In 2009, the

discharge of livestock and

poultry manure in China was 3.264 billion tons of

fresh weight, which was 1.6 times the total industrial solid waste discharge in the same period (Statistics Bureau of the People's Republic of China, 2010).

Feces will decompose into malodorous gases such as

ammonia,

sulfuric acid,

vinyl alcohol,

dimethyl sulfide,

hydrogen sulfide,

methylamine and

trimethylamine in the case of poor ventilation. These gases are harmful to

human health and aggravate

air pollution; second, they pollute water bodies. The arbitrary discharge of livestock and poultry

feces can easily cause

eutrophication of water bodies and deteriorate

water quality. The infiltration of

feces and

sewage into the ground can also cause

nitrate content in

groundwater The third is the spread of zoonotic diseases. There are more than 90 kinds of zoonotic diseases transmitted from animals to humans. The carriers of these zoonotic diseases are mainly livestock and poultry

feces and excreta. Proper disposal and

rational use will not only have a huge negative

impact on the

ecological environment, seriously affect people's health, but also

restrict the healthy development of the livestock and poultry breeding industry

[0003]

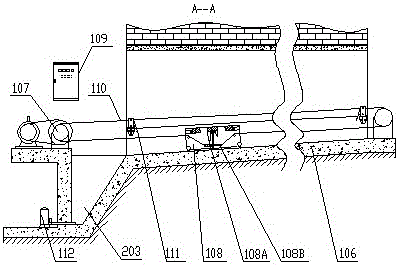

At present, the

manure cleaning methods commonly used in large-scale

pig farms at home and abroad mainly include water soaking

manure, water flushing

manure and dry manure cleaning process. At present, the most

common method is water soaking manure cleaning. The

disadvantage is that the manure stays in the pig house for a long time , part of the anaerobic fermentation in the manure

ditch produces a large amount of harmful gases such as

ammonia,

hydrogen sulfide, and

methane, which reduces the

appetite of pigs and endangers the health of pigs. People are forced to use high-energy forced ventilation to solve the problem of

toxic gas pollution. , but in winter, the forced ventilation makes the pig house unable to keep warm, and the pigs are susceptible to infectious diseases such as influenza. At the same time, a large amount of toxic and harmful gases also affect the work of the breeders and endanger the health of the breeders

The dry manure cleaning method, that is, the manure is diverted once it is produced, the dry manure is collected, cleaned, and transported away mechanically or manually, and the

urine and flushing

water flow out from the sewer and are treated separately. There are two kinds of manure cleaning and mechanical manure cleaning. The disadvantages of manual manure cleaning are that people and animals are prone to cross-infection, heavy labor, poor

working environment, and low productivity. The advantages of mechanical manure cleaning are that it can reduce labor intensity, save labor, and improve work efficiency. The production of manure cleaning equipment is still lacking in reliability. The equipment is complex, the incidence of failure is high, and maintenance is difficult. Whether it is manual manure cleaning or mechanical manure cleaning,

urine and flushing water and pig drinking water Mixed, the concentration of pollutants in the flushing water is high, which increases the treatment capacity and difficulty of flushing water

[0004]

Generally speaking, the above-mentioned manure

cleaning methods mainly have the following problems: (1) There is no separate collection and

delivery system for pig drinking water, and pig drinking water is directly mixed with feces,

urine and pen flushing water, which increases the amount of pollution and

treatment costsAt present, the field composting fermentation technology widely used mainly has the following problems: large area, long fermentation time (generally about 15-30 days for one fermentation), fermentation speed decreases or even stops in low temperature weather, and odor is difficult to collect and process, resulting in pollution environment and other issues

At present, most of the research is on trough composting. The efficiency or effect of aerobic composting is improved by means of ventilation and forced

oxygen delivery, turning or stirring. The problems of this method include high investment costs such as infrastructure and turning equipment, and the heat generated by fermentation. and odor are generally allowed to be discharged to the

atmosphere, causing serious secondary pollution; and the famous Dano (Dano) drum type aerobic reactor has the characteristics of high fermentation efficiency and

small footprint compared with field fermentation, but the fermentation The effect depends on factors such as the length of the drum. In order to prolong the

residence time of the fermentation raw materials in the drum reactor to ensure the fermentation effect, the length of the drum is usually designed to be more than 10 or even 20 times the

diameter of the drum, so the floor area is still large. The equipment manufacturing cost is high, and there are also disadvantages such as the contact area between the new fermentation

raw material (organic waste) and the fermented

raw material is too small, and the new fermentation

raw material lacks sufficient fermentation

bacteria, so the

reaction speed is slow.

[0006] At present, the

mortality rate of live pigs in

pig farms is generally 3-5%. Once an epidemic occurs, the proportion will be even greater. Incidents of

drinking water pollution caused by improper handling often occur, and unscrupulous traders resell sick and dead pigs to make huge profits. Threatening the

food safety of ordinary people, the isolation and treatment of these dead animal carcasses carrying harmful germs need to be solved urgently

At present, the methods of harmless treatment of sick and dead pigs mainly include high-temperature

incineration, landfill and high-temperature composting, etc. The high-temperature

incineration method requires extremely high equipment, and the one-time

investment cost is high. Conditions, and centralized

incineration also has a series of problems such as emission pollution, cumbersome collection and transfer procedures, and difficult supervision measures. In addition, the secondary pollution caused by the treatment process is also very serious.

At present, the landfill method is mostly used. The

disadvantage is that the cost of transportation and landfill is high, and the subsidy for sick and dead pigs is much lower than the cost of landfill. Moreover, most farm employees do not perform hygienic landfill due to lack of

hygiene and

safety knowledge, resulting in serious secondary pollution

High-temperature composting is also a kind of harmless treatment of sick and dead pigs. Its

disadvantage is that during the pretreatment process such as smashing sick and dead pigs, mechanical loss,

energy consumption and equipment cleaning will increase the

processing cost. , and the process of replacing vulnerable parts is prone to cross-infection, increasing the risk of

epidemic spread, and composting covers a large area, takes a long time, and is easily affected by climatic conditions. A large number of pathogenic microorganisms are carried in dead pigs, and traditional fermentation methods are difficult. Completely kill these pathogenic microorganisms

Breeding pig farms produce a large amount of

placenta and other

dirt in the process of breeding piglets. Because of its rich

nutrition, it is easy to be corrupted. If it is not treated in time, it is easy to cause pollution. At present, the common way of disposal is landfill, which is the same as the treatment of sick and dead pigs. The problem

[0007]

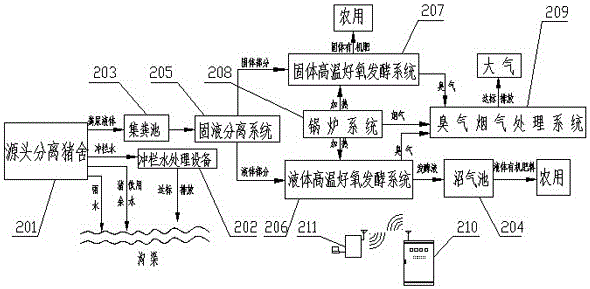

Pollutants in large-scale pig farms include not only pig feces and urine, flushing water, but also sick and dead pigs,

placenta, and odors and

smoke generated during the treatment process. At present, there is no suitable method to treat the above pollution at the same time thing

Chinese patent CN203568937 discloses a livestock and

poultry manure treatment system, including rain and sewage

separation system, dry-wet

separation system, solid-liquid separation system and ecological purification system. The existing problem is that the manure is mixed with flushing water and drinking water After solid-liquid separation, the liquid after solid-liquid separation contains a large amount of

organic matter and nutrients, and the content of COD and

ammonia nitrogen increases significantly, which not only leads to waste of resources, but also increases the amount and difficulty of subsequent

sewage treatment, increasing the

cost of treatment The separated

solid material is fermented by natural composting method, which occupies a large area of

production area, has low fermentation efficiency,

poor quality organic fertilizer, is easily affected by environmental factors, and is prone to secondary pollution. In addition, the system does not involve livestock and poultry farms Treatment of dead livestock and poultry carcasses and

placenta[0008]

Chinese patent CN201520168695.4 discloses a closed

biodegradation harmless treatment device for sick and dead livestock and poultry. The patent degrades dead livestock and poultry carcasses by adding biodegradable cadaveric agent and other auxiliary materials, and kills parasites and insects through anaerobic fermentation. Eggs, germs and viruses, the disadvantage is that the

decomposition efficiency of dead livestock and poultry carcasses under solid conditions is much lower than that under liquid conditions, anaerobic fermentation cannot completely kill harmful

pathogenic bacteria in dead livestock and poultry carcasses, and there is a risk of secondary pollution

[0009]

Patent CN102964149 discloses a pollution control method for livestock and poultry farms. This method does not deal with dead livestock and poultry carcasses and placentas, and the patent does not involve the use of hot

flue gas and fermentation heat from boiler

combustion, and uses SBR reaction It is difficult to meet the standard when the discharge of flushing water is large in the peak season of slaughtering, etc.

Login to View More

Login to View More  Login to View More

Login to View More