Patents

Literature

2372results about "Biological combination treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

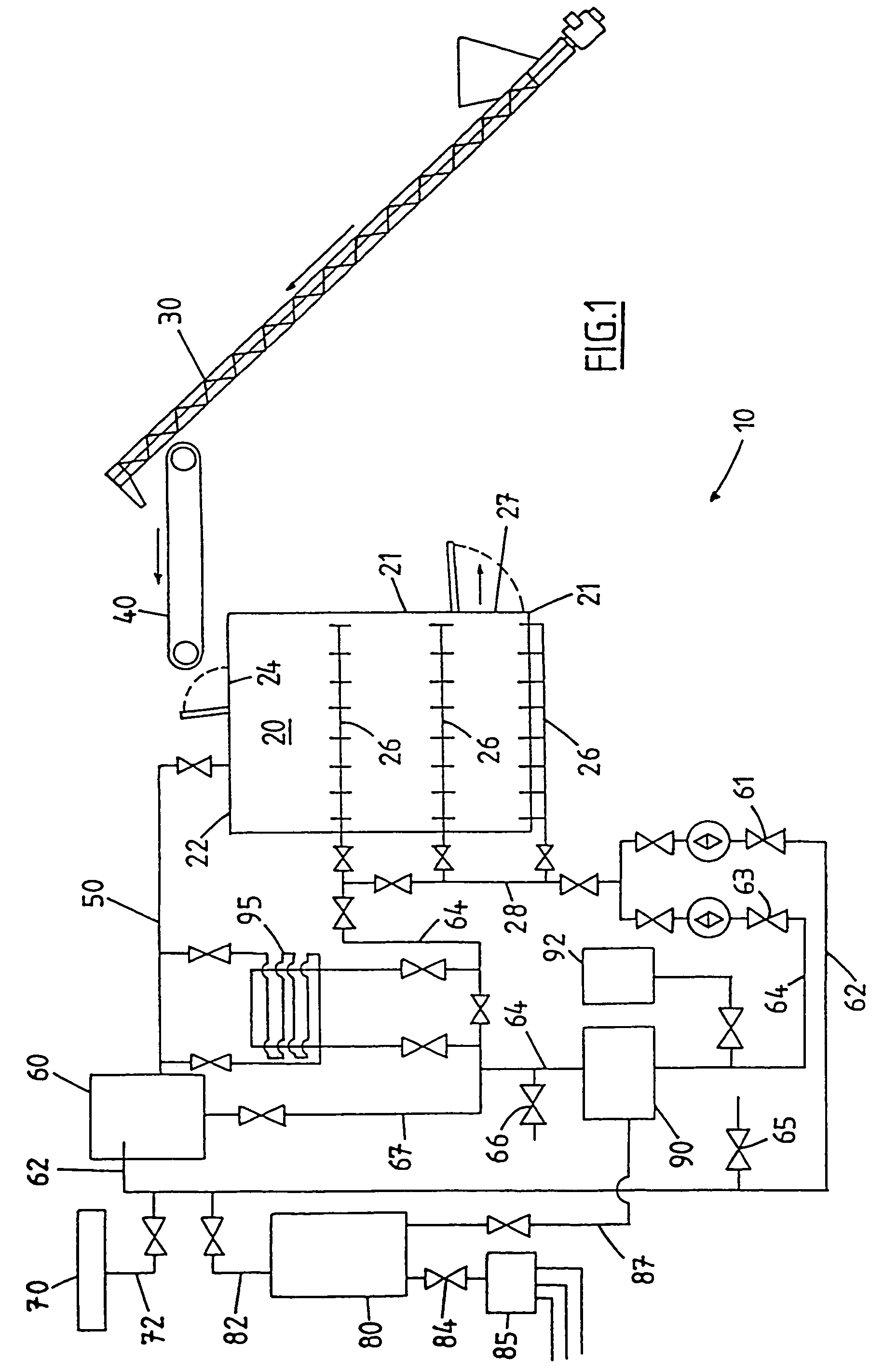

Systems and methods for converting organic waste materials into useful products

ActiveUS20080020456A1Bioreactor/fermenter combinationsBio-organic fraction processingOrganic fractionProduct system

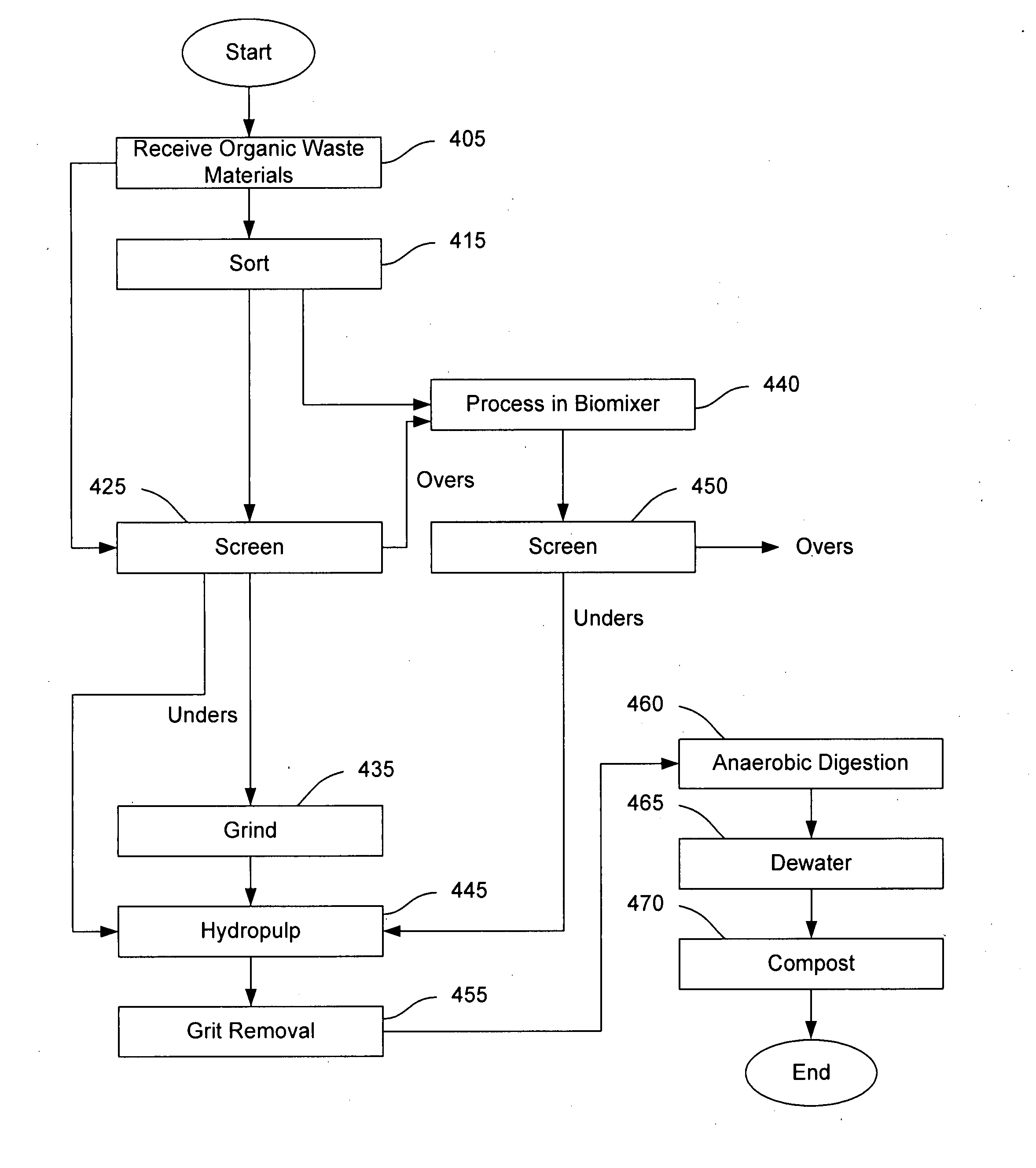

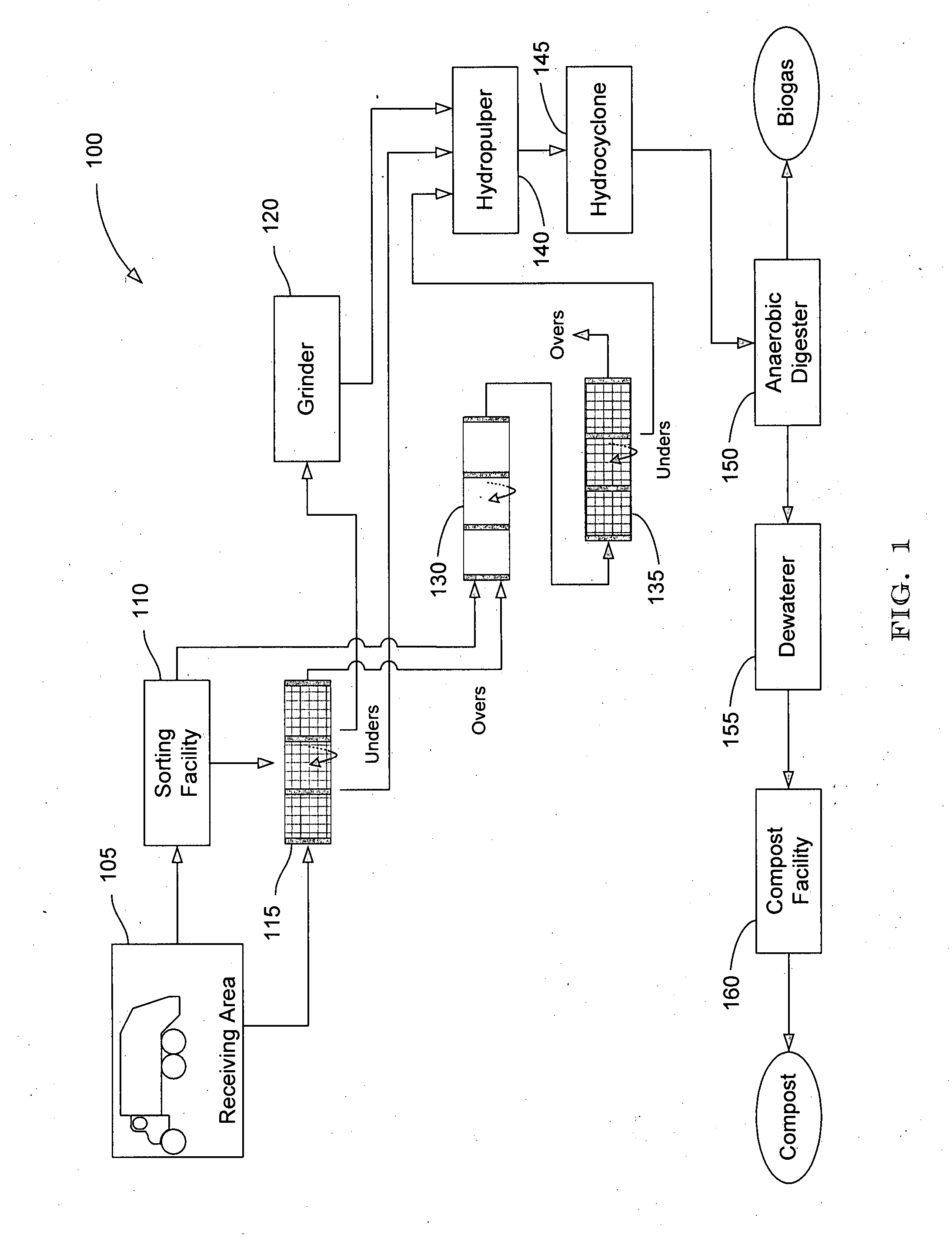

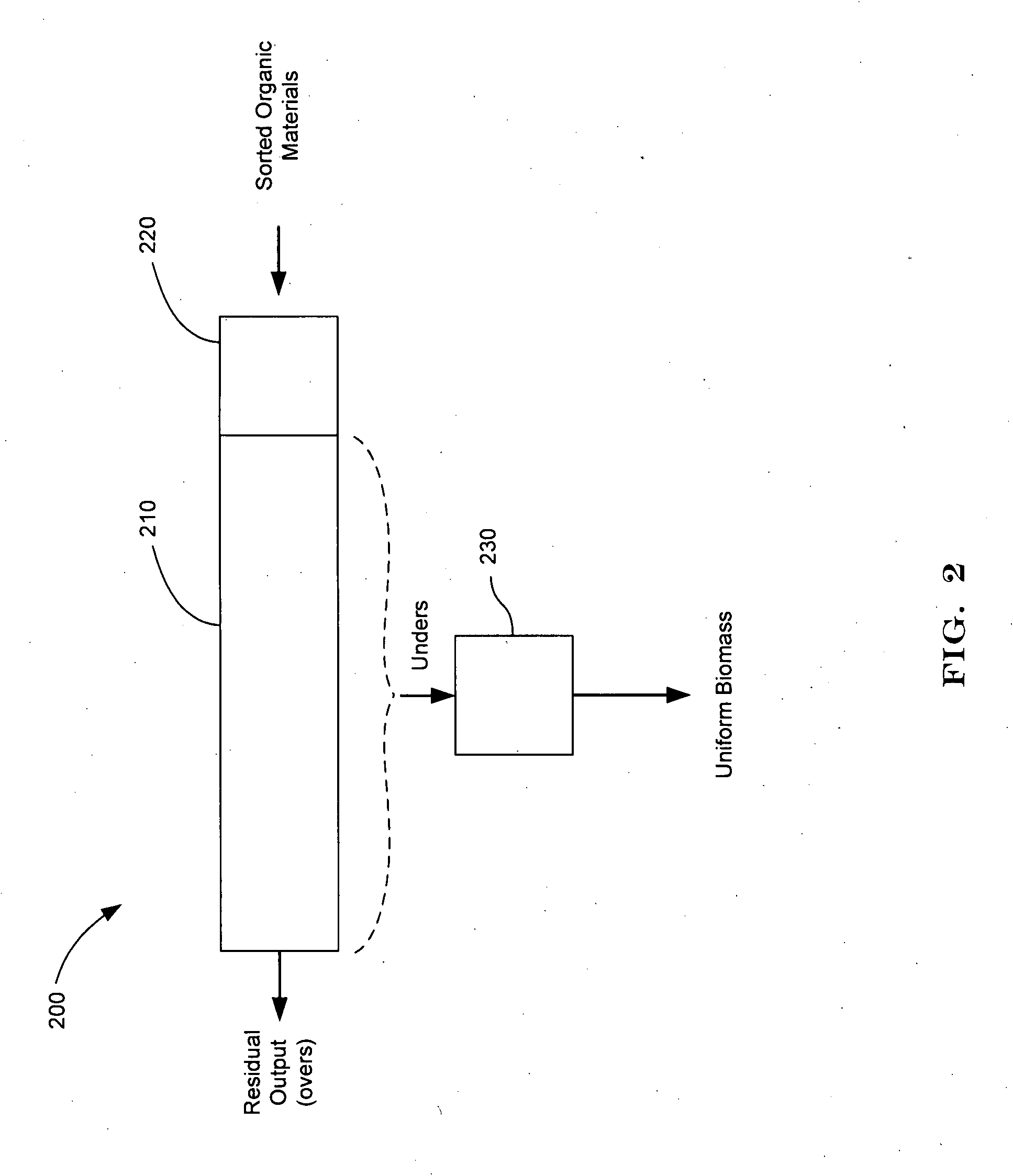

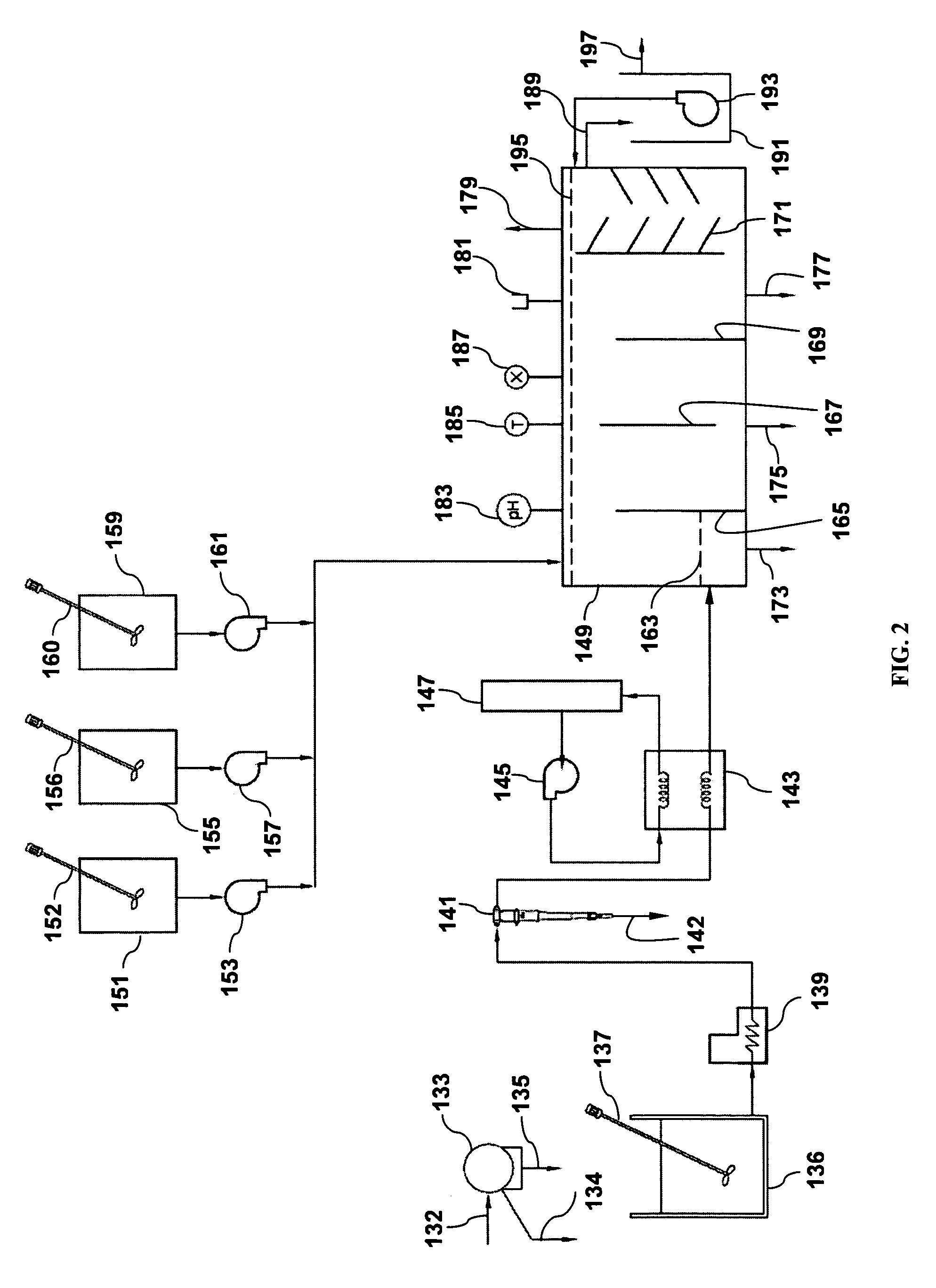

Systems and methods are provided for converting organic waste materials from a municipal waste stream to useful products. Organic waste materials having a wide range of compositions such as, for example, yard waste, food waste, paper, and the organic fraction of municipal solid waste are converted into a uniform biomass that is suitable for conversion to useful products, such as fuels. Through the use of a biomixer and a hydropulper, as well as through sorting and screening, the organic waste materials are progressively reduced in size and cleaned of contamination. The resulting uniform biomass is suitable for anaerobic digestion to produce biogas and a residual solid that is suitable for producing a high quality compost.

Owner:RECOLOGY

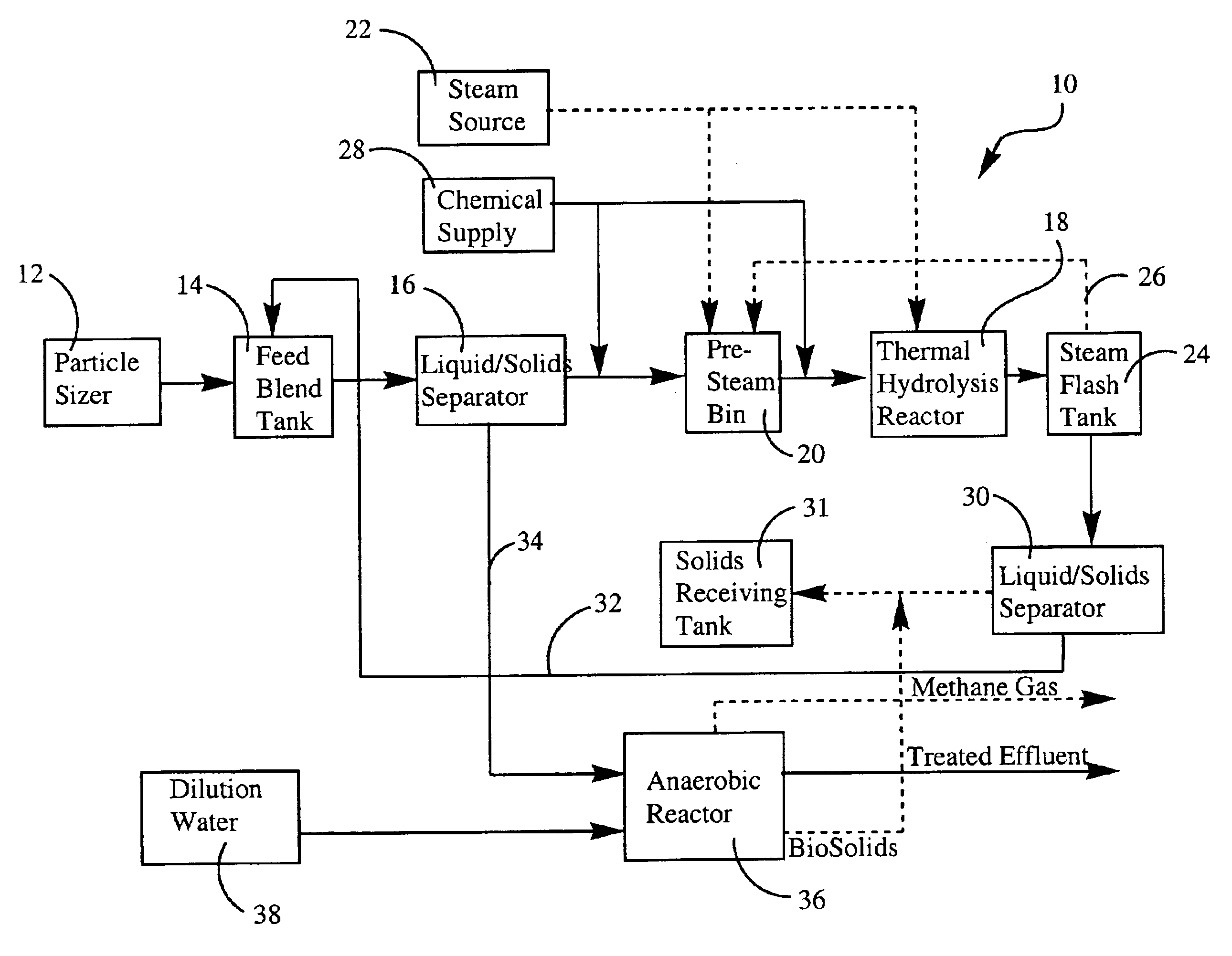

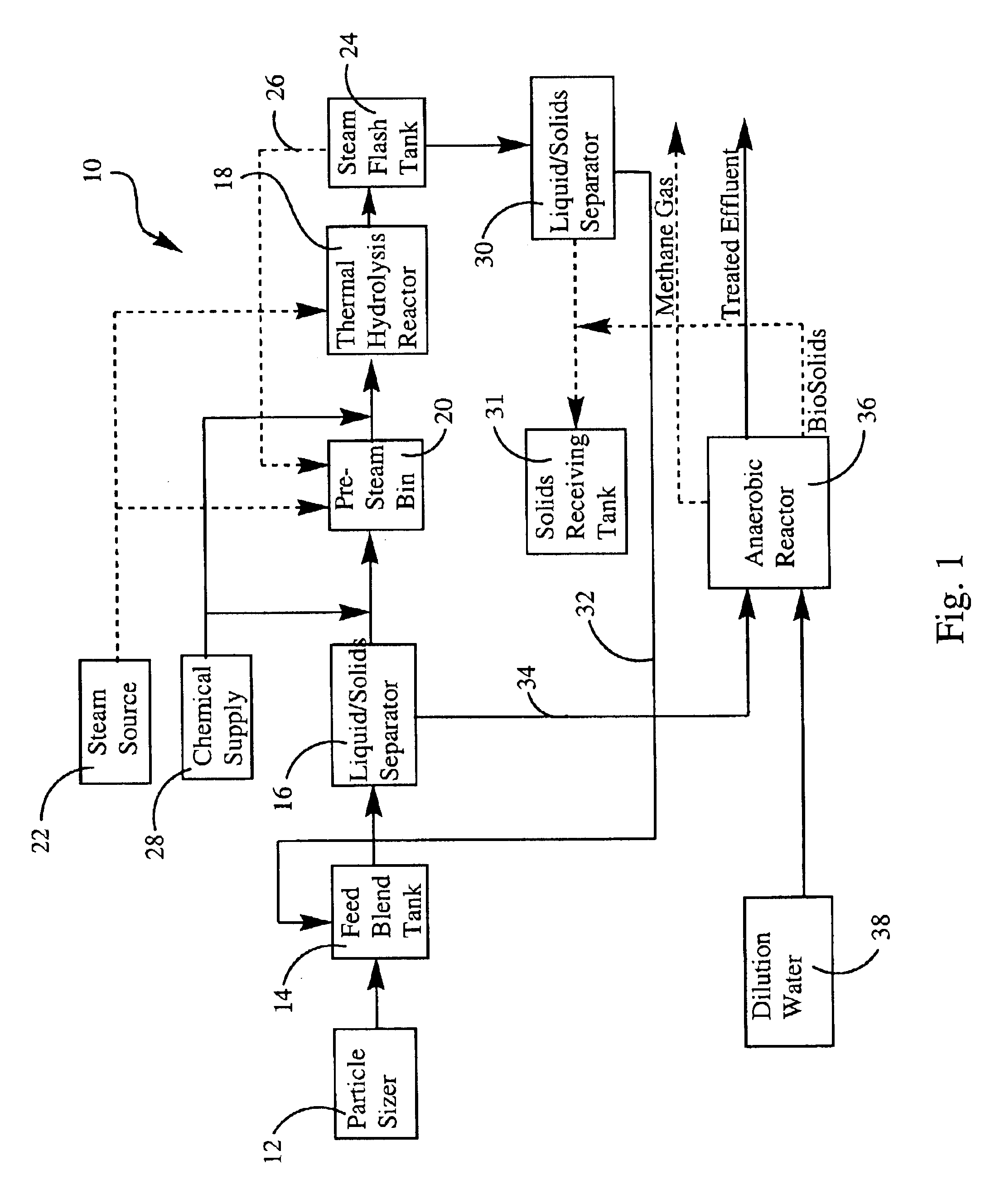

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

Digesters

Methods and devices are disclosed for converting predominantly organic waste materials, such as sludge, into useful byproducts.

Owner:TOLBERT & ASSOCS

Device for separating water from sludge

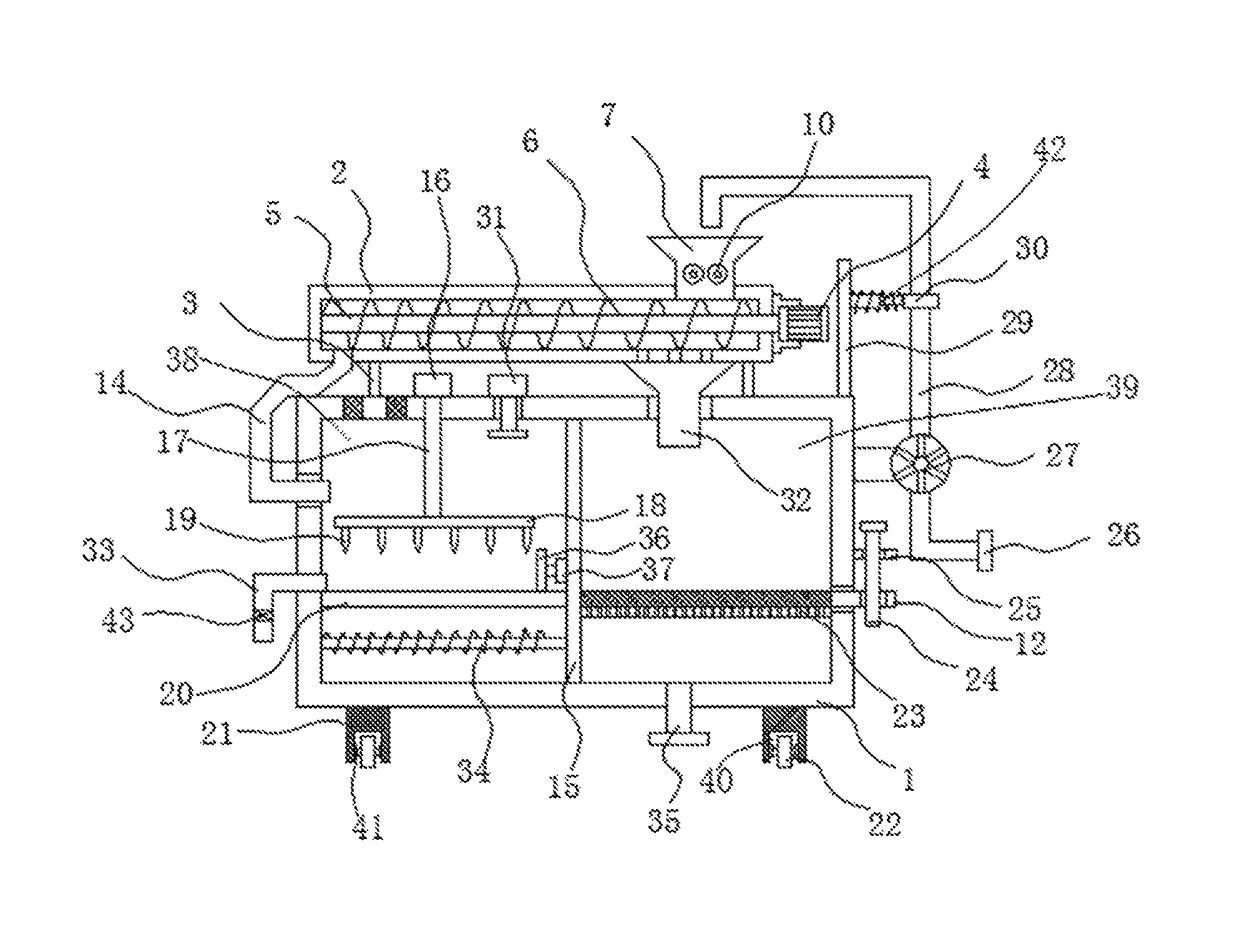

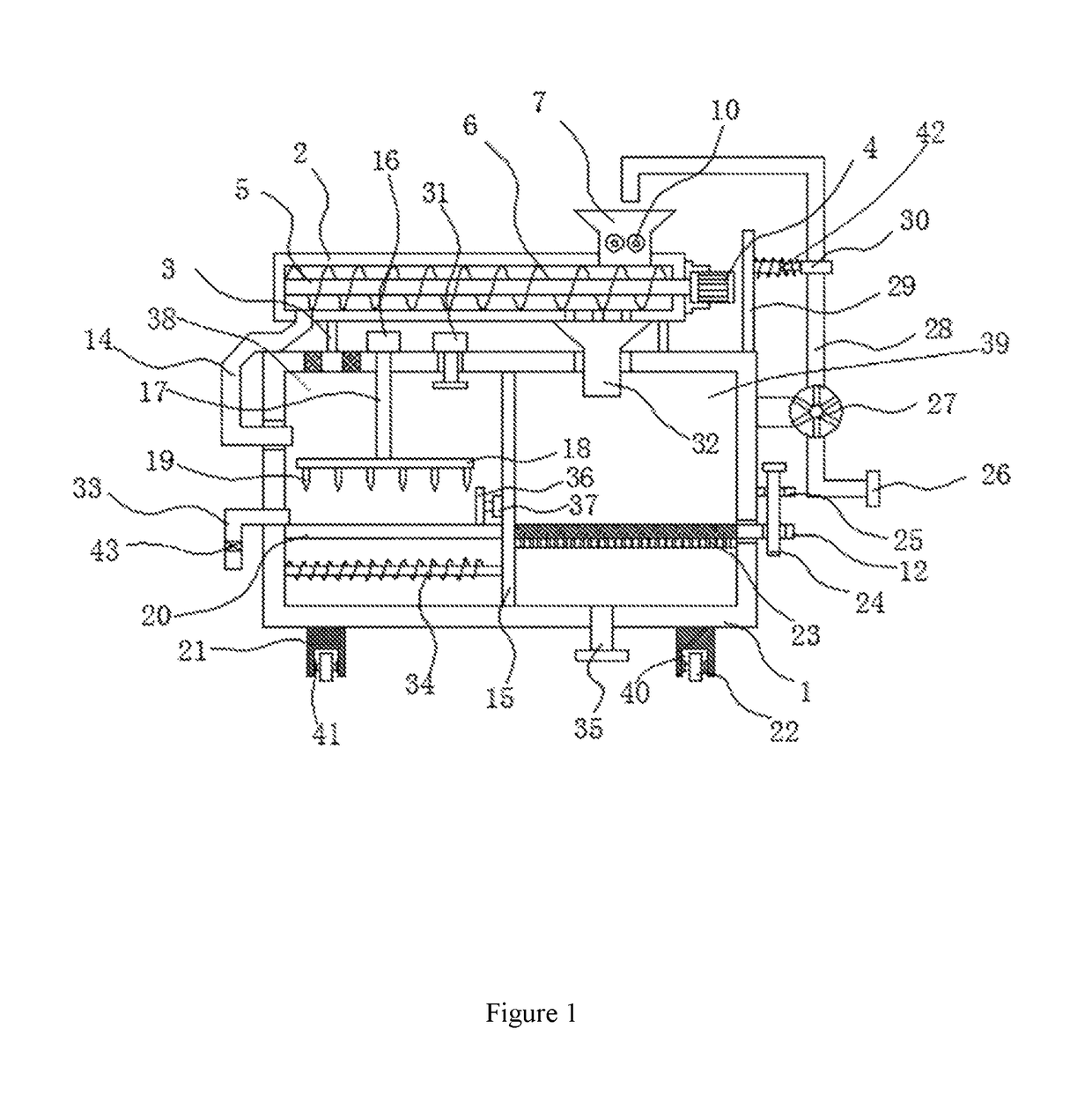

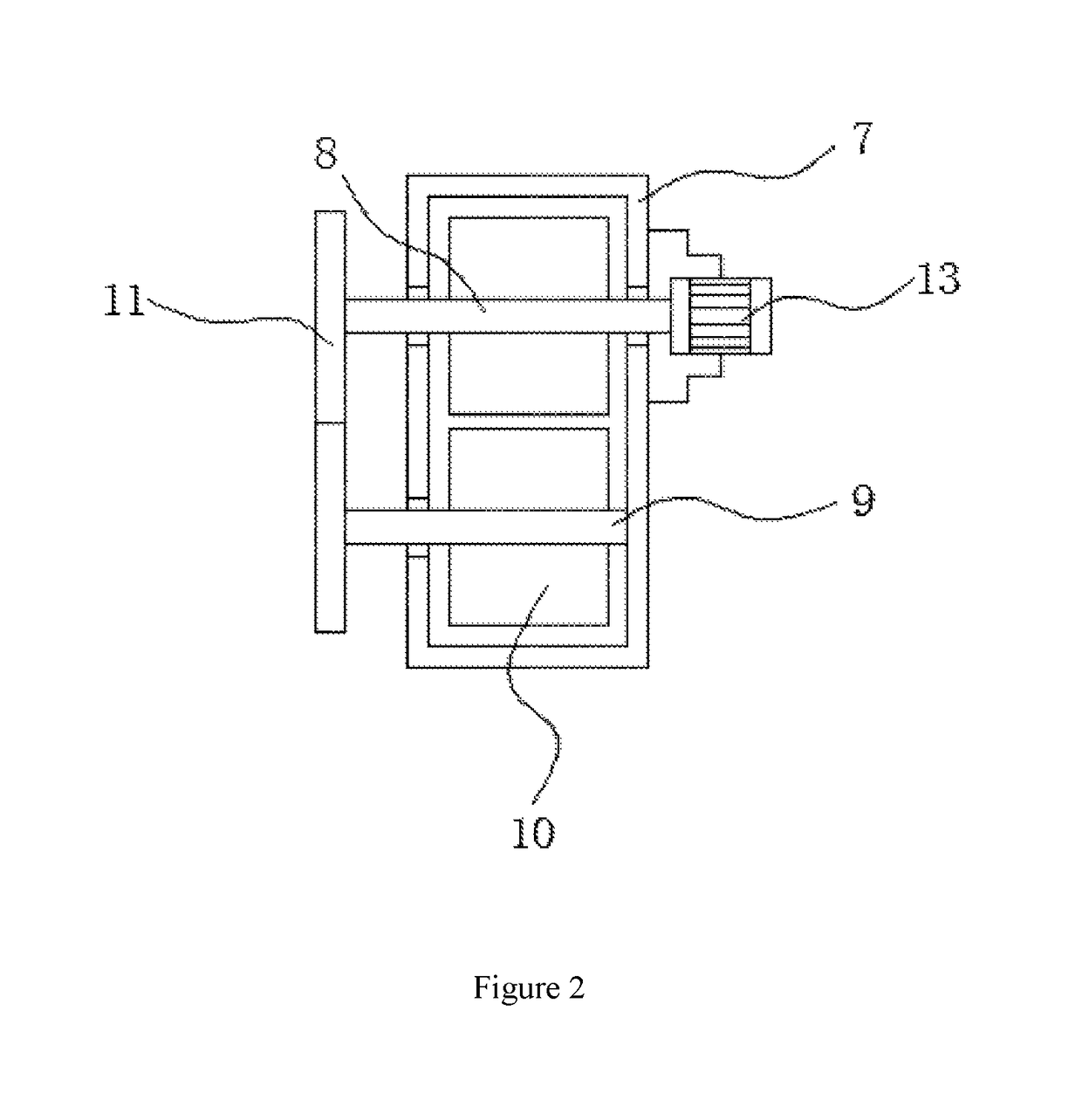

InactiveUS10053385B1Convenient guidanceEfficient and cheapSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSpiral bladeSludge

A device for separating water from sludge comprising a processing box, wherein a feeding cylinder is disposed above the processing box, and the feeding cylinder is fixedly connected to the processing box through a plurality of connecting rods; a rotating rod is rotationally connected into the feeding cylinder; a first rotating motor is fixedly connected to one side of the feeding cylinder; the output end of the first rotating motor penetrates through the side wall of the feeding cylinder, and is fixedly connected to the rotating rod; a spiral blade is fixedly sleeved with the rotating rod, and the outer side of the spiral blade is matched with the inner side wall of the feeding cylinder.

Owner:ZHU ZIYU

Process of preparing pig manure bio-organic fertilizer by microbial fermentation method

ActiveCN104261913AEffectively adjust the balanceEliminate compactionBio-organic fraction processingDi-calcium phosphate fertilisersPig breedingFermentation starter

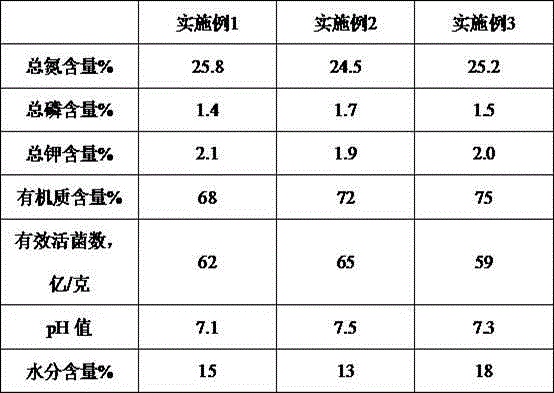

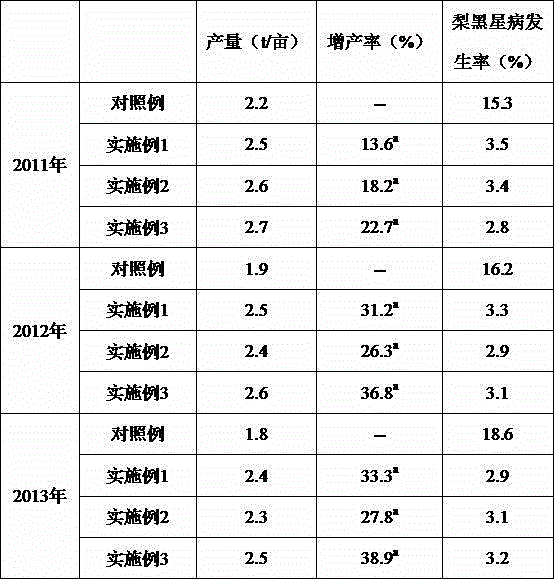

The invention discloses a process of preparing a pig manure bio-organic fertilizer by a microbial fermentation method. The process comprises the following step: by taking the pig manure as a raw material and supplementing straws, earthworm cast, seaweeds, and the like, performing a two-step fermentation process of a biological fermenting agent to prepare the pig manure bio-organic fertilizer. The process is high in resource utilization degree, easy for large-scale industrial production, beneficial to realizing resource utilization of live pig breeding wastes and capable of a pig breeding environmental pollution problem at present. The pig manure bio-organic fertilizer has the effects of the bio-organic fertilizer and the seaweed fertilizer, is rich in functional active ingredients of seaweeds and a large number of probiotics, capable of effectively regulating equilibrium of microorganisms in soil, decomposing organic or inorganic components such as organic substances and mineral substances in the soil, eliminating soil hardening, desertification, salinization and the like caused by abuse of a chemical fertilizer throughout the year, increasing the yield of crops, and has the special effects of improving the quality of the crops and improving the stress resistance of the crops. Besides, the pig manure bio-organic fertilizer is long in acting period, and is an ideal fertilizer for developing green ecological agriculture.

Owner:东辽县日月星有机肥有限公司

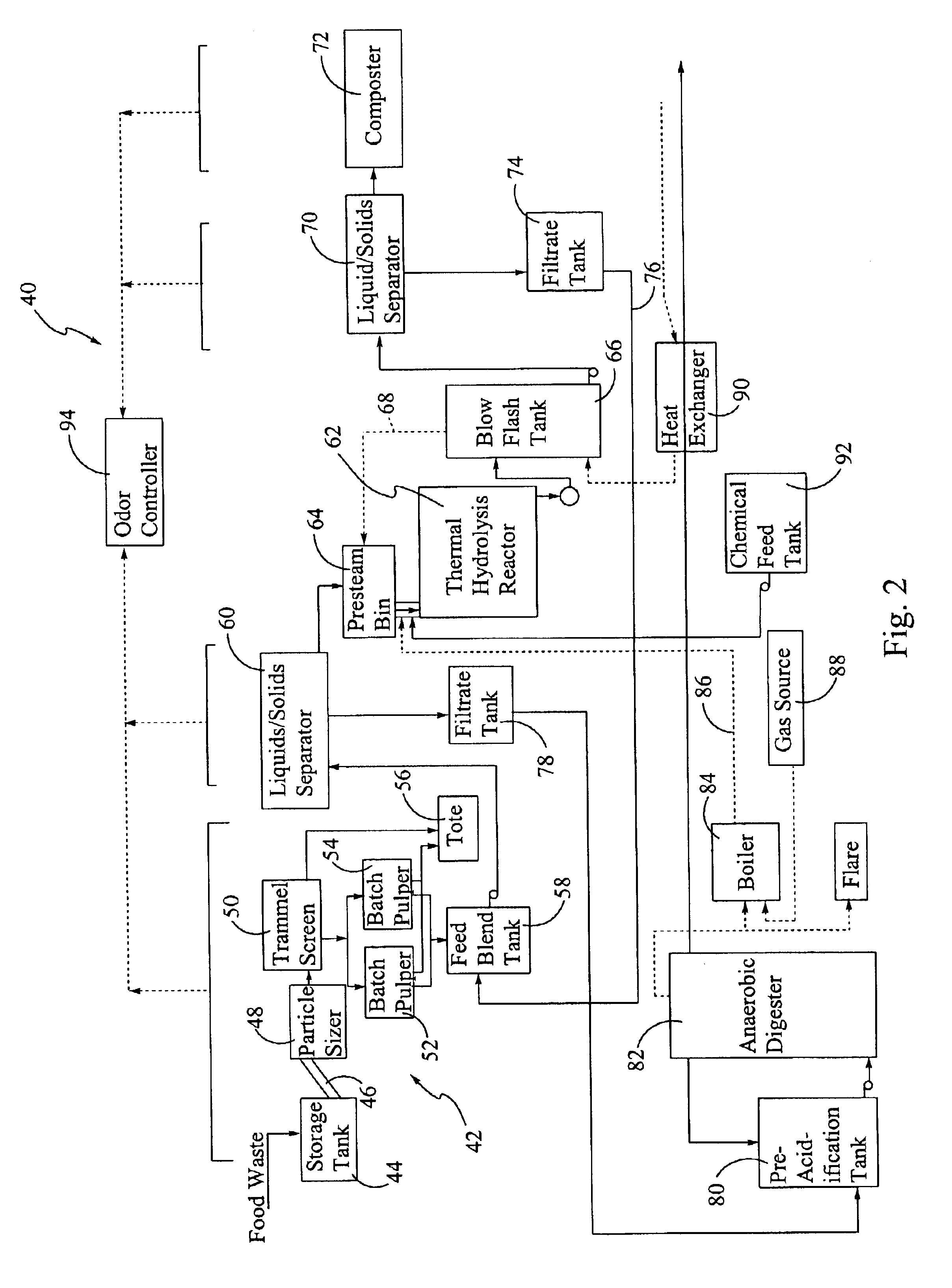

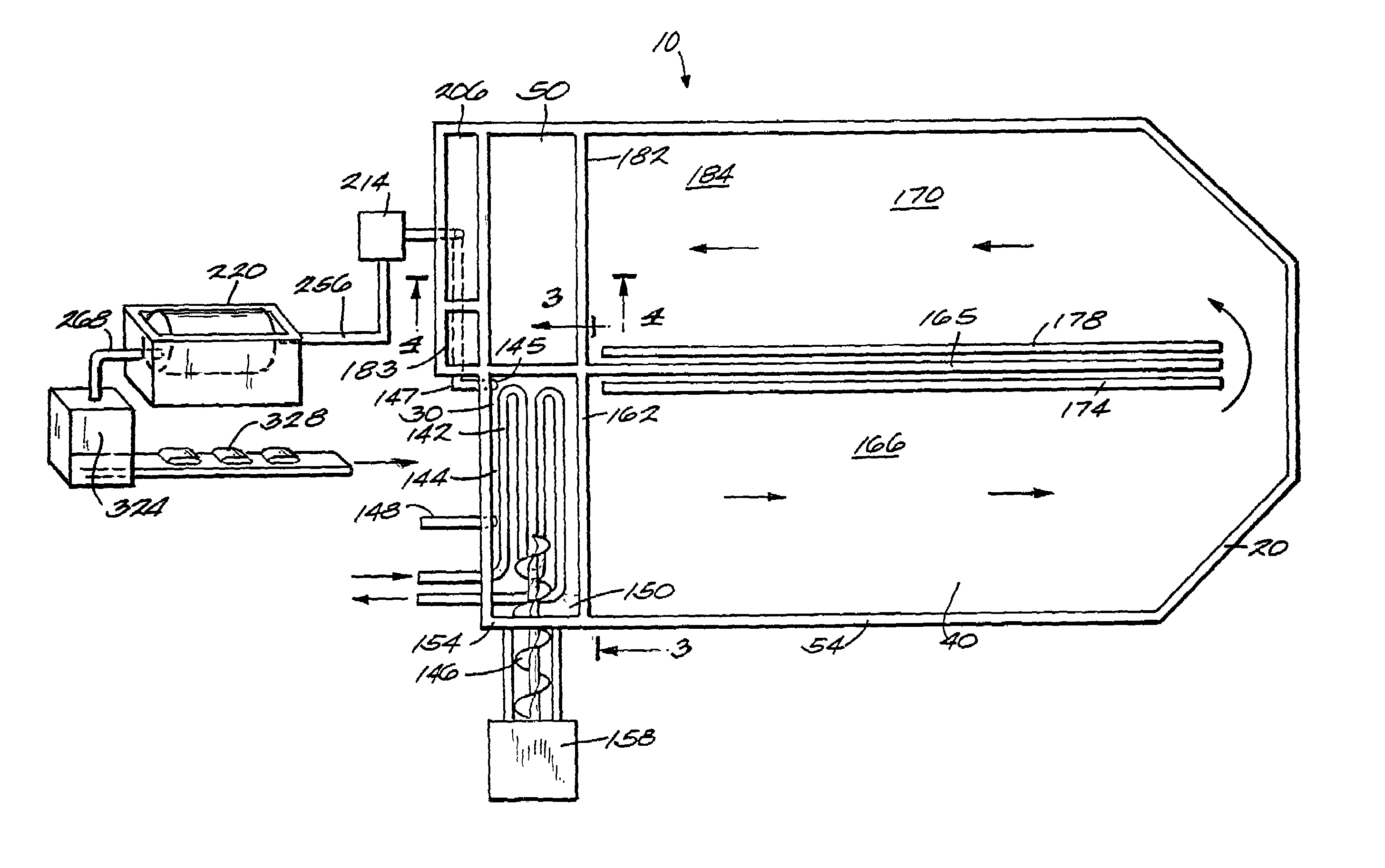

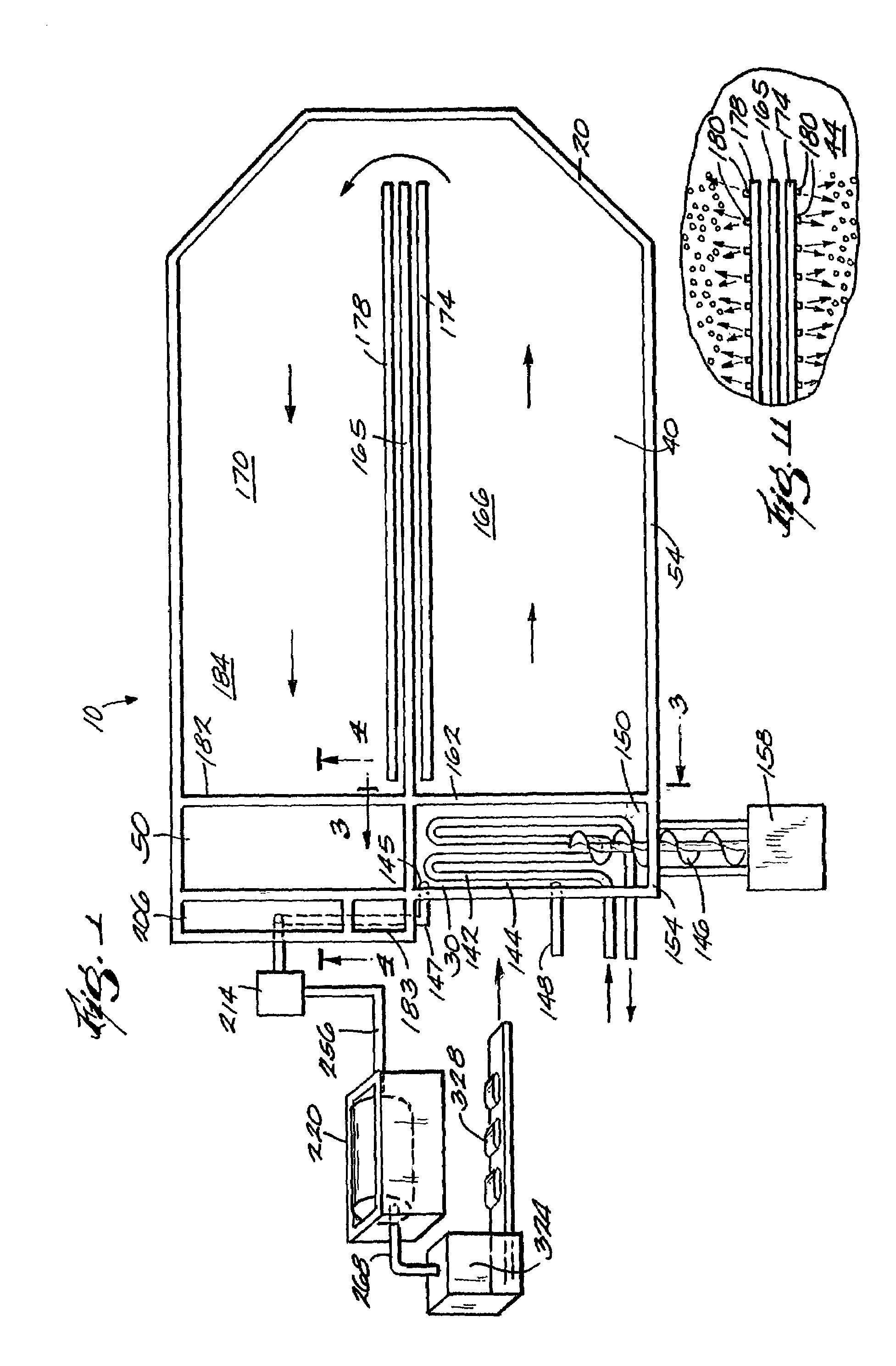

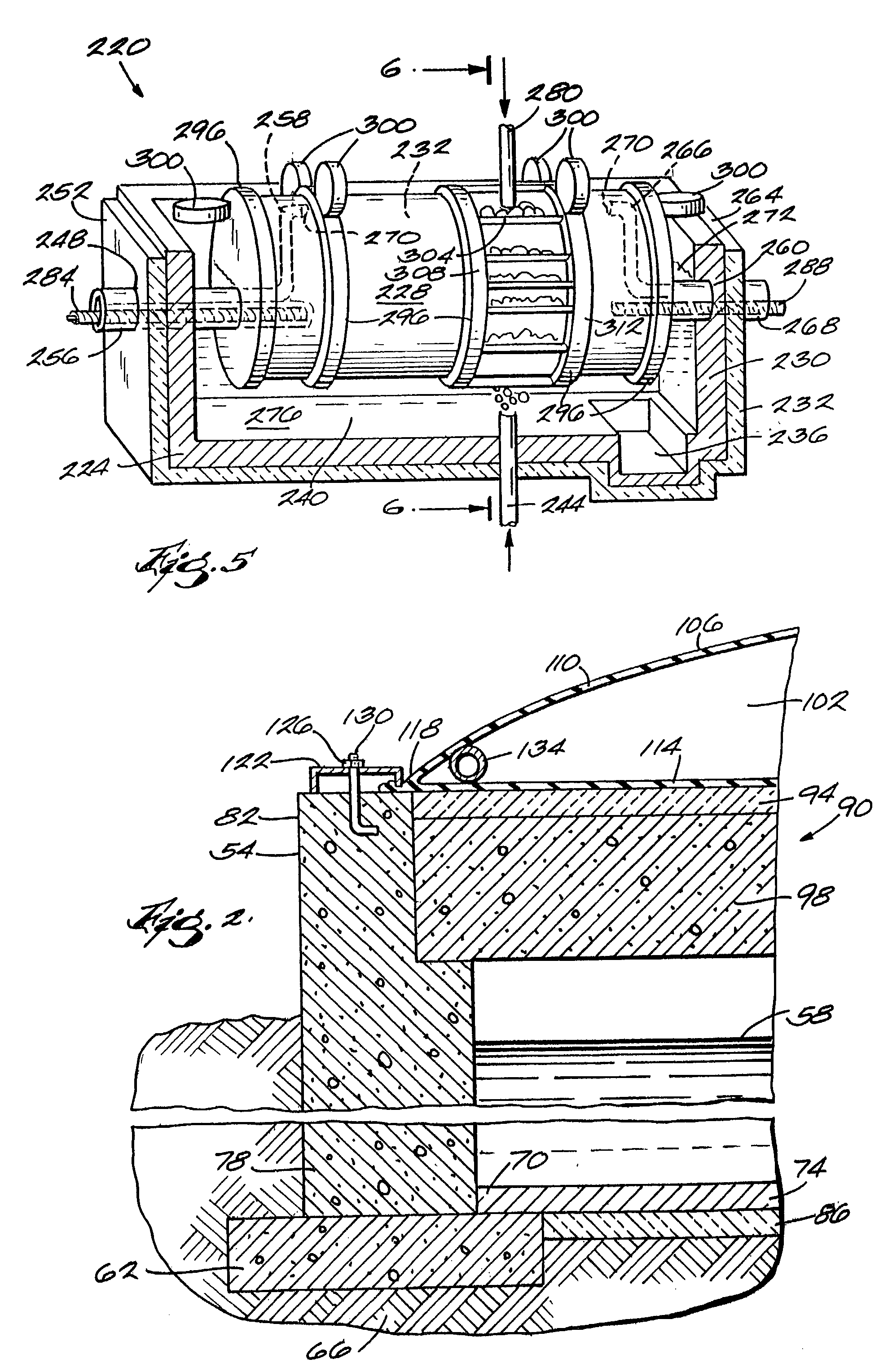

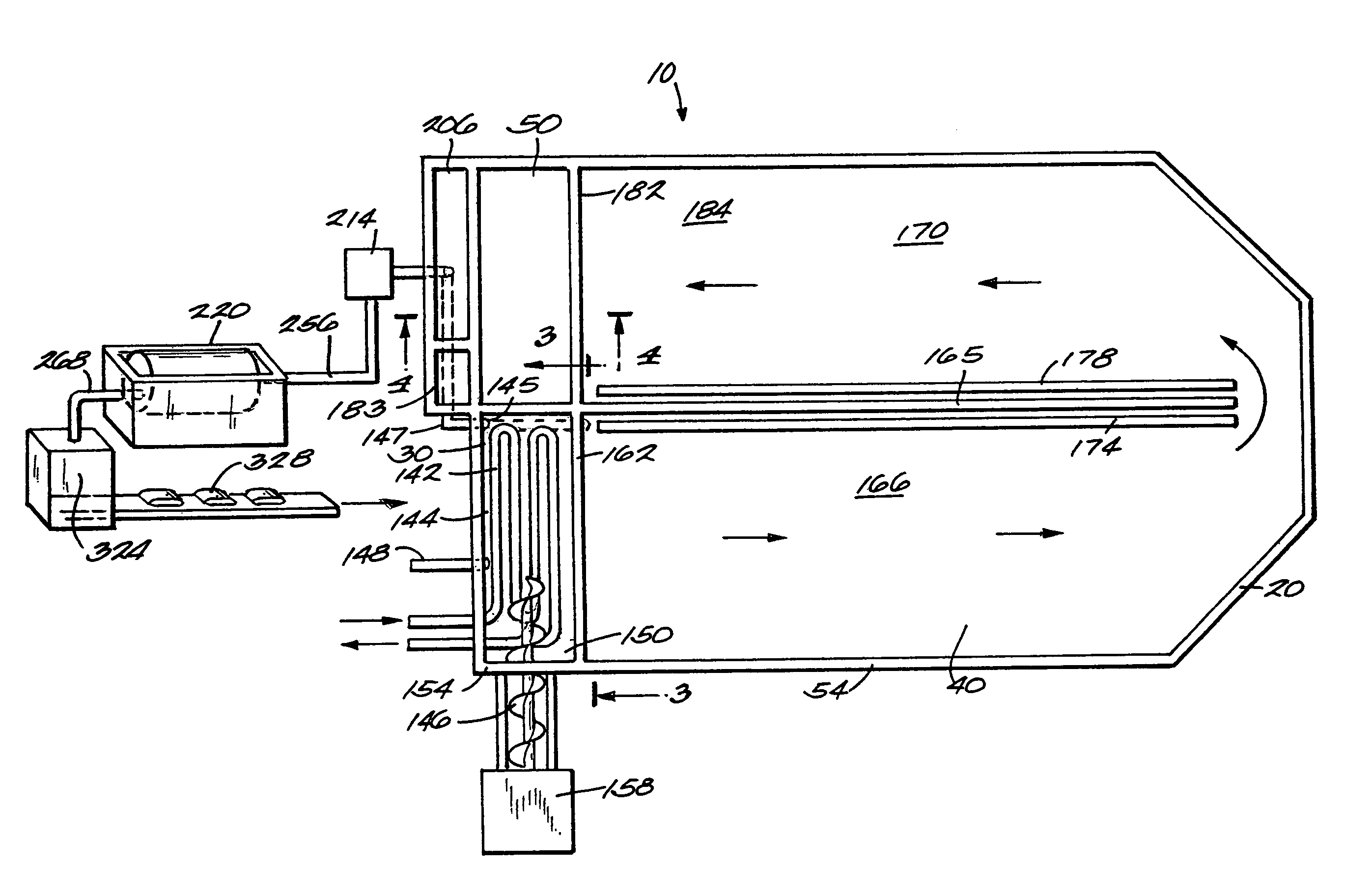

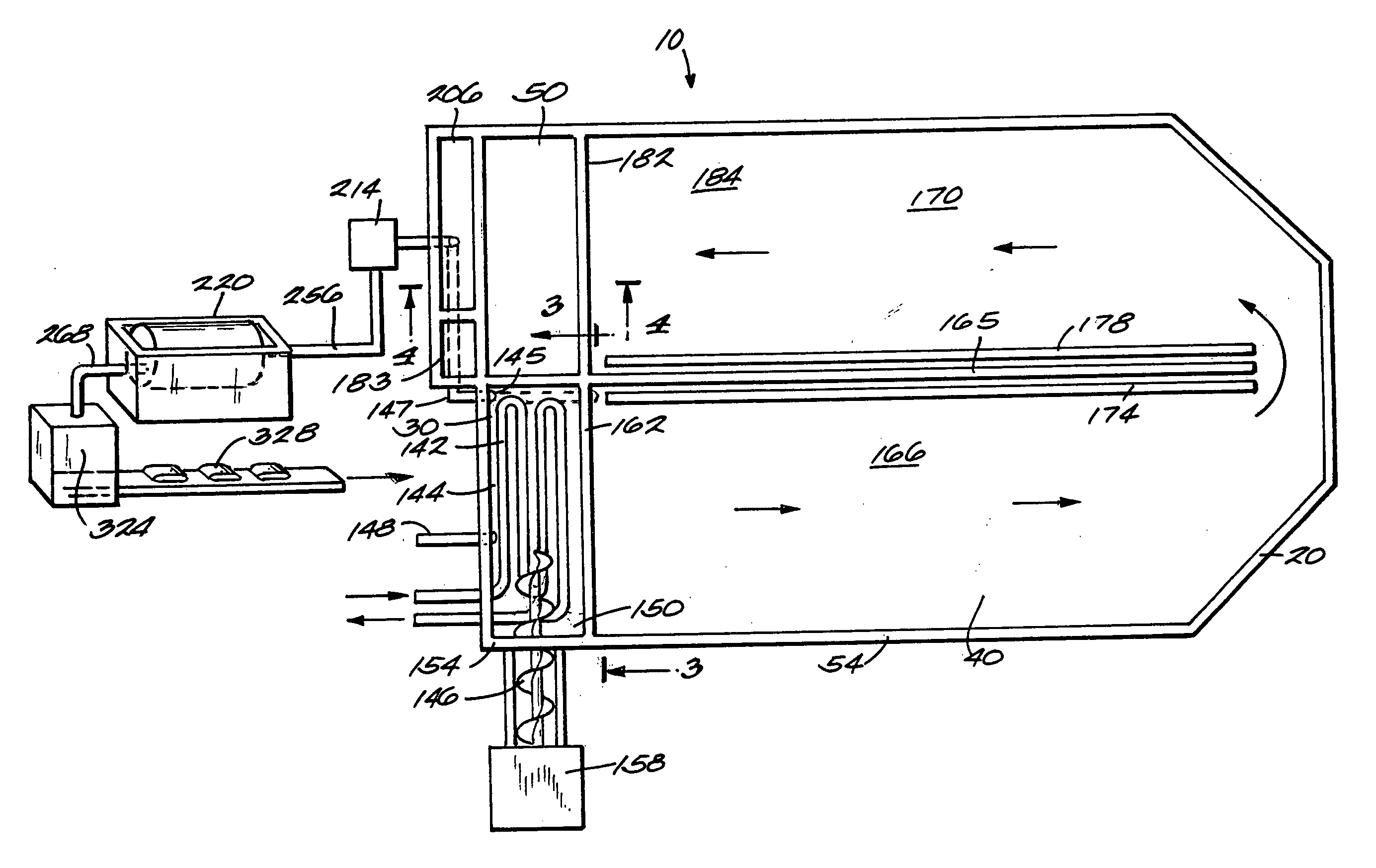

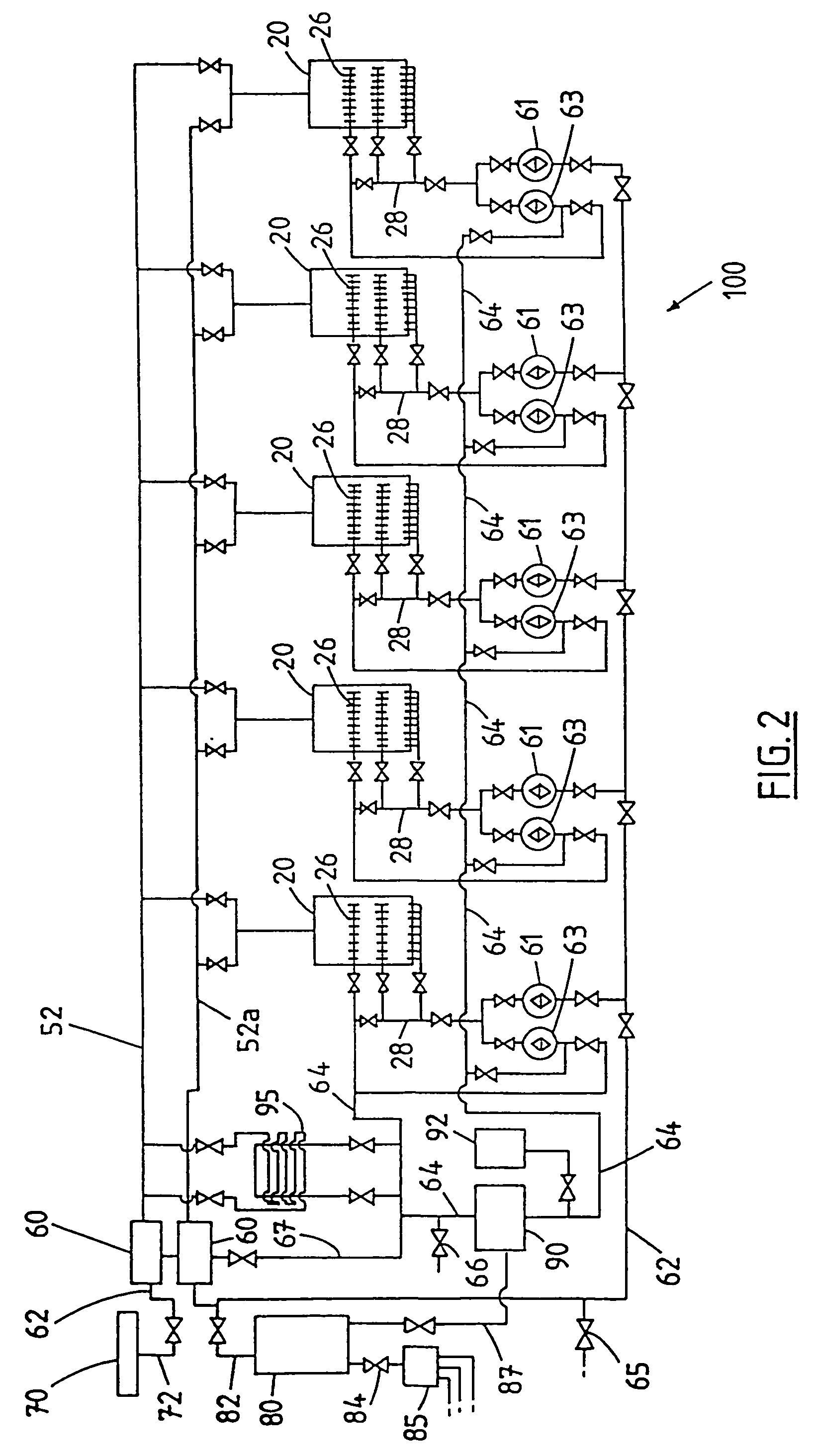

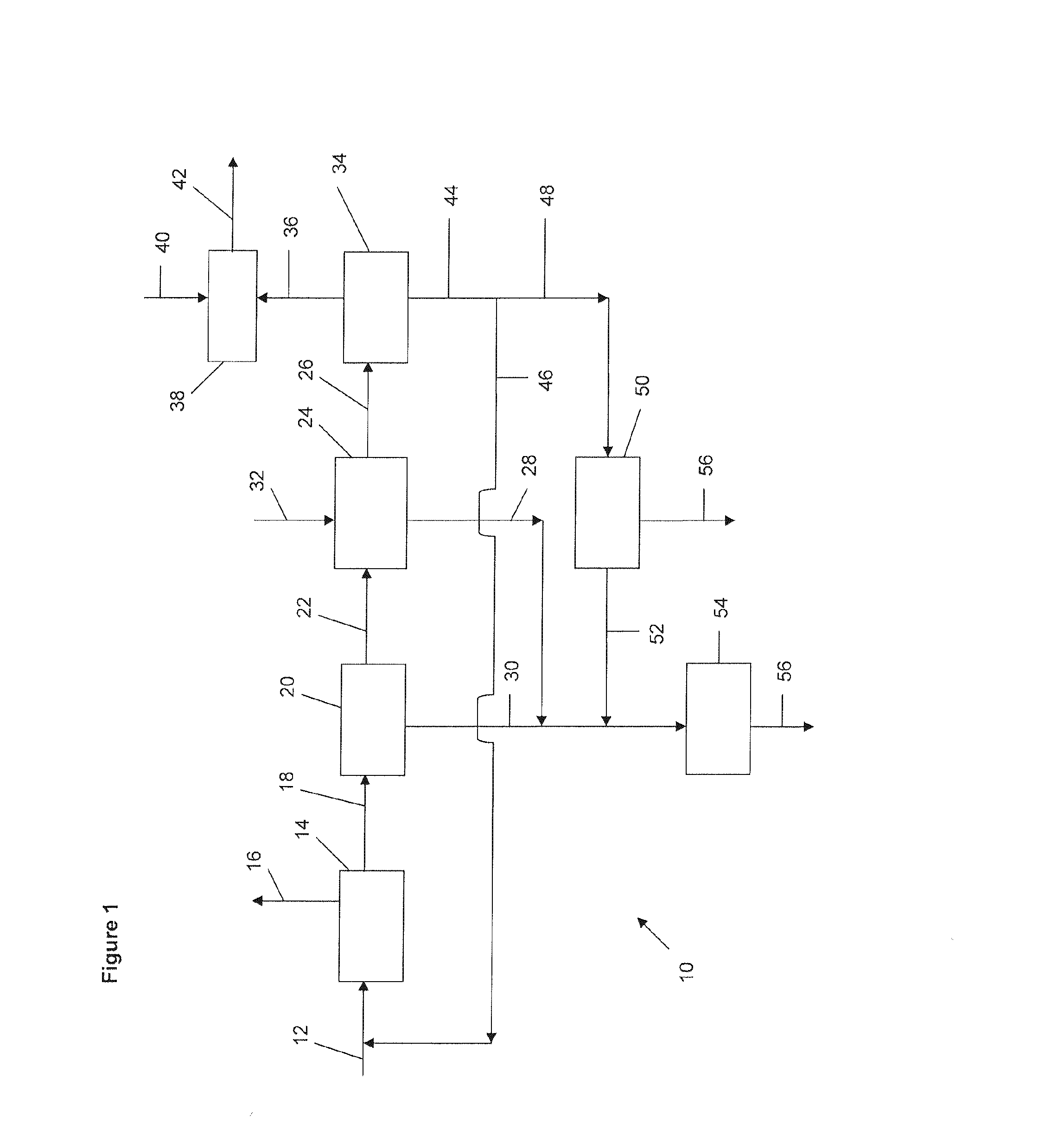

Method and apparatus for solids processing

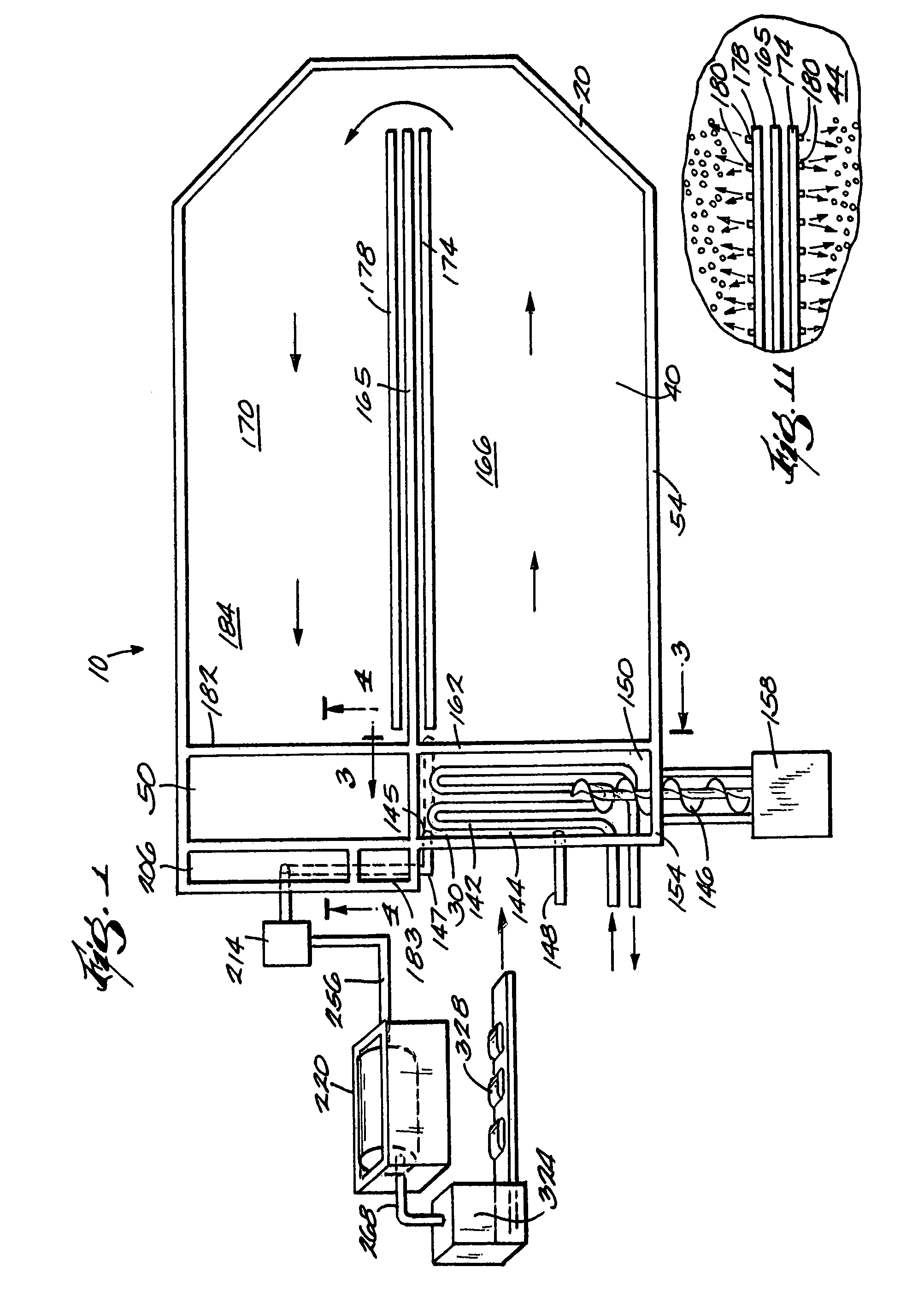

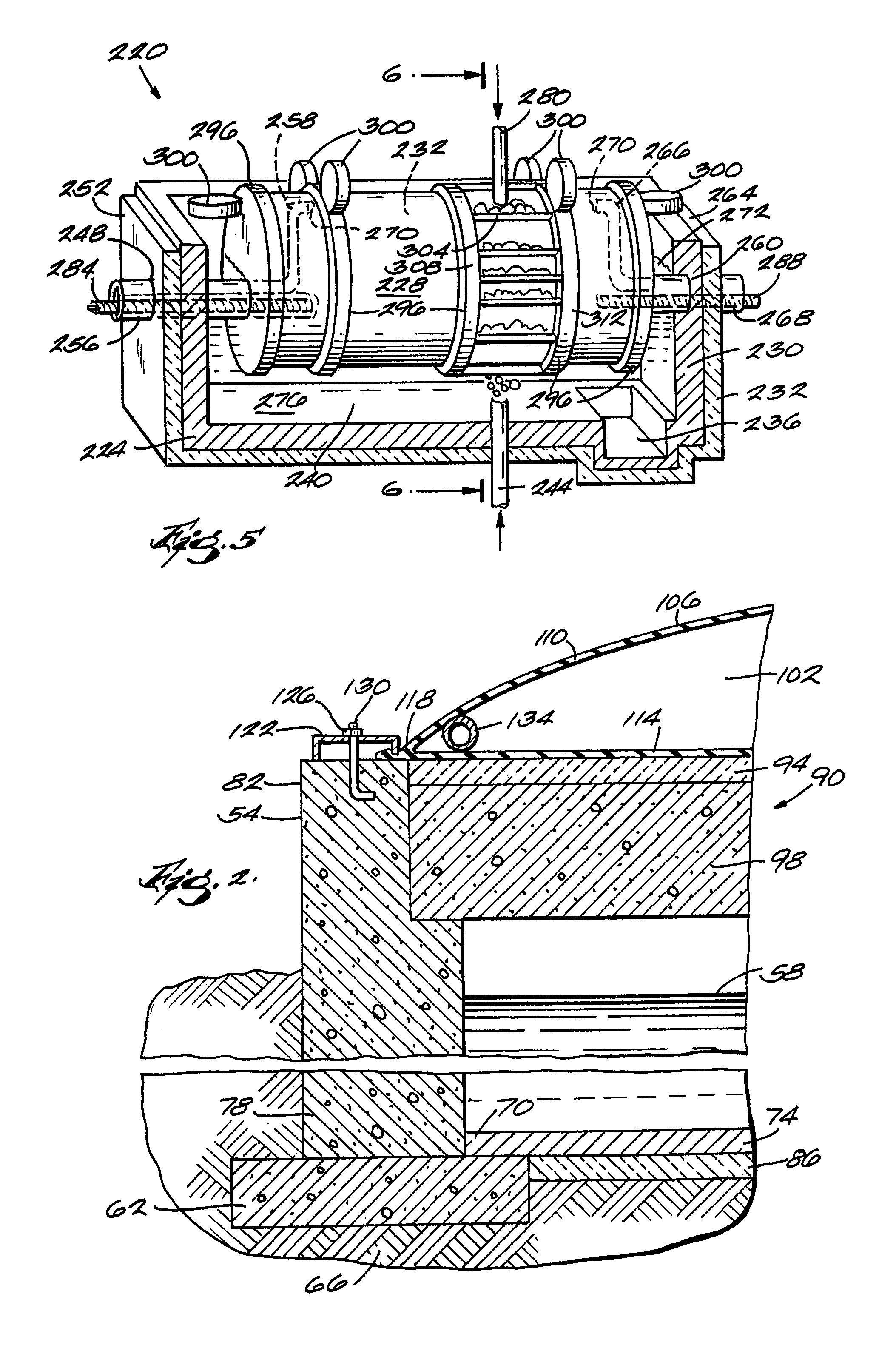

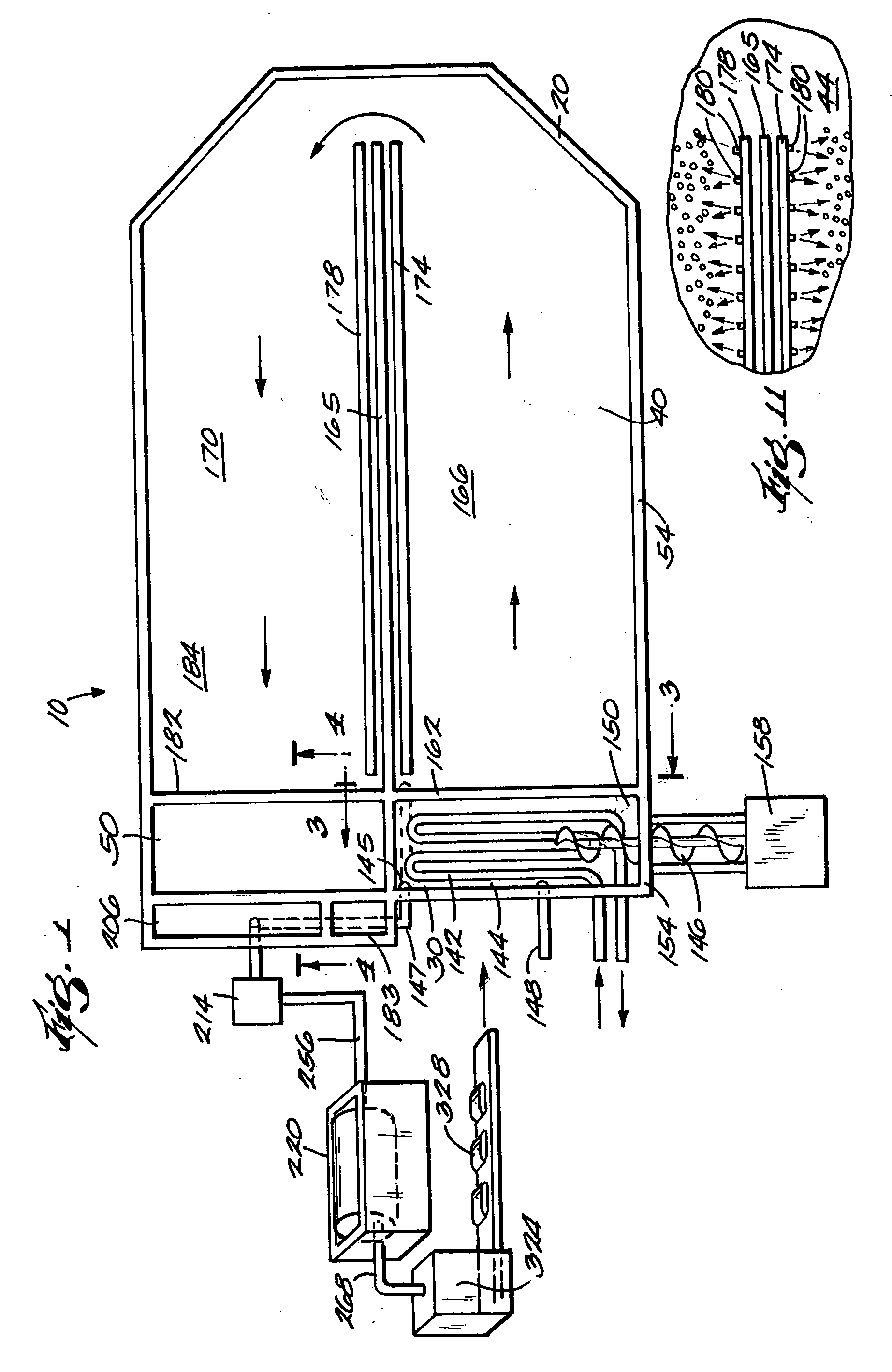

InactiveUS7078229B2Minimize end waste productMaximize energy efficiencyBioreactor/fermenter combinationsBio-organic fraction processingWaste processingProcess engineering

This invention provides a waste-processing system capable of processing high-solids wastes such as manure. This invention provides a compact U-shaped digester that allows for recycling of activated sludge to improve the efficiency of the process. Efficiency is also improved through a sludge heating design that creates a current in the digester and efficiently heats the sludge. A composter is provided to further process the sludge through aerobic digestion to create usable fertilizer. Finally, one embodiment provides a turbine that is fueled by biological gases from the digester to generate heat and electricity to be used by the system.

Owner:DVO LICENSING

Method and apparatus for solids processing

InactiveUS7179642B2Bioreactor/fermenter combinationsBio-organic fraction processingAnaerobic digestionWaste management

Owner:DVO LICENSING

Method for preparing organic fertilizer by using plant residues as raw material

InactiveCN104261911AAccelerates decay and degradationImprove decomposition abilityBio-organic fraction processingExcrement fertilisersMicrobial agentDecomposition

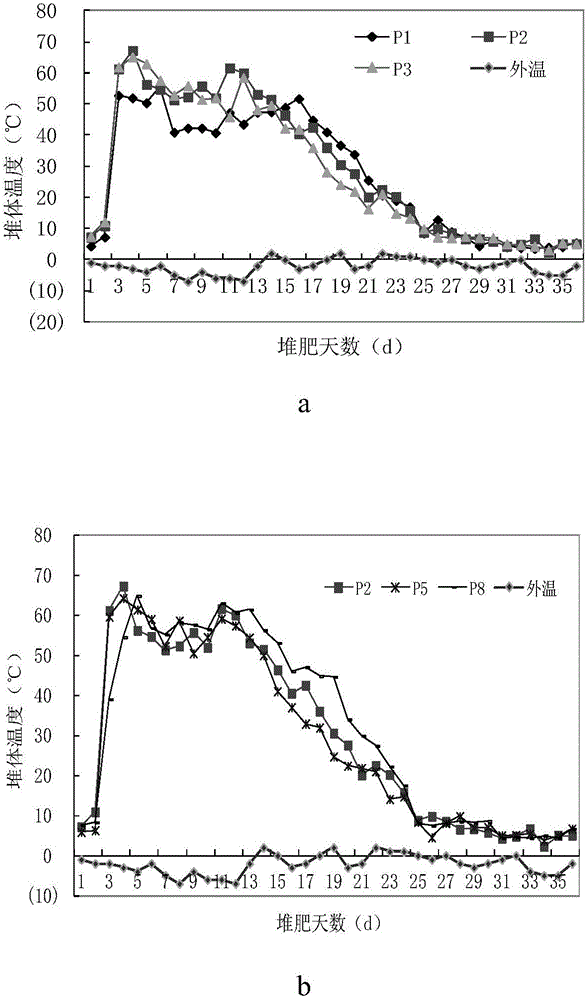

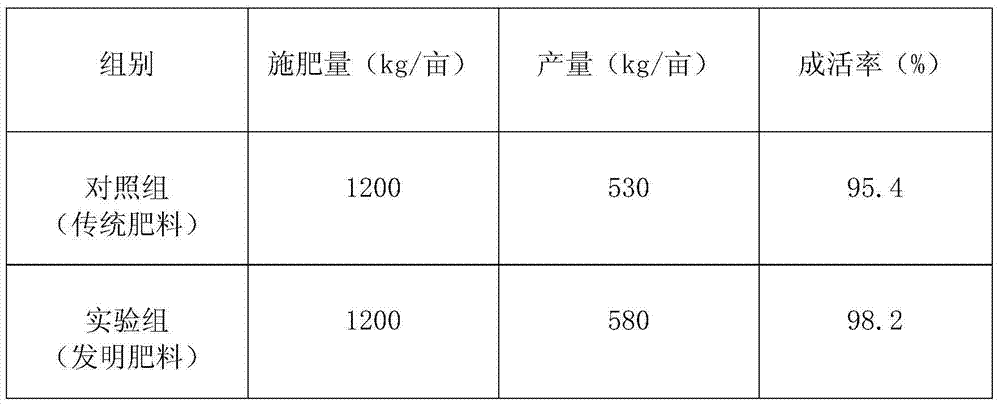

The invention relates to a method for preparing an organic fertilizer by using plant residues as a raw material. The method comprises the following steps: crushing the raw material to below 20mm, stirring and mixing the broken material with animal wastes or an inorganic fertilizer; controlling the C / N ratio of the mixed materials to be (15-35) to 1 and the pH to be 6-9; adding water, so that the moisture content in the mixed materials in the step (2) is 55-70wt%; adding a first composite microbial agent to ferment; after once fermentation, raising the temperature of windrows to above 50 DEG C; and spraying a water-dispersed second composite microbial agent to ferment for the second time. With plant residues heap corruption (composting) as a biological process for succession of a microbial community, through inoculation of exogenous complex microbial agents, efficient decomposition on agricultural wastes is facilitated; different composite microbial agents are respectively added at different composting stages; and a small amount of additives (animal wastes, urea, ammonium nitrate and the like) are added, so that the composting speed is increased, and the quality of the product organic fertilizer is really improved.

Owner:烟台中正新技术有限公司

Bioorganic fertilizer and preparation method thereof

InactiveCN104446813AReasonable formulaSmooth releaseBio-organic fraction processingExcrement fertilisersDiseaseMicrobial agent

The invention discloses a bioorganic fertilizer and a preparation method thereof, belonging to the technical field of fertilizers. The fertilizer is prepared from the following raw materials in parts by weight: 30-40 parts of pig manure, 20-35 parts of plant decomposed straws, 10-15 parts of wheat bran, 5-10 parts of grease, 5-10 parts of humic acid, 2-5 parts of urea, 5-10 parts of a compound microbial agent and 5-10 parts of a functional microbial agent. The bioorganic fertilizer disclosed by the invention has abundant nutritional elements and can be used for effectively improving the physical and chemical properties of soil, enhancing the capacity of preserving moisture and fertility of soil and preventing various physiologic diseases of plants, so that the output of crops is effectively improved.

Owner:DANGSHAN CHUNYUAN FERTILIZER CO LTD

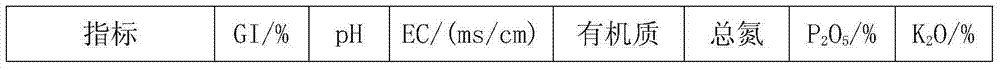

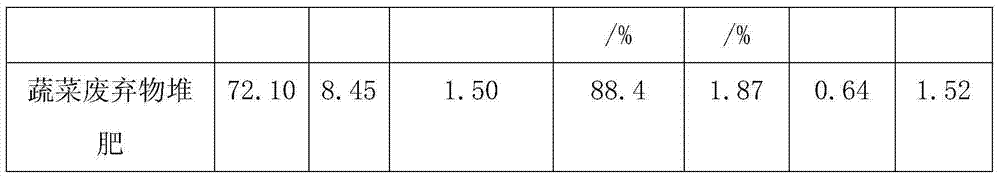

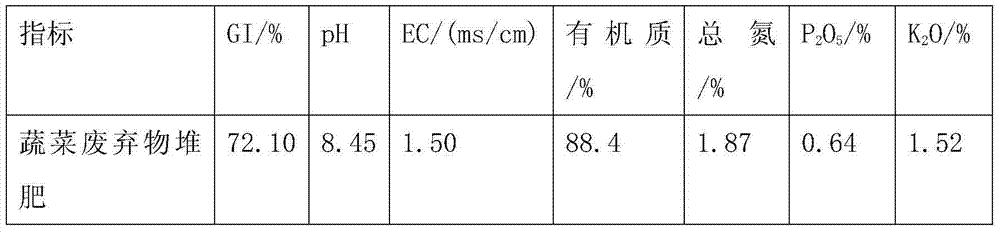

Solanaceous vegetable seedling medium prepared by taking vegetable waste compost as fertilizer source and preparation method of solanaceous vegetable seedling medium

InactiveCN104725085AShorten the maturity cycleLoose textureBio-organic fraction processingExcrement fertilisersLivestock manureMicrobial agent

The invention discloses a preparation method of preparing a solanaceous vegetable seedling medium by taking vegetable waste compost as a fertilizer source. According to the preparation method, vegetable waste is taken as a main raw material, crop straws and livestock manure are taken as auxiliary materials, a vegetable waste compost fertilizer is prepared by virtue of forced ventilation static composting and aerobic high temperature biological fermentation, the vegetable waste compost fertilizer, turf, vermiculite and perlite are adequately mixed in a certain volume ratio, a functional microbial agent is added into each mass of mixture, and the solanaceous vegetable seedling medium is prepared; the solanaceous vegetable seedling medium is good in permeability, water retention and fertilizer retention and balanced and reasonable in nutrient supply, the balance requirements of solanaceous vegetable crops to nutrient elements in seedling and growing stages can be met without adding any inorganic chemical fertilizer, and the survival rate and stress resistance of seedlings can be obviously increased; the harmless and resourceful treatment of vegetable waste are achieved, and the huge wasting of vegetable waste and environmental pollution are avoided; the preparation method has wide application value.

Owner:CHINA AGRI UNIV

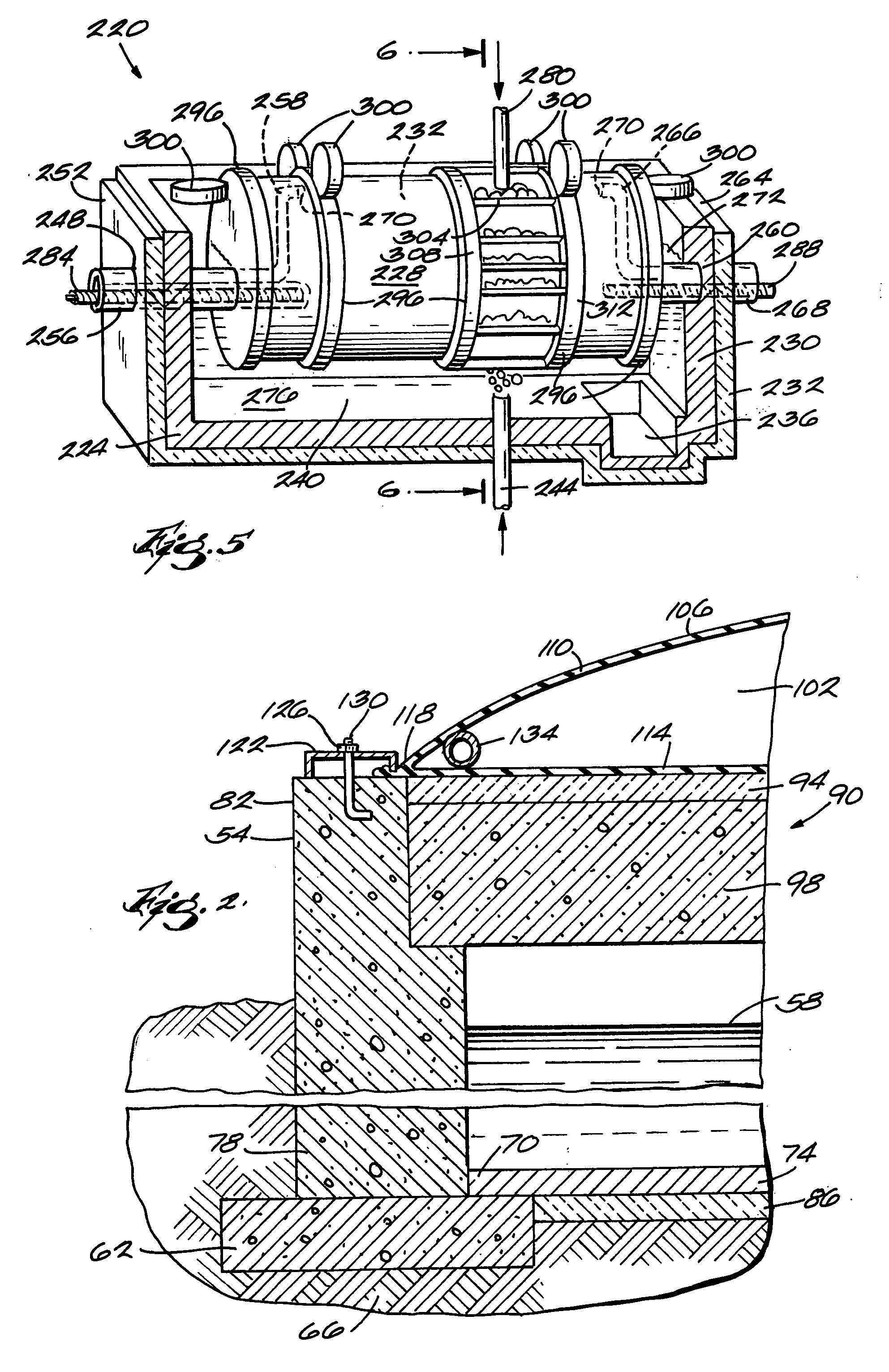

Method and apparatus for solids processing

InactiveUS20040087011A1Bioreactor/fermenter combinationsBio-organic fraction processingWaste managementAnaerobic digestion

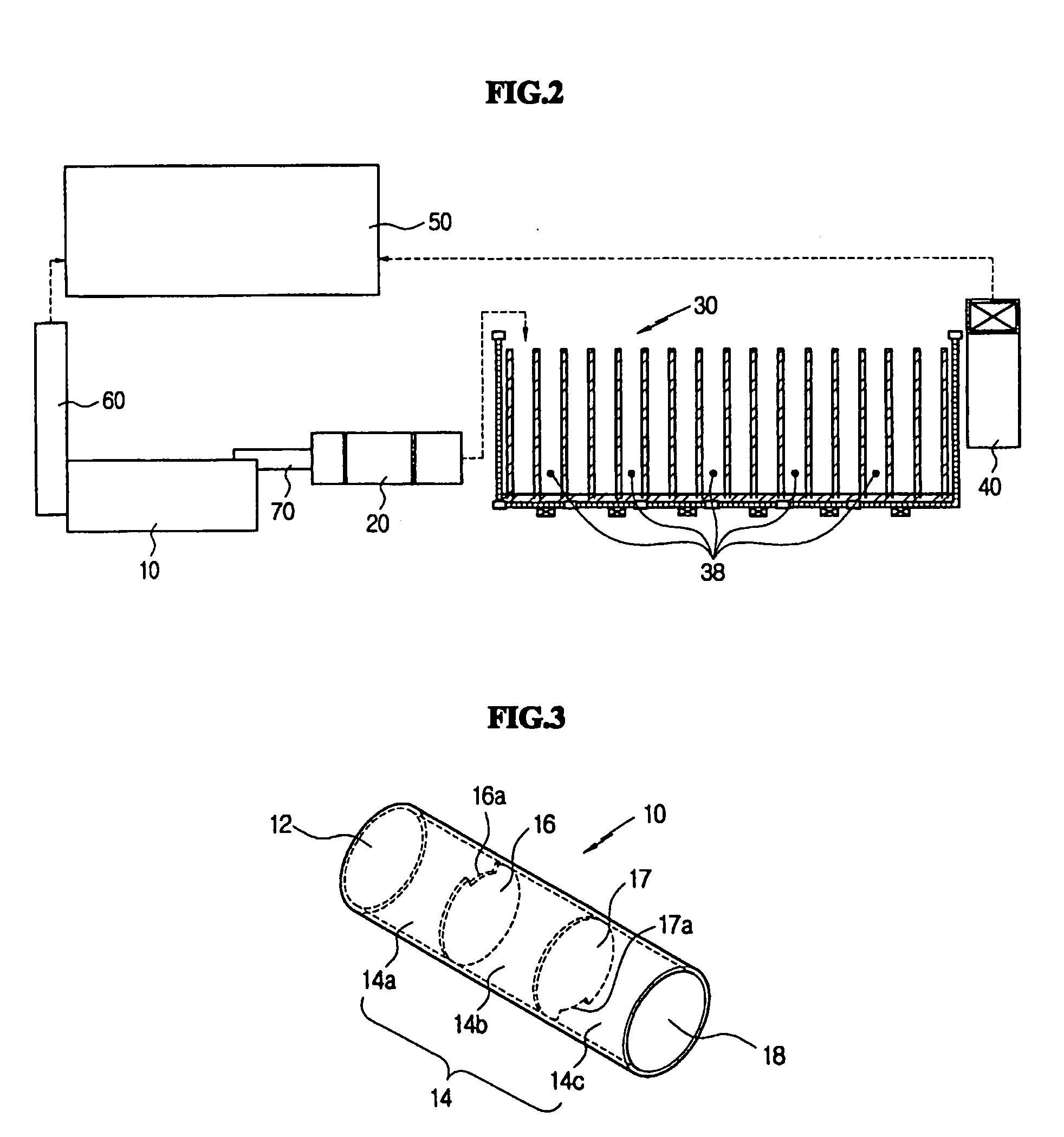

Apparatuses and methods for anaerobic digestion of high-solids waste are provided. The methods may include and the apparatuses may be used for moving the solid waste in a corkscrew-like fashion through a closed container. The method may further include moving the high-solids waste into contact with a heating device to facilitate the corkscrew-like movement. Other methods and apparatuses may use at least one of a partition and a conduit from which liquid or gas is discharged.

Owner:DVO LICENSING

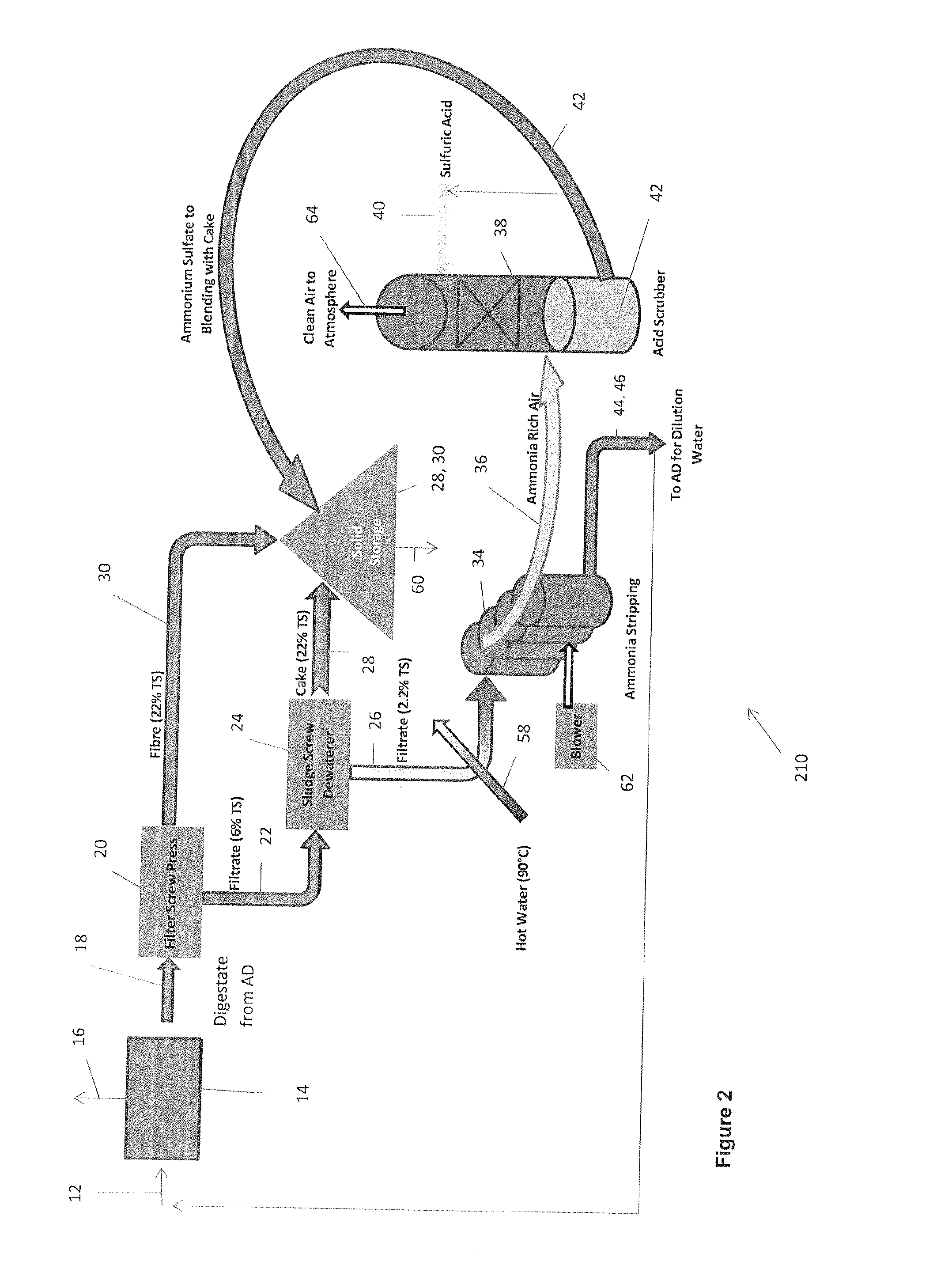

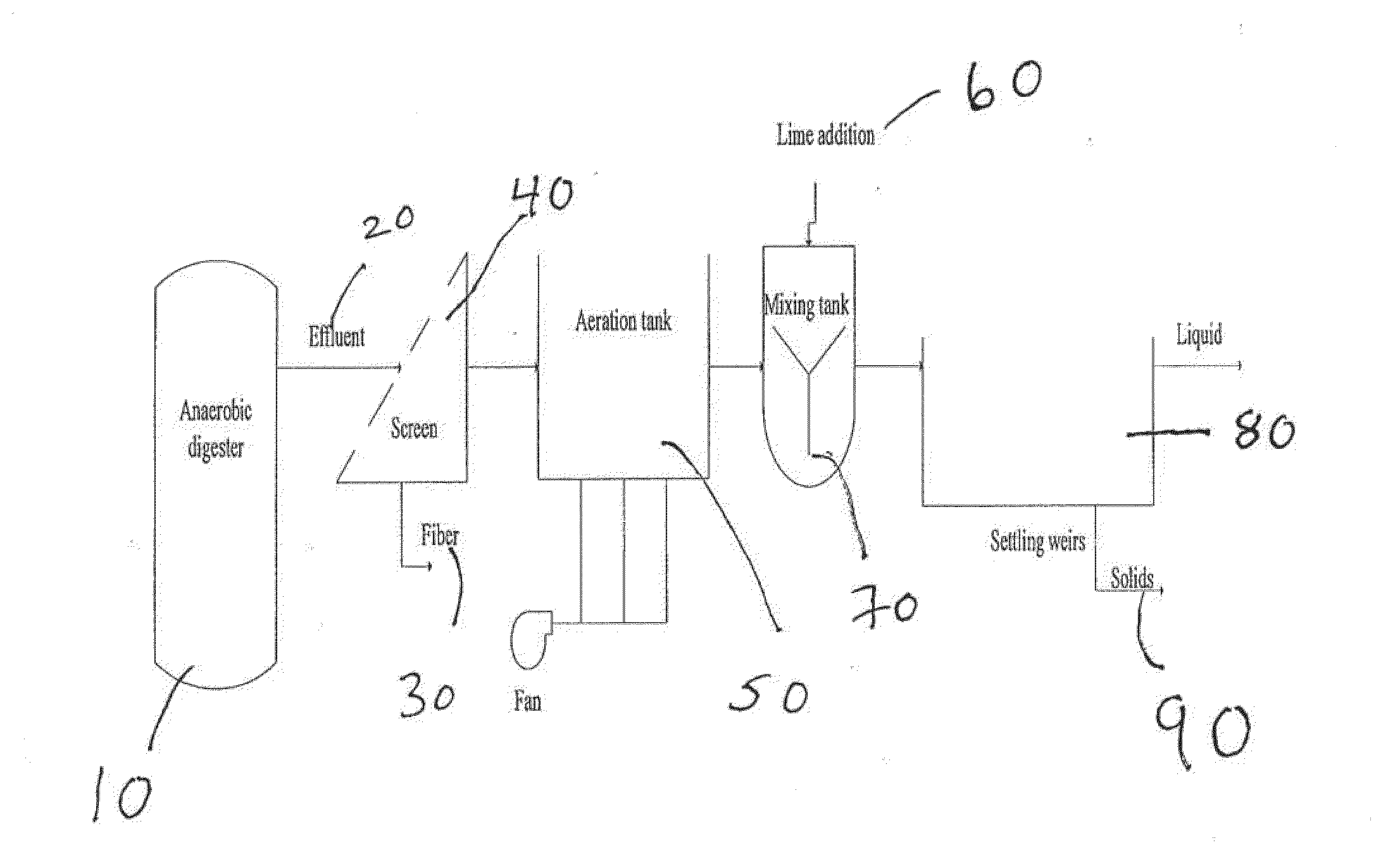

Organics and nutrient recovery from anaerobic digester residues

Sludge from an anaerobic digester is treated to recover one or more of fibers, or solids or liquids with a high nutrient content. The solids or liquids can be used as a fertilizer. The fibers can be used in a plant growing medium. Solids are separated from liquids in the sludge and dried. The solids may be dried to produce a flake or pellet. Ammonia in the liquids is recovered and used to produce a concentrated acidic ammonium salt solution. This solution may be mixed with the solids to produce a nitrogen enhanced solid. The fibers and solids or liquids can also be used in combination to produce an enhanced plant growing medium. A device and process for removing ammonia from a liquid can be used in the system or separately.

Owner:ANAERGIA

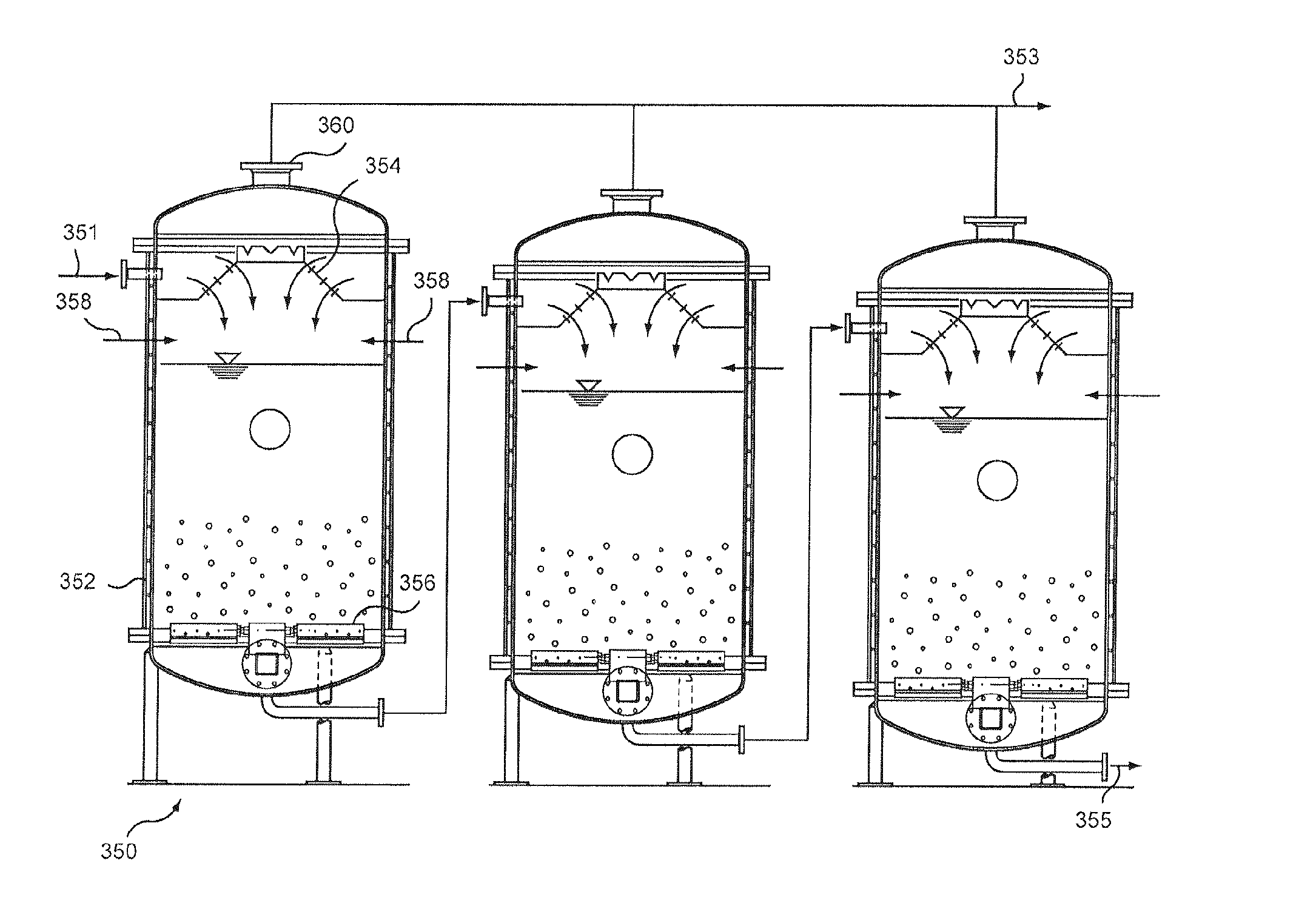

Organic waste material treatment process

InactiveUS7211429B1Bioreactor/fermenter combinationsBio-organic fraction processingSingle vesselPre-condition

An organic waste material treatment process comprising subjecting the organic waste material to conditions under which anaerobic digestion occurs followed by conditions under which aerobic composting occurs. Preferably, the organic waste material is pre-conditioned before anaerobic digestion by subjecting the organic waste material to aerobic composting conditions to facilitate a rise in temperature of the organic waste material. The treatment process is conducted in a single vessel, wherein air and water are evenly distributed to the contents of the vessel. A plurality of vessels may be interconnected, such that water may be extracted from one vessel, whose contents have undergone anaerobic digestion, then recirculated to an interconnected vessel to facilitate conditions for anaerobic digestion of the contents of the interconnected vessel.

Owner:ANAECO

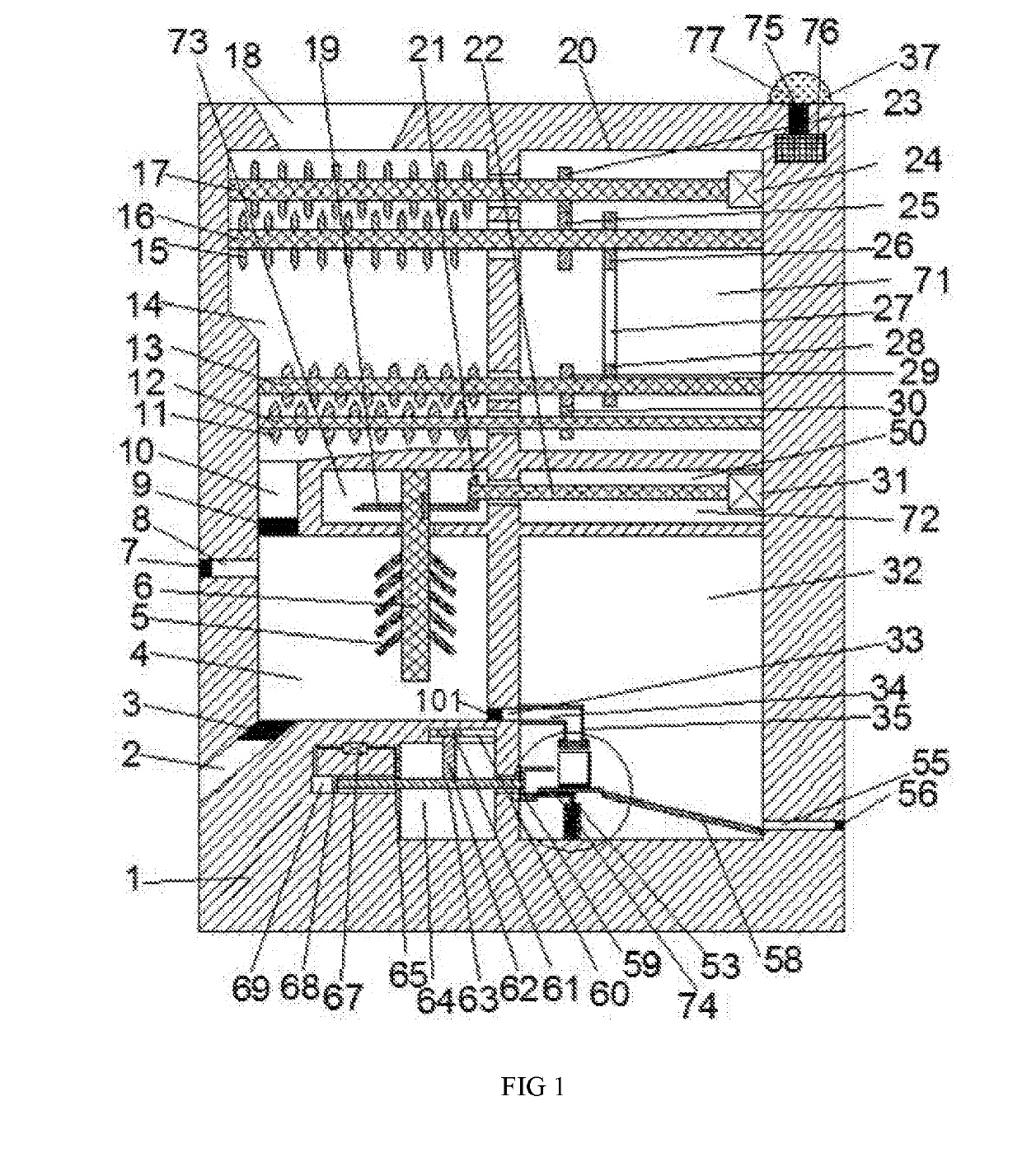

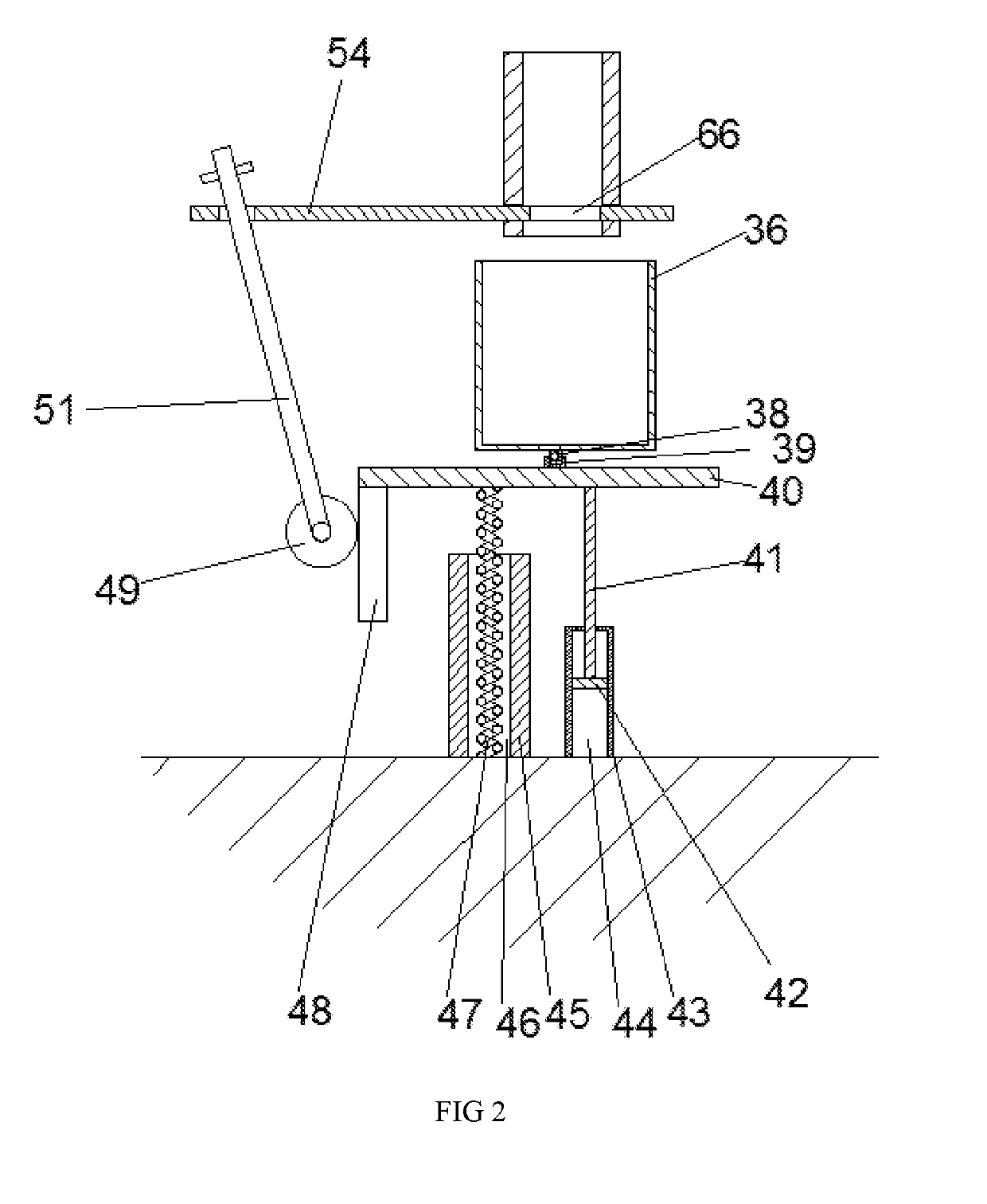

Environmentally Friendly Fertilizer Device Based on Big Data

ActiveUS20190135709A1Simple structureEasy to operateBio-organic fraction processingProductsEngineeringMechanical engineering

The invention discloses an environmentally friendly fertilizer device based on big data, comprising a work box and a crushing space set in the work box, wherein a crushing driving space is set in one end wall of the crushing space, wherein a crushing mechanism is set in the crushing driving space; by turning on a first electromagnetic switch, the kitchen garbage enters the crushing space from the feed inlet, so the kitchen garbage is crushed by the crushing space. A transmission space is arranged in the lower end wall of the crushing space, and a driving space is set in the lower end wall of the crushing driving space; a stirring space is set in the lower end wall of the transmission space; the crushed kitchen garbage enters the stirring space through a circulation pipeline and is stirred by the stirring mechanism, thereby the kitchen garbage can be fully fermented.

Owner:GE GUOSONG

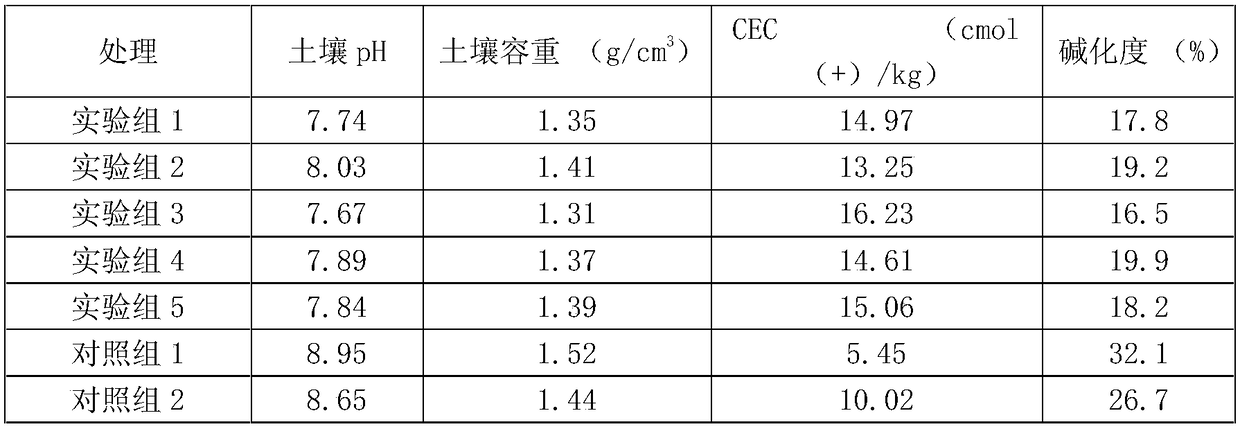

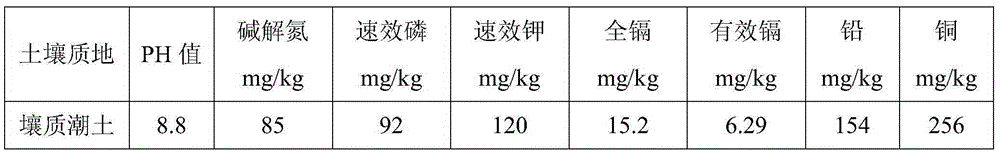

Special saline and alkaline land organic/inorganic compounded fertilizer as well as preparation method and application thereof

InactiveCN108484286AImprove adsorption capacityIncrease exchange volumeBio-organic fraction processingExcrement fertilisersSoil porosityInorganic compound

The invention discloses a special saline and alkaline land organic / inorganic compounded fertilizer as well as a preparation method and application thereof. The compounded fertilizer comprises raw materials, namely a mixture 1 and a mixture 2, wherein the weight ratio of the mixture 1 to the mixture 2 is (1.5-3.5):1; the mixture 1 comprises composite charcoal, a biological organic fertilizer, humicacid substances, furfural residues, an improvement preparation and inorganic nutrients which are mixed according to a certain ratio; the mixture 2 comprises a biological organic fertilizer, humic acid substances, furfural residues and water retention aids which are mixed according to a certain ratio. By adopting the product disclosed by the invention, soil structures can be improved, soil porosity can be improved, soil bulk density can be reduced, contents of organic matters in soil can be increased, the cation exchange amount of the soil can be increased, and the pH value of the soil and thetotal amount of water soluble salts in the soil can be reduced. In addition, the fertilizer has functions of slowly releasing acid substances and nutrients, is capable of activating soil, reducing immobilization of soil upon nutrients and increasing the utilization rate of the nutrients, is capable of continuously and stably improving soil, is free of adverse influence upon environments and plants, and is ecological and environmentally friendly.

Owner:湖南慧谷农业生态研究院有限公司

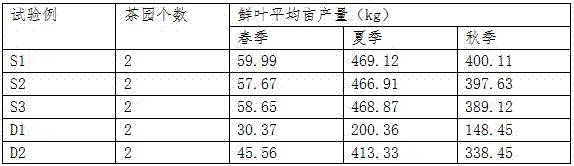

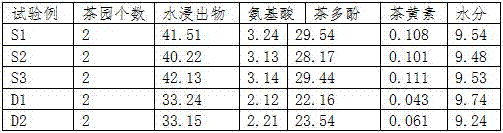

Method for planting tea tree

InactiveCN105210758ANutritional balancePromote absorptionBio-organic fraction processingExcrement fertilisersDiseaseFully developed

The invention relates to a method for planting a tea trees, which comprises eight steps that are preparing the land, planting, managing a tea garden, removing weeds and insects and pests, fertilizing, trimming and managing water, wherein the fermented bio-organic fertilizer is applied, thus the tea trees are environmental-friendly; the organic fertilizer is balanced in nutrition with various nutrient elements, so the tea trees are conducive to absorb nutrition and the soil is prevented from hardening; and during the growth period, the tee trees can generate effective health care components that are good for human body. By adopting the planting method to produce and manage the tea trees, the tea trees have the advantages of high production, good quality and strong disease-resisting ability and the tea leaves have the characteristics of beautiful color, fragrance and sweetness, thus satisfying the requirements of safety, good quality and nutrition; and the regional resource advantages and characteristic industrial advantages are fully developed, thus further motivating the mountainous farmers to get rid of poverty and become prosperous and bringing good social and ecological benefits.

Owner:贵州省凤冈县永田露茶业有限公司

Nutrient recovery process

ActiveUS20150329399A1Reduce concentrationHigh pHBio-organic fraction processingSludge processingAmmoniaSalt solution

An apparatus for recovering nutrients or water from digestate comprises one or more solid-liquid separation units, an ammonia stripping device, and a gas scrubbing unit. In a process, digestate is separated into a solids portion and a liquid portion. Ammonia is stripped from the liquid portion and converted into an ammonium salt solution which may be sold or used as, or blended with, a fertilizer product. Optionally, at least part of the remaining liquid portion may be concentrated to produce brine. The brine is mixed with the solids portion. The mixture may be dried and used as, or blended with, a fertilizer product. Optionally, a least part of the remaining liquid portion may be re-used as dilution water in a digester. A solids portion of the digestate, and one or both of an ammonium salt solution and a brine, may be used as fertilizer without thermal drying.

Owner:ANAERGIA

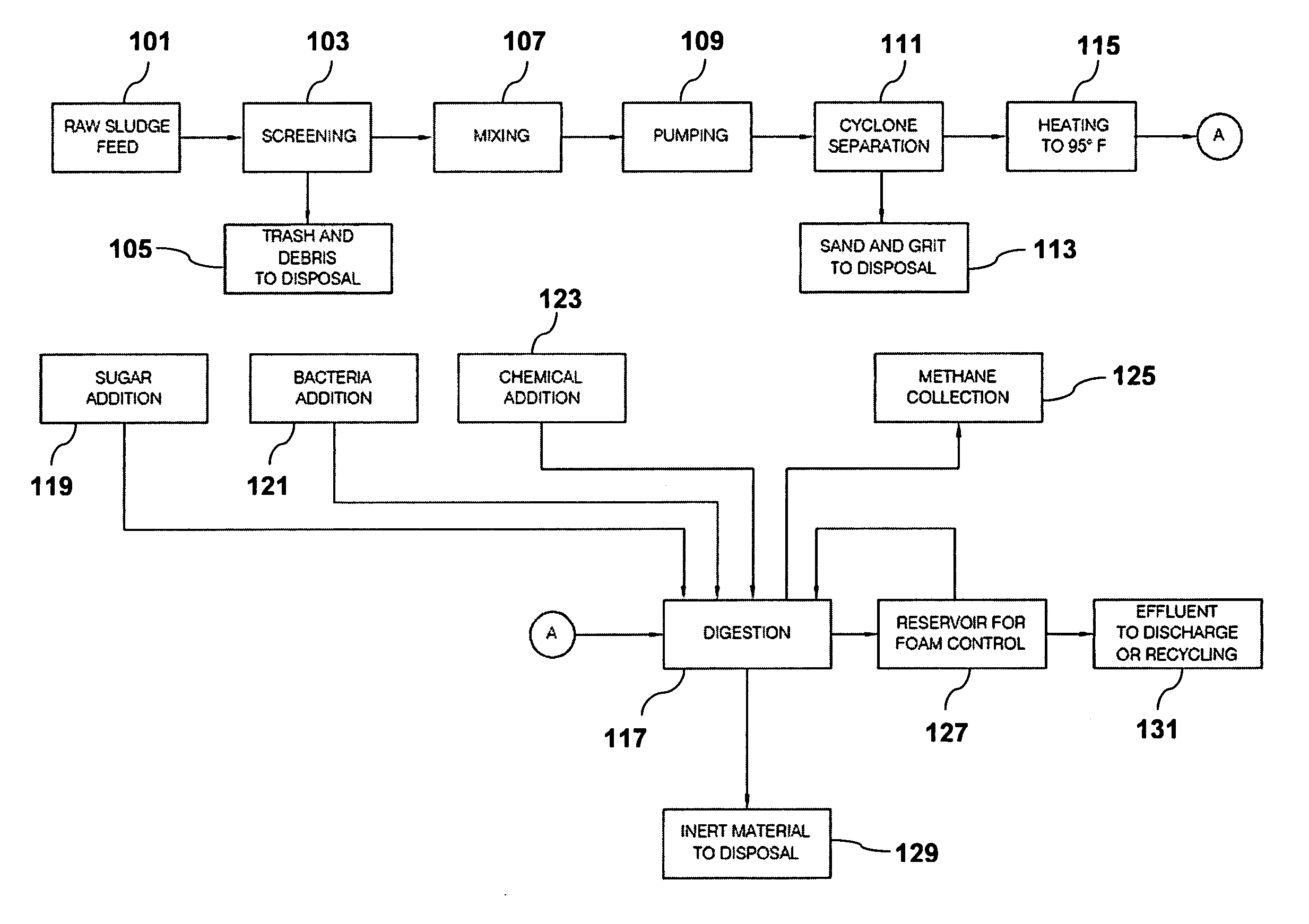

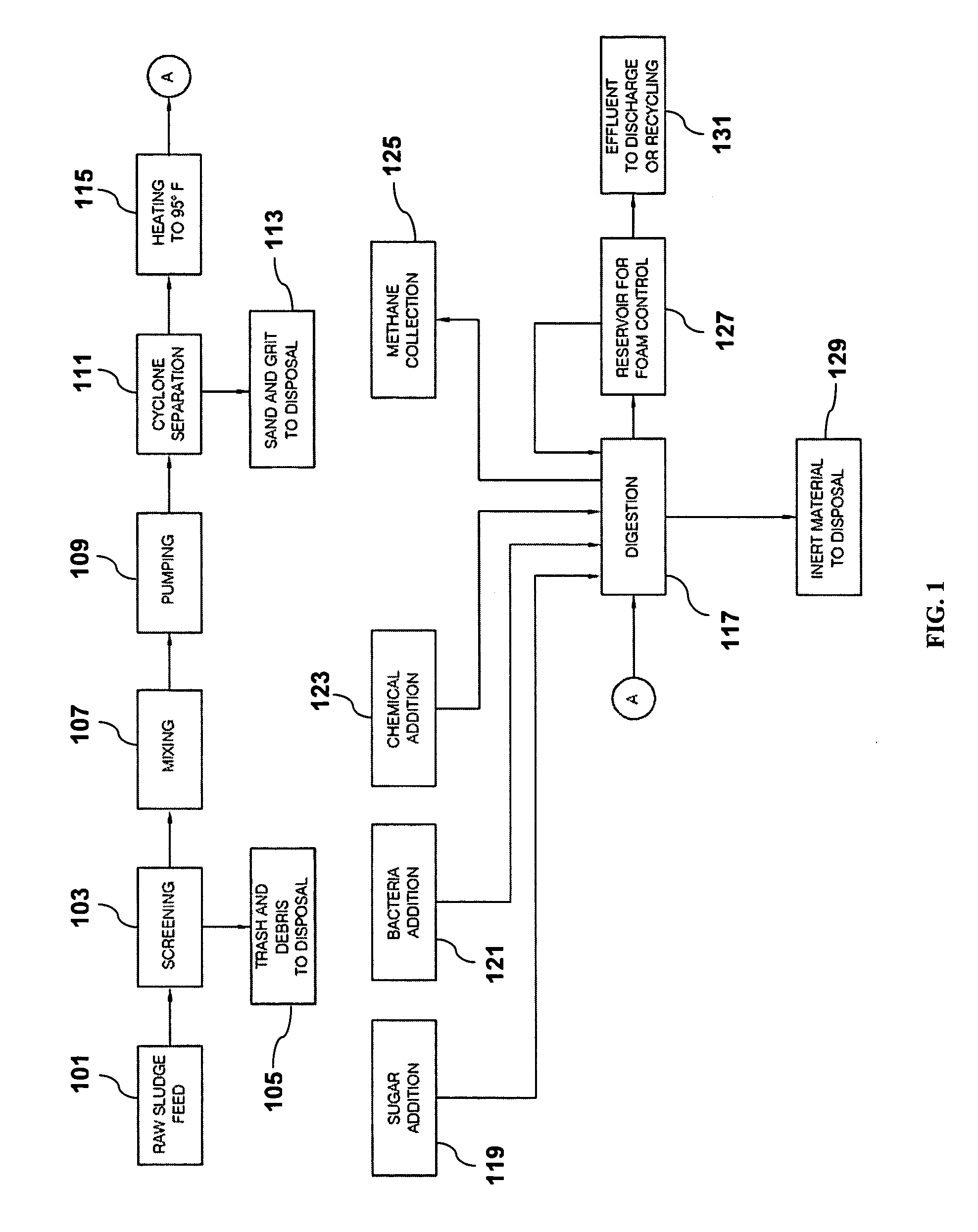

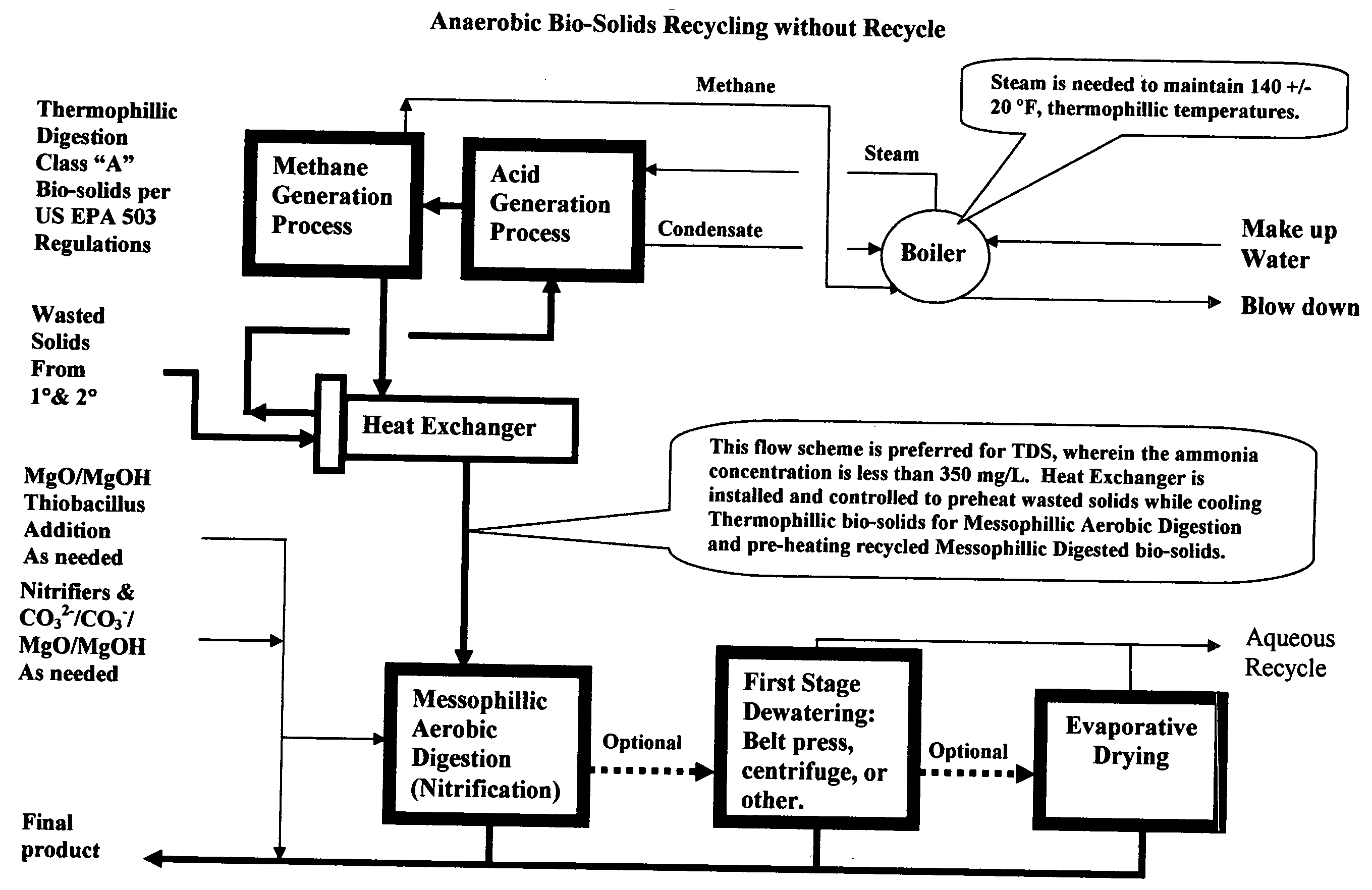

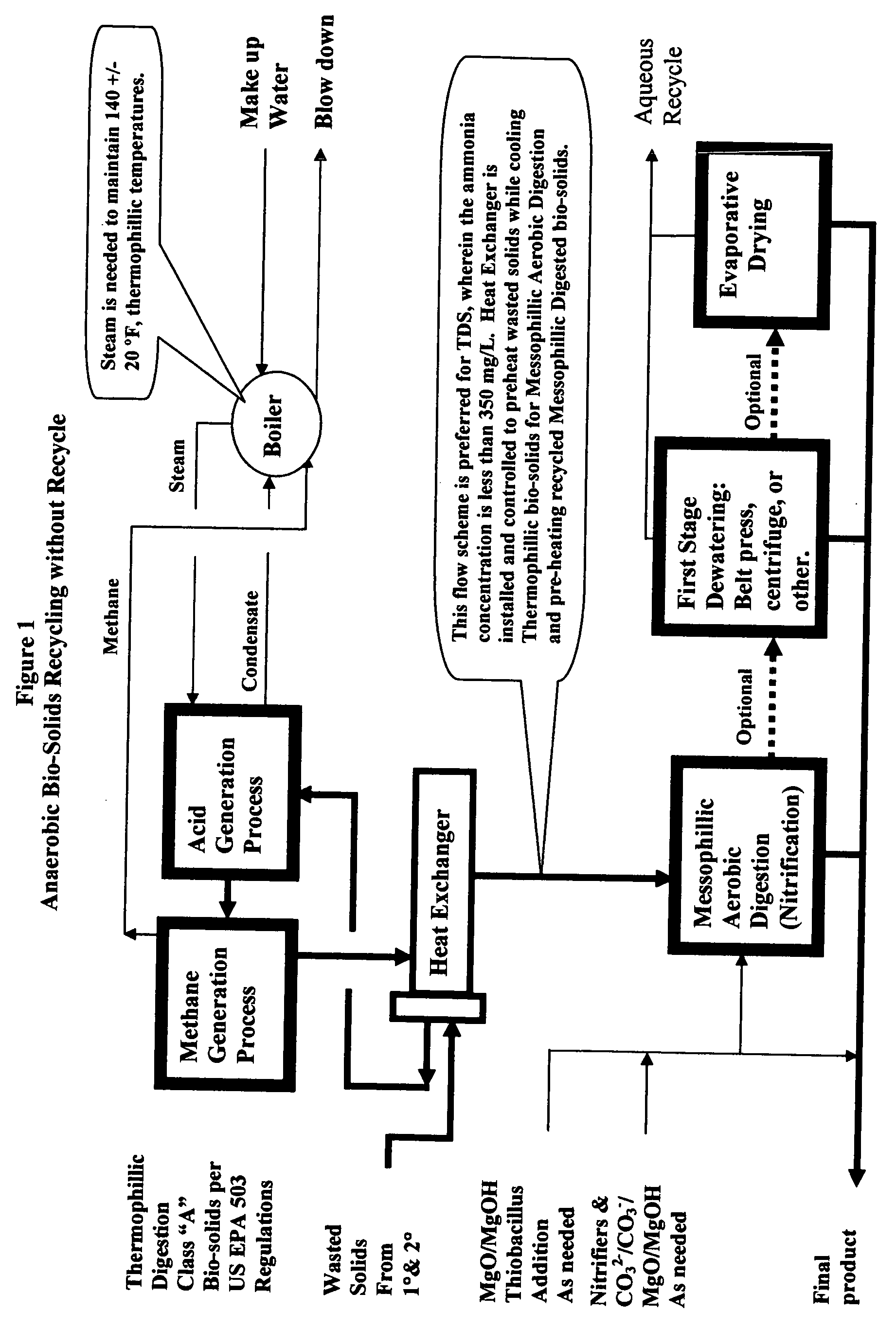

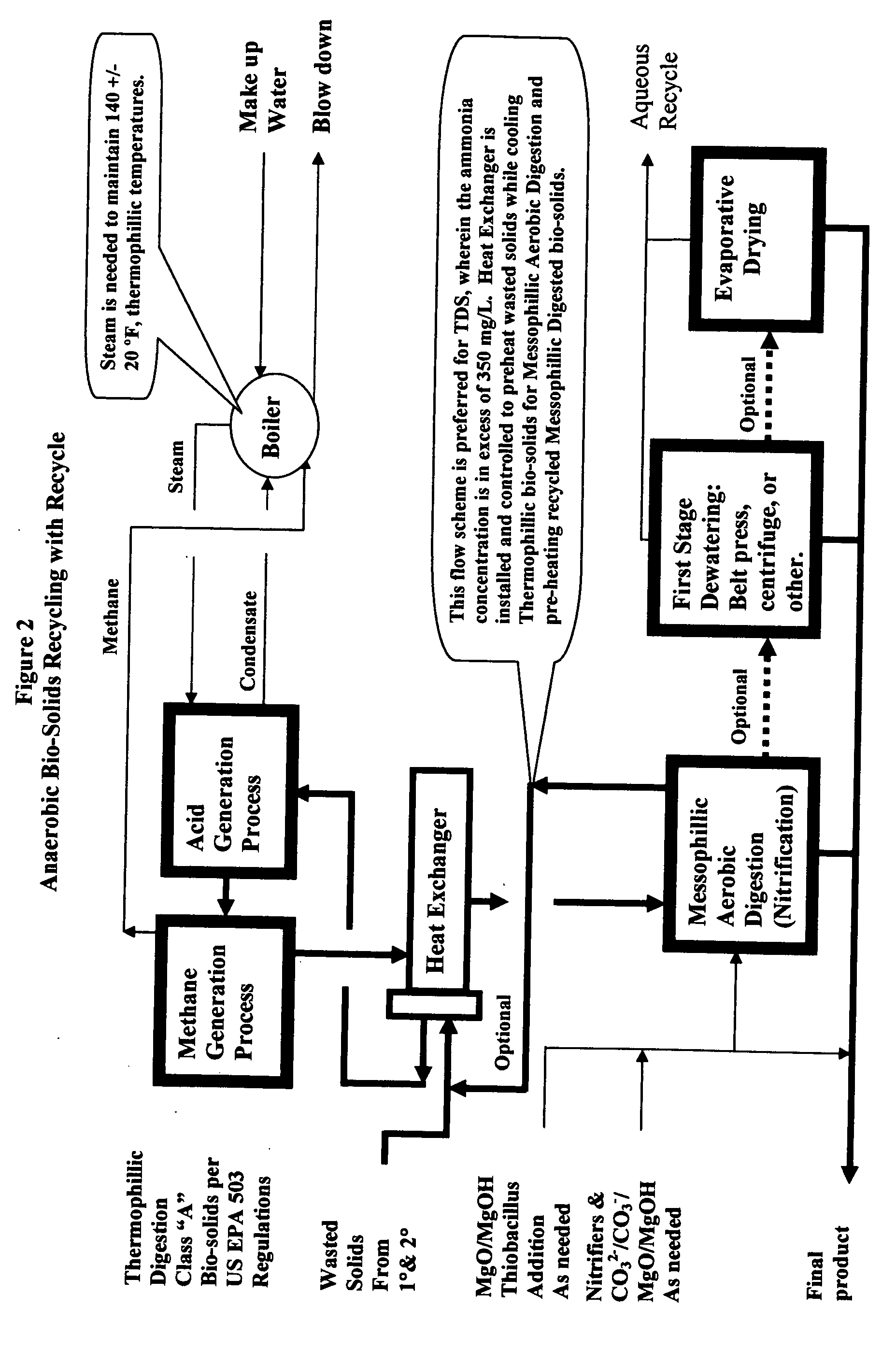

Methods, processes and apparatus for bio-solids recycling and the product of bio-solids from such methods, processes and apparatus

InactiveUS20050145566A1Effective, efficient and economically feasible digestionMinimal objectionable odorCalcareous fertilisersBio-organic fraction processingIron saltsDisinfectant

In the field of water treatment, this invention relates to economical methods, processes and apparatus for preparing Class A bio-solids wherein: dewatering costs and energy costs are efficient, the solids product has reduced ammonia and sulfide odor, and the concentration of solids in the aqueous solids may vary from approximately 3 to approximately 90 percent. This instant invention presents messophilic and thermophilic digestion in concert, wherein messophilic digestion incorporates strains of thiobacillus with nitrifiers to remove sulfide(s) and ammonia from bio-solids. Chemical dewatering of thermophilic digested bio-solids is accomplished incorporating a cationic, quaternized or an anionic polyacrylamide with at least one selected from a list consisting of: an aluminum salt, an iron salt, an amine comprising a quaternized nitrogen moiety and any combination therein. A quaternized polyacrylamide is presented alone. The use of magnesium oxide and / or magnesium hydroxide as a disinfectant / preservative for said bio-solids is also presented.

Owner:CLEARVALUE TECH

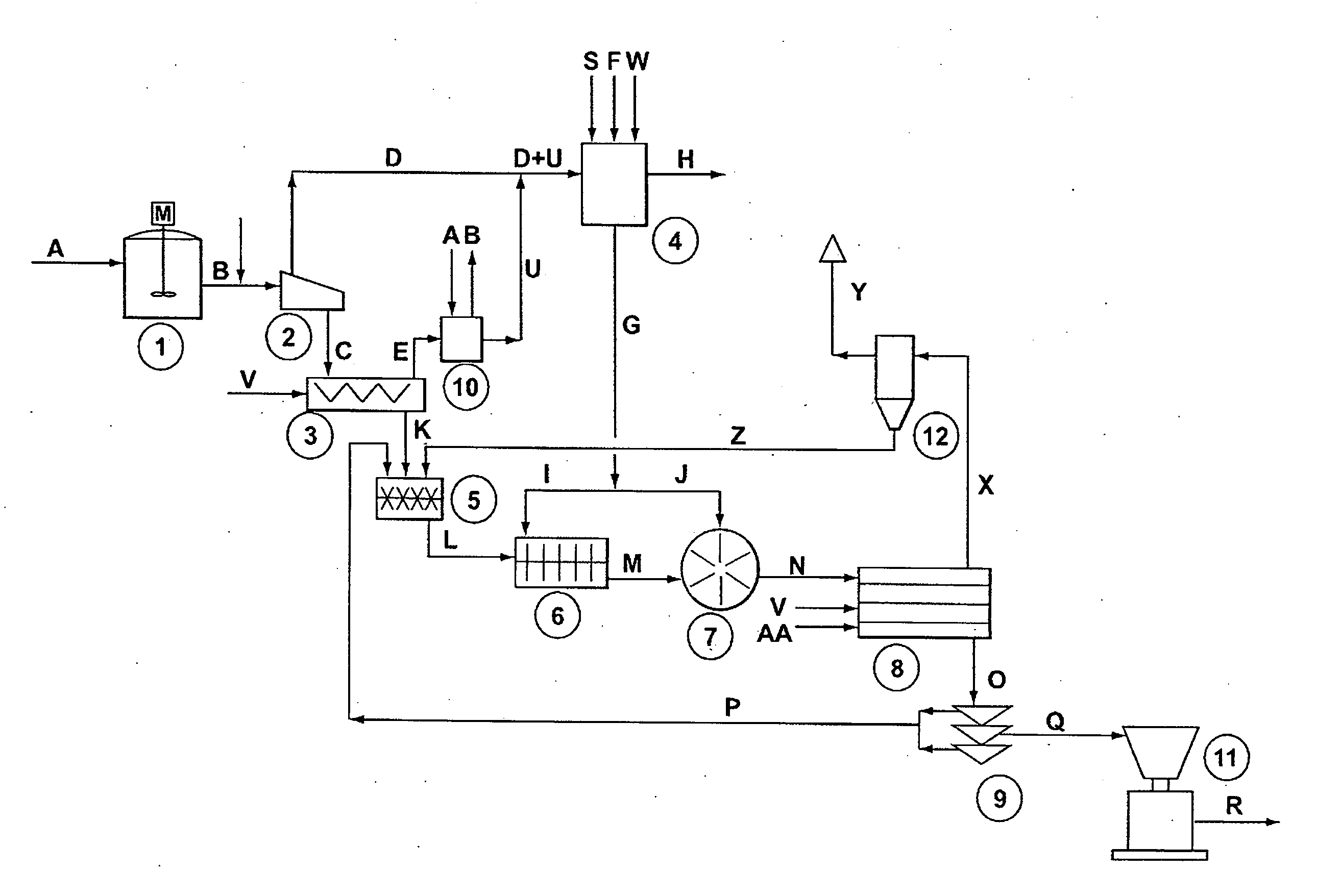

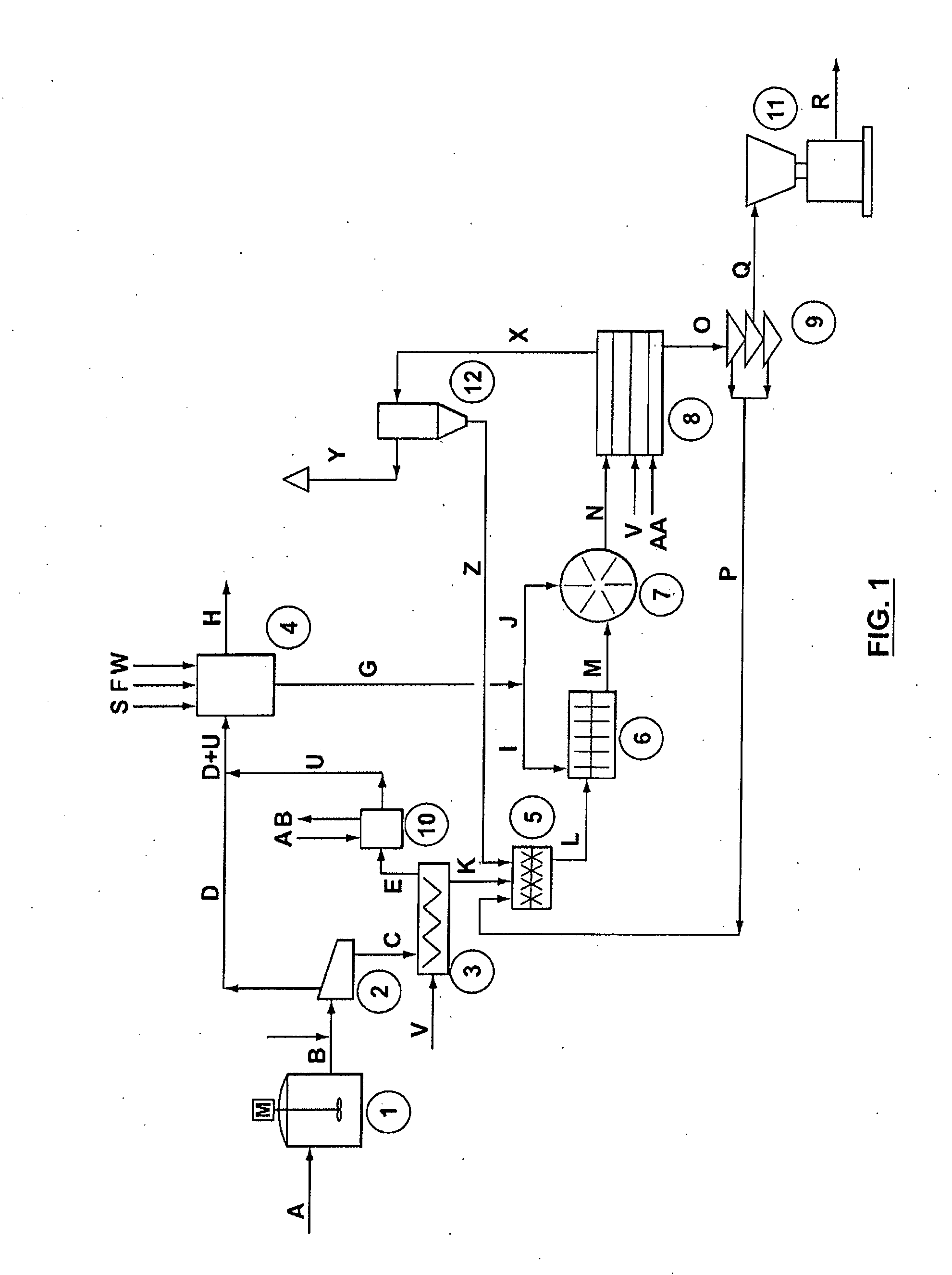

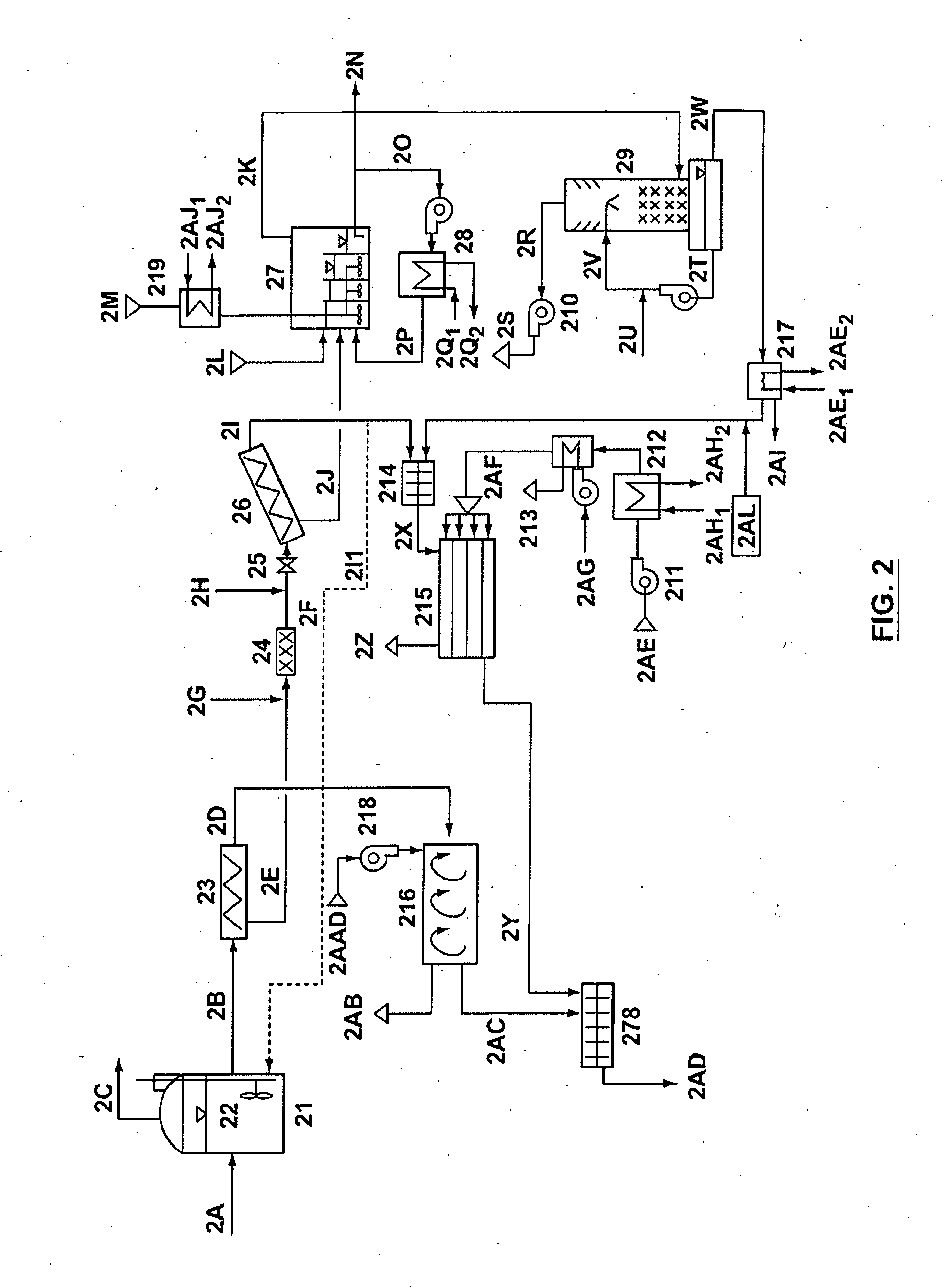

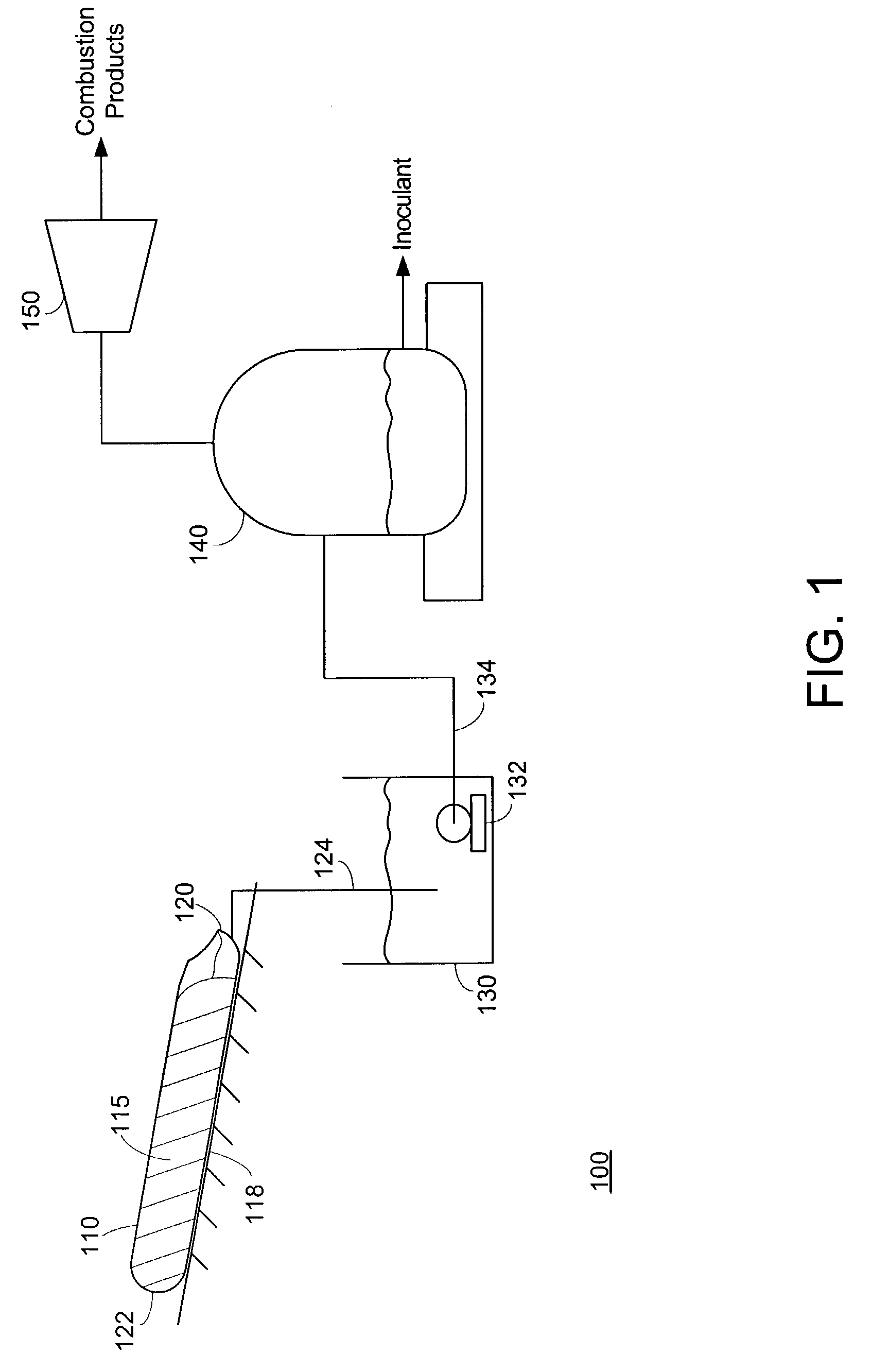

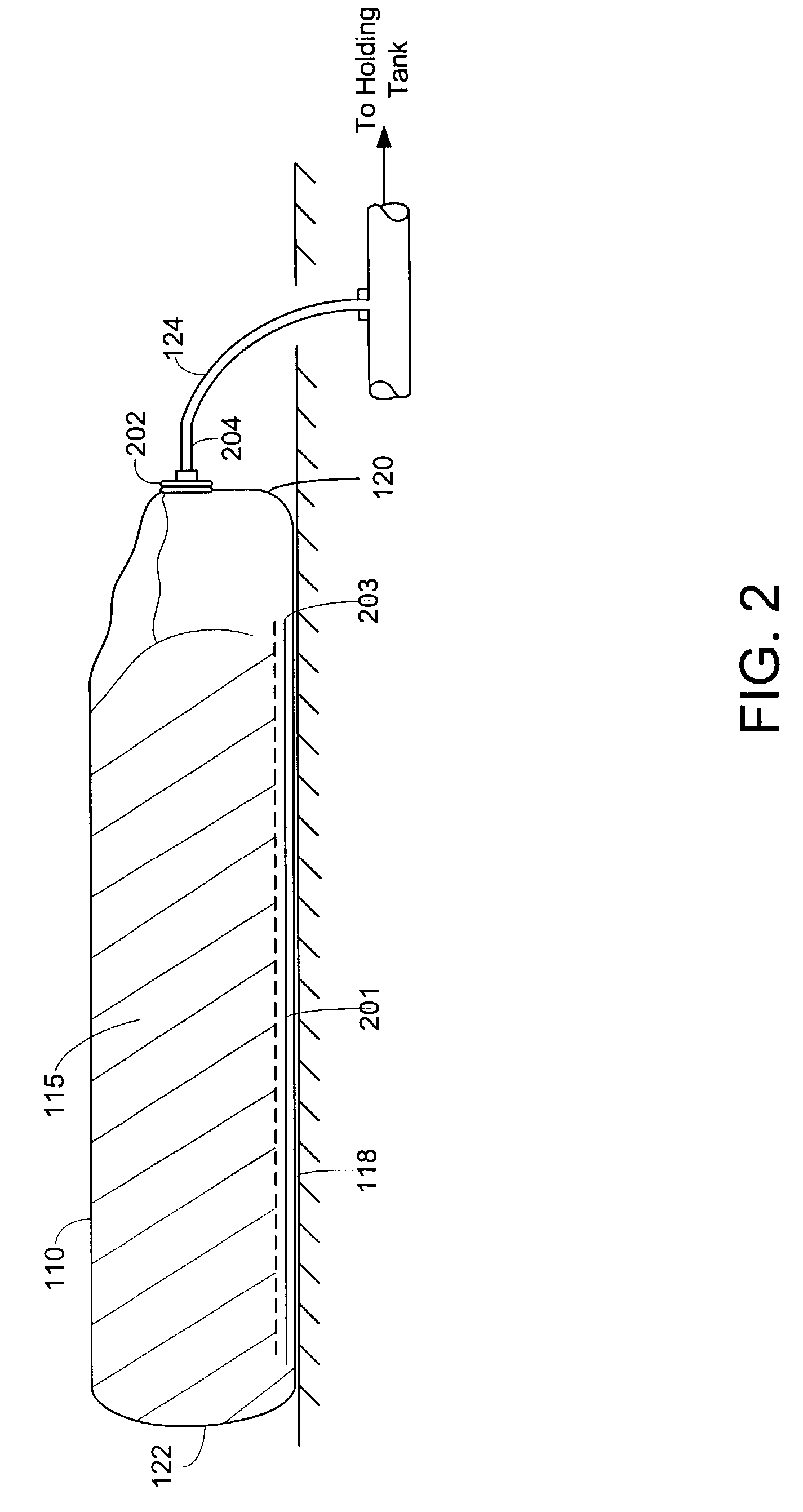

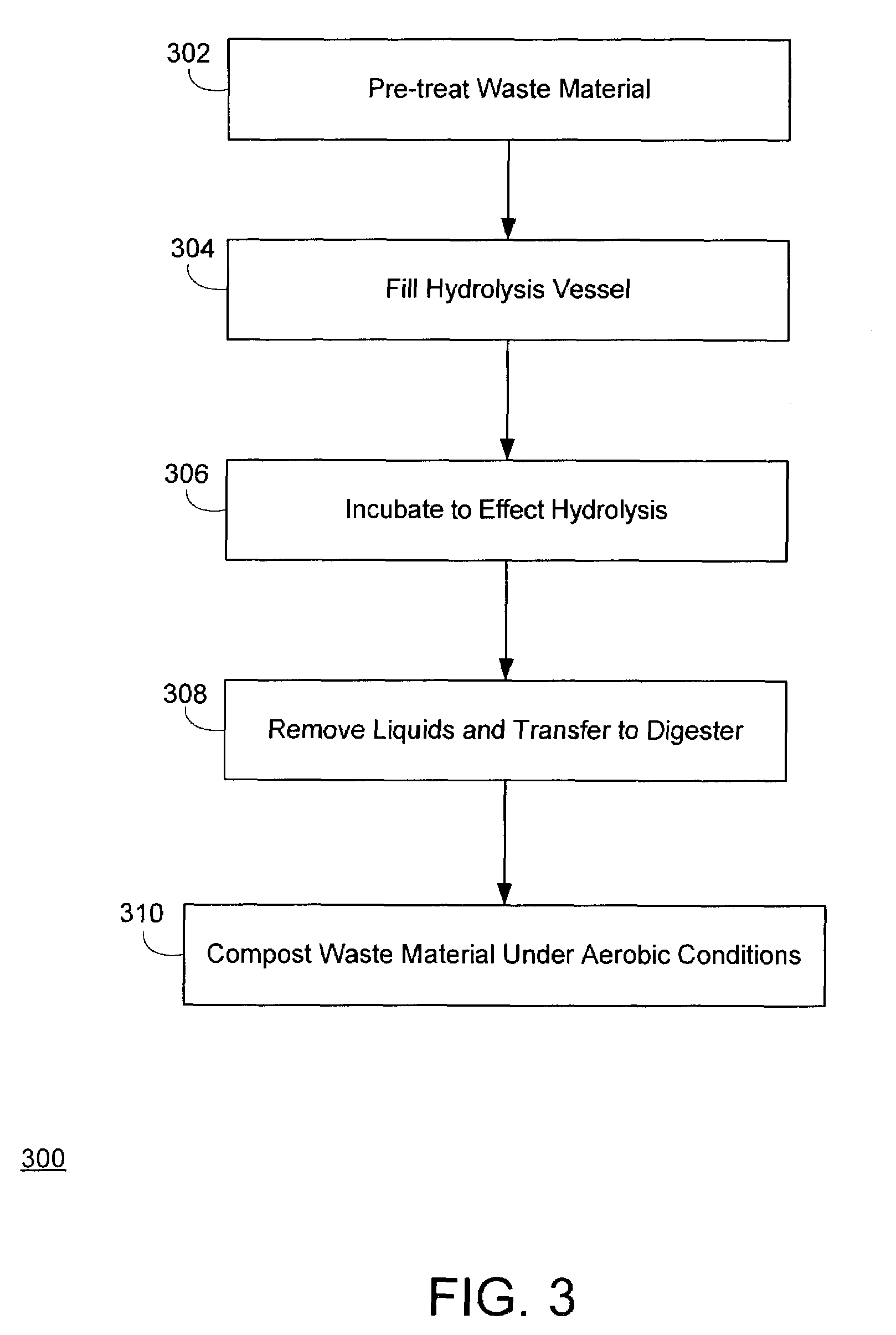

Process for treatment of organic waste materials

InactiveUS7015028B2Eliminate reduce emissionRapidly and inexpensively scale processBioreactor/fermenter combinationsBio-organic fraction processingElectricityLiquid product

A multi-stage process and system for treating organic waste materials includes steps of hydrolyzing the materials in an anaerobic vessel, transferring the liquid product of hydrolysis to an anaerobic digester, and further decomposing the waste materials under aerobic conditions to yield a compost product usable as a soil amendment. Biogas produced by digestion of the hydrolysis liquid product may be burned to generate electricity or heat, and the liquid digester product may be recirculated for use as an inoculant to aid hydrolysis of subsequently processed batches of waste materials.

Owner:RECOLOGY ENVIRONMENTAL SOLUTIONS INC

Method for preparing microbial fertilizer, nutrient solution, fodder and pesticide and for fermentation bed cultivation by utilizing indigenous microorganism probiotics

InactiveCN106831238AAchieve healthActivate reproductionBiocideBio-organic fraction processingFecesAmino acid

The invention relates to a method for preparing a microbial fertilizer, a nutrient solution, a fodder and a pesticide and for fermentation bed cultivation by utilizing indigenous microorganism probiotics. The microorganism probiotics are formed by fermenting eight pure natural materials, including indigenous bacteria, green juice, fresh fish amino acid, enzyme alcohol, Chinese prescription nutrient solution, lactic acid bacteria, natural calcium and water-soluble calcium phosphate potassium; the microorganism probiotics contain the mixed flock of various beneficial bacteria, such as, lactic acid bacteria, photosynthetic bacteria, bacillus and yeast; the fertilizer can be used for fertilizing and loosening soil; the agricultural products are free from residue, taste nice and are high in yield; the fodder can be used for guaranteeing no residue on the cultured animal meat product; the meat is tender and free from smell; after the microorganism nutrient solution is used, the microorganism pesticide can prevent and treat insect diseases; the chemical pesticide and the fertilizer residue can be eliminated and decomposed; when the fermentation bed is used for culturing, the excrement cleaning is not required; the animal excrement is decomposed by the fermented padding while beneficial mycoprotein is formed; the fodder can be eaten by the animals; the microbial fertilizer is odorless, zero-emission, environment-friendly, pollution-free to environment and beneficial to the health of human and animals.

Owner:刘富金

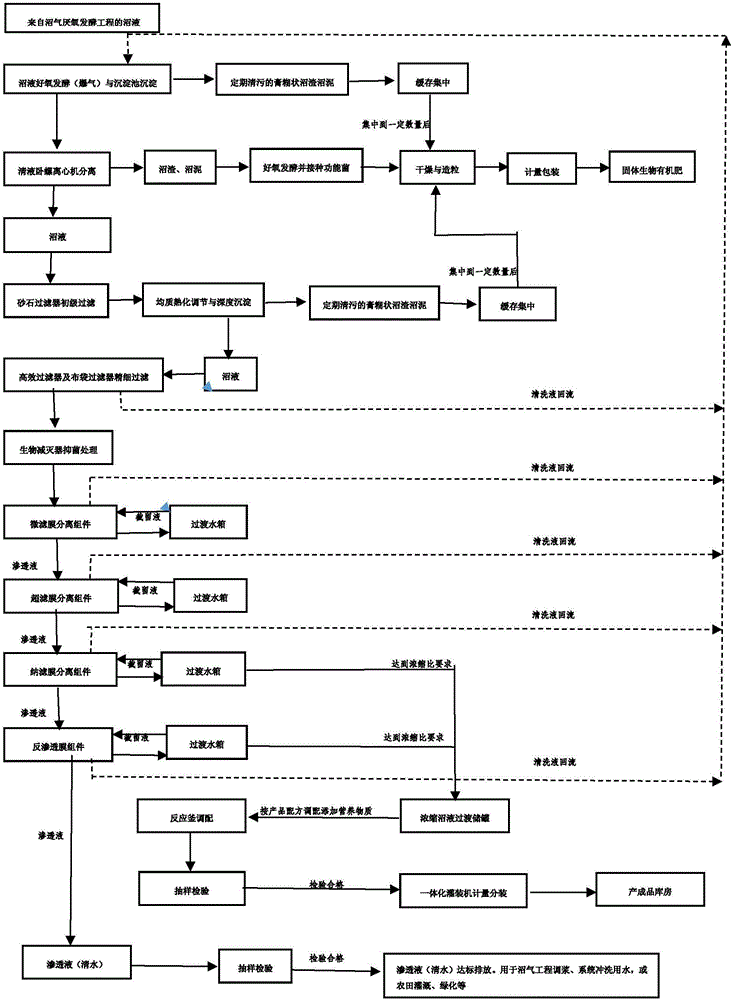

Production process for producing organic fertilizer through concentrating biogas slurry by using multistage membrane separation technology

InactiveCN106336253AFully removedReduce pollutionBio-organic fraction processingClimate change adaptationUltrafiltrationSeparation technology

The invention discloses a production process for producing an organic fertilizer through concentrating biogas slurry by using a multistage membrane separation technology; the production process comprises the following steps: a, pretreatment: carrying out pretreatment of biogas slurry after anaerobic fermentation through precipitation, aerobic fermentation, solid-liquid separation, primary filtration, homogeneous curing adjustment, deep precipitation, fine filtration and biological bacteria inhibition; b, multistage membrane separation before concentration: carrying out microfiltration membrane separation and ultrafiltration membrane separation of the biogas slurry after fine filtration and biological bacteria inhibition; c, multistage membrane concentration: carrying out multistage membrane concentration of the biogas slurry penetrated fluid obtained by ultrafiltration membrane separation through nanofiltration membrane concentration, reverse osmosis membrane concentration and concentration membrane protection; d, blending: adding large, medium and trace elements and other nutritional ingredients and functional components into the intercepted concentrate obtained by nanofiltration and reverse osmosis membrane separation, blending to obtain a liquid organic fertilizer, and sub-packaging; and e, product packaging. The production process has the advantages of flexible structure, advanced equipment and scientific process layout, can meet resource comprehensive utilization development of biogas slurry of all large and medium sized biogas projects.

Owner:NINGXIA SHUNBAO MODERN AGRI CO LTD

Bio-organic fertilizer and preparation method thereof

InactiveCN106748524ASolve pollutionRealize resource utilizationBio-organic fraction processingExcrement fertilisersLivestock manurePotassium

The invention discloses a bio-organic fertilizer. The bio-organic fertilizer comprises the following raw materials in parts by weight: 80-100 parts of livestock manure, 30-50 parts of rice bran, 50-80 parts of manioc waste, 10-30 parts of filter mud, 5-10 parts of plant ash, 5-10 parts of decoction residue, 1-5 parts of potassium fulvic acid, 1-5 parts of biological bacterium, 5-10 parts of zymophyte, and 1-5 parts of compound additive. According to the bio-organic fertilizer, livestock manure, rice bran, manioc waste, filter mud and other agricultural wastes are fermented twice to obtain the bio-organic fertilizer, thus the recycling is achieved, the wastes are turned into treasure, and the problem of organic matter caused environmental pollution can be solved. The invention further provides a preparation method of the bio-organic fertilizer. The preparation method is characterized in that the raw materials are uniformly mixed and then subjected to first fermenting and second fermenting; oxygen is charged during the first fermenting, so that the fermenting is sped up, and the fermenting time is reduced; the bio-organic fertilizer prepared by twice full fermenting is outstanding in effect, does not cause soil hardening, and is environmentally friendly.

Owner:广西南宁奥浦森肥业有限公司

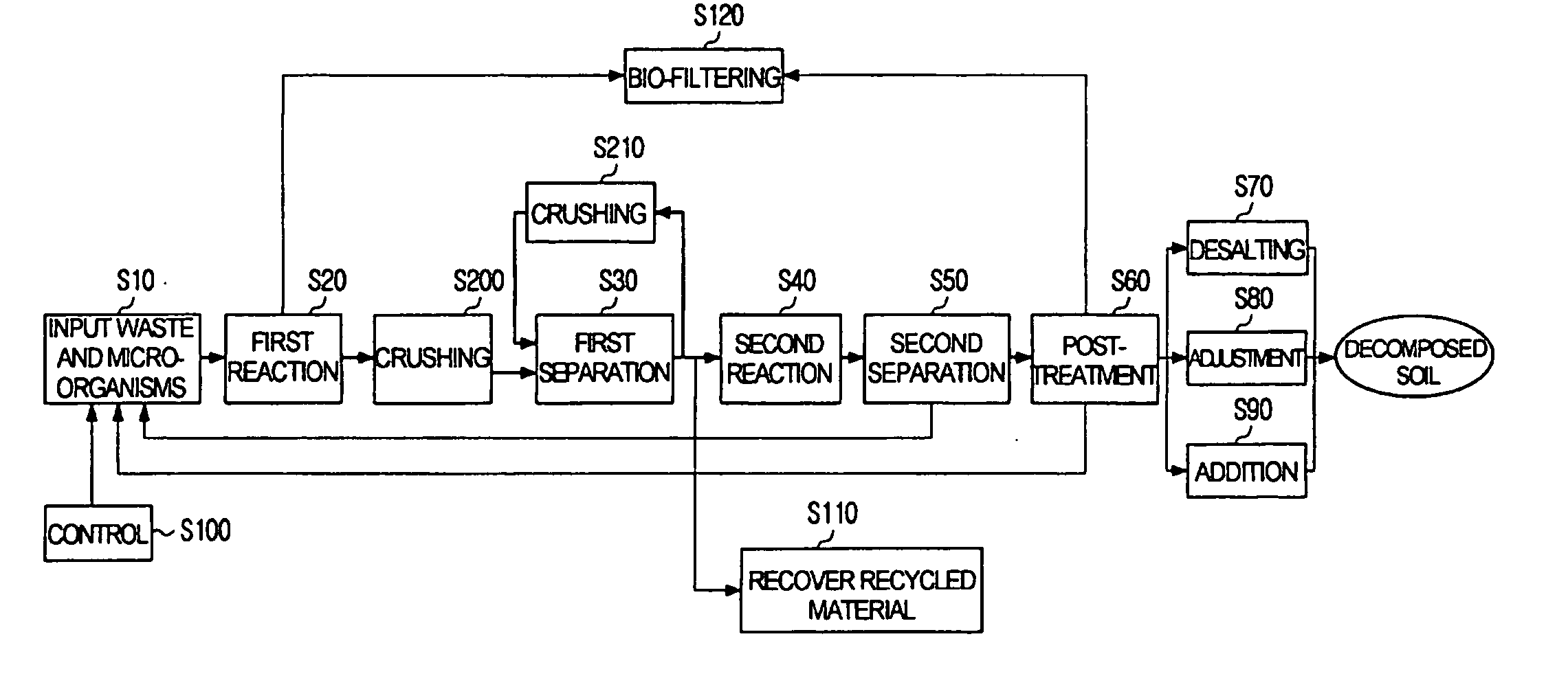

Municipal solid waste treatment method and apparatus

ActiveUS20050199028A1Quantity minimizationReduce the amount of wasteBioreactor/fermenter combinationsBio-organic fraction processingAir cycleForeign matter

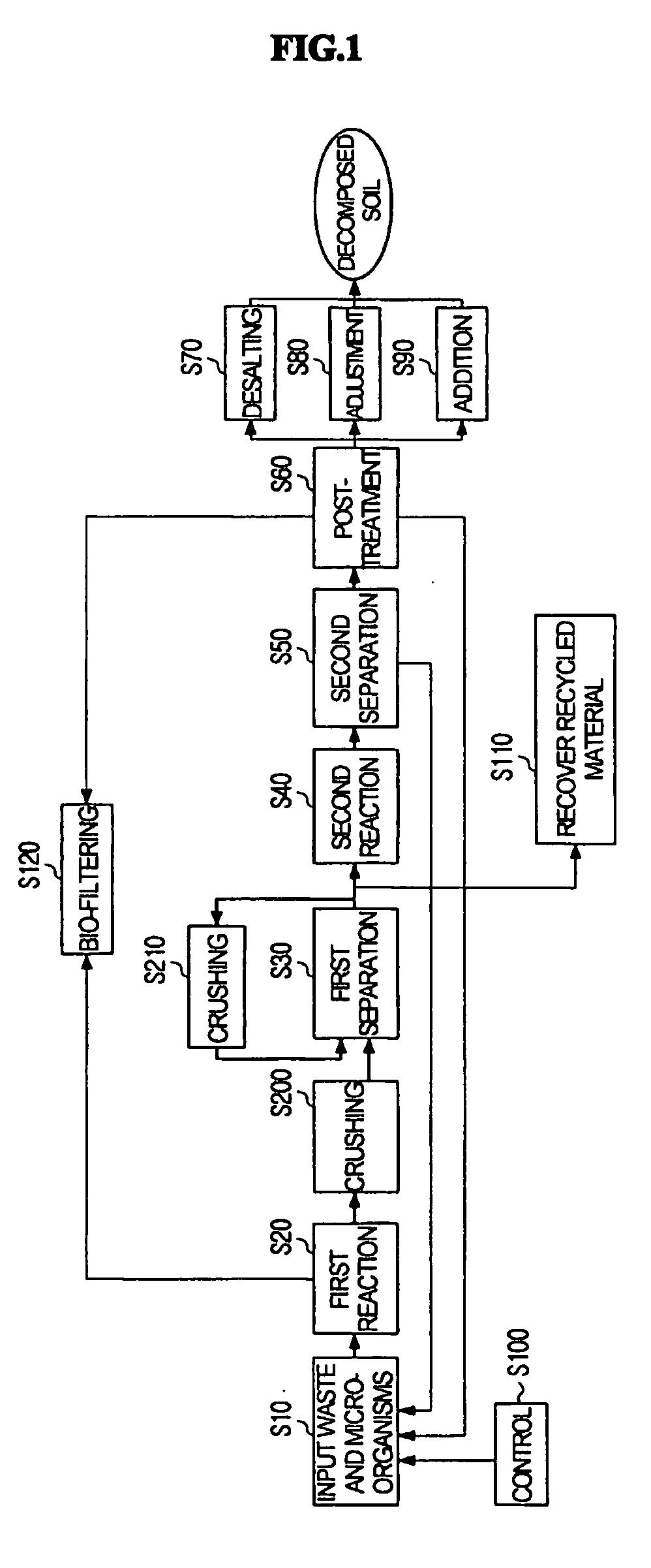

The present invention pertains to a method and an apparatus for treating municipal solid waste, and more particularly to a method and an apparatus for treating and recycling municipal solid waste not separately collected, and also for minimizing the amount of final waste to be buried. To this end, the present invention is characterized by comprising the steps of: an input step of inputting the municipal solid waste and microorganisms to a reactor; a first reaction step of firstly reacting the municipal solid waste with the microorganisms input to the reactor in the input step; a first separation step of transferring first intermediate matters completing the first reaction in the reactor to a first separator and then separating organic matters (it may also comprise small-sized inorganic matters passing through the screen of the first separator, also referred to as “second intermediate matters”) and inorganic matters, further comprising a recycled material recovering step of separating and recovering the recycled material by properties for recycling the inorganic matters; a second reaction step of transferring second intermediate matters passing through the first separator to a decomposing field constructed with good air circulation and then carrying out second reaction of the second intermediate matters; a second separation step of transferring third intermediate matters completing the second reaction in the decomposing field to a second separator and then separating foreign matters from the third intermediate matters; and a post-treatment step of post-treating fourth intermediate matters separated in the second separation step to make a final material.

Owner:BIOCON LTD

An organic fertilizer manufacturing process through dual processing with microbial strains and earthworms

InactiveCN104529571AImprove fertilityEasy to produceBio-organic fraction processingExcrement fertilisersFiberMicroorganism

An organic fertilizer manufacturing process through dual processing with microbial strains and earthworms is provided. An organic fertilizer is manufactured from plant fiber, poultry manure, the microbial strains and the earthworms. The produced organic fertilizer is capable of obviously improving soil fertility and loosening soil, is simple and convenient in a production process and low in cost, and brings farmers with the earthworms, and other by-products.

Owner:PUDING HEYE BIOLOGICAL ORGANIC FERTILIZER

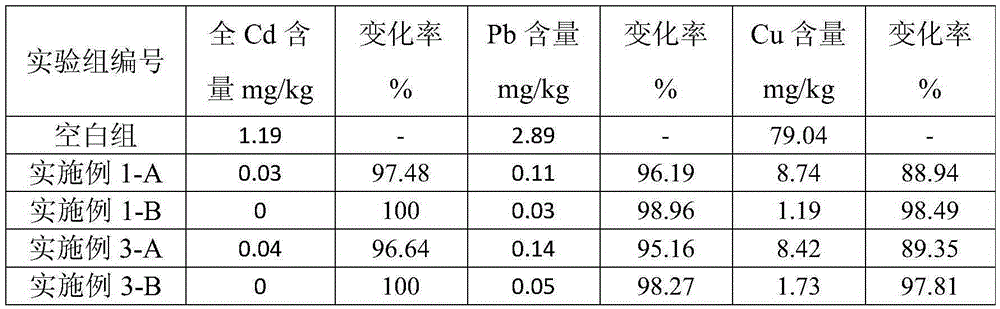

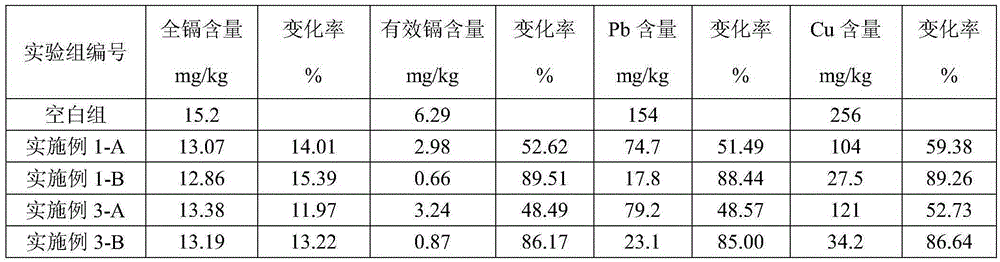

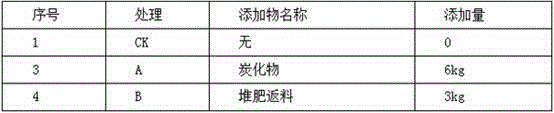

Biological organic repairing agent for soil pollution and application and preparation method thereof

InactiveCN105347884AReduce absorptionReduced enrichmentBio-organic fraction processingExcrement fertilisersBiotechnologyPollution

The invention relates to the field of soil fertilizer and provides a biological organic repairing agent for soil pollution and its application and preparation method. The biological organic repairing agent of the invention is composed of, by weight, 1.5-3 parts of eymogenic bacterium, 1-1.5 parts of wheat bran, 1.5-2 parts of molasses meal, 45-50 parts of ammonium humate, 45-50 parts of hydrolase dregs, 150-200 parts of soybean meal, 100-150 parts of humic acid powder, 80-100 parts of zeolite powder, 25-40 parts of a calcium magnesium phosphate fertilizer, 150-200 parts of cattle and sheep manure, 150-204 parts of plant straw, 25-40 parts of potassium humate, 1.5-3 parts of bacillus mucilaginosus, 1-1.5 parts of Gliocladium roseum, 1.5-2 parts of Streptomycesvinaceus-drappus, 1-1.5 parts of trichoderma spp, 1-1.5 parts of Paecilomyces lilacinus, 1-1.5 parts of bacillus subtilis and 1-1.5 parts of micrococcus. According to the invention, soil pollution control, improvement and nutrition are integrated.

Owner:HEBEI CIXIN ENVIRONMENTAL PROTECTION TECH CO LTD

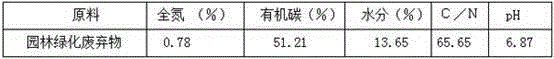

Garden plant waste composting method

InactiveCN104402546AWide variety of sourcesRealize harmless treatmentBio-organic fraction processingBiological combination treatmentGarden plantsEnvironmental engineering

The invention discloses a garden plant waste composting method. The method comprises the following steps: (1) collecting garden plant wastes, and sorting the wastes; (2) trimming the branches, and the cutting the trimmed branches into pieces; (3) placing the pieces into a fermentation tank, adding a conditioning agent and EM bacterium agent, and then adjusting the organic substance content, water content, and carbon / nitrogen ratio to carry out primary compost fermentation; (4) grinding the compost to obtain compost powder; (5) placing the compost powder into the fermentation tank again, adding a compost decomposing agent and compost auxiliary materials, evenly mixing, and controlling the water content, temperature, introduced gas amount, carbon / nitrogen ratio, carbon / phosphorus ratio, and pH to carry out secondary compost fermentation; (6) stacking the secondary compost in an aging warehouse, blowing air into the warehouse to promote heat dissipation and water evaporation, and finally storing the qualified decomposed compost in a warehouse after detection. The method has the advantages of simple operation, rapid fermentation, and low production cost and is suitable for massive production in factory. Furthermore, the quality of the produced compost is high.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

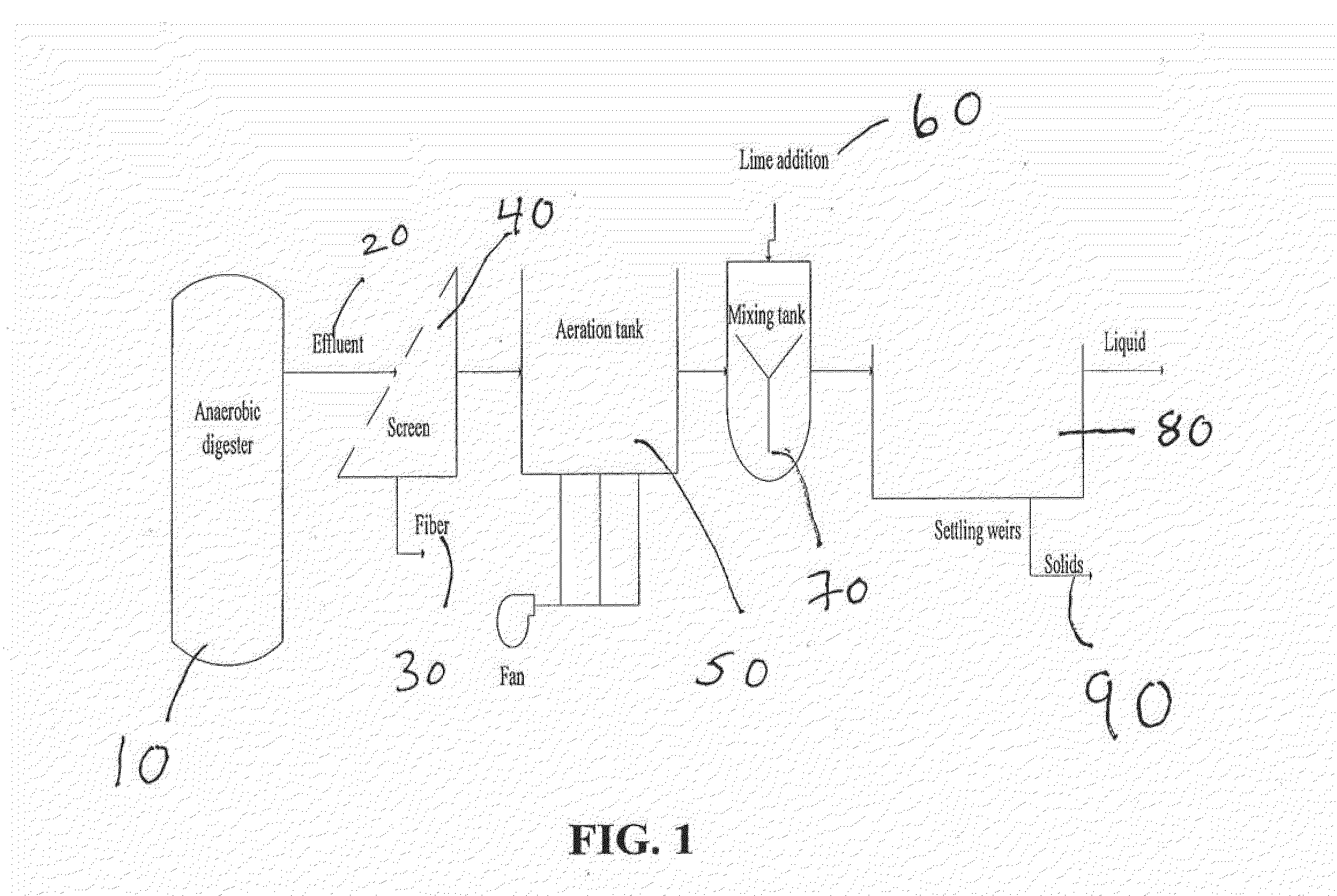

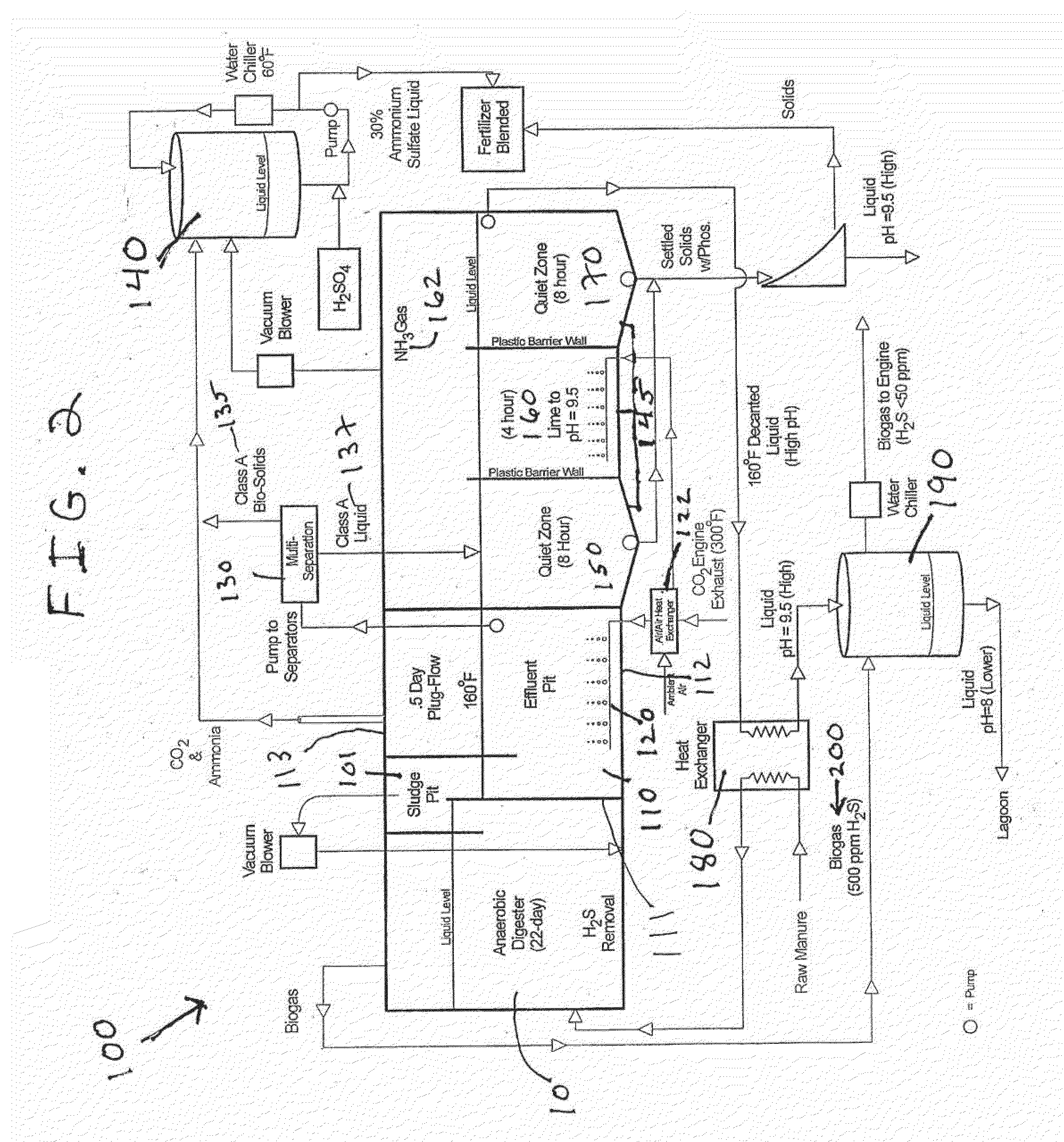

Nutrient recovery systems and methods

ActiveUS20120118035A1Large levelHigh recovery rateBio-organic fraction processingBioloigcal waste fertilisersAeration rateBiology

Methods, systems, and apparatuses for anaerobic digestion of waste fibrous material and the recovery of nutrients are provided. Methods, systems, and apparatuses disclosed herein provide mechanisms to release dissolved gases from anaerobic digester effluent. Methods, systems and apparatuses disclosed herein can recover one or more nutrients from anaerobic digested effluent using a range of temperatures, aeration rates, aeration times, pH ranges, and settling times.

Owner:DVO +2

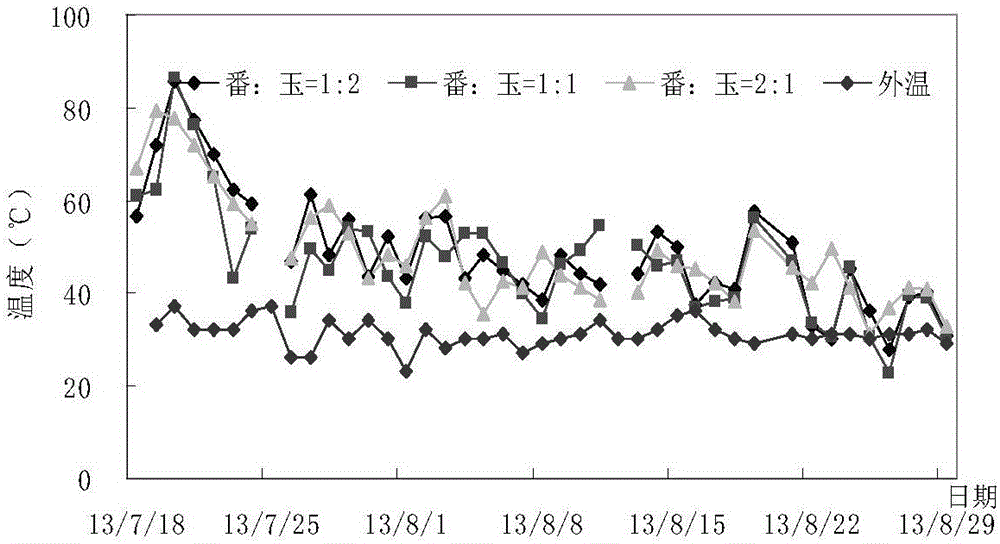

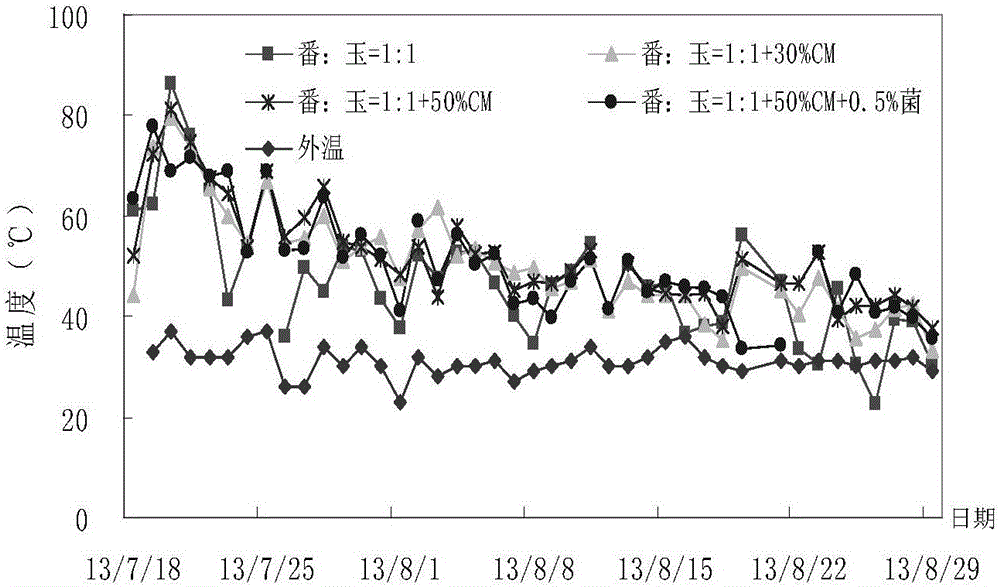

Vegetable residue, crop straw and livestock and poultry excrement combined composting process

ActiveCN106220260AReduce moisture contentSolve the low carbon nitrogen ratioBio-organic fraction processingExcrement fertilisersAgricultural scienceHigh carbon

The invention provides a vegetable residue, crop straw and livestock and poultry excrement combined composting process. An aerobiotic and anaerobic combined composting mode is adopted in the process. The process comprises the steps of material pretreating, mixing, composting, primary fermenting, secondary fermenting, thorough decomposing, sieving or smashing, compost preparing and the like. Crop straw with a high-carbon nitrogen ratio is used, and the problems of high moisture content, low carbon-nitrogen ratio and poor air permeability existing in the high-temperature aerobiotic composting process of vegetable residues are effectively solved; according to the process, the nutrients and moisture of the vegetable residues can be utilized, harmless treatment can be carried out on the vegetable residues, the crop straw and livestock and poultry excrement through high-temperature composting, organic compost is produced, and resource utilization of planting and breeding waste is achieved.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT HEBEI ACADEMY OF AGRI & FORESTRY SCI

Water and fertilizer retention organic fertilizer and preparation method thereof

InactiveCN104326848AExtended release timeImprove water and fertilizer retention performanceBio-organic fraction processingBioloigcal waste fertilisersSlagChelated zinc

The present invention discloses a water and fertilizer retention organic fertilizer made of the following raw materials by weight: 20-30 parts of sorghum straw charcoal powder, 6-8 parts of river silt, 2-3 parts of potassium mineral powder, 1-2 parts of calcium hydrogen phosphate, 4-5 parts of EDTA chelated zinc, 4-6 parts of died sweet potato, 5-6 parts of fulvic acid, 4-5 parts of durian shell, 3-4 parts of sunflower oil slag, 4-5 parts of potassium sulfate, 6-8 parts of ammonium nitrate, 35-45 parts of rape straw, 6-8 parts of gracilaria lemaneiformis, 8-10 parts of safflower seed oil residue, 20-30 parts of a soil conditioner, and the proper amount of water; the raw materials adopted by the fertilizer are wide in sources, are mainly non-pollution production waste, and effectively reduce the production cost, by a compounded coated granular structure, the fertilizer release time can be prolonged, soil water and fertilizer retention capacity can be improved, and the soil absorption, buffer and resistance properties can be improved.

Owner:MAANSHAN KEBANG ECO FERTILIZER

Biological organic fertilizer and production technology thereof

InactiveCN106883063ASpeed up rapid reproductionEasy to handleBio-organic fraction processingExcrement fertilisersFiberDigestion Treatment

The invention provides a biological organic fertilizer and a production technology of the biological organic fertilizer. The biological organic fertilizer comprises the following raw materials in parts by weight: 35-45 parts of vinasse, 25-35 parts of chicken manure, 5-16 parts of mushroom dreg, 7-15 parts of rice bran powder, 7-15 parts of straw and 0.01-0.03 part of a composite microorganism inoculant. The vinasse adopted by the biological organic fertilizer is small red sorghum 0 sauced vinasse, contains higher crude fat, crude fiber, crude protein and amino acid, is easy to corrupt, can accelerate rapid reproduction and digestion treatment of microorganisms, can shorten the production time of the organic fertilizer, and can increase microorganism culture content of the organic fertilizer; and the produced organic fertilizer can realize the characteristics of high crop yield, high nutrient substance content and high disease and insect resistance by selection of culture variety and quantity and improvement of the production technology.

Owner:遵义君宇生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com