Patents

Literature

1836 results about "Slewing bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A slewing bearing or slew[ing] ring is a rotational rolling-element bearing that typically supports a heavy but slow-turning or slow-oscillating load, often a horizontal platform such as a conventional crane, a swing yarder, or the wind-facing platform of a horizontal-axis windmill. (To "slew" means to turn without change of place.)

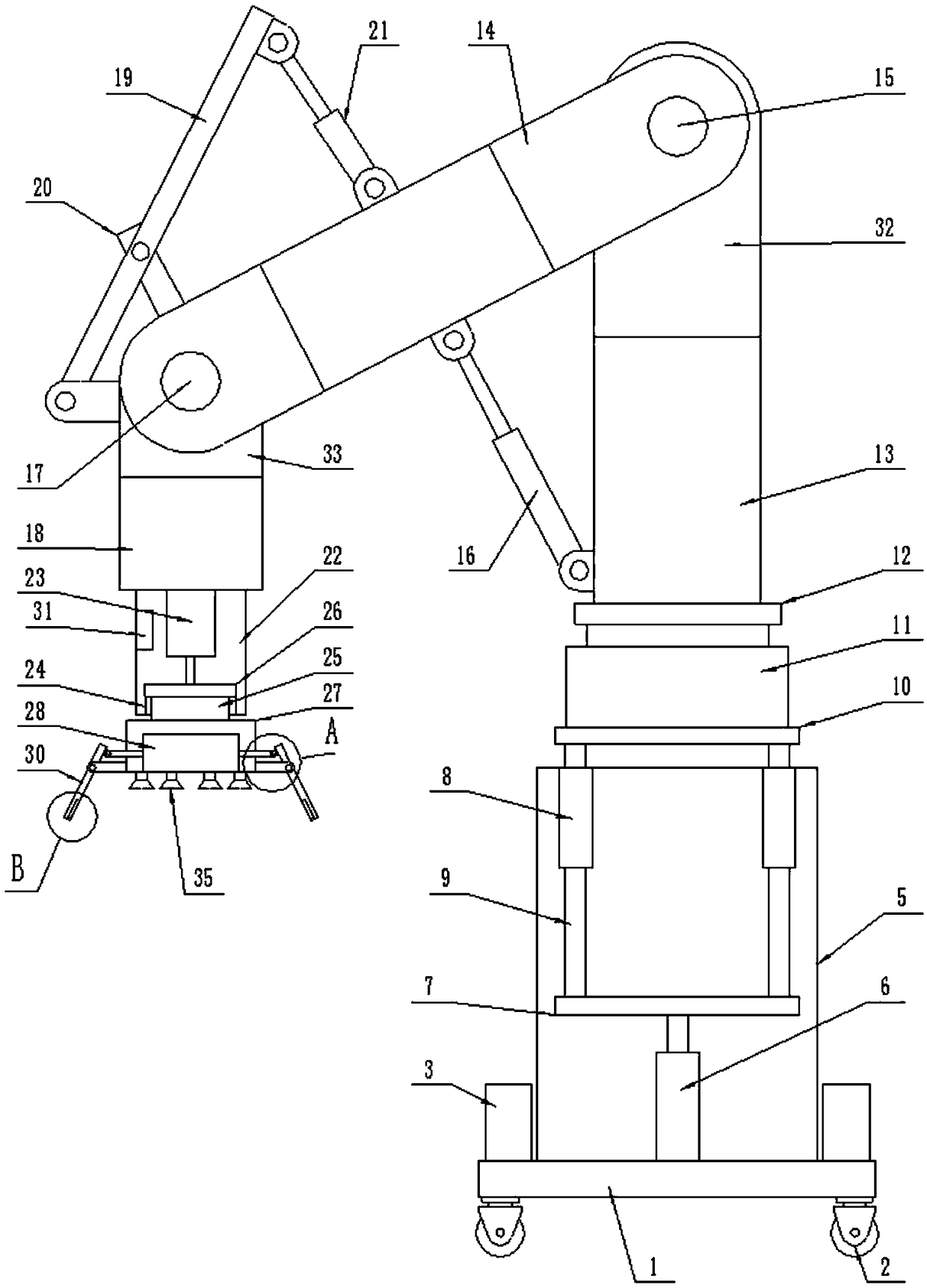

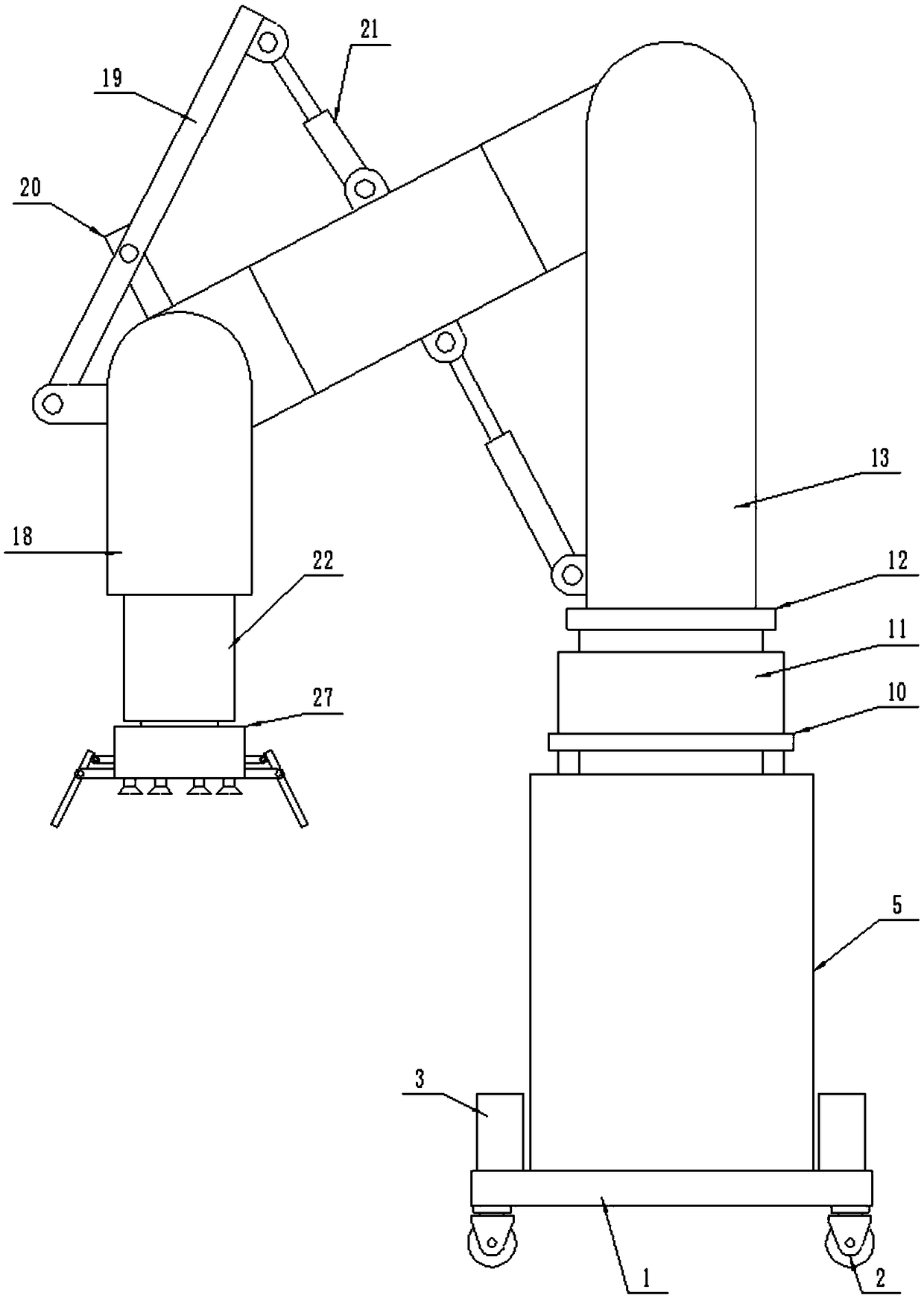

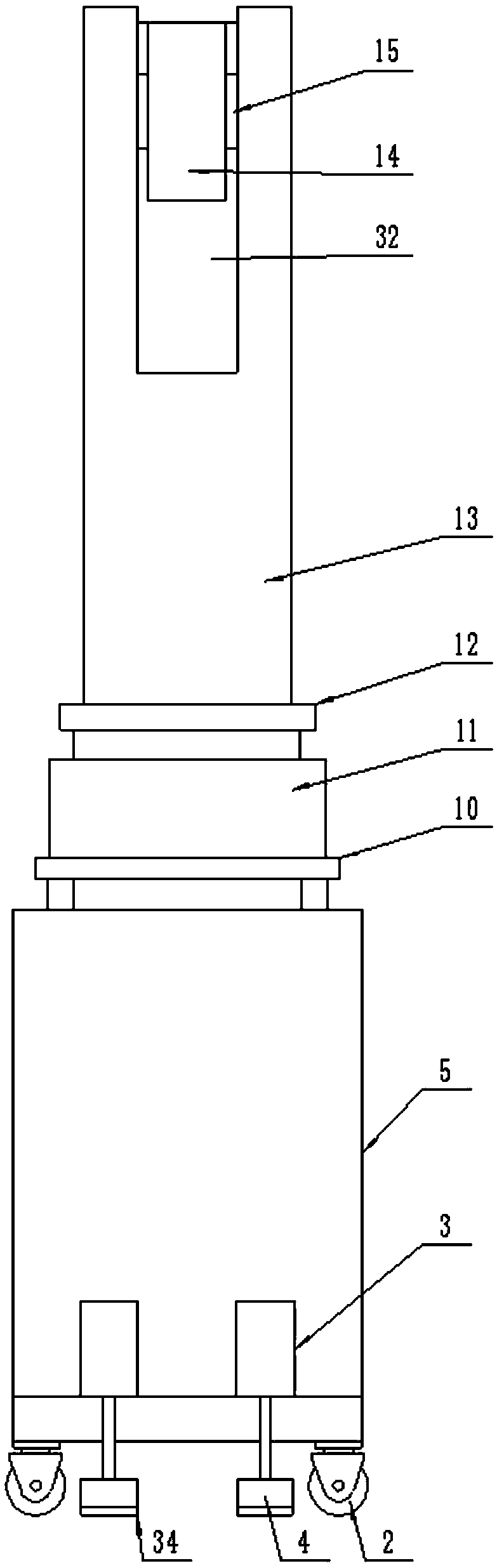

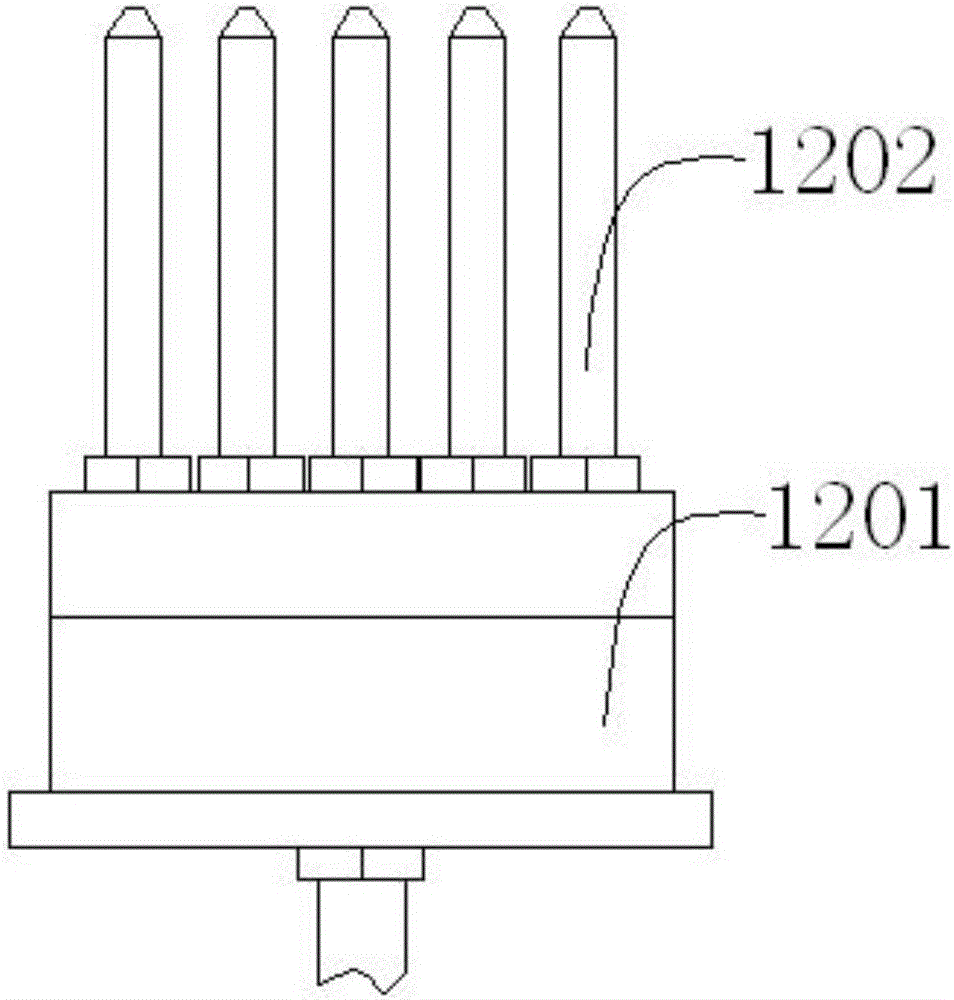

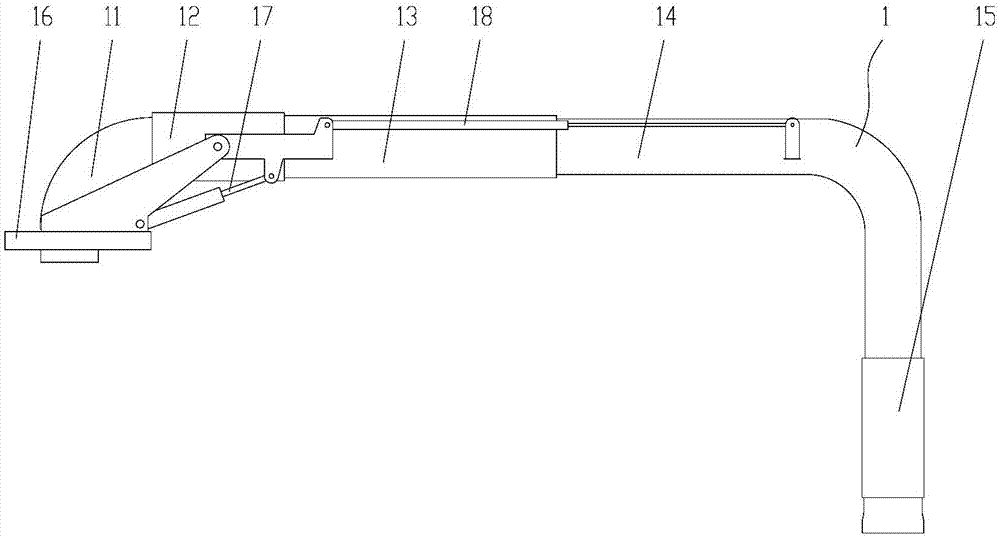

Height-adjustable stacking mechanical arm

InactiveCN108818507AEasy to grabStop fallingProgramme-controlled manipulatorGripping headsHydraulic cylinderEngineering

The invention discloses a height-adjustable stacking mechanical arm comprising a base, a lifting mechanism, an angle regulation mechanism and a clamping mechanism. Universal wheels are arranged at thelower end of the base. A parking cylinder is arranged at the upper end of the base. A parking fixed block is installed at the telescopic end of the parking cylinder. The lifting mechanism comprises arectangular shell, a lifting hydraulic cylinder, a first lifting push plate, a guide sleeve, a guide rod and a second lifting push plate. The angle regulation mechanism comprises a hydraulic rotationoil cylinder, a rotation base, a supporting arm, a first pitching arm, a first rotating shaft, a first bearing, a first pitching regulation hydraulic cylinder, a second rotating shaft, a second pitching arm, a second bearing, a regulation lever, a lever support, a second pitching regulation hydraulic cylinder, a rotation shell, a stepping motor, a rotation bearing, a drum and a turning plate. Theclamping mechanism comprises a clamping shell, a two-way cylinder and a hinge plate. Multiple vacuum suction cups are arranged at the lower end of the clamping shell. The height-adjustable stacking mechanical arm has the beneficial effects of being simple in structure and high in practicability.

Owner:吴晓蝶

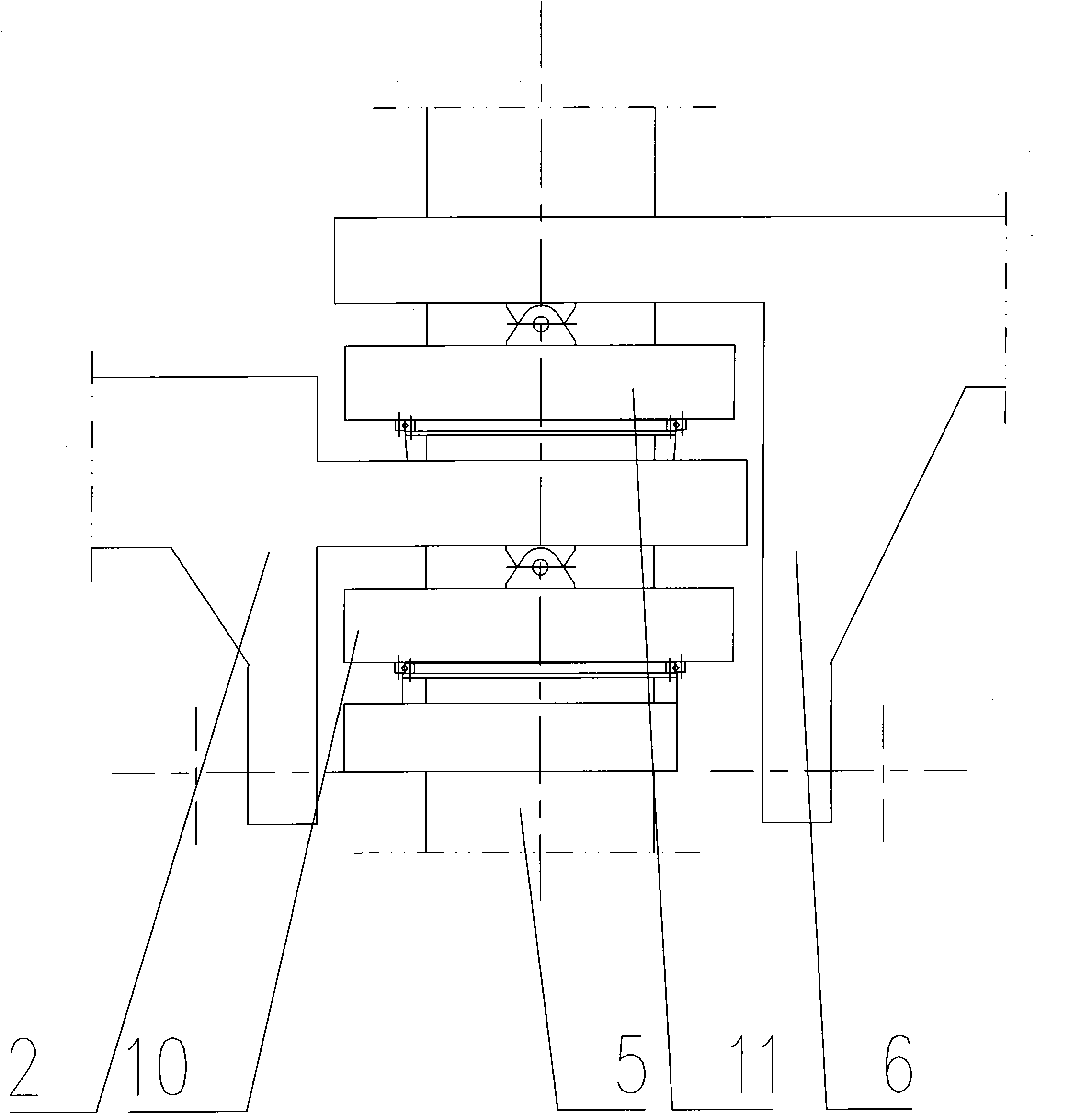

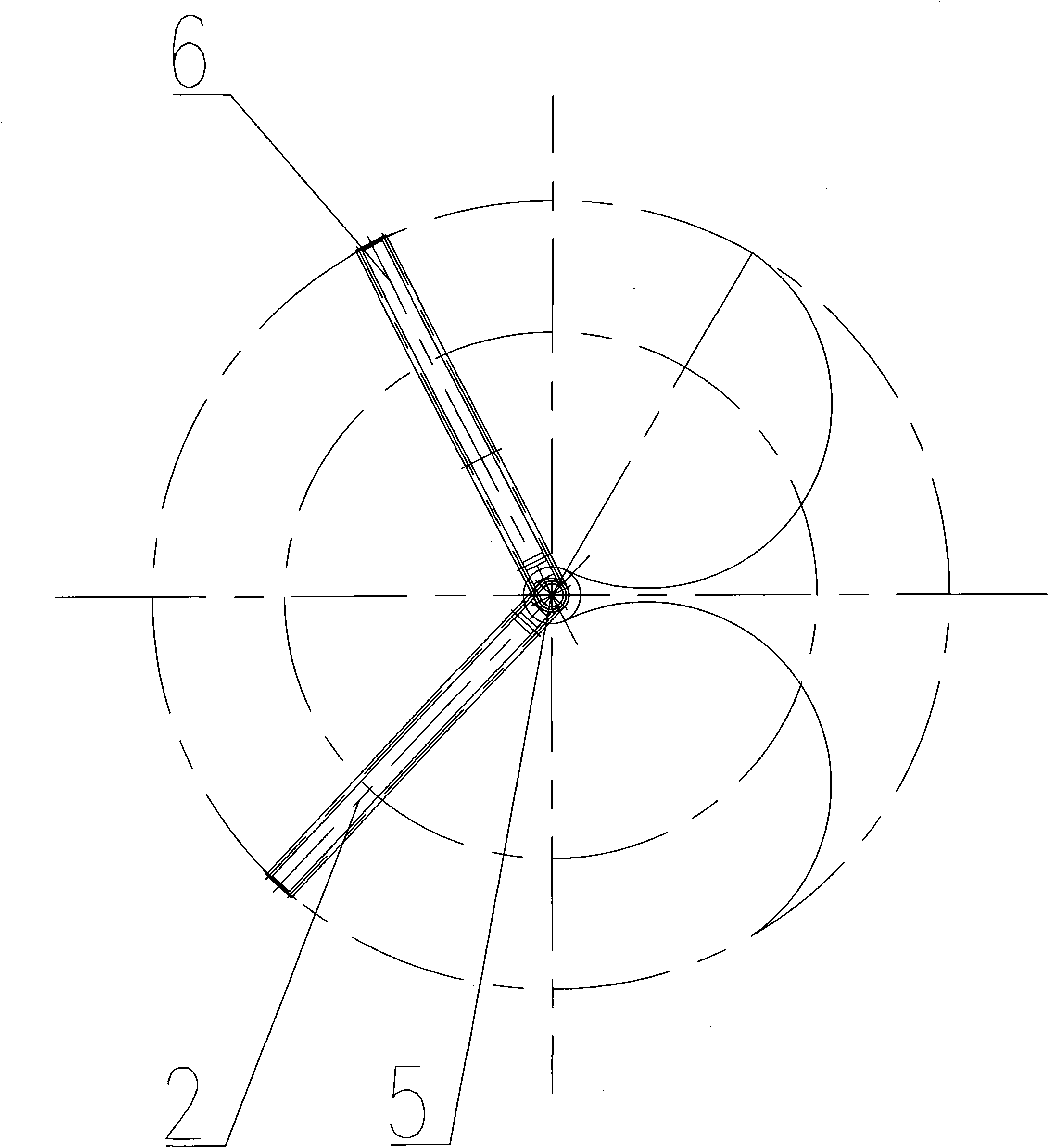

Method for quickly replacing pivotal bearing of bale panoramic tables

The invention relates to a quick-changing method of a bale revolving platform revolution shafting bearing, which is characterized in that four steel pipes are adopted as upright posts; the four upright posts are vertically distributed on the circumference of the base of the bale revolving platform; then a construction method that a jack is transposed and put to compensate a lifting point is adopted; four jacks not less than 200t are entirely utilized to lift a rotation platform at the upper part of a revolution shafting bearing, so as to ensure the revolution shafting bearing to be completely exposed on a groove at the base of bale revolving platform and to move the revolution shafting bearing in parallel for changing. The quick-changing method has the advantages of fast speed of changing the revolution shafting bearing, high safety performance, low construction cost, and high changing quality.

Owner:CHINA MCC 2 GRP CO LTD

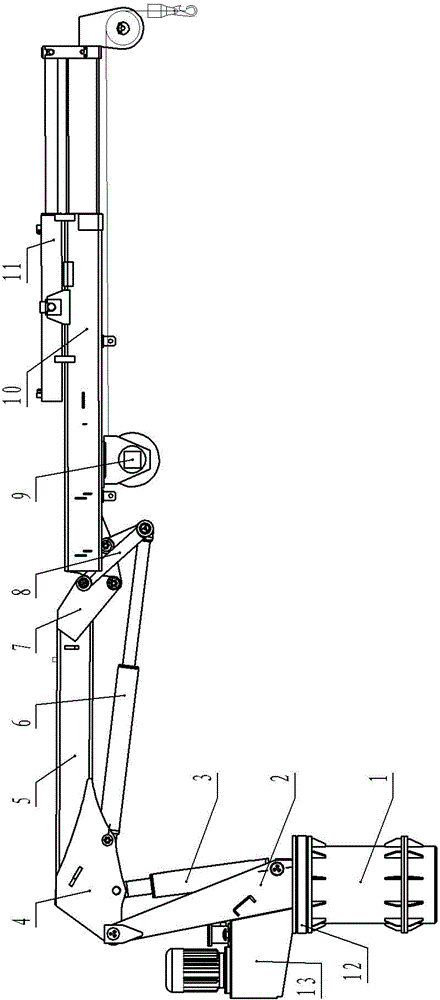

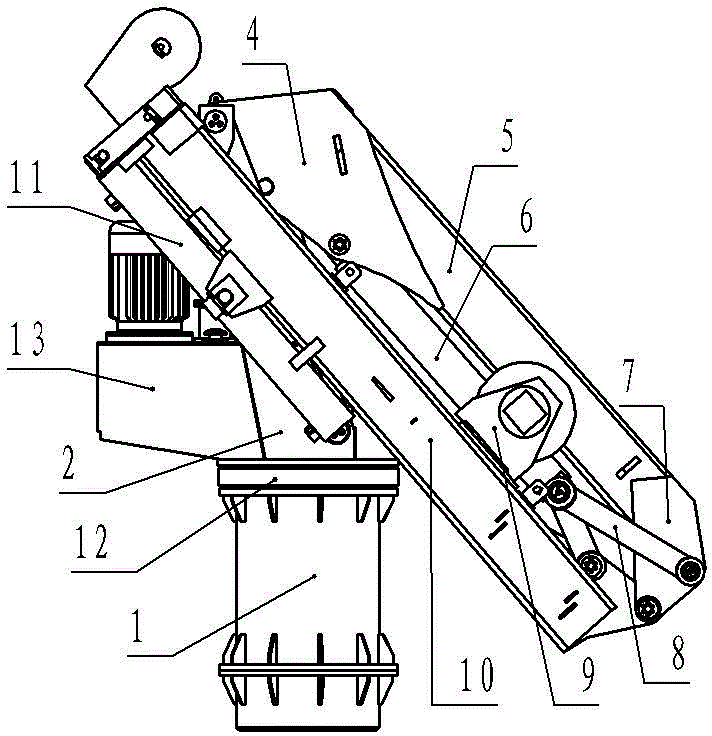

Hydraulic foldable arm telescopic crane for ships

InactiveCN104150372ACompact structureReduce the windward areaCranesManufacturing technologyElectric machinery

The invention discloses a hydraulic foldable arm telescopic crane for ships, belonging to the technical field of ship manufacturing. The crane comprises a base, a vertical column and a telescopic suspension arm, wherein the base is welded on a ship deck substrate; the telescopic suspension arm is controlled by a first cylinder; a hoisting winch is mounted at the lower end of the telescopic suspension arm; an inner arm which is folded through a third cylinder is hinged between the top of the vertical column and the telescopic suspension arm; a second cylinder for folding the telescopic suspension arm is arranged below the inner arm and is hinged with two ends of the inner arm, respectively; the bottom end of the vertical column is connected with the base through a slewing bearing; a pump station and a wireless remote receiver are mounted on the vertical column; the first cylinder, the second cylinder and the third cylinder are all communicated with the pump station; the wireless remote receiver is electrically connected with a motor of the pump station through a controller. By adopting the hydraulic foldable arm telescopic crane, the problem that the running speed of a ship body is affected as a crane for the ship can only operate in a single direction and cannot be folded up is solved.

Owner:GUANGXI WUZHOU YUNLONG PORT & SHIP MACHINERY MFG

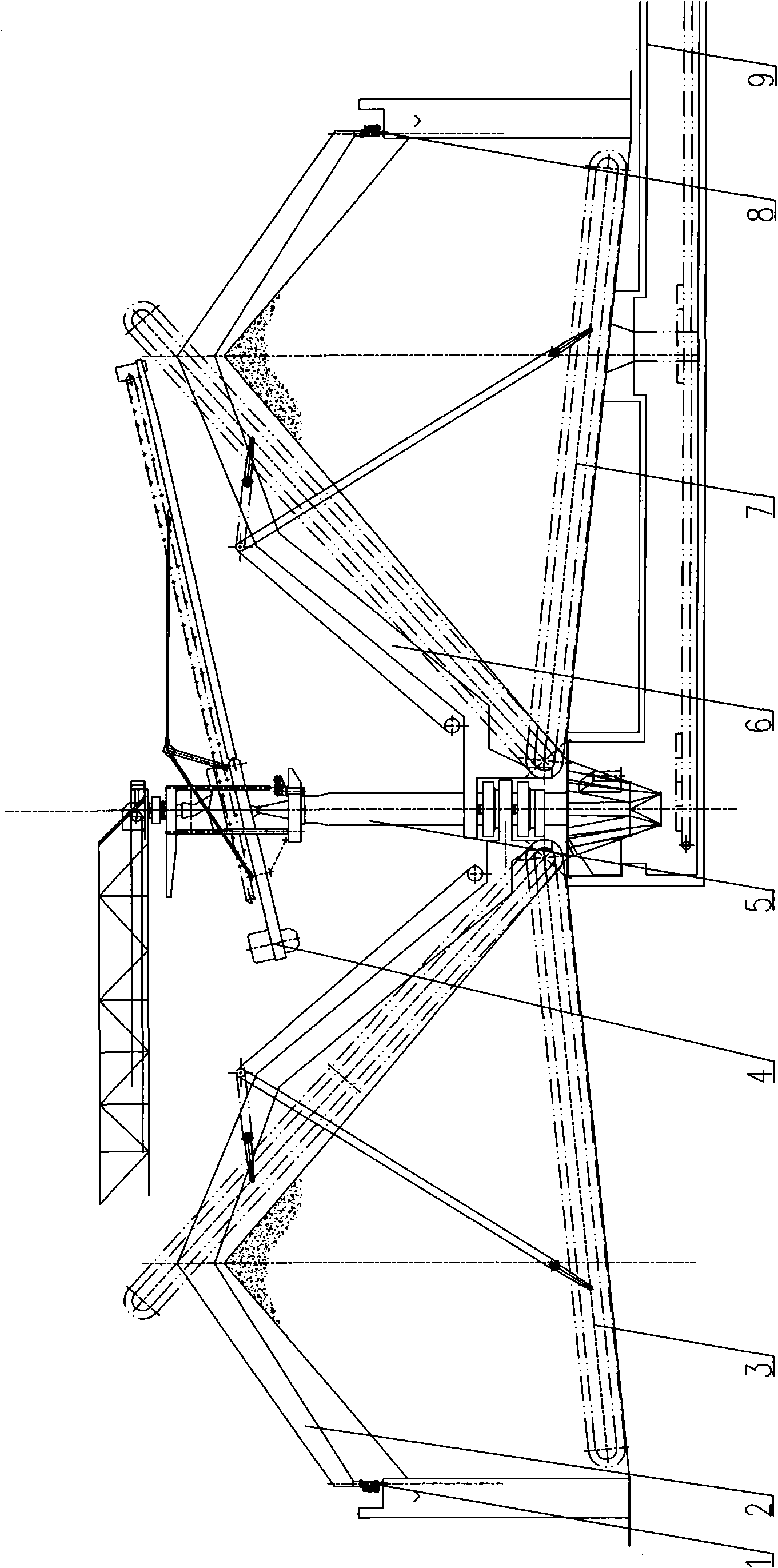

Double-portal type round stock ground scraper stacker-reclaimer

The invention discloses a double-portal type round stock ground scraper stacker-reclaimer, comprising a center stand column, a travelling device I, a portal I, a scraper reclaimer I, a rotary steel structure I, a cantilever stocker, a travelling device II, a portal II, a scraper reclaimer II and a rotary steel structure II, wherein the center stand column is fixed on ground foundation in the center of a stock ground; the cantilever stocker, the portal I and portal II respectively rotate by taking the center stand column as the center of rotation; the rotary steel structure I is connected with the center stand column by a rotary bearing, one end of the portal I is hinged with the rotary steel structure I, the other end is supported on the travelling device I operating on the round orbit on the upper part of a stock stop wall; one end of the scrapper reclaimer I is hinged with the lower part of the portal I, and the other end is hung on the portal I; the rotary steel structure I is positioned below the rotary steel structure II, and the device I and the device II are arranged in the same way. In the invention, two scraper reclaimers arranged on respective portal take two stocks simultaneously, thus realizing the purpose of mixing evenly, and having simple structure and high production efficiency.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

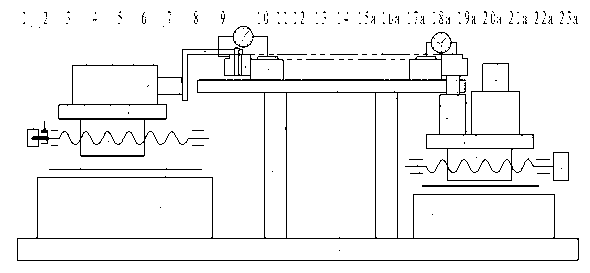

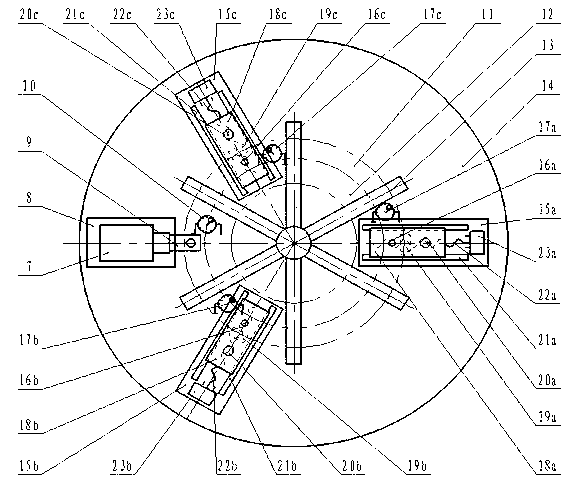

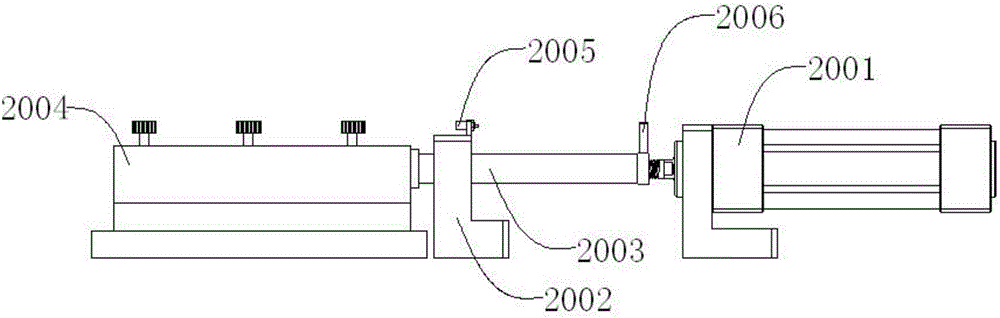

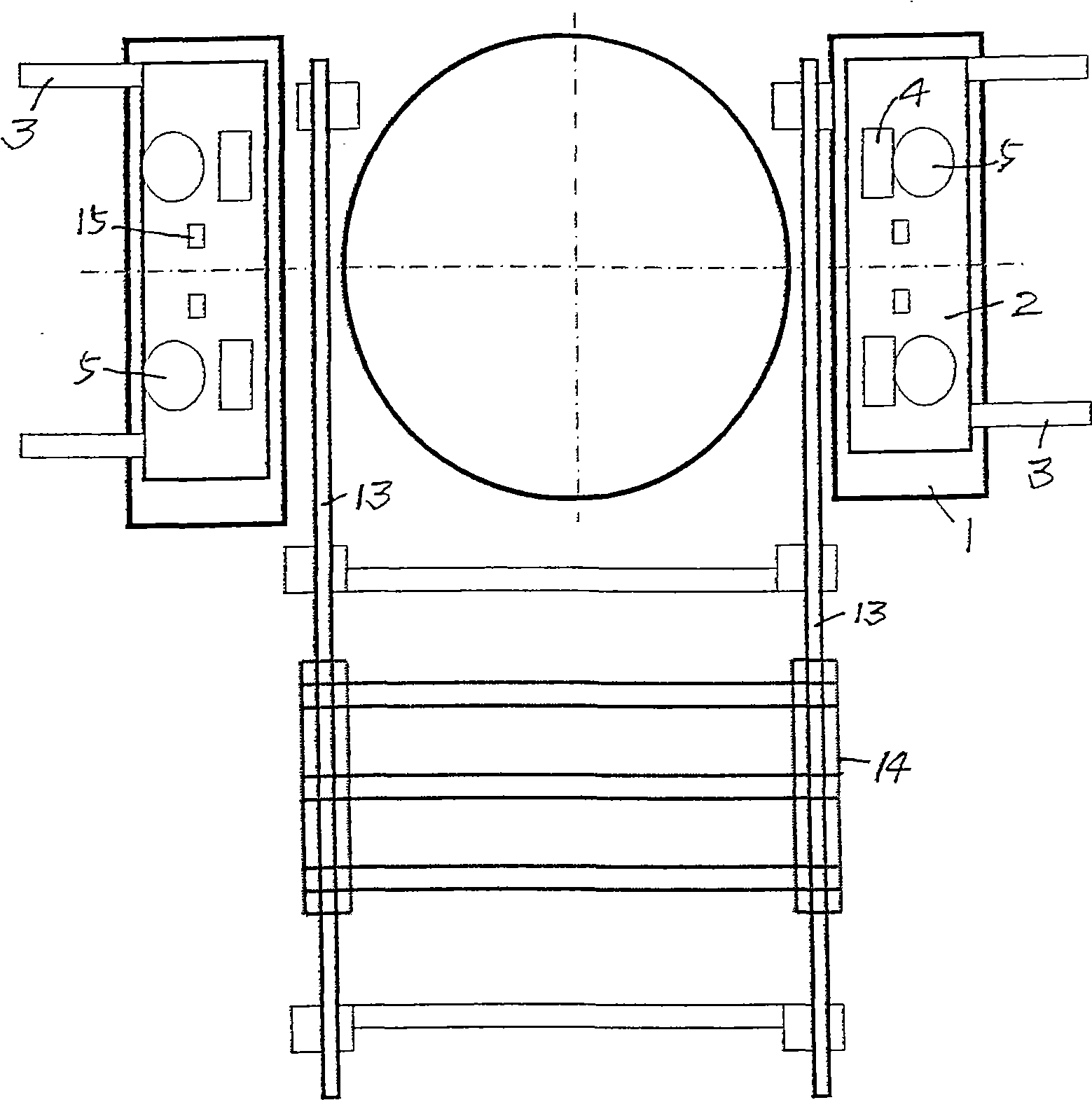

Slewing bearing ferrule circular degree error automatic detection and correction device

InactiveCN103341530ASmall starting torqueImprove running smoothnessElectric/magnetic contours/curvatures measurementsMetal working apparatusFourier transform on finite groupsEngineering

The invention provides a slewing bearing ferrule circular degree error automatic detection and correction device, and belongs to the technical field of industrial detection and correction. The slewing bearing ferrule circular degree error automatic detection and correction device comprises a lathe bed, ferrule supporting and slewing driving devices, circular degree error detection devices, circular degree error correction devices, lifting and warping-resisting devices and a data collecting operation and display system. The ferrule supporting and slewing driving devices support a slewing bearing ferrule to rotate for one circle, the data collecting operation and display system collects the data output by the circular degree detection devices, the circular degree error values, the correction positions and the correction strokes can be obtained, and the circular degree error correction devices automatically carry out pressure correction according to the calculated results. According to the slewing bearing ferrule circular degree error automatic detection and correction device, the lifting and warping-resisting devices are adopted so that interferences between detection and correction and planar warping of the ferrule can be avoided, three eddy-current sensors are adopted in the circular degree error detection devices, the discretion fast Fourier transform is carried out on the collected signals so that the interferences of the eccentric errors of the slewing bearing ferrule can be eliminated, and the detection accuracy is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

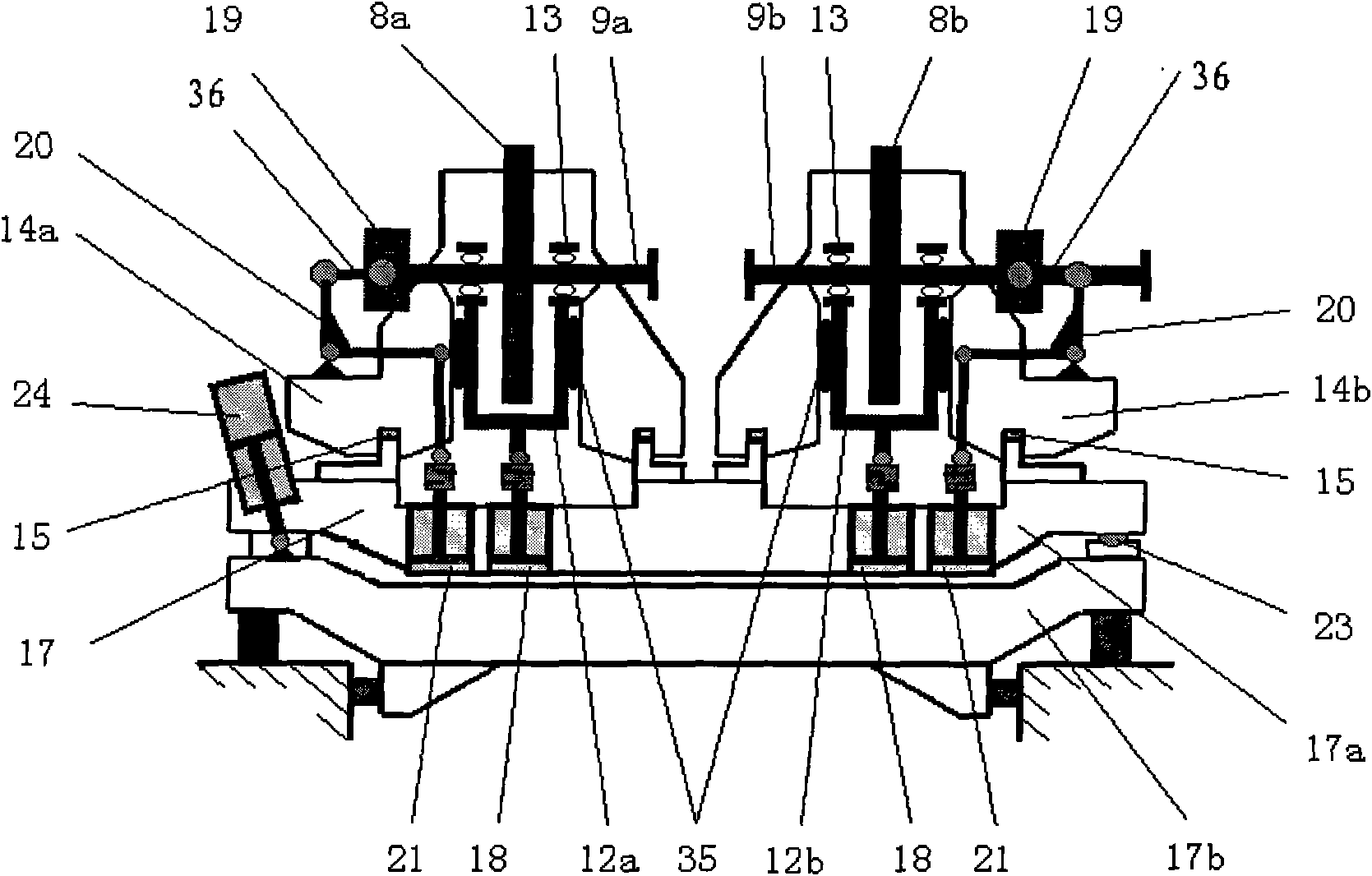

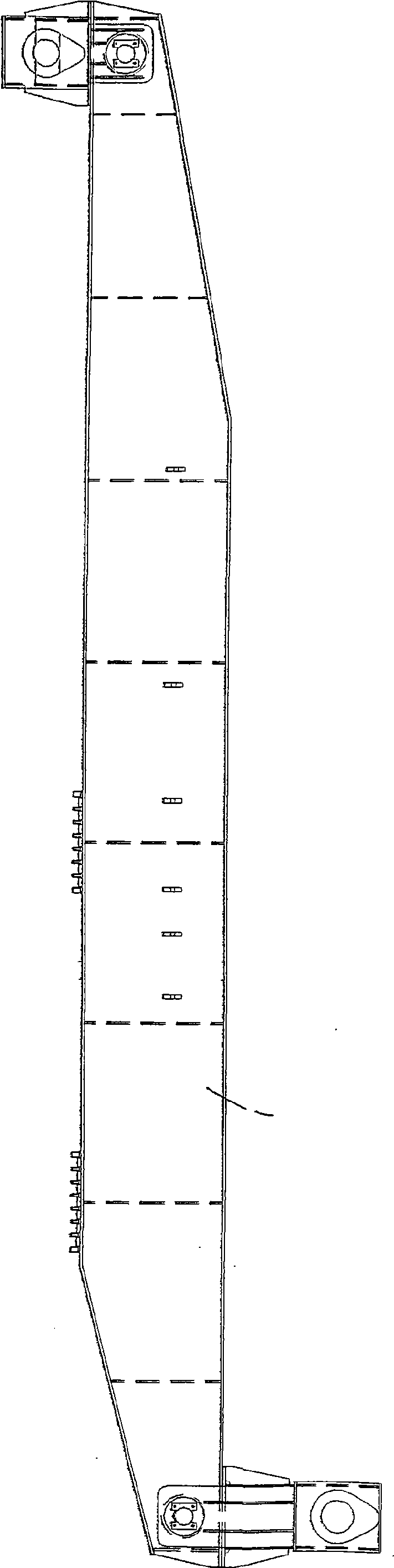

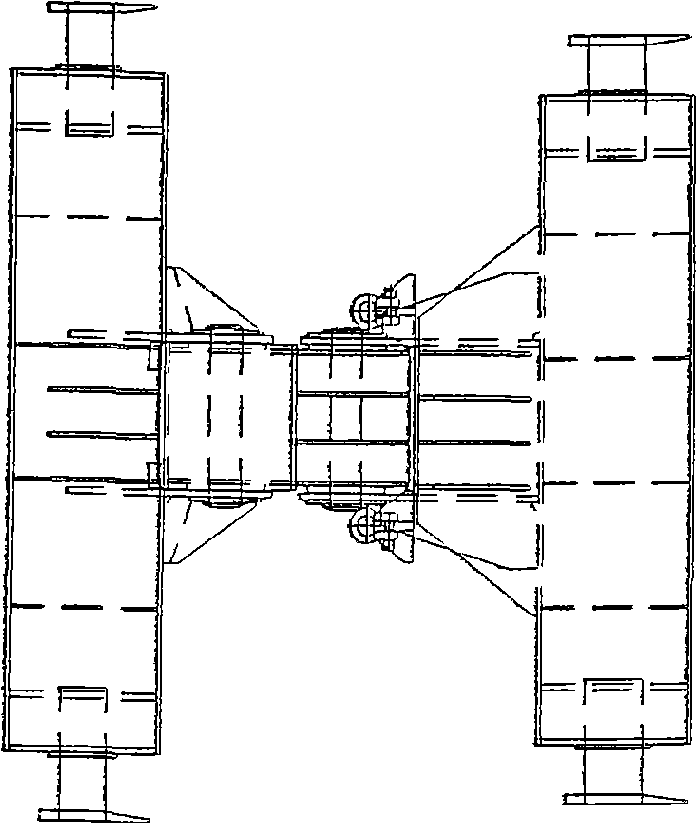

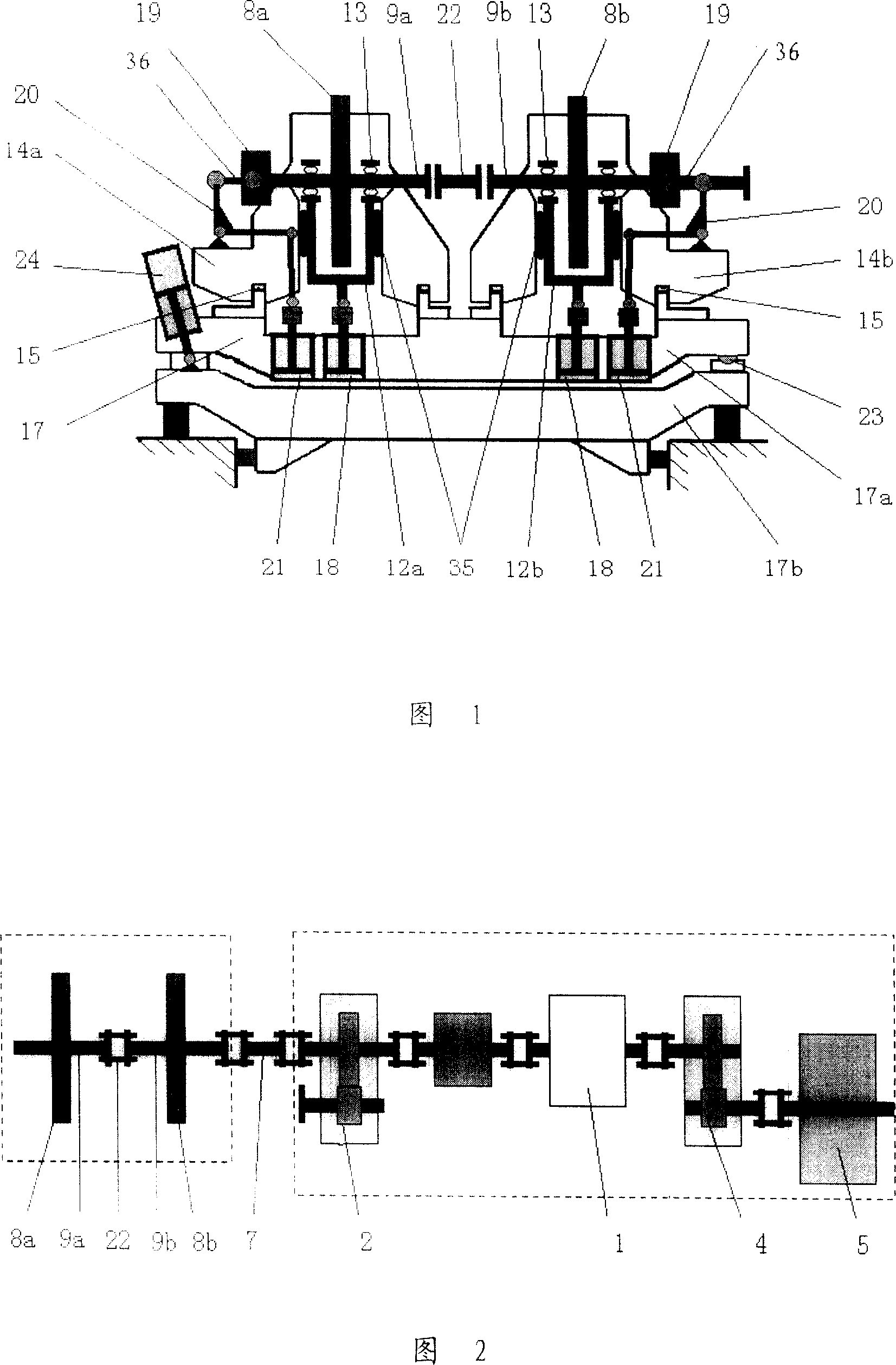

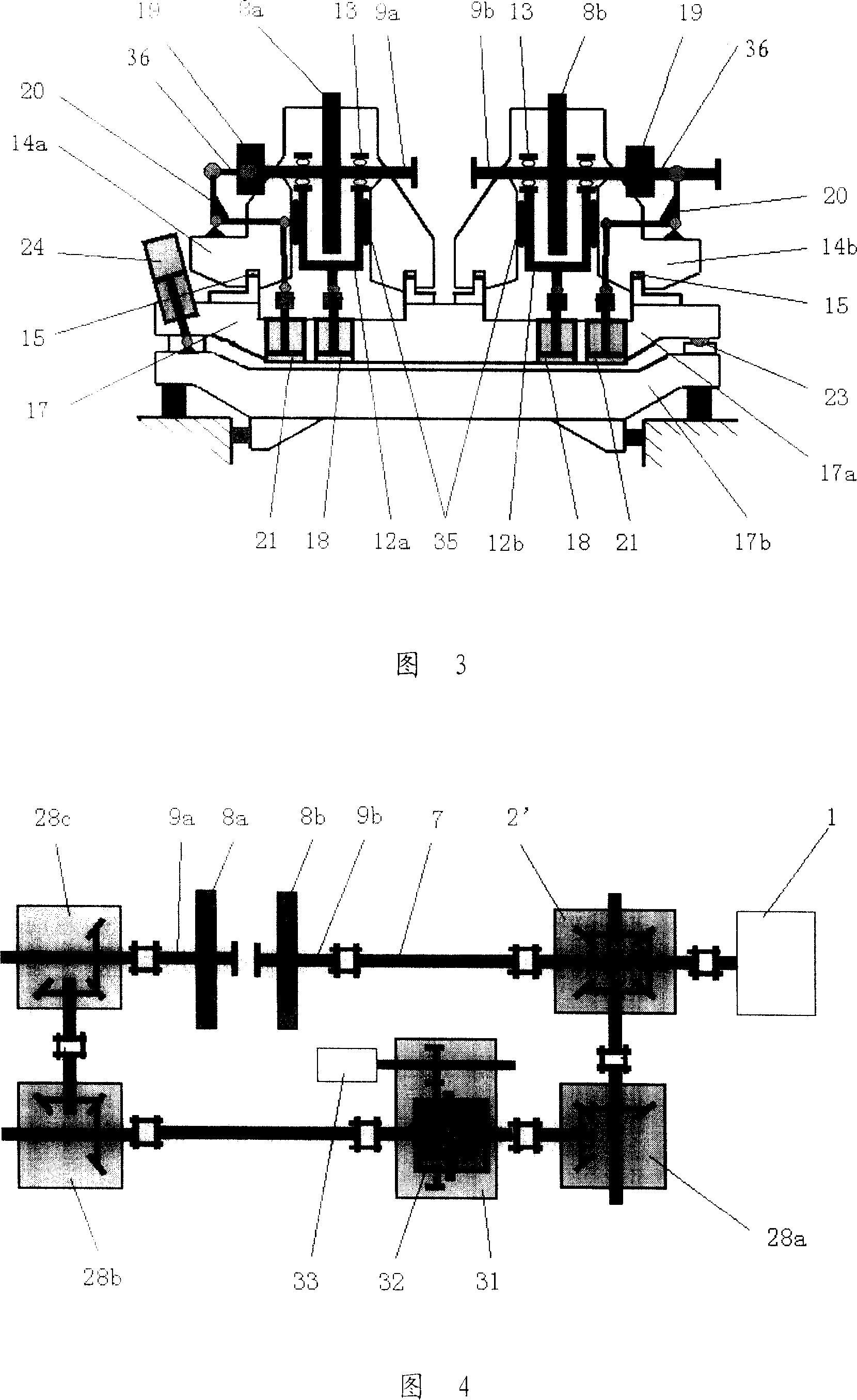

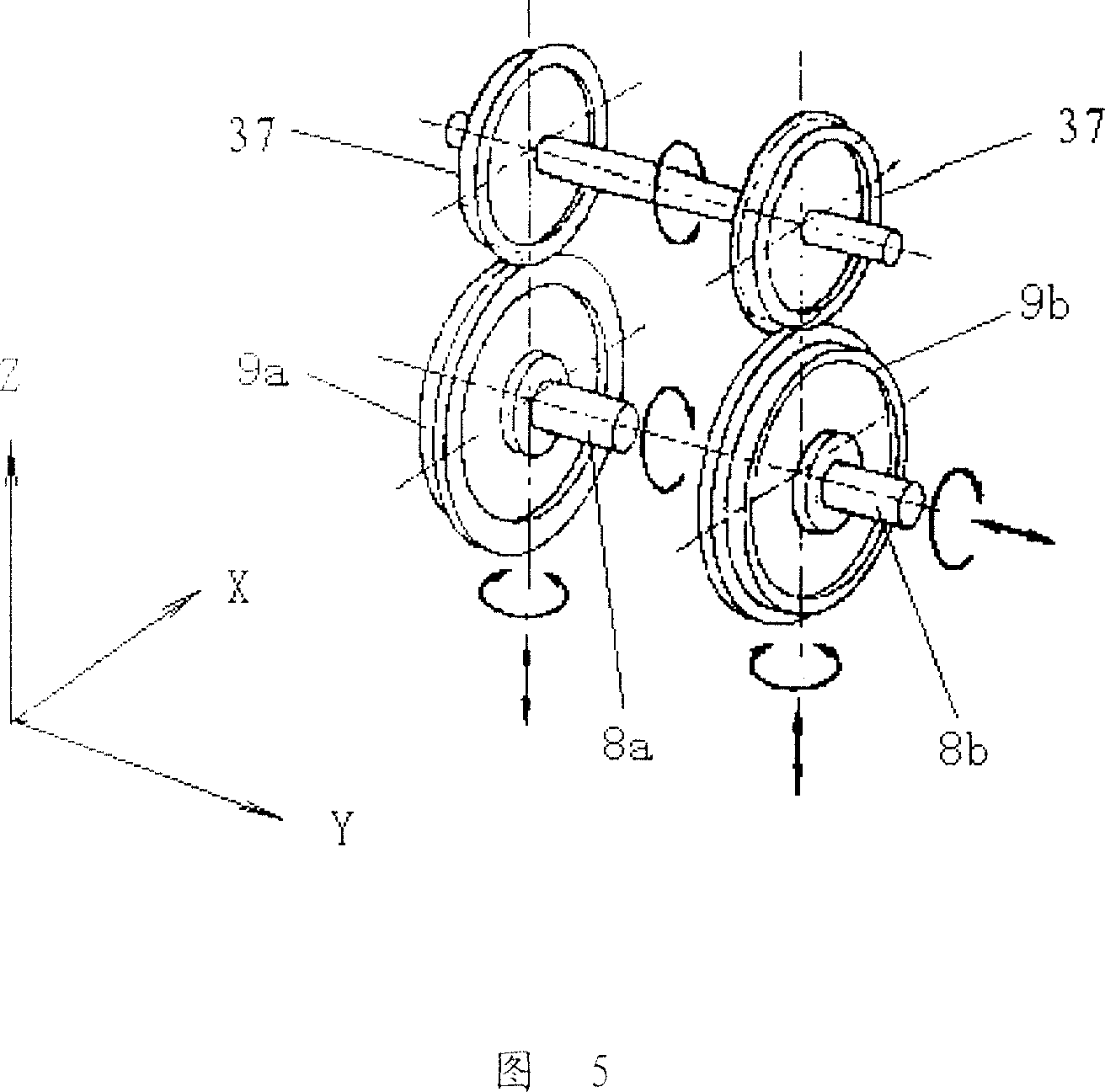

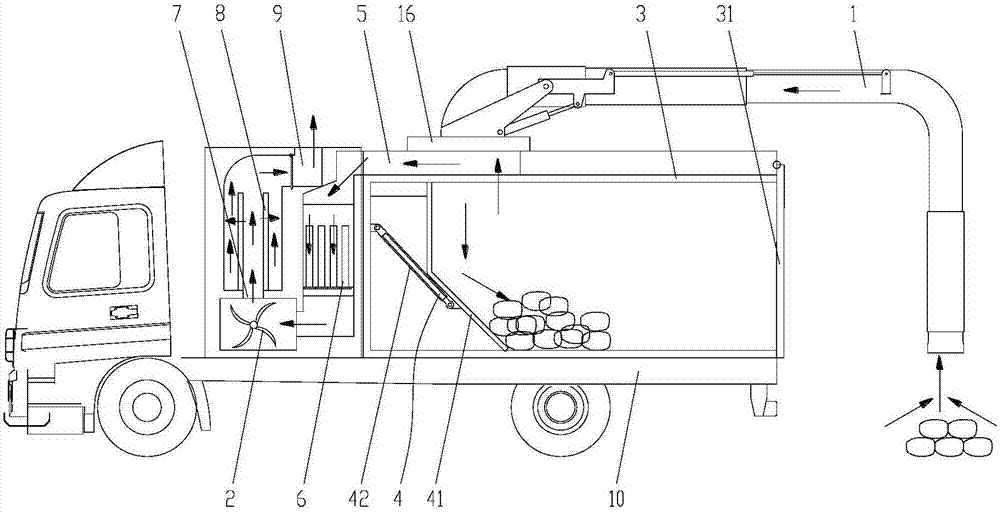

Emulation test bench for vehicle operating of rail locomotive based on differentia transmission

InactiveCN101587022AVertical irregularity is trueSimulation of vertical irregularitiesRailway vehicle testingEngineeringSlewing bearing

An emulation test bench for vehicle operating of rail locomotive based on differentia transmission is composed of a plurality of test units each having the structure as follows: a driving mechanism is connected with a left and a right rollers, which are supported on a left and a right U-shaped frames which are mounted on the inner walls of the left and right roller bases through vertical linear bearings on the side walls thereof; the left and right roller bases are mounted on a base, on which the bottoms of the left and right U-shaped frames are connected through a vertical hydraulic vibration exciter; the external ends of the left and right roller shafts are connected with a transverse hydraulic vibration exciter which is fixed on the base; and the left and right roller bases are mounted on the base through a revolving bearing and is connected with a revolving vibration exciter thereof. The test bench can simulate the motion of locomotives on railways, the smooth operation state of locomotives, perturbations on the lines irregular vertically and transversely and bended laterally and transversely, and the moving sate of locomotives on curved lines.

Owner:SOUTHWEST JIAOTONG UNIV

Integral replacing method of ladle turret with limited upper lifting space

The invention provides a method for replacing a whole large-ladle revolving platform when an upper lifting space is limited, which can quickly replace a revolving bearing and a pedestal and has higher safety, short construction period and lower construction cost. The method comprises the following steps: making a shoulder-pole beam pass through the upper middle of the revolving platform, and using two hooks of an overhead crane to hook both ends of the shoulder-pole beam; filling cushion blocks on upper parts of connecting rod holes for connecting rods to pass through on a box body, and making upper parts of the connecting rods contact the bottoms of the cushion blocks; taking four connecting rods on the upper part of the revolving platform as suspension centers, and using suspension bands to bundle the four connecting rods and the shoulder-pole beam; lifting the shoulder-pole beam, making a revolving body above the revolving bearing lifted for a certain distance along with the shoulder-pole beam, horizontally moving the shoulder-pole beam, and driving the revolving body to be deviated from an axial line of the revolving platform; using a hanger to lift away the prior revolving bearing and the prior pedestal, and placing a novel revolving bearing and a novel pedestal; and assembling the revolving body.

Owner:CHINA 19TH METALLURGICAL CORP

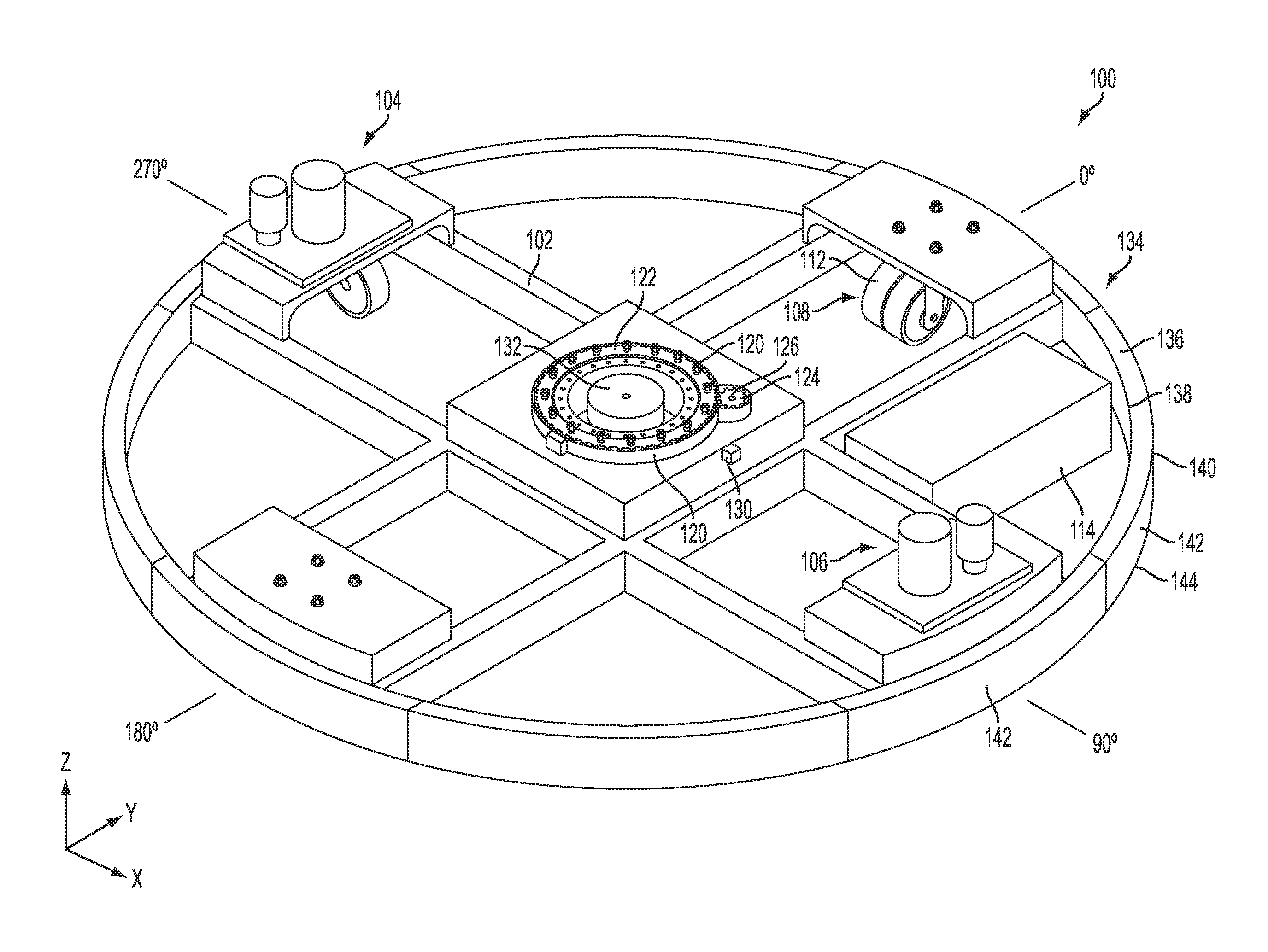

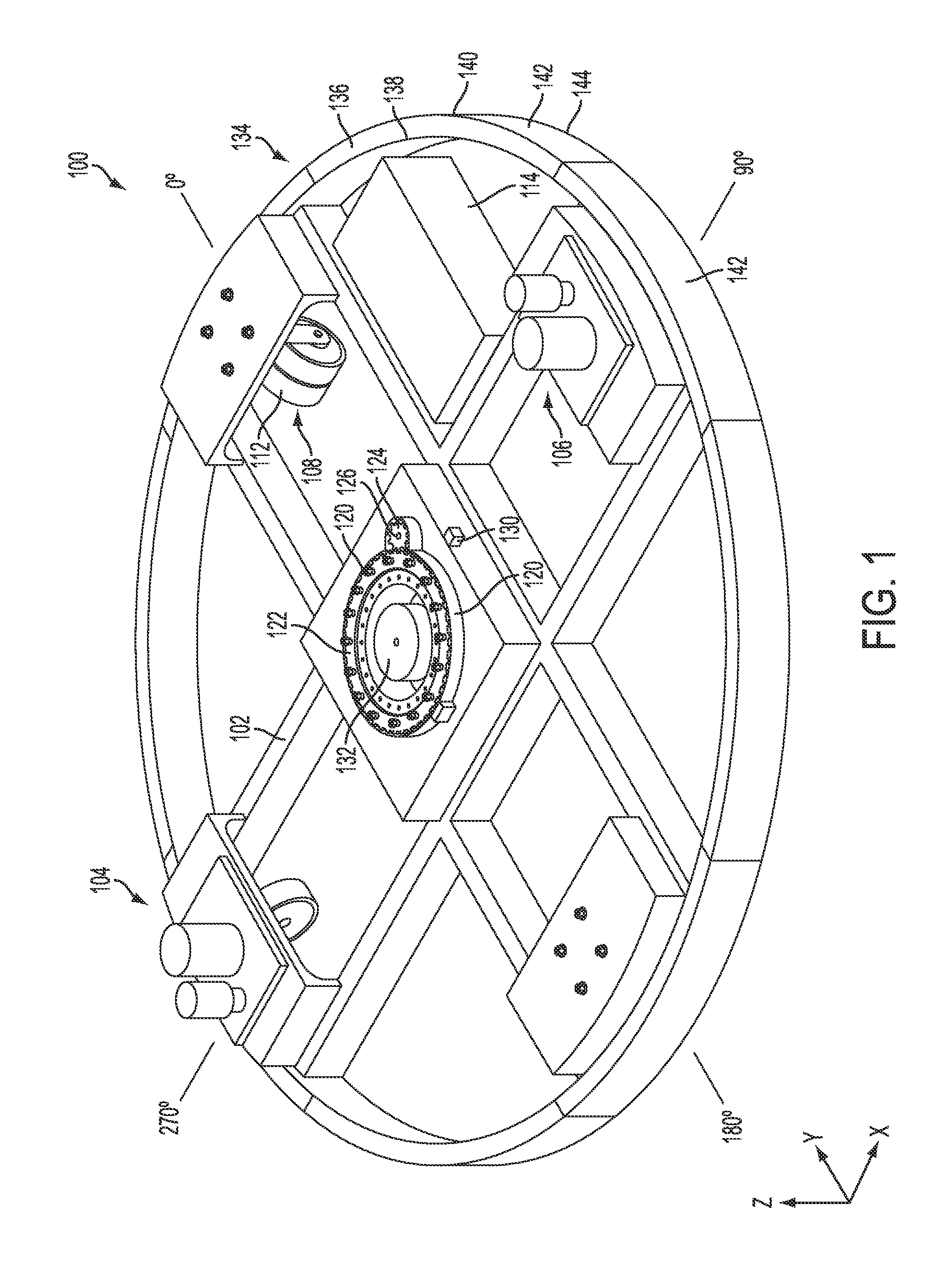

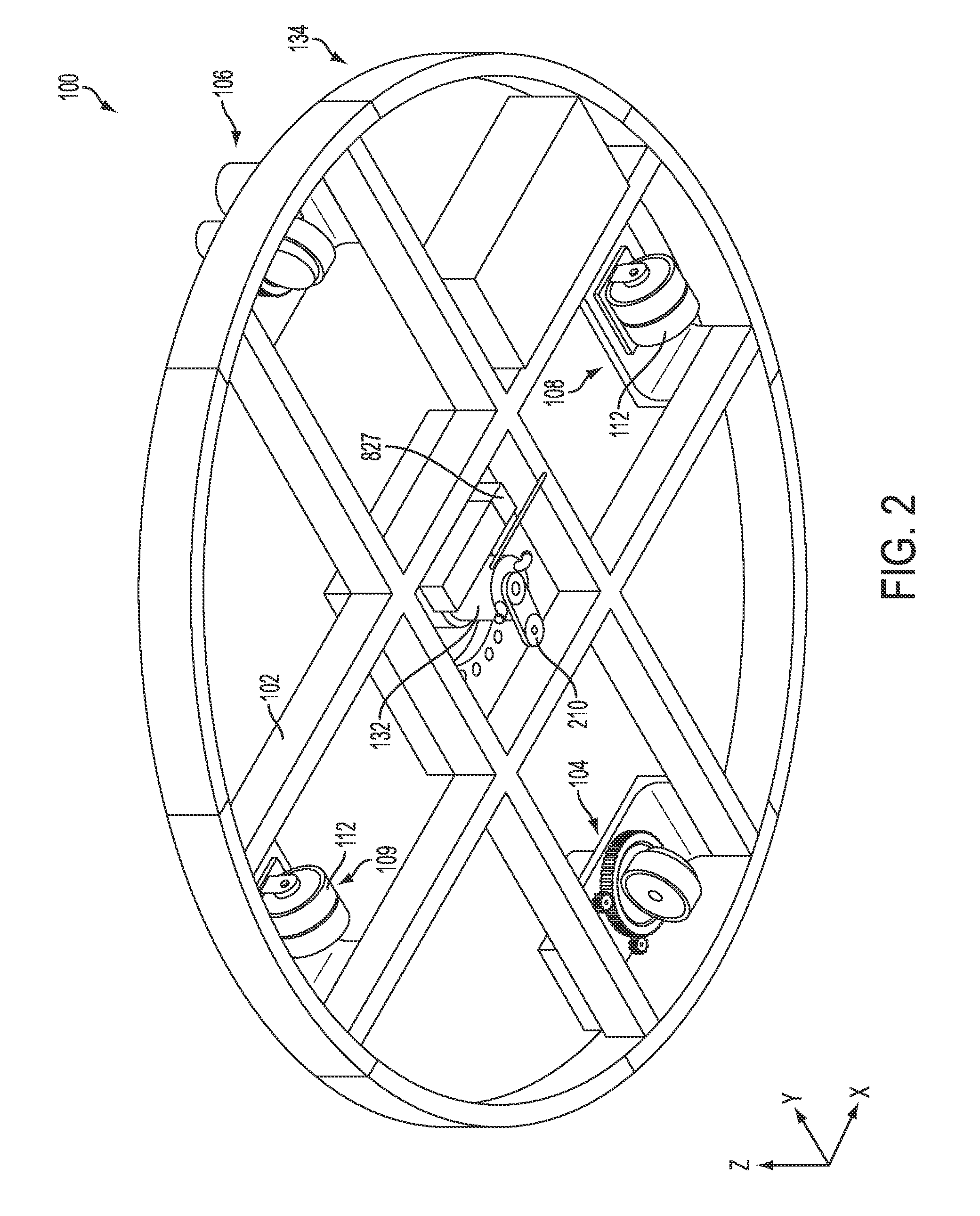

Trackless dark ride vehicle, system, and method

A motion assembly that produces pitch and roll motions includes lower and upper plates. A pivotable coupling having upper and lower shafts extending from its center is coupled between the upper and lower plates. At least two linear actuators are coupled between the plates. Extension and retraction of the actuators pivots the upper plate about the pivotable coupling relative to the lower plate. A vehicle includes two steerable propulsion wheels coupled to a chassis. A lower plate of a pitch and roll assembly, similar to that just described, couples to the chassis via a slew bearing. Seating is coupled to the upper plate. The seating rotates with respect to the chassis via controlled rotation of the slew bearing with reference to the chassis. The seating can be rotated to point in any direction with respect to the chassis regardless of the direction the steerable propulsion wheels move the chassis.

Owner:OCEANEERING INTERNATIONAL

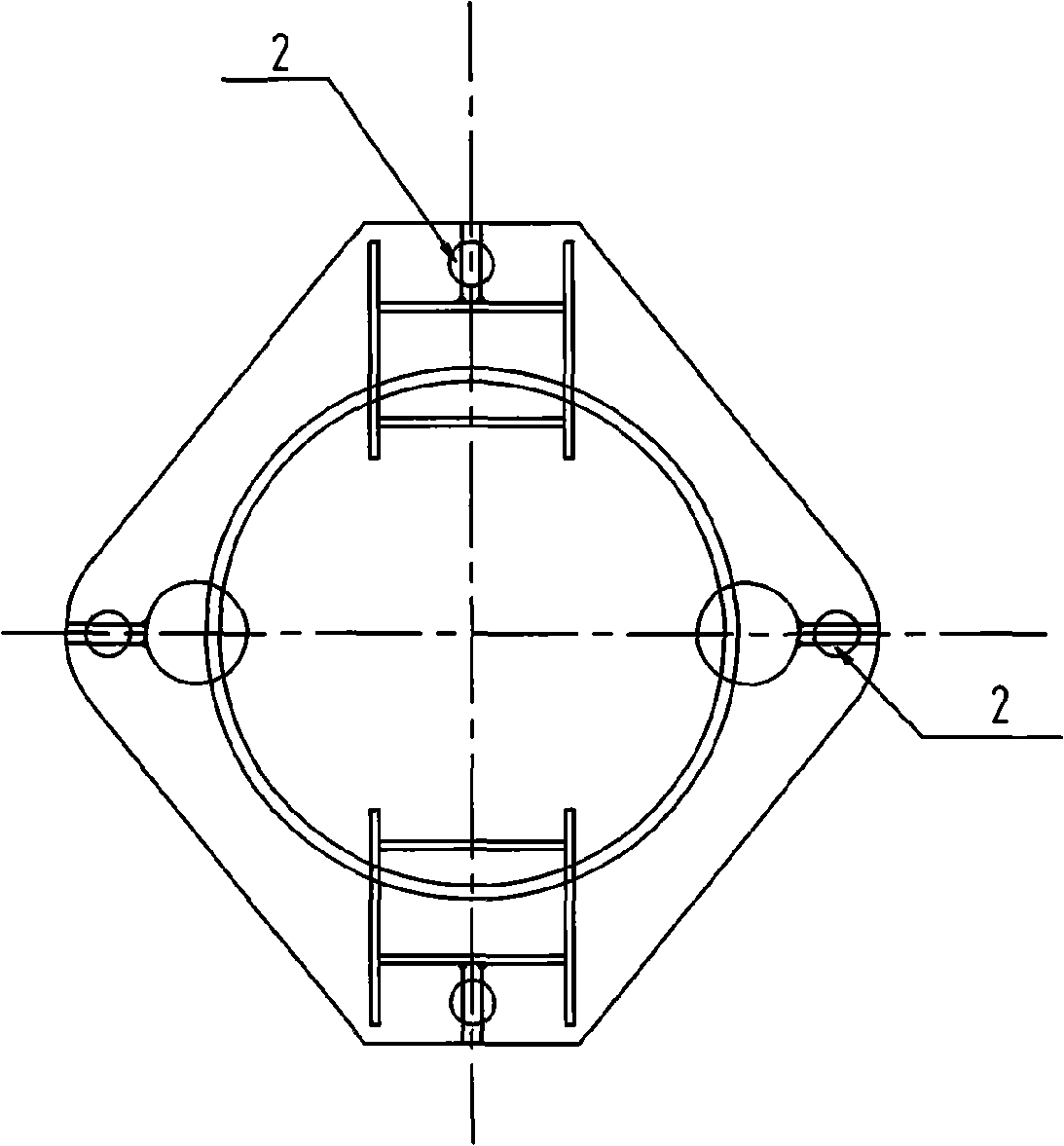

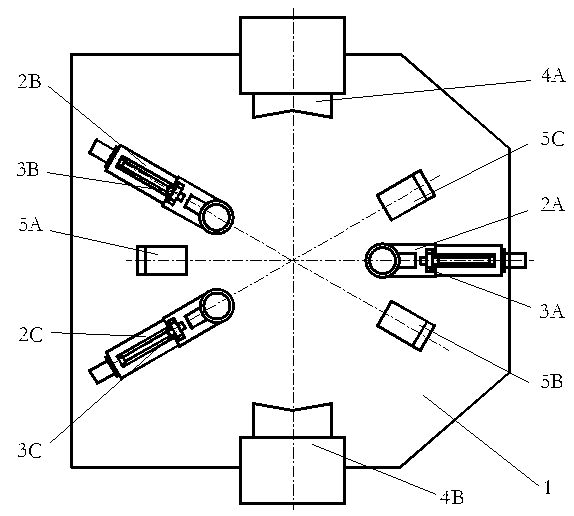

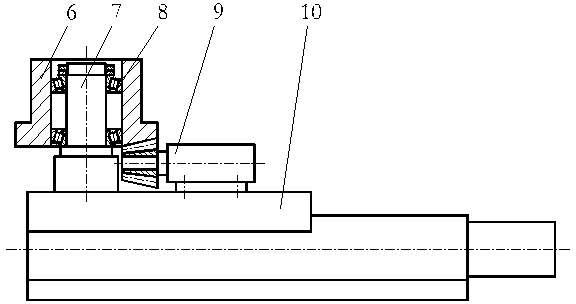

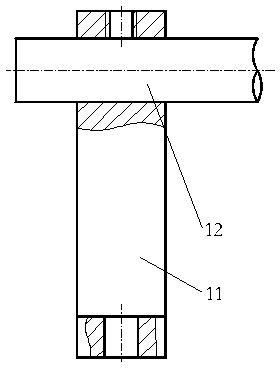

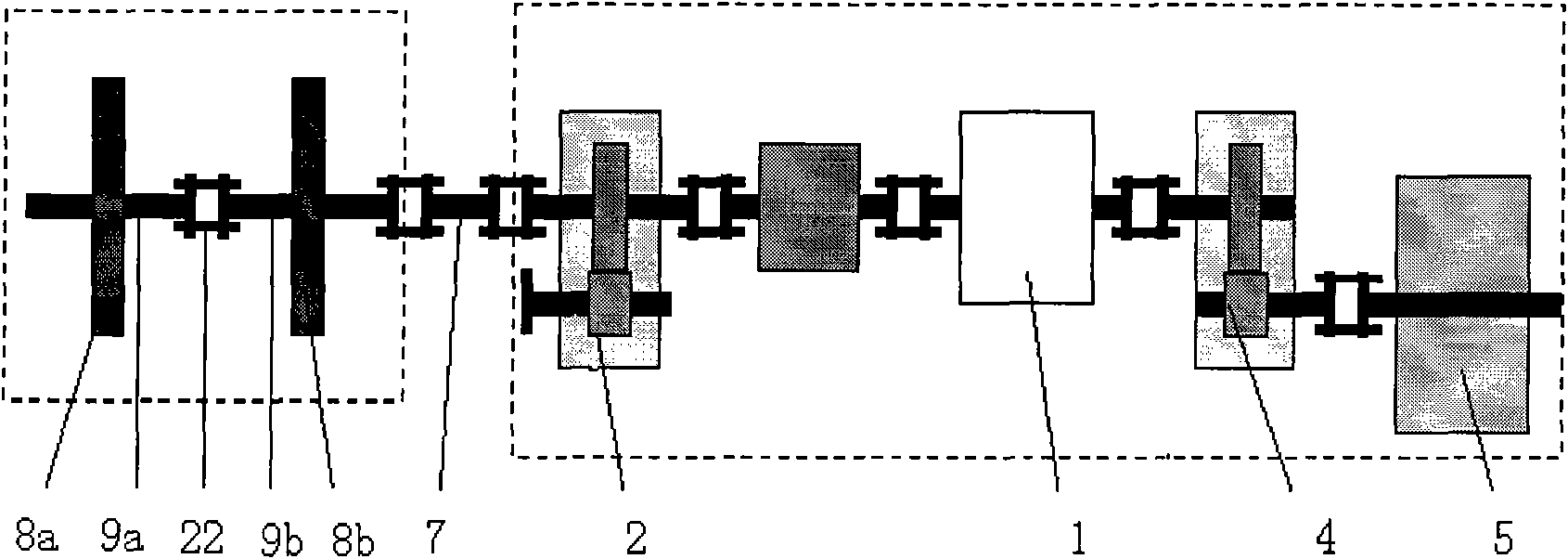

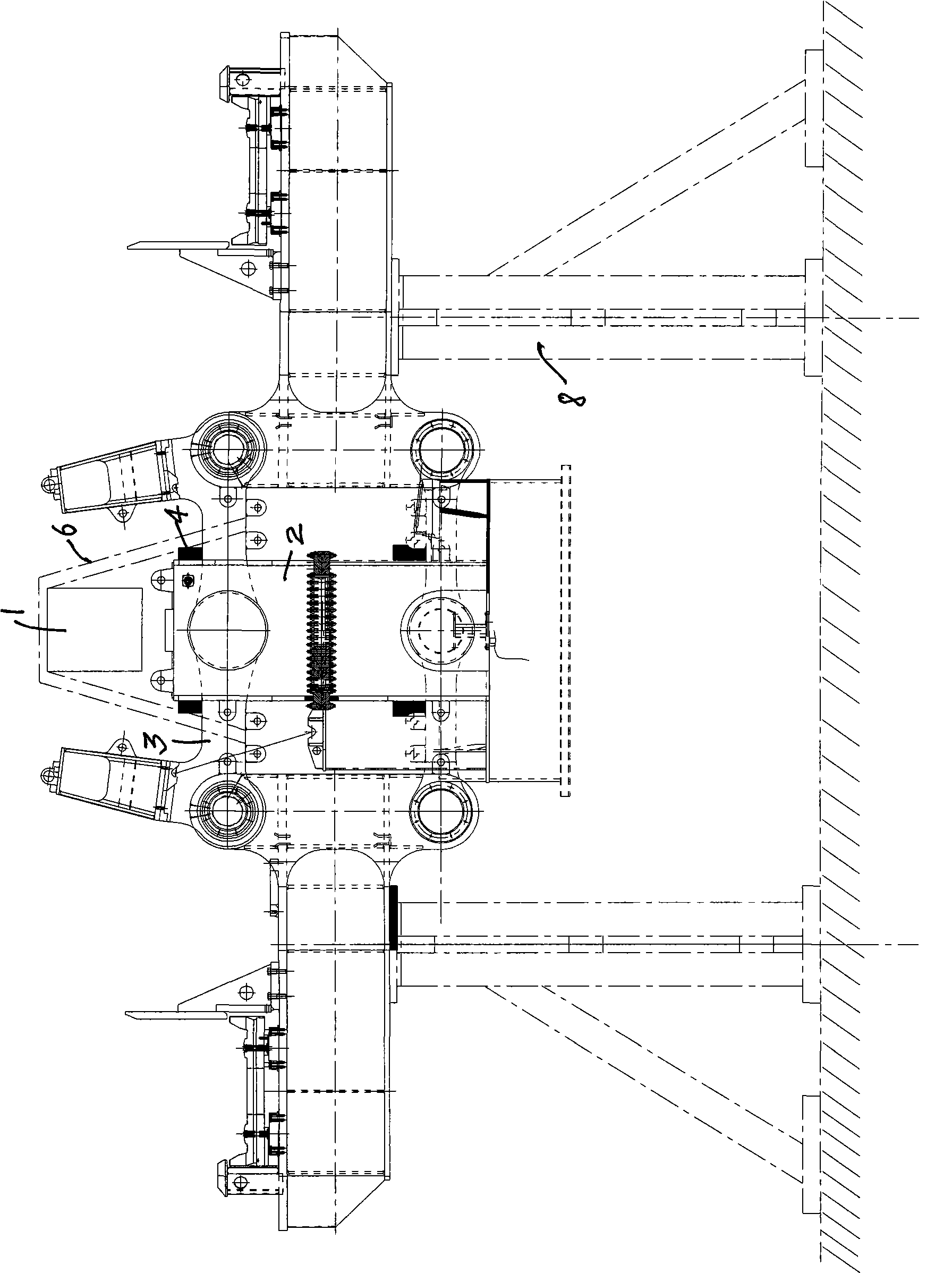

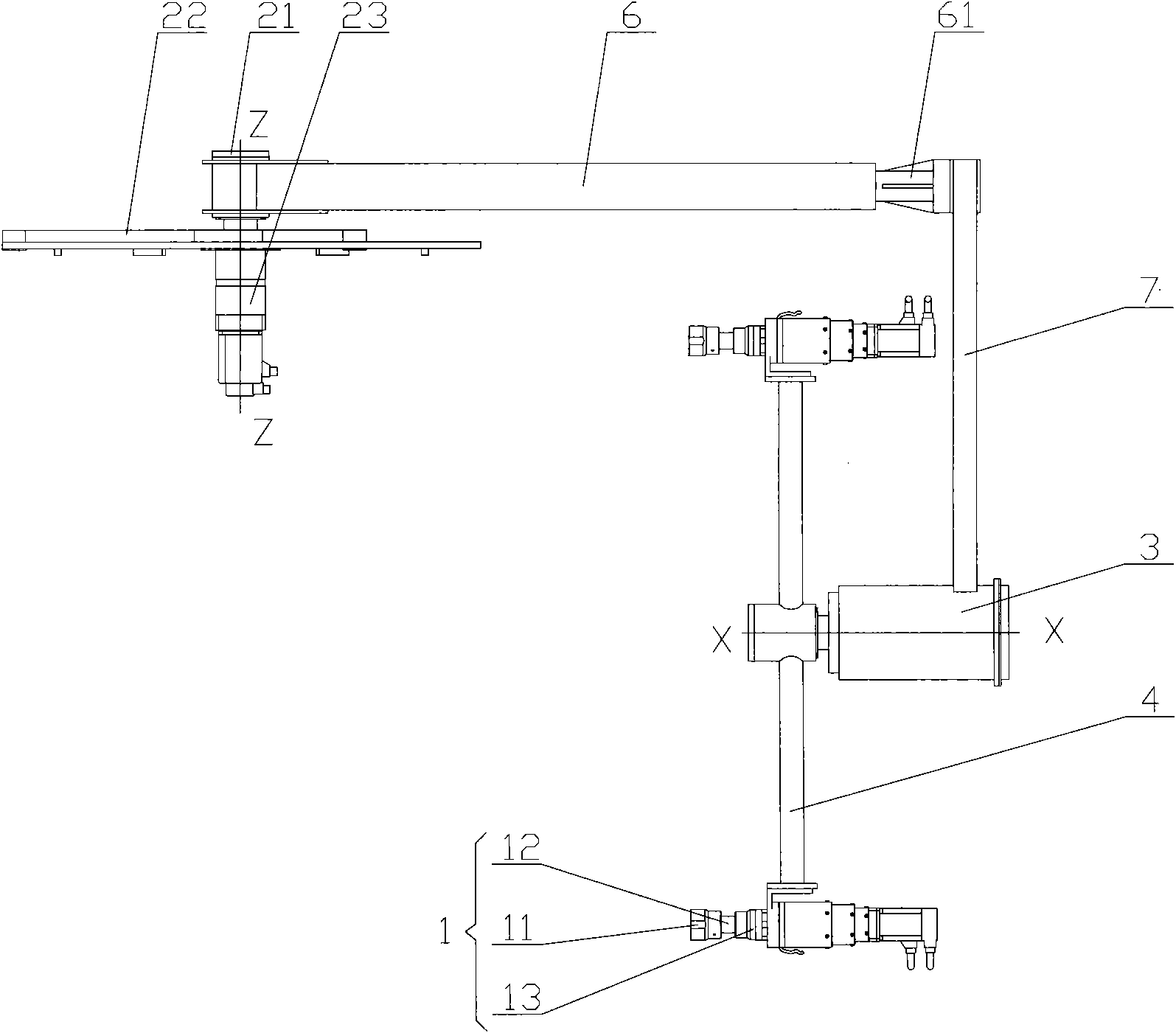

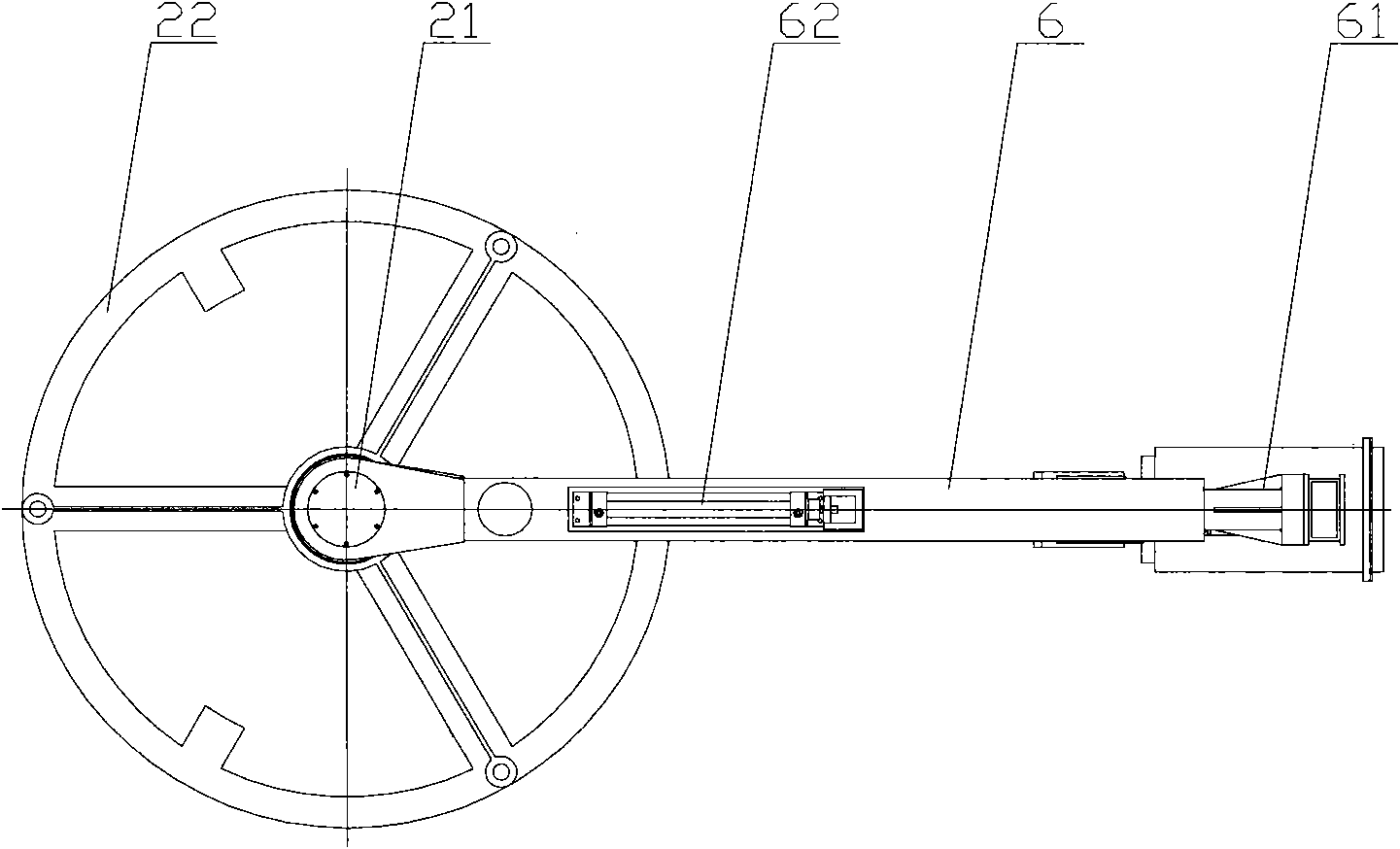

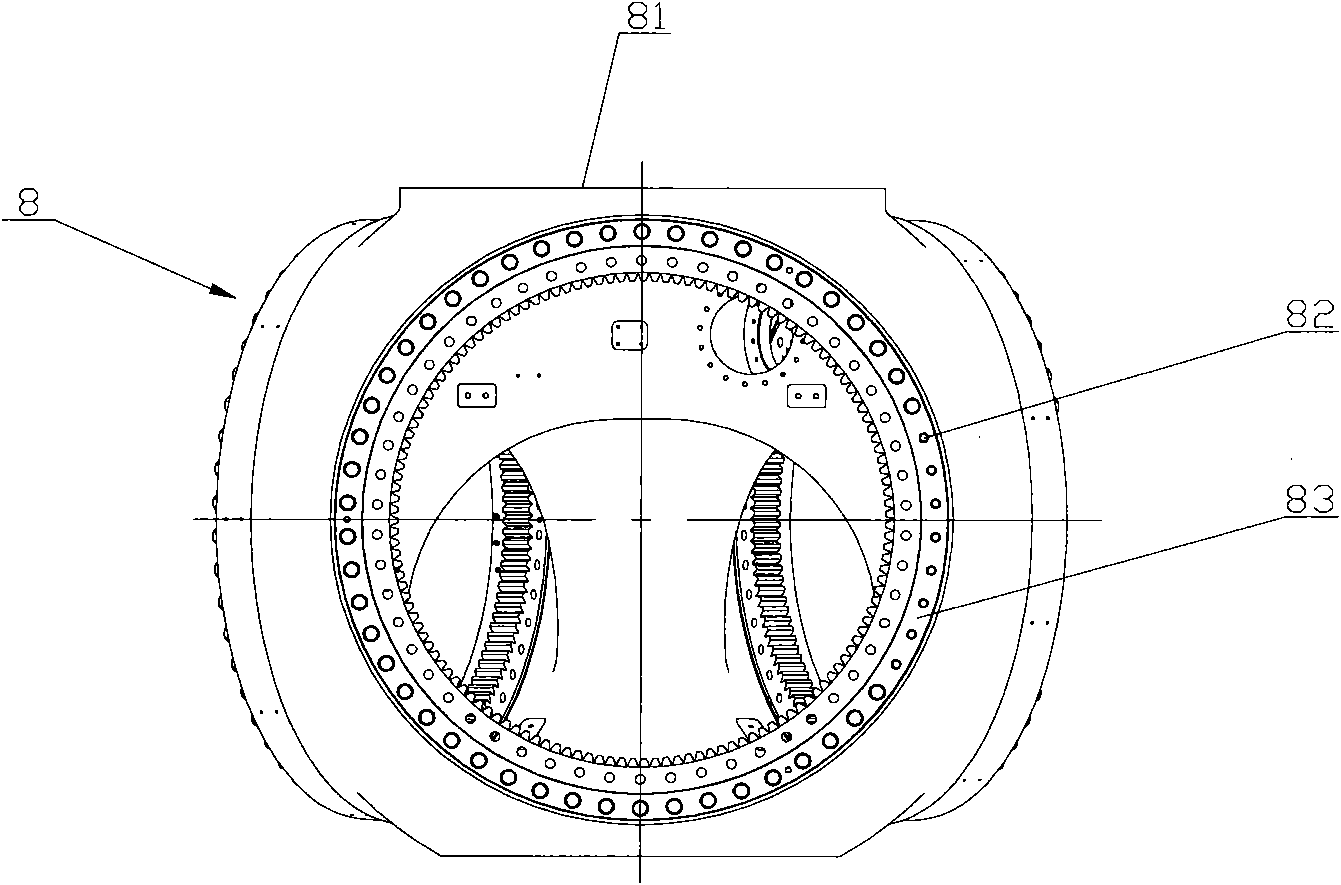

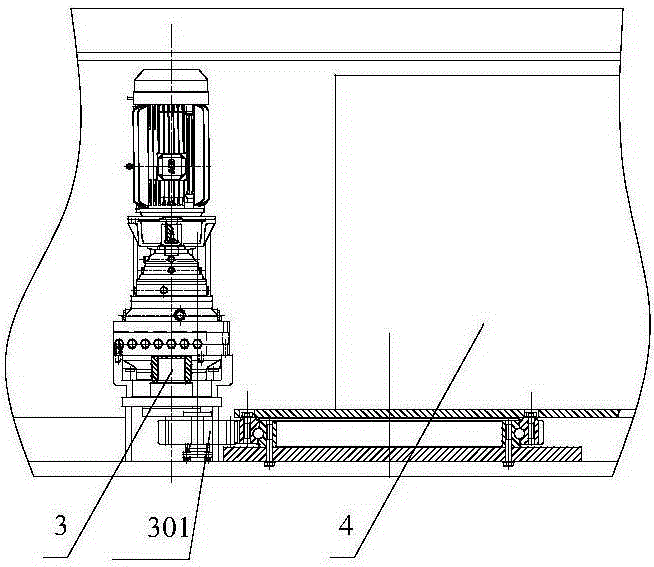

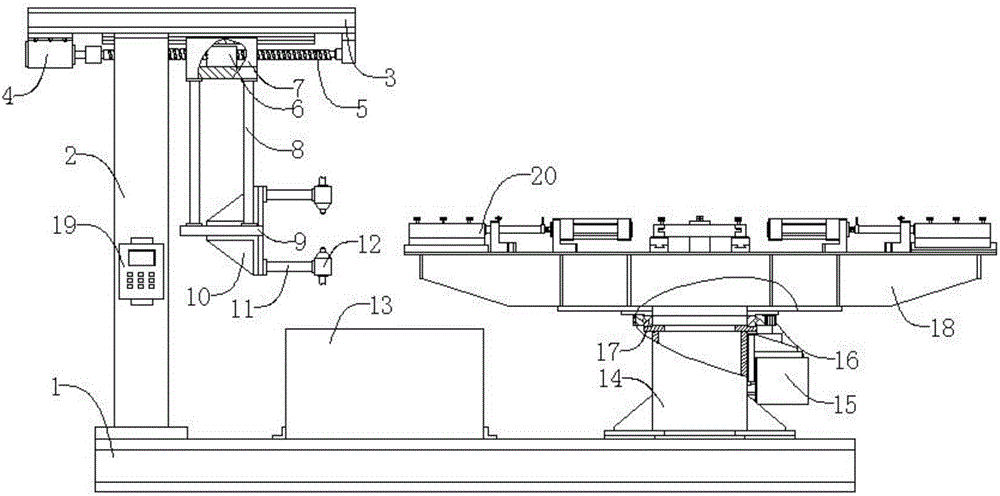

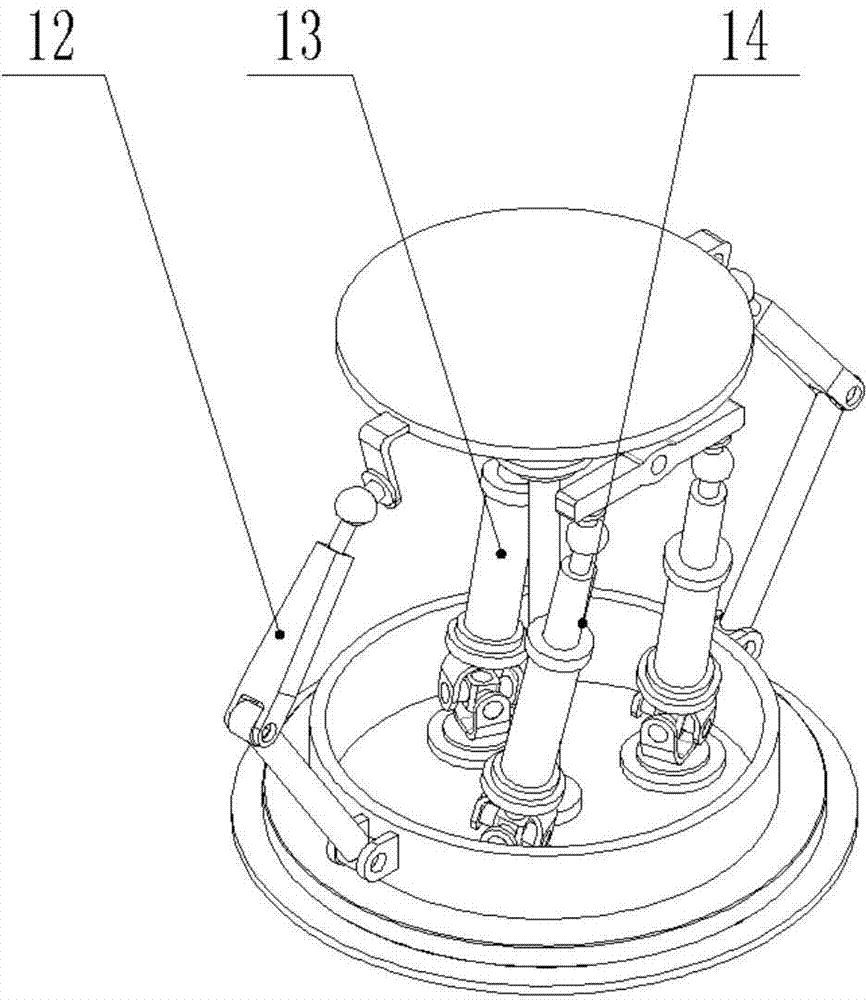

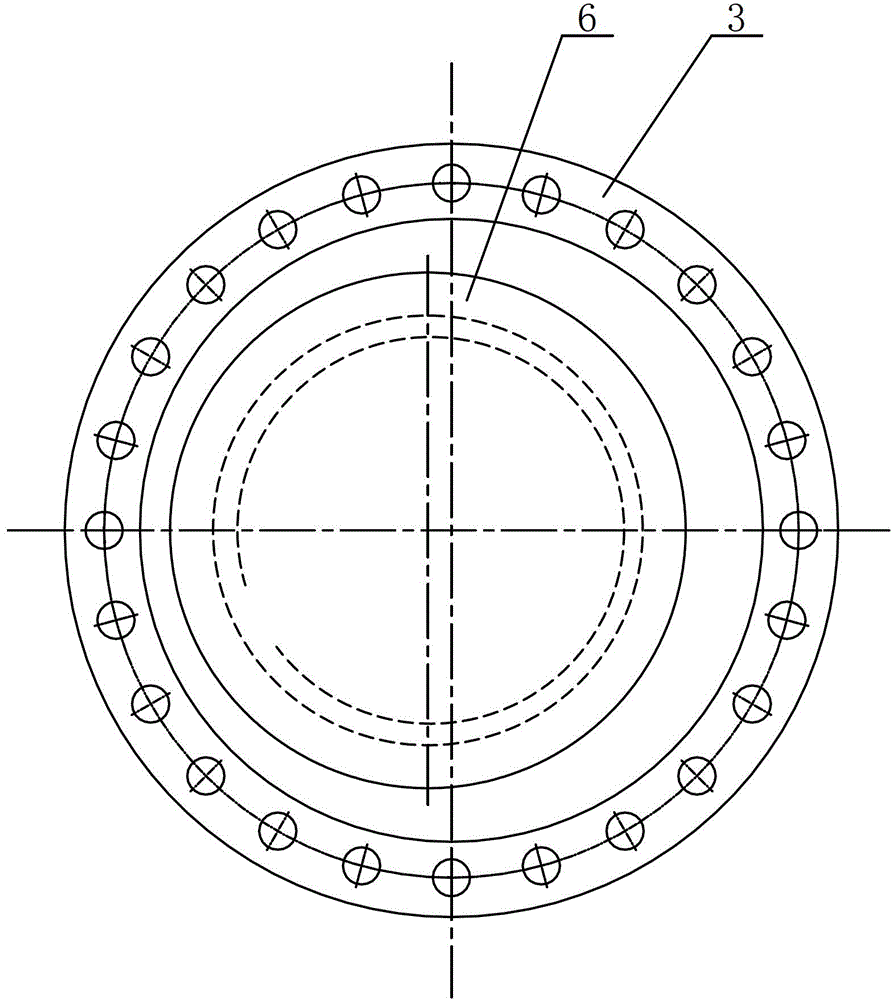

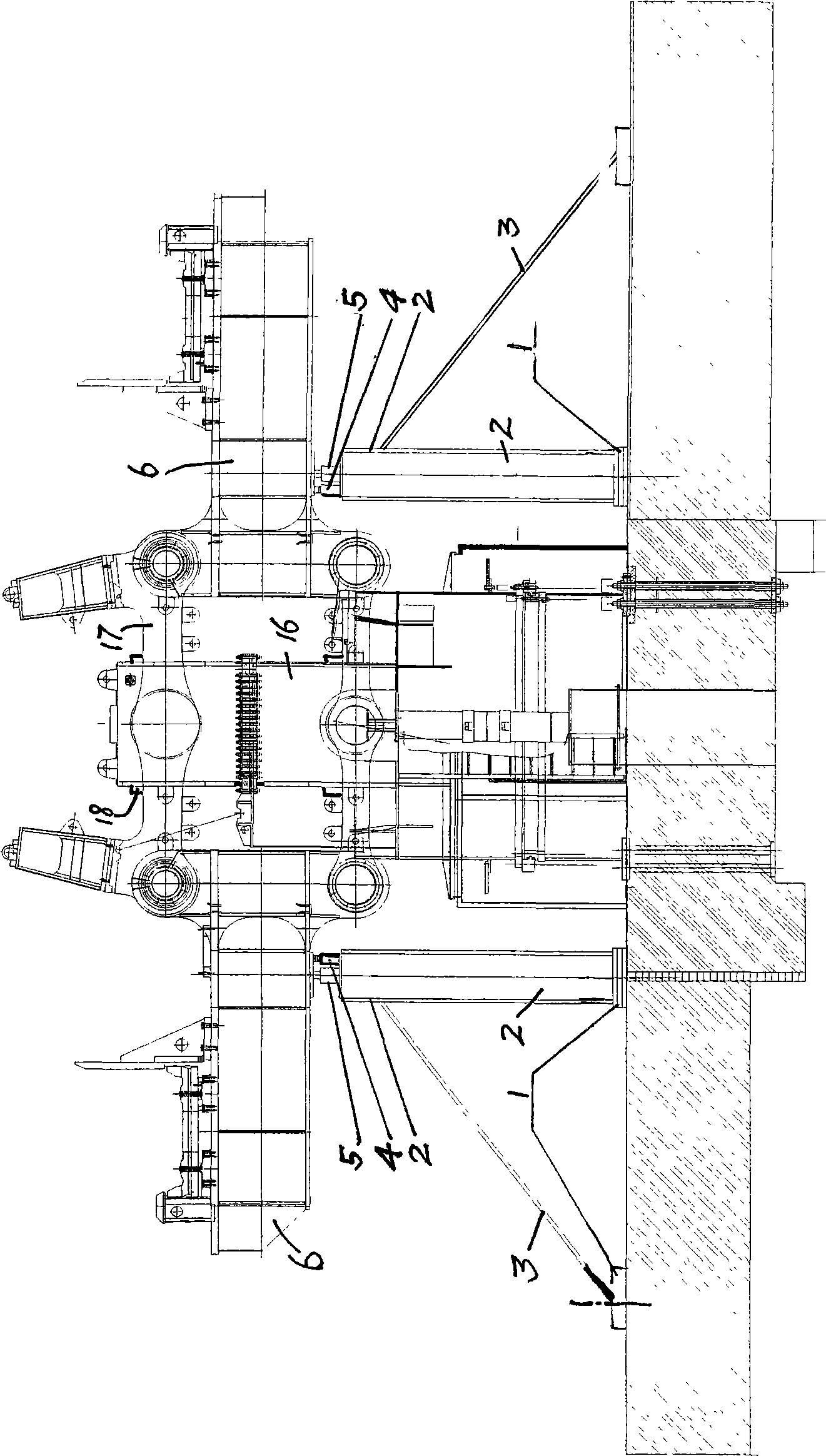

Bolt tightening machine for connecting slewing bearing and hub

ActiveCN101890635AImprove work efficiencyImprove tightening efficiencyMetal working apparatusEngineeringSlewing bearing

The invention discloses a bolt tightening machine for connecting a slewing bearing and a hub. The bolt tightening machine comprises a tightening shaft device (1) and a central rotating shaft (21), wherein the central rotating shaft (21) is connected with a positioning bracket rotating with the central rotating shaft (21); the positioning bracket is provided with a circumferential rotation drive device (3); the circumferential rotation drive device (3) is connected with a tightening shaft bracket (4) rotating with the circumferential rotation drive device (3); and the tightening shaft device (1) is arranged on the tightening shaft bracket (4). The bolt tightening machine also comprises a control device connected with the circumferential rotation drive device (3) and the tightening shaft device (1), so that the control device controls the tightening shaft device (1) to move to the position of each bolt needing tightening and completes the tightening action of the bolt. The bolt tightening machine can improve the efficiency of tightening the bolt on one hand, and can improve the quality of tightening the bolt on the other hand.

Owner:SANY ELECTRIC CO LTD

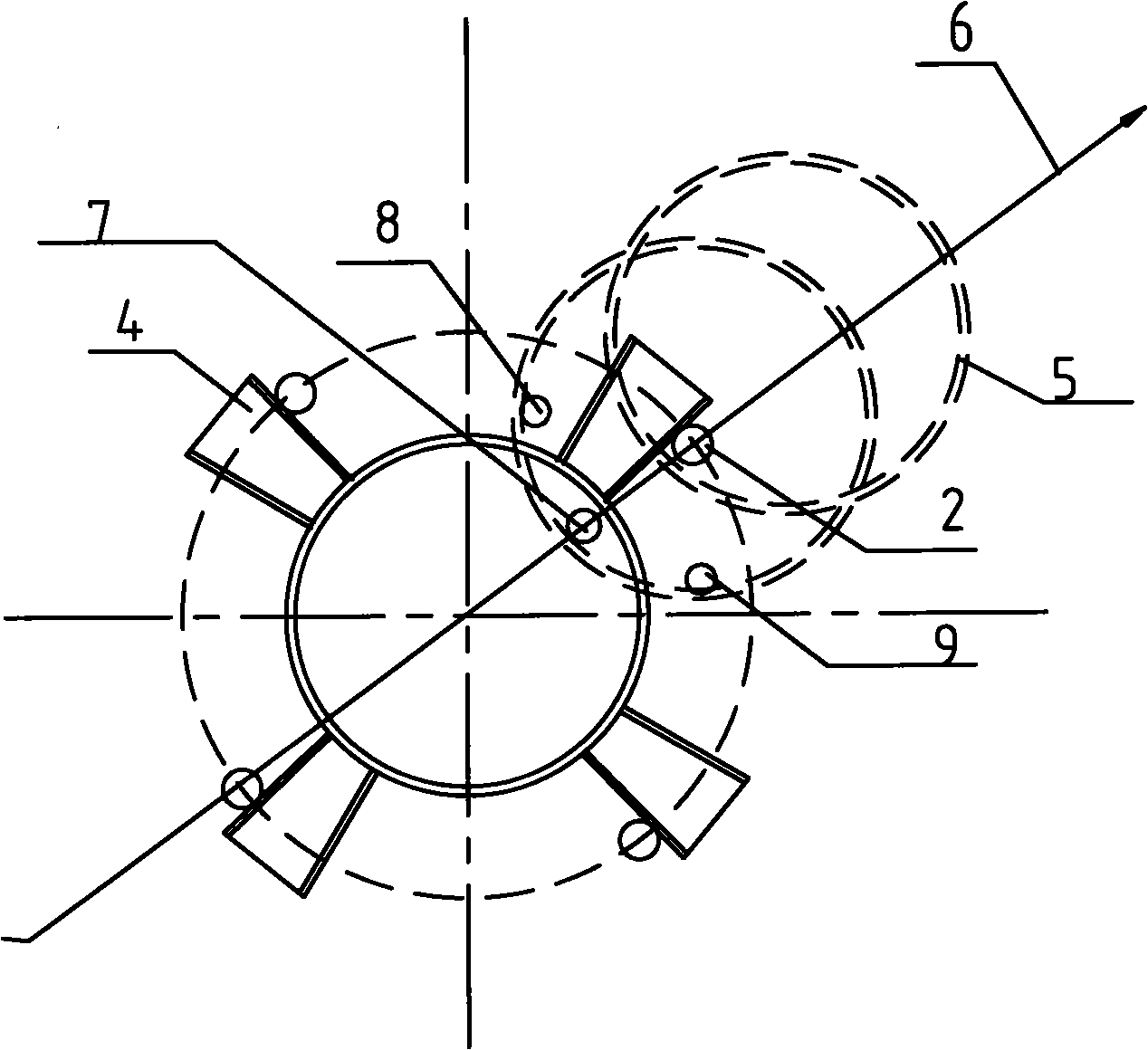

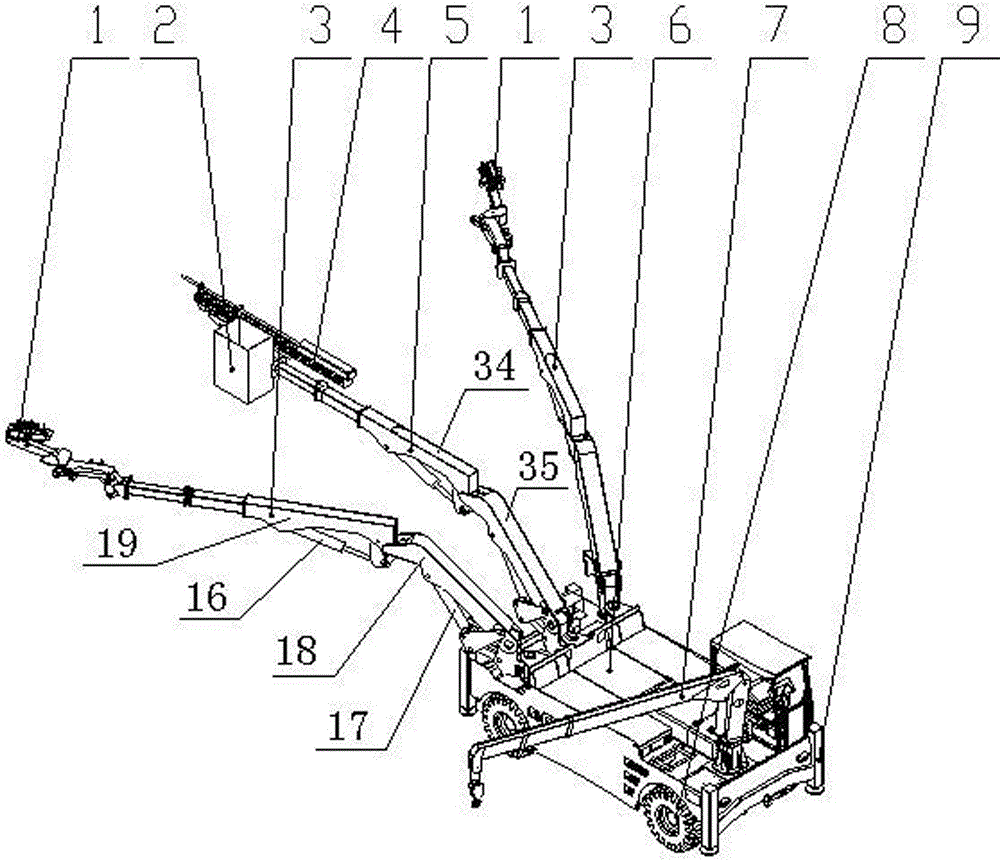

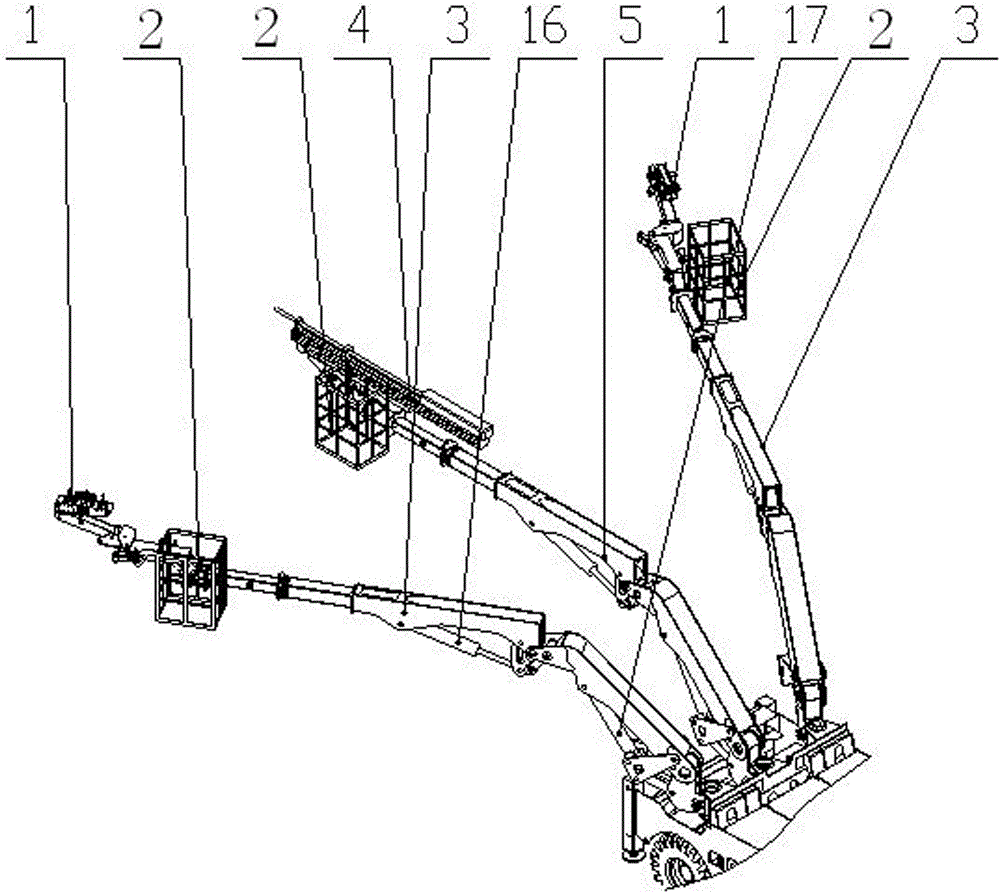

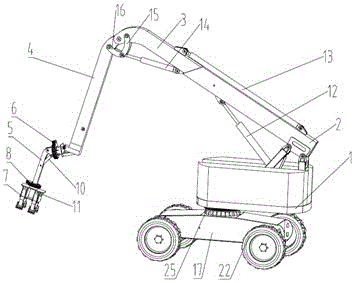

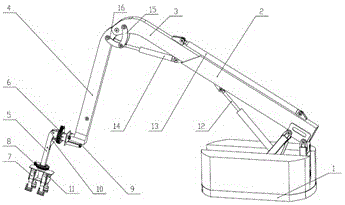

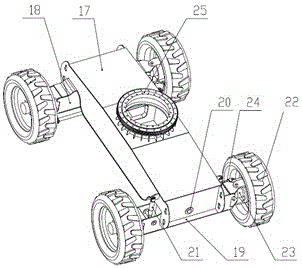

Multifunctional arching drill jambo

ActiveCN106401476AMeet the needs of various working conditionsUnderground chambersDerricks/mastsRobotic armButt joint

A multifunctional arching drill jambo comprises a main machine platform (6). The bottom of the main machine platform is provided with a chassis (8); the two sides of the main machine platform are provided with supporting legs (9); the front portion of the main machine platform is provided with a truck with crane (7) through a slewing bearing; the rear portion of the main machine platform is provided with two parallel mechanical arm racks (3) with mechanical arms (1) and a drill arm rack (5) with a rock drill system (4); the drill arm rack is arranged between the two mechanical arm racks; and the mechanical arms (1) and the rock drill system (4) are provided with quick-dismounting baskets (2). According to the multifunctional arching drill jambo, arch construction can be conducted while three kinds of steps of a tunnel are excavated, all the construction procedures of arch butt joint, bar-mat reinforcement hanging, cross rib welding, anchor rod installation and advance small pipe support can be achieved, and the efficiency of the multifunctional arching drill jambo is far higher than that of manpower.

Owner:CHANGSHA KEDA INTELLIGENT EQUIP INC CO

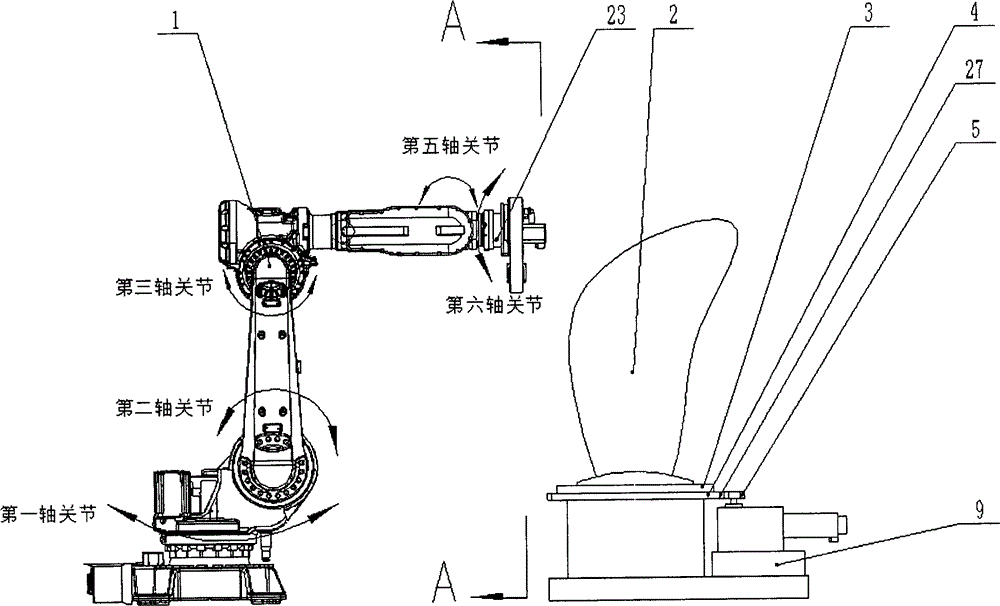

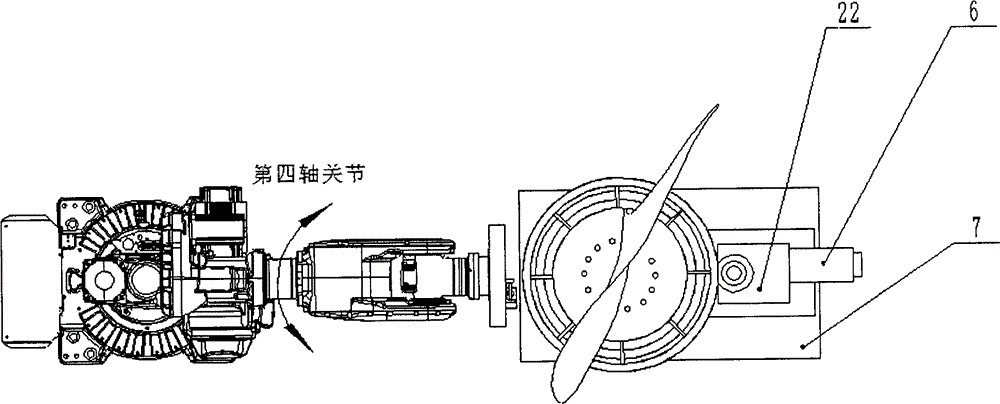

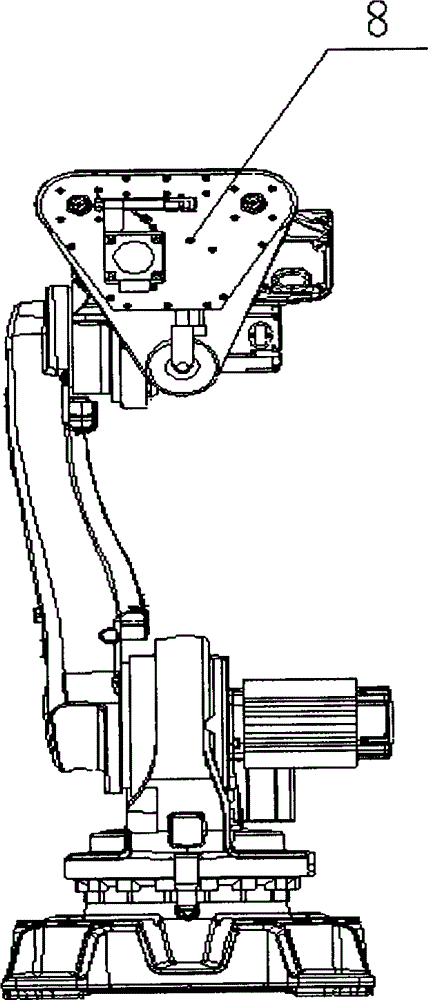

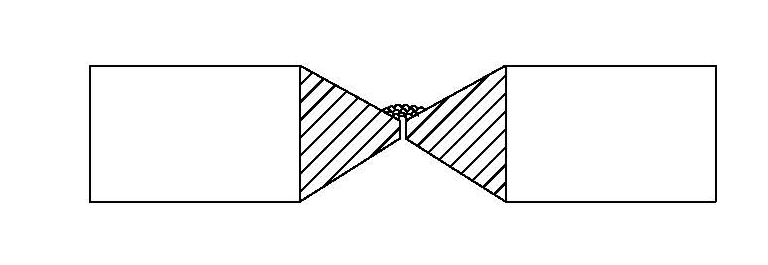

Industrial-robot-based abrasive belt grinding device for profiles of controllable pitch propeller and manufacturing method of abrasive belt grinding device

The invention discloses an industrial-robot-based abrasive belt grinding device for profiles of a controllable pitch propeller and a manufacturing method of the abrasive belt grinding device and mainly solves the problems caused in numerically-controlled machine tool type manufacturing, such as high cost, instability in machining precision and low efficiency due to manual grinding, occupational hazards of polishing and the like. The device mainly comprises a six-freedom-degree industrial robot, an abrasive belt grinding mechanism and a numerical control rotary table, wherein the abrasive belt grinding mechanism which is arranged in a triangular structure is connected with an end joint of the robot through a flange; a motor achieves high-speed rotation of an abrasive belt driving wheel through a synchronous belt; a pneumatic mode drives a tension wheel to achieve abrasive belt tension; a workblank of the controllable pitch propeller is installed and clamped in the center of the rotary table; and a servo motor drives an output gear of a reduction box to be meshed with a gear ring of a slewing bearing so as to achieve continuous 360-degree rotating and indexing. The abrasive belt grinding device is ingenious in structural design and high in grinding rigidity and universality, reduces the production cost greatly and has excellent practical and promotional values.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Spiral lifting mechanism and automatic guided vehicle (AGV)

The invention discloses a spiral lifting mechanism and an automatic guided vehicle (AGV). The spiral lifting mechanism comprises a jacking plate, an installation base board, a jacking mechanism and a jacking drive mechanism. The jacking mechanism comprises a thread pair and a slewing bearing, the outer ring of an outer thread part of the thread pair is a gear, the inner ring is in threaded connection with an inner thread part of the thread pair, the inner ring of the slewing bearing is fixedly connected with the installation base board, the outer ring of the slewing bearing is fixedly connected with the lower portion of the inner thread part of the thread pair, and the jacking plate is fixed to the outer thread part of the thread pair. The jacking drive mechanism comprises a lifting pinion and a lifting drive motor; the lifting pinion is fixedly connected with a motor shaft of the lifting drive motor; the lifting pinion is engaged with an outer-ring gear of the slewing bearing; the lifting drive motor is installed on the installation base board. The spiral lifting mechanism further comprises a rotary control mechanism, and the rotary control mechanism can rotate and lock the outer thread part of the thread pair.

Owner:HANGZHOU JIAZHI TECH CO LTD

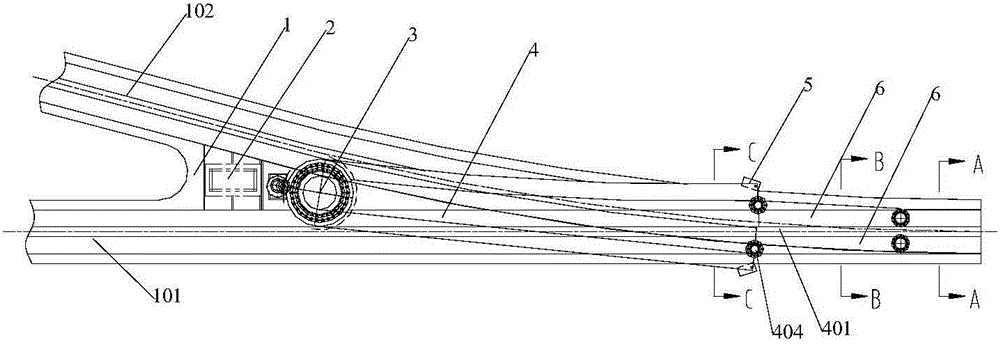

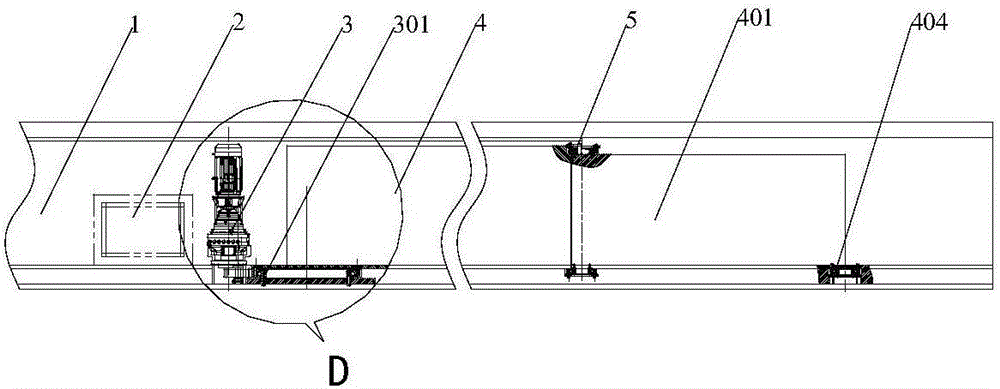

A monorail single turnout system of a suspension type rail transit system

The invention provides a monorail single turnout system of a suspension type rail transit system which can better adapt to complicated rail transit networks and realize automatic separation of turnouts. The monorail single turnout system comprises a turnout girder body having a main line and a branch line, a movable rail, a guide plate, correction rails and a locking device. The movable rail is located between the main line and the branch line; the front portion of the movable rail is installed on a first toothless slewing bearing and the movable rail is driven to swing by a first driving device. The guide plate is connected with the rear end of the movable rail through a second toothless slewing bearing. The correction rails are located between the lower side of the guide plate and the turnout girder body and are driven by a second driving device. The locking device is located on the turnout girder body and is used for locking the relative positions of the movable rail, the guide plate and the correction rails.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

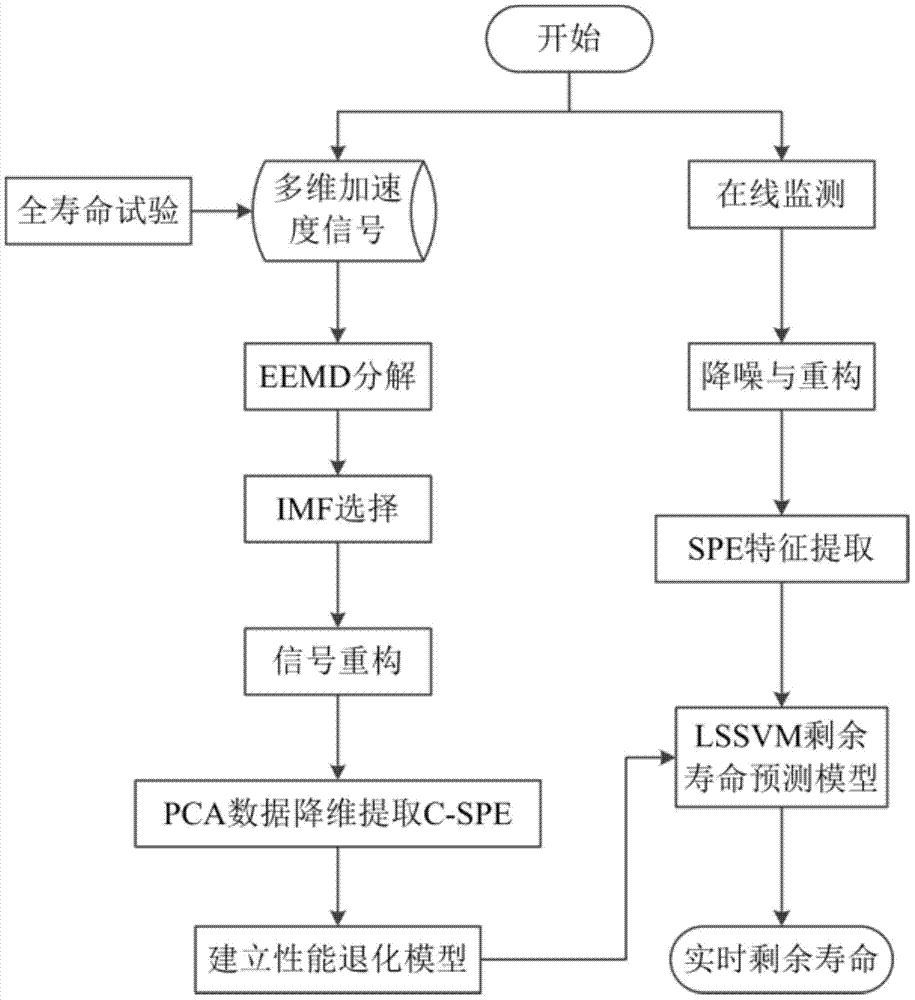

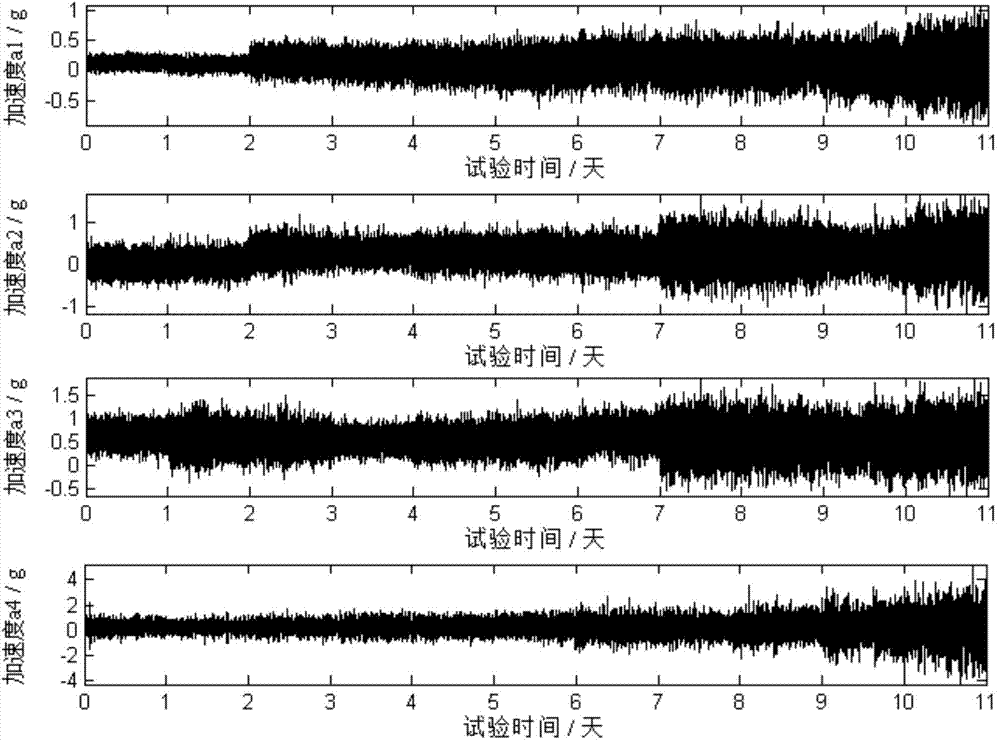

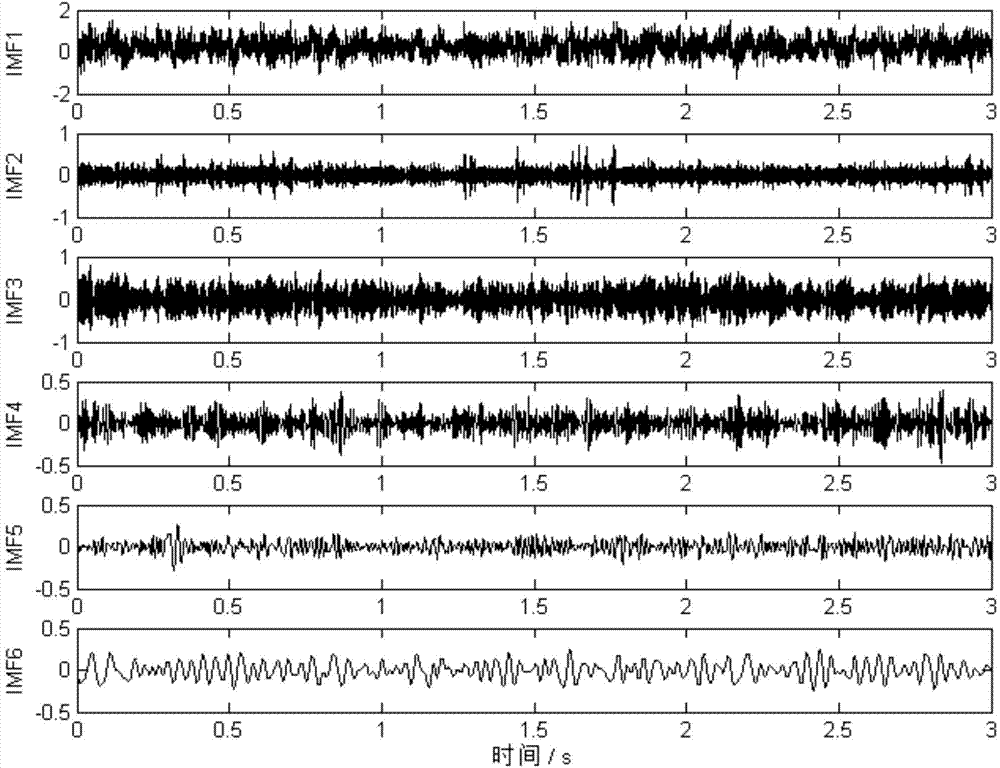

On-line large slewing bearing residual life prediction method based on multi-dimensional data drive

ActiveCN104713728ATo achieve the purpose of filtering and denoisingAvoid eigenvectorsMachine bearings testingVibration accelerationDecomposition

The invention discloses an on-line large slewing bearing residual life prediction method based on multi-dimensional data drive. The method includes the steps of firstly, conducting a full-life fatigue test on a slewing bearing, and obtaining multiple sets of vibration acceleration signal monitoring data of the whole test cycle of the slewing bearing; secondly, decomposing a vibration signal into a plurality of intrinsic mode functions (IMFs) through ensemble empirical mode decomposition (EEMD), and selecting a plurality of IMFs which can reflect performance degradation of the slewing bearing for signal reconstruction through principle component analysis (PCA) so that the aim of filtering noise elimination can be achieved; thirdly, conducting PCA on multi-dimensional acceleration signals at different stages and signals of the initial period of the test so as to obtain one-dimensional continuous SPE (C-SPE), reflecting the change situations of the multi-dimensional acceleration vibration signals on the basis of the one-dimensional C-SPE, calculating multiple time domain characteristics of the C-SPE, and establishing a performance degradation model of the slewing bearing. The method is few in manual intervention process, and the prediction result is closer to the engineering practice.

Owner:NANJING UNIV OF TECH +1

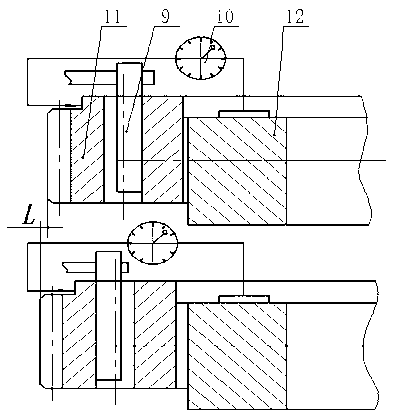

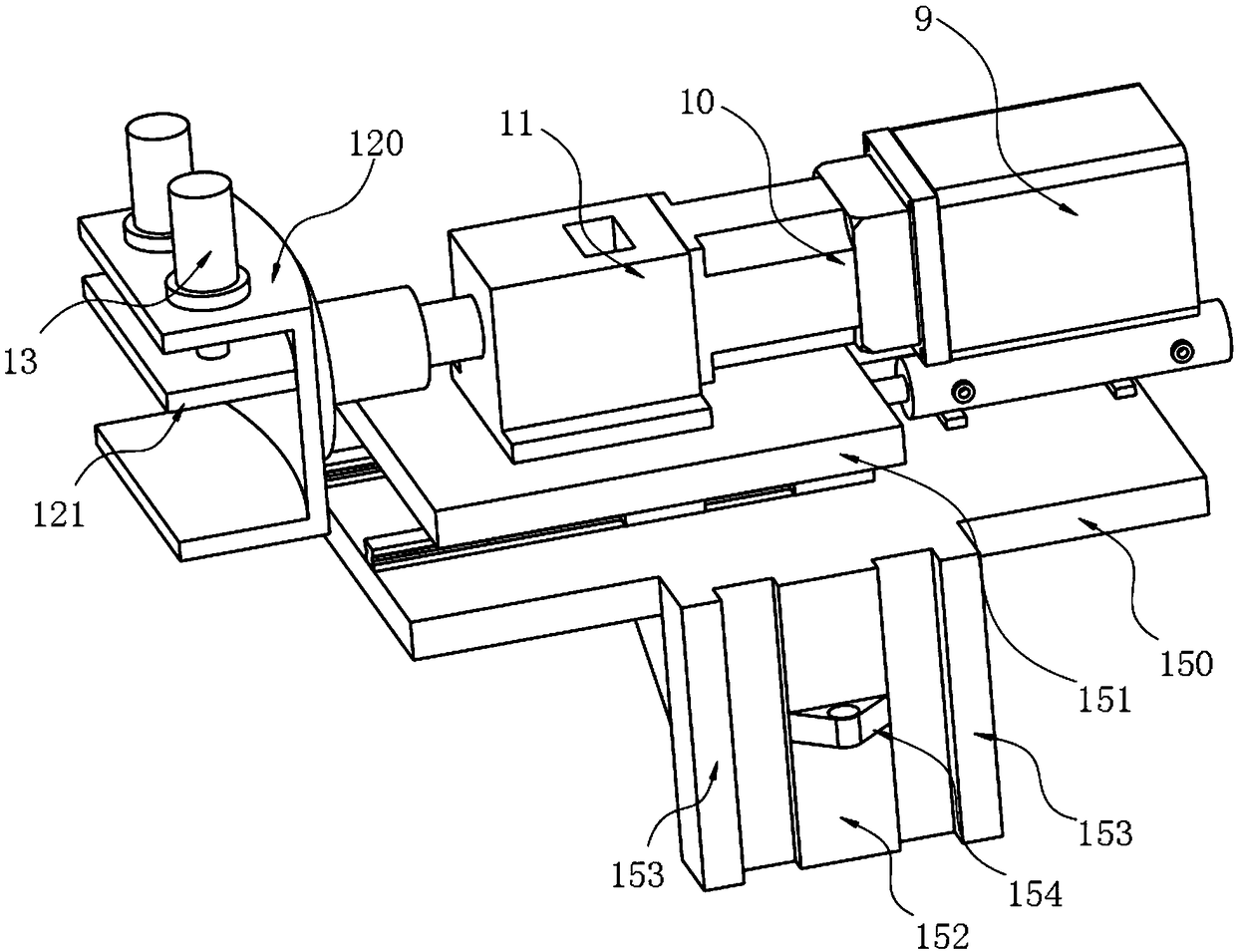

Gap detection device of large slewing bearing

ActiveCN102997885AAvoid damageImprove detection efficiencyMeasurement devicesAxial displacementBall screw

The invention provides a gap detection device of a large slewing bearing and belongs to the technical field of industrial measurement. The gap detection device comprises a radial error detection table, three groups of symmetrically-distributed axial error detection tables, a detection working table frame with a spiral pressing plate clamping mechanism, a slewing bearing to be detected, a controller and a displayer. Each axial error detection table comprises an axial servo motor, an axial rolling guide rail, an axial ball screw, a centering mechanism, an axial screw nut, an axial servo electric pushing rod, an axial working table plate, an axial base and an axial displacement sensor. The radial error detection table comprises a radial servo motor, a locking mechanism, a radial ball screw, a radial rolling guide rail, a radial screw nut, a radial working table plate, a radial servo electric pushing rod, a fork head, a radial base and a radial displacement sensor. The gap detection device of the large slewing bearing has the advantages of being high in detection accuracy, convenient to operate and high in detection efficiency.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Rotary automatic PCB cleaning device

ActiveCN106111607AEfficient removalImprove water resource utilizationCleaning using liquidsConductive pattern polishing/cleaningElectric machineWater resources

The invention discloses a rotary automatic PCB cleaning device. The rotary automatic PCB cleaning device comprises a base, two stand columns, a top frame, a first servo motor, a lead screw, a feed nut, a sliding seat, two supporting rods, a support plate, triangular supporting plates, extension rods, water jet cutter mechanisms, a trough, a supporting seat, a second servo motor, a gear, a slewing bearing, a working table, a controller and more than two feeding mechanisms, wherein the two stand columns are arranged in parallel along the base; the two supporting rods are symmetrically arranged along the sliding seat; the triangular supporting plates are arranged symmetrically along the support plate; a PCB is placed in a slot and is fixed by manually tightening hand screws; the second servo motor drives the working table to rotate at a set angle; after an electric push rod pushes a U-shaped clamping frame to move forwards in place, the first servo motor drives the sliding seat to move towards the U-shaped clamping frame by a set distance, then high-pressure water is pumped into the water jet cutter mechanisms, and chippings on the surface of the PCB and in holes of the PCB are eliminated. The device is simple in structure, good in cleaning effect, high in water resource utilization rate, high in degree of automation and high in cleaning efficiency.

Owner:苏州市相城区姑苏线路板厂

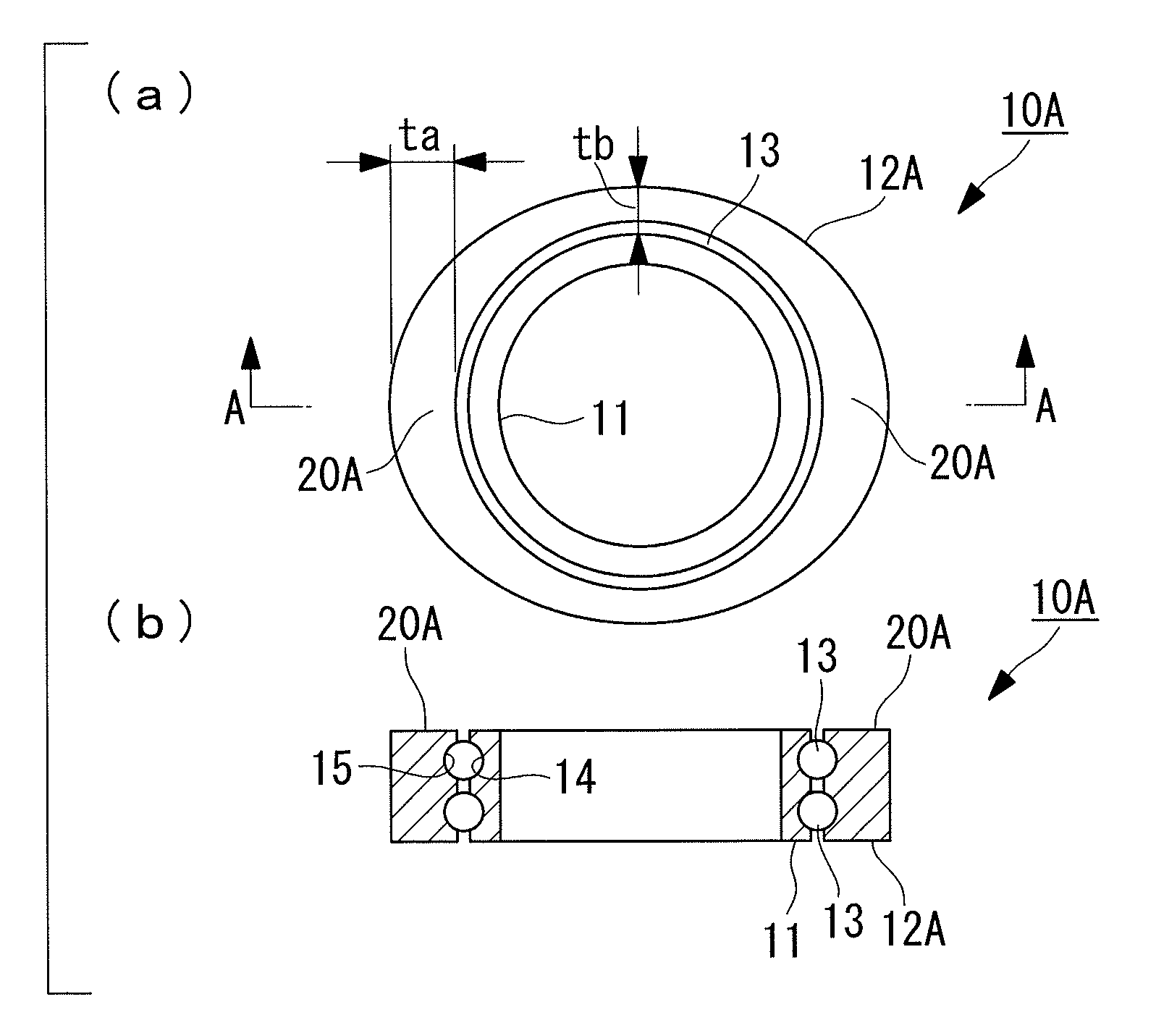

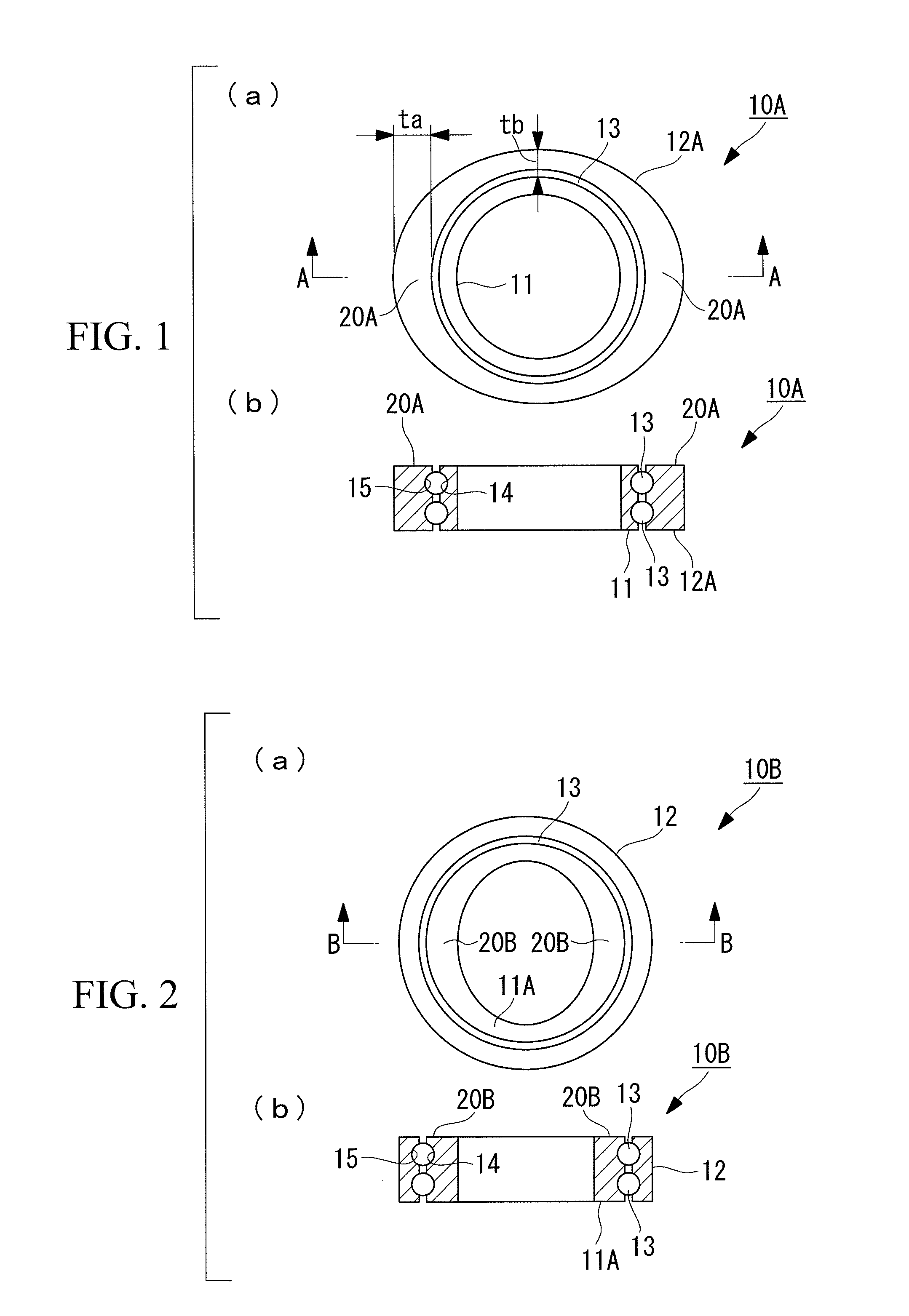

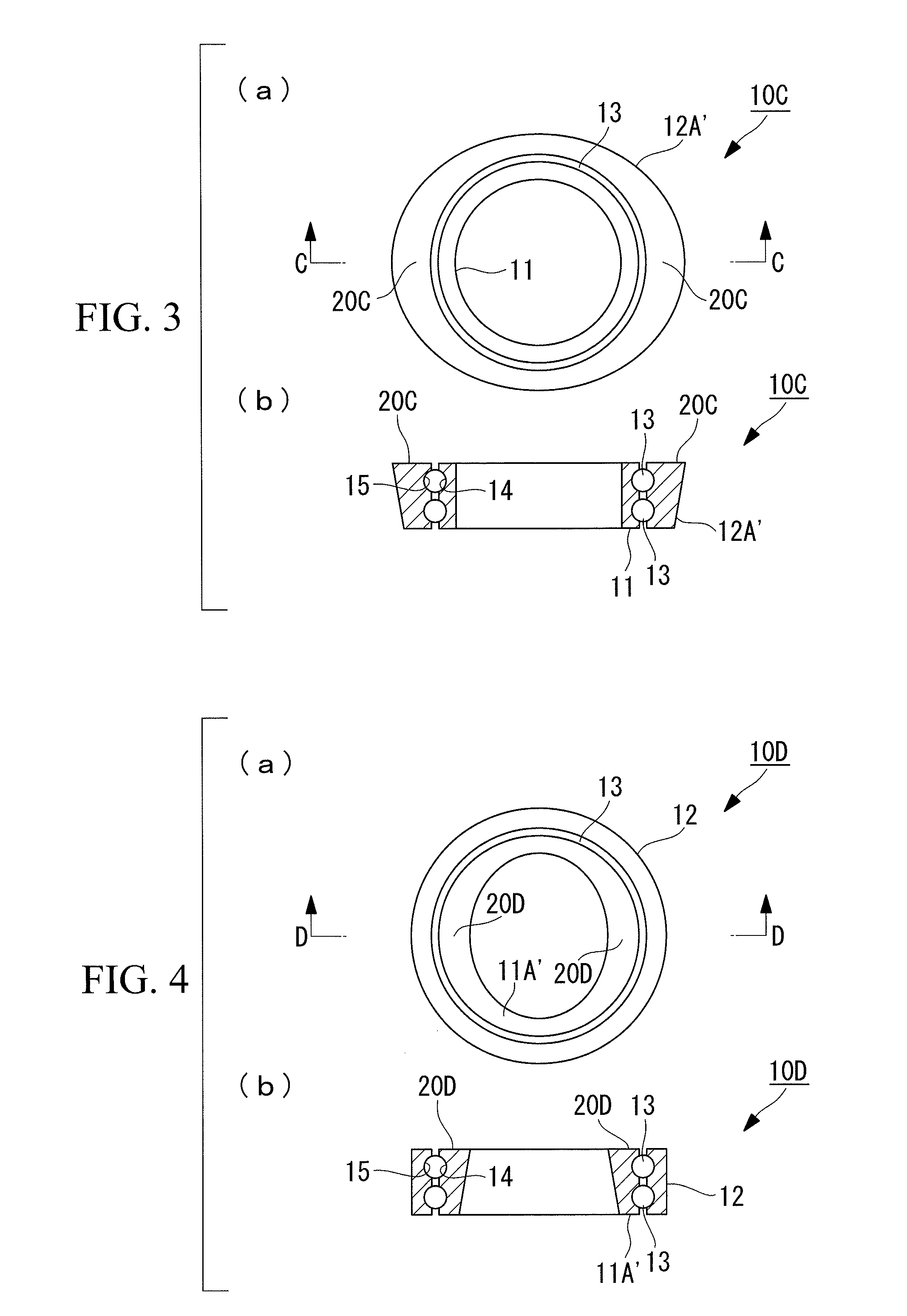

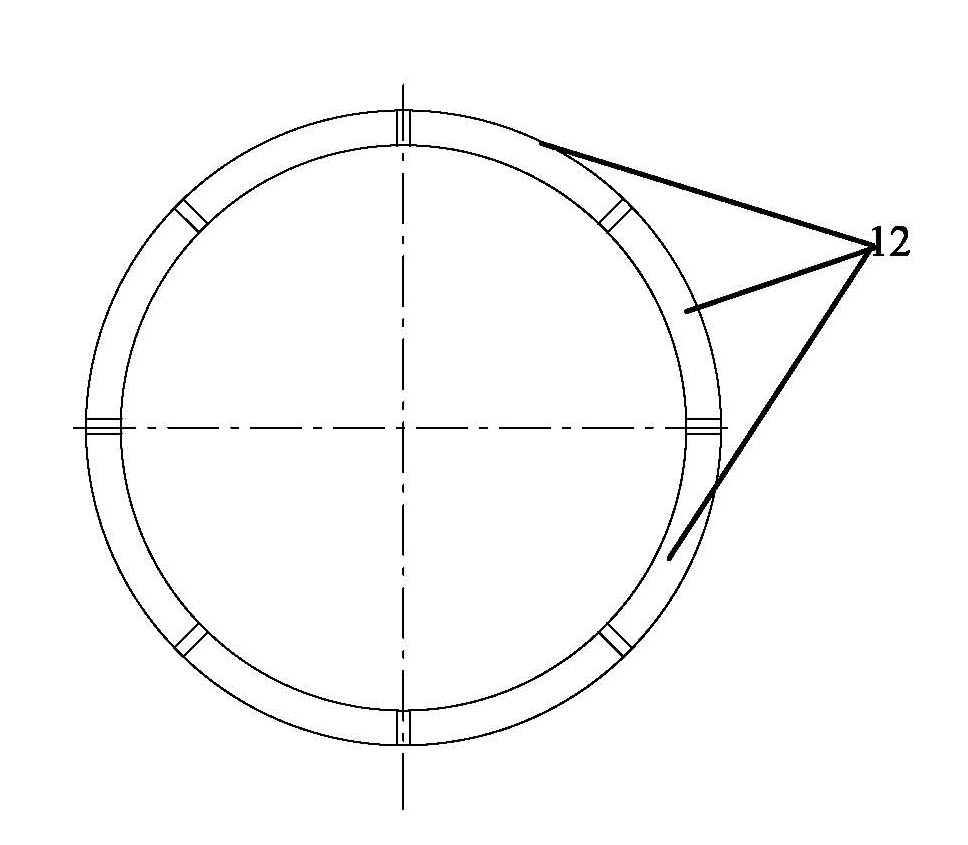

Slewing bearing structure

InactiveUS20130202234A1Simple structureInhibit transferRoller bearingsShaftsStructural deformationContact pressure

There is provided a slewing bearing structure capable of maintaining favorable bearing performance by adjusting and changing rigidity thereof while minimizing the increase in the weight thereof for preventing distortion of a pressure pattern caused by structural deformation from unfavorably affecting the bearing performance. A slewing bearing of a rolling bearing, in which a rolling element is put between bearing rings and formed on an inner ring and an outer ring, has a slewing bearing structure in which a rigidity strengthening portion, at which rigidity of the inner ring and / or the outer ring is increased more than that at peripheral portions, is formed at a circumferential area where a bearing contact pressure is high.

Owner:MITSUBISHI HEAVY IND LTD

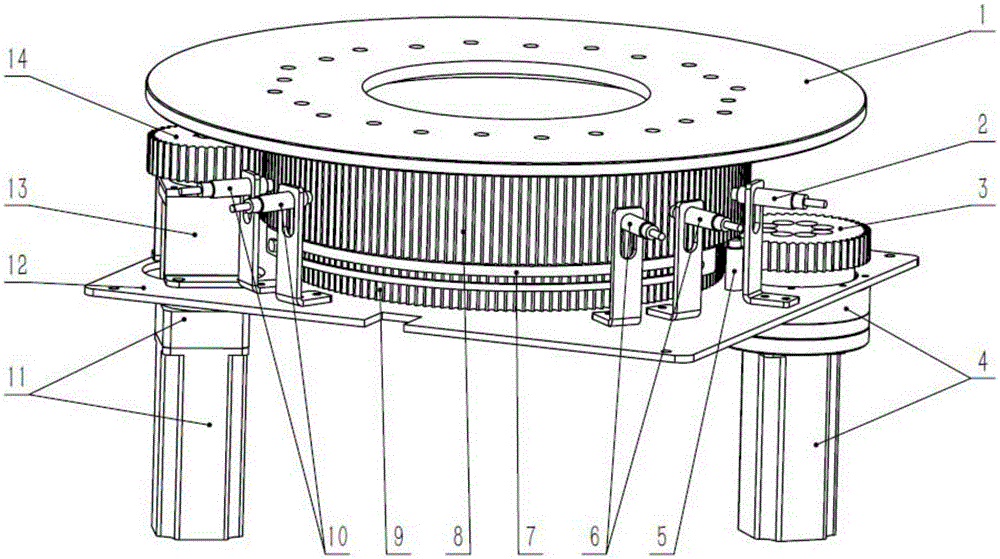

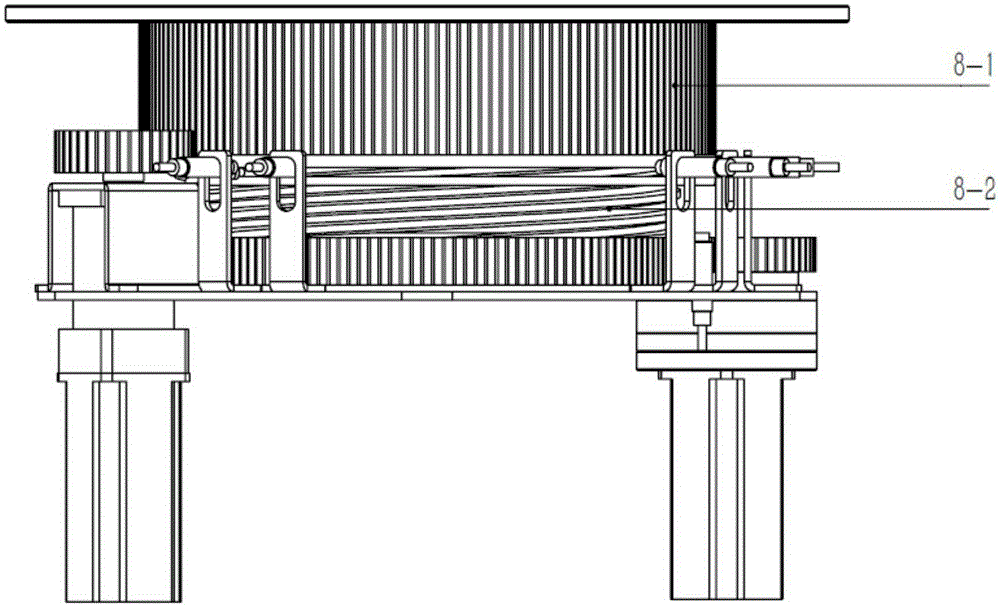

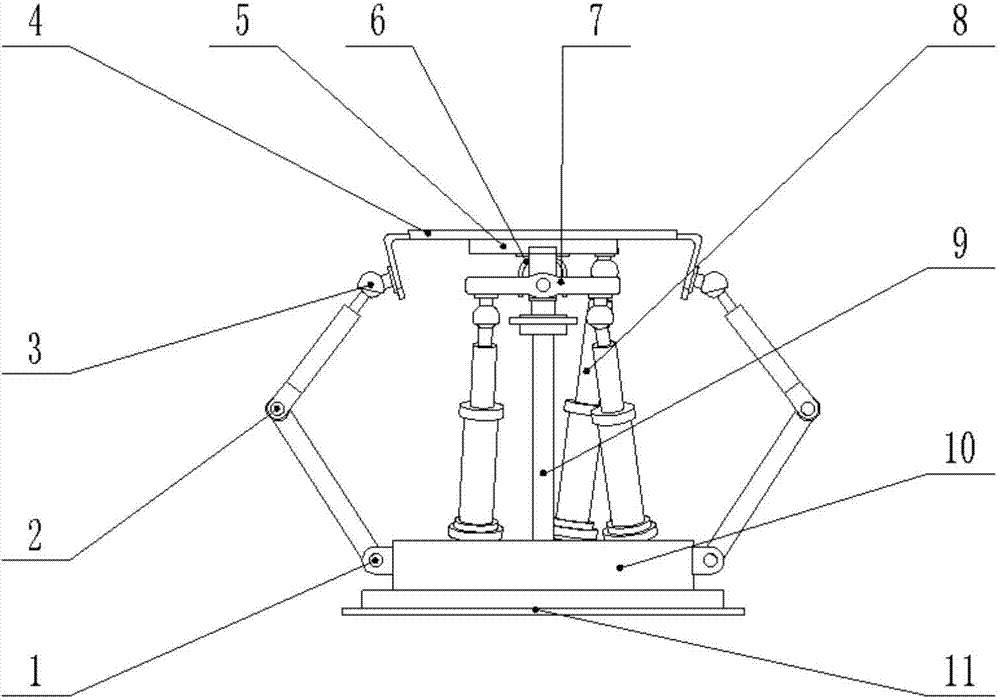

Three-degree-of-freedom series-parallel rotating platform

InactiveCN104760038AImprove carrying capacityProgramme-controlled manipulatorThree degrees of freedomSlewing bearing

The invention provides a three-degree-of-freedom series-parallel rotating platform. The three-degree-of-freedom series-parallel rotating platform comprises a parallel mechanism and a gyrating device, wherein the parallel mechanism is connected with a rack and a medium movement platform through a UPS branch chain, a UPS-R-UPS combined branch chain and a constraining branch chain; the upper end and the lower end of the UPS branch chain are respectively connected with the medium movement platform and the rack through an S pair and a U pair; two UPS sub-chains in the UPS-R-UPS combined branch chain are symmetrically distributed about an axis of the R pair at the initial position; the axis of the R pair is overlapped with the axis of a constraining branch chain U pair connecting movement platform; the gyrating device comprises two RRS branch chains which have the same structure, an upper movement platform and a lower movement platform; gyring bearings are arranged between the upper movement platform and the medium movement platform and between the lower movement platform and the rack; two ends of the two RRS branch chains are respectively connected with the upper movement platform and the lower movement platform through the R pair and the S pair; the two RRS branch chains are symmetrically arranged. The three-degree-of-freedom series-parallel rotating platform is high in bearing capacity and has a good application prospect.

Owner:YANSHAN UNIV

Railroad locomotive running simulation test bed

InactiveCN1995949AThe test environment is realThe test data is accurateRailway vehicle testingRoad surfaceSlewing bearing

The railway vehicle running simulation test bench comprises several testing units with each composed of drive mechanism connected with left and right rolling wheel supported on the left and right U shape frame that installed on the inner wall of the left and right rolling wheel base through the vertical linear bearing of the side wall, with the right and left rolling wheel installed on the base, left and right U shape frame's bottom connected to the base through the vertical hydraulic vibrator, outer ends of the right and left rolling shafts connected with the horizontal hydraulic vibrator that fastened on the base, the right and left rolling base installed on the base through revolution axis and connected with their own revolution vibrator. It can simulate the running of vehicles on the railway with all kinds of uneven road surface.

Owner:SOUTHWEST JIAOTONG UNIV

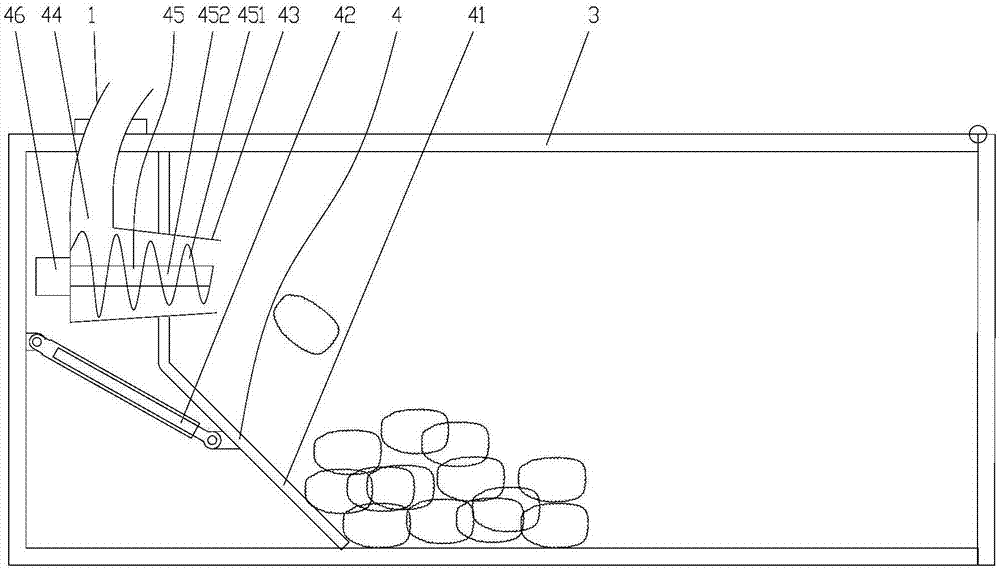

Suction type garbage collecting car

PendingCN107313382AImprove collection efficiencyWith filter functionRoad cleaningHydraulic motorRefuse collection

The invention relates to a suction type garbage collecting car. The suction type garbage collecting car comprises a car underpan. The car underpan is provided with a suction device and a sealed garbage box. A suction opening of the suction device communicates with the interior of the garbage box through an air sucking pipeline. An air exhausting opening of the suction device communicates with the outside atmosphere through an air exhausting pipeline. The top of the garbage box is provided with a suction arm which communicates with the interior of the garbage box. One end of the suction arm is rotationally connected with the garbage box through a slewing bearing. The slewing bearing is driven to rotate by a hydraulic motor so as to drive the suction arm to rotate. The other end of the suction arm is used for sucking garbage. The suction type garbage collecting car is reasonable in design and simple in structure, the garbage can be sucked and compressed, the garbage collecting efficiency is high, the functions of filtering, deodorizing and noise reducing are achieved, the air-exhausting and purifying effects are good, the noise pollution is small, the operation environment is greatly improved, and the environmental-friendly requirements are met.

Owner:福建海山机械股份有限公司

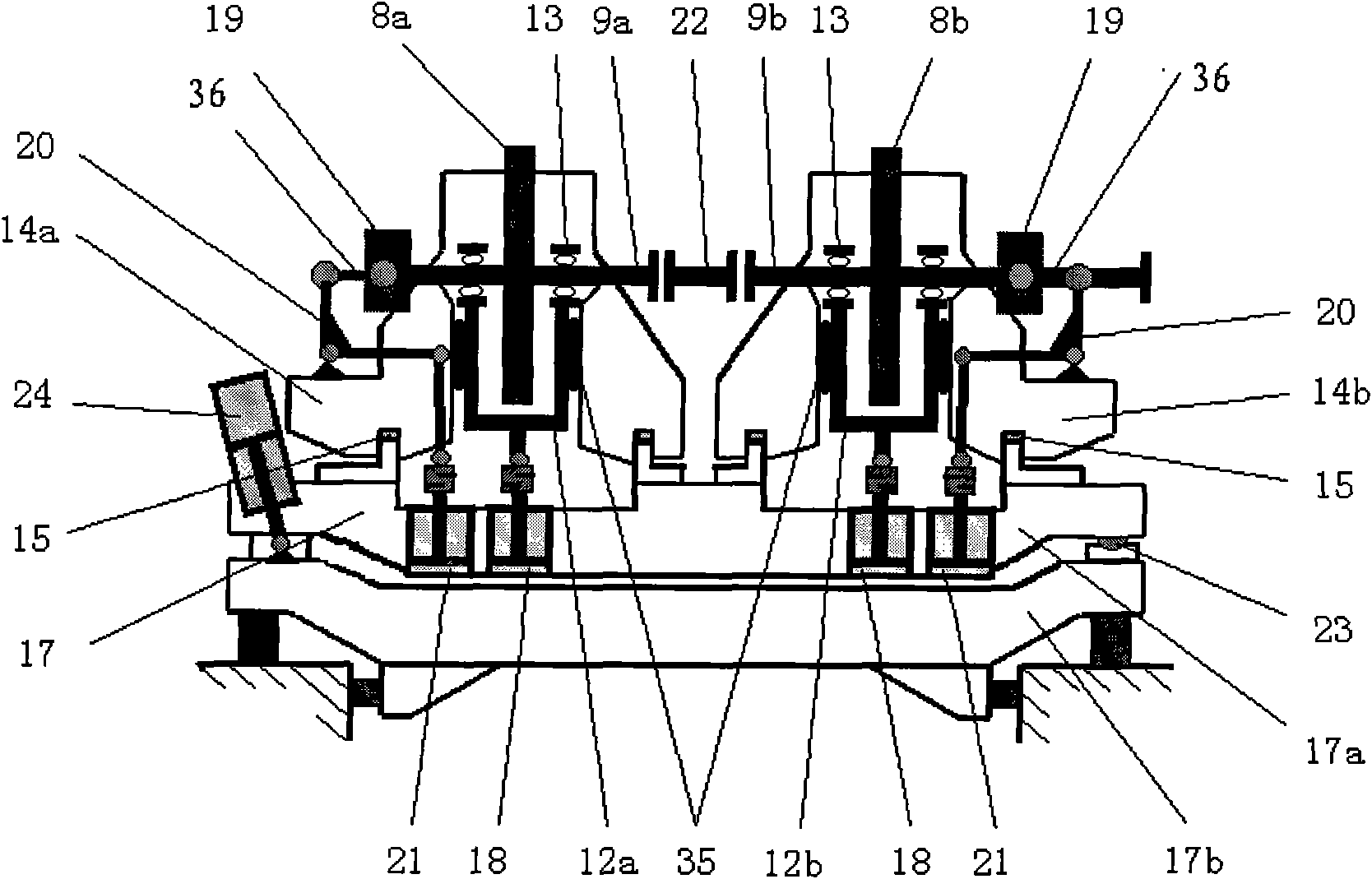

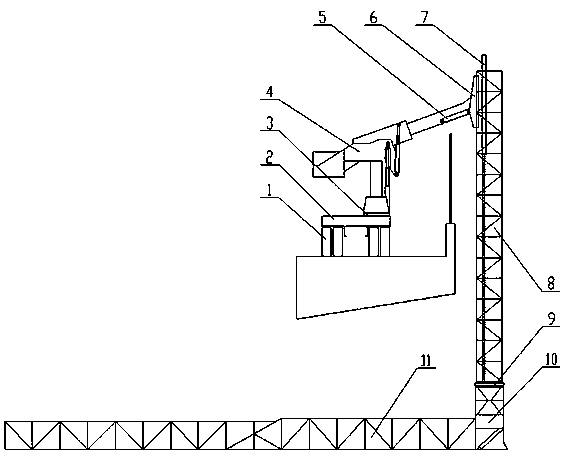

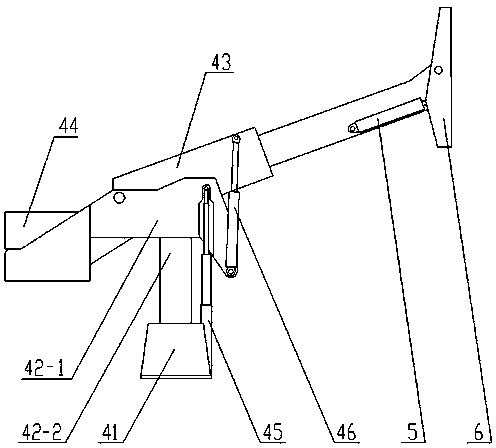

Multi-working-condition bridge detecting vehicle

ActiveCN104109997AHeightened effectIncreased width capabilityBridge structural detailsVehicle frameThree degrees of freedom

The invention discloses a multi-working-condition bridge detecting vehicle, and belongs to the technical field of bridge detecting. The multi-working-condition bridge detecting vehicle comprises a chassis (1), an auxiliary frame (2), a turnover mechanism (6), a lifting oil cylinder (7), a vertical arm (8), a second slewing bearing (9), a second slewing mechanism (10) and a telescopic arm (11). A first slewing mechanism (4) is installed on a first slewing bearing (3) and an amplitude-changing oil cylinder (5) which can adjust the turnover angle is arranged between the first slewing mechanism and the turnover mechanism (6). The first slewing mechanism is mainly composed of a base (41), a connecting body, a main arm (43), slewing lifting oil cylinders (45) and slewing amplitude-changing oil cylinders (46). According to the multi-working-condition bridge detecting vehicle, functions of the first slewing mechanism are divided, a plurality of independent units are integrated to form the first slewing mechanism, mutual motion mechanisms between the units are arranged, therefore, three freedom degrees, namely, lifting, amplitude changing and stretching and contracting, are newly added to the first slewing mechanism, the vertical striding capacity and the horizontal striding capacity of the detecting vehicle are greatly improved and the application range of the detecting vehicle is expanded.

Owner:XCMG XUZHOU TRUCK MOUNTED CRANE

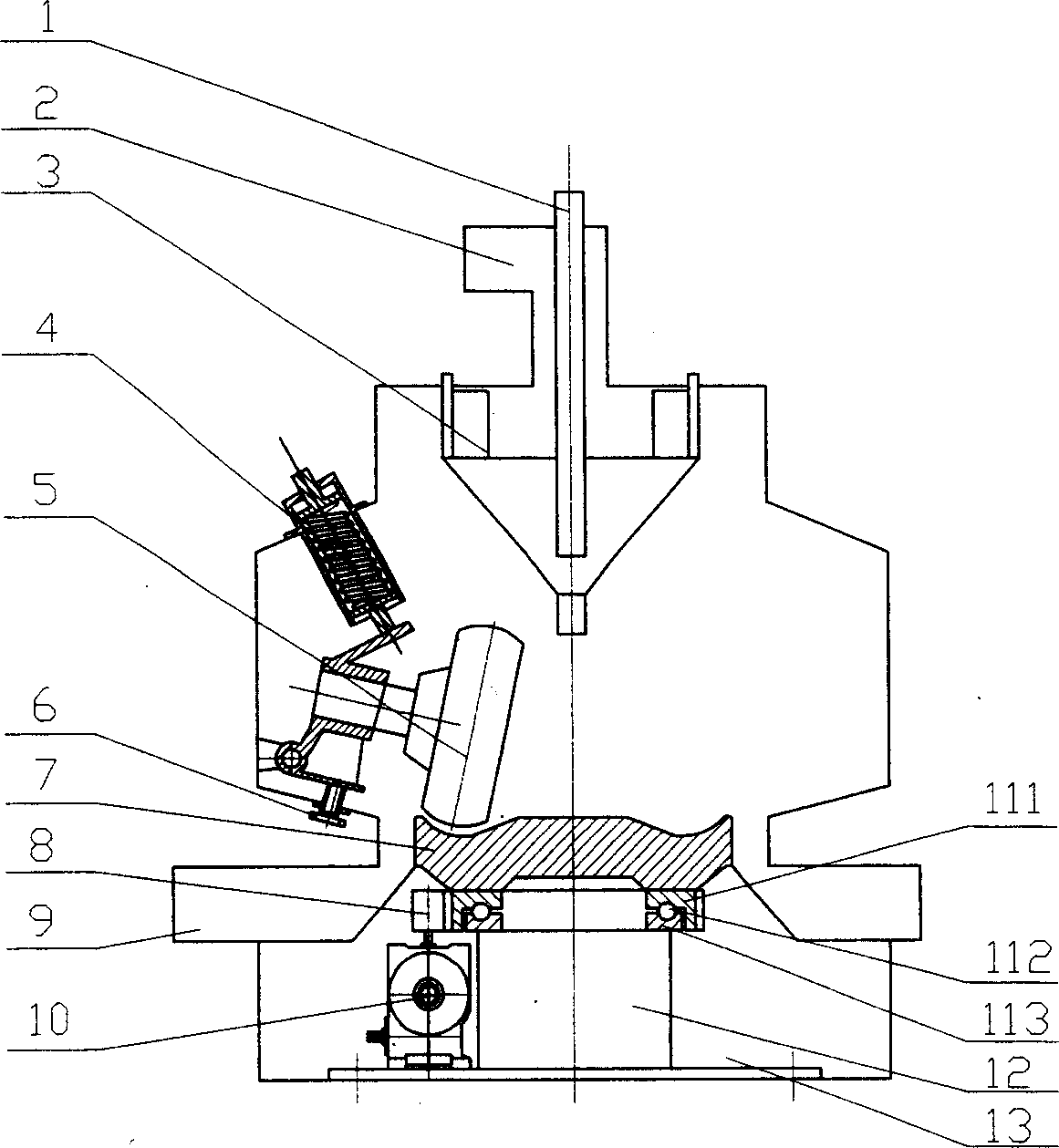

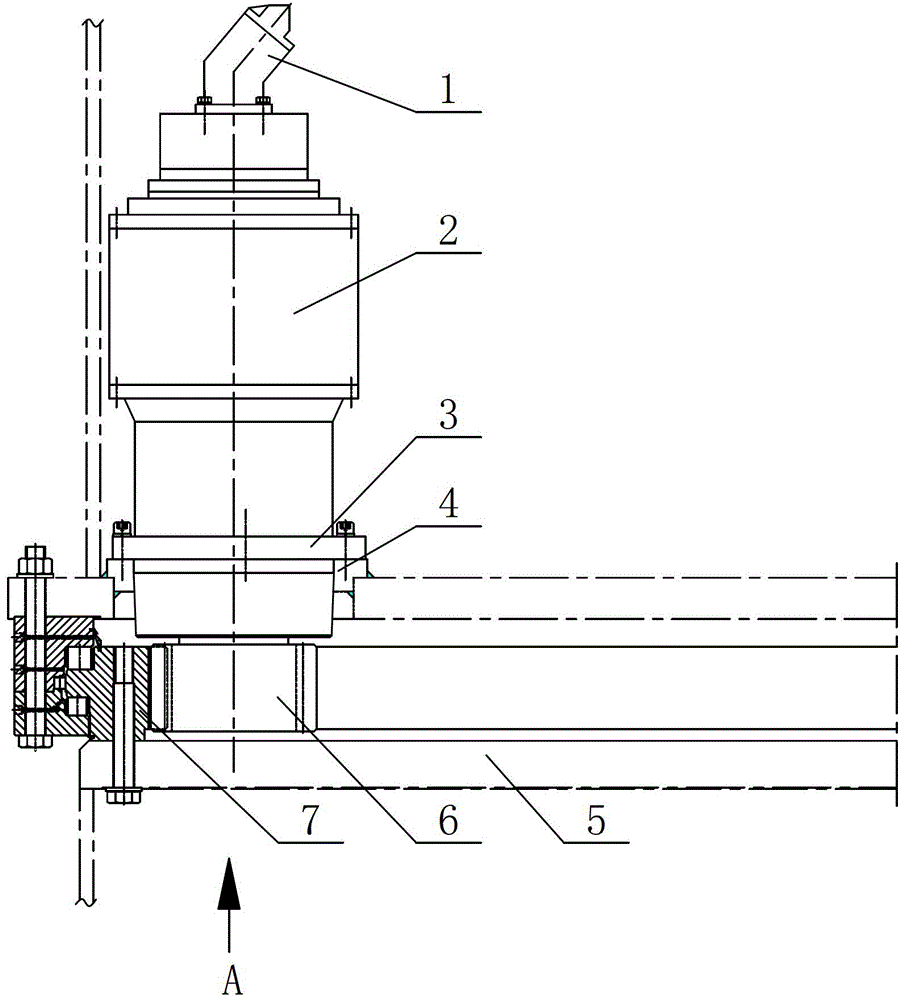

Vertical grinder

The invention discloses a vertical mill, which comprises the following parts: feed inlet, discharge port, grinding roll, grinding disk, pressuring device, grinding roll, grinding disc gap adjusting device, rotary bearing, bearing support, deceleration device and stand, wherein the stand is fixed on the ground; the bearing support is set on the stand or ground directly; the grinding disk is set on the bearing support through rotary bearing; the output end of deceleration device connects the rotary coil of rotary bearing through flange, gear or other driving part, which can be gear deceleration device and belt deceleration device or the combination with two devices on the bearing support, stand or ground directly.

Owner:夏纪勇

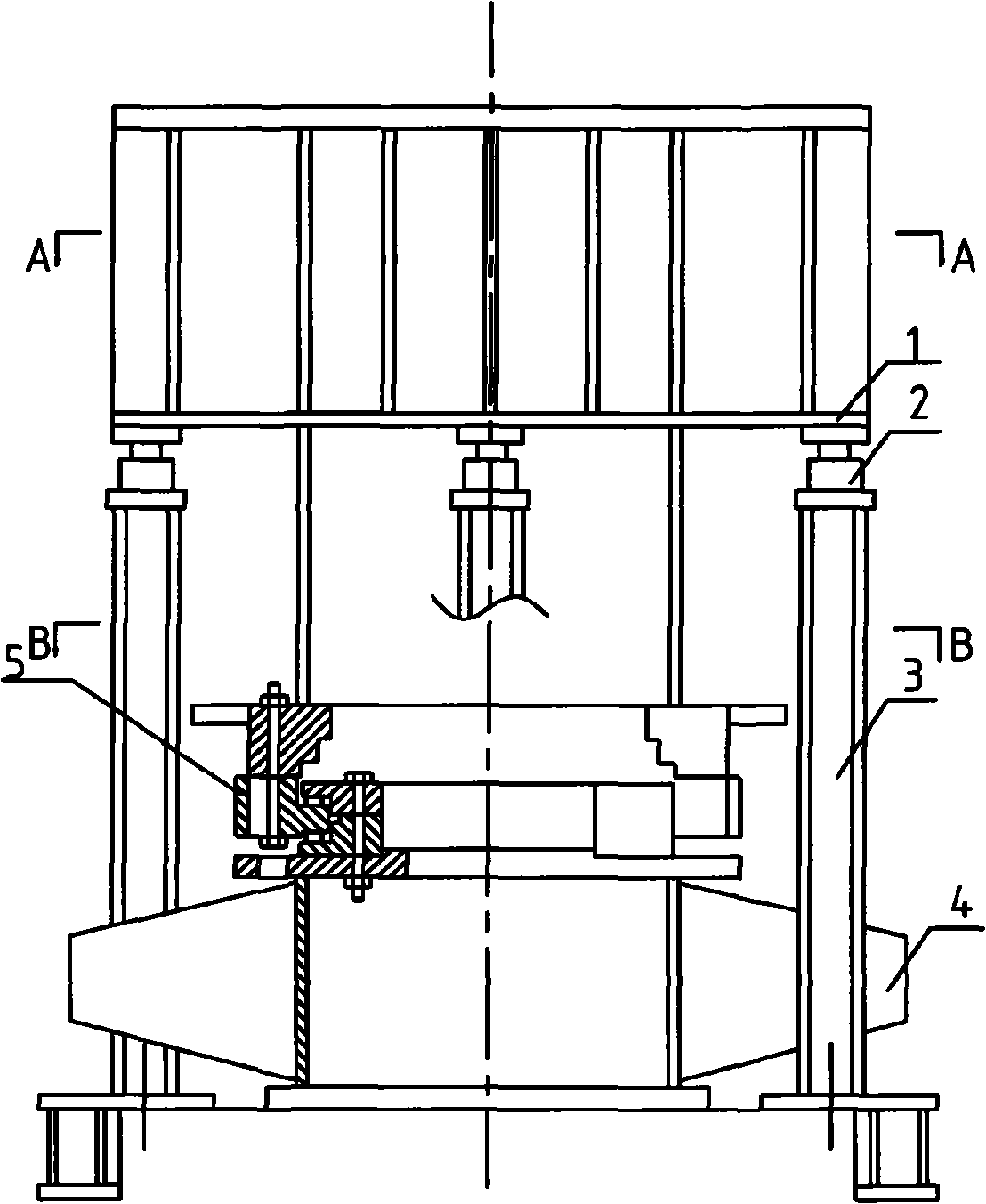

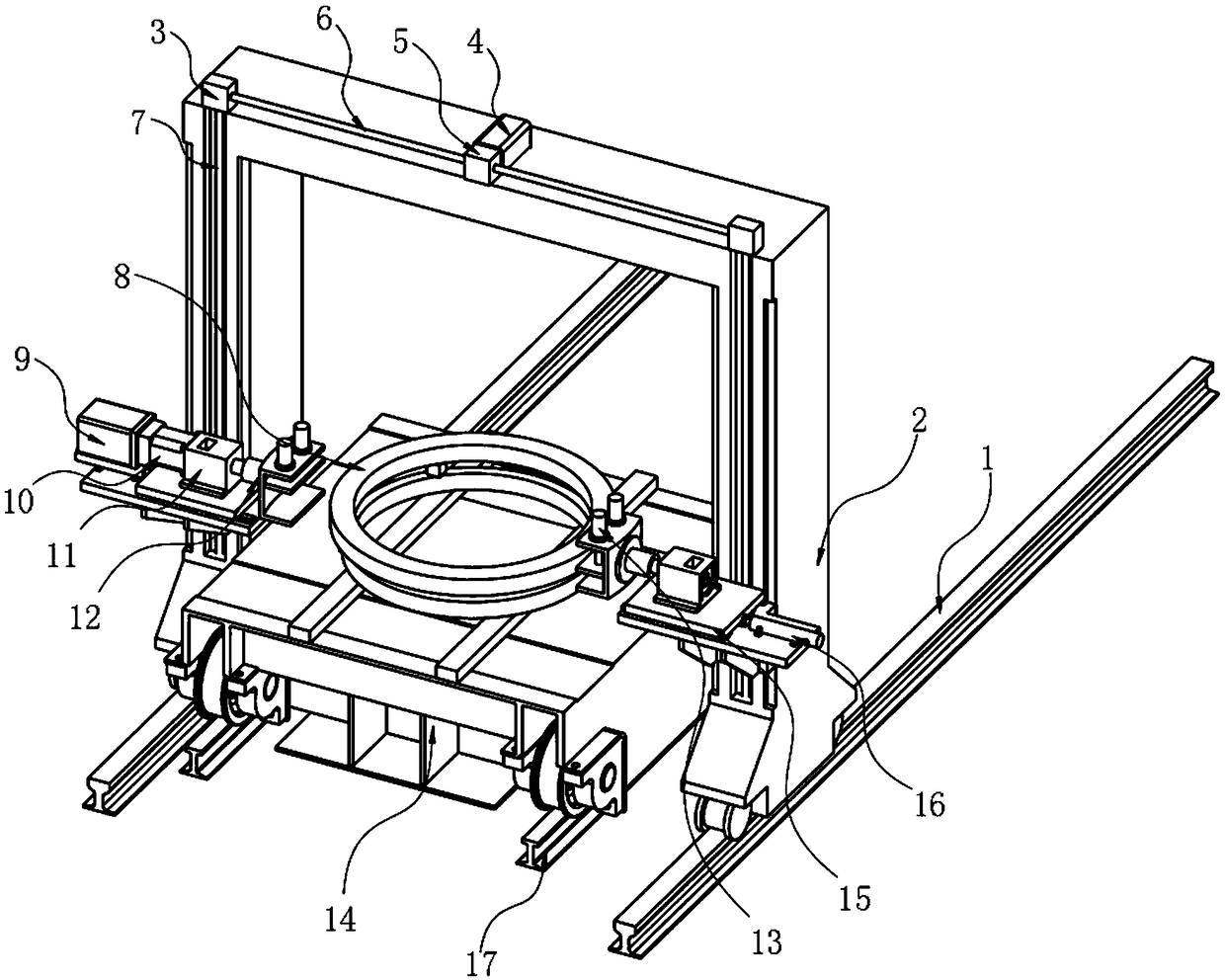

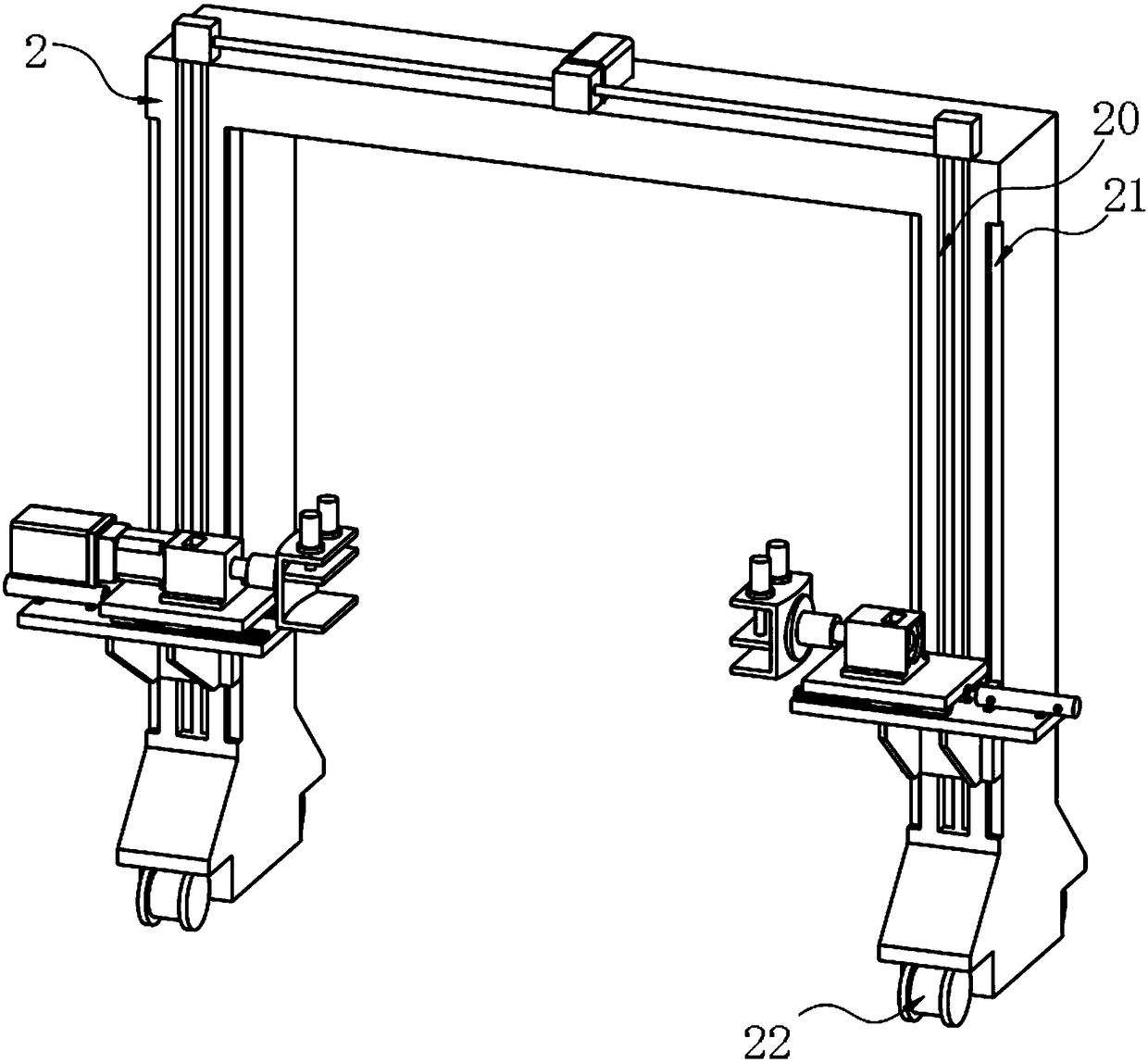

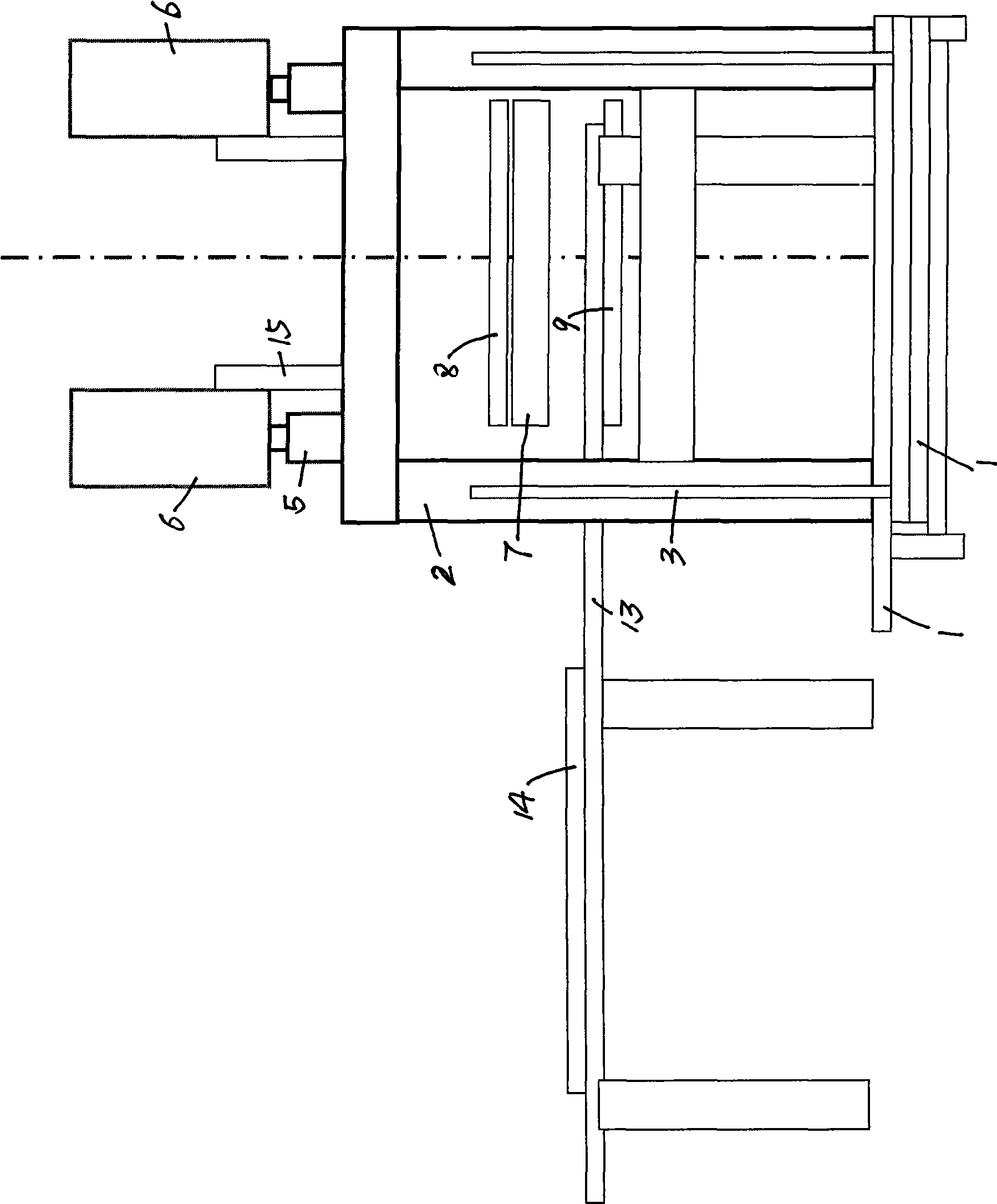

Slewing bearing overturning mechanism

InactiveCN109399109AEasy to processAvoid occupyingBase supporting structuresBraking devices for hoisting equipmentsReduction driveReducer

The invention relates to the technical field of machinery, in particular to a slewing bearing overturning mechanism. The slewing bearing overturning mechanism comprises two ground rails and a travelling trolley, wherein the two ground rails are parallel to each other; the travelling trolley is arranged between the two ground rails and above the two ground rails; a gantry bracket is arranged on thetwo ground rails; a pair of opposite guiding rail sliders is arranged on the side wall of the gantry bracket; a connecting assembly is arranged on the guiding rail sliders; a rotating motor and a third speed reducer are arranged behind the connecting assembly; a rotating device is arranged in front of the connecting assembly; an output shaft of the rotating motor is coaxially connected with an input shaft of the third reducer; and an output shaft of the third reducer is fixedly connected to the rear end of the rotating device through the connecting assembly. By using the slewing bearing overturning mechanism, the inner ring, the outer ring and assemblies of a slewing bearing are automatically overturned to facilitate the machining and assembling of the slewing bearing. The slewing bearingoverturning mechanism has the advantages that the structure is compact, the assembling is convenient, the occupation of a crane is avoided, the safety of workers is ensured, and the overturning efficiency is improved.

Owner:NANJING GONGDA CNC TECH

Crane slewing mechanism capable of adjusting gap between gears

The invention discloses a crane slewing mechanism capable of adjusting a gap between gears. The crane slewing mechanism comprises a motor, a reducer and a slewing bearing fixed on a base, wherein an output end of the motor is connected with the reducer, the reducer is detachably arranged on a base seat through a flange, an output shaft of the reducer is fixedly connected with a gear which is meshed with an outer gear ring of the slewing bearing, and the gear and the flange are in a eccentric structure. The crane slewing mechanism capable of adjusting the gaps between the gears is simple in structure and easy to realize. Due to the fact that the gear and the flange are in the eccentric structure, when a central distance needs adjusting, the meshing gap between the drive gear and the outer gear ring of the slewing bearing can be changed as long as the flange is rotated, and therefore the meshing gap can be adjusted conveniently.

Owner:无锡市华星船舶设备有限公司

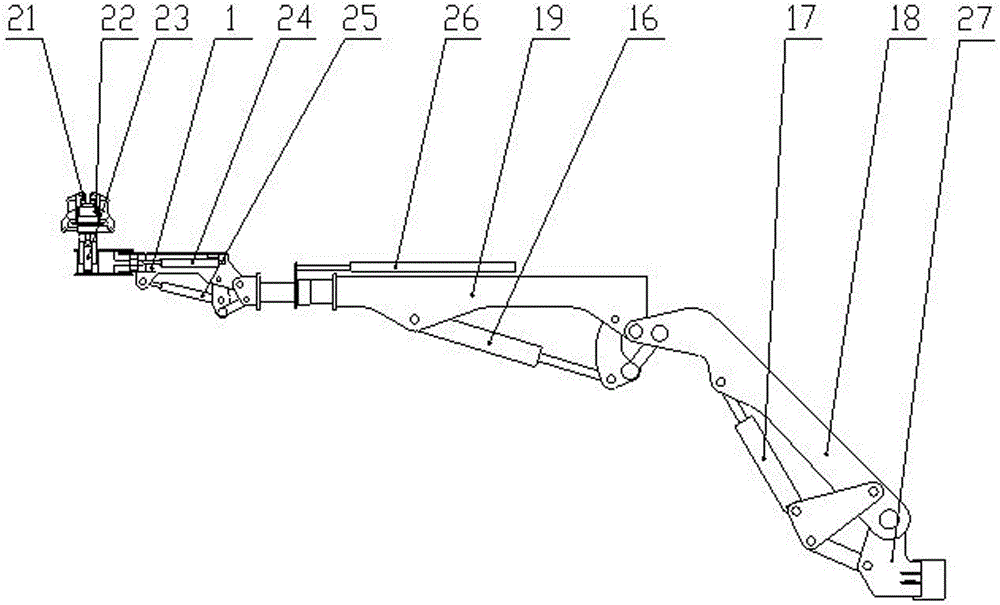

Formwork grabbing and lifting aligning machine and using method thereof

The invention discloses a formwork grabbing and lifting aligning machine and a using method thereof. The aligning machine comprises a get-on part and a get-off part; the get-on part comprises a base, a large arm hinged to the base, a telescopic arm, a small arm and a rotating arm, wherein the telescopic arm, the small arm and the rotating arm are in sliding connection with the large arm; the telescopic arm, the small arm and the rotating arm are sequentially connected end to end; the small arm and the rotating arm are connected through a rotating arm slewing bearing; the plane where the rotating arm slewing bearing is located is kept perpendicular to the plane formed by the small arm and the telescopic arm all the time; the tail end of the rotating arm is provided with a gripper; the rotating arm is connected with the gripper through a gripper slewing bearing; and the included angle between the gyration center line of the gripper and the rotating arm is zero. The formwork grabbing and lifting aligning machine is easy and convenient to operate, high in operation efficiency, high in operation quality and capable of reducing the manpower cost and improving the work efficiency.

Owner:平邑县经发企业服务有限公司

Rear Grain Cart Grain Handling Assemblies for an Agricultural Harvesting Combine

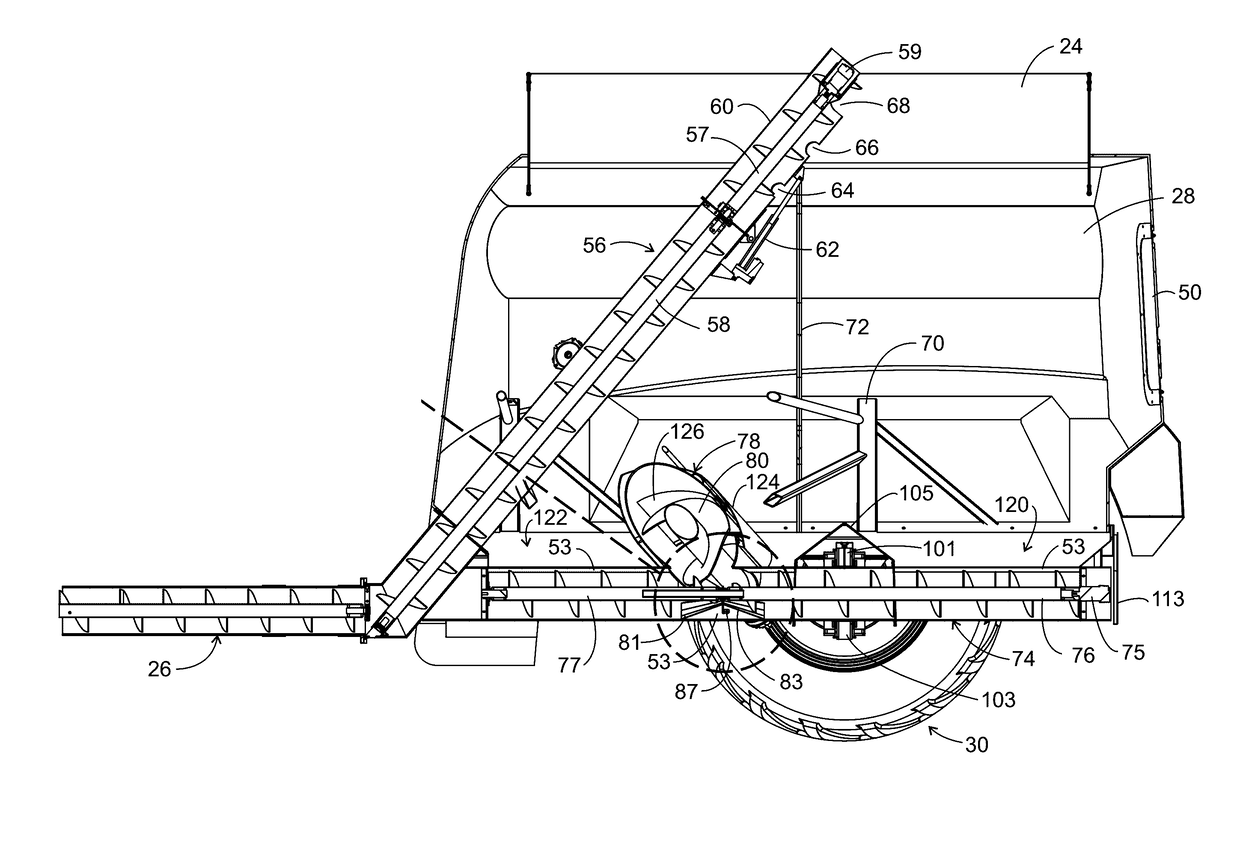

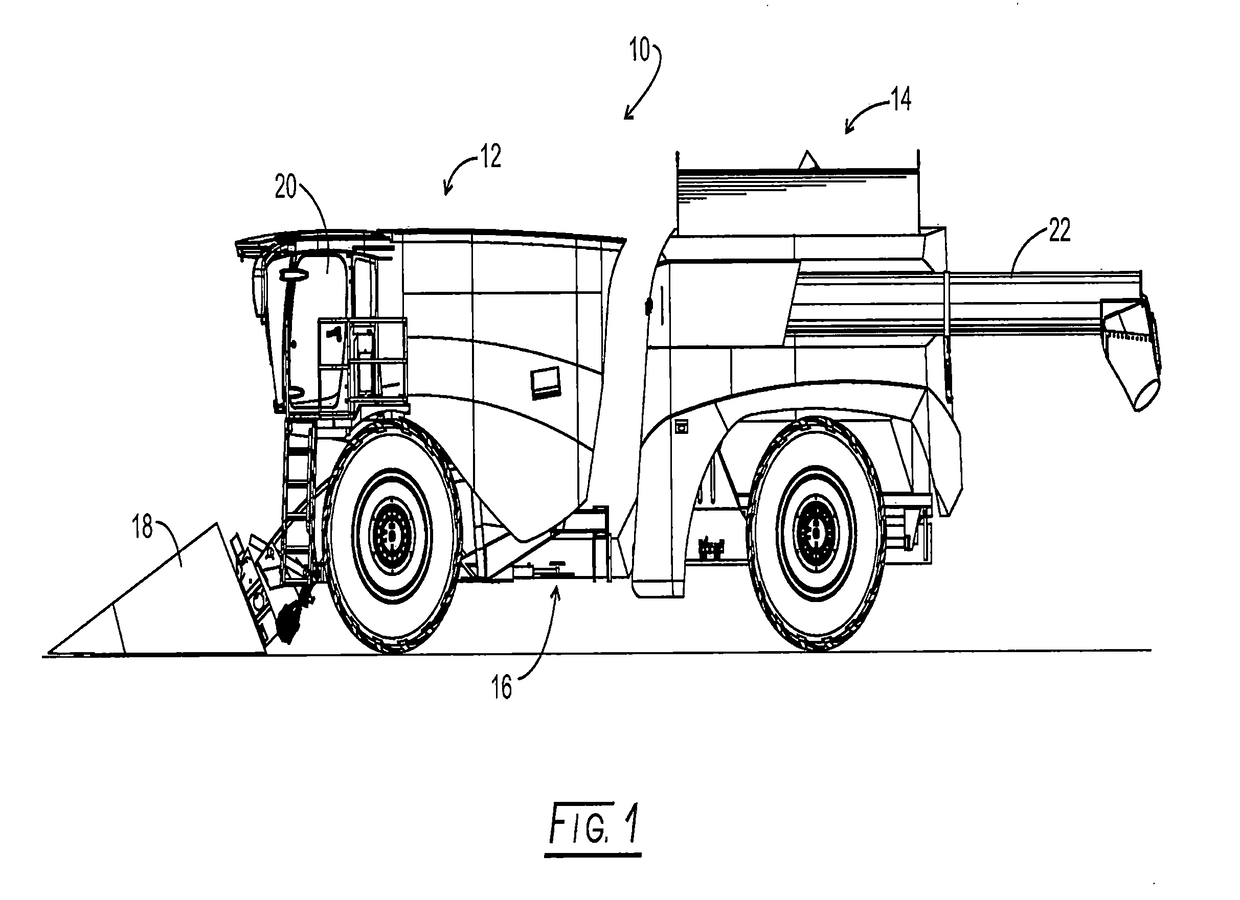

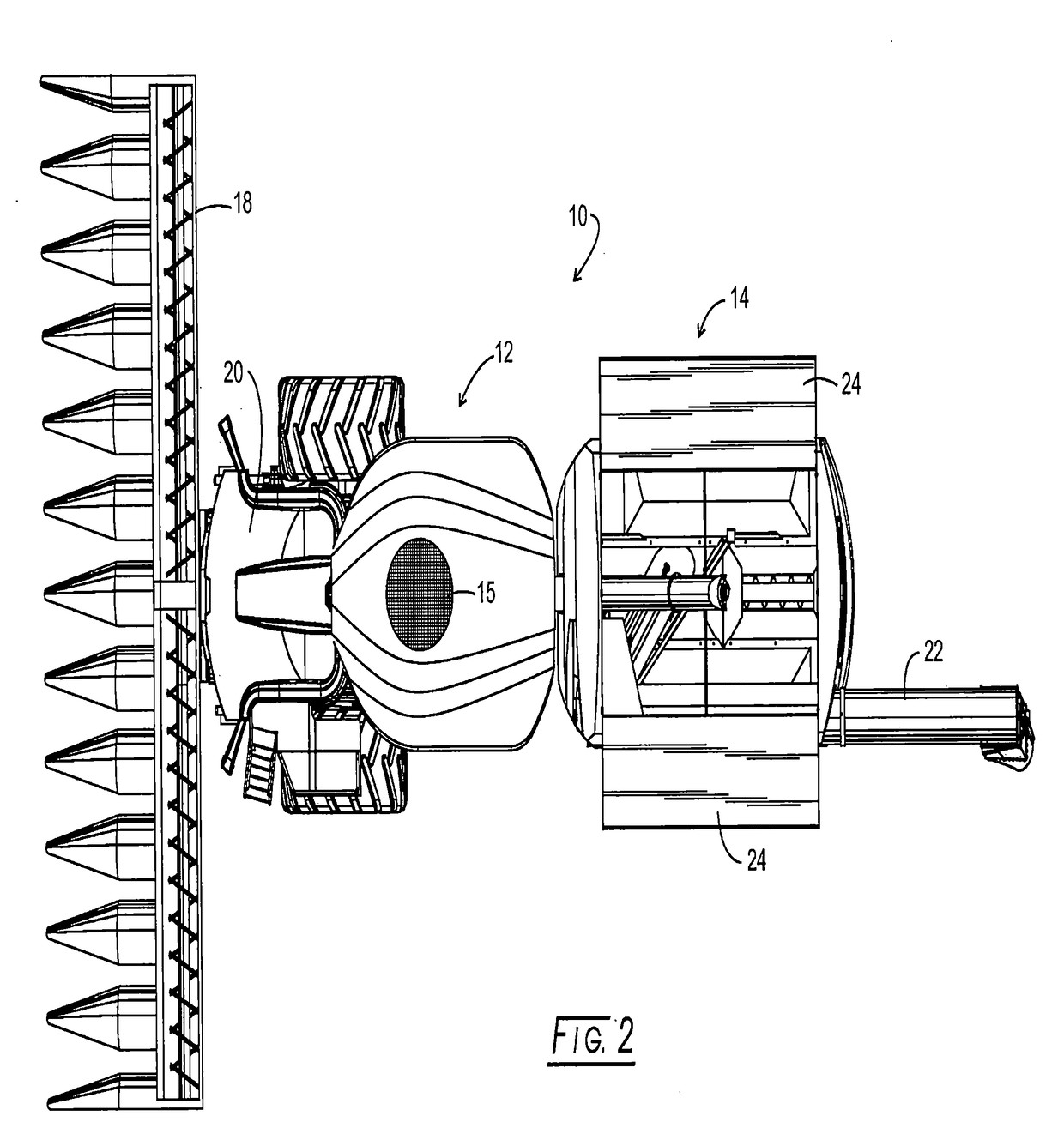

Disclosed is a grain harvesting articulated combine of a forward PPU, a rear grain cart, and an articulation joint that connects the forward PPU with the rear grain cart. The rear grain cart includes an ascending lift auger assembly that receives clean grain from the forward PPU and transports it upwardly for dumping into the rear grain cart. A generally horizontal drag auger assembly moves clean grain to a lower a lift auger assembly. A clean grain off-loading auger assembly is connected to the lower lift auger assembly by a slew bearing. The clean grain off-loading auger is retractable about its upper end and its upper end assembly is terminated with a spout adapted to direct clean grain generally downwardly. The clean grain off-loading auger assembly is rotatable from a grain off-loading position to a home position.

Owner:TRIBINE IND

Method for dismounting and replacing ladle turret revolving bearing

InactiveCN101486090AShorten maintenance timeImprove safety and reliabilityMelt-holding vesselsJackscrewEngineering

The invention aims to provide a method for disassembling a revolving bearing of a large-ladle revolving platform, which can quickly disassemble the revolving bearing and has higher safety, short construction period and lower construction cost. The method comprises the following steps: firstly, disassembling bolts which connect the prior revolving bearing inner race and a pedestal flange; secondly, filling a cushion block on the upper part of a connecting rod hole for a connecting rod to pass through on a box body, and making the upper part of the connecting rod contact the bottom of the cushion block; thirdly, using four jacks to synchronously lift four ladle arms, and making the prior revolving bearing and a revolving body above the prior revolving bearing move up for a certain distance together; fourthly, arranging a tray which is positioned on a guide rail under the prior revolving bearing; fifthly, disassembling bolts which connect the prior revolving bearing outer race and an upper revolving body, and making the prior revolving bearing fallen on the tray; sixthly, making the tray on the guide rail move in the radial direction along the revolving platform, and making the prior revolving bearing deviated from an axial line of the revolving platform; and seventhly, lifting away the prior revolving bearing.

Owner:CHINA 19TH METALLURGICAL CORP

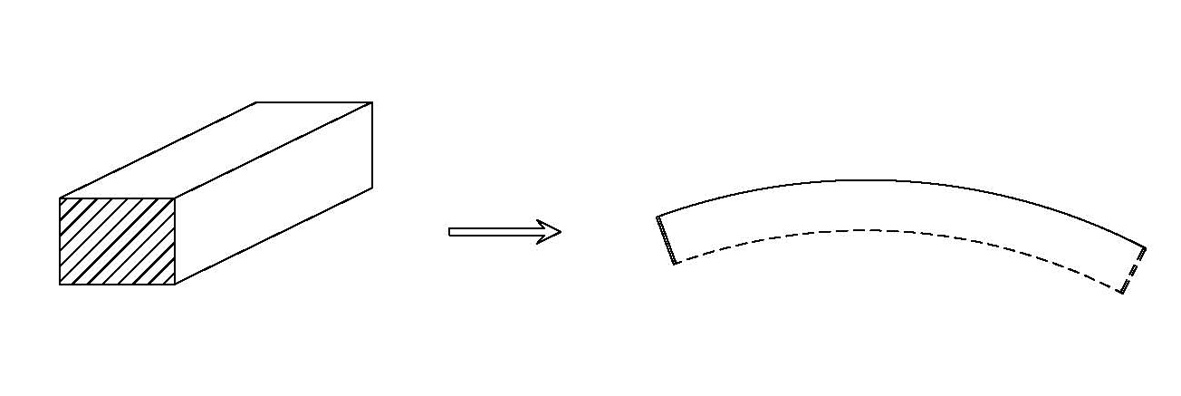

Rotary bearing flange of portal jib crane

ActiveCN101941646AEasy to manufactureImprove yieldBase supporting structuresBraking devices for hoisting equipmentsMachineSlewing bearing

The invention relates to a rotary bearing flange of a portal jib crane of a large-diameter rotary supporting bearing which is made by combining and utilizing the traditional metal processing skillfully. The technical scheme is as follows: the rotary bearing flange of the portal jib crane comprises a flange and a cylinder, and toggle plates are uniformly arranged at intervals on the flange and a transitional cylinder; the flange and the cylinder are welded together; and the flange is manufactured in the following steps: a bar is forged into a square blank with allowance and is then transferred to a machine after heat treatment, rough metal processing is carried out, and then the blank is pressed into required equally-divided ring blocks by an oil press, then the allowance is cut and chamfering is carried out, ground sample assembly is done on a platform, then the ring blocks are butt-welded into a ring, and then fine finishing is carried out on the ring until the flange of the given size is obtained. The rotary bearing flange of the portal jib crane has the beneficial effects of easy manufacturing, high yield and low cost.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

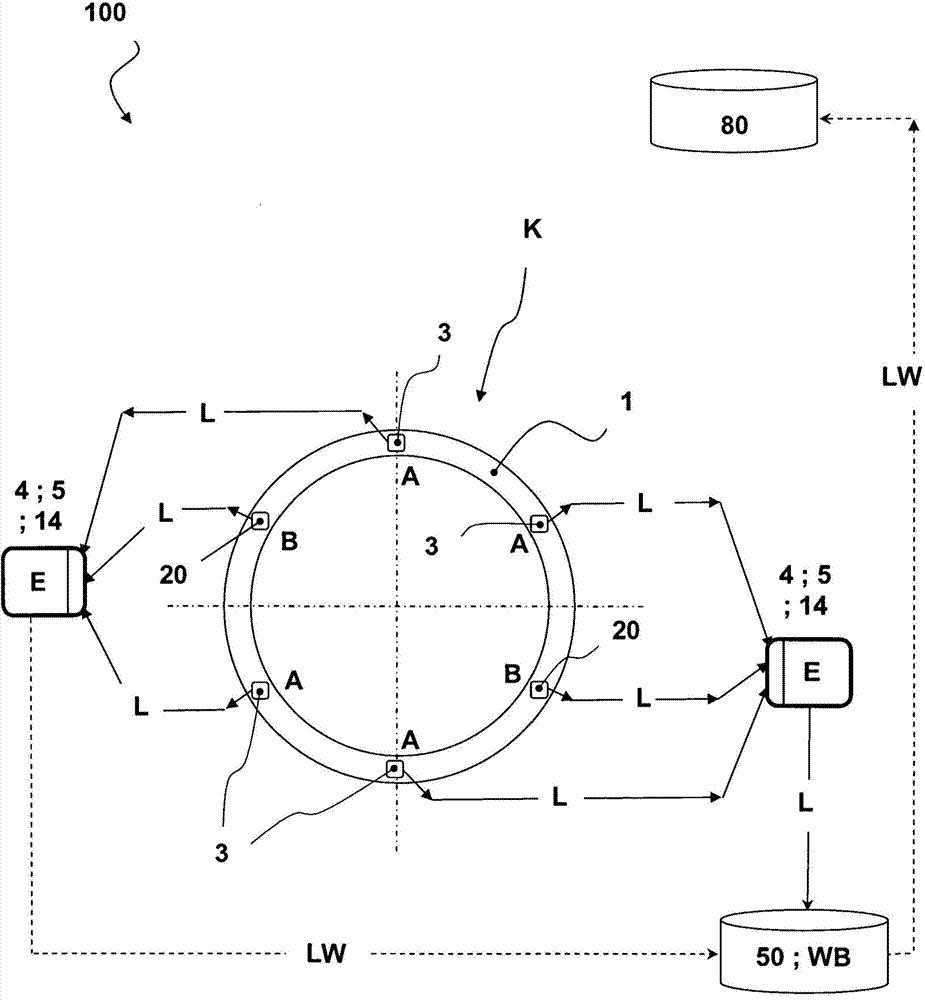

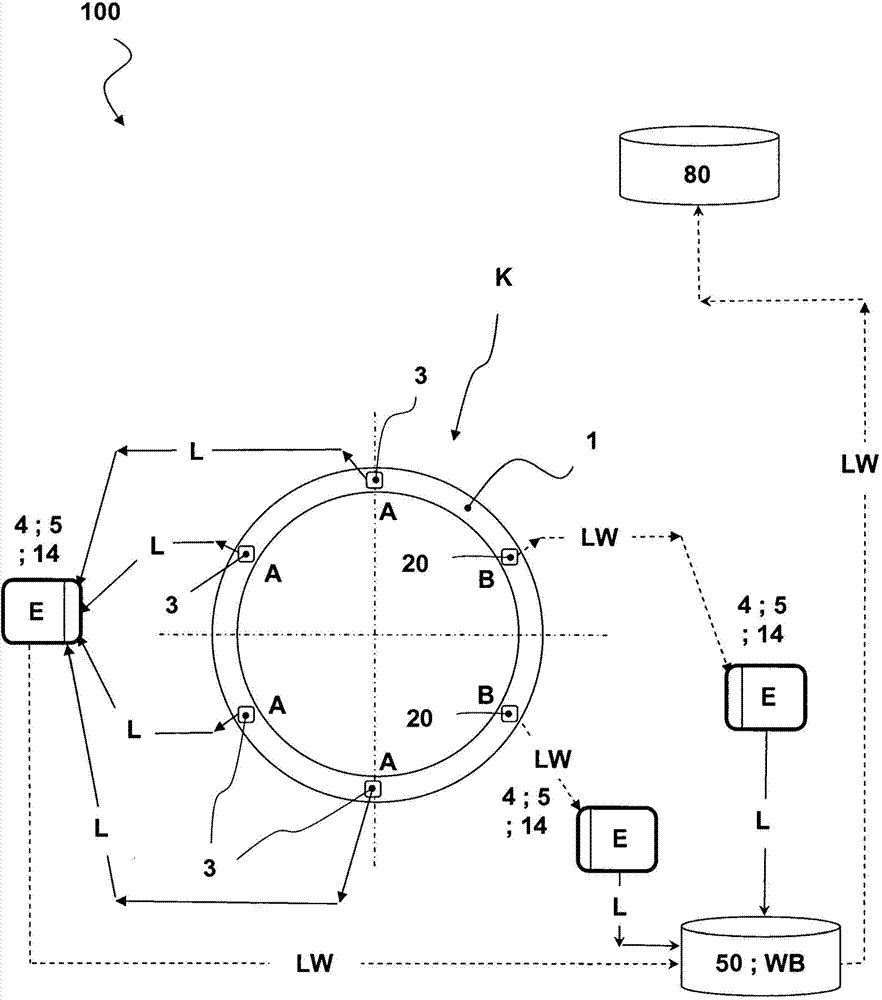

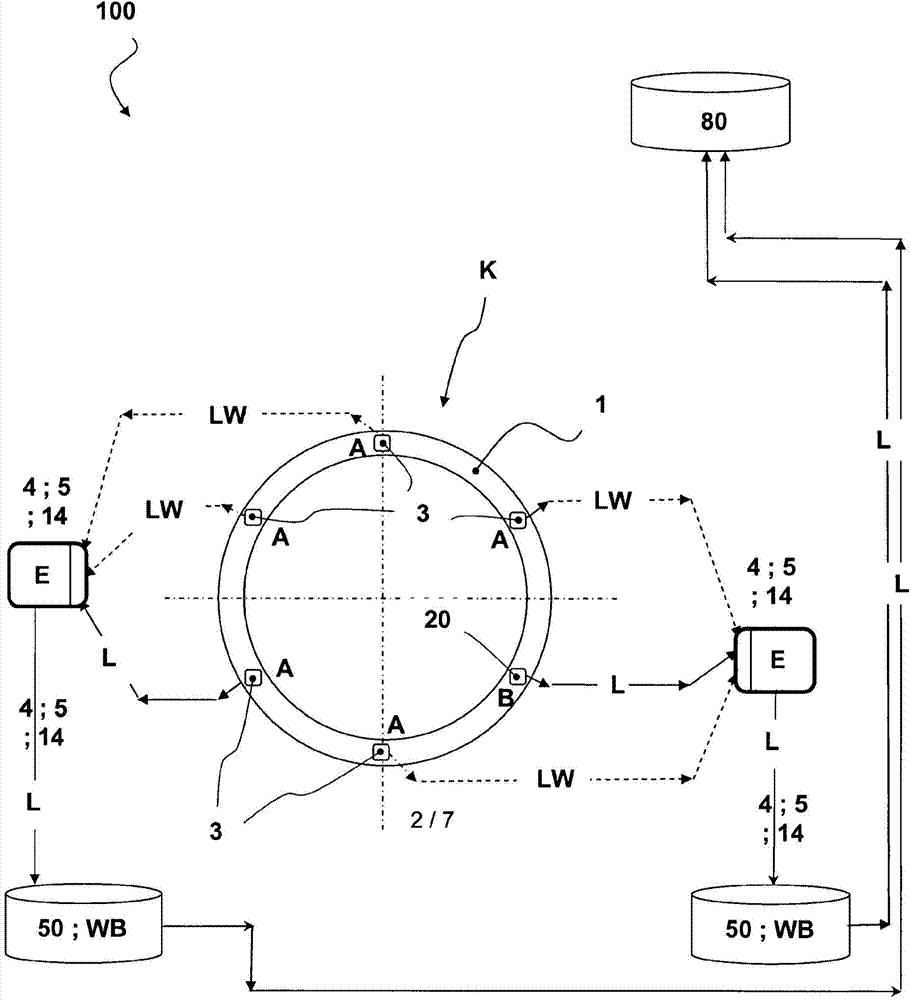

Method and apparatus for detecting and monitoring states

InactiveCN104520578AGas-turbine engine testingMachine bearings testingRolling-element bearingMonitoring system

The invention relates to a state-detecting and state-monitoring system (100) for the at least temporary, possibly periodic, preferably even permanent, value-, signal- or data-based acquisition and monitoring of state parameters of at least one assembly (K) or component, or even sub-elements of this assembly or component, in particular at least of a bearing or a rotary connection, for example in or on a wind turbine, and also relates to an associated method, characterized by: at least one, preferably more than two, contact sensor(s) (3) attached to or incorporated in the subassembly (K) or component, preferably which can be attached or incorporated directly or indirectly, can for example be attached or incorporated at an incorporating location (A), in particular at or on a planar or rounded surface (1) or contour of this assembly (K) by means of screwing / inserting / welding / brazing / adhesive bonding or clamping in the vicinity of a bearing ring in a wind turbine, preferably of a nose ring or support ring or retaining ring of a slewing bearing, alternatively which can be attached or can be incorporated directly at or on at least one inner or outer surface of a blade, main or tower bearing of a wind turbine.

Owner:IMO HOLDING GMBH

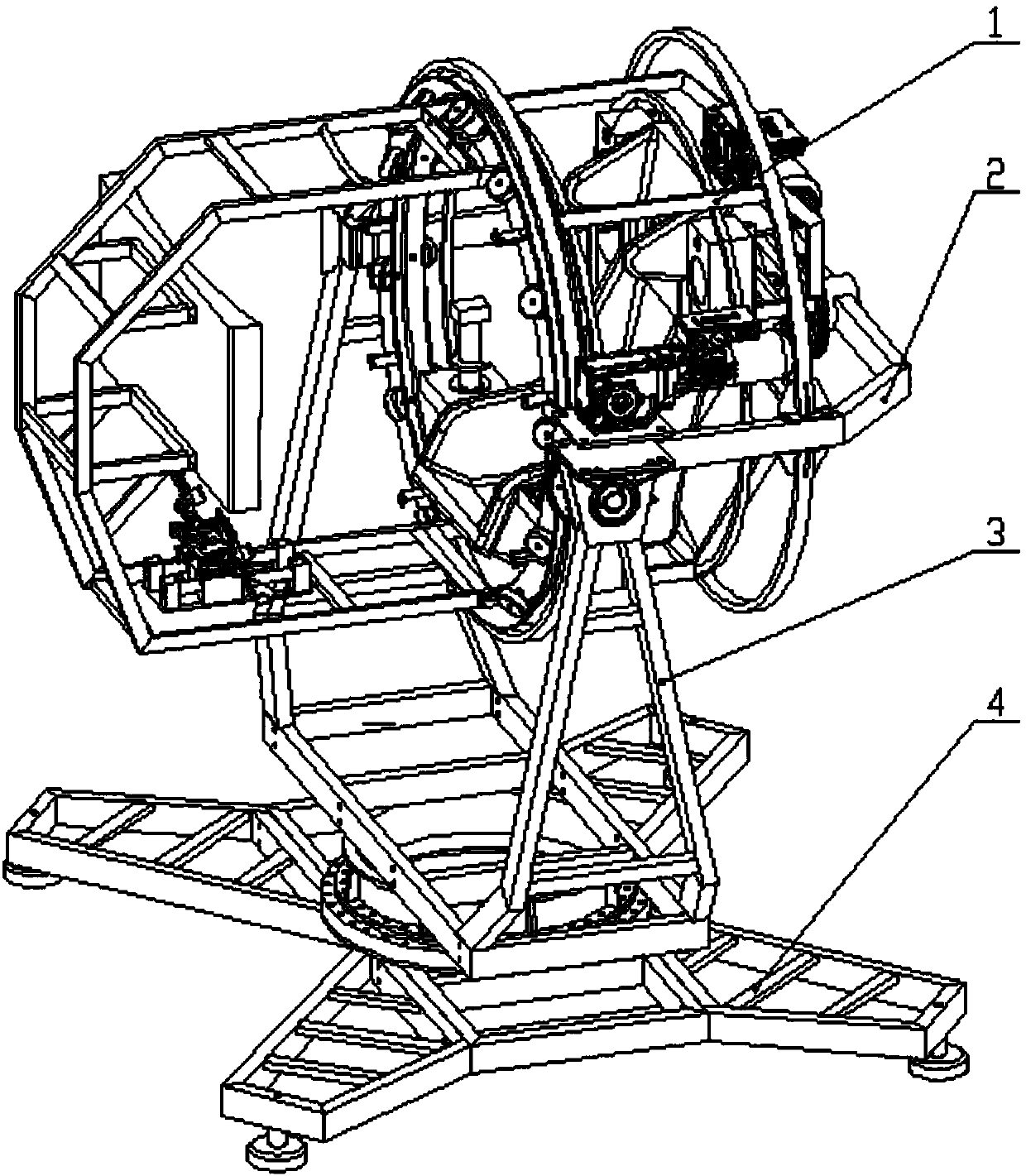

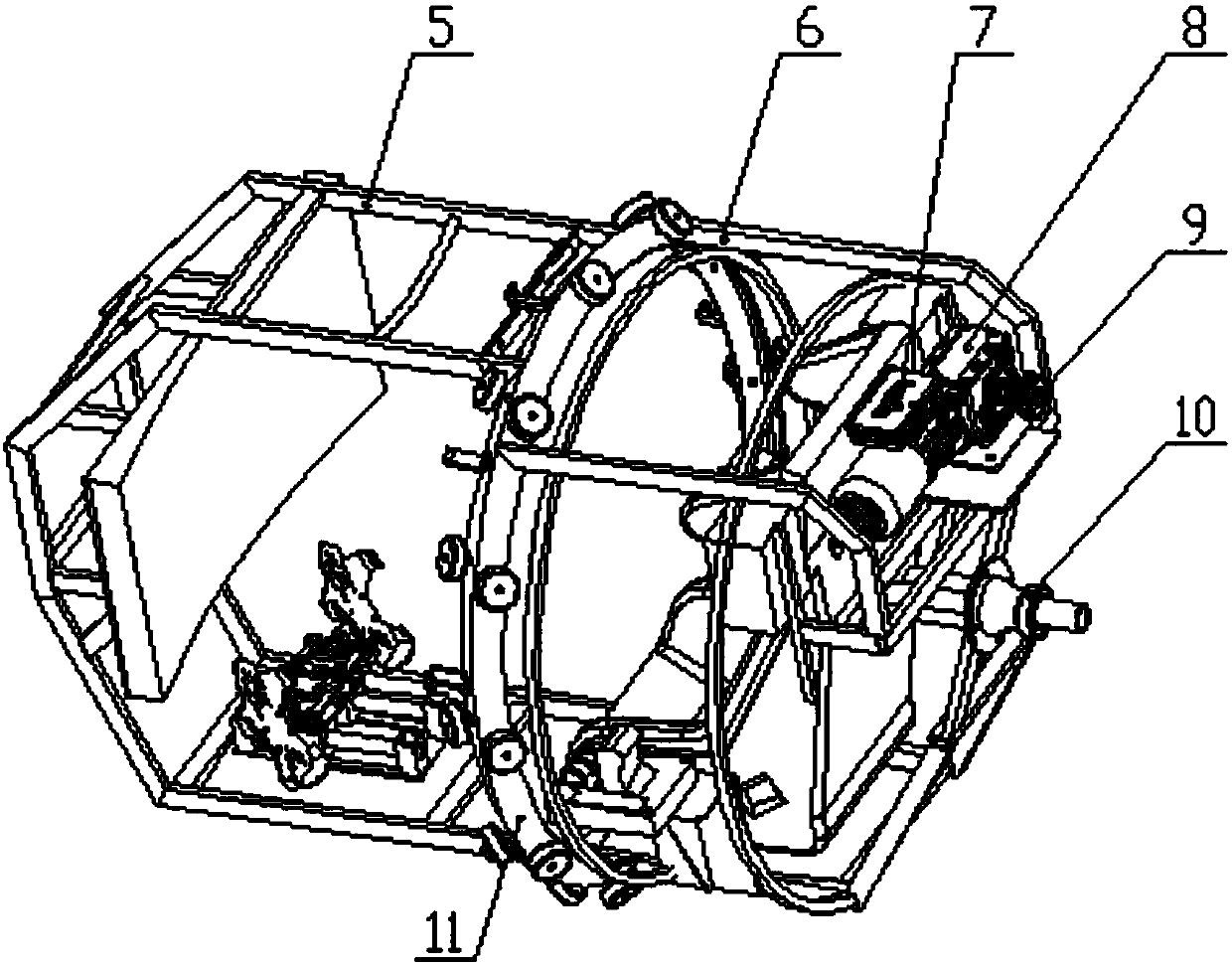

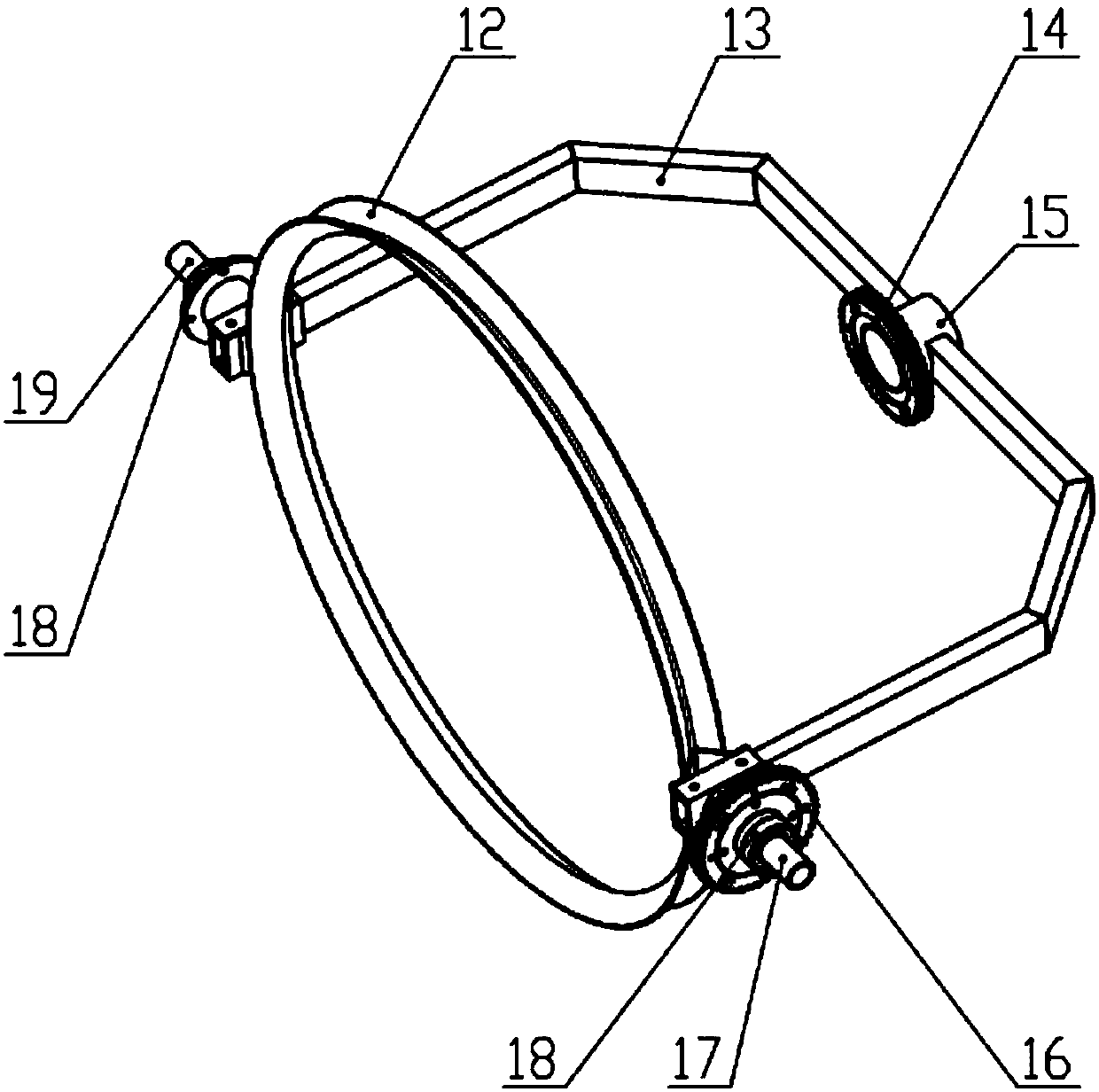

Three-axis simulation flight simulator executing mechanism

PendingCN108022473AImprove qualityImprove efficiencyCosmonautic condition simulationsSimulatorsReduction driveThree degrees of freedom

The invention discloses a three-axis simulation flight simulator executing mechanism. The mechanism includes a roll platform, a pitch platform, a yaw platform, and a base platform. The roll platform includes a front cabin, a rear cabin, a roll motor, a roll reducer, a roll sprocket pair minor sprocket, a roll cylindrical bore self-aligning roller bearing, and a large-diameter rubber roller pivotalbearing inner ring. The pitch platform includes a pivotal bearing outer ring, a U-shaped frame, a roll sprocket pair large sprocket, a roll bearing seat, a pitch sprocket pair large sprocket, a pitchright shaft, a pitch cylindrical bore self-aligning roller bearing, and a pitch left shaft. The yaw platform includes a U-shaped bracket, a pitch bearing seat, a pitch motor, a pitch reducer, a pitchsprocket pair minor sprocket and a yaw bearing seat. The base platform includes a base, a base bracket, a large-diameter pivotal bearing, a yaw motor, a yaw reducer, an open internal gear meshing pair small gear, and support feet. The mechanism of the invention can simulate that a single person operates an aircraft to perform three degrees of freedom of roll, pitch and yaw movements to realize asimulated flight function.

Owner:AVIC SHANGHAI AERONAUTICAL MEASUREMENT CONTROLLING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com