Jet drilling spray nozzle

A sprinkler and jet technology, which is applied in drilling with liquid/gas jets, etc., can solve the problems of inability to achieve good rock breaking effect by injection, unable to form spray distance and footage, unable to apply radial drilling, etc., so as to improve perforation efficiency, Improve rock breaking effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

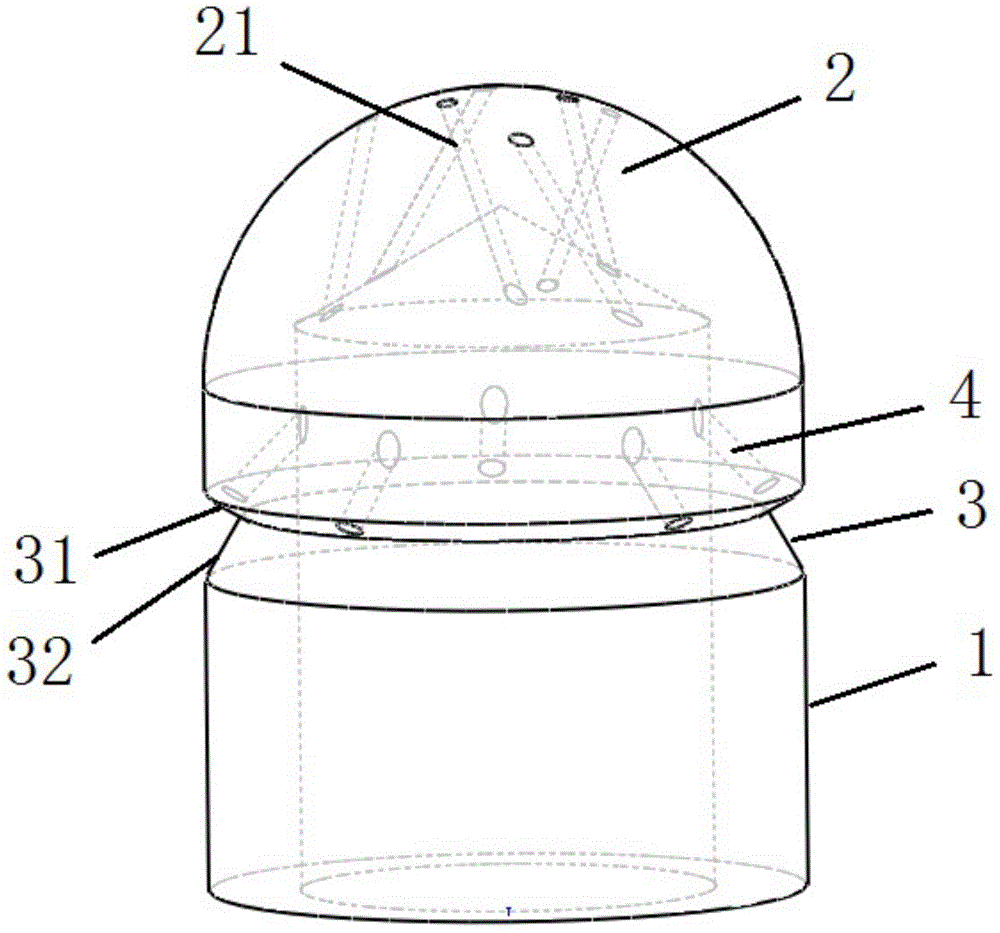

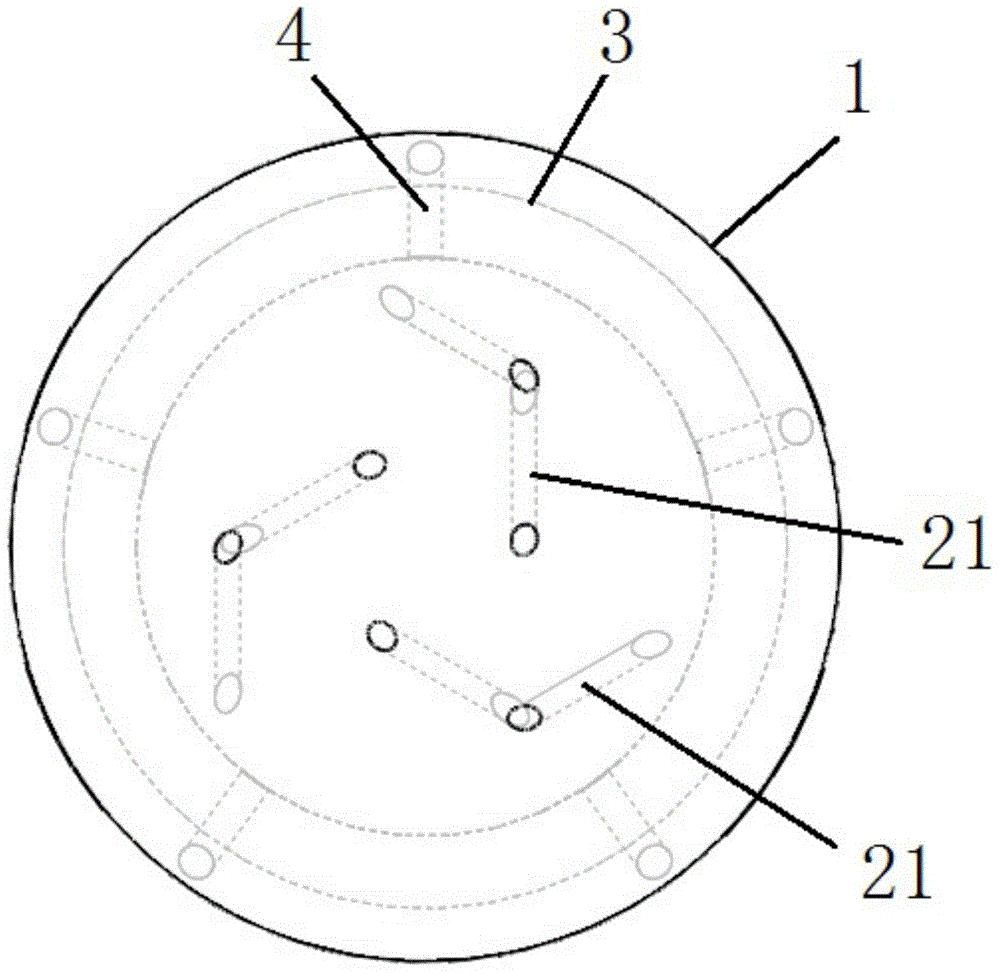

[0020] The jet drilling sprinkler head of the present invention, as Figures 1 to 2 As shown, the nozzle body 1 is included, and the nozzle hole group 2 is arranged on the top of the nozzle body 1 .

[0021] The orifice group 2 includes a plurality of jet orifices 21 uniformly distributed on the same circumference and arranged obliquely. The angle between each jet orifice 2 in the orifice group 2 and the axis of the nozzle body 1 is the same

[0022] A plurality of nozzle hole groups 2 are arranged concentrically, arranged sequentially from the center of the circle to the circumference. The jet nozzle holes 21 of adjacent nozzle hole groups 2 are arranged alternately.

[0023] The top of the nozzle body 1 is hemispherical. A V-shaped ring groove 3 is provided on the outer wall of the middle part of the nozzle body 1 .

[0024] A plurality of downwardly inclined rear spray holes 4 are arranged on the upper side wall 31 of the V-shaped ring groove 3, and the rear spray holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com