Washing machine inner bucket, washing machine and washing machine lint filtering method

A washing machine and inner tub technology, applied in the field of washing machines, can solve the problems of secondary pollution of clothes, troublesome cleaning, manual removal by users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The best embodiments of the washing machine inner tub and the washing machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

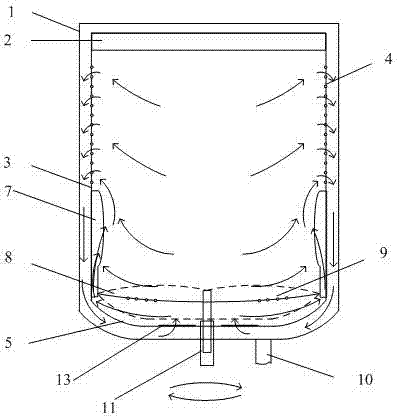

[0024] see image 3 , The washing machine mainly includes: a cabinet, an outer tub, an inner tub, a pulsator 8, a motor drive device 11, a computer board controller, a water inlet system, a drainage system, and the like. The outer bucket includes an outer bucket body, a drive shaft installation hole, a drain pipe, and the middle of the pulsator is covered with water holes.

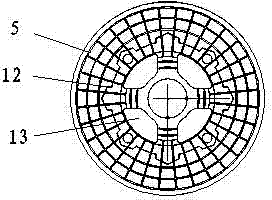

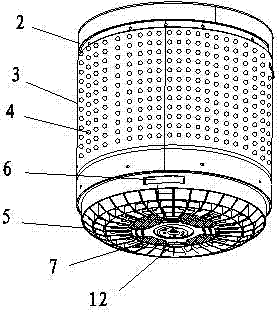

[0025] Specifically, see Figures 3 to 5 , The inner bucket described in this embodiment includes: a balance ring 2 , an inner bucket body 3 , an inner bucket bottom 5 , and a flange 12 at the bottom of the inner bucket. The inner barrel body 3 is evenly covered with smaller inner barrel body water holes 4, the side of the inner barrel bottom 5 has a larger inner barrel bottom water hole 6, and the inner b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com