Patents

Literature

408 results about "Vanadium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

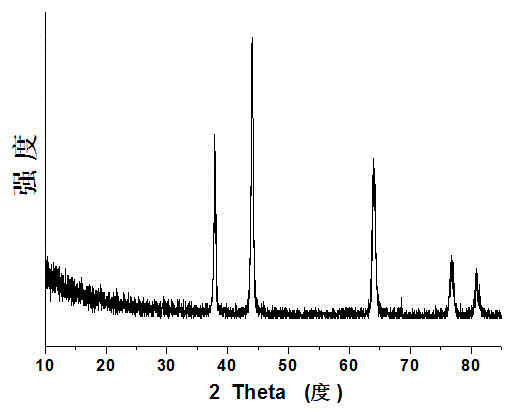

Vanadium nitride, VN, is a chemical compound of vanadium and nitrogen. Vanadium nitride is formed during the nitriding of steel and increases wear resistance. Another phase, V₂N, also referred to as vanadium nitride, can be formed along with VN during nitriding. VN has a cubic, rock-salt structure. There is also a low-temperature form, which contains V₄ clusters. The low-temperature phase results from a dynamic instability, when the energy of vibrational modes in the high-temperature NaCl-structure phase, are reduced below zero.

Metallurgical V-N microalloying and compound deoxidation cored wire

A metallurgical V-N microalloying and compound deoxidation cored wire contains a core wire and a cladding steel belt. The technical key point of the cored wire is as follows: the core wire of the cored wire consists of a vanadium-increasing agent, a nitrogen-increasing agent and a deoxidizing nitrogen-fixing agent of which particle sizes are less than 6mm, wherein the vanadium-increasing agent is ferrovanadium, nitrided ferrovanadium or vanadium pentoxide; the nitrogen-increasing agent is ferrosilicon nitride, silicomanganese nitride, ferromanganese nitride, ferrochromium nitride, silicon nitride, aluminum nitride or calcium cyanamide; and the deoxidizing nitrogen-fixing agent contains one or more of aluminum, calcium, magnesium and barium, and can also contain one or more of titanium, zirconium, niobium, manganese, chromium, silicon, carbon and iron. By adopting the cored wire, the V / N ratio of steel can get closer to the optimal proportion, the enhancing function of vanadium can be utilized furthest, vanadium resources can be saved, the recovery rate of nitrogen is high, the nitrogen content is stable, the compound deoxidation function can also be realized, the V-N microalloying cost can be reduced and the quality of steel can be increased.

Owner:侯巍 +2

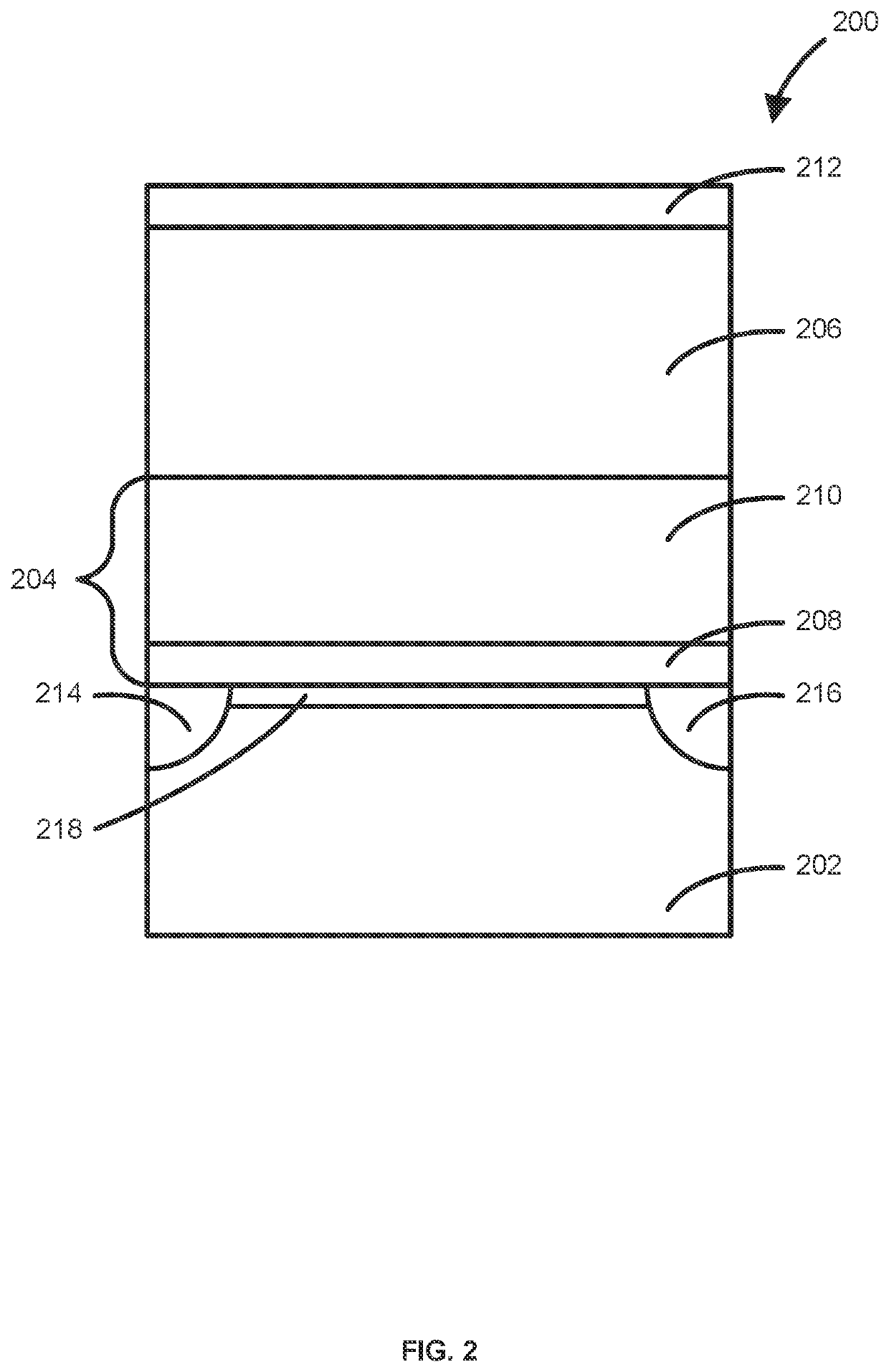

Method of forming vanadium nitride layer and structure including the vanadium nitride layer

PendingUS20210180184A1Readily apparentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingVanadium nitrideVanadium atom

Methods and systems for depositing vanadium nitride layers onto a surface of the substrate and structures and devices formed using the methods are disclosed. An exemplary method includes using a cyclical deposition process, depositing a vanadium nitride layer onto a surface of the substrate. The cyclical deposition process can include providing a vanadium halide precursor to the reaction chamber and separately providing a nitrogen reactant to the reaction chamber. The cyclical deposition process may desirably be a thermal cyclical deposition process.

Owner:ASM IP HLDG BV

Nitride and Carbide Anode Materials

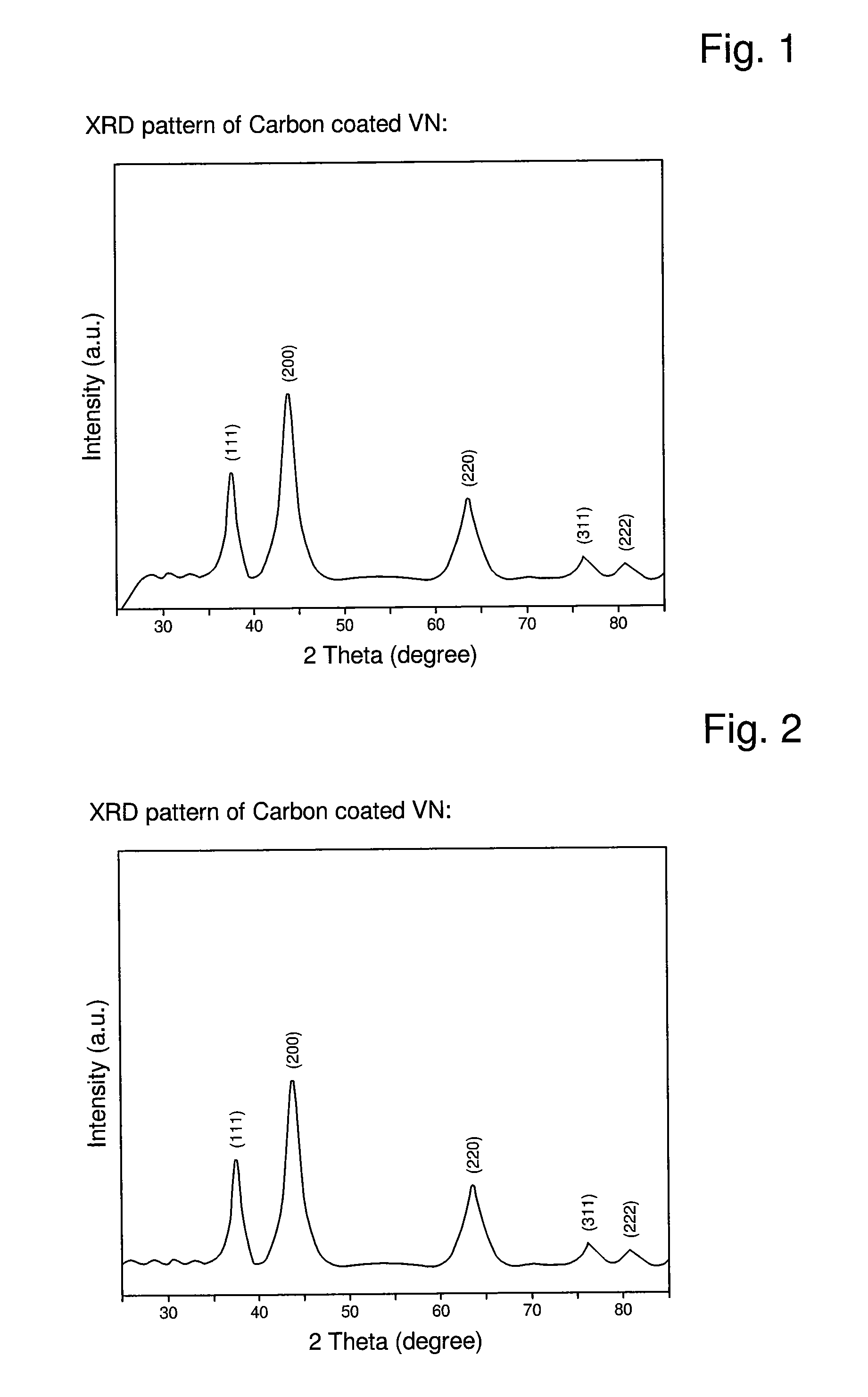

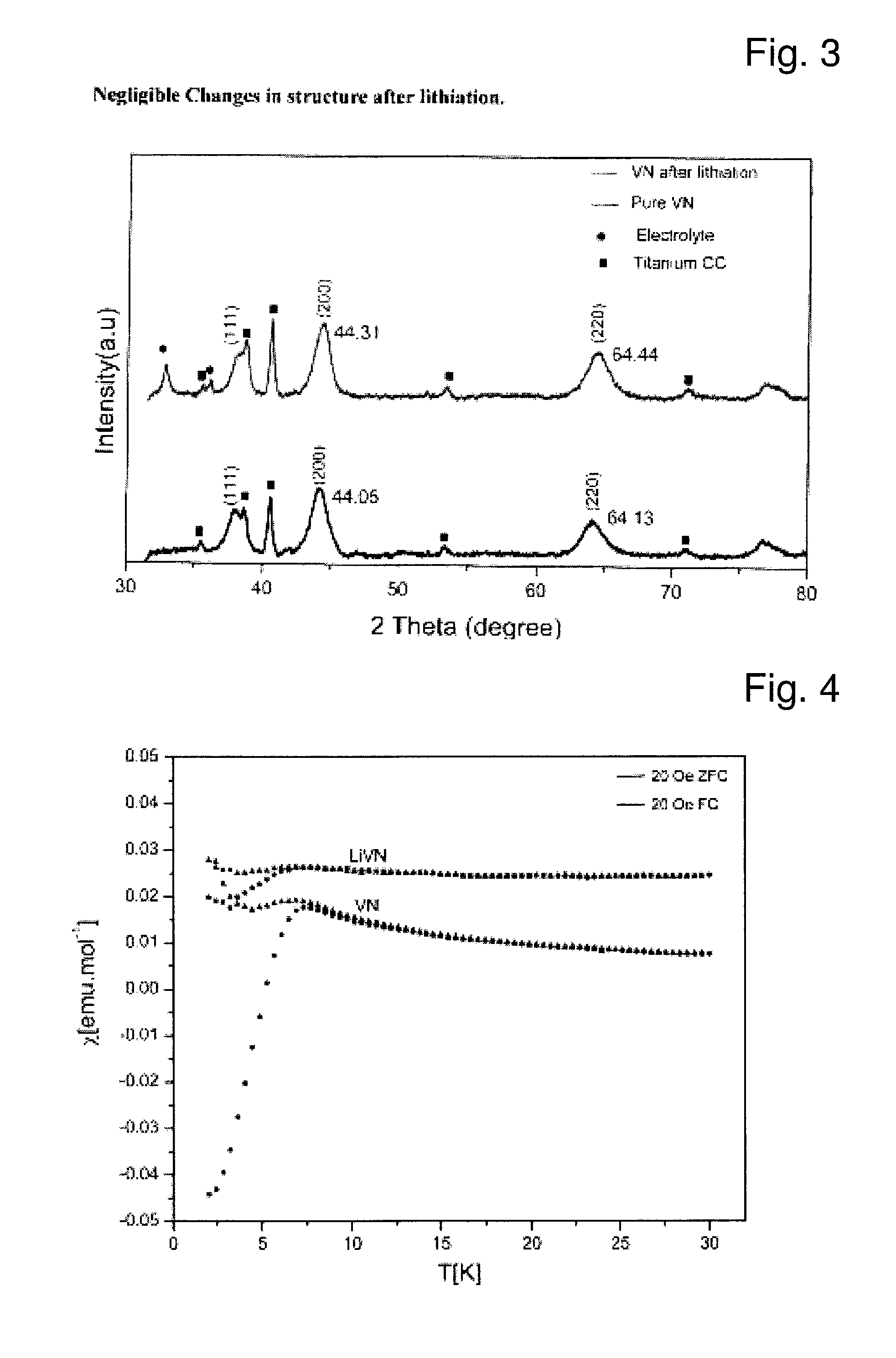

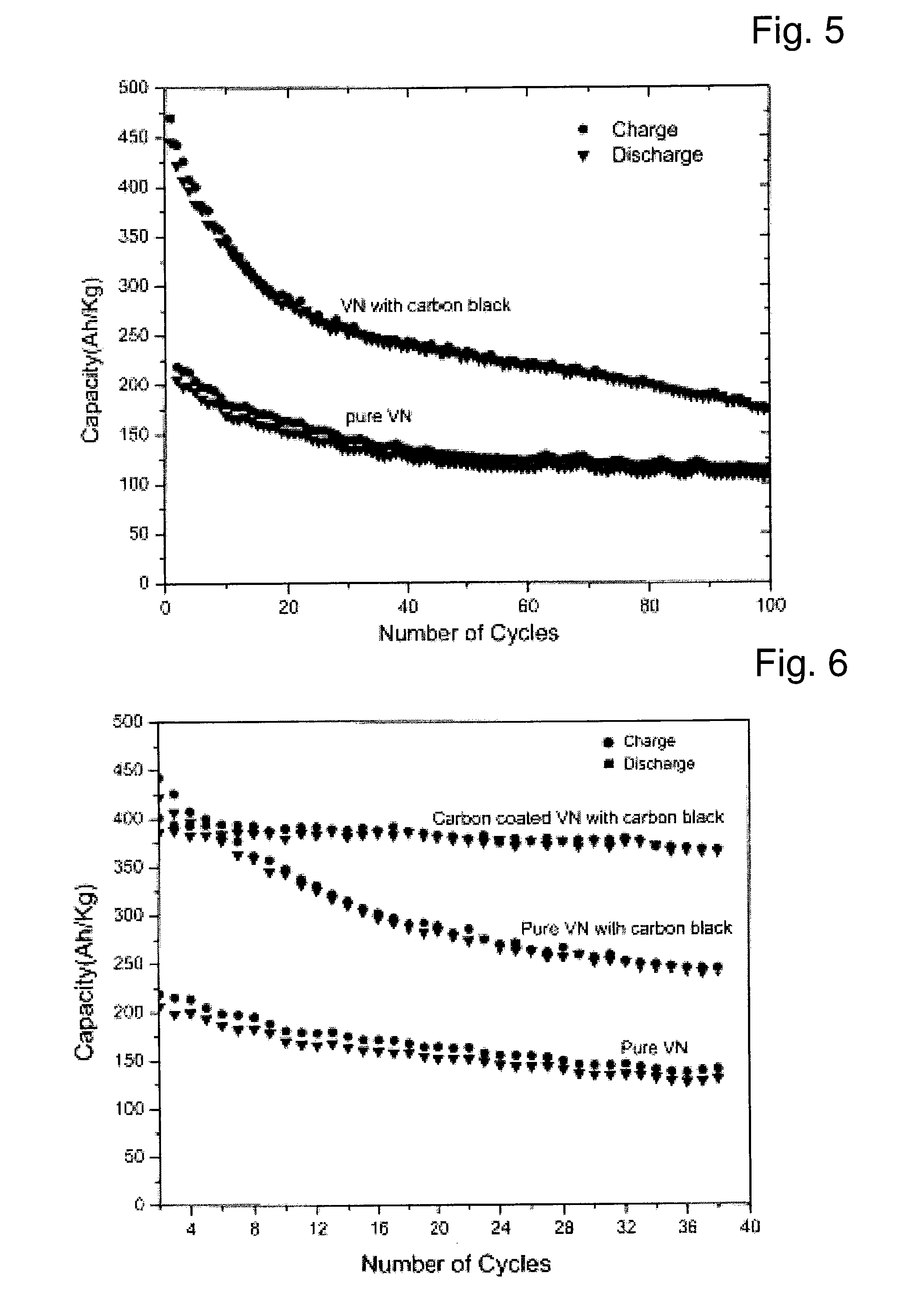

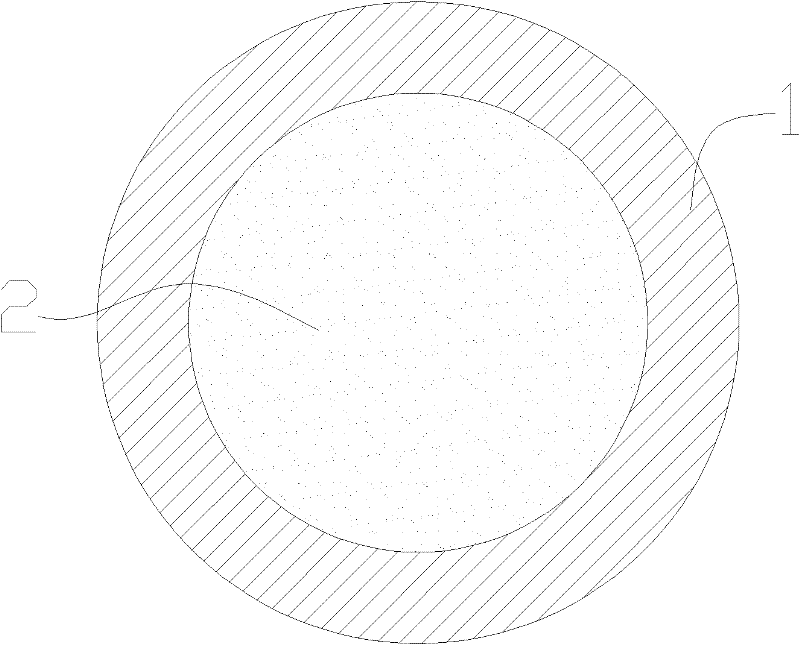

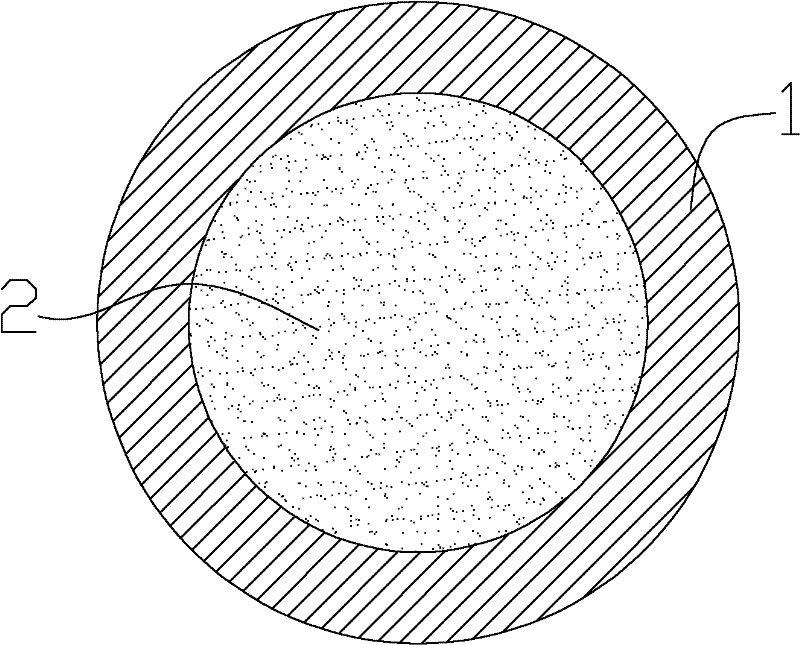

ActiveUS20100233546A1High chemicalHigh environmental stabilityFinal product manufactureConductive materialNanoparticleVanadium nitride

Described is an anode material which is a transition metal nitride or carbide in form of nanoparticles, preferably a nitride or carbide with one nitrogen or carbon per metal, and especially a nitride or carbide having rock salt structure. A preferred anode material is vanadium nitride, in particular carbon coated vanadium nitride having a mean particle size of <500 nm. Embedded in an electrically conducting environment, such nanoparticulate material, in particular the vanadium nitride shows exceptional good charging-discharging cycle stability.

Owner:BELENOS CLEAN POWER HLDG

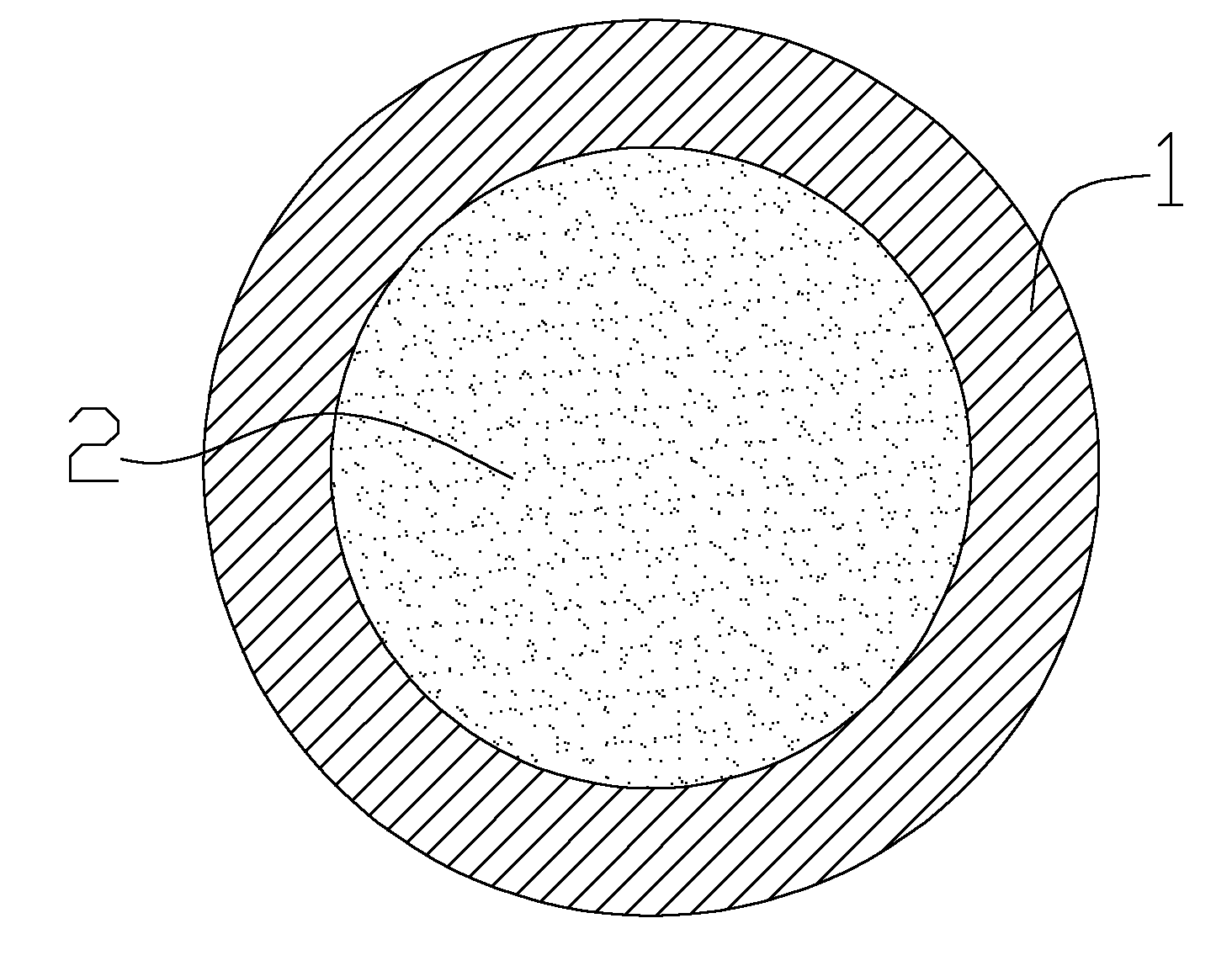

Core-spun thread and method for implementing molten steel vanadium-nitrogen alloying

The invention discloses a core-spun thread and method for implementing molten steel vanadium-nitrogen alloying, and the method can be used for feeding the core-spun thread into molten steel conveniently and preventing the thread from being jammed and broken and is beneficial to improving the recovery rate of nitrogen and vanadium. The core-spun thread comprises a core layer and skin, wherein the core layer contains vanadium nitride alloy and fluorite. The method mainly comprises the following steps: adding the fluorite to the core layer of the core-spun thread; and then feeding the core-spun thread into the molten steel. The method has the beneficial effects that the fluorite is added into the core layer, so that the melting point of steel slag is reduced and the steel slag fluidity is improved so as to facilitate the process of feeding the core-spun thread into the molten steel, thus reducing the loss of the core-spun thread in steel slag layers, being beneficial to improving the recovery rate of vanadium and nitrogen and preventing the core-spun thread from being jammed and broken during the feeding process.

Owner:PANZHIHUA IRON AND STEEL +2

Method for producing vanadium nitrogen alloy

The invention relates to a method for producing vanadium and nitrogen alloy and belongs to the technical field of metallurgy. The technical problem to be solved by the invention is to provide a method for producing a vanadium and nitrogen alloy at a lower cost. The method for producing the vanadium and nitrogen alloy comprises the following steps: a, uniformly mixing 60 to 80 parts of vanadium-containing raw material (in form of vanadium), 1 to 2 parts of additive (in form of iron), 20 to 40 parts of C-based reducer and 0 to 0.4 part of bonding agent, and performing pressing forming to obtaina formed material; and b, drying the formed material, reacting with nitrogenized gas at 1,300 to 1,500 DEG C under an anaerobic condition for 1.5 to 5 hours, cooling and obtaining the vanadium and nitrogen alloy, wherein the nitrogenized gas contains at least one of nitrogen and ammonia gas.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

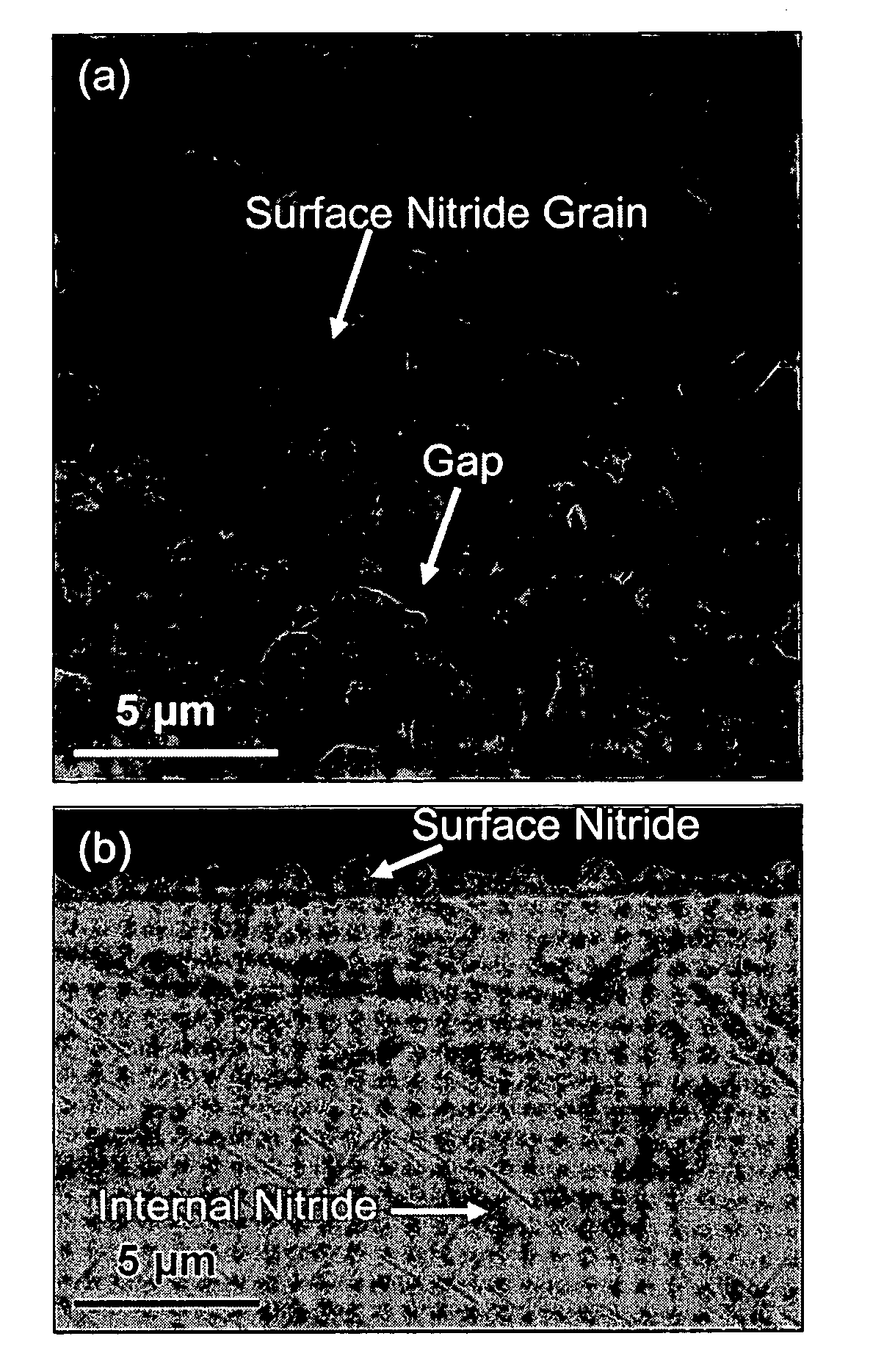

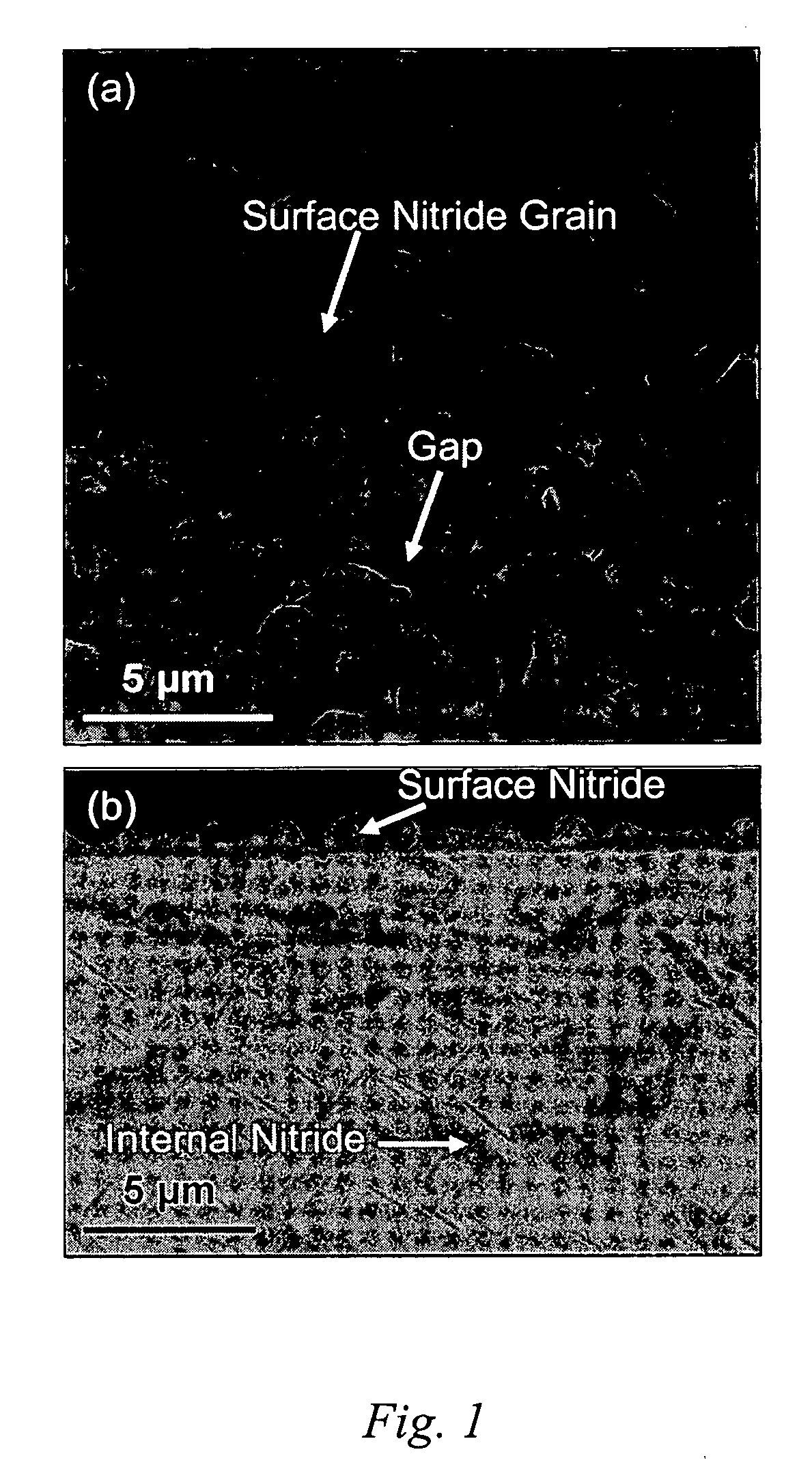

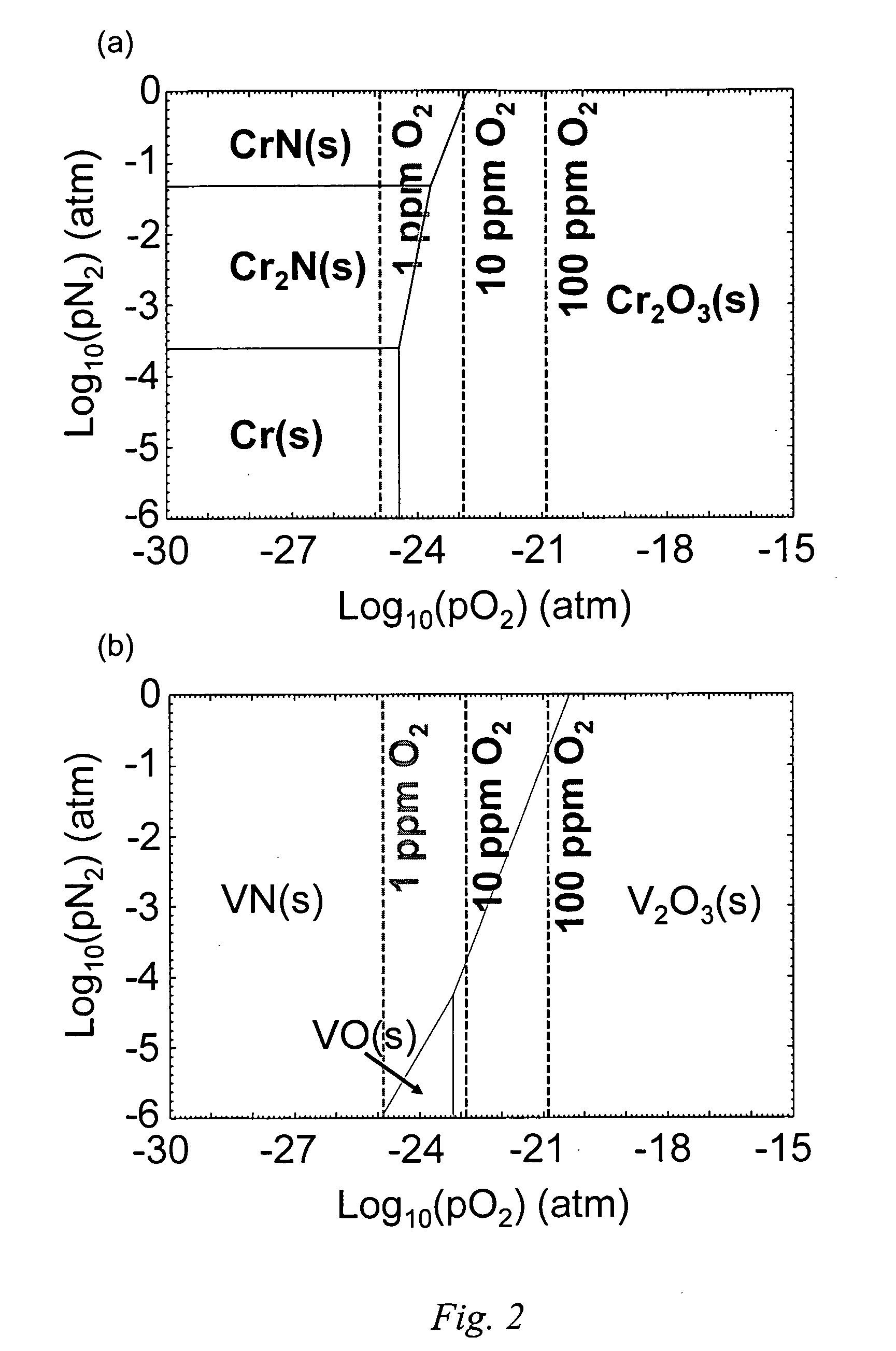

Iron-based alloy and nitridation treatment for PEM fuel cell bipolar plates

A corrosion resistant electrically conductive component that can be used as a bipolar plate in a PEM fuel cell application is composed of an alloy substrate which has 10-30 wt. % Cr, 0.5 to 7 wt. % V, and base metal being Fe, and a continuous surface layer of chromium nitride and vanadium nitride essentially free of base metal. A oxide layer of chromium vanadium oxide can be disposed between the alloy substrate and the continuous surface nitride layer. A method to prepare the corrosion resistant electrically conductive component involves a two-step nitridization sequence by exposing the alloy to a oxygen containing gas at an elevated temperature, and subsequently exposing the alloy to an oxygen free nitrogen containing gas at an elevated temperature to yield a component where a continuous chromium nitride layer free of iron has formed at the surface.

Owner:UT BATTELLE LLC

Erosion and corrosion resistant coating system for compressor

InactiveUS20110165433A1Improve corrosion resistanceImprove erosion resistanceLiquid surface applicatorsBlade accessoriesCoating systemVanadium nitride

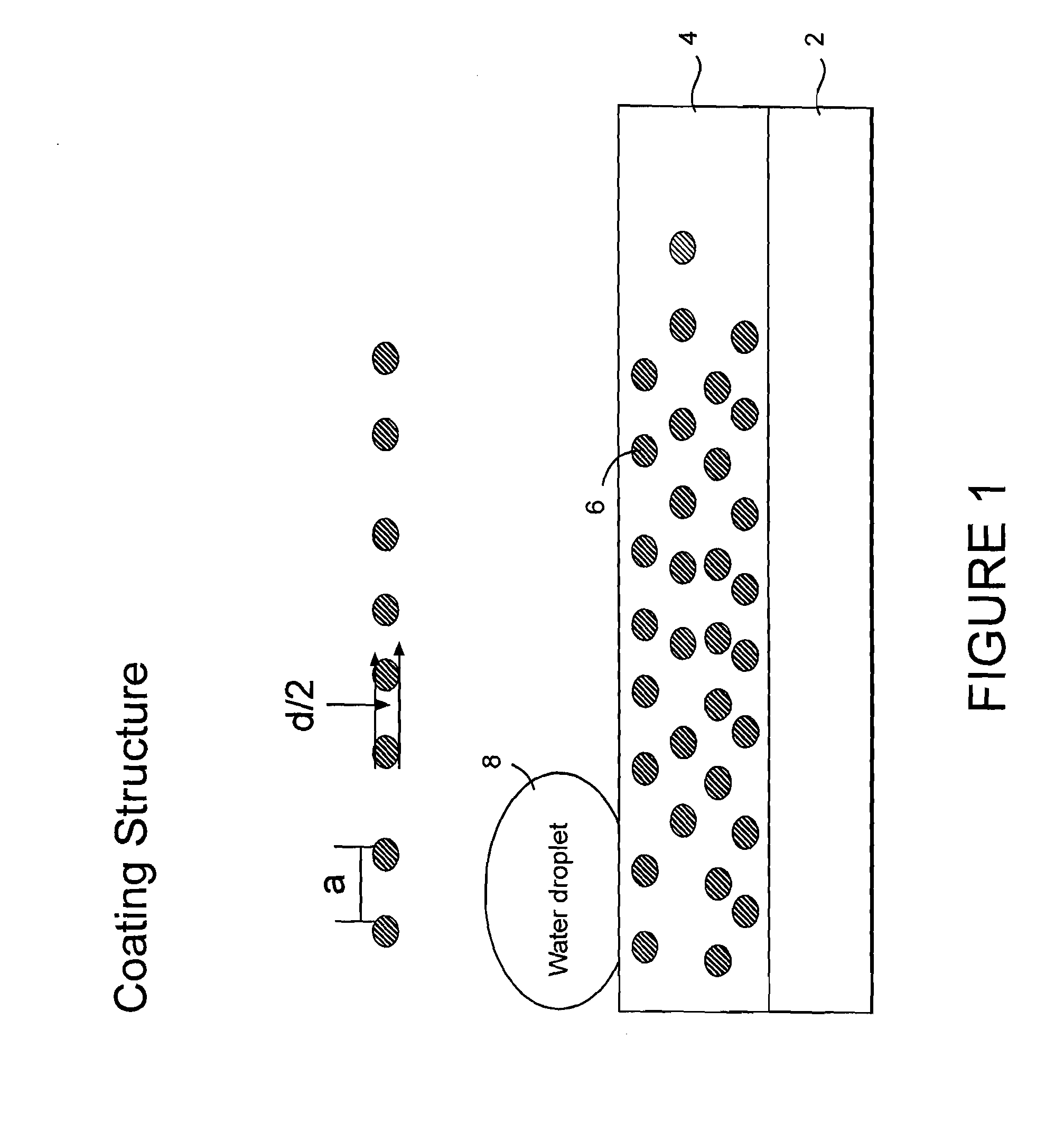

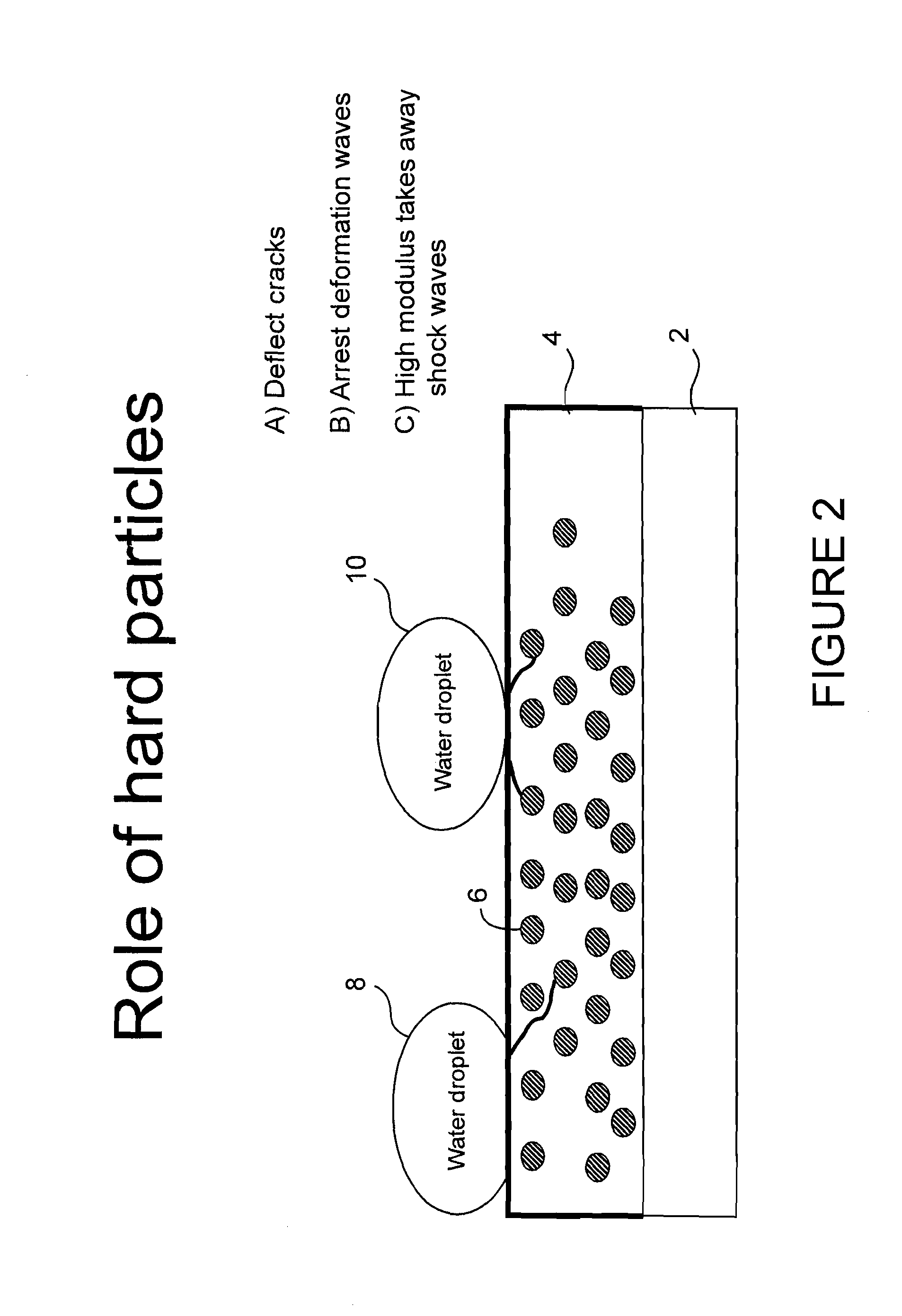

Process for providing a protective coating to a metal surface by applying a nickel or tantalum plate layer to the surface and dispersing particles of a hard material such as diamond, alumina, vanadium nitride, tantalum carbide and / or tungsten carbide within the nickel or tantalum plate layer as the plating is occurring.

Owner:GENERAL ELECTRIC CO

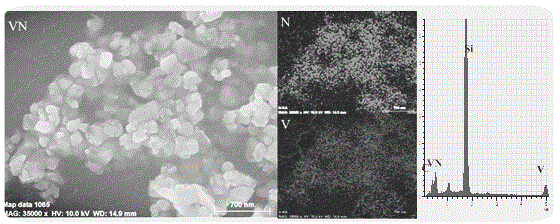

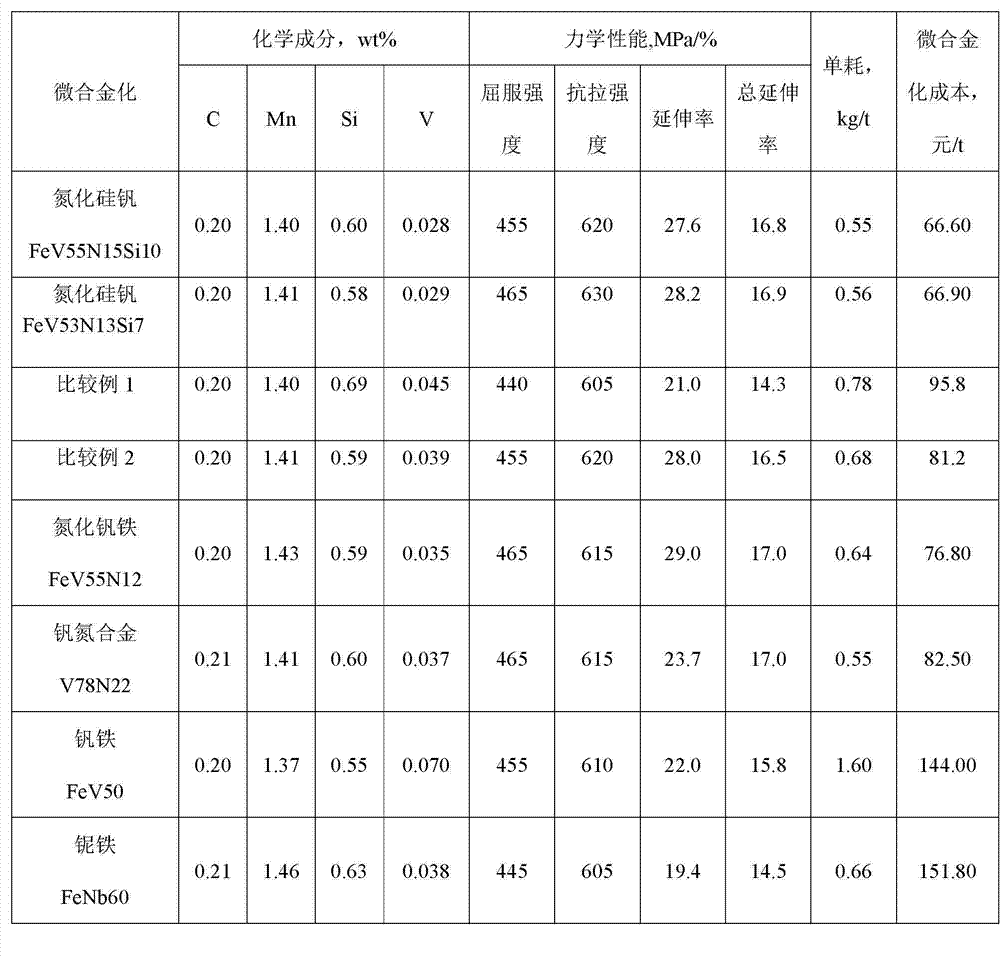

Silicon nitride ferrovanadium and production method thereof

The invention discloses silicon nitride ferrovanadium, which comprises the following components in percentage by weight: 15 to 50 percent of vanadium, 10 to 40 percent of silicon, 8 to 30 percent of nitrogen, 4 to 30 percent of iron, less than or equal to 1 percent of carbon, less than or equal to 0.01 percent of aluminum, less than or equal to 0.05 percent of sulfur, and less than or equal to 0.05 percent of phosphor. Compared with the prior art, the product combines high nitrogen content of the silicon nitride and microalloying effect of vanadium nitride, and overcomes the defects that the silicon nitride has high melting point and small density, and is completely decomposed and overflowed in high temperature molten steel, and the nitrogen content of the vanadium nitride is low; and compared with the vanadium nitride products, the product has higher nitrogen content, and according to the proportion of silicon and vanadium, the nitrogen content reaches 22 to 30 percent. Compared withsilicon nitride products, the composite nitrides have low melting point and large density, and are advantageous to absorption of molten steel. When the silicon nitride ferrovanadium is used in steel making production, the nitrogen content in the steel can be effectively improved, and the steel can be microalloyed.

Owner:WUAN YONGXING IND CO LTD

A low-cost process of increasing nitrogen and controlling nitrogen in rh molten steel

A low-cost RH molten steel nitrogen increasing process belongs to the technical field of steelmaking. The process route of "converter-ladle furnace refining-RH refining-continuous casting" is used for smelting; converter tapping adopts deoxidation alloying, and vanadium-iron alloy is added to match vanadium according to the target value of the steel type during the tapping process, and the molten steel temperature is raised according to the normal process in the ladle furnace , alloy fine-tuning and deep desulfurization treatment, after the molten steel is hoisted to the RH furnace, the lifting gas of the RH furnace is set to nitrogen, the flow rate is controlled according to 800-1200NL / min, and the vacuum treatment time is 8-10min. Blowing operation, to reach the level of nitrogen content in steel at 80-120ppm. The advantage is that it can partially replace the vanadium-nitrogen alloy and reduce the cost of the alloy; ensure the stability of the nitrogen content and reduce the performance fluctuation of the steel plate caused by the composition fluctuation; the RH refining stage uses nitrogen instead of argon to realize the dual functions of process and composition control, further reducing the steelmaking process cost.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

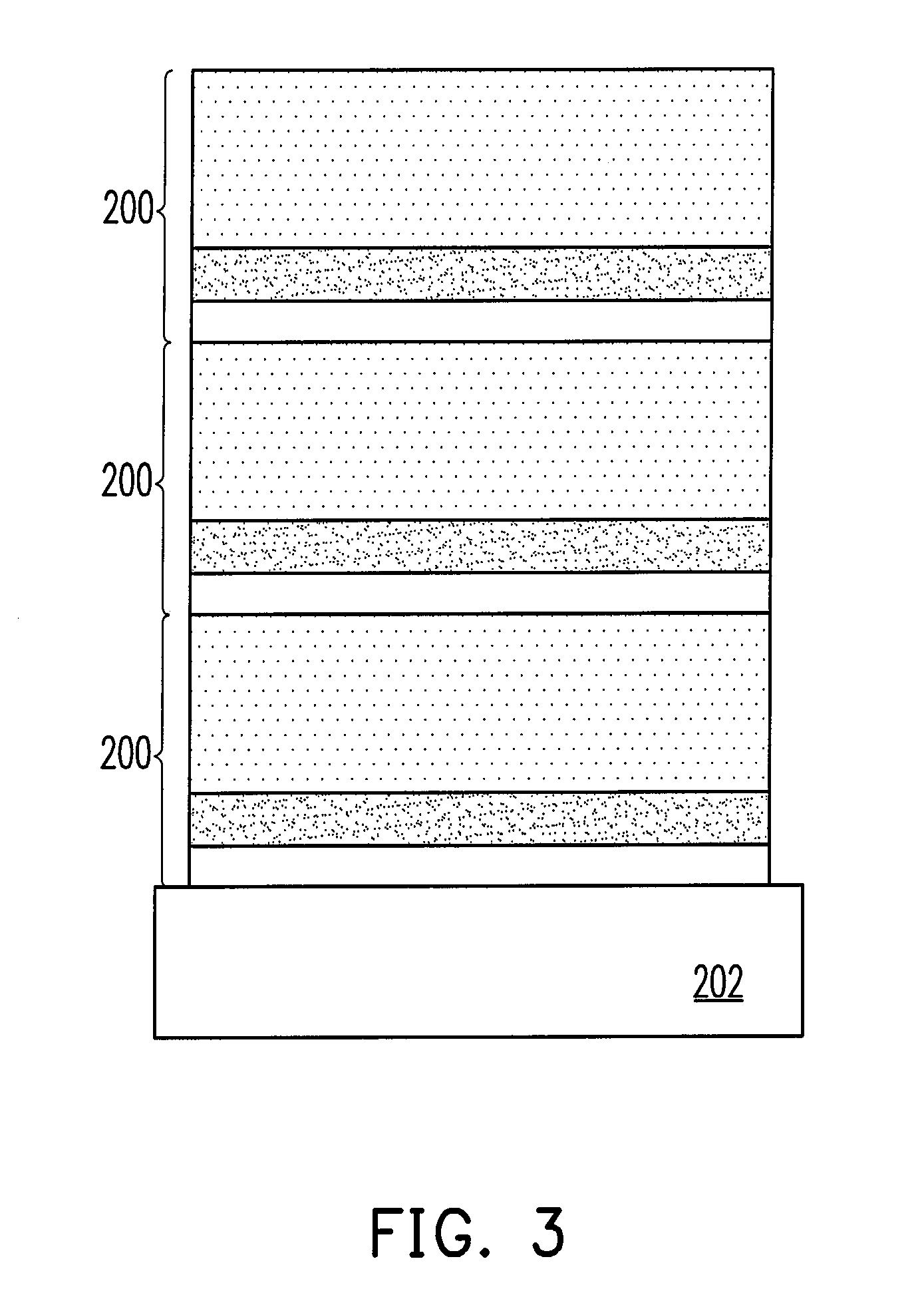

Structural material of diamond like carbon composite layers and method of manufacturing the same

ActiveUS20090169845A1Improve adhesionAvoid fragmentationVacuum evaporation coatingSputtering coatingDiamond-like carbonVanadium nitride

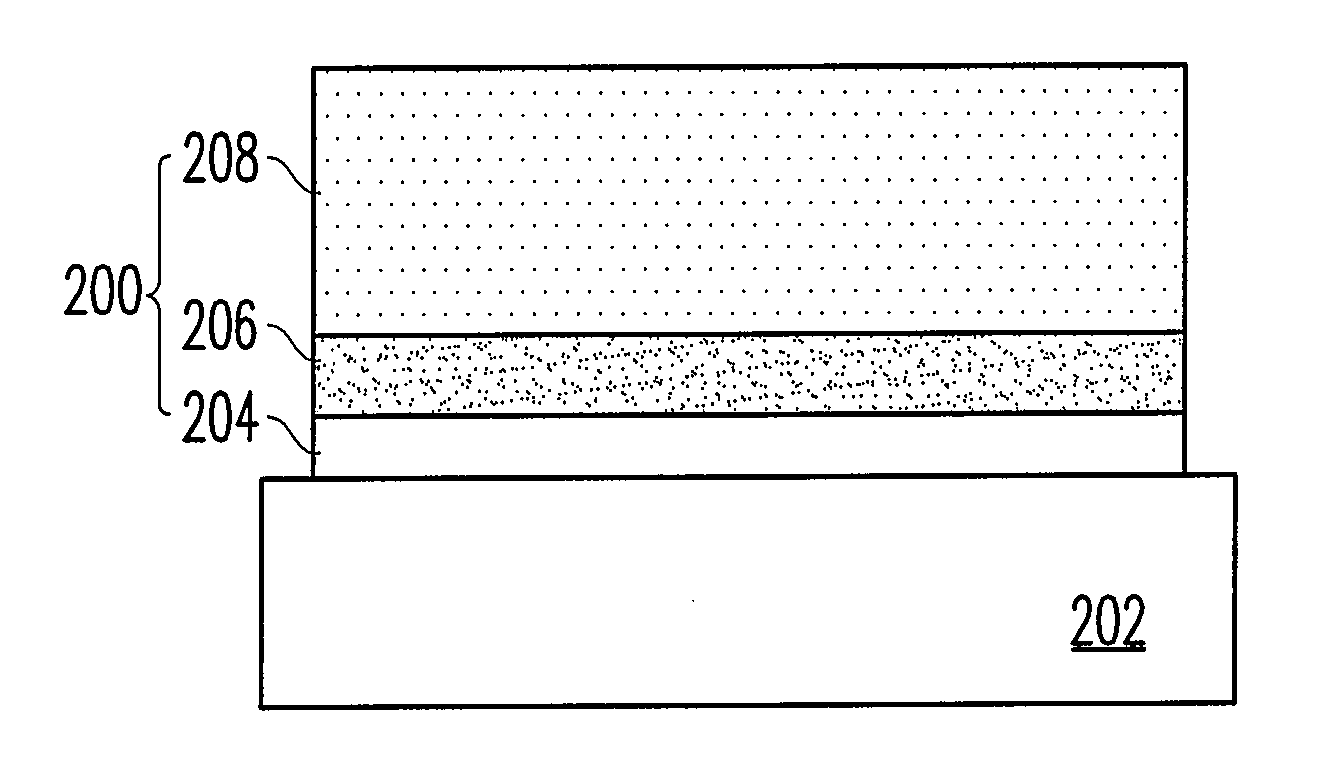

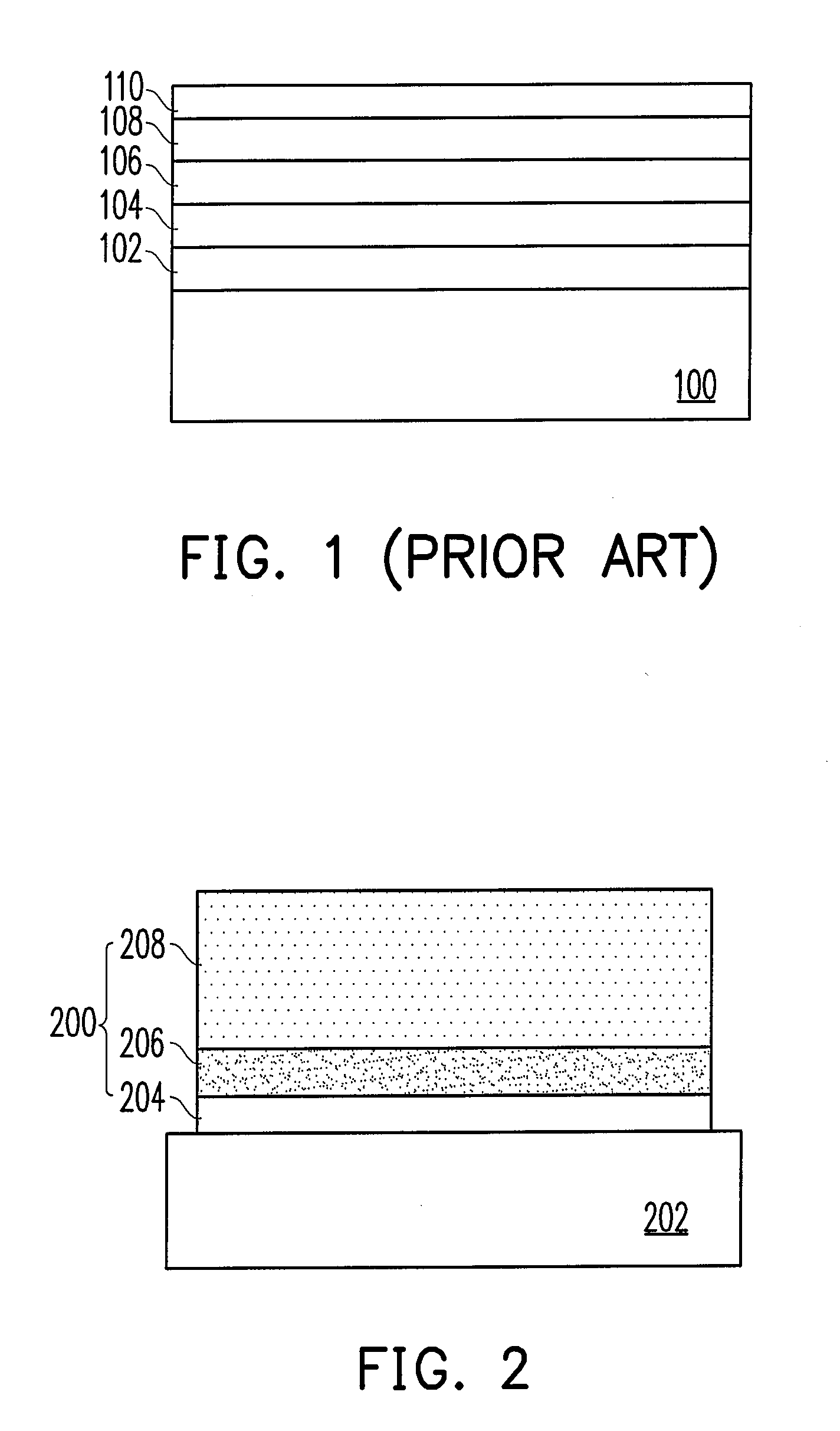

A structural material of diamond like carbon (DLC) composite layers is provided. The structural material includes a composite material which is consisted of a metal layer, a first metal nitride layer, and a DLC thin film. The metal layer includes aluminum (Al), copper (Cu), zirconium (Zr), nickel (Ni), or vanadium (V). The first metal nitride layer includes aluminum nitride (Al—N), zirconium nitride (Zr—N), vanadium nitride (V—N), or nickel nitride (Ni—N). The DLC thin film of the structural material of DLC composite layers has high quality tetragonally bonded amorphous carbon (ta-C) with a sp3(C—C) bonding ratio of more than 30%. Therefore, it is suitable for the work pieces in the mechanical, chemical, electricity, photoelectric, and heat transfer fields.

Owner:IND TECH RES INST

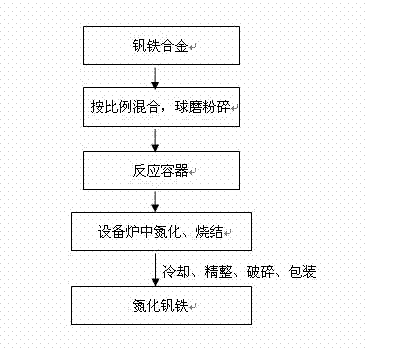

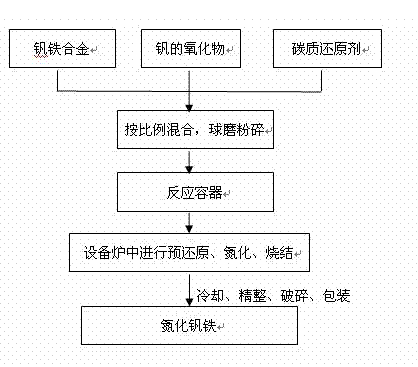

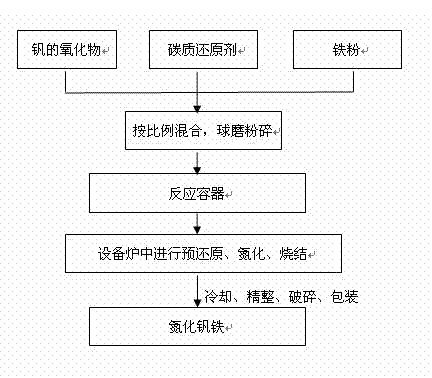

Production method for vanadium nitride ferroalloy

InactiveCN102644015AQuick responseReduce consumptionSolid state diffusion coatingVanadium nitrideReaction temperature

The invention relates to a production method for a vanadium nitride ferroalloy and belongs to the technical field of chemical metallurgy. The technical scheme provided by the invention is that the production method comprises the following steps of: 1-, performing crushing and fine grinding on a raw material after entering a ball mill; 2-, putting the powdery material after being finely ground in a reaction vessel coated with an anti-sticking agent, and then, delivering the reaction vessel filled with the powdery material into a preparation furnace; 3-, introducing reaction gas into the furnace; heating the preparation furnace, and performing a nitriding reaction and a sintering reaction on the powdery material in the preparation furnace; and 4-, discharging under the nitrogen protection for cooling to obtain the vanadium nitride ferroalloy. According to the production method for the vanadium nitride ferroalloy, a pre-reduction reaction, a carbonization reaction and the nitriding reaction are performed on the raw material in the preparation furnace in the manner of powder, and the three reactions are realized in the same equipment furnace, thereby, the production efficiency is high. Briquetting is not needed, and thus, the speed of the nitriding reaction is accelerated; the required reaction temperature is low; the energy consumption is low; and the equipment operating rate and the labor productivity are high. The production method for the vanadium nitride ferroalloy is more suitable for large-scale industrial production. Vacuum equipment is not needed; the raw material completely reacts in the manner of powder; the product quality is stable; and the vanadium yield is high.

Owner:HEBEI IRON AND STEEL

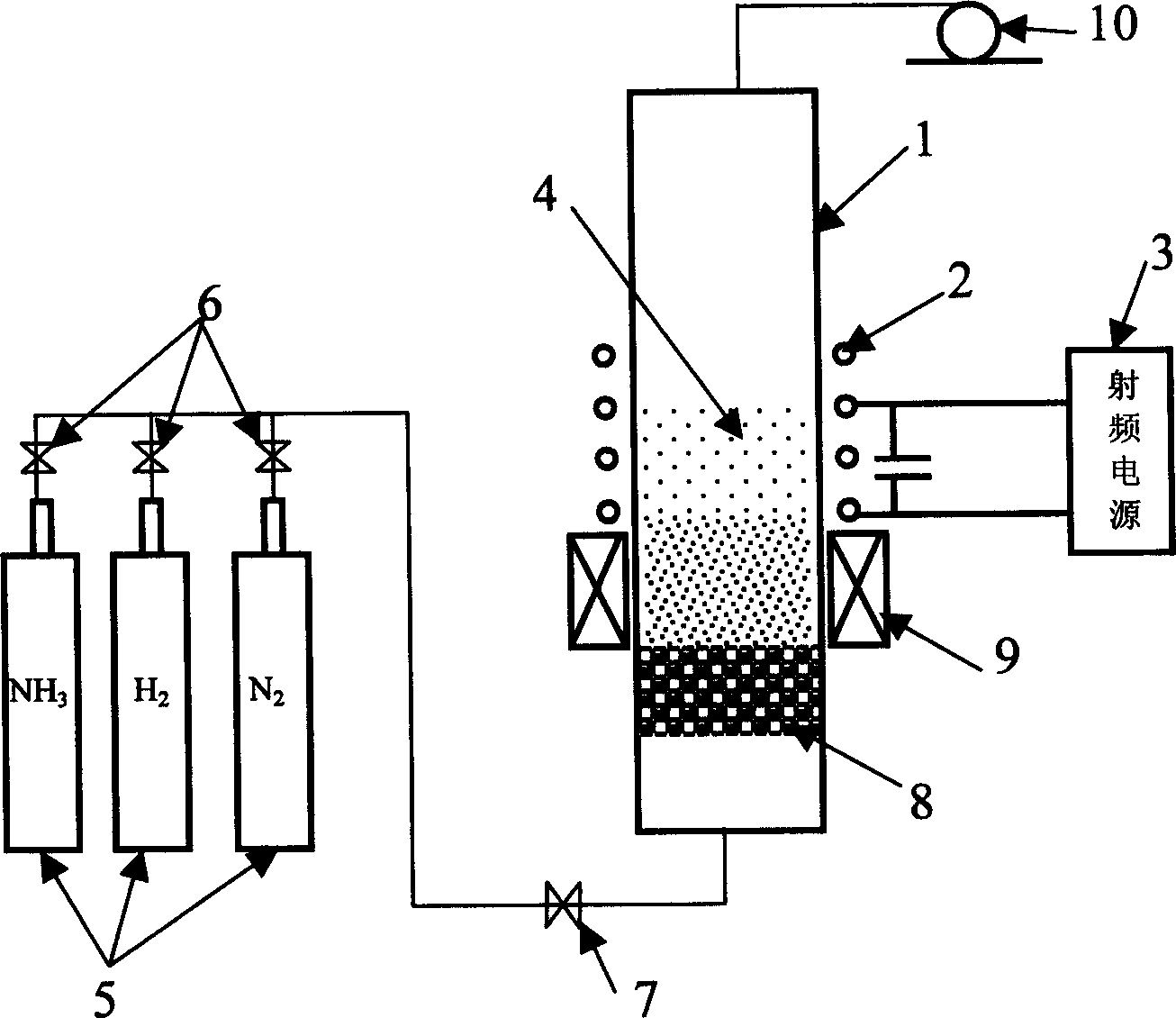

Method for preparing vanadium nitride and device

InactiveCN1562769AQuality improvementSimple processing methodNitrogen-metal/silicon/boron binary compoundsVanadium compoundsHydrogenVanadium nitride

The invention relates to a processing method of prepn. vanadium nitride by fluidized bed technology and corresponding special device. The characteristic is to create plasma body in reaction zone of fluidized bed by ratio frequency induction, the reaction gas ammonia, nitrogen and hydrogen are excited and ionized to create active hydrogen and nitrogen particle which is made reducting and nitrating reaction with vanadium oxide particle suspensing in fluidized zone to create vanadium nitride. The special device used by this invention includes fluidized bed, radio frequency inducting coil, radio frequency power source, heater, air supply tank, air current distributor, air-extracting system, air valve, general air valve controlling and adjusting reaction gas flow and the pipe line system.

Owner:SHANGHAI UNIV

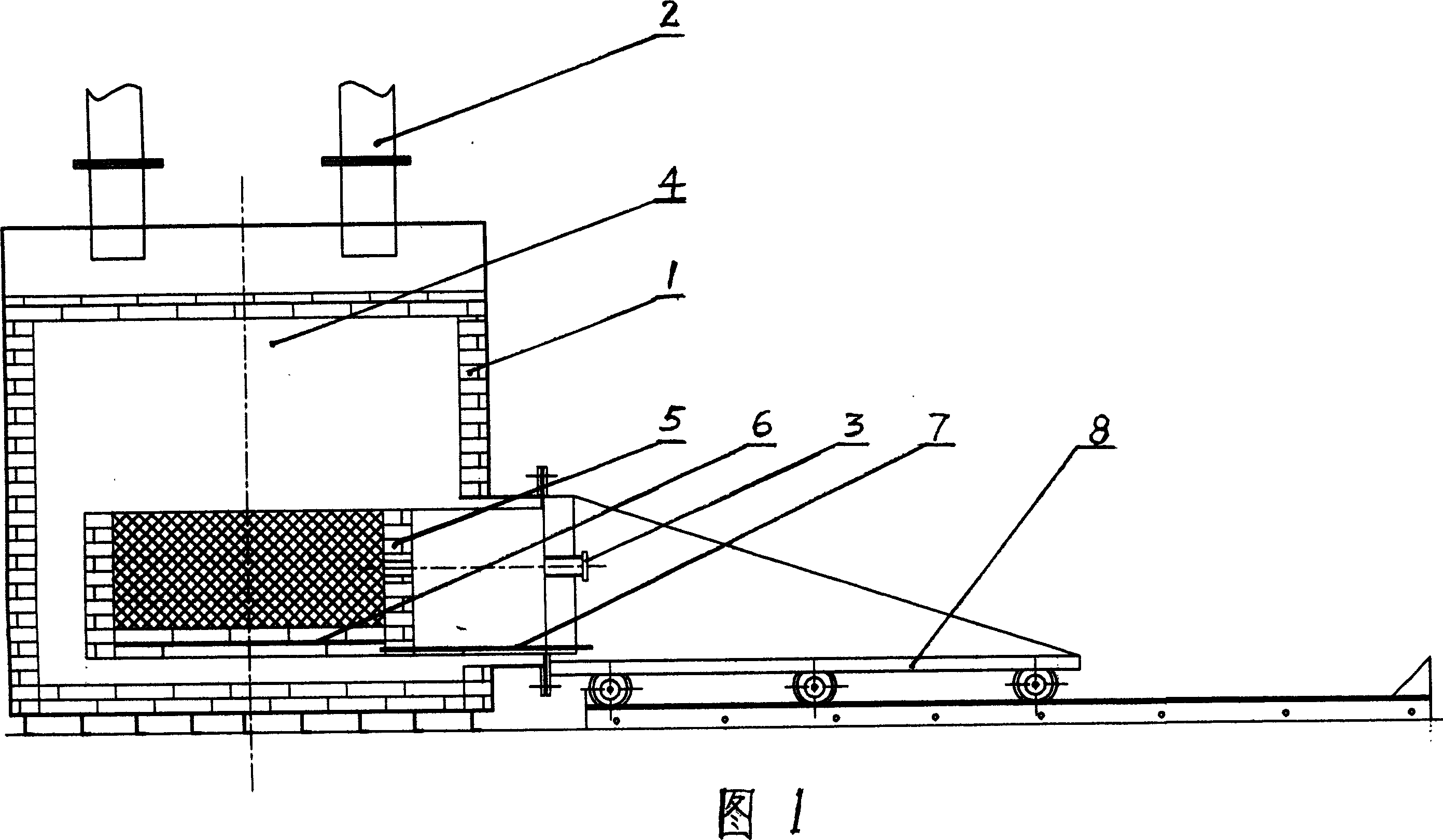

Method for preparing vanadium nitride and device

ActiveCN1562770AImprove thermal efficiencyShort heating timeNitrogen-metal/silicon/boron binary compoundsVanadium compoundsMicrowave ovenVanadium nitride

The invention specially relates to an industrial batch-type vanadium nitride producing method and devices. Grinded vanadium oxide powder and carbonaceous are used as raw materials, which binder is added in, to produce vanadium nitride by heating in microwave oven. The characteristic is mixing vanadium oxide, active carbon and binder according properly ratio, then briqueting and forming, putting the formed material into special microwave heating oven, unceasingly exhausting to keep vacuum, prereducing, carbononizing, nitrating and natural cooling, finally the product is taken out the oven. This product is used as additive agent of various kinds of alloy steel containing vanadium mainly.

Owner:湖南恒星进出口有限责任公司

Method for preparing alloy of vanadium nitride

This invention discloses a method for preparing VN alloy. The method comprises: utilizing powdery V2O5, NH4VO3 or poly(ammonium vanadate) as the raw material, mixing with carbonaceous powder, sending into a reactor continuously, introducing NH3 or mixed NH3-N2 with N2 volume percentage lower than 5%, reducing, carbonizing and nitriding at 400-850 deg.C for 4-10 h, cooling to 50-150 deg.C, discharging to obtain powdery VN alloy product, mixing with binder uniformly, pressing and drying to form blocks. The product comprises N13-18.5%, C 2-9%, and V 77-81%.

Owner:蔡惜辉

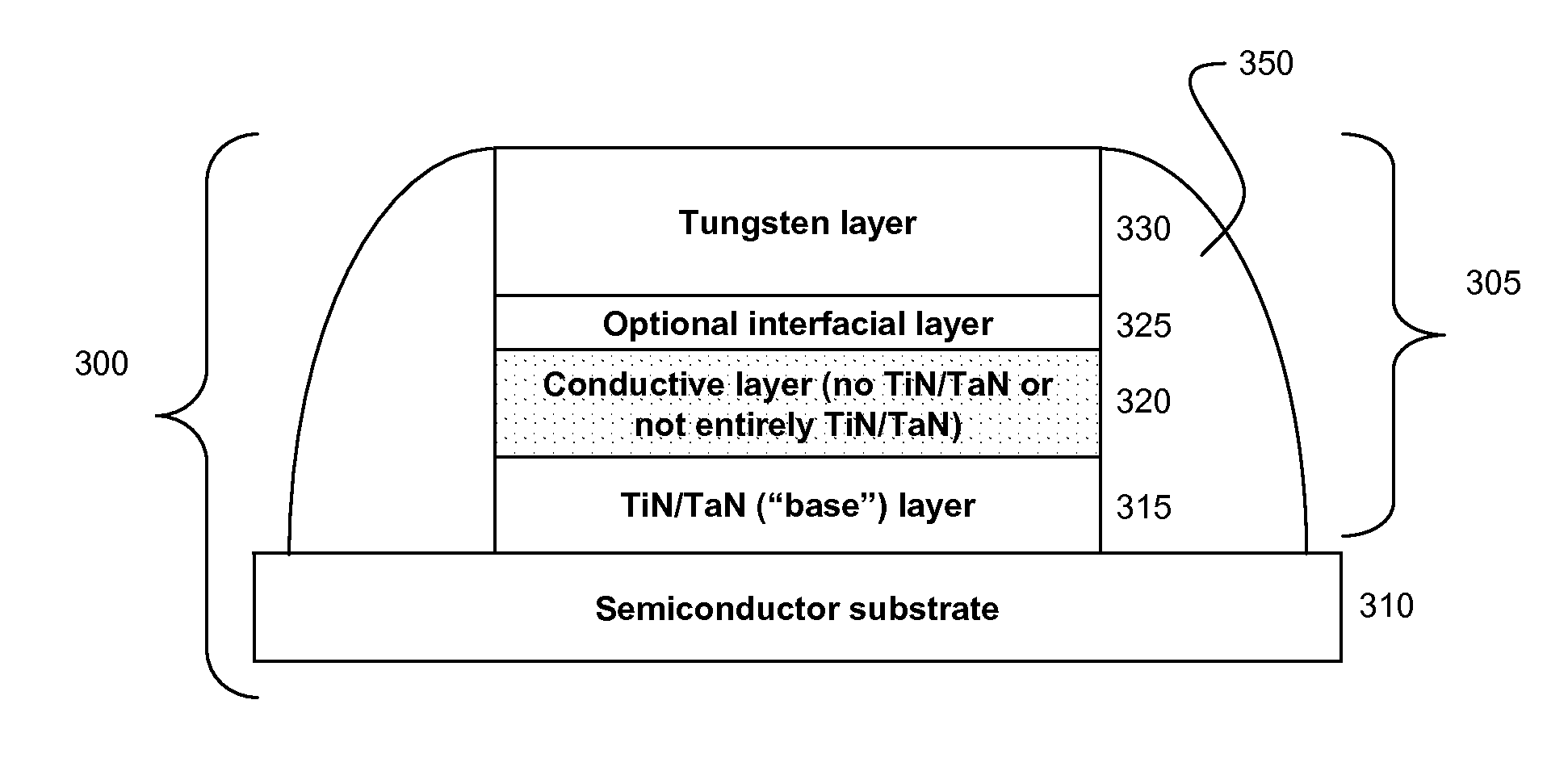

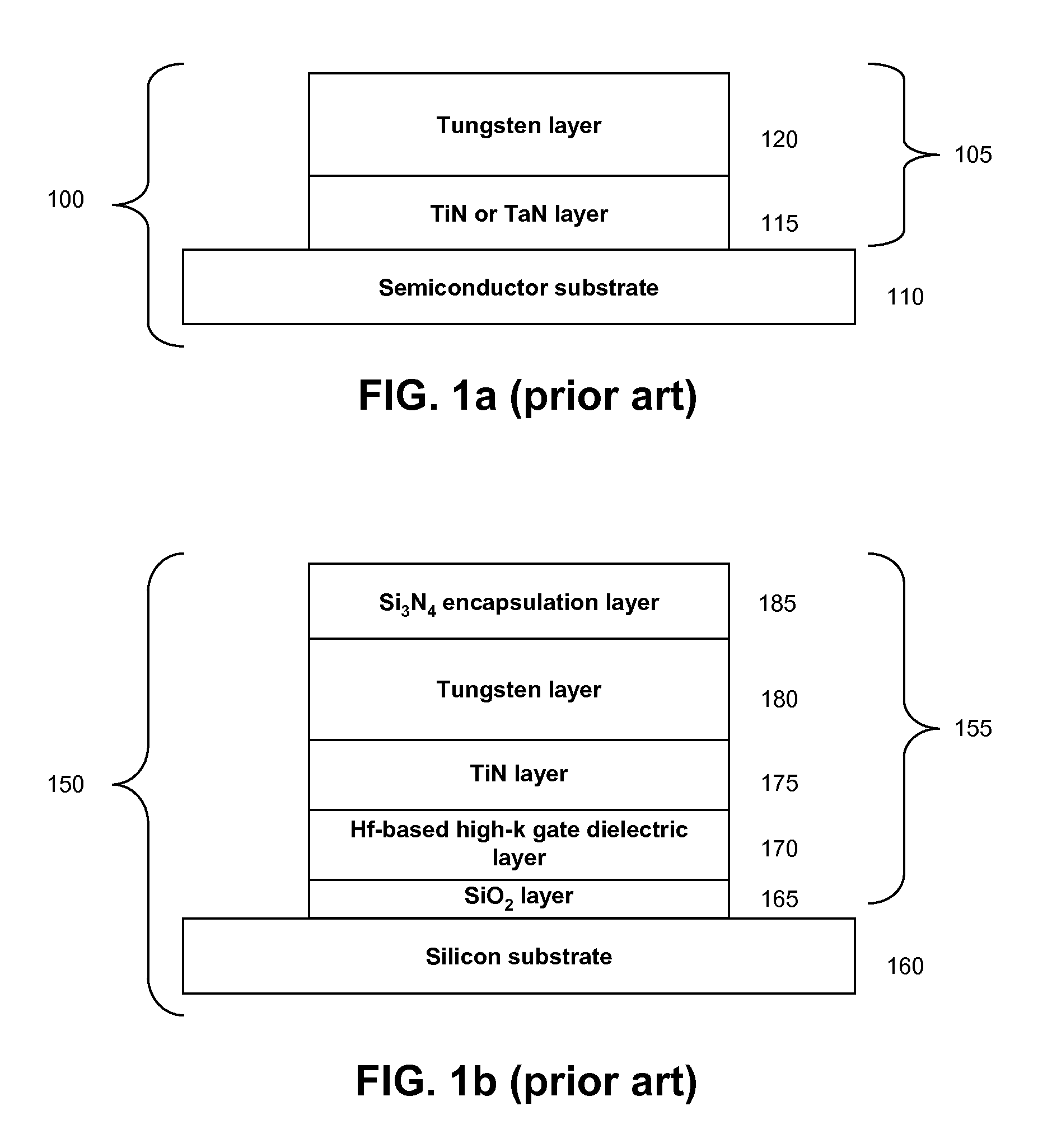

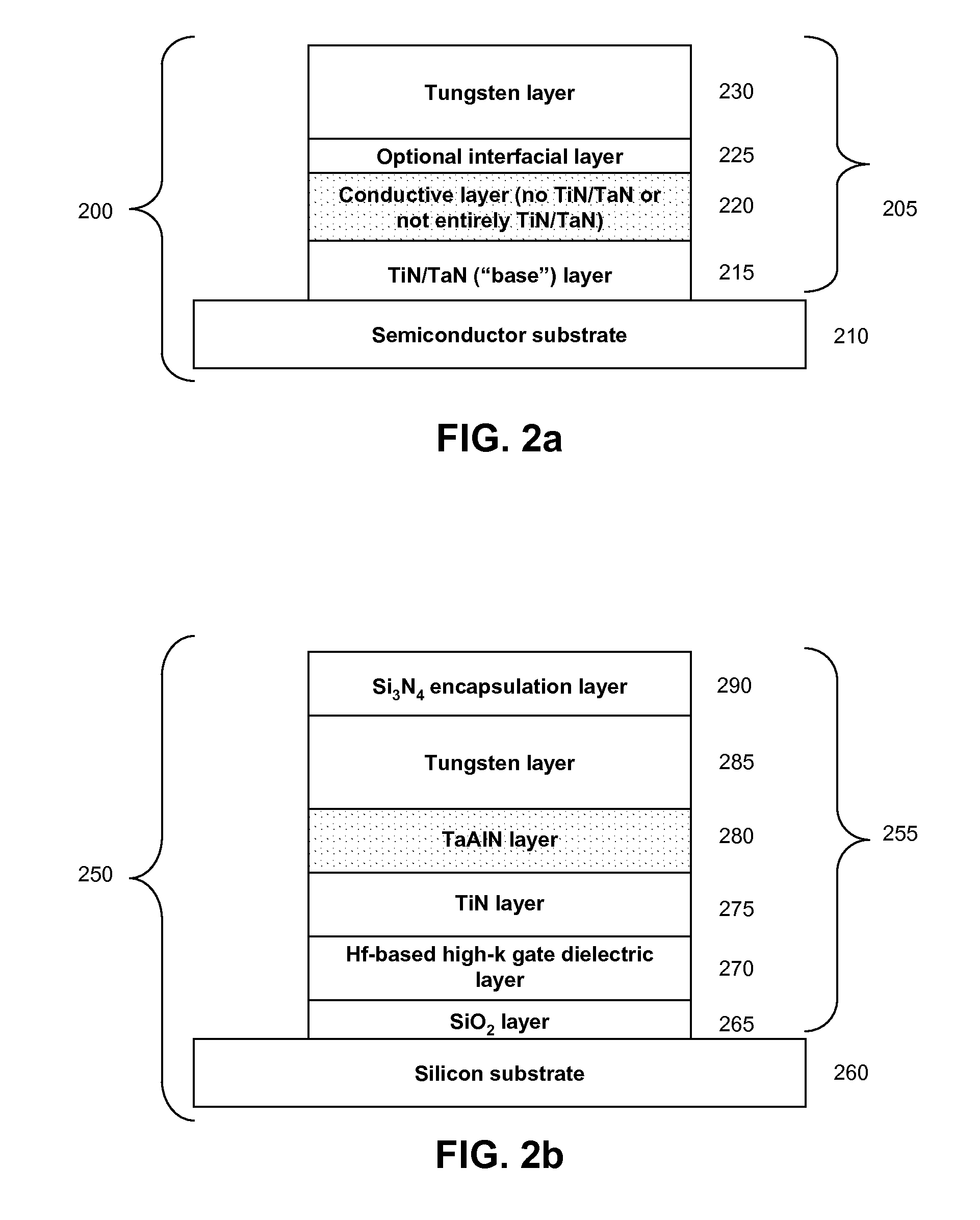

Large-grain, low-resistivity tungsten on a conductive compound

InactiveUS20120228773A1Semiconductor/solid-state device detailsSolid-state devicesTitanium nitrideHafnium

A layered structure and semiconductor device and methods for fabricating a layered structure and semiconductor device. The layered structure includes: a base layer including a material containing titanium nitride, tantalum nitride, or a combination thereof; a conductive layer including a material containing: tantalum aluminum nitride, titanium aluminum nitride, tantalum silicon nitride, titanium silicon nitride, tantalum hafnium nitride, titanium hafnium nitride, hafnium nitride, hafnium carbide, tantalum carbide, vanadium nitride, niobium nitride, or any combination thereof; and a tungsten layer. The semiconductor device includes: a semiconductor substrate; a base layer; a conductive layer; and a tungsten layer.

Owner:GLOBALFOUNDRIES INC

Preparation method of nitriding vanadium alloy

The present invention provides process of preparing vanadium nitride alloy. The process includes mixing vanadium oxide, carbon powder and density reinforcer, pressing to form, setting the shaped mixture into a reaction furnace, heating to 650 deg.c while introducing nitrogen or ammonia as the reacting and protecting gas into the furnace, further heating to 1000-1250 deg.c to produce carbonizing and nitriding reaction for 3 hr, cooling to 100 deg.c, and discharging the vanadium nitride alloy. The vanadium nitride alloy contains V 73-80 %, N 12-20 %, C 3-8 % and O 0.5-2.0 %, and has apparent density of 3000-4000 kg / cu m. The process has the features of low reaction temperature, short reaction period, low cost, etc, and the prepared vanadium nitride alloy with high nitrogen content is suitable for use in steel making.

Owner:SICHUAN UNIV

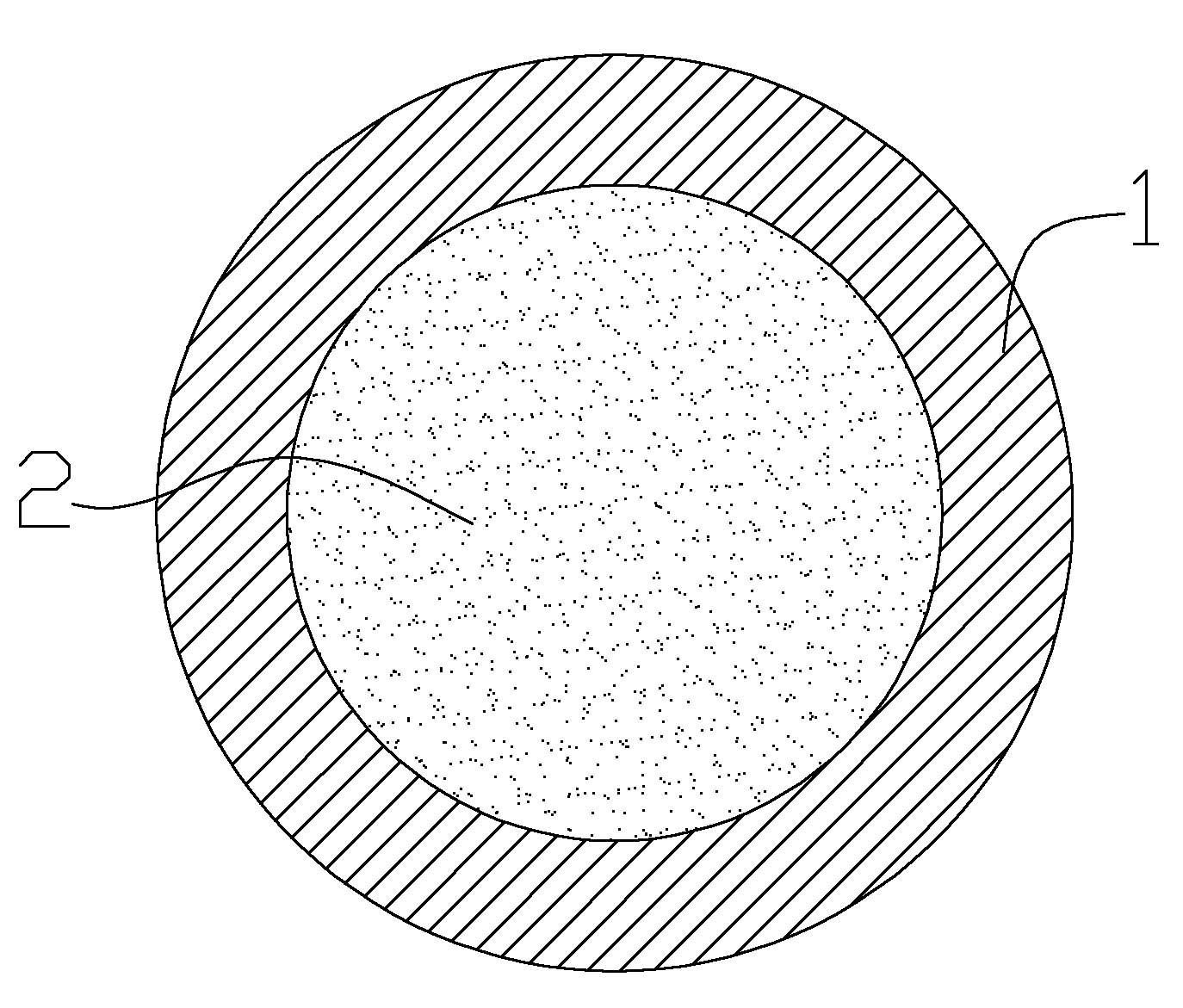

Molten steel alloying cored wire and method

The invention discloses a molten steel alloying cored wire and a molten steel alloying method, which can improve the recovery rate of vanadium, prevent wire lockage and breakage, and facilitates feeding the cored wire. The cored wire comprises a core layer and a skin, wherein the core layer contains a vanadium nitride alloy and an aluminum metal. The method mainly comprises the following steps of: adding a calcium-silicon alloy into the core layer of the cored wire; and feeding the cored wire into the molten steel. By adding the calcium-silicon alloy into the core layer, the free oxygen content in the molten steel can be reduced, and the possibility of combining vanadium and oxygen is reduced, so that more vanadium participates in alloying to improve the recovery rate of the vanadium.

Owner:PANZHIHUA IRON AND STEEL +2

Preparation method of vanadium nitride nano powder body

InactiveCN1380247AHigh yieldControl granularityNitrogen-metal/silicon/boron binary compoundsMicrometerVanadium nitride

The preparation method of vanadium nitride nano powder body includes the following steps: using industrial-grade V2O5 to make reduction reaction to prepare VOCl2 solution, making said solution react with (NH4)2CO3 or NH4HCO3 to synthesize vanadyl (IV) basic ammonium carbonate precursor, in the atmosphere of NH3 and under the moderate condition making the above-mentioned precursor undergo the processes of ammonization and nitrogenation so as to obtain the invented vanadium nitride nano powder body whose grain size is 20nm-1 micrometer, distribution of particle size is uniform and vanadium nitride content is greater than 98%.

Owner:SUN YAT SEN UNIV

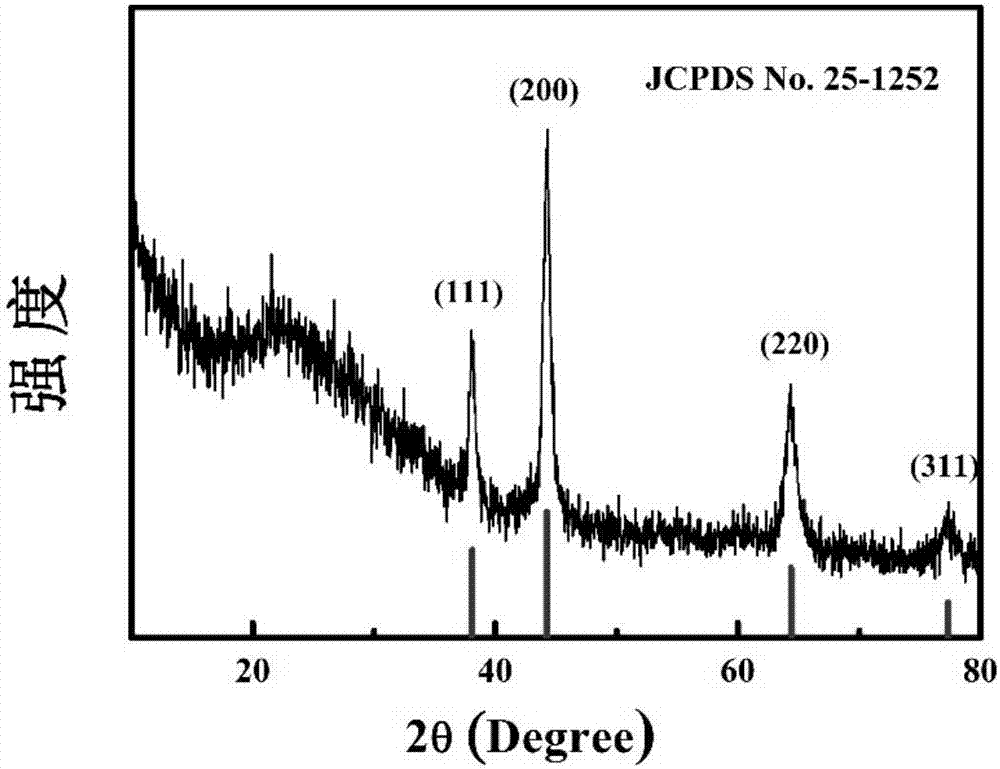

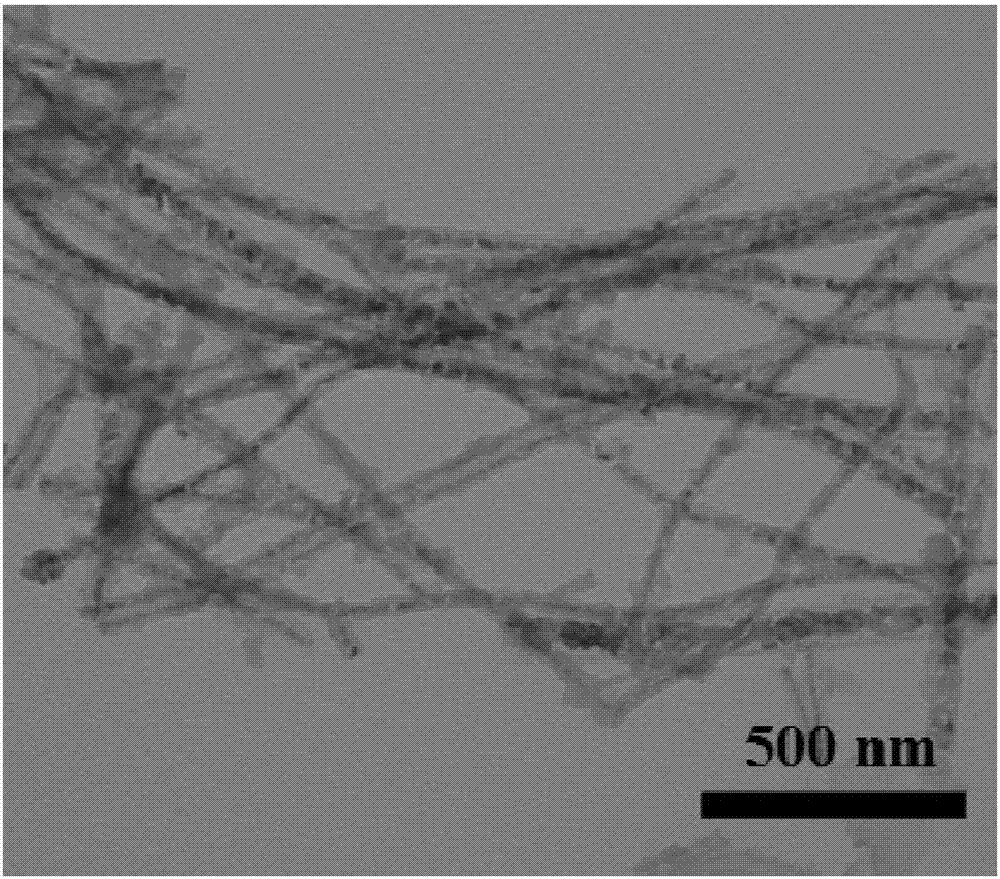

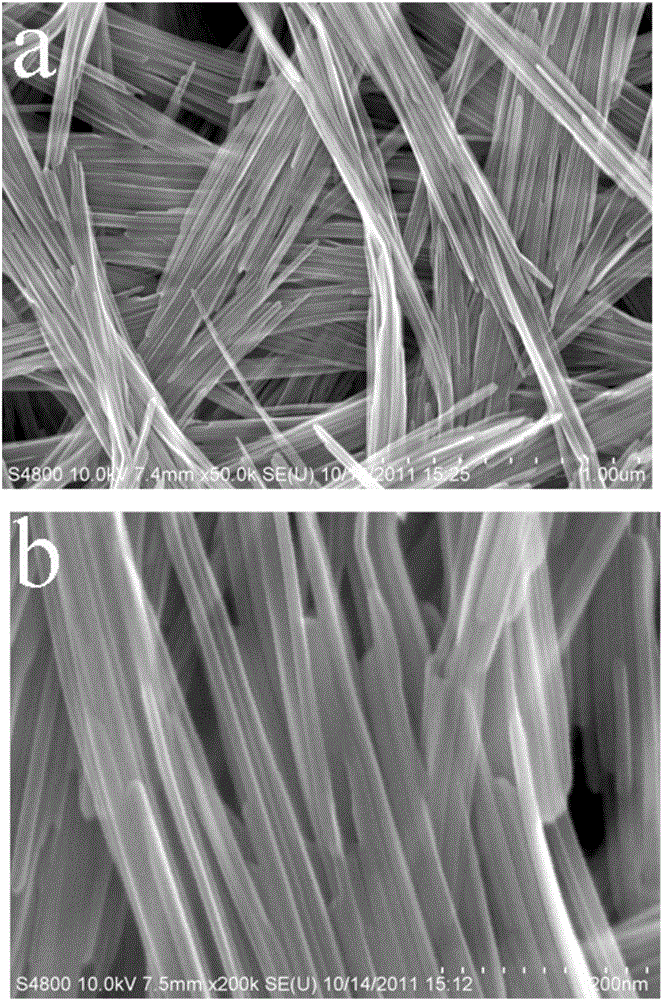

Composite cobalt-vanadium nitride nanowire electrocatalyst as well as preparation method and application thereof

ActiveCN108579788AIncrease the areaIncreased porous structurePhysical/chemical process catalystsElectrodesCarbon layerNanowire

The invention relates to a composite cobalt-vanadium nitride nanowire electrocatalyst as well as a preparation method and application thereof, and belongs to the field of electrocatalysis. The preparation method comprises the following steps of using cobalt and vanadium metal salt and urea as raw materials; using water as a solvent; using carbon cloth as a substrate; loading cobalt-vanadium nanowire precursor arrays on the surface of the carbon cloth substrates by a hydrothermal method; then, soaking the materials into a glucose solution at a certain concentration for a period of time; next, putting the materials into ammonia gas atmosphere; performing high-temperature calcination; finally putting the materials into a plasma reaction furnace for activation; finally obtaining the compositecobalt-vanadium nitride nanowire electrocatalyst. The material has a porous and carbon layer coating structure; large specific surface area and good conductivity are realized; the excellent performance is realized in the electrocatalytic whole water decomposition reaction; the current density in the electrocatalytic oxygen evolution reaction and the electrocatalytic hydrogen evolution reaction isrespectively superior to commercial IrO2 and Pt / C. Meanwhile, the process has the advantages that the operation is simple; the preparation cost of the catalyst is low; the stability is high; good industrial application prospects are realized.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing vanadium nitride

InactiveCN101372321AAvoid meltingNo clumpingNitrogen-metal/silicon/boron binary compoundsVanadium CompoundsVanadium nitride

The invention provides a method for preparing vanadium nitride. Vanadium compounds with a valence state more than four or a mixture of the compounds and organic carbon or inorganic carbon are compacted together with a binder for molding, and then the mold product is gradually heated till the temperature reaches 1,100-1,900 DEG C in a 100-4,000Hz induction heating furnace, and the product obtained is reduced and nitrified to obtain the vanadium nitride. The method has the advantages of high thermal efficiency and low power consumption.

Owner:冯良荣

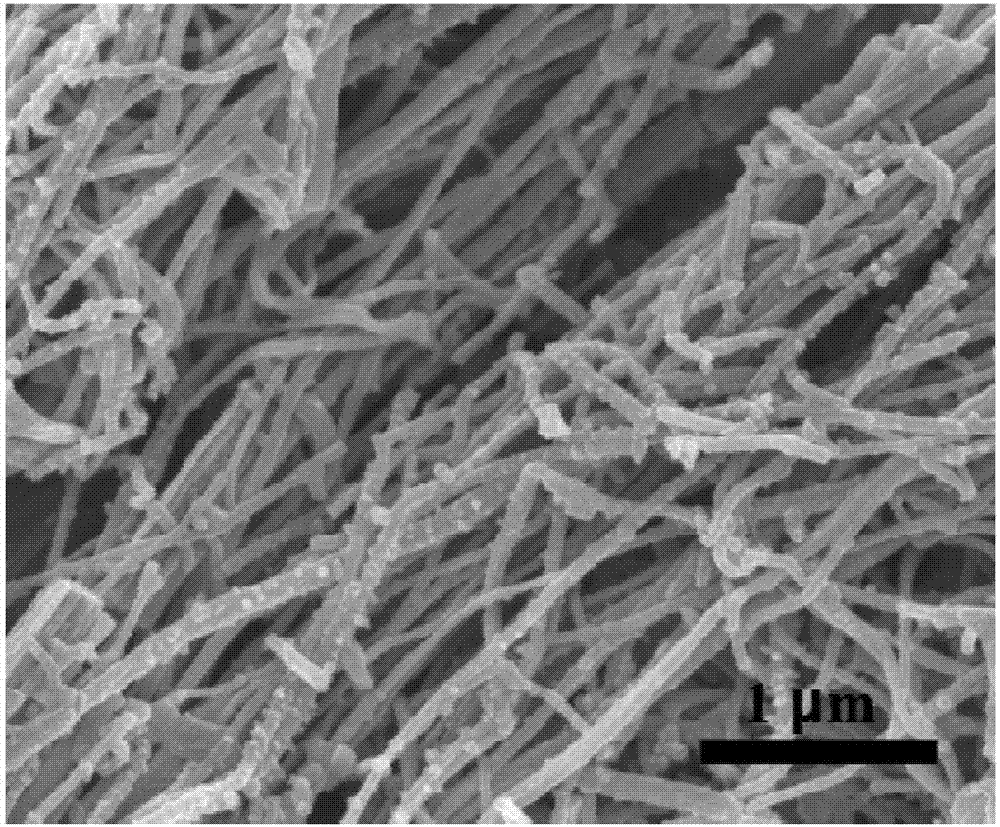

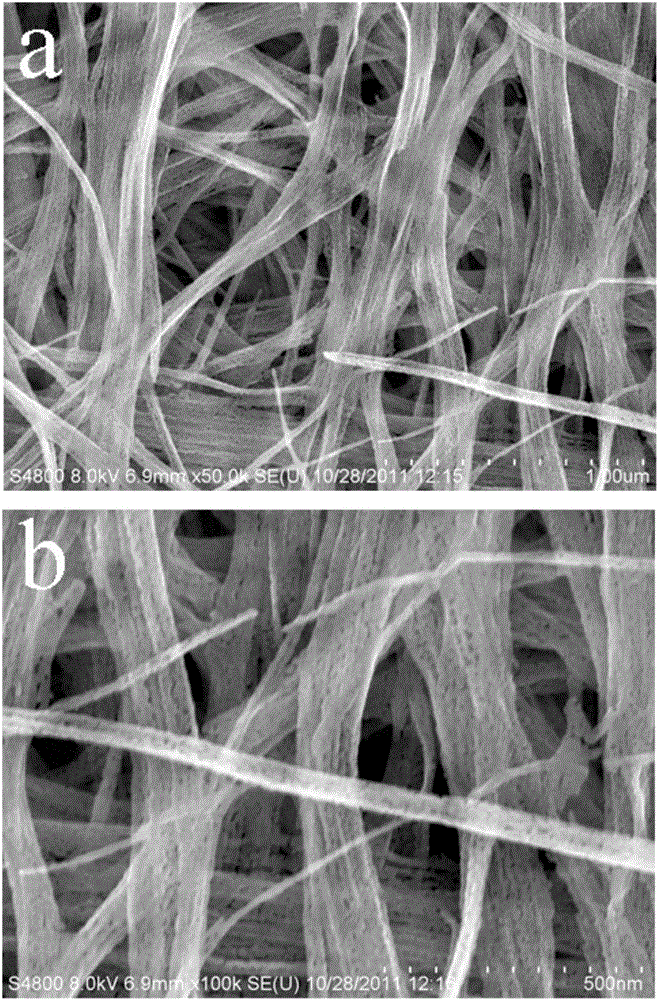

Nitrogen-doped carbon-coated vanadium nitride electrode material as well as preparation method and application thereof

ActiveCN107256956AImprove electrochemical performanceLower requirementMaterial nanotechnologyCell electrodesNanowirePolypyrrole

The invention relates to a nitrogen-doped carbon-coated vanadium nitride electrode material as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly, preparing a vanadium pentoxide nanowire precursor from vanadium pentoxide as a main raw material; by taking a pyrrole monomer as a main raw material, coating the surface of the vanadium pentoxide nanowire precursor with polypyrrole; finally performing calcining, thereby obtaining the electrode material. The preparation method is simple, high in repeatability and relatively low in equipment and chemical requirement; the prepared electrode material can be not only applied to a lithium-sulfur battery anode material, but also used as a lithium ion battery cathode material, can be compounded with graphene and is excellent in electrochemical property.

Owner:SHANDONG UNIV

Process for producing vanadium nitrate

InactiveCN1587064AWide variety of sourcesLow priceNitrogen-metal/silicon/boron binary compoundsVanadium compoundsApparent densityAdhesive

The production process of vanadium nitride as one kind of vanadium alloy additive including pre-treatment of mixing of ammonium vanadate powder and carbon powder in a rotary kiln at 600-800 deg.c and slight negative pressure for 2-3 hr; grinding the mixture, mixing with adhesive and pressing into block; treating the blocks inside nitrogen containing protective atmosphere in a vertical tubular kiln at 1100-1900 deg.c for 4-6 hr to produce carbonization and nitridation producing vanadium nitride; and cooling to below 100 deg.c and taking out. The vanadium nitride product contains V in 77-81 wt%, N in 9-16 wt%, C in 2-8 wt% and O in 0.2-1.0 wt% and has apparent density of 3-3.9 g / cu cm, and is suitable for use in making steel.

Owner:CHANGZHOU MAOSHENGTE ALLOY PROD

Preparation method of vanadium nitride

InactiveCN104016314AEliminate emissionsEliminate consumptionNitrogen-metal/silicon/boron binary compoundsEthylic acidMetallic materials

The invention belongs to the technical field of metal materials and in particular relates to a preparation method of a high-performance steel and iron material additive-vanadium nitride. According to the technical scheme, the method comprises the following steps: preparing vanadium nitride by adopting a liquid-phase solvothermal method, wherein a liquid phase adopts a water solution or an alcohol solvent; a vanadium source is selected from bivalent, trivalent or tetravalent chloride of vanadium, sulfate, nitrate and acetate; and a nitrogen source is selected from ammonia gas, urea, hydrazine, ammonium chloride, ammonium carbonate, ammonium acetate and ammonium sulfate. According to the method, carbon or hydrogen does not need to be adopted as a reducing agent in the preparation process, so that the discharge of greenhouse gas in the preparation process is avoided and the impurity carbon element in vanadium nitride is eliminated; the alloy synthesis temperature is lower than 400 DEG C; and the nitrogen content of vanadium nitride synthesized by adopting the method maximally and theoretically can be 21%.

Owner:JINAN SHUNYUAN NEW MATERIAL TECH

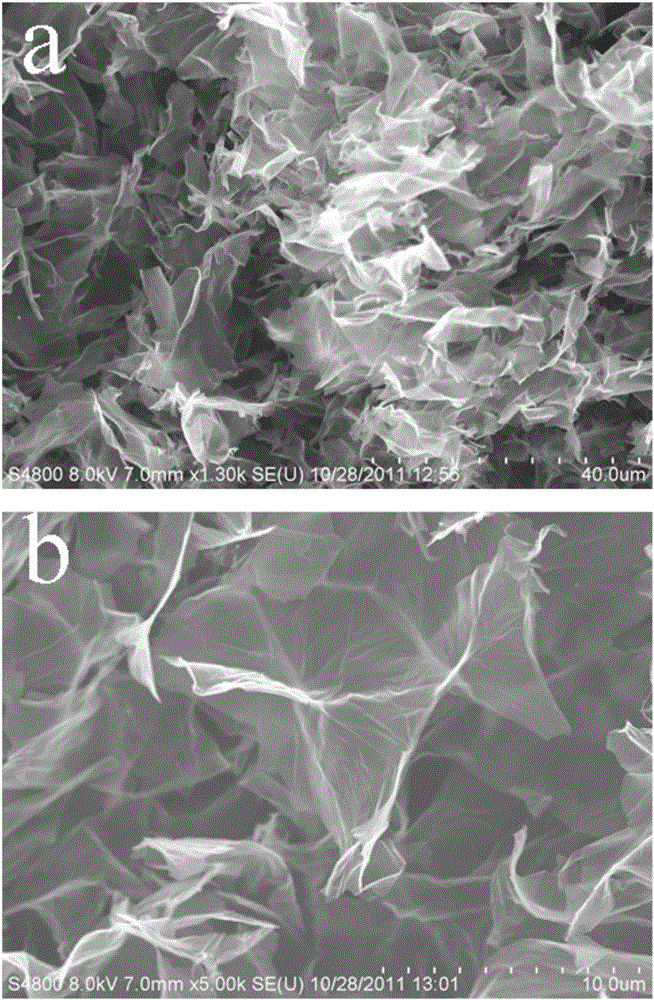

Self-supporting flexible composite electrode film, preparation method and application thereof

ActiveCN105895382ASimple manufacturing processImproved magnification performanceHybrid capacitor electrodesHybrid/EDL manufactureComposite filmComposite electrode

The invention relates to a self-supporting flexible composite electrode film, a preparation method and application thereof. The film is made from a vanadium-nitride porous nano wire and a nano graphite flake material; and the two materials are interwoven mutually on a micro level to form an interpenetration network structure. The preparation method of the film comprises: a vanadic anhydride nano wire is prepared and high-temperature ammonification is carried out on the vanadic anhydride nano wire to prepare vanadium-nitride porous nano wire; a dispersion solution of a nano graphite flake is prepared; the vanadium-nitride porous nano wire is added into the dispersion solution of the nano graphite flake and then a surfactant is also added, and a mixed dispersion solution is prepared under the ultrasonic effect; and then a self-supporting flexible composite film is prepared. The prepared self-supporting flexible composite film can be used as an electrode to prepare a solid flexible super capacitor. The preparation process is simple; and electrochemical performances like the capacity and multiplying power are excellent and the anti-bending flexibility is high.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Cubic Boron Nitride Compact

InactiveUS20080302023A1Poor EDM-cuttabilityImprove conductivityPigmenting treatmentOther chemical processesBorideAluminium carbide

A polycrystalline cubic boron nitride compact which comprises greater than 75 volume % and not greater than 90 volume % cubic boron nitride particles, the cubic boron nitride particles comprising particles of at least two average particle sizes, and a binder phase constituting the balance of the compact and comprising at least one titanium compound selected from titanium boride, titanium nitride, titanium carbide and titanium carbonitride and at least one aluminium compound selected from aluminium oxide, aluminium boride, aluminium nitride, aluminium carbide and aluminium carbonitride.

Owner:GOUDEMOND IAIN PATRICK +2

Production method of vanadium nitride

ActiveCN101948977AFacilitate the reduction reactionReduce water contentNitrogen-metal/silicon/boron binary compoundsMetallurgyVanadium nitride

The invention relates to a production method of vanadium nitride. The production method includes that: powdery vanadium oxide, carbon powder and catalyst are mixed and pressed into raw material spheres, the surface of raw material sphere is wrapped with vanadium nitride superfine powder and is added into a vertical furnace continuously, meanwhile nitrogen is introduced into the vertical furnace to be taken as reaction gas, material is heated to 1200-1600 DEG C, reduction and nitridation reactions are taken place on the material in the temperature range, time duration is less than 40-60min, and the material is cooled to certain temperature under protective atmosphere and then is taken out the furnace, thus obtaining the vanadium nitride product. The invention can solve the problem of bonding while discharging which is caused by the vertical furnace; and the invention has the advantages that production cycle is short, utilization ratio of energy and gas is high, production efficiency is high, production mode is flexible, product quality is high, and production cost is low.

Owner:江阴市中赢有色金属新材料有限公司

Method for producing vanadium nitride

InactiveCN101172585ANo clumpingHardening will not occurNitrogen-metal/silicon/boron binary compoundsVanadium compoundsHydrogenVanadium nitride

The invention provides a preparation method of vanadium nitride. Vanadium compound with the valence state of above quadrivalence or the mixture of the compound and organic carbon or inorganic carbon are formed through briquetting with adhesive agent, vanadium is pre-reduced into a lower valence state with the hydrogen with reducing property at 700 DEG C, then the temperature is gradually increased to 1100 to 1900 DEG C, therefore, the vanadium nitride product is gotten through reduction and nitridation. The block-shaped product is formed by contracting the material and no further agglomeration and adhesive bonding phenomenon occurs among blocks. The invention has the advantage that the melting and agglomeration phenomenon of the high valence vanadium compound near by the melting point is avoided.

Owner:冯良荣

Production of vanadium nitride by industrial mcirowave oven

InactiveCN1644510ASimple equipmentLow reaction temperatureNitrogen-metal/silicon/boron binary compoundsVanadium compoundsMicrowave ovenVanadium nitride

Production of vanadium nitride by industrial microwave oven is carried out by mixing vanadium oxide, carbon powder with binder by proportioning, pressing into blanking block, putting them into industrial microwave oven, heating synthesizing with furnace pressure 1 atm-1 atm+500Pa, highest reacting temperature 1000deg.C-1800deg.C, reacting for 0.2-6hrs, cooling the material below 300deg.C, and drawing charge. Its advantages include simple heating process, low cost, short production period and easy control.

Owner:长沙隆泰科技有限公司

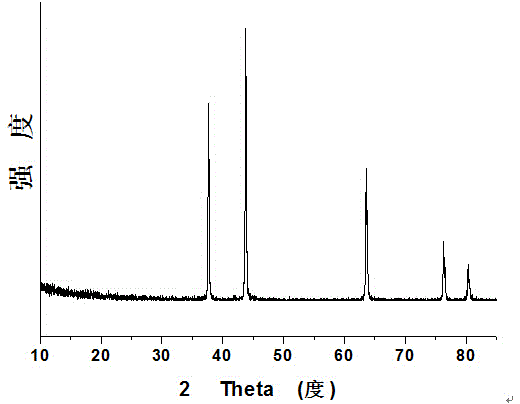

Silicon vanadium nitride and production method thereof

The invention relates to silicon vanadium nitride which comprises the following components in percentage by weight: 52-55 wt percent of vanadium, 13-15 wt percent of nitrogen, 6-10 wt percent of silicon and the balance of iron and inevitable impurities, wherein the mass ratio of vanadium to nitrogen is 3.6-4.5. A silicon vanadium nitride alloy can be prepared through high-temperature self-propagating reaction. According to the silicon vanadium nitride alloy disclosed by the invention, by adding the element silicon in the alloy, controlling the element silicon content in the alloy and controlling the contents of vanadium and nitrogen as major elements and the ratio of vanadium and nitrogen, the absorptivity and the stability of the silicon vanadium nitride alloy are greatly improved; and in addition, the silicon vanadium nitride alloy is a vanadium microalloy in most vanadium saving at present and has excellent market competitiveness.

Owner:LIAONING XINYE NEW MATERIAL

Process for preparing nano vanadium nitride and nano vanadium carbonitride powder

ActiveCN1899955AAbundant raw materialsRich sourcesNitrogen-metal/silicon/boron binary compoundsNitrogen and non-metal compoundsReaction temperatureShielding gas

The preparation process of nanometer vanadium nitride powder and nanometer vanadium carbo-nitride powder with the material including powdered ammonium vanadate, carbon reductant and small amount of RE catalyst includes the following steps: dissolving in deionized water or distilled water through stirring to prepare solution; heating the solution and drying to obtain precursor powder containing vanadium source and carbon source; reacting the precursor powder with introduced reducing gas inside a high temperature reaction furnace at 800-950 deg.c for 30-60 min to obtain nanometer vanadium nitride powder and nanometer vanadium carbo-nitride powder of size smaller than 100nm and with homogeneous size distribution. The process of the present invention has the features of low reaction temperature, short reaction time, low production cost, etc and is suitable for industrial production.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com