Patents

Literature

34results about How to "Surface quality effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process additional method for vehicle exterior panel

InactiveCN101398680ASurface quality effectImprove surface qualityProgramme controlComputer controlSlip lineEngineering

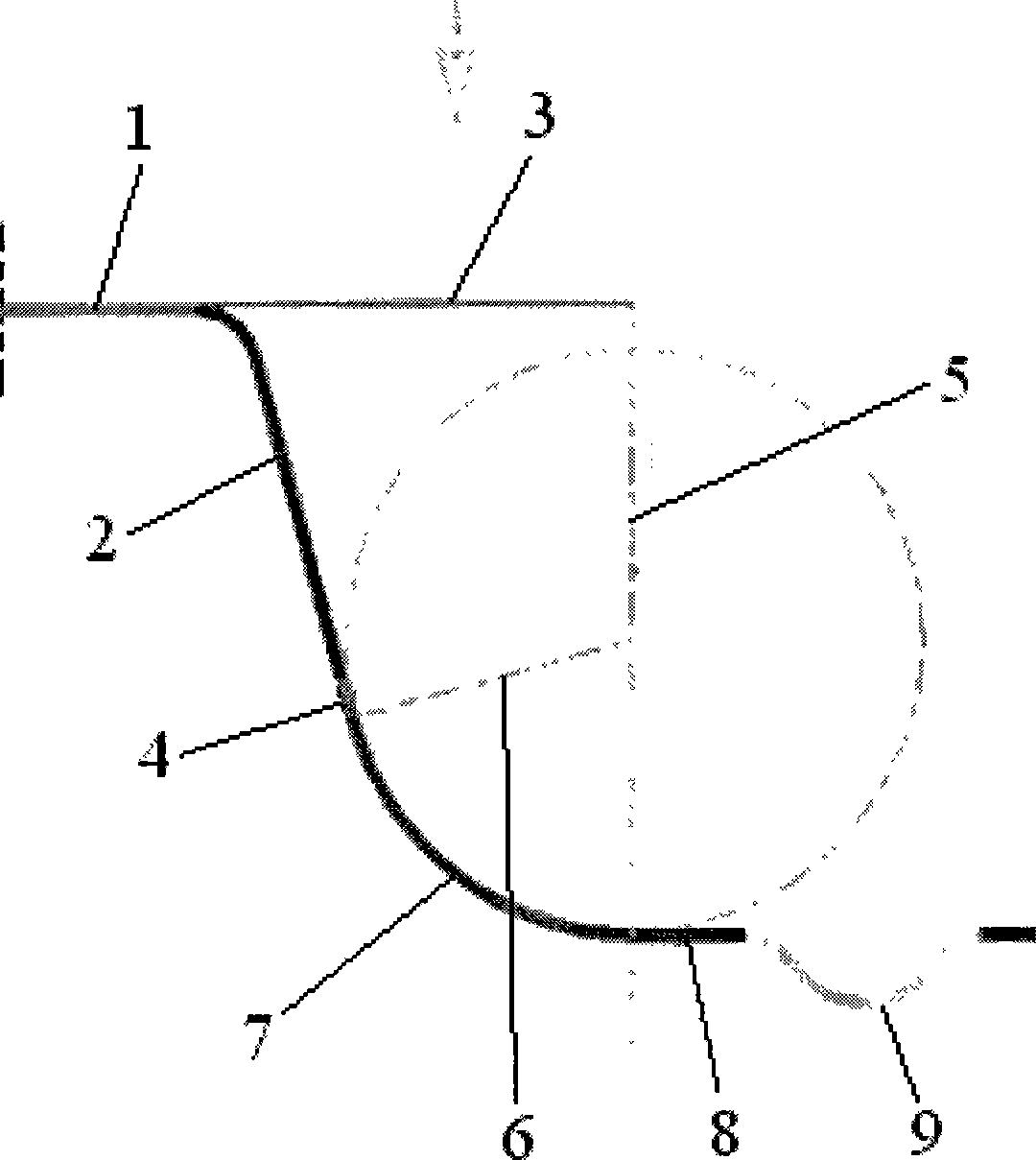

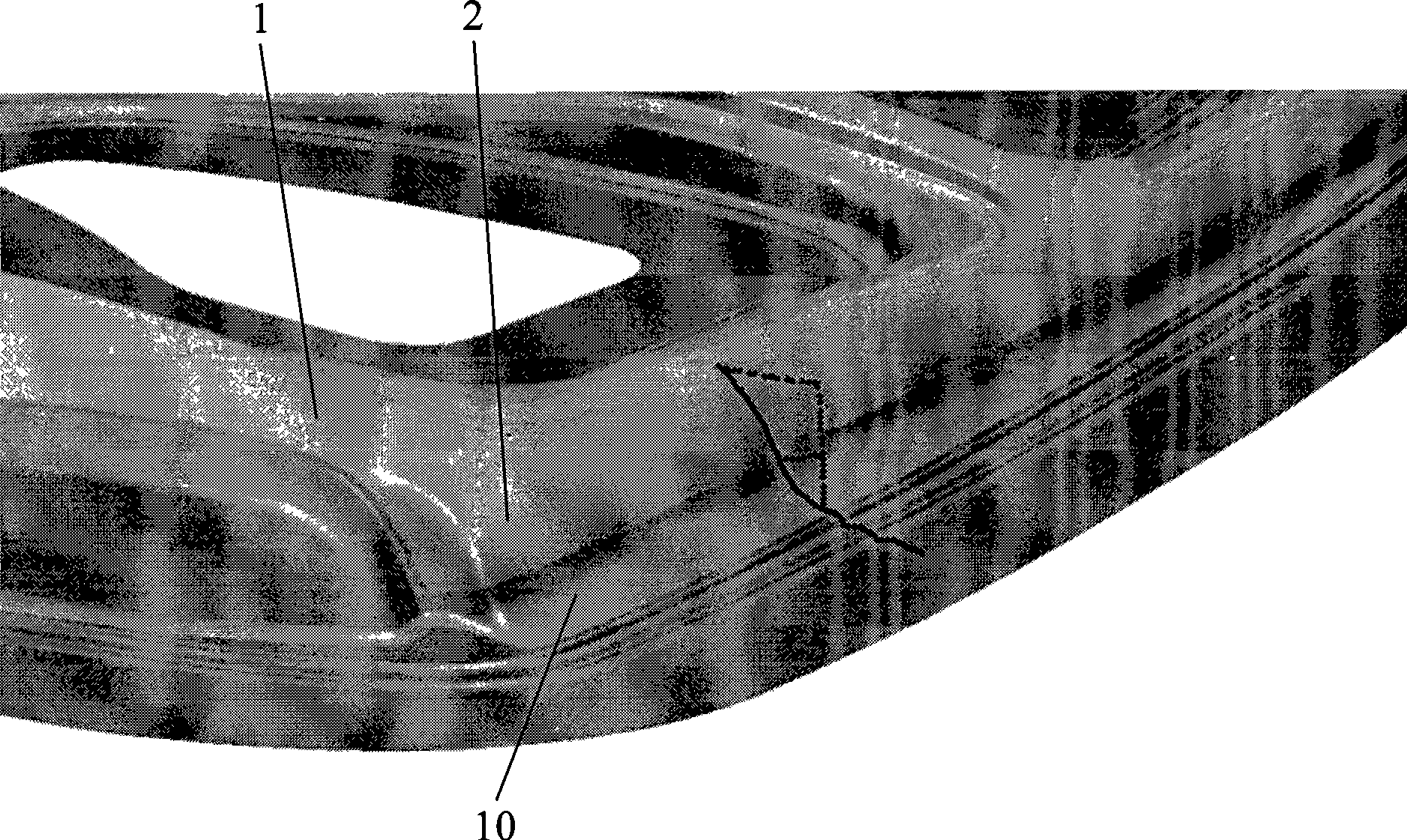

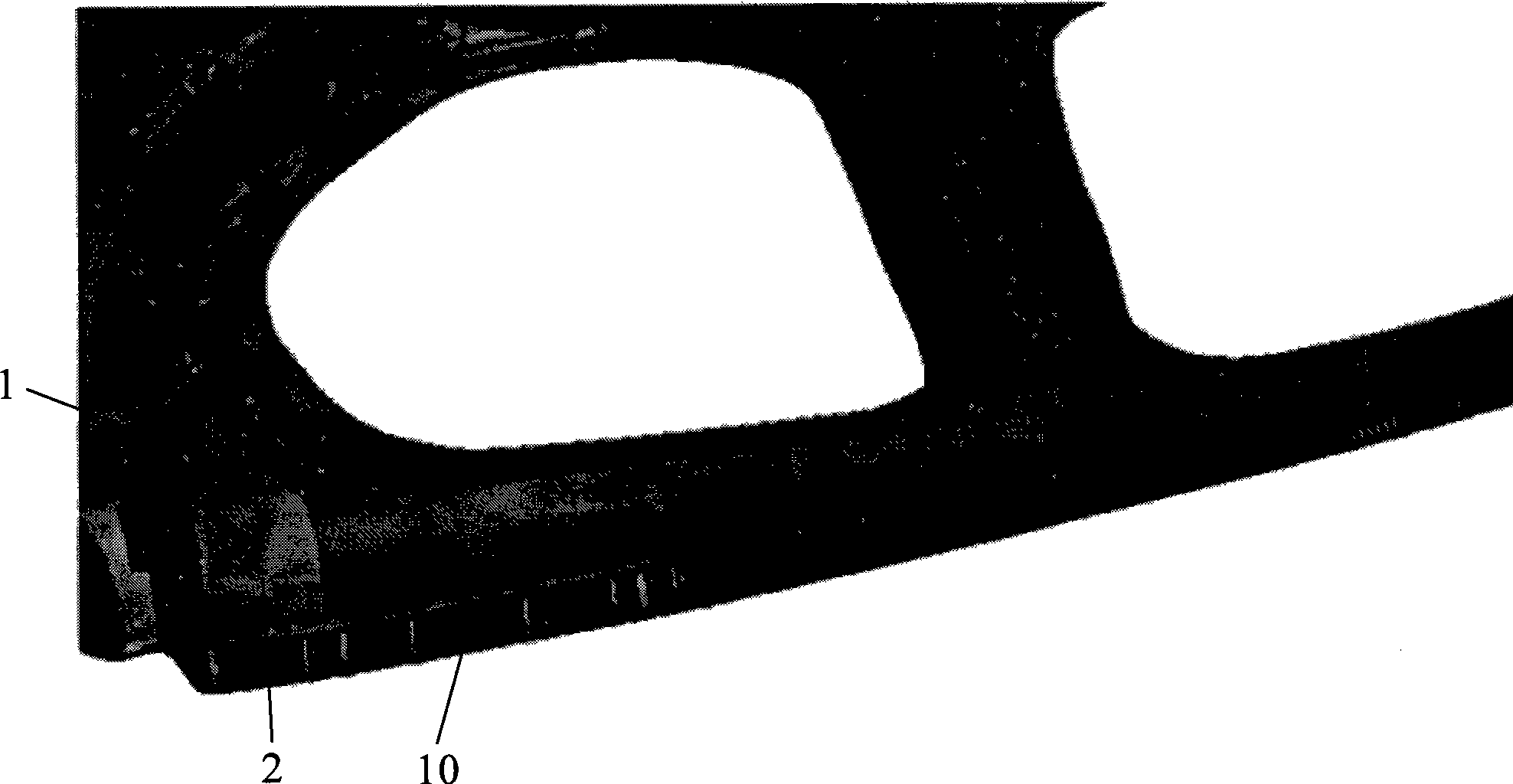

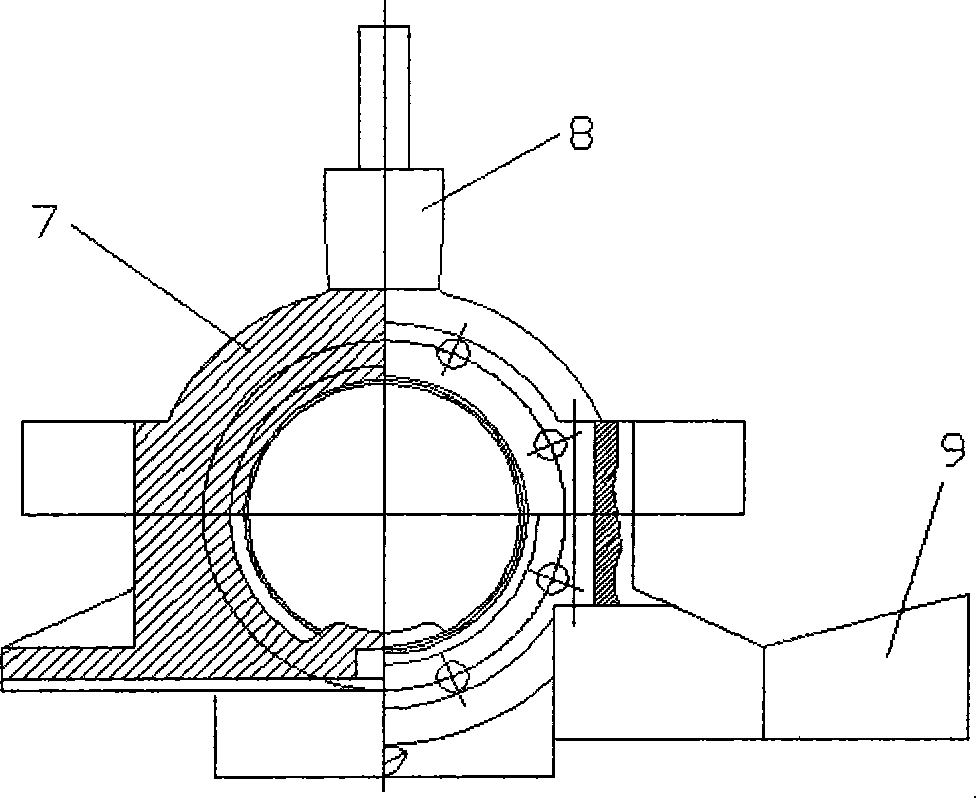

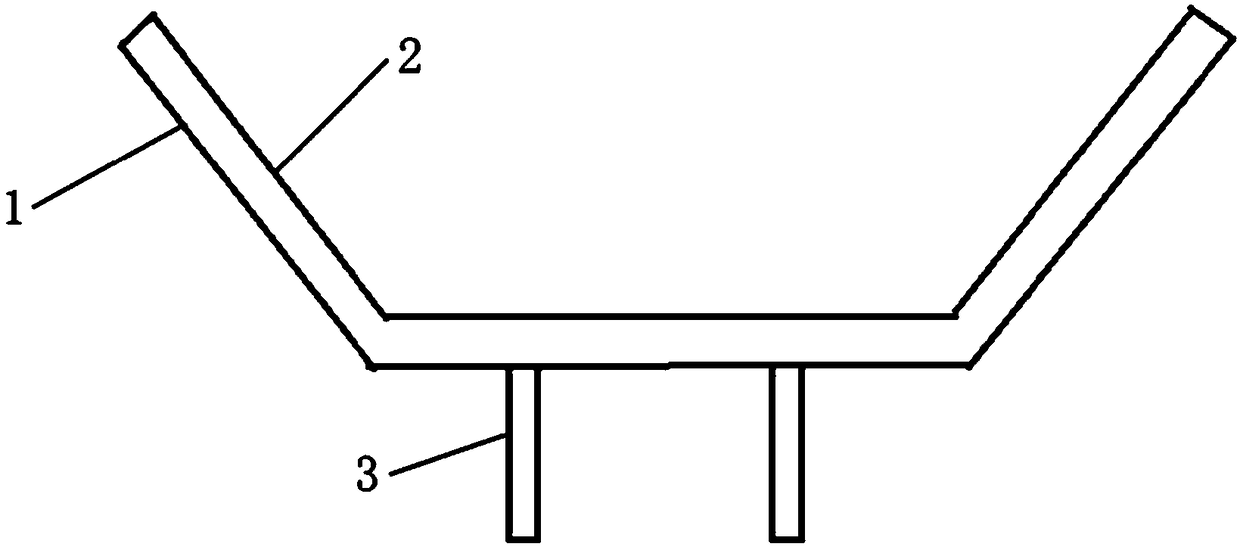

The invention discloses a technical supplement method of a vehicle external panel, wherein, the technical supplement towards the section of the external panel comprises the steps as follows: a horizontal line is made from the tangent point of the upper surface and a circular bead of the lateral wall; the extension line of the lateral wall is made from the endpoint of the lateral wall; the vertical line of the horizontal line is made from the endpoint of the horizontal line to get a first vertical line; the vertical line of the extension line of the lateral wall is made from the endpoint of the extension line of the lateral wall to get a second vertical line; the intersection point of the first vertical line and the second vertical line is considered as the center of a circle, and the length of the second vertical line is considered as the semidiameter to make a circle to get a cavity die circular bead; the horizontal line is made from the intersection point of the cavity die circular bead and the first vertical line to get a swaging line. The technical supplement method provided by the invention not only can ensure that the surface of the finally molded external panel does not have a slip line, thereby improving the surface quality of the vehicle external panel, but the technical supplement method also reduces the designing and manufacturing period of a die and improves the production efficiency.

Owner:BYD CO LTD

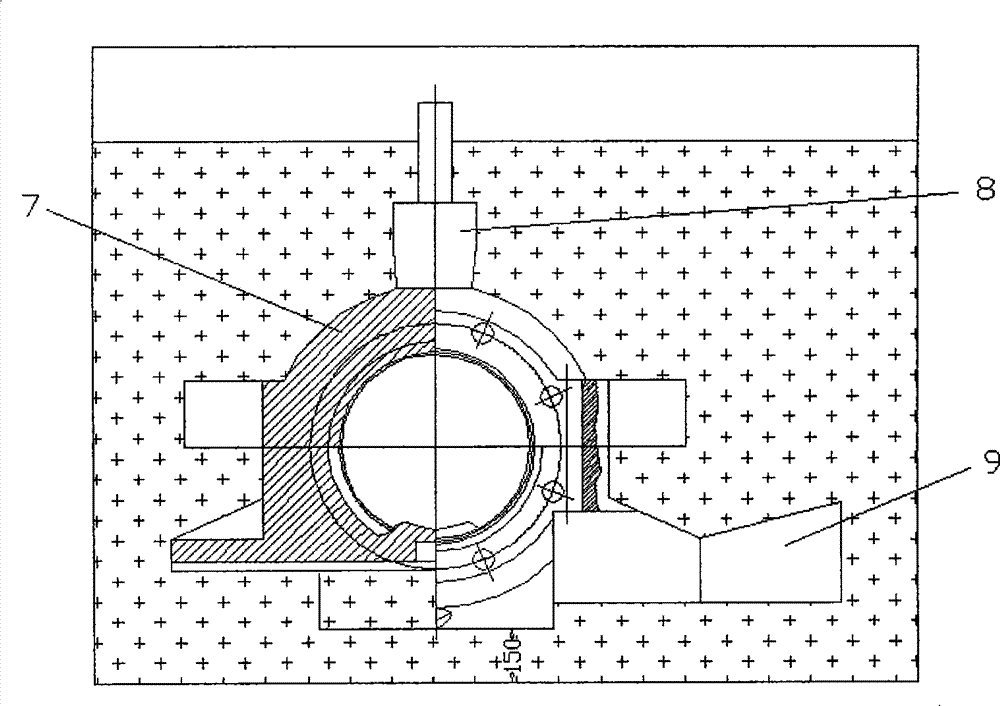

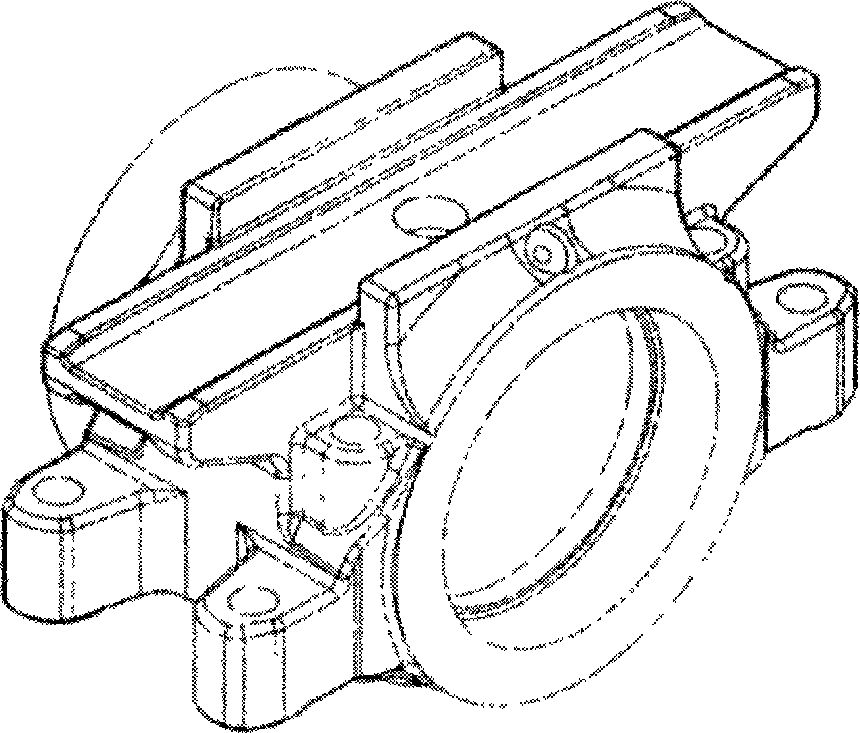

Evanescent mode vacant-shell casting technique of double-saddle balance shaft shell

InactiveCN104275438AIncreased sturdinessImprove stabilityFoundry mouldsFoundry coresMetallurgyEvanescent mode

The invention relates to an evanescent mode vacant-shell casting technique of a double-saddle balance shaft shell. The evanescent mode vacant-shell casting technique comprises the following steps: (1) producing a double-saddle balance shaft shell and a riser foam mold by foaming copolymerization (STMMA), independently producing a pouring gate, bonding a double-saddle balance shaft shell module and the pouring riser to form a combined model; (2) roasting the combined model in a roasting room at the temperature of 50 to 60 DEG C for 24h; (3) placing the roasted combined model into a high-temperature-resisting and high-strength paint pool to be painted, then roasting the combined model in the roasting room, painting and roasting the combined model for four times, and controlling the thickness at 1.2mm to 1.8mm; (4) combining the roasted combined models again on an iron rack in a way that four combined models form on pouring body, and roasting the combined model; (5) boxing, filling sand and compacting; (6) vacuumizing a sand box, and burning the model in rich oxygen to form a vacant shell; and (7) casting.

Owner:渠县金城合金铸业有限公司

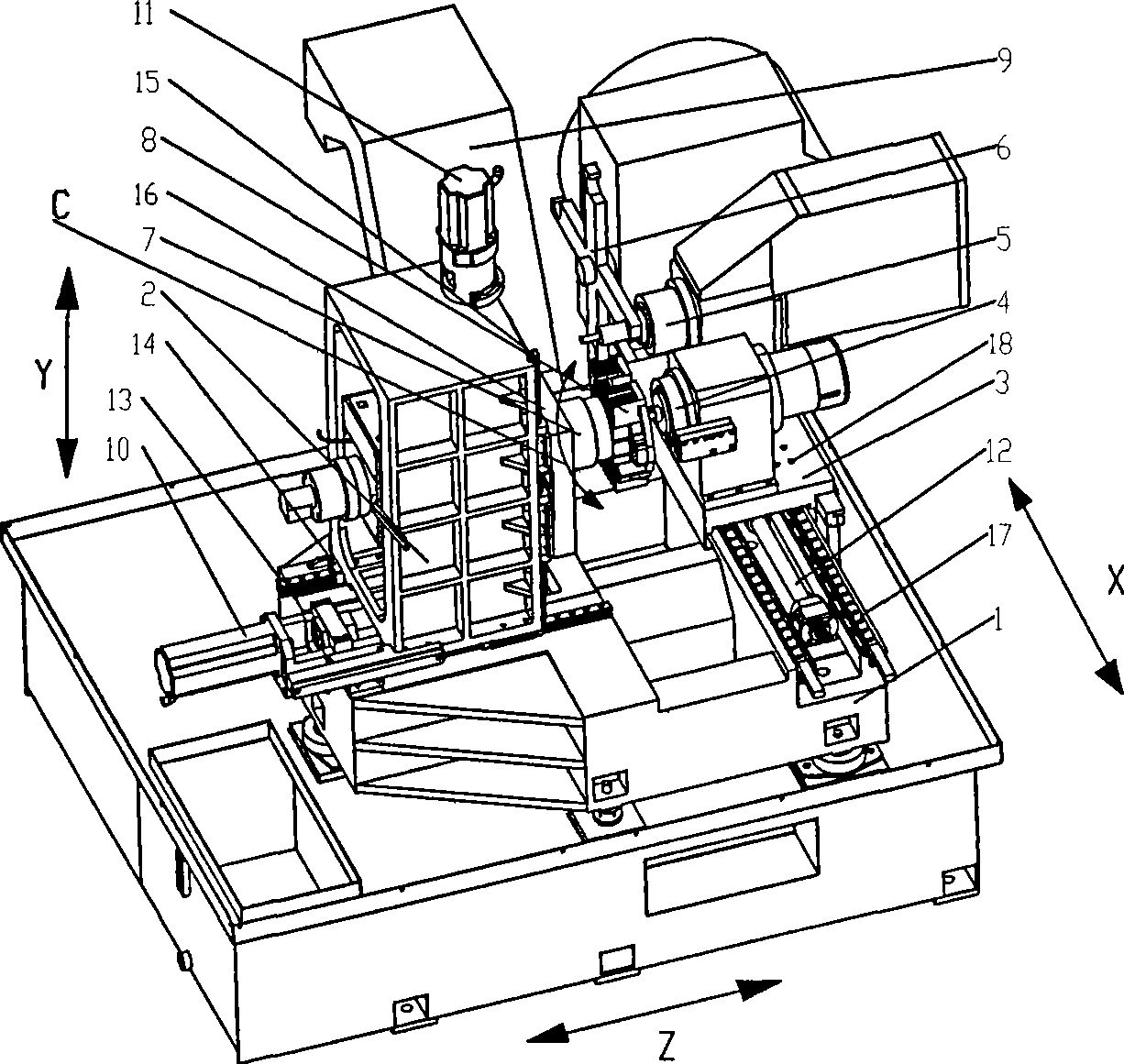

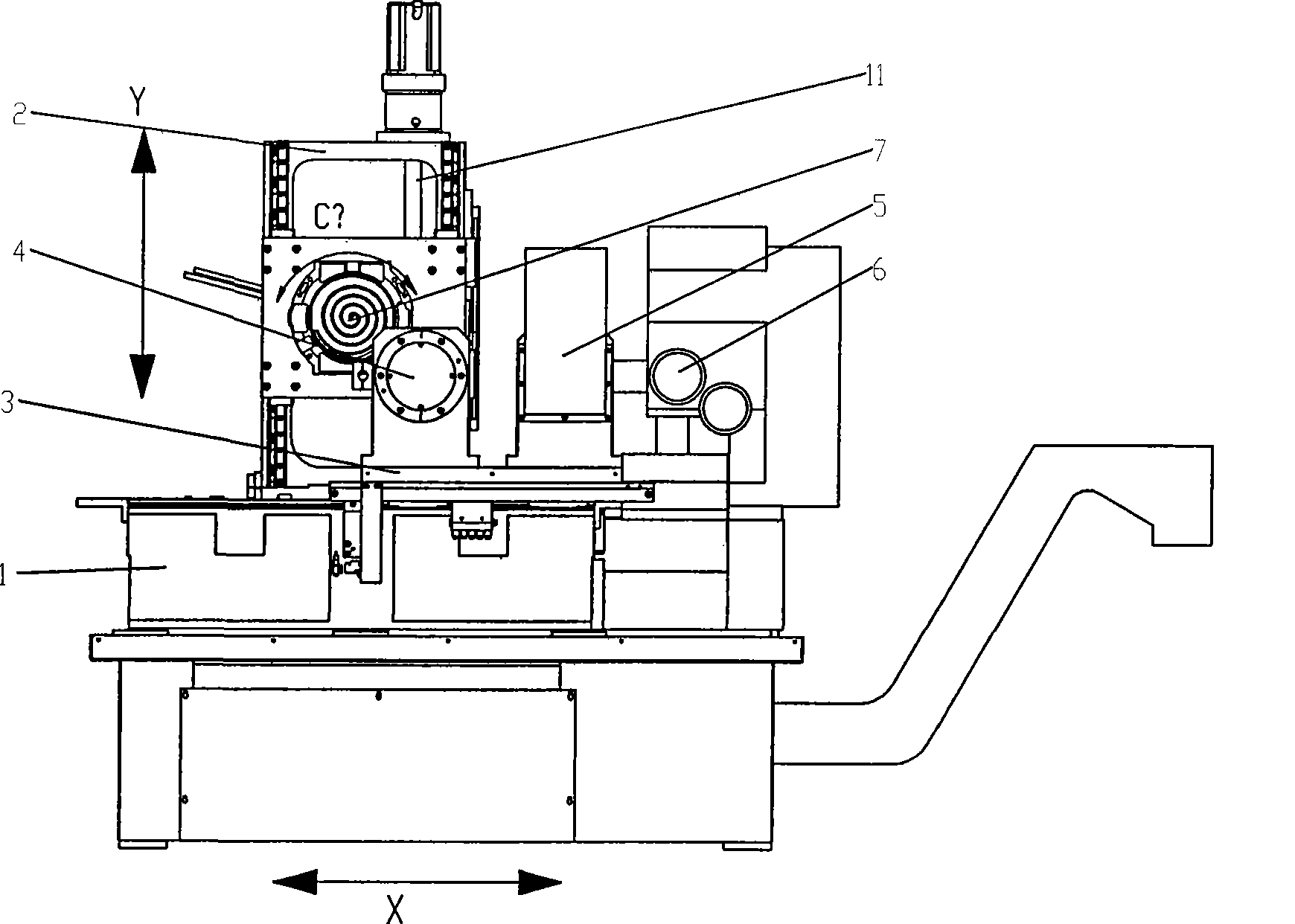

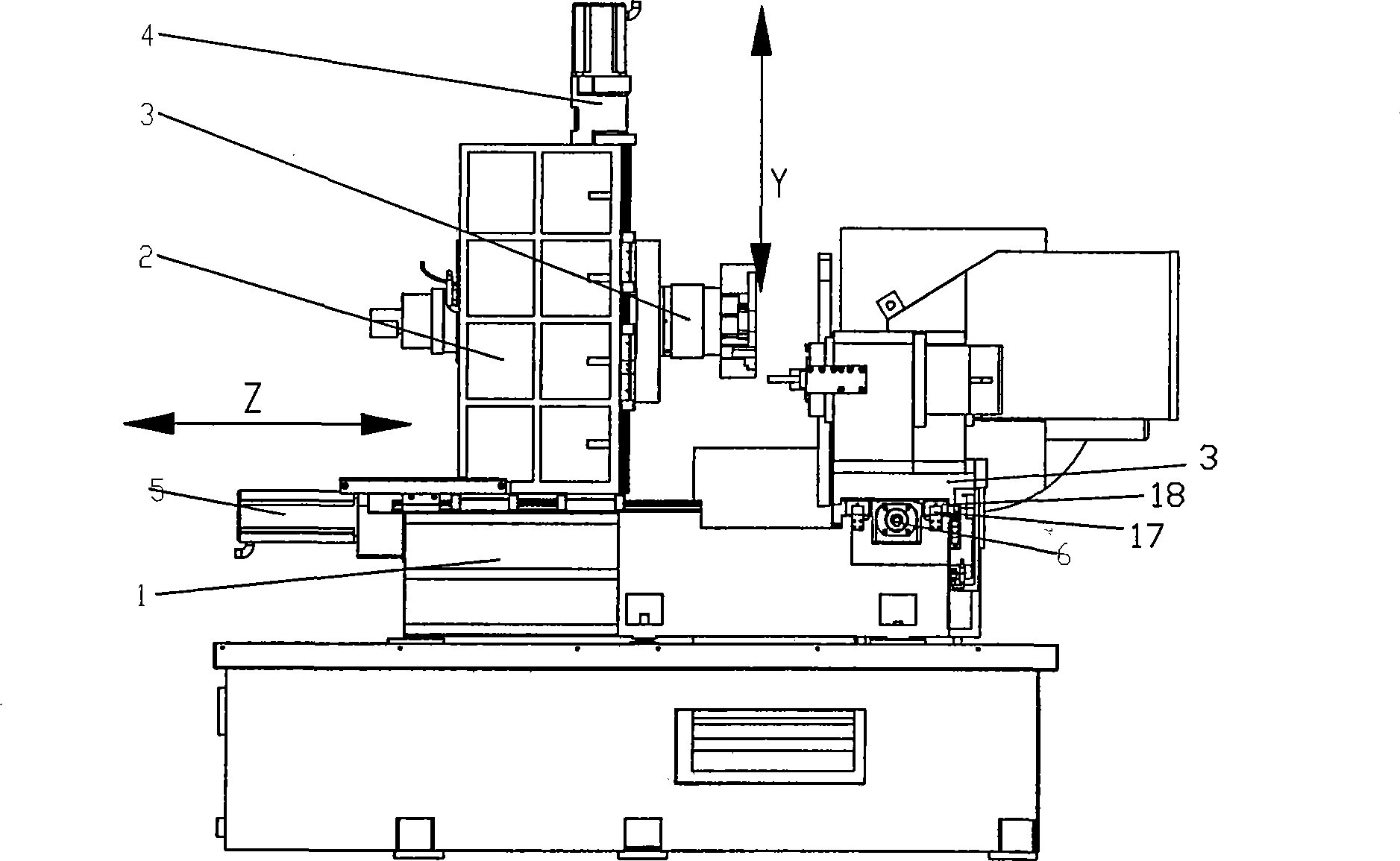

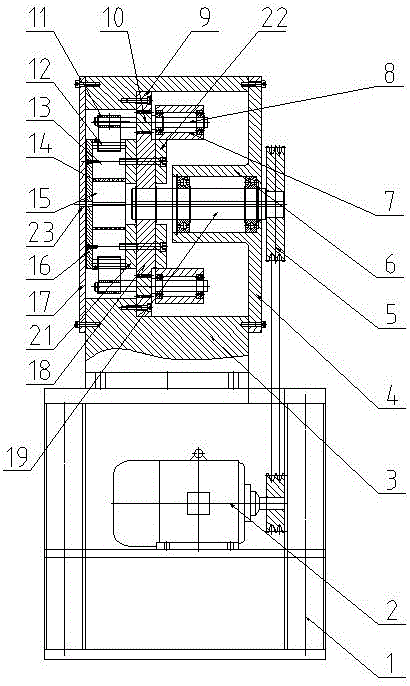

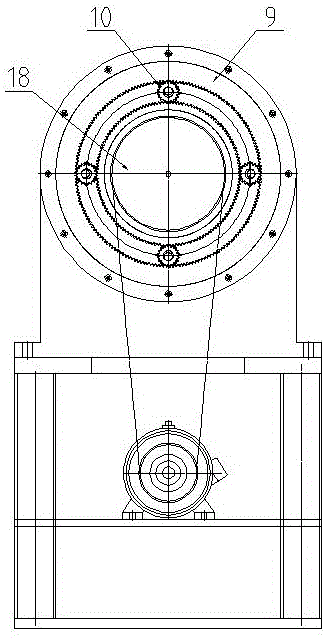

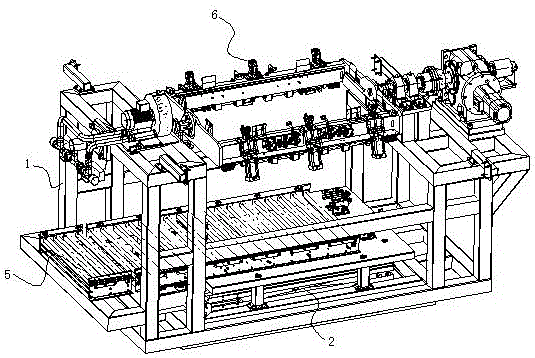

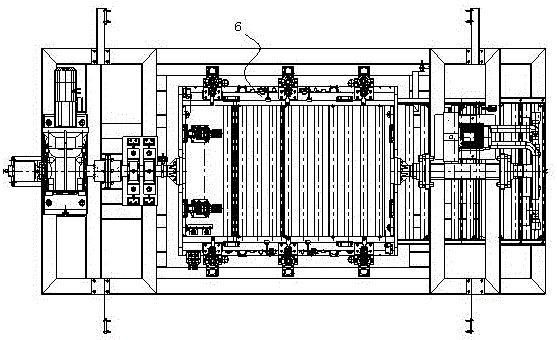

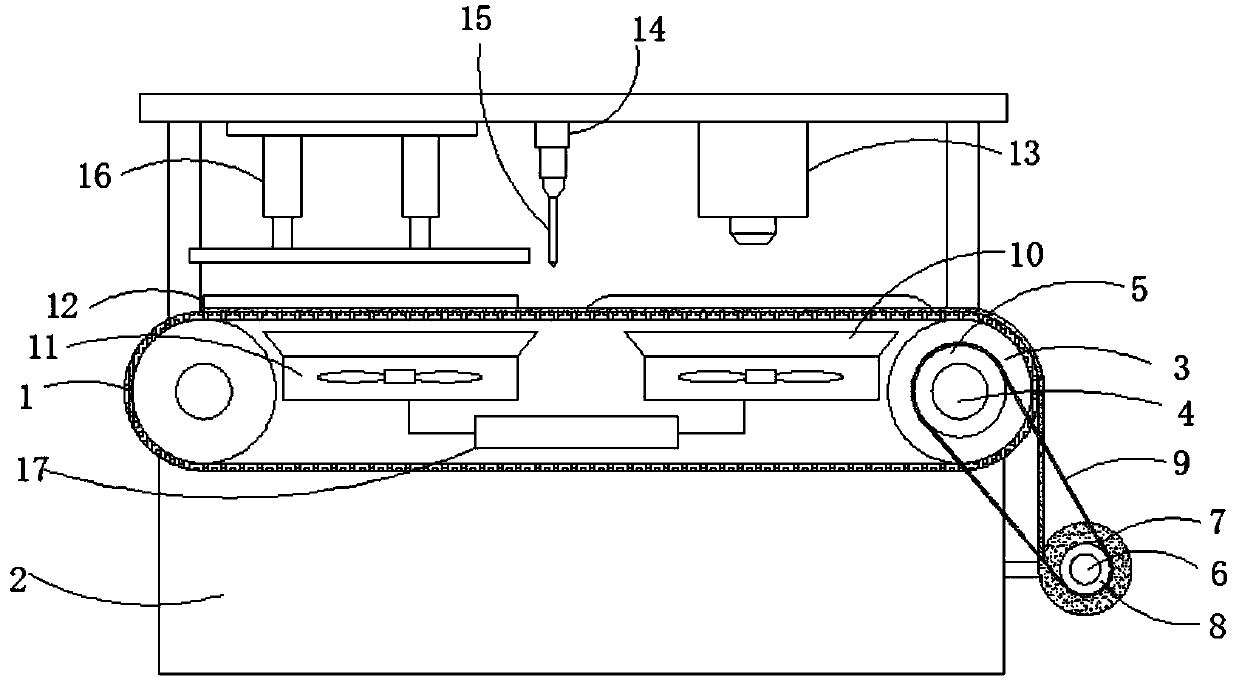

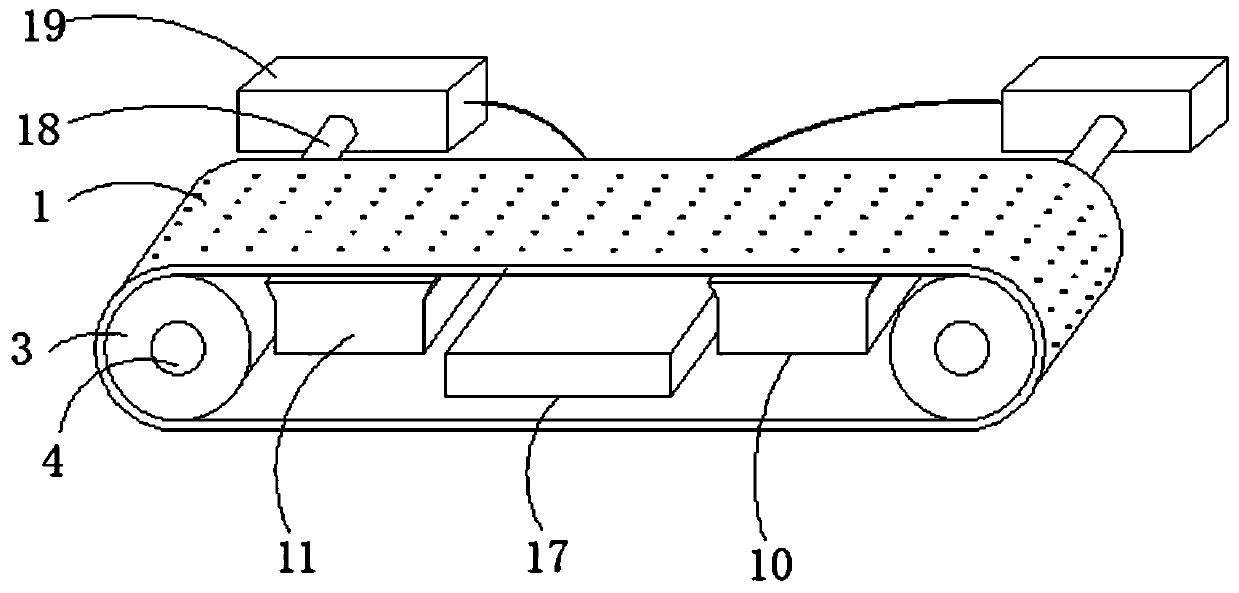

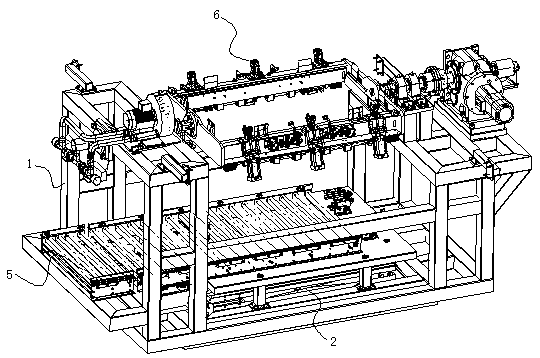

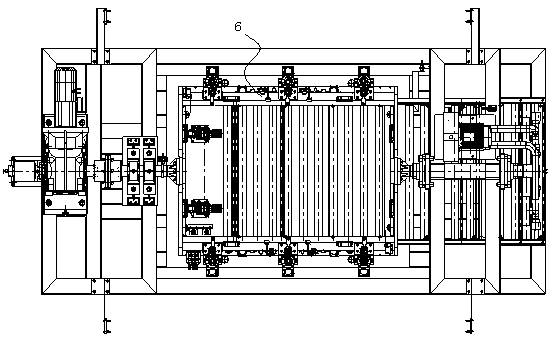

Horizontal type swirl machining center

InactiveCN101434038AGuaranteed accuracyGuaranteed position control accuracyLarge fixed membersMetal working apparatusNumerical controlEngineering

The invention relates to a horizontal vortex machining center, which relates to a high-grade digital control machine tool product for processing a key component of a vortex compressor. The horizontal vortex machining center consists of a lathe bed, an upright post, a precise milling electrical main shaft, a machining center main shaft, a machining center tool magazine, a workpiece moment motor main shaft, a Z-axis guide rail, a Z-axis slider, a Y-axis guide rail, a Y-axis slider, an X-axis guide rail, an X-axis slider, etc., wherein the X-axis guide rail is arranged on the lathe bed; the precise milling electrical main shaft is arranged on the X-axis slider; the Z-axis guide rail is arranged on the lathe bed; the upright post is arranged on the Z-axis slider; the Y-axis guide rail is arranged on the upright post; the workpiece moment motor main shaft is arranged on the Y-axis slider; the machining center main shaft is arranged on the X-axis slider; the workpiece moment motor main shaft is a C gyro shaft and horizontally arranged on the Y-axis slider. The horizontal vortex machining center guarantees the precision requirement of workpieces, is easy to remove scrap iron, and avoids influence on the surface quality of the workpieces due to accumulation of the scrap iron.

Owner:GUANGZHOU CITY AGILE MFG

Economical steel with excellent comprehensive mechanical properties for hot-dip galvanized automobile outer plate and production method thereof

InactiveCN112159926AImprove mechanical propertiesImprove surface qualityHot-dipping/immersion processesEconomic benefitsMechanical property

The invention discloses economical steel with excellent comprehensive mechanical properties for a hot-dip galvanized automobile outer plate and a production method thereof, and belongs to the technical field of steel for hot-dip galvanized automobiles. The steel for the hot-dip galvanized automobile outer plate comprises the following main chemical elements of, in percentage by mass, 0.001%-0.005%of C, 0.09%-0.15% of Si, 0.40%-0.55% of Mn, 0.05%-0.07% of Ti, 0.02%-0.06% of Als, 0.035%-0.055% of P, less than or equal to 0.015% of S, less than or equal to 0.005% of N, 0.001%-0.006% of Nb, lessthan or equal to 0.0015% of B and the balance Fe and inevitable impurities. The steel for the hot-dip galvanized automobile outer plate has the advantages of being excellent in forming performance, excellent in comprehensive mechanical property, good in performance stability, high in surface quality and low in production cost, industrial large-batch stable production is achieved, and economic benefits of enterprises are good.

Owner:MAANSHAN IRON & STEEL CO LTD

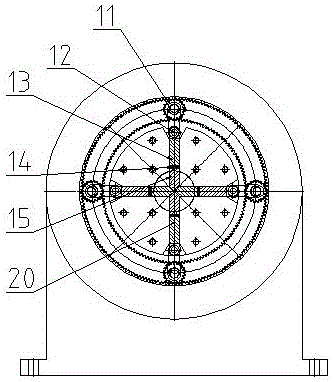

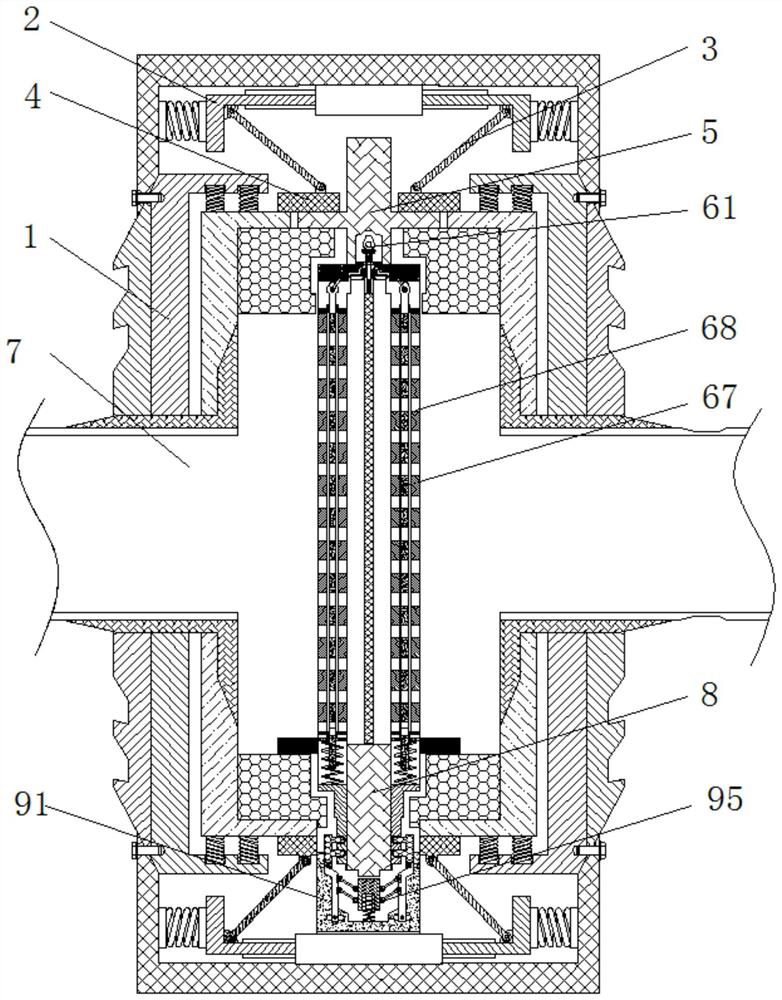

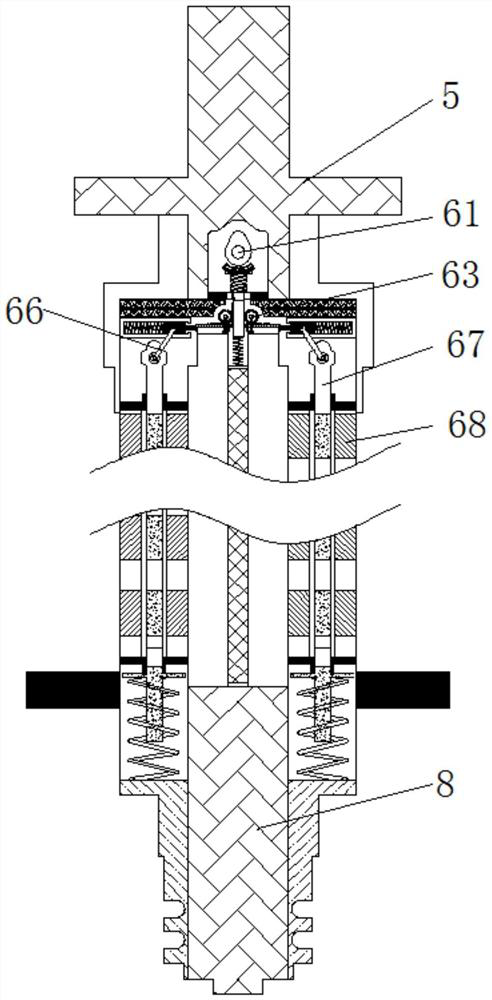

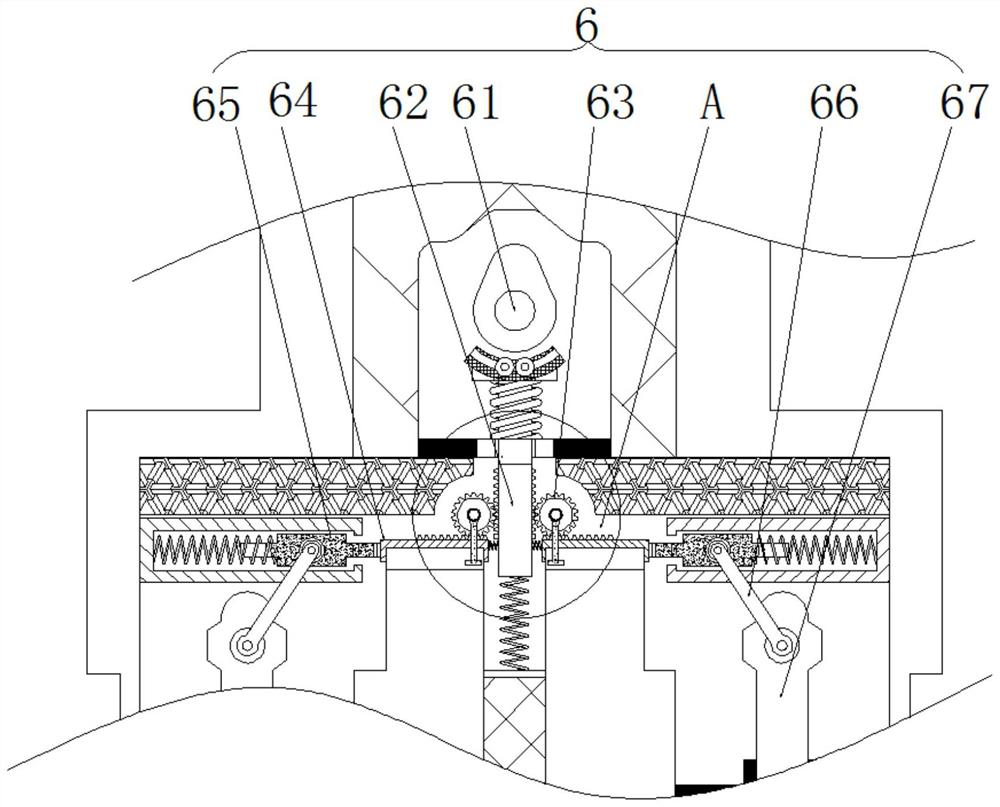

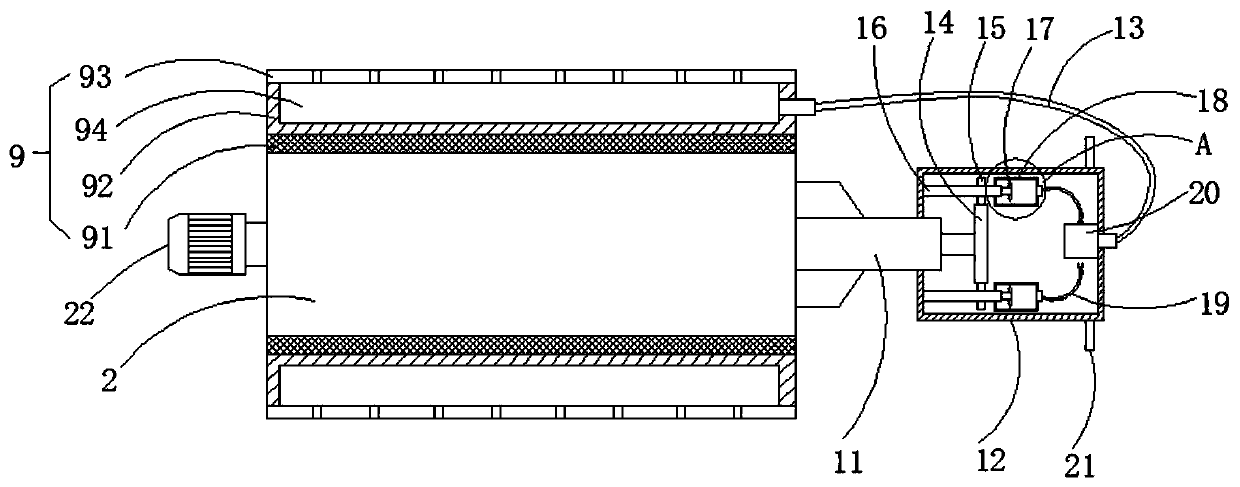

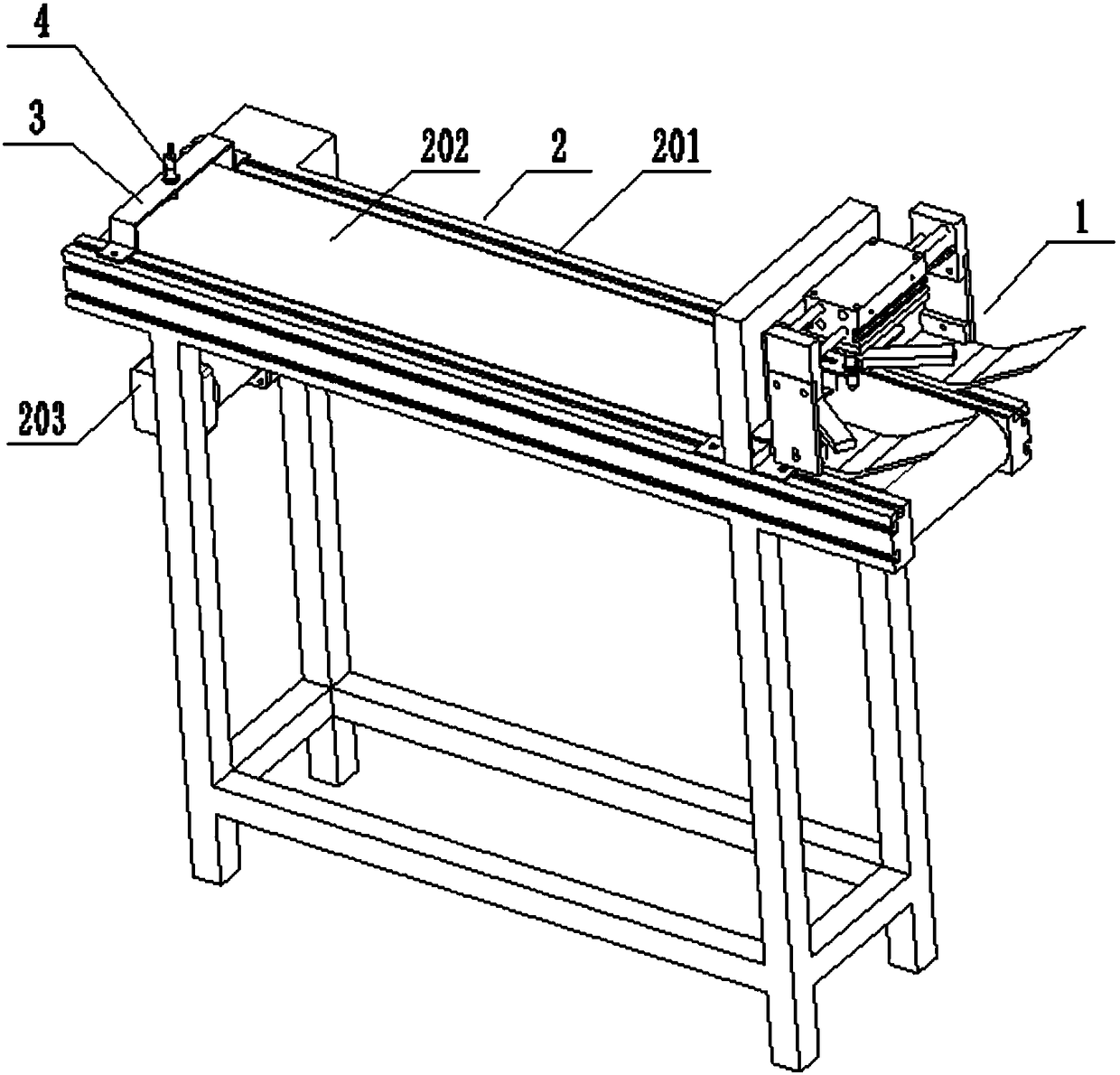

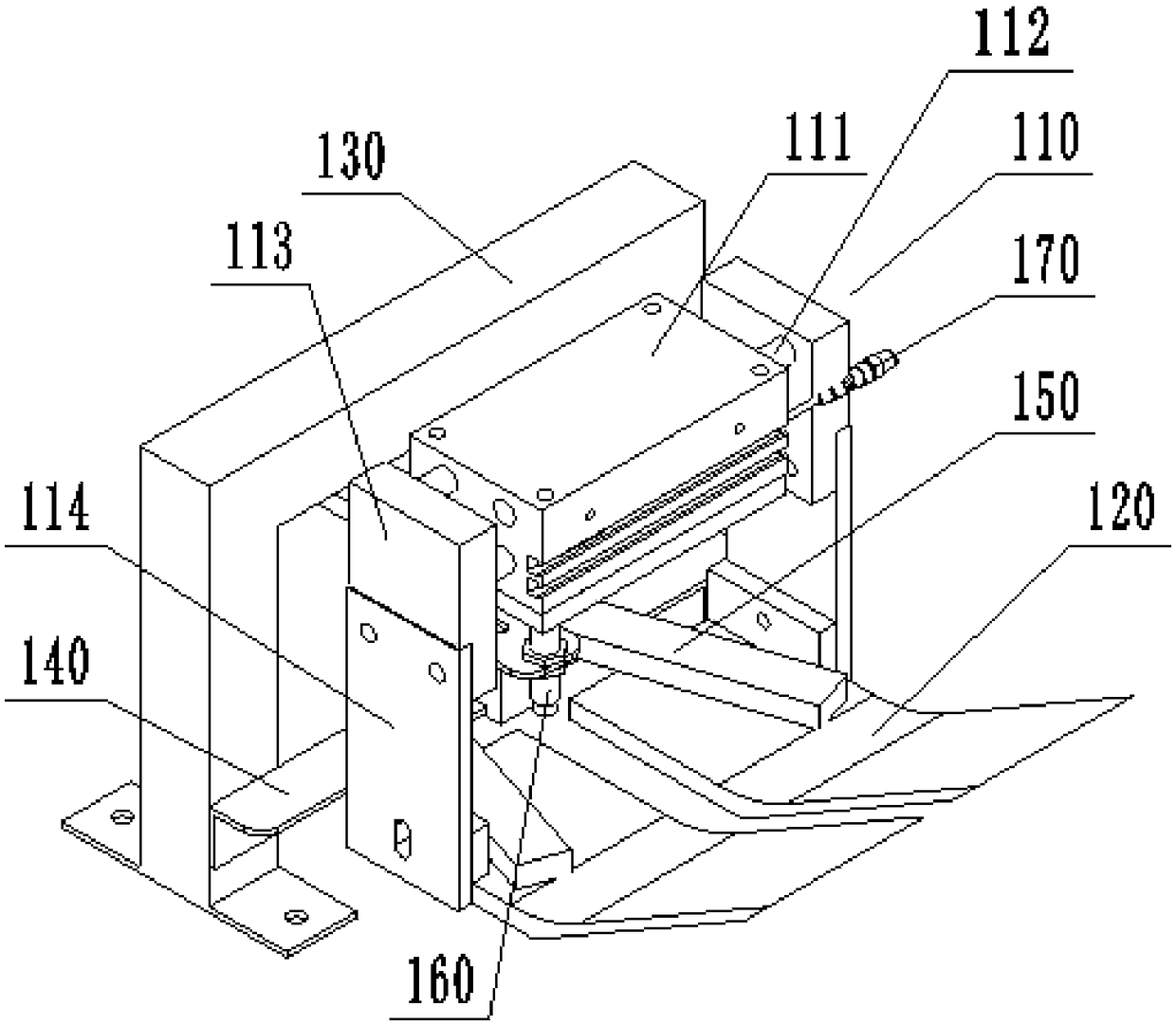

Stranded welding wire hammering machine

The invention relates to a stranded welding wire hammering machine. The stranded welding wire hammering machine comprises a hammering machine base (3), wherein a mandrel (19) is installed in the center of the hammering machine base (3) in a penetrating manner, a big gear wheel (18) is arranged at the left end of the mandrel (19), a gear ring (9) is arranged on the periphery of the big gear wheel (18), a plurality of second bearing pedestal (7) are arranged on the periphery of the right side of the big gear wheel (18), one eccentric shaft (8) is installed on each second bearing pedestal (7) in a penetrating manner, one pinion (10) is arranged on each eccentric shaft (8), a plurality of limiting sliding grooves (20) are evenly formed in a left fixing plate (21) outwards along the center of the left fixing plate (21), one hammer forging die (15) and one transmission block (13) are arranged in each limiting sliding groove (20), one crank (11) is arranged at the left end of each eccentric shaft (8), and one end of each crank (11) is connected with the corresponding transmission block (13). The working efficiency of the stranded welding wire hammering machine is high, the phenomena that stranded welding wires are slub and have internal stress can be eliminated, and the ideal surface state of the stranded welding wires can be achieved.

Owner:河北联之捷焊业科技有限公司

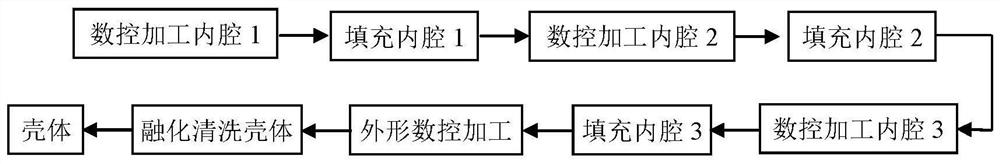

Thin-wall part precision numerical control machining cleaning method and filler

PendingCN114798567ALow costImprove processing efficiencyCleaning using liquidsNumerical controlAnhydrous ethanol

According to the thin-wall part precision numerical control machining cleaning method and the filler, materials used by the formula filler are all industrial materials and are wide in source, easy to purchase and low in cost; the melting temperature of the filling material is 120 DEG C, and a common oil bath pan can meet the melting temperature requirement and meet the influence of cutting heat generated in the machining process on the precision of machined thin-wall parts. After being cooled and solidified, the filler in the formula can be well combined with a metal material, after a thin wall of a part is machined, the filler can be melted and removed from the thin-wall part at the temperature of 95 DEG C, the melted and collected filler can be repeatedly used, meanwhile, the melted and residual filler on the metal surface can be easily removed through gasoline and absolute ethyl alcohol, and the surface quality of the thin-wall part cannot be affected. The problem that the precision and dimensional tolerance of the part cannot meet the design requirements due to the fact that the thin-wall part is prone to deformation during machining is solved, the machining efficiency is improved, and the cost for machining the high-precision thin-wall part is reduced.

Owner:NO 20 RES INST OF CHINA ELECTRONICS TECH GRP

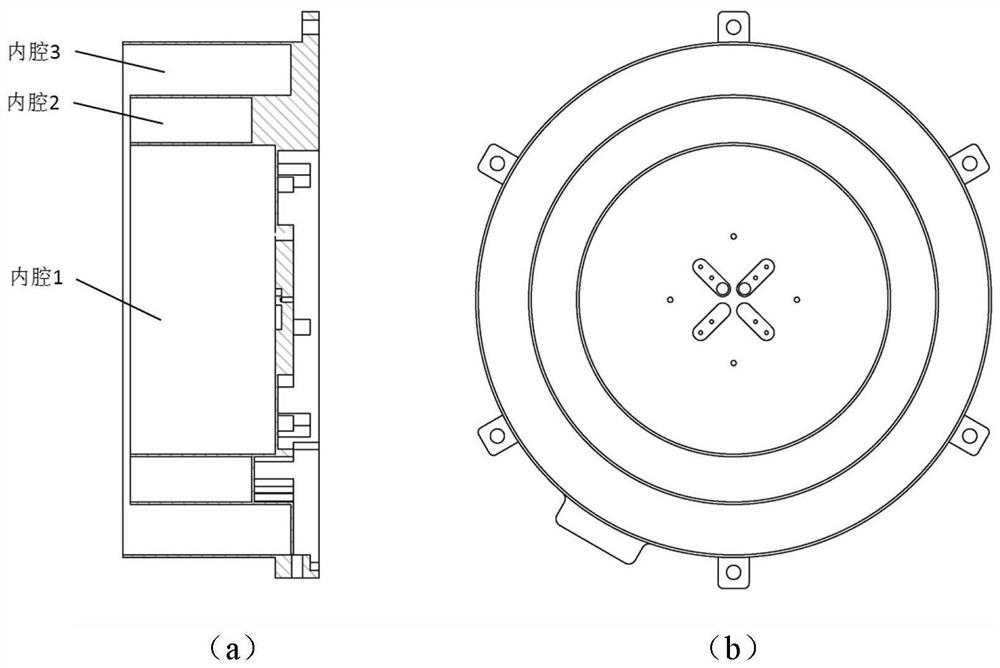

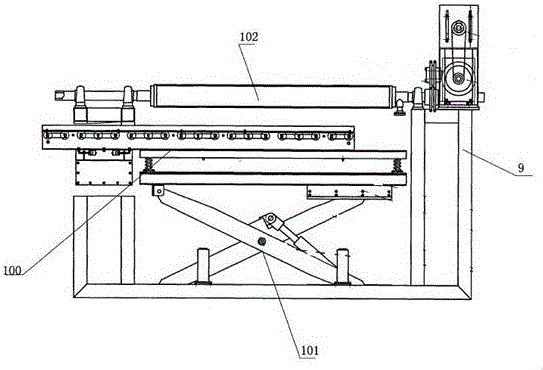

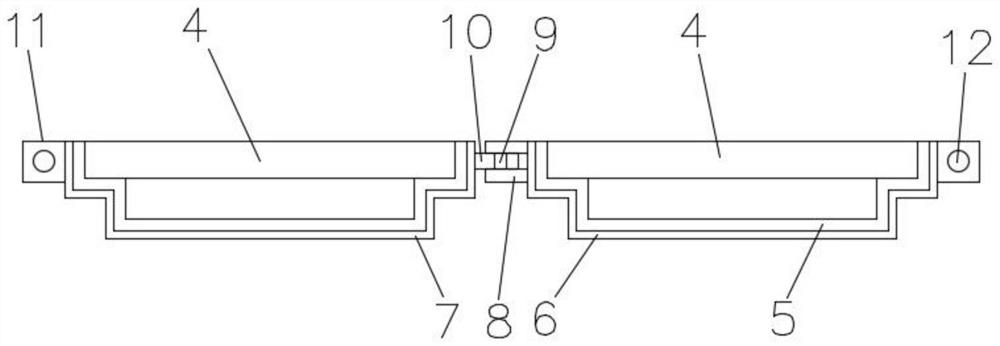

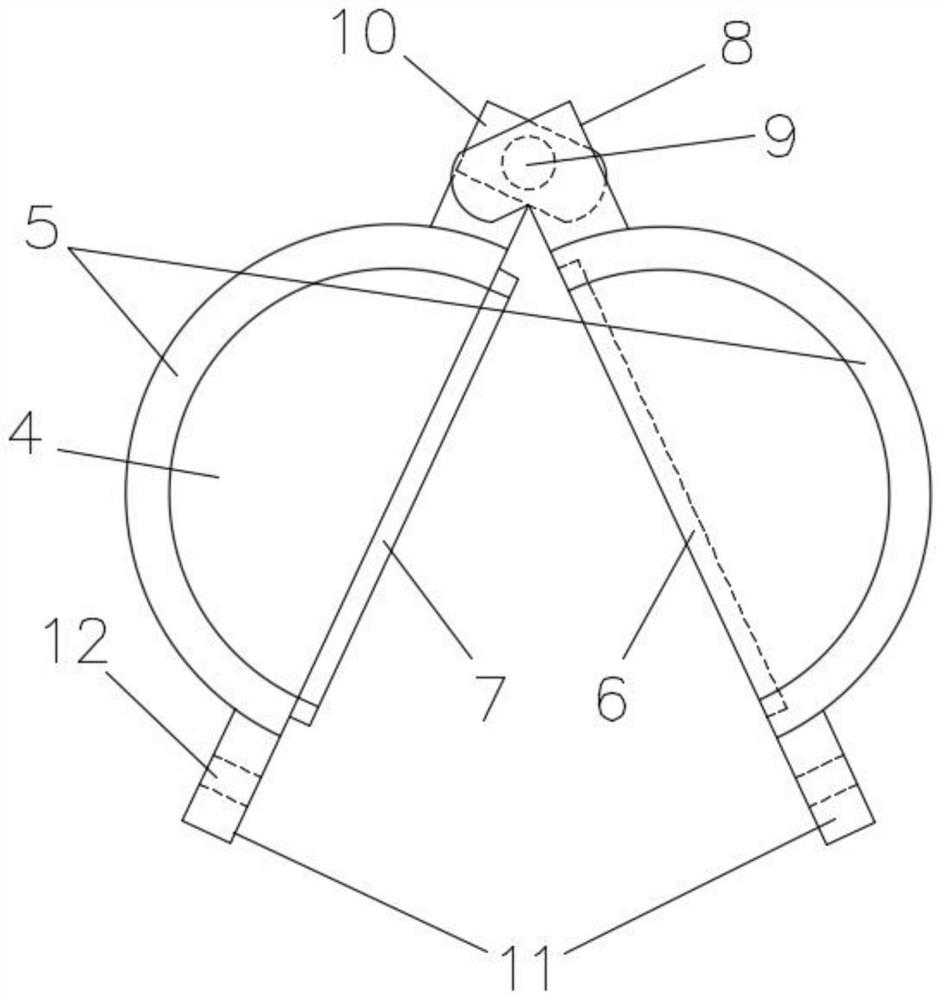

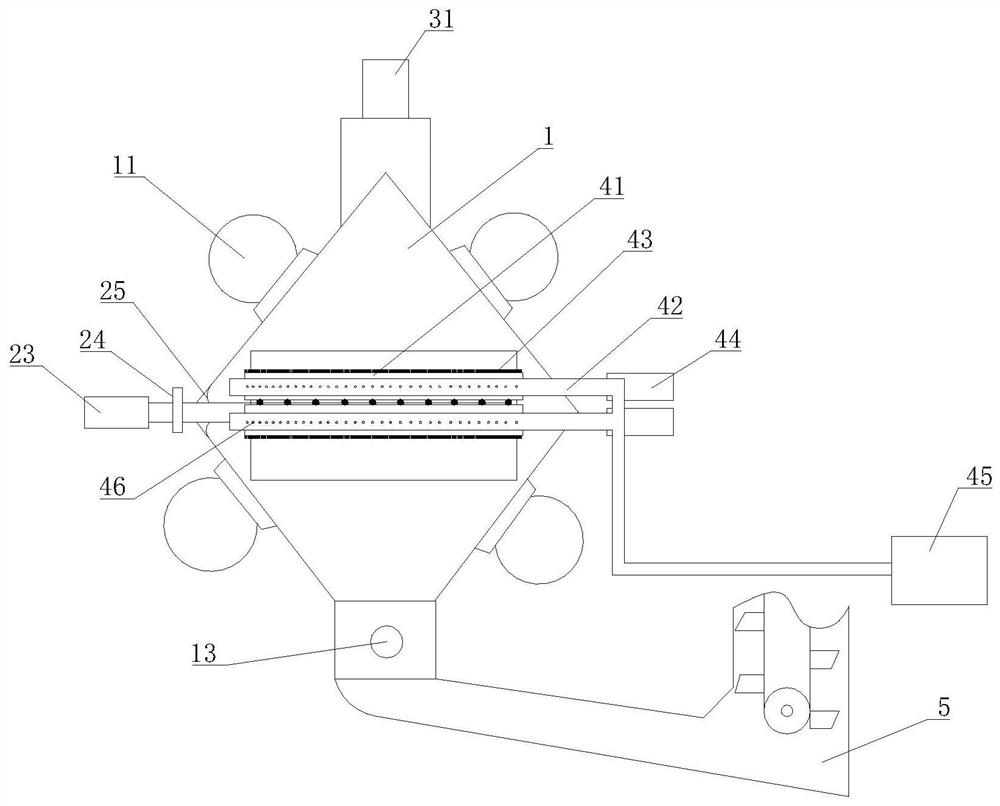

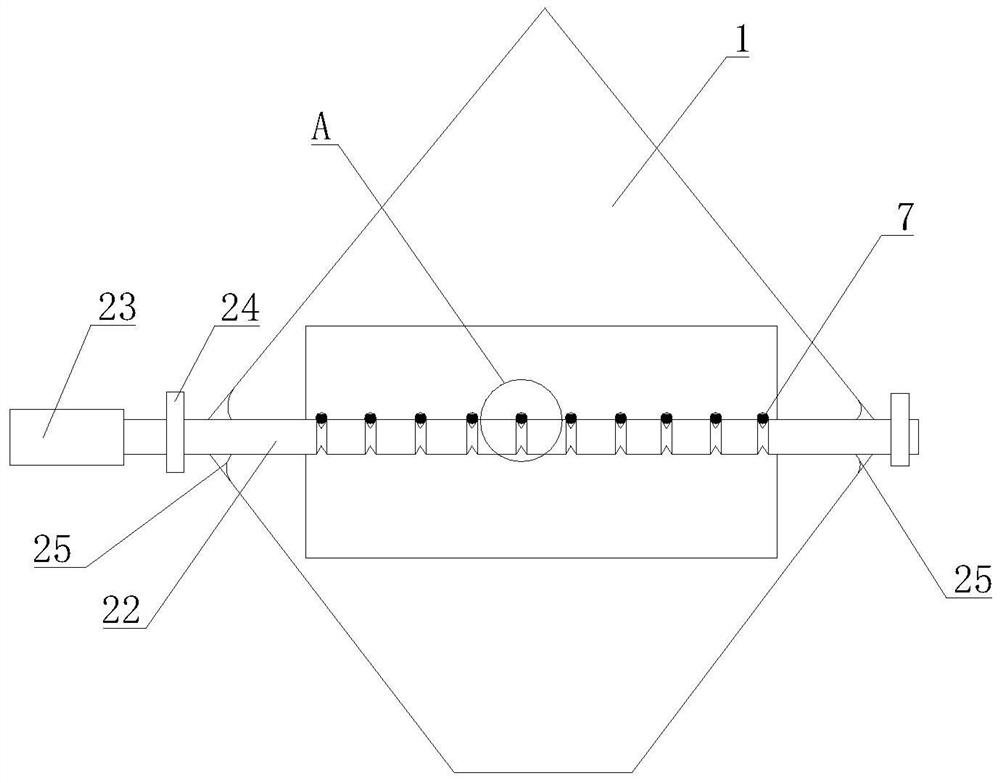

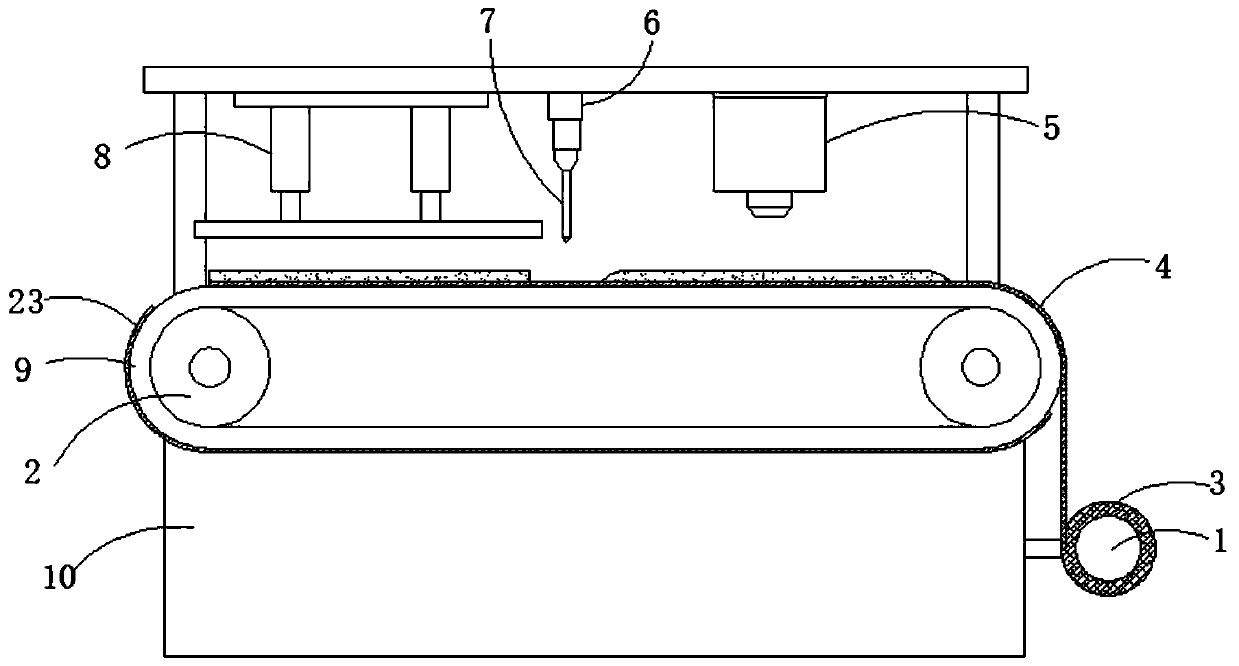

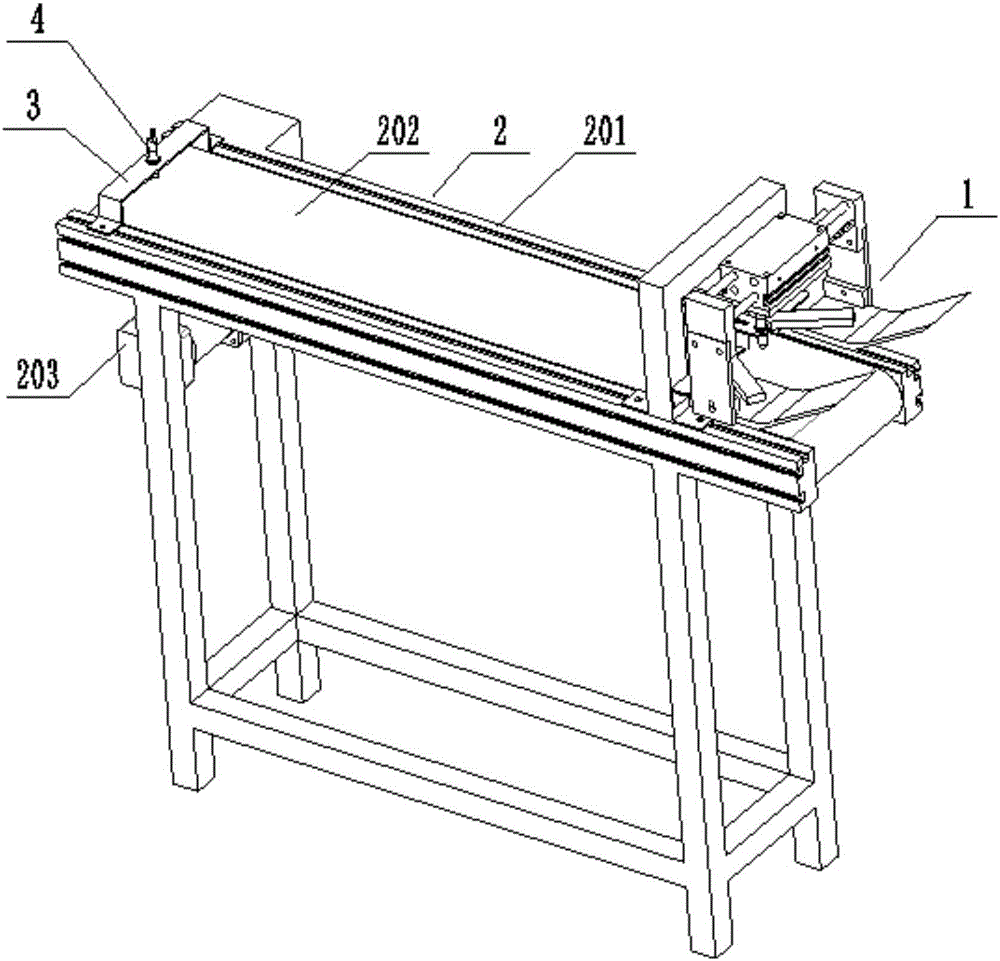

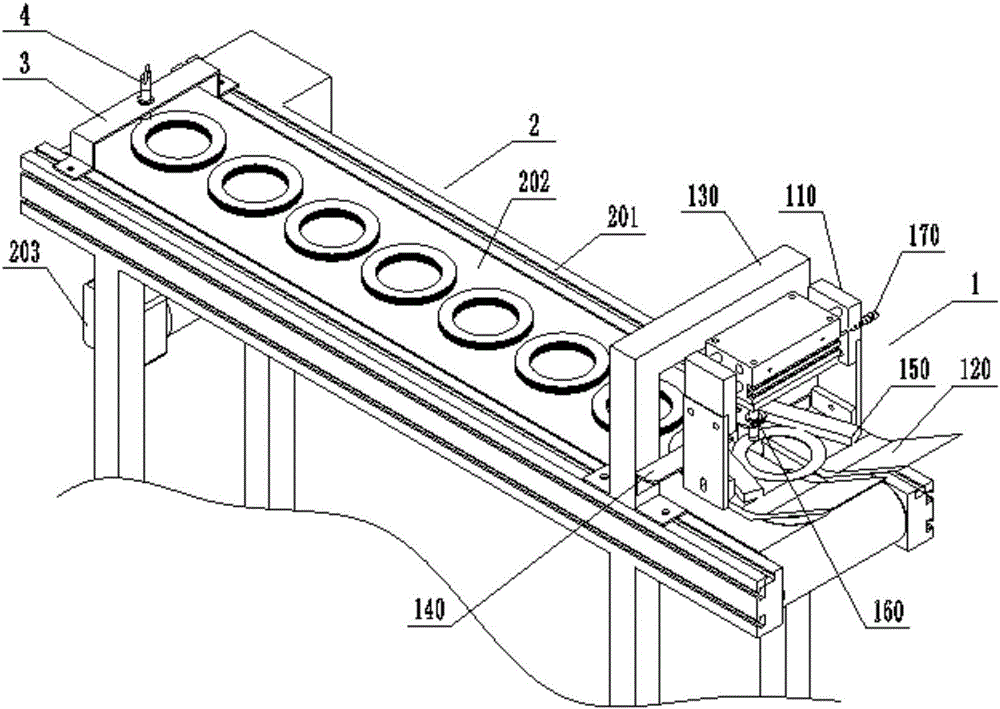

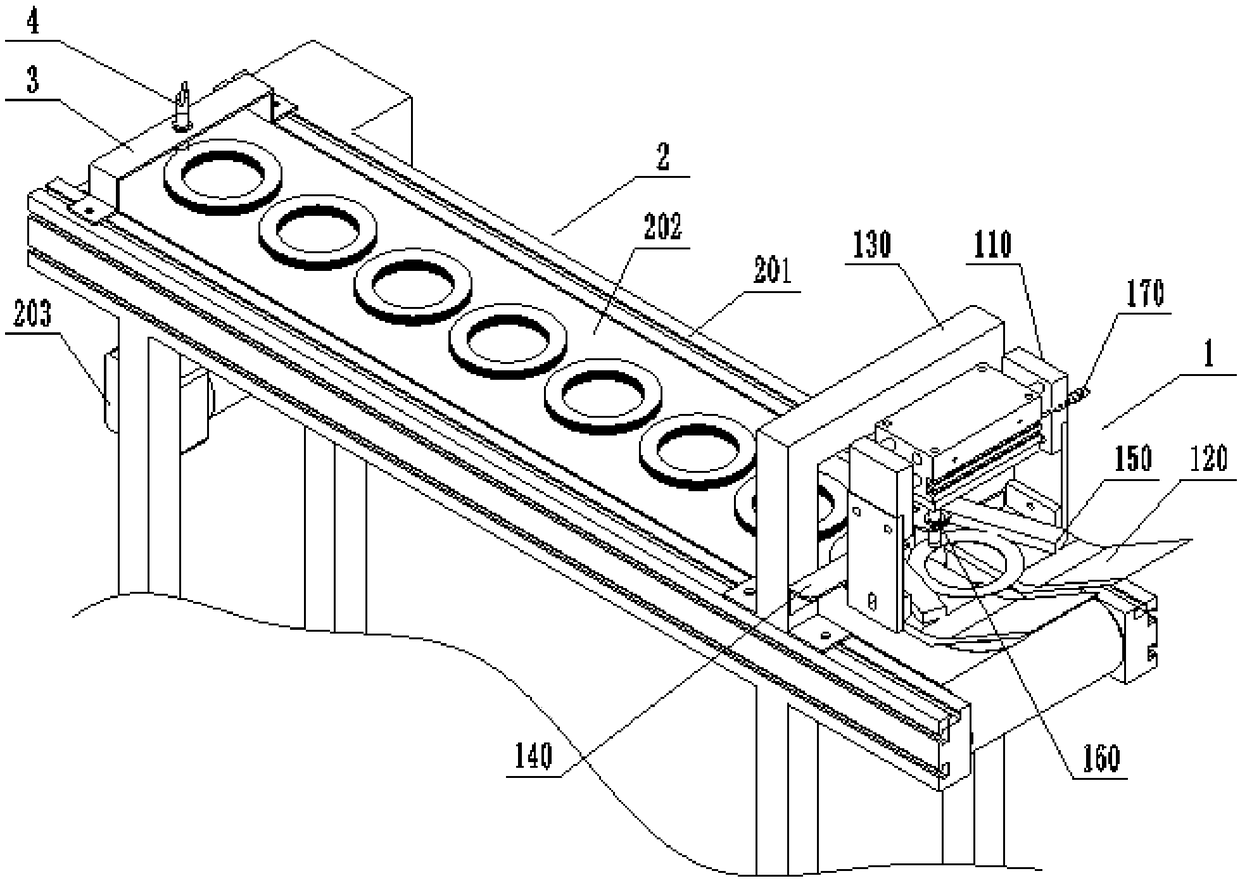

Automobile interior trim part slush molding bed

The invention relates to an automobile interior trim part slush molding bed which comprises a lifting mechanism, a horizontal conveying mechanism and a turnover mechanism. The automobile interior trim part slush molding bed is characterized in that the turnover mechanism comprises a turnover frame, a powder box automatic locking mechanism installed on the turnover frame and a mold automatic locking mechanism of a self-locking structure. The automobile interior trim part slush molding bed has the advantages that a mold and a powder box do not need to be manually locked, the locking speed is high, self locking is achieved through the self structure in the mold locking process, and it is ensured that the mold is not disengaged from the turnover frame.

Owner:NANTONG CHAODA EQUIP CO LTD

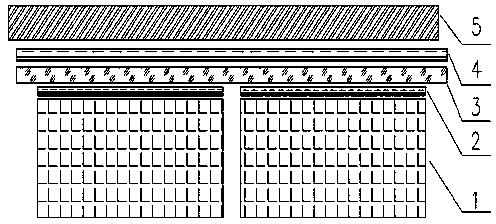

Concrete prefabricated part formwork, concrete prefabricated part formwork platform and concrete prefabricated part forming method

PendingCN109278168AEasy to operateLow costMouldsCeramic shaping liningsStructural engineeringMachining process

The invention relates to a concrete prefabricated part formwork, a concrete prefabricated part formwork platform and a concrete prefabricated part forming method. The concrete prefabricated part formwork comprises a plate surface for forming a prefabricated part, the formwork is a steel plate, and the steel plate is provided with a polished surface formed by polishing; and the plate surface is formed by the polishing surface. The polishing surface can be formed by polishing the steel plate, the machining process is simple, the cost is low, and the production efficiency is high; and after polishing, the oxide skin is effectively prevented from being adhered to the concrete to cause the non-uniform color of the prefabricated part, and the surface quality of the prefabricated part is not affected.

Owner:HENAN WUJIAN CONSTR GRP +1

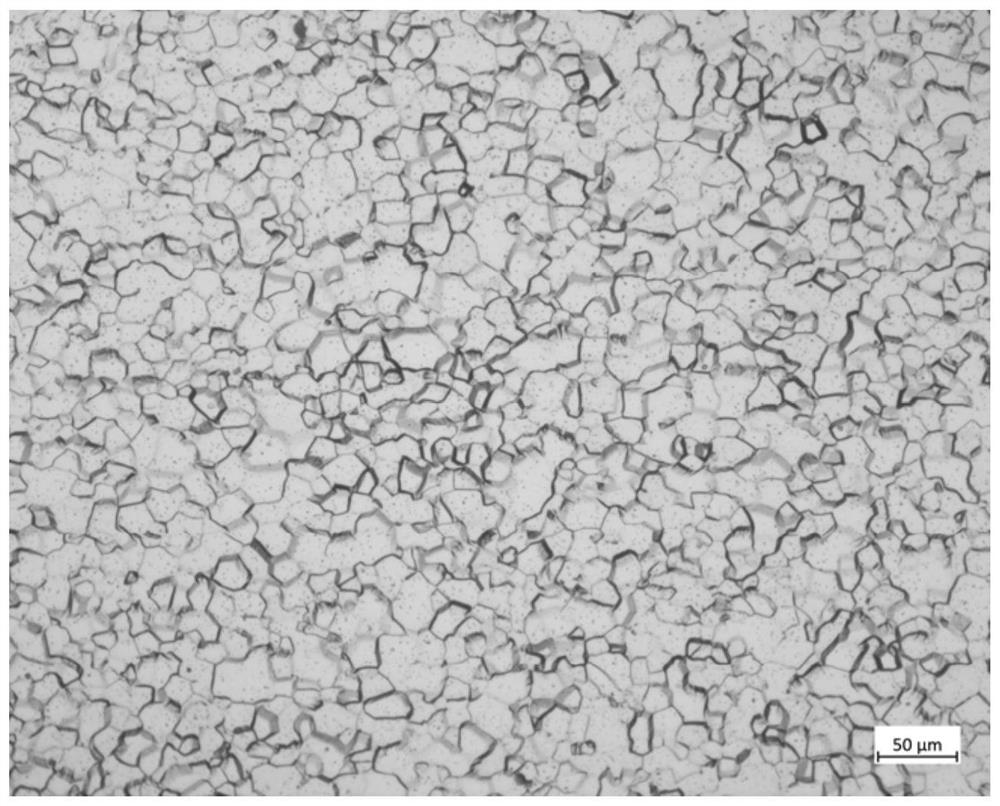

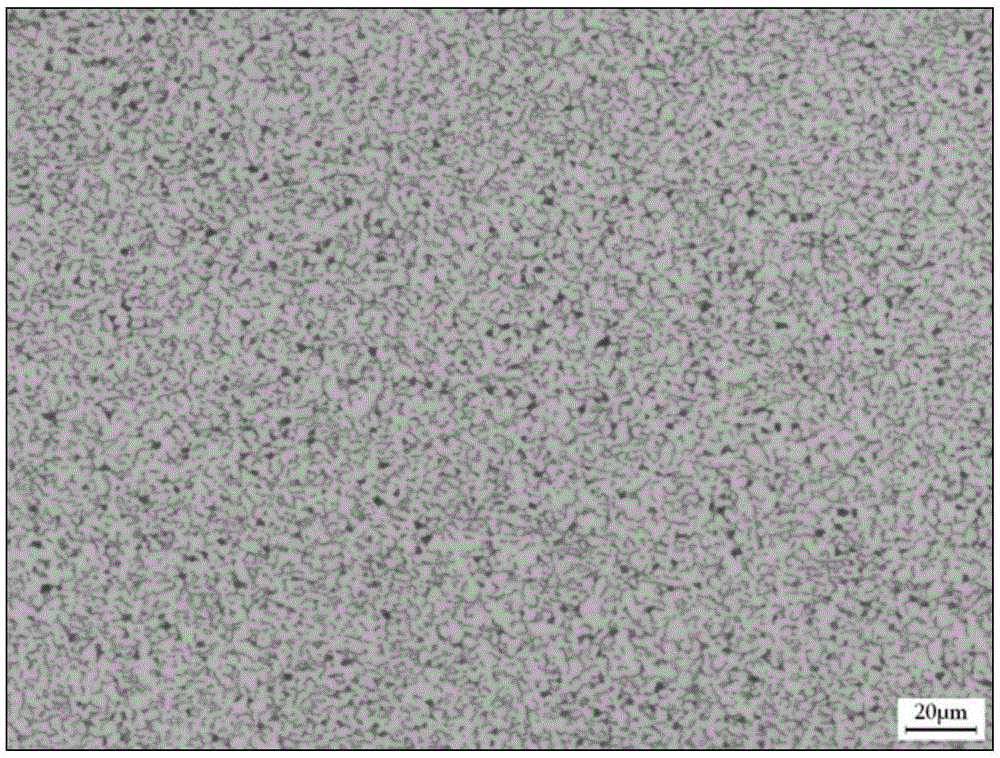

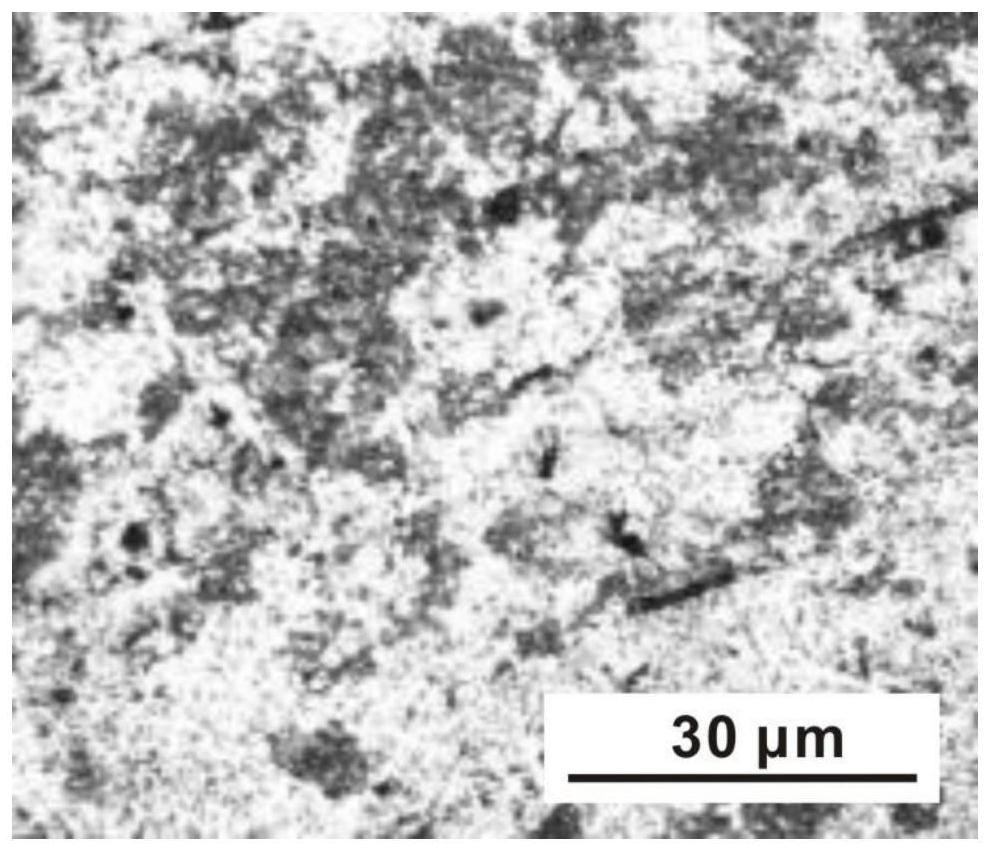

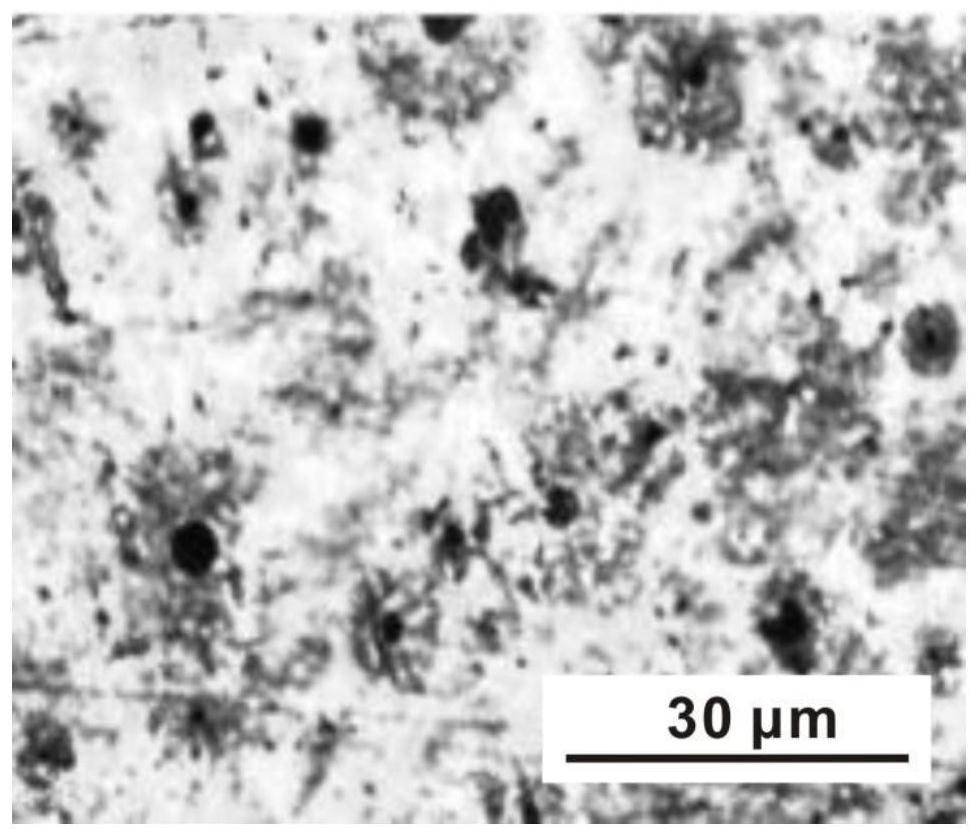

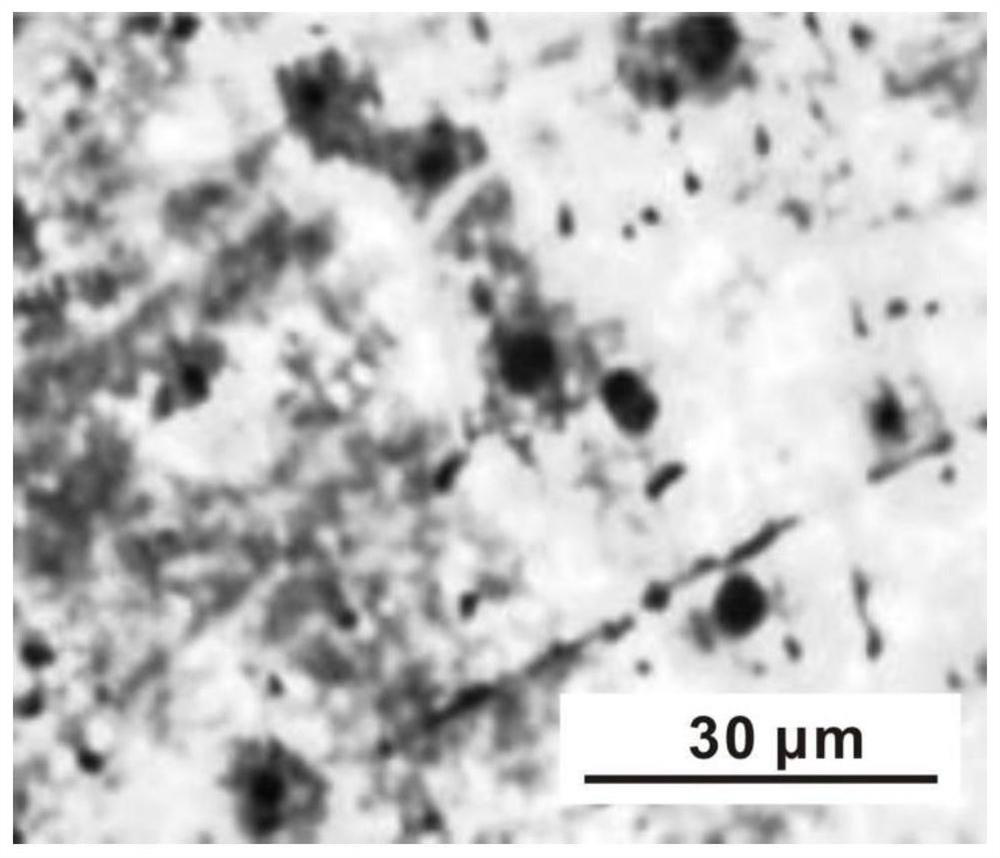

A processing method of fine-grained superplastic ta15 titanium alloy sheet

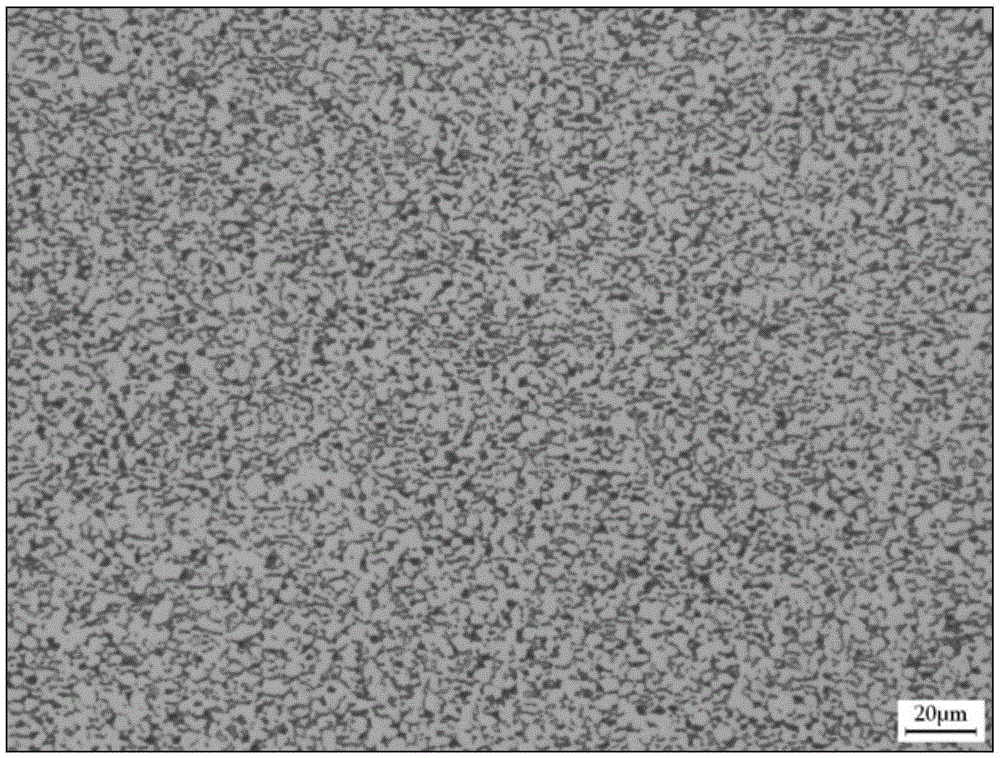

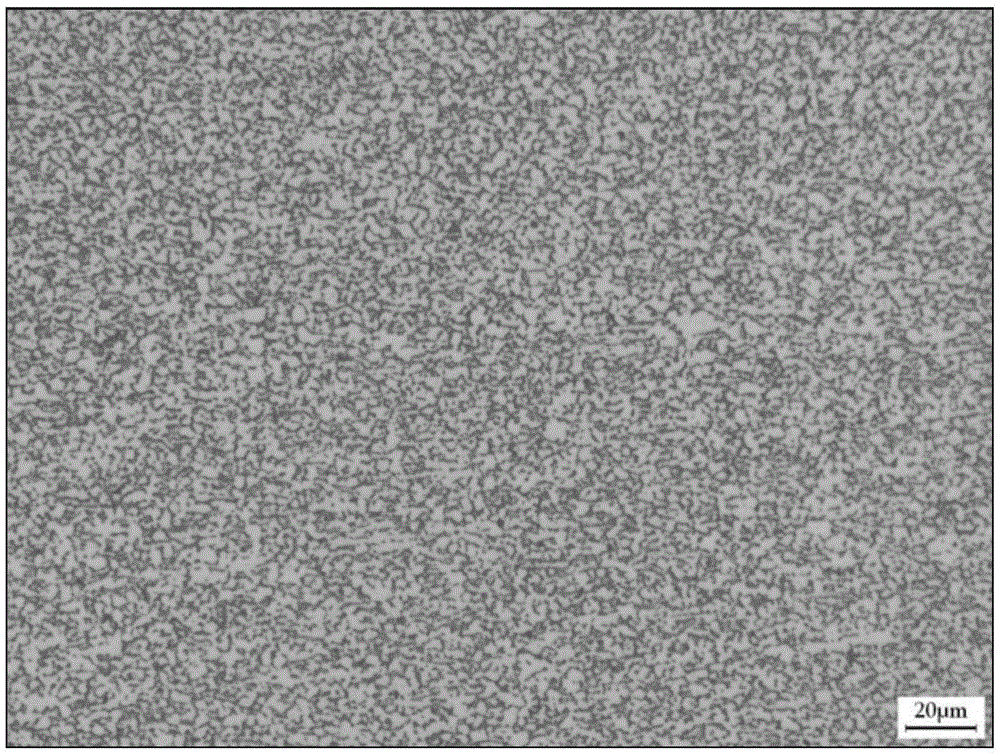

ActiveCN103978032BSmall horizontal and vertical performance gapUniform deformationMetal rolling stand detailsMetal rolling arrangementsControllabilityTitanium alloy

The invention provides a processing method of a fine-grain superplastic TA15 titanium alloy sheet. The processing method includes steps of firstly, heating a TA15 titanium alloy sheet blank; secondly, performing first rolling to obtain first semi-finished sheet blanks; thirdly, heating the first semi-finished sheet blanks; fourthly, performing second rolling to obtain second semi-finished sheet blanks; fifthly, manufacturing several second semi-finished sheet blanks into a ply rolling pack; sixthly, heating the ply rolling pack; seventhly, performing third rolling and annealing, performing alkaline washing, acid pickling, sanding and shearing after unpacking, and obtaining a fine-grain superplastic TA15 titanium alloy sheet. The fine-grain superplastic TA15 titanium alloy sheet processed by the processing method is uniform in texture, fine in grains and excellent in superplasticity and consistence of performance, and has excellent process controllability and stability in batch production.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

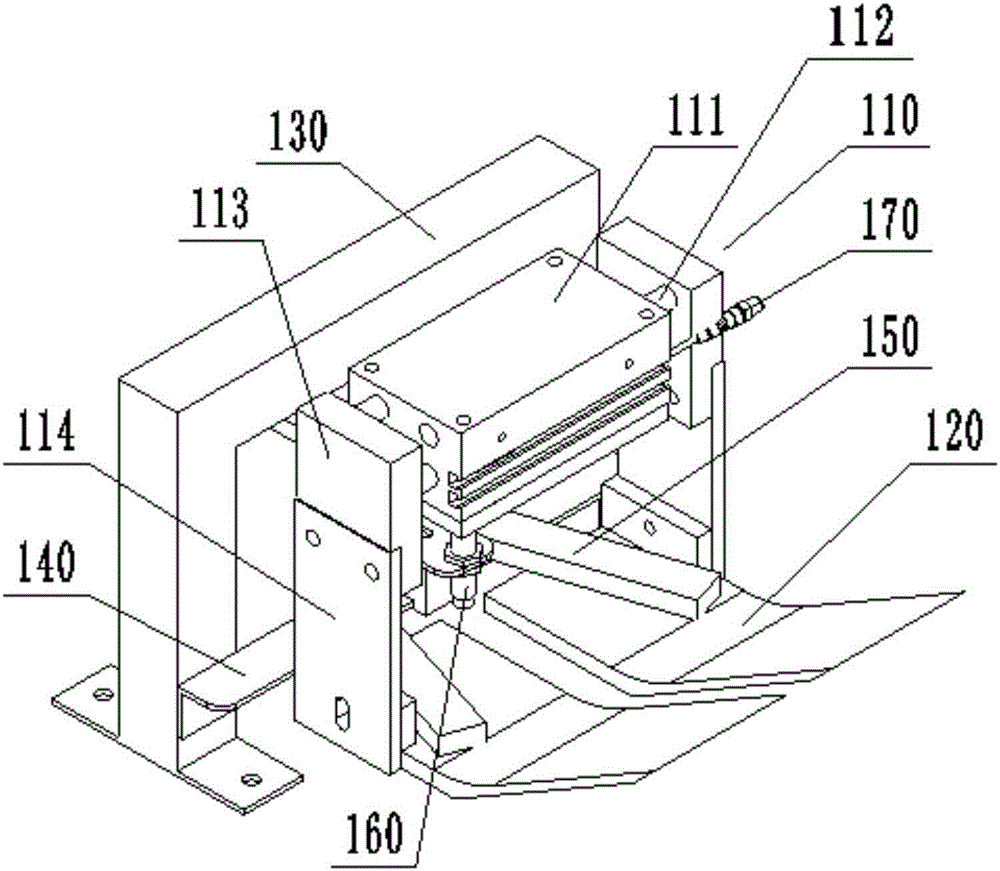

Control method of circuit system of counting and stacking machine

InactiveCN108100612ASurface quality effectEasy to packConveyorsControl devices for conveyorsAutomatic controlControl engineering

Owner:安徽华天机械股份有限公司

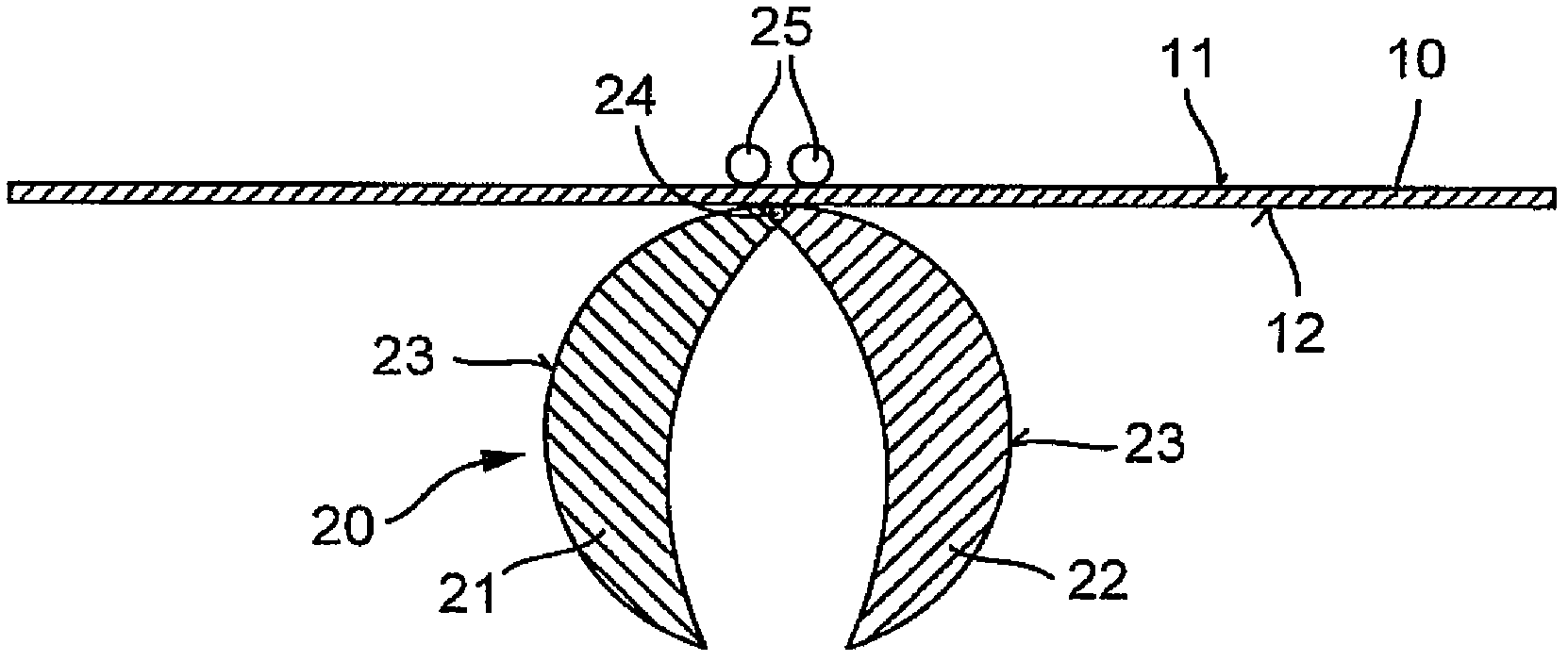

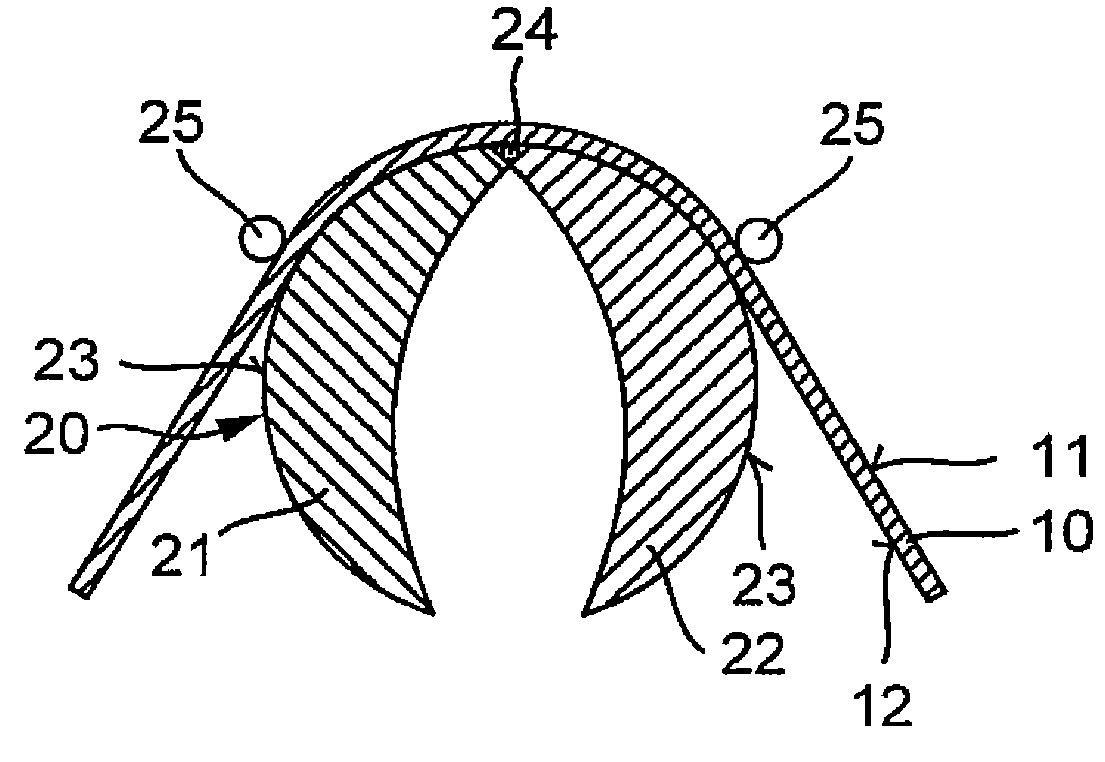

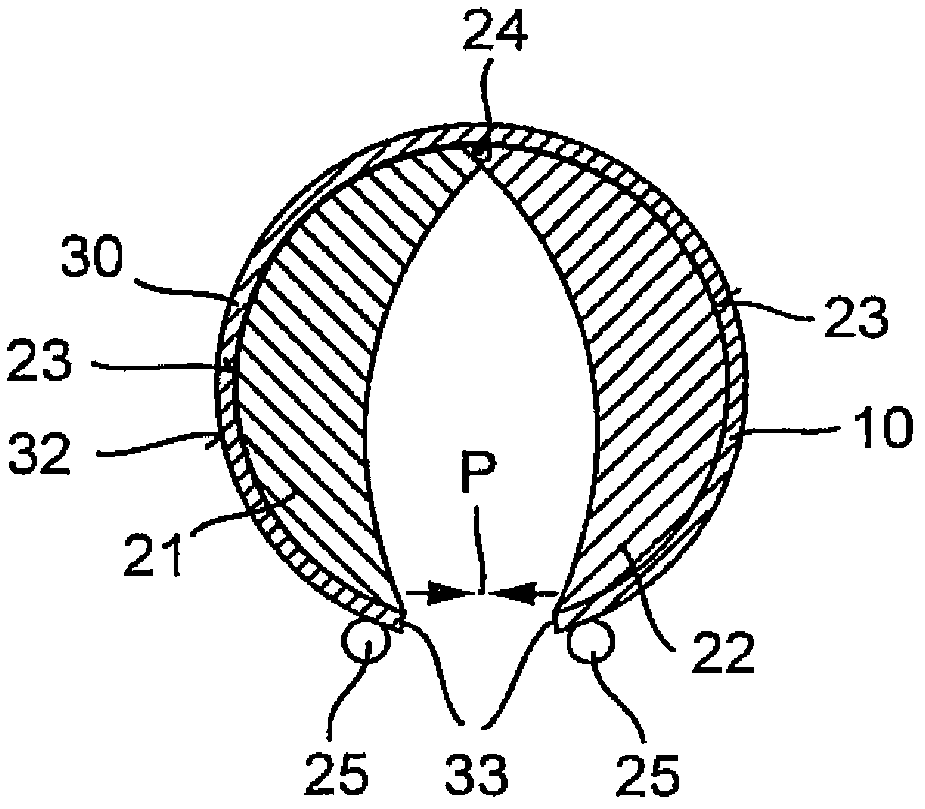

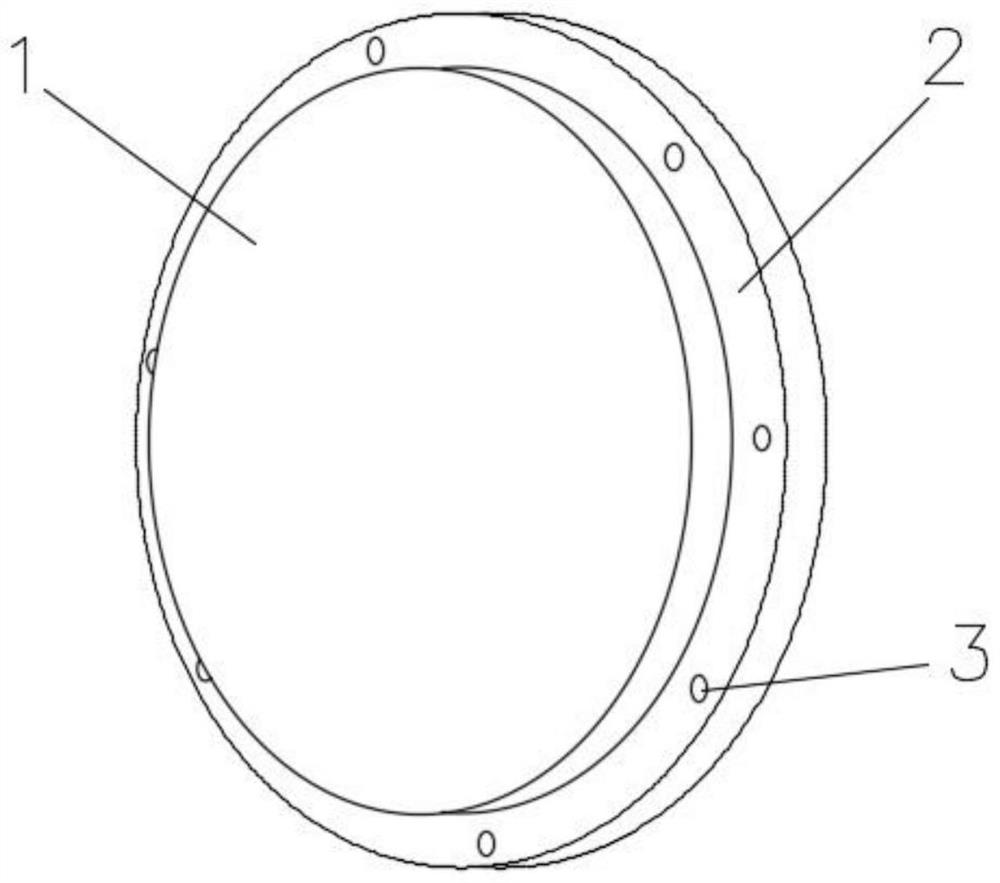

Curved glass or glass ceramic moulded part and method for producing same

ActiveCN102424517ASurface quality effectGlass reforming apparatusThin material handlingViscosityGlass-ceramic

The process comprises introducing a green glass blank (10) in a temperature state in which its viscosity enables a deformation, and molding the green glass blank on a curved support surface (23) of a molding tool (20). The green glass blank is: molded on the support surface during the remolding process using a movable blank-holder (25); deformed in the region between the blank holder and the support surface and by two oppositely traversed blank holder; ceramized after its deformation; and provided with a decorative coating and / or a functional coating before its transformation. The process comprises introducing a green glass blank (10) in a temperature state in which its viscosity enables a deformation, and molding the green glass blank on a curved support surface (23) of a molding tool (20). The green glass blank is: molded on the support surface during the remolding process using a movable blank-holder (25); deformed in the region between the blank holder and the support surface and by two oppositely traversed blank holder; ceramized after its deformation; and provided with a decorative coating and / or a functional coating before its transformation. The blank-holder is: moved along the curved support surface during the remolding process; unrolled by rollers on the green glass blank; moved into a final forming position in which it rests on the deformed green glass blank; and kept in the cooling phase of the green glass blank formed glass or glass ceramic mold part in the final forming position. An INDEPENDENT CLAIM is included for a glass- or glass ceramic-mold part.

Owner:SCHOTT AG

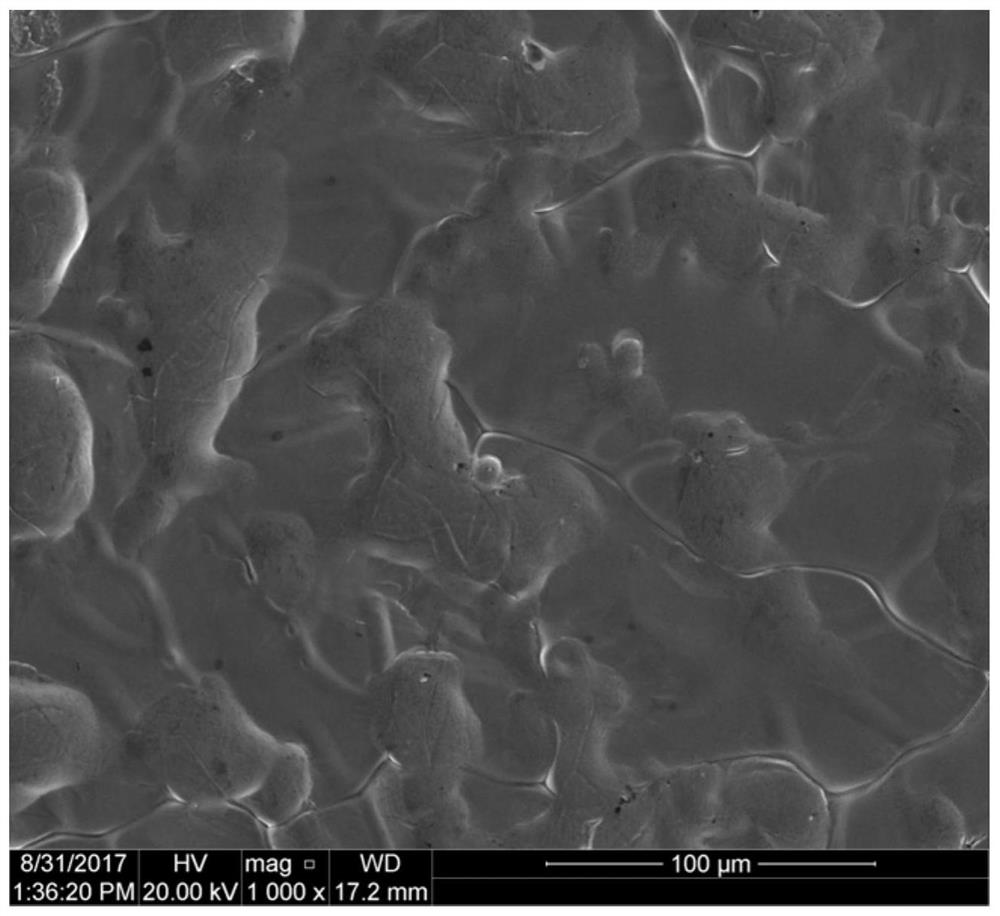

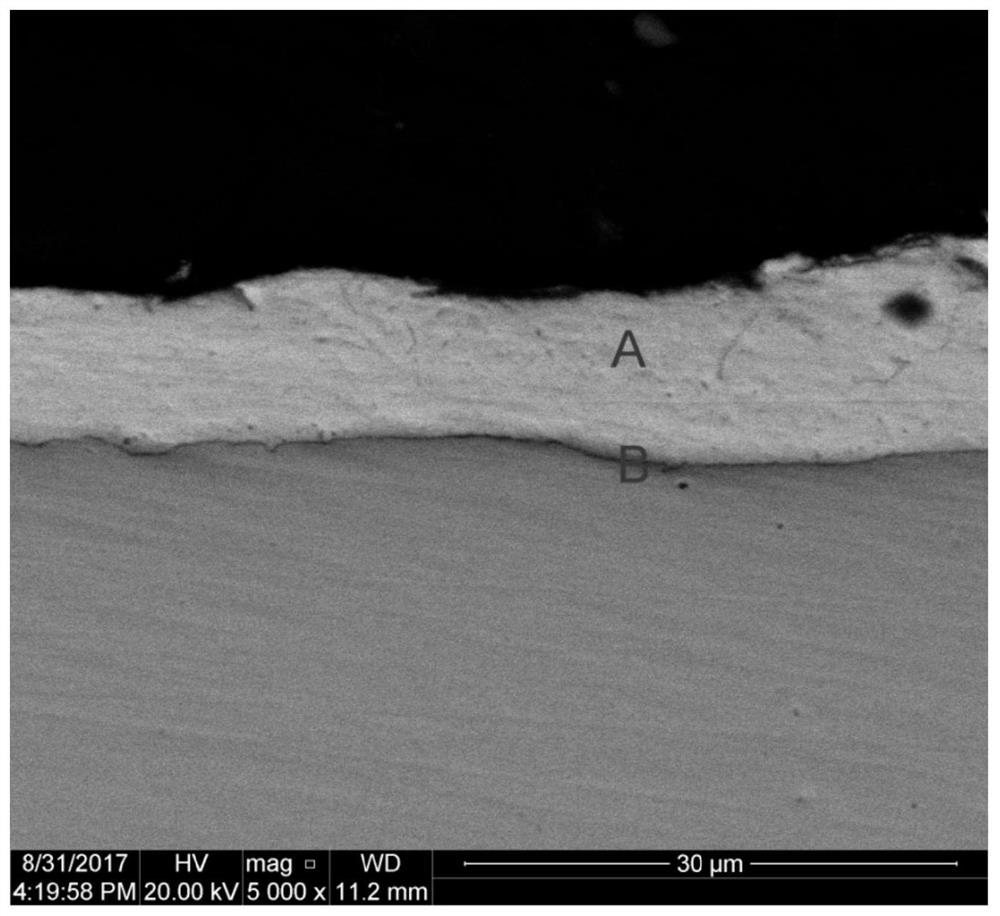

Preparation process and application of aluminum-chromium alloy target material

PendingCN114769595AMeet the use requirementsQuality improvementVacuum evaporation coatingSputtering coatingInsulation layerMachining

The invention belongs to the technical field of target material preparation, and particularly relates to a preparation process and application of an aluminum-chromium alloy target material, and the preparation process of the target material comprises the following steps: S1, preparing alloy powder; s2, the prepared alloy powder is loaded into a sheath, the left half block and the right half block of the sheath are spliced and fixed in a bolt and nut fixing mode, and cold isostatic pressing treatment is carried out; s3, carrying out primary degassing treatment on the alloy target blank; s4, carrying out first hot isostatic pressing treatment on the alloy target blank formed in the step S3, carrying out second degassing treatment, and then taking out the sheath; s5, the blank obtained after second-time degassing treatment is loaded into a sheath, and second-time hot isostatic pressing treatment is carried out; s6, the blank subjected to second-time hot isostatic pressing treatment is taken out of the sheath, machining and cleaning treatment are carried out, and vacuum heat treatment is carried out; and S7, the surface of the alloy target material obtained in the step S6 is modified with an anti-corrosion layer and a heat insulation layer. The composite material is high in compactness, uniform in crystal grain and relatively good in mechanical property.

Owner:漳州市合琦靶材科技有限公司

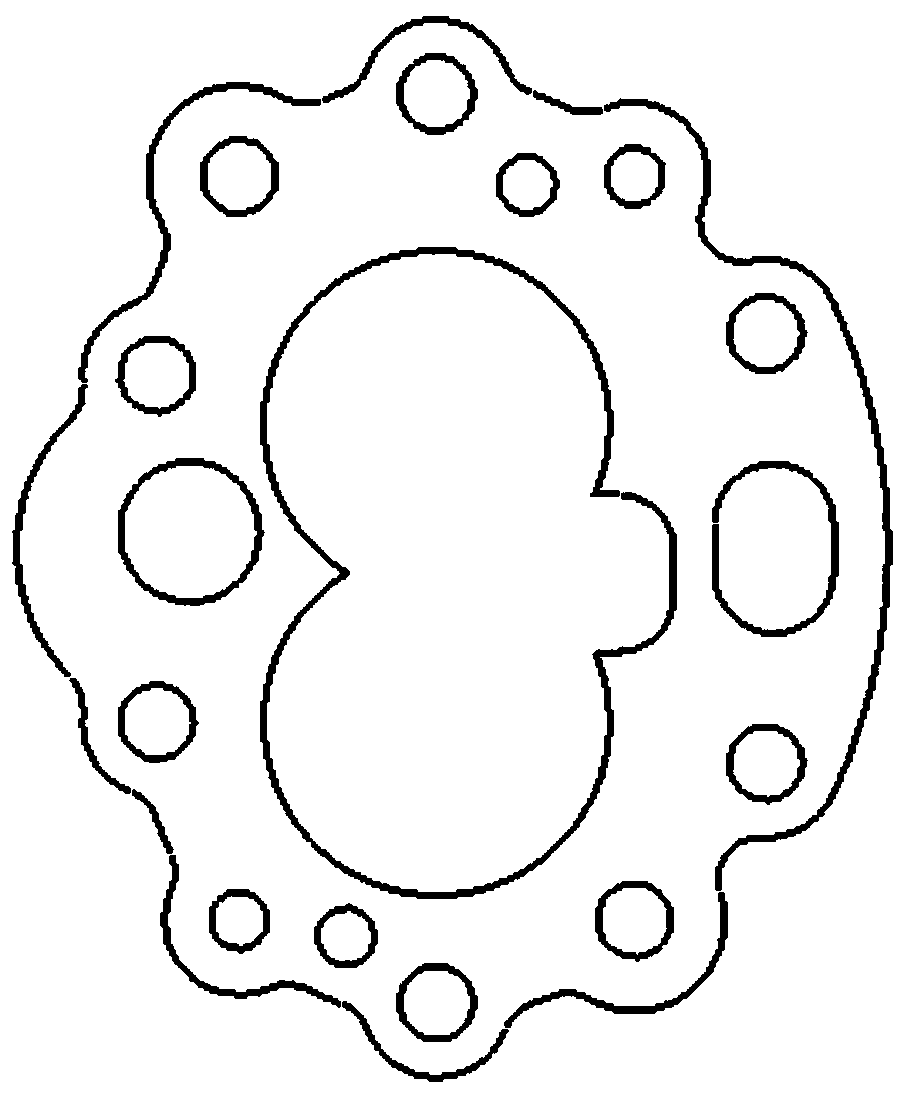

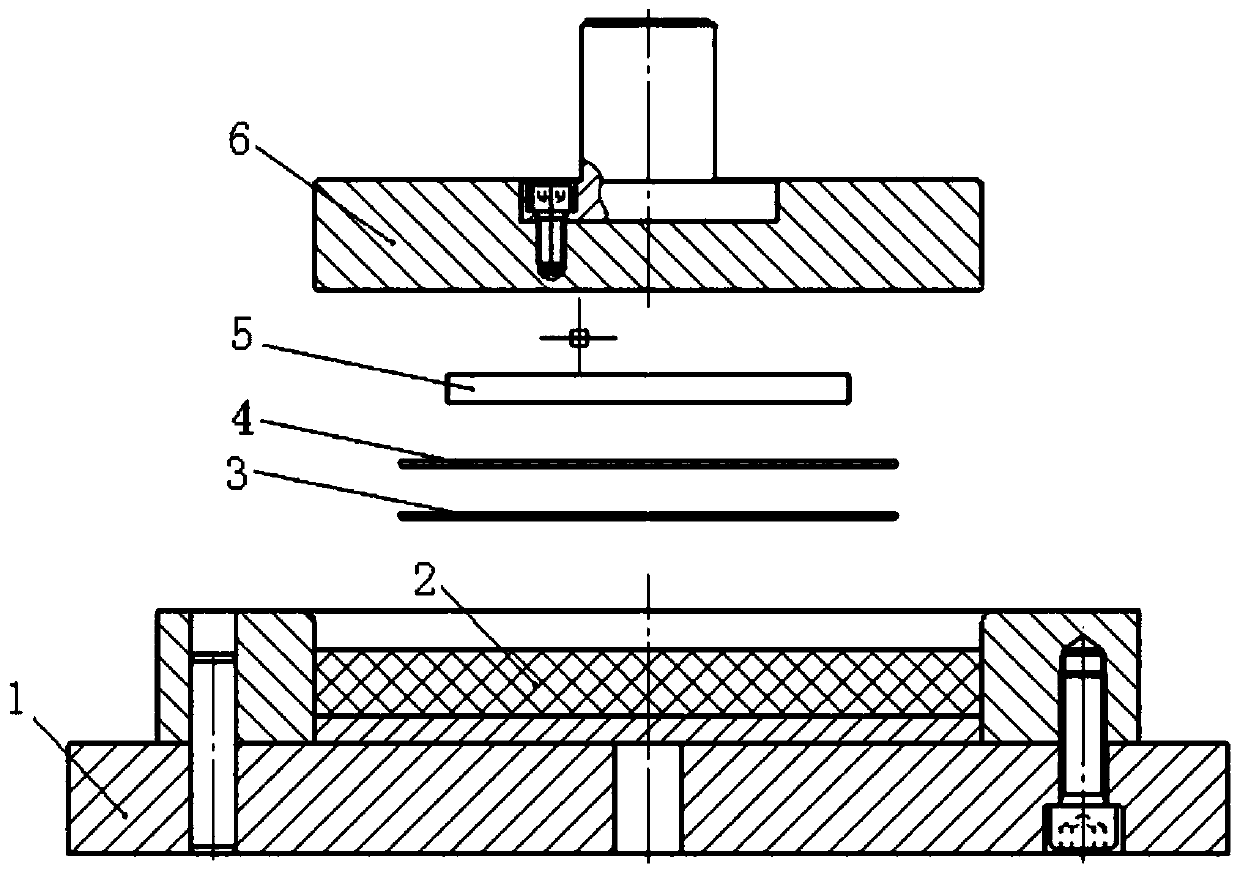

Tin foil sealing gasket machining device and method

ActiveCN111055340AGuaranteed smoothAvoid creasesMetal working apparatusPolymer scienceMachine building

The invention belongs to the field of machine manufacturing, and relates to a tin foil sealing gasket machining device and method. The machining device comprises an upper die, a forming punch-die, a polyurethane rubber gasket and a lower die, wherein the upper die, the forming punch-die, the polyurethane rubber gasket and the lower die are sequentially arranged from top to bottom. In addition, themachining device further comprises an aluminum foil pad arranged on the upper surface of the polyurethane rubber gasket. A blank to be punched is arranged between the forming punch-die and the aluminum foil pad. According to the machining method of the tin foil sealing gasket, a workpiece is blanked as soon as possible; the surface quality of the workpiece is ensured; and wrinkles are prevented from being formed on the workpiece appearance and the hole edge.

Owner:XIAN AERO ENGINE CONTROLS

Silicon ingot bonding method

InactiveCN103436968ASurface quality effectReduce light edgeAfter-treatment detailsMetalPhotovoltaics

The invention relates to a silicon ingot bonding method, and belongs to the solar energy photovoltaic technology field. A technical scheme adopted by the silicon ingot bonding method comprises the following steps: 1, coating upper surfaces of silicon ingots with a glue layer, and bonding the glue layer with a glass pad strip; and 2, coating the metal pad strip with a glue layer after a glass pad strip and the silicon ingots are stably bonded, and pressing the glued surface of the metal pad strip on the glass pad strip. The silicon ingot bonding method is characterized in that the surfaces of the silicon ingots are glued and are bonded with the glass pad strip; and after the silicon ingots and the glass pad strip are stably bonded, the metal pad strip is glued, the metal pad strip is bonded on the glass pad strip to make the silicon ingots positioned at the bottom and the glass pad strip positioned at the upper portion of the silicon ingots, and bubbles generated by the glue layer between the silicon ingots and the glass pad strip upward overturns onto the surface of the glass pad strip from the original surfaces of the silicon ingots before initial curing, so the influences of the bubbles to the quality of the surfaces of the ingots are effectively avoided, and data comprising luminance edges, silicon drop and small edge breaking are reduced, thereby the slice yield is improved.

Owner:JIANGSU MEIKE SILICON ENERGY

Adjustable intelligent cooling water manufacturing and filtering device for continuous casting machine

InactiveCN113996096AAvoid boilingQuality improvementSolid sorbent liquid separationFiltration circuitsGear wheelControl engineering

The invention relates to the technical field of continuous casting machine auxiliary equipment, and discloses an adjustable intelligent cooling water manufacturing filtering device for a continuous casting machine. The filtering device comprises an adjusting assembly; the adjusting assembly comprises a cam; and the lower part of the cam is movably connected with a lifting toothed plate. Through cooperation of a cam, a lifting toothed plate, a transmission gear, a toothed rod, a movable block and a hinged inclined rod, the relative positions of filter holes in a porous adjusting plate and filter holes in a filter plate are adjusted, the filter precision is improved, and therefore heat pulsation is eliminated. The device can reduce diamond deformation and corner cracks of the casting blank and improve the casting quality. The connecting block is driven to move downwards through the self weight of the filter element, and the filter element base is fixed through the matching of the short connecting rod, the mounting plate and the clamping plate; meanwhile, the whole filter element is fixed through cooperation of the upper right-angle movable plate, the lower right-angle movable plate, the diagonal draw bar and the pressing block, so that the installation process of the filter element is simple and convenient, the repair and maintenance time of the filter device is shortened, the downtime of production equipment is shorter, and then more economic benefits can be created.

Owner:象山恒辉机械制造厂

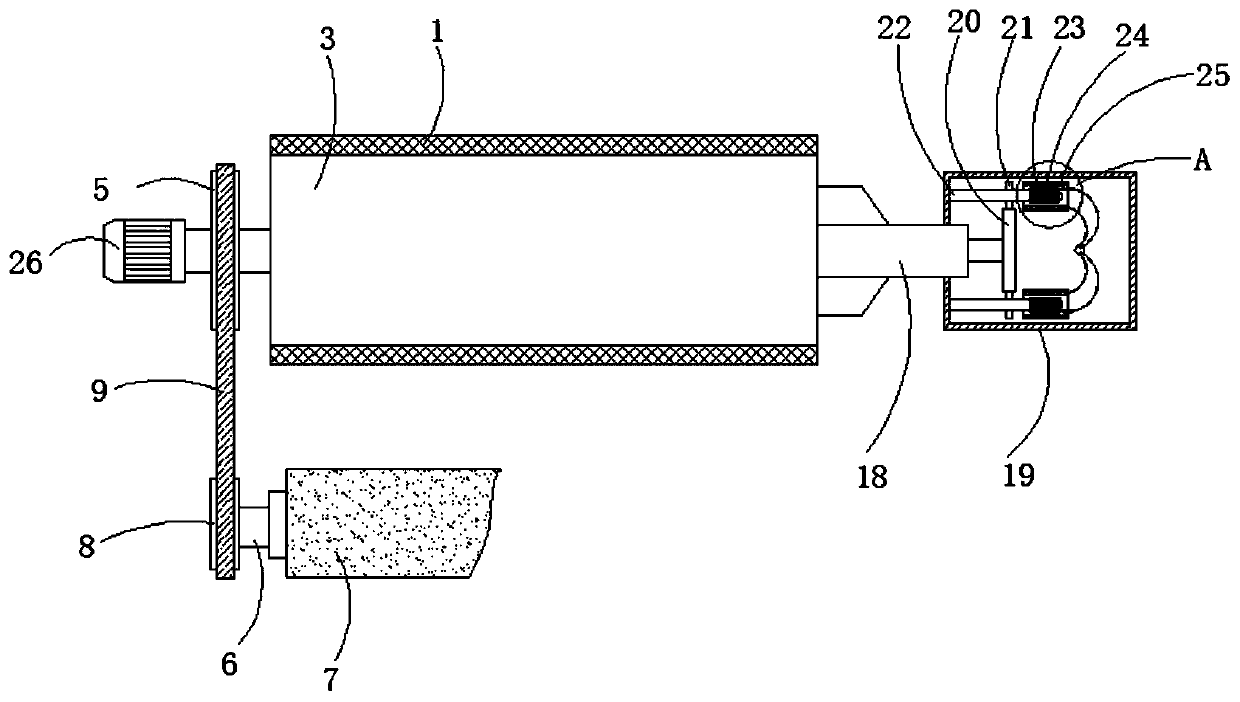

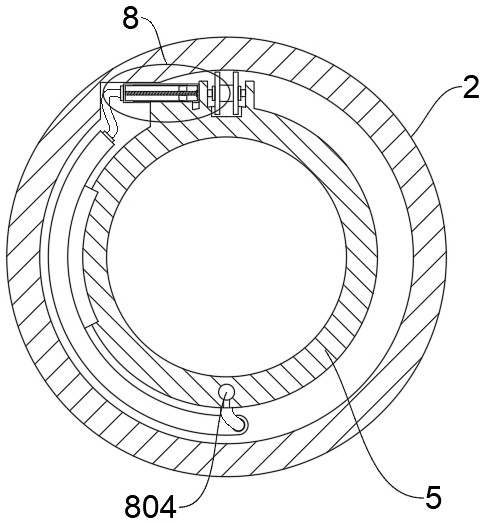

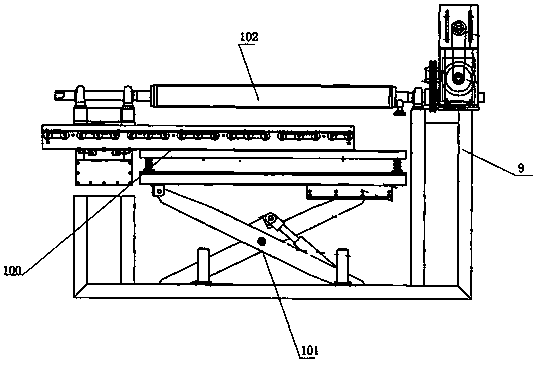

Mesh belt solid medium isolation structure for shaving board production

InactiveCN110843071ASurface quality effectReduce cleanup stepsWood working apparatusFlat articlesPulp and paper industryMechanical engineering

The invention discloses a mesh belt solid medium isolation structure for shaving board production. A layer of kraft paper is laid on a mesh belt and can be synchronously fed along with the mesh belt,wherein an auxiliary roller for bearing a kraft paper roll is rotationally connected to the feeding end of a base below the mesh belt; a kraft paper adsorption piece is arranged below the feeding endof the conveying face of the mesh belt; a cutting assembly used for cutting off the kraft paper is arranged above the conveying face of the mesh belt; and the cutting assembly is positioned between apowder laying machine and a pressing plate assembly above the mesh belt. The mesh belt solid medium isolation structure for shaving board production is used for isolating the mesh belt from wood boardraw materials, adhesion between wood boards and the mesh belt in the pressing plate process is prevented, the influence of adhesion on the surface quality of a shaving board is prevented, the cleaning steps of the mesh belt are reduced, and the production quality and efficiency are improved. In the mesh belt solid medium isolation structure for shaving board production, the auxiliary roller for bearing the kraft paper roll and a conveying wheel share one driving source, and the whole structure is compact.

Owner:益阳万维竹业有限公司

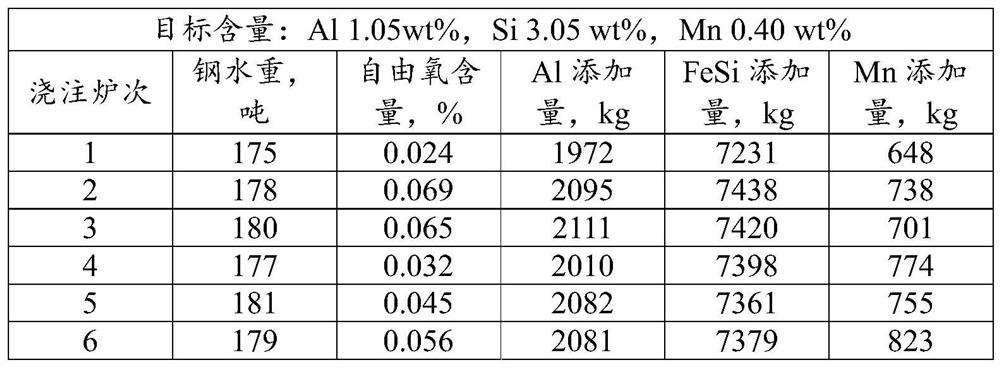

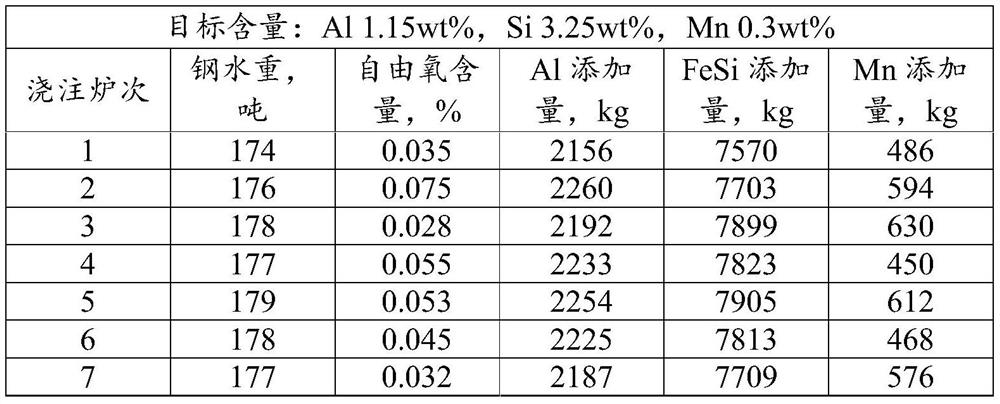

Method for producing high-alloy non-oriented silicon steel, high-alloy non-oriented silicon steel and application

PendingCN114686637AReduce the fluctuation rangeHigh precisionManufacturing convertersProcess efficiency improvementAlloy composition

The invention relates to the technical field of metallurgy, in particular to a method for producing high-alloy non-oriented silicon steel, the high-alloy non-oriented silicon steel and application of the high-alloy non-oriented silicon steel. According to the method, by optimizing the adding amount, the adding sequence and the adding time of the alloy, the fluctuation interval of the content of each alloy component is effectively reduced, and the precision of the content of each alloy component is remarkably improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

A pure natural decontamination and sterilization cleaning powder

ActiveCN104629924BGood removal effectEfficient removalNon-ionic surface-active compoundsDetergent compounding agentsChemical synthesisAdditive ingredient

The invention discloses a pure natural decontamination and sterilization cleaning powder, which is characterized in that it is uniformly mixed with natural plant powder camellia oleifera seed powder, tea tea seed powder and chaff powder, and the mass fractions of the above components are respectively : Camellia oil tea seed powder 45% ~ 65%, tea seed powder 15% ~ 40%, chaff powder 15% ~ 25%. Aiming at the problems and defects of existing chemically synthesized cleaners, a pure natural decontamination and sterilization cleaner is provided, which is based on camellia oil tea seed powder with decontamination effect as the basic raw material, supplemented with tea seed powder and chaff powder. Powder, the cleaning powder has remarkable decontamination ability, almost no foam when washing, saves water, and the ingredients are pure natural plant powder, which is harmless to human body and skin, has bactericidal skin care effect, and has no pollution to the environment.

Owner:熊中山

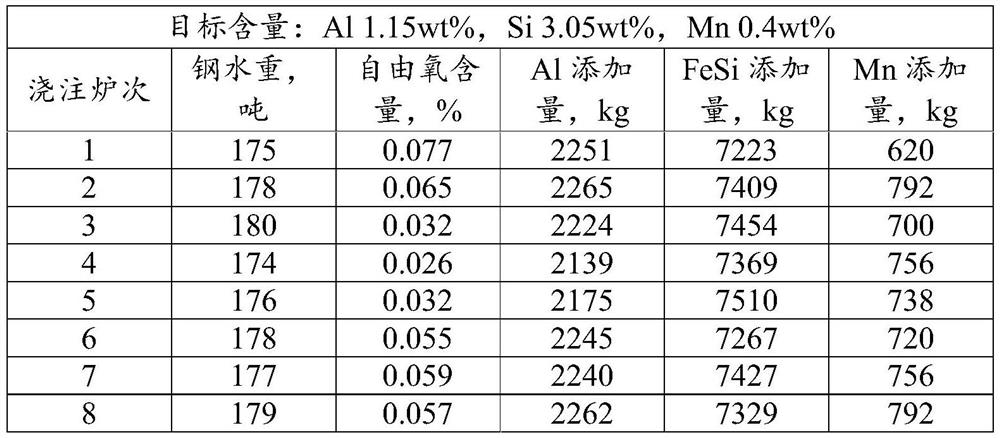

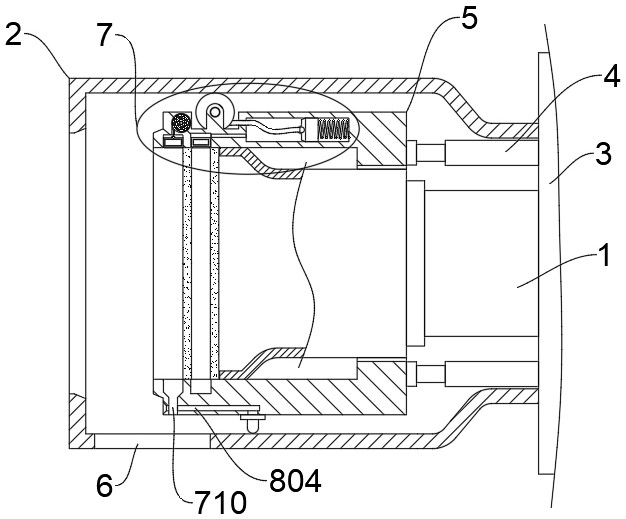

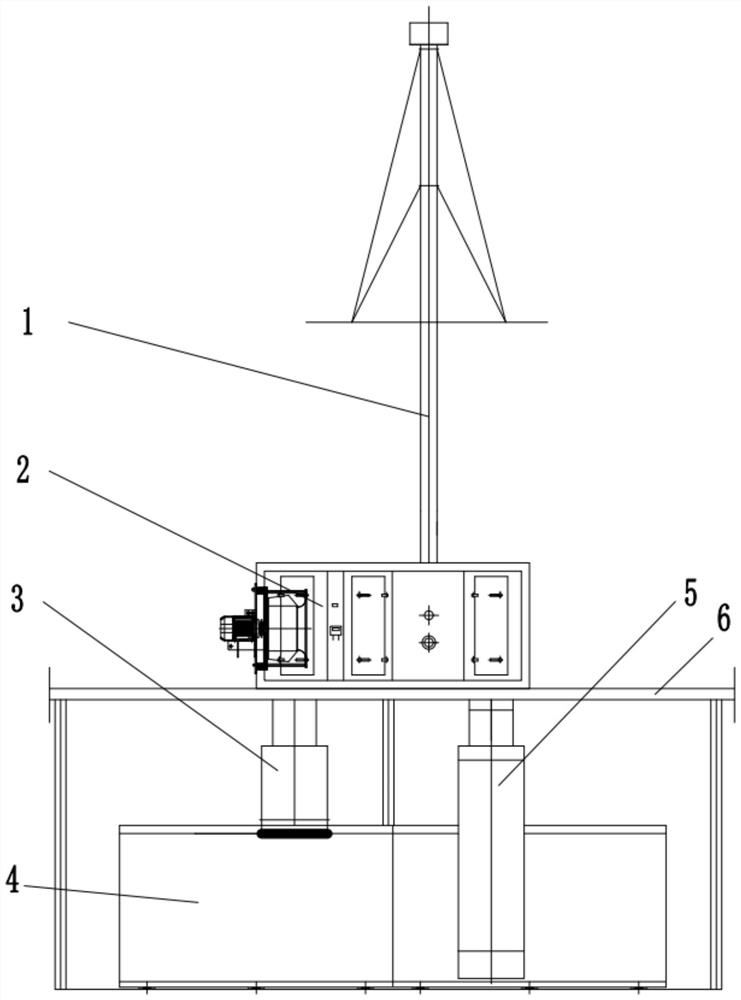

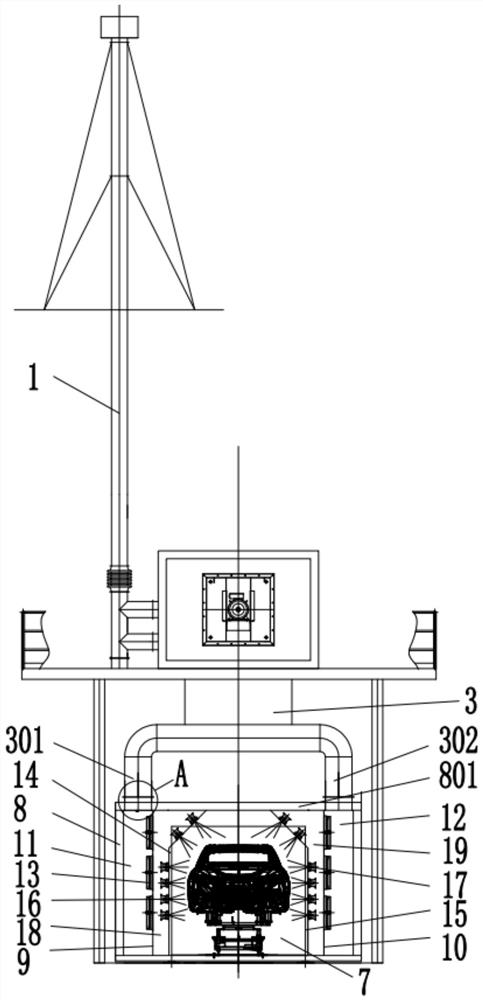

A film and television projector lens protection structure and projector

ActiveCN113253560BSurface quality effectSimple mechanical structureProjectorsCleaning using toolsDust controlMechanical engineering

The present invention relates to the technical field of projectors, more specifically, a protective structure for the lens of a film and television projector and the projector, including a lens body and a mounting seat, the lens body is movably arranged on the mounting seat, and also includes: a protective tube, set On the mounting base, the lens body is set in the protective tube; the dust removal sleeve is set in the protective tube and connected with the lens body; and the dust removal assembly is set on the dust removal sleeve , used to remove the dust attached to the lens body; the whole process adopts a simple mechanical structure, which not only has a high degree of automation, but also avoids the traditional work of manually cleaning the lens, and cleans the lens in time to avoid dust from causing damage to the surface quality of the lens. influences.

Owner:深圳市正光影像器材有限公司

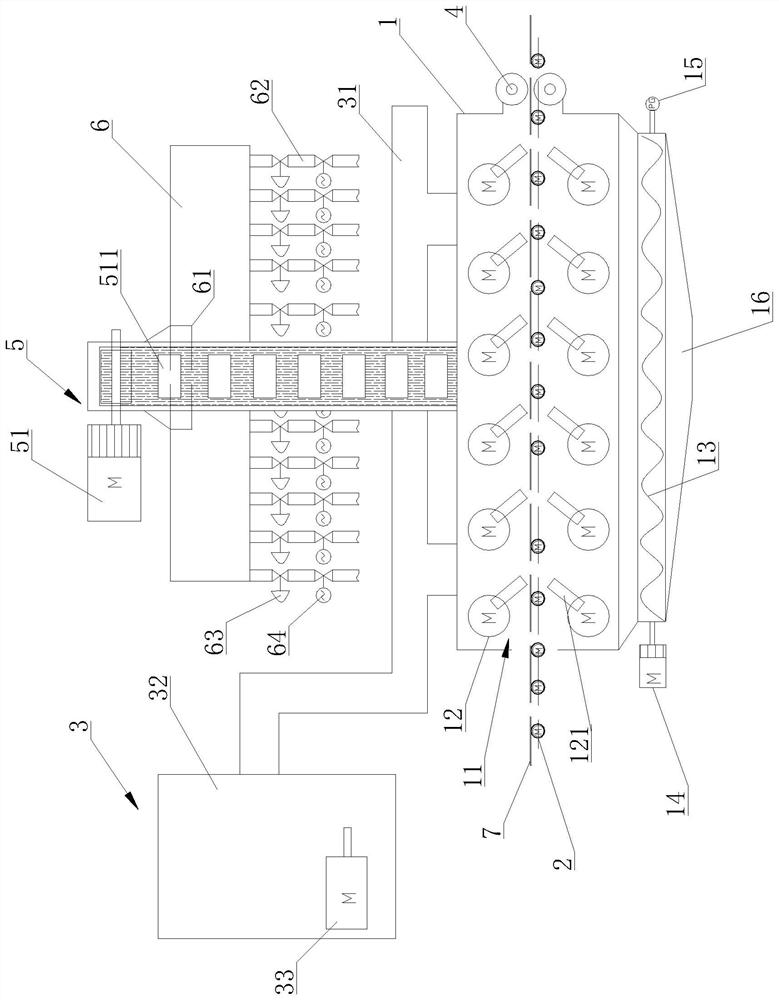

Coating workshop steel sand shot blasting machine

ActiveCN110315438BIncrease friction areaImprove shot blasting effectAbrasive machine appurtenancesAbrasive blasting machinesDust controlEngineering

The invention discloses a coating workshop steel grit blasting machine. The coating workshop steel grit blasting machine comprises a shot blasting chamber (1), wherein a conveying roller way (2) is arranged in the shot blasting chamber (1) in a penetrating manner; the outlet end of the shot blasting chamber (1) is provided with a reverse dust removal device (4); the shot blasting chamber (1) is connected with a belt type elevator (5) through an auger mechanism; a steel grit collector (6) is arranged between the belt type elevator (5) and the shot blasting chamber (1), a steel grit filtering device (61) is arranged at the inlet end of the steel grit collector (6), a plurality of sand discharging pipelines (62) are arranged at the lower end of the steel grit collector (6), and the sand discharging pipelines (62) are provided with a quick-cutting valve (63) and a regulating valve (64). The coating workshop steel grit blasting machine is high in safety coefficient, high in working efficiency, good in dust removal effect and shot blasting effect and not easy to block.

Owner:FUSTEEL CO LTD

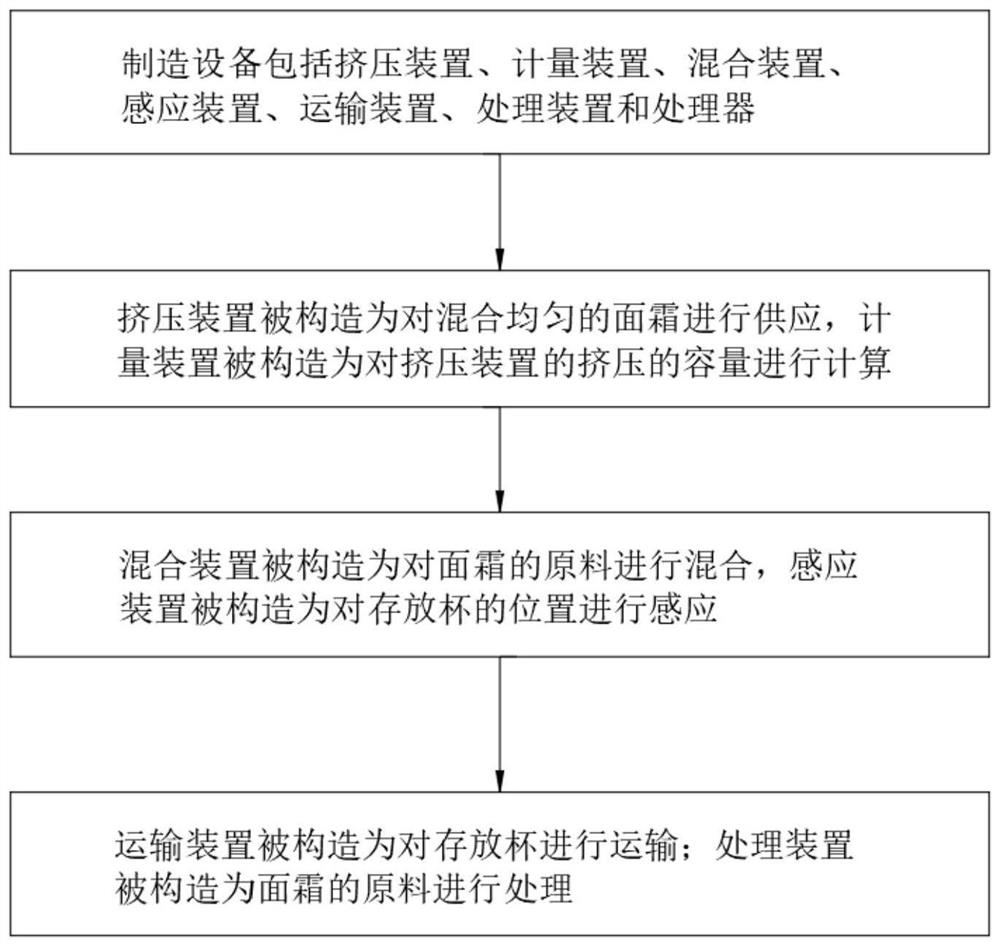

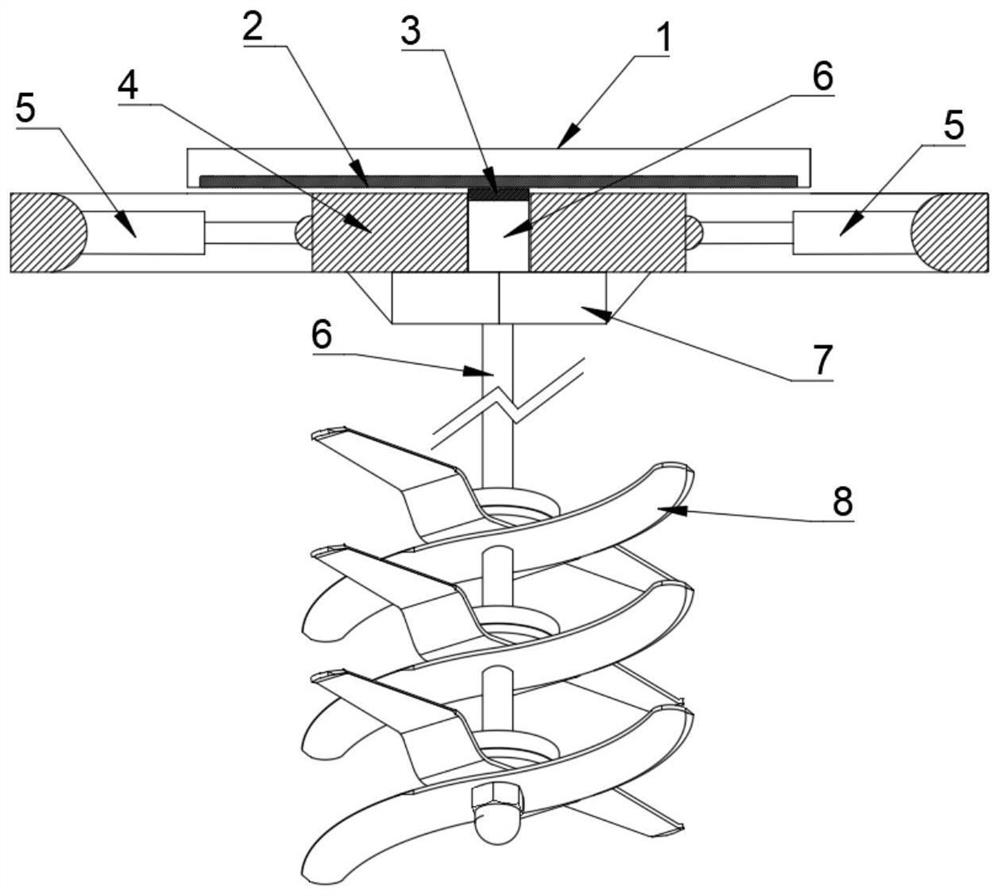

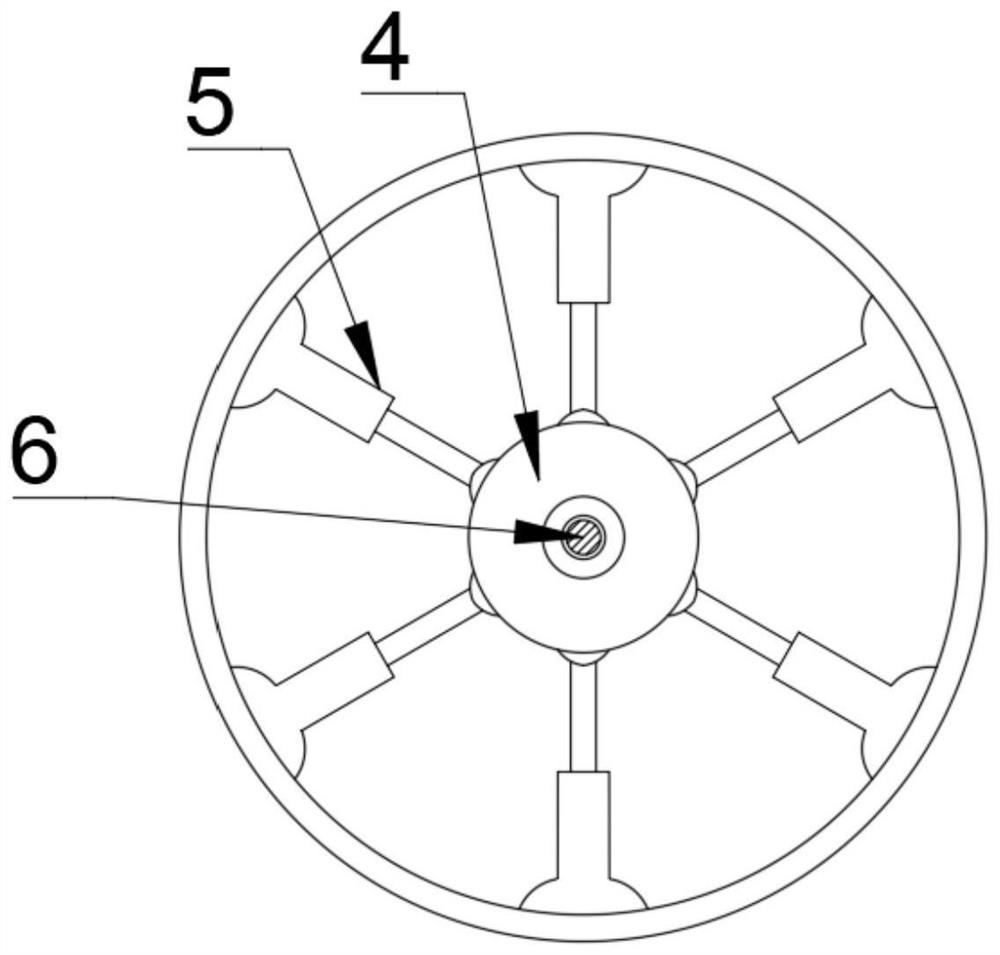

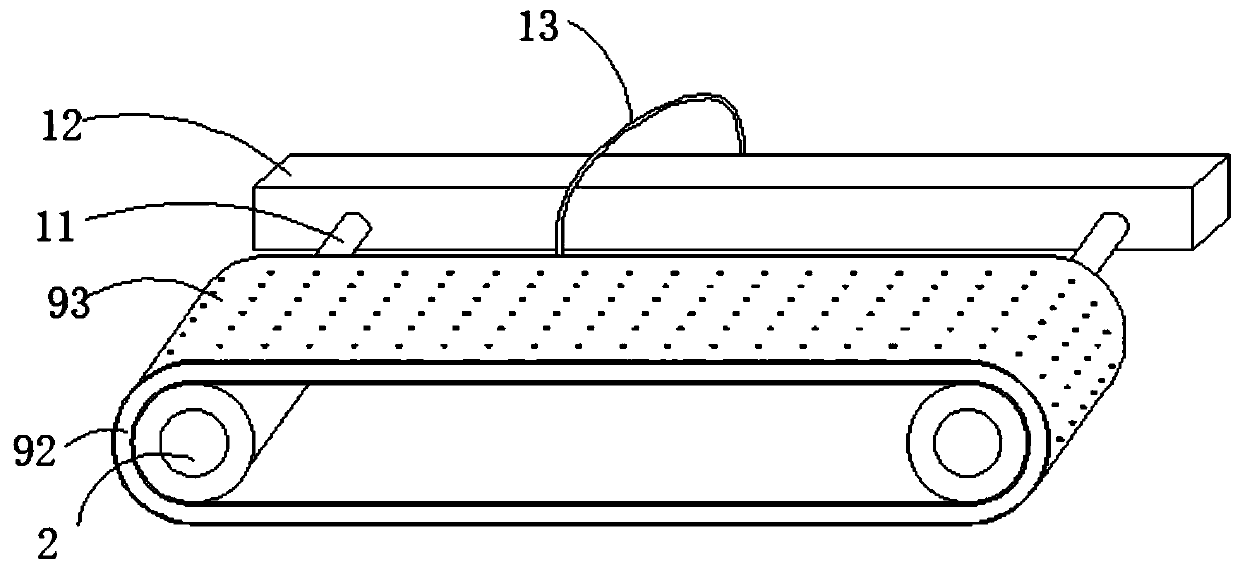

Translucent whitening cream and manufacturing equipment thereof

InactiveCN112402272AGuaranteed transdermal absorptionConvenient careCosmetic preparationsTransportation and packagingGlycerolAlkaloid

The present invention provides a translucent whitening cream and a manufacturing equipment thereof, the translucent whitening cream comprises a water locking agent, a whitening adjuvant, a humectant,a thickener, an adjuvant and a flavoring agent, the water locking agent is designed to isolate saliva in the oral cavity, the water locking agent comprises 11-15% of liquid paraffin, 4-6% of Vaseline,1-4% of beeswax, 2-4% of octadecanol, 4-8% of octadecanoic acid, 1-2% of span 80, 0.1-1% of gelatin, 0.1-0.5% of lauryl sodium sulfate and 3-5% of glycerin, the whitening adjuvant comprises 10-15% ofsorbitol, 5-10% of propylene glycol, 15-25% of silicon dioxide, 0.6-1.0% of sodium carboxymethyl cellulose, 0.2-0.4% of xanthan gum, 0.025% of borneol, 0.01% of borax, 1.5-3.0% of lauryl sodium sulfate, 0.4-0.7% of menthol, 0.5-0.8% of edible essence and 0.5-1.0% of titanium dioxide. According to the invention, the water locking agent does not contain alkaloid and substances with strong irritation, will not cause damage and irritation to the skin, is high in safety for long-term use, does not contain chromone with strong activity, and will not cause pollution to the skin after long-term use.

Owner:陈珲

Anti-adhesion mesh belt for shaving board production

ActiveCN110815486ASurface quality effectReduce cleanup stepsWood working apparatusDomestic articlesEngineeringProcess engineering

The invention discloses an anti-adhesion mesh belt for shaving board production. Kraft paper is laid on the mesh belt, wherein a negative pressure cavity for adsorbing the kraft paper is formed in themesh belt; a negative pressure assembly is arranged in an adsorption driving box on one side of the mesh belt; the air inlet end of the negative pressure assembly is connected with the negative pressure cavity; the driving force of the negative pressure assembly is shared with a conveying roller of the mesh belt; the conveying speed of the kraft paper is the same as that of the mesh belt; and a cutting assembly for cutting off the kraft paper is arranged above the mesh belt. According to the anti-adhesion mesh belt for shaving board production, the kraft paper is arranged on the mesh belt, the kraft paper can be used for separating the mesh belt from wood board particles, so that the wood board and the mesh belt are prevented from being adhered in the board pressing process, the influenceof adhesion on the surface quality of the shaving board is prevented, the cleaning steps of the mesh belt are reduced, and the production quality and efficiency are improved; and the negative pressure of the negative pressure cavity of the mesh belt is driven by the rotation of the conveying roller, so that the whole machine is compact in structure, energy is fully utilized, and energy conservation and environmental protection are achieved.

Owner:益阳万维竹业有限公司

A method for on-line inspection and confirmation of roll groove dropouts for the production of special steel wire rods

ActiveCN109482642BImprove surface qualitySurface quality effectMeasuring devicesRollsWire rodEngineering

The invention discloses a roller rolling groove chipping on-line inspection confirmation method for production of a special steel wire rod, and relates to the technical field of special steel wire rodrolling. The method comprises the following steps of carrying out special steel wire rod defect identification and determining the sampling part and a sampling mode. According to the on-line inspection confirmation method, the defect type and the defect part of the special steel wire rod are identified, so that the influence of defects on a roller on a finished product is reduced to the maximum extent, and the surface quality of the special steel wire rod is improved.

Owner:NANJING IRON & STEEL CO LTD

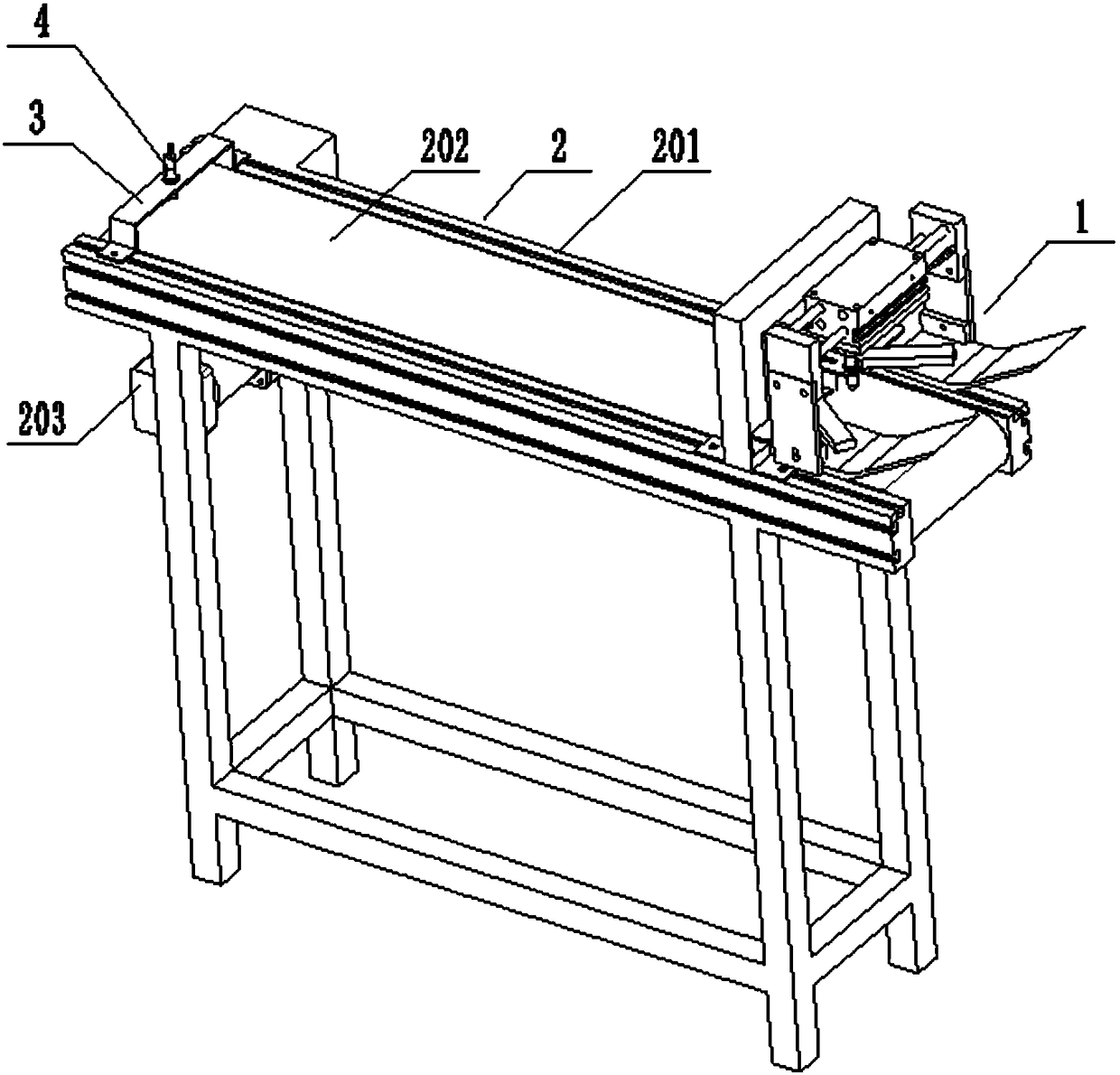

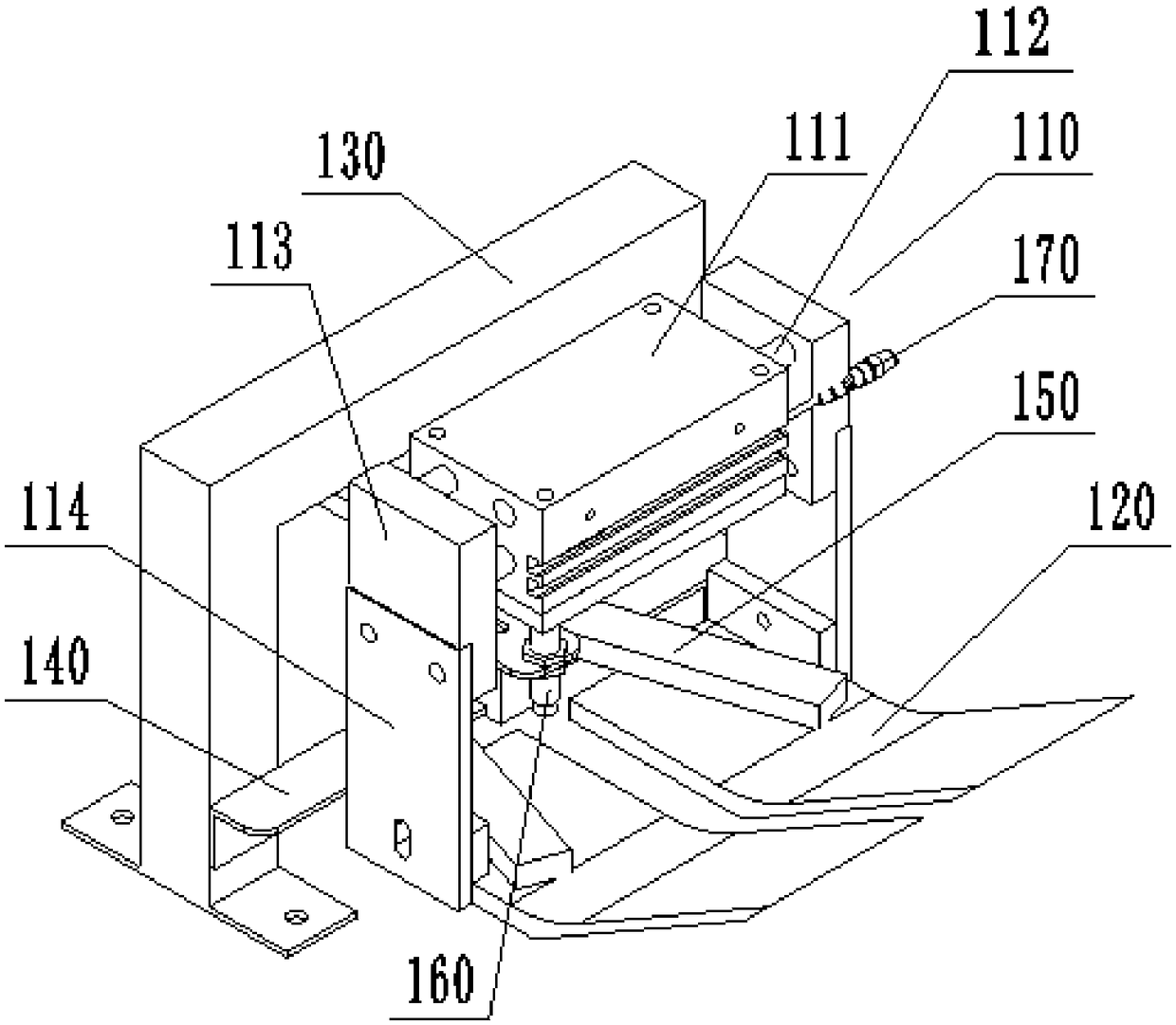

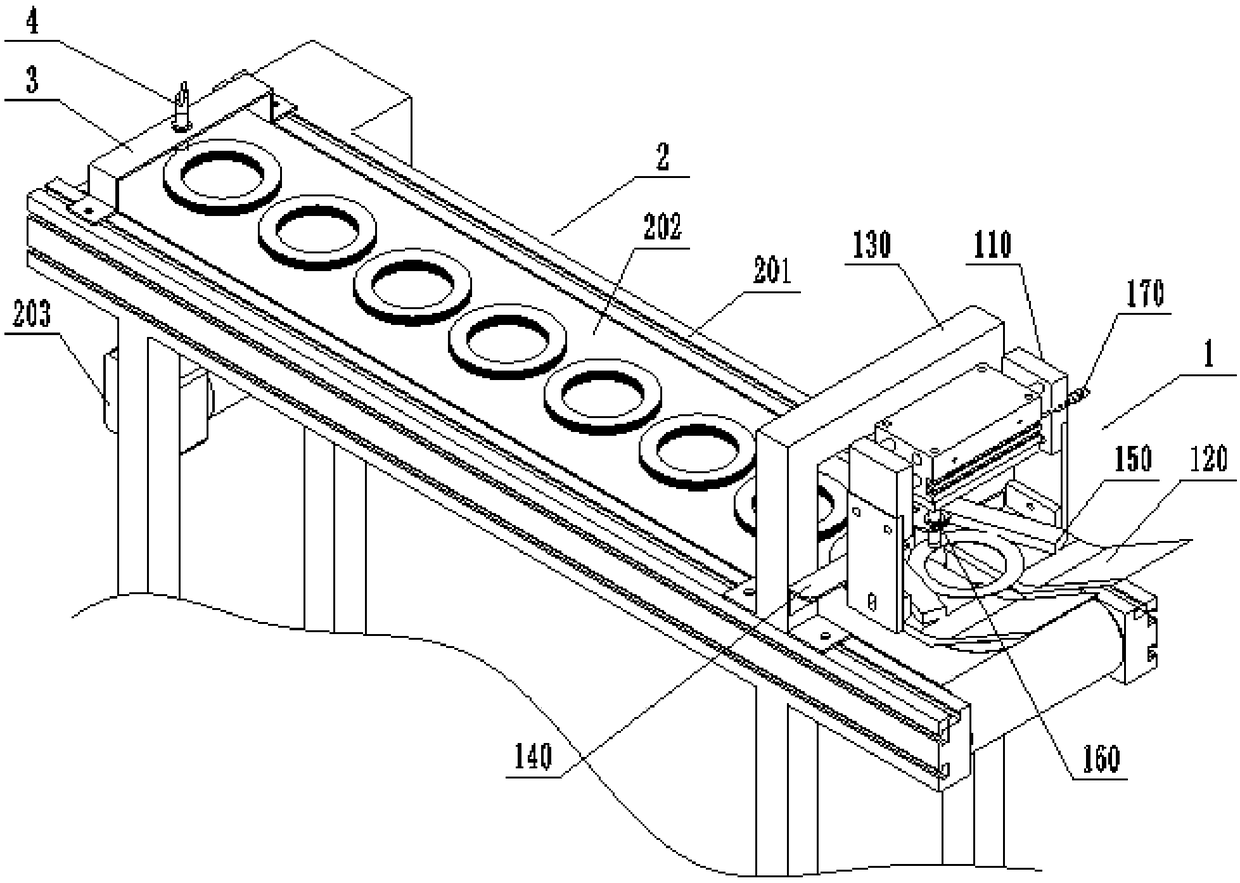

Slush-molded bed for automotive interior parts

The invention relates to an automobile interior trim part slush molding bed which comprises a lifting mechanism, a horizontal conveying mechanism and a turnover mechanism. The automobile interior trim part slush molding bed is characterized in that the turnover mechanism comprises a turnover frame, a powder box automatic locking mechanism installed on the turnover frame and a mold automatic locking mechanism of a self-locking structure. The automobile interior trim part slush molding bed has the advantages that a mold and a powder box do not need to be manually locked, the locking speed is high, self locking is achieved through the self structure in the mold locking process, and it is ensured that the mold is not disengaged from the turnover frame.

Owner:NANTONG CHAODA EQUIP CO LTD

Automatic material distribution counting and stacking machine and control method thereof

InactiveCN106628363ARealize automatic controlWill not affect the quality of the blade surfacePackaging automatic controlStack machineMechanical equipment

The invention discloses an automatic material distribution counting and stacking machine and a control method thereof and belongs to the field of automatic mechanical equipment. The equipment comprises a material distribution mechanism and a conveying mechanism. The material distribution mechanism comprises a driving cylinder and a material receiving plate. The material receiving plate is used for receiving or putting down materials, and the driving cylinder drives the material receiving plate to be opened or closed. The conveying mechanism receives the materials falling from the material receiving plate and conveys the materials. The material distribution mechanism is provided with a material distribution proximity switch, when the material receiving plate receives the materials, the material distribution proximity switch generates induction signals and transmits the signals to a counter, and therefore automatic counting can be achieved. A magnetic switch is arranged on a cylinder body of the driving cylinder, a magnetic ring installed in a piston rod in the cylinder body can be inducted, and therefore electric signals are generated. Blades cam be stacked through the equipment, automatic operation is achieved, counting is accurate, high efficiency is achieved, no manual intervention is needed, the surfaces of the blades are not damaged, and high safety is achieved. The control method of the automatic material distribution counting and stacking machine can control the equipment to complete counting and stacking operation of the blades.

Owner:安徽华天机械股份有限公司

A kind of short fiber reinforced carbon/resin composite material hot pressing molding demoulding method

ActiveCN112157929BImprove surface qualityExcellent anti-hot pressure sticking performancePolyethylene glycolBoron nitride

The invention discloses a short fiber reinforced carbon / resin composite material hot pressing molding demoulding method, which includes the following contents: (1) C and N co-infiltration technology on the surface of a 65Mn separator for hot pressing molding demoulding, adopting dripping methanol to pass ammonia The 65Mn separator is carbonitrided by the gas method; (2) a mold release agent for hot pressing molding, the specific components are 10%-30% flake graphite powder, 20%-40% nano-scale cubic nitriding The mixed powder of boron powder and 30%-50% nano-scale zirconia powder is composed of polyethylene glycol as a binder. The process of the invention is simple, the process parameters are easy to control, the smoothness after grinding and polishing of the separator for hot-pressing molding, the anti-hot-pressing inlay performance and the anti-hot-pressing die-bonding performance are improved, and the hot-pressed short fiber reinforced carbon / mold is significantly improved. Surface quality and production efficiency of resin composites.

Owner:湖南科嘉新材料有限公司 +3

Manufacturing method of isolation board for sintering

ActiveCN102274820BSimple processLow costCellulose coatingsPretreated surfacesPolyvinyl alcoholIsolation layer

The invention discloses a manufacturing method of an isolation board for sintering. The method comprises the following steps of: 1, preparing polyvinyl alcohol or cellulose into an aqueous solution, adding metal oxide powder and stirring uniformly to obtain slurry; 2, uniformly coating slurry on one or two faces of a metal board with a flat surface; and 3, putting the slurry-coated metal board into a drying oven for drying to obtain the isolation board for sintering. The manufacturing method has the advantages of simple procedures, low cost and high production efficiency. The manufactured isolation board for sintering can be used repeatedly. After the isolation board is used, organic matters are volatilized, oxide powder particles fall, and slurry can be repainted on the recycled metal board after soot cleaning, so that an isolation board for sintering is manufactured for repeated use. The isolation board for sintering manufactured with the method is taken as an isolation layer between laminated plate blanks, so that sintering adhesion of the plate blanks can be prevented effectively, the surfaces of the plate blanks are protected, and the surface quality of the sintering plate blanks is not influenced simultaneously.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Automatic control method of counting stacking machine

InactiveCN108146706ASurface quality effectEasy to packPackaging automatic controlAutomatic controlStack machine

The invention discloses an automatic control method of a counting stacking machine and belongs to the field of automatic mechanical equipment. The method includes the steps that a driving cylinder ofa material distributing mechanism drives a material receiving plate to be folded, and material receiving is prepared; metal blades fall onto the material receiving plate and are received and positioned; the driving cylinder drives the material receiving plate to be opened, the metal blades fall onto a conveying mechanism, and meanwhile counting is performed; the material receiving plate is foldedagain, the steps are repeated so that the metal blades can be overlaid and stacked on a conveying mechanism; when stacking is performed till a set number is achieved, the conveying mechanism drives the stacked metal blades to move forwards by certain distance and then stops; and the operation is repeated so that a row of stacked metal blades can be obtained on the conveying mechanism, and the counting and stacking operation of the metal blades is completed. The automatic control method of the counting stacking machine can be used for stacking the blades, automatic operation is achieved, counting is accurate, efficiency is high, manual intervention is avoided, the blades are not damaged, and the safety is high.

Owner:安徽华天机械股份有限公司

Drying chamber capable of replacing air valve by adjusting inserting plate

PendingCN113465311AGuaranteed drying efficiencyUniform gas flowDrying gas arrangementsDrying chambers/containersCavity wallEngineering

The invention discloses a drying chamber capable of replacing an air valve by adjusting an inserting plate, and relates to the technical field of drying. The drying chamber comprises a temperature rising and heat supply unit, a steel platform, an air pipeline and a drying working area, the temperature rising and heat supply unit is installed on the steel platform, and the two ends of the bottom of the temperature rising and heat supply unit are connected with an air supply pipe and an exhaust pipe correspondingly. Stand columns are evenly and fixedly installed at the bottom of the steel platform, the bottom of the air supply pipe is divided into a left air pipe and a right air pipe, and the bottom of the left air pipe and the bottom of the right air pipe communicate with a top sealing plate at the top of an inner cavity wall. According to the drying chamber, the left air pipe and the right air pipe both seamlessly communicate with the inner cavity wall, so that drying gas has no chance to escape to the external space, and compared with an air valve adjusting mode in the past, the scheme avoids air pollution caused by leakage of a rotating shaft of the air valve and avoids the phenomenon that external air pipe yellowing and oil dripping is caused by leakage of the air valve, and the surface quality of equipment is poor.

Owner:DESIGN INST NO 9 MINISTRY OF MECHINE BUILDING

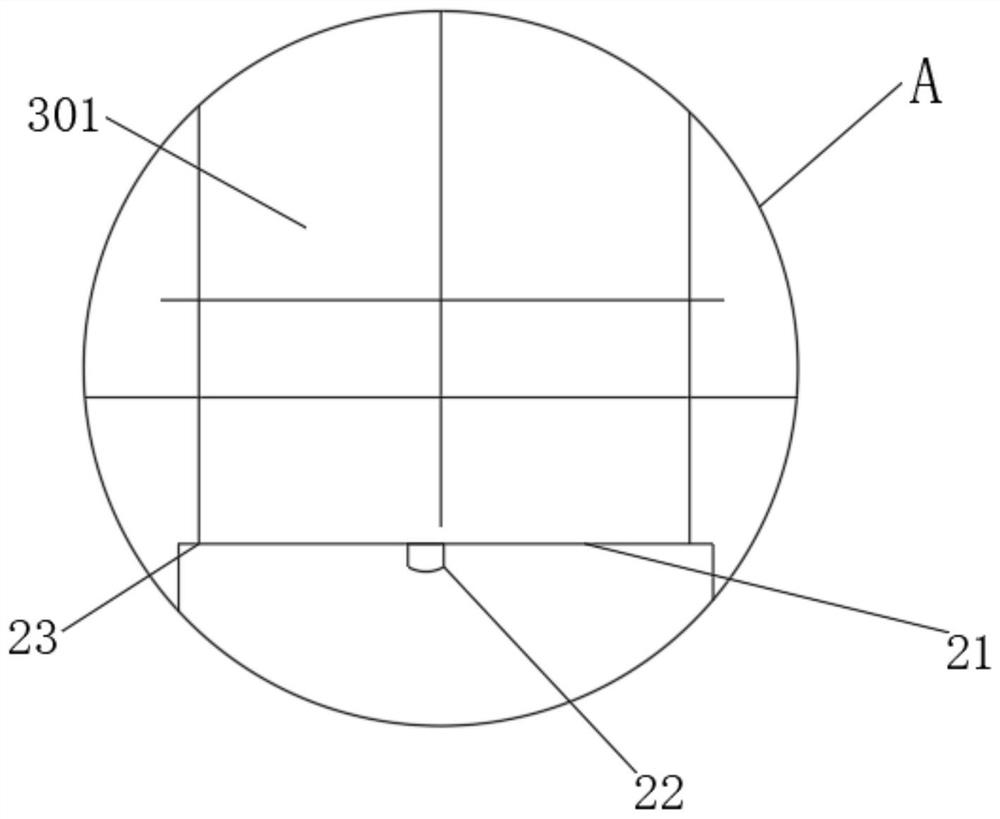

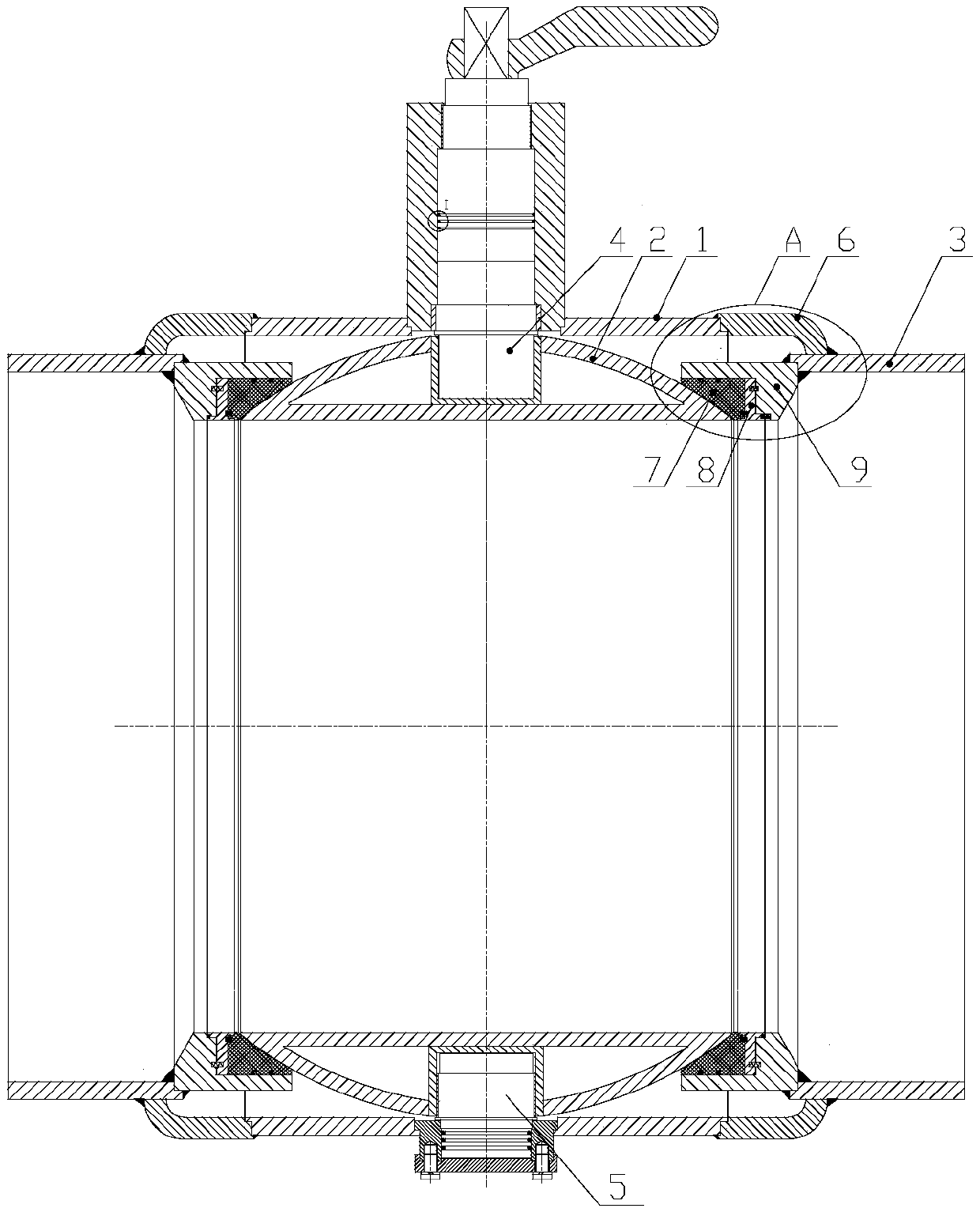

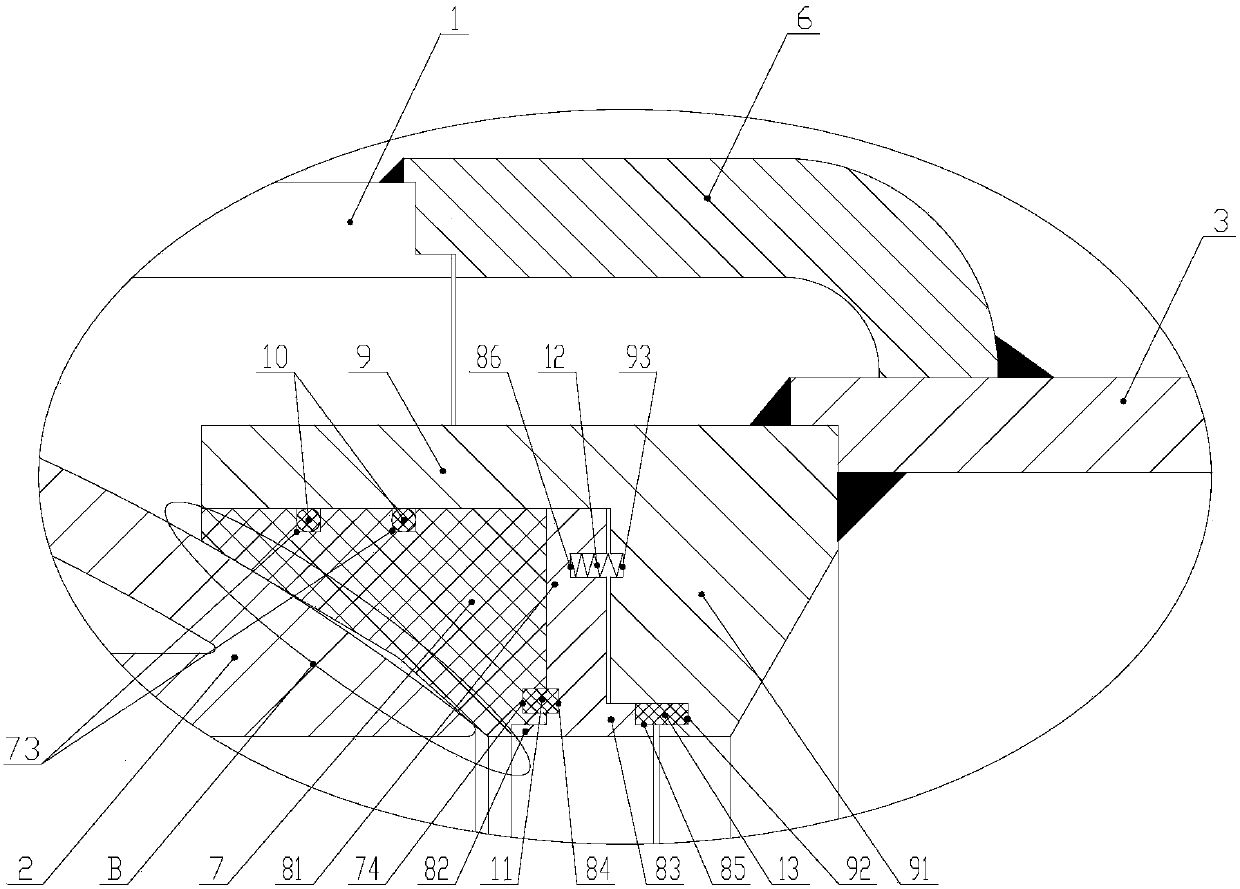

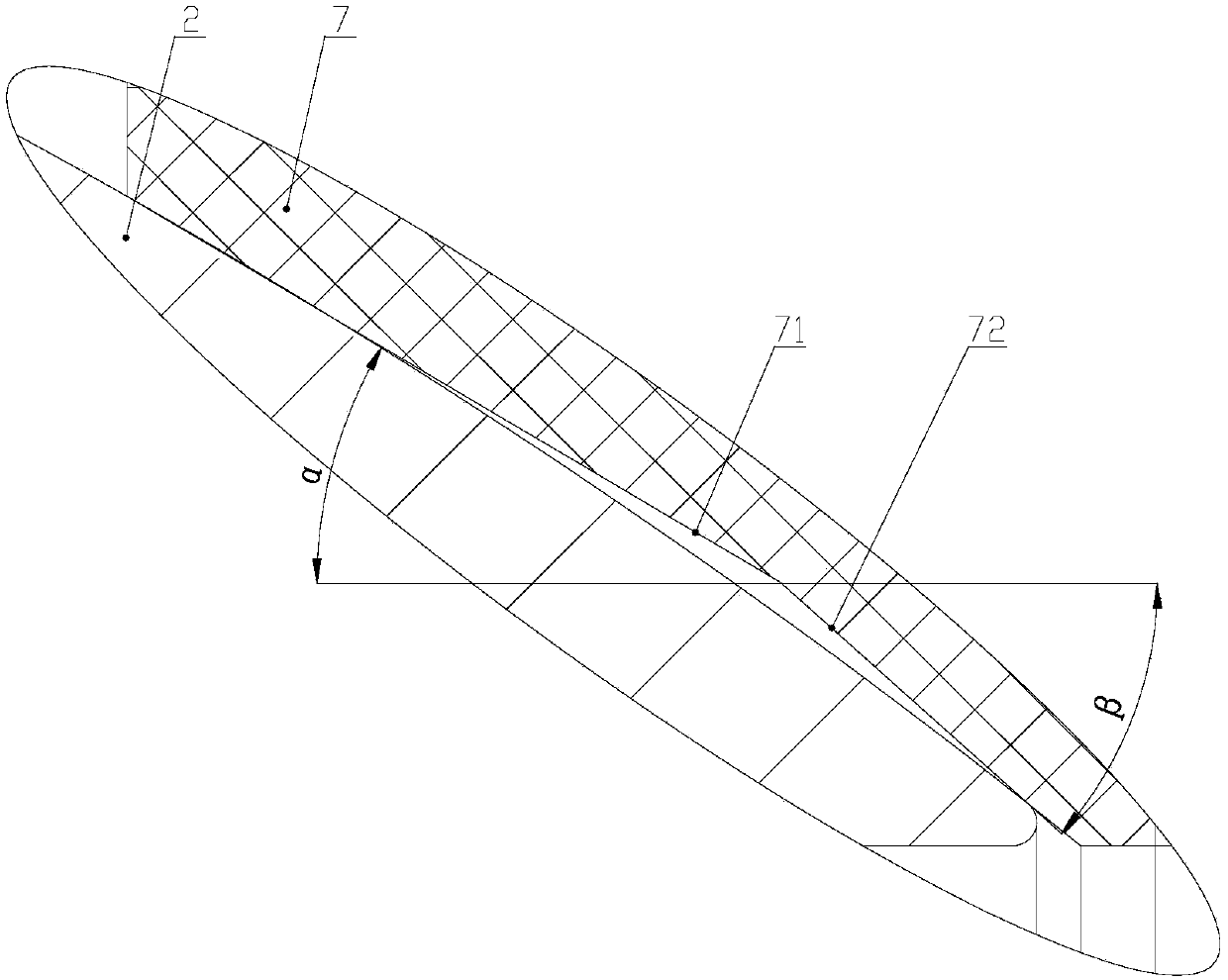

A sealing structure of a super-large caliber full-welded ball valve

The invention provides an ultra-large diameter all-welded ball valve sealing structure. The ultra-large diameter all-welded ball valve sealing structure comprises a ball, a ball pad, a ball pad base and a connecting pipe which are sequentially connected from interior to exterior. The face, attached to the ball, of the ball pad is provided with a first slope and a second slope which are tangent to the ball, and the position, tangent to the ball, of the first slope is located above the position, tangent to the ball, of the second slope. Multi-stage sealing is adopted in the sealing structure, the ball pad is pressed on the ball, two inclined edges of the ball pad are tangent to the ball to form double-stage sealing, the fluid leakage amount is reduced, and the sealing performance is improved. Sealing rings are arranged on the connecting face of the ball and the ball pad, the connecting face between the ball pad and the ball pad base and the connecting face between the ball pad base and the connecting pipe, and fluid leakage is avoided. According to the ball valve sealing structure, few components are arranged, and the structure is simple.

Owner:三角洲篷房智能制造(江苏)有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com