Tin foil sealing gasket machining device and method

A processing device and processing method technology, applied in metal processing, etc., can solve problems such as no introduction, scratches on the surface of polyurethane rubber, etc., and achieve the effect of avoiding the formation of wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

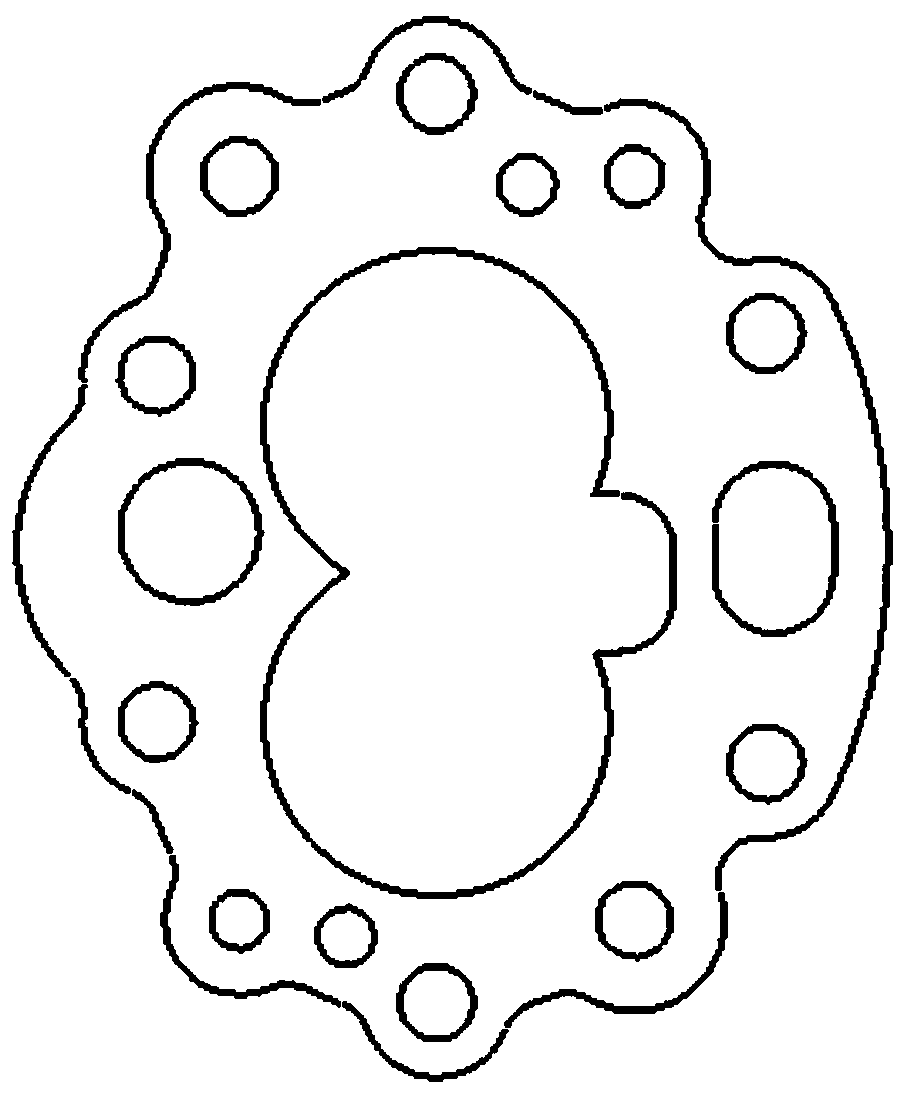

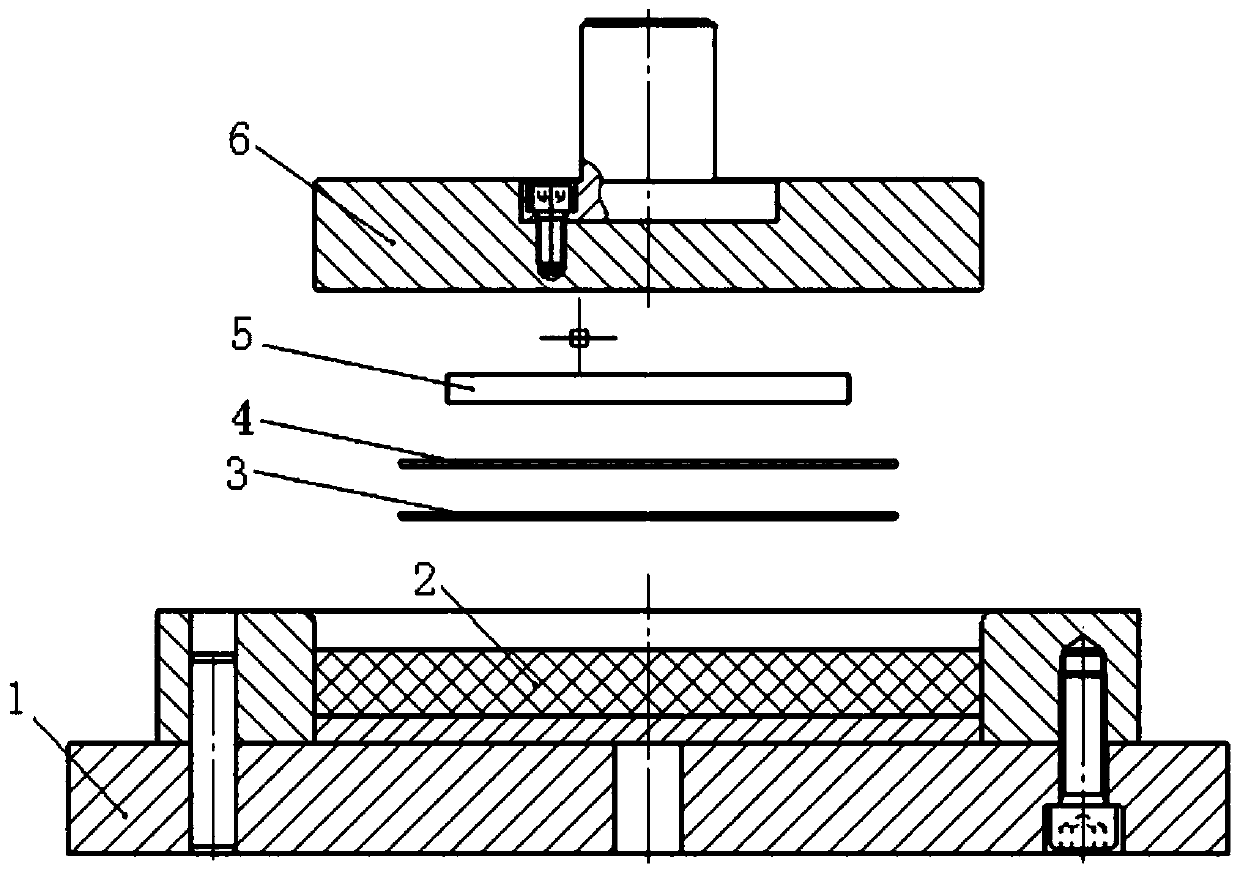

[0023] The present invention starts with figure 1 The processing process of the shown tin foil gasket is analyzed. The tin foil gasket is specially used for an aero-engine control system. It uses lead-tin alloy foil material, grade PbSn4.5~2.5, thickness 0.05mm, and is very soft, almost no rigidity . In the processing method in the prior art, the polyurethane rubber is deformed under pressure during the working process, causing the lead-tin alloy foil placed on the surface to deform under the action of friction, and the polyurethane rubber returns to its original shape after blanking. Pewter foils, however, cannot elastically recover and form wrinkles on the surface. Therefore, the present invention puts a layer of auxiliary material pad between the polyurethane rubber and the punched blank. This pad has certain rigidity and is easy to punch out, especially a 0.05mm thick aluminum foil pad. Adding this pad can not only avoid the impact of polyurethane rubber on the surface q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com