Molten steel alloying cored wire and method

A cored wire and alloying technology is applied in the field of nitrogen alloying and vanadium in molten steel. Lower, less volatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

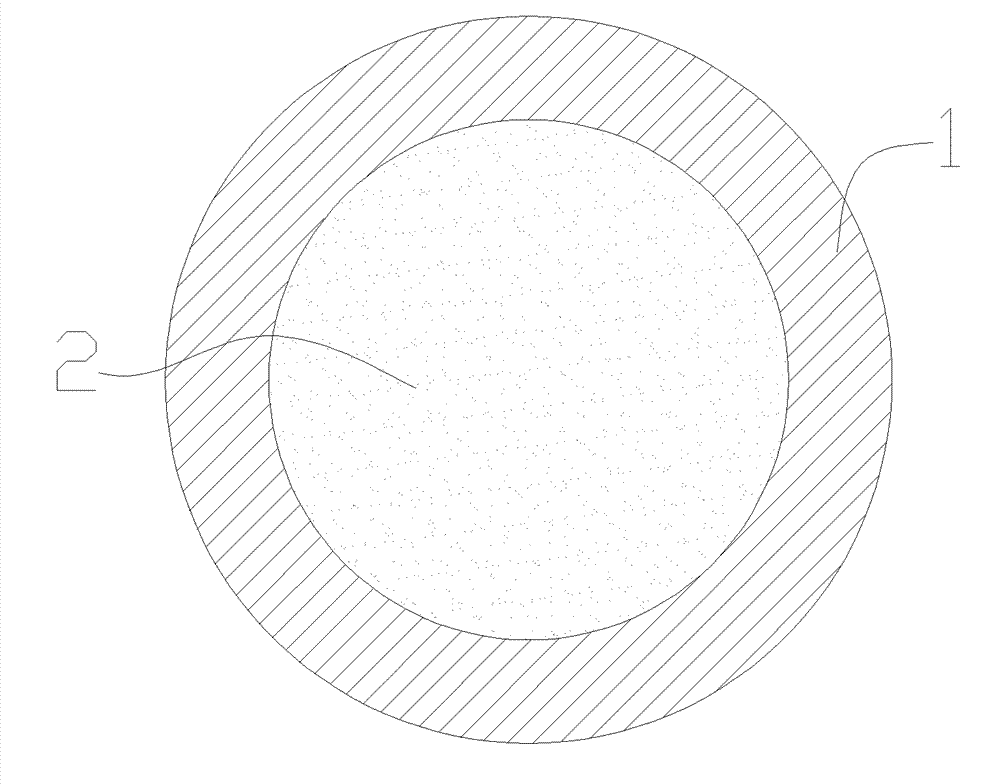

[0036] The cored wire used for alloying of molten steel includes a core layer composed of a vanadium nitride alloy and a silicon-calcium alloy. The weight ratio of the vanadium nitride alloy to the silicon-calcium alloy is: vanadium nitride alloy: 90%, silicon-calcium alloy: 10%, both vanadium nitride alloy and silicon-calcium alloy are powders, with a particle size of 2mm or less, the core layer is wrapped with a skin made of cold rolled strip steel, and the outer diameter of the entire cored wire At 12mm, the vanadium recovery rate is 96%.

Embodiment 2

[0038] The cored wire used for alloying of molten steel includes a core layer composed of a vanadium nitride alloy and a silicon-calcium alloy. The weight ratio of the vanadium nitride alloy to the silicon-calcium alloy is: vanadium nitride alloy: 65%, silicon-calcium alloy: 35%, both vanadium nitride alloy and silicon-calcium alloy are powders, with a particle size of 3mm or less, the core layer is wrapped with a skin made of cold rolled strip steel, and the outer diameter of the entire cored wire At 12mm, the vanadium recovery rate is 97.8%.

Embodiment 3

[0040] The cored wire used for alloying of molten steel includes a core layer containing vanadium nitride alloy, silicon-calcium alloy and vanadium-iron alloy, and the weight ratio of the above-mentioned vanadium nitride alloy to silicon-calcium alloy and vanadium-iron alloy is: Vanadium nitride alloy: 80%, silicon-calcium alloy: 10%, vanadium-iron alloy: 10%. Vanadium nitride alloy, silicon-calcium alloy and vanadium-iron alloy are all powder materials with a particle size of 3mm or less. The core layer is wrapped with a skin made of cold-rolled strip steel. The outer diameter of the entire cored wire is 13mm. The recovery rate of vanadium is 96.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com