Patents

Literature

1226results about "Conductive pattern polishing/cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

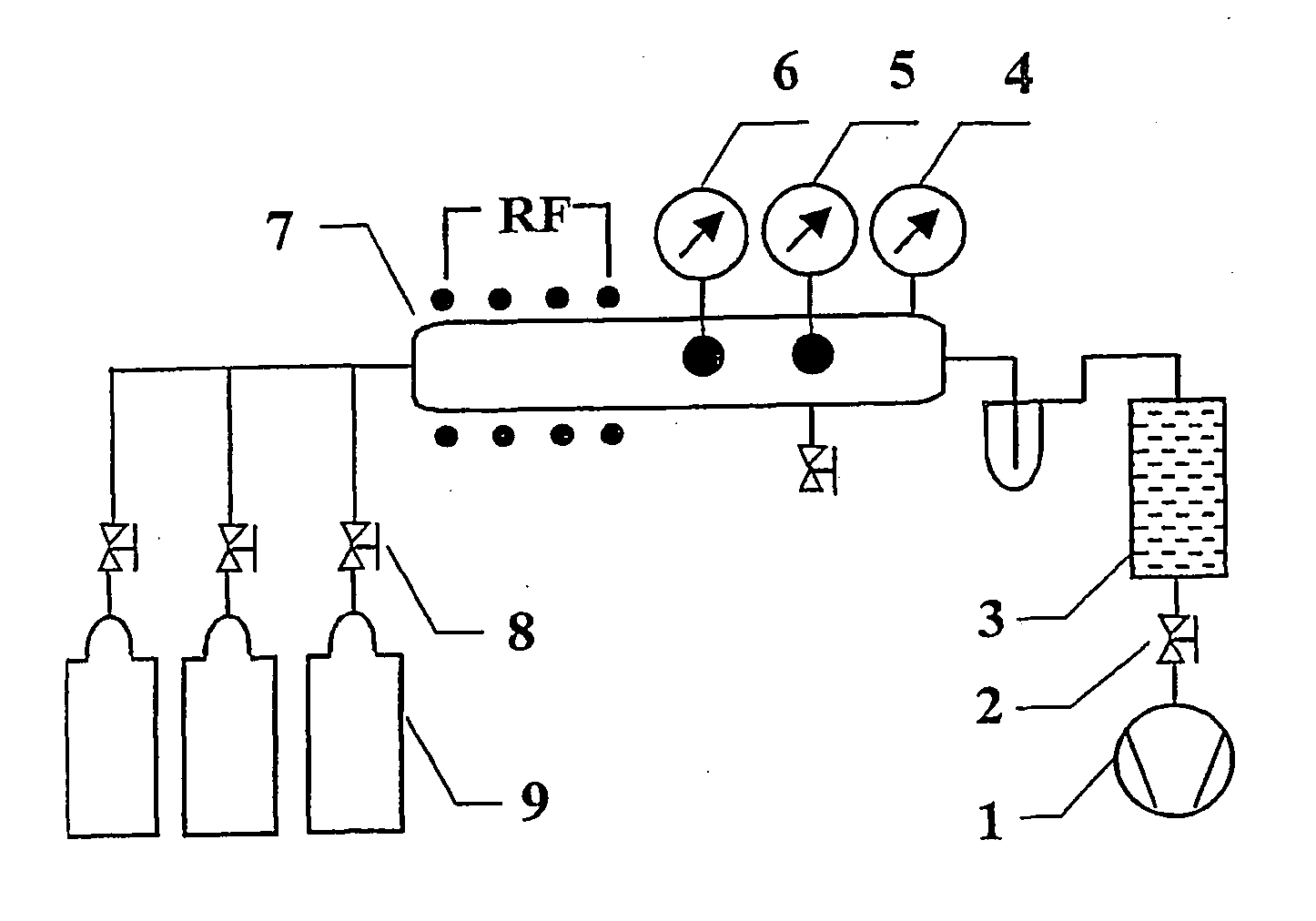

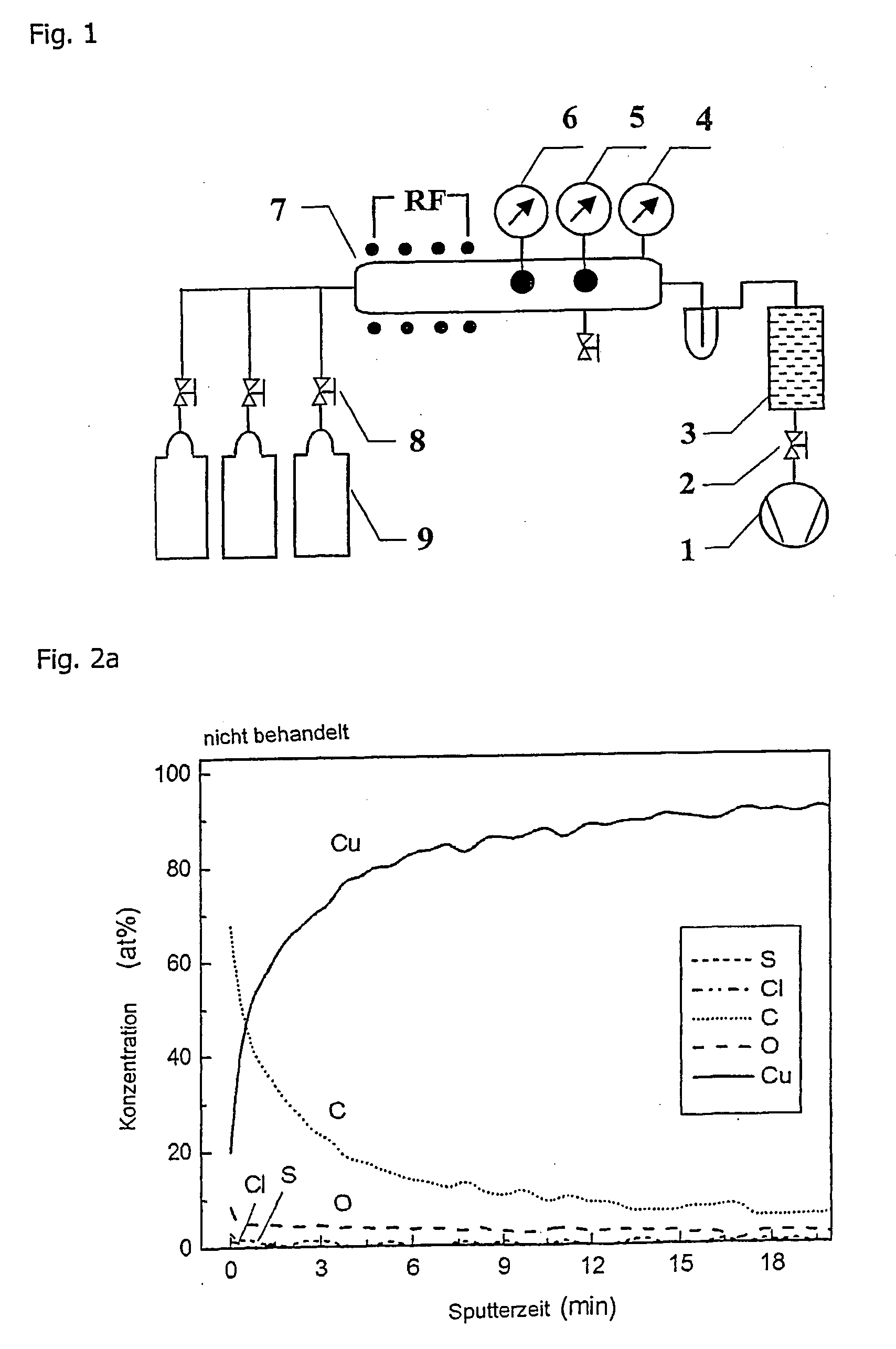

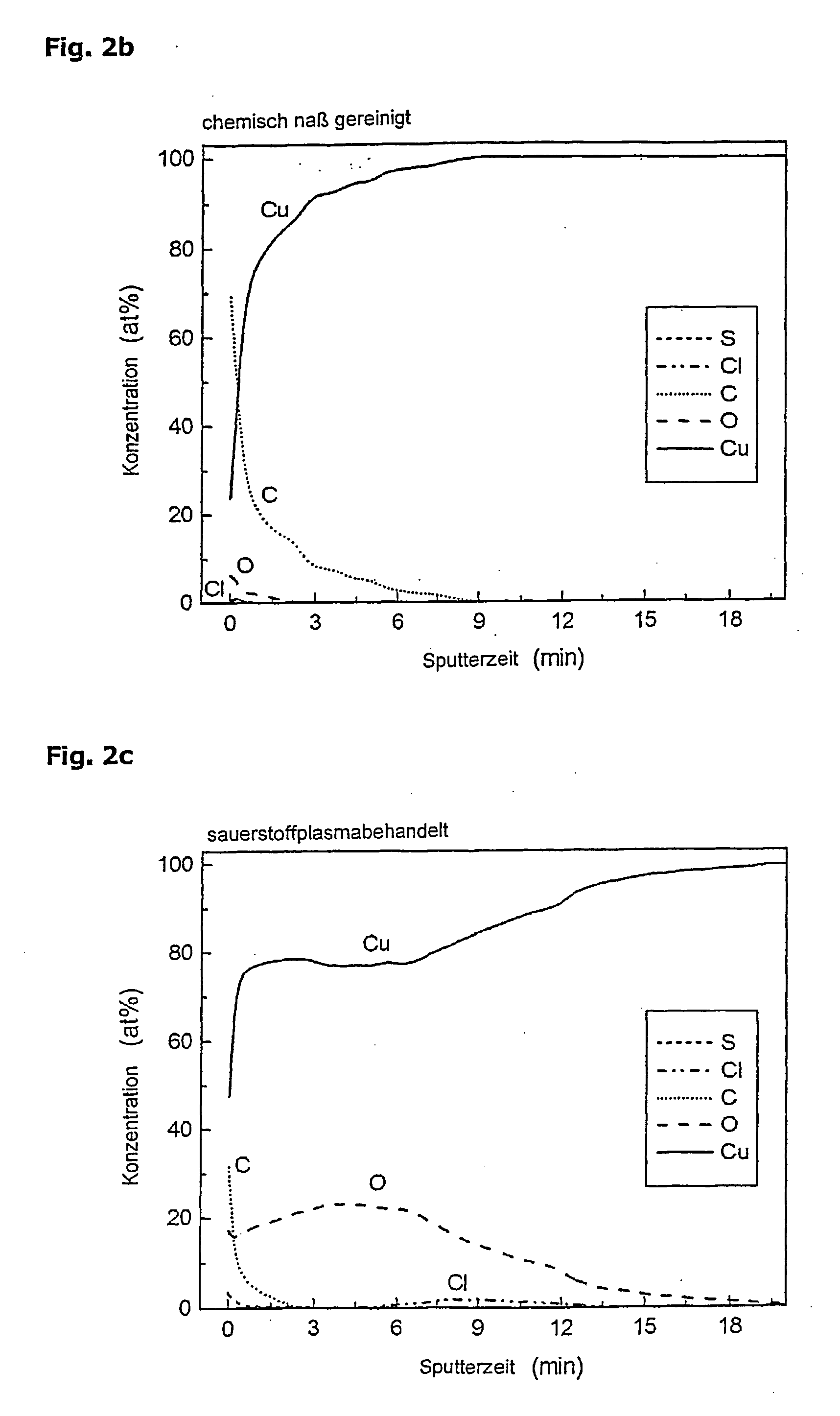

Plasma treatment for purifying copper or nickel

InactiveUS20060054184A1Reduce connection resistanceReduce impuritySoldering apparatusElectrostatic cleaningAlloyOxygen

A method for treating electronic components made of copper, nickel or alloys thereof or with materials such as brass or plated therewith and includes the steps of arranging the components in a treatment chamber, generating a vacuum in the treatment chamber, introducing oxygen into the treatment chamber, providing a pressure ranging between 10−1 and 50 mbar in the treatment chamber and exciting a plasma in the chamber, allowing the oxygen radicals to act on the components, generating a vacuum in the treatment chamber, introducing hydrogen into the treatment chamber, providing a pressure ranging between 10−1 and 50 mbar in the treatment chamber and exciting a plasma in the chamber and allowing the hydrogen radicals to act on the components.

Owner:KOLEKTOR GRP D O O

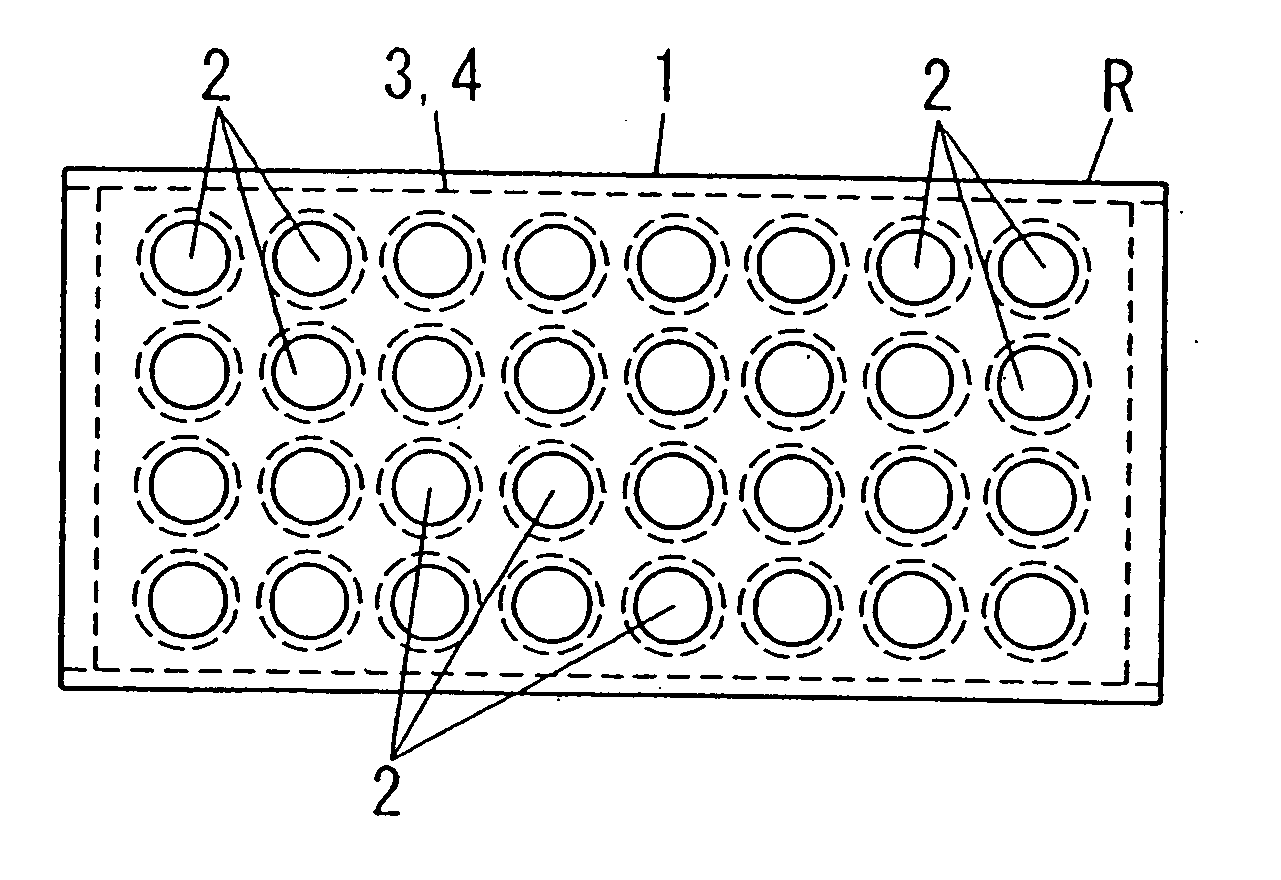

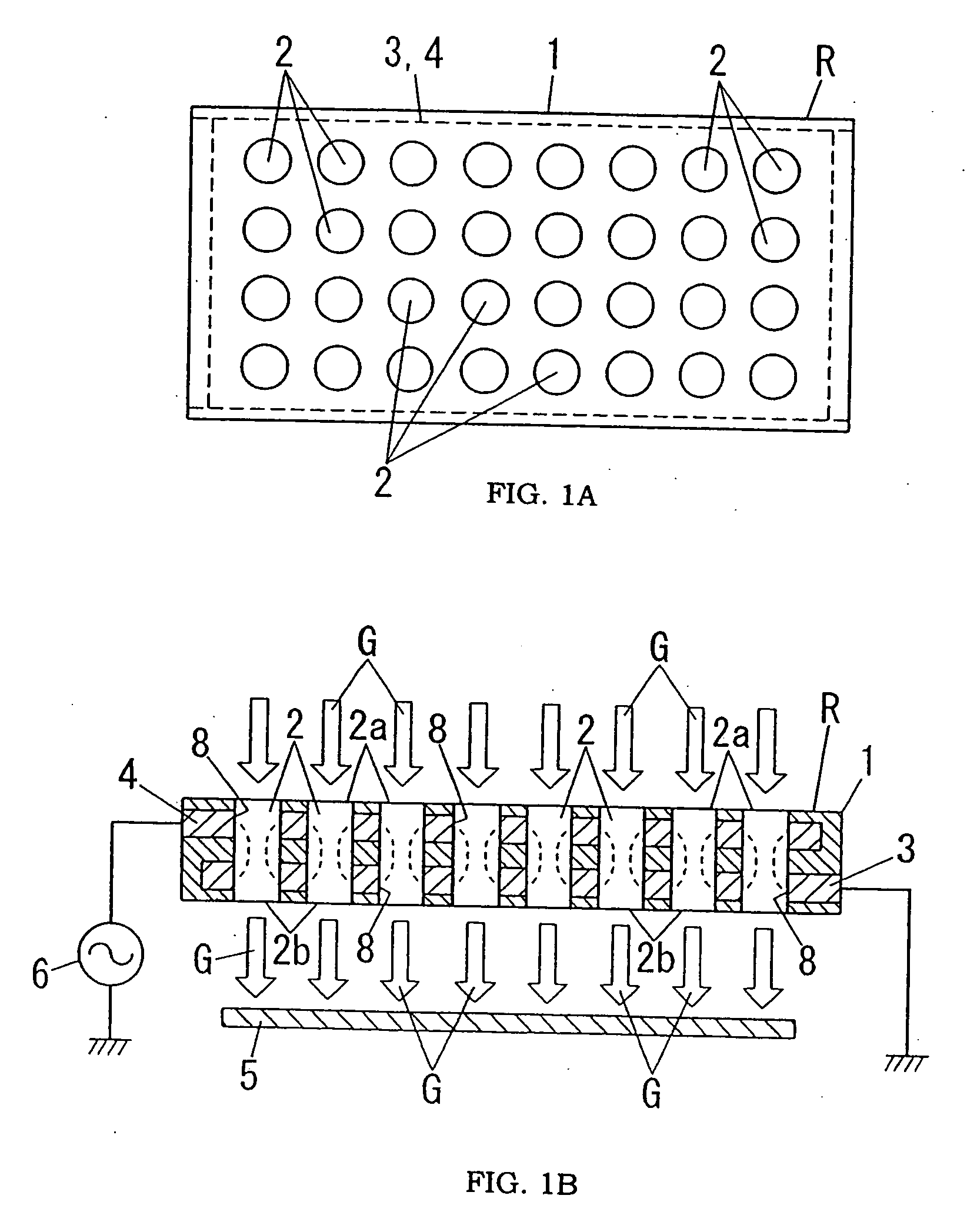

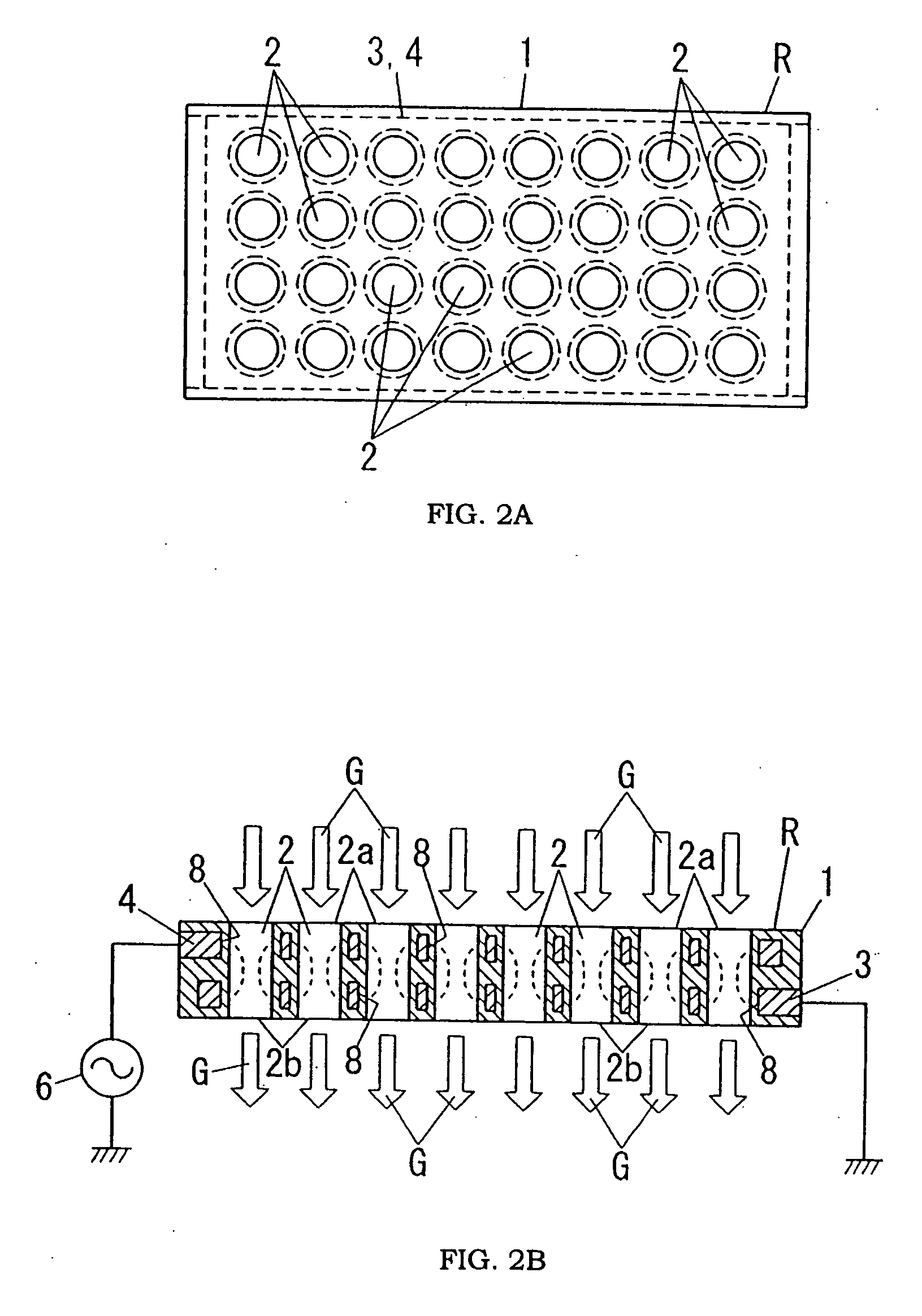

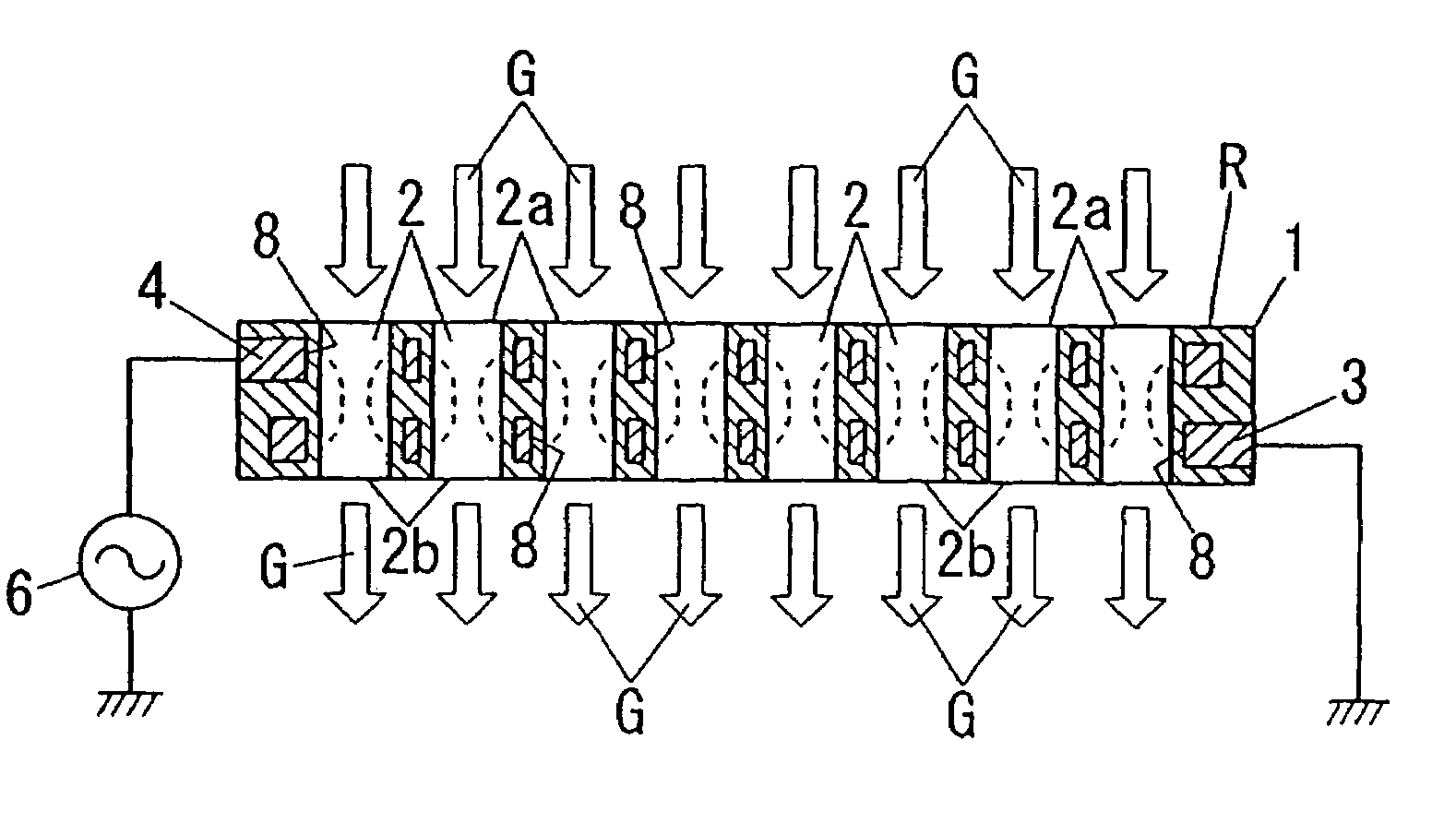

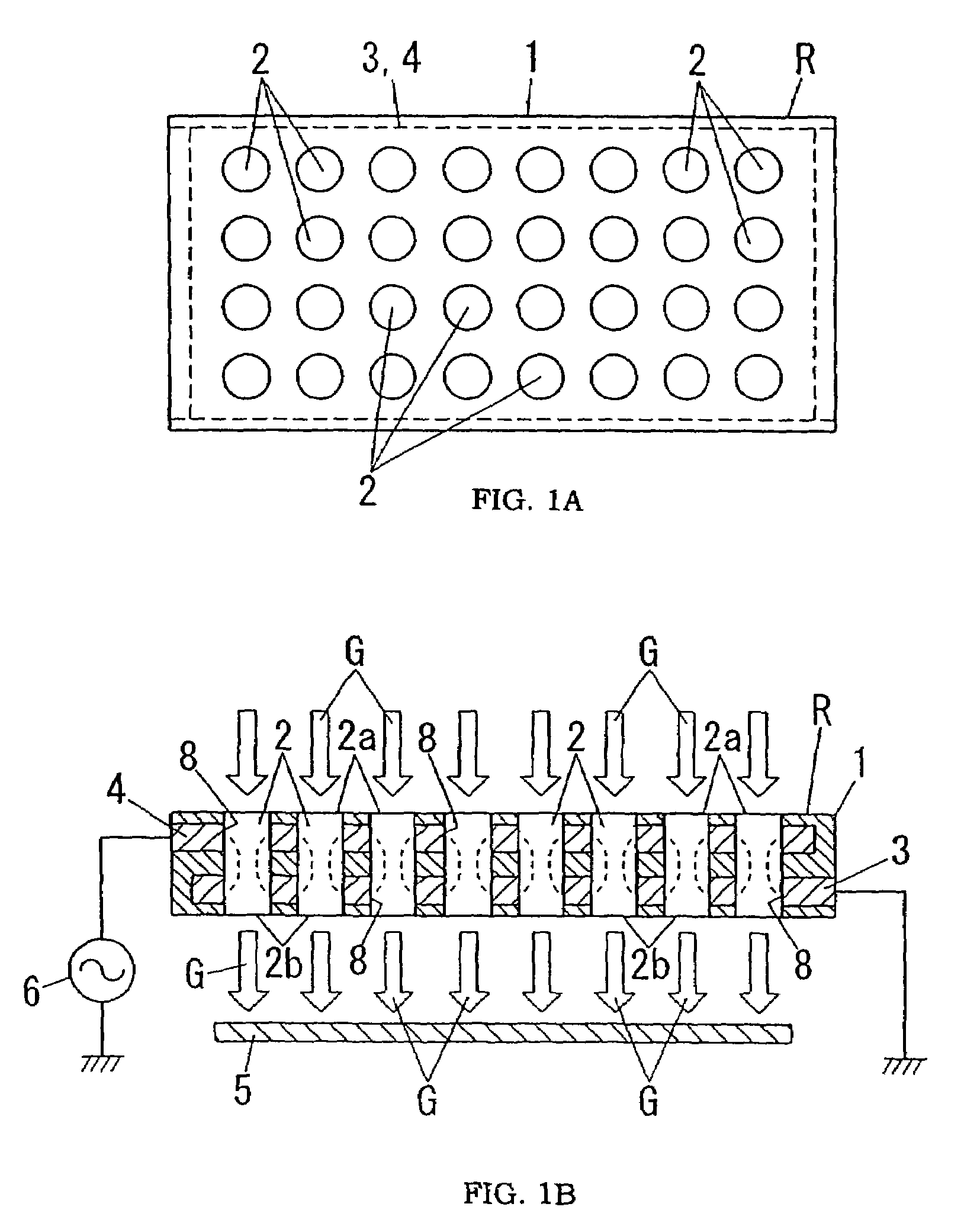

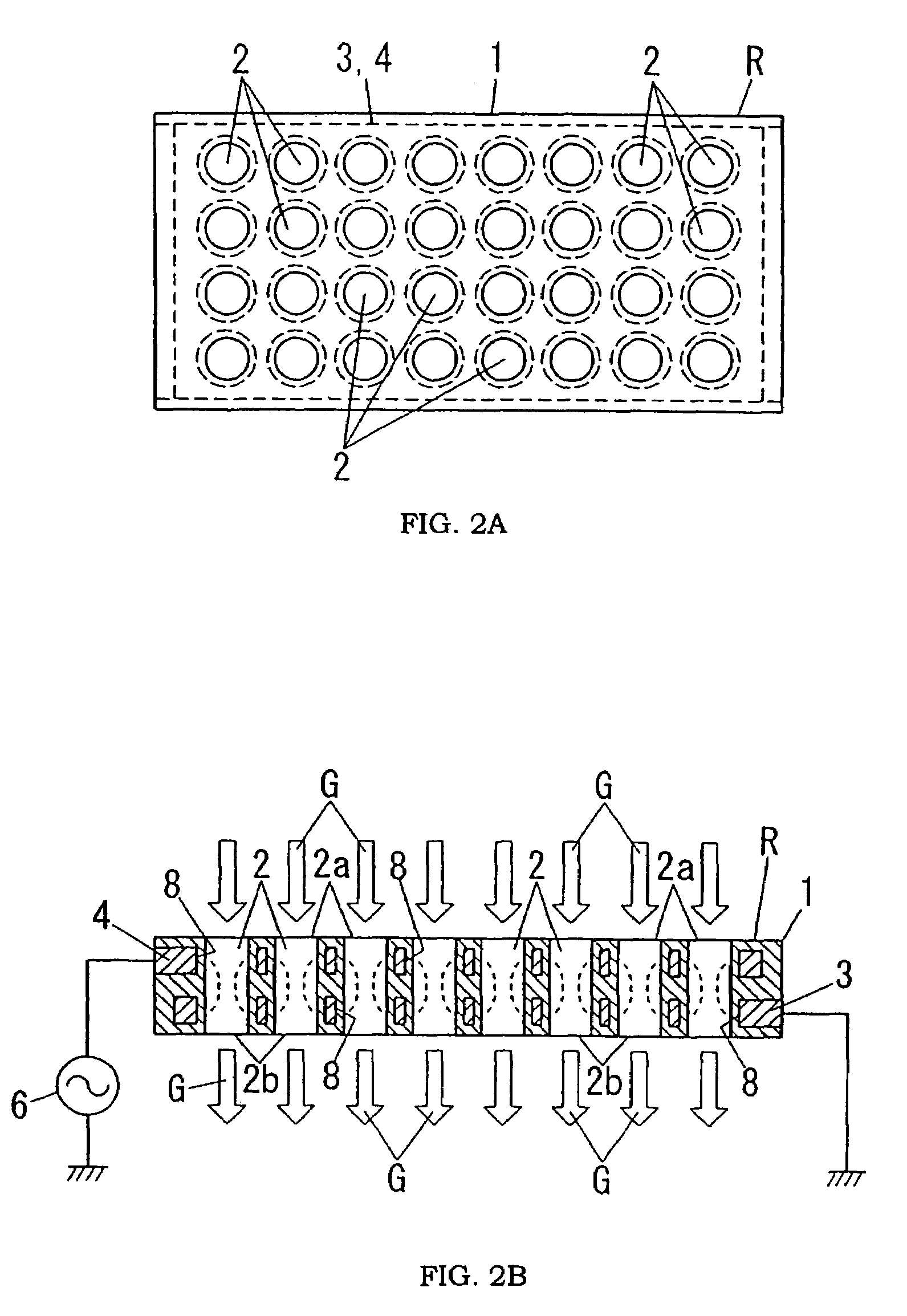

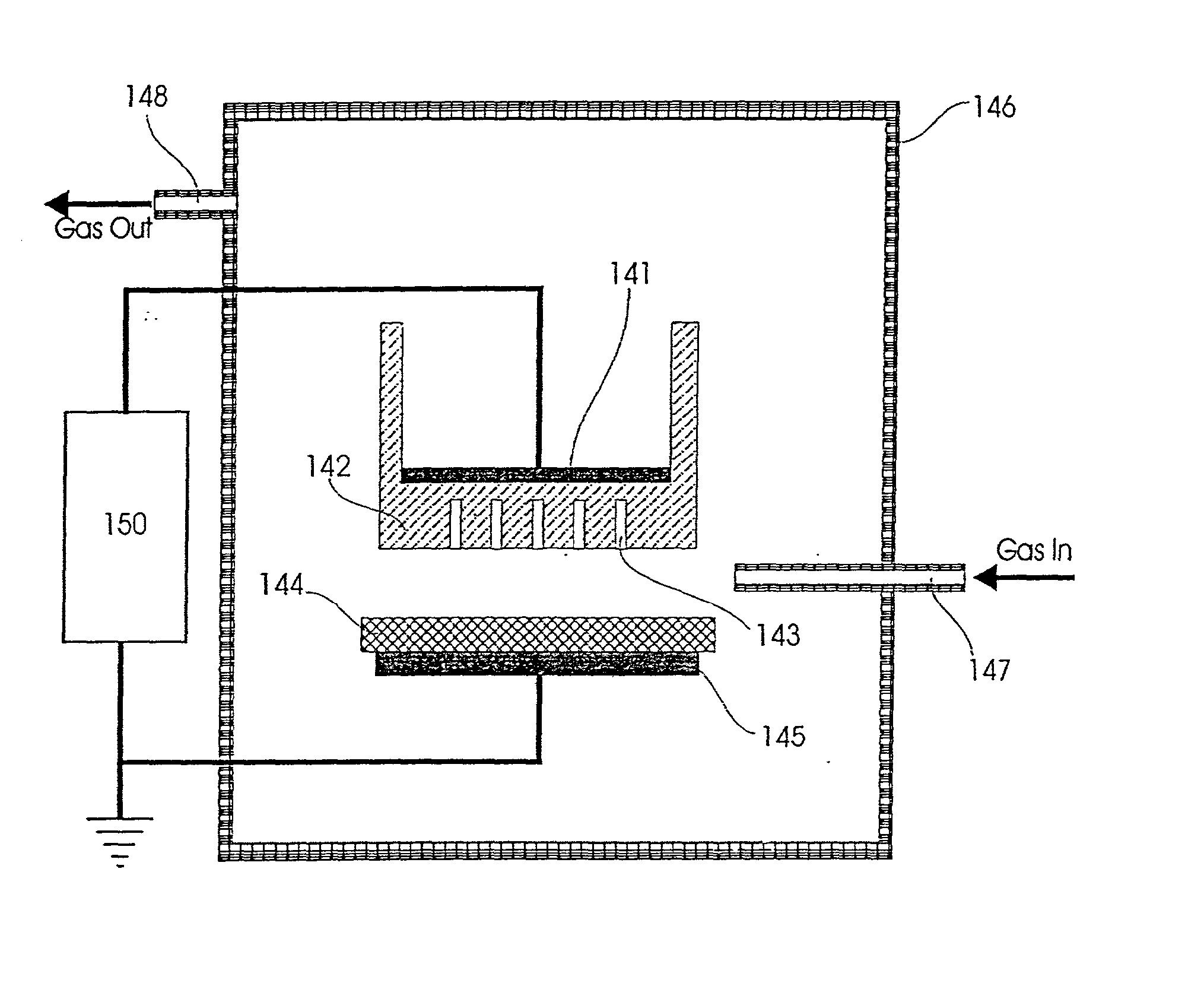

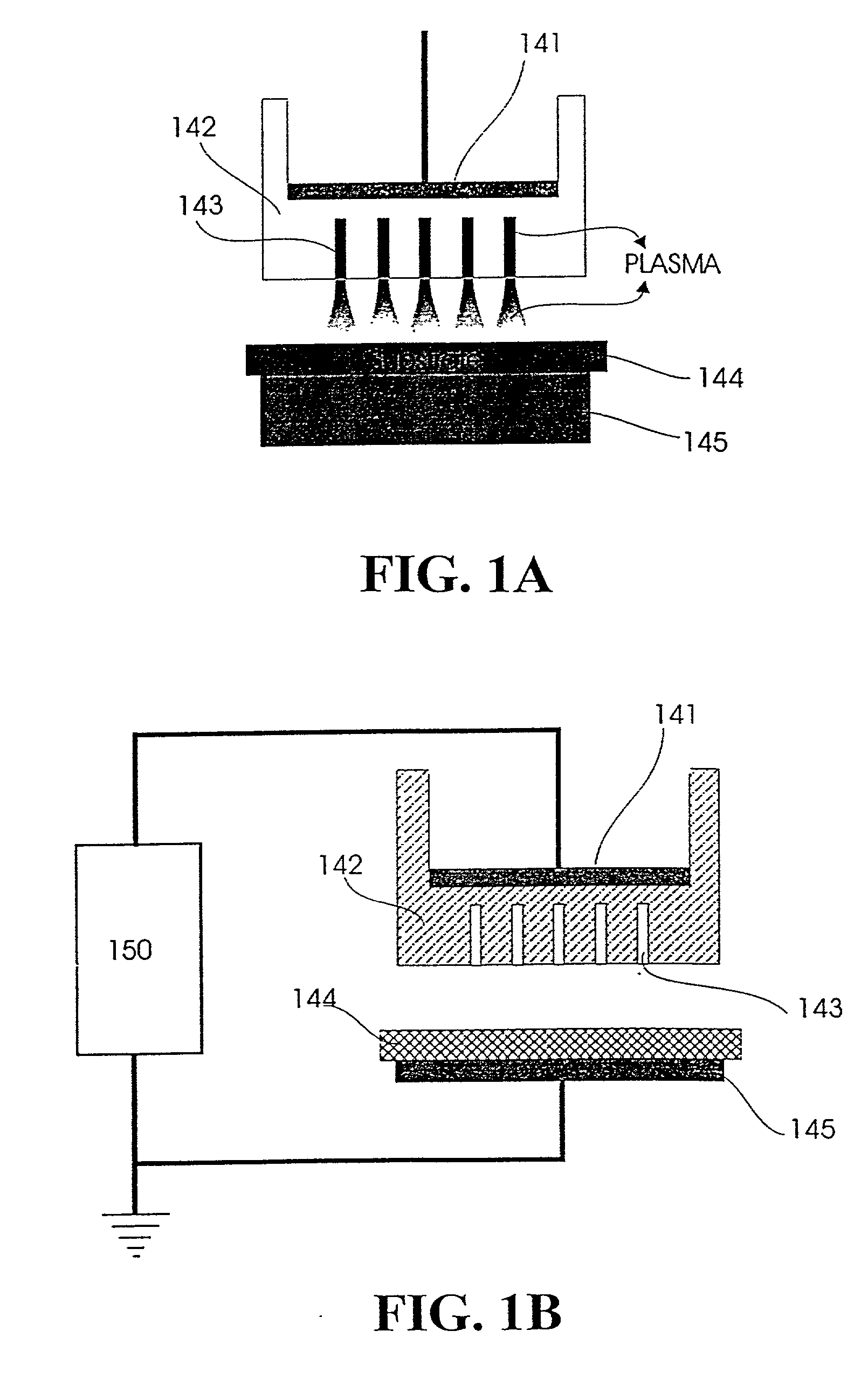

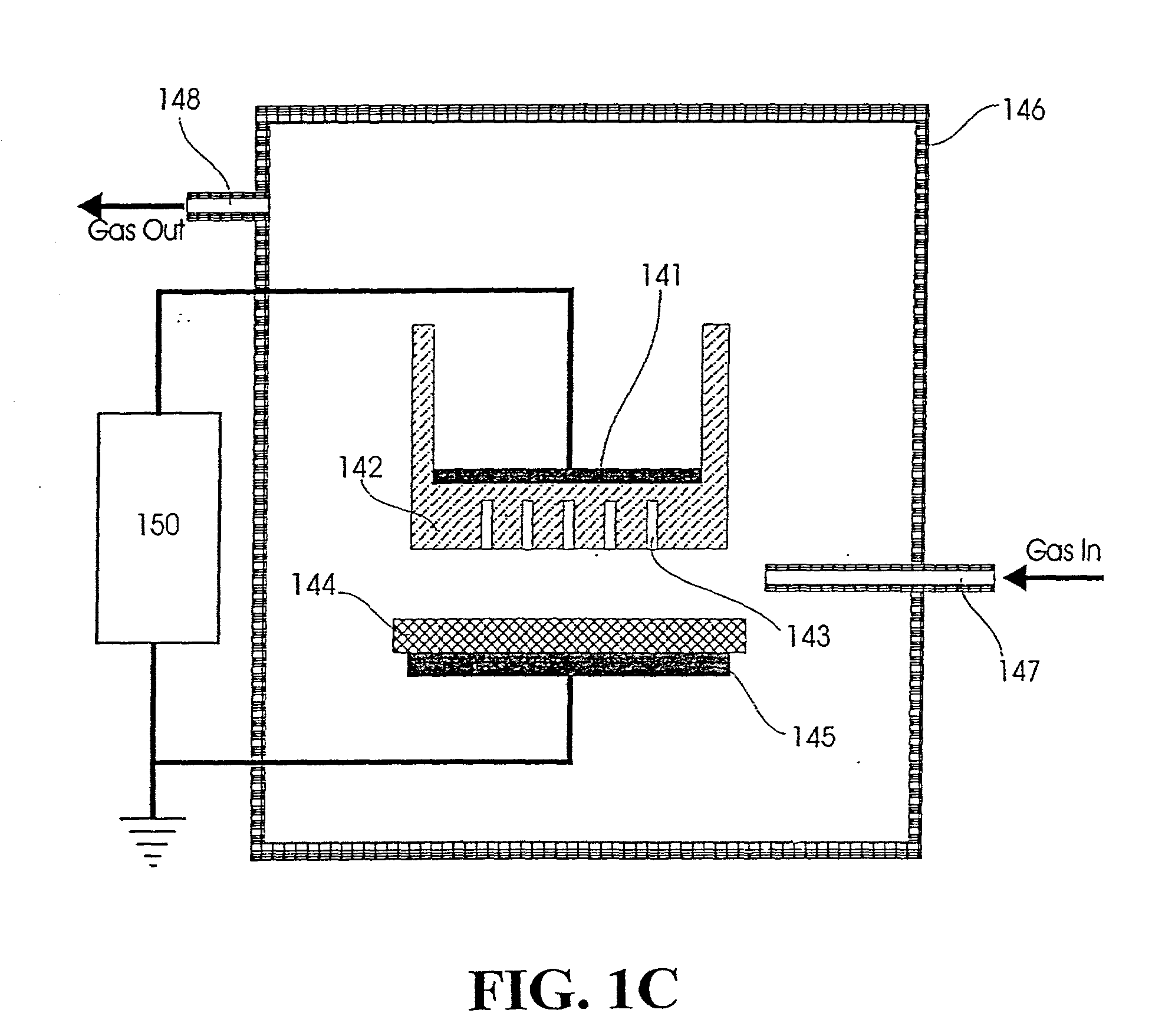

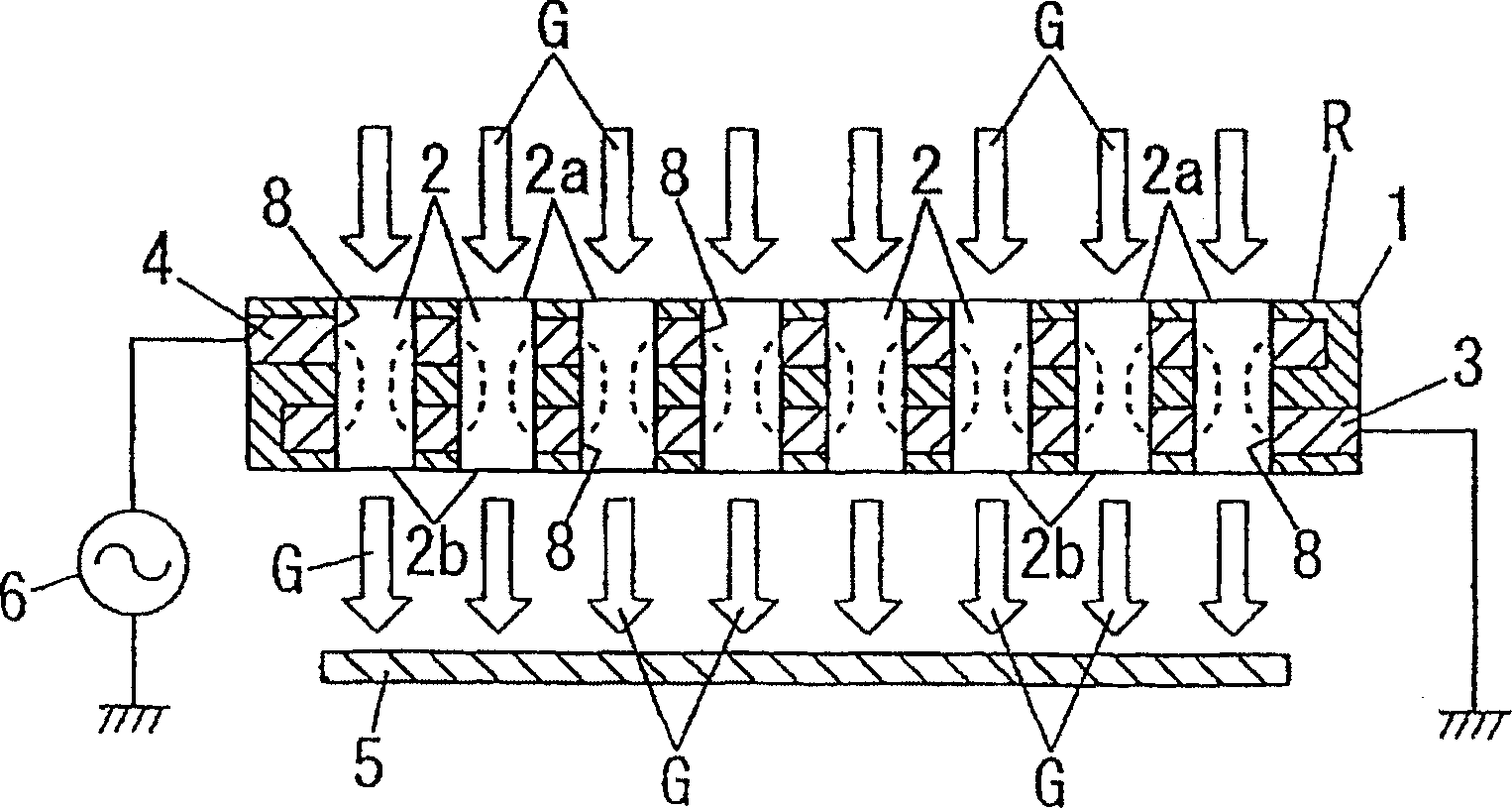

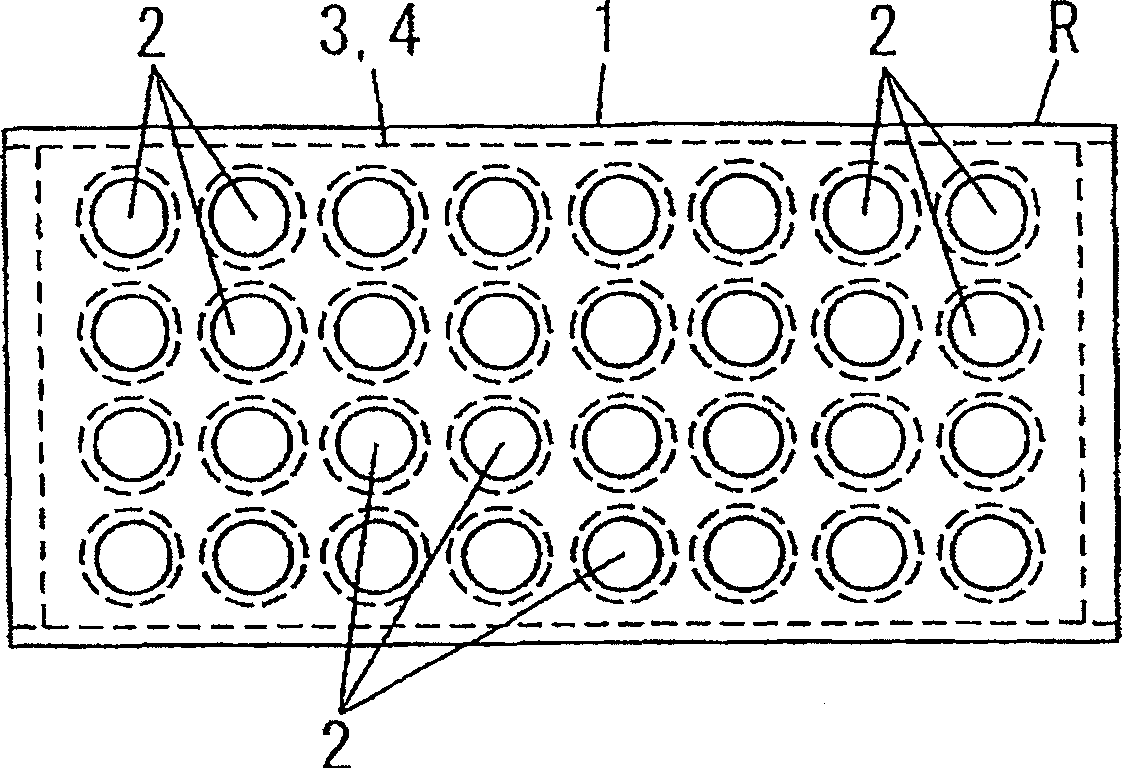

Plasma treatment apparatus, method of producing reaction vessel for plasma generation, and plasma treatment method

InactiveUS20060042545A1Large treatment areaLow gas consumptionMolten spray coatingElectric discharge tubesEngineeringVoltage

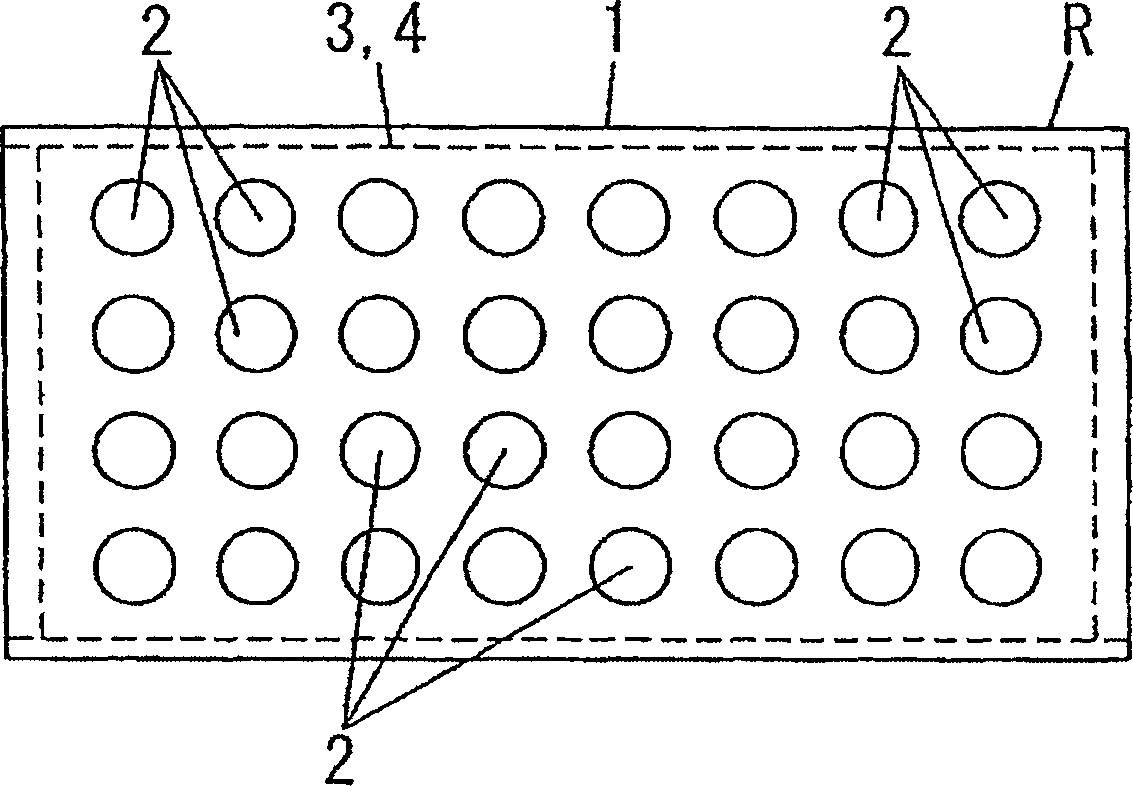

A plasma treatment apparatus is provided, which enables to increase a treatment area and provide good treatment uniformity. This apparatus comprises a pair of electrode plates having a plurality of through holes and an insulating plate having a plurality of through holes. The insulating plate is disposed between the electrode plates such that positions of the through holes of the electrode plates correspond to the positions of the through holes of the insulating plate. A plurality of discharge spaces are formed by the through holes of the electrode plates and the through holes of the insulating plate. By applying a voltage between the electrode plates, while supplying a plasma generation gas into the discharge spaces, plasmas are generated simultaneously in the discharge spaces, and sprayed on an object to efficiently perform a large-area, uniform plasma treatment.

Owner:MATSUSHITA ELECTRIC WORKS LTD

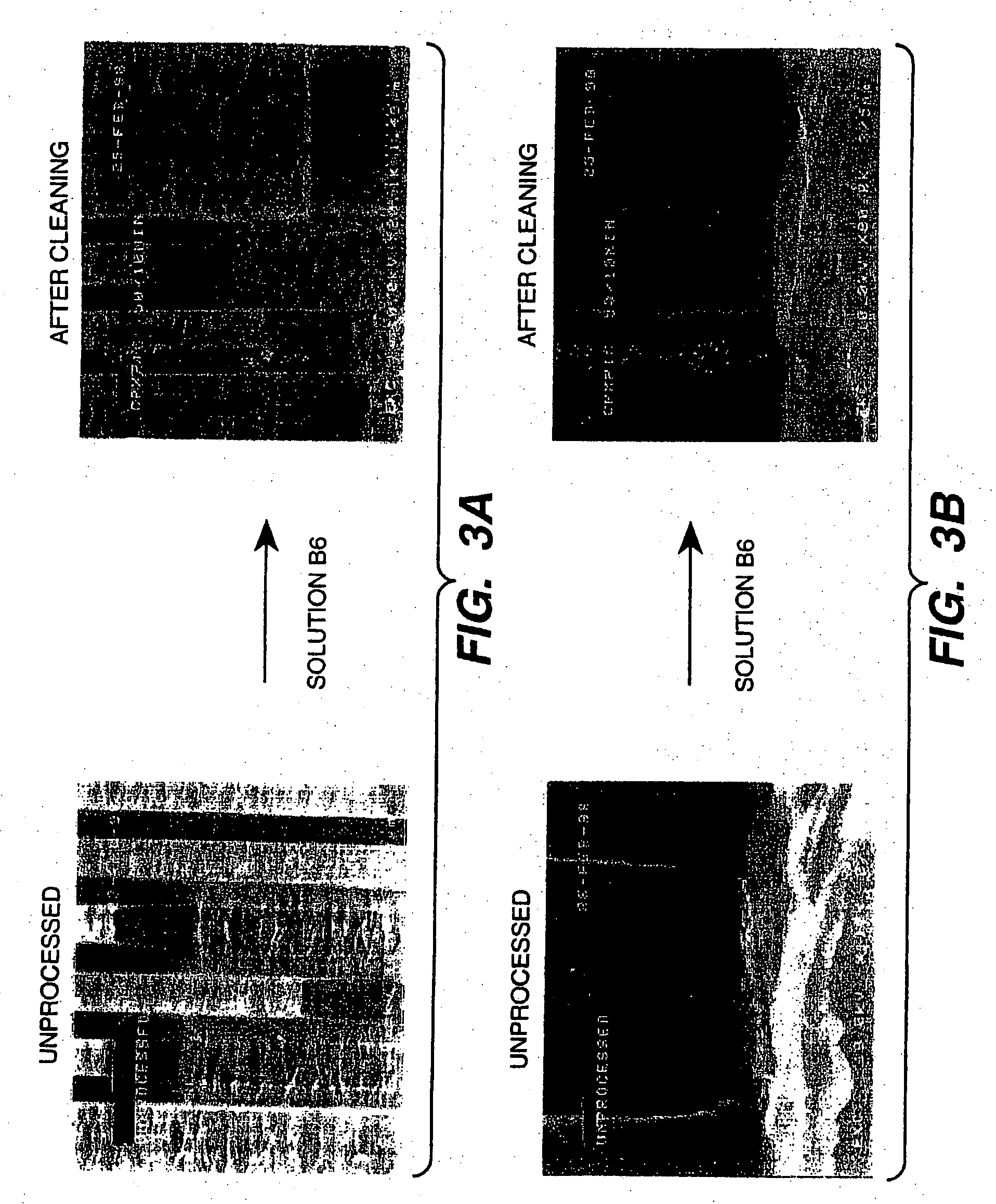

Removing solution

InactiveUS20060138399A1Eliminate residueImprove solubilityDetergent mixture composition preparationSolid-state devicesHydrogen fluorideOrganic acid

The present invention provides a resist-removing solution for low-k film and a cleaning solution for via holes or capacitors, the solutions comprising hydrogen fluoride (HF) and at least one member selected from the group consisting of organic acids and organic solvents. The invention also provides a method of removing resist and a method of cleaning via holes or capacitors by the use of the solutions.

Owner:DAIKIN IND LTD

Solvent compositions containing chlorofluoroolefins or fluoroolefins

Compositions and methods based on the use of fluoroalkene containing from 3 to 4 carbon atoms and at least one carbon-carbon double bond, such as HFO-1214, HFO-HFO-1233, or HFO-1354, having properties highly beneficial in solvent cleaning applications.

Owner:HONEYWELL INT INC

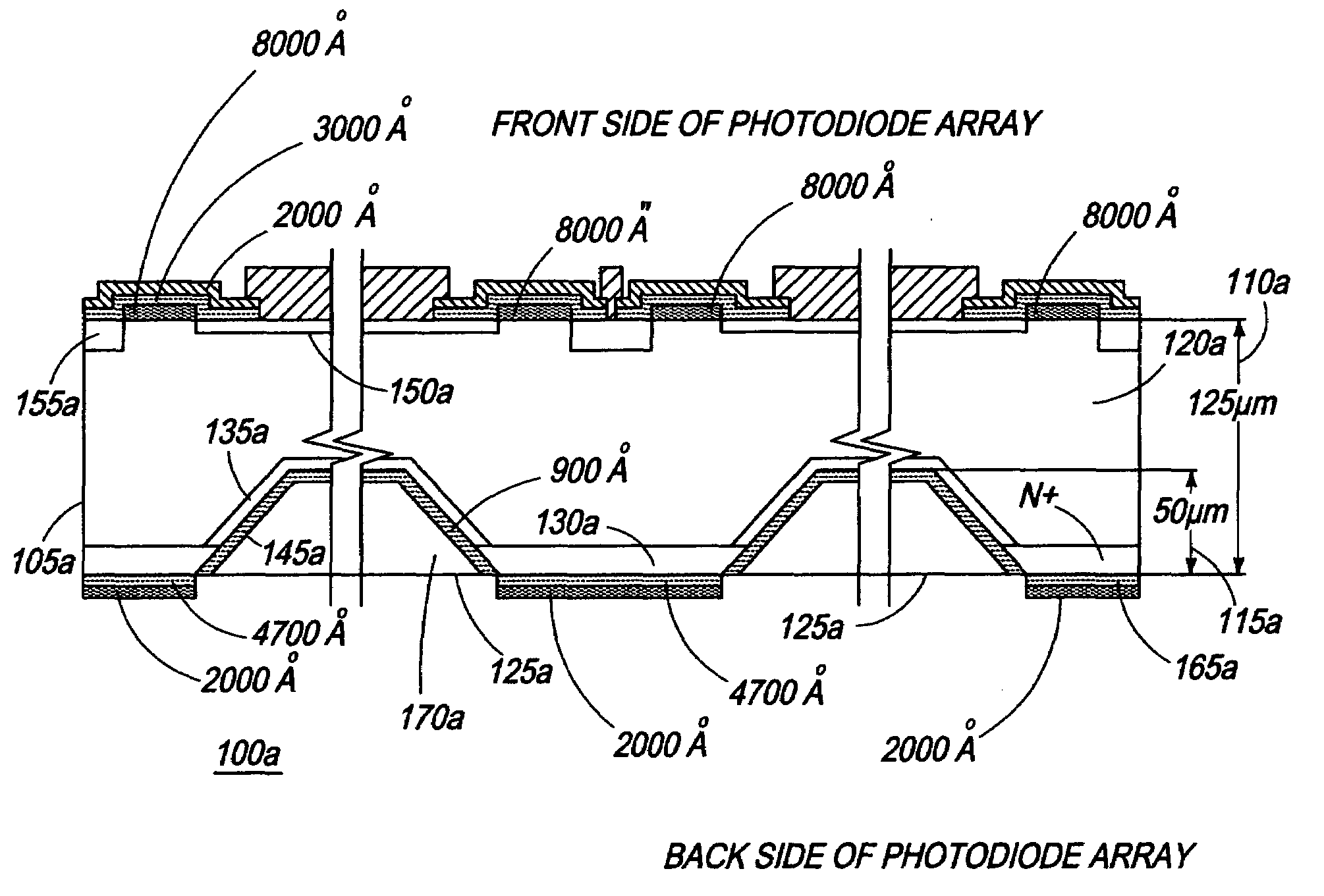

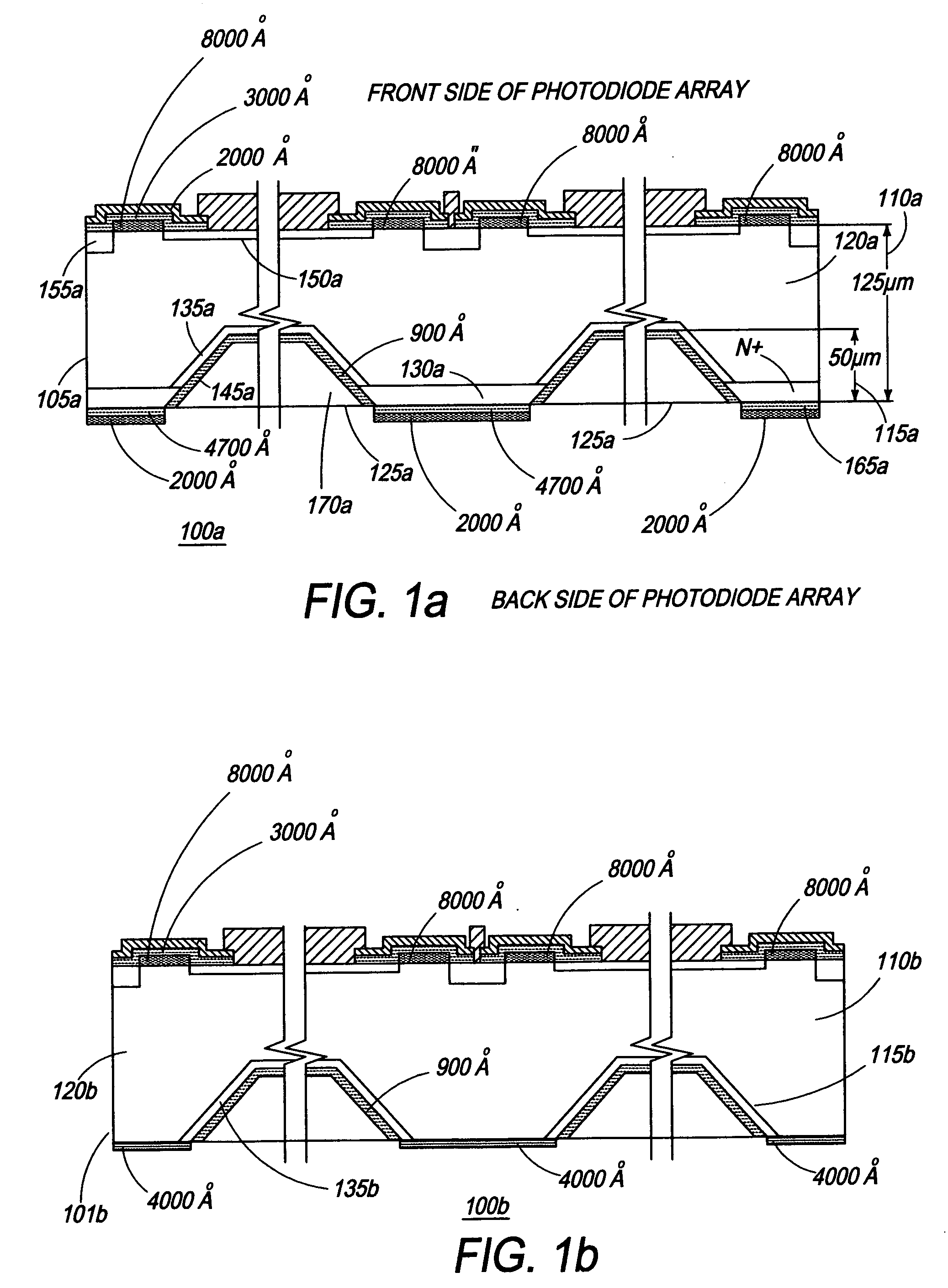

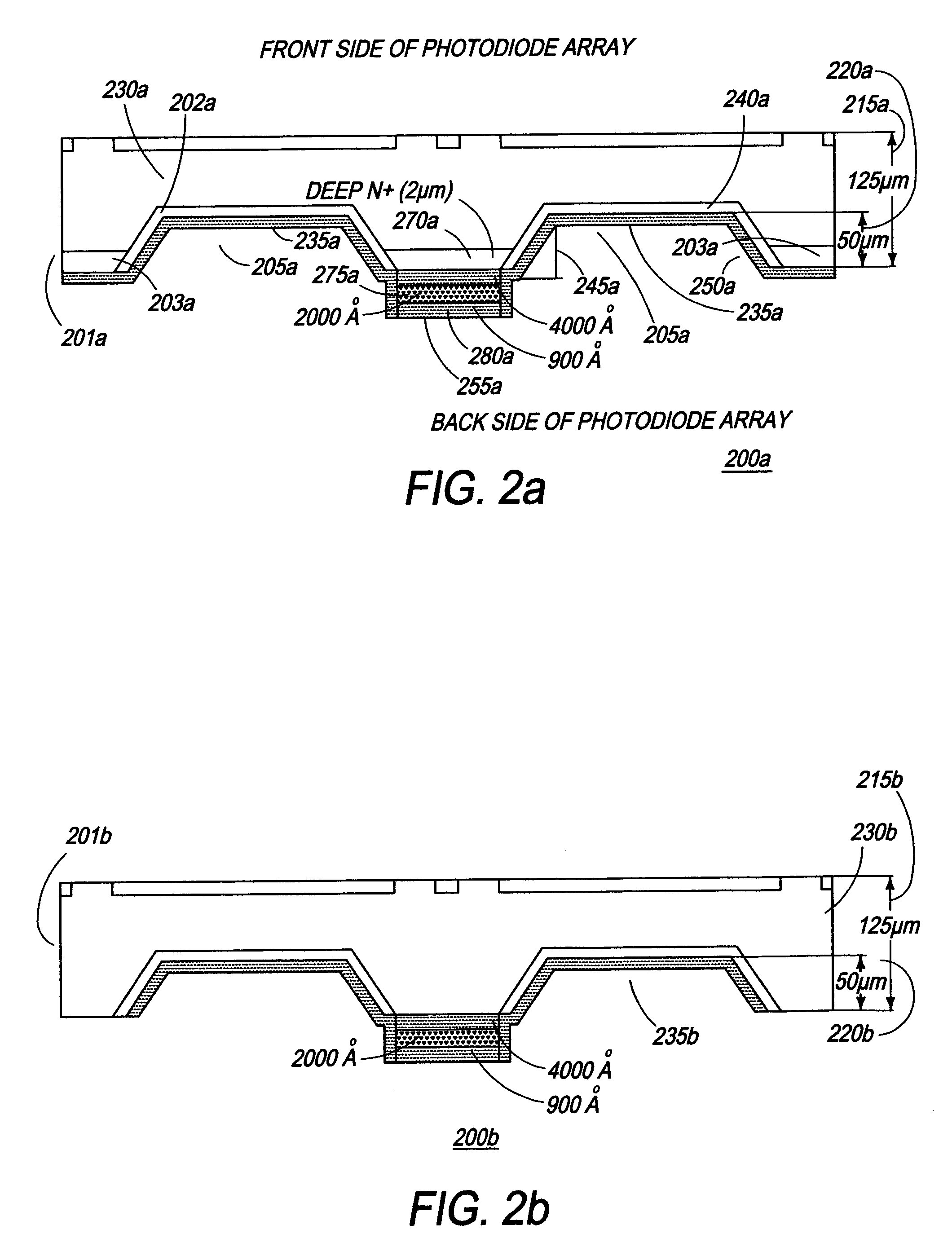

Thin wafer detectors with improved radiation damage and crosstalk characteristics

ActiveUS20080128846A1Reduces its damage susceptibilityImprove application flexibilityPrinted circuit aspectsSoldering apparatusCapacitanceDetector array

The present invention is directed toward a detector structure, detector arrays, and a method of detecting incident radiation. The present invention comprises several embodiments that provide for reduced radiation damage susceptibility, decreased affects of crosstalk, reduced dark current (current leakage) and increased flexibility in application. In one embodiment, a photodiode array comprises a substrate having at least a front side and a back side, a plurality of diode elements integrally formed in the substrate forming the array, wherein each diode element has a p+ fishbone pattern on the front side, and wherein the p+ fishbone pattern substantially reduces capacitance and crosstalk between adjacent photodiodes, a plurality of front surface cathode and anode contacts, and wire interconnects between diode elements made through a plurality of back surface contacts.

Owner:OSI OPTOELECTRONICS

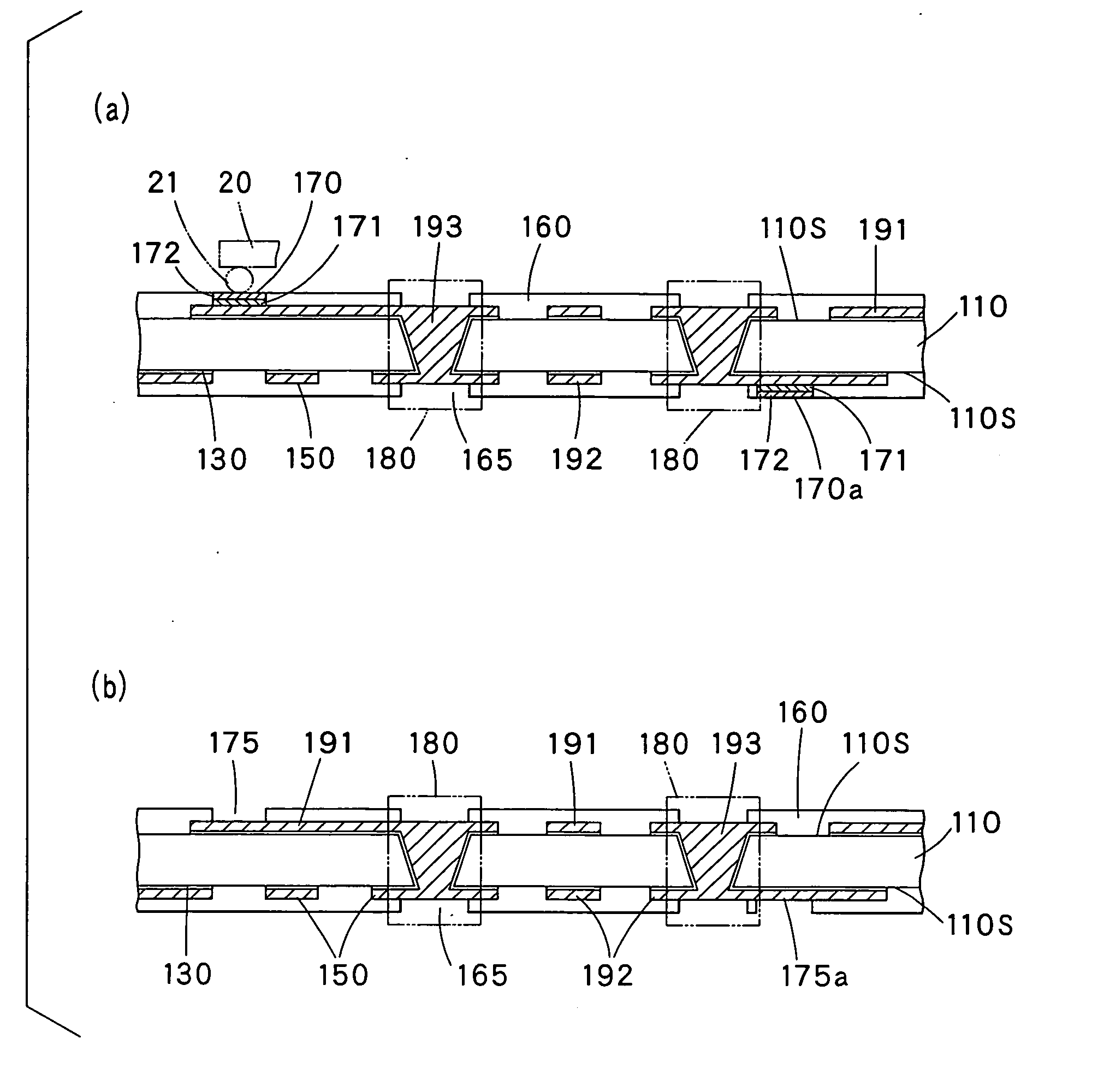

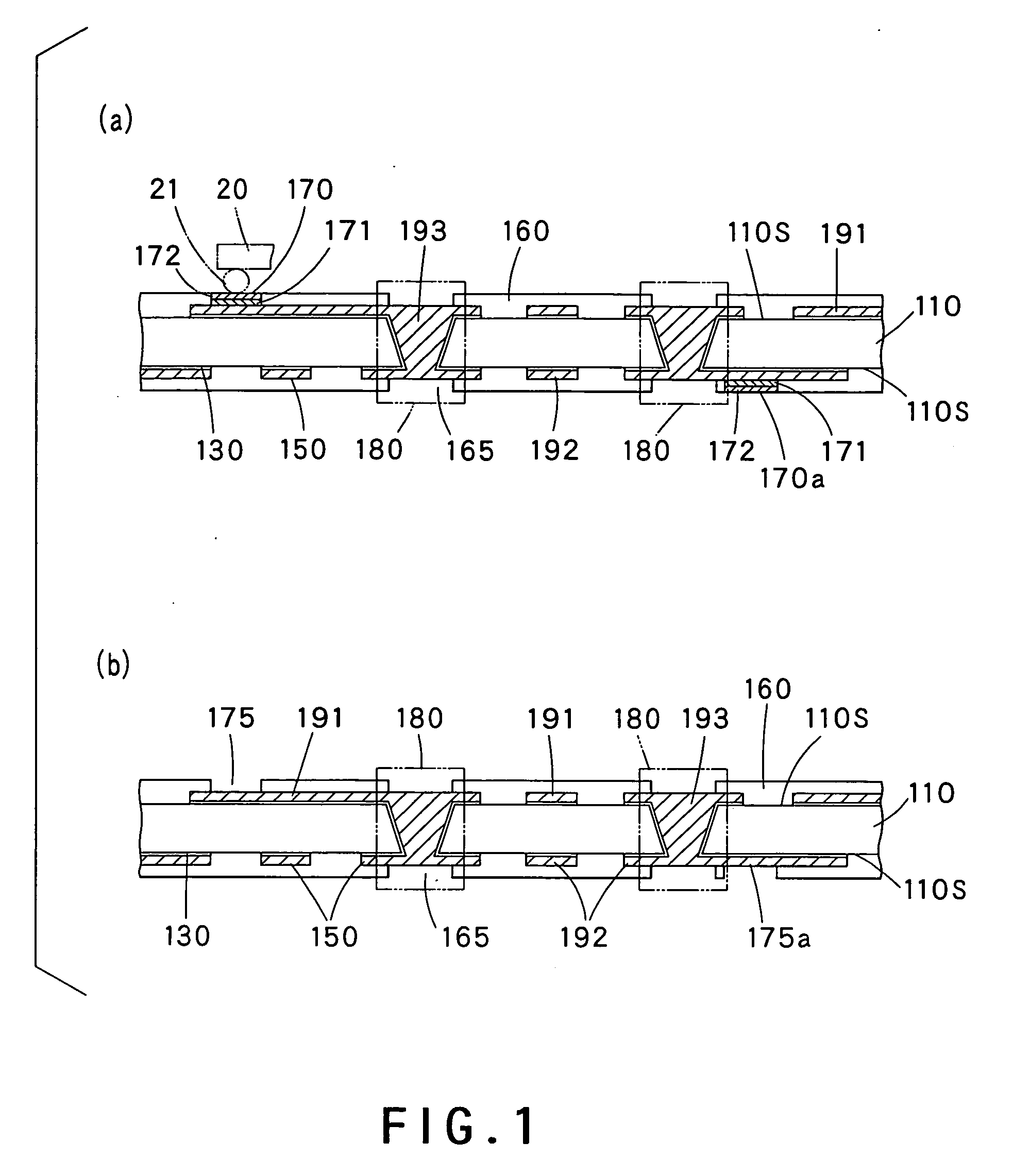

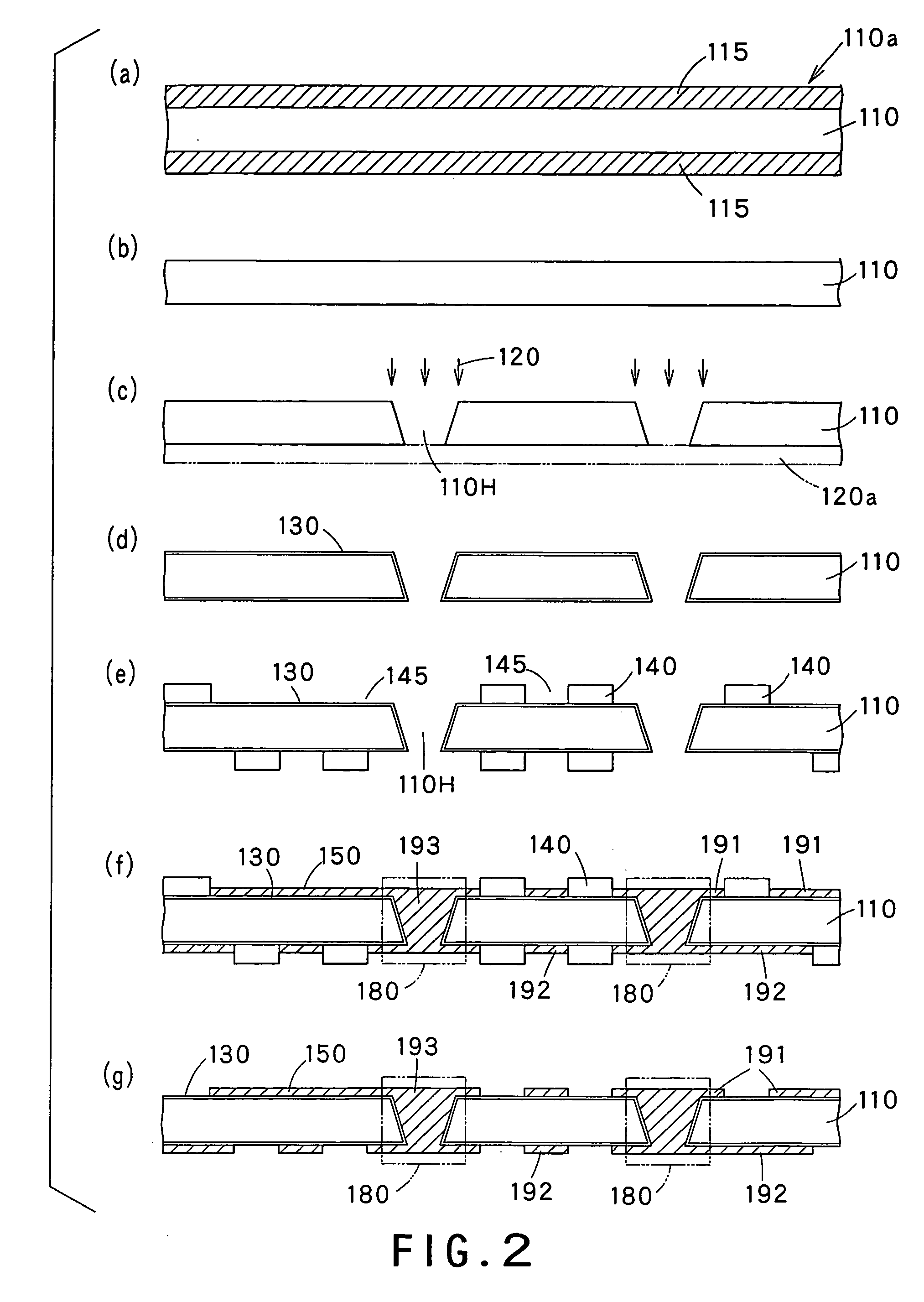

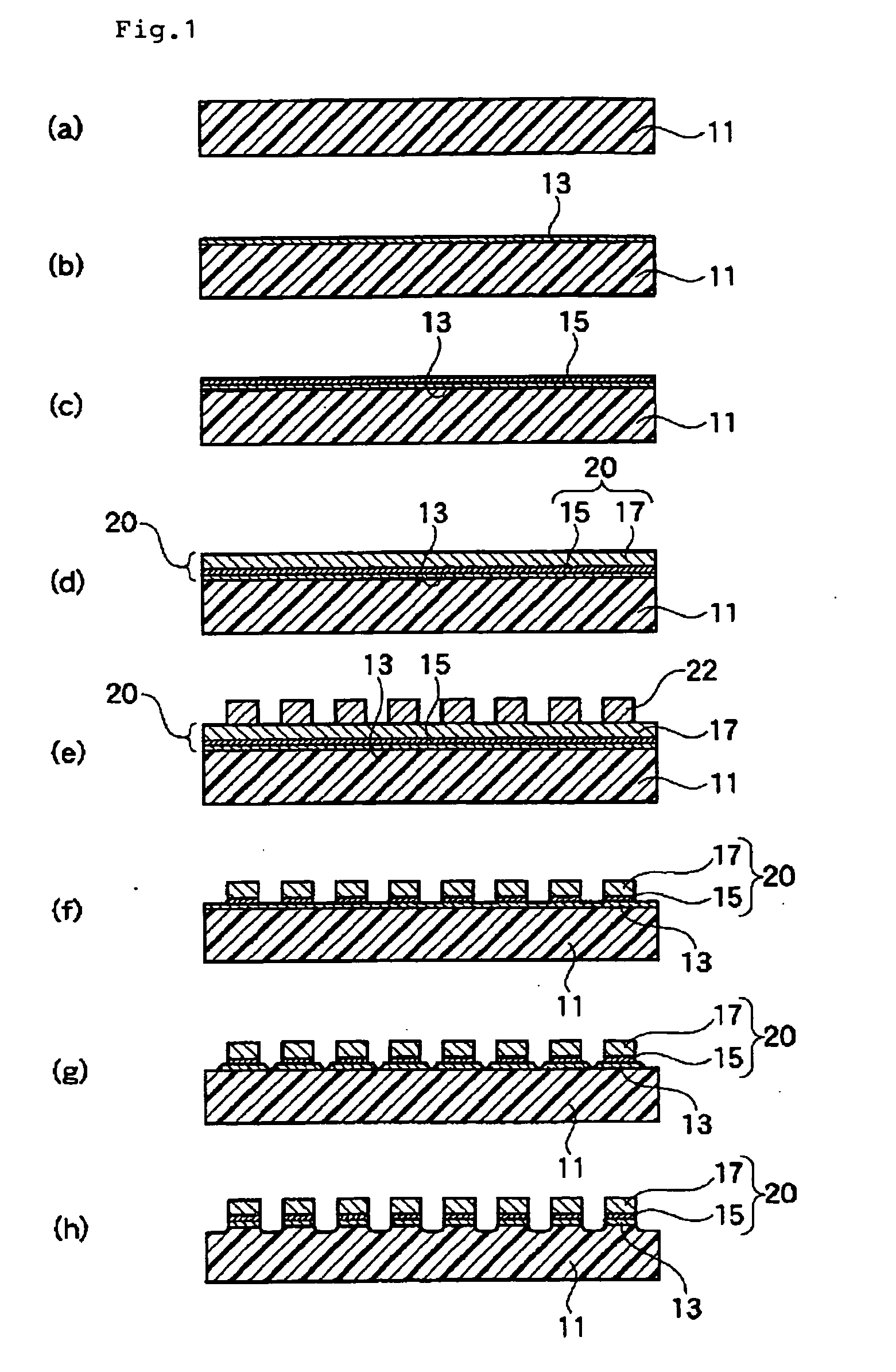

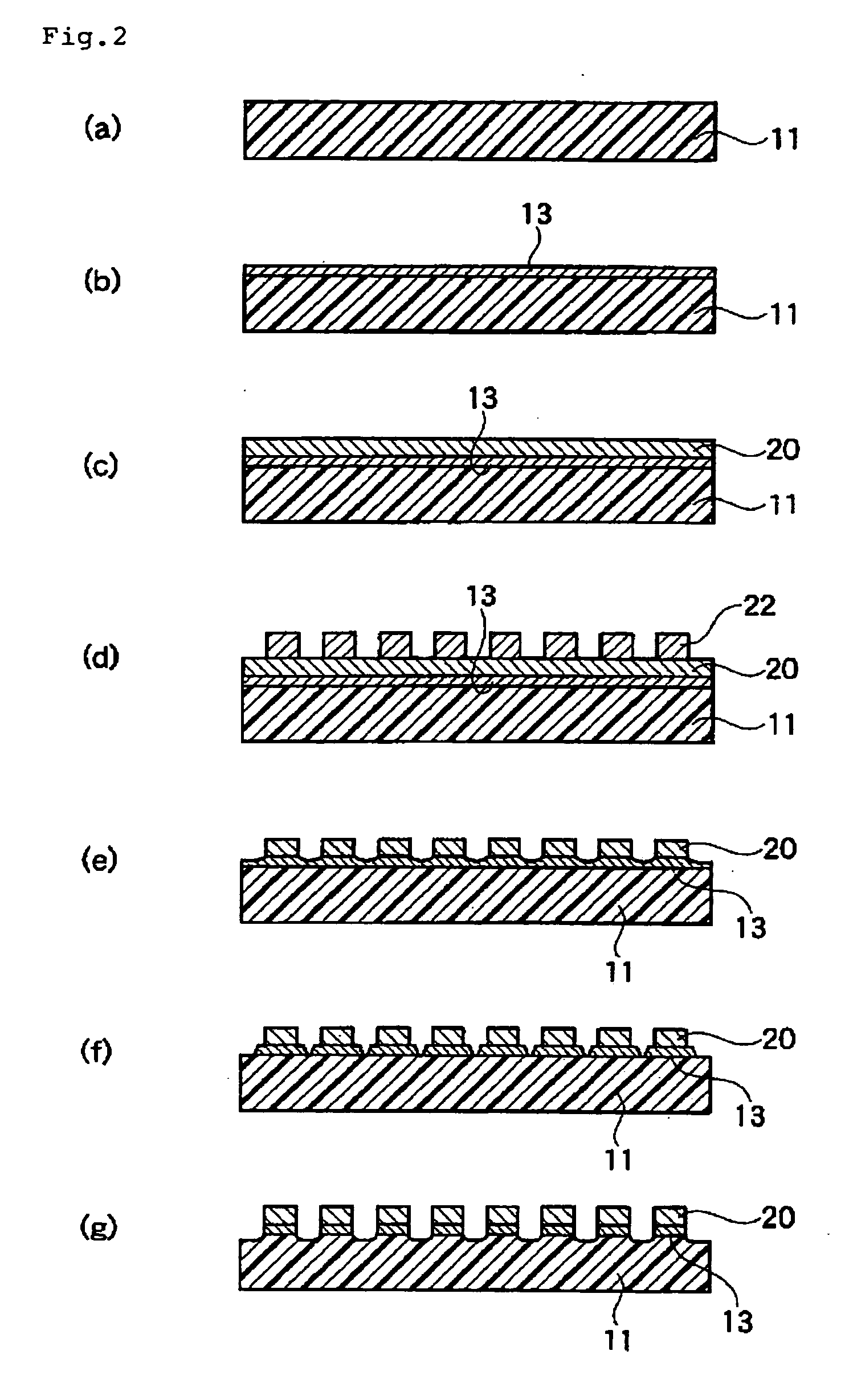

Double-sided wiring board, double sided wiring board manufacturing method, and multilayer wiring board

InactiveUS20060289203A1Improve productivitySemiconductor/solid-state device detailsPrinted circuit aspectsResistSolder mask

A single wiring layer is formed on each of both the roughened surfaces of a core substrate by a semiadditive method. The wiring layers formed on the surfaces of the core substrate are electrically connected through a through hole formed in the core substrate. The through hole is formed in the core substrate by laser machining. The through hole is filled up with conductive a plug. Both the surfaces of the core substrate are coated with solder resist layers, respectively, with predetermined terminal parts of the wiring layers exposed through openings formed in the solder resist layers. End surfaces of the conductive plug filling up the through holes, and the surfaces of the wiring layers are planarized by mechanical or chemical-mechanical polishing.

Owner:DAI NIPPON PRINTING CO LTD

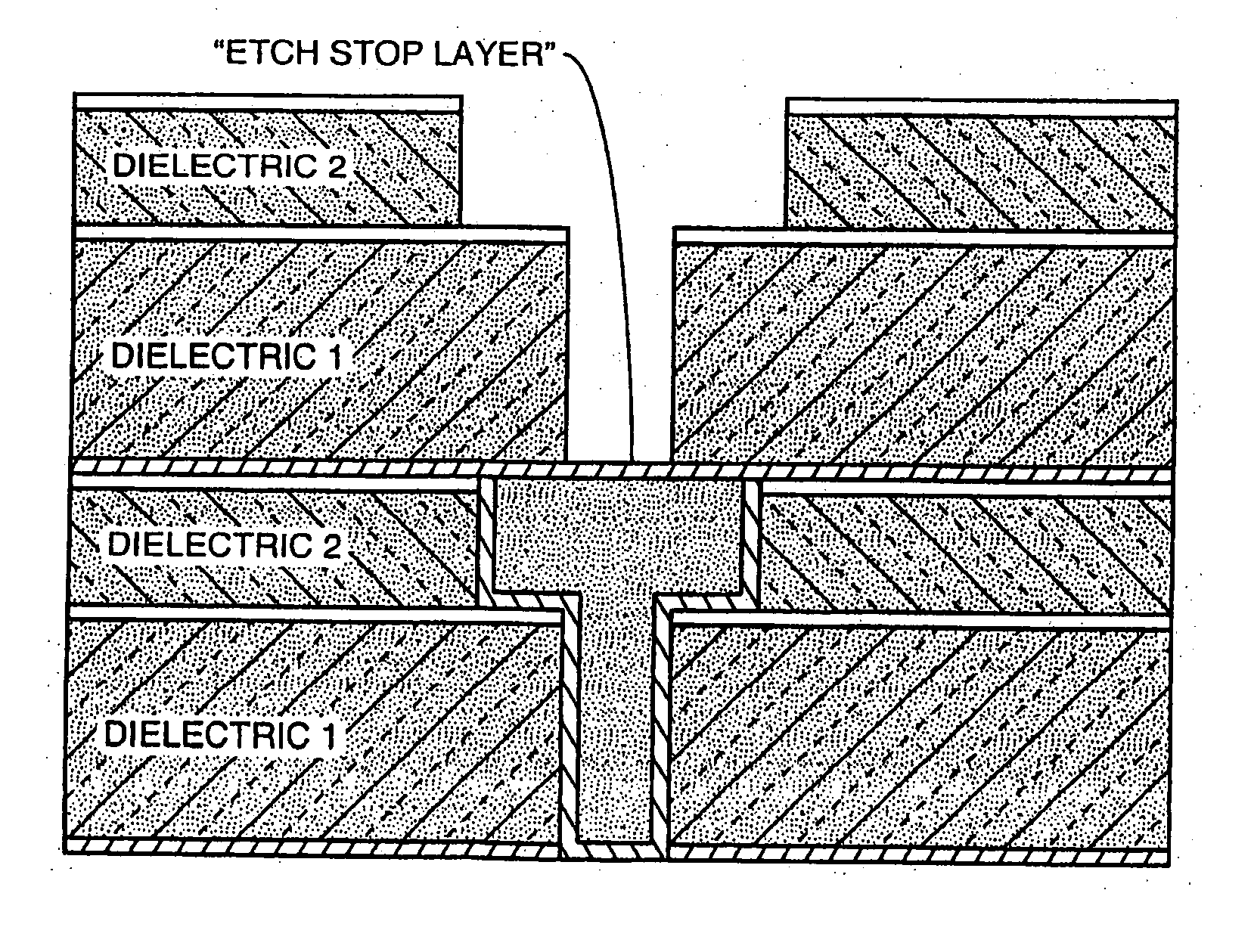

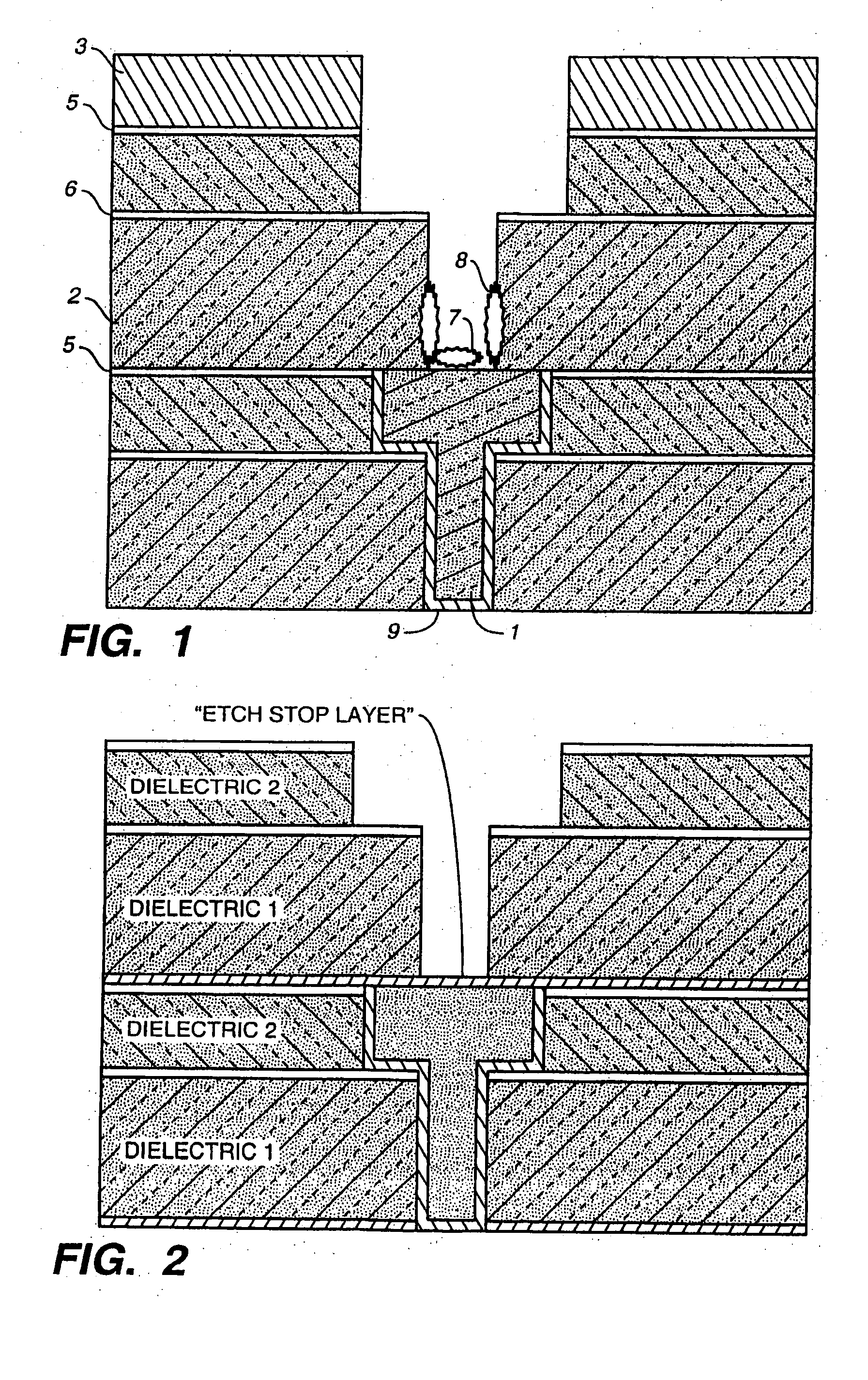

Remover compositions for dual damascene system

InactiveUS20050266683A1Avoid corrosionAvoid inhibitionNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingDielectricAnti-reflective coating

A new remover chemistry based on a choline compound, such as choline hydroxide, is provided in order to address problems related to removal of residues, modified photoresists, photoresists, and polymers such as organic anti-reflective coatings and gap-fill and sacrificial polymers from surfaces involved in dual damascene structures without damaging the dielectrics and substrates involved therein. An etch stop inorganic layer at the bottom of a dual damascene structure may or may not be used to cover the underlying interconnect of copper. If not used, a process step of removing that protective layer can be avoided through a timed etch of the via in trench-first dual damascene processes.

Owner:EKC TECH

Plasma processing apparatus, method for producing reaction vessel for plasma generation, and plasma processing method

InactiveUS7543546B2Large treatment areaLow gas consumptionMolten spray coatingElectric discharge tubesProcess regionEngineering

A plasma treatment apparatus is provided, which enables to increase a treatment area and provide good treatment uniformity. This apparatus comprises a pair of electrode plates having a plurality of through holes and an insulating plate having a plurality of through holes. The insulating plate is disposed between the electrode plates such that positions of the through holes of the electrode plates correspond to the positions of the through holes of the insulating plate. A plurality of discharge spaces are formed by the through holes of the electrode plates and the through holes of the insulating plate. By applying a voltage between the electrode plates, while supplying a plasma generation gas into the discharge spaces, plasmas are generated simultaneously in the discharge spaces, and sprayed on an object to efficiently perform a large-area, uniform plasma treatment.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Cleaning agent for removal of, removal method for, and cleaning method for water-soluble, lead-free solder flux

InactiveUS20120090646A1Maintain good propertiesImprove securityNon-surface-active detergent compositionsDetergent mixture composition preparationGlycol ethersWater soluble

An object of this invention is to provide a cleaner for the removal of water-soluble, lead-free soldering flux, the cleaner capable of cleaning off, in a short period of time, water-soluble flux residues generated during soldering with lead-free solder using water-soluble flux, the cleaner further having excellent dissolution property as well as excellent narrow gap cleaning property. The cleaner for removing water-soluble, lead-free soldering flux of the present invention comprises 5 to 100 parts by weight of a glycol ether compound (A) per 100 parts by weight of water.

Owner:ARAKAWA CHEM IND LTD

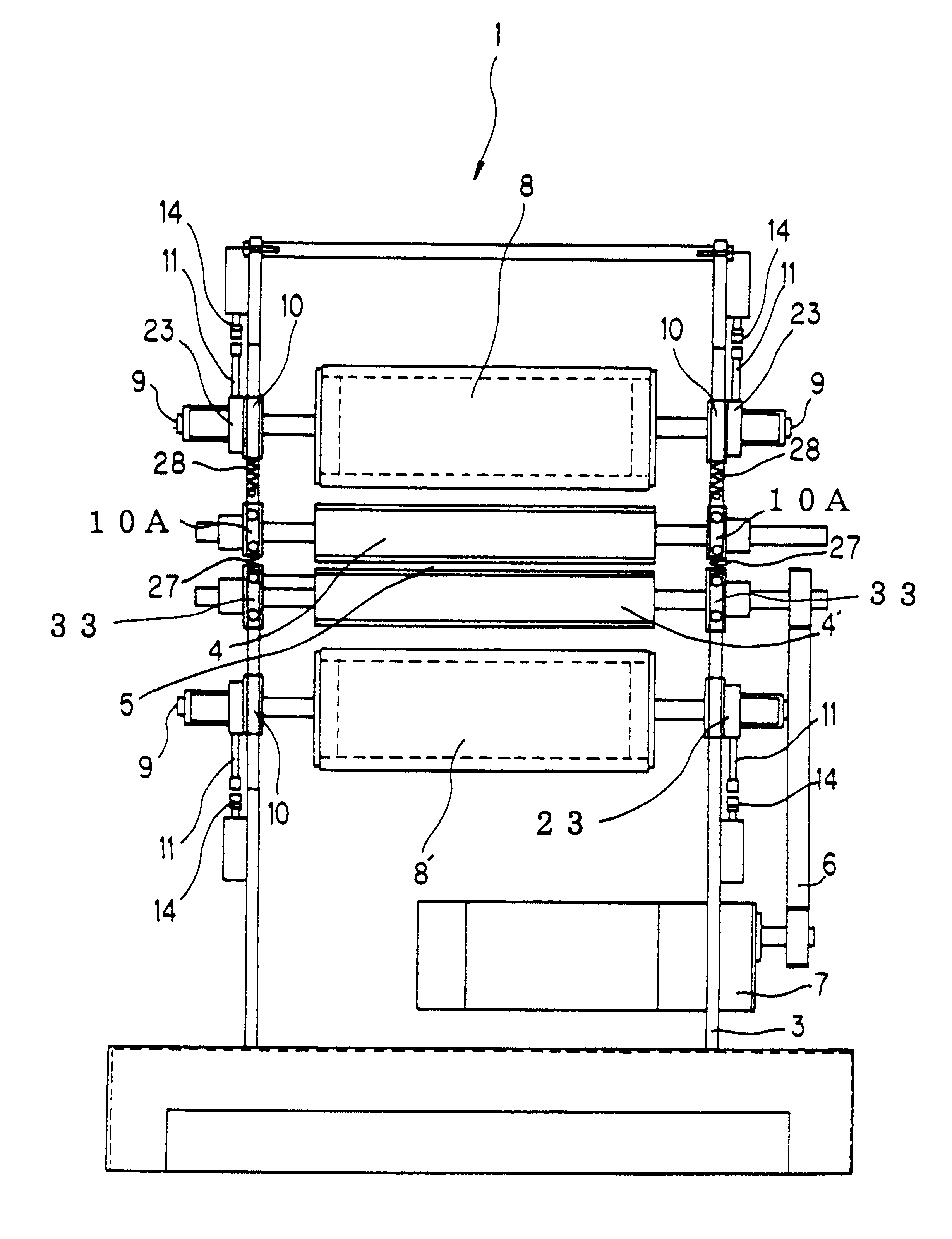

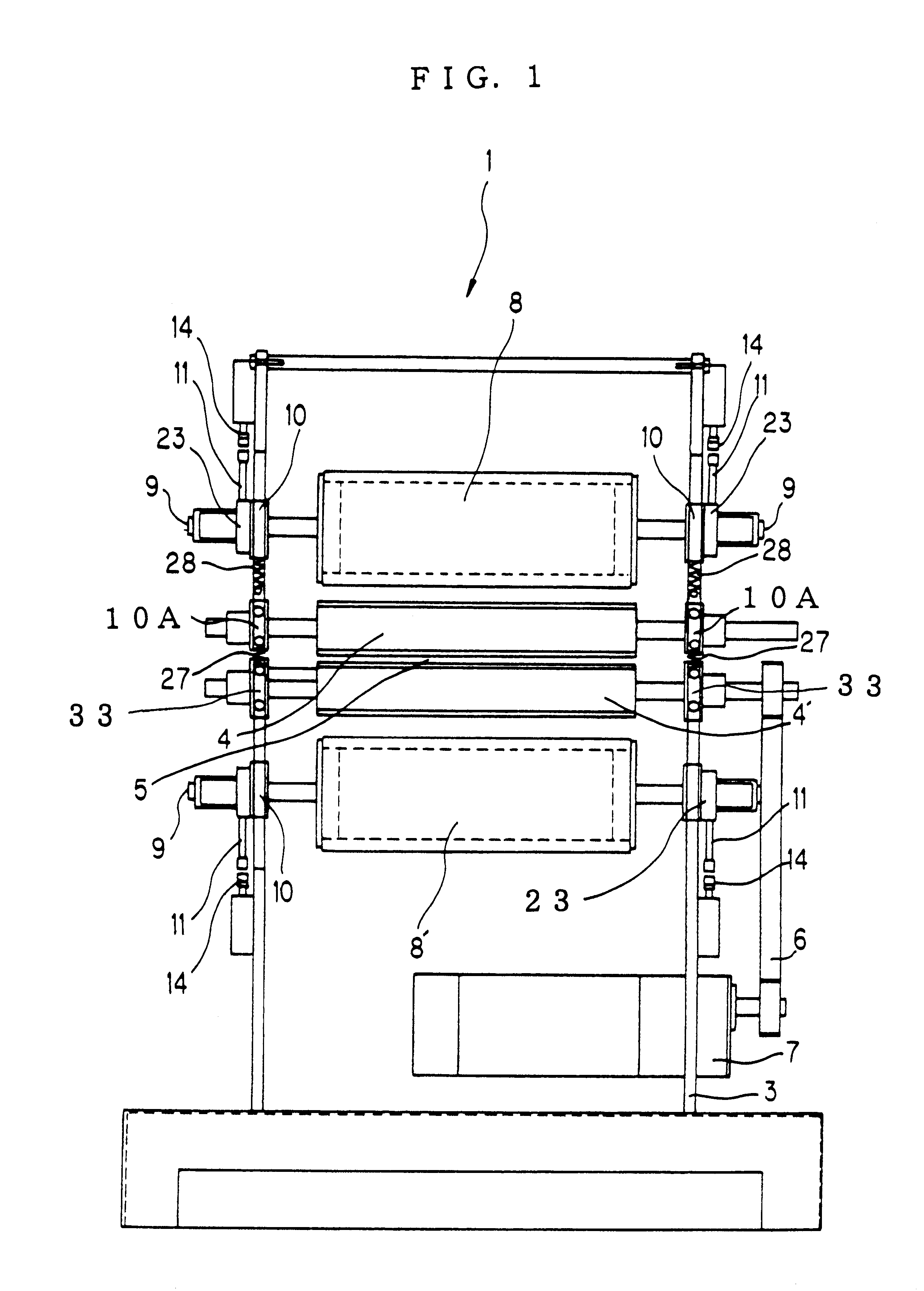

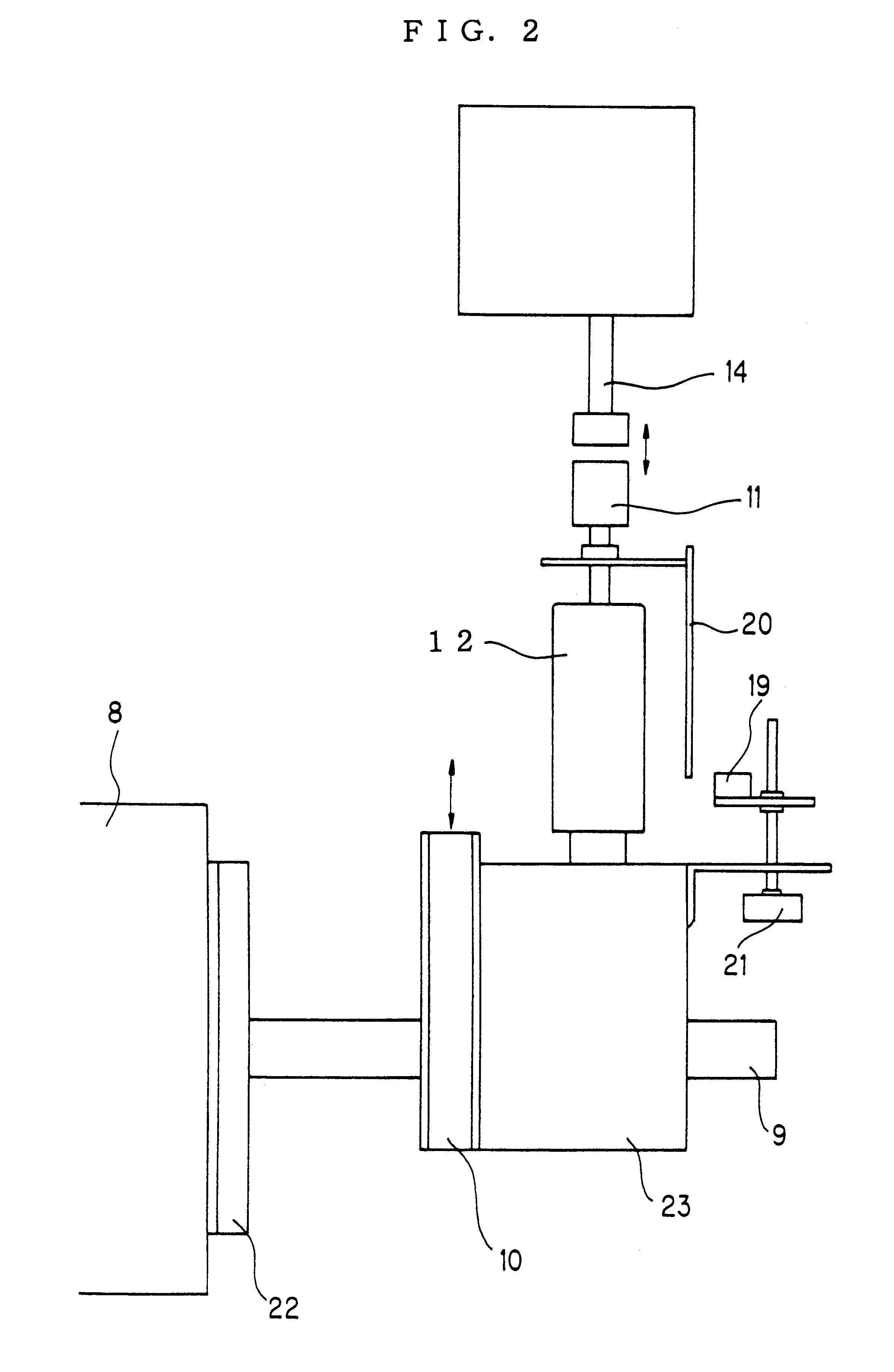

Substrate or sheet surface cleaning apparatus

InactiveUS6237176B1Efficient captureEfficient removalLiquid processingCarpet cleanersFixed bearingSurface cleaning

A substrate or sheet surface cleaning apparatus is provided with at least one tacky rubber roller and at least one adhesive tape roll which is brought into close contact with the tacky rubber roller. The roller and roll are rotatably supported at opposite ends of their shafts by bearings which are slidable in a vertical direction. Pressed rods are arranged integrally on the slidable bearings for the roll. By urging the pressed rods with pressing rods driven by d.c. motors via gear trains while controlling the d.c. motors by a position sensor, the pressure between the roll and the roller and the pressure between the roller and the substrate or sheet are optimized so that dirt or particles can be efficiently removed from an opposing surface of the substrate or sheet. Another substrate or sheet surface cleaning apparatus is provided two tacky rubber rollers arranged in an up-and-down parallel relationship and two adhesive tape rolls arranged above the upper roller and below the lower roller, respectively. Position adjusters with one or more springs disposed therein are arranged between slidable bearings supporting the upper roller and fixed bearings supporting the lower roller to correct tilting, if any, of the upper roller.

Owner:RAYON IND

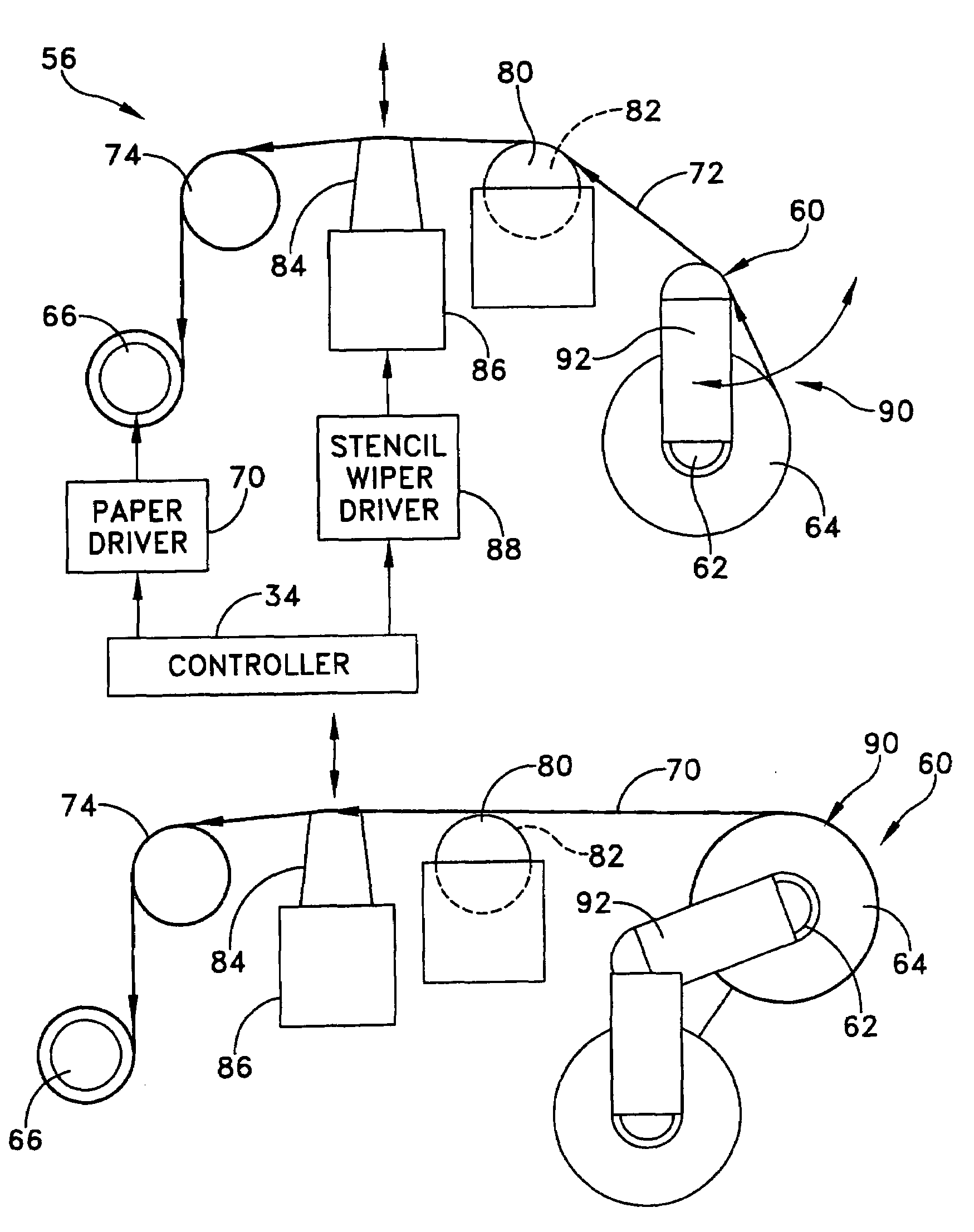

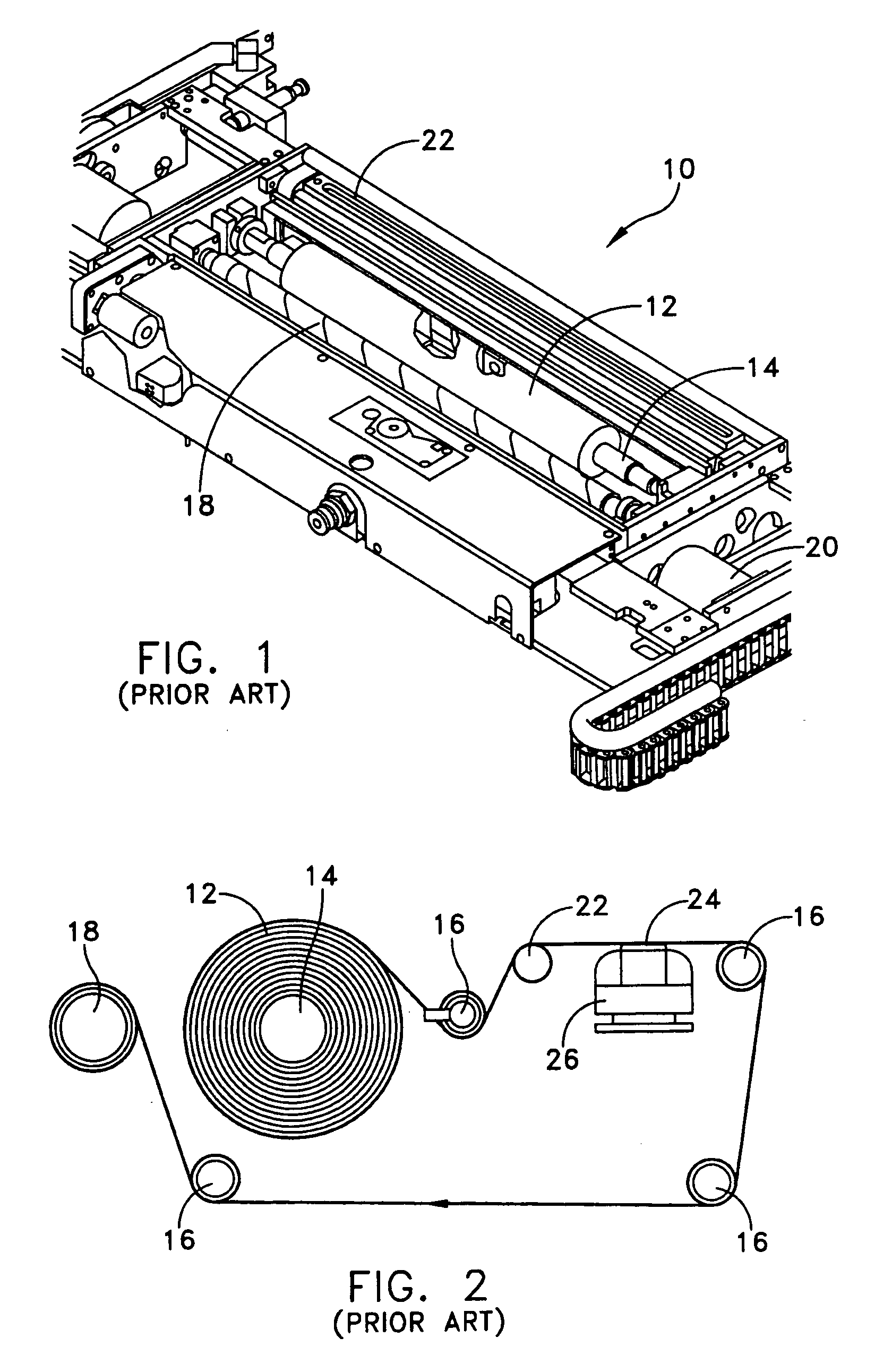

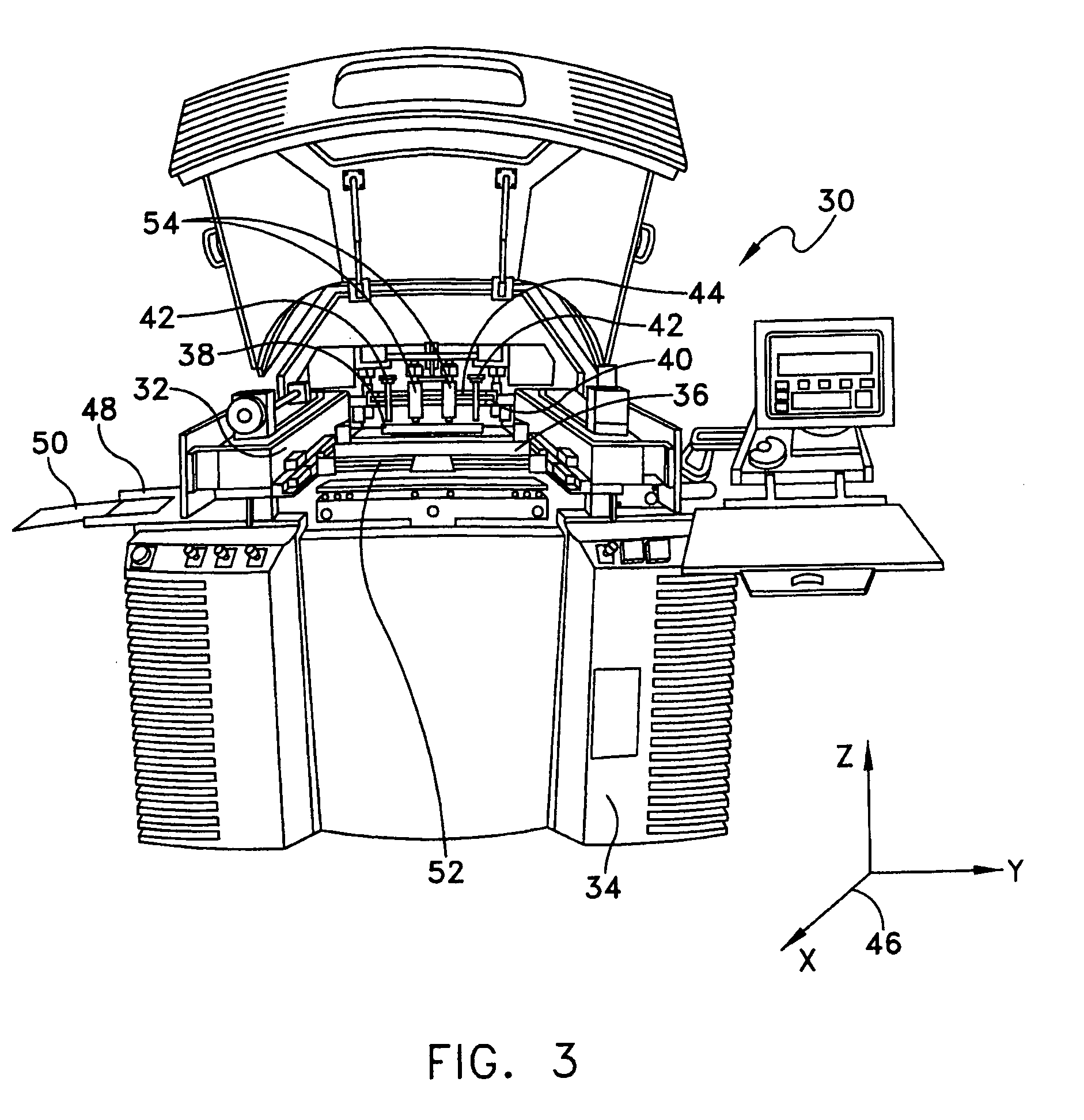

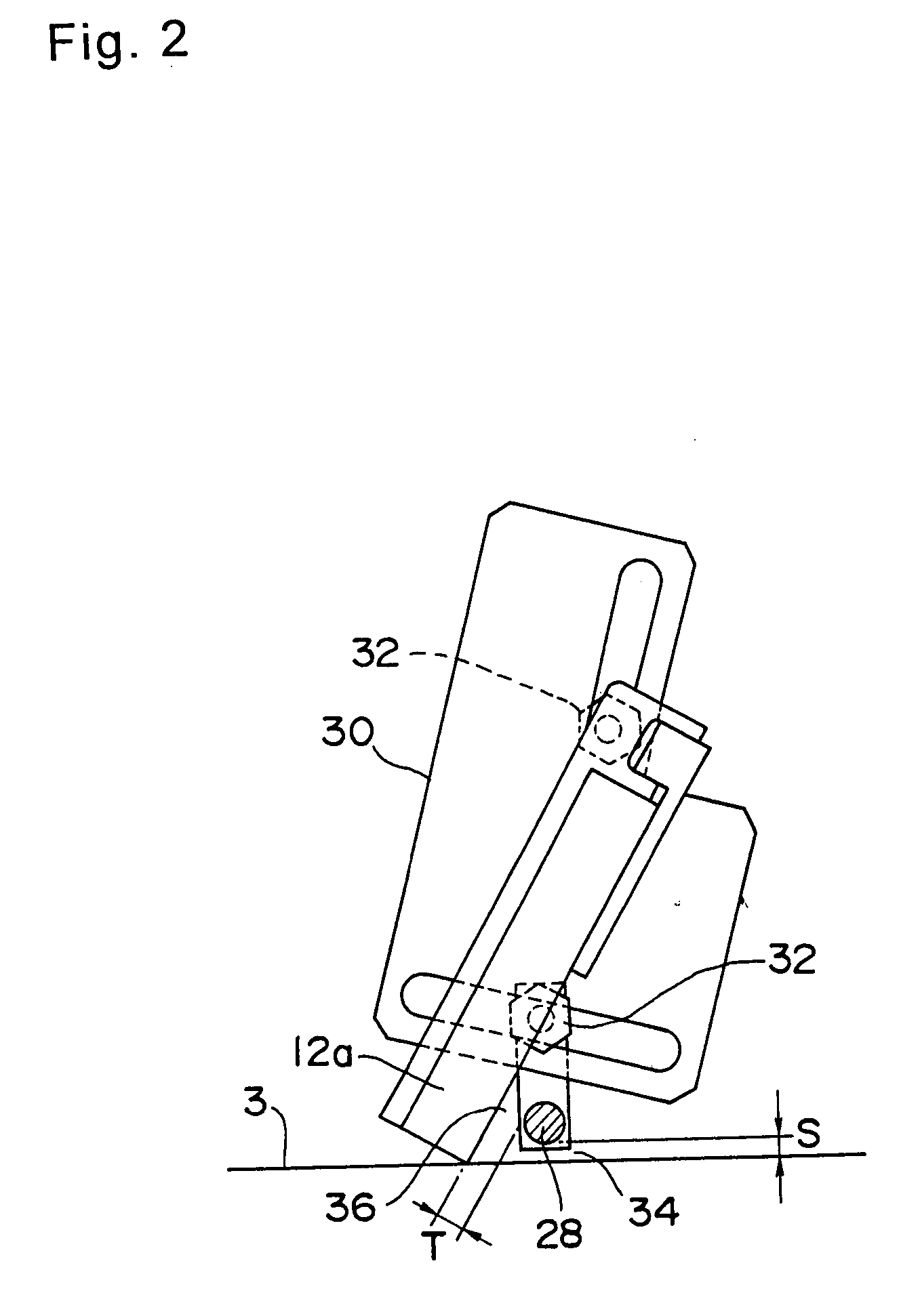

Methods and apparatus for changing web material in a stencil printer

A quick-change material module of a stencil wiper assembly for wiping a stencil of a stencil printer includes a supply roller to receive a roll of material, a take-up roller to receive used material, and a drive to move the material across the stencil between the supply roller and the take-up roller. The supply roller is designed to move between an operating position in which the module functions to wipe the stencil and a changing position in which the supply roller is accessible to change the roll of material. A pivot mechanism is further disclosed for pivoting the supply roller between the operating and changing positions. A frame supports the supply roller, the take-up roller, and the drive. The pivot mechanism includes at least one pivot arm having one end rotatably attached to the supply roller and an opposite end pivotably attached to the frame. A method for changing a roll of material within a quick-change material module of a stencil wiper assembly designed to wipe a stencil of a stencil printer is further disclosed.

Owner:KPS SPECIAL SITUATIONS FUND II LP

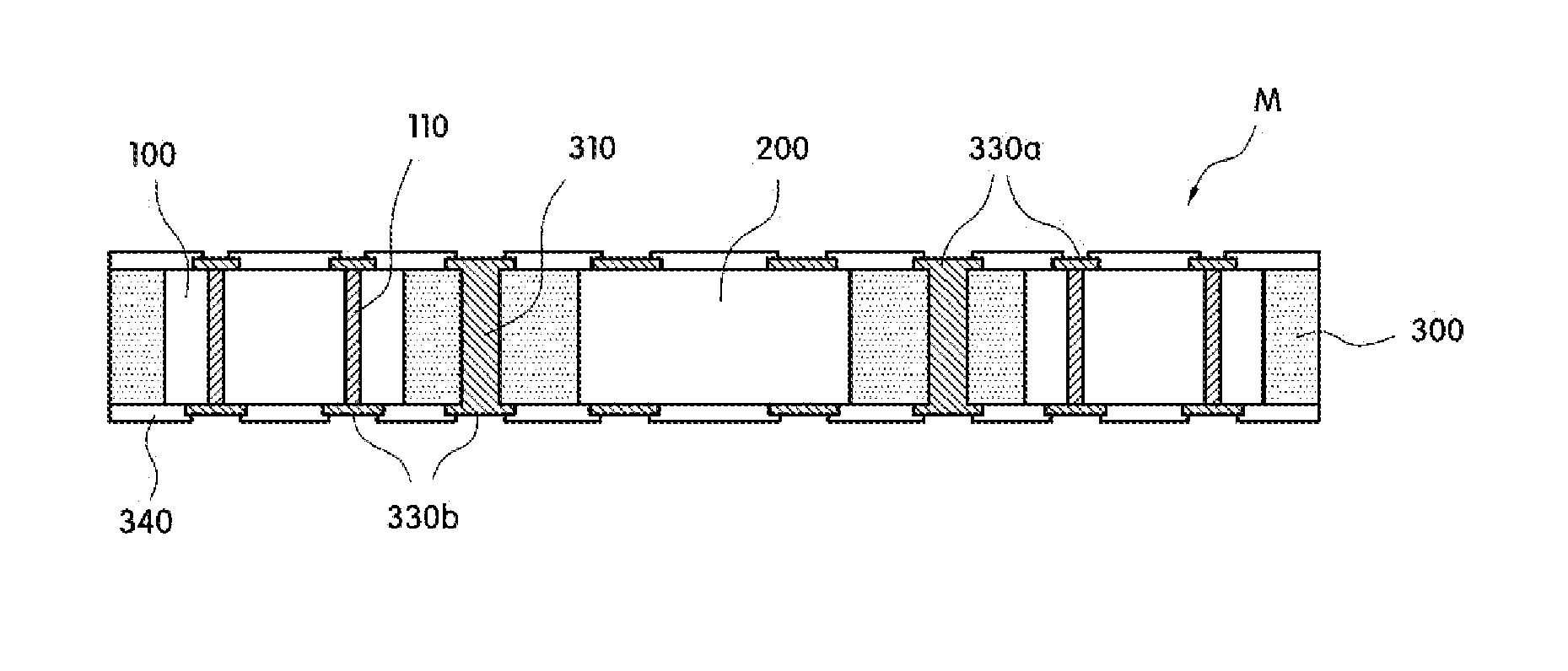

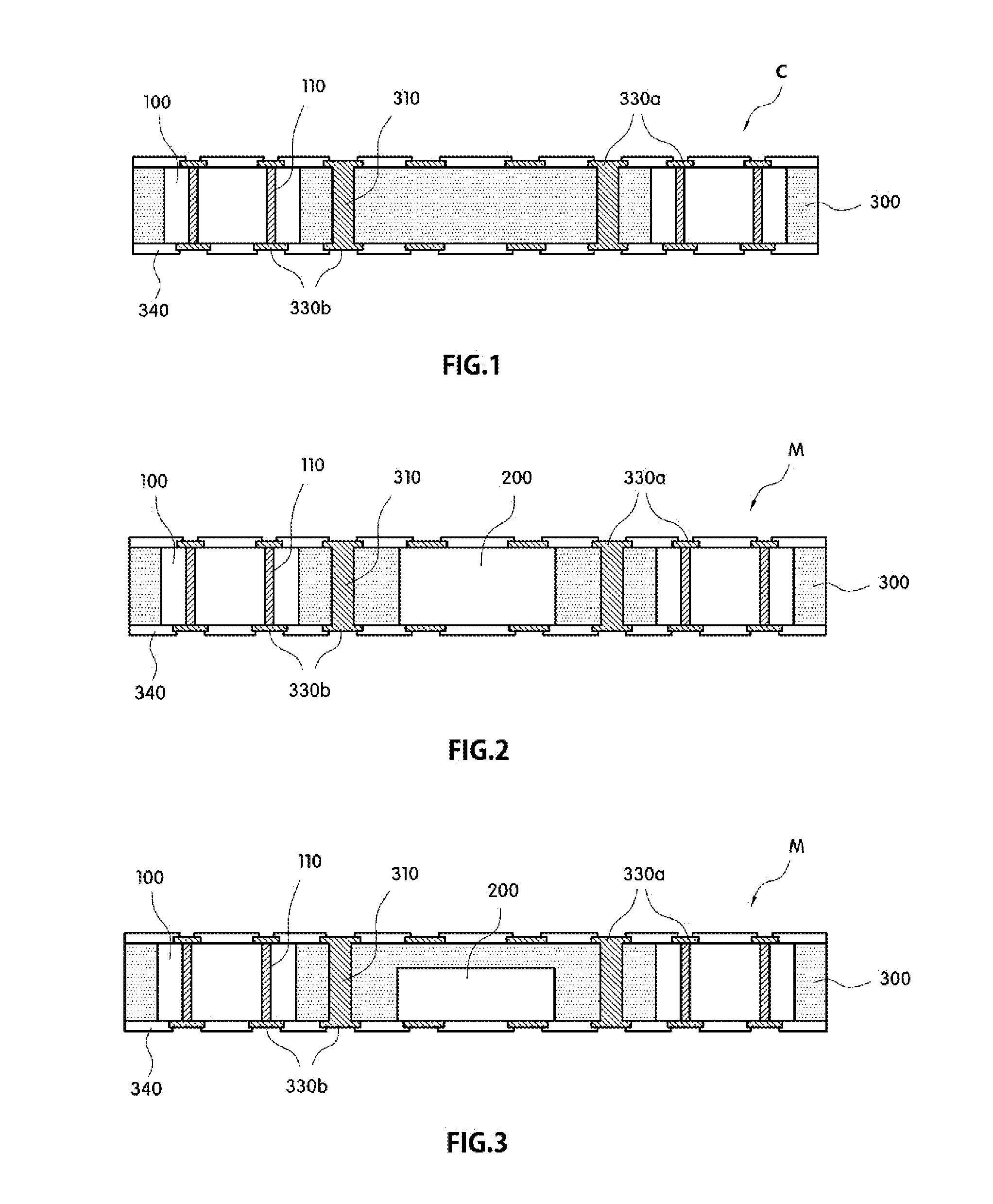

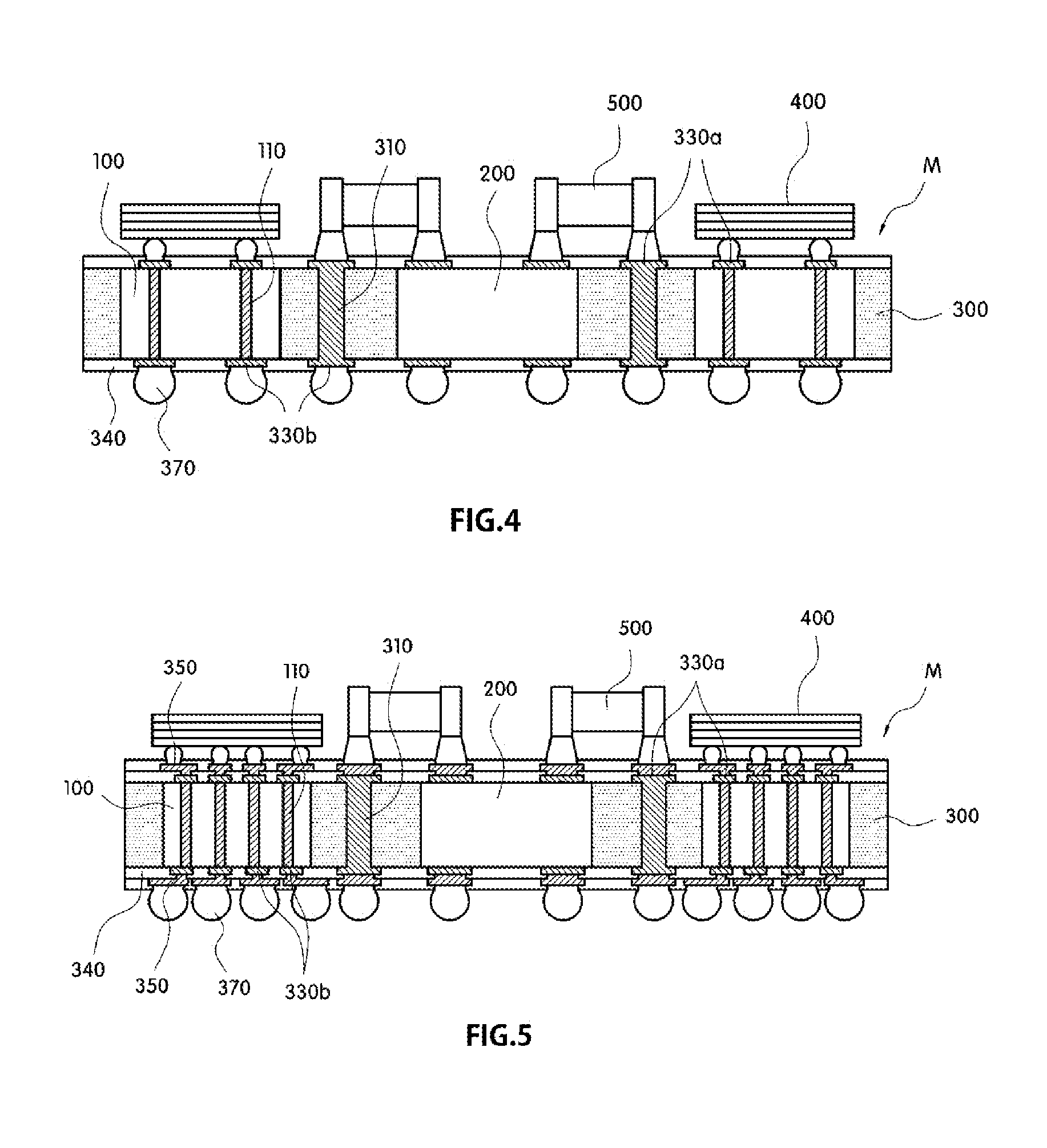

Circuit Board Having Interposer Embedded Therein, Electronic Module Using Same, and Method for Manufacturing Same

InactiveUS20150359098A1Highly integratedMaintain mechanical strengthFinal product manufactureSemiconductor/solid-state device detailsElectricityComputer module

The present invention relates to a circuit board having an interposer embedded therein, including: an interposer, the top side and back side of which are electrically connected by a first through-electrode; and a molding member having the interposer embedded therein and the top side and back side of the interposer exposed. According to the present invention, the molding member of an insulator and the interposer of a semiconductor can be appropriately selected and coupled according to the required fine pitch of a through-hole, and the interposer is molded on substantially the same level as a semiconductor chip, and thus no additional process for embedding the interposer needs to be added.

Owner:HANA MICRON

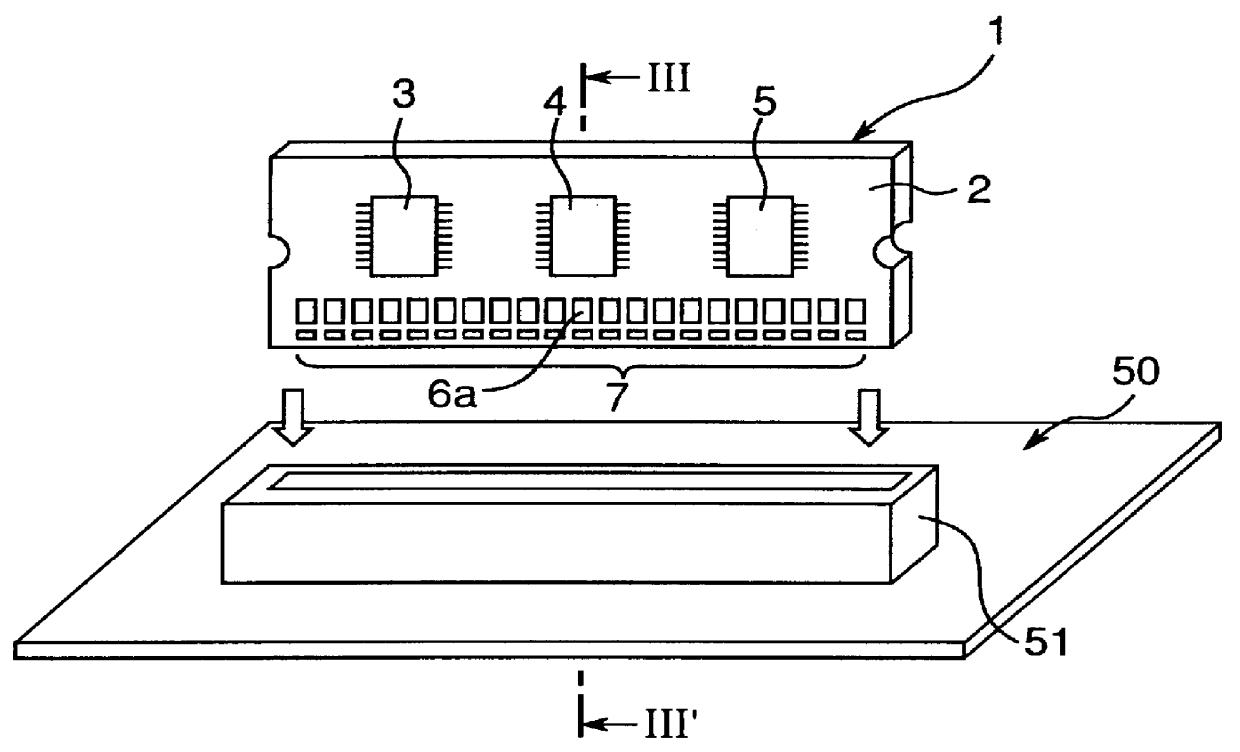

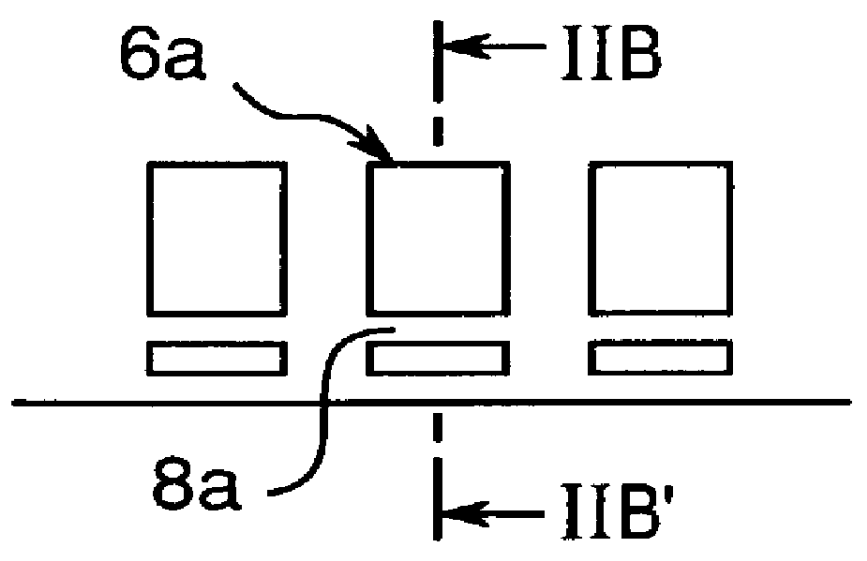

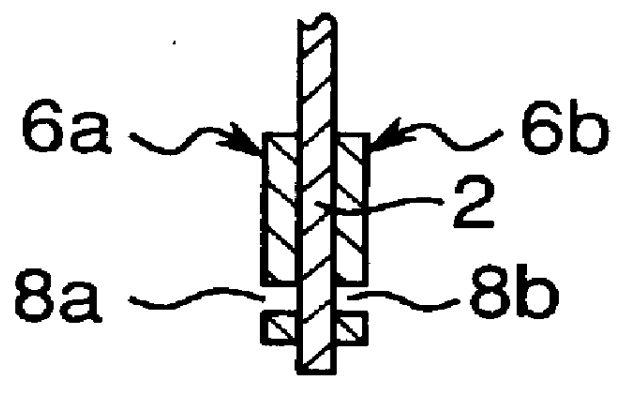

Memory module with obstacle removing terminal structure

InactiveUS6115260AImproved terminal structureEfficiently expelledCoupling device connectionsPrinted electric component incorporationForeign matterEngineering

A terminal structure in a memory module includes a male connector having a plurality of terminal strips adapted to be engaged with the terminal tongues in the female socket. Each of the terminal strips has an obstacle removal portion defined therein for removing foreign matter present on at least one of the terminal tongues.

Owner:MITSUBISHI ELECTRIC CORP

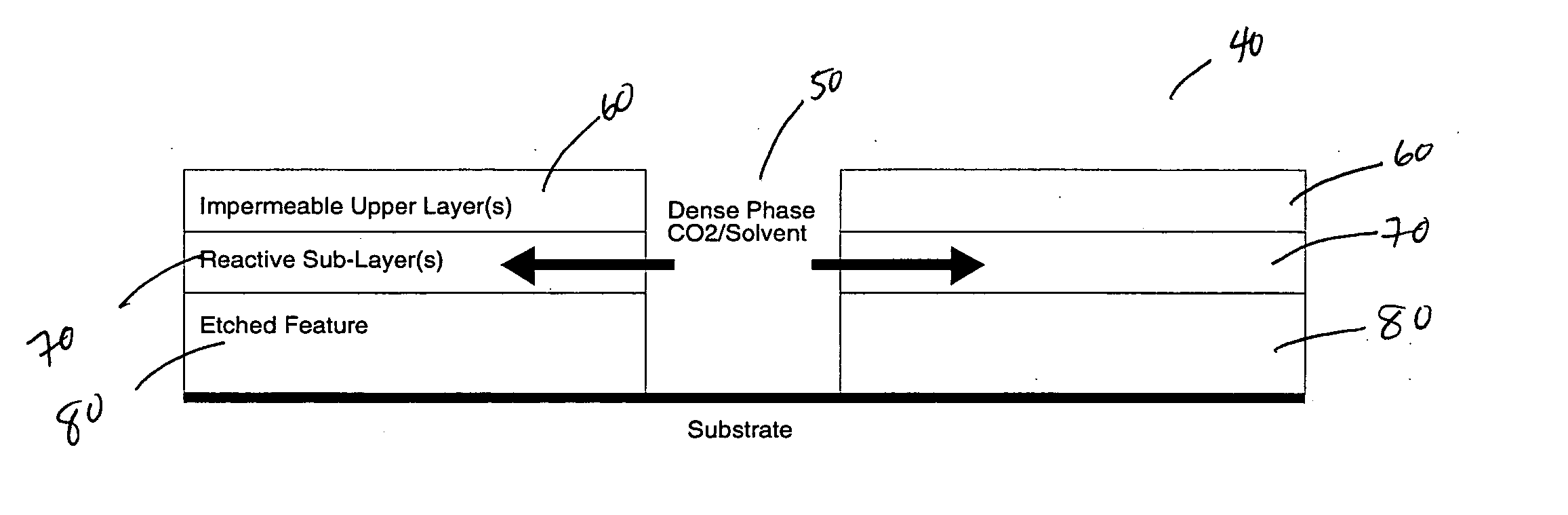

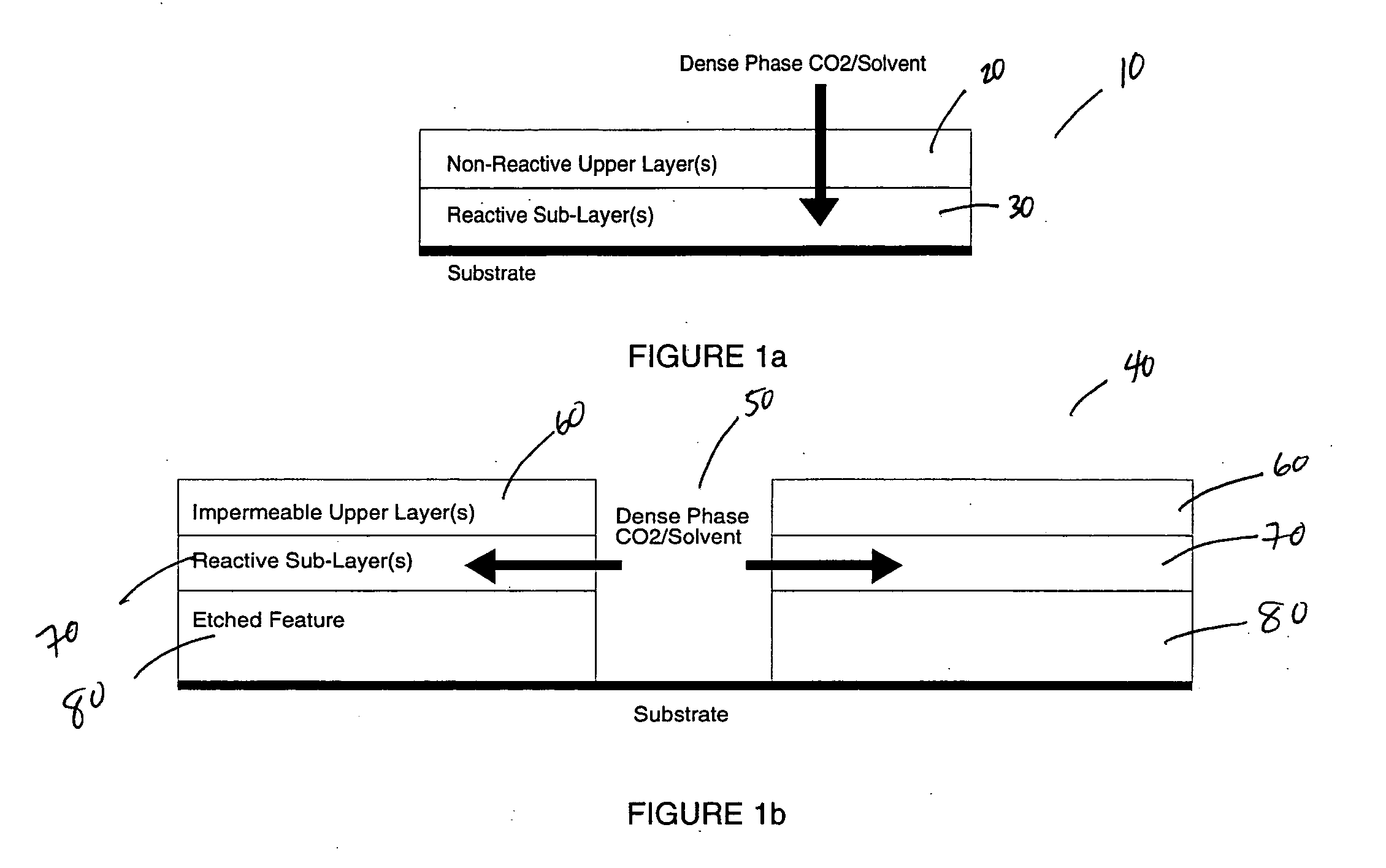

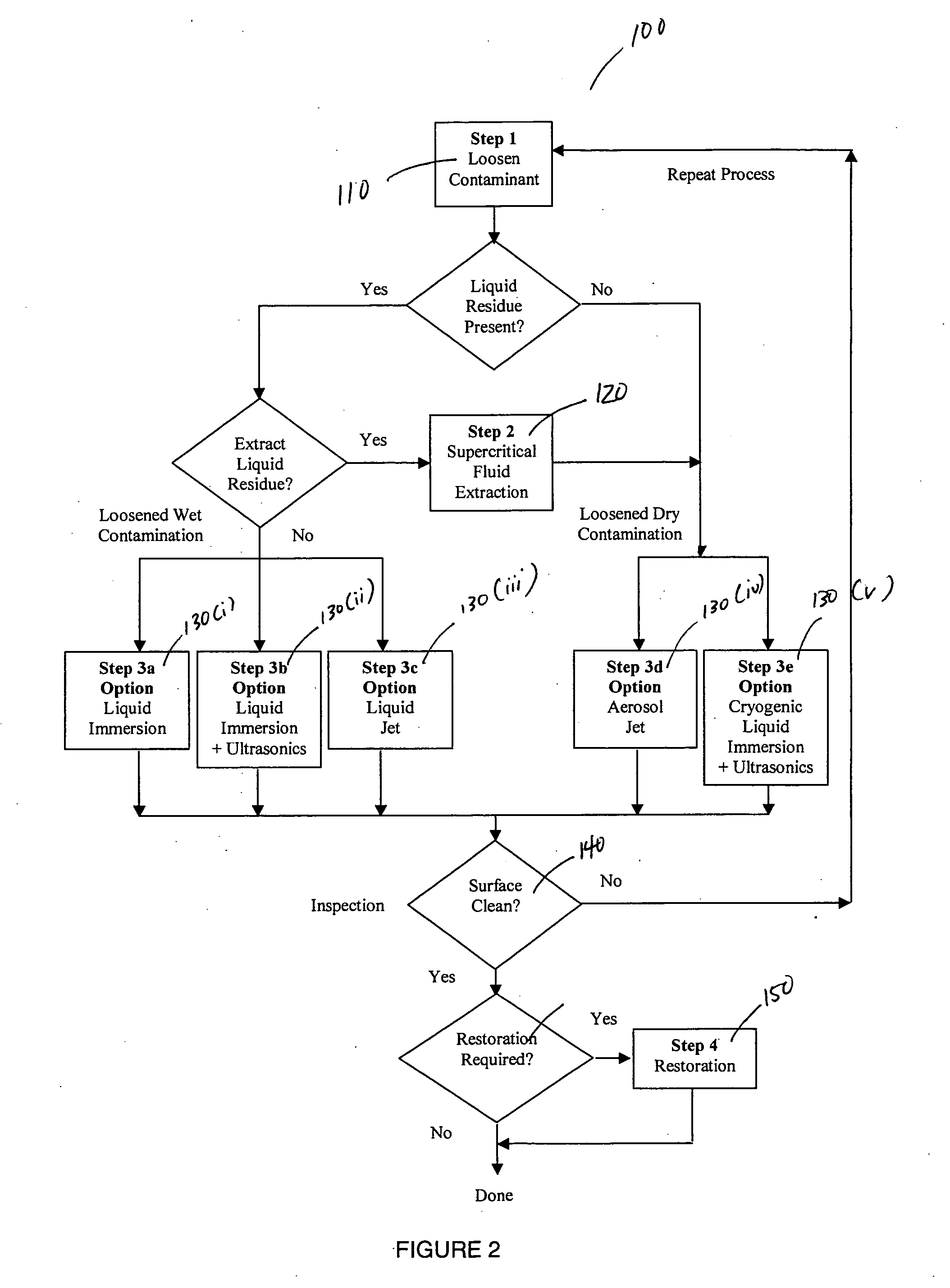

Dense fluid compositions and processes using same for article treatment and residue removal

InactiveUS20060081273A1Photomechanical apparatusSemiconductor/solid-state device manufacturingFluid compositionLiquid based

A method for removing contaminants from an article is described herein. In one embodiment, there is provided a method comprising loosening at least a portion of the contaminants by treating the article with a treatment method involving a processing fluid and / or dense processing fluid to provide a partially treated article comprising loosened contaminants; contacting the partially treated article with a dense rinse fluid comprising a dense fluid, optionally a co-solvent, and optionally an entrainer to remove liquid-based contaminants; and removing at least a portion of the loosened contaminants by exposing the partially treated article with at least one exposure method to provide a treated article wherein the selection of the at least one exposure method depends upon whether the loosened contaminants are wet or dry.

Owner:AIR PROD & CHEM INC

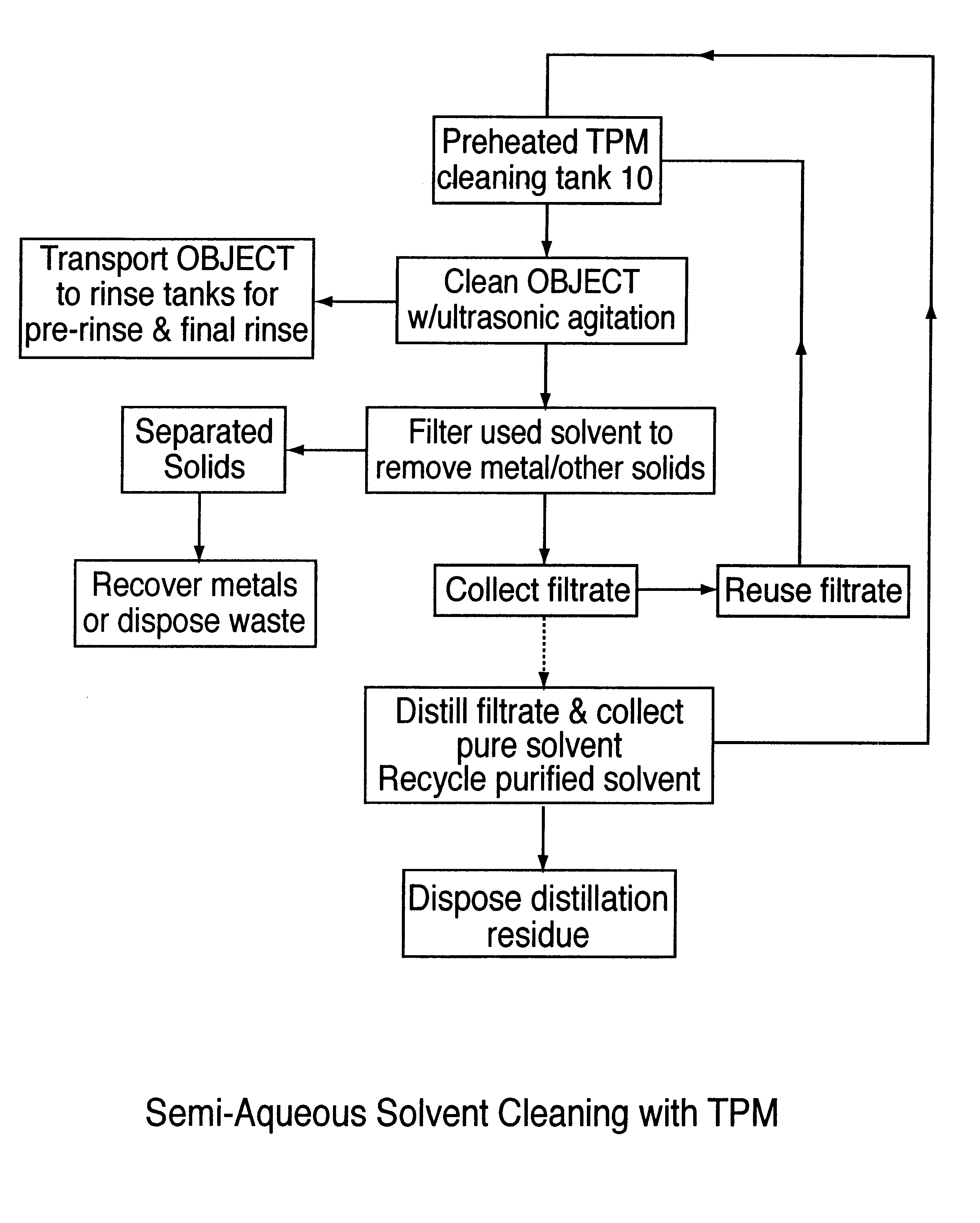

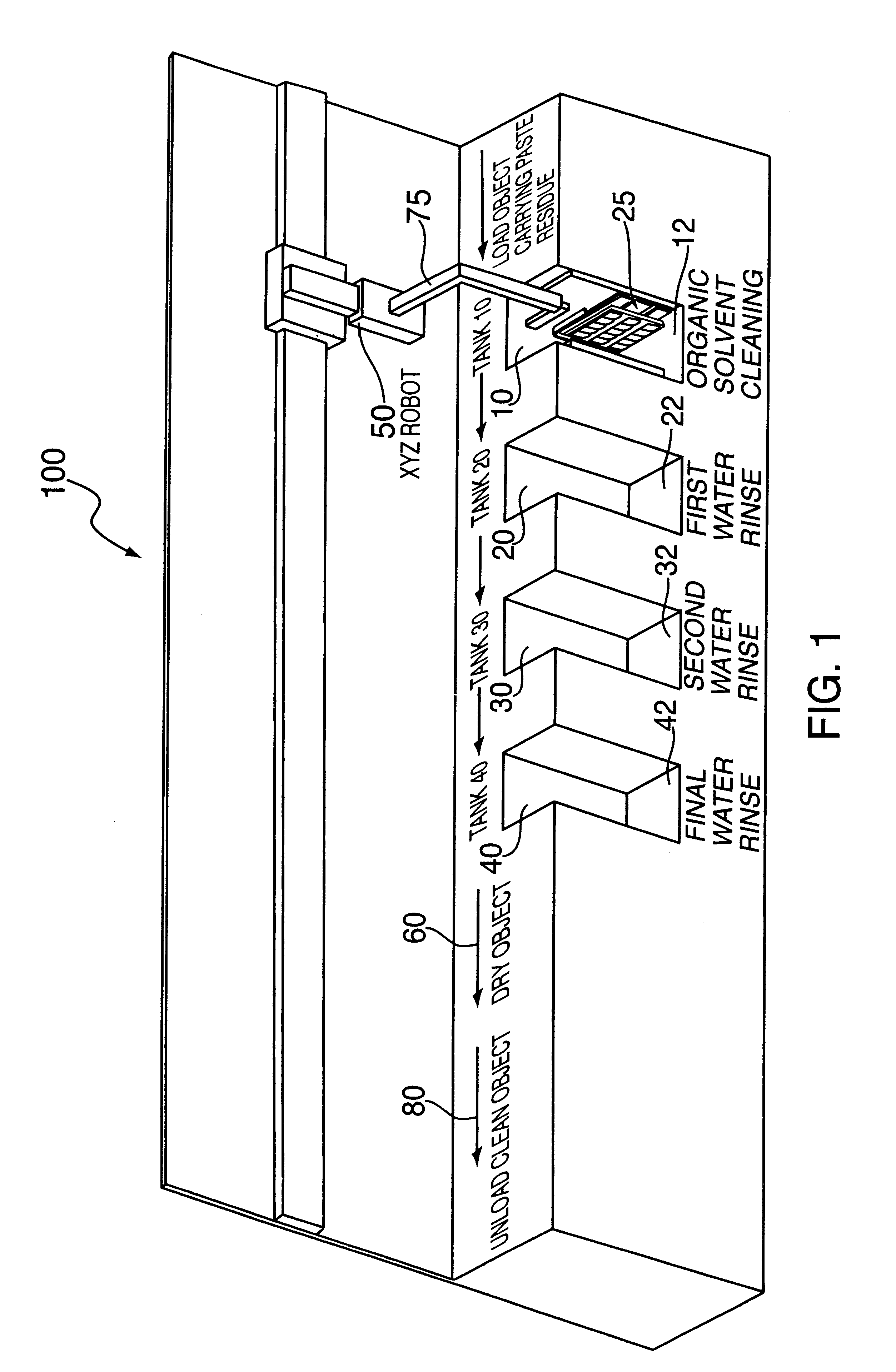

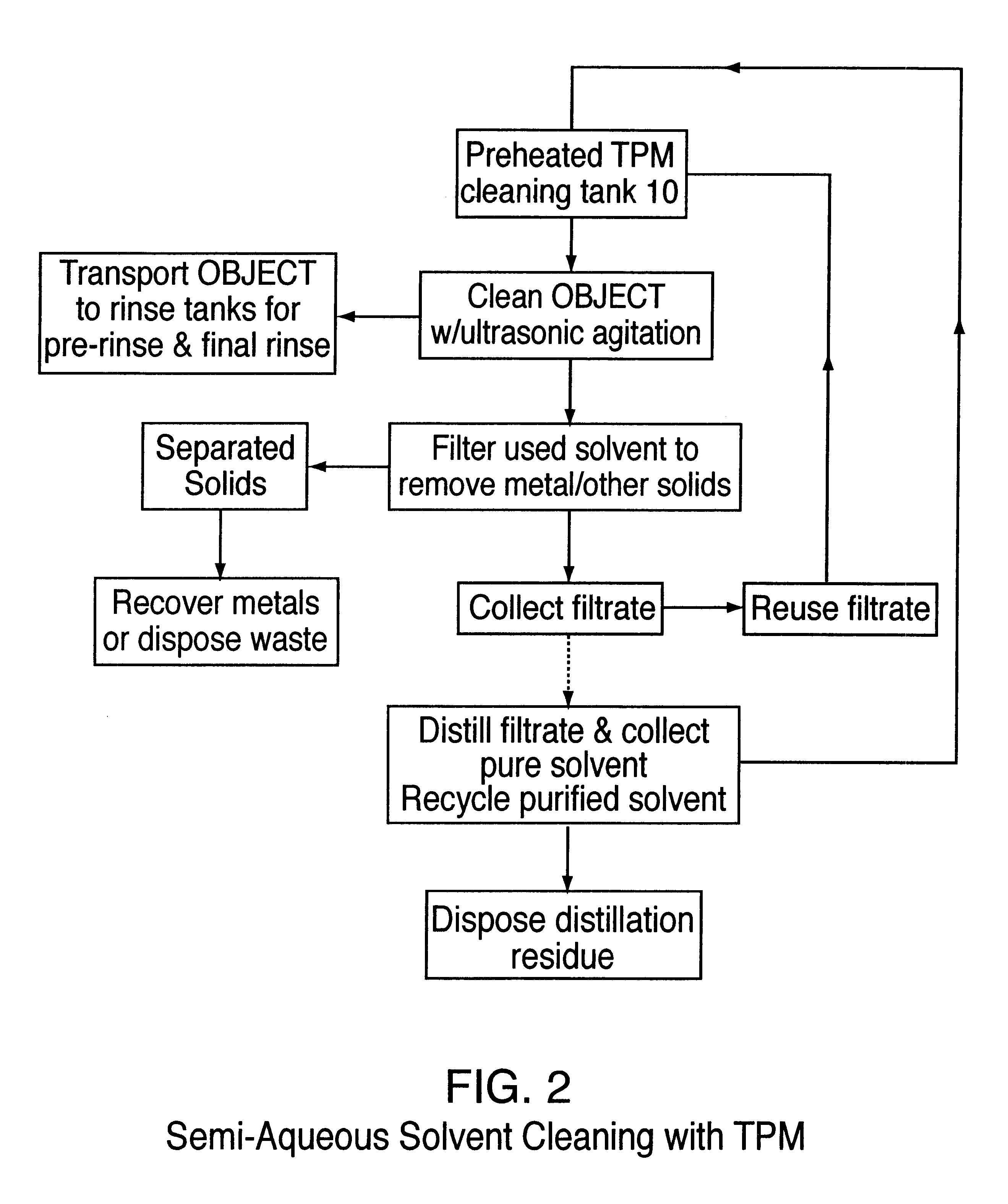

Semi-aqueous solvent cleaning of paste processing residue from substrates

A process of cleaning of objects that relate to semiconductor fabrication processes, such as, for example, conductive paste screening in the production of multilayer ceramic substrates and composite solder paste by stencil printing in electronic circuit assembly. Specifically, the process removes a metal / polymer composite paste from screening masks and associated paste making and processing equipment used in printing conductive metal pattern onto ceramic green sheet in the fabrication of semiconductor packaging substrates. The process also cleans solder paste residue from stencil printing equipment used in electronic module assembly surface mount technology for SMT discretes, solder column attachment, and BGA (Ball Grid Array) attachment on ceramic chip carrier or for screening solder paste onto printed circuit board. More particularly, paste residue is cleaned from metal, ceramic, and plastic substrates by a non-alkaline semi-aqueous cleaning method employing high boiling propylene glycol alkyl ether or mixtures of propylene glycol alkyl ether and propylene glycol solvents.

Owner:INT BUSINESS MASCH CORP

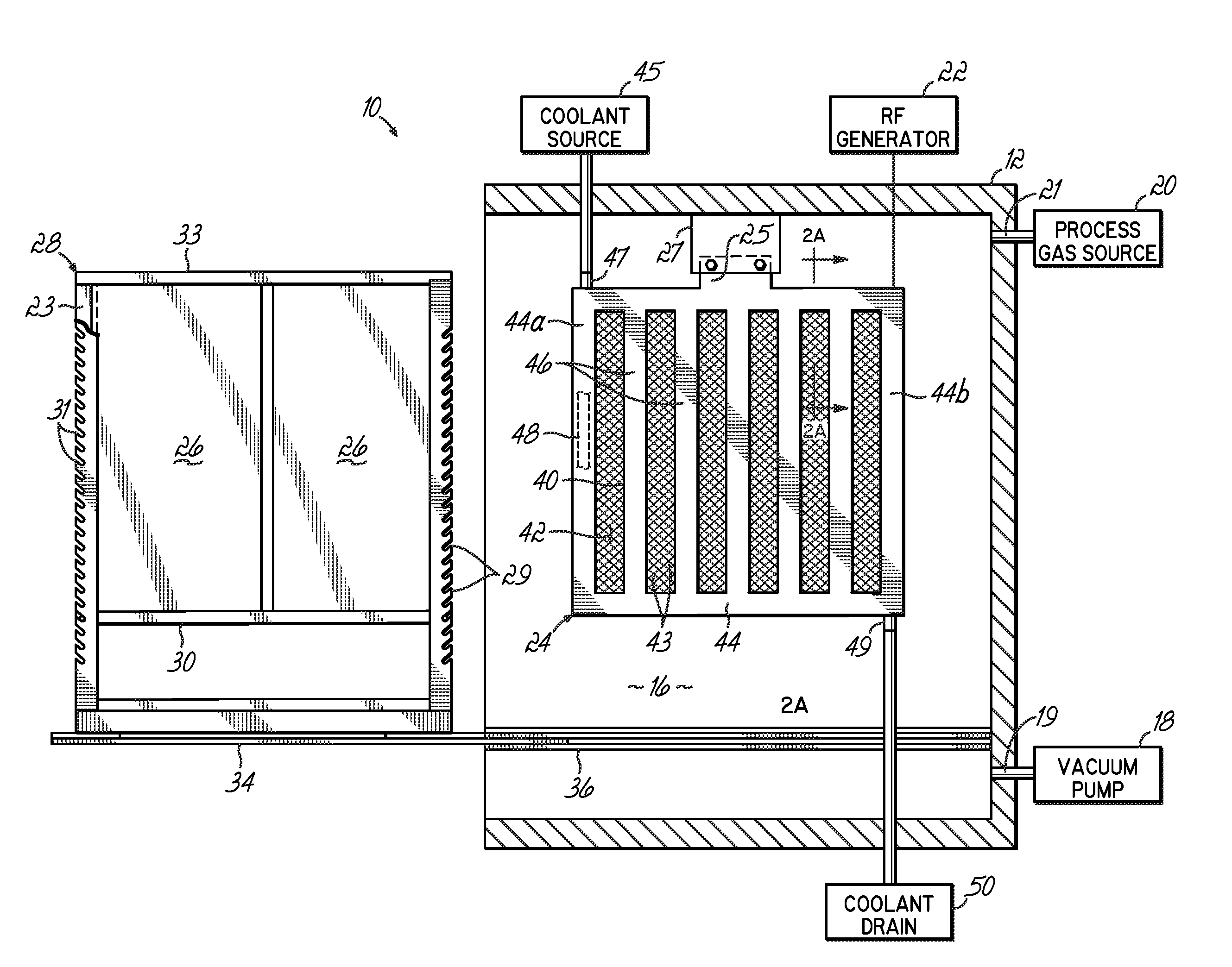

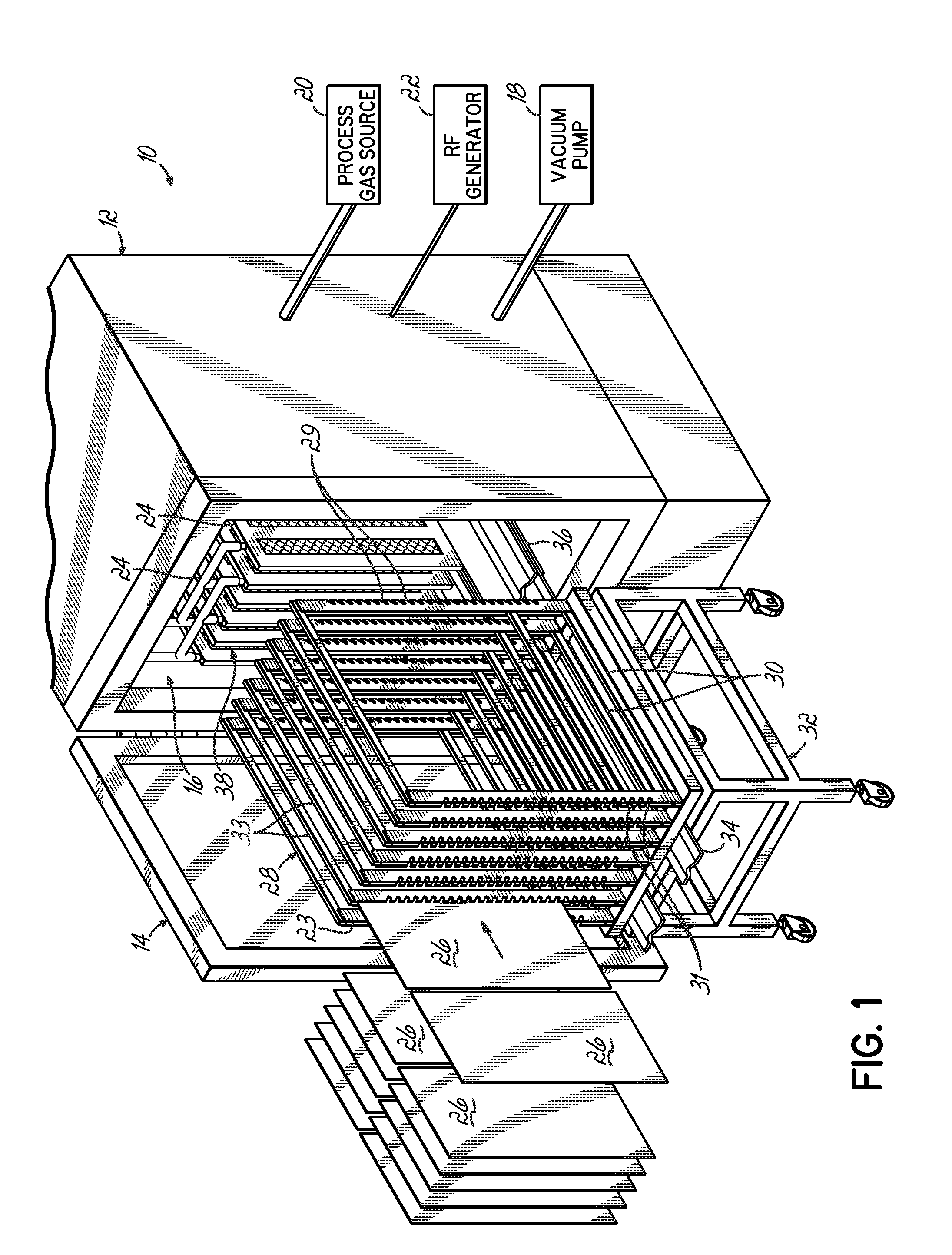

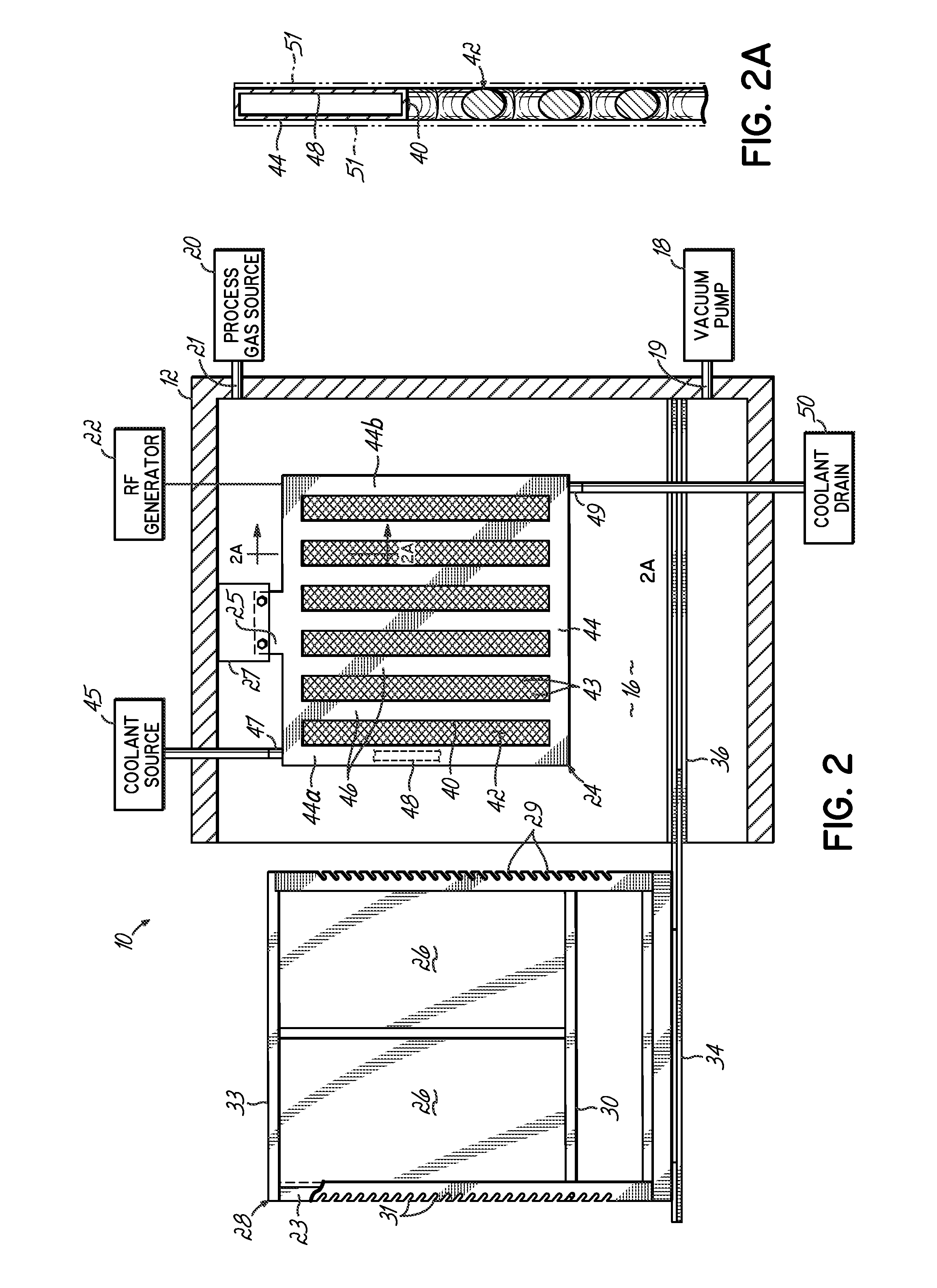

Plasma processing system and plasma treatment process

InactiveUS20060163201A1Electric discharge tubesDecorative surface effectsPolymer substrateEngineering

A plasma treatment system for treating multiple substrates with a plasma. The treatment chamber of the plasma treatment system includes at least one pair of electrodes, typically vertically oriented, between which a substrate is positioned for plasma treatment. Each electrode includes a perforated panel that permits horizontal process gas and plasma flow, which improves plasma uniformity. A process recipe is defined that is effective for removing thin polymer areas, such as flash or chad, attached to and projecting from a polymer substrate.

Owner:NORDSON CORP

Solvent compositions containing chlorofluoroolefins

InactiveUS20050096246A1Satisfies needOvercome deficienciesCompressorTransportation and packagingDouble bondSolvent composition

Compositions and methods based on the use of fluoroalkene containing from 3 to 4 carbon atoms and at least one carbon-carbon double bond, such as 1,2,-dichloro-3,3,3-trifluoropropene (HFO-1223xd) having properties highly beneficial in solvent cleaning applications.

Owner:HONEYWELL INT INC

Etchant and replenishment solution therefor, and etching method and method for producing wiring board using the

ActiveUS20050109734A1Suppress too much dissolutionExcessive dissolutionDecorative surface effectsPrinted circuit aspectsDissolutionMetallic Nickel

An etchant of the present invention includes an aqueous solution containing hydrochloric acid, nitric acid, and a cupric ion source. An etching method of the present invention includes bringing the etchant into contact with at least one metal selected from nickel, chromium, nickel-chromium alloys, and palladium. Another etching method of the present invention includes bringing a first etchant that includes an aqueous solution containing at least the following components A to C (A. hydrochloric acid; B. at least one compound selected from the following (a) to (c): (a) compounds with 7 or less carbon atoms, containing a sulfur atom(s) and at least one group selected from an amino group, an imino group, a carboxyl group, a carbonyl group, and a hydroxyl group; (b) thiazole; and (c) thiazole compounds; and C. a surfactant) into contact with a surface of the metal, and then bringing a second solution that includes an aqueous solution containing hydrochloric acid, nitric acid, and a cupric ion source into contact with the surface of the metal. According to the etchant and the etching methods of the present invention, it is possible to etch at least one metal selected from nickel, chromium, nickel-chromium alloys, and palladium quickly and suppress excessive dissolution of copper.

Owner:MEC CO LTD

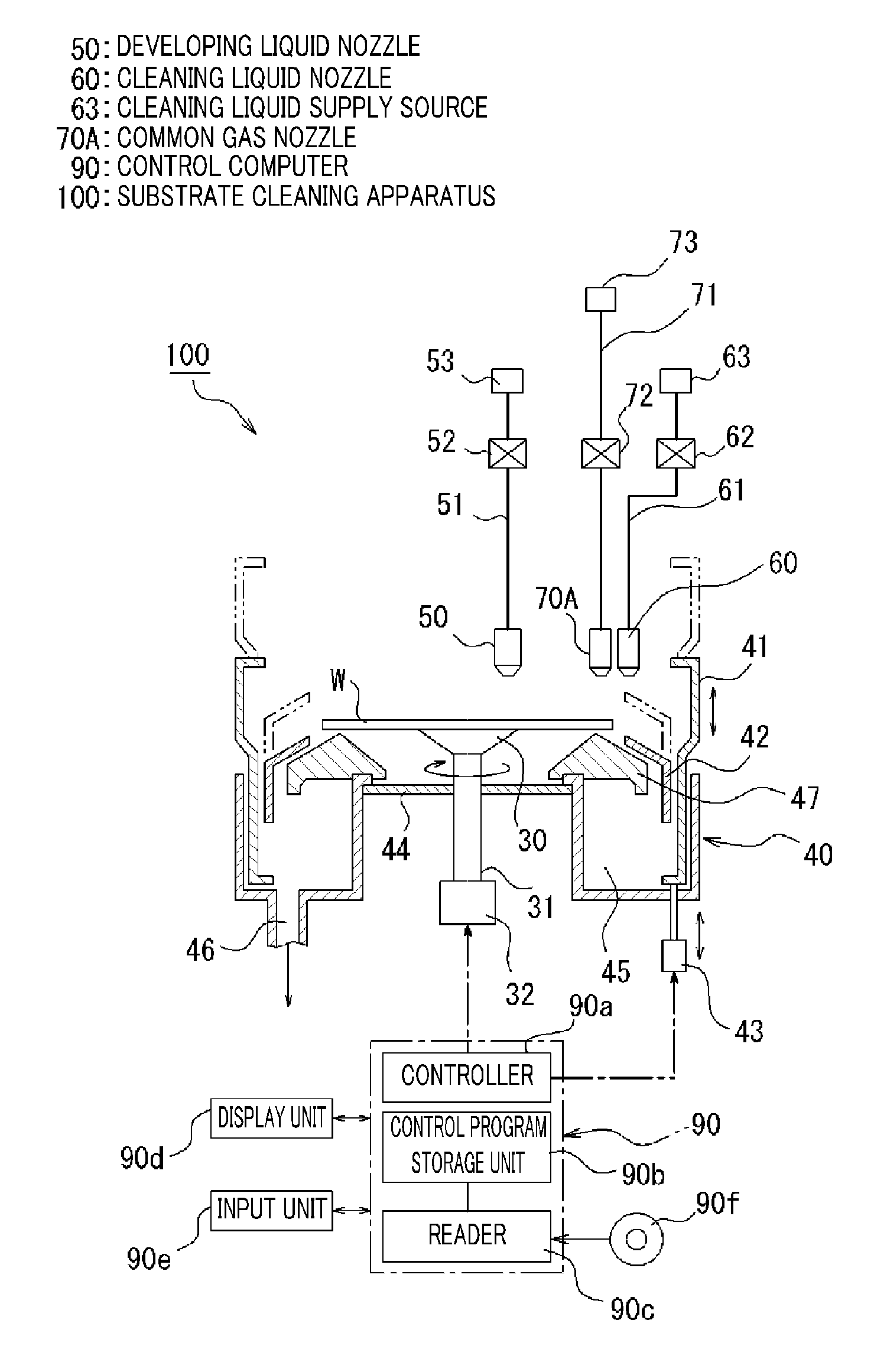

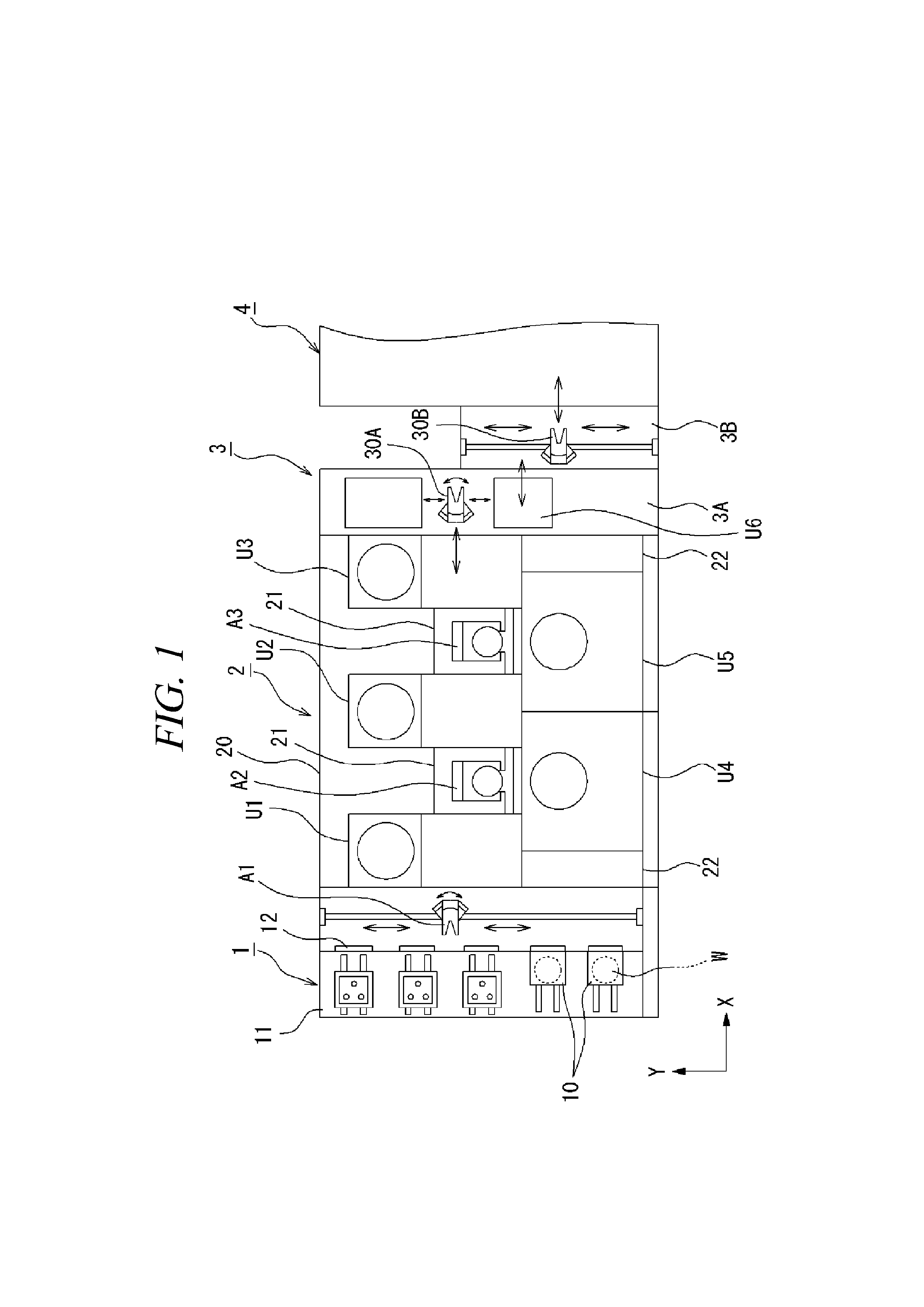

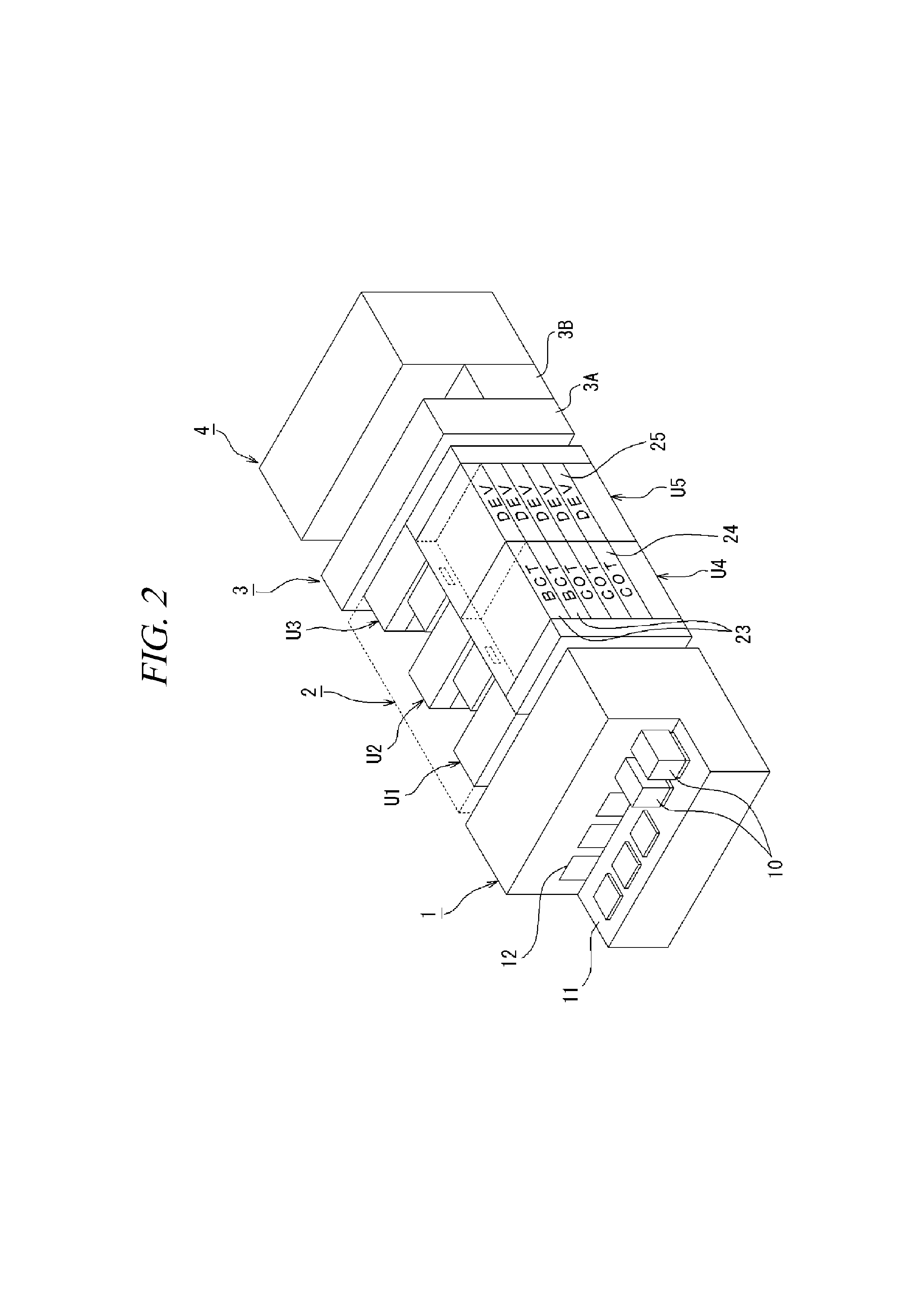

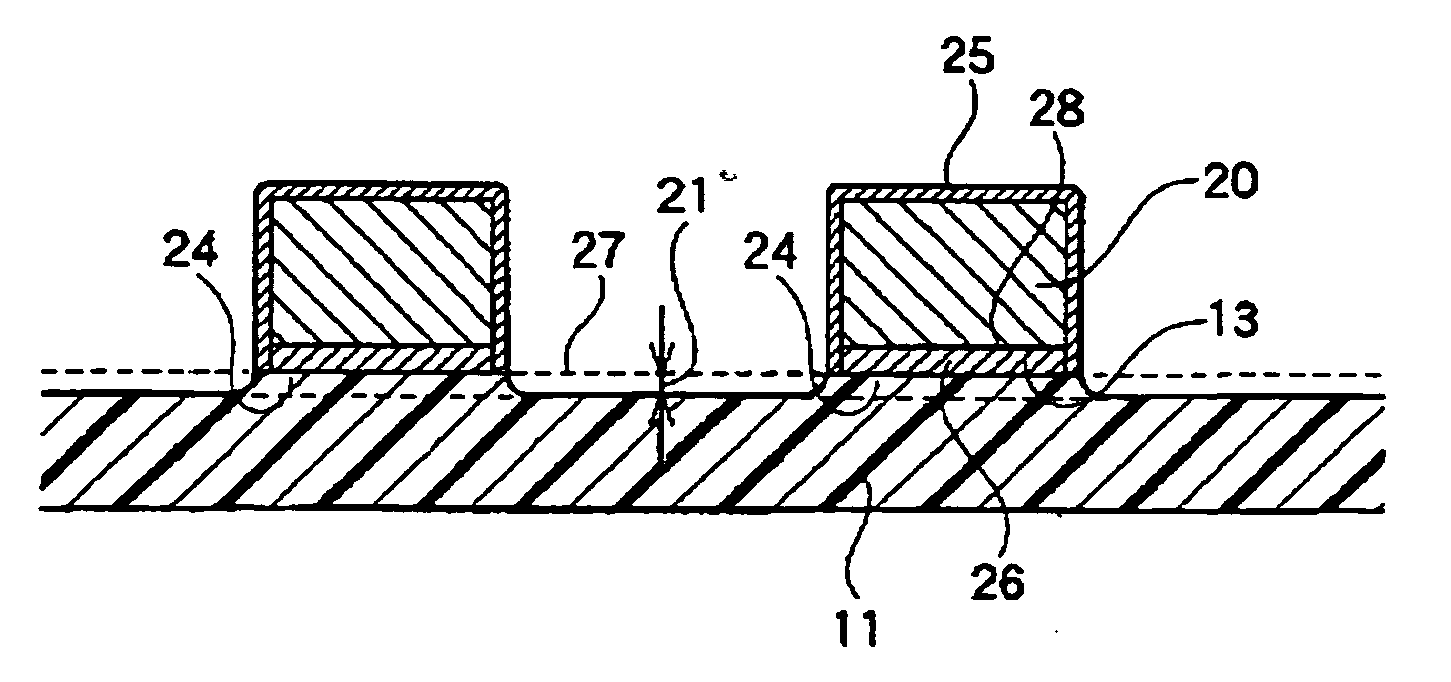

Substrate cleaning method, substrate cleaning apparatus and storage medium for cleaning substrate

ActiveUS20130174873A1Avoid circuit damageAvoid damageLighting and heating apparatusSemiconductor/solid-state device manufacturingEngineeringSubstrate surface

A substrate cleaning method is capable of preventing a liquid stream on a substrate from being cut and circuit patterns thereon from being damaged. The substrate cleaning method includes a liquid film forming process that forms a liquid film on an entire substrate surface by supplying a cleaning liquid L from a central portion of the substrate W toward a peripheral portion thereof while rotating the substrate; a drying region forming process that discharges a gas G on the substrate surface and removes the cleaning liquid on the substrate surface; and a residual liquid removing process that removes the cleaning liquid remaining between the circuit patterns by discharging a gas G while moving in a diametrical direction of the substrate.

Owner:TOKYO ELECTRON LTD

Printed wiring board, its manufacturing method, and circuit device

ActiveUS20070111401A1Avoid changeLong-term stabilitySolid-state devicesSemiconductor/solid-state device manufacturingSputteringMetal

A printed wiring board manufacturing process comprises forming a conductive metal layer on at least one surface of an insulating film with a sputtered metal layer in between, selectively etching the conductive metal layer and the sputtered metal layer to produce a wiring pattern, treating the laminated film with a first treatment liquid capable of dissolving nickel of the sputtered metal layer, and treating with a second treatment liquid capable of dissolving chrome of the sputtered metal layer and also capable of eliminating the sputtered metal layer in the insulating film to remove a superficial surface of the insulating film exposed from the wiring pattern together with the residual sputtered metals in the superficial surface. A printed wiring board comprises an insulating film and a wiring pattern, wherein the insulating film in an area exposed from the wiring pattern has a thickness smaller by 1 to 100 nm than that of an area under the wiring pattern. The process eliminates the sputtered metals combined with the insulating film together with the superficial surface of the insulating film, and therefore the insulating film surface between wires does not contain any residual metals and a short circuit between wires is prevented.

Owner:HEFEI ESWIN MATERIALS TECH CO LTD

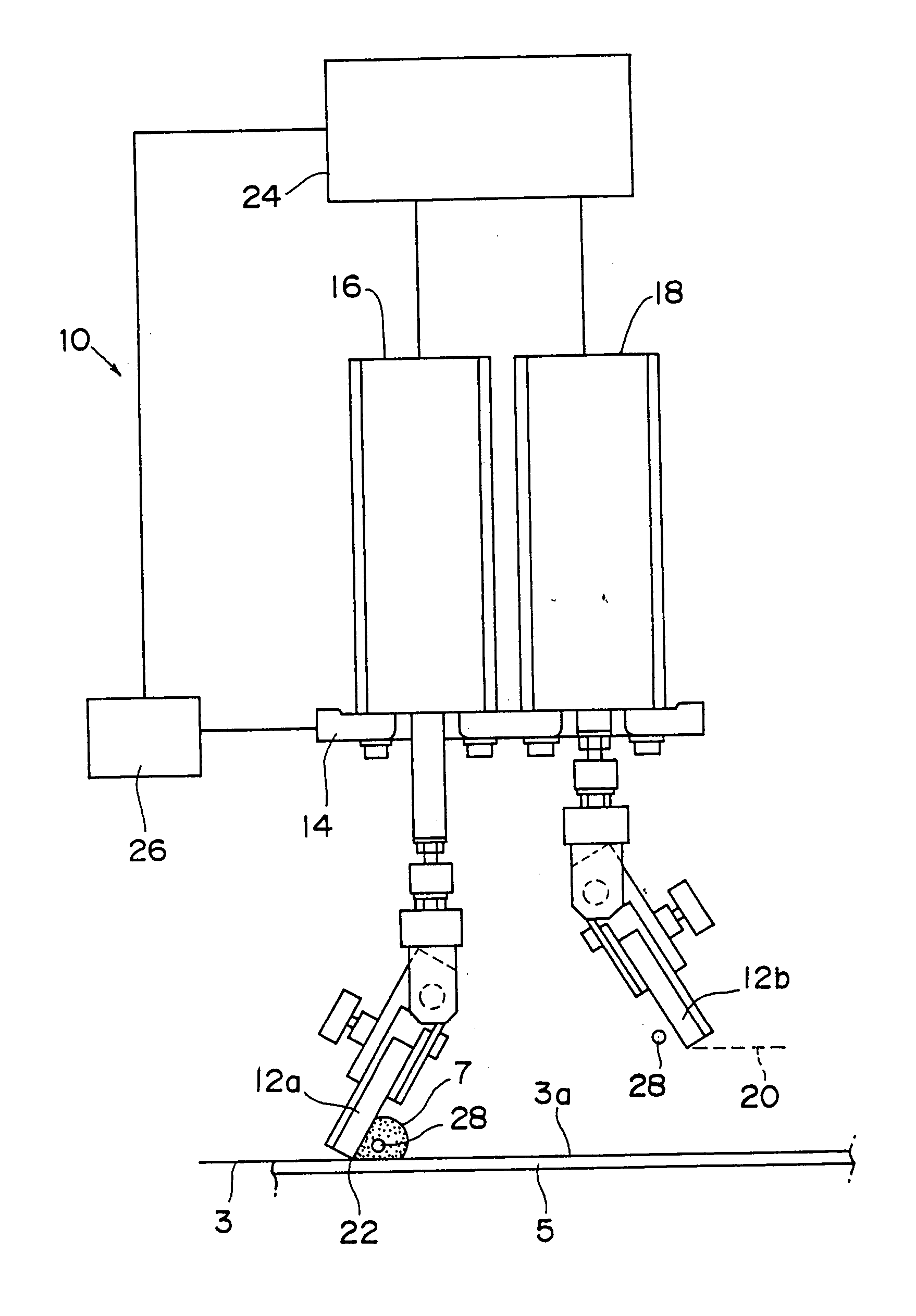

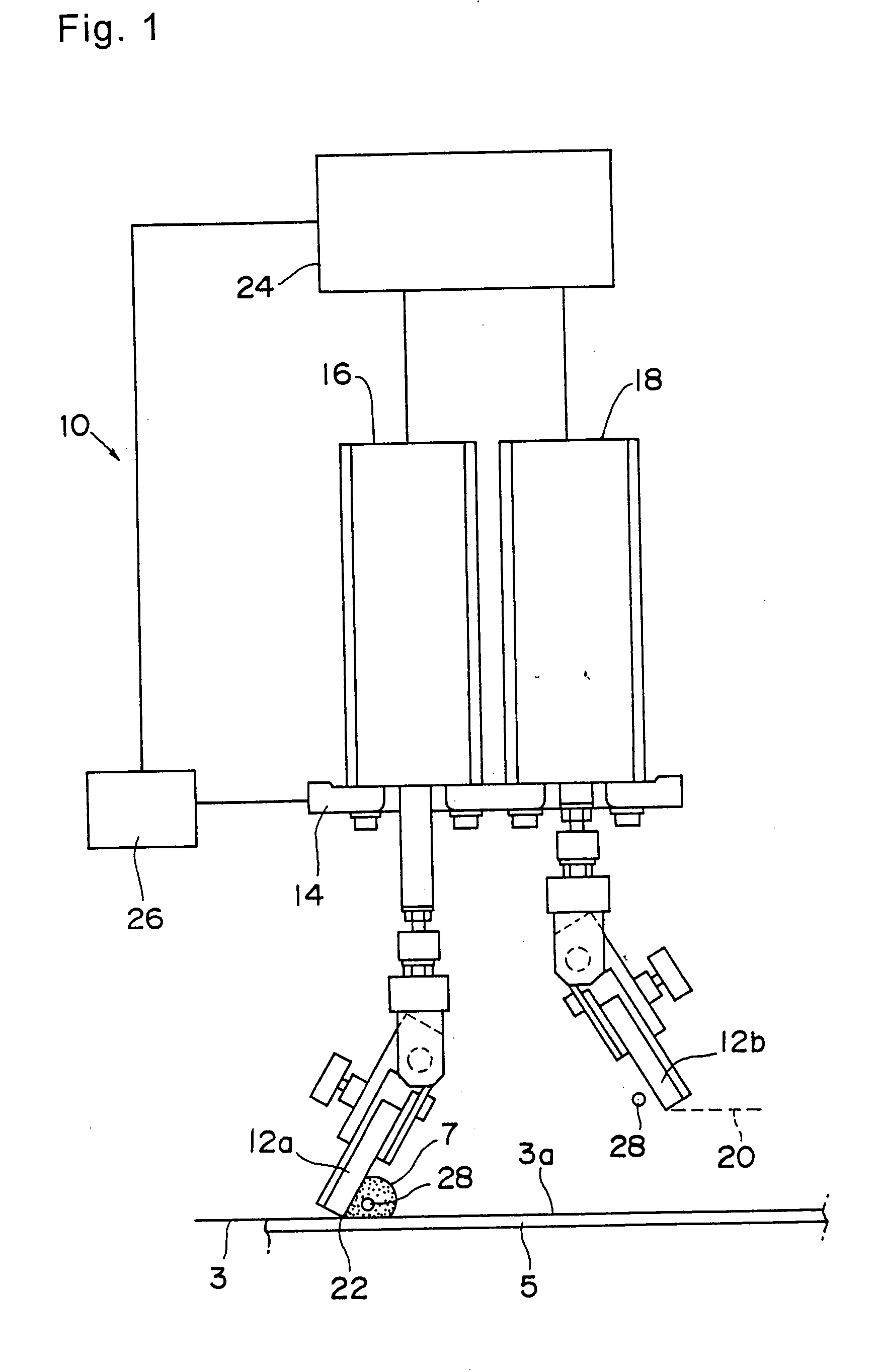

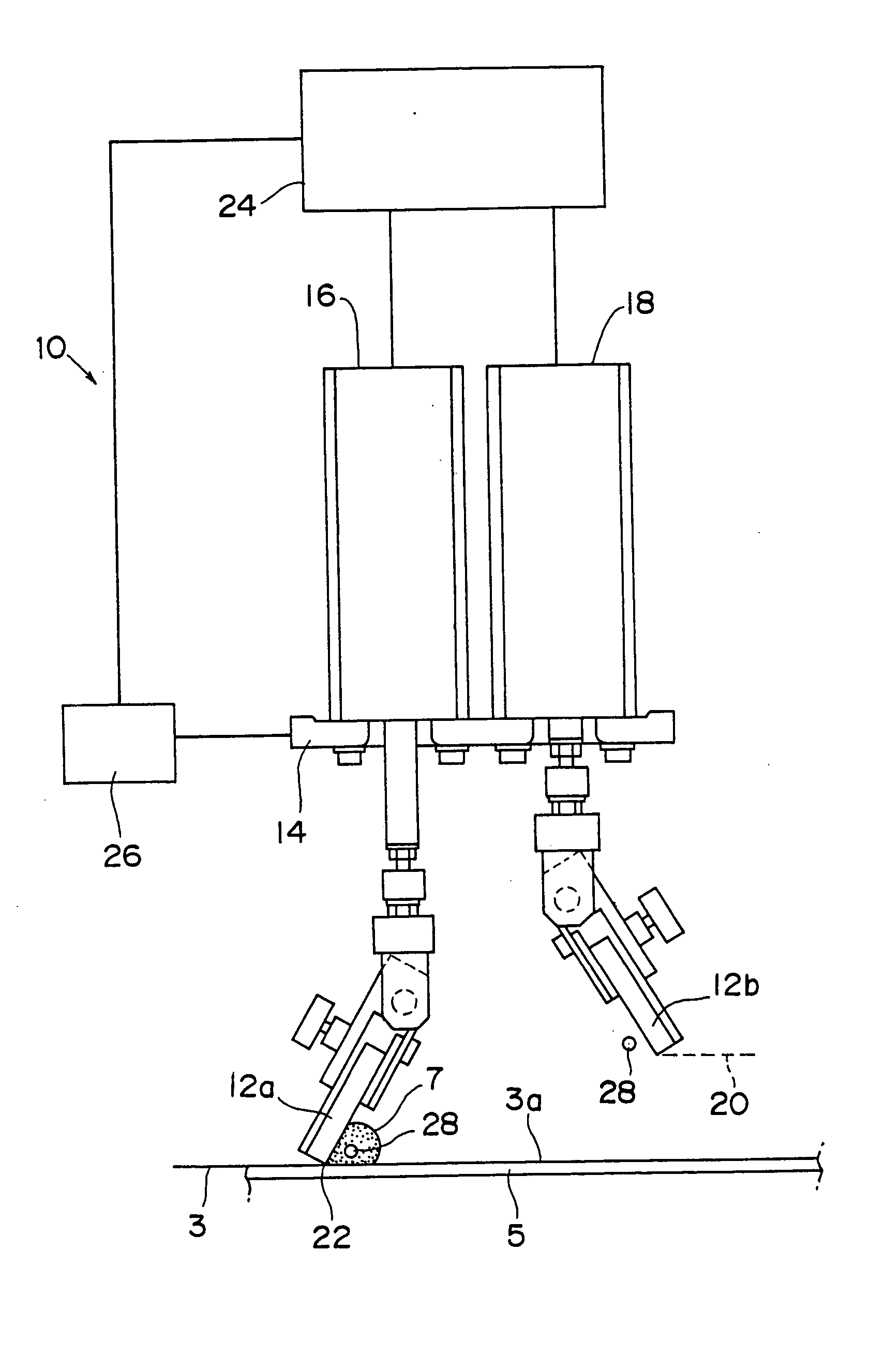

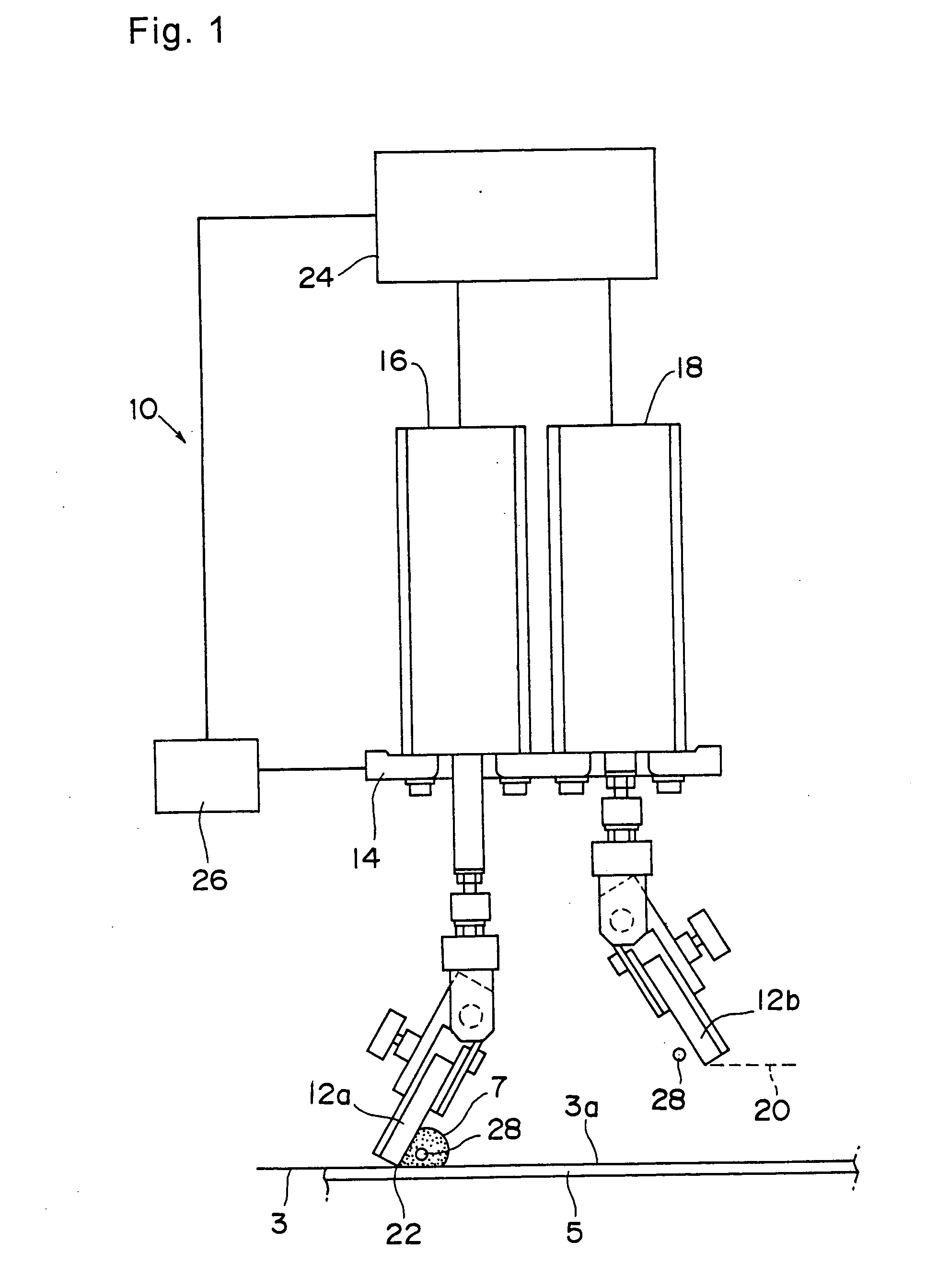

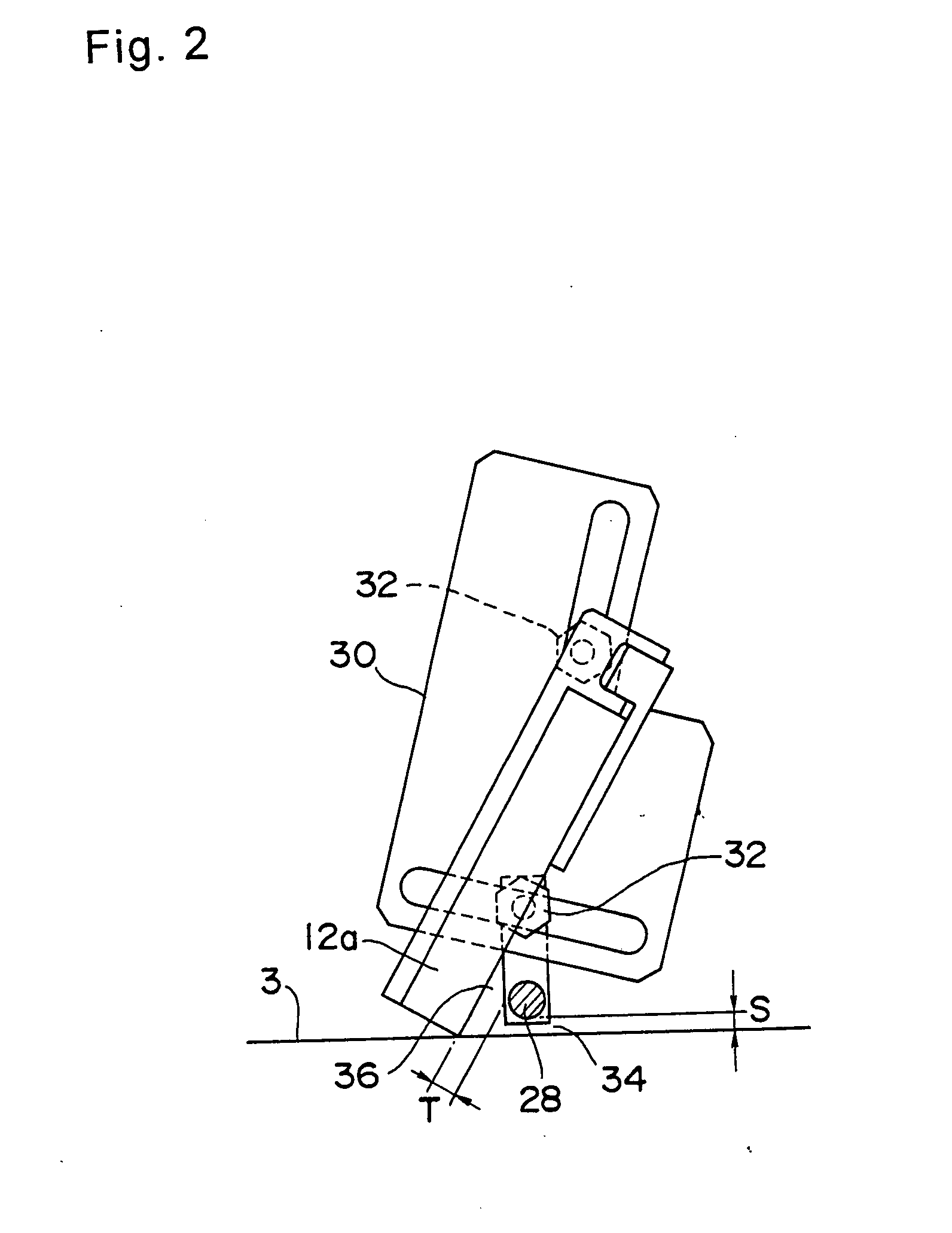

Solder past printing apparatus and printing method

InactiveUS20040108368A1Evenly filledTakingLiquid surface applicatorsScreen printersEngineeringSolder paste

When solder paste passes through a first gap (34) located between a pressurizing member (28) and a printing mask (3) during solder paste printing, a pressure directed toward the printing mask is applied from the pressurizing member to the solder paste.

Owner:PANASONIC CORP

Method and apparatus having plate electrode for surface treatment using capillary discharge plasma

A method and an apparatus for treating a workpiece using a plasma discharge are disclosed in the present invention. In treating a workpiece using a plasma discharge, the apparatus includes at least one plate electrode electrically coupled to a power source, a dielectric body having first and second sides, wherein the first side is coupled to the at least one plate electrode and the second side has at least one capillary extending substantially therethrough in a direction of the first side of the dielectric body, and a counter electrode electrically coupled to the power source.

Owner:PLASMION

Solder paste printing apparatus and printing method

InactiveUS20040035306A1TakingReduce printing timeMechanical cleaningInking apparatusEngineeringPrinting ink

When solder paste passes through a first gap (34) located between a pressurizing member (28) and a printing mask (3) during solder paste printing, a pressure directed toward the printing mask is applied from the pressurizing member to the solder paste.

Owner:PANASONIC CORP

Plasma processing apparatus, method for producing reaction vessel for plasma generation, and plasma processing method

InactiveCN1700953AHigh degree of freedom designSimple designMolten spray coatingSemiconductor/solid-state device manufacturingComputer sciencePlasma processing

PROBLEM TO BE SOLVED: To provide a plasma processing apparatus capable of expanding a processing area and of carrying out uniform processing, and allowing design to be easily changed in response to an object of processing.

Owner:MATSUSHITA ELECTRIC WORKS LTD

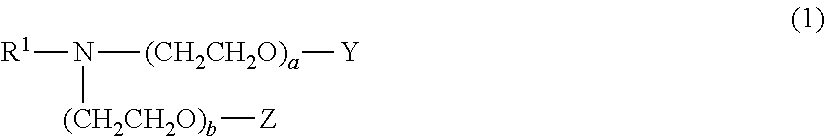

Cleaning solution for electromaterials and method for using same

InactiveUS6346505B1Effective removal of particleExcellent particle removal effectDetergent mixture composition preparationSemiconductor/solid-state device manufacturingHydrogen fluorideHydrogen

A cleaning solution for electromaterials including hydrogen fluoride and either oxygen or hydrogen gas dissolved in water. The cleaning solution may alternatively include hydrogen fluoride, hydrochloric acid or nitric acid, and hydrogen or oxygen gas dissolved in water. Alternatively, the cleaning solution includes hydrogen fluoride, hydrogen peroxide and oxygen gas dissolved in water. The present invention also provides a method for cleaning electromaterials including applying an ultrasonic vibration to cleaning solution applied to electromaterials.

Owner:KURITA WATER INDUSTRIES LTD

Water-based cleaning agent for electronics and preparation method thereof

ActiveCN103194319AImprove cleaning efficiencyMeets friendly requirementsOrganic detergent compounding agentsSurface-active detergent compositionsWater basedSurface mounting

The invention provides a water-based cleaning agent for electronics and a preparation method thereof. The water-based cleaning agent comprises the following ingredients in percentage by weight: 20-50% of glycol ethers, 25-40% of propylene glycol ethers, 15-25% of alcamines, 0-0.5% of corrosion inhibitor and 10-15% of surfactant. According to the water-based cleaning agent provided by the invention, the efficiency of cleaning lead-free soldering residues can be increased, and the requirements for environment friendliness are met, so that the cleaning agent can safely pass through a variety of test applications. The water-based cleaning agent provided by the invention is also applied to the SMT (Surface Mounting Technology) industry, e.g. the fields of PCBA (Printed Circuit Board Assembly), furnace fixtures, equipment, screen plates, steel meshes and the like and has an excellent cleaning effect.

Owner:深圳市同方电子新材料有限公司

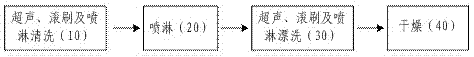

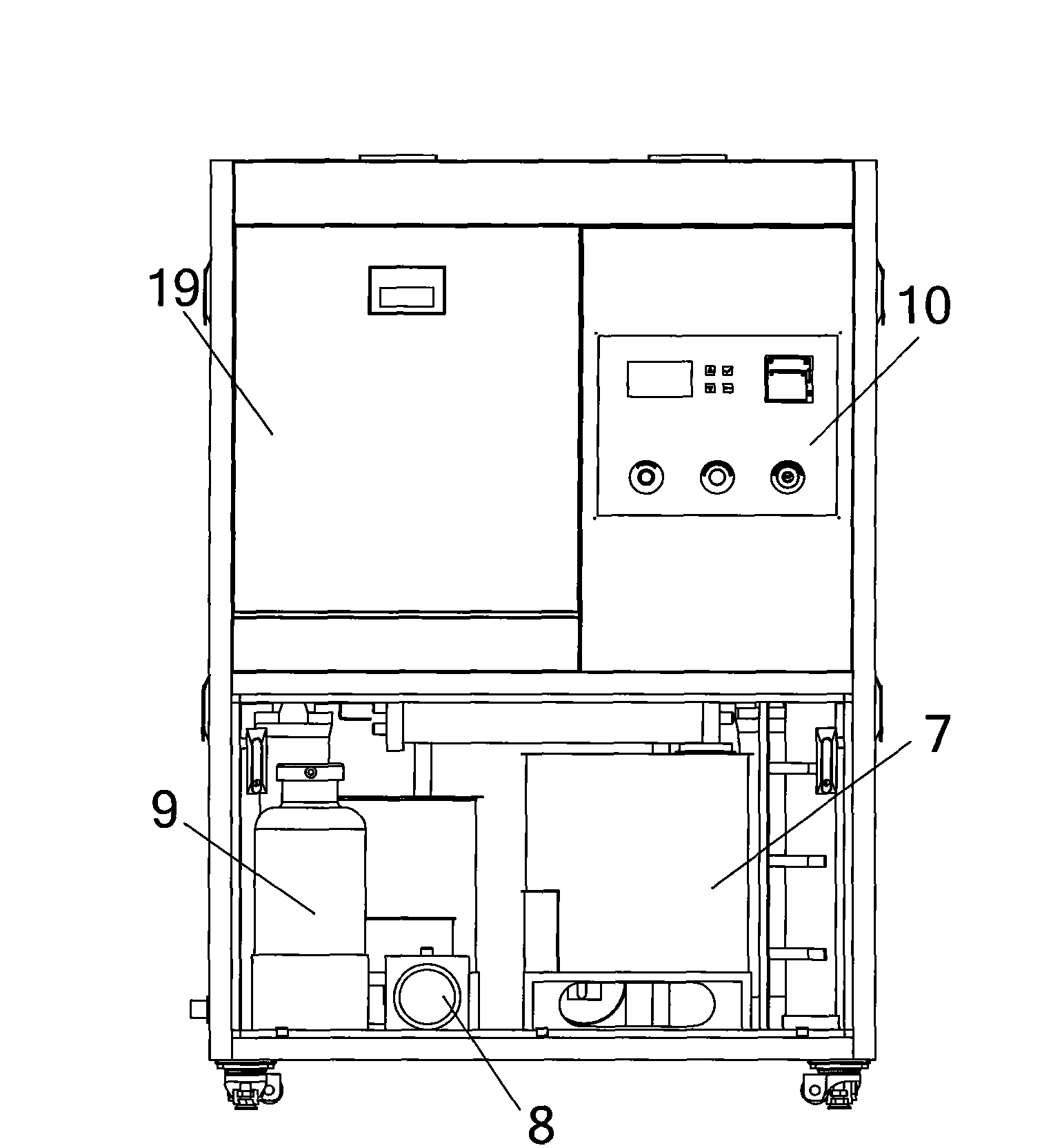

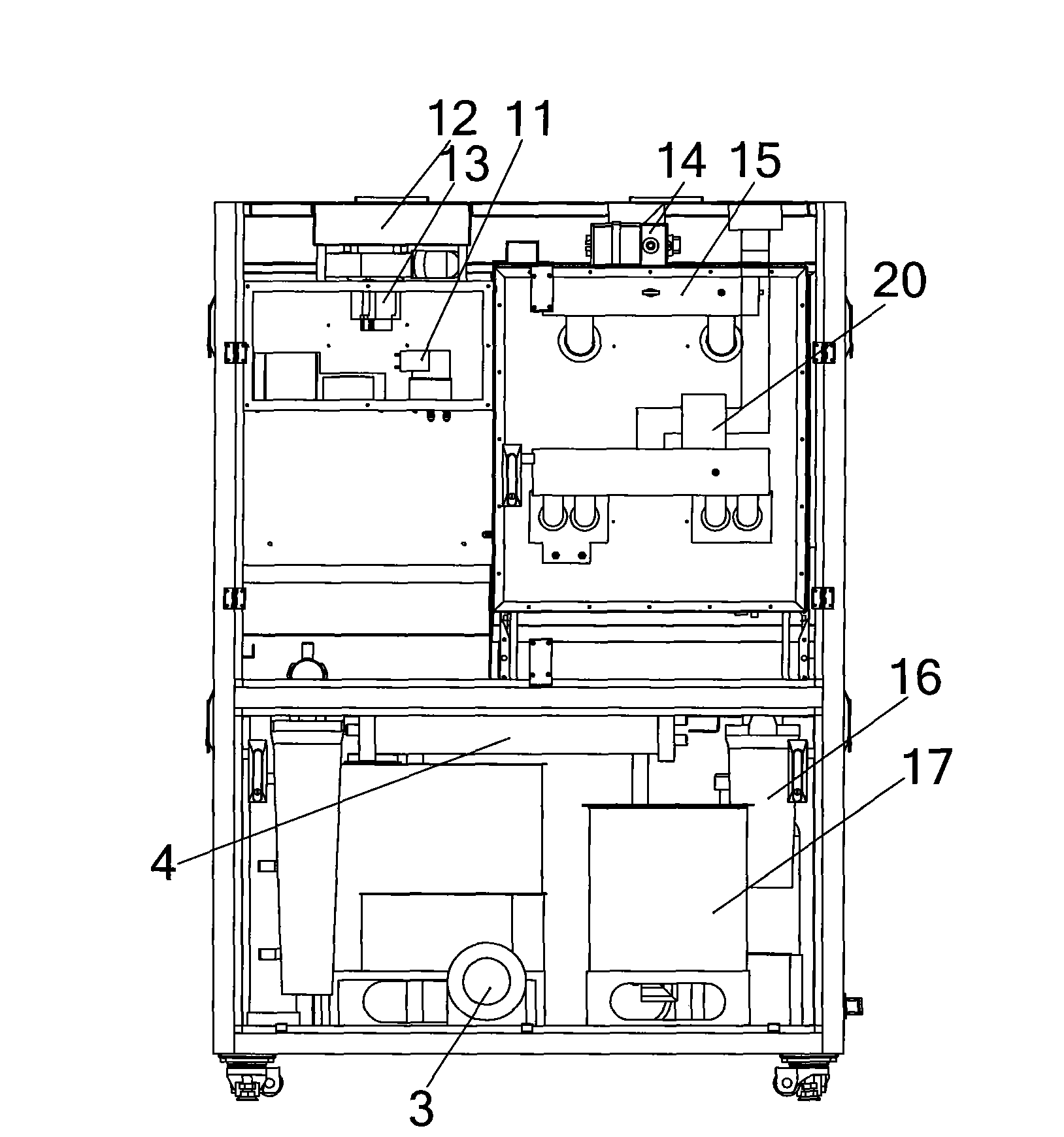

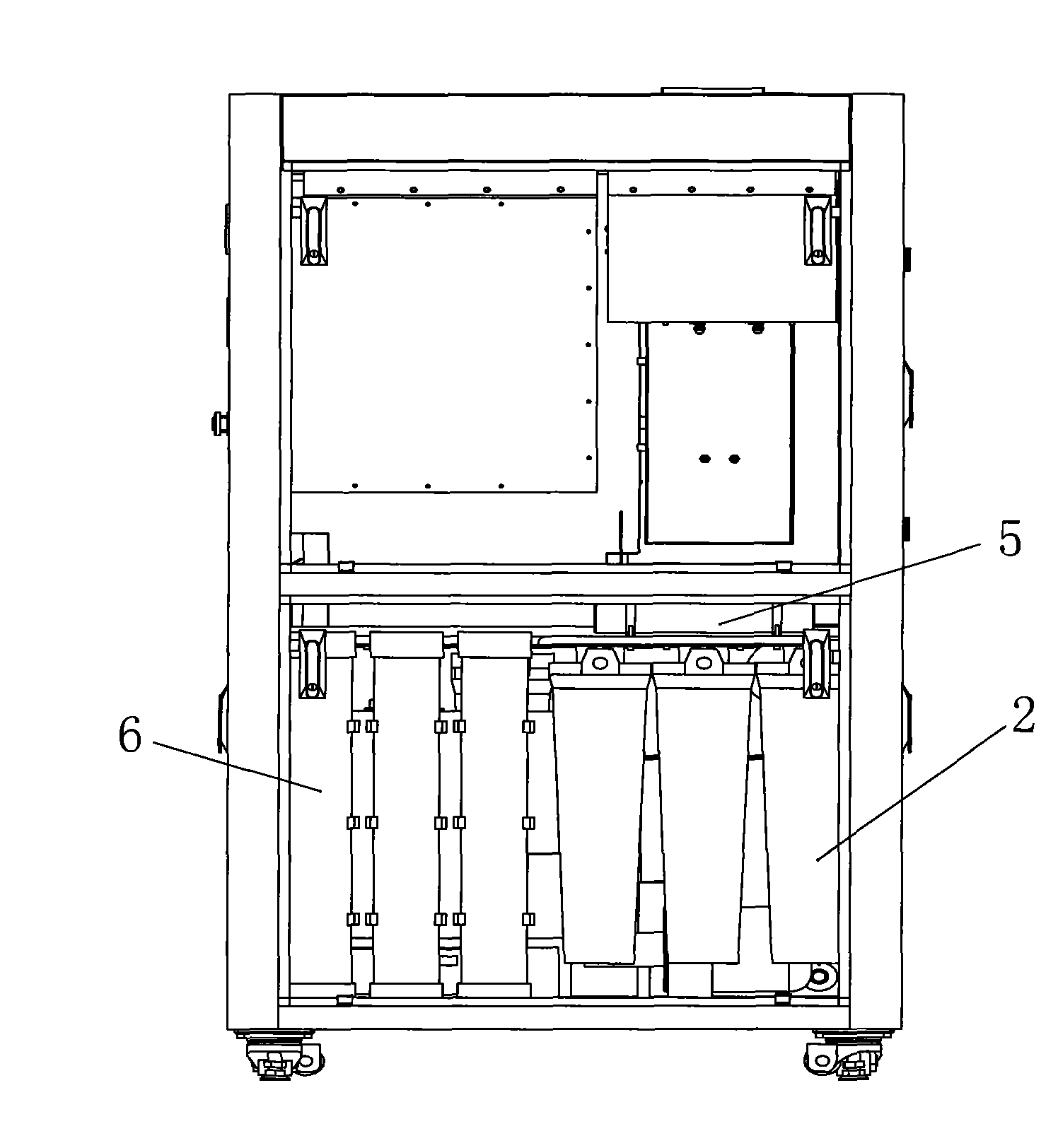

Printed circuit board cleaning machine

InactiveCN101583246AImprove washing efficiencyGood washing effectWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisElectricityWater saving

The embodiment of the invention provides a printed circuit board cleaning machine, belonging to the technical field of printed circuit cleaning. The cleaning machine comprises a chassis, a master control system, a backing water treatment system, a cleaning system, a drying system, a waste water treatment system and a water detection system; the systems are all arranged in the chassis, the main control system is electrically connected with other systems and controls the operation of other systems; wherein, a water inlet and a water outlet are arranged on the backing water treatment system, the water outlet of the backing water treatment system is connected with the cleaning system, and the water outlet of the cleaning system is connected with the waste water treatment system; the drying system is connected with an air inlet of the cleaning system; the detection ends of the water detection system are respectively arranged on the water outlet ends of the backing water treatment system and the cleaning system, which are used for detecting the effluent water of the backing water treatment system and the cleaning system. The cleaning machine has the advantages of high cleaning efficiency, good cleaning effects, cleaning water saving and environmental protection.

Owner:常州至易环保科技有限公司

Cleaning solution for substrates of electronic materials

InactiveUS7084097B2Easy to cleanAdsorption of particles can be preventedSurface-active detergent compositionsNon-surface-active detergent compositionsOrganic acidMetallic materials

The present invention relates to a cleaning solution capable of removing efficiently at the same time particles and metallic impurities from a substrate surface without corroding metallic materials.The cleaning solution for cleaning substrates of electronic materials comprises an organic acid compound and at least one selected from the group consisting of dispersants and surfactants.

Owner:KANTO CHEM CO INC

Method and agent for surface processing of printed circuit board substrate

InactiveUS20110259373A1Improve tightnessEfficient removalInsulating layers/substrates workingLiquid/solution decomposition chemical coatingOrganic solventElectrical connection

A surface processing method and a surface processing agent for effectively removing smear produced in a via or the like are disclosed. The smear is to be removed without etching an inner metalized layer without using expensive permanganates that might impose a greater load on an environment and operators. By removing the smear, the tightness in adhesion between an inner metalized circuit layer and plating metal as well as reliability in electrical connection may be improved. To this end, a surface processing method for a resin-containing substrate of a printed circuit board is provided in which the smear left in an opening, such as a blind via, a through-hole or a trench, formed in the substrate, may be removed without etching a metalized inner layer. The surface processing method immerses the interconnect substrate in a weakly acidic to weakly alkaline first processing solution at least containing hydrogen peroxide and subsequently in a second processing solution at least containing an alkali compound and an organic solvent.

Owner:C UYEMURA & CO LTD

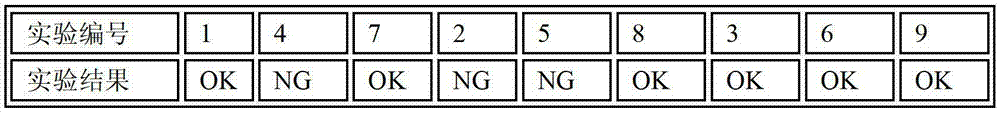

Pattern electroplating method for two-sided and multi-layer flexible printed circuit board

ActiveCN101119614ANo disconnection issuesLower impedanceConductive material chemical/electrolytical removalConductive pattern polishing/cleaningEngineeringHeight difference

The present invention discloses a figure plating method which in used in double face or multilevel printing line board and has the following steps in orders: baiting, mechanical hole boring, hole discoloring, dry film pressing, exposing, developing, line etching, dry film eliminating, chemical cleaning, dry film pressing again, exposing again, developing again, figure plating, dry film eliminating again, and chemical cleaning again. The present invention does line etching to the copper-clad plate and the etching liquid contacting; no height difference exists between a hole tray and the connected line; the figure plating is carried on after the line etching so that no hole tray and line disconnection happens. The present invention also makes the copper-clad plate after dry film pressing again and developing again contact with the plating liquid; the part which needs to be welded comprises a through hole, the hole tray surface and a plate edge connecting head copper-clad layer and the copper layer of the parts is thick relatively with low impedance so as to improve the welding capability; the flexure, namely the line figure surface, is not plated with copper-clad layer and the copper layer of the parts is thin relatively so as to improve the bending capability.

Owner:靖江市华信科技创业园有限公司

Popular searches

Energy based chemical/physical/physico-chemical processes Chemical vapor deposition coating Plasma technique Organic non-surface-active detergent compositions Photosensitive material processing Inorganic non-surface-active detergent compositions Thermoelectric device junction materials Semiconductor devices Detergent solvents Perfluorocarbons/hydrofluorocarbons capture

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com