Friction material and product for transmission and braking

A friction material and anti-friction material technology, applied in the direction of friction lining, gear transmission mechanism, other chemical processes, etc., can solve the problems of poor heat conduction and heat resistance, increase process and cost, etc., and achieve low production cost, disc Small attack force, good heat resistance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

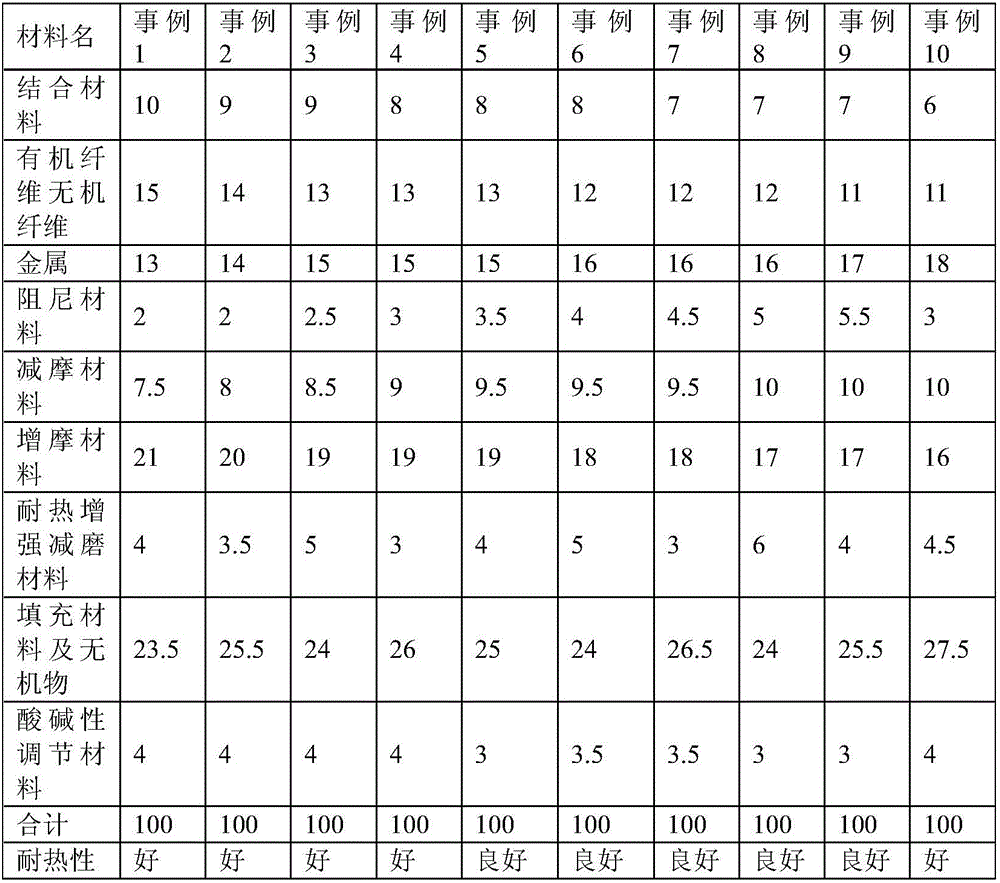

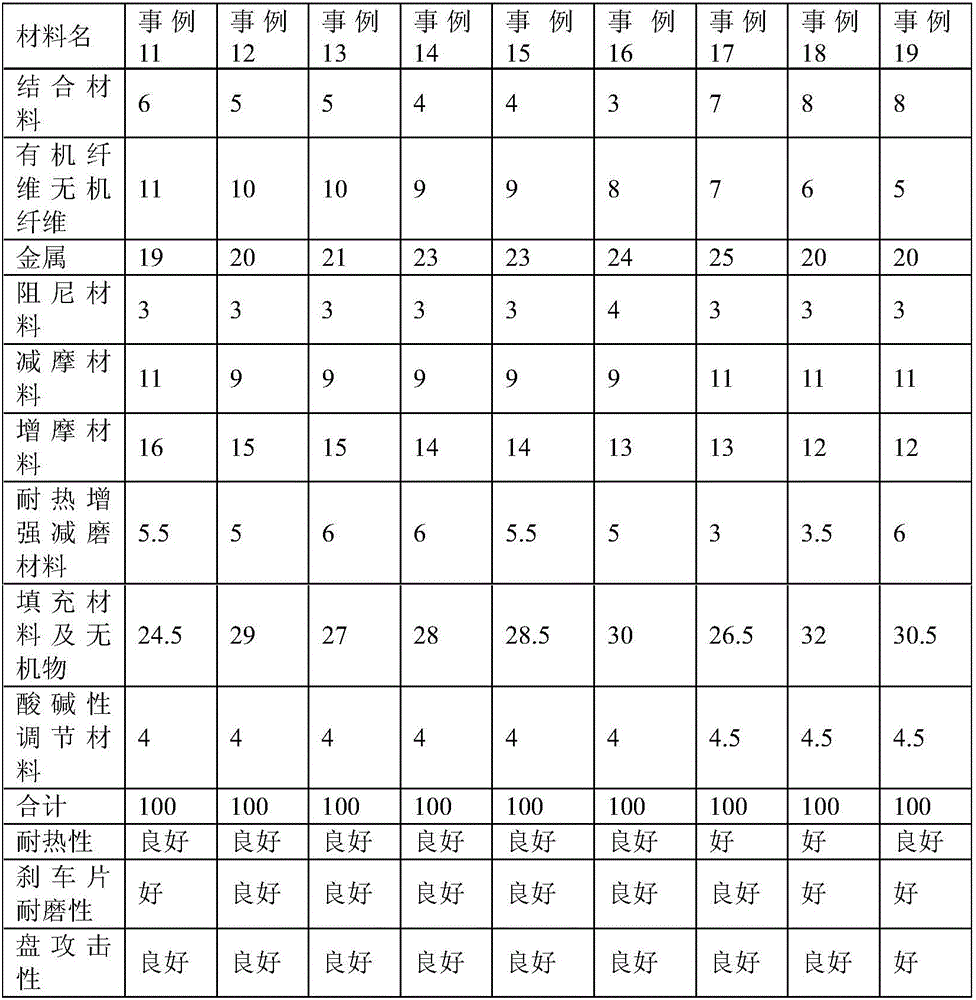

[0024] Hereinafter, the present invention will be explained in detail with reference to examples. However, the present invention should not be construed as being limited to the following examples.

[0025] The bonding material includes one or more combinations of phenolic resin, melamine resin, epoxy resin, melamine resin, modified phenolic resin, sumac resin, natural rubber and styrene-butadiene rubber.

[0026] The organic fibers include one or more combinations of aromatic polyamide (aramid) fibers, cellulose fibers and polyacrylic fibers.

[0027] The inorganic fibers include one or more combinations of potassium titanate fibers, glass fibers, ceramic fibers and aluminum fibers.

[0028] Fibrous substrates can be used in staple or powder form.

[0029] Filling materials include organic filling materials and inorganic filling materials, organic filling materials include various rubbers of nitrile rubber (NBR), styrene-butadiene rubber (SBR) and butadiene rubber (BR), rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com