Patents

Literature

1327 results about "Friction reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reducing Friction by Applying Oil. A common way of reducing friction is to lubricate the surfaces of machines, which slid over each other with oil. With a layer of oil between the machine surfaces, friction is reduced as the parts slid over each other.

Friction Reduction Fluids

InactiveUS20080064614A1Good drag reduction effectImproved viscousPipeline systemsFlushingFriction reductionReducer

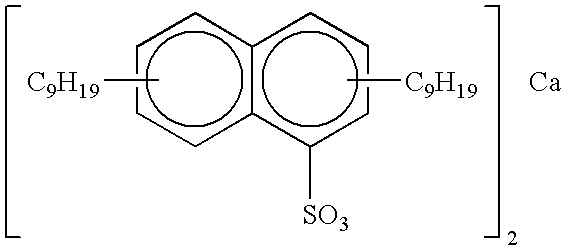

The invention provides an oilfield suspending friction reducer treatment composition fluid comprising from about 0.001 weight percent to about 0.5 weight percent of a drag reducing surfactant; at least one drag reducing enhancer selected from the group consisting of polymeric drag reduction enhancers, monomeric drag reduction enhancers, and mixtures thereof.

Owner:SCHLUMBERGER TECH CORP

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

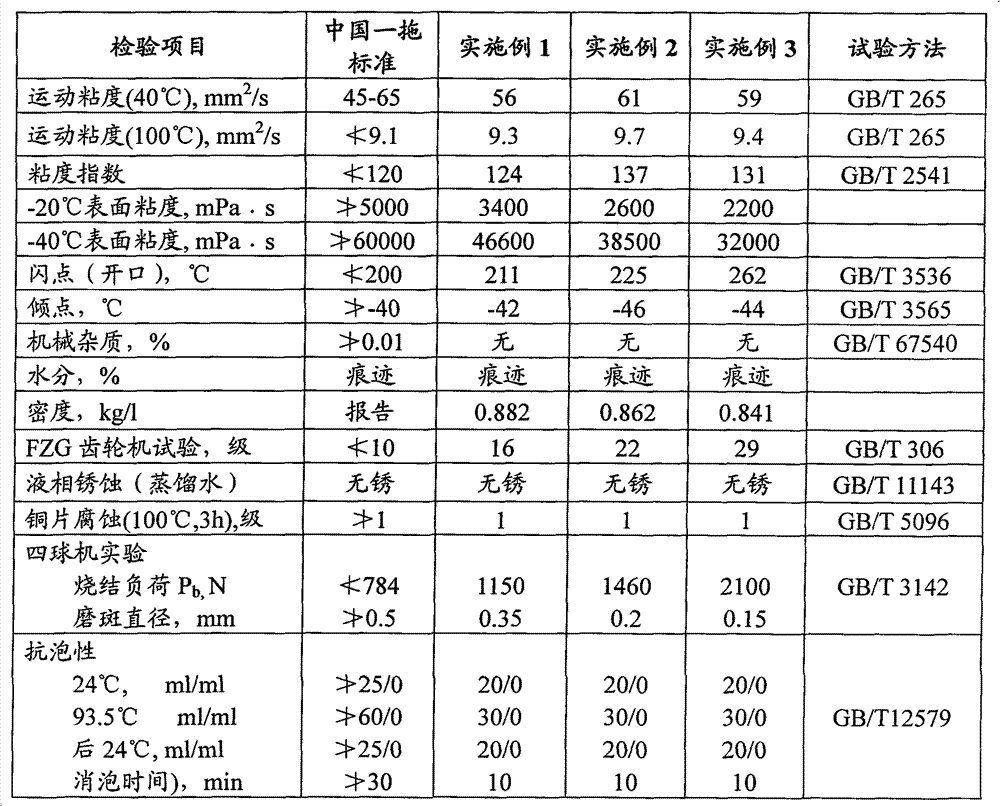

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

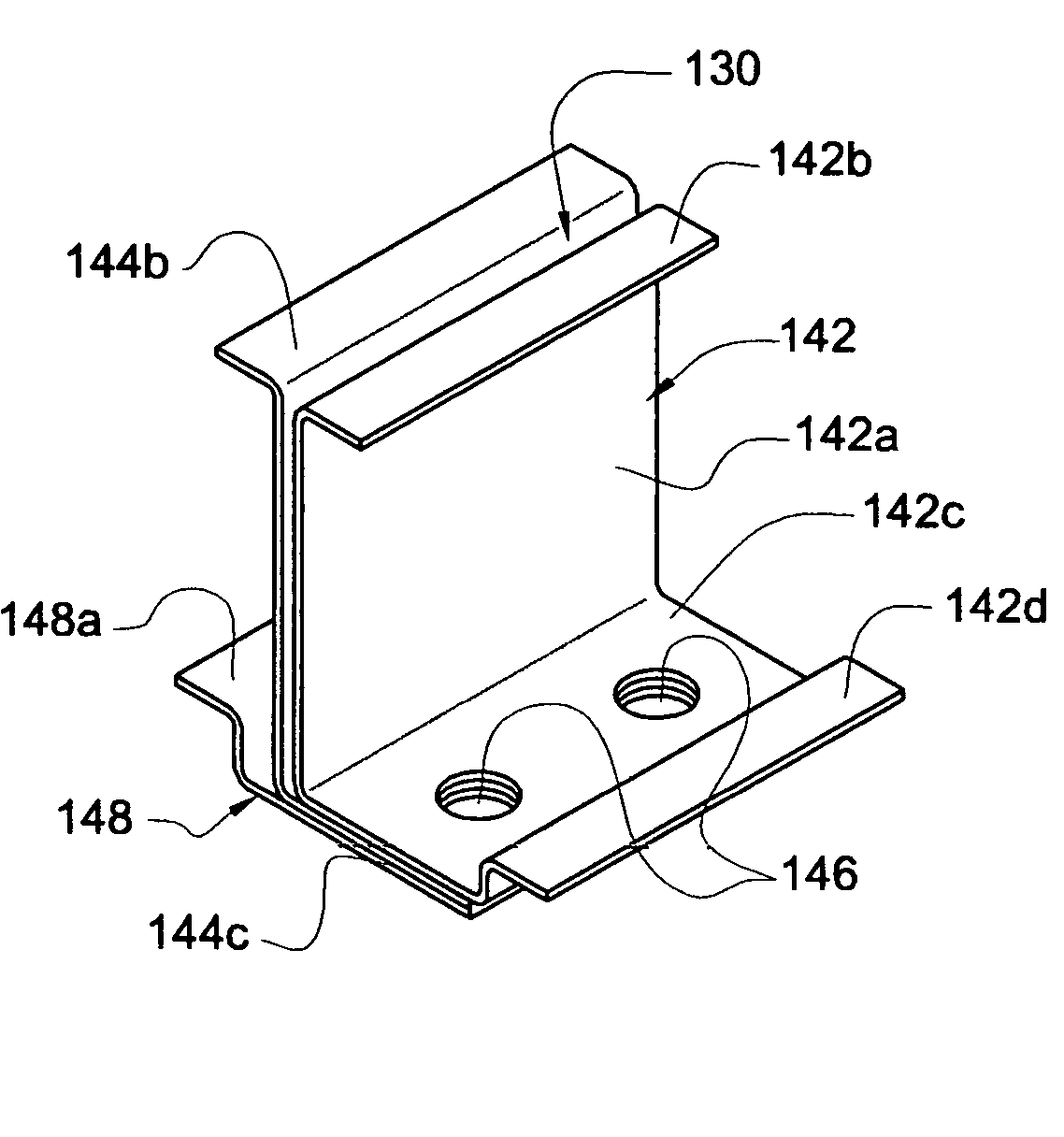

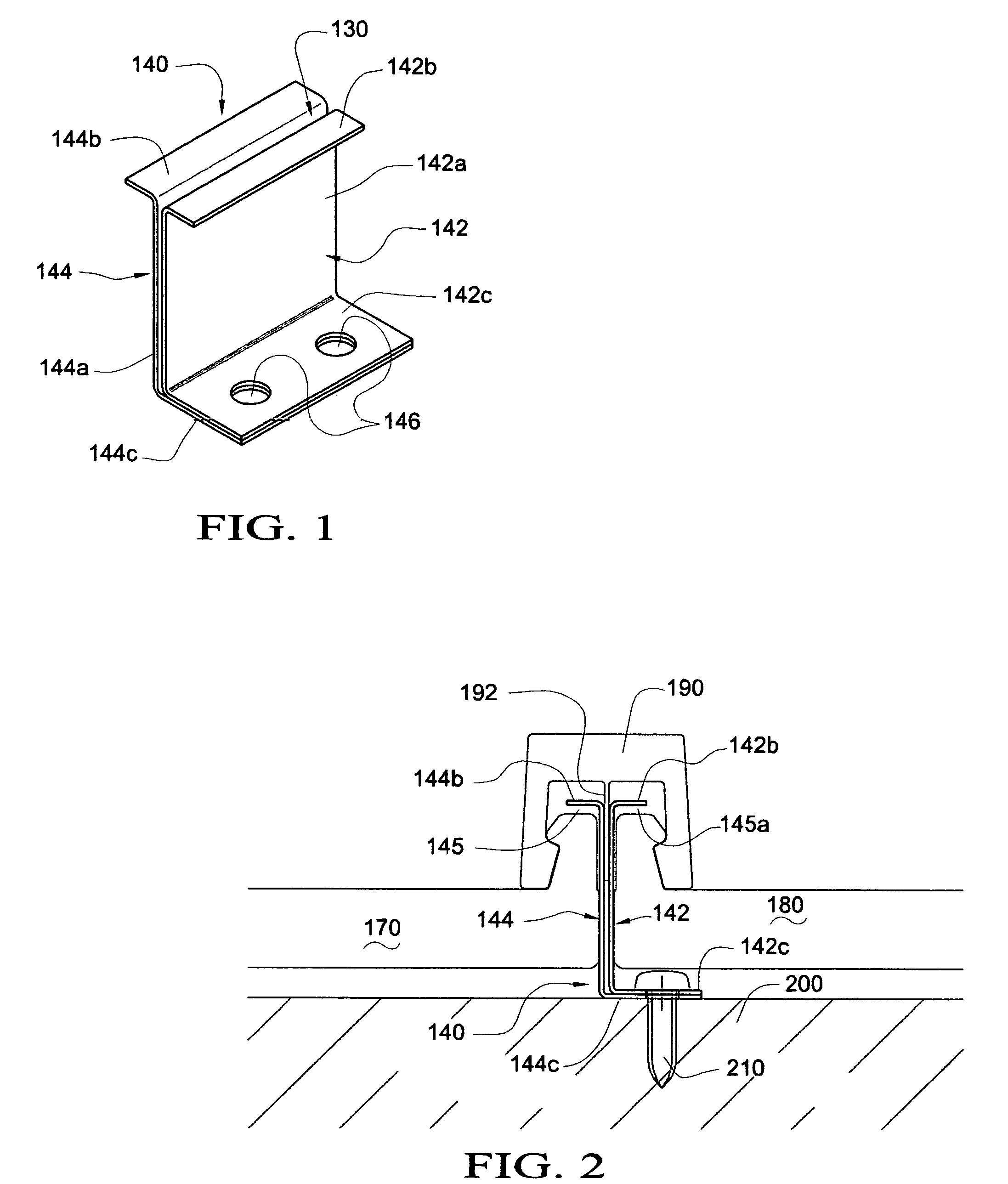

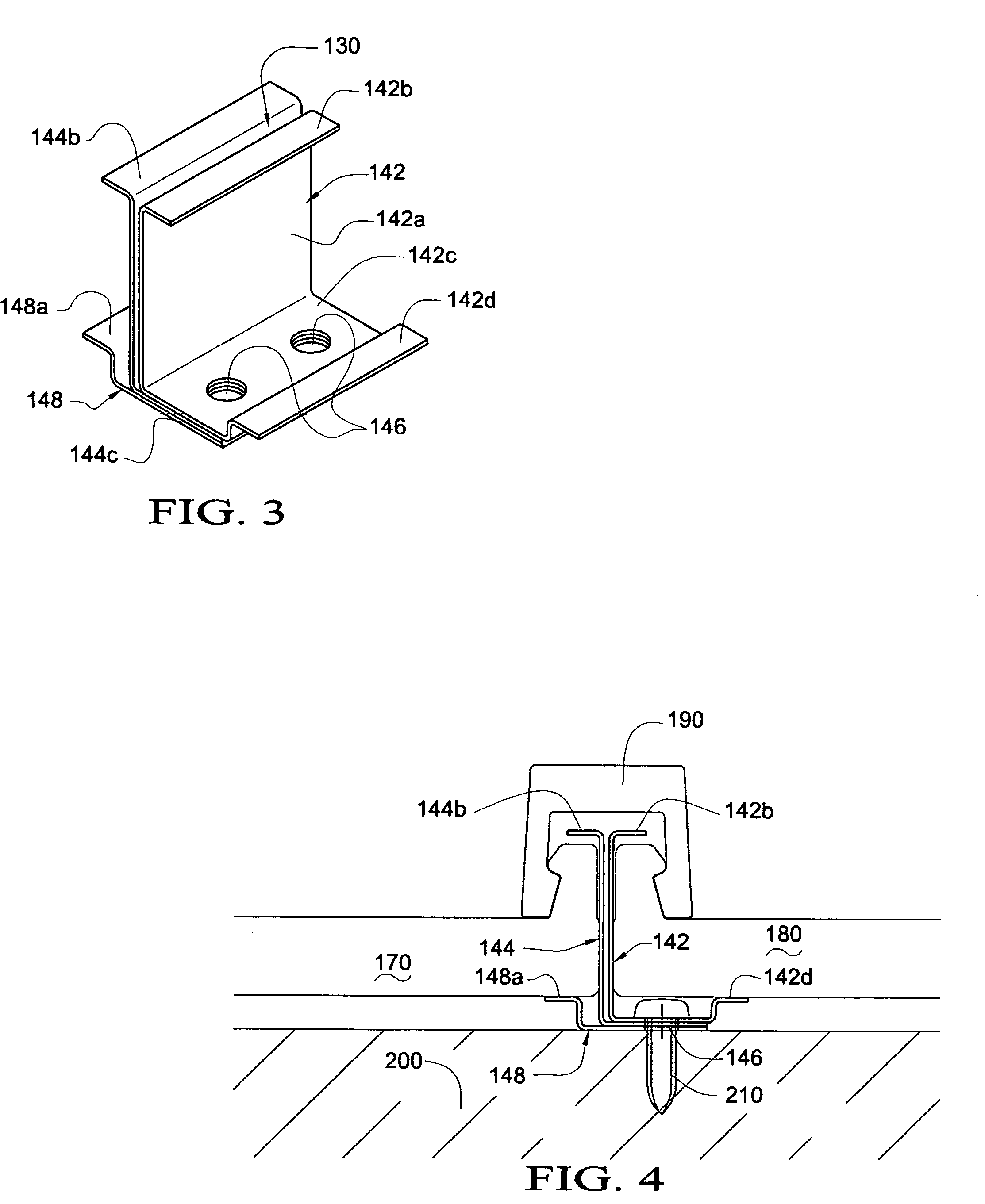

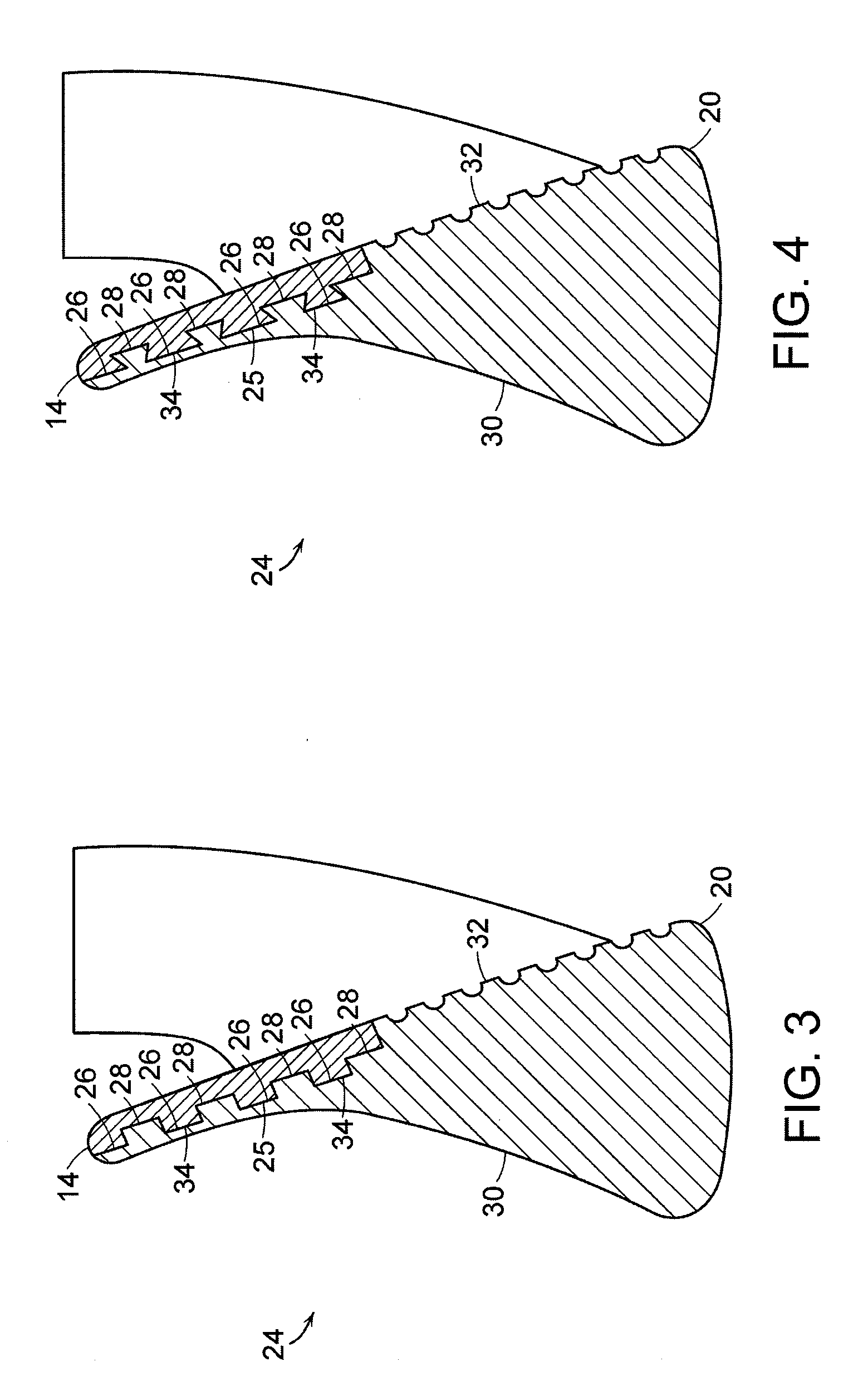

Panel clip assembly for use with roof or wall panels

InactiveUS7313893B2Reduce noiseReduce wearRoof covering using slabs/sheetsCeilingsFriction reductionEngineering

A clip assembly secures standing seam skylight or roofing panels to substrates and allows for a full range of movements by the panels while eliminating or reducing frictional noises. The clip assembly may also be used with wall panel systems. The clip assembly includes a first clip member and a second clip member each having an upright member and an upper flange member and a lower flange member extending therefrom. The assembly further includes a gap formed between the upright member of the first clip member and the upright member of the second clip member. In one aspect the clip assembly includes a base which allows the assembly to slide.

Owner:EXTECH EXTERIOR TECH

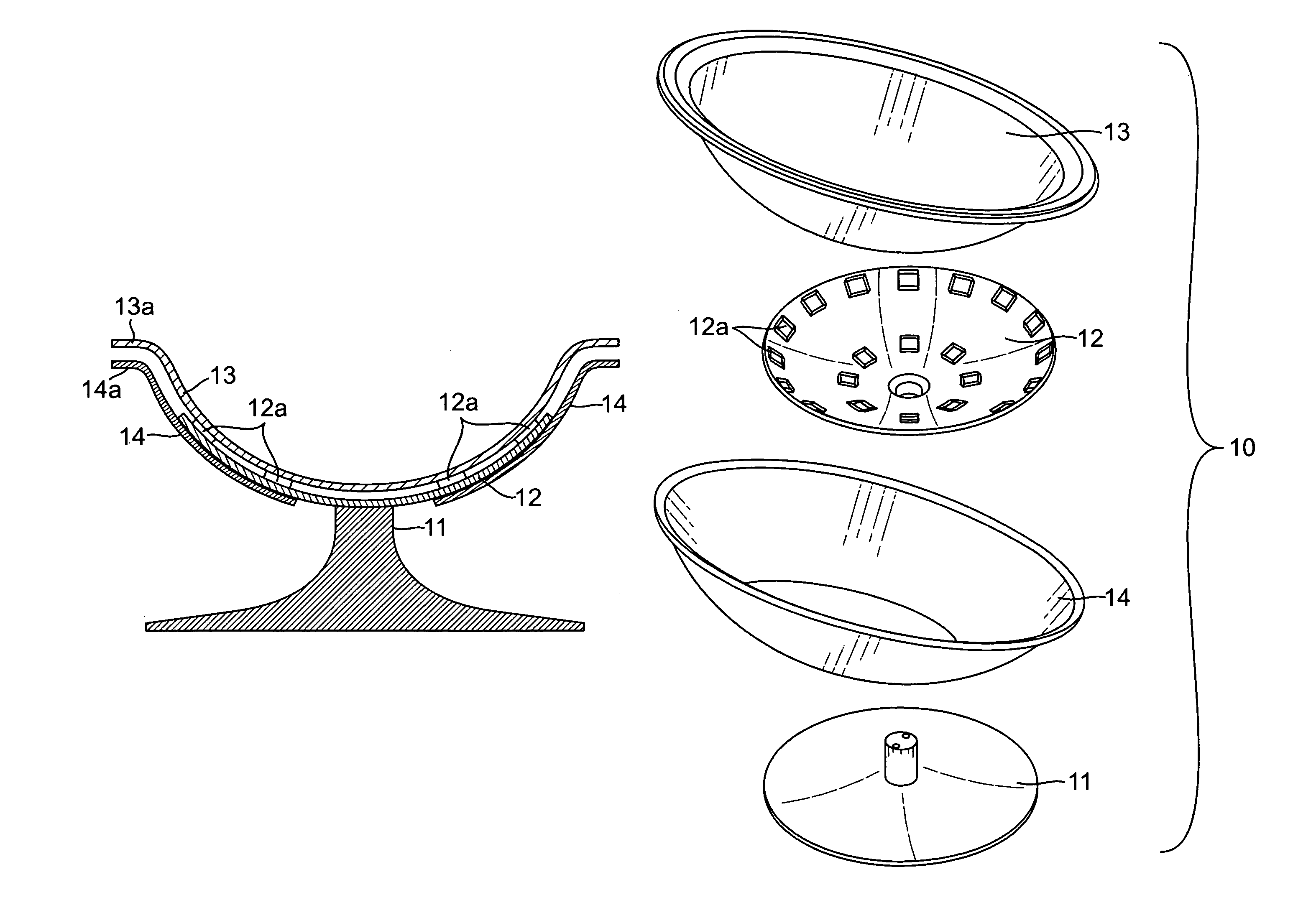

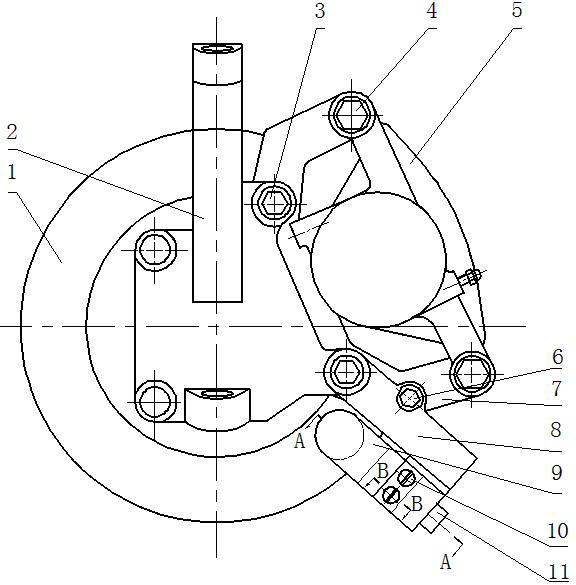

Swivel and reclining chair

InactiveUS7938489B2Simple structureOperating chairsDental chairsFriction reductionMechanical engineering

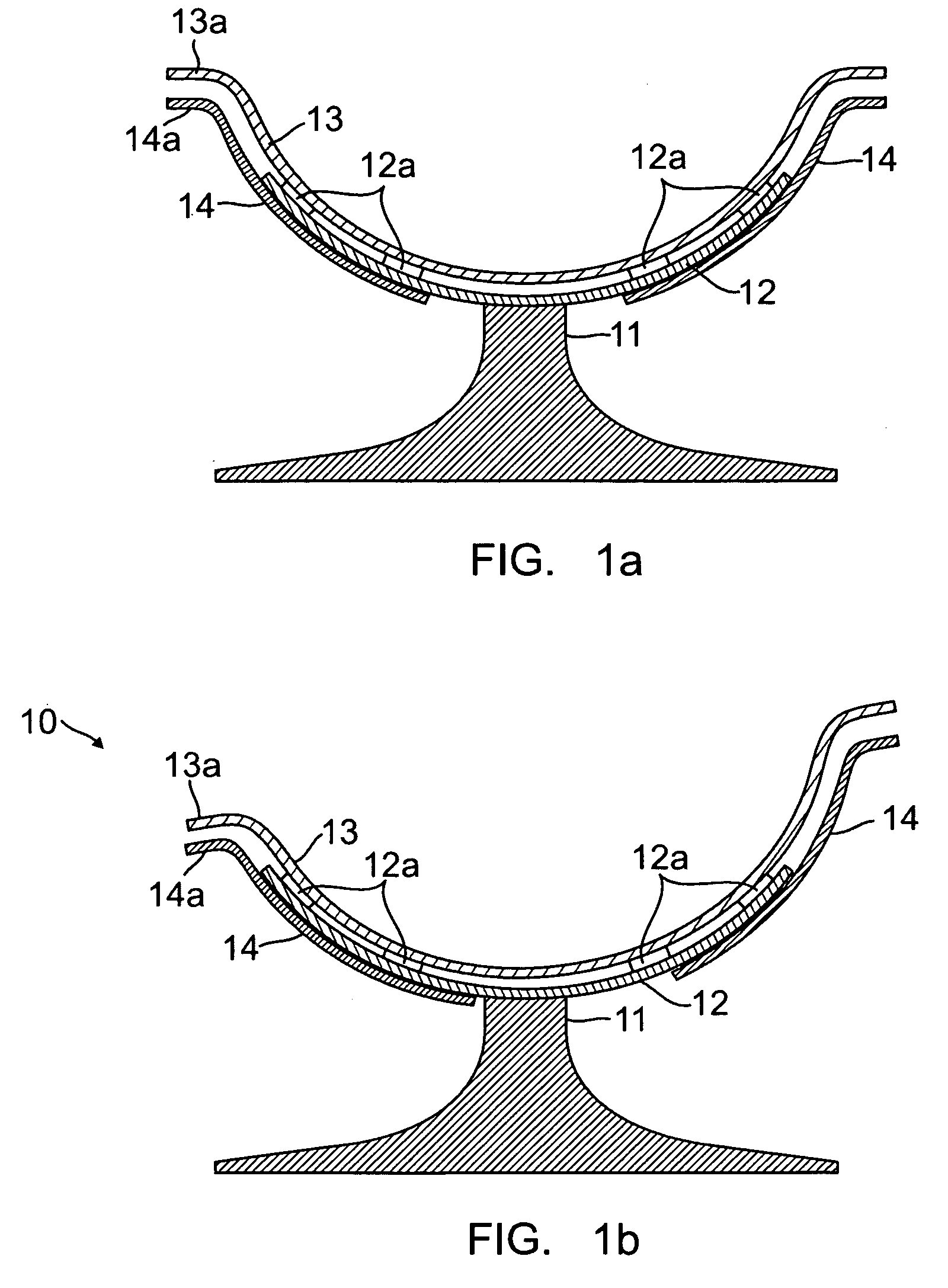

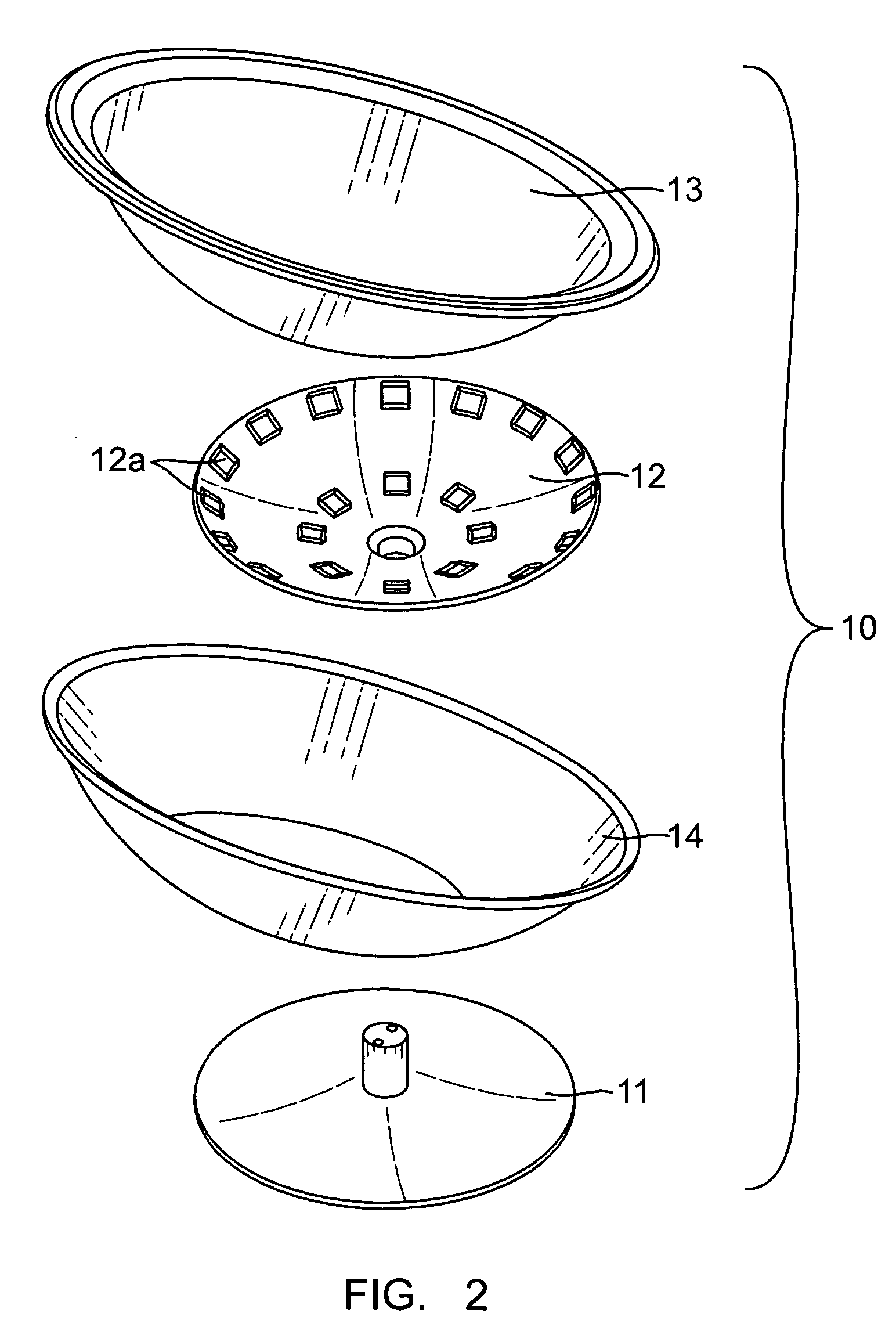

A swivel and reclining chair has a base support, a base bowl mounted on the base support, and a seating bowl slidably disposed in and over the base bowl. A plurality of friction reduction features are disposed on the inside surface of the base bowl. The outer surface of the seating bowl is spherical in shape and rests on the friction reduction features. The seating bowl is larger in area than the base bowl, and can freely slide in two dimensions as well as rotate in a spherical surface. Optionally, a guard ring is disposed outside of the base bowl and is attached to the base bowl at their rims.

Owner:NAZARI JOSEPH

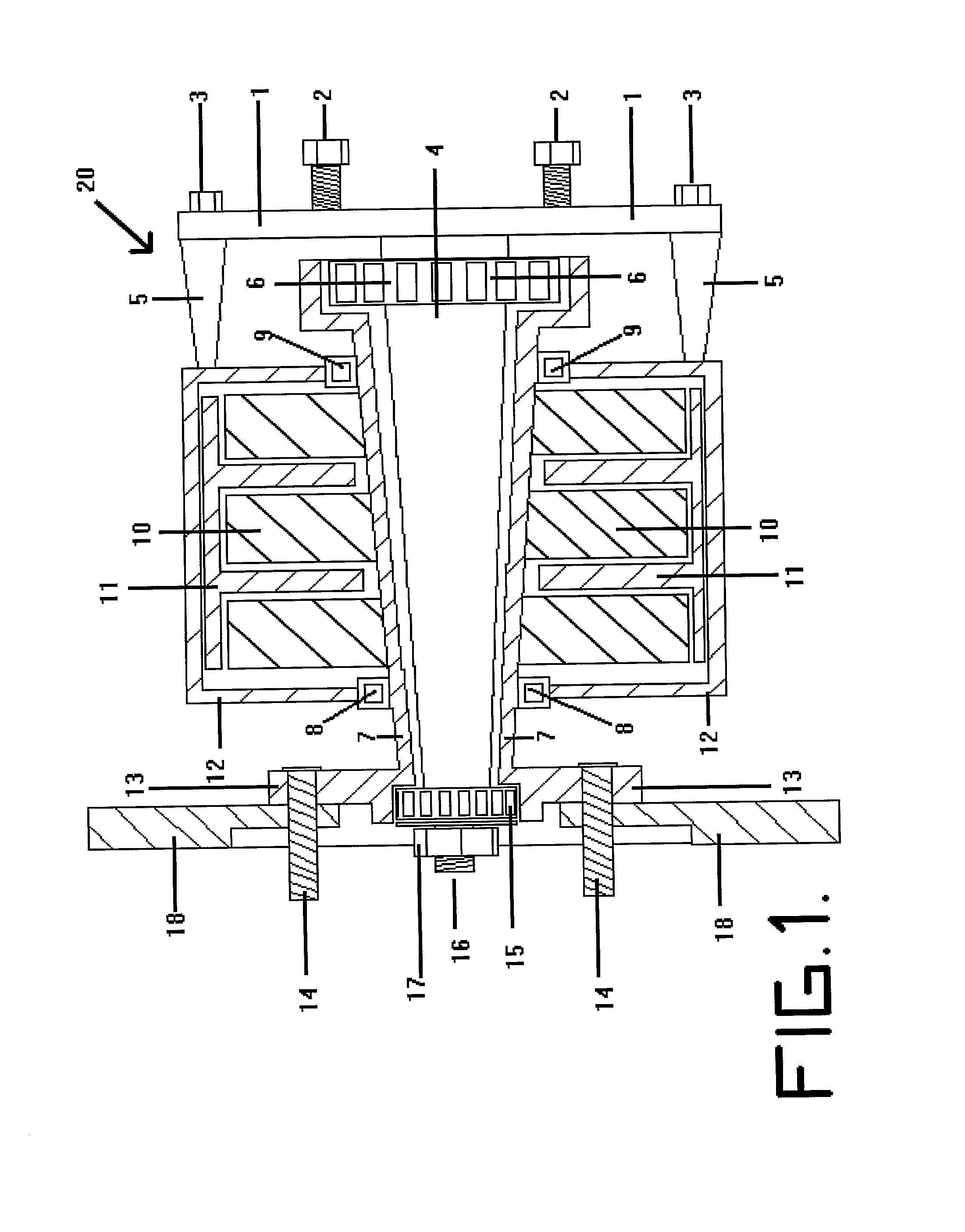

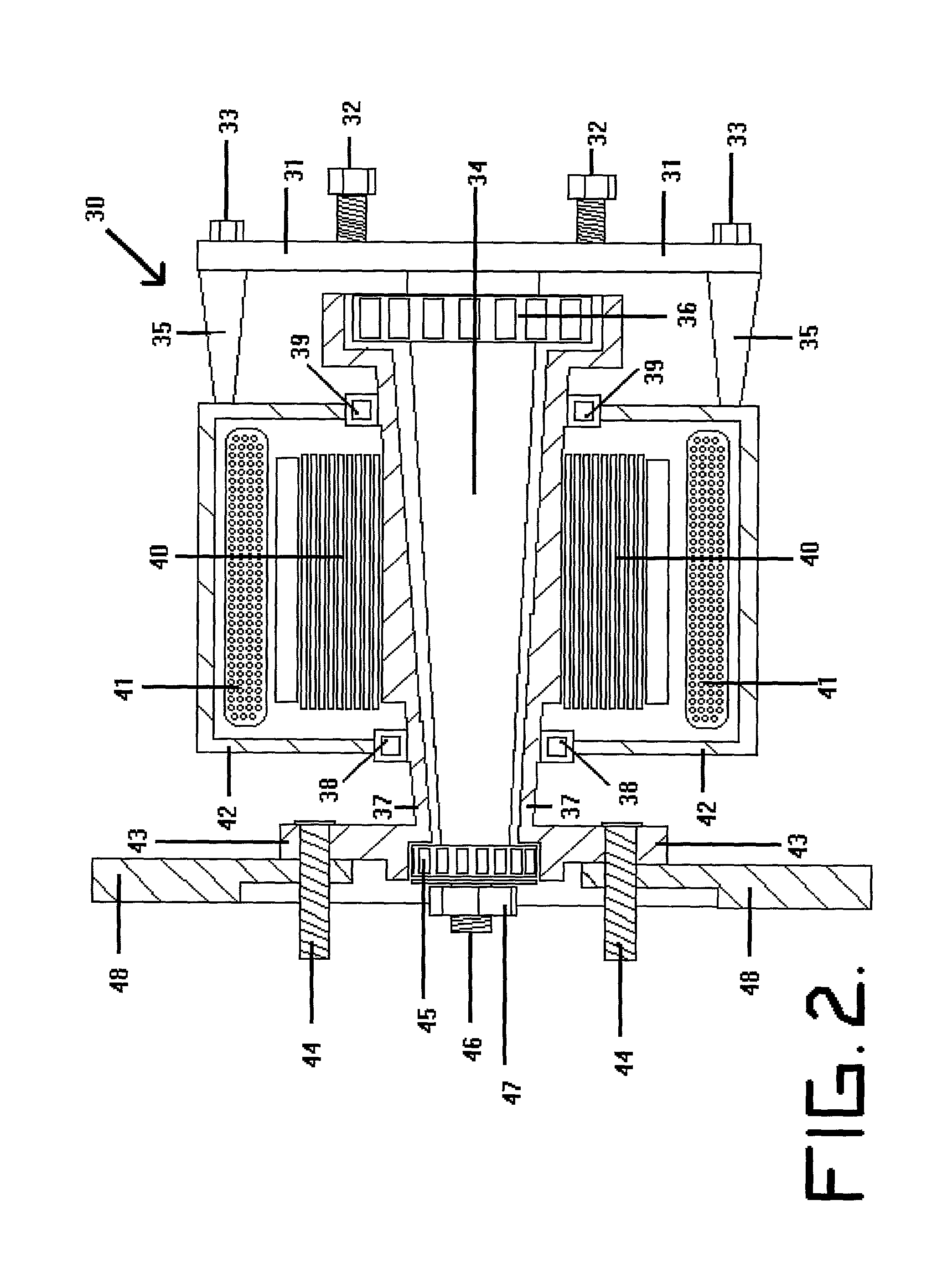

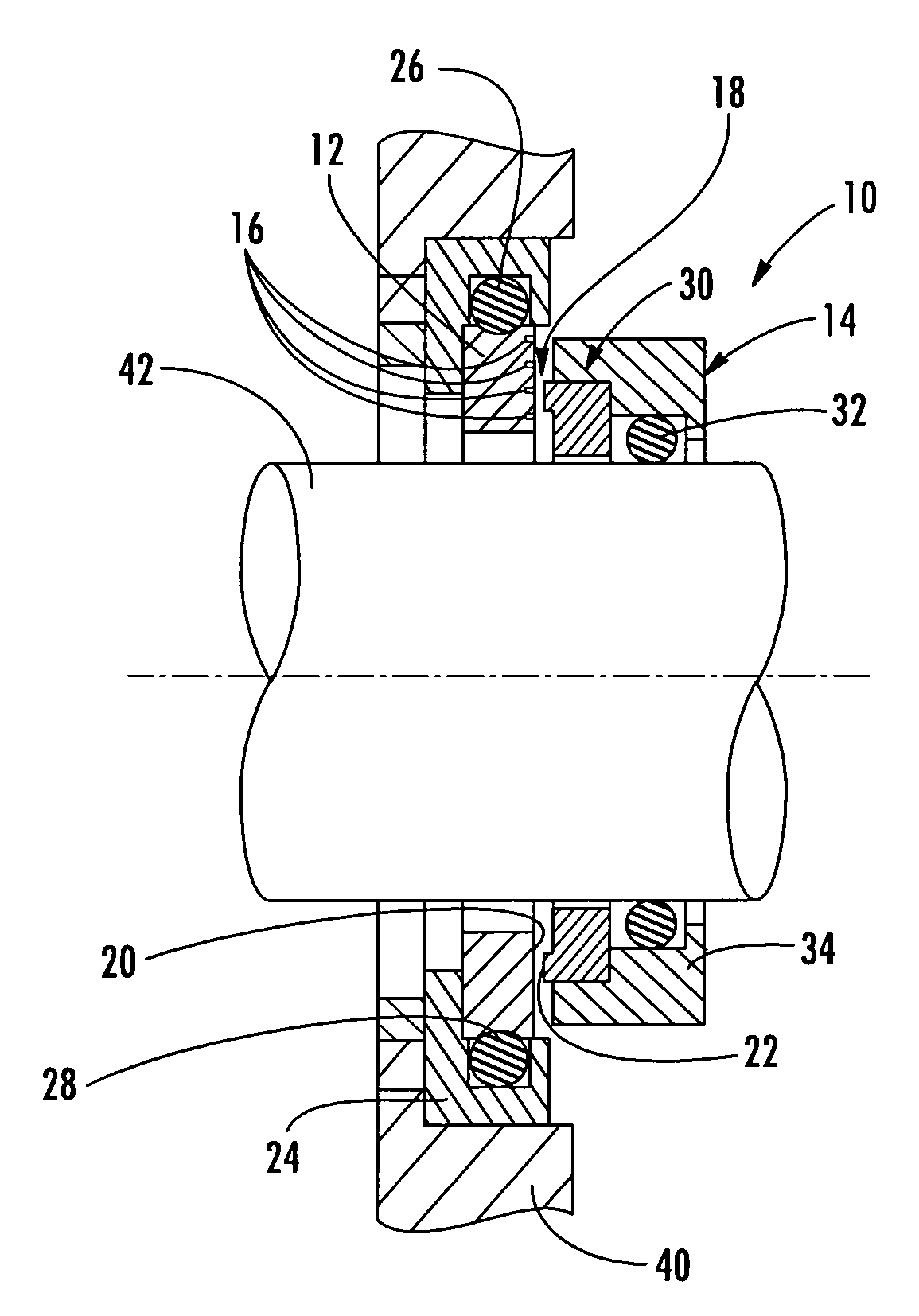

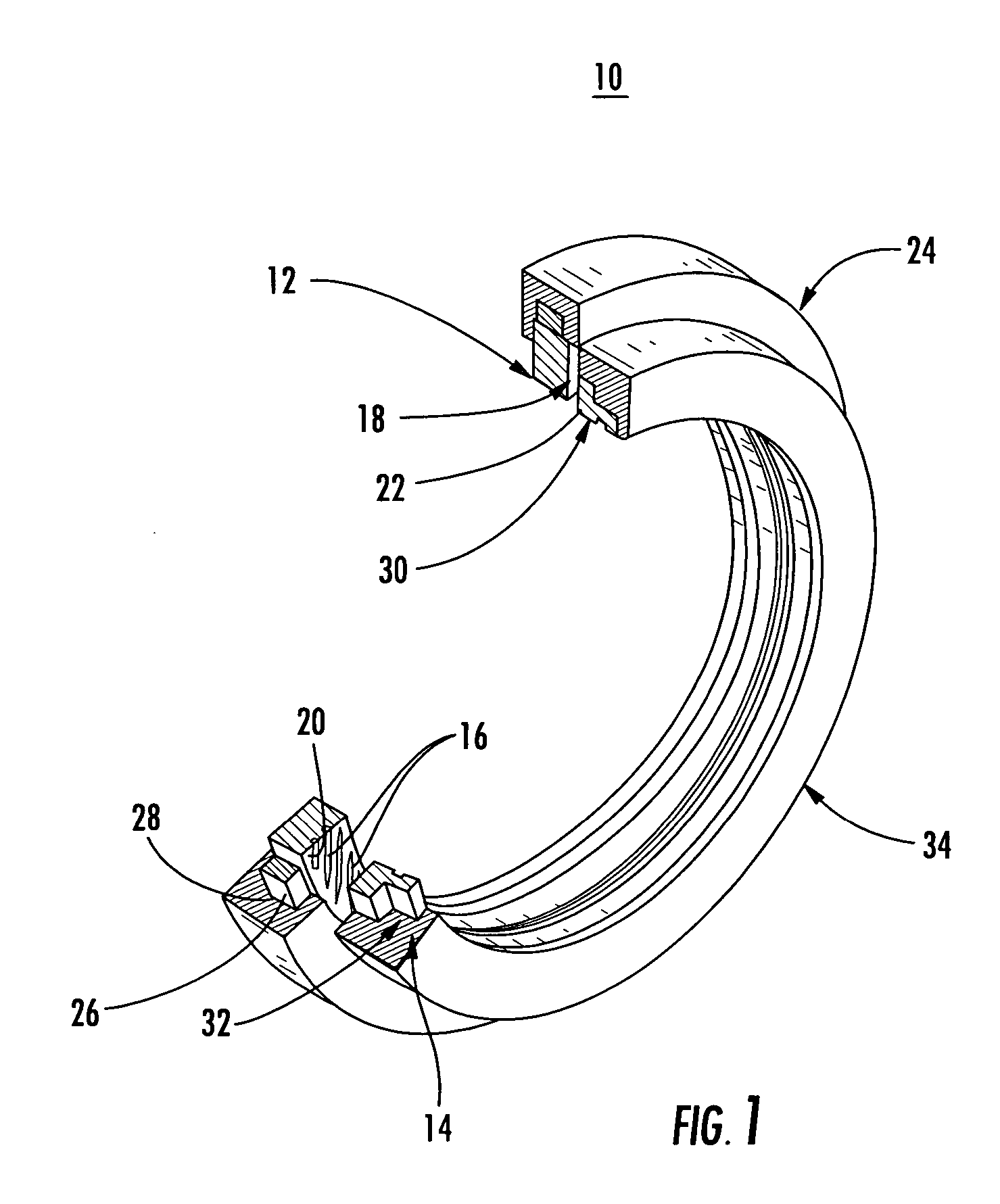

Smart Sonic bearings for frictional force reduction and switching

InactiveUS20020126922A1High compression stiffnessReduce sensitivityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesFriction reductionStatic friction

An ultrastiff precision sonic bearing assembly and method thereof for controlling an effective coefficient of friction between two elements in slidable contact configured along an interface under a force sufficient to maintain contact and having static friction therebetween, by inducing a repetitive motion in one of the elements parallel to the interface thereby altering the effective coefficient of friction therebetween. The bearing assembly also provides for additional and independent electronic control over the average thickness thereof and senses the force thereon to allow the bearing assembly stiffness to be altered.

Owner:GRQ INSTR

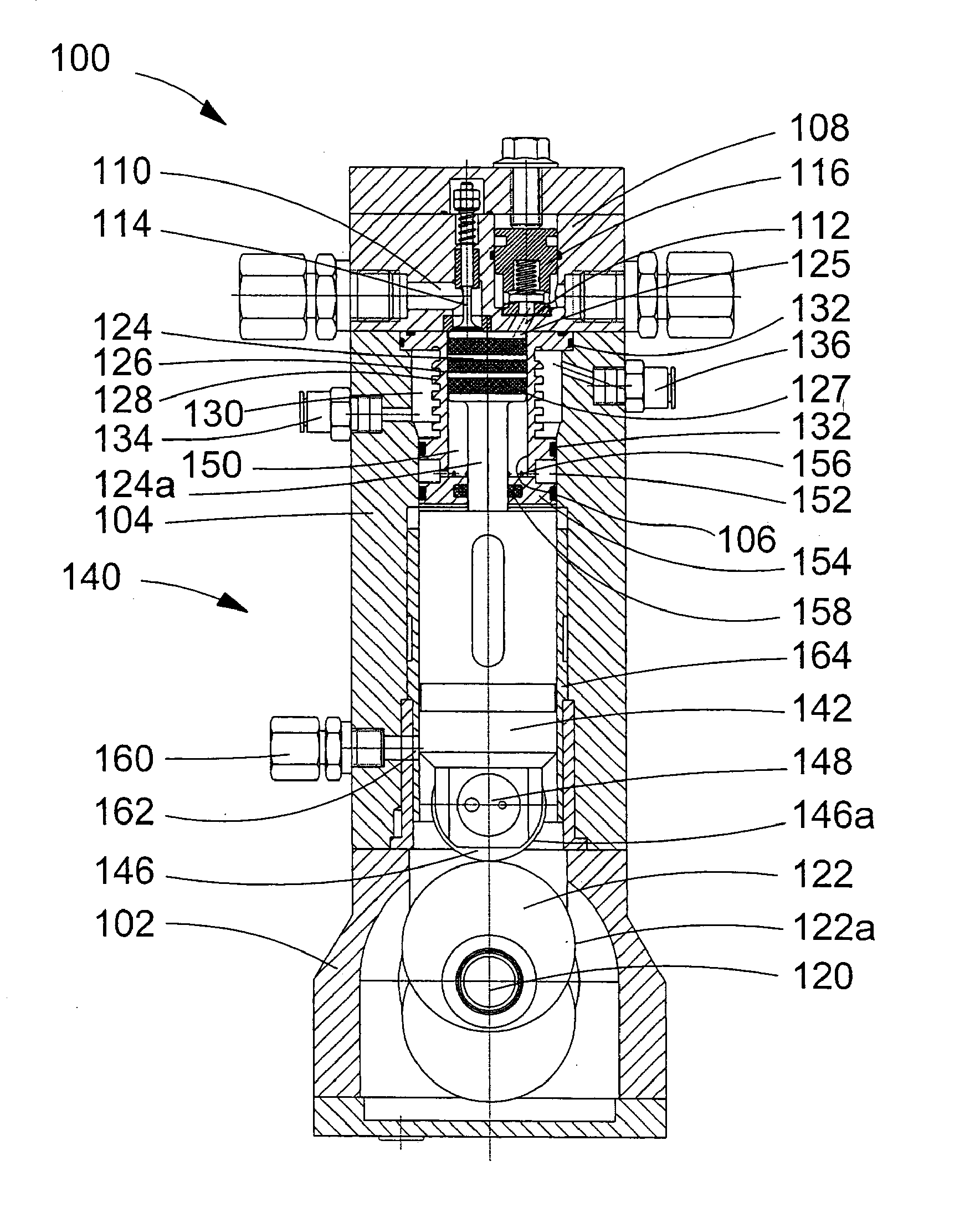

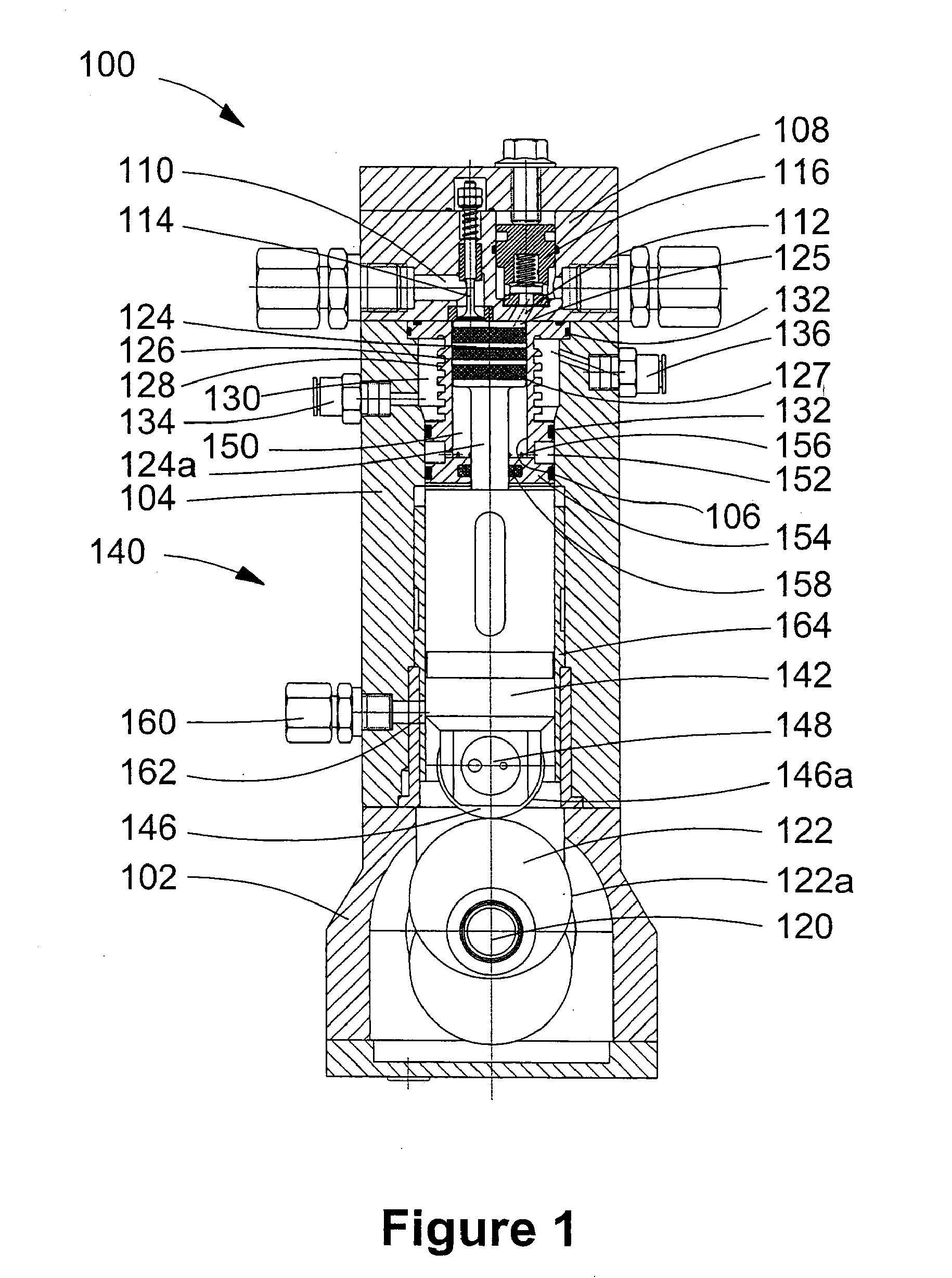

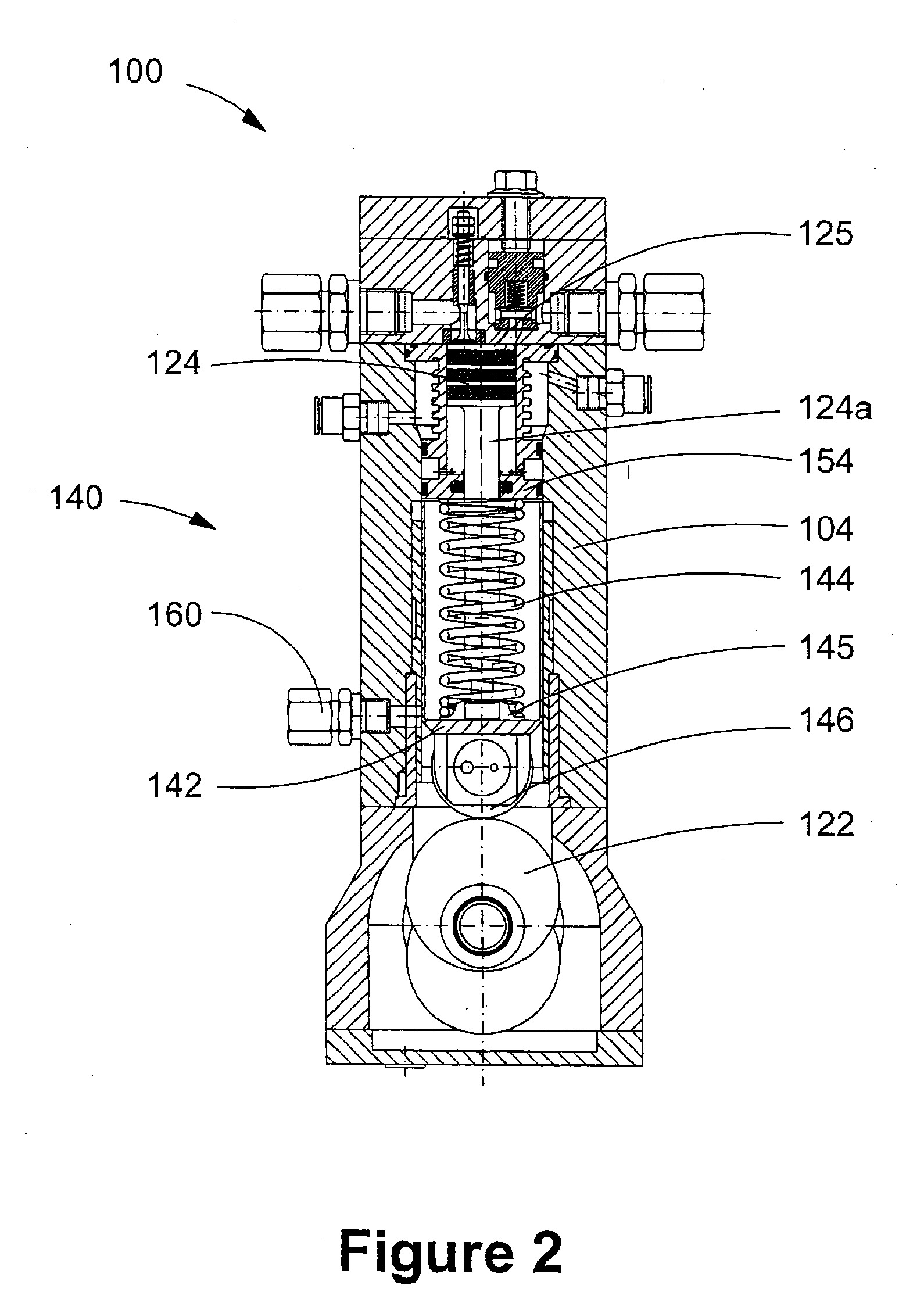

High-Pressure Gas Compressor And Method Of Operating A High-Pressure Gas Compressor

ActiveUS20080213115A1Reduce in quantitySimple manufacturing processPositive displacement pump componentsFlexible member pumpsFriction reductionInlet valve

A high-pressure gas compressor comprises a single-acting cam driven piston with a pressure compensation chamber disposed between the piston and the cam. A roller tappet assembly transmits reciprocating motion from the cam to the piston. A pressurized gas directed to the pressure compensation chamber offsets forces acting on the piston from the compression chamber gas pressure, thereby reducing Hertzian pressure between the tappet roller and the cam. Overall efficiency and durability can be improved by reducing friction between compressor components, for example by employing thin film coatings to reduce friction, pressurized oil lubrication systems and higher cylinder bore diameter to piston stroke ratios. The service life of gas seals and compression efficiency can be improved by thermal management strategies, including liquid-cooled compressor cylinder liners and intercoolers between compression stages. Employing a poppet-style intake valve and reducing parasitic volume in the compression chamber can improve compressor volumetric efficiency.

Owner:WESTPORT FUEL SYST CANADA INC

Catheter

The invention provides a catheter, e.g. a urinary catheter, comprising two parts joined in a fixed connection. One part is made for manipulation of the other part, which other part is made for insertion into the body. The catheter comprises a sleeve attached to the outer surface of one of parts and which protects against bacterial contamination of the catheter and against smudging of surroundings with lubricants, water or similar friction reduction substances which may be pre-applied to the catheter to facilitate safe insertion. The invention fuirther provides a sleeve for the above mentioned catheter.

Owner:COLOPLAST AS

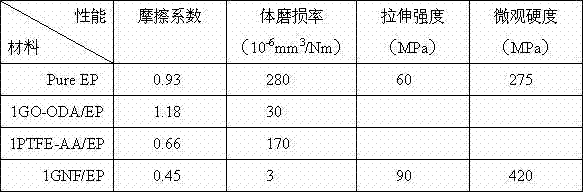

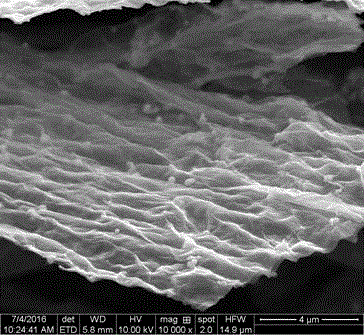

Graphene-nano polytetrafluoroethylene composite filler as well as preparation method and application thereof

The invention belongs to the technical field of friction material, and in particular relates to a graphene-nano polytetrafluoroethylene composite filler with a function of reducing friction, as well as a preparation method and the application of the composite filler. The composite filler comprises the following main components in parts by weight: 1 part of modified graphene and 1-20 parts of modified nano polytetrafluoroethylene; the preparation method of the composite filler comprises the following steps: separately reacting graphene and nano polytetrafluoroethylene with amination reagent and carboxylation reagent to obtain the modified graphene and the modified nano polytetrafluoroethylene; carrying condensation reaction so that the modified graphene and the modified nano polytetrafluoroethylene are connected with each other by a covalent bond to obtain the graphene-nano polytetrafluoroethylene composite filler. The function of friction reduction of the graphene and the function of lubrication of the nano polytetrafluoroethylene are utilized at the same time; after the composite filler is added to a polymer material, the friction coefficient and the wear rate of the material can be reduced, and the mechanical property of the material can be improved.

Owner:FUDAN UNIV

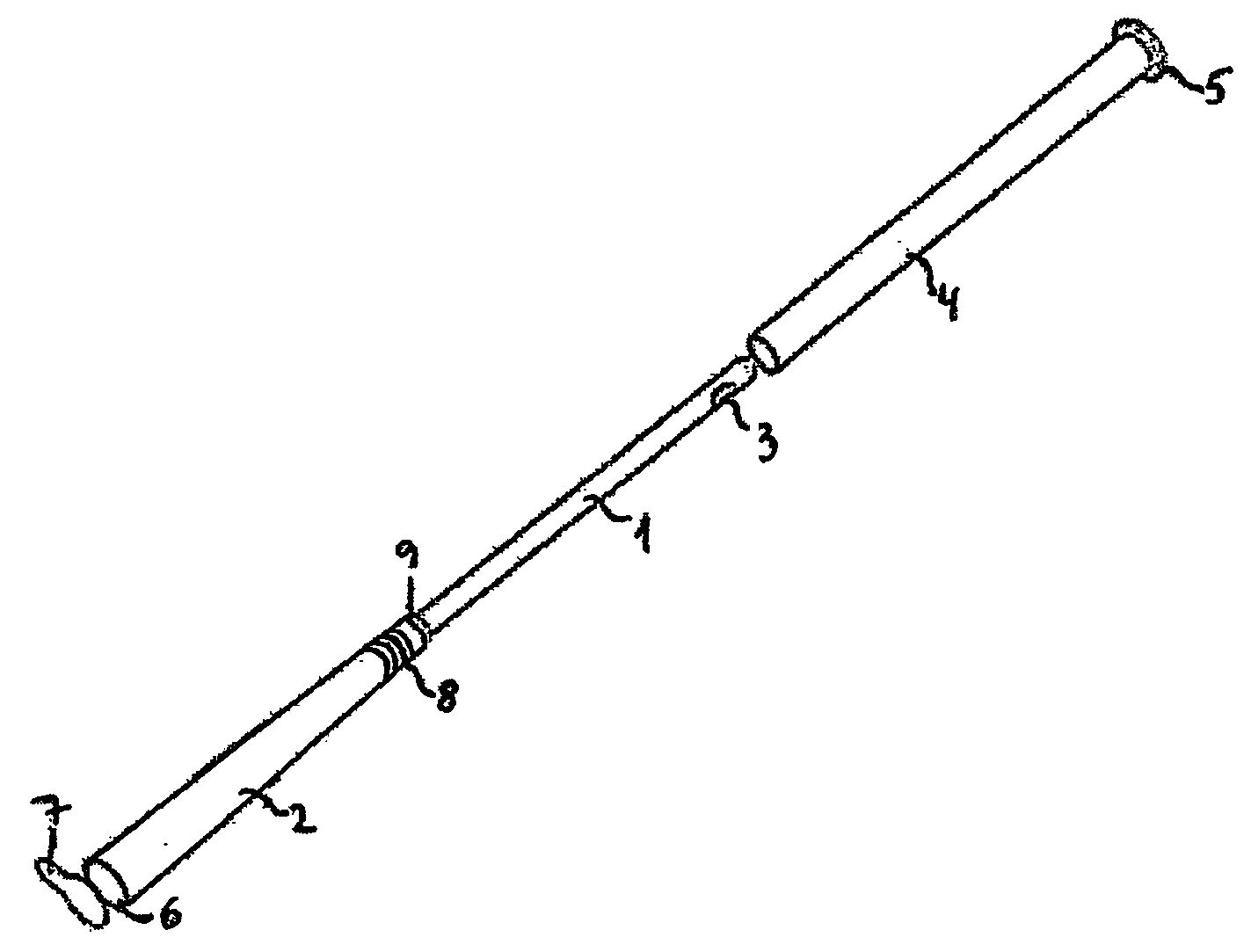

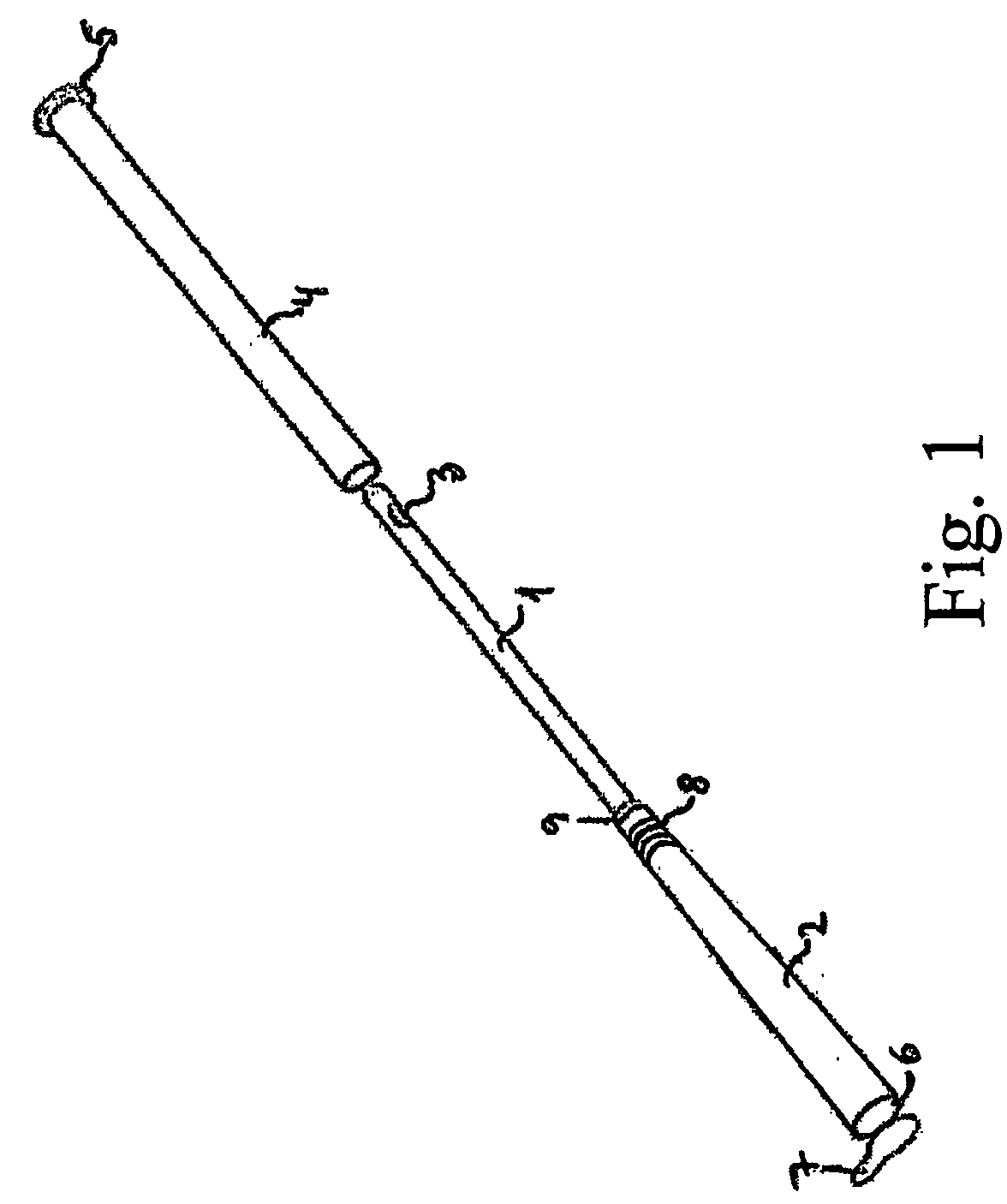

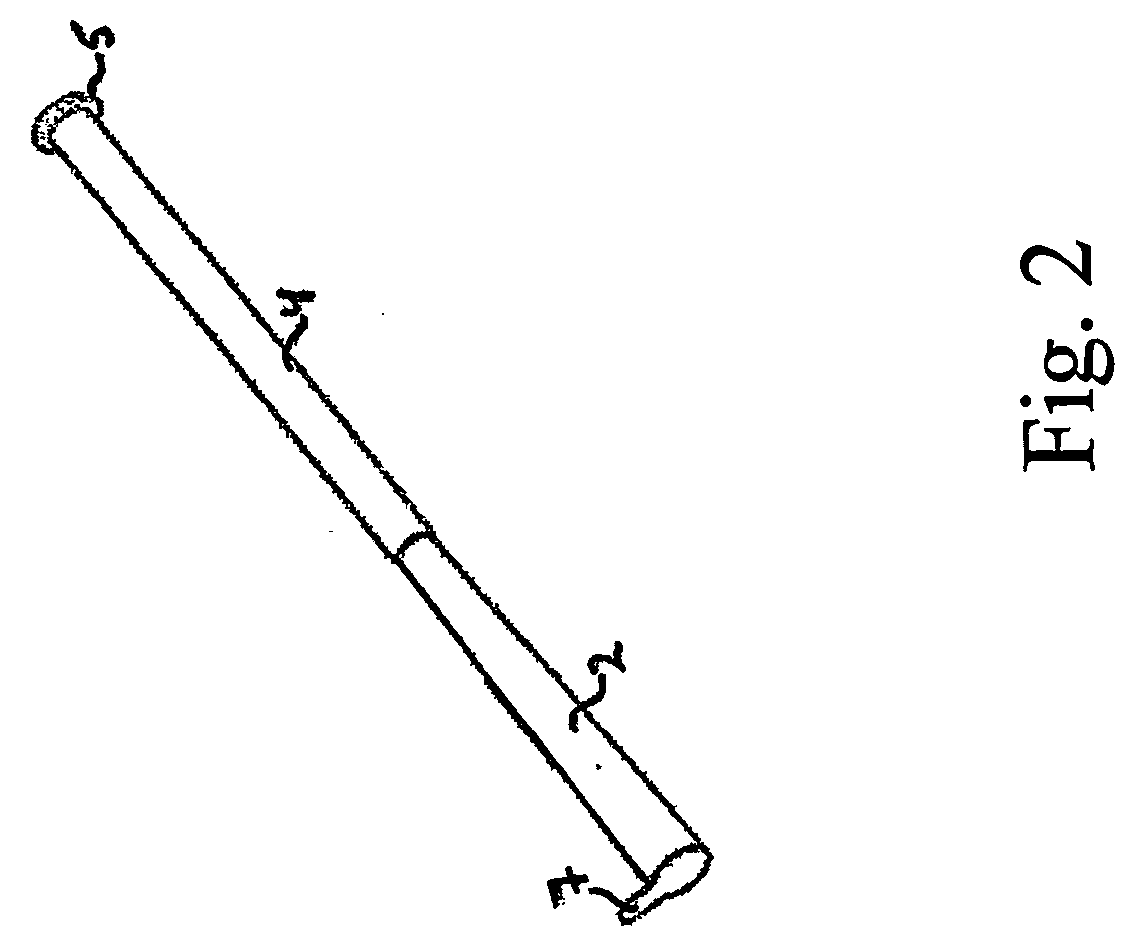

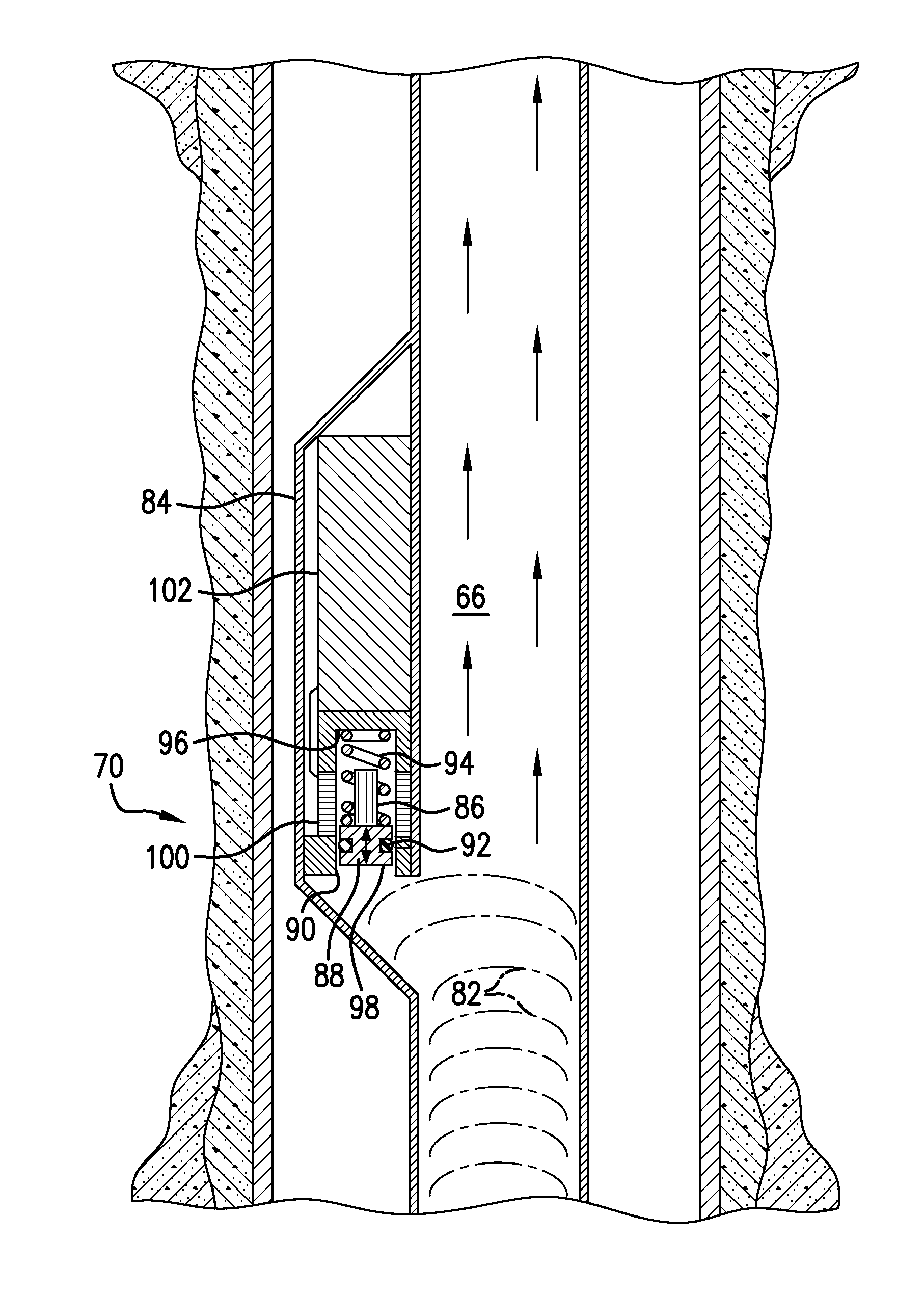

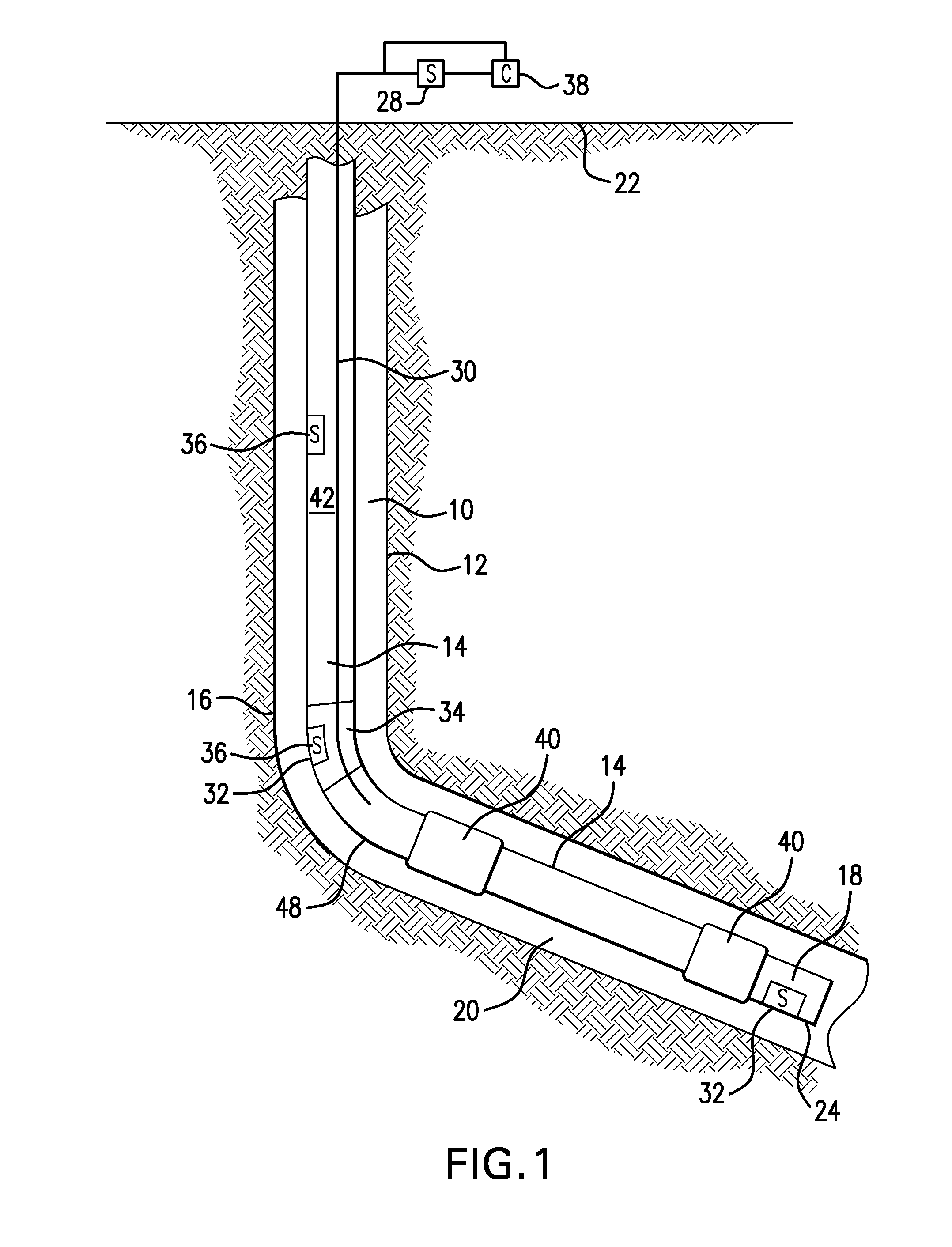

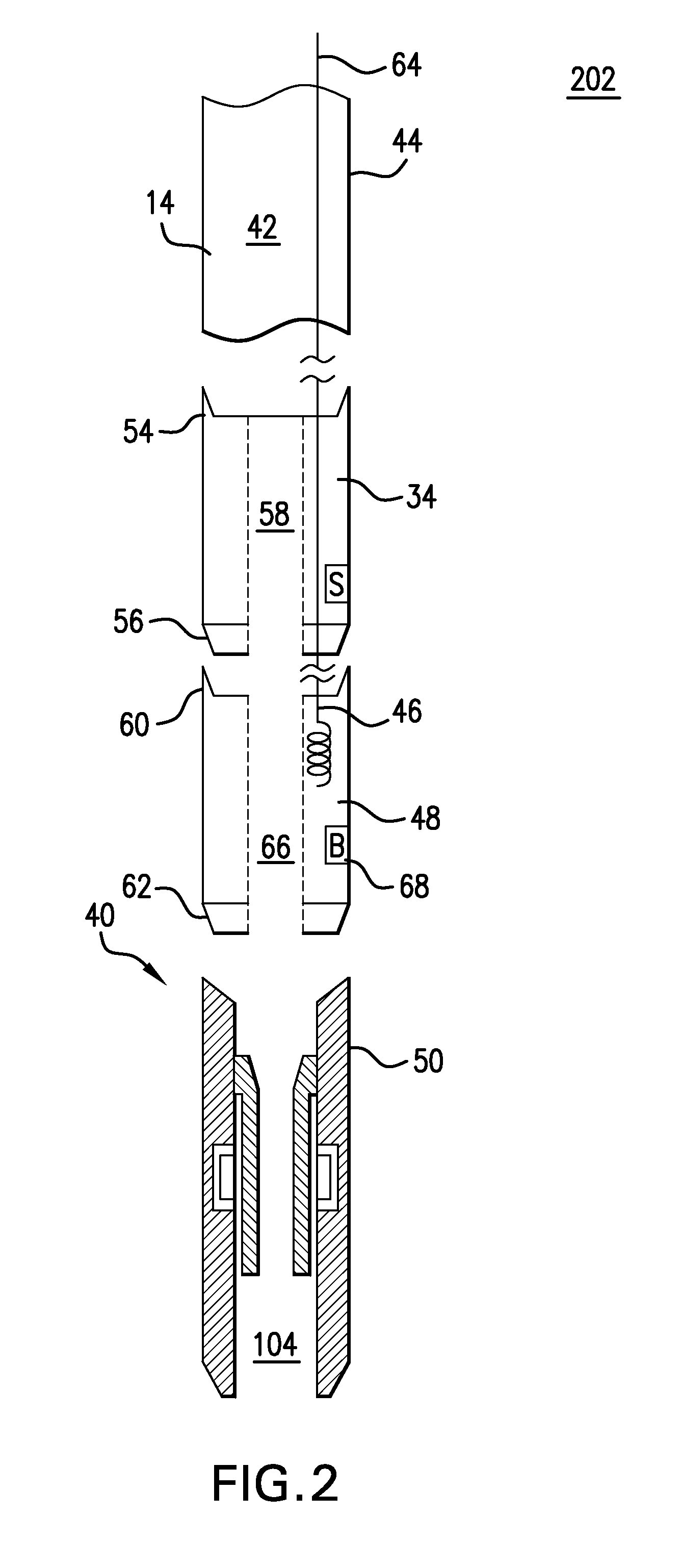

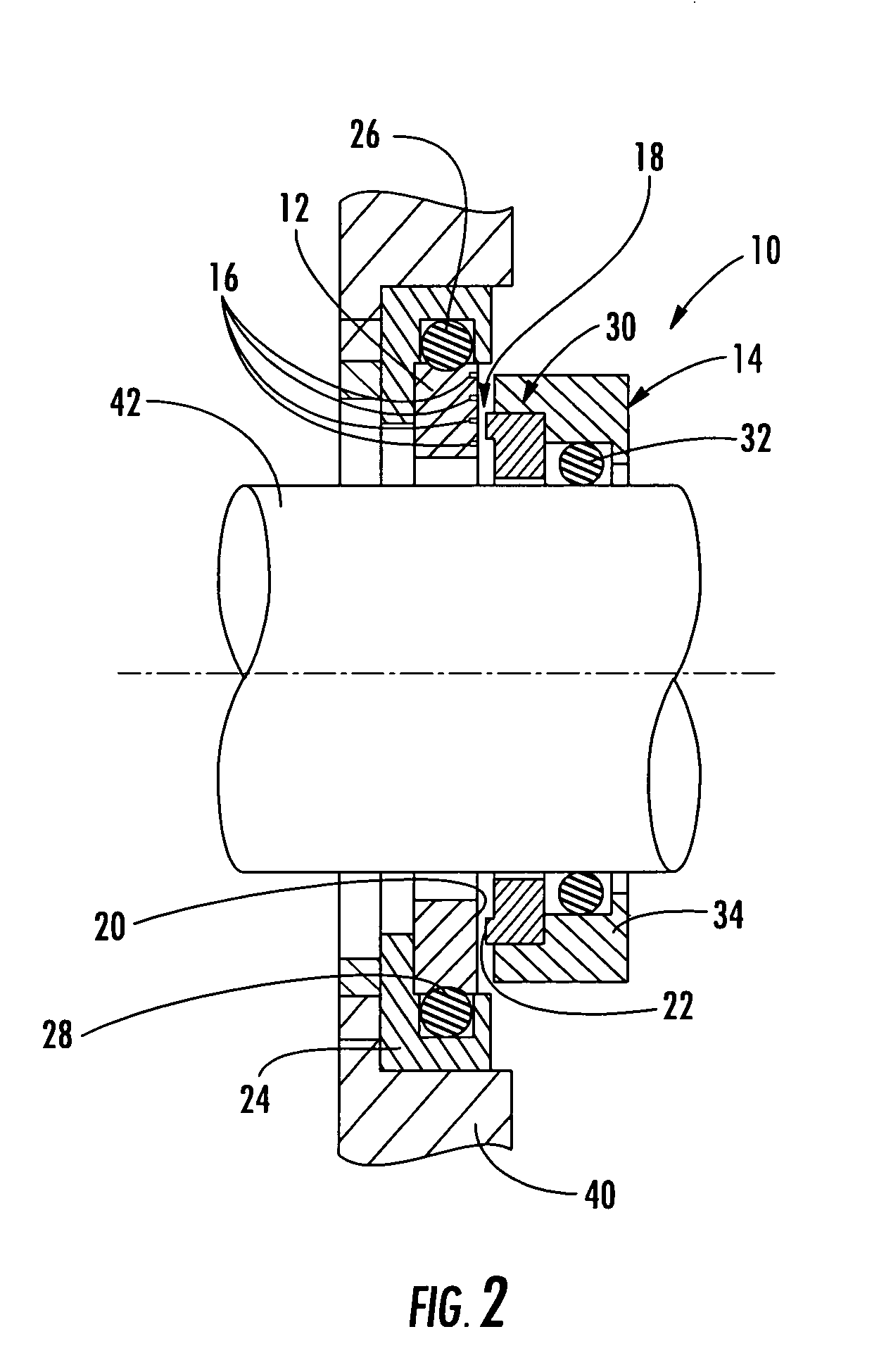

Friction reduction assembly for a downhole tubular, and method of reducing friction

A friction reduction assembly for a downhole tubular. The friction reduction assembly includes an electrically activated friction reduction sub. The sub includes a flowbore fluidically connected to a flowbore of the tubular and remaining open for fluid flow therethrough during both activated and non-activated states of the friction reduction sub. A friction reducer responsive to an indication of lockup of the tubular, wherein friction between the tubular and surrounding casing or borehole is reduced in an electrically activated state of the friction reduction sub. A method of reducing friction in a downhole tubular is also included.

Owner:BAKER HUGHES INC

Penetrating lubricant composition

InactiveUS6919300B2Improve the lubrication effectPleasant odorOrganic chemistryLiquid carbonaceous fuelsFriction reductionEngineering

A protective lubricating composition is provided which will penetrate readily to closely fitting frictional parts and form a protective non-migrating lubricating film improving lubrication between the moving parts reducing friction and wear and preventing corrosion. The lubricant composition may be combined with solvents and propellants to make a sprayable lubricant composition.

Owner:ASHLAND OIL INC

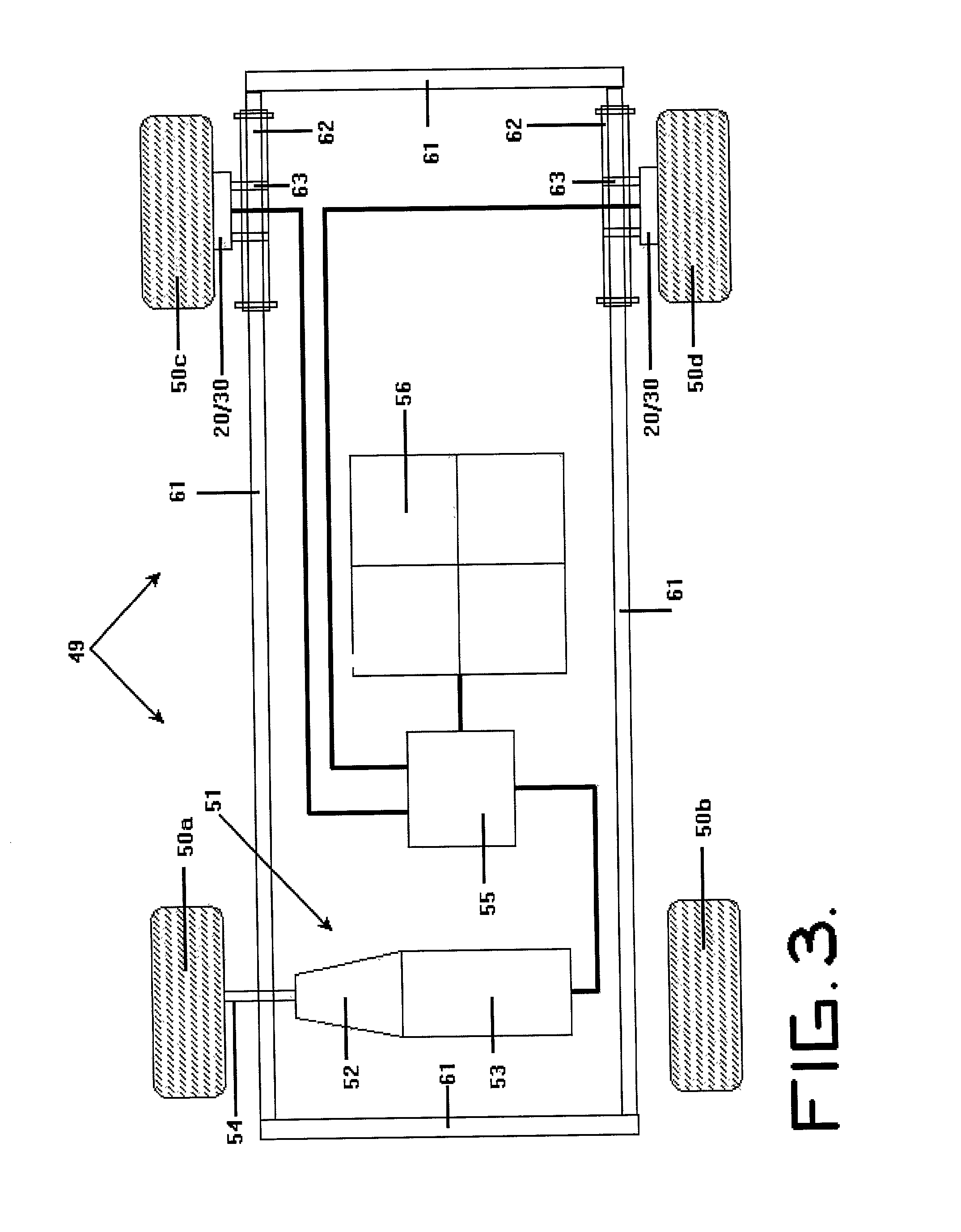

Electric power generation system for electric vehicles

An electrical power generating system is described for generating electrical energy for an electric vehicle, via the motion of the non-drive wheels, which converts kinetic energy to electrical energy to replenish the batteries of said vehicle. The preferred version places one or more alternator / generator(s) at the non-driven wheels of the vehicle. Each alternator / generator is unitarily formed with respect to a mounting plate unitarily formed with respect to said mounting plate and said vehicle's suspension, and each alternator / generator includes a rotating field means integrated with the rotating mounting plate attached to the wheel and a stationary stator means stationarily attached to the frame through the suspension. Conventional electrical contact means attached to between said rotating field means and said stationary stator means for generating electrical current for said vehicle. Since the mechanical loading on the spindle bearing assemblies has been substantially increased, the bearing assemblies of the invention are of a heavy-duty design. That is, such bearing assemblies are large enough to handle the weight of said vehicle, including that of the alternator, as well as the weight of the wheel assembly, including tire and brakes. As the vehicle moves forward or backward, the rotational force applied to the vehicle's wheels will rotate the integrated rotating field means relative to the stationary stator means to produce alternating current (AC). Alternating current is converted to direct current (DC) either by a diode bridge, transformer, or controller, for distribution to the EV's electrical system. DC electricity is used to recharge storage batteries, provide electricity for the drive motor and operate the vehicle's electrical equipment. Thus, the regenerative system, does not add any additional load on the drive motor. Wheel bearing assemblies are usually used for all wheels on vehicles and the very nature of bearing assemblies are to reduce friction. By the incorporation of alternators into the wheel bearing assemblies, a vehicle can generate electricity when moving, without additional workload to the drive train; since wheel bearing assemblies are a necessary and integral part of any rolling vehicle and by their very nature reduce friction and resistance.

Owner:SMITH VINCENT A +2

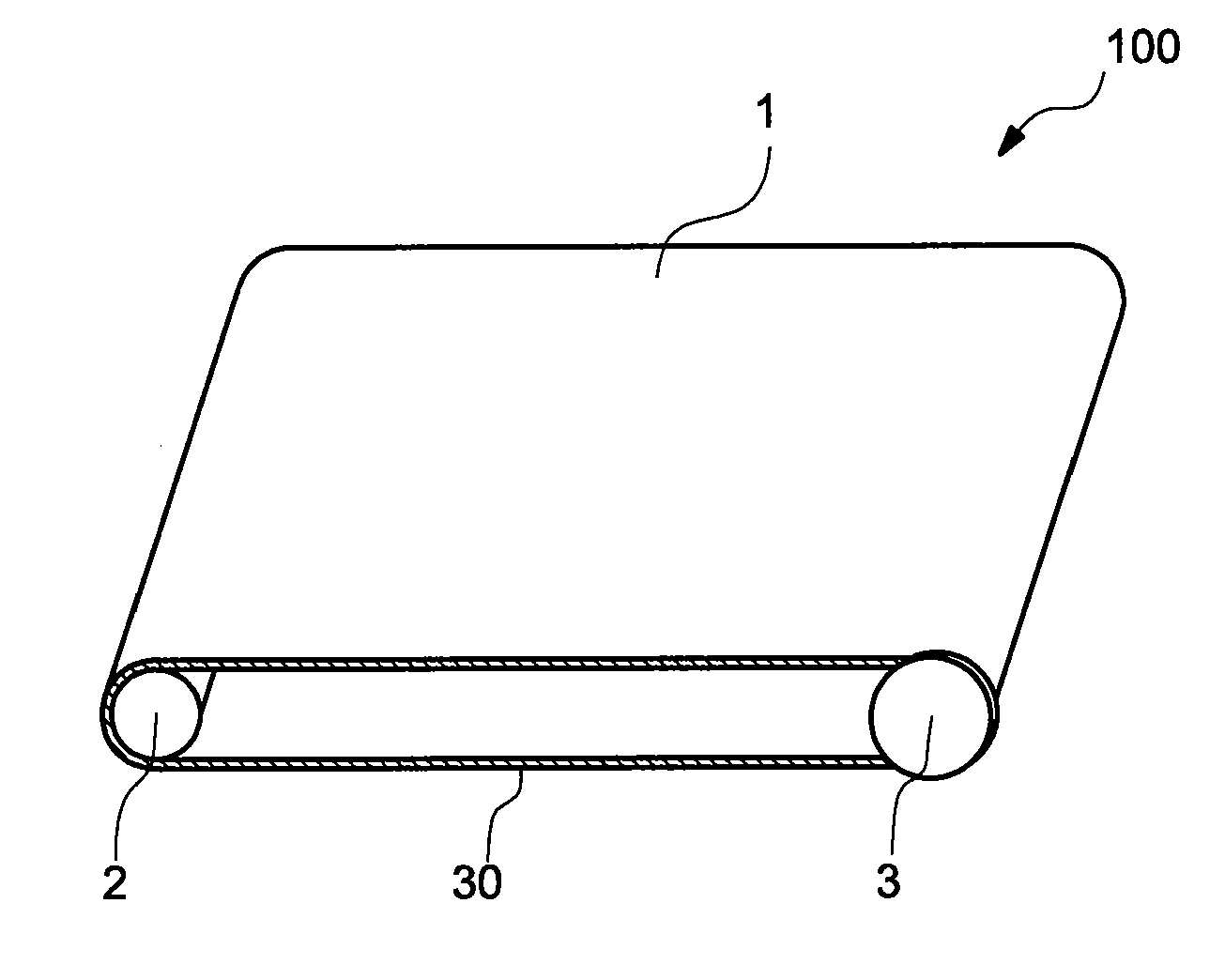

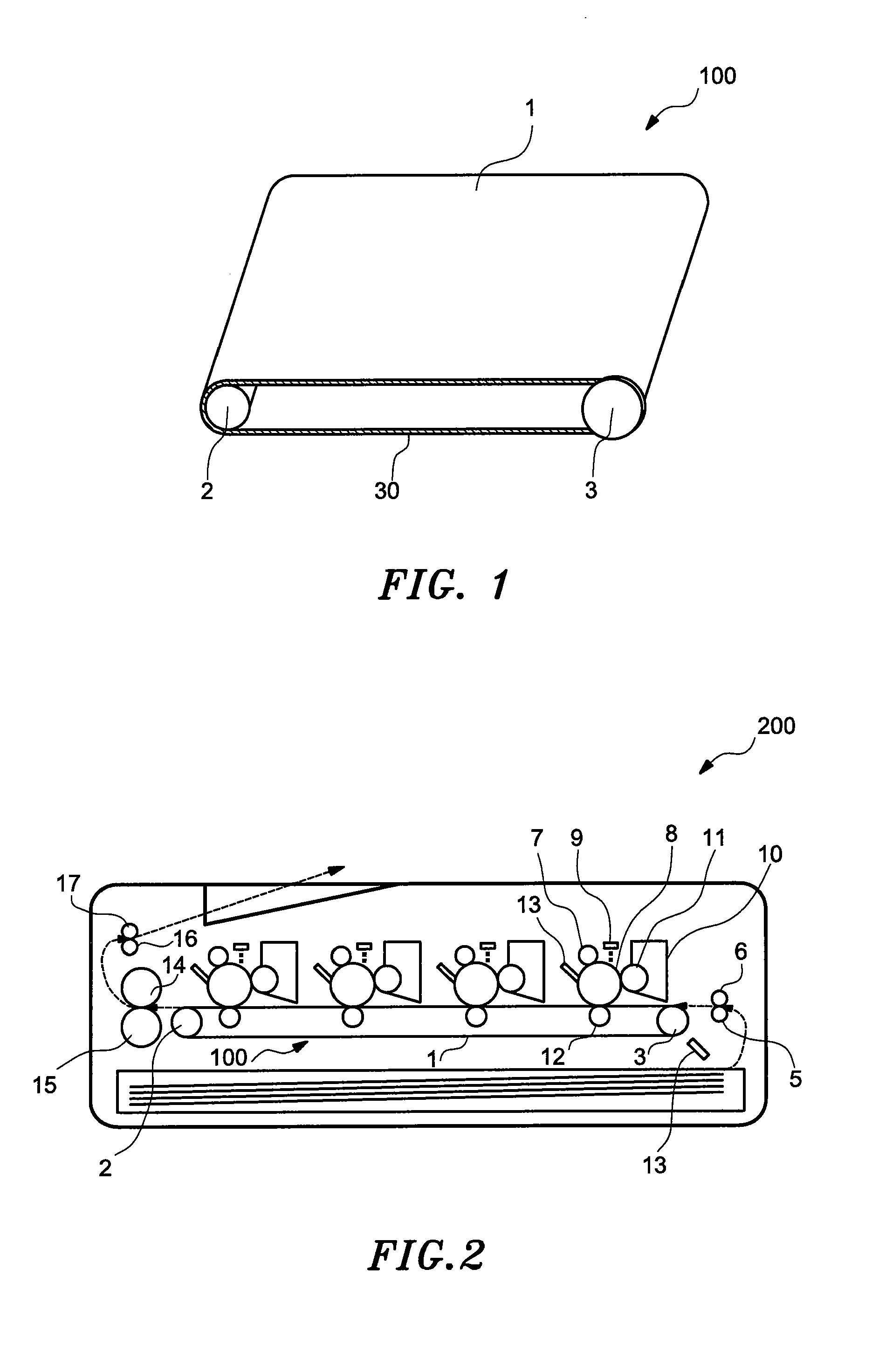

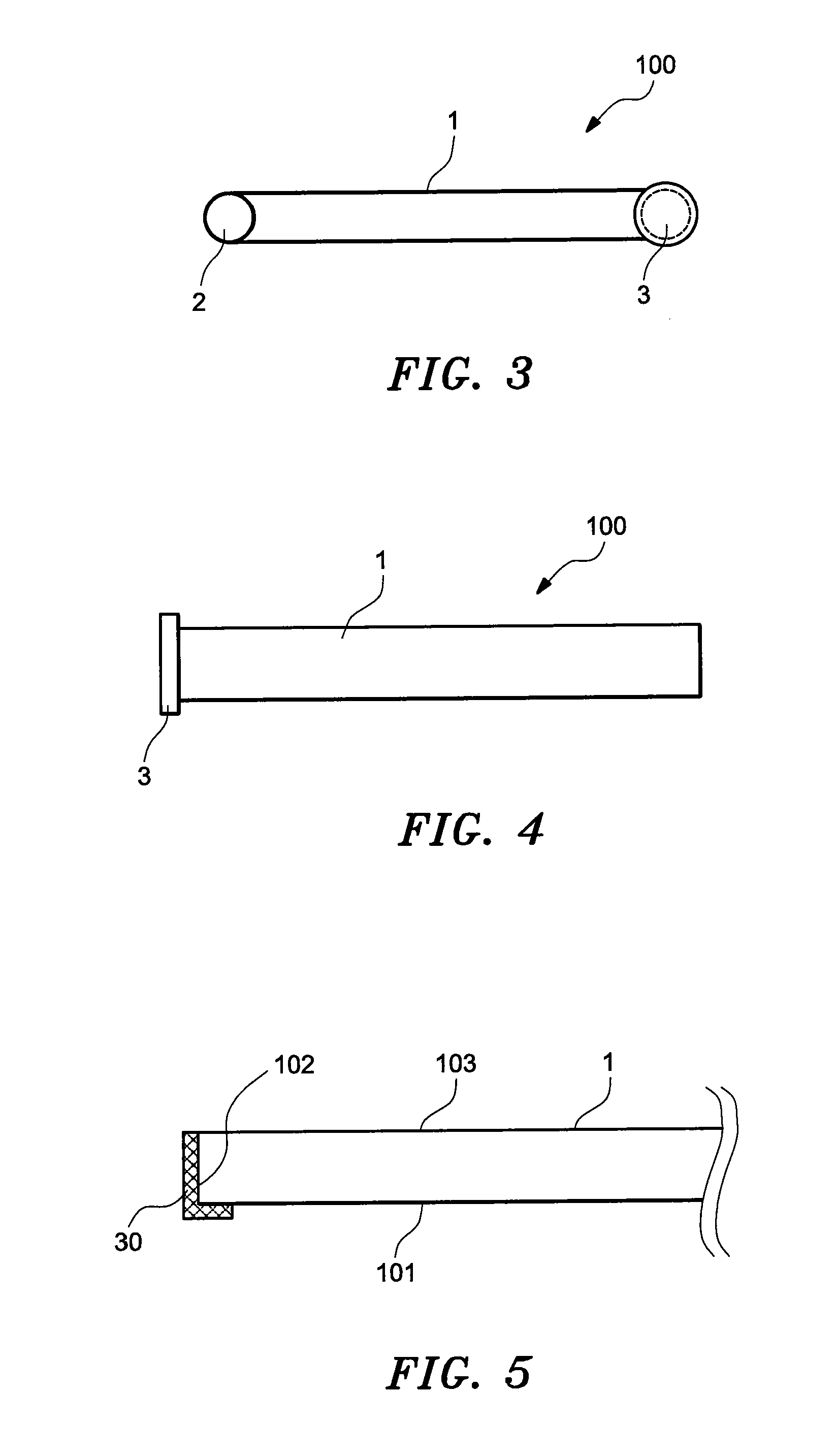

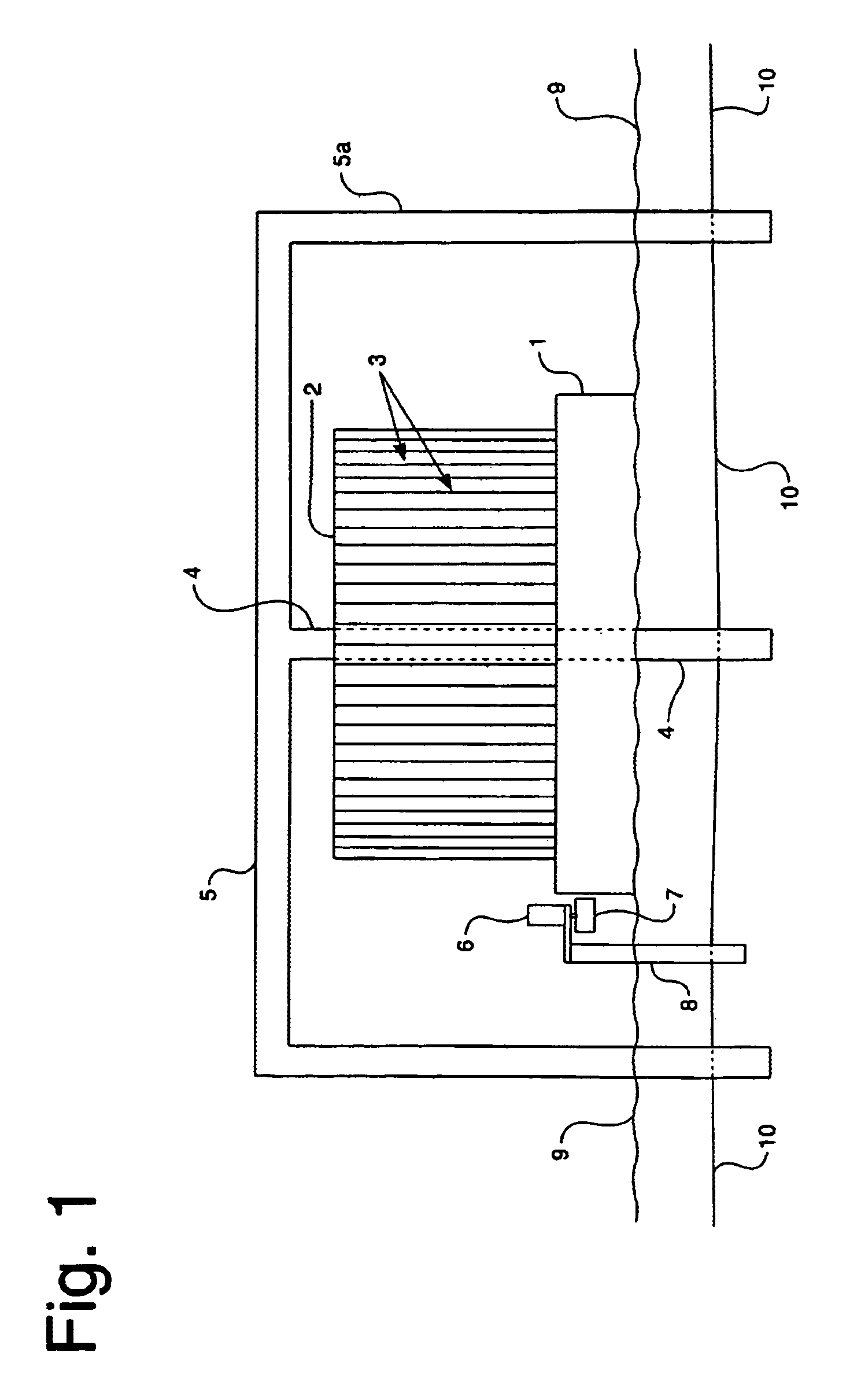

Belt Rotating Device and Image Forming Apparatus

A belt rotating apparatus capable of improving a durability with respect to flexion fatigue of a belt and capable of reducing the occurrence of the breakage of the belt; and an image forming apparatus having the belt rotating device are supplied. The belt rotating device includes a belt that is wound on a roller driven by a predetermined driving means; and a meander prevention member that is slidably contacted with an end surface of the belt for preventing a meander of the belt. In the belt rotating device, a friction reduction agent for reducing slide friction with respect to the meander prevention member is used to coat at least an end surface of the belt.

Owner:OKI DATA CORP

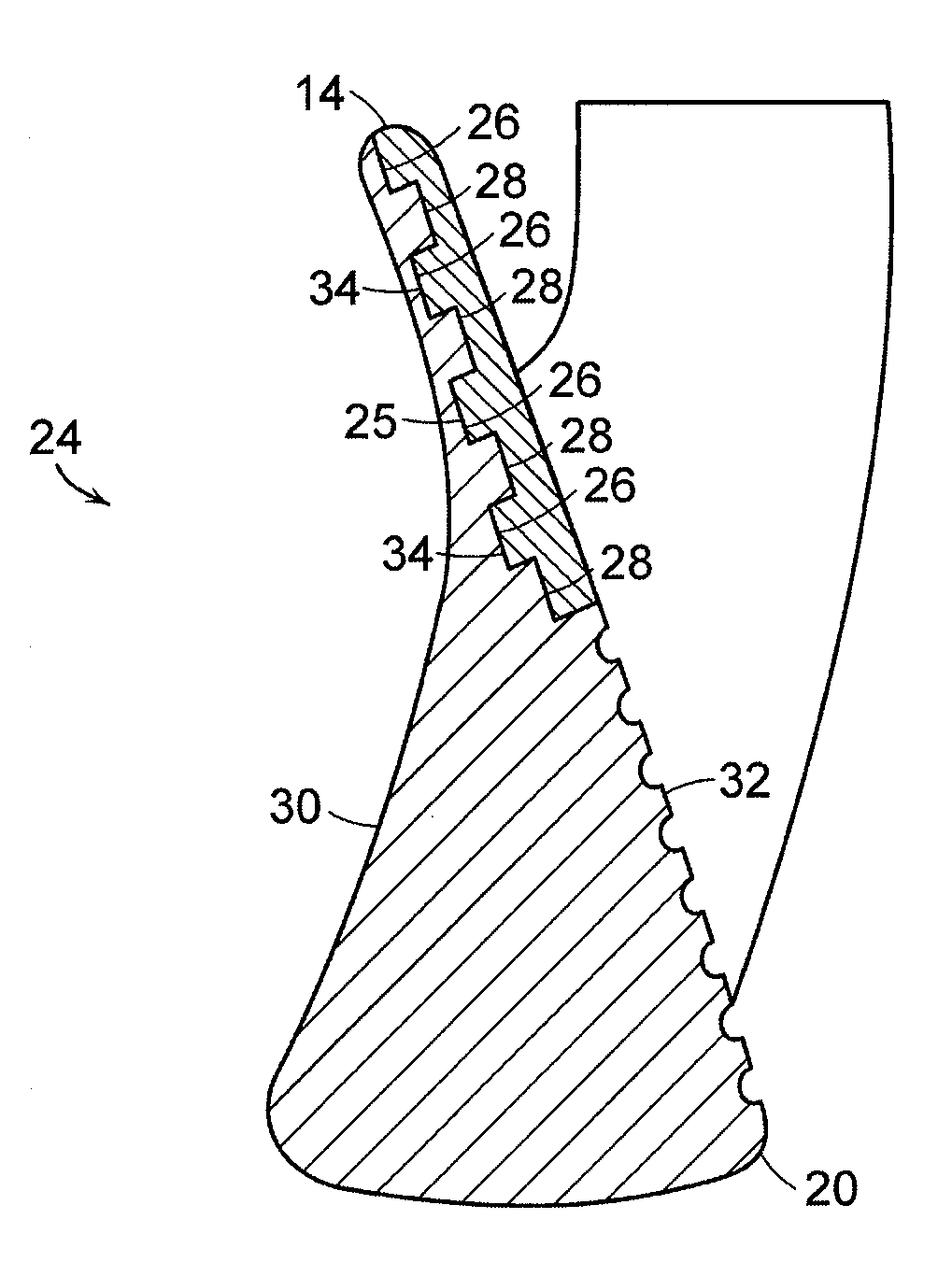

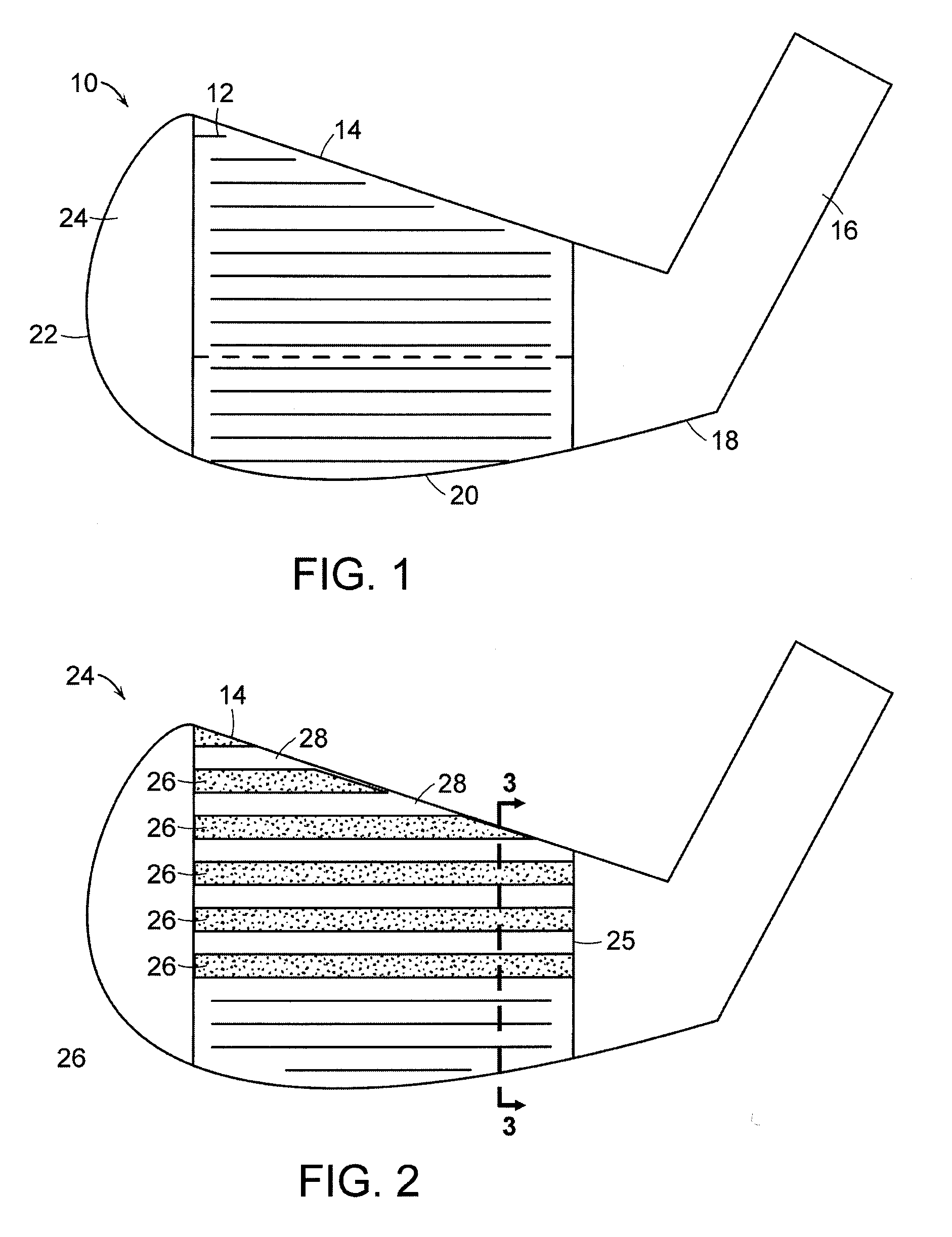

Multi-metal golf clubs

InactiveUS20080076597A1Improve performanceAnodisationElectrolytic inorganic material coatingFriction reductionGolf Ball

A composite material golf club head is provided having a body made from a first metal and a face insert press fitted to a portion of the body and made from a second metal. The metals are chosen so that the first metal is heavier than the second metal. The second metal is disposed towards the front and top of the body, and is preferably hard-anodized. In addition, an interlocking structure, for example rectangular or dove tail shaped channels, is provided in the body so that the face insert becomes embedded in the interlocking structure to anchor the face insert to the body. Portions of the golf club head, such as the face insert or sole plate, are anodized to protect against corrosion. The anodized coating is colored to improve aesthetic characteristics or infused with a polymer to increase or reduce friction.

Owner:COBRA GOLF

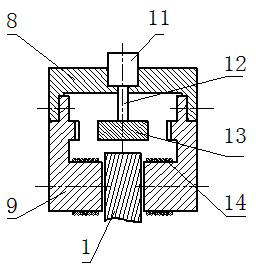

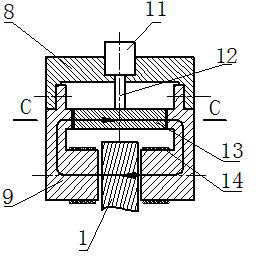

Electromagnet and friction composite disc type brake and brake method

InactiveCN102128227AShort duration of actionReduce usage intensityAxially engaging brakesBrake actuating mechanismsFriction reductionElectromagnetic field

The invention provides an electromagnet and friction composite disc type brake and a brake method. Both a steering knuckle and a brake caliper bracket are fixedly connected with an electromagnet brake fixing device, and the electromagnet brake fixing device is fixedly connected with magnet cores. The magnet cores are symmetrically arranged on the two sides of a brake disc, and coil windings are wound on the magnet cores. Permanent magnet bodies and the magnet cores are oppositely arranged, and air gaps are arranged between the permanent magnet bodies and the magnet cores. When an automobile brakes, electromagnet fields distributed on the axes of the coil windings are generated after the coil windings are electrified, and the directions of the electromagnet fields generated by the coil windings on the two sides of the brake disc are consistent. The permanent magnet bodies rotate 90 DEG, the directions of the permanent magnet fields of the permanent magnet bodies are consistent with the directions of the electromagnet fields of the coil windings, and the brake disc is braked by the superposition of the electromagnet fields and the permanent magnet fields. The size of the brake force is adjusted by adjusting the different rotating angles of the permanent magnet bodies or the size of electrifying current in the coil windings. The action time of the brake is shortened, the brake efficiency is enhanced, the use strength of the friction brake is reduced, the abrasion of brake pads is alleviated, and the brake force is easy to control.

Owner:JIANGSU UNIV

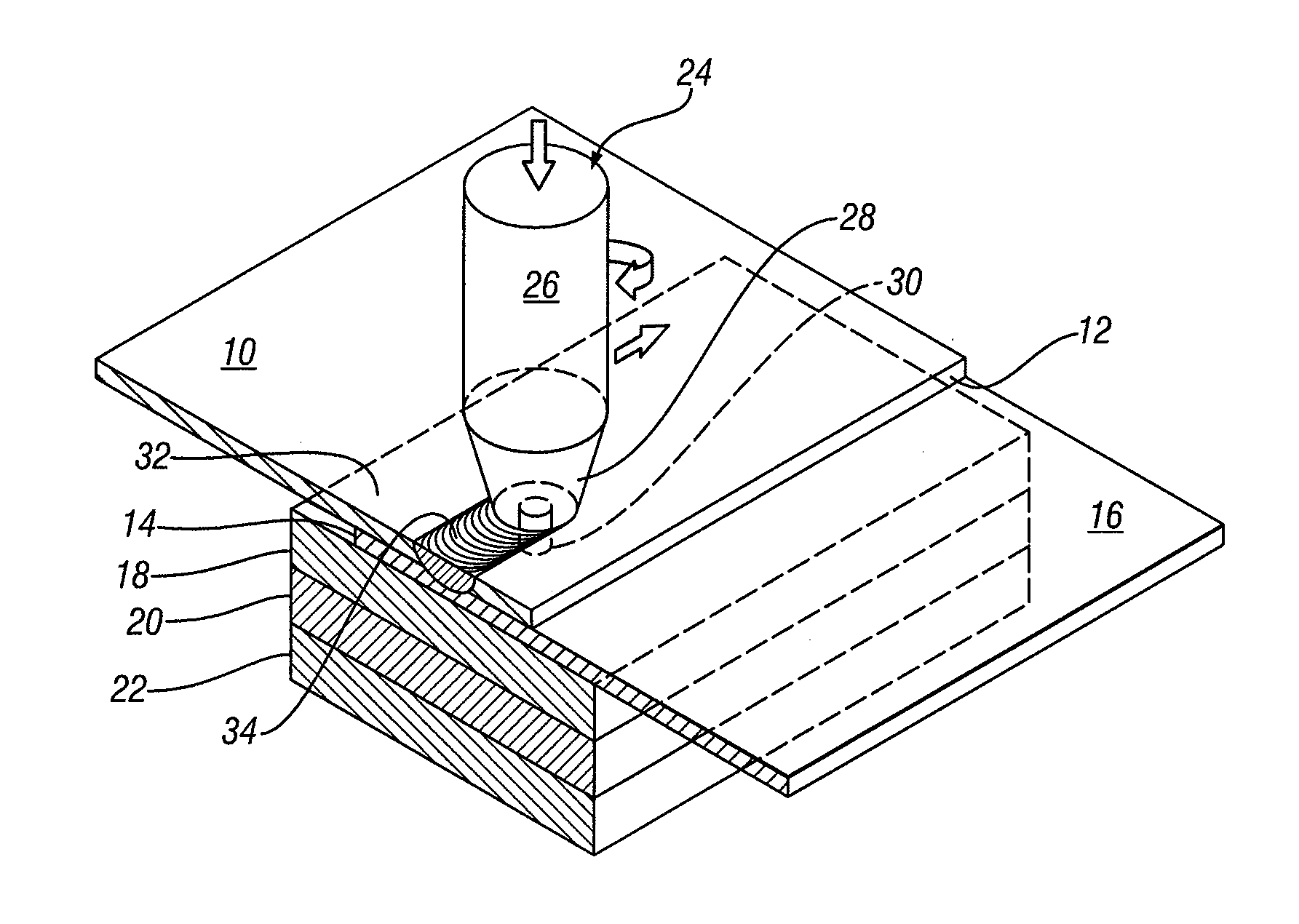

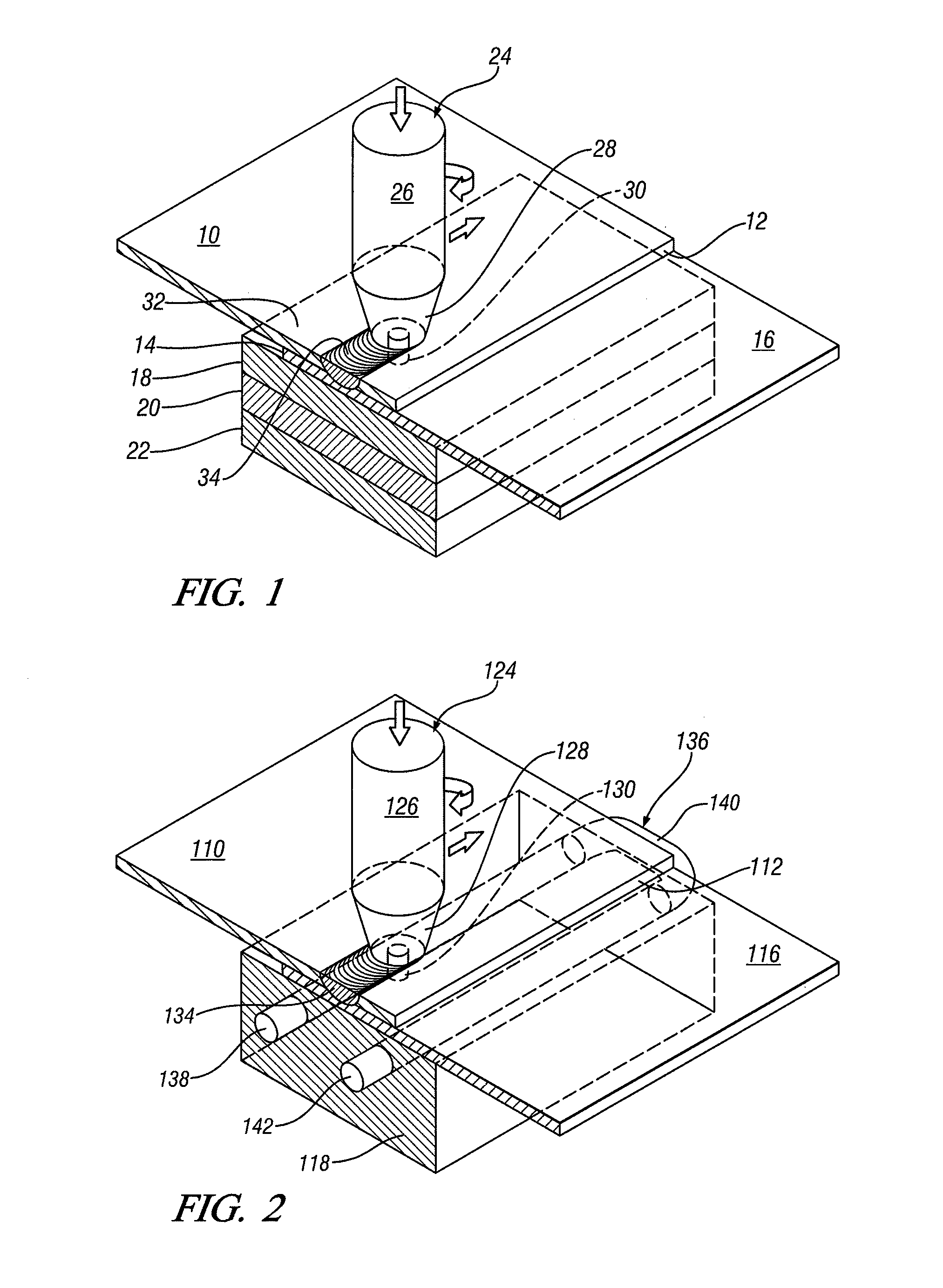

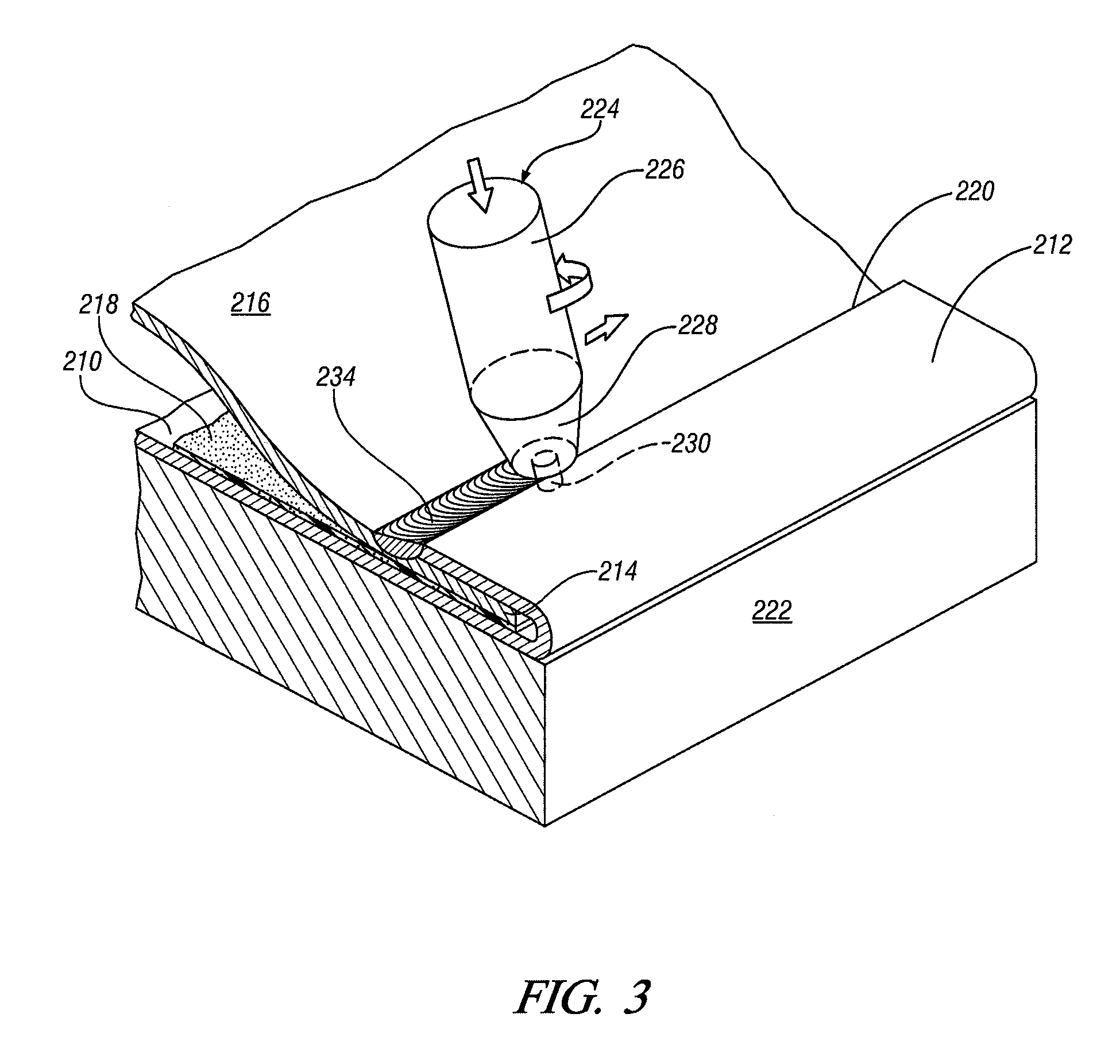

Reducing sheet distortion in friction stir processing

InactiveUS20090200359A1Lower yield strengthEnable unwanted deformationVehicle componentsWelding/soldering/cutting articlesFriction reductionSpot welding

Local heat may be generated through surfaces of sheet metal workpieces by supporting the workpiece(s) on a hard surfaced anvil and engaging the opposite surface of the workpiece with a rotating, and optionally translating, friction stir tool that is pressed against the work surface. Advantages are realized in friction stir processing (e.g. seam or spot welding) of such sheet metal workpieces by using an anvil with appreciable thermal conductivity, or a liquid cooled anvil body, to suitably cool the site(s) of the workpiece engaged by the friction stir tool to minimize or eliminate distortion of the workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

Hydrodynamic magnetic seal

ActiveUS20060244221A1Reduce frictionImprove sealingEngine sealsFriction reductionElectrical and Electronics engineering

A hydrodynamic magnetic seal includes a magnetic mating ring and a sealing ring attracted to the magnetic mating ring. The magnetic mating ring and / or the sealing ring include hydrodynamic grooves configured to create a separation film between the magnetic mating ring and the sealing ring to reduce friction.

Owner:EATON INTELLIGENT POWER LIMITED

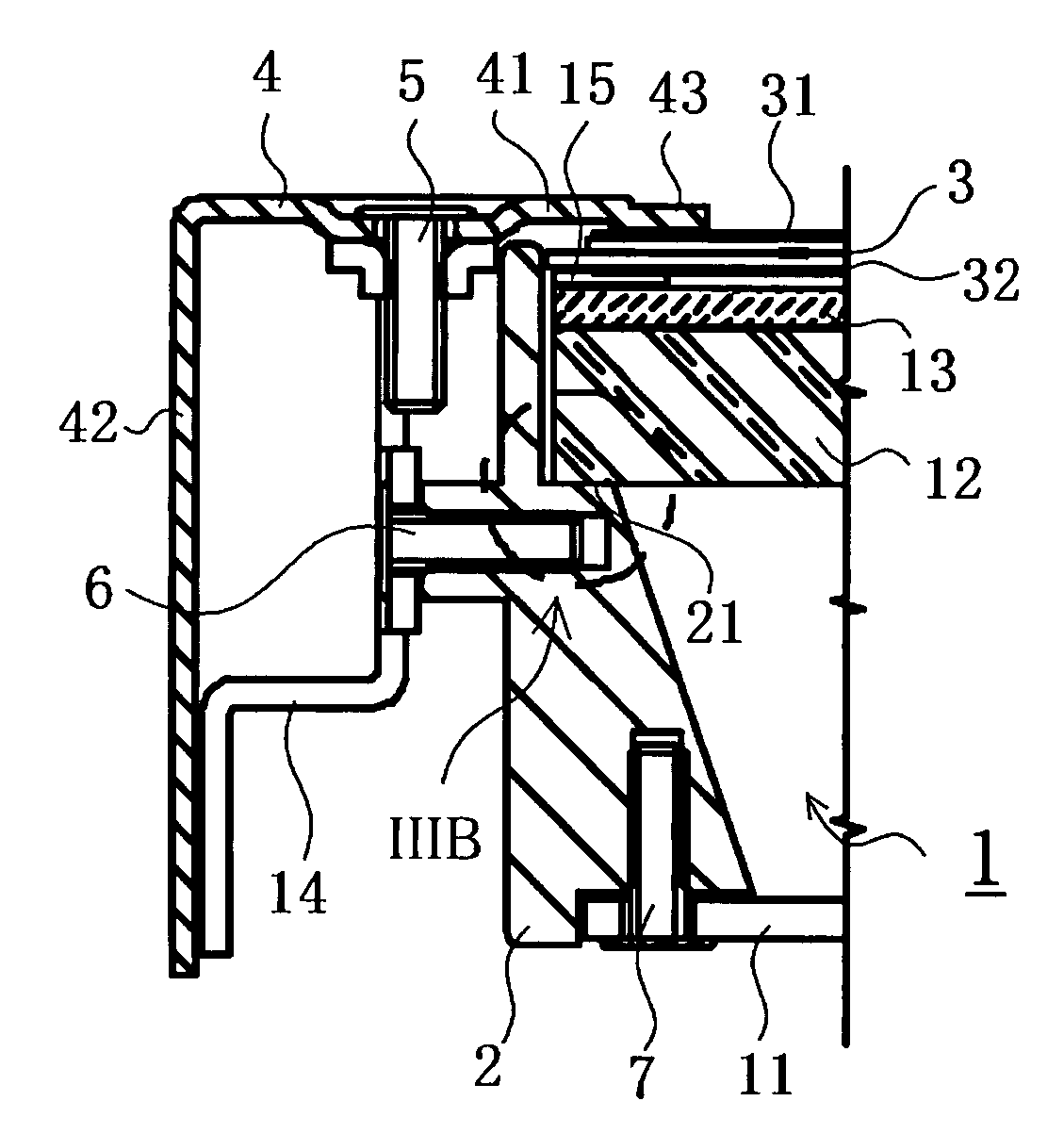

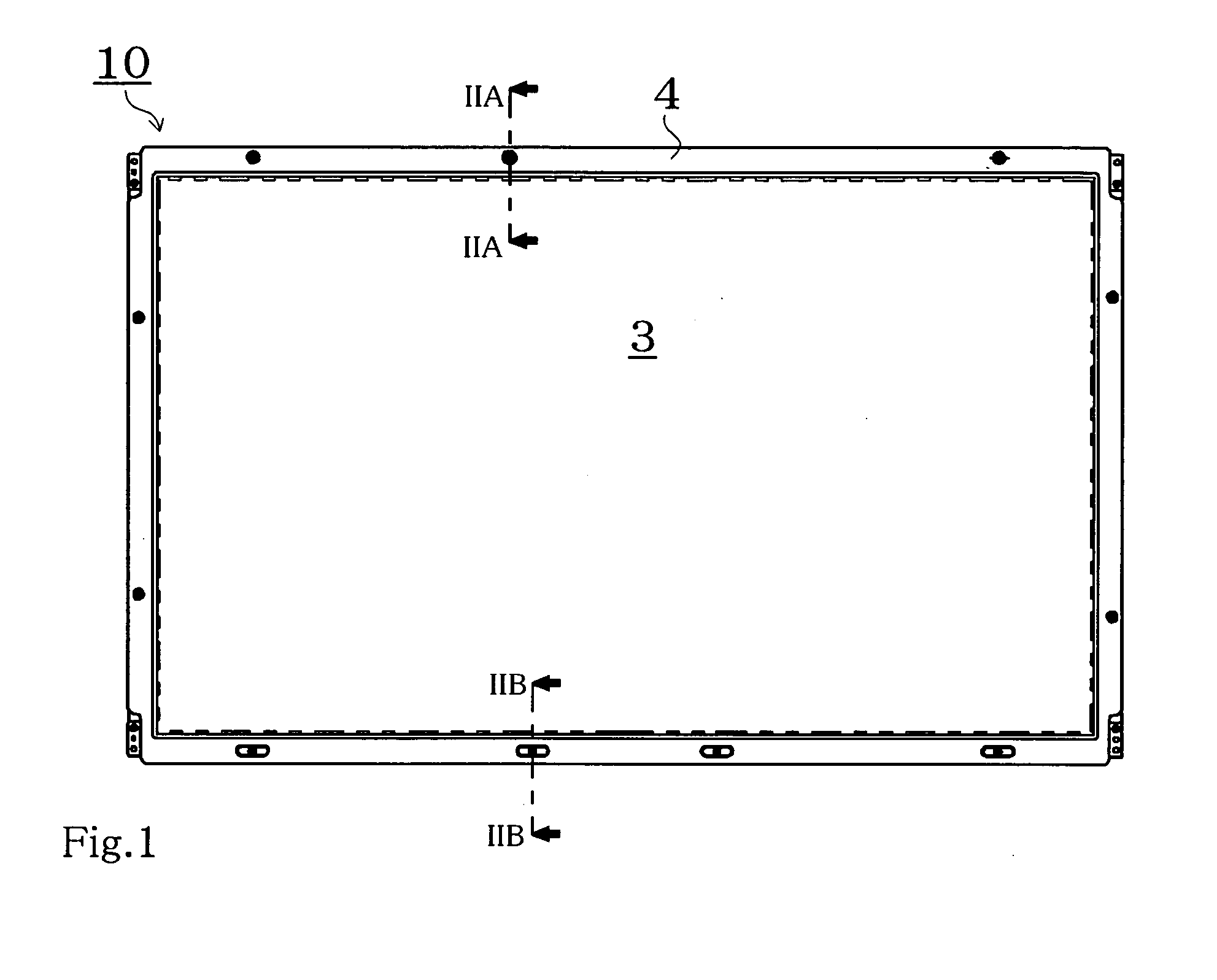

Liquid crystal display device

ActiveUS20050088809A1Cancel noiseReduce morbidityStatic indicating devicesDigital data processing detailsFriction reductionDiffusion

In a liquid crystal display device provided with a backlight unit, creak reduction means is provided at least on one part of the areas where members constituting the liquid crystal display device such as the liquid crystal panel, the diffusion plate, the reinforcing plate, the frame of the liquid crystal display device and the back surface reflector for the backlight unit come into contact with each other. The creak reduction means may be a slippery film whose surface is fluorinated such as a fluororesin film, a polyacetal resin film, a polyethylene film, and a silicon coating film, or protrusions or protruding fins, or a friction reduction means such as silicon oil or fluorine oil, or a mutual displacement absorbing means such as a flexible sheet. By adopting such a constitution, it is possible to prevent noise from being generated due to mutual friction between the liquid crystal panel and the various members such as the diffusion plate, the reinforcing plate, the frame and the reflector for the backlight unit as a result of thermal expansion.

Owner:SATURN LICENSING LLC

Low-friction sliding mechanism, low-friction agent composition and method of friction reduction

ActiveUS20060263604A1Reduce coefficient of frictionImprove fuel efficiencyCrankshaftsGear lubrication/coolingSimple Organic CompoundsFriction reduction

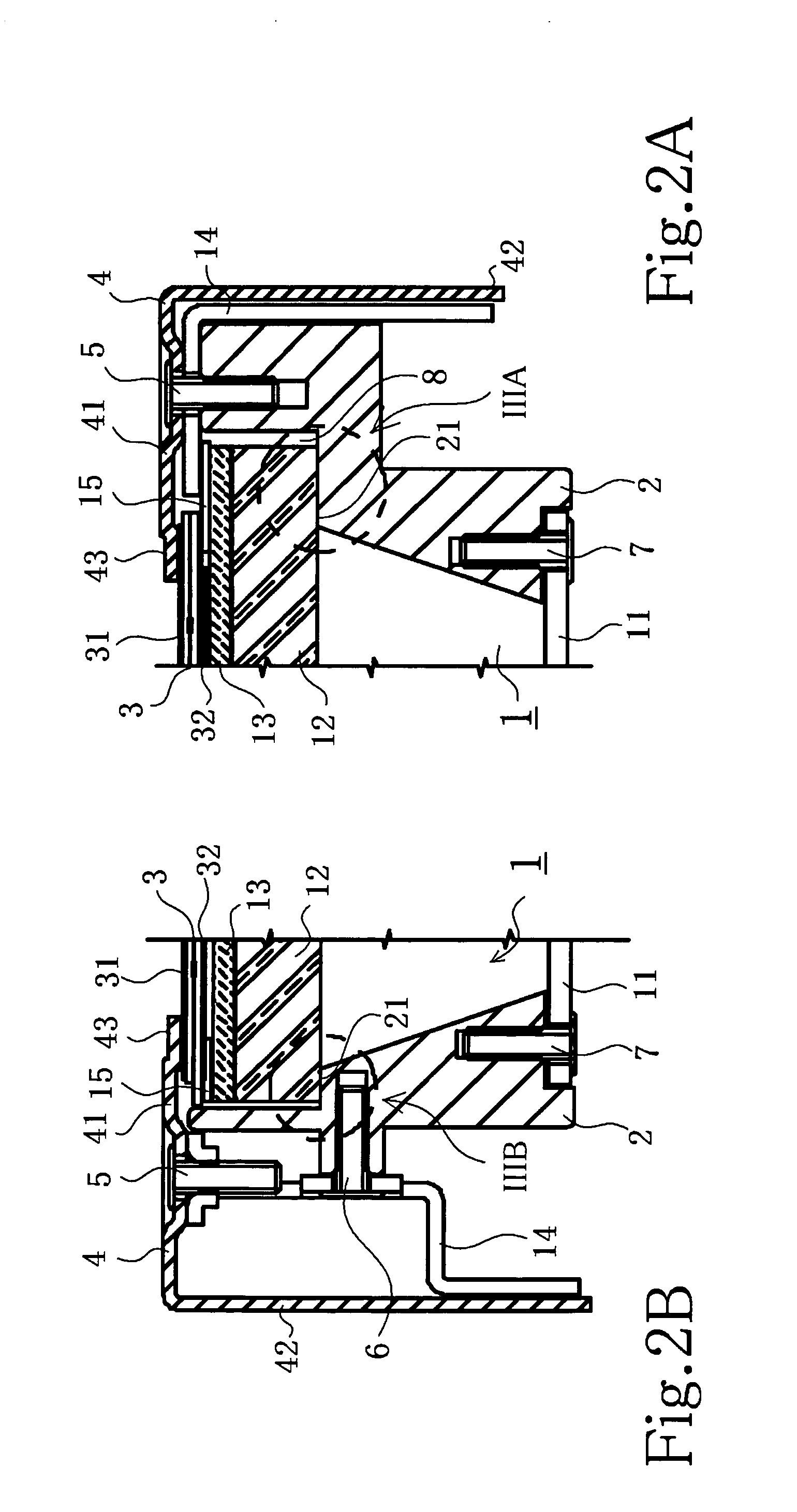

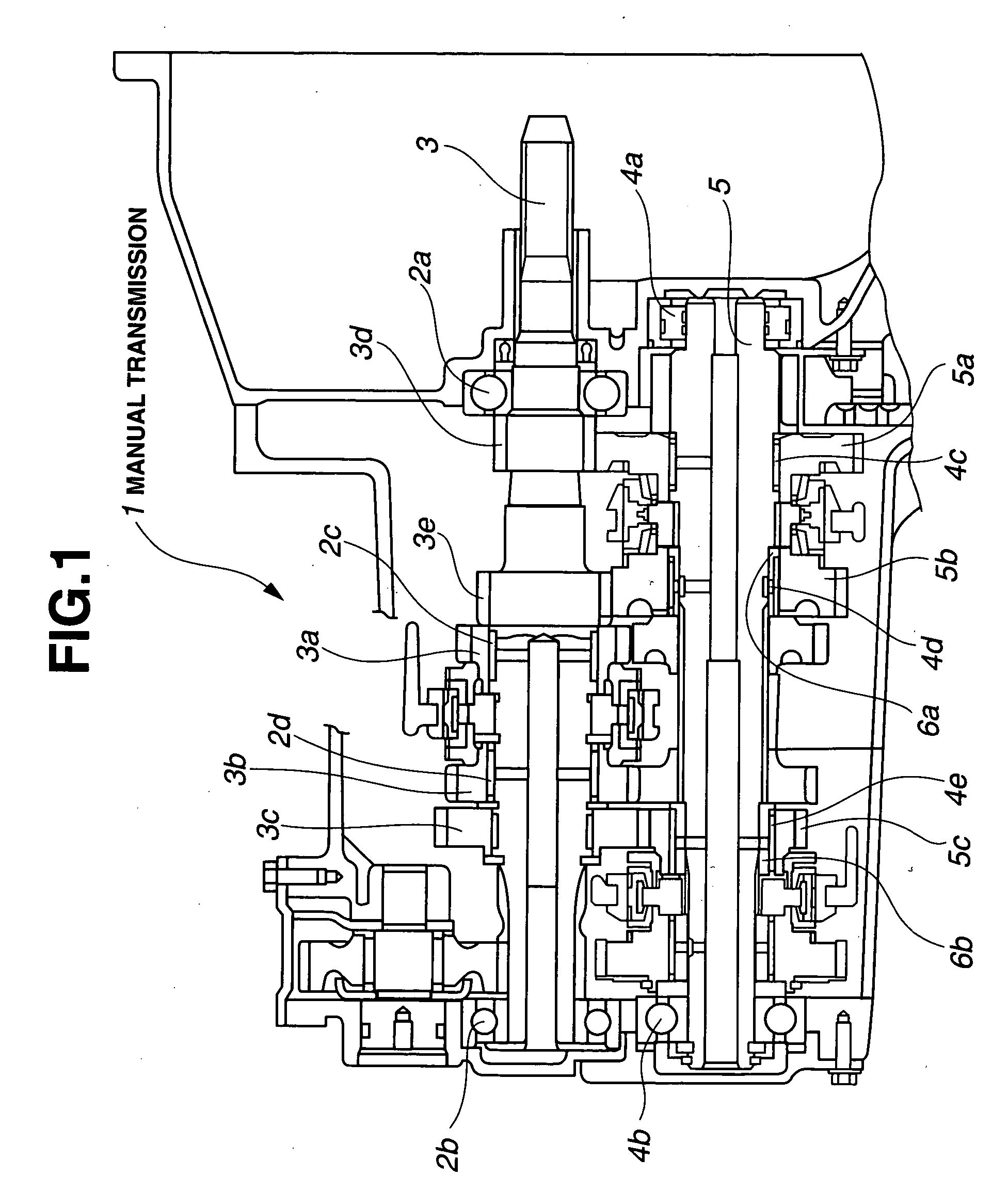

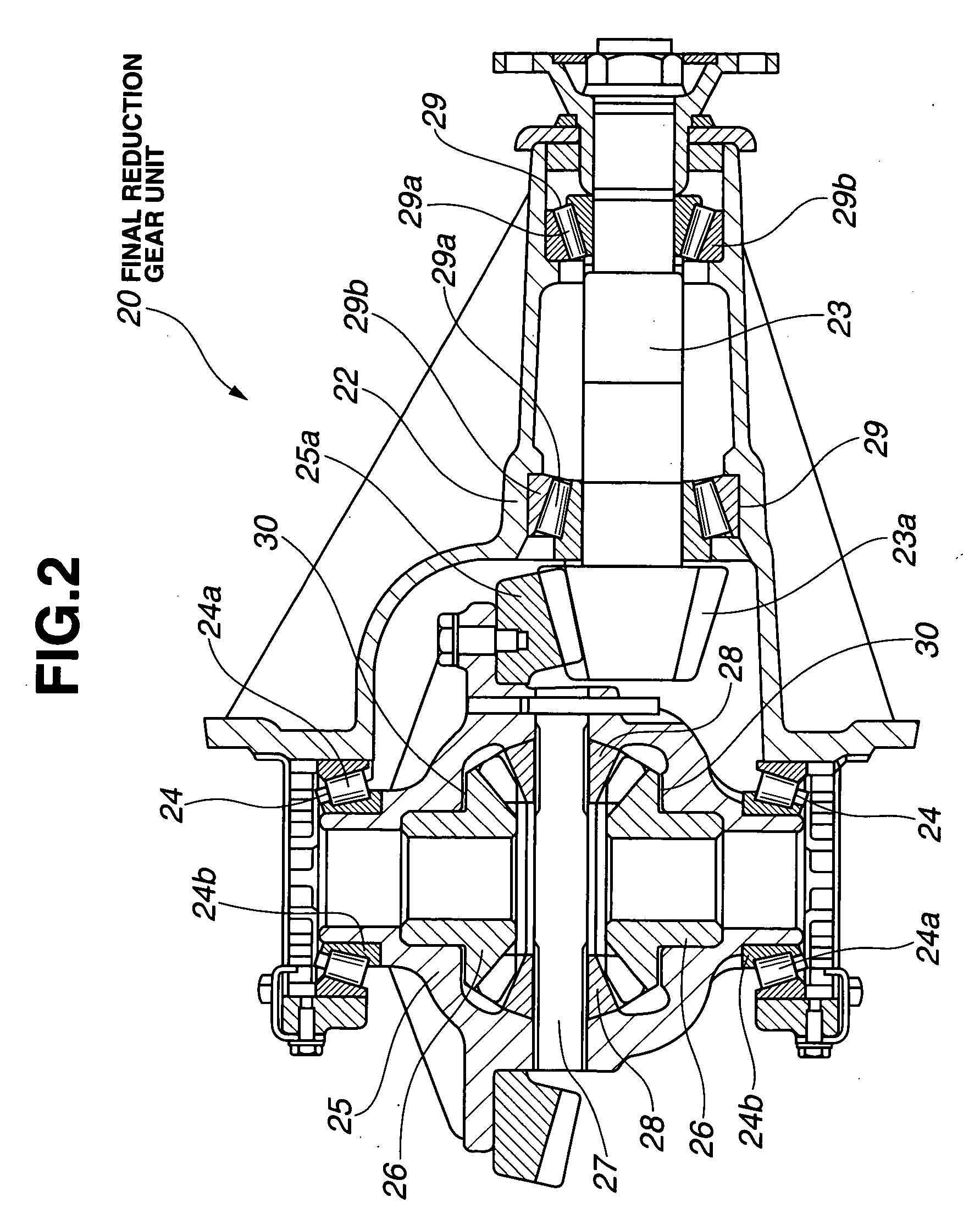

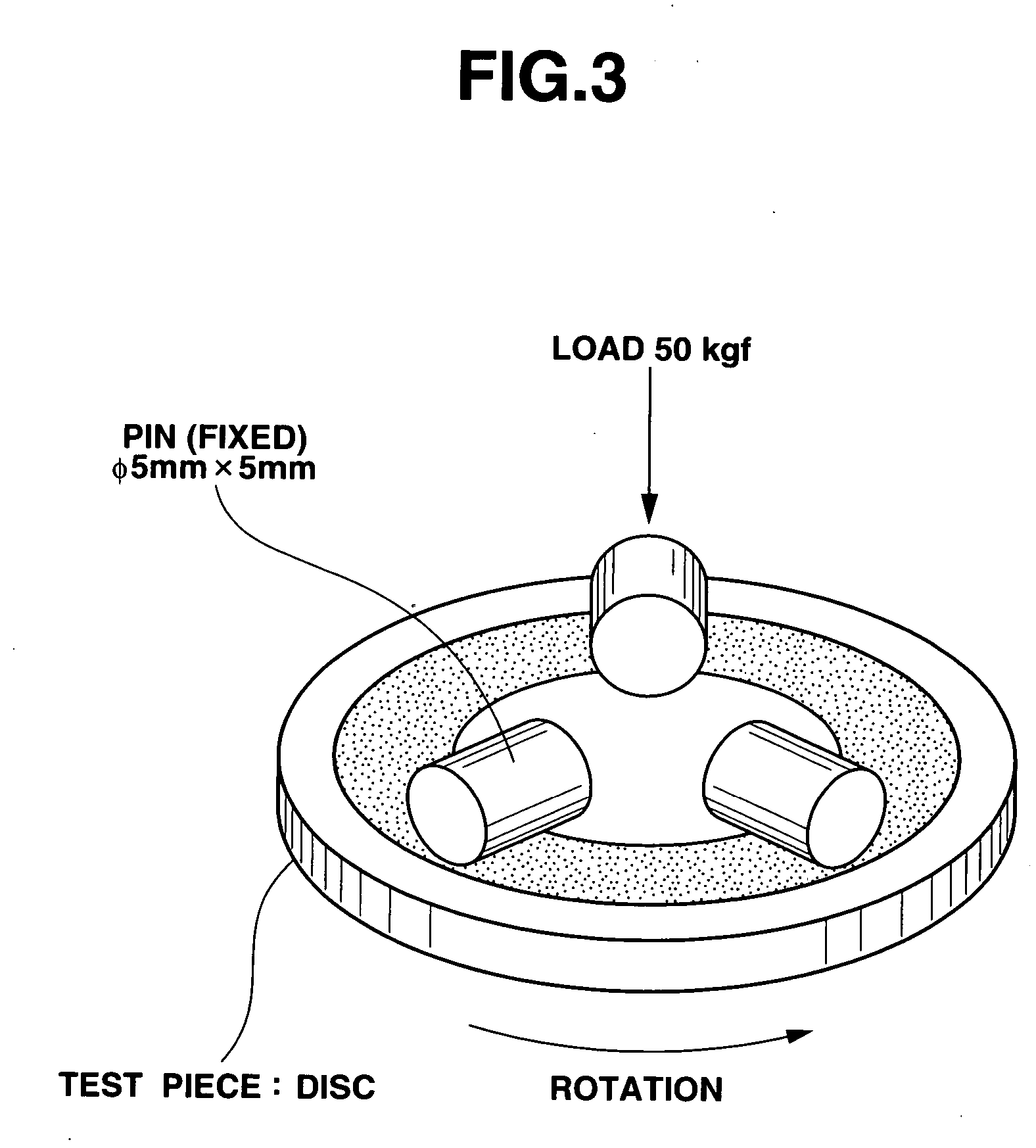

The invention provides a low-friction sliding mechanism, a low-friction agent composition, a friction reduction method, a manual transmission and a final reduction gear unit that can exert very excellent low friction characteristics to sliding surfaces present under various applications, and, in particular, that have more excellent low friction characteristics than that of a combination of an existing steel material and an organic Mo compound. The low-friction sliding mechanism has an oxygen-containing organic compound or an aliphatic amine compound interposed between sliding surfaces that a DLC coated sliding member and a sliding member form. The low-friction agent composition contains an oxygen-containing organic compound or an aliphatic amine compound. The friction reduction method includes supplying the low-friction agent composition between sliding surfaces that a DLC coated sliding member and a sliding member form. The manual transmission includes, as at least one of sliding members, a DLC coated sliding section. The final reduction gear unit includes, as at least one of sliding members, a DLC coated sliding section.

Owner:NISSAN MOTOR CO LTD +2

Low friction rotary knife

InactiveUS20050126015A1Minimize blade—housing friction—andSkinning instrumentsBone cleaning devicesFriction reductionContact position

Owner:BETTCHER INDUSTRIES

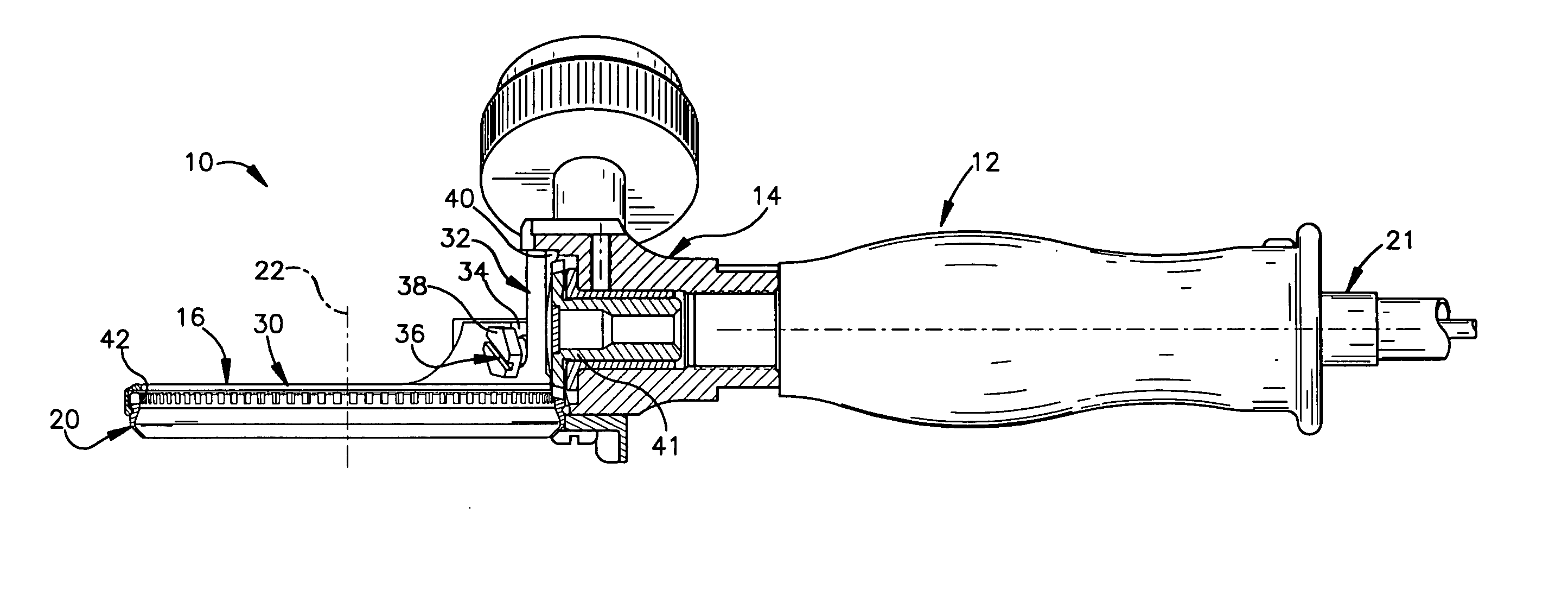

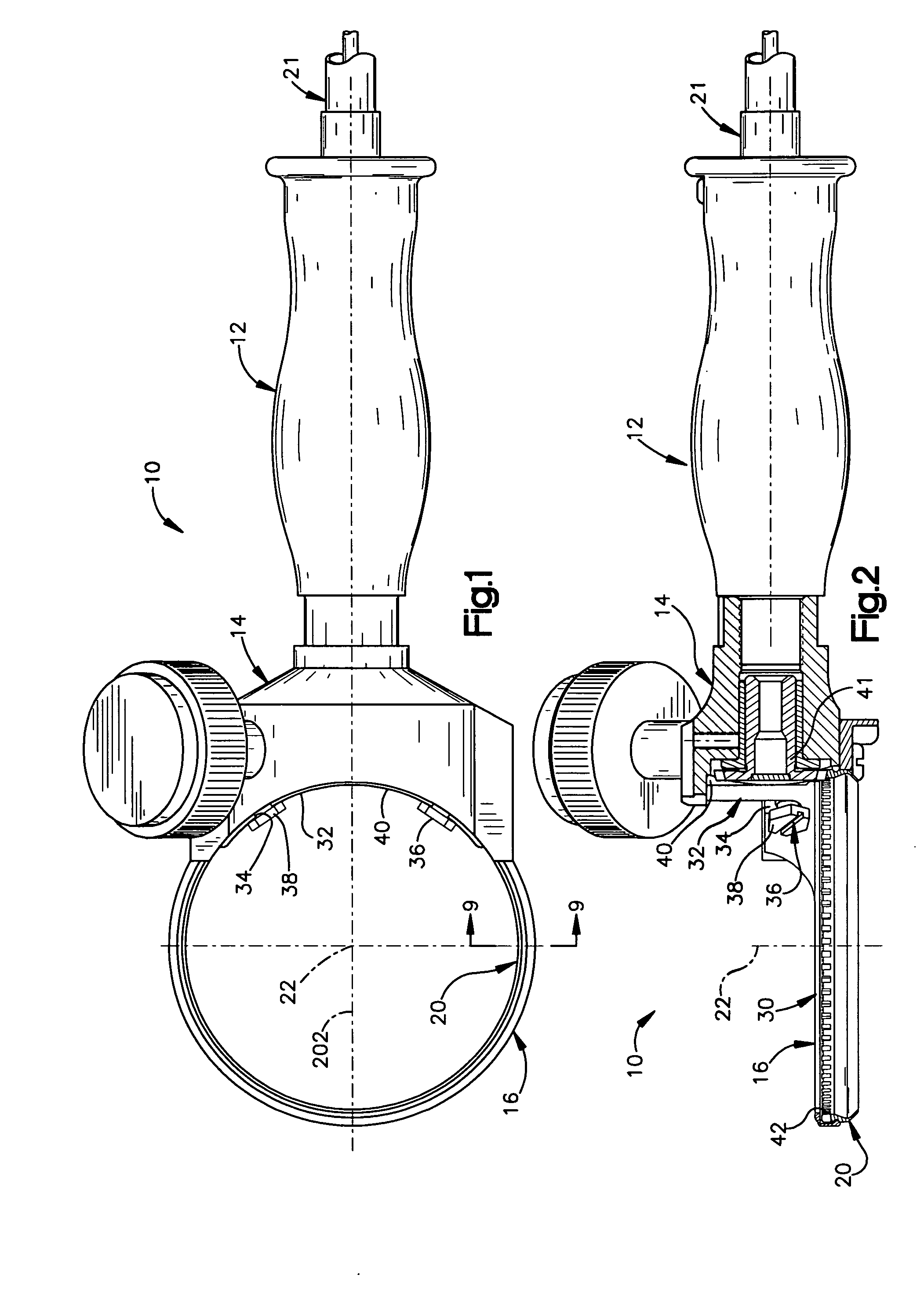

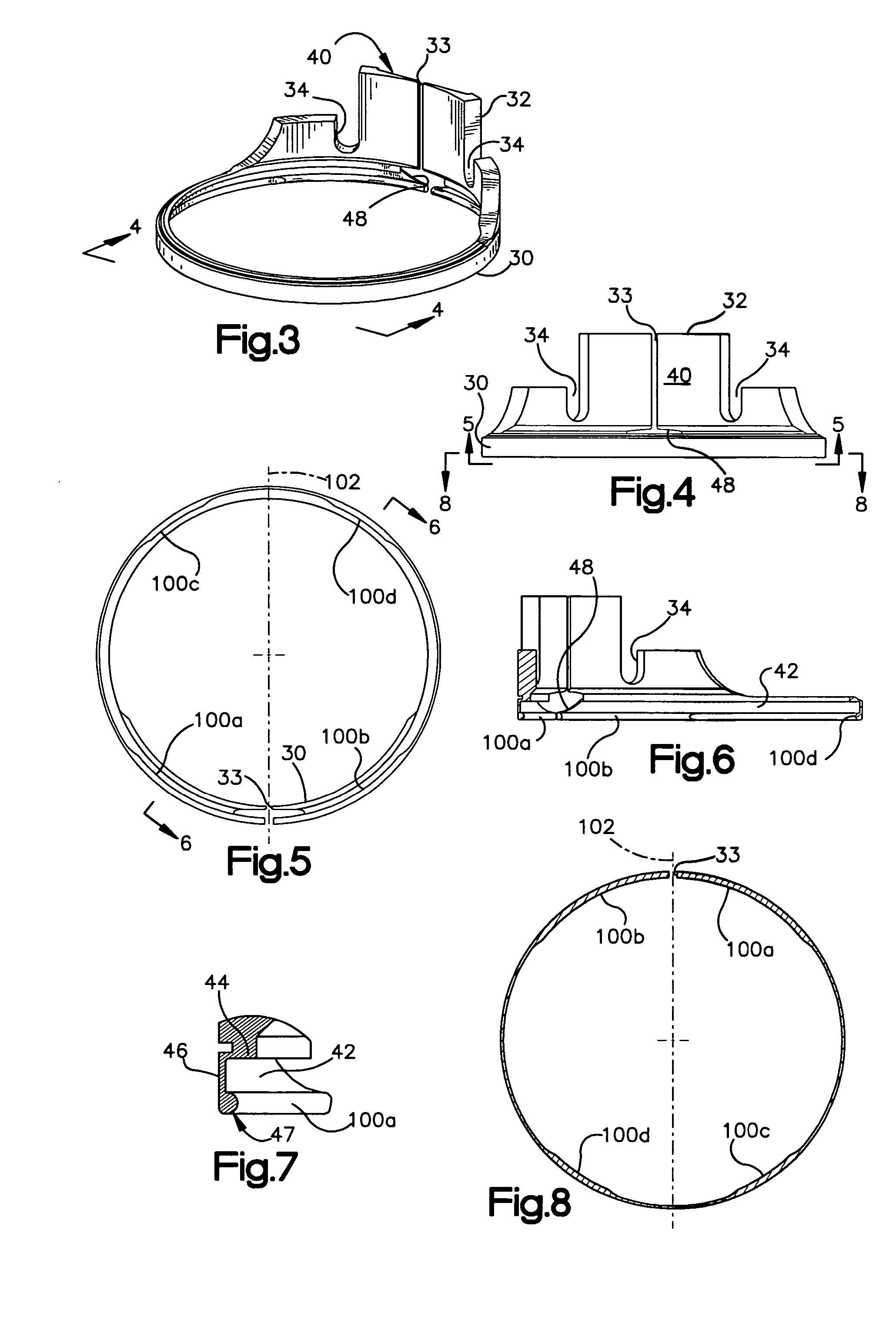

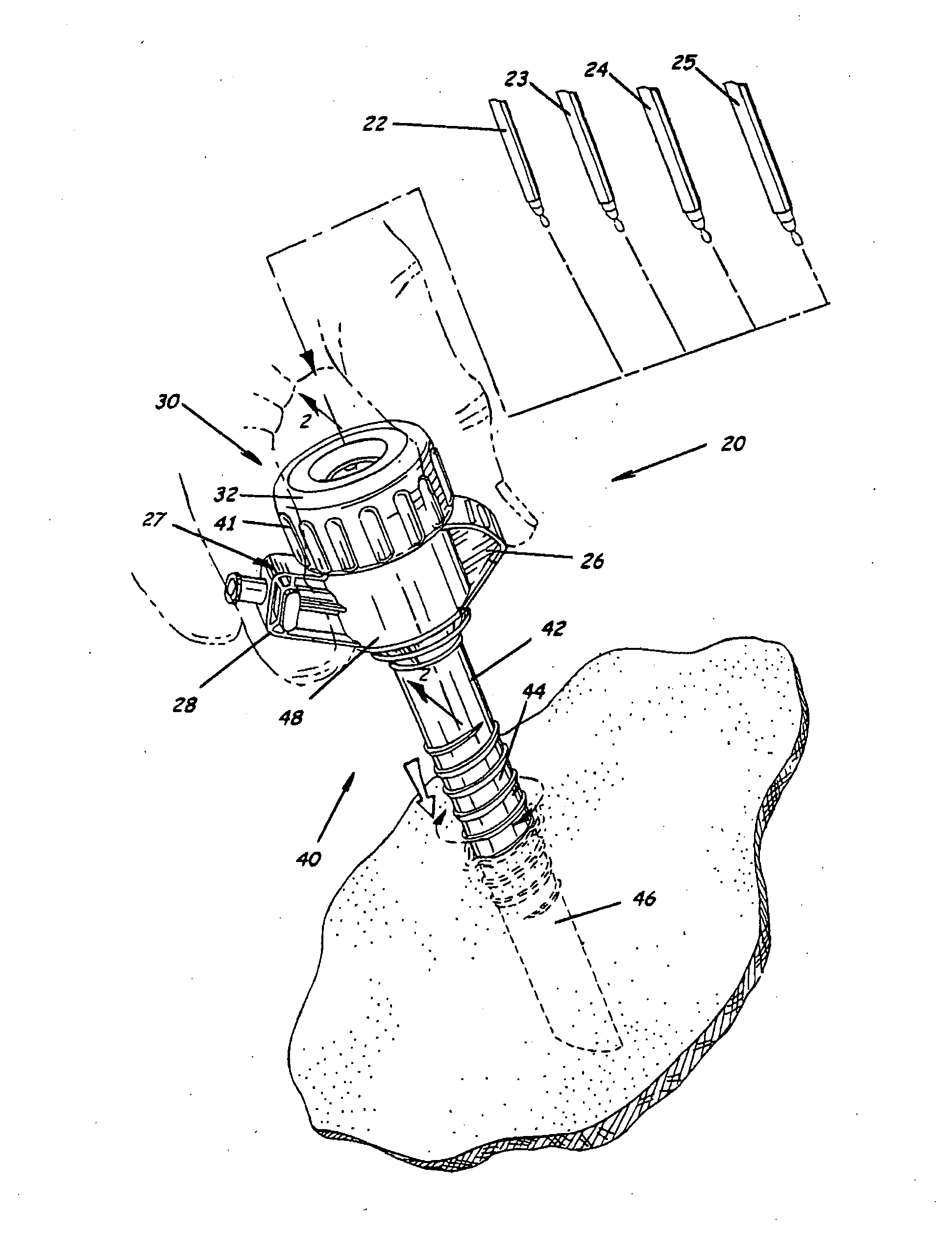

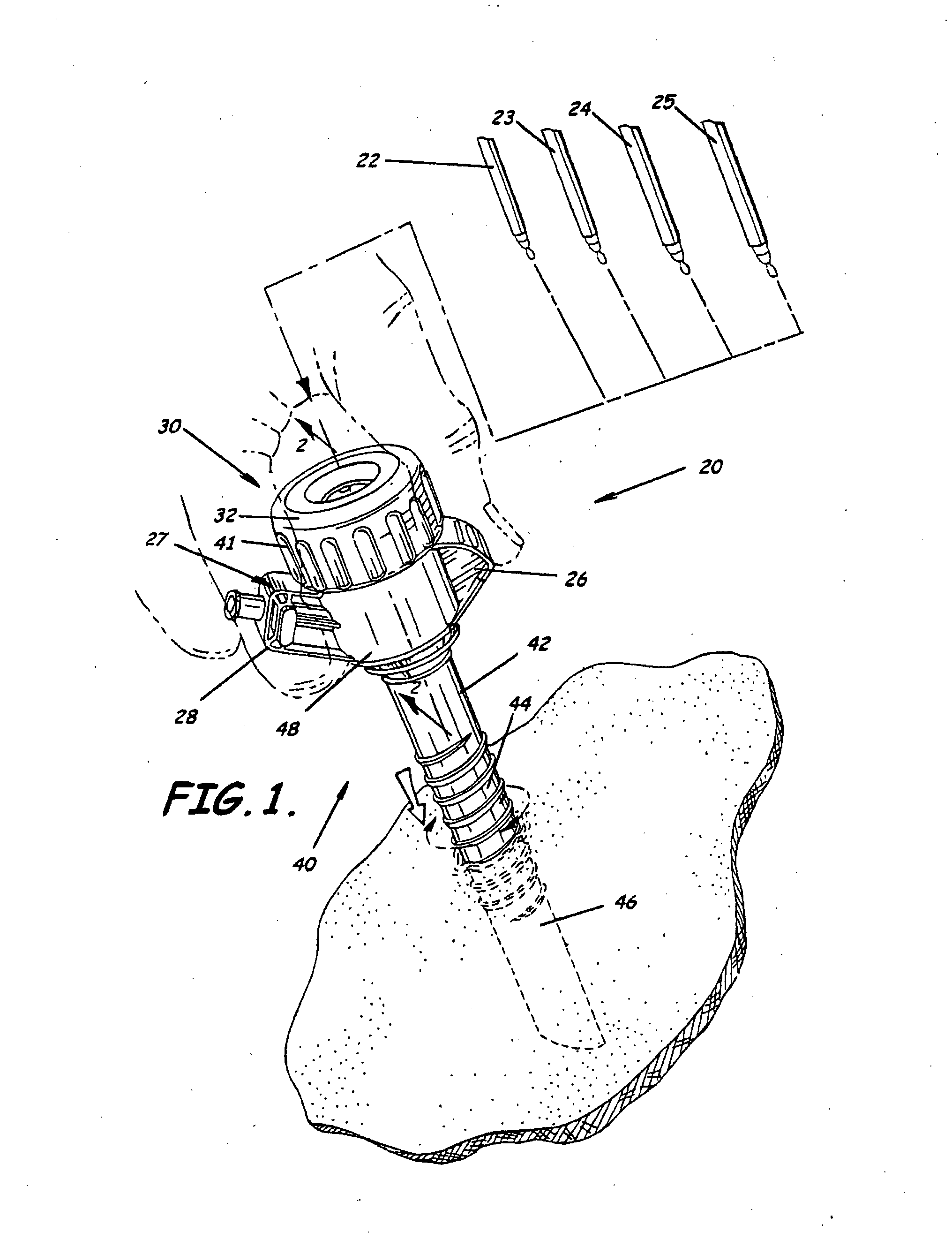

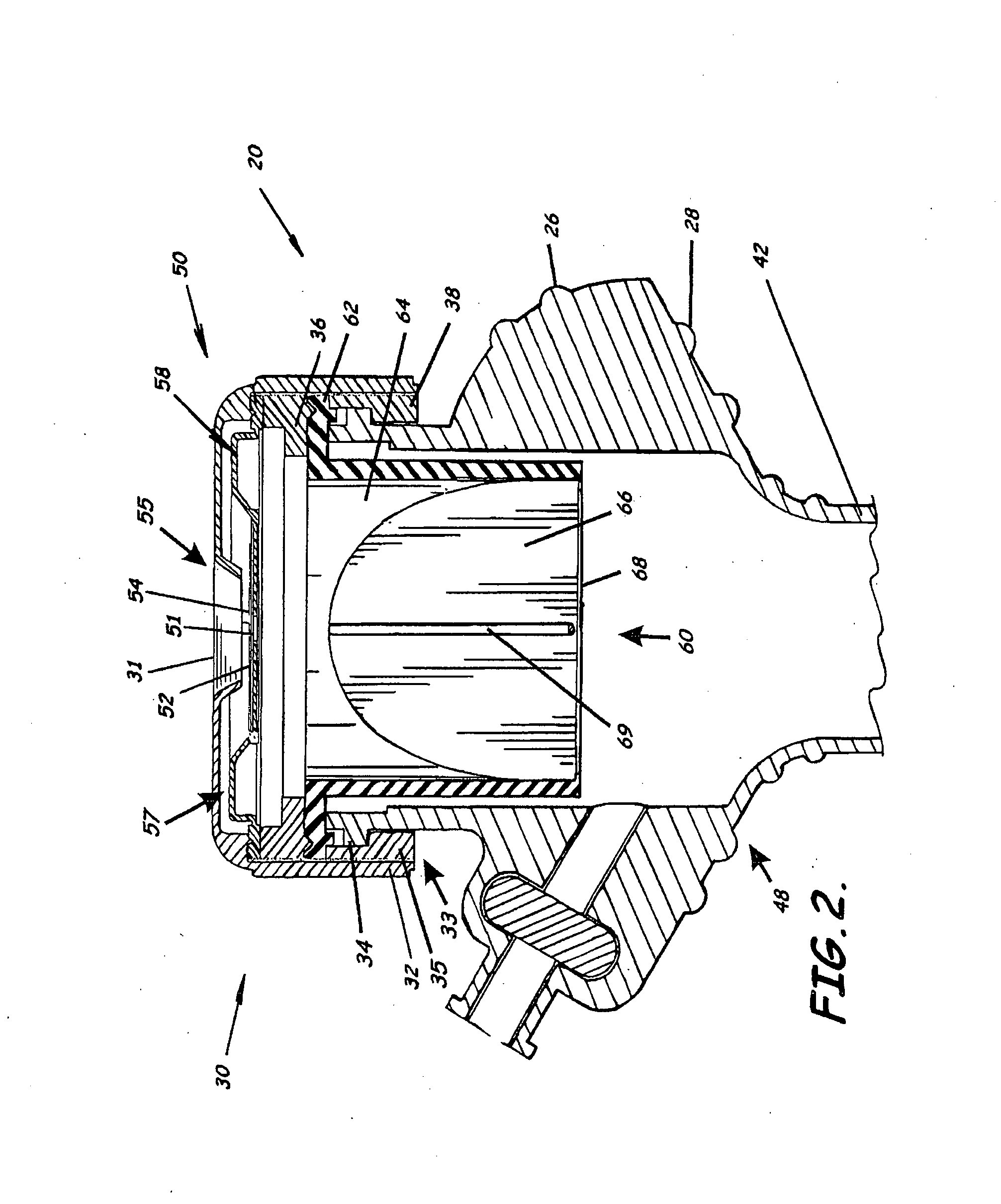

Trocar and cannula assembly having conical valve and related methods

ActiveUS20080033363A1Easy to insertEasy to retractCannulasInfusion syringesFriction reductionProximate

A trocar system for endoscopic surgery, cap assembly, and related methods are provided. The cap assembly includes a valve housing with an opening formed in line with an axis of the valve housing and also includes a valve positioned adjacent the opening of the valve housing. The valve body includes a proximal valve section including a valve ring positioned within the valve housing, and a distal valve section extending axially from the proximal valve section. The distal valve section includes a valve extension having a proximal and distal end portions, and a substantially conically shaped medial portion connected to and extending therebetween, wherein a plurality of friction-reduction features, preferably tear-drop shaped knobs, are disposed proximate the distal end portion and extending a distance in the medial portion of the valve. A valve opening is positioned in the distal end portion of the valve extension, adapted to individually and separately receive the elongate tools so that when any one of the elongate tools of varying diameter is positioned therethrough, electrostatic adhesion between the valve and the tool is minimized and a seal is maintained between peripheries of the valve extension surrounding the valve opening and outer peripheries of the inserted elongate tool.

Owner:KARL STORZ ENDOVISION INC

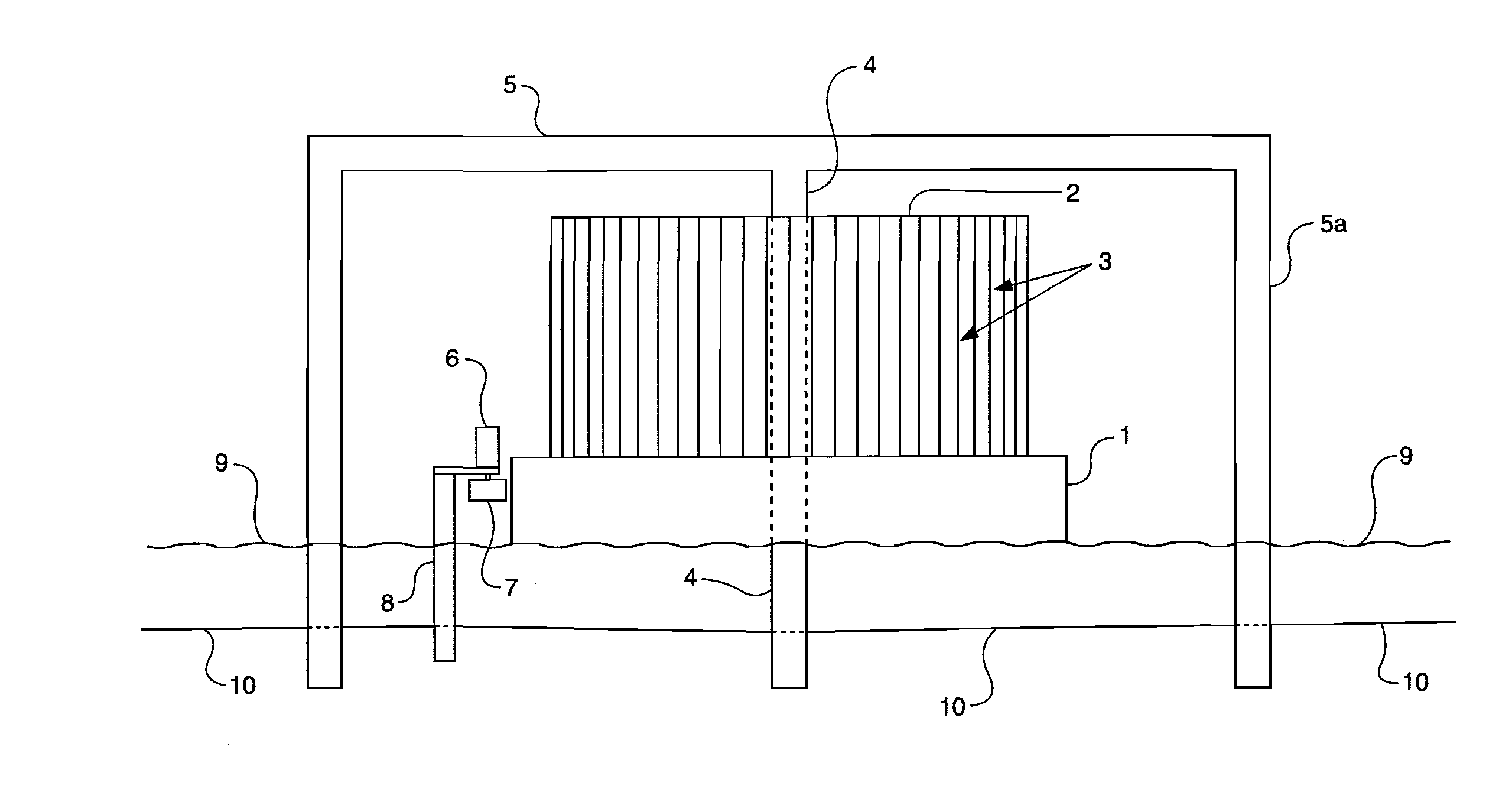

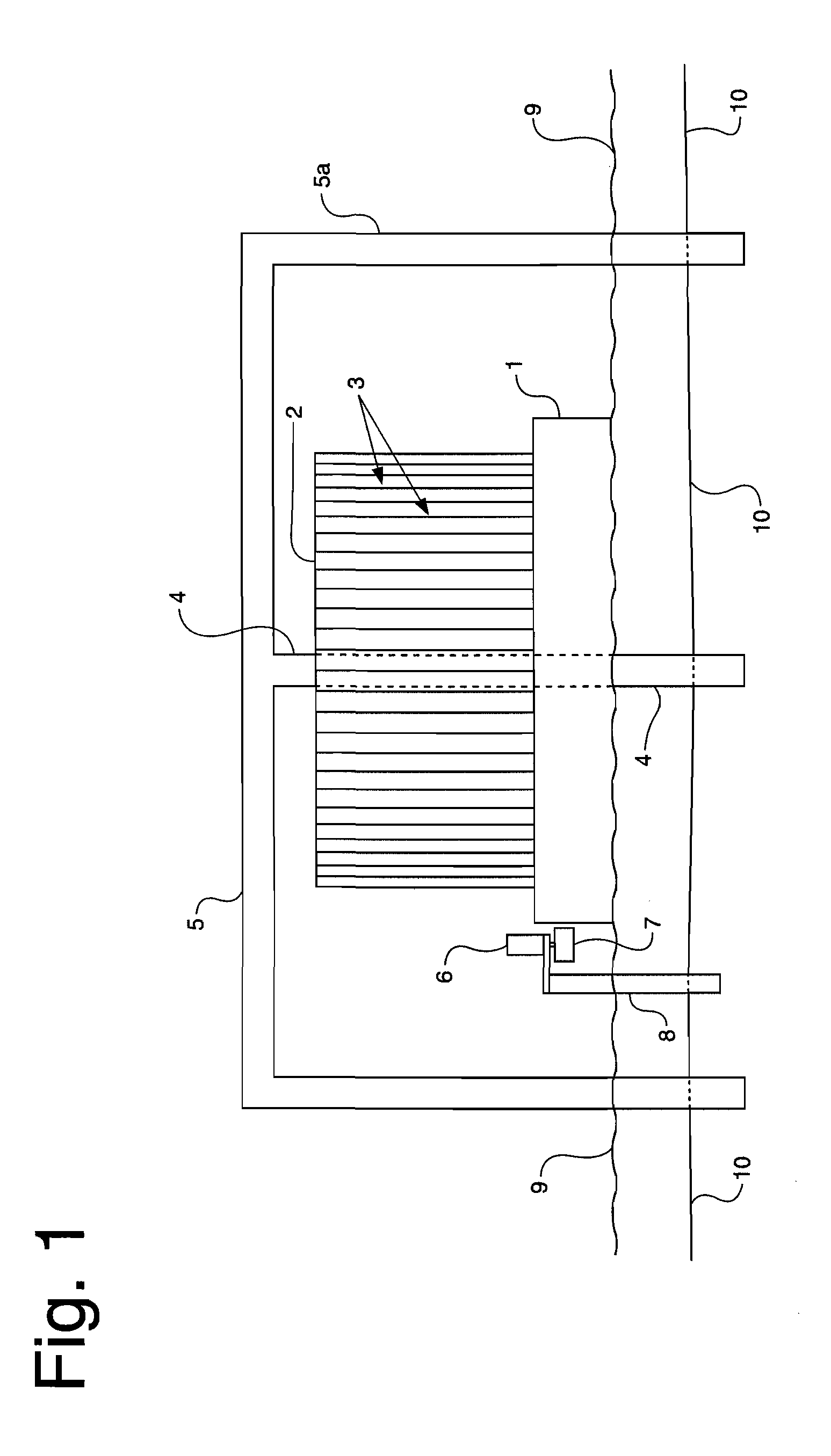

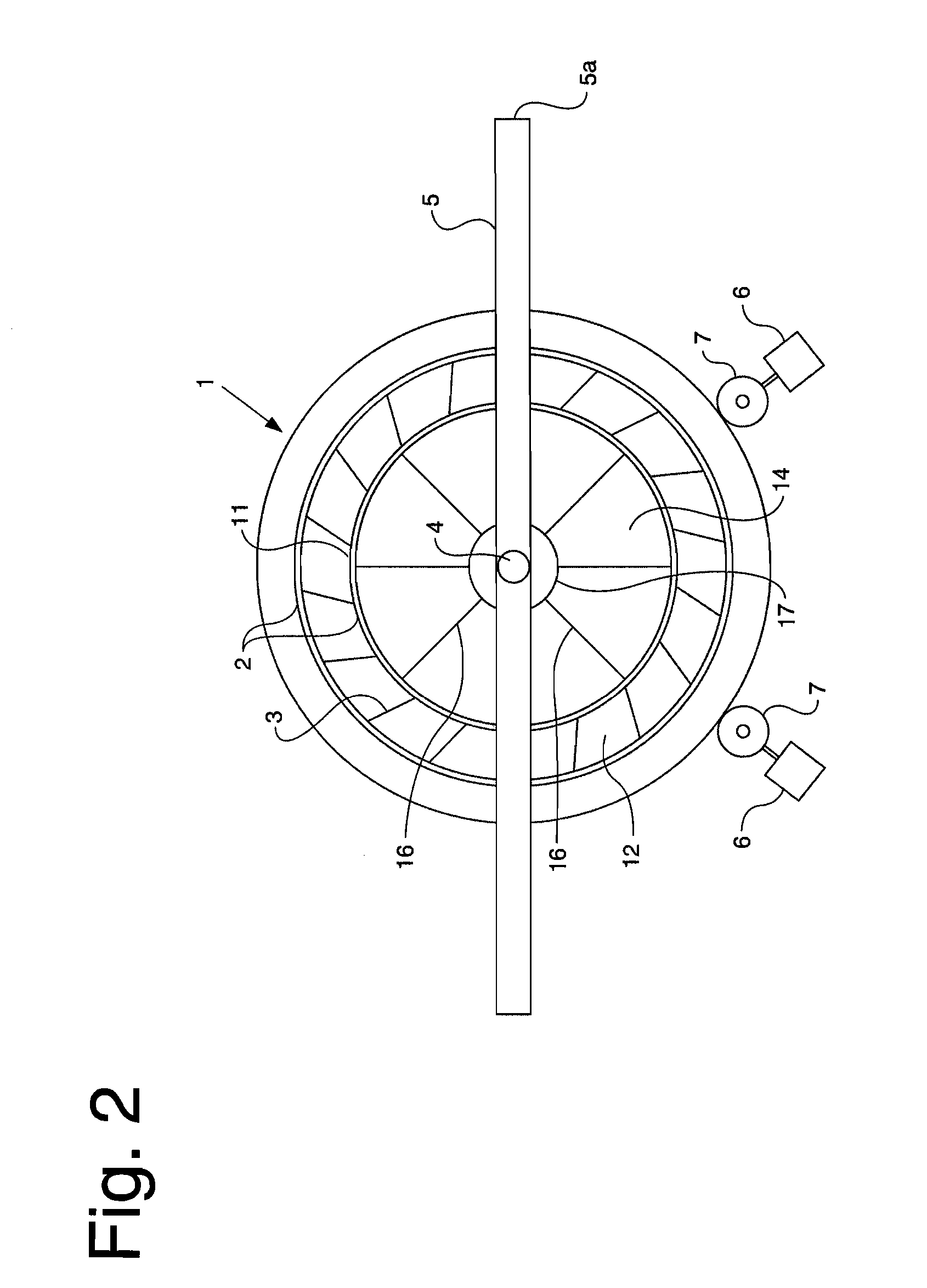

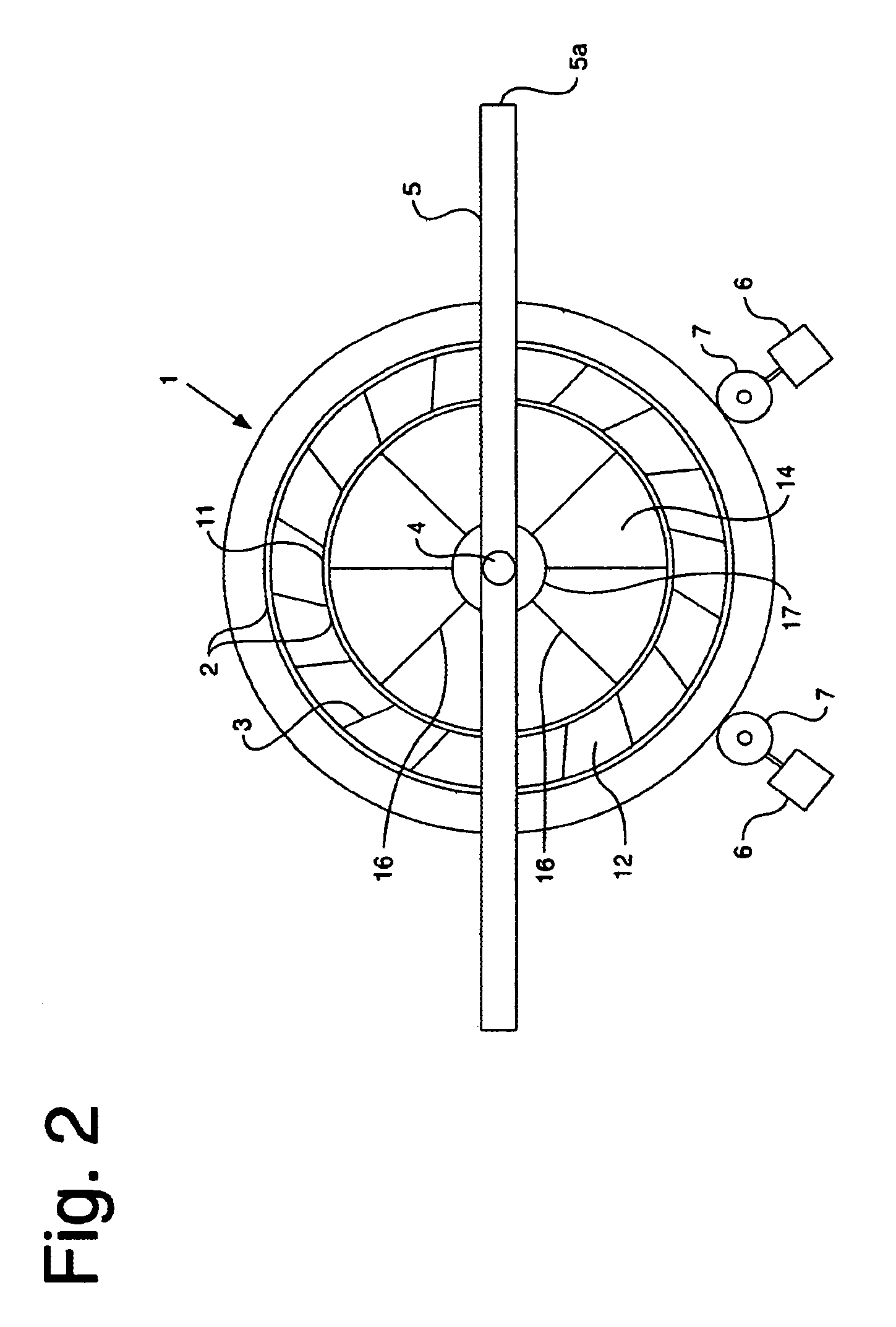

Reduced Friction Wind Turbine Apparatus and Method

InactiveUS20070241567A1Reduce downward forceReduces potential drag forceWind motor supports/mountsWind motor combinationsFriction reductionEngineering

A fluid flow energy capture device for power generation has a rotor with a substantially vertical axis and a plurality of vanes. A mount for the rotor allows the rotor to rotate in response to fluid flow such as wind contacting the plurality of vanes, and the mount puts the rotor in rotationally driving communication with a generator. The rotor has an open center which allows fluid communication from spaces between the vanes to above the rotor. A plurality of guide surfaces define channels that bias fluid flow to be tangential to the rotor.

Owner:NATURAL FORCES

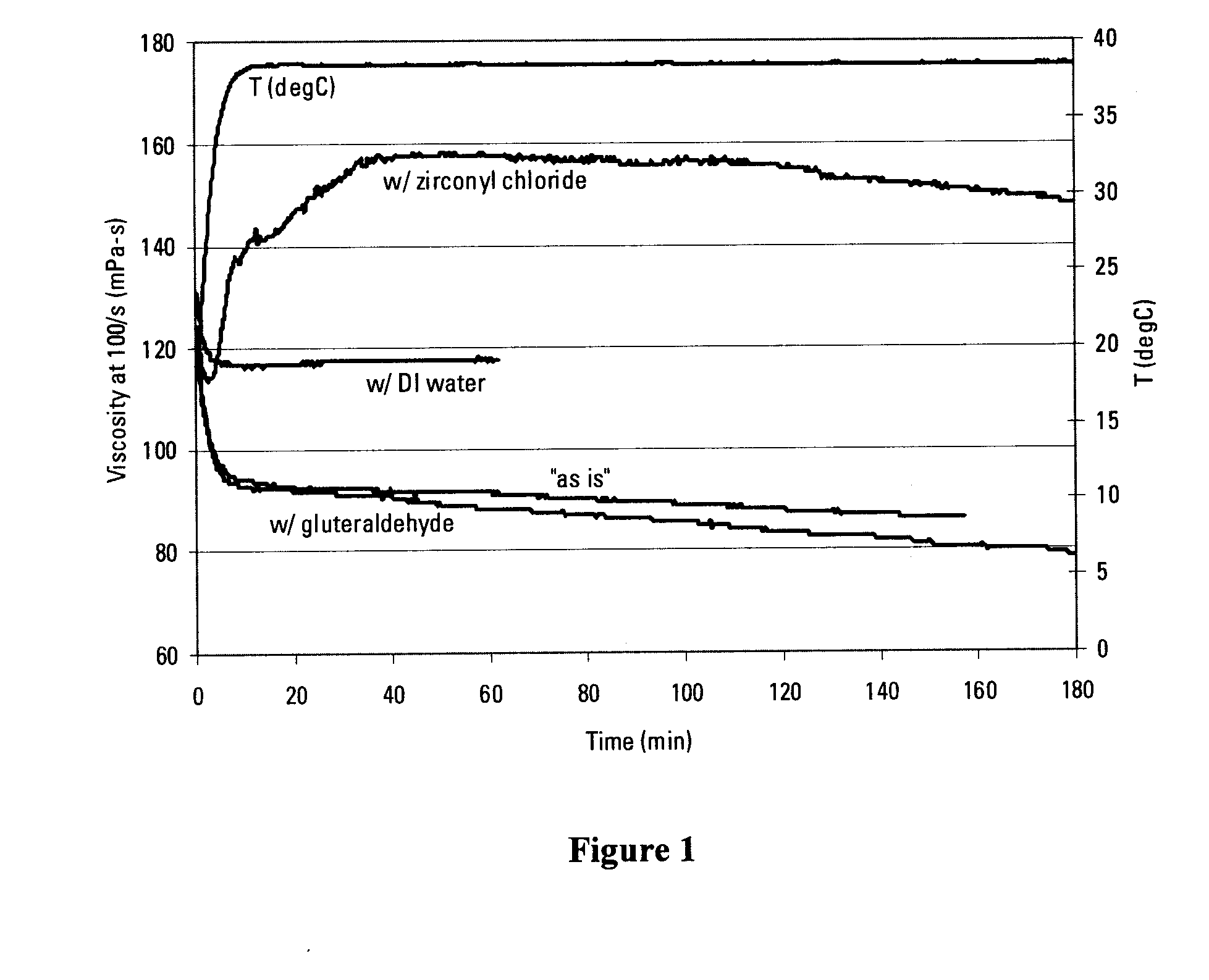

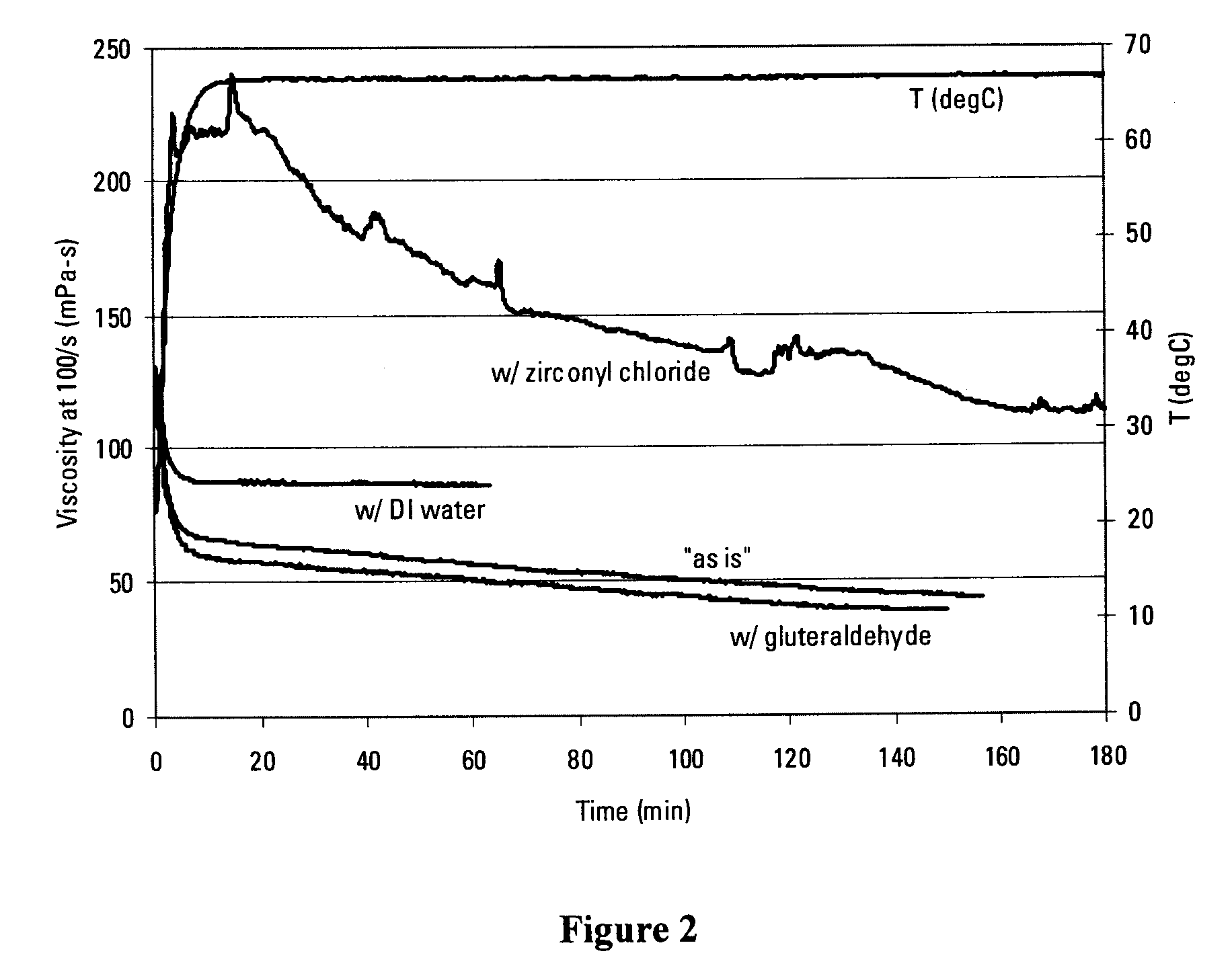

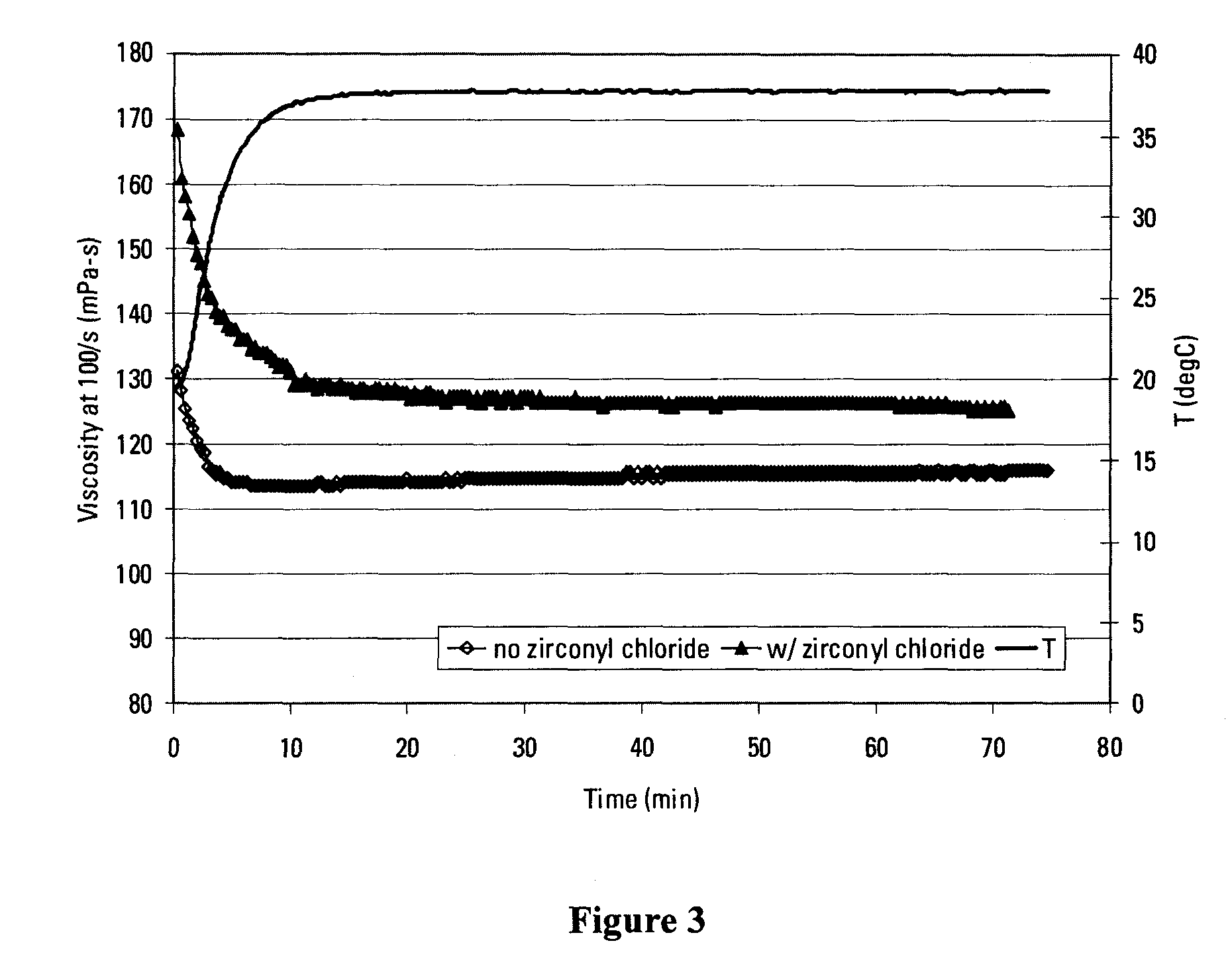

Treatment and Reuse of Oilfield Produced Water For Operations In A Well

ActiveUS20100248997A1Premature fluid viscosity lossWithout viscosity lossFluid removalFlushingFriction reductionFluid viscosity

The invention discloses method of treatment and reuse of oilfield produced water. The method comprises: providing an aqueous medium comprised at least in part of oilfield produced water; contacting the aqueous medium with a zirconium compound; whereby the fluid viscosity and / or fluid drag reduction ability of the combination of the aqueous medium and zirconium compound is improved compared to the aqueous medium alone; introducing the combination in to the well; and allowing the combination to contact the formation. In another embodiment, the aqueous medium is further contacted by a friction-reduction additive. Still in another embodiment, the aqueous medium is further contacted by a gelling additive. Still in another embodiment, the fluid is energized with a gas.

Owner:SCHLUMBERGER TECH CORP

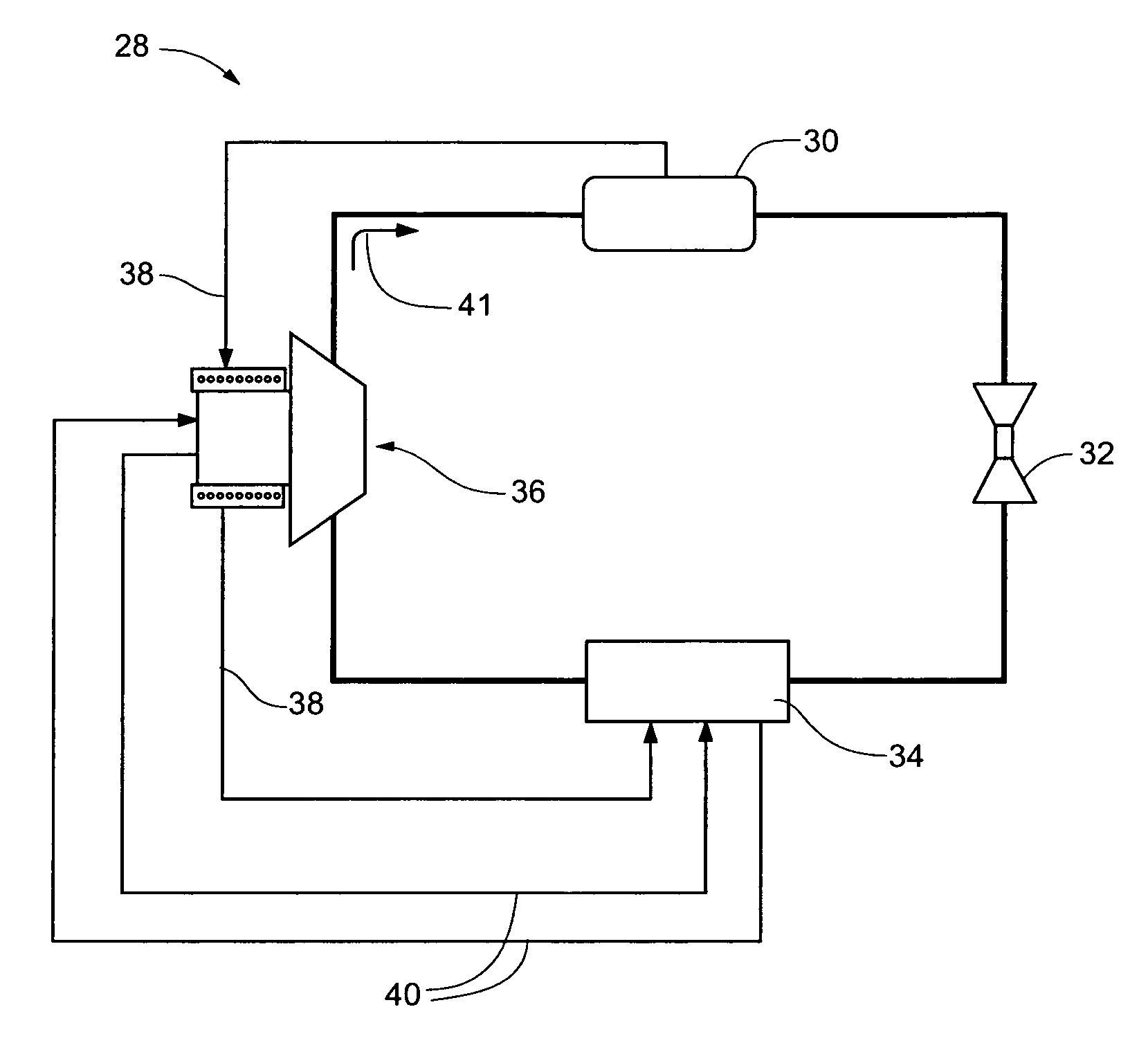

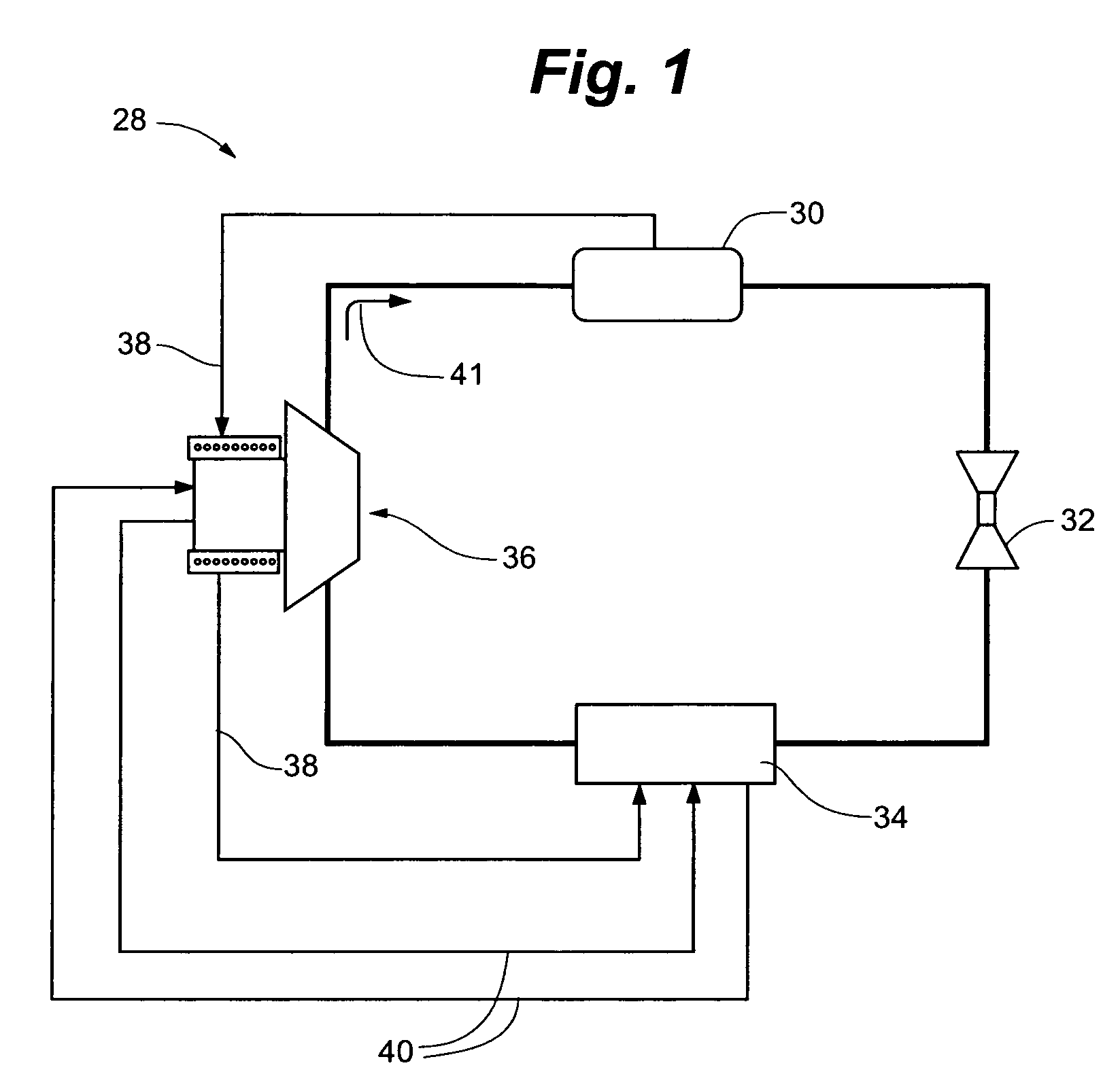

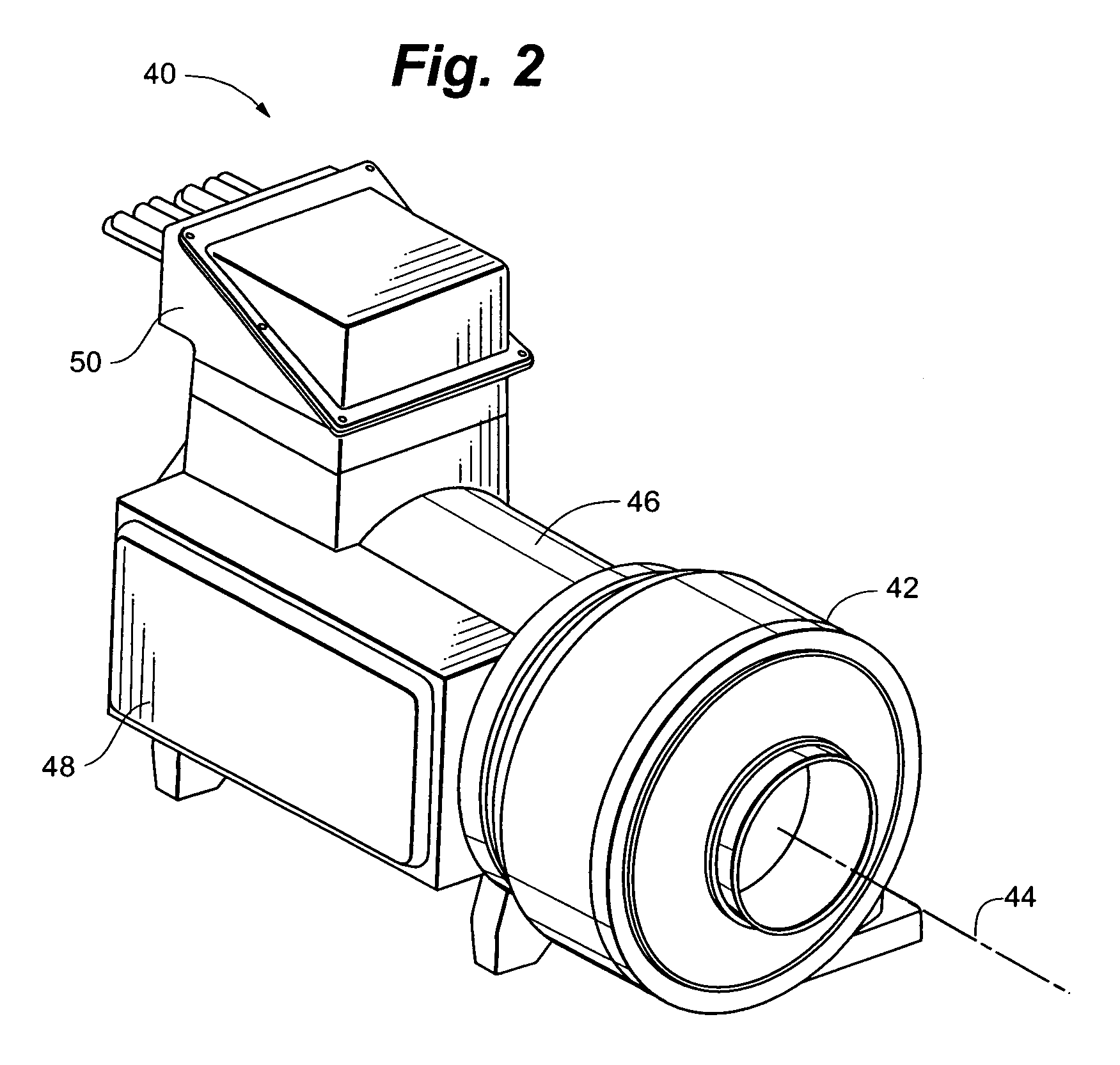

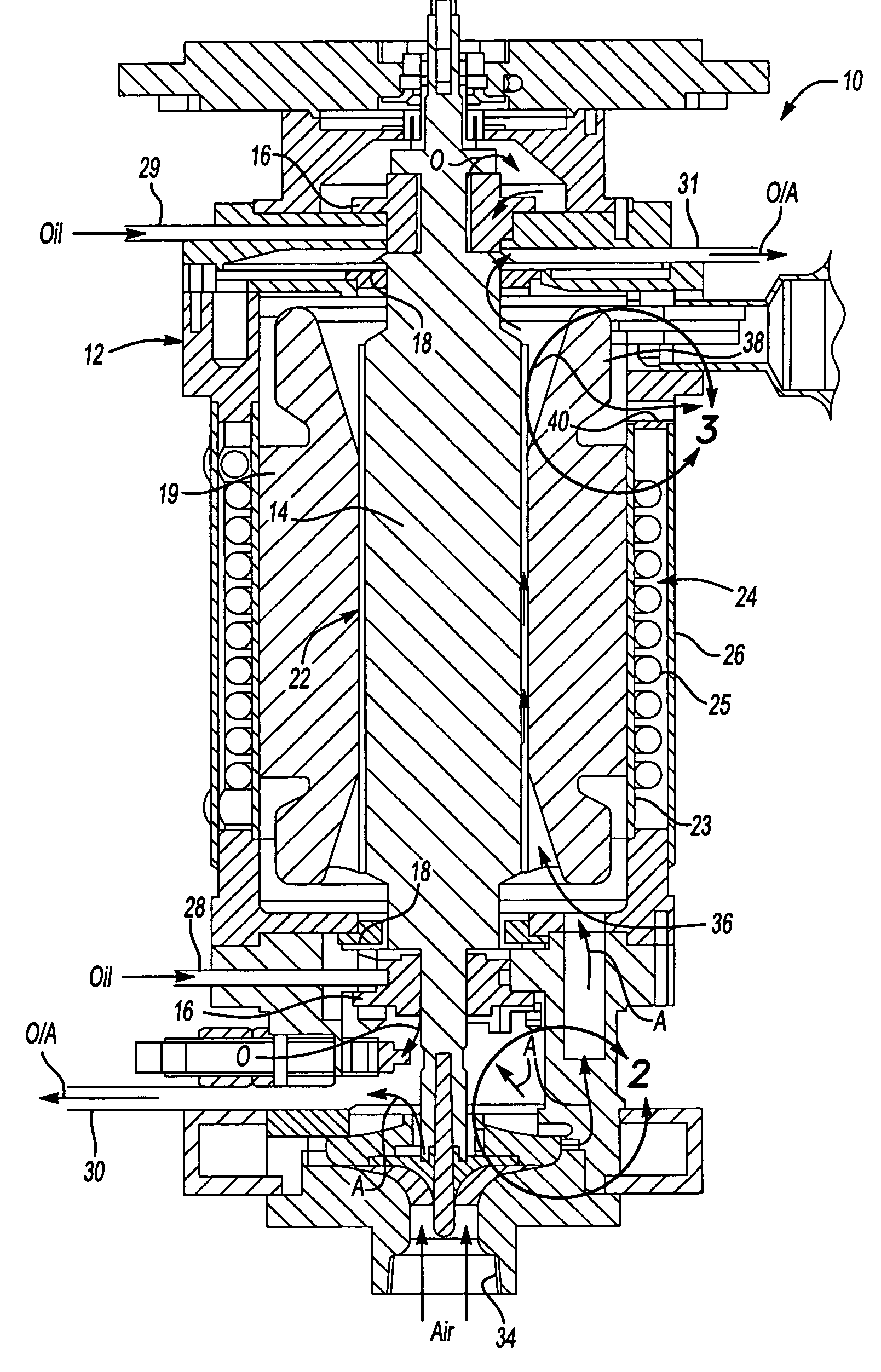

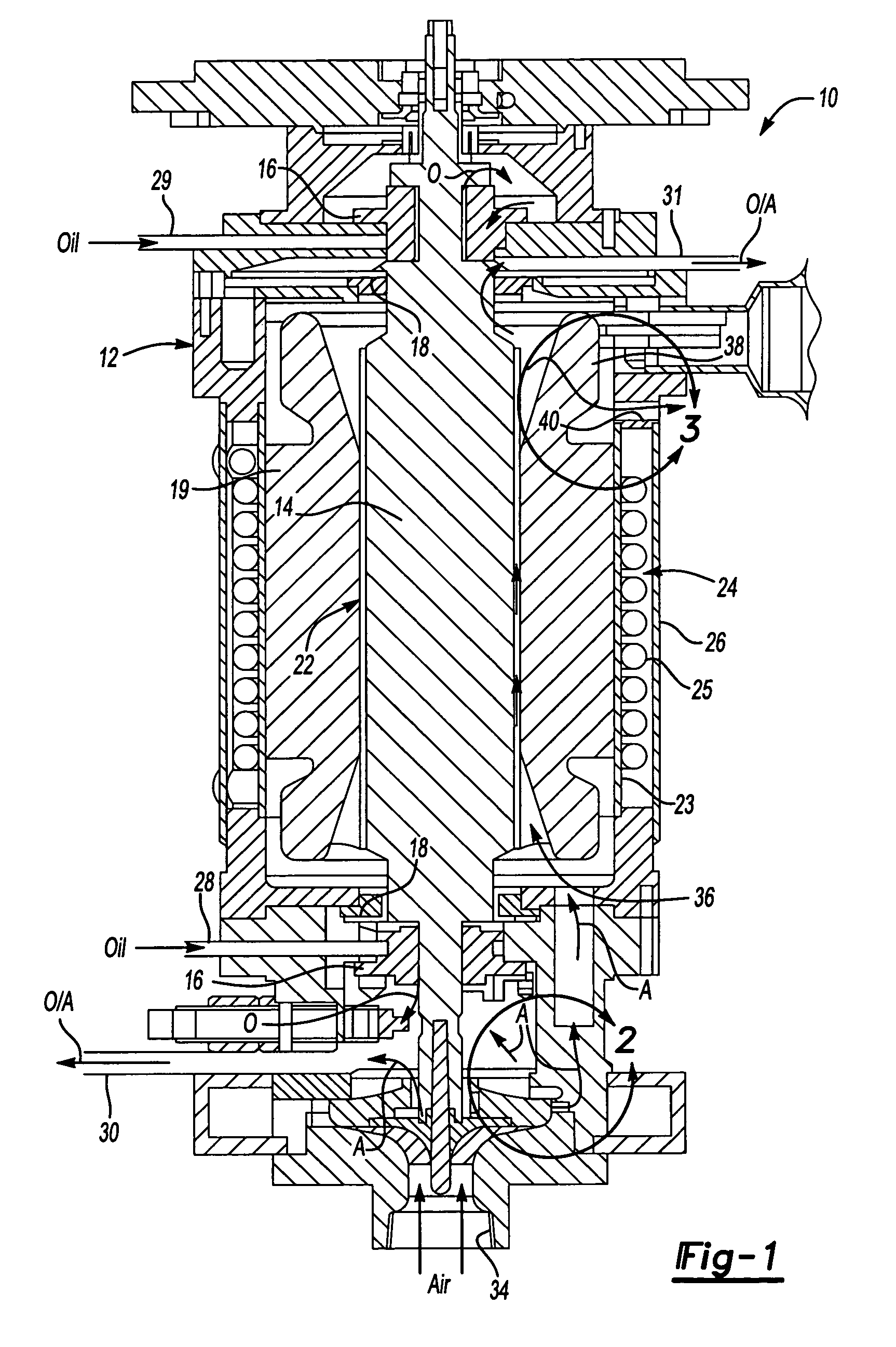

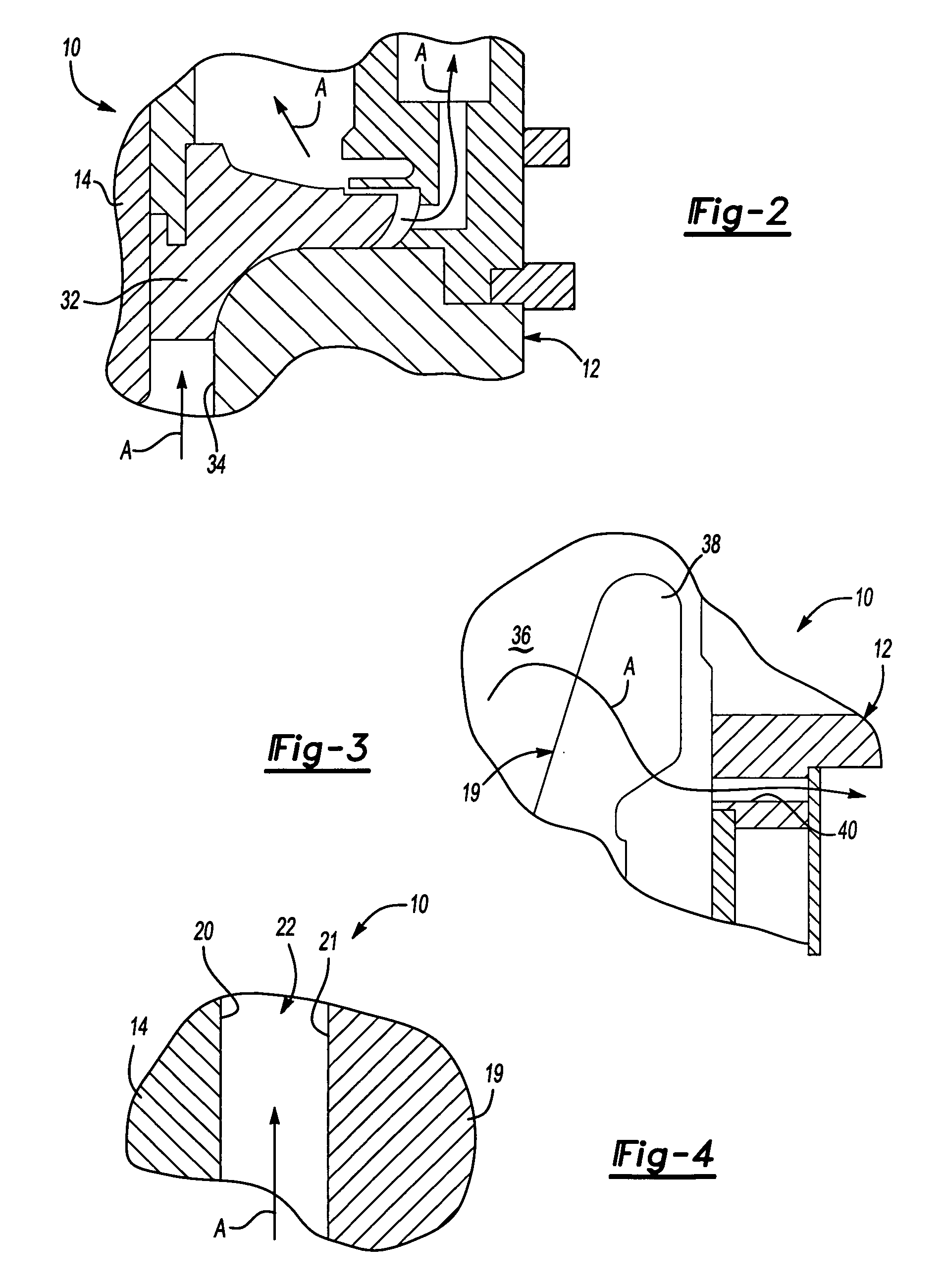

High capacity chiller compressor

ActiveUS8156757B2Improve efficiencyHigh outputWind motor controlEfficient regulation technologiesFriction reductionMagnetic bearing

A high efficiency, low maintenance single stage or multi-stage centrifugal compressor assembly for large cooling installations. The assembly is highly efficient by virtue of a variable frequency drive (VFD) that drives a permanent magnet motor and matches compressor speed with compressor load, a direct drive impeller that eliminates gearing losses, and magnetic bearings that reduce frictional losses. The back-emf produced by the motor provides an intermediate power source for the magnetic bearings in the event of a loss of electrical power. A cooling system provides direct cooling of the rotor with gas refrigerant, and cooling of the stator with liquid refrigerant. Modular construction allows the compressor to be retrofit with upgrades. An inlet guide vane system operates without need for oil lubrication. The use of light metal castings and elimination of gearing reduces the weight to one-third or less of comparably powered conventional units.

Owner:DAIKIN IND LTD

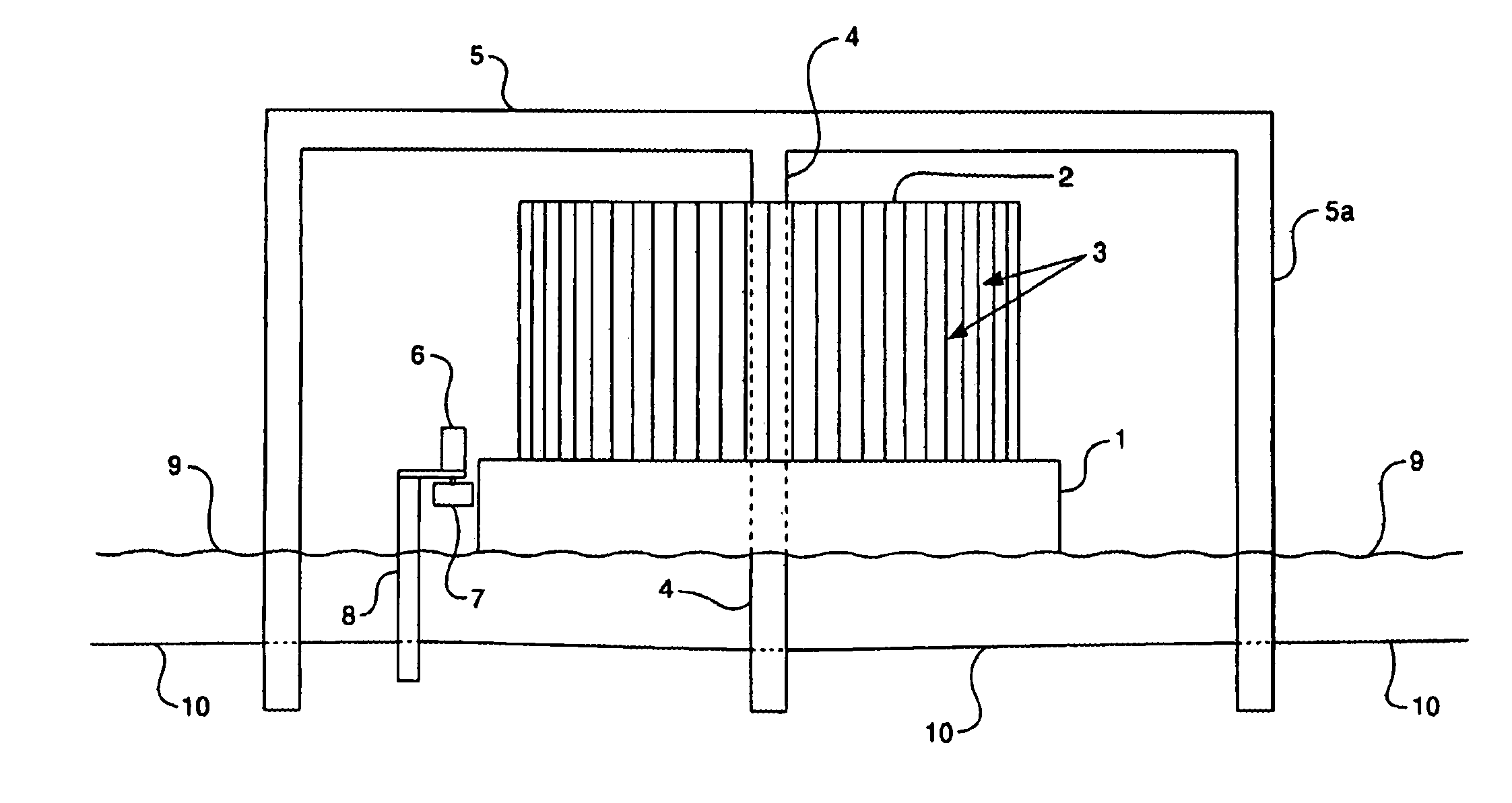

Reduced friction wind turbine apparatus and method

InactiveUS7235893B2Reduce wind resistanceReduce resistanceWind motor supports/mountsWind motor combinationsFriction reductionElectricity

The present invention is a wind power apparatus for driving an electric generator. The wind power apparatus comprises a frame, a vertical axle mounted on the frame and a buoyant hull. The buoyant hull is rotational disposed on the axle. The buoyant hull has a curvilinear side surface. The wind power apparatus further comprises a fan. The fan is mounted on the buoyant hull such that wind rotating the fan rotates the buoyant hull. The wind power apparatus further has a drive wheel. The drive wheel is disposed in close cooperation with the curvilinear of the surface of the buoyant hull such that rotation of the buoyant hull rotates the drive wheel. The drive wheel is adapted to be in driving engagement with an electric generator such that rotation of the drive wheel turns the electric generator to generate electricity.

Owner:NATURAL FORCES

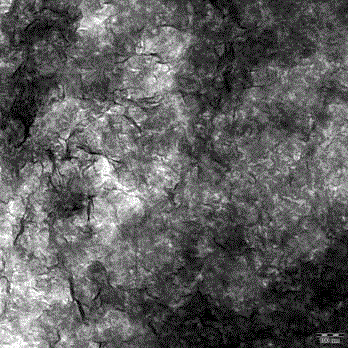

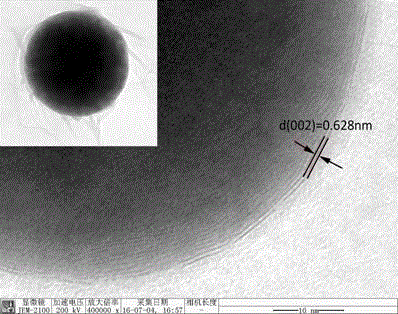

Rapid laser preparing method for composite with graphene loaded with spherical inorganic fullerene molybdenum disulfide

InactiveCN106398802AEasy to operateSolve the cumbersome processMaterial nanotechnologyGrapheneFriction reductionSuspended particles

The invention discloses a preparing method for a composite with graphene loaded with spherical inorganic fullerene molybdenum disulfide. The preparing method includes the following steps that sheetlike molybdenum disulfide and an oxidized graphene solution are mixed, and the mixture is ultrasonically dispersed into a suspension; the mixed suspension is irradiated with pulse lasers and converted into an interlayer structure under the effect of the pulse lasers and a liquid-phase solution solvent, wherein the interlayer structure is formed by the reduced oxidized graphene and nanometer / submicron inorganic fullerene molybdenum disulfide small spheres loaded on the surface of the reduced oxidized graphene alternately; after irradiation, the suspension is centrifuged, the obtained sediment is dried, and the composite with the reduced oxidized graphene loaded with the spherical inorganic fullerene molybdenum disulfide is obtained. According to the preparing method, the mixed suspension is irradiated directly with a laser beam, suspended particles instantaneously (in the nanosecond order) obtain high energy and are ablated and rapidly (in the nanosecond order) cooled with a solution, and therefore reduction of the oxidized graphene and conversion of the structure of the sheetlike molybdenum disulfide into the spherical inorganic fullerene structure are achieved in a one-step mode; the method is easy to operate, low in cost and free of impurity pollution, and the obtained composite shows excellent friction reduction performance in the friction process.

Owner:UNIV OF JINAN

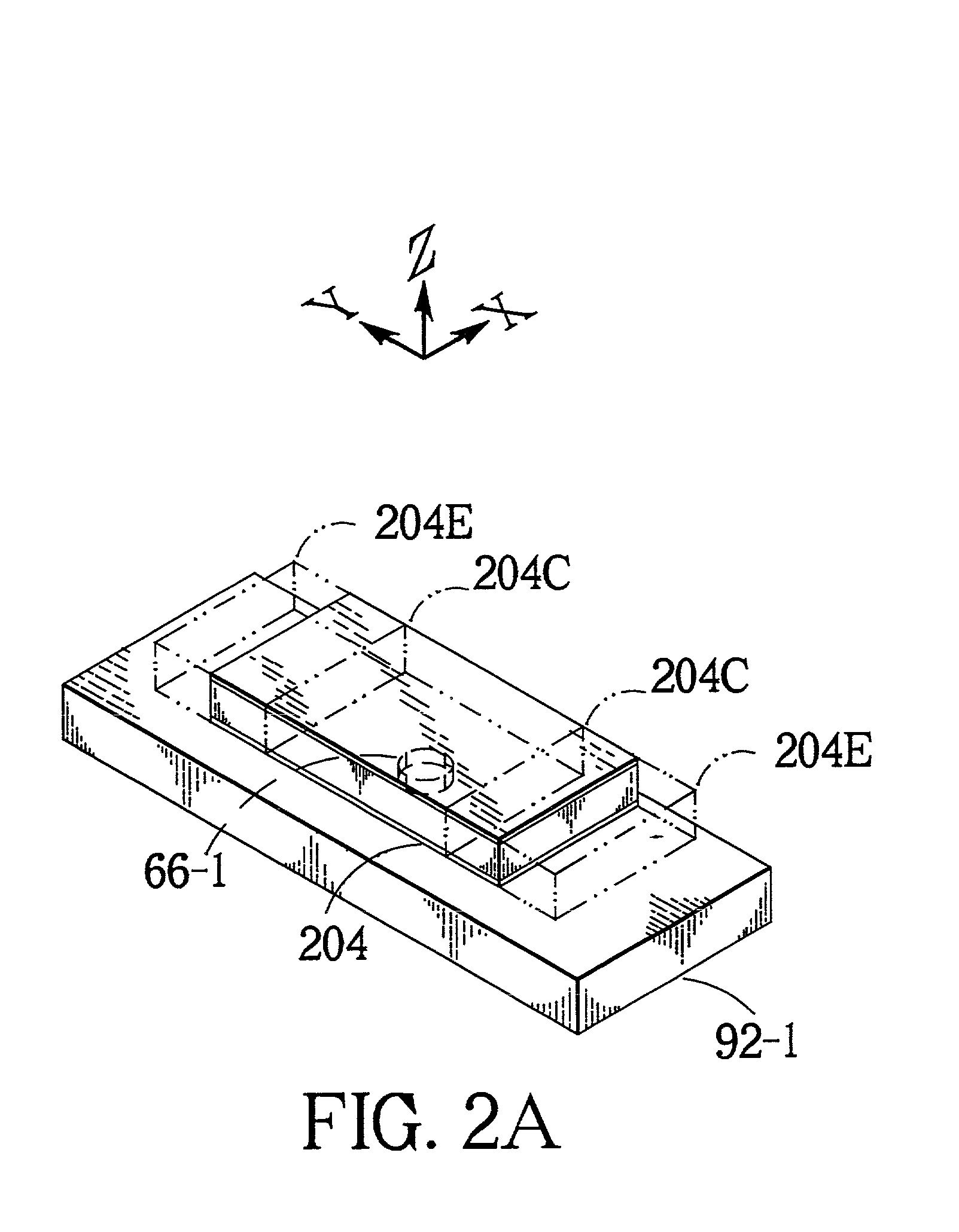

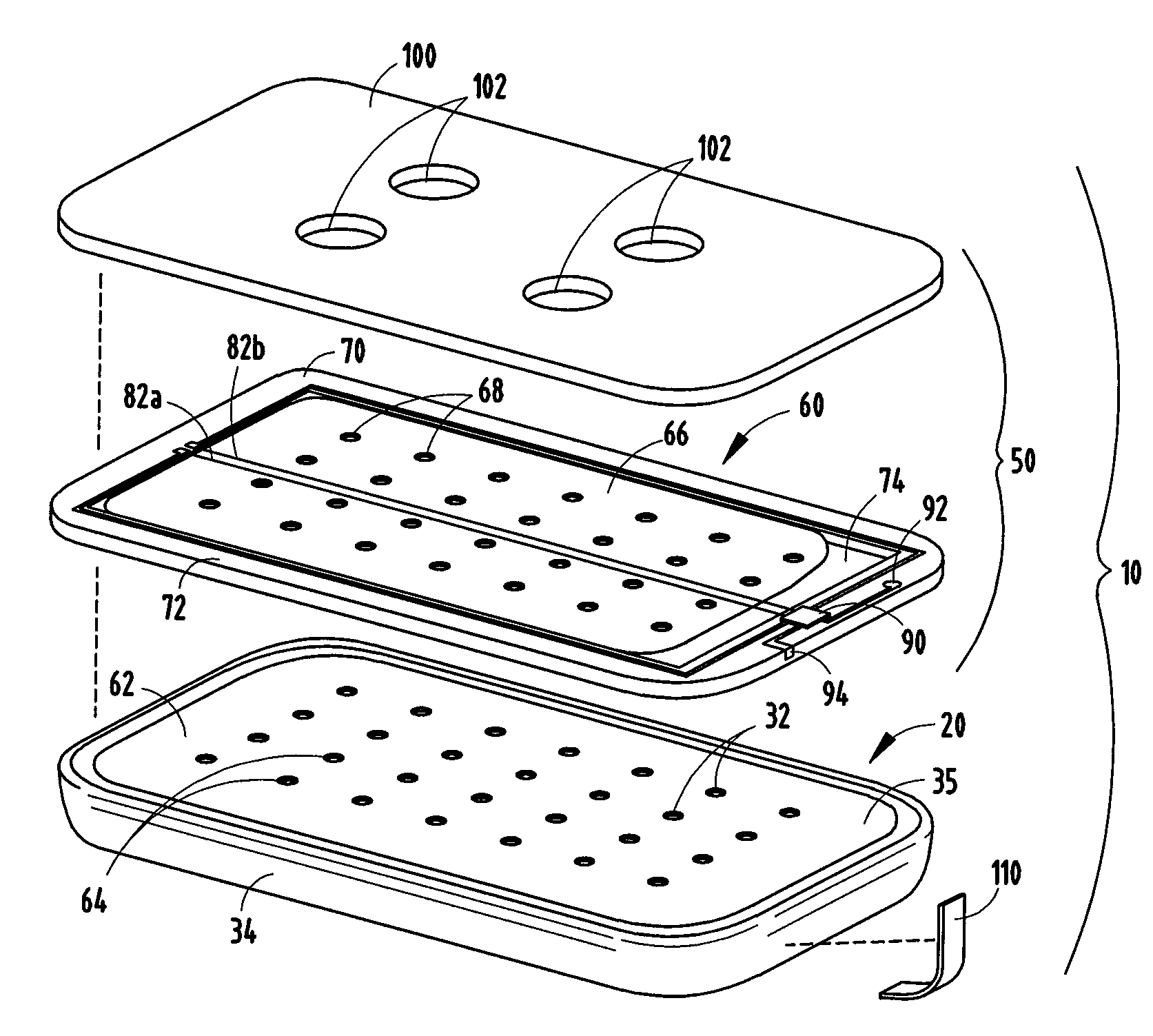

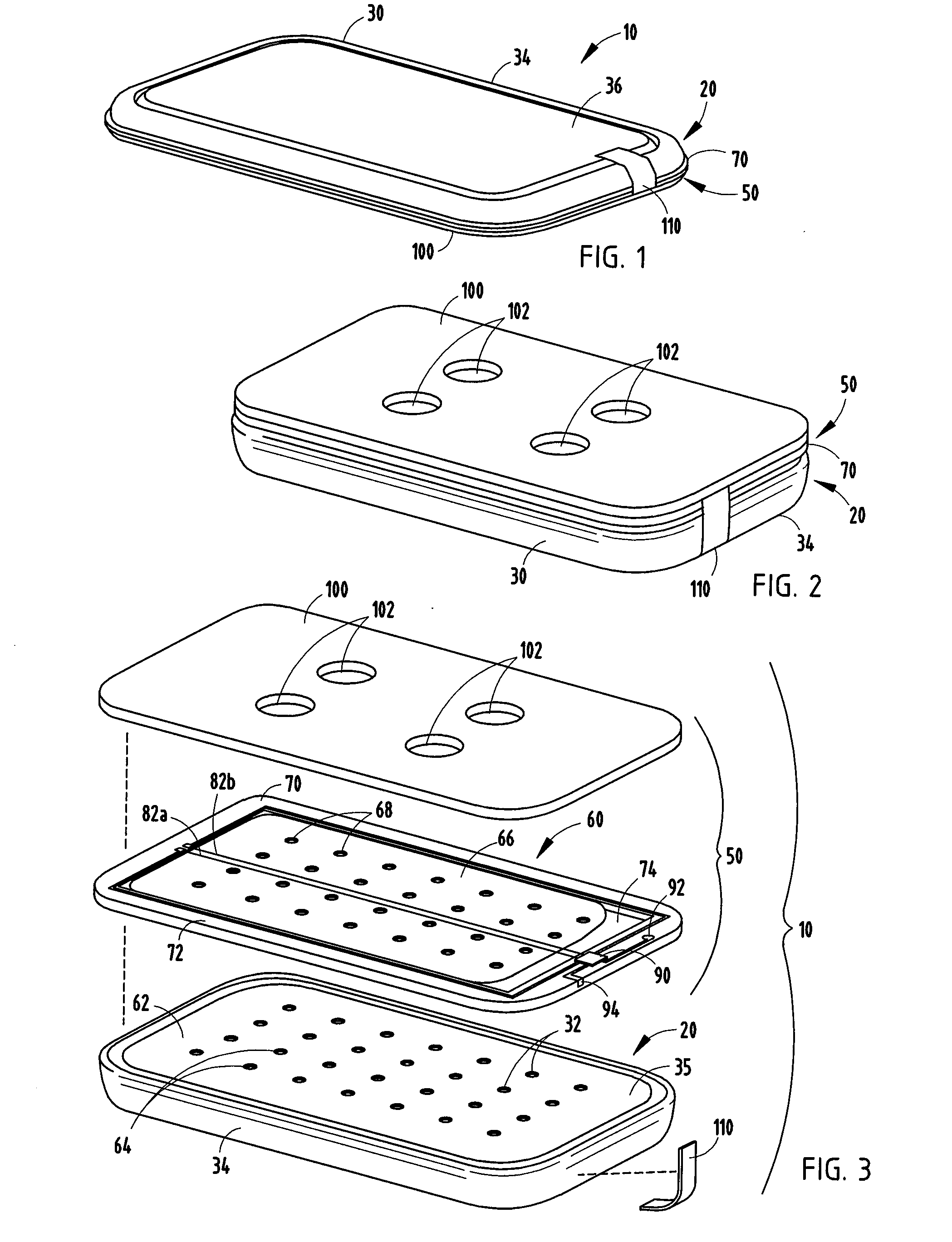

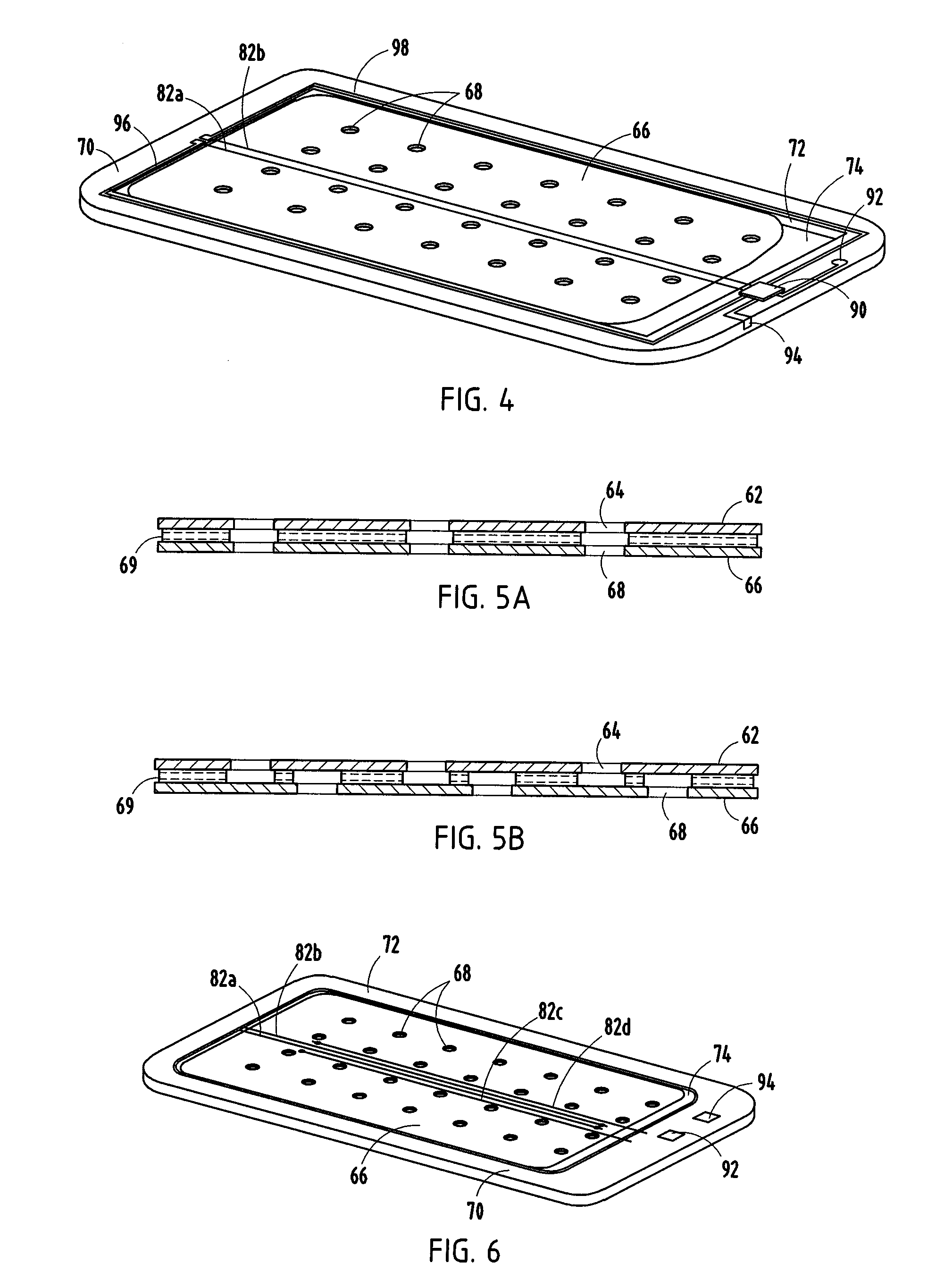

Battery having fluid manager and sliding valve with friction reduction members

ActiveUS20090081519A1Fuel and secondary cellsFuel cell auxillariesFriction reductionShape-memory alloy

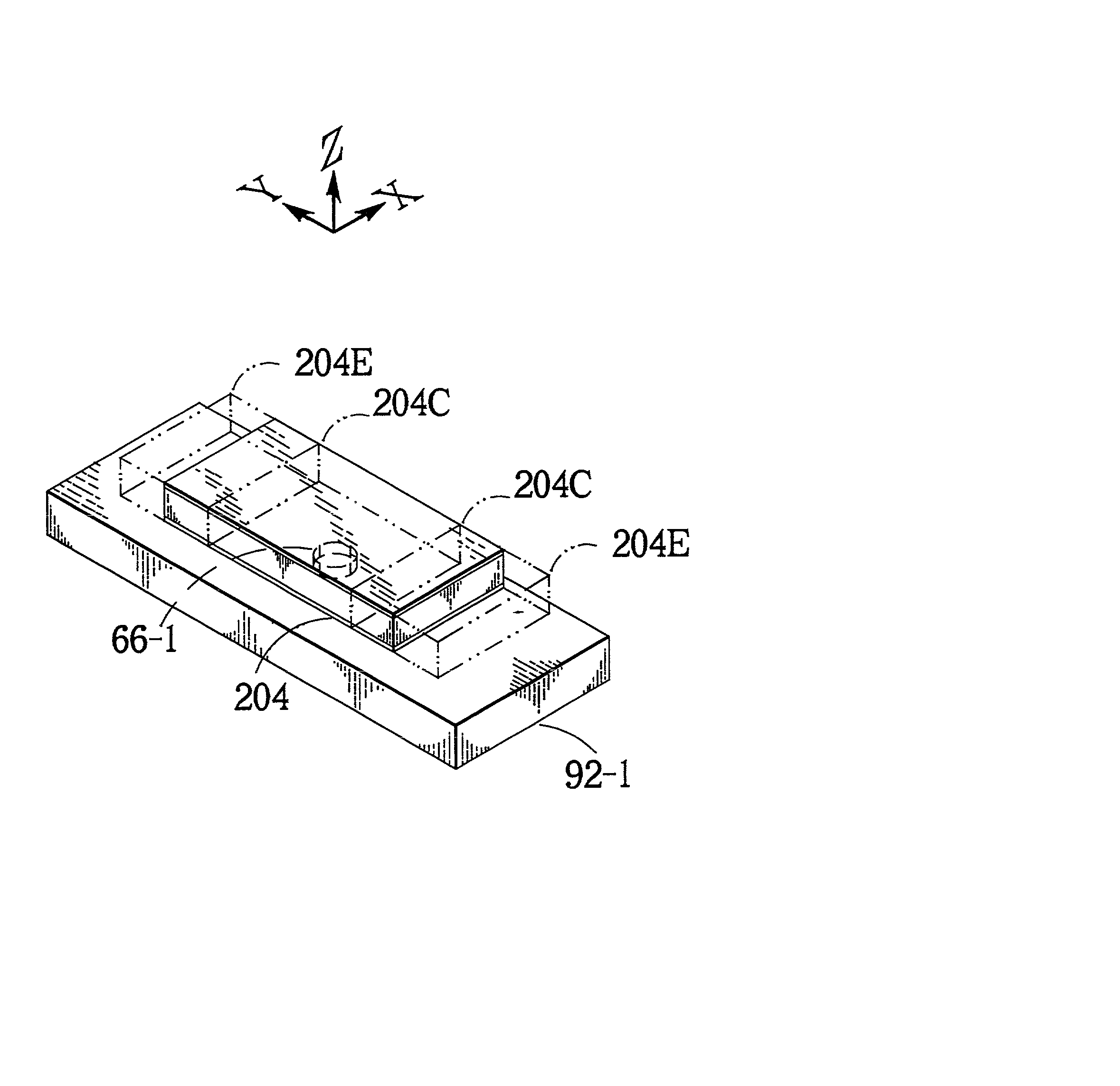

A fluid consuming battery (10) is provided with a fluid regulating system (50) for regulating fluid entry into the battery. The battery (10) includes a fluid consuming cell (20) having a cell housing with fluid entry ports for the passage of a fluid into the cell housing. A first fluid consuming electrode and a second electrode are disposed within the cell housing. The fluid regulating system (50) includes a valve having a moving plate (66) disposed adjacent to a fixed plate (62). The moving plate and fixed plate both have fluid entry ports (68, 64) that align in an open valve position and are misaligned in a closed valve position. The fluid regulating system (50) also includes an actuator that may include one or more shape memory alloy (SMA) components (82a, 82b) for moving the moving plate (66) relative to the fixed plate (62) to open and close the valve. In one embodiment, a friction reduction medium (502) employing lubricating oil (69) and a plurality spherical members (500) is disposed between the moving plate (66) and fixed plate (62) to provide enhanced valve operation.

Owner:ENERGIZER BRANDS

Rotary machine cooling system

ActiveUS7160086B2Reduce air volumeMinimized in sizePositive displacement pump componentsPiston pumpsImpellerFriction reduction

A rotary machine cooling system is provided that includes a housing having an inlet and outlet. A rotor supported in the housing for rotation about an axis with the rotor including an outer surface. A stator is disposed within the housing about the rotor having an inner surface adjacent to the outer surface of the rotor. A gap is formed between the inner and outer surfaces sufficient to reduce friction and permit convection cooling. The gap is in fluid communication with the inlet and outlet, and a pumping device pumps a cooling gas from the inlet into the gap and through said outlet. The pumping device includes an impeller affixed to an end portion of the rotor to create an axial airflow into the gap. Preferably, the present invention air cooling system is used in conjunction with a liquid cooling system arranged exteriorly to the stator. The liquid cooling system reduces the amount of air needed to flow between the gap to remove the desired amount of heat from the machine.

Owner:SUNDYNE LLC

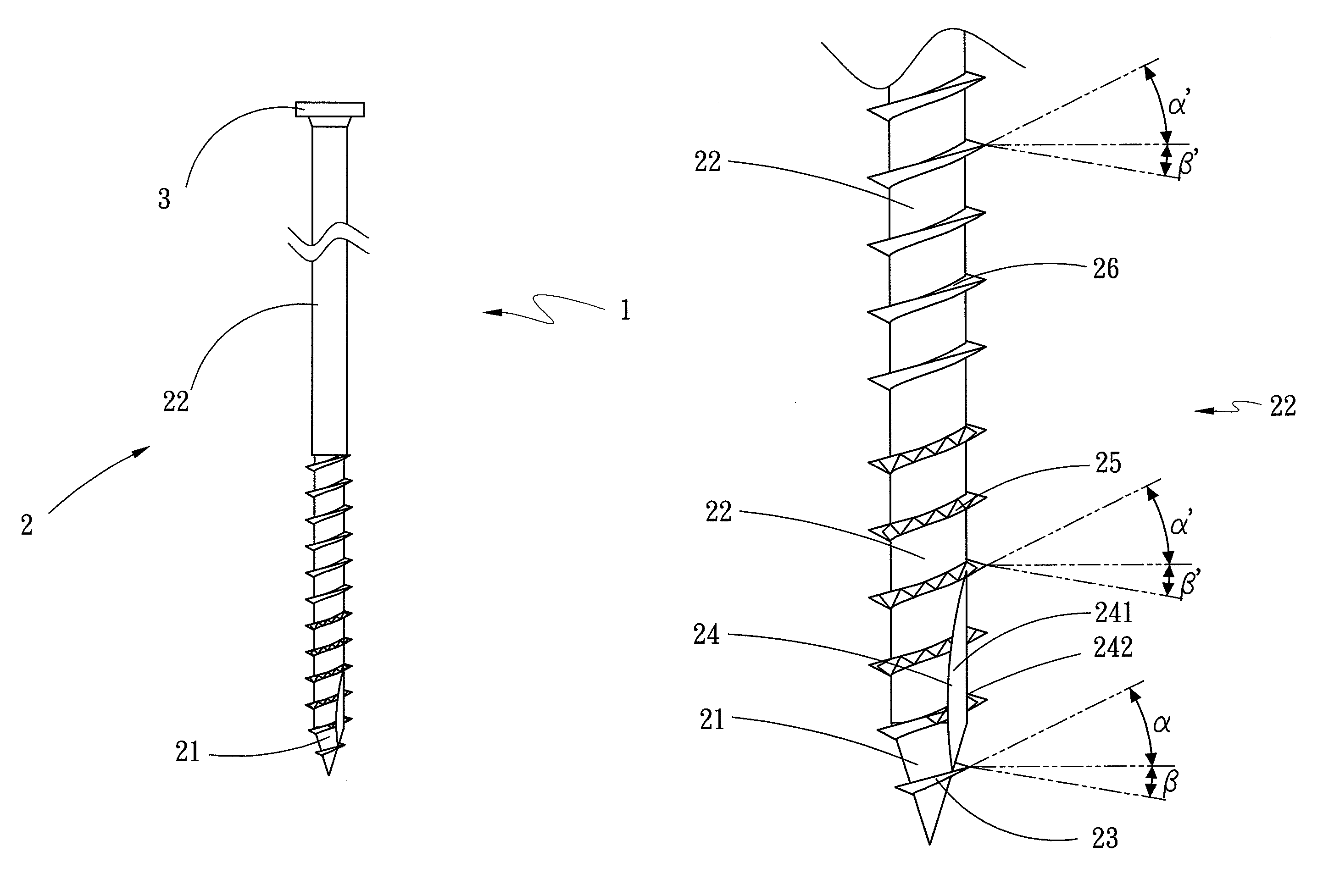

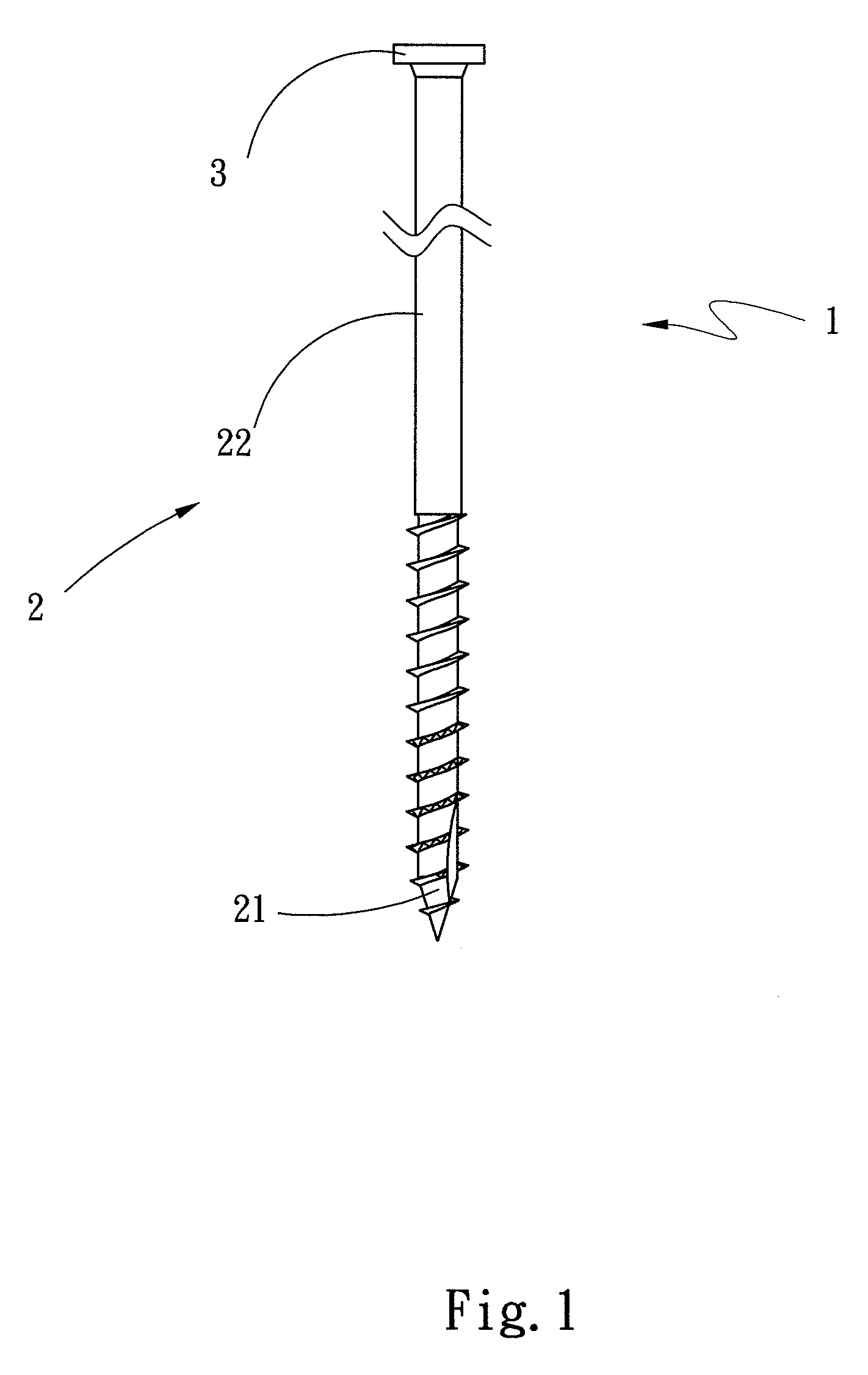

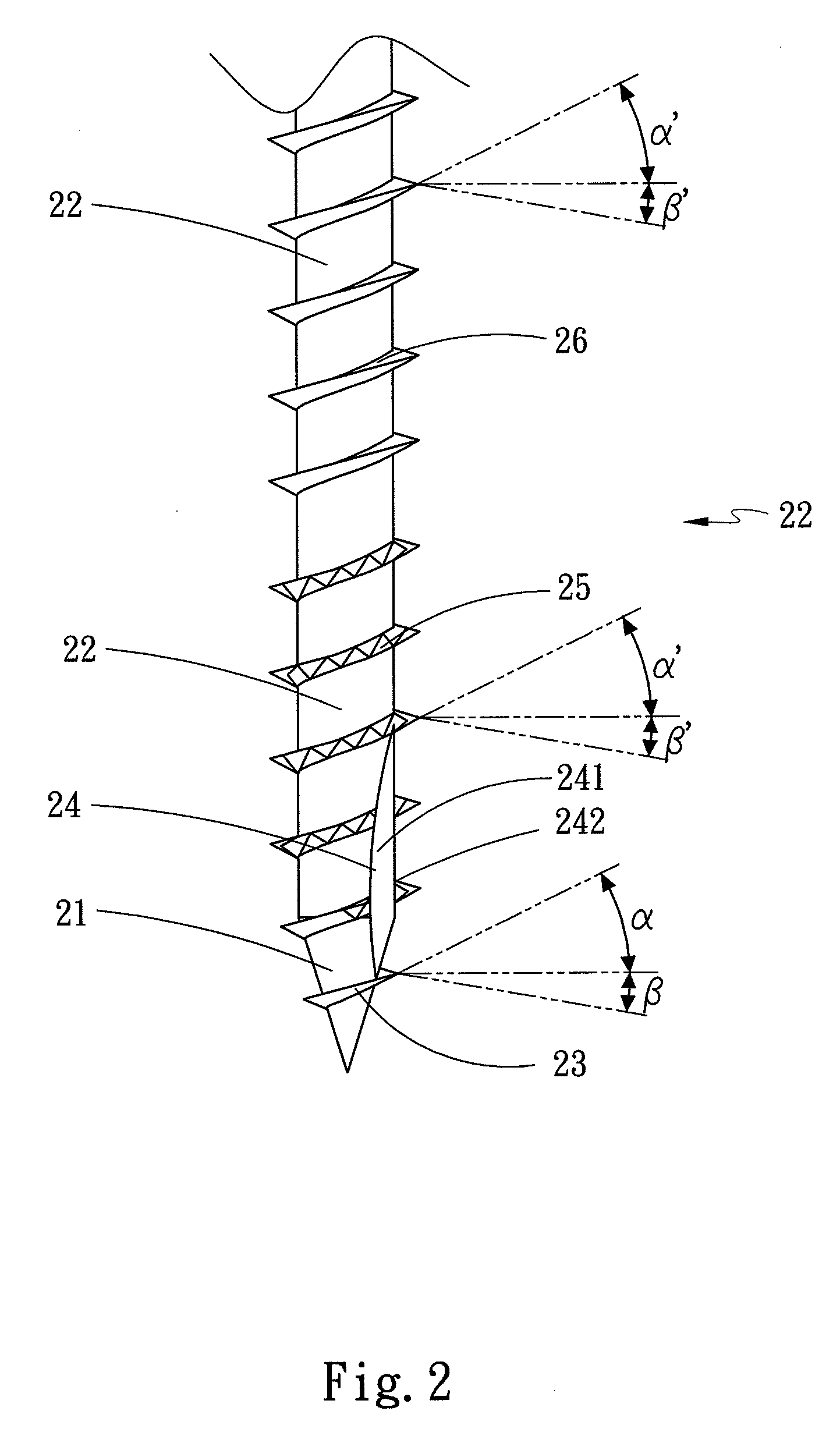

Screw

Owner:BI MIRTH CORP

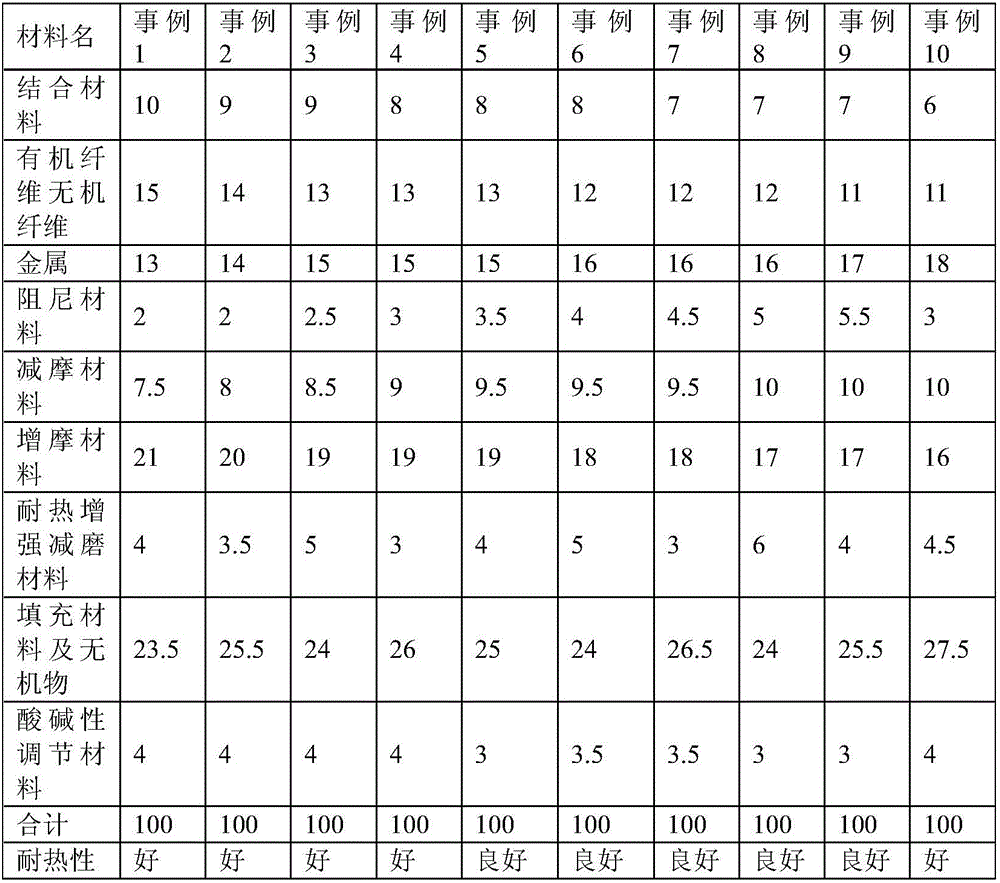

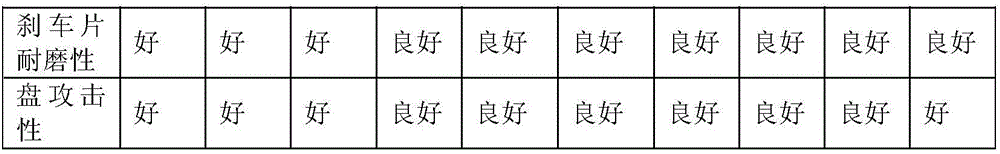

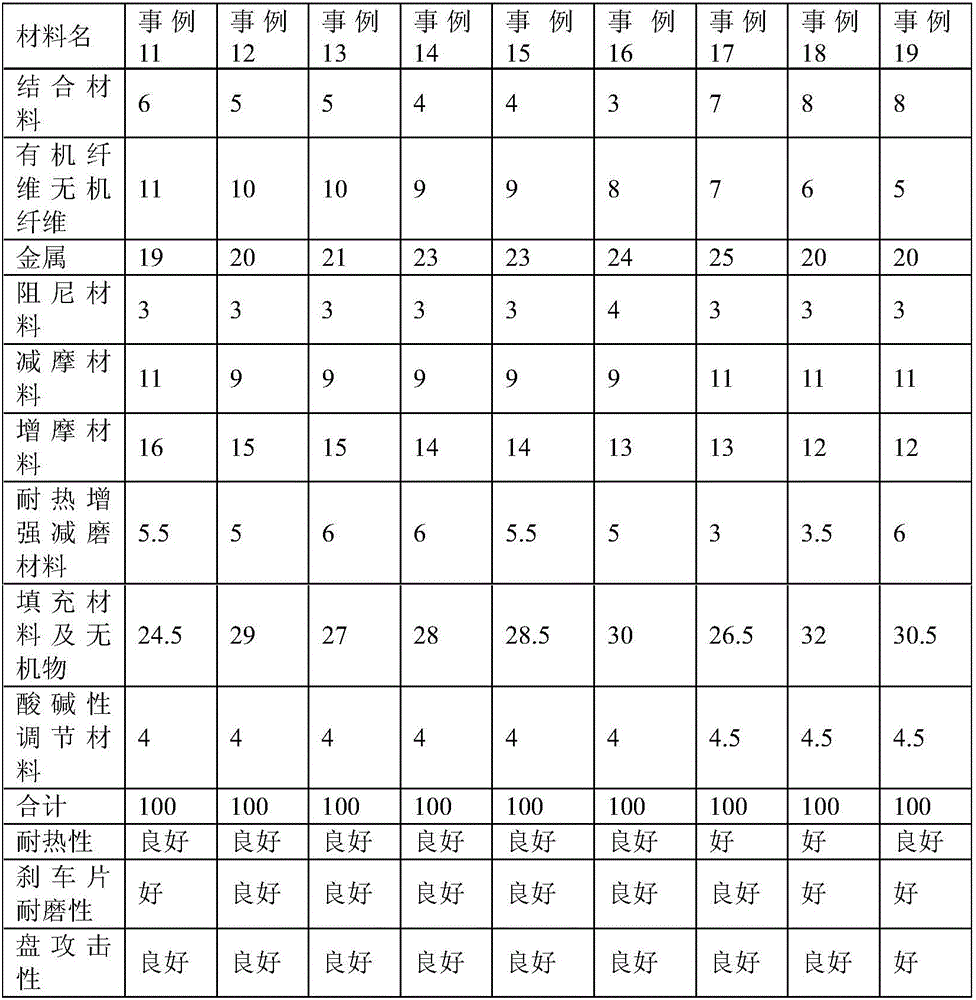

Friction material and product for transmission and braking

InactiveCN106118597AImprove heat resistanceImprove thermal conductivityOther chemical processesFriction liningAlkalinityFriction reduction

A friction material for transmission and braking comprises a binding material, a fiber material, a damping material, a friction reduction material, a friction increase material, a filling material, an acidity and alkalinity adjusting material, a metal material and a heat-resistant reinforcing material. The friction material has the advantages of being stable in friction coefficient, good in abrasion resistance, small in impact on brake discs and good in heat resistance and heat conductivity.

Owner:晋江市凯燕新材料研究院股份有限公司

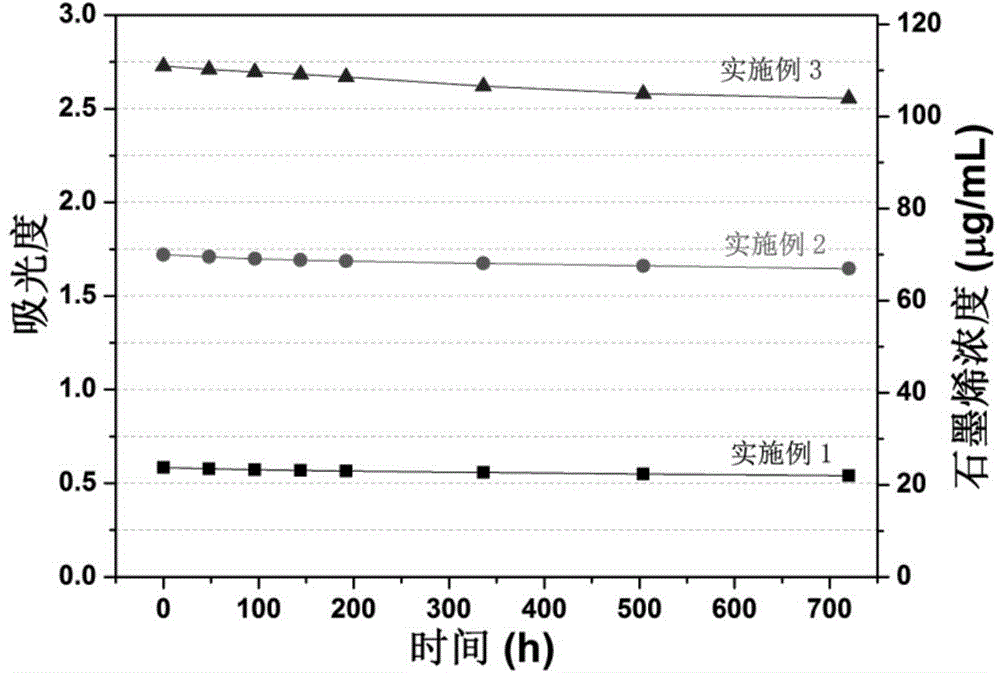

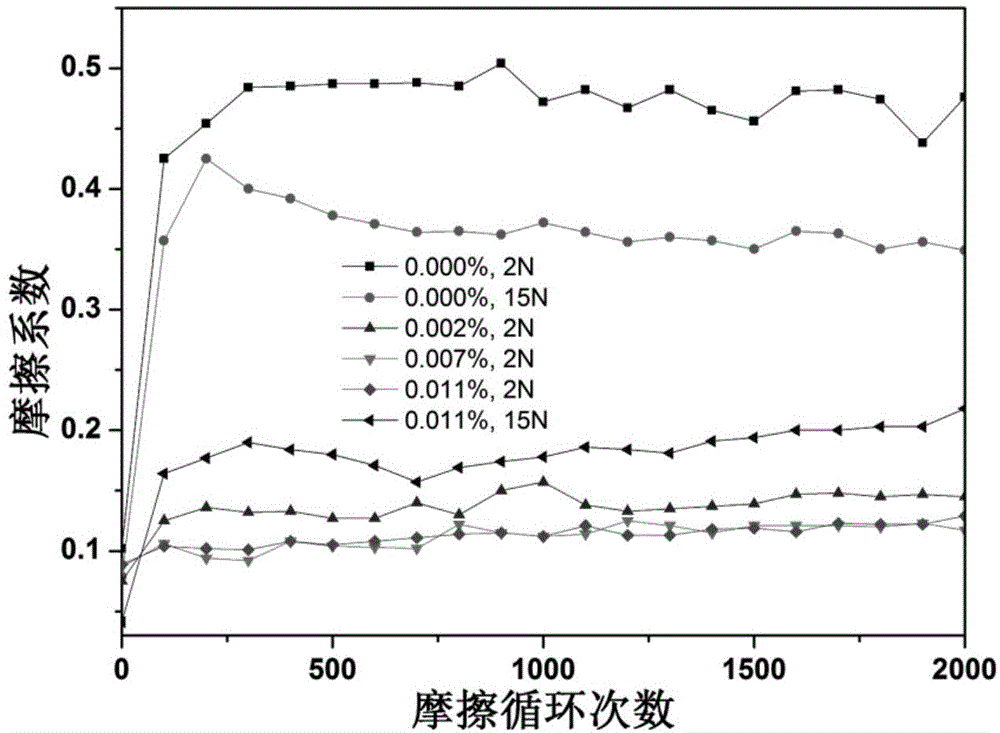

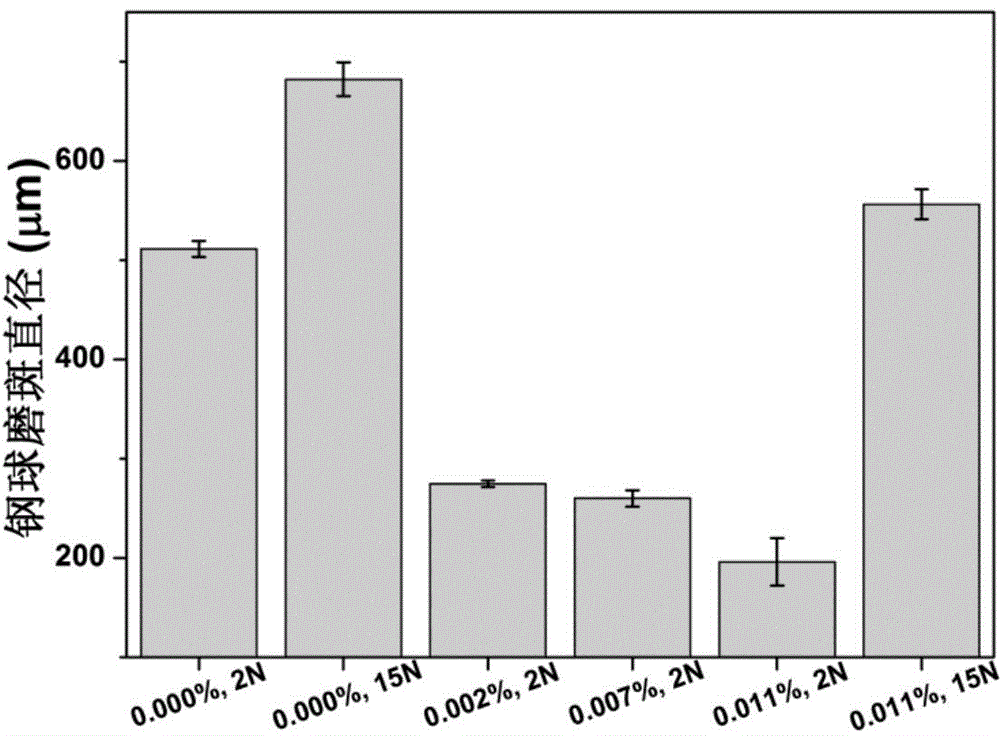

Method for preparing graphene water-based lubricating agent in situ

InactiveCN104593130ASimple preparation processEasy to prepareLubricant compositionWater basedFriction reduction

The invention discloses a method for preparing a graphene water-based lubricating agent in situ, belonging to the field of application of graphene serving as a nanometer lubricating additive. The lubricating agent consists of graphene nanoparticles, a surface modifier and purified water. The method comprises the following preparation steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing graphene powder in the liquid; 3, performing ultrasonic cavitation treatment on the graphene dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation treatment on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing graphene prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the graphene is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the graphene, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property, high machinability and environment friendliness of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com