Washing method of washing machine and washing machine thereof

A washing method and washing machine technology, applied in the field of washing machines, can solve the problems of low washing ratio and washing efficiency, single washing form, weak water flow intensity, etc., and achieve the effects of lightening load, reducing noise, and reducing entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments.

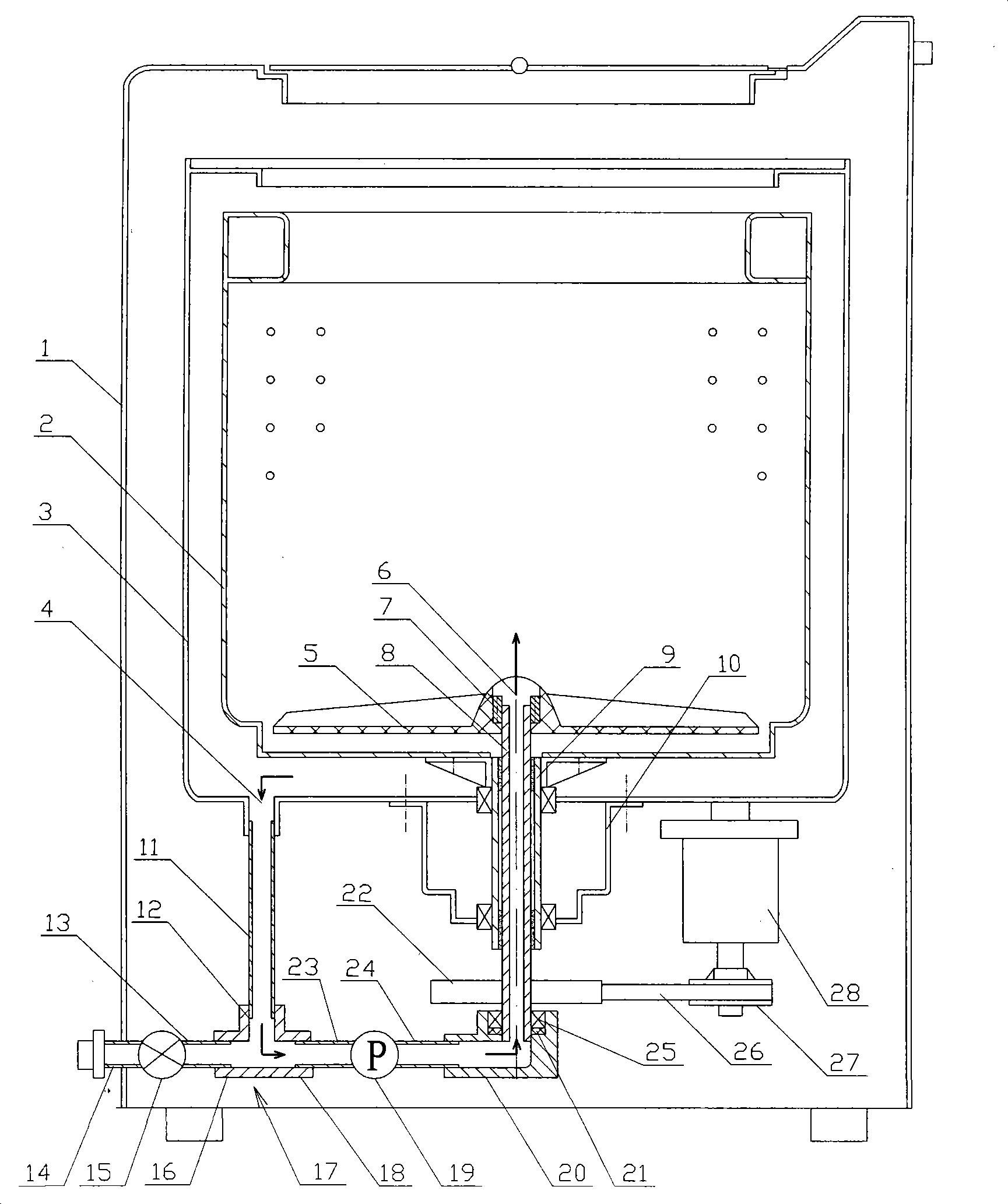

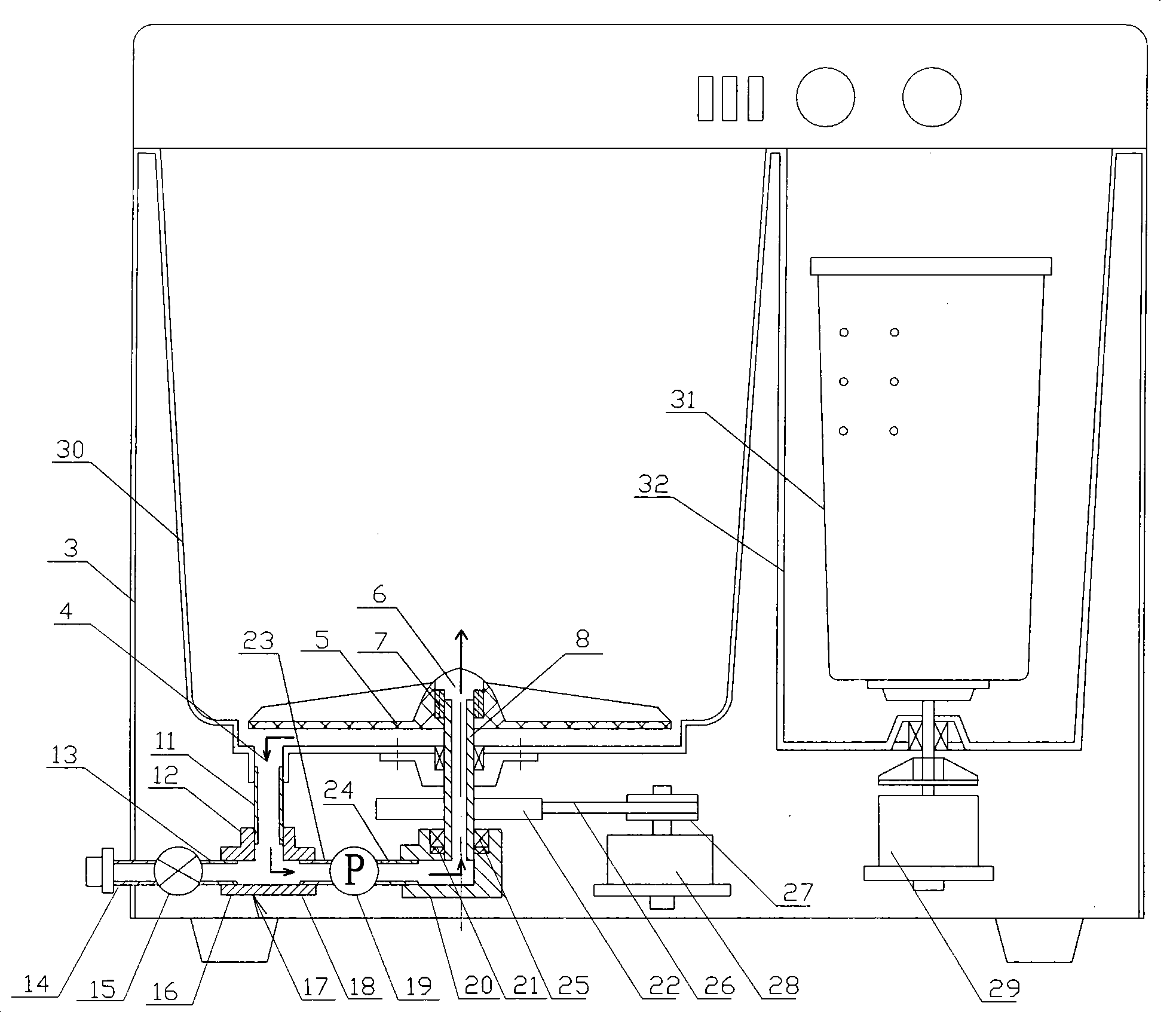

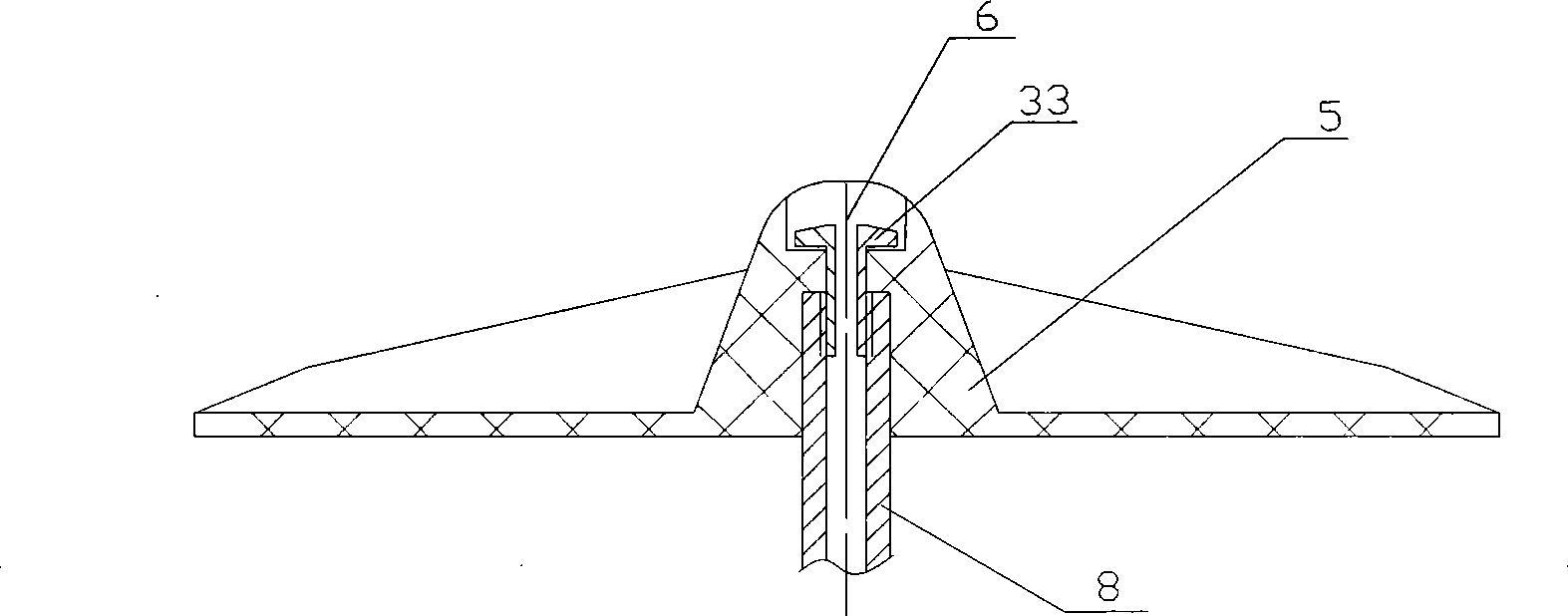

[0029] The washing method of the washing machine of the present invention, during washing, the agitator rotates to agitate the laundry and the washing water in the washing tub. It is characterized in that while the agitator is running, the drain pump pumps the washing water out of the water storage tub and stirs it through the hollow The shaft and the hollow core hole of the agitator spray upwards and lift the laundry.

[0030] As a washing machine adopting the method of the present invention, it can be applied to a sleeve-type fully automatic washing machine with a rotating washing / dewatering bucket and a single-tub type or parallel double-tub washing machine with a fixed washing / storage bucket. The following is an example of a barrel-type fully automatic washing machine and a side-by-side double-tub washing machine:

[0031] See figure 1 . This is a schematic cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com