Patents

Literature

2192 results about "Rock breaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

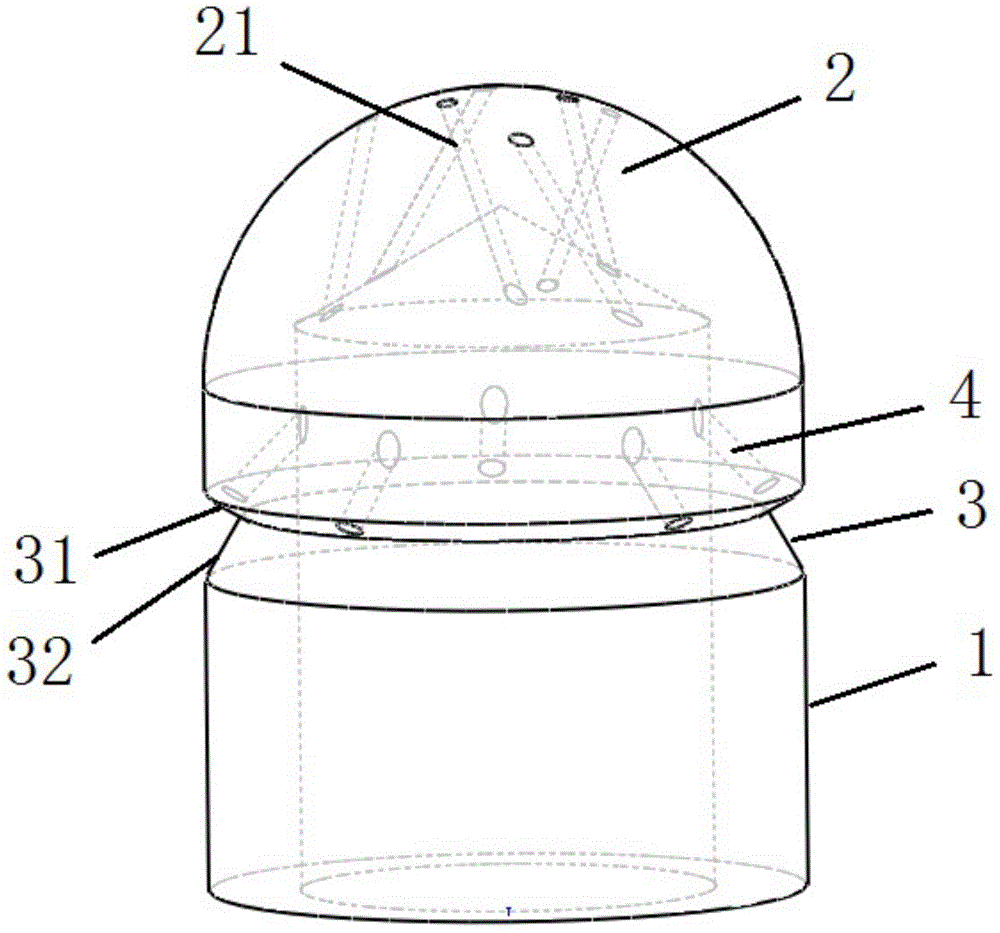

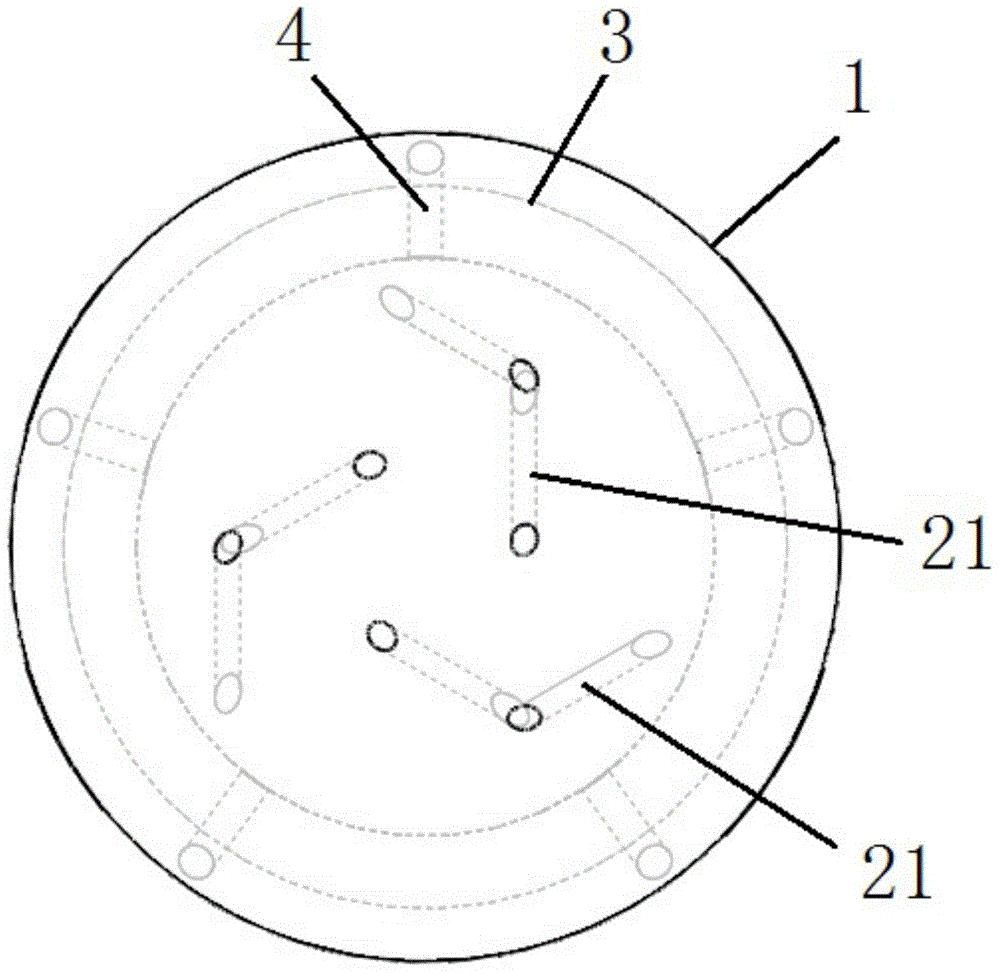

Jet drilling spray nozzle

InactiveCN104832093ASimple structureReduce volumeLiquid/gas jet drillingWell drillingCapillary Tubing

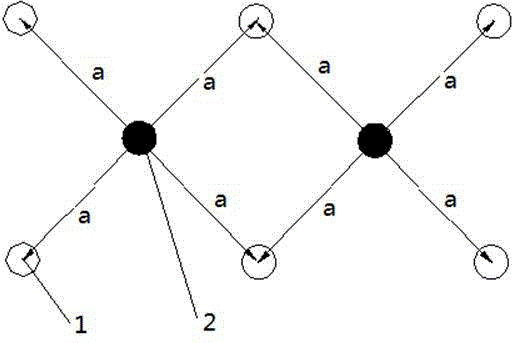

A jet drilling spray nozzle comprises a spray nozzle body. A spray hole set is formed in the top of the spray nozzle body and comprises a plurality of jetting spray holes evenly distributed in the same circumference and obliquely arranged. The jet drilling spray nozzle is simple in structure and small in size, radial water conservancy jetting operation can be easily performed through an underground guiding tool, and the jet drilling spray nozzle can also be applied to cleaning and plugging a capillary tube. Due to the arranged spray hole set, spiral jetting is formed in a hole channel, the effects of forming striking breakage, shearing breakage and stretching breakage are formed, the rock breaking angle and the rock breaking range are increased, the rock breaking effect is improved, the reacting force in the axial direction is greatly reduced, and the self-advancing capacity of the spray nozzle is improved.

Owner:JEREH ENERGY SERVICES

Hydro-oscillator for well drilling

InactiveCN102704842AIncrease frictional resistanceIncrease drilling speedVibration devicesVibration drillingWell drillingHarmonic vibration

The invention relates to a hydro-oscillator for well drilling. The hydro-oscillator consists of a hydraulic driving assembly, a fixed valve assembly, a bottom assembly and a vibrating pipe nipple, wherein the vibrating pipe nipple is connected with the hydraulic driving assembly; a rotor is connected with a vibrating valve; the fixed valve assembly is arranged on the bottom assembly; and a power shell is connected with the bottom assembly. A drilling fluid is used for driving the rotor to rotate, and the rotor is used for driving the vibrating valve to vibrate, so that flow holes of the vibrating valve and a fixed valve are staggered with each other, and simple harmonic pressure waves are modulated and are upwardly transmitted to a disc spring for driving the vibrating shell to perform continuous simple harmonic vibration in the axial direction, so that the friction resistance between a drilling column and a well wall is improved effectively, and the drilling speed is increased; and meanwhile, pressure waves are downwardly transmitted to drill bit jet flow, so that periodic change of rock breaking pressure is facilitated, and rocks are crushed effectively. The hydro-oscillator has the characteristics of simple structure, convenience for operating, safety, reliability, low pressure drop, high adaptability, no influence on the drilling tool structure and the like, and plays an important role in increasing the drilling speed and reducing cost.

Owner:CHINA PETROCHEMICAL CORP +1

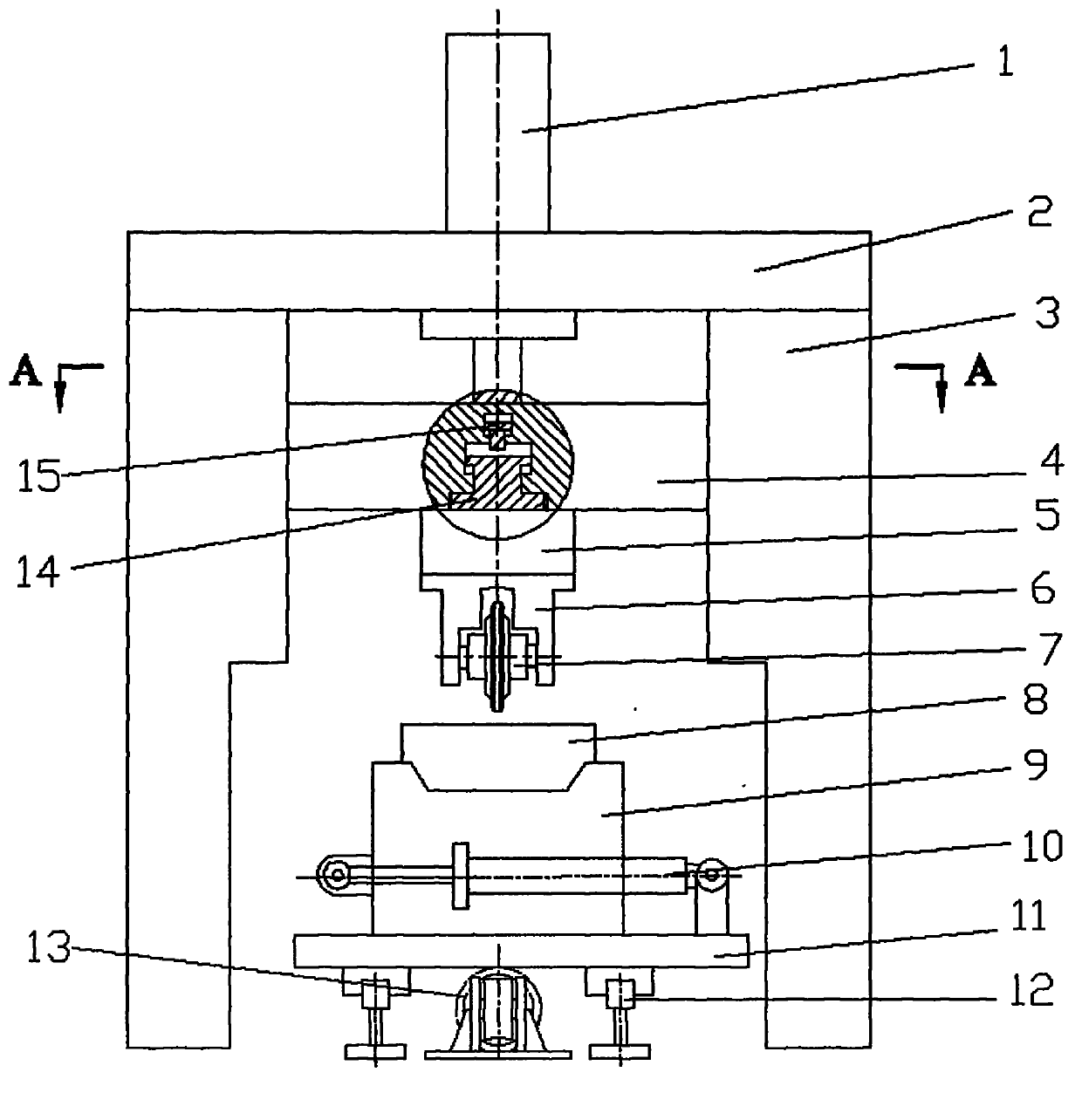

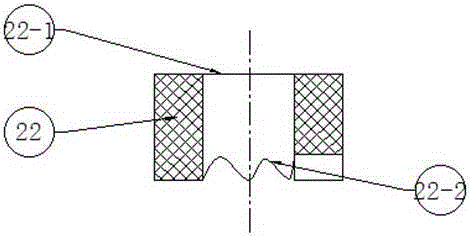

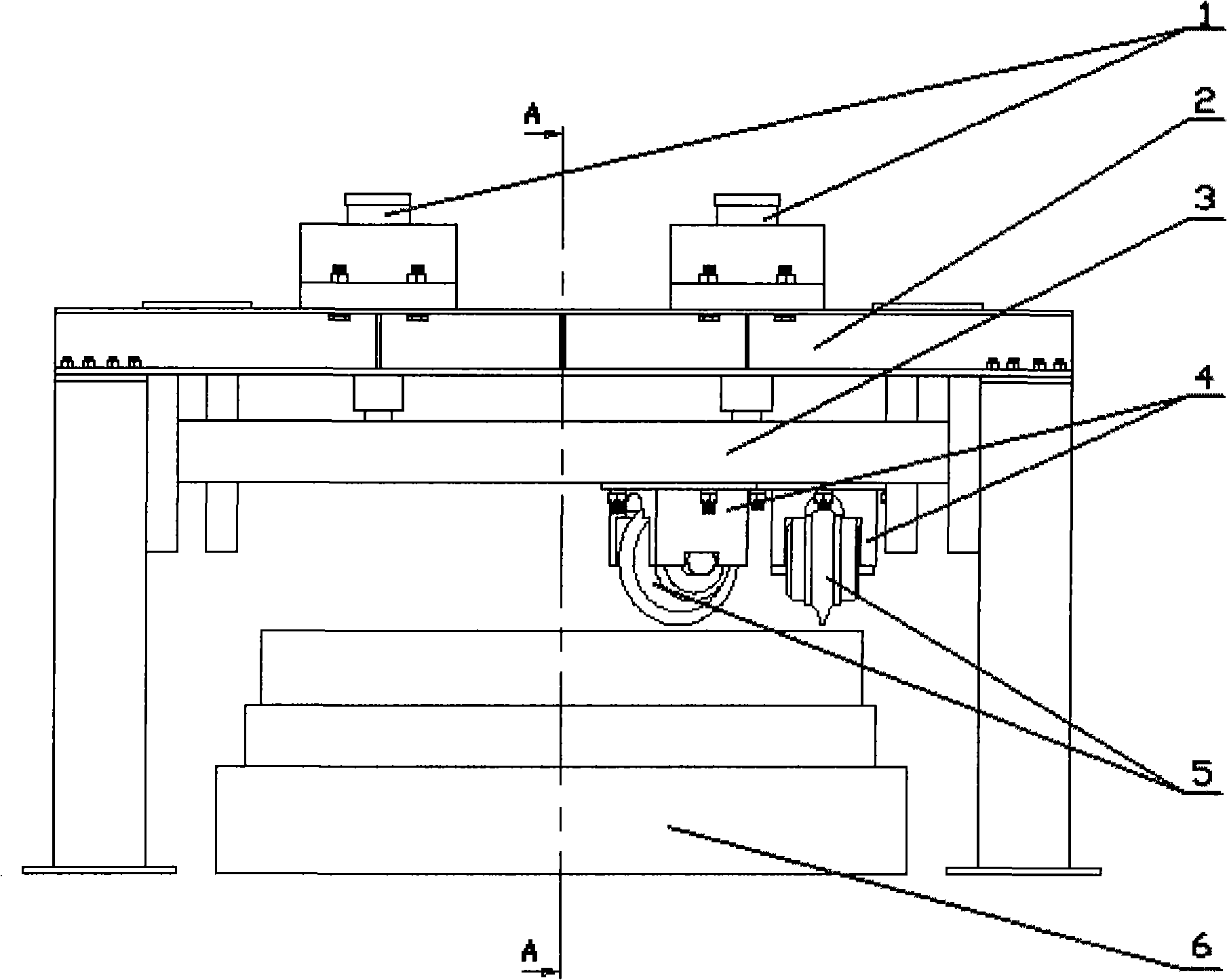

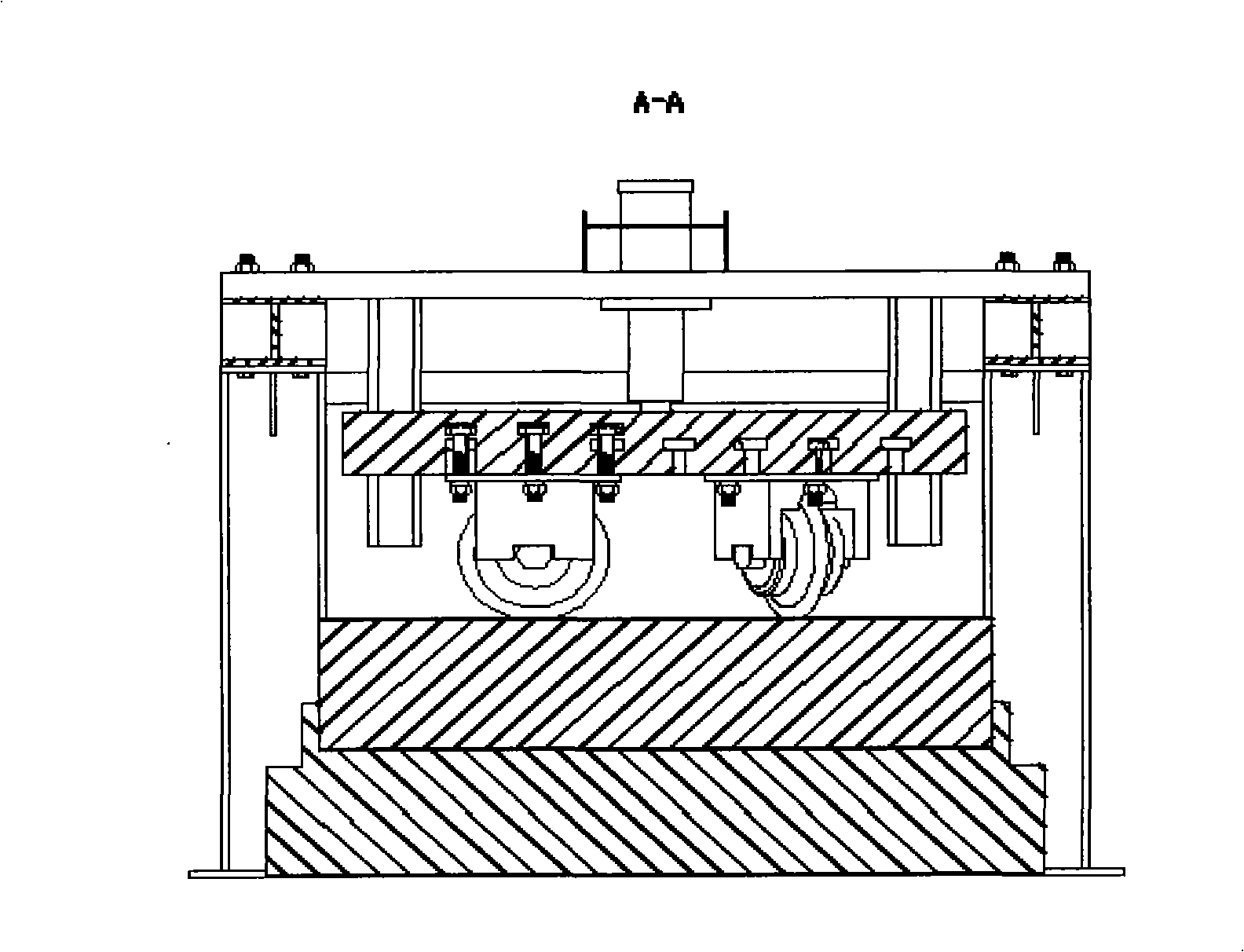

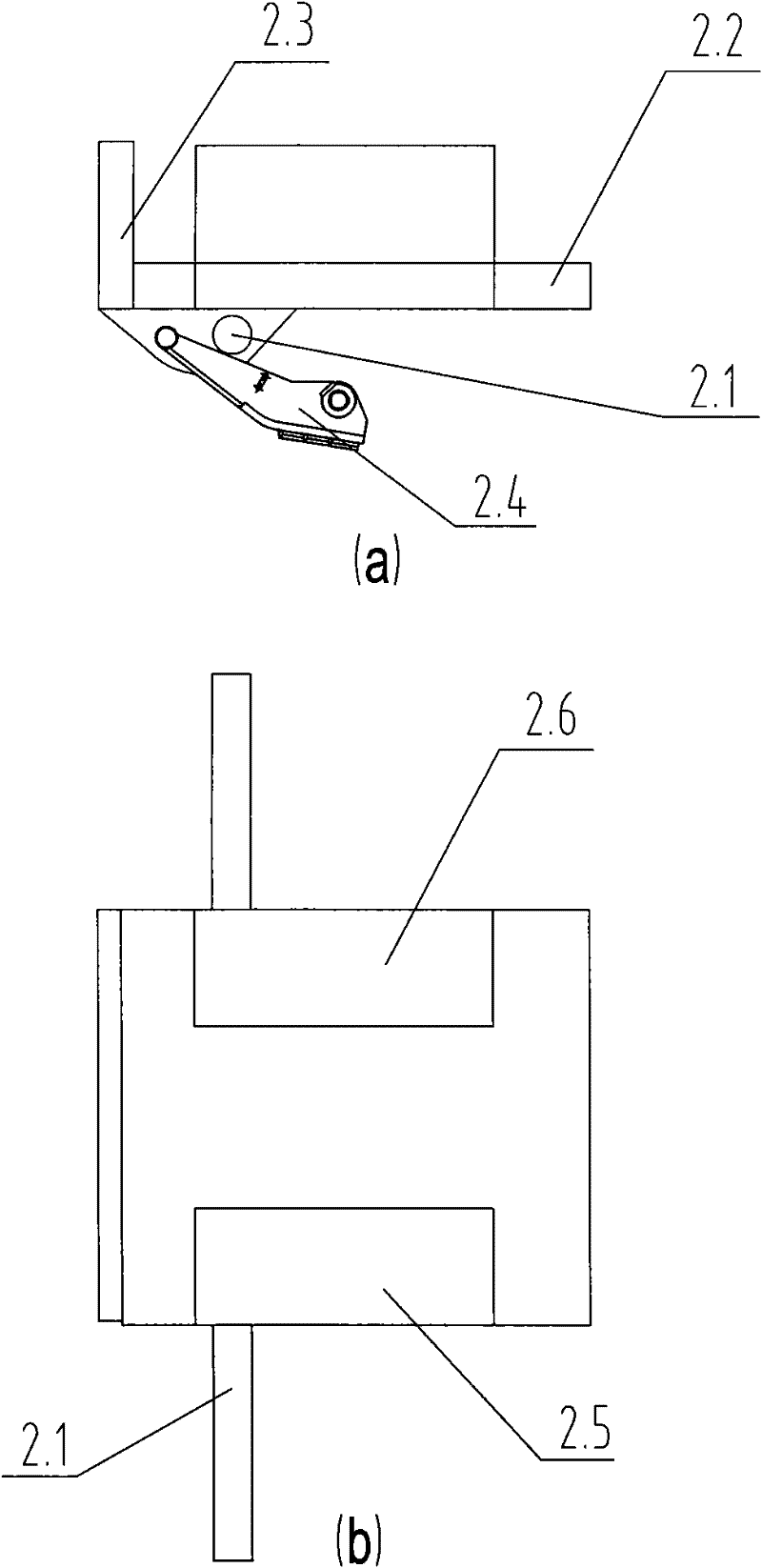

A hard rock hobbing cutter rock breaking characteristic testing device

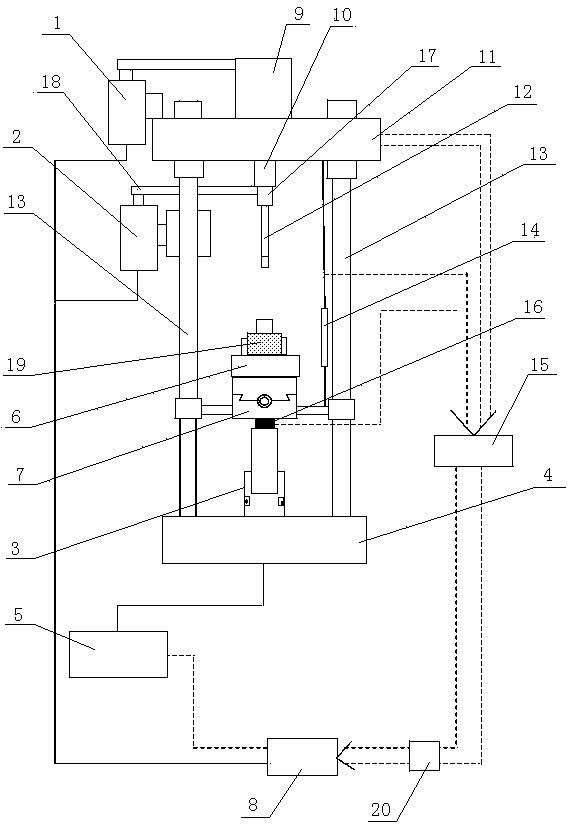

InactiveCN103969141AObservable breakage featuresInvestigating abrasion/wear resistanceInvestigating machinabilityHobbingData acquisition

A hard rock hobbing cutter rock breaking characteristic testing device used in the field of tunnel engineering is provided. A rock silo supporting seat is positioned on a guide rail pair and realizes longitudinal motion by a longitudinal-moving hydraulic cylinder; a rock silo is positioned on the rock silo supporting seat and realizes lateral movement by lateral moving hydraulic cylindersfixed on the rock silo supporting seat; rock samples are positioned inside the rock silo. Two columns are vertically arranged at both sides of the rock silo, top ends of the columns are connected by a beam and thus a gantry structure is formed. A vertical hydraulic cylinder is fixed on the beam, and the lower part of the vertical hydraulic cylinder is connected with a walking beam. Under the walking beam, a hobbing cutter is installed to simulate the process of hobbing cutter rock breaking, or a similar hobbing cutter wearing module is installed to simulate the process of similar hobbing cutter wearing. An industrial computer, a data acquisition card, a three-axis force sensor, an acoustic emission device and a high-speed digital camera system are used to monitor the processes of hobbing cutter rock breaking and wearing. The device is capable of simulating the process of rolling-type rock breaking of the hobbing cutter, the process of rolling and impact-combined type rock breaking of the hobbing cutter and the process of similar hobbing cutter wearing.

Owner:CENT SOUTH UNIV

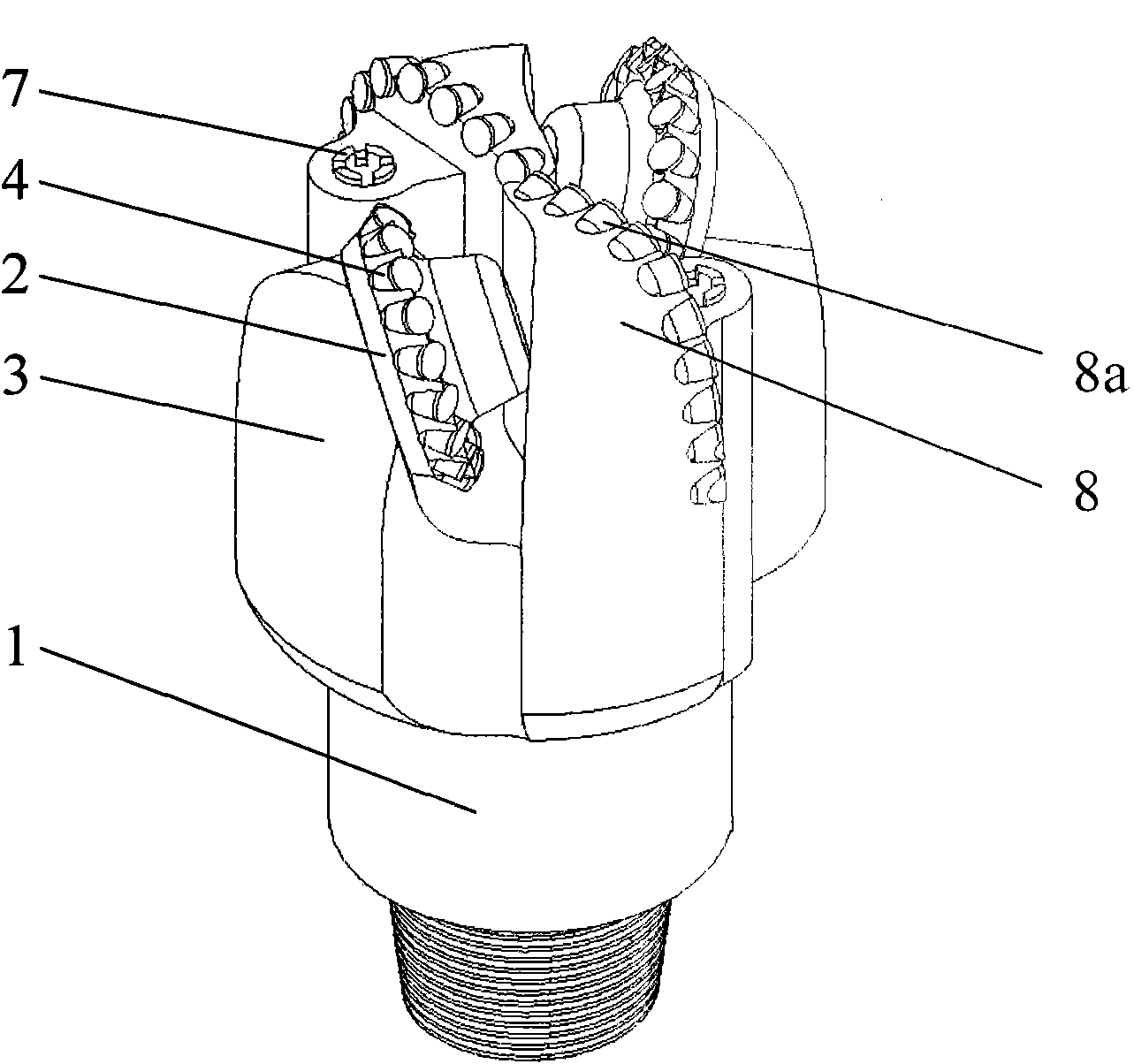

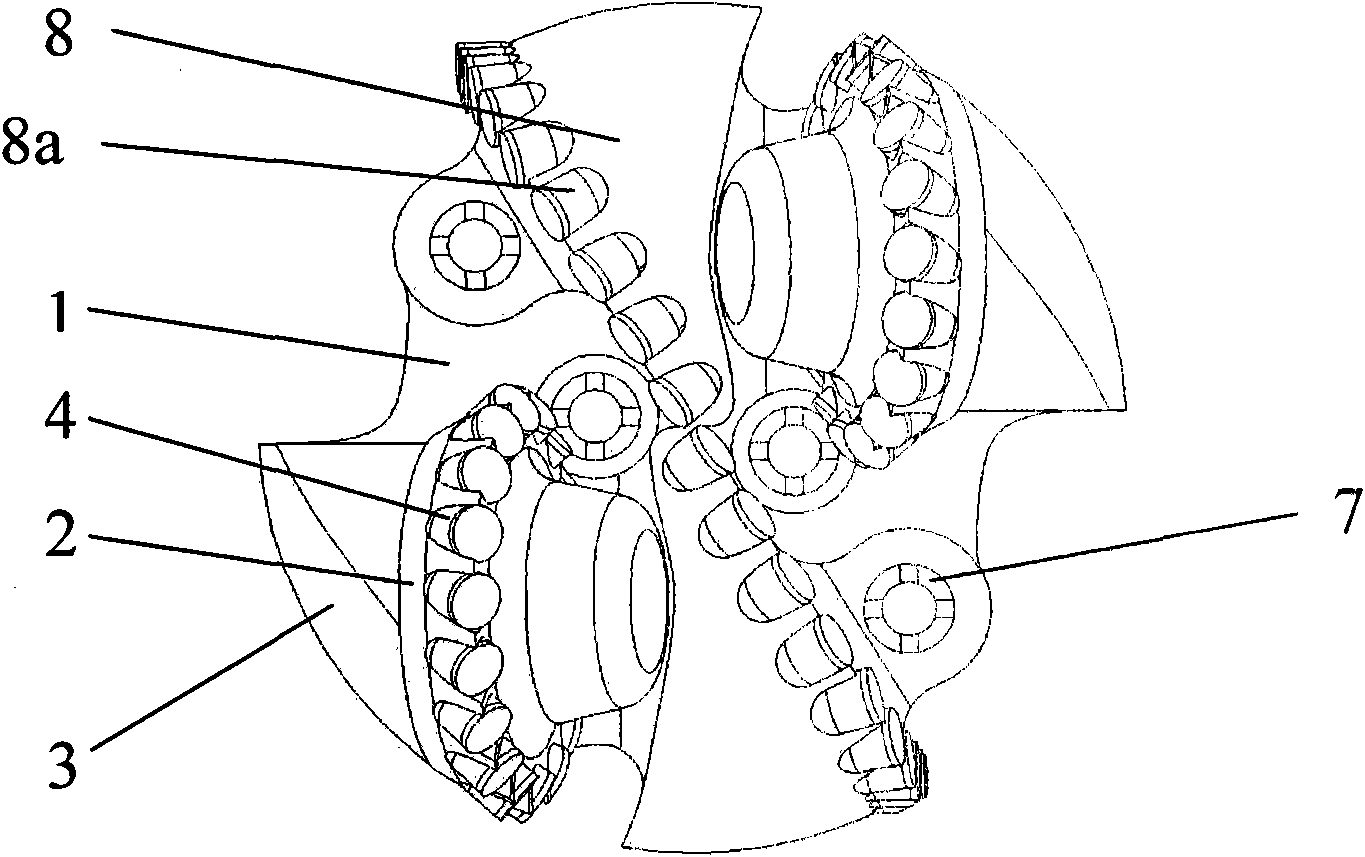

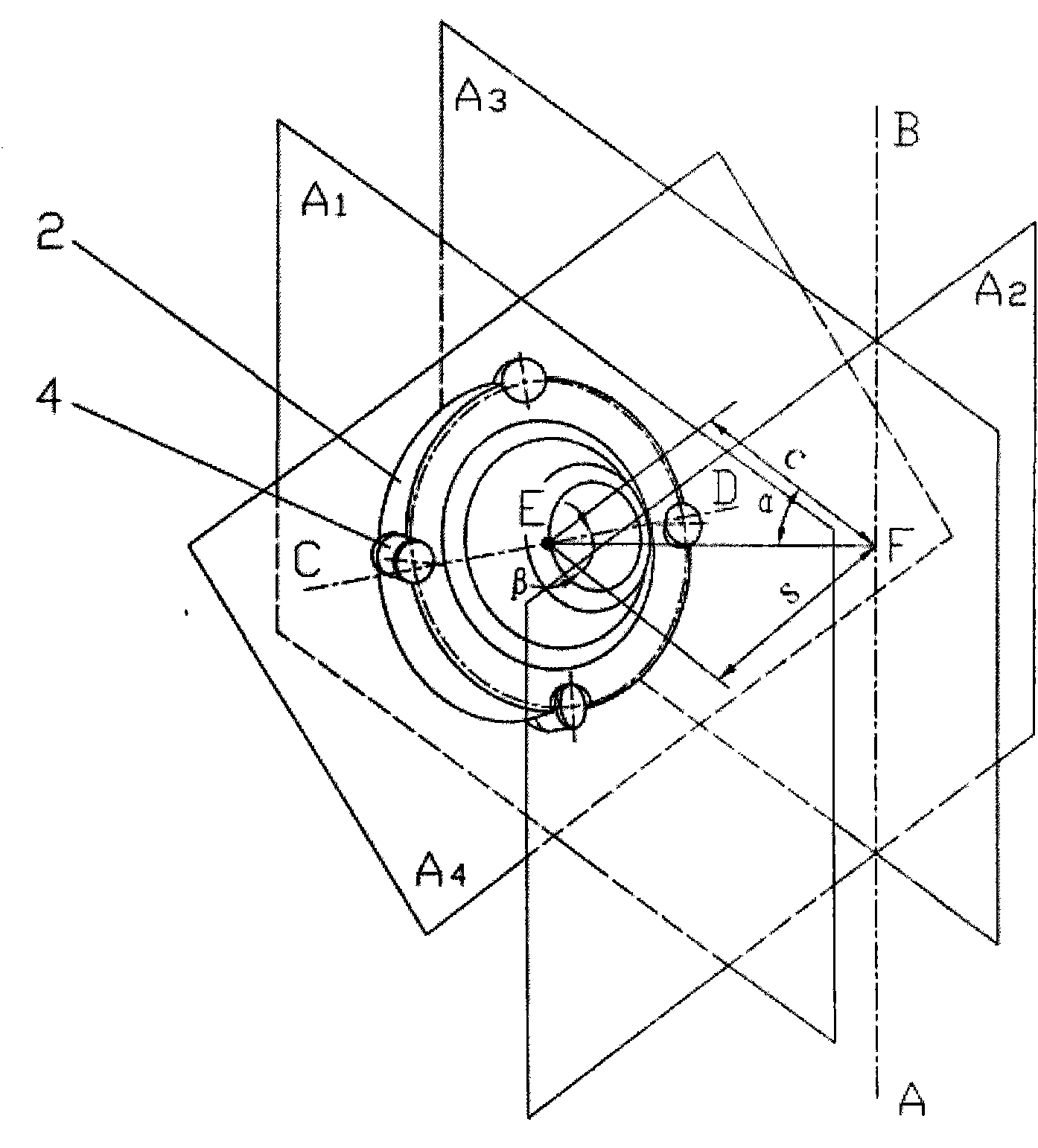

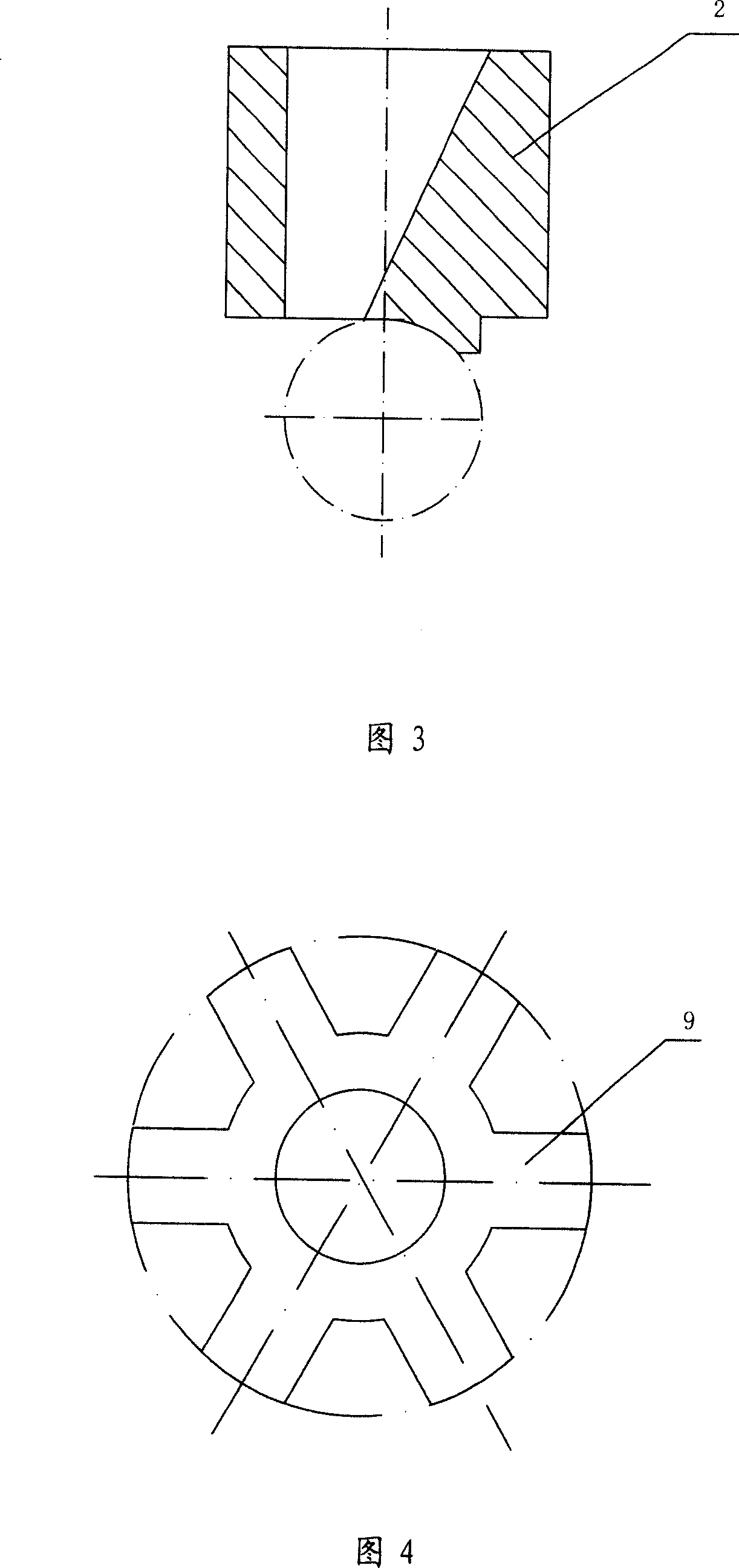

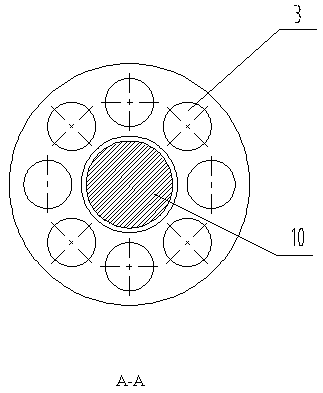

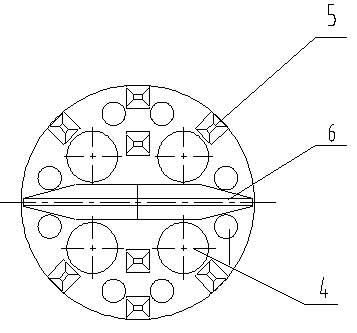

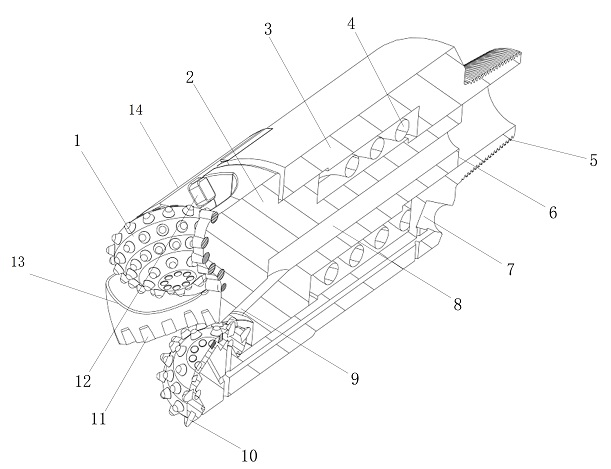

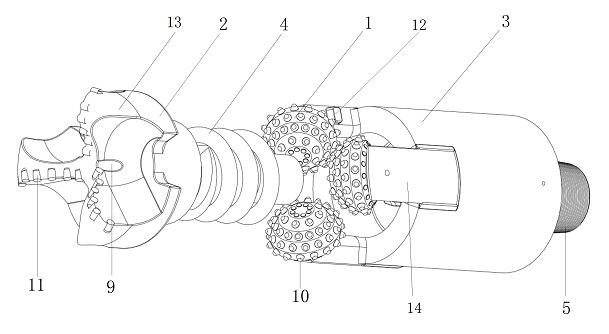

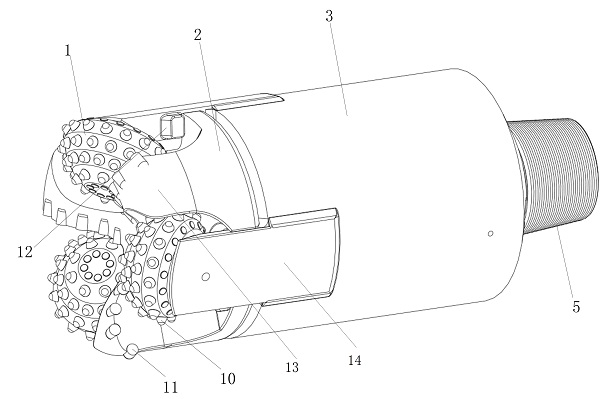

Combined drill breaking rocks by cutting method

ActiveCN101892810APromote fragmentationEffective intakeDrill bitsConstructionsWorking lifeCooling effect

The invention discloses a combined drill breaking rocks by a cutting method. The combined drill comprises a drill body (1) and a rotating wheel (2), wherein a wheel palm (3) is arranged on the drill body (1); the rotating wheel (2) is arranged on the shaft neck (6) of the wheel palm (3) and is in rotary connection with the wheel palm (3); an external row of cutting gear rings (4) are arranged on the rotating wheel (2); the deviation angle alpha of the rotating wheel (2) is in a range that the absolute value of alpha is more than or equal to 20 degrees and less than or equal to 90 degrees; and a fixed cutting structure (8) with fixed cutting teeth (8a) is arranged on the drill body (1). Cutting teeth on the rotating wheel break the rocks in an alternatively scraping mode and cooperates with the cutting teeth on the fixed cutting structure to form a net-like breaking region on the pit bottom rocks, so the combined drill has the advantages of high rock-breaking efficiency, uniform wear, good cooling effect, long service life of the teeth, long working life of the bearing and long service life of the drill.

Owner:CHENGDU WEIYI PETROLEUM TECH

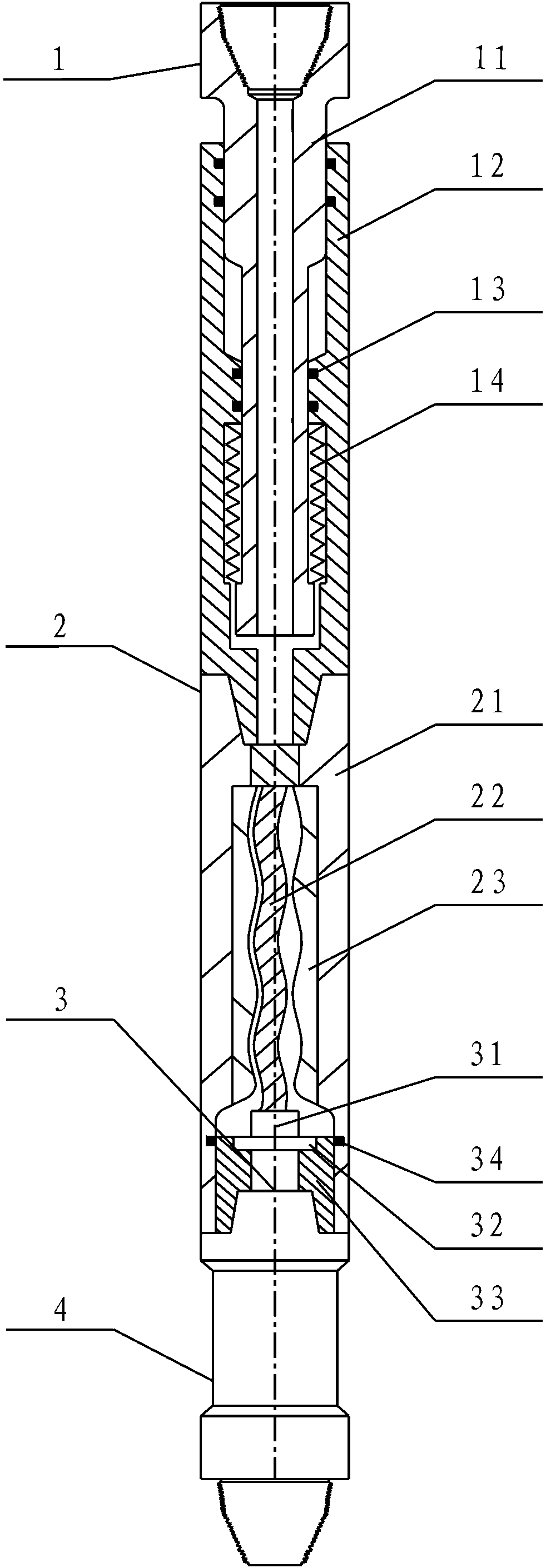

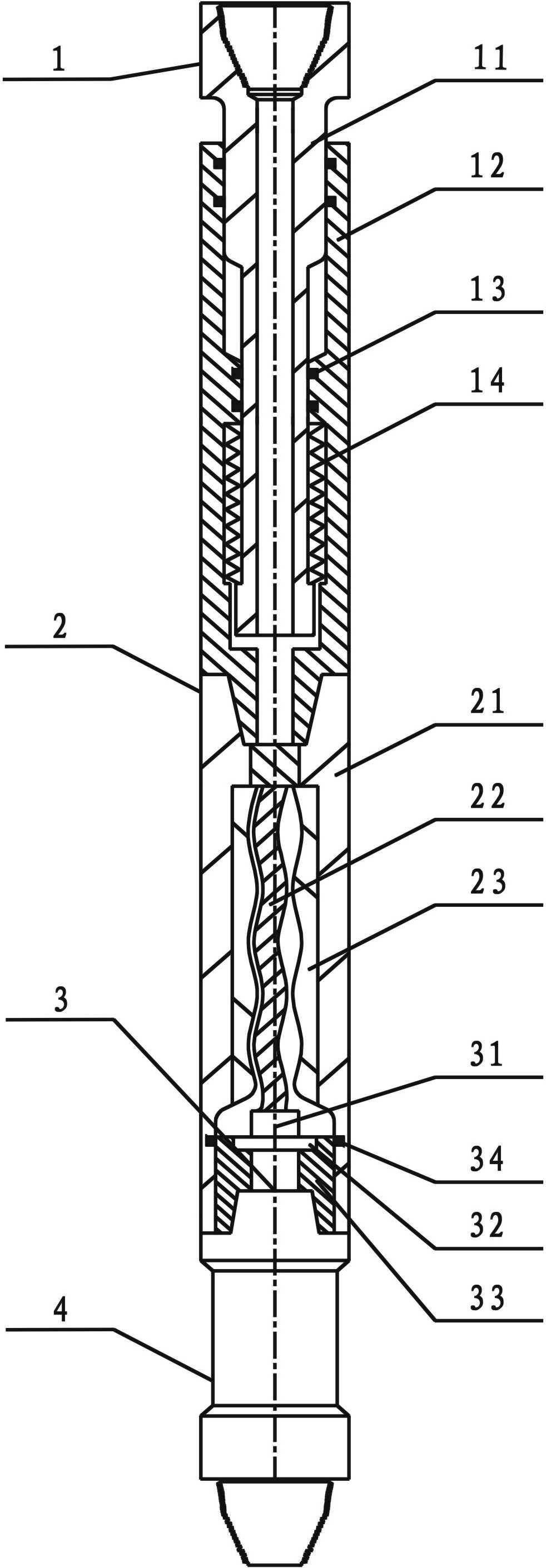

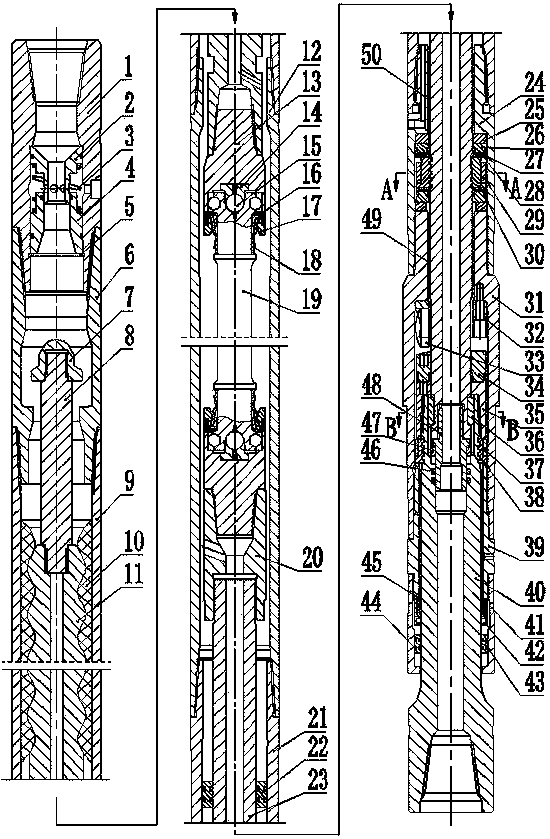

Downhole tool for achieving efficient rock breaking through spin vibration

InactiveCN105239929AQuality improvementImprove high temperature resistanceBorehole drivesVibration drillingDrive shaftSpins

The invention relates to a downhole tool for achieving efficient rock breaking through spin vibration, and belongs to the technical fields of petroleum and natural gas exploitation and drilling tools. According to the technical scheme, drilling fluid drives a turbine to rotate, a turbine rotor drives a transmission shaft to rotate to drive a disc valve set to periodically rotate, the open area changes, a periodic pressure pulse is generated to act on a vibration nipple to generate reciprocating vibration, the friction resistance between a drilling column and the well wall is effectively improved, and mechanical drilling speed is increased; the lower end of a tooth-shaped impact hammer head is provided with a tooth-shaped curved surface which is meshed with a tooth-shaped curved surface of a lower-end transmission connector, and the lower-end transmission connector is driven by a transmission shaft to generate rotating motion, so that the tooth-shaped impact hammer head is driven to rotate to generate axial reciprocating impact on the lower-end transmission connector under the joint action of the tooth-shaped impact hammer head and a force accumulating spring. According to the downhole tool, the structure is simple, the friction resistance is small, effective bit pressure and effective vibration are increased, the mechanical rotating speed is increased, and the cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

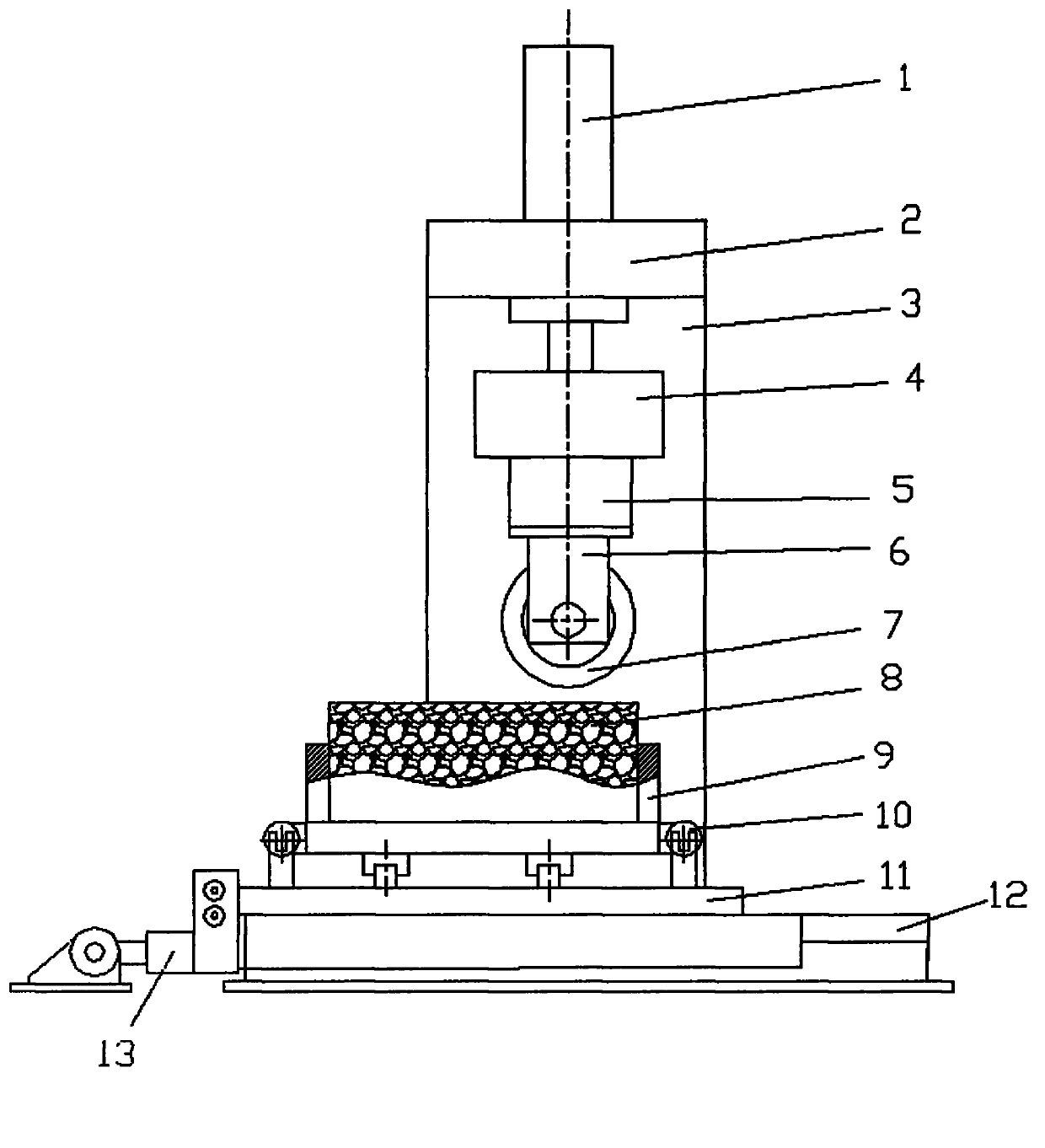

Tool bit rock breaking mechanism and abrasion tester

InactiveCN101299013AIdea novel scienceFunction increaseInvestigating abrasion/wear resistanceInvestigating machinabilityTool bitHydraulic cylinder

The present invention provides a cutter rock-breaking mechanism which is applied in the technical field of the cutter experiment and an abrasion resistant tester thereof. The abrasion resistant tester comprises a hydraulic cylinder, a structural frame, a bearing plate, a cutter support, a disc-shaped hob and a rotation worktable. When the cutter rock-breaking mechanism and the abrasion resistant tester work, the disc-shaped hob is connected with the cutter support through a bolt. The cutter support is jointed and fixed on the bearing plate through the bolts. The hydraulic cylinder exerts a certain load to impact the disc-shaped hob to the rock sample on the worktable and generate a certain penetration. Afterwards the worktable is rotated through a power system to execute cutting test to the rock passively. The cutter rock-breaking mechanism and the abrasion resistant tester execute cutting with a single cutter to do the abrasion resistance test of the cutter. The bearing plate is provided with a groove. The regulation to the cutter space and the phase angle is realized through the variation of the jointing position of the cutter support on the bearing plate. The regulation to the inner deflection angle of the cutter is realized by changing the cutter supports with different angles. The positioning and rotation of the rock are realized through the rotating worktable. The designing of the device is novel and scientific. The knife angle, phase angle and inner deflection angle which affect larger to the rock breaking and abrasion of cutter are researched. The device settles the problem that two hob cutters simultaneously cut the rock.

Owner:NORTHERN HEAVY IND GRP CO LTD

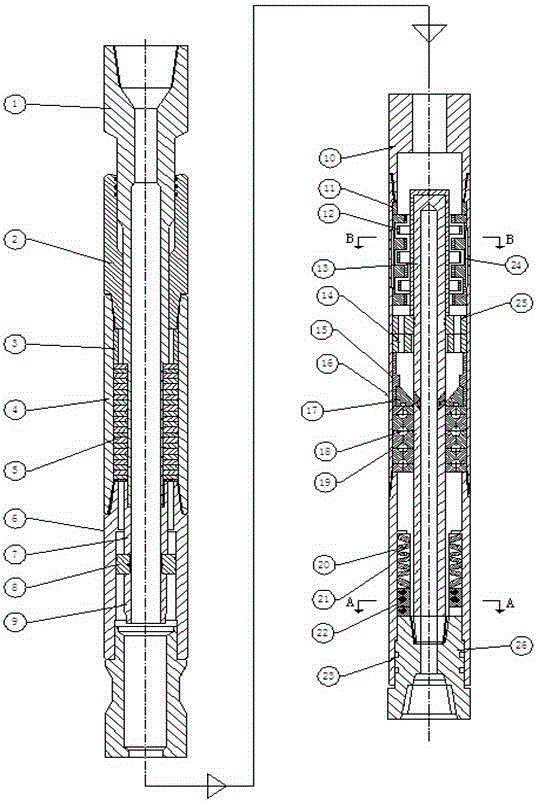

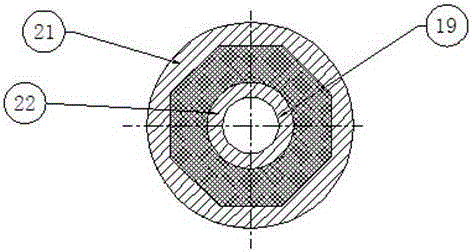

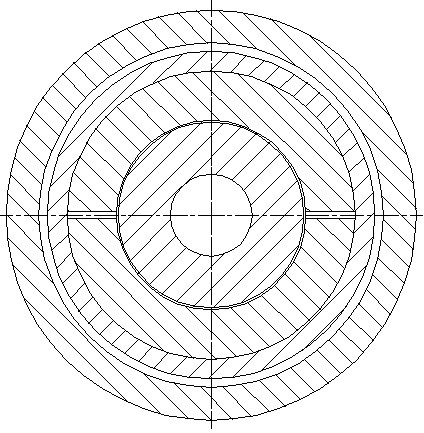

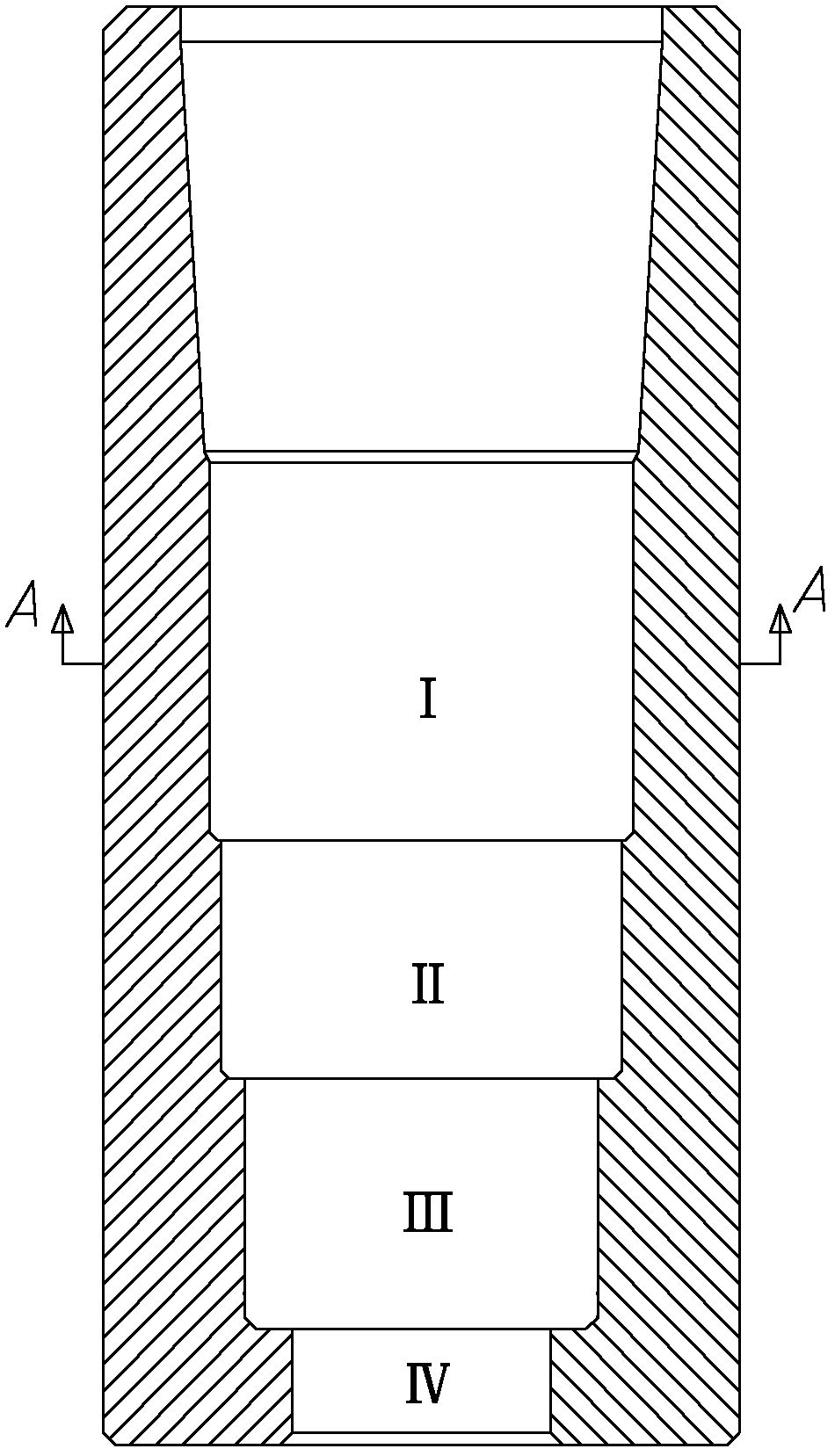

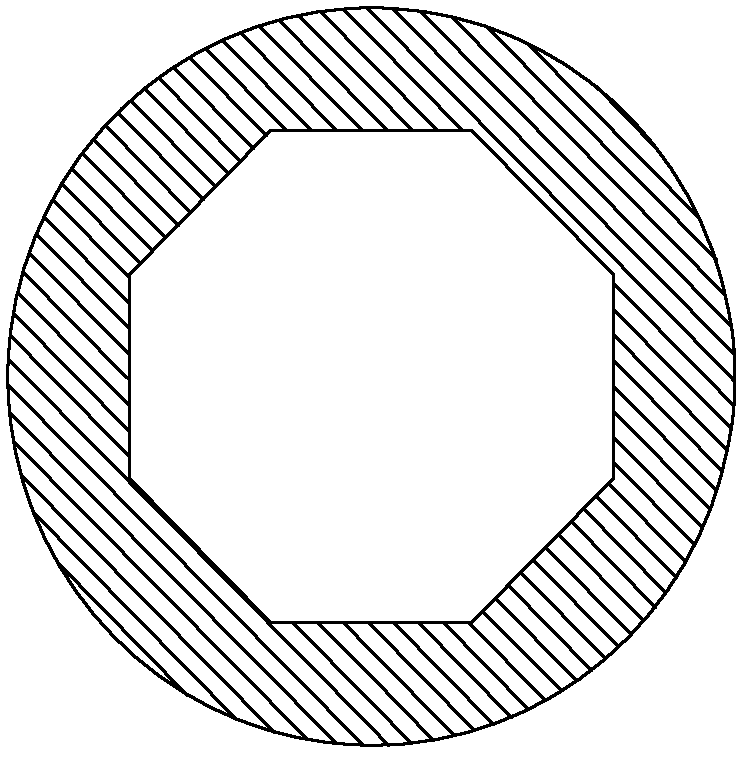

Rotary screw drill tool

InactiveCN104033113AImprove rock breaking abilityExtended service lifeDrilling rodsDrilling casingsSplit ringWell drilling

The invention discloses a rotary screw drill tool used in fields of petroleum drilling and the like and solves the problem about crushing efficiency of hard rocks in extradeep wells. The technical scheme includes that a bypass valve shell, a fall prevention joint, a motor shell, a universal shaft shell, an outer shell, a bearing shell, an outer cam shell, a bottom piston shell and a lower shell are sequentially connected through screw threads; an upper shaft and a lower shaft are connected through a spline, and eight spline pins are evenly and circumferentially distributed between the upper shaft and the lower shaft; a roller holder is fixed on the outer cam shell through three bolts which are circumferentially and evenly distributed, a cam is circumferentially fixed on the cam bushing through three evenly distributed bolts, a roller is mounted on a roller holder, the cam bushing is connected to the lower shaft in a threaded manner, and a lower split ring is clamped in the lower shaft through a serrated trough and is fixed through a lower retaining ring. By the arrangement, the lower shaft of the screw drill tool is enabled to generate soft axial impact with a certain frequency and stable in size, efficiency of rock breaking of a drill is improved, mechanical drilling rate is increased, and drilling cost is thereby lowered.

Owner:SOUTHWEST PETROLEUM UNIV

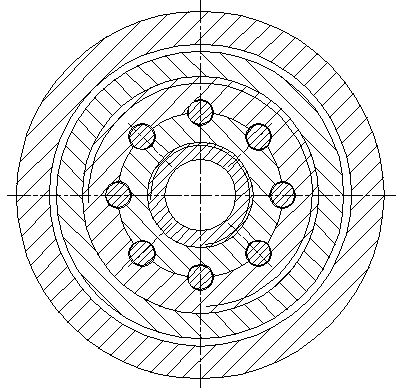

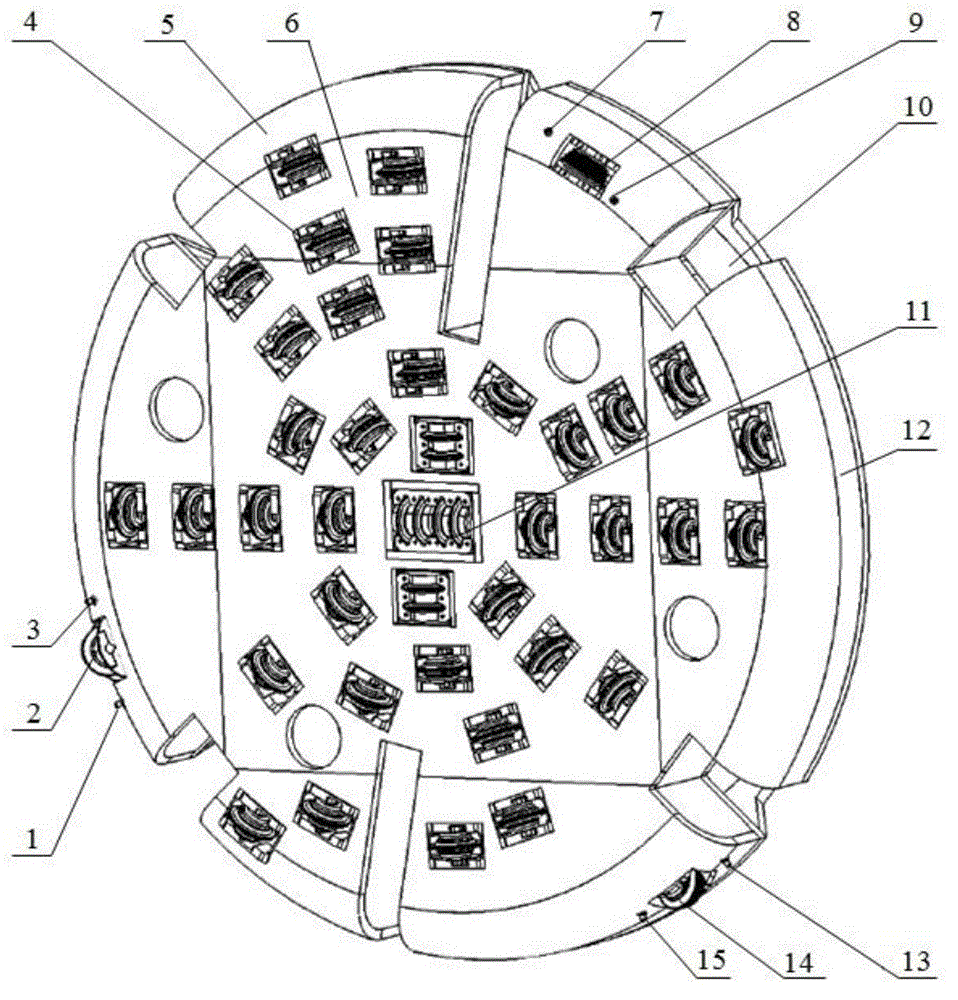

Multifunctional drill bit rock breaking experiment device and method capable of testing triaxial strength parameter of rock

ActiveCN107505207AIncrease profitShort timeMaterial strength using tensile/compressive forcesStress–strain curveRock sample

The invention discloses a multifunctional drill bit rock breaking experiment device capable of testing the triaxial strength parameter of rock. The device comprises a main body device, a pressure head structure, a confining pressure system, an acoustic emission system, a temperature control system and a pore material injection system. The device has the benefits as follows: the real temperature, crustal stress and pore pressure of a stratum can be simulated in a closed environment, a triaxial mechanical test and a drill bit rock breaking test can be completed simultaneously, a stress-strain curve of a rock sample, dynamic vibration of a drill bit and a drill column, bit pressure and influences of footage on the rock sample can be determined, an experiment basis is provided for research of mechanical properties of complex oil and gas reservoirs and drill bit rock breakage under multiple conditions, a rock breaking experiment can be conducted while conventional mechanical properties of the rock are tested, two experiments can be completed once after the designed temperature and pressure conditions are met, the total time consumption is reduced, and the utilization rate of underground rock cores can be effectively increased.

Owner:SOUTHWEST PETROLEUM UNIV

Static blasting construction method for highway tunnel

The invention discloses a static blasting construction method for a high-ground-stress soft-rock highway tunnel. The method comprises the steps of establishing of a tunnel excavation mode: a three-step method is used for excavation when surrounding rock is at the V level, and an upper and down step method is used for excavation when the surrounding rock is at the IV and III levels; cut hole construction: a diamond cutting mode and a wedge cutting mode are used for cutting holes according to different levels of the surrounding rock; rock breaking through splitting of a hydraulic splitter to form an excavation free face: the hydraulic rock splitter is used for splitting rock along a cut hole after construction of the cut hole to form the excavation free face for the next step; construction of an auxiliary hole and periphery holes of an upper step; construction of an auxiliary hole and periphery holes of a lower (middle) step; static blasting and de-slagging and hole periphery trimming; and circulation operation. According to the static blasting construction method, the rock breaking capacity and the rock breaking efficiency are high, high adaptability is provided for different surrounding rock, the technology can be implemented easily, the construction is safe and reliable, and the method is particularly applicable to highway tunnels with special construction requirements.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +2

Rock breaking seismic source and active source three-dimensional seismic combined advanced detection system using tunnel boring machine

A rock breaking seismic source and active source three-dimensional seismic combined detection system uses a tunnel boring machine for three-dimensional seismic combined detection by active seismic source and rock breaking seismic source methods. Long-distance advanced prediction and position recognition of a geological anomalous body are realized using the active source seismic method. Machine construction is adjusted and optimized according to the detection result; real-time short-distance accurate prediction of the body is realized using the cutter head rock breaking vibration having weak energy but containing a high proportion of transverse wave components as seismic sources and adopting an unconventional rock breaking seismic source seism recording and handling method. An area surrounding rock quality to be excavated is represented and assessed. A comprehensive judgment is made to the geological condition in front of the working face with the results of active source and rock breaking seismic source three-dimensional seismic advanced detection.

Owner:SHANDONG UNIV

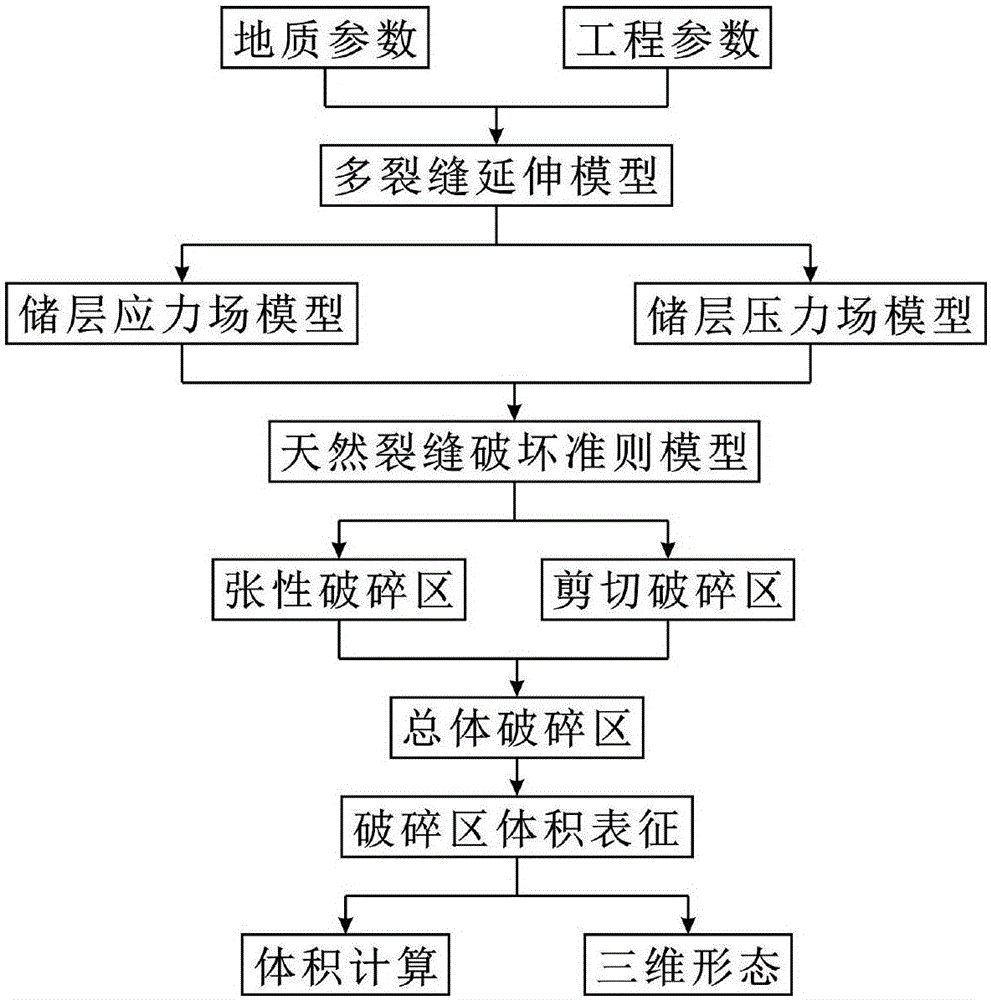

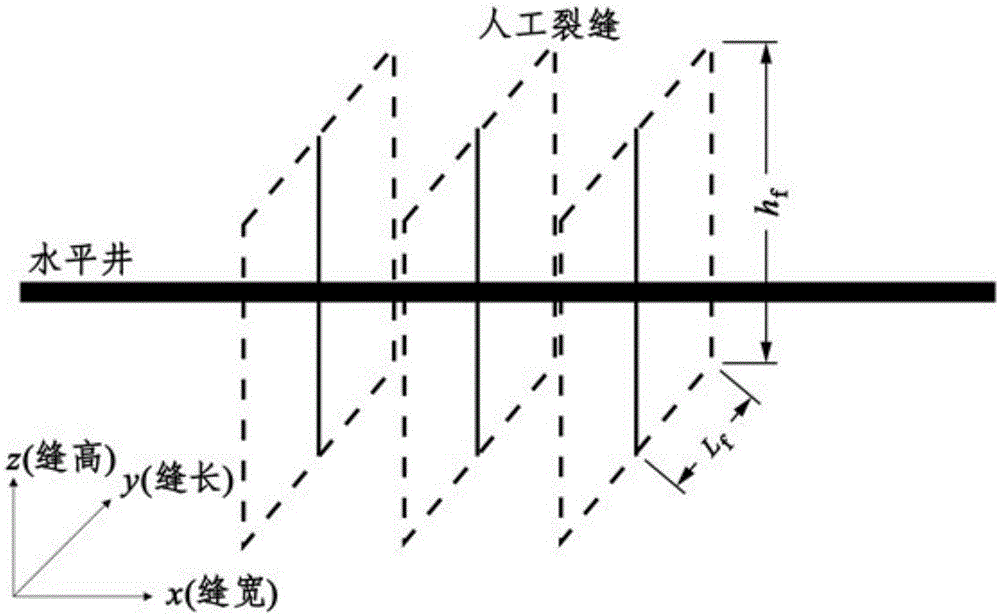

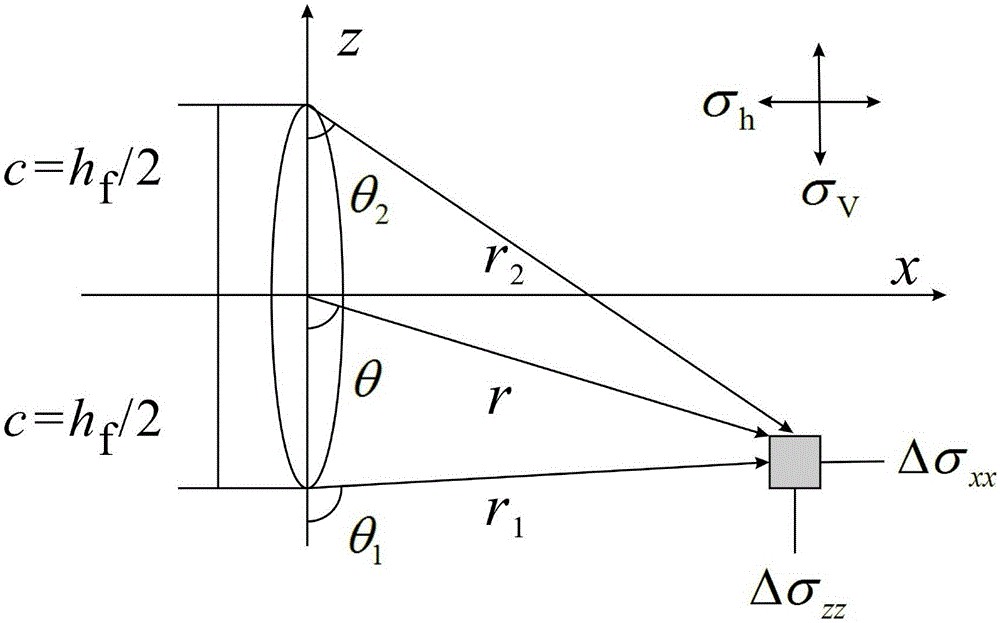

Calculating method for size of fracturing and broken region of horizontal well for shale

ActiveCN105019877AAccurate quantitative evaluationSolve problems that cannot be widely promoted and appliedFluid removalCalculation methodsPoromechanics

The invention discloses a calculating method for the size of a fracturing and broken region of a horizontal well for shale. The calculating method comprises following steps of: A, utilizing the theory of crack propagation available to establish a hydraulic fracture extension model during a shale fracturing process; B, utilizing the theory of rock mechanics available to establish a model for stress field variation during a shale fracturing process; C, utilizing the theory of seepage mechanics available to establish a model for pressure field variation during a shale fracturing process; D, utilizing the rock breaking theory available to establish a rule model for natural fractures; E, combining the above four steps to calculate and represent the size of the fracturing and broken region by means of a calculation flow. The calculating method for the size of the fracturing and broken region of the horizontal well for shale has following beneficial effects: time and money spent on calculating the size of the broken region during fracture of the horizontal well for shale are saved so that the valuation of the size of the fracturing and broken region can be extensively prompted and applied.

Owner:SOUTHWEST PETROLEUM UNIV

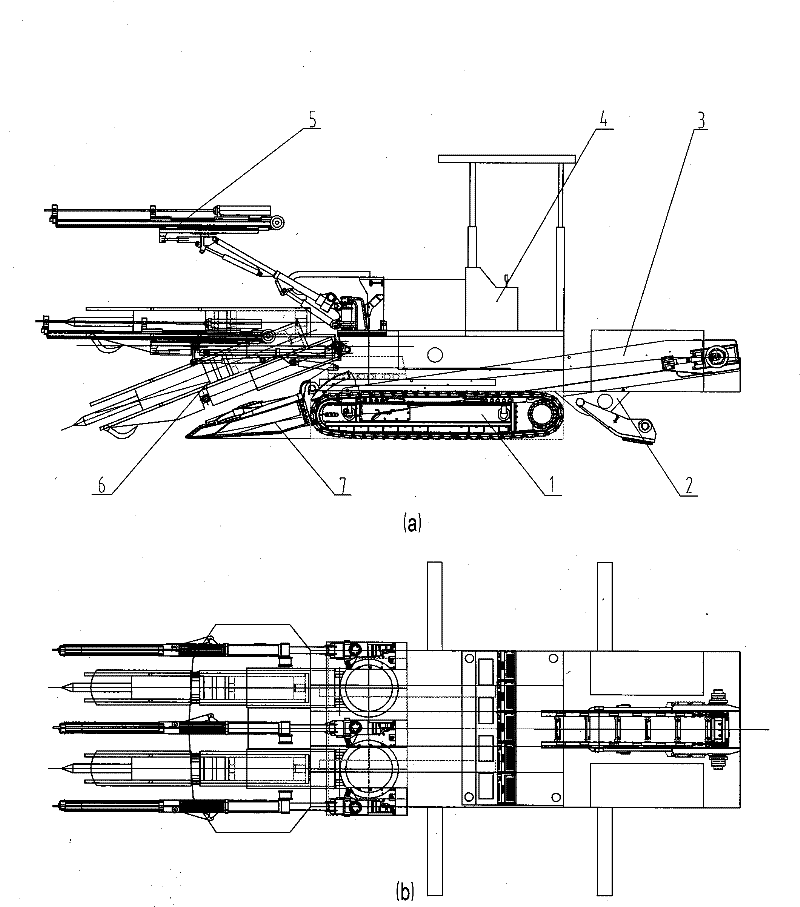

A hard rock hydraulic crushing roadheader

The invention relates to hard rock excavation equipment, in particular to a hard rock hydraulic crushing type excavation machine. It integrates the functions of drilling, rock breaking, material collection, transportation, walking and dust removal, and can realize fast and efficient excavation of all-rock roadways above f10 and above. The roadheader includes a running part, a rear support part, a transport part, a main body part, a rock drilling part, a rock breaking part and a shoveling part. Part, the rear part of the body part is provided with a rear support part and a transport part. The invention can solve the problems of low operation efficiency, harsh working environment and the like existing in the prior art. The whole equipment can realize the efficient, safe and high-quality rapid excavation of the whole hard rock roadway, replacing the more dangerous drilling and blasting method commonly used in hard rock excavation and the comprehensive excavation method with low efficiency in hard rock excavation.

Owner:SANY HEAVY EQUIP

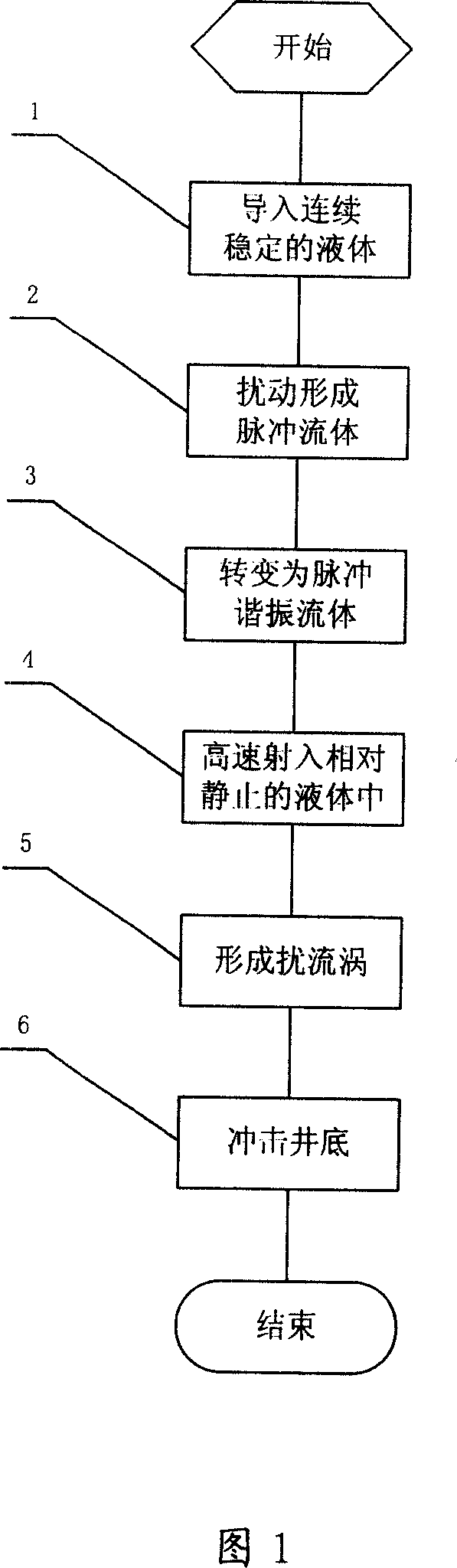

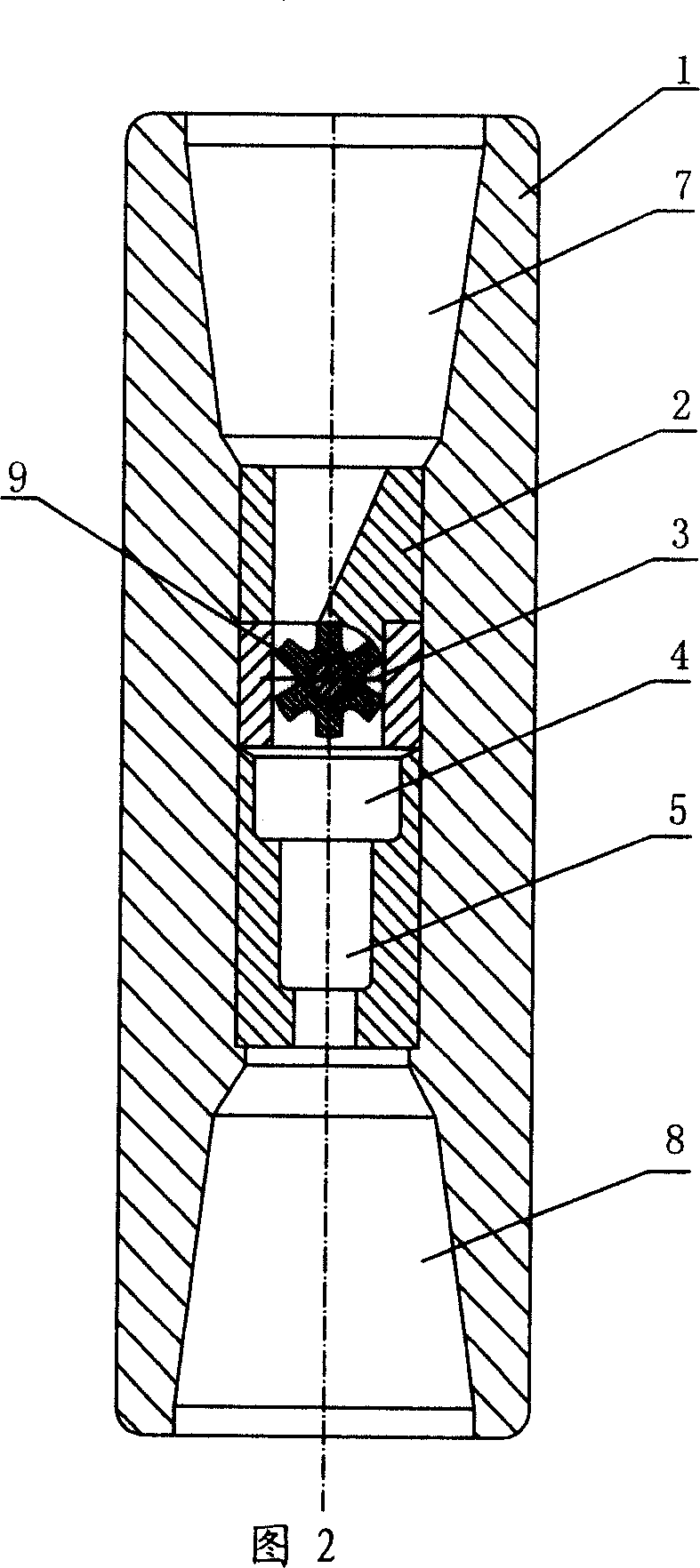

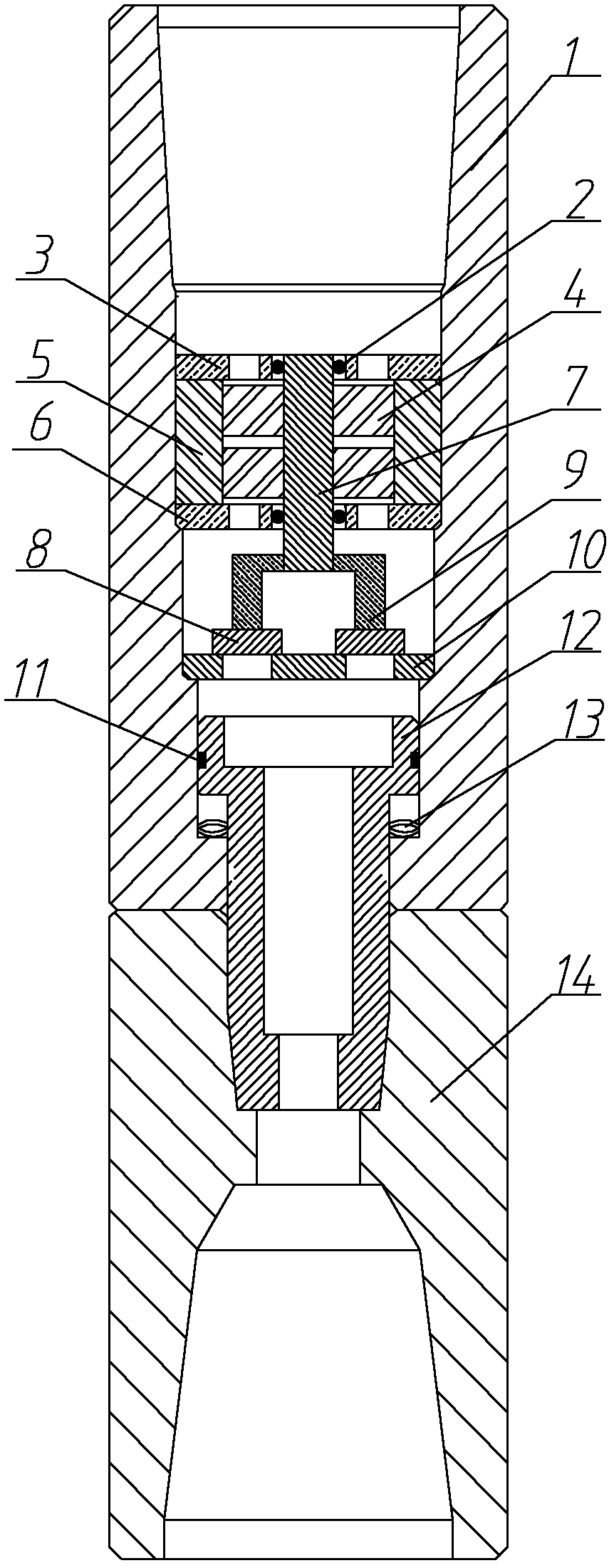

Waterpower pulse cavitation jet well drilling device, method and drill bit

InactiveCN101105115AExtended service lifeSolution to short lifeDrill bitsLiquid/gas jet drillingResonance oscillationCavitation

The invention discloses a hydraulic pulse drilling device with cavitation jet, which comprises a columnar body, wherein a fluid inlet section is provided at one end of the body, a fluid outlet section is provided at the other end of the body, and a fluid diversion portion for deviating the flow direction of the fluid, a pulse generator allowing the continuous fluid to generate pulse and a self-oscillation portion for allowing the fluid with pulse to generate resonance oscillation are sequentially provided between the fluid inlet section and fluid outlet section. The invention also discloses a self-resonating cavitation jet nozzle for drilling head, which improves the rock breaking effect of drilling head and rock cleaning effect at well bottom. The invention also discloses a hydraulic pulse drilling method with cavitation jet, which comprises during drilling work, converting continuous and stable fluid flow for impacting well bottom to pulse resonance flowing fluid; and injecting the pulse resonance flowing fluid into relatively static fluid to generate cavitation phenomena. The impact of well bottom with oscillating pressure reduces clip hold down effect, improves the rock cleaning and rock breaking capacity by jetting, and saves drilling cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

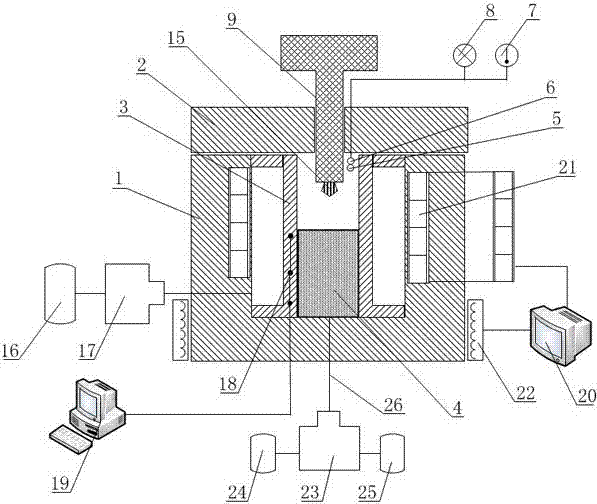

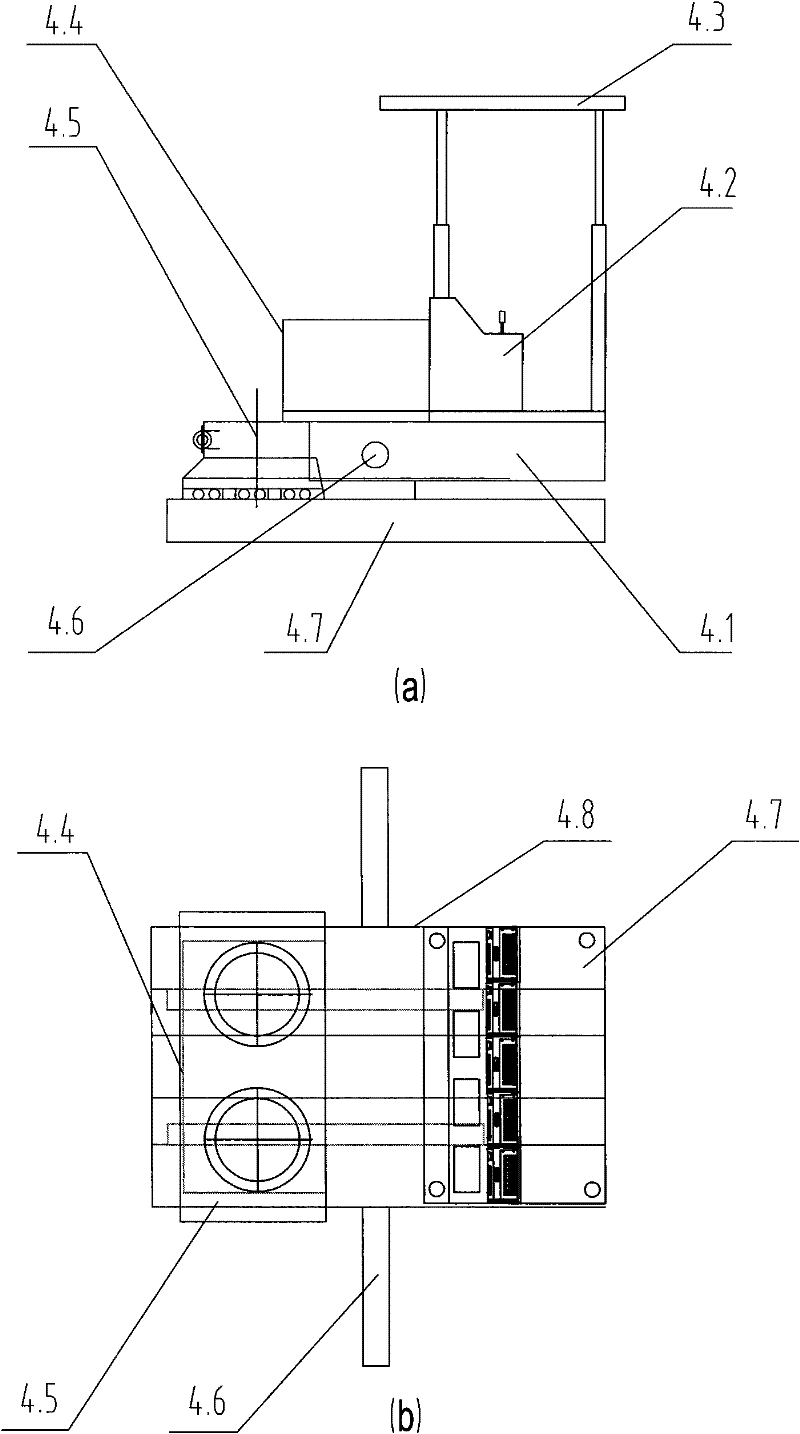

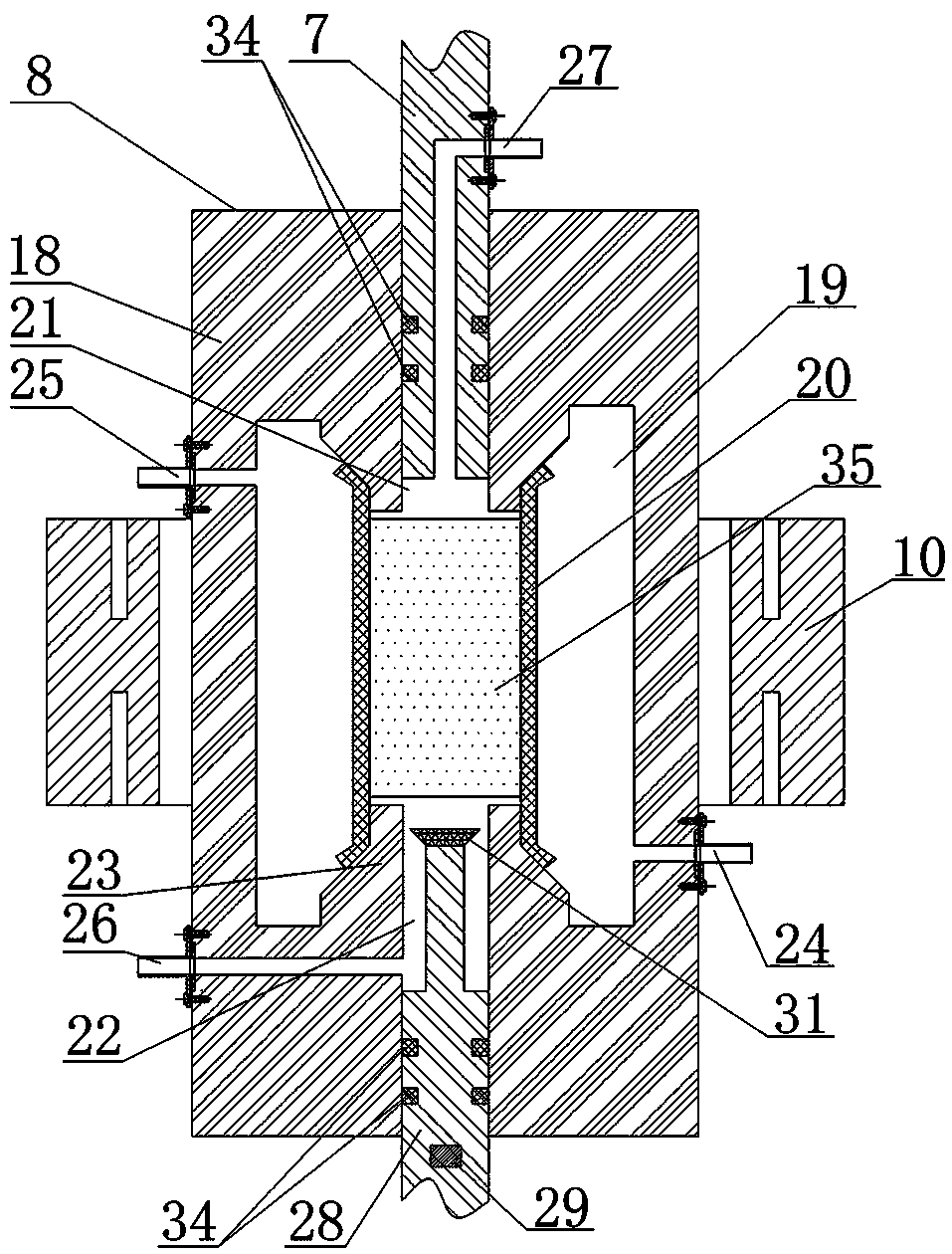

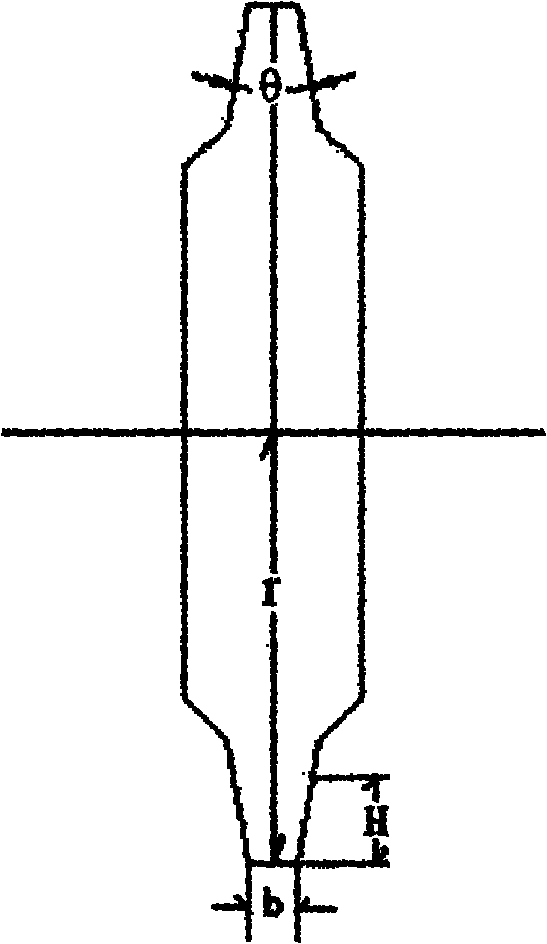

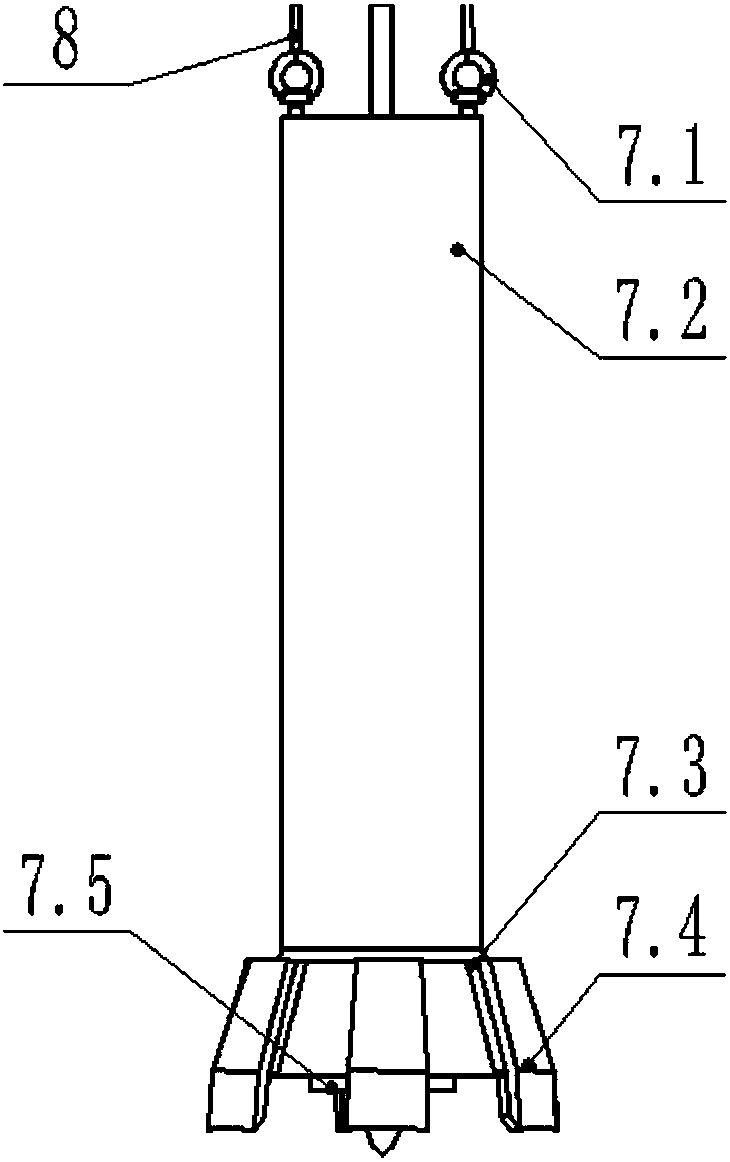

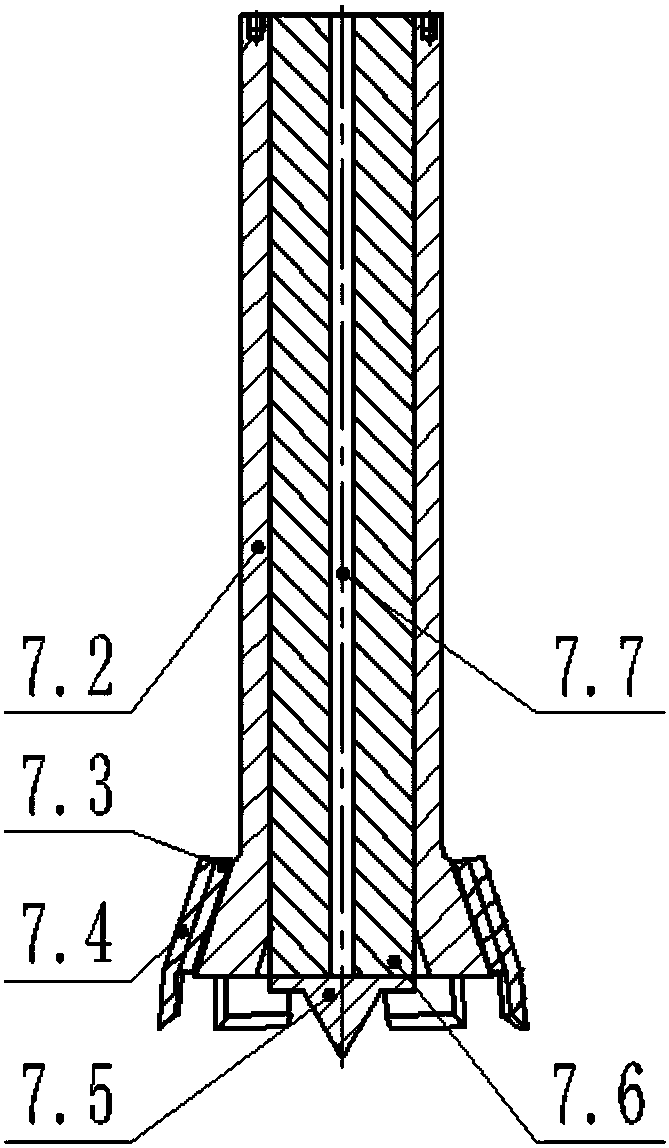

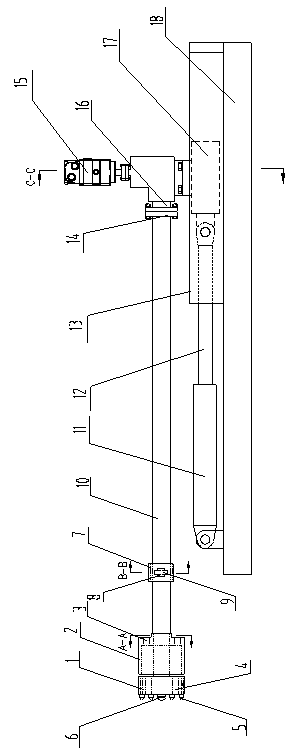

Method and device for testing rock drillability of deep well drilling and extra-deep well drilling

ActiveCN103806907AMeet temperature requirementsMeet pressure requirementsBorehole/well accessoriesExperimental testingWell drilling

The invention discloses a method and device for testing rock drillability of deep well drilling and extra-deep well drilling. The device comprises a machine frame (1), a high temperature and high pressure loading mechanism and a micro drill bit rock breaking drilling depth measurement mechanism, wherein the high temperature and high pressure loading mechanism and the micro drill bit rock breaking drilling depth measurement mechanism are arranged on the machine frame (1). The device exerts confining pressure, pore pressure and fluid column pressure on rock samples in cavities in three axes, overburden pressure is exerted on the rock samples through a hydraulic pump, and therefore the high pressure environment of the stratum of the bottom of a well can be simulated, the relation between the drilling depth and the time is tested through a displacement sensor at the position of a micro drill bit, optimization of the drilling pressure, the rotating speed and the drilling fluid type and drilling machinery drilling speed prediction are achieved. The method and the device have the advantages that the requirements for the bottom hole temperature and the pressure can be met in the deep well drilling process and the ultra-deep well drilling process, the function of testing multiple sets of rock drillability values through a single time of experimental testing of deep well drilling is achieved, the efficiency of the single time of experimental testing is greatly improved, and experimental cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

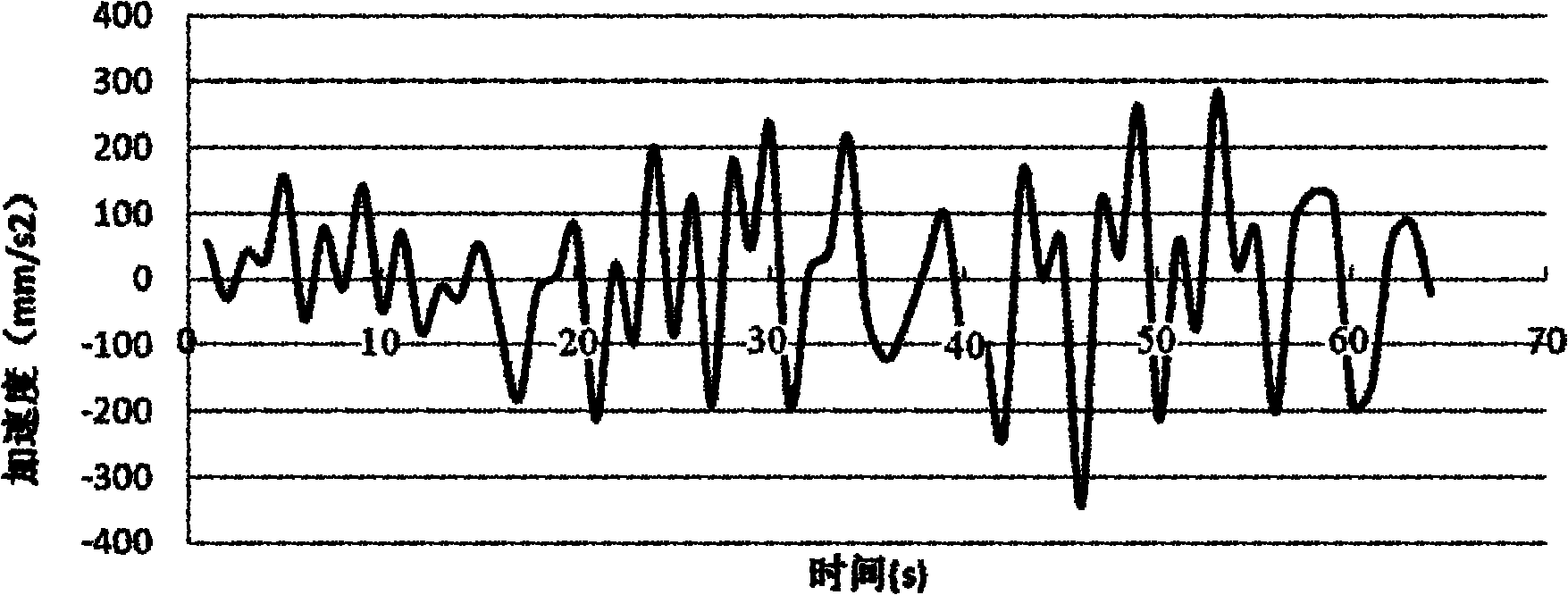

Calculation method for predicting wear amount of disc hob of roadheader

InactiveCN102278961ASimple data calculation and processingLife expectancyMeasurement devicesSpecial data processing applicationsEngineeringProlongation

The invention discloses a heading machine disc cutter wear extent pre-estimate calculating method. According to the method, a known heading machine structure parameter and a known technique parameter in a construction process are referred, and a corresponding relation between disc cutter rotation frequency and wear extent is directly established. The calculating method comprises the following steps: (1) measuring the disc cutter acceleration change in a rock breaking process, and obtaining disc cutter rotation frequency; (2) establishing a corresponding relation between the disc cutter rotation frequency and friction work; (3) establishing a corresponding relation between the disc cutter rotation frequency and the wear extent. The disc cutter wear extent at different times and different positions are obtained finally. According to the invention, an accurate disc cutter wear extent pre-estimate calculating formula is established, operation and data processing are simple, and a problem that determining the disc cutter wearing degree and predicting disc cutter life are needed in construction is solved. The invention provides a theory for optimization design of a cutterhead and cutterarrangement scheme and prolongation of disc cutter service life.

Owner:TIANJIN UNIV

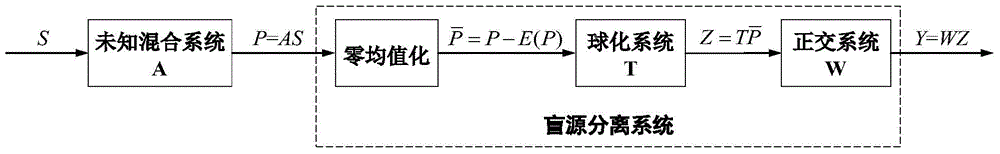

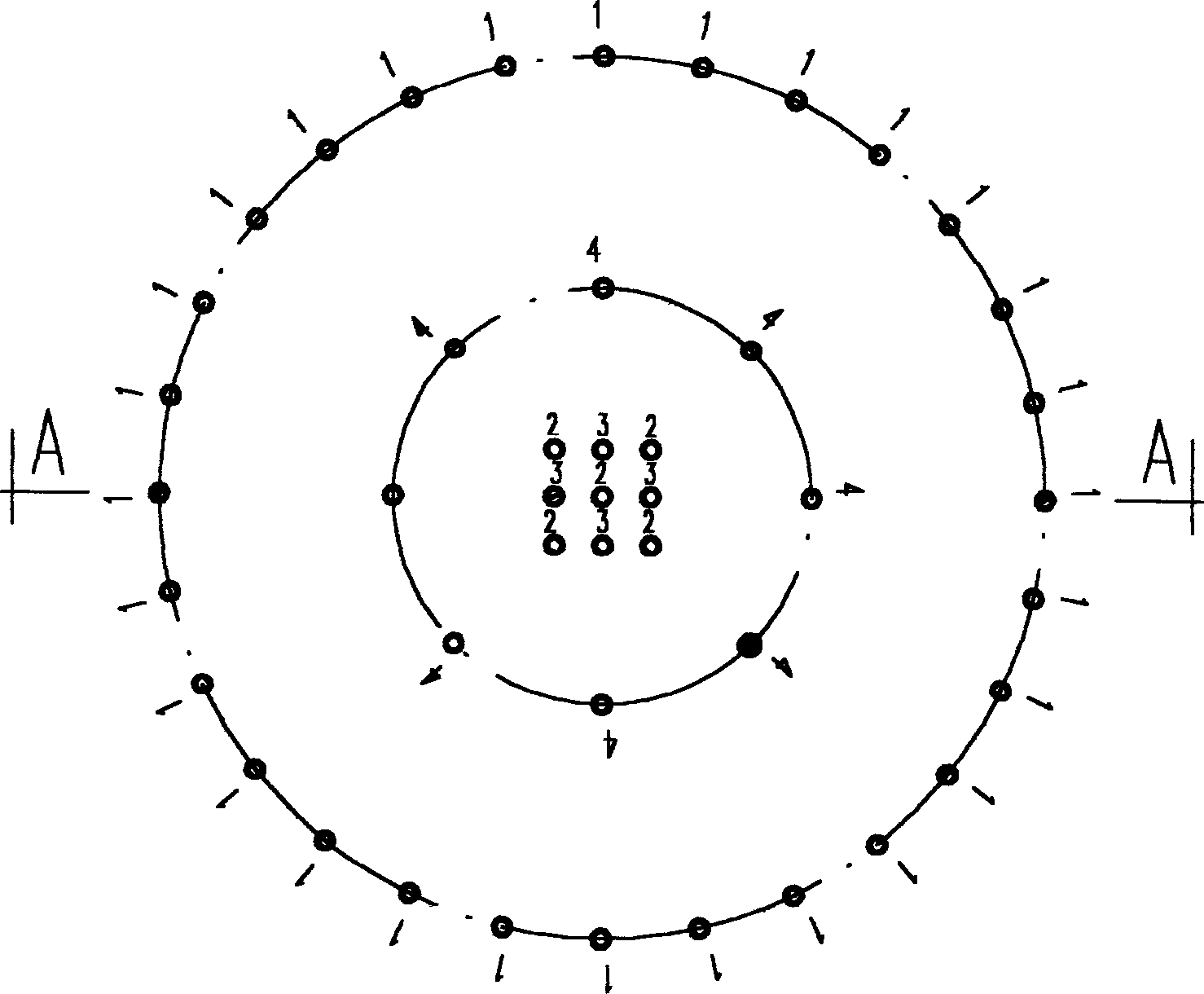

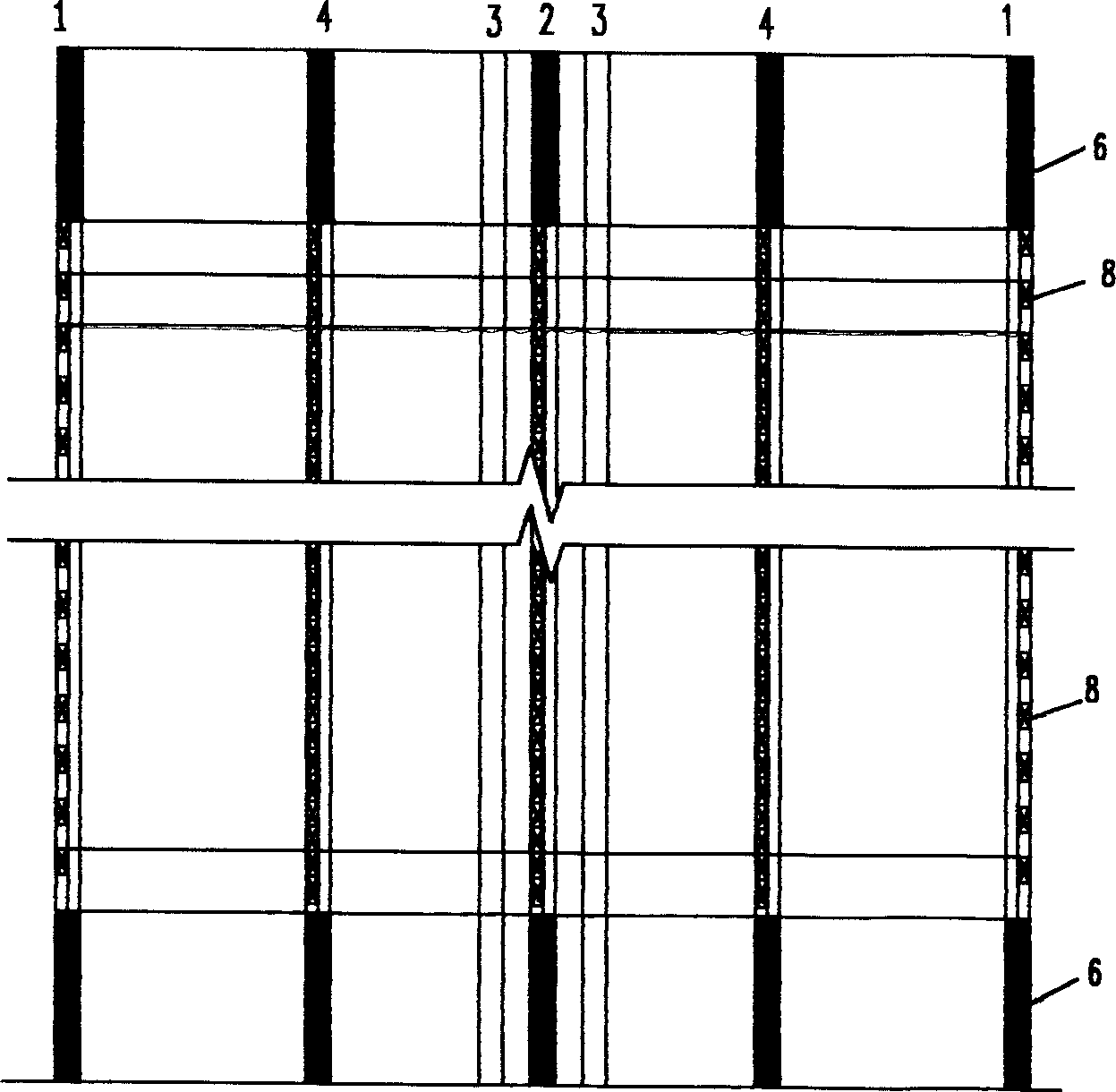

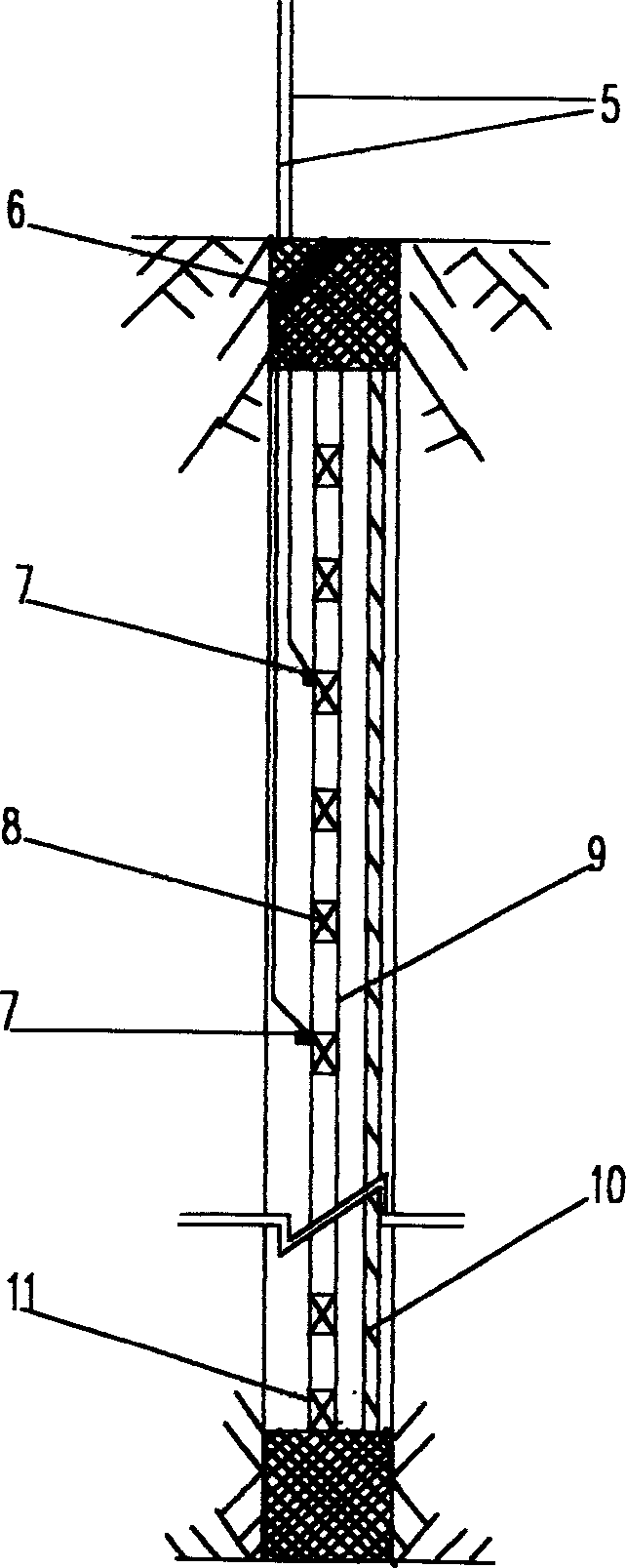

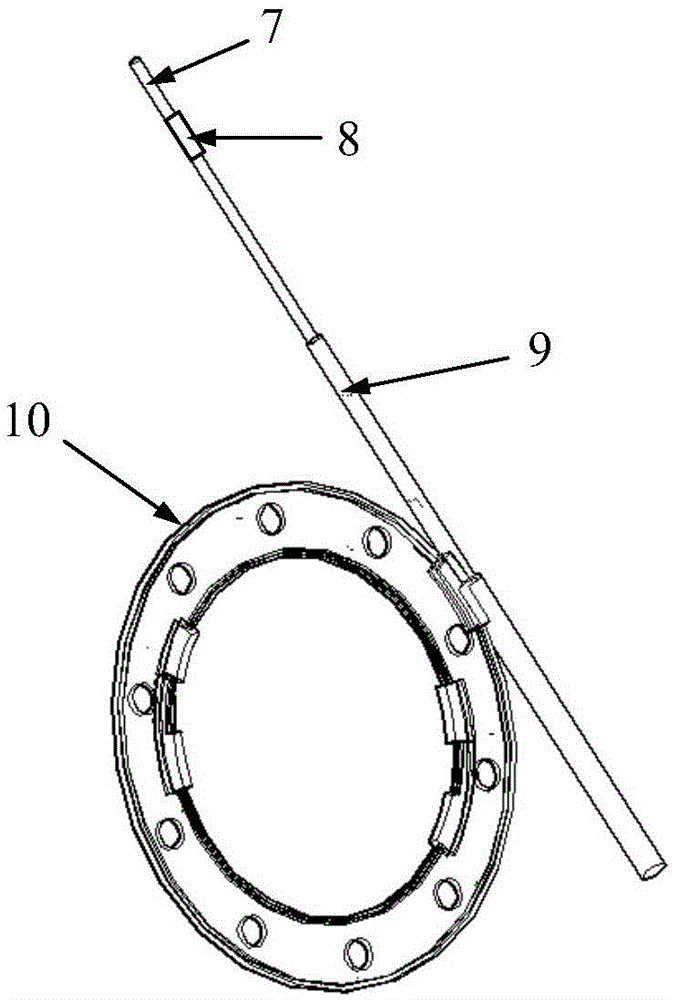

Tunnel boring machine rock breaking seismic source three-dimensional seismic advanced detection device and method

ActiveCN104678427ADoes not affect normal workflowQuick layoutSeismologySensor arrayIndependent component analysis

The invention discloses a tunnel boring machine rock breaking seismic source three-dimensional seismic advanced detection device and method. The device comprises a seismic source sensor array, a receiving sensor and a supporting device thereof, a noise sensor, and a multichannel seismic wave data collecting instrument, wherein the multichannel seismic wave data collecting instrument is connected with the seismic source sensor array, the receiving sensor and the noise sensor and receives seismic wave signals and noise signals of a noise source. Aiming at the special situation of the construction tunnel of a tunnel boring machine, the device adopts a seismic source signal blind source separation method based on an independent component analysis theory, a seismic source signal reconstruction method and a method for performing powerful interference signal degeneration on receiving sensor signals to finally obtain geological conditions in front of a working surface of the tunnel boring machine and the surrounding rock mass of a tunnel and corresponding mechanical parameters, can realize the advanced prediction of geological anomalous bodies, can further be used for evaluating the quality of surrounding rocks of a region to be excavated, and provides reference for the optimization of tunnel boring machine operating parameters and guarantee of construction safety.

Owner:山东百廿慧通工程科技有限公司

Bore construction method by bore explosion

The present invention provides a deep shaft one-step explosion well-forming construction method, and it is characterized by that three types of blast-holes can be drilled on the full face of the deepshaft, first type is of rock presplitting holes which are distributed along periphery of circular well to make peripheral smoothwall blasting, second type is of rock breaking holes which are distributed on the inner side of peripheral presplitting holes, and third type is of pulverizing holes with are distributed in the axis zone of shaft. The presplitting hole adopts non-coupled air column spaced charging powder, and the breaking hole and pulverizing hole adopt conventional non-coupled continuously-charging powder.

Owner:中国人民解放军工程兵第四十一旅

Coalbed methane horizontal well supercritical CO2 jet flow cavity construction and multi-segment synchronous deflagration fracturing method

InactiveCN105625946AAids in stress unloadingImprove permeabilityLiquid/gas jet drillingFluid removalHigh energyHigh pressure

The invention relates to a coalbed methane horizontal well supercritical CO2 jet flow cavity construction and multi-segment synchronous deflagration fracturing method. The method comprises the following steps: completing coalbed methane horizontal well drilling, introducing a coiled tubing into an supercritical CO2 rotary jet flow rock-breaking device to the bottommost end of a shaft, and performing pore broadening on the shaft by using an underground supercritical CO2 rotary jet flow rock-breaking device in order to form a cylindrical pore which is 1.0-1.5 meters in diameter and is 2-4 meters in length underground; after first-segment pore broadening is finished, lifting a rotary jet-flow tool to perform second-segment pore broadening work and so forth to finish pore broadening work of all well segments, wherein the segment distances are 80-100 meters; putting a solid explosive into a pore broadening cavity by using the coiled tubing after finishing pore broadening, and introducing a screen pipe; lastly, pressurizing by using a ground high-pressure CO2 pump to ignite the explosive, and mixing generated high-energy gas with a supercritical CO2 fracturing coalbed. By adopting the method, a plurality of complex volume cracks can be generated in the coalbed, explosive fracturing contributes to coalbed stress unloading after pore broadening, and the coal rock permeability can be improved effectively, so that the yield of a coalbed methane horizontal well is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

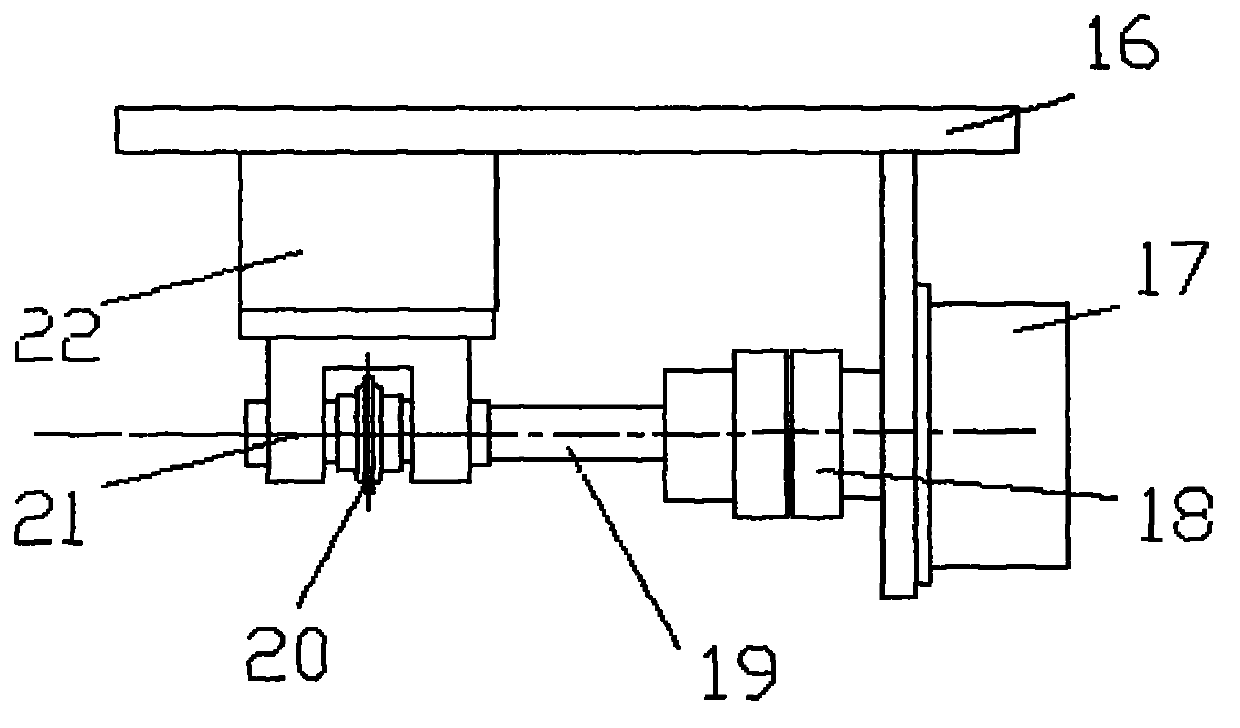

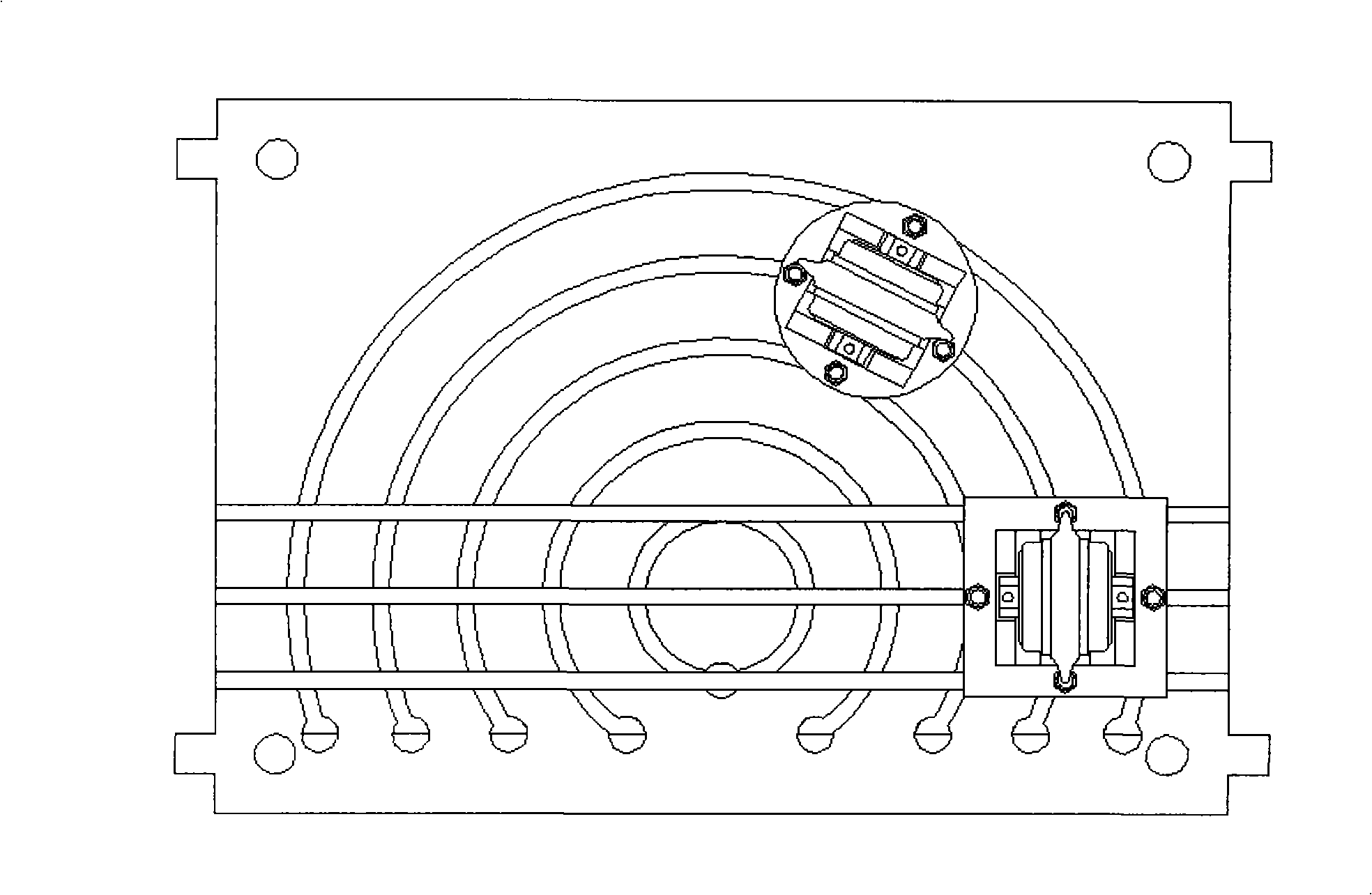

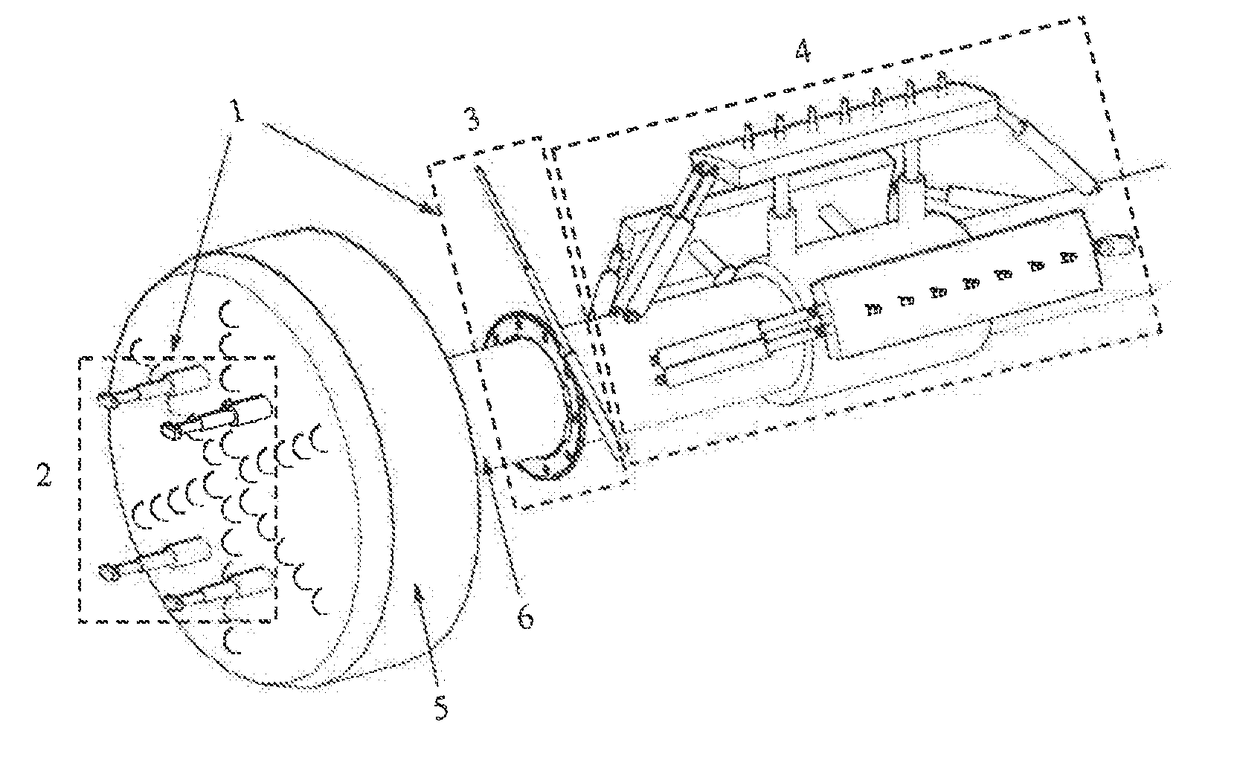

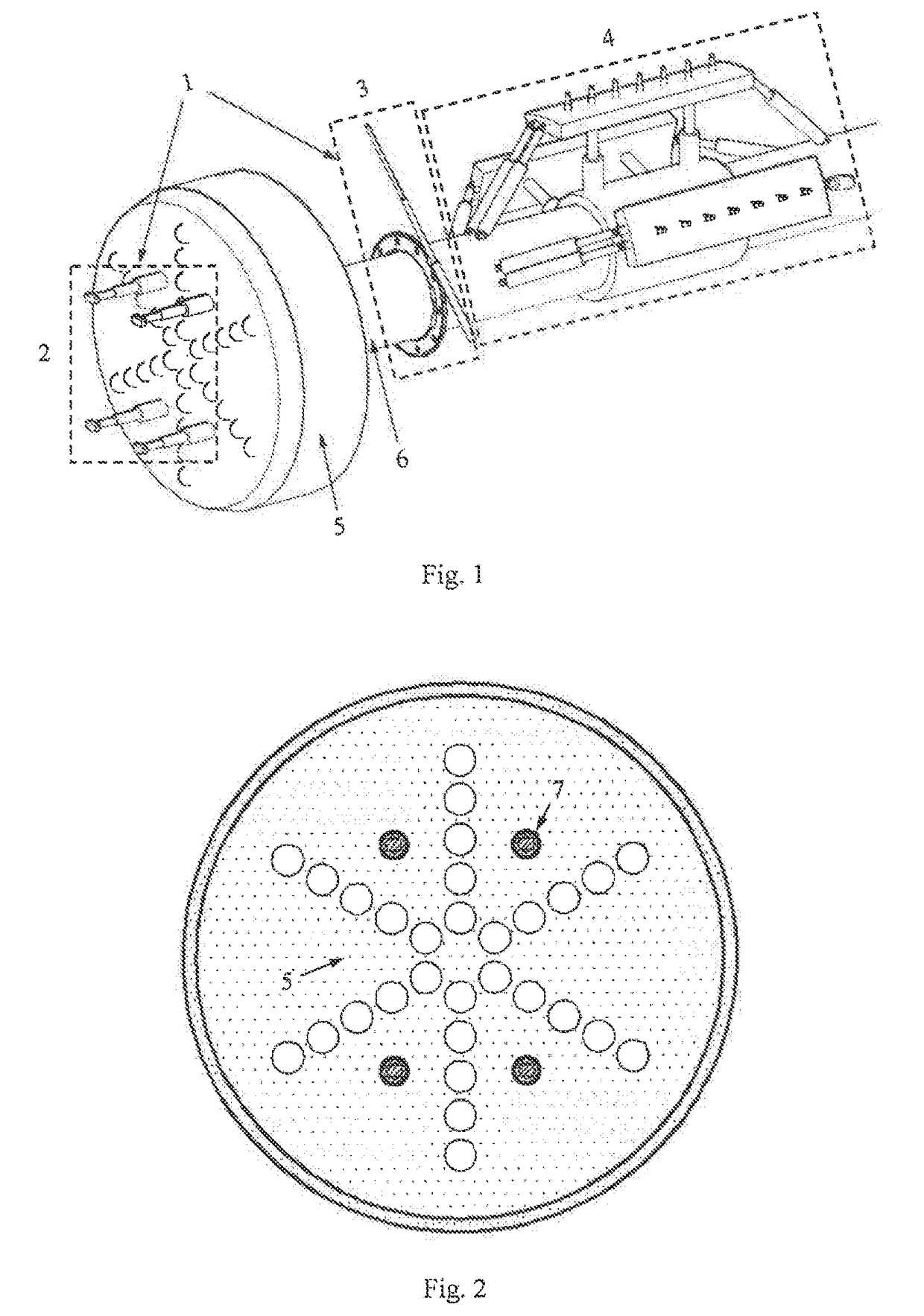

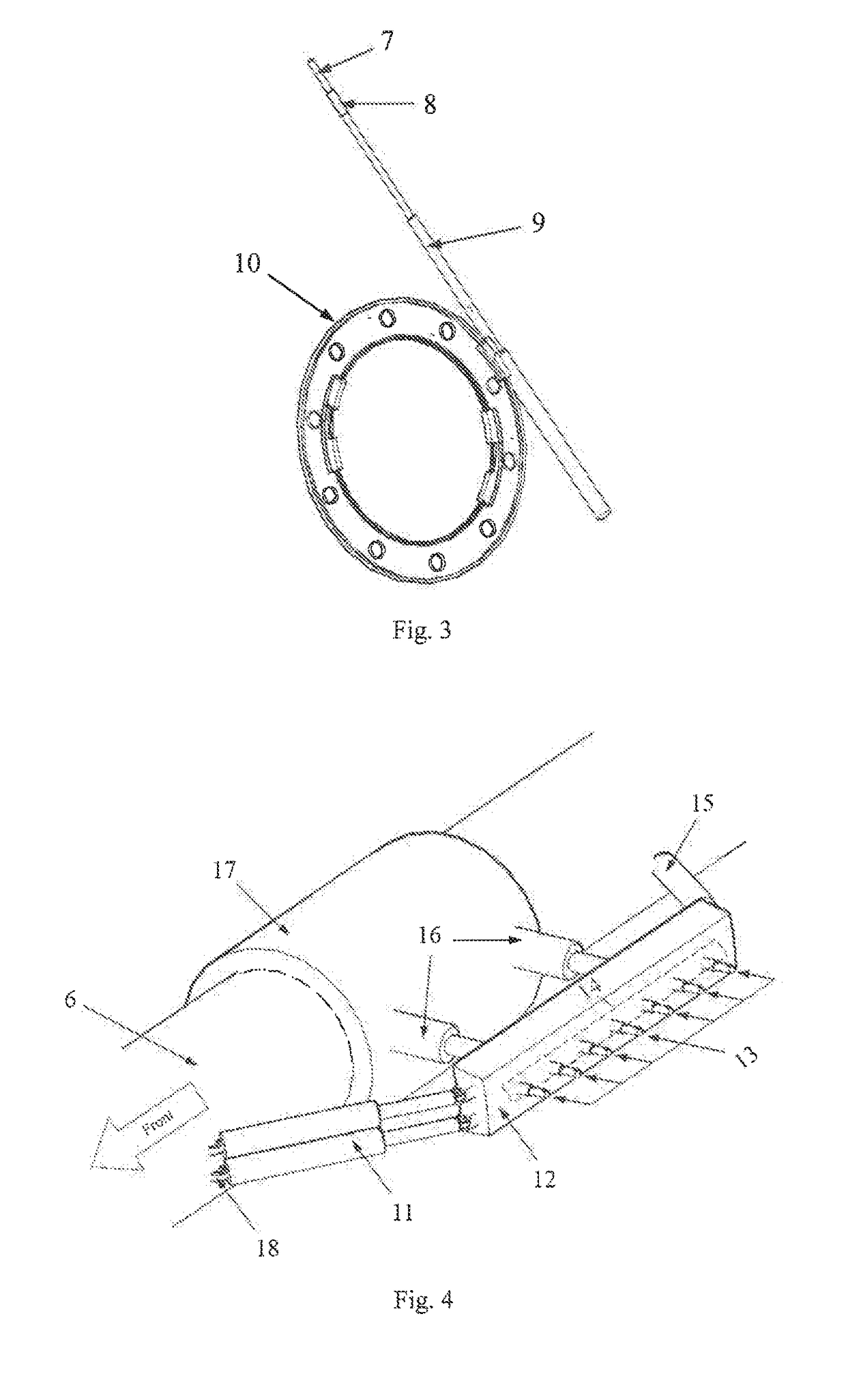

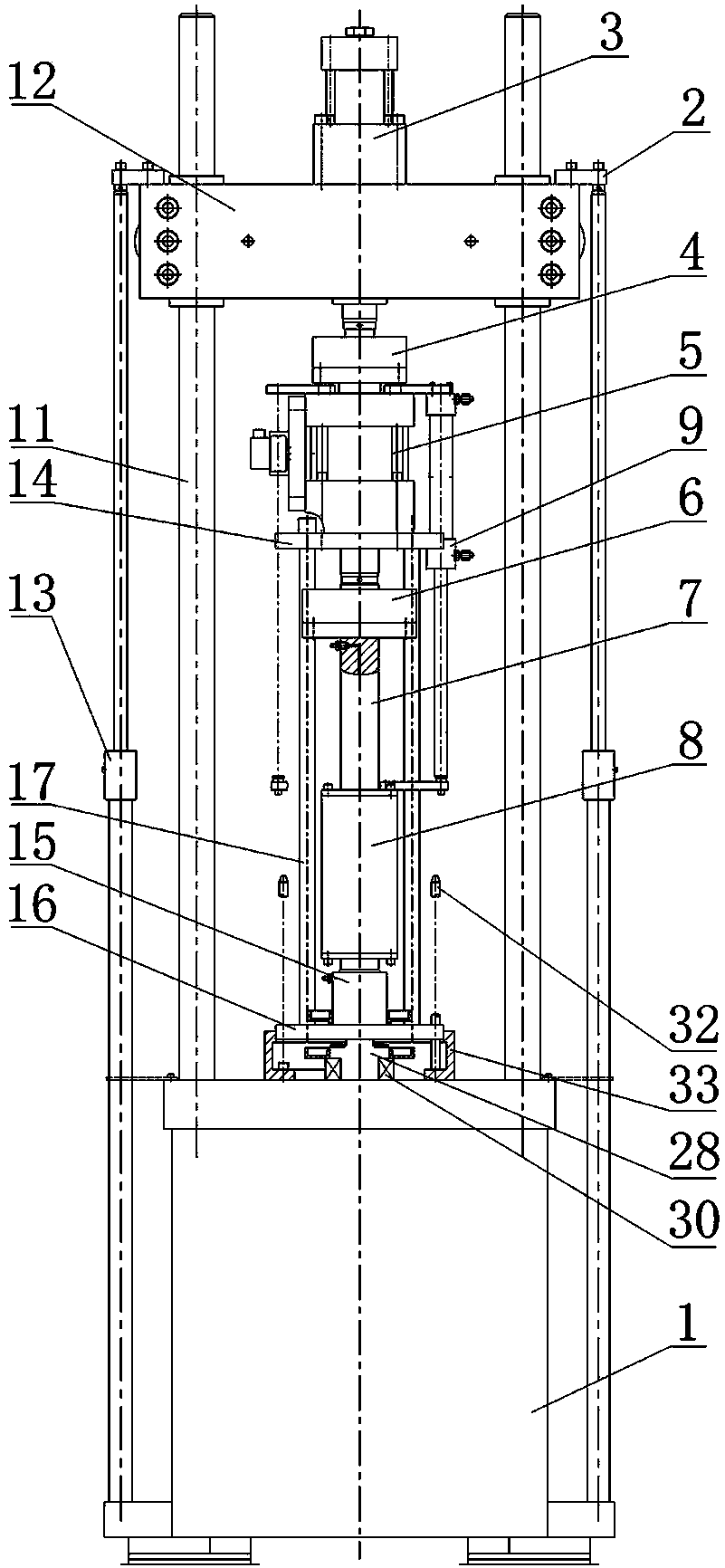

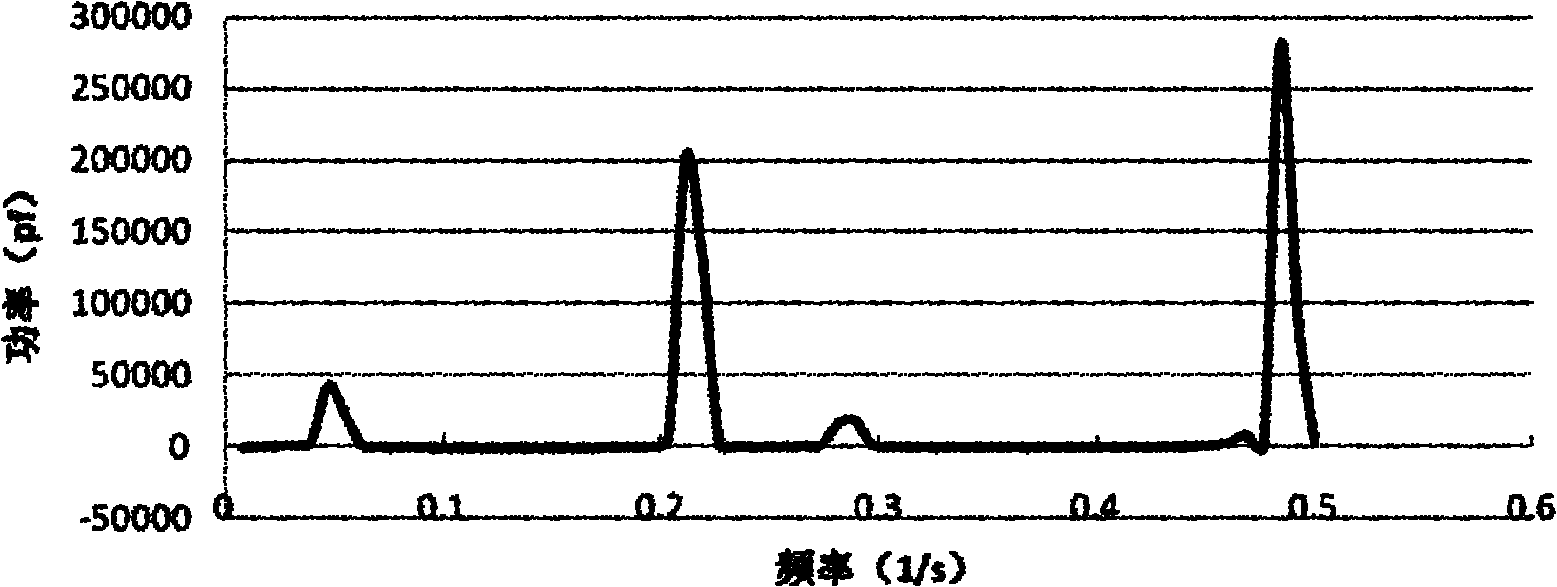

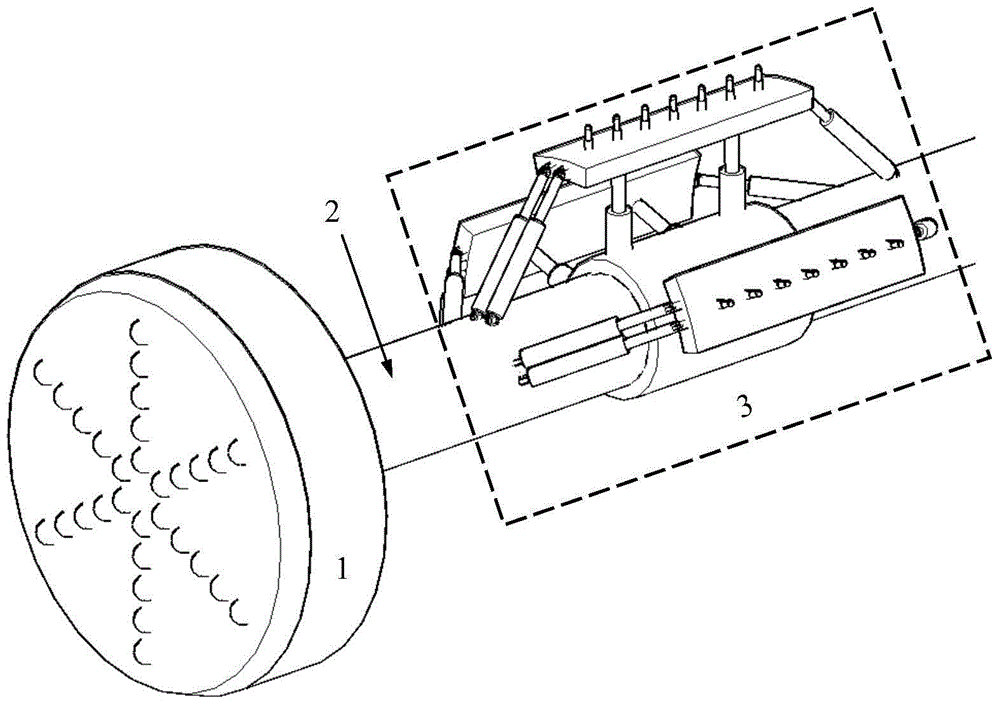

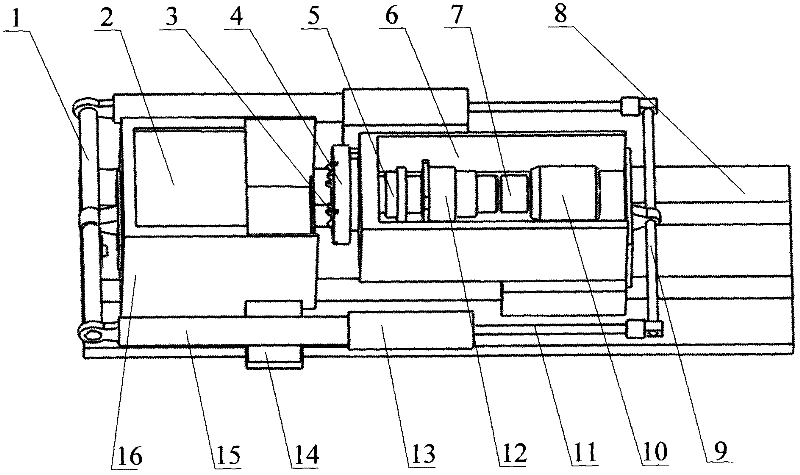

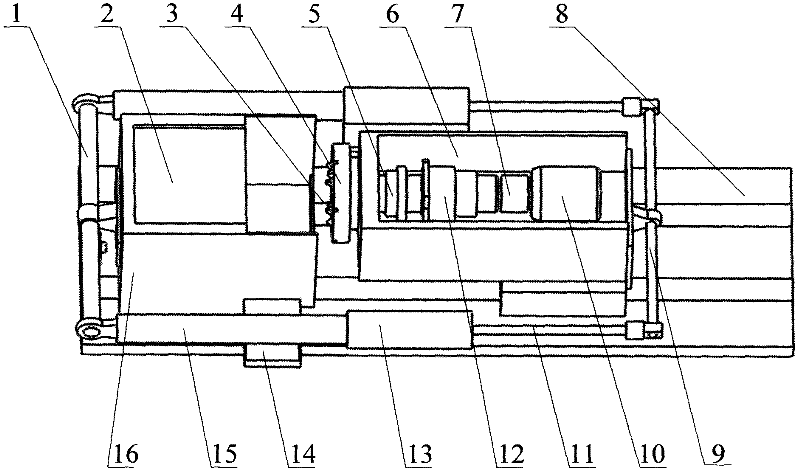

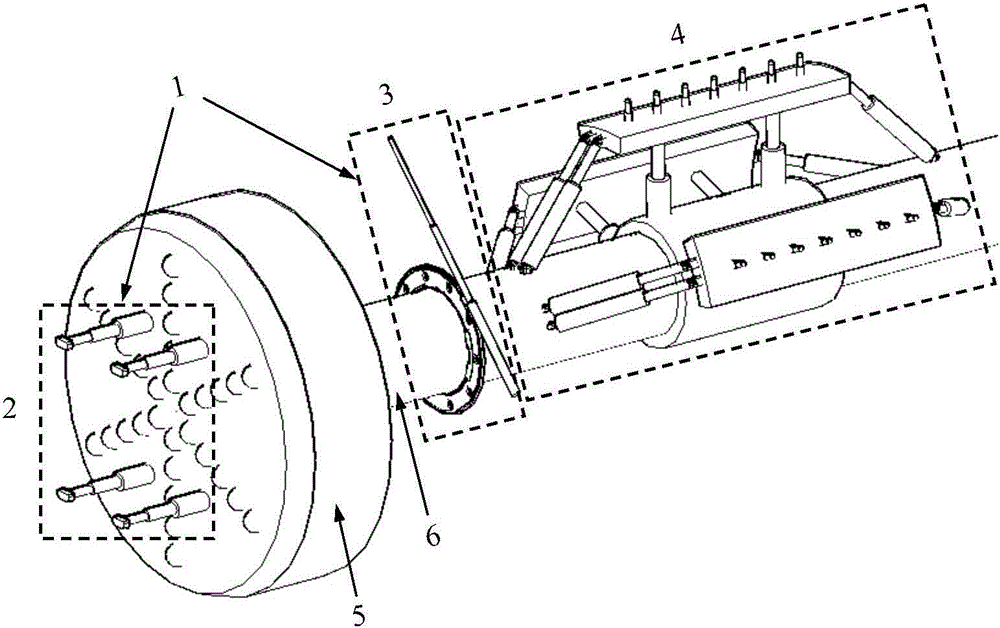

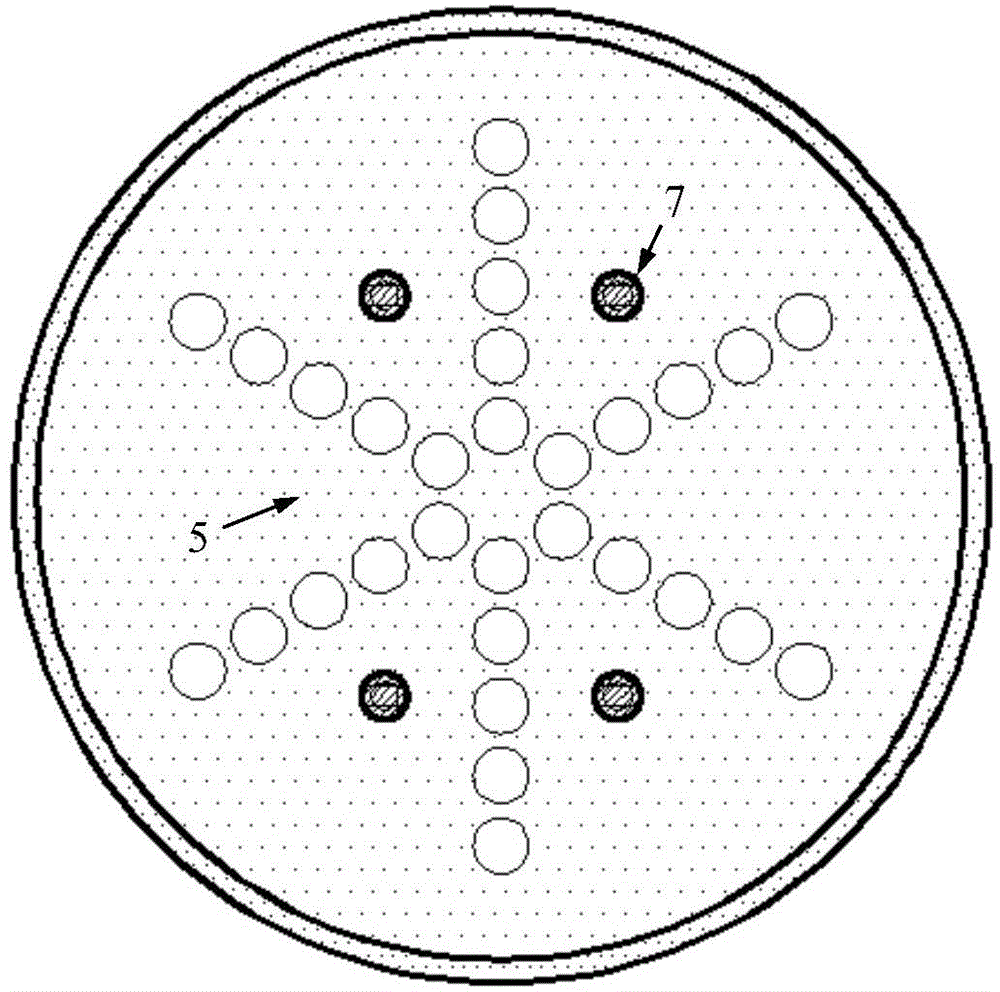

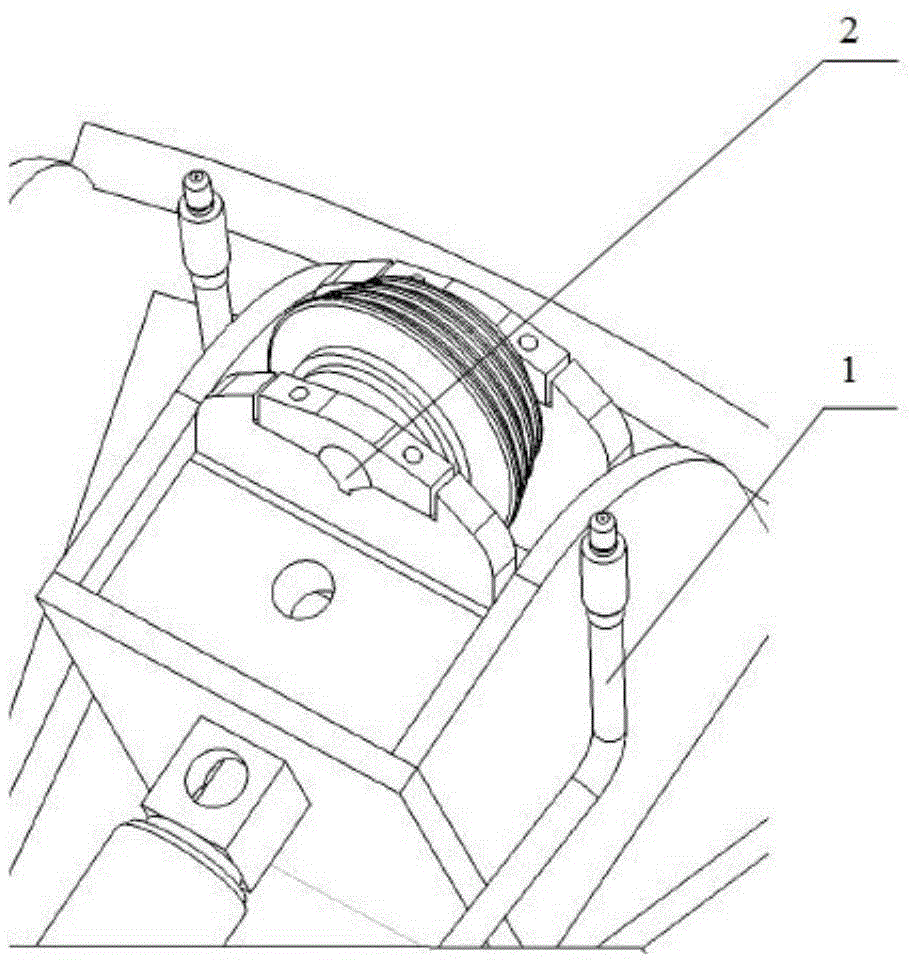

TBM rock breaking test apparatus

ActiveCN102359919AThere is no fixed problemImprove reliabilityMachine part testingInvestigating abrasion/wear resistanceCouplingEngineering

The TBM rock breaking test apparatus provided by the invention comprises a wheel box (6), a rock box (16), a cutterhead (4) and a worktable (8). The wheel box is provided with a motor (10), a torque speed sensor (7) and a decelerator (12); two ends of the torque speed sensor are connected with the motor and the decelerator respectively; the decelerator is connected with the cutterhead arranged onthe wheel box; a cutter (3) is arranged on the cutterhead; and the wheel box and the rock box are slidingly connected with the worktable. A rear distance rod (1) is connected to an external side of the rock box; a front distance rod (9) is connected to an external side of the wheel box; thrust mechanisms are symmetrically arranged on the worktable on two sides of the rock box and the wheel box; rear ends of the thrust mechanisms are connected with the rear distance rod, and front ends of the thrust mechanisms are connected with the front distance rod; the wheel box and the rock box are pushedto simultaneously carry out compressing or loosening movement on the worktable to realize tool feed and retracting. The apparatus can simulate real working process of the cutter to measure a plurality of key parameters of the cutter, such as cutting force, axial thrust, penetration and cutter space.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

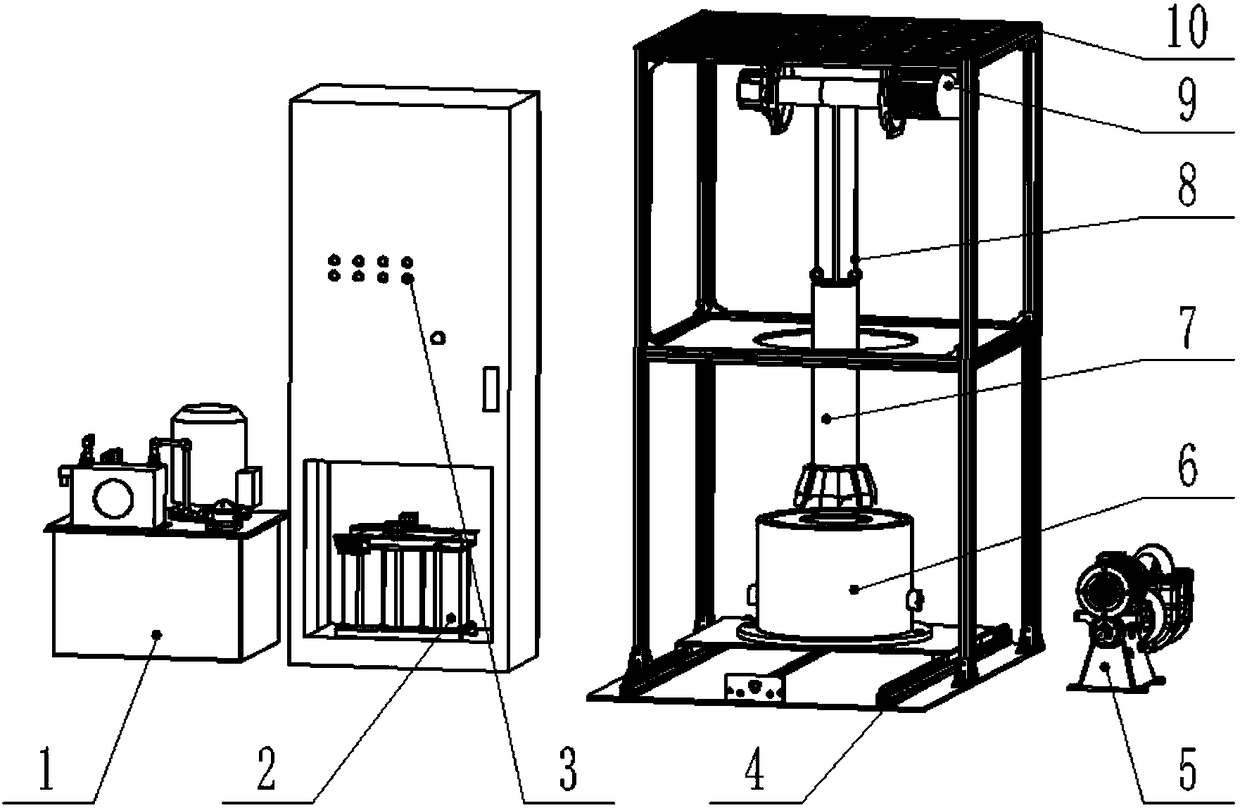

Electric pulse rock-breaking dill bit and experimental facility thereof

ActiveCN108222838AImprove energy efficiencyImprove drilling qualityMachine part testingDrill bitsLow voltageElectrical impulse

The invention discloses an electric pulse rock-breaking dill bit and an experimental facility thereof. The electric pulse rock-breaking experimental facility comprises a confining pressure pumping station, a pulsed power supply, a PLC control device, a confining pressure cylinder horizontal-moving device, a water inlet and outlet pump, a confining pressure cylinder assembly, a high-pressure electric pulse rock-breaking drill bit body, and the like. The high-voltage pulsed power supply is used for transmitting high-voltage pulse electricity from a high voltage electrode to a low voltage electrode through a cable, the high-voltage pulse electricity meeting certain conditions breaks through rocks firstly to generate a discharge channel, a plasma channel expands when heated, when the pressureexceeds the stress intensity of the rocks, and the rocks are broken and the high-voltage pulse discharge drilling is realized. The high-pressure electric pulse rock-breaking experimental facility cansimulate the high voltage environment of deep drilling in the earth, electric pulse drilling experiments carried out on high temperature and high pressure deep wells and ultra-deep wells are more close to actual drilling environments, experimental studies on the geometrical shape, distribution, spacing and electrode materials of electrodes of high-voltage electric pulse rock-breaking drill bit inthe deep wells and the ultra-deep wells can be realized, and the high-voltage pulse discharge drilling has broad development prospects.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

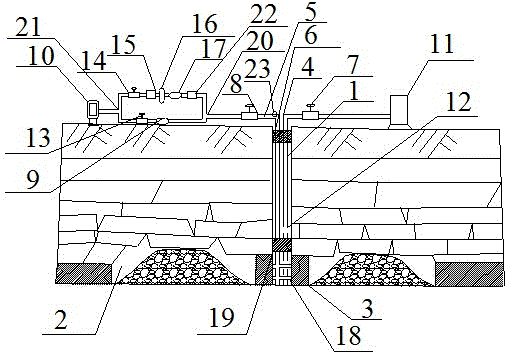

System and method for increasing drainage quantity of coal bed gas of ground well drainage goaf

ActiveCN105114038AExtend the effective service periodLow extractionFluid removalMining engineeringCoal pillar

The invention discloses a system and a method for increasing drainage quantity of coal bed gas of a ground well drainage goaf and belongs to the technical field of coal bed gas drainage. The method includes: constructing a drainage well between adjacent goaf holes, sequentially sending a drainage pipe and a flow injection pipe in, and arranging sealing sections I and II; opening a valve I and a valve III, injecting 30-60 MPa of supercritical CO2 into the flow injection pipe until pressure indicating number declines suddenly; opening a valve II to enable a ground drainage station to drain the coal bed gas, recording initial gas flow, repeating replacement of coal bed gas with CO2 when coal bed gas flow declines 30% of the initial gas flow again, and stopping coal bed gas drainage until the coal bed gas flow declines to 16% of the initial gas flow finally. By the system and the method, concentration of drained coal bed gas is increased effectively, and cost for separation and purification is lowered; supercritical CO2 jet flow is adopted to break coal columns, so that threshold pressure is low, breaking speed is high, no pollution is caused to a coal bed gas reservoir, and rock breaking efficiency can be improved substantially.

Owner:TAIYUAN UNIV OF TECH

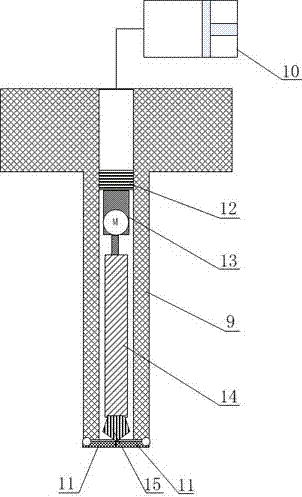

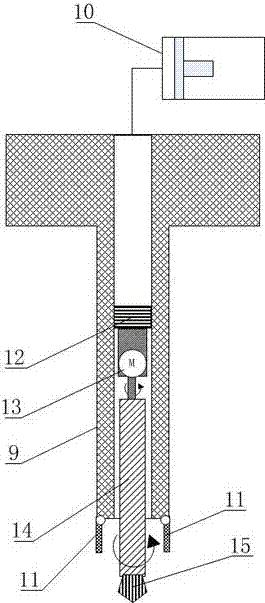

Resonant pulse vibrating drilling device

ActiveCN102191915ASolve efficiency problemsSolve the costLiquid/gas jet drillingBorehole drivesWell drillingHardness

The invention discloses a resonant pulse vibrating drilling device belonging to the technical field of drilling devices. The resonant pulse vibrating drilling device comprises a shell body, a system and a lower joint, wherein the system is arranged in the shell body; the upper part of the resonant pulse vibrating drilling device is connected with a well drilling pipe column, and the lower part ofthe resonant pulse vibrating drilling device is connected with a drill bit through the lower joint; the shell body is internally provided with a through hole for installing the system arranged in theshell body; the system arranged in the shell body comprises a power system, a pulse modulation system and a resonant pulse and reciprocating vibration system; and the lower joint is connected to the resonant pulse and reciprocating vibration system. The resonant pulse vibrating drilling device effectively solves the problems of low rock breaking efficiency and high well drilling cost of the traditional drill bit and is especially suitable for well drilling acceleration of a stratum with high deep hardness and grindability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

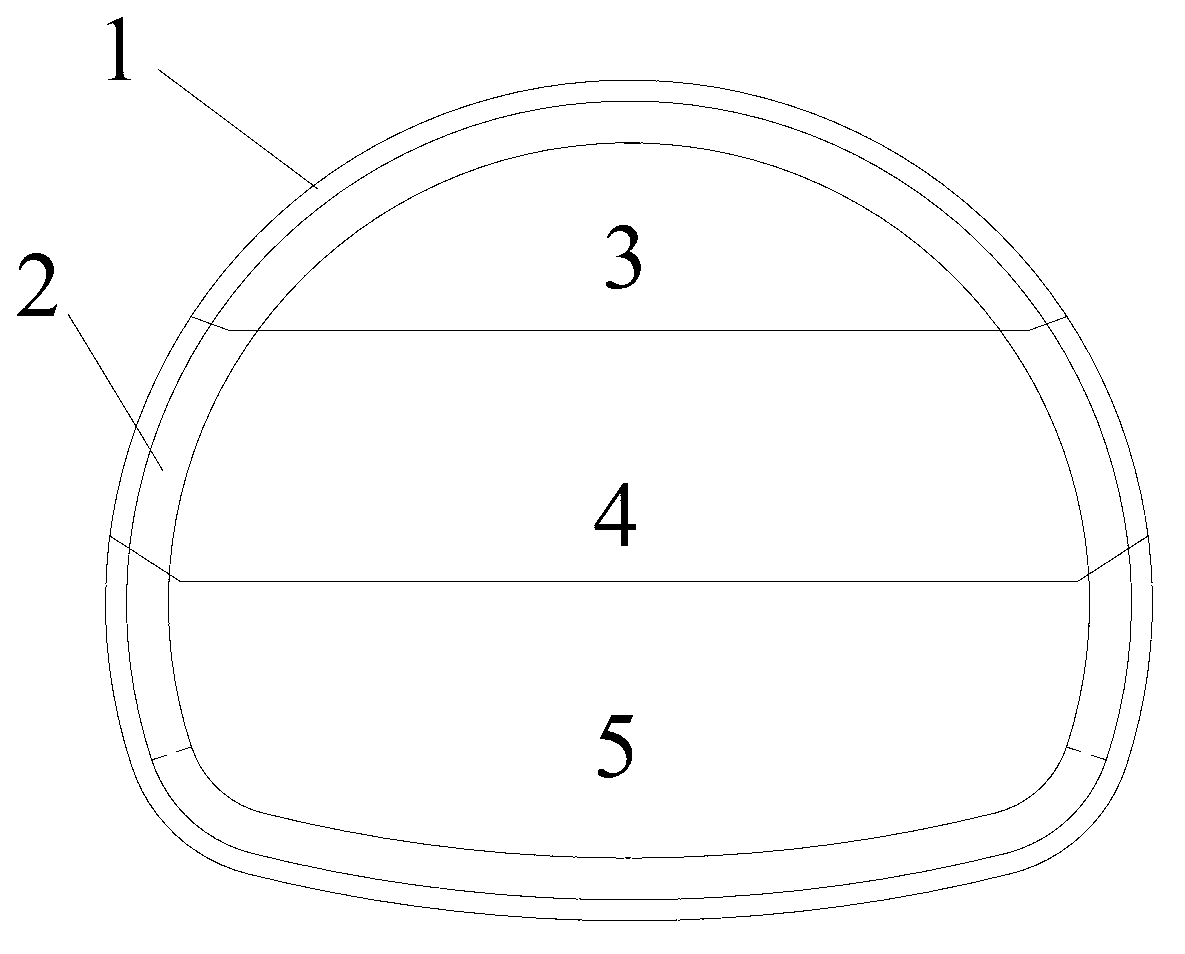

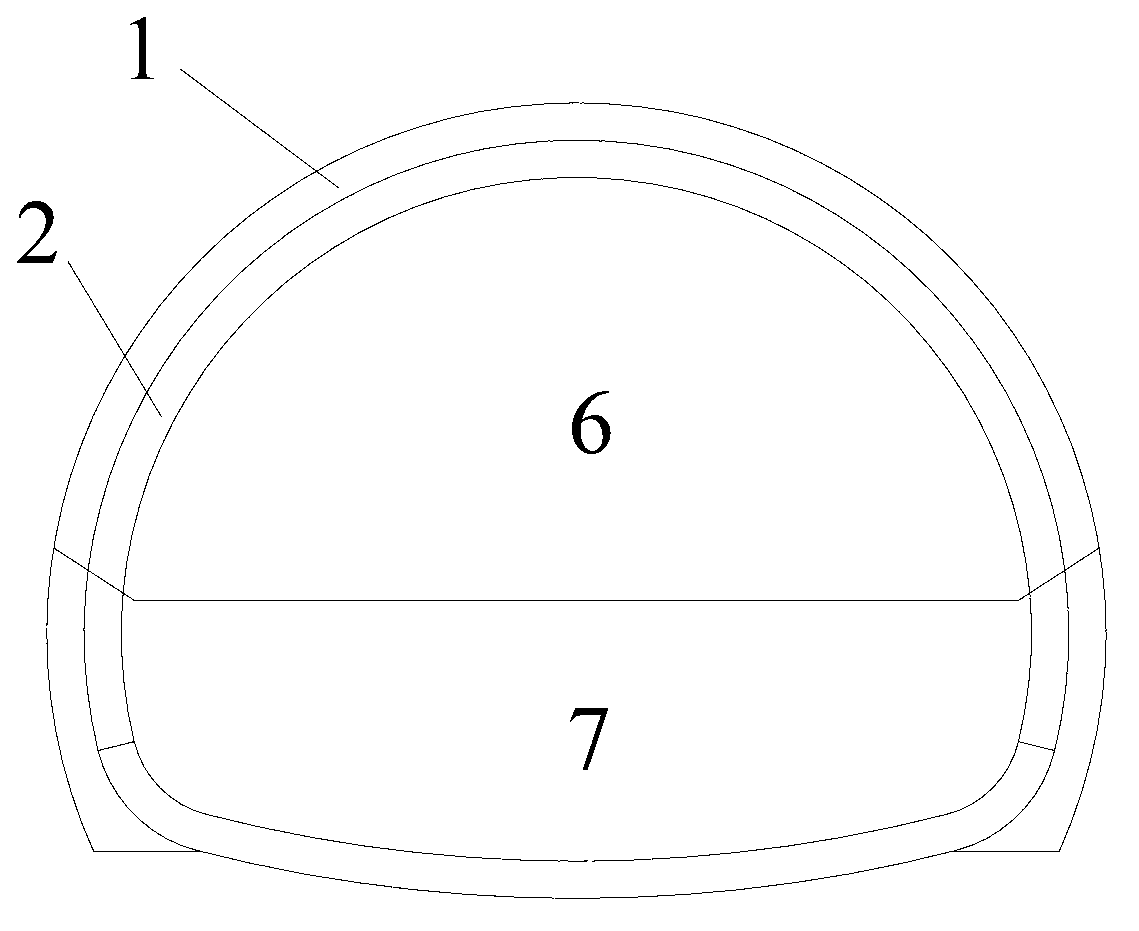

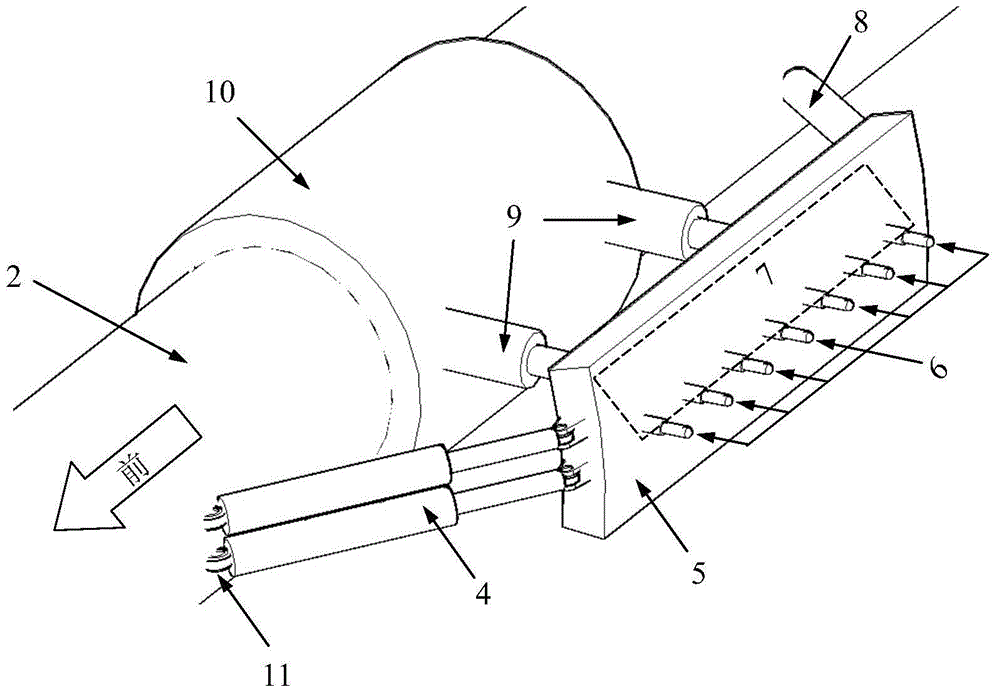

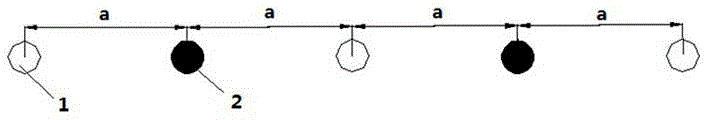

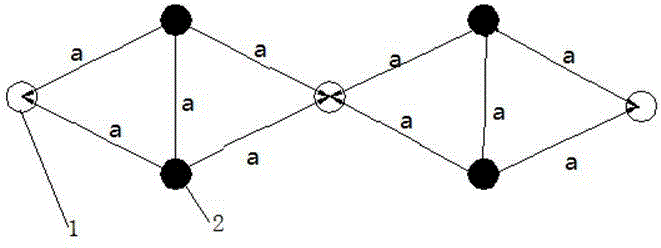

Miniature TBM (Tunnel Boring Machine) excavation system for tunnel excavation in physical simulation test

InactiveCN103364218AImprove excavation efficiencyImprove accuracyStructural/machines measurementTunnelsEngineeringRock tunnel

The invention relates to a miniature TBM (Tunnel Boring Machine) excavation system for tunnel excavation in a physical simulation test and belongs to the technical field of geotechnical engineering. The system comprises a cutter head, a protective shield, a gripper, a transmission shaft, a pulling jack, a guide rail, a motor, a base and the like; one end of the pulling jack is fixed to a support rack; a piston at the other end of the pulling jack is used for pulling the base and the motor to move forwards or backwards together; the motor is used for driving the transmission shaft to rotate to push the cutter head to move forwards to cut tunnel face rock mass; jacks on two sides of the gripper can push gripper arms to exert specified pressure to wall rock. The system can accurately simulate the rock breaking process of the cutter head, takes the interaction between the wall rock and the gripper, the interaction between the tunnel face and cutter head and the interaction between the wall rock and the protective shield into consideration, can be applied for simulating a shield TBM to excavate a soft rock tunnel, a subway or the like in a common geomechnical model test and can also be applied for simulating excavation of a TBM for a deep-lying hard rock tunnel to study the relationship between rock-machine interaction and rock burst.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Tunnel boring machine rock breaking seismic source and active source three-dimensional seismic combined advanced detection system

ActiveCN104678428AFlexible layoutQuick layoutSeismic energy generationSeismic signal receiversShortest distanceSafety control

The invention discloses a tunnel boring machine rock breaking seismic source and active source three-dimensional seismic combined advanced detection system. The system comprehensively utilizes two modes of active source seismic source and rock breaking seismic source to perform three-dimensional seismic combined advanced detection, adopts an active source seismic method with high shock energy to realize long distance advanced prediction and positioning recognition of geological anomalous bodies before operation of a tunnel boring machine, performs adjustment and optimization on the following construction of the tunnel boring machine according to a detection result, adopts cutterhead rock breaking vibration with weak shock energy and high ratio of transverse wave components as a seismic source, adopts an unconventional rock breaking seismic source seismic record processing method to realize the real-time short-distance accurate prediction of the geological anomalous bodies, performs representation and evaluation on the quality of surrounding rock in a region to be excavated, finally comprehensively judges the geological condition of a part in front of a working surface according to combined results of active source and rock break seismic source three-dimensional seismic advanced detection, and provides a support for the optimization of tunnel boring machine operating parameters and construction safety control.

Owner:山东百廿慧通工程科技有限公司

Deep hole static rock breaking method for underground coal mine

InactiveCN104533418AGentle rock breaking processThe rock breaking process is gentleDisloding machinesUnderground miningSwelling pressureHardness

The invention provides a deep hole static rock breaking method for an underground coal mine. According to the deep hole static rock breaking method provided by the invention, according to the Protodikonov's hardness coefficient of a broken rock body, main holes and auxiliary holes are distributed in the broken rock body in different structures, parameters of the main holes and the auxiliary holes includes apertures, hole distances, hole depths and hole angles, the main holes is filled with a blasting agent by virtue of a grouting method or an explosive rolling method, the main holes are sealed, the auxiliary holes is not filled with the blasting agent, and the auxiliary holes serve as artificial free surfaces to release swelling pressure and can guide the generation and the development of a crack; with the arrangement of the multi-row holes, the main holes and the auxiliary holes are distributed at intervals with equal distances. The deep hole static rock breaking method can be used for solving the problem that of the blasting agent is used for carrying out deep hole rock breaking on a natural rock body in a triaxial stress state in the underground coal mine, is safe, mild, controllable and effective and is particularly suitable for high gas mines.

Owner:山西吉昌泰矿山工程技术有限公司

Torsional impact rock-breaking experiment device and experiment method

InactiveCN104198311ARealize the function of torsional percussion drillingMaterial strength using repeated/pulsating forcesInvestigating material hardnessHydraulic cylinderElectric machine

The invention relates to a torsional impact rock-breaking experiment device and an experiment method. A main rack of the torsional impact rock-breaking experiment device is formed by arranging two vertical columns between a cross beam and a base; a lifting table is arranged between the two vertical columns and is connected with the vertical columns in a sliding manner; a crossed sliding table is arranged on the lifting table; a four-claw clamping disk is mounted on the crossed sliding table; a rock sample is fixed on the four-claw clamping disk; a displacement sensor is arranged between the lifting table and the cross beam; the upper end of a piston rod of a hydraulic oil cylinder is connected with a load sensor and presses the bottom of the crossed sliding table; the hydraulic oil cylinder is connected with a hydraulic pump; a main motor is connected with a torque rotating speed meter and a drilling rod respectively through a synchronization belt; a side motor is connected with an overrun clutch arranged on the drilling rod through a triangular belt; the displacement sensor, the load sensor and the torque rotating speed meter are respectively connected with a data acquisition system; the data acquisition system is connected with a computer; a control system is mounted in the computer. The torsional impact rock-breaking experiment device can research a rock-breaking effect under a torsional impact condition and analyze a stick-slip effect in an actual drilling process and a rock-breaking mechanical property and a breaking rule under a torsional impact load.

Owner:NORTHEAST GASOLINEEUM UNIV

Method for designing rock breaking cutterhead combined by flexible expanding excavation hobbing cutters and water jets

The invention relates to a method for designing a rock breaking cutterhead combined by flexible expanding excavation hobbing cutters and water jets, and belongs to the field of design methods of full-fracture-surface-rock heading machine cutterhead structures. According to the design method, flexible multi-edge expanding excavation hobbing cutter assemblies and high-pressure water jet devices are combined to replace a side hobbing cutter of an original cutterhead to break rock, the side hobbing cutter is removed from the edge position of the original cutterhead, the first flexible multi-edge expanding excavation hobbing cutter assembly, the second flexible multi-edge expanding excavation hobbing cutter assembly and the third flexible multi-edge expanding excavation hobbing cutter assembly are installed, and the flexible multi-edge expanding excavation hobbing cutter assemblies are composed of flexible multi-edge expanding excavation hobbing cutters installed in a flexible multi-edge expanding excavation hobbing cutter protruding-out device, and the flexible multi-edge expanding excavation hobbing cutter assemblies are same in structure. On the cutterhead, the high-pressure water jet devices are installed on the two sides of the first flexible multi-edge expanding excavation hobbing cutter assembly, the two sides of the second flexible multi-edge expanding excavation hobbing cutter assembly and the two sides of the third flexible multi-edge expanding excavation hobbing cutter assembly respectively. The rock breaking cutterhead combined by the flexible expanding excavation hobbing cutters and the water jets is small in vibration, and therefore tunneling service life of the cutterhead is prolonged, noise is reduced, and economic losses in engineering are reduced.

Owner:DALIAN UNIV OF TECH

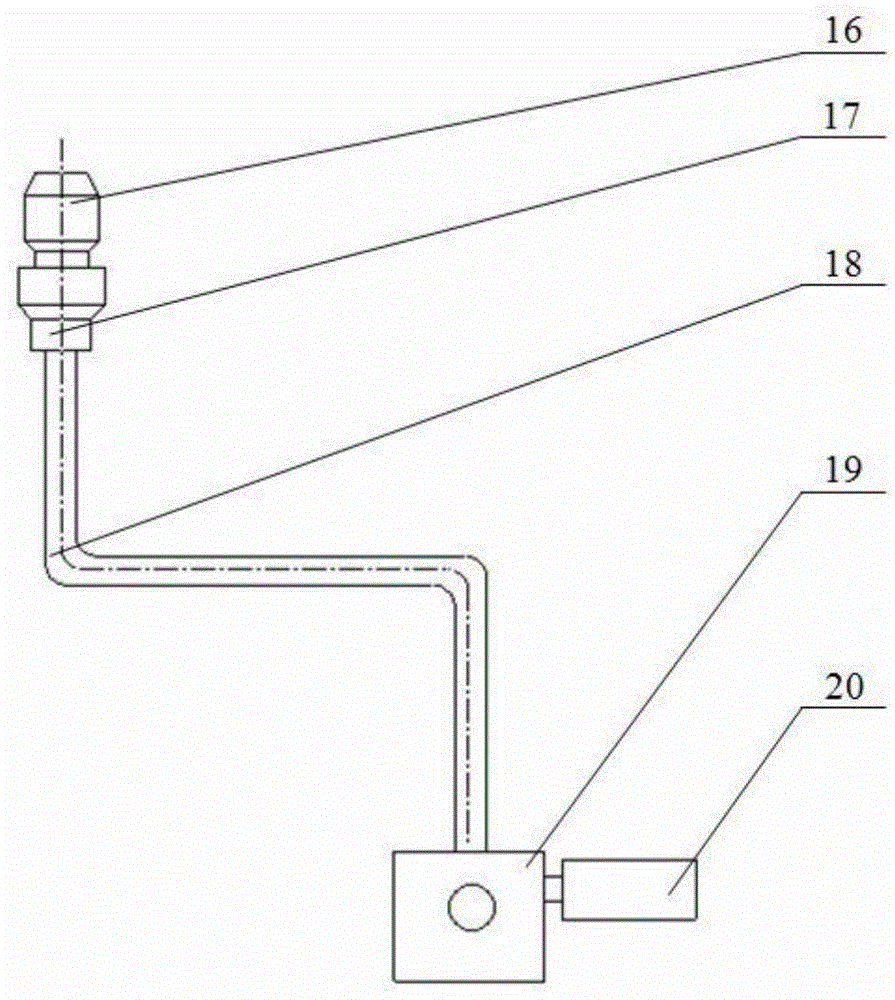

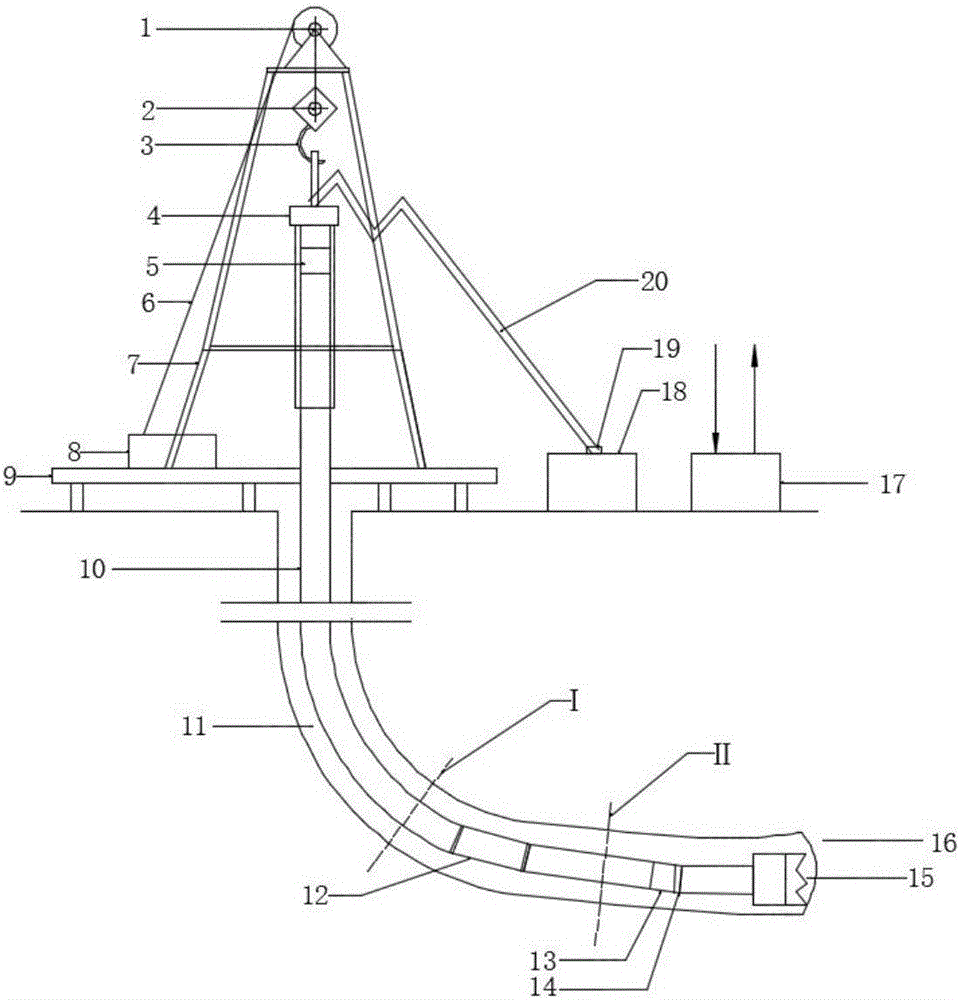

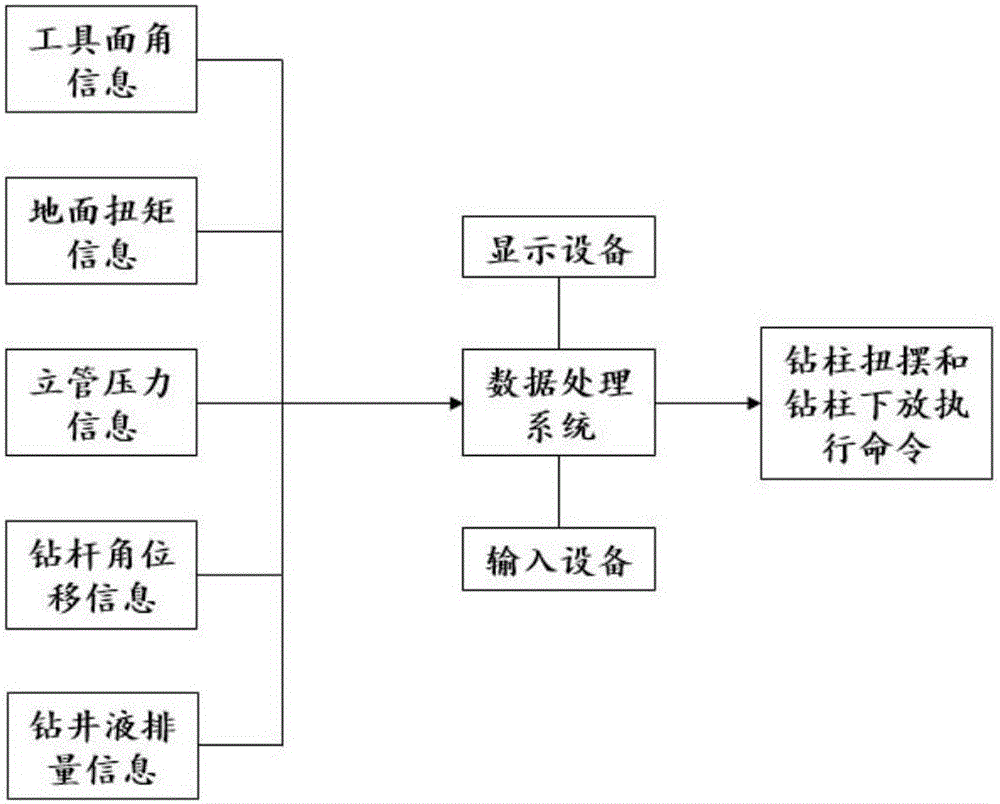

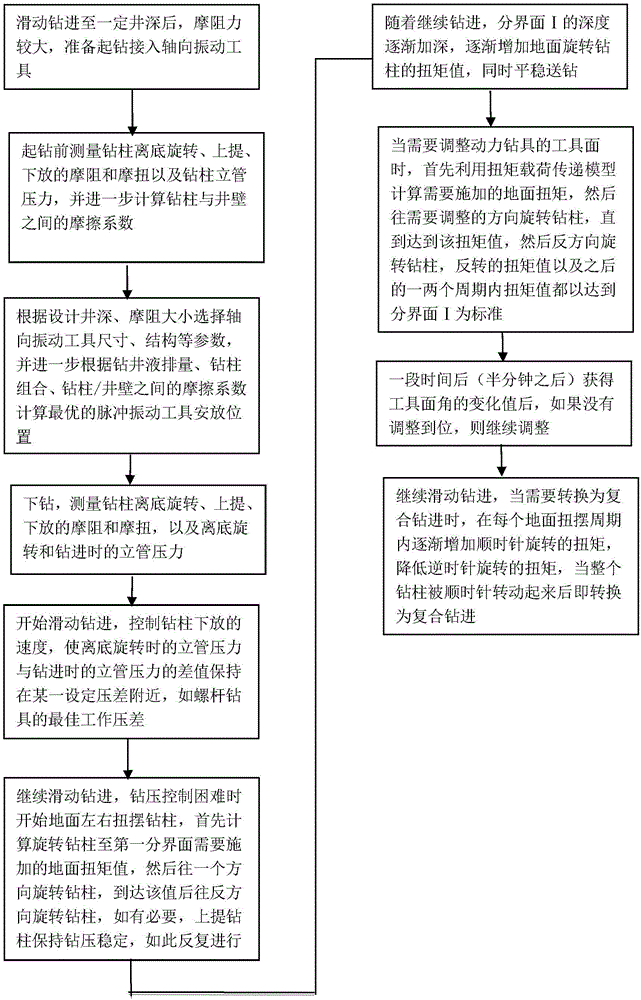

Complex structural well friction resistance reduction and power drill tool face adjusting method

InactiveCN106437513AReduce frictional resistanceReduce resistanceDrilling rodsDirectional drillingTop driveWell drilling

The invention belongs to the technical field of well drilling, and relates to a complex structural well friction resistance reduction and power drill tool face adjusting method. A whole originally pure sliding drilling string is divided into three portions, the upper portion of the drilling string rotates in a reciprocating manner under the action of torque applied by a surface well drilling top drive, the middle of the drilling string axially vibrates / creeps under the action of an axial vibration resistance reduction tool, and static friction between the drilling string and a well wall is transformed into dynamic friction, so that axial feeding resistance of the drilling string is reduced. A drill bit on the lower portion of the drilling string can axially vibrates, so that bit pressure fluctuates, rock breaking torque and reaction torque fluctuate, the fluctuating reaction torque acts on the lower portion of the drilling string close to the drill bit, the lower portion of the drilling string rotates in a reciprocating manner, and friction resistance can be reduced. The method is convenient in operation and scientific in principle, power drill tool face adjusting time can be saved, drilling is continued while a tool face is adjusted, the drilling efficiency of a complex structural well, particularly the complex structural well with long horizontal displacement is improved, and well drilling cost is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Self-adapting hybrid bit

InactiveCN102561953AOptimize the distribution of rock breaking volumeOptimize allocationDrill bitsAxial forcePetroleum oil

The invention discloses a hybrid bit for petroleum gas exploitation and other exploration drilling applications, wherein cones and blades are simultaneously arranged on a bit main body and are uniformly distributed in a staggering manner, and the cones are arranged on a tooth palm of the bit main body; the hybrid bit further comprises a movable blade body movably arranged in the bit main body and only capable of telescopically moving within a limited range along an axial direction, an elastic element for providing axial force for the movable blade body is also arranged between the movable blade body and the bit main body, the blades are arranged at the front end of the movable blade body, and a compression face for bearing mud pressure is arranged at the tail end of the movable blade body. The self-adapting hybrid bit disclosed by the invention is capable of controlling the relative positions of the cones and the blades in a self-adapting manner according to stress, thereby optimizing the rock breaking quantity distribution of the cones and the blades and guaranteeing a faster rock breaking speed, and the applicability is more extensive. Besides, by the self-adapting design, the rigid impact of common bits and rock stratum is optimized to flexible impact, so that the bit is greatly protected.

Owner:SOUTHWEST PETROLEUM UNIV

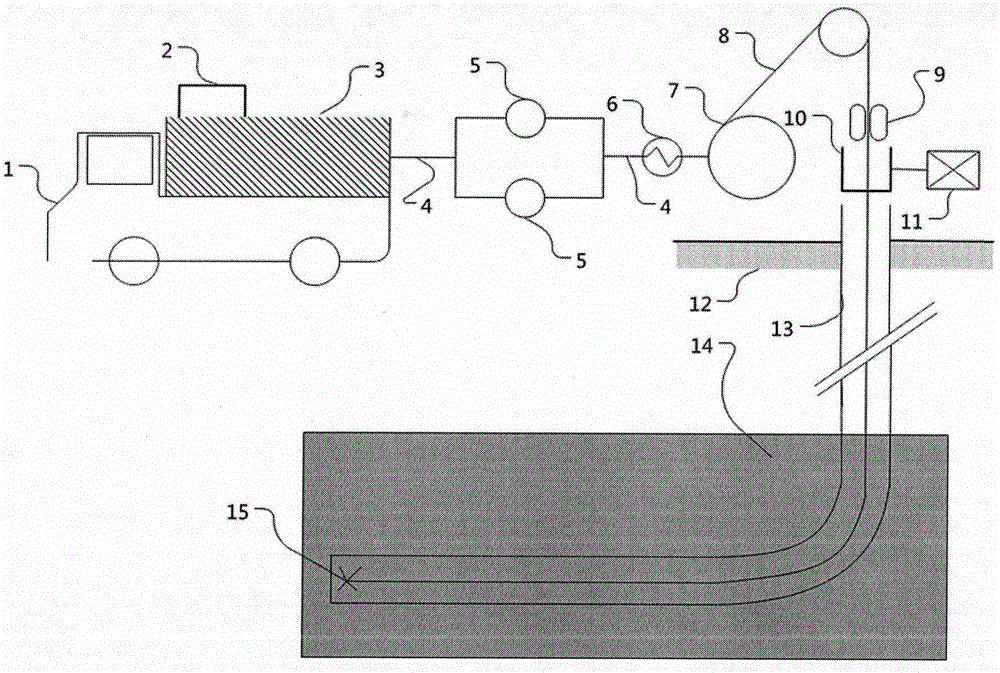

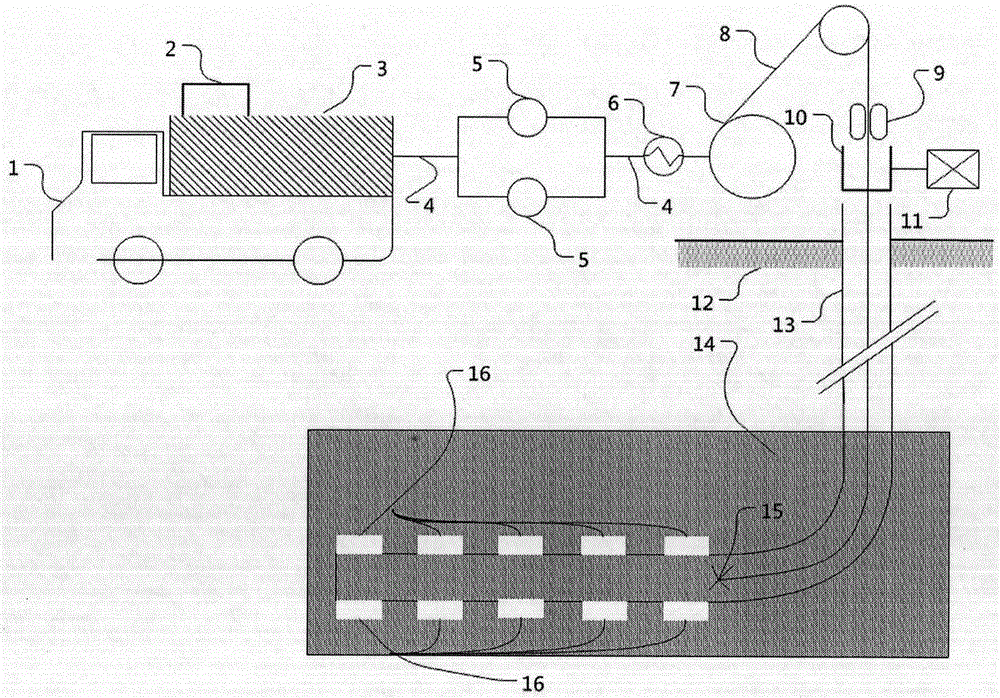

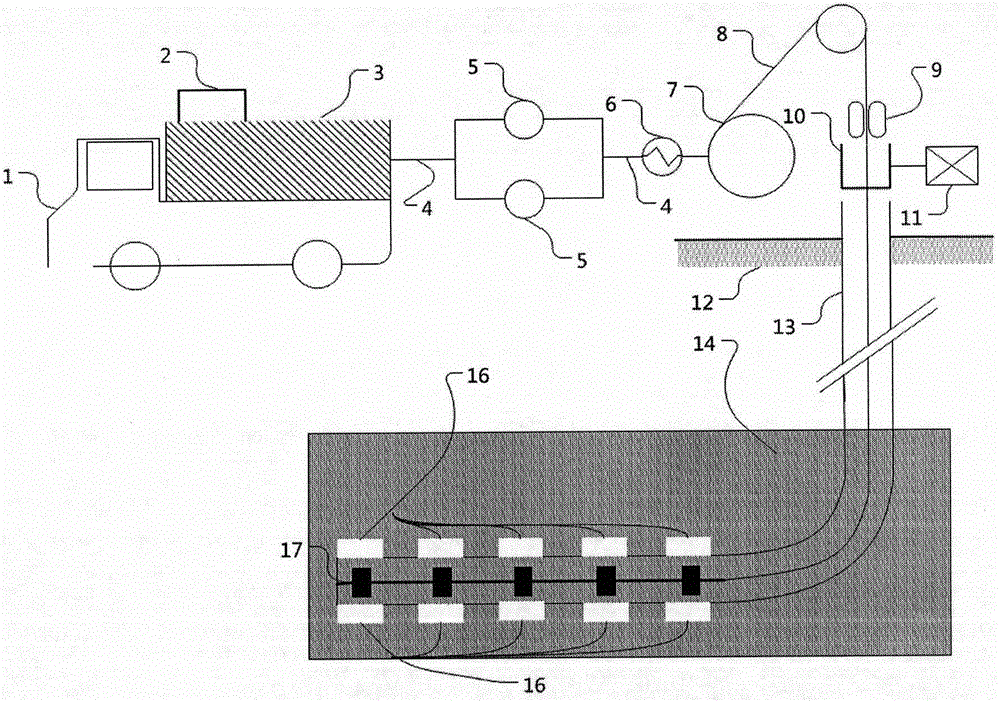

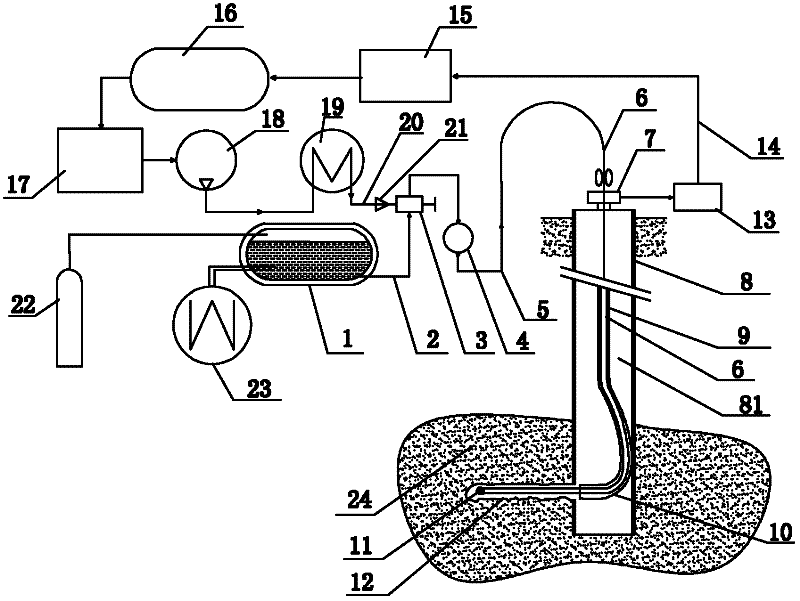

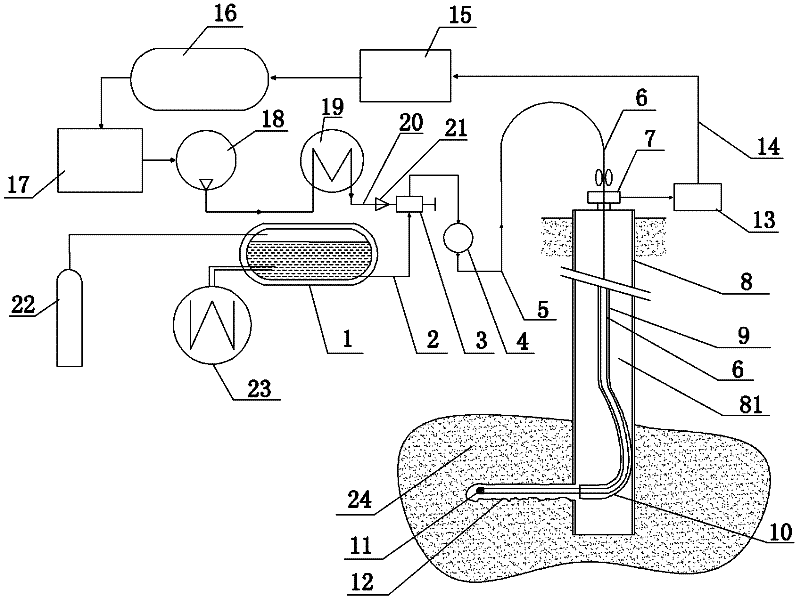

Radial horizontal drilling system using supercritical carbon dioxide and drilling method thereof

InactiveCN102409976ANo pollutionImprove protectionLiquid/gas jet drillingDirectional drillingUnconventional oilPollution

The invention discloses a radial horizontal drilling system using supercritical carbon dioxide and a drilling method thereof. The drilling system comprises a liquid carbon dioxide supplying device, a drilling device, an in-well pressure control device, a solid, liquid and gas three-phase separating device and a carbon dioxide recycling device, wherein the drilling device is arranged in a shaft, and includes an oil pipe, a steering gear mounted at the bottom of the oil pipe, and a flexible drill stem sleeved in the oil pipe; the flexible drill stem passes through the steering gear and then realizes steering; the flexible drill stem has a hollow drill stem channel; a supercritical carbon dioxide jet drill is mounted at the end of the part, in a horizontal direction, of the flexible drill stem; a nozzle, which is communicated with the drill stem channel, is formed on the jet drill; the in-well pressure control device is disposed at the opening of a well; the solid, liquid and gas three-phase separating device and the carbon dioxide recycling device are disposed on the ground. The radial horizontal drilling system disclosed by the invention uses supercritical carbon dioxide fluid as rock breaking fluid, thus avoiding pollution to oil reservoir layers, effectively protecting the oil reservoir layers, greatly increasing rock breaking efficiency, and realizing cyclic utilization of the carbon dioxide; and the radial horizontal drilling system using supercritical carbon dioxide and the drilling method thereof have important application value to increase of production of old wells and to development of unconventional oil-gas reservoir.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com