Washing machine and inner circulation spraying component thereof

A washing machine and internal circulation technology, which is applied in the field of washing machines, can solve the problems of deviation of the spraying point area, splashing water, and unstable water flow, etc., and achieve the effect of uniform and stable spraying area, small design area, and improved washing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

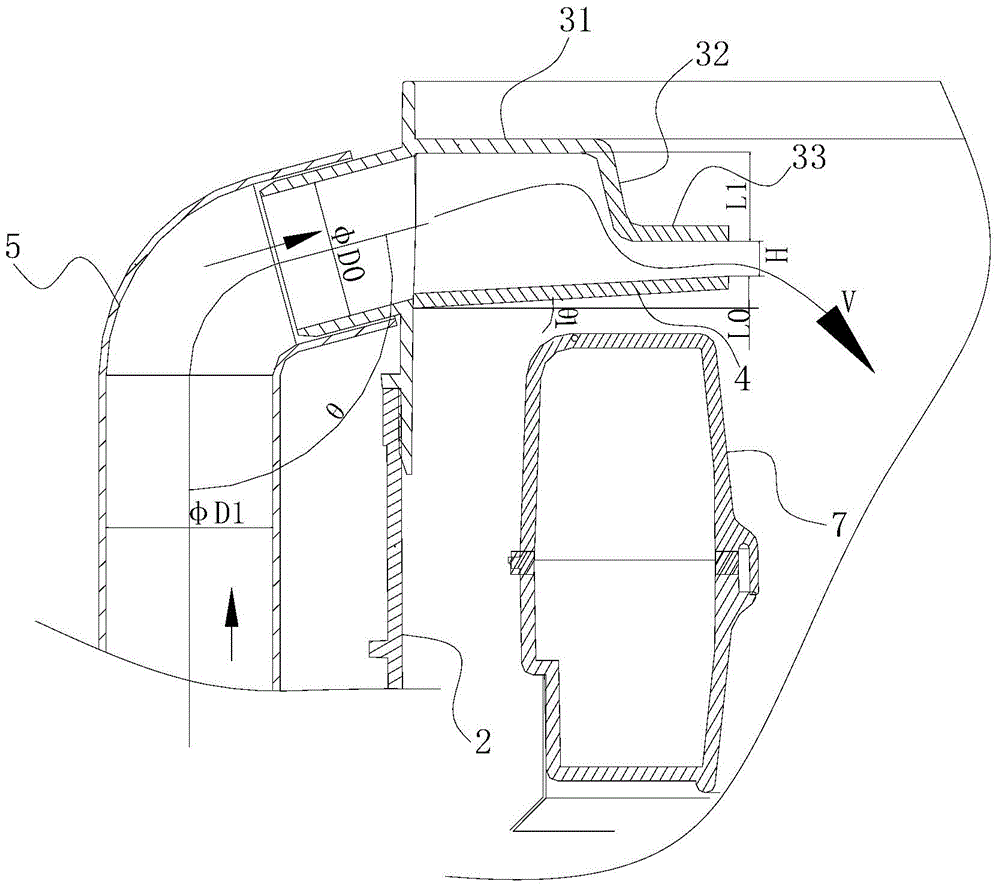

[0055] In this embodiment, the ratio of the width L3 of the water spout to the diameter D0 of the water inlet is 1<L3 / D0<30, and the ratio of the height H of the water spout to the diameter D0 of the water inlet is 0.2<H / D0<1; the ratio of height difference L1 to water inlet pipe diameter D0 is 0<L1 / D0<0.2.

[0056] Such as Figure 11 As shown, in this embodiment, the transition plate 32 is arc-shaped, and the center of the circle is located on the side of the water inlet 61 . Therefore, the water flowing in from the water inlet 61 is blocked by the transition plate 42 so that the water is collected first and then dispersed, so that the water flow is stable. And from the water spray port 62, a waterfall-like spray water flow is formed.

Embodiment 2

[0058] Such as Figure 12 As shown, the second plate 33 described in this embodiment is provided with a multi-segment bent water-retaining rib 66, the two ends of which are located on the edge of the water nozzle 62, and the water-distributing rib 66 and the nozzle between the two ends The edges of the nozzle 62 cooperate to form a closed area B, and the arc chamfer at the bend of the diversion water retaining rib 66 is located in the closed area B, that is to say, the diversion water retaining rib 66 is bent, and its protruding direction corresponds to the water inlet 61, so that the water flows from the water inlet 61 into the spray outlet cavity and then disperses through the diversion water retaining rib 66 and then flows out from the water nozzle 62.

Embodiment 3

[0060] Such as Figure 13 As shown, the transition plate 32 described in this embodiment is arc-shaped in the first embodiment and the second plate 33 is provided with the shunt water retaining rib 66 in the second embodiment, which is blocked by the arc-shaped transition plate 32 , press down the water to flow to the water retaining plate 4, and finally flow down along the diversion water retaining rib 66 and cooperate with the water retaining plate 4 to form a "lantern-like" water curtain effect, and the soft water flows on the clothes or the gland. Directly penetrate into the clothes or spread evenly along the surface of the gland, avoiding the phenomenon of splashing water; the combination of the spray water outlet makes the shape of the spray water more beautiful and the spray area larger (see Figure 10 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com