Method for extracting high-purity squalene by taking olive oil as raw material

A technology of squalene and olive oil, applied in the direction of adsorption purification/separation, distillation purification/separation, chemical change purification/separation, etc., can solve the problems of not obtaining higher purity squalene, etc., and achieve short heating time, The effect of cost reduction and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Apply saponification acidification, secondary molecular distillation and silica gel column chromatography to separate and purify squalene in olive oil, comprising the following steps:

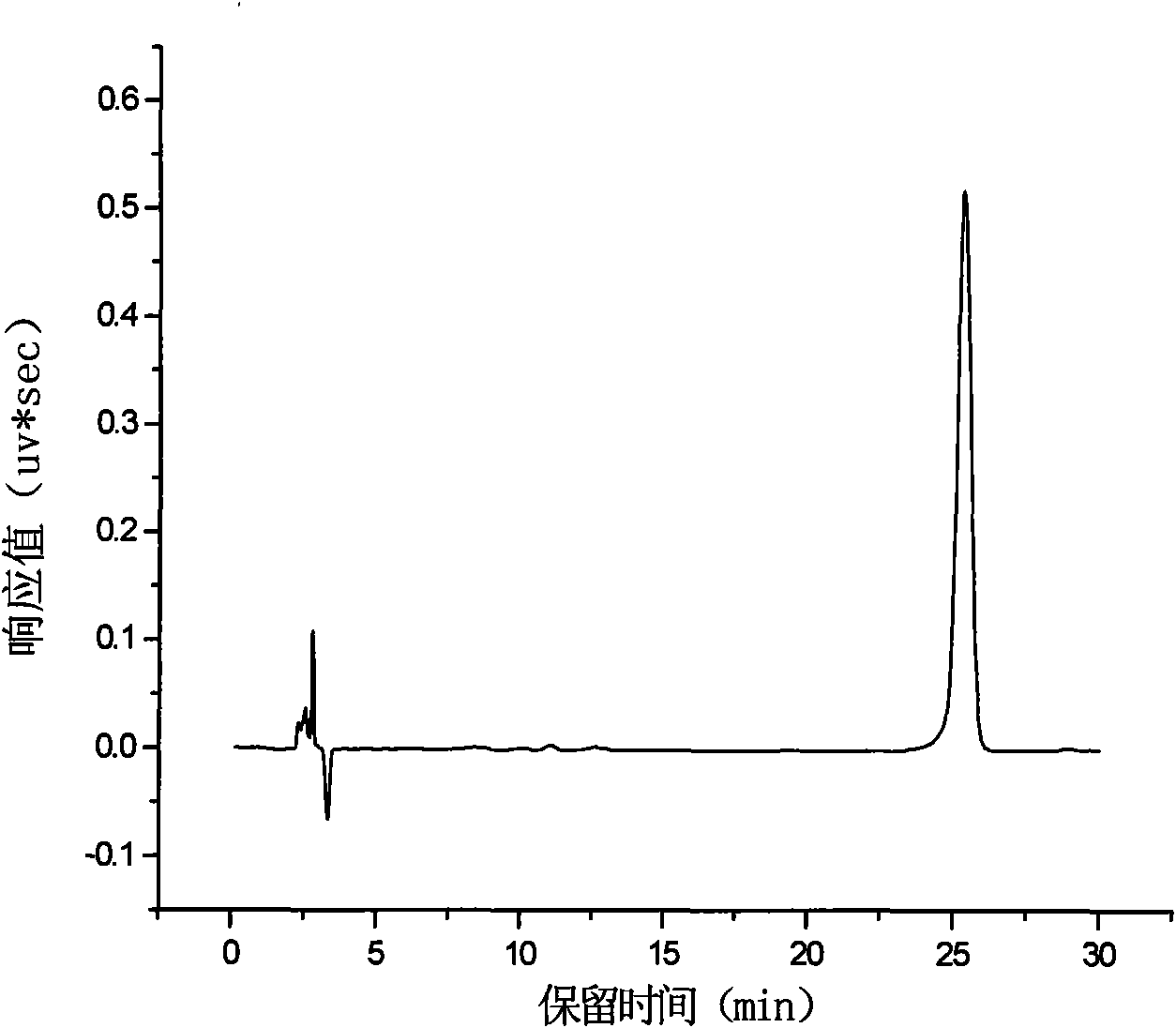

[0026] 1) Preparation of olive oil unsaponifiables: Take 30g of olive oil, 6g of KOH, and 60mL of 95% ethanol, put them into a three-necked flask, use nitrogen as a protective gas to react under constant stirring, and reflux in a water bath at 100°C for 10h. After stopping the reaction, quickly add 200mL of distilled water, extract the unsaponifiable matter with 250mL of petroleum ether five times, add HCL and 5% NaCl aqueous solution to wash the ether phase, and finally wash with water until the lotion is neutral. Add an appropriate amount of anhydrous Na 2 SO 4 Absorb the residual moisture in the ether phase, and remove the solvent by rotary evaporation at 60°C to obtain the olive oil unsaponifiable matter, which can be detected by liquid chromatography to obtain a purity of 43.71% of...

Embodiment 2

[0030] Basic technology is with embodiment 1, and concrete operation parameter is as follows:

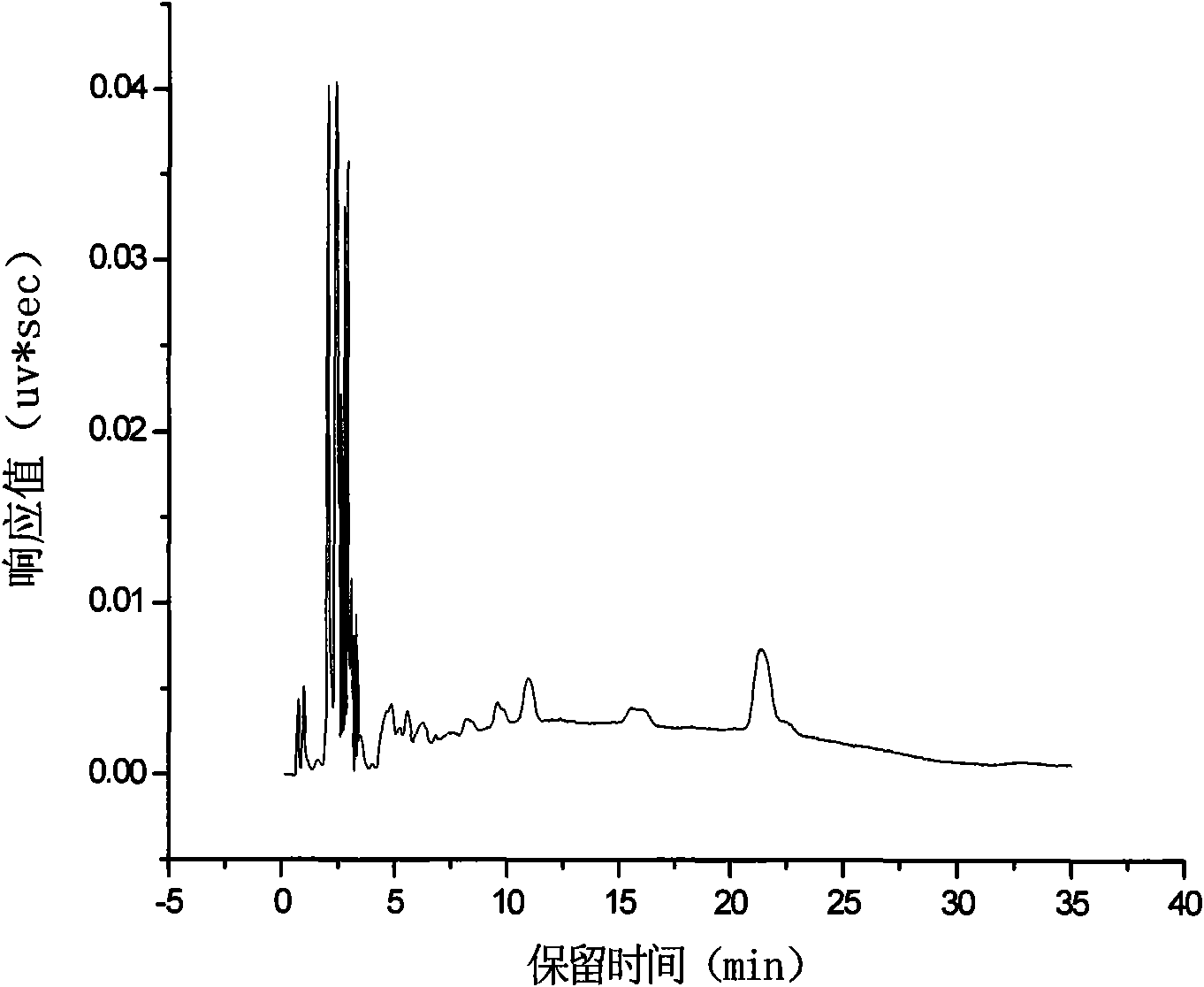

[0031] 1) Preparation of olive oil unsaponifiable matter: Take 30g of olive oil, 6g of KOH, and 60mL of 95% ethanol, add them into a three-necked flask, use nitrogen as a protective gas to react under constant stirring, and reflux in a water bath at 60°C for 1h. After stopping the reaction, quickly add 200mL of distilled water, extract the unsaponifiable matter with 250mL of petroleum ether five times, add HCL and 5% NaCl aqueous solution to wash the ether phase, and finally wash with water until the lotion is neutral. Add an appropriate amount of anhydrous Na 2 SO 4 Absorb the residual moisture in the ether phase, and remove the solvent by rotary evaporation at 60°C to obtain the unsaponifiable product of olive oil, in which the purity of squalene is 47.33%.

[0032]2) Separation of crude squalene by two-stage molecular distillation: the unsaponifiable matter of olive oil was sen...

Embodiment 3

[0035] Basic technology is with embodiment 1, and concrete operation parameter is as follows:

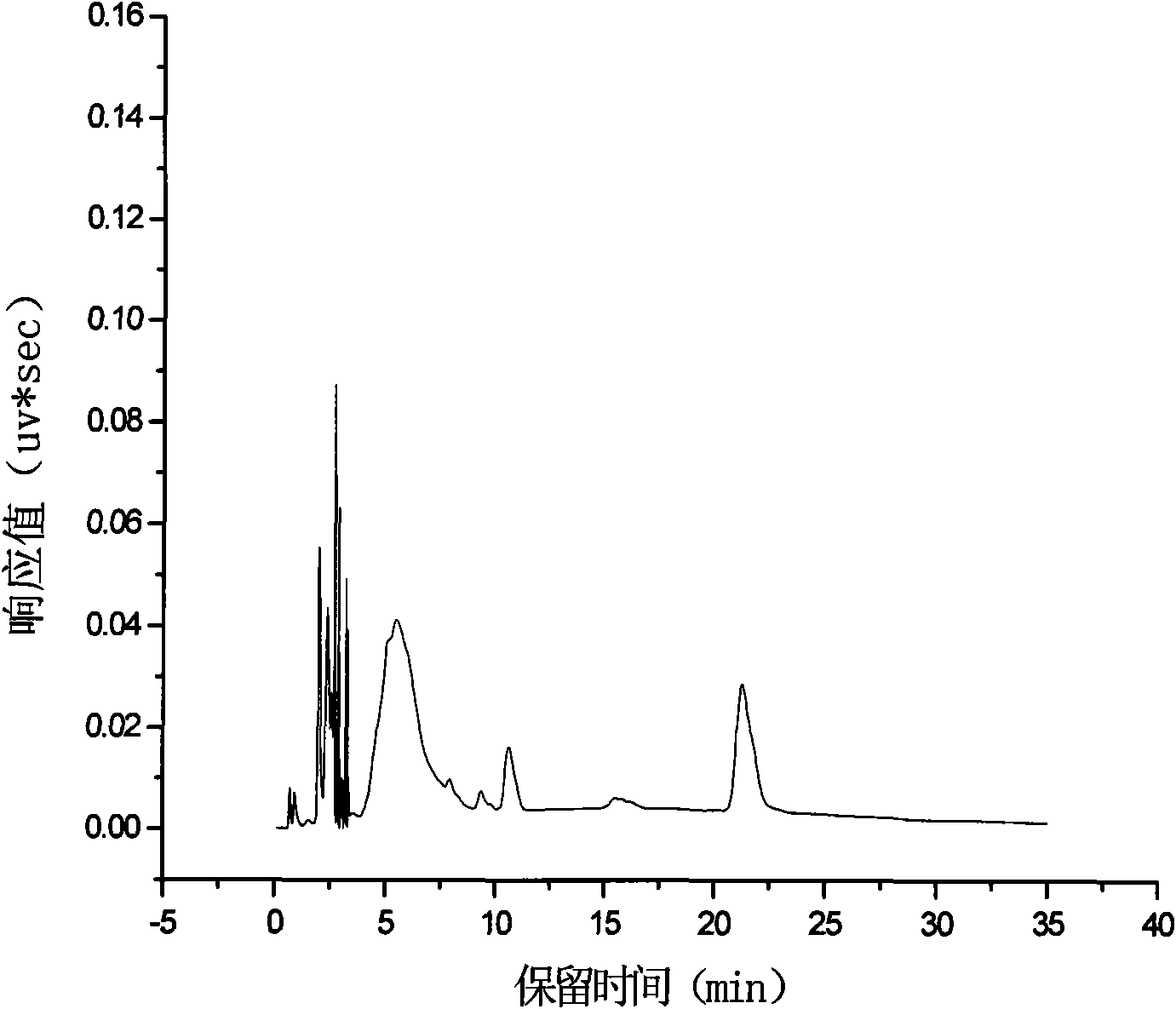

[0036] 1) Preparation of olive oil unsaponifiable matter: Take 30g of olive oil, 6g of KOH, and 60mL of 95% ethanol, add them into a three-necked flask, use nitrogen as a protective gas, react under constant stirring, and reflux in a water bath at 120°C for 5h. After stopping the reaction, quickly add 200mL of distilled water, extract the unsaponifiable matter with 250mL of petroleum ether five times, add HCL and 5% NaCl aqueous solution to wash the ether phase, and finally wash with water until the lotion is neutral. Add an appropriate amount of anhydrous Na 2 SO 4 Absorb the residual moisture in the ether phase, and remove the solvent by rotary evaporation at 60°C to obtain the olive oil unsaponifiable product, in which the purity of squalene is 44.60%.

[0037] 2) Separation of crude squalene by two-stage molecular distillation: send olive oil unsaponifiables into a primary mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com