Method for producing high-alloy non-oriented silicon steel, high-alloy non-oriented silicon steel and application

A technology of oriented silicon steel and alloy, which is applied in the field of high-alloy non-oriented silicon steel, can solve the problems of poor surface quality of continuous casting slabs, fewer continuous casting furnaces, and large fluctuations in chemical composition content, so as to reduce the fluctuation range and realize the addition amount , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

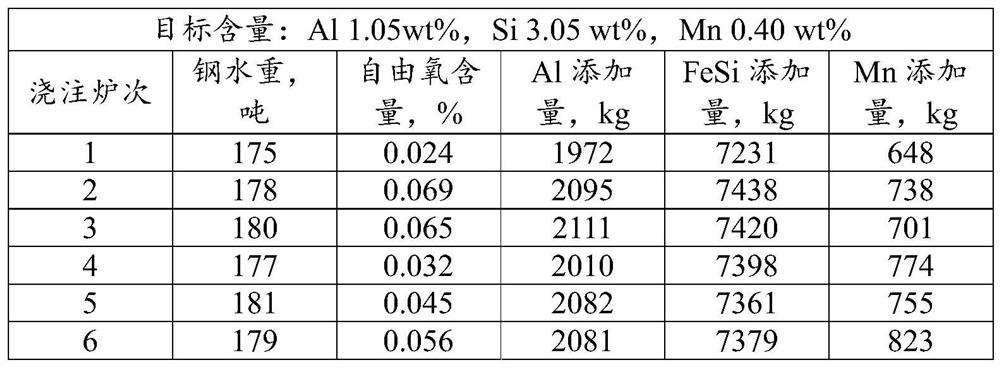

Embodiment 1

[0040] The present embodiment provides a method for producing high-alloy non-oriented silicon steel, comprising the following steps:

[0041](1) KR desulfurization: After the molten iron reaches the KR desulfurization station, the first slag removal is performed, and then the conventional KR desulfurization treatment is performed, so that the sulfur content in the molten iron after KR desulfurization is 0.0009-0.0014wt%, and the desulfurization is completed. 3-5min, carry out slag scraping for the second time, so that the scraping rate of iron-clad slag is 94%, and the molten iron after KR desulfurization is obtained;

[0042] (2) converter tapping: conventional converter steelmaking is carried out to the molten iron after KR desulfurization, converter tapping is performed after the converter steelmaking is finished, and metal tin is added based on the target tin content in the converter tapping process to obtain pre-alloyed molten steel;

[0043] (3) RH refining: RH decarburi...

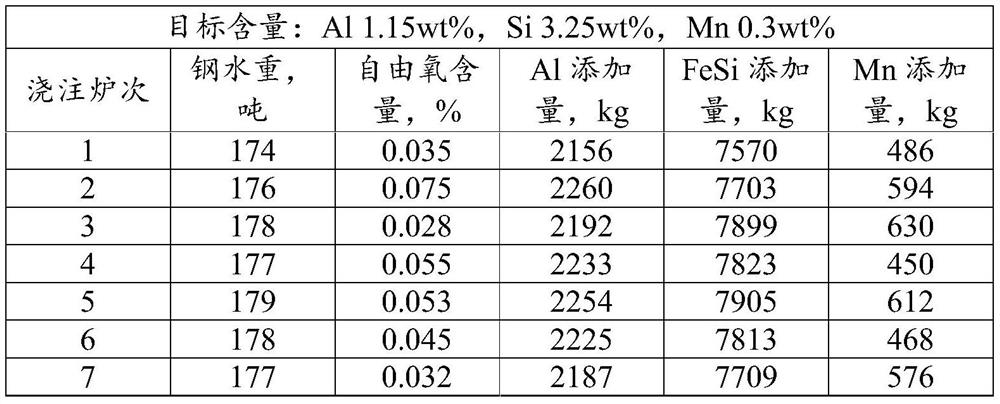

Embodiment 2

[0056] The present embodiment provides a method for producing high-alloy non-oriented silicon steel, comprising the following steps:

[0057] (1) KR desulfurization: After the molten iron reaches the KR desulfurization station, the first slag removal is performed, and then conventional KR desulfurization treatment is performed, so that the sulfur content in the molten iron after KR desulfurization is 0.0007-0.0013wt%, and the desulfurization is completed. 3-5min, carry out slag scraping for the second time, so that the scraping rate of iron-clad slag is 97%, and the molten iron after KR desulfurization is obtained;

[0058] (2) converter tapping: conventional converter steelmaking is carried out to the molten iron after KR desulfurization, converter tapping is performed after the converter steelmaking is finished, and metal tin is added based on the target tin content in the converter tapping process to obtain pre-alloyed molten steel;

[0059] (3) RH refining: RH decarburizat...

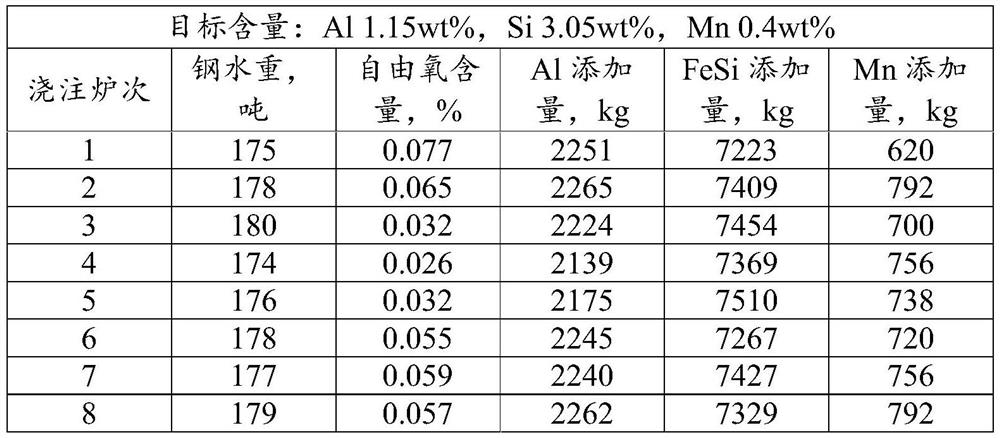

Embodiment 3

[0072] The present embodiment provides a method for producing high-alloy non-oriented silicon steel, comprising the following steps:

[0073] (1) KR desulfurization: After the molten iron reaches the KR desulfurization station, the first slag removal is performed, and then conventional KR desulfurization treatment is performed, so that the sulfur content in the molten iron after KR desulfurization is 0.0007-0.0013wt%, and the desulfurization is completed. 3-5min, carry out slag scraping for the second time, so that the scraping rate of iron-clad slag is 97%, and the molten iron after KR desulfurization is obtained;

[0074] (2) converter tapping: conventional converter steelmaking is carried out to the molten iron after KR desulfurization, converter tapping is performed after the converter steelmaking is finished, and metal tin is added based on the target tin content in the converter tapping process to obtain pre-alloyed molten steel;

[0075] (3) RH refining: RH decarburizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com