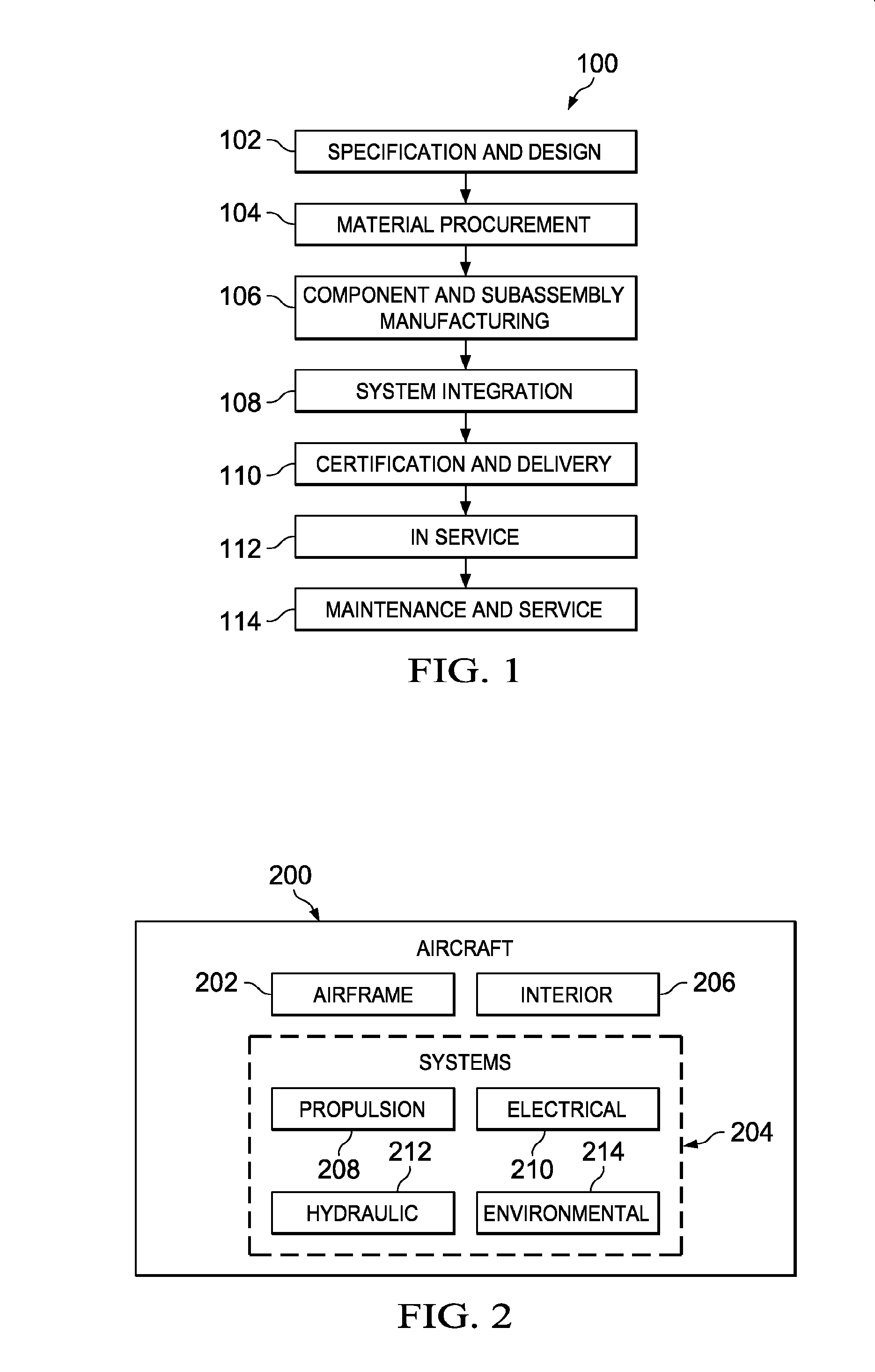

Patents

Literature

283results about "Worms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

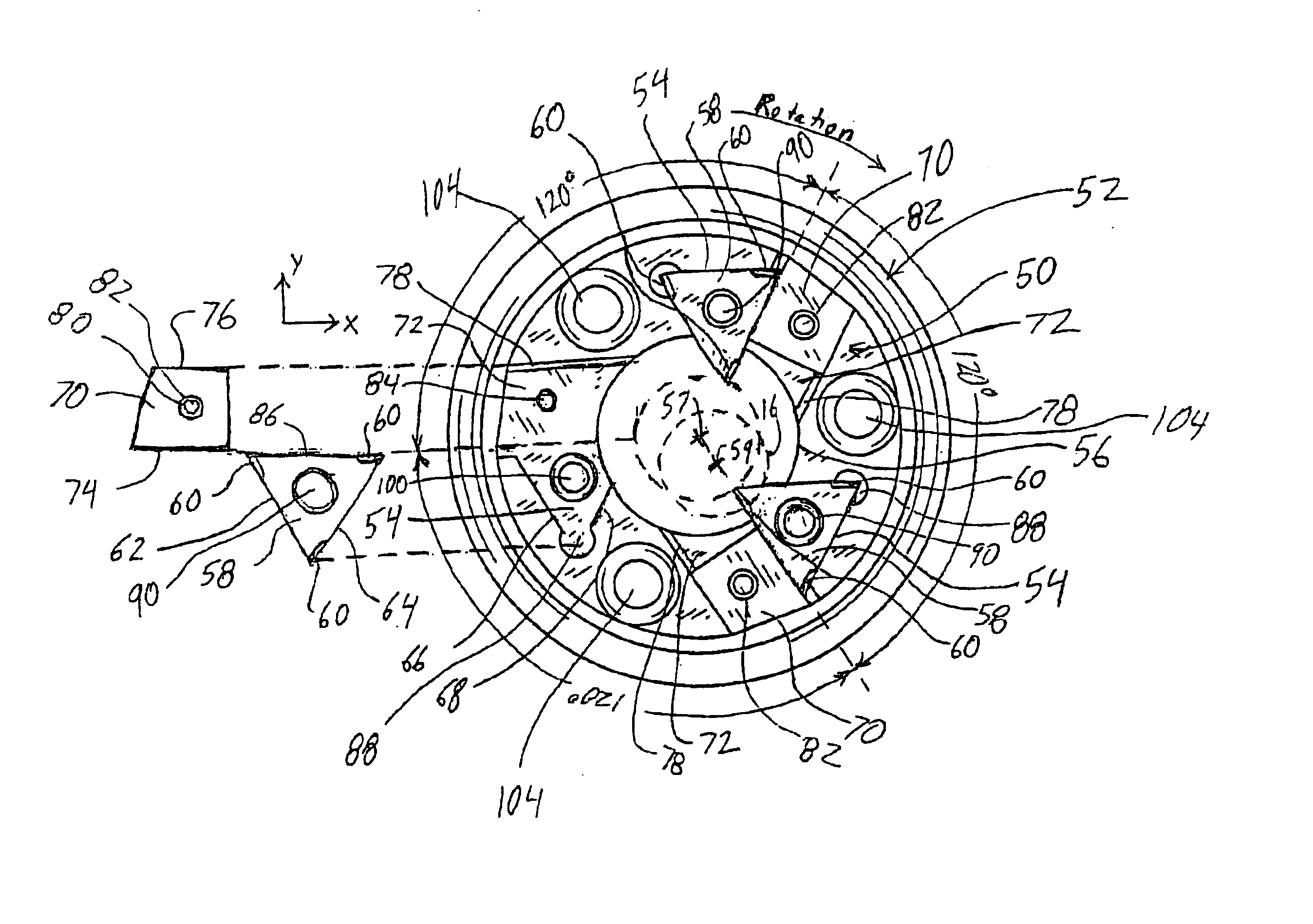

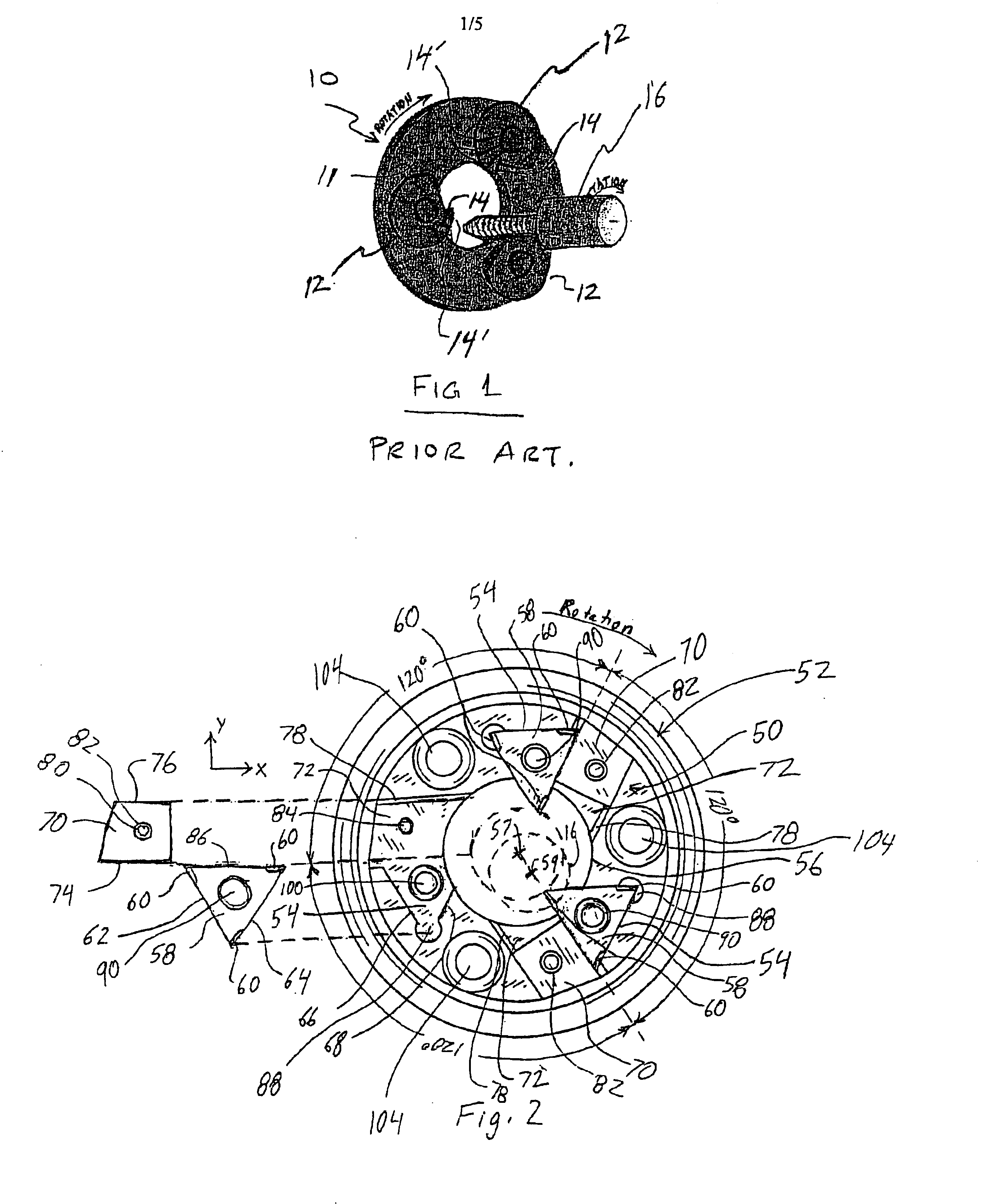

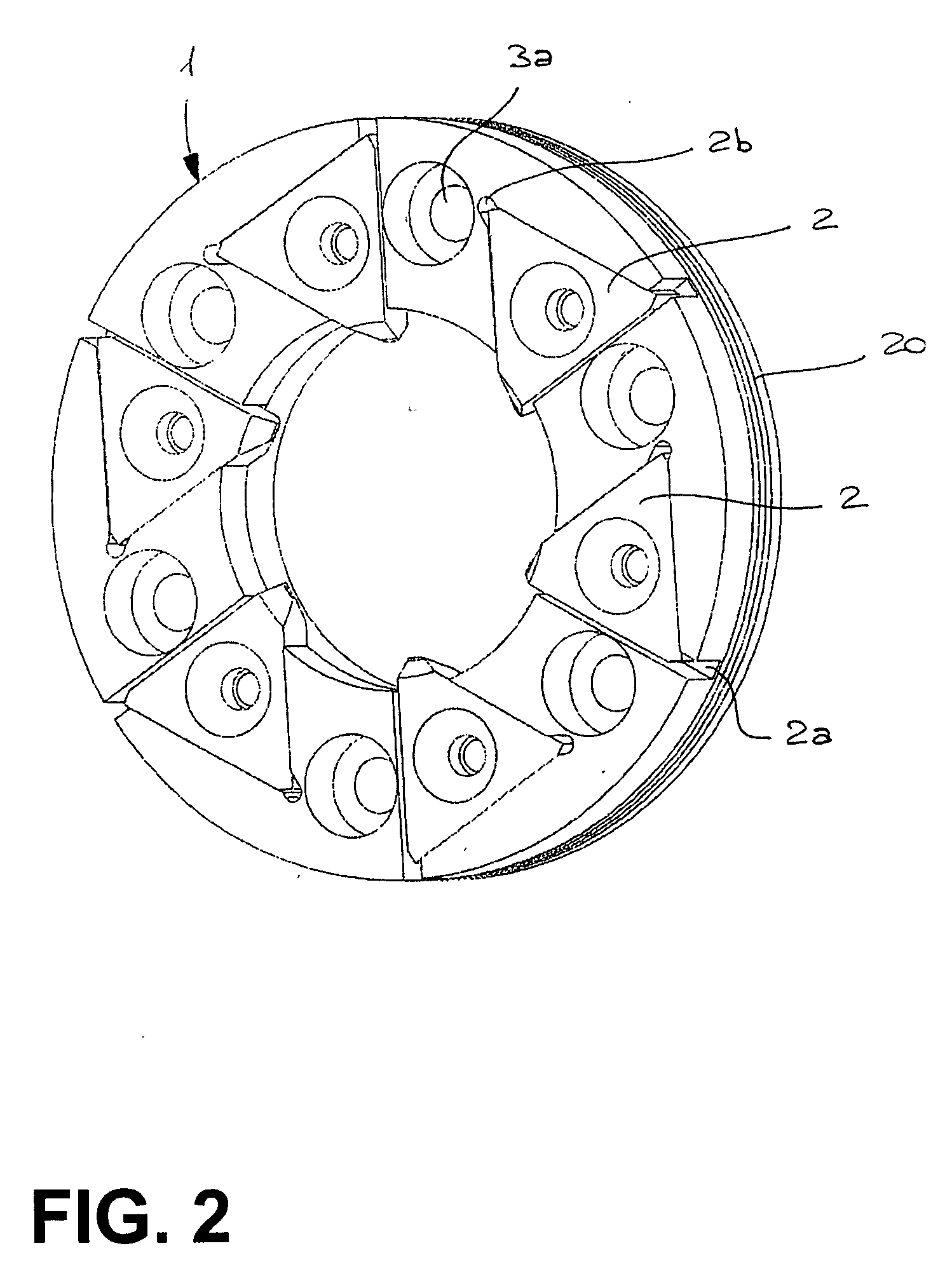

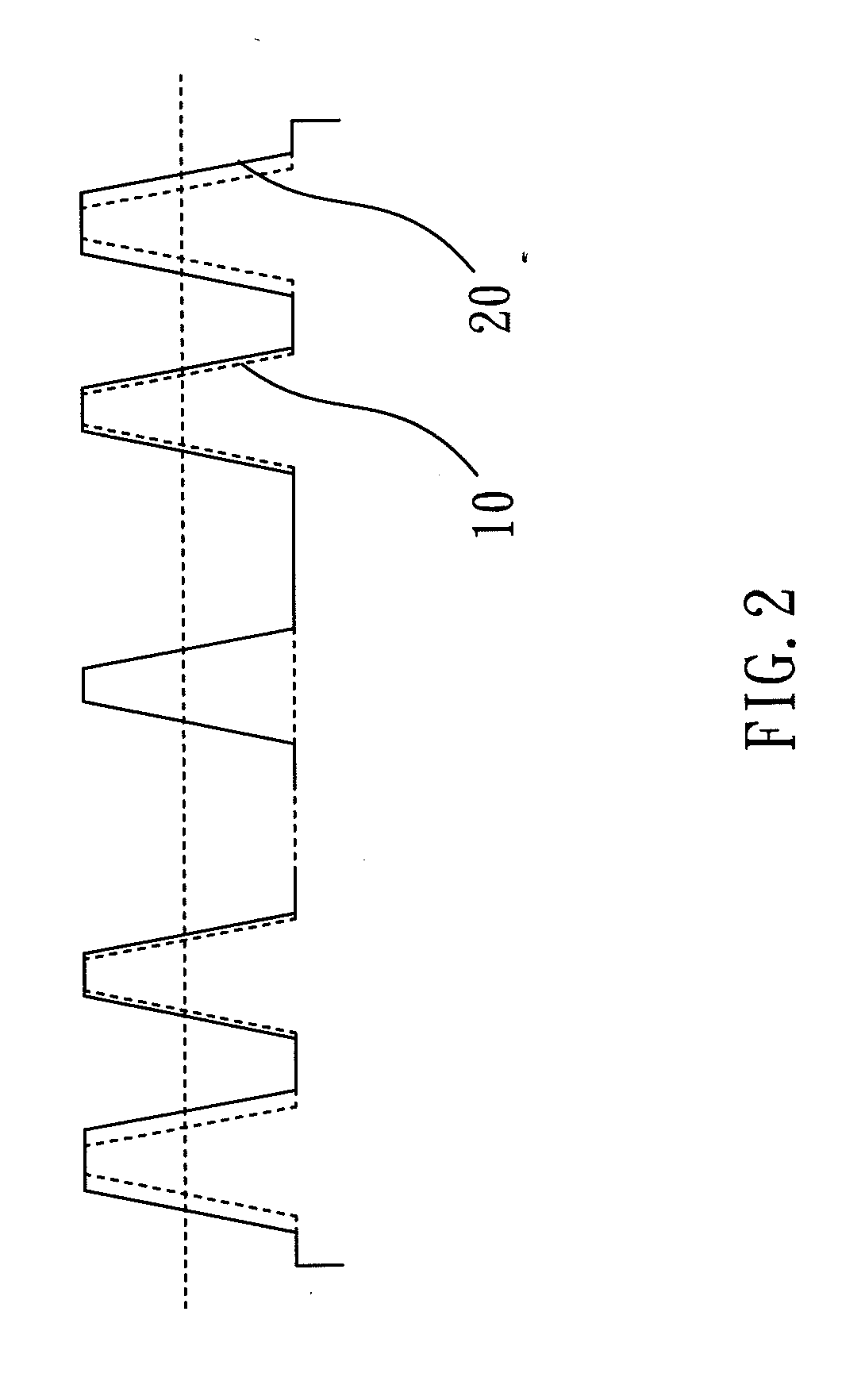

Milling head for thread whirling

A milling head for thread whirling, the milling head includes a plurality of cutting elements evenly disposed around a center hole, each cutting element in the plurality of cutting elements includes at least two cutting surfaces formed thereon. Any one of the at least two cutting surfaces is selectable to extend within the center hole for contacting a work-piece. Each cutting element in the plurality of cutting elements is disposed in a recess formed in a face of the milling head, with each recess defining at least two walls. Each of the at least two walls contacts a side of the cutting element to align the cutting element in a predetermined relationship with respect to the milling head. In one embodiment, the plurality of cutting elements include first and second sets of cutting elements. The first set of cutting elements is evenly disposed around the center hole and contact the work-piece to produce a thread form on the work-piece. The second set of cutting elements is evenly disposed around the center hole and contacts the work-piece to remove material proximate the outside diameter of the work-piece.

Owner:REM SALES

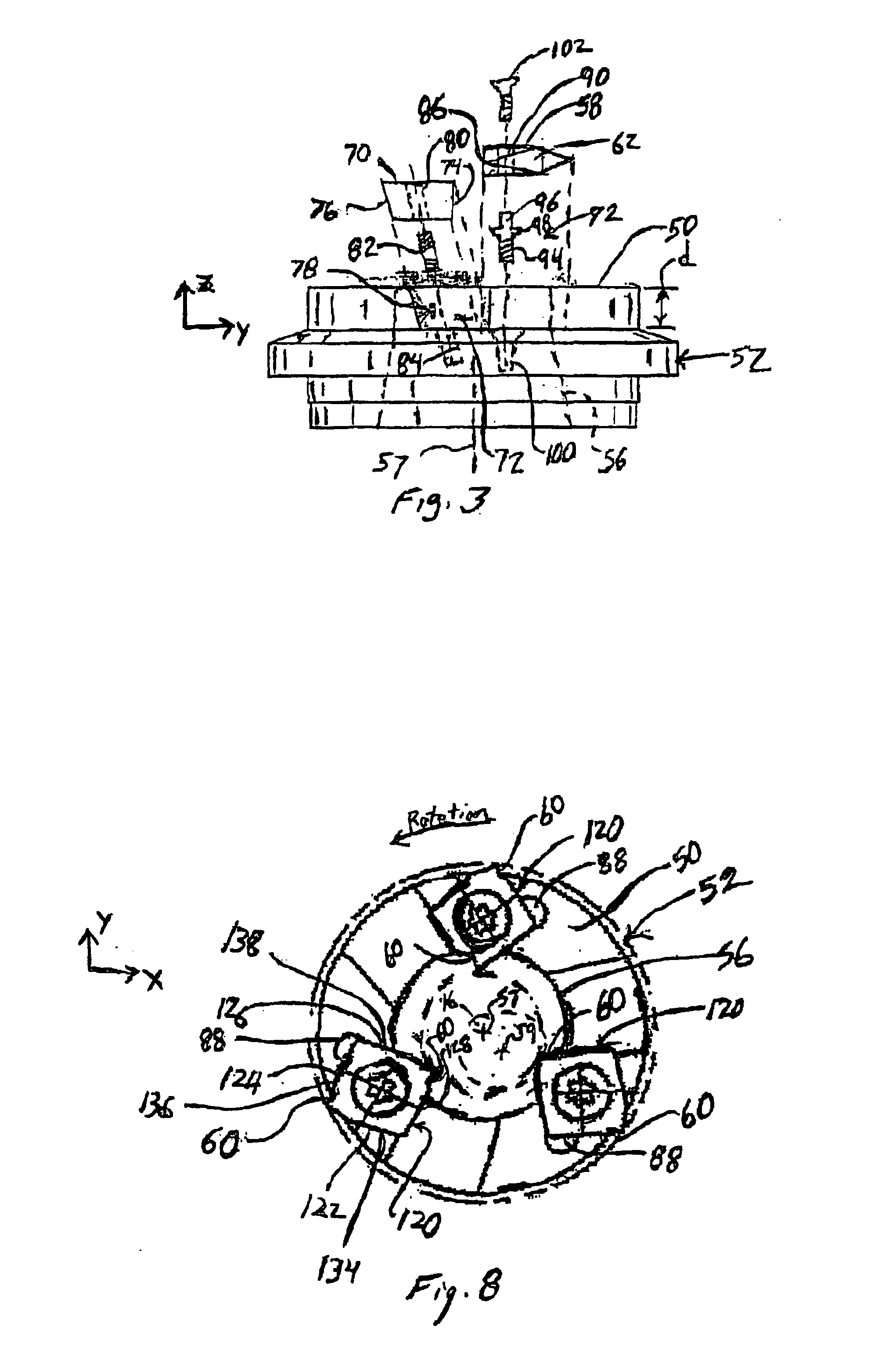

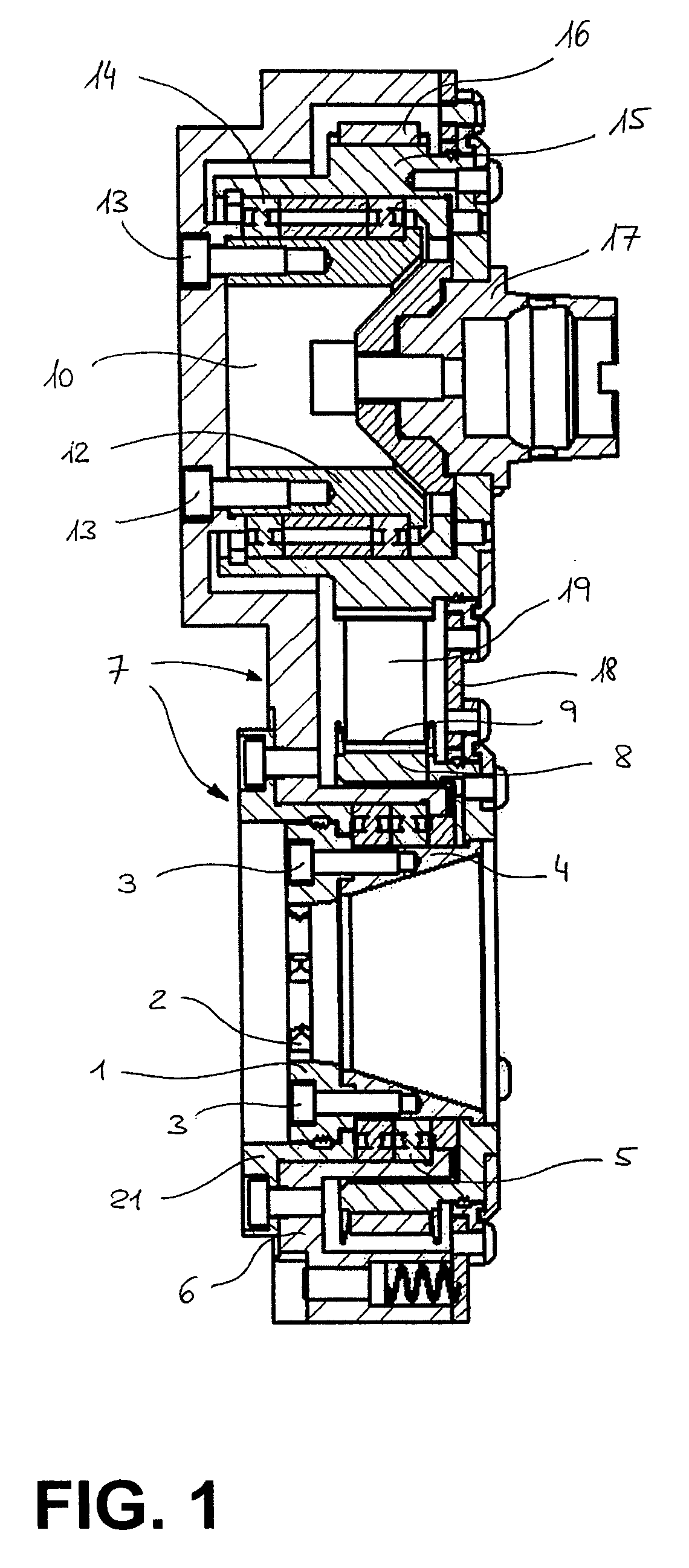

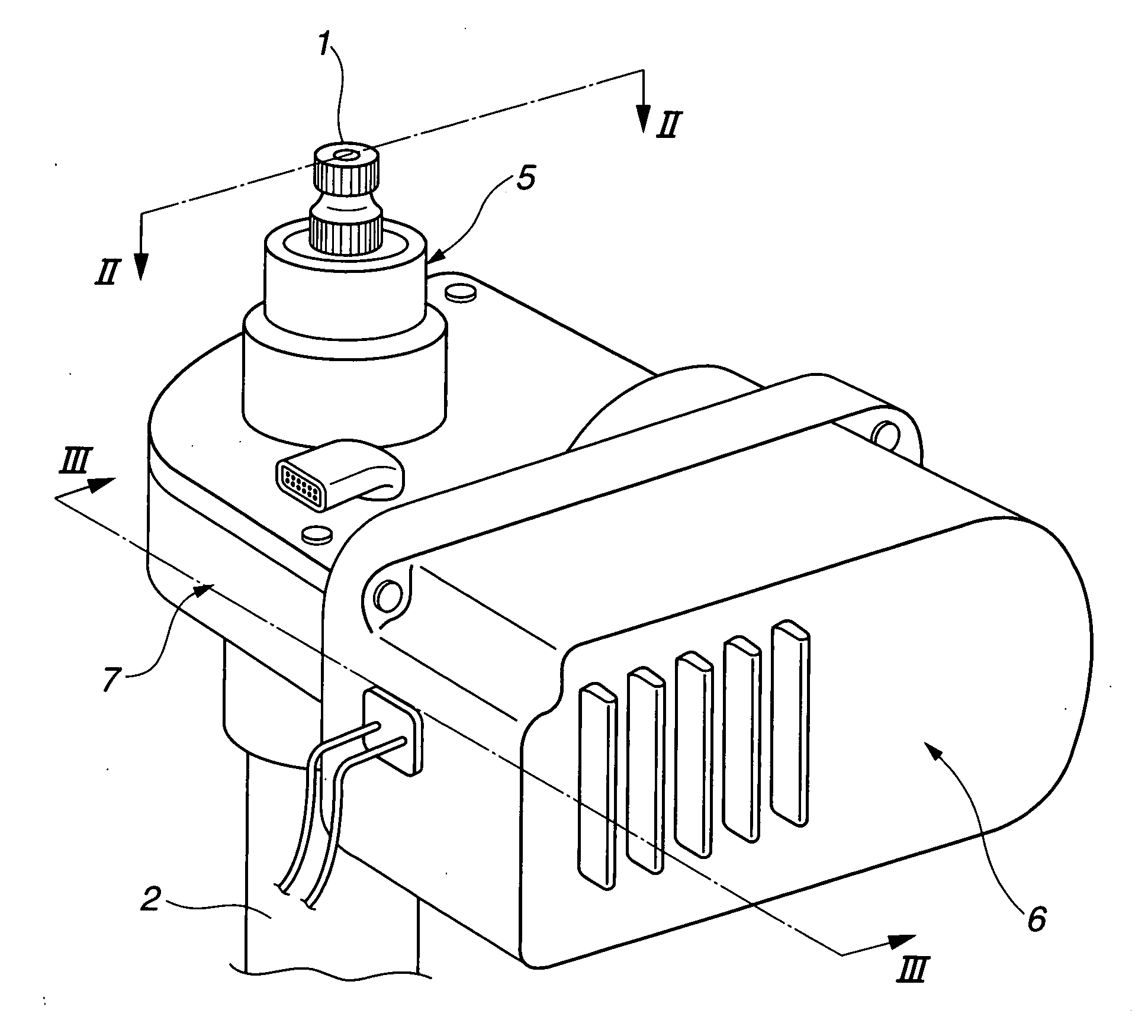

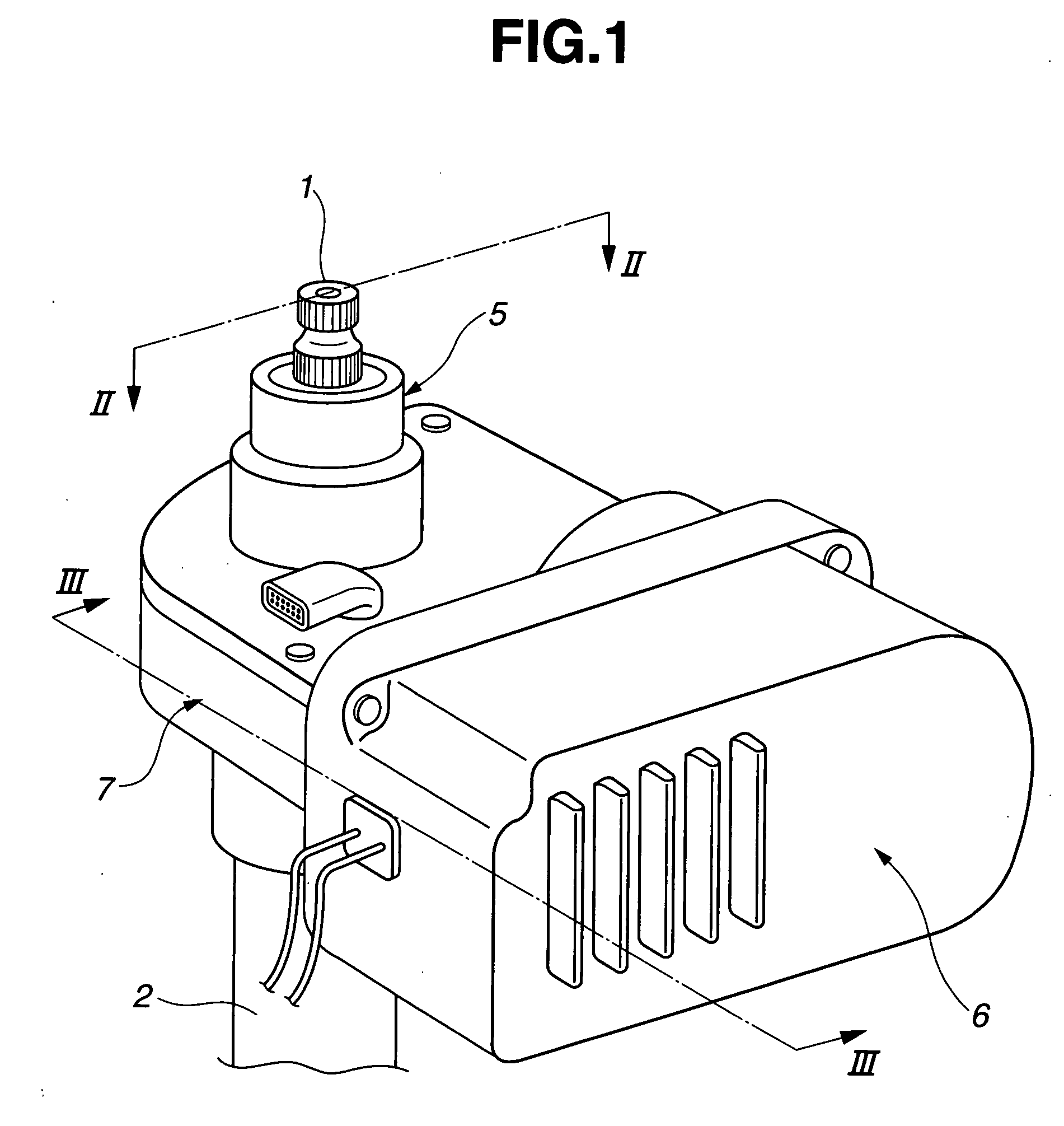

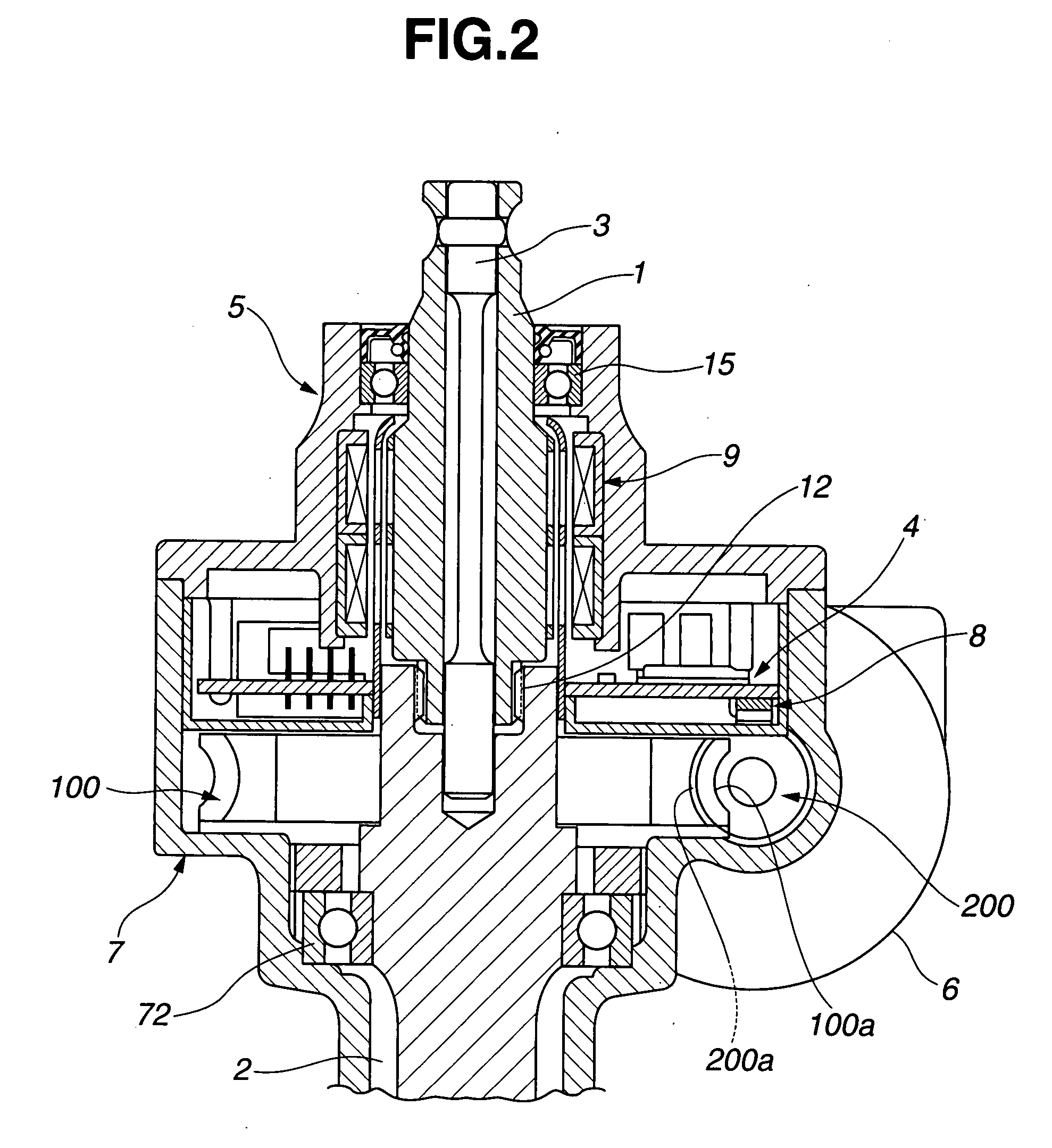

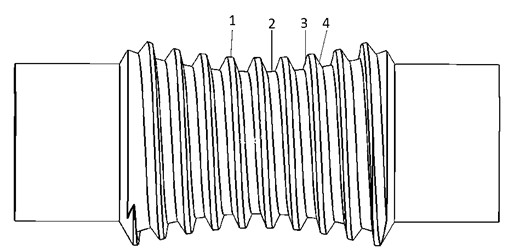

Whirling head and its use

The frame of the whirling head comprises the rigid casing (7), in which the part (10) contains the drive pulley (15) solidly attached to the coupling member (17) connected to the drive shaft of the spindle (26). By means of the belt (19), this pulley (15) drives the pulley (8) solidly attached to the connecting cone (4), which in turn comprises the internal milling cutter (1) which cuts the thread of the screw shaft (27) supported between the bar advance unit (28) and the tailstock centre (29). The latter is mounted as an exchangeable tool on the return unit (32).

Owner:WILLEMIN MACODEL

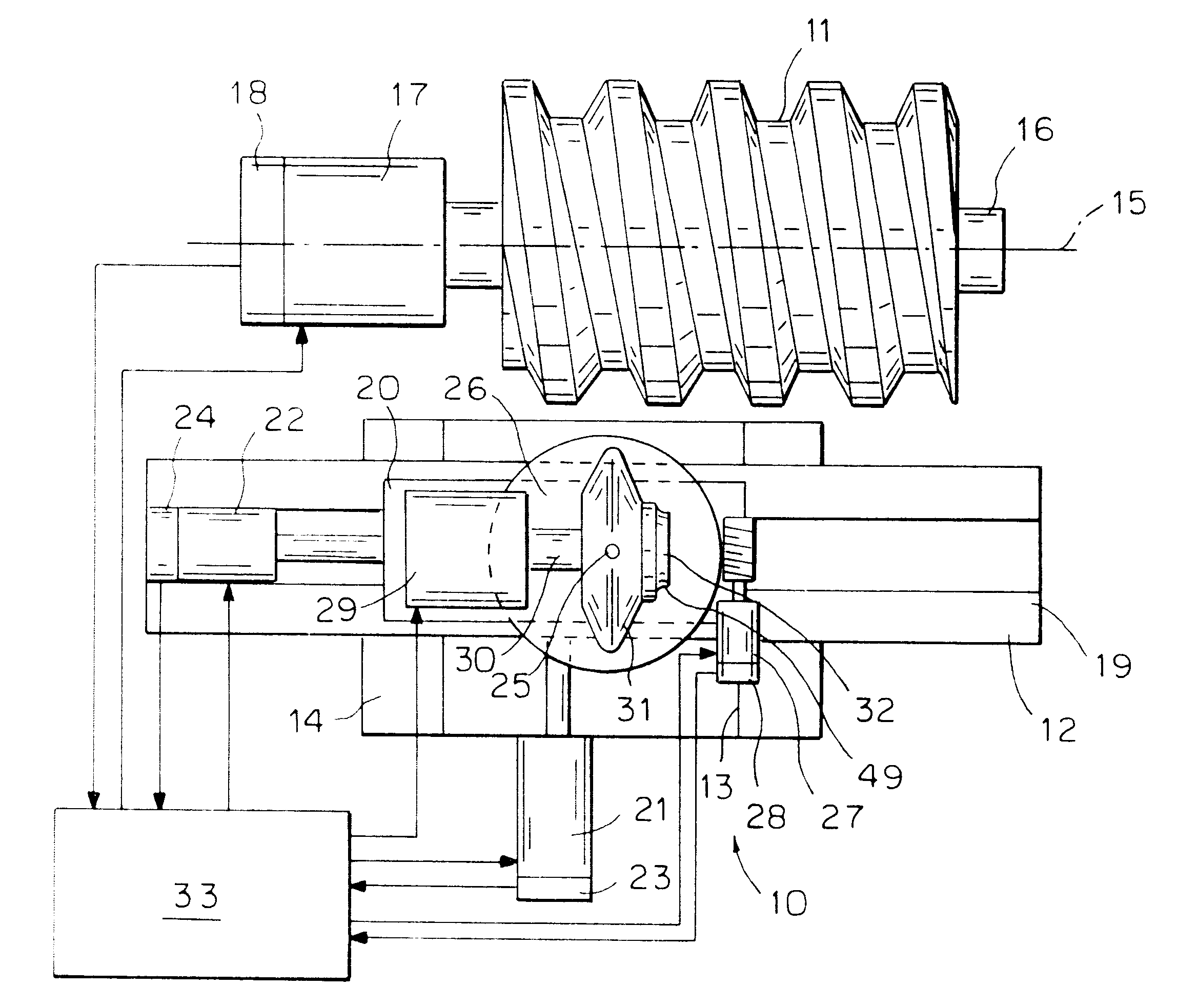

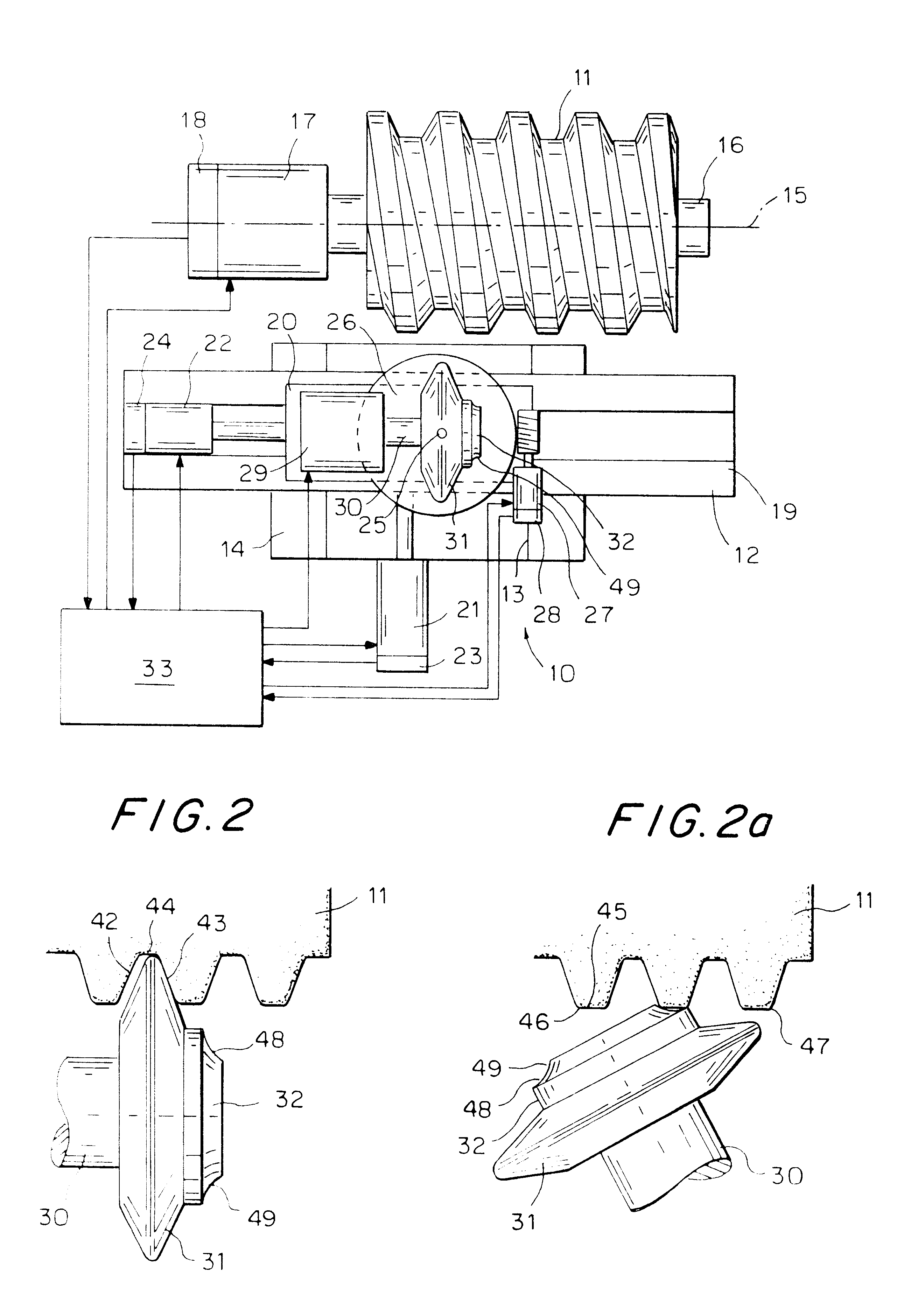

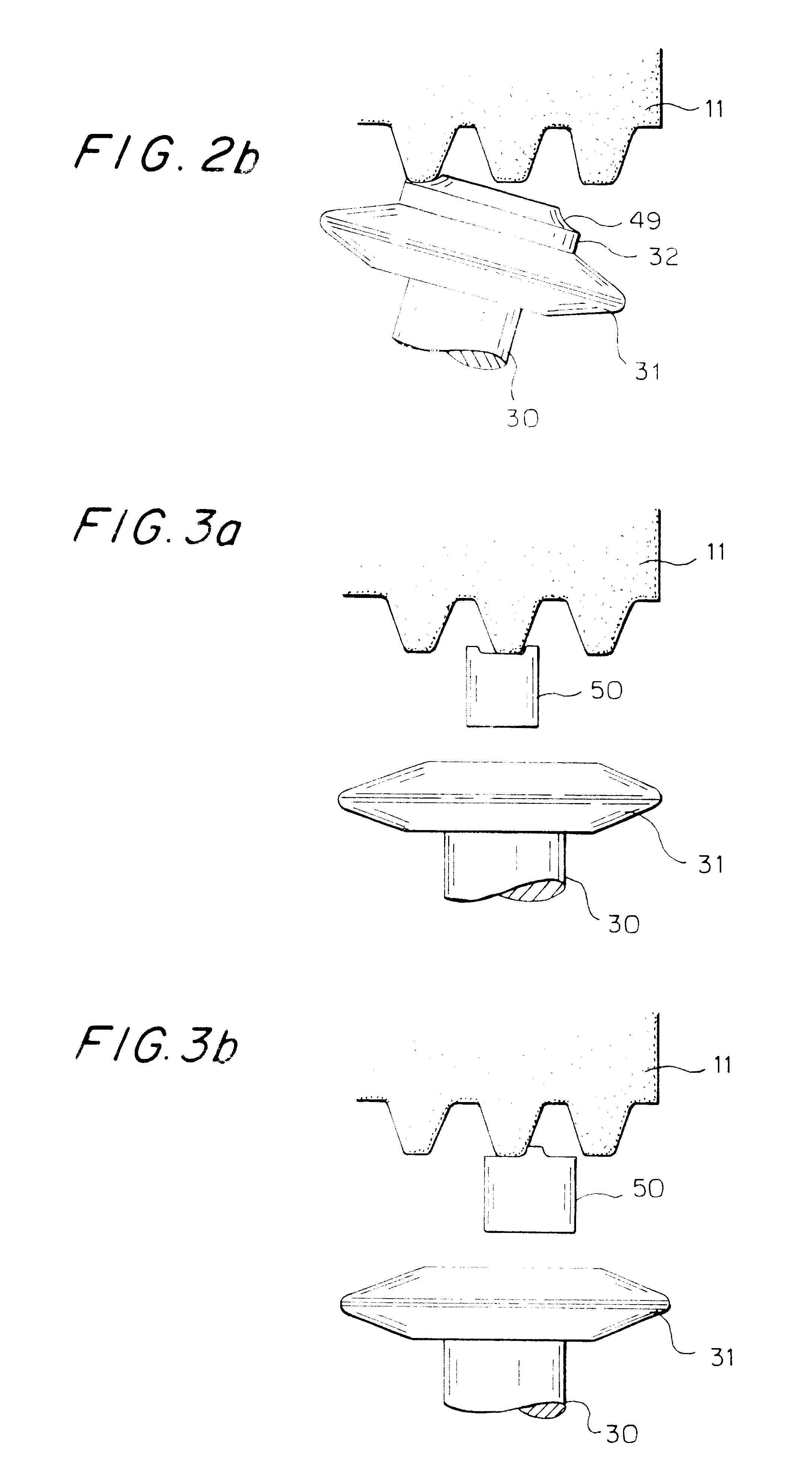

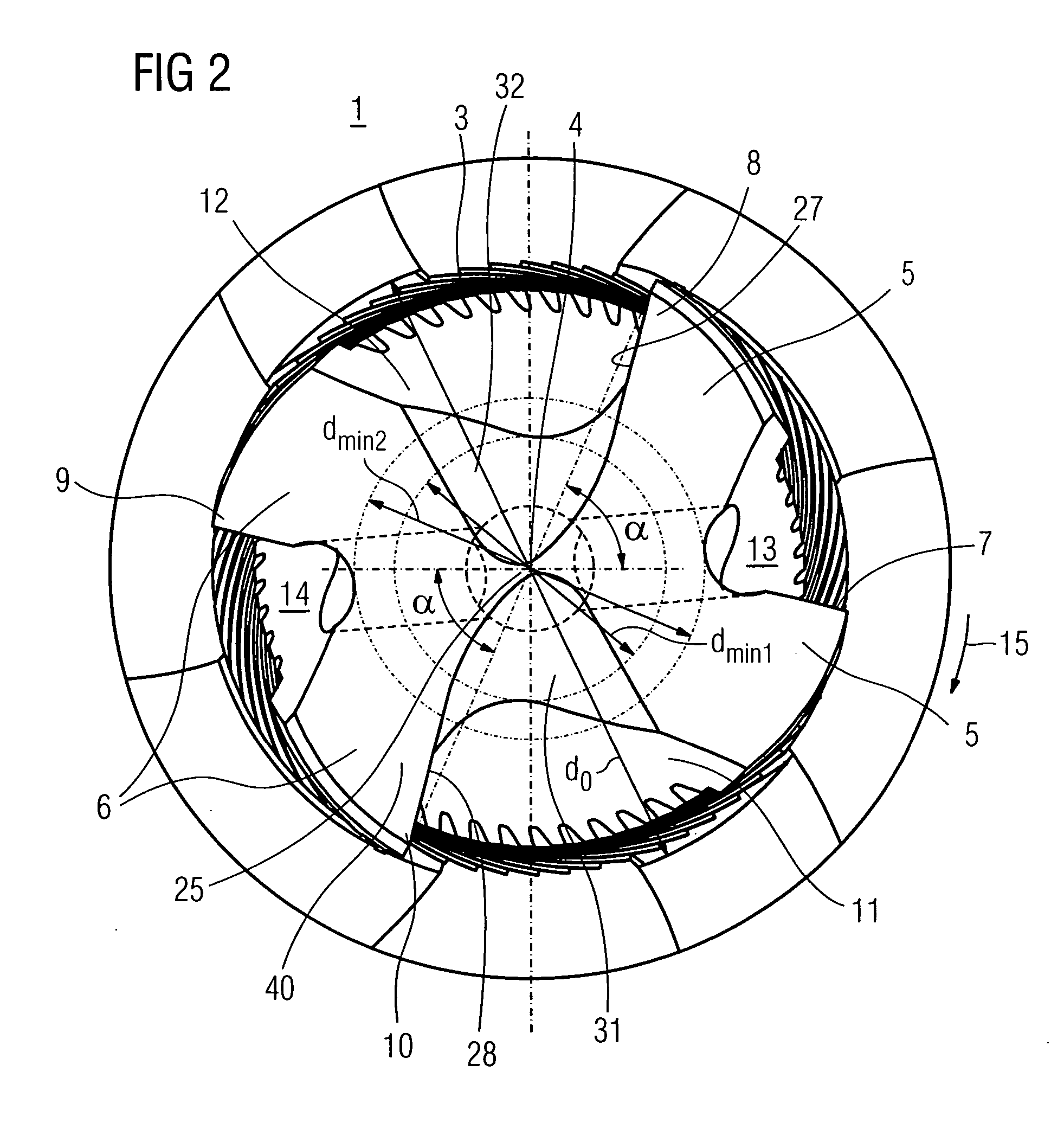

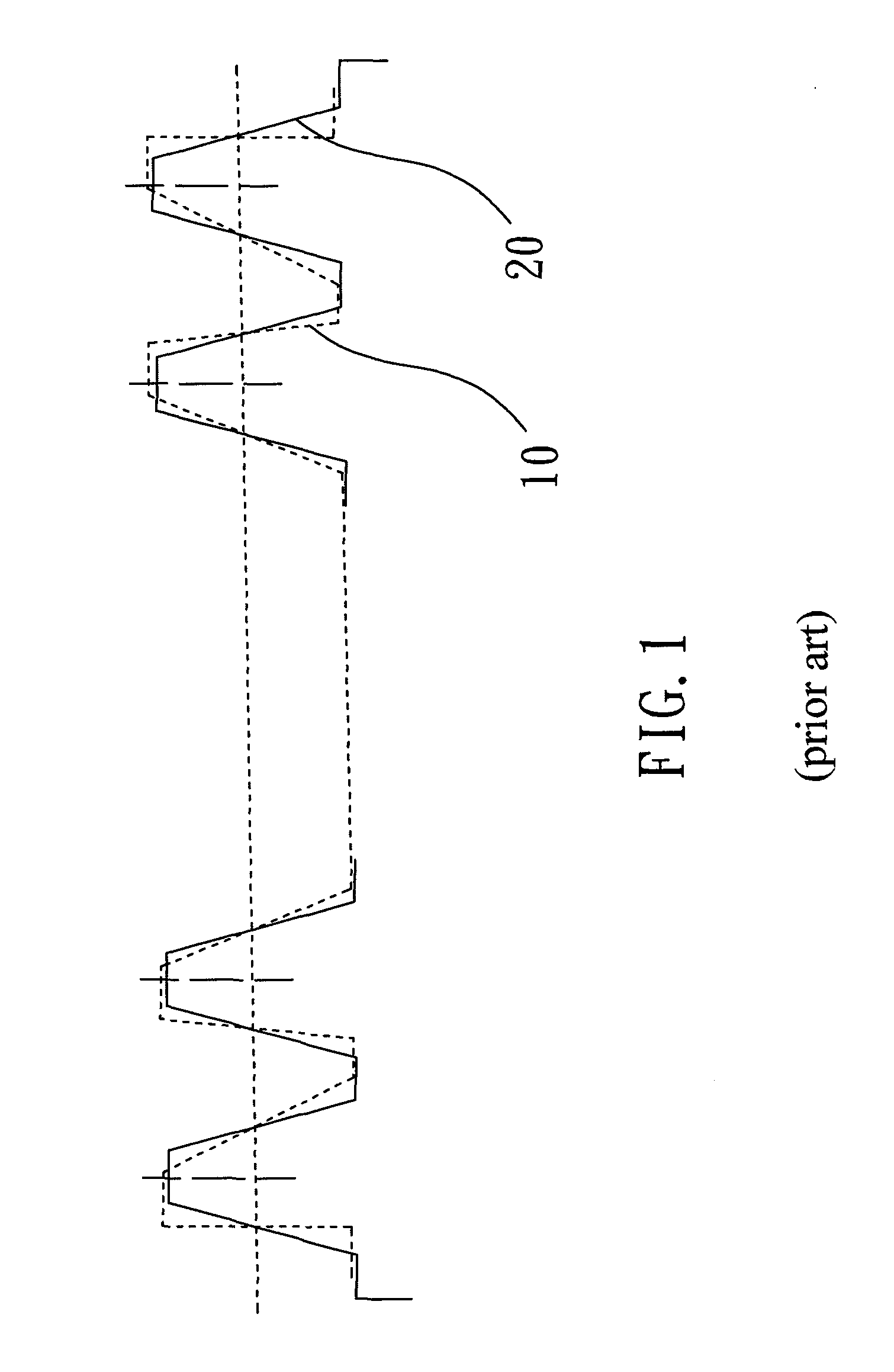

Device and method for profiling grinding worms

InactiveUS6234880B1Short dressing timeLittle effortGrinding drivesBelt grinding machinesEngineeringMechanical engineering

A radius-forming dressing roll (32) having a frustoconical working region (48) and an adjoining concave-toroidal working region (49) is mounted on the dressing spindle (30) coaxially to a dressing disc (31). In a first step, the flanks (42, 43) of the grinding-worm thread are profiled with the disc (31). After the dressing spindle (30) has been pivoted, the two tip radii (46, 47) and the cylindrical outer circumference (45) are profiled with the dressing roll (32). With little resetting effort and high flexibility, the method permits profiling with short dressing times.

Owner:REISHAUER

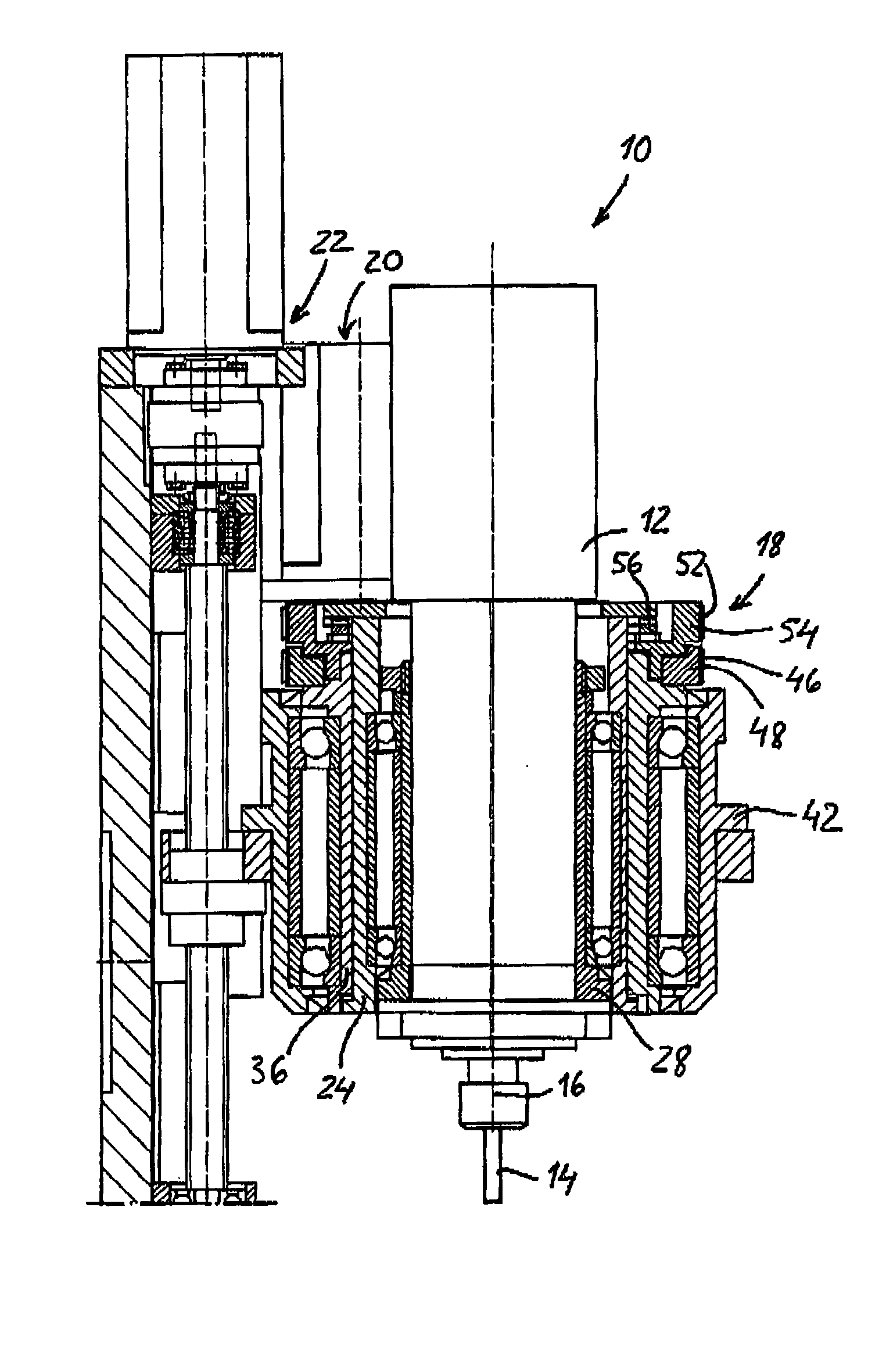

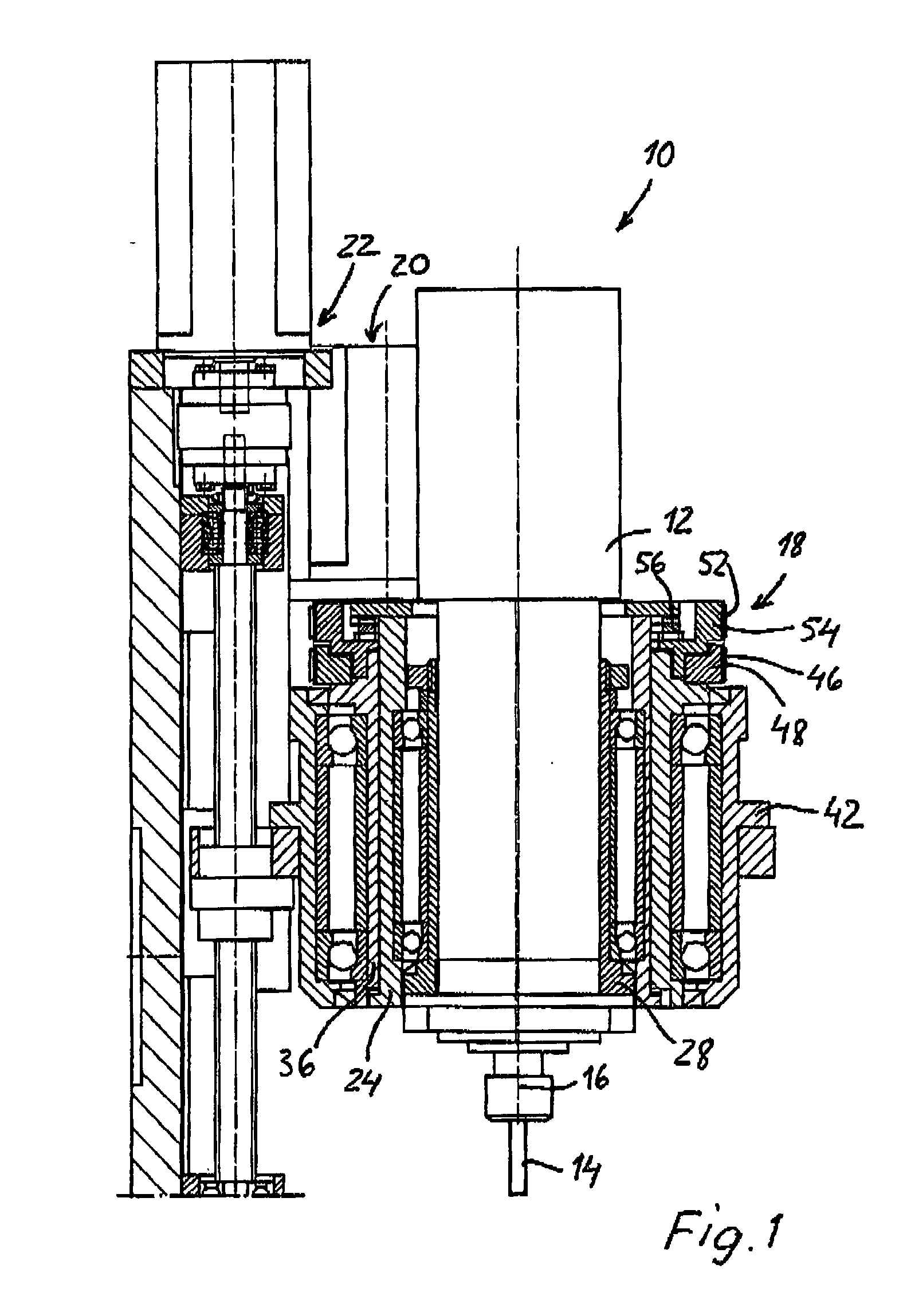

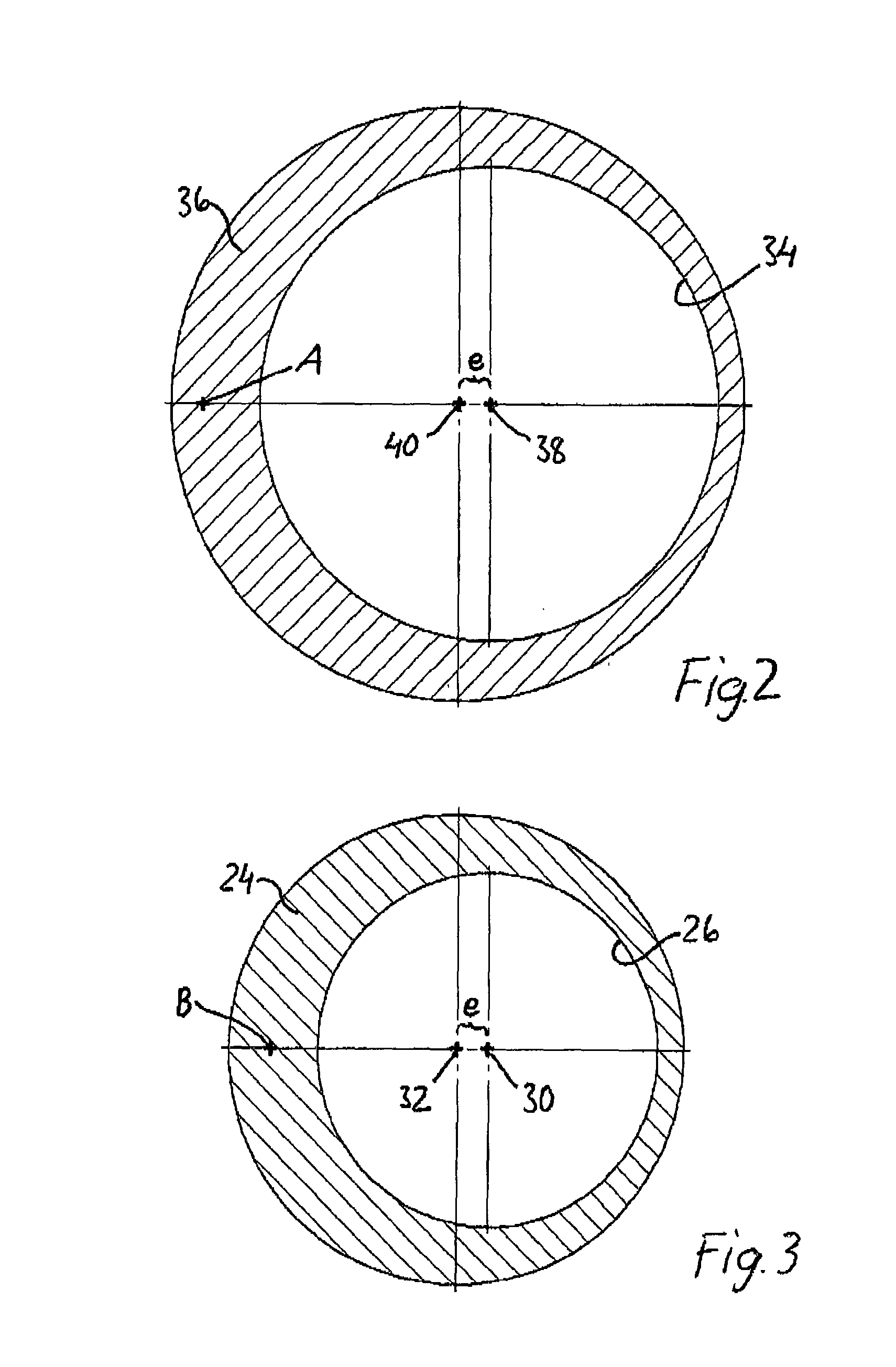

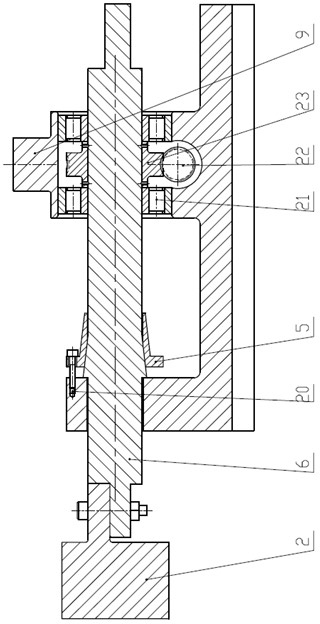

Numerically controlled orbital machining apparatus

An orbital machining apparatus for producing a cylindrical or conical hole in a workpiece includes a cylindrical cutting tool. The apparatus includes a radial offset mechanism configured for controlling the radial distance of the center axis of the cutting tool from a principal axis, the principal axis being substantially parallel to the center axis of the tool and coaxial with a longitudinal center axis of the hole to be machined. The radial offset mechanism includes an inner cylindrical body having an eccentric cylindrical hole, the eccentric hole having a longitudinal center axis that is parallel to and radially offset from a longitudinal center axis of the inner body, the eccentric hole being configured to radially and rotatably support a spindle unit for operating the cutting tool; and an outer cylindrical body having an eccentric cylindrical hole, the eccentric hole of the outer body having a longitudinal center axis that is parallel to and radially offset from a longitudinal center axis of the outer body a distance which is equal to the distance between the center axis of the eccentric hole of the inner body and the center axis of the inner cylindrical body, the inner cylindrical body being radially supported in the eccentric hole of the outer cylindrical body and rotatable therein so as to adjust the radial distance of the center axis of the cutting tool from the principal axis.

Owner:NOVATOR

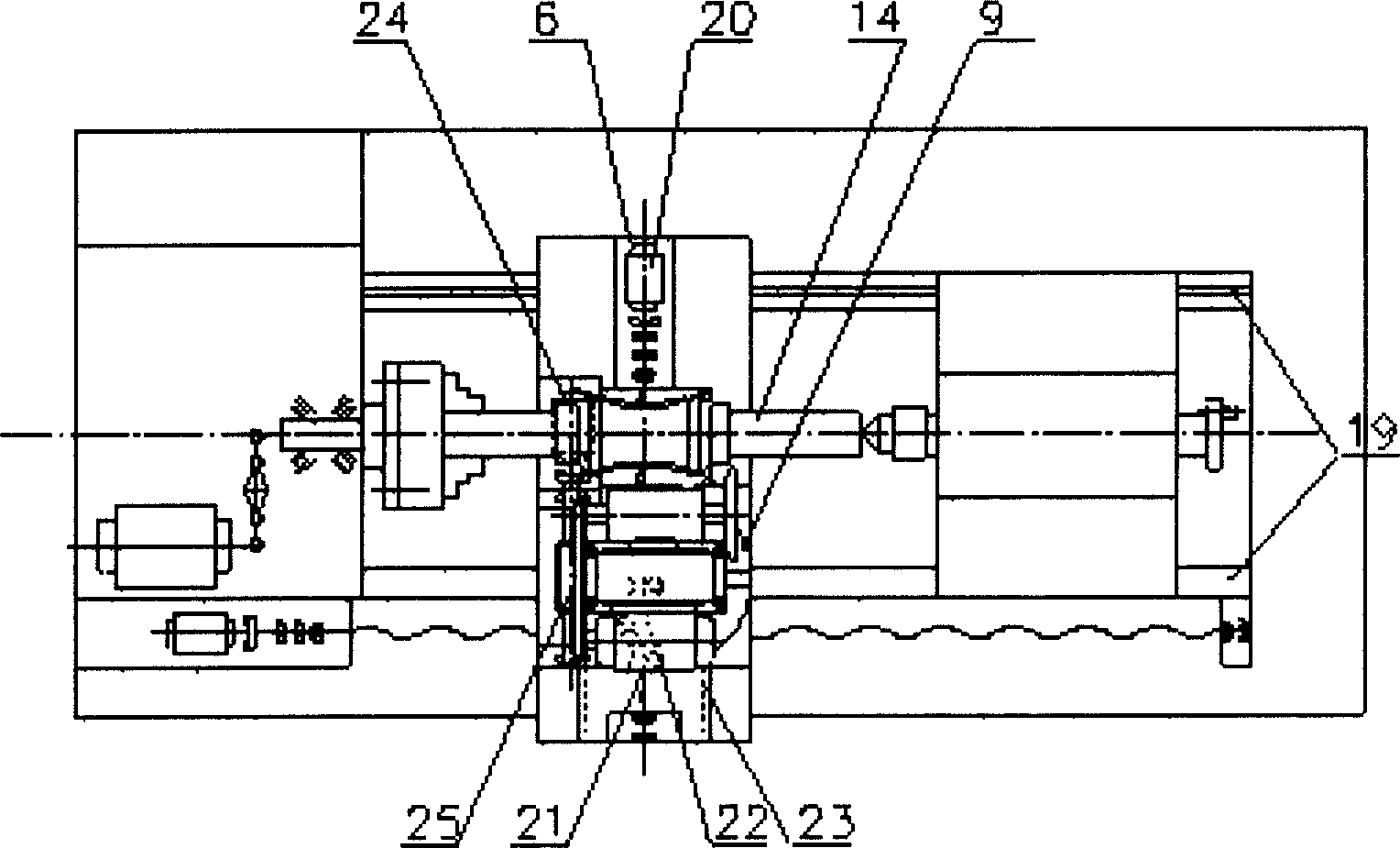

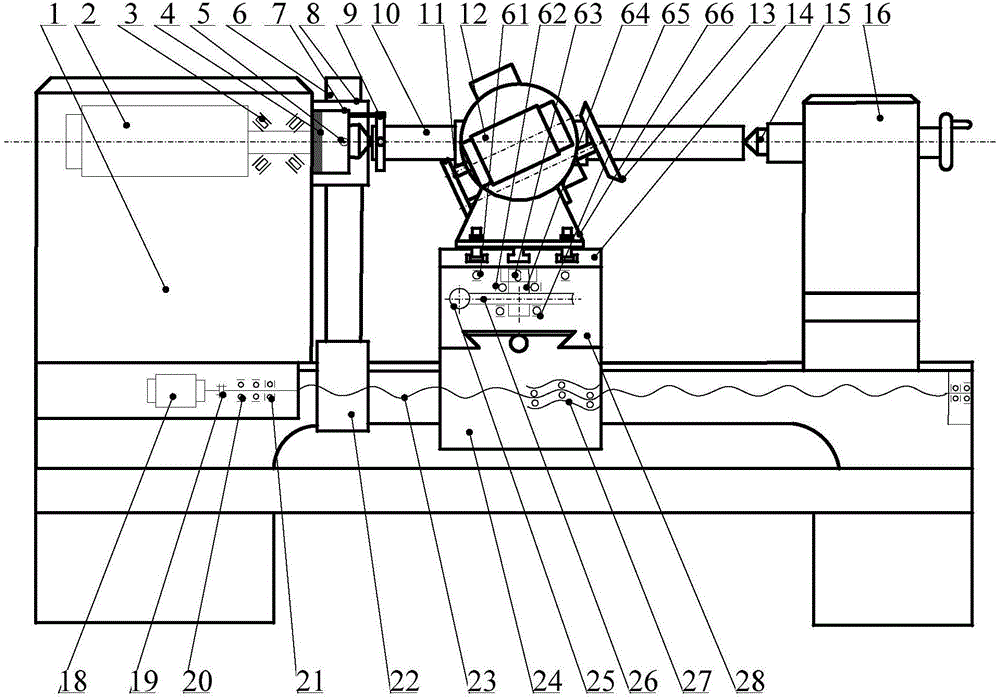

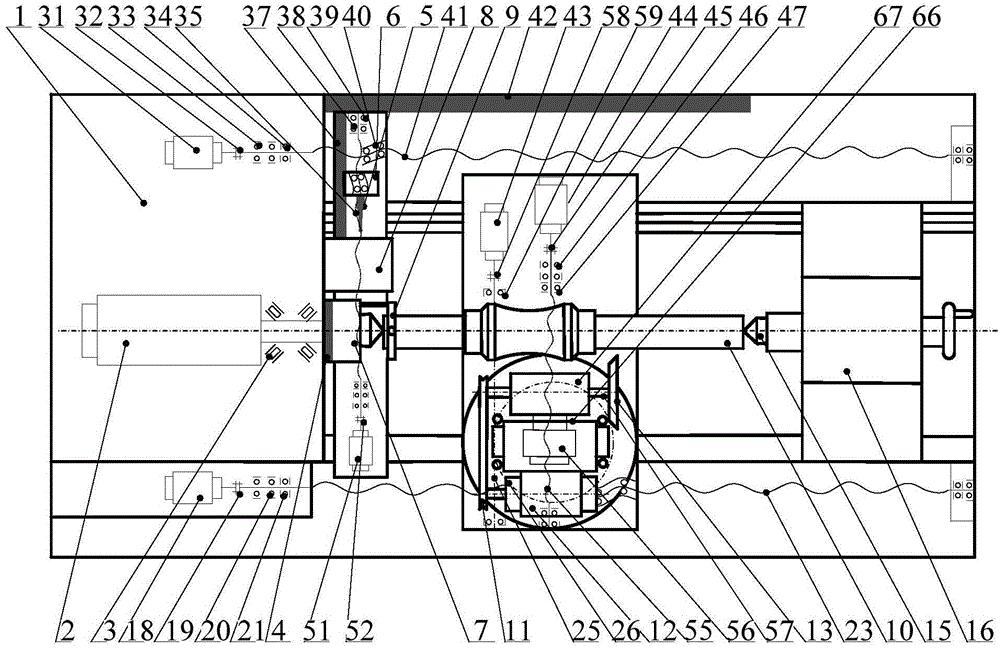

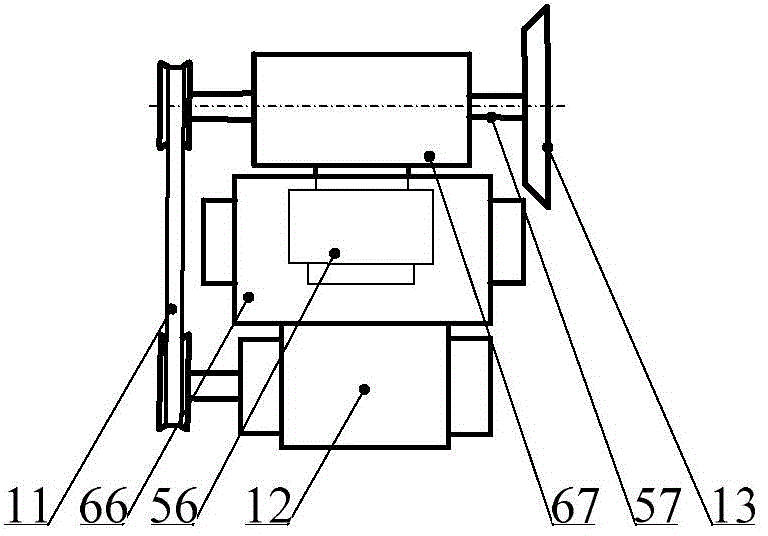

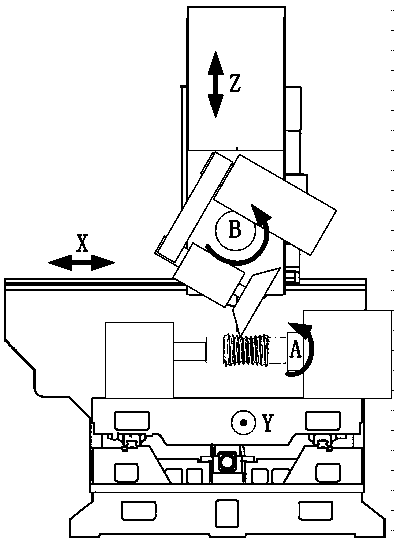

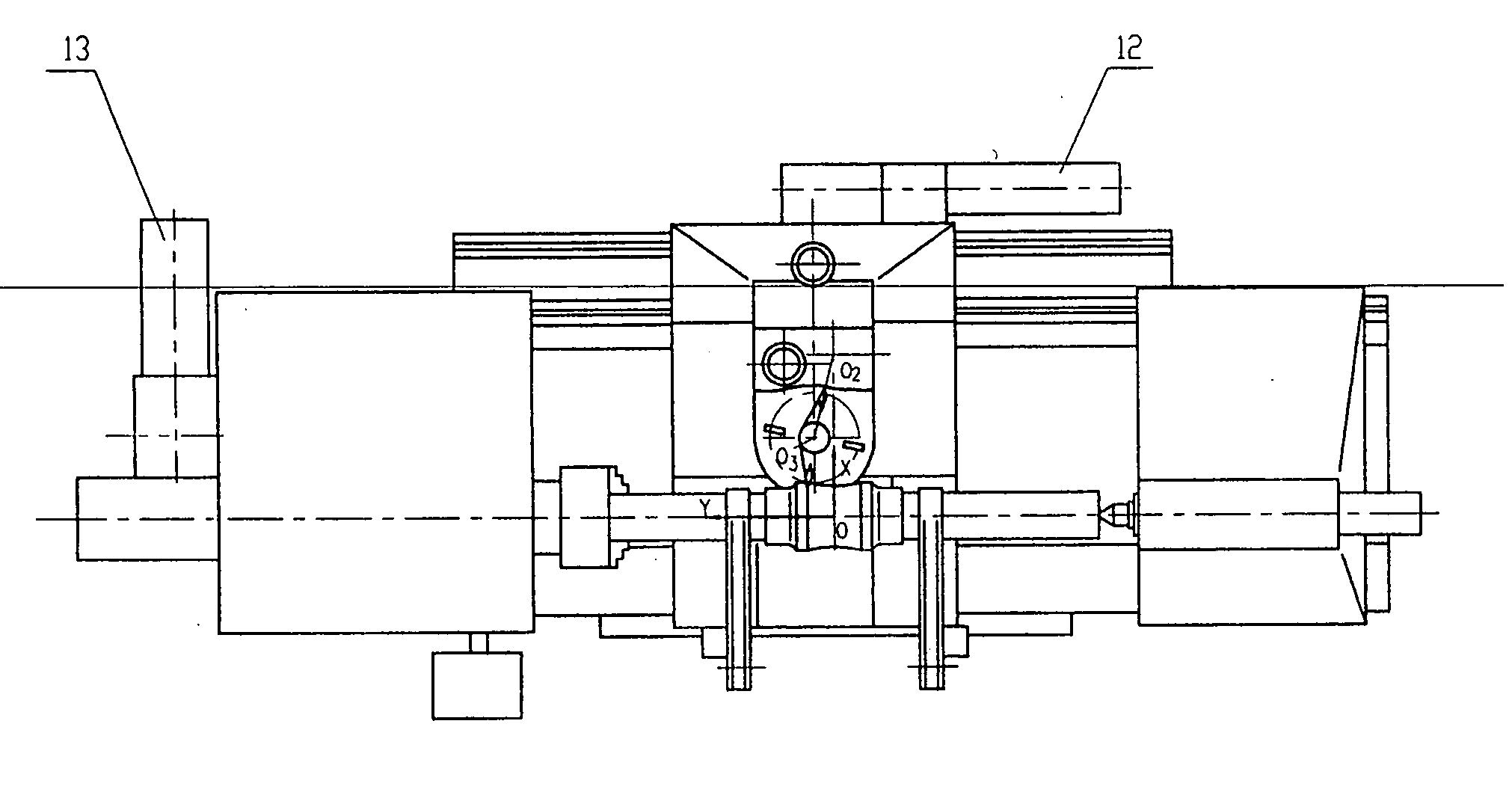

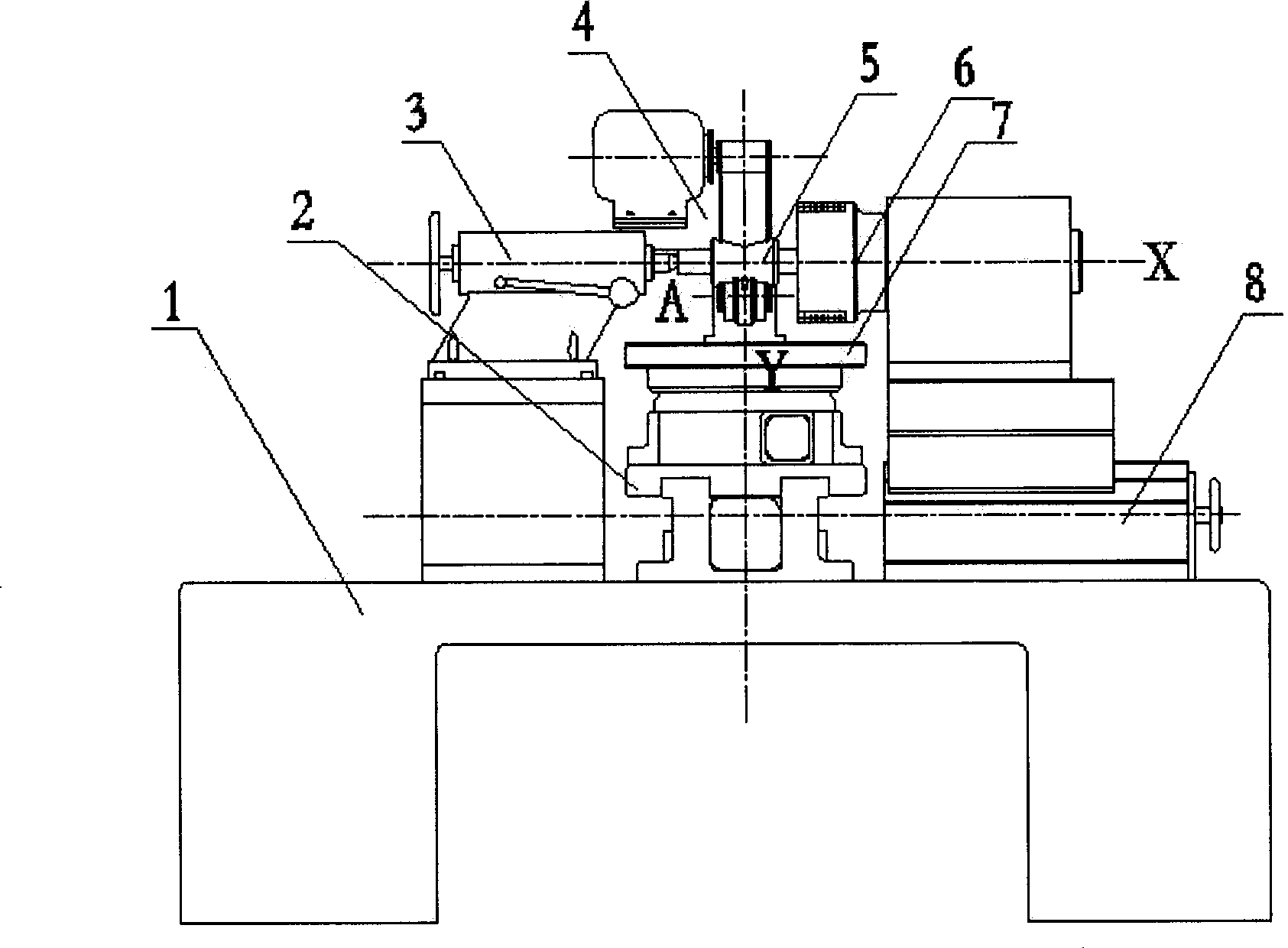

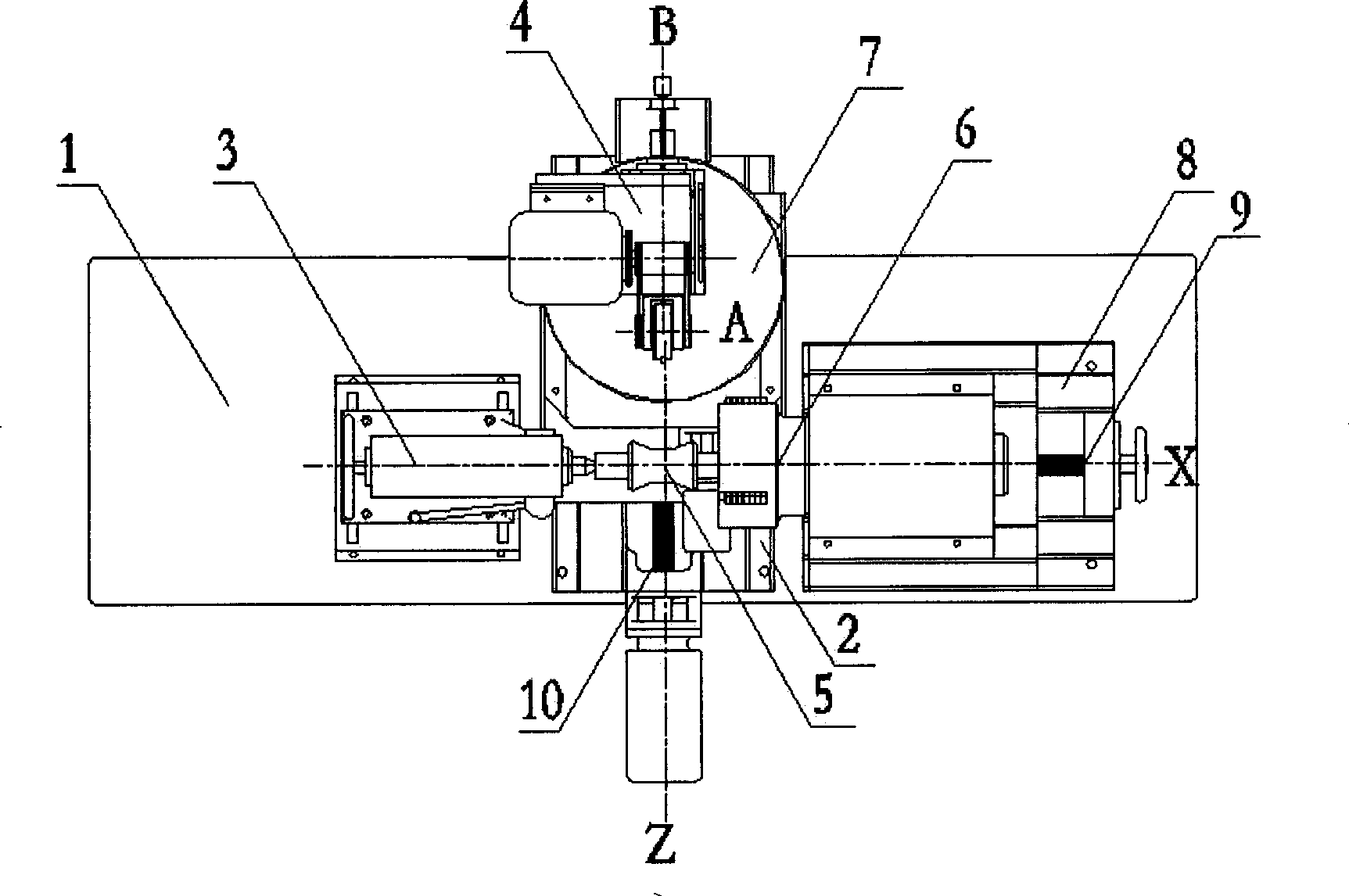

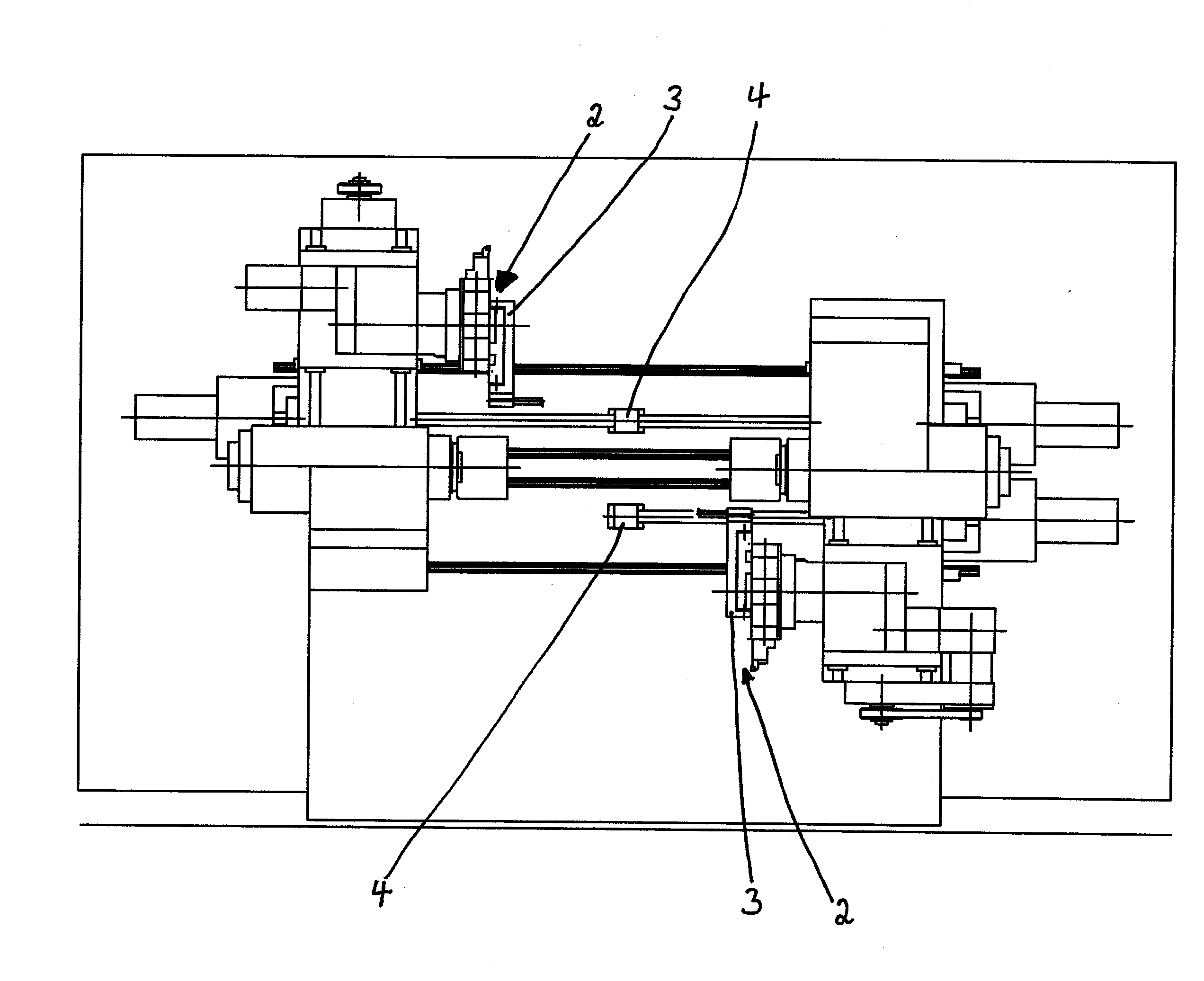

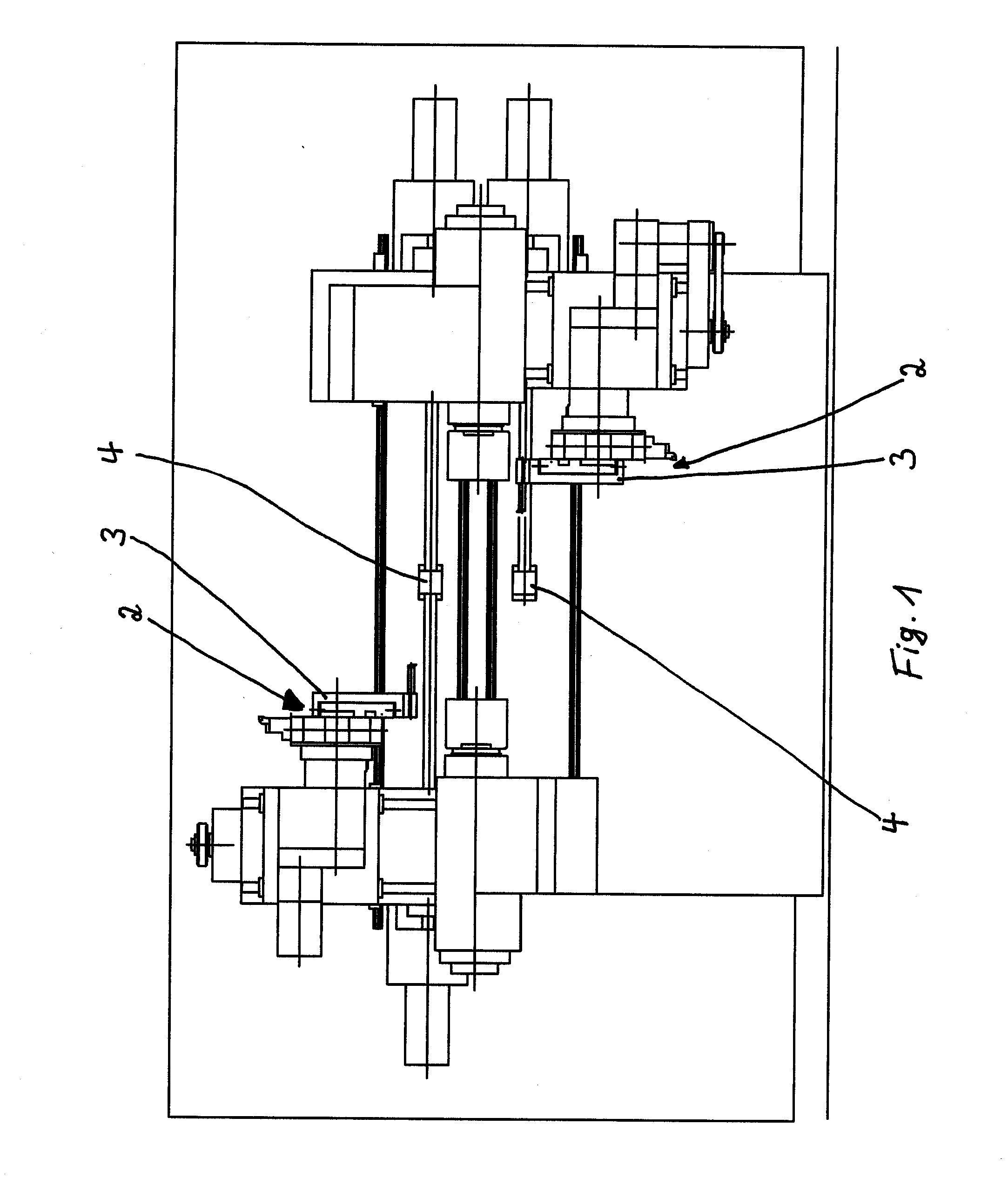

CNC (computerized numerical control) combined turning and grinding machine tool for four-linkage enveloping worms and processing method thereof

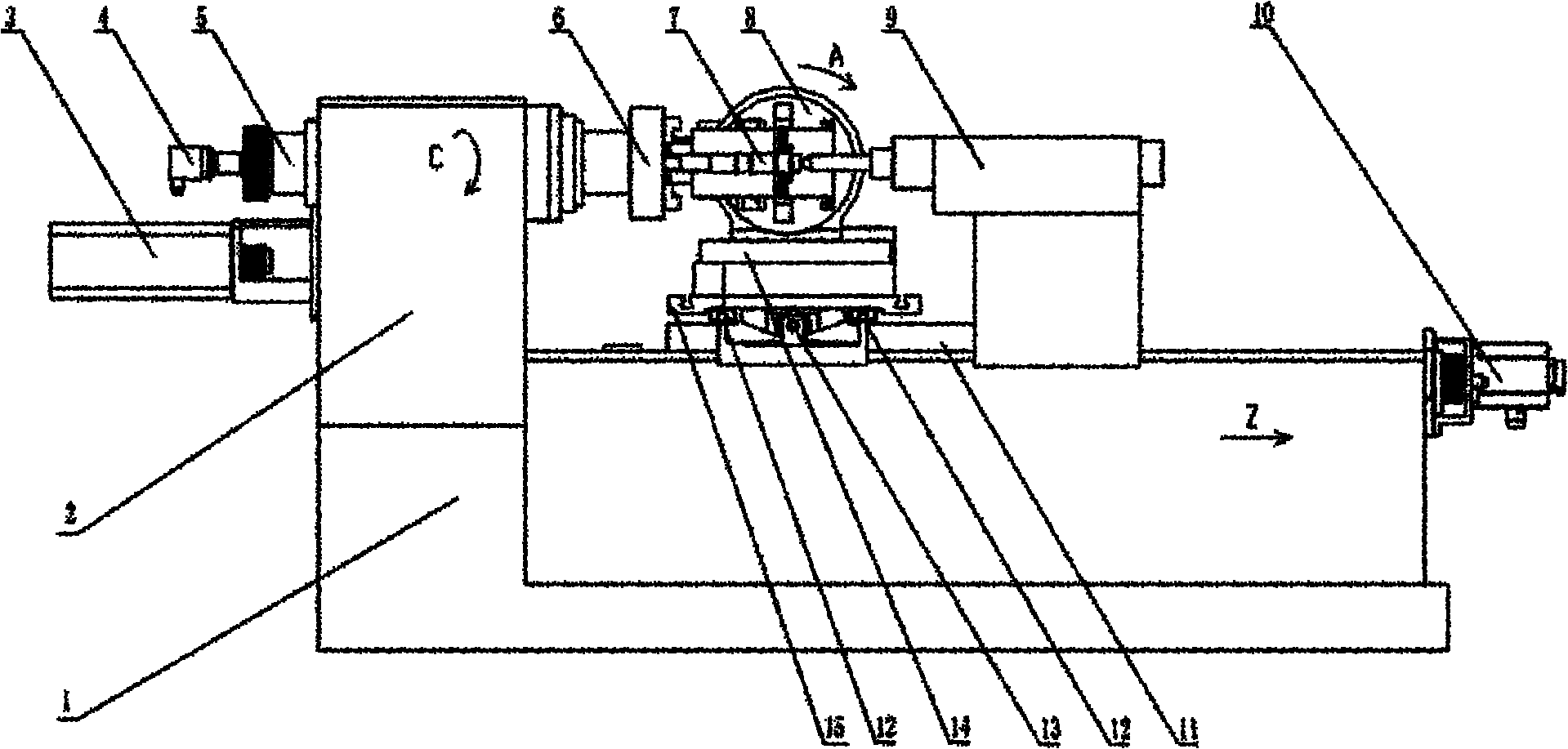

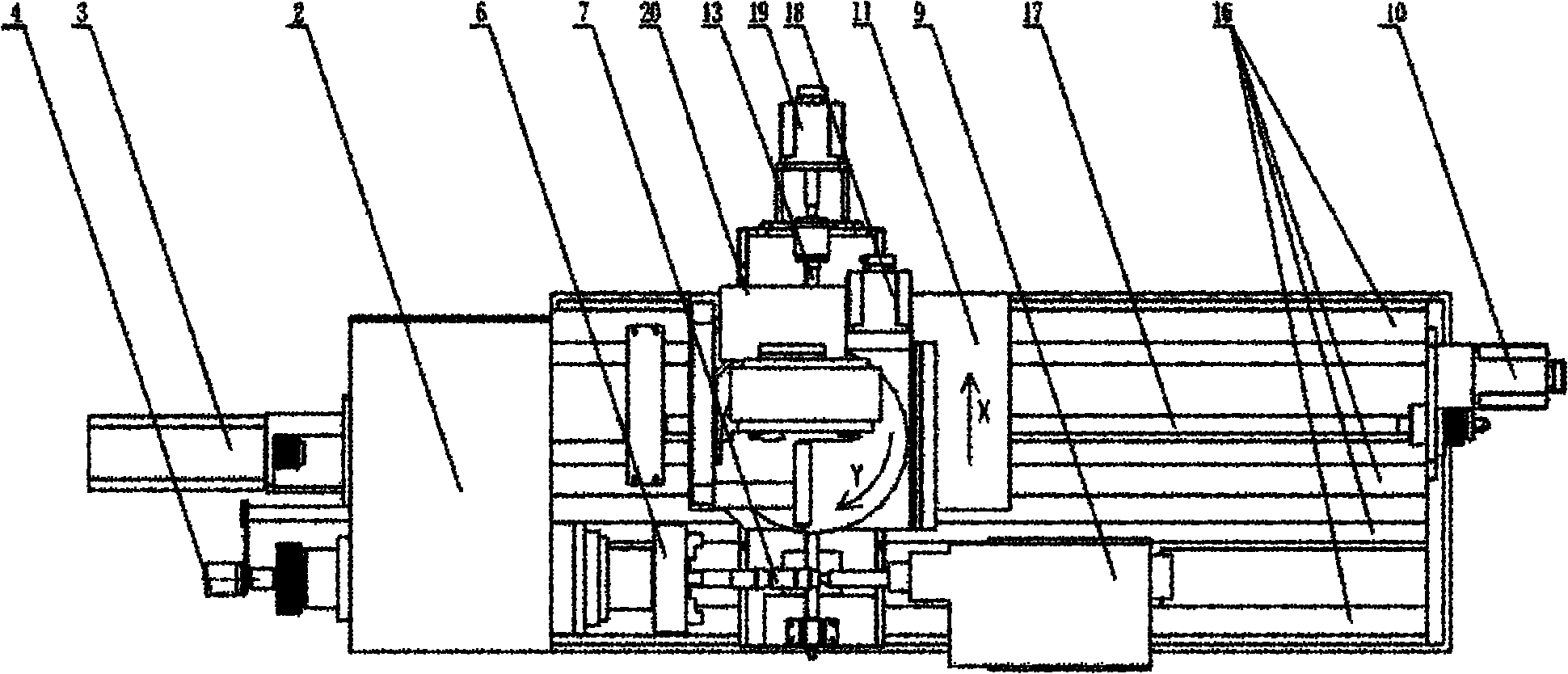

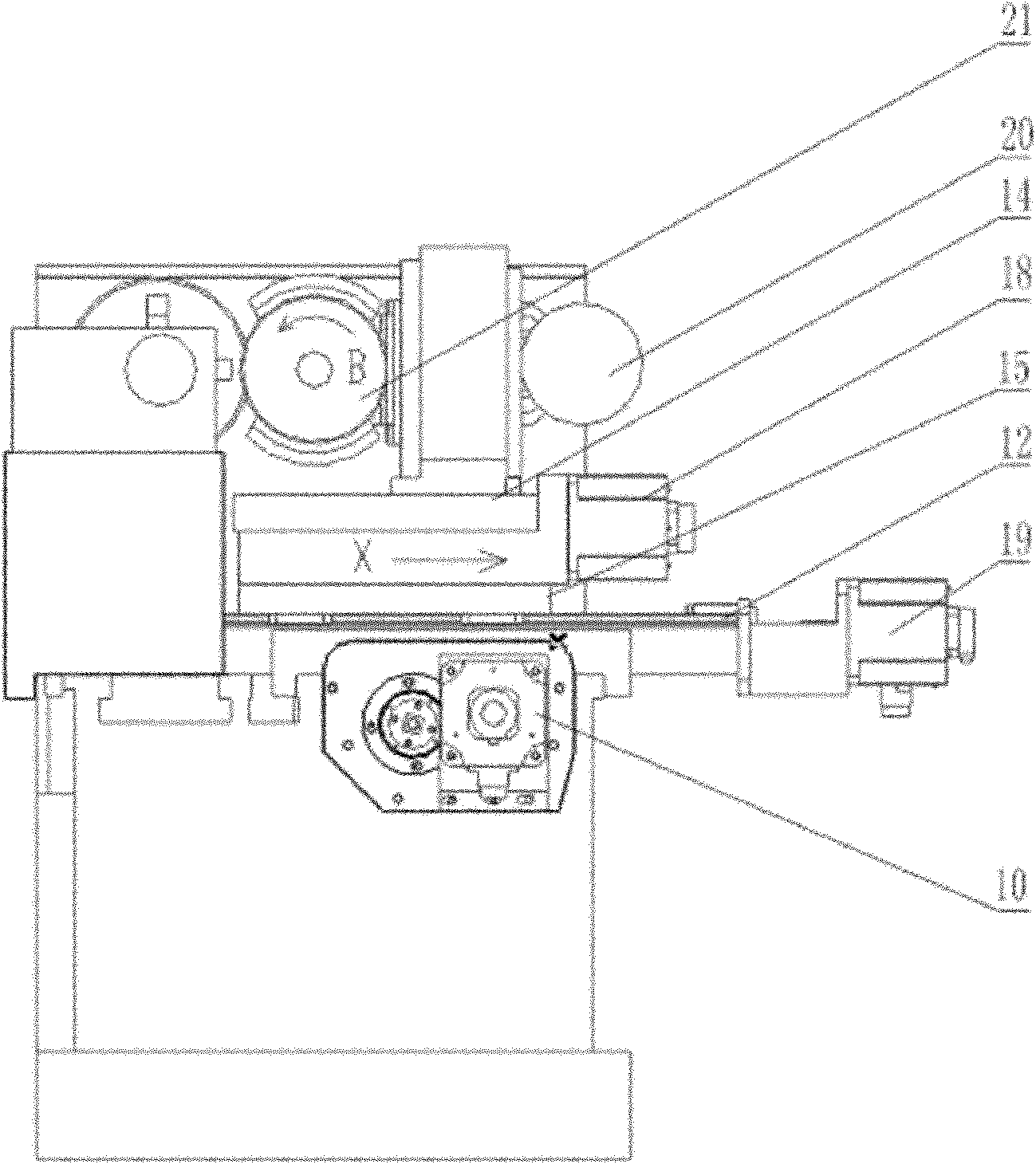

The invention relates to the technical field of machinery, specifically relates to a CNC (computerized numerical control) combined turning and grinding machine tool for four-linkage enveloping worms and a processing method thereof. The machine tool and processing method thereof provided by the invention are characterized in that a main shaft motor 3 drives a main shaft 5 and an enveloping worm 7 to rotate around a C-axis by a synchronous belt, a Z-axis servo motor 10 drives a ball screw 17 to lead a large support plate 11 to move along a Z-direction guide rail 16 by the synchronous belt, an X-axis servo motor 19 drives a ball screw 13 to lead a small support plate 15 to move along an X-direction guide rail 12 by a coupler, a Y-axis servo motor 18 drives a CNC rotary table 14 to rotate around a Y axis by gears, a CNC tool rest or grinding head is fixedly connected to the CNC rotary table, a grinding head motor 20 drives a grinding wheel 21 to rotate around a B-axis by the synchronous belt, and the grinding wheel and the motor synchronously rotate around an A-axis by turning a hand wheel. Compared with the prior art, the machine tool disclosed by the invention is simple and novel instructure, convenient and safe in operation, high in processing efficiency and wide in application range; and in addition, the machine tool can rotate at a high speed, and the operations of turning and grinding are completed on a same machine tool, therefore, the machine tool is complete in function, high in reliability, strong in environment adaptivity, and more accurate in transmission precision and machining precision.

Owner:上海合纵重工机械有限公司

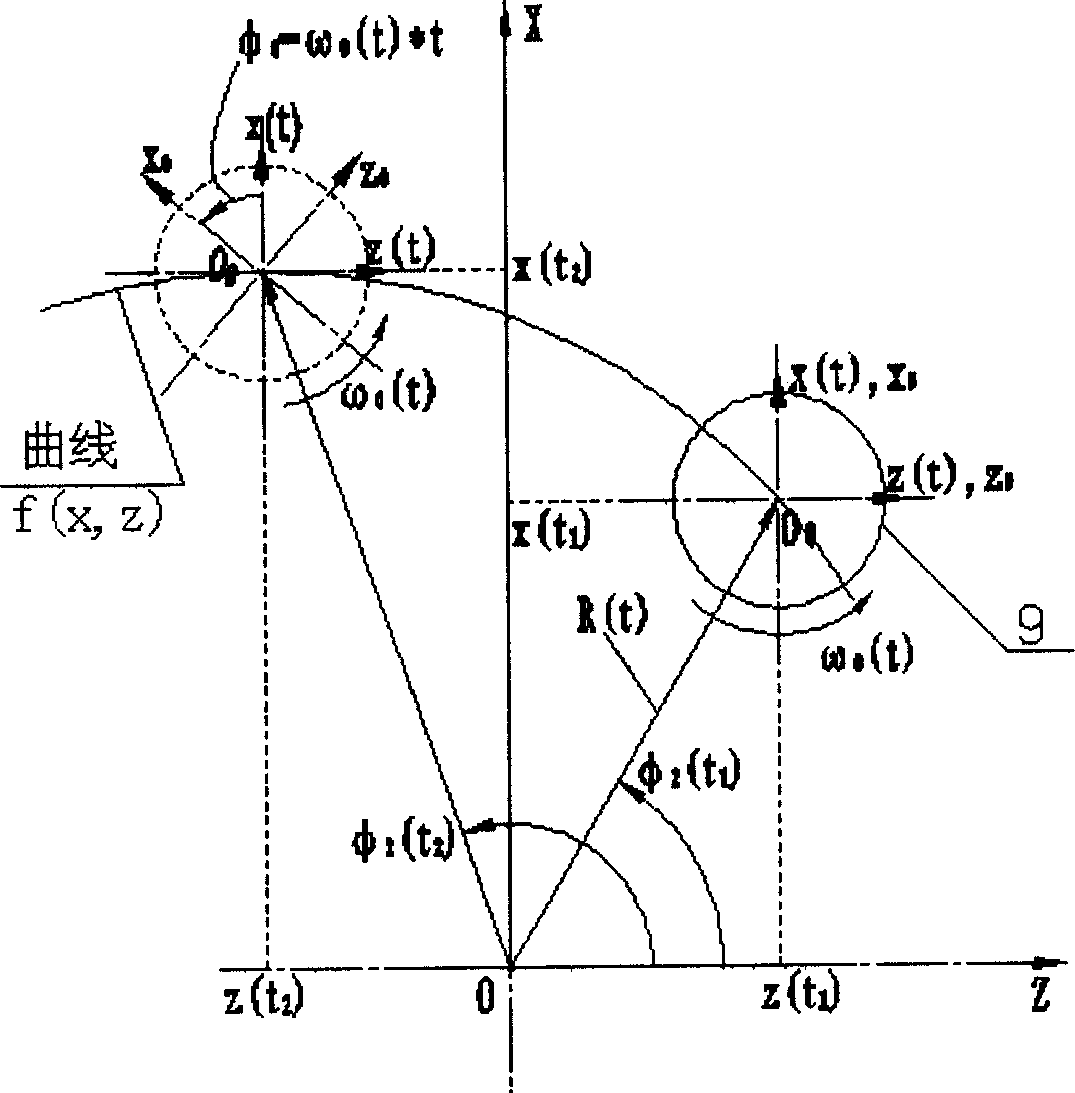

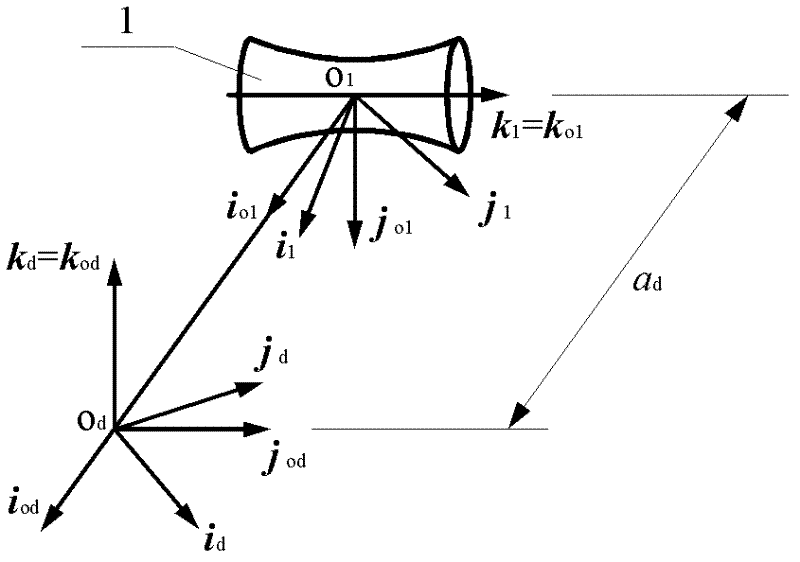

Toroid worm numerical control machine capable of making up center distance

The invention relates to an annular worm digit-control machine which can simulate central distance, wherein it comprises four coupled coordinate motions that the main axle has a rotation A around its axle (parallel to Z); the work bench has the translate motions X, Z which are vertical and in horizontal plane, and the tool bench has the rotation Y around its axle 00 (vertical to the XZ plane); the work bench rotates with the transmission ratio i=A / Y with the main axle, and couples with X, Z, and rotates around the simulated round center (the round center of annular worm) to use the machine with small central distance to process the concave and convex annular worms with large central distance, with low cost and compact structure.

Owner:CHONGQING UNIV

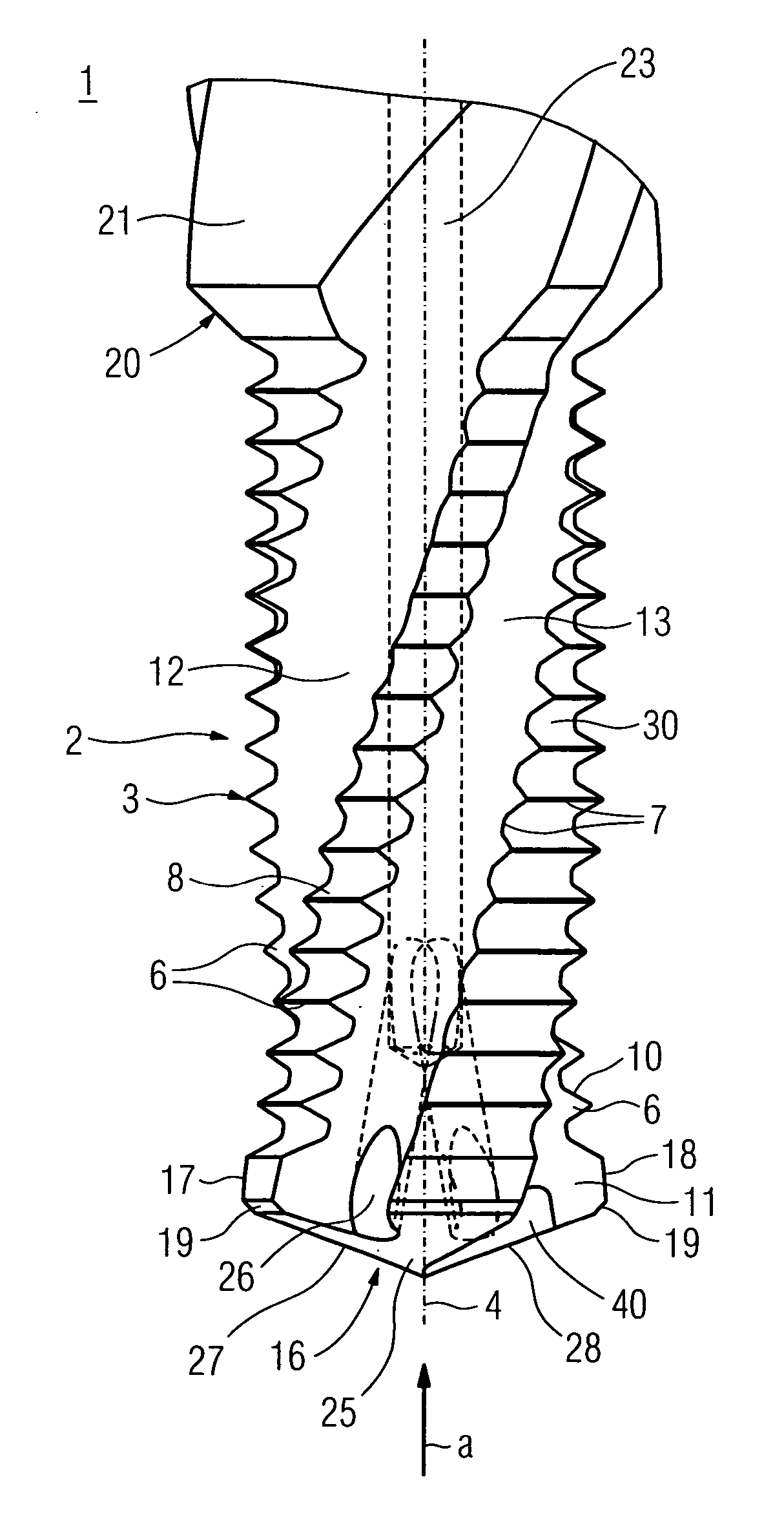

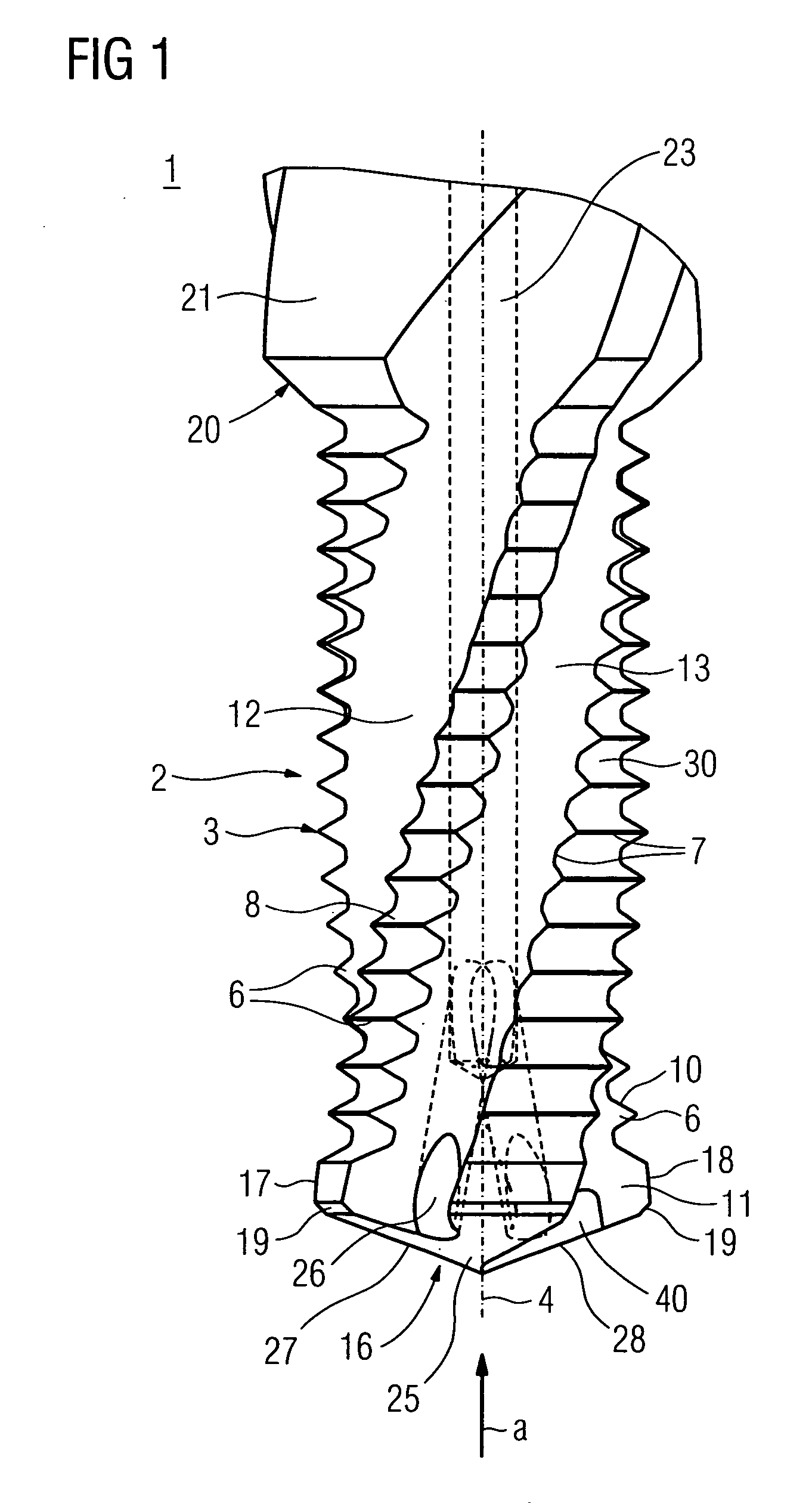

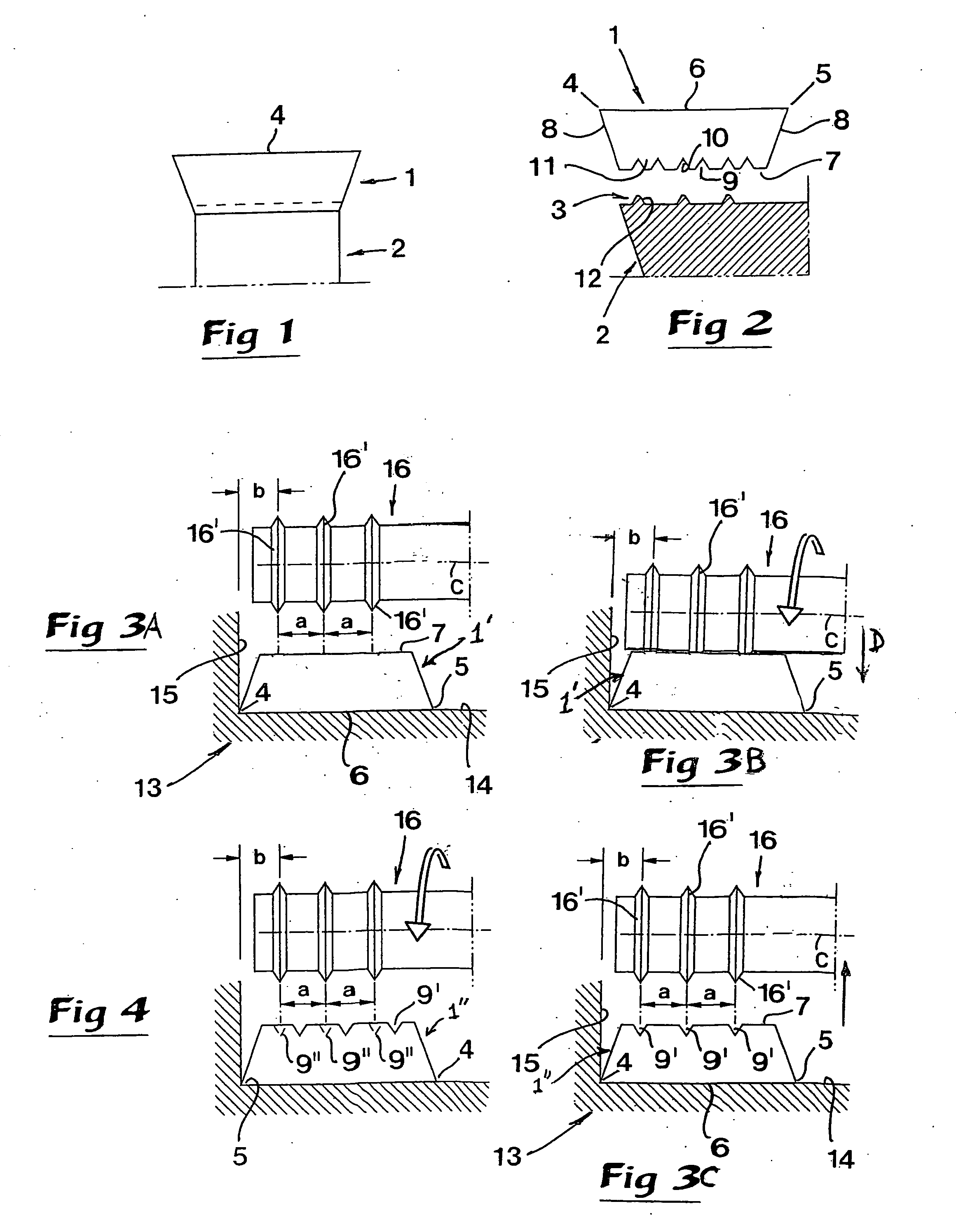

Drill thread milling cutter

InactiveUS20060216125A1Improve cutting effectGood chip breaking effectThread cutting toolsWood turning toolsMilling cutterEngineering

The invention relates to a drill thread milling cutter (1) for producing a bore and for the subsequent milling of a thread in the bore, said drill thread milling cutter (1) having a working region (2), on the circumference (3) of which a number of drilling and milling cutting edges are arranged. A number of milling cutting edges (7, 8, 9, 10) greater than the number of drilling cutting edges (17) by a factor greater than 2 are arranged or are effective in the direction of rotation.

Owner:EMUGE WERK RICHARD GLIMPEL & FAB FUR PRAZISIONSWERKZEUGE

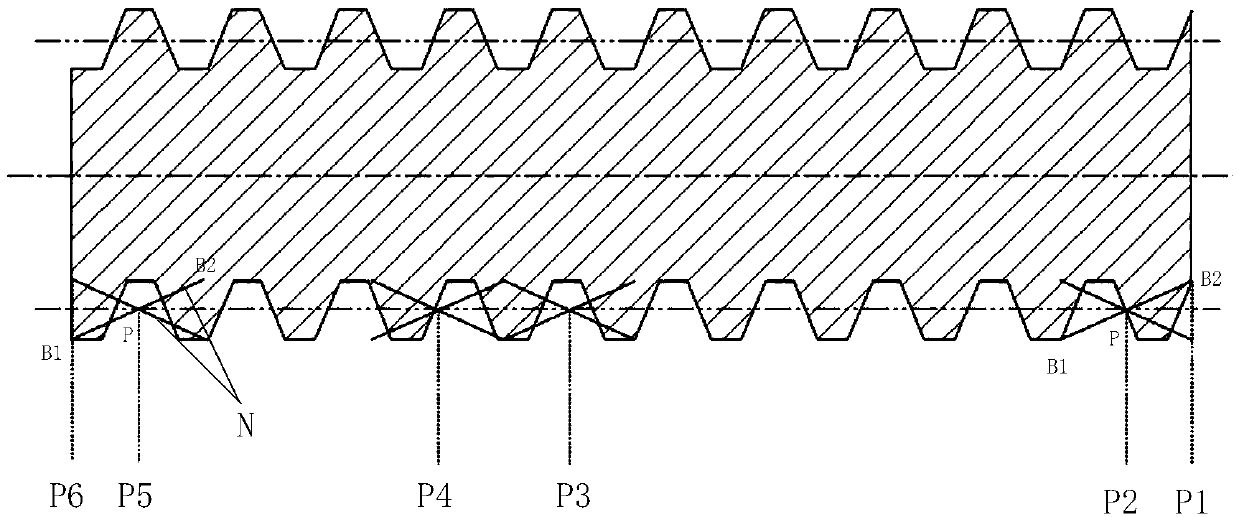

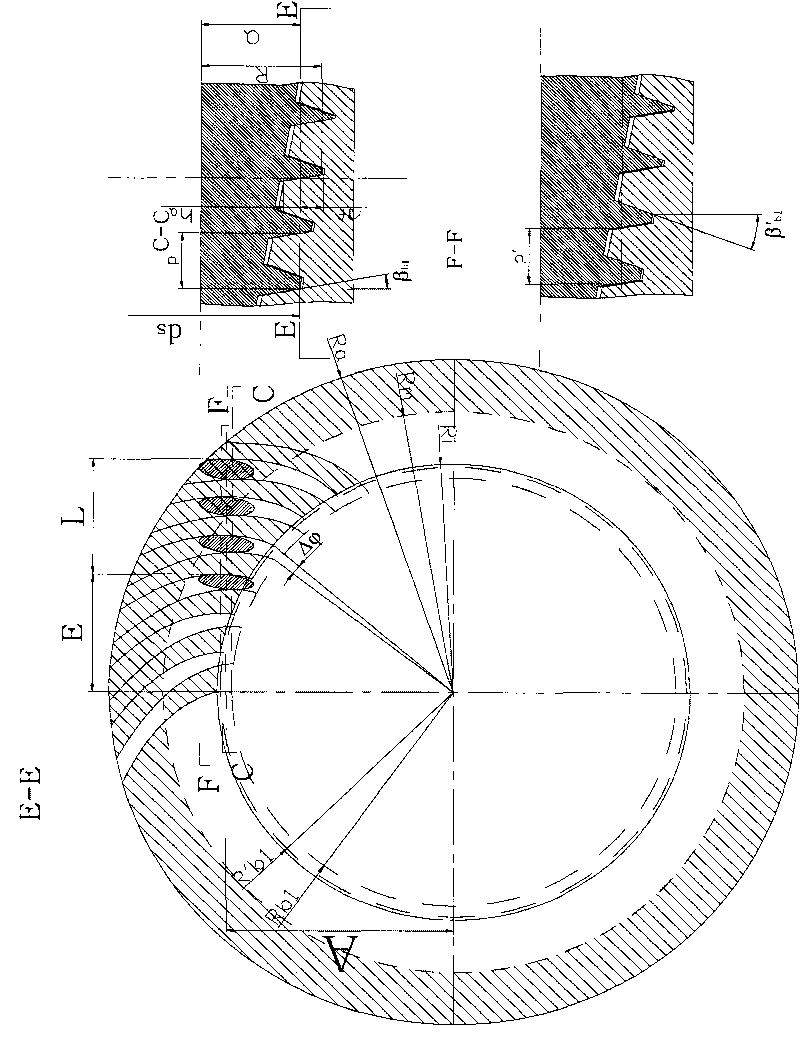

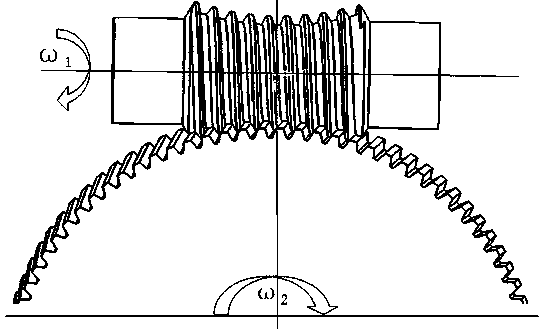

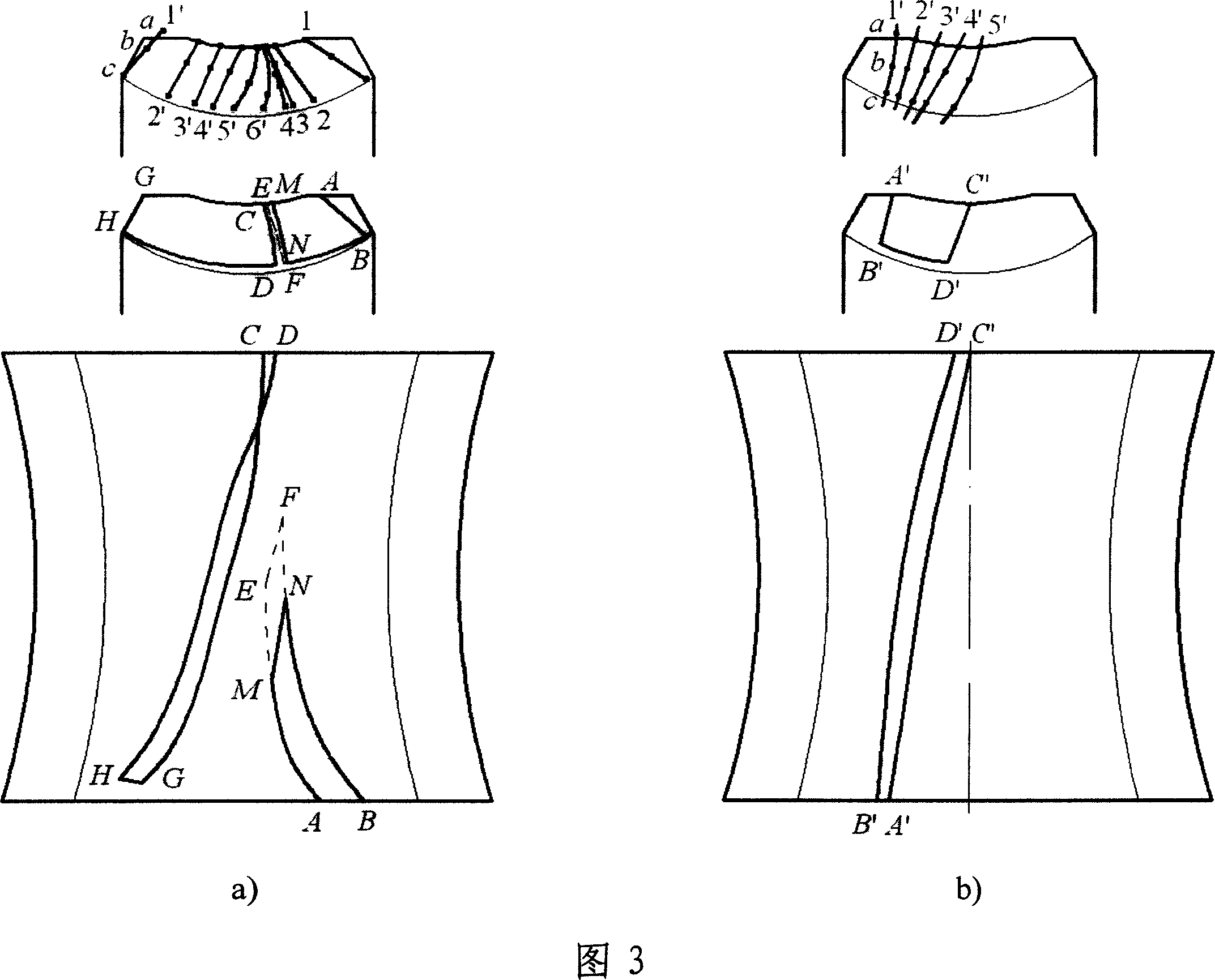

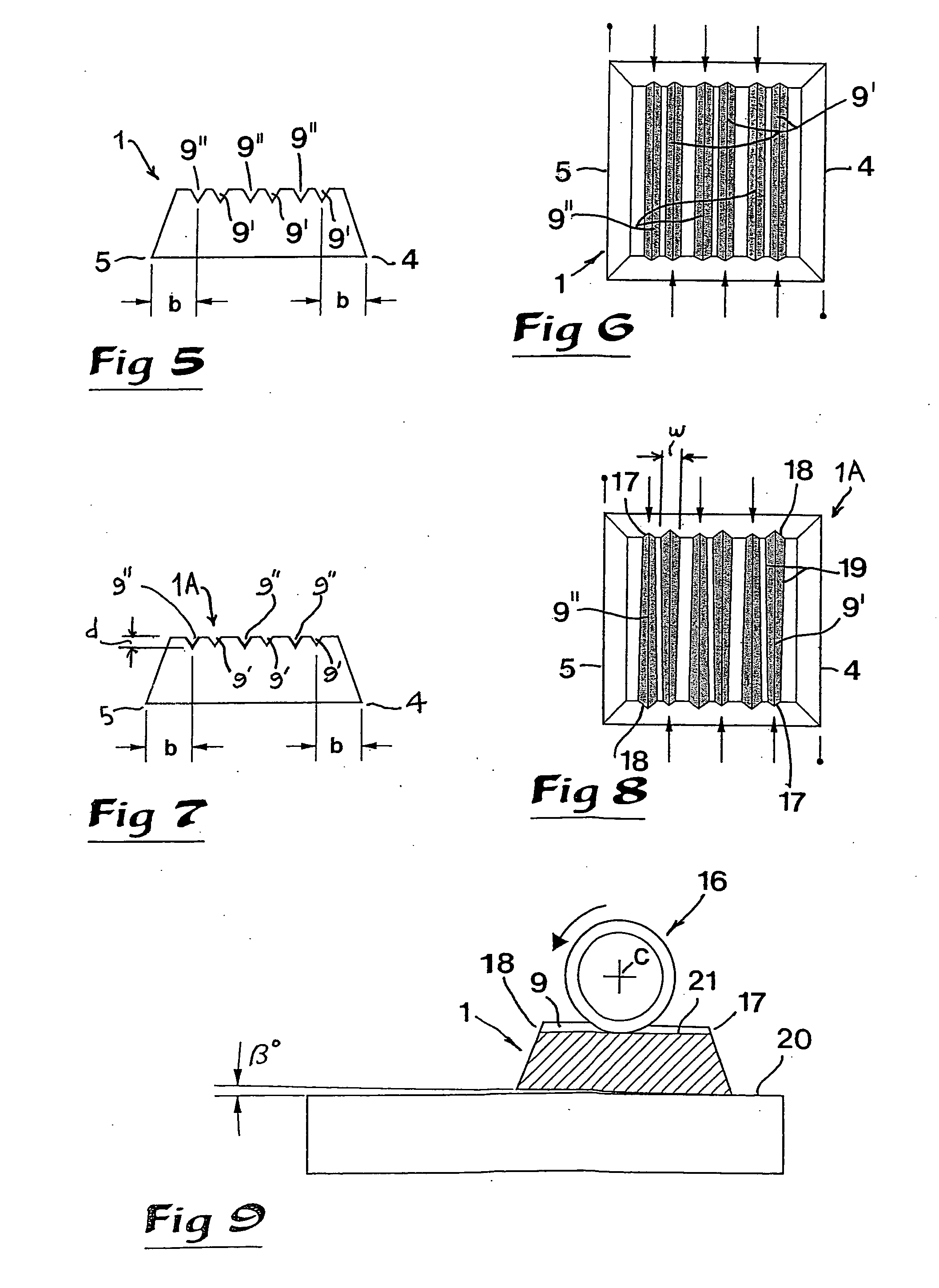

Double-sided precision grinding method and equipment for enveloping toroidal worm tooth surface

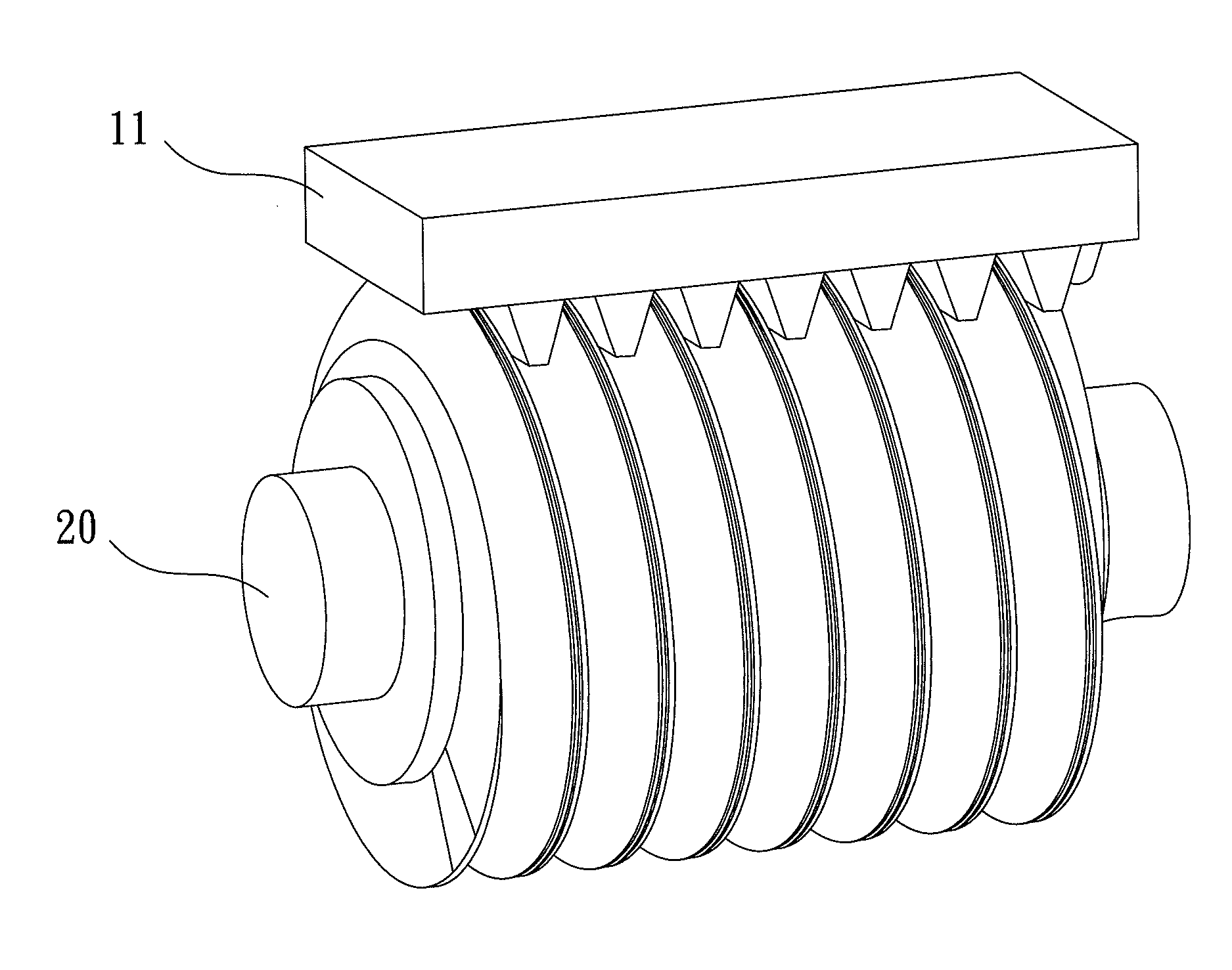

InactiveCN102275016ARealize round grindingImprove machining accuracyCopying process control systemsWormsDrive wheelProcessing accuracy

The invention relates to a processing method of mechanical grinding or polishing and equipment thereof, in particular to a method for grinding and polishing the toothed surface of a toroid enveloping worm with a sanding belt or a polishing belt as a tool, and equipment thereof. The method realizes double-side grinding processing of the toothed surface of the toroid enveloping worm in terms of theenvelope generating grinding principle by a form copying method. The equipment for realizing the grinding of the toothed surface of the toroid enveloping worm by the method is composed of the sandingbelt or a polishing belt, a driving wheel and a compression module, wherein the sanding belt or the polishing belt is driven by the driving wheel and moves around the compression module correspondingto the ground toothed surface of the toroid enveloping worm to form continuous grinding main movement; and the relative movement relationship between the toroid enveloping worm and the grinding head of the sanding belt is adaptive to the type of the worm to be processed. Compared with the prior art, the method of the invention has the advantages of realizing double-side grinding, effectively controlling the tooth thickness of the worm, accurately relief-grinding the hob rear angle of the worm, and performing grinding at high efficiency, etc.; therefore, the method is an effective method for improving the processing accuracy and grinding efficiency of the toroid enveloping worm.

Owner:CHONGQING UNIV

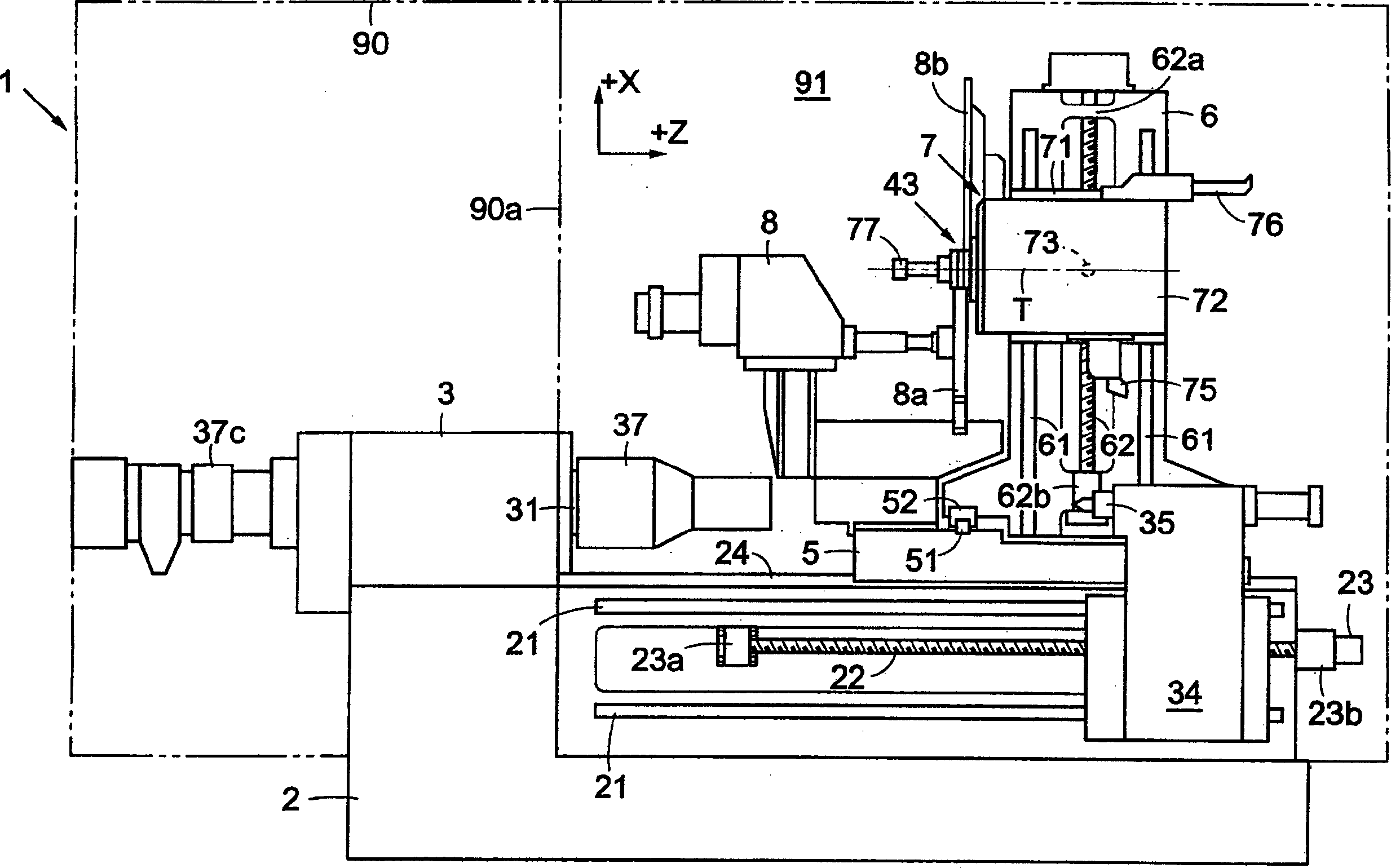

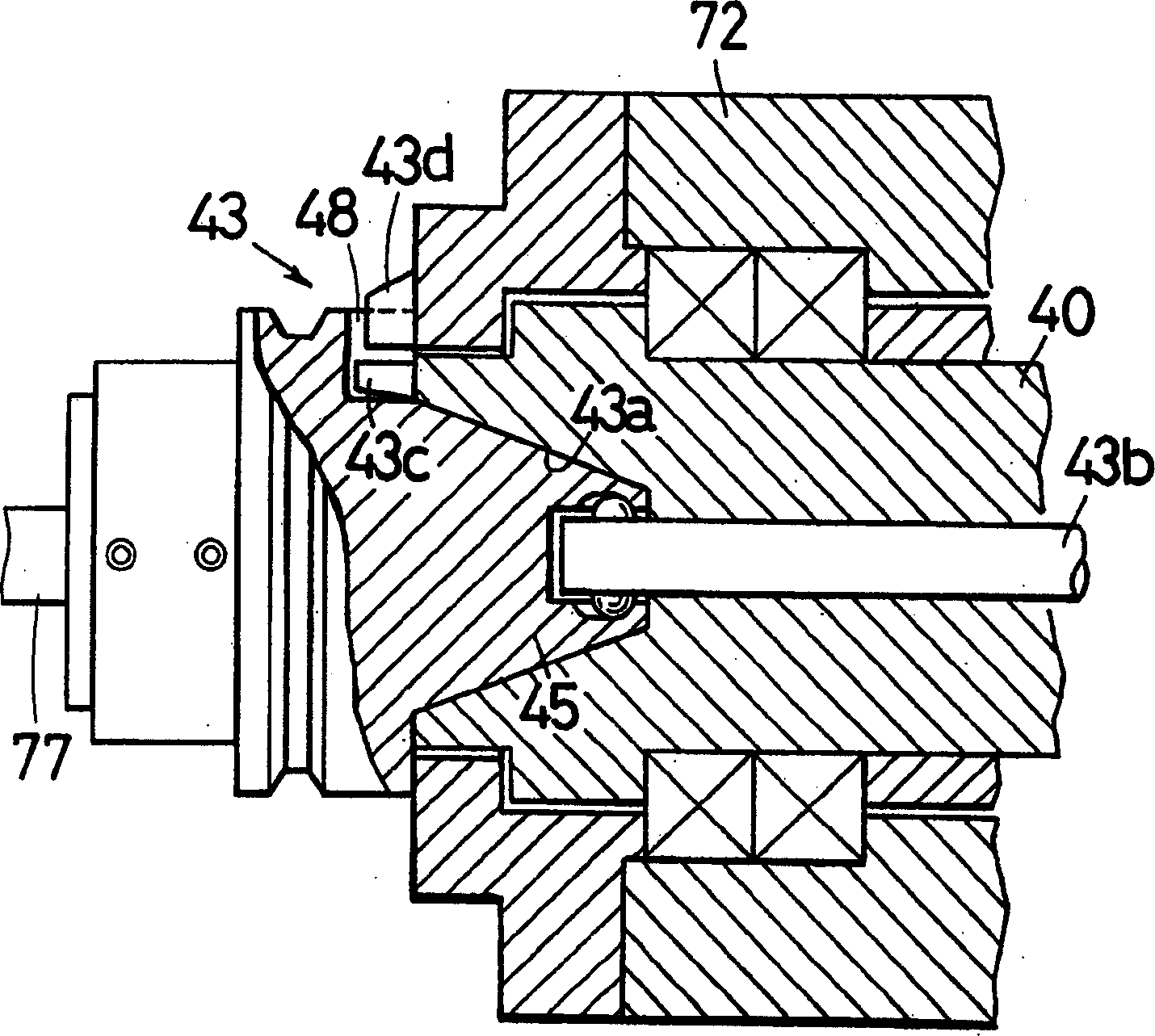

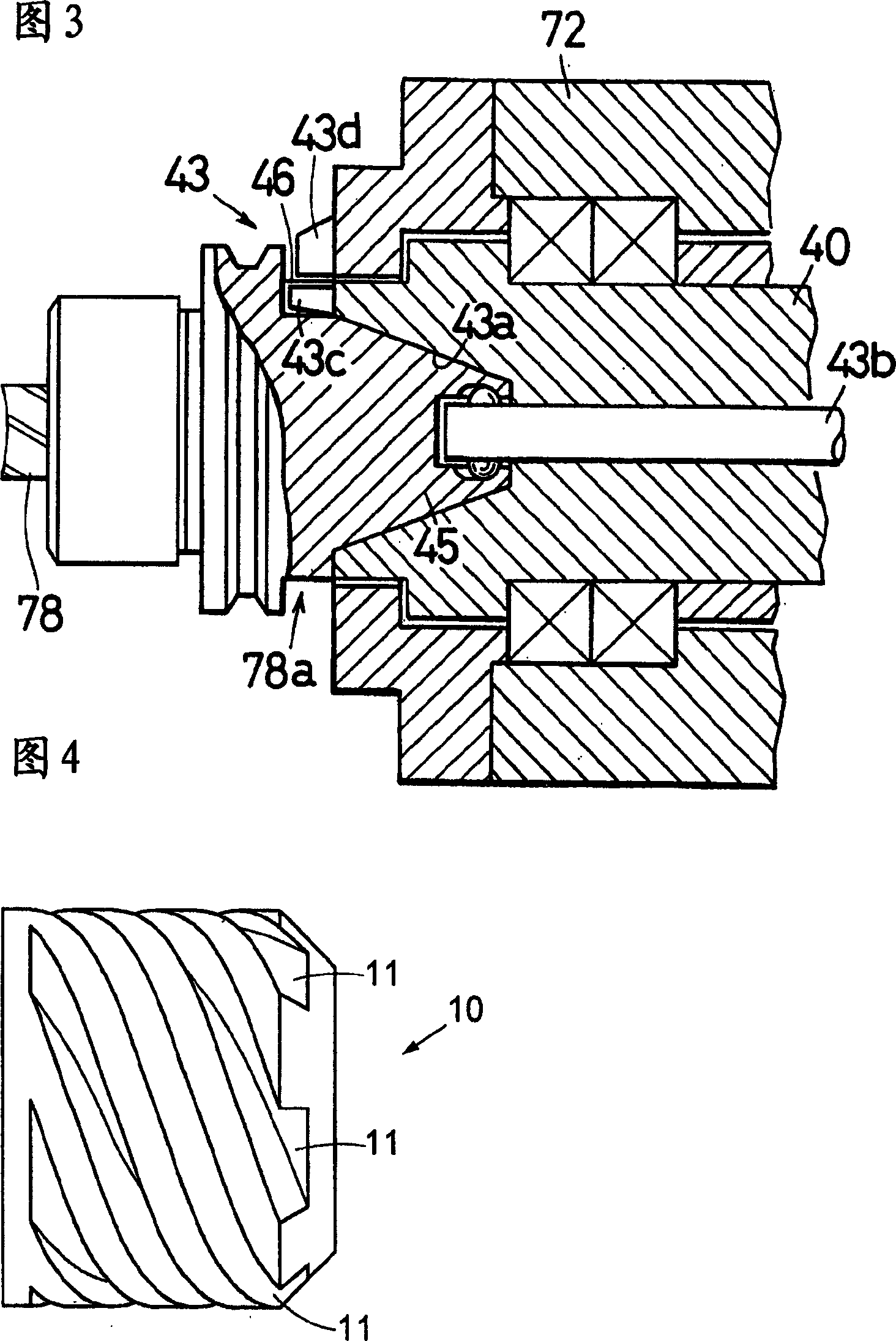

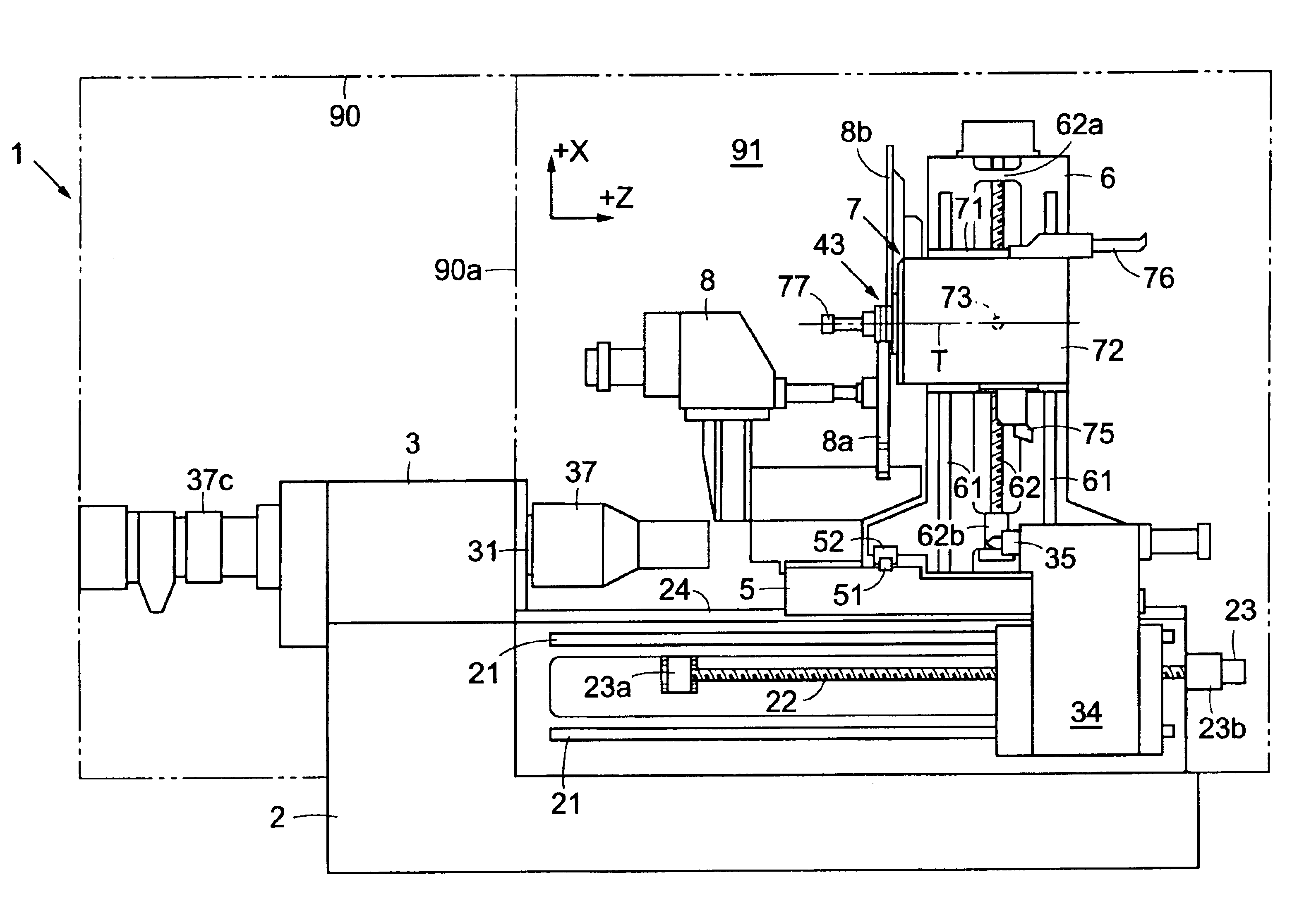

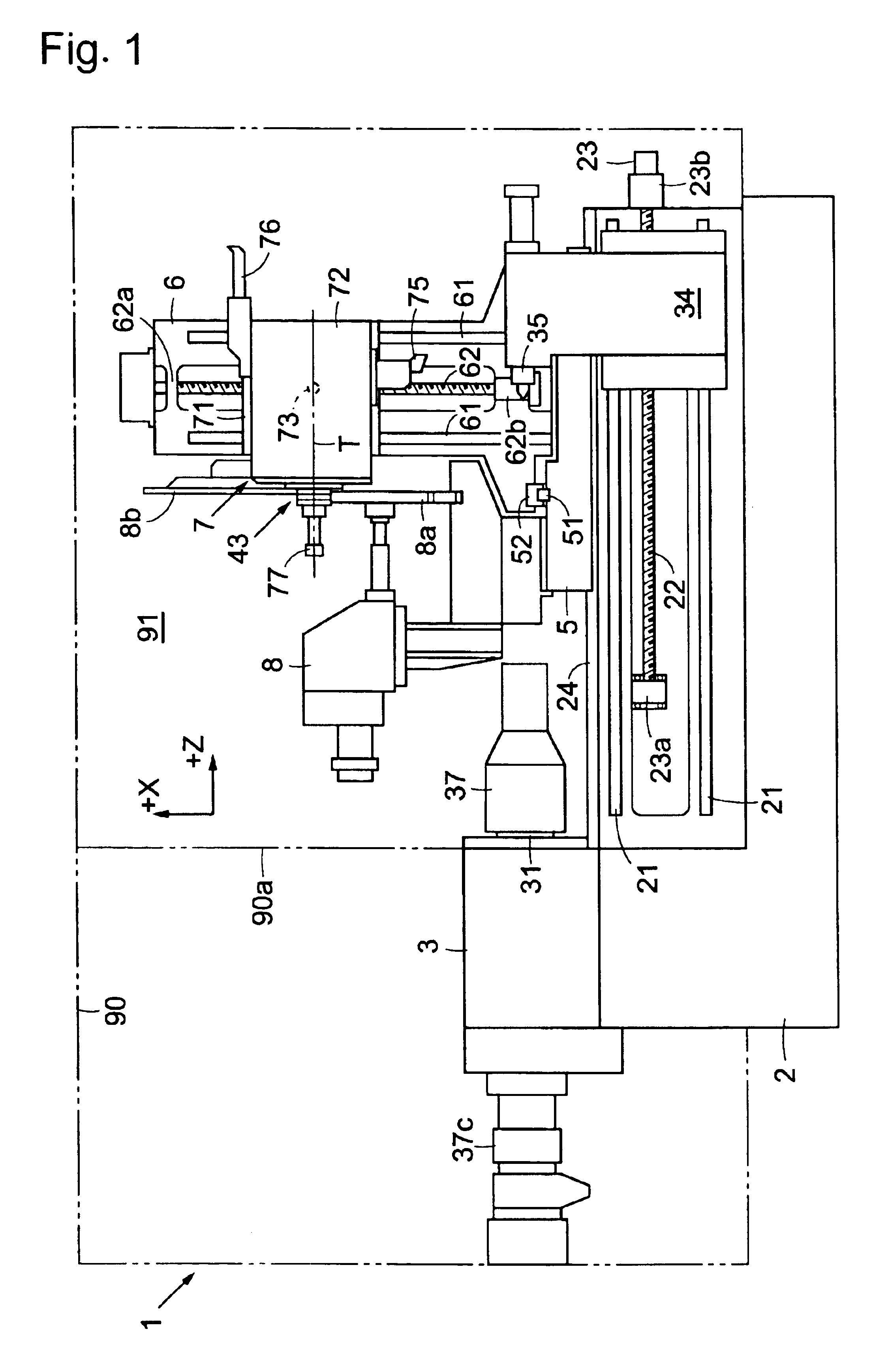

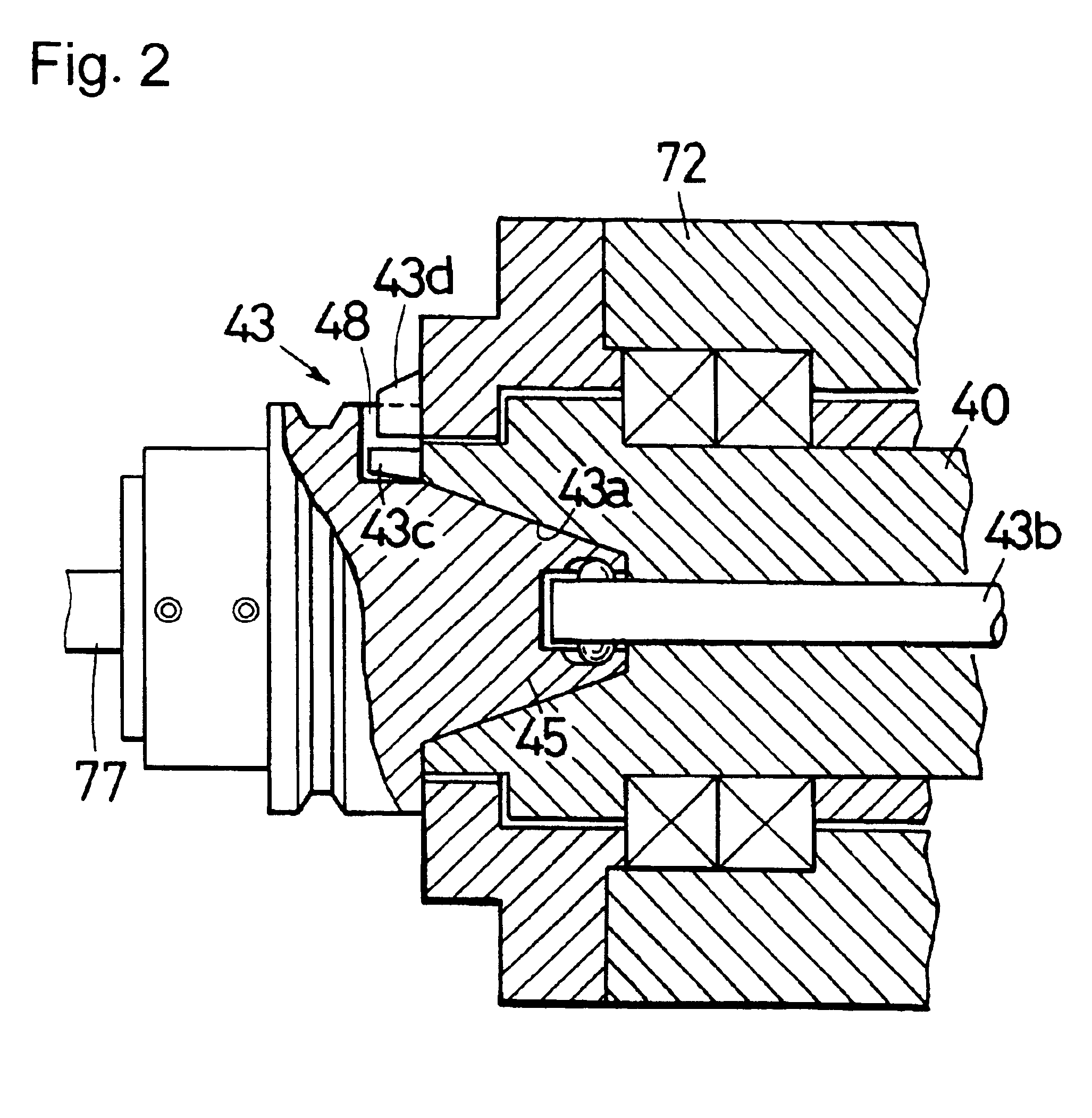

Composite working machine tool and working method in composite working machine tool

InactiveCN1491765ATool changing apparatusOther manufacturing equipments/toolsRelative motionMachine tool

The multi-function machine tool of the present invention has a tool rest main body which is disposed movably relative to the main spindle of the machine tool in a first linear direction parallel to the axial line of the main spindle and a second linear direction perpendicular to the axial line of the main spindle, a turning tool rest 72 which is disposed so that this turning tool rest can turn relative to the tool rest main body about a turning axis 73 oriented in a direction that is perpendicular to the first and second linear directions, and control means which control the rotational motion of the main spindle, the turning motion of the turning tool rest about the turning axis, and the relative motion of the tool rest main body. Furthermore, the control means can cause the turning tool rest to perform a turning motion about an arbitrary position that differs from the position of the turning axis by concurrently and synchronously causing a turning motion of the turning tool rest about the turning axis, and a circular-arc motion based on the relative motion of the tool rest main body in the first linear direction and second linear direction.

Owner:MORI SEIKI HITECH

Multi-function machine tool and machining method in multi-function machine tool

InactiveUS6868304B2Tool changing apparatusOther manufacturing equipments/toolsEngineeringRelative motion

The multi-function machine tool of the present invention has a tool rest main body which is disposed movably relative to the main spindle of the machine tool in a first linear direction parallel to the axial line of the main spindle and a second linear direction perpendicular to the axial line of the main spindle, a turning tool rest 72 which is disposed so that this turning tool rest can turn relative to the tool rest main body about a turning axis 73 oriented in a direction that is perpendicular to the first and second linear directions, and control means which control the rotational motion of the main spindle, the turning motion of the turning tool rest about the turning axis, and the relative motion of the tool rest main body. Furthermore, the control means can cause the turning tool rest to perform a turning motion about an arbitrary position that differs from the position of the turning axis by concurrently and synchronously causing a turning motion of the turning tool rest about the turning axis, and a circular-arc motion based on the relative motion of the tool rest main body in the first linear direction and second linear direction.

Owner:MORI SEIKI HITECH

Worm grinding wheel gear grinding surface distortion compensation method

ActiveCN104942380ACompensate distortion errorAbrasive surface conditioning devicesGear teeth manufacturing toolsGear grindingGear wheel

The invention belongs to the field of gear manufacturing, and relates to a worm grinding wheel gear grinding surface distortion compensation method which solves the problem of tooth surface distortion of a bevel wheel gear with axial modification in the grinding process. According to the worm grinding wheel gear grinding surface distortion compensation method, dressing movement is different from a standard worm grinding wheel dressing process, deflection movement of a diamond rolling wheel is needed, and axial screw lead and a spiral angle of the grinding wheel are changed. The method comprises the steps that firstly, according to the wheel gear grinding technology, the worm grinding wheel is divided into a coarse grinding zone, a fine grinding zone and a middle transition zone in the width direction, the diagonal grinding principle is utilized, and appropriate diagonal ratio is selected to make a strict mapping relation exist between the section in the width direction of the wheel gear and the section in the width direction of the worm grinding wheel; secondly, according to distortion amounts of the left tooth surface and the right tooth surface of each section of the wheel gear to be machined, distortion compensation of each tooth surface is achieved by utilizing two methods of combining a deflecting rolling wheel and changing the axial screw lead of the grinding wheel. Due to the fact that excursion exists in the deflection center of the diamond rolling wheel, when deflection exists on the rolling wheel, calculation and compensation need to be conducted on the position variation quantity of a tooth profile of the rolling wheel.

Owner:CHONGQING UNIV

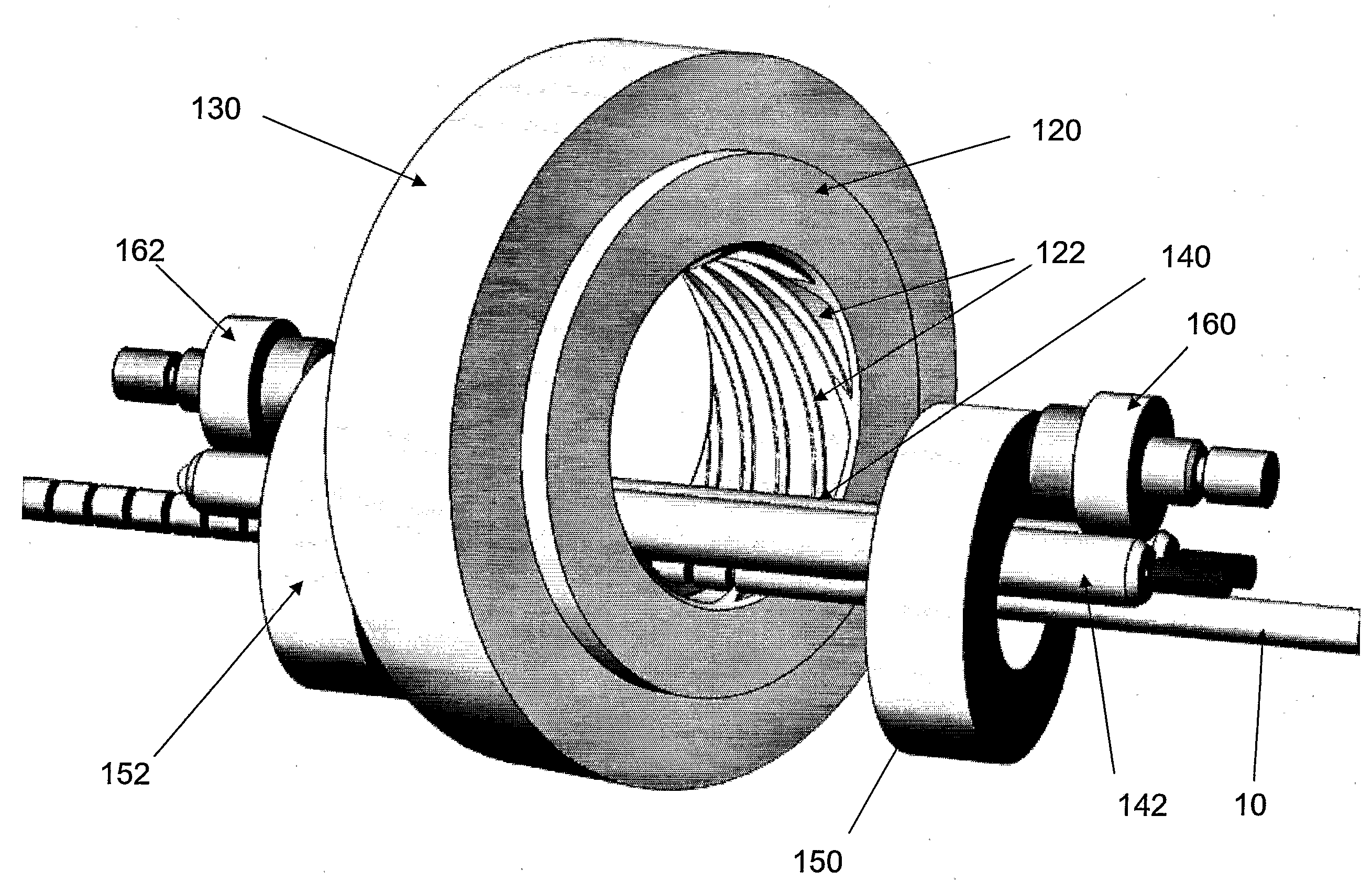

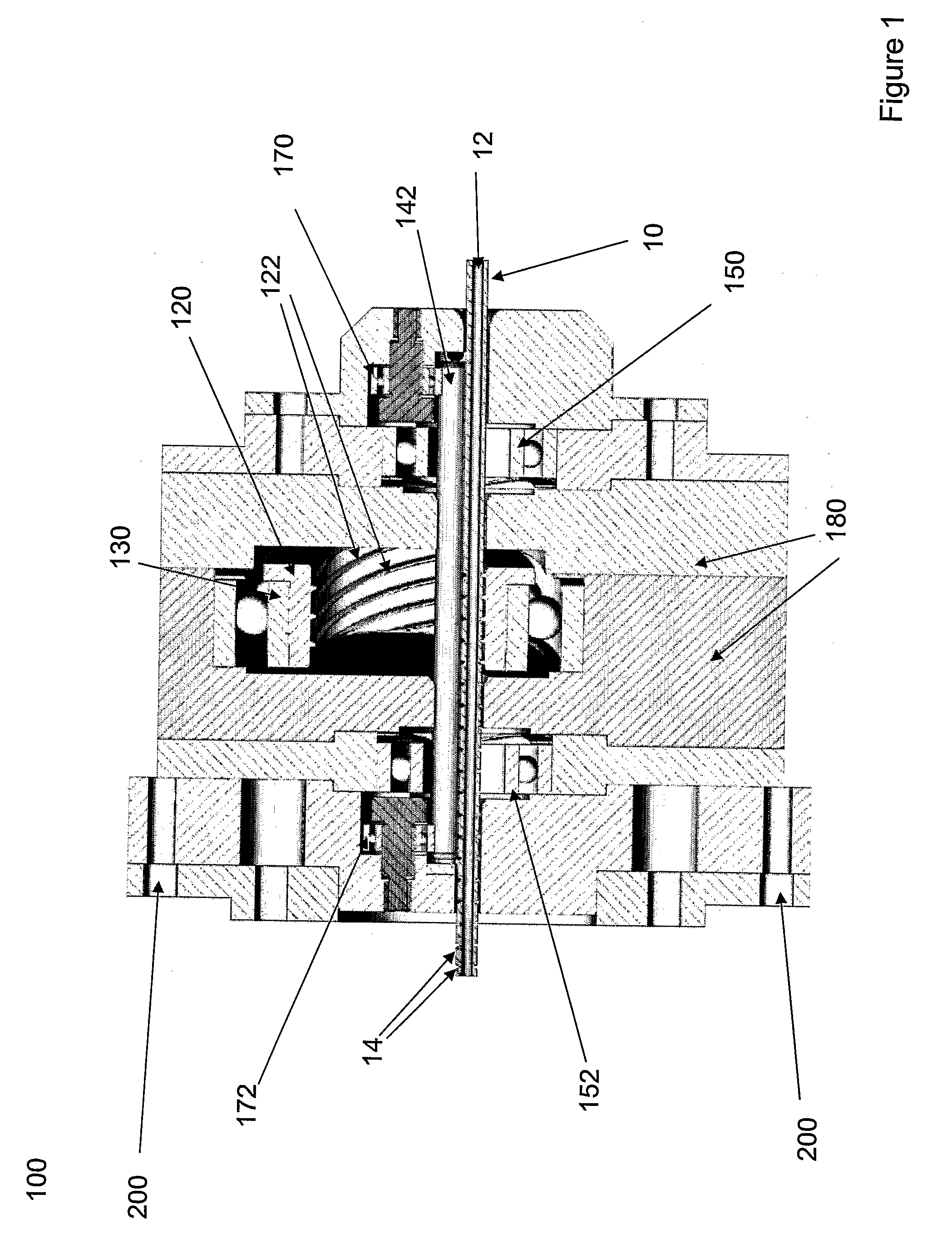

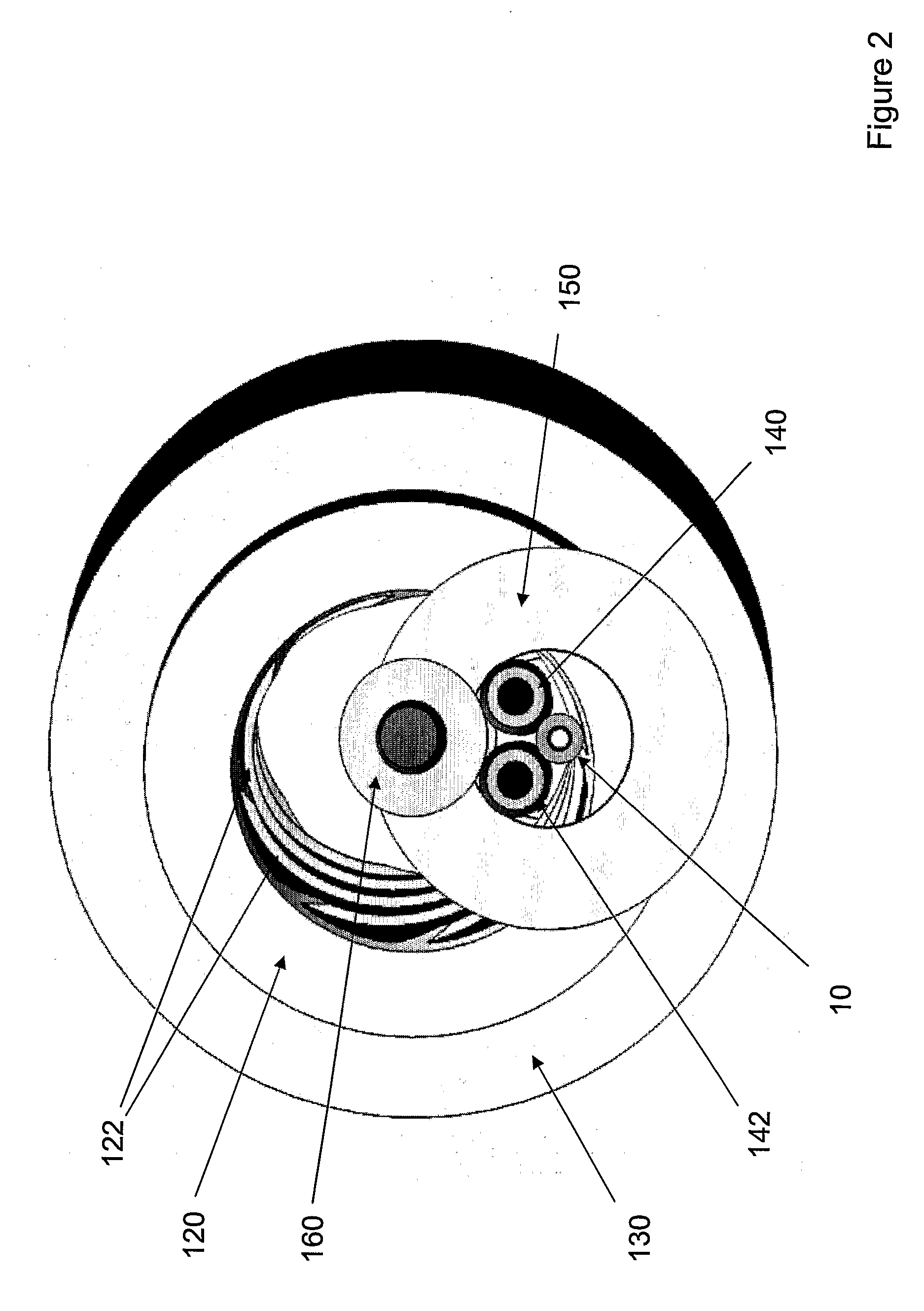

Apparatus and method for forming annular grooves on the outer surface of a cable or tube

ActiveUS20100021254A1Shorten the timeEasy to produceThread cutting machinesMilling machinesElectric cablesEngineering

The present invention provides an apparatus (100) for forming circumferential grooves (14) in the exterior surface of a linear member (10), such as a tube. The grooves are formed by rotating a cylindrical cutting element (120) around the tube such that cutting means in the cylindrical cutting element form the grooves. One rotation of the cylindrical cutting element causes multiple grooves to be formed in the surface of the tubes.

Owner:PPC BROADBAND FIBER LTD

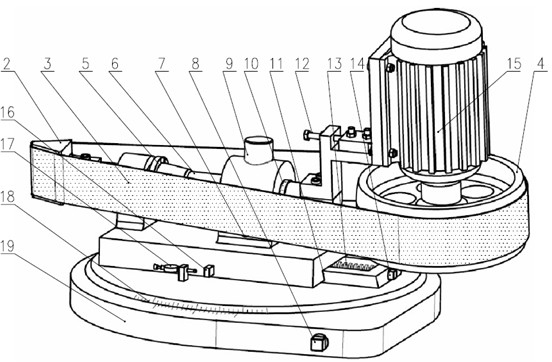

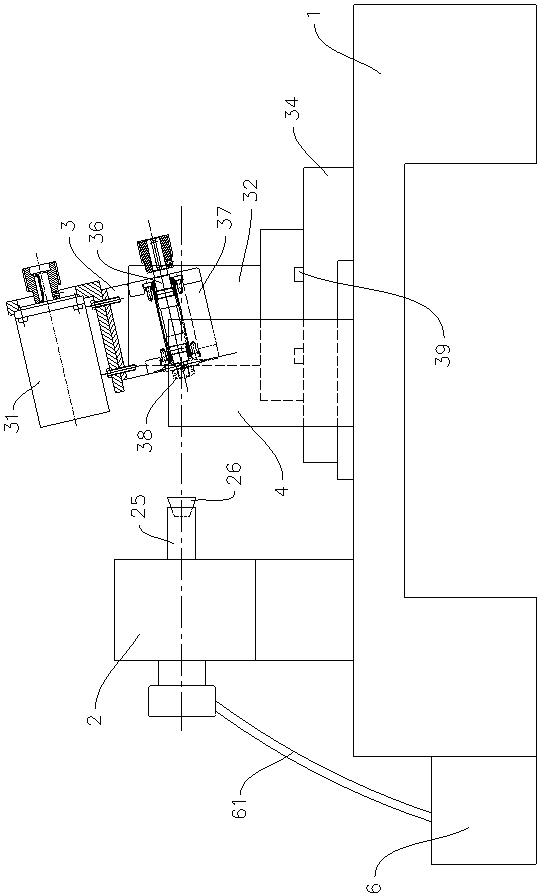

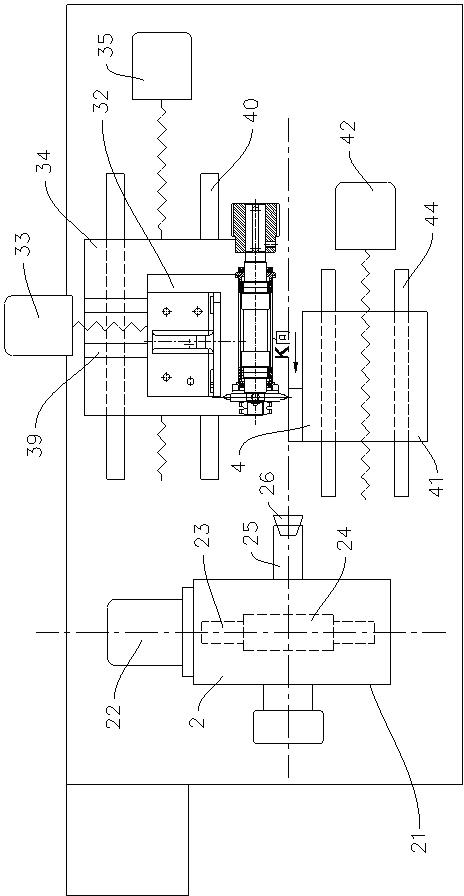

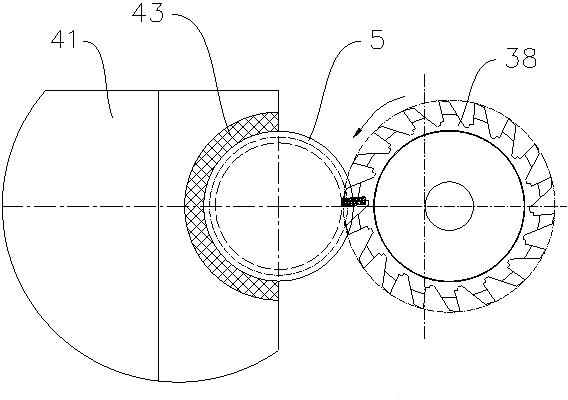

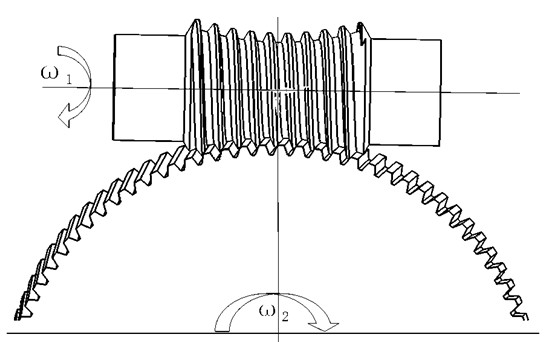

Multi-start worm milling machine

ActiveCN102500832AHigh indexing accuracyProne to errorGear-cutting machinesWormsMilling cutterAgricultural engineering

The technology provides a multi-start worm milling machine with high indexing accuracy. The multi-start worm milling machine comprises a base, a main shaft box and a cyclone milling head, wherein the main shaft box is used for driving a processed worm to rotate, the cyclone milling head is used for milling the processed worm and comprises a milling cutter, the main shaft box comprises a box body, a main shaft actuating mechanism, a main shaft transmission mechanism and a main shaft, the main shaft actuating mechanism drives the main shaft to rotate through the main shaft transmission mechanism, the main shaft actuating mechanism is a main servo motor, and the main shaft transmission mechanism adopts a worm gear for transmission.

Owner:NANJING CAIYUN MASCH & ELECTRONICAL MFG GRP CO LTD

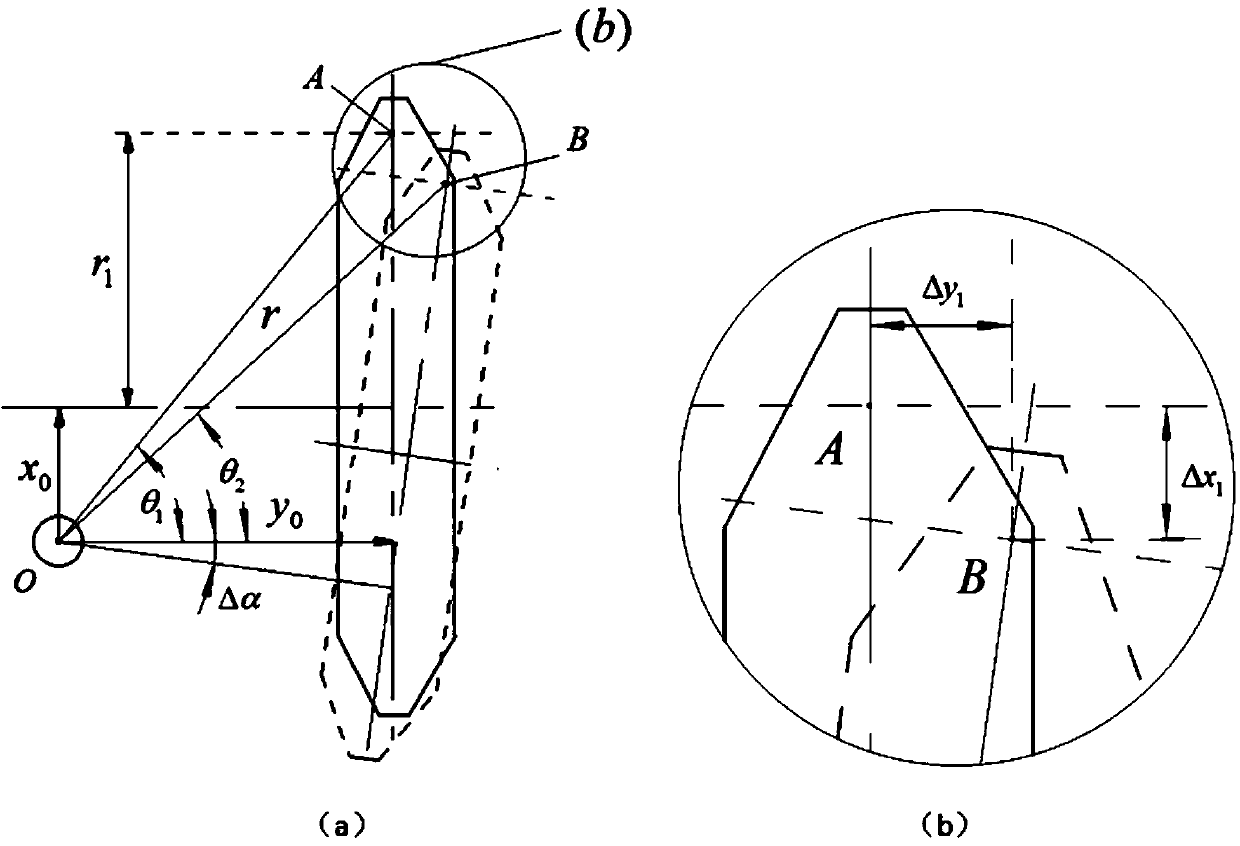

Online detection and correction machining method for enveloping worm tooth surface

ActiveCN104148745ALow resolutionImprove processing efficiencyMeasurement/indication equipmentsWormsHelical lineEngineering

The invention discloses an online detection and correction machining method for an enveloping worm tooth surface. Ground finish is carried out on the enveloping worm tooth surface through four-axis linkage in combination with a virtual rotation center principle, online detection is conducted on the enveloping worm tooth surface through three-axis linkage in combination with a spherical measuring head, and machining precision of the enveloping worm tooth surface is obtained through comparison of a practical torus helical line obtained through measurement with a theoretical helical line; whether the machining precision of the enveloping worm tooth surface meets requirements is judged, source tracking processing is carried out on a machining error if the requirements are not reached, grinding program correction and machining tool adjustment is conducted on the machining error value obtained by means of source tracking, and then tooth surface correction ground finish is carried out; the process is repeated until the machining precision of the enveloping worm tooth surface meets the requirements. The method solves the problem of low precision of the enveloping worm tooth surface fundamentally, can be applied to machining tooth surfaces of planar double enveloping worms, toroid enveloping torus worms, involute enveloping torus worms and other enveloping worms, and has principle universality and wide application value.

Owner:XIHUA UNIV

Variable-Tooth-Thickness Worm-Type Tool and Method For Using The Same To Fabricate Gears

InactiveUS20130089386A1Reduce distortionEasy to controlGear teeth manufacturing toolsMetal working apparatusSpiral bladeDegrees of freedom

A variable-tooth-thickness worm-type tool comprises a main body and a spiral blade distributed on the main body and featuring variable tooth thickness. The main body and the spiral blade are respectively described with a rack cutter coordinate system and a tool coordinate system. The vector parameters based on the rack cutter coordinate system are transformed into vector parameters based on the tool coordinate system so as to simulate the main body with a rack cutter and develop the spiral blade to have variable tooth thickness. Thus, when a gear blank is tooled, the distance between the centers of the tool holder and the workpiece holder can be set as a constant, and the feed in the radial degree-of-freedom can be neglected, with twists of tooth flanks being inhibited.

Owner:NATIONAL CHUNG CHENG UNIV

Methods for designing and manufacturing double-lead linear contact bias worm drive

InactiveCN101710350ADesign method is simple and preciseSimple structureSpecial data processing applicationsWorm wheelsNumerical controlHobbing

The invention provides methods for designing and manufacturing double-lead linear contact bias worm drive, belonging to the fields of machinery principle and machinery manufacture. The double-lead linear contact bias worm drive belongs to the spiroid drive mode in the worm gear drive. The designing method in the invention has the following steps: 1. determining basic parameters according to the power, the transmission ratio and the rotating speed required to be transmitted; 2. performing parameter designing by taking a specified reference circle as a standard on the basis of preliminary calculation of the outer diameter of a worm gear; and 3. calculating each parameter in terms of the formula deduced from the above parameter designing. The manufacturing method in the invention comprises a mitting method, a fly-cutter hobbing method and a numerical control turning method. The invention has a simple and precious designing method, which can simplify the structure of the worm gear and machining and manufacturing; the current machine tool and cutter can be used to perform machining on tooth surfaces without adding other devices or using special machine tools and cutters except for adopting a special machine tool for efficient and high precision machining.

Owner:JILIN UNIV

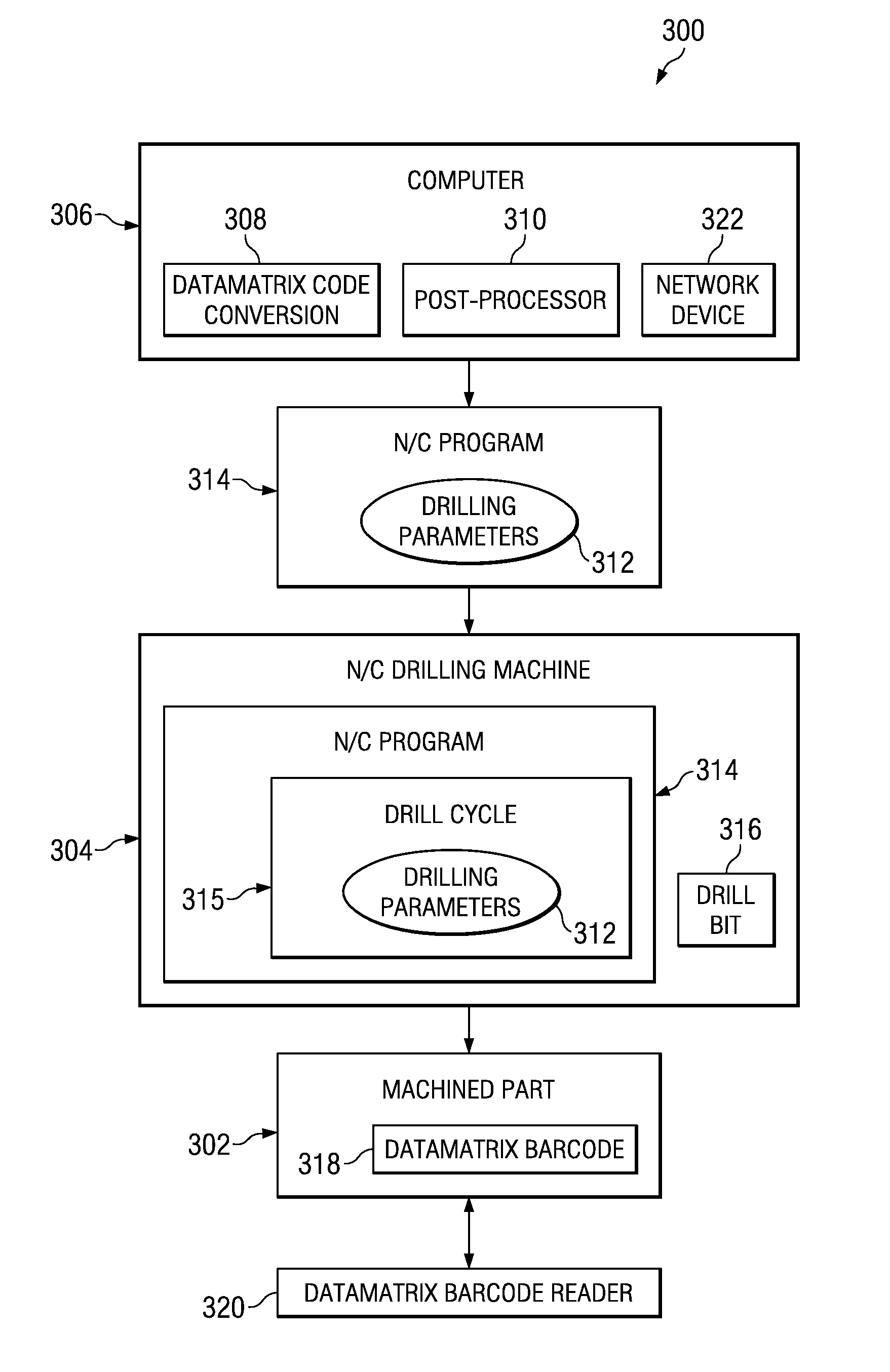

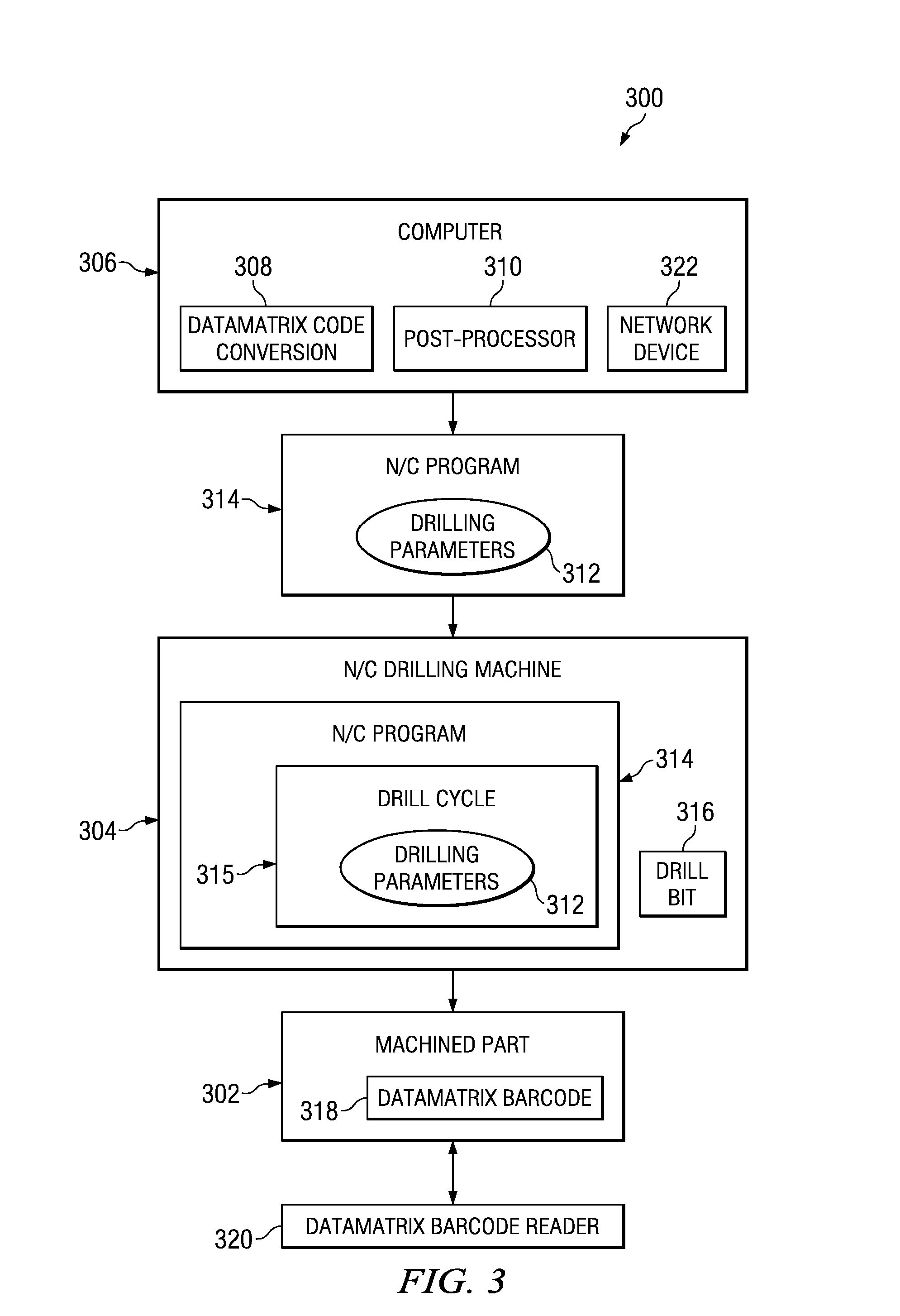

Method and apparatus for generation of datamatrix barcodes utilizing numerical control drilling patterns

InactiveUS20090125143A1Thread cutting auxillary apparatusPlaning/slotting machinesDigital dataNumerical control

The illustrative embodiments provide a method, apparatus, and computer usable program product for generating datamatrix barcodes on parts. A digital datamatrix code associated with a machined part on a numerically controlled machine tool is converted into an x-y drilling pattern contained in a numerically controlled program. A drill cycle associated with a numerically controlled program defines a pattern of dots to be drilled in the machined part to form a dot pattern. A dot pattern is drilled as a series of partially drilled holes on a surface of the machined part to form a datamatrix barcode mark.

Owner:THE BOEING CO

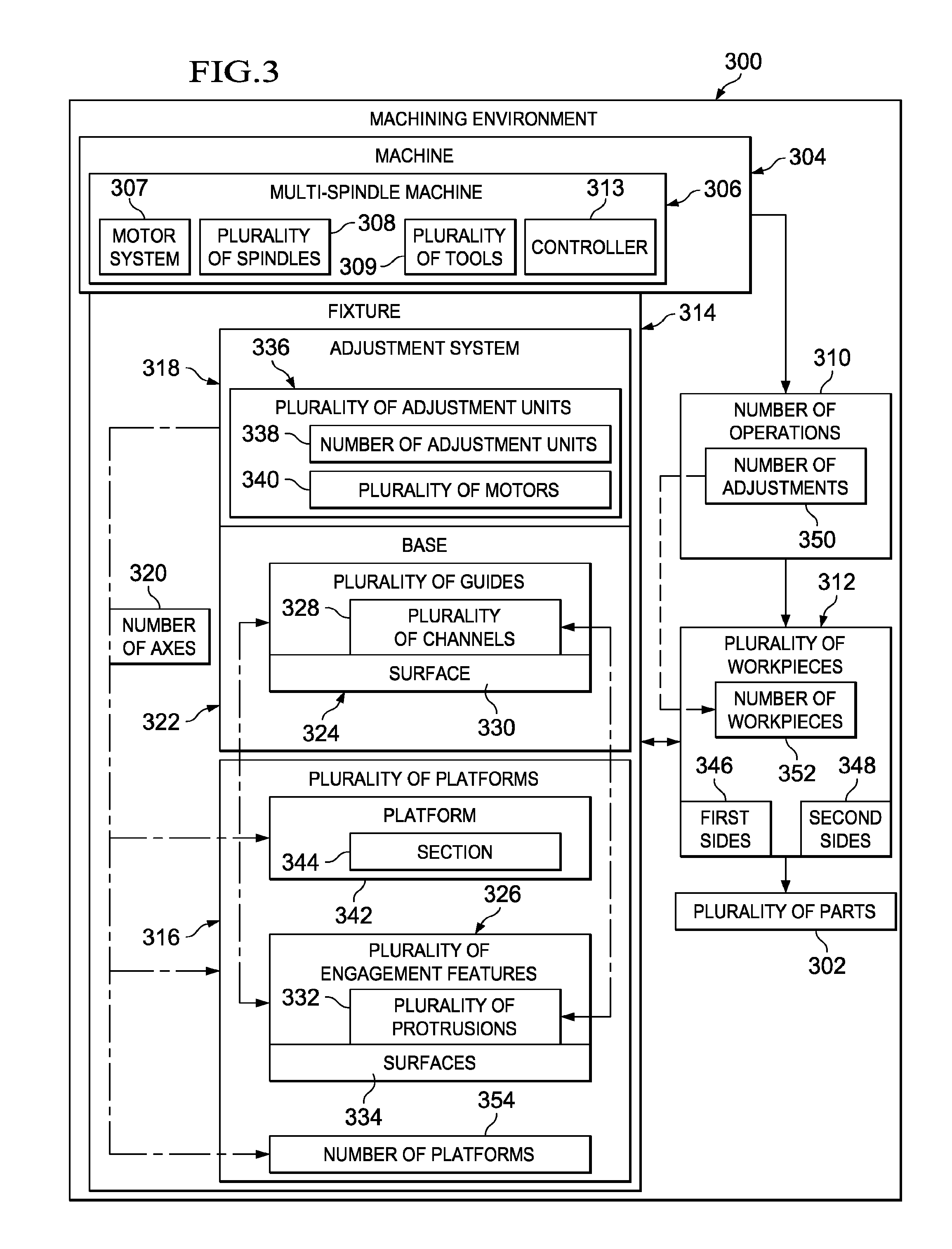

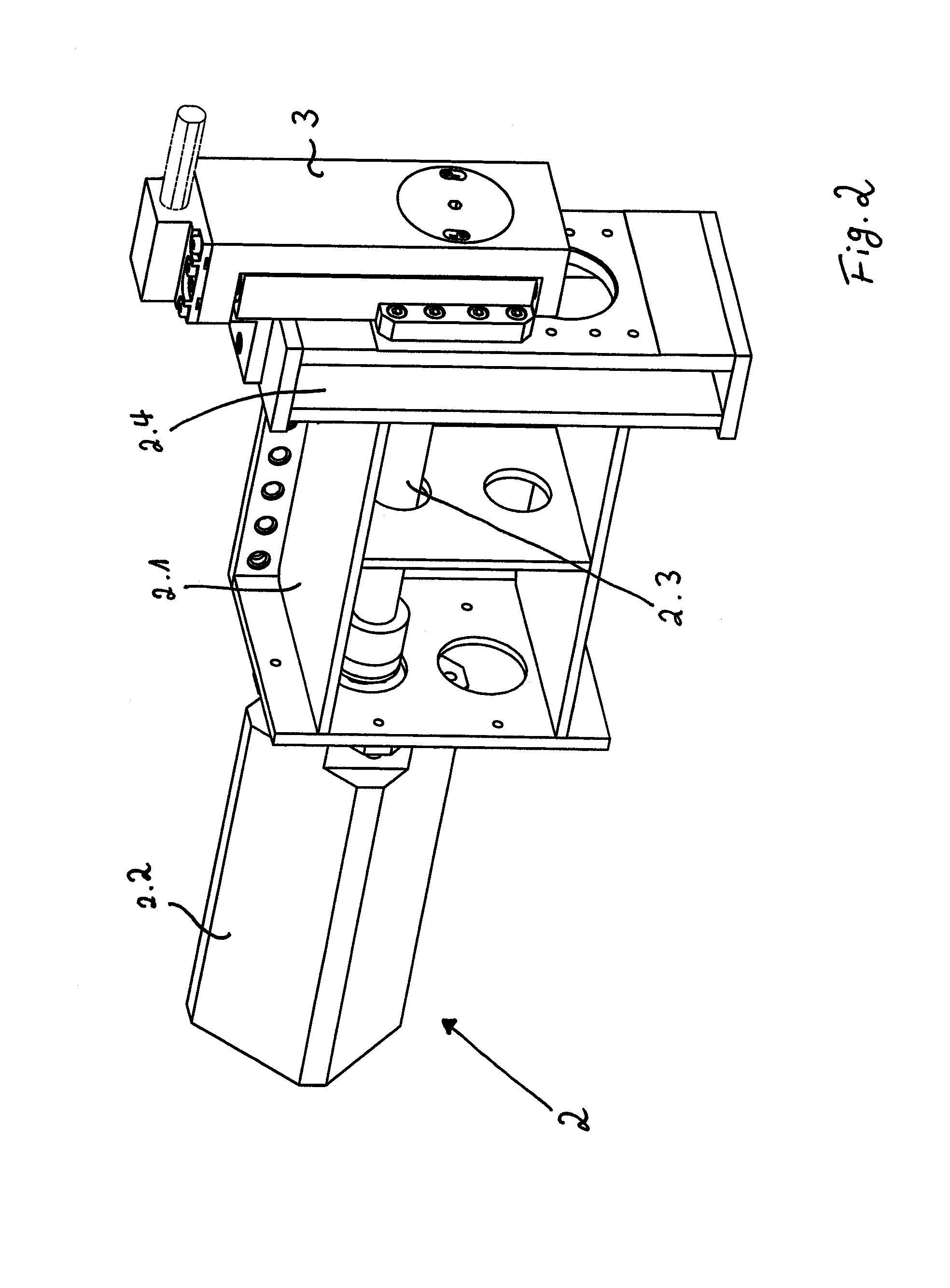

Adjustable Fixture for a Multi-Spindle Machine

A method and apparatus for processing workpieces to form parts. Tools associated with a multi-spindle machine may be positioned with respect to a plurality of workpieces on a fixture comprising a plurality of platforms and an adjustment system. Each platform may be individually moveable with respect to others in the plurality of platforms about a number of axes. The plurality of platforms may be configured to hold the plurality of workpieces in which each platform may be configured to hold a workpiece in the plurality of workpieces during operations performed by the multi-spindle machine. The adjustment system may be configured to move each of the plurality of platforms about the number of axes independently from the others in the plurality of platforms. The operations may be performed on the plurality of workpieces using the multi-spindle machine and the fixture to form a plurality of parts.

Owner:THE BOEING CO

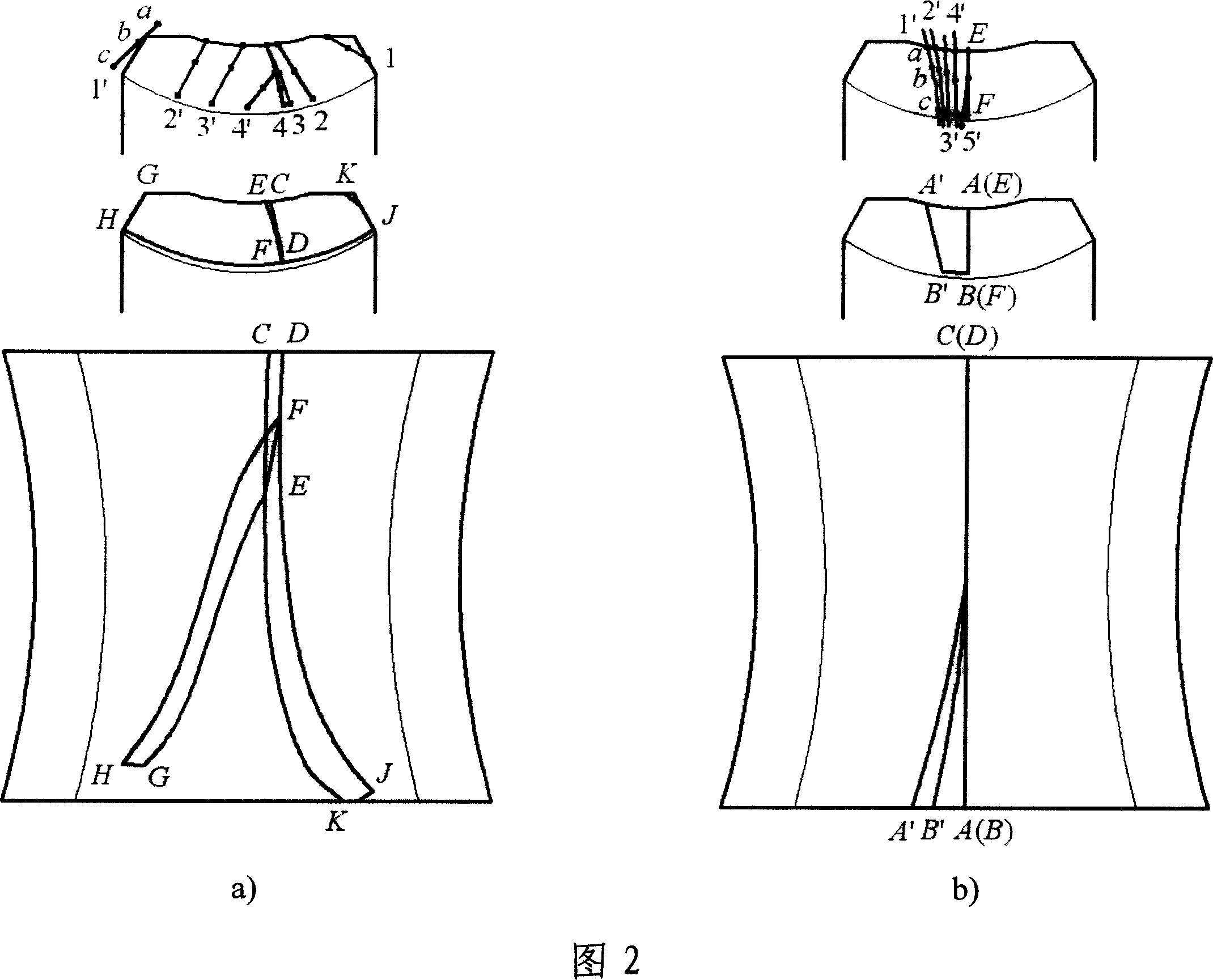

Five-axis grinding wheel grinding processing method for planar enveloping hourglass worm

A five-axis grinding wheel grinding processing method for a planar enveloping hourglass worm adopts a five-axis numerical control machine tool, the grinding plane of a grinding wheel coincides with the tooth surface of a virtual gear and the grinding wheel rotates around the rotating axis of the virtual gear through five-axis linkage of the machine tool according to a forming principle of the planar enveloping hourglass worm, a worm workpiece rotates around own axis simultaneously, the rotating speeds and directions of the grinding wheel and the worm workpiece are determined according to the rotating direction and the transmission ratio of a worm gear pair, the distance between the axis of the virtual gear and the axis of the worm workpiece is equal to the center to center distance of the worm gear pair, so that the tooth surface of the planar enveloping hourglass worm is ground through planar enveloping of the grinding wheel. The five-axis process technology is applied to grinding processing of the planar enveloping hourglass worm for the first time, and the grinding range and the grinding precision of the planar enveloping hourglass worm can be increased remarkably by using the flexibility and precision of the five-axis processing machine tool.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD

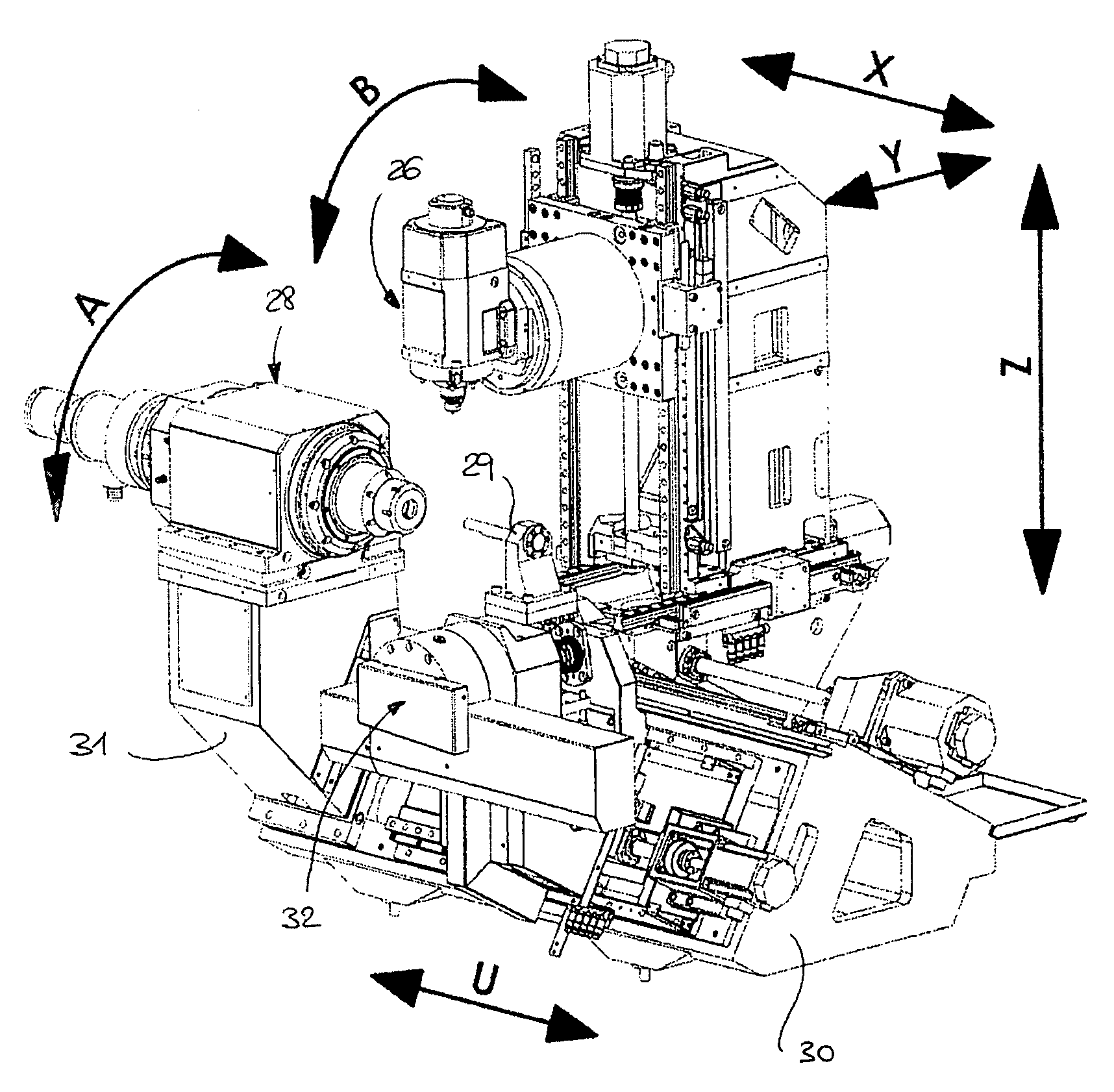

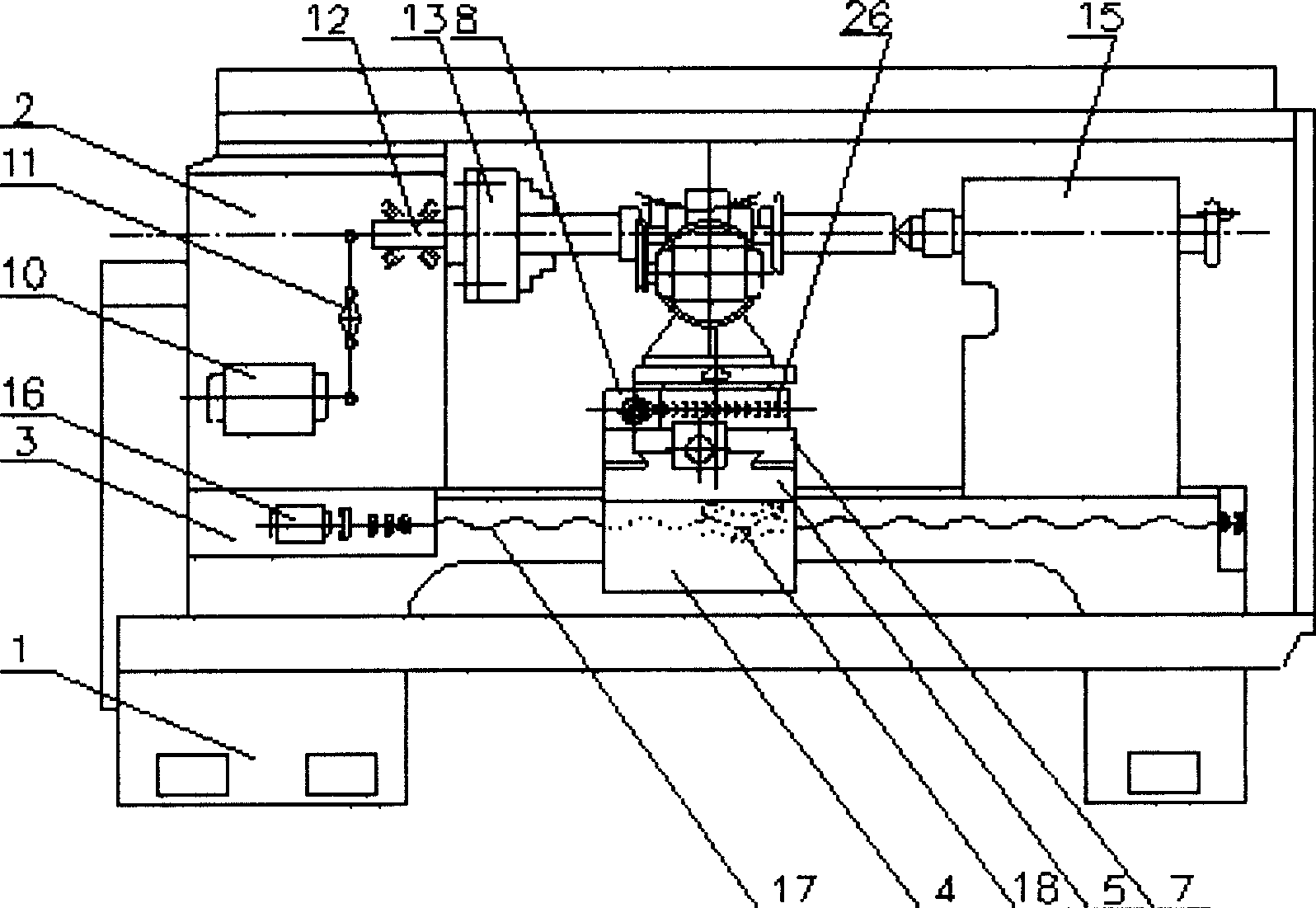

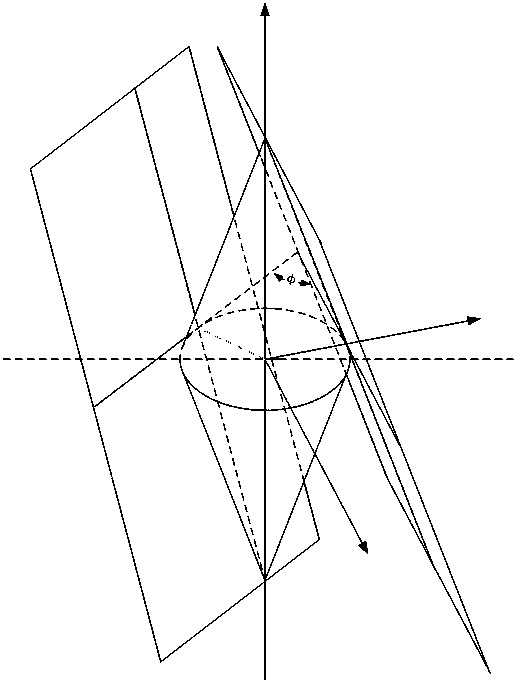

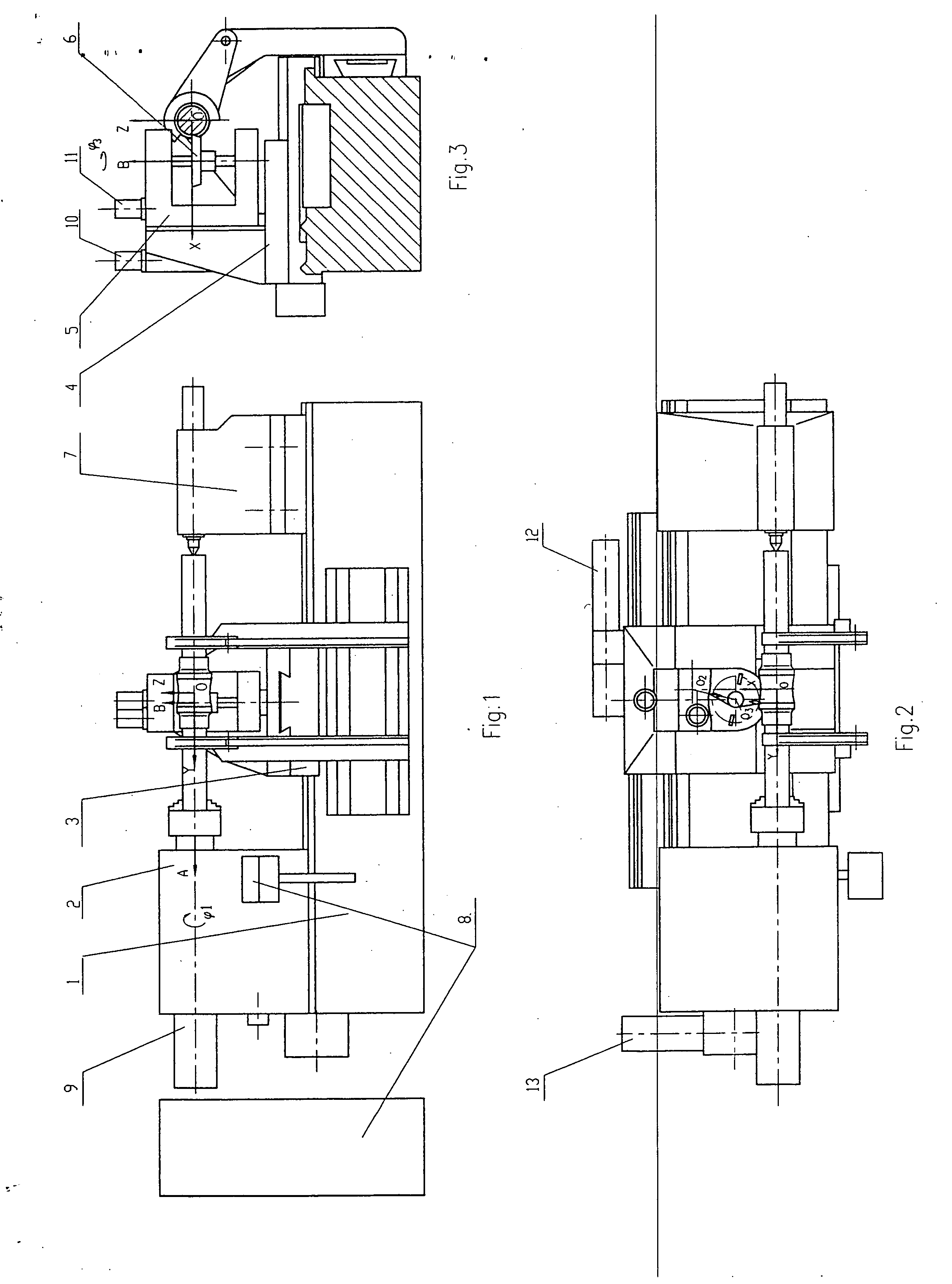

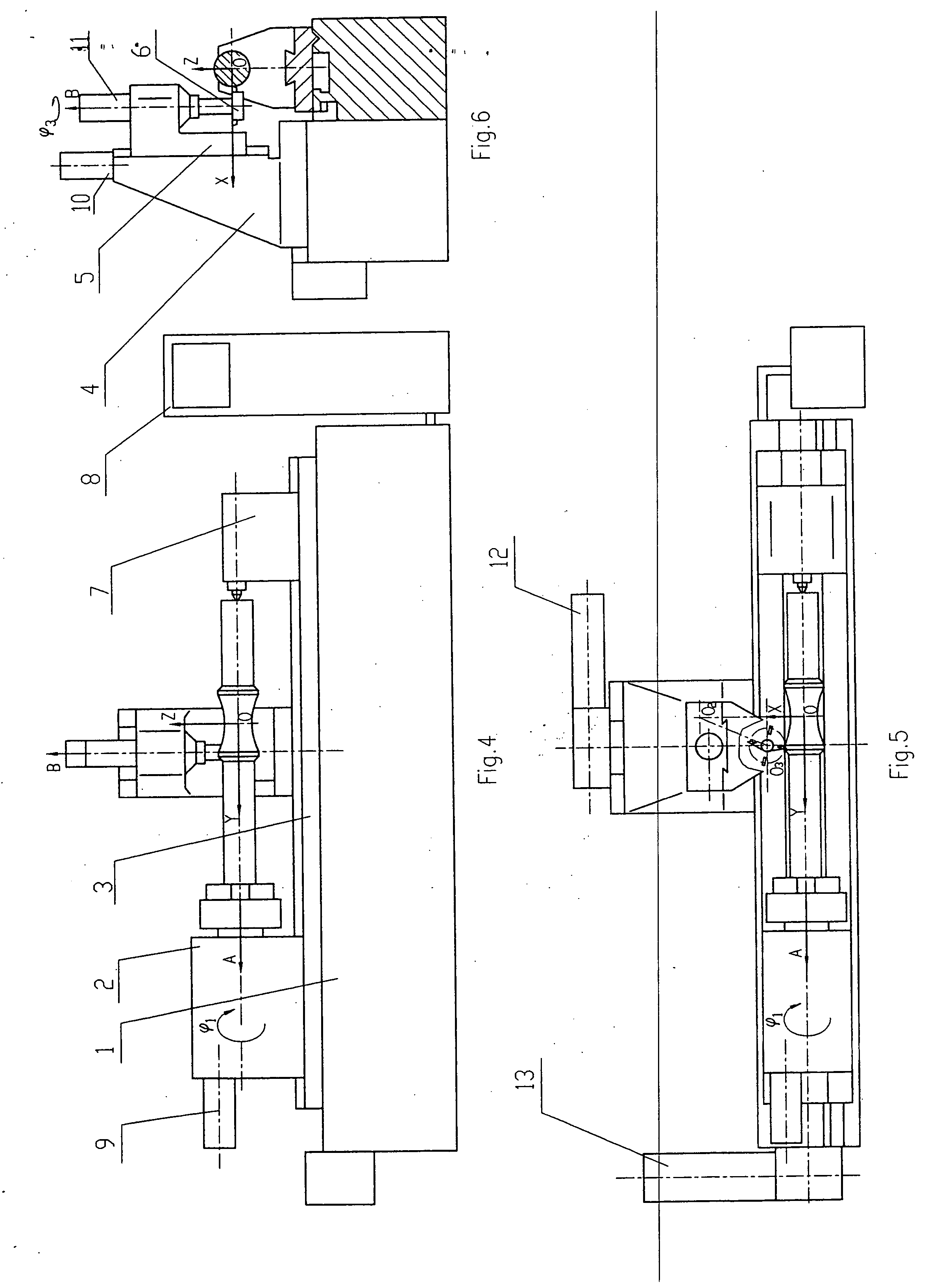

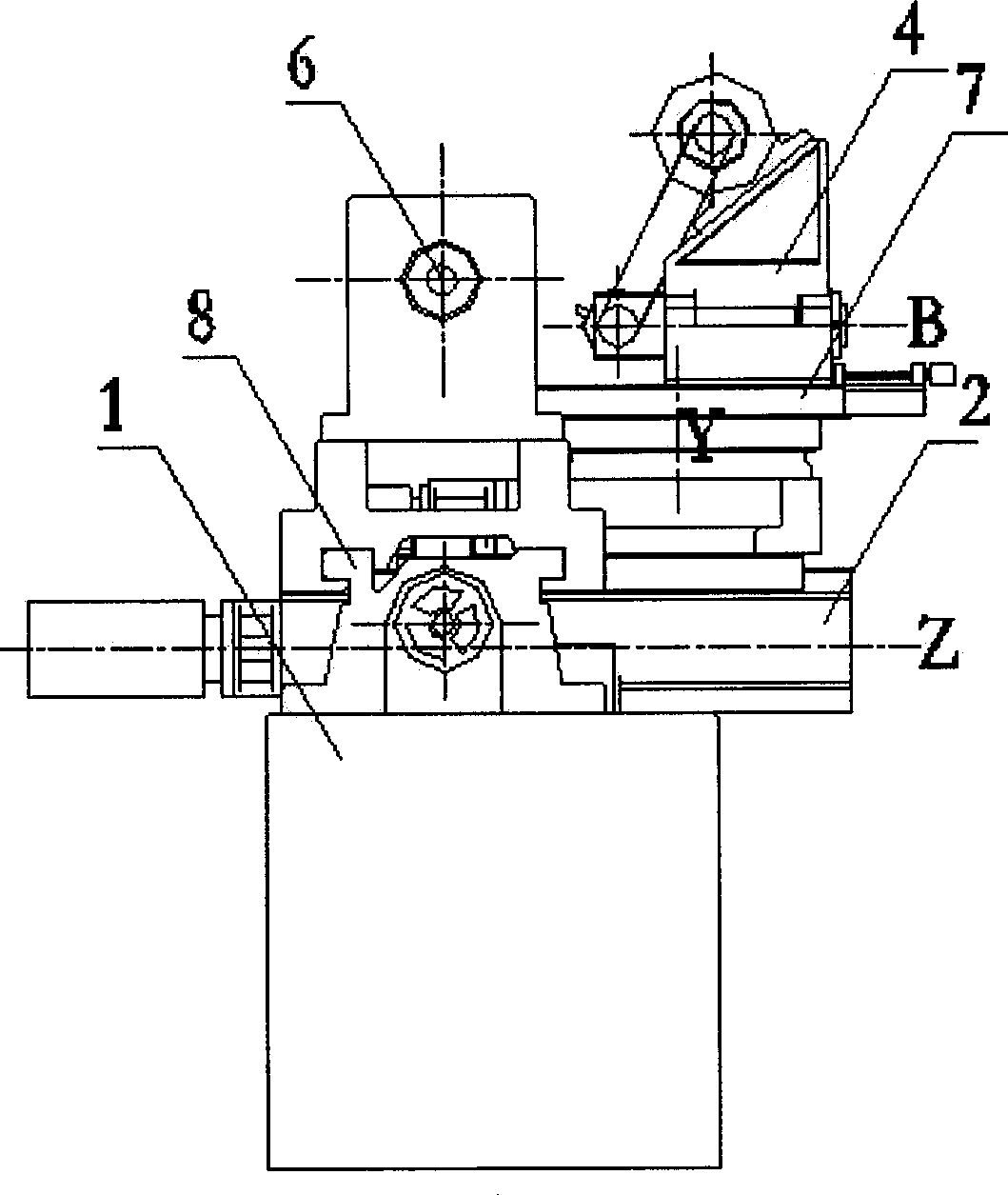

Five-simultaneously-working-axis computerized numerical controlled tooth cutting machine tool for plane enveloping toroidal worms

The present invention provides a five-simultaneously-working axis computerized numerical controlling system tooth cutting machine tool for toroidal worms, comprising two parts a body of the machine tool and a controlling cabinet. The body comprises a bed, a spindle box with a spindle, a longitudinal sliding table, a traverse slider, a vertical guideway mounted on the slider and a tailstock, a cutter rest that supports a rotating cutter head is mounted on the vertical guideway. The spindle rotates about A-axis thereof, the table longitudinally slides along Y-axis relative to the bed, the cutter head rotates about B-axis thereof and transversely shifts X-axis as well as the cutter head makes up or down shift along Z-axis of the vertical guideway. The controlling cabinet is equipped with the programs for controlling spindle rotation and for controlling the shifting along longitudinal, transverse and vertical directions as well as the rotation of the cutter head so as to make the rotation about or the shifts along five axes of A, B, Y, X and Z have simultaneously work together to control the shifting of the cutting edges of the cutter on the cutter head and simulate the rotating motion of an inclined plane in space in order to envelop cut the tooth flanks of plane enveloping toroidal worms. The effect of this invention shows that the rotating speed of cutter shaft and workpiece shaft can make the cutting velocity up to 200 m / min, and the working efficiency is six to seven times higher than that of worm grinding, the productivity can greatly be improved.

Owner:TIANJIN TEDA DEV CENT FOR WORM

Worm gear unit and method of producing same

InactiveUS20090000120A1Satisfactory mechanical strengthMetal-working apparatusToothed gearingsEngineering

Owner:HITACHI LTD

Numerical control five-axle linkage planar double enveloping worm cyclone cutting machine tool

The invention discloses a digital control five-axis three-linkage enveloping worm whirlwind stock-removing machine which mainly consists of a lathe bed, a cross slide, a tailstock, a spindle, and a vertical planker; a turning mechanism is arranged on the cross slide; a whirlwind tool rest is installed on the turning mechanism; a cutter head is installed on the whirlwind tool rest; a plurality of cutting knifes are symmetrically installed on the cutter head; the central rotation axis of the spindle is an X axis; the central rotation axis of the turning mechanism is a Y axis; a horizontal kinematic axis of the cross slide is a Z axis; the central rotation axis of the cutter head is an A axis; the rotating shafts of a cutter head mounting bracket and a motor mounting bracket on the whirlwind tool rest are a B axis; the machine tool has the movement along the five axis-A, B, X, Y, Z; and linkage function can be realized along the directions of the three axis-X, Y, and Z; by controlling of the movement of the cutting edge of the cutting knife, a planar enveloping hourglass worm gear surface can be processed out. The digital control five-axis three-linkage enveloping worm whirlwind stock-removing machine has the advantages of processing the enveloping worm rapidly with high precision under high speed cutting state; and the production efficiency can be greatly improved.

Owner:ZHEJIANG UNIV +1

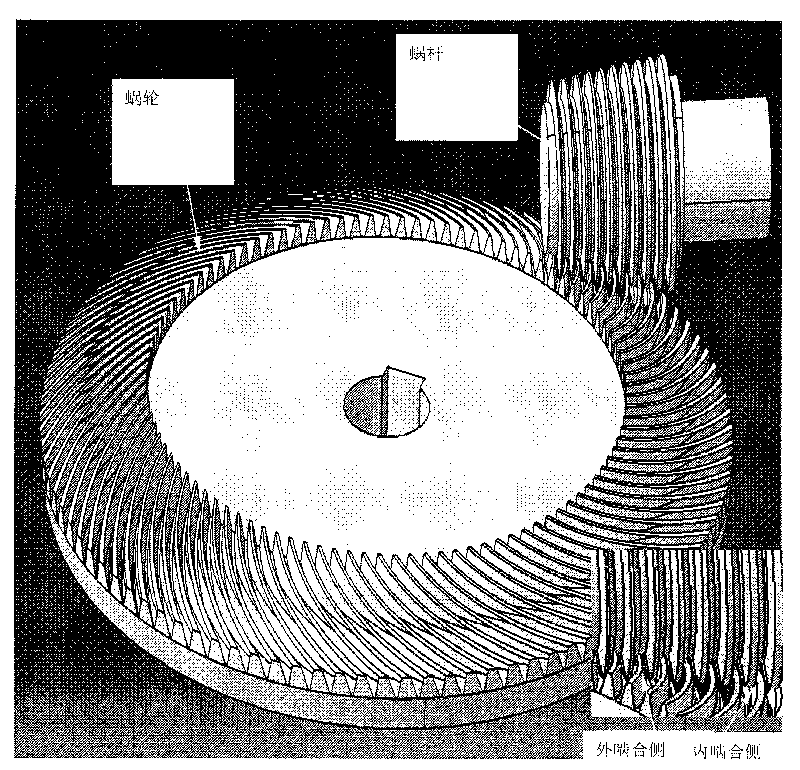

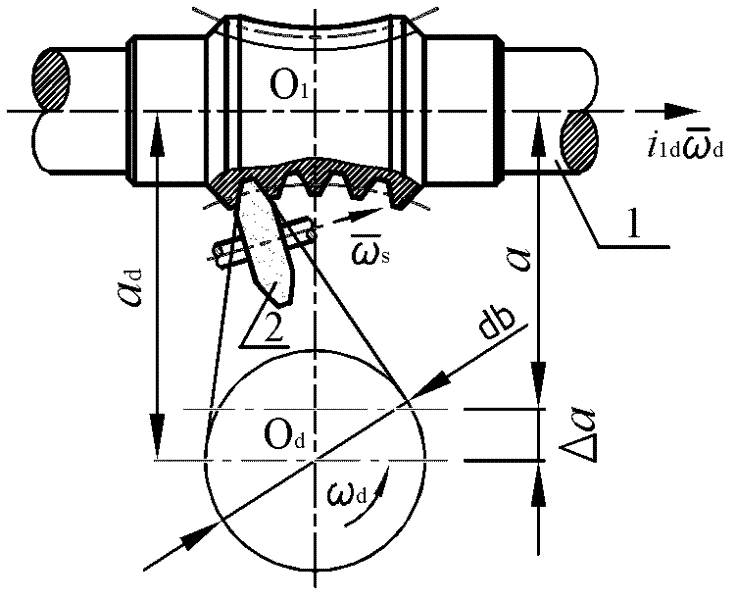

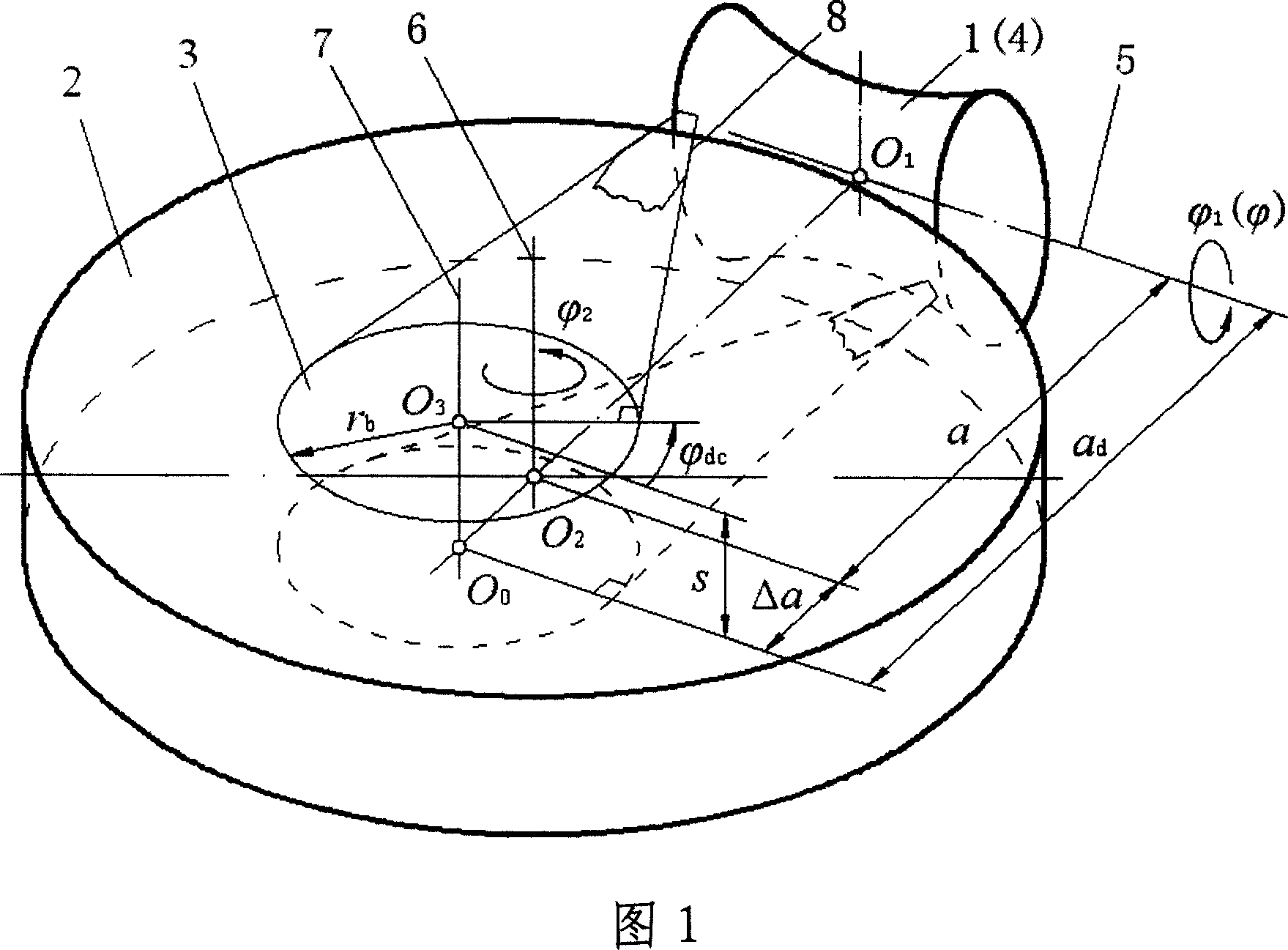

Modified double-toroid secondary enveloping toroid worm gear pair and manufacturing method thereof

InactiveCN102389996AEvenly distributedSparsely distributedToothed gearingsWorm wheelsGrinding wheelMechanical engineering

The invention relates to a modified double-toroid secondary enveloping toroid worm gear pair and a manufacturing method thereof. The technical scheme of the manufacturing method disclosed by the invention comprises the following steps of: grinding and spreading a toroid worm gear blank (1) by a double-toroid disc-shaped grinding wheel (2), wherein the process center distance is ad=a+delta a, and the process transmission ratio is i1d=i12+delta i; and adopting pure center distance profiling or adopting comprehensive profiling, determining profiling parameter ad and i1d by a trial method, calculating a worm gear engaging-out end reflecting line, and ensuring that the worm gear engaging-out end reflecting line can completely enter a first conjugate subarea of a worm wheel tooth surface. The cutting gear of a worm wheel is same as the relative standard transmission, only that a generative face of an applied toroid hob is consistent with a spiral surface of the modified worm gear. Accordingto the modified double-toroid secondary enveloping toroid worm gear pair disclosed by the invention, the worm wheel tooth surface does not exist a secondary contact area and can utilize the full length of a worm gear, a worm gear engaging-in end of the worm gear can keep the certain double-line contact length, and the manufacturing process is simpler and more flexible; and the modified double-toroid secondary enveloping toroid worm gear pair can also naturally inherit the advantages of standard double-toroid sedondary enveloping transmission.

Owner:WUHAN UNIV OF SCI & TECH

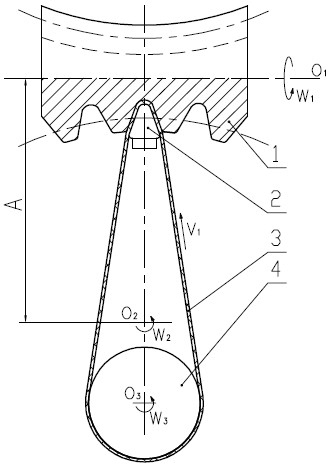

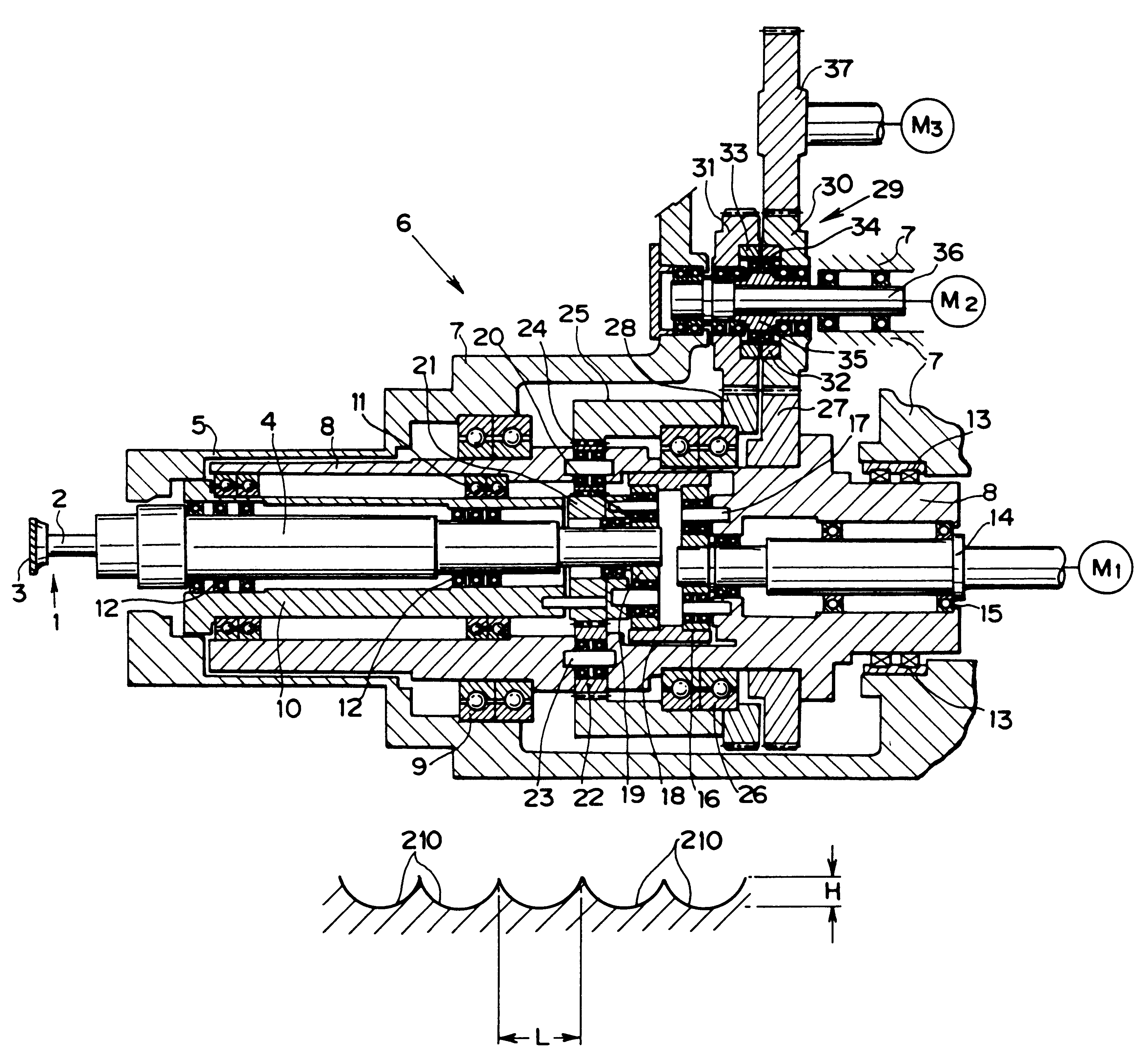

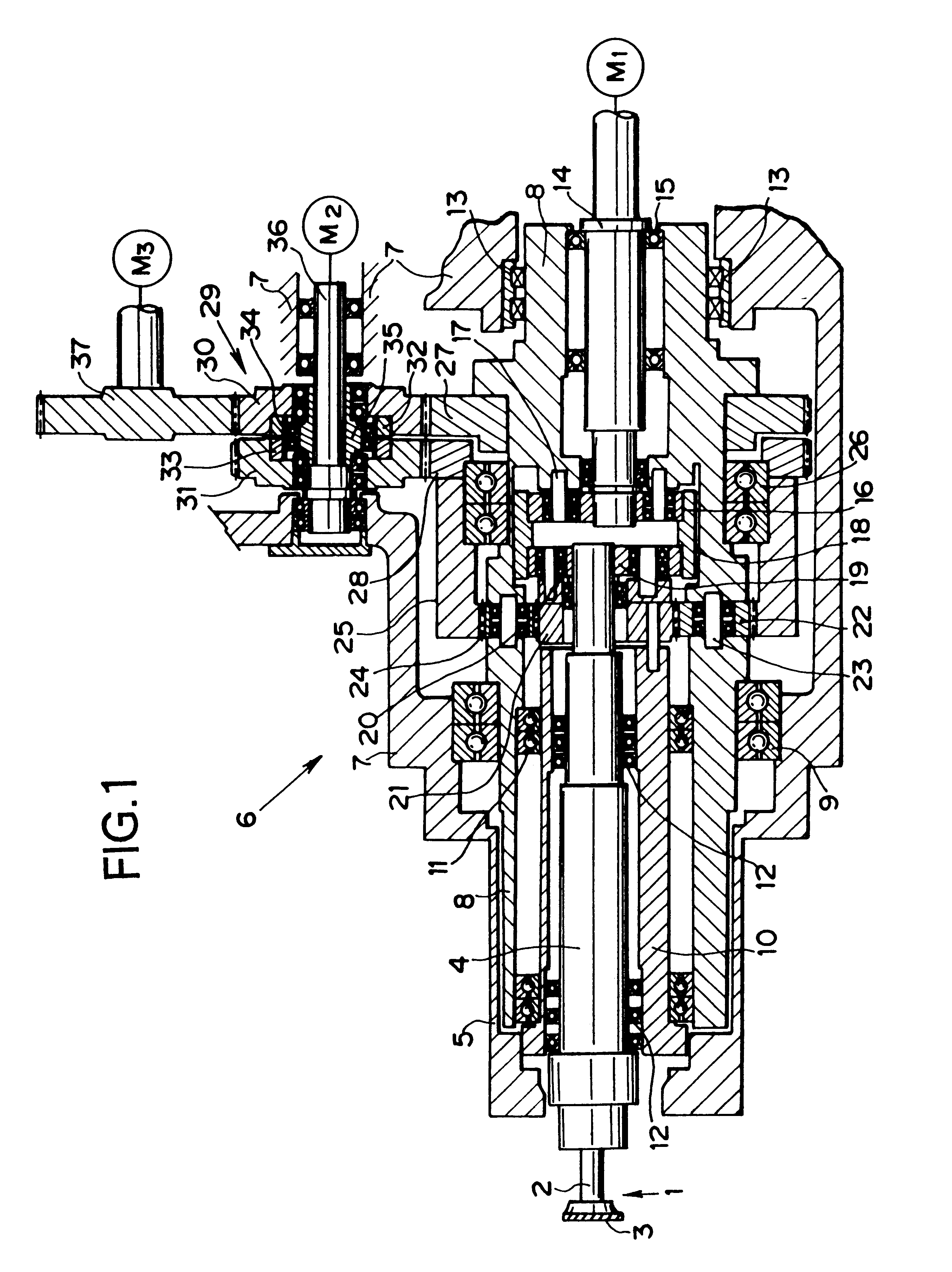

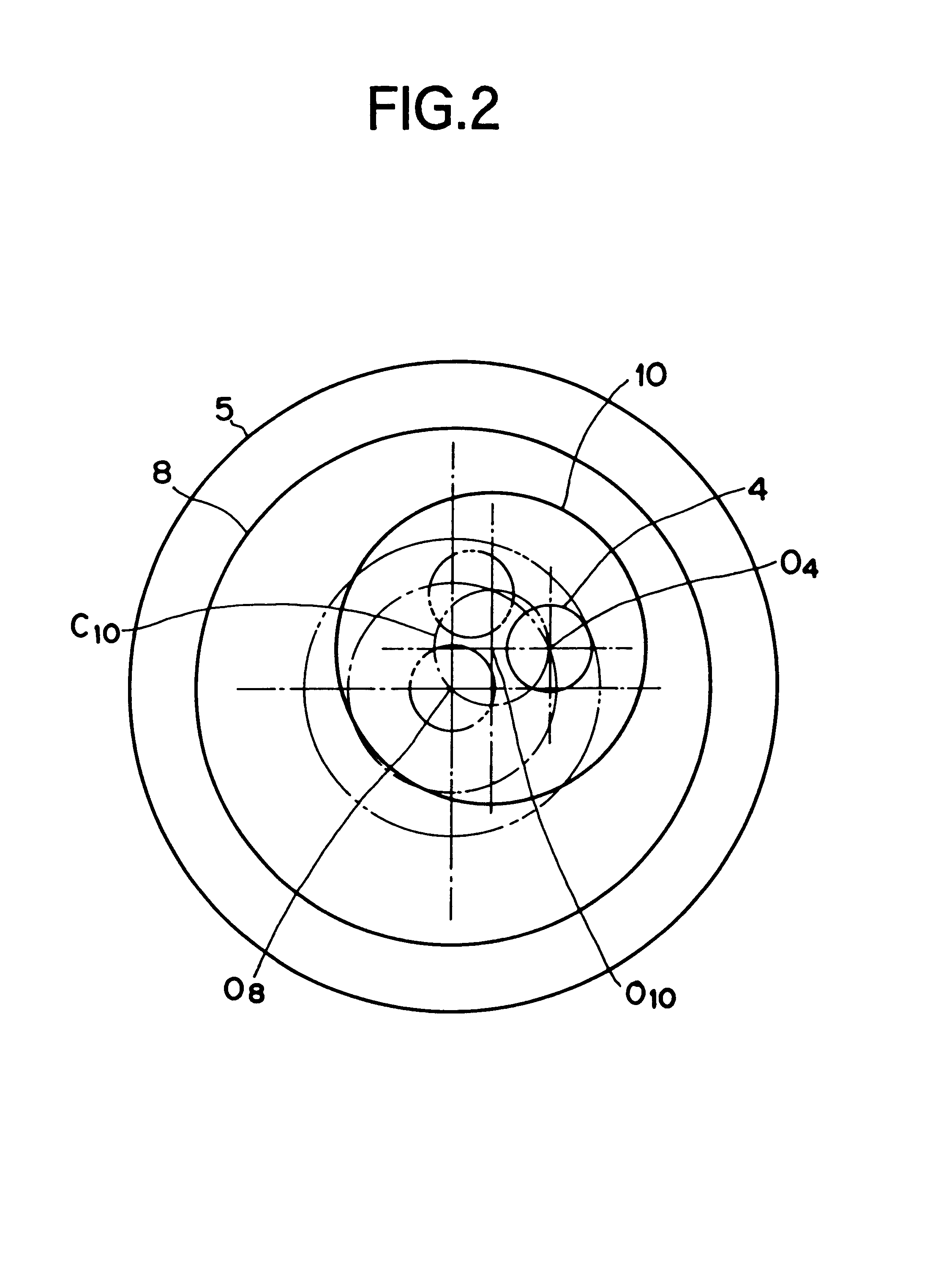

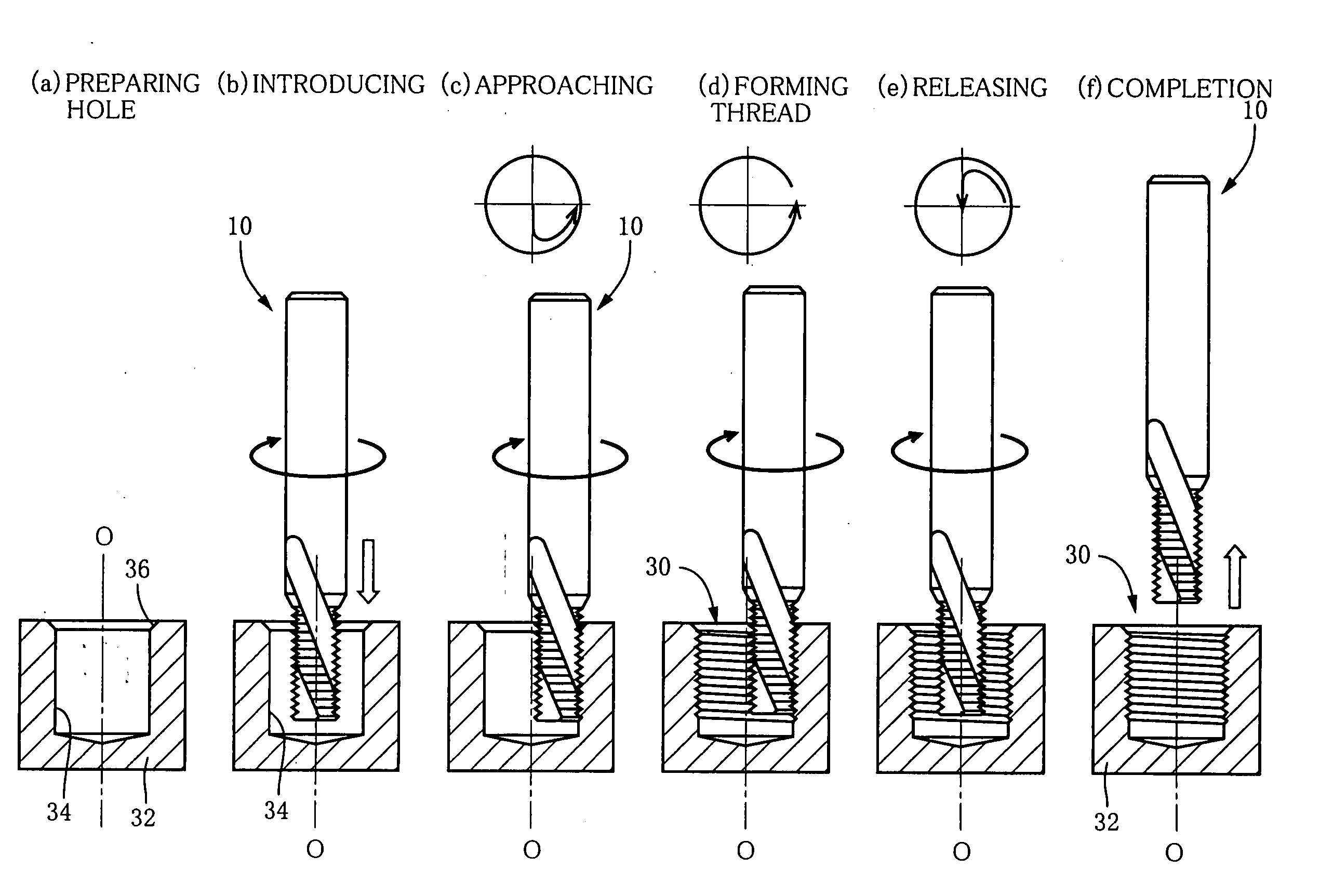

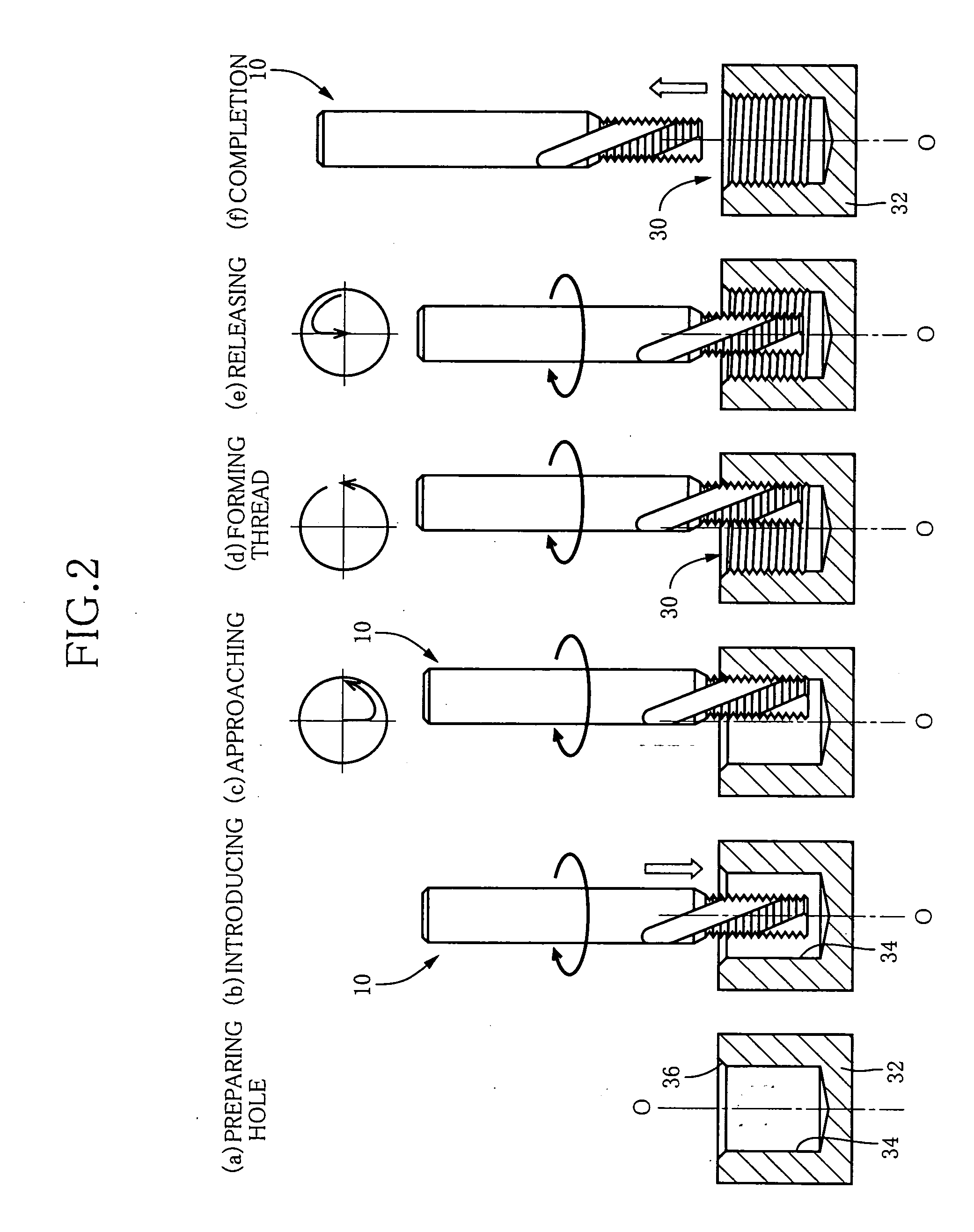

Machining apparatus and machining method

InactiveUS6840722B1Increased durabilityImprove efficiencyTurning machine accessoriesGrinding drivesEngineeringMachining

A machining apparatus for machining a workpiece by rotating and revolving either the workpiece or a tool 1 to contact with each other. The machining apparatus comprises rotation / revolution ratio setting motors M1 and M3 for setting a ratio of a number of rotations to a number of revolutions of the workpiece or the tool 1, to a numerical value having a fraction below a decimal point, by changing the number of revolutions. The workpiece is machined by setting the number of revolutions and the number of rotations at the ratio.

Owner:TOYOTA JIDOSHA KK

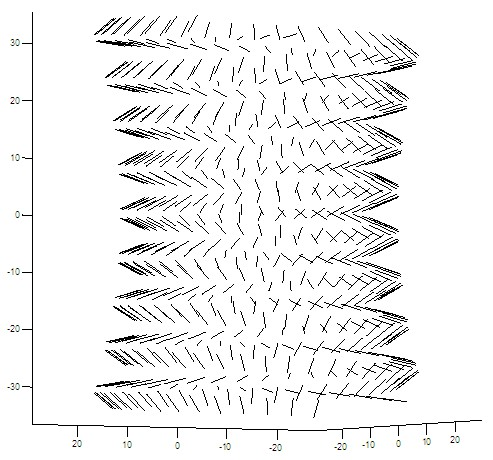

Five-axis side milling method for planar double-enveloping worm

The invention relates to a five-axis side milling method for a planar double-enveloping worm, which includes the processing steps of selecting a side milling cutter, determining side milling process parameters, roughing the bottom surface of a worm tooth root by means of five-axis linkage, roughing tooth surfaces on two sides of the worm by means of side milling, performing quenching heat treatment, finishing the bottom surface of the tooth root by means of five-axis linkage and finishing the tooth surfaces on the two sides of the worm by means of five-axis linkage side milling. The five-axis side milling method is characterized in that a side milling tool path is completely generated according to a tooth surface meshing contact line of the worm, a roughing side milling tool path is generated by offsetting the contact line along the normal direction of the tooth surfaces by the distance of roughing allowance, and a finishing side milling tool path is generated by completely overlapping a tool side blade with the tooth surface contact line. The five-axis side milling method effectively solves the problem of uneven roughing allowance of the planar double-enveloping worm, and finishing efficiency and tooth surface processing accuracy are improved.

Owner:SHANGHAI JIAO TONG UNIV

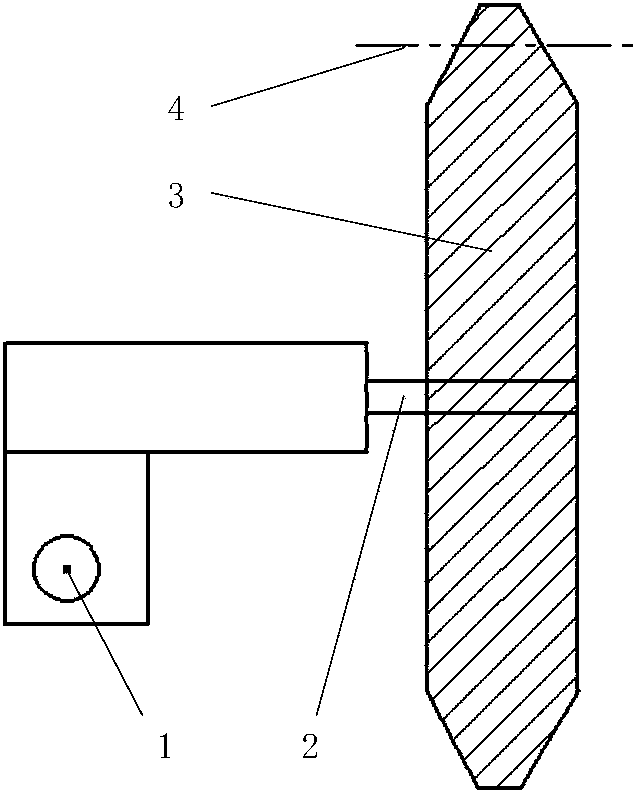

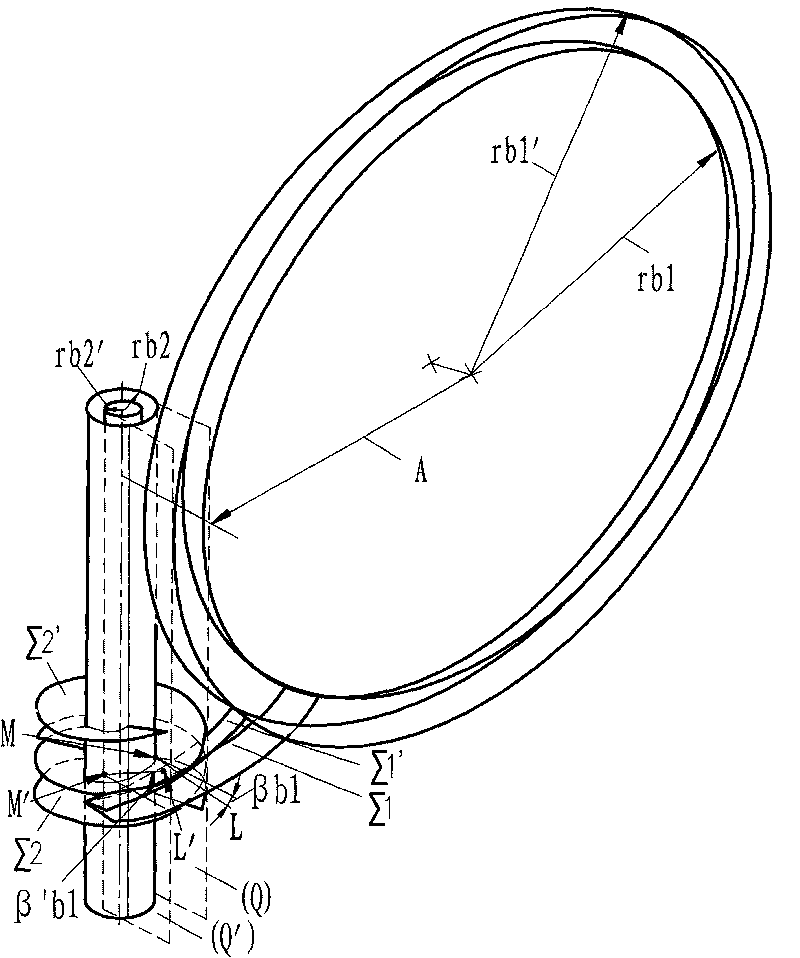

Two freedom degree straight line ring surface worm transmission and method for manufacturing same

InactiveCN101012865AImprove contact qualityToothed gearingsPortable liftingEngineeringMechanical engineering

The invention discloses a novel dual-freedom straight annular worm transmitter and relative production. The invention comprises a worm rod (1), a worm (2), a blade base (3), a worm roller (4), a worm axle (5), a worm axle (6), a blade base axle (7), and a straight blade (8). The straight blade (8) processes dual-freedom motion to form the screw face of annular worm rod (1), to obtain the dual-freedom straight annular worm rod. And the worm roller (4) has same face with the screw face of annular worm, to process the tooth of worm (2). The annular worm rod (1) and the worm (2) form the dual-freedom straight annular worm rod transmission, with the advantages of straight annular worm, better contact area and contact quality.

Owner:CHINA AGRI UNIV

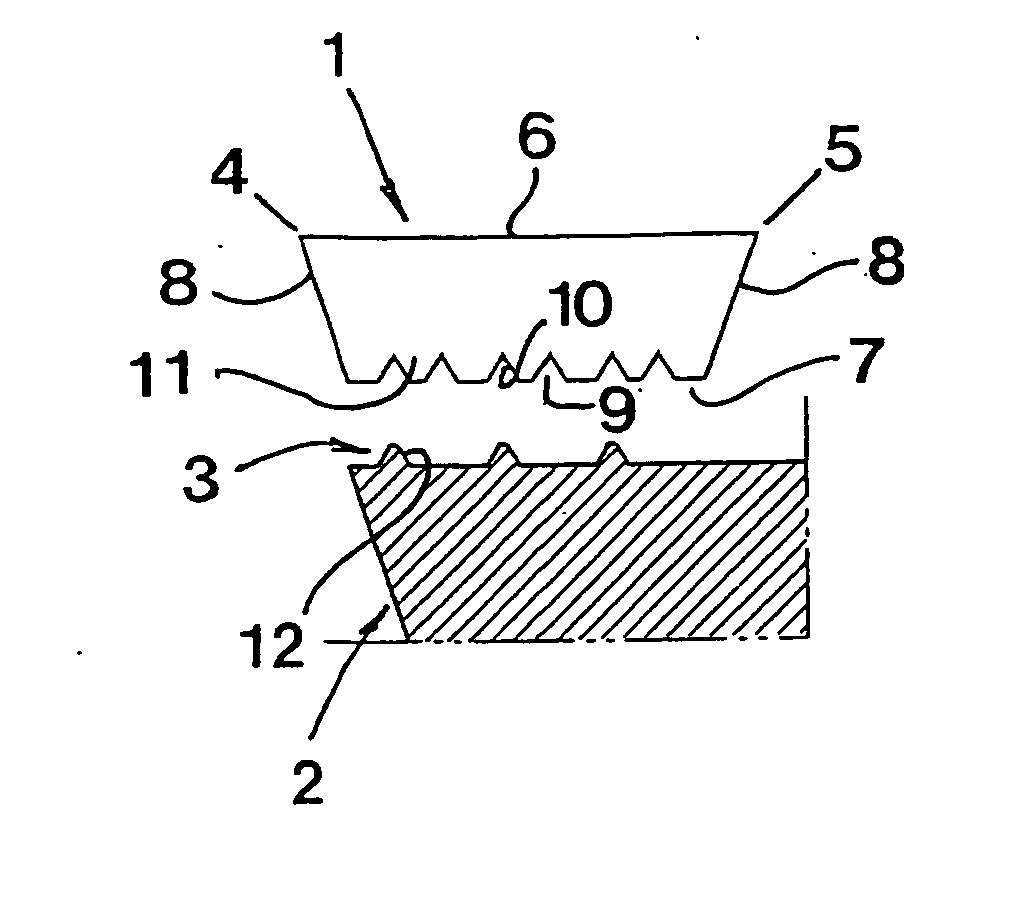

Method for the manufacture of indexable cutting inserts as well as an indexable cutting insert and a cutting tool having such a cutting insert

InactiveUS20050135884A1Improve stabilityGuarantee meticulous positional precisionMilling cuttersCutting insertsKnife bladesEngineering

An indexable cutting insert has at least first and second cutting edges and first and second edge-location surfaces associated with the first and second cutting edges, respectively. The insert-manufacturing procedure includes forming the first edge-location surface with reference to the first cutting edge, and then forming the second edge-location surface with reference to the second cutting edge. There results an indexable cutting insert having at least two spaced-apart chip-removing cutting edges and a plurality of location surfaces adapted to engage a base body for determining the spatial positions of respective cutting edges, wherein each location surface determines the spatial position of no more than one of the cutting edges.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Process and Device for Producing Threads, Especially for Boring Rods or the Like

InactiveUS20080232916A1Improve productivityLathesTurning machine accessoriesEngineeringHigh velocity

The present invention proposes a process for producing threads, especially for boring rods or the like, wherein the workpiece and the lathe tool have a relative rotary motion at a high velocity about an axis of the workpiece and a relative longitudinal motion at a low velocity compared to the above velocity, and wherein an oscillating radial relative rotary motion is brought about, furthermore, between the lathe tool and the workpiece, wherein the radial oscillating motion is generated mechanically, the radial oscillating motion being synchronized, in particular, with the relative rotary motion. The present invention pertains, furthermore, to a device for producing threads by a means for generating the radial mechanical oscillating motion, where the radial oscillating motion is synchronized, in particular, with the relative rotary motion.

Owner:FMS DREHTECHN SCHAFFHAUSEN

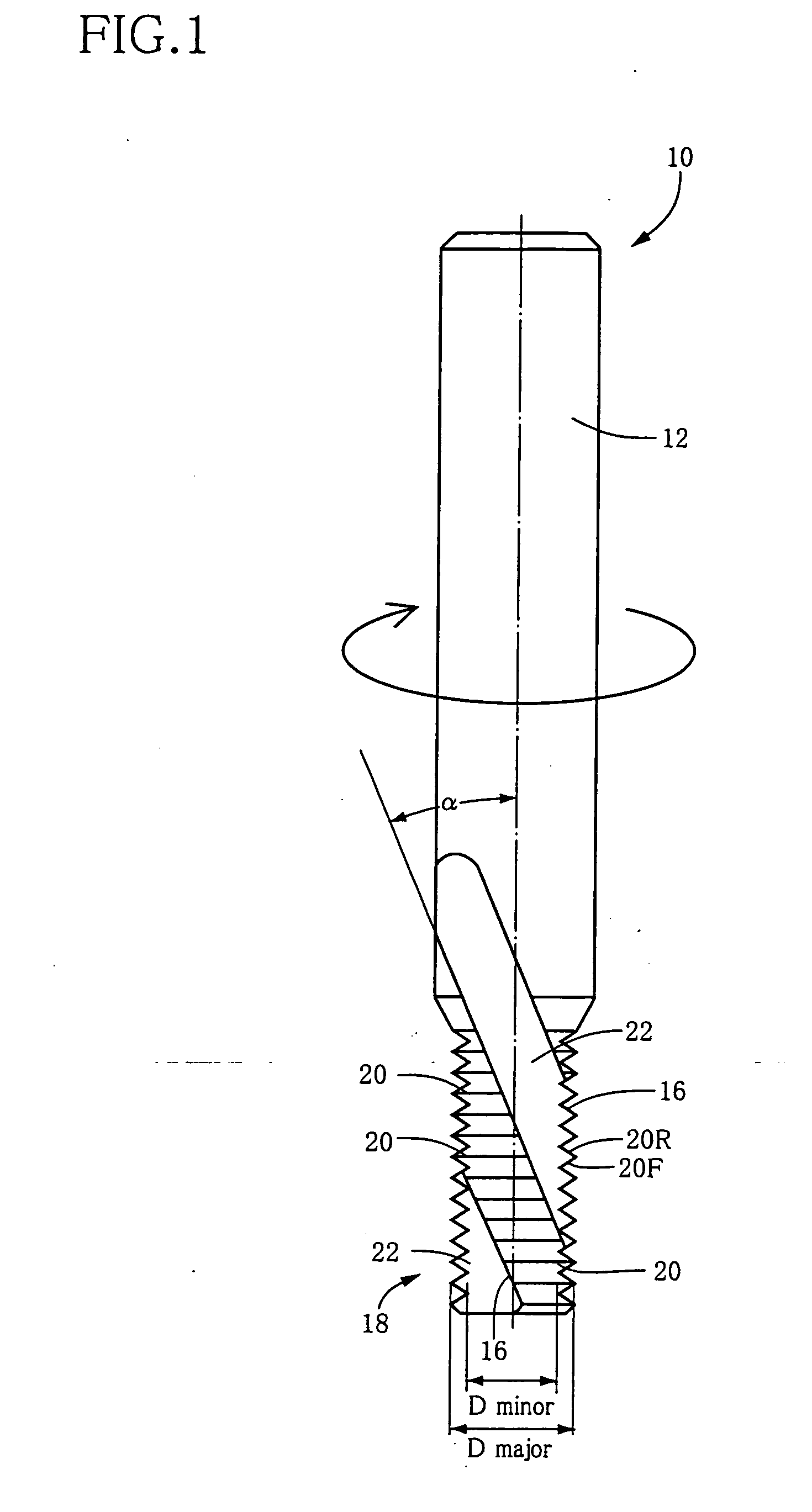

Thread mill having flute twisting in direction opposite to rotating direction

ActiveUS20060233623A1Good cutting sharpnessImprove accuracyThread cutting toolsThread cutting machinesFluteMilling cutter

A thread mill that is to be moved along a helical interpolation path while being rotated about an axis of the thread mill in a rotating direction, for forming a thread in a circumferential surface of a workpiece. The thread mill includes a cylindrical main body having (a) at least one spiral flute formed in an outer circumferential surface of the cylindrical main body, and (b) at least one cutting edge each provided by a rear-side one of widthwise opposite edges, as viewed in the rotating direction, of a corresponding one of the at least one spiral flute. Each of the at least one spiral flute extends in a direction opposite to the rotating direction as viewed in a direction away from a proximal end of the cylindrical main body toward a distal end of the cylindrical main body. Also disclosed is a method of forming the thread by using the thread mill.

Owner:OSG

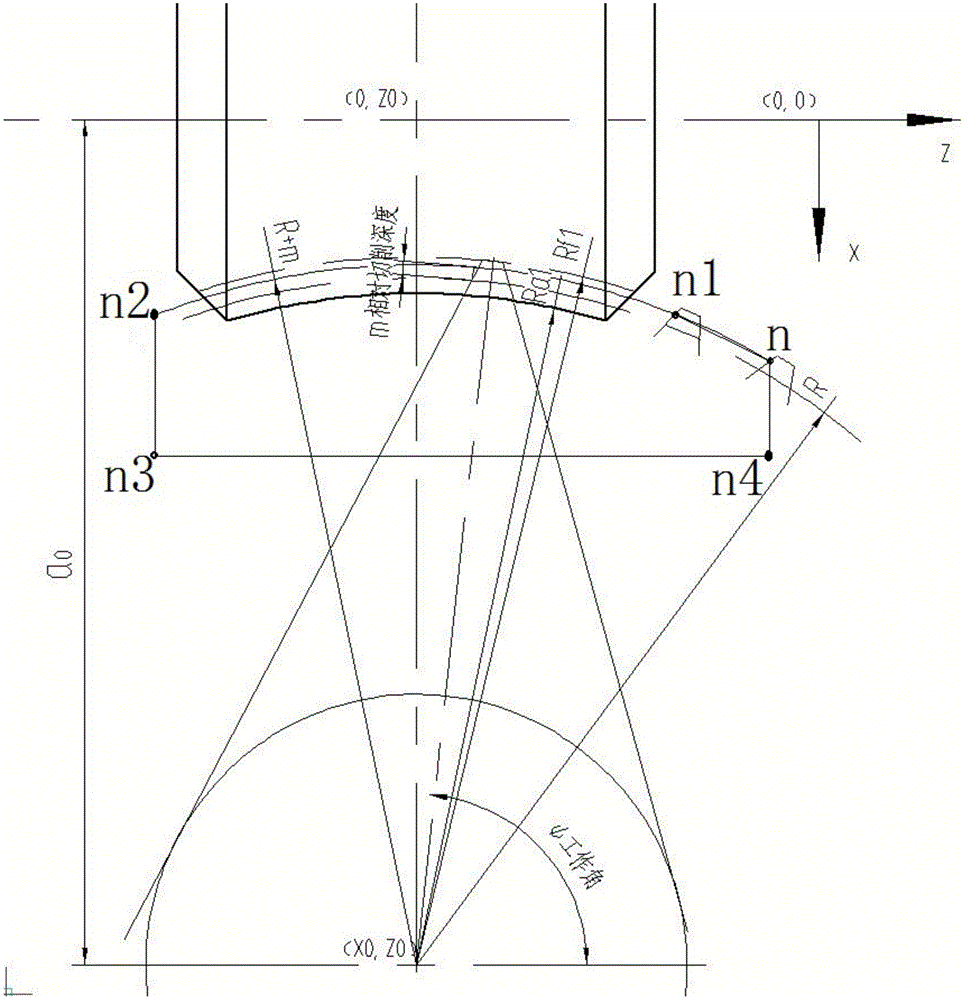

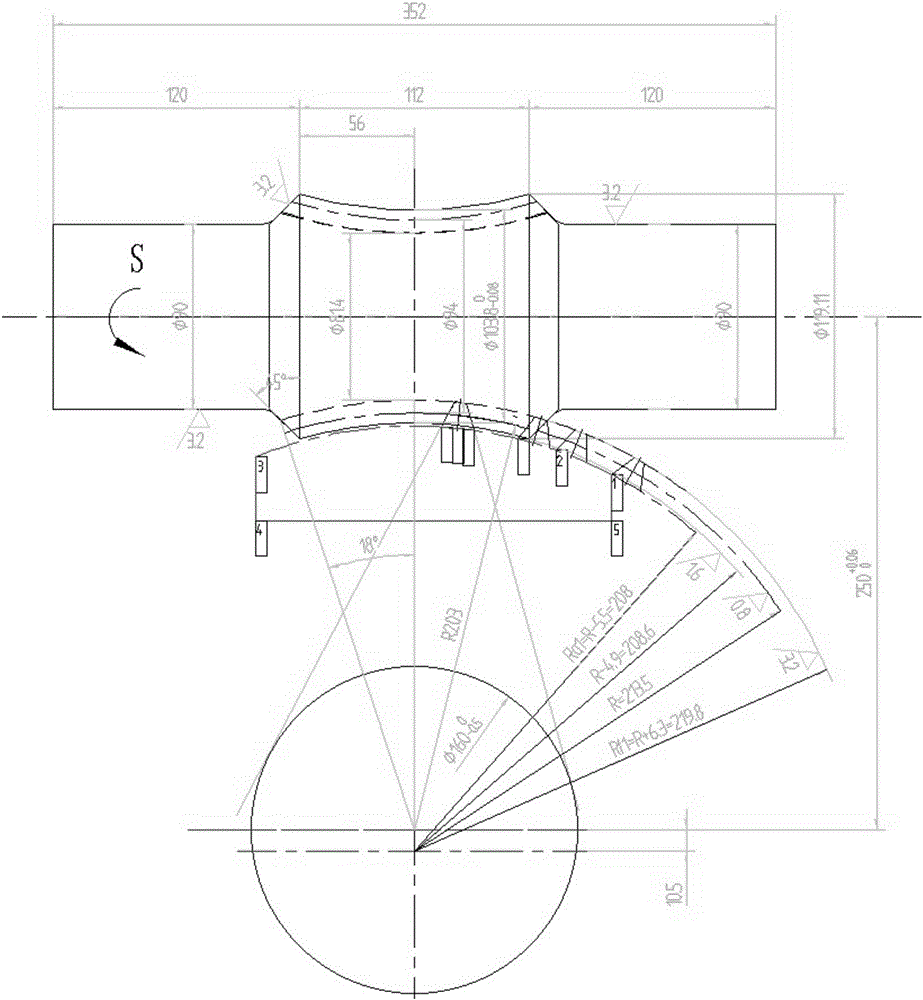

Method for processing helical surface of toroidal worm by numerically controlled lathe

The invention relates to the technical field of turning methods, in particular to a method for processing a helical surface of a toroidal worm by a numerically controlled lathe. The method comprises the following steps of: clamping a to-be-processed worn on the numerically controlled lathe, wherein the plane where the to-be-processed worm is located is S, n and n1 are separately two instantaneous positions, generated when a toothed slot changes as the toroidal worm rotate, of a point on the side surface of a toothed slot in the axial section extending section; moving the tool nose on the corresponding surface of a cut-off tool to the point n, performing bootstrap program for enabling the corresponding tool nose to move to the point n1, carrying out interpolation motion by taking R+m as a cutting radius from the point n1, processing out a circular-arc helical line of one side surface, withdrawing the tool to the initial point n, and cutting a circular-arc helical line of the other side surface in the similar way, thereby completing cutting of the helical surface of the worm. A to-be-processed initial point is determined by performing the bootstrap program, so that the position of the to-be-processed initial point can be accurately determined, dependence on a special numerical-control machine tool is avoided, technical requirements on an operator worker are reduced, manufacturing cost is reduced, the to-be-processed point can be found once, and processing efficiency is greatly improved.

Owner:SINOSTEEL XIAN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com