Methods for designing and manufacturing double-lead linear contact bias worm drive

A technology of worm drive and design method, applied in the direction of worm, worm gear, calculation, etc., can solve the problems of design and manufacturing difficulties of tapered worm drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

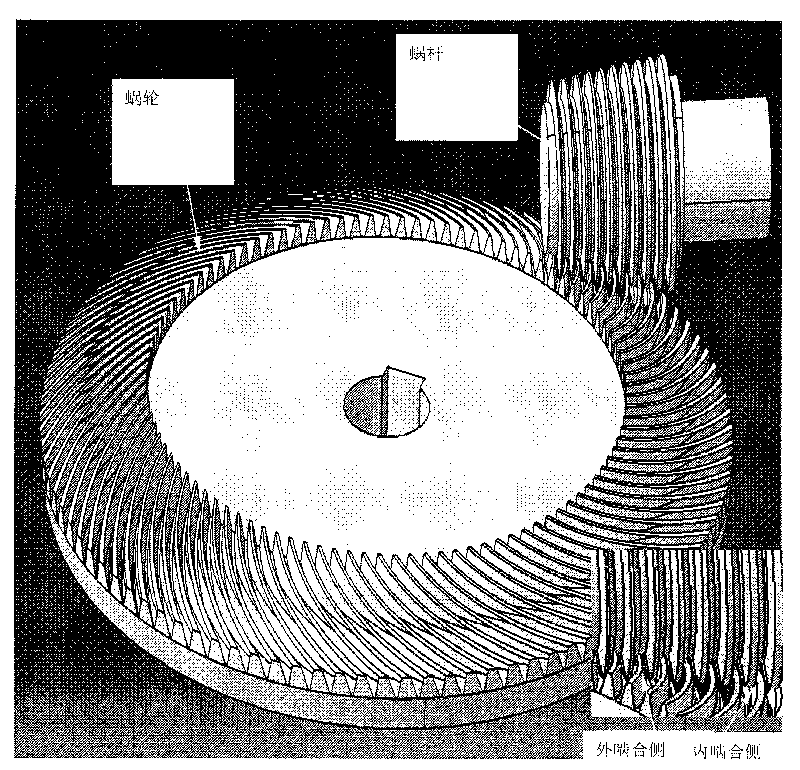

[0348] 1. Design example of conical worm and worm gear transmission

[0349] A. Cylindrical worm drive design example:

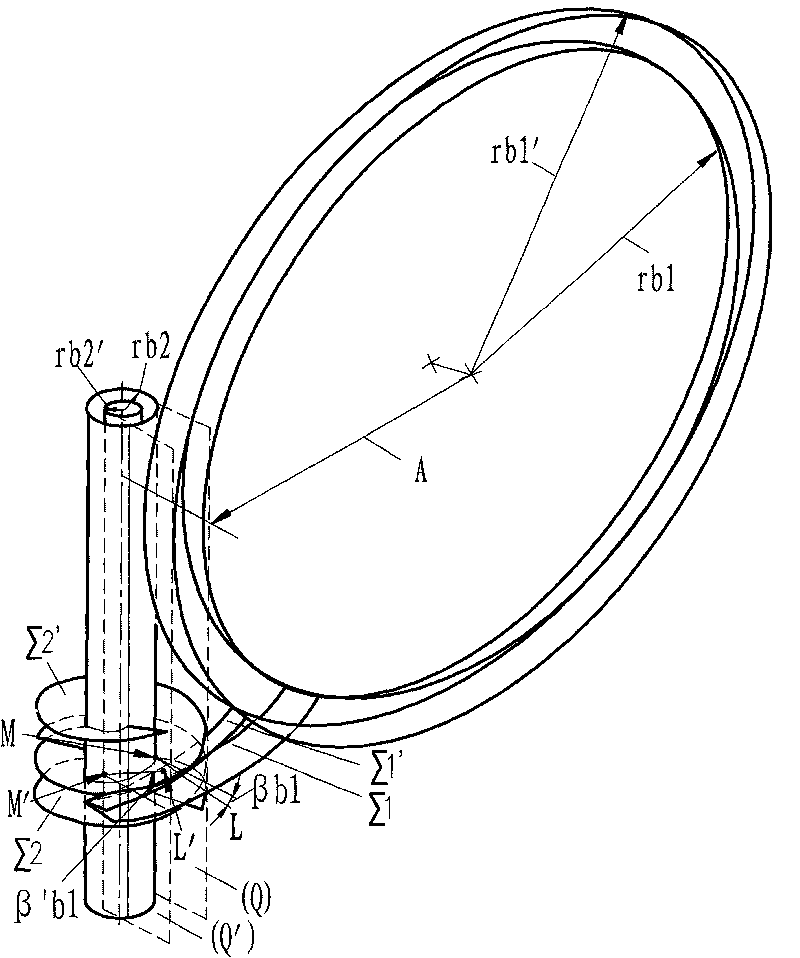

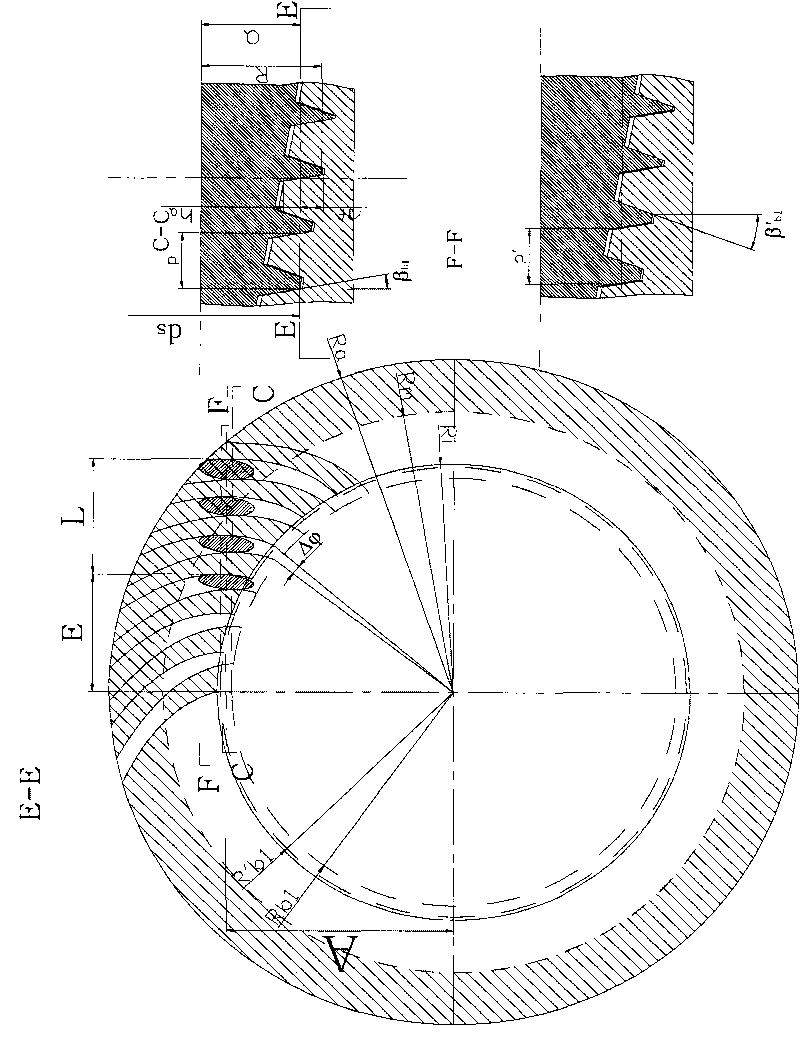

[0350] It is known that the center distance A=100, the transmission ratio i12 and the number of teeth z, z=55. Roughly calculate the outer diameter of the worm d, d=kA=2R, k = 1 2 ~ 7 12 , d=54; selected helix angle β b1 , β′ b1 , β b1 = 20°, β' b1 =30°, calculate base cylinder radius, Rb2 = 4.758, R b1 =95.242, R' b2 = 3.251, R' b1 =103.251; take n=10%z=5

[0351] 1) Preliminary calculation of the outer diameter R of the worm gear a , take R a =152

[0352] 2) Calculate the radius R of the worm gear index circle m , R m ≈109.1

[0353] 3) According to R m Calculate the modulus m, m = 2 R m z = 3.967

[0354] 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com