Patents

Literature

1865 results about "Fermentation system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

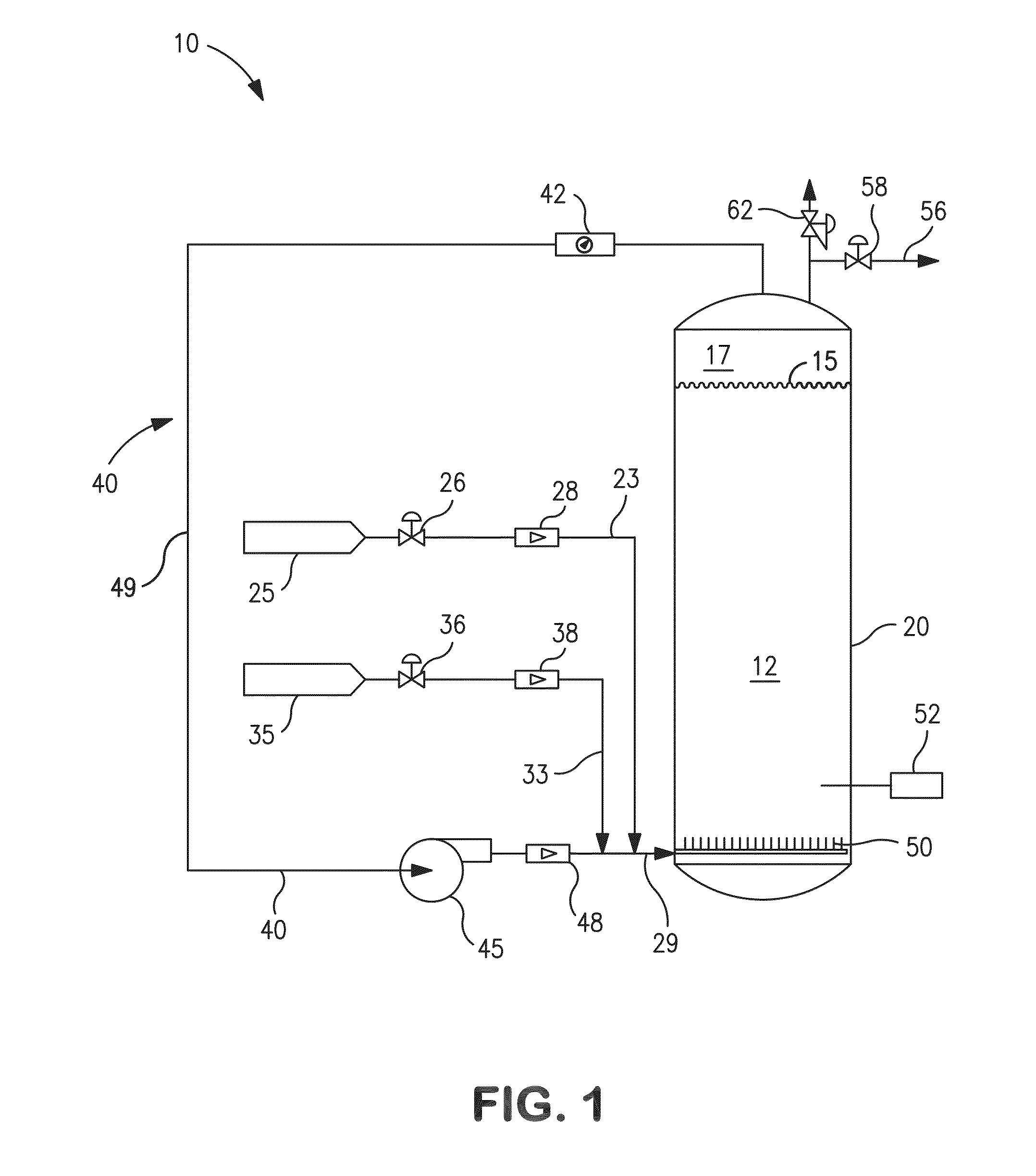

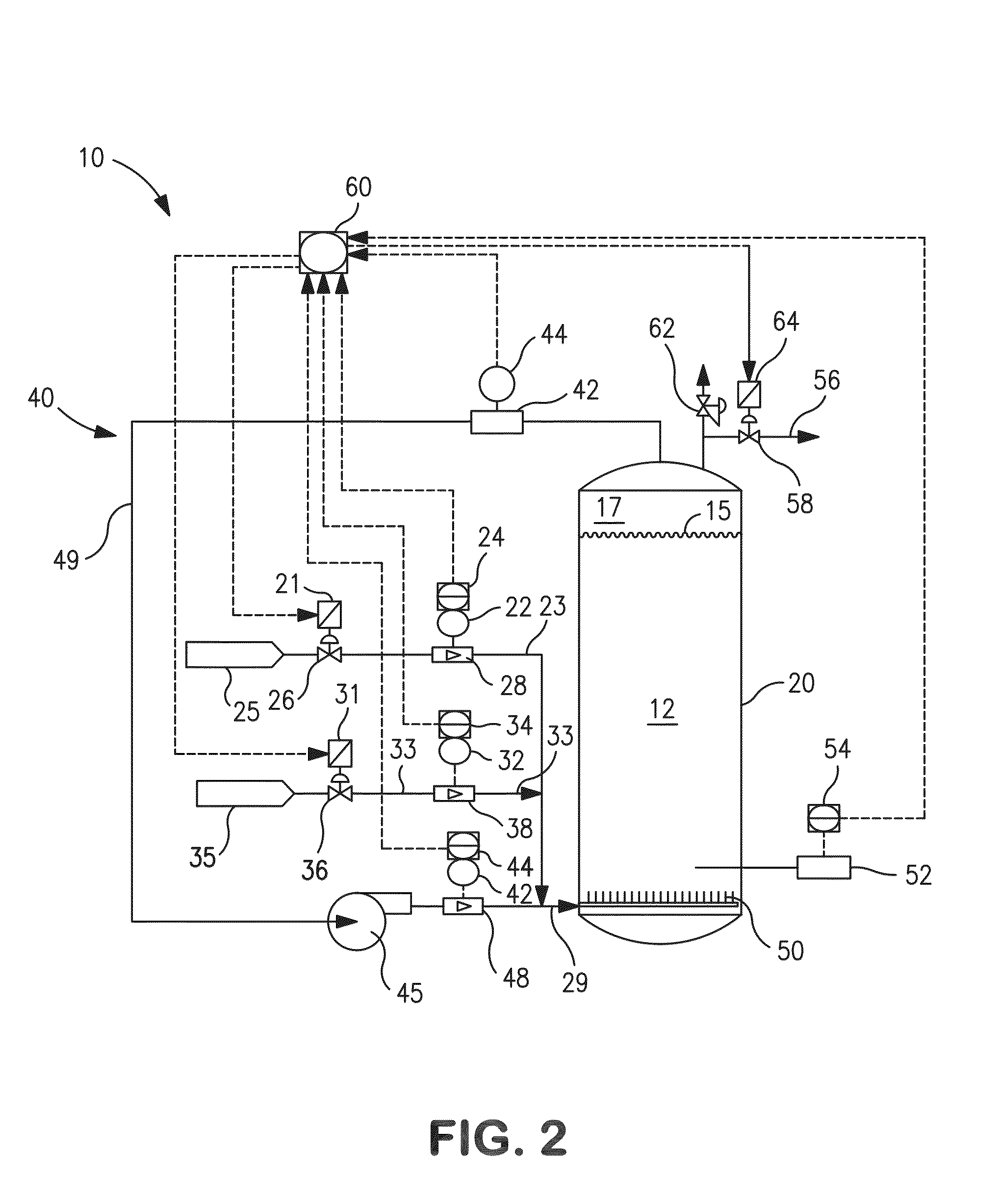

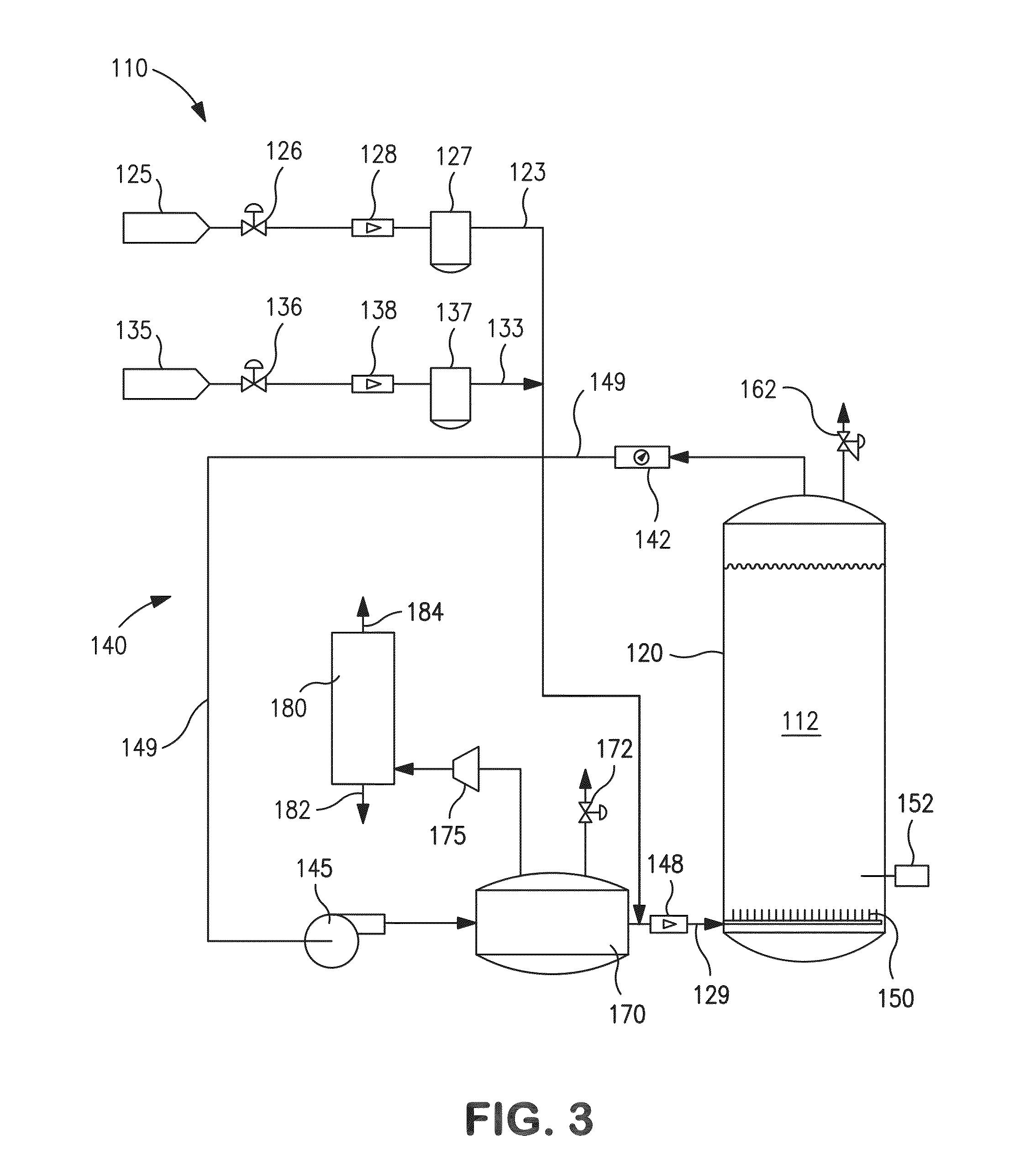

Devices and Methods for Integrated Continuous Manufacturing of Biological Molecules

ActiveUS20080269468A1Bioreactor/fermenter combinationsFactor VIIContinuous perfusionChemical physics

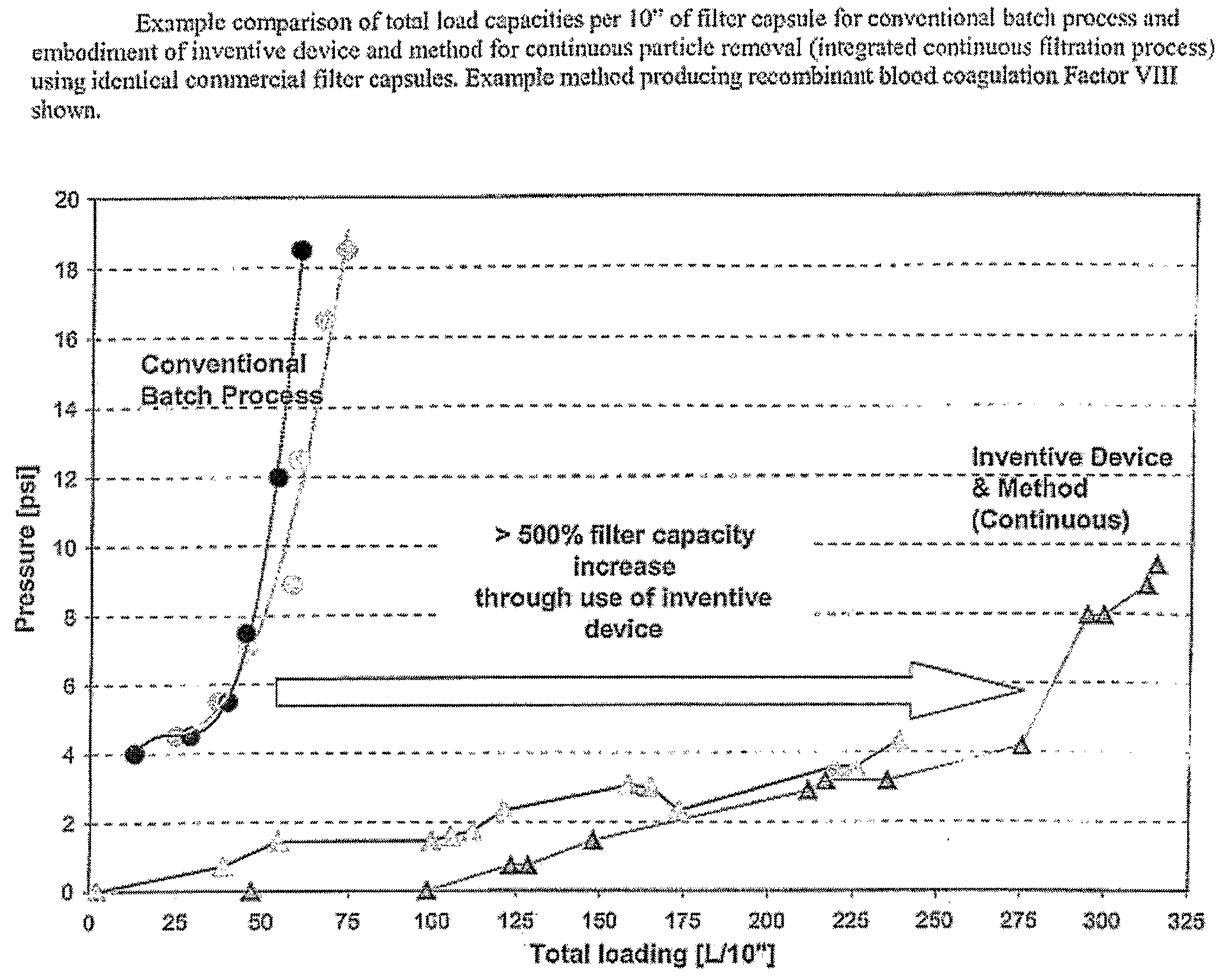

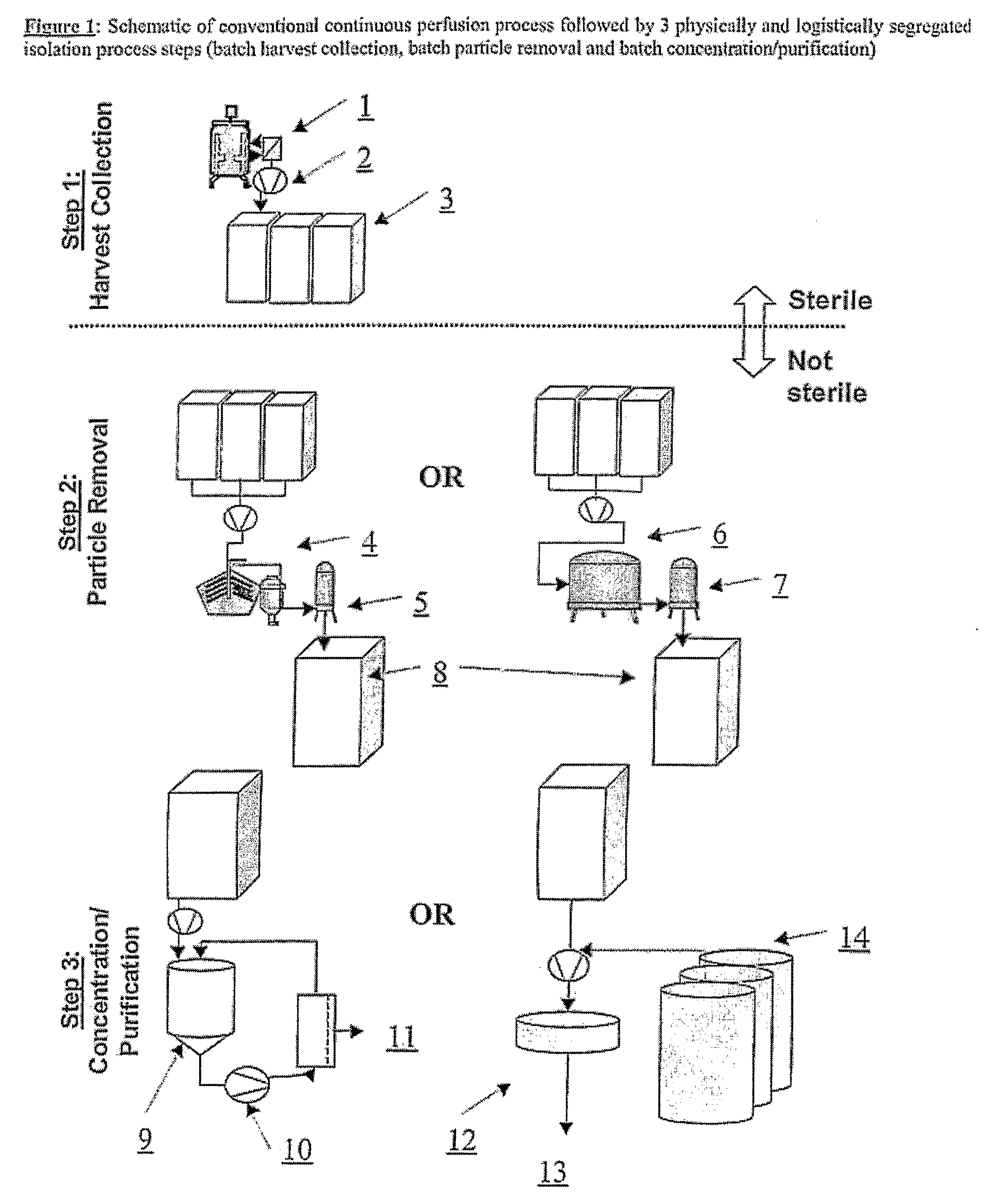

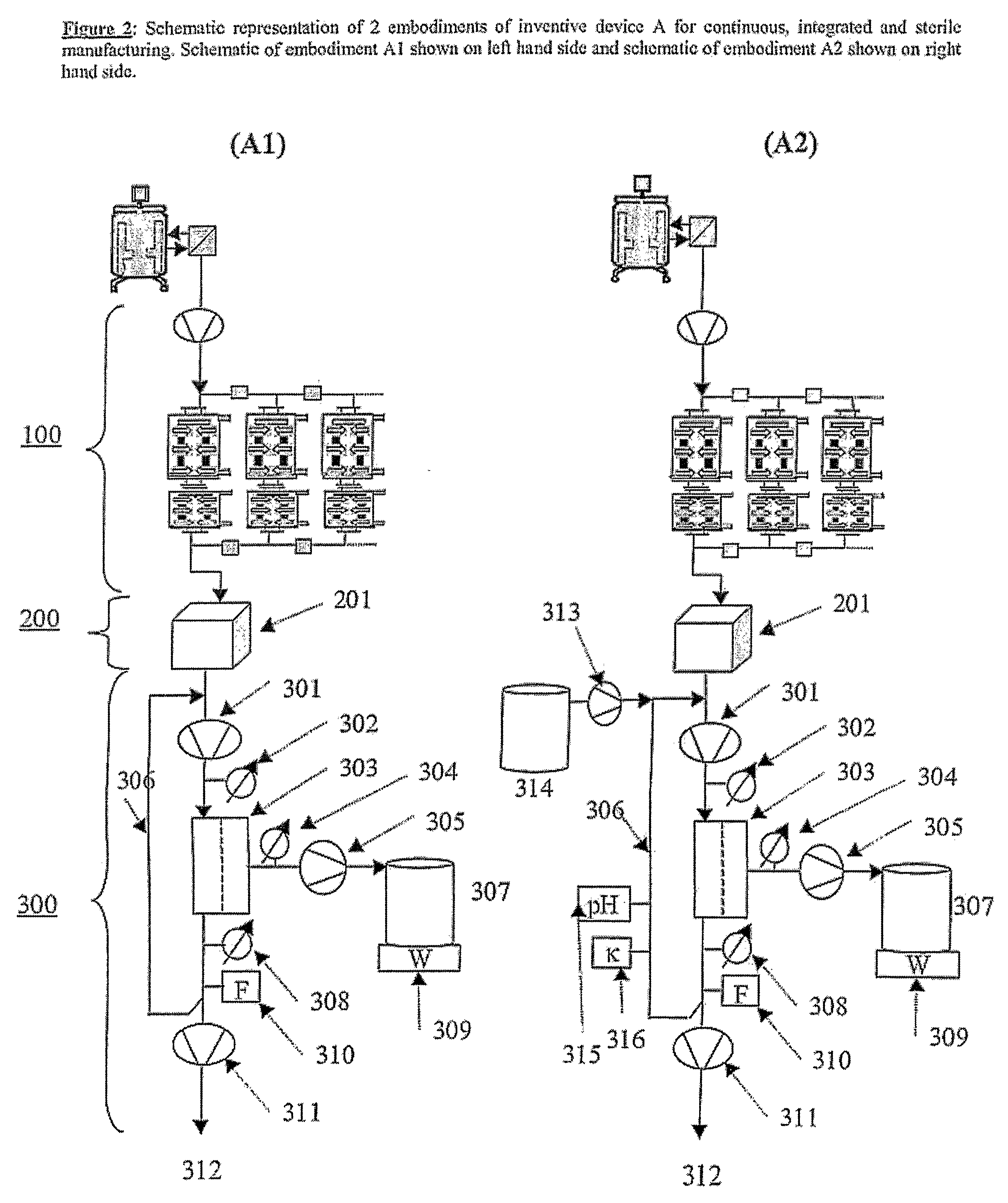

The present invention relates to a process and apparatus for purifying a molecule of interest from a heterogeneous clarified fluid mixture. The apparatus of the invention generally comprises a continuous perfusion fermentation system, a continuous particle removal system integrated with the perfusion fermentation system; and a continuous purification system integrated with the particle removal system, which is maintained under sterile conditions. The process comprises filtering a heterogeneous clarified fluid mixture by continuous ultrafiltration at a specific flow rate below the transition point of the molecule of interest in the pressure-dependent region of the flux versus TMP curve, wherein the specific flow rate is maintained substantially constant throughout the continuous ultrafiltration.

Owner:BAYER HEALTHCARE LLC

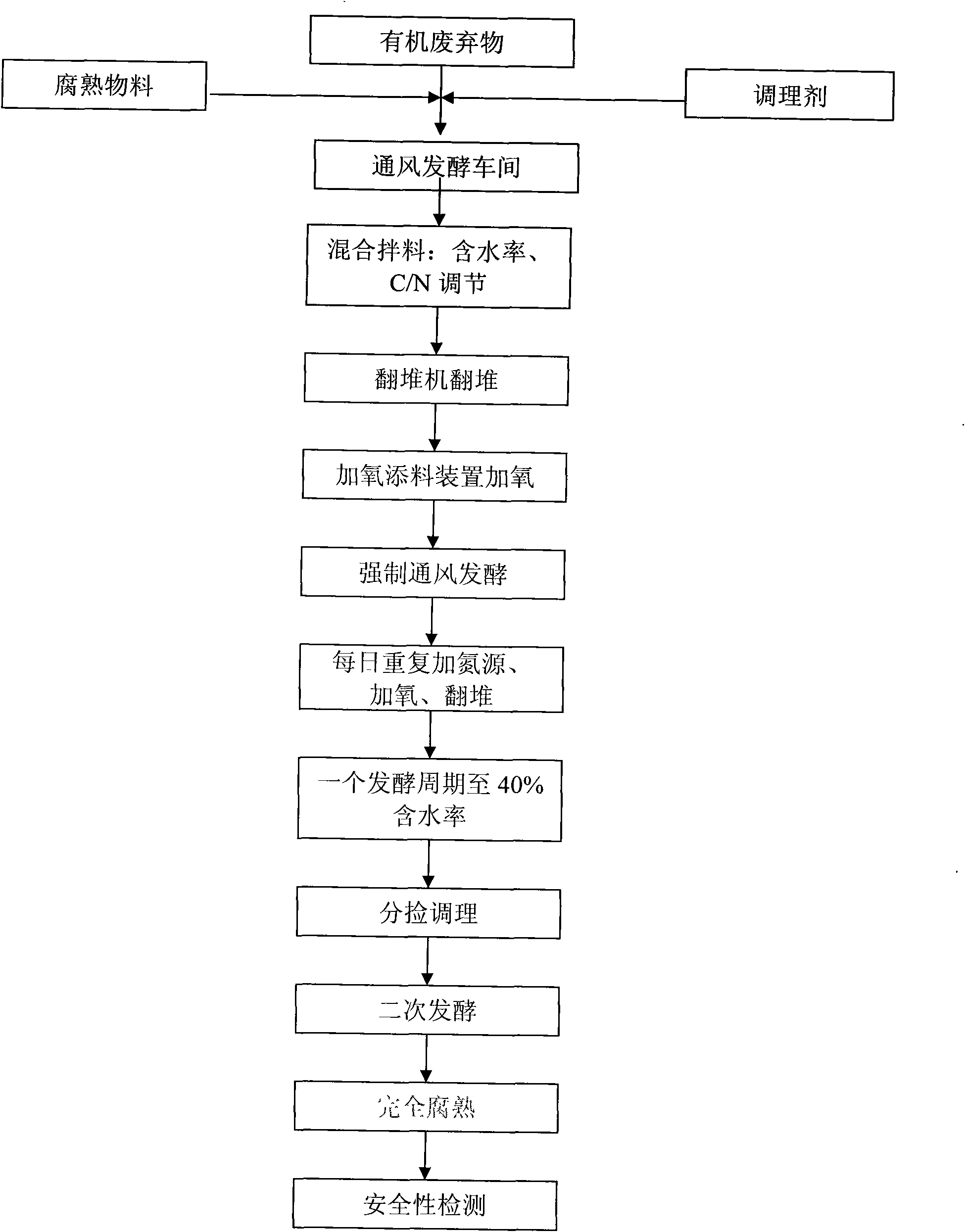

Scale high-speed composting treatment method of organic wastes

InactiveCN101555169ASave money on dehydrationIncreased automation of compostingBio-organic fraction processingClimate change adaptationMicroorganismSludge

A scale high-speed composting treatment method of organic wastes comprises the following steps: the organic wastes are taken as fermentable substrates; thoroughly decomposed materials are reused as desiccants and strains; the physicochemical property of the organic wastes is adjusted to the condition required by aerobic fermentation microorganism; forced aeration fermentation is carried out in airiness fermentation plants; the fermentation temperature of fermentation materials is increased to over 70 DEG C in a very short time and high temperature fermentation is maintained for 1-15 days; organic wastes with high water content are quickly dehydrated to below 20-60% in short time and then are transferred to a static forced aeration fermentation system for secondary fermentation; therefore, the water ratios of the fermentation materials are further reduced, the fermentation temperature drops to the ambient temperature and always remains the same, and the materials are thoroughly decomposed. The method realizes scale high-speed composting treatment of the organic wastes and boosts resource treatment of such organic wastes as municipal and industrial sludges.

Owner:肇庆奥特生态环保有限公司

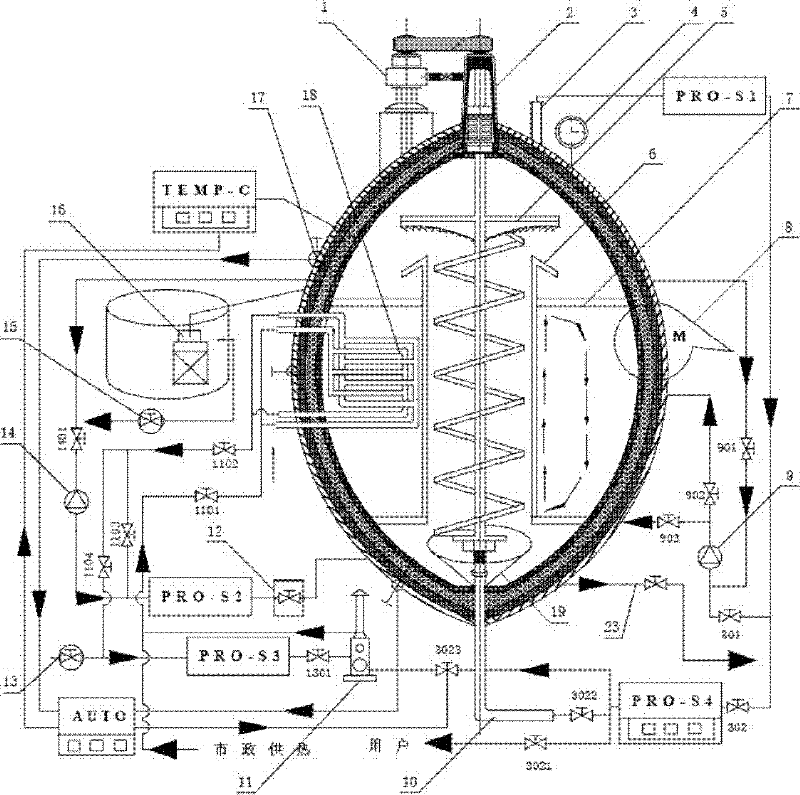

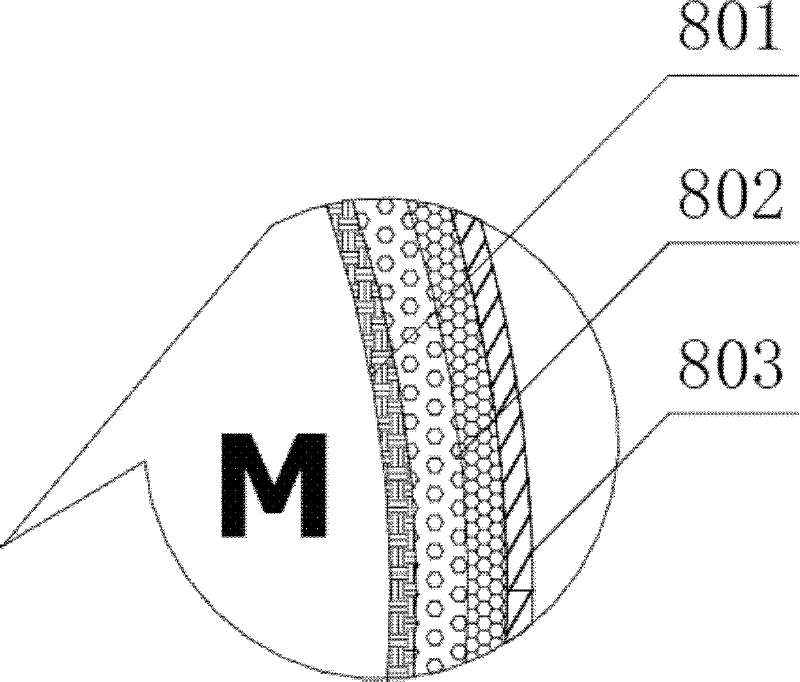

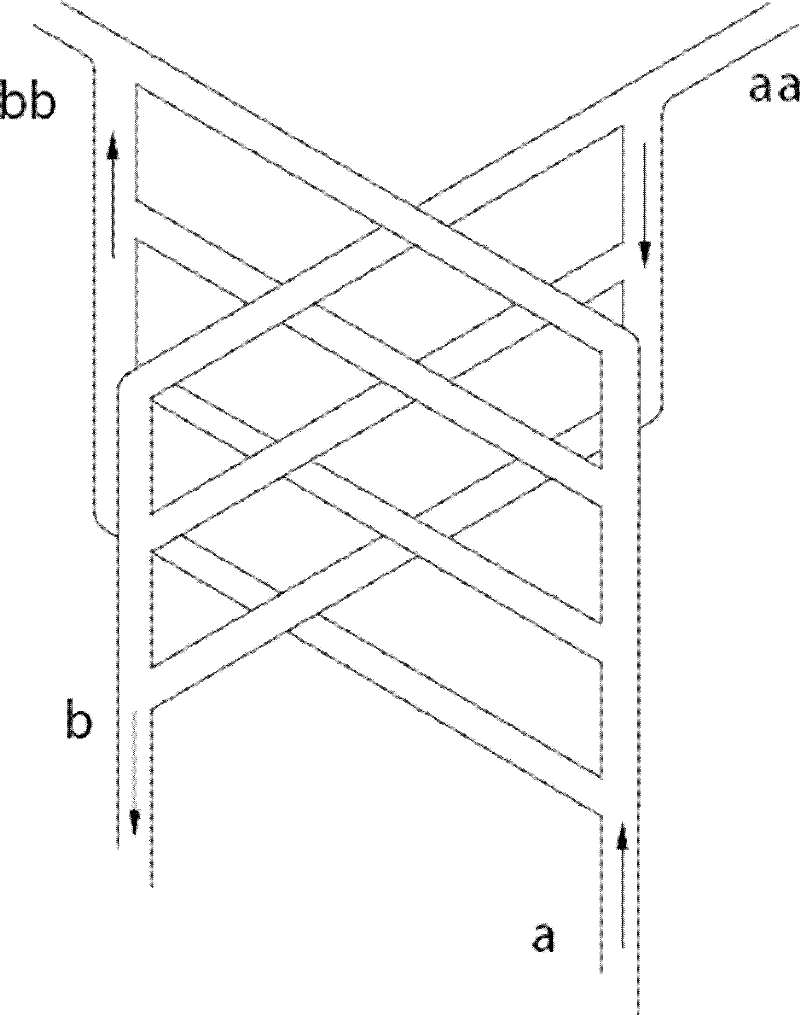

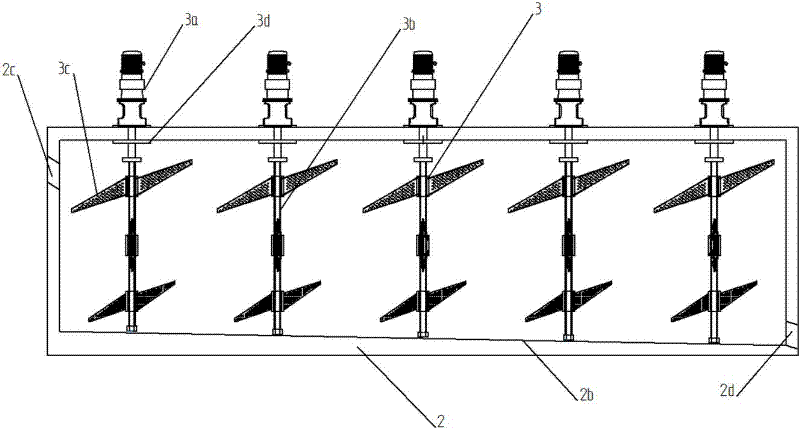

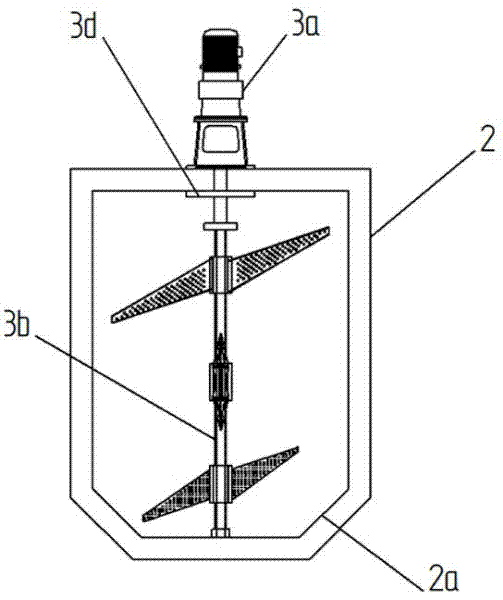

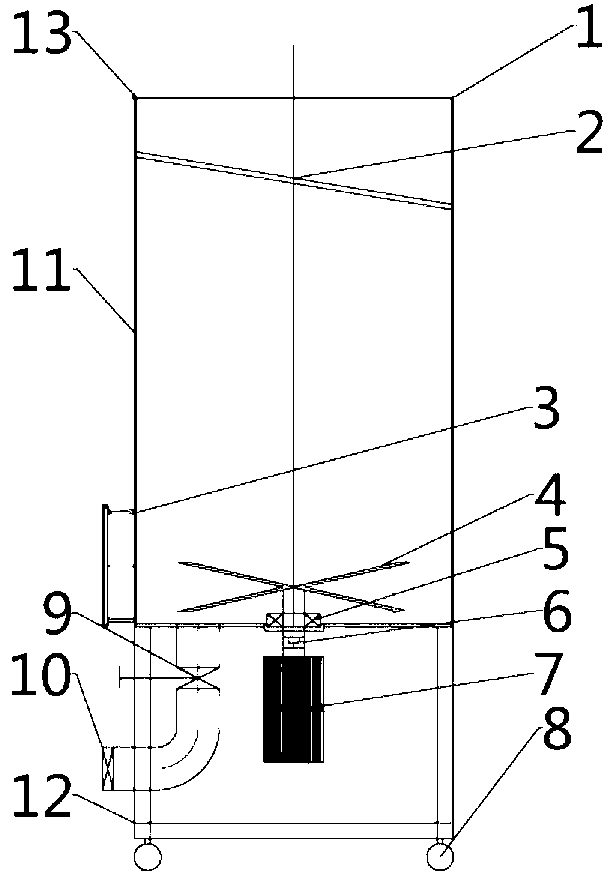

Multi-cycle stirring egg-shaped anaerobic fermentation system

ActiveCN102517199ASimple structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSlurry

The invention discloses a multi-cycle stirring egg-shaped anaerobic fermentation system. The system comprises a fermentation tank body and a driving device arranged on the fermentation tank body, wherein the fermentation tank body is egg-shaped, the center of the inner cavity of the fermentation tank body is provided with an inner barrel type spiral stirrer, the outside of the inner barrel type spiral stirrer is provided with a stirrer inner barrel, a temperature heating device is arranged between the wall of the fermentation tank body and the stirrer inner barrel, the bottom of the inside ofthe tank is provided with an umbrella-shaped gas flow distribution device; the upper part of the fermentation tank body is provided with a vent pipe and a pressure control device, the bottom of the fermentation tank body is provided with an umbrella-shaped gas flow distribution device gas inlet pipe and a mud-discharging and sand-discharging outlet; and the side wall of the fermentation tank bodyis communicated with a biogas circulation system, a biogas slurry circulation system, a gas-liquid circulation system, a heating system, a temperature control system and a biogas residue and biogas slurry storage pool respectively. The multi-cycle stirring egg-shaped anaerobic fermentation system adopts multi-cycle stirring to increase the stirring efficiency of the system; and the anaerobic fermentation environment is improved, the fluid is mixed evenly, the temperature difference slightly fluctuates, the energy consumption of the system is low, the fermentation rate is high and the system is suitable for popularization and application.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

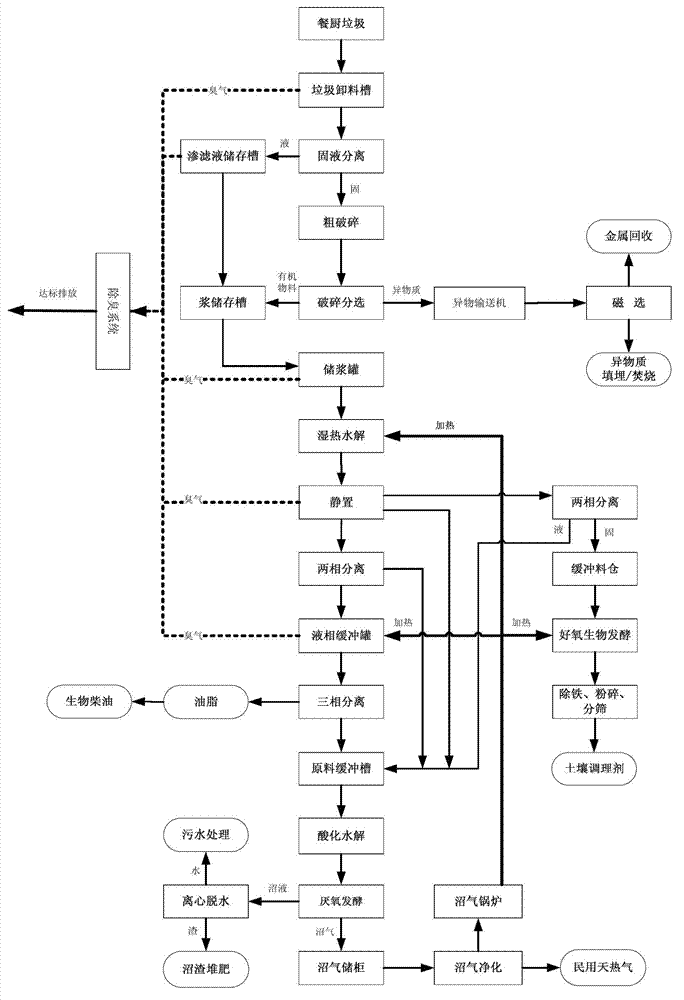

Harmless disposal method of kitchen garbage

InactiveCN102921704AShorten the processing chainPromote engineering applicationSolid waste disposalFurniture waste recoveryOil and greaseEconomic benefits

The invention relates to a harmless disposal method of kitchen garbage, which comprises the following steps of: (1) pretreatment: after unloading the kitchen garbage, performing solid-liquid separation, rough crushing, crushing and sorting and performing magnetic separation, and recycling metal substances mixed in the kitchen garbage; (2) hydrothermal hydrolysis: after the pretreatment, adopting the hydrothermal hydrolysis to fully inactivate viruses and bacteria in the kitchen garbage, separating out animal and vegetable fatty oil from the kitchen garbage, and hydrolyzing organic materials at the same time; (3) using the fatty oil obtained in the step (2) as an industrial fatty oil material or further performing deep processing to obtain fatty acid methyl ester or biodiesel; mixing and proportioning the pasty organic materials and then conveying into an anaerobic fermentation system; and conveying large granular organic materials into an aerobic biological fermentation device. The method provided by the invention realizes harmless disposal of the kitchen garbage mainly by the pretreatment and the hydrothermal hydrolysis process, increases the conversion rate of biological energy of the kitchen garbage and increases the economic benefit of kitchen garbage recycling products.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD +2

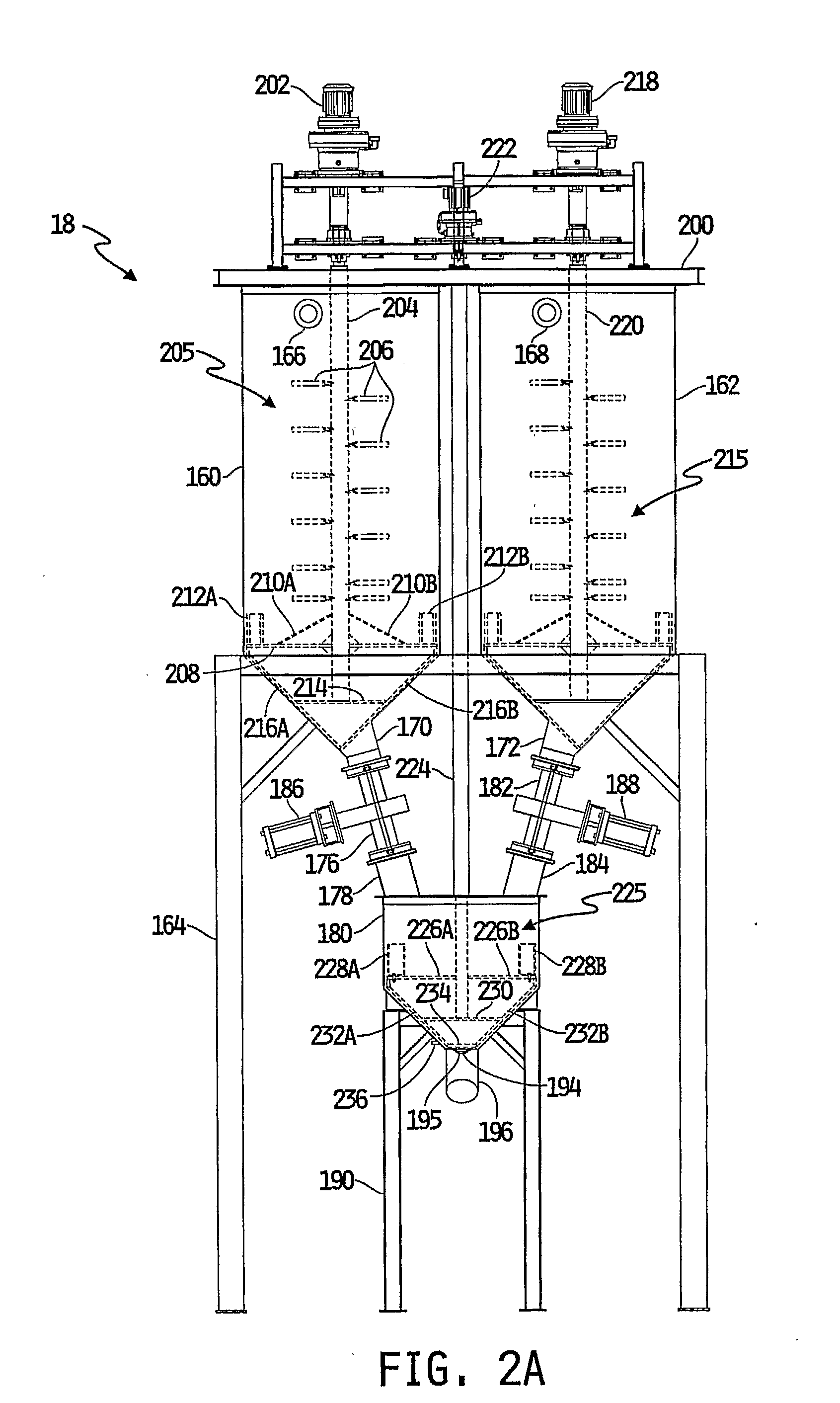

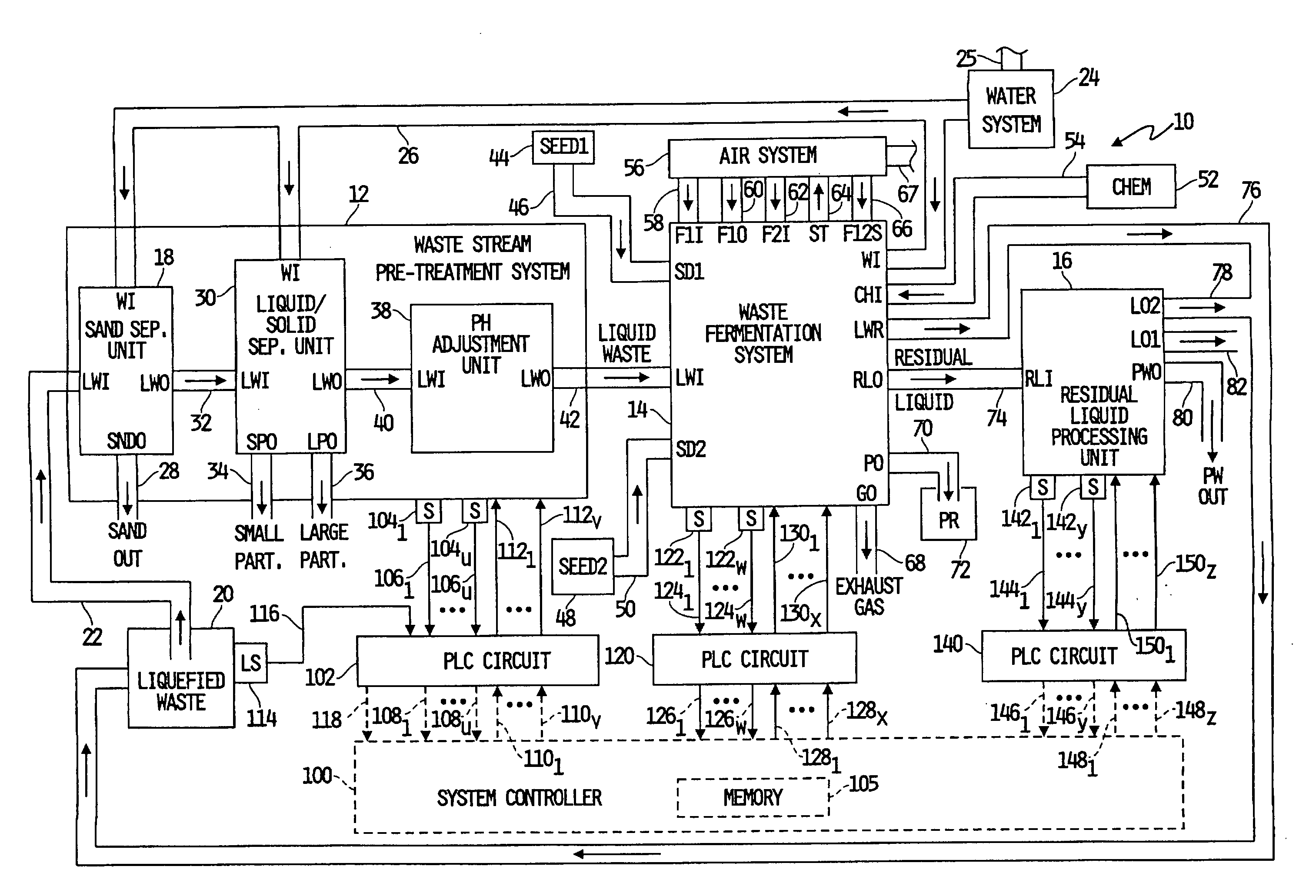

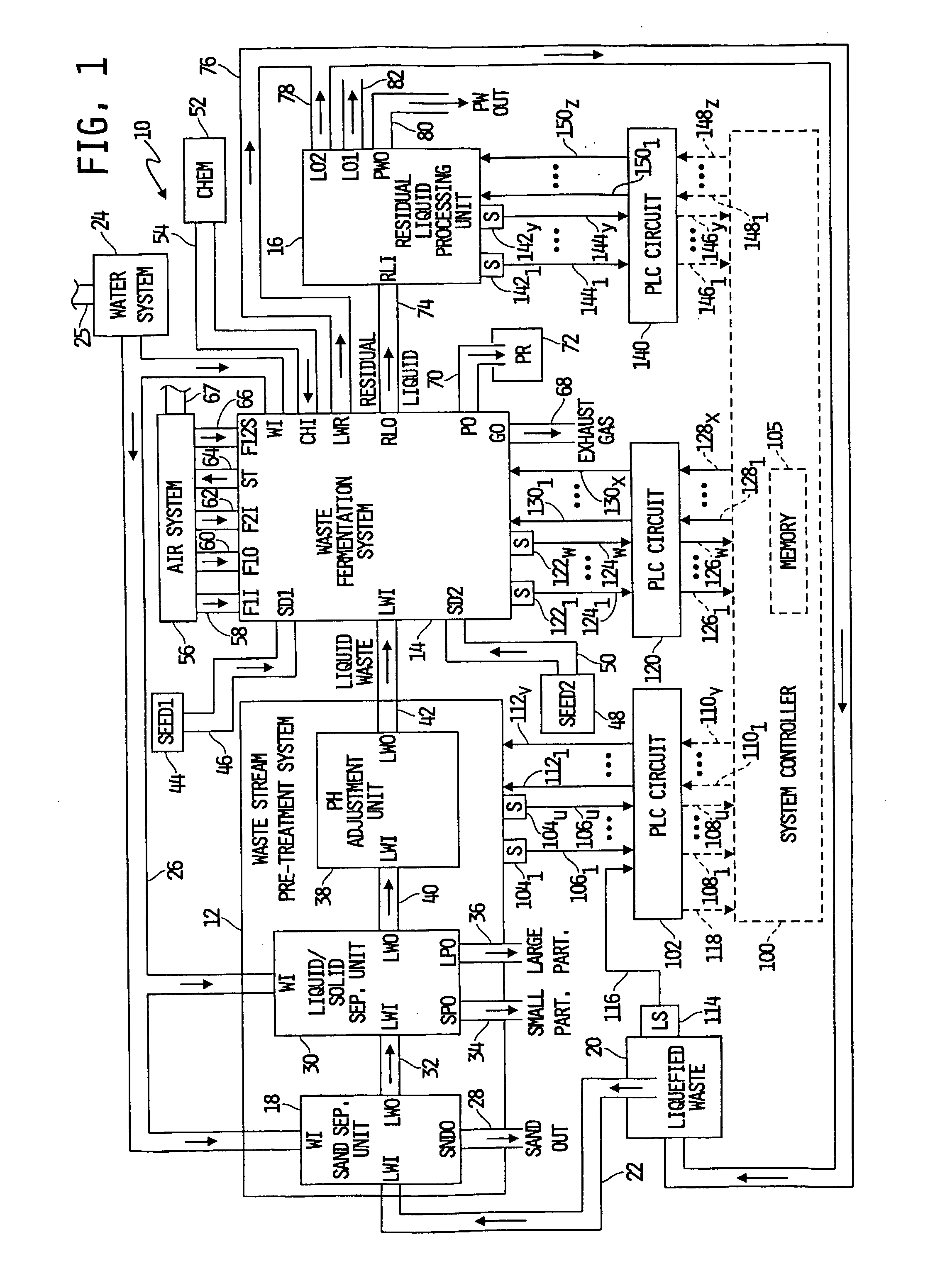

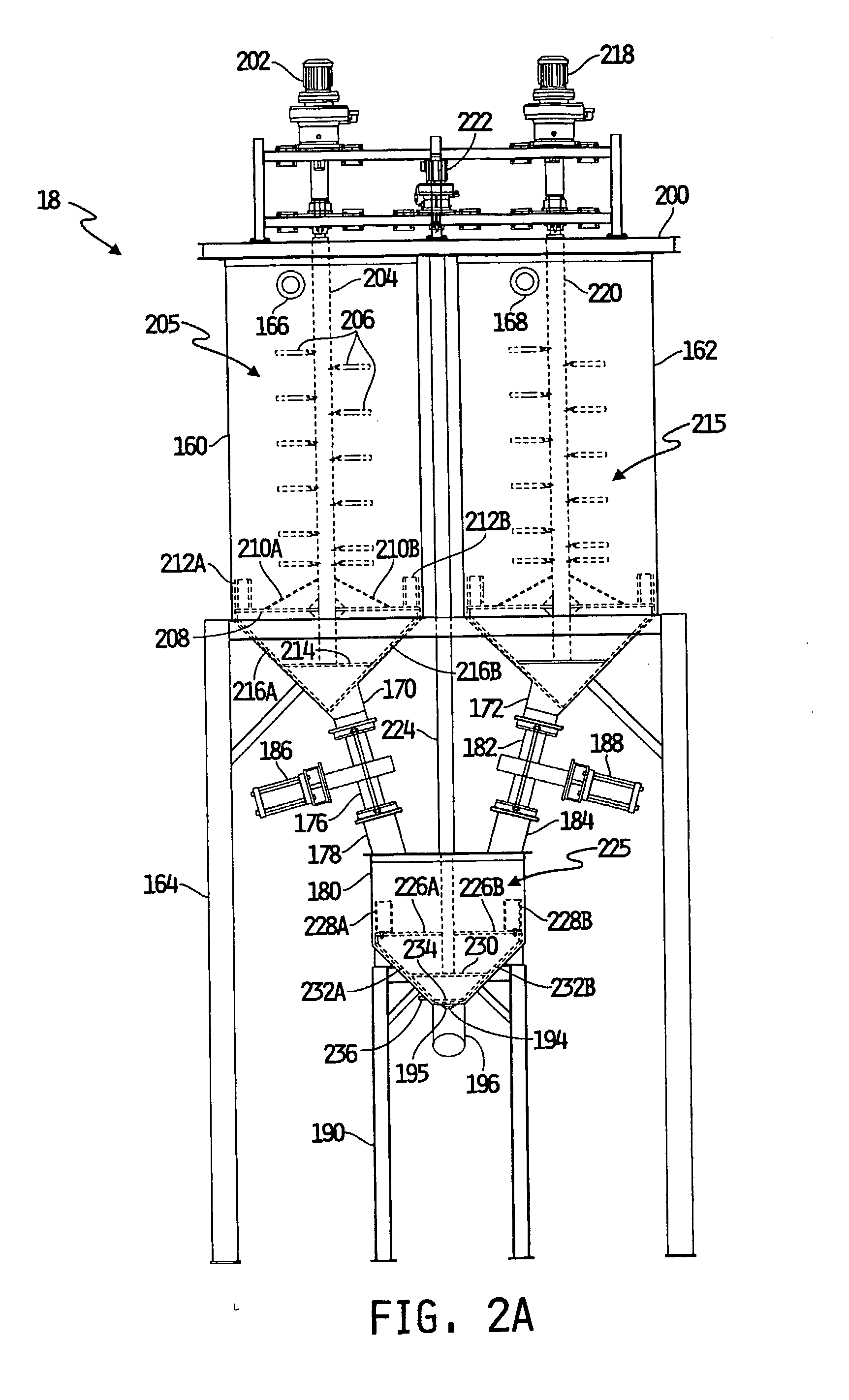

System for the treating biomaterial waste streams

InactiveUS20070175825A1Animal corpse fertilisersExcrement fertilisersWaste streamEnvironmental engineering

A process for treating a biomaterial waste stream is described. The process may form part of a waste fermentation system. The treating process can degrade at least a portion of the biomaterial waste stream into other components or materials. These other components or materials may be reintroduced into a fermentation process as a nutrient for a fermenting organism.

Owner:BIOMASS PROCESSING TECH

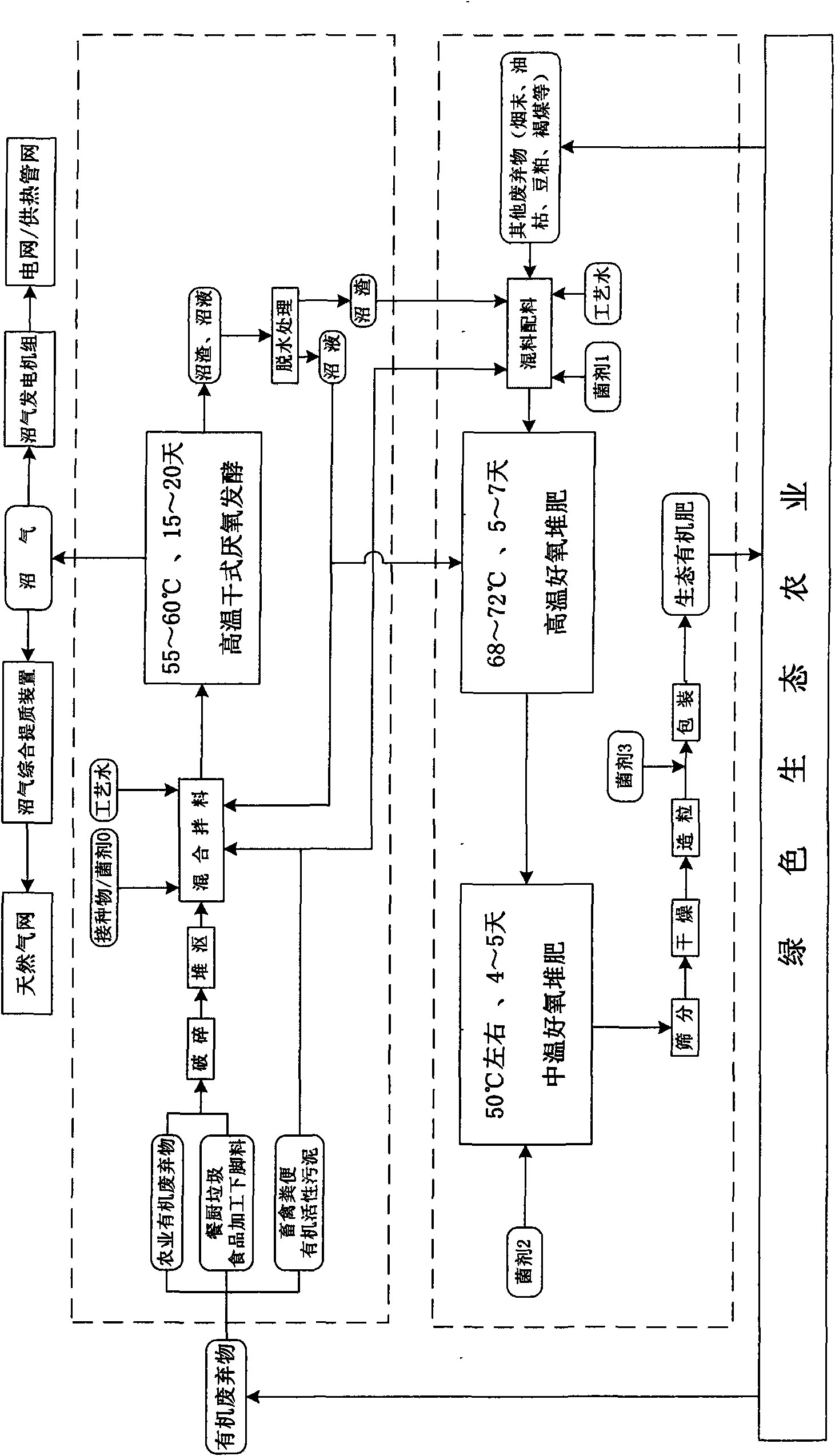

Comprehensive processing technology of organic wastes

ActiveCN101637778AImprove efficiencyStable nutrientsBio-organic fraction processingSolid waste disposalThermal energyProcess systems

The invention provides a comprehensive processing technology of organic wastes, belonging to the technical field of environmental protection, and in particular relates to resourcing comprehensive processing technology of organic wastes. The invention comprises the following steps: a. preparing materials: placing liquid or solid organic wastes into different storing tanks; b. pretreating: crashingthe organic wastes to particles with the granuality of being equal to or less than 30 mm, conveying the well-crashed materials into a stackretting tank for stackretting; c. mixing and matching variousorganic wastes and process water, wherein, the carbon nitrogen ratio (C / N) of the materials is 20-30:1, and the concentration of TS is 30%-35%; d. adding the inoculum, adopting high temperature dry anaerobic fermentation to carry out anaerobic fermentation on pretreated materials; and e. manufacturing from the biogas residues generated in step d into efficient multifungus composite ecological organic fertilizer, backflowing the generated biogas liquid to adjust the state of the anaerobic fermentation system or ensure the biogas liquid to enter the aerobic composting process flow, and introducing the generated biogas to a thermoelectricity cogeneration unit to provide electrical energy and thermal energy required by the process system. In the invention, composite microorganism agent and biogas residues and other base stocks are adopted for composite preparation, thus greatly improving fertilizer efficiency, lowering cost, having effects of diversification of nutrients, stable fertilizer efficiency and non pollution, and being suitable for being applied for various crops.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

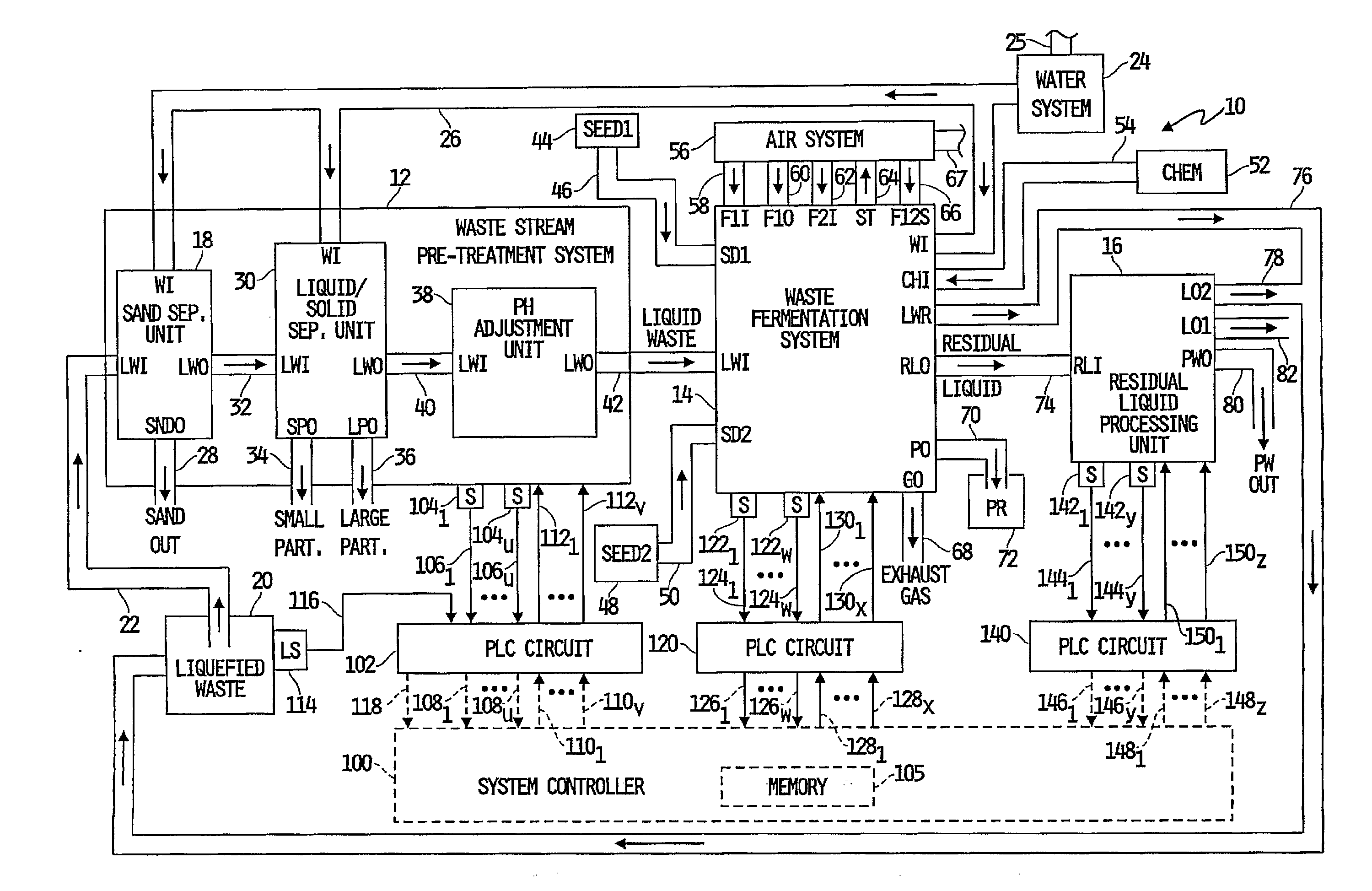

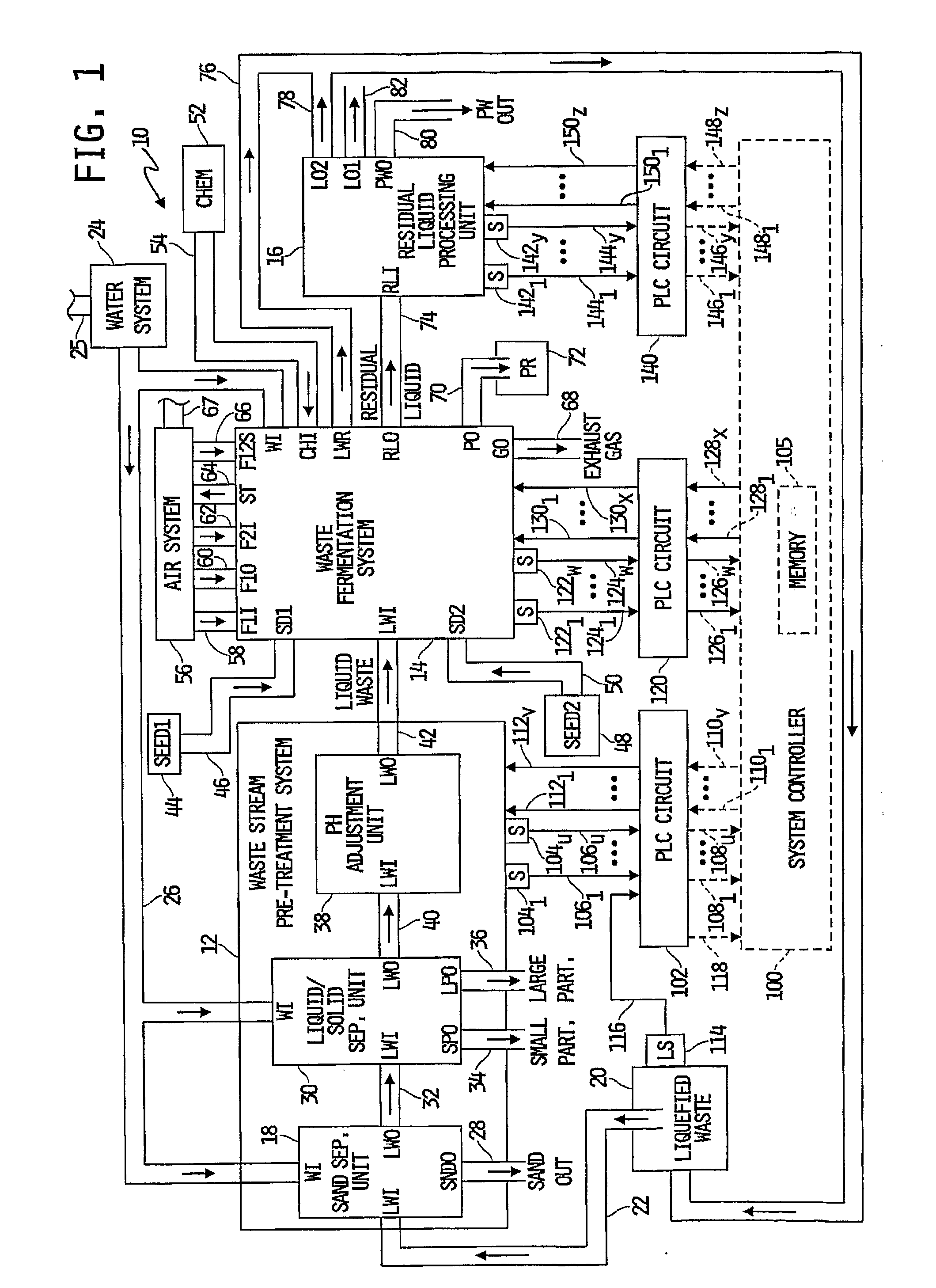

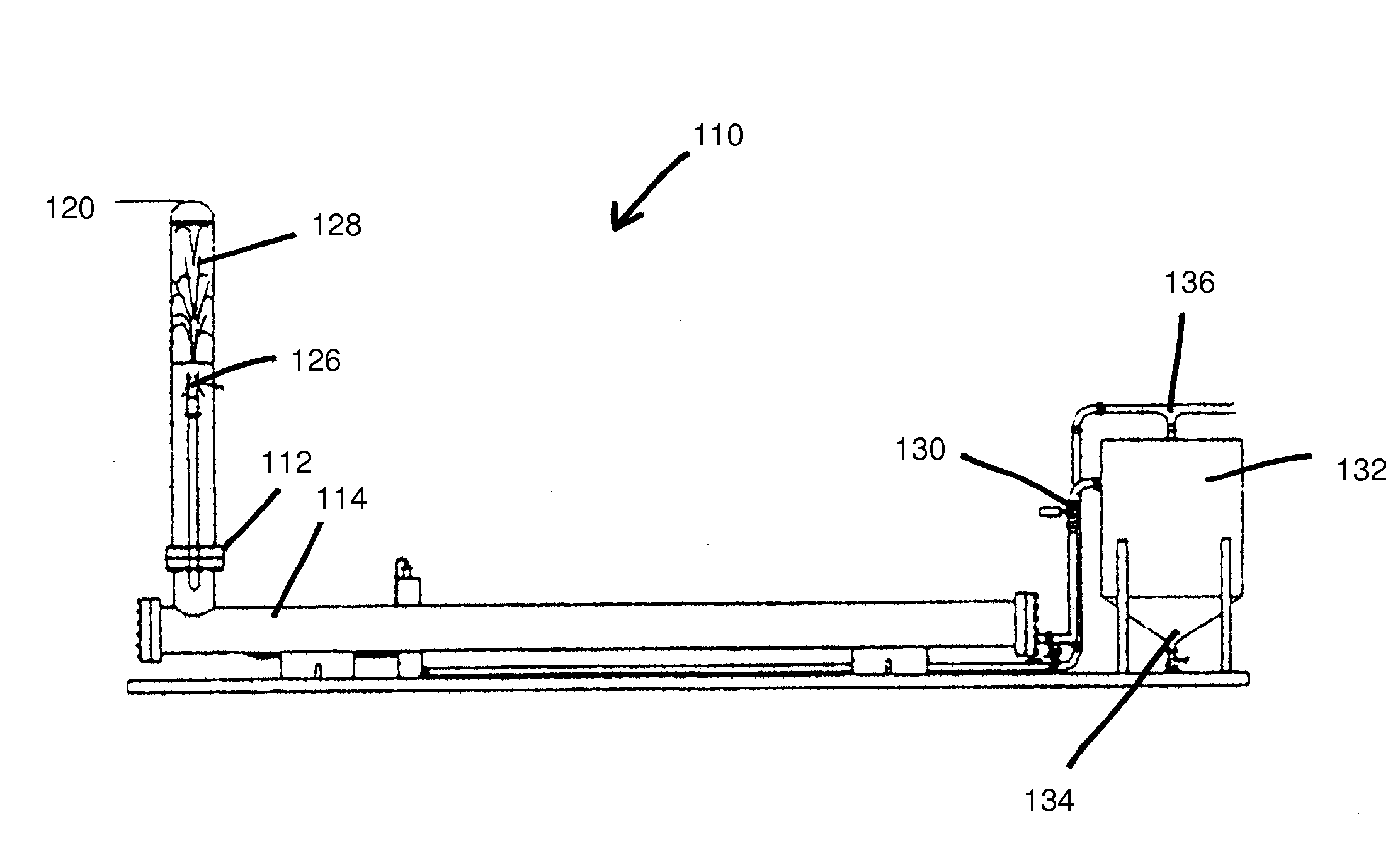

System for Processing a Biomaterial Waste Stream

InactiveUS20070221552A1Liquid separation auxillary apparatusWater treatment parameter controlWaste streamActuator

A system for processing a biomaterial waste stream includes a waste fermentation system for converting the biomaterial waste stream to fermenting organism and a residual liquid. The waste fermentation system has a waste inlet port (LWI) receiving the biomaterial waste stream, a product outlet port (PO) for removing the fermenting organism and a liquid outlet (RLO) for removing the residual liquid. A number of sensors produce sensory information relating to operation of the waste fermentation system, and at least one control circuit monitors the sensory information and controls operation of the waste fermentation system by controlling one or more actuators associated with the waste fermentation system.

Owner:BIOMASS PROCESSING TECH

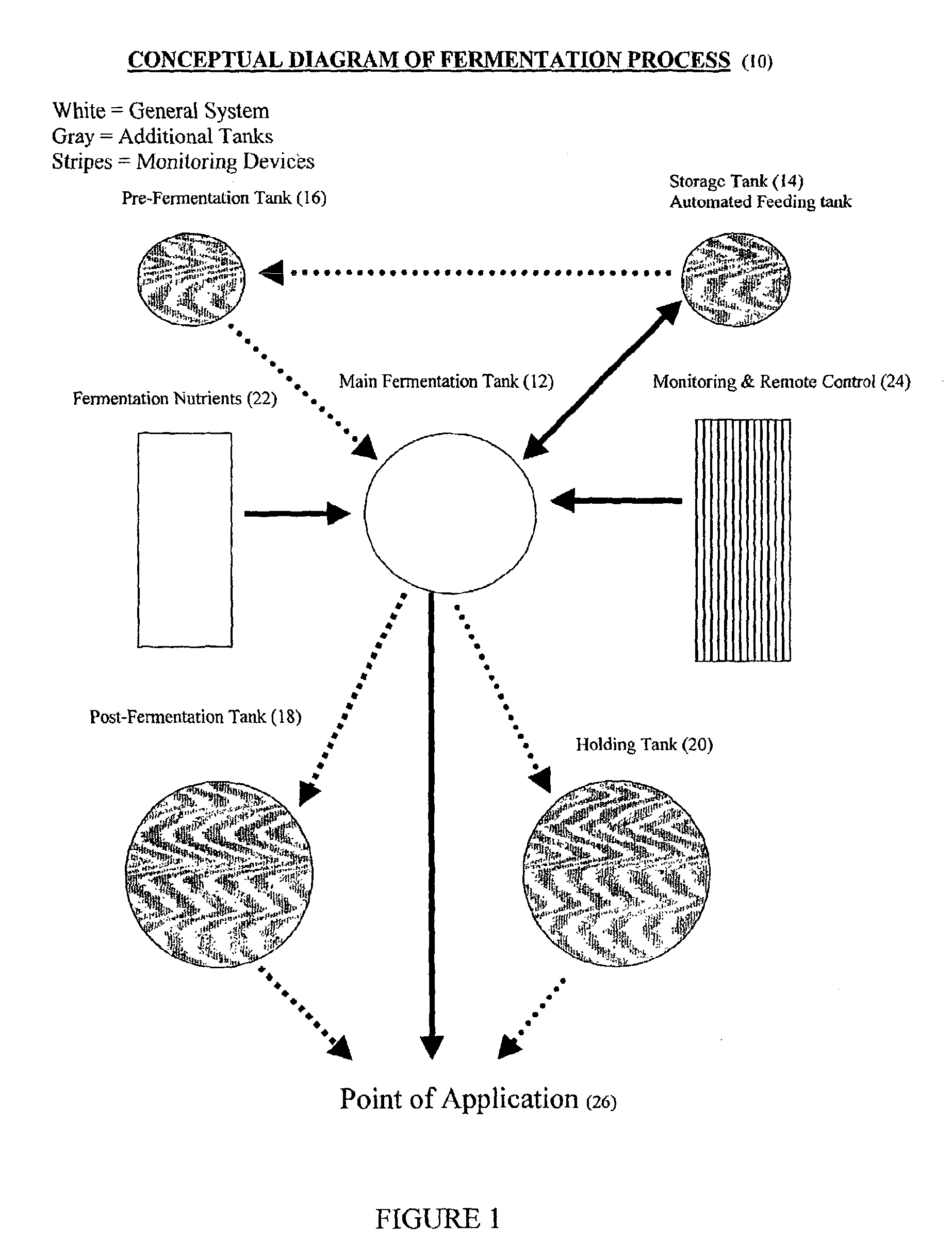

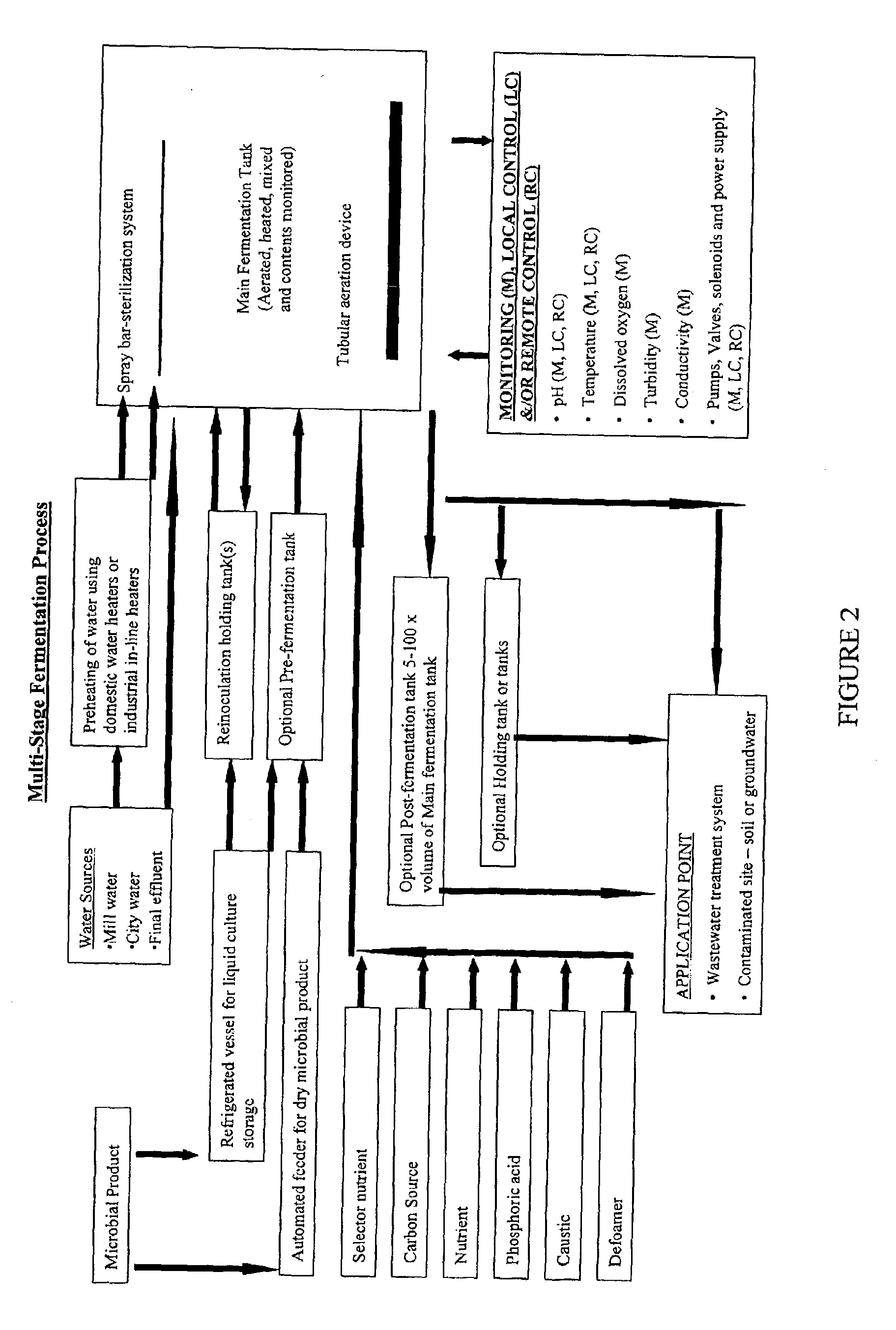

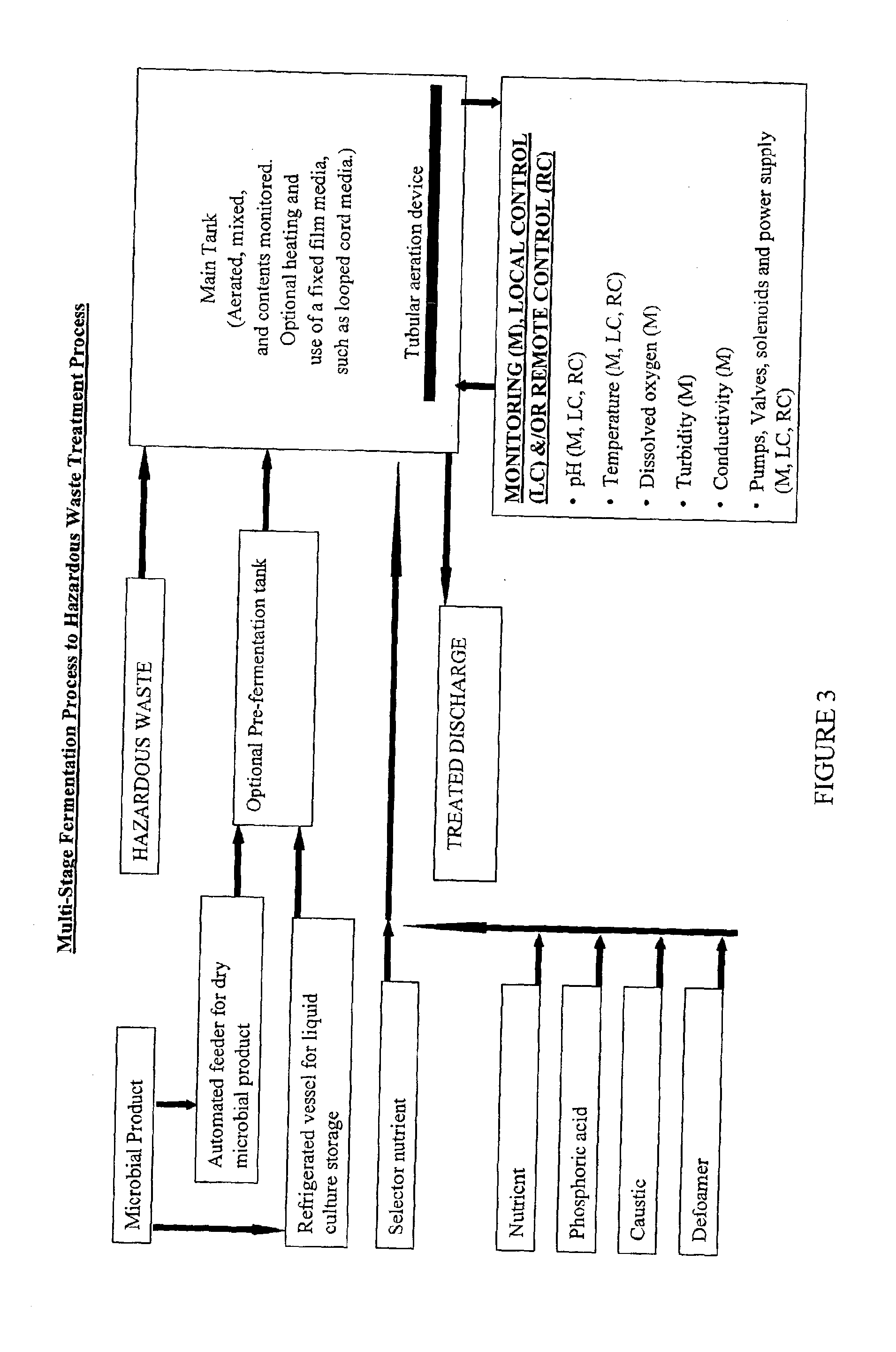

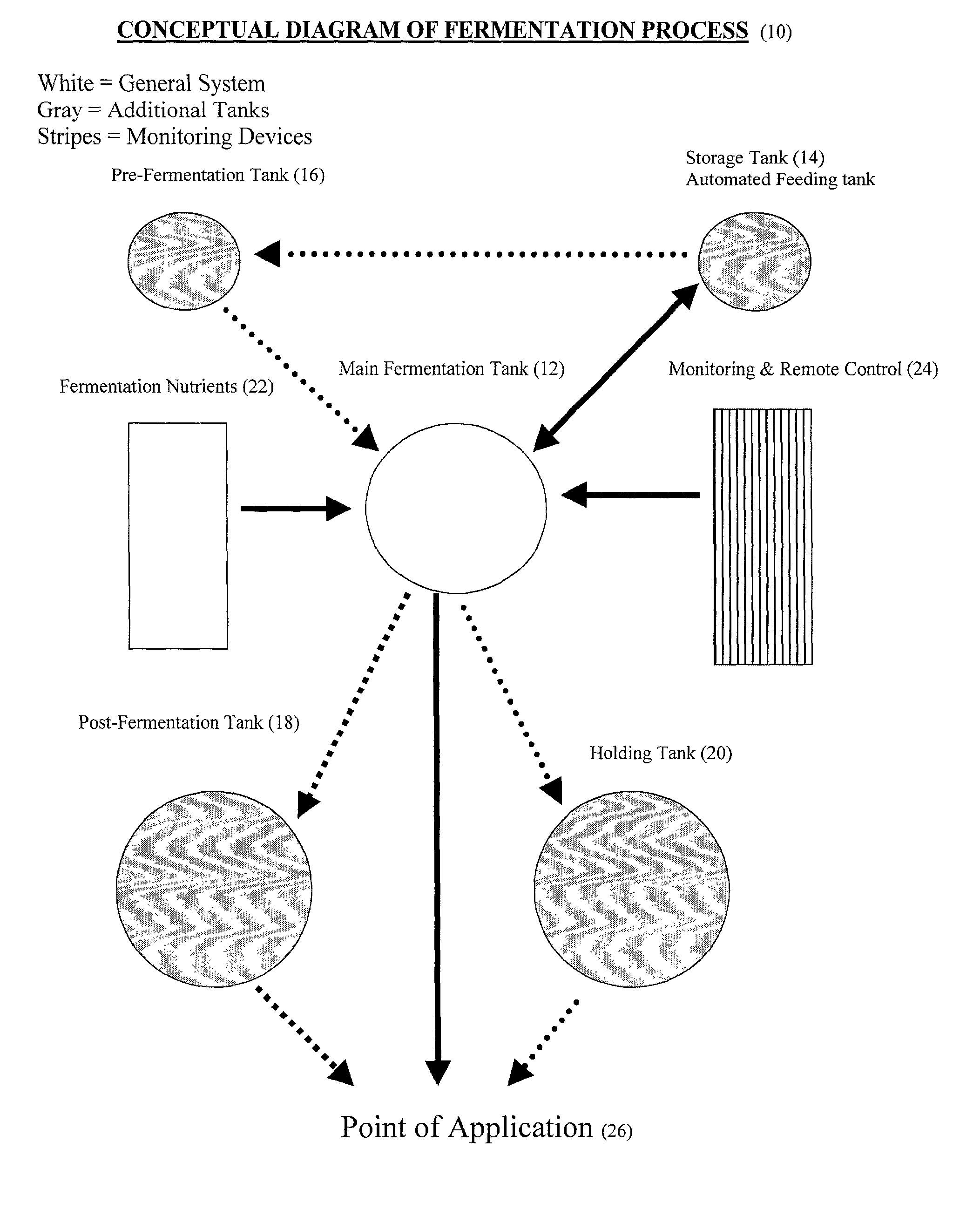

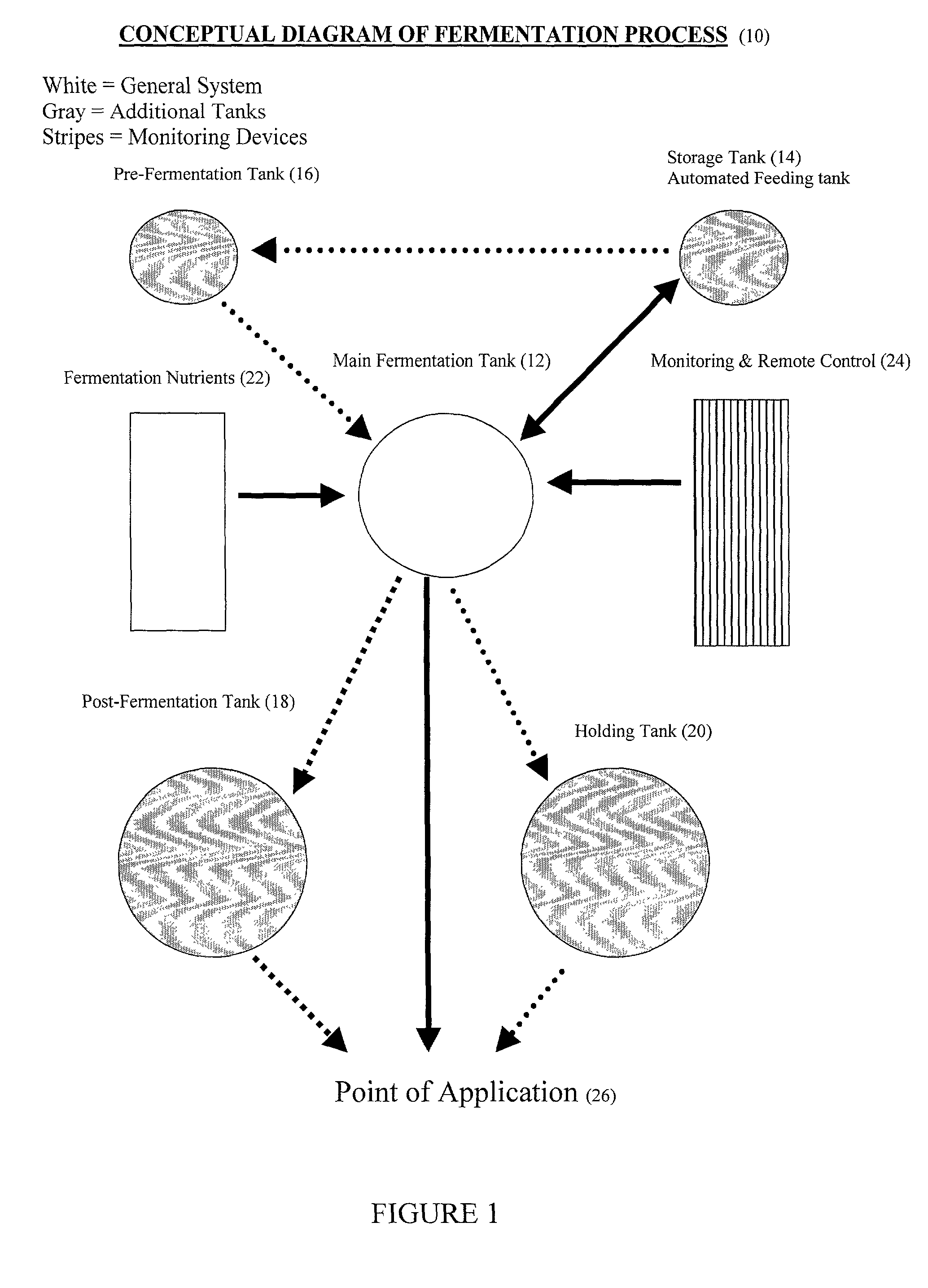

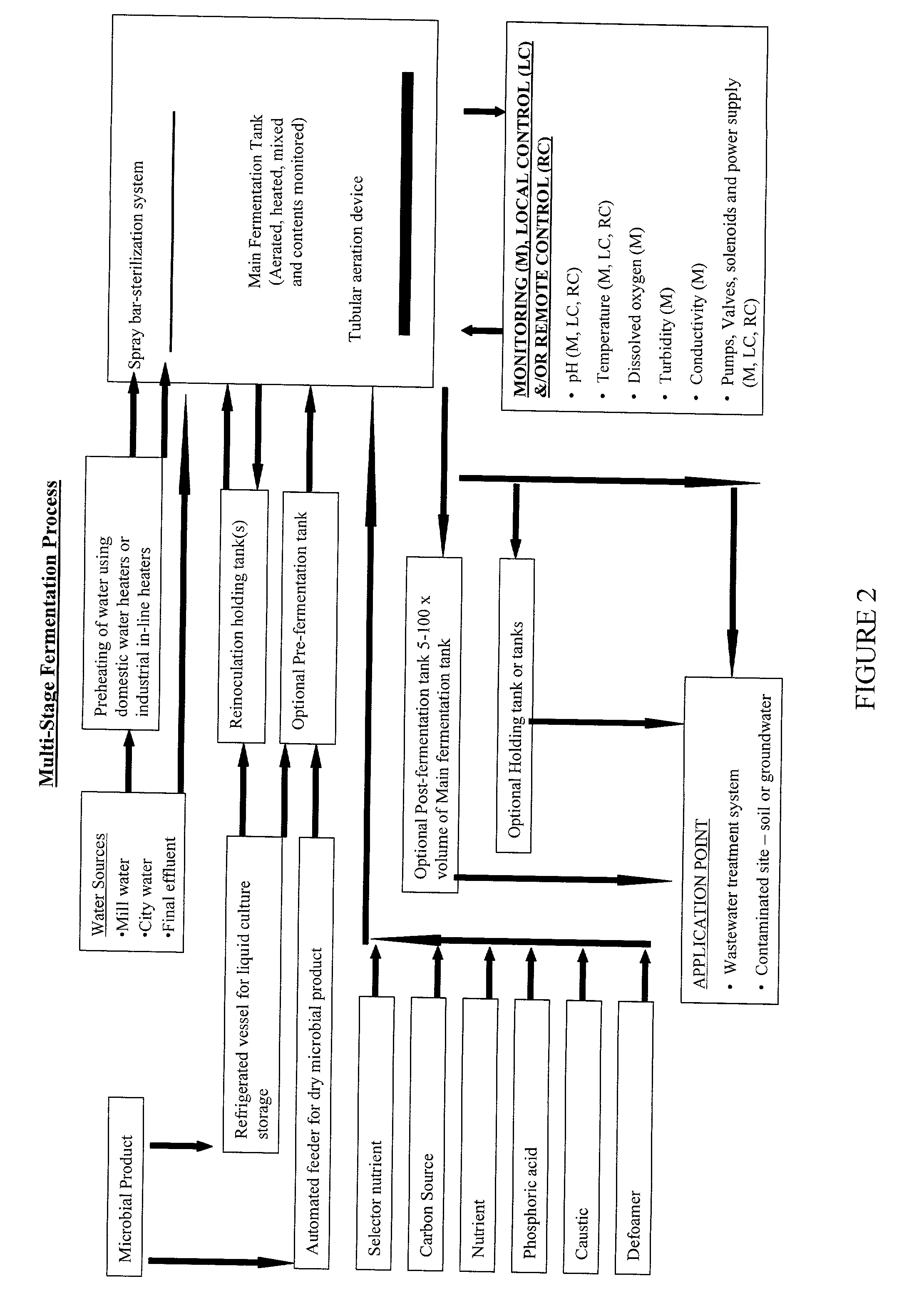

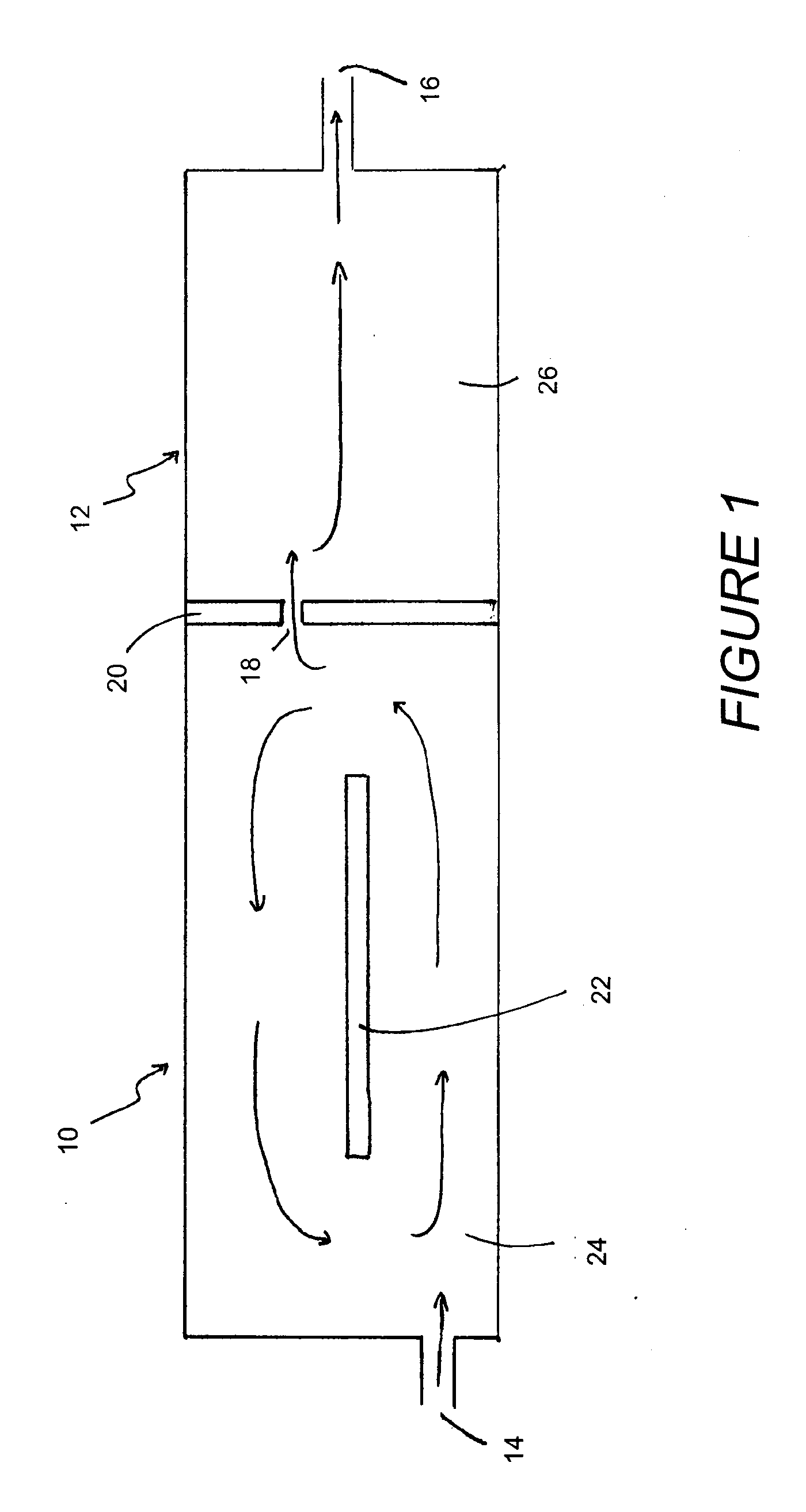

Fermentation systems, methods and apparatus

ActiveUS20030190742A1Eliminate needImprove wastewater treatment efficiencyWater treatment parameter controlWater treatment compoundsOrganismal ProcessWastewater

The present invention relates to apparatus, methods, and applications for treating wastewater, and more particularly to biological processes for removing pollutants from wastewater. This invention further relates to apparatus and methods for growing microbes on-site at a wastewater treatment facility, and for economically inoculating sufficient microbes to solve various treatment problems rapidly

Owner:ADVANCED INNOVATORS INC

Fermentation systems, methods, and apparatus

InactiveUS20020117445A1Eliminate needImprove wastewater treatment efficiencyWater treatment parameter controlTreatment using aerobic processesOrganismal ProcessWastewater

The present invention relates to apparatus, methods, and applications for treating wastewater, and more particularly to biological processes for removing pollutants from wastewater. This invention further relates to apparatus and methods for growing microbes on-site at a wastewater treatment facility, and for economically inoculating sufficient microbes to solve various treatment problems rapidly.

Owner:WHITEMAN G ROBERT

Control of contaminant yeast in fermentation processes

InactiveUS20100291649A1Growth inhibitionReduce the populationFungiBiofuelsMicroorganismNatural source

A fermentation process for the production of ethanol from natural sources, such as corn, comprising introducing a fermentable sugar, an inoculant yeast, and a stabilized chlorine dioxide into a fermentation system is disclosed. The stabilized chlorine dioxide is added preventatively to the fermentation system to substantially prevent growth of contaminating microorganisms such as contaminant yeast.

Owner:EI DU PONT DE NEMOURS & CO

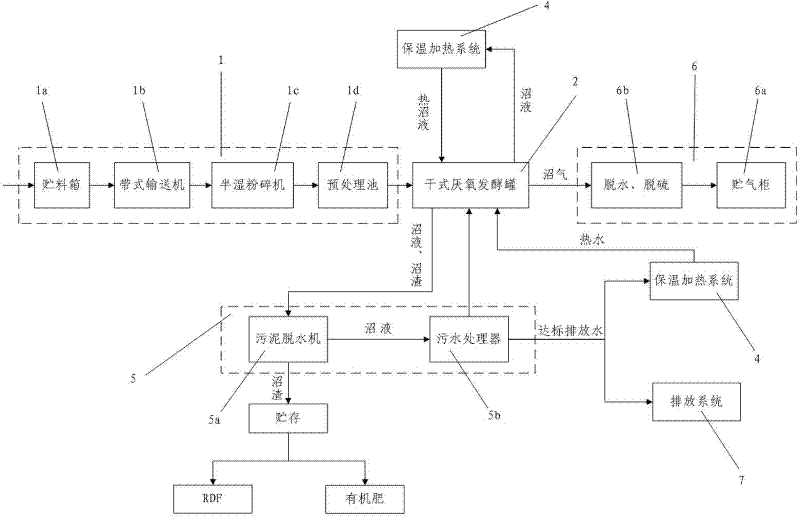

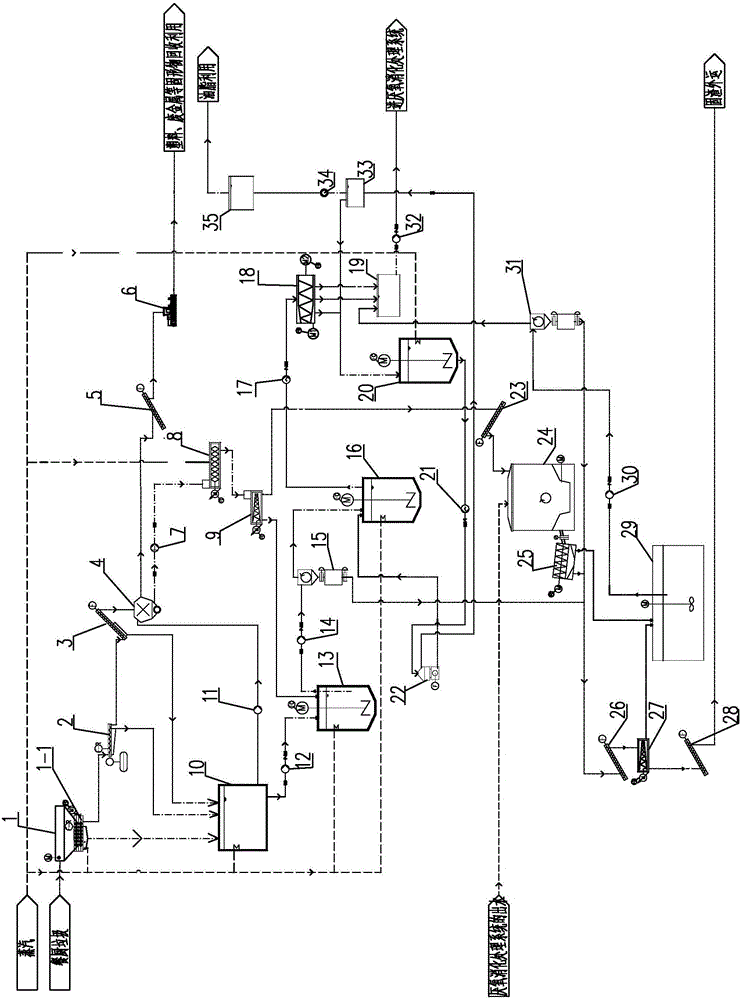

Organic waste dry anaerobic high-temperature fermentation system and fermentation process

ActiveCN102517200AHarmlessAchieve reductionBio-organic fraction processingGas production bioreactorsReduction treatmentControl system

The invention relates to an organic waste dry anaerobic high-temperature fermentation system and a fermentation process. The fermentation system comprises a feeding system (1), a dry anaerobic fermentation tank (2) with an agitating system (3), a heat preservation and heating system (4), a biogas slurry and biogas residue treatment system (5), an exhaust system (6) and a control system. The organic waste dry anaerobic high-temperature fermentation system and the fermentation process have the beneficial effects that harmless treatment, reduction treatment and resource treatment can be carried out on domestic organic wastes, so that the cyclic utilization of the wastes is realized; and moreover, the treatment efficiency is high, and the energy consumption and the treatment cost are low.

Owner:云南昆船环保技术有限公司

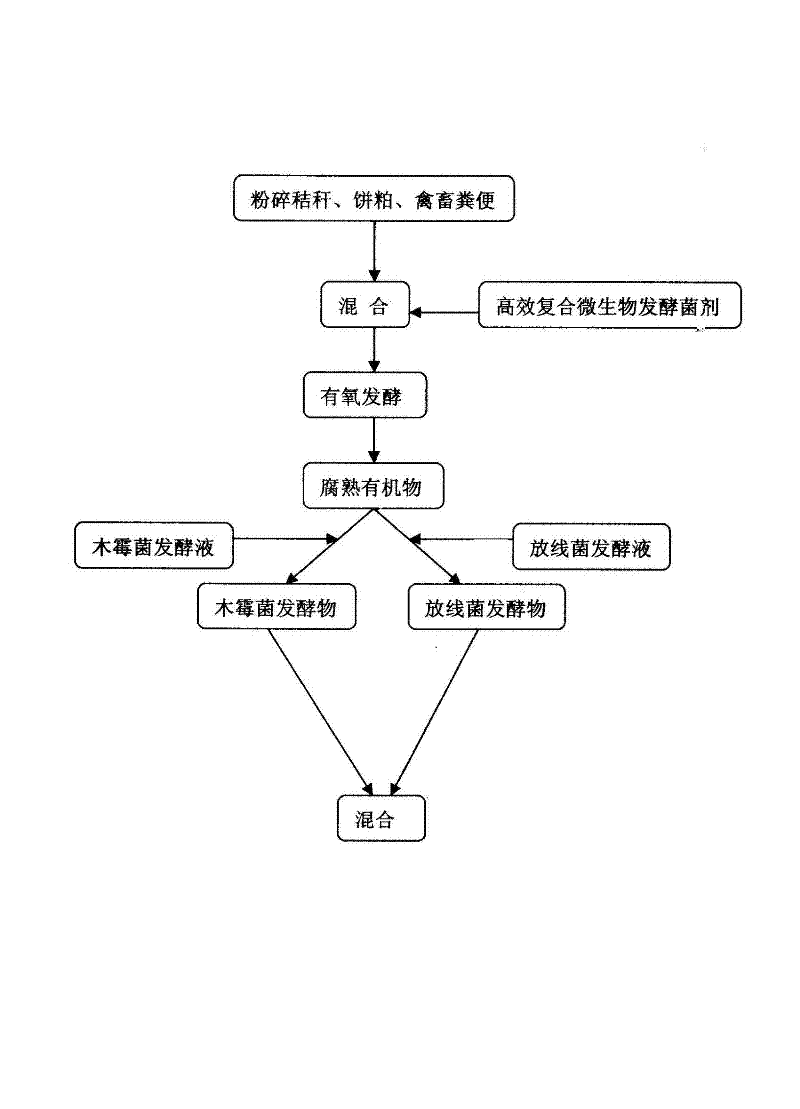

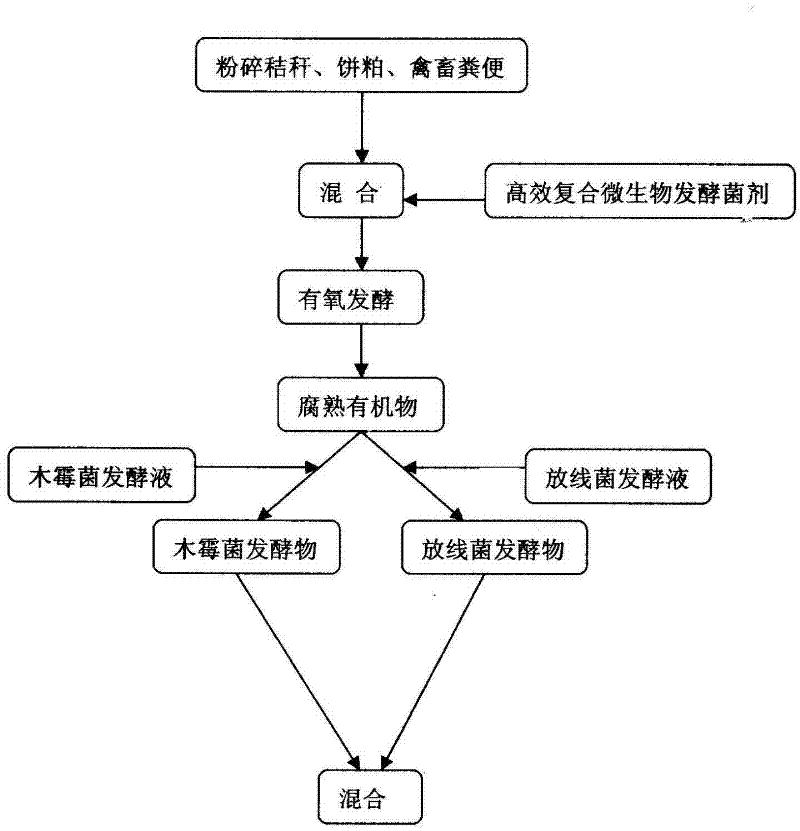

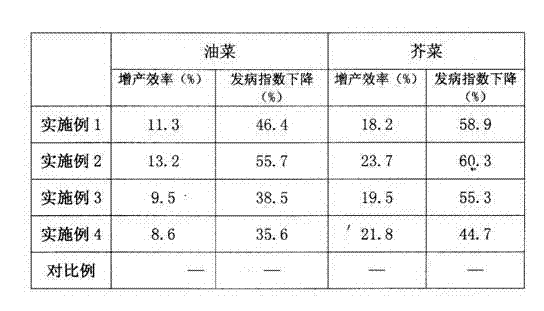

Disease-preventing bio-organic fertilizer prepared from straw and its preparation method

InactiveCN102442849APrevent intrusionReduce the frequency of sprayingBio-organic fraction processingEnergy inputSlurryDisease cause

Relating to the technical field of renewable energy, the invention specifically relates to a method for producing biogas and organic fertilizers with straw. The method of the invention comprises the steps of: (1) straw pretreatment; (2) straw composting; (3) anaerobic fermentation; and (4) fermentation product utilization. The method of the invention substantially improves the degradation rate of straw and gas output. Meanwhile, pretreatment by a composite bacterial agent can stabilize the pH value of a fermentation system, and is in favor of the normal occurrence of anaerobic fermentation, so that the content of methane in biogas can be raised. The method in the invention greatly saves cost, almost has no sewage discharge, and improves the utilization rate of renewable energy. The biogas produced by anaerobic fermentation of crop straw can be used as a resident cooking fuel or for power generation after treatment by the purification procedures of desulphurization and dehydration. On the other hand, the residue generated from anaerobic fermentation of straw can be separated into a biogas residue and biogas slurry that are then prepared into solid and liquid organic fertilizers, which are easy for crops to adsorb. Therefore, the comprehensive utilization rate of straw resources can be substantially enhanced.

Owner:雷震

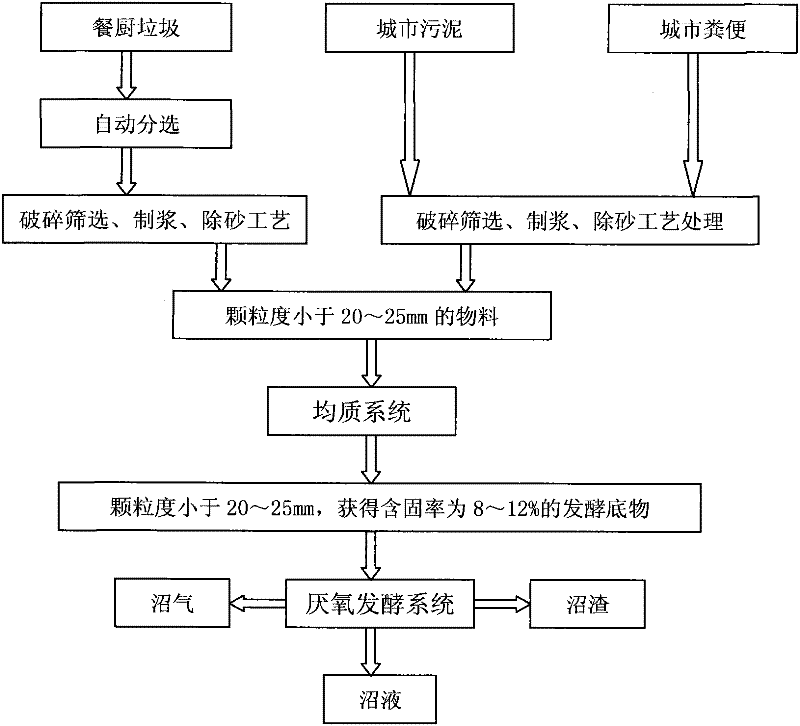

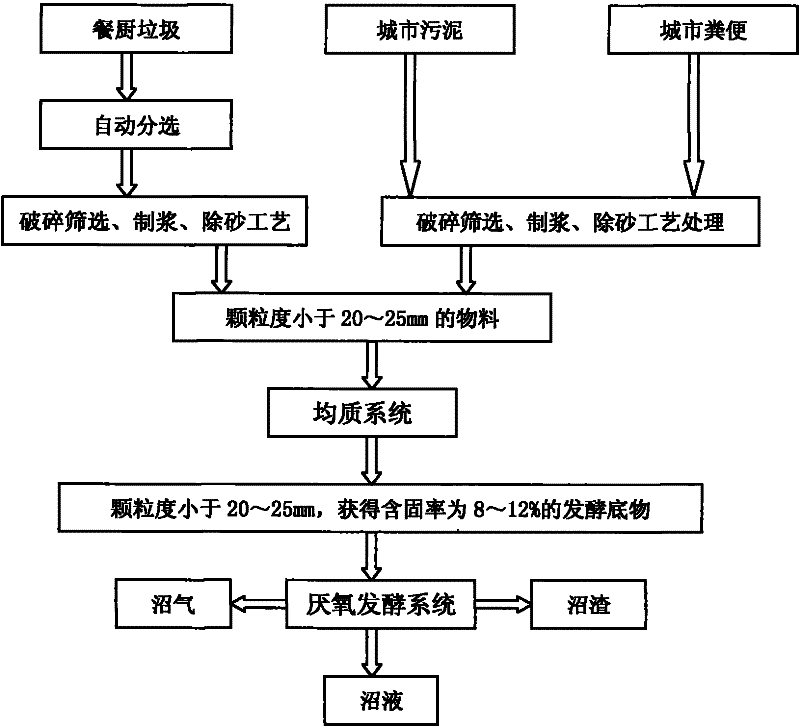

A method for preparing biogas from kitchen waste, urban sludge and urban excrement

InactiveCN102286541AFully fermentedOvercoming the deficiency of high energy consumption in high temperature fermentationWaste based fuelFermentationParticulatesFeces

A method for preparing biogas by joint anaerobic fermentation of food waste, urban sludge and urban excrement, comprising the following steps: (1) pretreatment system: food waste, urban sludge and urban excrement undergo a pretreatment process to obtain granules (2) homogeneous system: the materials processed in step (1) enter the homogenizing tank one after another, mix evenly and degrade part of the suspended matter, so that the particle size of the solid material is less than 20-25mm, and obtain Fermentation substrate with a solid content rate of 8 to 12%; (3) anaerobic fermentation system: the fermentation substrate treated in step (2) is transported to an anaerobic fermentation tank by a pump and adopts a continuous fermentation process and a mesophilic anaerobic fermentation The anaerobic fermentation method combined with jet stirring produces biogas, biogas residue and biogas slurry. The combined anaerobic fermentation preparation method of the present invention has the effects of complete material fermentation and high gas production rate.

Owner:ZHONGCHENG HONGTIAN BEIJING ENVIRONMENT TECH DEV

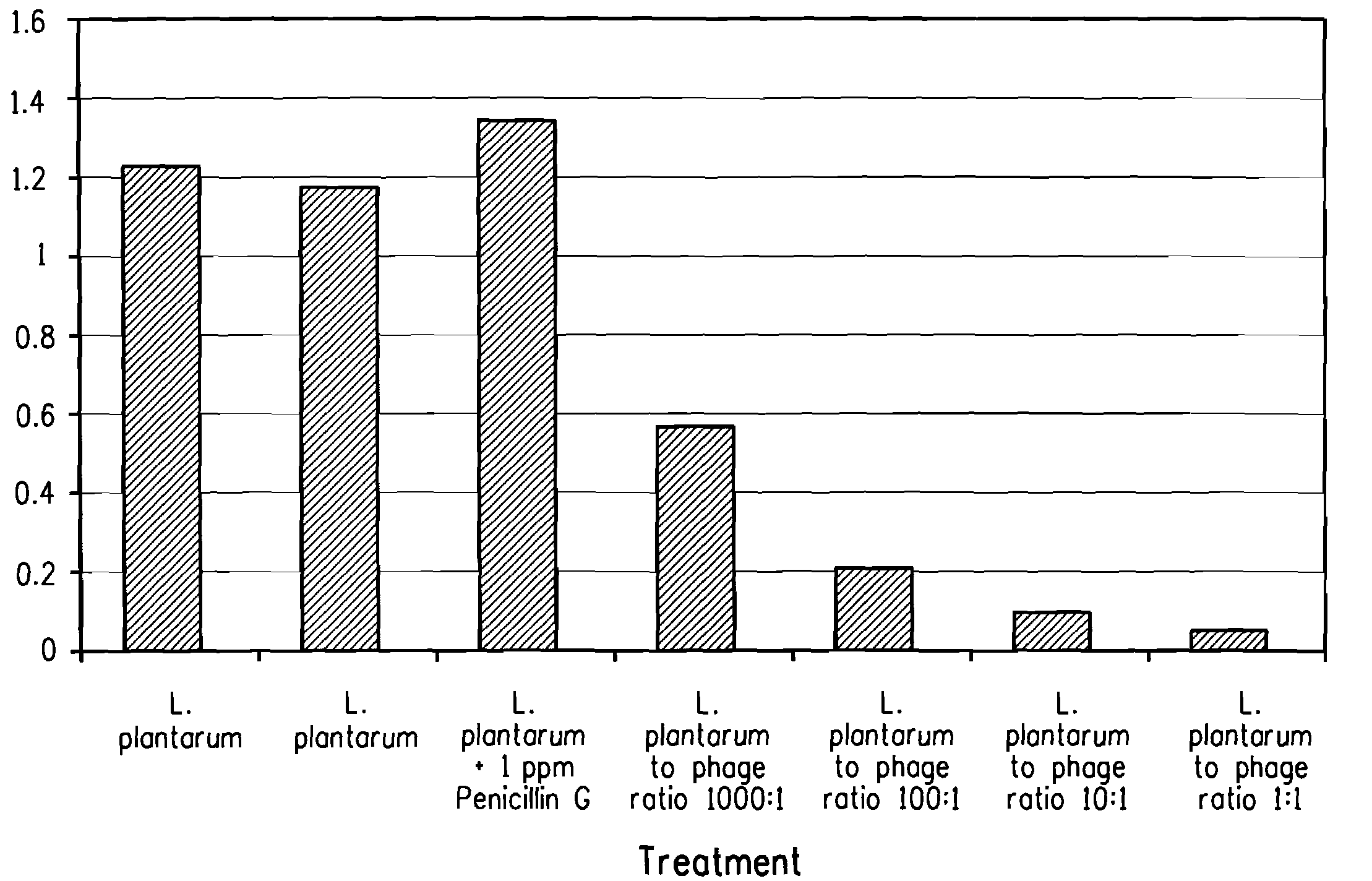

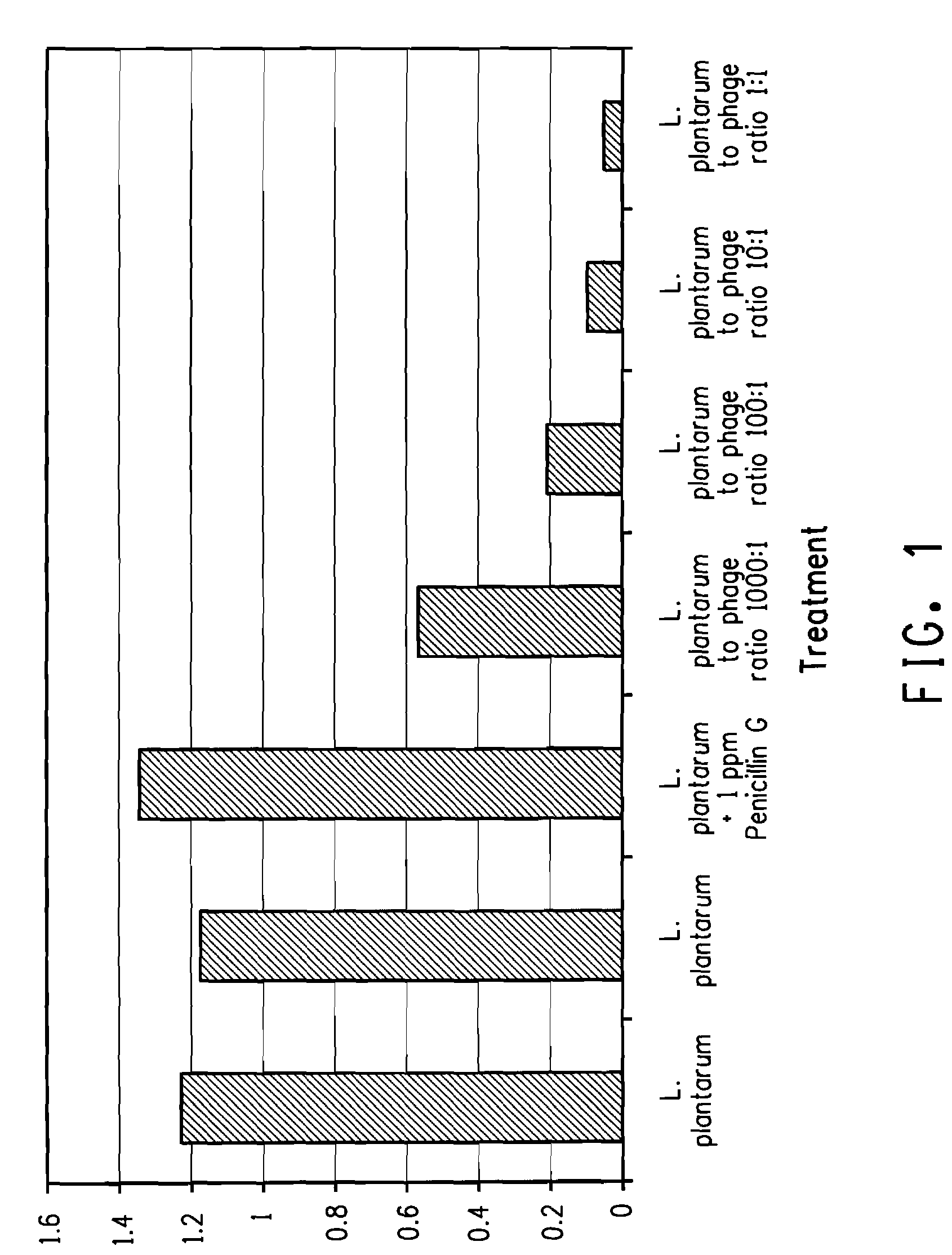

Utilization of bacteriophage to control bacterial contamination in fermentation processes

Owner:EI DU PONT DE NEMOURS & CO

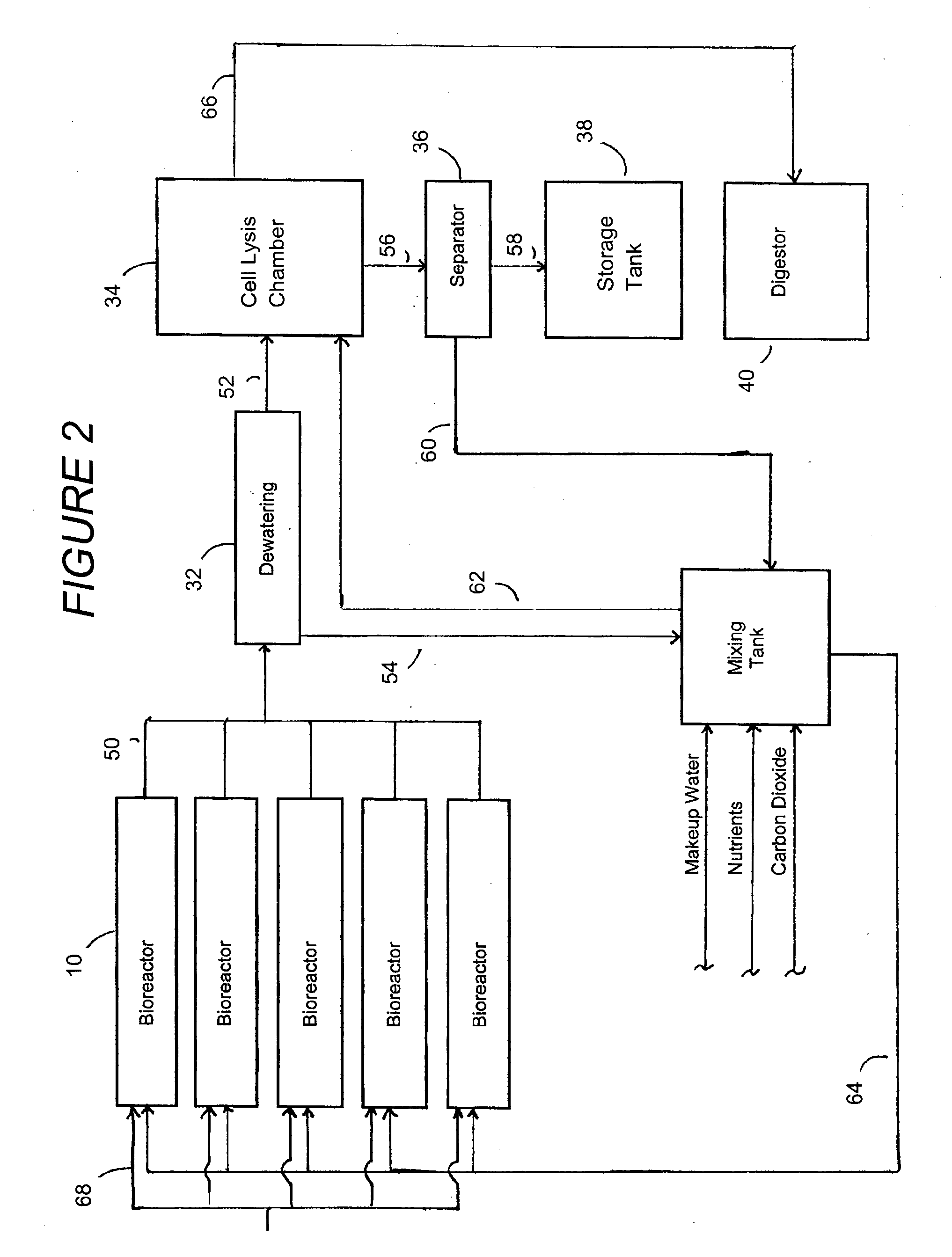

System for fermentation using algae

ActiveUS20090170184A1Adjustable sizeBioreactor/fermenter combinationsBiological substance pretreatmentsLysisNuclear engineering

The system for fermentation using algae of the present invention includes a first reactor and a second reactor being in fluid communication with each other. A first valve placed between the first reactor and the second reactor controls the fluid connection between the reactors. A gas inlet, in fluid connection to the first reactor, is located at an end opposite the second reactor. A devolatization unit or cell lysis chamber is connected to the second reactor by a second valve. A biomass stream having gas, liquid and biosolids contents passes through the first reactor with gas. The biomass stream mixes and dissolves the gas in the reactors. The cellular structure of the biomass stream ruptures in the devolatization unit, allowing the processed materials, such as oil, gas, and biosolids, to be harvested for use.

Owner:MISSING LINK TECH

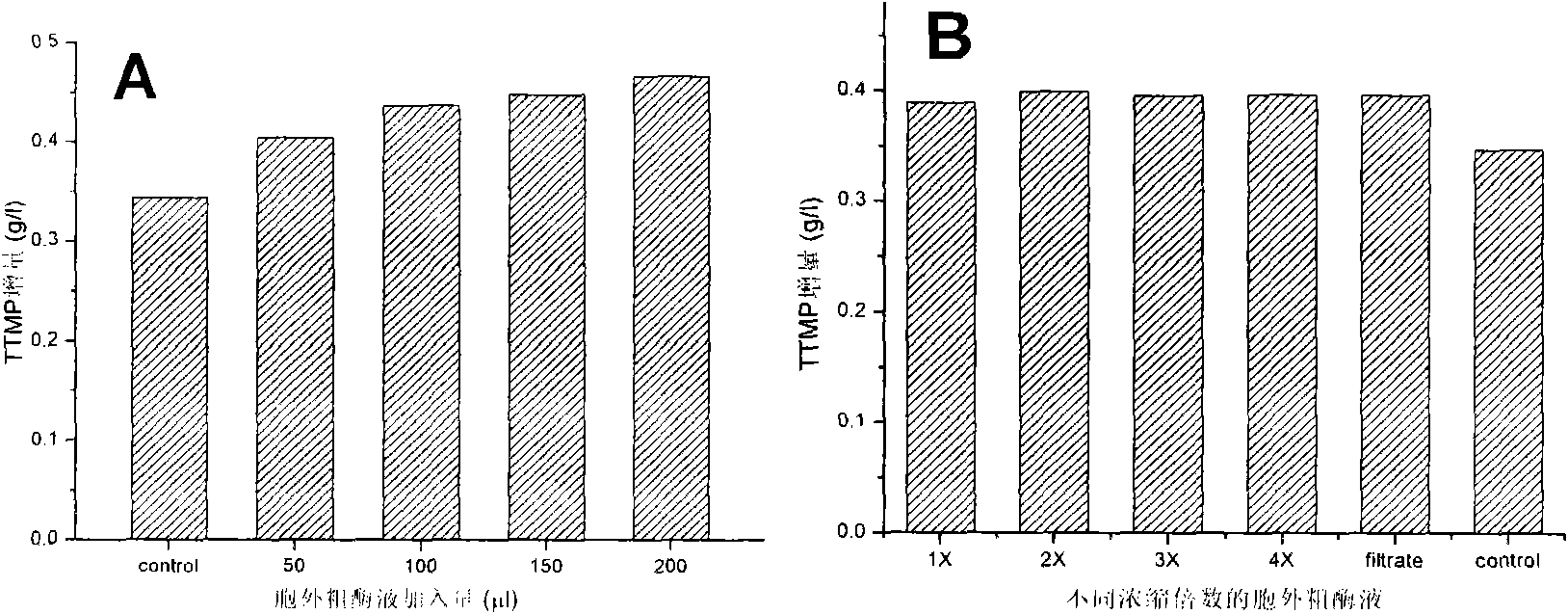

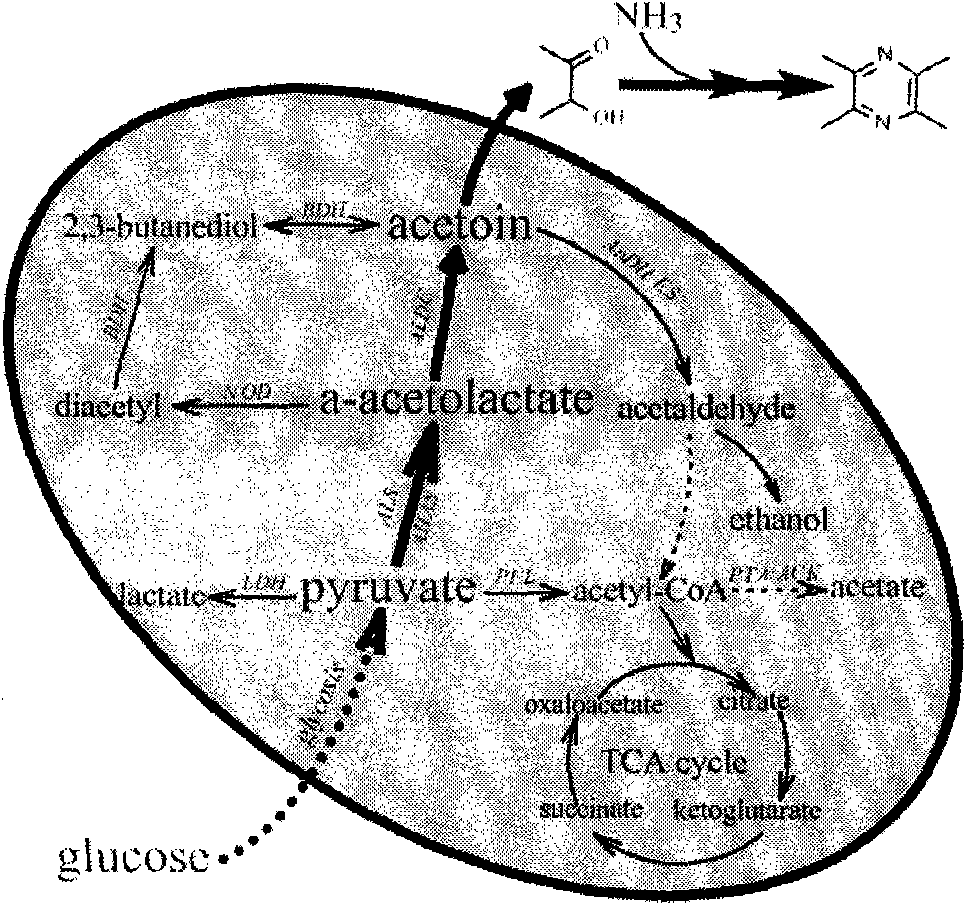

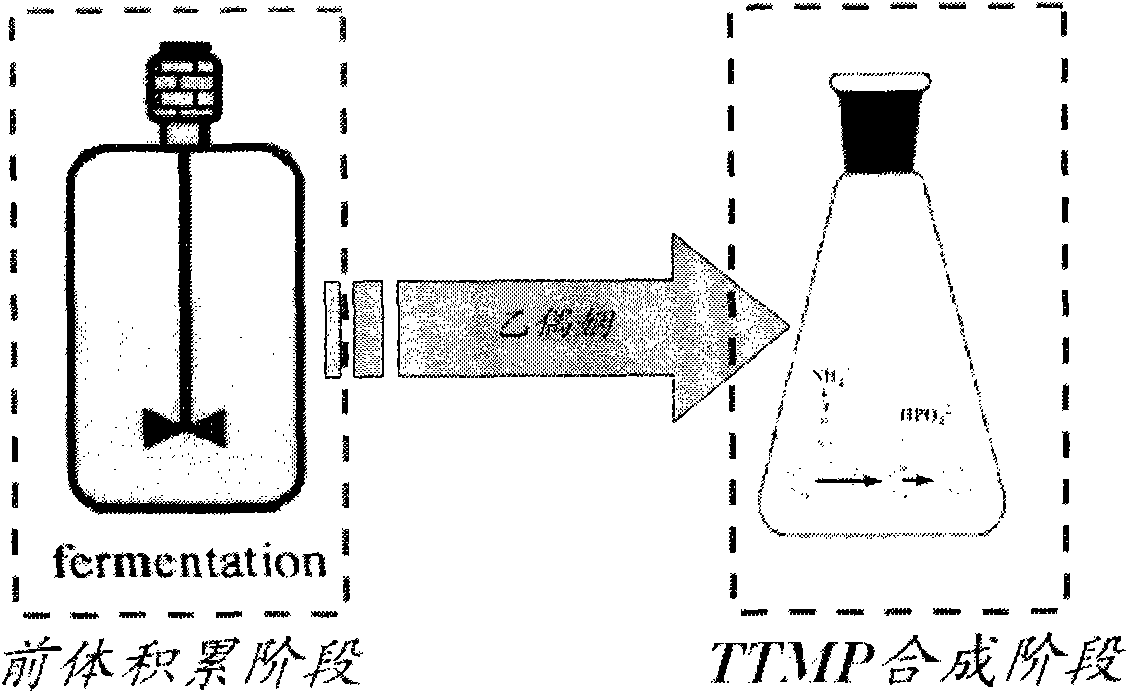

Method and strain for producing tetramethylpyrazine

InactiveCN101955980APromote rapid proliferationRich sourcesBacteriaMicroorganism based processesBacillus licheniformisHigh concentration

The invention discloses a method and a strain for producing tetramethylpyrazine (TTMP), in particular a two-step production process that a microorganism accumulates precursor acetoin by using the fermentation of reducing sugar and the acetoin and ammonia undergo a non-enzymatic reaction to synthesize the TTMP, and belongs to the technical field of bioengineering. The microorganism is any one of bacillus subtilis (CCTCC NO:M 208157), bacillus licheniformis (CGMCC NO:3961), bacillus licheniformis (CGMCC NO:3962) and bacillus licheniformis (CGMCC NO:3963). The strain obtains biomass and accumulates endogenous precursor acetoin by using the fermentation of the reducing sugar, and the acetoin and the ammonia in a fermentation system undergo the non-enzymatic reaction to synthesize the TTMP. The method has the advantages that: the obtained bacteria quantity is higher, the accumulation amount of the acetoin is effectively improved (38 to 44g / L); the high-concentration endogenous precursor acetoin and the ammonia can quickly react under proper conditions to form the TTMP (16 to 20g / L); and the use ratio (40.3 percent) of precursors is obviously improved due to the accumulation of endogenous acetoin and an in-situ fermentation environment.

Owner:JIANGNAN UNIV

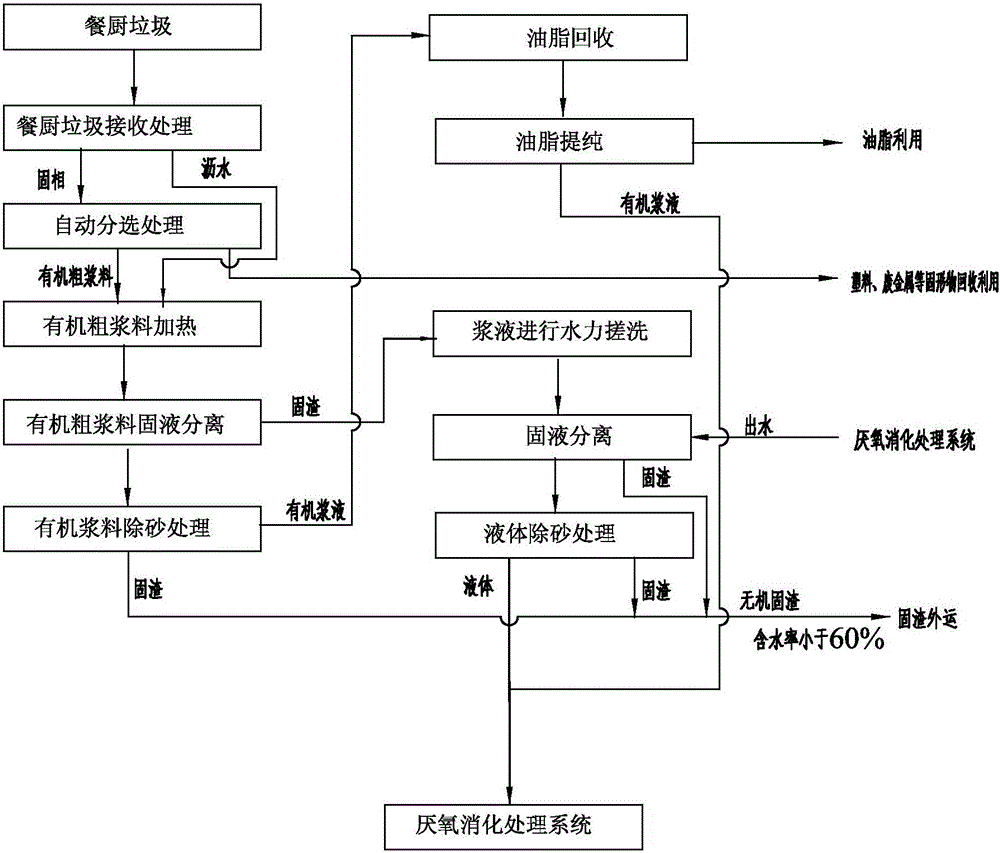

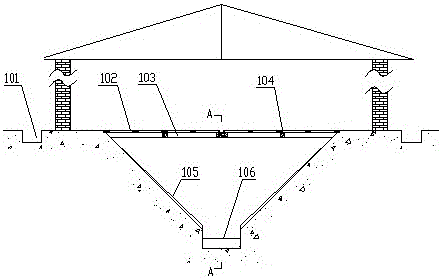

Pretreatment method of anaerobic digestion treatment of kitchen garbage

ActiveCN105925361ANo cloggingAvoid cloggingSolid waste disposalFatty-oils/fats refiningPretreatment methodPunching

The invention relates to a pretreatment method of an anaerobic digestion treatment of kitchen garbage. The pretreatment method comprises the following steps: removing bulks, pouring kitchen garbage into a hopper, coarsely grinding and extruding the kitchen garbage, delivering kitchen garbage to a sorting machine, delivering the leachate to a water pot through a leachate collecting tank; sorting out inorganic impurities, punching, grinding, and pulping kitchen garbage, stirring under heating, carrying out solid-liquid separation, delivering solid dregs to an organic substance recovering tank, removing impurities from organic slurry by a first whirl sand removing machine, then extracting oil from organic slurry by a three phase centrifuge; purifying the oil phase by an oil extracting machine, delivering the residual organic slurry to a solid-liquid mixing box; mixing the solid dregs in the organic substance recovering tank and effluent from an anaerobic fermentation system to form slurry, washing the slurry by water, carrying out solid-liquid separation, removing impurities from the separated liquid by a second whirl sand removing machine, and then delivering the liquid to the solid-liquid mixing box. The pretreatment method has the advantages that various greases in kitchen garbage are maximally extracted, inorganic solid impurities are prevented from entering the anaerobic fermentation system, and thus the operation of following treatments becomes stable.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

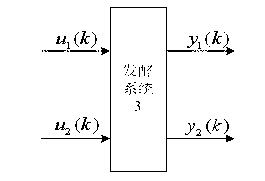

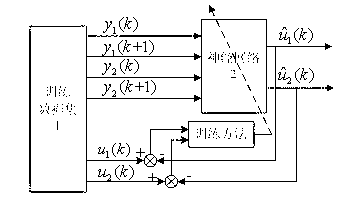

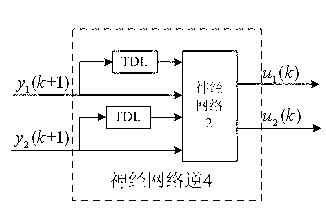

Biological fermentation adaptive control system and control method based on neural network inverse

InactiveCN103064292AAchieve linearizationAchieve decouplingAdaptive controlWeight coefficientTime delays

The invention provides a biological fermentation adaptive control system and a control method based on neural network inverse. The control method comprises the following steps: constructing the neural network inverse by using a neural network and a time division multiplexing time delay link, enabling the neural network to achieve an inverse system function of a biological fermentation system by adjusting the weight coefficient of the neural network, connecting the neural network inverse and the biological fermentation system in series to form a pseudo-linear compound system, decoupling the pseudo-linear compound system in a linearization mode into two pseudo-linear subsystems with single input and single output, presetting desired signals, according to the control inputs of each pseudo-linear subsystem and the outputs of the biological fermentation system of current time and prior moment, constantly renewing the parameters of a model-free adaptive controller and the control input of each pseudo-linear subsystem of the following moment, enabling the outputs of the biological fermentation system to follow the preset desired signals effectively, thereby achieving the model-free adaptive control of the biological fermentation system, and improving the control performance of a biological fermentation process.

Owner:镇江市江大科技有限责任公司 +1

System and method for micro-aeration based fermentation

InactiveUS20130323714A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAeration systemNitrogen

A method and apparatus for micro-aeration of large scale fermentation systems is provided. The micro-aeration system includes a fermentation reactor, a sparging apparatus, and a micro-aeration gas mixture delivered to the fermentation reactor via the sparging apparatus. The micro-aeration gas mixture is a very low oxygen concentration mixture comprising an oxygen containing gas and an inert carrier gas that is preferably recycled through the fermentation reactor. The inert carrier gas is preferably nitrogen whereas the oxygen containing gas is oxygen or and is introduced to the fermentation reactor at a minimum superficial velocity of about 0.02 m / sec to produce a uniform dispersion of the oxygen / air throughout the fermentation broth while concurrently mixing the entire fermentation broth. The micro-aeration method and apparatus further comprises a controller operatively coupled to one or more control valves for regulating the micro-aeration conditions in the fermentation reactor.

Owner:PRAXAIR TECH INC

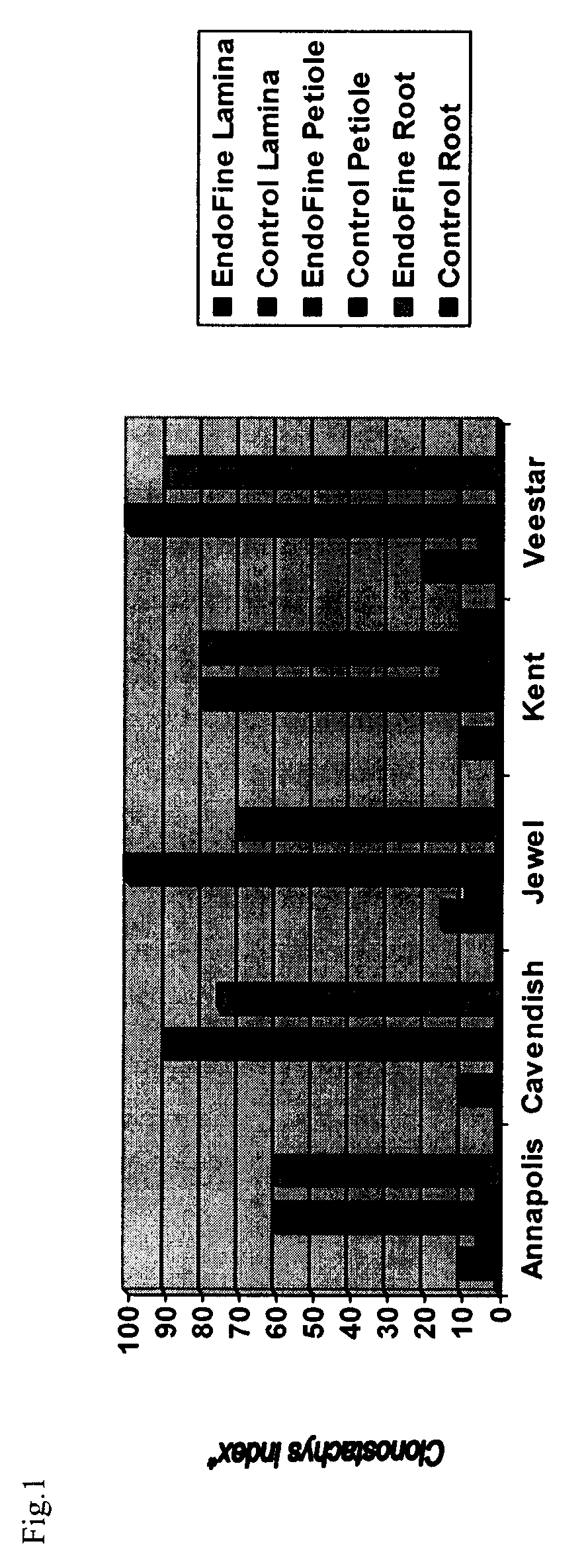

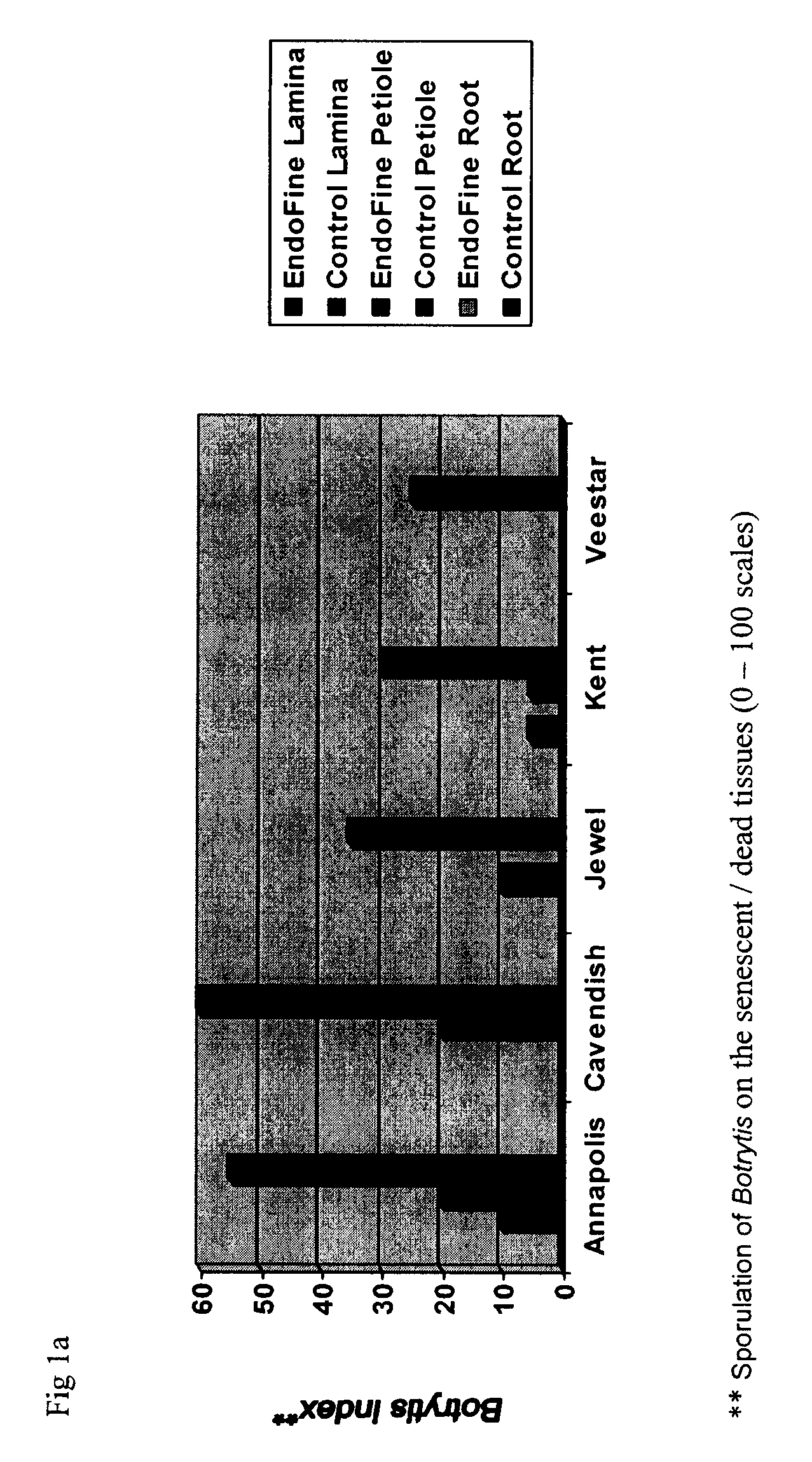

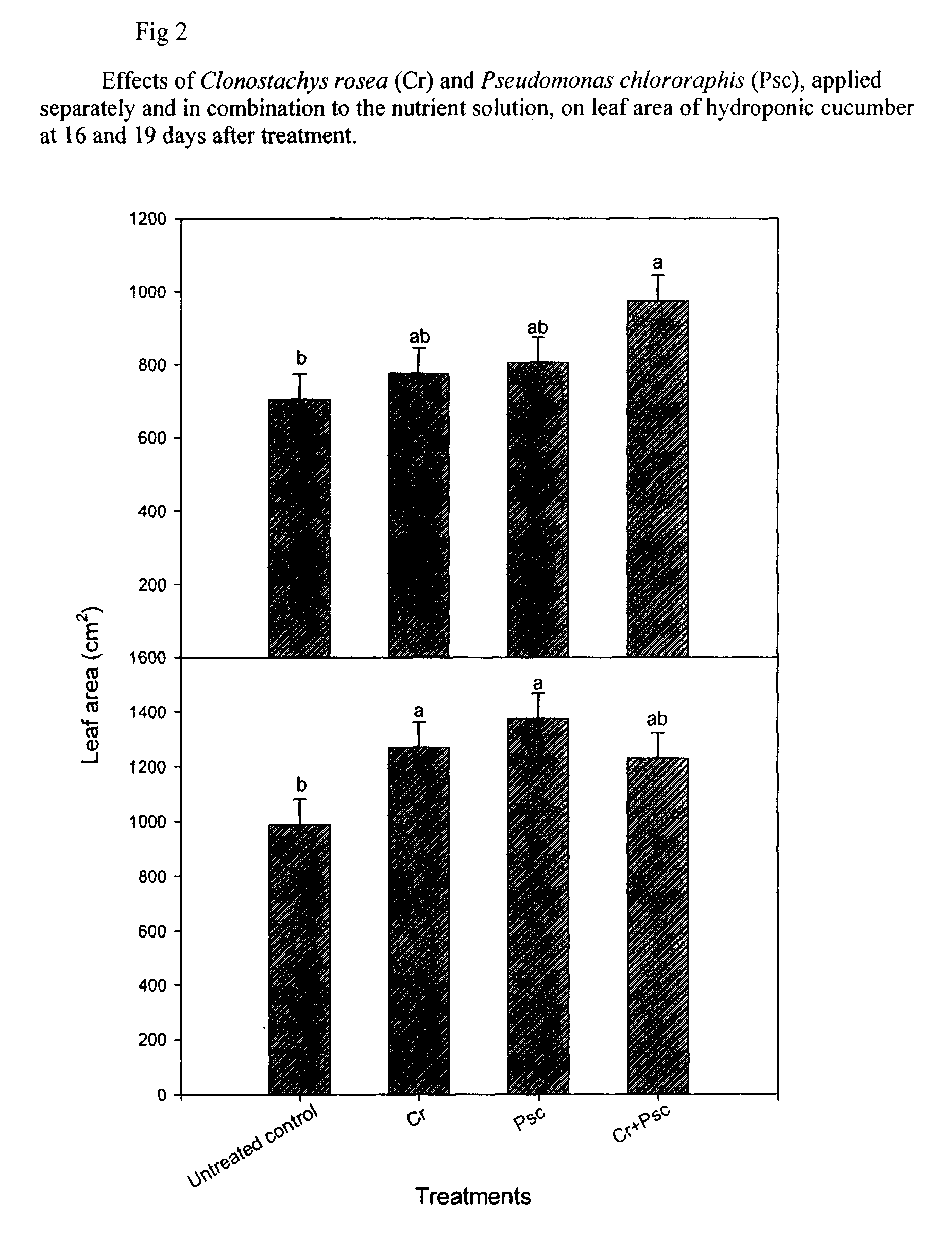

Production and use of endophytes as novel inoculants for promoting enhanced plant vigor, health, growth, yield reducing environmental stress and for reducing dependency on chemical pesticides for pest control

InactiveUS20090105076A1Improve scalabilityPrevent degradationBiocidePlant growth regulatorsBiotechnologyFungal endophyte

A process and method for the production of endophytes as plant inoculant products, specifically Clonostachys rosea strain 88-710, for the promotion of plant vigor, health, growth and yield are disclosed. The endophyte, Clonostachys rosea strain 88-710 produces a fungal conidial preparation by utilizing a discrete solid substrate fermentation system, namely Potato Dextrose Agar or Malt Extract Agar. Additionally, the endophyte, Clonostachys rosea strain 88-710, can act as an inoculant to stimulate and have an additive effect with rhizobium bacteria on the production of nitrogen fixing nodules on legumes and growth enhancement e.g. beans, soybeans, peas and alfalfa. As well, Clonostachys rosea strain 88-710, can combine with rooting hormones, e.g. indole-3-butyric acid (IBA) to provide inoculant and rooting benefits to cuttings / transplants of plants.

Owner:ADJUVANTS PLUS INC

Method for synchronously fermenting normal alkane to produce mixed long-chain dicarboxylic acid by using microorganism

The invention discloses a method for biosynthesizing and producing long-chain Alpha, Omega-dicarboxylic acid, in particular relates to a high yielding method of a C11-C14 mixed long-chain dicarboxylic acid (DCm). A used microorganism is a mutant new strain ly-m of a Candida tropicalis. The method is characterized in that culture media using each single normal alkane of C11-C18 and light wax oil as substrates are respectively connected to strains of the microorganism at first; on the first stage, a system is controlled to mainly grow cells, and also produce a certain quantity of dicarboxylic acid; on the second stage, the fermentation system is controlled to mainly produce acid and also grow cells; and on the third stage, the system is controlled to only produce the acid without growing cells. When the method is used for fermenting 200# light wax oil (a normal alkane mixture of C11-C14) to produce the DC11-DC14 mixed long-chain dicarboxylic acid (DCm), the Candida tropicalis ly-m and the 200# light wax oil are fermented in a fermentation tank with a volume of 210m3 for 160 hours, and the content of DCm in a fermentation clear liquid can reach 175g / L.

Owner:青岛智库生物科技有限公司

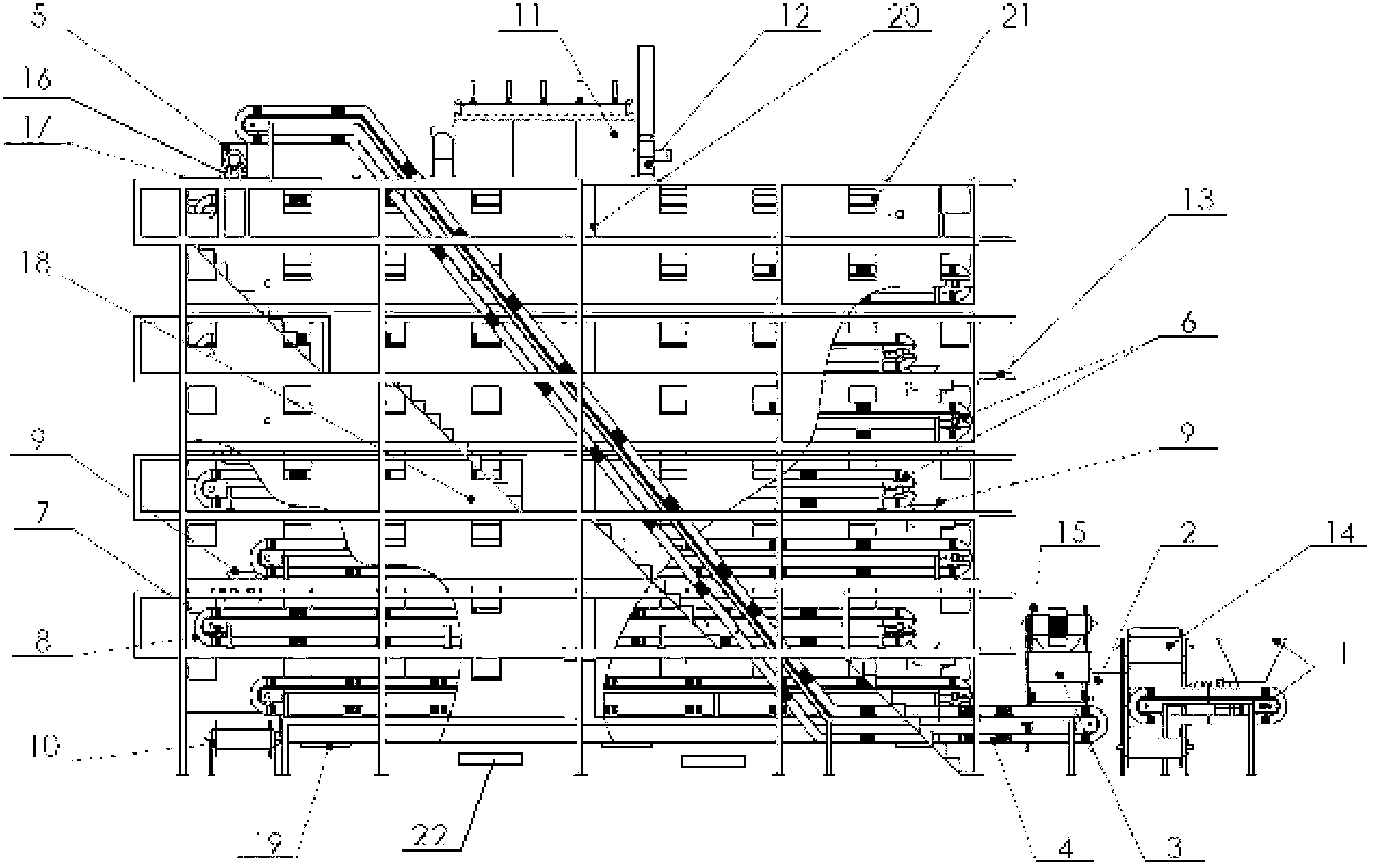

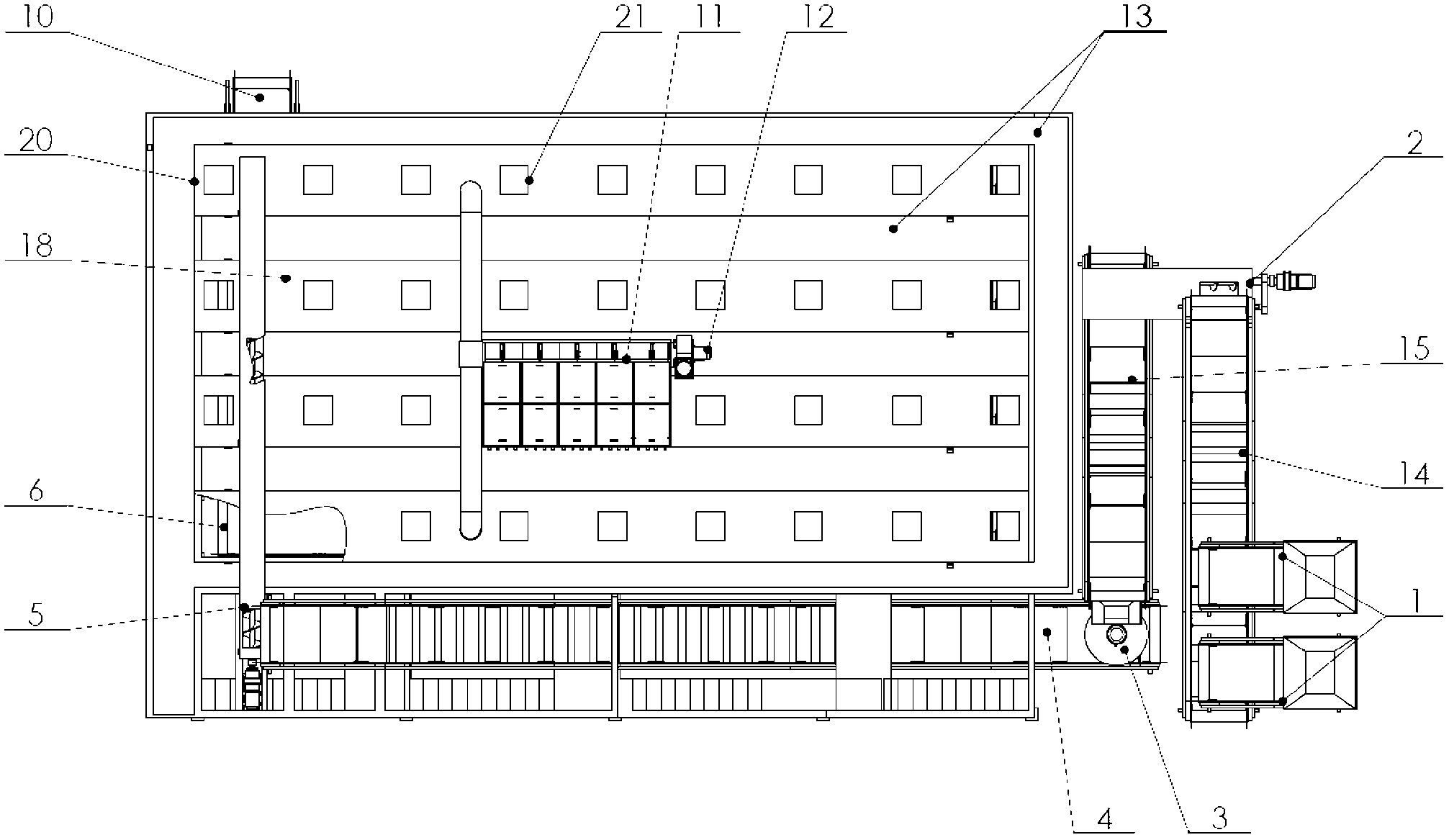

Automatic environmental protection fermentation system of organic material

ActiveCN103288506AIncrease usageSave landBio-organic fraction processingFeeding-stuffBiochemical engineeringPulp and paper industry

The present invention discloses an automatic environmental protection fermentation system of an organic material. The automatic environmental protection fermentation system comprises plural sets of fermentation conveying units, wherein a plurality of fermentation conveyors are sequentially and three-dimensionally installed from low to high at levels to form the fermentation conveying unit, and each level is provided with a plurality of the material fermentation conveyors forming a straight line connection. According to the present invention, a material is input from the input end of the fermentation conveyor positioned on the high level and fermented, fermentation is completed in a level-by-level conveying descending process from high to lower, and the material is output through the output end of the fermentation conveyor positioned on the lower level; and the three-dimensional level-by-level design is adopted, such that an utilization rate and fermentation efficiency of the material fermentation plant are substantially increased, and a recovery treatment is performed on foul fermentation exhaust gas so as to achieve cleaning environmental protection production and solve the technical problems in the traditional technology.

Owner:GUANGXI LIYUANBAO SCI & TECH

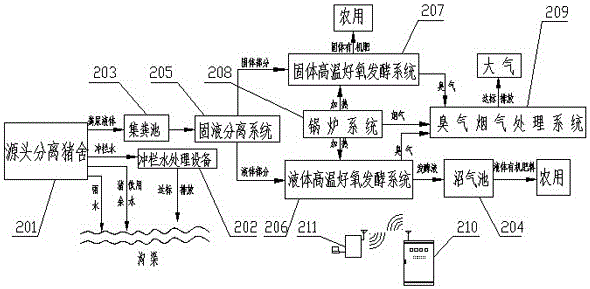

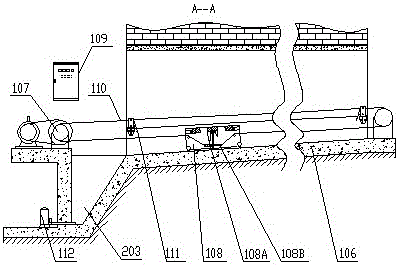

Breeding pollution comprehensive treatment system and method of large-scale pig farm

ActiveCN106824972AIn line with the cycleReduce the burden onBio-organic fraction processingSolid waste disposalPig farmsSludge

The invention discloses a breeding pollution comprehensive treatment system and method of a large-scale pig farm. The system comprises a source separation pigsty, a pigsty washing water treatment system, a solid-liquid separation system, a solid high-temperature aerobic fermentation system, a liquid high-temperature aerobic fermentation system, an odor and flue gas treatment system, a boiler system and a detection control system. The source separation pigsty is designed to be a pigsty with fecaluria separated from rainwater, pigsty washing water and drinking residual water. A sludge pump pumps the fecaluria to a solid-liquid separation device. Solids separated out from the solid-liquid separation device are conveyed to the solid high-temperature aerobic fermentation system. Liquid separated out from the solid-liquid separation device is conveyed to the liquid high-temperature aerobic fermentation system. A fermentation odor exhaust opening of the solid high-temperature aerobic fermentation system, a fermentation odor exhaust opening of the liquid high-temperature aerobic fermentation system and exhausted flue gas of the boiler system are connected with the odor and flue gas treatment system through pipelines. The boiler system comprises a boiler, a circulation pump, a hot water pipeline and a water return pipeline. Sensors of the detection control system are arranged in the above systems, and the detection control system carries out connection control over the above systems. According to the system and method, pollution of the large-scale pig farm is comprehensively treated, and zero emission, zero pollution and resourceful utilization of pollutants of the large-scale pig farm are achieved.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

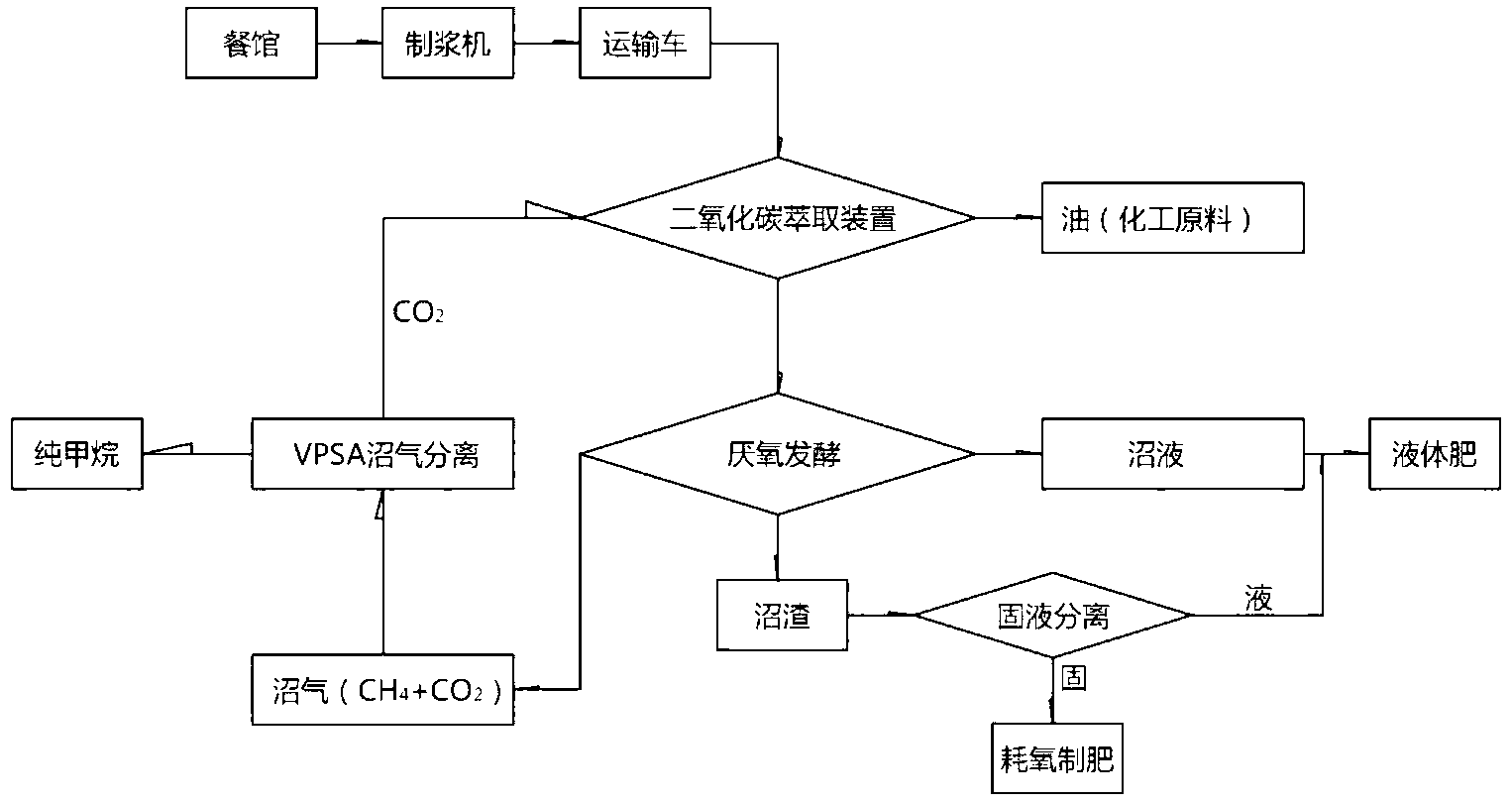

Kitchen waste processing method

ActiveCN103056145AIncrease productivityAvoid secondary pollutionWaste processingSolid waste disposalOil and greaseWaste processing

The invention relates to the field of kitchen waste processing, in particular to a kitchen waste processing method which comprises the following steps that: 1) materials easy to smash in kitchen waste is separated through a pulping machine in a restaurant, and waste grout is prepared; 2) the waste grout is inputted into a feeding tank through a pumping tank truck to be fermented; 3) the fermented waste grout is extracted to obtain oil through a CO2 supercritical method in an extraction tank, and non oil materials enter into a fermentation system to carry out anaerobic fermentation to obtain biogas; and 4) methane and CO2 are obtained through separation and purification from the biogas through a gas separation device. According to the kitchen waste processing method, the yield of the oil and the gases is high, intermediate products produced in the processing process can be recycled, biogas residues obtained through the separation can be used for making fertilizers, obtained products of the kitchen waste processing is prevented from causing secondary environment pollution, and environment protection is benefited.

Owner:北京时代桃源环境科技股份有限公司

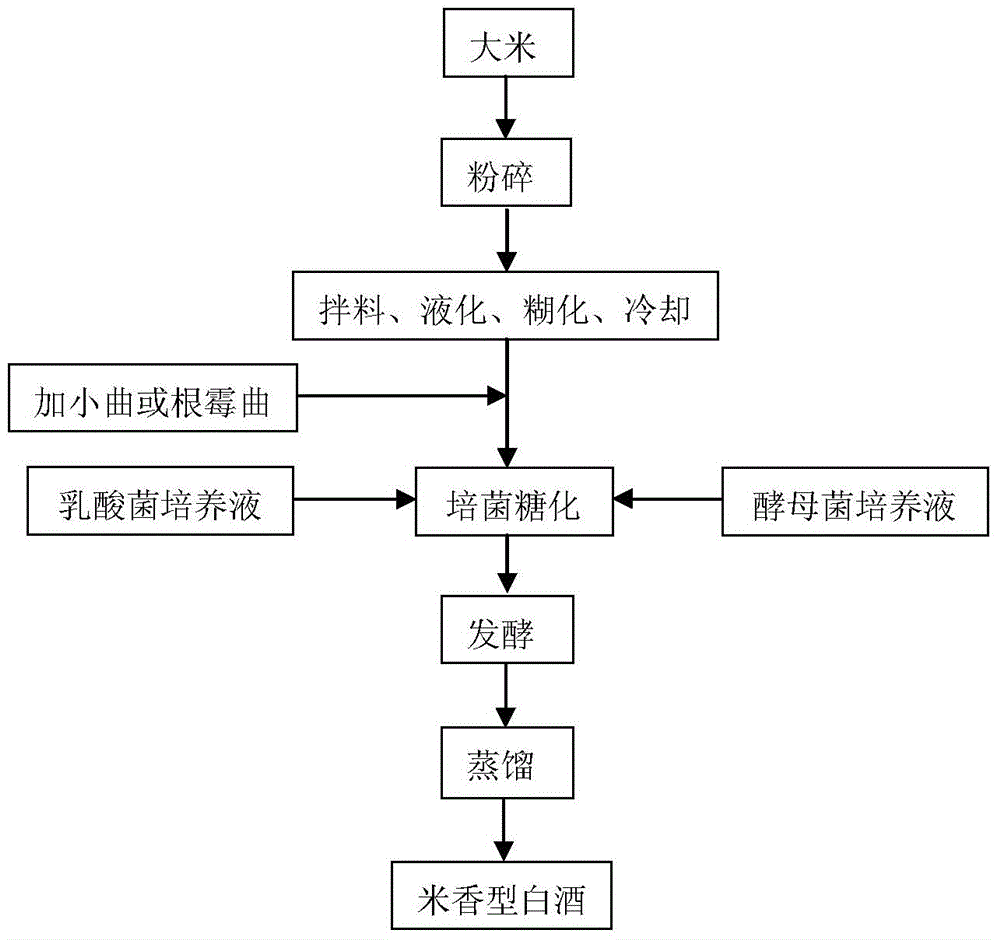

Method for producing rice-flavor liquor based on liquid fermentation

ActiveCN104450399ARealize production mechanizationReduce labor intensityMicroorganism based processesAlcoholic beverage preparationRhizopusFood flavor

The invention discloses a method for producing rice-flavor liquor based on liquid fermentation, belonging to the technical field of liquor brewing. The method comprises the steps of crushing raw materials, liquefying gelatinization, culture saccharification, fermentation and distilling, wherein the step of culture saccharification is carried out under the state of tiny oxygen consumption and comprises cooling a saccharification liquid, adding glucoamylase, and subsequently adding xiaoqu yeast powder or rhizopus yeast, a lactobacillus culture solution and a microzyme culture solution. According to the method, mechanical production of xiaoqu liquor is achieved by cooking liquefaction of starchy grains and then liquid state culture saccharification, and therefore the defect of unstable quality caused by such factors as climate, environment during saccharification of culture bacteria is improved; simultaneously liquor brewing yeasts which are purely cultured and can produce high yield of esters and appropriately low yield of higher alcohols, lactobacillus and a part of commercial enzyme preparations are subjected to synergistic saccharification with conventional saccharification fermentation agents, thereby partially purifying the fermentation system, making up the deficiency of the conventional saccharification fermentation agents and greatly increasing the content of ester substances in rice-flavor liquor; and controlling the content of higher alcohols can remarkably improve the quality of the rice-flavor liquor.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Organic solid waste regeneration resource treatment method and apparatus system thereof

ActiveCN102921711AReduce moistureReduce salt contentBio-organic fraction processingSolid waste disposalEnvironmental engineeringEnergy supply

The invention provides an organic solid waste regeneration resource treatment method, which has a subcritical hydrolysis process and an anaerobic fermentation process, wherein the anaerobic fermentation process supplies energy for the subcritical hydrolysis process, and the subcritical hydrolysis process is an end treatment process, and comprises treatment of biogas residues generated by anaerobic fermentation. With the organic solid waste treatment method and the apparatus system thereof, energy self-circulation within the system can be achieved, wherein biogas generated by the anaerobic fermentation system is adopted as energy supply of the subcritical hydrolysis system, and the biogas residues generated by anaerobic fermentation can be treated into a fertilizer by the subcritical hydrolysis system, such that problems in the prior art are solved, energy consumption is substantially reduced, and environmental protection and pollution reduction are easily achieved, wherein the problems in the prior art comprise that: the biogas residues generated by anaerobic fermentation do not have a discharging way, and the subcritical hydrolysis system requires the external function.

Owner:国环电气科技(上海)有限公司

Optimised fermentation media

InactiveUS20110300593A1Improve growth efficiencyMaintaining and increasing production rateBacteriaSulfur compoundsAlcohol2,3-Butanediol

The invention relates to improvements in the production of alcohols by microbial fermentation, particularly to production of alcohols by microbial fermentation of a substrate comprising CO. It more particularly relates to the provision of an inorganic organic sulfur source to a fermentation system such that one or more micro-organisms convert a substrate comprising CO to alcohols. In a particular embodiment, a microbial culture is provided with sodium polysulfide, wherein a substrate comprising CO is converted to products including ethanol and 2,3-butanediol.

Owner:LANZATECH NZ INC

High-efficiency defoaming agent for biological fermentation system and preparation process of high-efficiency defoaming agent

ActiveCN102940982AImprove eliminationSustained inhibition of reproductionFoam dispersion/preventionBiotechnologyFood grade

The invention relates to a high-efficiency defoaming agent for a biological fermentation system and a preparation process of the high-efficiency defoaming agent. The high-efficiency defoaming agent comprises 15-25 parts of organopolysiloxane, 0.5-3 parts of hydrophobic gaseous phase white carbon black, 5-15 parts of polyether modified silicone oil, 0.2-2 parts of silicon resin, 4-10 parts of a food-grade emulsifier, 0.2-2 parts of a food-grade dispersing thickening agent, 0.2-2 parts of a sodium hydroxide solution with the mass concentration of 10% and 40-80 parts of deionized water. The preparation process of the defoaming agent comprises that the organopolysiloxane, the hydrophobic gaseous phase white carbon black and the silicon resin are subjected to high-temperature bonding. If the viscosity of the organopolysiloxane is lower than 20000CST, a method for adding the emulsifier in an aqueous phase can be used, a method for adding the emulsifier in an oil phase can also be used, and if the viscosity of the organopolysiloxane is higher than 20000CST, the method for adding the emulsifier in an oil phase can be used for preparing the defoaming agent. The defoaming agent is fast in defoaming speed and high in foam inhibition ability. The defoaming agent is particularly excellent in terms of defoaming and foam inhibition effects in the microbial fermentation system, and no side effect is produced for production.

Owner:道尔达(西安)新材料有限公司

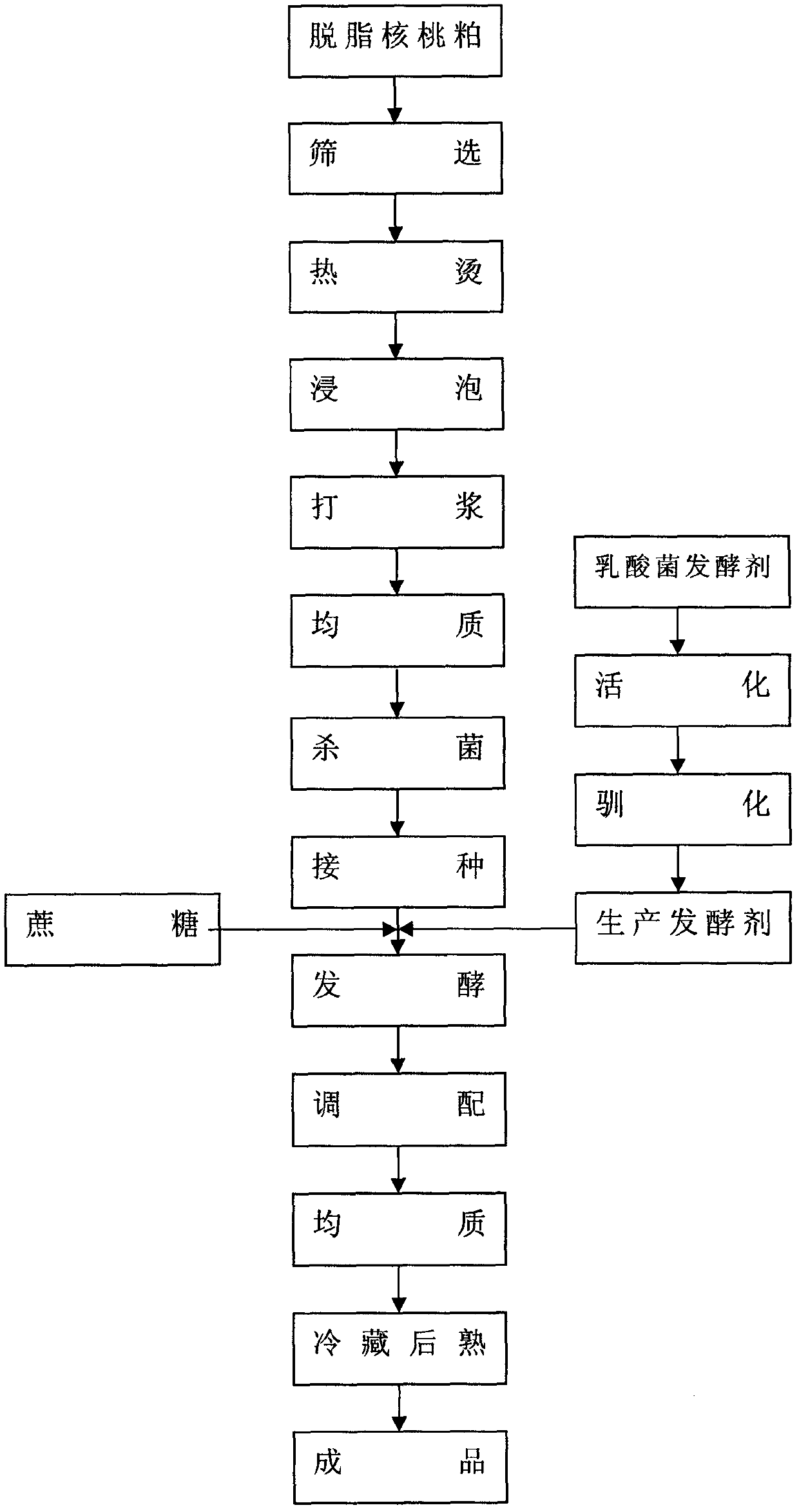

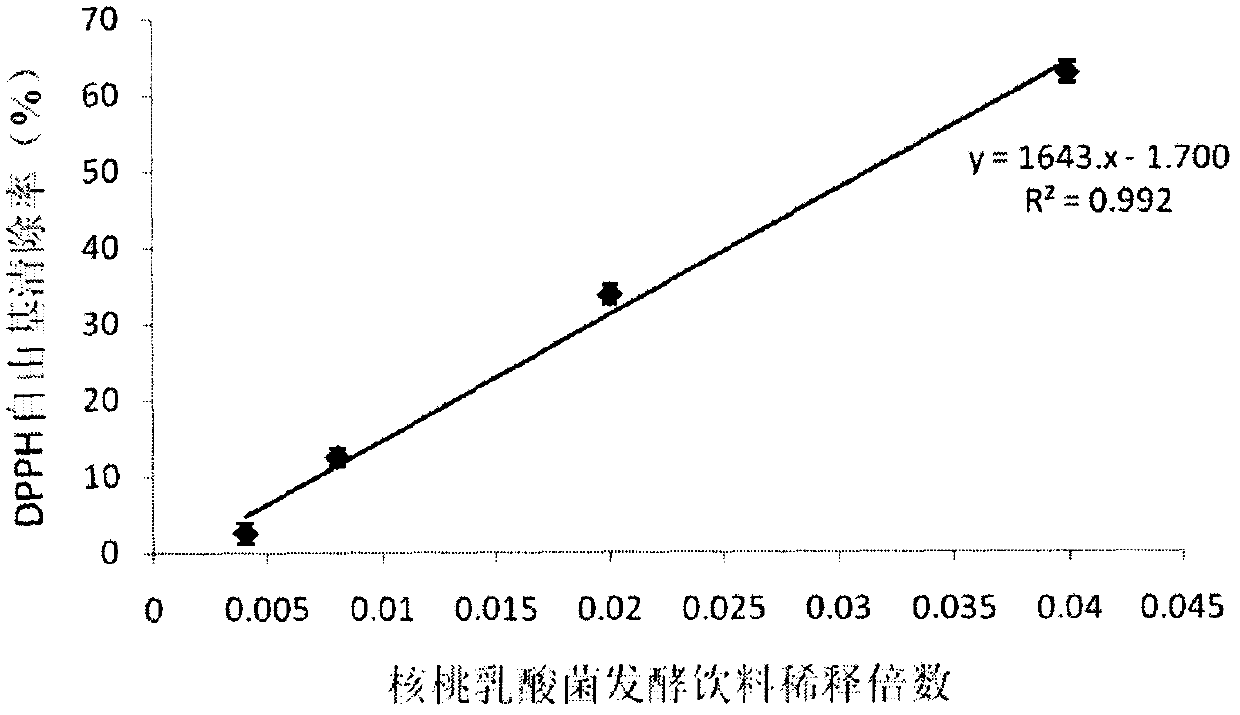

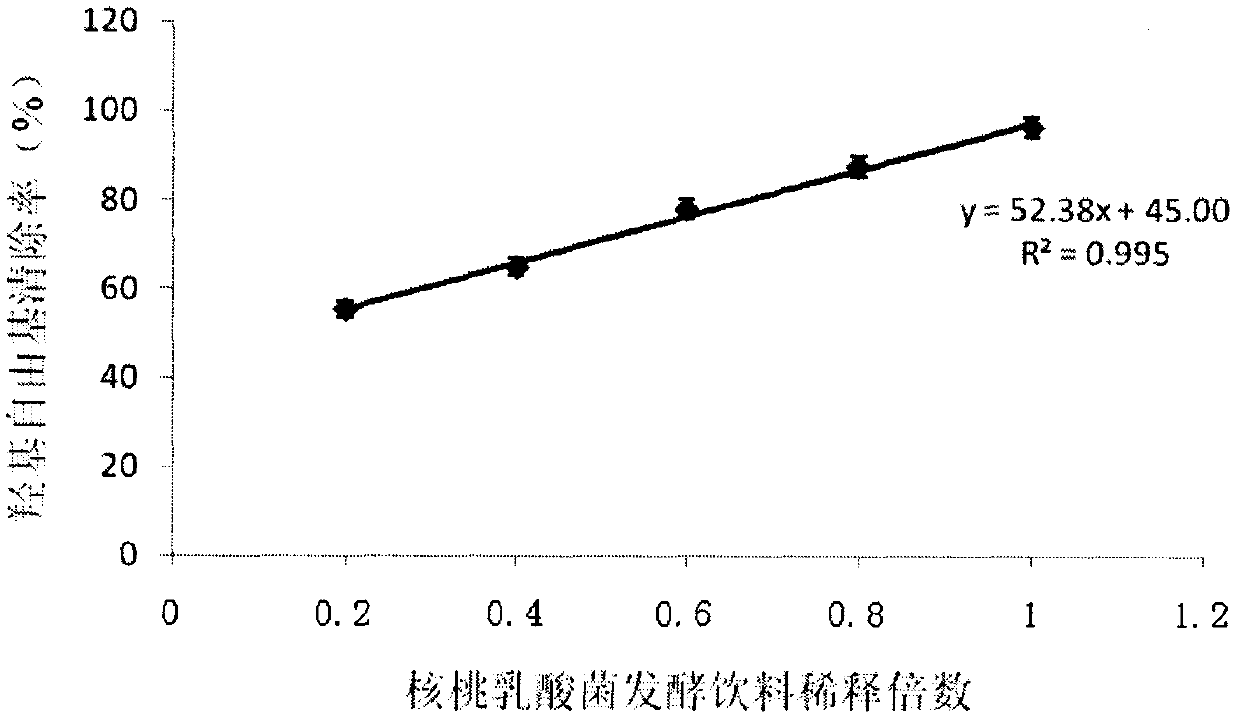

Walnut lactic acid bacteria fermented beverage and preparation method thereof

ActiveCN102630999AIncrease added valueImproves antioxidant activityMilk preparationVegetable proteins working-upBiotechnologyFunctional food

The invention discloses walnut lactic acid bacteria fermented beverage and a preparation method of the walnut lactic acid bacteria fermented beverage. The fermented drink is prepared by taking walnut protein as a raw material, and fermenting the walnut protein through lactic acid bacteria. The specific process procedure comprises the following steps: pulping defatted walnut into walnut milk, performing homogeneity, sterilization and cooling, then mixing the walnut milk with lactic acid bacteria for fermentation, wherein the strain adopted by the fermentation is a mixed strain of lactobacillusbulgaricus and streptococcus thermophilus, and is suitable for a pure walnut milk fermentation system through multi-time domestication. The beverage disclosed by the invention is rich in plant protein and lactic acid bacteria, has higher antioxidant activity, is fermented natural protein beverage with the advantages of walnut and lactic acid bacteria fermented food, and can be applied to the field of functional food or nutritional health-care products.

Owner:HEBEI GOLDEN DRAGON EDIBLE OIL

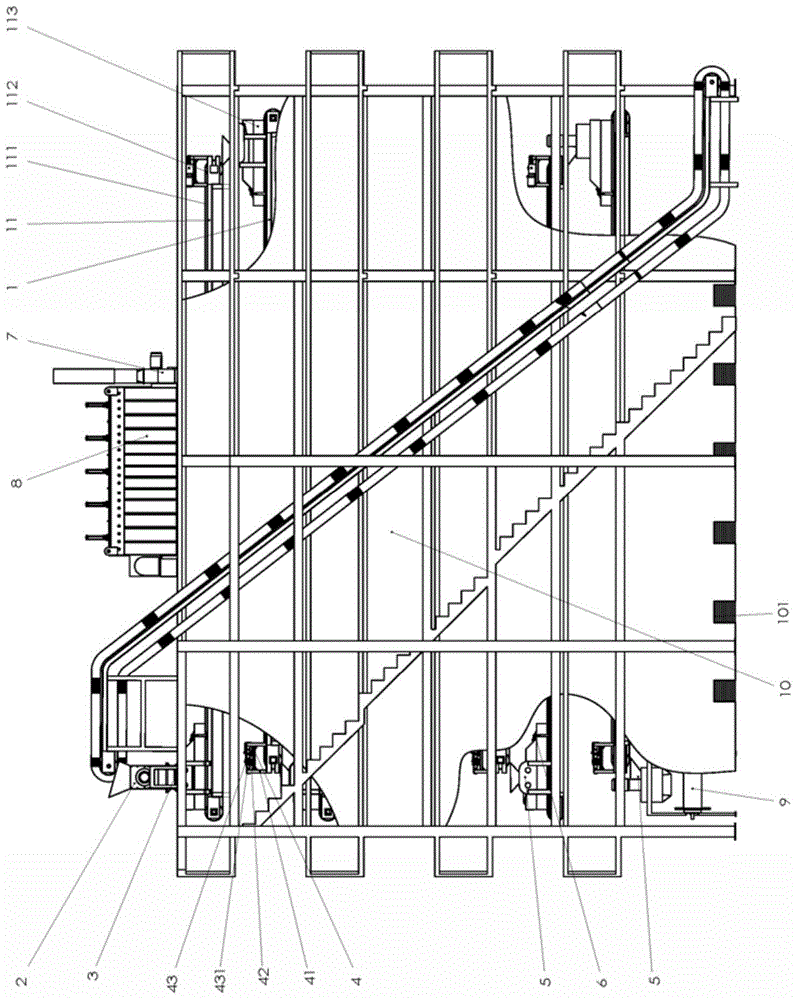

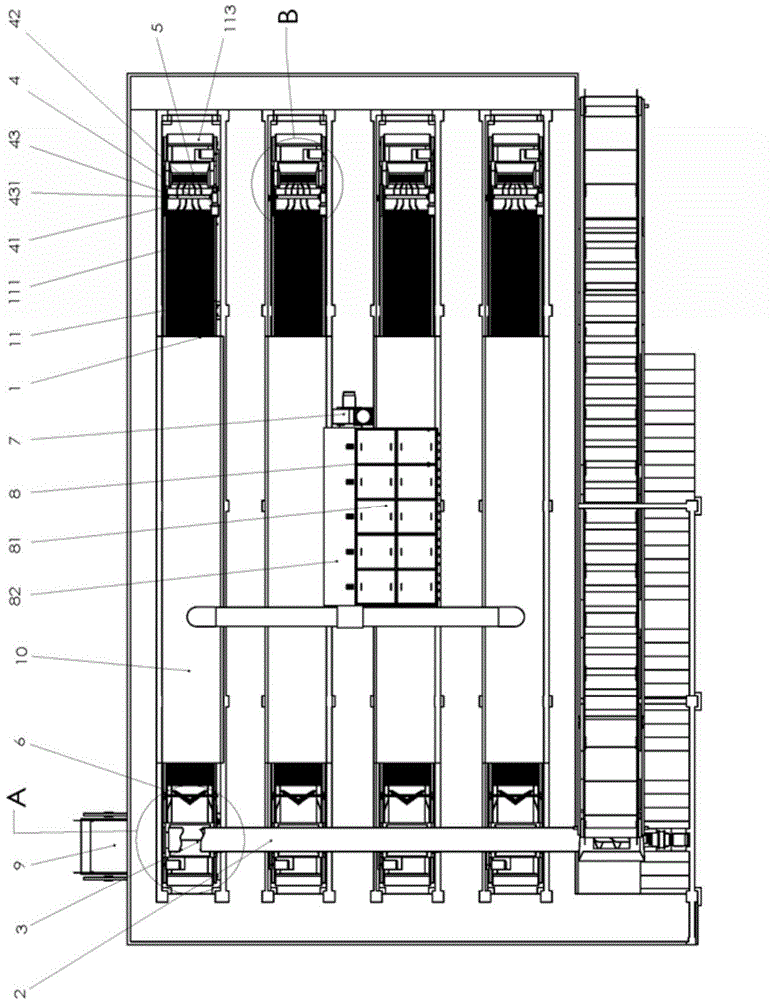

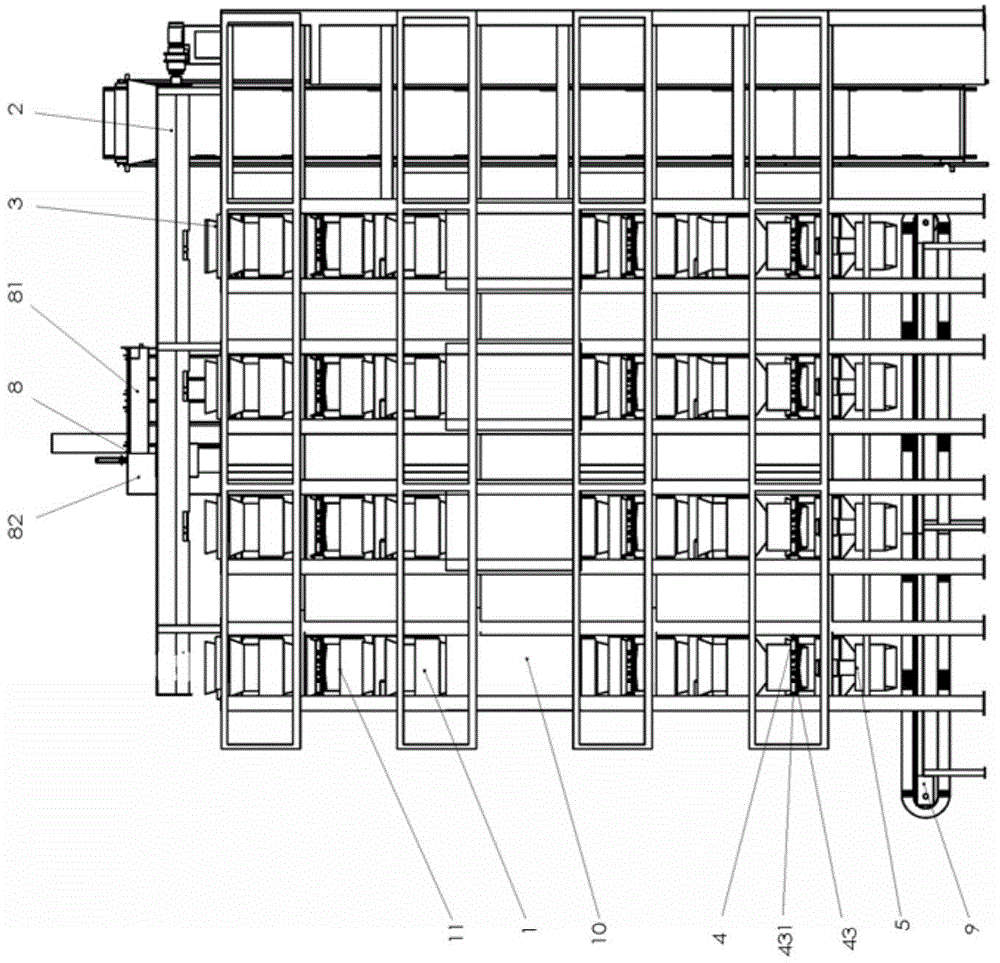

Three-dimensional environmentally-friendly fermentation system

ActiveCN103980021AIncrease the degree of mixingImprove breathabilityBio-organic fraction processingOrganic fertiliser preparationVertical planeEngineering

The invention relates to a three-dimensional environmentally-friendly fermentation system. The three-dimensional environmentally-friendly fermentation system comprises a plurality of conveying sets for conveying fermentation materials, a feeding device, breaking devices, a ventilation device and a tail gas purifying device, the number of the conveying sets is greater than 1, each of the conveying sets is formed through the three-dimensional installation of a plurality of conveyers in a low-to-high layering manner, each layer of the conveyers is provided with a plurality of linearly connected conveyers, adjacent layers of the conveyers are arranged on a vertical plane in an interlaced manner, each layer of each set is provided with one breaking device, the system also comprises a material molding device, and the material molding device is installed above the feeding end of the top layer feeding conveyer and below the feeding device. The three-dimensional environmentally-friendly fermentation system can greatly improve the equipment fermentation efficiency.

Owner:GUANGXI LIYUANBAO SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com