Complex structural well friction resistance reduction and power drill tool face adjusting method

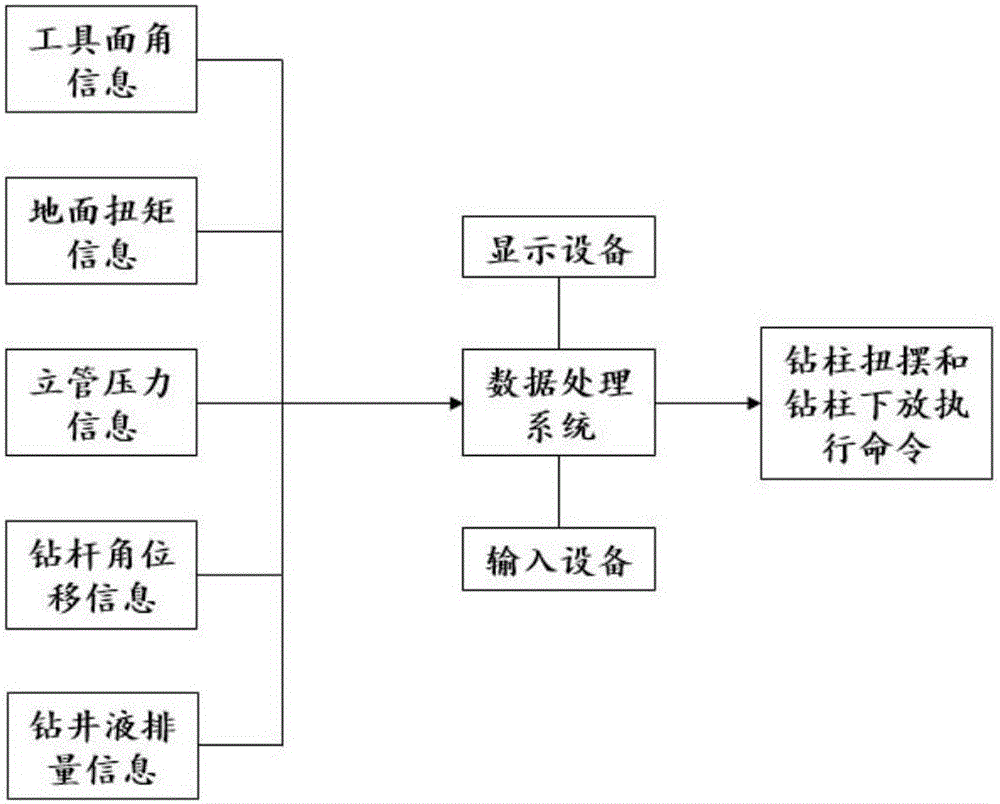

A dynamic drilling tool and complex structure technology, applied in drilling equipment and methods, automatic drilling control systems, drill pipes, etc., can solve problems such as reducing the effect of friction reduction, difficulty in implementation, and inability to accurately judge the corresponding relationship between ground torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

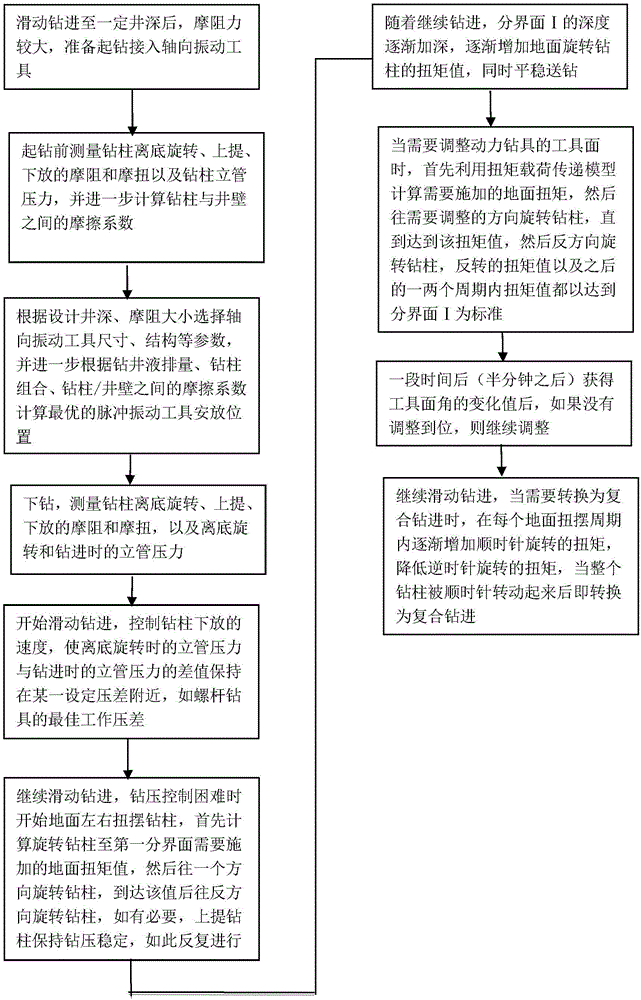

[0030] This embodiment is realized in the friction reduction and power drilling tool face adjustment device for wells with complex structures, and the specific process is as follows:

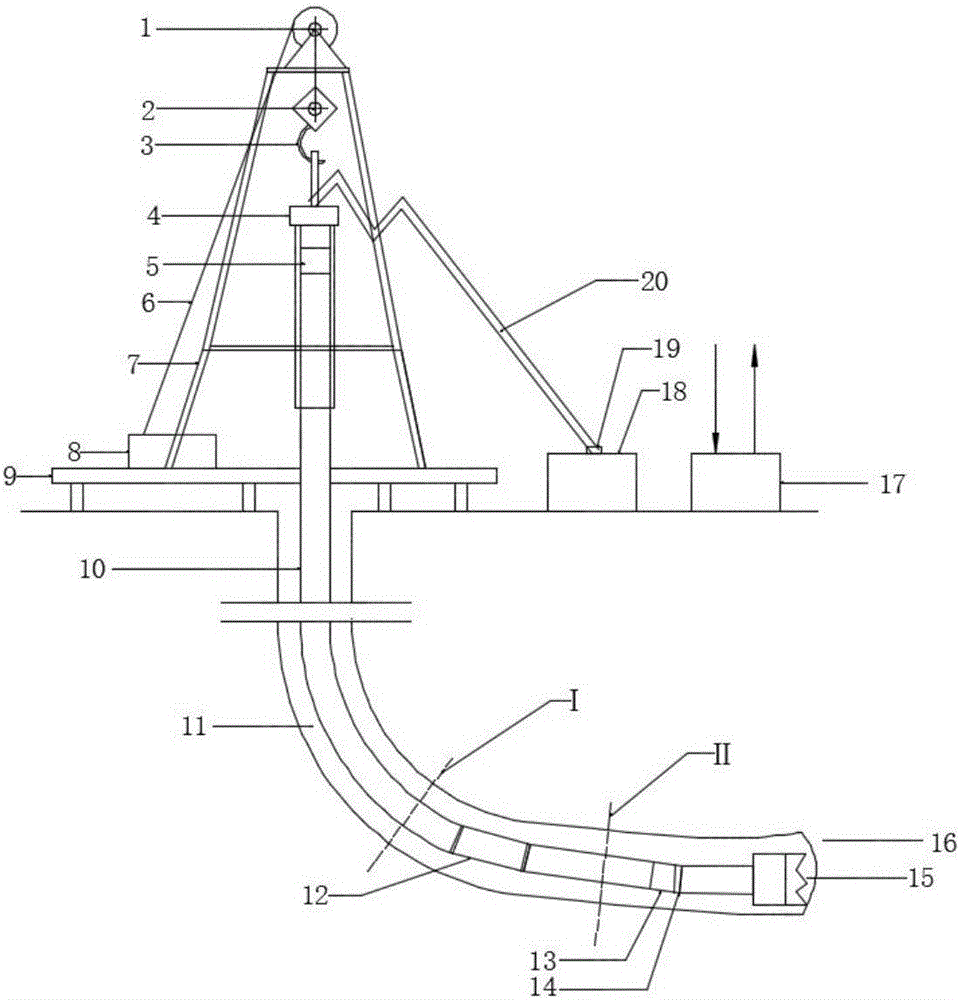

[0031] (1) After sliding drilling in directional wells to a certain well depth, since the drill string 10 lying on the lower side of the wellbore 11 is longer and has greater frictional resistance, the mechanical penetration rate of sliding drilling is relatively slow, for example, less than 1m / hour. Pull out the drill and access the axial vibration drag reduction tool 12; measure the load value and ground torque value of the hook 3 under the three working conditions of the drill bit rotating from the bottom, lifting the drill string and lowering the drill string, and the time when the drill is rotating from the bottom. The standpipe pressure value P off , and then use the "soft model" calculated by the frictional torque proposed in the document "Torque and Drag in Directional Wells-Prediction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com