Industrial-robot-based abrasive belt grinding device for profiles of controllable pitch propeller and manufacturing method of abrasive belt grinding device

An industrial robot, abrasive belt grinding technology, applied in abrasive belt grinders, metal processing equipment, grinding/polishing equipment, etc. At the bottom, it is difficult to ensure the processing quality and other problems, so as to shorten the auxiliary time, eliminate occupational hazards, and improve the stability of grinding accuracy and processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing. Embodiments of the present invention include, but are not limited to, the following examples.

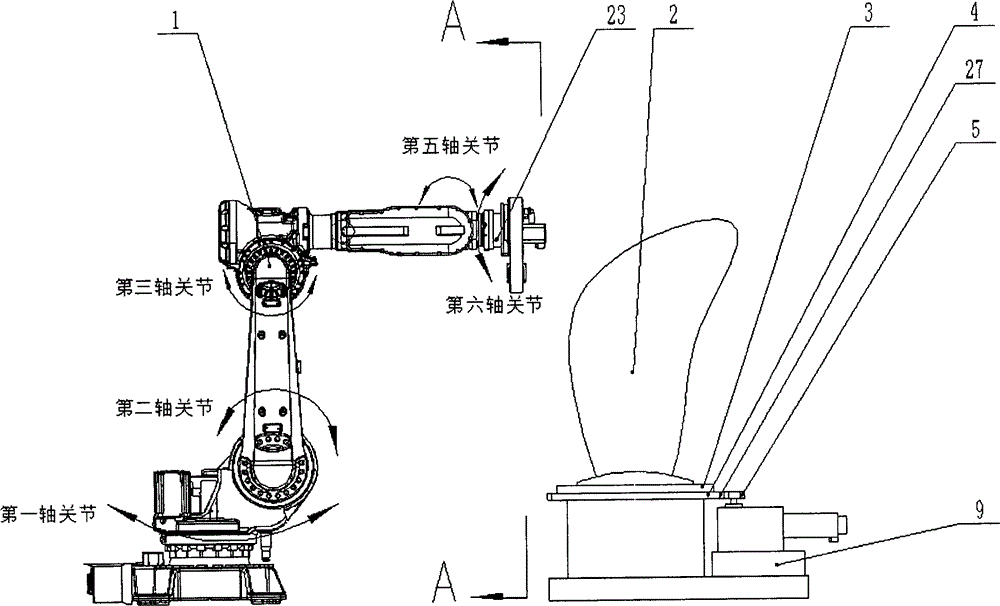

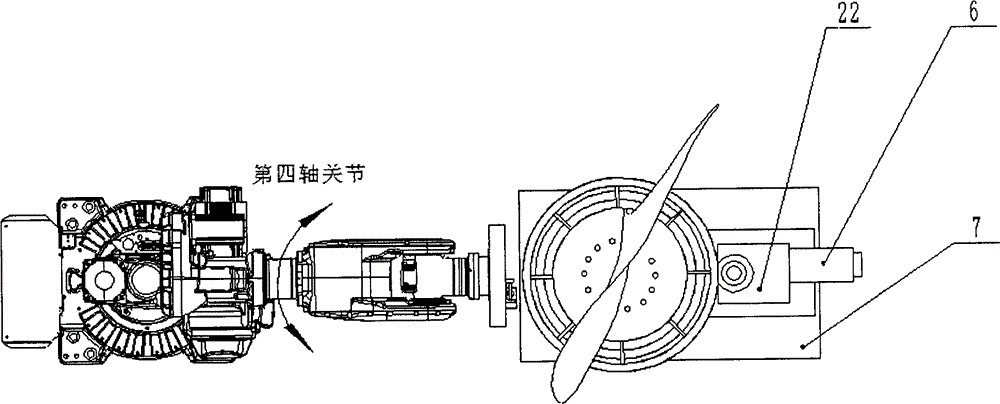

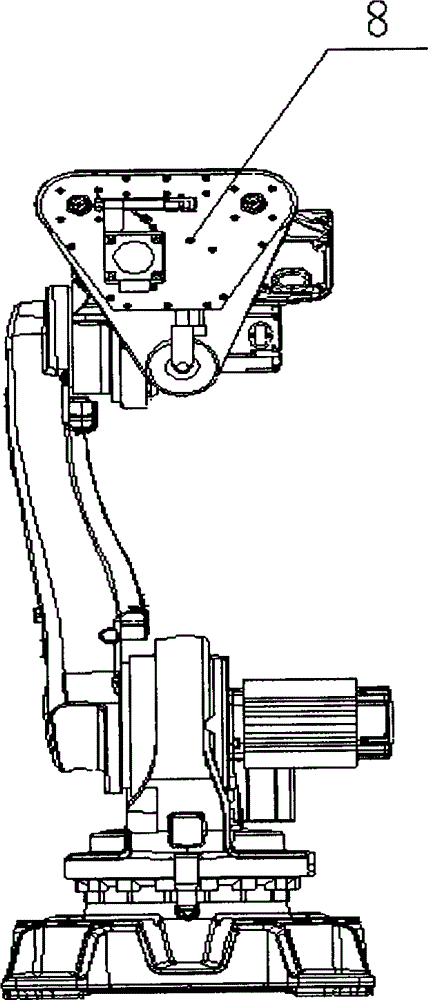

[0035] Such as figure 1 , figure 2 , image 3 Shown is the front view, side view and A-A direction view of a preferred example of the controllable pitch propeller surface abrasive belt grinding device based on the industrial robot of the present invention. It mainly includes a six-degree-of-freedom joint industrial robot 1 installed on the ground through multi-joint joint motion to synthesize different trajectory attitudes for controlling the abrasive belt grinding mechanism device 8, and is set in the working space of the industrial robot and driven by a servo motor 6 to reduce the relevant speed. The box 22 drives the gear meshing to realize the 360° CNC-driven rotary table 3, which is installed and fixed on the CNC rotary table to be processed. The blank part 2 of the marine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com