Patents

Literature

1582 results about "Machine building" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machine building is a component of a broader production group, machine building and metalworking, which also includes the manufacture of metal articles and structural members and the repair of machines and equipment.

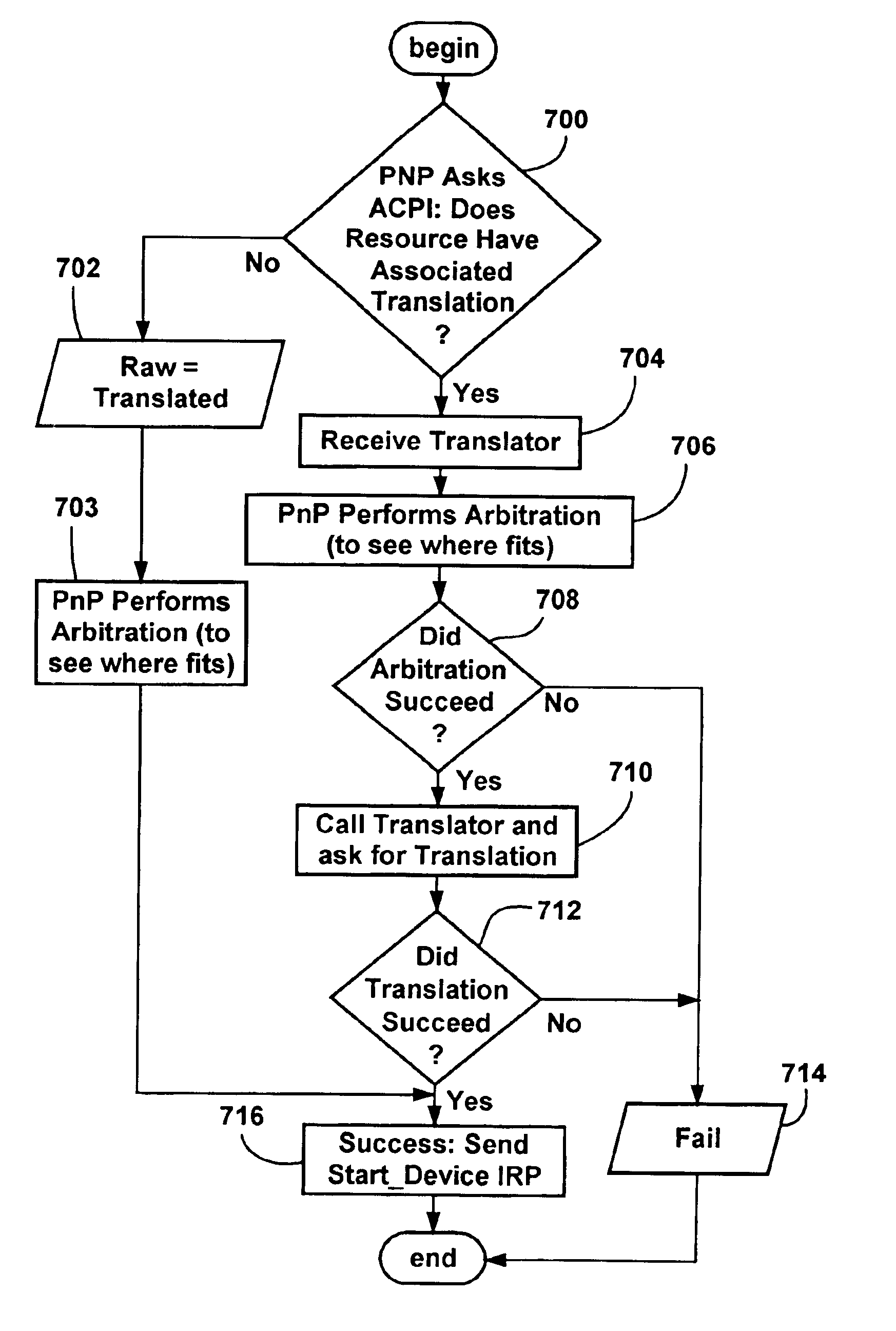

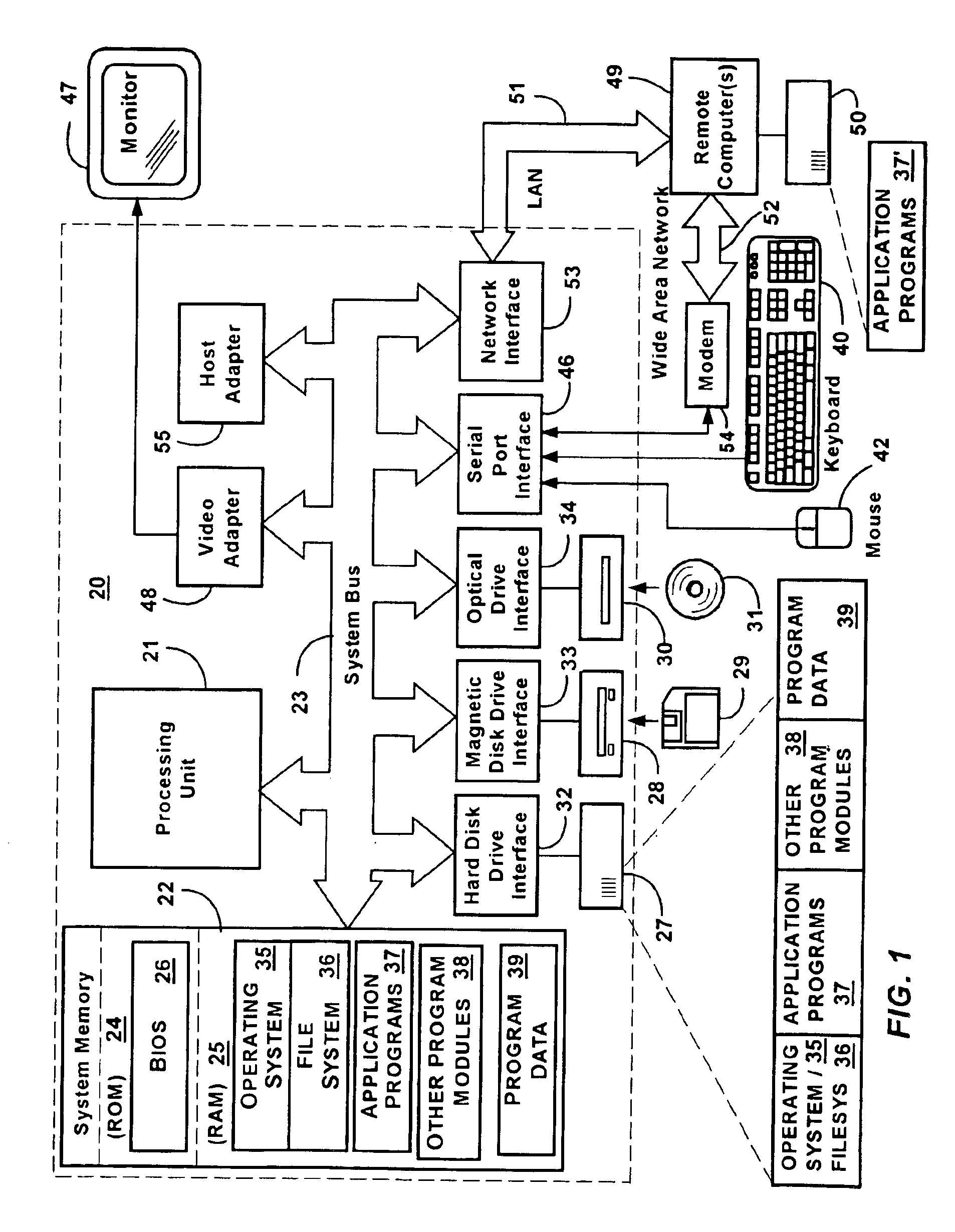

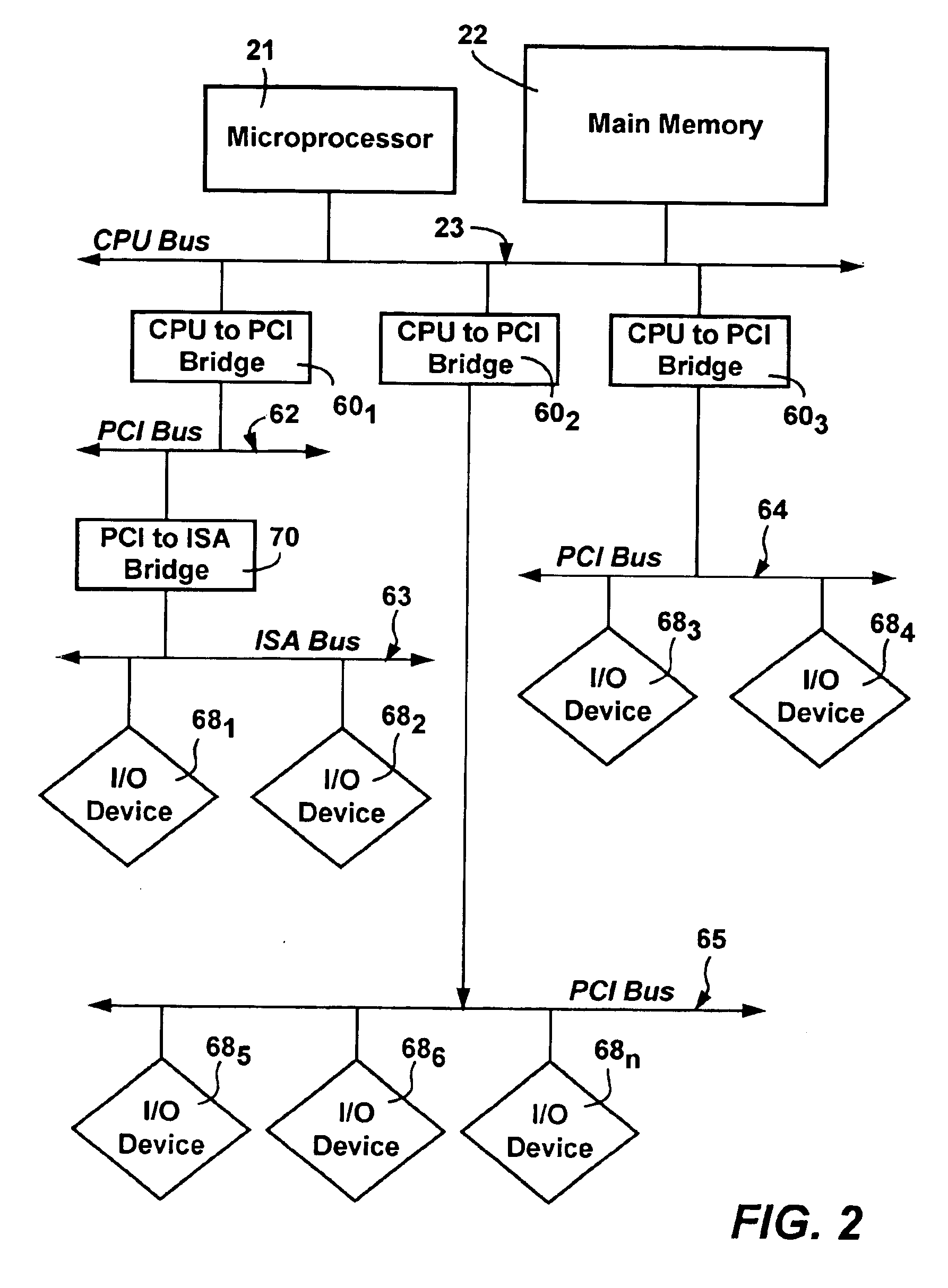

Dynamically configuring resources for cycle translation in a computer system

InactiveUS6970957B1Program controlGenerating/distributing signalsAdvanced Configuration and Power InterfaceOperational system

Owner:MICROSOFT TECH LICENSING LLC

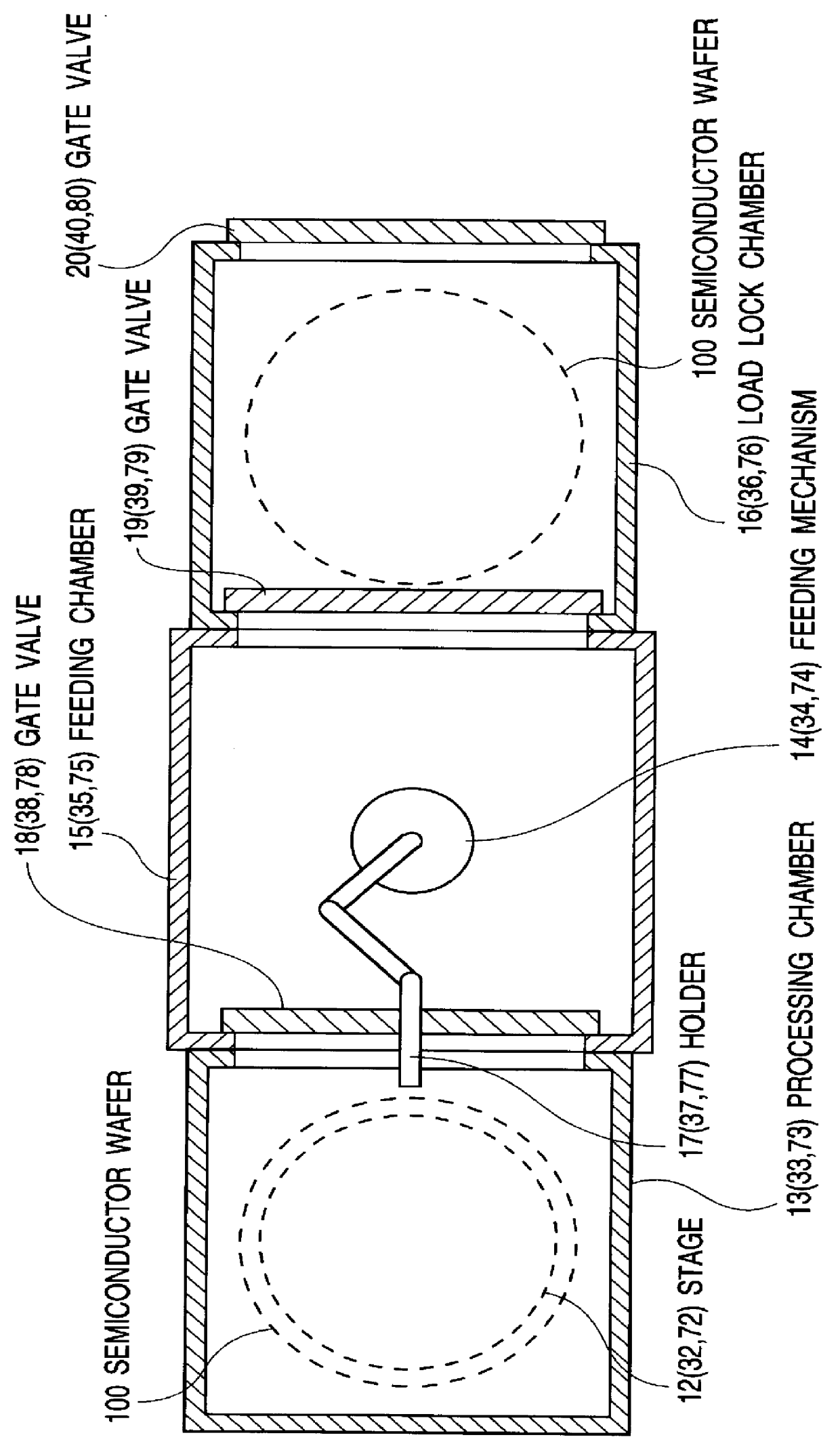

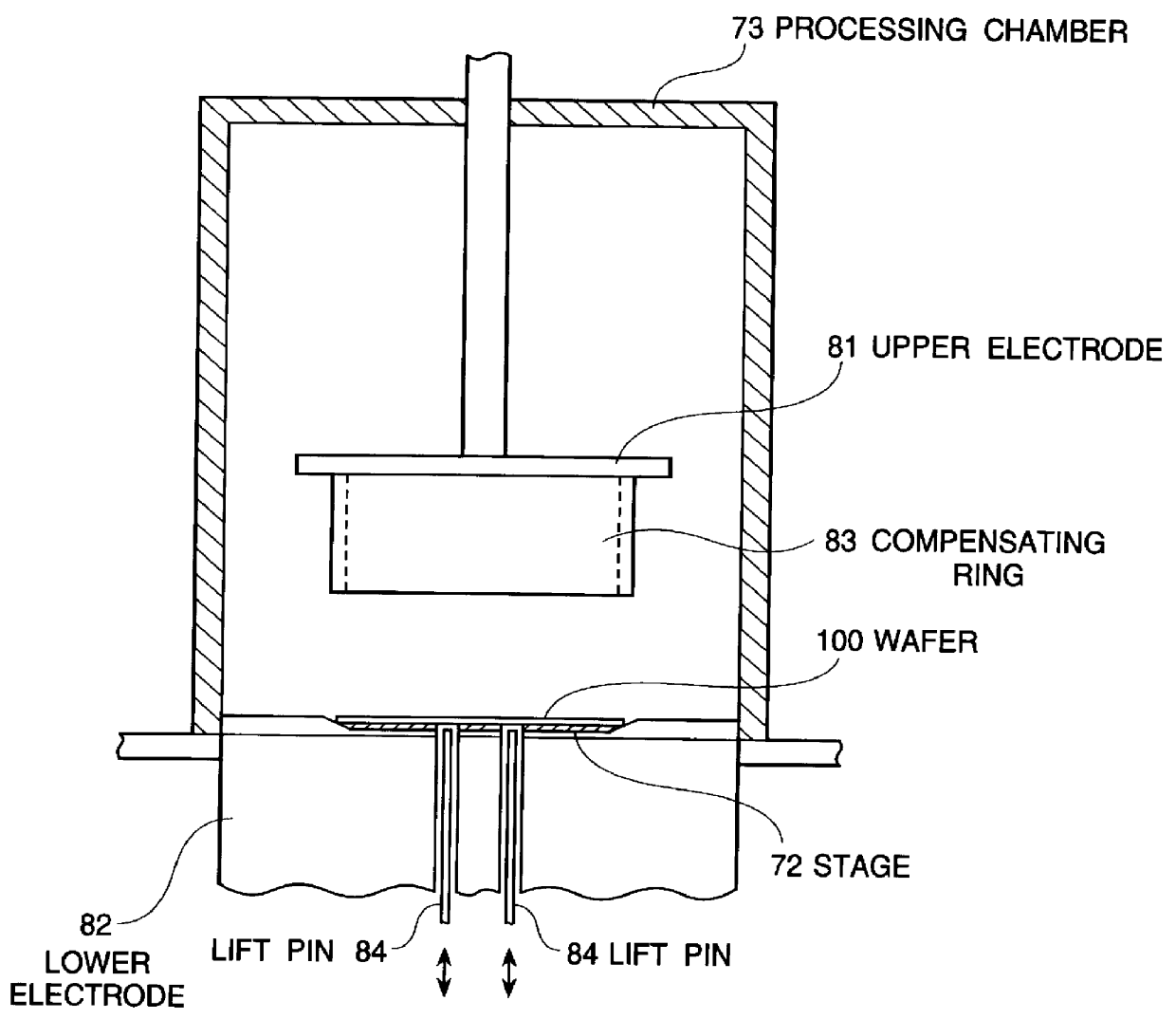

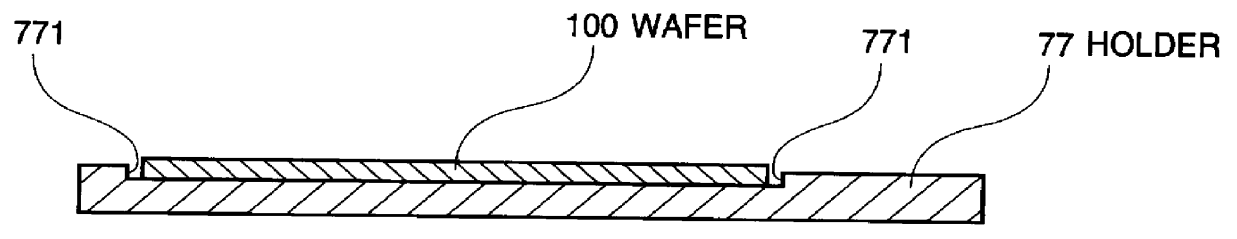

Semiconductor device manufacturing machine and method for manufacturing a semiconductor device by using the same manufacturing machine

A semiconductor device manufacturing machine comprises a mechanism provided in a processing chamber, for lifting up a ring-like peripheral member, and a holder provided at a tip end of a feeding mechanism located in a feeding chamber, and capable of holding either or both a semiconductor wafer and the ring-like peripheral member, so that, in the processing chamber maintained in a vacuum condition, the ring-like peripheral member is lifted up by the lifting mechanism and transferred to the holder of the feeding mechanism, and the ring-like peripheral member held by the holder of the feeding mechanism is moved from the processing chamber through the feeding chamber to a load lock chamber and further can be removed from of the semiconductor device manufacturing machine. Thus, the ring-like peripheral member is held and transferred by the holder for holding and transferring the semiconductor wafer, and therefore, the ring-like peripheral member can be exchanged without breaking the vacuum condition of the processing chamber.

Owner:NEC ELECTRONICS CORP

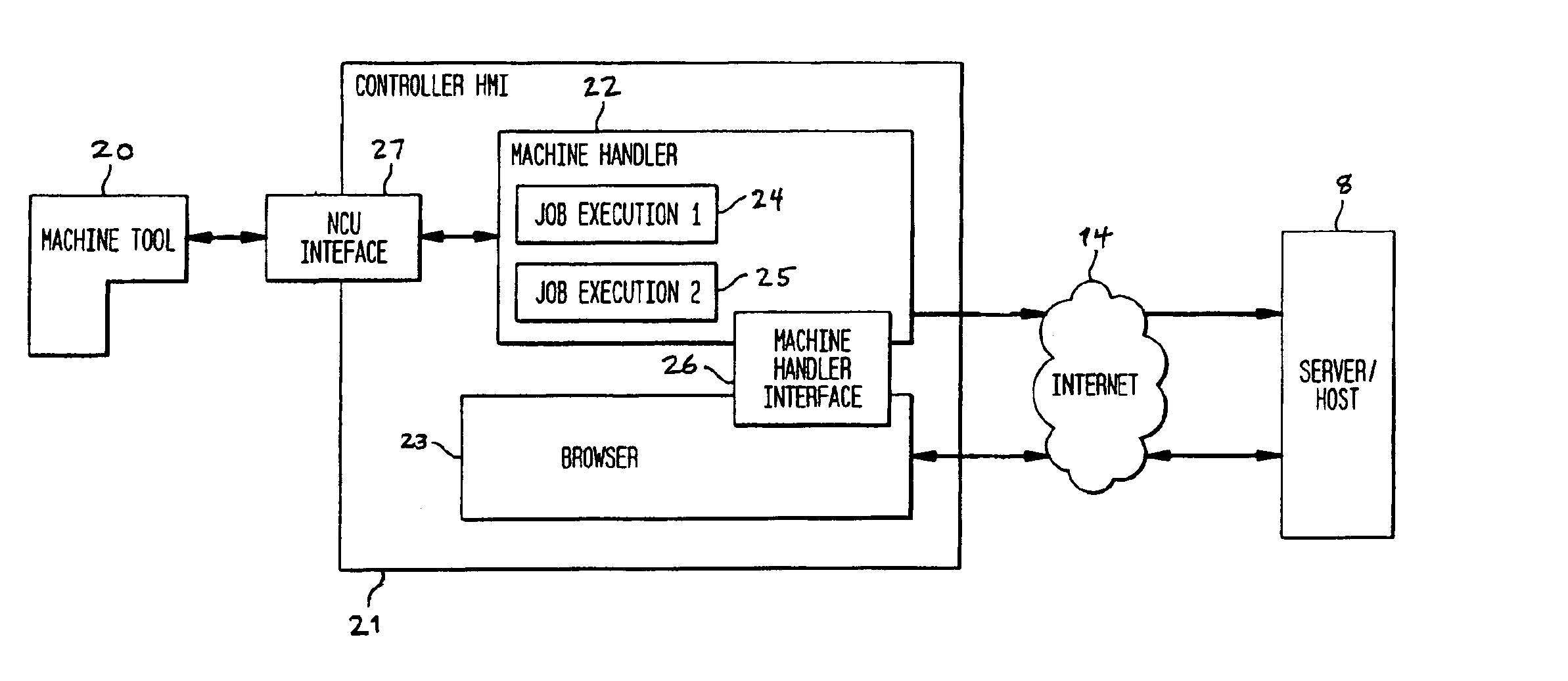

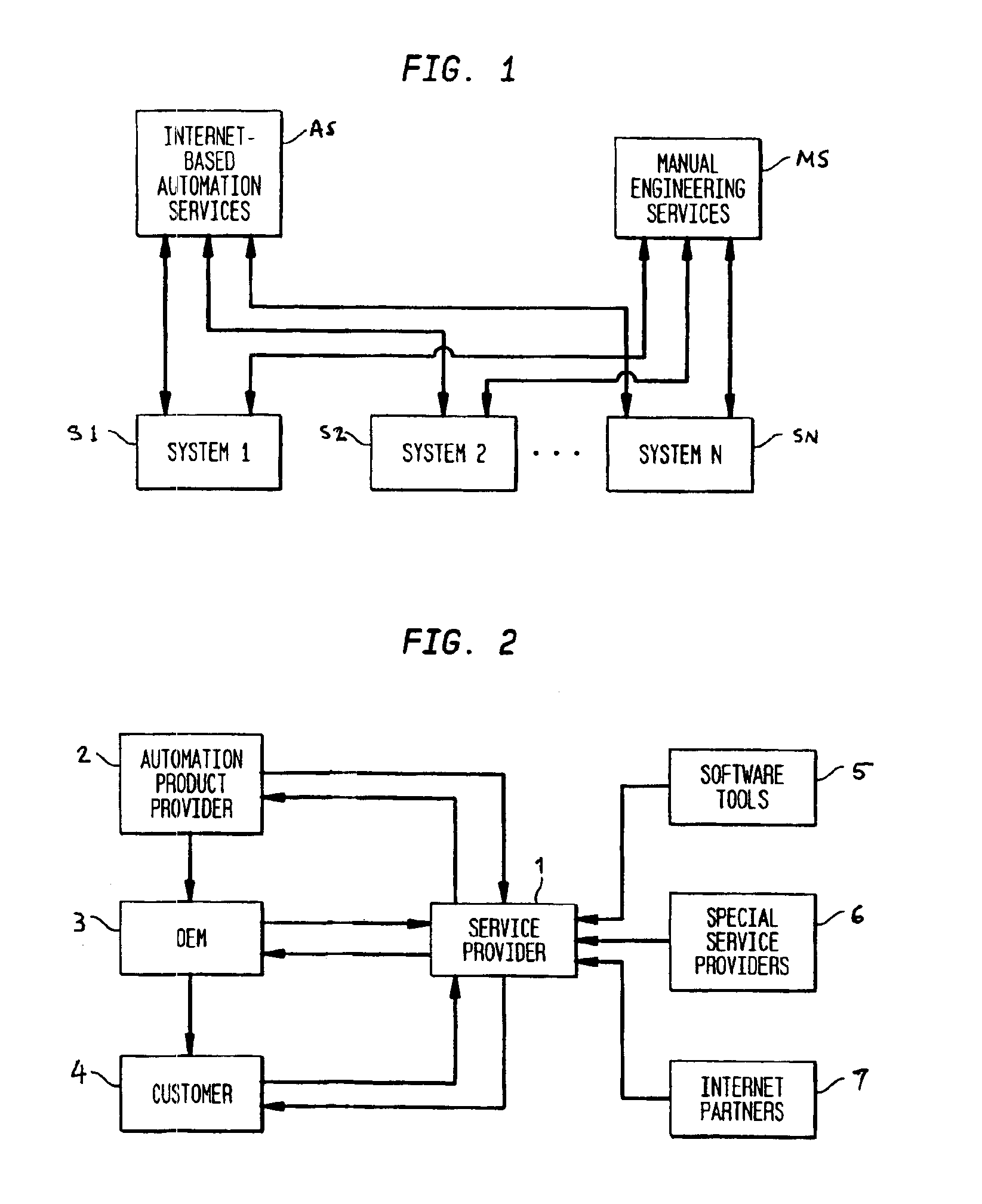

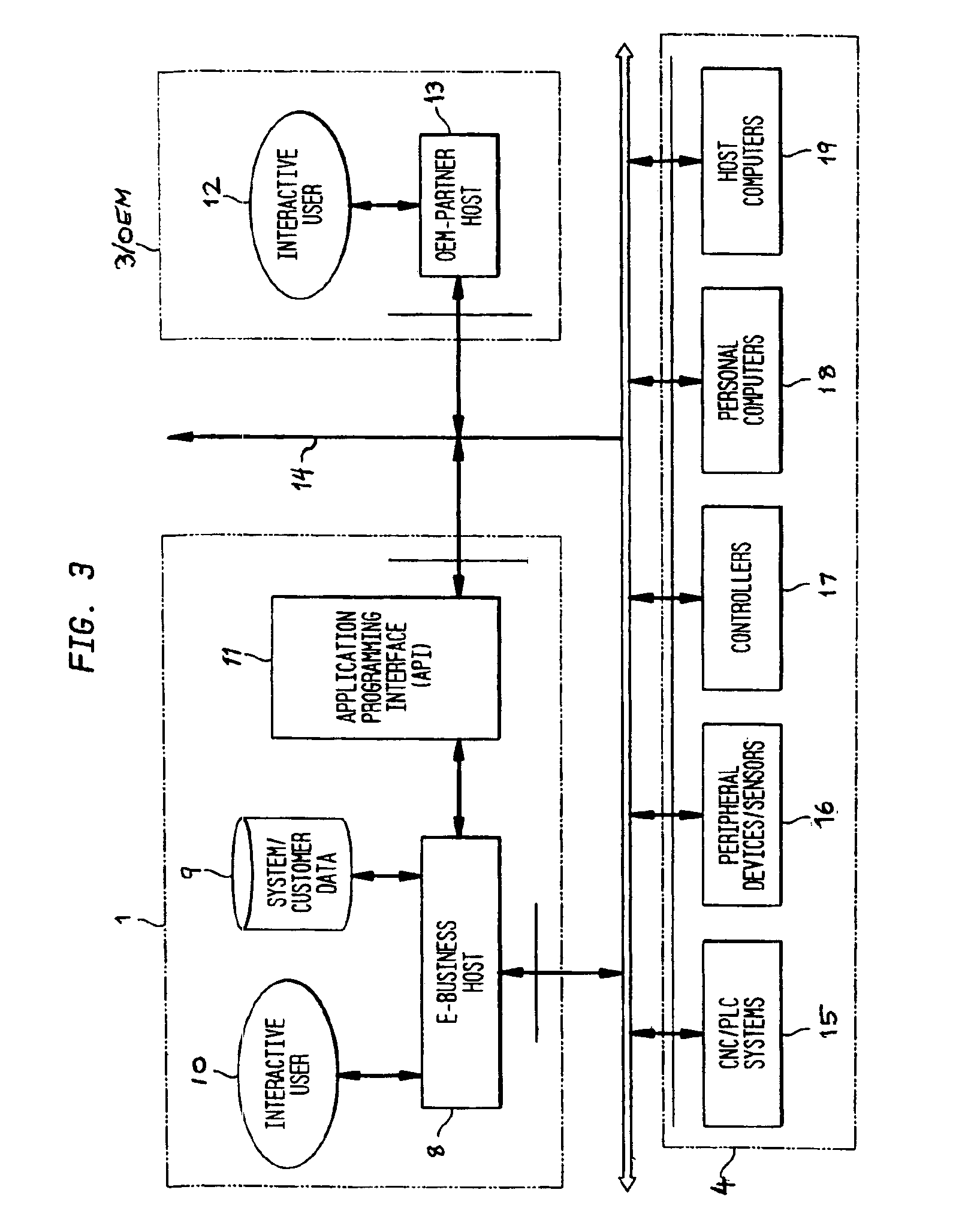

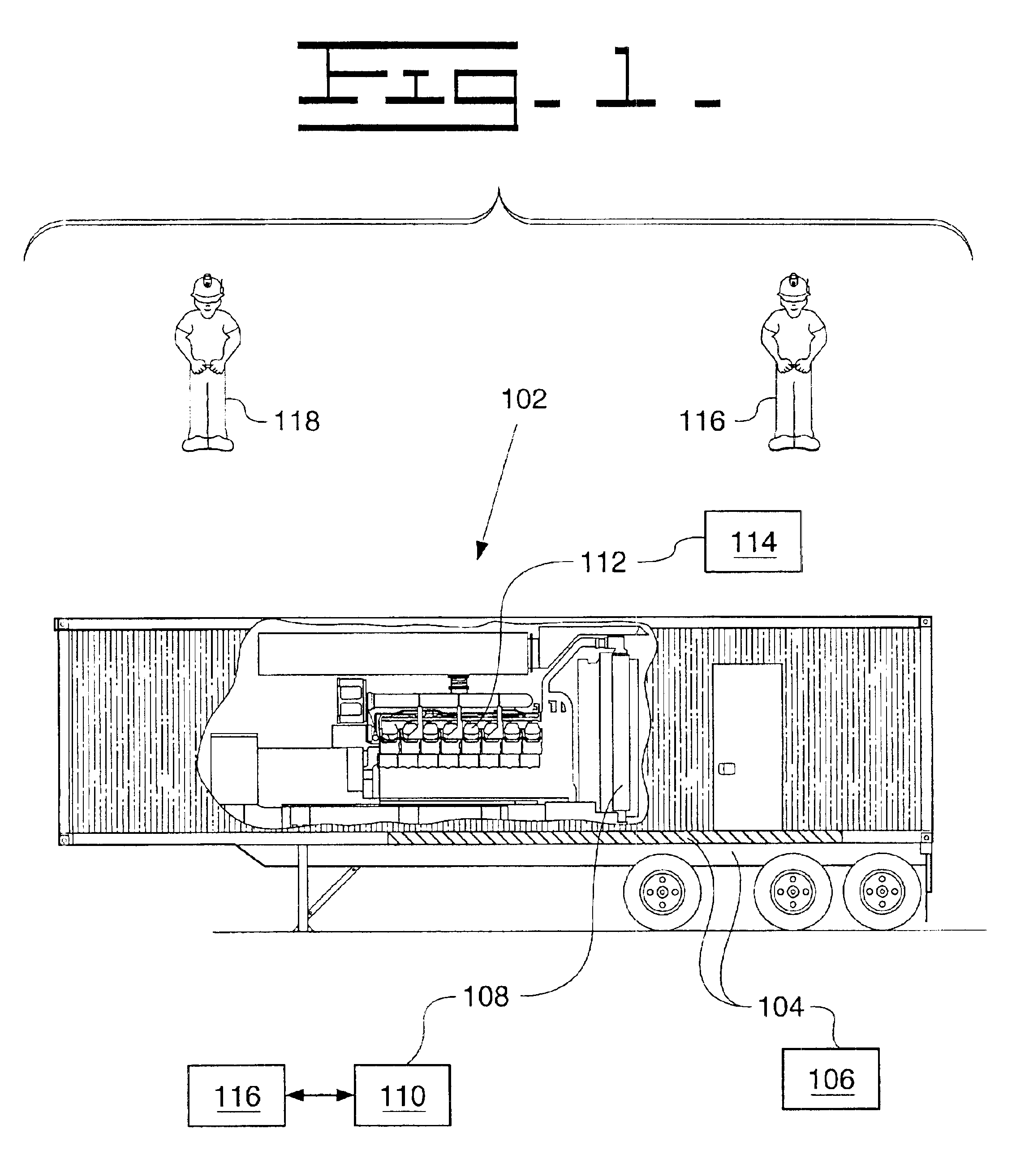

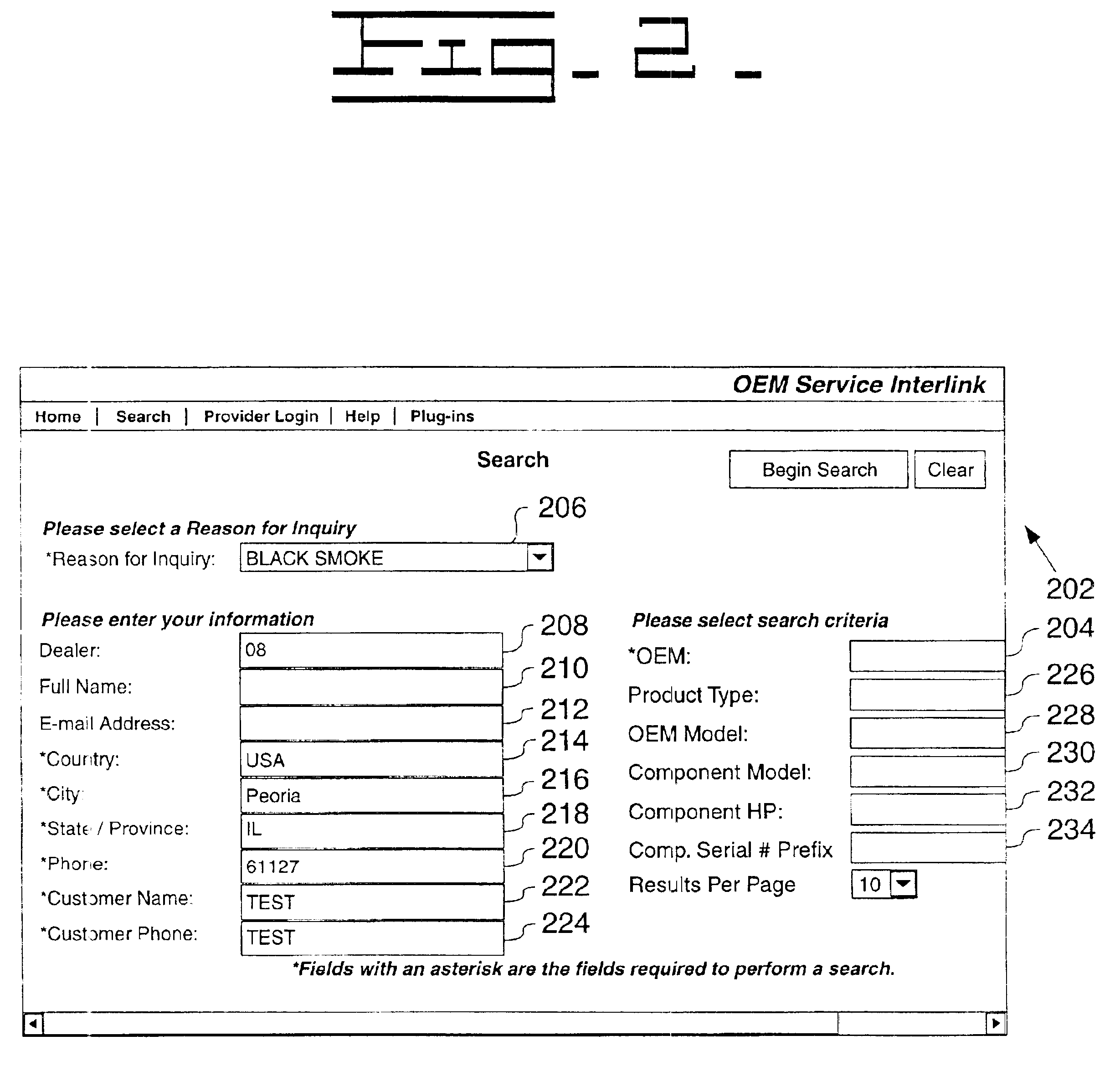

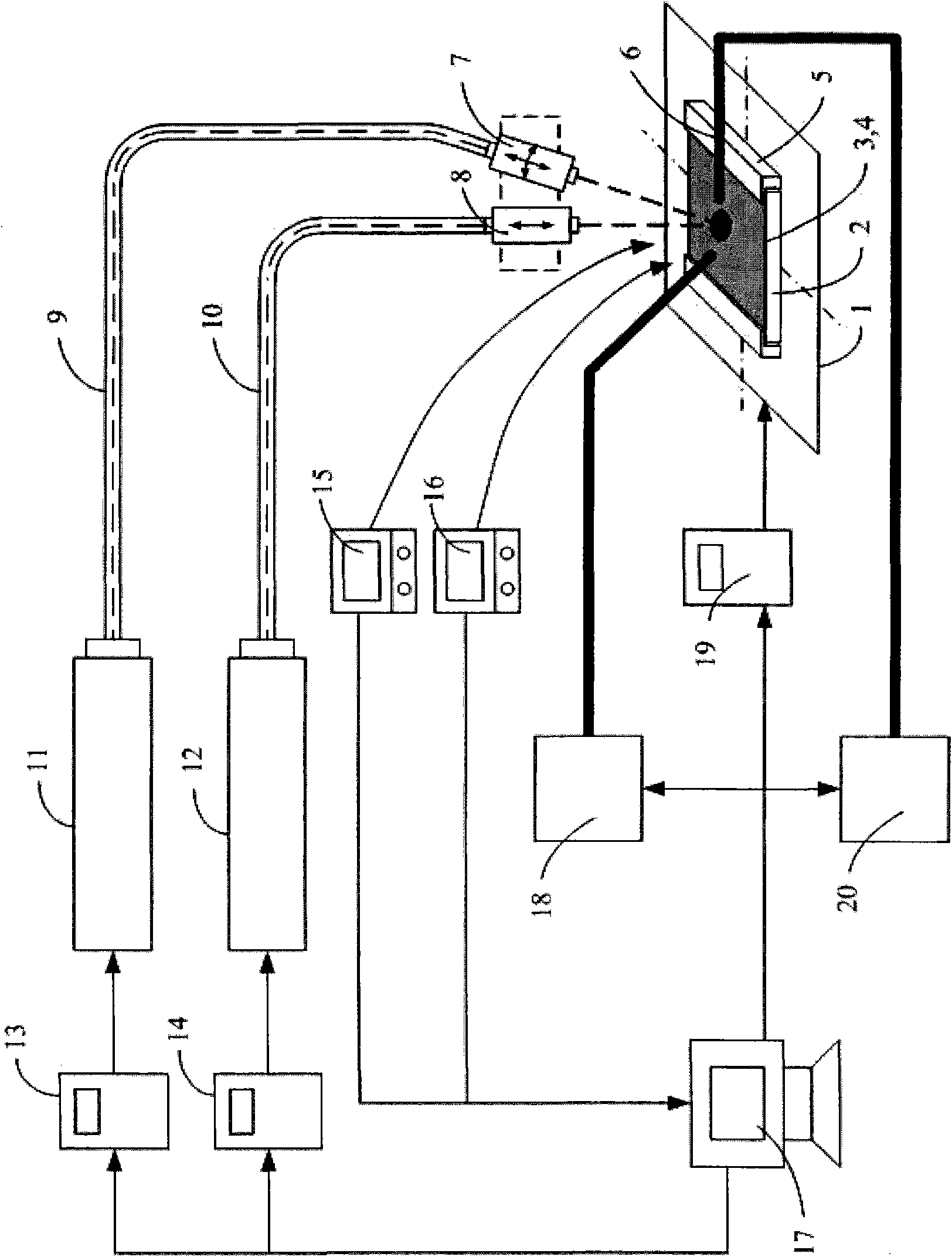

Method and system for the electronic provision of services for machines via a data communication link

InactiveUS6954680B2Improve usabilityTechnology managementMultiple digital computer combinationsTelecommunications linkMachine building

With this invention, expert knowledge from machine manufacturers is applied quickly at any time to a machine via the internet, by providing a main computer (host) for the production and provision of machine-related data and / or services and a machine-side working computer (client), which is connected to the main computer via a data communication link and (client) machine state data can be acquired in real time and transmitted to the main computer, and machine-related data and / or services generated by the main computer as a function of such machine state data can be received by an analysis and evaluation unit.

Owner:SIEMENS AG

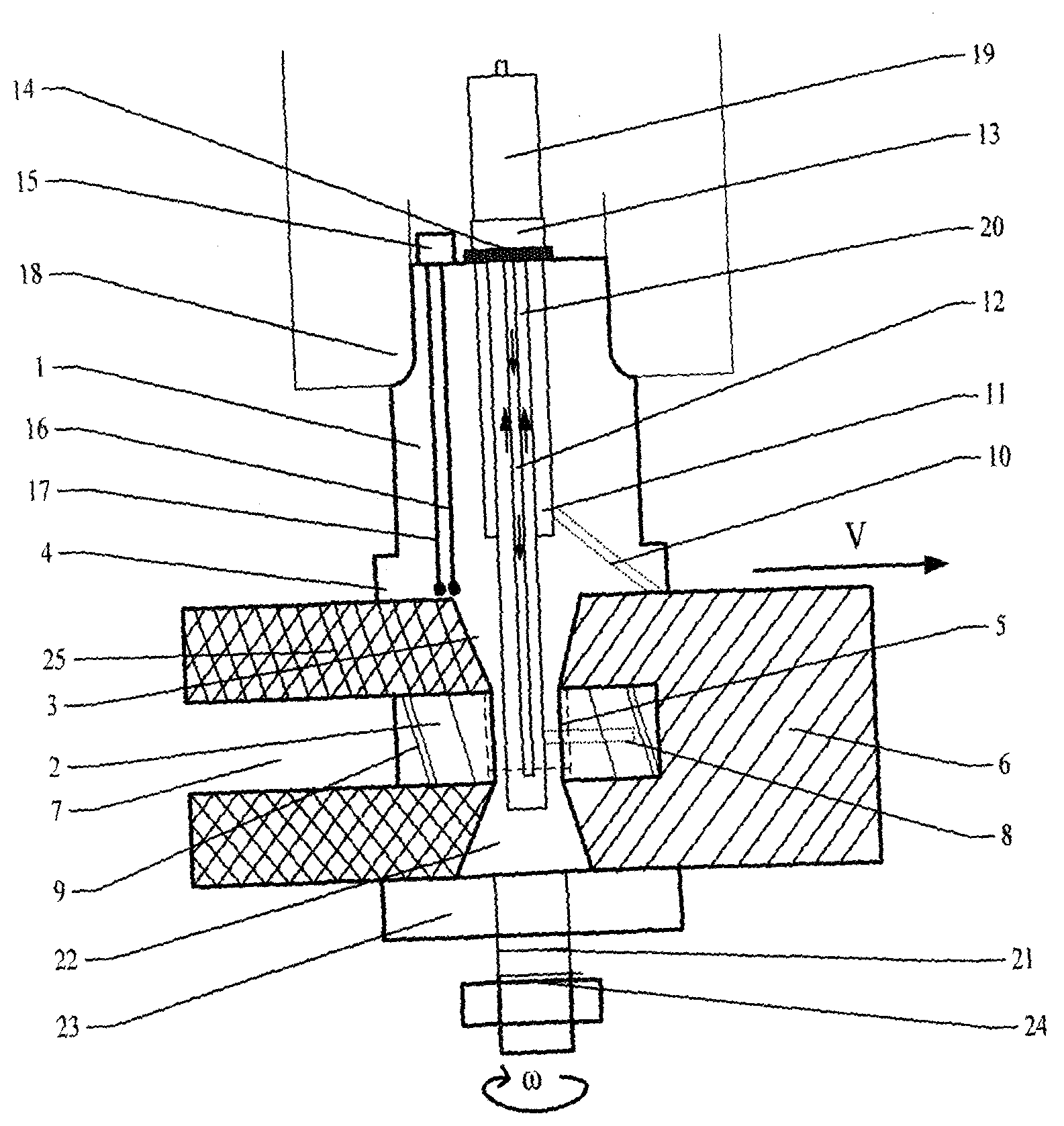

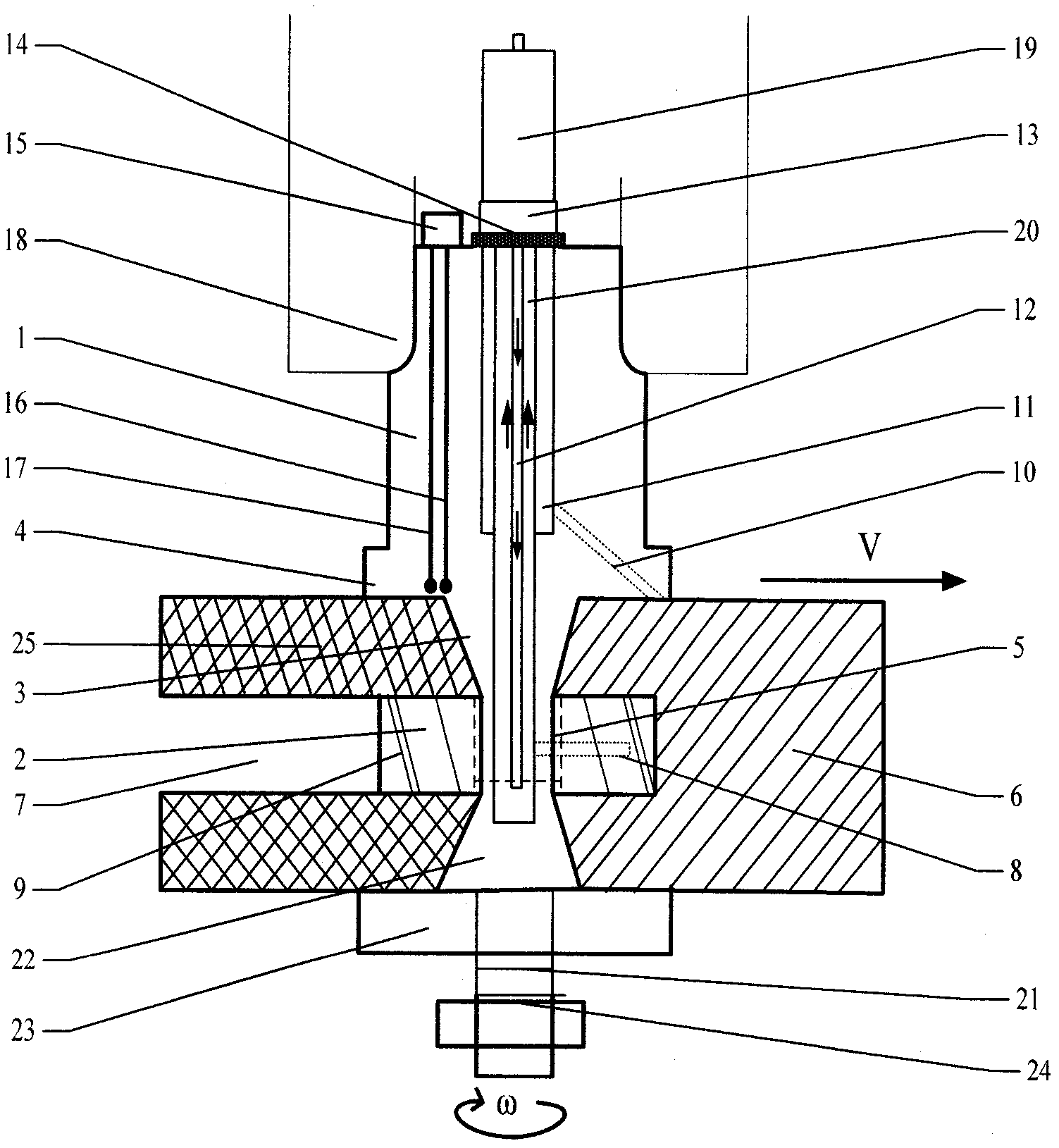

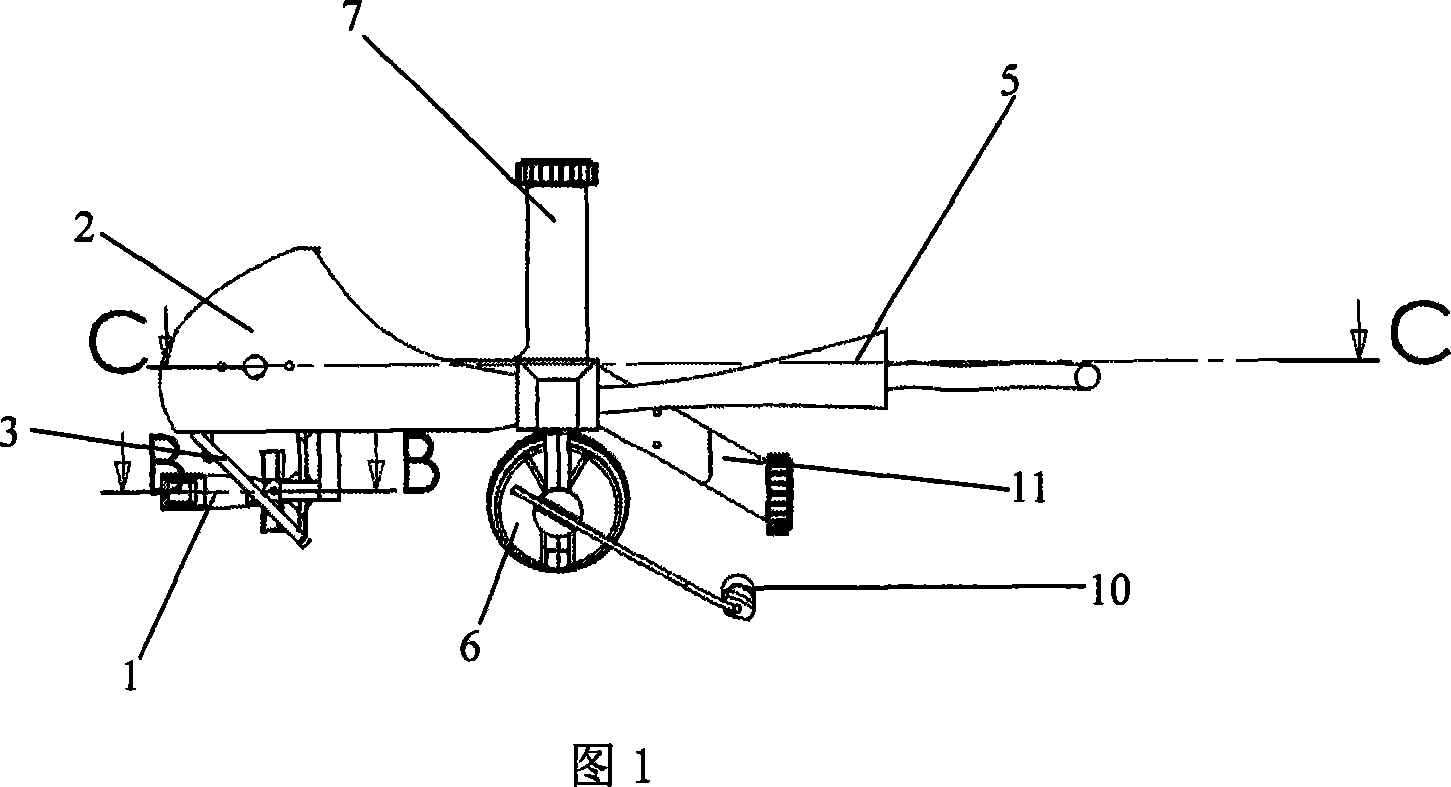

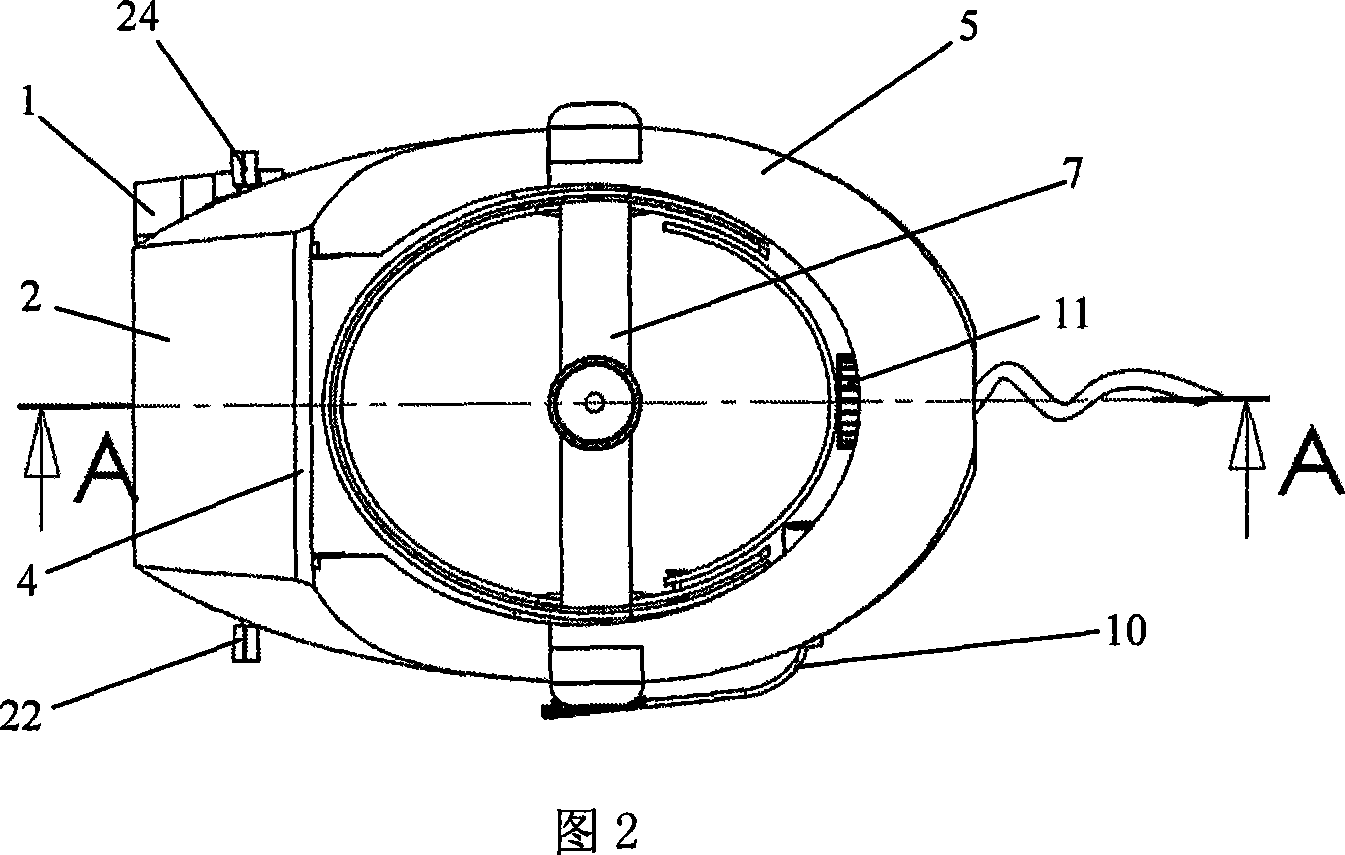

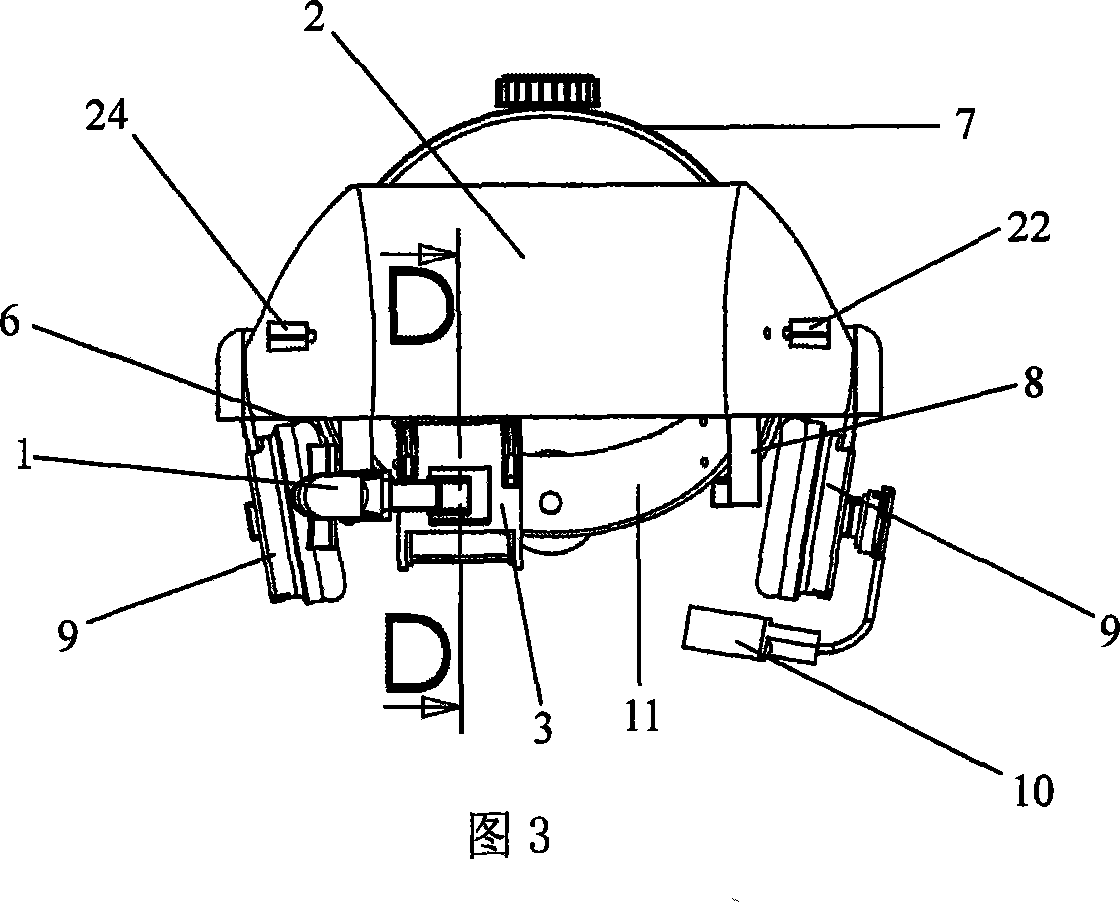

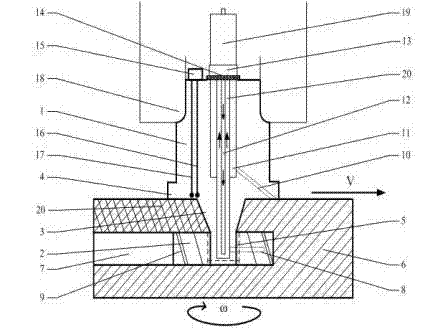

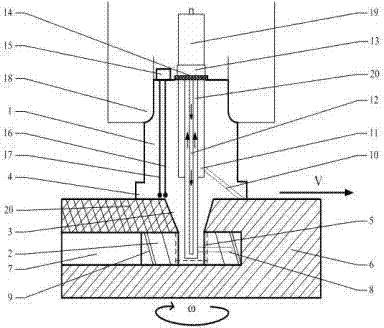

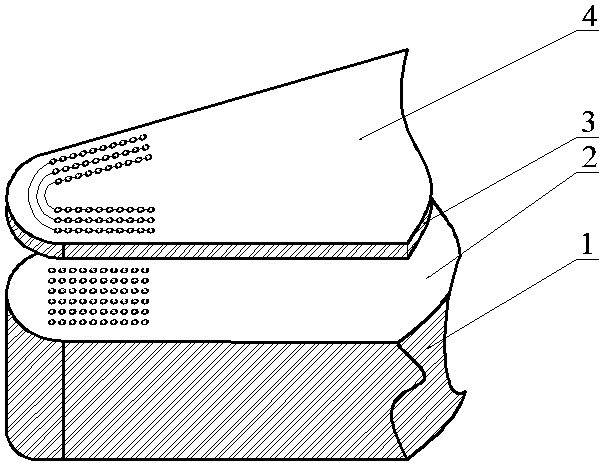

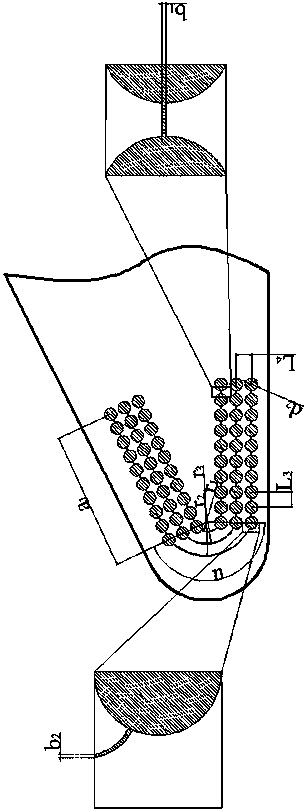

Cutting-stirring friction welding composite processing device for floating double-shaft-shoulder double-stirring needle and manufacture method thereof

InactiveCN102490018AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsNon-electric welding apparatusInduction systemTemperature sensing

The invention discloses a cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and a manufacture method thereof, and particularly relates to a combined or composite processing device capable of simultaneously carrying out milling or cutting processing and stirring friction welding processing and a method thereof. The cutting-stirring friction welding composite processing device for the floating double-shaft-shoulder double-stirring needle integrates a cutting system or a milling system, a stirring friction welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure induction system, a milling liquid supply system and a sensing-free system. The cutting-stirring friction welding composite processing device has functions of temperature control, gas protection, pressure detection, cooling liquid protection, milling head replacing and floating double-shaft-shoulder self-supporting stirring friction welding. The method for carrying out cutting-stirring friction welding composite processing on workpieces can meet strength requirements of mechanical processing of ferrous light metal materials, carbon steel materials and alloy steel materials. The cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and the manufacture method of the cutting-stirring friction welding composite processing device reduce manufacture procedures, save processing cost, have the advantages of being high in efficiency, excellent in quality, high in stability and saving in energy, break through limitation of conventional machining technology, form a new method and a new thought for machinery processing, and have wide application prospects in industries of heating, air conditioners, ice manufacture, freshness keeping, medicine preparation, construction, aquatic products and foods.

Owner:CHONGQING UNIV

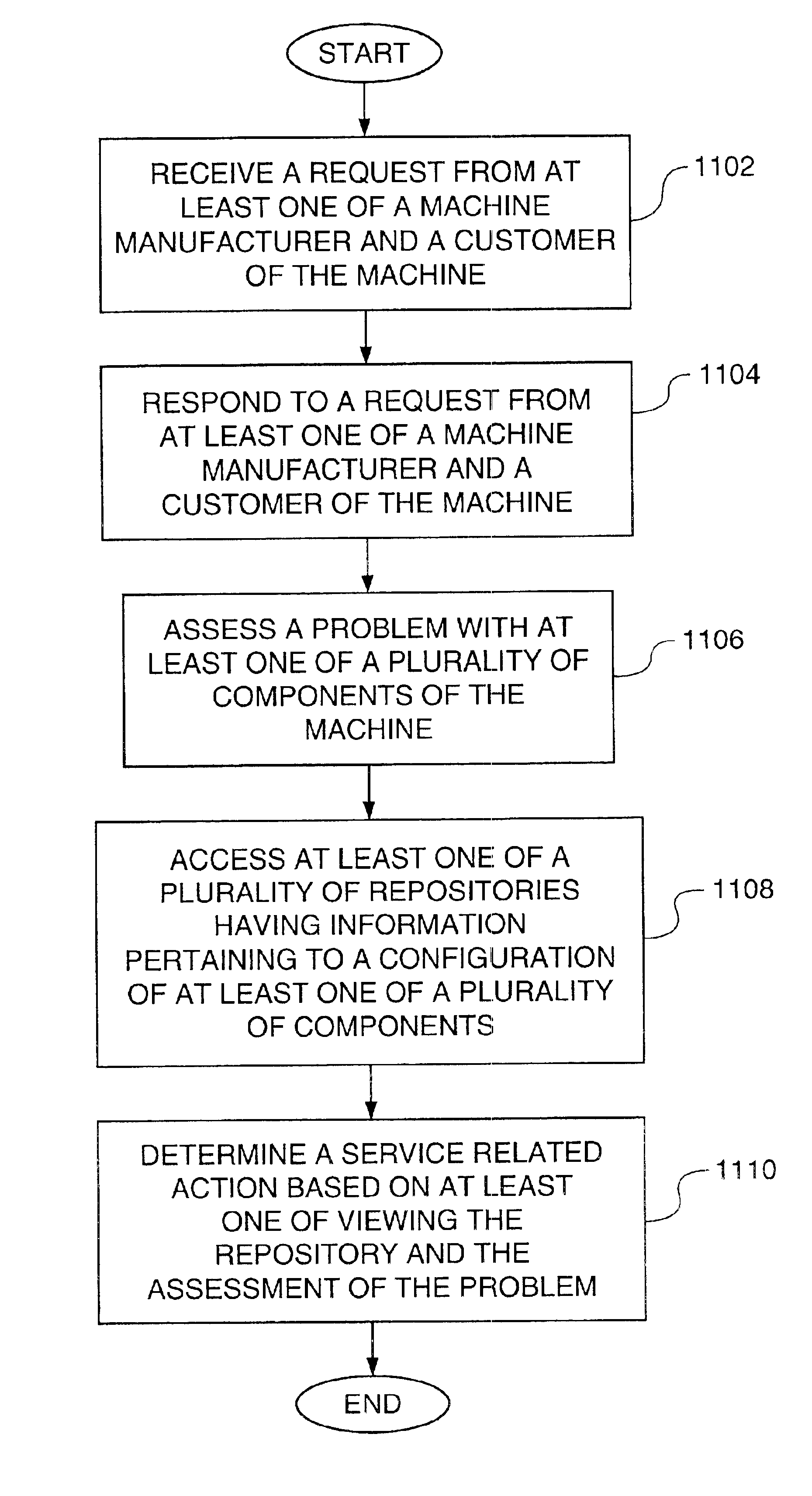

Service interlink

InactiveUS6892936B2Vehicle testingRegistering/indicating working of vehiclesMachine buildingComputer science

A system and method of servicing a machine is disclosed. The machine has a plurality of components manufactured by a plurality of suppliers. At least a first component being manufactured by a first supplier and at least a second component being manufactured by a second supplier. In the method a response to a request from a machine manufacturer or a customer of the machine is made. A problem with at least one of the plurality of components of the machine is accessed. In accessing the problem at least one of a plurality of repositories having information pertinent to the problem and to a configuration of at least one of the plurality of components is accessed. A service related action is contemplated based on at least one of viewing the repository and the assessment of the problem in combination with the information pertaining to at least one of the plurality of components.

Owner:CATERPILLAR INC

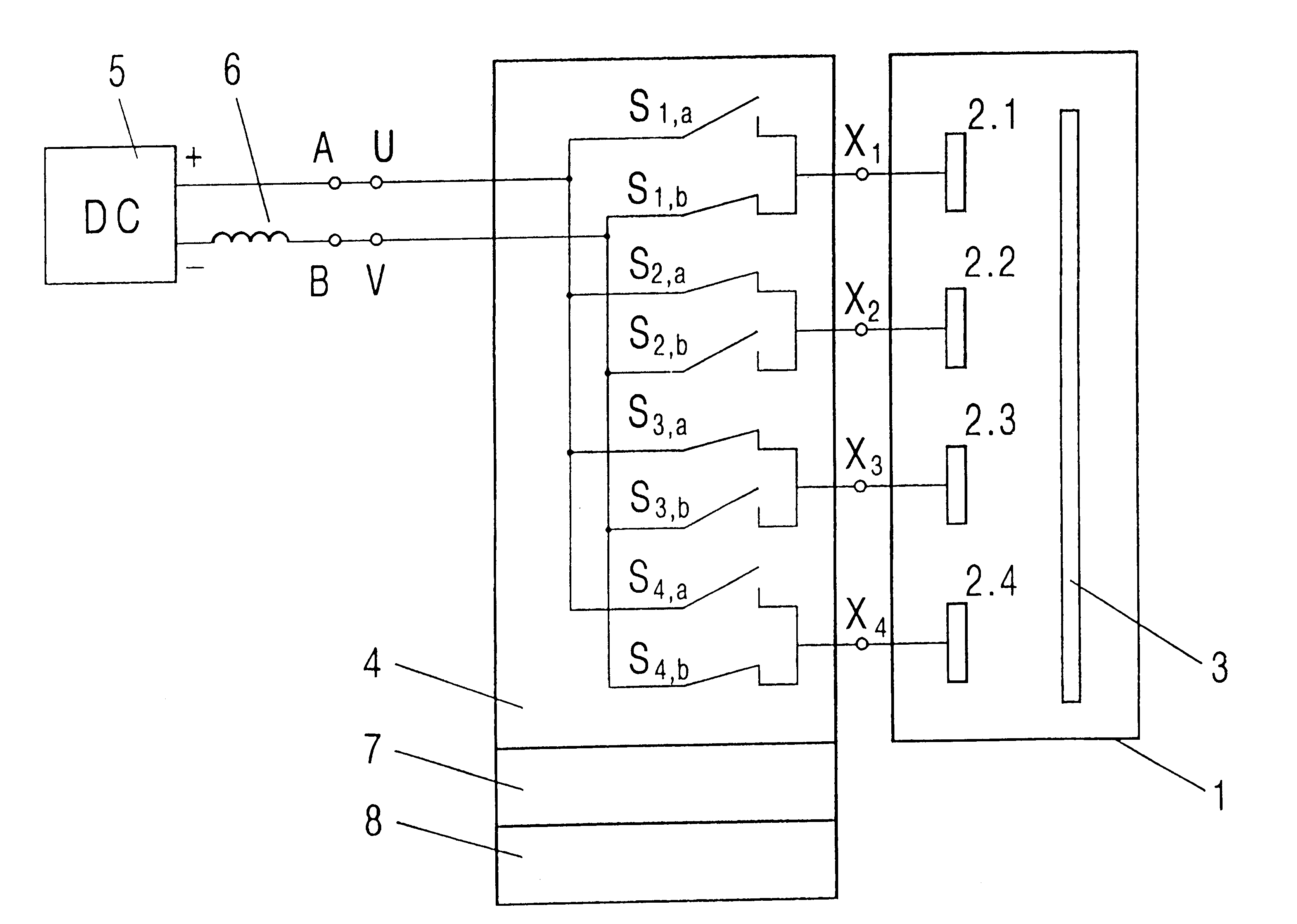

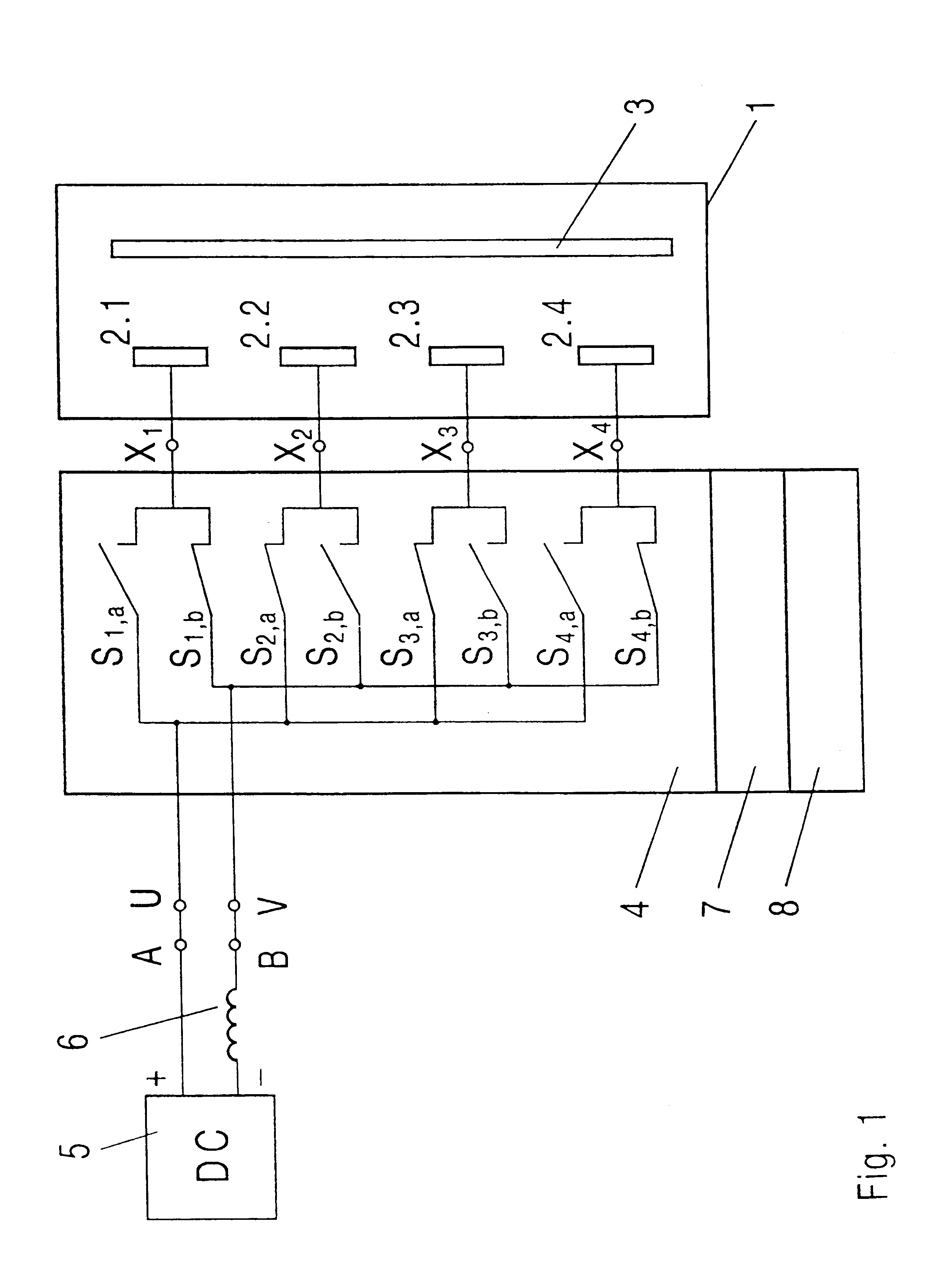

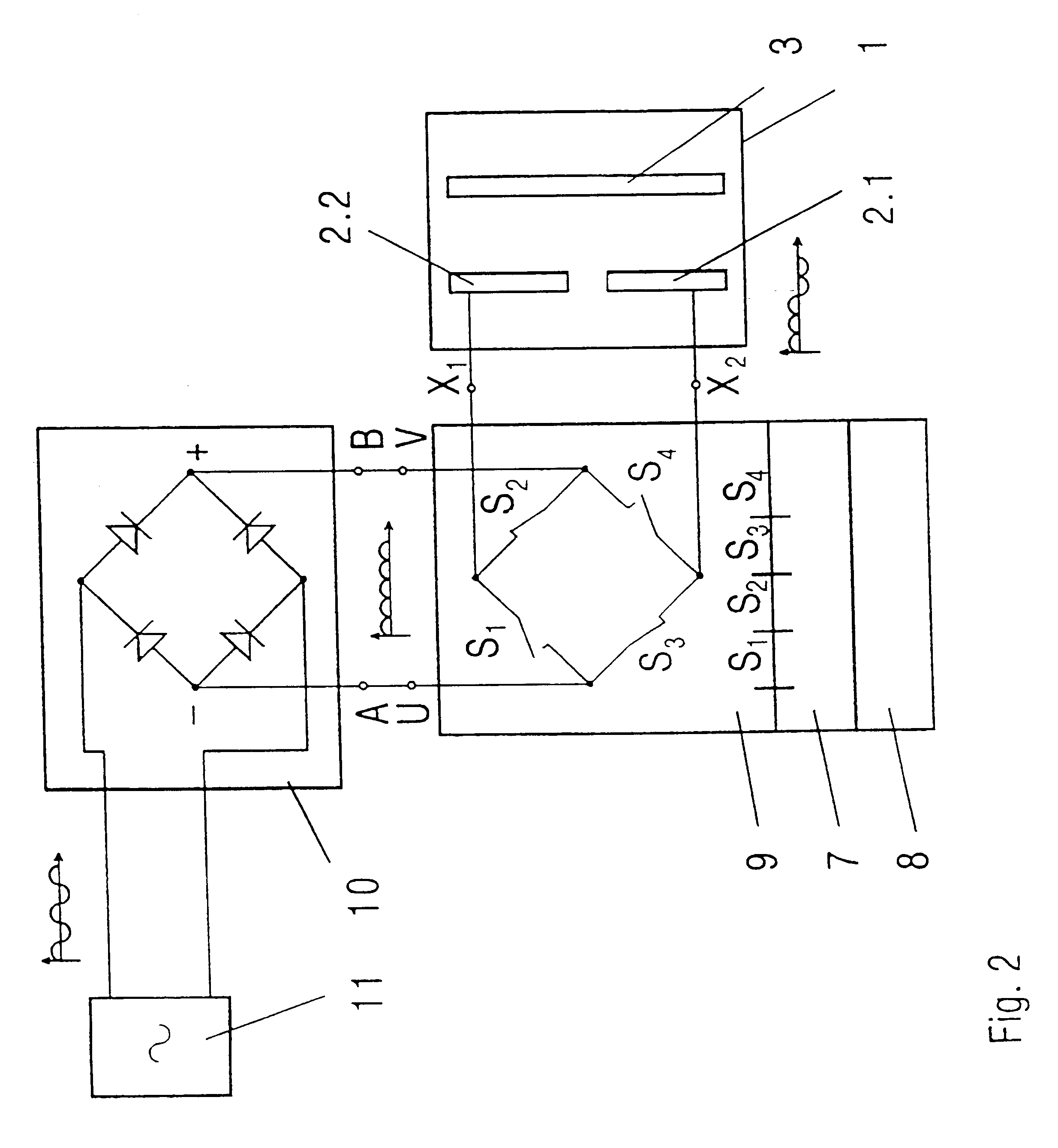

Process and system for operating magnetron discharges

InactiveUS6340416B1Improve efficiencyReduce output lossCellsElectric discharge tubesLoad carryingSupply energy

Magnetron discharges are pulse-operated to avoid the so-called "arcing". In the case of magnetron discharges from alternating current-fed magnetrons, the process is limited to the minor power of the energy supply because of the load-carrying capacity of the required electric components. When the magnetron discharges are fed by direct current, their effectiveness deteriorates because of the deposition of layers on the anode surfaces. The new process should enable a high supply power and prevent arcing. In magnetron discharges with at least two magnetron electrodes, the energy is supplied in such a way that at least one magnetron electrode is a cathode or anode and a number n1 of direct current pulses of said polarity is supplied. The poles of at least one magnetron electrode are then reversed and a number n2 of direct currents of this polarity are supplied. The process is carried on in this manner, the frequency of the direct current pulses being higher than that of the polarity reversals. The energy supply effectiveness is thus improved. This process and system enable the production of layers having the most different properties, for example for the glass, packaging, electronic, and machine construction industries.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

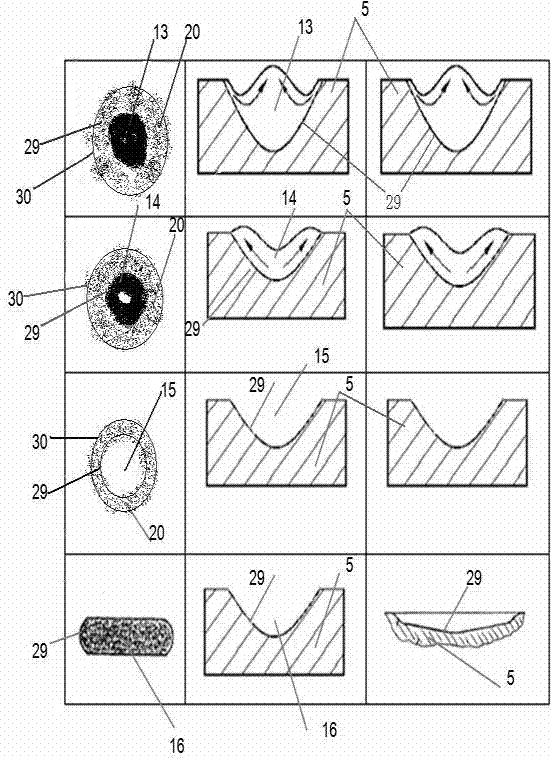

Compound model processing method and device for cutter

ActiveCN102962656AReduce wearImprove performanceMeasurement/indication equipmentsLaser beam welding apparatusNumerical controlHigh energy

The invention provides a compound model processing method and device for a cutter, relating to the active processing of microtexture compound morphologies on the main friction and abrasion surfaces of the cutter, and belonging to the field of machinery manufacture. Three microstructural models, namely micro concave cavities, fused bulges and micro grooves respectively, are processed at the main friction and abrasion parts of the cutter through high energy laser beams or high energy electron beams. With the adoption of the compound model processing method and device for the cutter, the continuous service life of the cutter is prolonged, the cutting quality of the cutter is improved, the surface quality and the cutting and cooling performances after the processing of a workpiece are improved, and the machining cost of metal cutting is lowered. The invention also discloses the processing device for applying the compound mould processing method; and the device is integrated with a high energy technique and a numerical control technique, so that predetermined compound microstructural morphologies and distributions thereof can be processed on the main cutting working face of the cutter efficiently and stably. Processing objects for the method and the device thereof provided by the invention are various cutters during the cutting processing.

Owner:JIANGSU UNIV

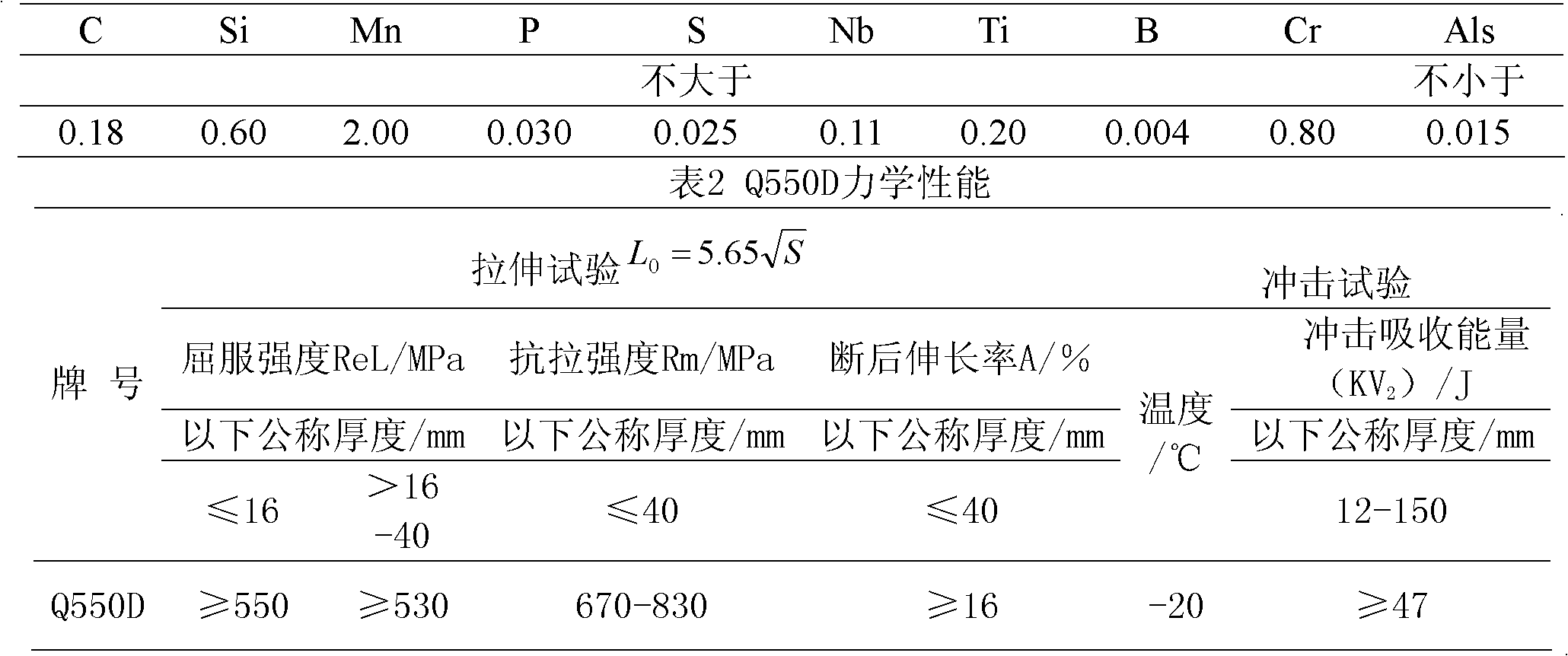

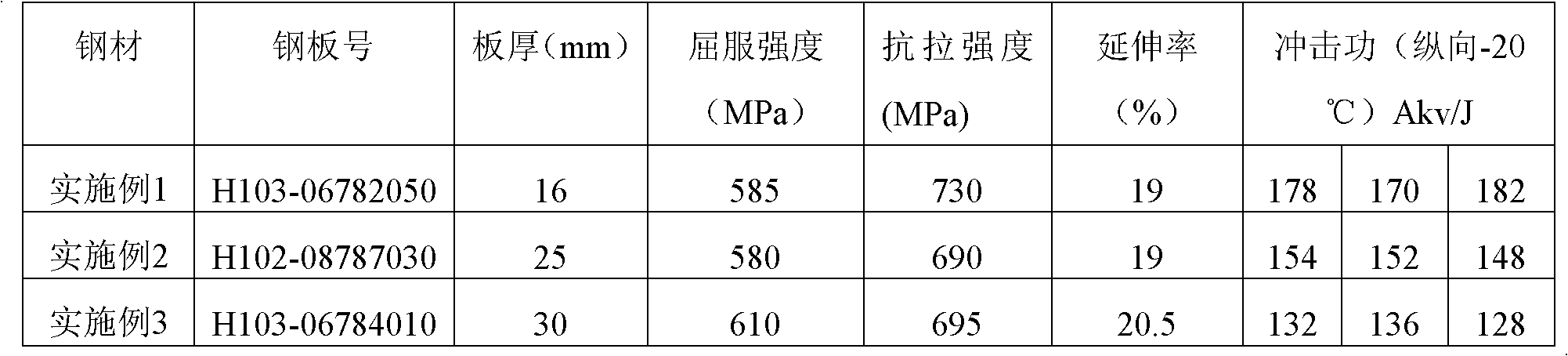

550Mpa yield-strength low-carbon bainitic steel for engineering machinery and preparation method thereof

The invention relates to a low-carbon bainitic steel for engineering machinery, which is prepared from the following chemical components in percentage by weight: 0.05-0.10% of C, 0.20-0.50% of Si, 1.50-1.80% of Mn, at most 0.010% of S, at most 0.018% of P, at most 0.10% of Nb, at most 0.10% of Mo, 0.010-0.040% of Ti, 0.0010-0.0030% of B, 0.20-0.50% of Cr, 0.015-0.050% of Al and the balance of Fe and trace impurity. The existing equipment is utilized; molten iron pretreatment, reblowing converter smelting, LF (ladle furnace) refining, RH refining, and plate blank continuous casting are carried out; and the contents of part of elements are adjusted, microalloying treatment, TMCP (thermomechanical rolling process) production, controlled rolling and water cooling are carried out, and no heat treatment is required, thereby obtaining the bainitic steel for engineering machinery, which has the advantages of high strength and favorable low-temperature toughness. The bainitic steel for engineering machinery is widely used in the fields of engineering machinery manufacturing and the like, such as large-size load-bearing steel structures, large-size earth mover, autocranes, excavators, mining machines, hydraulic supports, electric wheel dump trucks, mine cars and the like.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

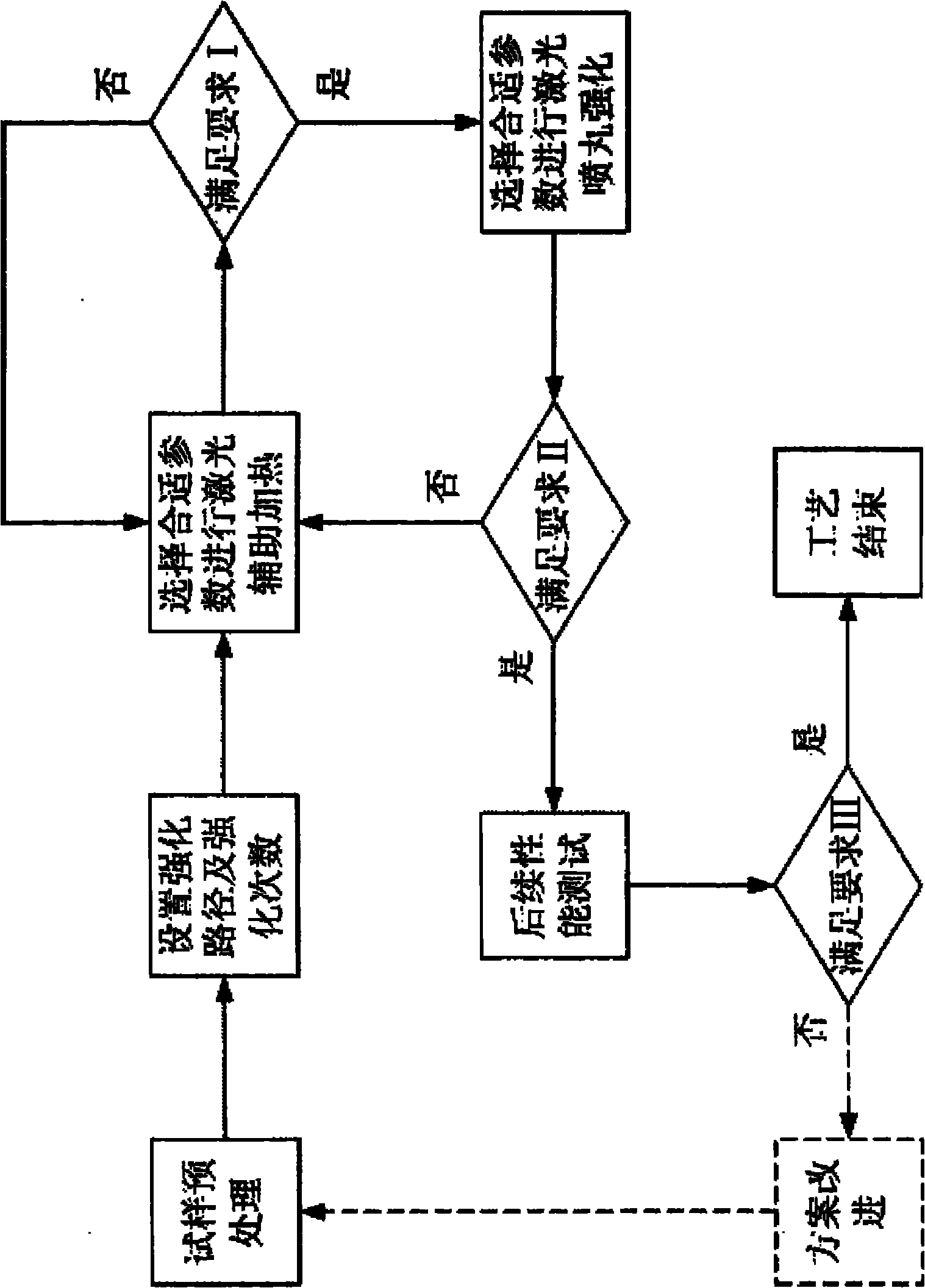

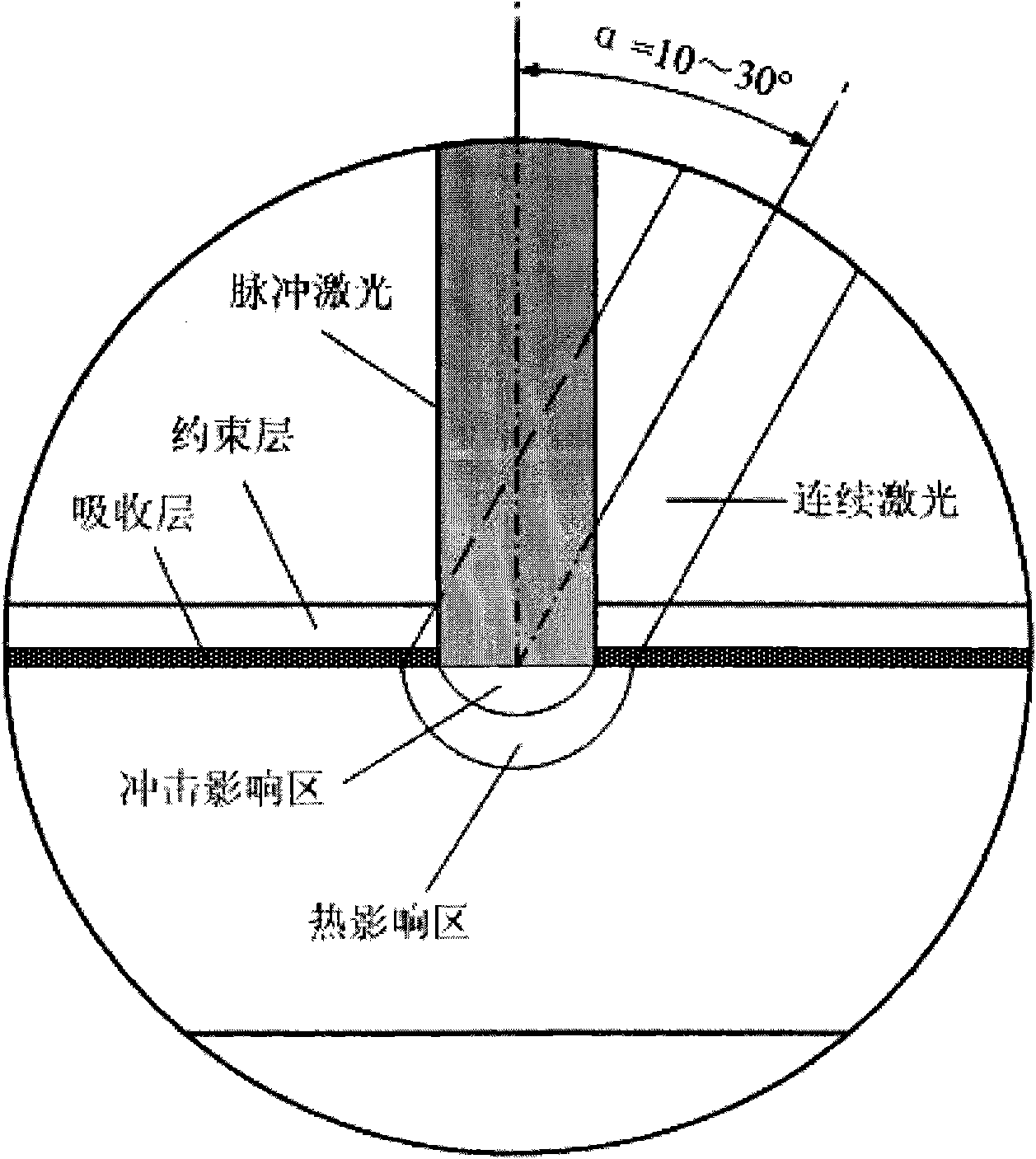

Device and method for laser shot blasting reinforcement of hard and brittle material

The invention discloses a device and a method for laser shot blasting reinforcement of a hard and brittle material, and relates to the field of mechanical manufacture of hard and brittle material processing and laser application. The device comprises a laser aid heating system, a laser shot blasting reinforcement system, a workpiece clamp system, a computer numerical control system, a measurement feedback system and a protective gas circulating system. The method comprises a laser aid heating stage and a laser shot blasting reinforcement stage, namely performing aid heating treatment on the area to be reinforced by adopting high-power continuous laser, wherein for most metal materials, the plastic performance is improved along with the rise of temperature; and after the temperature of the heating area reaches a predetermined heating temperature, implementing laser shot blasting reinforcement treatment by adopting high-power pulse laser. The device and the method can implement the laser shot blasting reinforcement on the hard and brittle material so as to broaden the application range of the laser shot blasting reinforcement technology, and meanwhile compound the advantages of continuous laser and pulse laser so as to broaden the application field and the application prospect of laser manufacture.

Owner:JIANGSU UNIV

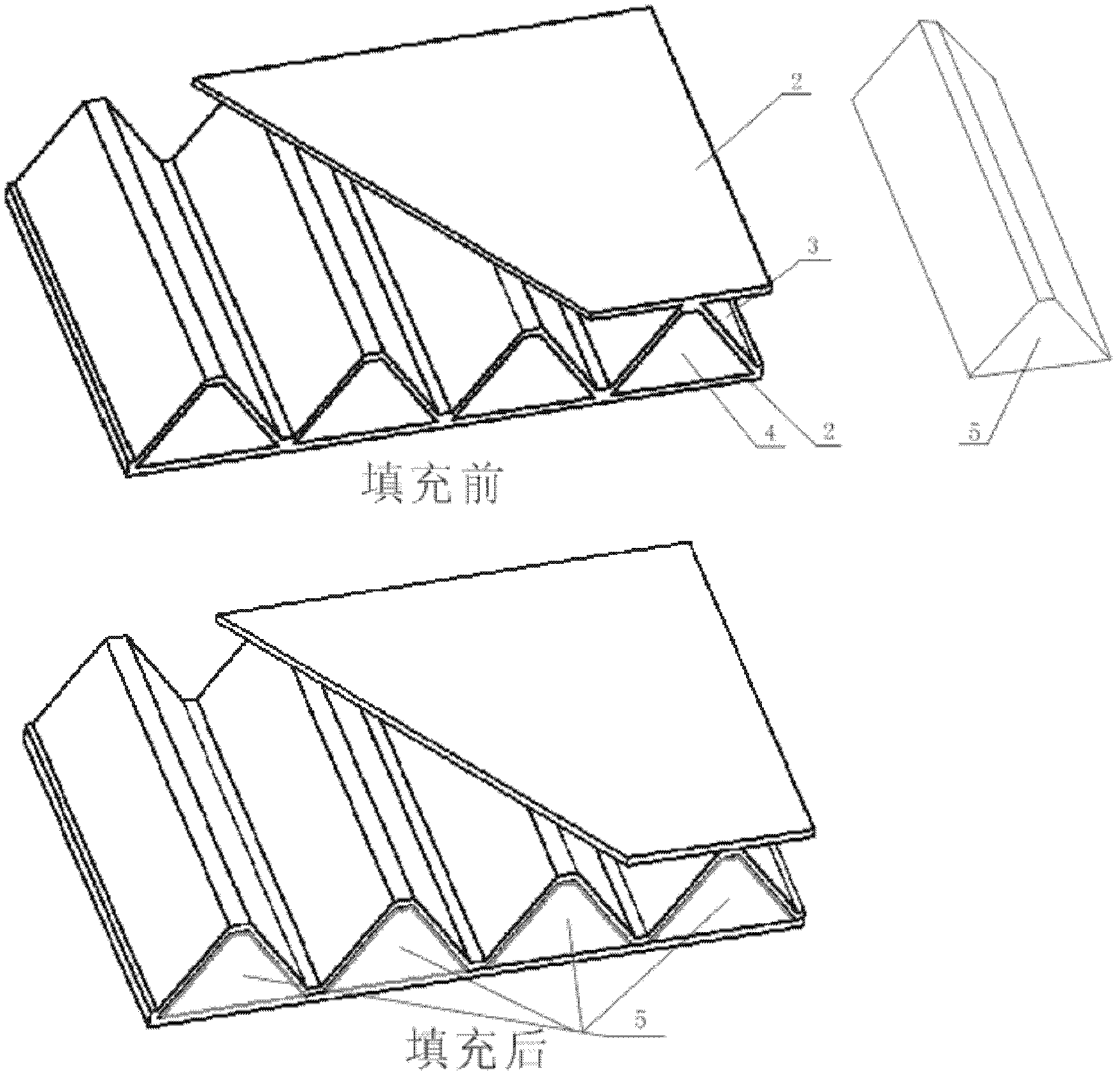

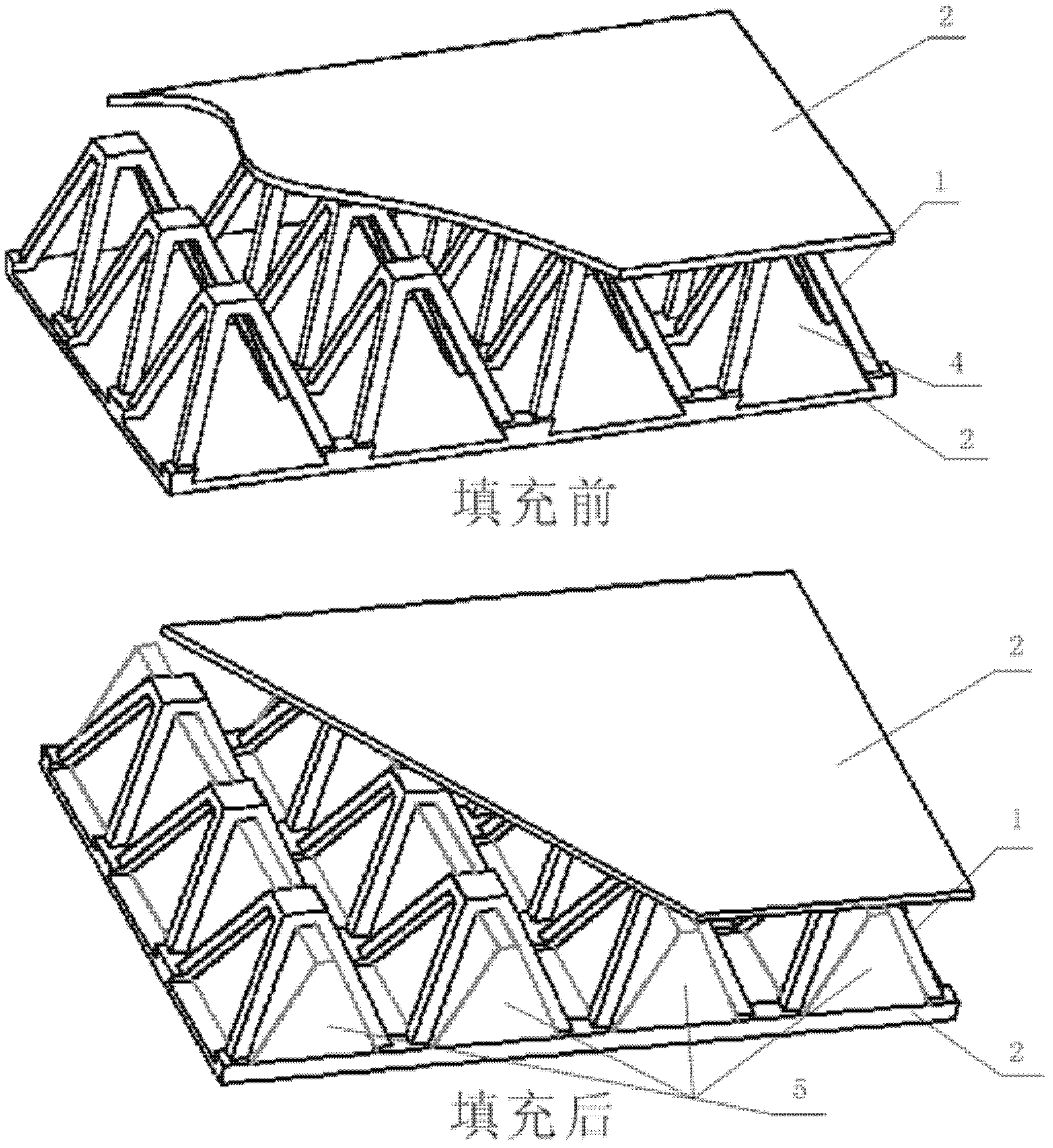

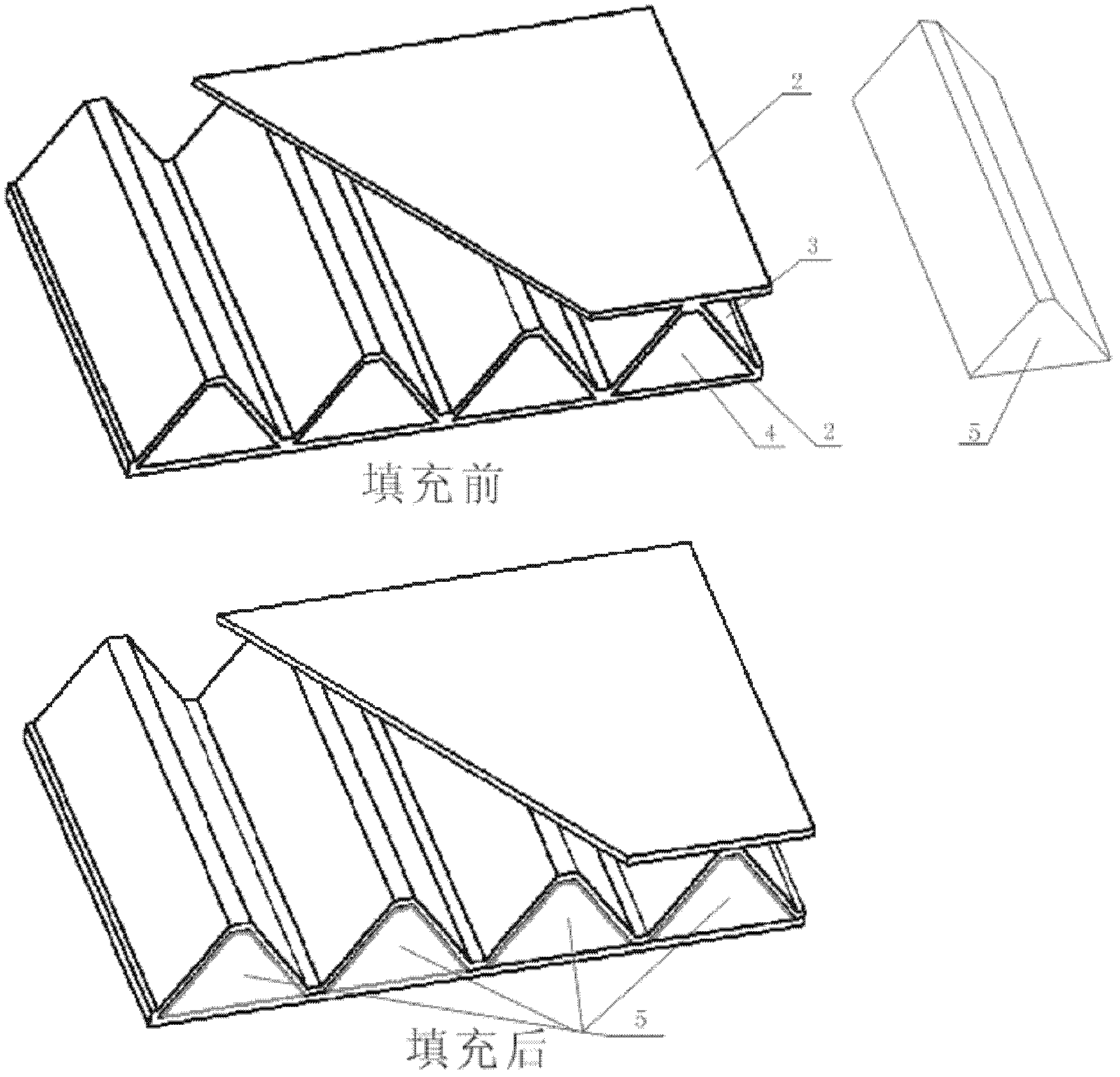

Lattice-gradient foamed aluminum composite material and preparation method thereof

InactiveCN102416713AImprove performanceGood mechanical propertiesMetal layered productsMetallic materialsHigh intensity

A preparation method of a lattice-gradient foamed aluminium composite material comprises the adhesive bonding and combination of a lattice metal material (including a ripple structure and a pyramid structure) and a cut foamed aluminium to obtain a multifunctional gradient composite porous material. The invention realizes the combination of a lattice metal material and foamed aluminium, and obtains a lattice-gradient foamed aluminium composite structural material sandwich plate with a geometric gradient. The lattice metal-gradient foamed aluminium composite material sandwich plate has wide application prospects in fields of safety protection, traffic transportation, mechanical manufacturing, and military affairs, has very effective performance with respect to structure weight reduction, impact deformation improvement, magnetic shielding and the like, can bring into play its high strength, high rigidity and excellent damping performance especially in mechanical manufacturing industry, and also has low manufacturing cost.

Owner:XI AN JIAOTONG UNIV

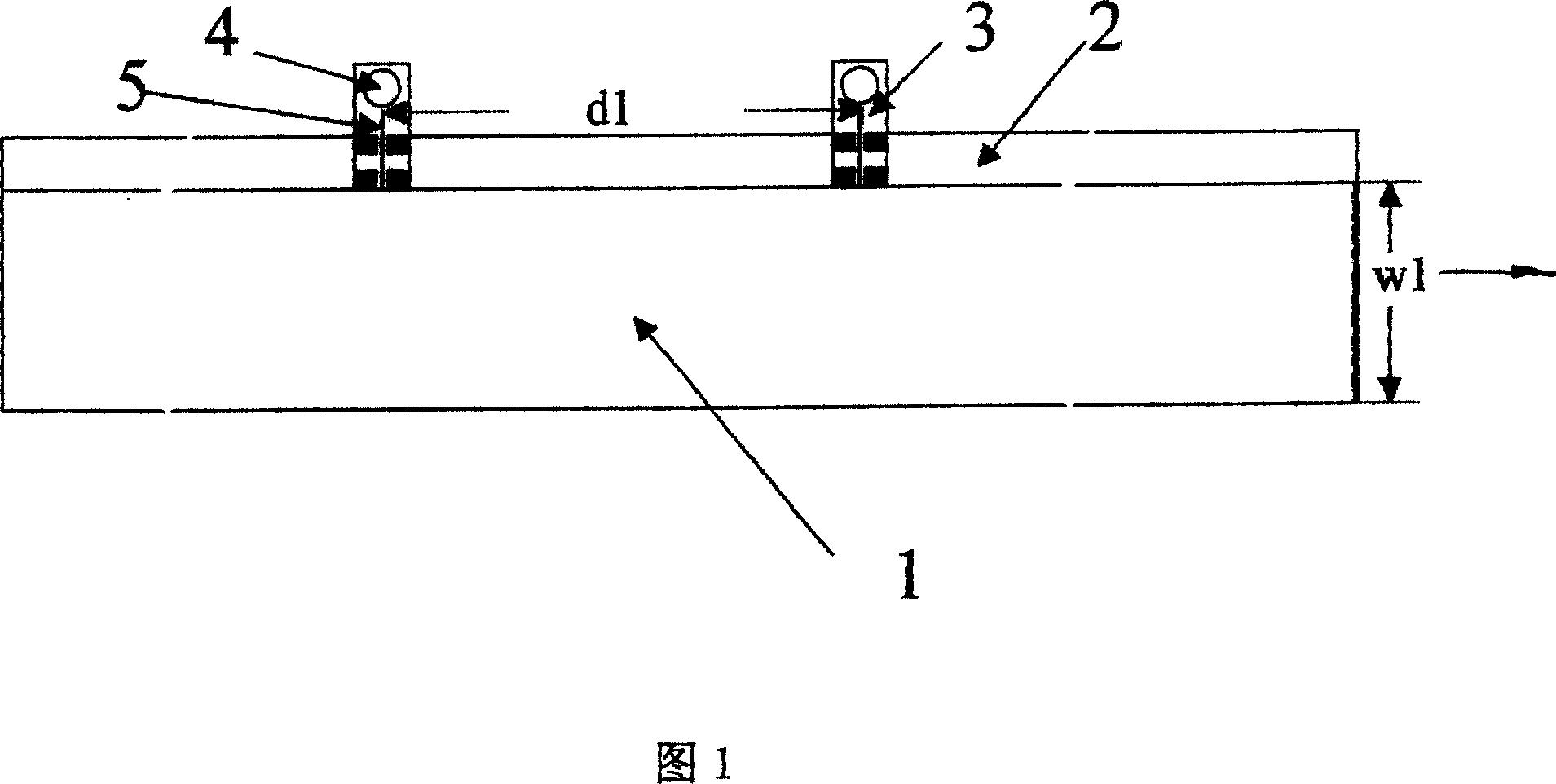

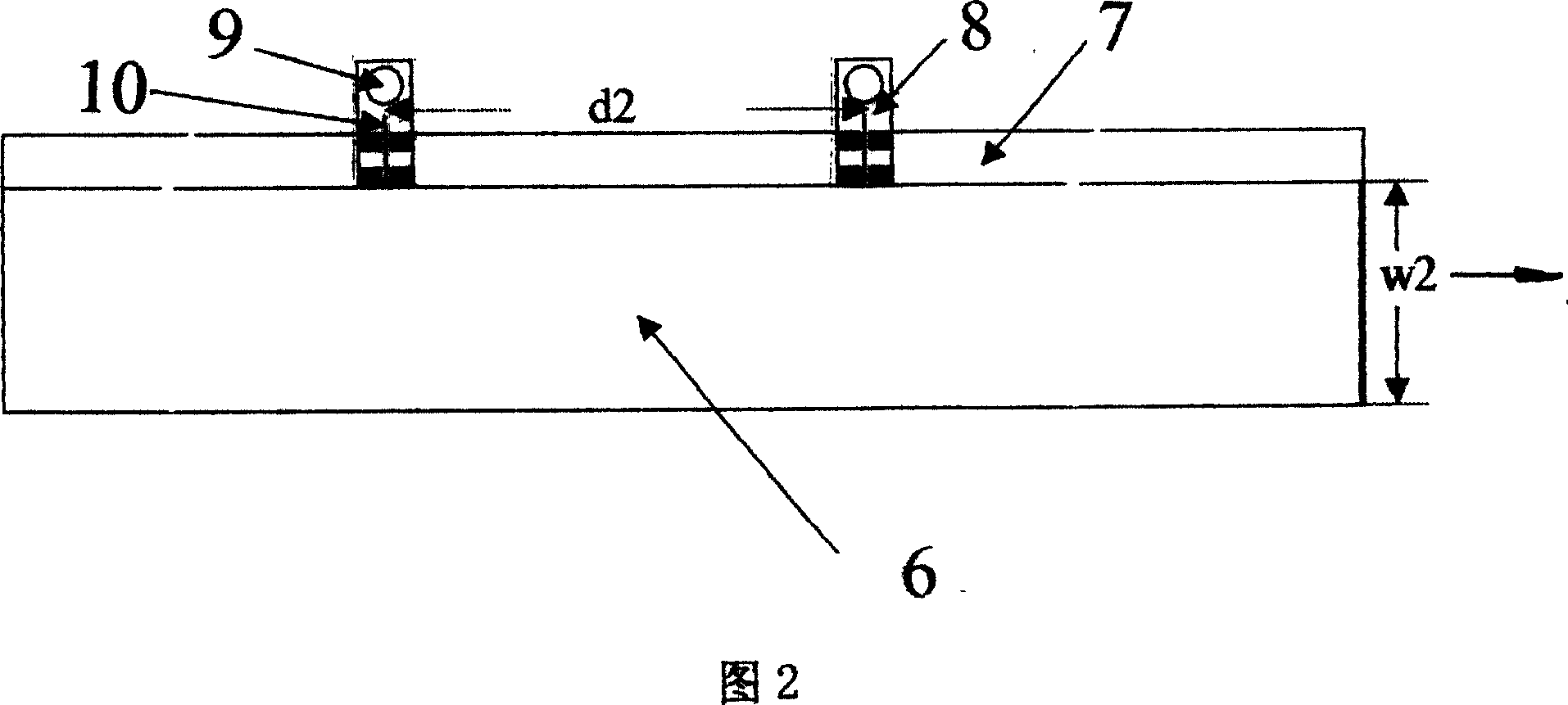

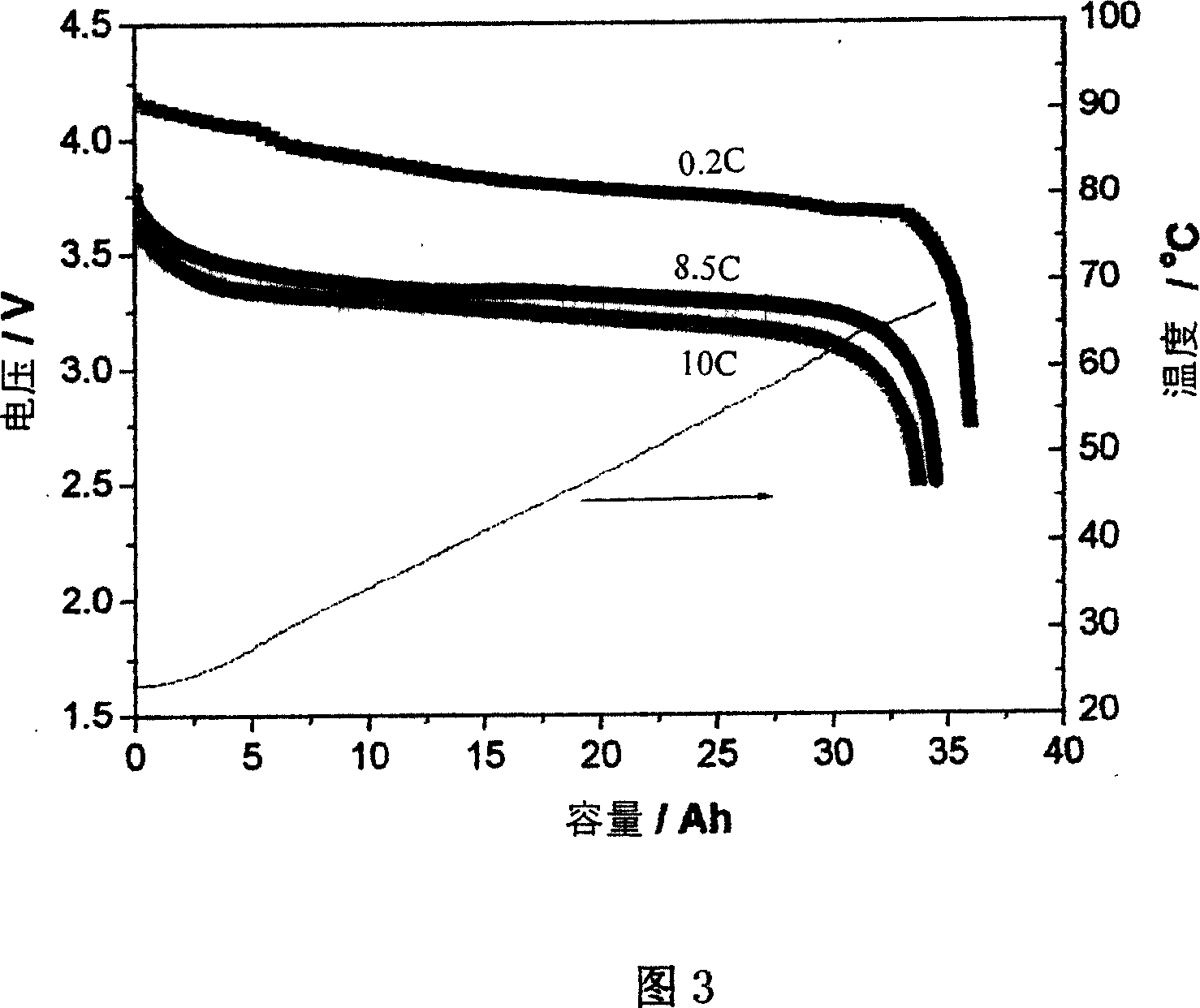

High power lithium ion cell

ActiveCN1949580AImprove securityImprove cycle lifeElectrode carriers/collectorsSecondary cellsLithiumMachine building

The invention belongs to a high power Li ion battery, comprising anode, cathode, diaphragm and nonaqueous electrolyte, where anode and cathode coatings containing active materials are continuous coatings, one side of each of the anode and cathode in the coiling direction has a current collector margin where anode and cathode ears are arranged. And it is characterized in that: anode ear section area S1, anode ear distance d1 and anode coating width w1 meet: 1*10-5 H01M 10 / 40 H01M 4 / 02 H01M 4 / 64 2 9 1 2005 / 10 / 14 1949580 2007 / 4 / 18 100433440 2008 / 11 / 12 2008 / 11 / 12 2008 / 11 / 12 No.18 Inst., China Electronic Science and Technology Group Corp. Tianjin 300381 Liu Xingjiang Zhang Yao Zhu Guangyan Yang Kai Yu Jinhan Wu Bincheng lifeng 12101 The Patent Agency of Tianjin Machine-building Industry Administering Bureau No.15 Jinzhong Bridge Street, Hongqiao, District, Tianjin 300091

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

1100Mpa grade non modified high-strength steel and production process thereof

InactiveCN1861831ARoll force/gap control deviceTemperature control deviceExtensibilityChemical composition

This invention relates to 1100Mpa grade of quenched and tempered high tensile strength plate and its preparation method, the weight ratio of its chemical ingredients are as fellows: C 0.29-0.35%, Si 0.22-0.45%, Mn 1.40-1.75%, P, S 0.002-0.035%, Als 0.015-0.04%, V 0.05-0.12%, Ti 0.015-0.030, Cr 0.04-0.30%, Ni, Cu 0.01-0.30%, N 80-120ppm, the other is Fe and inevitable impurity. The process of preparation is as fellows: smelting-refining out of the furnace- continuous casting-hot band rolling-cold rolling the band steel. The bank steel which is prepared by this way had excellent mechanical property and extensibility, its processes of preparation is stable and easy, low consumption of energy and high production efficiency, and it can range to round steel. It is a material which can widely apply to light industry and mechanical manufacturing.

Owner:HANGZHOU IRON & STEEL GRP

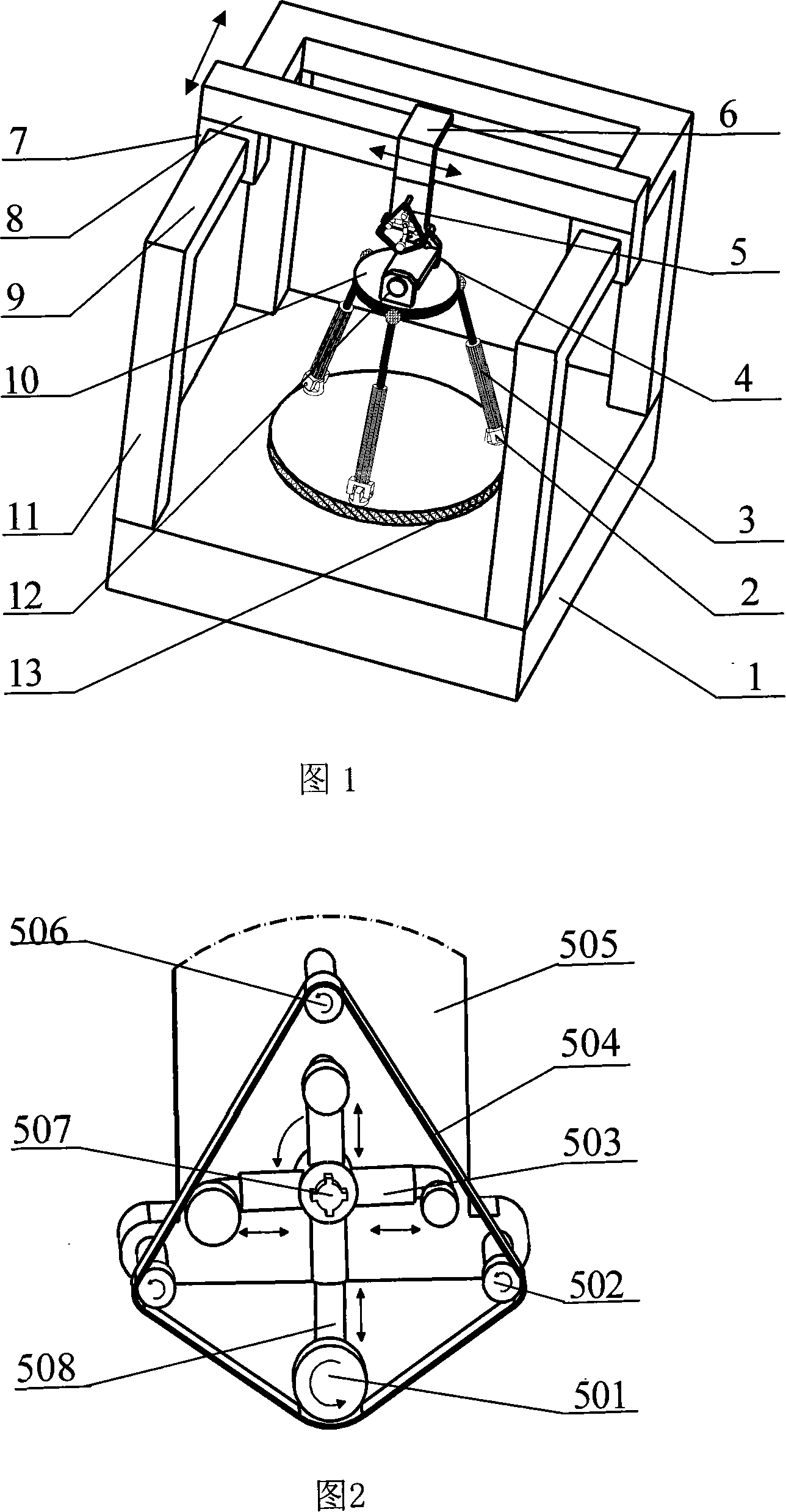

Blade polishing integral processing machine tool with curve surface adaptive

InactiveCN101148021AAchieve double-sided polishingLarge space for exerciseGrinding machinesDrive wheelMachine building

The present invention relates to one kind of vane polishing and grinding machine with high camber adaptability, and belongs to the field of machine building technology. The vane polishing and grinding machine one fixed stage comprising the pedestal and the frame connected together, one longitudinal slipway-block pair and one transverse slipway-block pair for two-dimensional moving, one upper platform with workpiece fixture and one lower platform connected through three branches, and one polishing and grinding tool system including one sand belt, one tool board, two tightening wheels, one driving wheel and one wheel changing mechanism. The vane polishing and grinding machine with one worktable of three-rod parallel mechanism has high precision, high rigidity, expanded work space, capacity of polishing and grinding large vane and high operation efficiency.

Owner:JILIN UNIV

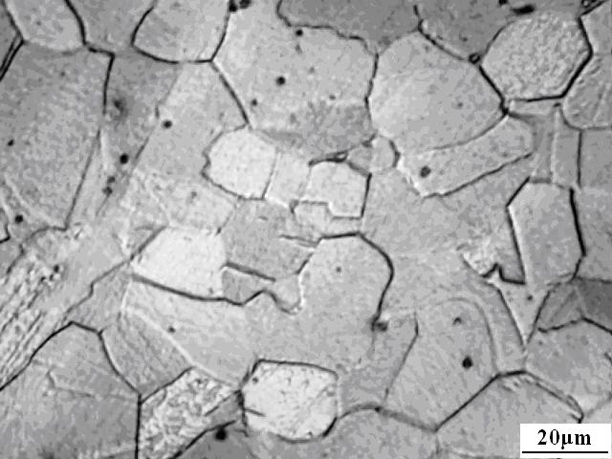

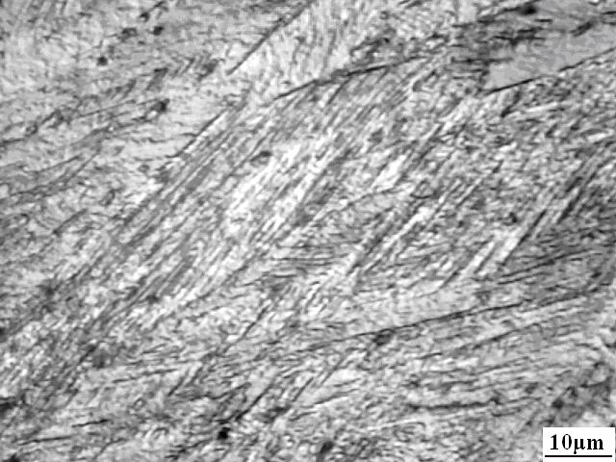

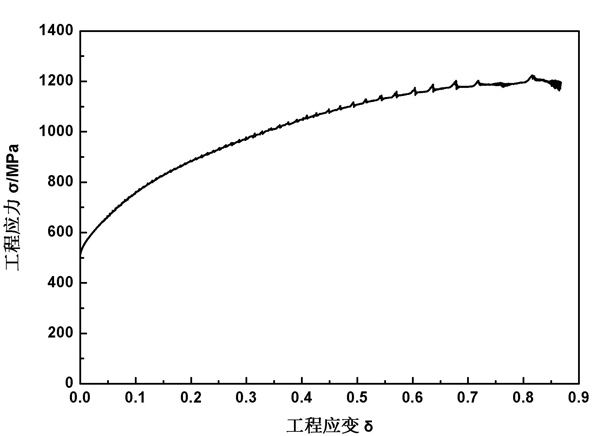

High-strength high-plasticity copper-containing high-carbon TWIP steel and preparation process thereof

The invention relates to high-strength high-plasticity copper-containing high-carbon TWIP steel and a preparation process thereof. In the preparation process, the carbon content is improved on the basis of Fe-Mn-C series TWIP steel, a non-carbide forming element Cu and rare earth Ce serving as alloying elements are added into the steel, and a solution treatment process at the high temperature of between 900 and 1,050 DEG C and a hot rolling process are combined, so that gap defects in an ingot structure are reduced and the intrinsic strength and plasticity of the high-carbon copper-containing TWIP steel are fully exerted. The prepared alloy steel has the outstanding characteristic that product of strength and plasticity for reflecting the comprehensive mechanical property of the alloy steel is obviously improved; the yield strength of the alloy steel is 513.7MPa, the tensile strength is 1,223.7MPa, the elongation is 86.8 percent, and the product of strength and plasticity reaches 106,217.2MPa. percent which is 20 percent higher than highest data 87,882MPa. percent of multiple kinds of TWIP steel reported by domestic and foreign documents at present; and novel high-strength high-toughness steel is prepared for the mechanical manufacturing industry and equipment industry.

Owner:FUZHOU UNIV

Human-computer interaction helmet for type computer

InactiveCN101077232AEasy to use and flexibleImprove reliabilityInput/output for user-computer interactionGraph readingAviationDisplay device

The present invention is one kind of human-computer interactive helmet for dressed computer. The human-computer interactive helmet includes a micro display and location regulator, a box, a sight line tracker, a back baffle, a helmet support, a top tightness regulating belt, a back tightness regulating belt, an earphone and a microphone. It has sight line tracking function and can complete human-computer interaction phonetically. The present invention may be applied widely in aviation, spaceflight, machine building and other fields with occupied hands.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

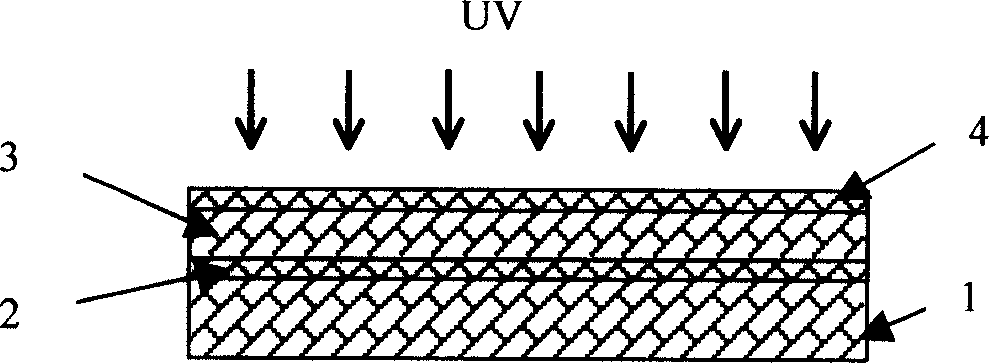

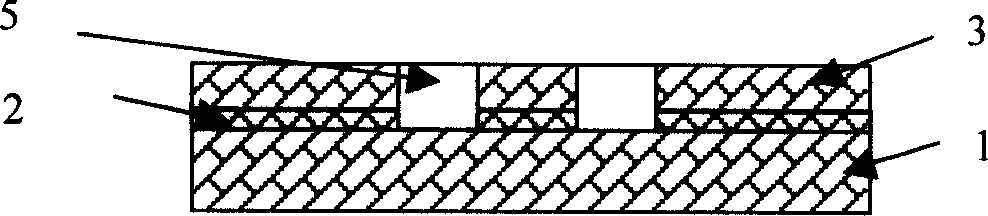

Method for producing microelectromoulding metal mould

InactiveCN1715455AReduce internal stressGood side wall verticalityElectroforming processesMicro structureHigh surface

The microelectromolding metal mold making process belongs to the field of micro machine building technology. The microelectromolding metal mold making process includes the steps of: pre-treatment of mold base, making microelectromolding mother mold, microelectromolding, post-treatment and detection. The present invention adopts so-called 'no-back board growth process', in which micro structure pattern is electromolded directly on nickel substrate via ultraviolet irradiation on photoetching mask. During making microelectromolding mother mold, one seed layer is added between the SU-8 photoresist and the substrate; and in the post-treatment, vacuum annealing is adopted. The microelectromolding metal mold made in the method of the present invention has the merits of high side wall verticality and high surface smoothness. The present invention is suitable for fine machining of organic polymer, including plastic.

Owner:DALIAN UNIV OF TECH

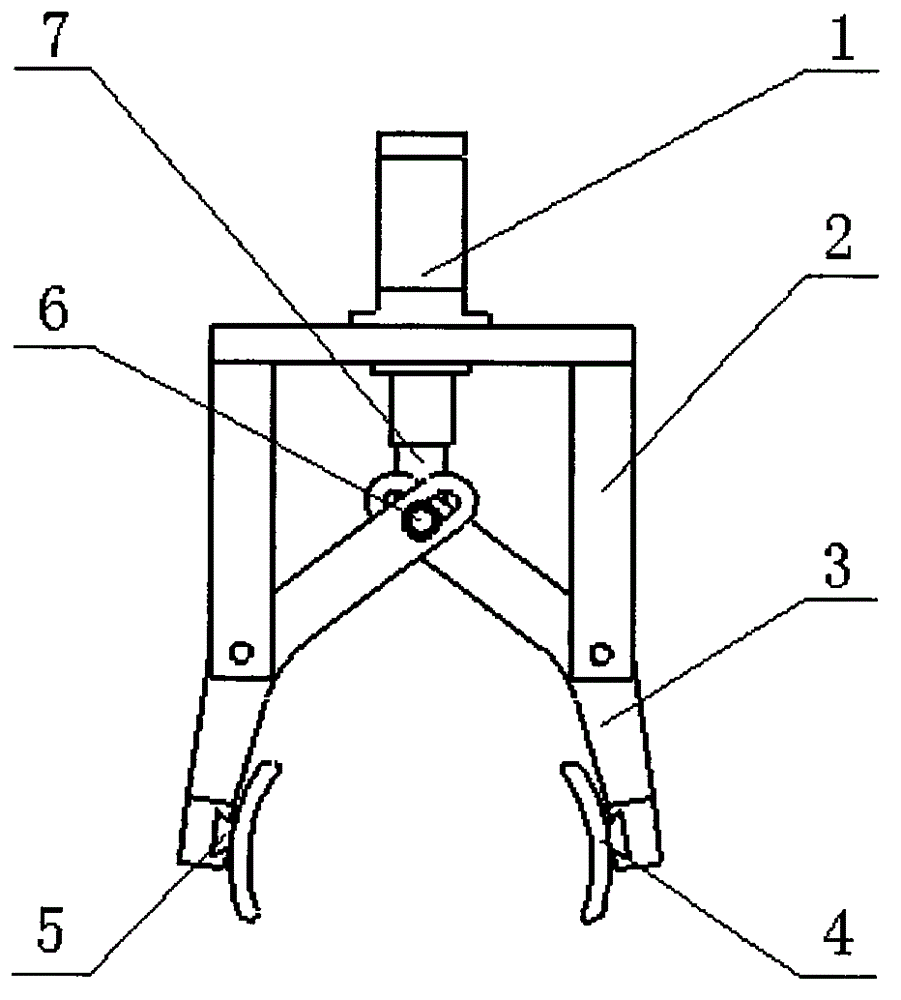

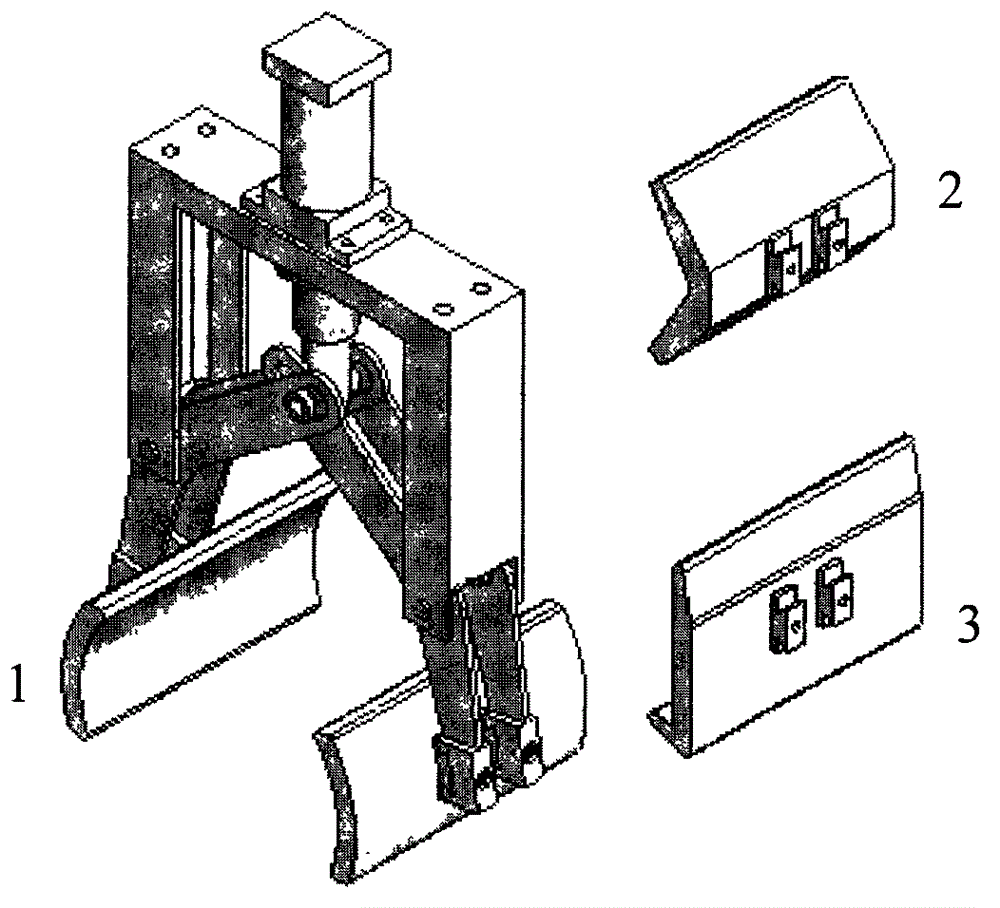

Design of replaceable simple-joint robot flexible hand

InactiveCN102717389AMeet the clamping requirementsEasy to installGripping headsHydraulic cylinderRobot hand

The invention belongs to the field of mechanical manufacturing and provides a design of adopting replaceable simple-joint finger to clamp a series of workpieces of different shapes aiming at the defects that the hands of a common robot palletizer and a transfer robot are single in finger structure and have less possibility of reliably clamping the workpieces of different shapes and different sizes at present. The mechanism adopts a hydraulic system for driving; by virtue of controlling the stroke of the piston rod of a hydraulic cylinder and controlling the folding and unfolding states of the finger according to the clamping force requirements of workpieces of different shapes, corresponding clamping forces can be provided for satisfying the workpiece clamping requirements; the strokes of the designed piston rod are consistent; the fingers of the robot hand are connected with a connecting rod through dovetail grooves; the size of each dovetail groove on the connecting rod is fixed, the fingers of different shapes and sizes can be conveniently replaced only if matched dovetail groove interfaces are arranged, so as to meet the clamping requirements of different workpieces. The mechanism can be used for saving materials, saving the replacement time, increasing the working efficiency, rapidly designing and manufacturing corresponding replaceable fingers according to the shape and size requirements of different workpieces and meeting the high-efficiency production requirement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Low carbon martensite aged stainless steel with high strength high toughness and high decay resistance performances

InactiveCN101886228AHigh strengthImprove corrosion resistanceUltimate tensile strengthPrecipitation hardening

The invention belongs to the ferronickel base martensite precipitation-hardening alloy technical field, in particular relates to a low carbon martensite aged stainless steel with high strength high toughness and high decay resistance performances, novel material mainly applied to the important fields of aviation, space flight, machinery manufacturing and atomic energy. The steel comprises the following components by weight percent: 0.08-0.15% of C, 11.0-12.0% of Cr, 4.0-5.0% of Ni, 0.2-1.0% of Ti, 0.5-1.0% of Mo, 2.0-3.0% of Cu, 2.0-3.0% of Co, 0.1-0.5% of Nb, 0.5-1.5% of Mn, 0.5-1.5% of Si, less than 0.01% of N, less than 0.01% of V, less than 0.01% of Al and balance of Fe. The invention can obtain high strength high toughness and decay resistance performances by appropriate collocation of five precipitation strength elements of Ni, Ti, Mo, Cu and Nb.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

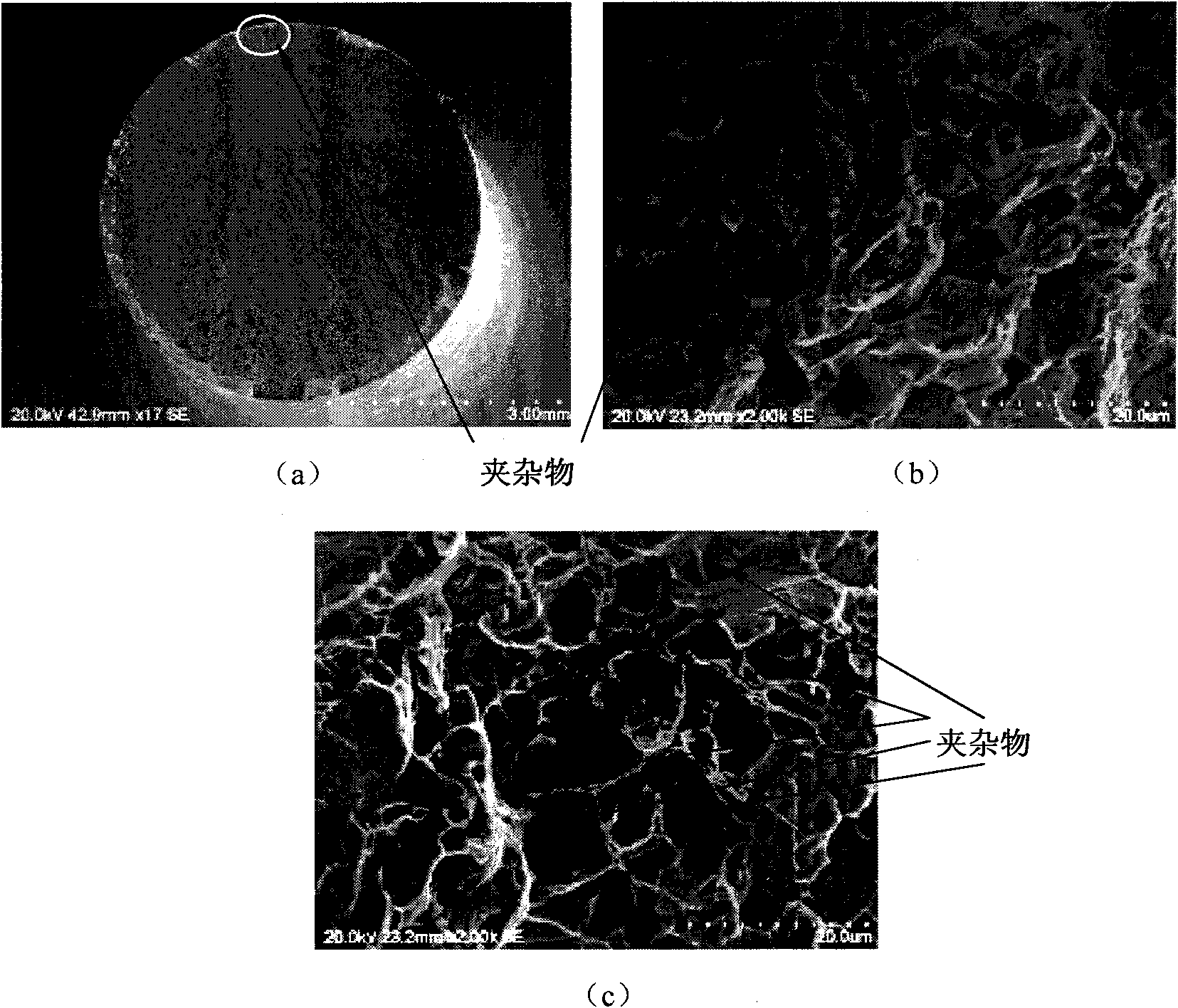

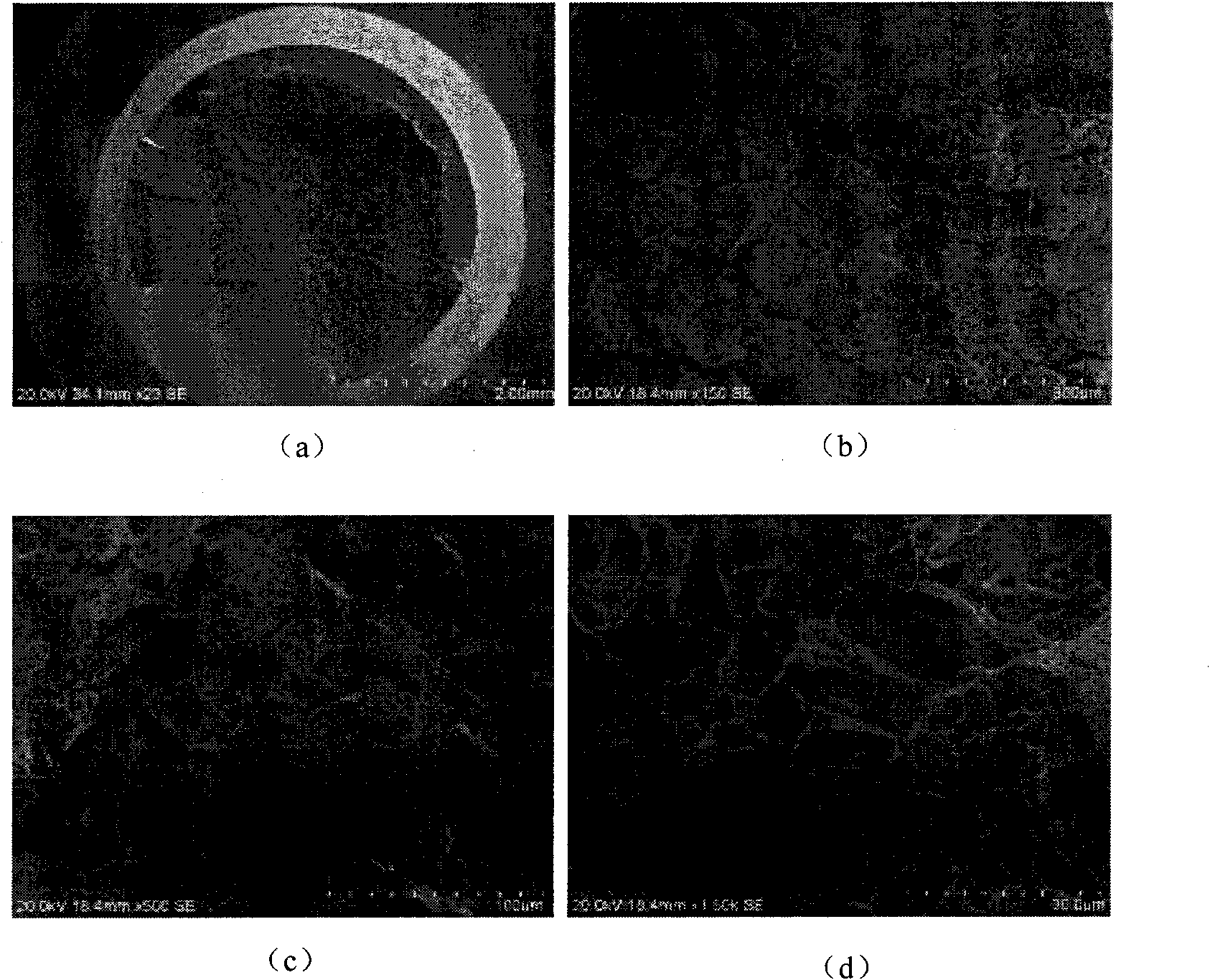

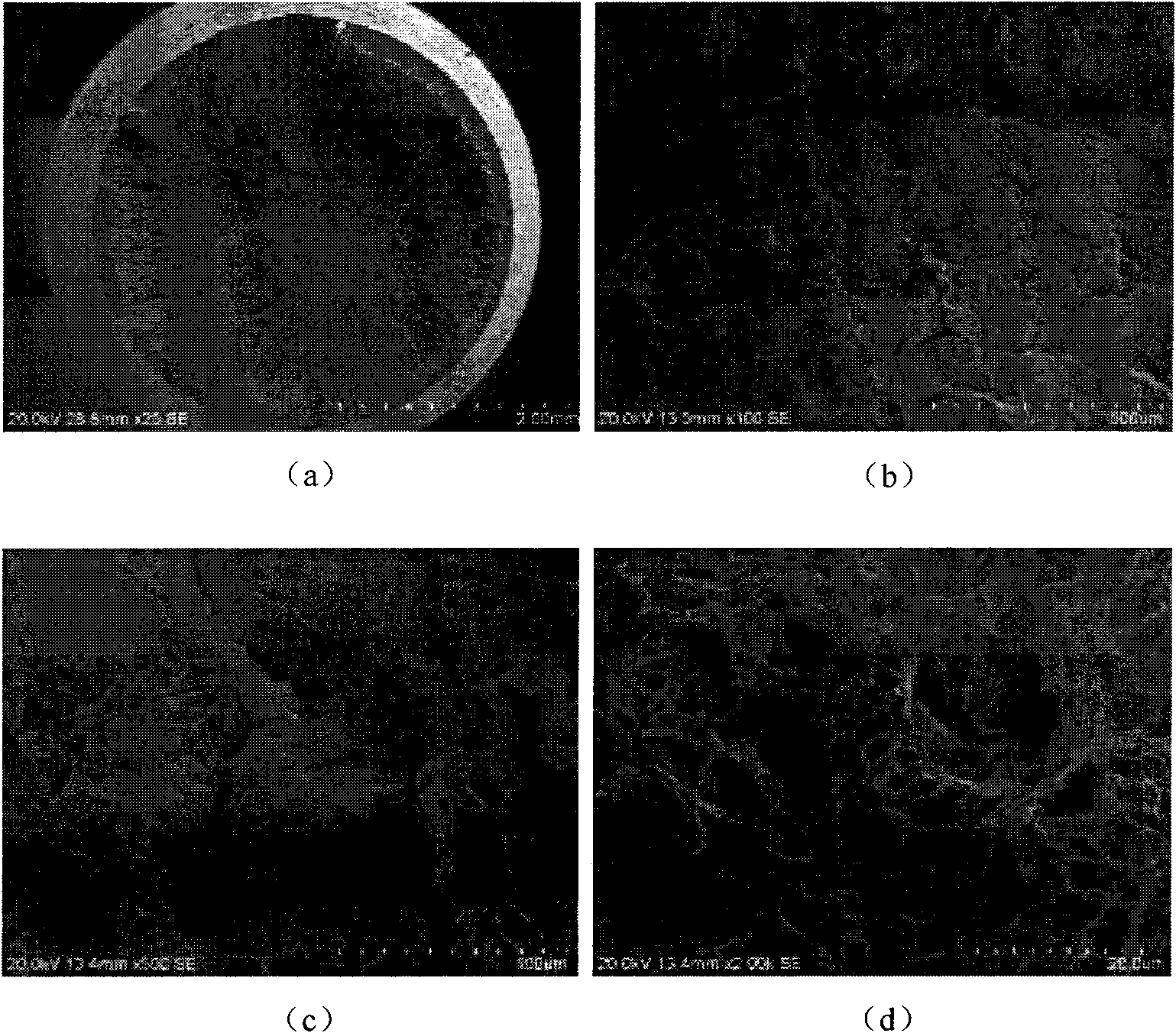

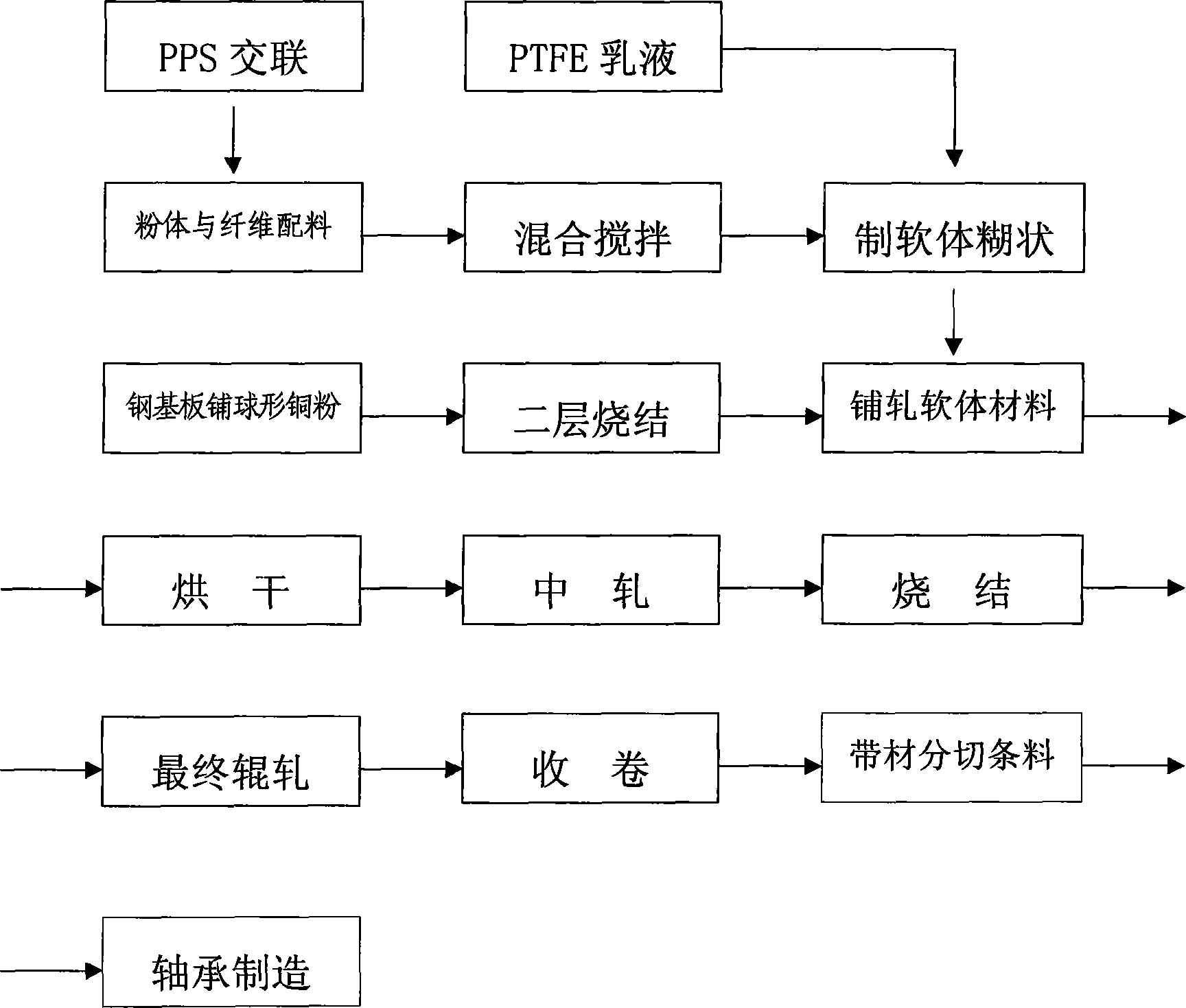

Lead-free self-lubricating bearing and its production

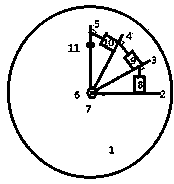

The invention relates to a mechanical components industry regulation hole coaxial between the methodology and regulation components, in particular the aviation, aerospace, civil and other mechanical structure of the multi-hinge assembly point. Double eccentric bushing from the eccentric bushing and the eccentric bushing composition, the eccentric bushing diameter and the outer diameter of a round circle of eccentric and the eccentric bushing diameter and the outer diameter of a round of the same circle of eccentric, and, Bushing end of the shaft is the first shoulder. Double eccentric bushing used in the eccentric bushing and the eccentric bushing with a certain amount of tolerance, through the inner and outer sleeve of repeated eccentric rotation adjustment can be realized coaxial connection points more than the match, and for each hub Heart of the biggest angle adjustment of not more than 360 degrees, adjust volume small. This greatly reduces the difficulty of assembling and because of the internal and external sleeve with tolerance, as well as components and assembly hub between the matching hole in the machining tolerances can be very good at that in the assembly, so there is no need to conduct a follow-up processing, reducing assembly time.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

Filled polyamide molding materials having improved processing behavior

InactiveUS6956081B2Improve surface qualityImprove thermal performanceSpecial tyresShell moldingMachine building

Owner:EMS CHEM AG

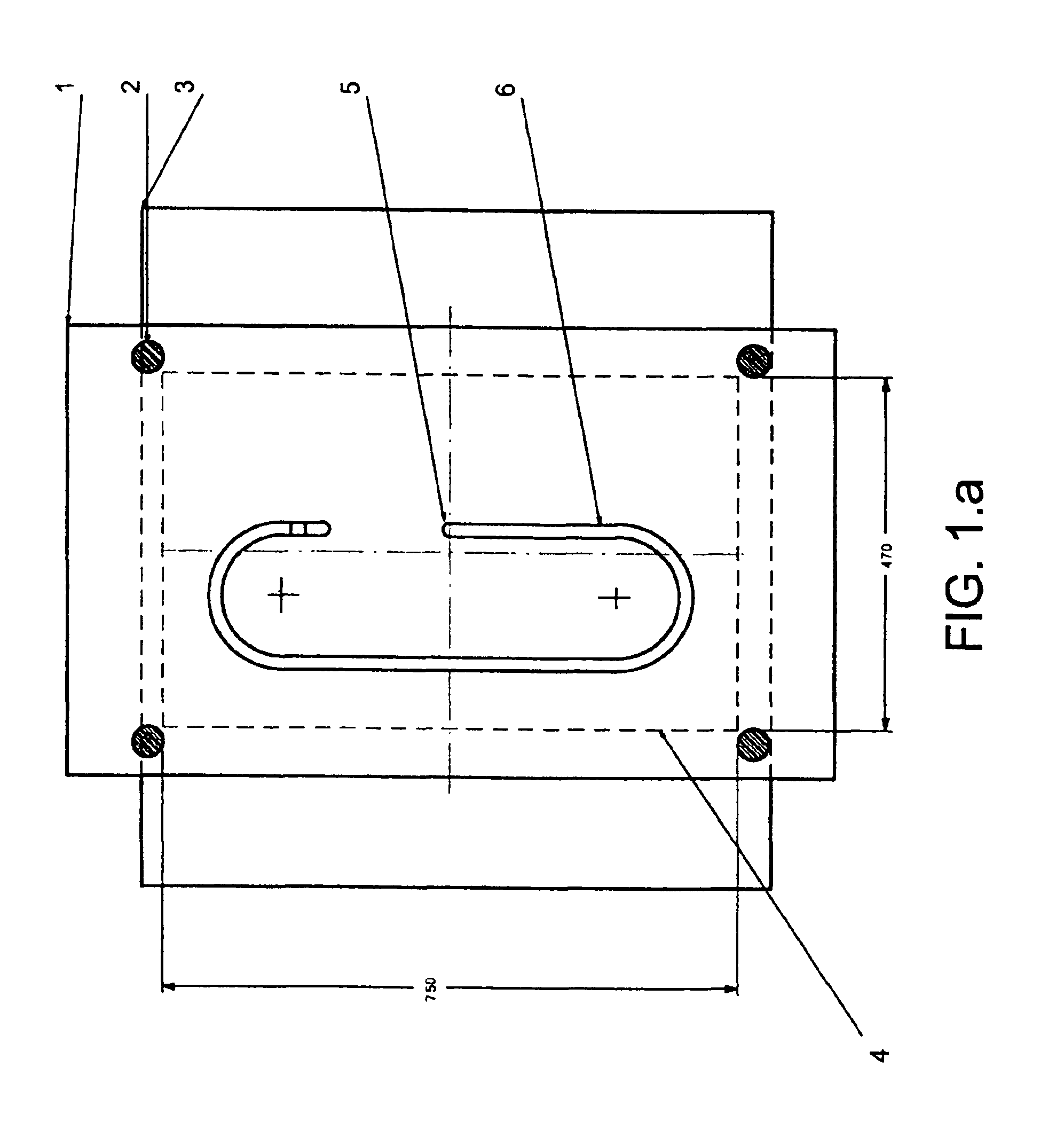

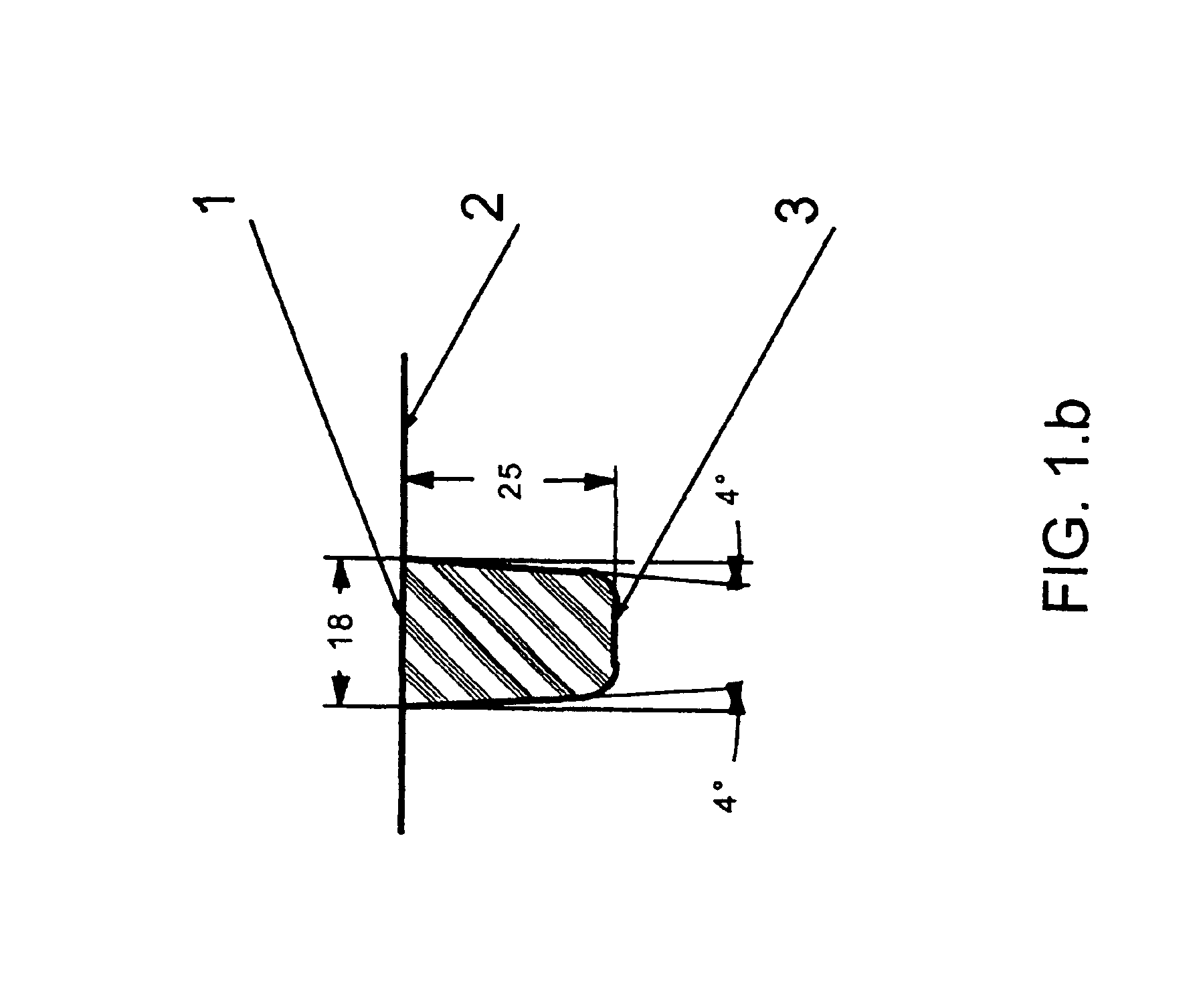

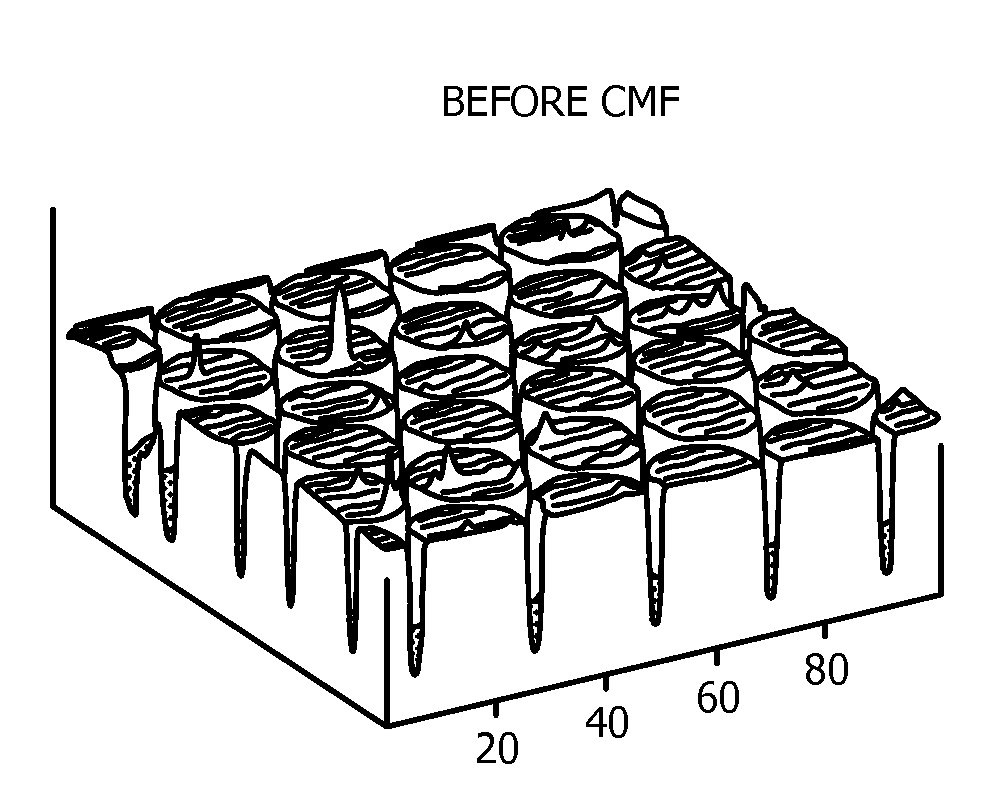

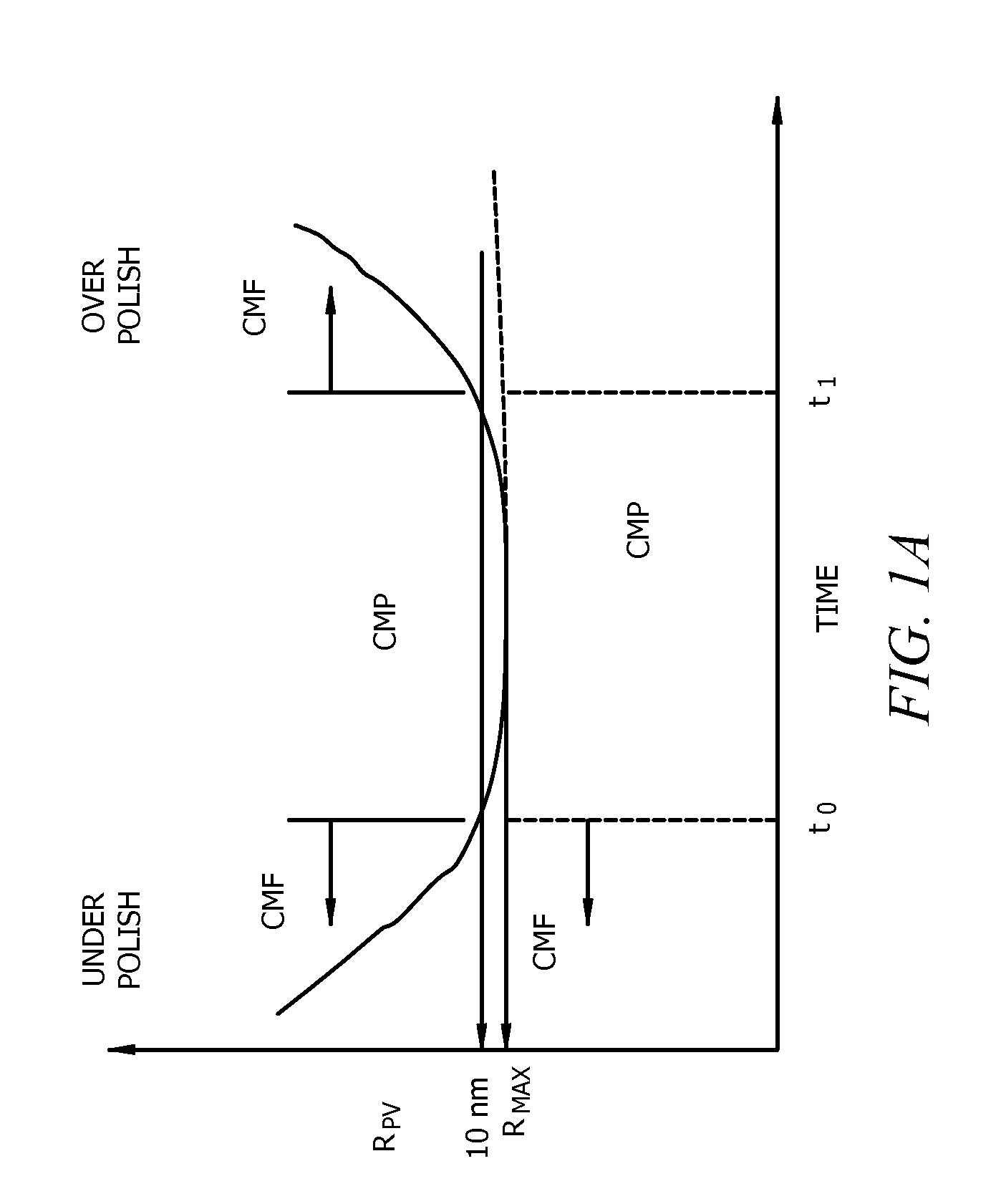

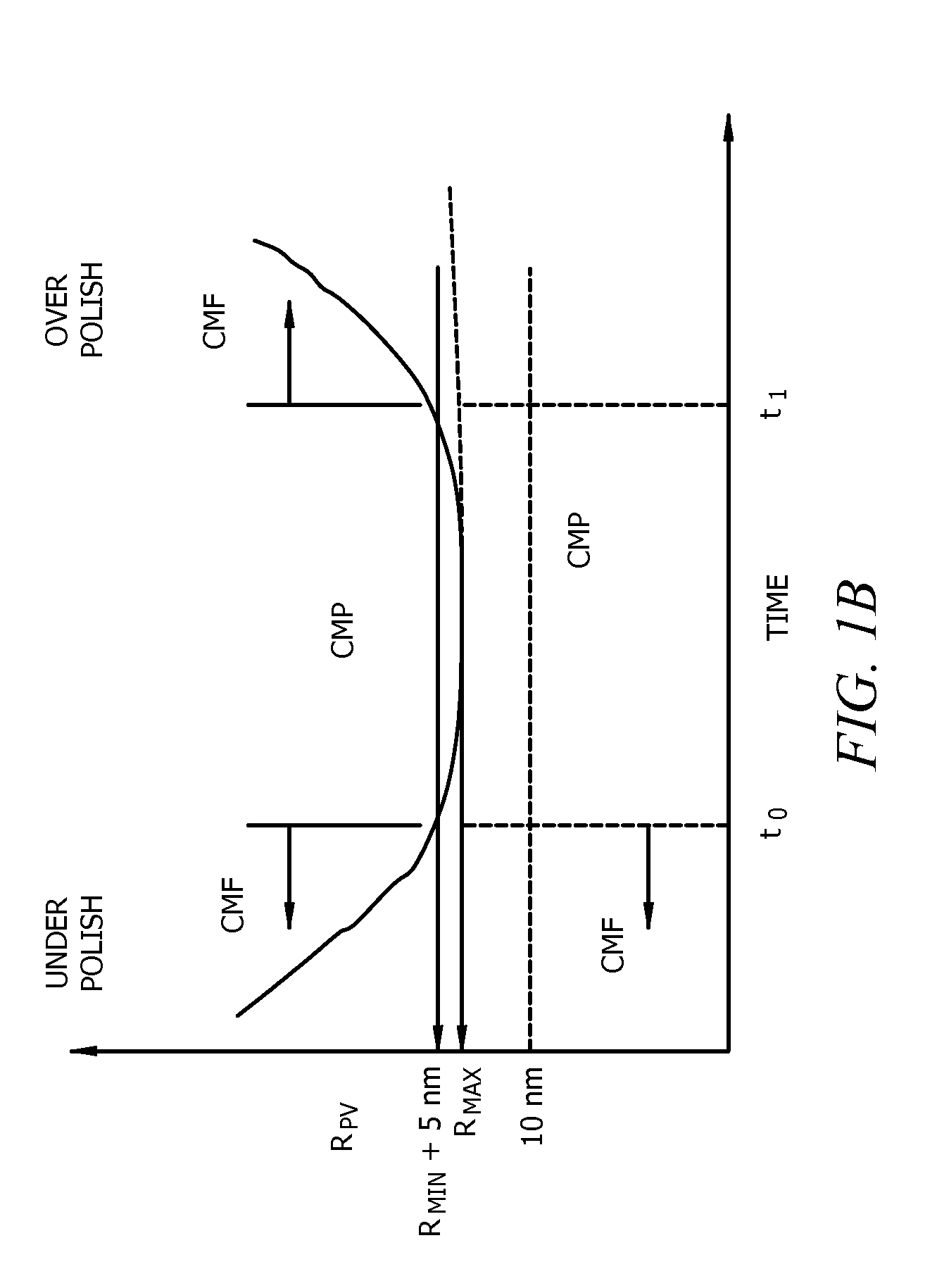

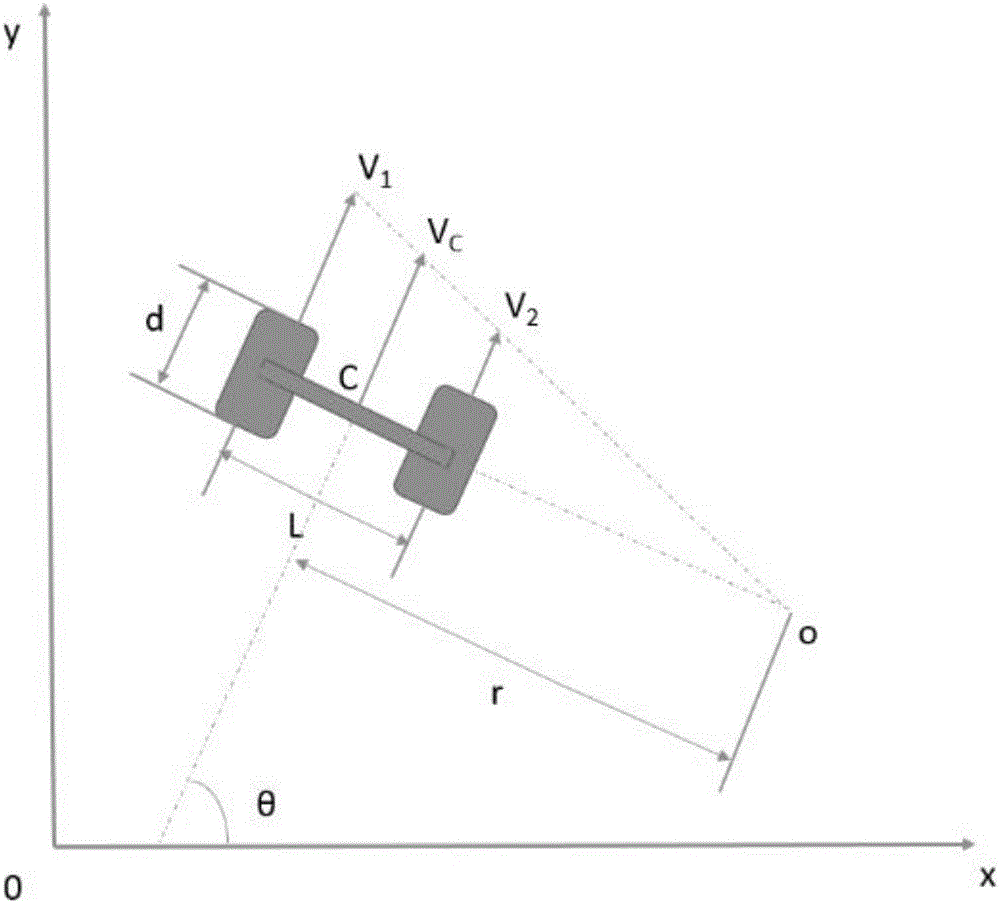

Chemical mechanical fabrication (CMF) for forming tilted surface features

InactiveUS20100260977A1Fast polishingLow polishing rateDecorative surface effectsLayered productsHigh elevationSurface roughness

A method of chemical-mechanical fabrication (CMF) for forming articles having tilted surface features. A substrate is provided having a patterned surface including two different layer compositions or a non-planar surface having at least one protruding or recessed feature, or both. The patterned surface are contacted with a polishing pad having a slurry composition, wherein a portion of surface being polished polishes at a faster polishing rate as compared to another portion to form at least one tilted surface feature. The tilted surface feature has at least one surface portion having a surface tilt angle from 3 to 85 degrees and a surface roughness<3 nm rms. The tilted surface feature includes a post-CMF high elevation portion and a post-CMF low elevation portion that defines a maximum height (h), wherein the tilted surface feature defines a minimum lateral dimension (r), and h / r is ≧0.05.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

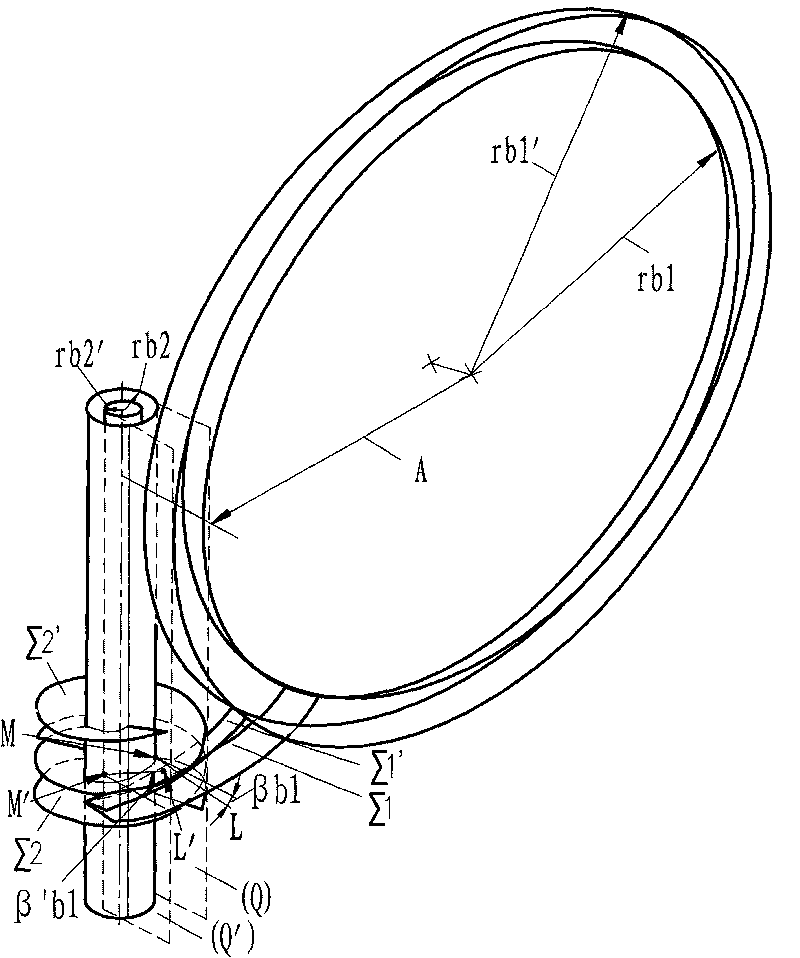

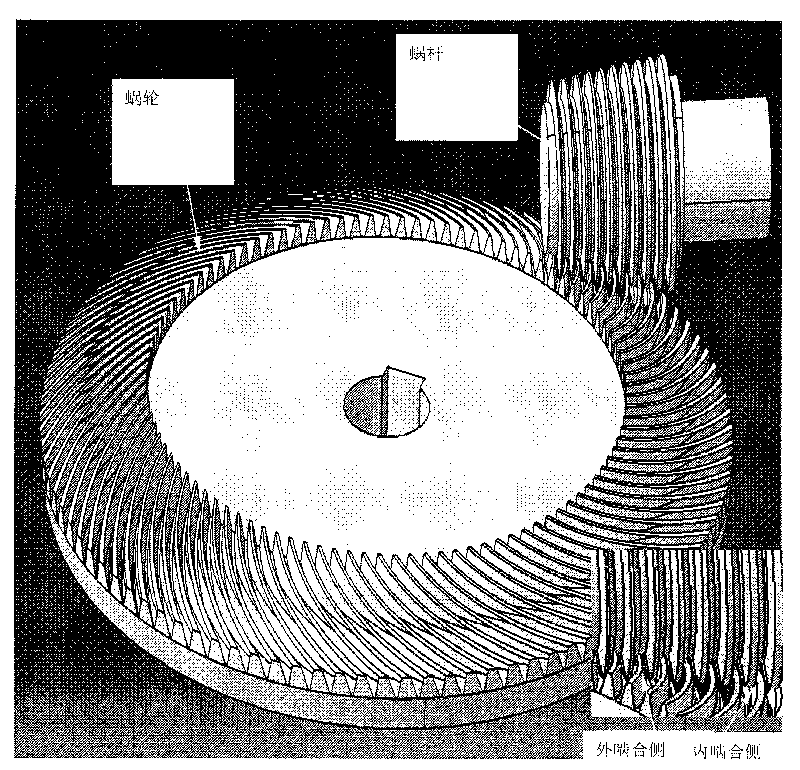

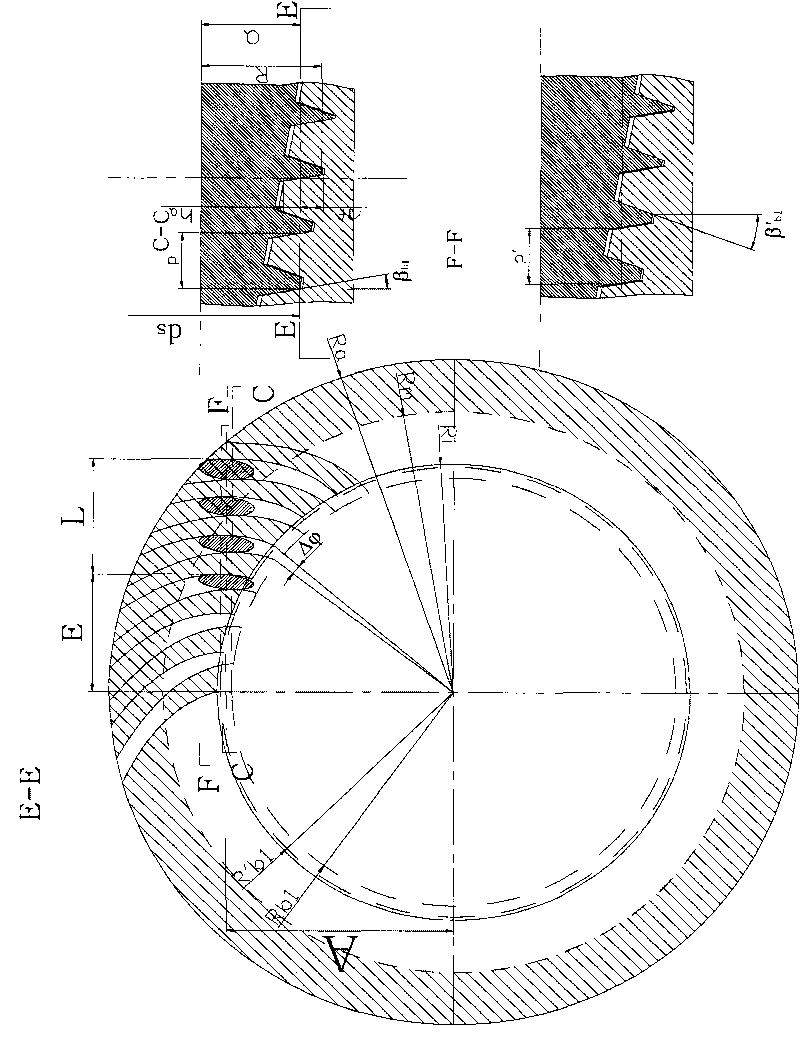

Methods for designing and manufacturing double-lead linear contact bias worm drive

InactiveCN101710350ADesign method is simple and preciseSimple structureSpecial data processing applicationsWorm wheelsNumerical controlHobbing

The invention provides methods for designing and manufacturing double-lead linear contact bias worm drive, belonging to the fields of machinery principle and machinery manufacture. The double-lead linear contact bias worm drive belongs to the spiroid drive mode in the worm gear drive. The designing method in the invention has the following steps: 1. determining basic parameters according to the power, the transmission ratio and the rotating speed required to be transmitted; 2. performing parameter designing by taking a specified reference circle as a standard on the basis of preliminary calculation of the outer diameter of a worm gear; and 3. calculating each parameter in terms of the formula deduced from the above parameter designing. The manufacturing method in the invention comprises a mitting method, a fly-cutter hobbing method and a numerical control turning method. The invention has a simple and precious designing method, which can simplify the structure of the worm gear and machining and manufacturing; the current machine tool and cutter can be used to perform machining on tooth surfaces without adding other devices or using special machine tools and cutters except for adopting a special machine tool for efficient and high precision machining.

Owner:JILIN UNIV

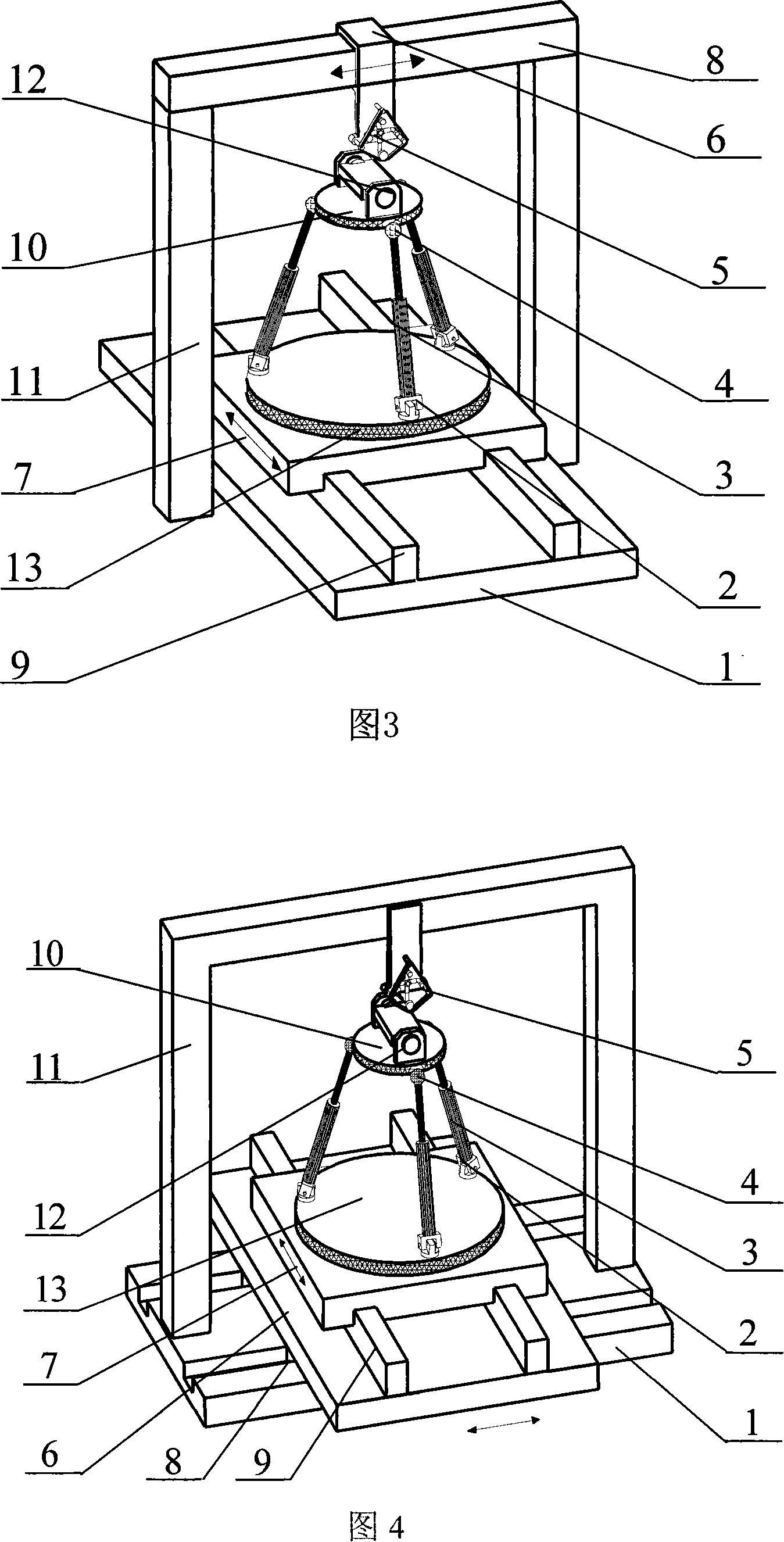

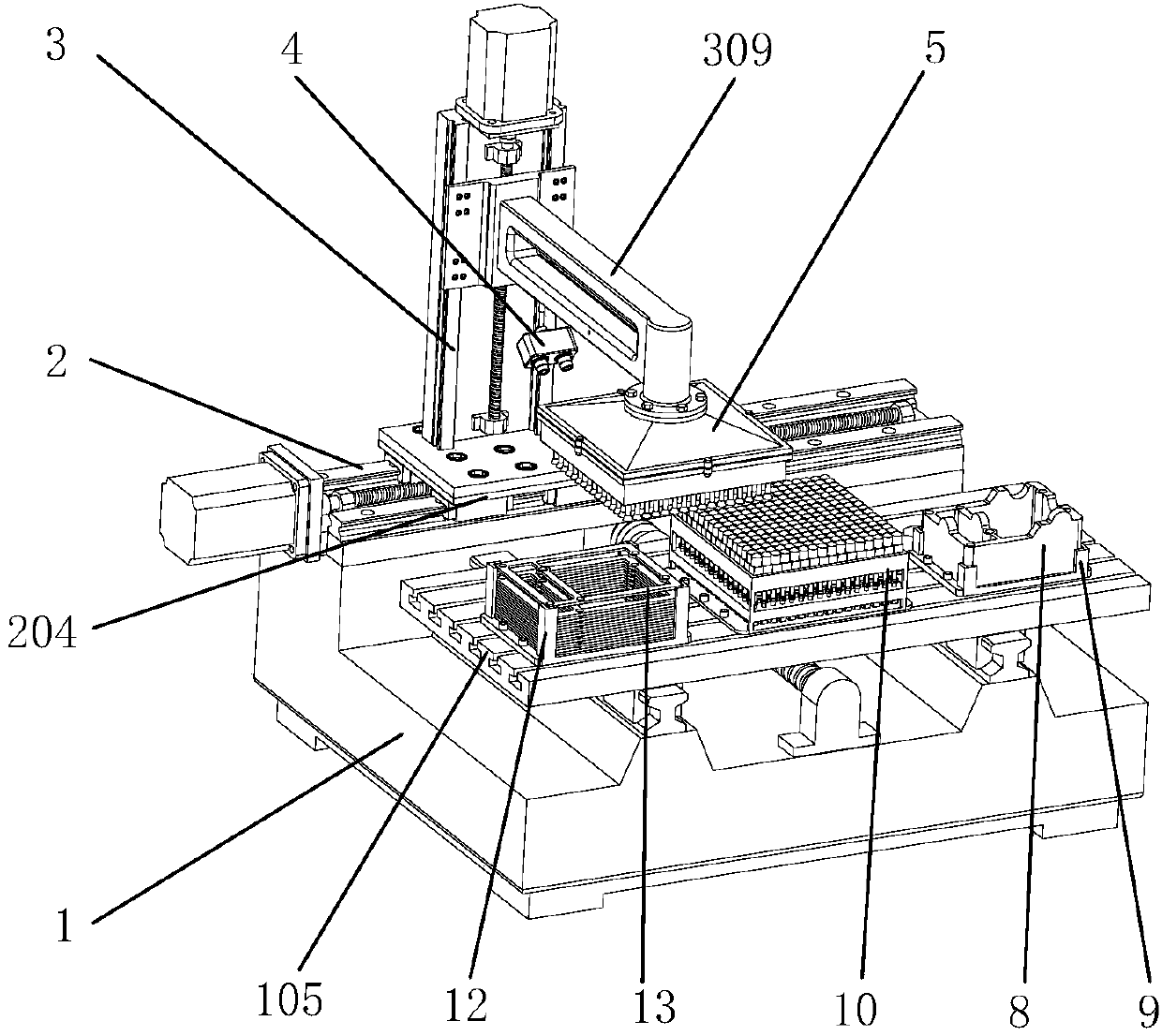

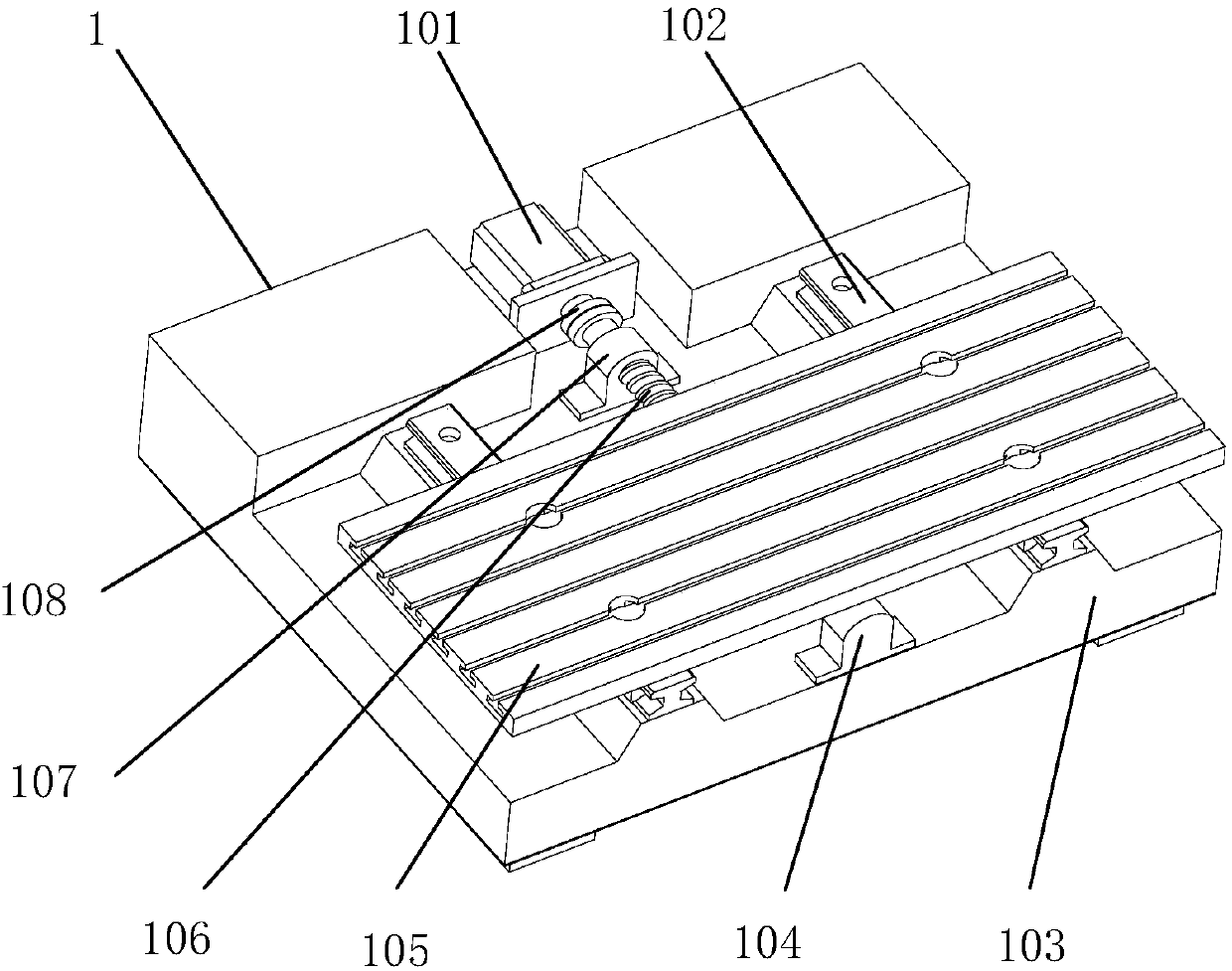

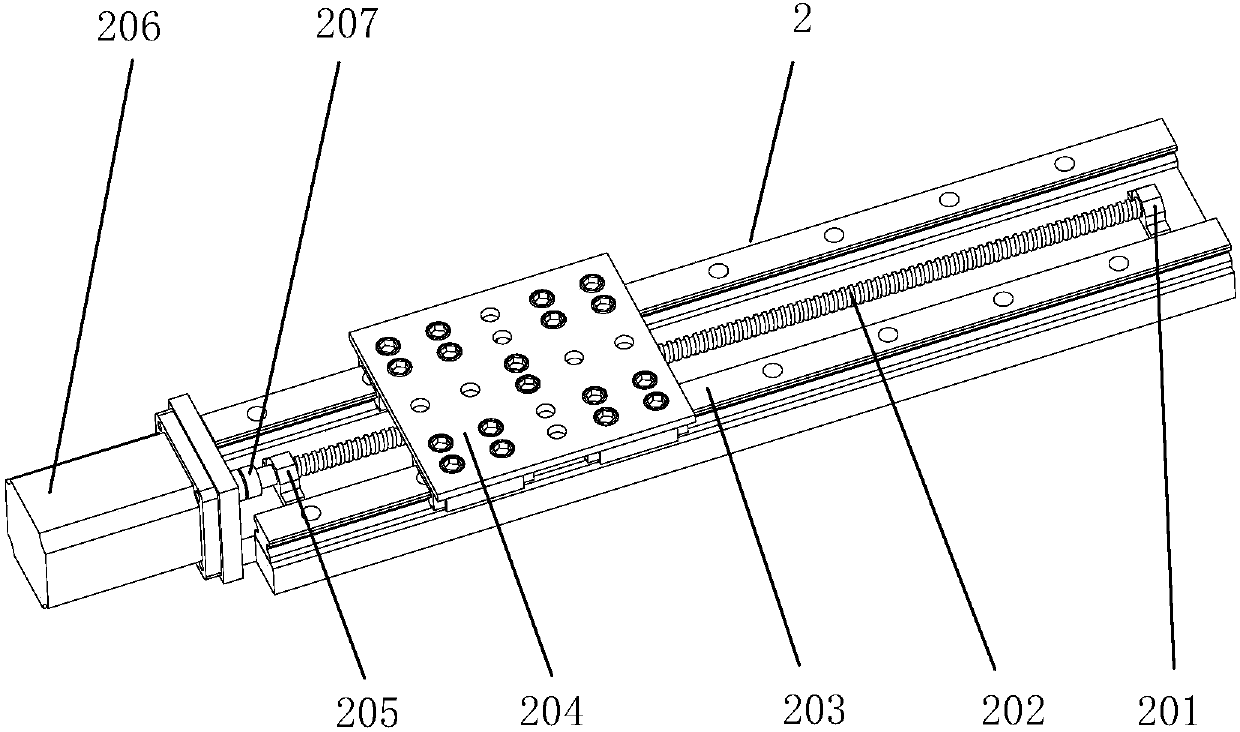

Multi-point sucking disc automatic-sucking installing machine for three-dimensional flexible gasket

PendingCN107825407ASolve the problem of forming a three-dimensional gasket and assembling it preciselyNovel structureProgramme-controlled manipulatorGripping headsBall screwEngineering

The invention relates to a multi-point sucking disc automatic-sucking installing machine for a three-dimensional flexible gasket, and belongs to the field of mechanical manufacturing. A transverse moving device, a longitudinal ball screw used for completing longitudinal movement of T-shaped grooves, longitudinal sliding rails and the like are fixedly installed on a base; a transverse moving mechanism is vertically distributed with the longitudinal ball screw and the longitudinal sliding rails; a T-shaped groove workbench is fixed on the longitudinal sliding rails, and the T-shaped groove workbench can longitudinally move along the longitudinal sliding rails; a vertical moving device is fixed on a transverse sliding plate of the transverse moving device, and the vertical moving device can transversely move along with the transverse sliding plate; and a sucking disc is fixed on a cross arm of the vertical moving device, and can move up and down along with the cross arm, and the sucking disc is located above the T-shaped groove workbench. According to the installing machine, the gasket is converted from two-dimensional to three-dimensional, meanwhile, accurate and automatic assembly is carried out, so that labor is liberated, and assembly efficiency of a system is improved.

Owner:JILIN UNIV

Cutting-stirring friction-welding combined machining equipment and manufacturing method thereof

ActiveCN102501074AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsMaintainance and safety accessoriesTemperature sensingSensing system

The invention discloses cutting-stirring friction-welding combined machining equipment and a manufacturing method thereof. The cutting-stirring friction-welding combined machining equipment integrates a milling system or a cutting system, a stirring friction-welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure sensing system, a milling liquid supply system and a non-sensing system. The invention provides a united or combined machining device which can carry out milling or cutting and stirring friction-welding in parallel simultaneously and a method thereof. The cutting-stirring friction-welding combined machining equipment has the functions of temperature control, gas protection, pressure detection, cooling liquid production, milling head replacement and dual-shaft shoulder self-supporting. According to the manufacturing method of the cutting-stirring friction-welding combined machining equipment, the manufacturing processes are reduced and the machining cost is saved. The limitation of the conventional mechanical machining technology is broken through, and a new method and a new idea about the mechanical manufacturing and machining are formed. The cutting-stirring friction-welding combined machining equipment and the manufacturing method in the invention have wide engineering applications to the heating industry, the air conditioning industry, the ice making industry, the freshness retaining industry, the pharmacy industry, the construction industry, the aquatic product industry and the food industry.

Owner:罗键

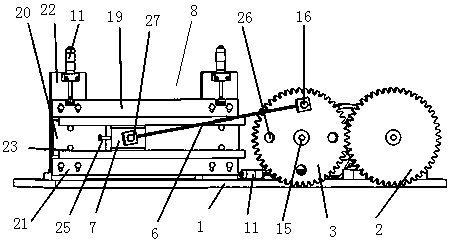

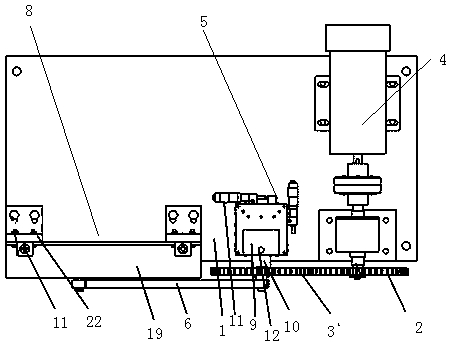

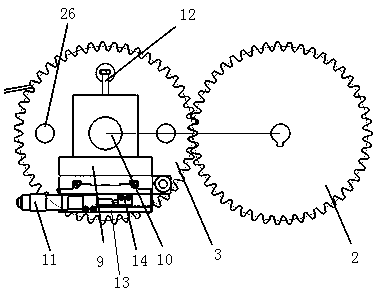

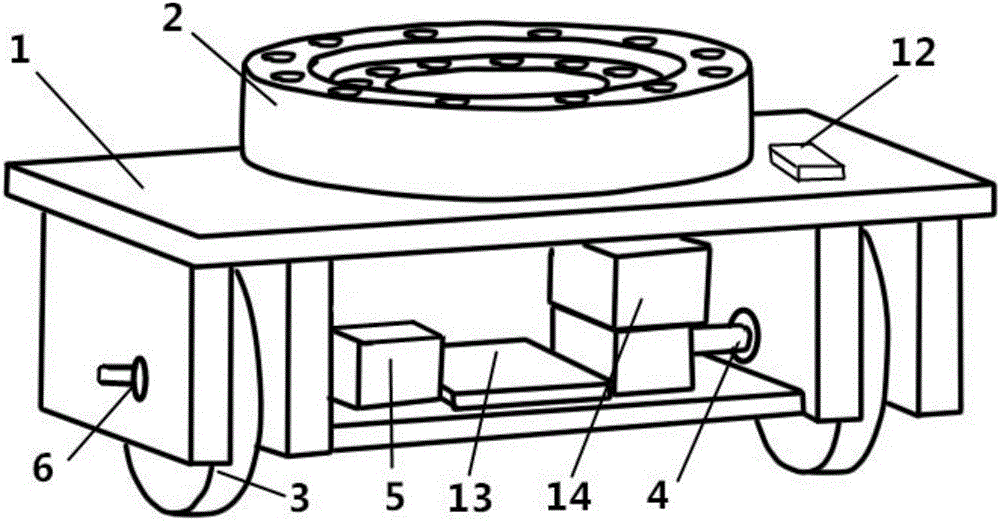

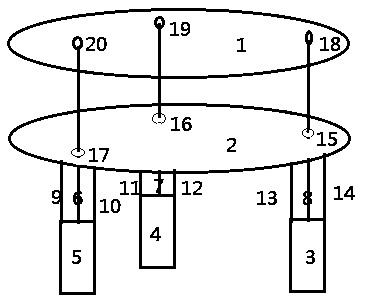

Adjustable multi-gap gear-connecting rod mechanism dynamics experiment simulation system

InactiveCN111366361AAdjust the sizeSimple design and processingMachine part testingKineticsGear wheel

The invention relates to the technical field of mechanical manufacturing simulation experiment devices, and specifically relates to an adjustable multi-gap gear-connecting rod mechanism dynamics experiment simulation system. The system comprises a base. The system is characterized in that a gear rotor assembly and a crank sliding block assembly are arranged above the base, and the gear rotor assembly is composed of a driving gear, a driven gear, a driving motor and a driven gear fine adjustment platform. Front-back and left-right displacement of the driven gear is adjusted through the driven gear fine adjustment platform. Therefore, the gear backlash between the driven gear and the driving gear is adjusted. A slider-crank assembly is arranged on the side surface of the driven gear. The crank sliding block assembly is composed of a connecting rod, a sliding block and a gap adjusting sliding rail. The size of the sliding pair gap can be adjusted by adjusting the gap of the gap adjustingguide rail, and the beneficial effects are that the structure is simple, and the gear pair tooth side gap, the rotating pair radial gap and the sliding pair gap can be accurately adjusted at the sametime conveniently and rapidly are achieved.

Owner:HARBIN INST OF TECH AT WEIHAI

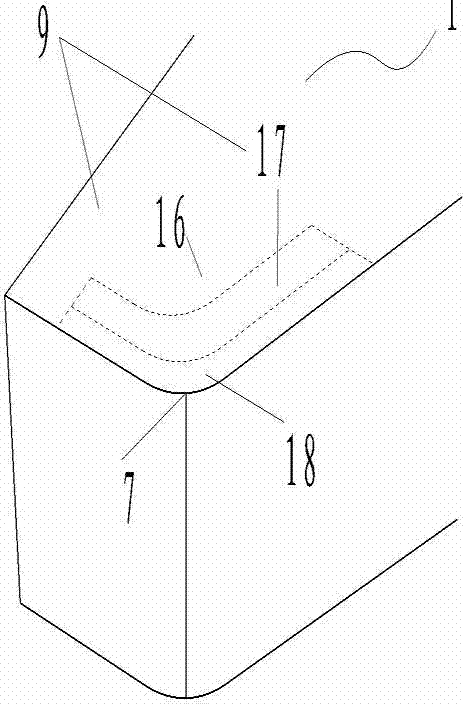

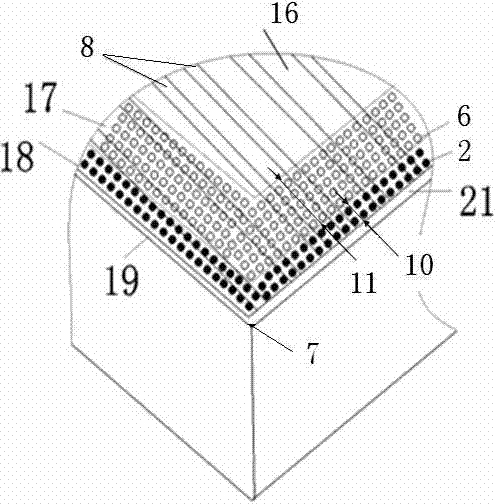

Surface cross-scale composite micro-modeling tool and preparation method

The invention discloses a surface cross-scale composite micro-modeling tool and a preparation method, and belongs to the technical field of machine manufacturing. The surface of a tool material is subjected to micro-modeling treatment of a recessed cavity morphology, a micron-size recessed cavity and a nanoscale groove are machined in a friction and abrasion sensitive area on the surface of a hardcoating, a combined way that the groove communicates with the cavity is adopted for distribution, and the cross-scale composite micro-modeling coating tool is obtained. In this way, the film-base combined strength of the coating tool is improved, and the wettability and lubrication performance of the surface of the coating tool are improved.

Owner:JIANGSU UNIV

Preparation method of thermoplastic konjac glucomannan nanocomposite material

The invention discloses a preparation method of a thermoplastic konjac glucomannan nanocomposite material. The method comprises the following steps of (1) preparing konjac glucomannan to be pretreated; (2) performing grafting with vinyl monomers to prepare thermoplastic konjac glucomannan; (3) uniformly mixing the thermoplastic konjac glucomannan and a nanometer graphene oxide solution, and performing drying to obtain a mixture; (4) stirring and mixing the mixture, a cross-linking agent and a plasticizer in a mixing machine, and performing drying to obtain a blended material; (5) putting the blended material into a double-screw extruder; performing melt blending and extrusion pelletization,so as to obtain the thermoplastic konjac glucomannan nanocomposite material. The thermoplastic konjac glucomannan nanocomposite material is a novel composite material, and has excellent adsorbability, thermostability and mechanical toughness; the comprehensive performance is excellent; biodegradation and regeneration are realized; the environment-friendly effect is achieved; no environment pollution exists; the processing performance in the extrusion molding, blow molding, injection molding and foaming process is good; the thermoplastic konjac glucomannan nanocomposite material can be widely applied to the fields of chemical engineering, medicine, environment protection, machine building and the like.

Owner:SICHUAN BIOTECH FORCE TECH

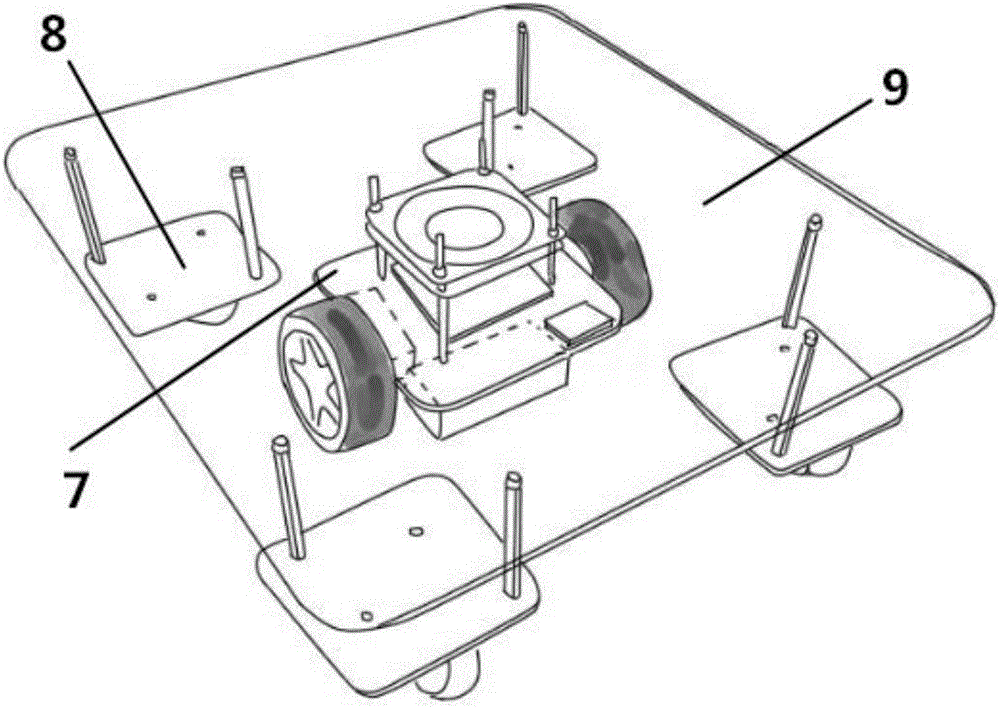

Angle-controllable power differential omnidirectional wheel, and control method and omnidirectional moving platform thereof

InactiveCN106379409ALow costEasy to maintainNon-deflectable wheel steeringVehiclesHeavy equipmentAzimuth

The invention discloses an angle-controllable power differential omnidirectional wheel, and a control method and an omnidirectional moving platform thereof, and relates to the technical field of machinery manufacturing and assembly and intelligent control. The angle-controllable power differential omnidirectional wheel comprises a wheel frame main body, a rotary support bearing, two wheels, two elastic shaft couplers, two speed reducing motors, a gyroscope and a controller. According to the control method of the omnidirectional wheel, the rotating speed of two wheels is subjected to closed loop control so that the practical azimuthal angle of the omnidirectional wheel tracks the expected value; the flexible steering is realized; the cost is low; the omnidirectional moving requirements of the heavy equipment or cargo transportation can be met. The omnidirectional platform comprises the omnidirectional wheel and a platform bottom plate connected with the omnidirectional wheel through the rotary support bearing; the non-steering flexible movement of the platform bottom plate is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

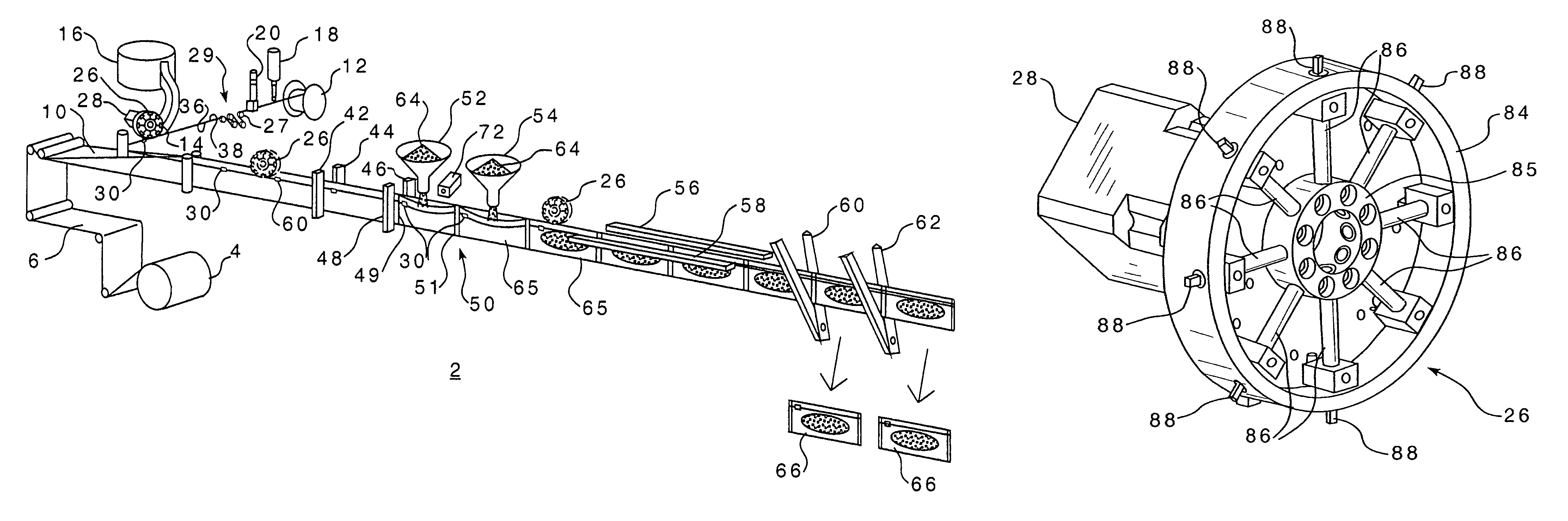

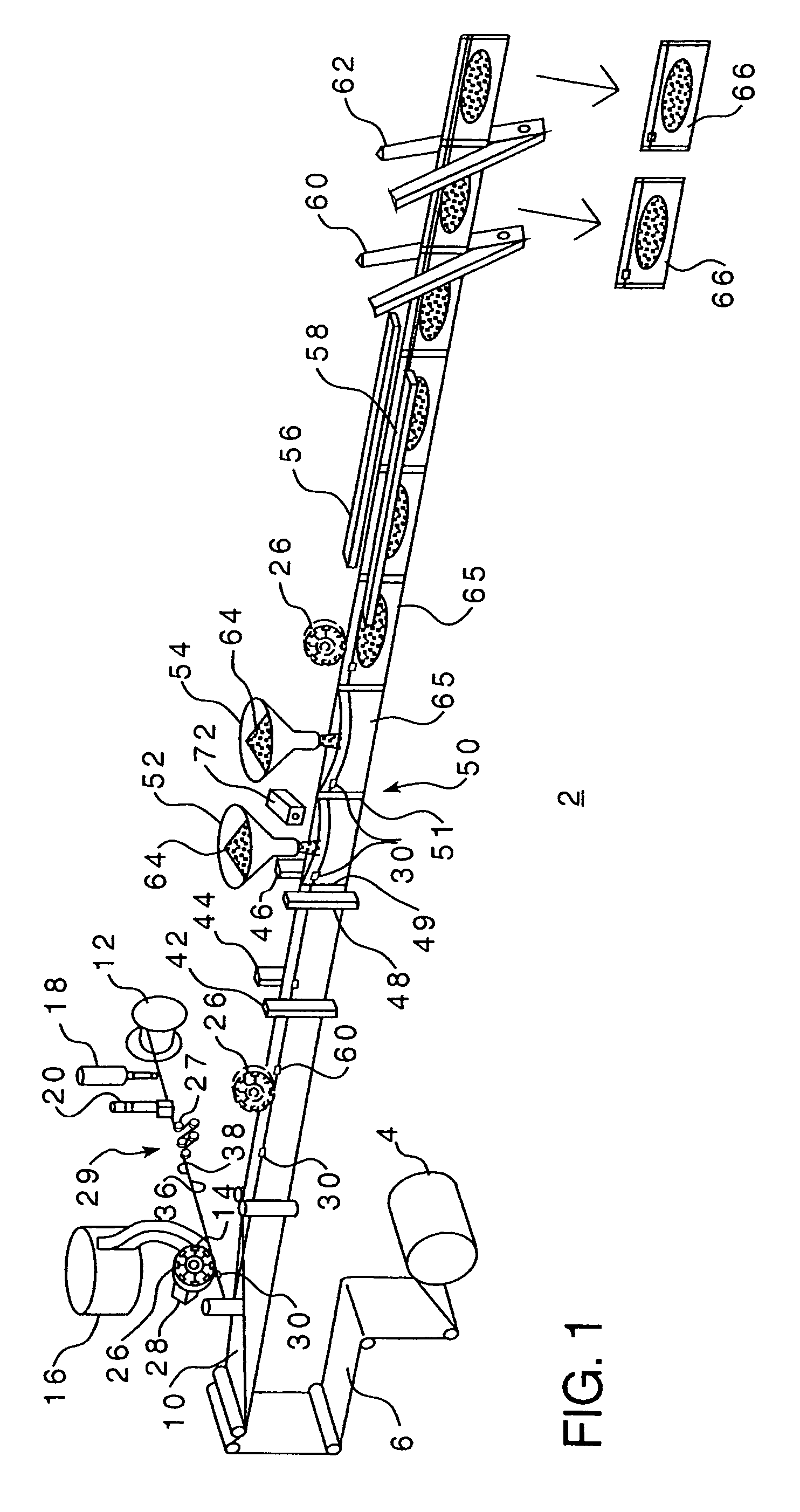

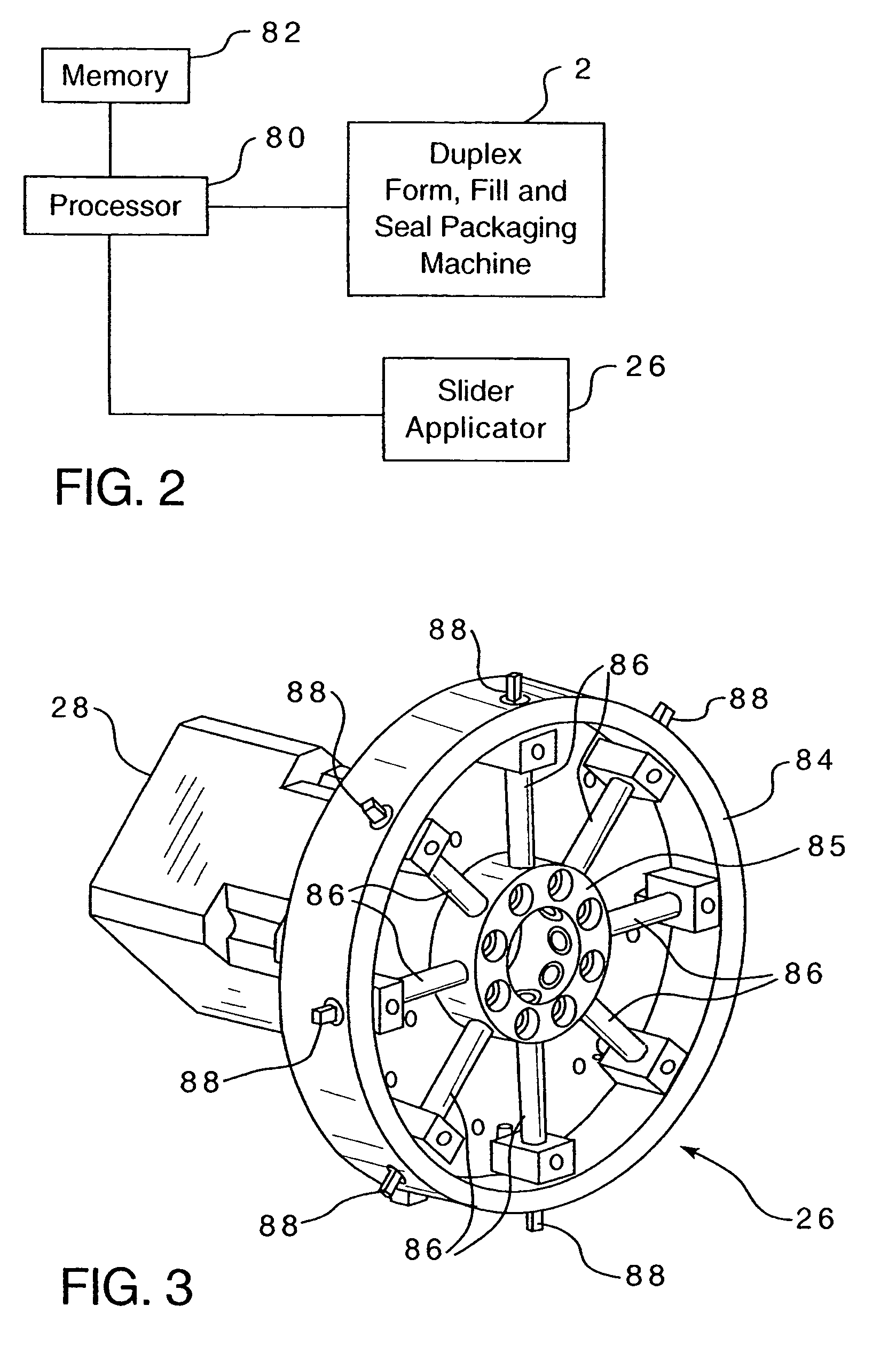

Method of applying sliders, duplex packaging machine and slider applicator therefor

A method of making and filling reclosable packages using a duplex machine includes the steps of providing a zipper profile, package film and a plurality of sliders; feeding the zipper profile; applying the sliders to the zipper profile; coupling the zipper profile to the folded web; sealing two edges of the folded web to form adjacent pouches; filling the pouches; sealing the pouches proximate a third edge thereof; and separating the pouches in order to form individual packages. The method employs a single rotating slider applicator having a programmable servo motor which is programmed in order to synchronize the application of the sliders to the moving zipper profile with the two at a time form, fill, seal and separate packaging operations of the duplex machine. A duplex machine is also disclosed.

Owner:REYNOLDS PRESTO PRODS

Design method of magnetic latching parallel-stepping, rotating and swinging extensible joint

ActiveCN103475288AExtended use timeFast mechanical speedJointsDynamo-electric converter controlMachine buildingFuture of robotics

The invention provides a design method of a magnetic latching parallel-stepping rotating and swinging extensible joint, and belongs to the technical fields of mechanical manufacturing, intelligent control, robotics, automation control and electromagnetism. According to the main content of the technology, a magnetic latching parallel-stepping swinging face, a magnetic latching parallel-stepping rotating disc and a magnetic latching parallel-stepping driver are combined together to form the mechanical joint which can swing, rotate and be stretched out and drawn back, a driving unit of the magnetic latching parallel-stepping rotating disc, a driving unit of the magnetic latching parallel-stepping swinging face and a driving unit of the magnetic latching parallel-stepping driver are respectively composed of a unit magnetic lathing driver so that parallel execution can be achieved, the joint can rotate to a required angle within the time of a pulse, meanwhile, the swinging face can swing to a required direction and a required angle, and the joint can be stretched out or drawn back to a required length.

Owner:天津奥纳富霖科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com