Five-axis grinding wheel grinding processing method for planar enveloping hourglass worm

A five-axis linkage and plane envelope technology, applied in the direction of worms, belts/chains/gears, components with teeth, etc., can solve the problems of cumbersome adjustment of special grinding heads, difficulty in ensuring accuracy, and limited processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

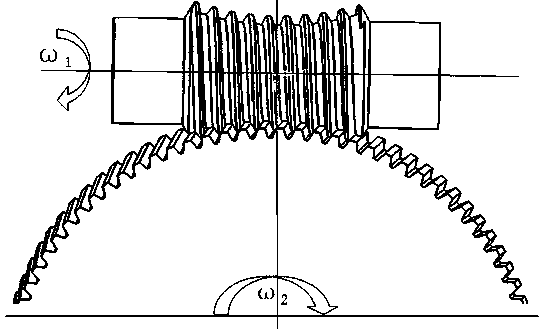

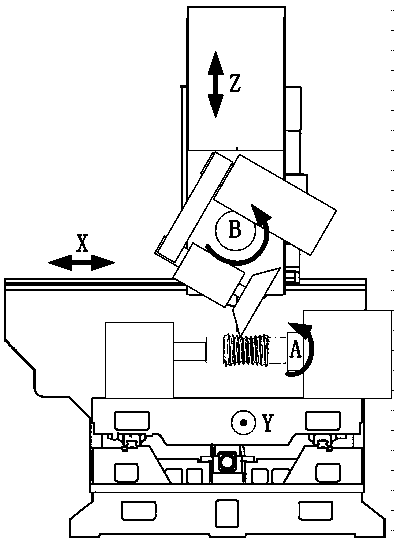

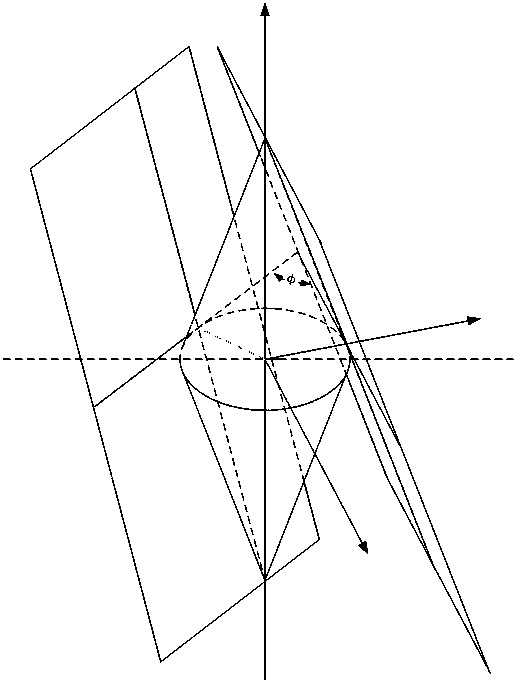

[0035] Such as figure 2 As shown, the five-axis linkage grinding wheel grinding method of the plane enveloping torus worm adopts a five-axis linkage CNC machine tool. The structure of the five-axis linkage CNC machine tool is a single swing head and a single turntable structure, including X-axis and Y-axis , Z axis, rotation axis A, and rotation axis B. The grinding spindle is installed on the rotation axis B. The grinding wheel grinding surface is flat. The axis coincides and rotates with the rotation axis A. According to the forming principle of the plane enveloping toroidal worm, through the five-axis linkage of the machine tool, the grinding plane of the grinding wheel coincides with the tooth surface of the virtual gear, and rotates around the virtual gear rotation axis. At the same time, the workpiece The worm rotates around its own axis. The rotational speed and direction of the two are determined by the direction of rotation and the transmission ratio of the worm pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com