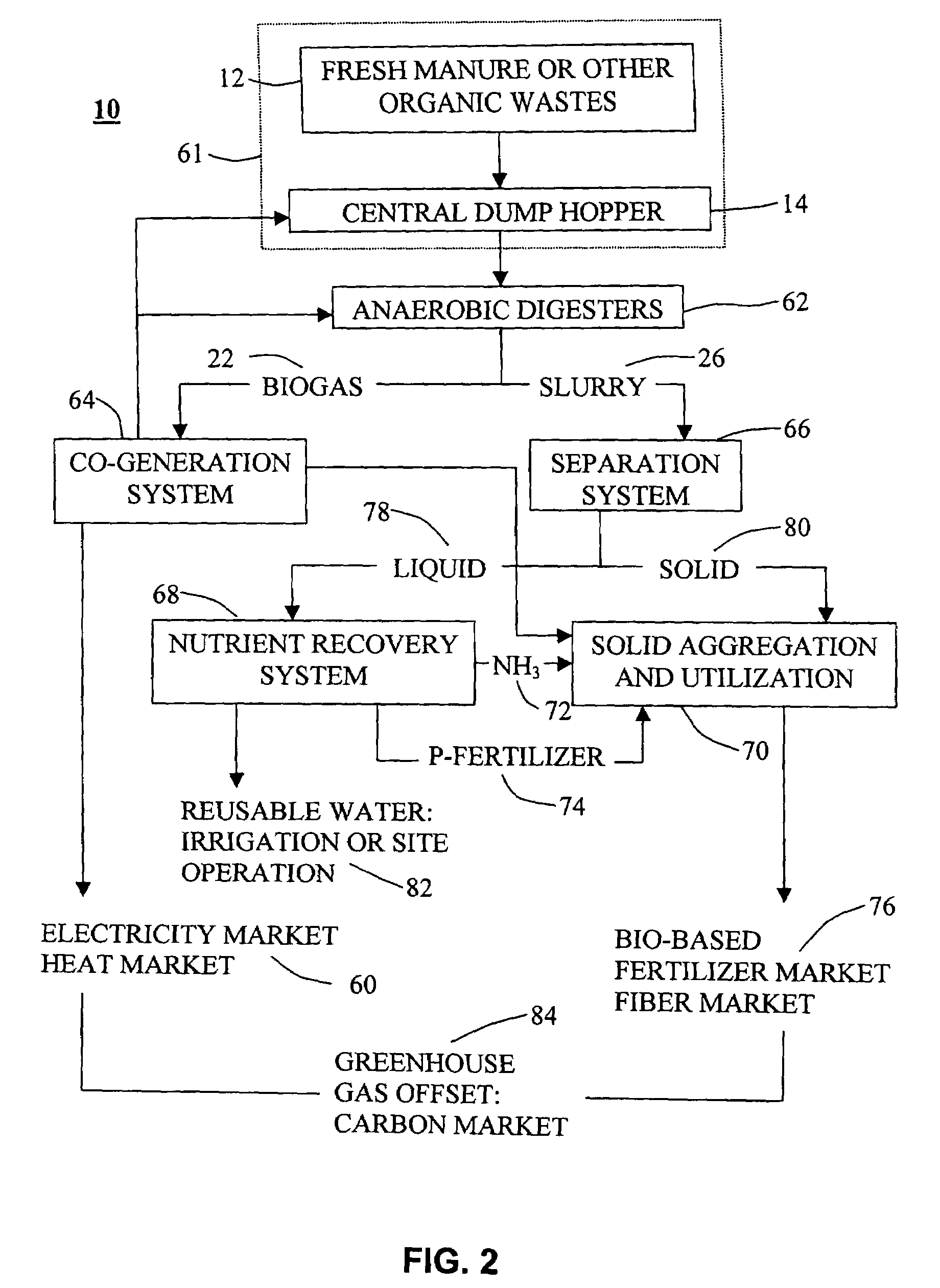

Process for removal and recovery of nutrients from digested manure or other organic wastes

InactiveUS7014768B2Eliminate the effects ofIncrease temperatureBioreactor/fermenter combinationsBio-organic fraction processingCogenerationNitrogen gas

A process for removal and recovery of nutrients and recycling of water from digested manure or other organic wastes. A first step involves separating waste from an anaerobic digester into digested liquids, digested solids, and biogas. A second step involves precipitating solids from the digested liquids. A third step involves stripping ammonia from the digested liquids. A fourth step involves injecting an exhaust stream of carbon dioxide drawn from the co-generator into the digested liquids to reduce the pH and raise the temperature of the digested liquid. A fifth step involves recycling the digested liquids back to the anaerobic digester for use in diluting in coming solid wastes. A sixth step involves passing the excess ammonia stripped from the digested liquid through the digested solids to recover nitrogen through aborption with the resultant digested solids being usable as a biofertilizer with a high nitrogen content. A seventh step involves capturing the biogas for use in a co-generation system.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

Pigpen fermentation bed and use thereof

The present invention relates to a fermentation bed for pigsty, comprising a groove for storing bedding materials, wherein the bedding materials formed by fermenting organic materials are laid in the groove. Using the fermenting bed to raise pigs can digest and decompose excrement such as feces and urine quickly, such that no flushing and no smell for the pigsty are in result by proper management and maintenance. The influence to the environment and residents around farms are greatly eased and the economic benefit is raised obviously.

Owner:CHINA AGRI UNIV

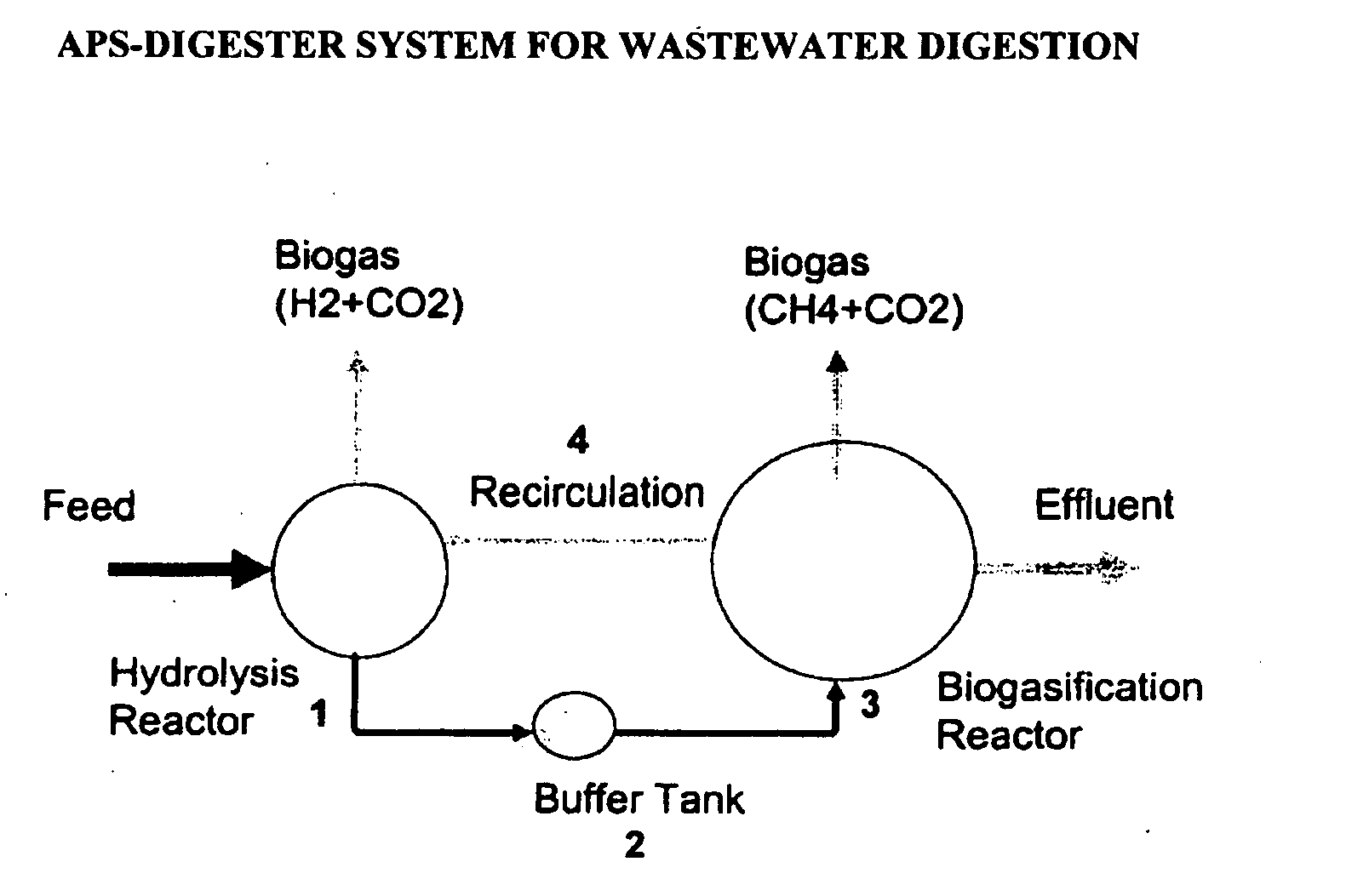

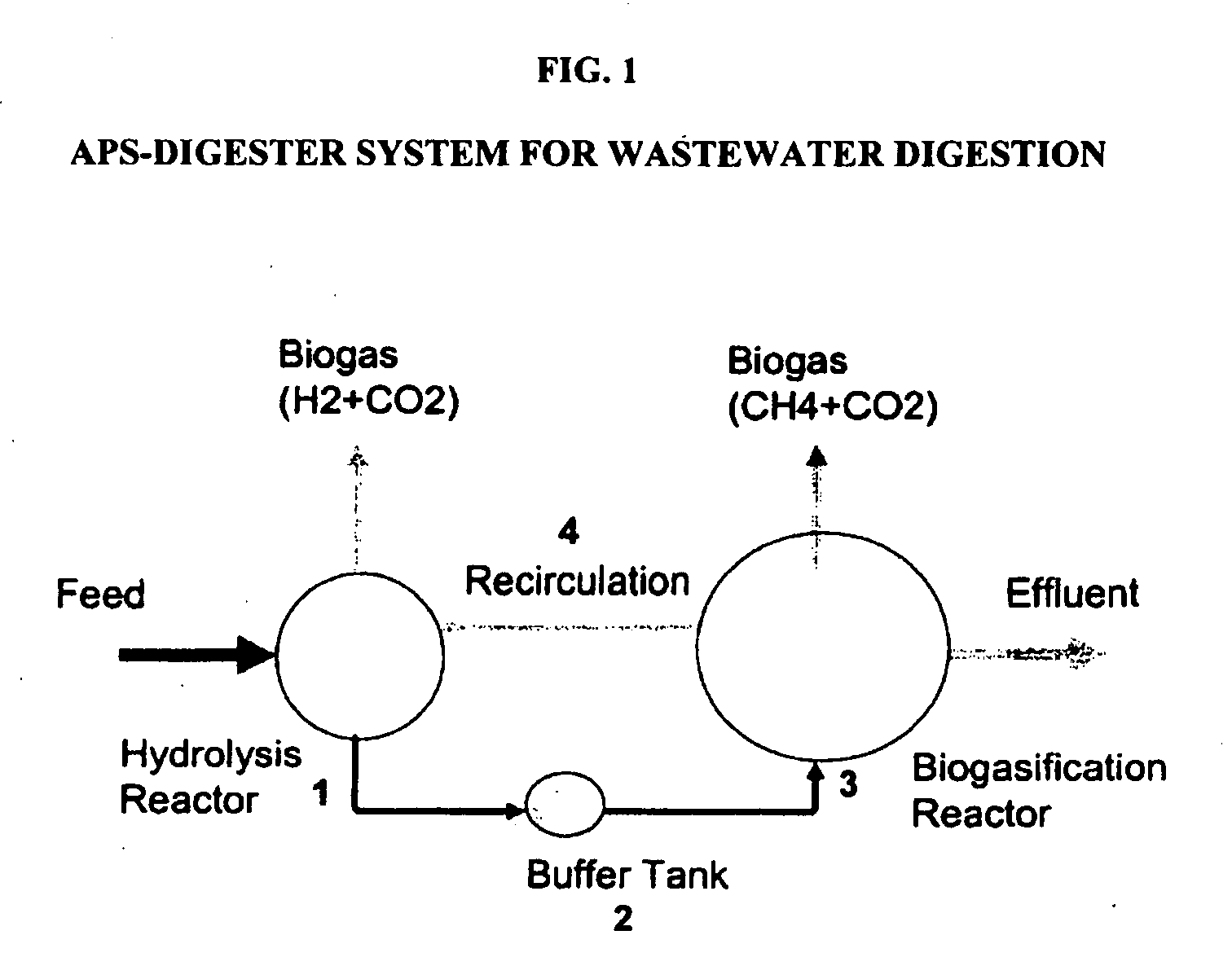

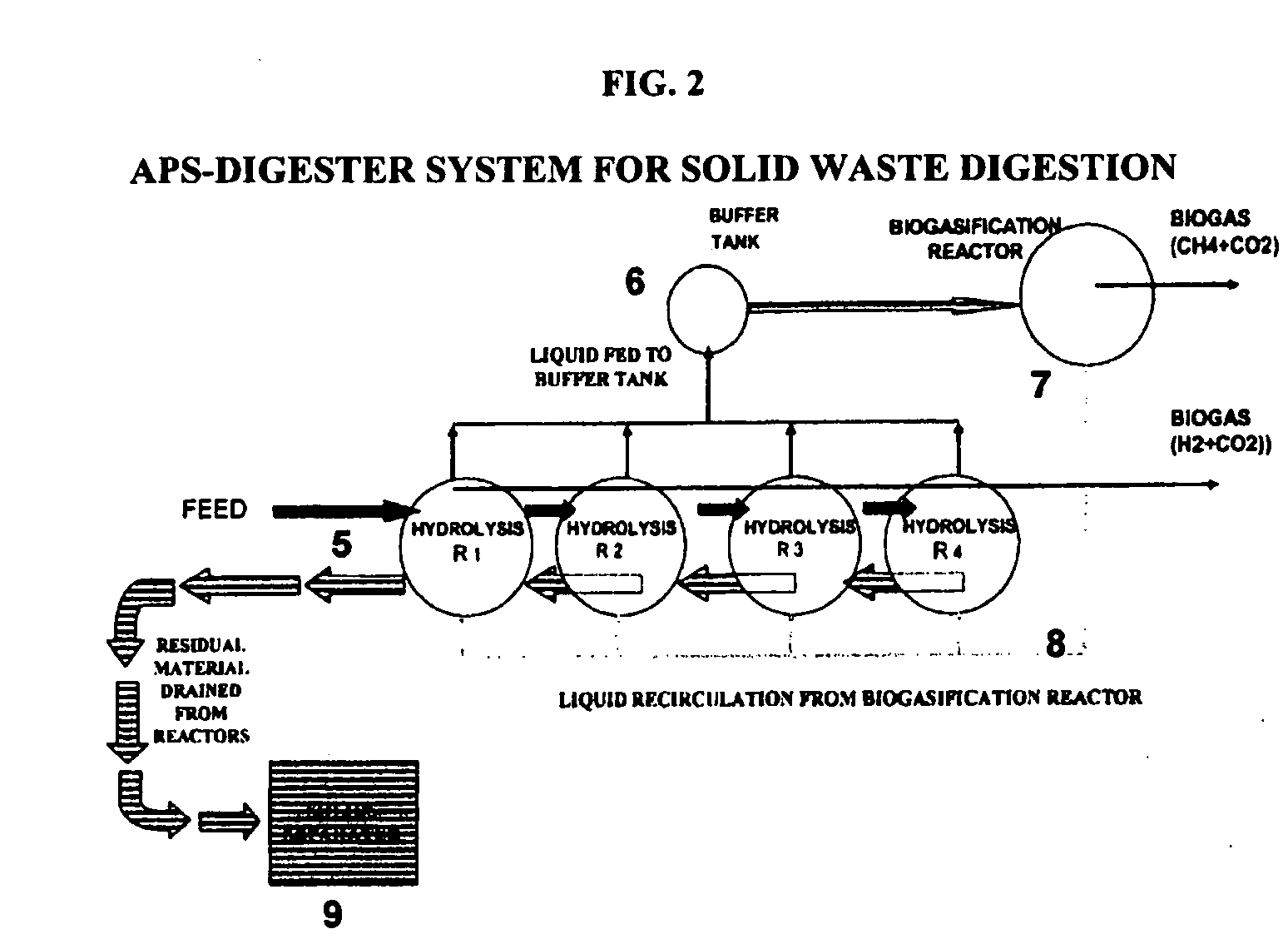

Anaerobic phased solids digester for biogas production from organic solid wastes

InactiveUS20070158264A1Improve energy conversion efficiencyLess air emissionLiquid degasificationBiological substance pretreatmentsHigh rateBuffer tank

The present invention provides methods for the generation of methane by a two phase anaerobic phase system (APS) digestion of organic substrates. Also provided is a device for practicing the methods of the invention. The APS-digester system is a space-efficient, high-rate solids digestion system. The APS-digester system consists of one or more hydrolysis reactors, a buffer tank and one biogasification reactor.

Owner:RGT UNIV OF CALIFORNIA

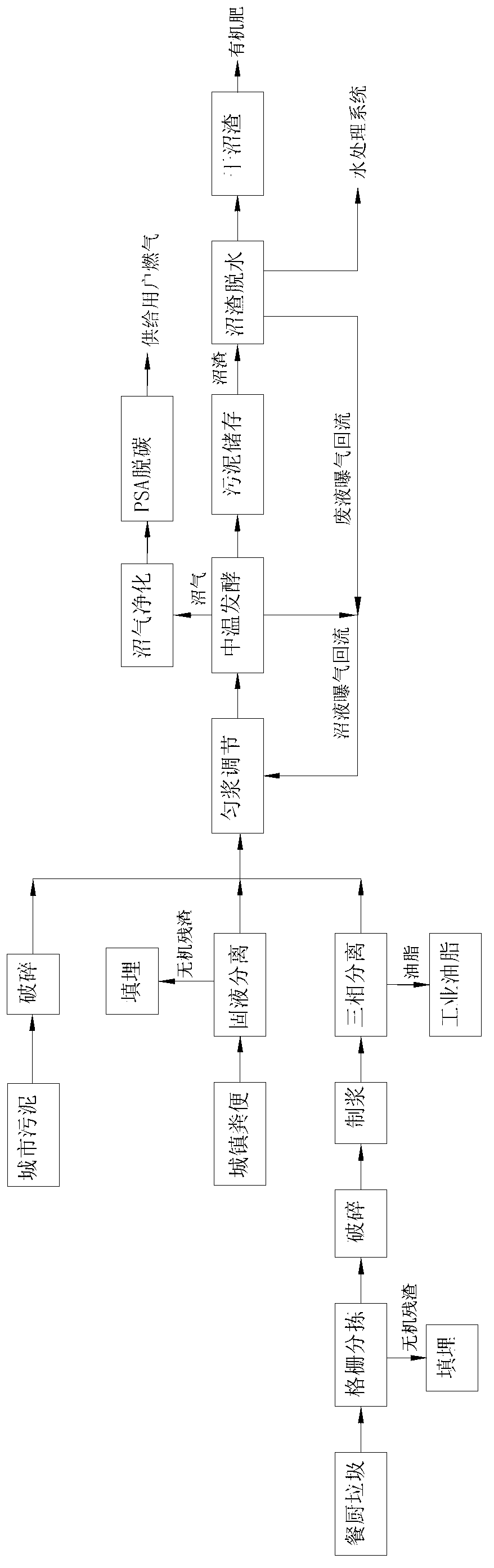

Comprehensive treatment method for kitchen waste, town excrement and municipal sludge

InactiveCN102836863AEasy to handleRealize resourcesBio-organic fraction processingSolid waste disposalSludgePre treatment

The invention discloses a comprehensive treatment method for kitchen waste, town excrement and municipal sludge, relating to the technical field of harmless resourceful treatment for waste. The comprehensive treatment method comprises the following steps of: pretreating the kitchen waste; pretreating the excrement waste; pretreating the municipal sludge; homogenizing; adjusting; fermenting at a medium temperature; dehydrating biogas residue; and performing biogas treatment. The degradation rate of organic matters in the waste reaches over 80 percent.

Owner:BEIJING CENTURY GREEN ENVIRONMENTAL ENG &TECH +2

Efficient methane-generating pit using poultry excrement and methane generation process

InactiveCN102531310AReduce moisture contentEasy to produceWaste based fuelBiological sludge treatmentProcess engineeringBiogas production

The invention relates to a methane-generating pit using poultry excrement, which is integrally horizontally placed under the water plane. Partition walls are arranged in the middle of the methane-generating pit for dividing the whole methane-generating pit into a plurality of unit methane-generating pits, and medium channels arranged on the partition walls are communicated with each other. An annular fermentation tank is arranged above the periphery of the methane-generating pit, a plurality of superconductive heat pipes are arranged on the inner side of the annular fermentation tank, and the superconductive heat pipes are inserted into the methane-generating pit. A material inlet and a material outlet are respectively arranged at two ends of the methane-generating pit and under the unit methane-generating pits at two ends of the methane-generating pit, a methane collector is arranged above each unit methane-generating pit, and the methane collectors are directly communicated with a gas storage tank through pipelines. The methane-generating pit has the advantages of being high in material concentration, integrating material inlet, deslagging, methane generating, stirring, temperature controlling, regulating and the like, being high in mechanization degree, large in treating quantity, fast in digesting rate and the like and can meet requirements for scale production, and concentration of inlet materials of a continuous methane-generating pit can reach about 15%.

Owner:范立河

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com