Patents

Literature

29731 results about "Spray nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A spray nozzle is a precision device that facilitates dispersion of liquid into a spray. Nozzles are used for three purposes: to distribute a liquid over an area, to increase liquid surface area, and create impact force on a solid surface. A wide variety of spray nozzle applications use a number of spray characteristics to describe the spray.

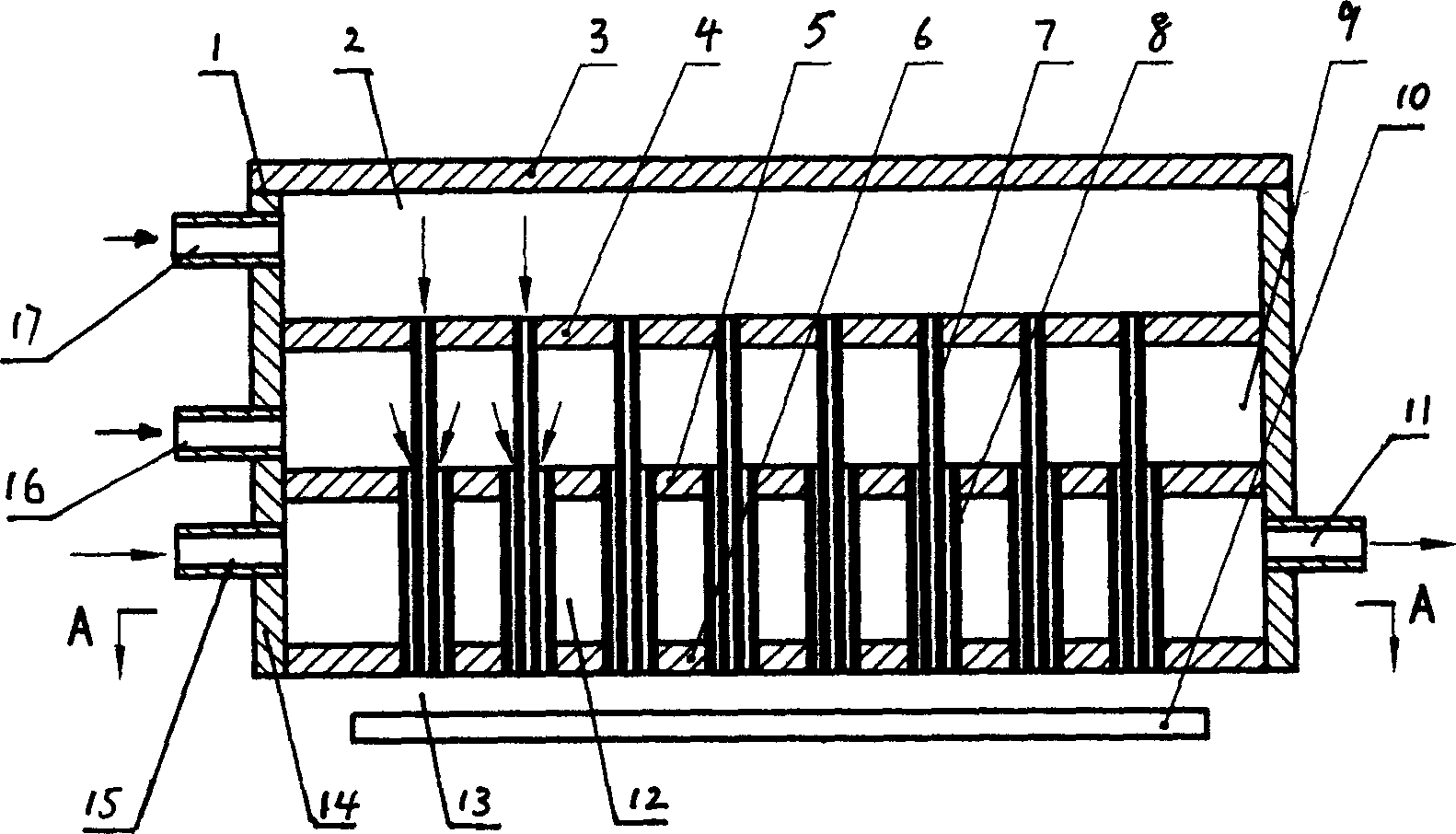

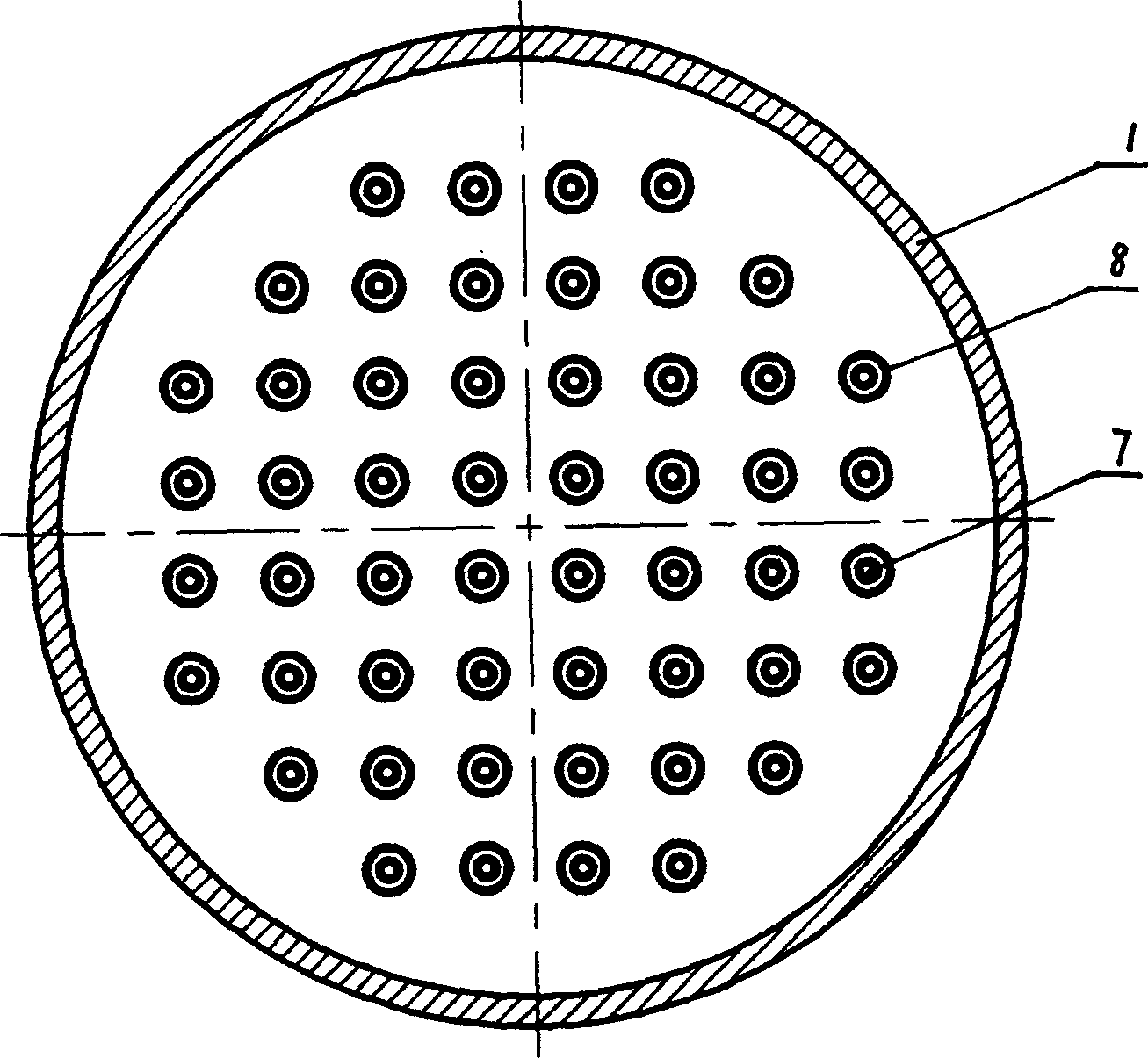

Bilayer inlet gas spray nozzle in use for metal-organic chemical vapor deposition device

This invention discloses a two-layer gas inlet blow head of a metal organic chemical gas phase deposit device including a closed shell having an upper gas inlet cavity and a lower gas inlet cavity, an upper escape pipe communicating with the upper gas cavity and reaction chamber is set between the upper-middle and the base plate and a lower escape pipe communicating with a lower gas inlet cavity and the reaction chamber is set between the lower plate and base plate characterizing that diameter of the lower escape pipe is layer than the upper and the upper is put in the lower. A cooling cavity is designed, the first reaction gas enters into the reaction chamber at the substrate surface from the upper and lower escape pipes separately.

Owner:南昌硅基半导体科技有限公司

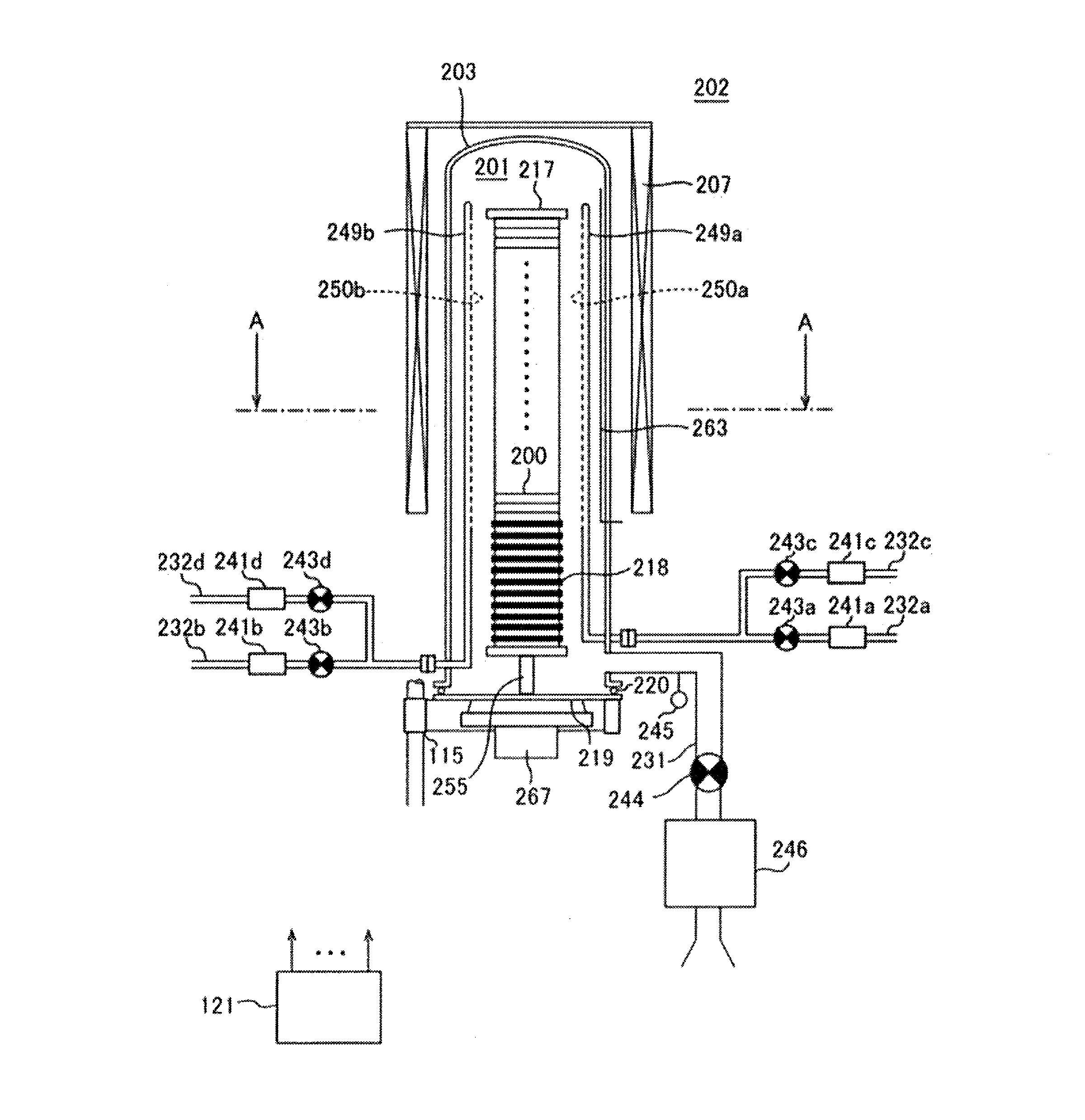

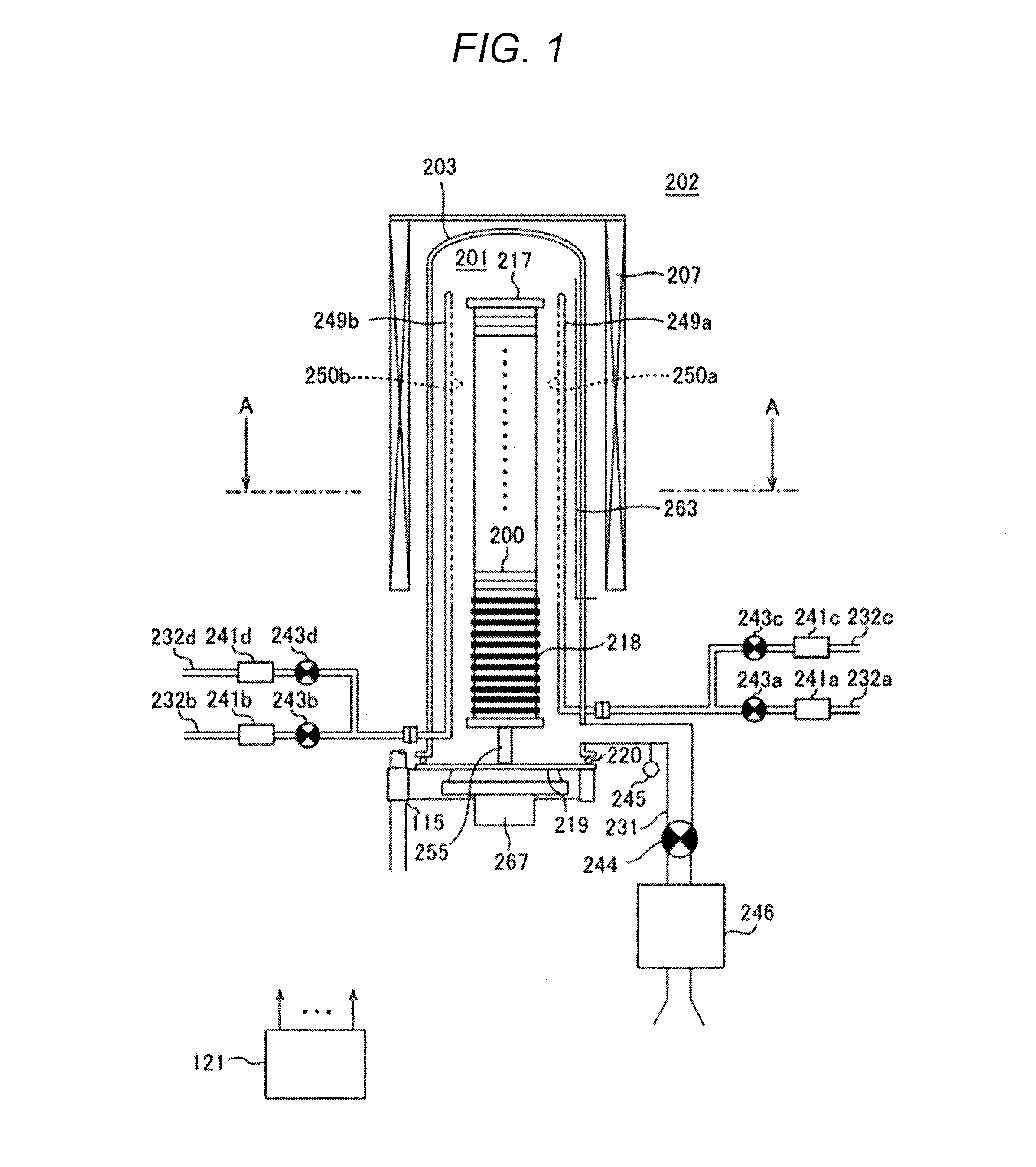

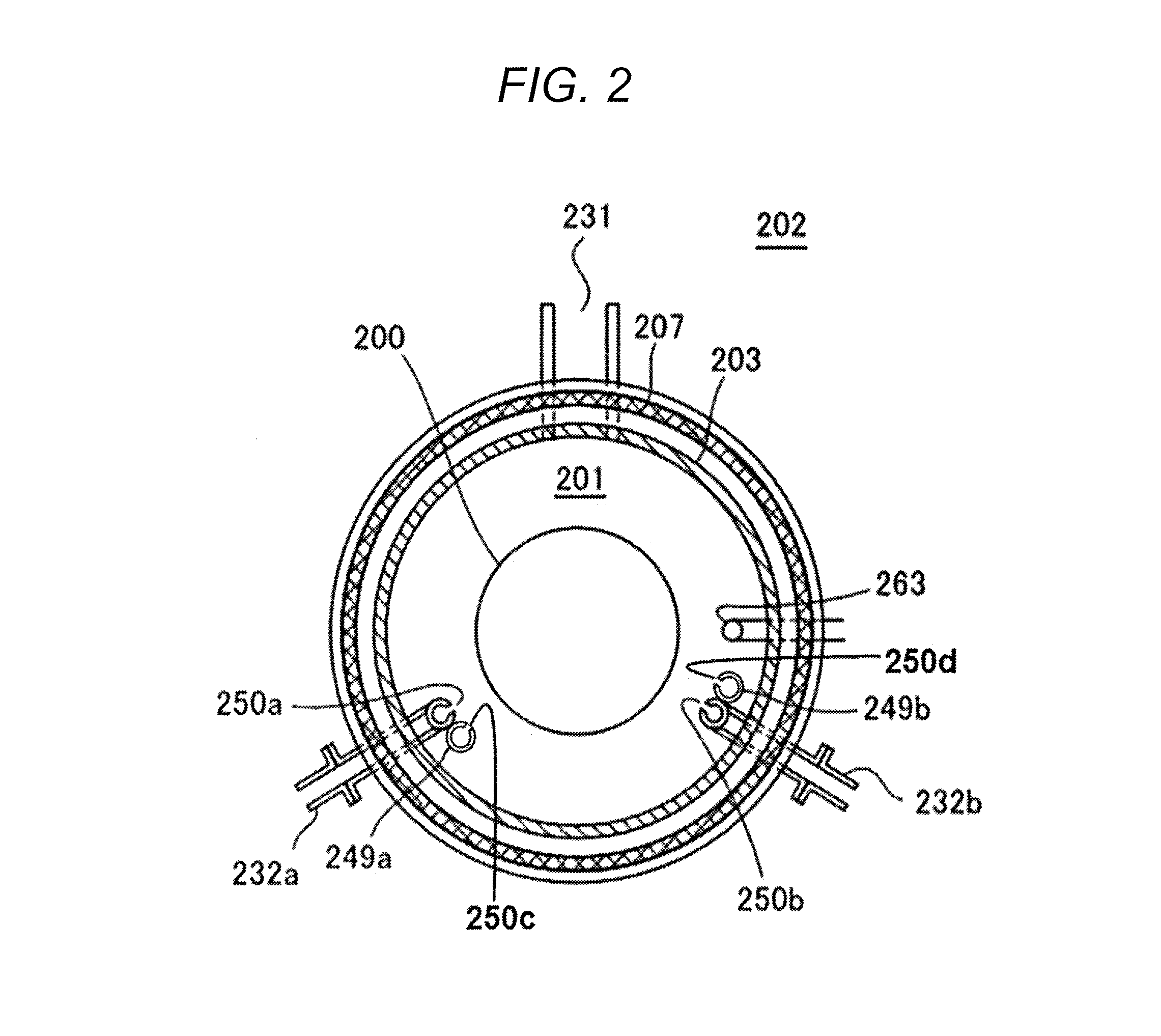

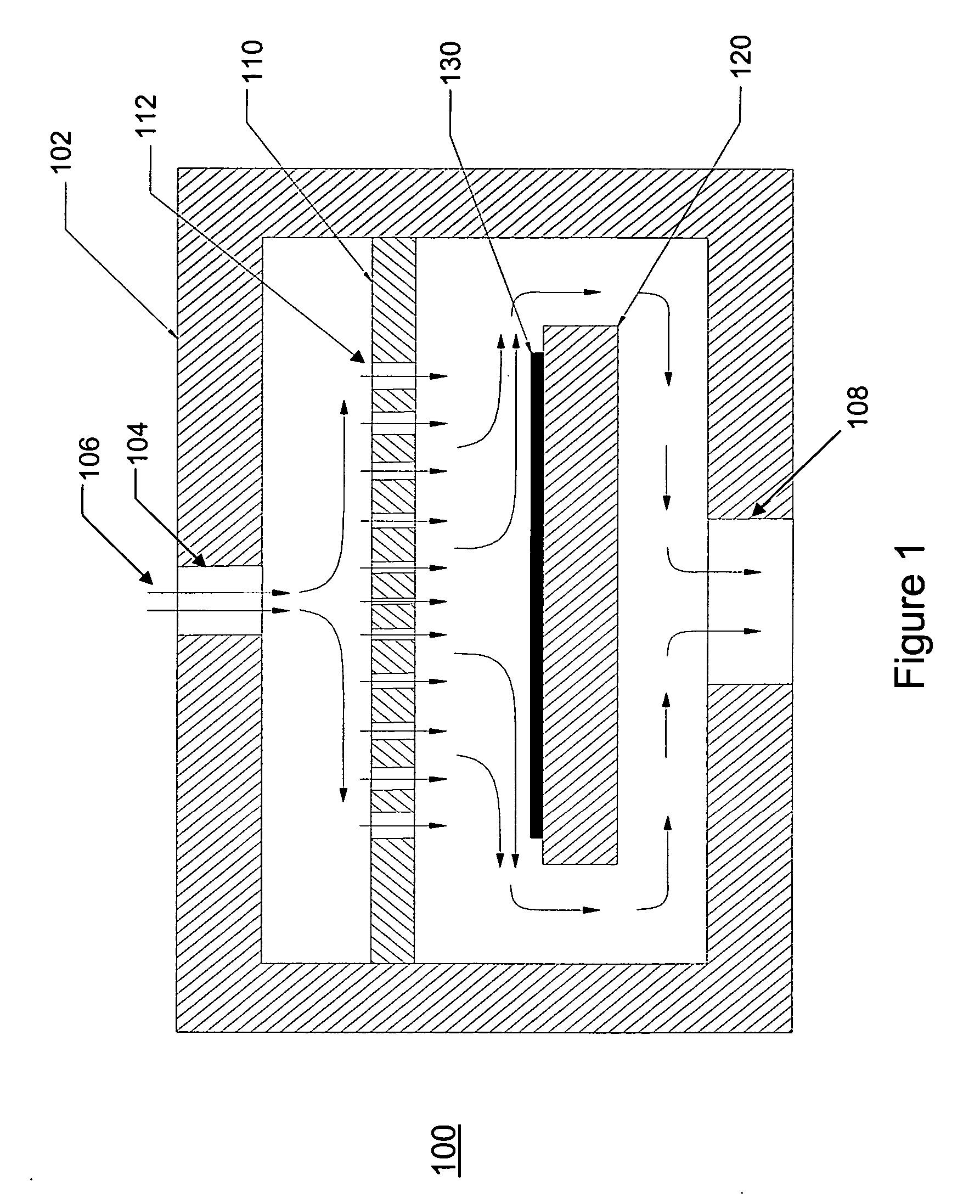

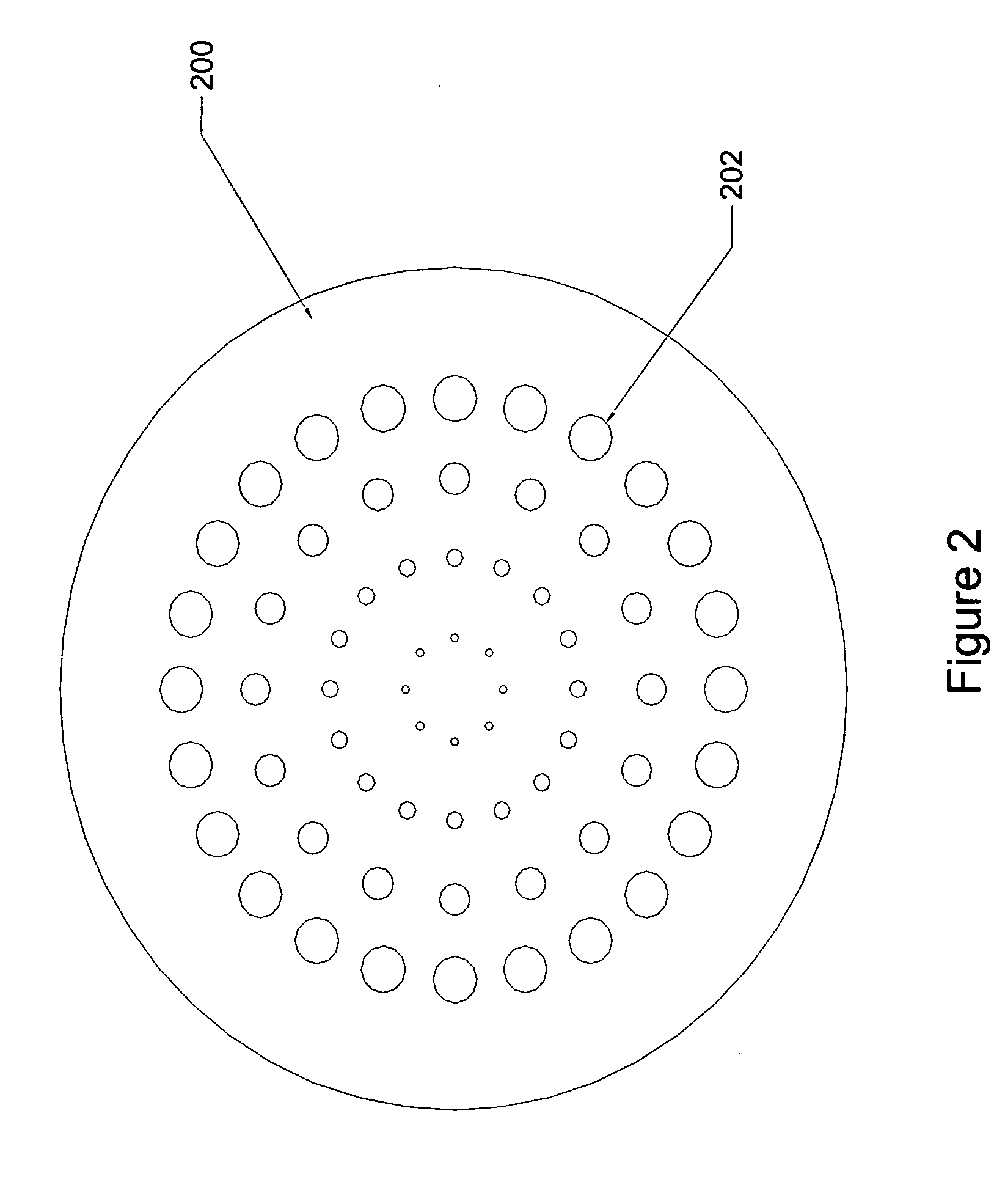

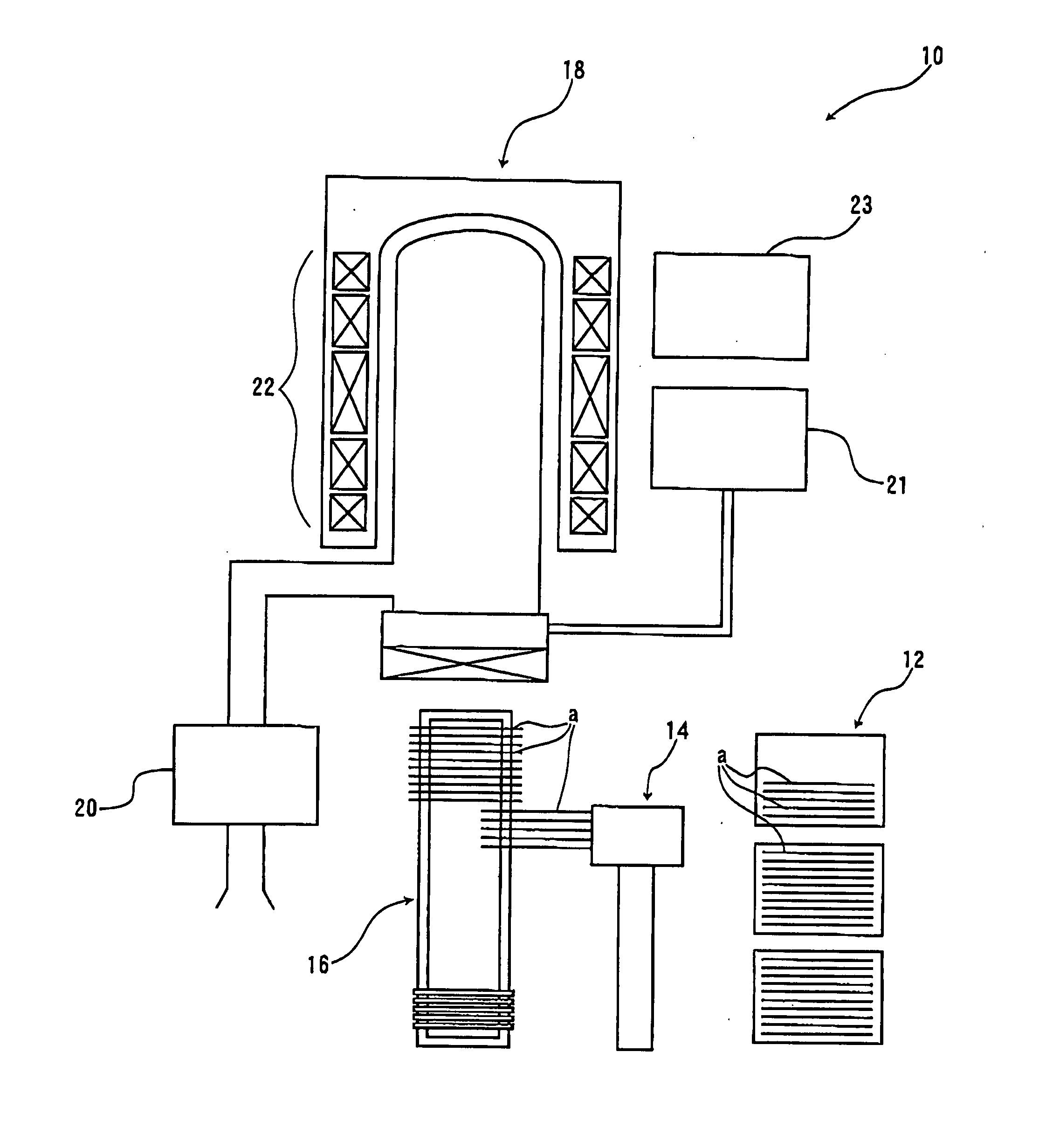

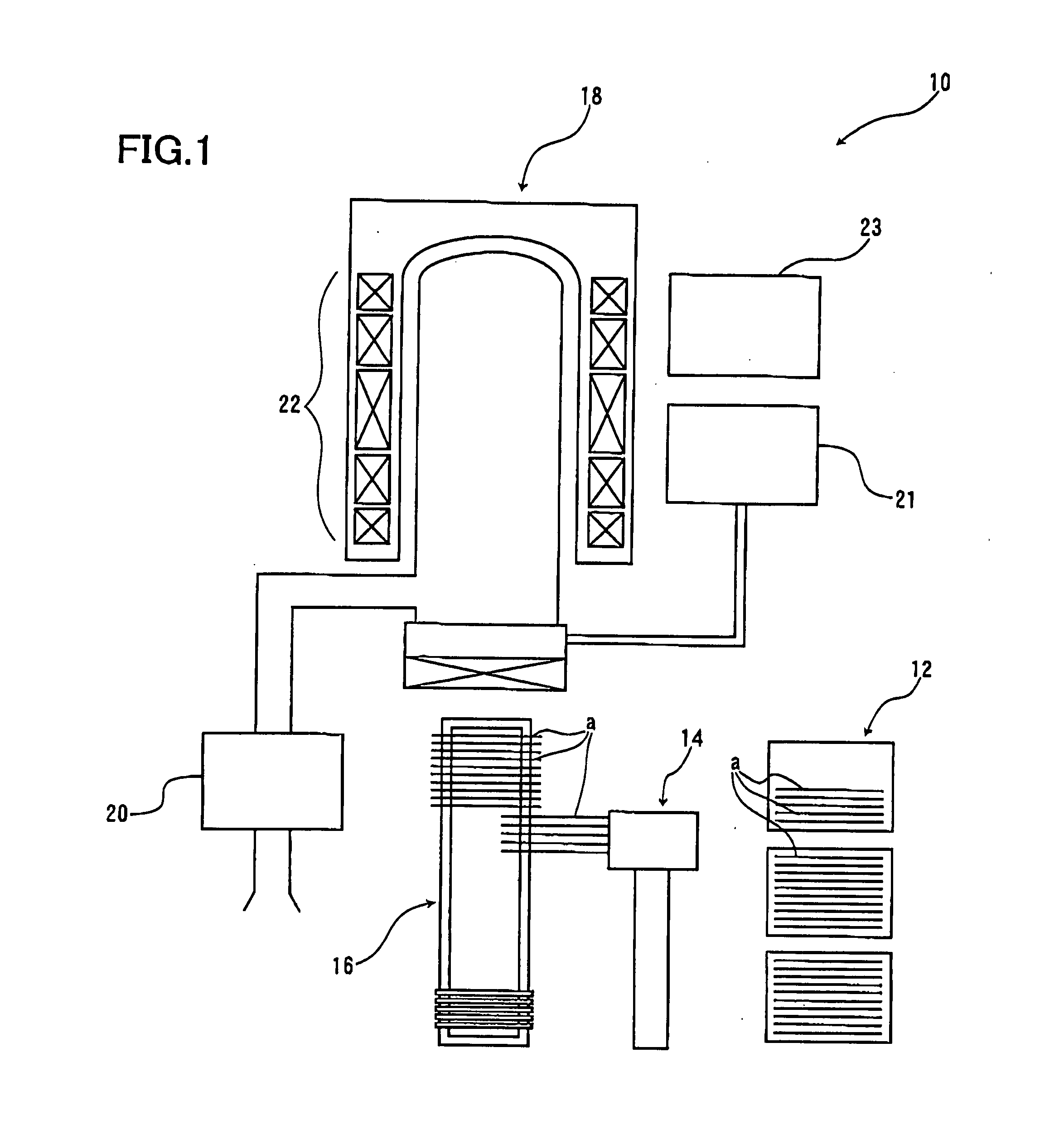

Gas supply nozzle, substrate processing apparatus, and non-transitory computer-readable recording medium

ActiveUS20170051408A1Improve film thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSpray nozzleEngineering

Provided is a technology including a nozzle base end portion which is provided in a processing chamber processing a substrate to extend in a vertical direction and into which a processing gas processing the substrate is introduced, a nozzle distal end portion which is configured in a U shape and in which a gas supply hole supplying the processing gas is provided to a side surface of the substrate, and a gas residence suppressing hole which is provided in a downstream end of the nozzle distal end portion and has a diameter larger than that of the gas supply hole.

Owner:KOKUSA ELECTRIC CO LTD

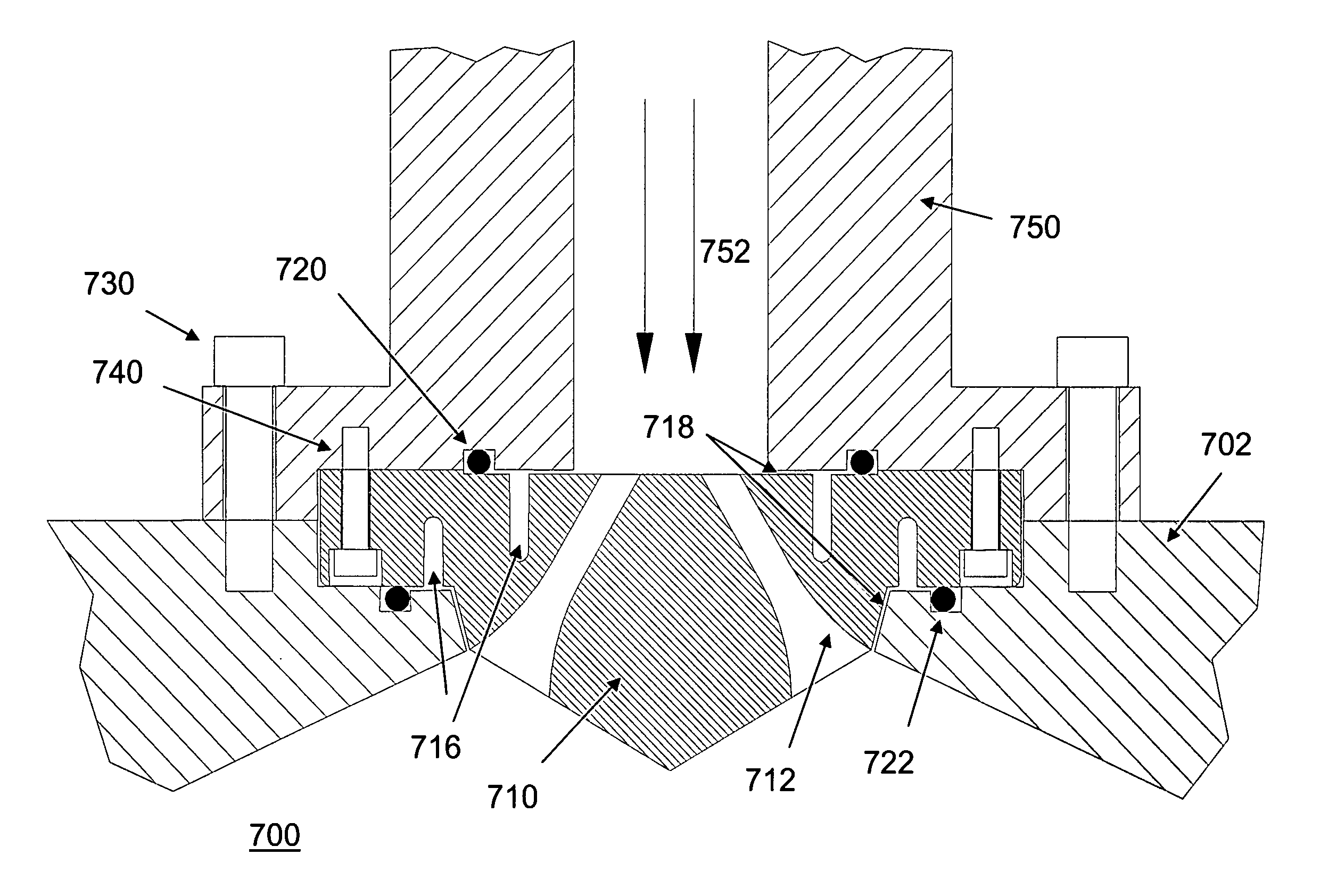

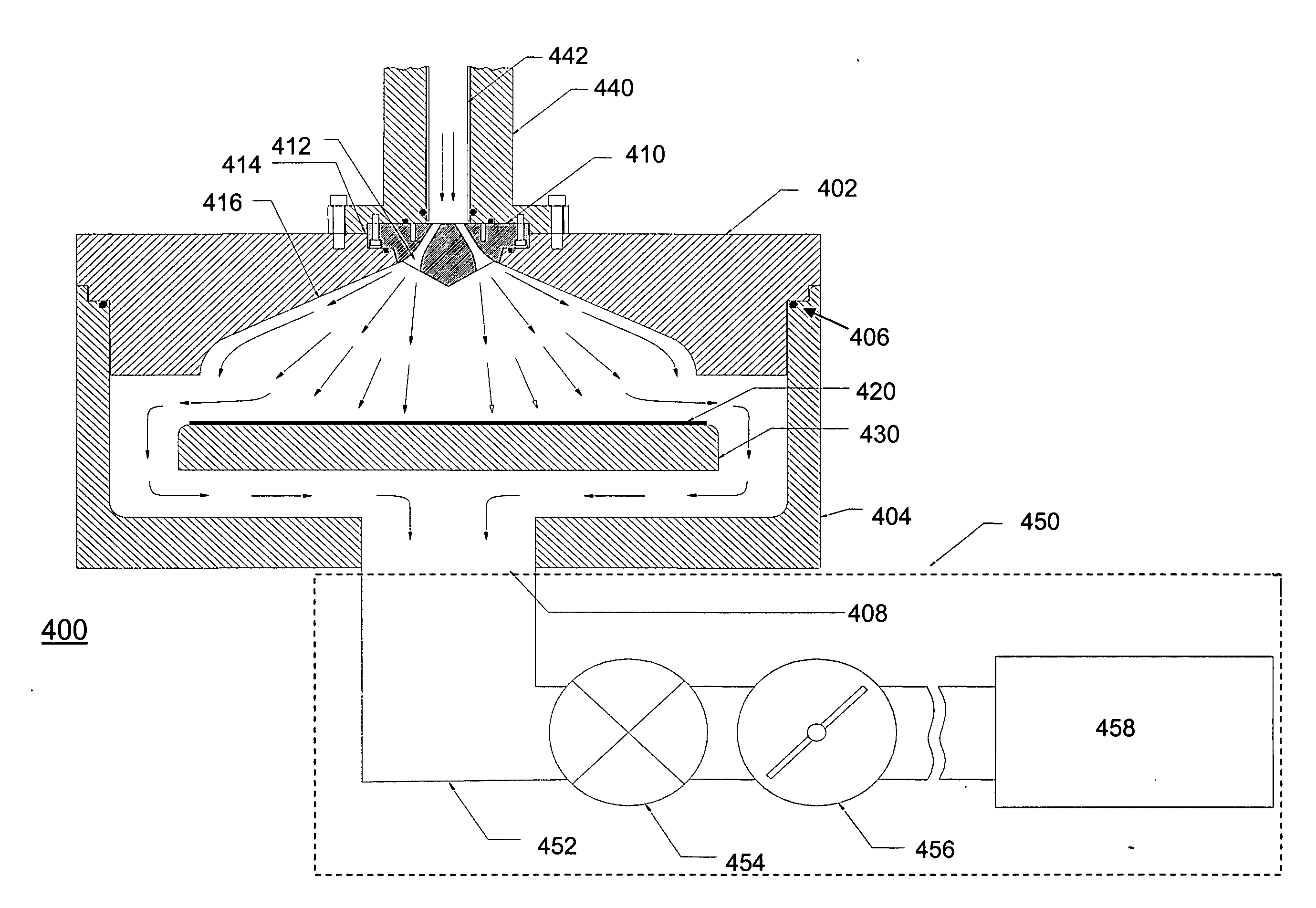

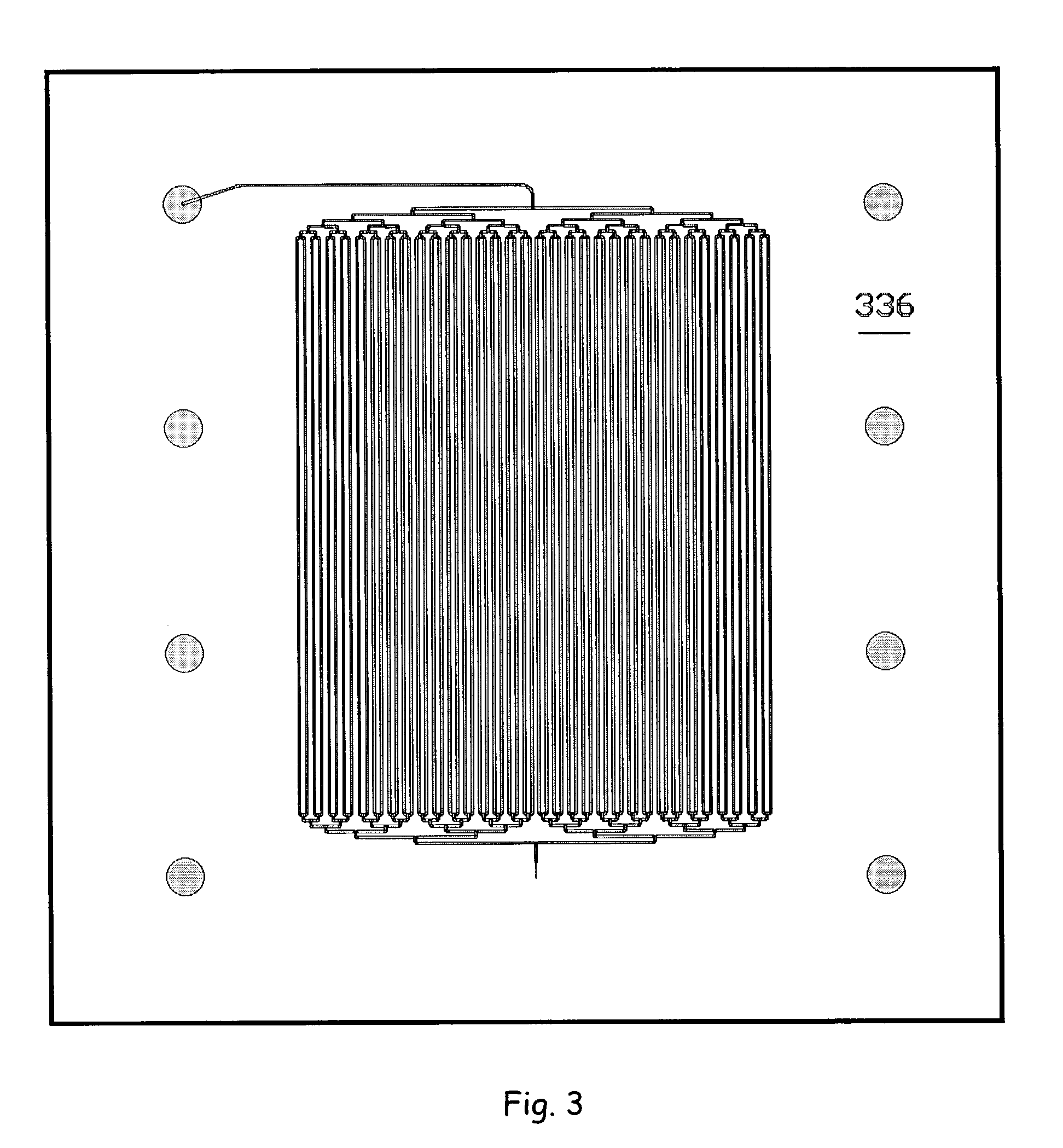

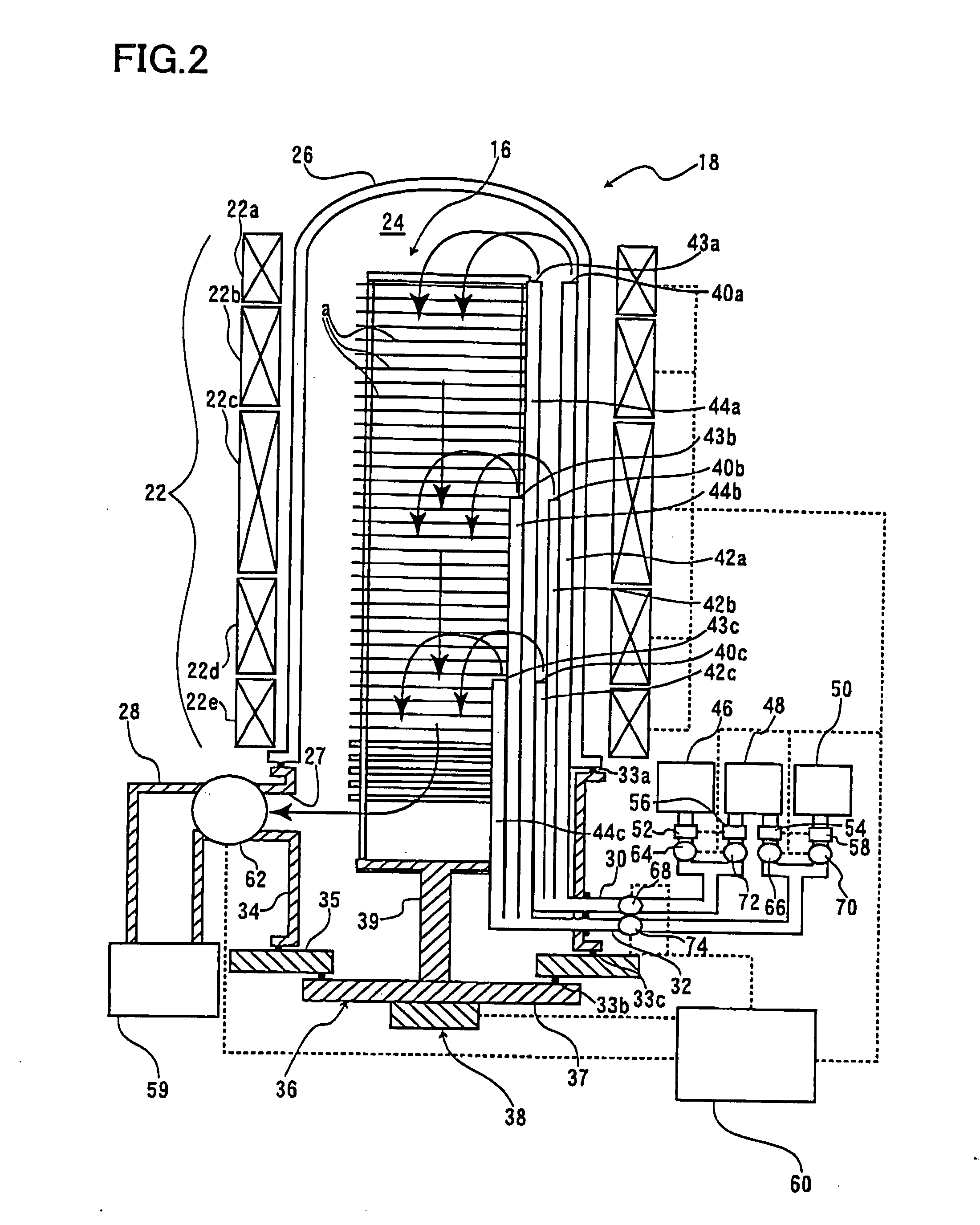

High strip rate downstream chamber

ActiveUS8298336B2Avoid radiationAbsorb thermal expansionElectric discharge tubesDecorative surface effectsSpray nozzleThermal expansion

A gas chamber contains upper and lower chamber bodies forming a cavity, a heating chuck for a wafer, a remote gas source, and an exhaust unit. Gas is injected into the cavity through channels in an injector. Each channel has sections that are bent with respect to each other at a sufficient angle to substantially eliminate entering light rays entering the channel from exiting the channel without reflection. The channels have funnel-shaped nozzles at end points proximate to the chuck. The injector also has thermal expansion relief slots and small gaps between the injector and mating surfaces of the chamber and gas source. The temperature of the injector is controlled by a cooling liquid in cooling channels and electrical heaters in receptacles of the injector. The upper chamber body is funnel-shaped and curves downward at an end of the upper chamber body proximate to the chuck.

Owner:LAM RES CORP

High strip rate downstream chamber

ActiveUS20060219361A1Avoid radiationAbsorb thermal expansionElectric discharge tubesDecorative surface effectsSpray nozzleGas passing

A gas chamber contains upper and lower chamber bodies forming a cavity, a heating chuck for a wafer, a remote gas source, and an exhaust unit. Gas is injected into the cavity through channels in an injector. Each channel has sections that are bent with respect to each other at a sufficient angle to substantially eliminate entering light rays entering the channel from exiting the channel without reflection. The channels have funnel-shaped nozzles at end points proximate to the chuck. The injector also has thermal expansion relief slots and small gaps between the injector and mating surfaces of the chamber and gas source. The temperature of the injector is controlled by a cooling liquid in cooling channels and electrical heaters in receptacles of the injector. The upper chamber body is funnel-shaped and curves downward at an end of the upper chamber body proximate to the chuck.

Owner:LAM RES CORP

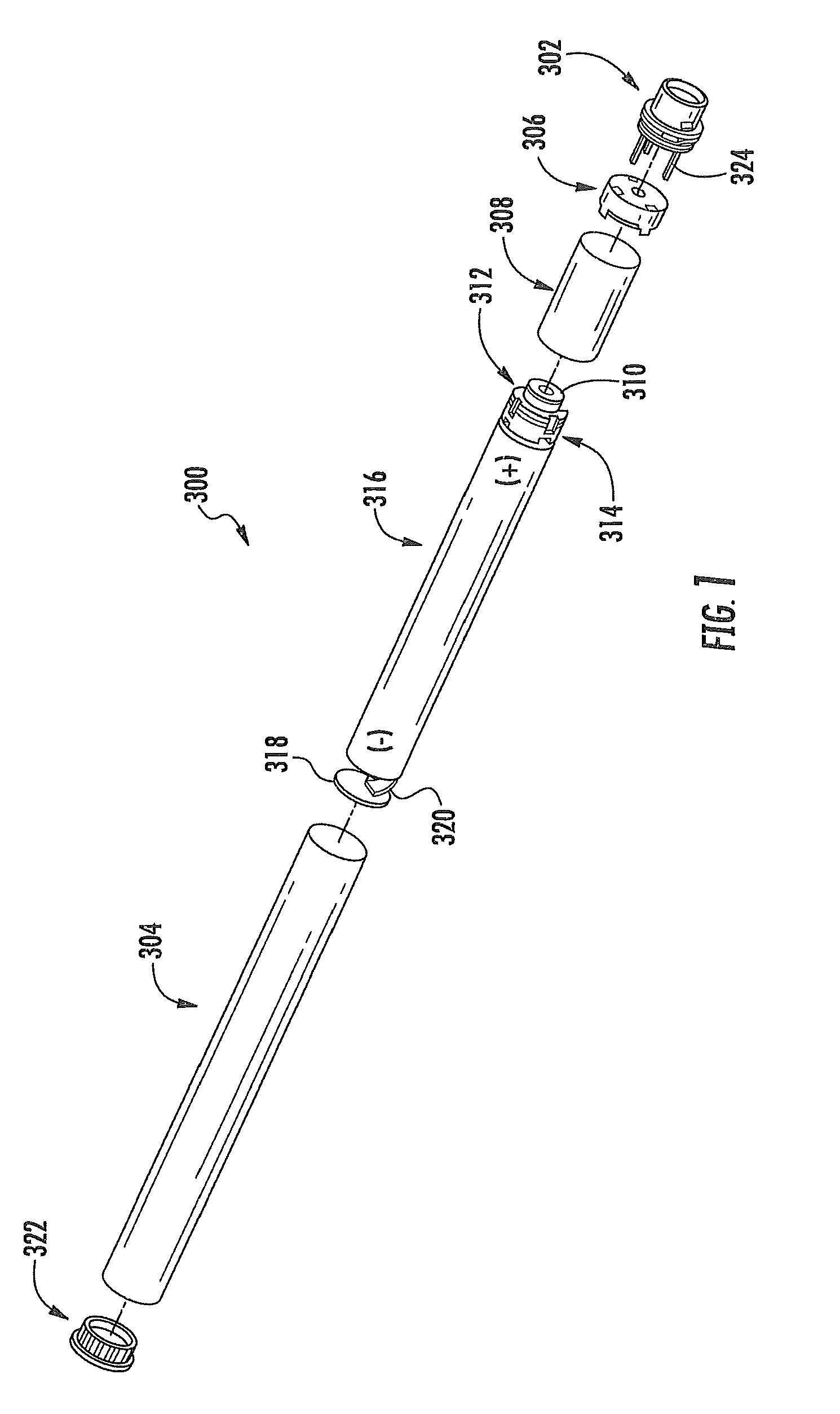

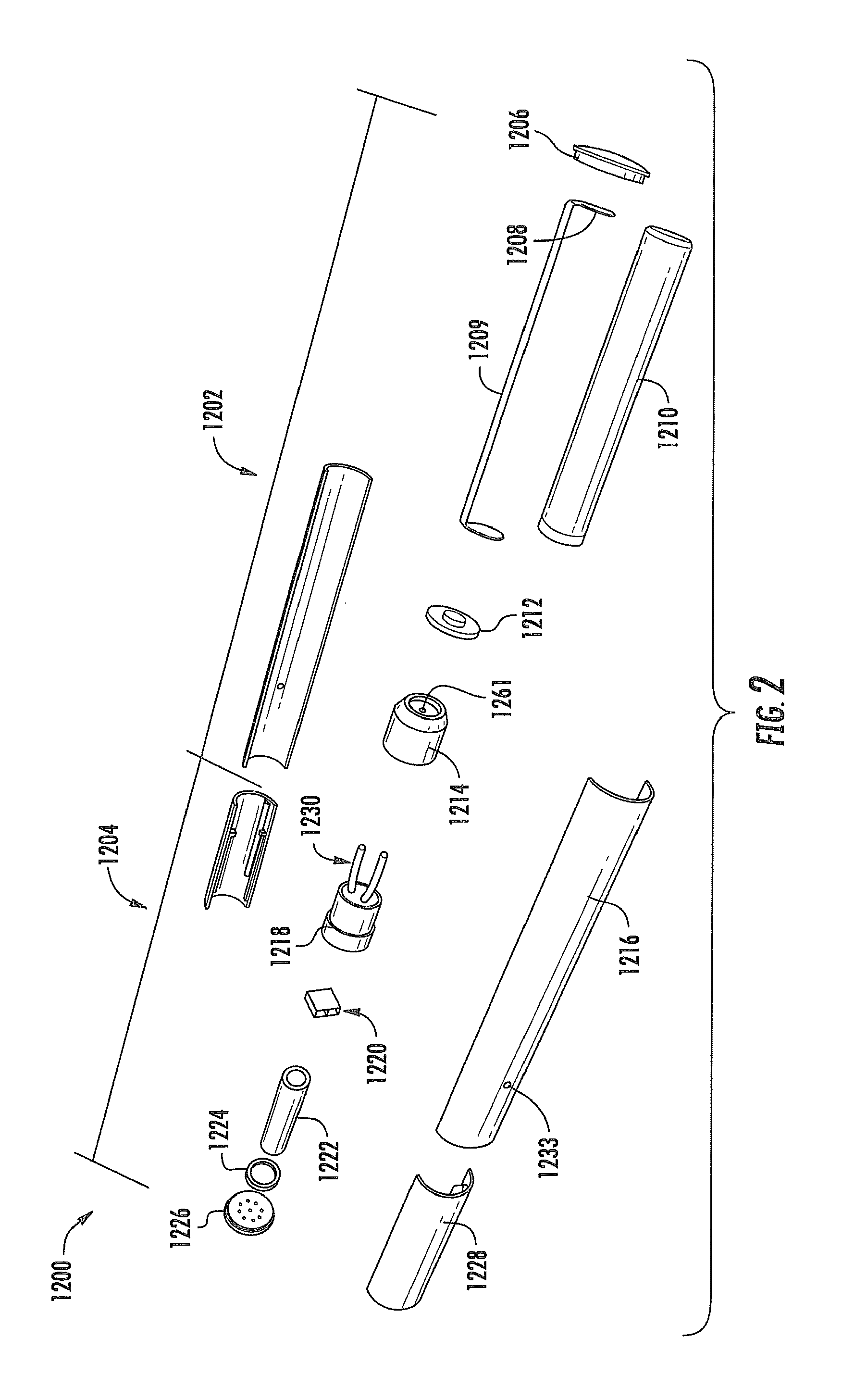

Aerosol Delivery Device Including a Bubble Jet Head and Related Method

The present disclosure relates to aerosol delivery devices. The aerosol delivery devices include mechanisms configured to deliver an aerosol precursor composition from a reservoir to an atomizer including a vaporization heating element to produce a vapor. For example, a bubble jet head may be configured to dispense the aerosol precursor composition to the atomizer. The bubble jet head may be fixedly coupled to the atomizer. The bubble jet head may include a precursor inlet, an ejection heating element, and a precursor nozzle. The atomizer may include a vaporization heating element.

Owner:RAI STRATEGIC HLDG INC

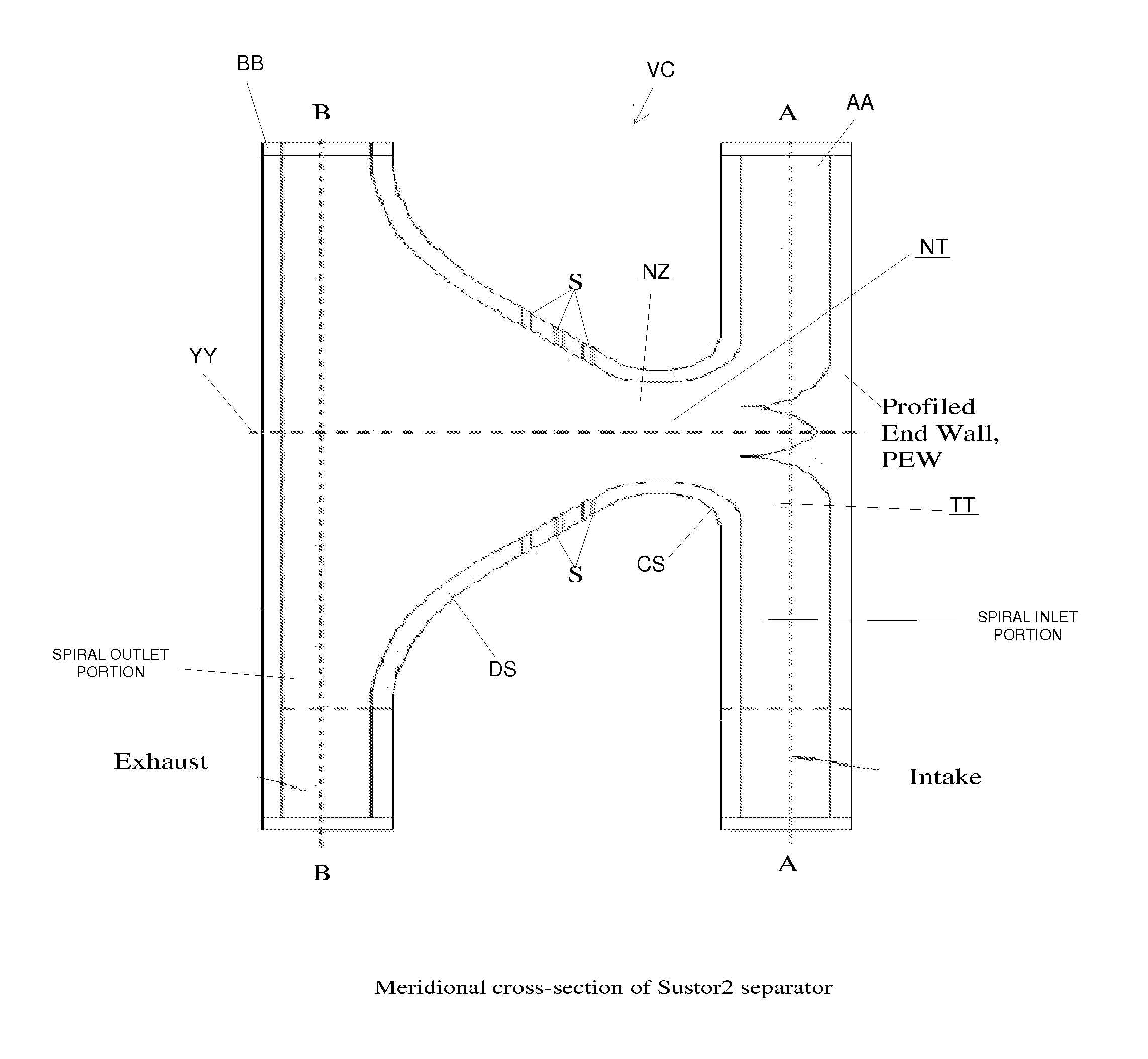

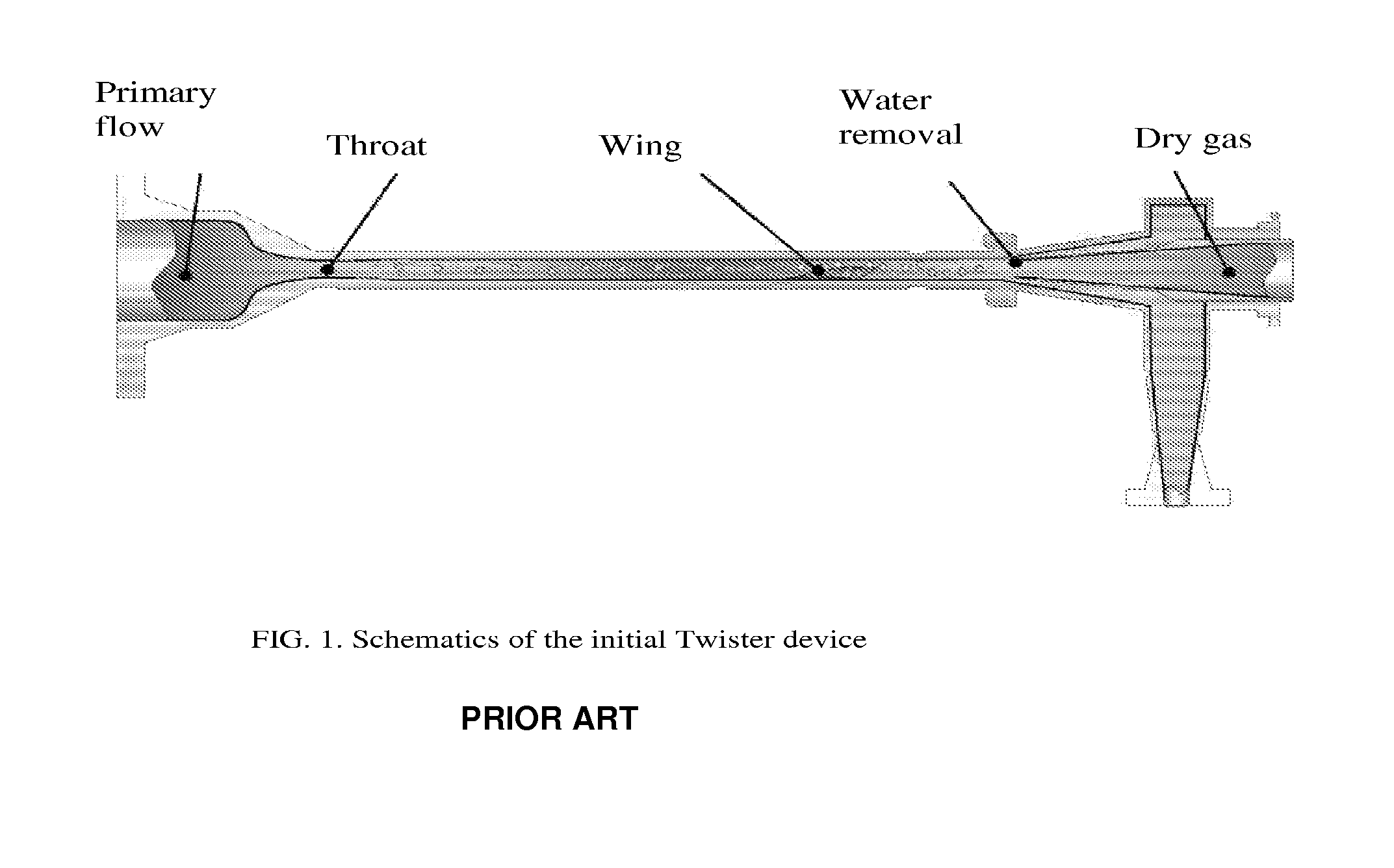

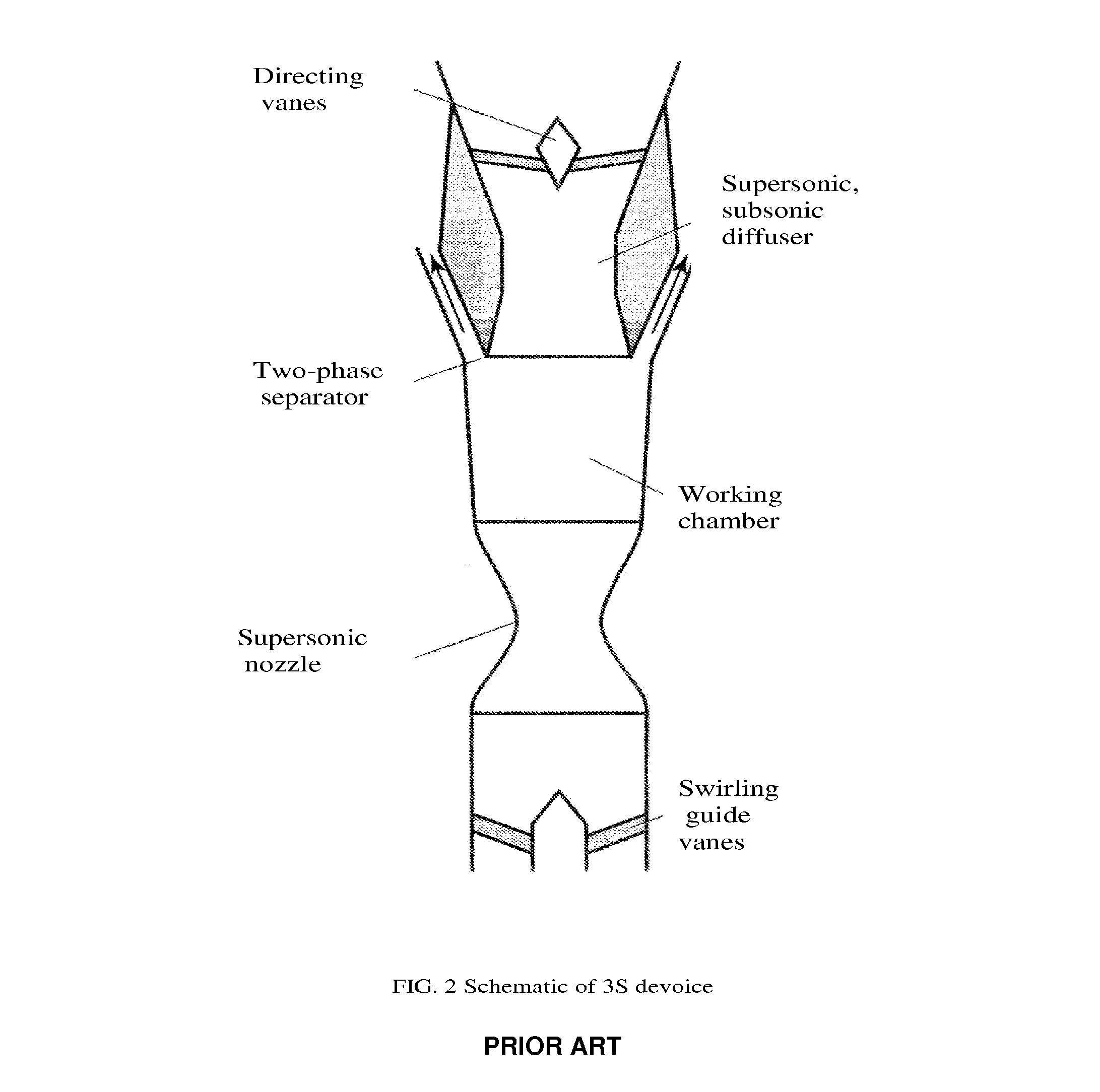

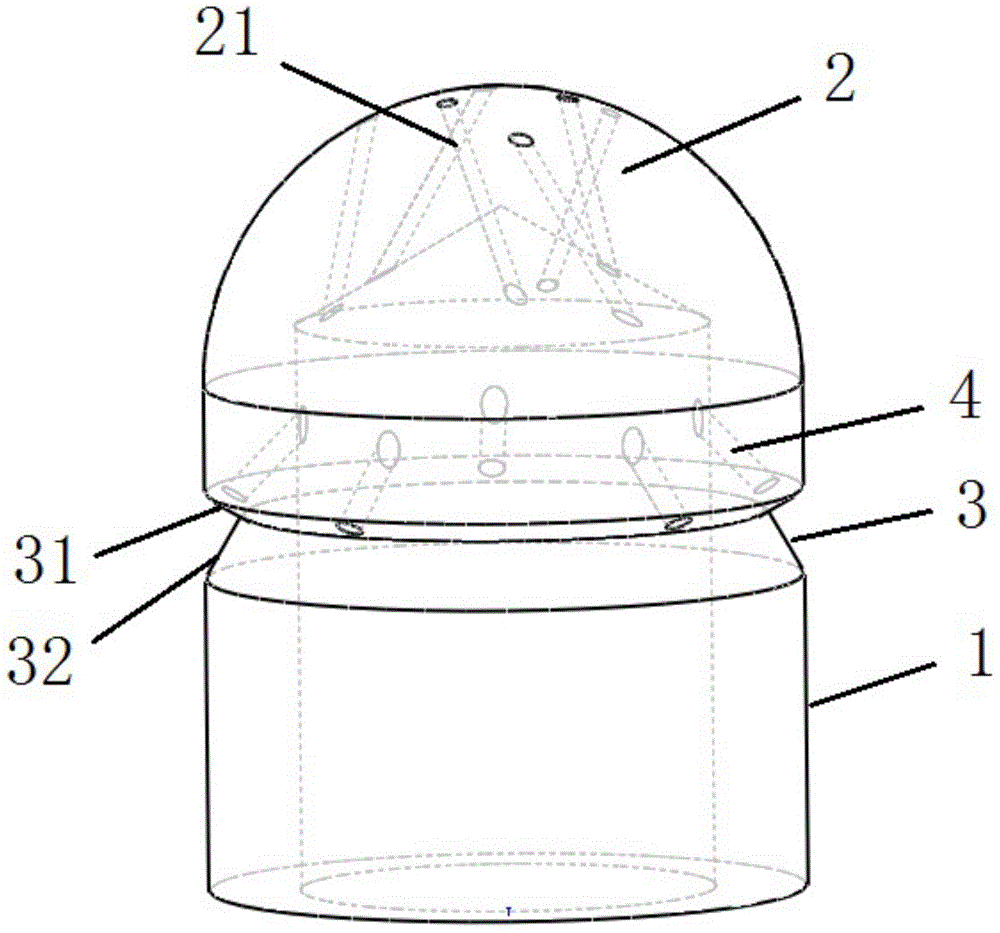

Supersonic swirling separator 2 (Sustor2)

Sustor2 provides deep cooling of a gas flow, practically total condensation of a vapor, and fast and effective removal of the condensed liquid with a significantly reduced pressure losses compared with the prior art. Sustor2 performs the said operations by developing a strong swirling flow starting from its entrance, followed by spiral flow convergence in the inlet disc-like part, and then in a converging-diverging nozzle, by centrifugal removal of droplets, and removal of the liquid film through slits, then by spiral flow divergence and leaving the vortex chamber through tangential outlet.A gas enters from a pipeline (see the arrow in the A-A cross-section shown in FIG. 7) connected to Sustor2 by a flange and the inlet transition pipe ITP in FIG. 7, spirally converged in the disc-like part, marked by A-A in FIG. 6, enters the converging-diverging nozzle (FIG. 6). The flow is high-speed and swirling even at the near-entrance region of the vortex chamber. This swirl results in the centrifugal force that presses the through-flow to the sidewall. The flow accelerates near the nozzle throat up to a supersonic velocity with subsonic axial and supersonic swirl velocity components. This acceleration results in the gas temperature drop down to 200K and even less values. The reduced temperature causes rapid condensation of vapor into droplets. The centrifugal force pushes the droplets to the sidewall where they are removed through slits. Next the dried gas spirally diverges and leaves the vortex chamber through the tangential outlet. This results in the pressure recovery and transformation of the swirl kinetic energy into the longitudinal kinetic energy of the gas. Both the effects decrease pressure losses which is the Sustor2 advantage compared with the prior art.

Owner:BORISSOV ANATOLI +2

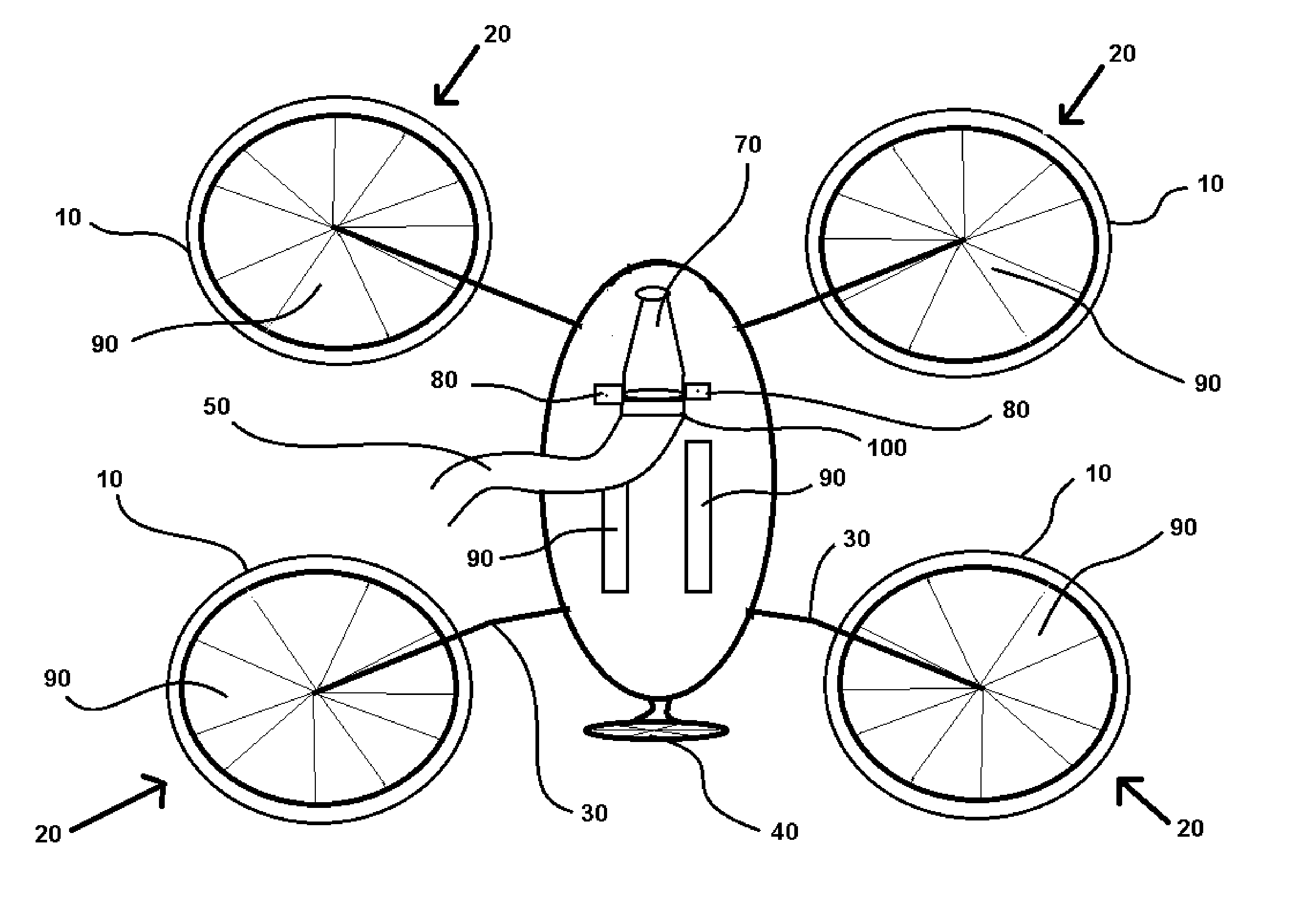

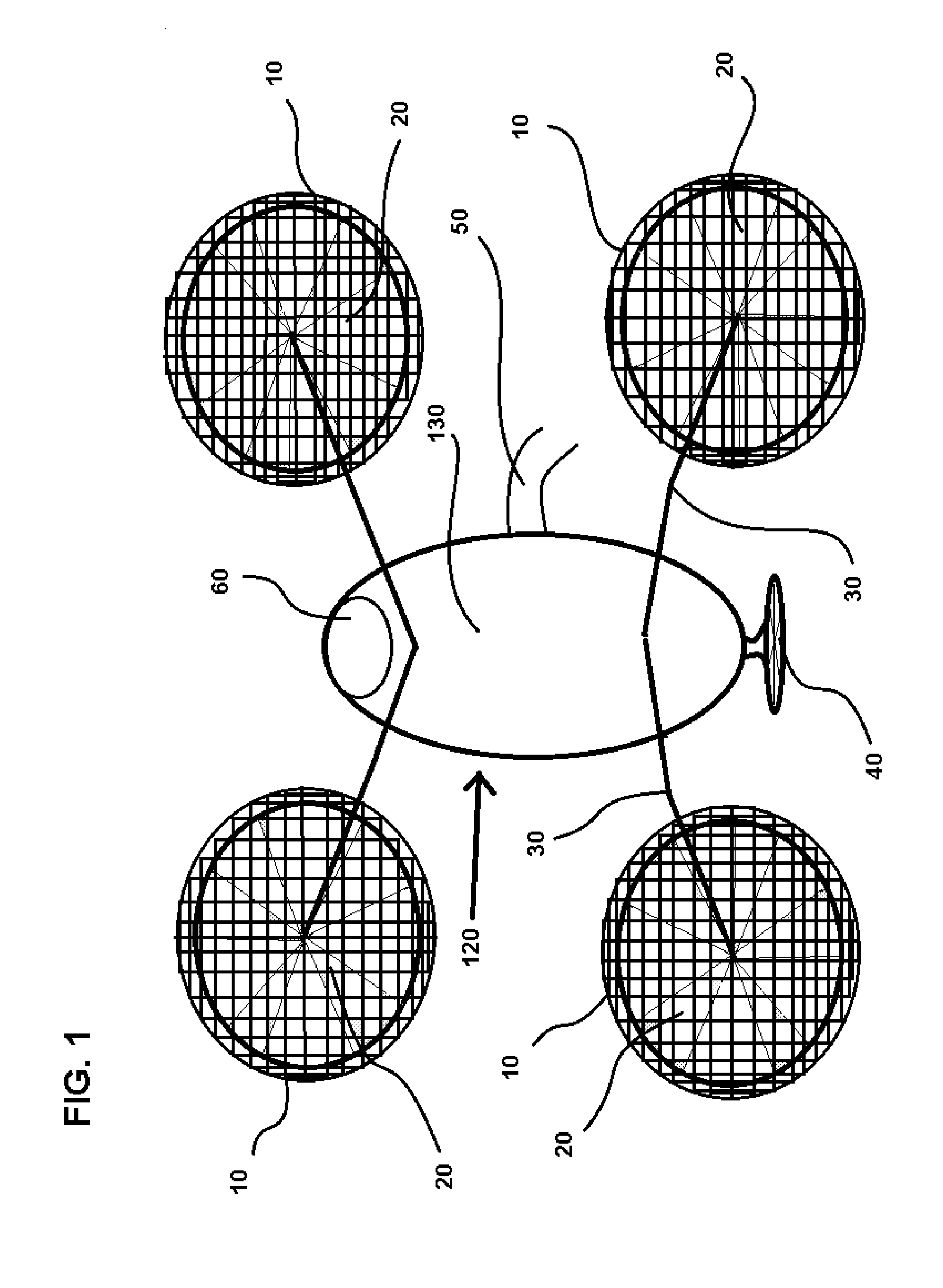

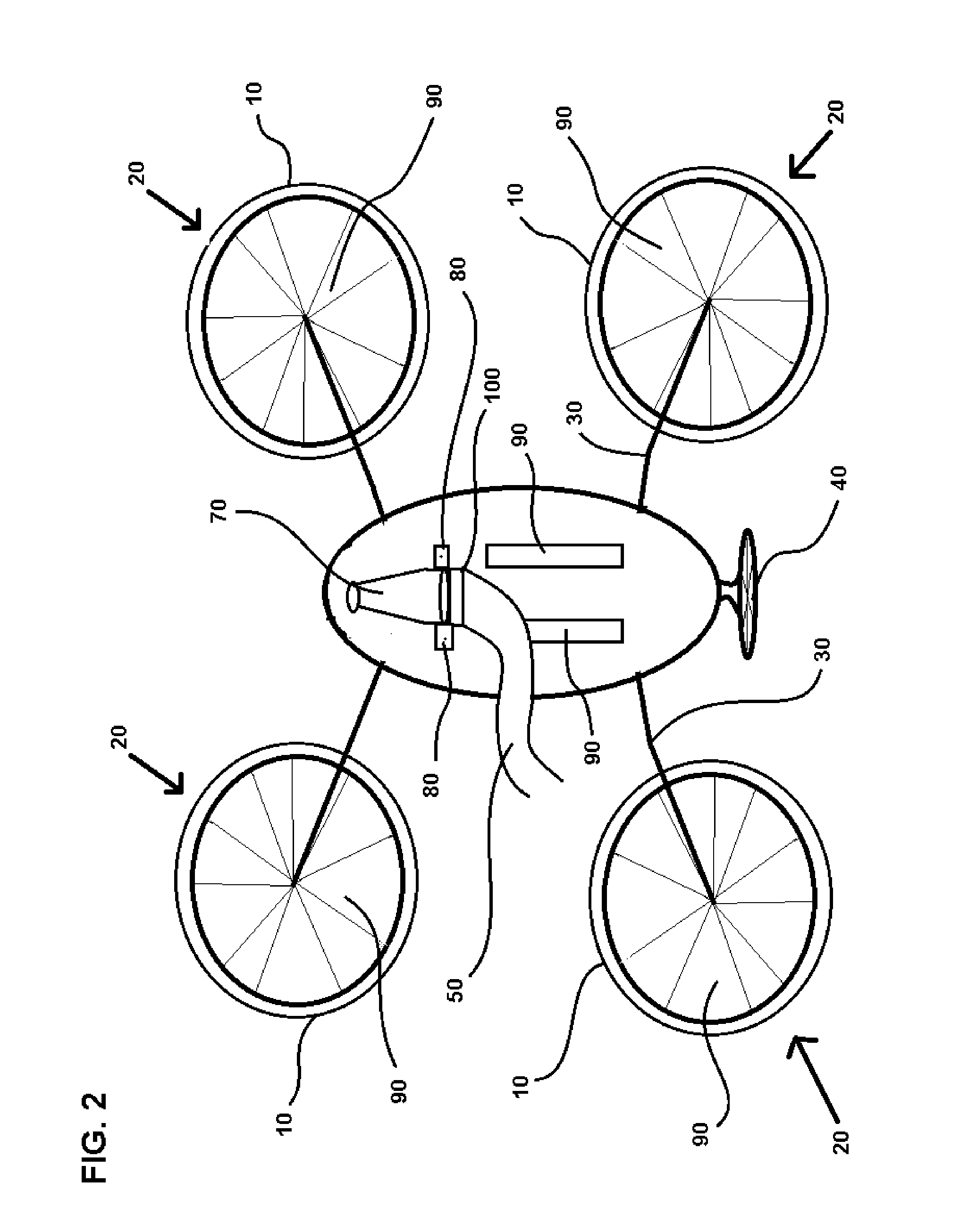

UAV Fire-fighting System

An unmanned aerial vehicle (UAV) designed to extinguish fires from the air while remaining tethered to the ground via a tether system fashioned to provide the UAV with power and extinguishant. The UAV is preferably electrically powered and is stabilized in the air via a system of gyroscopes fashioned to work in concert with a series of electric motors capable of moving to counteract the opposing recoil force exhibited as water escapes the nozzle of the tether. A command and control unit on the ground supplies the UAV with electricity and water via the tether. The UAV is preferably stored within and launched from the command and control unit. Controls and sensor readings are communicated to a controller—be it autonomous or human—on the ground, preferably within or proximal to the command and control unit.

Owner:MOORE JASON

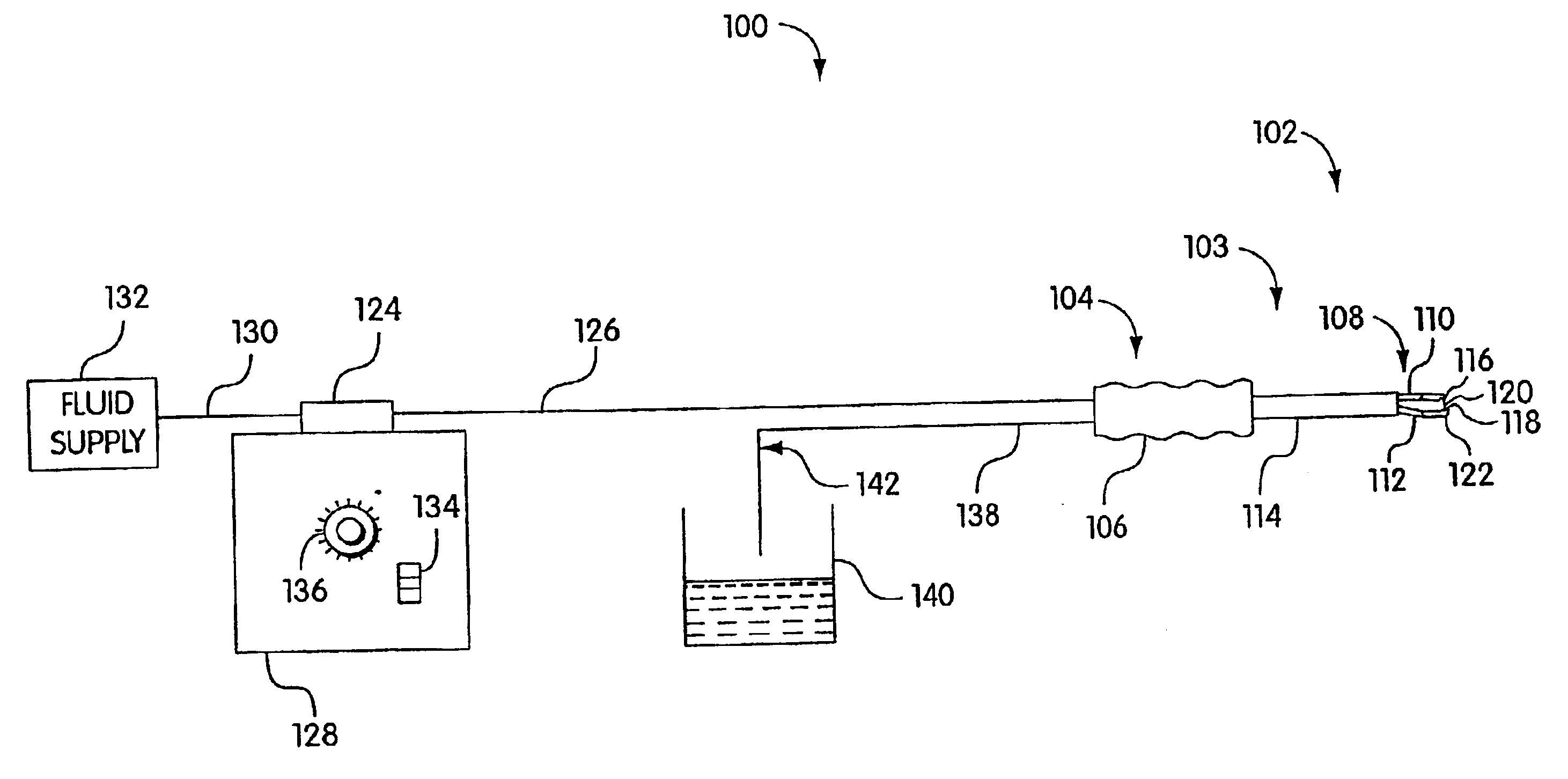

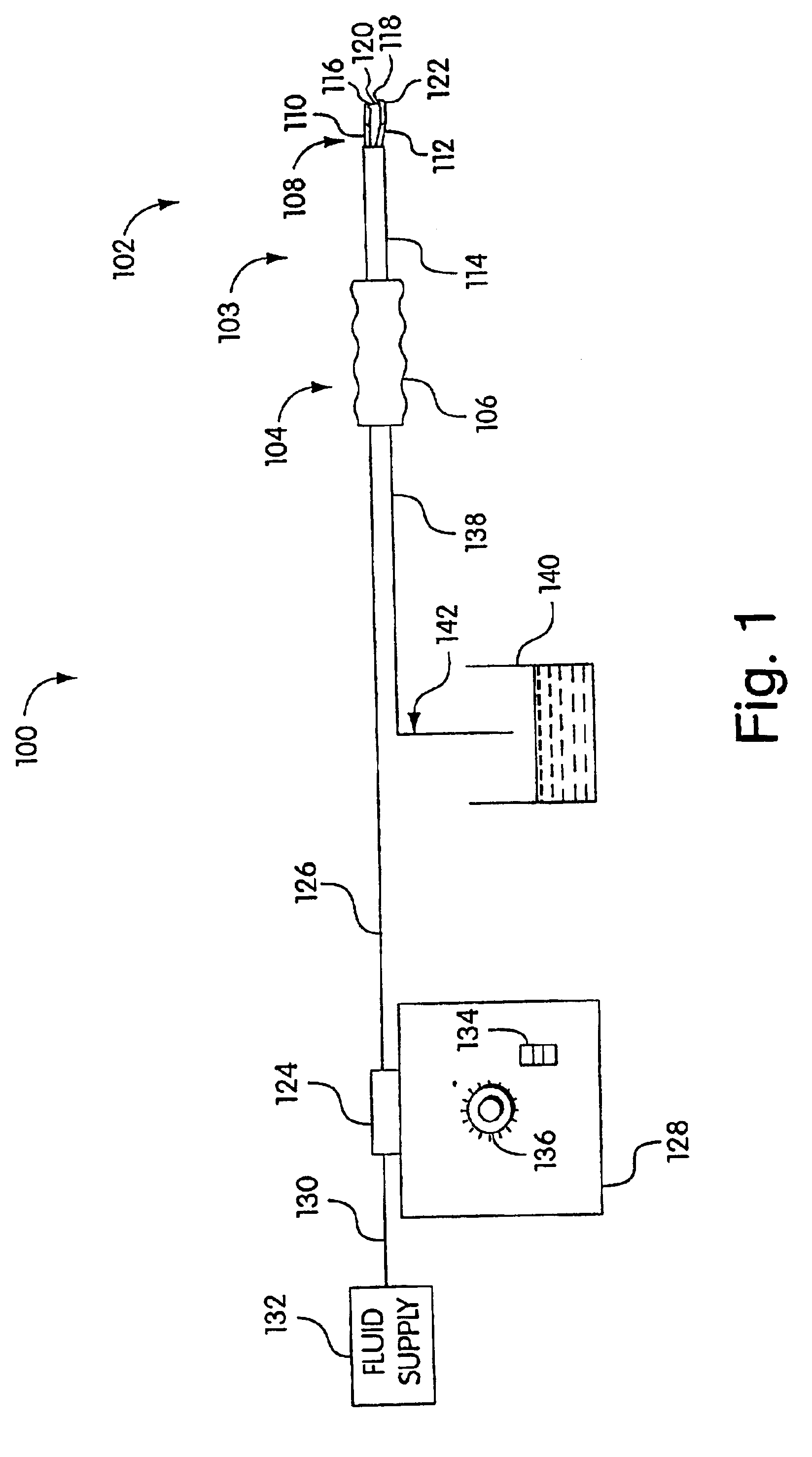

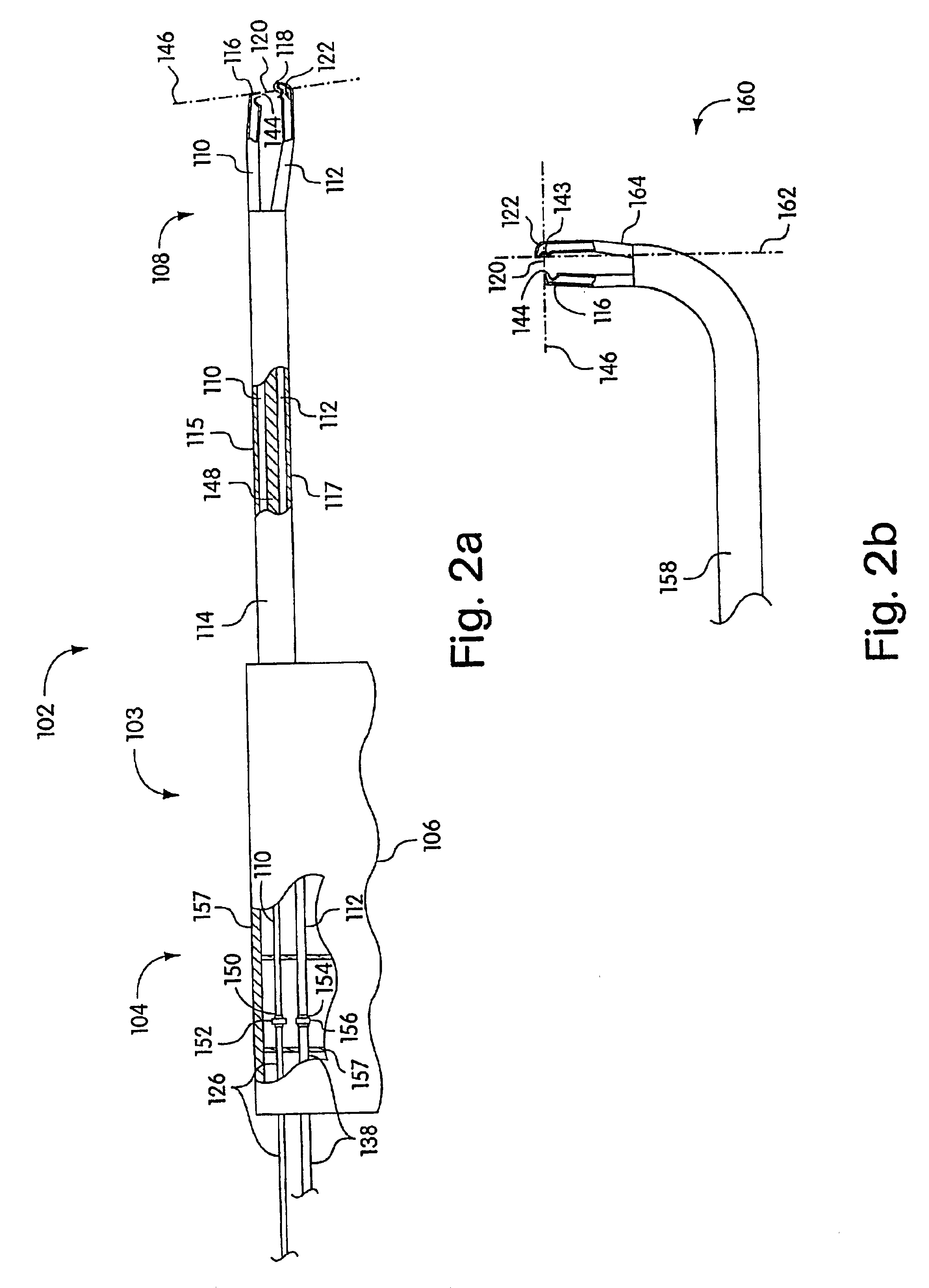

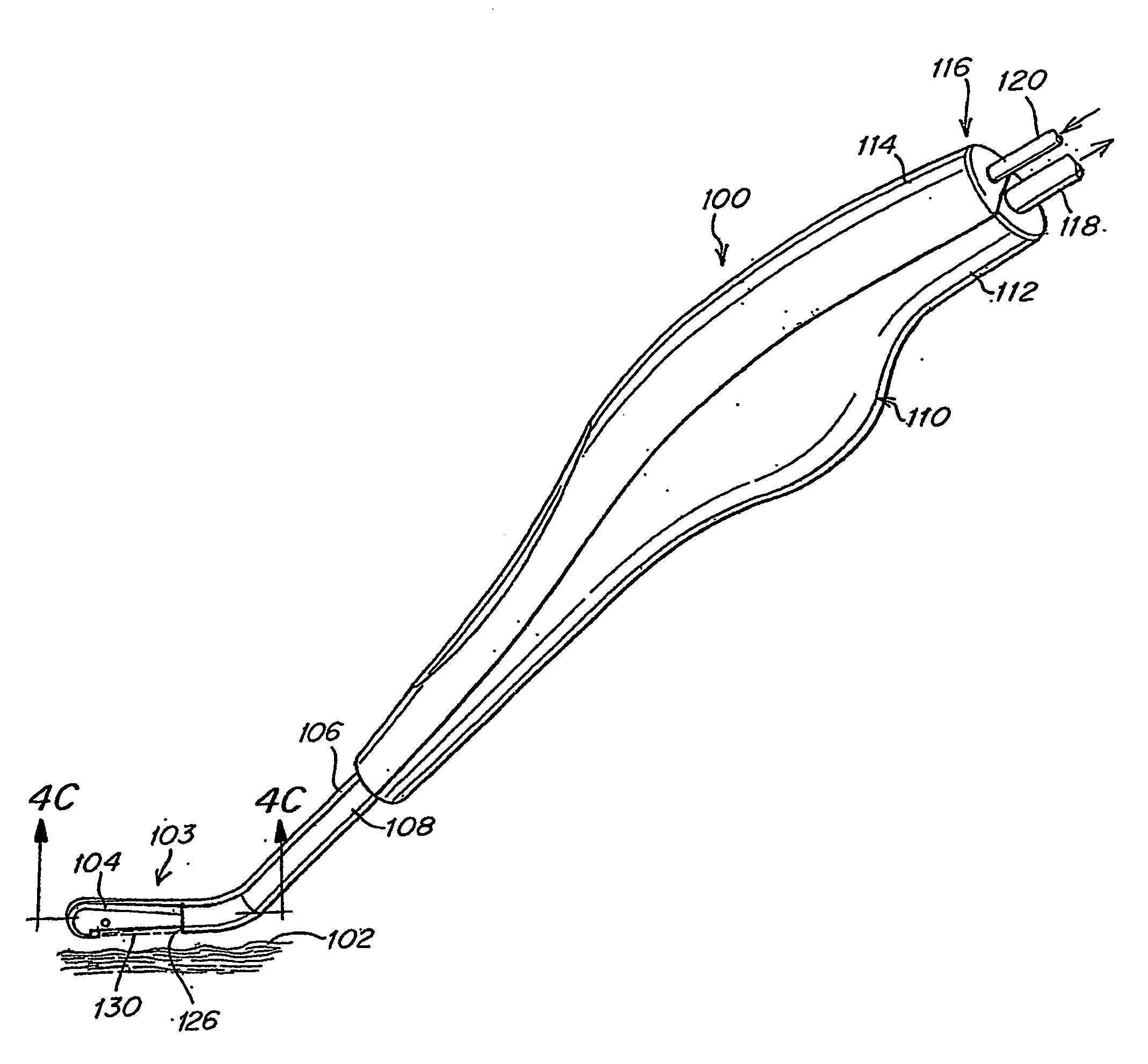

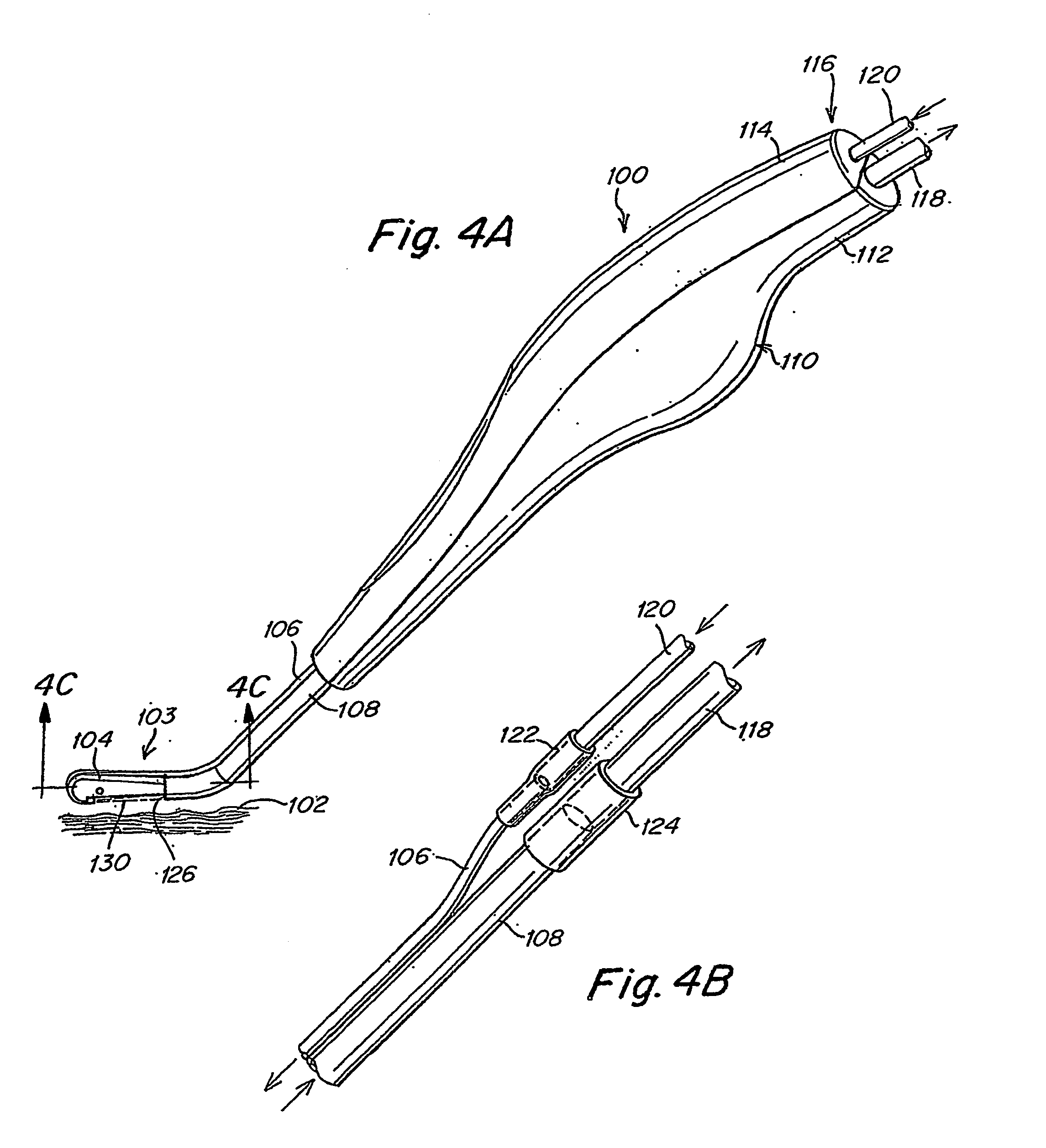

Fluid jet surgical instruments

The invention provides a variety of surgical instruments for forming a liquid jet, which are useful for performing a wide variety of surgical procedures. In some embodiments, the invention provides surgical liquid jet instruments having a pressure lumen and an evacuation lumen, where the pressure lumen includes at least one nozzle for forming a liquid jet and where the evacuation lumen includes a jet-receiving opening for receiving the liquid jet when the instrument is in operation. In some embodiments, the pressure lumen and the evacuation lumen of the surgical liquid jet instruments are constructed and positionable relative to each other so that the liquid comprising the liquid jet, and any tissue or material entrained by the liquid jet can be evacuated through the evacuation lumen without the need for an external source of suction. The invention also provides a variety of surgical liquid jet instruments that are constructed and configured specifically for use in a surrounding liquid environment or a surrounding gaseous environment. The invention also provides a variety of surgical liquid jet instruments that are rotatably deployable from an undeployed position, for insertion into the body of a patient, to a deployed position, in which there is a separation distance between the liquid jet nozzle and the jet-receiving opening that defines a liquid jet path length. The invention also provides surgical methods utilizing the inventive surgical liquid jet instruments, and methods for forming components of the surgical liquid jet instruments.

Owner:HYDROCISION

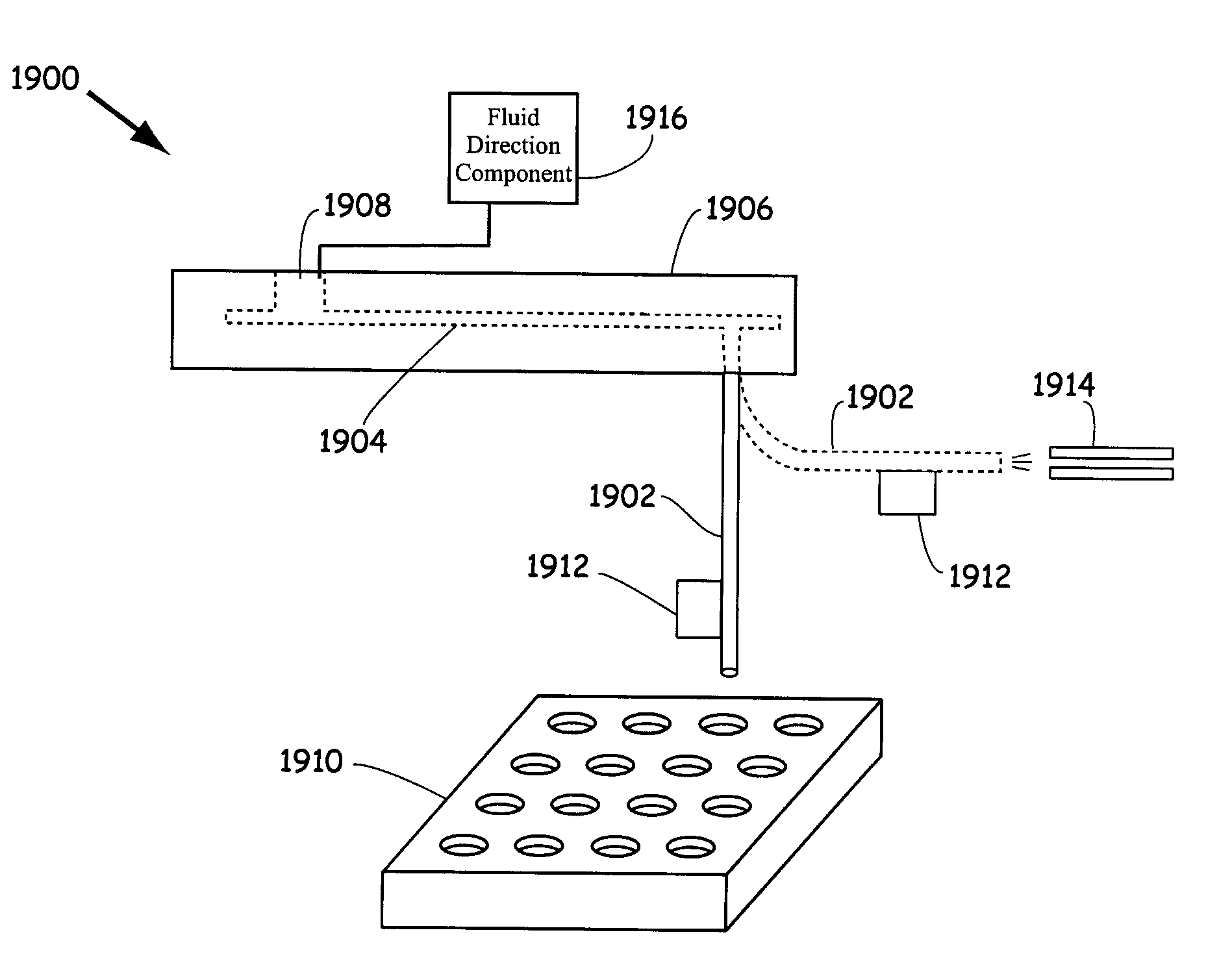

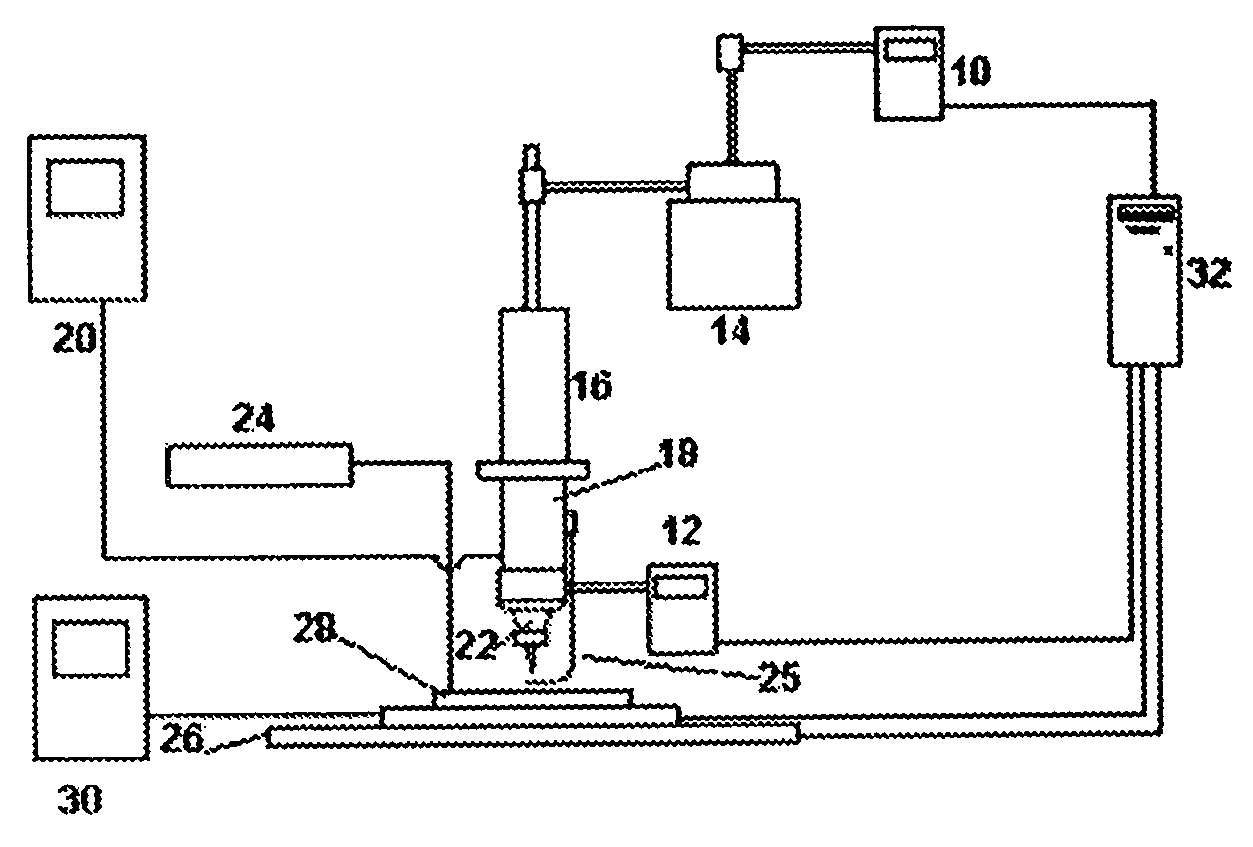

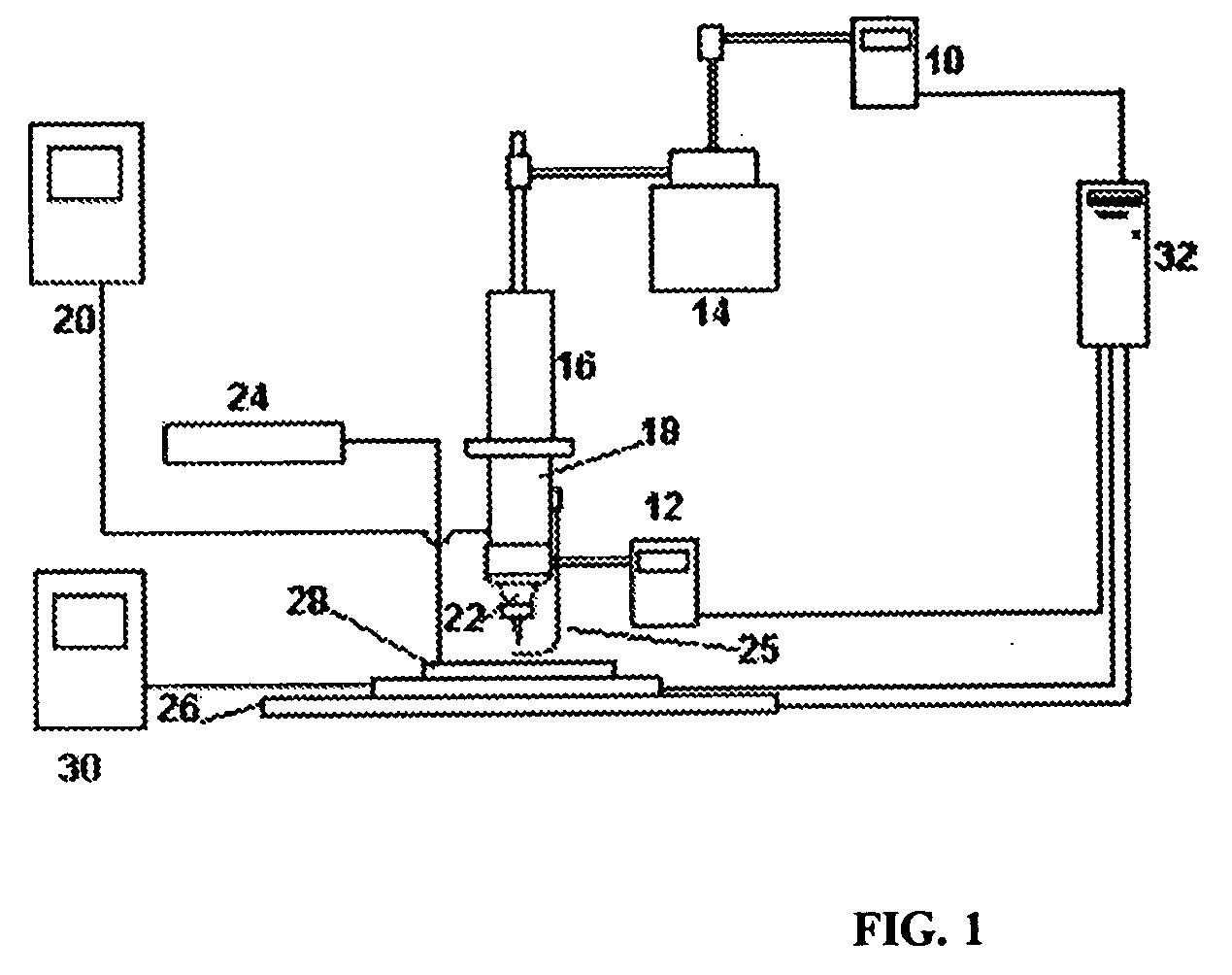

Microfluidic sample delivery devices, systems, and methods

ActiveUS7303727B1Improve throughputResidue reductionParticle separator tubesComponent separationSpray nozzleMass spectrometry

Methods and apparatus for delivering fluidic materials to sample destinations, including mass spectrometers for analysis are provided. In preferred embodiments, sample aliquots are electrosprayed from tapered spray tips of capillary elements into the orifices of mass spectrometric inlet systems. In certain embodiments, fluidic samples are orthogonally sprayed from capillary elements or other fluid conduits, whereas in other embodiments samples are sprayed after devices are rotated or otherwise translocated from sample sources to sample destinations. In still other embodiments, samples are sprayed from flexed or deflected capillary elements at selected sample destinations.

Owner:CAPLIPER LIFE SCI INC

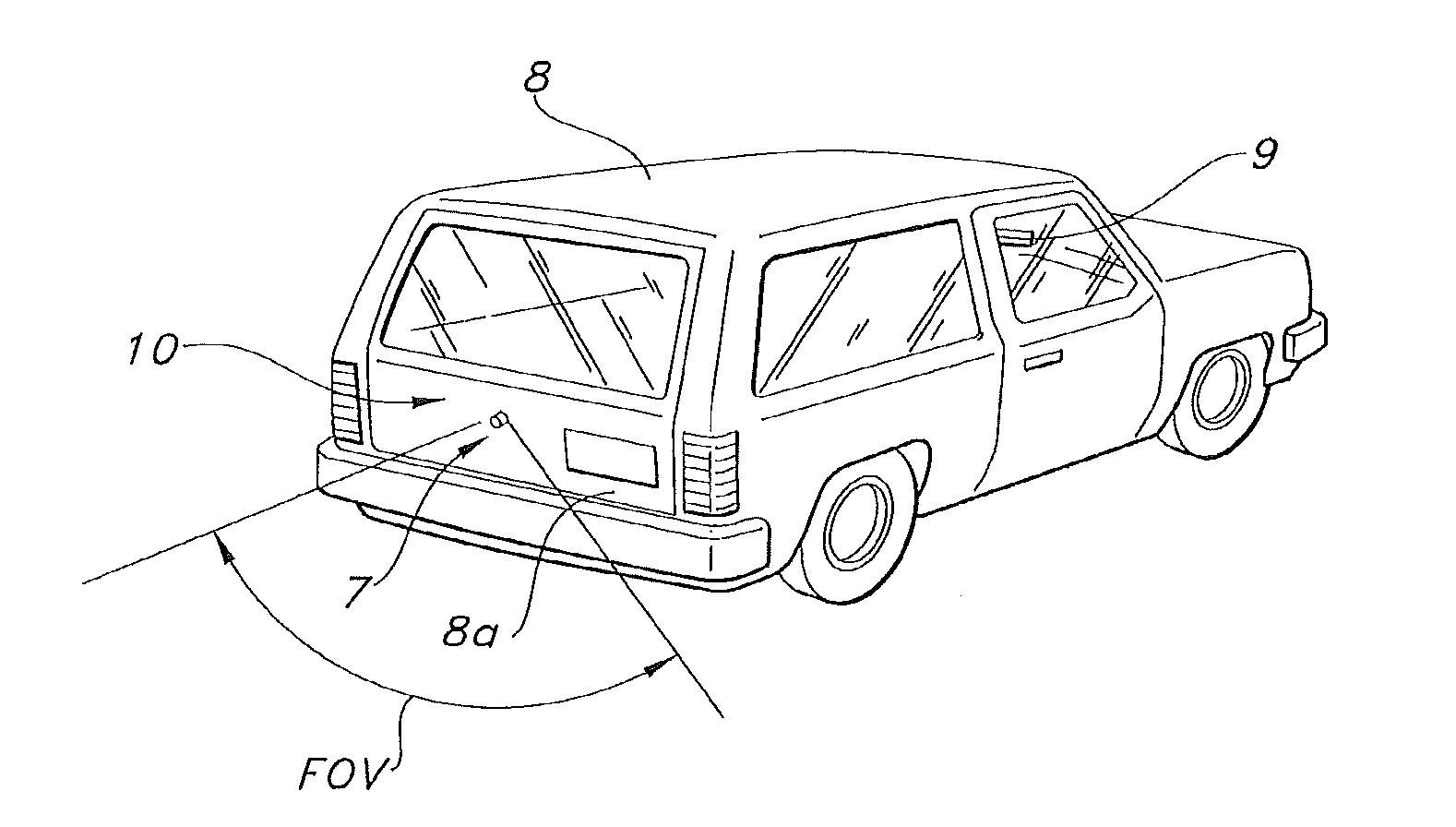

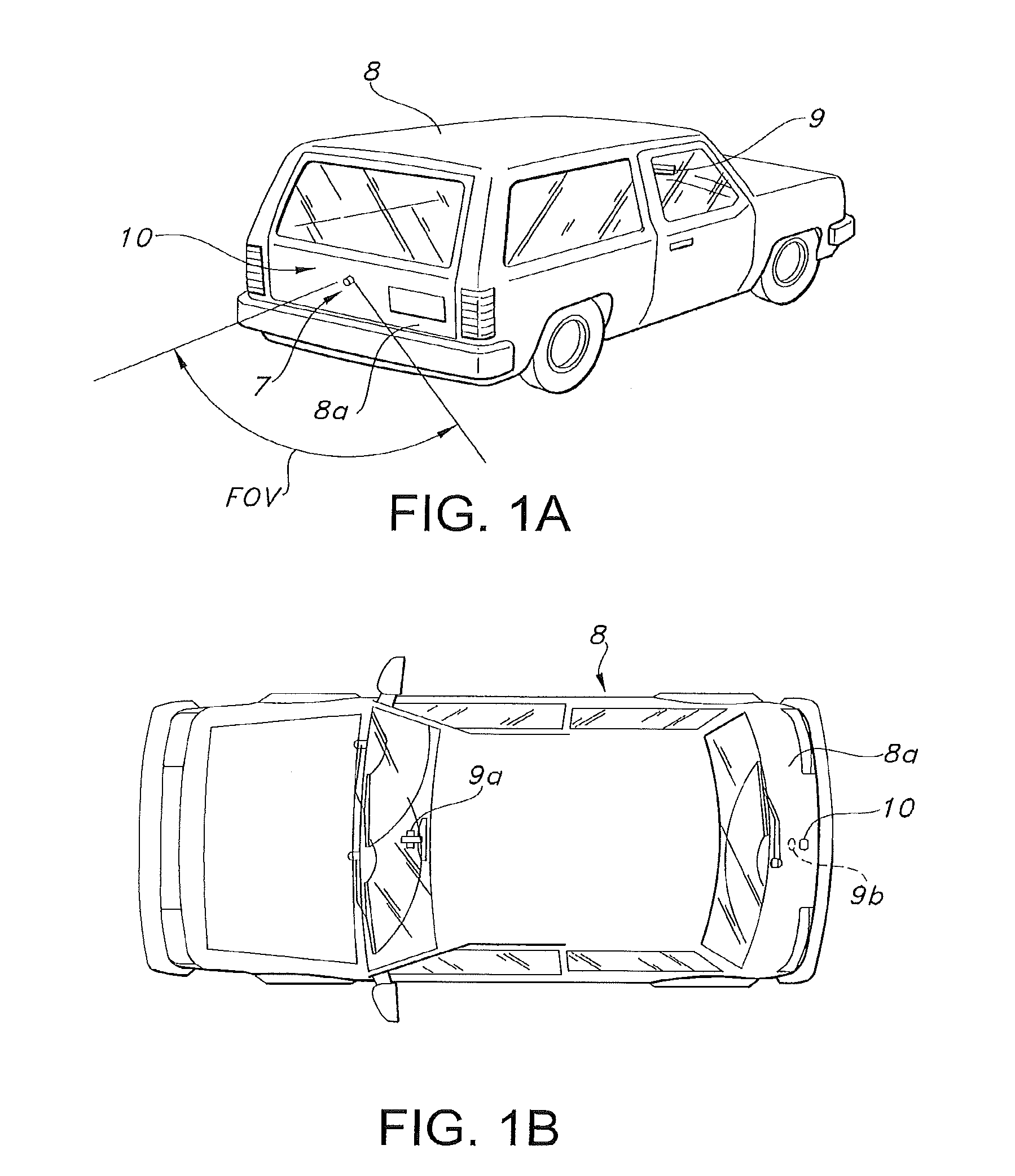

Integrated automotive system, nozzle assembly and remote control method for cleaning an image sensor's exterior or objective lens surface

ActiveUS20140060582A1Easy to cleanPromote effectiveElectrostatic cleaningSpray nozzlesCamera lensRemote control

An external lens washing system has an aiming fixture configured to support and constrain an external lens which is exposed to the elements and apt to become soiled with debris. A nozzle assembly is configured to be supported and aimed toward the external lens by the aiming fixture and has at least one laterally offset washing nozzle projecting from the aiming fixture to a spray washing fluid toward the external lens surface, spraying at a shallow, glancing spray aiming angle to impinge upon and wash the lens external surface. Optionally, an integrated image sensor and lens washing assembly is configured for use with a remote control method for cleaning an exterior objective lens surface and includes a sealed image sensor housing assembly including an integral, remotely controllable lens cleaning system with an optimized configuration for aiming one or more cleansing sprays from one or more laterally offset fluidic oscillators.

Owner:DLHBOWLES INC

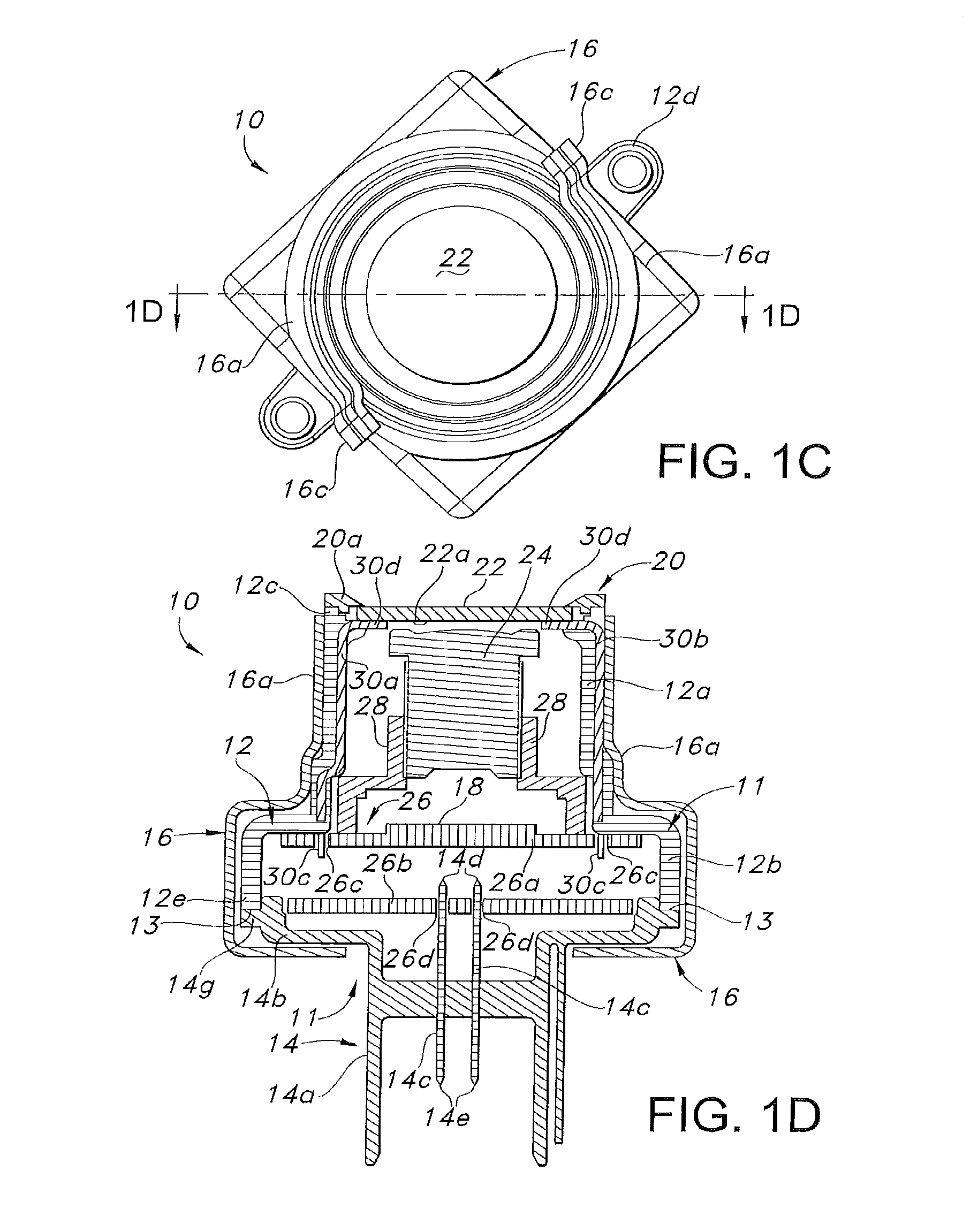

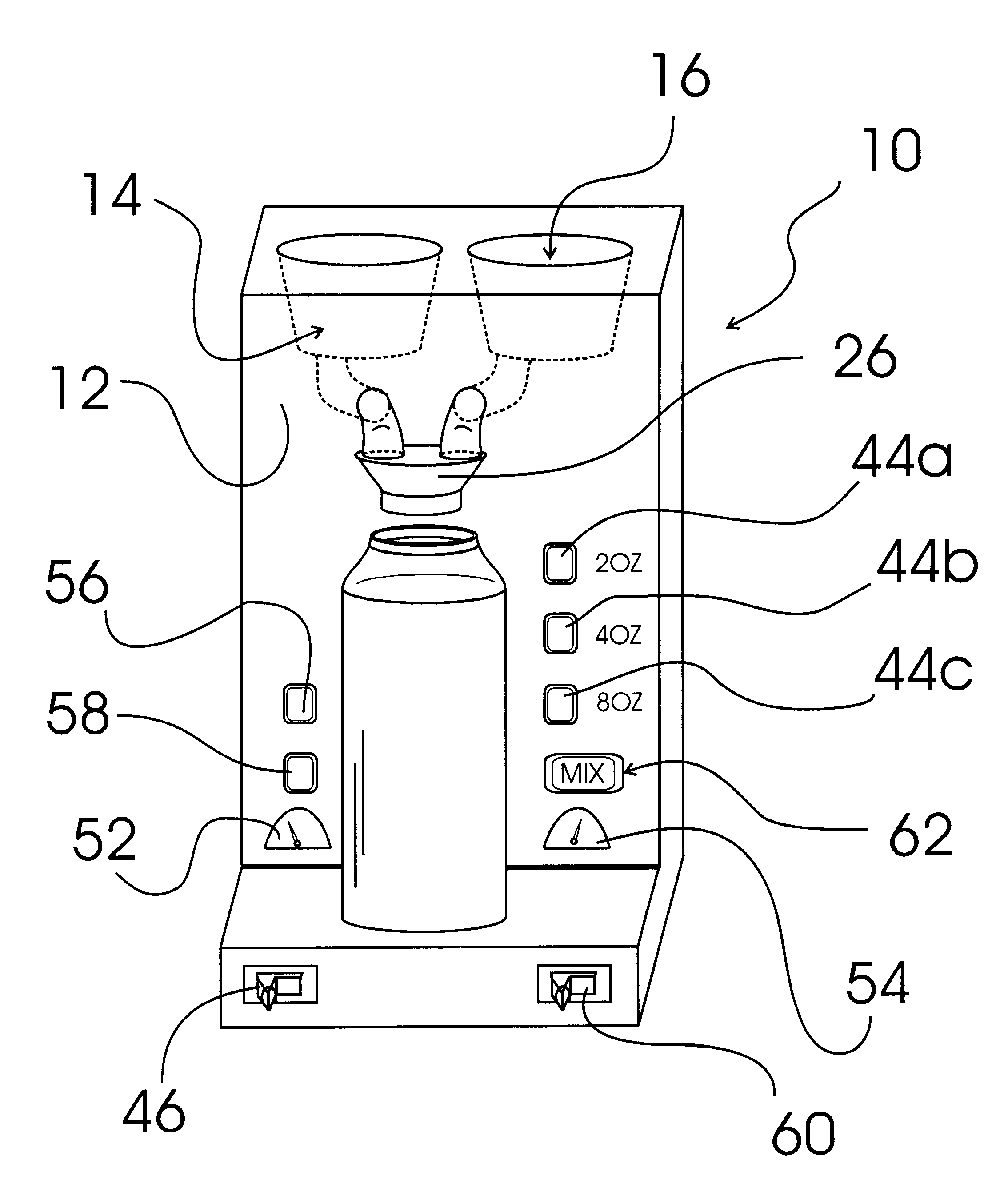

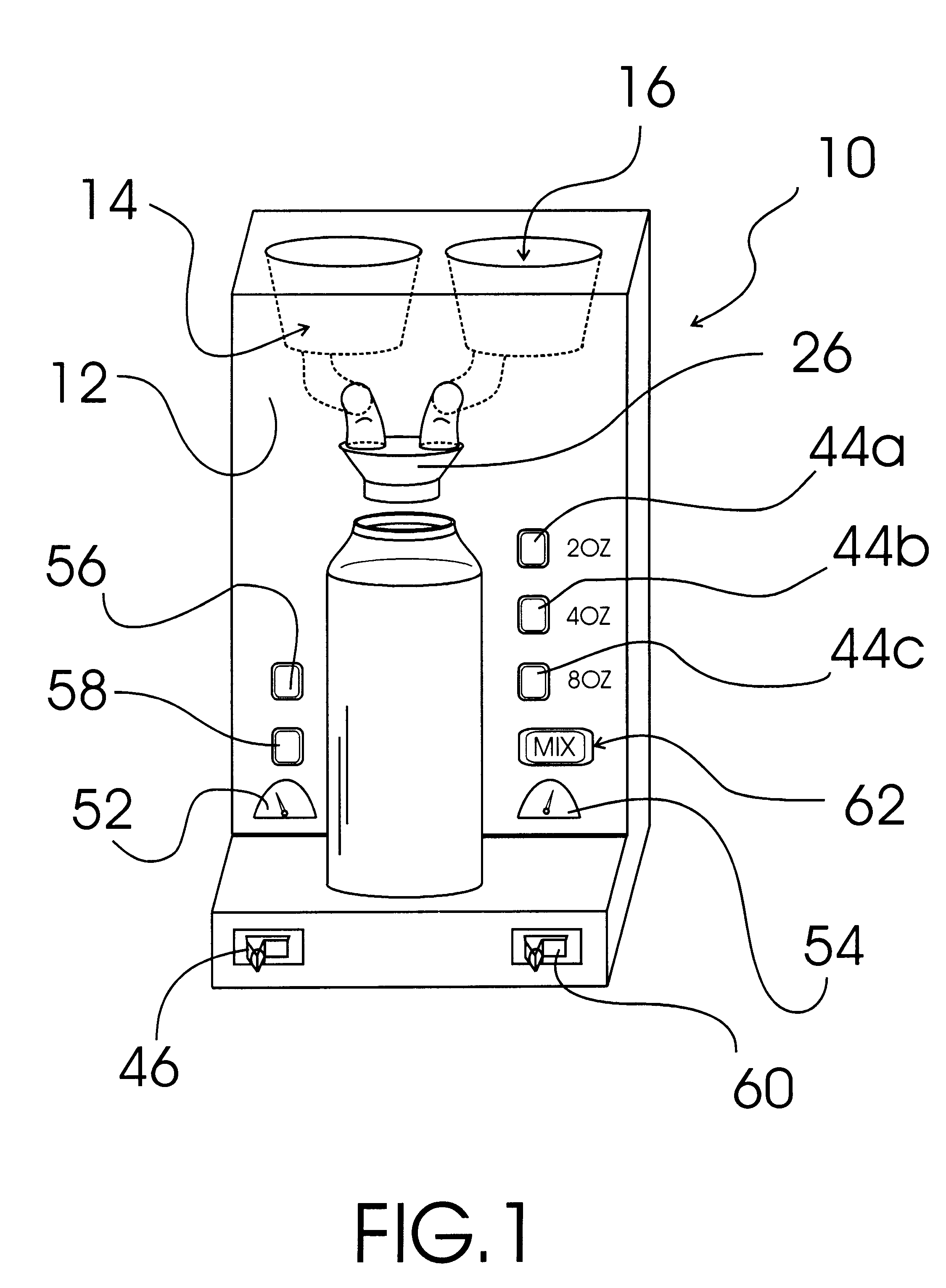

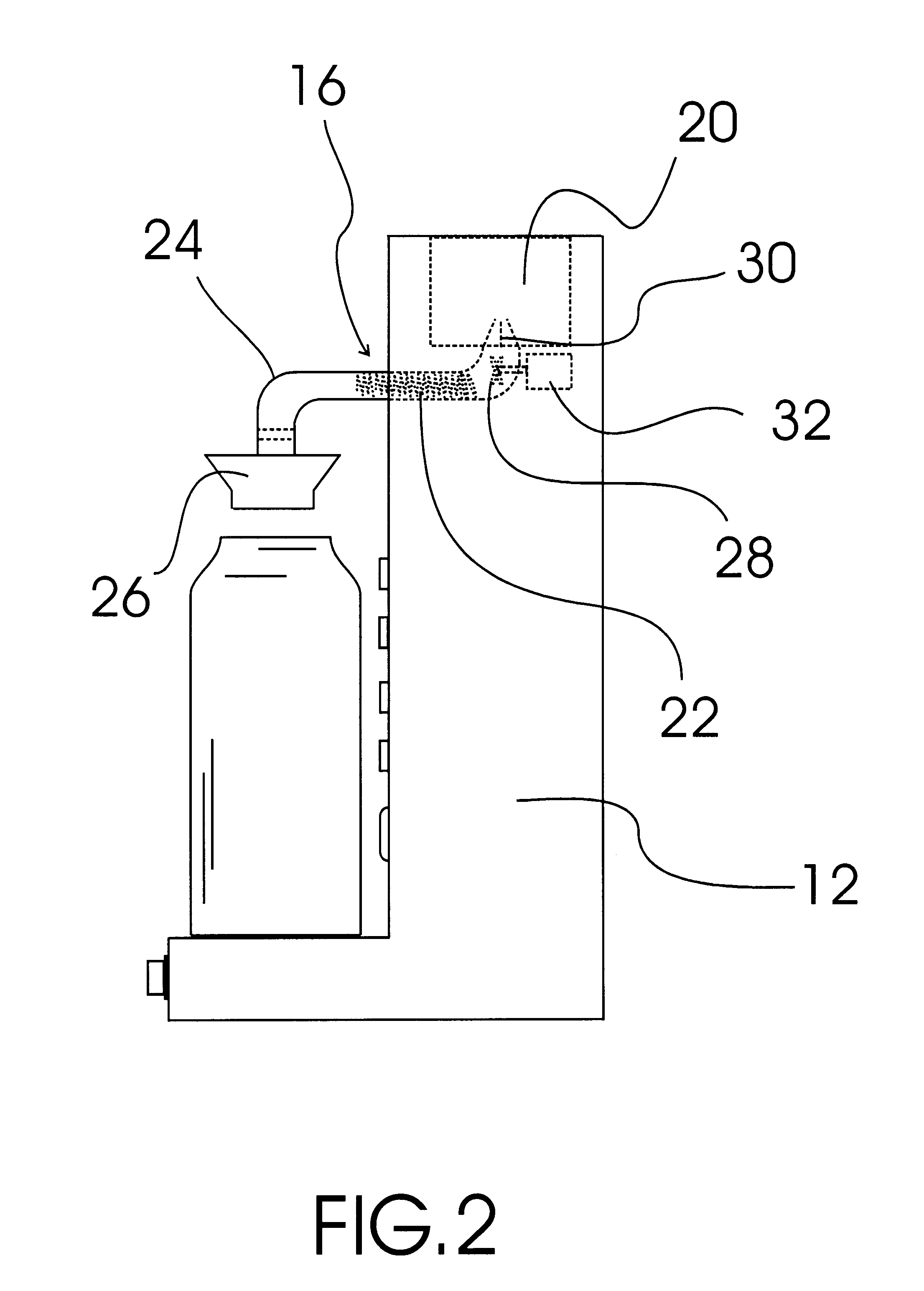

Heated beverage machine

A beverage preparing machine that includes reservoirs for storing a quantity of powdered drink mix, such as a powdered baby formula mix, and a volume of water, a water dispensing mechanism that includes a heating element for dispensing a given volume of heated water into a mixing nozzle and a powdered drink mix dispensing assembly for simultaneously dispensing a volume of powdered drink mix into the mixing nozzle. The mixing nozzle having a dispensing opening for filling a container such as a baby bottle.

Owner:CLUBB BOBBYE L

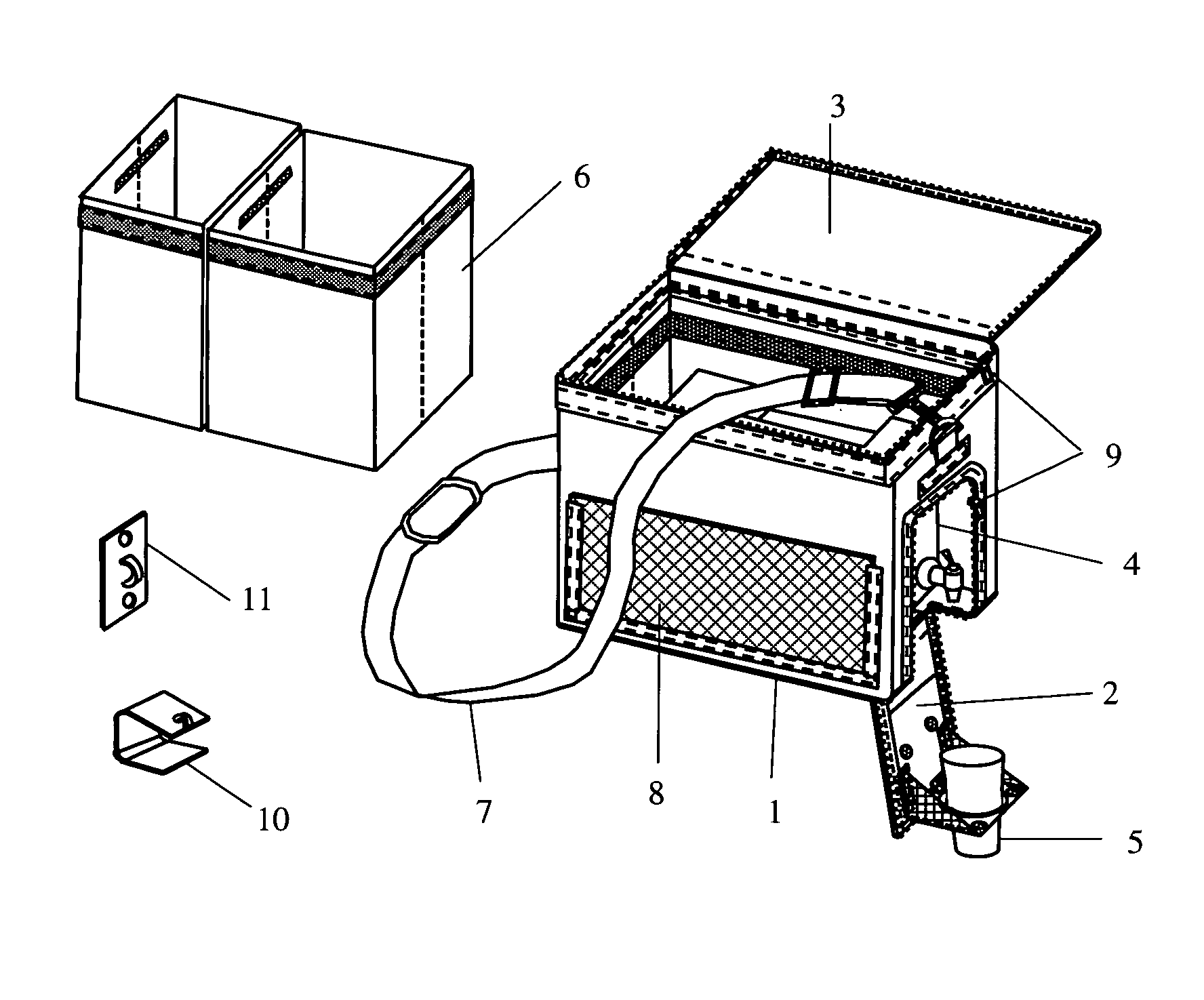

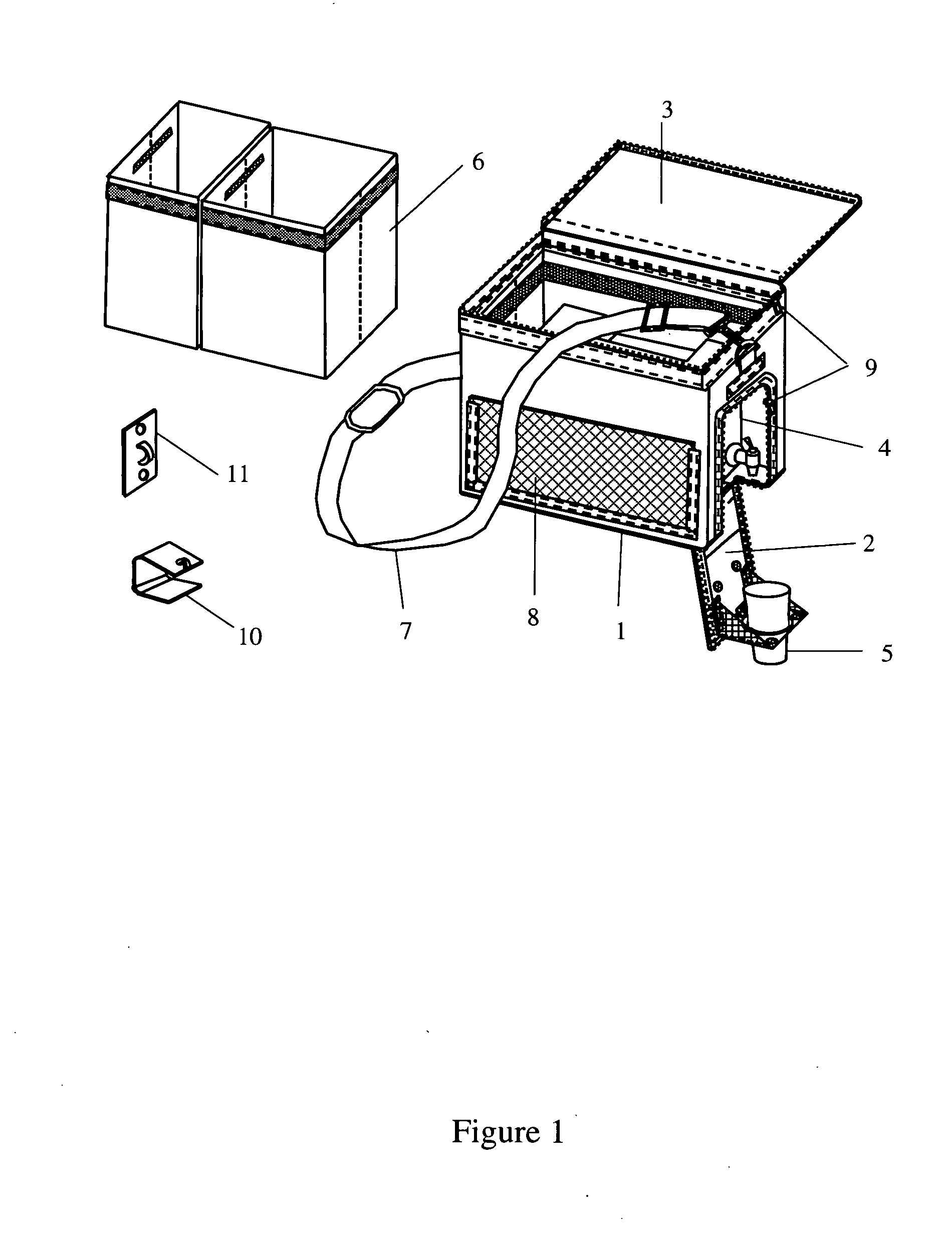

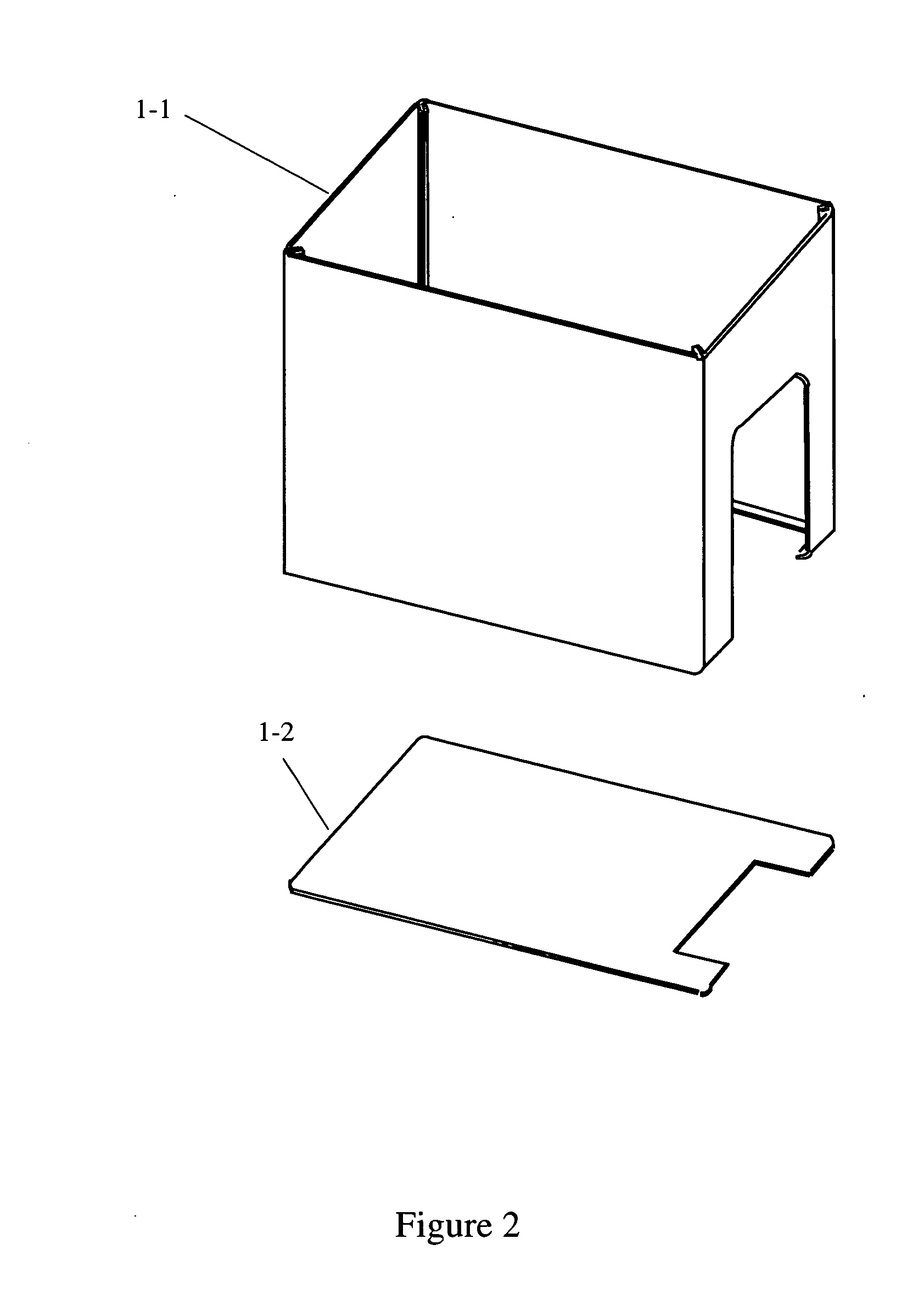

Multipurpose nozzle access door, content management insert, and anchor for a flexible cooler and dispenser alternative

InactiveUS20150008242A1Prevent non-resisted shiftingDomestic cooling apparatusLighting and heating apparatusSpray nozzleEngineering

A multipurpose nozzle access door, content management insert, and anchor for a flexible cooler and dispenser alternative is an insulated beverage cooler / utility bag body that accepts a waterproof and water tight content management insert. The content management insert lines the inside of the cooler body and is fastened to selected portion of the interior of the cooler body. In concert the liner covers the entire inner cavity which is the storage space of the cooler. Individually the liner permits arrangement, separation, variable insulation of items placed in the cooler storage space. The cooler has a cascading door with a cancelable cup holder attached. Additionally, the cooler has two types of anchors that allow the carrying strap to act as the linkage between the cooler body and either one of the anchors so that the cooler can be restrained near a fixed point.

Owner:KPABAR JR THOMAS KOLACO

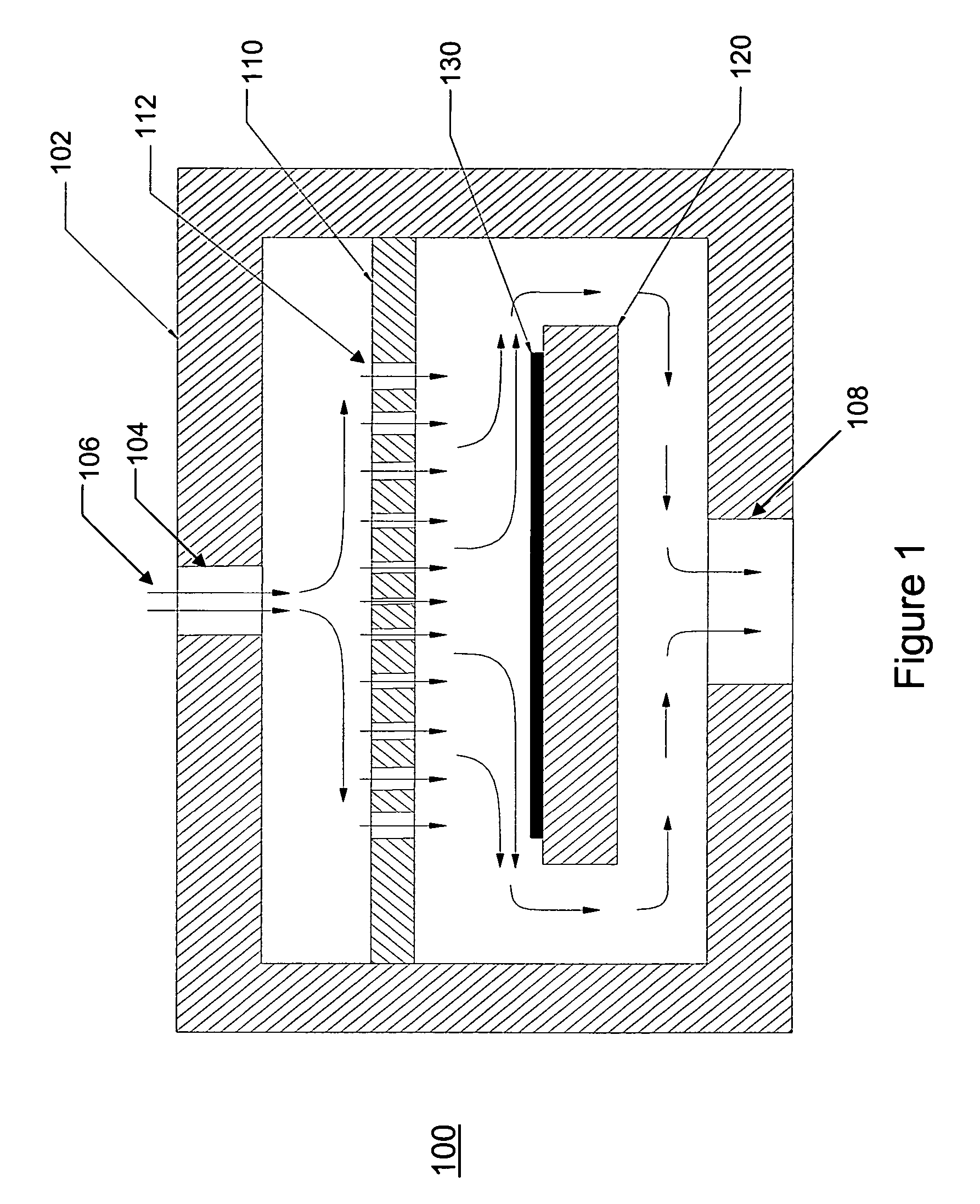

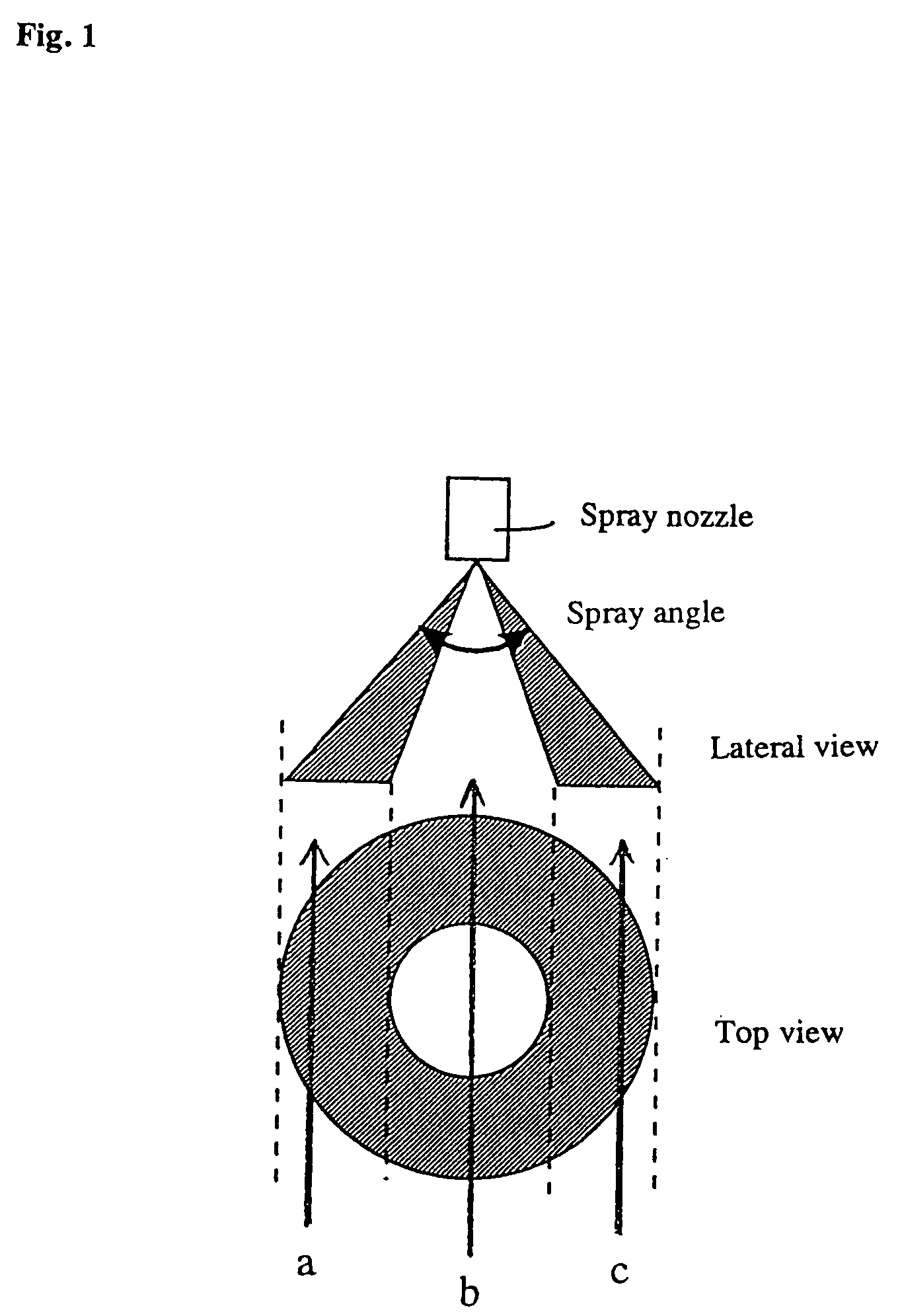

Water-absorbent resin and production process therefor

InactiveUS7183456B2Efficiently and uniformlyMaintain good propertiesSynthetic resin layered productsCellulosic plastic layered productsAbsorption capacitySpray nozzle

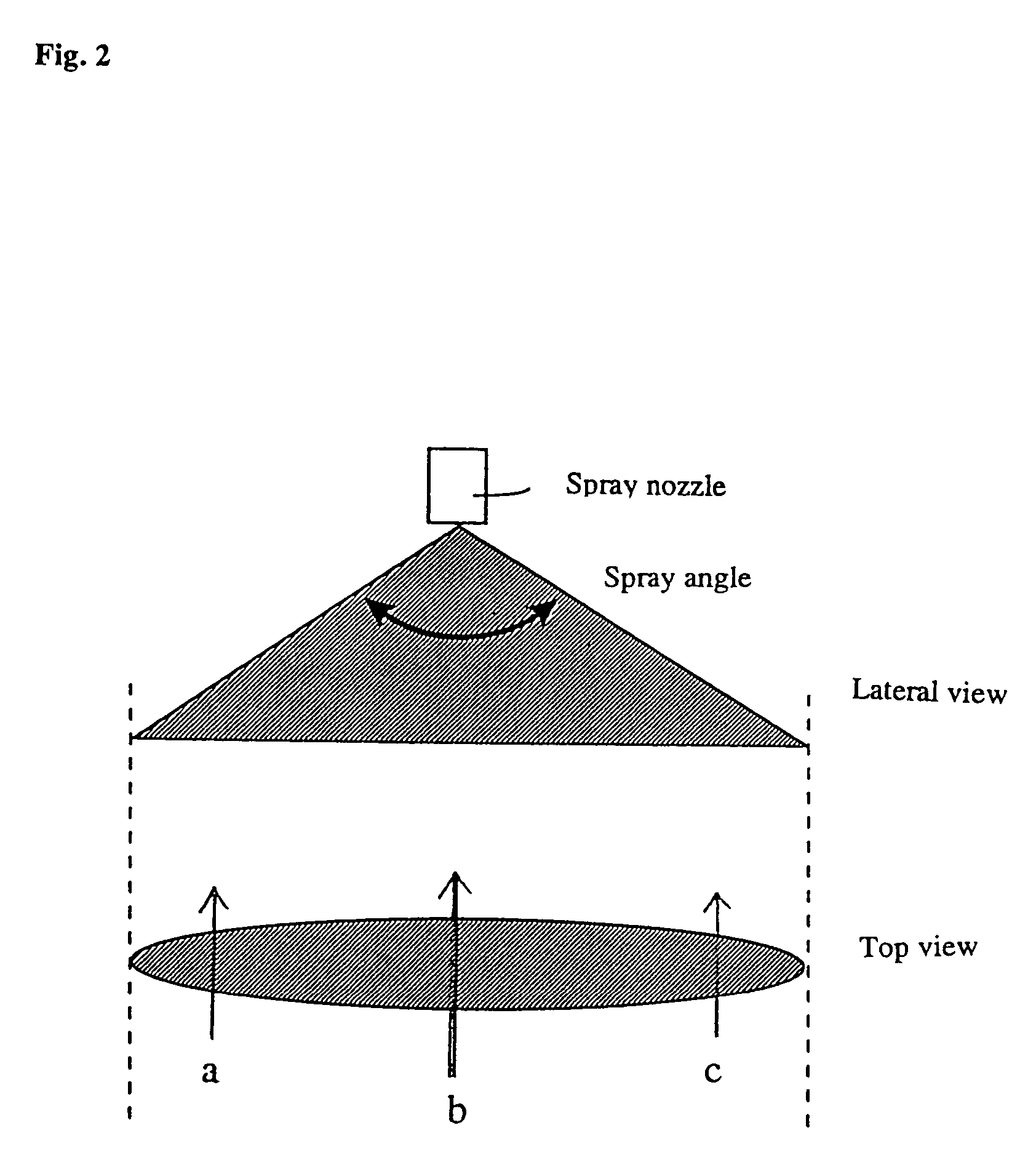

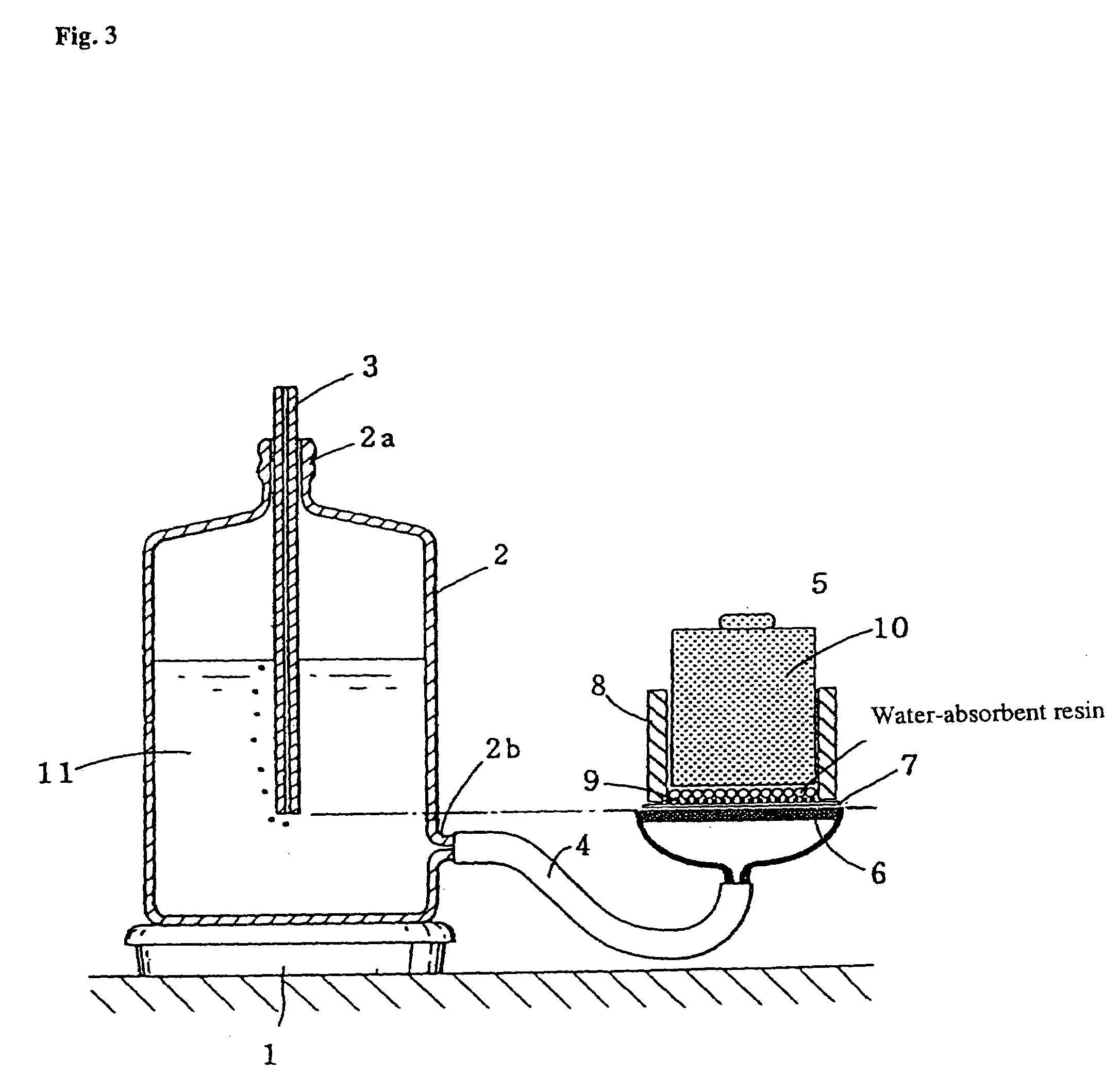

In a production process for a water-absorbent resin, comprising the steps of: blending a liquid material and a water-absorbent resin; and heating the resultant mixture in order to produce a modified water-absorbent resin, the present invention is to provide: a method for uniformly and efficiently treating a water-absorbent resin favorably in view of industry, and as a result, a good-balanced water-absorbent resin having various excellent properties, such absorption capacity without a load, absorption capacity under a load, and single-layer absorption capacity under a load in contact with an aqueous liquid. The production process comprises the step of spray-blending a water-absorbent resin (A) and a liquid material (B) with a blending apparatus equipped with a spray nozzle (C), wherein the liquid material (B) is sprayed from the spray nozzle (C) and its spray pattern is a circular and hollow cone shape or a double-convex-lens and elliptic cone shape. In addition, the production process comprises the step of heat-treating a water-absorbent resin under an atmosphere having a dew point of not higher than 60° C. and a temperature of not lower than 90° C., wherein the water-absorbent resin is obtained after a drying step following a pulverization step.

Owner:NIPPON SHOKUBAI CO LTD

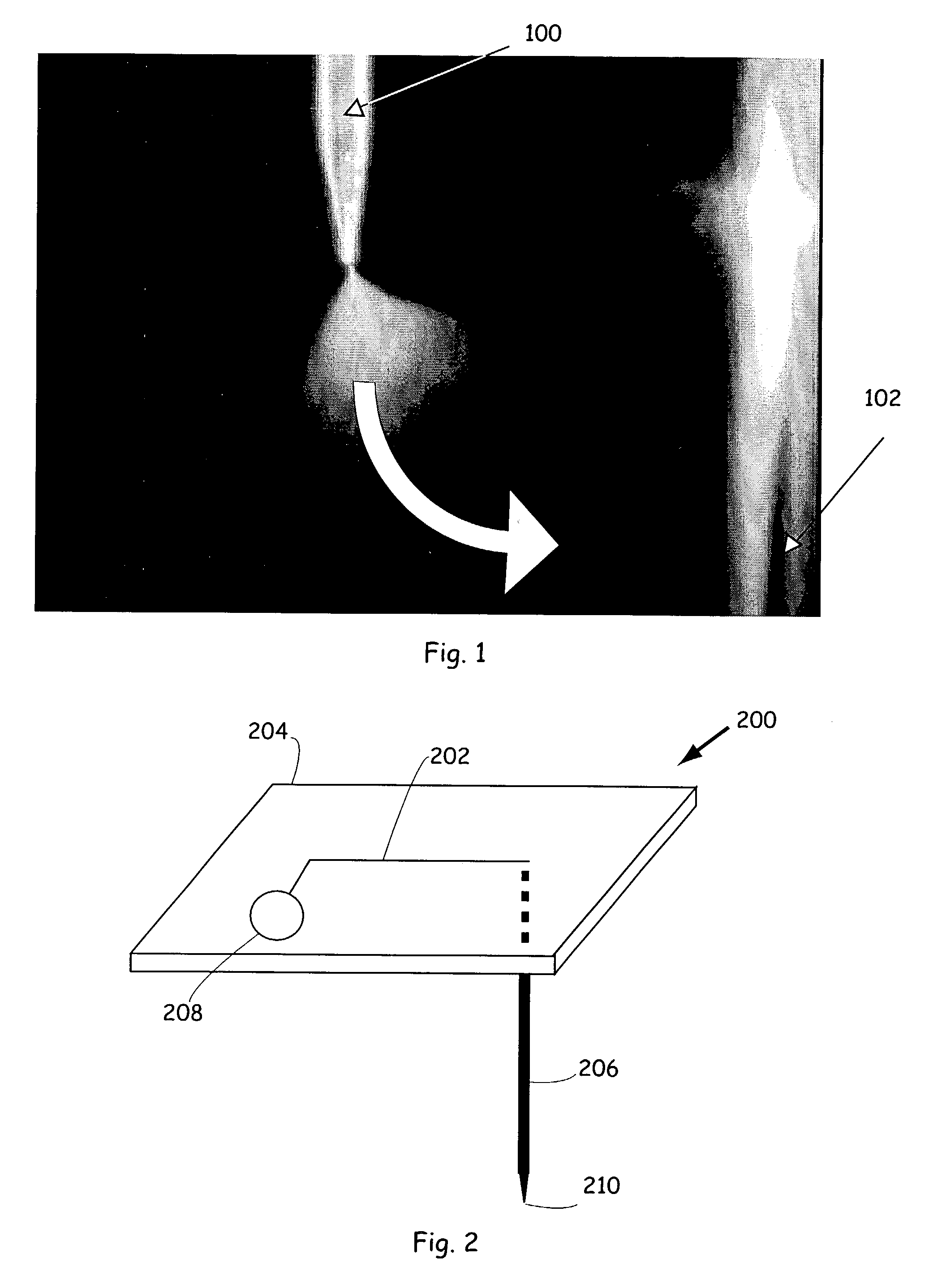

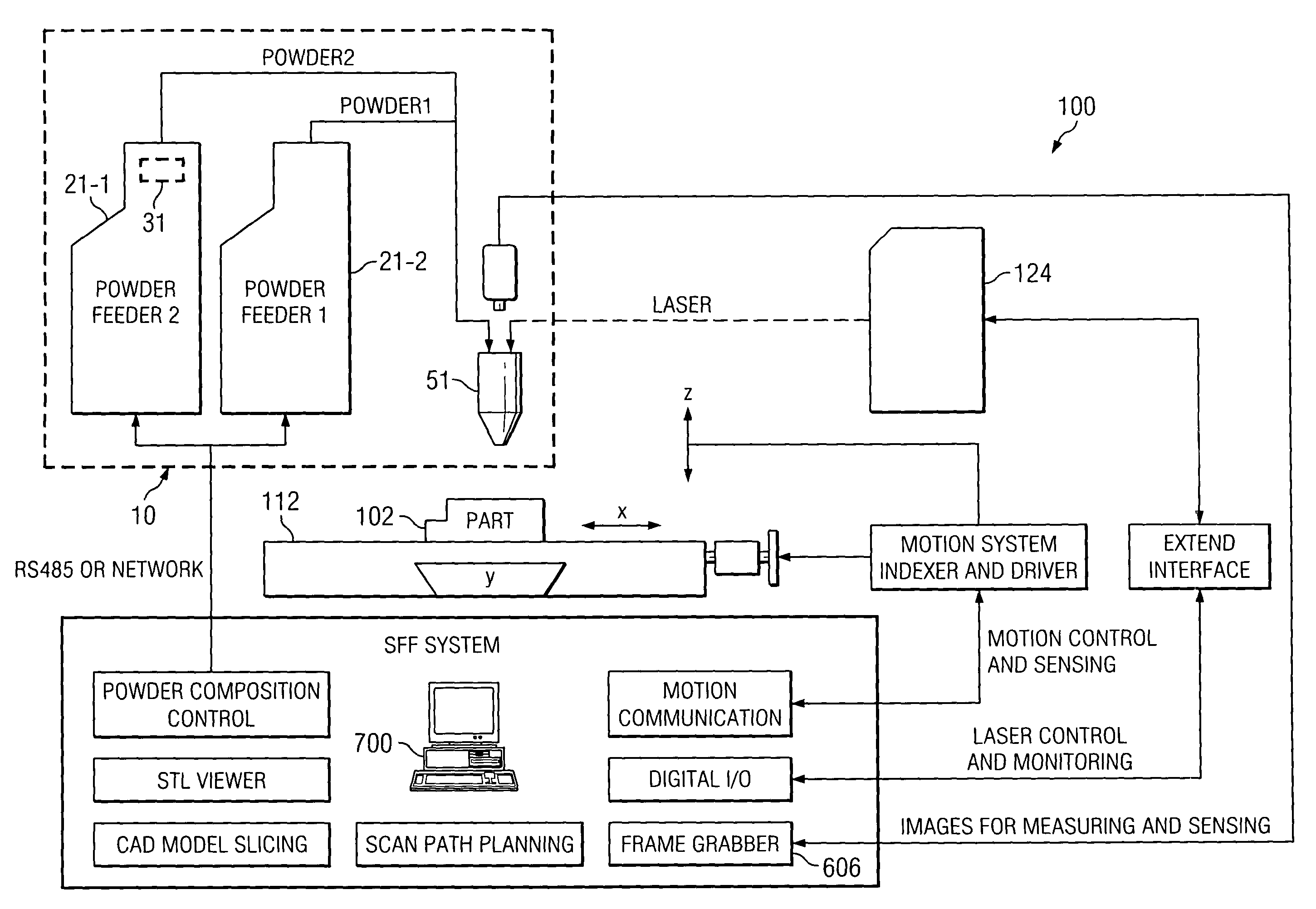

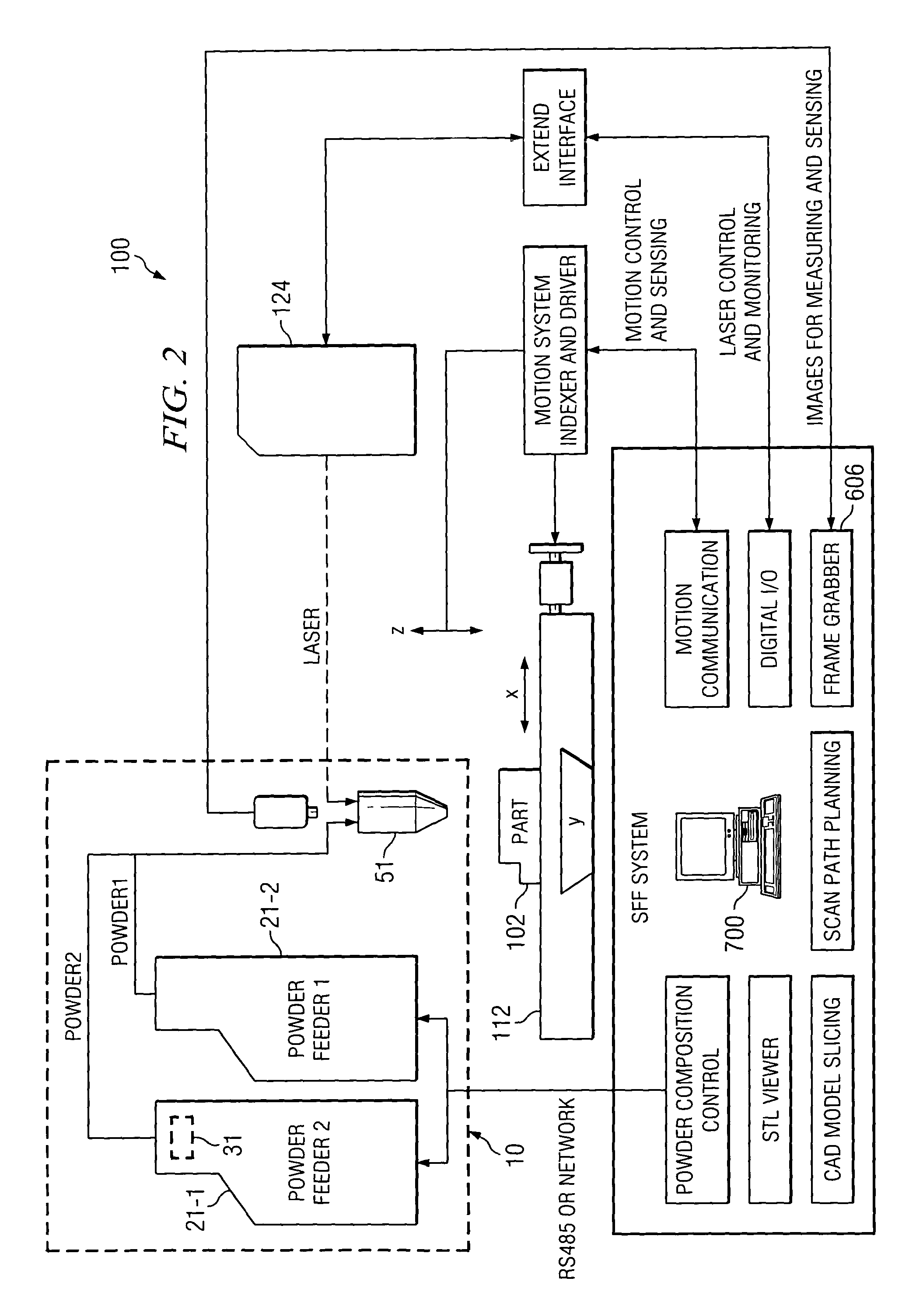

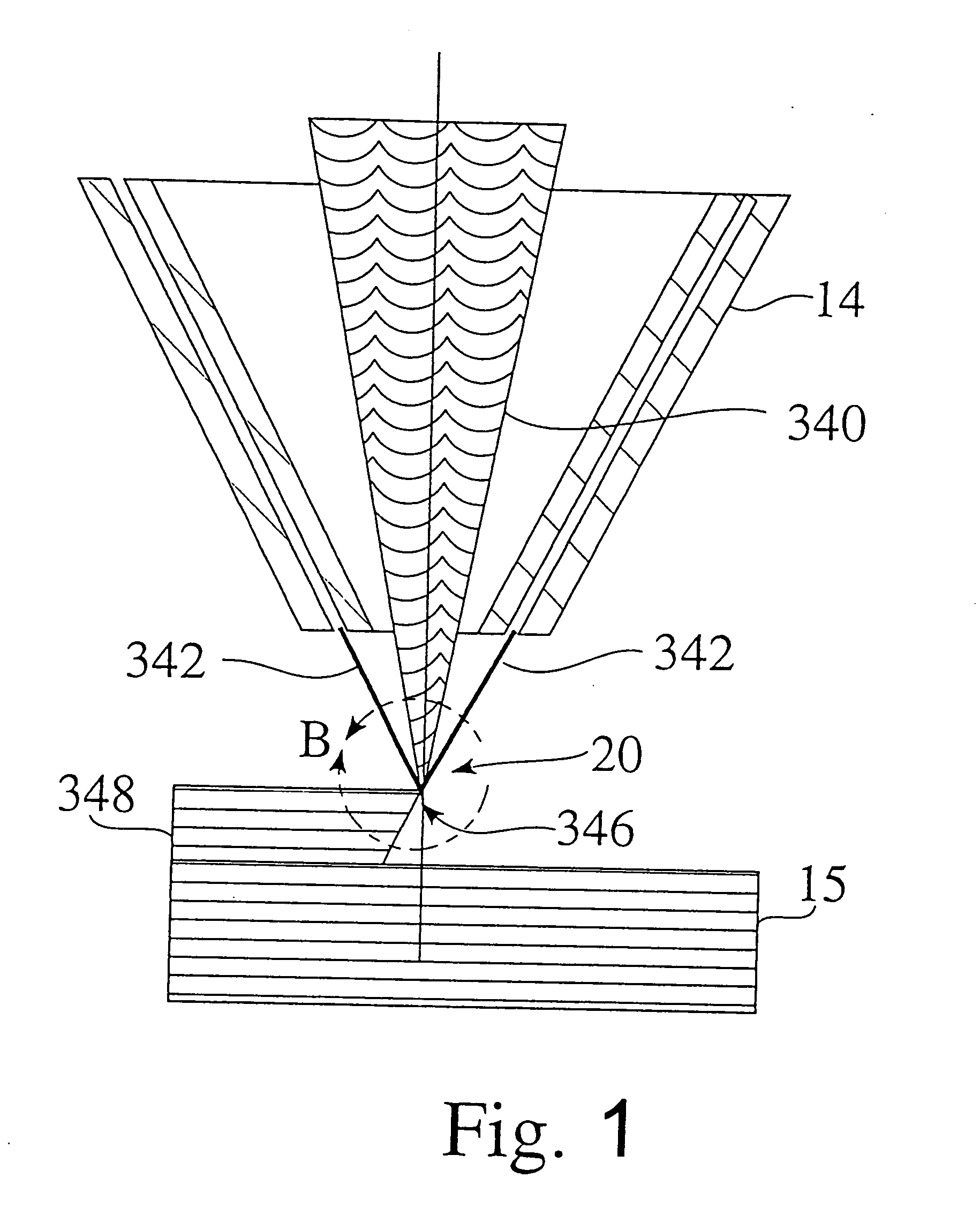

System and method for controlling the size of the molten pool in laser-based additive manufacturing

InactiveUS6995334B1High geometric accuracyEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankLaser Nozzle

According to one embodiment of the invention, a method for controlling the size of the molten pool in a laser based additive manufacturing process includes coaxially aligning an imaging device with a laser nozzle and imaging a molten pool, created by a laser, on a substrate with the imaging device. The method further includes comparing at least one characteristic of the molten pool with a respective characteristic of a target molten pool, and adjusting, in substantially real-time, a laser power of the laser based on the comparison in order to correlate the characteristic of the molten pool with the respective characteristic of the target molten pool.

Owner:SOUTHERN METHODIST UNIVERSITY

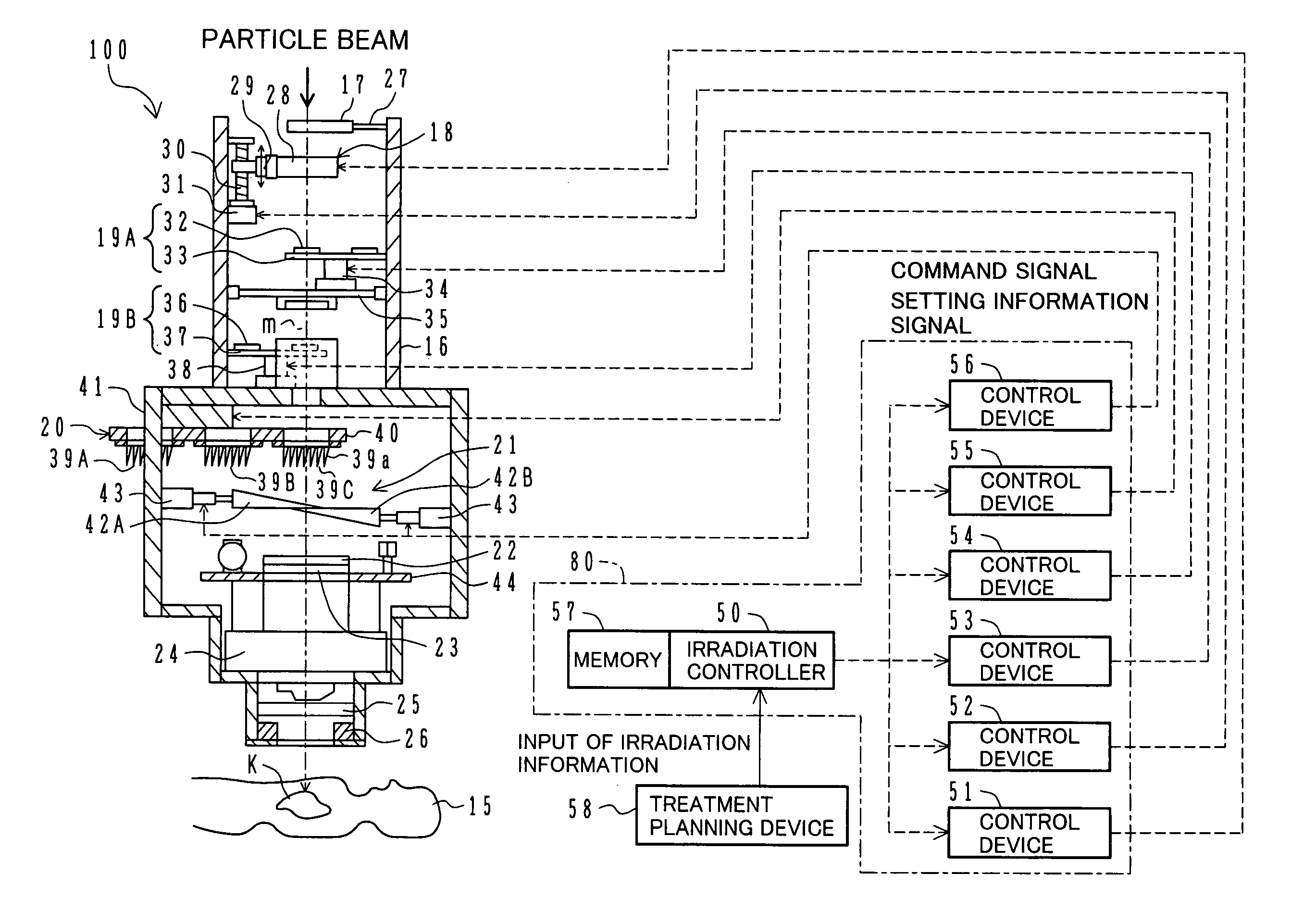

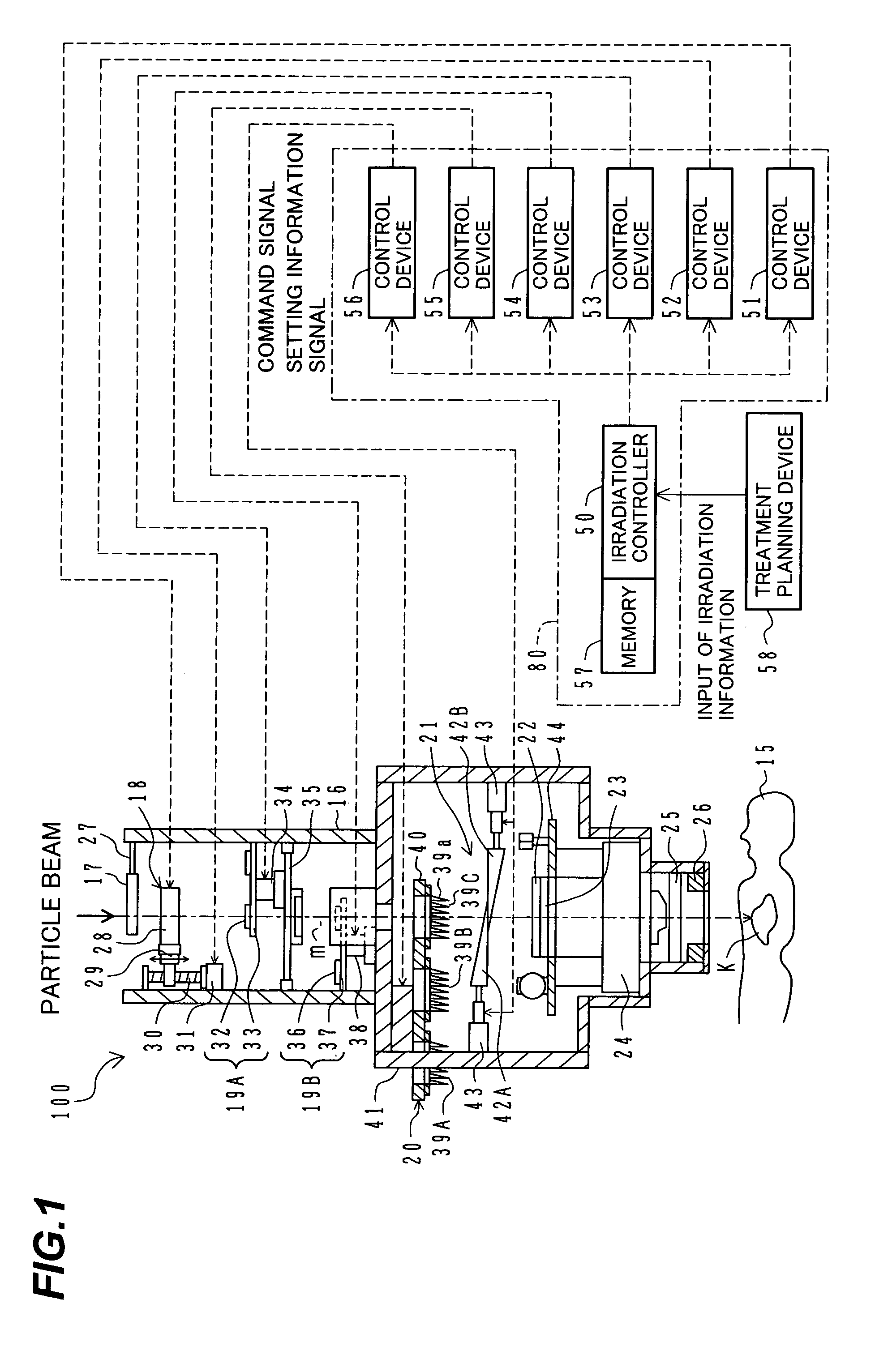

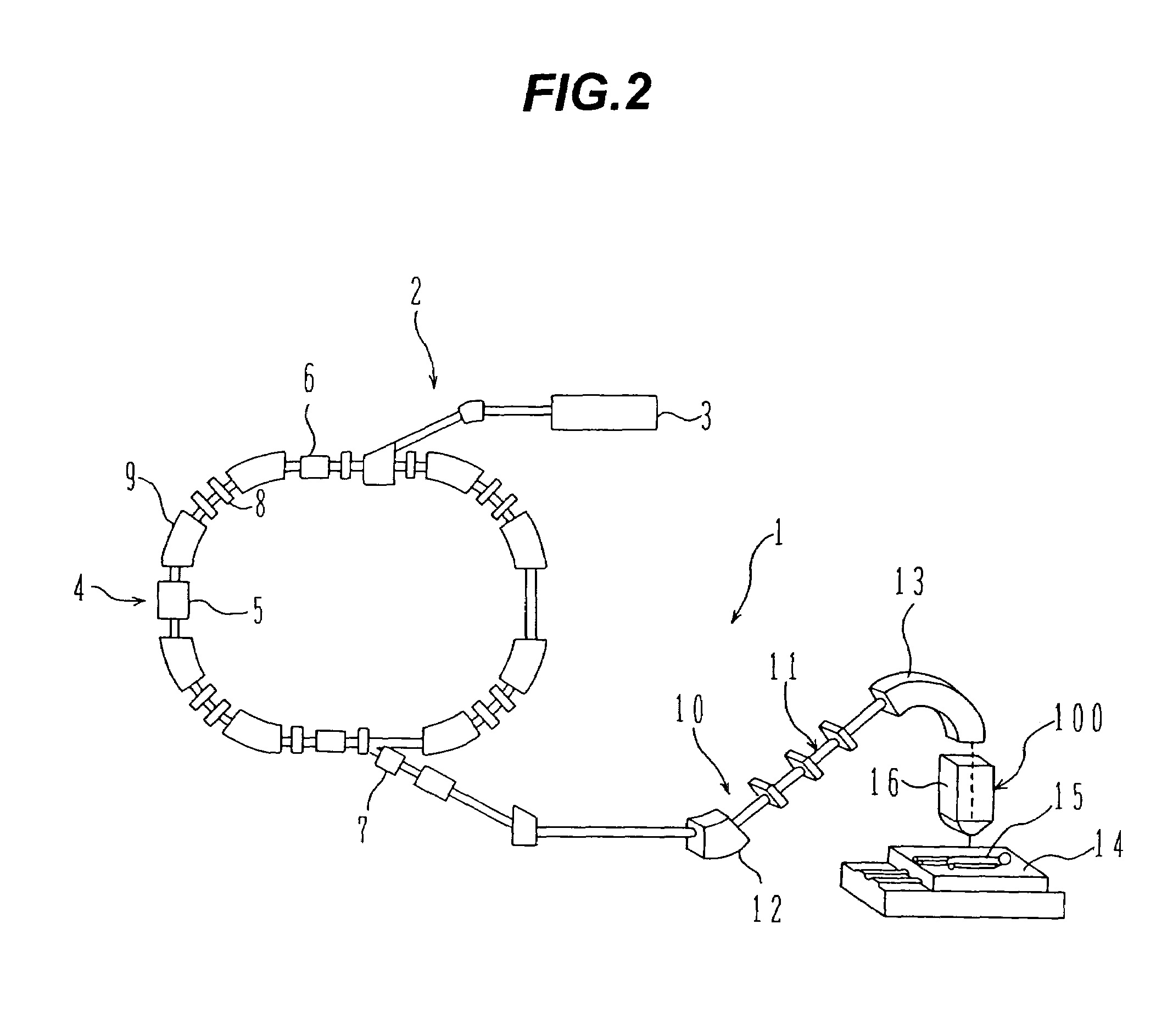

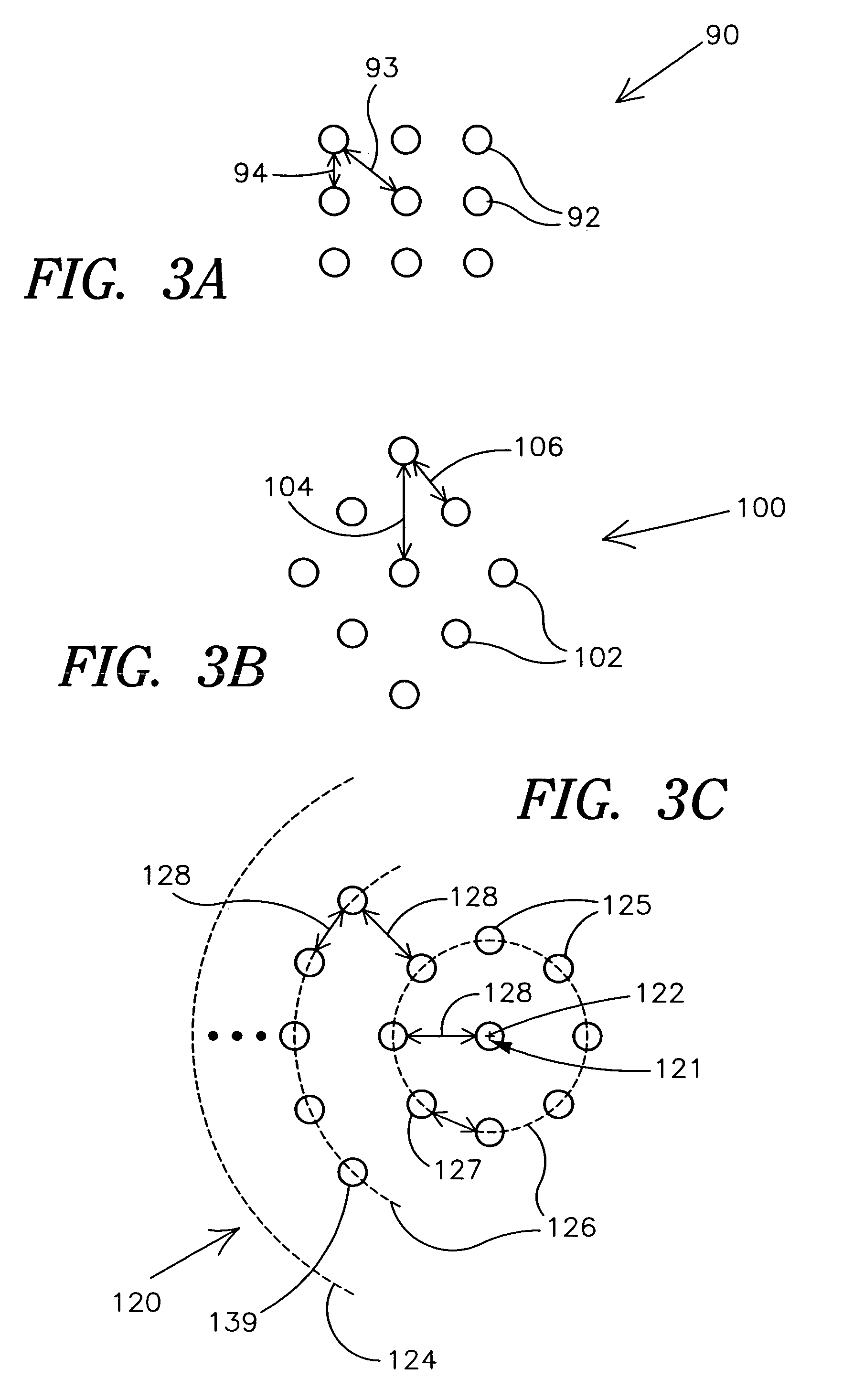

Particle beam irradiation equipment and particle beam irradiation method

ActiveUS7449701B2Improve dose uniformityLong rangeRadiation/particle handlingElectrode and associated part arrangementsField sizeParticle beam

Particle beam irradiation equipment and a method of adjusting irradiation nozzle, which can ensure a long range and high dose uniformity at any field size are provided. The particle beam irradiation equipment comprises charged particle beam generation equipment and an irradiation nozzle for irradiating a charged particle beam extracted from the charged particle beam generation equipment to an irradiation target. The irradiation nozzle comprises a first scatterer device including a first scatterer for spreading out the charged particle beam into a Gaussian-like distribution, and multiple stages of second scatterer devices including second scatterers for producing a uniform intensity distribution of the charged particle beam having been spread out into a Gaussian-like distribution by the first scatterer. For forming irradiation fields having sizes different from each other, the second scatterer devices are disposed downstream of the first scatterer device in the direction of travel of the charged particle beam at the spacing depending on the difference in the field size.

Owner:HITACHI LTD

Method and apparatus for treating the teats of an animal

InactiveUS7377232B2Good choiceImprove versatilityLiquid surface applicatorsCathetersAnimal scienceMedicine

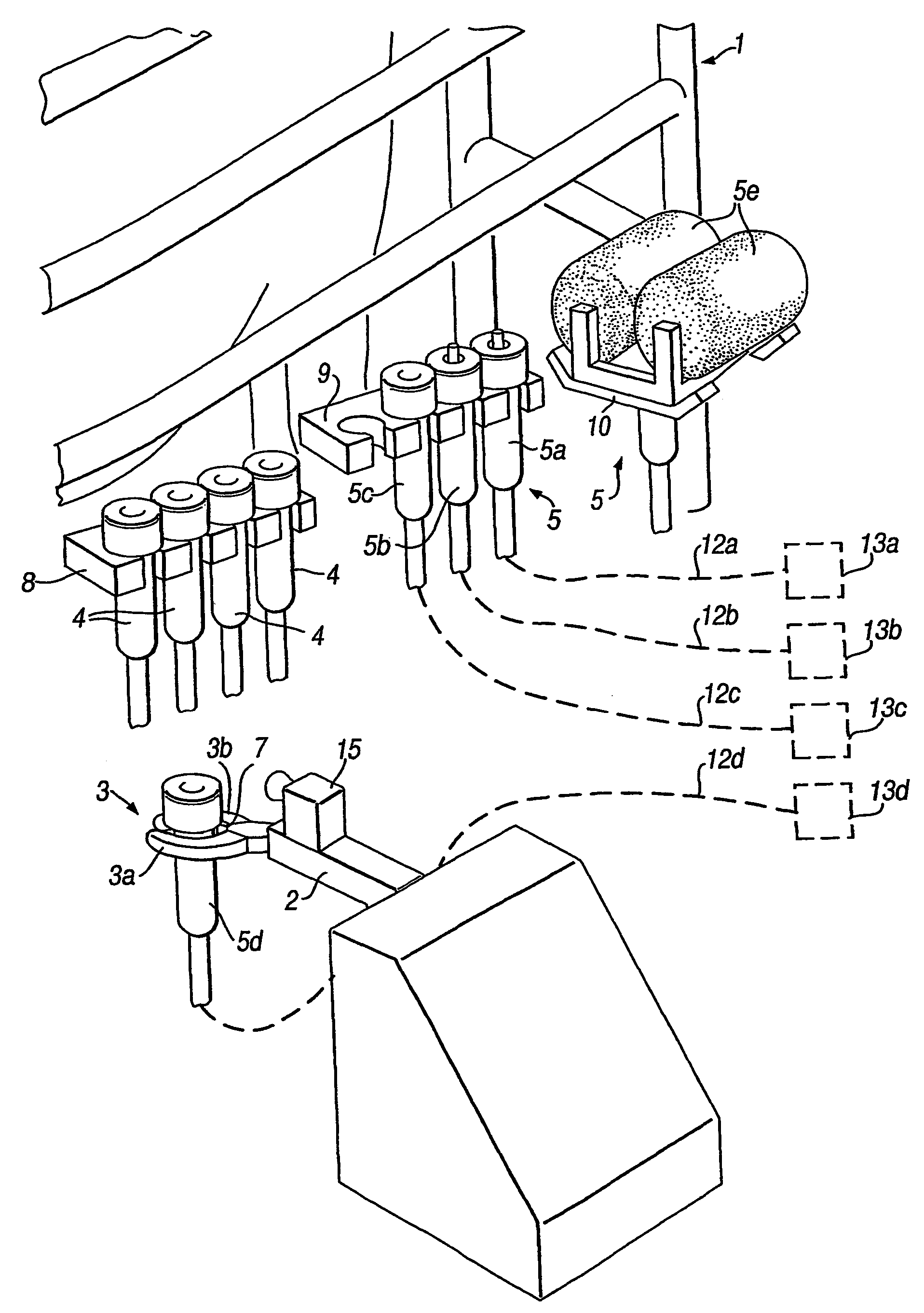

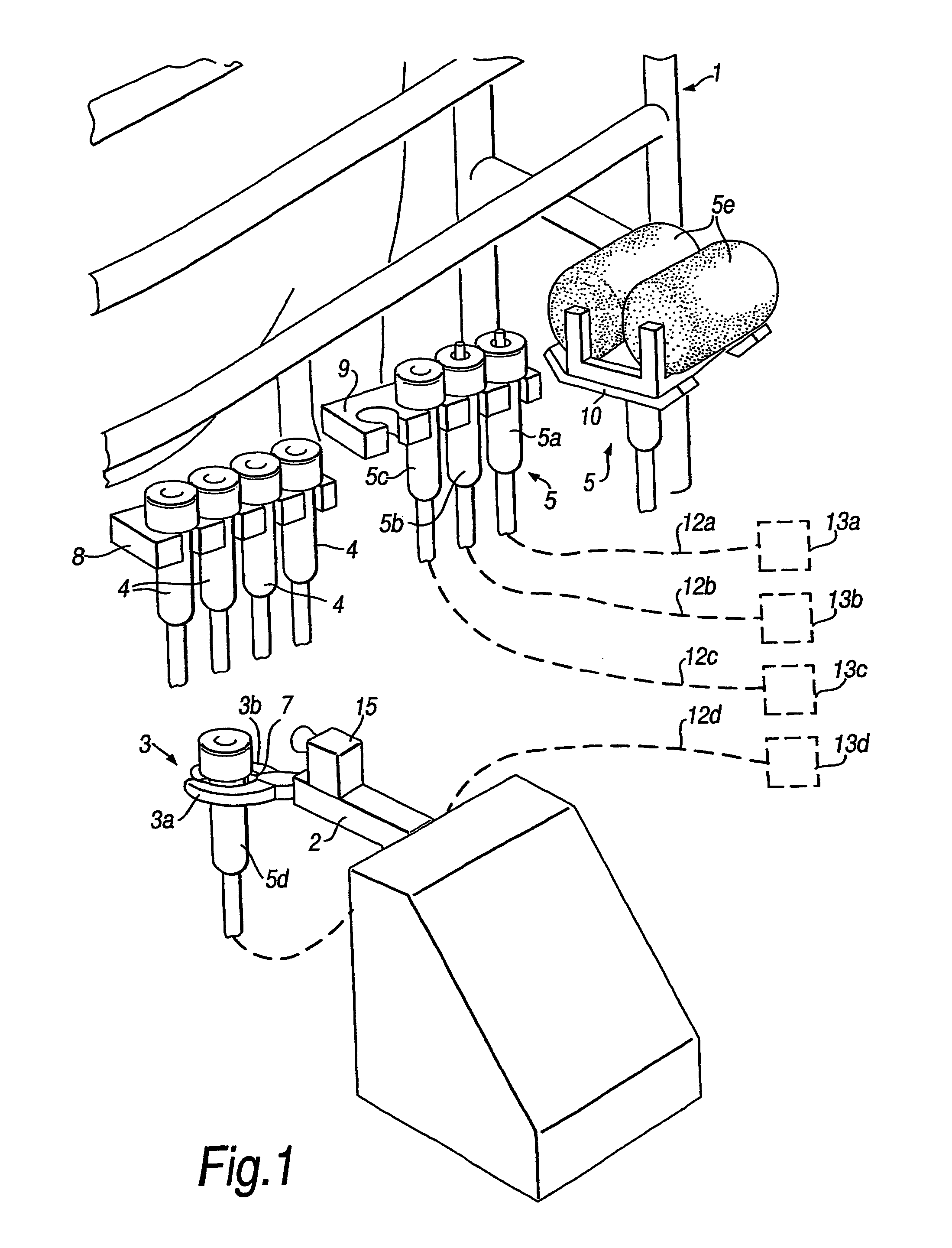

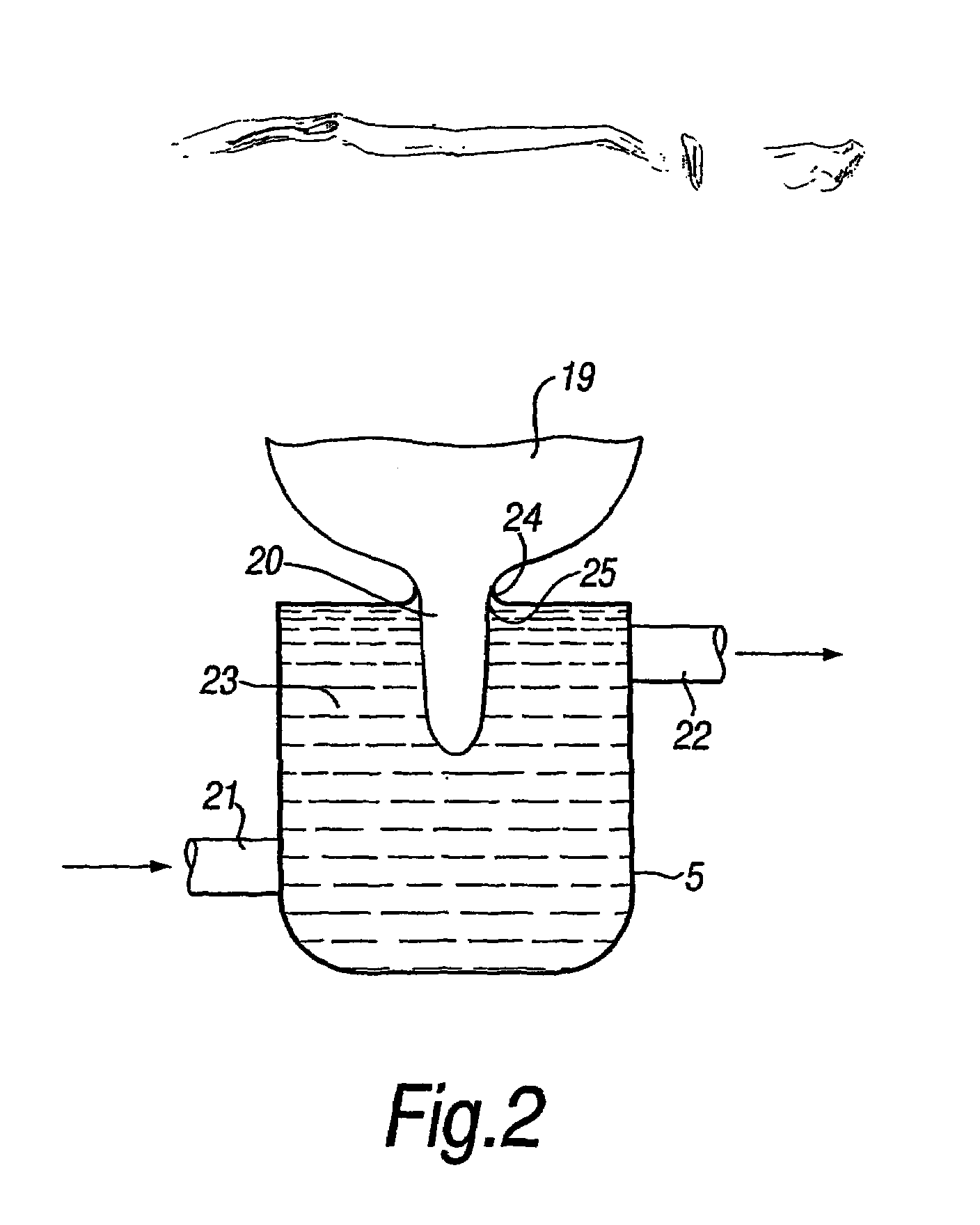

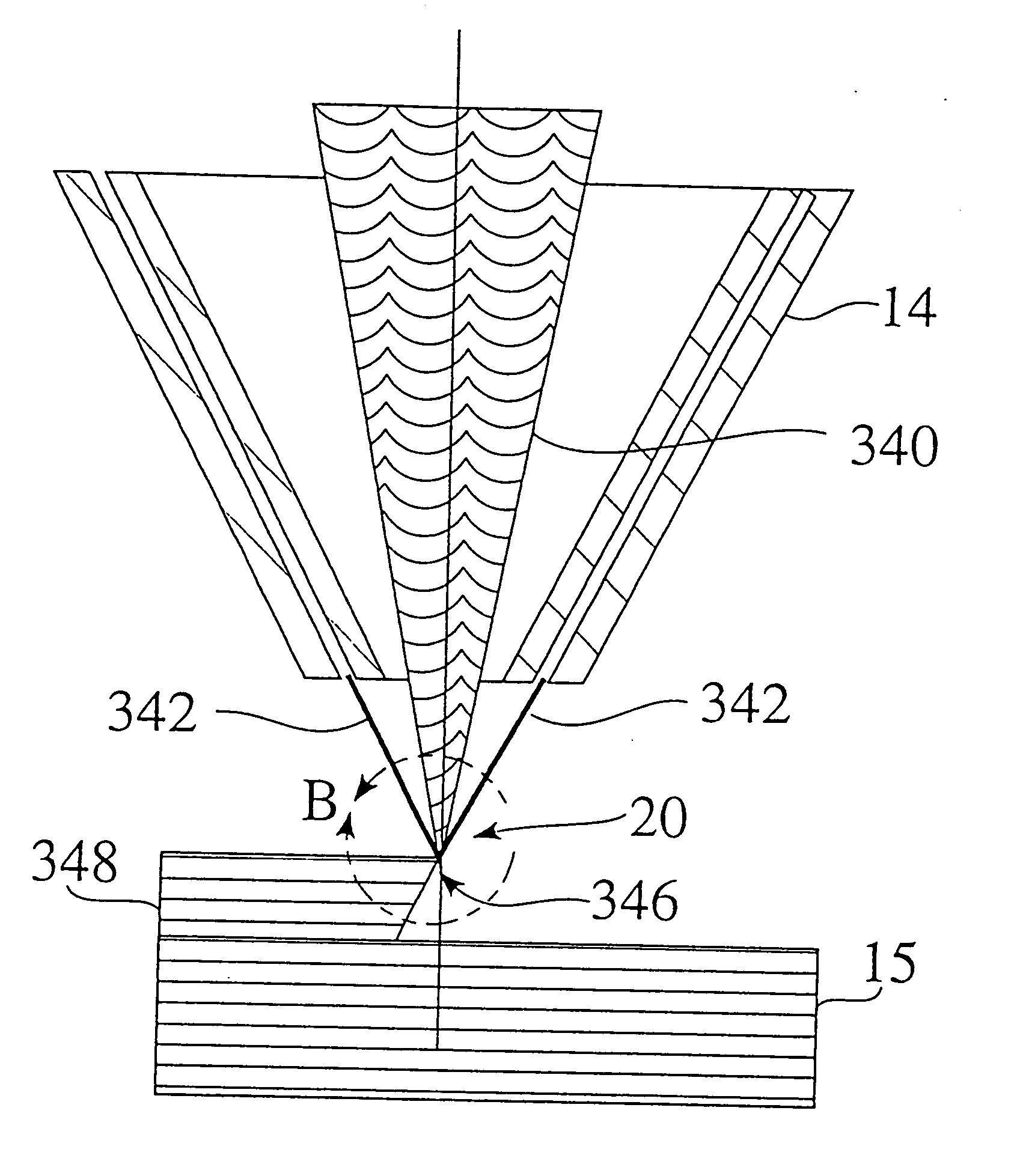

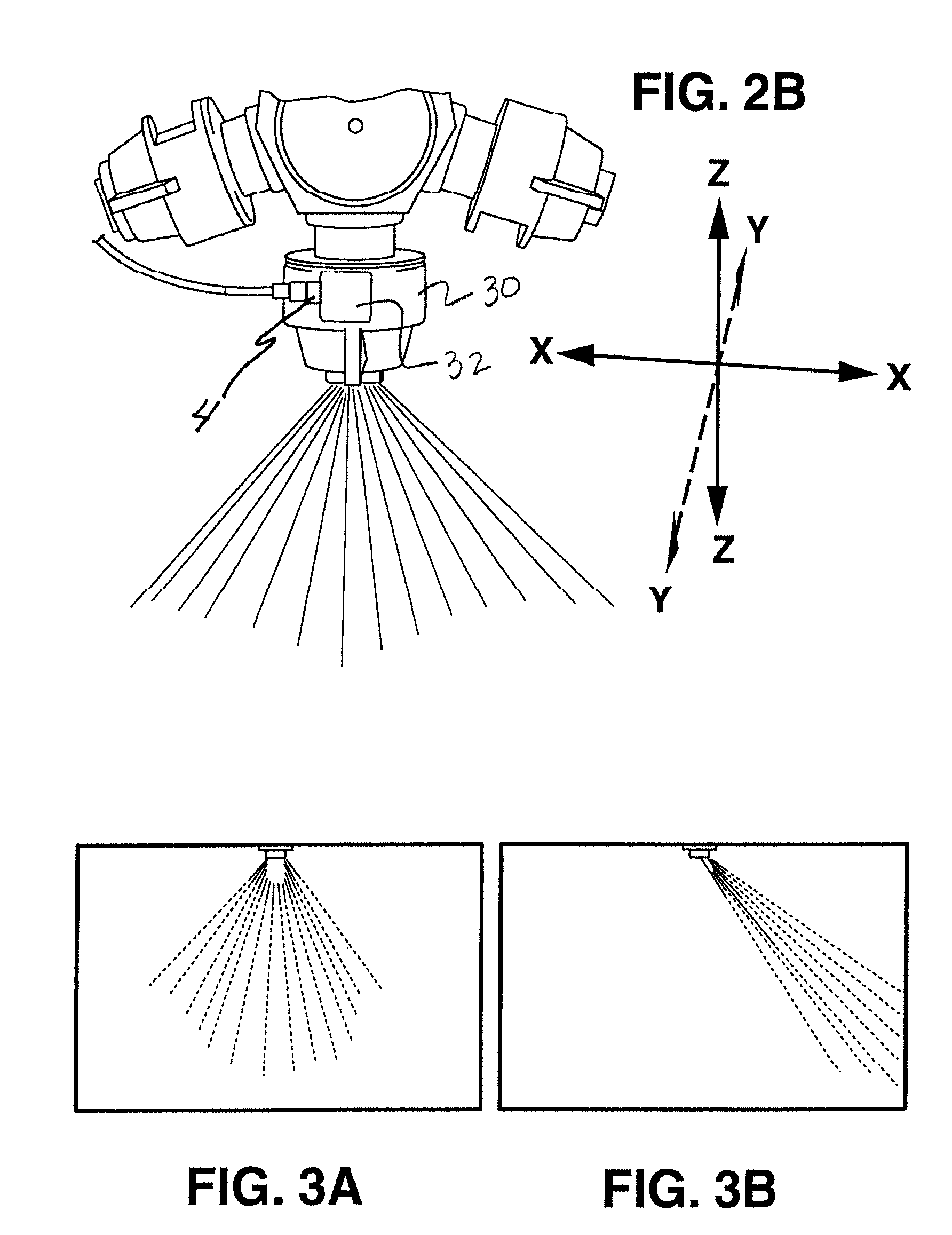

In an automatic milking installation including a robot arm (2) with a gripper (3) for attaching teat cups (4) to the teats of an animal, e.g. a cow, to be milked, for applying a teat dip to the teats after milking different members, such as spray nozzles (5a, 5b), dipping cups (5c, 5d) and sponge or cloth rollers (5e), are provided for applying different teat dip compositions. Under the control of a computer, the robot arm collects the member (5) appropriate for supplying the selected composition and takes it to a position appropriate for application of that composition. The selection can e effected in dependence upon the teat skin condition, e.g. detected by a camera (15) and / or environmental conditions.

Owner:DELAVAL HLDG AB

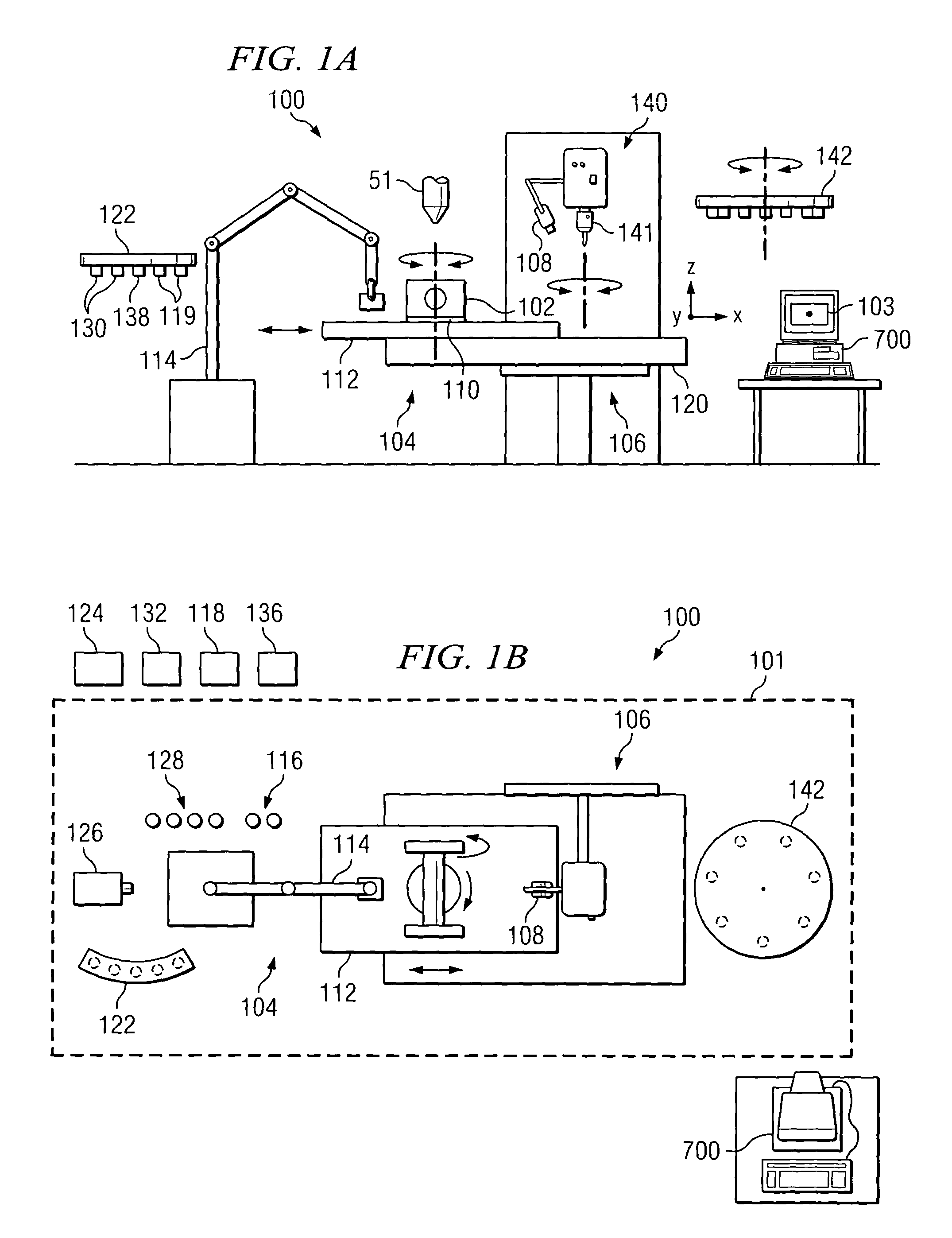

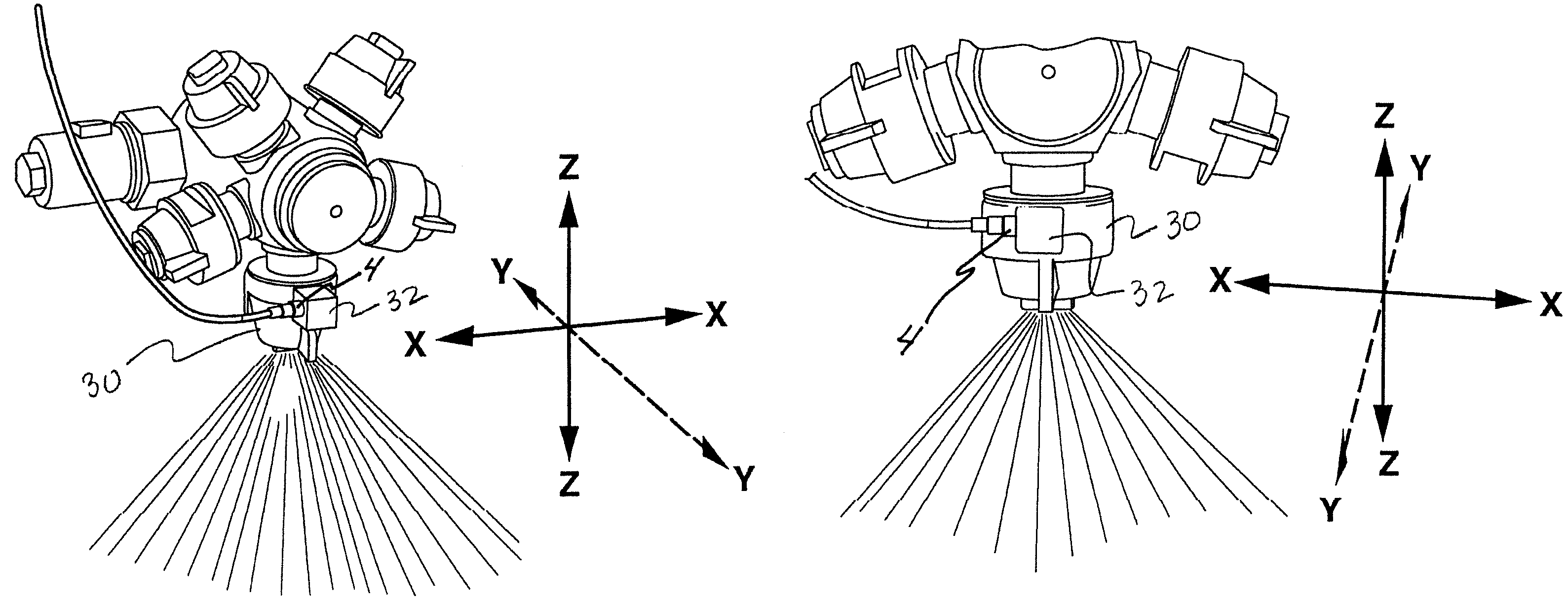

Greater angle and overhanging materials deposition

InactiveUS20060003095A1Easy to collectAdditive manufacturing apparatusMolten spray coatingLaser processingSpray nozzle

Apparatuses and methods for producing greater angle or overhanging deposits on a structure. Nozzles for propelling powder at a target or structure for subsequent laser processing are preferably at a greater angle of powder entry than currently used. The nozzles are arranged around the laser beam and can be individual or disposed around an annular ring. The individual nozzles can be interchangeable with the annular ring. Discrete nozzles can be used in addition to or in place of the other nozzles, allowing angles of powder entry up to approximately 180°. The nozzles may be translated or rotated with respect to the target along or about multiple axes. Also a method for temporarily supporting an overhang using weaker material under the overhang. The weaker material can be removed after the overhang is fabricated and solidified.

Owner:OPTOMEC DESIGN CO

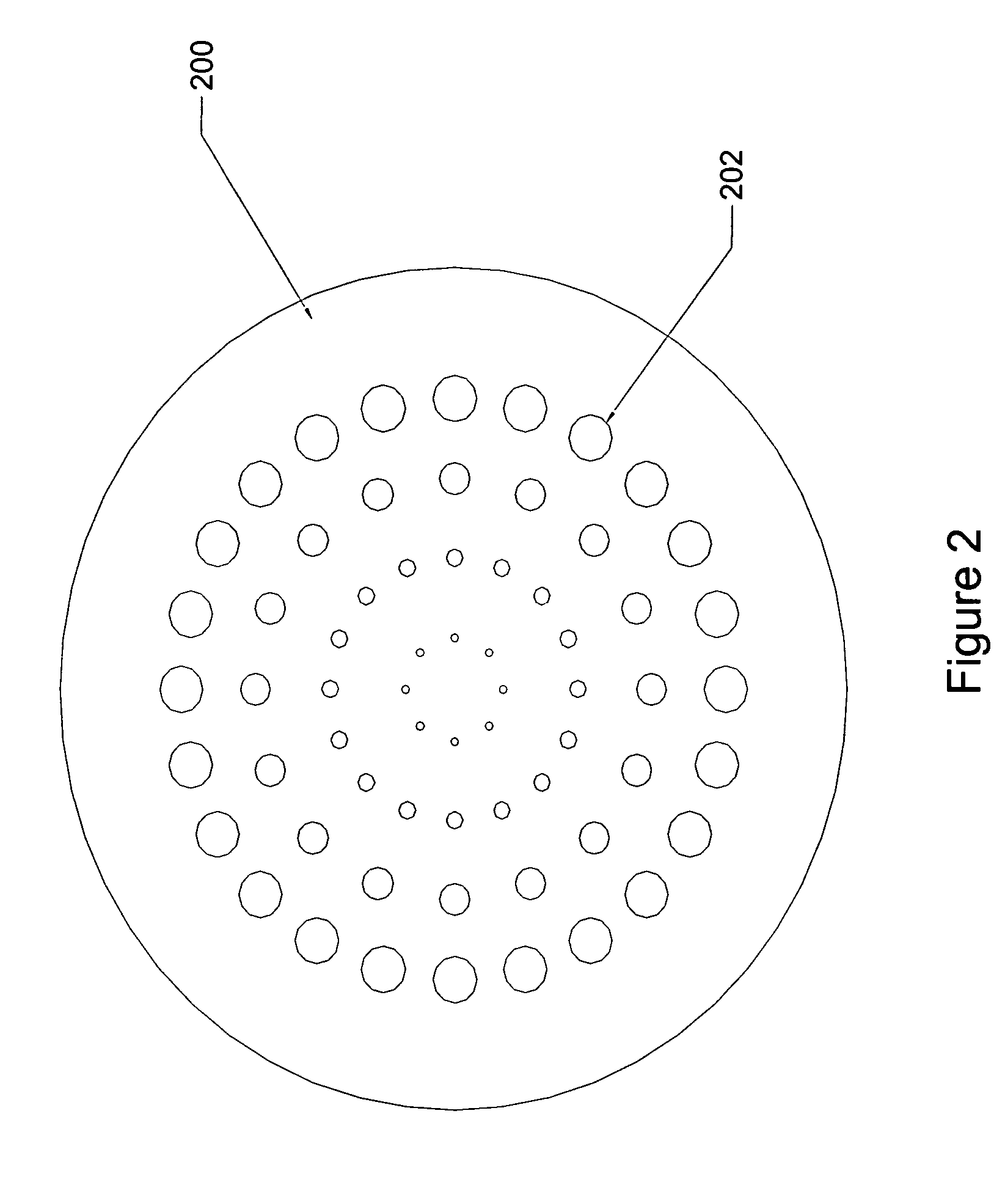

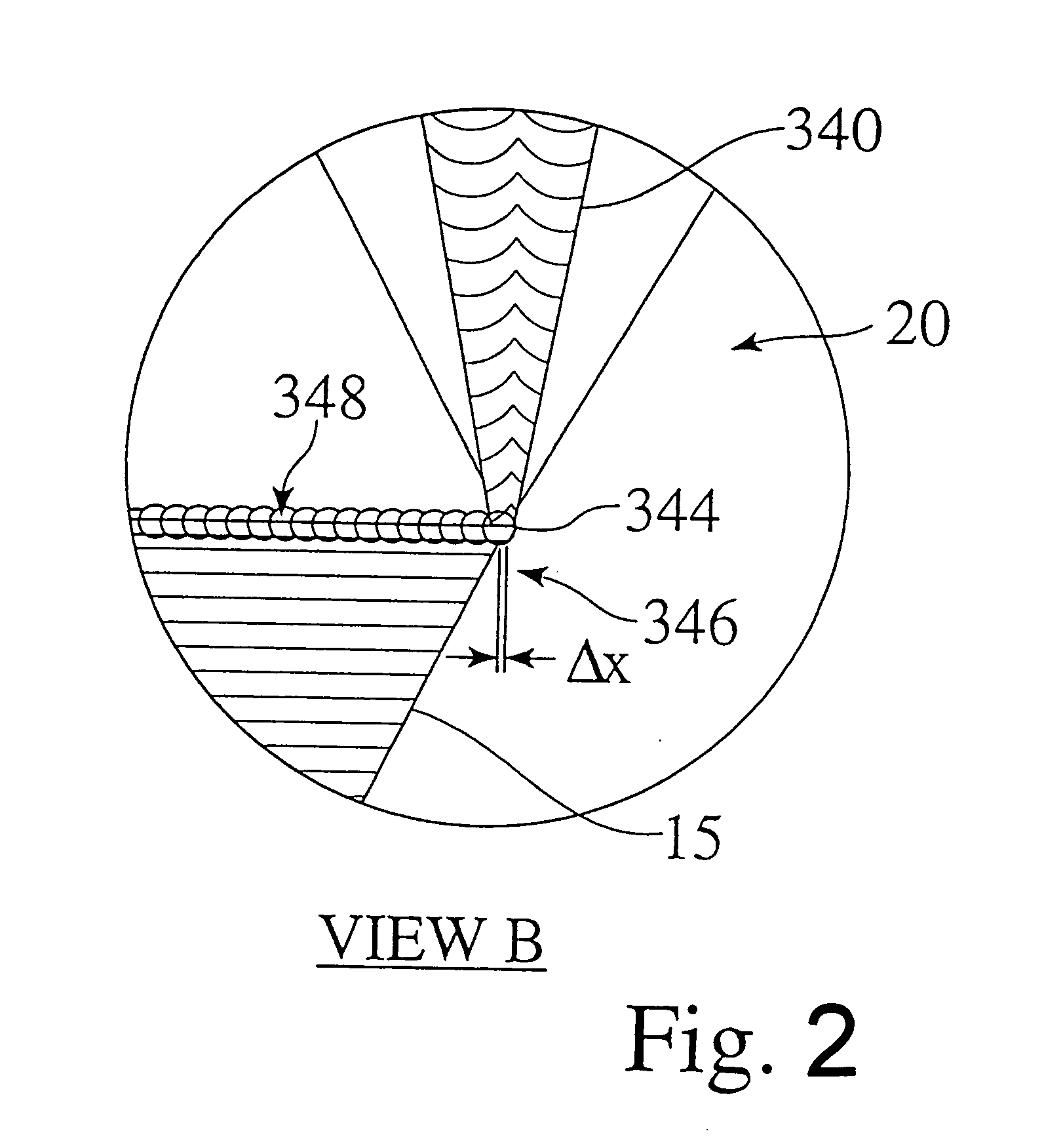

High mass throughput particle generation using multiple nozzle spraying

InactiveUS7498063B2High mass throughputImprove throughputSurgeryPretreated surfacesElectricityNanoparticle

Spraying apparatus and methods that employ multiple nozzle structures for producing multiple sprays of particles, e.g., nanoparticles, for various applications, e.g., pharmaceuticals, are provided. For example, an electrospray dispensing device may include a plurality of nozzle structures, wherein each nozzle structure is separated from adjacent nozzle structures by an internozzle distance. Sprays of particles are established from the nozzle structures by creating a nonuniform electrical field between the nozzle structures and an electrode electrically isolated therefrom.

Owner:RGT UNIV OF MINNESOTA

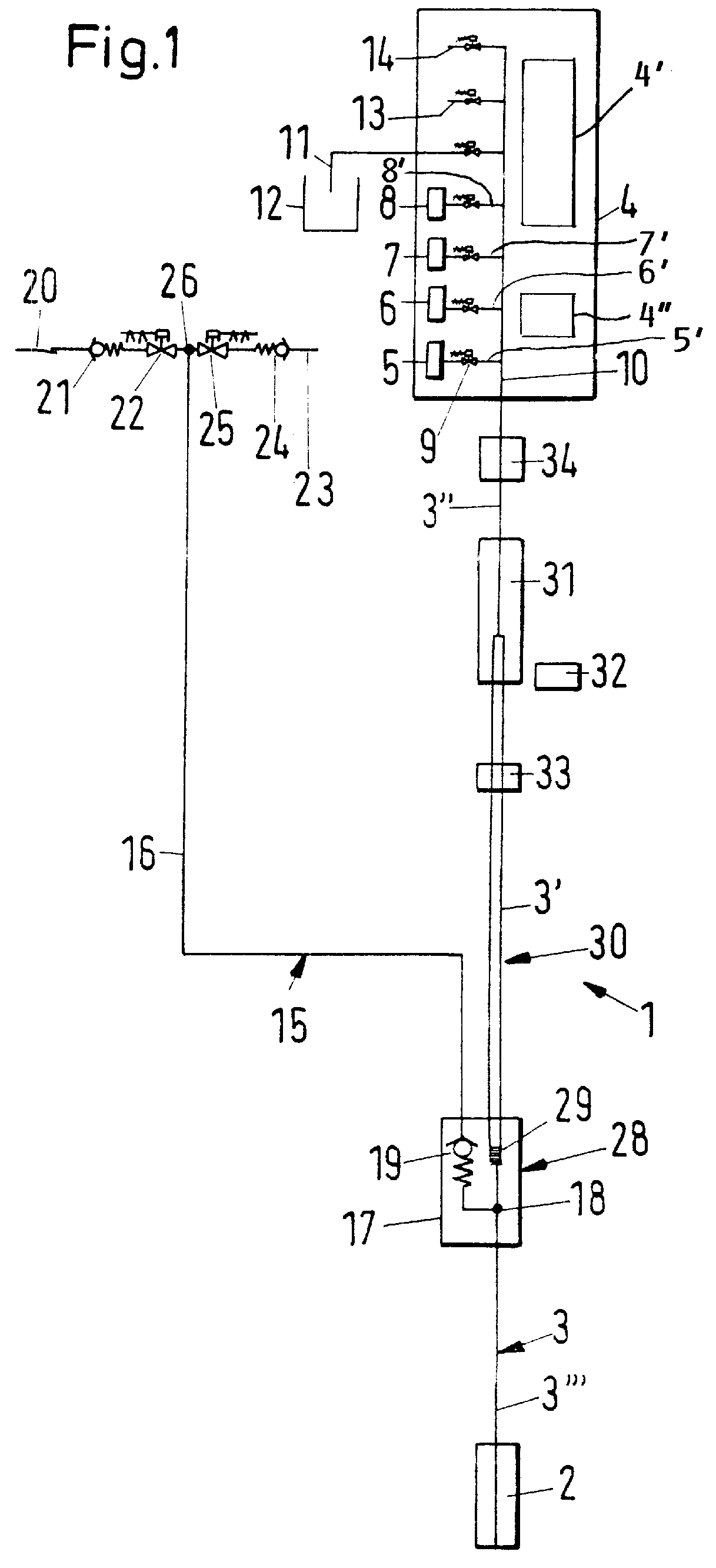

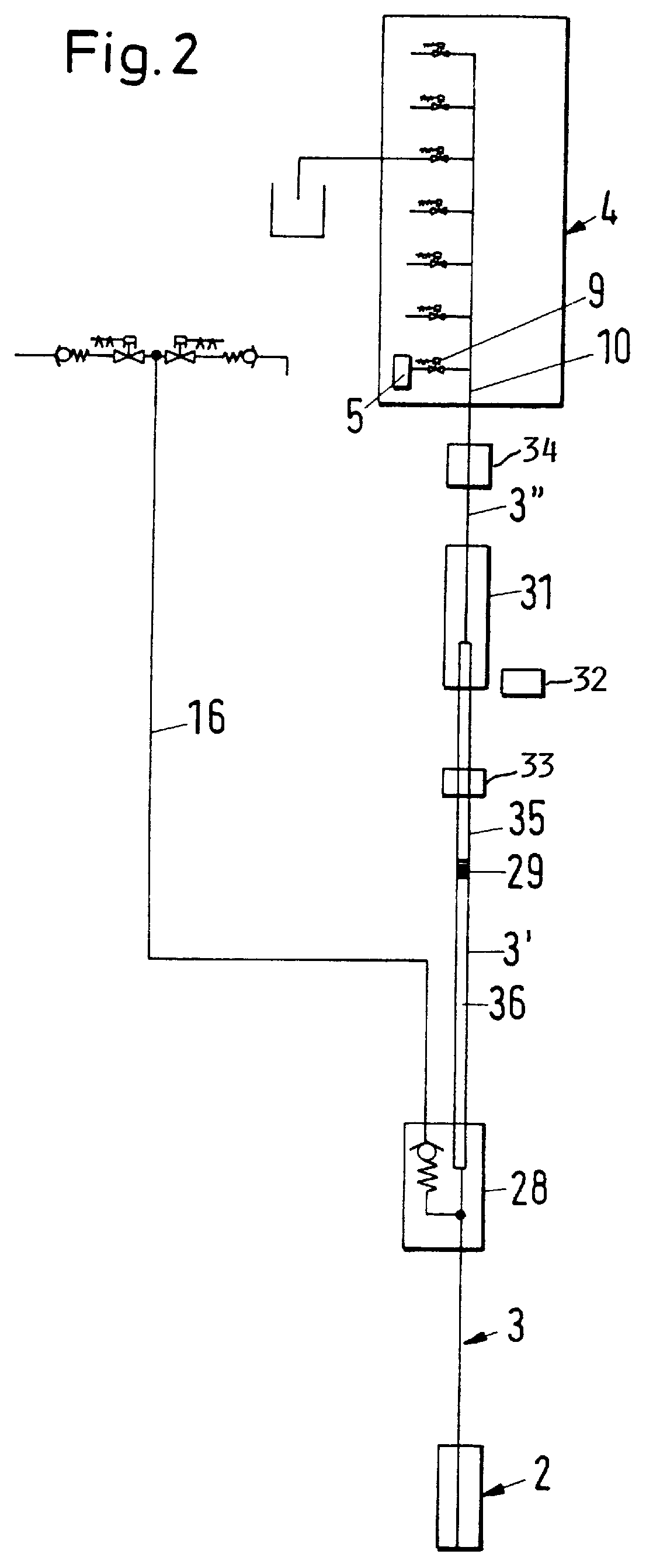

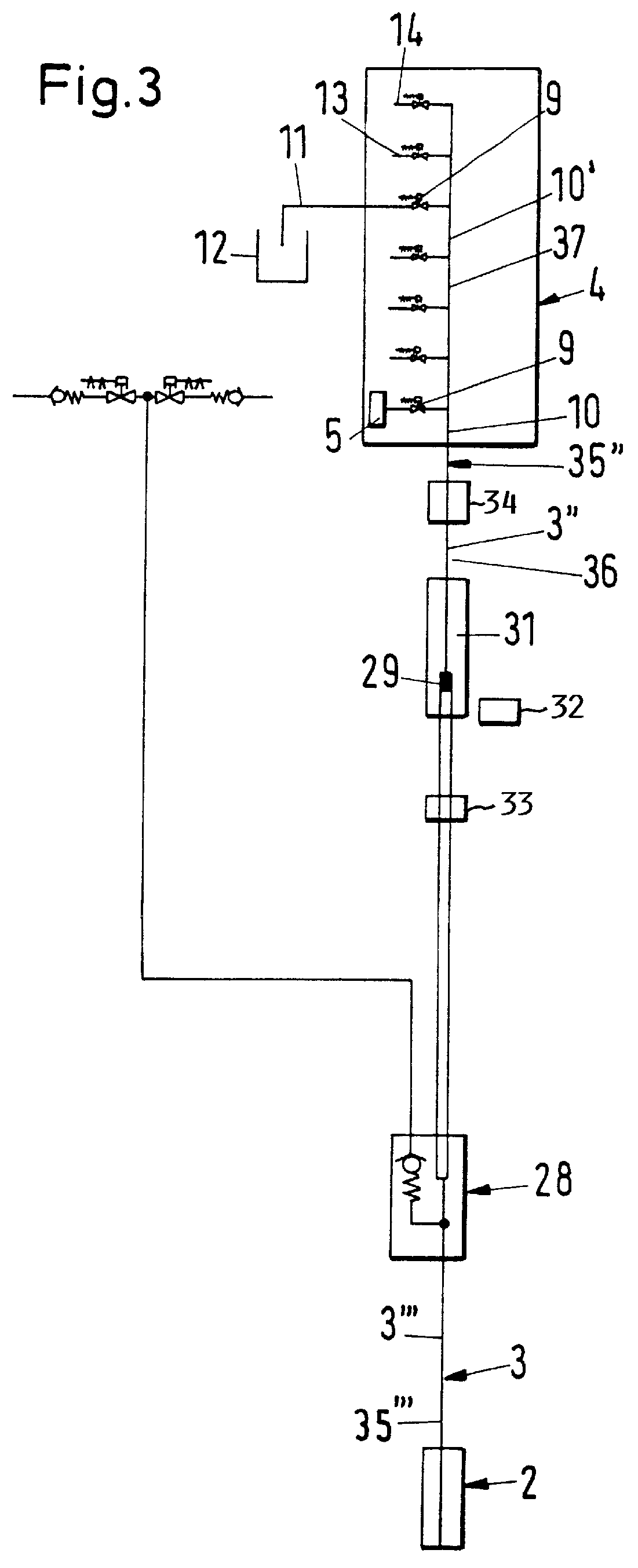

Paint spraying equipment and method of cleaning the same

InactiveUS6037010ALow costReduce the amount of wastePretreated surfacesLiquid spraying apparatusSpray nozzleEngineering

In a method of cleaning a paint application system when switching between two different types or colors of paint, at least a predominant portion of the first paint (35) remaining in a paint line (3) is caused to flow back into its paint supply container (5). Then the entire paint line is flushed out using a flushing medium, before supplying the second paint through the paint line. In this manner, the paint remaining in the painting system at the end of a painting cycle is not wasted, but rather is saved to later be reused. A paint application apparatus includes a paint supply switching device (4), at least two paint supply containers (5 to 8), a paint spray nozzle (2), and a paint line (3) connecting the color switching device (4) to the spray nozzle (2). Two receiver stations (28) and (31) are interposed in the paint line (3), and a shuttle element in the form of a pipe cleaner swab (29) is arranged in the paint line (3) so as to be able to shuttle back and forth between the two receiver stations. A pressure medium or flushing medium can be introduced into the paint line (3) between the first receiver station (28) and the spraying nozzle (2), so as to push the pipe cleaner swab (29) through the paint line (3) to the second receiver station (31). Thereby, the paint remaining in the paint line (3) is pushed back into the paint supply container.

Owner:LACTEC GESELLSCHAFT FUR MODERNE LACKIERTECHNIK GMBH

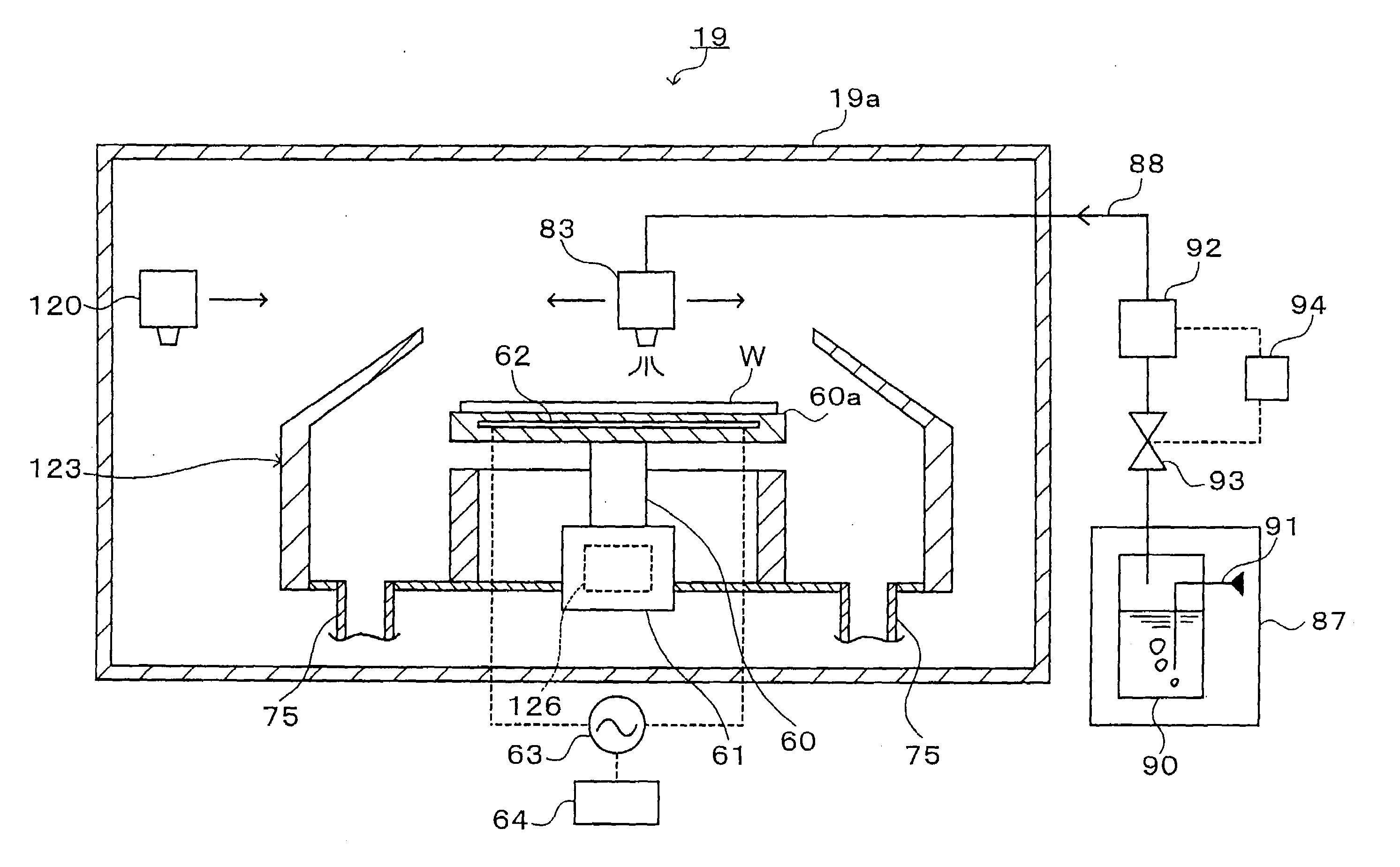

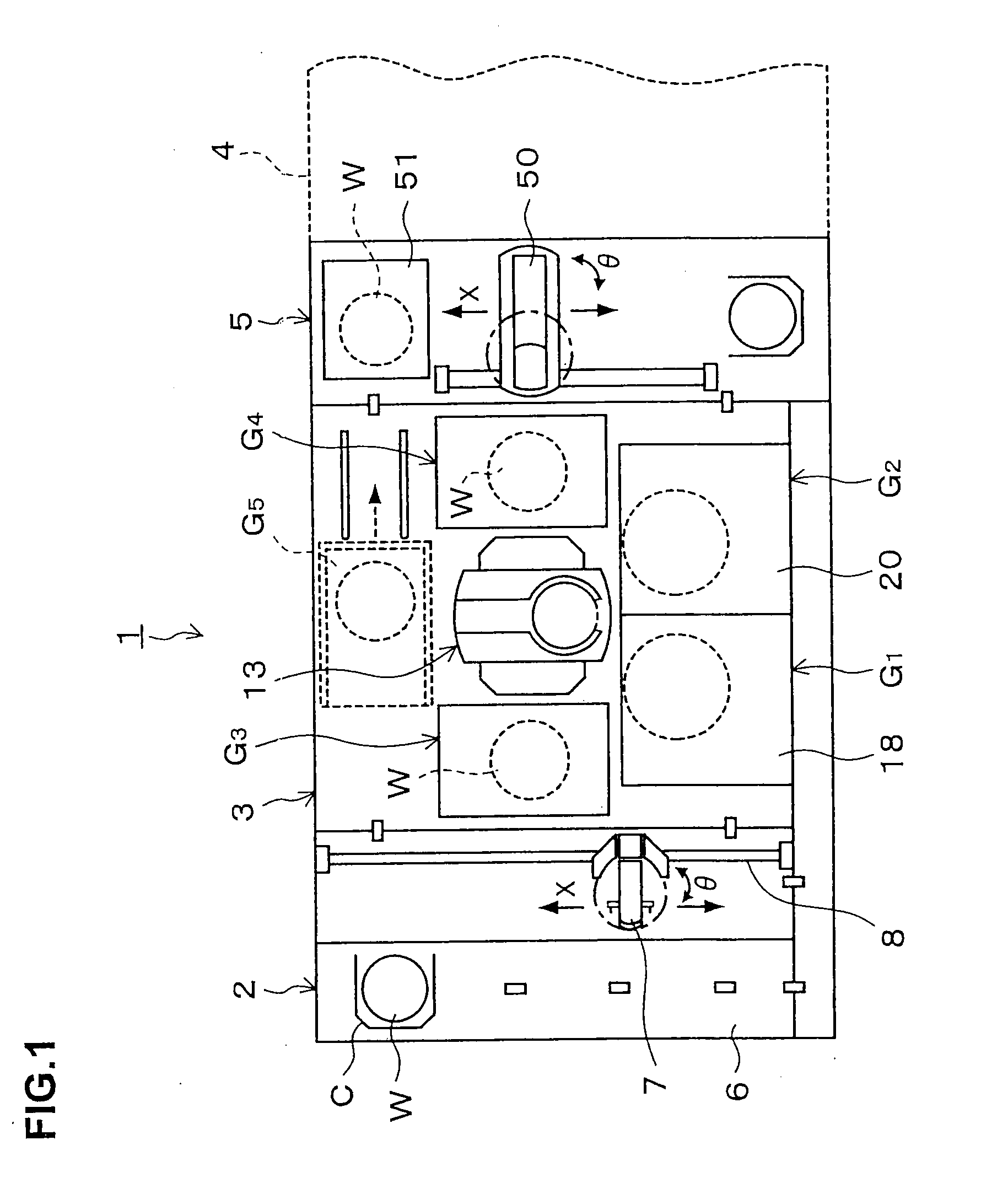

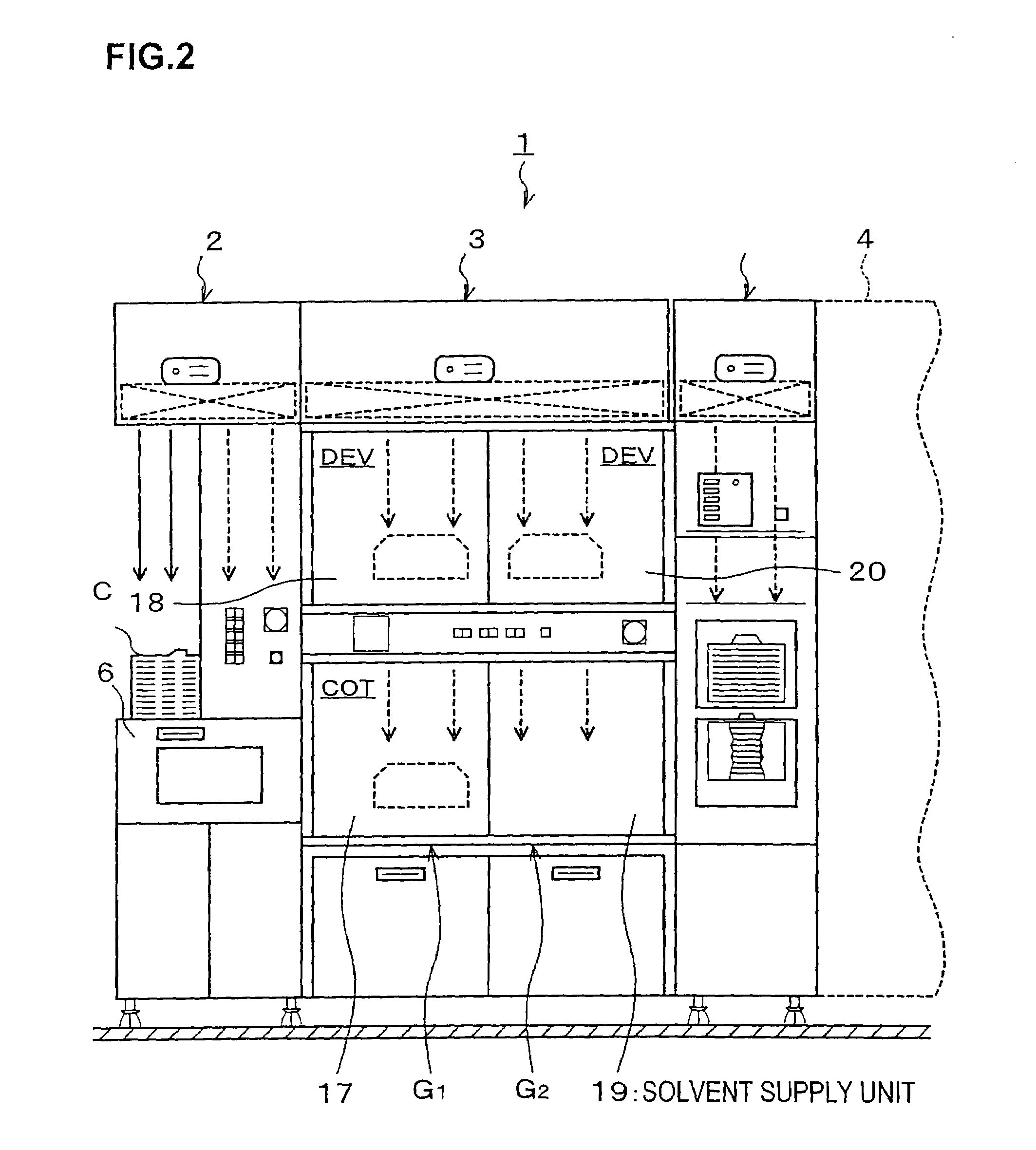

Method for improving surface roughness of processed film of substrate and apparatus for processing substrate

InactiveUS20100020297A1Improve surface roughnessIncrease productionSemiconductor/solid-state device manufacturingPhotosensitive material processingSpray nozzleSurface roughness

A treatment apparatus for treating a substrate on a surface of which a treatment film has been formed and subjected to exposure processing and developing treatment. The treatment apparatus includes a nozzle for supplying a solvent gas of the treatment film to the surface of the treatment film on the substrate, and a moving mechanism for moving the nozzle which is supplying the solvent gas, relative to the substrate. The nozzle has an elongated discharge portion at least longer than a diameter of the substrate and partition plates at a front and a rear in the moving direction of the nozzle.

Owner:TOKYO ELECTRON LTD

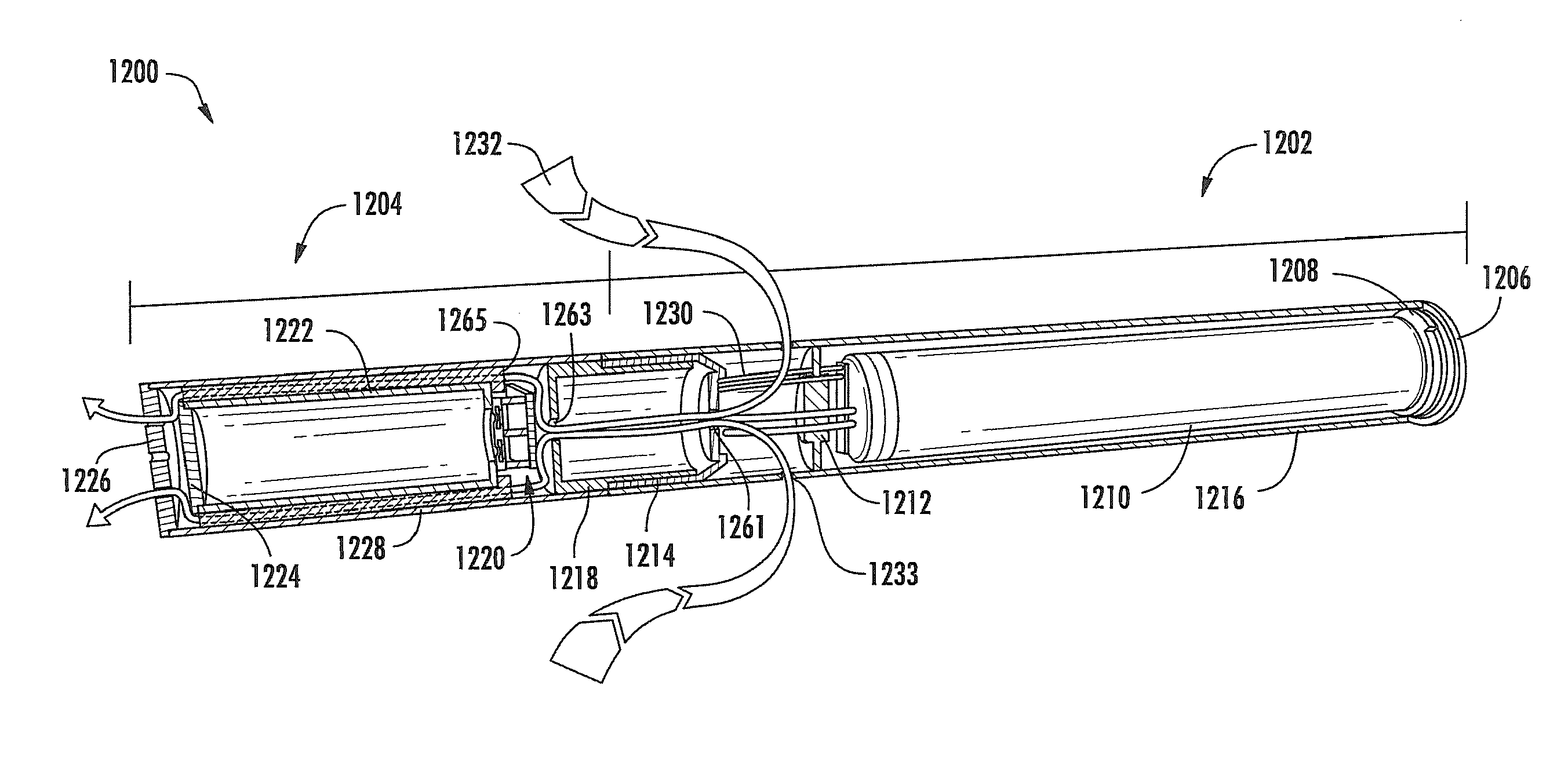

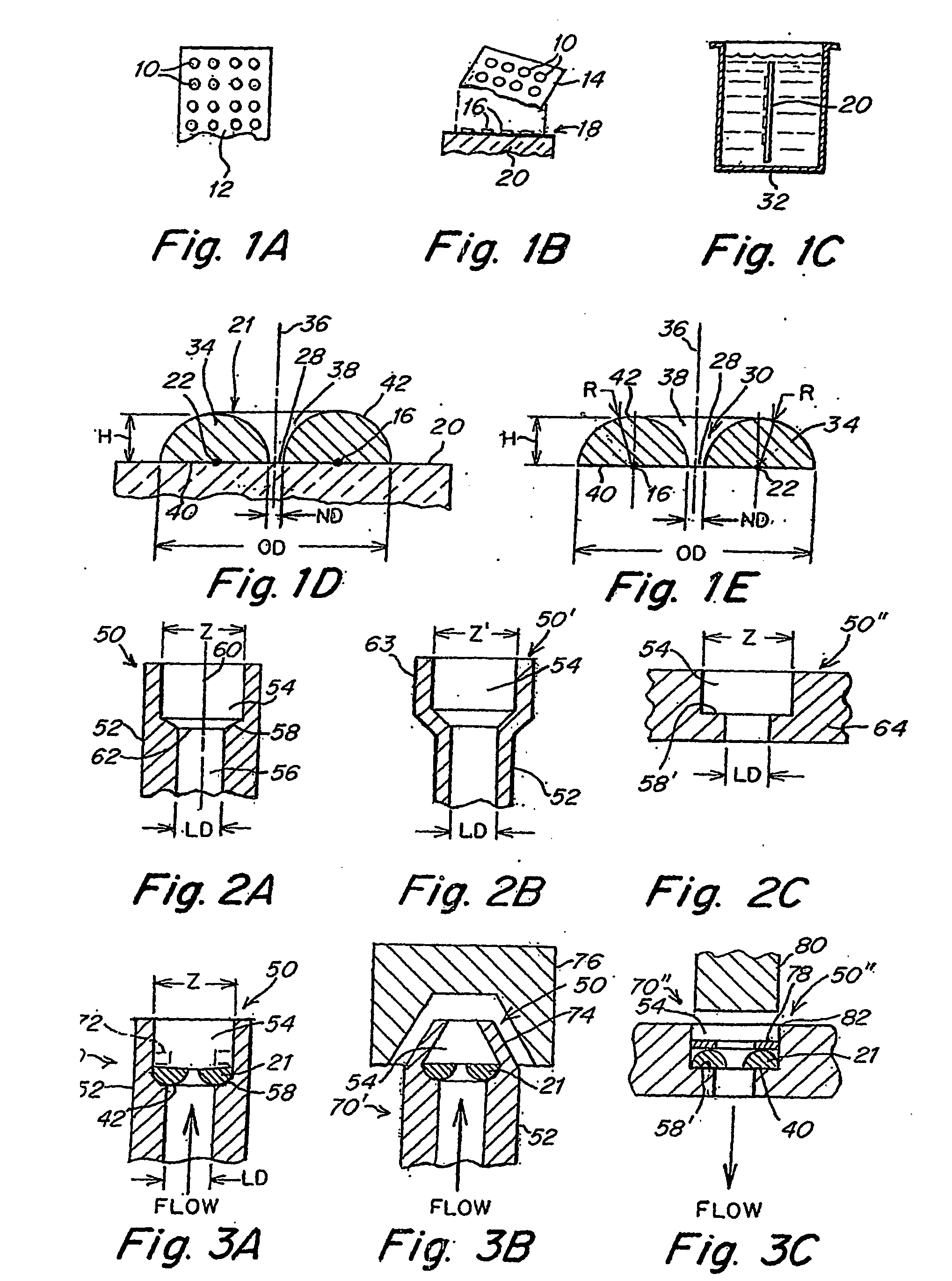

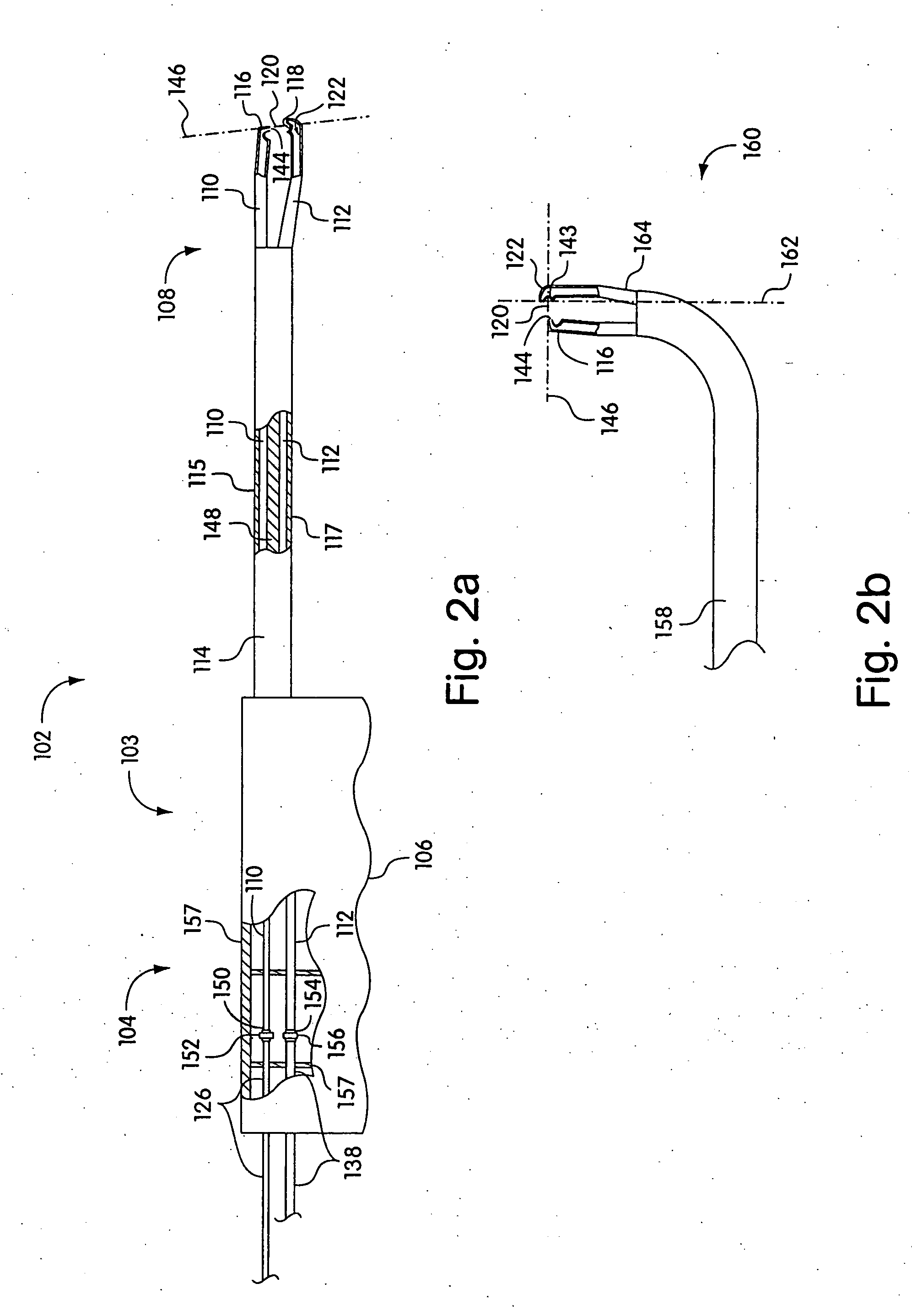

Nozzle assemblies for liquid jet surgical instruments and surgical instruments employing the nozzle assemblies

Disclosed are nozzles and nozzle assemblies of liquid jet-forming surgical instruments, surgical instruments employing such nozzles and / or nozzle assemblies, and methods of fabricating the nozzle assemblies in forming surgical instruments. Also, disclosed are liquid jet-forming surgical instruments including both liquid jet-forming nozzles and optional evacuation lumens, which when provided can be configured to receive the liquid jet and evacuate the liquid forming the liquid jet. Certain embodiments of such surgical instruments include inventive nozzle alignment component(s) to facilitate alignment of the nozzles and evacuation lumen upon assembly. In certain embodiments, surgical instruments are provided that include a nozzle that is shaped to form a liquid jet, which has surfaces that are optically smooth. In certain embodiments, the nozzle has a configuration enabling the nozzle to form a liquid jet that has the ability to remain collimated over longer distances than is typically achievable with conventional liquid jet surgical instrument nozzles having the same ratio of nozzle length to minimum inner diameter of the jet opening. In certain embodiments, nozzle assemblies comprising an operative assembly of at least two subcomponents, which together provide a nozzle are provided. In certain embodiments, the at least two sub-components may comprise a nozzle-providing component, such as a nozzle ring, and a holder that is configured to retain and position the nozzle-providing component in the nozzle assembly. In certain embodiments, the nozzle-providing component can comprise a liquid flow passage having a diameter that continuously decreases along at least a portion of its length.

Owner:HYDROCISION

Apparatus, methods and precision spray processes for direct write and maskless mesoscale material deposition

InactiveUS20040197493A1Reduce package sizeElectric discharge heatingVacuum evaporation coatingOptoelectronicsBiological materials

Apparatuses and processes for maskless deposition of electronic and biological materials. The process is capable of direct deposition of features with linewidths varying from the micron range up to a fraction of a millimeter, and may be used to deposit features on substrates with damage thresholds near 100° C. Deposition and subsequent processing may be carried out under ambient conditions, eliminating the need for a vacuum atmosphere. The process may also be performed in an inert gas environment. Deposition of and subsequent laser post processing produces linewidths as low as 1 micron, with sub-micron edge definition. The apparatus nozzle has a large working distance-the orifice to substrate distance may be several millimeters-and direct write onto non-planar surfaces is possible. This invention is also of combinations of precision spray processes with in-flight laser treatment in order to produce direct write electronic components, and additionally lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

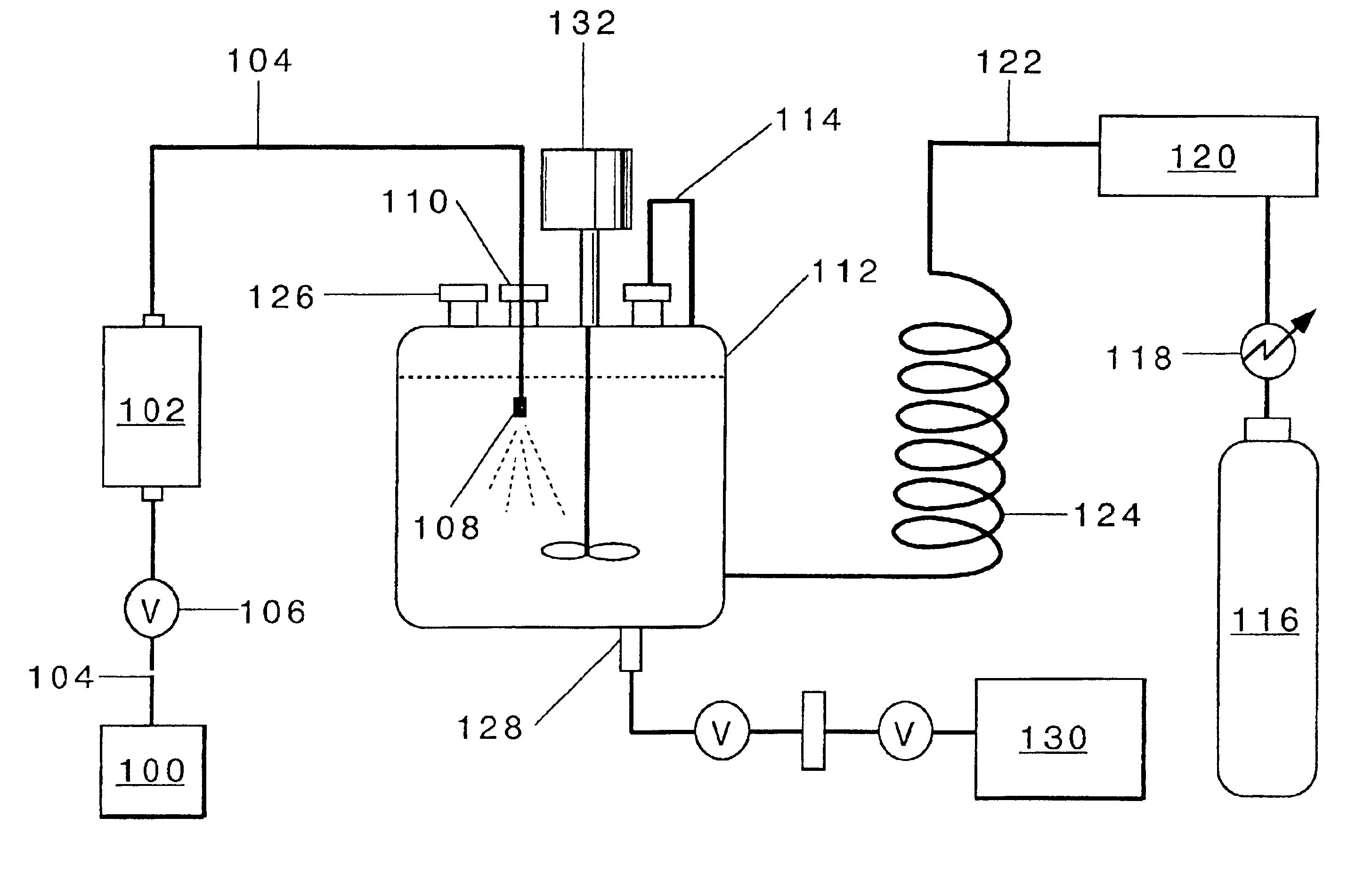

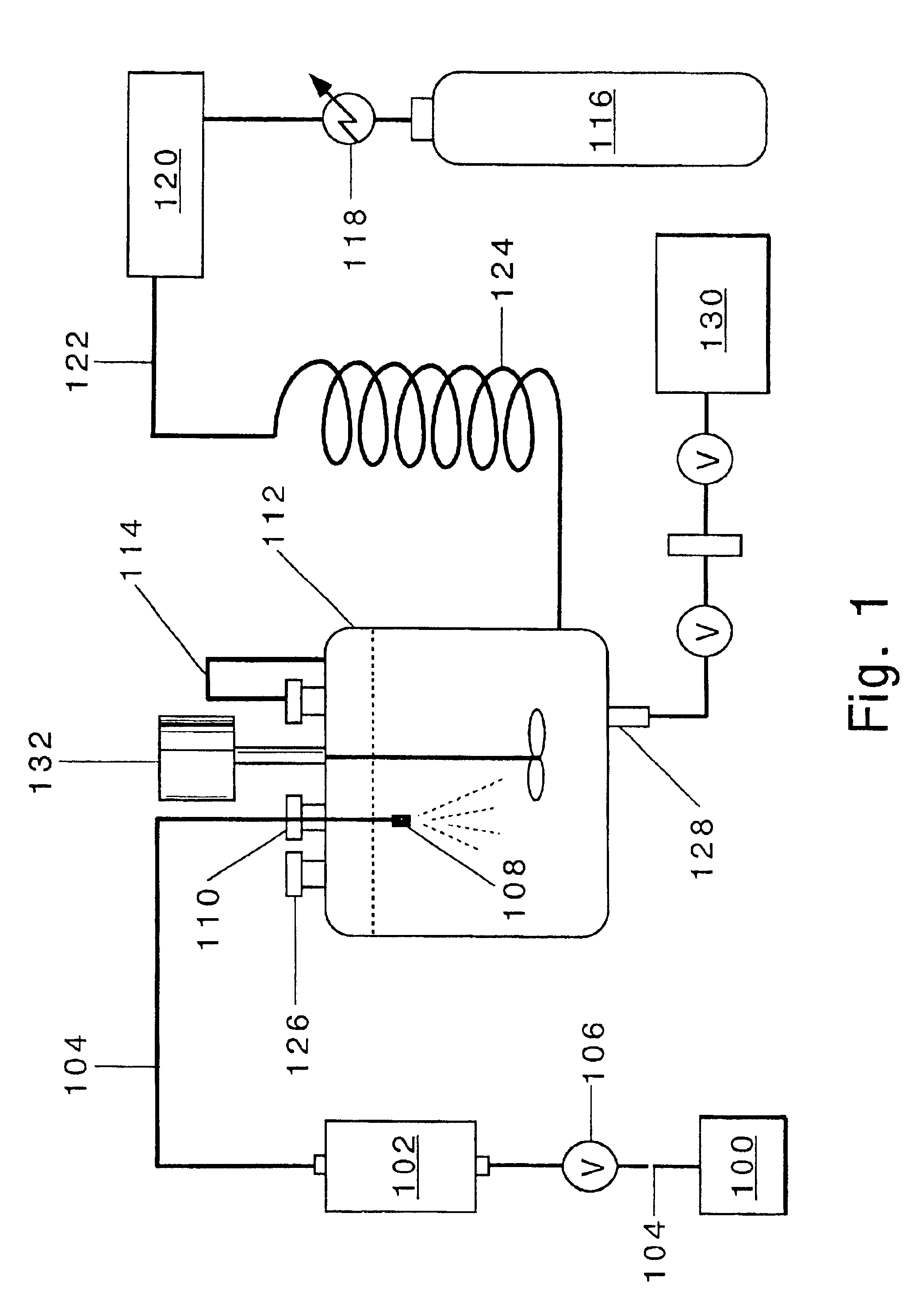

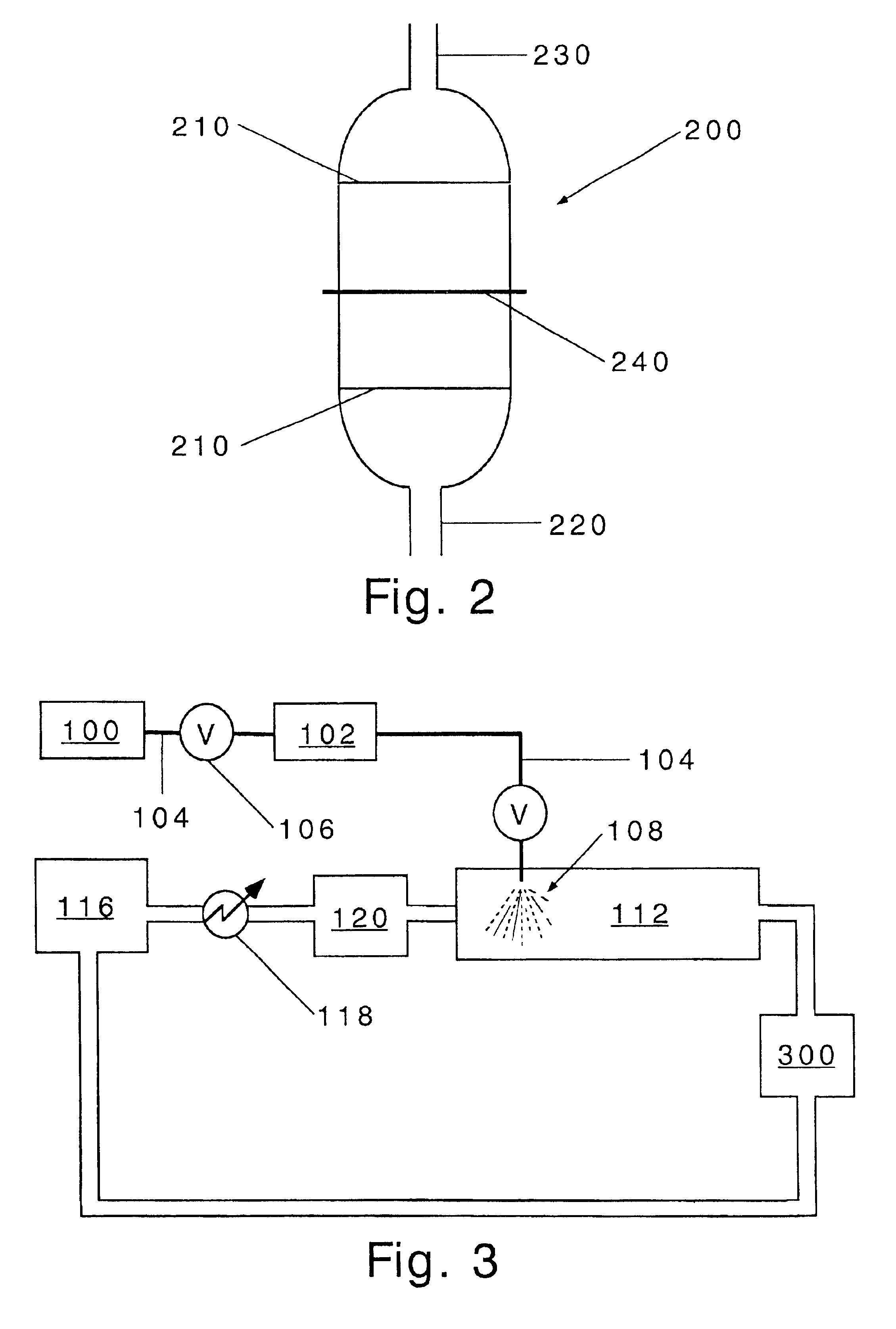

Process for production of nanoparticles and microparticles by spray freezing into liquid

InactiveUS6862890B2Improve efficiencyImprove efficacyPowder deliveryNervous disorderPorosityNanoparticle

The present invention provides a system and a method for the production of microparticles and nanoparticles of materials that can be dissolved. The system and method of the present invention provide quicker freezing times, which in turn produces a more uniform distribution of particle sizes, smaller particles, particles with increased porosity and a more intimate mixing of the particle components. The system and method of the present invention also produce particles with greater surface area than conventional methods. One form of the present invention provides a method for the preparation of particles. An effective ingredient is mixed with water, one or more solvents, or a combination thereof, and the resulting mixture is sprayed through an insulating nozzle located at or below the level of a cryogenic liquid. The spray generates frozen particles.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

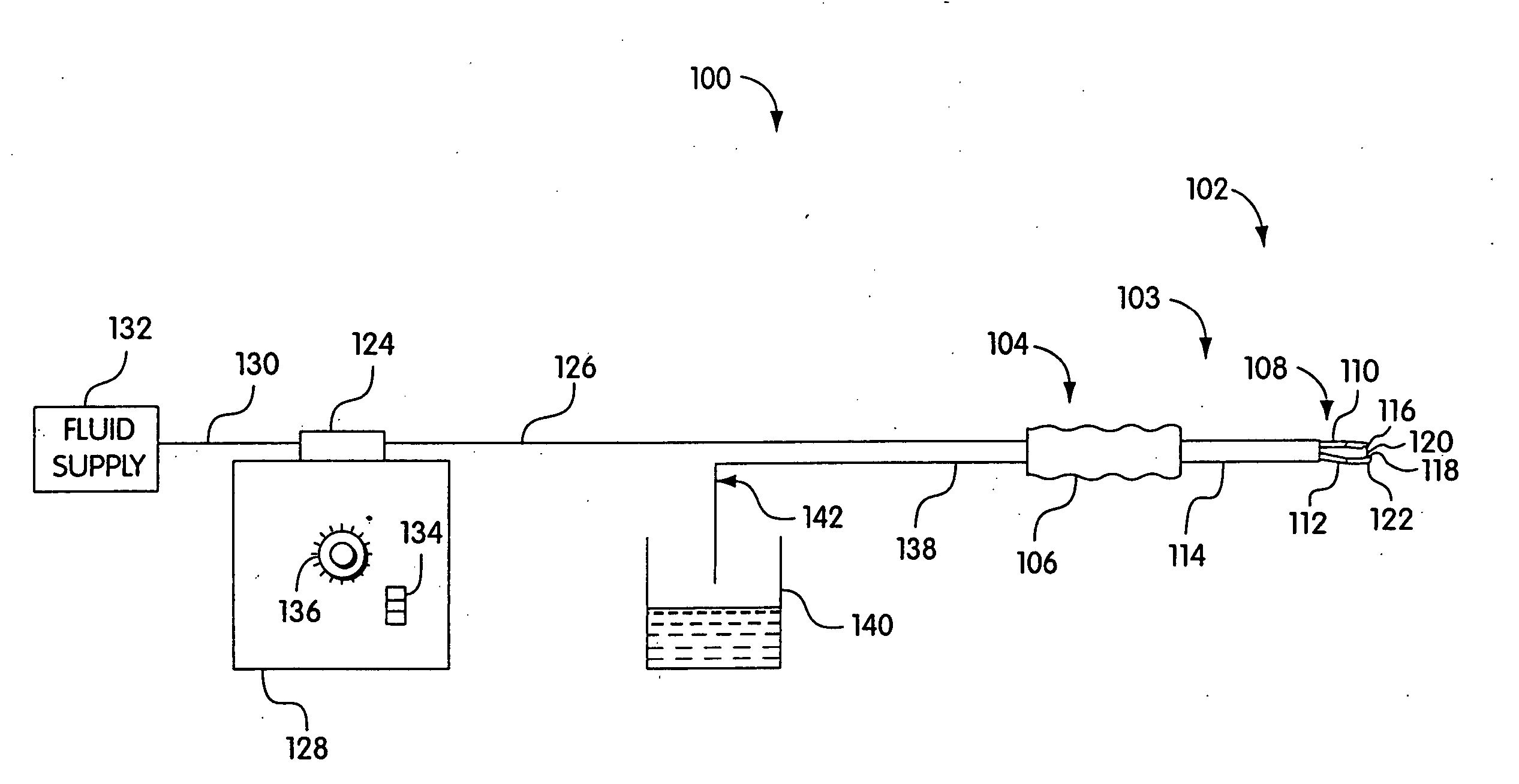

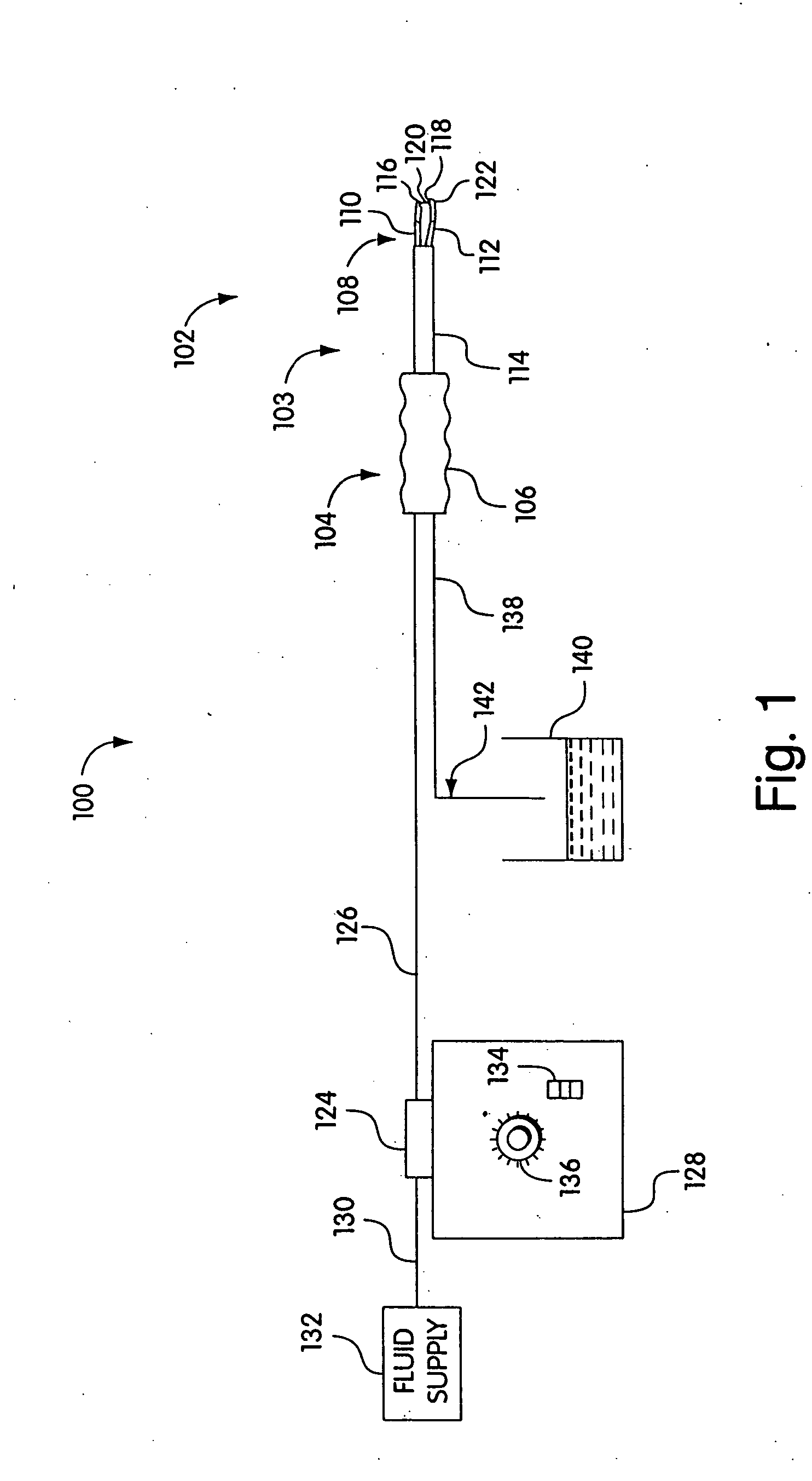

Fluid jet surgical instruments

InactiveUS20050159765A1High burst resistanceFluid jet surgical cuttersMedical syringesLiquid jetSurgical approach

The invention provides a variety of surgical instruments for forming a liquid jet, which are useful for performing a wide variety of surgical procedures. In some embodiments, the invention provides surgical liquid jet instruments having a pressure lumen and an evacuation lumen, where the pressure lumen includes at least one nozzle for forming a liquid jet and where the evacuation lumen includes a jet-receiving opening for receiving the liquid jet when the instrument is in operation. In some embodiments, the pressure lumen and the evacuation lumen of the surgical liquid jet instruments are constructed and positionable relative to each other so that the liquid comprising the liquid jet, and any tissue or material entrained by the liquid jet can be evacuated through the evacuation lumen without the need for an external source of suction. The invention also provides a variety of surgical liquid jet instruments that are constructed and configured specifically for use in a surrounding liquid environment or a surrounding gaseous environment. The invention also provides a variety of surgical liquid jet instruments that are rotatably deployable from an undeployed position, for insertion into the body of a patient, to a deployed position, in which there is a separation distance between the liquid jet nozzle and the jet-receiving opening that defines a liquid jet path length. The invention also provides surgical methods utilizing the inventive surgical liquid jet instruments, and methods for forming components of the surgical liquid jet instruments.

Owner:HYDROCISION

Substrate treatment device

InactiveUS20080135516A1Prevent particle generationExcellent etching propertiesAfter-treatment apparatusPolycrystalline material growthSpray nozzleProduct gas

It is intended to provide a substrate treatment device capable of adjusting both of a growth speed and an etching speed in a selective epitaxial growth, avoiding particle generation from nozzles, and achieving good etching characteristics. A substrate treatment device for selectively growing an epitaxial film on a surface of a substrate by alternately supplying a raw material gas containing silicon and an etching gas to a treatment chamber, the substrate treatment device being provided with a substrate support member for supporting the substrate in the treatment chamber, a heating member provided outside the treatment chamber for heating the substrate and an atmosphere of the treatment chamber, a gas supply system provided inside the treatment chamber, and a discharge port opened on the treatment chamber, wherein the gas supply system comprises first gas supply nozzles for supplying the raw material gas and second gas supply nozzles for supplying the etching gas.

Owner:KOKUSA ELECTRIC CO LTD

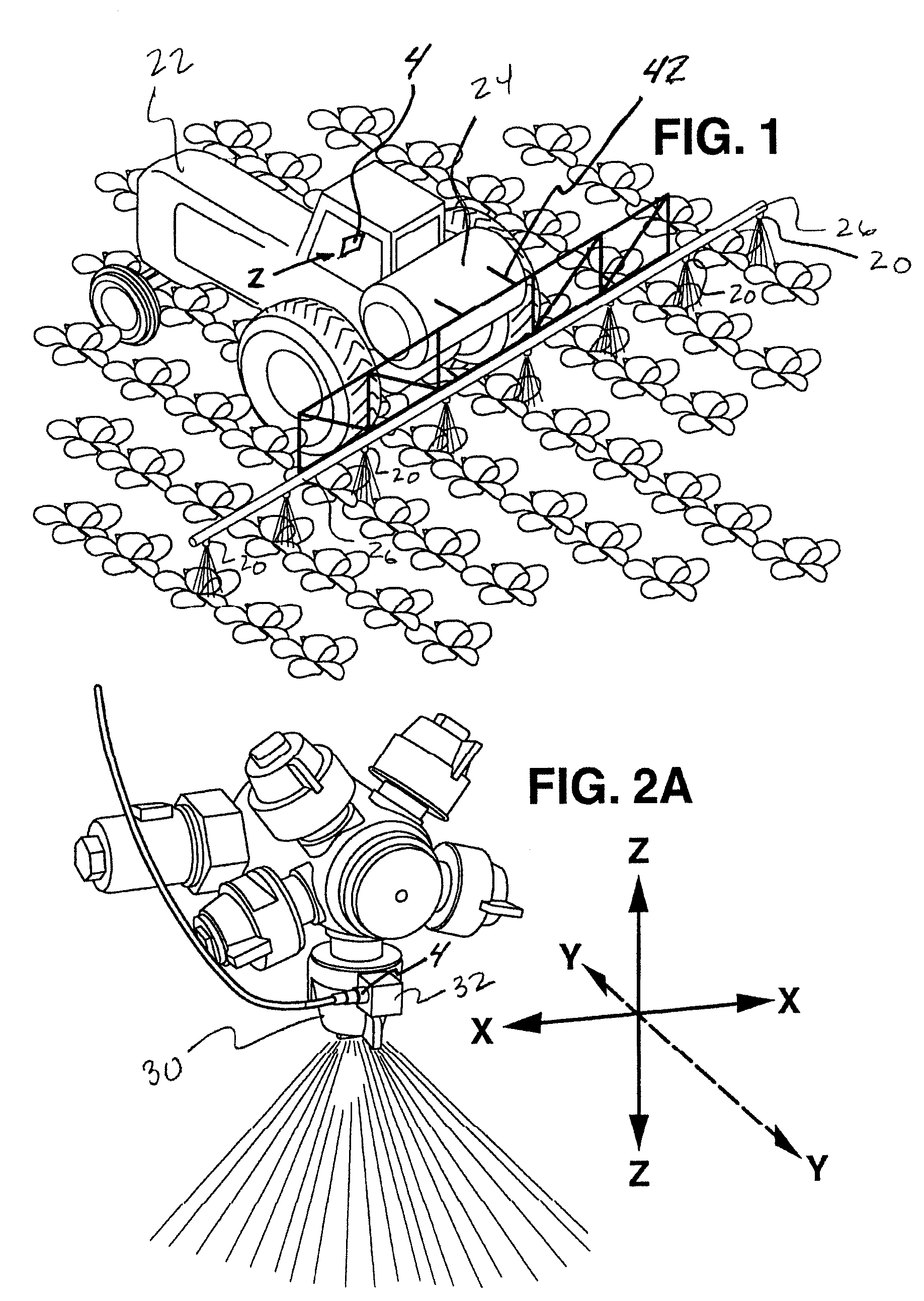

Flow control and operation monitoring system for individual spray nozzles

ActiveUS7311004B2Vibration measurement in solidsVibration measurement in fluidAccelerometerMonitoring system

An apparatus and process for monitoring fluid flow through a nozzle is disclosed. A vibration sensor, such as an accelerometer, is mounted to a nozzle. The vibration output received from the sensor is then analyzed to determine whether or not the nozzle is operating properly. Through the present invention, information can be obtained regarding variations in flow rate, and / or variations in spray pattern and droplet size spectra. If the nozzle flow pulsates, the vibration sensor may also provide information regarding whether the nozzle is pulsating according to a desired frequency duty cycle or waveform.

Owner:CAPSTAN

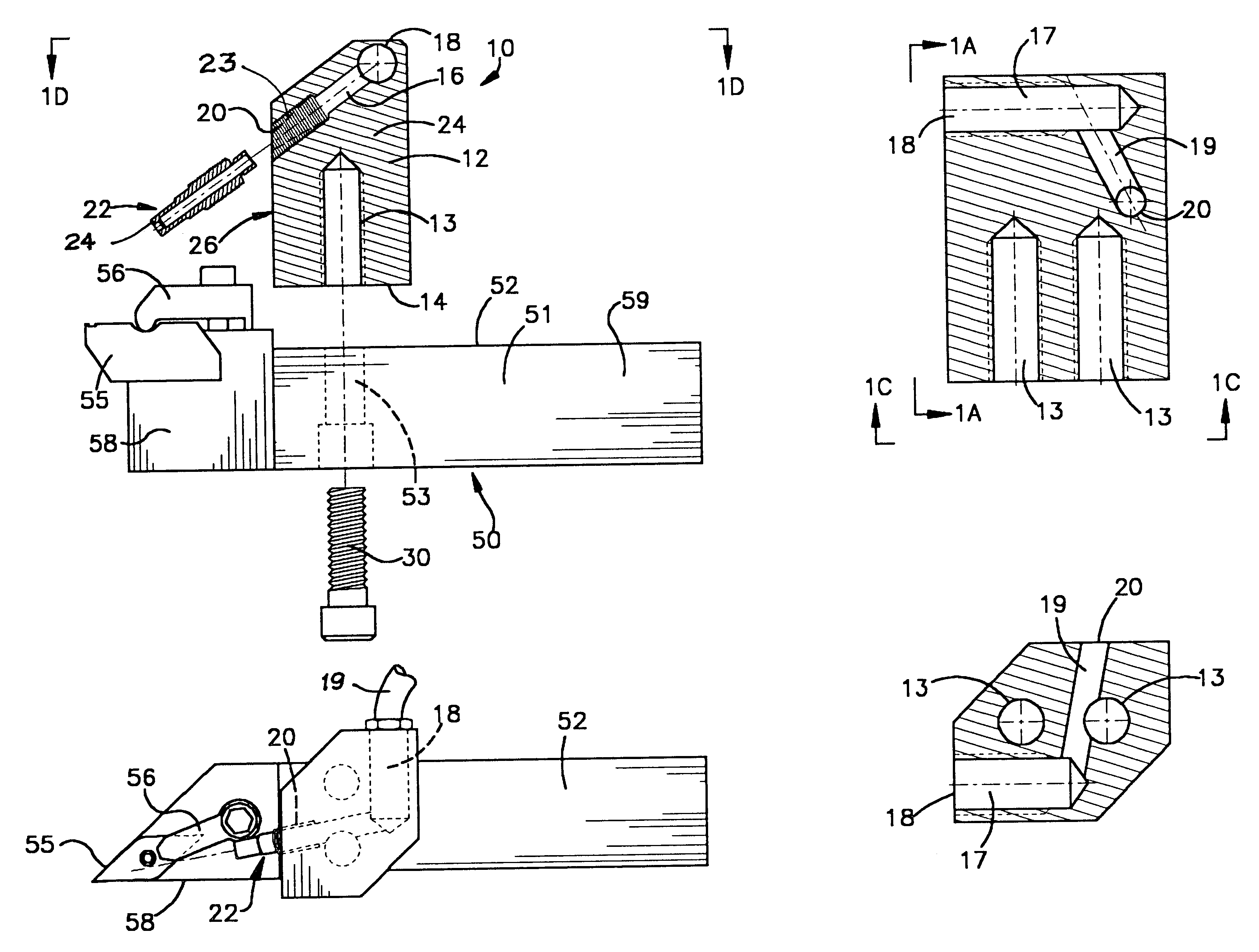

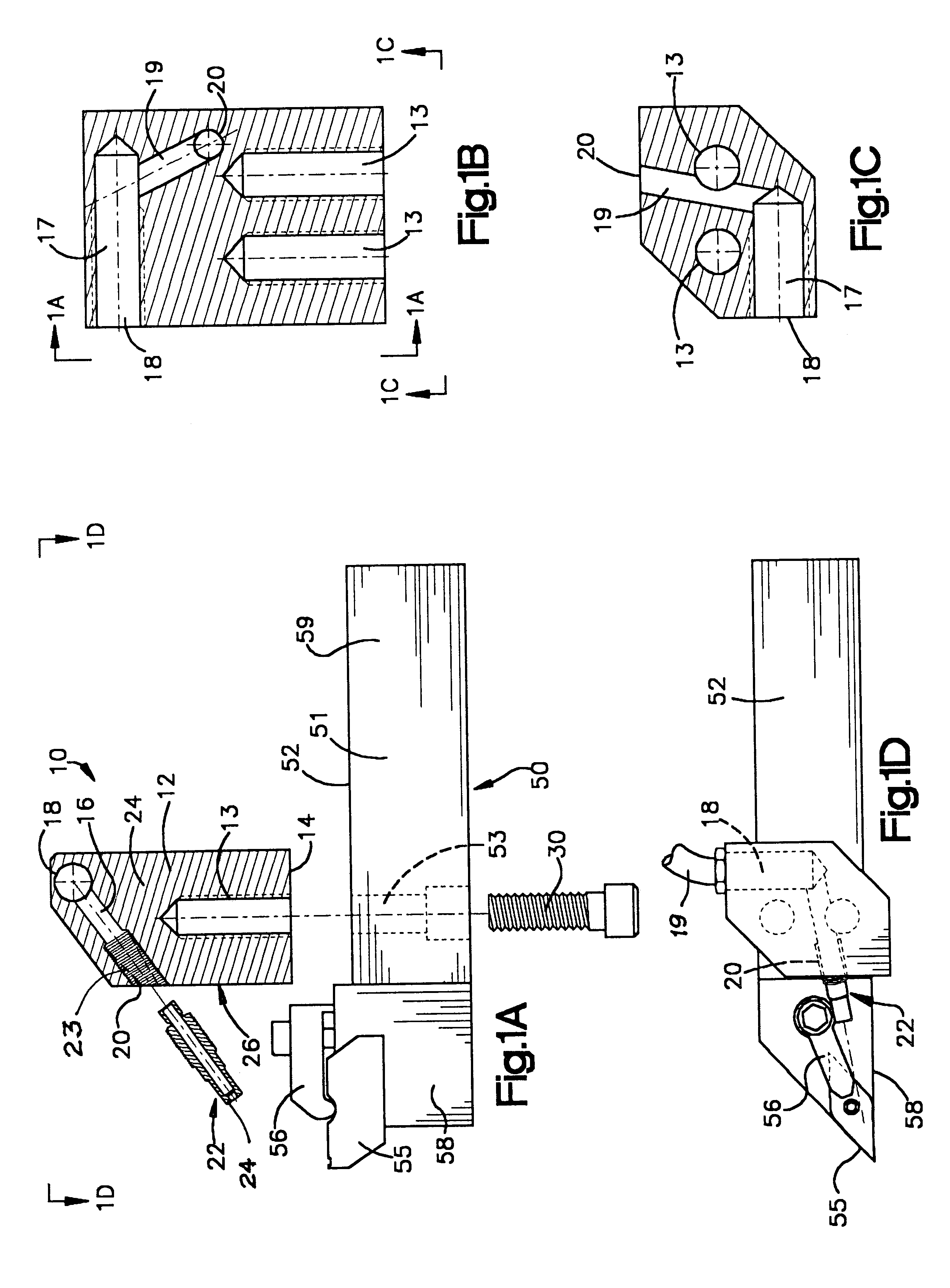

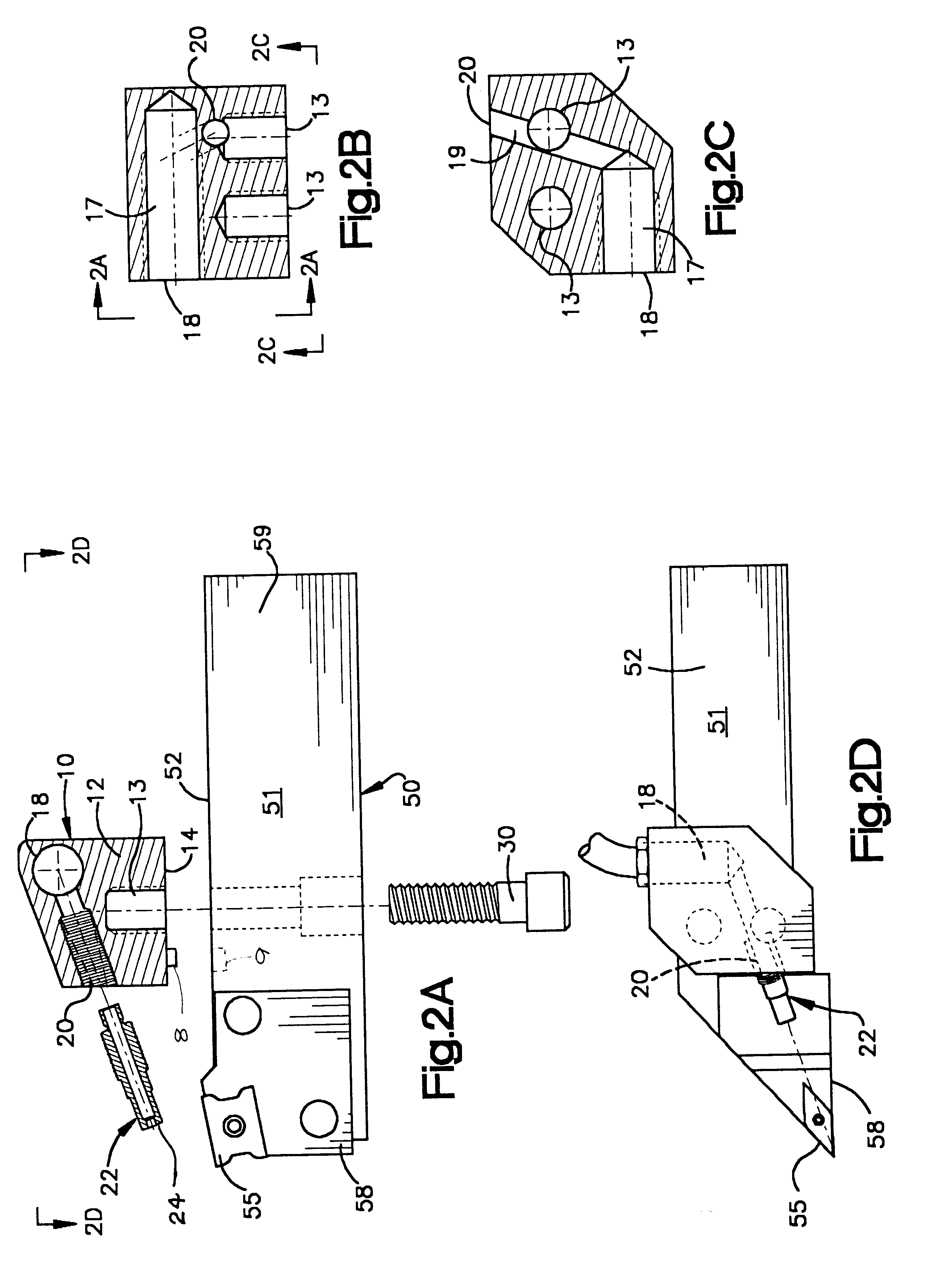

Universal tool holder coolant delivery adapters

InactiveUS6299388B1Increase COOOptimized coolant deliveryTurning toolsShaping cuttersLine tubingSpray nozzle

Universal tool holder coolant delivery adapters have adapter bodies which are removably attachable to a tool holder by at least one fastening device, the adapter located between an attachment end of the tool holder and a distal end of the tool holder, the distal end of the tool holder having a cutting tool attached thereto, the adapter bodies having an internal coolant passageway including an intake port and an exit port, the intake port adapted for attachment to a pressurized coolant supply line and the outlet port adapted for attachment to or configured in the form of a coolant spray nozzle, the coolant spray nozzle being closely positioned and substantially aligned with the cutting interface of the cutting tool and a workpiece.

Owner:SLABE MACHINE PROD

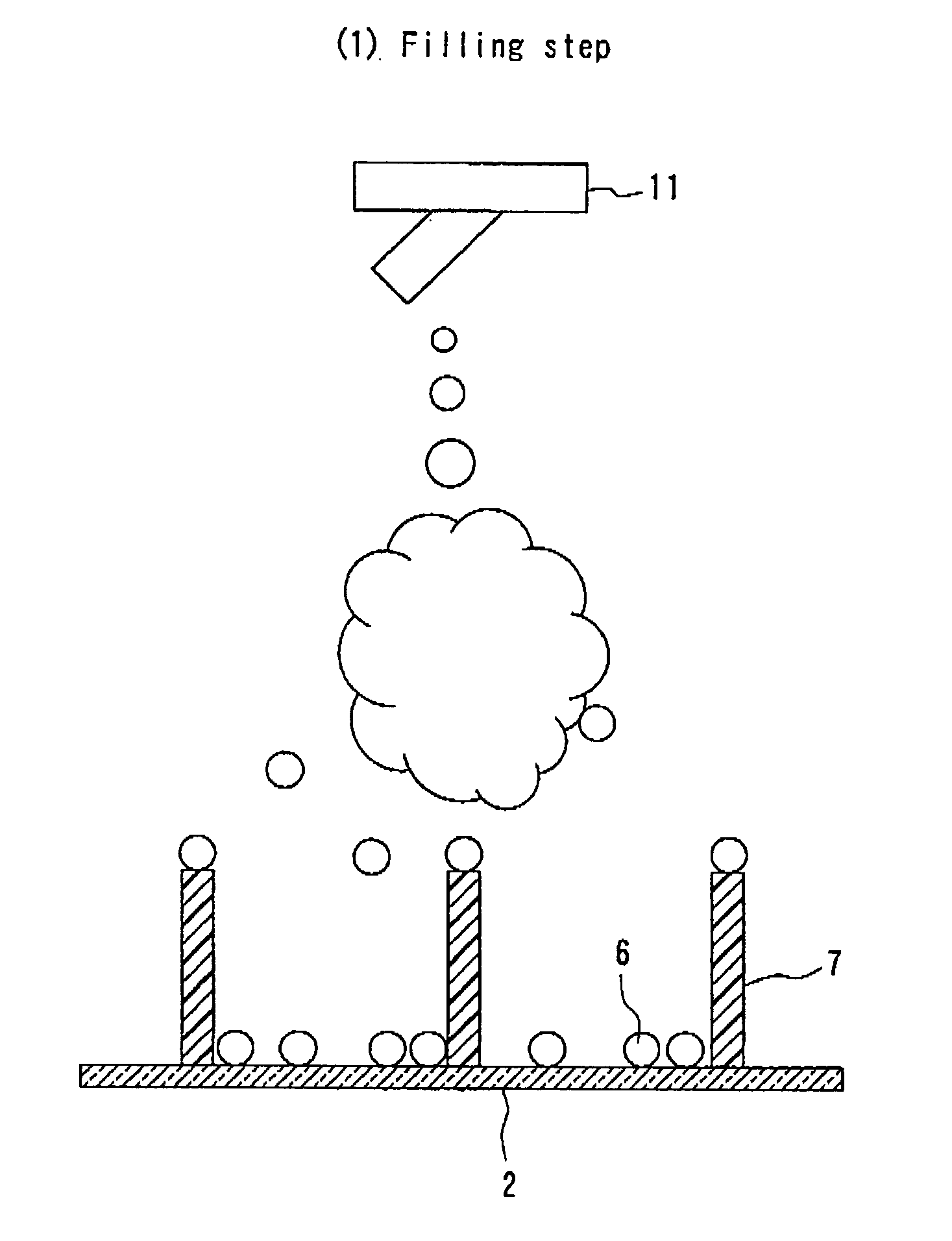

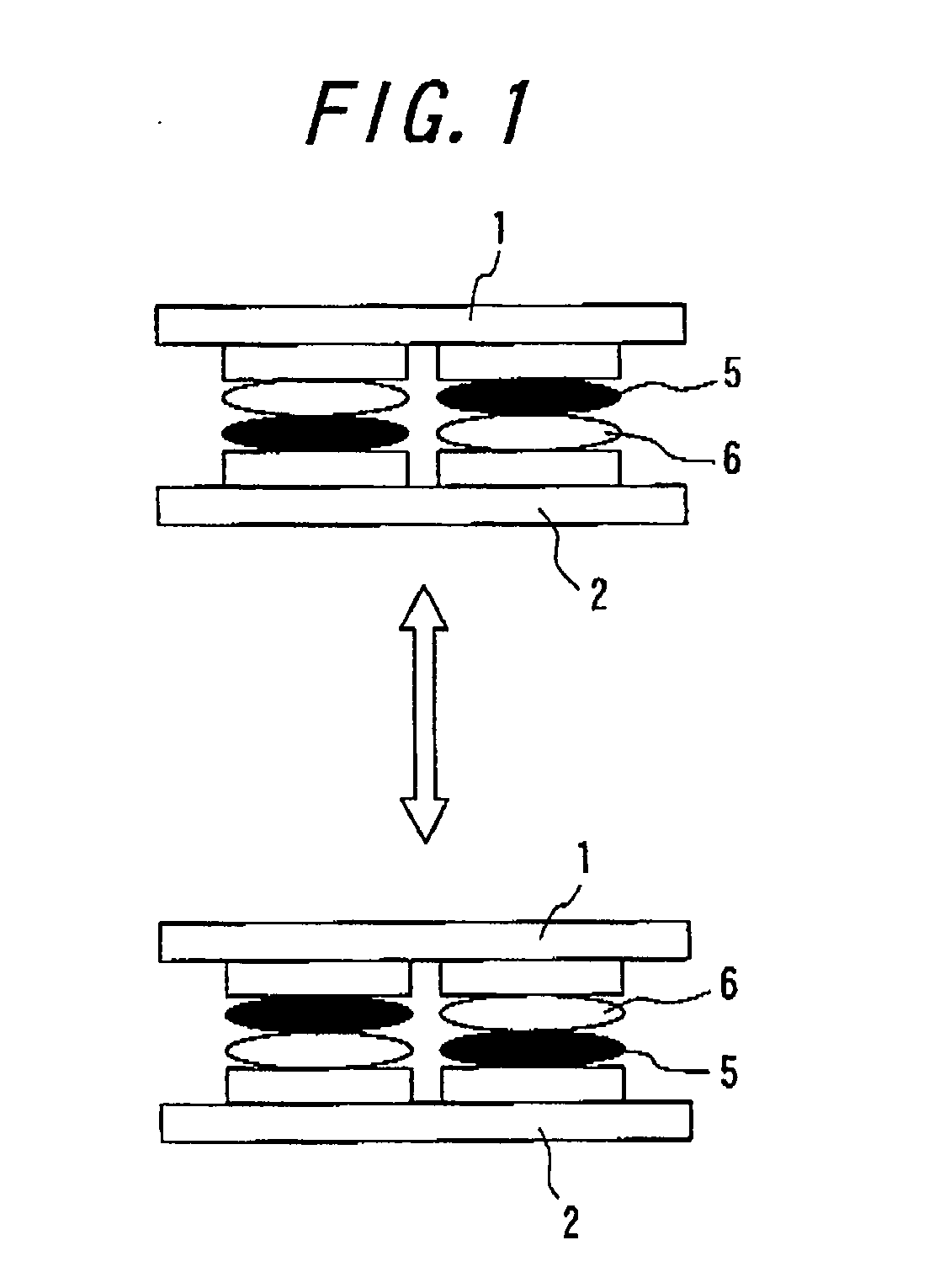

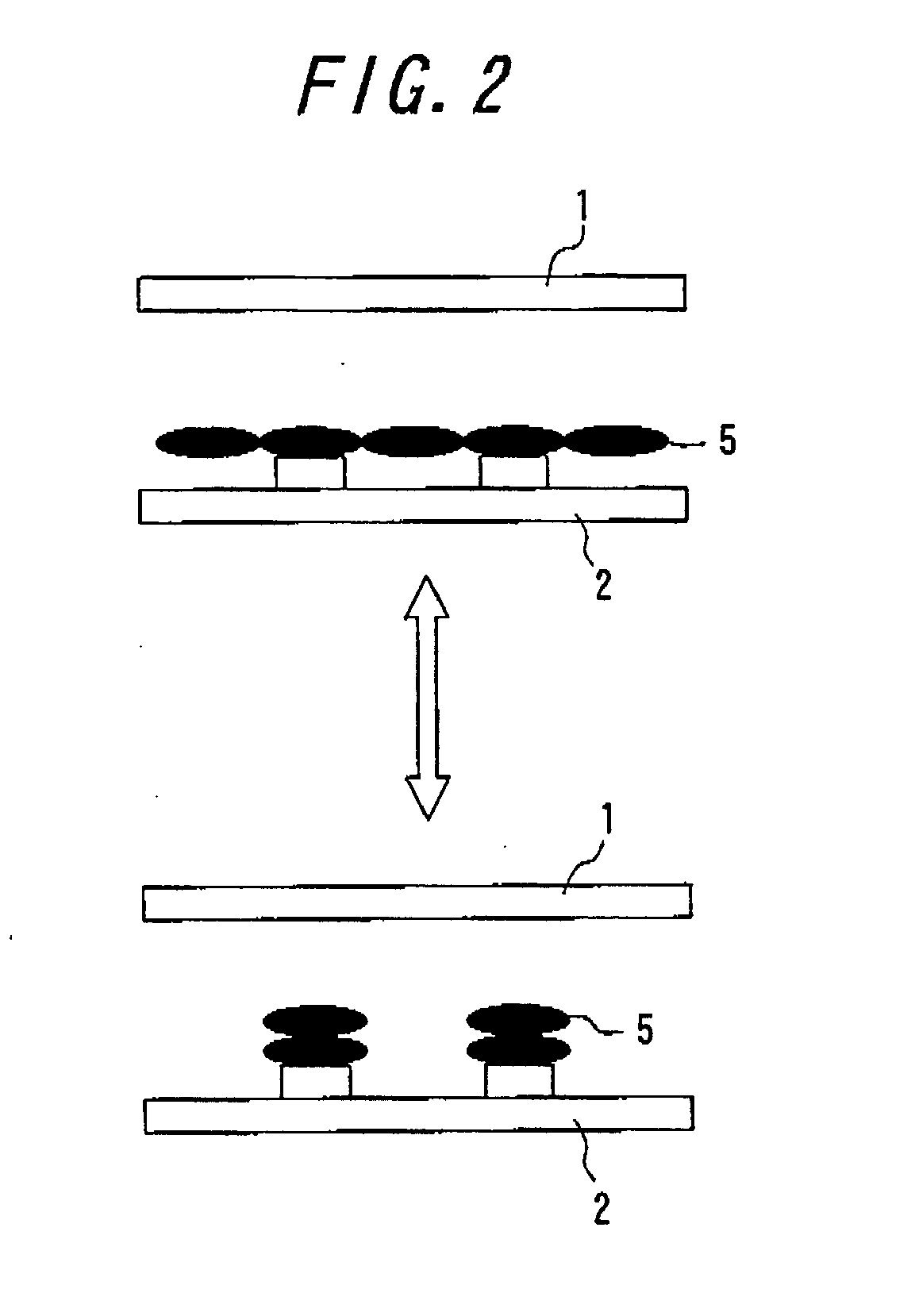

Image display panel manufacturing method, image display device manufacturing method, and image disiplay device

InactiveUS20060231401A1Drawback can be obviatedQuick responseElectrolysis componentsVolume/mass flow measurementSpray nozzleEngineering

In the case of filling and setting the liquid powders or the particles in a plurality of cells formed by the partition walls on the substrate, the method includes the steps of: setting a nozzle at an upper portion of a container; setting the substrate, on which the partition walls are arranged, at a lower portion of the container; scattering the liquid powders or the particles dispersed in a gas from the nozzle arranged at the upper portion in the container; and filling the liquid powders or the particles in the cells on the substrate arranged at the lower portion in the container. After this filling, the method further includes: a filling step for filling a predetermined amount of the liquid powders or the particles in spaces constituting the image display cells isolated by the partition walls; a removing step for removing unnecessary liquid powders or unnecessary particles remaining on the partition walls in the filling step; a substrate stacking step for stacking the transparent substrate and the opposed substrate via the partition walls and applying a sealing agent at a peripheral portion of the substrate so as to make an atmosphere between the transparent substrate and the opposed substrate uniform; and an electrode adhering step for connecting a circuit for displaying the image to the electrode so as to form a module.

Owner:BRIDGESTONE CORP

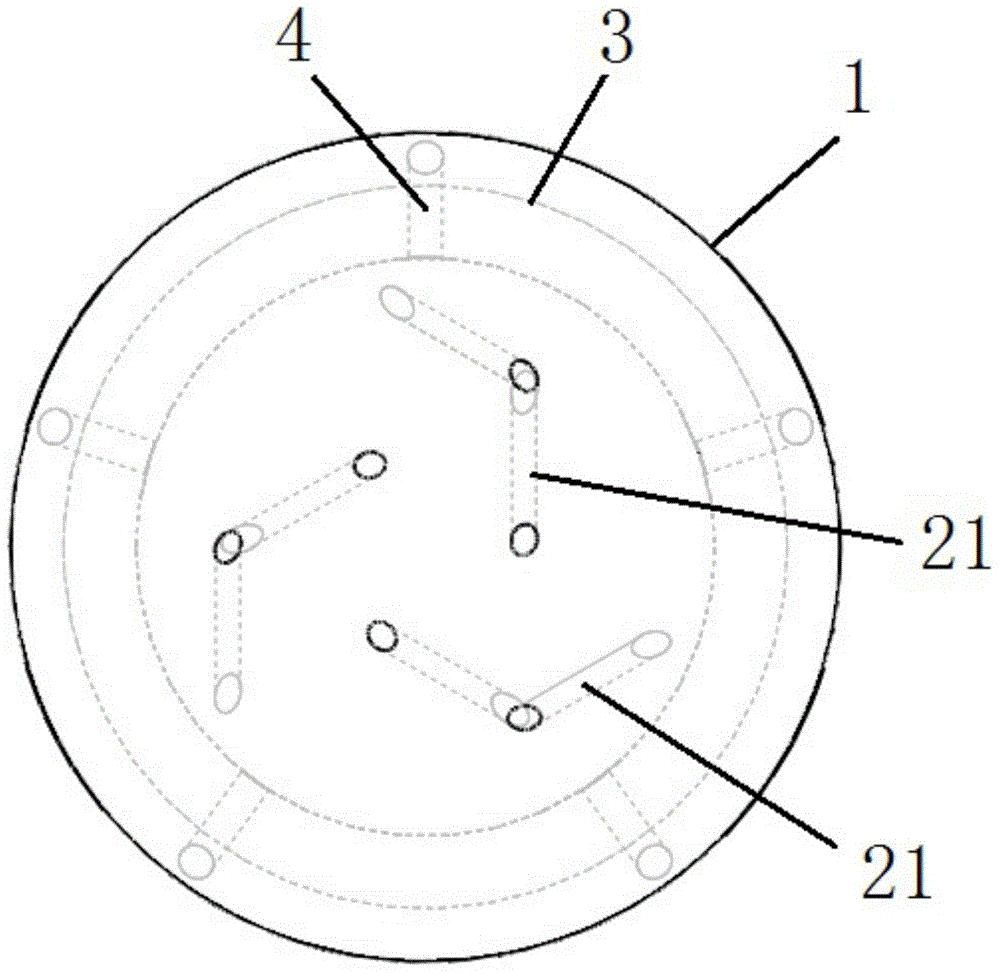

Jet drilling spray nozzle

InactiveCN104832093ASimple structureReduce volumeLiquid/gas jet drillingWell drillingCapillary Tubing

A jet drilling spray nozzle comprises a spray nozzle body. A spray hole set is formed in the top of the spray nozzle body and comprises a plurality of jetting spray holes evenly distributed in the same circumference and obliquely arranged. The jet drilling spray nozzle is simple in structure and small in size, radial water conservancy jetting operation can be easily performed through an underground guiding tool, and the jet drilling spray nozzle can also be applied to cleaning and plugging a capillary tube. Due to the arranged spray hole set, spiral jetting is formed in a hole channel, the effects of forming striking breakage, shearing breakage and stretching breakage are formed, the rock breaking angle and the rock breaking range are increased, the rock breaking effect is improved, the reacting force in the axial direction is greatly reduced, and the self-advancing capacity of the spray nozzle is improved.

Owner:JEREH ENERGY SERVICES

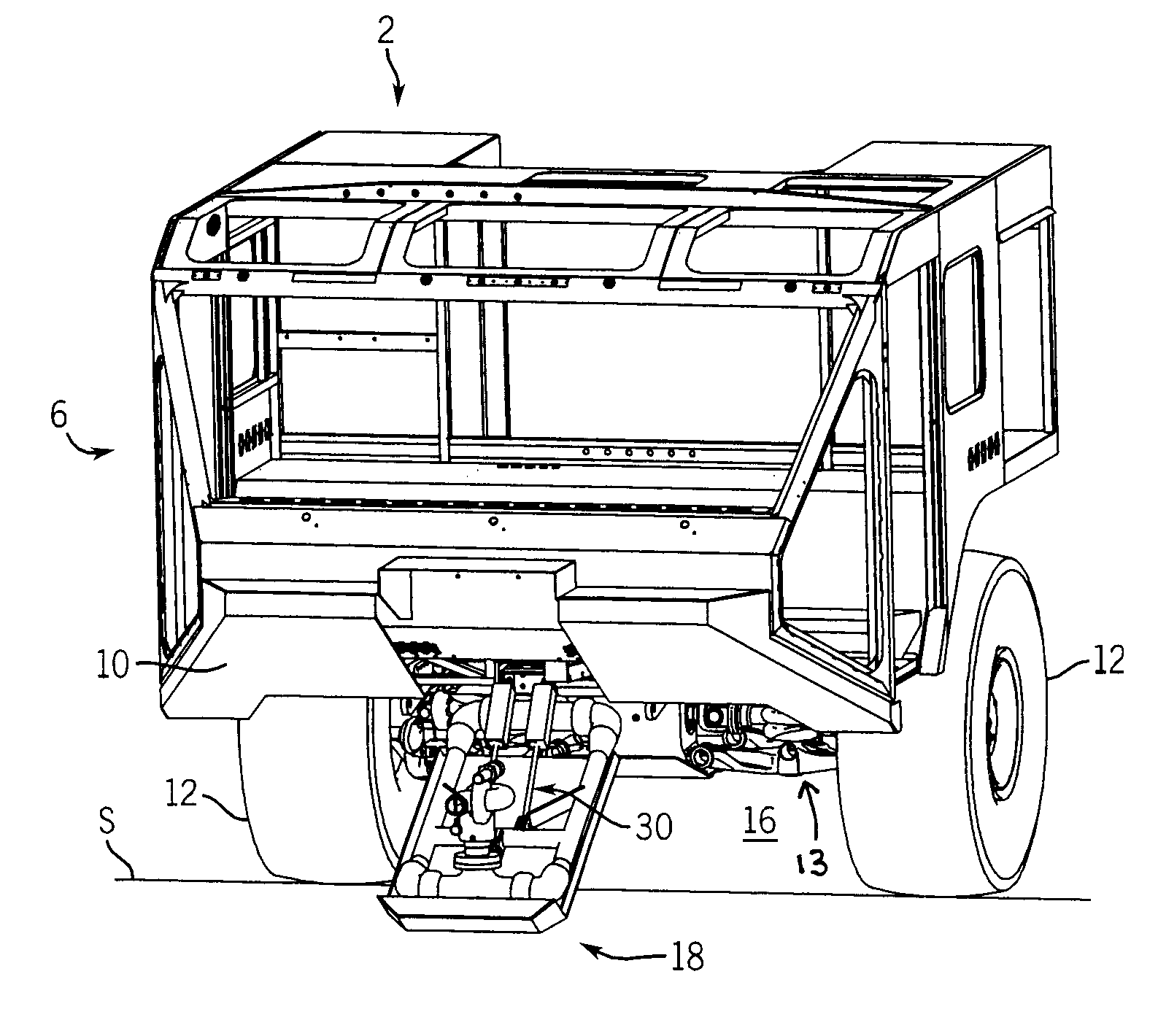

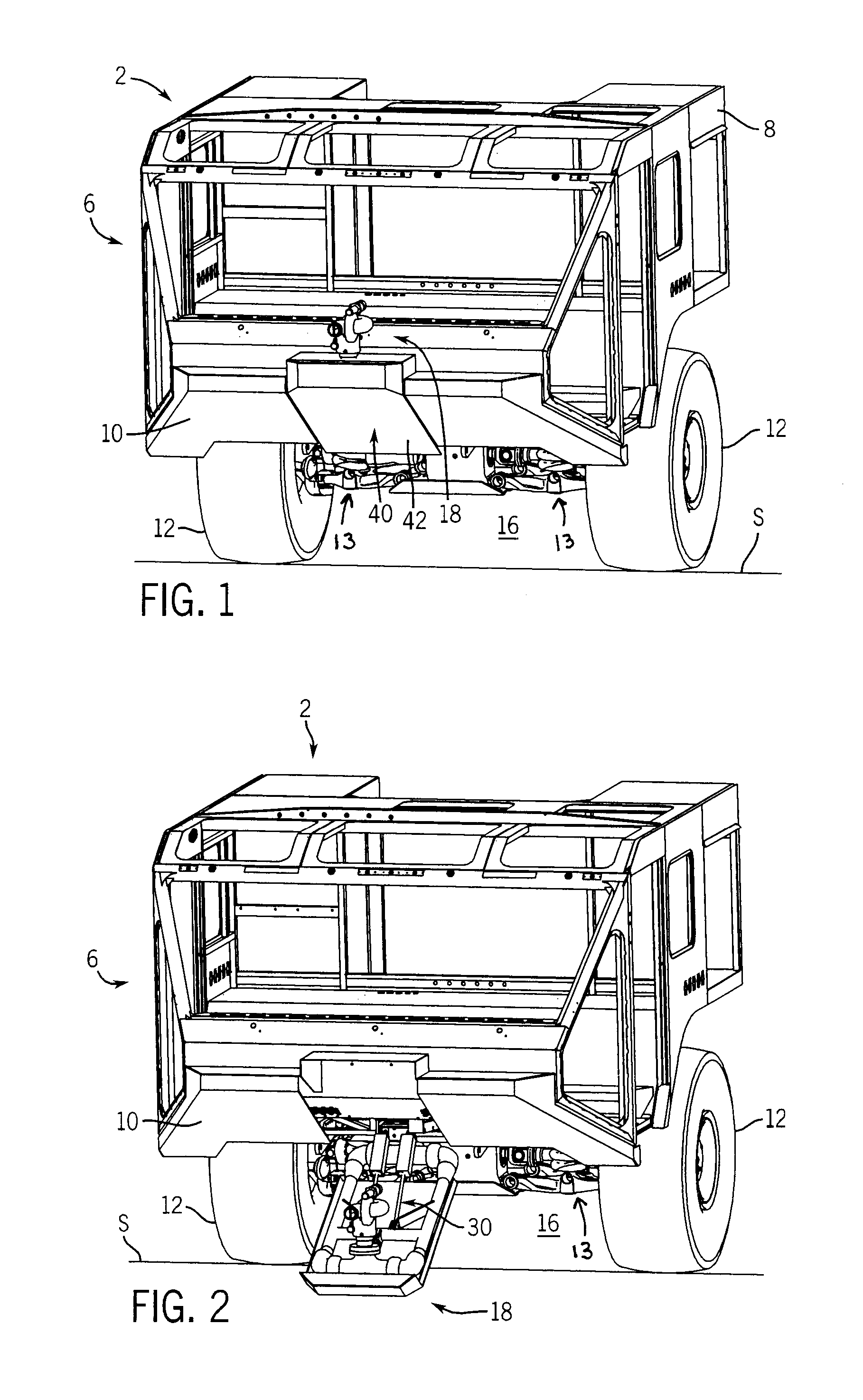

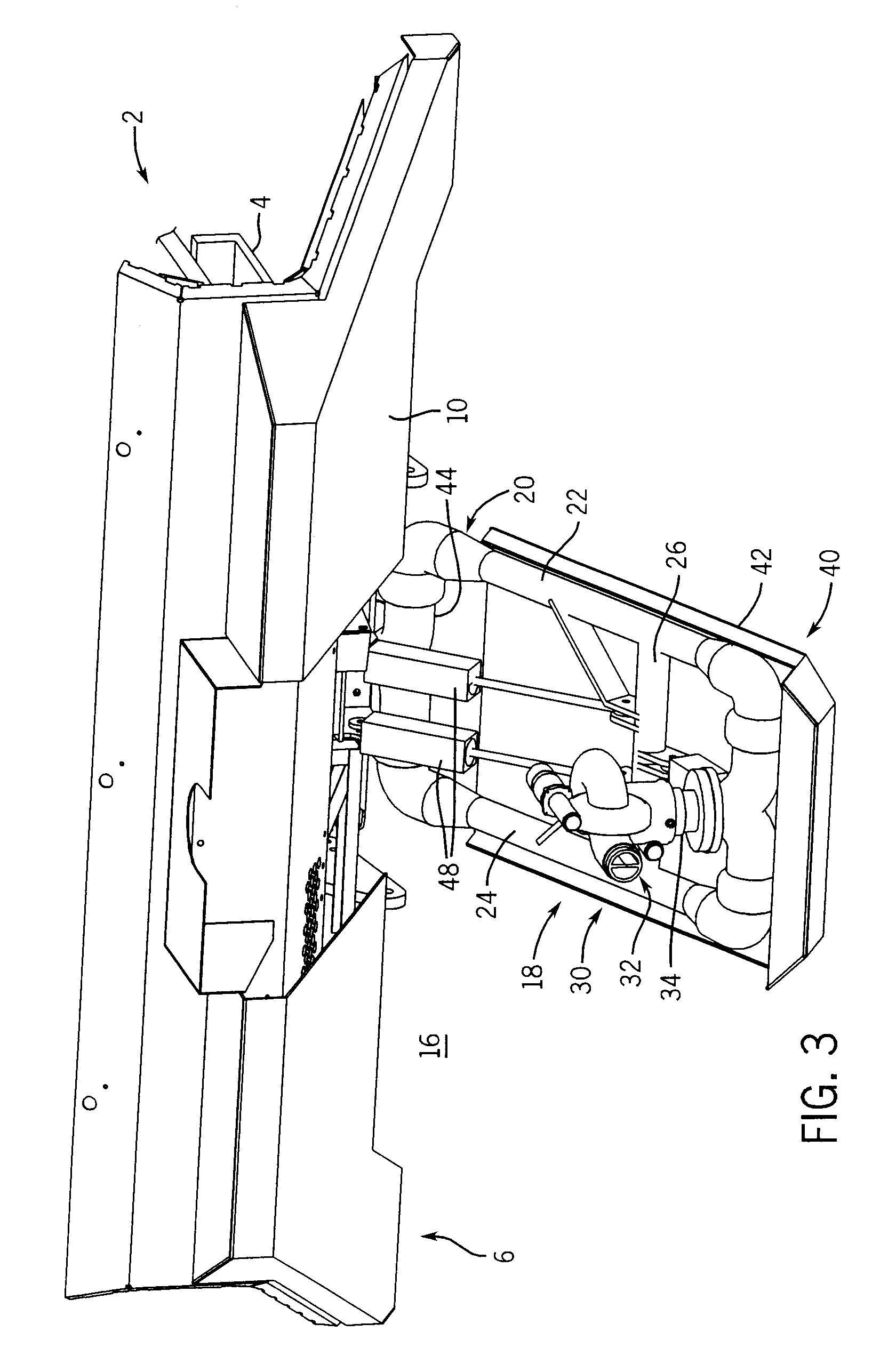

Fluid dispensing arrangement and skid pan for a vehicle

A fluid dispensing arrangement and skid pan for use with a fire fighting vehicle, with the vehicle defining an under-vehicle volume. The fluid dispensing arrangement comprises a fluid source, a nozzle support coupled to the vehicle and movable within at least a part of the under-vehicle volume. A nozzle assembly is supported by the nozzle support and is in fluid communication with a fluid source. An actuator is coupled to the nozzle support to move the nozzle support within at least a part of the under-vehicle volume.

Owner:OSHKOSH CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com