Printed circuit board cleaning machine

A printed circuit board and cleaning machine technology, which is applied in the secondary processing of printed circuits, cleaning/polishing of conductive patterns, cleaning methods and utensils, etc. Unable to determine whether the deionized water is qualified, etc., to achieve the effect of high plate washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

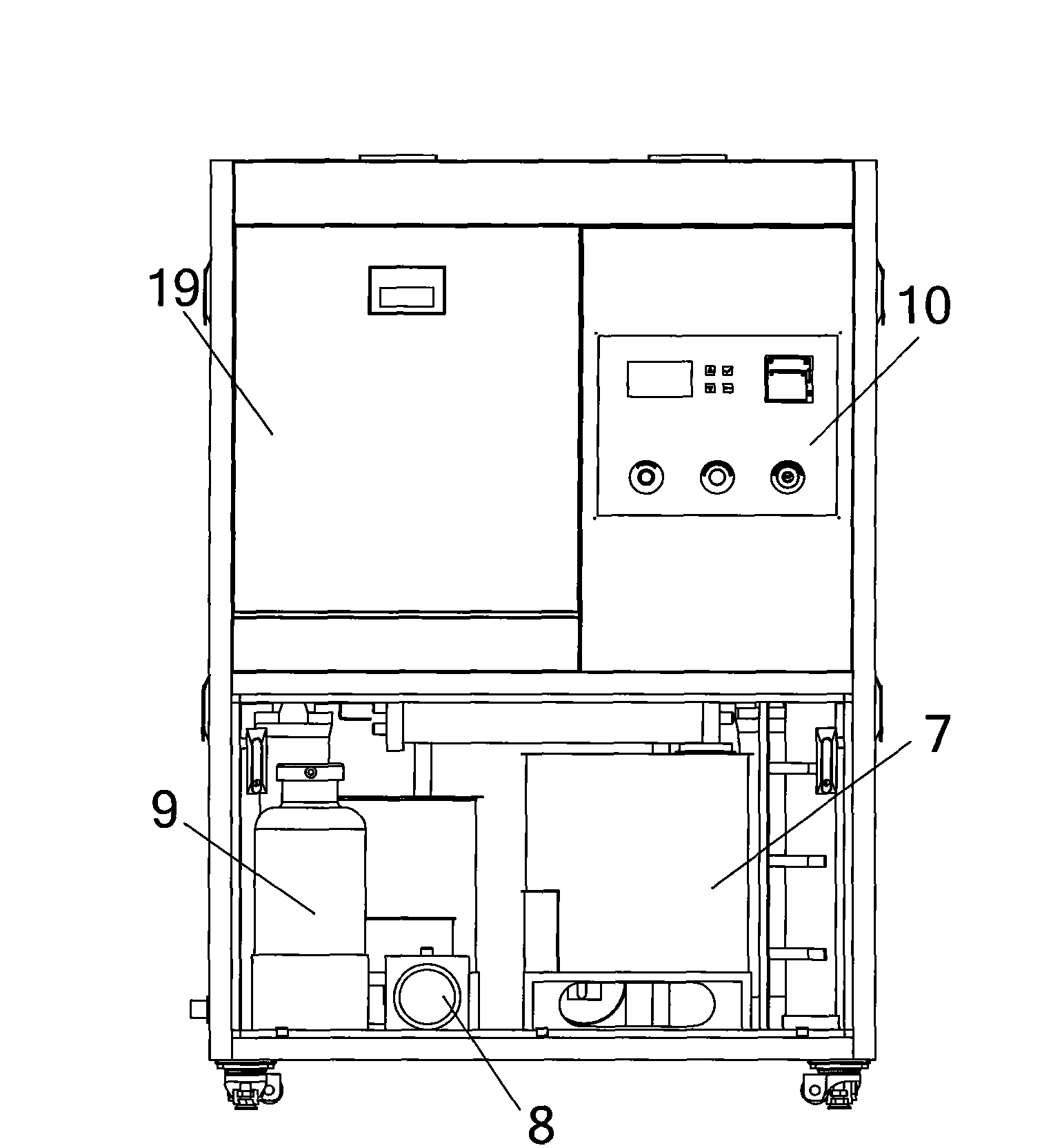

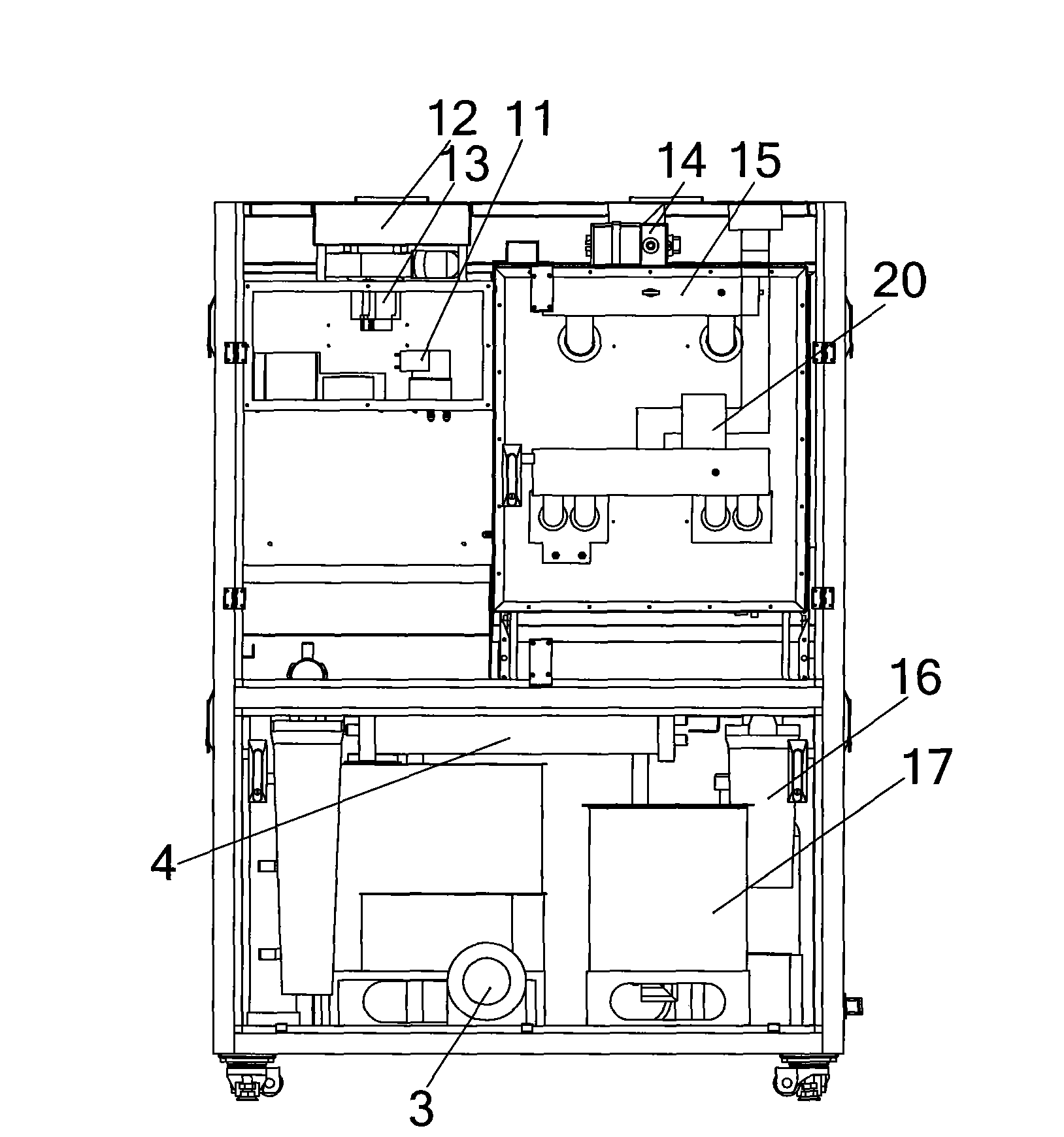

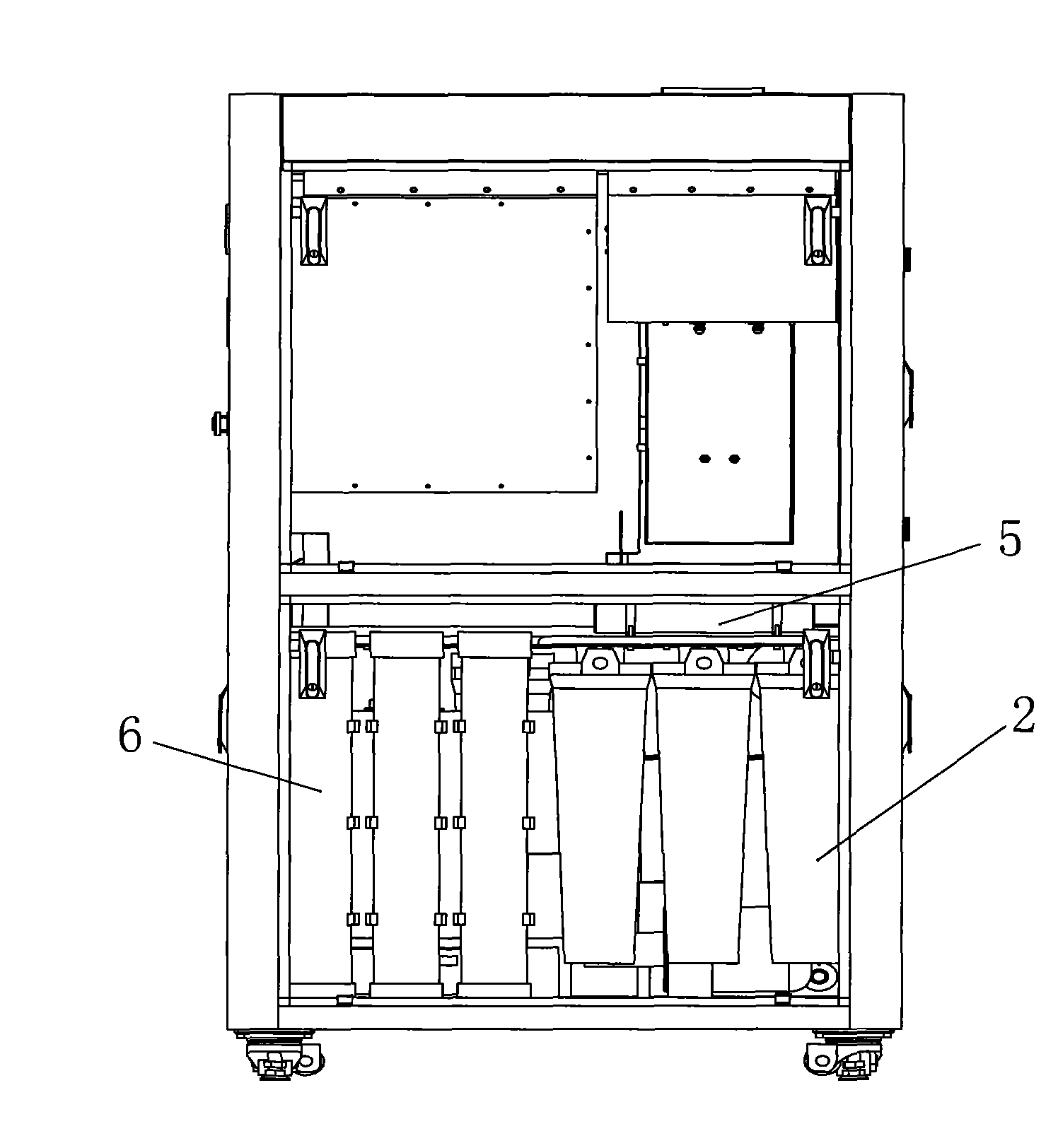

[0052] This embodiment provides a printed circuit board cleaning machine, which is used to automatically clean and dry the PCB circuit board after welding, such as Figure 1-4 As shown, the printed circuit board cleaning machine specifically includes:

[0053] The chassis, main control system, pre-stage water treatment system, cleaning system, drying system, waste water treatment system and water detection system are all installed in the chassis, and the main control system is electrically connected to each system to control the operation of each system; , the pre-stage water treatment system is provided with a water inlet and a water outlet, the water outlet of the pre-stage water treatment system is connected to the cleaning system, and the water outlet of the cleaning system is connected to the wastewater treatment system;

[0054] The drying system is connected to the air inlet of the cleaning system;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com