Nano-dispersed copper alloy with high airtightness and low free oxygen content and its short-flow preparation process

一种制备工艺、氧含量的技术,应用在金属加工设备、运输和包装等方向,能够解决纳米弥散铜合金自由氧含量高、低自由氧含量纳米弥散铜合金、气密性低等问题,达到自由氧含量低、尺寸稳定性高、气密性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

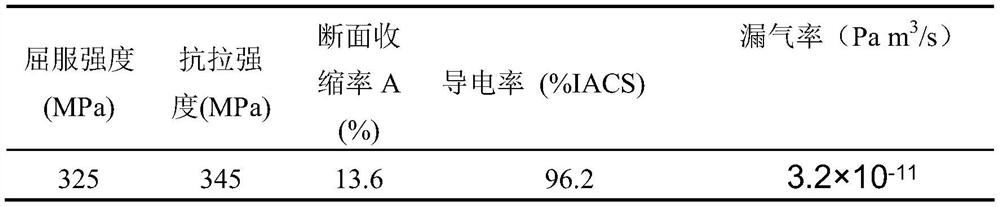

Embodiment 1

[0039] Cu-0.1wt%Ca-0.1wt%La alloy is smelted under inert gas protection at 1200°C, prepared by high-purity nitrogen atomization, sieved, and high-energy ball milled to obtain ultrafine powder (average particle size less than or equal to 20 microns). Al and Cu are smelted at 1218-1230°C to form a Cu-Al alloy with an Al content of 0.04wt%. The alloy powder is prepared by atomization with high-purity nitrogen gas, and the alloy powder with a particle size of less than 40 meshes is sieved, and mixed with an oxidant Mix and ball mill, internally oxidize the mixed powder with an oxidant at 386-395°C for 2 hours, then carry out internal oxidation at 892-900°C for 3 hours, crush the above-mentioned internally oxidized powder, and reduce with hydrogen at 885-893°C 6 hours, mixed with Cu-Ca-La alloy ultrafine powder according to the ratio of 15:1, cold isostatic pressing of the above mixed powder, pure copper sheath in argon chamber, hot extrusion at 900°C water seal, extrusion ratio 15 ...

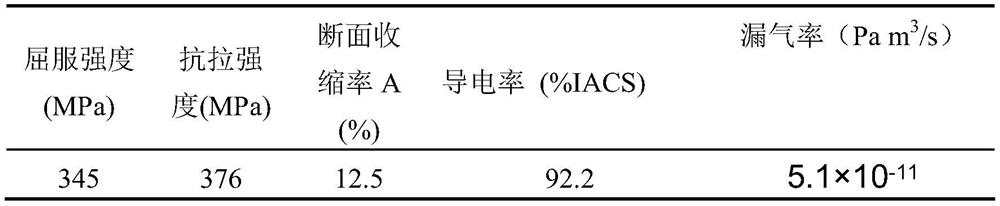

Embodiment 2

[0043] The Cu-0.1wt%Ca-0.1wt%La alloy is smelted under inert gas protection at 1200°C, prepared by high-purity nitrogen atomization, sieved, and high-energy ball milled to obtain ultrafine powder (average particle size less than or equal to 20 microns). Al and Cu are smelted at 1200-1222°C to form a Cu-Al alloy with an Al content of 0.12wt%. The alloy powder is prepared by atomization with high-purity nitrogen gas, and the alloy powder with a particle size of less than 40 meshes is sieved, and mixed with an oxidant Mix and perform ball milling, internally oxidize the mixed powder with an oxidizing agent at 392-400°C for 2 hours, then oxidize at 893-898°C for 3 hours, crush the above-mentioned internally oxidized powder, and reduce with hydrogen at 895-900°C for 6 hours, Mix with Cu-Ca-La alloy ultrafine powder according to the ratio of 13:1, cold isostatic press the above powder, argon chamber pure copper sheath, 900 ℃ water seal hot extrusion, extrusion ratio 15:1, Swaged aft...

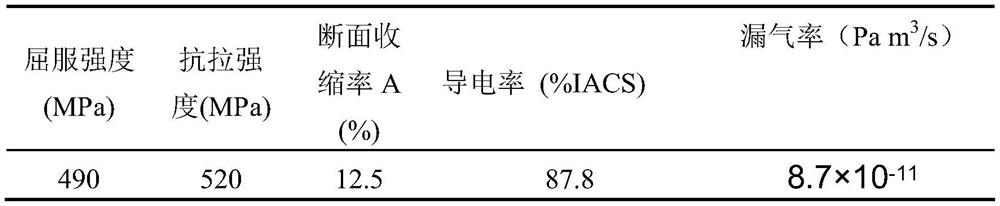

Embodiment 3

[0047] The Cu-0.1wt%Ca-0.1wt%La alloy is smelted under inert gas protection at 1200°C, prepared by high-purity nitrogen atomization, sieved, and high-energy ball milled to obtain ultrafine powder (average particle size less than or equal to 20 microns). Al and Cu are smelted at 1215-1230°C to form a Cu-Al alloy with an Al content of 0.30wt%. The alloy powder is prepared by atomization with high-purity nitrogen gas, and the alloy powder with a particle size of less than 40 meshes is sieved, and then mixed with an oxidant Mix and perform ball milling, internally oxidize the mixed powder with an oxidizing agent at 382-393°C for 2 hours, then oxidize at 887-896°C for 3 hours, crush the above-mentioned internally oxidized powder, and reduce with hydrogen at 892-898°C for 6 hours, Mix with Cu-Ca-La alloy ultrafine powder according to the ratio of 10:1, cold isostatic press the above powder, argon chamber pure copper sheath, 900 ℃ water seal hot extrusion, extrusion ratio 15:1, Swage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com