Method for preparing vanadium nitride and device

A production method and technology for nitriding vanadium, applied in the field of vanadium alloy, can solve the problems of low output, large consumption of reduction and nitriding gas, low production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

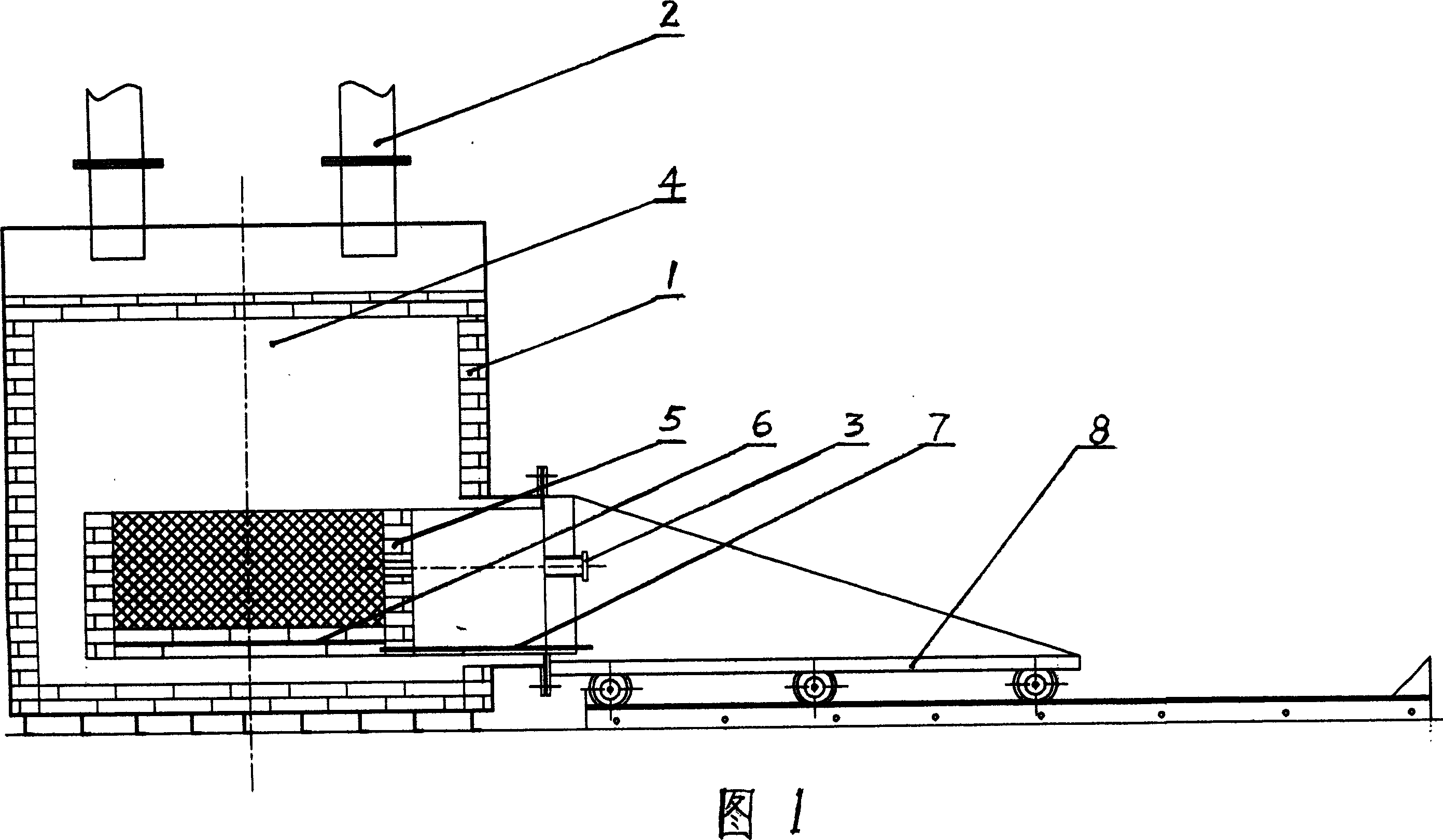

[0007] 900kg of 90% V with a purity of 98.56% has been ground into 120 mesh 2 o 5 Powder, 332kg of graphite powder and 125kg of 1% carboxymethylcellulose aqueous solution are mixed and pressed into pieces of φ80×30mm. Then put the block into the crucible 5, and automatically push it into the microwave oven by the control system. After the furnace door is closed and sealed, the vacuum system starts to start and pump air. When the vacuum reaches 40 Pa, start heating, pre-reduce at 650°C for 1 hour, and then carbonize at 1400°C for 2 hours. After the carbonization is finished, stop pumping, let in nitrogen, and nitriding at 1000°C for 2 hours. After the heating is over, the product is automatically released when it is naturally cooled to 180°C in the furnace, and the apparent density of 617kg is 3810g / cm 3 , containing V78.32%, N12.22%, C6.41%, O1.55% vanadium nitride.

Embodiment 2

[0009] 700kg of 90% V with a purity of 98.32% has been ground into 120 mesh 2 o 5 Powder, 250kg of graphite powder and 88kg of 1% carboxymethyl cellulose aqueous solution are mixed and pressed into pieces of φ80×30mm. Then put the block into the crucible 5, and automatically push it into the microwave oven by the control system. After the furnace door is closed and sealed, the vacuum system starts to start and pump air. When the vacuum reaches 100 Pa, start heating, pre-reduce at 600°C for 0.5 hours, and then carbonize at 1300°C for 1.5 hours. After the carbonization is completed, stop pumping, feed nitrogen, and nitriding at 1100°C for 2.5 hours. After heating, the product is automatically released when it is naturally cooled to 170°C in the furnace, and the apparent density of 486kg is 3570g / cm 3 , containing V77.89%, N9.05%, C8.15%, O3.25% vanadium nitride.

Embodiment 3

[0011] 1000kg of 80% V with a purity of 98.17% has been ground into 200 mesh 2 o 5 Powder, 333kg of graphite powder and 130kg of 1% carboxymethyl cellulose aqueous solution are mixed and pressed into pieces of φ80×30mm. Then put the block into the crucible 5, and automatically push it into the microwave oven by the control system. After the furnace door is closed and sealed, the vacuum system starts to start and pump air. When the vacuum reaches 30 Pa, start heating, pre-reduce at 680°C for 1 hour, and then carbonize at 1450°C for 2 hours. After the carbonization is completed, stop pumping, feed nitrogen, and nitriding at 1200°C for 3.5 hours. After the heating is over, the product is automatically released when it is naturally cooled to 150°C in the furnace, and the apparent density of 682kg is 4170g / cm 3 , containing V79.28%, N13.34%, C5.07%, O0.81% vanadium nitride.

[0012] The vanadium nitride product obtained by applying the production method and equipment of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com