System and method for managing livestock excrement and placenta of livestock and poultry in large-scale farms

A technology for sick and dead livestock and poultry and farms, which is applied to the pollution control system of large-scale livestock and poultry excrement liquid and placenta of sick and dead livestock and poultry, and the field of liquid organic fertilizer and solid organic fertilizer, which can solve the problem of fertilizer value reduction and failure occurrence High efficiency, pollution and other problems, to achieve the effect of reducing the concentration of COD and ammonia nitrogen, reducing the cost of treatment, and improving the efficiency of manure cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

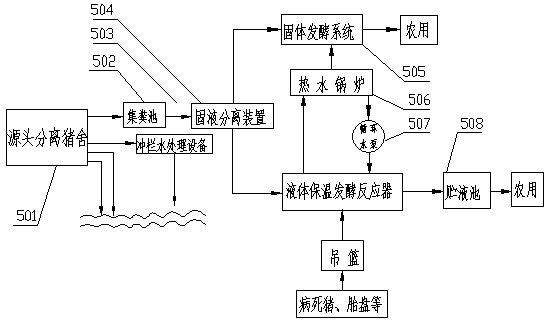

[0070] Treatment of livestock and poultry excrement and urine in large-scale farms without disease, dead livestock and poultry and placenta:

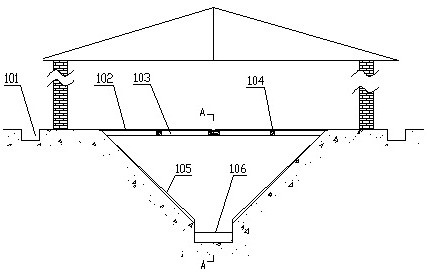

[0071] (1) The livestock and poultry house blocks the rainwater, and the rainwater is drained through the drainage ditch 101 outside the house in time to realize the separation of rain and sewage; when the livestock and poultry drink water, the water leaked from the automatic drinking fountain and mouth gap of the livestock and poultry falls into the U-shaped water collection cavity, and through the drainage pipes, it is discharged to the drainage ditch 101 outside the house in time to separate drinking and sewage; the daily excrement (feces and urine) of livestock and poultry leaks down through the slatted floor 102, and falls on the inverted splayed slope 105 or in the dung clearing ditch 106, the feces and urine falling on the inverted slope 105 will naturally slide into the dung cleaning ditch 106 under the action of gravity, and the...

Embodiment 2

[0082] Treatment of livestock and poultry excrement and urine in large-scale farms with dead livestock and placenta:

[0083] (1) The livestock and poultry house blocks the rainwater, and the rainwater is drained through the drainage ditch 101 outside the house in time to realize the separation of rain and sewage; when the livestock and poultry drink water, the water leaked from the automatic drinking fountain and mouth gap of the livestock and poultry falls into the U-shaped water collection cavity, and through the drainage pipes, it is discharged to the drainage ditch 101 outside the house in time to separate drinking and sewage; the daily excrement (feces and urine) of livestock and poultry leaks down through the slatted floor 102, and falls on the inverted splayed slope 105 or in the dung clearing ditch 106, the feces and urine falling on the inverted slope 105 will naturally slide into the dung cleaning ditch 106 under the action of gravity, and the dung scraping system is...

Embodiment 3

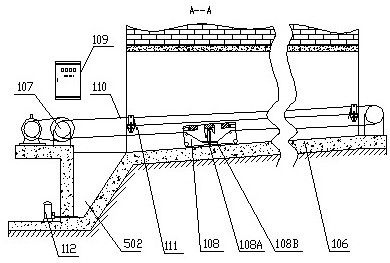

[0096] (1) The livestock and poultry house blocks the rainwater, and the rainwater is drained through the drainage ditch 101 outside the house in time to realize the separation of rain and sewage; when the livestock and poultry drink water, the water leaked from the automatic drinking fountain and mouth gap of the livestock and poultry falls into the U-shaped water collection cavity, and through the drainage pipes, it is discharged to the drainage ditch 101 outside the house in time to separate drinking and sewage; the daily excrement (feces and urine) of livestock and poultry leaks down through the slatted floor 102, and falls on the inverted splayed slope 105 or in the dung clearing ditch 106, the feces and urine falling on the inverted slope 105 will naturally slide into the dung cleaning ditch 106 under the action of gravity, and the dung scraping system is started regularly every day, and the driving device 107 is driven by the driving rope 110. The manure scraper 108 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com