Patents

Literature

1433results about How to "Short heating time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

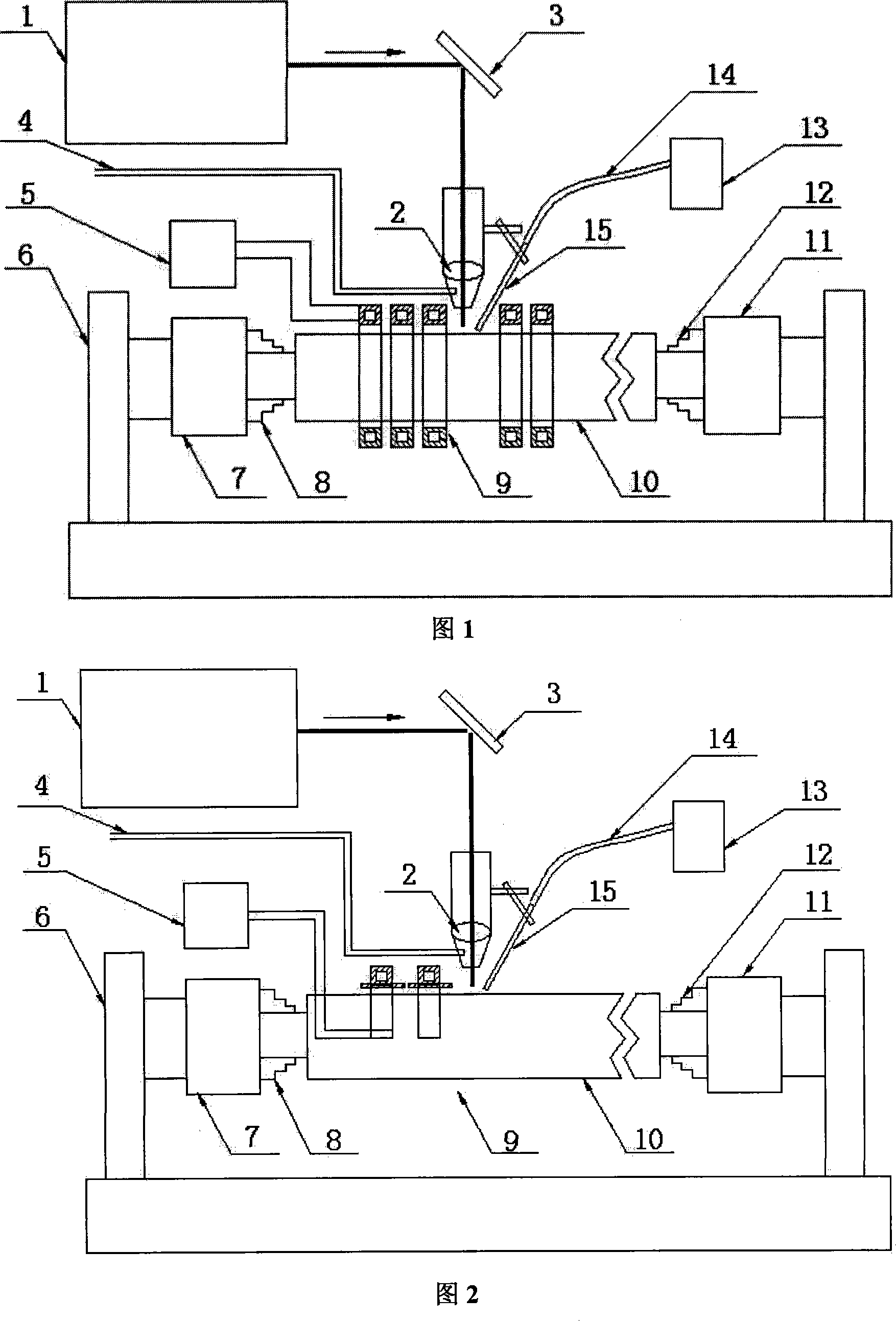

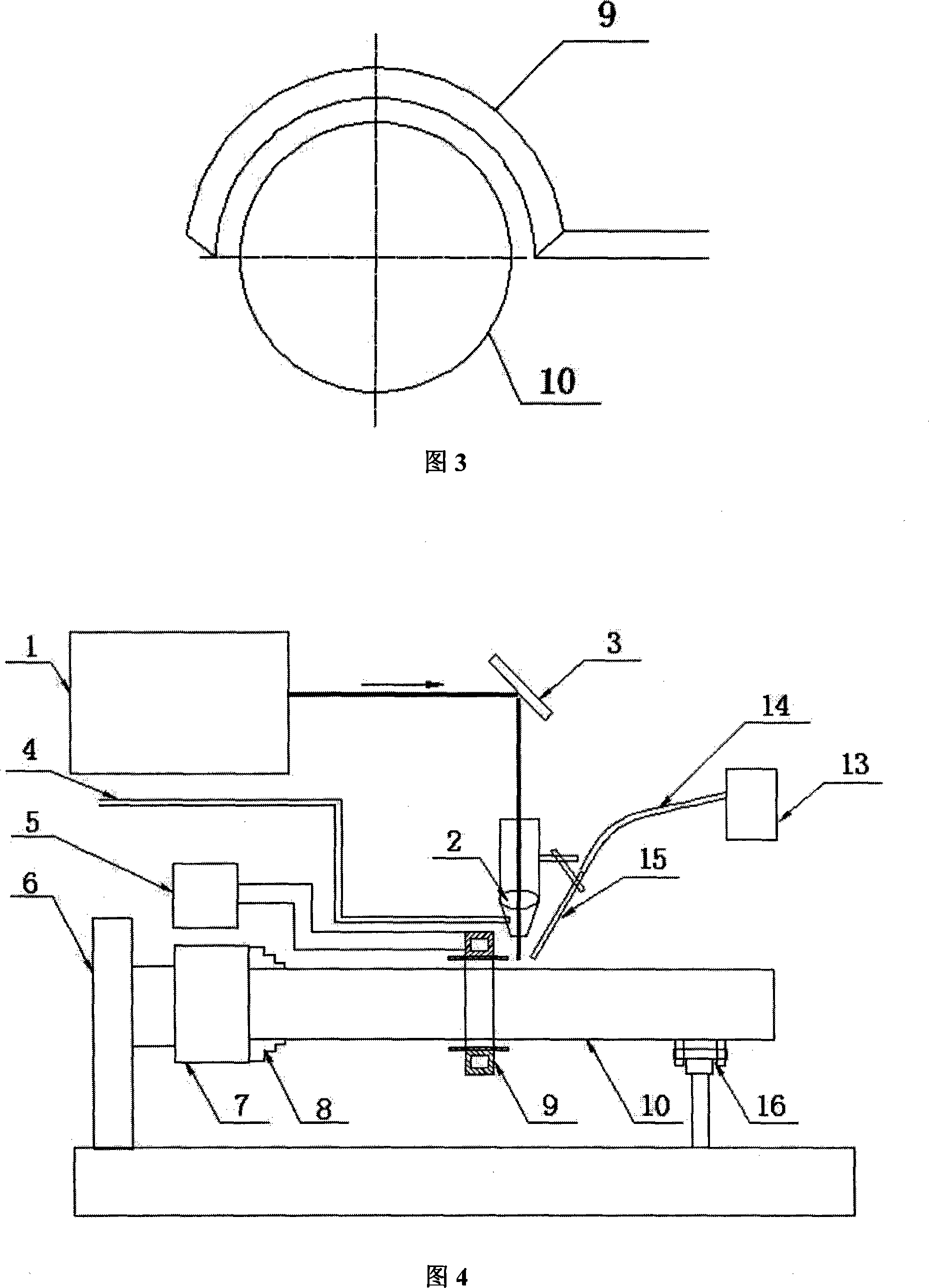

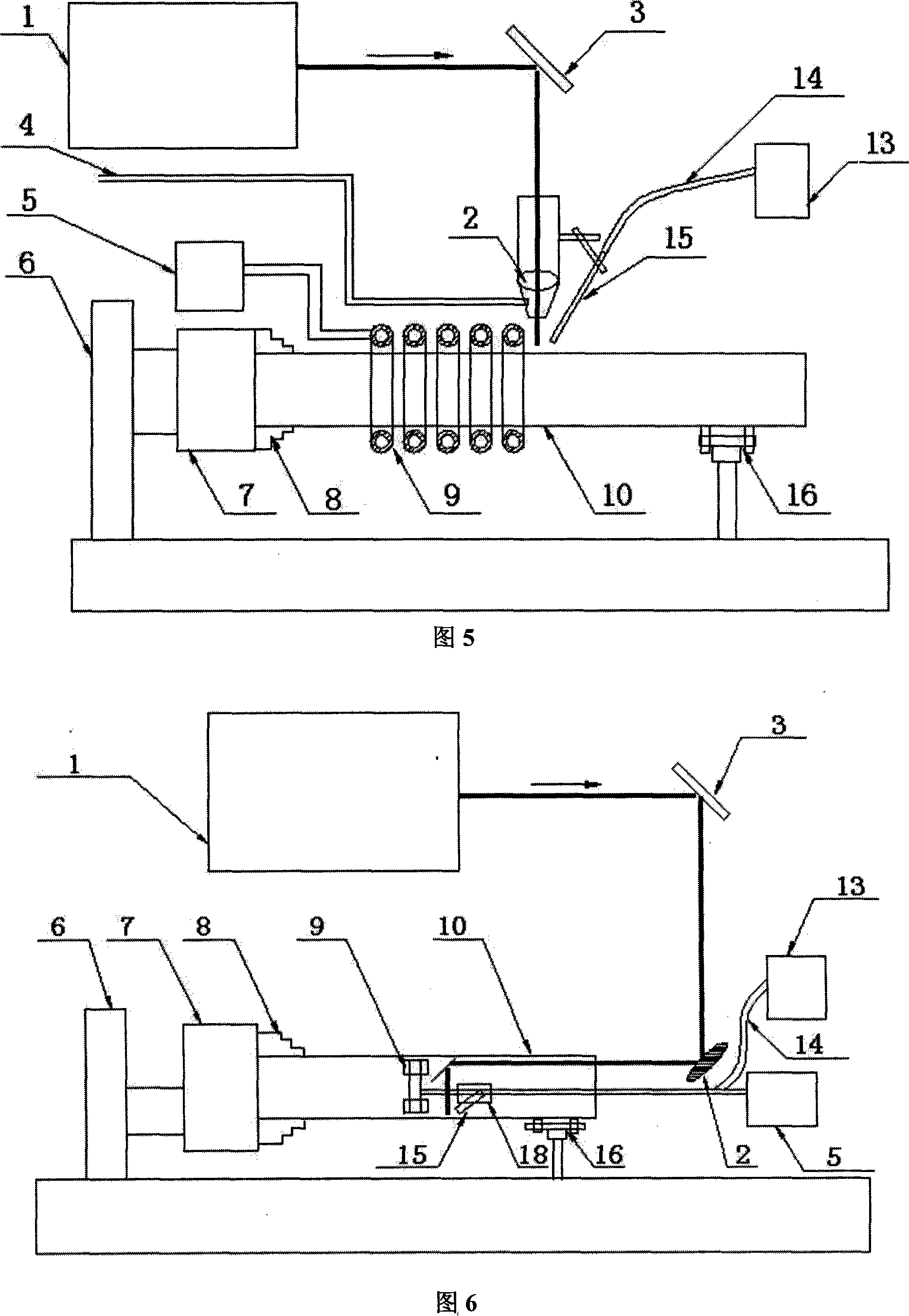

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

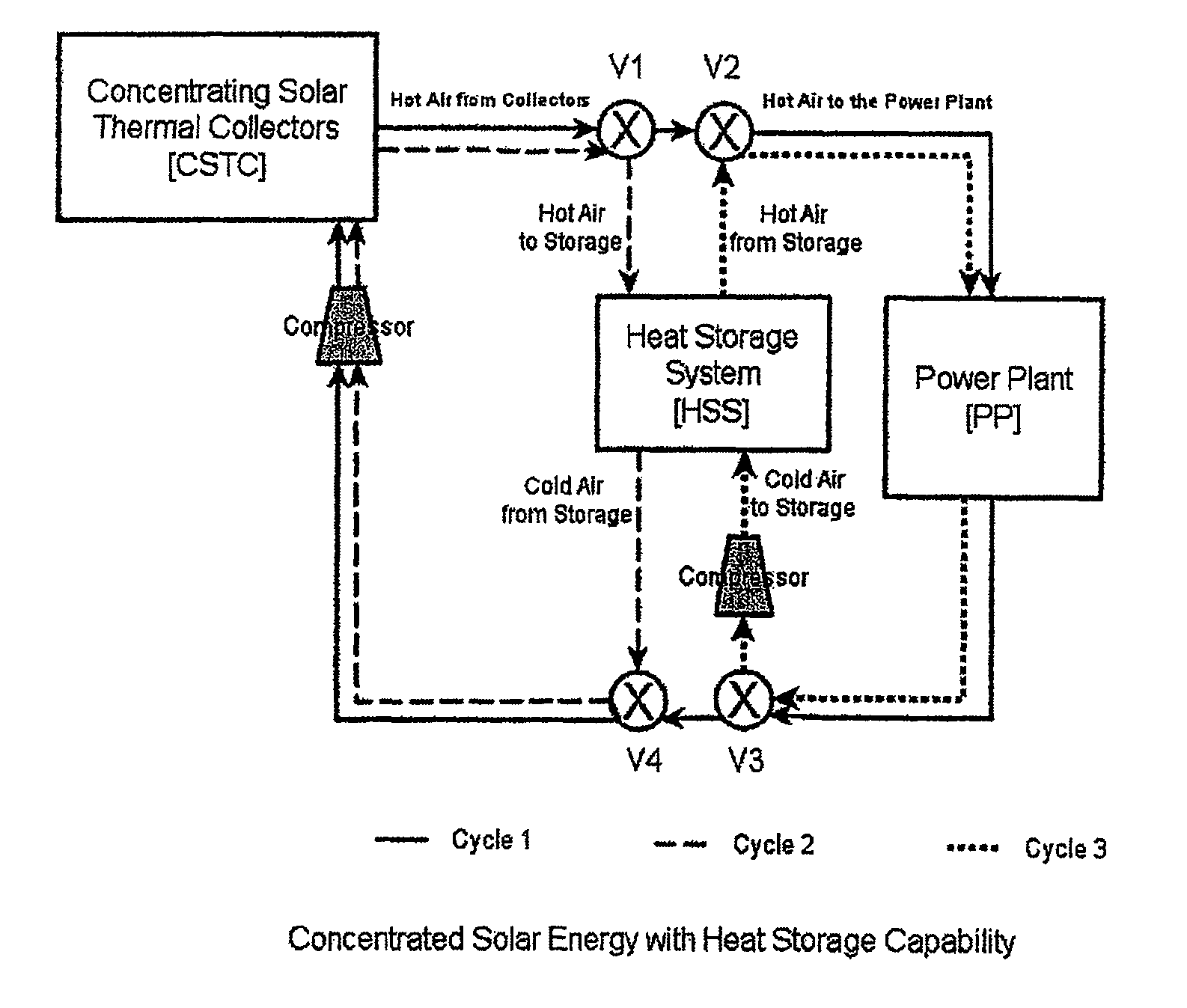

Solar power plant and method and/or system of storing energy in a concentrated solar power plant

ActiveUS7954321B2Big advantageLower energy requirementsSolar heating energyAuxillary drivesPower stationEngineering

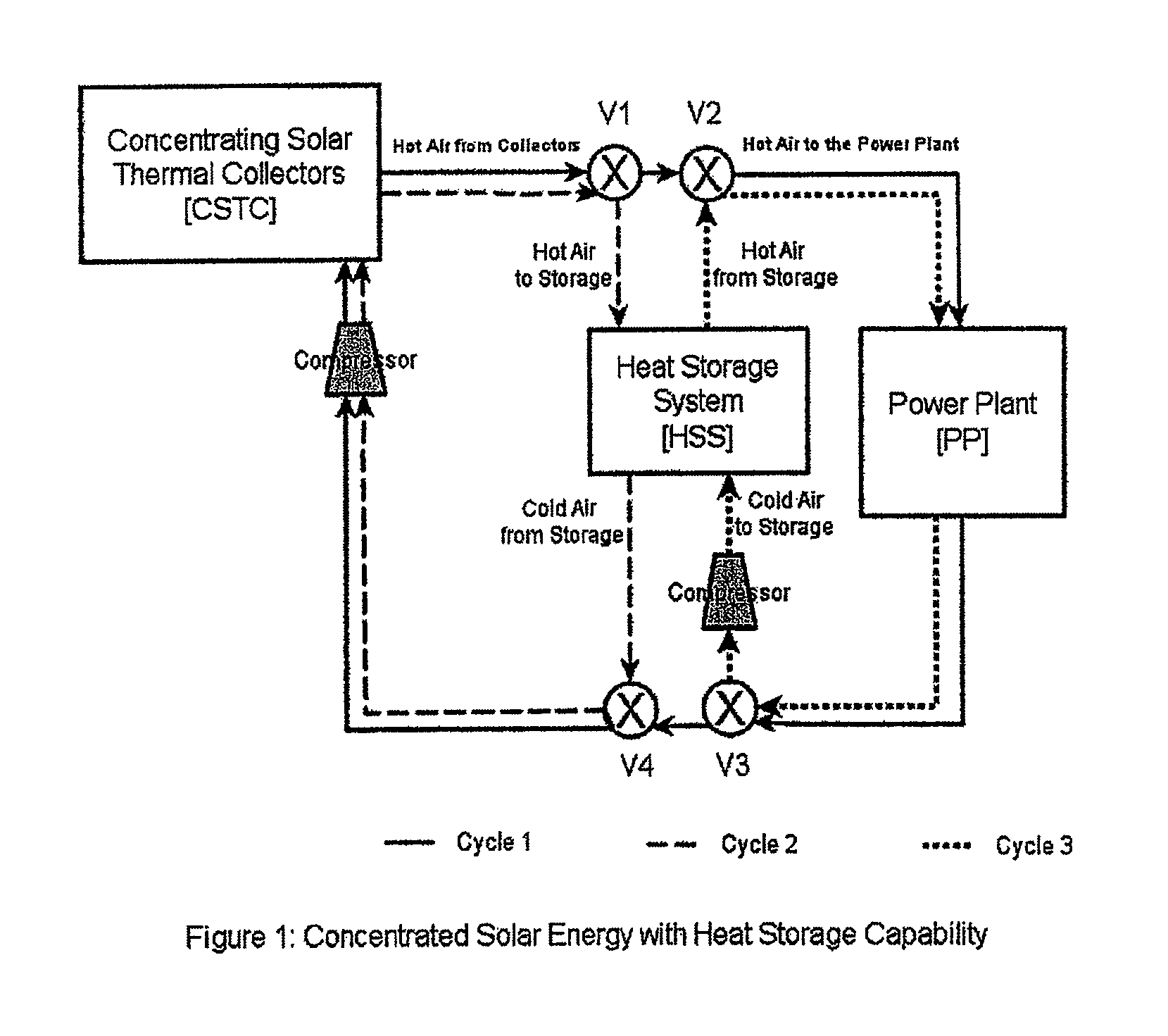

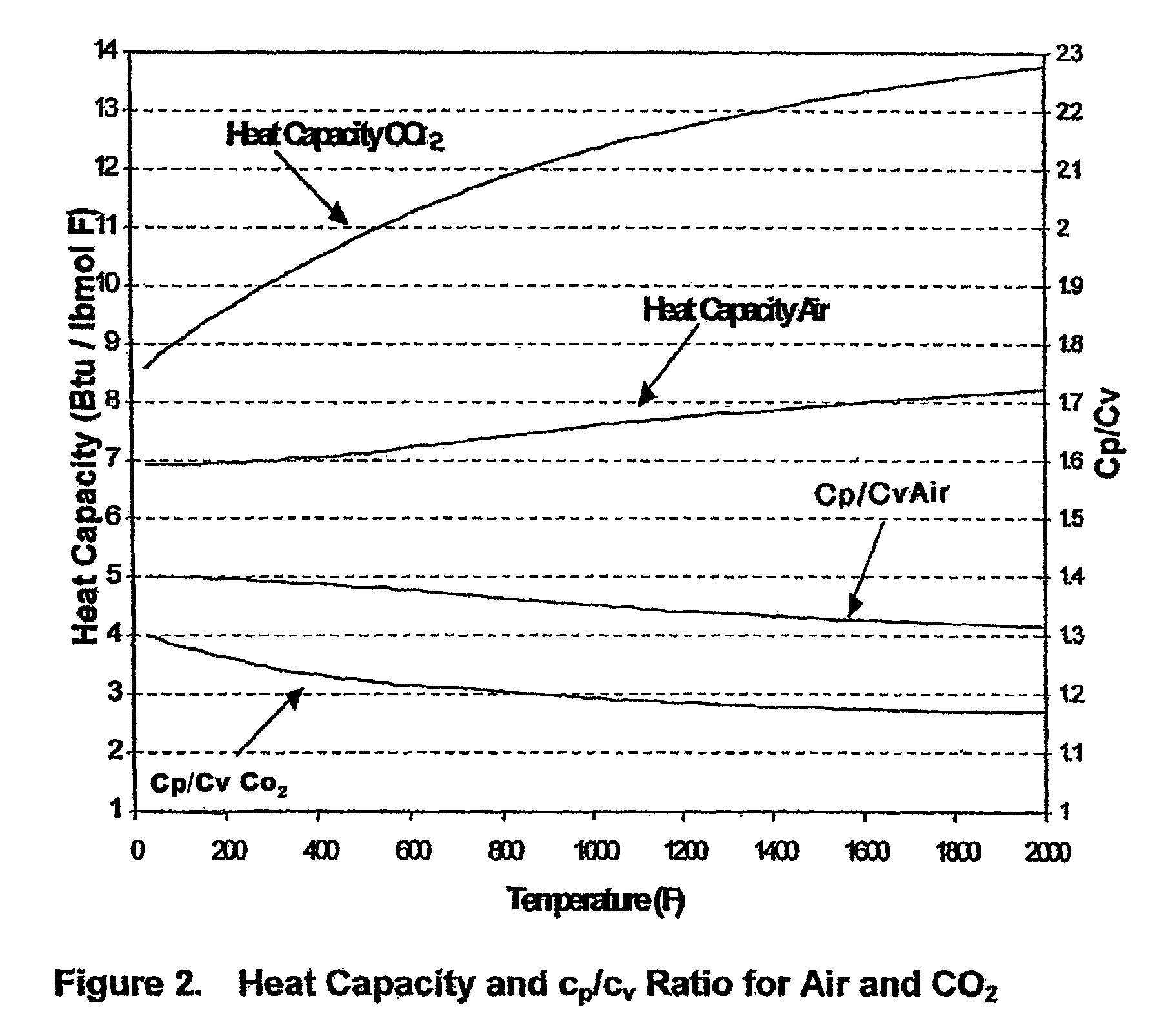

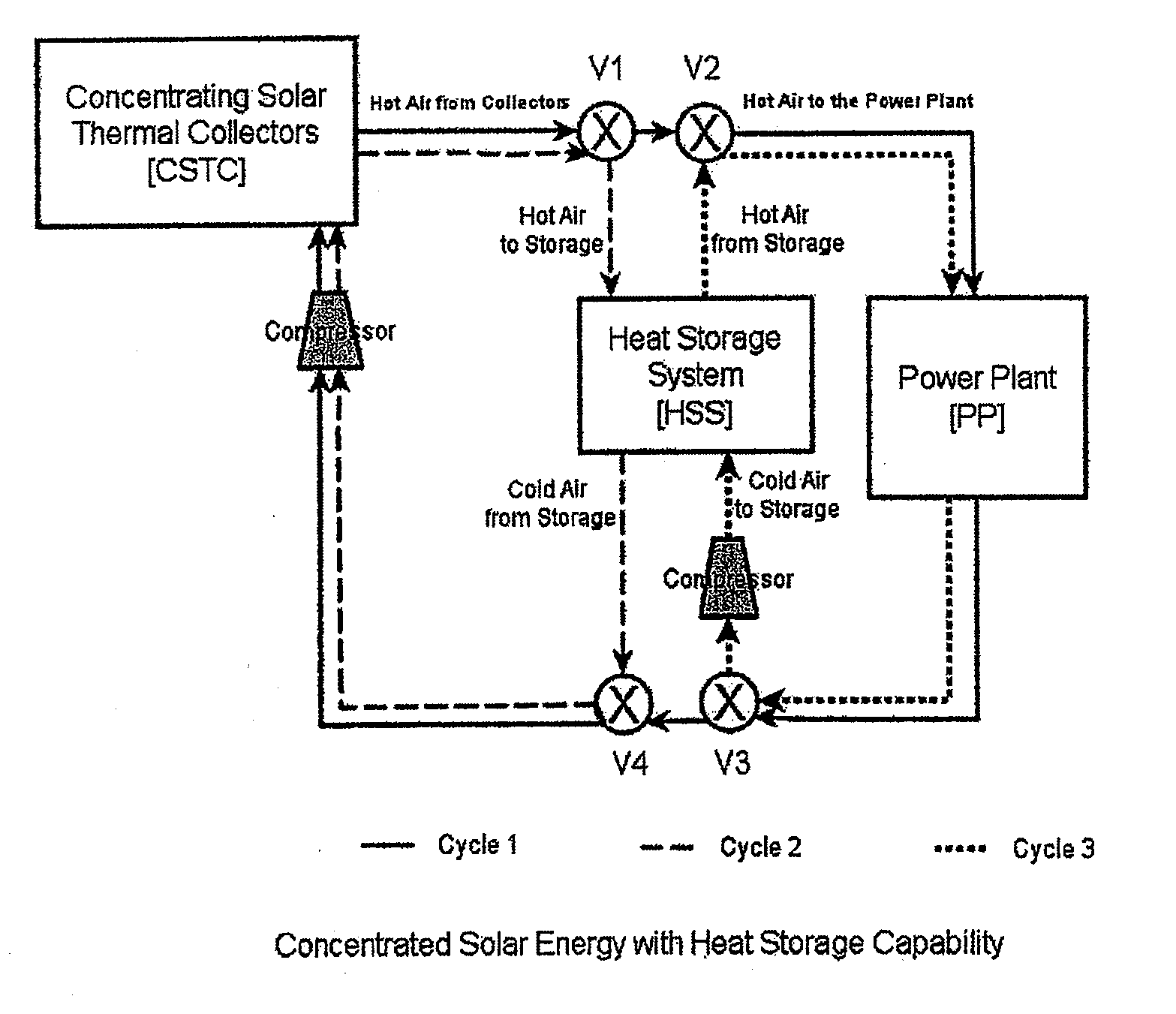

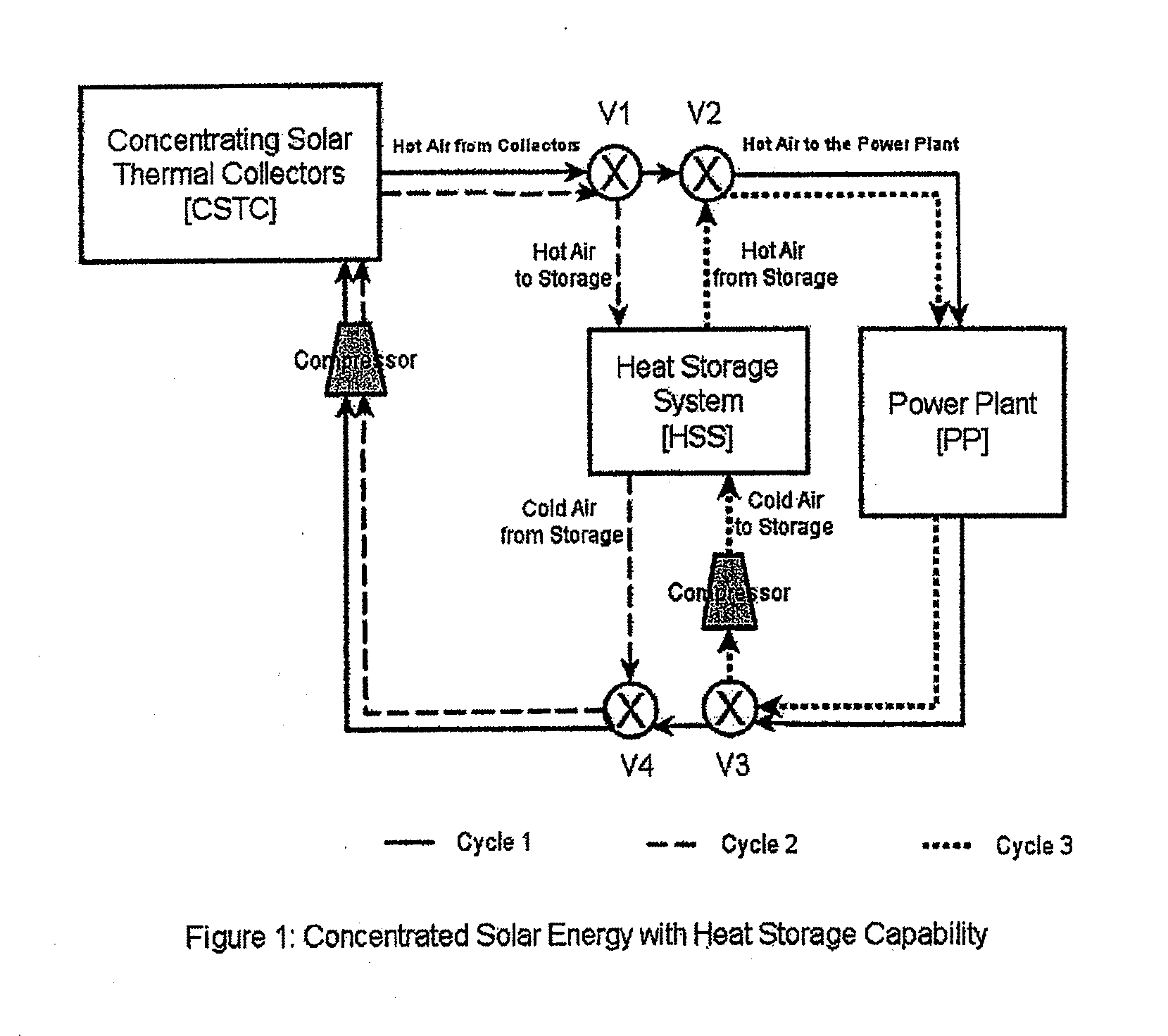

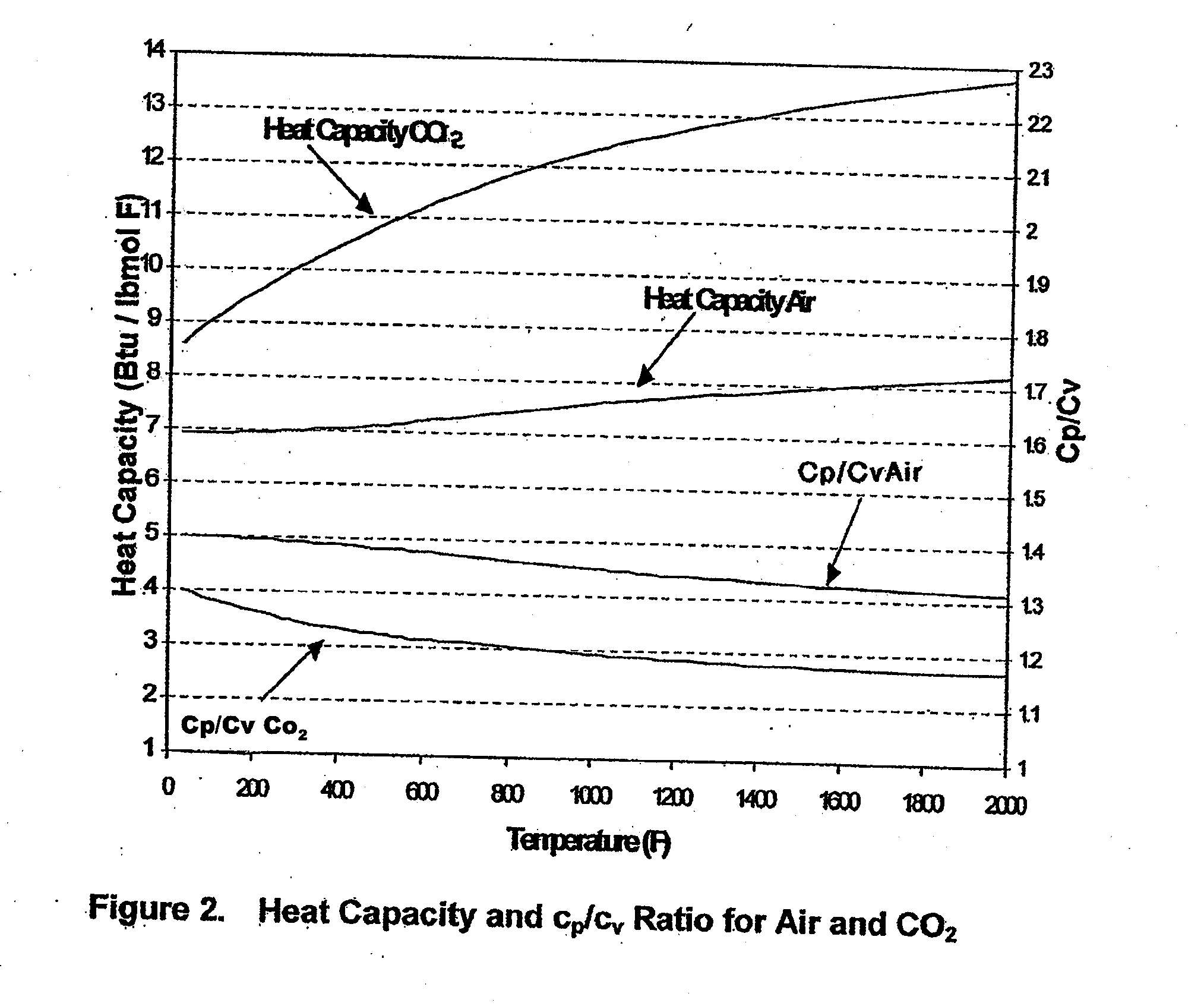

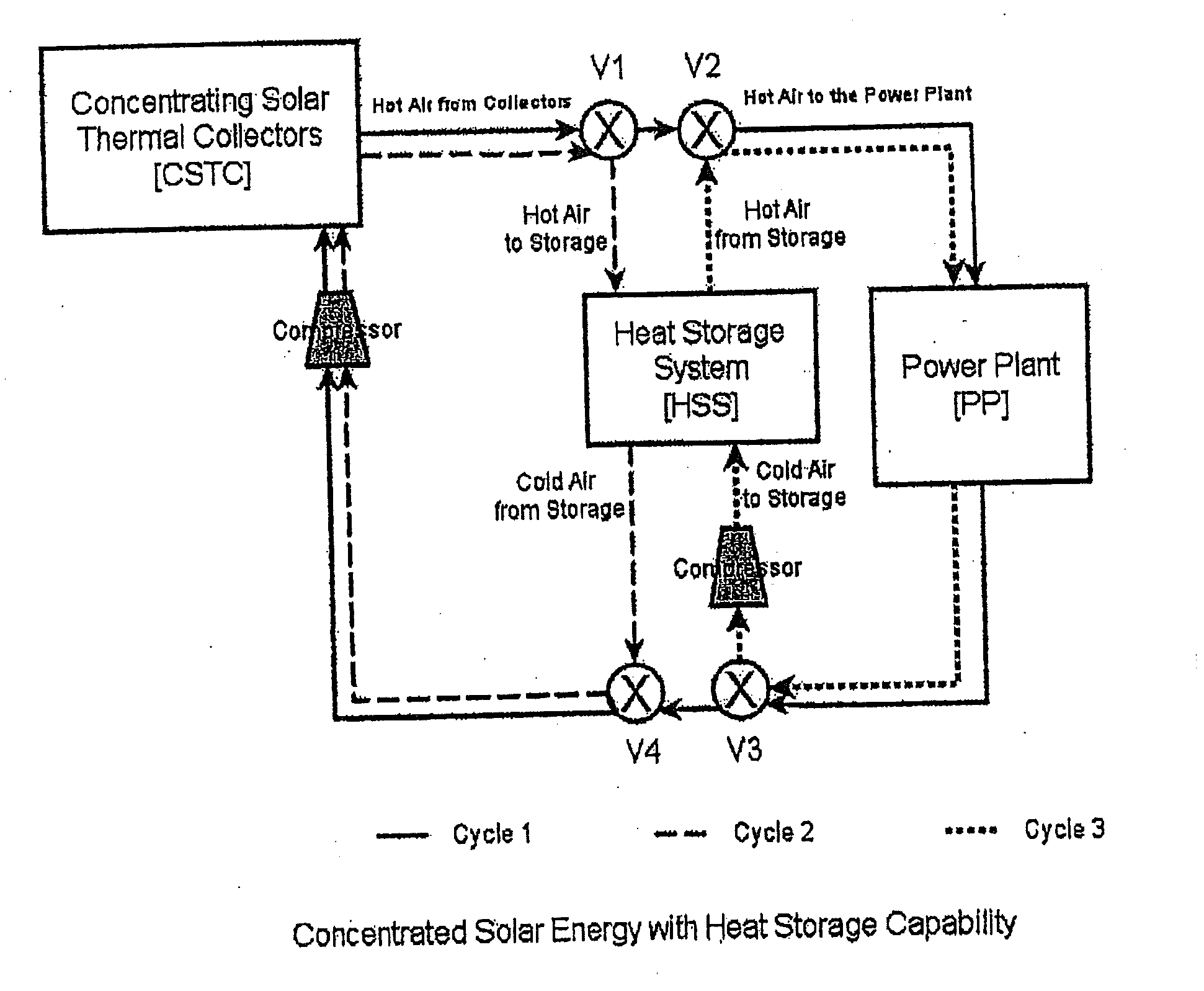

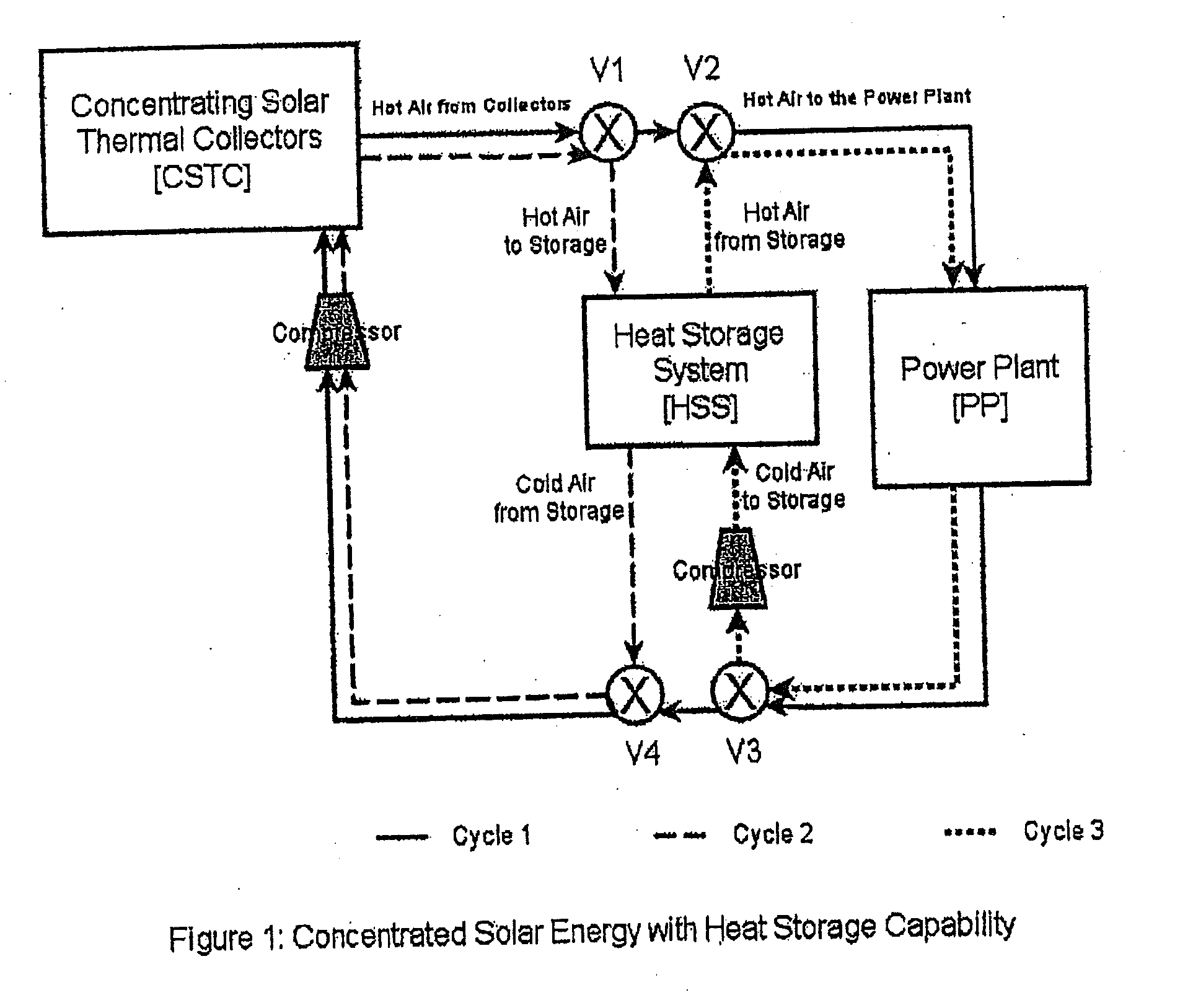

A method for storing heat from a solar collector CSTC in Concentrating Solar Power plants and delivering the heat to the power plant PP when needed. The method uses a compressed gas such as carbon dioxide or air as a heat transfer medium in the collectors CSTC and transferring the heat by depositing it on a bed of heat-resistant solids and later, recovering the heat by a second circuit of the same compressed gas. The storage system HSS is designed to allow the heat to be recovered at a high efficiency with practically no reduction in temperature. Unlike liquid heat transfer media, our storage method itself can operate at very high temperatures, up to 3000° F., a capability which can lead to greater efficiency. Due to material constraints and cost considerations in the rest of the system the maximum temperature is presently limited to between 1700° F. and 2000° F. The method can be applied to all current solar collector designs. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Solar power plant and method and/or system of storing energy in a concentrated solar power plant

ActiveUS20100176602A1Big advantageLower energy requirementsSolar heating energyAuxillary drivesPower stationEngineering

A method for storing heat from a solar collector CSTC in Concentrating Solar Power plants and delivering the heat to the power plant PP when needed. The method uses a compressed gas such as carbon dioxide or air as a heat transfer medium in the collectors CSTC and transferring the heat by depositing it on a bed of heat-resistant solids and later, recovering the heat by a second circuit of the same compressed gas. The storage system HSS is designed to allow the heat to be recovered at a high efficiency with practically no reduction in temperature. Unlike liquid heat transfer media, our storage method itself can operate at very high temperatures, up to 3000° F., a capability which can lead to greater efficiency. Due to material constraints and cost considerations in the rest of the system the maximum temperature is presently limited to between 1700° F. and 2000° F. The method can be applied to all current solar collector designs. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Solar power plant and method and/or system of storing energy in a concentrated solar power plant

ActiveUS20110277471A1Big advantageLower energy requirementsSolar heating energyFrom solar energyPower stationEngineering

A method for storing heat from a solar collector CSTC in Concentrating Solar Power plants and delivering the heat to the power plant PP when needed. The method uses a compressed gas such as carbon dioxide or air as a heat transfer medium in the collectors CSTC and transferring the heat by depositing it on a bed of heat-resistant solids and later, recovering the heat by a second circuit of the same compressed gas. The storage system HSS is designed to allow the heat to be recovered at a high efficiency with practically no reduction in temperature. Unlike liquid heat transfer media, our storage method itself can operate at very high temperatures, up to 3000° F., a capability which can lead to greater efficiency.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Method for manufacturing dendrobium officinale fresh juice stock solution

InactiveCN102008654ANot easy to clarifyNot easy to filterMetabolism disorderAlcoholic beverage preparationFlavorAdditive ingredient

The invention discloses a manufacturing method for extracting and processing fresh juice stock solution by using dendrobium officinale as a raw material. The method furthest protect the color, flavor, nutrition and effective ingredients of dendrobium officinale fresh juice by surface sterilization of the collected fresh dendrobium officinale and technology of juicing, enzymolysis, vacuum degasification, micro-filtration, ultra-filtration, sterile filling, high-temperature instantaneous sterilization and the like, and meanwhile, the product is favorable for storing and realizing industrialized production. The dendrobium officinale is processed into the dendrobium officinale fresh juice stock solution which is easy to store, convenient to carry, simple to administrate, good in mouthfeel and easy to absorb and has health-care nutritional components and medicinal functions; the fresh juice stock solution does not contain any additive; and the content of the fresh juice stock solution reaches over 99 percent. The dendrobium officinale fresh juice stock solution can be administrated separately, also can be added into mineral water to form health-care beverage, also can be dissolved into wine to form nourishing health-care wine, and can be added into high-grade dishes to form nourishing dishes for eating.

Owner:杨军

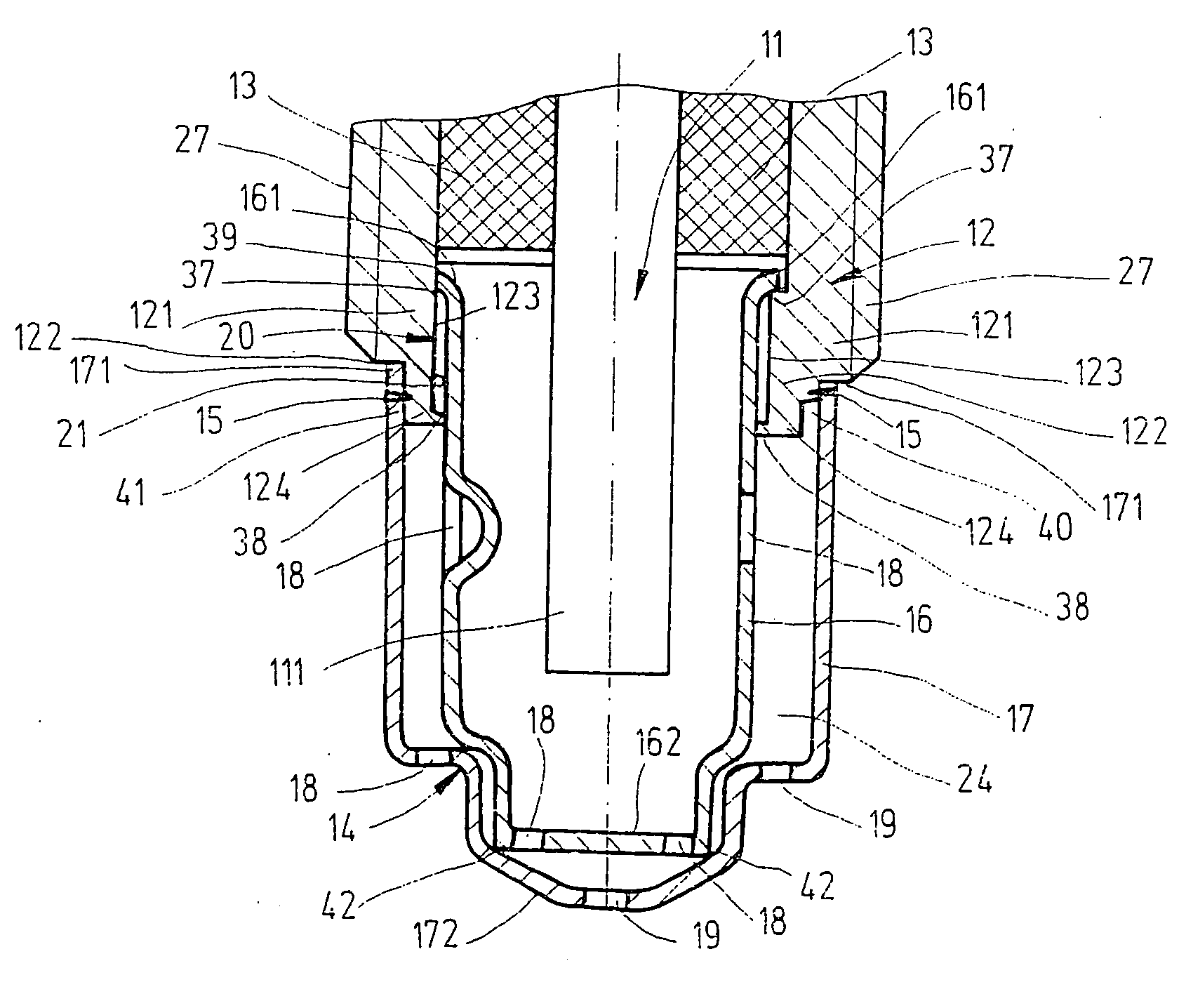

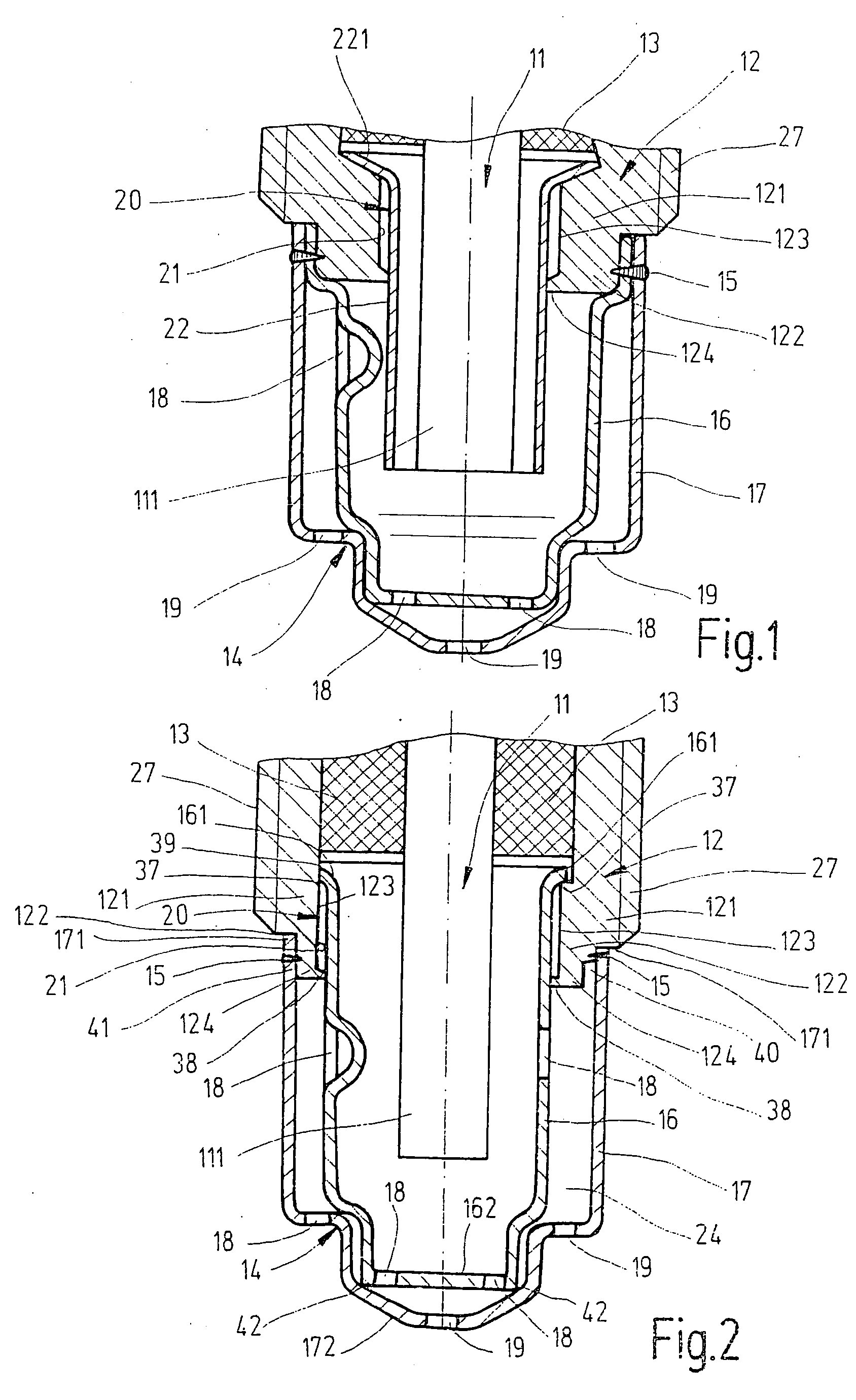

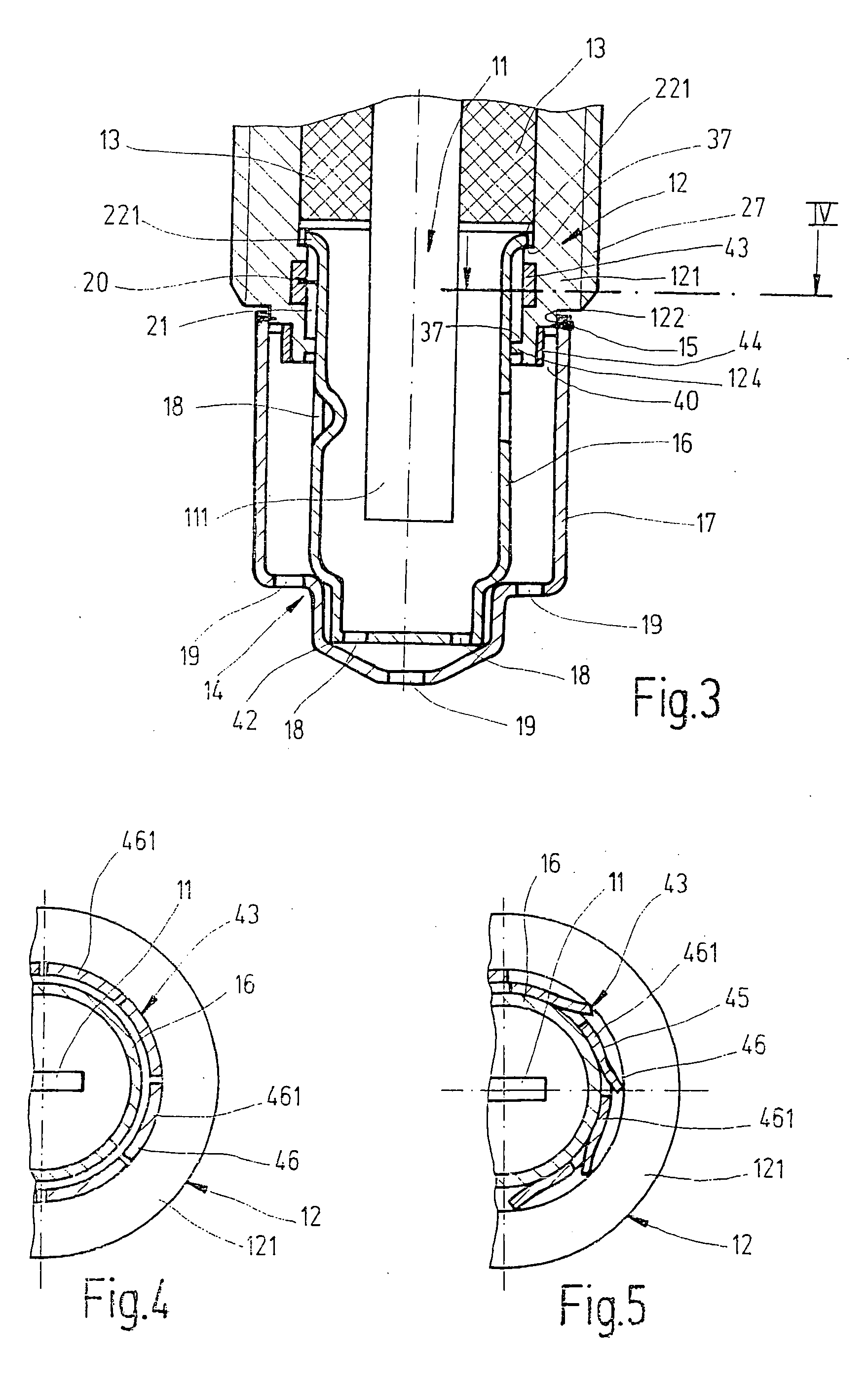

Sensor

ActiveUS20080223110A1Large capacityLow thermal conductivityAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansWater vaporEngineering

A sensor is provided, in particular a gas sensor for determining the concentration of a gas component in a measuring gas, which has a sensor element that projects from a housing by a measuring-gas-side end section exposed to the measuring gas, and a sheath tube having gas passageways, which is placed over the measuring-gas-side end section and affixed on the housing. To prevent condensation of water vapor contained in the measuring gas in the measuring space enclosed by the housing and the sheath tube, and thus the production of water droplets that reach the hot sensor element, sheath tube and / or sensor element are / is thermally decoupled from the housing. The thermal decoupling is produced using, for instance, a flange sleeve made of a material having poor thermal conductivity, which separates the sheath tube from the housing by a flange and, via a sleeve section, is inserted in the space between the housing and the measuring-gas-side end section of the sensor element.

Owner:ROBERT BOSCH GMBH

High-density polyethylene glued board producing method

InactiveCN101284384AReduce CooldownSave energyWood veneer joiningLow-density polyethyleneWeather resistance

A method for manufacturing a HDPE wood plywood mainly includes: rolling dense pin holes on the cementing surface of a veneer; replacing urea formaldehyde, phenolic aldehyde and other adhesives with HDPE plastic film; laying up in the common conventional plywood lay-up method and only laying the HDPE film instead of the adhesives; heating and pressuring the lay-up on a hot press machine and then pressuring and cooling on a cold press machine. The problems that the HDPE is immiscible with the wood, and can not be taken for the adhesive of the wood are solved by applying the principle of mechanical locking; The heat loss and the time consumption of the hot press machine can be avoided when the lay-up is cooled, for pressing is carried out on the hot press machine and the cold press machine respectively. The plywood product has formaldehyde-pollution-free production, high strength, durability, weather resistance, acid and alkali resistance, high water resistance, good appearance and low price. The manufacturing process has no pollution, and is environment-friendly, energy-saving, efficient and simple.

Owner:林群祥

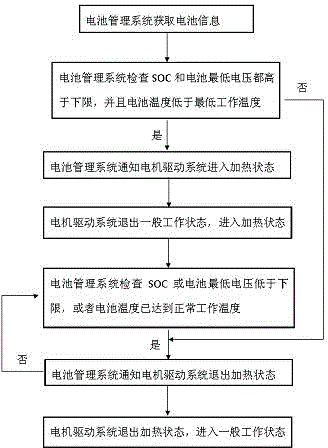

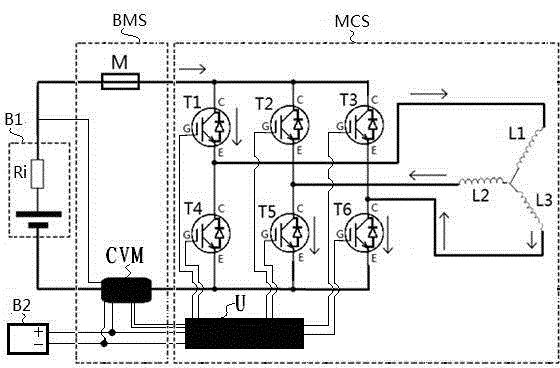

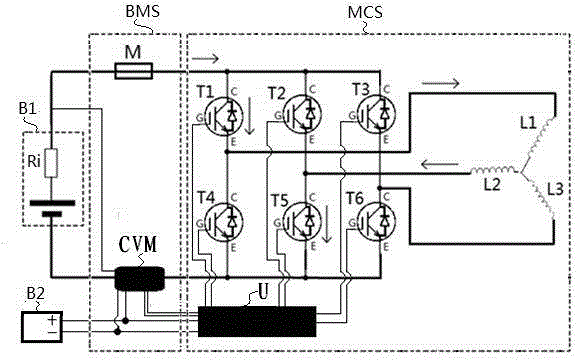

Battery heating structure built into motor driven system, and method thereof

ActiveCN104538701AImprove heating efficiencyGuaranteed uniformityBatteries circuit arrangementsSecondary cellsLower limitPower battery

The invention discloses a battery heating structure built into a motor driven system, and a method thereof. The method includes the following steps: a battery management system detects and acquires the voltage and the temperature of a power battery pack, and calculates remaining power information; the battery management system notifies the motor driven system to enter a heating state if the detected remaining power of the power battery pack is higher than a lower normal work limit, the lowest voltage is higher than a lower limit and the temperature is lower than a lower normal work temperature limit; the battery management system notifies the motor driven system to quit the heating state if not; the motor driven system quits a general work state and enters the heating state; the battery management system checks the state of the power battery pack in the heating state, and notifies the motor driven system to quit the heating state when the remaining power of the power battery pack or the lowest voltage is lower than the lower limit or the temperature of the power battery pack reaches the normal work temperature; and the motor driven system quits the heating state and enters the general work state. The battery heating built into the motor driven system, and the method thereof realize uniform heating and fast heating speed.

Owner:FAWER AUTOMOTIVE PARTS

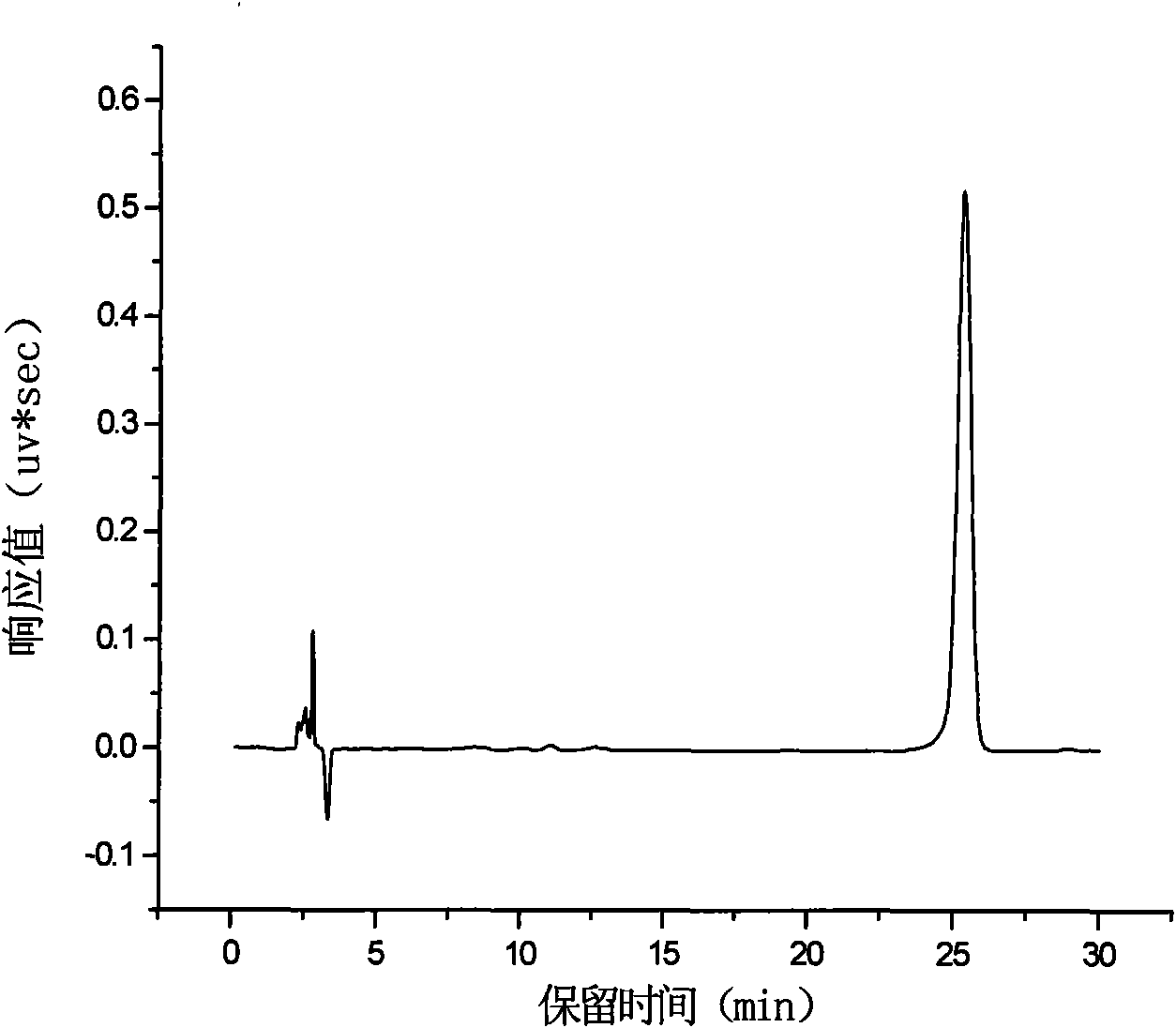

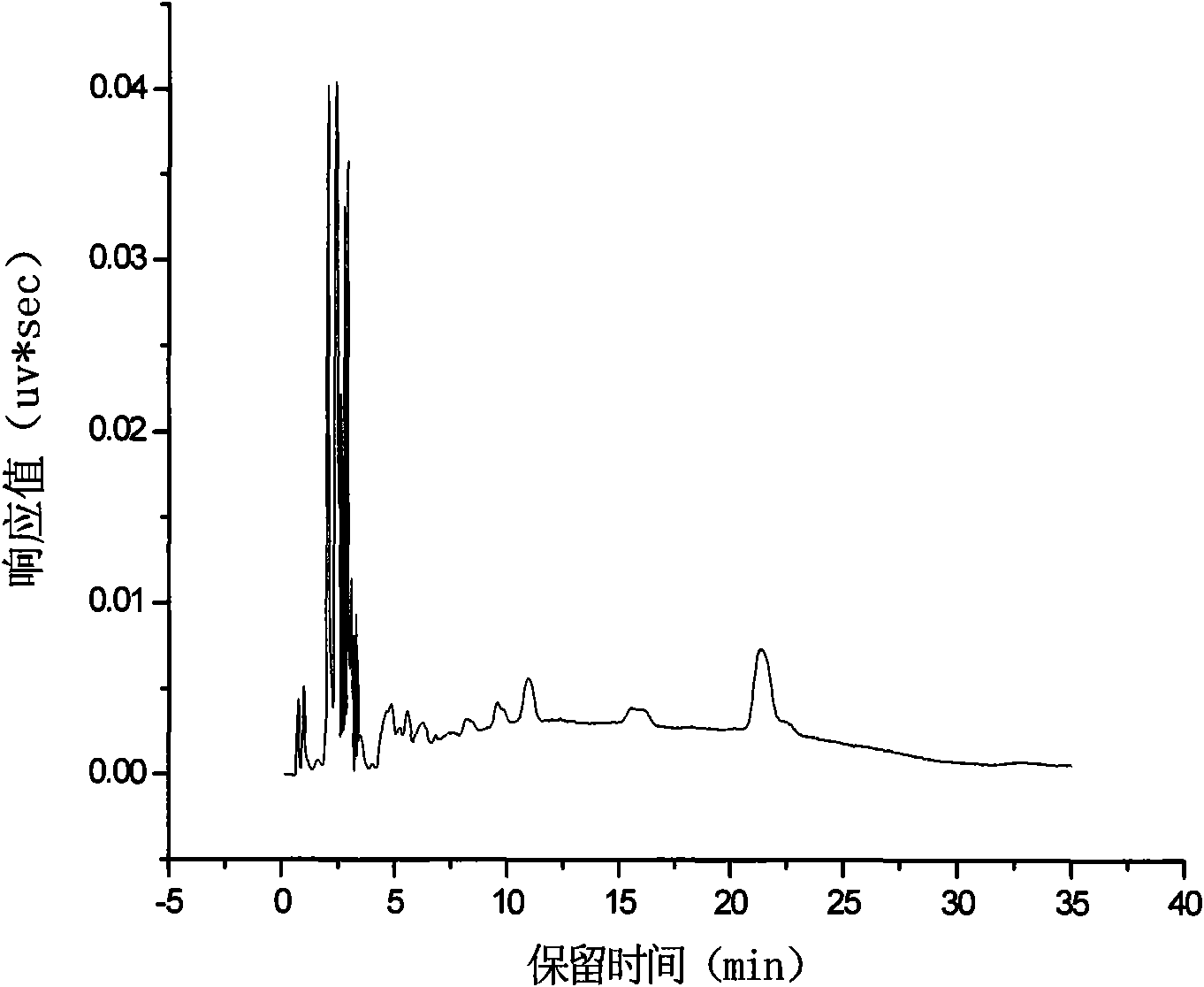

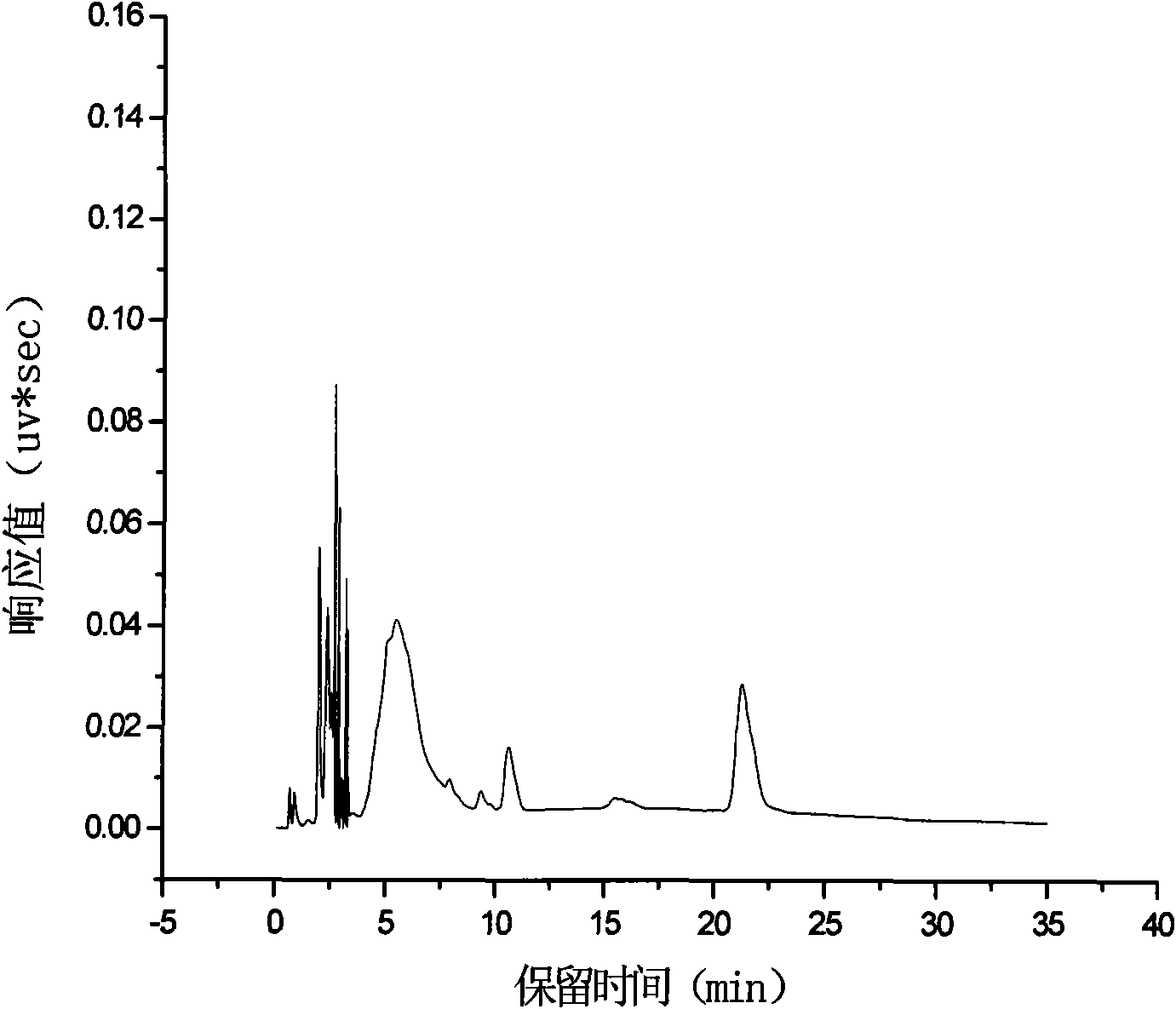

Method for extracting high-purity squalene by taking olive oil as raw material

ActiveCN101597204AIncrease productionImprove qualityDistillation purification/separationAdsorption purification/separationDistillationEvaporation

The invention relates to a method for extracting high-purity squalene by taking olive oil as a raw material. A technological route formed by adopting a secondary molecular distillation and silica gel column chromatography is as follows: an olive oil unsaponifiable substance is taken, squalene is separated and purified by using two stages of molecular distillation, primary molecular distillation is carried out under the conditions of the evaporation surface temperature of 100 to 200 DEG C, the systemic pressure of 0.001 to 0.01mbar and the scraping film rotor speed of 150 to 300rpm, and secondary molecular distillation is carried out to the obtained distillate; the secondary molecular distillation is carried out under the conditions of the evaporation surface temperature of 150 to 300 DEG C, the systemic pressure of 0.001 to 0.01mbar and the scraping film rotor speed of 200 to 350rpm, and the obtained distillate is a squalene crude product; ethyl acetate-normal hexane with different concentrations is used as a mobile phase to carry out gradient elution, the obtained eluent is collected according to time and a solvent is evaporated, the same fractions are merged through chromatographic detection, and the high-purity squalene can be obtained, wherein the content of the raw material olive oil of the squalene is enhanced from 3.6% to about 98%; and especially, by considering the requirement of industrialized production to select an extraction condition especially, the large-scale production of the squalene taking the olive oil as the raw material can be realized.

Owner:JIANGSU ZODIAC MARINE BIOTECH

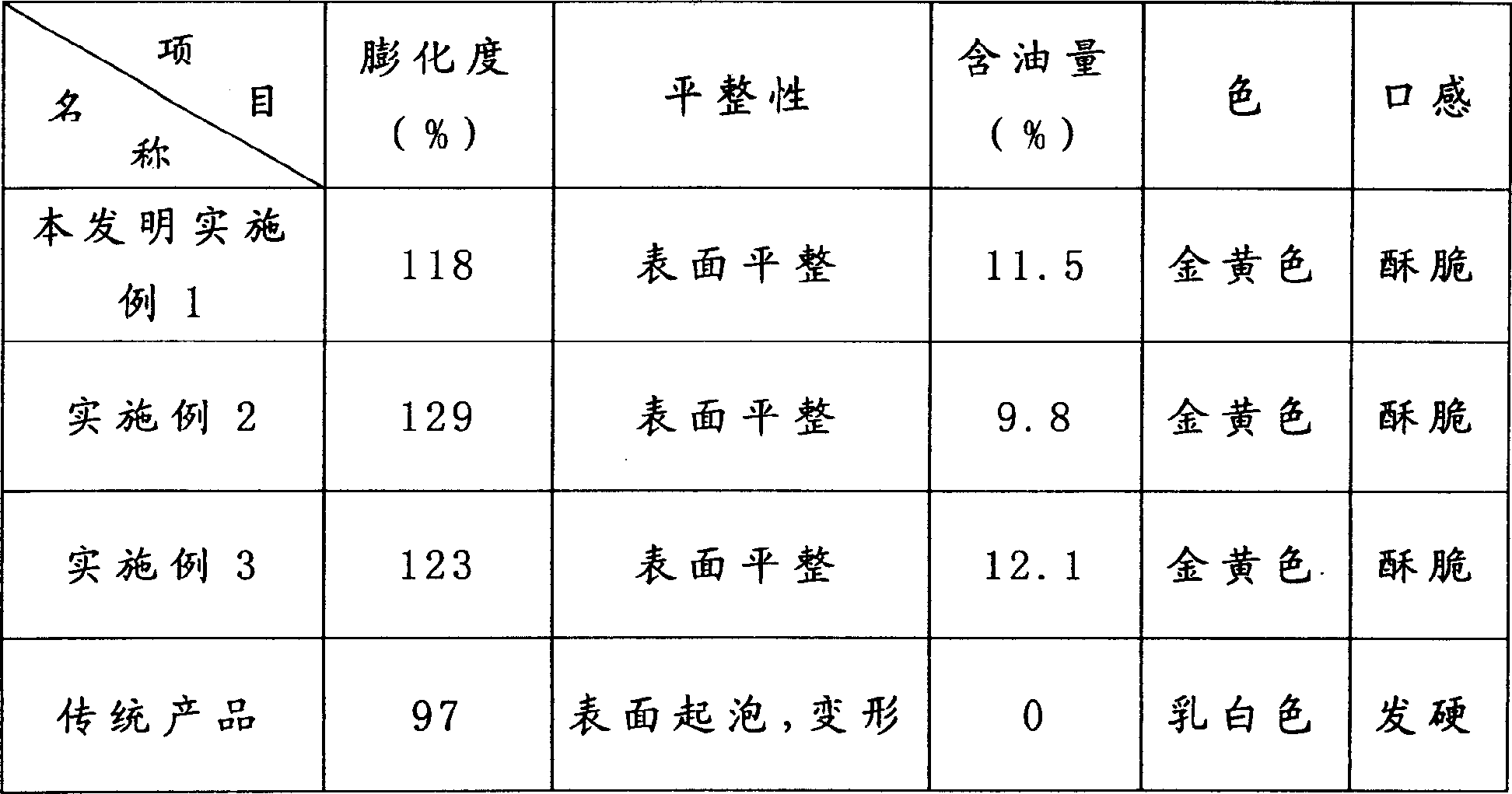

Potato crisp utilizing micro wave processing and its processing method

InactiveCN1891072AEasy to storePreserve nutrientsFood preservationFood preparationChipped potatoesMicrowave

The present invention discloses a kind of potato crisps processed by microwave and its processing method. Said processing method includes the following steps: washing potato flakes, scalding said potato flakes in boiling edible salt water, cooling, draining, freezing, drying, adding palm oil and egg yolk powder, mixing them with potato flakes, uniformly stirring them, roasting them by using microwave and spraying flavouring material so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

Preparation method of soluble fish protein ammonia acid fertilizer

InactiveCN104557339AReduce lossesSimple methodBio-organic fraction processingAnimal corpse fertilisersProduct processingNutrients substances

The invention relates to a preparation method of a soluble fish protein ammonia acid fertilizer, belongs to the field of biological technical processing, and particularly belongs to the field of fertilizer additive preparation. The preparation method comprises the following steps: crushing and pulping leftovers from fishery product processing or deep-sea low-value shrimp into fish pulp, mixing with water, adding lactic acid bacillus and protease, and fermenting for 3-8 days respectively through continuous ventilation and interval ventilation at a temperature of 40-45 DEG C to obtain the soluble fish protein ammonia acid fertilizer. The preparation method disclosed by the invention is simple, and short in heating treatment time, so that the heating cost is saved and the loss of nutrient substances is reduced. The fish protein ammonia acid soluble fertilizer prepared by adopting the preparation method has a good application effect, and particularly has remarkable effect on fruits and vegetables.

Owner:ZHOUSHAN YUANFENG MARINE BIOTECH

Method for refining and concentrating citrus essential oil

InactiveCN102559386AProtect heat sensitive ingredientsReduce lossesEssential-oils/perfumesDistillationHeat sensitive

The invention discloses a method for refining and concentrating citrus essential oil, which belongs to the technical field of natural plant essential oil refining and includes 1 preparation of crude essential oil; 2 degassification of the crude essential oil; 3 molecular distillation of the crude essential oil; 4 quality inspection of concentrated essential oil and other steps. The molecular distillation technology is used for refining and concentrating the citrus essential oil, heat-sensitive components in the essential oil can be protected effectively, no additive is added, and solvent is free of residue. The method achieves efficient separation of terpene compounds and terpene oxides in the citrus essential oil, enables relative content of residual oxides after distillation to be increased to 5-20 times of that of original oxides, and remarkably improves aroma value of the essential oil. Product aroma is strong and fresh, and characteristic aroma is remarkable. The method can be popularized and applied in citrus production places and related enterprises.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

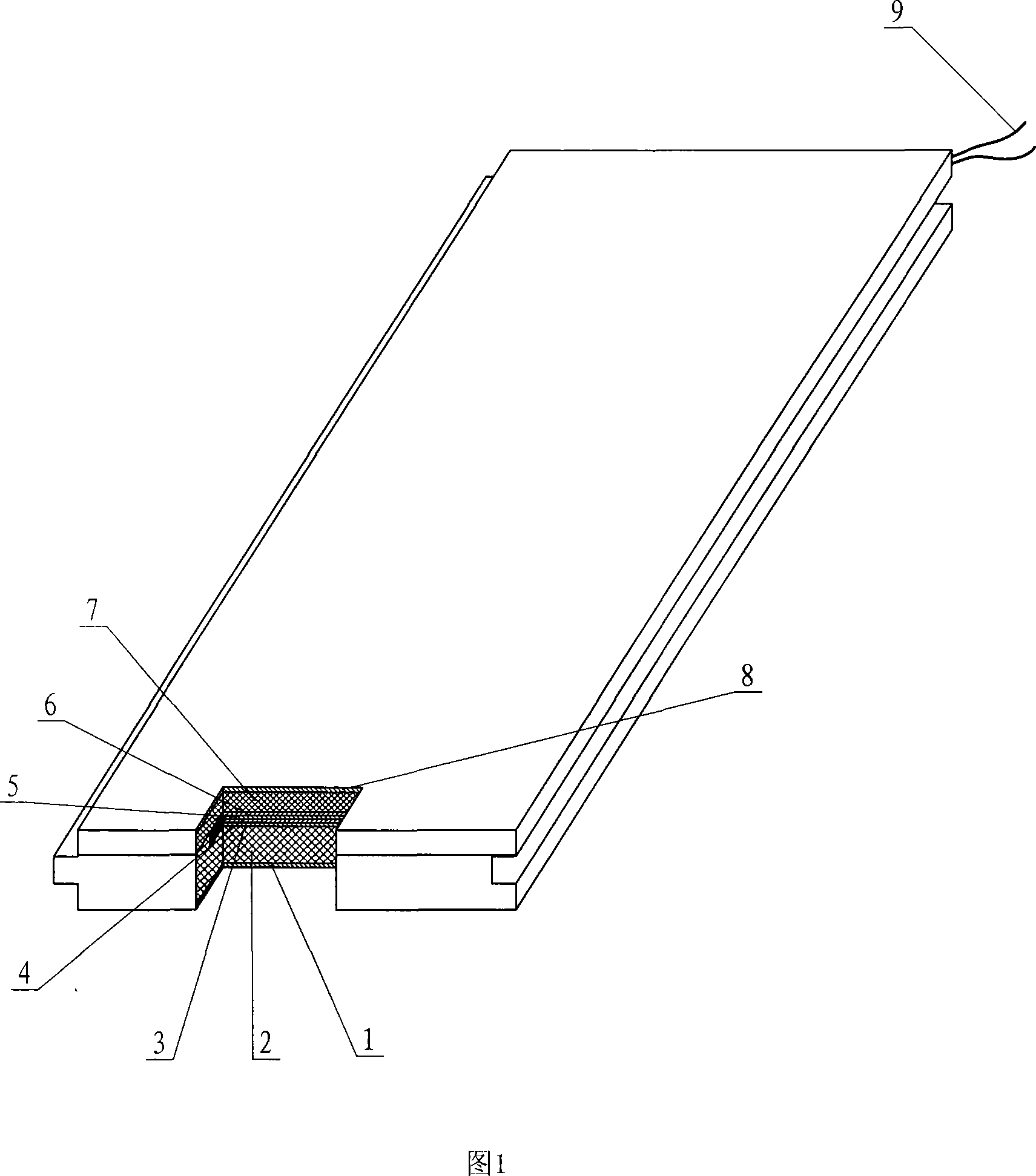

Electric heat floor

The invention relates to a wood electro-thermal floor with far infrared electro-thermal wave of health physiotherapy, which is installed conveniently and quickly. It comprises floor base and electrical heating layer. The technical point is that insulation thermal reflecting layer, far infrared electrical heating layer, insulation heat-transferring layer and solid-wood panel layer with face paint layer are set in turn upwards from the floor base. Because electro-thermal physiotherapy structure with far infrared electro-thermal wave of health physiotherapy is added on prior solid-wood floor, characteristics are shown as follows. Because the physiotherapy far infrared electro-thermal structure is set in the interlayer of floor, the thermal efficiency is high. The room is heated while physiotherapy wave absorbed by foot is provided for human. It is provided with high thermal efficiency, small starting current, no pollution, no noise, energy saving, good anti-aging performance and long service life. It also has the action that by infrared ray radiation of carbon fiber, human blood cycle is promoted; cell viability is strengthened and human health function is improved. It is killing two birds with one stone.

Owner:庞志忠

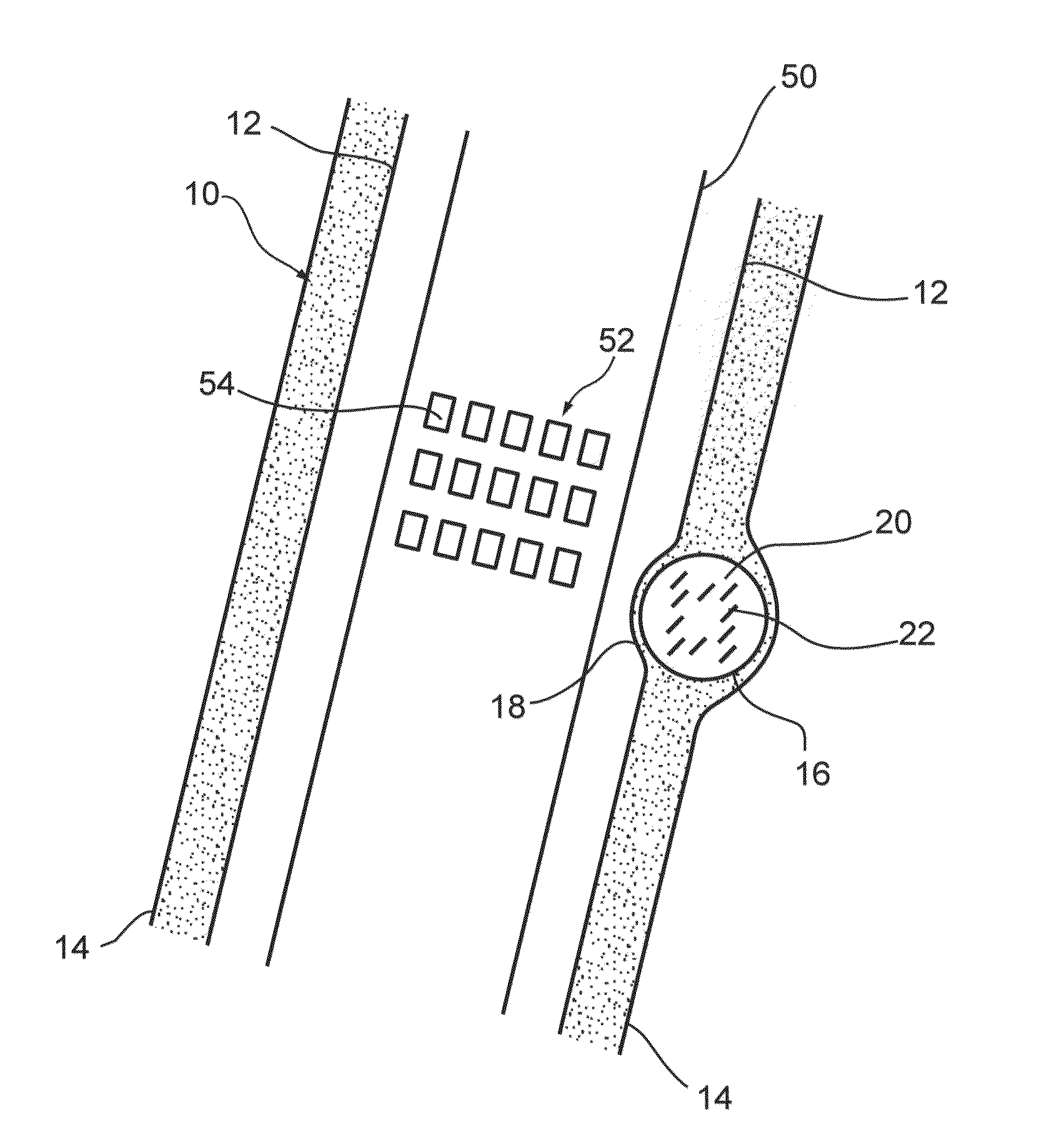

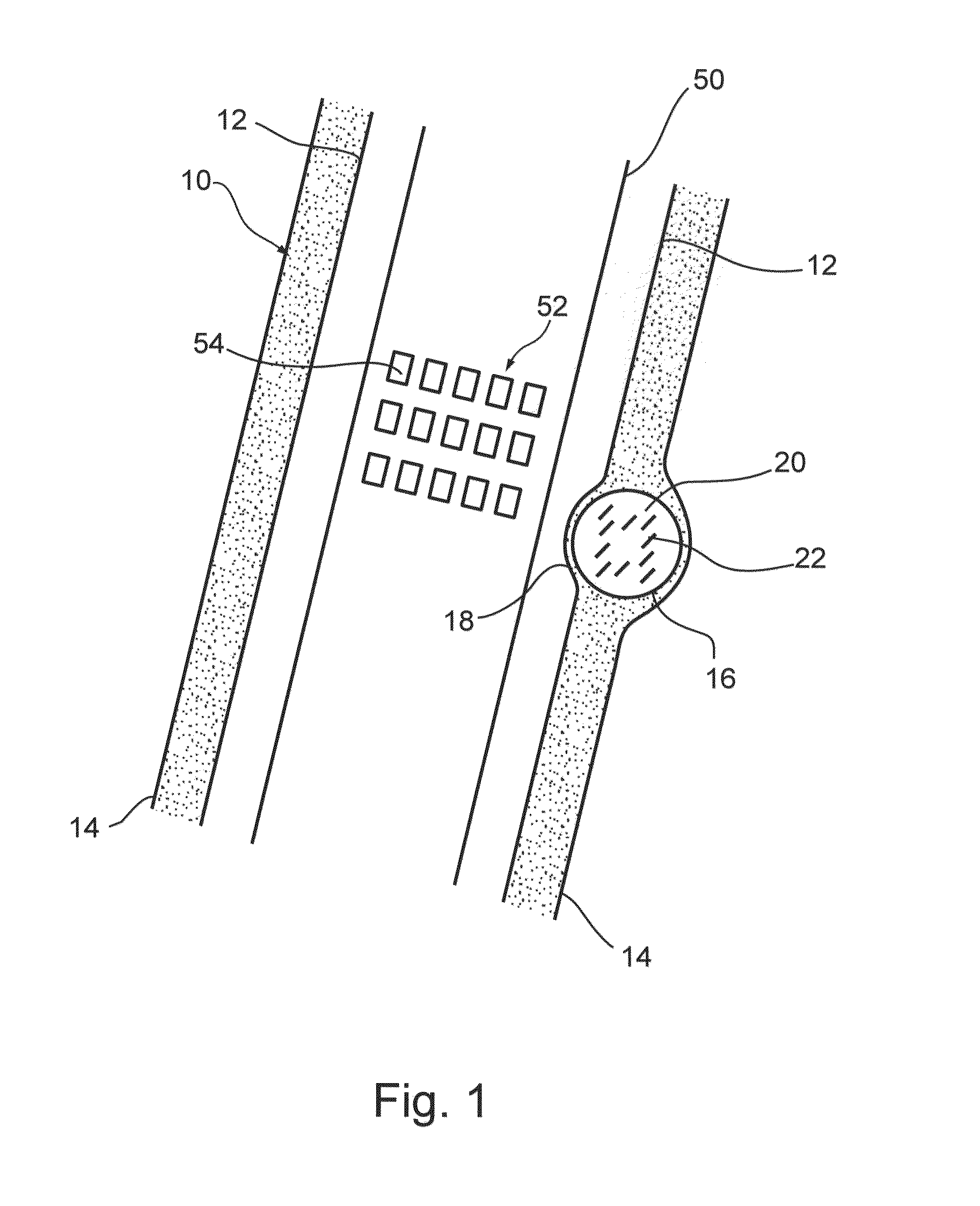

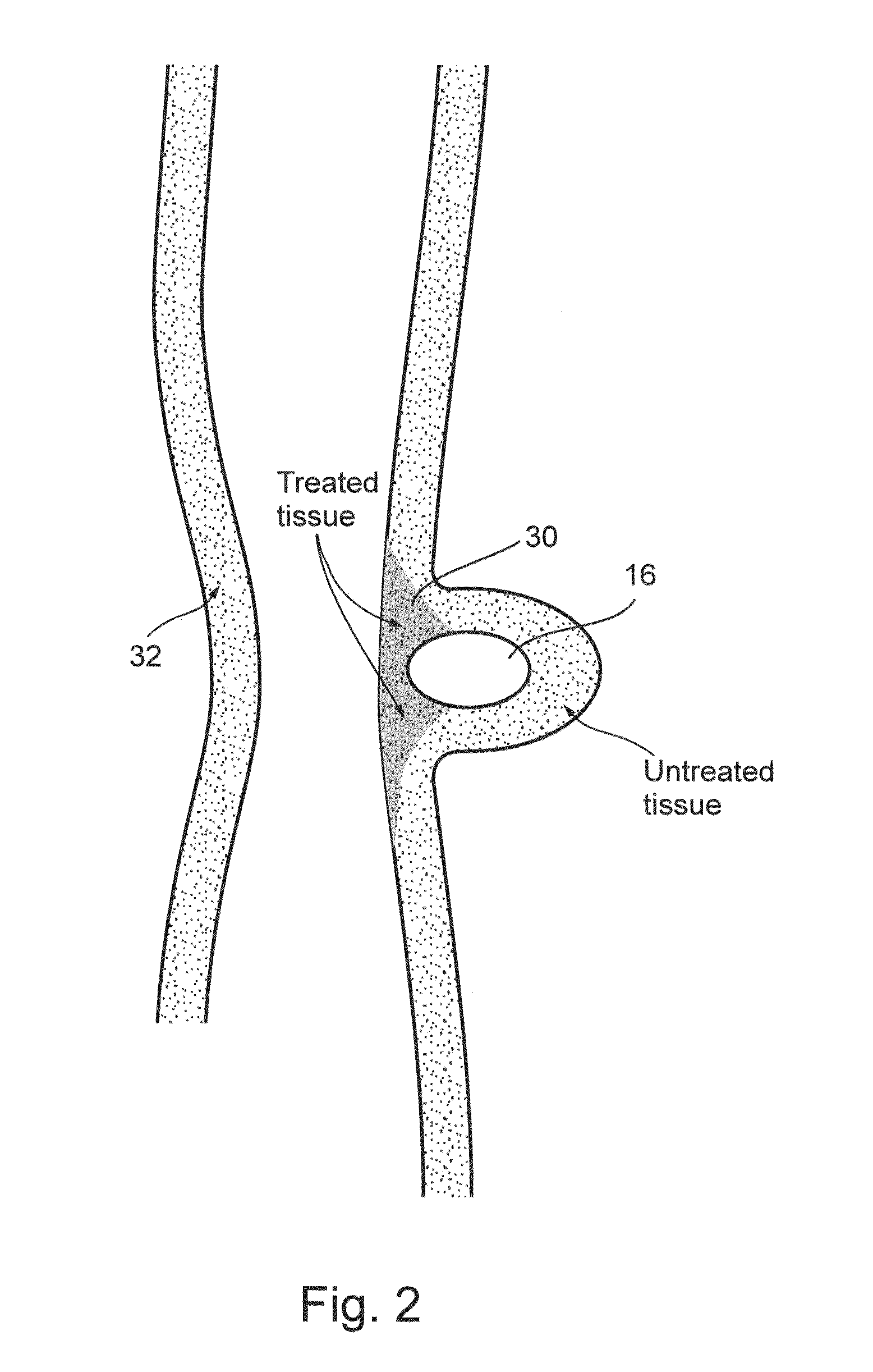

Treating weakened vessel wall such as vulnerable plaque or aneurysms

ActiveUS20100081933A1Reduce riskShort heating timeUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyVulnerable plaqueMaximal rate

Described is a method of stabilizing blood vessel wall abnormality. The method includes ultrasonically heating at least a portion of the blood vessel wall having the abnormality; monitoring a parameter related to a property of at least a portion of the heated portion of the blood vessel wall; and stopping the heating when the monitored parameter changes by a predetermined factor or after the monitored parameter changes in a slow enough rate. The slow enough rate may be, for instance, a predetermined fraction of a maximal rate change observed during heating.

Owner:RAMOT AT TEL AVIV UNIV LTD

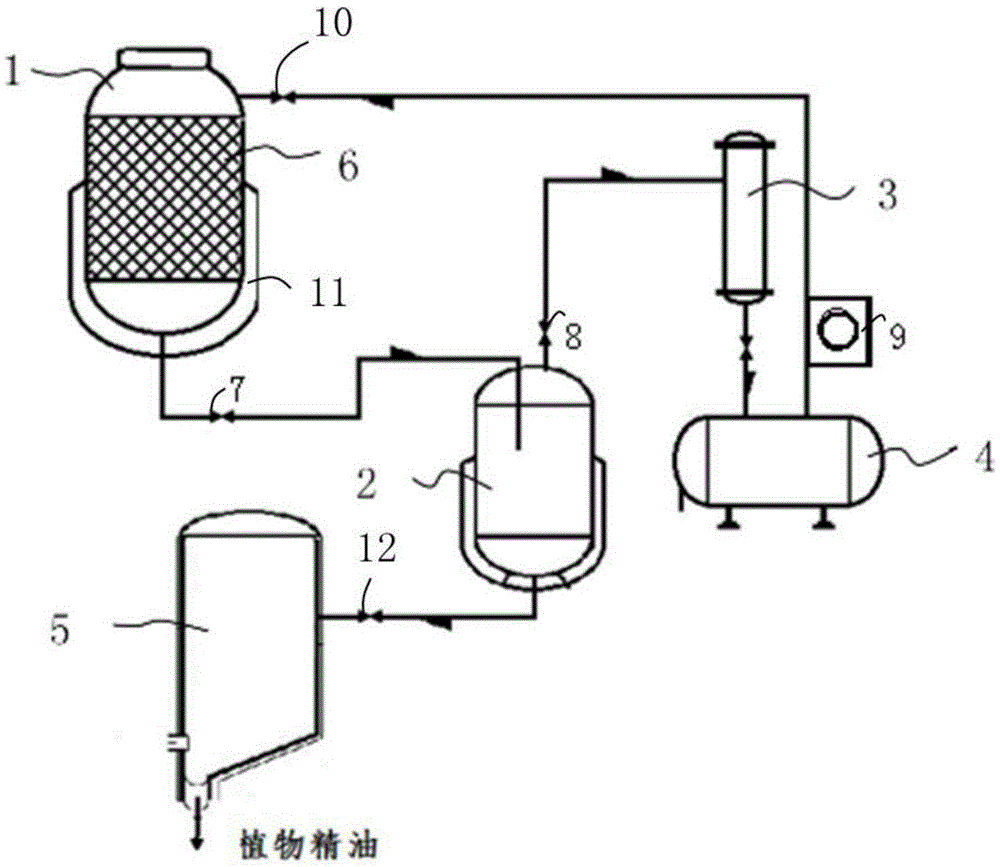

Microwave-assisted subcritical essential oil extracting method

InactiveCN105482897AUndamagedFast extraction rateEssential-oils/perfumesDistillation1,1,1,2-Tetrafluoroethane

The invention discloses a microwave-assisted subcritical essential oil extracting method. The microwave-assisted subcritical essential oil extracting method includes the steps that fresh plant tissues are frozen and then are smashed; 1,1,1,2-tetrafluoroethane is used as an extraction solvent and is led into the smashed plant tissues to perform microwave extraction; during microwave extraction, the extraction temperature is controlled to be 8-12 DEG C, the extraction pressure is controlled to be 0.8-6 Mpa, the microwave frequency is controlled to be 300-2400 MHZ, and the power is controlled to be 200-1200w; after a liquid phase in the system is separated out and microwave extraction is completed, the 1,1,1,2-tetrafluoroethane is recovered from the liquid phase, and the rest of the liquid phase is an essential oil stock solution; the essential oil stock solution is subjected to molecular distillation to obtain essential oil. By the adoption of the microwave-assisted subcritical essential oil extracting method, the essential oil free of any residual solvent can be obtained at lower temperature, the effective ingredients of the essential oil are not destroyed, and the natural quality of the essential oil can be kept to the most degree.

Owner:JIANGSU NAIQUE BIOLOGICAL ENG

Method for preparing vanadium nitride and device

ActiveCN1562770AImprove thermal efficiencyShort heating timeNitrogen-metal/silicon/boron binary compoundsVanadium compoundsMicrowave ovenVanadium nitride

The invention specially relates to an industrial batch-type vanadium nitride producing method and devices. Grinded vanadium oxide powder and carbonaceous are used as raw materials, which binder is added in, to produce vanadium nitride by heating in microwave oven. The characteristic is mixing vanadium oxide, active carbon and binder according properly ratio, then briqueting and forming, putting the formed material into special microwave heating oven, unceasingly exhausting to keep vacuum, prereducing, carbononizing, nitrating and natural cooling, finally the product is taken out the oven. This product is used as additive agent of various kinds of alloy steel containing vanadium mainly.

Owner:湖南恒星进出口有限责任公司

Manufacturing method of light wood-plastic composite panel

The invention discloses a production method for a lightweight wood-plastic compound plate. The method includes that thermoplastic plastic powder, the average grain diameter of which is 40 meshes or above, is first mixed with at least one of a plasticizer, a tackifier, a dispersant or a foaming agnet; the mixture is preheated to 40 to 130 DEG C; then after being uniformly mixed with dried organic cellulose filler powder the average grain diameters of which is 40 meshes or above, the mixture is put into a pre-heated plastic mold cavity and pressed for 3 to 15 minutes at the mold pressing temperature of 150 to 200 DEG C and a pressure of 5 to 20MPa; the air is discharged for 0 to 3 times during the pressing process and finally the mixture is cooled under pressure keeping. The shaping process flow and the heating time of the invention are short; the organic cellulose filler and the plastic are hard to be degraded; besides, the pressure is low and the pressing time is short; not only is the production period shortened, but also energies are saved. Besides, the method of the invention is also beneficial to controlling the aperture ratio, the aperture size and the distribution as well as the porosity of the wood-plastic plate by virtue of the grain diameter of the powder, additives and the shaping technique.

Owner:SICHUAN UNIV

Method for extracting rice protein powder by utilizing enzyme-alkali method

The invention provides a method for extracting rice protein powder by utilizing enzyme-alkali method. The method in the invention takes rice residue as raw materials and comprises the following steps: washing with water, eliminating sugar, carrying out milling refining on the colloid, eliminating residue starch by utilizing starch enzyme, pre-extracting alkali protease, adding alkali for extraction, centrifuging and taking the supernate to mix to neutrality, inactivating enzymes and sterilizing, and spraying and drying to obtain the rice protein powder. The rice protein powder produced by utilizing the process has faint yellow color, delicate taste and good solubility, and can be maintained well from physicochemical function. The invention has simple process, few investment device, high yield and purity of products, good solubility, and easily-controlled product quality, is suitable for practice popularization and provides a new route for the extraction of rice protein.

Owner:长沙湘博医药科技有限公司

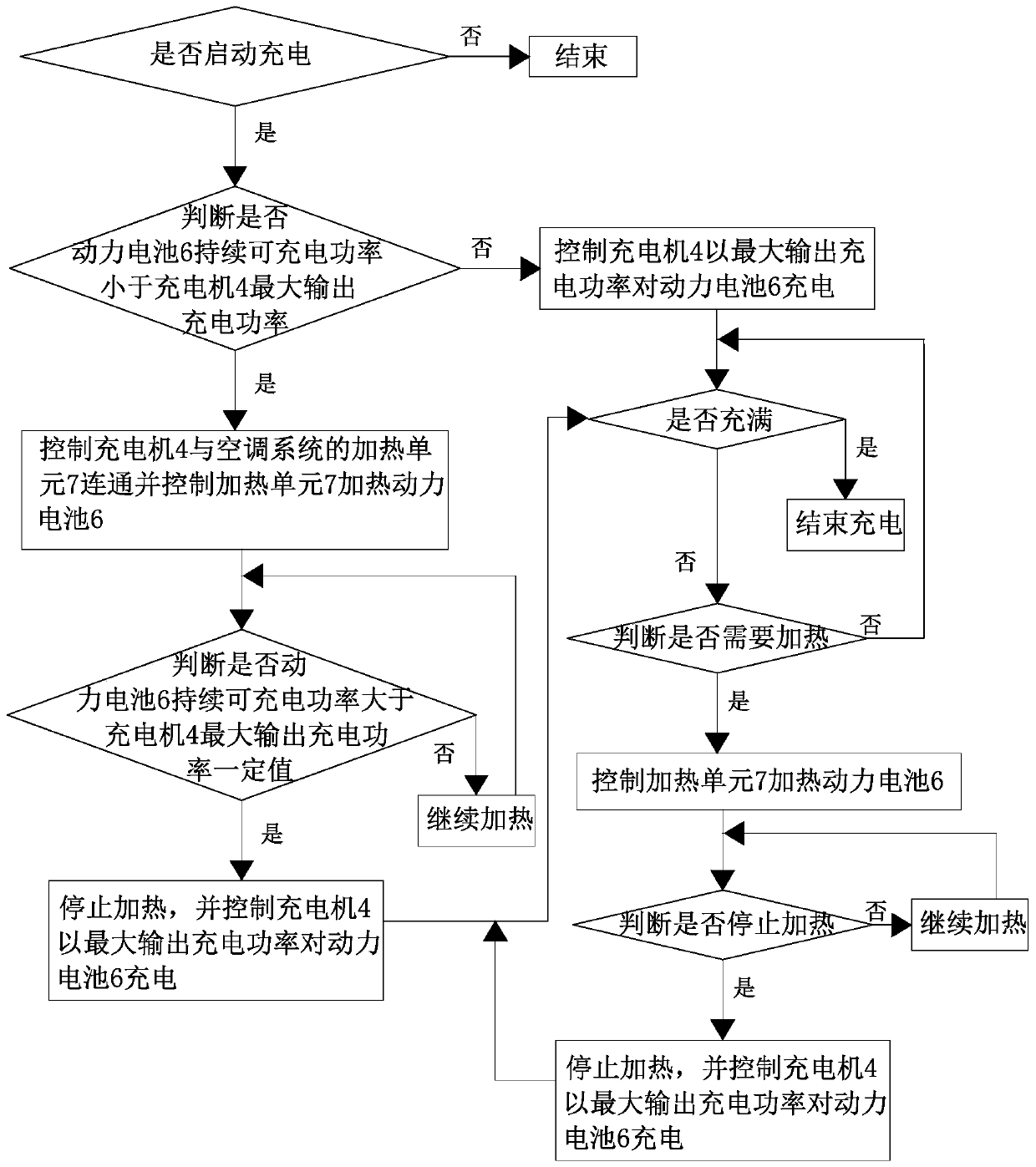

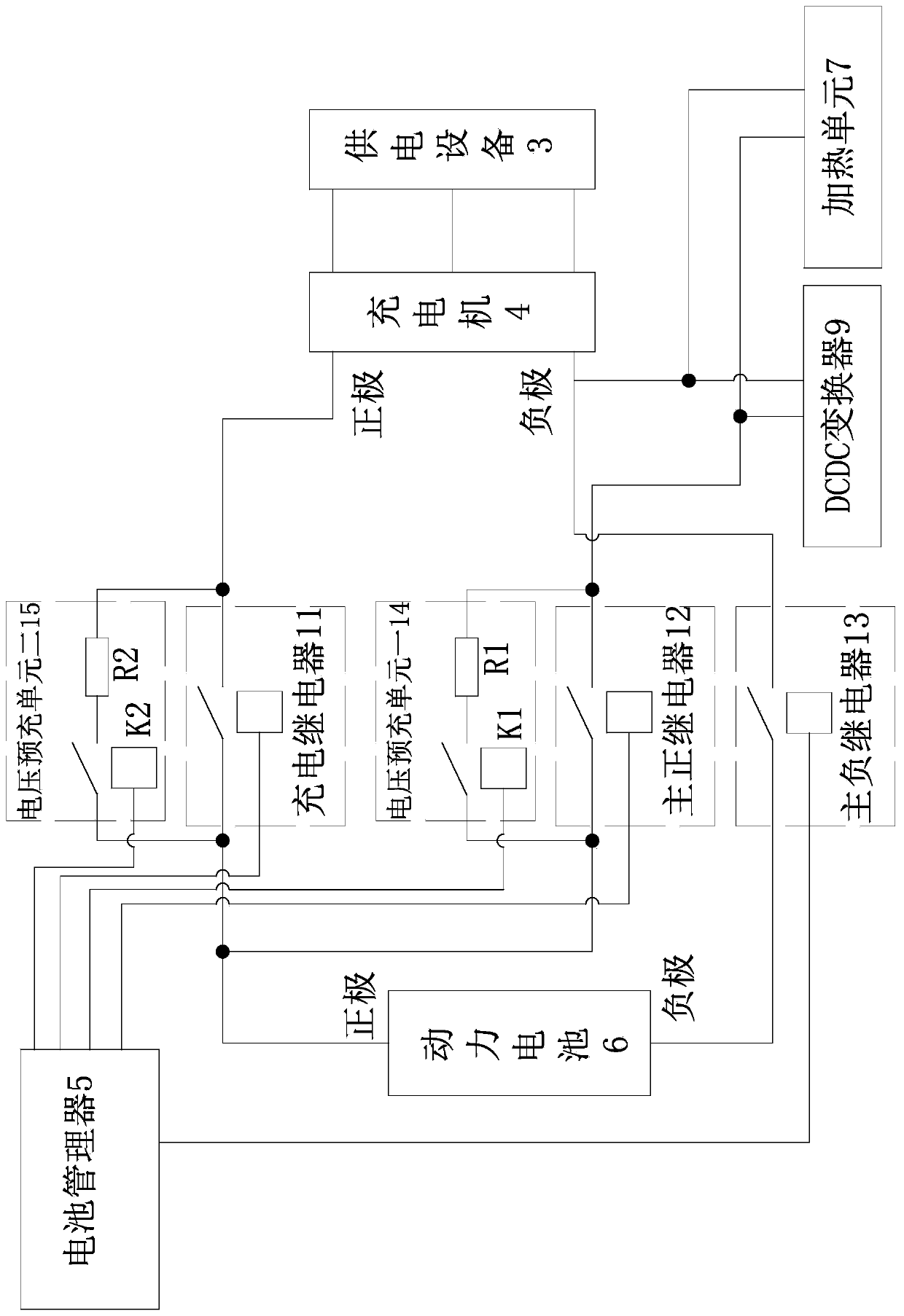

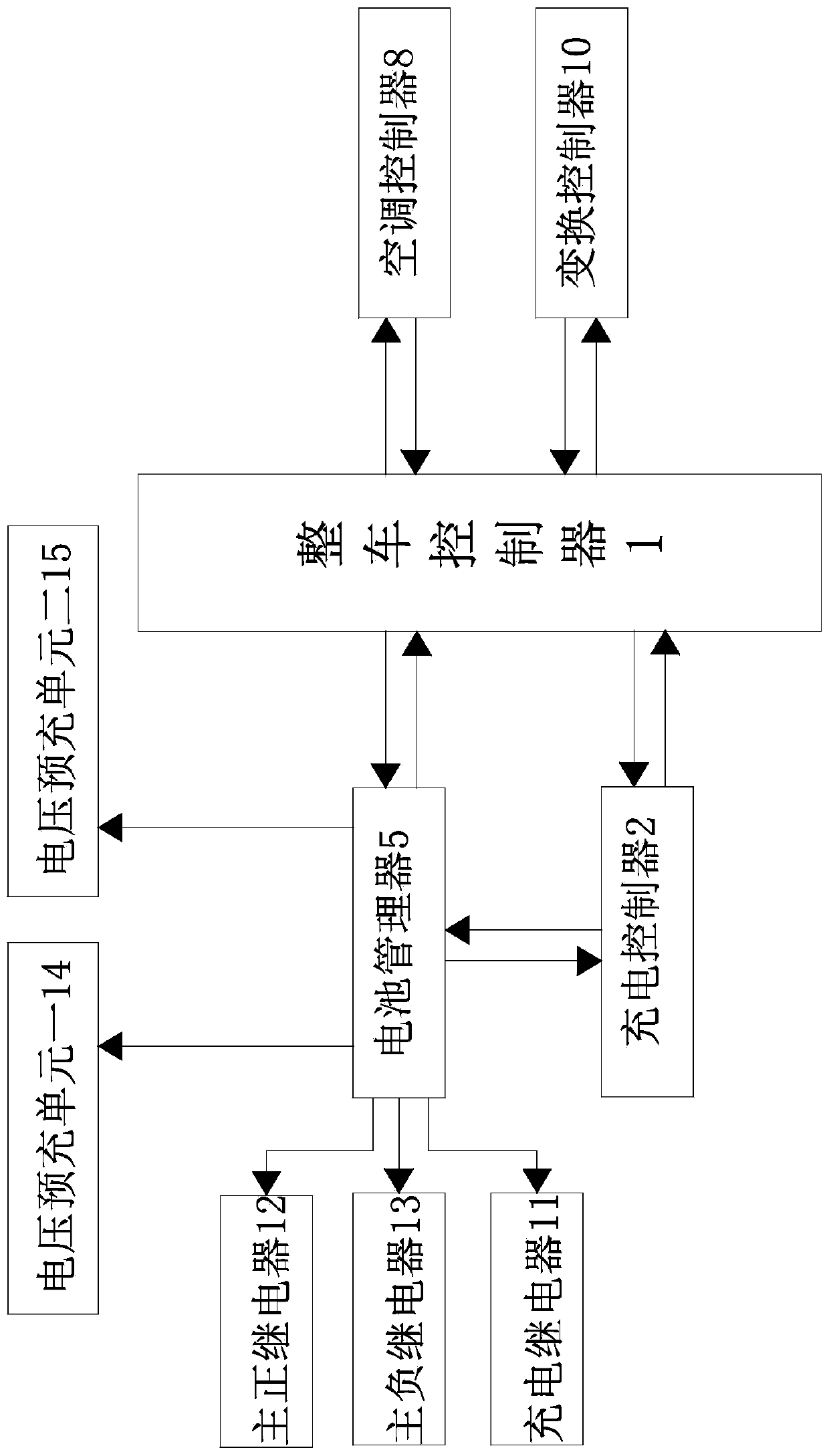

Charging and heating method and system of charging-type hybrid electric vehicle power battery

ActiveCN110077281AShorten the timeShort heating timeVehicular energy storageBattery/fuel cell control arrangementPower batteryElectrical battery

The invention provides a charging and heating method and system of a charging-type hybrid electric vehicle power battery, and belongs to the technical field of hybrid electric vehicles. The problem ofprolonging the whole charging process of the vehicle power battery at a low temperature in the prior art is solved. The charging and heating method of the charging-type hybrid electric vehicle powerbattery includes the following steps that A, charging is started; B, whether heating is needed or not is judged; C, heating control is carried out; and D, heating is quitted. The charging and heatingsystem of the charging-type hybrid electric vehicle power battery includes a vehicle controller, a relay unit, an air conditioner controller, a charging controller, and a battery manager capable of obtaining continuous rechargeable power of the power battery, wherein the battery manager, the charging controller and the air conditioner controller are connected with the vehicle controller, and the charging controller and relay unit are connected with the battery manager. According to the charging and heating method and system of the charging-type hybrid electric vehicle power battery, time of the whole charging process of the vehicle power battery at the low temperature can be shortened.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

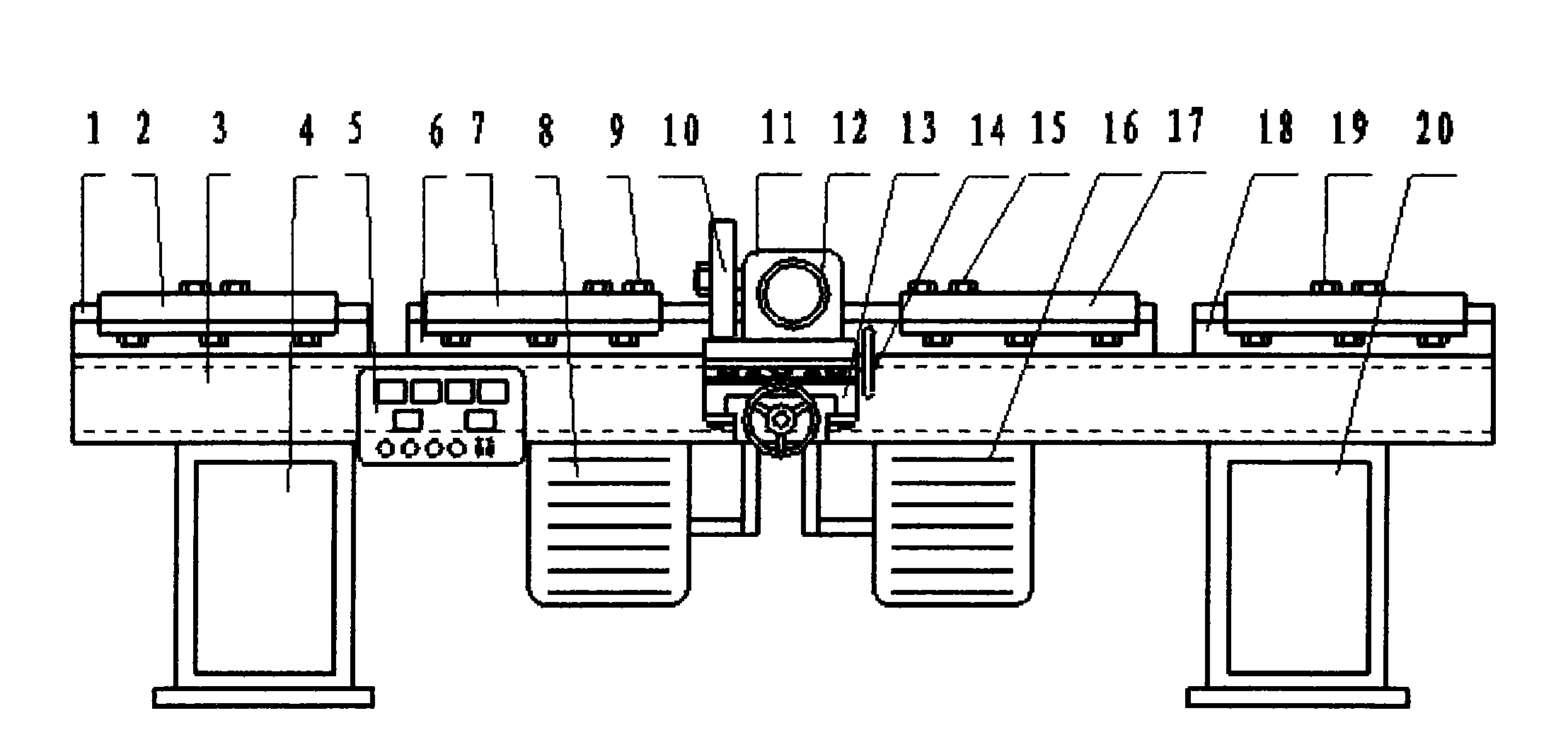

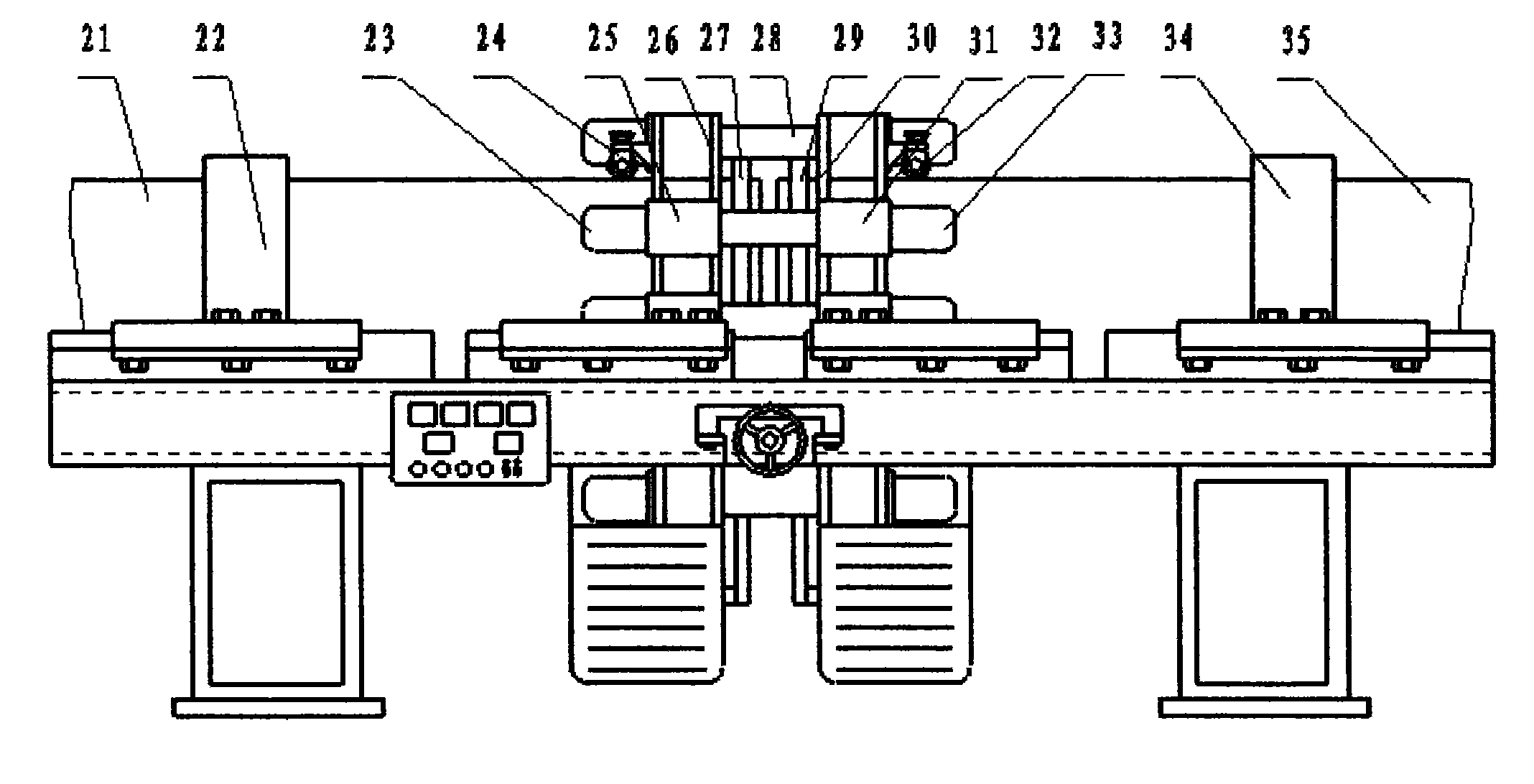

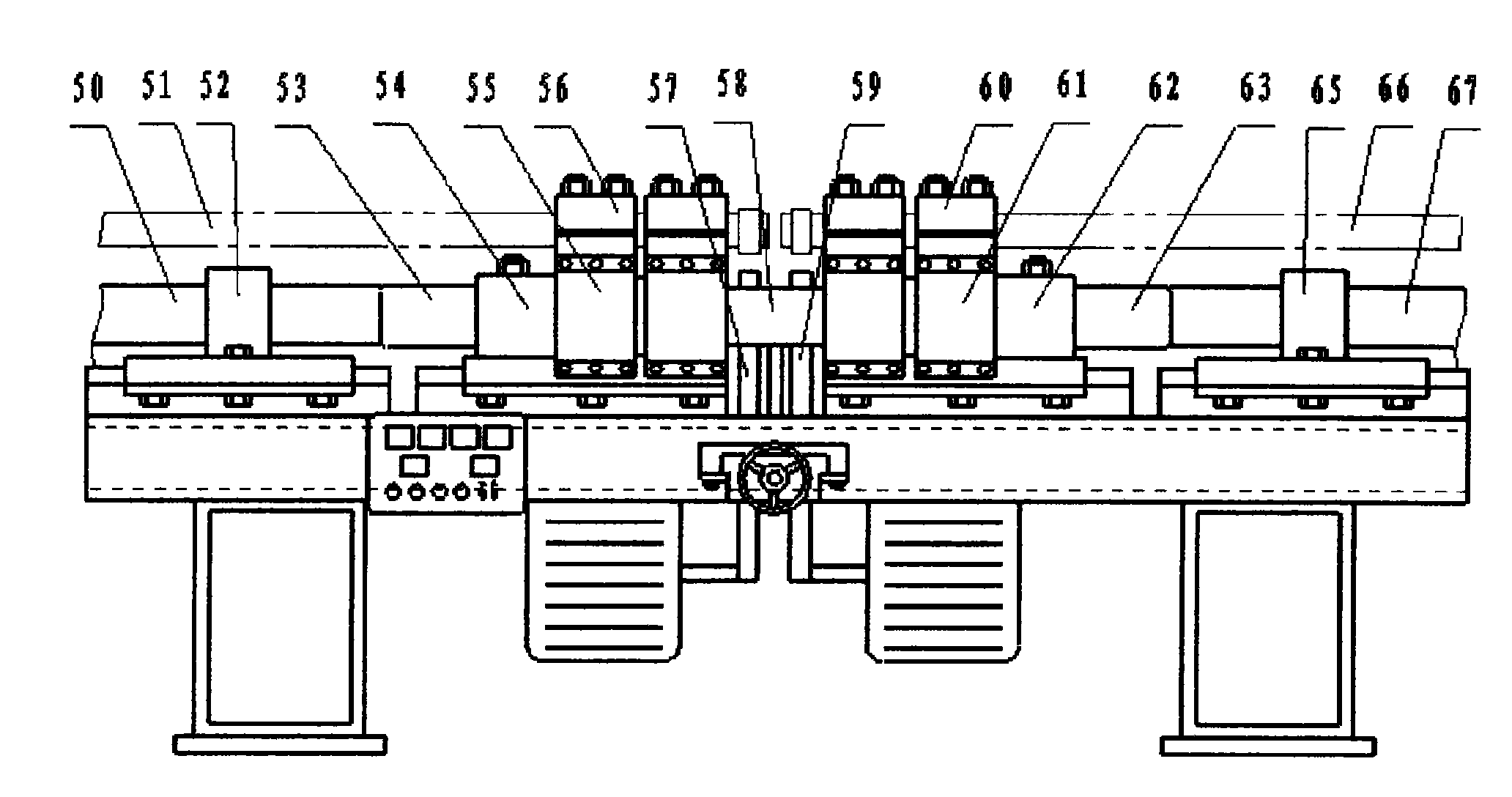

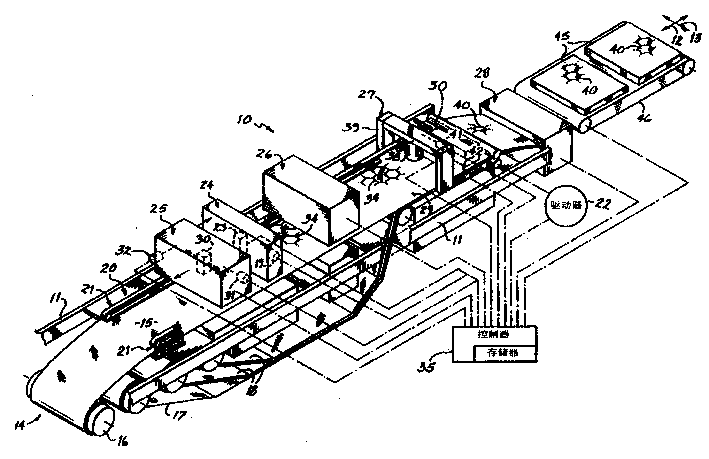

Steel induction heating solid phase welding method and butt welding machine tool

InactiveCN101623794ARealize welding automationLow priceWelding/cutting auxillary devicesAuxillary welding devicesButt weldingTransformer

The invention relates to a steel induction heating solid phase welding method and a butt welding machine tool. The butt welding machine consists of a machine body and a butt welding clamp, wherein the machine body mainly comprises a machine tool body, an electric cabinet, a welding controller, a left main guide rail, a left main slide rail, a left induction heating transformer, a tool holder, a right induction heating transformer, a right main guide rail, a right main slide rail and a hydraulic cabinet; and the hydraulic steel tube and steel rail butt welding clamp mainly comprise a left hydraulic cylinder, a left hydraulic cylinder fixing seat, a left steel rail fixing clamp, a left induction heating ring, a connecting rod of a piston rod, a right induction heating ring, a right steel rail fixing clamp, a right hydraulic cylinder fixing seat and a right hydraulic cylinder. The butt welding clamp is arranged on the end face to be welded of the steel product; and the induction heating rings are sleeved on the end face to be welded of the steel product respectively; an induction heating power supply is connected with the primary of the induction heating transformer by a cable, and the secondary of the induction heating transformer is connected with the induction heating rings respectively; and the induction heating rings can heat the end faces to be welded of two steel products to a thermoplastic state in a shot time, and the upsetting pull force is generated on the welding clamp, so that the two steel products are welded together.

Owner:陈炯

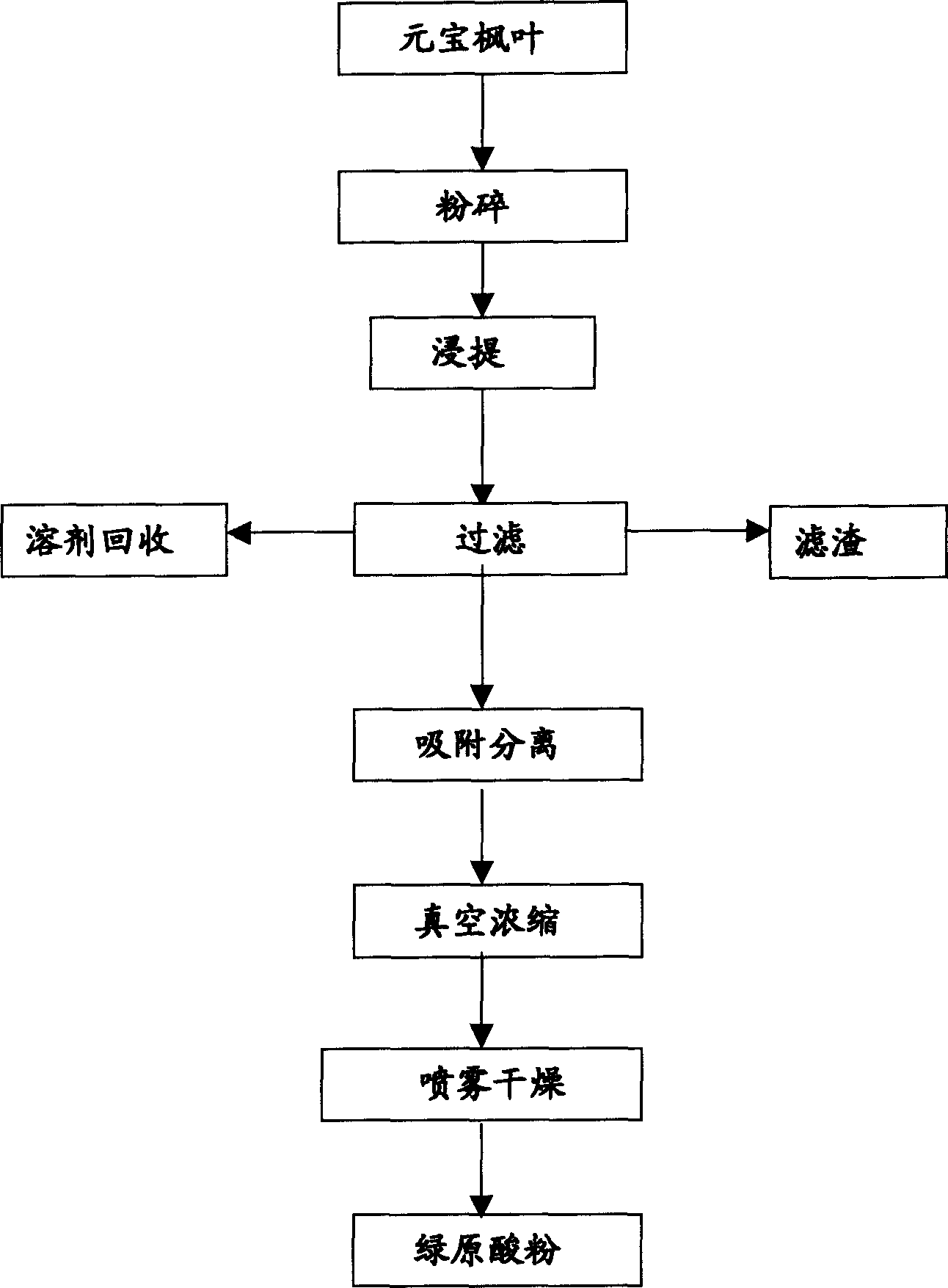

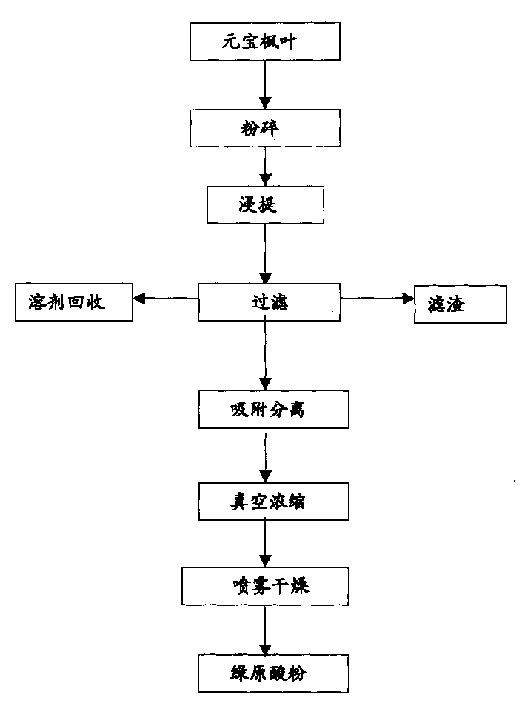

Technology for extracting chlorogenic acid from shoe-shaped maple leaves

InactiveCN1524843AImprove leaching rateGood effectOrganic compound preparationCarboxylic acid esters separation/purificationLiquid ratioChlorogenic acid

The invention relates to a process for extracting medicinal herb component, specifically a process for extracting chlorogenic acid from shoe-shaped ingot maple leaves, wherein low-temperature extraction is employed and under the conditions of controlled time, pH value and feed liquid ratio. The advantages of the process are high leaching ratio, simplicity of operation, low cost, and no toxin.

Owner:杨凌元宝枫生物制品有限公司

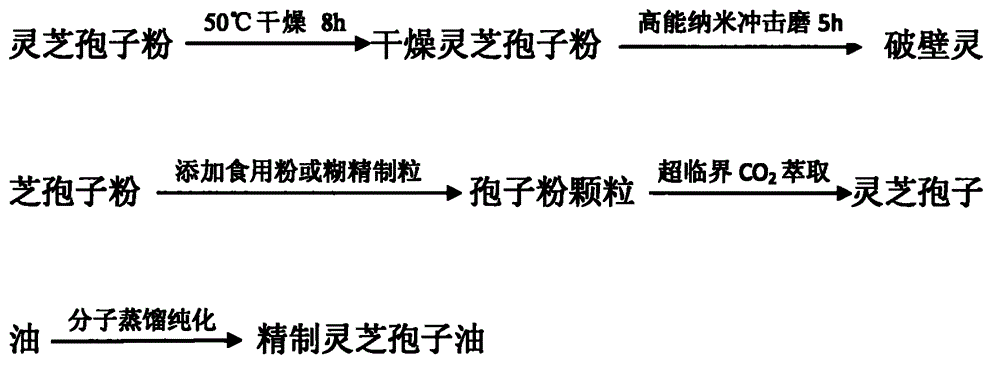

High-bioactivity ganoderma spore oil and supercritical preparation method thereof

ActiveCN102973616AReduce lossesOptimize the breaking processMetabolism disorderImmunological disordersSporeDistillation

The invention aims to disclose high-bioactivity ganoderma spore oil and a preparation method thereof, and belongs to the field of Chinese medicament. The method comprises the following steps: breaking walls of ganoderma spore powder by adopting a high-energy nano impact mill, performing dry granulation, supercritical CO2 extraction, molecular distillation and purification, and thus obtaining the ganoderma spore oil. The operation process of the method is carried out in an anhydrous environment, so that oxidation of the spore oil in the processing process is reduced, and the obtained product is stable in property; the freezing transparent test time of the ganoderma spore oil prepared by the method exceeds 5.5 hours; and the measured unsaturated fatty acid content is between 60 and 80 percent, the total triterpenoid content is 2 to 3 percent, the total ergosterol content is 2 to 5 mg / g, the ganoderic acid A content is more than 1 mg / g, the peroxide value is less than 5mmol / kg, and the acid value is less than 10 mg KOH / g.

Owner:厦门爱逸零食研究所有限公司

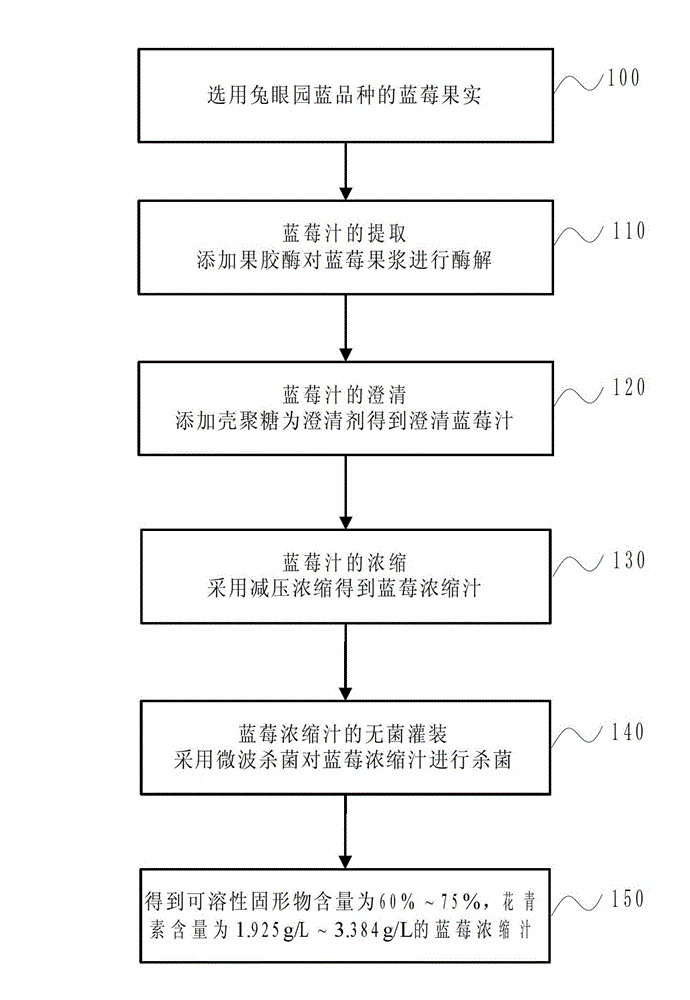

Preparation process of blueberry concentrated juice with high content of anthocyanin

The invention provides a preparation process of blueberry concentrated juice with high content of anthocyanin. According to the preparation process provided by the invention, pectase is adopted for performing enzymolysis on blueberry pulp, chitosan is adopted as a clarifying agent for obtaining clear blueberry juice, a decompression concentration process is adopted for preparing the blueberry concentrated juice, and microwave sterilization is adopted for sterilizing the blueberry concentrated juice. The preparation process comprises the following steps of: selecting blueberry fruits in vaccinium ashei gardenblue species; extracting the blueberry juice, and adding the pectase to perform the enzymolysis on the blueberry pulp; clarifying the blueberry juice, and adding the chitosan as the clarifying agent for obtaining the clear blueberry juice; concentrating the blueberry juice, and adopting the decompression concentration to obtain the blueberry concentrated juice; and performing sterile filling on the blueberry juice, and adopting the microwave sterilization to sterilize the blueberry concentrated juice, wherein the content of soluble solids in the blueberry concentrated juice is 60%-75%, and the content of the anthocyanin is 1.925g / L-3.384g / L. The preparation process provided by the invention can not only effectively prevent the loss of the anthocyanin in the blueberry concentrated juice, but also shorten the concentration time, control the production cost of the preparation process and effectively protect color, luster, fragrance and other sensory qualities of the blueberry juice.

Owner:ANHUI AGRICULTURAL UNIVERSITY

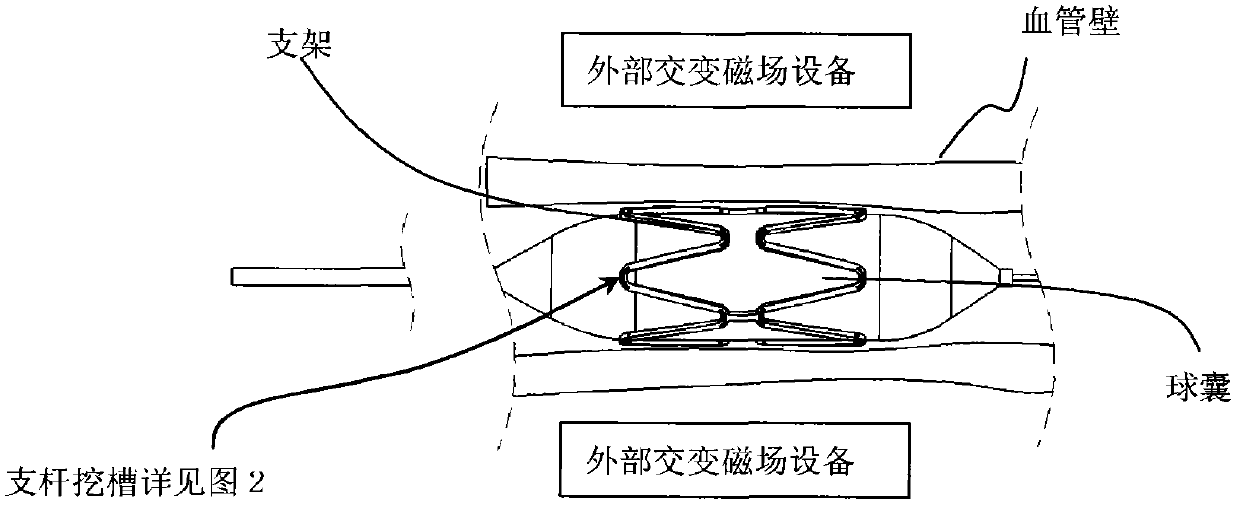

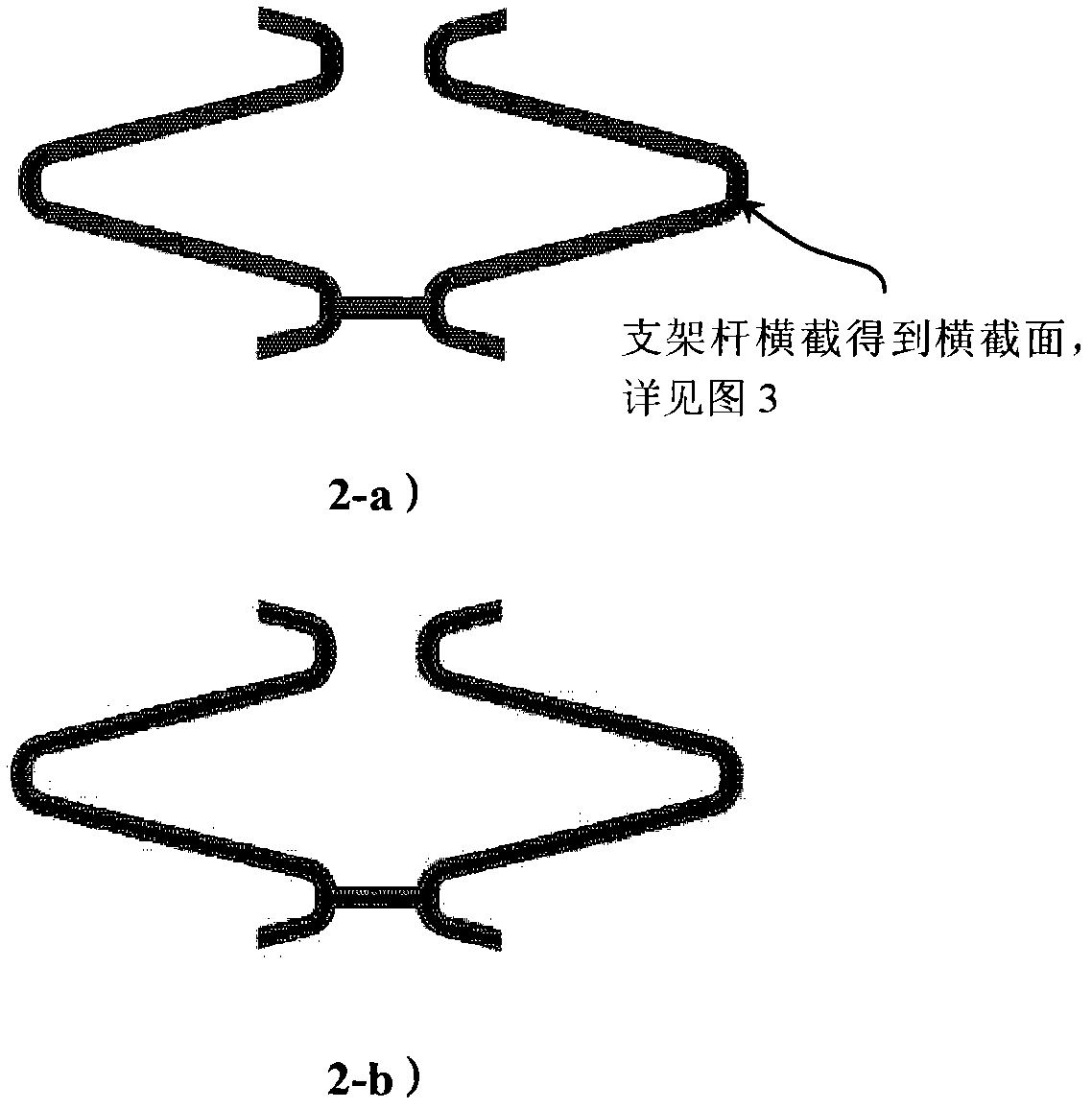

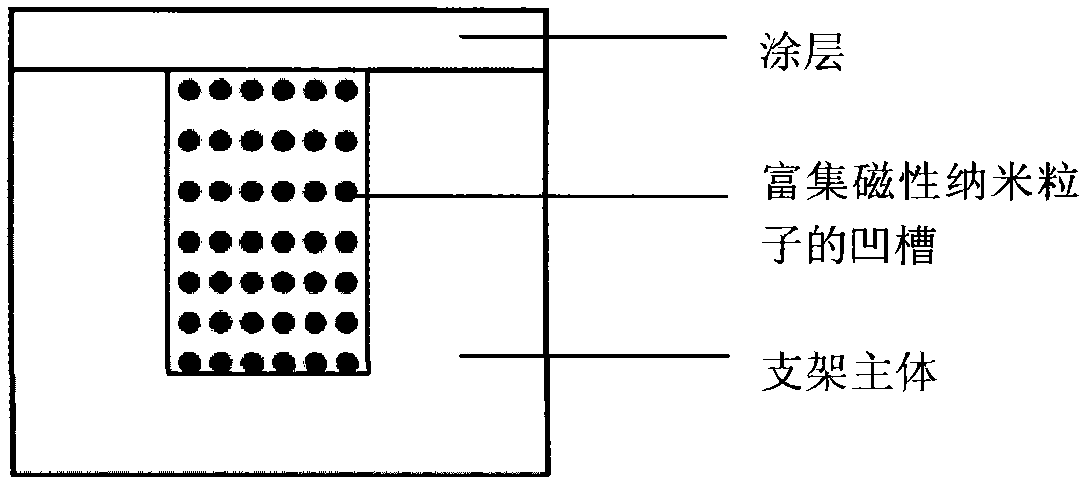

Biodegradable stent with groove and preparation method thereof

ActiveCN102379762AReduced expansion and retractionEquivalent lowStentsSurgeryBiodegradable polymerBlood vessel

The invention relates to the field of medical apparatuses, in particular to a biodegradable polymer stent with grooves and a preparation method thereof. The biodegradable polymer stent comprises a stent main body, magnetic nano particles and a coating layer, wherein the grooves are excavated at parts bearing stent deformation or all parts of the stent main body, and the magnetic nano particles are arranged in the grooves. The temperature of the magnetic nano particles is increased through an external alternating magnetic field to heat the stent. After the stent is heated and expanded, the stent is cooled, fixed and formed in a body, the retraction rate can be decreased to less than 10 percent, and the consequences such as collapse, displacement and the like are avoided. At the same time, by heating the stent through the magnetic nano particles, the thermal damages to the wall of a blood vessel can be minimized.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

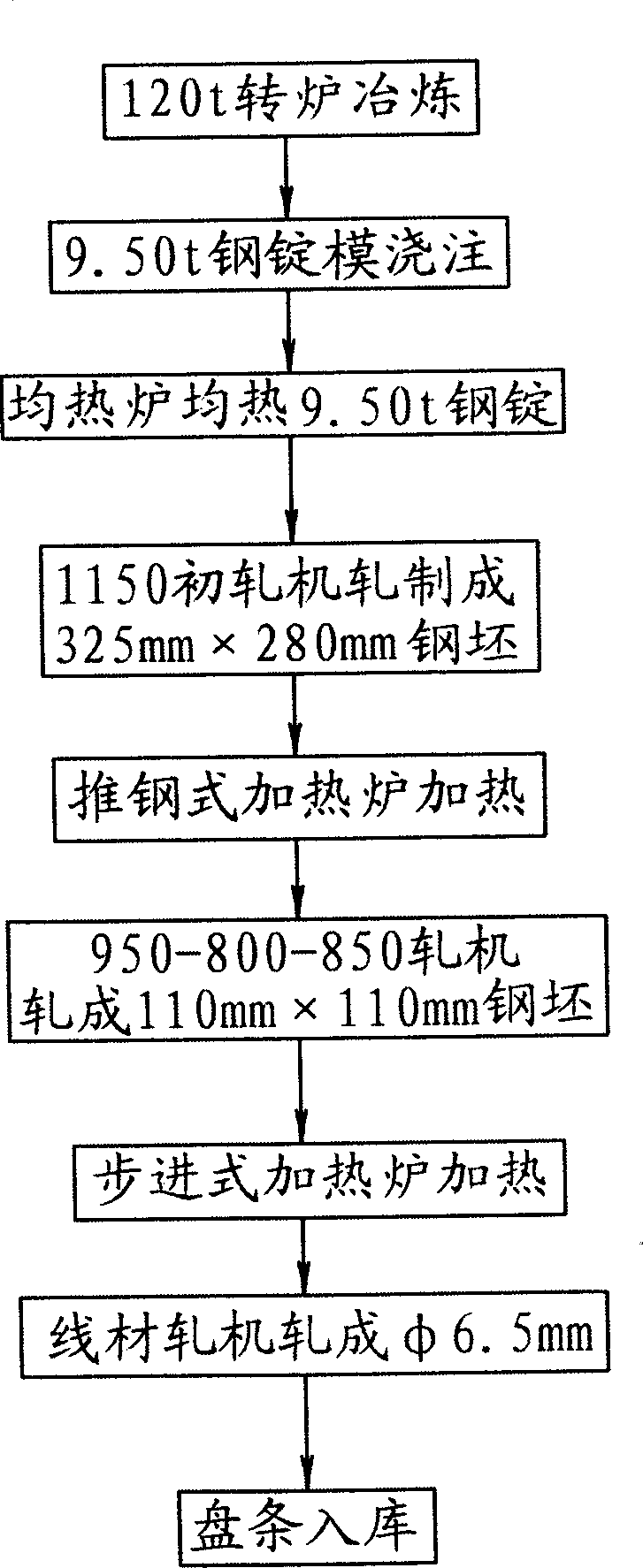

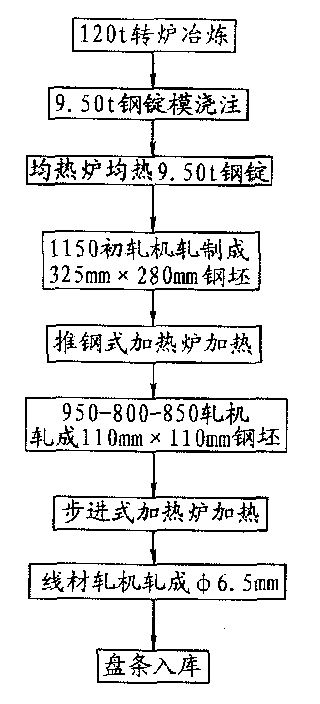

Heating method of preventing for high-carbon steel blank or steel ingot from decarbonizing

InactiveCN1438334AShort heating timeEnergy savingFurnace typesHeat treatment furnacesCarbon steelFuel oil

The invention discloses heating method which can avoid decarbonization of high carbon billet or steel ingot. In the whole process of high carbon steel heating or preheating, heating, heat preservation period, it uses strong oxidizing gas to heat billet or steel ingot. The gas is controlled by air overplus coefficient, the coefficient (air and fuel, such as the ratio of coal gas, heavy oil) is 1.2-1.4.

Owner:攀枝花钢铁有限责任公司钢铁研究院

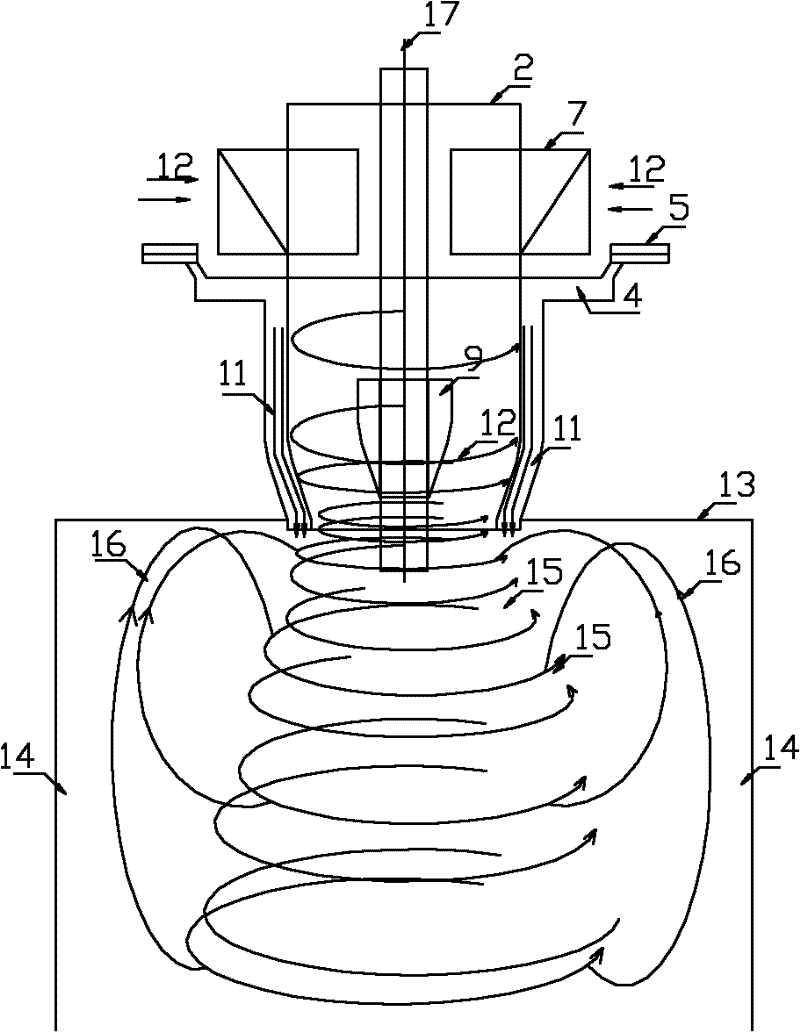

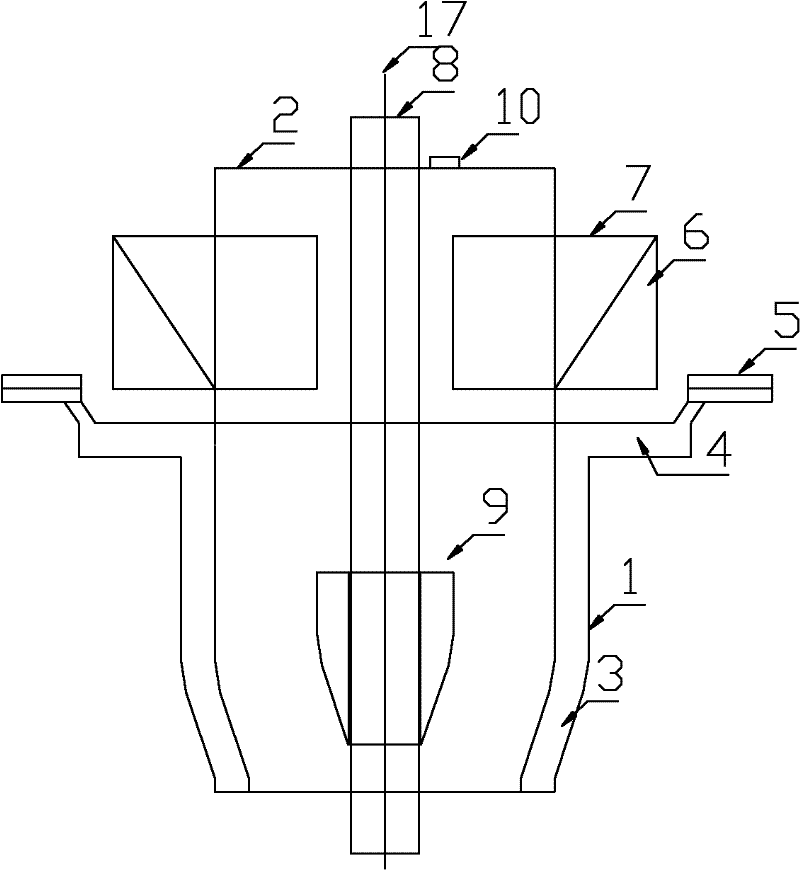

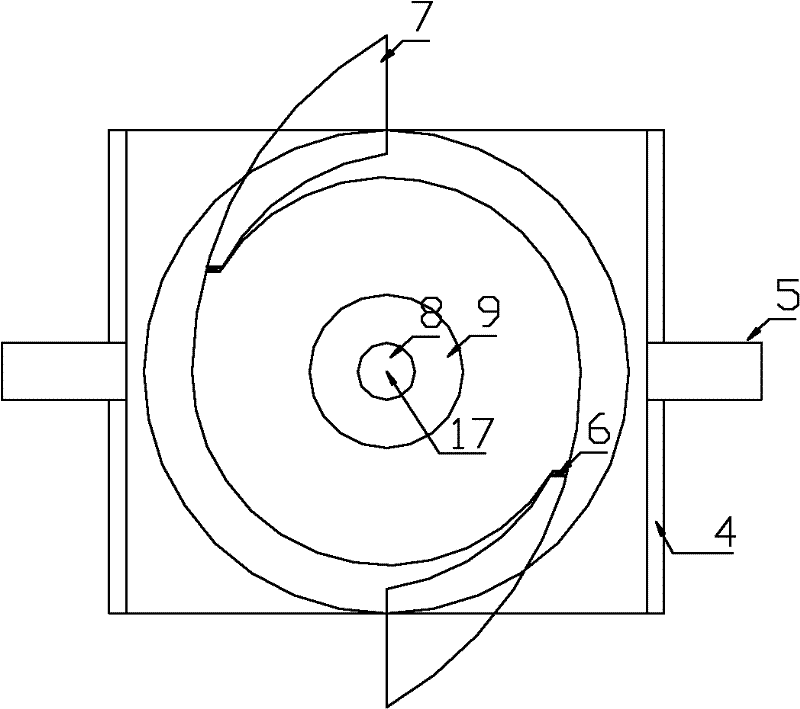

A spin-floating entrainment metallurgical process and its reactor

The invention relates a floating entrainment metallurgical process. In this process, the reaction gas and the powdery materials are injected into the reaction furnace, aiming to obtain a controllable highly rotating and floating state and reach the ignition point under the high-temperature radiation of the reaction furnace to combust intensely. Meanwhile, the rotating fluid injected in the reaction furnace will drive the furnace gas, and forms a relatively low-temperature circular backflow protection area around the rotating fluid. The reaction gas is tangentially fed into the rotating generator along numbers of rotary channels to form a controllable rotating airflow, in addition, a conical exit air controller that can be moved up and down is adopted to control the exit area of the rotating generator, thus controlling the velocity of the reaction gas into the reaction furnace; the powdery materials fall freely around the reaction gas and are involved in the high-speed rotating airflow, forming a rotating fluid, of which the powdery materials are highly dispersed into the reaction gas, moving downwards along the radial high-speed rotating axle. For the purpose of this invention, a steplessly adjusted reactor is as well referred to in this invention.

Owner:YANGGU XIANGGUANG COPPER

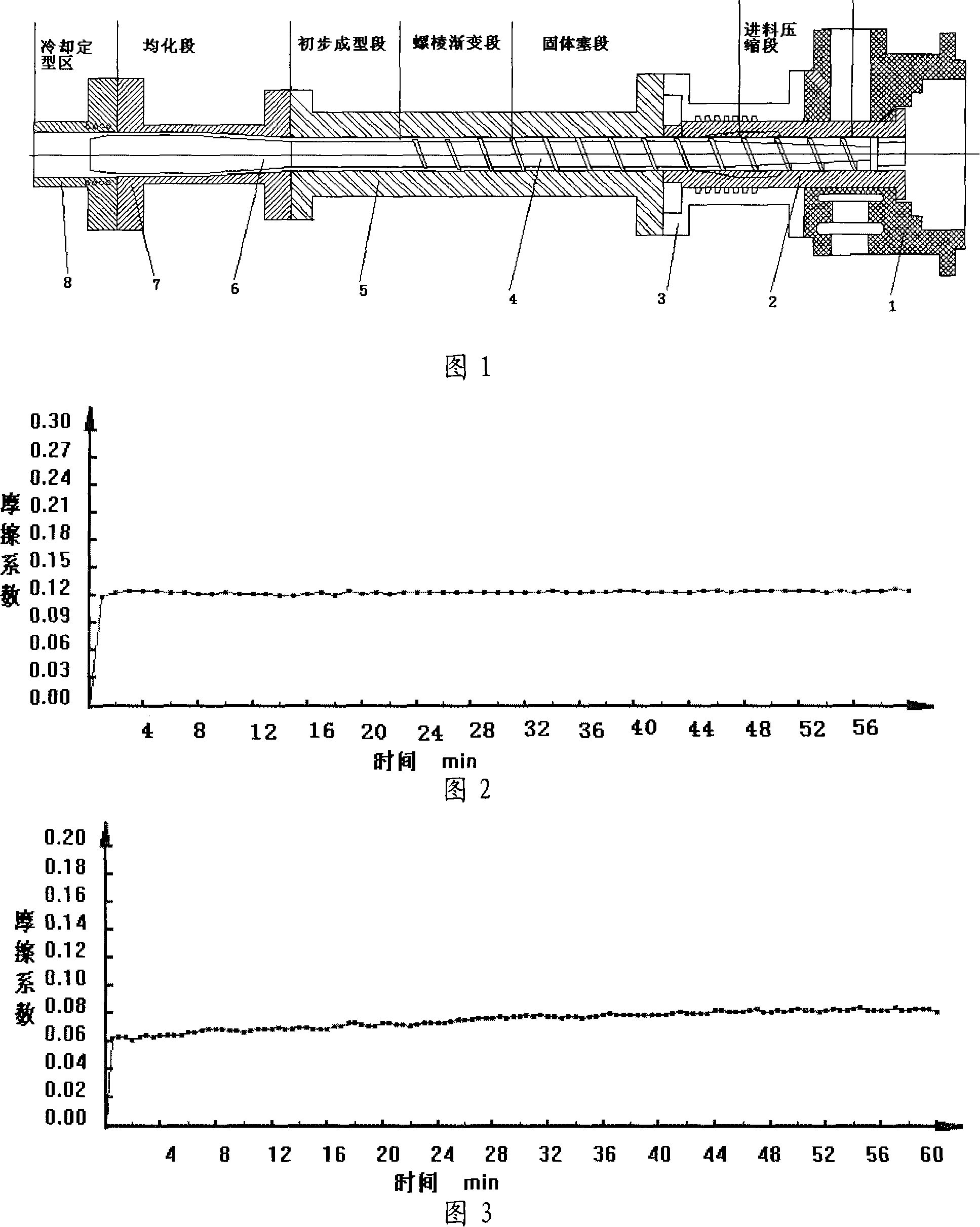

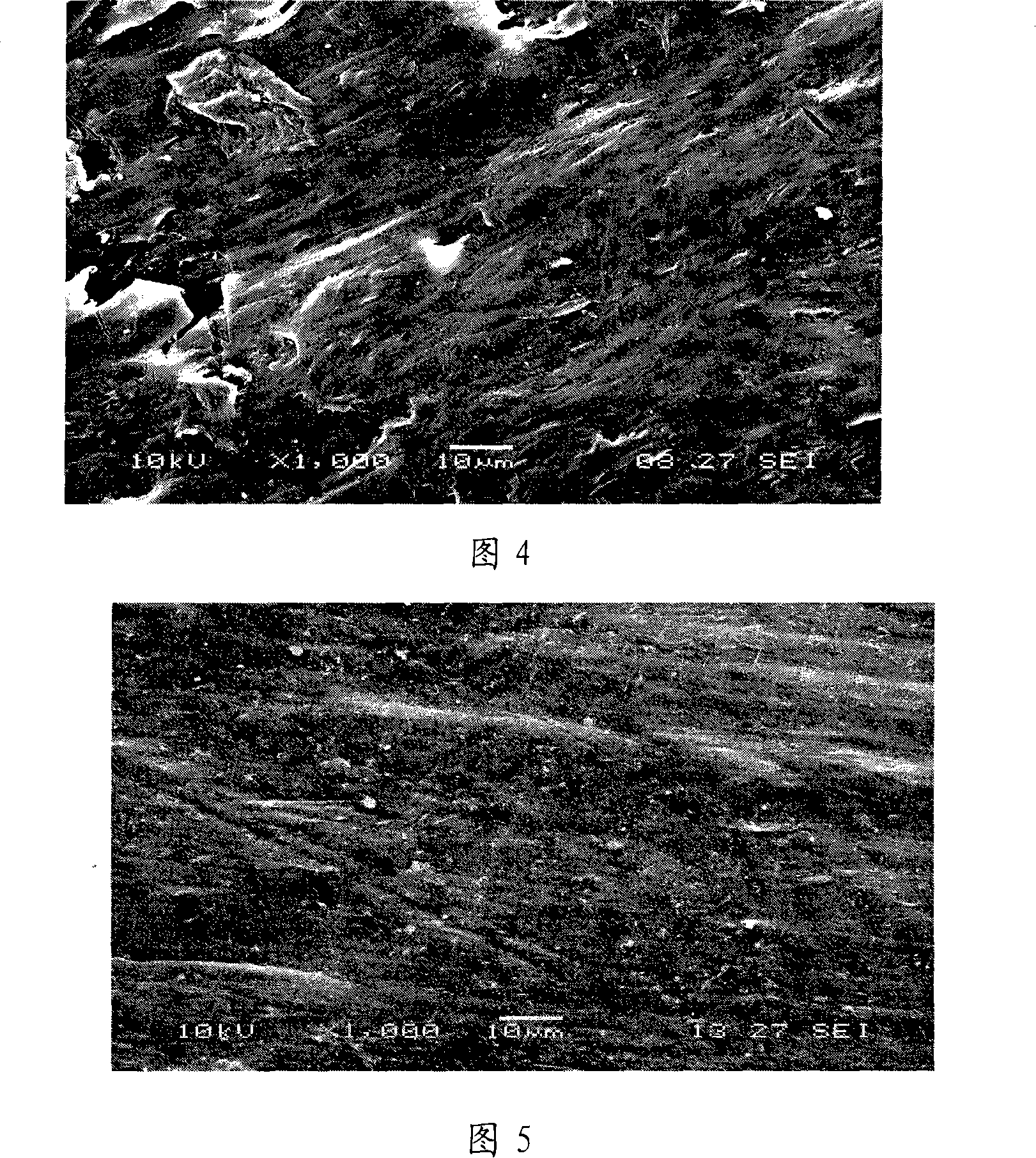

Ultrahigh molecular weight polyethylene tube single screw extruder barrel forming method and the forming device thereof

InactiveCN101117017AImprove performanceRealize continuous extrusion moldingTubular articlesMolten stateEngineering

The present invention relates to a molding method and a molding device for an ultra-high Molecular Weight Polyethylene (UHMWPE) tubular product single-screw extruding machine barrel. With extrudability and calendering properties of ultra-high Molecular Weight Polyethylene in an elastomeric state, when the ultra-high Molecular Weight Polyethylene in an elastomeric state in extrusion force action fills a molding chamber which is formed between a feed rod screw and a machine barrel, preliminary molding of the ultra-high Molecular Weight Polyethylene tubular product is achieved; with continuous action of the extrusion force, preliminary molding tubular products achieve a homogenization process of temperature and geometric dimension through a shaping mandrel and a shaping set; then the tubular products complete cooling and shaping processes rapidly when passing a cooling set. The invention solves difficult technical problems that nearly no ultra-high Molecular Weight Polyethylene with a viscous state can process single-screw extruding molding in a molten state; on the premise of keeping excellent performance of the ultra-high Molecular Weight Polyethylene well, a goal of continuous production of the ultra-high Molecular Weight Polyethylene tubular product is achieved.

Owner:WUHAN XIAOHONG ULTRA HIGH MOLECULAR WEIGHT NEW MATERIALS TECH

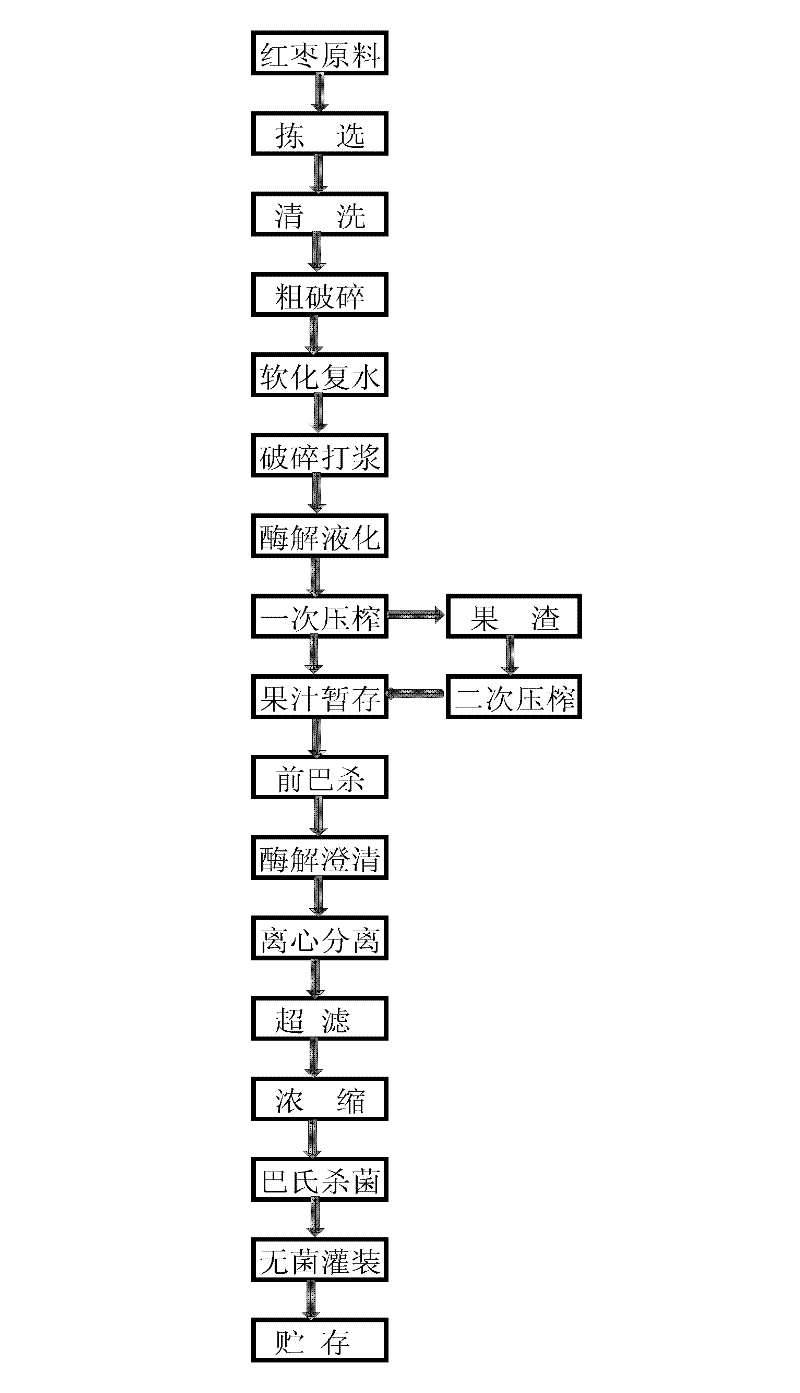

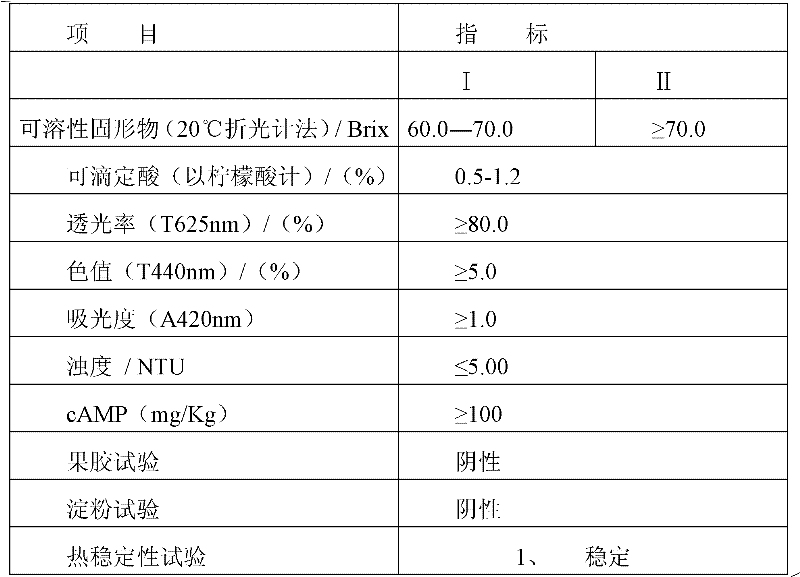

Method of preparing concentrated clear red jujube juice with high cAMP content

The invention discloses a method of preparing concentrated clear red jujube juice with high cAMP content, which comprises the following steps: taking out red jujube after rehydration, denucleating and then crushing pulp for preparing the red jujube thick liquid; conveying the red jujube after enzymolysis by pectinase into a juicer for squeezing, and filtering to obtain the red jujube juice; adding pectinase, amylase and cellulose into the red jujube juice for heat-preservation and enzymolysis for 60-90 minutes; and clearing, conducting concentration sterilization, and finally bulking. The concentrated clear red jujube juice prepared by the invention is clear and transparent, has the cAMP content being larger than or equal to 100 mg / Kg and soluble solid state material being larger than or equal to 60.0 Brix, is deposit-free and suspension-free, has brownish red color and does not have impurities which can be seen by naked eyes; and the concentrated juice is diluted to the soluble solidstate material being 60.0 Brix, and the juice has inherent fragrance and flavor of red jujubes and is free from extraneous odor.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

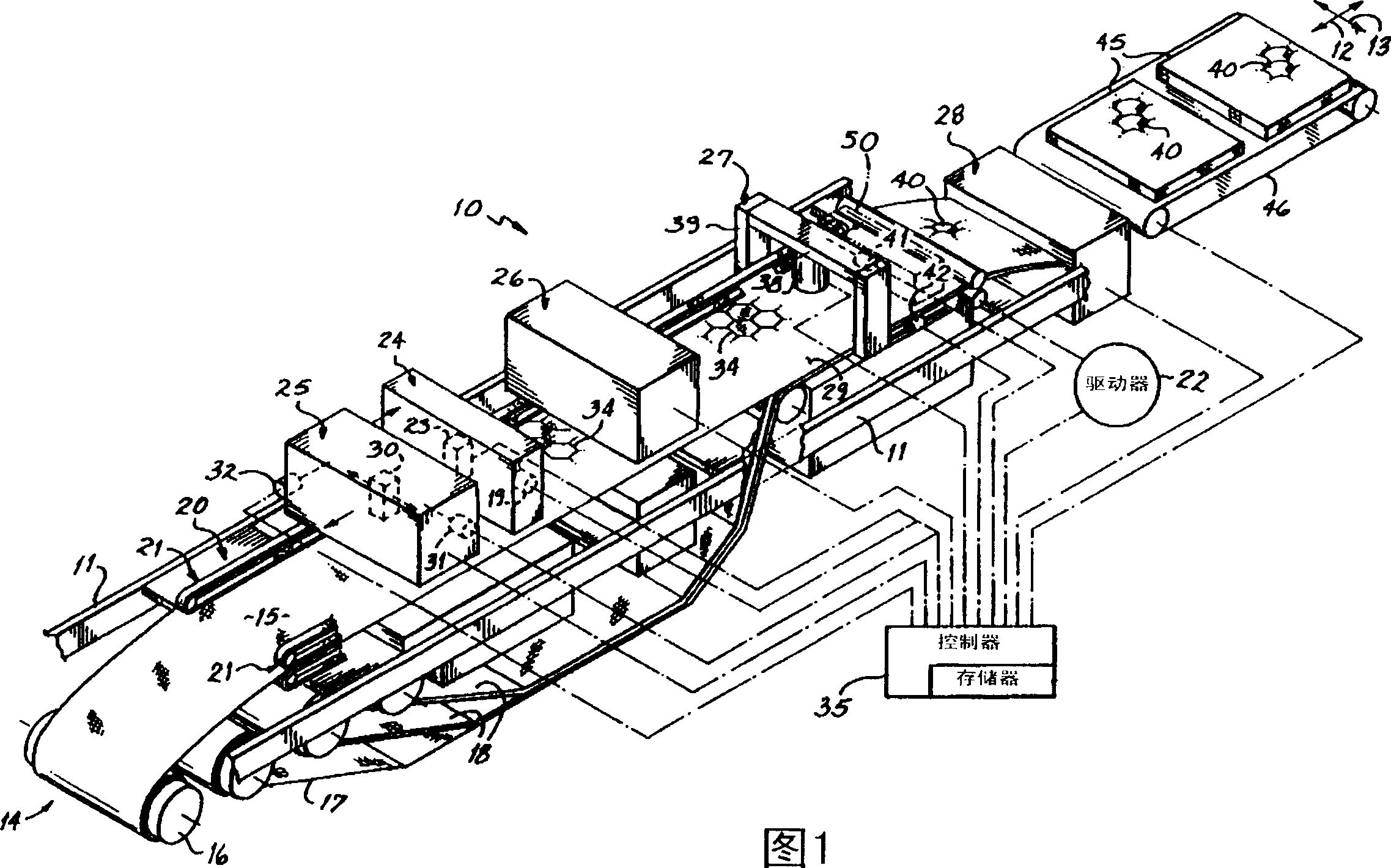

Method nad apparatus for UV ink jet printing on fabric and combination printing and quilting thereby

InactiveCN1377313AChanging the time of exposure to energyIncrease or decrease the time of energy exposureSewing-machine elementsLayered productsUV curingRadiant heater

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors across a bridge that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads, so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate.

Owner:L & P PROPERTY MANAGEMENT CO

Process for extracting, preparing and purifying gamma methyllinolenate from algae

InactiveCN1448383AHigh purityEconomical and reasonable processCarboxylic acid esters separation/purificationBulk chemical productionSolventNitrogen gas

Algae powder is added into methanol as entainer, the mixture is homogenated and supercritical extracted with CO2 as solvent and general ester is obtained after concentration. The general ester is dissolved and esterified in methanol containing acetyl chloride to obtain general fatty methyl ester, which is distilled with the distillate being collected. The distillate is mixed with acetone, crystallized in 4 deg.c, -10 deg.c and -30 deg.c successively, filtered to eliminate separated matter, the filtrate is concentrated and mixed with urea and methanol, and the mixture is reflux for 1 hr under the protection of nitrogen, cooled, set, filtered to eliminate crystal, mixed with water, petroleum ether extracted to obtain gamma-methyl linolenate after petroleum ether is recovered via distillation. The obtained gamma-methyl linolenate is purified via high vacuum distillation at 100-150 deg.c.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com