Patents

Literature

326results about How to "Reduced enrichment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous casting crystallizer protective scoria for weathering steel and manufacturing method thereof

InactiveCN101125357AReduce the formation of rare earth oxidesReduced enrichmentScoriaHeat transmission

The present invention relates to a continuous casting mold protecting powder and the manufacturing method of the mold protecting powder for a weathering steel. Adopting the making art of spraying particle, the mold protecting powder is made from the materials such as premelting material, quartz sand, fluorite, industrial calcined soda, magnesite, medium supper soot carbon, graphite, lithium carbonate and so on, chemical ingredients of the mold protection powder in weight percentage are as follows: SiO2 30.0 to 37.0 percent, CaO 30.0 to 37.0 percent, Al2O3 2.0 to 5.0 percent, MgO 3.0 to 6.0 percent, Li2O 1.5 to 2.5 percent, Na2O 5.5 to 8.5 percent, F 4.5 to 7.5 percent, TC(totally carbon) 4.5 to 6.5 percent, 0< Fe2O3 less than or eqal to 1.0%, binary alkalinity CaO / SiO2 is 0.95 to 1.05. The mold protecting powder regarding the invention melts evenly inside the mold and has weak reaction with the rare earth wire, excellent lubricating performance to the casting blank, even and proper heat transmission between the continuous casting mold and the casting blank, therefore reducing the ingot bleeding rate and the occurance rate of surface vertical flaws.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Functional fertilizer and repair agents for repairing soil heavy metal

ActiveCN103788960AReduce the content of high-priced heavy metal ionsLow ion contentAgriculture tools and machinesOrganic fertilisersSolubilitySoil heavy metals

The invention discloses functional fertilizer and repair agents for repairing soil heavy metal. Modified attapulgite, chitosan, biochar and sodium thiosulfate are compounded, and on one hand, the absorption performance of the attapulgite and the biochar and the chelation of the chitosan are used for fixing heavy metal ions in soil and preventing the heavy metal ions in the soil from migrating through leaching and runoff. On the other hand, the sodium thiosulfate is used for restoring the high-valence-state heavy metal ions (like hexavalent chromium ions) to low-valence-state ions (like trivalent chromic ions), and therefore virulence and solubleness of the ions are reduced.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

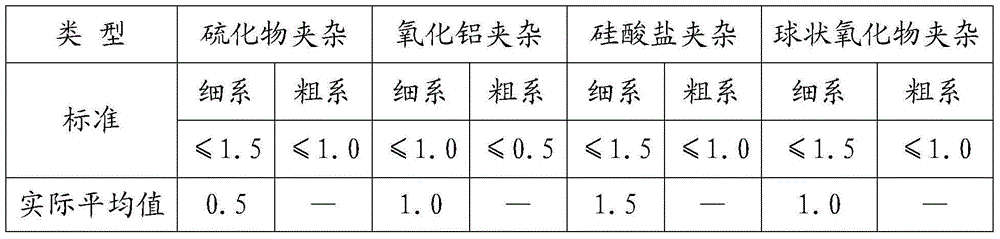

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

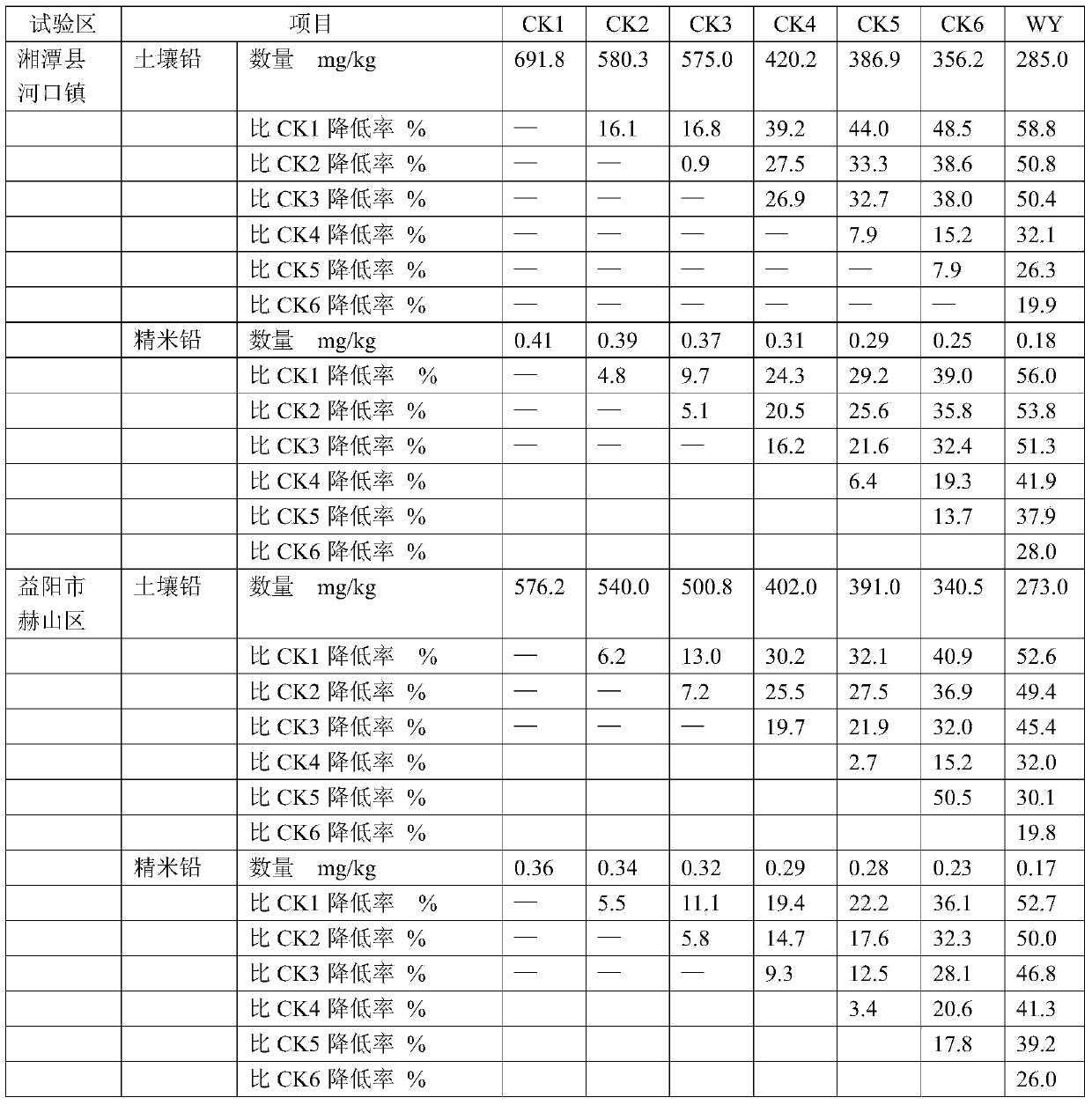

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

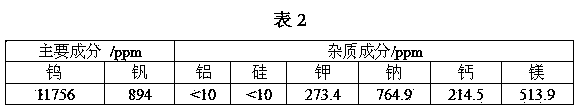

Method for recycling waste SCR (Selective Catalytic Reduction) catalyst

ActiveCN103849774AReduce processing costsReduce processProcess efficiency improvementNatural resourceWater baths

The invention discloses a method for recycling a waste SCR (Selective Catalytic Reduction) catalyst. The method comprises the following steps: blowing off dust of the waste SCR catalyst, washing and drying the waste SCR catalyst and grinding the waste SCR catalyst into powder, then adding sodium carbonate into the powder to mix evenly, and finally, roasting the powder in a high-temperature furnace to obtain a roasted material; grinding the roasted material again, adding the ground roasted material into a dilute sulphuric acid solution, preserving heat and stirring in a water bath for hours, using ammonia water to adjust pH value to be 8-11, and then filtering to obtain a recycling liquid containing vanadium, tungsten or molybdenum. The invention provides a novel method for recycling and processing the waste SCR catalyst, so that the problem that the waste SCR catalyst occupies a large quantity of land and causes secondary pollution can be effectively solved; and meanwhile, heavy metal components in the waste SCR catalyst are fully used, so that valuable natural resources are saved. In addition, the problem that the vanadium, the tungsten or the molybdenum in the normal method of recycling the waste catalyst is difficultly separated and purified can be avoided, the technical process of recycling the waste SCR catalyst is shortened and the recycling cost is reduced.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Method for extracting high-purity squalene by taking olive oil as raw material

ActiveCN101597204AIncrease productionImprove qualityDistillation purification/separationAdsorption purification/separationDistillationEvaporation

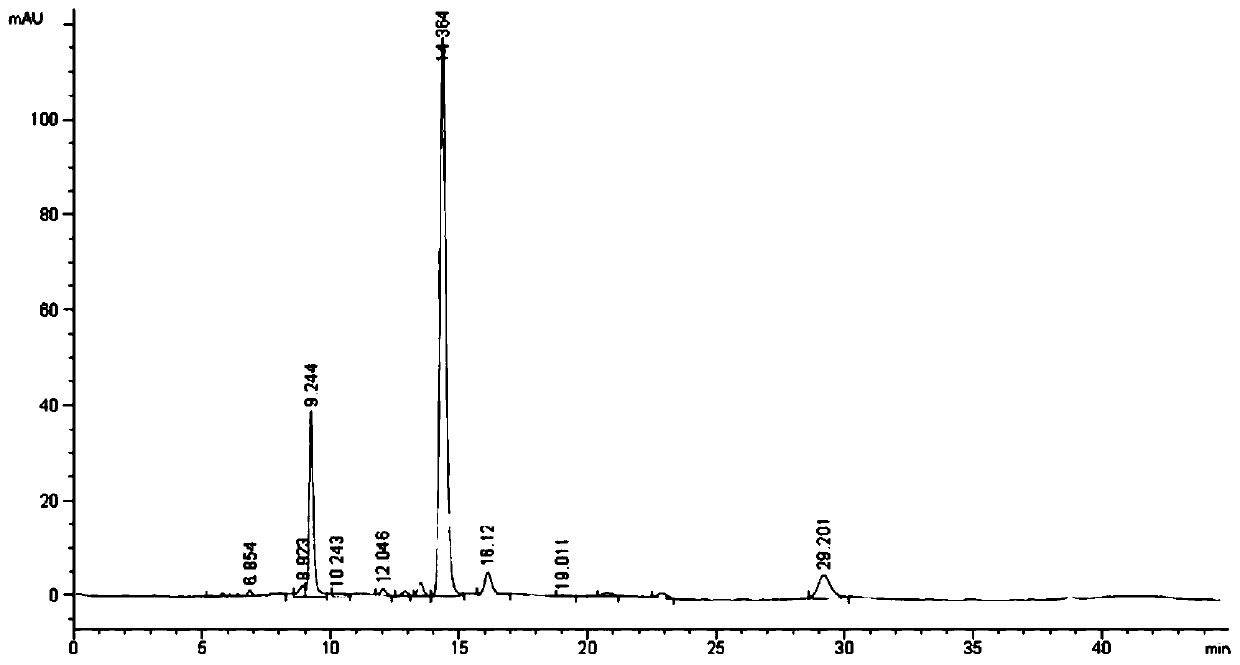

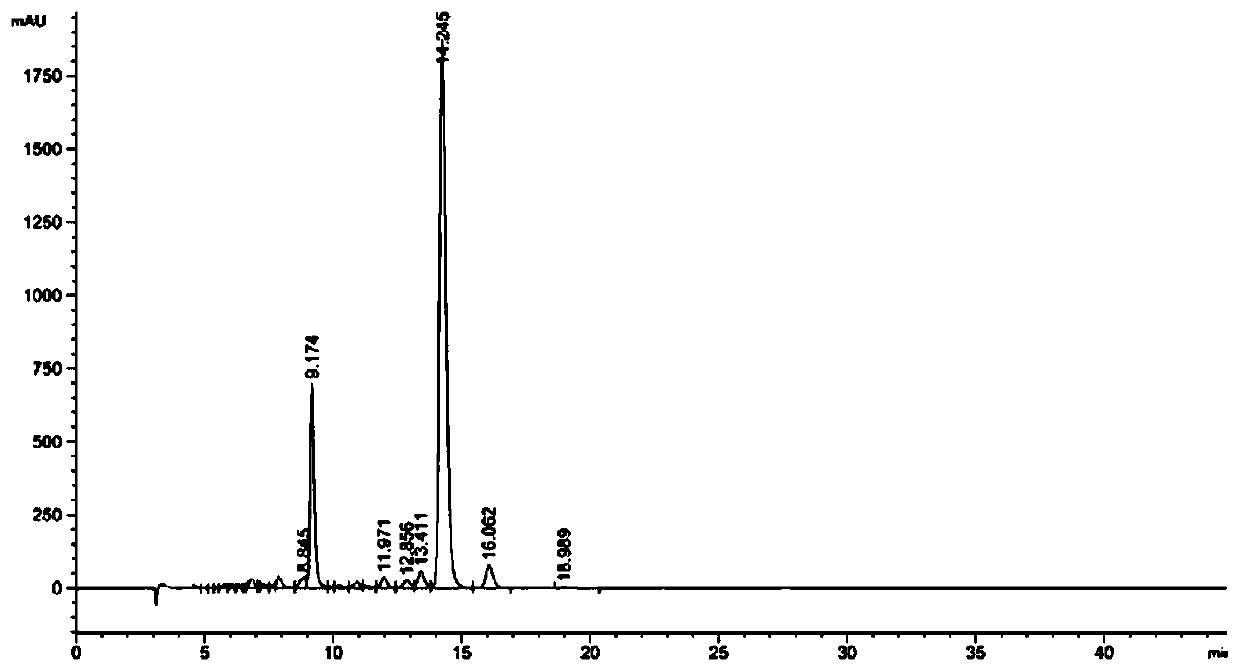

The invention relates to a method for extracting high-purity squalene by taking olive oil as a raw material. A technological route formed by adopting a secondary molecular distillation and silica gel column chromatography is as follows: an olive oil unsaponifiable substance is taken, squalene is separated and purified by using two stages of molecular distillation, primary molecular distillation is carried out under the conditions of the evaporation surface temperature of 100 to 200 DEG C, the systemic pressure of 0.001 to 0.01mbar and the scraping film rotor speed of 150 to 300rpm, and secondary molecular distillation is carried out to the obtained distillate; the secondary molecular distillation is carried out under the conditions of the evaporation surface temperature of 150 to 300 DEG C, the systemic pressure of 0.001 to 0.01mbar and the scraping film rotor speed of 200 to 350rpm, and the obtained distillate is a squalene crude product; ethyl acetate-normal hexane with different concentrations is used as a mobile phase to carry out gradient elution, the obtained eluent is collected according to time and a solvent is evaporated, the same fractions are merged through chromatographic detection, and the high-purity squalene can be obtained, wherein the content of the raw material olive oil of the squalene is enhanced from 3.6% to about 98%; and especially, by considering the requirement of industrialized production to select an extraction condition especially, the large-scale production of the squalene taking the olive oil as the raw material can be realized.

Owner:JIANGSU ZODIAC MARINE BIOTECH

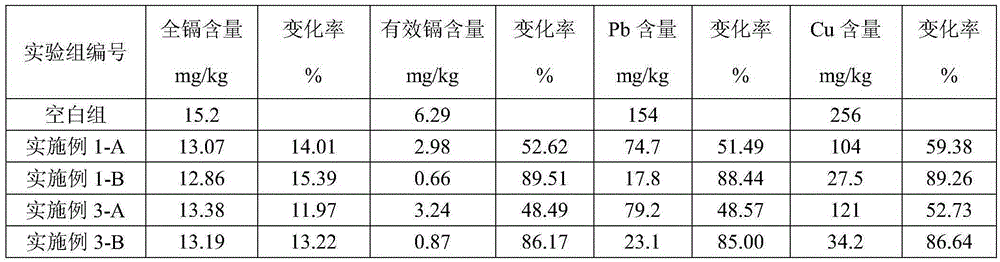

Composite soil passivator for reducing contents of cadmium and lead as well as preparation method and application method of composite soil passivator

ActiveCN104193546AImprove physical and chemical propertiesConducive to cultivationFertilizer mixturesCalcium magnesiumSepiolite

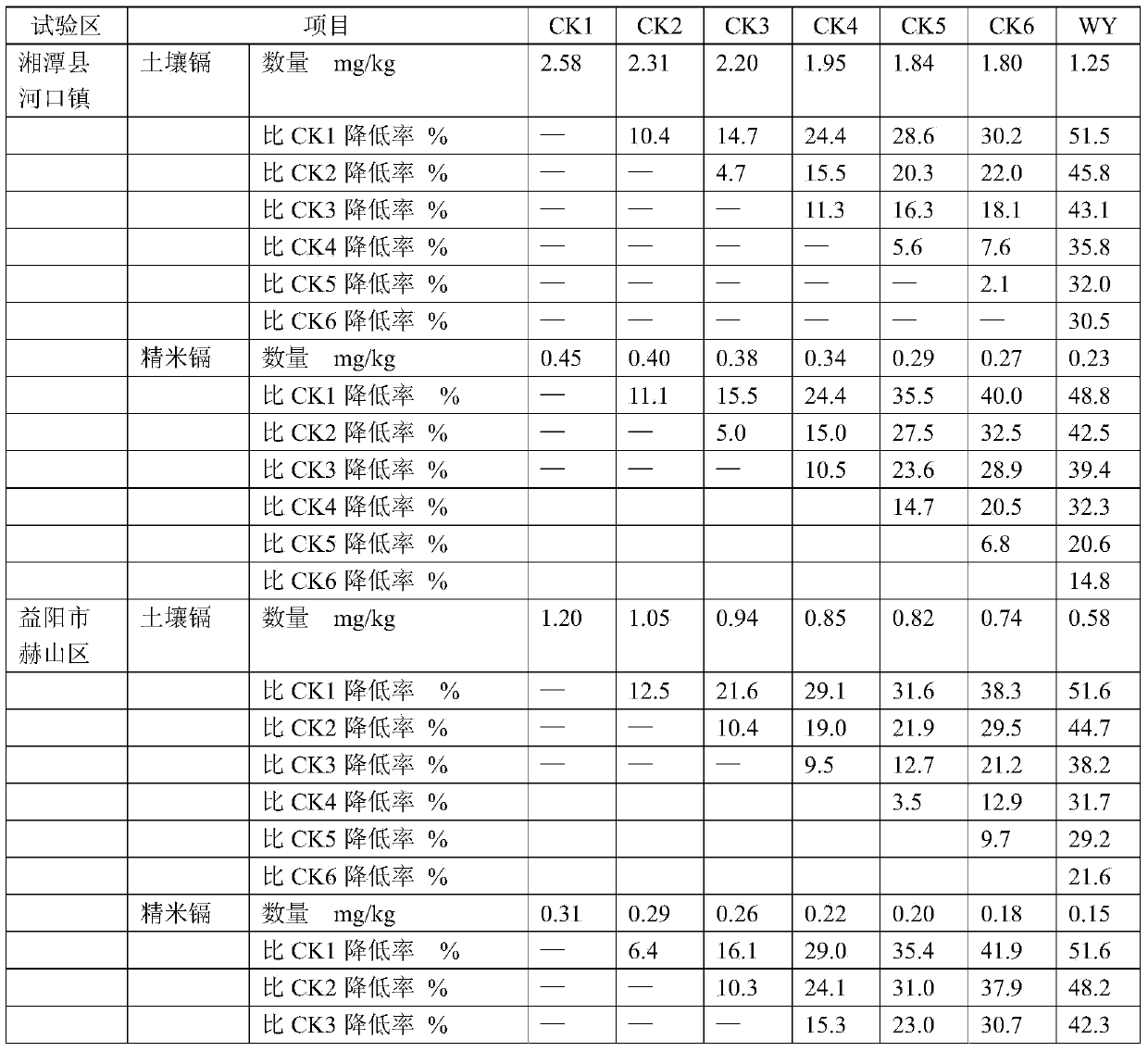

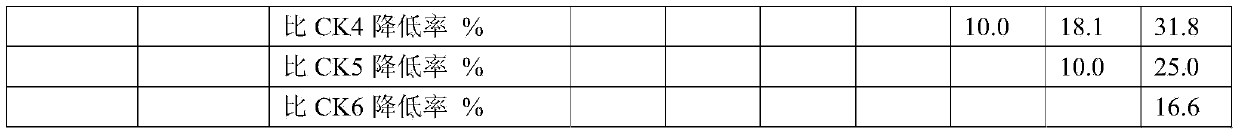

The invention discloses a composite soil passivator for reducing contents of cadmium and lead as well as a preparation method and an application method of the composite soil passivator. The composite soil passivator comprises the following components in percentage by weight: 5-15wt% of composted chicken manure, 5-15wt% of composted mixture of rice chaff and husk, 5-15wt% of turf, 10-20wt% of silicon-calcium-magnesium-potassium fertilizer, 5-15wt% of talcum powder, 25-35wt% of sepiolite, 10-20wt% of stacking fermented sugarcane filter mud and 1.5-2.5wt% of microbial fermentation liquor. The composite soil passivator can be widely applied to the mild and moderate cadmium / lead polluted rice fields to ensure that active cadmium and lead of the soil in the heavy metal polluted rice fields are respectively reduced by 51.5-51.6% and 52.6-58.8%, the cadmium and lead contents of the polished rice are respectively reduced by 48.8-51.6% and 52.7-56.0% and the pH value of the soil is improved by 0.97-1.04; and the composite soil passivator has the functions of restoring the acidized soil, improving the soil fertility and improving the physicochemical property of soil and has huge popularization and application values.

Owner:湖南润邦生物工程有限公司

Method for producing sulfuric acid dew-point corrosion-resistant round steel 09CrCuSb

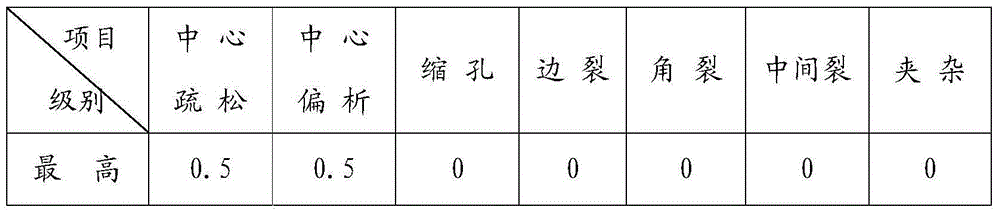

InactiveCN105200349AImprove corrosion resistanceReduce hardnessManufacturing convertersProcess efficiency improvementChemical compositionSmelting process

The invention discloses a method for producing sulfuric acid dew-point corrosion-resistant round steel 09CrCuSb, wherein the method comprises the following steps: 1) reasonably determining the chemical composition and the inclusion control level of round steel 09CrCuSb; 2) determining the revolving furnace smelting process and N, H and O gas contents; 3) formulating an appropriate continuous casting secondary cooling schedule to make a casting blank keep away from a cracking temperature in a straightening zone, reasonably adopting crystallizer cooling water parameters and vibration negative slip parameters, and controlling casting blank surface cracks; and 4) determining a reasonable heating schedule and a rolling process, choosing low temperature for fast sintering, and reasonably distributing materials, so as to reduce enrichment of Cu elements on the steel surface and avoid the round steel from generating star-shaped cracks; and by controlling the rhythm of steel rolling, avoiding scratches of the round steel surface. By adding alloy elements such as Cr, Cu and Sb, a passivation film is formed on the steel surface; by formulating reasonable smelting, continuous casting and steel rolling processes, the round steel composition is effectively ensured, corrosion resistance can conform to relevant standards and requirements; and through the process, generation of the cracks of the copper-containing steel is avoided.

Owner:TIANJIN IRON & STEEL GRP

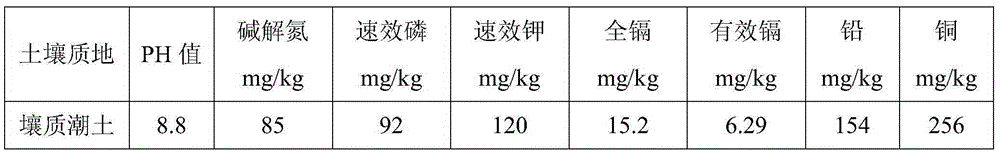

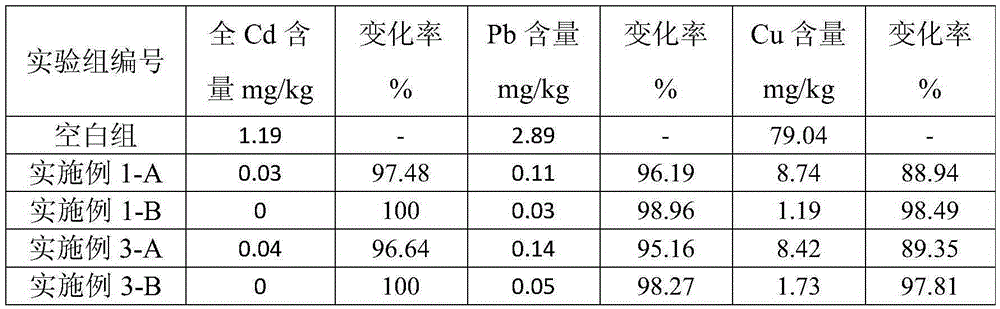

Biological organic repairing agent for soil pollution and application and preparation method thereof

InactiveCN105347884AReduce absorptionReduced enrichmentBio-organic fraction processingExcrement fertilisersBiotechnologyPollution

The invention relates to the field of soil fertilizer and provides a biological organic repairing agent for soil pollution and its application and preparation method. The biological organic repairing agent of the invention is composed of, by weight, 1.5-3 parts of eymogenic bacterium, 1-1.5 parts of wheat bran, 1.5-2 parts of molasses meal, 45-50 parts of ammonium humate, 45-50 parts of hydrolase dregs, 150-200 parts of soybean meal, 100-150 parts of humic acid powder, 80-100 parts of zeolite powder, 25-40 parts of a calcium magnesium phosphate fertilizer, 150-200 parts of cattle and sheep manure, 150-204 parts of plant straw, 25-40 parts of potassium humate, 1.5-3 parts of bacillus mucilaginosus, 1-1.5 parts of Gliocladium roseum, 1.5-2 parts of Streptomycesvinaceus-drappus, 1-1.5 parts of trichoderma spp, 1-1.5 parts of Paecilomyces lilacinus, 1-1.5 parts of bacillus subtilis and 1-1.5 parts of micrococcus. According to the invention, soil pollution control, improvement and nutrition are integrated.

Owner:HEBEI CIXIN ENVIRONMENTAL PROTECTION TECH CO LTD

Method for restoring soil with heavy metal pollution

InactiveCN108080408AReduced enrichmentImproved ability to adsorb heavy metal ionsAgriculture tools and machinesContaminated soil reclamationSoil heavy metalsChromium

The invention relates to a method for restoring soil with heavy metal pollution. According to the method, a restoring agent is adopted for restoring, the restoring agent contains modified montmorillonite, the modified montmorillonite adopts natural montmorillonite, and the soil restoring agent is obtained after the montmorillonite is modified through inorganic salt and organic matter and then composited with other components. The soil restoring agent has the characteristics that raw materials are easy to obtain, the cost is low, and the effect on adsorbing heavy metal is good, is especially suitable for restoring the soil immersed by industrial sewage, and has good adsorption removal effect on common heavy metal ions such as chromium, copper, zinc, cadmium and lead in the soil. The soil restoring agent is simple in preparation method, high in repeatability and suitable for mass production.

Owner:台州泰捷化工科技有限公司

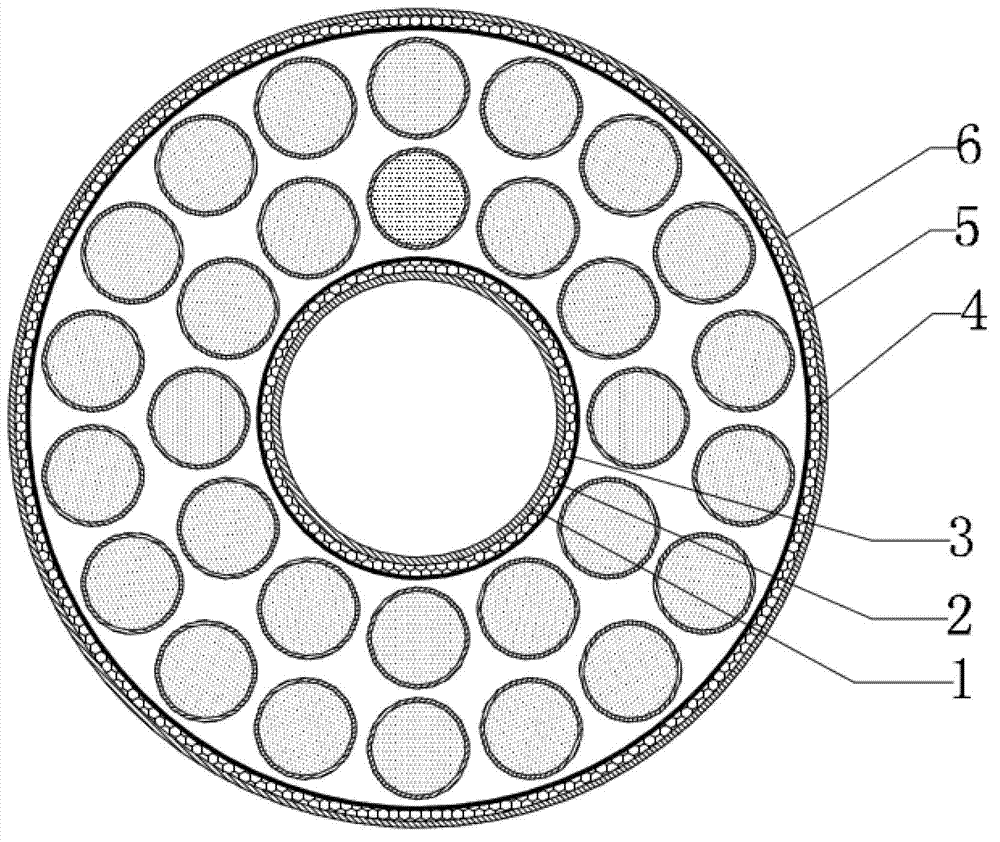

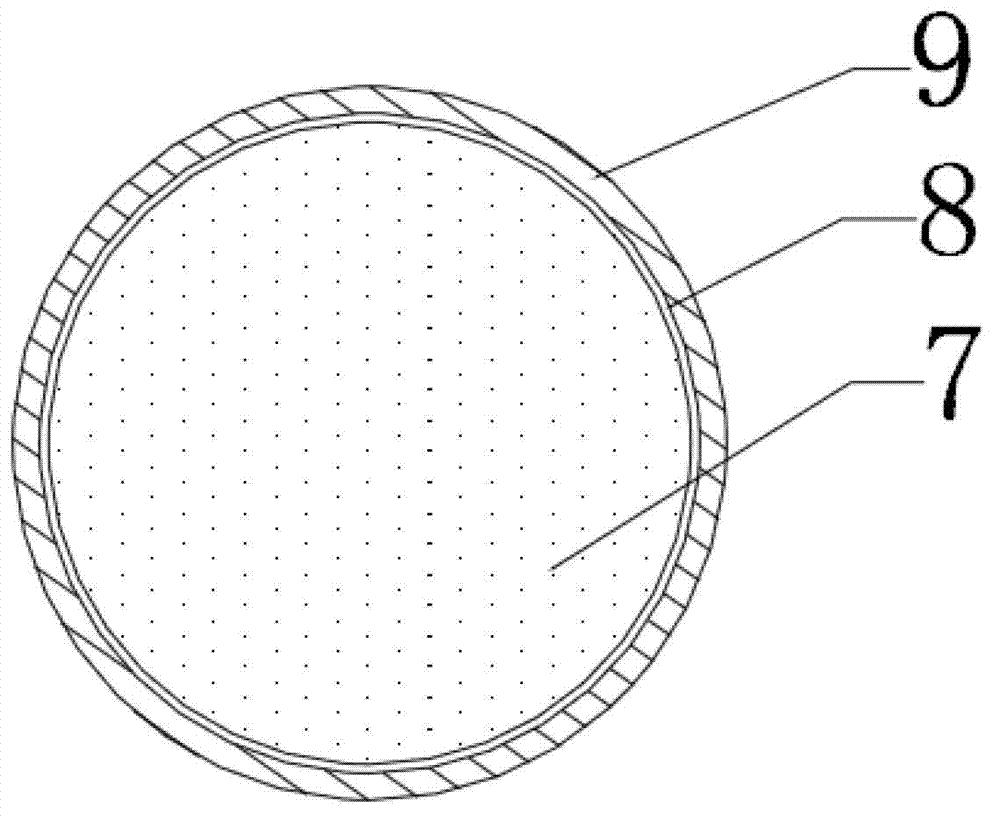

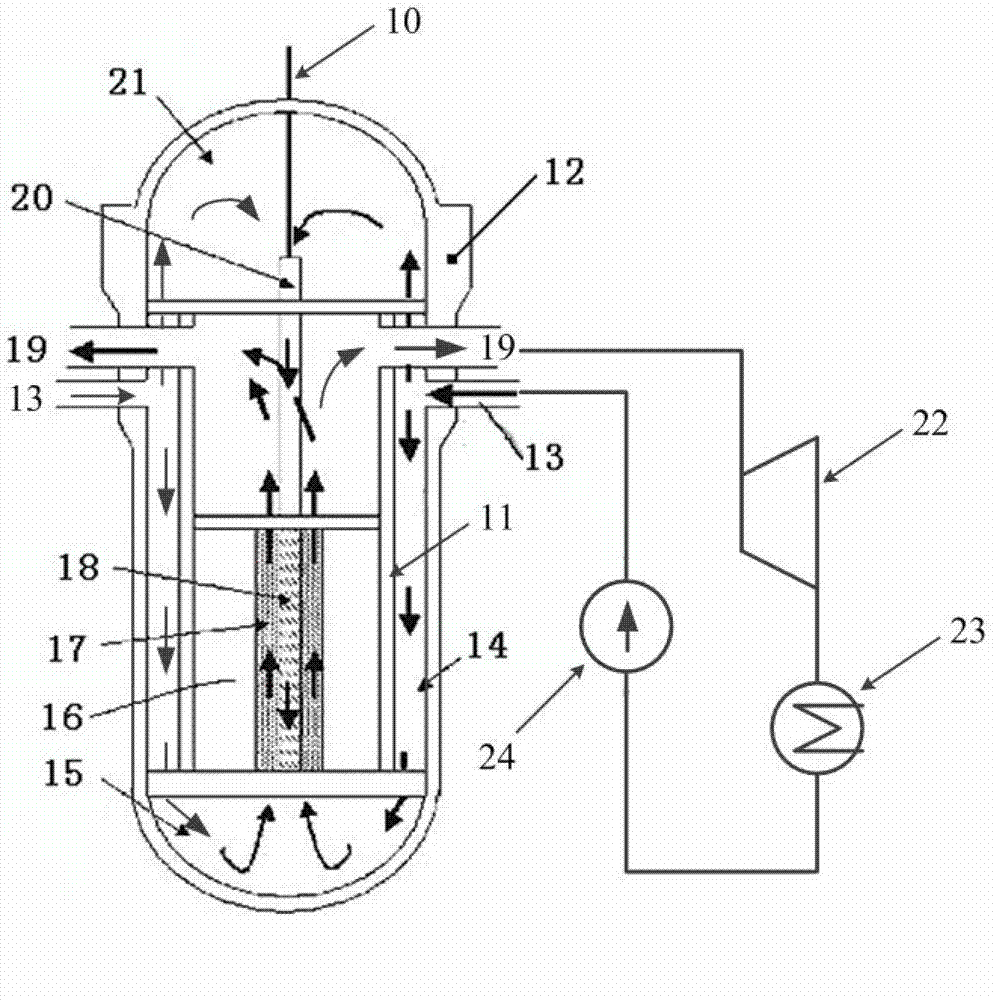

Sleeve type rod-shaped fuel assembly and supercritical water-cooling nuclear reactor utilizing same

ActiveCN103093838AReduce complexitySlow down evenlyNuclear energy generationFuel element assembliesNuclear reactor coreNuclear reactor

The invention relates to a sleeve type rod-shaped fuel assembly and a supercritical water-cooling nuclear reactor utilizing the same. The fuel assembly is of an annular sleeve type and comprises a water hole wall, an inner thermal insulation layer, an inner ring liner tube, an outer ring liner tube, an outer thermal insulation layer and an assembly wall from inside to outside, wherein fuels are filled between the inner ring liner tube and the outer ring liner tube. The supercritical water-cooling nuclear reactor utilizing the assembly comprises a pressure container, wherein the pressure container comprises a pressure shell, a reactor core and a control rod drive mechanism; the reactor core and the control rod drive mechanism are arranged in the pressure shell, the upper part and the lower part of the pressure shell are respectively divided into an upper cavity and a lower cavity by an upper partition board and a lower partition board, a plurality of the sleeve type rod-shaped fuel assemblies are vertically placed into the reactor core, the water hole walls and the assembly walls of the sleeve type rod-shaped fuel assemblies stretch upwards, penetrate through the upper partition board and are connected with the upper cavity, and a water inlet corresponding to each sleeve type rod-shaped fuel assembly is formed in the joint between the lower partition board and the sleeve type rod-shaped fuel assemblies in the reactor core. The reactor has the characteristics of simple system and high thermal efficiency; and the fuel assembly has the characteristics of being more uniform in moderation, simpler in structure and saving in uranium resources.

Owner:XI AN JIAOTONG UNIV

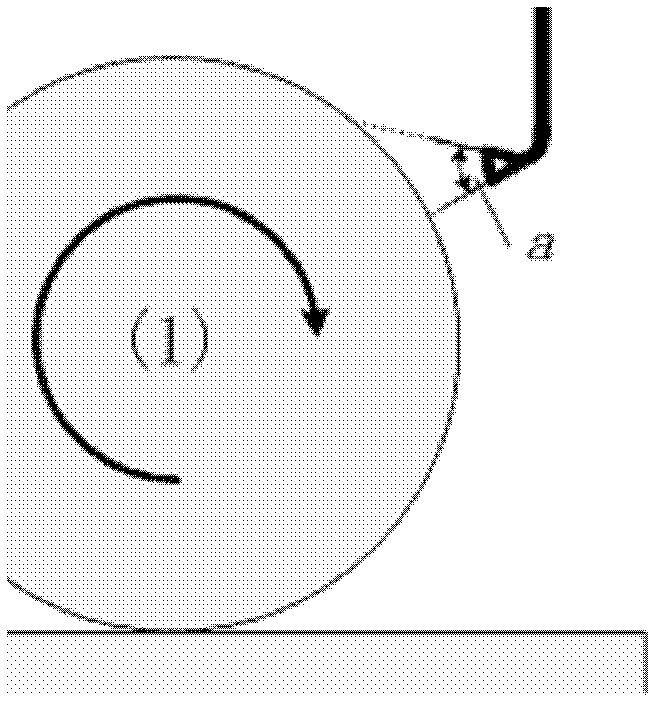

Sandwich-type polycrystalline diamond compact and preparation method thereof and used binding agent

The invention discloses a sandwich-type polycrystalline diamond compact and a preparation method thereof and a used binding agent. The binging agent is made through matching of Co powders, Ni powders, TaC powders and B powders according to a certain proportion. The sandwich-type polycrystalline diamond compact comprises two layers of cemented carbide matrixes and a polycrystalline diamond layer arranged between the two layers of cemented carbide matrixes. The polycrystalline diamond layer and diamond powders are matched in a certain proportion through the binding agent, the polycrystalline diamond layer and the substrate are composited with each other through high-temperature high-pressure sintering, and a superhard composite material with three layers of materials is formed. The cemented carbide layers play the role of a protecting layer, the stress state of the compact when the polycrystalline diamond layer is drilled in is improved, and tipping is avoided. The nanocrystalline metal binding agent can facilitate sintering in high temperature and high pressure, so that the boding density between the diamond (D-D bond) is improved, a good sintering promoting function is achieved, forming of a tough sintering body is facilitated, the impact toughness, the wear-resisting performance and the heat-resisting performance of the sandwich-type polycrystalline diamond compact are increased, and the technological difficulty of high-wearing feature and high impact toughness of the polycrystalline compact is overcome.

Owner:ZHONGNAN DIAMOND CO LTD

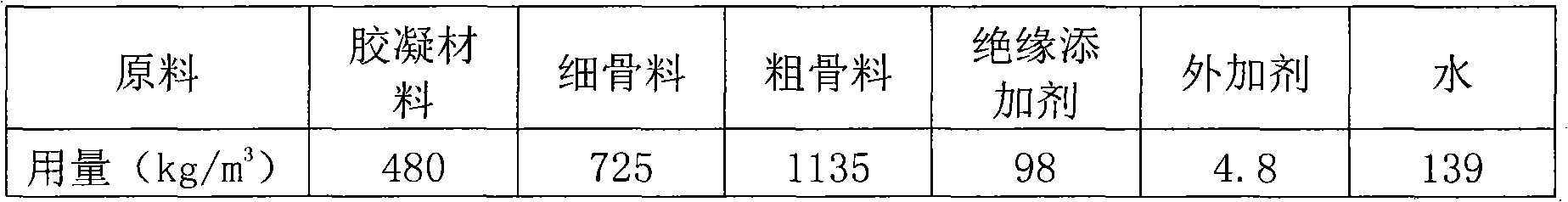

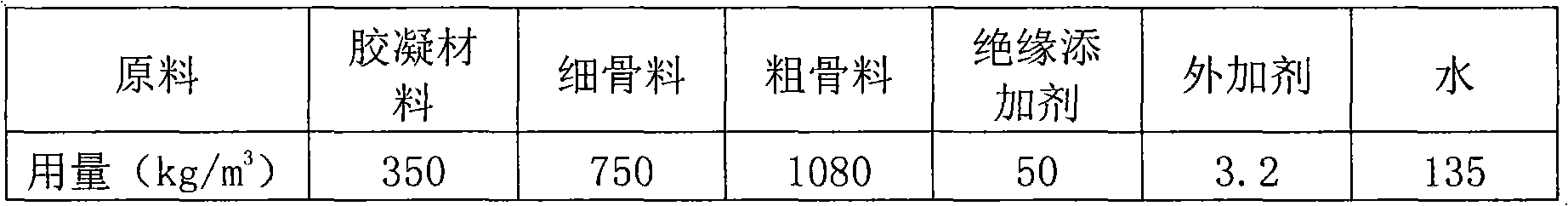

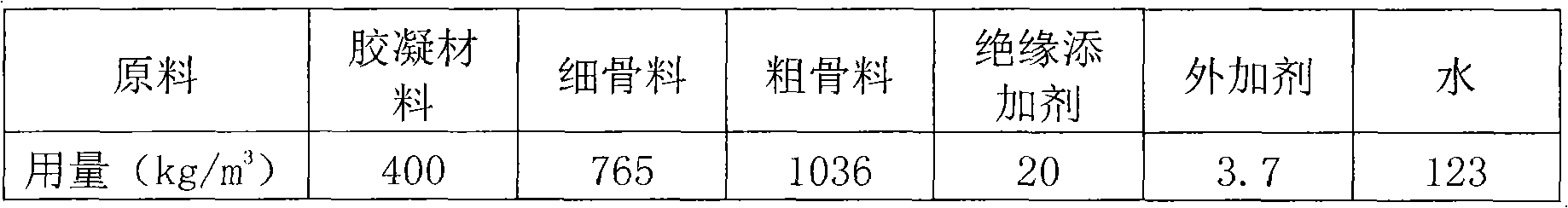

Insulating concrete material and preparation technology

The invention relates to an insulating concrete material and a preparation method thereof. The concrete material is prepared by mixing a cementing material, coarse aggregate, fine aggregate, insulating additive, admixture and water, wherein the using amount of the cementing material is 350 to 700kg / m<3>; the using amount of the coarse aggregate is 850 to 1,150kg / m<3>; the using amount of the insulating additive is 20 to 150kg / m<3>; the admixture in an amount which is 0.2 to 2.0 percent based on the mass of the cementing material is used; and the volume rate of sand is 35 to 52 percent; and the ratio of water to the cementing material is 0.23 to 0.40. The electrical resistivity of the concrete material can be improved obviously, and the insulating concrete material is prepared, and can be used for the field with the insulating requirement on a concrete structure.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Hematoxylin and eosin staining kit for circulating tumor cells (CTC)

ActiveCN104931324ALess blood leukocyte interferenceGood effectPreparing sample for investigationIonChemistry

The invention discloses a hematoxylin and eosin staining kit for circulating tumor cells (CTC). The kit comprises stationary liquid, immunomagnetic microspheres, a staining reagent as well as confining liquid, wherein the confining liquid comprises an ion detergent and a protein protectant; the surfaces of immunomagnetic microspheres are carried with a combined antibody for resisting EpCAM and Her2; the staining reagent is a compound fluorescence staining reagent containing FITC-CK19 or FITC-Her2, Cy3-CD45 and DAPI. The hematoxylin and eosin staining kit for circulating tumor cells (CTC) has the advantages that the interference of blood leucocytes is low, the CTC cells are specifically enriched and captured, and the staining effect on CTC cells is good.

Owner:NINGBO MEIJING MEDICAL TECH

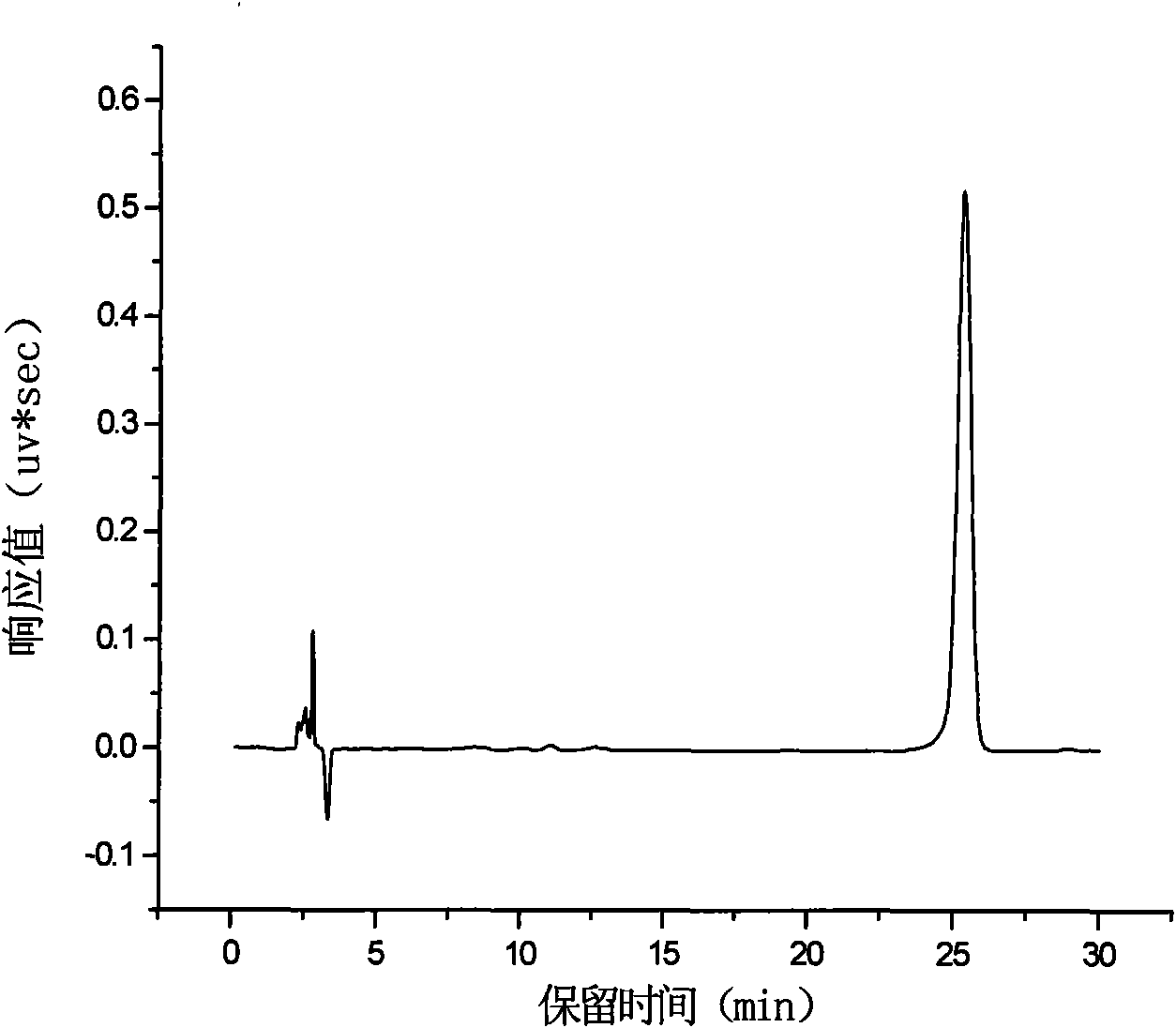

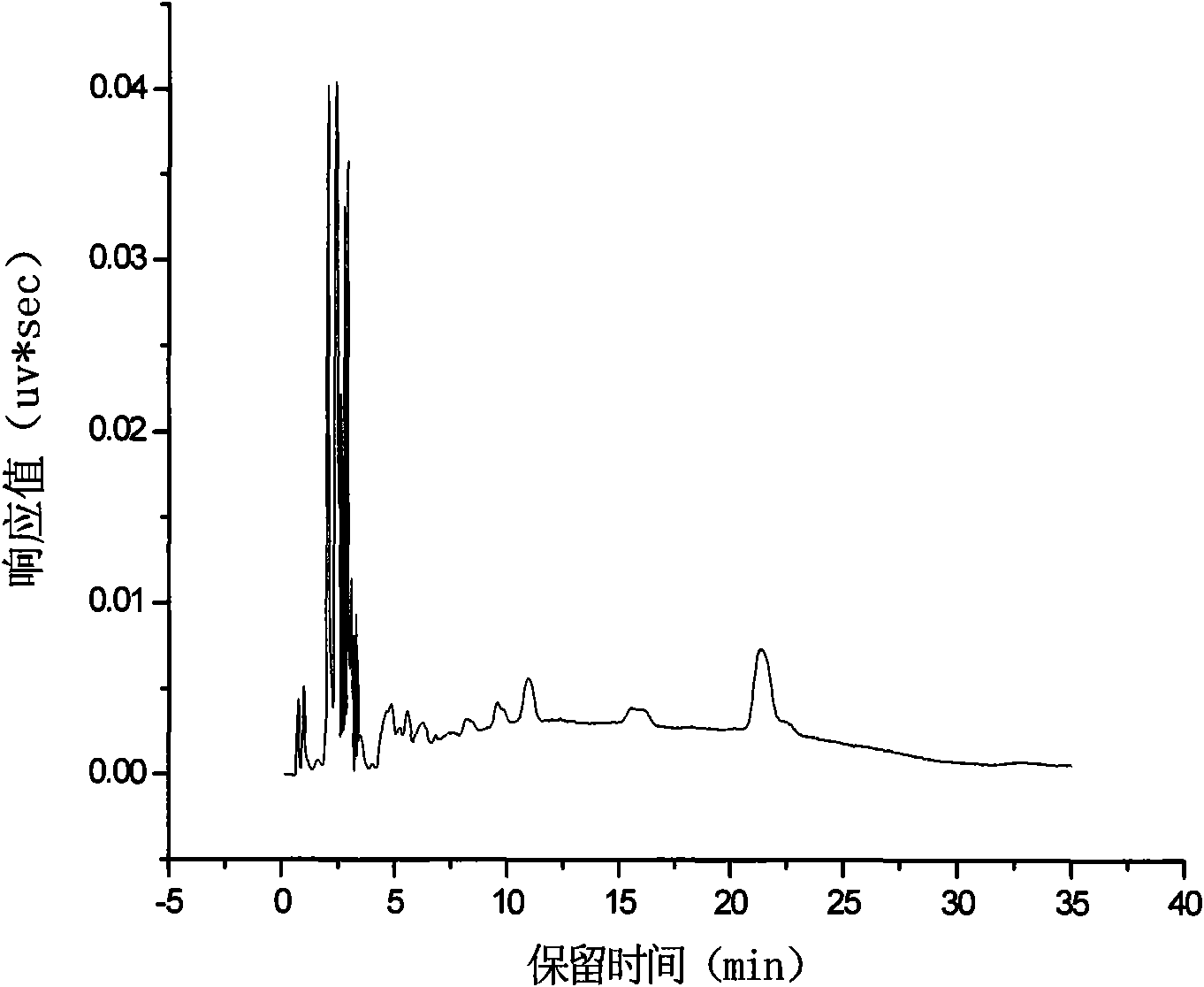

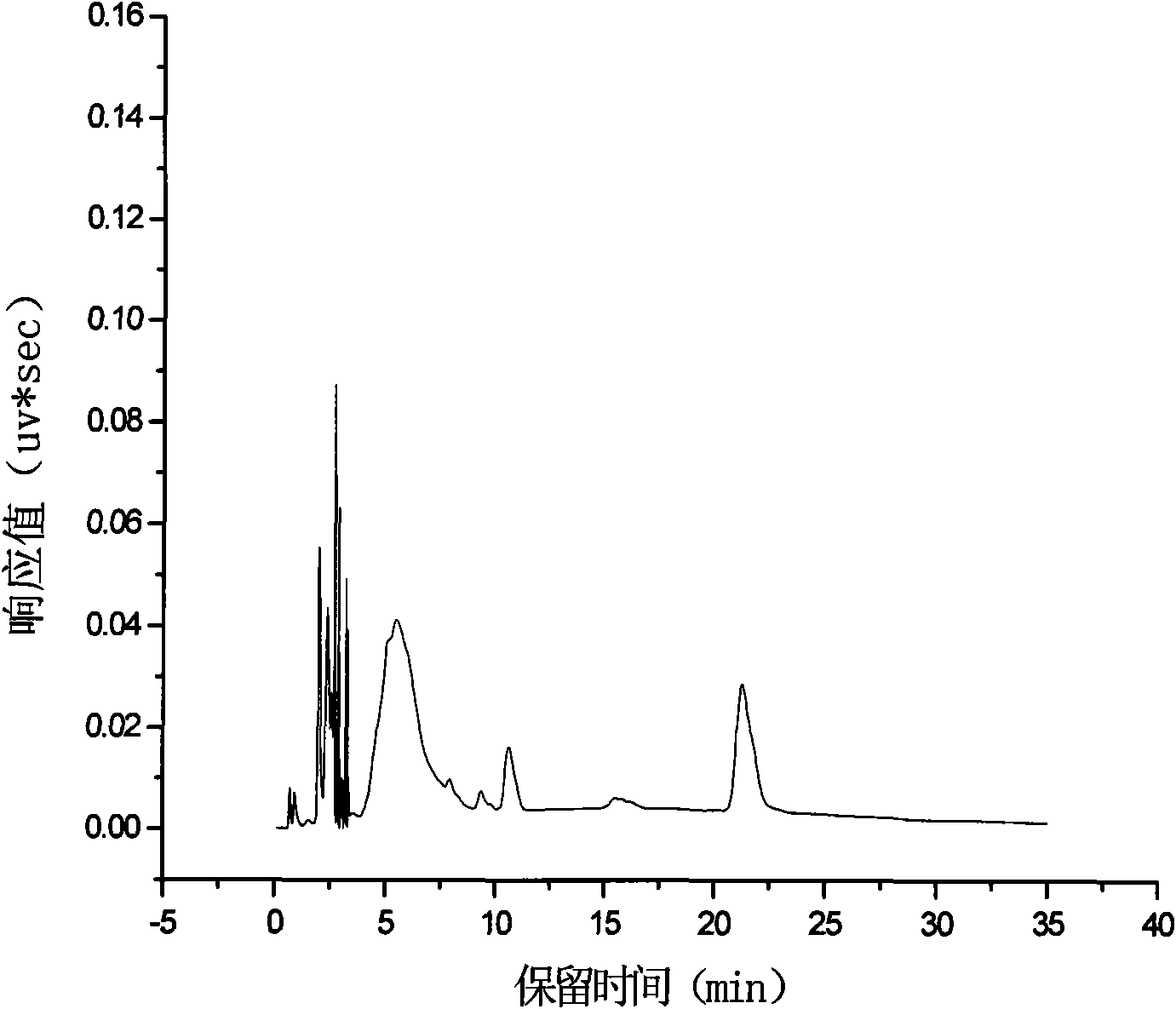

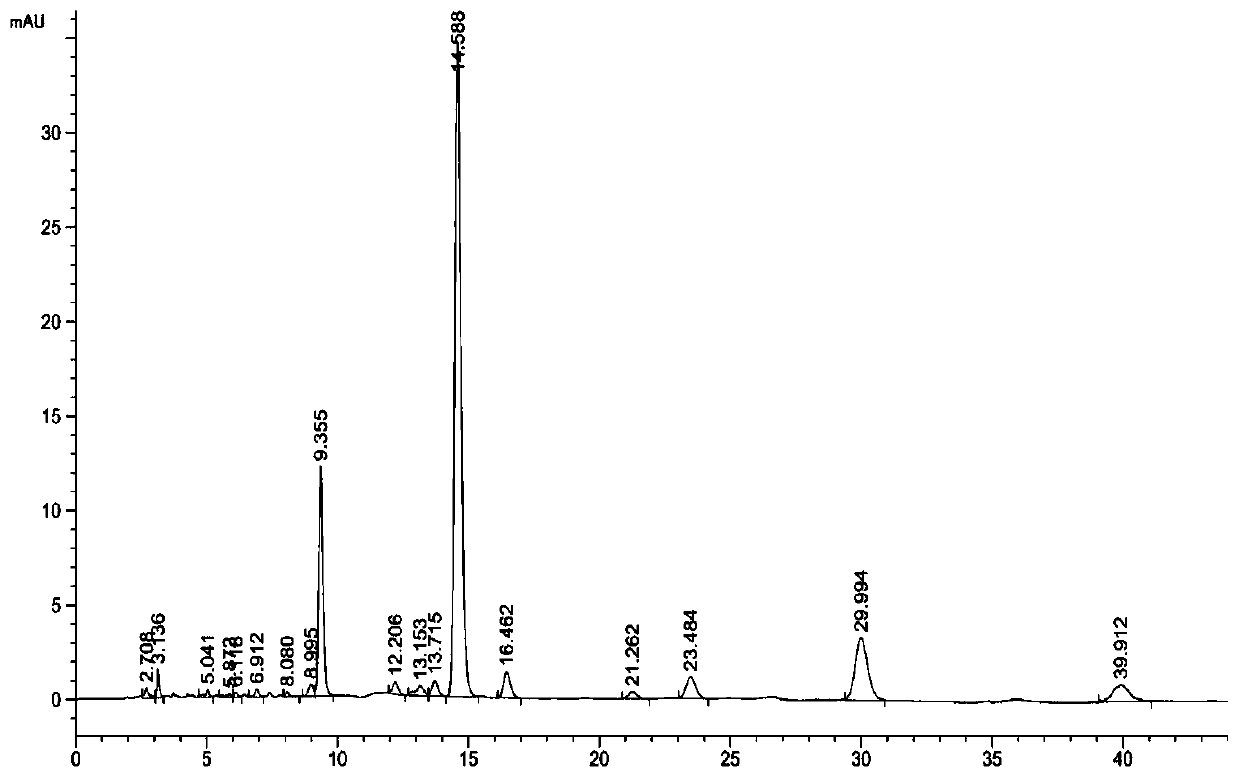

Method for extracting and separating high-purity cannabidiol from low-content industrial hemp floral leaves

ActiveCN111470953AIncrease contentHigh purityOrganic chemistryOrganic compound preparationCannabielsoinDigestion

The invention discloses a method for extracting and separating high-purity cannabidiol (CBD) from low-content industrial hemp floral leaves. The method adopts the modes of digestion, macroporous resinadsorption and desorption, reverse chromatography and crystallization to finally obtain a cannabidiol pure product with the purity of 99% or above. In order to separate other cannabinoids, extractionand decoloration processes can be added between the digestion process and the macroporous resin adsorption and desorption process, and a polymer reversed-phase filler is used for reversed-phase chromatography, so that cannabidivarin (CBDV), cannabinol (CBN) and tetrahydrocannabinol (THC) in the floral leaves can be separated. The method disclosed by the invention is high in digestion, extractionand decoloration process yield and high in impurity removal rate; the macroporous resin and reversed-phase column chromatography have the advantages of high loading capacity and favorable separation effect. Requirements of development of a plurality of industrial hemp products are met, and the method has great application advantages in the pharmaceutical field and is suitable for industrial popularization.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

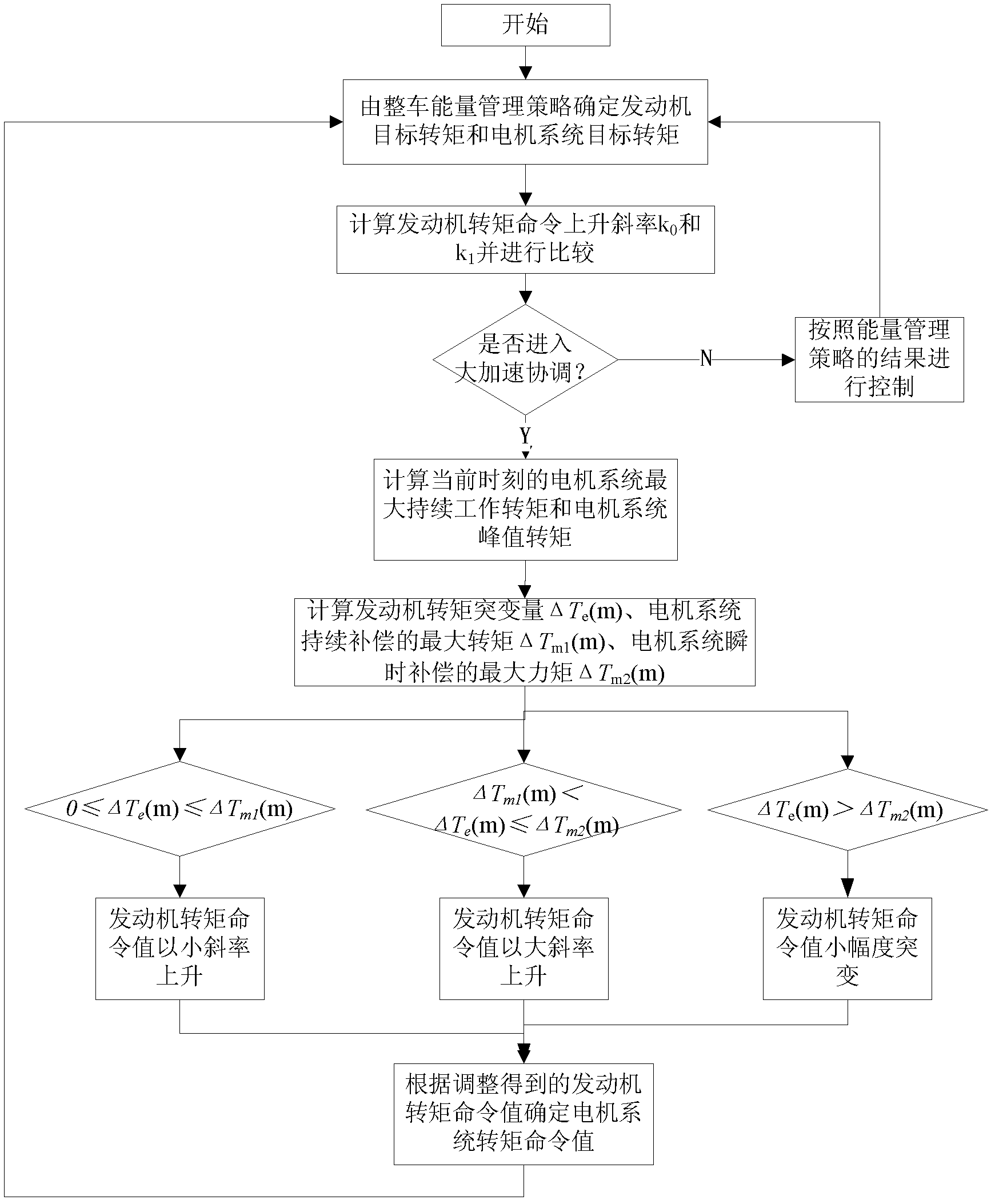

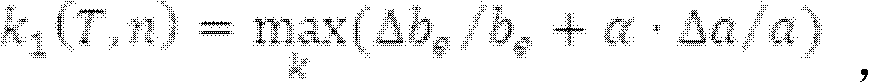

Dynamic coordination control method for high acceleration process of hybrid vehicle

InactiveCN102582624AReduced enrichmentTaking into account the dynamic performance of the whole vehicleHybrid vehiclesEnergy managementEngineering

The invention discloses a dynamic coordination control method for a high acceleration process of a hybrid vehicle, which comprises the following steps: (1) determining an engine target torque Te'(m) and a target torque Tm'(m) of a motor system, which are distributed in a steady state; (2) judging whether entering a dynamic coordination process of high acceleration, if so, entering a step (3), if not, returning to the step (1); and (3) performing dynamic coordination according to an engine torque command Te(m-1) at a former moment, the engine target torque Te'(m) and the target torque Tm'(m) of the motor system, obtained by an energy management policy so as to obtain an engine torque command value Te(m) and a torque command value Tm(m) of the motor system; and the method of the invention fully utilizes the compensation capability of the motor, guarantees the dynamic property of the high acceleration process, effectively reduces the engine concentration and improves the economical efficiency of the high acceleration process.

Owner:JILIN UNIV

Heavy metal soil remediation agent

PendingCN108002922AReduced enrichmentImproved ability to adsorb heavy metal ionsCalcareous fertilisersAgriculture tools and machinesChromiumRaw material

The invention relates to a heavy metal contaminated soil remediation agent. The remediation agent contains modified montmorillonite, wherein the modified montmorillonite is natural montmorillonite, the modified montmorillonite is modified through inorganic salt and organic matters and then is compounded with other components so as to prepare the soil remediation agent. The soil remediation agent has the characteristics of using raw materials easy to obtain, being low in cost, and better adsorbing heavy metals. The soil remediation agent is particularly suitable for remediation of soil impregnated with chemical wastewater, and can better adsorb and remove common heavy metal ions like chromium, copper, zinc, cadmium and lead in soil. The method for preparing the soil remediation agent is simple, has high repeatability and is suitable for large-scale production.

Owner:台州泰捷化工科技有限公司

High-activity nitrification inhibition type multifunction fertilizer synergist and preparation method thereof

InactiveCN102910973AEasy to prepareInhibitory activityAgriculture gas emission reductionFertilizer mixturesVitamin CPhosphate

The invention relates to a high-activity nitrification inhibition type multifunction fertilizer synergist and is applicable to the field of agriculture and forestry. The high-activity nitrification inhibition type multifunction fertilizer synergist is composed of following raw materials of, by weight, 3-35% of vitamin C, 3-35% of N-acyl sodium glutamate, 3-35% of 3,4-dimethylpyrazole phosphate (DMPP), 3-35% of farm-oriented rare earth, 5-35% of fulvic acid, 0.5-2.5% of compound sodium nitrophenolate, 15-45% of vermiculite and 15-45% of medical stones. The raw materials are smashed, screened by a 30-100 mesh screen, then stirred and mixed according to a certain ratio to obtain the fertilizer synergist. The fertilizer synergist is applicable to slow-acting nitrogen fertilizers or composite nitrogen fertilizers which use ammonium nitrogen fertilizers or urea as raw materials and is capable of being matched with the ammonium nitrogen fertilizers or the urea to be simultaneously applied to various types of soil, the fertilizer efficiency period of nitrogen fertilizers with the added multifunction fertilizer synergist can be prolonged to 90-110 days, abilities of drought resistance and disease resistance can be obviously improved, soil microorganism activities and crop root system activities can be stimulated, effectiveness and utilization efficiencies of soil fertilizers can be improved, and residual effects on crops are obvious.

Owner:GUANGXI NEW ORIENTATION CHEM IND

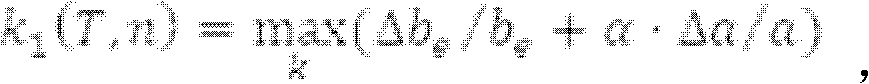

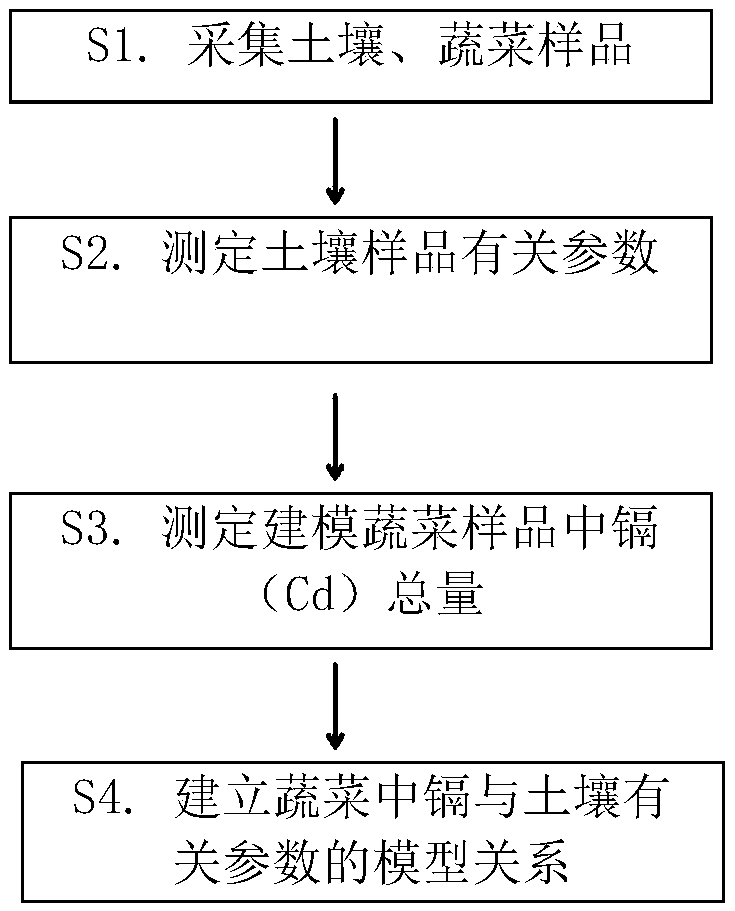

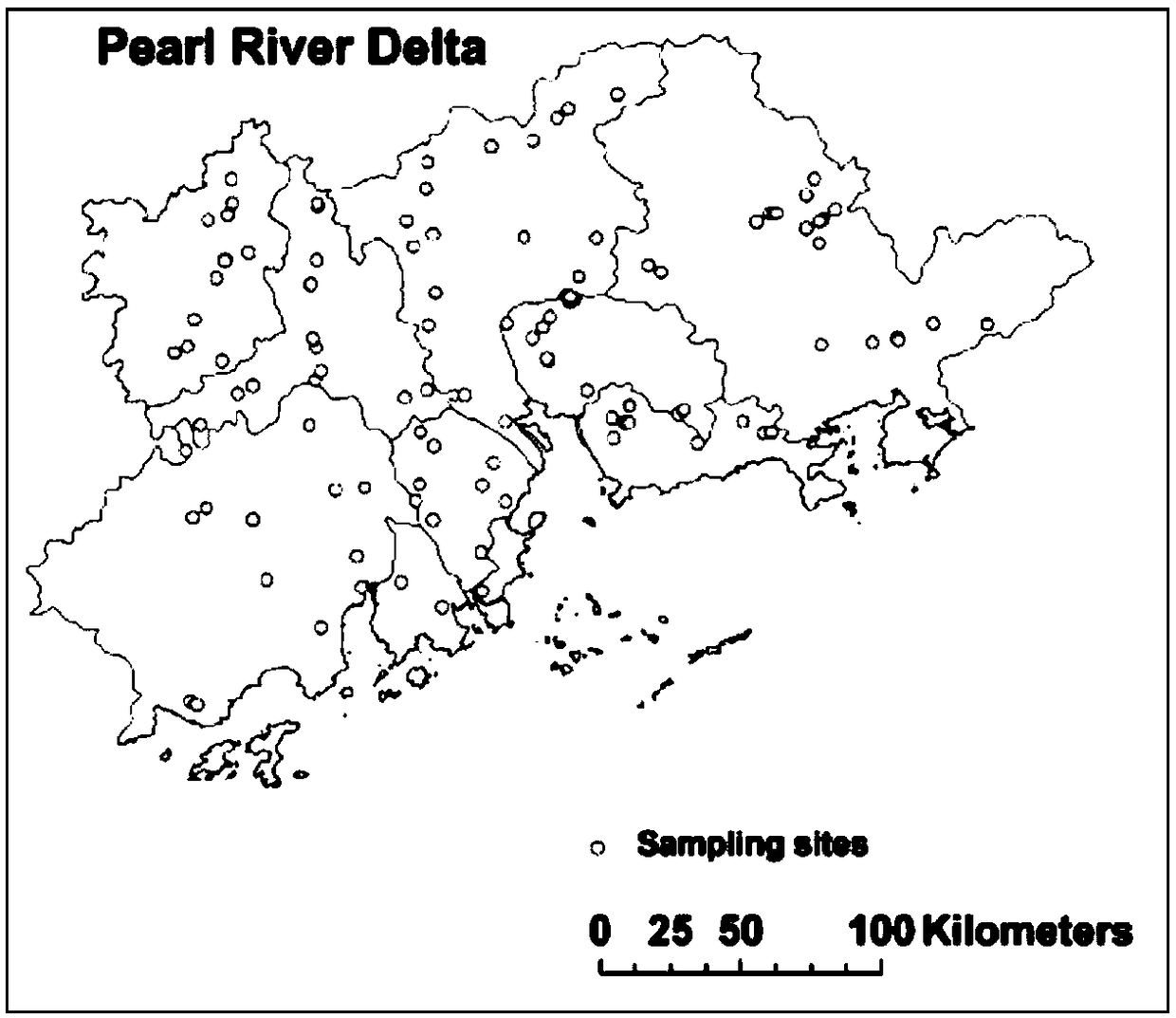

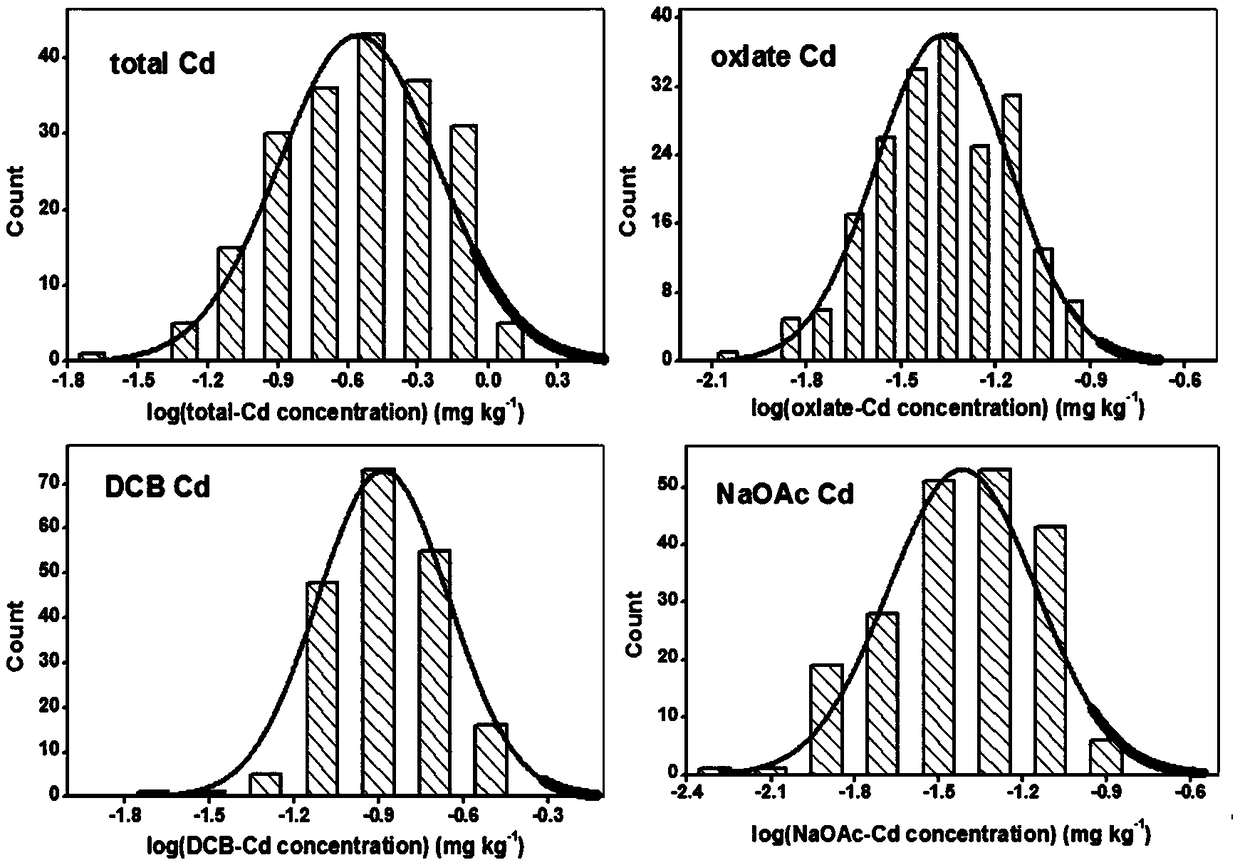

Modeling method for prediction model of cadmium content in vegetables and application thereof

InactiveCN109142650AEarly warning riskReduced enrichmentMaterial analysis by electric/magnetic meansEarth material testingSodium acetateSodium bicarbonate

The invention belongs to the field of agriculture and environment, and relates to a modeling method for a prediction model of the cadmium content in vegetables and application thereof. The modeling method comprises the following steps that a soil sample is collected, the iron-extractable (FeDCB-soil) content of sodium hydrosulfite-trisodium citrate-sodium bicarbonate (DCB) in soil, the cadmium-extractable (Cdoxalate-soil) content of oxalic acid / ammonium oxalate (Oxalate) and the aluminum-extractable (AlNaoac-soil) content of acetic acid / sodium acetate (NaOAc) in the soil are measured, and a model relationship among the content of FeDCB-soil, Cdoxalate-soil and AlNaoac-soil and the content of vegetable cadmium (Cdplant) is established. The formula of the established model is shown in the formula. The model is suitable for the prediction of the cadmium content of the vegetables in the soil, can improve the prediction accuracy of the cadmium content of the vegetables, and provide reference for vegetable safety production layout.

Owner:GUANGDONG PROVINCIAL ACADEMY OF ENVIRONMENTAL SCI

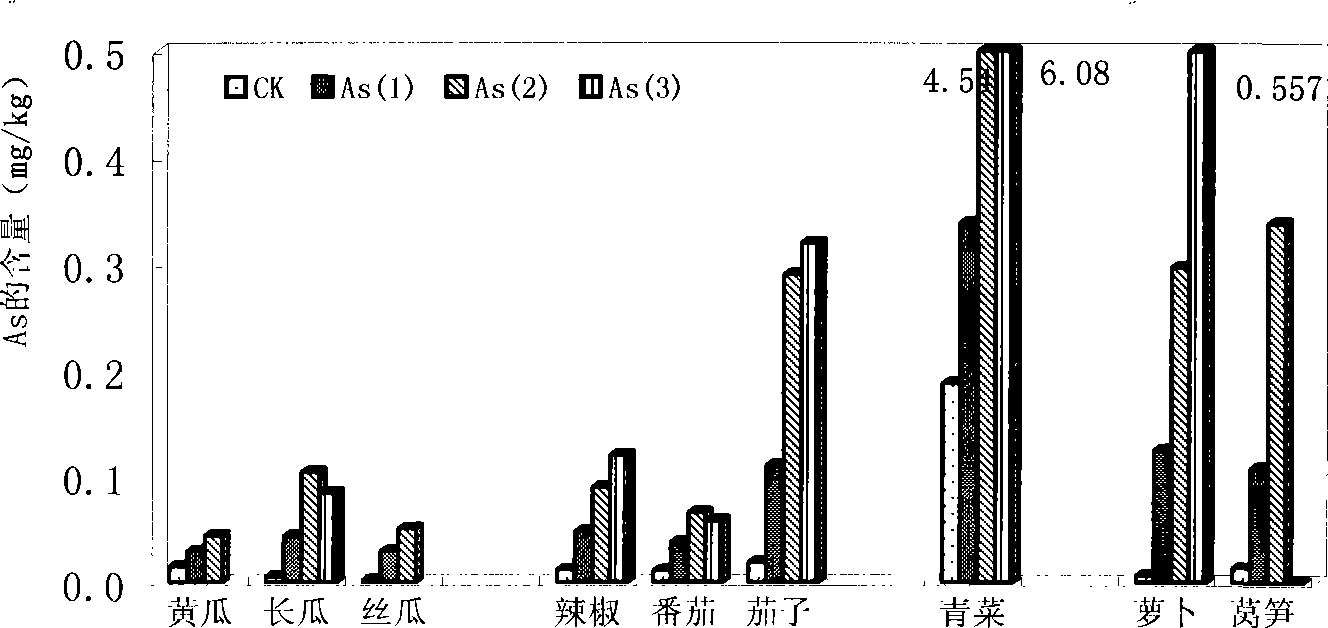

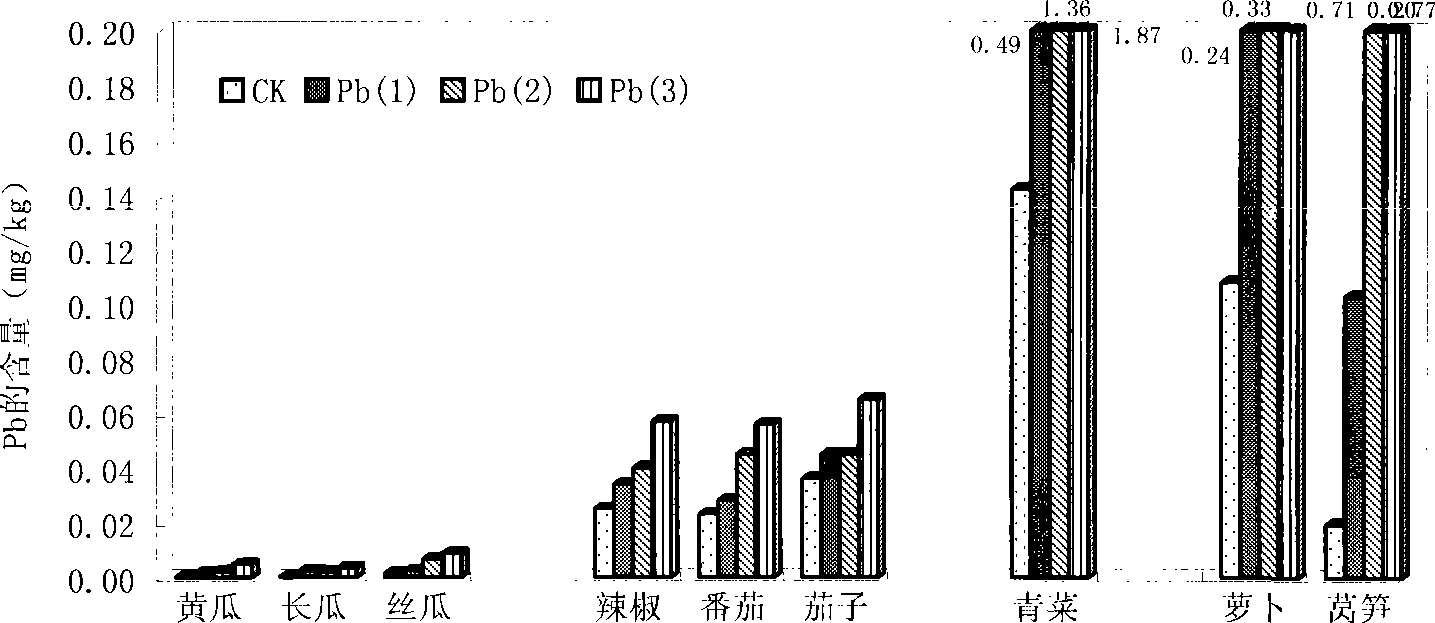

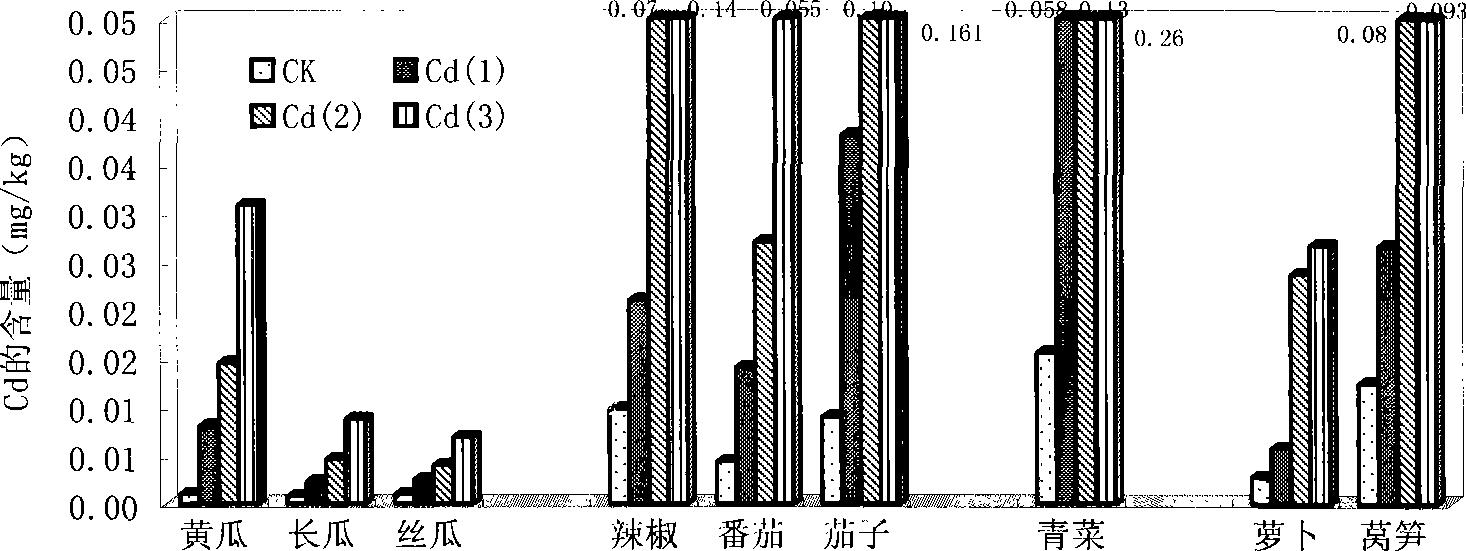

Screening method for heavy metal low accumulated and low enriched vegetable variety

The invention discloses a method for sifting a vegetable breed with low-accumulated / low-enriched heavy metals and belongs to the technical field of the quality safety of a farm product. The method comprises the following steps: (1) a potted plant mode is carried out in a greenhouse or a big shed; (2) sifting is carried out from four classes of vegetables, namely lefty vegetable, rhizome, solanaceous fruit and melon; (3) according to the limited values of the detected elements Hg, As, Pb and Cd for heavy-metal pollution in the vegetables regulated by the state and the concentration grads of 0 time, 0.5 time, 1.5 times and 4.5 times, heavy metals are added into potted soil manually; (4) vegetables are subjected to seedling, planting and management; and (5) the contents and the outputs of the heavy metals in an edible part of a product are mensurated; the product which meets the highest concentration treatment, has no marked reduction of average output per plantlet compared with the contrast and does not exceed the standard of the contents of the heavy metals is selected as the vegetable breed with low-accumulated / low-enriched heavy metals. The method has simple operation, wide applicability, economy and high efficiency, and can be popularized and applied to the departments of vegetable layout, planning and production.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

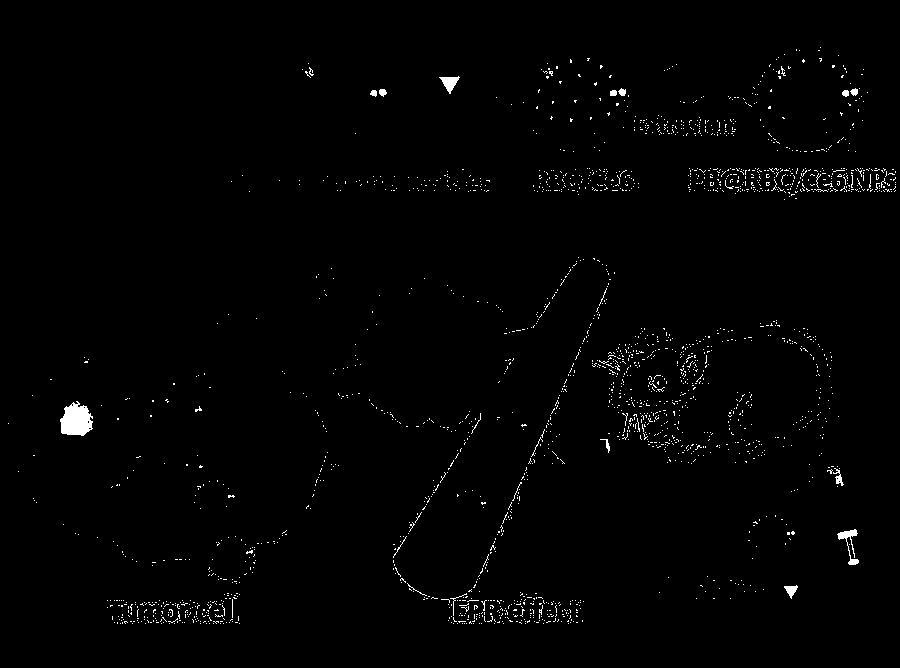

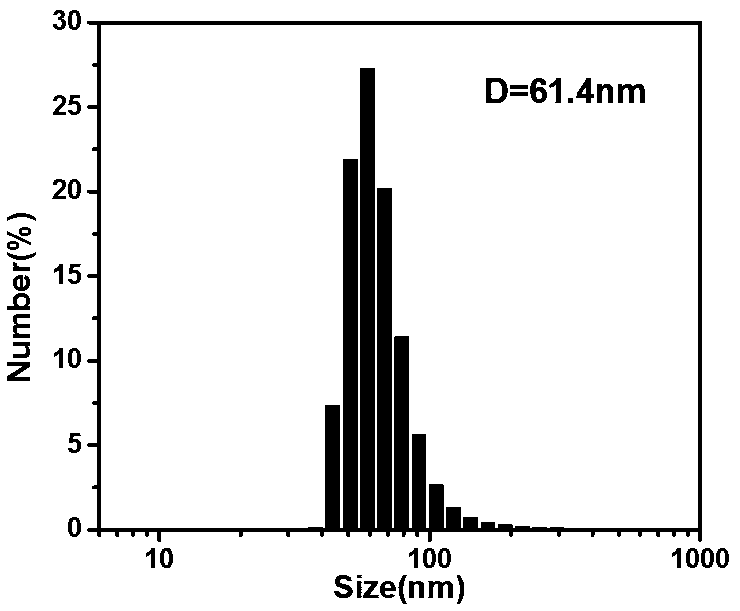

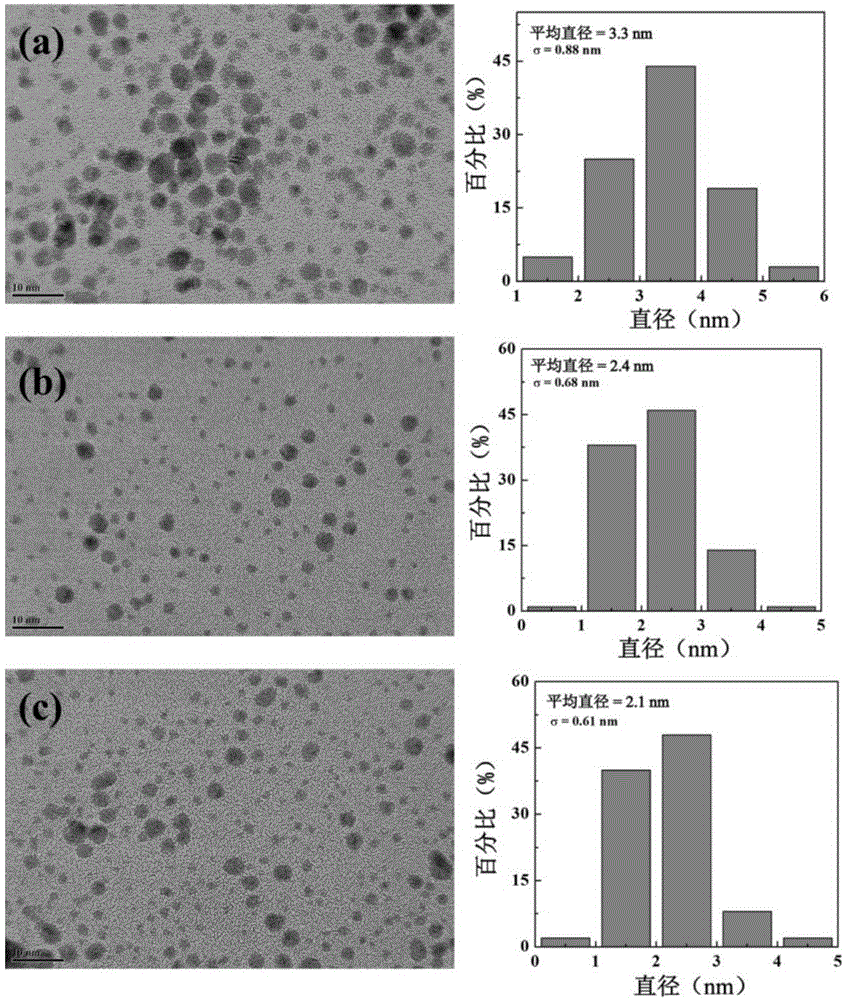

Method for preparing Ce6 embedded erythrocyte membrane coated prussian blue nanoparticle

ActiveCN108836949AGood biocompatibilityExtend cycle timeEnergy modified materialsPharmaceutical non-active ingredientsErythrocyte membraneChemical synthesis

The invention relates to the field of medicine chemical synthesis and in particular relates to a method for preparing erythrocyte membrane vesica coated prussian blue nanoparticles from prussian blue,erythrocyte membrane vesicae and a photosensitizer which is finally embedded, and specific methods of different steps. The method for preparing the erythrocyte membrane vesica coated prussian blue nanoparticles with the embedded photosensitizer Ce6 specifically comprises the following steps: (1) preparing prussian blue nanoparticles; (2) preparing erythrocyte membrane vesicae; (3) embedding the photosensitizer Ce6 into the erythrocyte membrane vesicae; and (4) coating the prussian blue nanoparticles with the erythrocyte membrane vesicae into which the photosensitizer is embedded. The composite nano medicine delivery system provided by the invention has the advantages that the circulation time of medicines in bodies is increased, a large medicine carrying amount is achieved, and high biocompatibility is achieved.

Owner:SOUTHWEST UNIVERSITY

Microbe and solidifying agent combined in-situ remediation method of heavy metal contaminated soil

ActiveCN105149342AImprove adsorption capacityLow oxygenContaminated soil reclamationIn situ remediationPollution soil

The invention provides a microbe and solidifying agent combined in-situ remediation method of heavy metal contaminated soil. The microbe and solidifying agent combined in-situ remediation method comprises the following steps: mixing magnetotactic bacteria and heavy metal contaminated soil; irrigating heavy metal contaminated soil mixed with magnetotactic bacteria; arranging a magnetic field on heavy metal contaminated soil; collecting heavy metal contaminated soil containing magnetotactic bacteria; leaching the collected heavy metal contaminated soil and back-filling; adding a solidifying agent into heavy metal contaminated soil subjected to magnetotactic bacteria adsorption treatment, and curing for 30-45 days; and circularly repeating the steps till the content of heavy metals in soil reaches the safe standard, wherein the solidifying agent consists of SiO2, Fe2O3, Al2O3 and C3N3S3Na3. The microbe and solidifying agent combined in-situ remediation method belongs to in-situ remediation, is simple to operate, low in cost and good in remediation effect, avoids secondary contamination of soil, and is suitable for remediation of large-area contaminated soil.

Owner:江苏环保产业技术研究院股份公司

Anode material and preparation method thereof

ActiveCN104183842AImprove bindingStable structureCell electrodesSecondary cellsPolymeric surfacePhysical chemistry

The invention discloses an anode material and a preparation method of the anode material. The preparation method of the anode material comprises the following steps: (1) dissolving fluorine-containing polymer in a solvent to form solution A, and dissolving metal salt in the same solvent to form a solution B; (2) mixing and stirring the solution A and the solution B uniformly, adding unmodified anode material powder in the obtained mixed solution, stirring, drying, and calcining at 300-750 DEG C to obtain a fluorine ion doped and metal fluoride clad anode material with treated polymer surface membrane. The cores of the anode material particles are doped with fluorine ions, and the surface of the anode material particle is modified by the metal fluoride layer and the polymer surface membrane. According to the preparation method of the anode material, fluorine ion doping, metal fluoride cladding and the polymer surface membrane treatment are carried out by one step and the synthetic efficiency is high, and the obtained anode material is suitable for use under high charge cut-off voltage and has high thermal stability.

Owner:DONGGUAN AMPEREX TECH +1

Mercapto-peptide, preparation method and applications thereof

PendingCN105566439AAchieve in-situ passivationPromote growthAnimal corpse fertilisersClimate change adaptationPotassium hydroxideWaste treatment

The invention discloses a mercapto-peptide, a preparation method and applications thereof, and belongs to the technical field of protein waste treatment and utilization. The mercapto-peptide is water soluble, the average molecular weight is 3000 to 20000 daltons, and nitrogen accounts for 12.0 to 14.0 wt% of mercapto-peptide. According to the preparation method, a proper amount of potassium hydroxide and water is added into protein wastes especially protein containing animal leftovers, which contain a large amount of disulfide bonds, such as feathers, quills, hoofs, horns, hairs, blood, and the like; and then reactions are carried out at a constant temperature of 70 to 186 DEG C for 0.5 to 40 hours so as to obtain the mercapto-peptide. The produced water-soluble mercapto-peptide can be used as an in-situ passivating agent to passivate heavy metal ions (cadmium, lead, copper, zinc, arsenic, alum, mercury, etc.) in soil, the effective state concentration of heavy metal ions in soil can be reduced, and thus the heavy metal content of planted crops becomes qualified. Furthermore, the mercapto-peptide can be used as a base fertilizer and topdressing, and is capable of promoting the degradation of organic substances in soil, improving the fertilizing effect, and promoting the growth of plants.

Owner:HUBEI UNIV

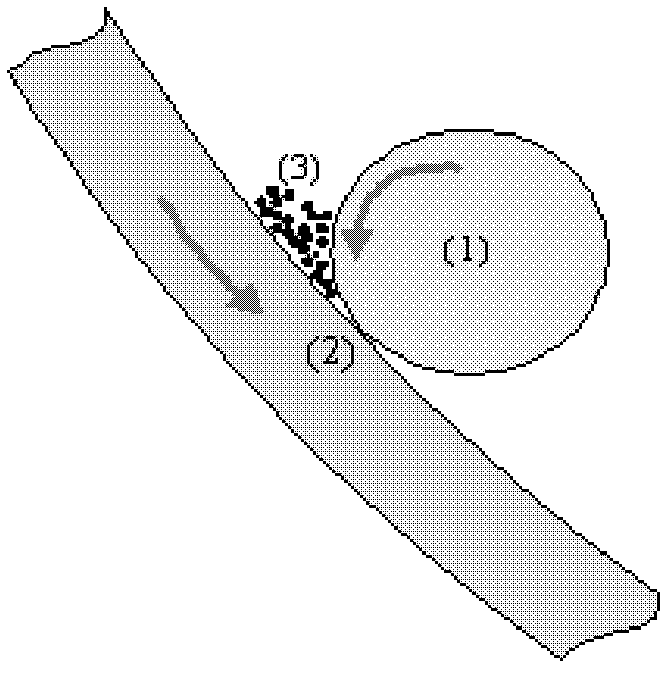

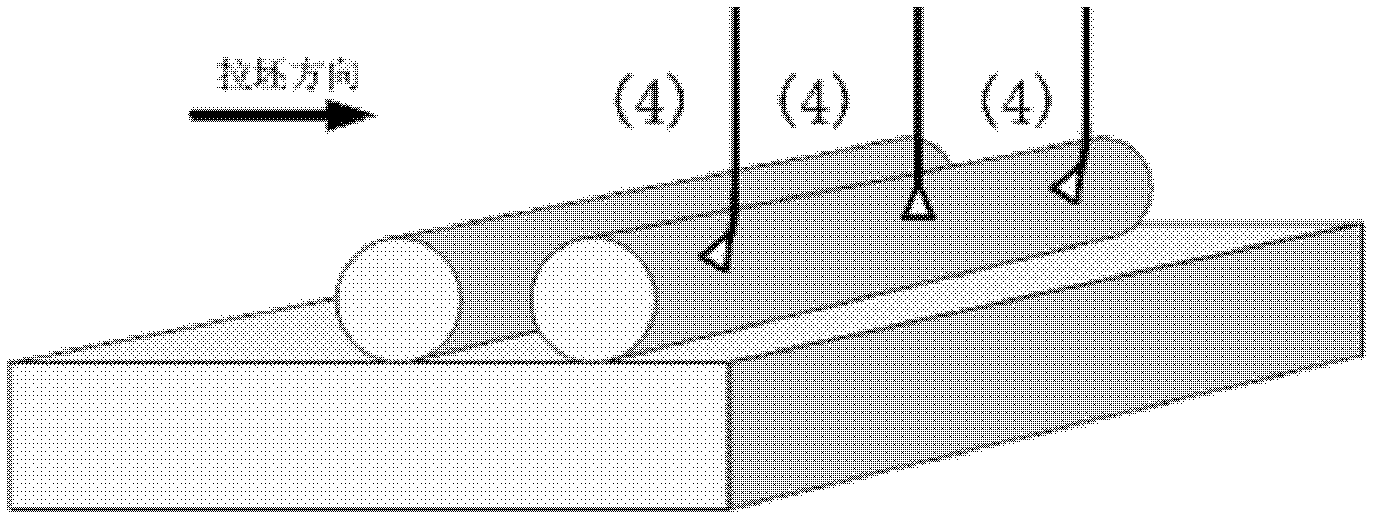

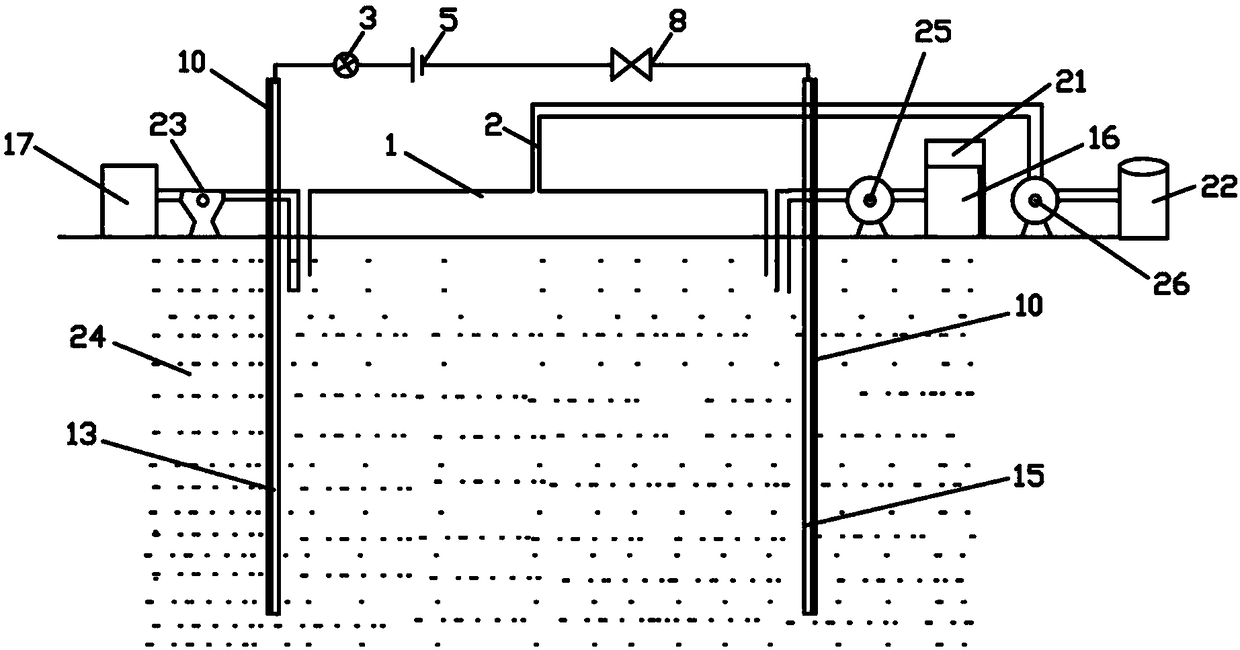

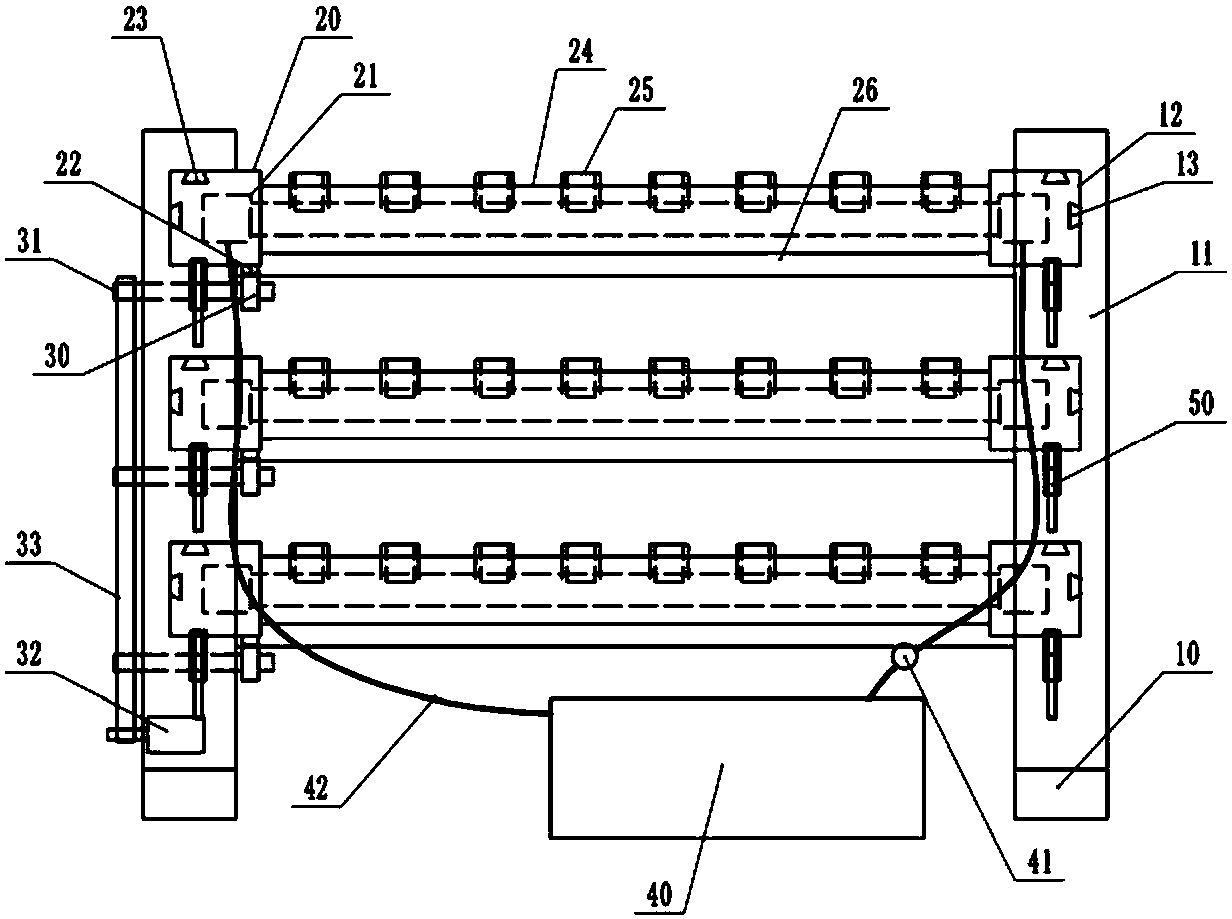

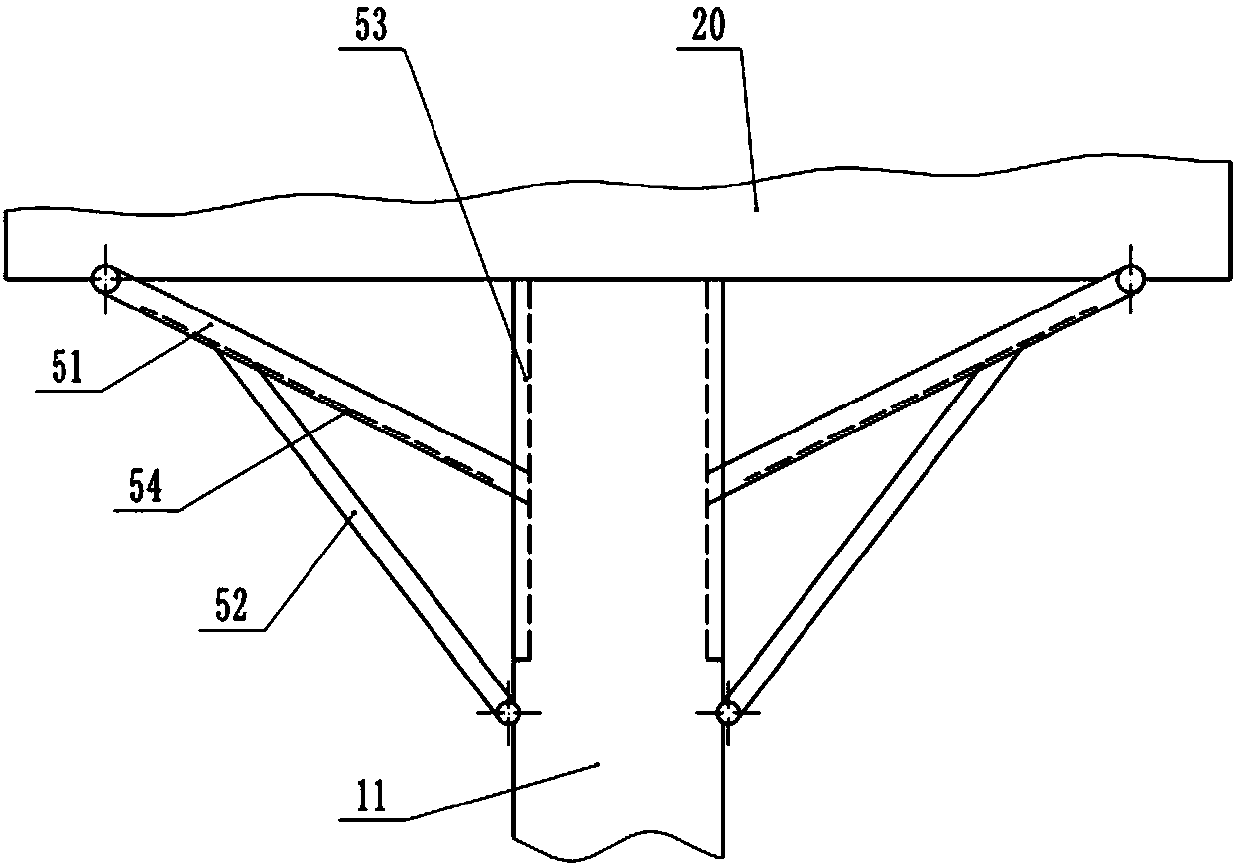

Method for controlling cementation of casting roller on fan-shaped section of continuous casting machine

The invention relates to a quality assurance technology for continuous casting machine equipment and a casting blank. Aggregates such as iron sheets falling from the surface of the blank, covering slag residues, secondary cooling water scales and the like are accumulated, and part of aggregates are remelted or sintered and cemented on the surface of a casting roller to form a hard cementing substance, so that the casting roller stops rotating. In order to eliminate influence on the normal operation of the equipment and solve the quality problem of the casting blank, the invention provides a method for reducing the cementing substance enriched on the surface of the roller, namely an aerial fog water spray device is arranged near an inner arc roller of a fan-shaped section in front of a bending section, a straightening section and a horizontal section of an arc continuous casting machine and sprays aerial fog cooling water onto the surface of the roller to form a water film, so that the temperature of the casting roller is reduced, and a lubricating effect is achieved between the continuous casting blank and the casting roller. The cleaning frequency of a segmental roller on the fan-shaped section can be effectively reduced, the segmental roller is overhauled once every 15 to 17 weeks instead of once every 8 to 10 weeks originally, and the operation service life of the fan-shaped section is effectively improved; and compared with an off-line overhaul mode, the overhaul mode has the advantages that: maintenance cost is reduced by over 30 percent, and the operation rate of the casting machine is improved by over 2 percent.

Owner:TIANJIN IRON & STEEL GRP

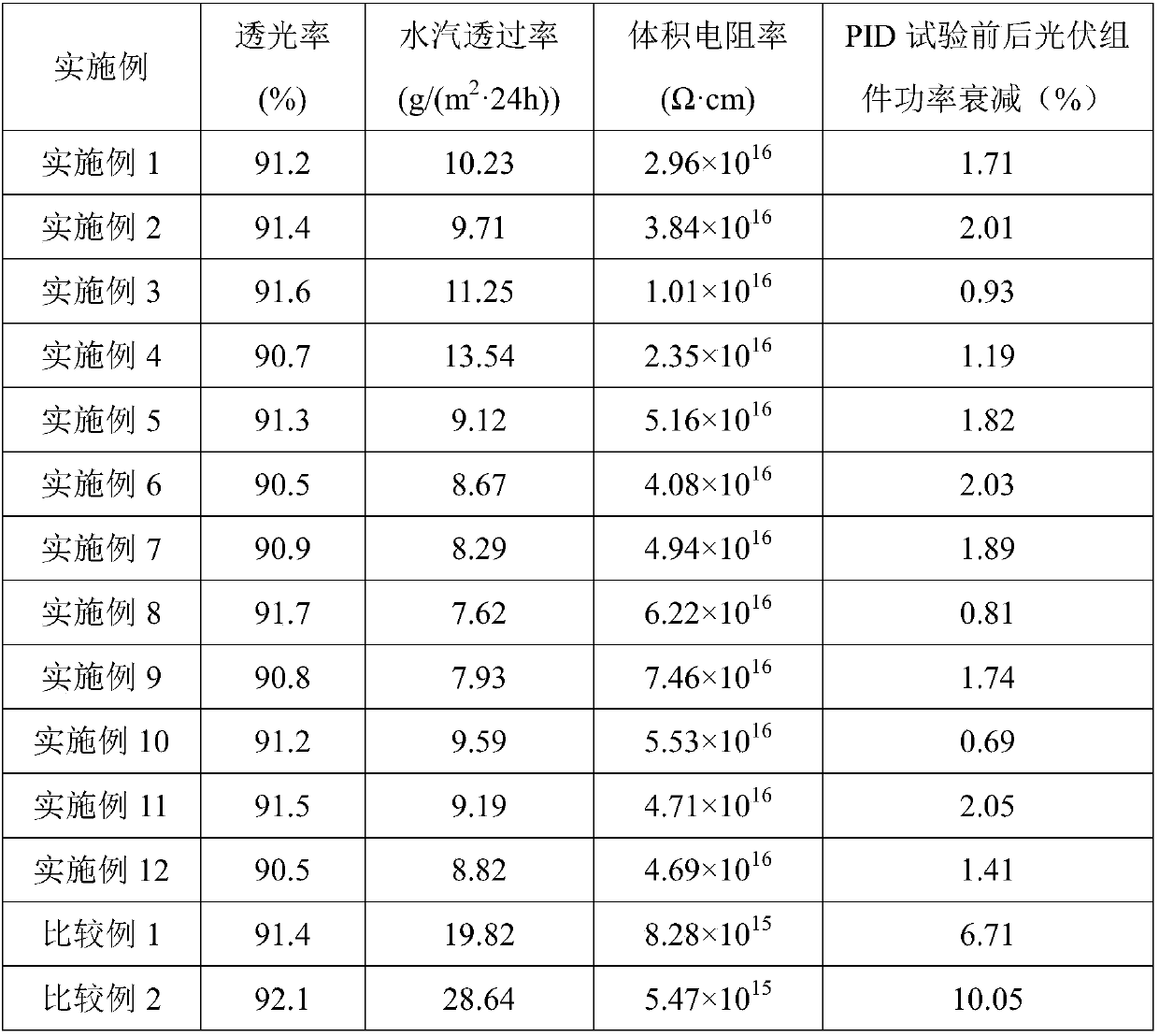

Photovoltaic encapsulation material EVA adhesive film resisting potential induced attenuation

ActiveCN108034372AImprove anti-PID performanceHigh volume resistivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesLow-density polyethyleneWater vapor

The invention discloses a photovoltaic encapsulation material EVA adhesive film resisting potential induced attenuation. EVA with the VA content being 8 to 21wt percent and low-density polyethylene orvinyl copolymer with the melting rang being 70 to 130 DEG C are mixed into matrix resin; then the matrix resin, complex absorbing sodium ion and other assistants are subjected to premixing, melt extrusion, casting and film formation, cooling, slitting and rolling processes, so that the adhesive film is formed. The ion mobility is reduced through proper reducing of the VA content, the improvementof the volume resistivity of the EVA adhesive film and the reducing of the content of acetic acid in a photovoltaic system from the source. The volume resistivity of the EVA adhesive film is improvedthrough the adding of the high-melting polyethylene or vinyl copolymer, and meanwhile water vapor transmittance is reduced. Environment of sodium ion on the surface of a battery is reduced through theadding of the complex absorbing sodium ion, passivation phenomenon caused in a battery piece antireflection layer is weakened or even eliminated, and the potential induced attenuation resistance of the adhesive film is improved.

Owner:福斯特(滁州)新材料有限公司

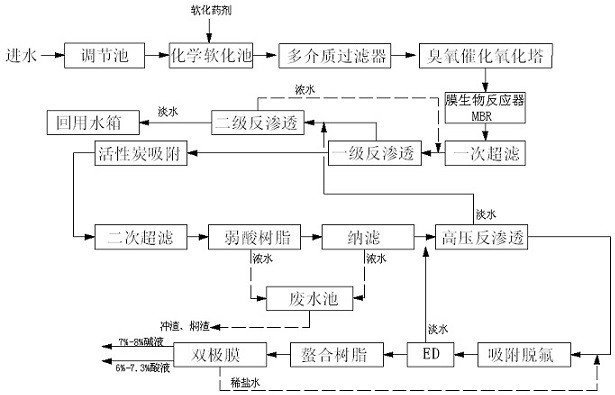

Iron and steel enterprise high-salinity wastewater treatment process

ActiveCN112374705AReduce purchasing costsRealize resource utilizationGeneral water supply conservationWater contaminantsWater useCatalytic oxidation

The invention discloses an iron and steel enterprise high-salinity wastewater treatment process, and belongs to the technical field of industrial wastewater treatment. According to the technical scheme, the process comprises the steps: treating high-salinity wastewater through an adjusting tank, a chemical softening tank, a multi-medium filter, an ozone catalytic oxidation tower, a membrane bioreactor (MBR), primary ultrafiltration, two-stage low-pressure reverse osmosis, activated carbon adsorption, secondary ultrafiltration, weak acid resin, nanofiltration, high-pressure reverse osmosis, adsorption defluorination, electrodialysis (ED), and treatment with chelating resin and a bipolar membrane in sequence; the quality of recycled water is better than that of industrial new water, the recycled water can be used as desalted water, and the produced by-products hydrochloric acid and sodium hydroxide can be recycled for the process system, other water treatment systems of iron and steel enterprises and the like, so that the outsourcing cost is saved, and resource utilization is realized. The process is low in energy consumption, low in cost, simple in equipment, easy to operate, stablein treatment effect and beneficial to water optimization and sustainable development of iron and steel enterprises.

Owner:HANDAN IRON & STEEL GROUP +1

Smelting method for non-magnetic stainless steel

ActiveCN103060523AReduce wire breaksIncrease rolling plasticityElectric furnaceProcess efficiency improvementSteel qualitySlag

The invention relates to a smelting method for non-magnetic stainless steel. The smelting method comprises the following steps in sequence: I, electric furnace smelting: tapping when components of molten steel meet the following requirements that the content of C is 1.2 to 2.0 percent, the content of Cr is 18 to 19 percent, the content of Ni is 9 to 10 percent, the content of P is less than or equal to 0.02 percent and the balance is Fe and inevitable impurities; II, argon oxygen decarburization (AOD) smelting: blowing oxygen into the molten steel in an AOD furnace, heating and decarbonizing until the content of C is less than or equal to 0.02 percent, adding ferrosilicon for reduction, removing pre-reducing slag until the binary basicity of the reducing slag is 1.8 to 2.0 percent, adding 8 to 10 kg of lime into per ton of molten steel to generate new slag after slag removal, regulating the slag by using 10 to 20 kg of Ca-Si powder and 10 to 20 kg of Al powder until the slag is light green or yellowish white, blowing argon to slag for at least 4 minutes to ensure that the content of S in the molten steel is less than or equal to 0.001 percent; III, LF (ladle furnace) smelting: heating the molten steel by using electricity when the molten steel reaches an LF station, feeding the molten steel to a Ca-Si line, adding ferroboron, and blowing the argon with stirring; and IV, continuous casting. According to the stainless steel which is prepared by using the smelting method for the non-magnetic stainless steel, the occupied positions of S among steel crystals are reduced, and the plasticity of the stainless steel is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

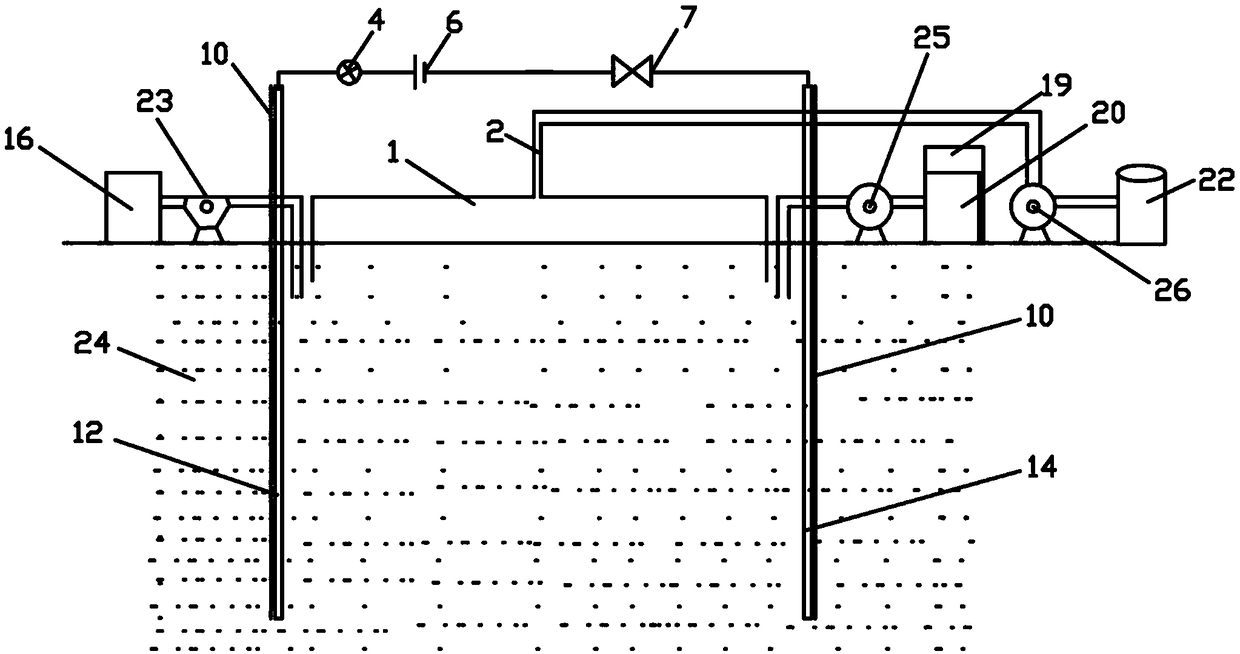

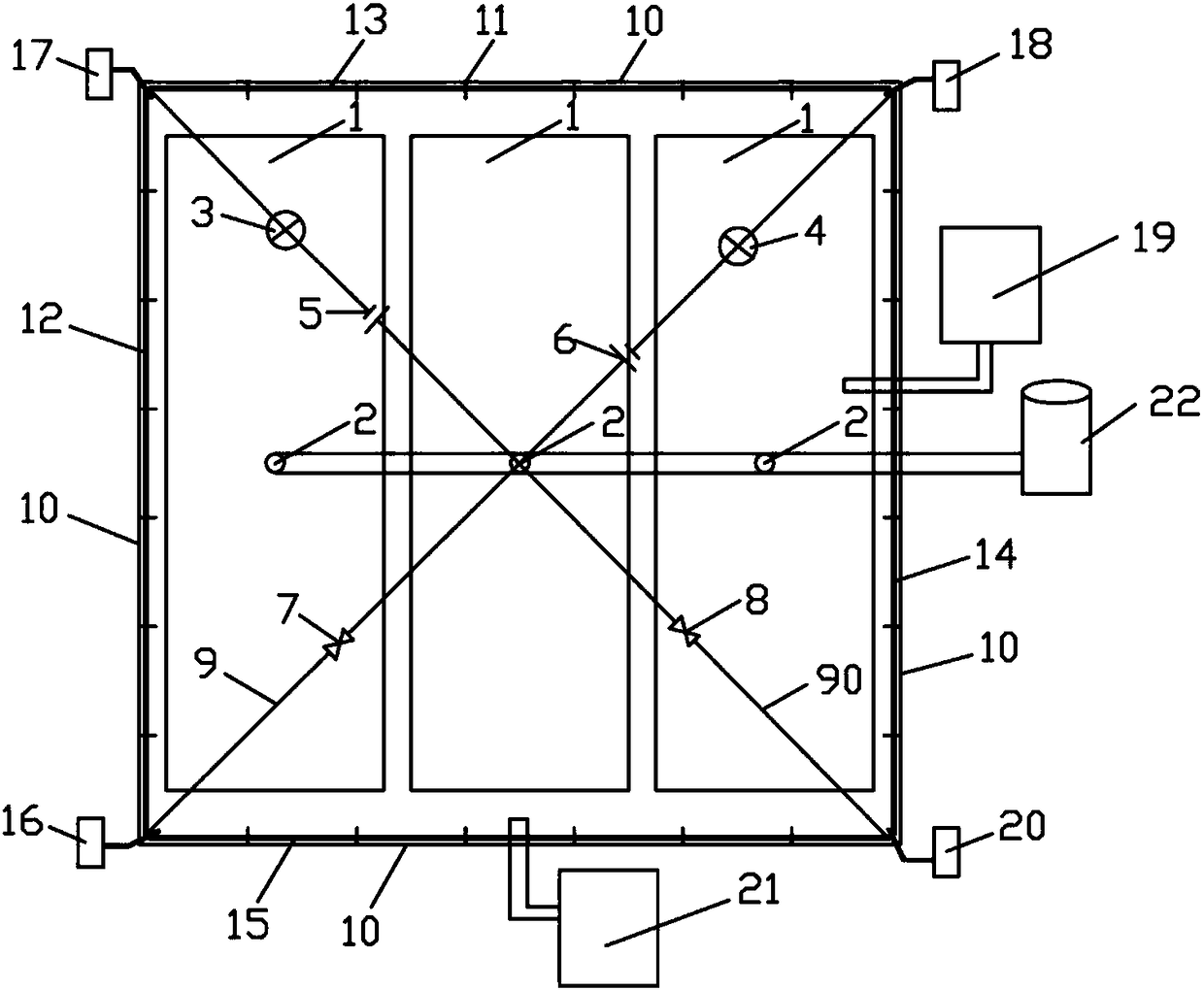

In-situ restoration system and method for river-lake bottom mud polluted by heavy metals

PendingCN108341569AImprove corrosion resistanceImprove repair effectSludge treatment by de-watering/drying/thickeningWater contaminantsElectrokinetic remediationSewage discharge

The invention relates to the technical field of in-situ restoration and dewatering for pollution of river-lake bottom mud and particularly relates to an in-situ restoration system and method for the river-lake bottom mud polluted by heavy metals. The system comprises a steel-plate mold frame with a square-shaped structure, wherein the lower part of the steel-plate mold frame is inserted and driveninto the river-lake bottom mud; a volatile organic pollutant gas collecting bag is arranged at the upper part of the steel-plate mold frame and is connected to a volatile organic pollutant gas disposal system by a gas suctioning pipeline; the four corners of the steel-plate mold frame are respectively provided with a non-volatile organic pollutant disposal device I, a heavy-metal and volatile organic pollutant disposal device, a non-volatile organic pollutant disposal device II and a non-volatile organic pollutant disposal device III; the steel-plate mold frame is also provided with an electric restoration system and a sewage discharging system. The in-situ restoration system and method have the beneficial effects that electric restoration and dewatering technologies are applied in disposal of the river-lake bottom mud simultaneously, the economic-practical effects and the environment-friendly effect are achieved, the effect is better, the method is simple in operation, and no secondary pollution is generated.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

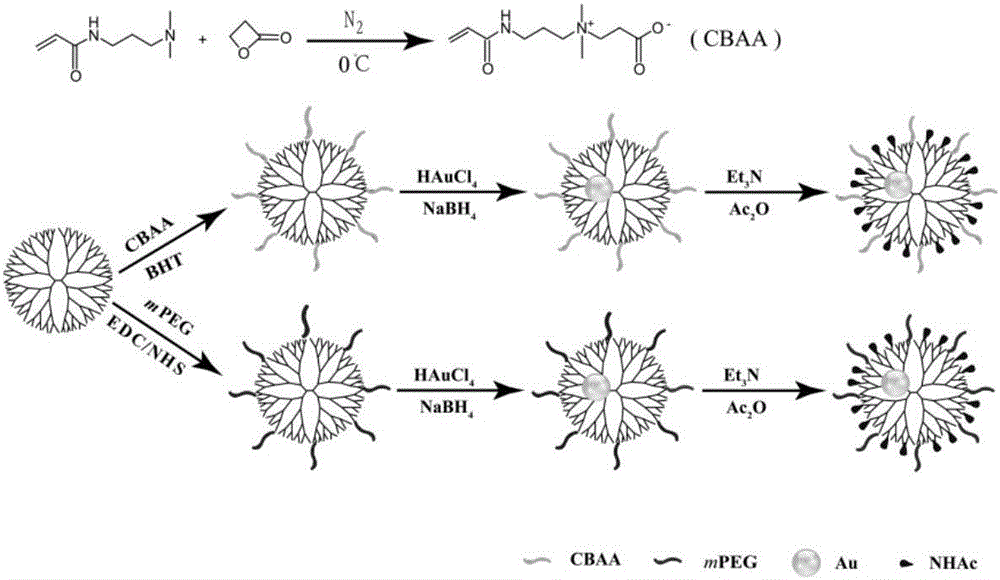

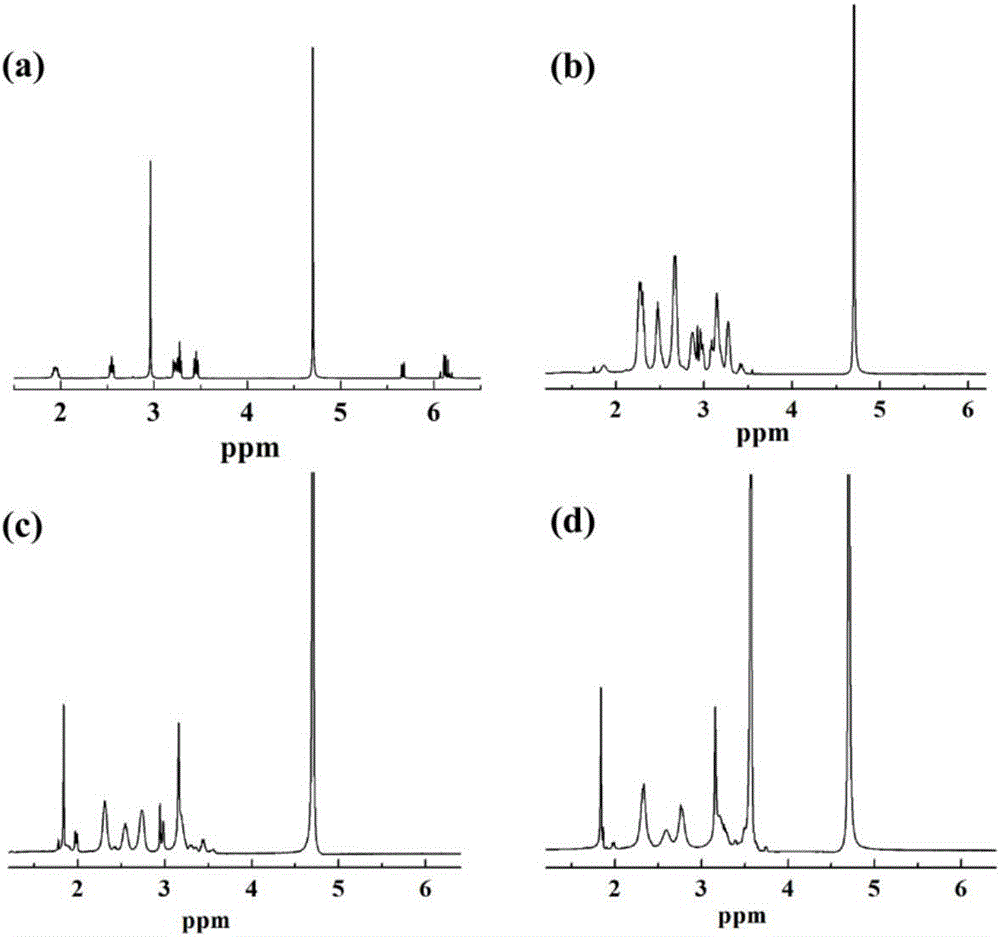

CT contrast agent with gold nanoparticles wrapped with zwitter-ion modified dendrimer and preparation method and application of CT contrast agent

InactiveCN106512028AGood biocompatibilityImprove adsorption capacityX-ray constrast preparationsMaterial analysis by transmitting radiationDendrimerAcetic anhydride

The invention relates to a CT contrast agent with gold nanoparticles wrapped with zwitter-ion modified dendrimer and a preparation method and application of the CT contrast agent. The surface of the dendrimer is modified with the zwitter-ion carboxybetaine acrylic amide (CBAA), and the gold nanoparticles are wrapped with the dendrimer, wherein the dendrimer is fifth-generation polyimide dendrimer G5.NH2. The preparation method comprises the steps that the CBAA and the fifth-generation polyimide are stirred and reacted at the room temperature to obtain CBAA-G5.NH2, an HAuCl4 solution is added, NaBH4 is added for reduction, triethylamine and acetic anhydride are added finally, and then the CT contrast agent is obtained. Compared with a traditional contrast agent modified by mPEG, the consuming quantity of in-vitro macrophages is low, protein adsorption in the protein adsorption resistance experiment is low, the in-vivo rat blood circulation time is longer, liver gathering in the mouse CT experiment is low, the renal metabolism is slower, and the CT contrast agent can also be used for rat blood pool radiography and rabbit lymphonodus VT imaging.

Owner:DONGHUA UNIV +1

Planting method of green vegetables

InactiveCN107616086AReduce the accumulation of toxic substancesVegetables are growing wellAgriculture gas emission reductionCultivating equipmentsGreen VegetableAgriculture

The invention belongs to the technical field of agriculture, and particularly discloses a planting method of green vegetables. The planting method comprises the following steps of 1, sowing, 2, cultivating, 3, transplanting, 4, cultivation, and 5, harvesting. Compared with the prior art, in the process of planting the vegetables according to the planting method, the vegetables can sufficiently absorb light, and thus the growth momentum of the vegetables is excellent.

Owner:贵州省务川县锦祥林生态农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com