Molten steel alloying cored wire and method

A technology of alloying and cored wire, which is applied in the field of nitrogen alloying and vanadium in molten steel, can solve the problems of large fluctuation range, low vanadium recovery rate, and affecting product quality stability, and achieve small fluctuation range and high recovery rate , the effect of reducing the free oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

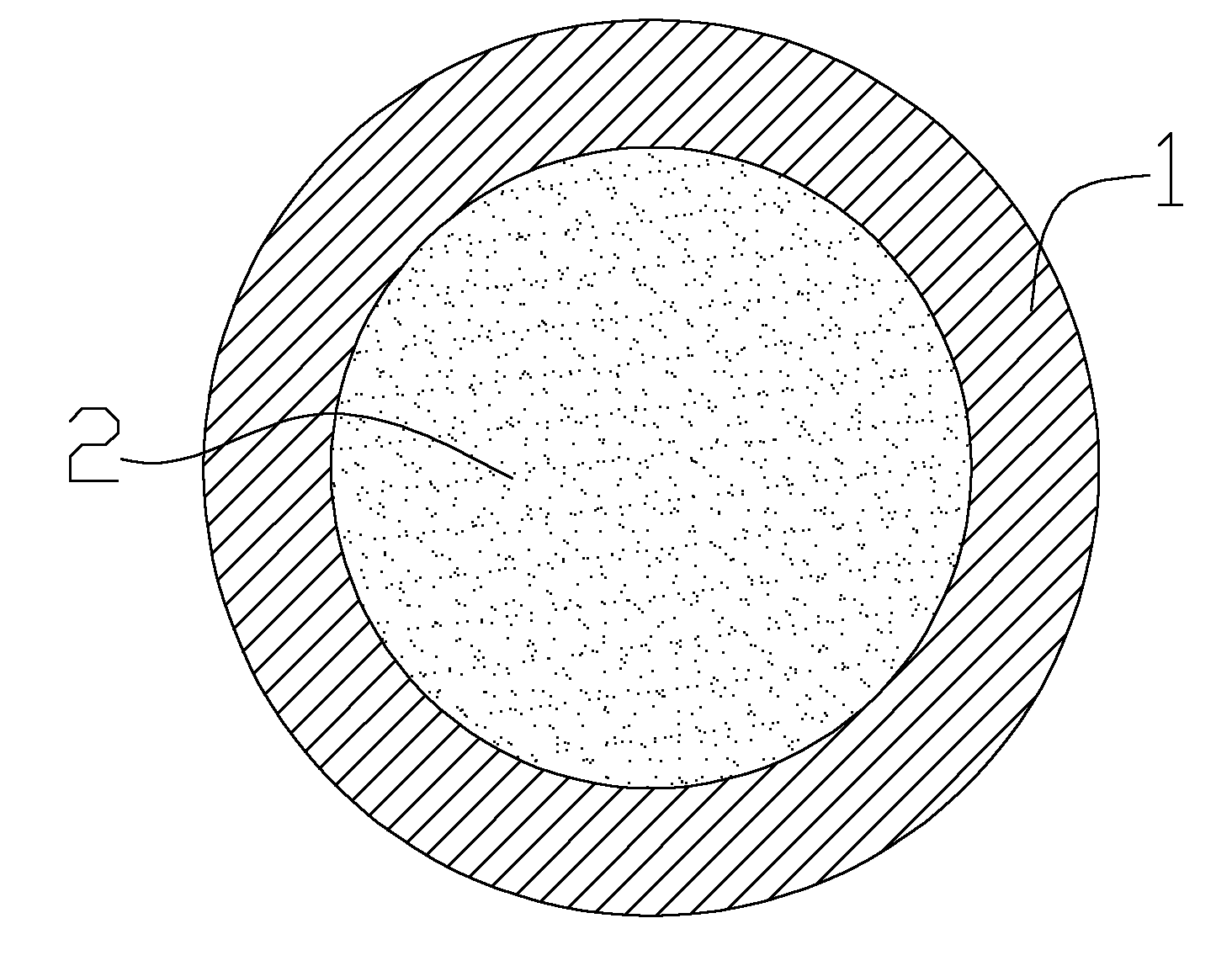

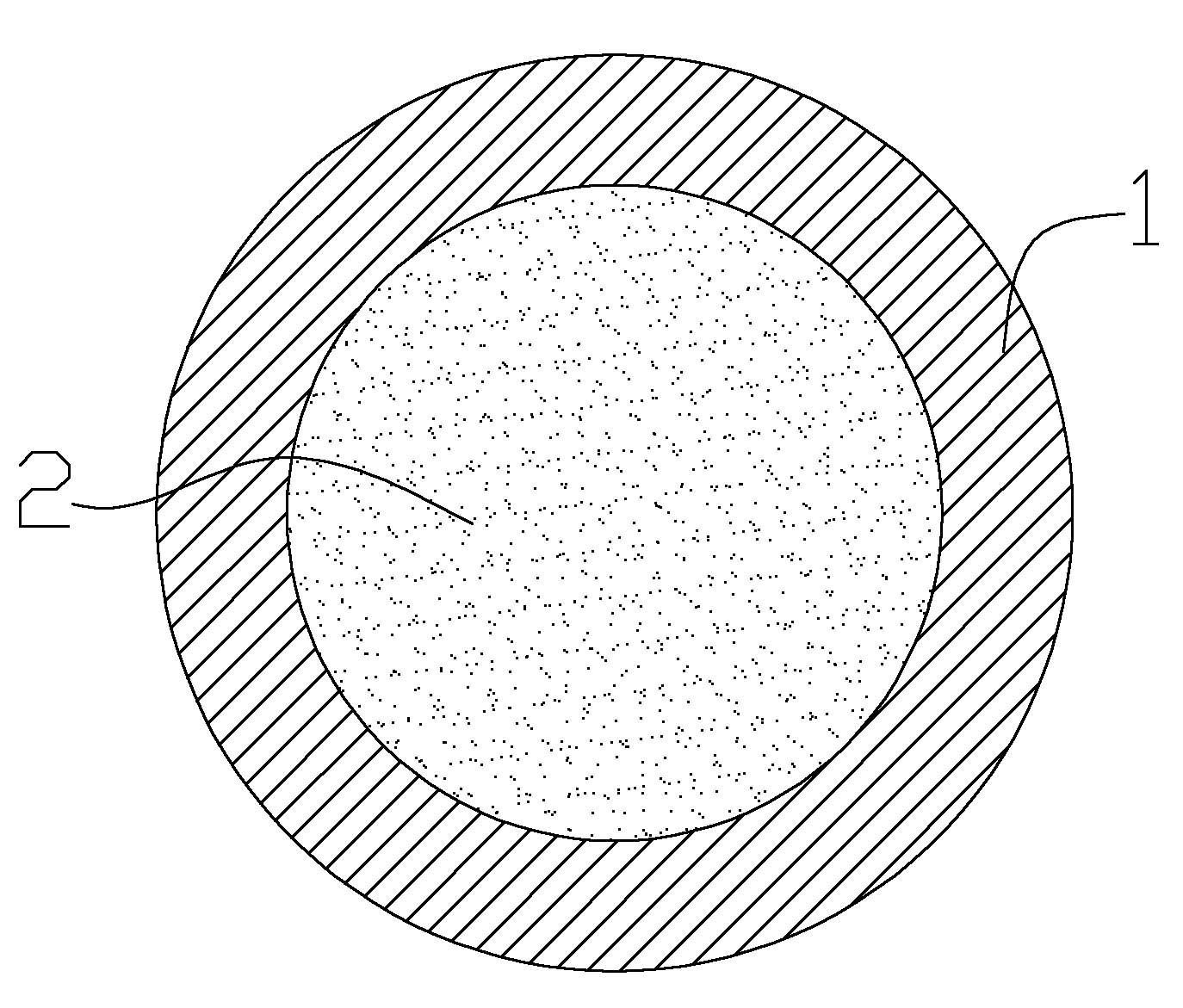

[0036]A cored wire for alloying molten steel, including a core layer, the core layer is composed of a vanadium nitride alloy and a silicon-calcium alloy, and the weight ratio of the above-mentioned vanadium nitride alloy and silicon-calcium alloy is: vanadium nitride alloy: 90%, silicon-calcium alloy: 10%, both vanadium nitride alloy and silicon-calcium alloy are powder materials, the particle size is less than 2mm, the core layer is wrapped with a sheath made of cold-rolled strip steel, and the outer diameter of the entire cored wire It is 12mm, and the recovery rate of vanadium is 96%.

Embodiment 2

[0038] A cored wire for alloying molten steel, including a core layer, the core layer is composed of a vanadium nitride alloy and a silicon-calcium alloy, and the weight ratio of the above-mentioned vanadium nitride alloy and silicon-calcium alloy is: vanadium nitride alloy: 65%, silicon-calcium alloy: 35%, both vanadium nitride alloy and silicon-calcium alloy are powder materials, the particle size is less than 3mm, the core layer is wrapped with a sheath made of cold-rolled strip steel, and the outer diameter of the entire cored wire It is 12mm, and the recovery rate of vanadium is 97.8%.

Embodiment 3

[0040] A cored wire for alloying molten steel, including a core layer, the core layer contains a vanadium nitride alloy, a silicon-calcium alloy and a vanadium-iron alloy, and the weight ratio of the vanadium nitride alloy to the silicon-calcium alloy and the vanadium-iron alloy is: Vanadium nitride alloy: 80%, silicon-calcium alloy: 10%, vanadium-iron alloy: 10%. Vanadium nitride alloy, silicon-calcium alloy and vanadium-iron alloy are powder materials with a particle size of less than 3mm. The core layer is wrapped with a sheath made of cold-rolled strip steel. The outer diameter of the entire cored wire is 13mm. The vanadium recovery rate is 96.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com