Patents

Literature

196results about How to "Improve cleaning ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing machine provided with ultra-fine bubble generating device

InactiveCN105986400AImprove dissolution rateReduce usageOther washing machinesTextiles and paperPollutant emissionsUltra fine

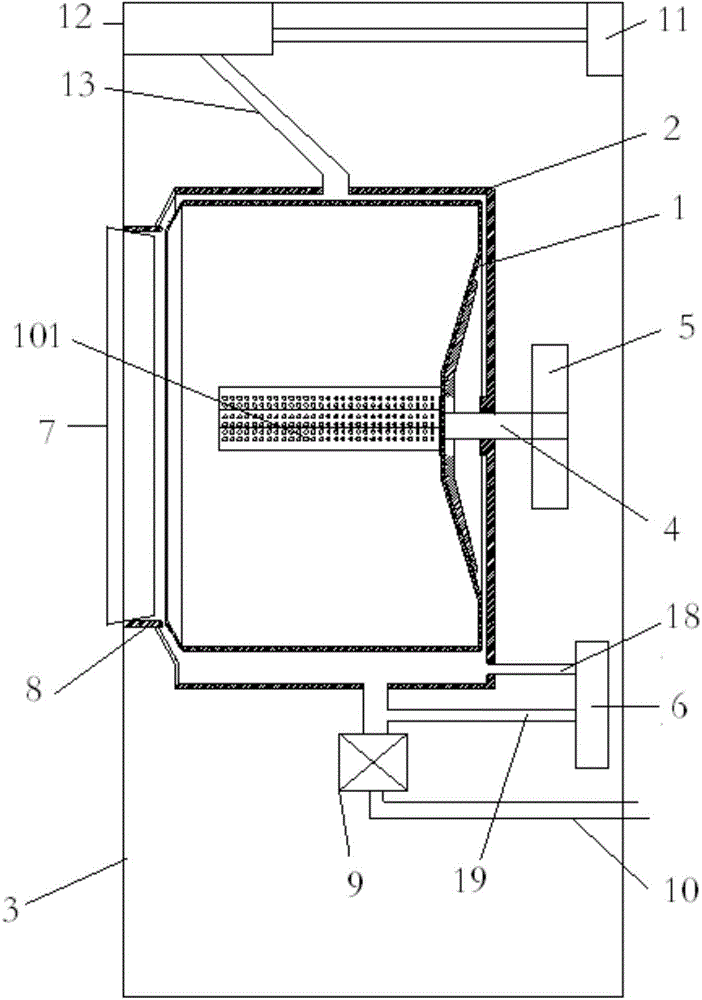

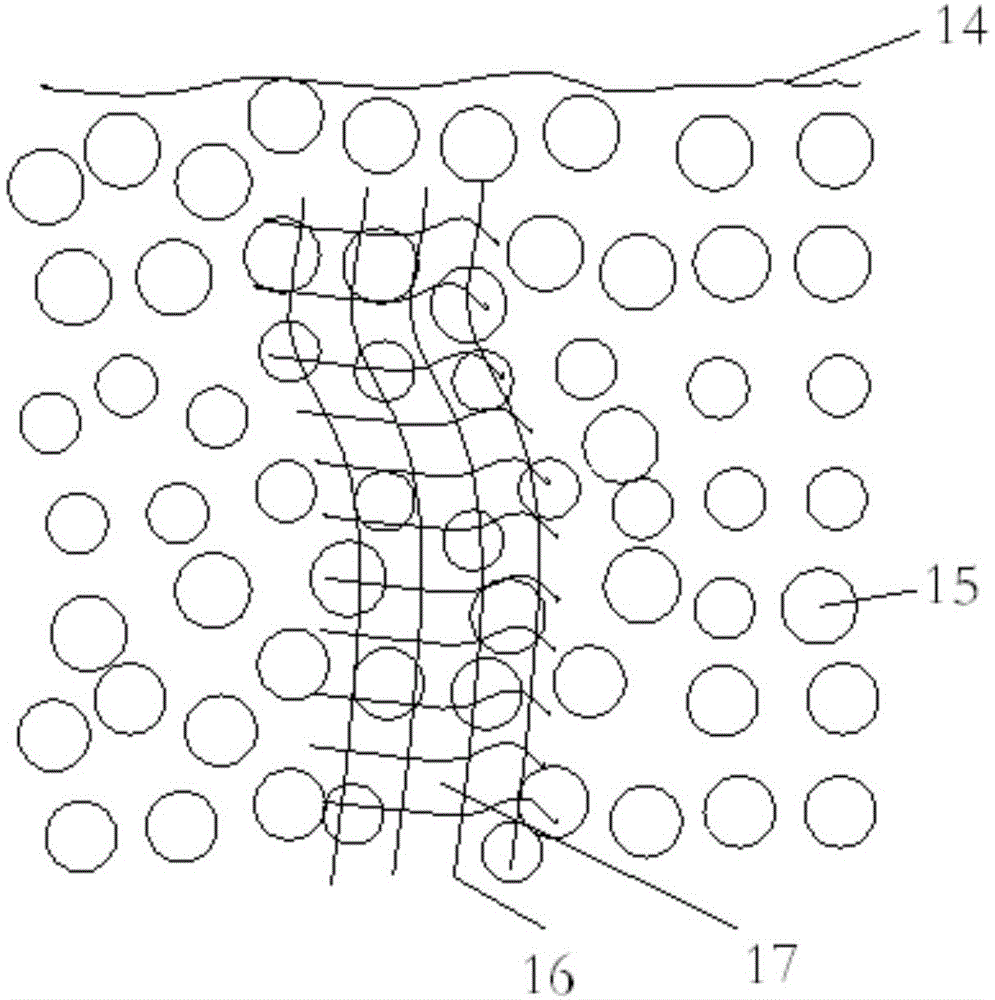

The invention relates to the field of household appliances, in particular to a washing machine provided with an ultra-fine bubble generating device. The washing machine comprises a case body and an outer tub installed in the case body, wherein an inner tub is rotatably arranged in the outer tub, at least one ultra-fine bubble generating device is arranged between the case body and the outer tub, a gas-liquid mixing outlet of each ultra-fine bubble generating device is communicated with the outer tub, ultra-fine bubbles produced by the ultra-fine bubble generating device enter washing body through the gas-liquid mixing outlet to make a washing agent fully dissolved. The washing ratio of clothes is improved, meanwhile pollutant discharge is reduced, and environmental pollution is reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

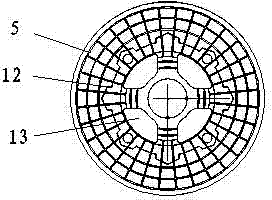

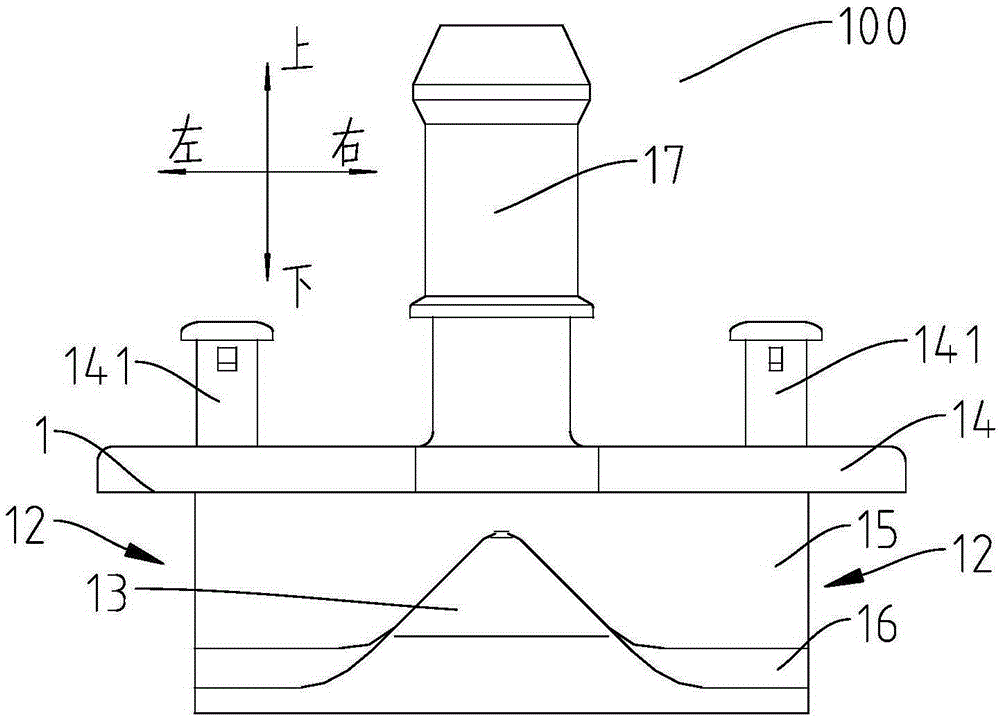

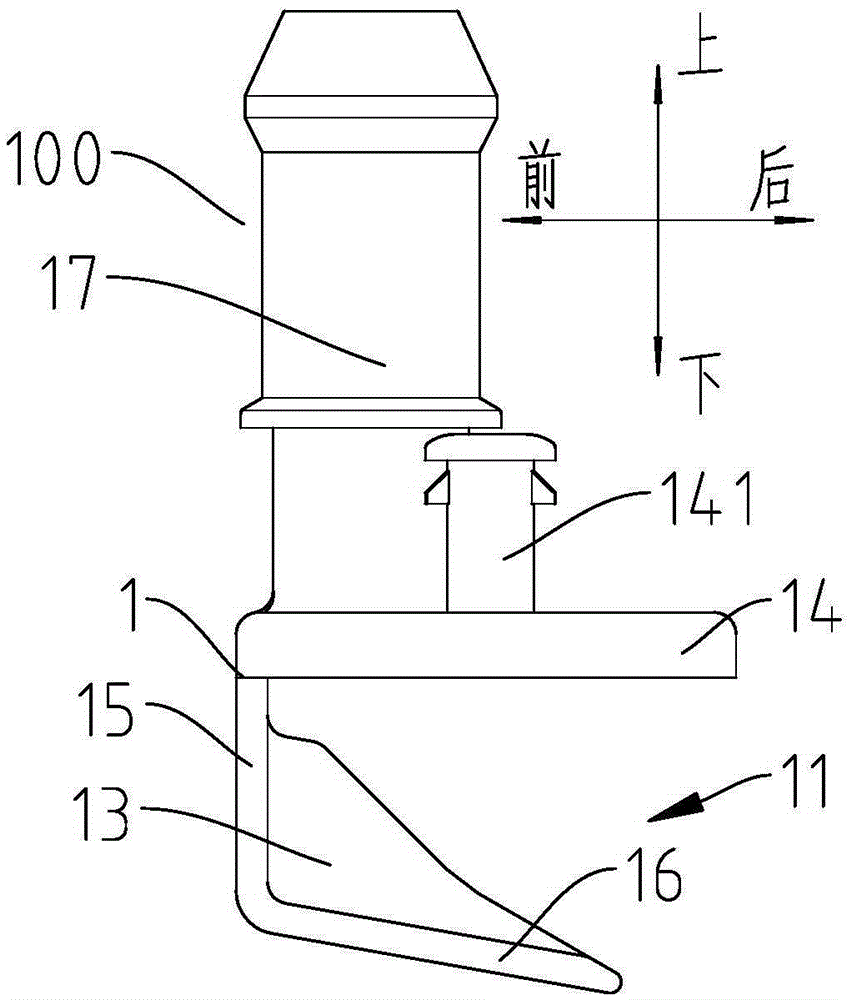

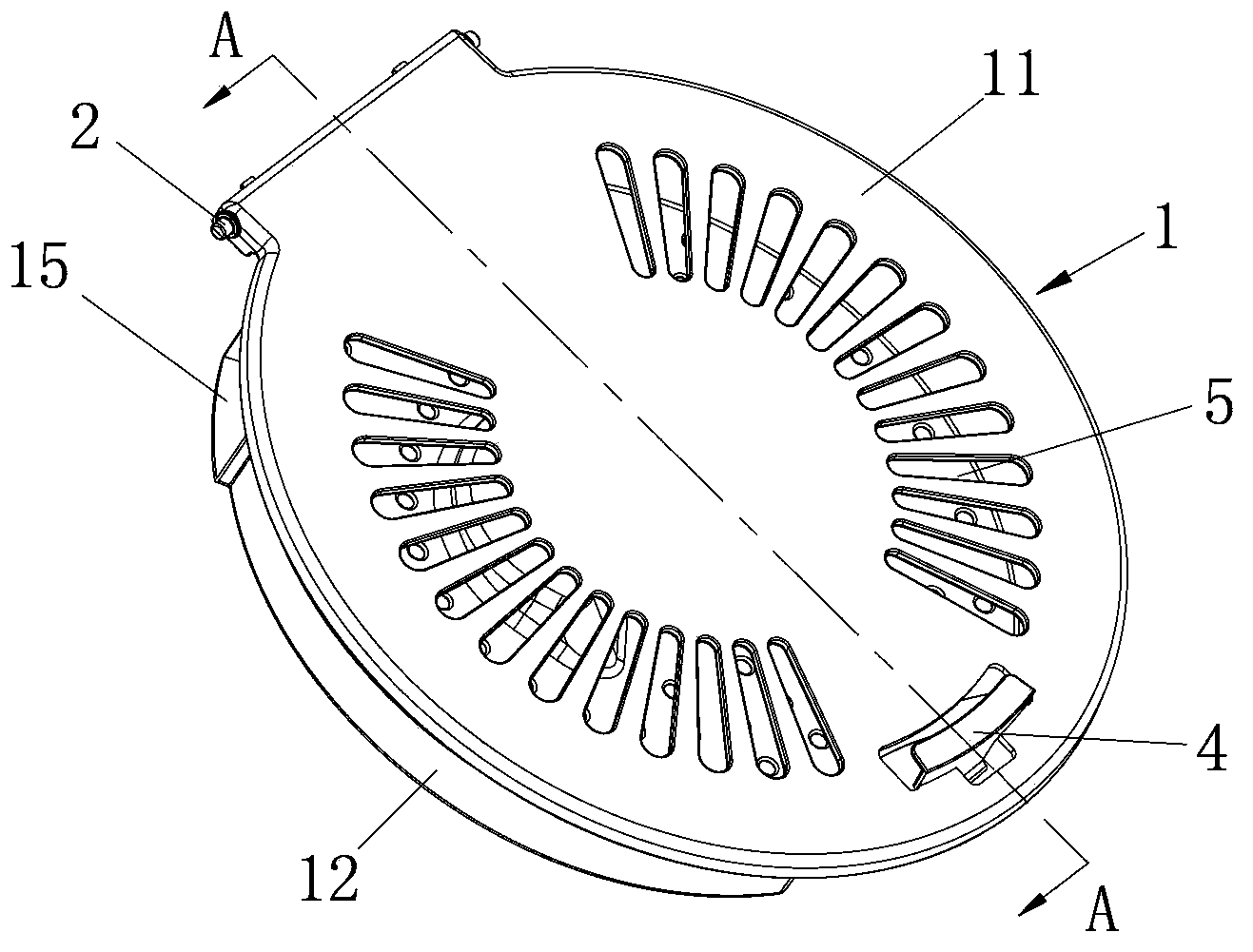

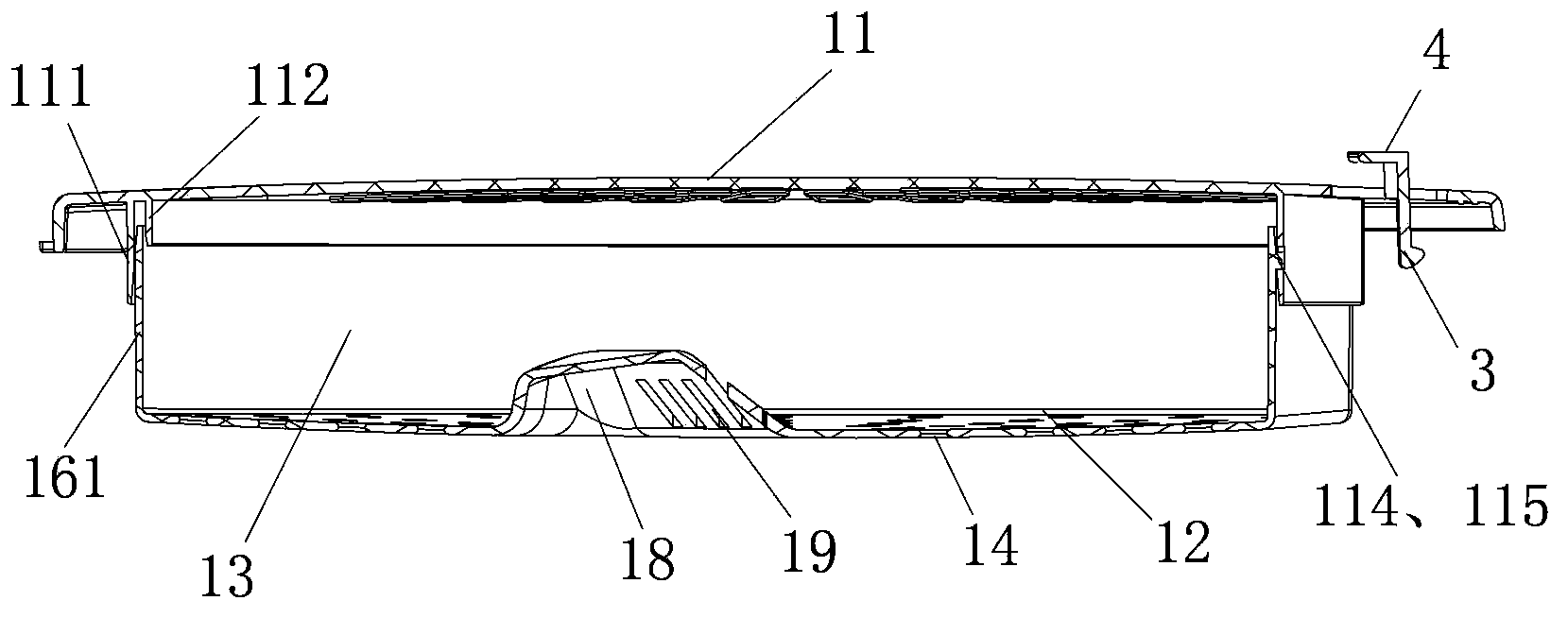

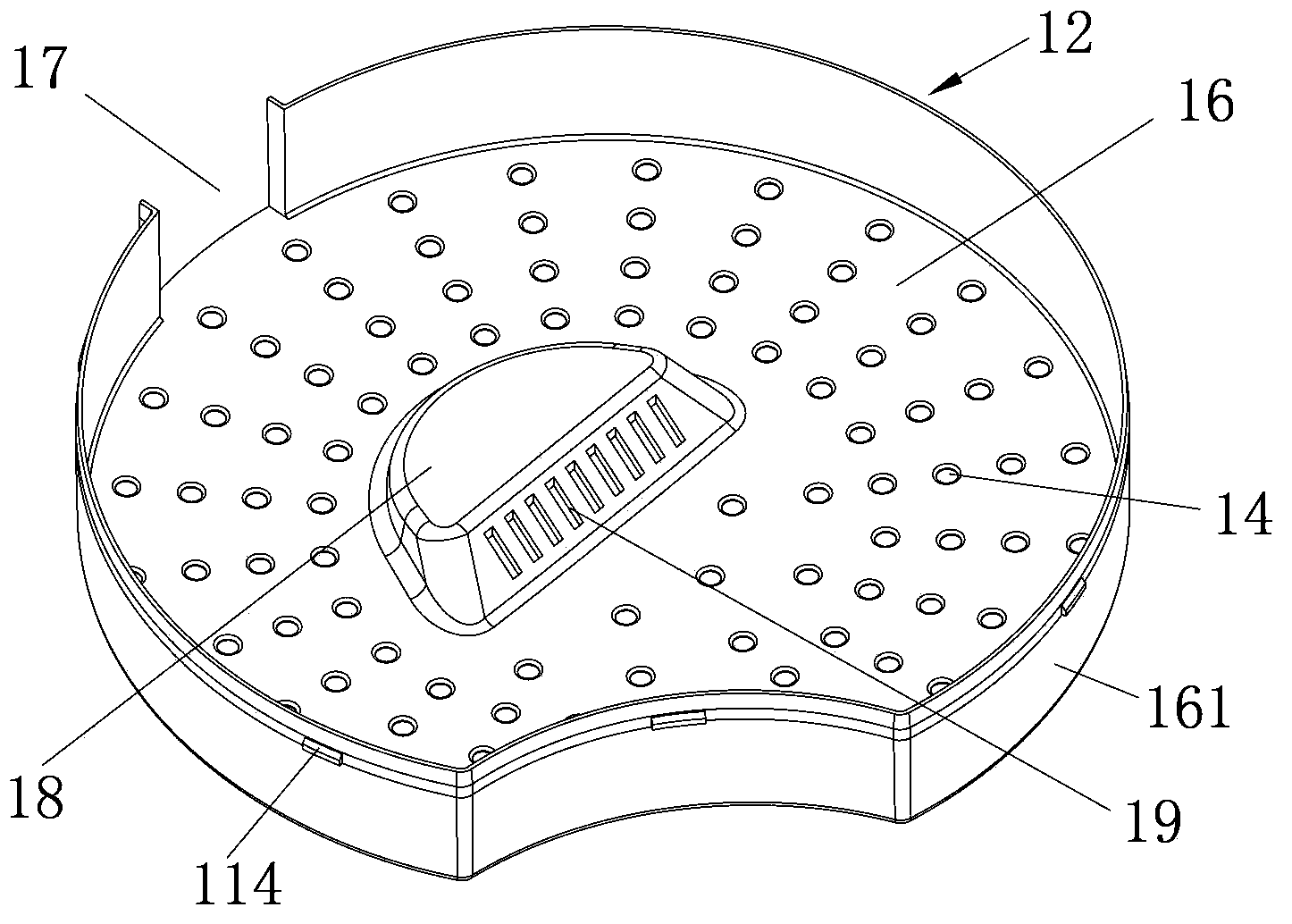

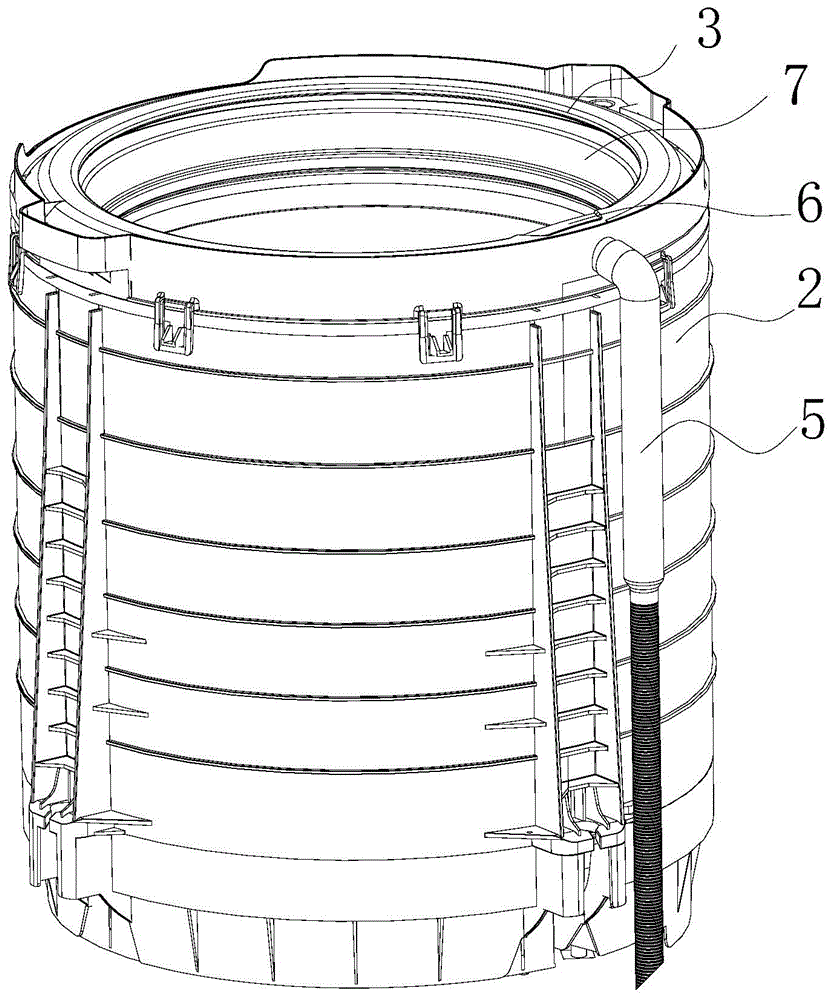

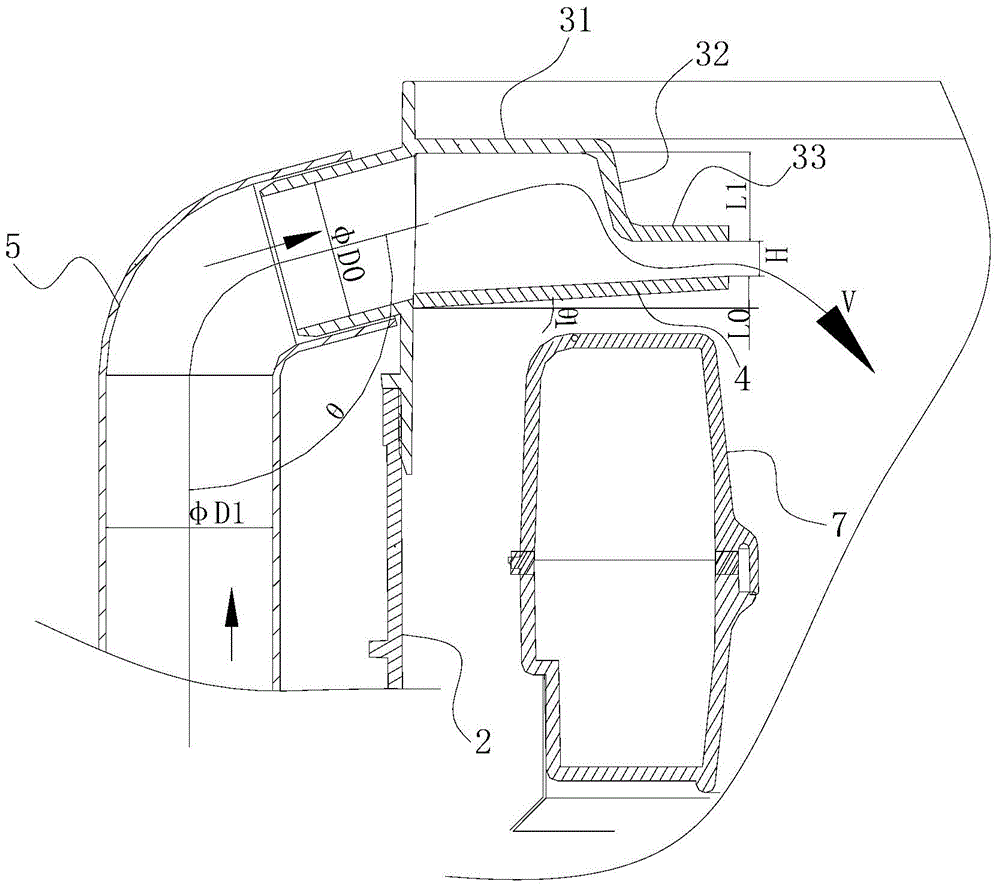

Washing machine inner bucket, washing machine and washing machine lint filtering method

ActiveCN104746315AImprove cleaning ratioAutomatic exclusion implementationOther washing machinesWashing machine with receptaclesLaundry washing machineProcess engineering

Disclosed is a washing machine inner bucket. The washing machine inner bucket comprises a balance ring, an inner bucket body, an inner bucket bottom and an inner bucket bottom flange plate, wherein small water holes are formed in the inner bucket body, big water holes are formed in the side wall of the inner bucket bottom, and a filter is arranged in the inner bucket bottom flange plate. The invention furthermore relates to a washing machine using the inner bucket and a lint filtering method. Automatic collection and exclusion of lint is achieved by improving structure of an existing washing machine inner bucket, and the filter is cleaned during the drainage process. The washing machine inner bucket, the washing machine and the washing machine lint filtering method are low in cost, save both time and effort, effectively enhance cleaning rate of the washing machine, and meet requirements of customers.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

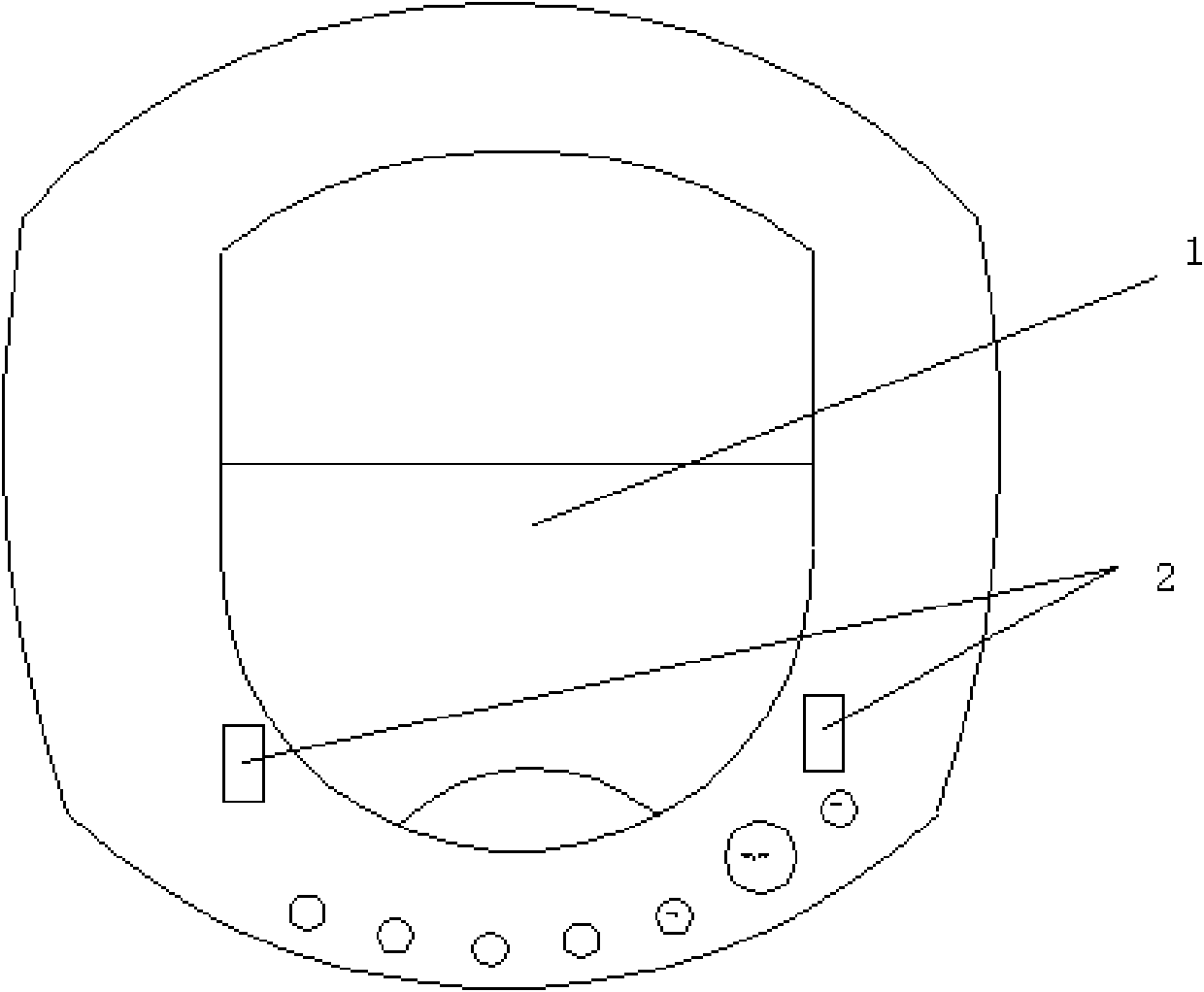

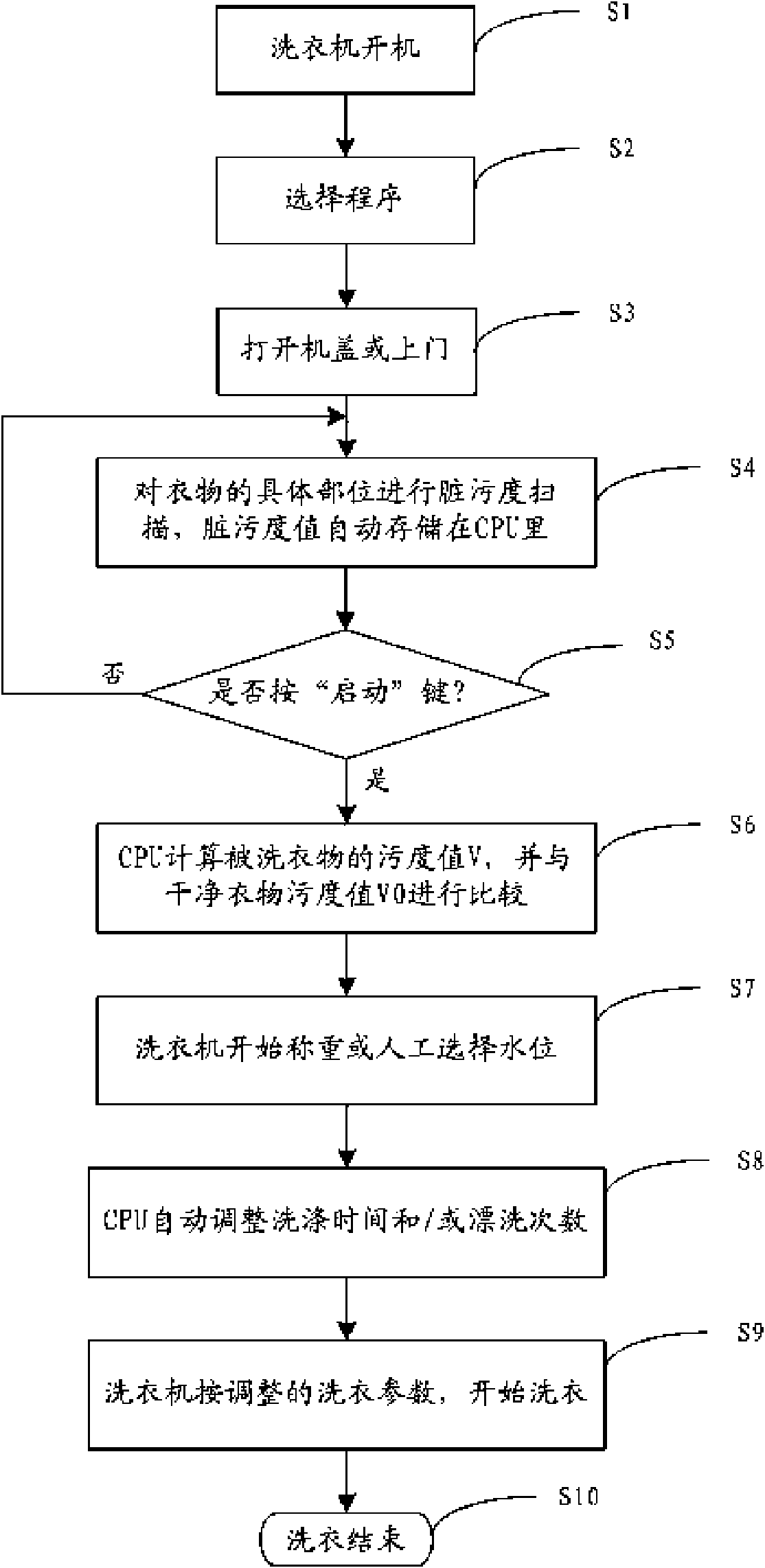

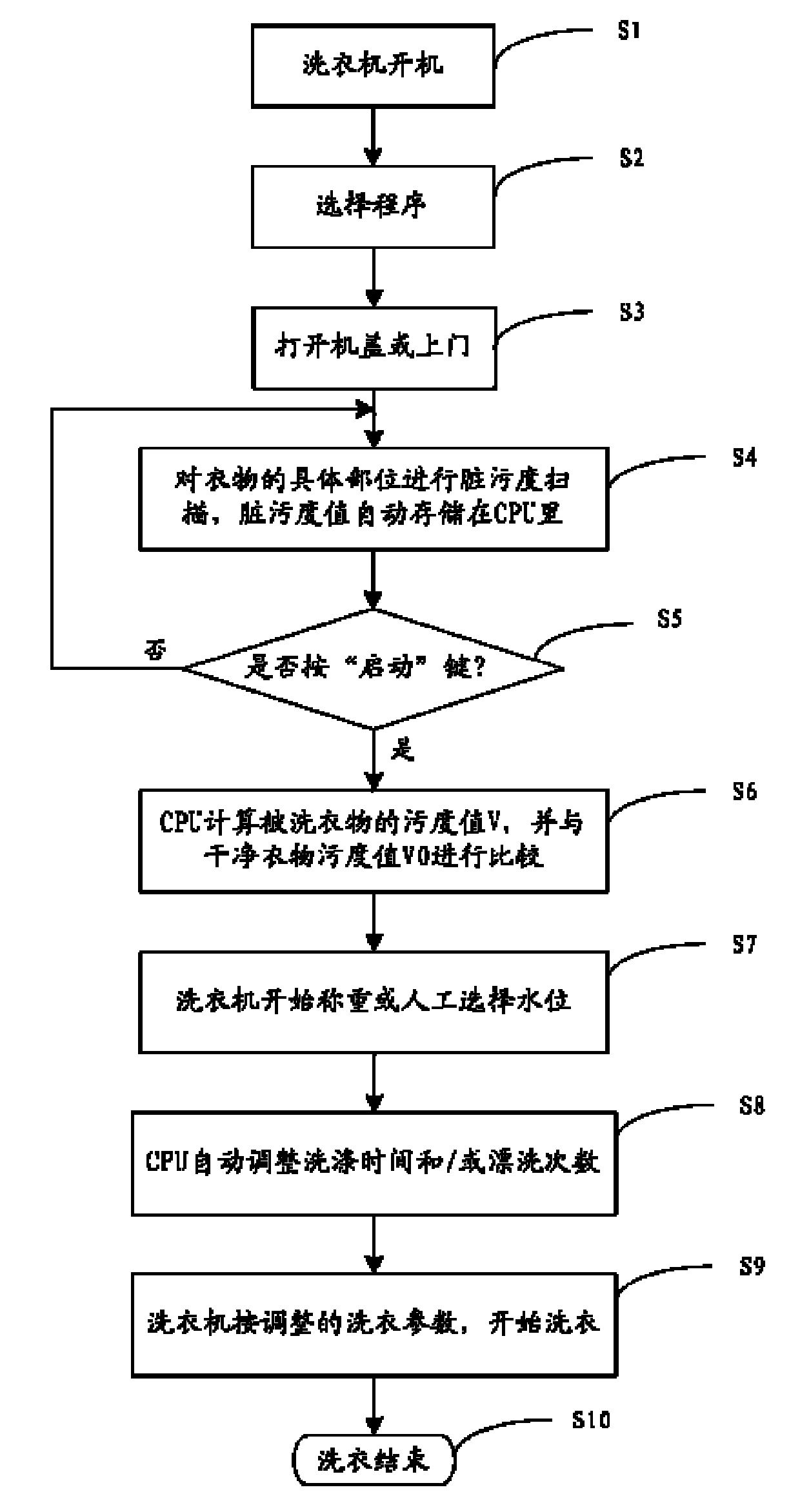

Method for automatically regulating clothes washing parameters and washing machine using same

ActiveCN102021786AImprove cleaning ratioAutomatically adjust washing timeOther washing machinesControl devices for washing apparatusIndustrial engineeringEngineering

The invention relates to a method for automatically regulating clothes washing parameters, which is applied to a full-automatic washing machine provided with a dirty degree sensor. The method comprises the following steps of: previously setting the dirty degree values V0 of clean clothes in a computer panel; starting the full-automatic washing machine, and firstly detecting the dirty degree of clothes to be washed to obtain the dirty degree values V of the clothes to be washed; then carrying out dirty degree comparison, that is to say, comparing the dirty degree values V of the clothes to be washed with the dirty degree values V0 of the clean clothes; and finally automatically regulating washing time and / or rinsing times according to a dirty degree comparison result by combining with a clothes washing procedure and clothes weight by the full-automatic washing machine. By automatically distinguishing the dirty degree of the clothes, the invention can really wash for a time according to how dirty the clothes are, thereby enhancing the wash ratio. The invention also relates to a washing machine using the method for automatically regulating the clothes washing parameters.

Owner:HAIER GRP CORP +2

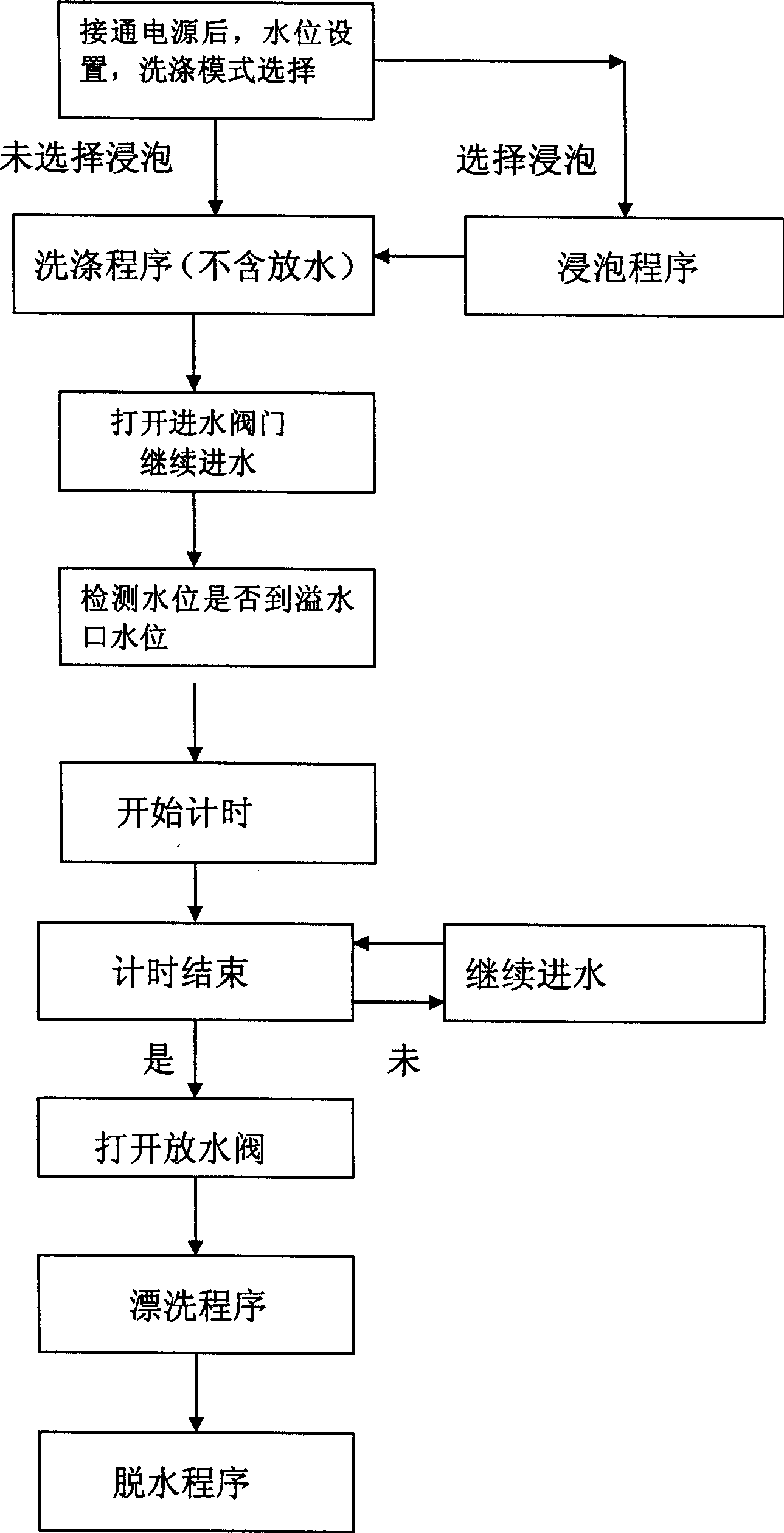

Washing methods of automatic washing machine and automatic washing of using the method

InactiveCN1796646AReduce secondary pollutionImprove cleaning ratioControl devices for washing apparatusWashing machine with receptaclesWater savingInlet valve

A washing method of automatic washer includes controlling water inlet valve to let washer flow water in continuously; checking whether water level in washer is reached on water overflow level or not and starting up timing if water overflow level is reached as well as closing water inlet valve when timing is on preset time; enabling to drain out oil stain in clothes, washing powder foam, detergent foam and floated ¿C dirt from overflow outlet before water is discharged when washing procedure is finished in order to raise cleaning ration.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

Washing method of agitatory washer and its washer

InactiveCN1381634AReduce entanglementIncrease the strength of the currentOther washing machinesWashing machine with receptaclesWater flowEngineering

Owner:HAIER GRP CORP +1

Washing method of washing machine and washing machine thereof

InactiveCN101381935AReduce wear rateReduce wearOther washing machinesWashing machine with receptaclesWater storageLow noise

The invention provides a washing method for washing machines, as well as a washing machine thereof. The washing method is characterized in that while a stirrer rotates during wash, a drainage pump pumps washing water out from a water storage bucket and jets the washing water upwards through a hollow stirrer shaft and a hollow core hole of the stirrer so as to lift washed clothes. During wash, as the drainage pump pumps the high-pressure water out from the hollow stirrer shaft and the hollow core hole of the stirrer so as to spray and lift the washed clothes, the washed clothes are effectively prevented from receiving the long-term wear of a stirrer vane, and the washed clothes are allowed to receive the wash and rinse of high-pressure water flow, the stir of the stirrer and the wash in various washing forms at the same time. The invention has the advantages of low wear, low intertwining, low noise, high cleaning rate, high washing efficiency and the like.

Owner:宁小静

Two-impeller three-power washing machine and control method thereof

ActiveCN102720032ASpeed up kneadingEnhances the effect of tumbled laundryOther washing machinesWashing machine with receptaclesImpellerEngineering

The invention belongs to the field of a washing machine, and particularly relates to a two-impeller three-power washing machine and a control method thereof. The two-impeller three-power washing machine comprises an outer tub, an inner tub, a main impeller, an auxiliary impeller and a three-power speed reducing clutch, wherein the main impeller and the auxiliary impeller are located at the bottom of the inner tub; the auxiliary impeller is located above the center of the main impeller; the inner tub, the main impeller and the auxiliary impeller are concentrically mounted on a power rotation shaft of the three-power speed reducing clutch; the outer edge of the main impeller uplifts along the bottom of the wall of the inner tub; the longitudinal section from any point on the outer edge of the main impeller to the center of the impeller is of an L-shaped structure in arc transition; and the auxiliary impeller is of a basin-shaped structure with an uplifted outer edge. The two-impeller three-power washing machine has the characteristics of high cleaning rate, high washing uniformity and the like.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Wave washing machine

InactiveCN101008143ATo achieve the purpose of not being entangledReduce or save useOther washing machinesPortable liftingPulp and paper industryTransmitter

The invention relates to a washing machine, especially an improvement on prior tub-type washing machine. The invention is characterized in that: the inner tub in washing washes reversely and clockwise via several wave rings, to form wave-type wave wheel. And the invention comprises wave ring, mixing ring, motor, power transmitter, air pump or electrolyze device. The invention has multiply washing functions, with high effect.

Owner:戴文育

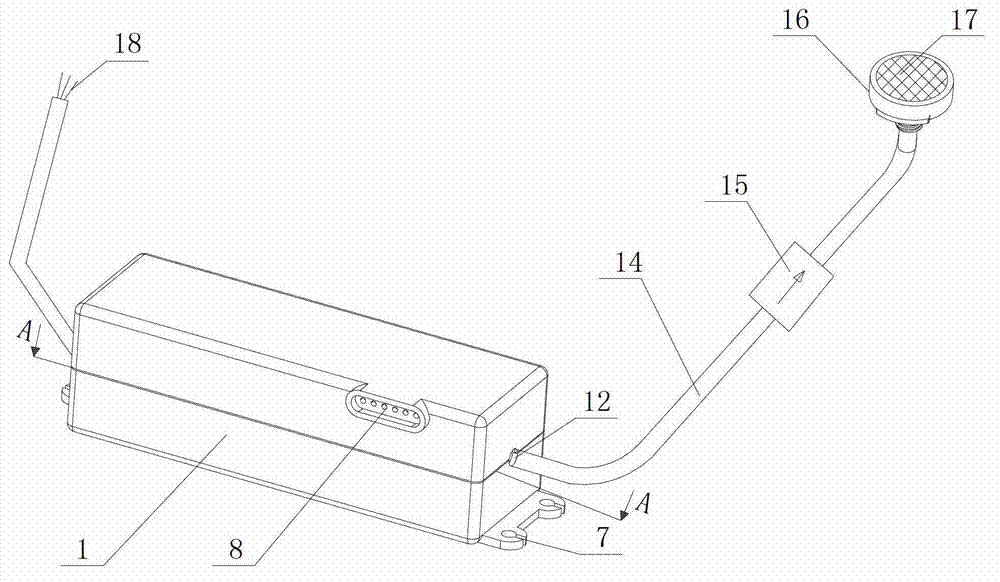

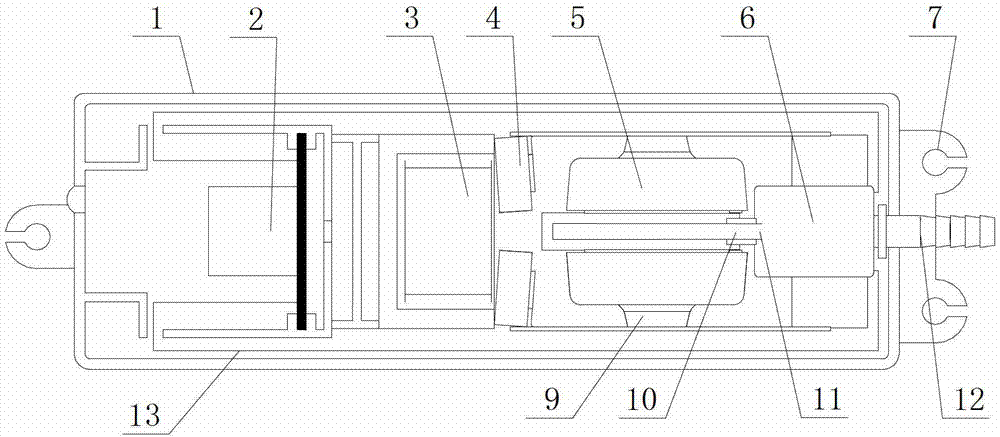

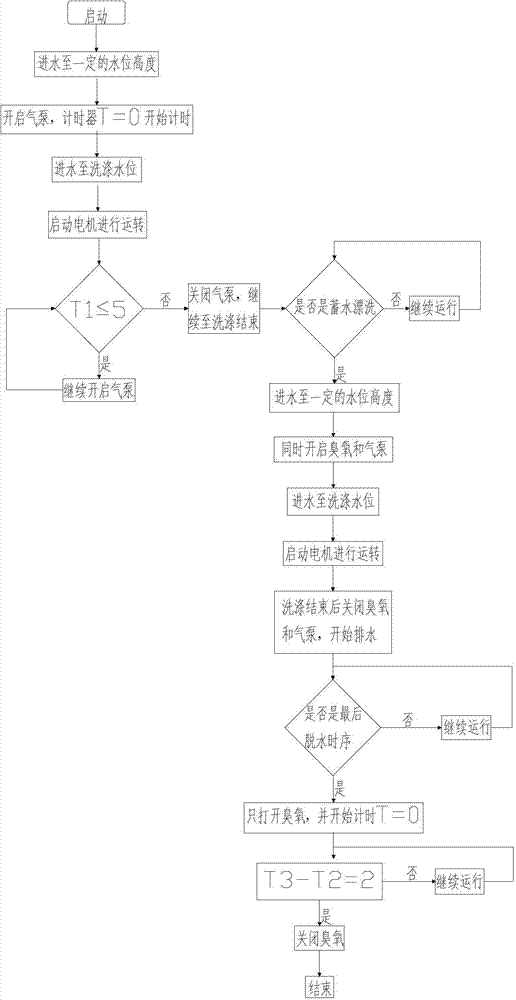

Cleaning sterilizing device for washing machine, washing machine using cleaning sterilizing device and control method thereof

InactiveCN102877271AReduce usageImprove cleaning ratioOther washing machinesControl devices for washing apparatusWater storageOzone generator

The invention relates to a cleaning sterilizing device for a washing machine, a washing machine using the cleaning sterilizing device and a control method thereof, wherein the cleaning sterilizing device comprises an ozone bubble generating device, a bubble generator and a control device; the ozone bubble generating device comprises an ozone generator and an air pump; the ozone bubble generating device is connected with the bubble generator; and the control device can control the ozone bubble generating device and the bubble generator to individually form air bubbles or ozone bubbles or control the ozone bubble generating device and the bubble generator to simultaneously generate air bubbles and ozone bubbles. Through a corresponding control method, only air bubbles are injected in the water cleaning process of the washing machine to reduce the mutual friction of clothes in the washing process; the air bubbles and the ozone bubbles are simultaneously injected in the water storage and rinsing process; and only the ozone bubbles are injected in the final dewatering procedure to sterilize the clothes. The washing machine using the cleaning sterilizing device has the advantages of high clean ratio, high sterilizing capability, low ozone consumption and low energy consumption, and is helpful for realizing energy conservation and discharge reduction.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

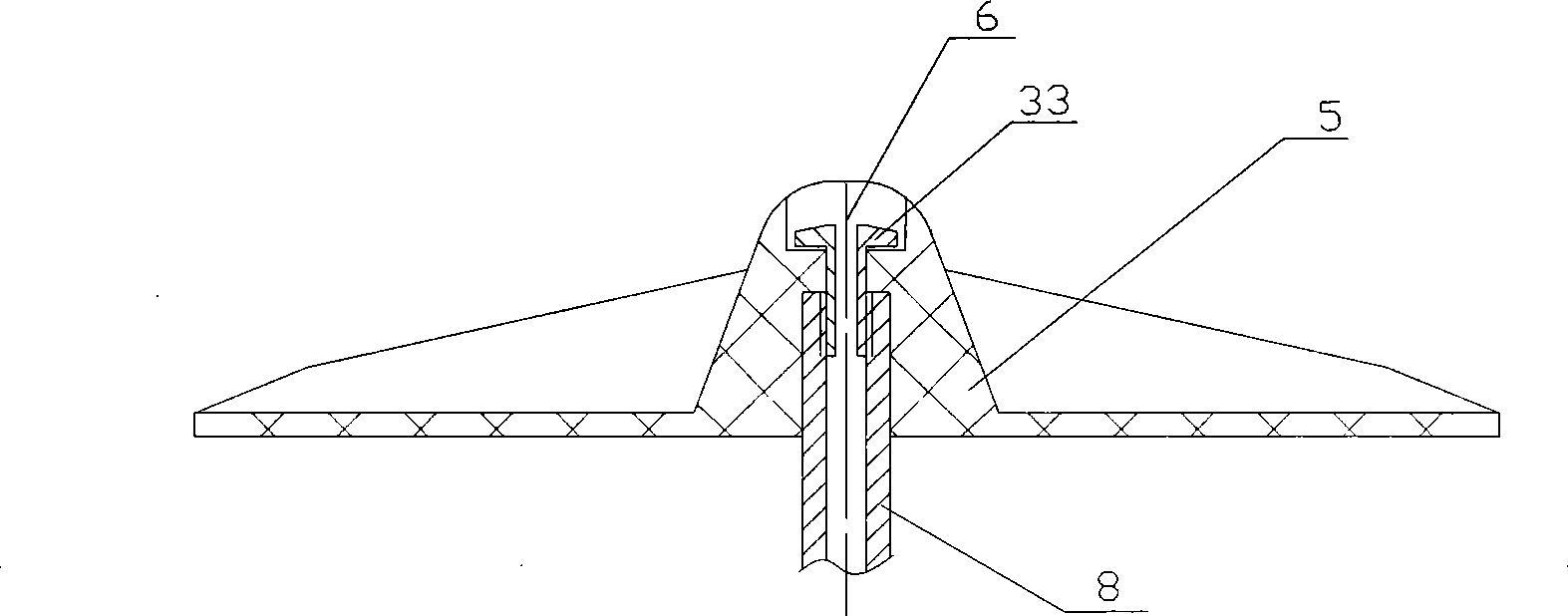

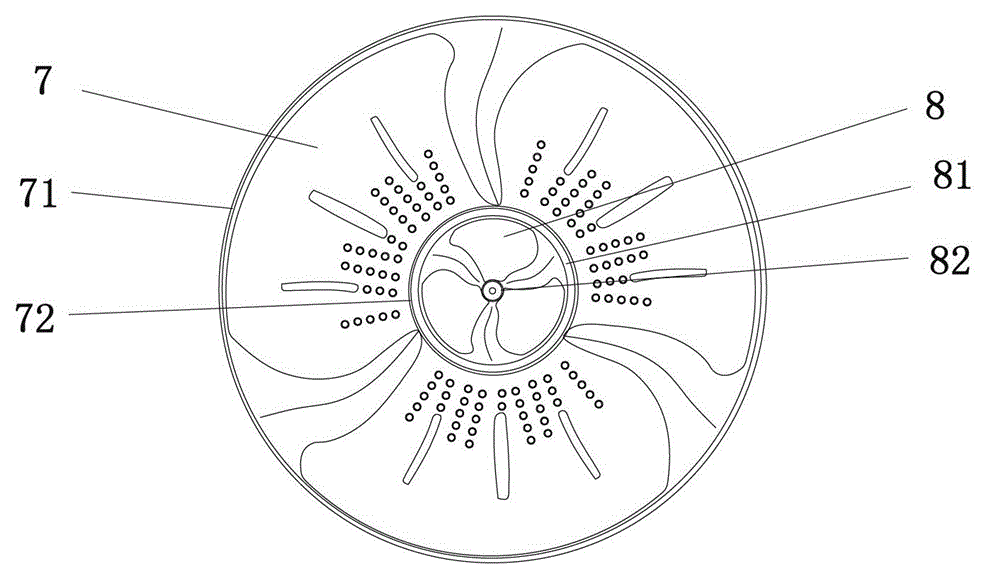

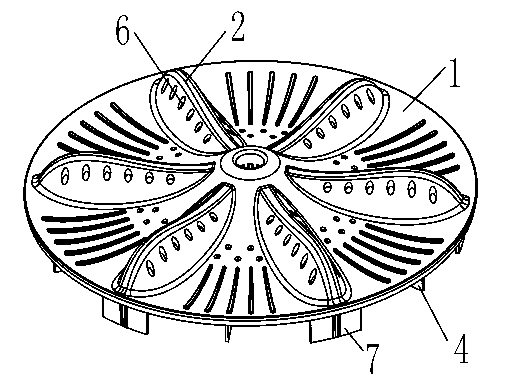

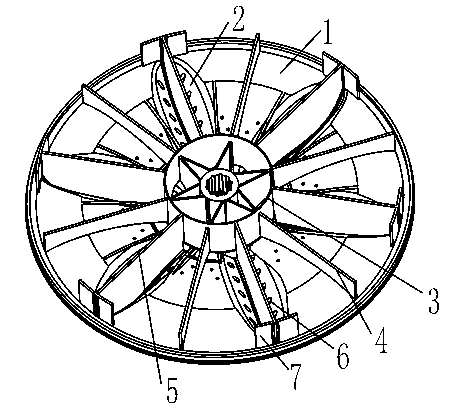

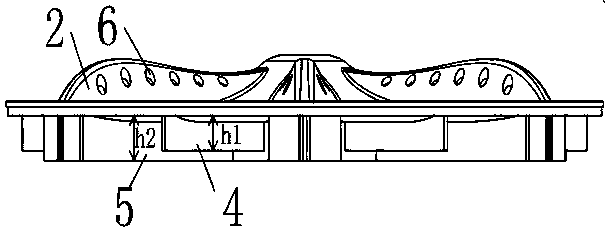

Impeller and impeller washing machine

ActiveCN103628272AAvoid entanglementEasy flipWashing machine with receptaclesTextiles and paperSolubilityImpeller

The invention relates to an impeller and an impeller washing machine. The impeller comprises a base plate, wherein convex ribs are arranged on the upper surface of the base plate, recesses are formed in the lower surface of the base plate corresponding to the convex ribs, a water repelling rib is arranged in at least one recess, and a through hole is formed in the recess provided with the water repelling rib. In positive and negative rotating processes of the impeller, the water repelling rib enables water to be sprayed out from the through hole in the inclined side face to form a spurting water flow to impact clothes, so as to form a strong washing power to scatter the clothes and prevent the clothes from winding; the clothes are lifted so as to be well overturned. In addition, the water flow sprayed carries a lot of bubbles, so that a cavitation effect is generated to effectively increase the solubility of washing powder and improve the cleanness of the clothes. Therefore, according to the invention, the clothes are comprehensively washed, a washing effect is ideal and the clean ratio is remarkably improved.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

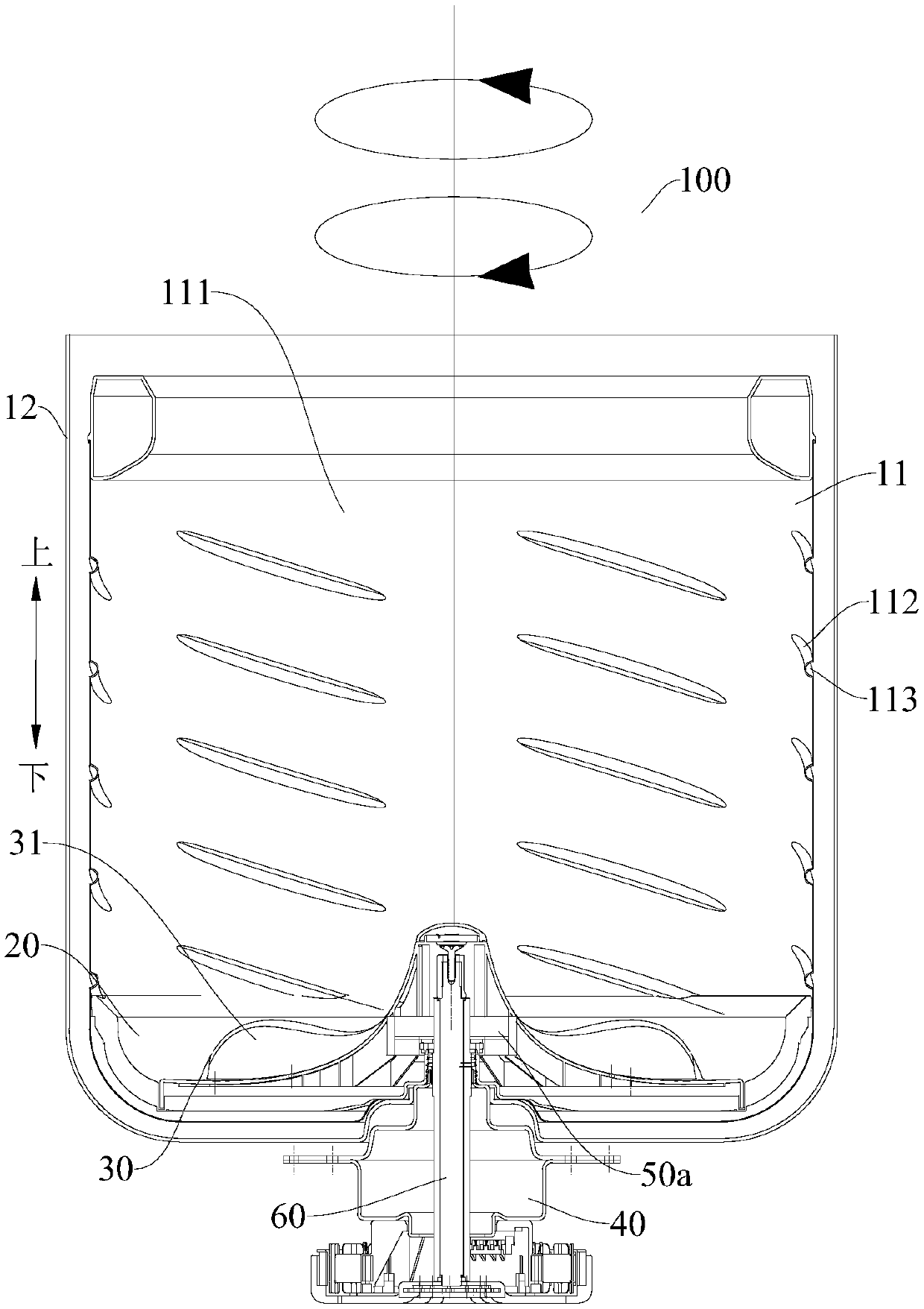

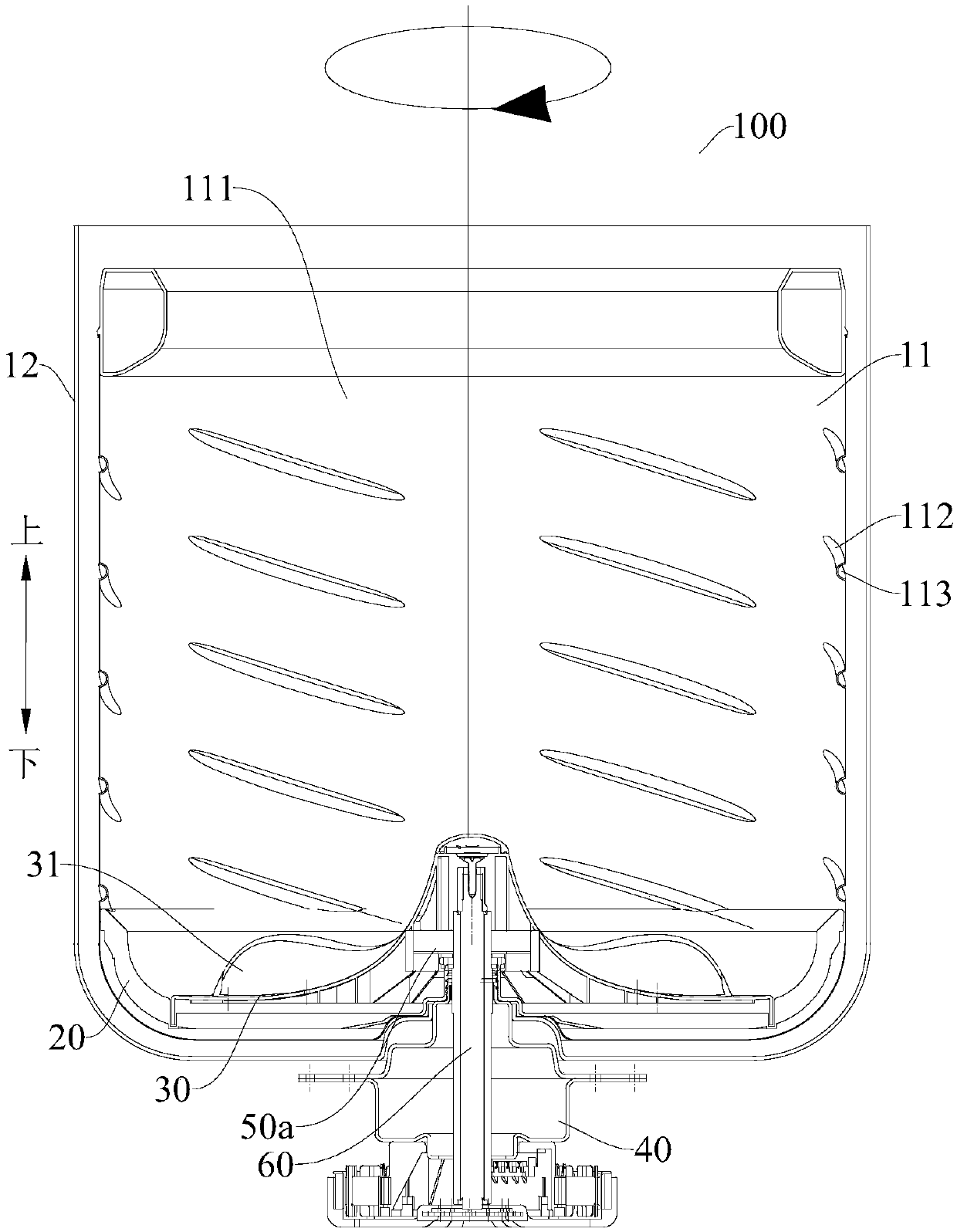

Clothes treating apparatus and control method thereof

ActiveCN109652953AEasy to washImprove rinsing performanceOther washing machinesControl devices for washing apparatusWater flowVertical displacement

The invention discloses a clothes treating apparatus and a control method thereof. The clothes treating apparatus comprises an inner cylinder, a rotatable pulsator, a driving device and a clutch device, the inner cylinder defines a cavity with an open top, the driving device is used for driving the pulsator to rotate, the clutch device can be switched among a separation state, a first joint stateand a second joint state, the pulsator is free from vertical displacement in the separation state and can be driven to rotate in the first joint state, the inner cylinder and the pulsator can synchronously rotate in the first joint state, and the pulsator can be driven to rotate and can vertically shift relative to the inner cylinder in the second joint state. According to the clothes treating apparatus, when the clutch device is switched to the second joint state, the pulsator rotates and can vertically shift, three-dimensional stirring effects of water flow can be achieved, and washing and rinsing effects and use experience of the clothes treating apparatus are improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

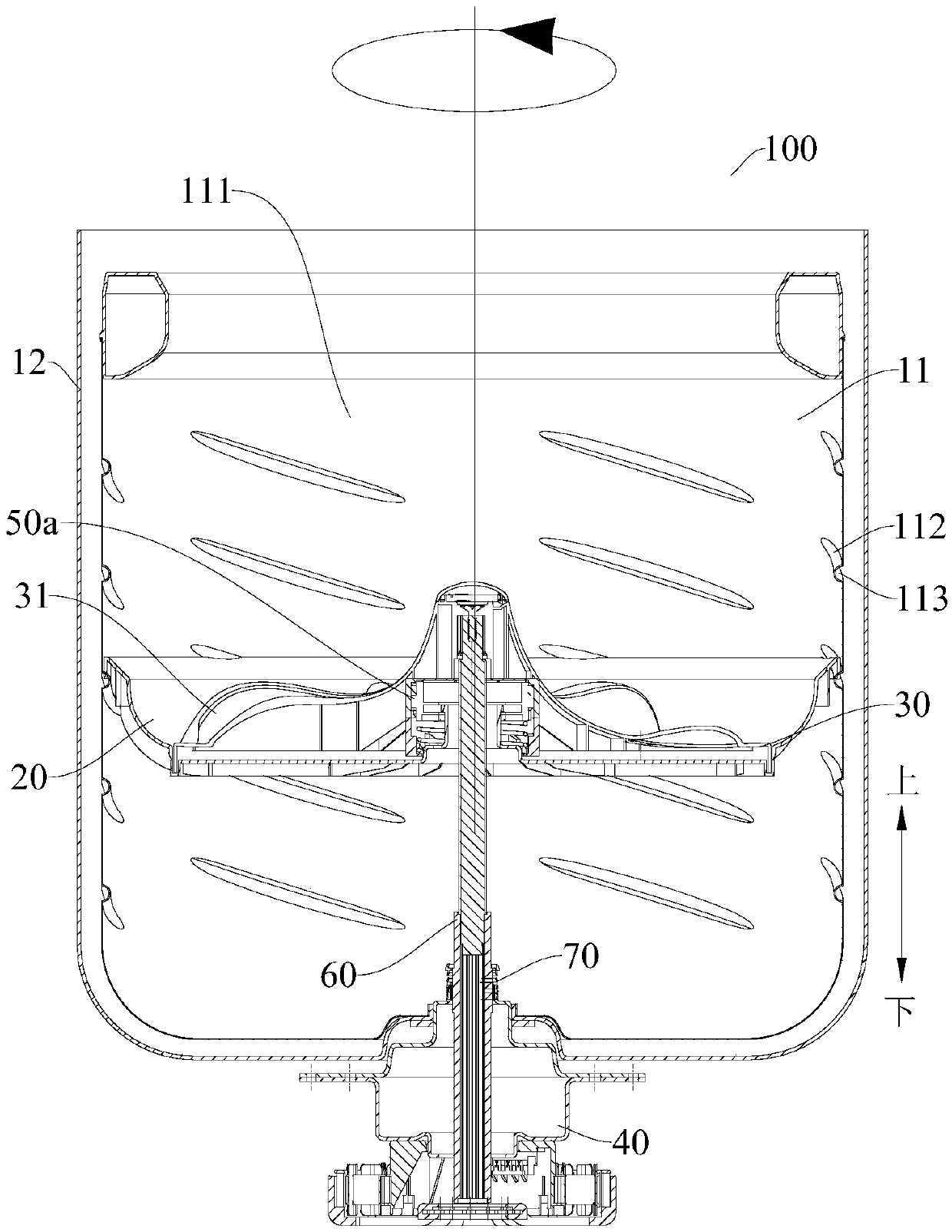

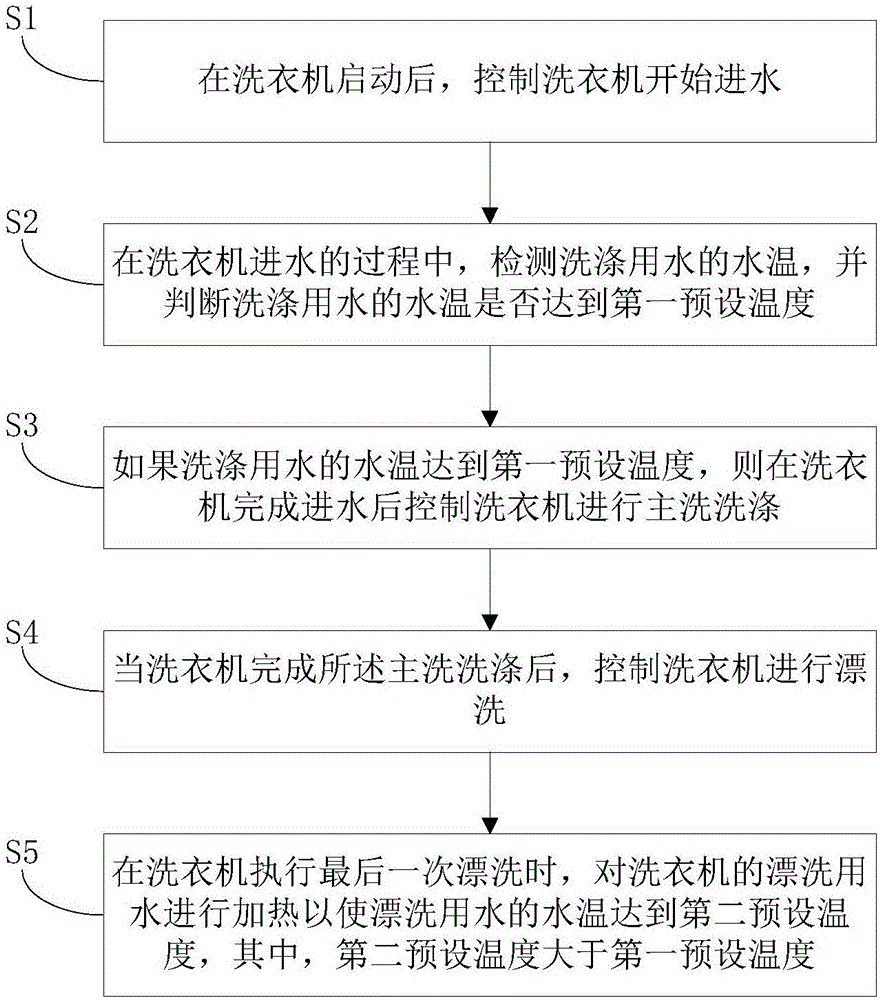

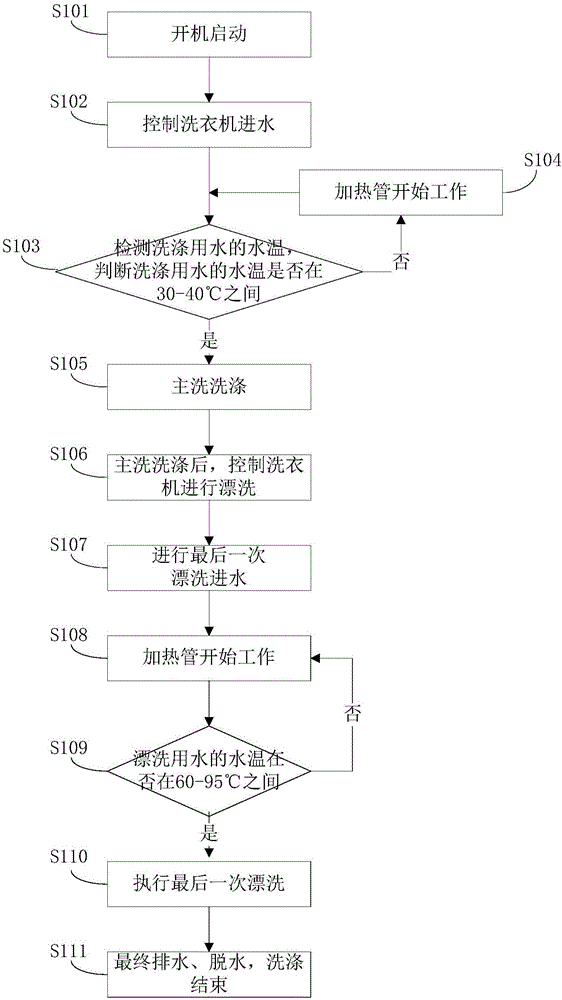

Washing machine and washing control method thereof

InactiveCN106283496AImprove cleaning ratioImprove solubilityOther washing machinesControl devices for washing apparatusEngineeringConsumptive water use

The invention discloses a washing machine and a washing control method thereof. The method includes the following steps that the washing machine is controlled to begin water feeding after being started; in the water feeding process of the washing machine, the temperature of washing water is detected, and whether the temperature of the washing water reaches a first preset temperature or not is judged; if the temperature of the washing water reaches the first preset temperature, the washing machine is controlled to carry out main washing after completing water feeding; the washing machine is controlled to carry out rinsing after completing main washing; when the washing machine carries out the last time of rinsing, rinsing water of the washing machine is heated to make the temperature of the rinsing water reaches a second preset temperature, wherein the second preset temperature is higher than the first preset temperature. According to the method, a washing agent can be fully dissolved in the washing process through working of a heating pipe, and thus the clean ratio of clothes can be increased; high-temperature rinsing is carried out in the final rinsing process through working of the heating pipe, and thus the effect of sterilizing and disinfecting clothes can be achieved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

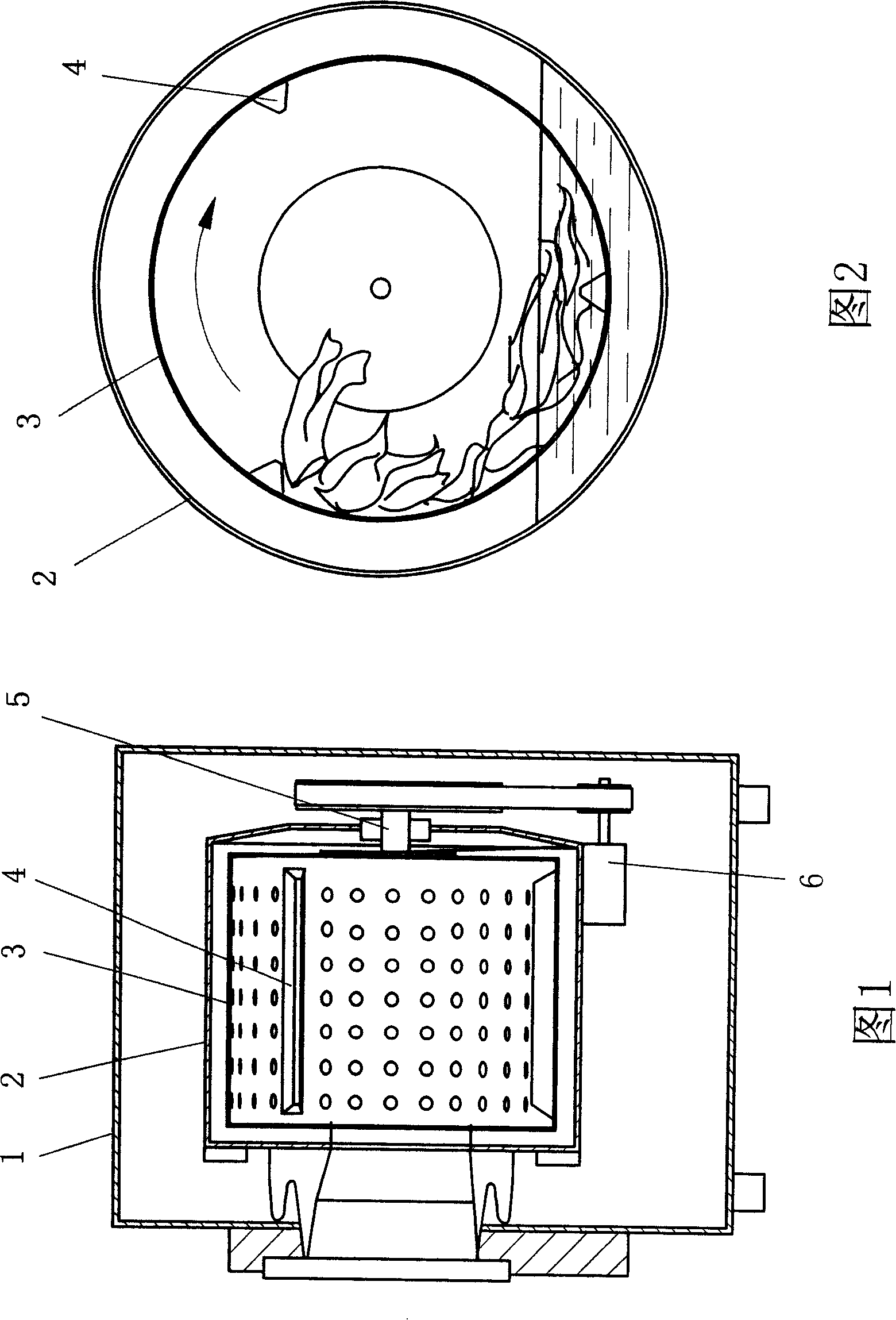

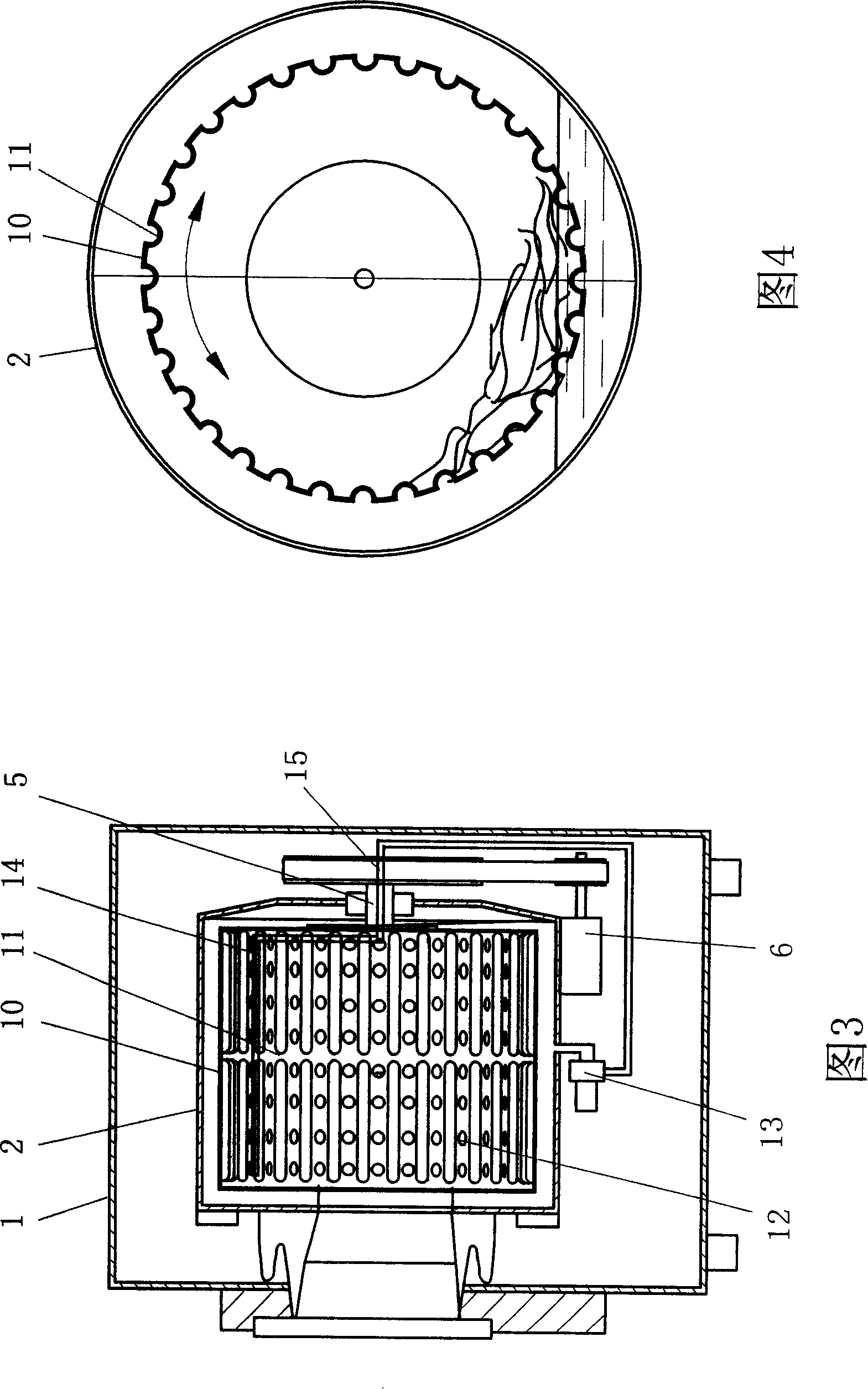

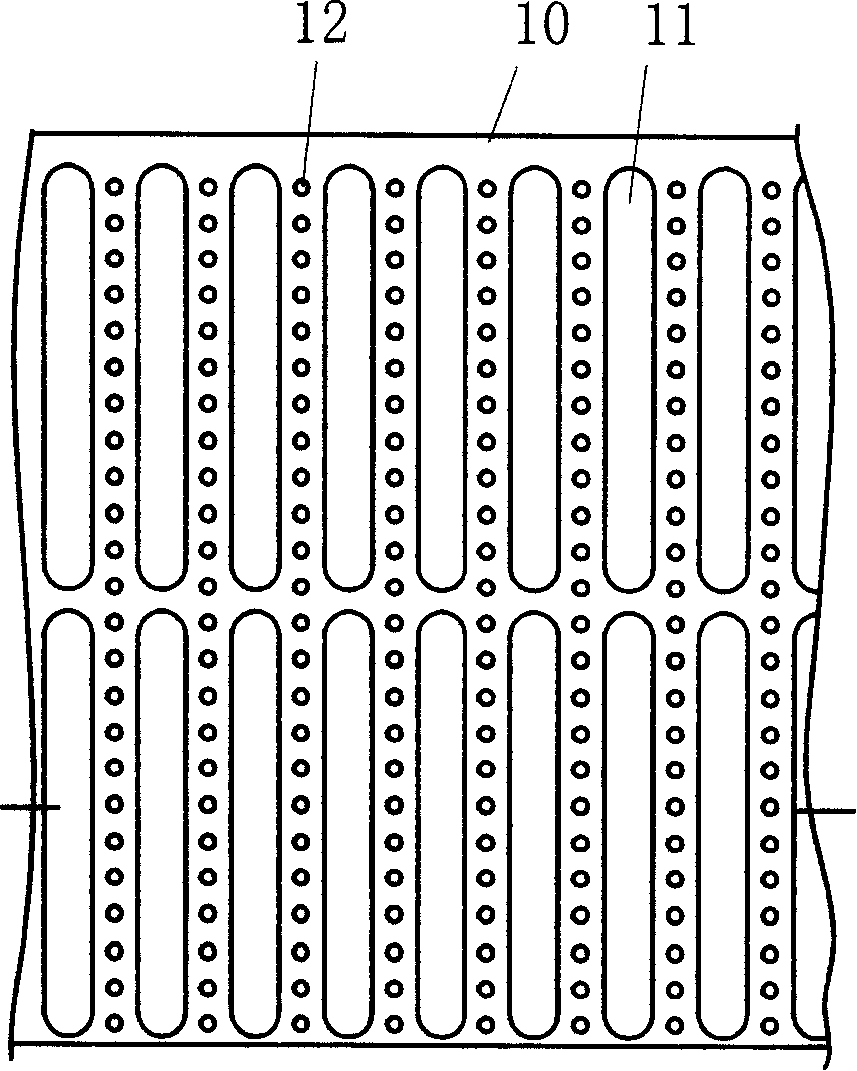

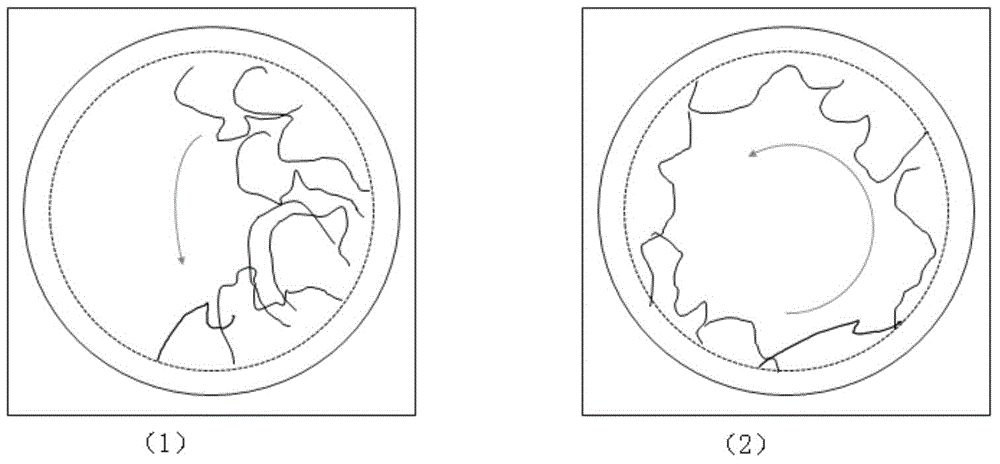

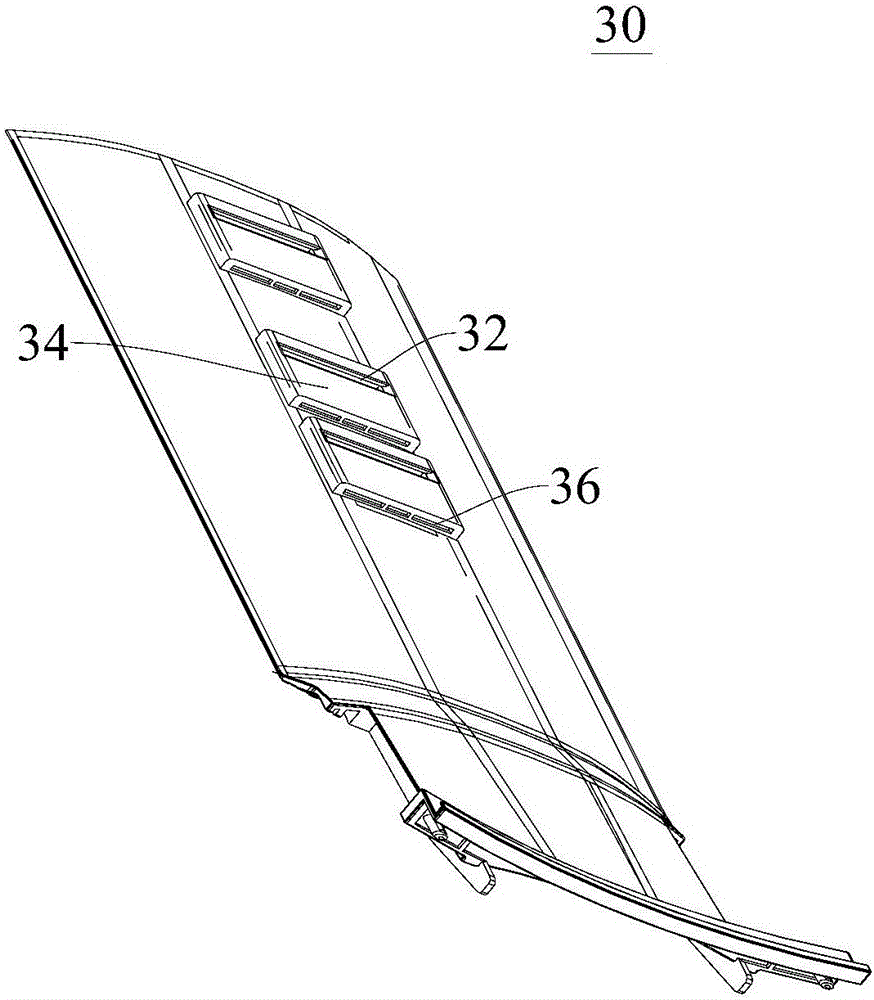

Washboard type roller washing method and washing machine applying the same method

ActiveCN101210369AConserve waterImprove cleaning ratioOther washing machinesWashing machine with receptaclesWater savingDrive motor

A washboard-type drum washer comprises a housing, a water tank and a drum arranged in the housing, a rotation shaft arranged at the bottom of the drum and a drive motor connected with the rotation shaft. The drum washer is characterized in that a plurality of axial densely-arranged ribs are provided on the inner wall of the drum, and water drain holes are provided among the ribs. The washing method provided by the invention can repeatedly scrub the clothes by using the ribs provided on the drum, and the clothes can be further scrubbed after rotating to change the position, so that the clothes can be washed like hand washing on a washboard by scrubbing and rotating the clothes by multiple times, thus saving water and improving the cleaning ratio. High dewatering rate can be obtained by high-speed drying by arranging the water drain holes among the ribs. The ribs stamped on the drum can improve the strength and the rigidity of the drum, thus improving the service life of the washing machine.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

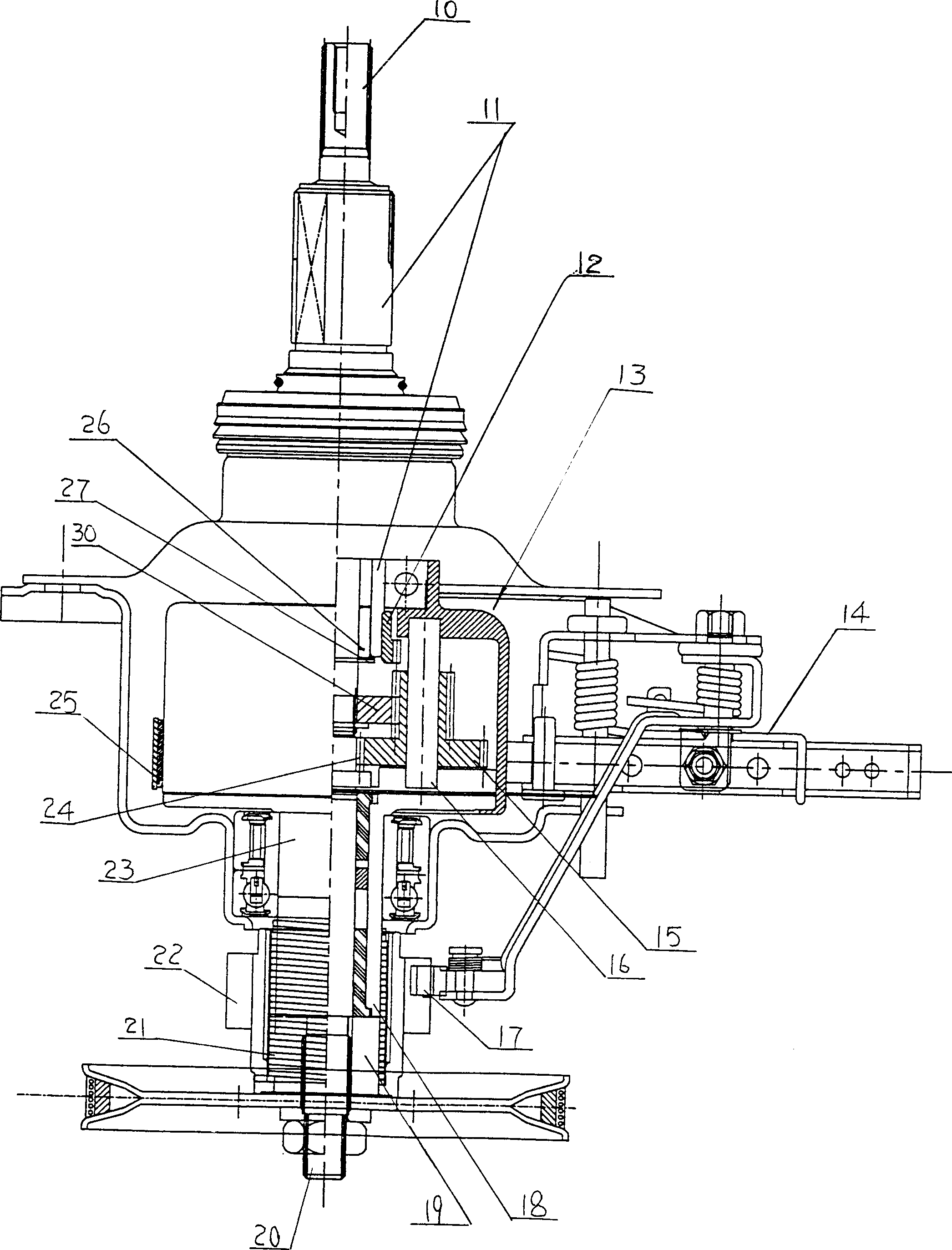

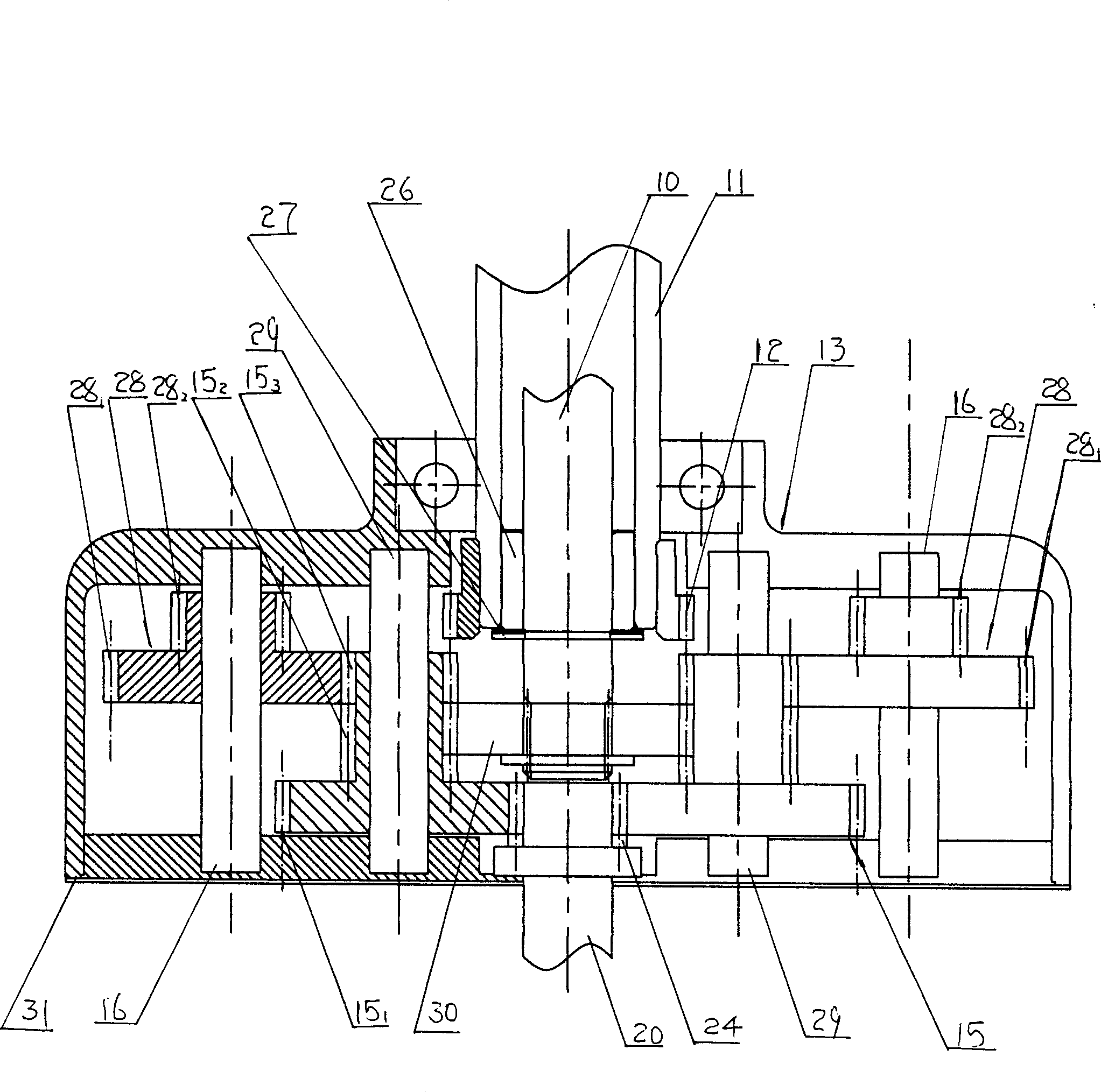

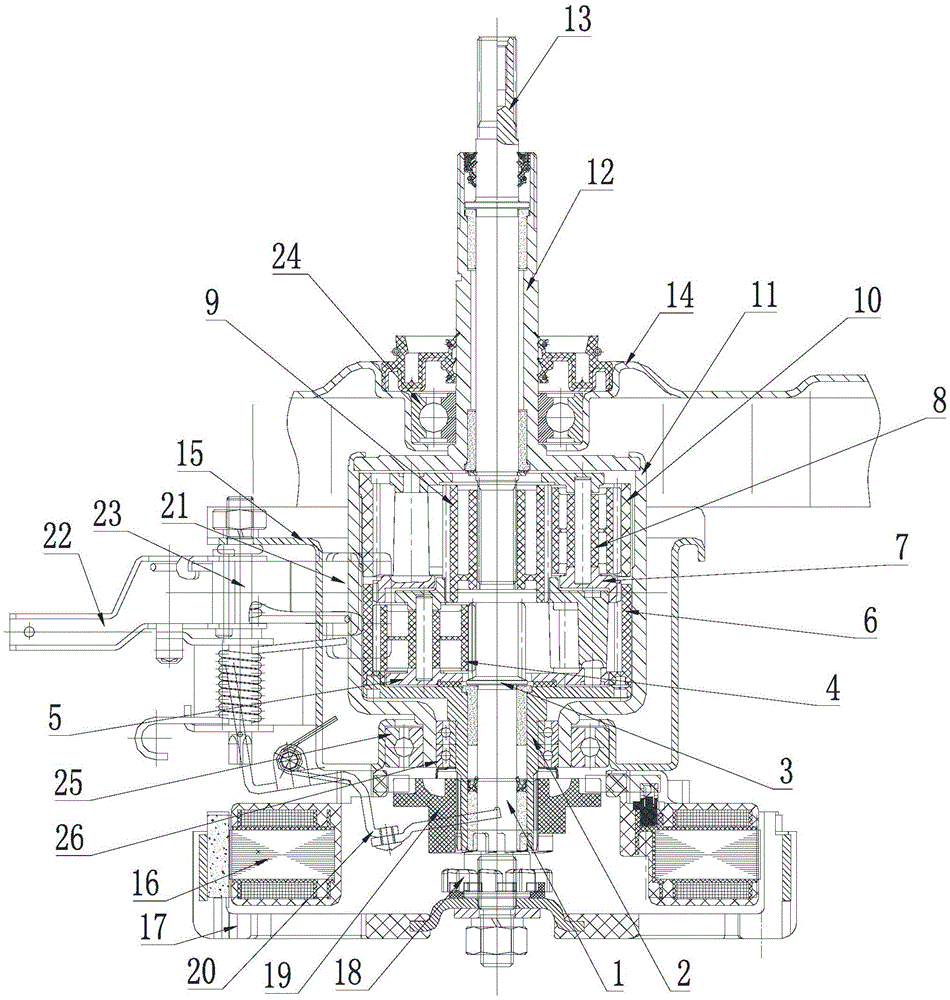

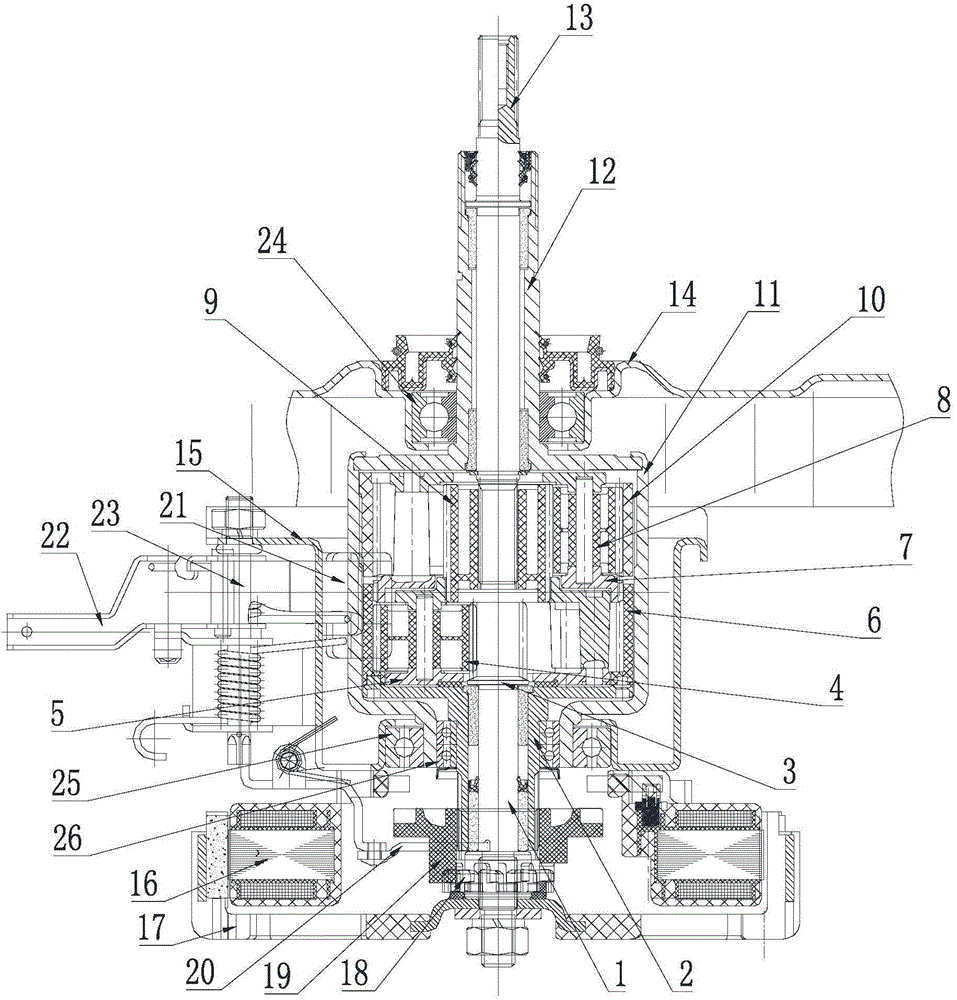

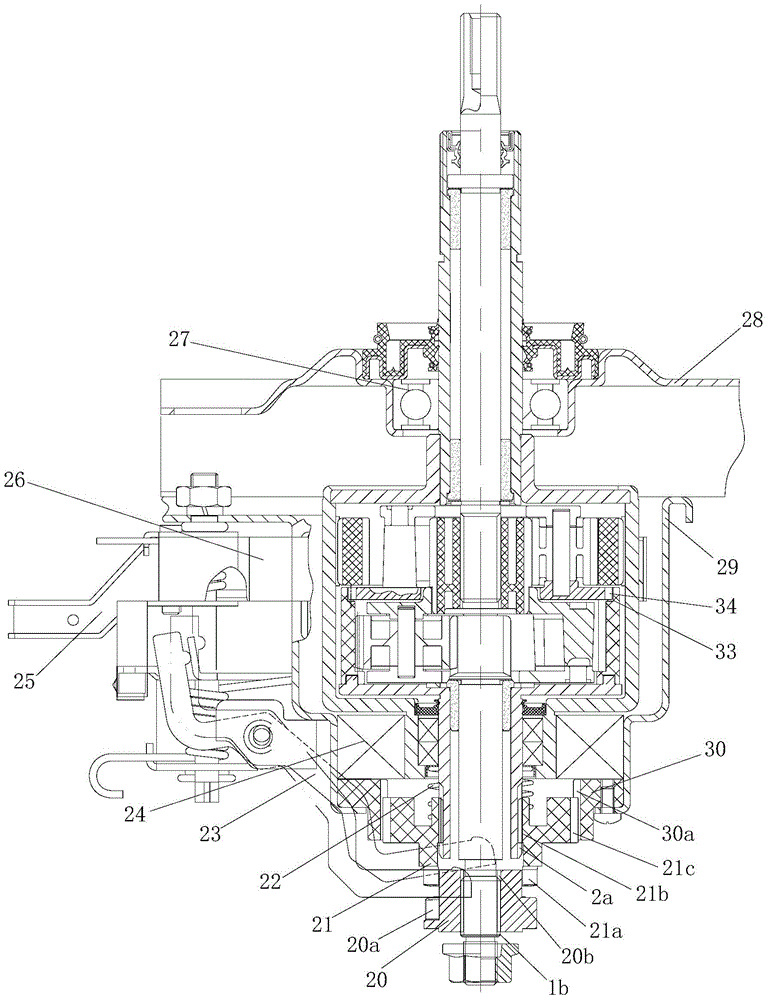

Washing machine and deceleration clutch for same

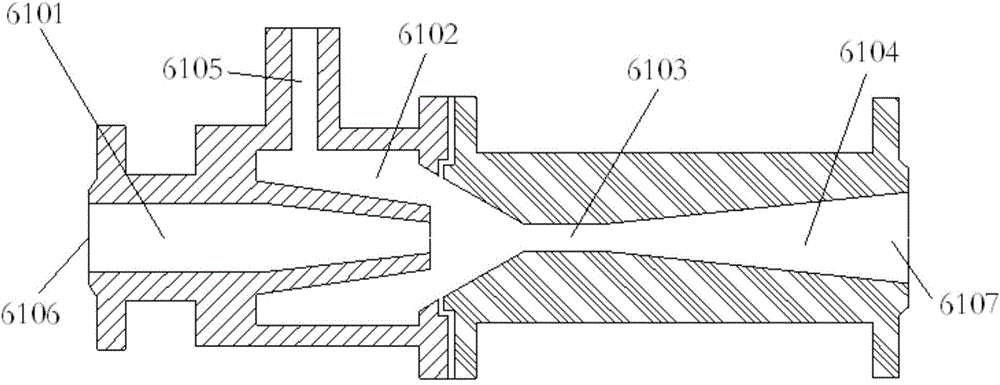

ActiveCN105734904AImprove transmission efficiencyReduce energy consumptionOther washing machinesTextiles and paperCircular discLaundry washing machine

The invention relates to a deceleration clutch for a washing machine.The deceleration clutch comprises a motor, an input shaft, an input shaft sleeve, a wheel system, an output shaft and an output shaft sleeve.One end of the input shaft is connected with a rotor of the motor, and the other end of the input shaft is connected with the wheel system.The portion, close to the rotor of the motor, of the input shaft is provided with a torque shaft sleeve of a disc structure, the torque shaft sleeve is provided with spline teeth, and the torque shaft sleeve and the input shaft are integrally formed.The deceleration clutch is simple in structure and convenient to assemble.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

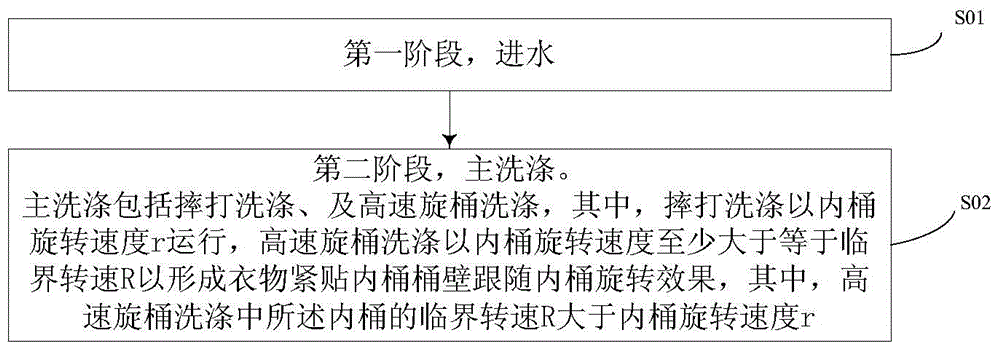

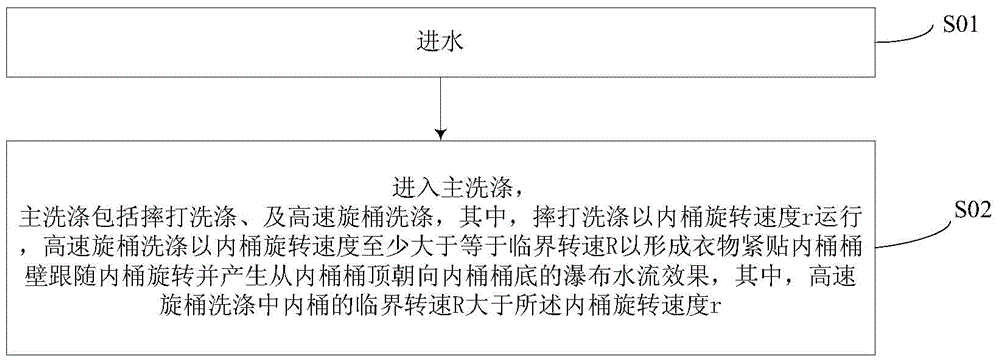

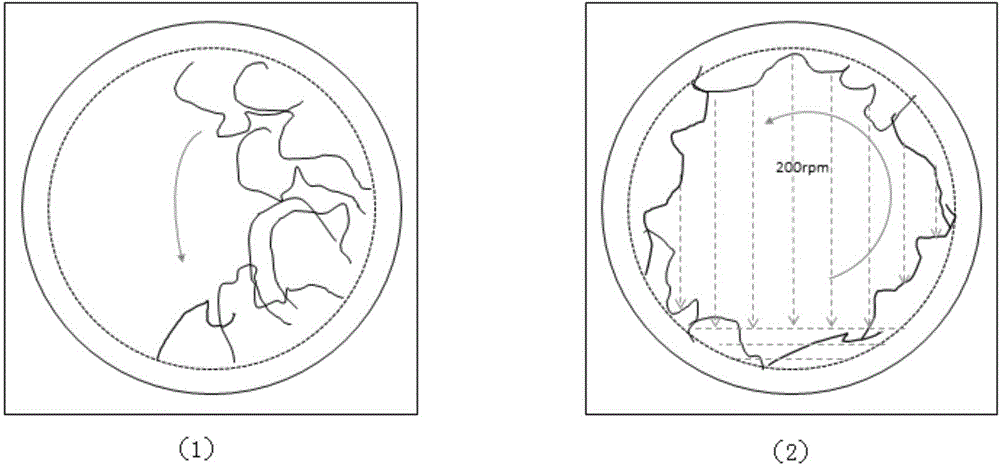

Drum washing machine and washing control method thereof

ActiveCN105088635AImprove solubilityEnhance washing mechanical strengthOther washing machinesControl devices for washing apparatusProcess engineeringHigh velocity

The invention provides a drum washing machine and a washing control method thereof. The washing control method comprises following steps of a first stage of injecting water; and a second stage of main washing processes comprising a beat washing process and a high-speed rotating-barrel washing process. The beat washing process operates at a rotating speed r of the inner barrel, and the high-speed rotating-barrel washing process is carried out in a way that the rotating speed of the inner barrel is at least higher than or equal to a critical rotating speed R, clothes stick close to the barrel wall of the inner barrel and rotate along with the inner barrel, and the critical rotating speed R of the inner barrel in the high-speed rotating-barrel washing process is higher than the rotating speed r of the inner barrel. By employing the drum washing machine and the washing control method thereof, the washing mechanical strength can be enhanced, the washing effect can be improved, and the drum washing machine is time-saving and power-saving.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

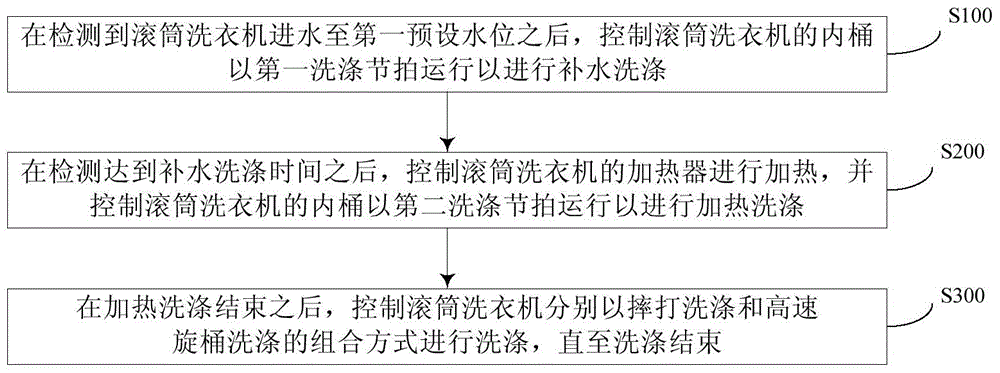

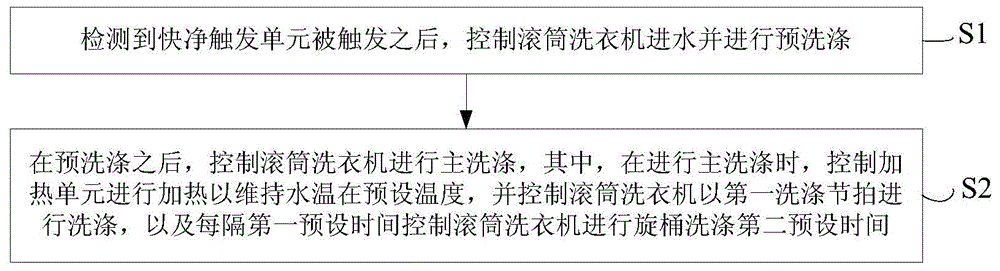

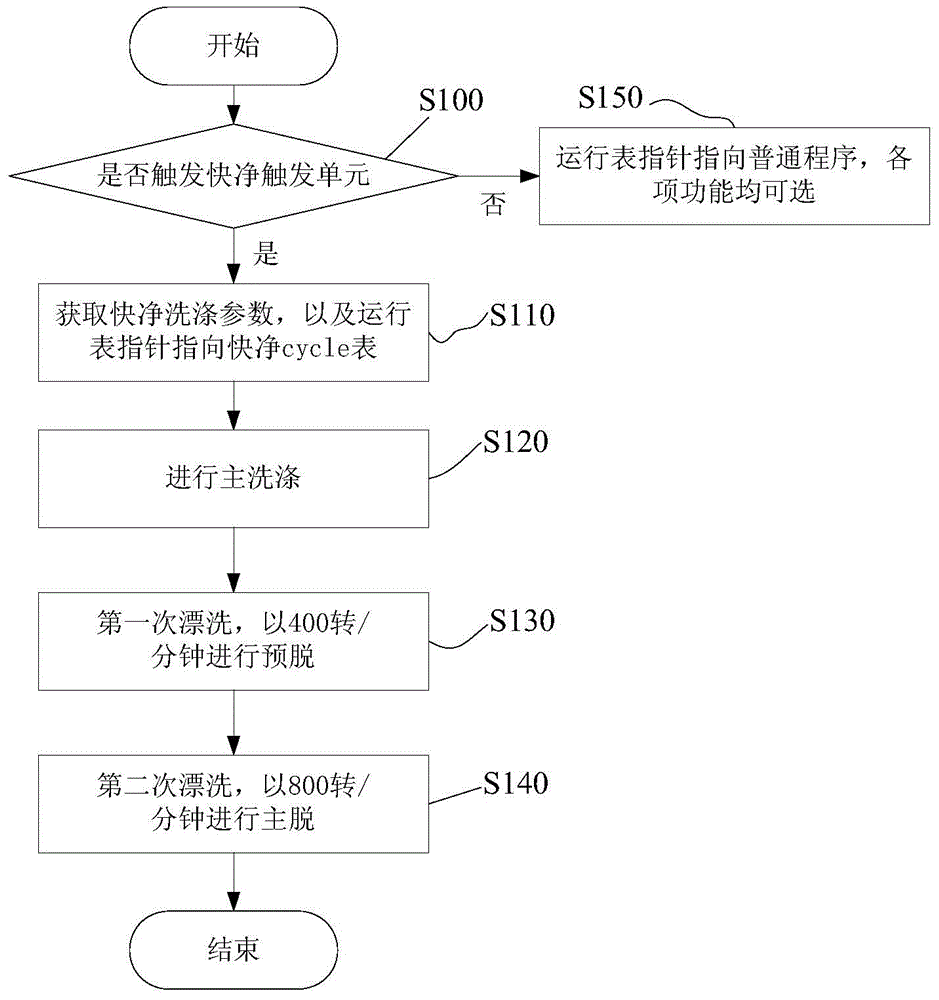

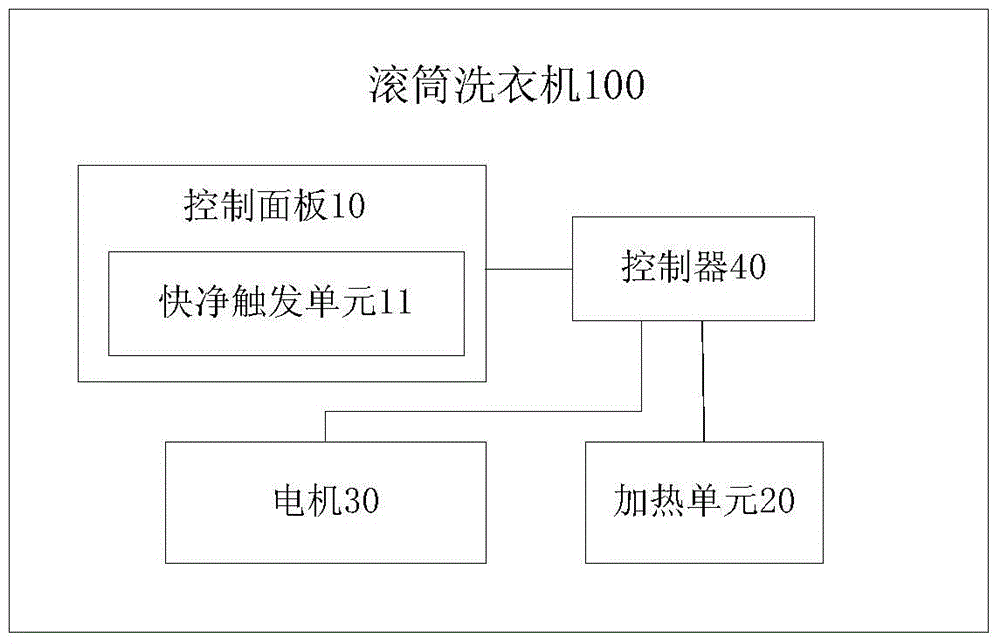

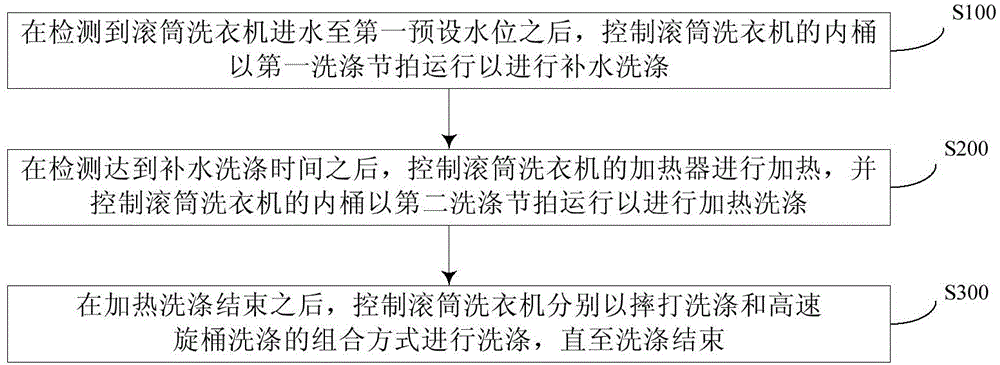

Drum washing machine and control method thereof

ActiveCN105088656AImprove washing effectShorten washing timeOther washing machinesControl devices for washing apparatusEngineeringPre washing

The invention provides a control method of a drum washing machine. The drum washing machine comprises a control panel and a heating unit. The control panel comprises a quick cleaning trigger unit. The control method comprises the steps of controlling the drum washing machine to perform a water feeding procedure and a pre-washing procedure when detecting that the quick cleaning trigger unit is triggered, and, after the pre-washing procedure, controlling the drum washing machine to perform a main washing procedure. When the drum washing machine performs the main washing procedure, the heating unit is controlled to heat water to keep the water at the preset temperature, and the drum washing machine is controlled to perform washing with a first washing rhythm and is controlled to perform drum-rotating washing for a second preset period of time at intervals of a first preset period of time. The control method of the drum washing machine can save washing time and improve the washing effect. The invention also discloses the drum washing machine.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

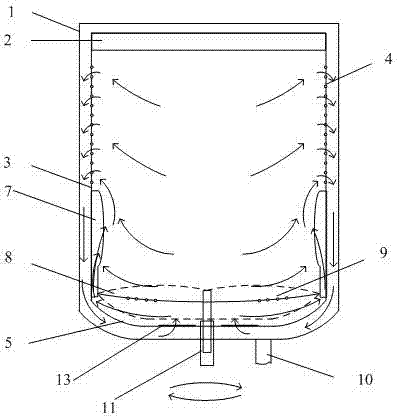

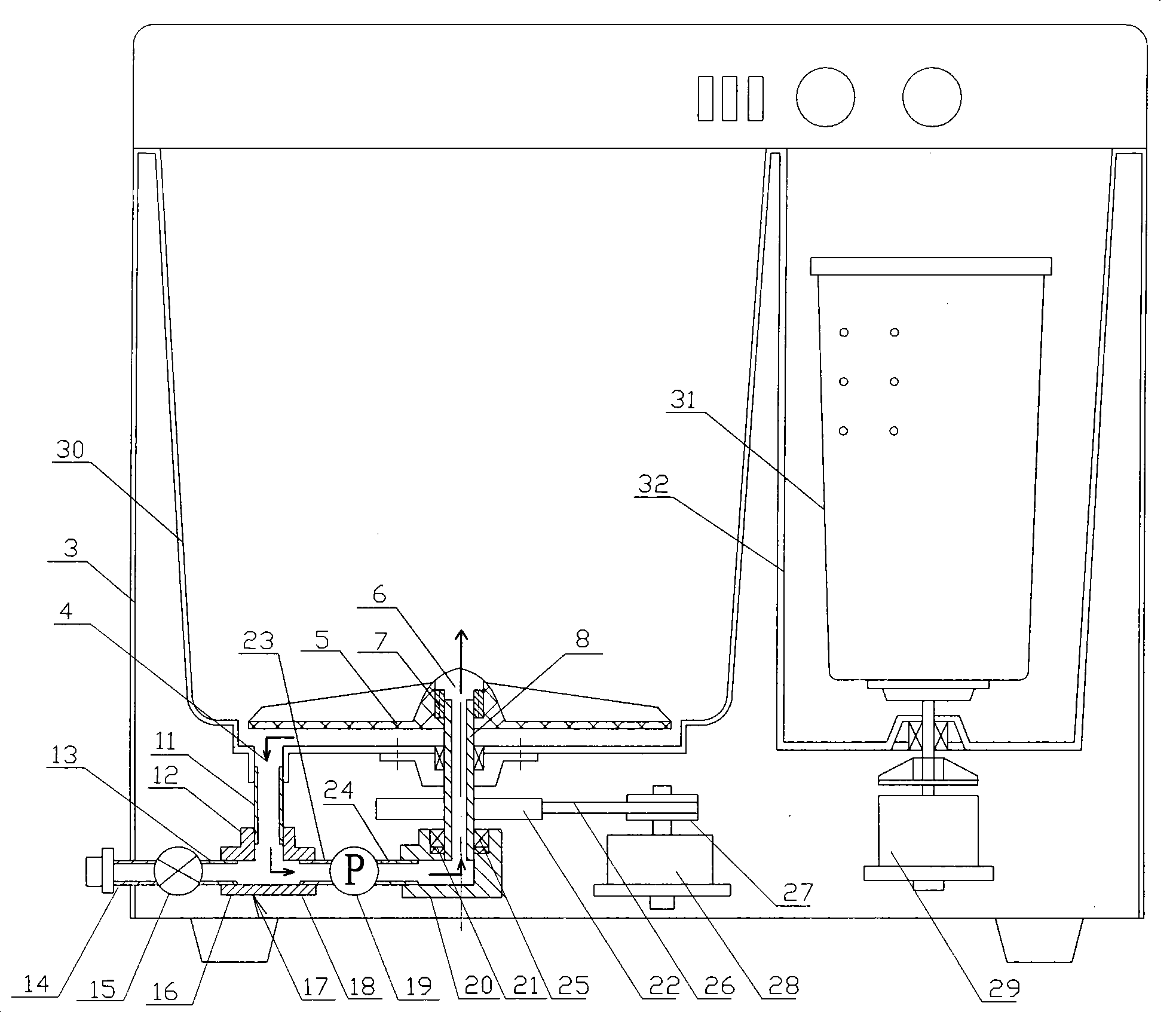

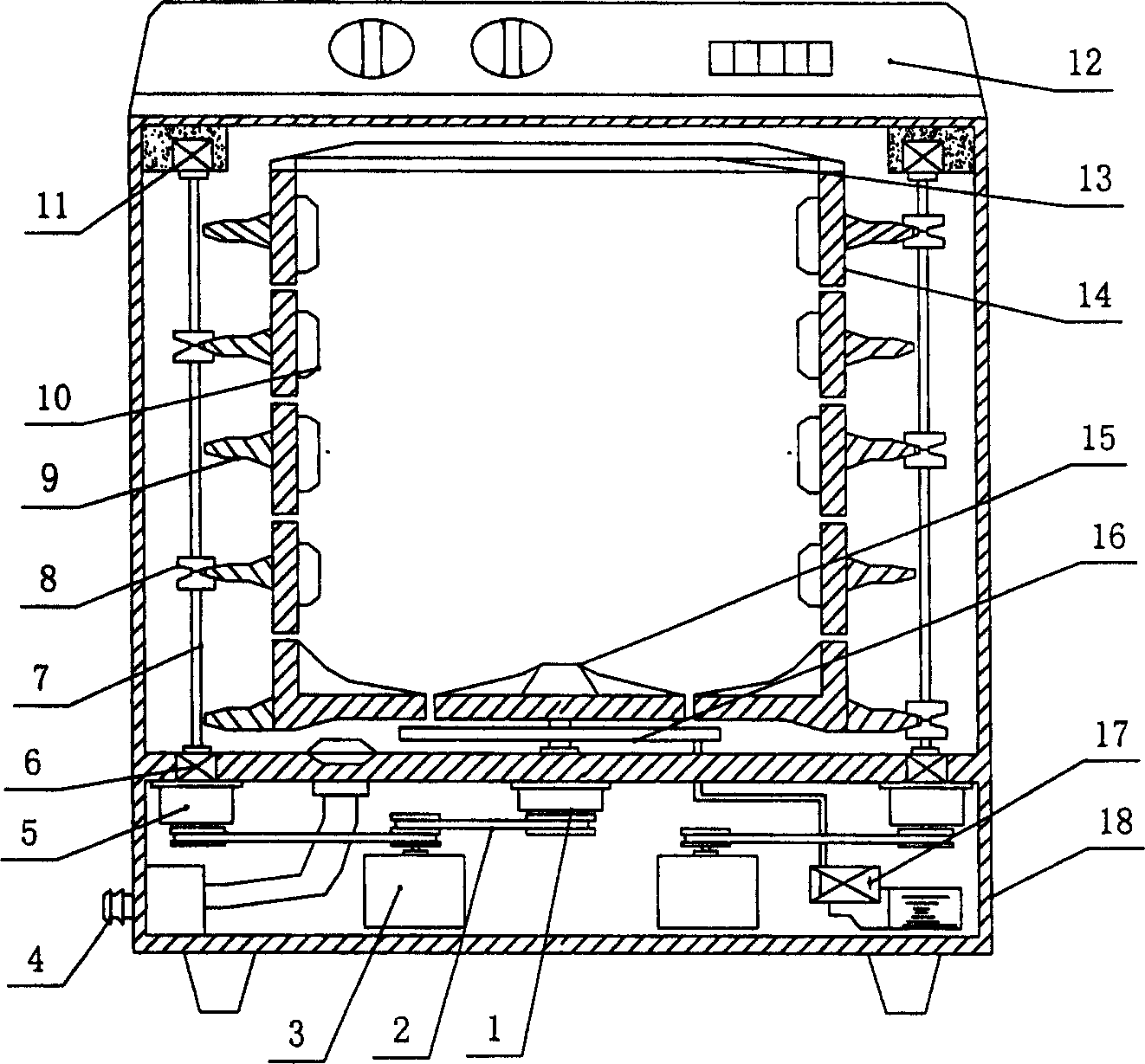

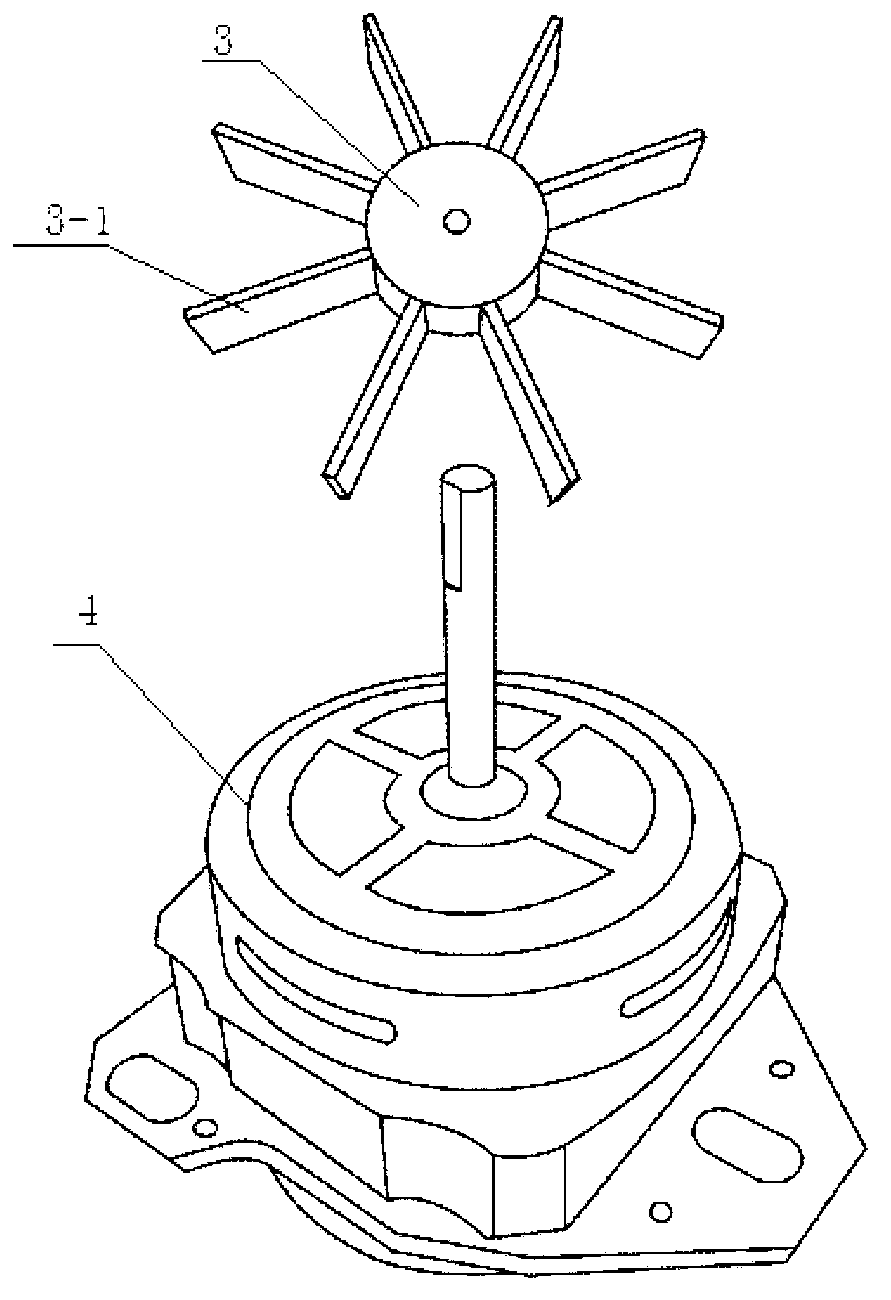

Water circulating device for low temperature fast dissolving of detergent and efficient washing of roller washing machine and working method thereof

ActiveCN103276561AImprove cleaning ratioLower turn-to-stop ratioOther washing machinesControl devices for washing apparatusWater flowWater cycling

The invention relates to a water circulating device for low temperature fast dissolving of detergent and efficient washing of a roller washing machine. The water circulating device comprises a water rotating wheel arranged at the bottom of the roller washing machine and between an outer barrel and an inner barrel, wherein the water rotating wheel comprises a middle shaft and paddle blades fixedly arranged on the middle shaft, and a motor which drives the water rotating wheel to rotate is arranged at the bottom of the outer barrel. The water circulating device achieves strong rotation and spewing for water currents at the bottom of the roller washing machine, then accelerates fast high dissolving of the detergent, and avoids the problem that the detergent is difficult to dissolve due to the facts that the detergent precipitates and stacks at dead angles below the inner barrel formerly. The water circulating device for the low temperature fast dissolving of the detergent and the efficient washing of the roller washing machine achieves double power washing for clothes simultaneously through rotation of a roller and rotating water currents, and achieves a good effect of reducing wear rate of the clothes by reducing the rotation stop rate and the rotation speed of the roller on the basis of improving the cleanly washing rate of the clothes. The water circulating device for the low temperature fast dissolving of the detergent and the efficient washing of the roller washing machine can use a low power motor to drive the water rotating wheel, achieves a good cleanly washing effect of low temperature fast dissolving detergent, and achieves energy conservation and emission reduction really.

Owner:李守林

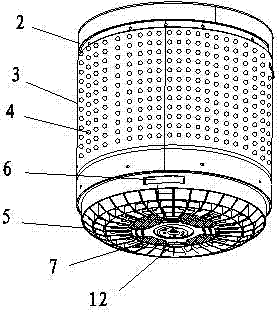

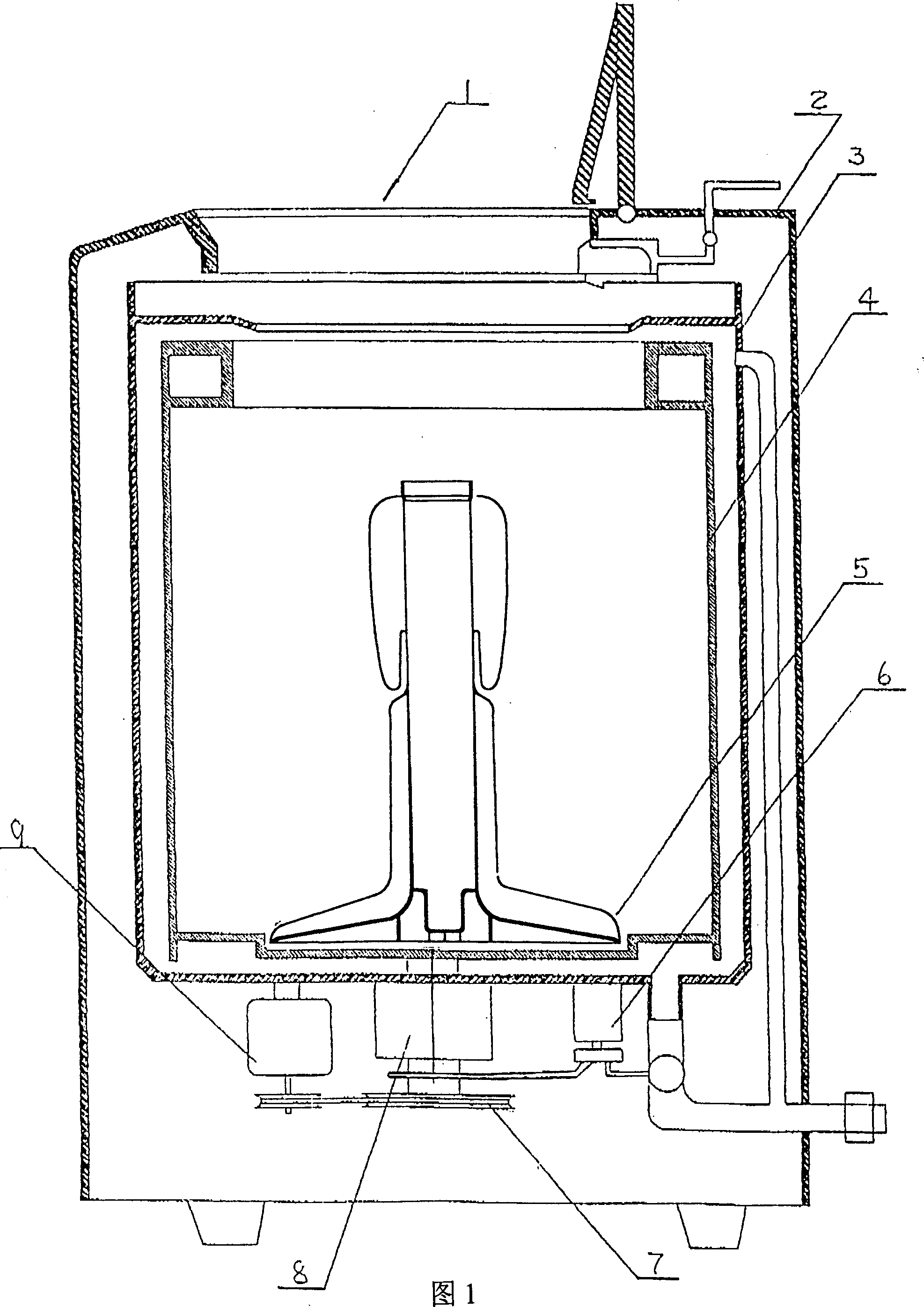

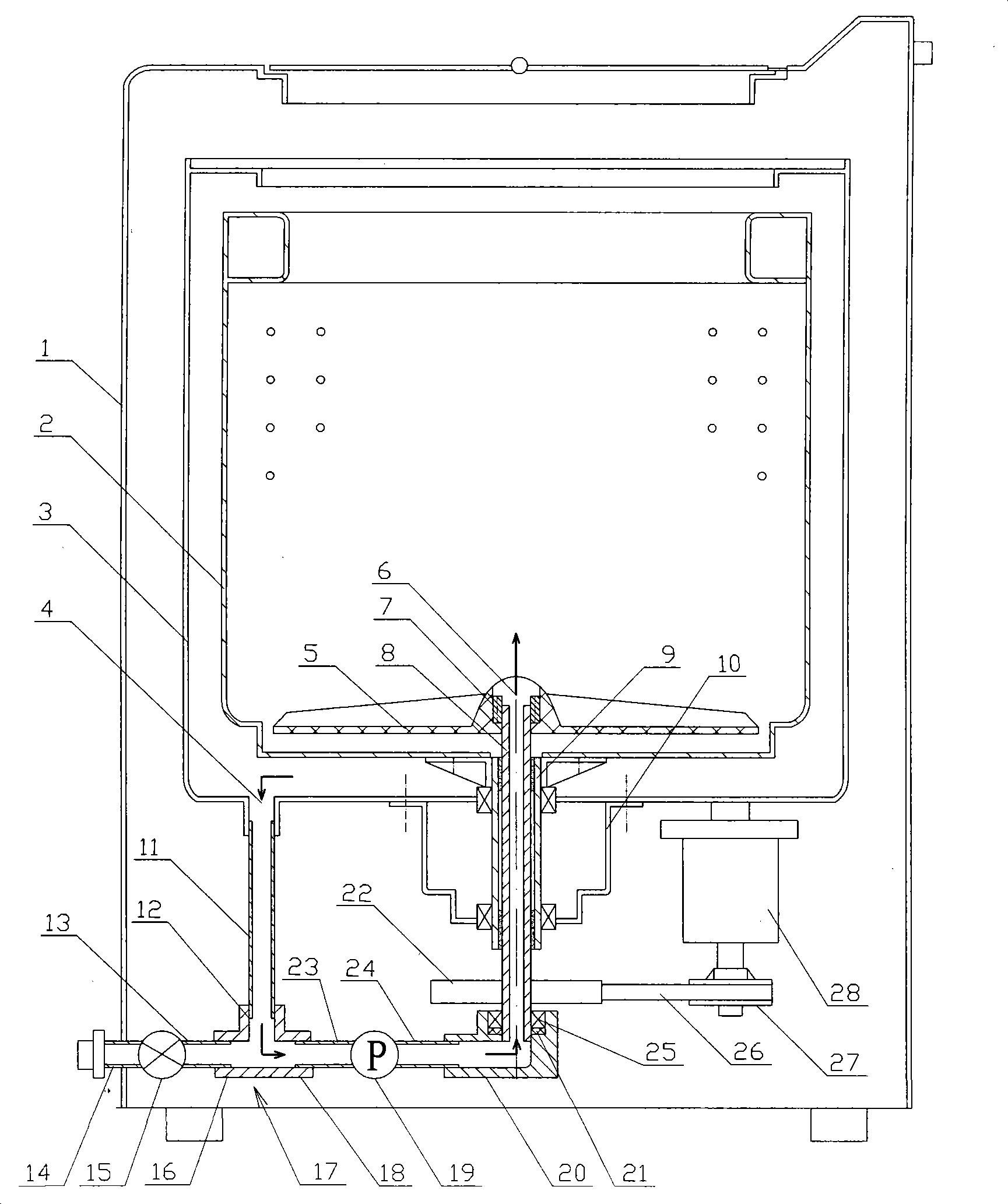

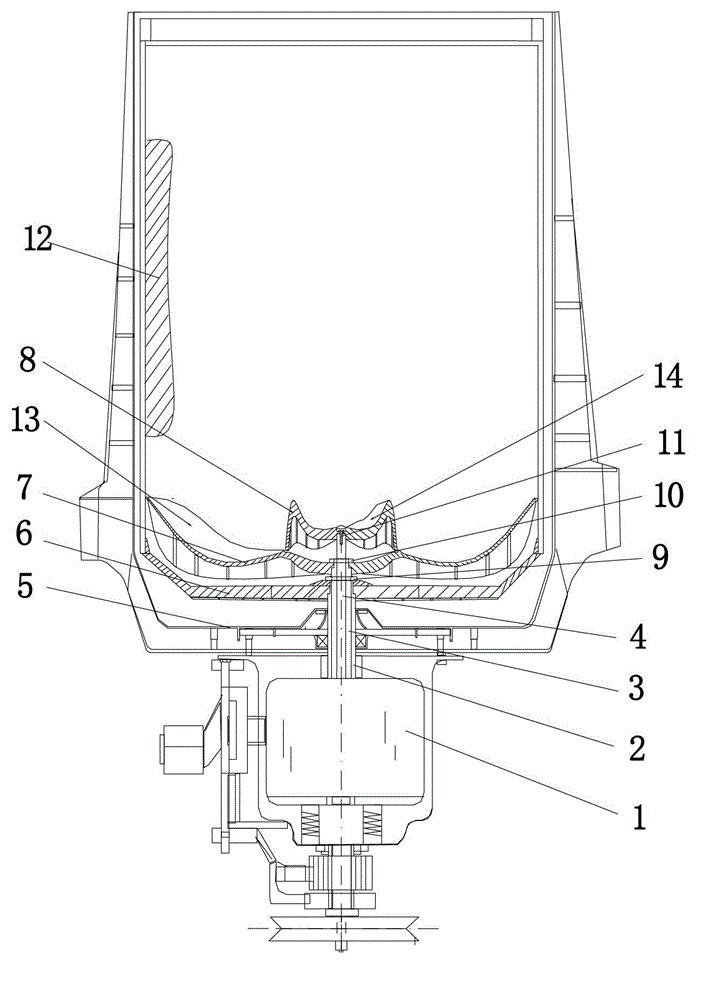

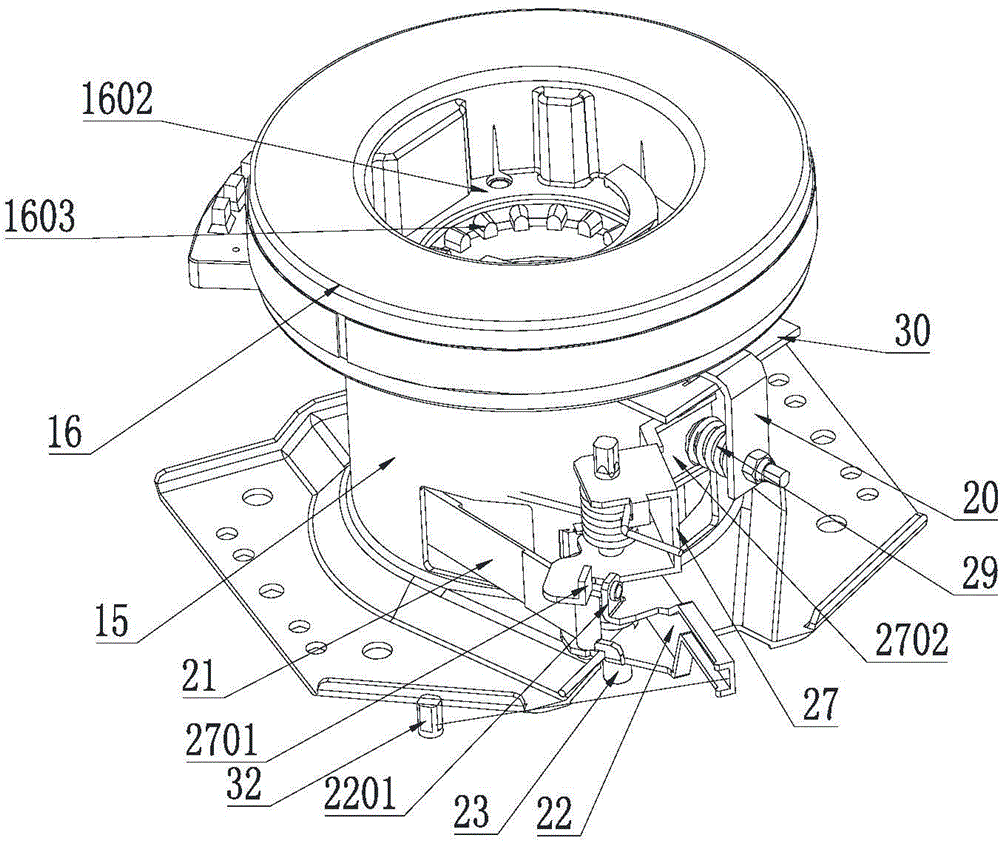

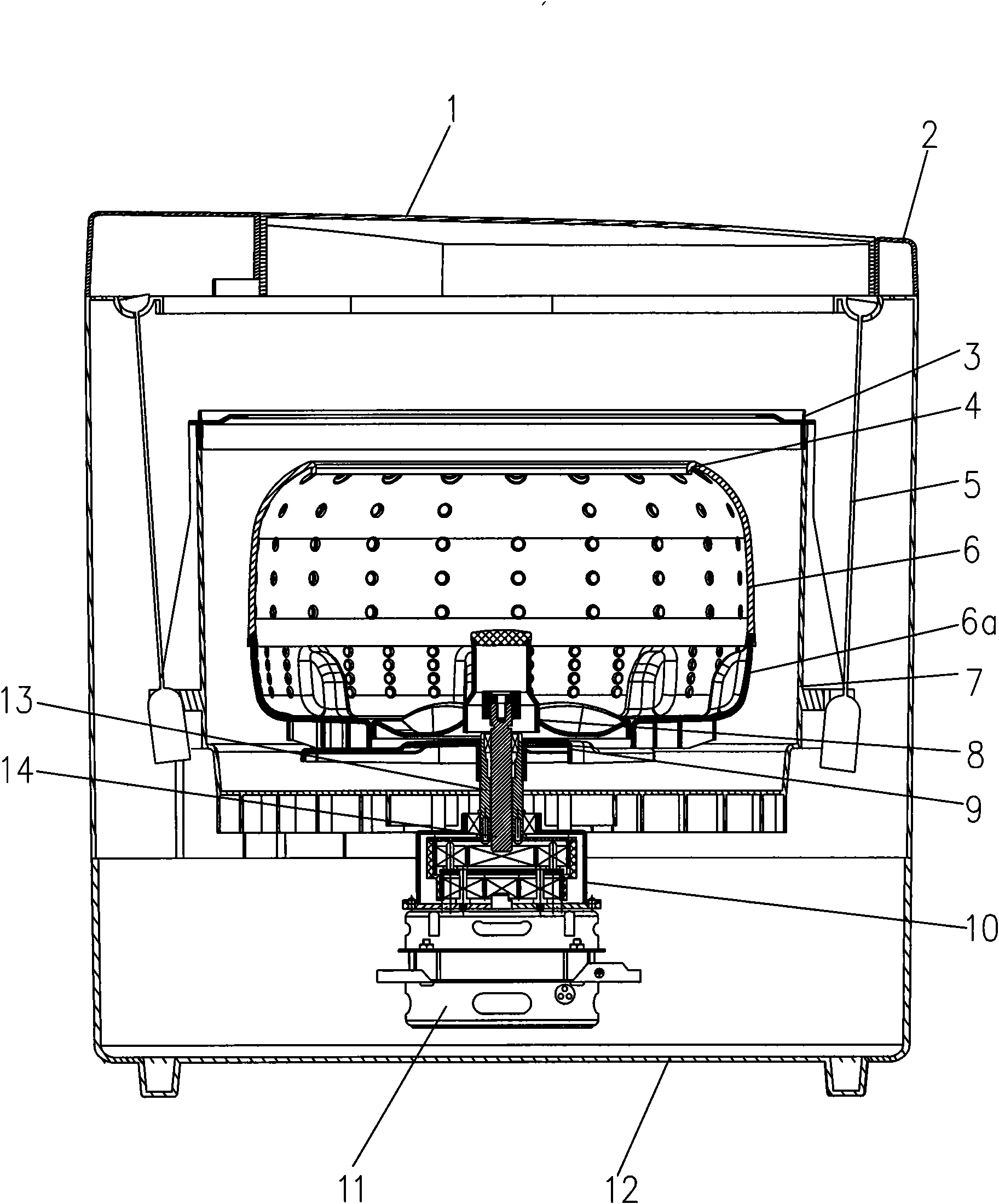

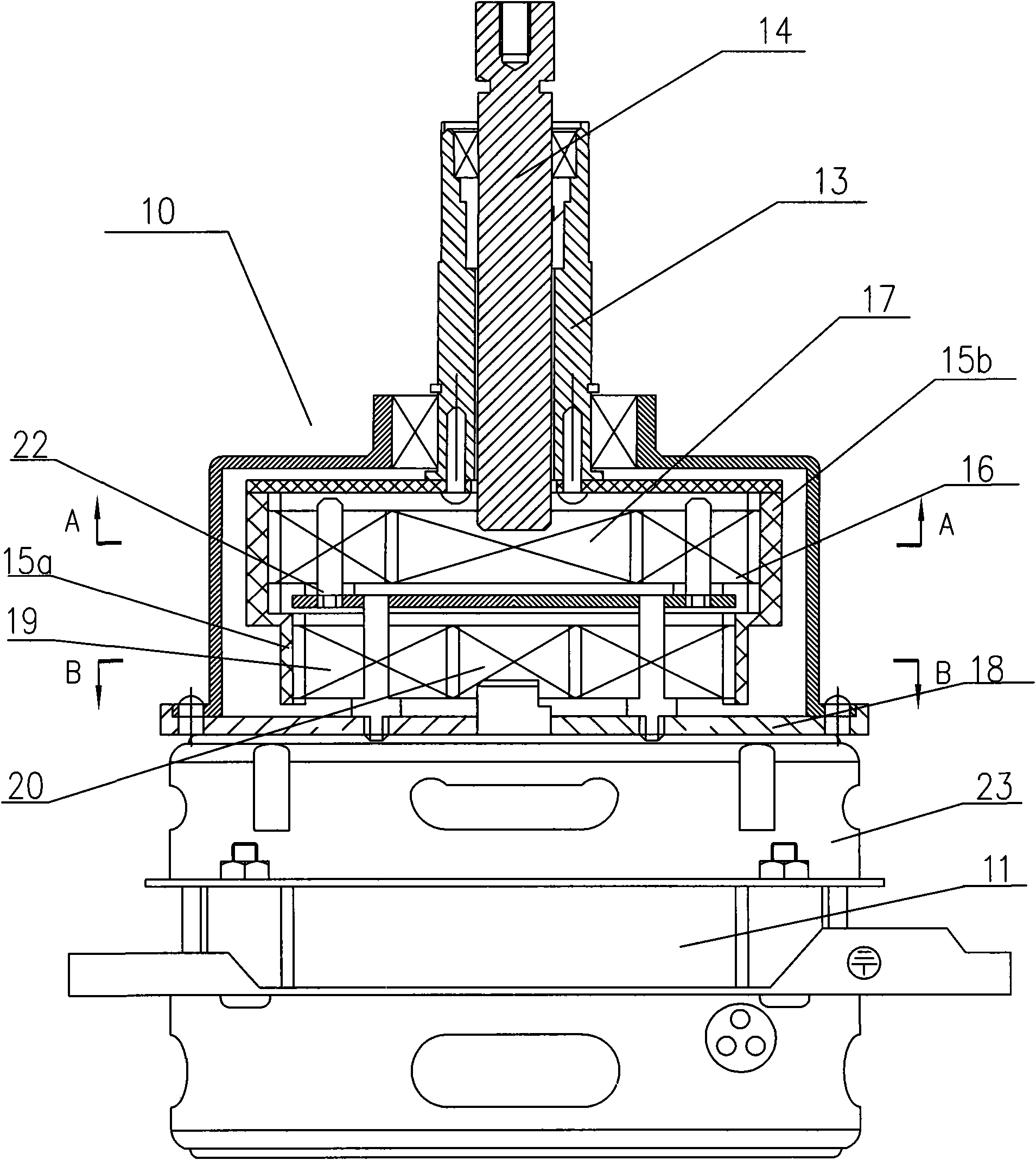

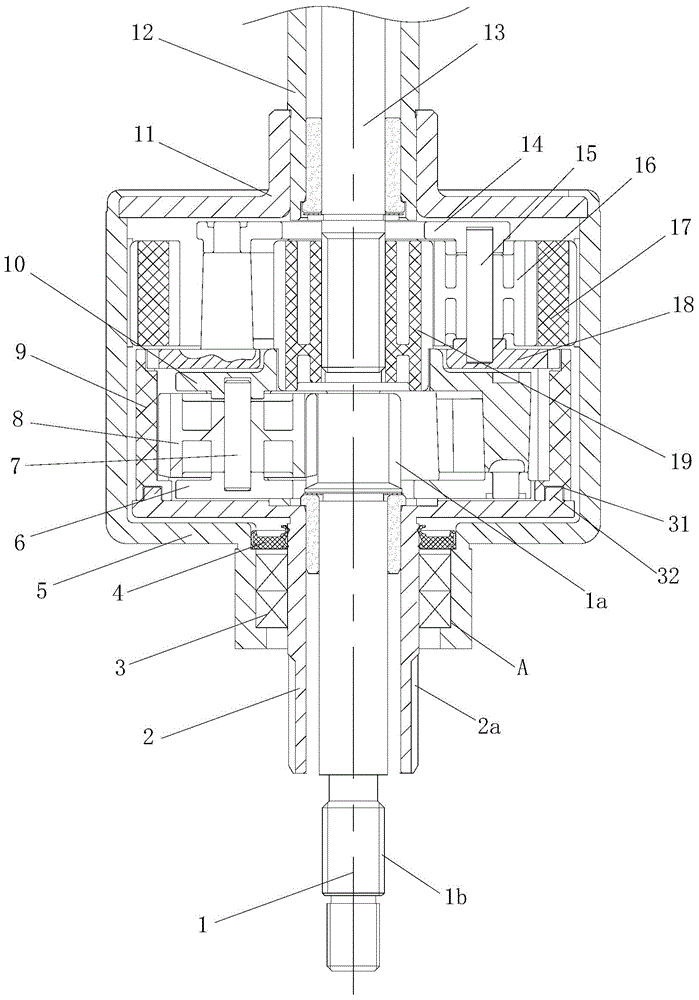

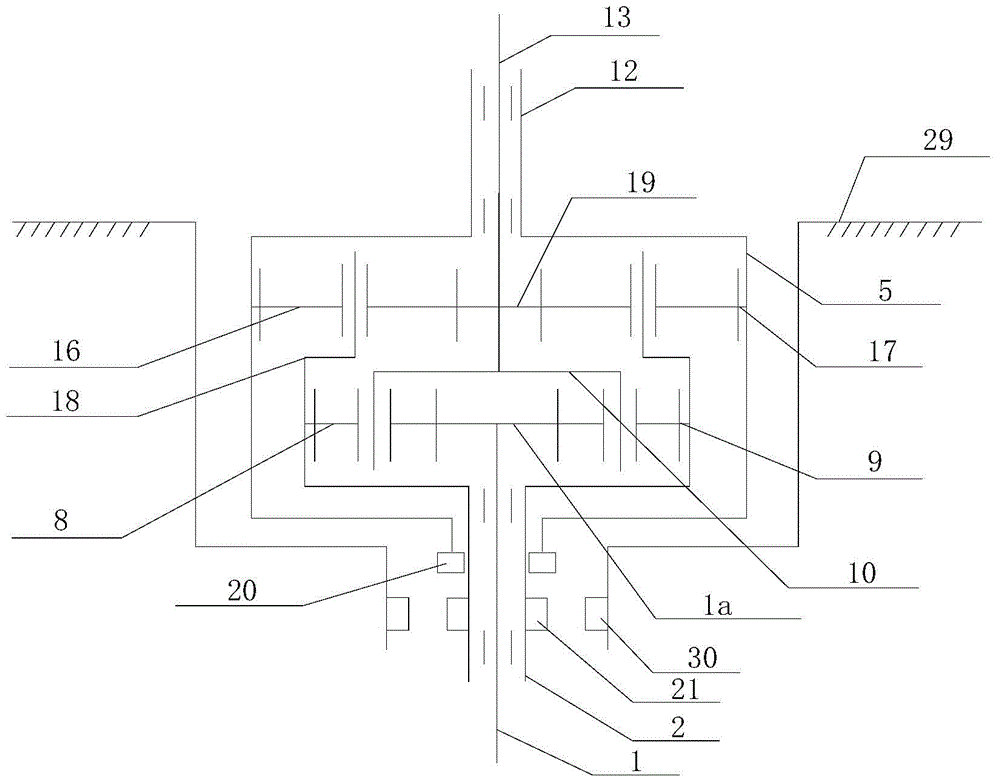

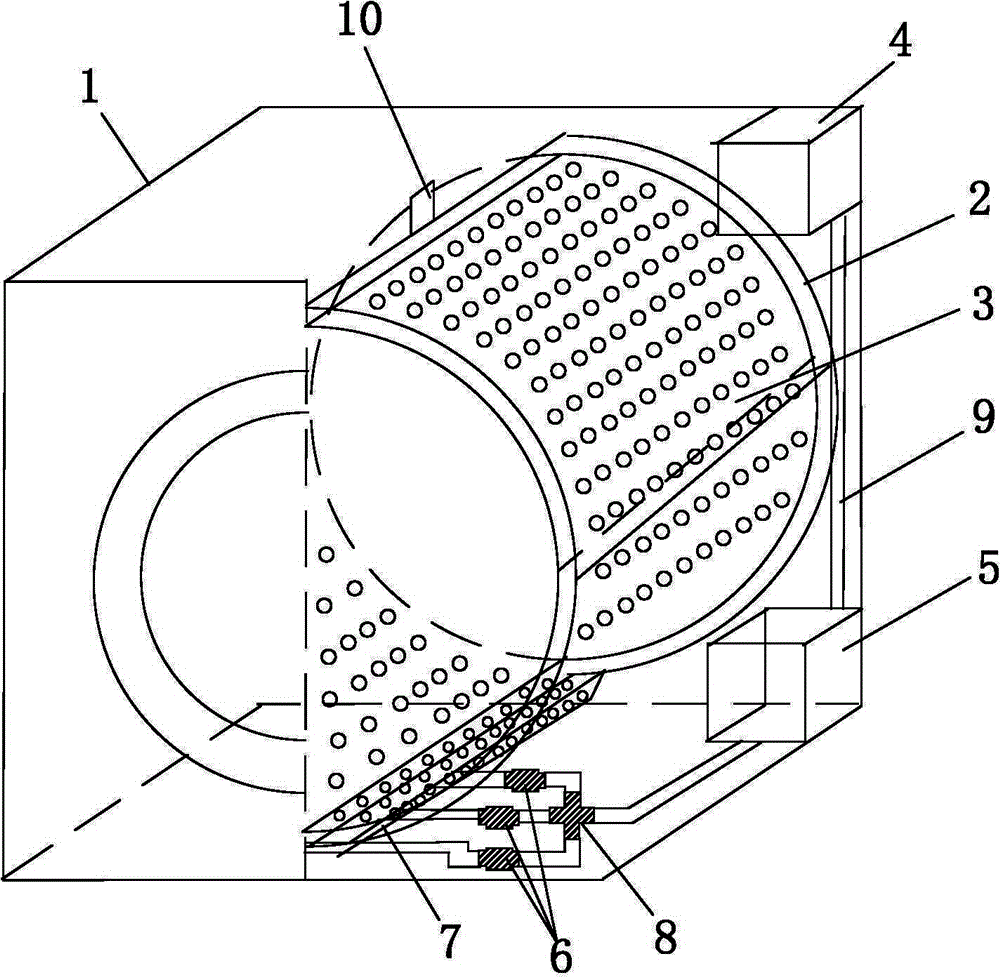

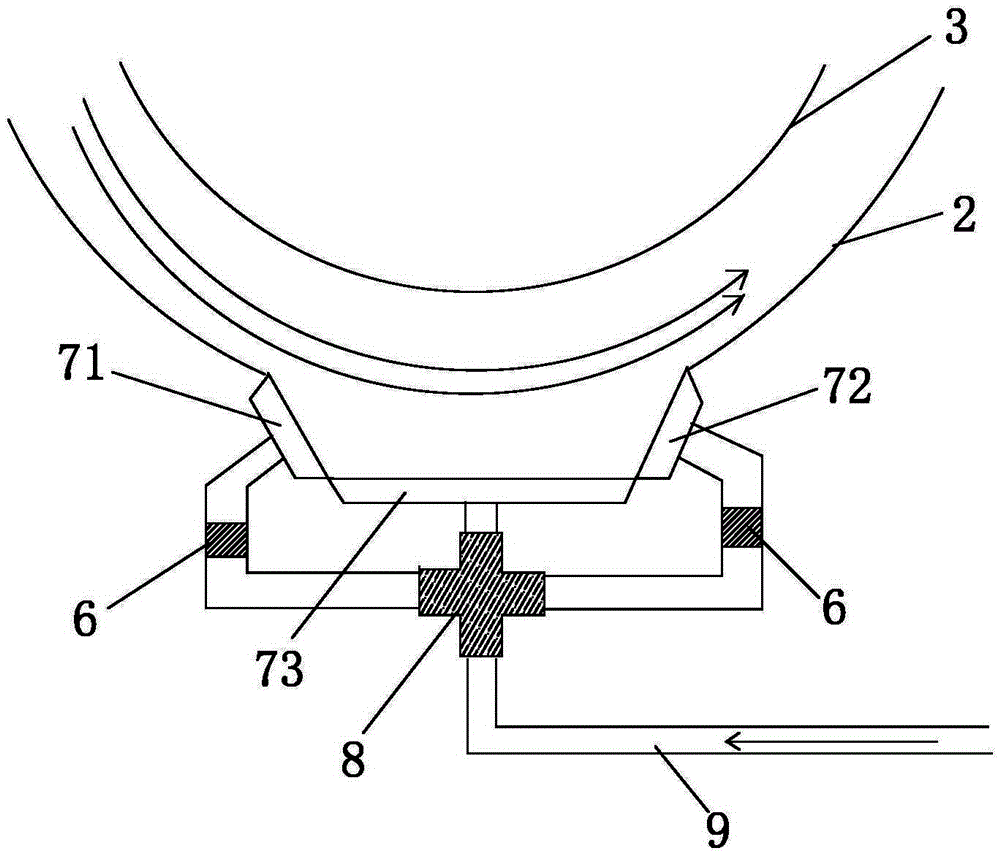

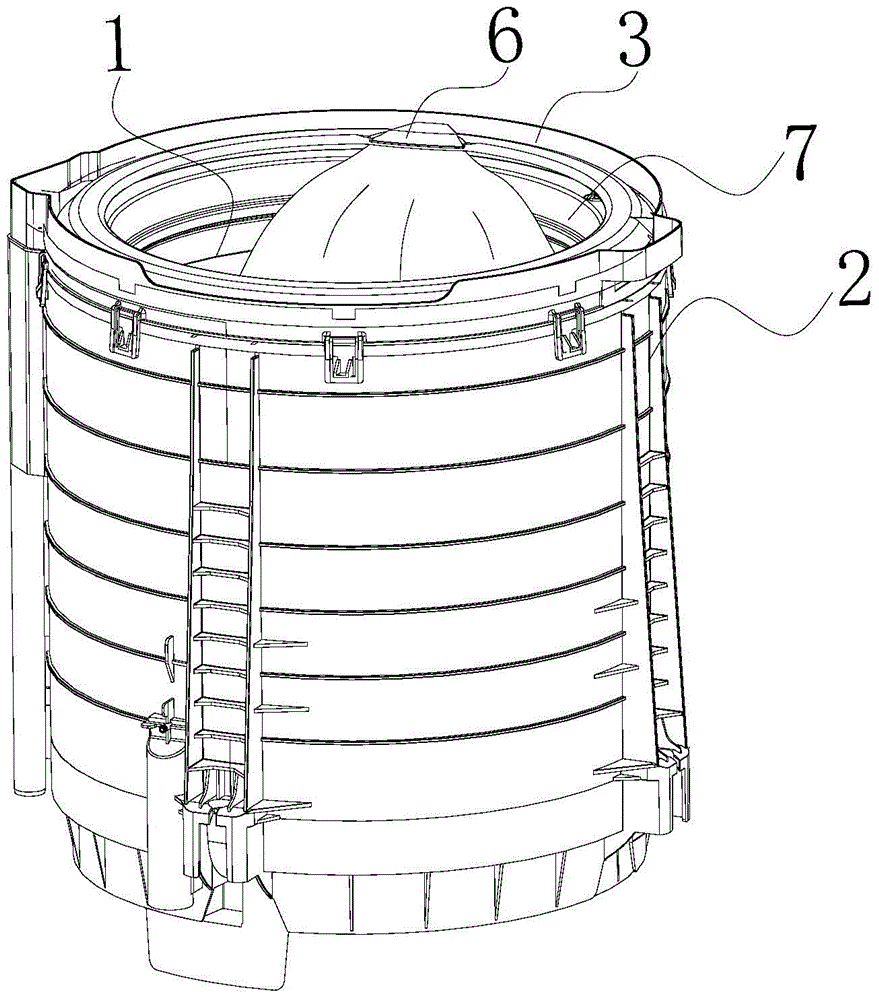

Impeller type fully-automatic washing machine and driving device thereof

ActiveCN101994225AImprove cleaning ratioPowerful backwashOther washing machinesWashing machine with receptaclesImpellerLaundry washing machine

The invention provides an impeller type fully-automatic washing machine. The impeller type fully-automatic washing machine comprises a chassis (2) and a water-accommodating bucket (7), wherein the water-accommodating bucket (7) is arranged in the chassis (2); a dehydrating bucket (6) is arranged in the water-accommodating bucket (7); an impeller (8) is arranged at the bottom of the dehydrating bucket (6); a driving device (10,11) is arranged below the dehydrating bucket (6); the driving device comprises a motor (11) and a transmission device (10); the transmission device (10) is arranged between the dehydrating bucket (6) and the motor (1), is directly driven by the motor to drive the dehydrating bucket (6) and the impeller (8) to rotate along the opposite direction and comprises one or two groups of planetary reduction gears. The gears are directly driven by the motor to distribute a plurality of groups of power in a speed-reducing mode, wherein the impeller is driven by one group of power to rotate; and the dehydrating bucket is driven by the other one group of power to rotate, so that the washing and dehydrating requirements of the fully-automatic washing machine are met through simple transmission. The impeller type fully-automatic washing machine has a simple structure and high reliability and greatly reduces the manufacturing cost.

Owner:HANYU GRP CO LTD

Drum washing machine and washing method thereof

PendingCN105088633AImprove solubilityEnhance washing mechanical strengthControl devices for washing apparatusWashing machine with receptaclesWater flowPulp and paper industry

The invention provides a drum washing machine and a washing method thereof. The washing method comprises following steps of a first stage of injecting water; and a second stage of main washing processes comprising a beat washing process and a high-speed rotating-barrel washing process. The beat washing process operates at a rotating speed r of the inner barrel, and the high-speed rotating-barrel washing process is carried out in a way that the rotating speed of the inner barrel is at least higher than or equal to a critical rotating speed R, clothes stick close to the barrel wall of the inner barrel and rotate along with the inner barrel, and a waterfall water flow effect from the barrel top of the inner barrel towards the barrel bottom of the inner barrel is generated, and the critical rotating speed R of the inner barrel in the high-speed rotating-barrel washing process is higher than the rotating speed r of the inner barrel. By employing the drum washing machine and the washing method thereof, the washing mechanical strength can be enhanced, the washing effect can be improved, the drum washing machine is time-saving and power-saving, and a 3D water flow visual effect is achieved at the same time.

Owner:WUXI LITTLE SWAN CO LTD

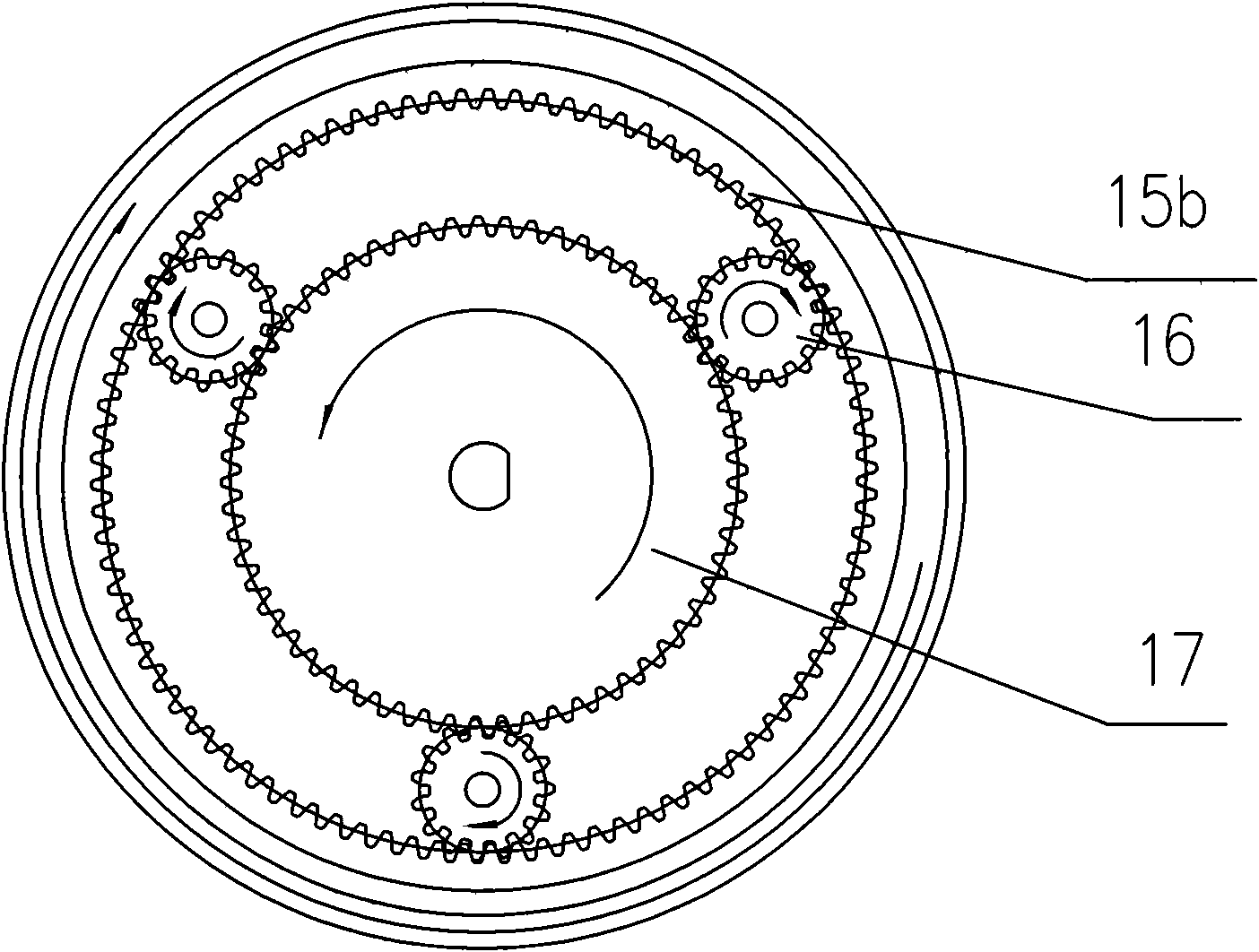

Slowdown clutch for washing machine

ActiveCN104790177AImprove reliabilitySimple structureGearboxesOther washing machinesClutch controlReduction drive

The invention discloses a slowdown clutch for a washing machine. The slowdown clutch comprises an input shaft, an input shaft sleeve, a brake wheel, a speed reducer, a dewatering shaft, an output shaft, a lower shell and a clutch device, wherein the speed reducer is installed in an inner cavity of the brake wheel, the dewatering shaft and the brake wheel are connected into a whole, the input shaft, the input shaft sleeve, the brake wheel and the output shaft are all connected with the speed reducer, the speed reducer is a double-planet gear train composed of a first planet gear train body and a second planet gear train body, the input shaft sleeve and a wheel carrier of the second planet gear train body are connected into a whole, and the input shaft sleeve is movably connected with the brake wheel; the clutch device comprises a positioning disc fixedly installed on the lower shell, a torque transmission shaft sleeve fixedly installed on the input shaft, a clutch disc installed on the input shaft sleeve and capable of being connected with or disconnected from the positioning disc and the torque transmission shaft sleeve, and a clutch control mechanism used for controlling the clutch disc to be connected with or disconnected from the positioning disc and the torque transmission shaft sleeve. The slowdown clutch has the advantages of being simple and compact in structure, low in manufacturing cost, safe and reliable in transmission, efficient, long in service life and low in noise.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

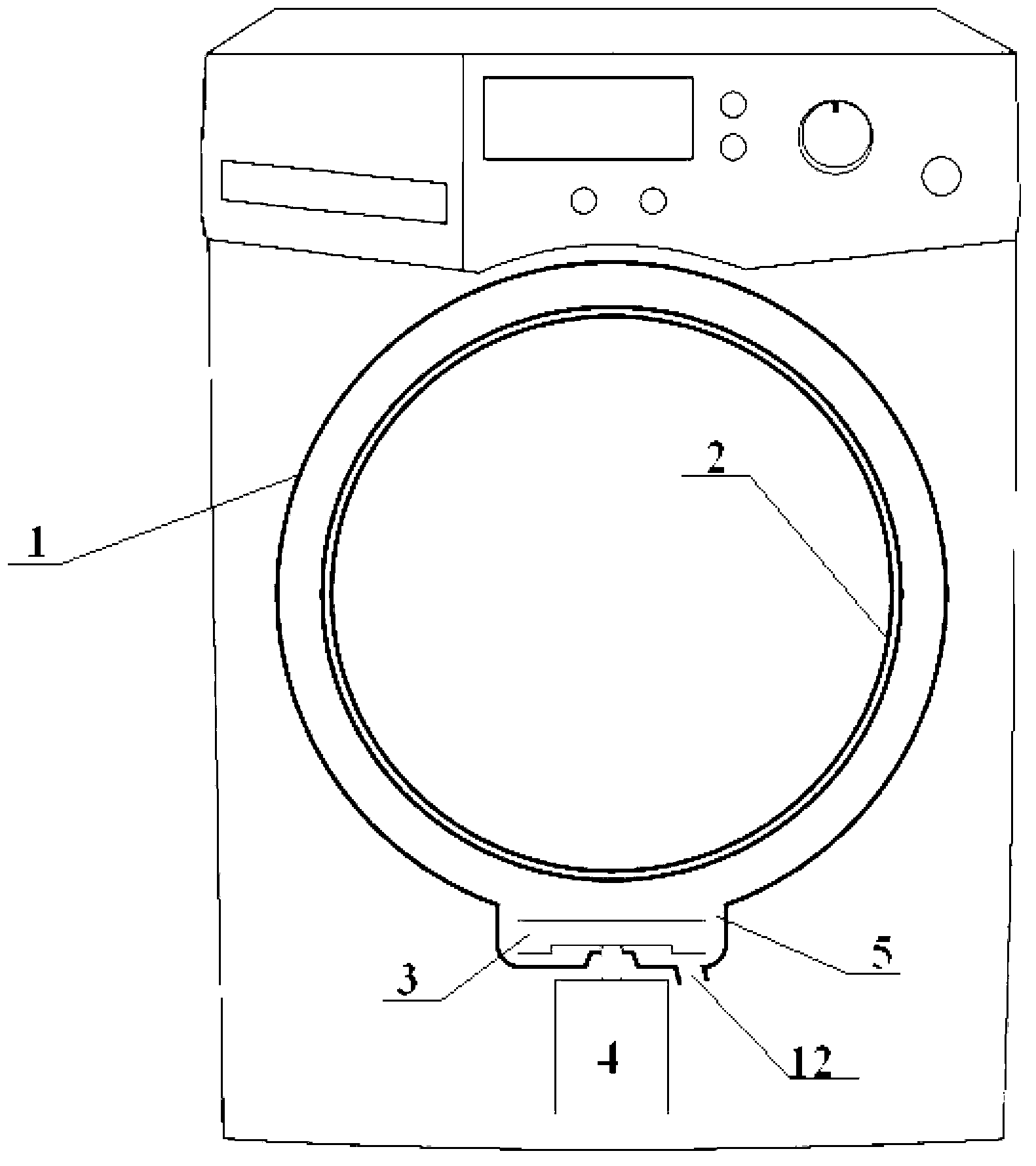

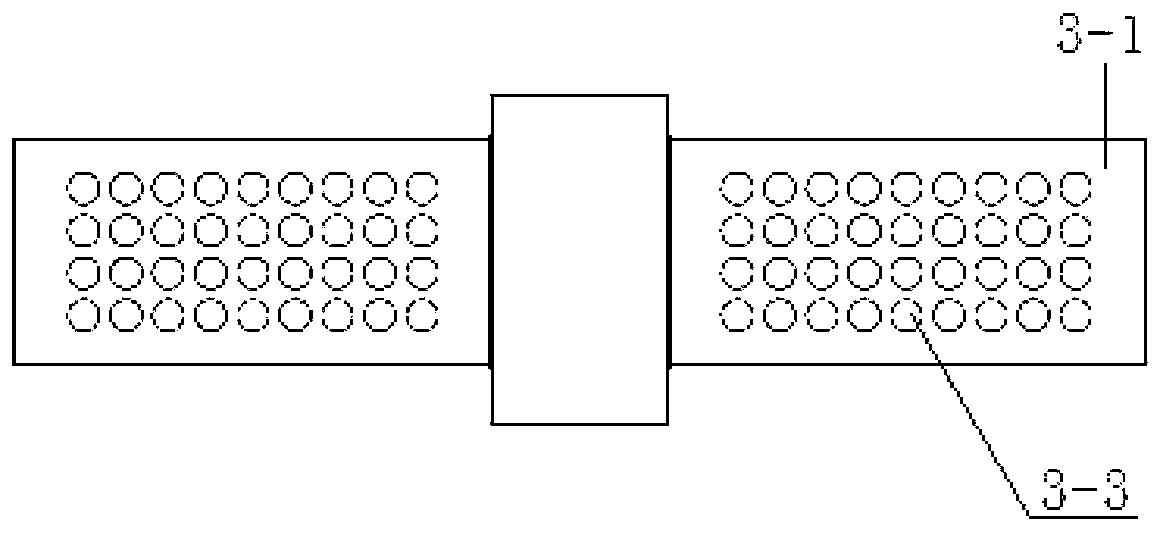

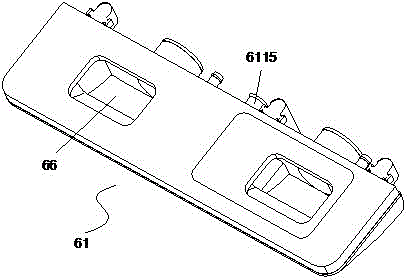

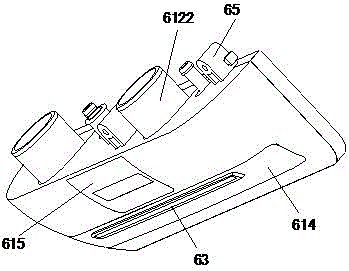

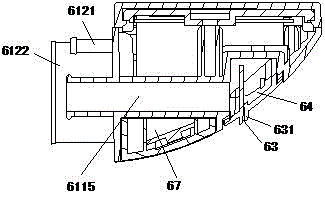

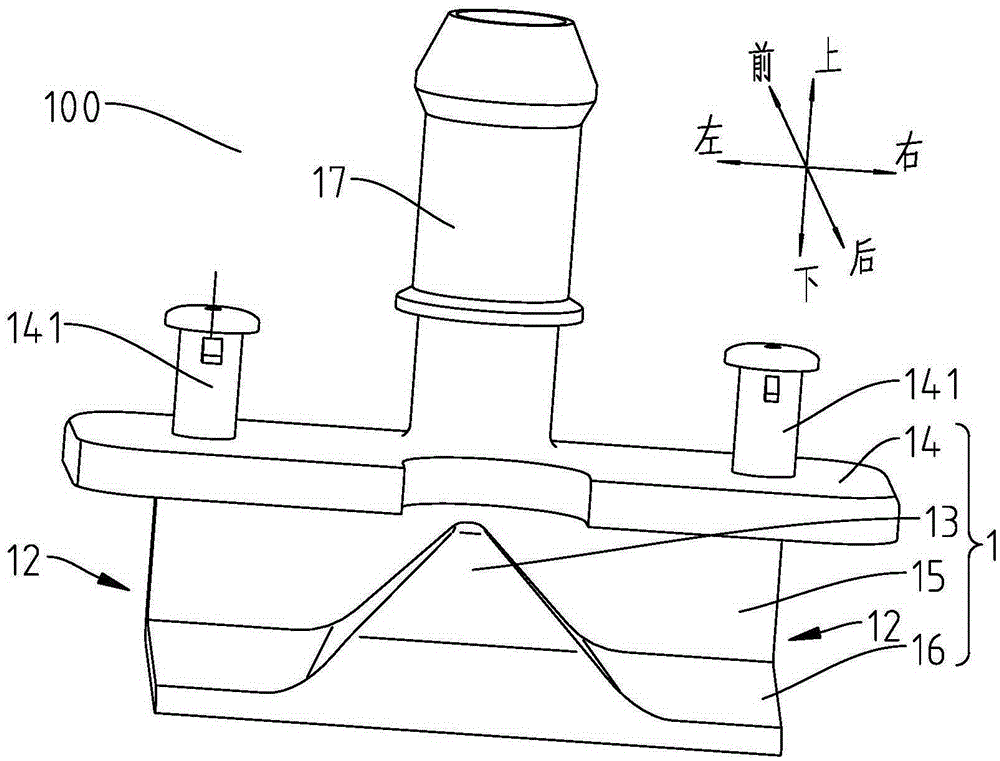

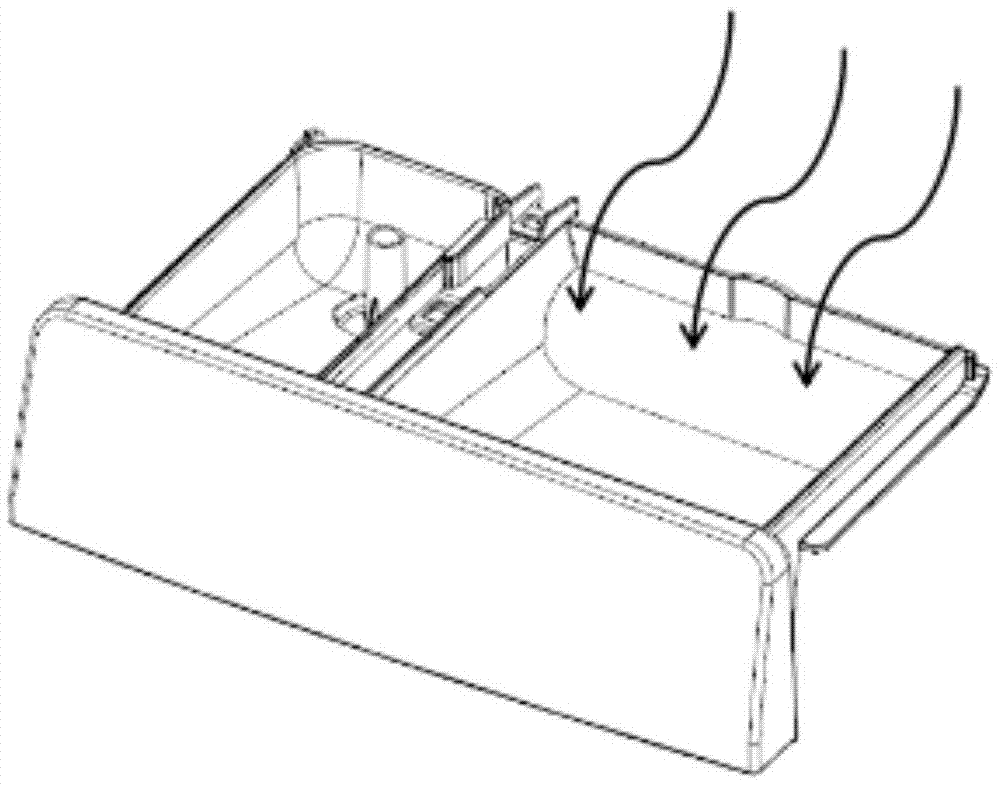

Detergent box, automatic washing machine with detergent box, and water intake method for same

ActiveCN106609441AImprove cleaning ratioShort time spentOther washing machinesWashing machine with receptaclesWater columnEngineering

The invention provides a detergent box, an automatic washing machine with a detergent box, and a water injection method for the same. The detergent box comprises a box body. The box body comprises a water outlet part, a flow stabilization chamber and a drainage part, wherein the water outlet part is strip-shaped; the flow stabilization chamber is used for rectification of water flows entering the box body and is used to make the water flows flow out evenly from the water outlet part; and the drainage part is used to lead the water flows entering the box body to the flow stabilization chamber. The detergent box of the washing machine provided by the invention is characterized in that the strip-shaped water outlet part and the flow stabilization chamber are disposed in the box body; the water flows entering the box body are rectified by the flow stabilization chamber and flow out evenly from the water outlet part; the water outlet part is strip-shaped, so the water flows flowing out from the water outlet part are strip-shaped water columns, and the width of the water columns is large; and waterfall water flows are formed during falling, so a spraying scope is large when water is sprayed on an inner cylinder of the washing machine, contact between clothes and spraying water flows is increased, and a cleaning ratio of the washing machine is increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Washing machine

PendingCN106757959AImprove work performanceImprove cleaning ratioOther washing machinesWashing machine with receptaclesImpellerWater flow

The invention discloses a washing machine which comprises an outer cylinder, an inner cylinder, a plurality of water flow passage plates, an impeller disk and a plurality of floating blocks. The inner cylinder is arranged in the outer cylinder and spaced apart from the outer cylinder. The water flow passage plates are spaced apart along the circumference of the inner cylinder. Each of the water flow passage plates and an inner wall of the inner cylinder limit a water flow passage. Each of the water flow passage plates is provided with a plurality of sprays arranged along its length. The impeller disk is rotatably provided at the bottom of the inner cylinder. A water exclusive chamber is defined between the impeller disk and the bottom of the inner cylinder. One side of the impeller disk facing the water exclusive chamber is provided with a water drainage rib. A plurality of floating blocks is movably provided on one side of the water flow passage plates facing away from the water flow passage to open and close the corresponding water sprinklers according to the water level of the inner cylinder. The washing machine improves the strength and the amount of the jet spray water flow, improves the washing ratio of the washing machine, and reduces the washing water amount.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

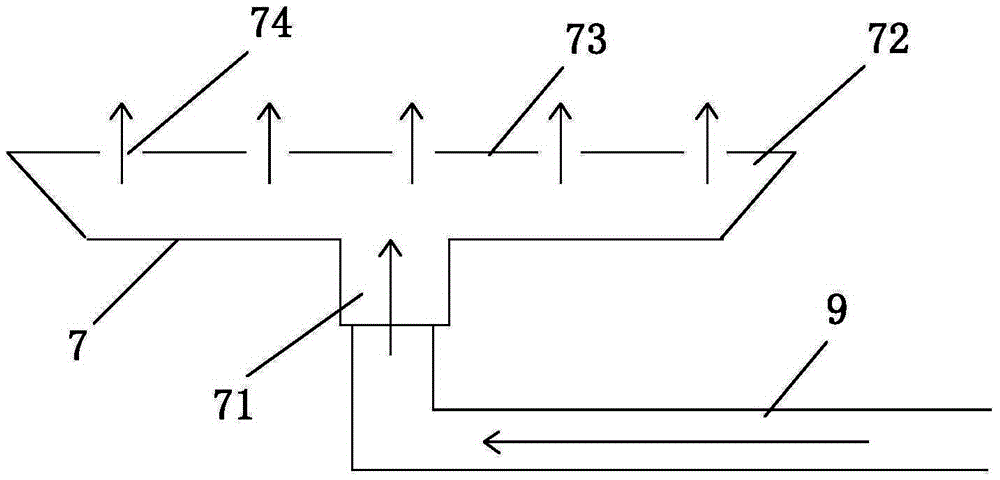

Air-blowing-type roller washing machine and clothes-washing method thereof

ActiveCN105220399AExtension of timeShorten washing timeOther washing machinesControl devices for washing apparatusCheck valveEngineering

The invention discloses an air-blowing-type roller washing machine and a clothes-washing method thereof. The washing machine comprises an internal cylinder, an external cylinder, at least two air chambers used for externally blowing air and an air pump. All the air chambers are independent. The air-blowing direction of at least one air-blowing chamber is the same as the forward-rotating direction of the internal cylinder. The air-blowing direction of at least another air-blowing chamber is the same as the backward-rotating direction of the internal cylinder. During washing, an air chamber in the air-outlet direction same as the rotation direction of the internal cylinder is controlled to blow air into the external cylinder in order to generate bubbles. All the air chambers are communicated with the same air pump by means of an air-flow distributor. Check valves are arranged among the air-flow distributor and all the air chambers. An air-heating device is arranged between the air-flow distributor and the air pump. During washing / rinsing operation of the washing machine, the internal cylinder rotates forward and an air chamber in the air-blowing direction same as the forward-rotating direction of the internal cylinder is controlled to blow air. The internal cylinder rotates backward and an air chamber in the air-blowing direction same as the backward-rotating direction of the internal cylinder is controlled to blow air. During washing, hot air is blown by air chambers and natural air is blown by air chambers. The air-blowing-type roller washing machine has a simple structure and helps to save clothes-washing time and increase clothes-washing efficiency.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

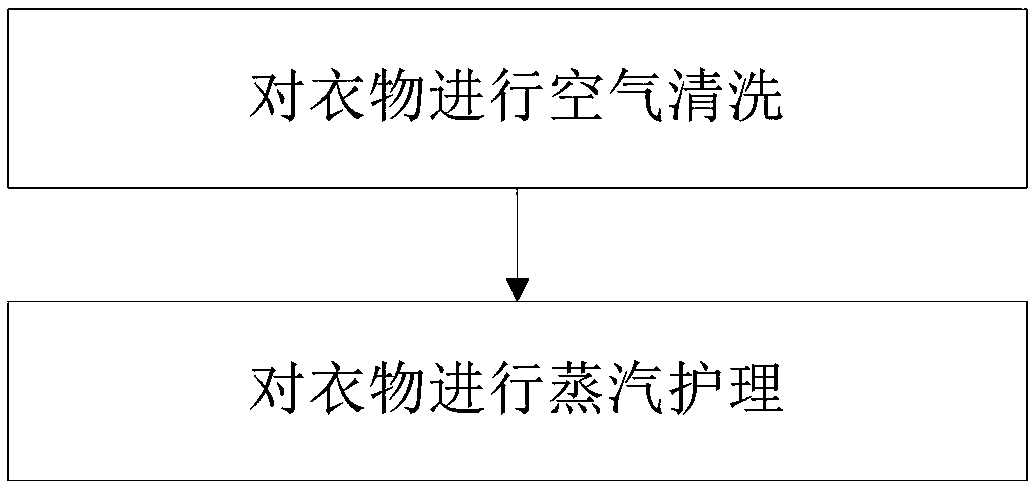

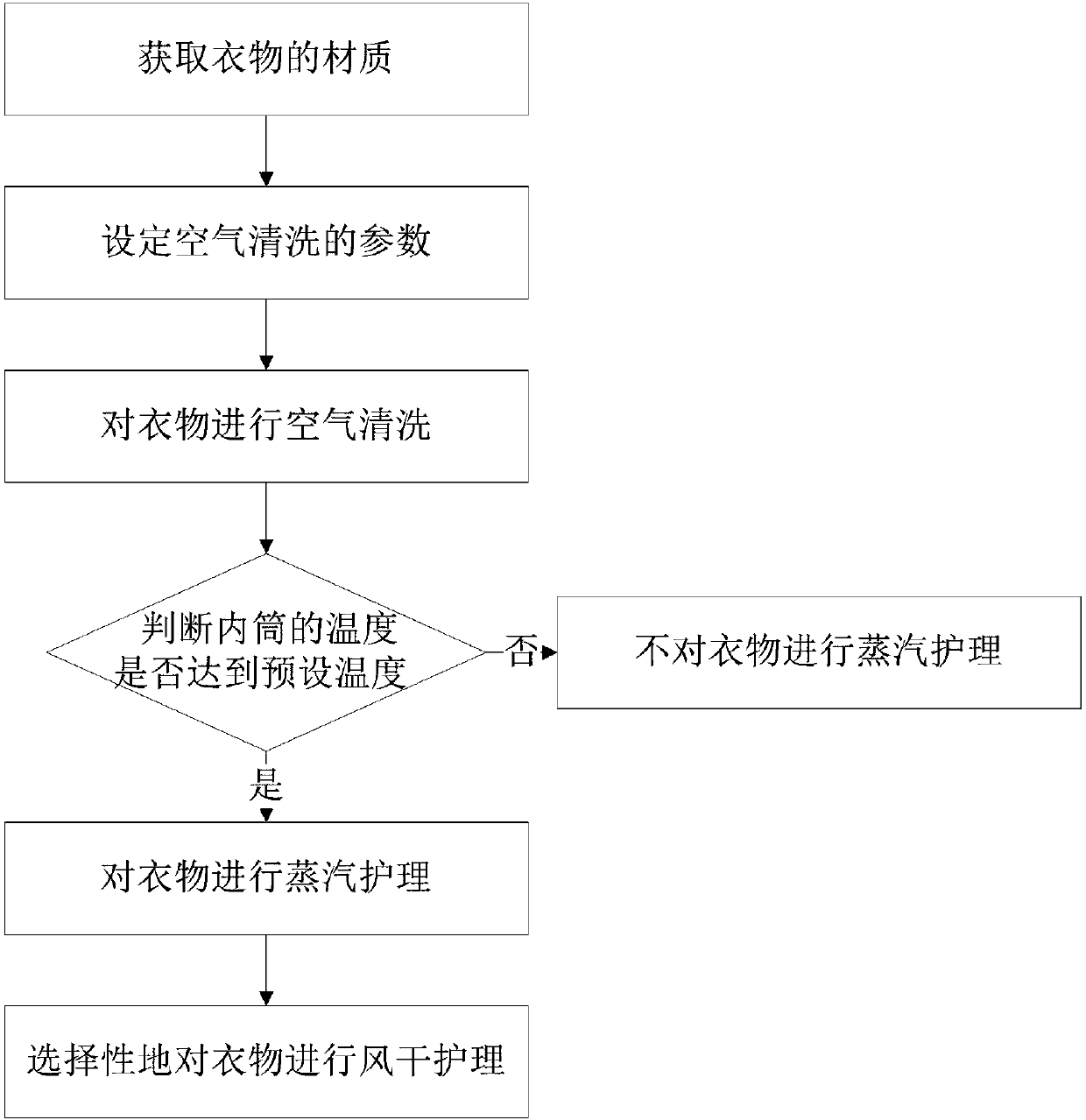

Clothes processing device and clothes processing method for same

ActiveCN110042619AIncrease elasticitySoft fabricOther washing machinesTextiles and paperFiberAir cleaning

The invention belongs to the technical field of clothes processing, and aims at solving the problem that a traditional washing mode cannot meet the requirement of users for cleaning middle and top grade material clothes. In order to solve the problem, the clothes processing method comprises the steps of performing air cleaning on clothes, and performing steam nursing on the clothes. By performingair cleaning on the clothes, fiber of the clothes can be stretched sufficiently, elasticity of the clothes is improved, the fabric of the clothes is more flexible, by performing steam nursing on the clothes, stains on the clothes can be rapidly removed, and the clothes can be sterilized to a certain degree. Due to the clothes combined processing mode, the fabric of the clothes is more flexible andhas elasticity, the clothes wearing comfort is improved, the cleaning effect is good, the cleanness is high, no damage is caused to clothes, and therefore the user experience is improved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Spray and sprinkler device for roller washing machine and roller washing machine

ActiveCN106702685ASimple structureEasy to replaceOther washing machinesTextiles and paperSprinkler systemEngineering

The invention discloses a spray and sprinkler device for a roller washing machine and a roller washing machine. The spray and sprinkler device for the roller washing machine comprises a spray and sprinkler base; a water inlet, a clothes spray and sprinkler mouth and a door seal spray and sprinkler mouth, and the inner side of the spray and sprinkler base is provided with a clothes spray and sprinkler passageway connected with the water inlet and the clothes spray and a sprinkler mouth and a door seal spray and sprinkler passageway connected with the water inlet and the door seal spray and sprinkler mouth. According to the spray and sprinkler device for the roller washing machine, the device is good in universality, the clothes and door seal can be washed at the same time, the cleaning rate and the cleaning efficiency of the clothes are high, and the rinse performance of the whole machine is good.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

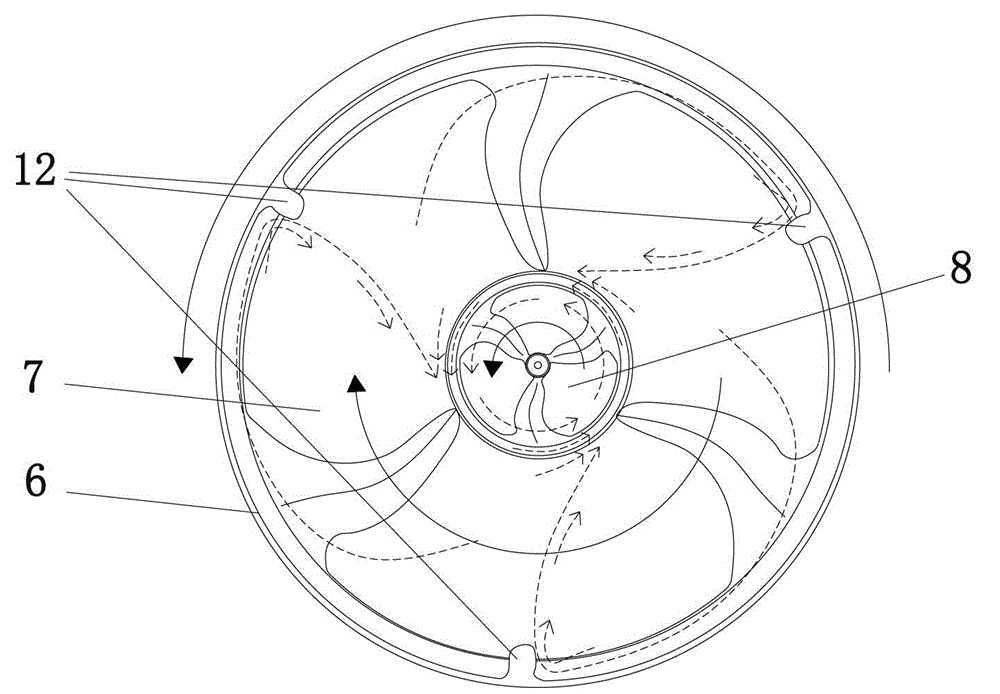

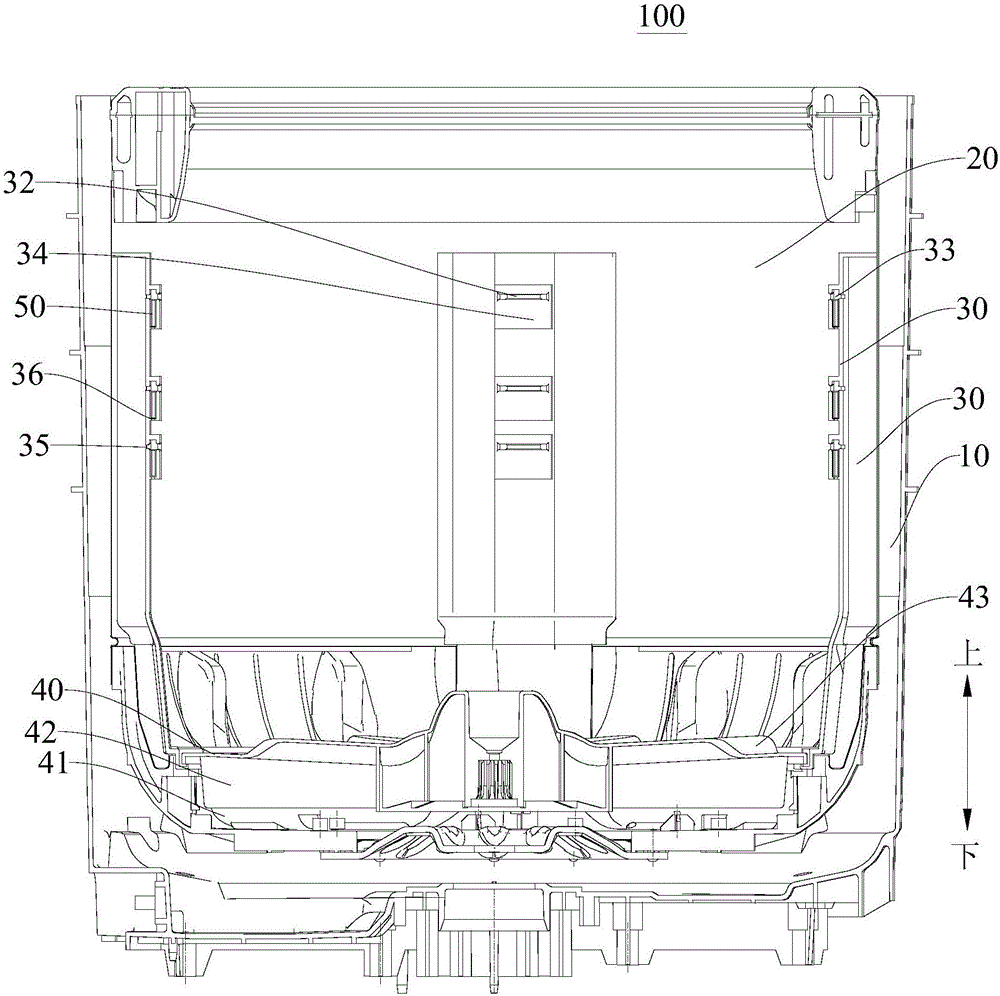

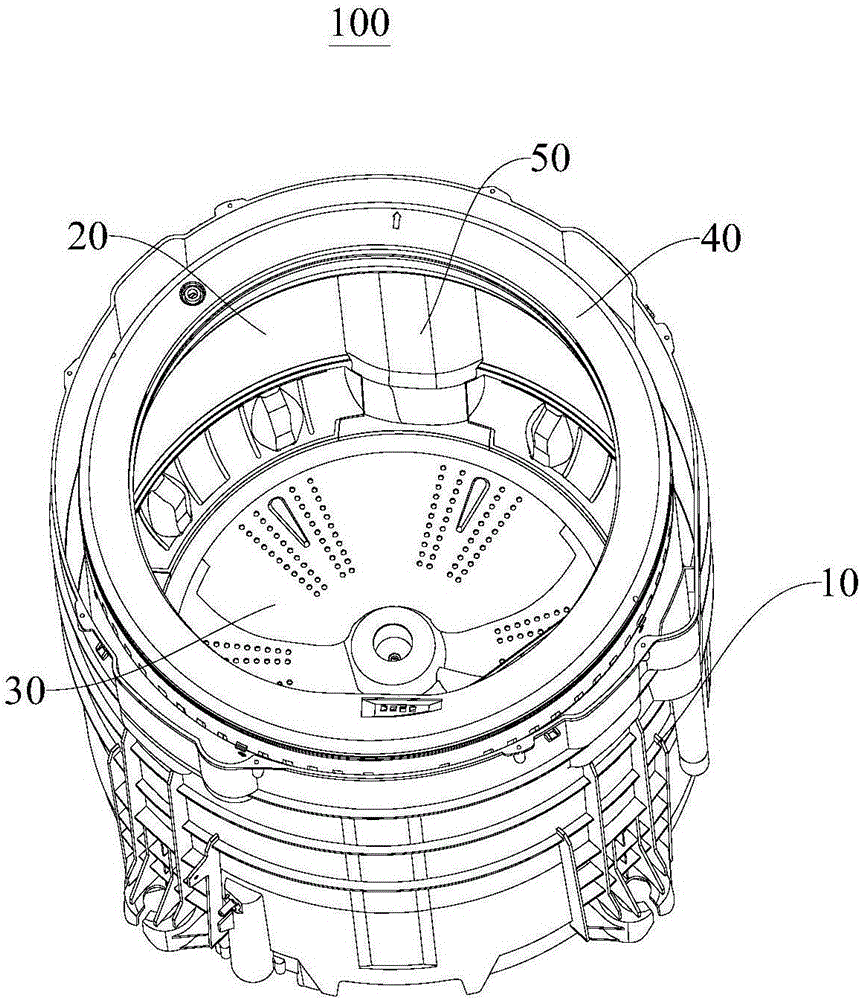

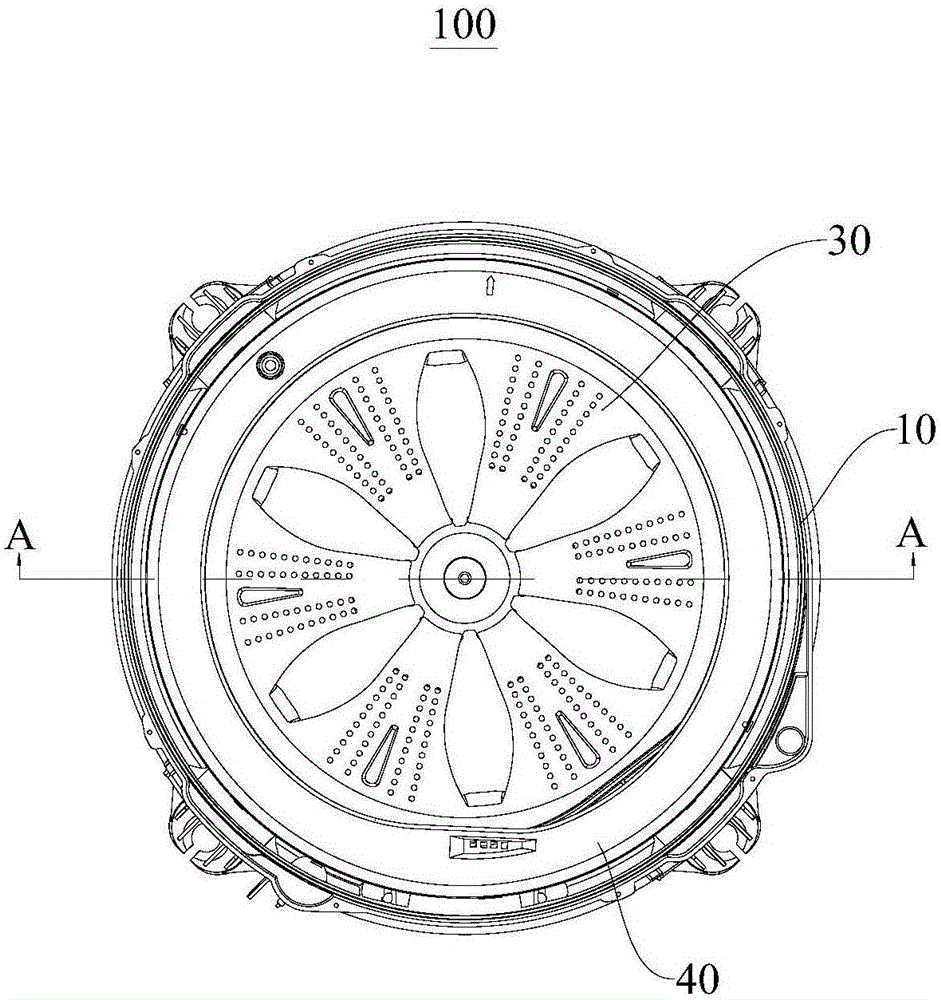

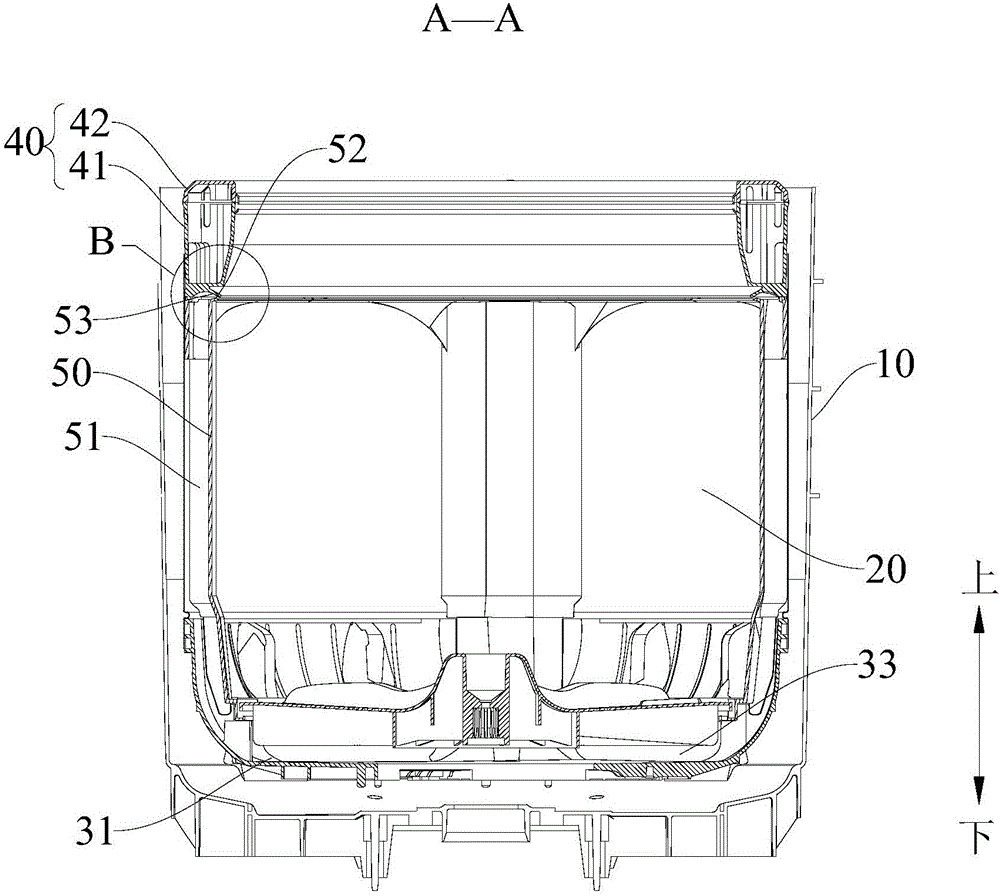

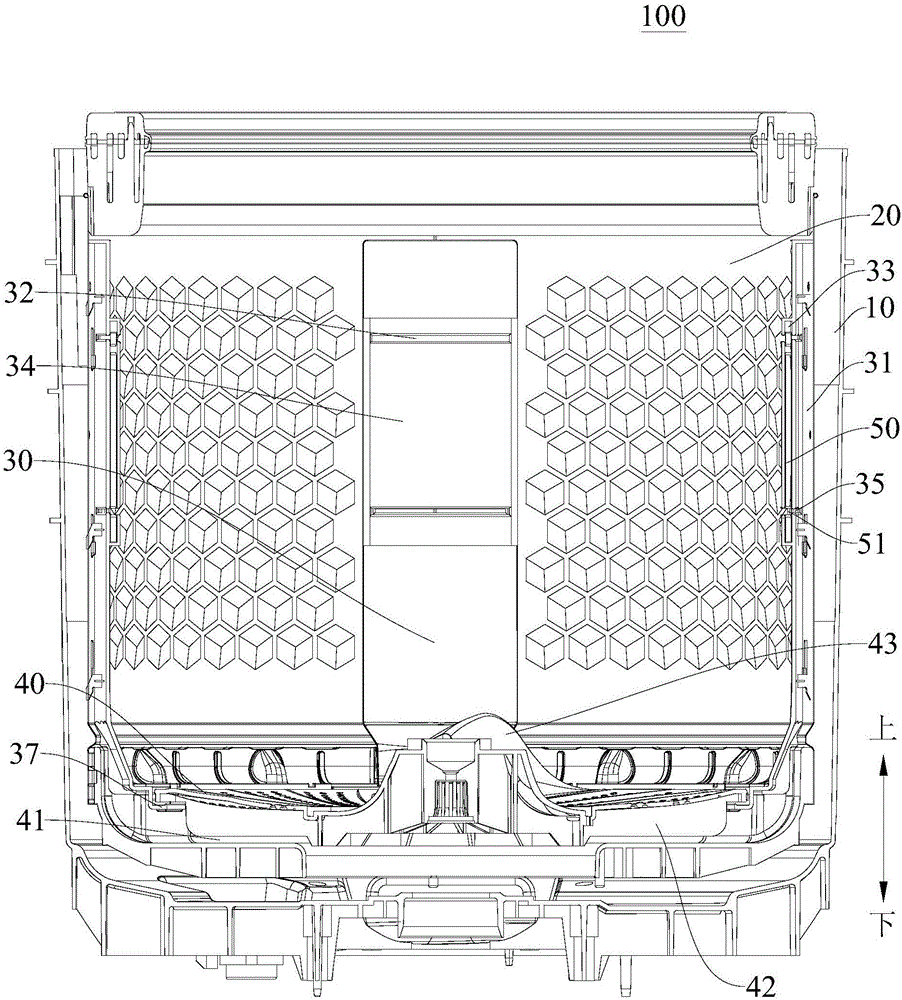

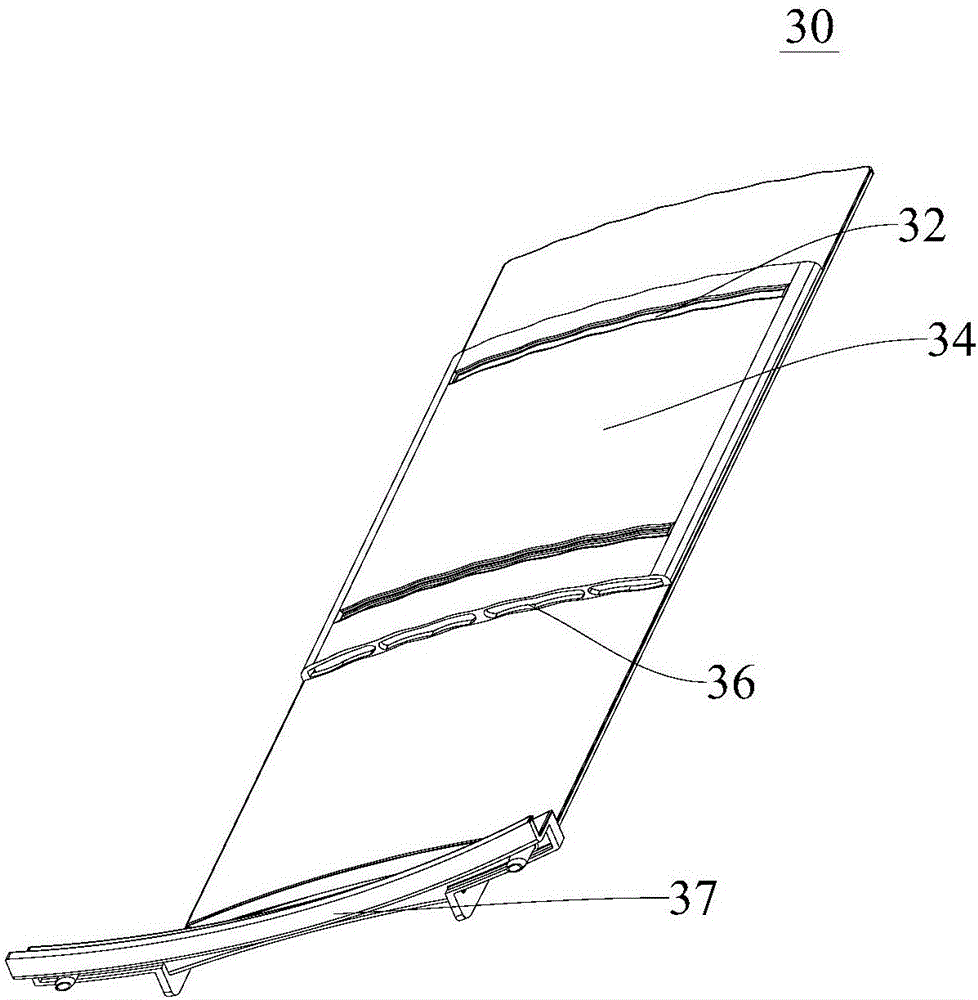

Washing machine

ActiveCN106436130AImprove cleaning ratioRinse evenlyOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention discloses a washing machine. The washing machine comprises an inner cylinder, an outer cylinder, a corrugated disk and a balance ring component. The inner cylinder is located within the outer cylinder with an interval in between. A plurality of water flow plates are placed at regular intervals along the circumference of the inner side wall of the inner cylinder. Each water flow plate and the inner side wall of the inner cylinder constitute a water flow path. The corrugated disk is located at the bottom of the inner cylinder. The corrugated disk and the inner cylinder bottom constitute a water segregation cavity. The water segregation cavity is communicated with the water flow path. The side of the corrugated disk away from the water segregation cavity is placed with water discharge rib. The balance ring component is placed on the upper side. The balance ring component and the upper ends of a plurality of water flow paths constitute a plurality of flow spray cavity. Each flow spray flow cavity is communicated with the water flow path. A plurality of water separation guide ribs placed at regular intervals are located in each flow spray cavity. The inner circle of the upper end of each water flow path and the inner circle edge of the lower end of balance ring component constitute spray blast mouths. The washing machine has the advantage of simple structure, low production cost, high safety, average water output and high clean ratio.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Spraying structure provided washing machine inner cover and washing machine comprising same

ActiveCN103668867AIncrease profitRinse evenlyOther washing machinesWashing machine with receptaclesWater flowEngineering

The invention discloses a spraying structure provided a washing machine inner cover and a washing machine comprising same. The inner cover which is mainly formed by at least two layers of structural pieces comprises an upper cover and a lower cover; the spraying structure comprises a spraying water chamber which is formed between the upper cover and the lower cover, a plurality of spraying holes and an inner cover water inlet; the plurality of spraying holes are formed at the bottom of the spraying water chamber; the inner cover water inlet is correspondingly communicated with a spraying water outlet of the washing machine when the inner cover is closed and is disconnected with the spraying water outlet of the washing machine when the inner cover is open; the inner cover water inlet is an opening which is formed in the lateral wall of the spraying water chamber and corresponding to the spraying water outlet of the washing machine; positions at the spraying water chamber bottom, which are corresponding to the water inlet direction of the inner cover water inlet, are provided with water diversion protruding ribs; water discharging grooves which discharge water outside are formed in the water diversion protruding rib positions which are back to the inner cover water inlet direction. According to the spraying structure provided washing machine inner cover, water flows which vertically flow into a dewatering bucket uniformly spill on clothes to enter into the clothes comprehensively due to the spraying holes, the water utilization rate is high, and rinsing is uniform.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

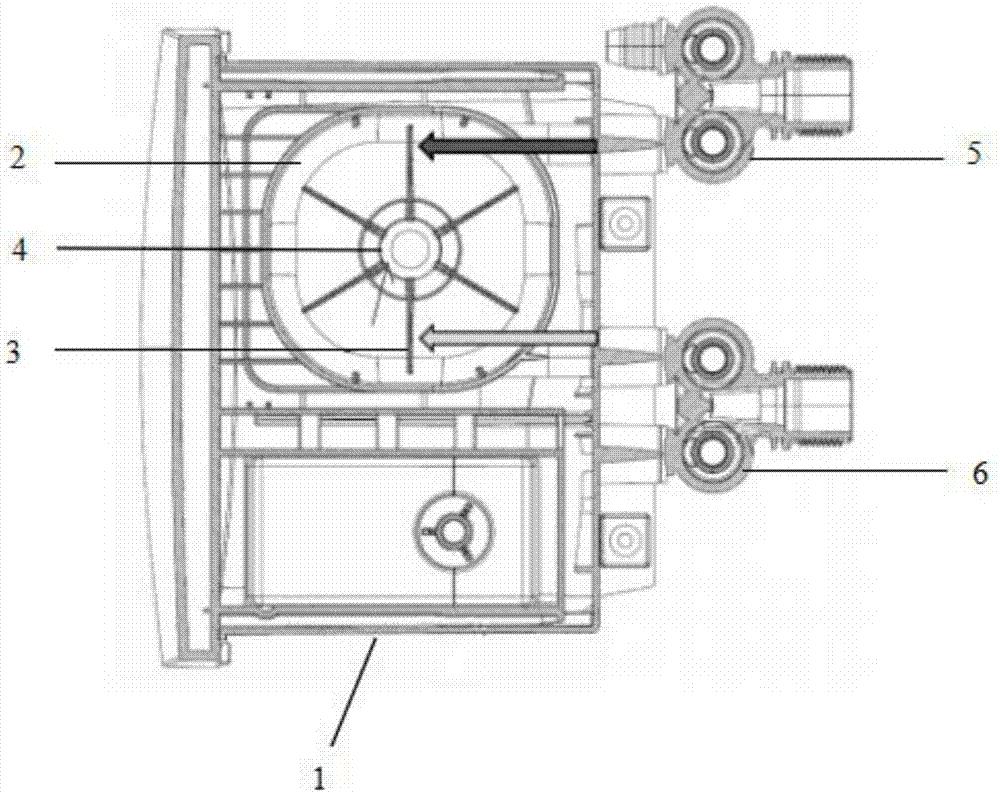

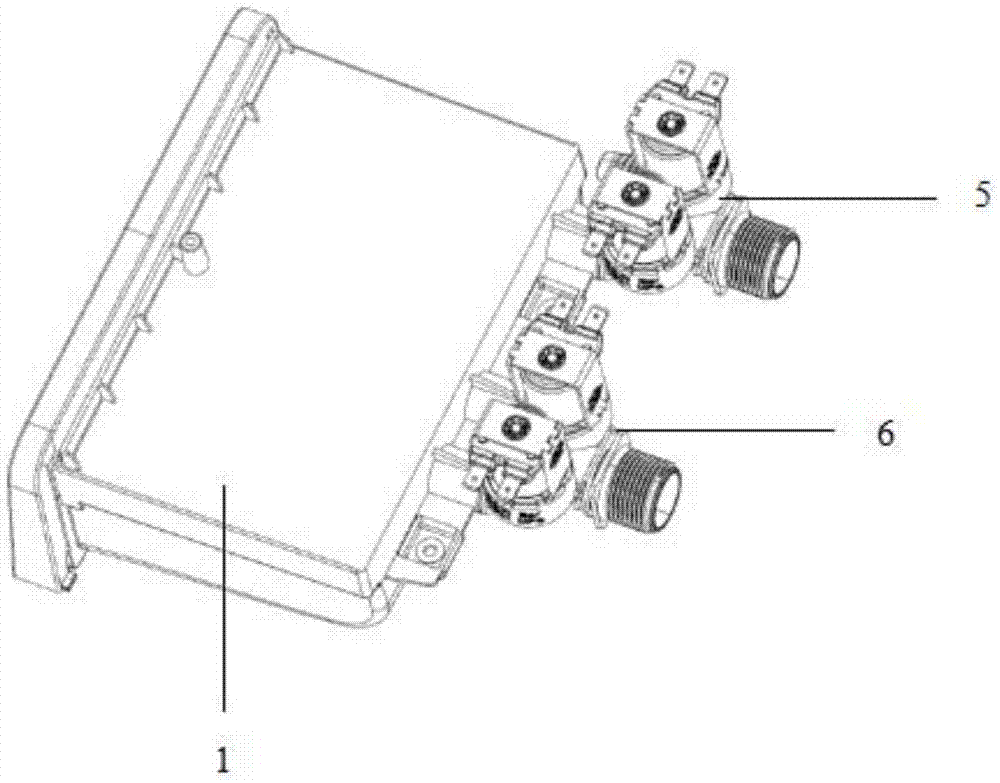

Washing box component and washing machine with washing box component

ActiveCN106939495AImprove solubilityAvoid pollutionOther washing machinesTextiles and paperHigh energyInlet valve

The invention discloses a washing box component of a washing machine. The washing box component of the washing machine comprises a washing box body, wherein the washing box body is provided with at least two water inlet valves connected with a water inlet pipe; a turbo type mechanism is arranged in the washing box body; the water inlet valves are alternately opened or closed, or different quantities of water is introduced into the turbo type mechanism to enable the turbo type mechanism to rotate along a clockwise or anticlockwise direction; through the high-speed impact of the water feeding of the water valve, a turbo can repeatedly act and rotate in the washing box, and therefore, detergent is fully stirred to realize the full solving of the detergent. The washing machine with the washing box component has the advantages of high washing ratio, high energy level and good user use experience, and the detergent is difficult in causing pollution and residues.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

Washing machine and inner circulation spraying component thereof

ActiveCN104452168ASimple structureSimple processOther washing machinesWashing machine with receptaclesSpray nozzleWater flow

The invention discloses a washing machine and an inner circulation spraying component thereof. The washing machine comprises an inner barrel, an outer barrel and an inner circulation spraying system. An outer barrel cover is disposed on the outer barrel. The inner circulation spraying system mainly comprises the spraying component, a circulation pipe and a circulation pump, wherein the spraying component is disposed on the outer barrel cover and comprises a water retaining plate, a nozzle formed by matching with the outer barrel cover and a water inlet which is formed in the periphery of the outer barrel cover, communicated with the nozzle and connected with the circulation pipe, and two sides, along the water flow direction, of the water retaining plate are connected with the outer barrel cover through lateral retaining ribs to form spraying water outlet cavities. Spraying water flows of the spraying component is controlled by circulation pipe inner diameter change in ordination with water inlet inclination angle control. The spraying component is simple in structure and low in cost, splashing is avoided when the inner circulation spraying system sprays at any water level, stable spraying areas and even spraying are achieved, and clothes washing is facilitated.

Owner:FOSHAN HAIER DRUM WASHING MACHINE

Washing machine

ActiveCN106436195ASimple structureCompact structureOther washing machinesWashing machine with receptaclesImpellerThermal spraying

The invention discloses a washing machine. The washing machine comprises an outer cylinder, an inner cylinder, multiple water passing flow channel plates, an impeller disc and floating plates, wherein the inner cylinder is arranged in the outer cylinder and is arranged to be spaced from the outer cylinder, the multiple water passing flow channel plates are arranged in the peripheral direction of the inner cylinder at intervals, each multiple water passing flow channel plate and the side wall of the inner cylinder define a water passing flow channel, each multiple water passing flow channel plate is provided with multiple water spraying ports formed in the length direction of the plate at intervals, the impeller disc is rotatably arranged at the bottom of the inner cylinder, a water insulation cavity communicated with the water passing flow channels is defined between the impeller disc and the inner cylinder, water draining ribs are arranged on the side, facing the water insulation cavity, of the impeller disc, and one movable floating plate is arranged on each water passing flow channel plate and used for opening at least one water spraying port formed in the water passing flow channel plate according to the water level of the inner cylinder and closing other water spraying ports in the corresponding water passing flow channel plate. By the adoption of the washing machine, the strength of waterfall spraying waterflows and the water spraying amount are improved, the washing ratio of the washing machine is improved, and water consumption for washing is reduced.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com