Patents

Literature

3646results about How to "Reduce residual stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precision spray processes for direct write electronic components

InactiveUS6251488B1Keep for a long timeIncrease probabilityMolten spray coatingVacuum evaporation coatingElectrical resistance and conductanceElectronic component

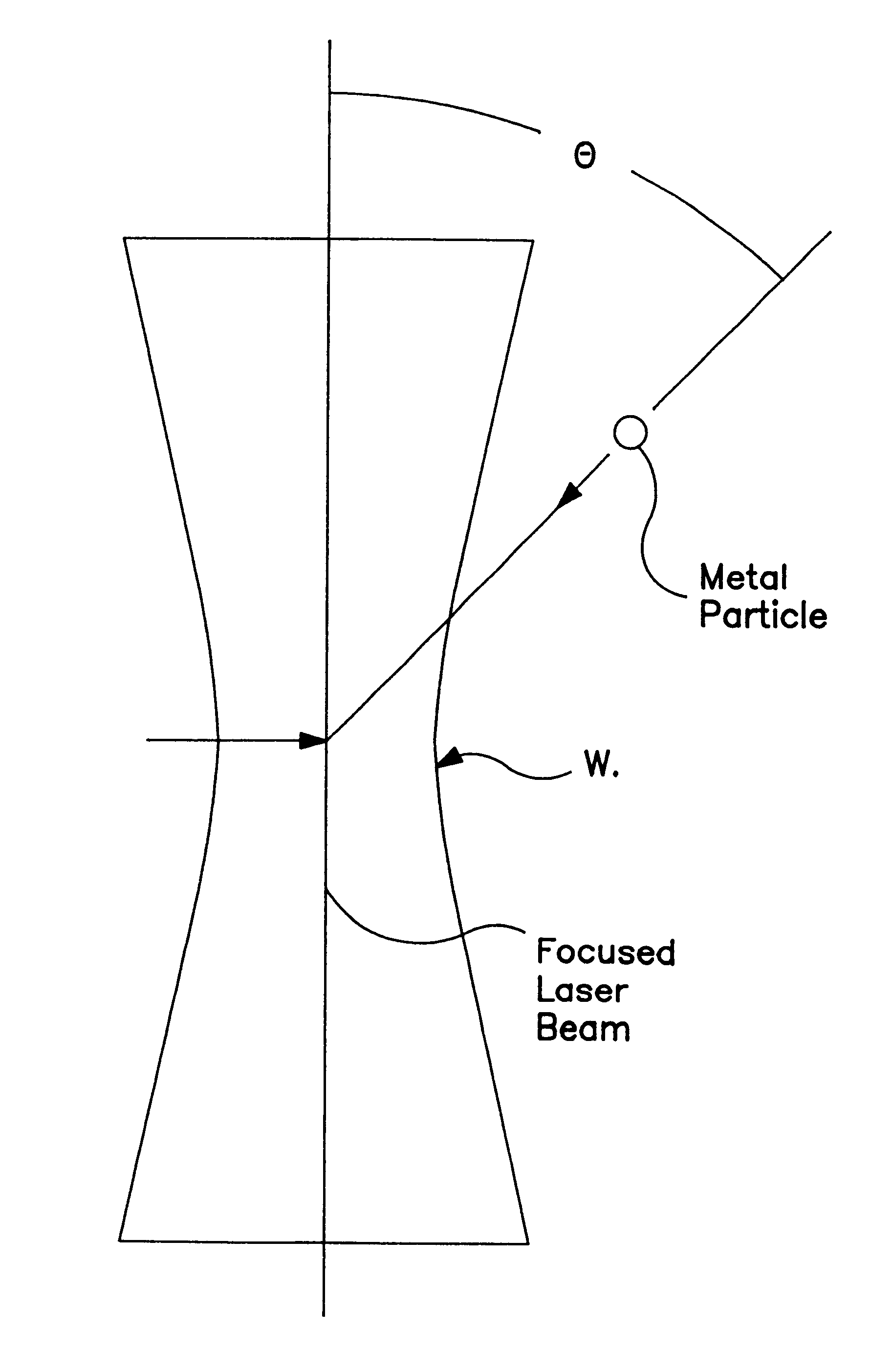

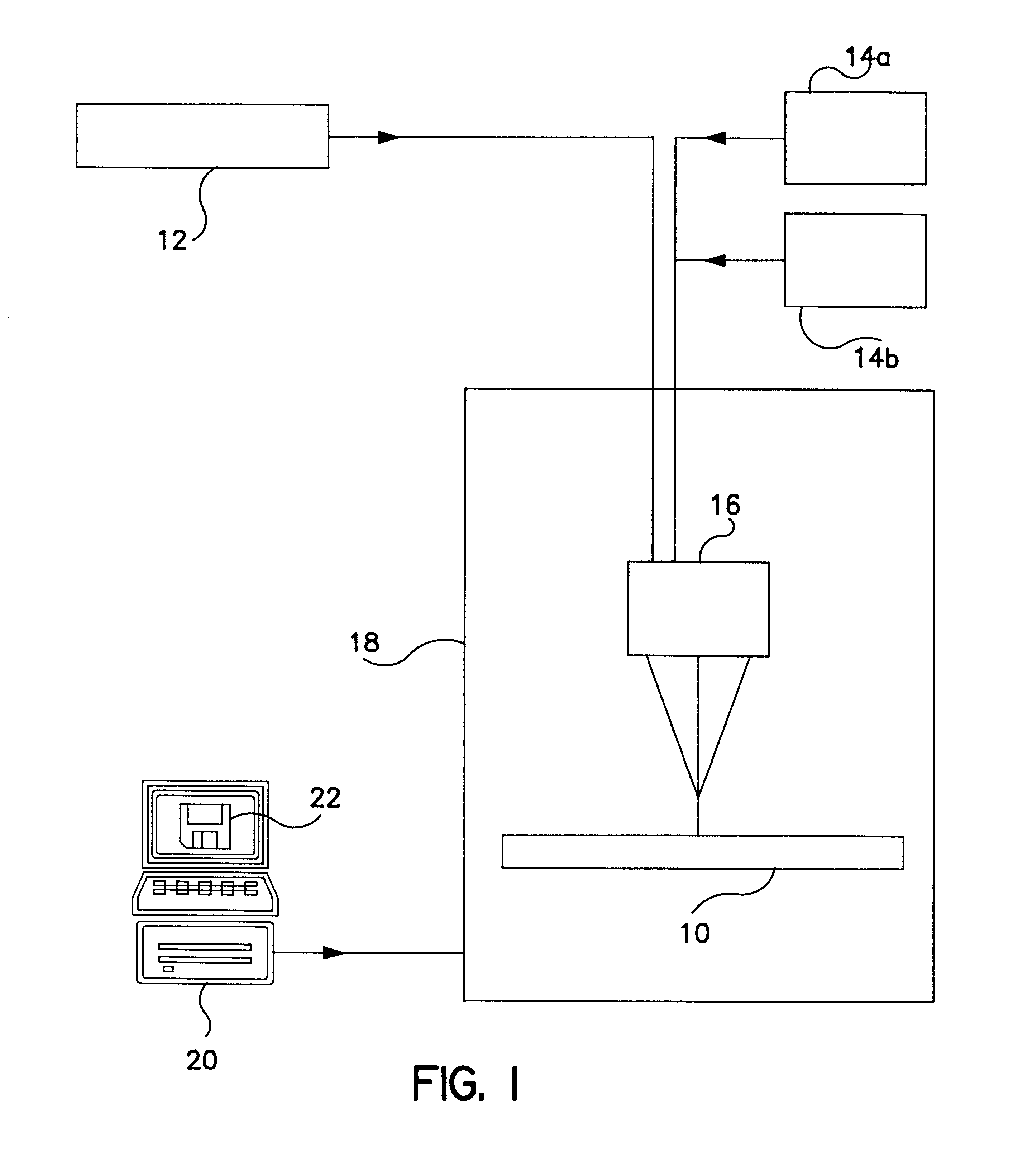

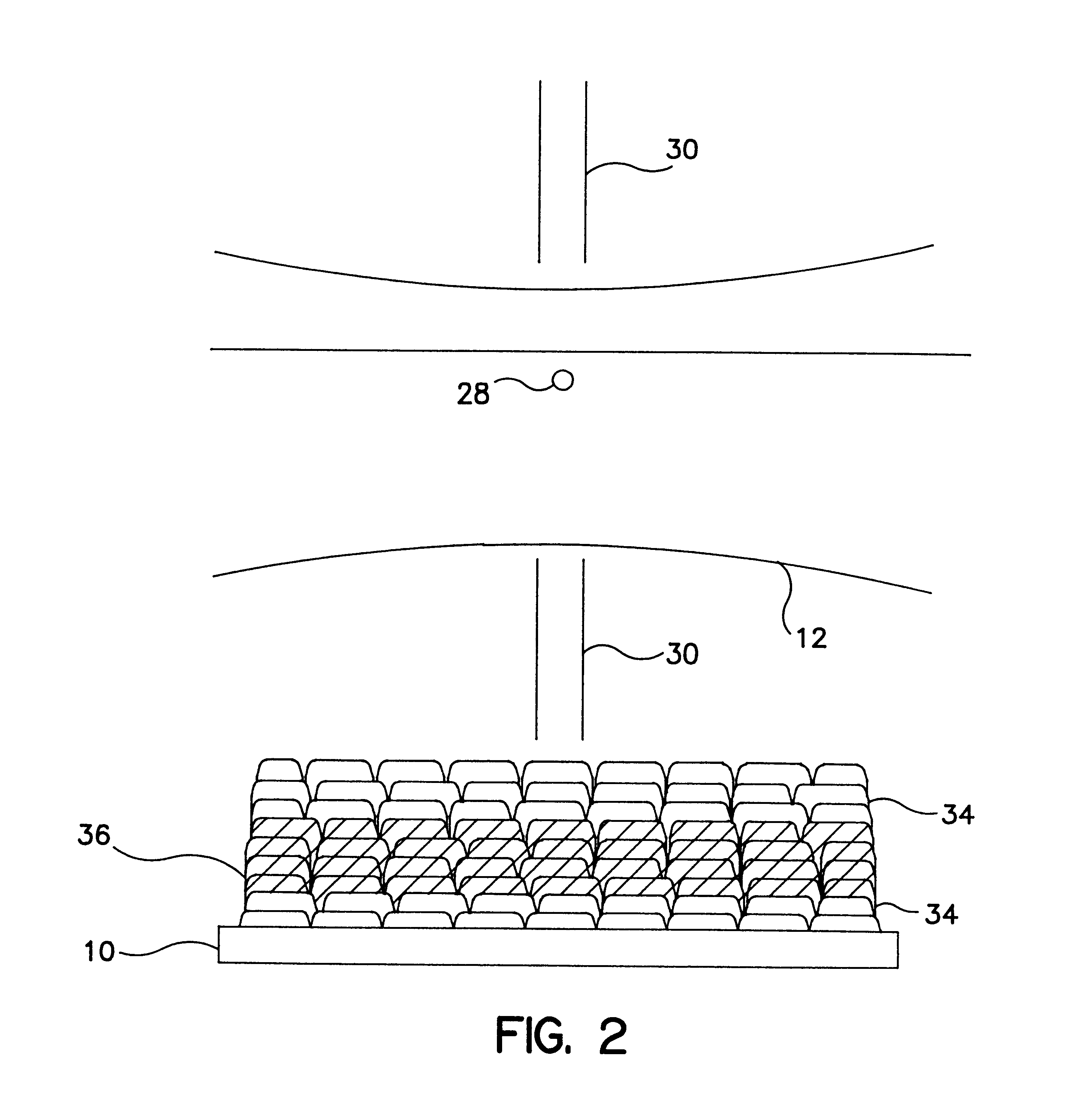

This invention combines the precision spray process with in-flight laser treatment in order to produce direct write electronic components. In addition to these components, the process can lay down lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging. This process is revolutionary in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

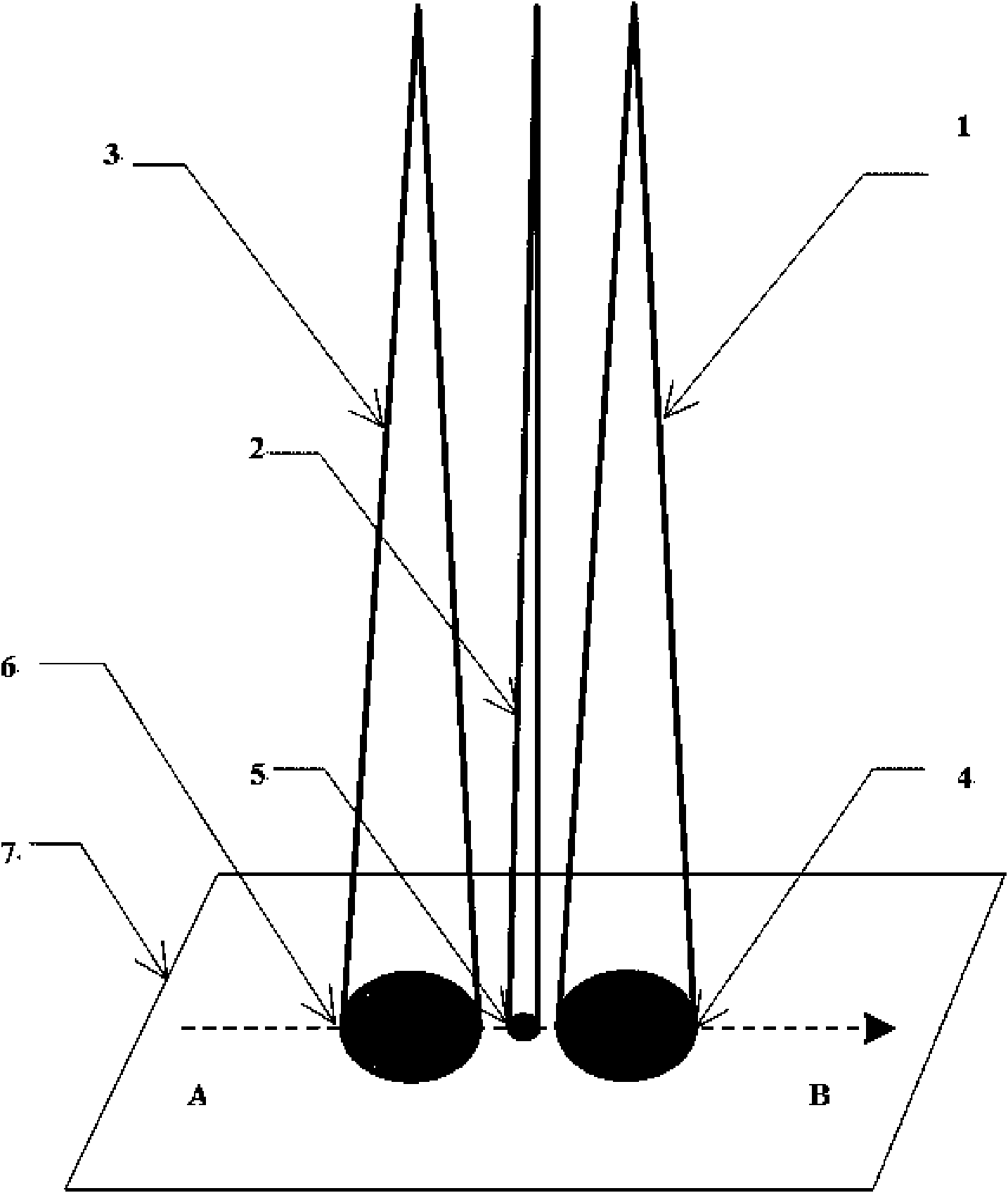

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

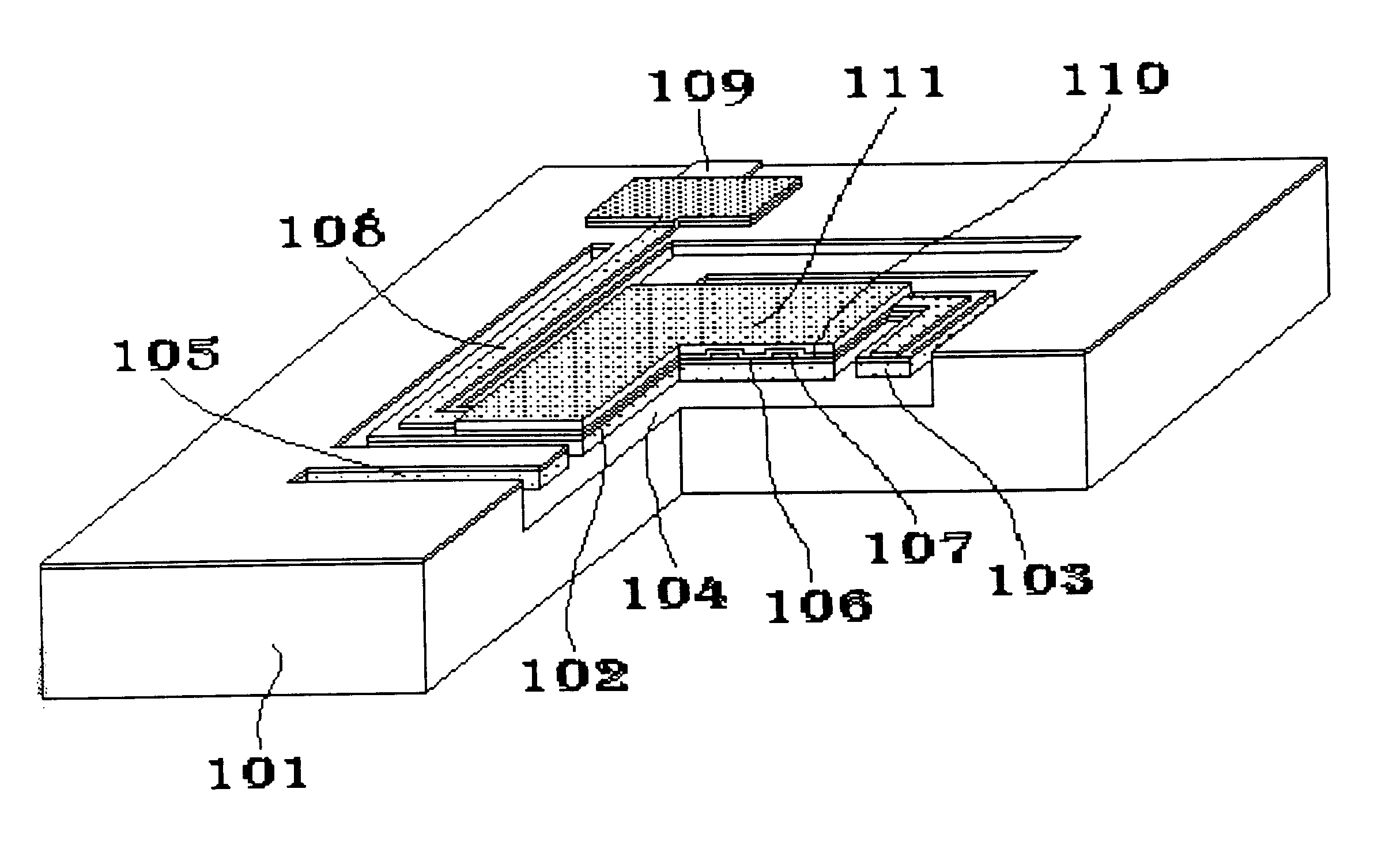

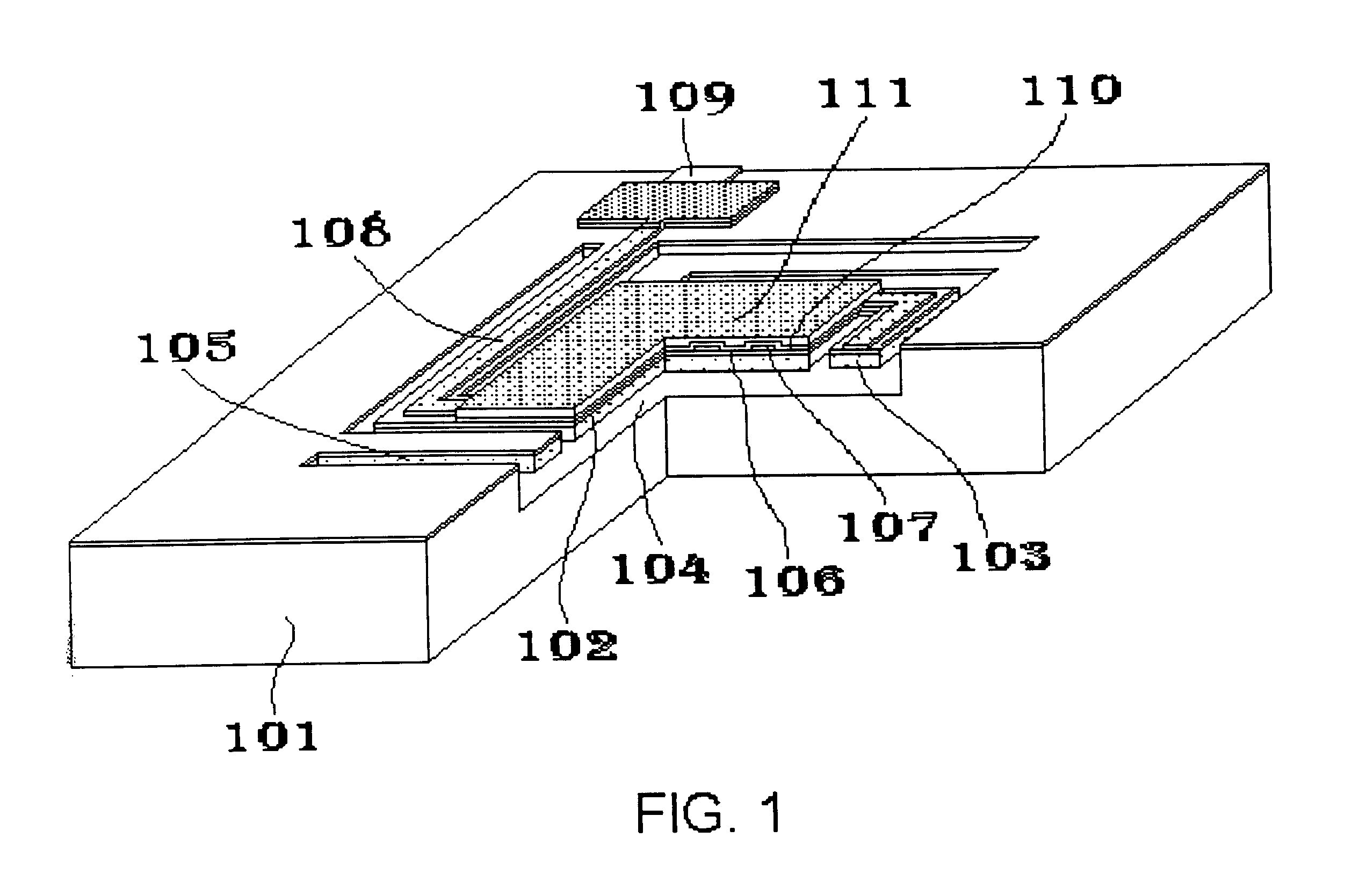

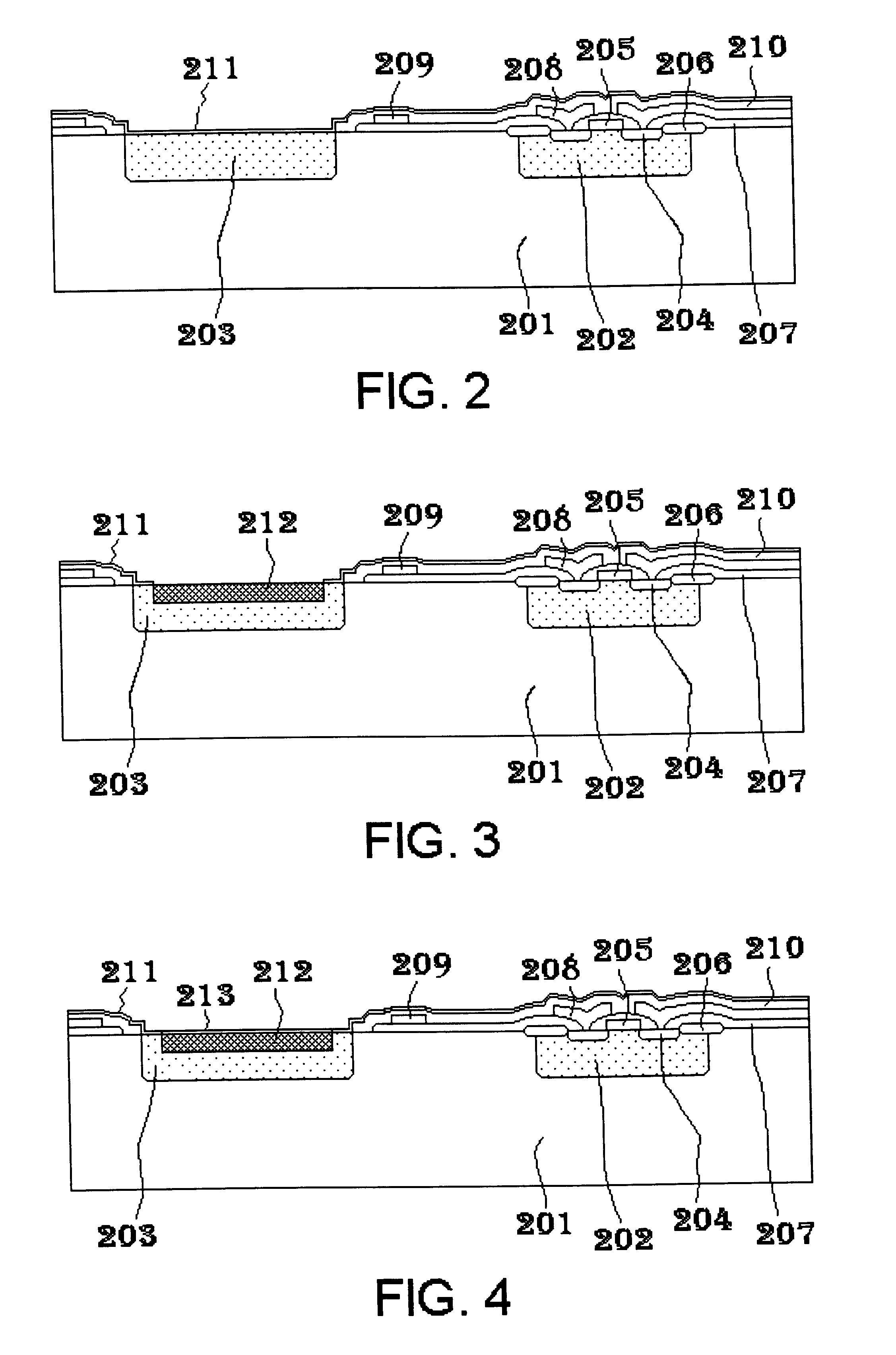

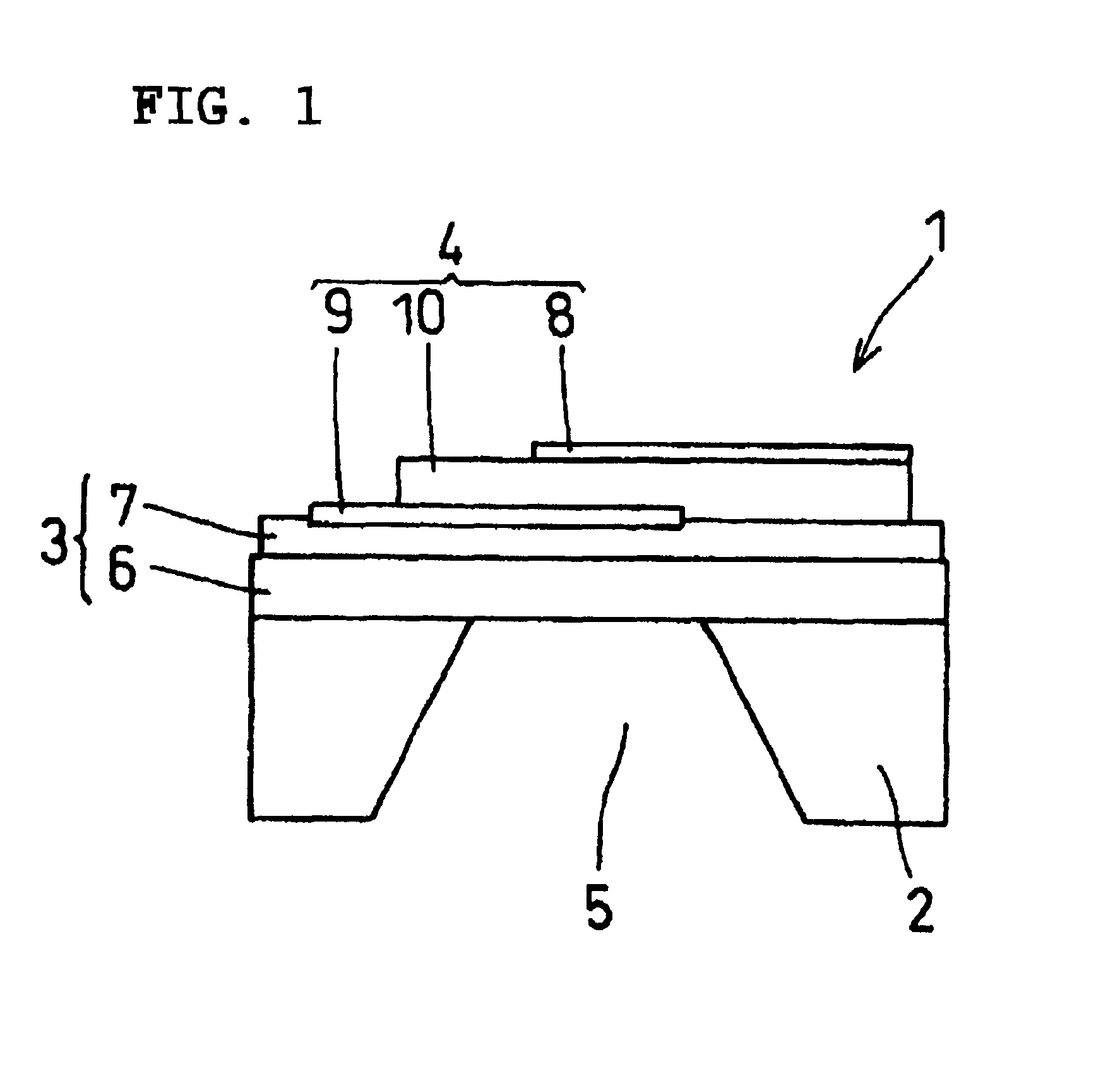

Microbolometer infrared sensors

InactiveUS6359276B1High mechanical strengthReduce residual stressSolid-state devicesMaterial analysis by optical meansThermal isolationMicrobolometer

A microbolometer infrared sensor utilizes a porous silicon bridge as its thermal isolating and mechanical supporting structure. Porous silicon formed from single crystal silicon on lightly doped p-type silicon has a thermal conductivity lower than silicon dioxide and silicon nitride, and, therefore, when used as a mechanical supporting structure, can offer better thermal isolation performance. The porous silicon layer can be fabricated much thicker than silicon dioxide and silicon nitride membranes since there is almost no residual stress therein. A thicker porous silicon bridge has higher mechanical support strength. The porous silicon process is a low temperature process. It facilitates a fabrication strategy of microelectronics first and micromechanics last.

Owner:TU XIANG ZHENG

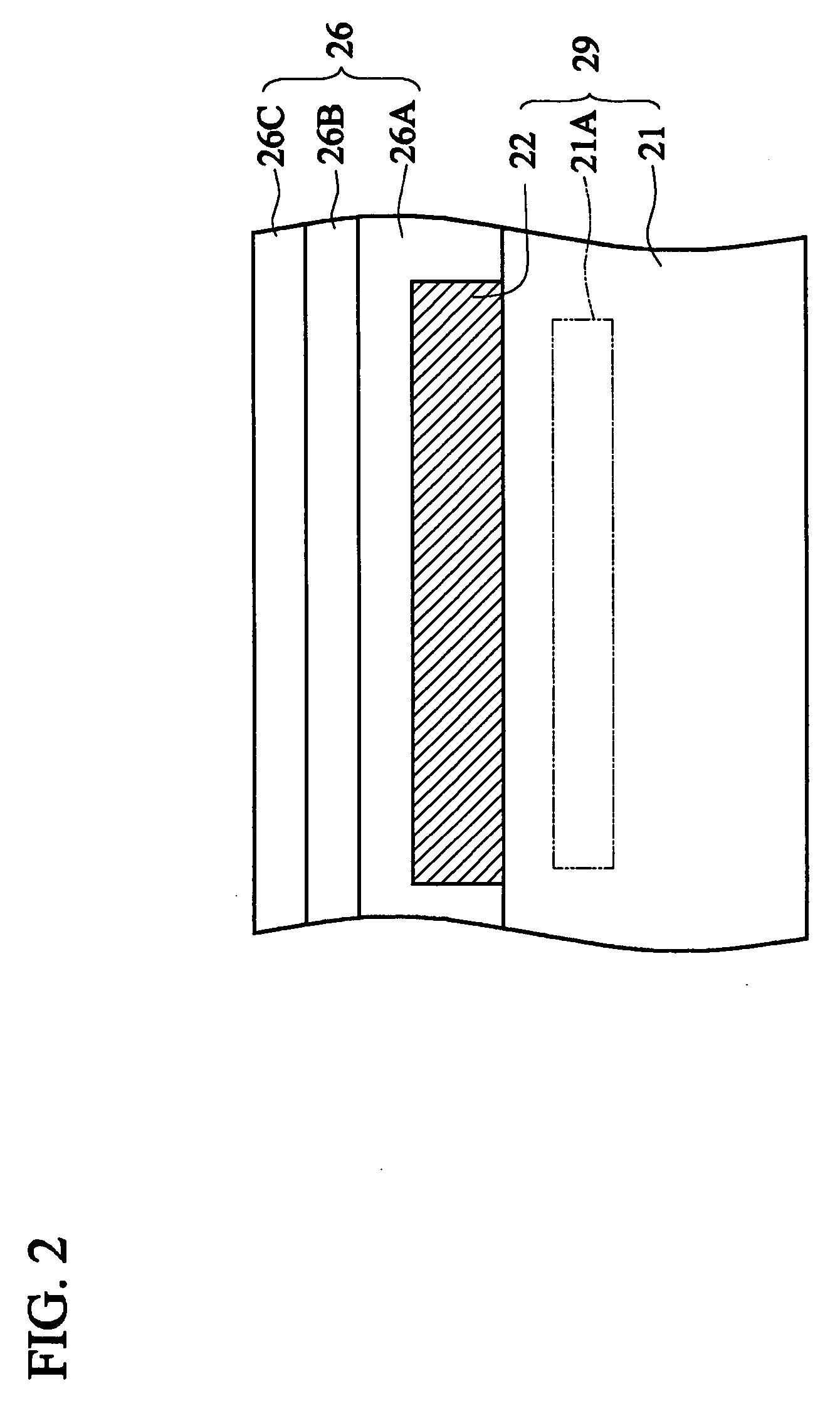

Piezoelectric resonator, piezoelectric filter, duplexer, communication apparatus, and method for manufacturing piezoelectric resonator

InactiveUS6906451B2Improve flatnessOutstanding crystallinityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksOxygenPiezoelectric thin films

A piezoelectric thin film resonator having a stabilized temperature characteristic of resonant frequency, a method for manufacturing the same, and a communication apparatus using the piezoelectric thin film resonator are provided. The piezoelectric thin film resonator is provided with a substrate having an opening, first and second insulation films which are provided on one surface of the substrate while covering the opening and which primarily include SiO2 and Al2O3, respectively, Al2O3 having oxygen defect and being in an amorphous state, and a piezoelectric thin film which is provided on the second insulation film and is sandwiched between electrodes and which primarily includes ZnO.

Owner:MURATA MFG CO LTD

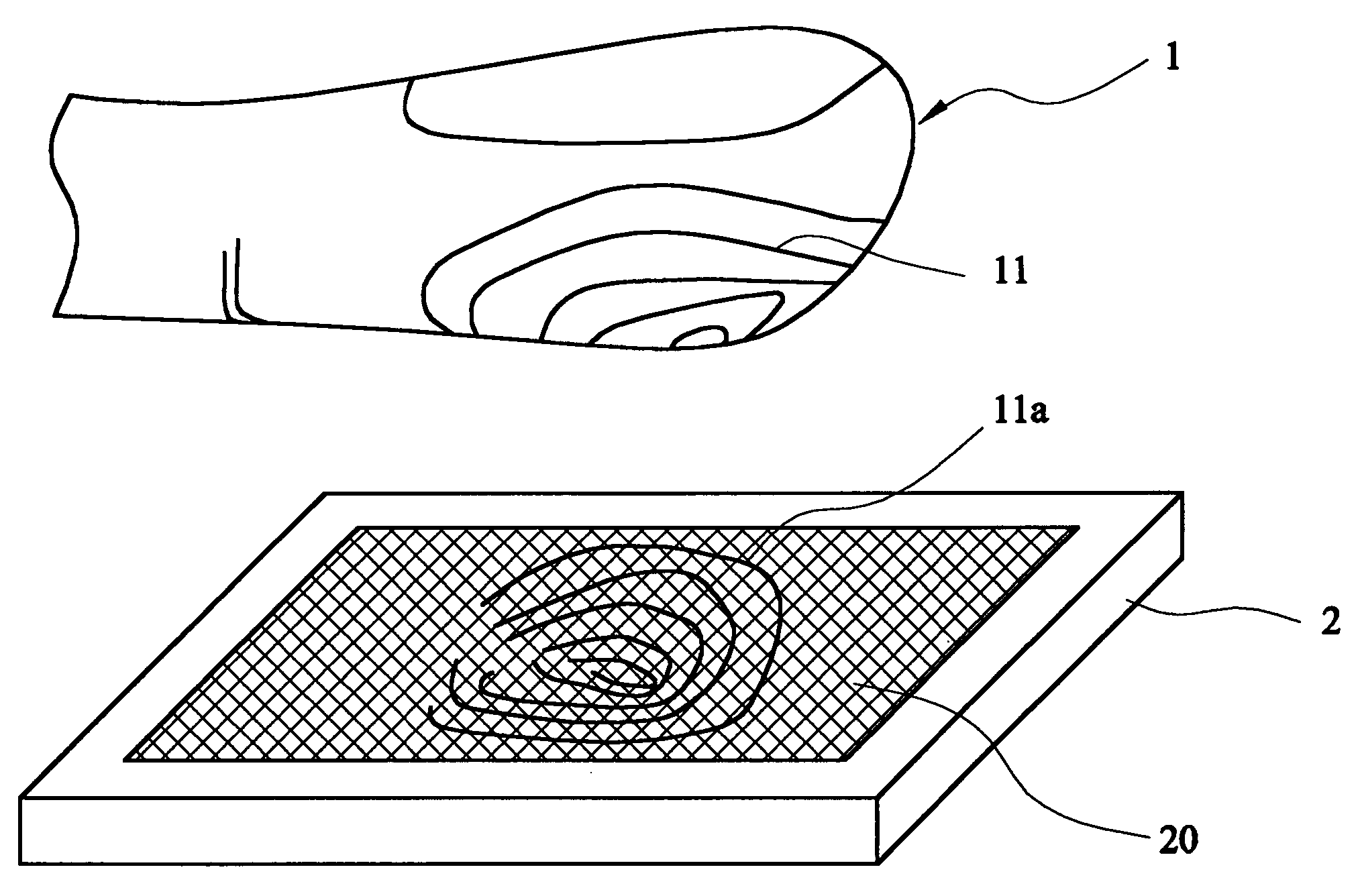

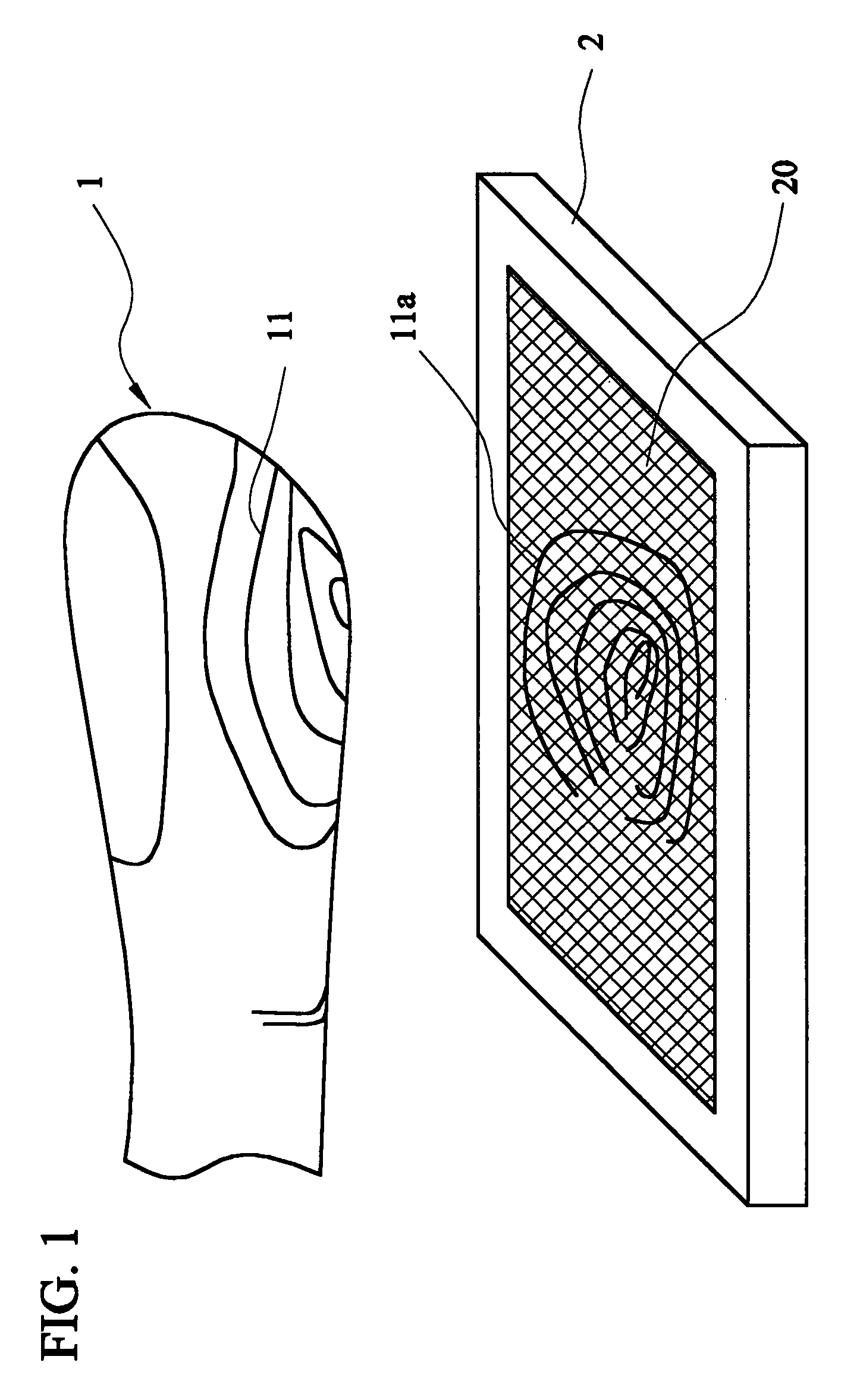

Chip-type sensor against ESD and stress damages and contamination interference

ActiveUS20050231213A1Improve the induction effectExtended service lifeResistance/reactance/impedenceCharacter and pattern recognitionProtection layerContamination

A chip-type sensor against ESD and stress damages and contamination interference includes a substrate structure and a protection layer covering over the substrate structure. The protection layer includes, from bottom to top, a first layer for providing a first stress against the substrate structure, a second layer for providing a second stress against the substrate structure, and a third layer for providing a third stress against the substrate structure. The first stress and the third stress belong to one of a tensile stress and a compressive stress, and the second stress belongs to the other of the tensile stress and the compressive stress.

Owner:XIANGQUN SCI & TECH

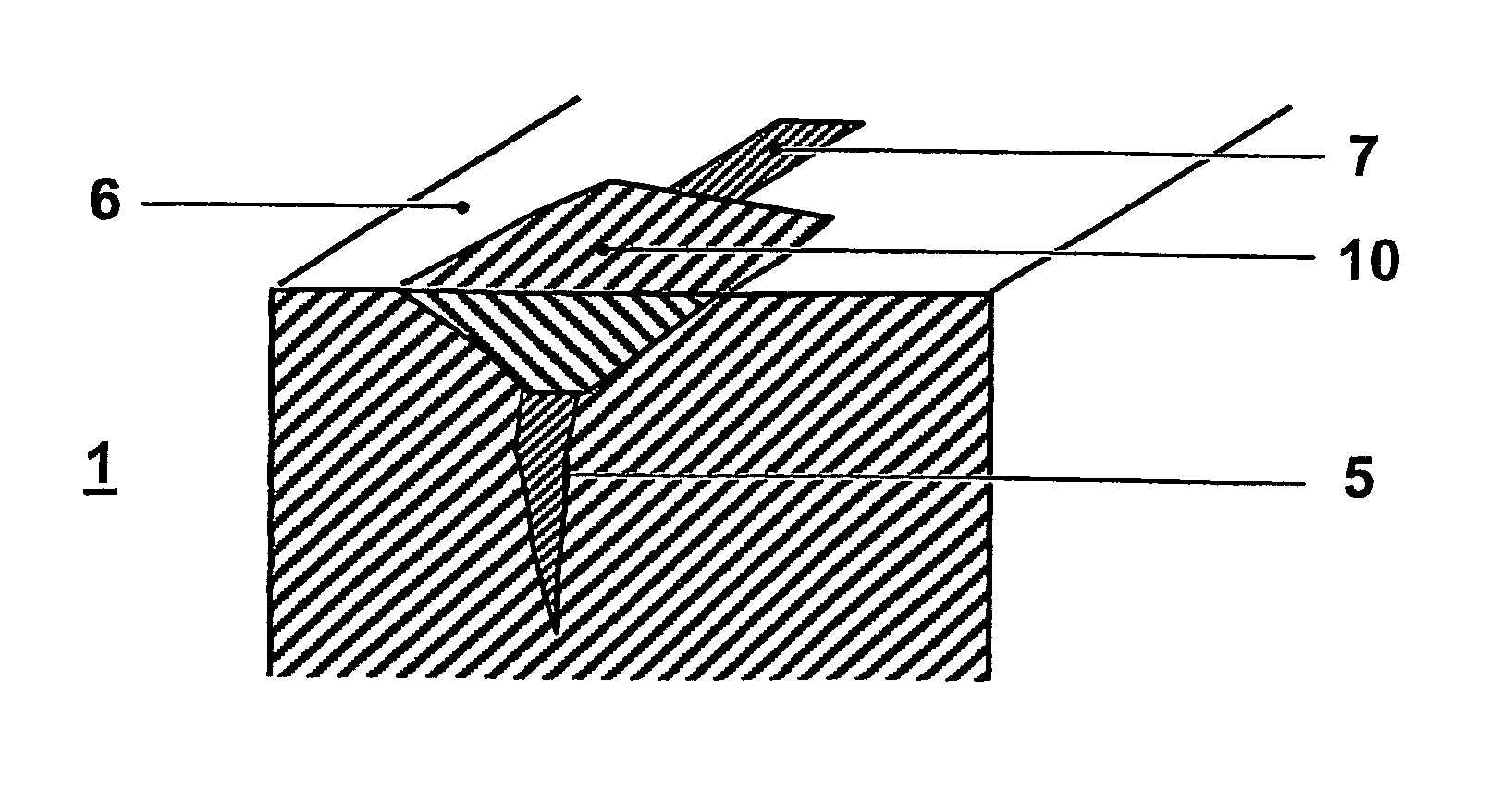

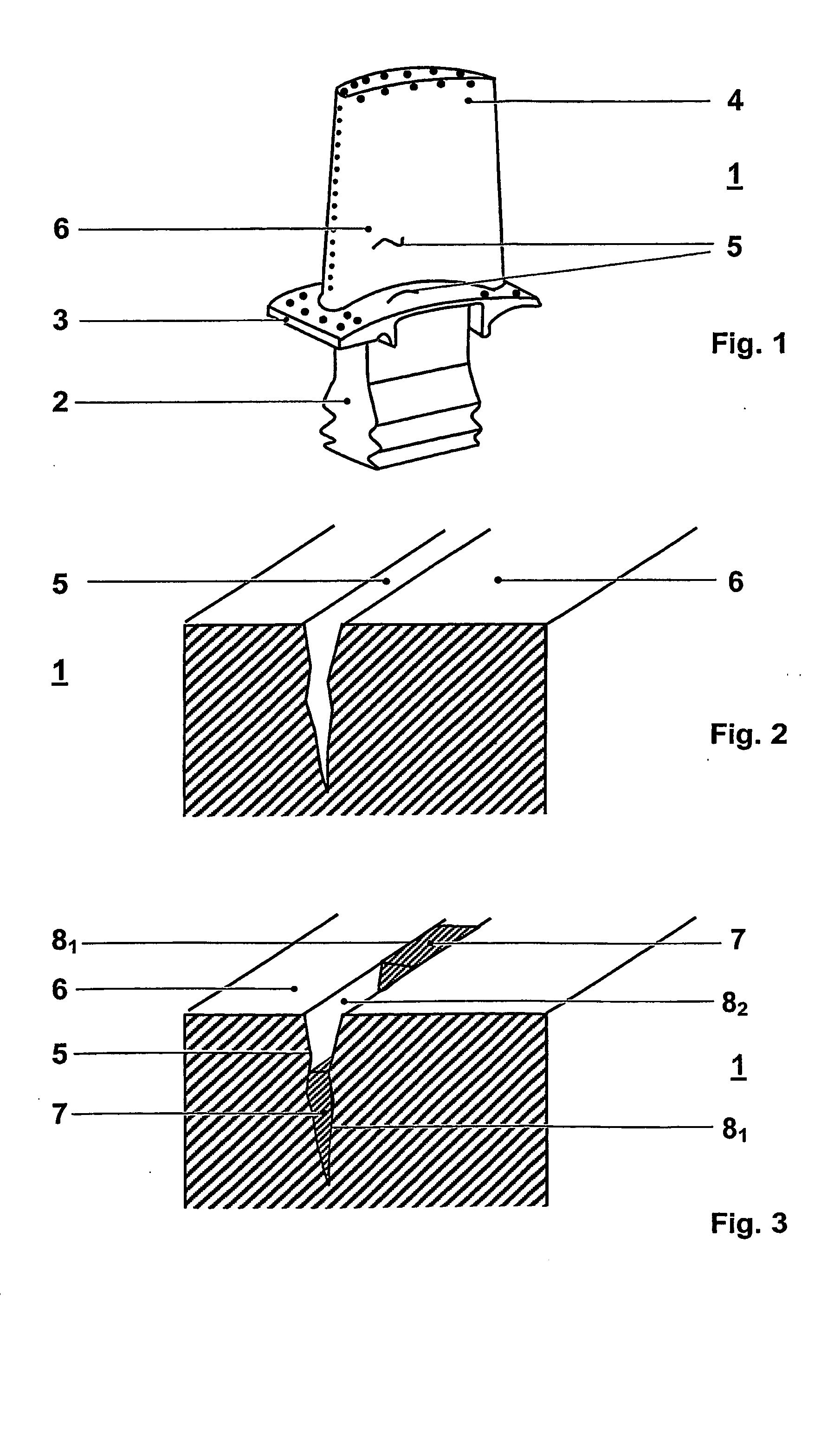

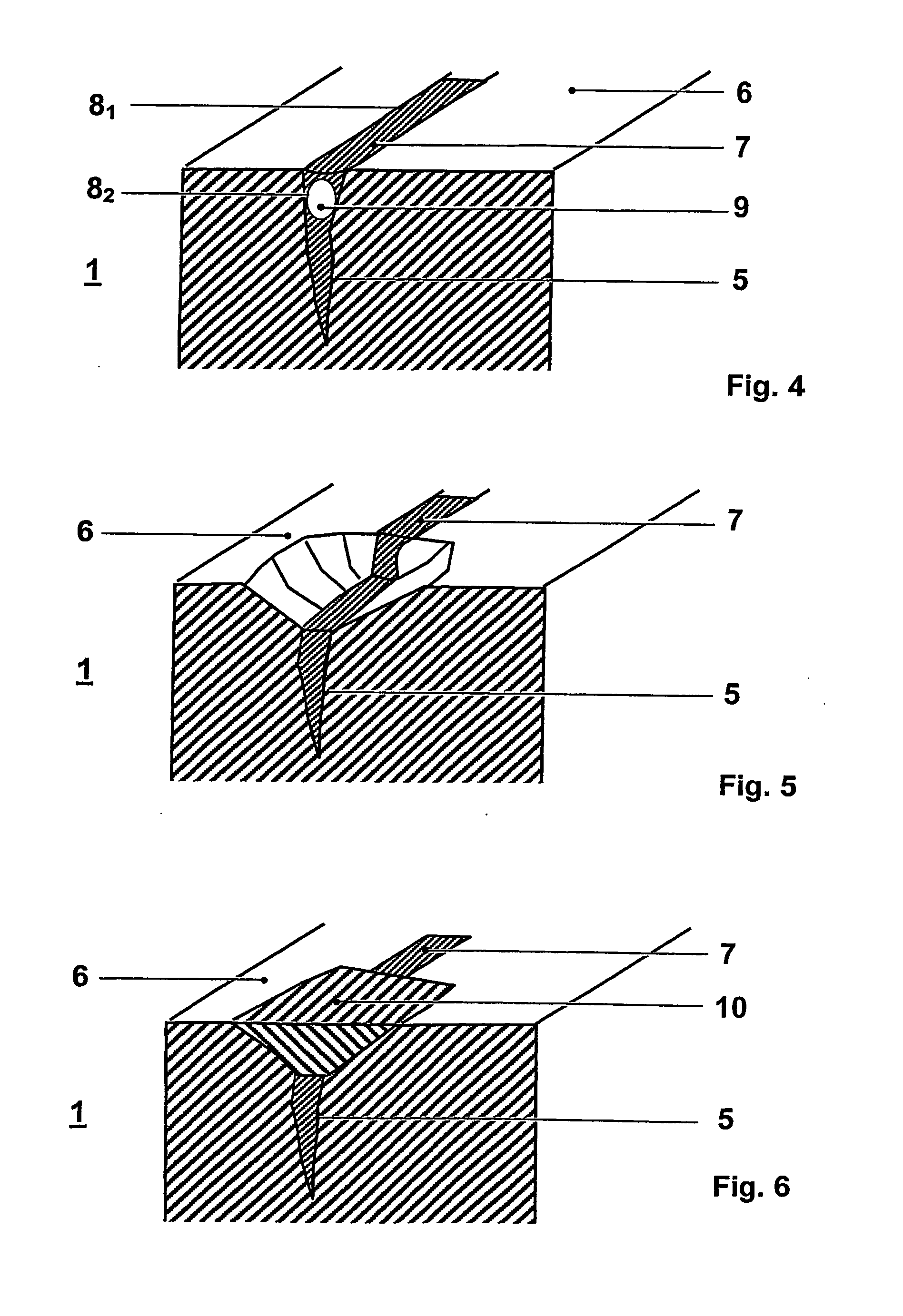

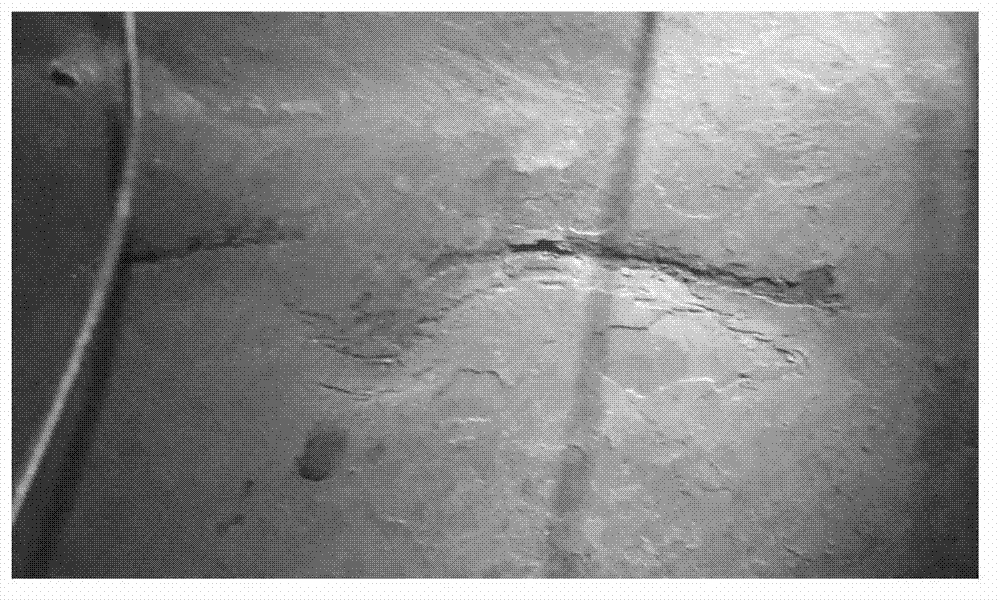

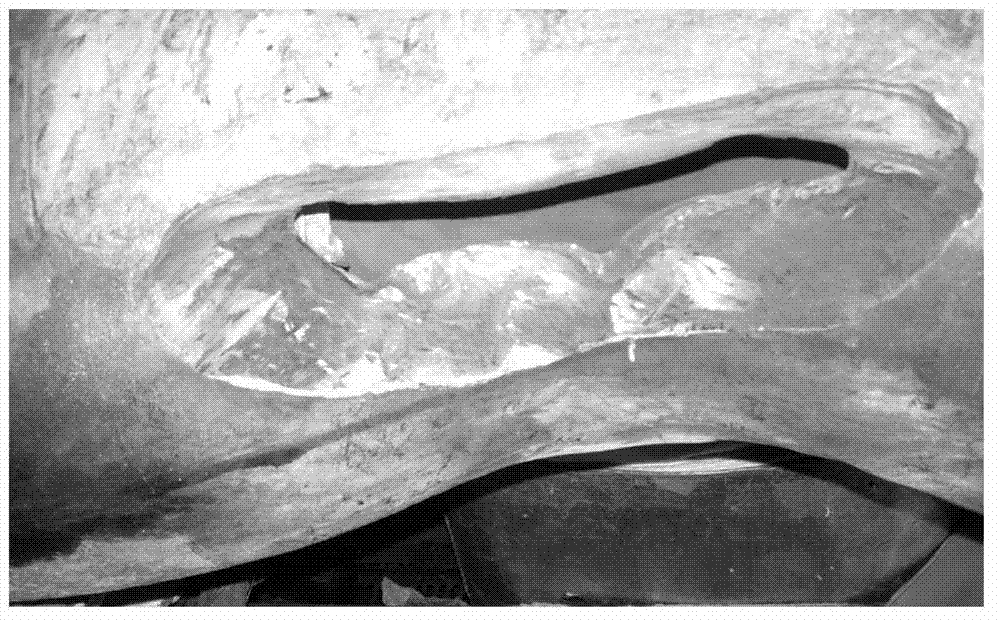

Crack repair method

InactiveUS20050067466A1Rapid and inexpensive mannerMinimize cracksTurbinesArc welding apparatusCrazingGas turbines

A method of repairing cracks on a surface of a component such as gas turbine components includes the steps of repairing the cracks of the component by brazing, detecting remaining cracks on the surface or below the surface, which were not properly filled with braze material during the repair brazing operation, and repairing the crack zones with a focussed low-heat input welding method using an appropriate weld filler materials.

Owner:ALSTOM TECH LTD

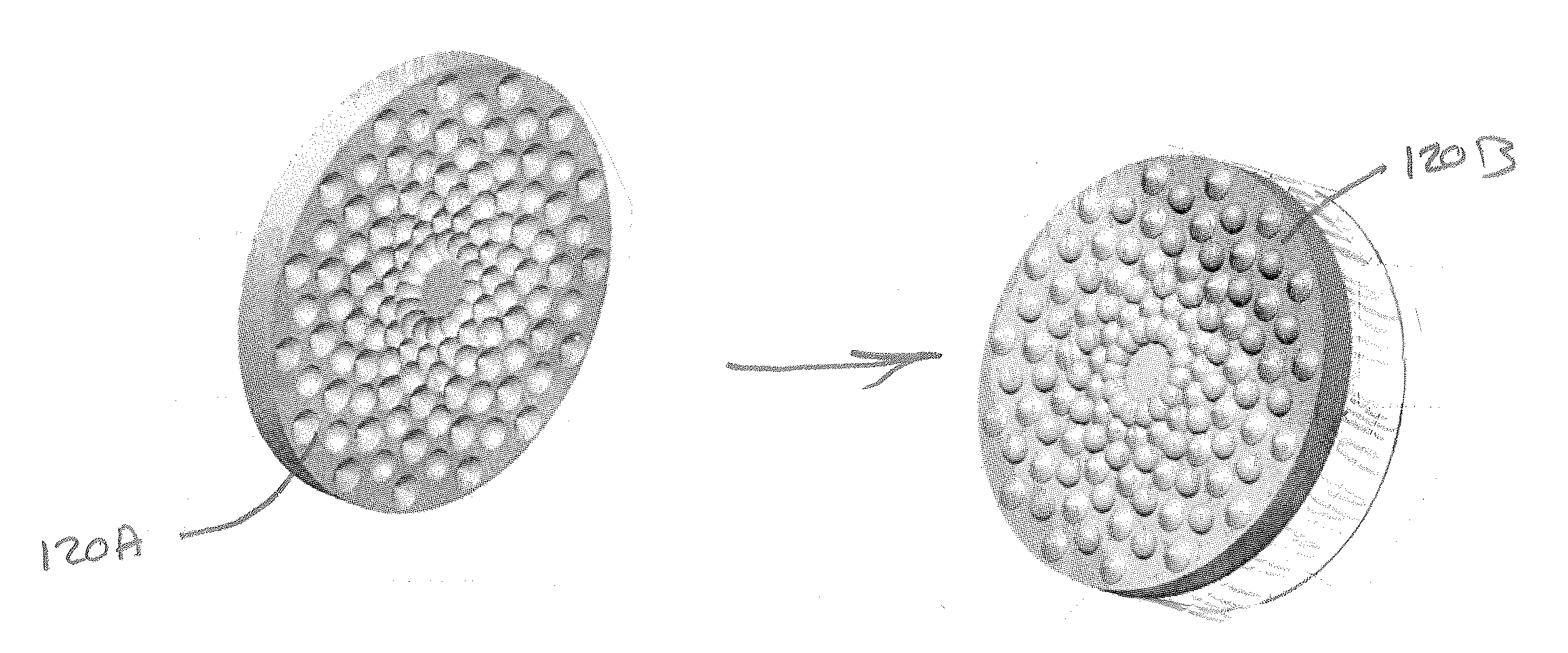

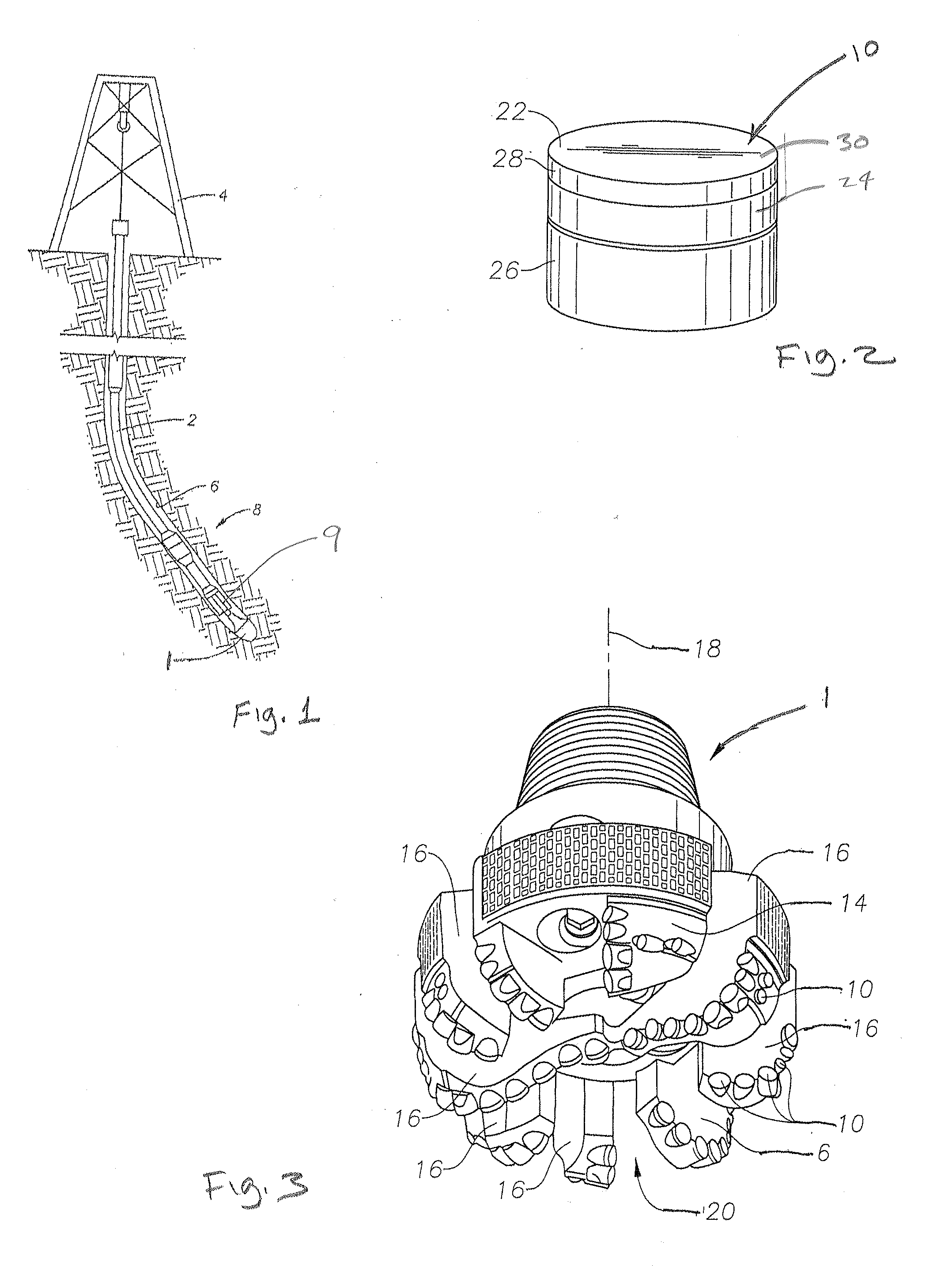

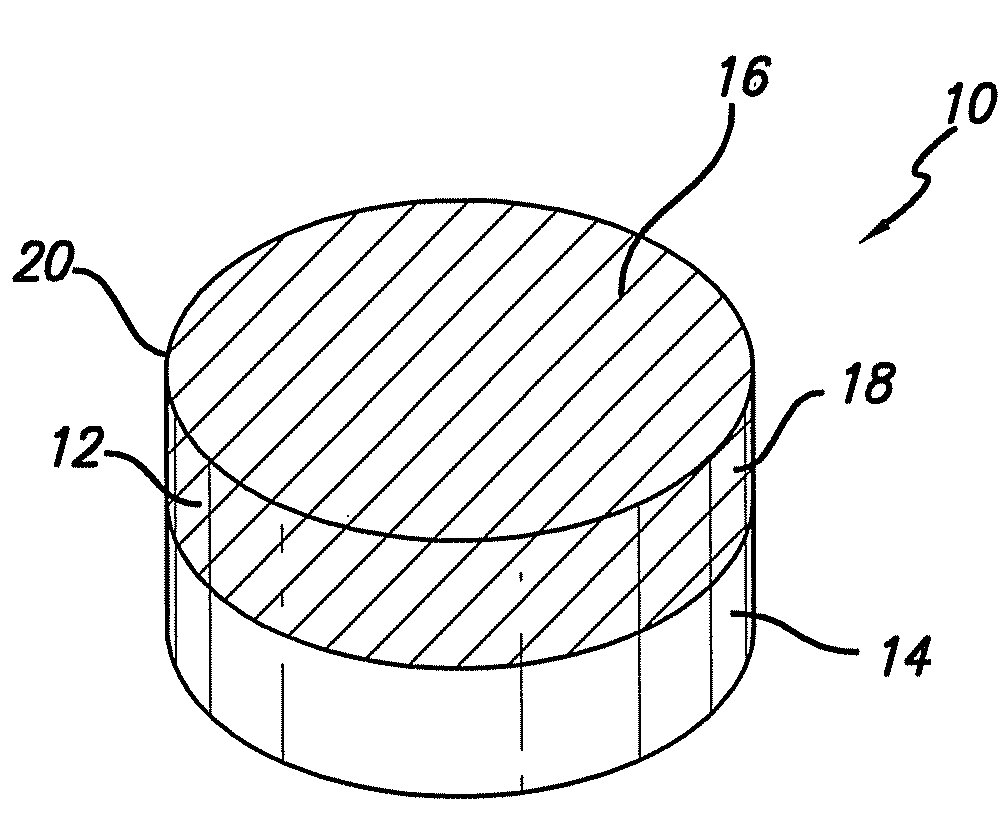

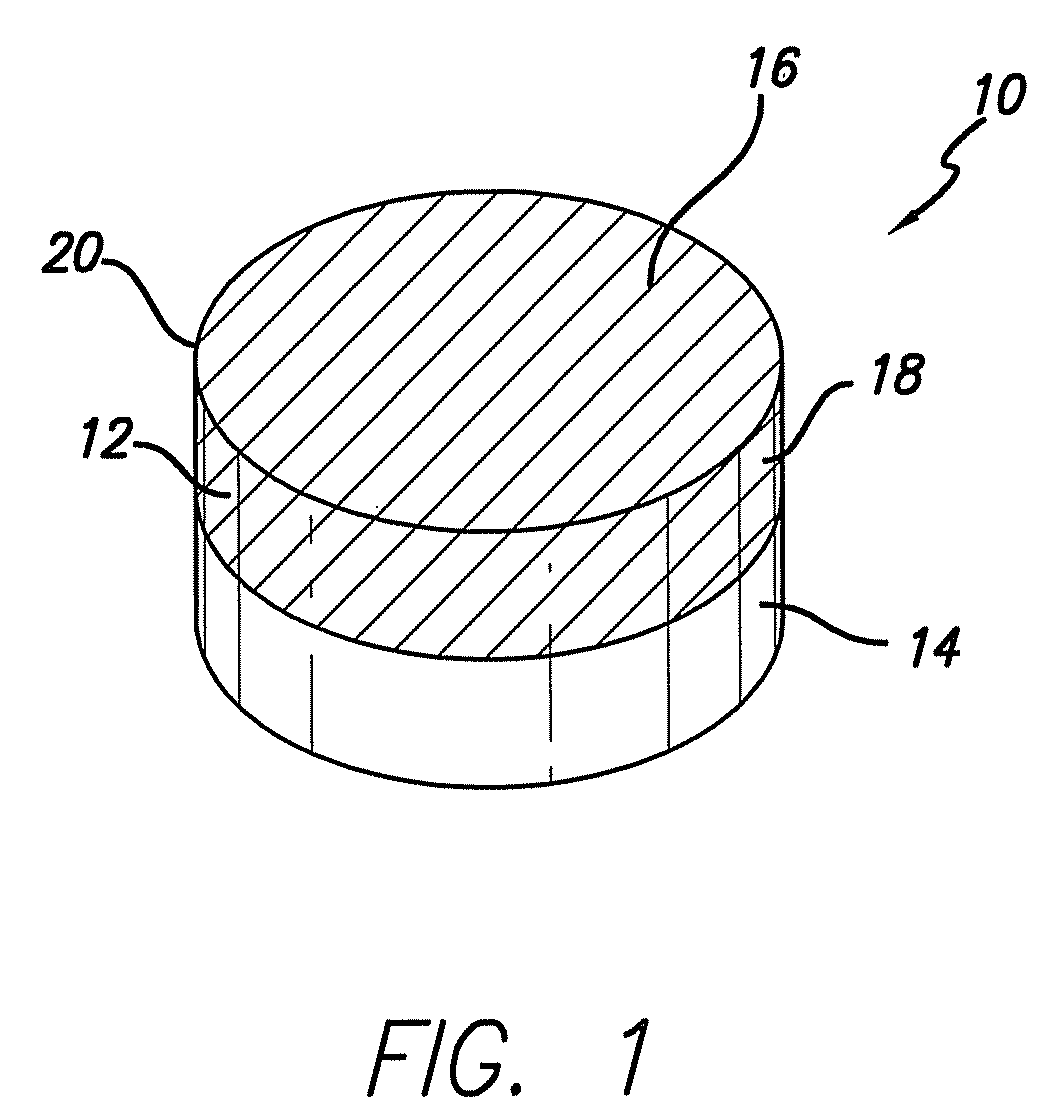

Sacrificial Catalyst Polycrystalline Diamond Element

InactiveUS20110171414A1Reduce formationLow level of contaminationPigmenting treatmentDrill bitsMetallurgyPolycrystalline diamond

A superhard composite material comprising a polycrystalline diamond cutter (PDC) having a cutting surface and cutting edges having a polycrystalline diamond thickness of about 3 mm is integrally formed with a sacrificial catalyst source that is removed later in the processing of the of the cutter.

Owner:NAT OILWELL VARCO LP

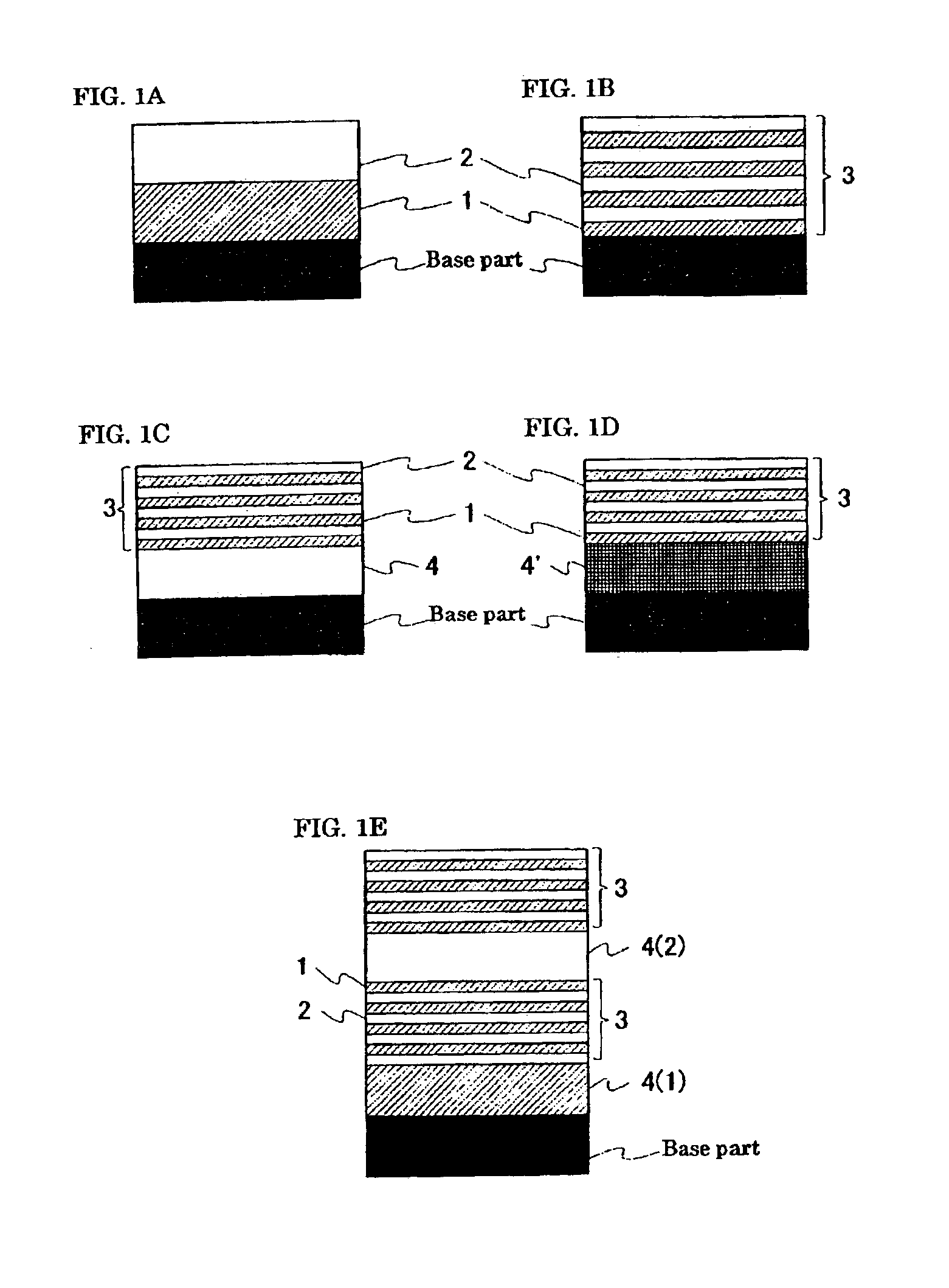

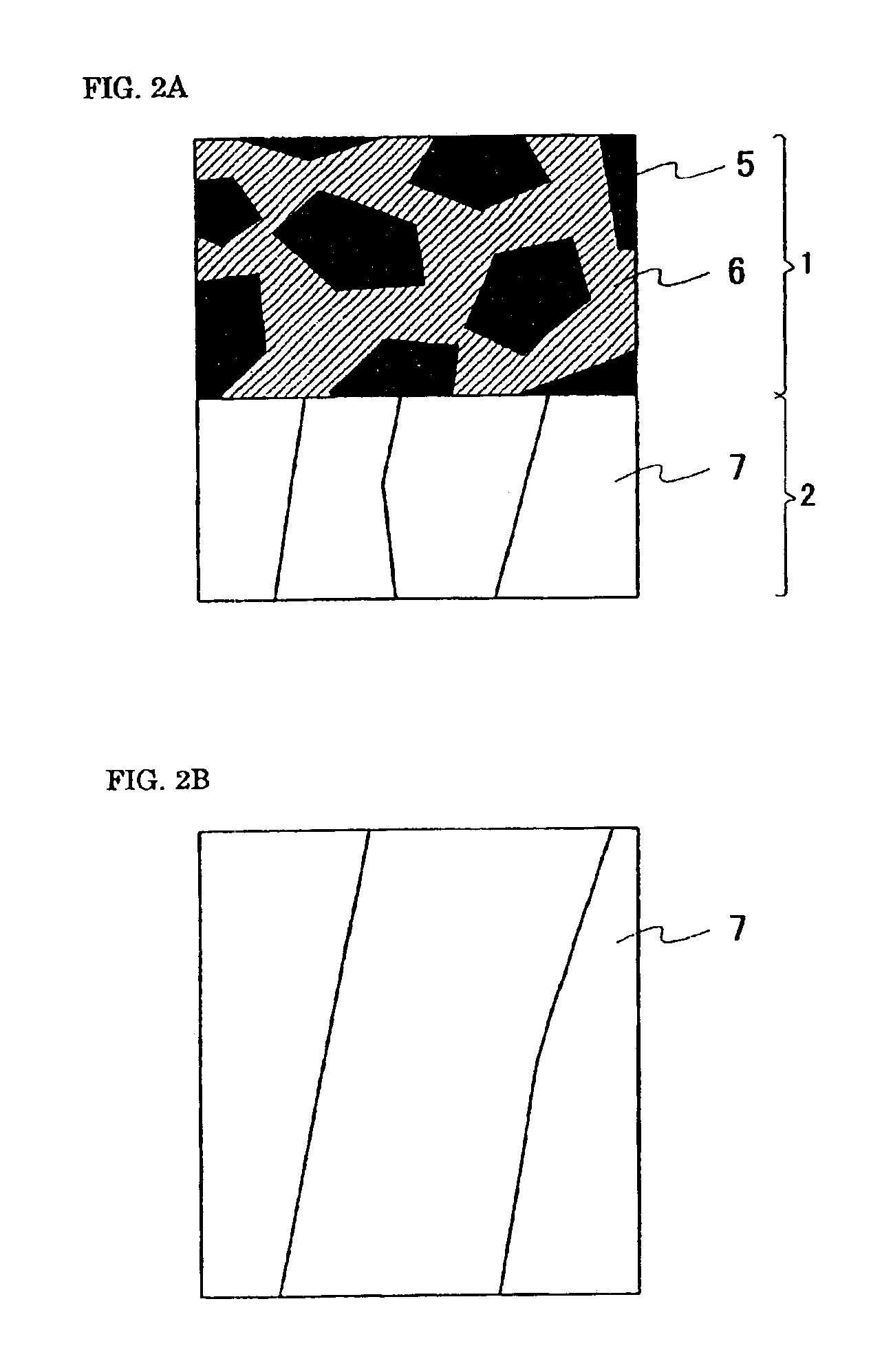

Coated tool

ActiveUS7060345B2High hardnessImprove wear resistancePigmenting treatmentMilling cuttersCarbideNitrogen oxide

Coating-film furnished coated tools that are lubricative while maintaining resistance to wear are realized by coated tools in which a plurality of coating films is furnished on a base part. Furnished as the coating are one or more layers of, respectively: a first film composed of one compound selected from nitrides, carbides, carbonitrides, oxynitrides and carboxynitrides of TiSi; and a second film composed of one compound selected from nitrides, carbides, carbonitrides, oxynitrides and carboxynitrides of one metal M selected from Ti, Cr, and TiCr. The first film and the second film are laminated in alternation.

Owner:SUMITOMO ELECTRIC IND LTD

Laser fusing and coating process of wear resistant and anticorrosion alloy coatings at surface of slide plate of railroad turnout

InactiveCN101338425ANo pollution in the processImprove productivityMetallic material coating processesNumerical controlWear resistant

A laser cladding process of an exterior wear-resisting anti-corrosive alloy coating of a slide chair of a railway switch comprises processes as follows: firstly, the surface of the slide chair is pre-heated, which means the surface of the slide chair is degreased and de-rusted under room temperature; and the surface is cleaned up by alcohol; then alloy powder is prefabricated, which means iron-base, nickel-base or cobalt base alloy powders that are ready for cladding are preplaced on the processed surface of the slide chair, and a scraping straightedge provided with a rail is used for adjusting the pretreated metal powder so that the alloy powder can be distributed on the surface of the slide chair evenly and has proper thickness to meet the thick requirement of the coating after cladding; and finally, the slide chair is hardened by the laser cladding; the laser of CO2 gas is adopted; a numerical control machine is used as a working table and the surface of the slide chair is hardened by the laser cladding. The laser cladding process has the characteristics of no pollution, high production rate, low energy consumption, the little finishing allowance of cladding coating and low combined cost.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

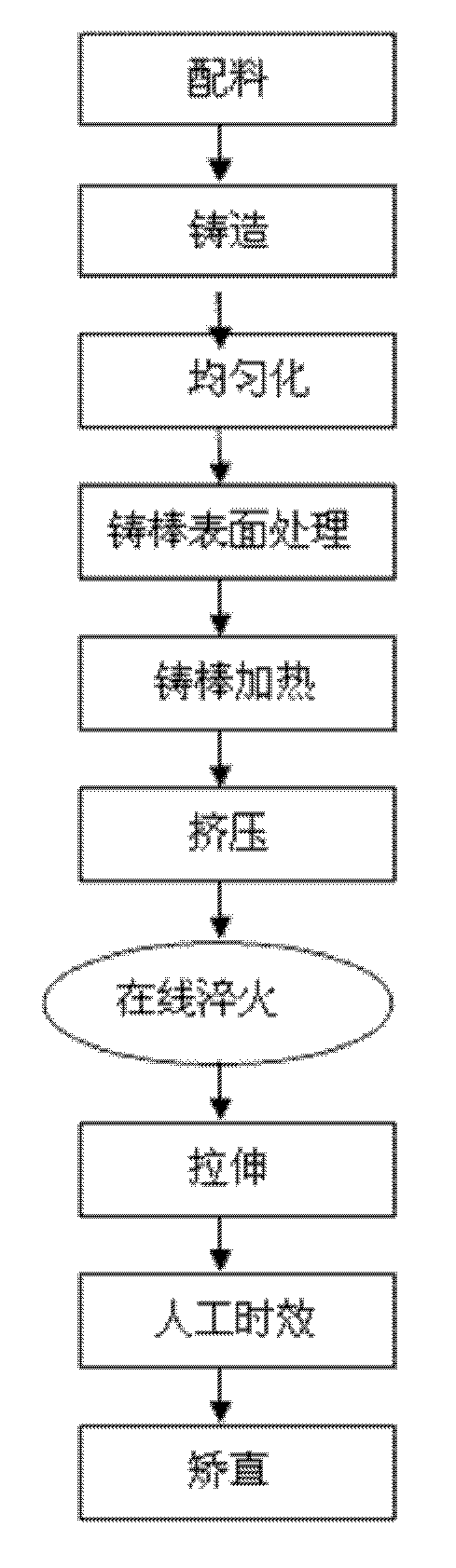

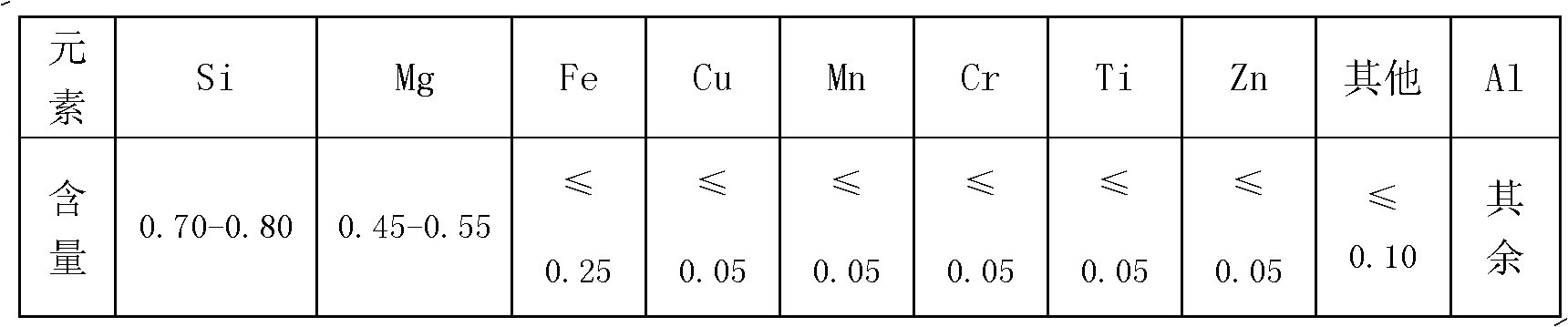

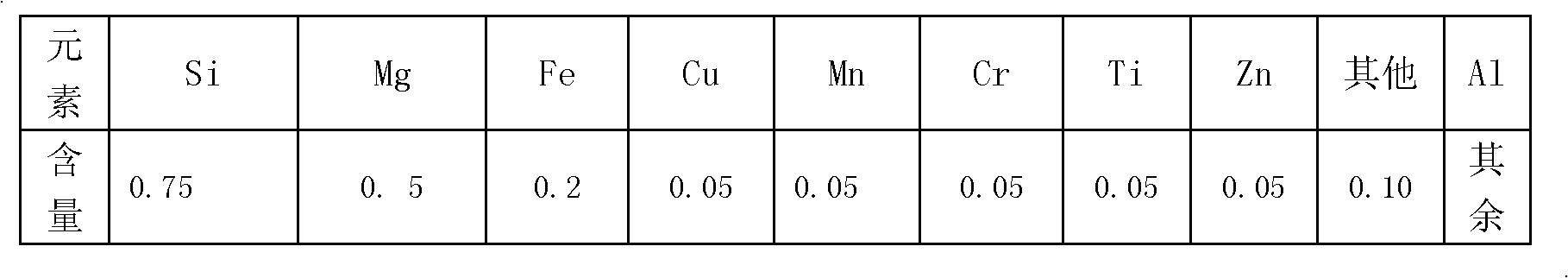

Extruding processing technology of aluminium alloy tubing with large diameter

InactiveCN102492877AReduce residual stressHigh strength propertiesExtrusion control devicesFailure rateHigh energy

The invention discloses an extruding processing technology of an aluminium alloy tubing with large diameter. The method comprises steps of a. proportioning, b. casting, c. uniformization, d. surface treatment on casting rod, e. casting rod heating, f. extrution, g. on-line quenching, h. stretching, i. artificial aging and j. straightening, etc. Strict control on each parameter can solve problems of extruding production of tubing with large diameter, eliminate disadvantages of long production period, low production efficiency, high energy consumption, huge environmental pollution and expensiveauxiliary equipment of rolling and drawing, save cost, simplify arrangement of auxiliary equipment and further reduce failure rate of an apparatus. The energy consumption of the present invention is merely 1 / 4 that of rolling and drawing, and water consumption is 1 / 8 that of a steam jet pump set; therefore, the invention brings obvious economic effects.

Owner:CHINA ZHONGWANG

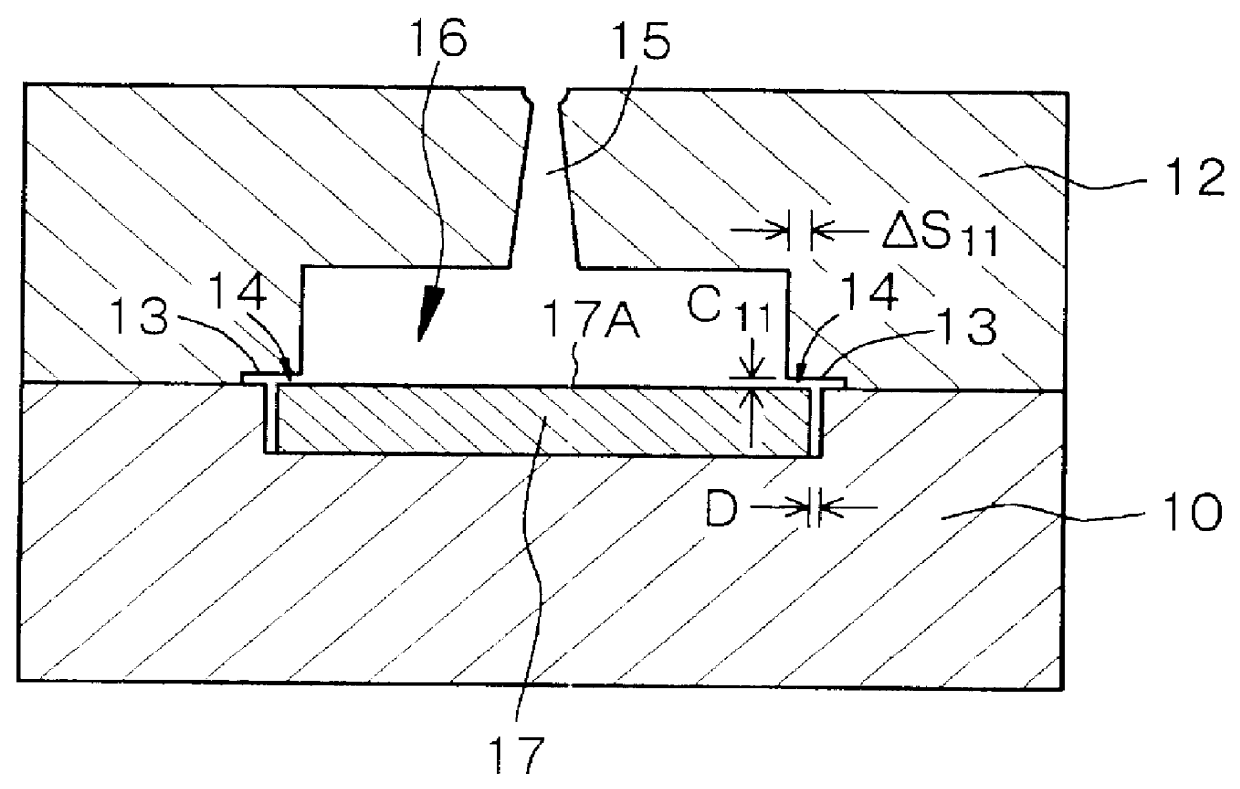

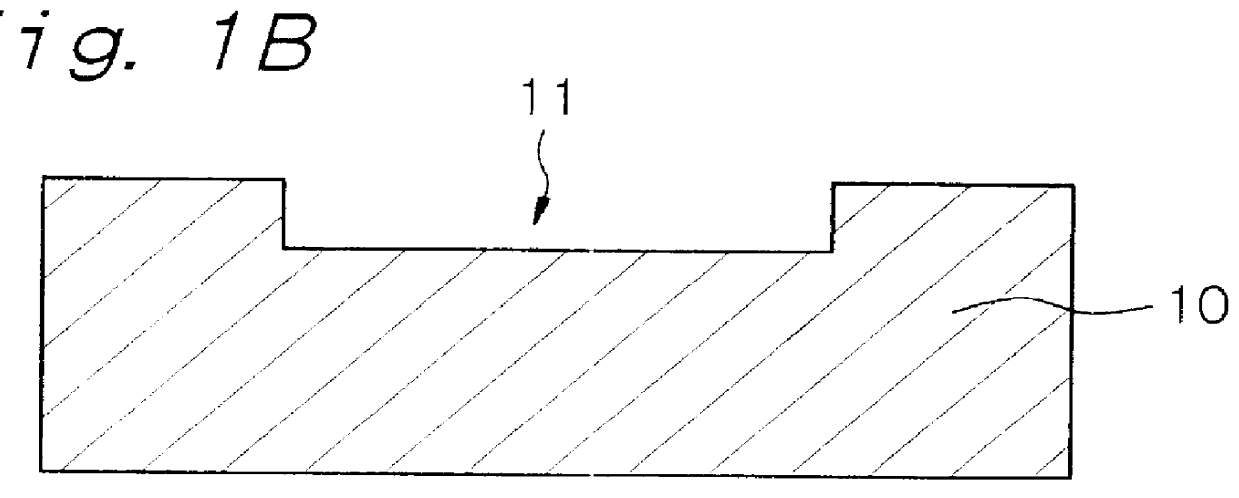

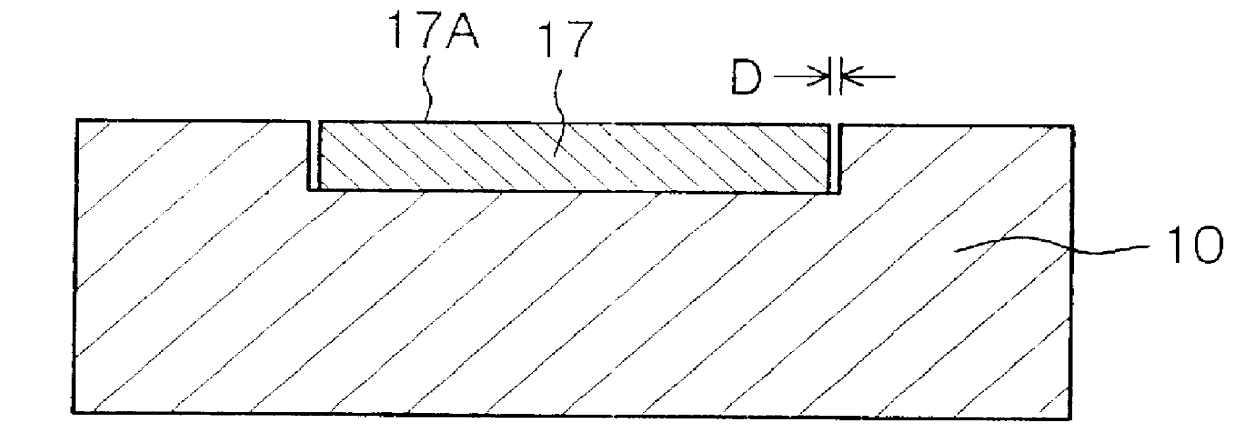

Mold assembly for molding thermoplastic resin and method of manufacturing molded article of thermoplastic resin

InactiveUS6165407AReduce residual stressReduce injection pressureConfectioneryOptical articlesMaterials scienceThermal conductivity

A mold assembly for molding a thermoplastic resin, which comprises; (a) a first mold member and a second mold member for manufacturing a molded article of a thermoplastic resin, (b) an insert block provided in the first mold member, said insert block constituting part of a cavity, having a thickness of 0.1 mm to 10 mm and being formed of a material having a thermal conductivity of 2x10-2 cal / cmxsecx DEG C. or less, and (c) a molten thermoplastic resin introduction portion provided in the second mold member, wherein an insert block covering portion is formed in the second mold member, and when the first mold member and the second mold member are clamped to each other, (A) a clearance between the insert block and the insert block covering portion is equal to, or less than, 0.03 mm, and (B) an amount of overlapping of the insert block and the insert block covering portion is equal to, or greater than, 0.5 mm.

Owner:MITSUBISHI ENG PLASTICS CORP

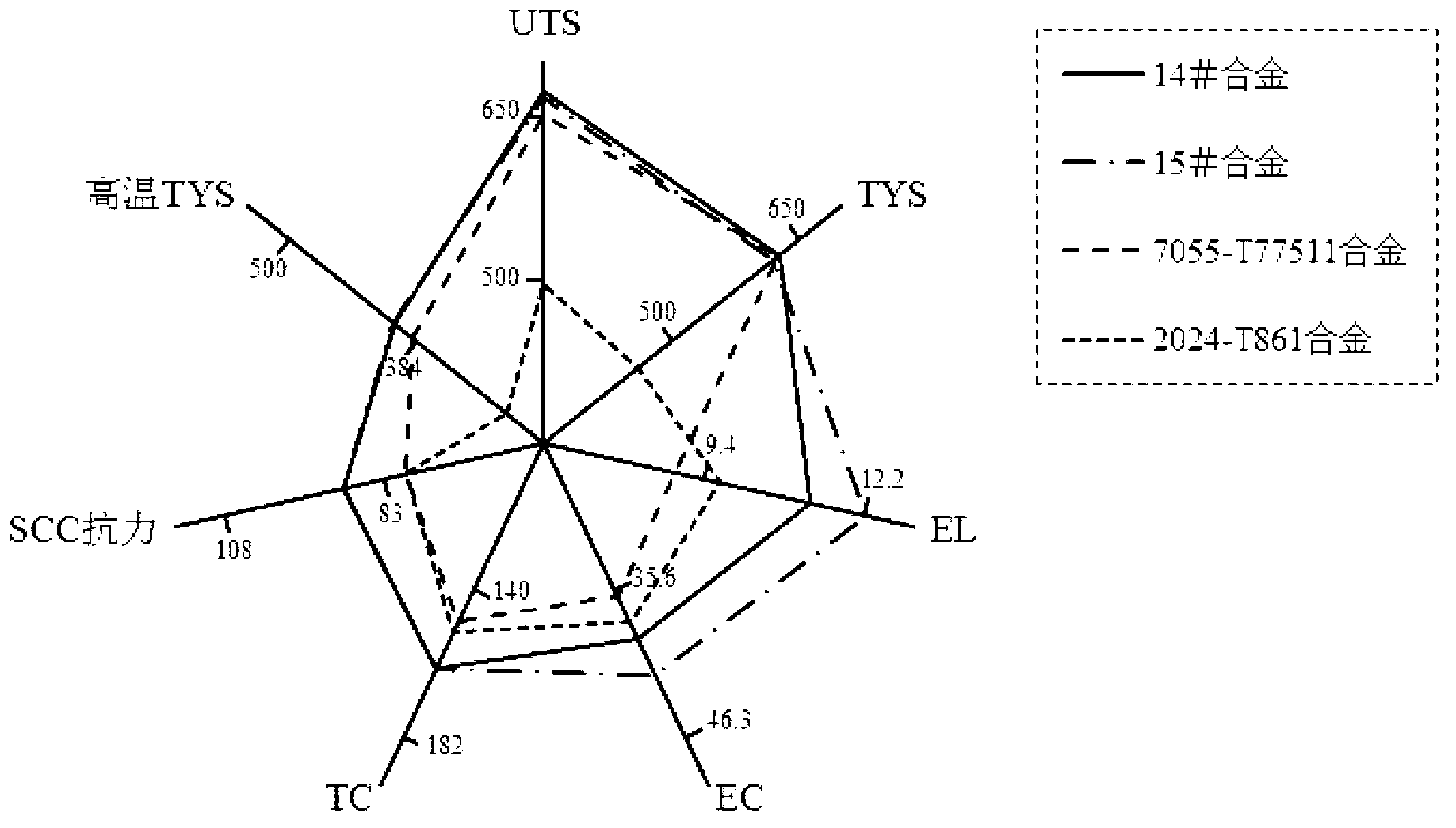

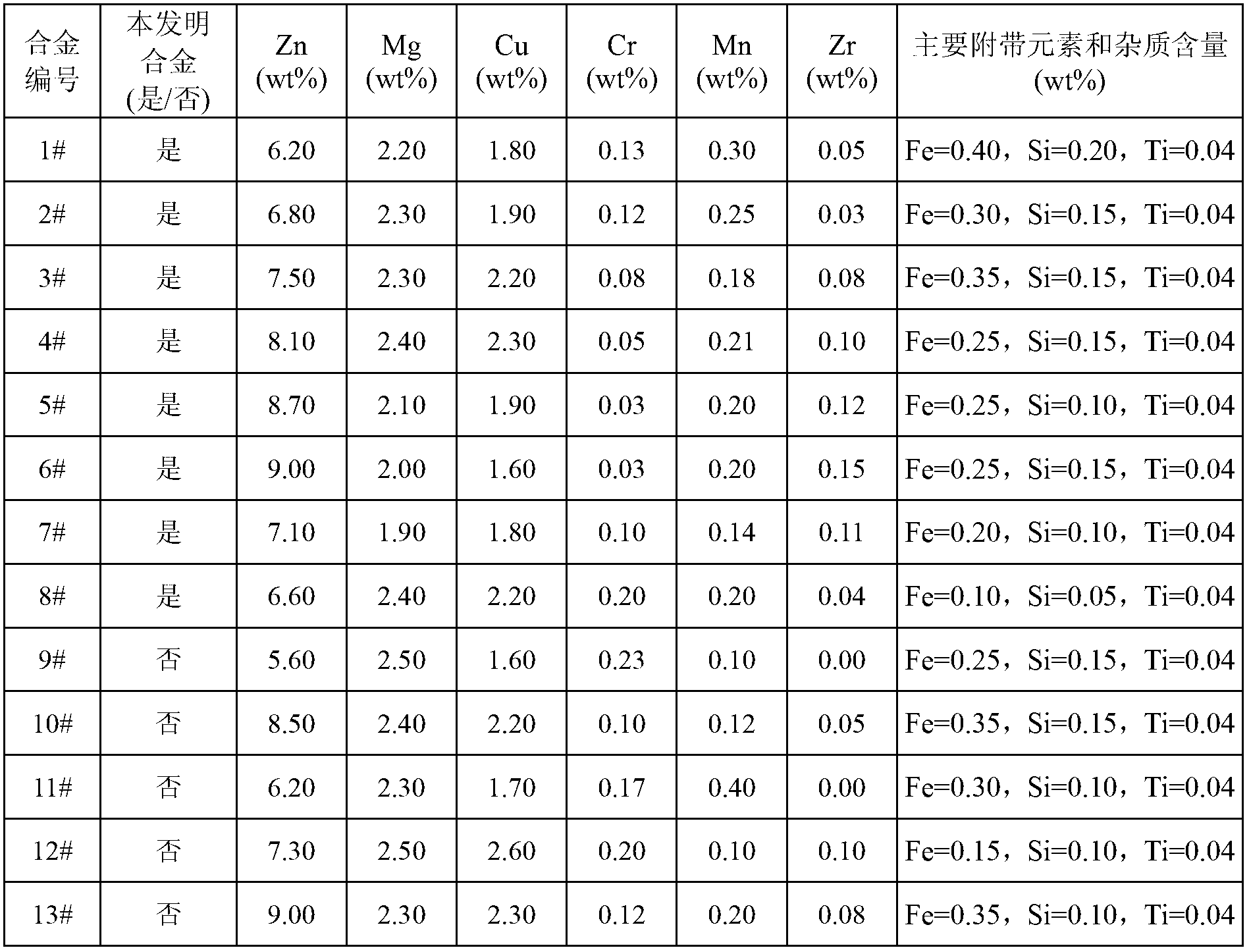

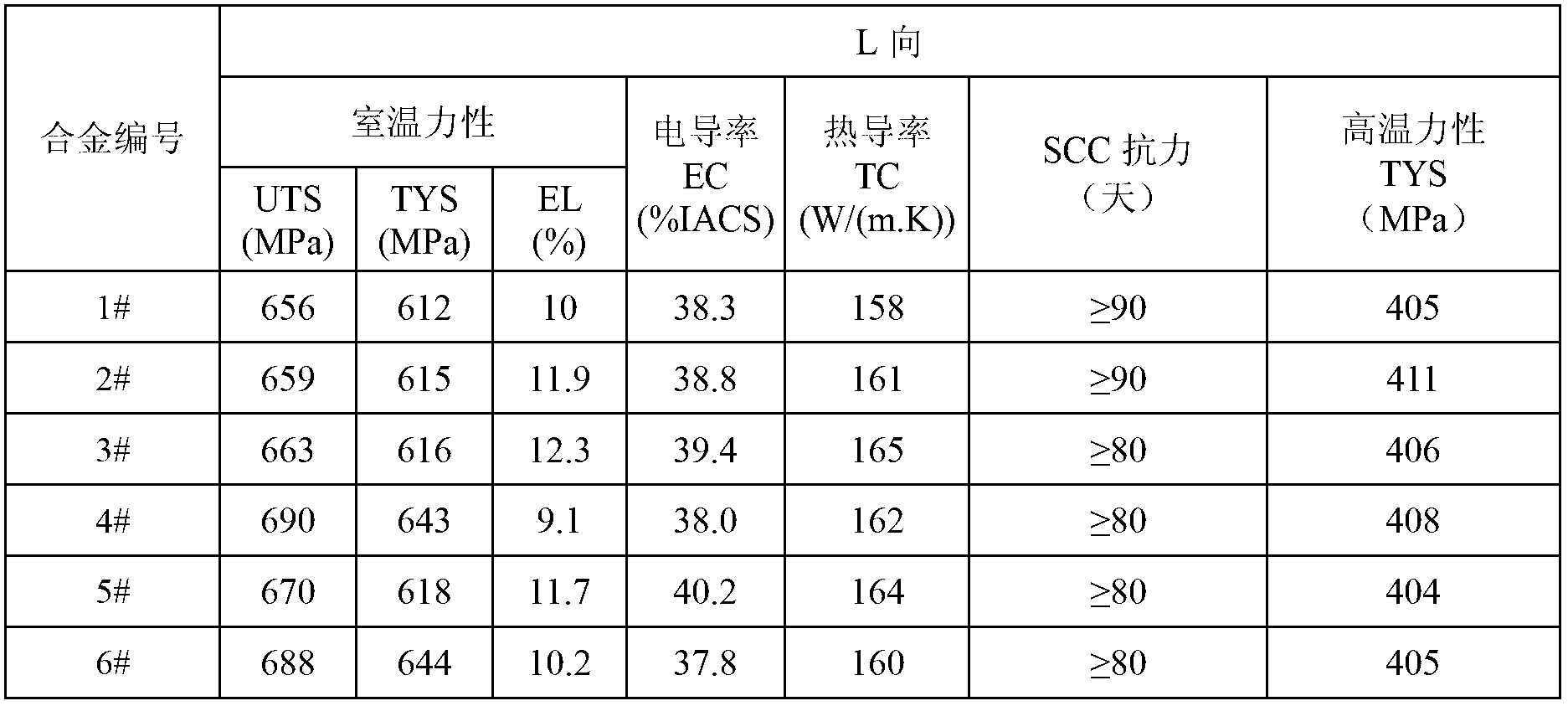

Aluminum alloy product suitable for structure and function integration, and preparation method thereof

The invention relates to an aluminum alloy product suitable for structure and function integration, and a preparation method thereof. The aluminum alloy product comprises the components of, by weight, 5.5-10.0% of Zn, 1.5-2.8% of Mg, 1.5-2.5% of Cu, 0.01-0.50% of Cr, 0.05-0.50% of Mn, 0.01-0.20% of Zr, and balance of of Al and incidental elements and impurities. In the aluminum alloy product: (a) Zn+Mg+Cu is no lower than 10.0% and no higher than 14.0%; (b) (Zn / Mg)+Cu is no lower than 4.4 and no higher than 6.5; (c) Cr+Mn+Zr is no lower than 0.10 and no higher than 0.60; and (d) the content of Cr is no higher than that of Mn, and content of Mn is no higher than that of Cr+0.20. The aluminum alloy product has high strength, high electric conductivity, and good thermal conductivity. Also, the aluminum alloy product has low residual stress, good surface quality, and good dimensional precision. The invention also relates to a preparation method of the aluminum alloy product.

Owner:GRIMAT ENG INST CO LTD

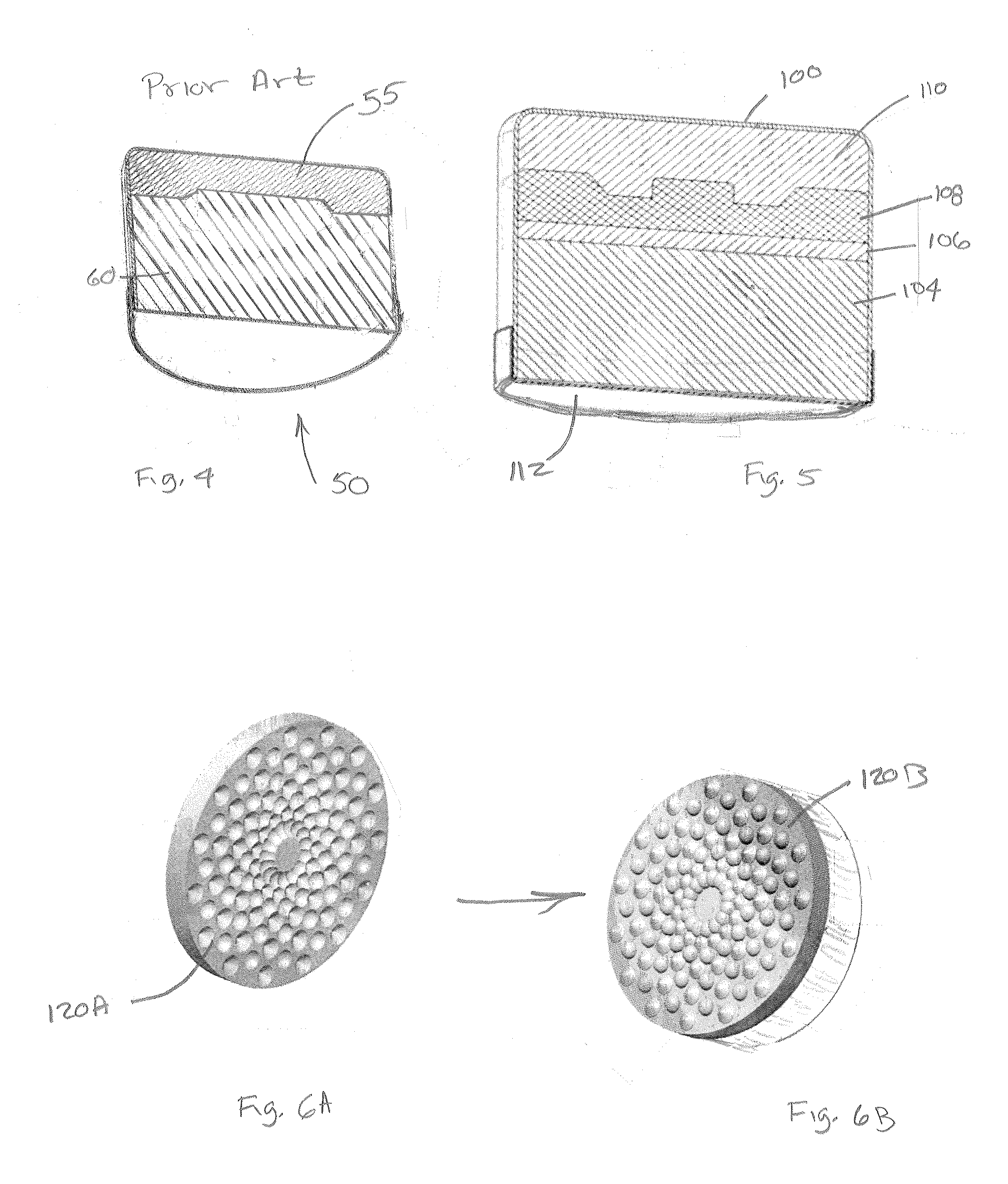

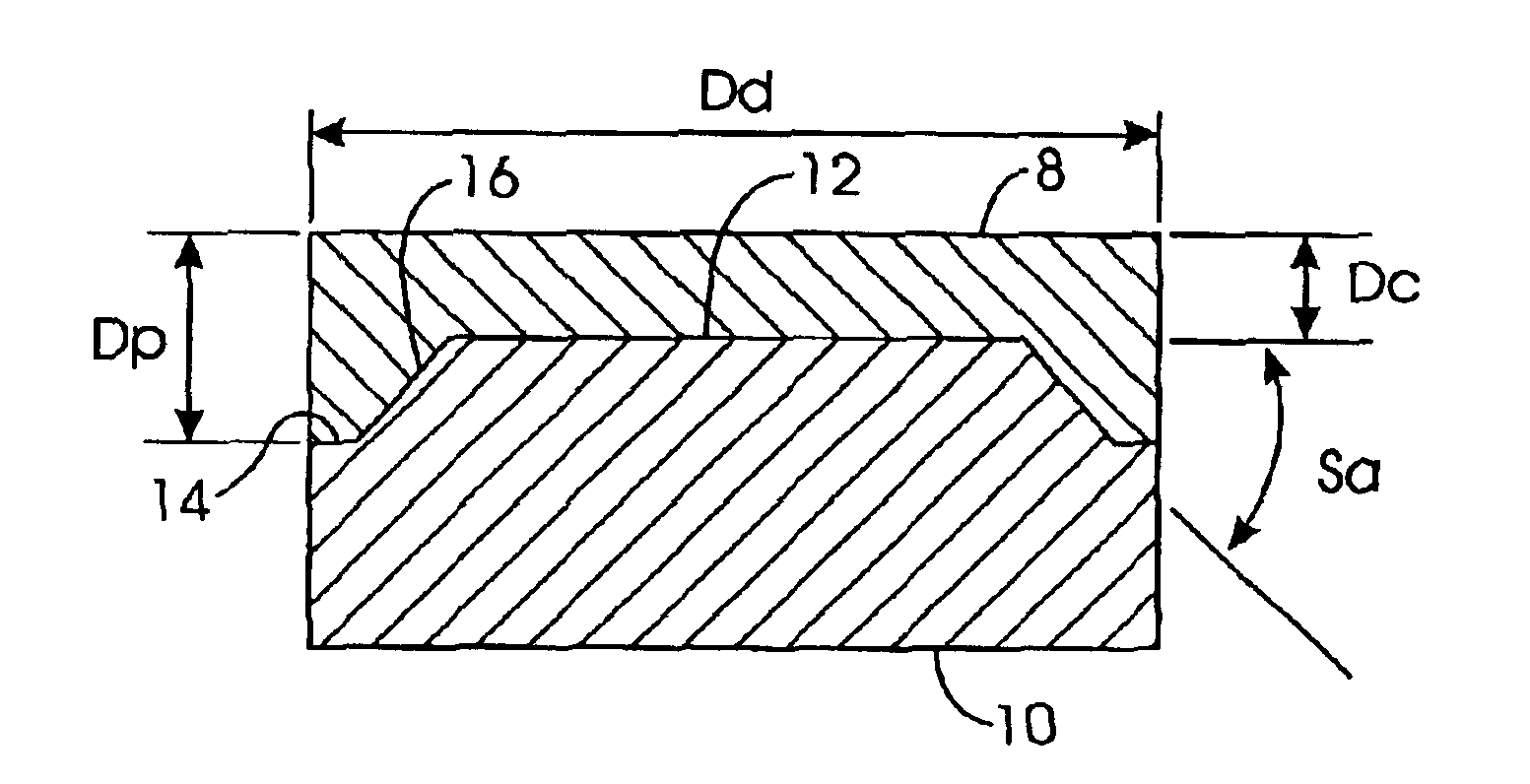

Abrasive tool inserts with diminished residual tensile stresses and their production

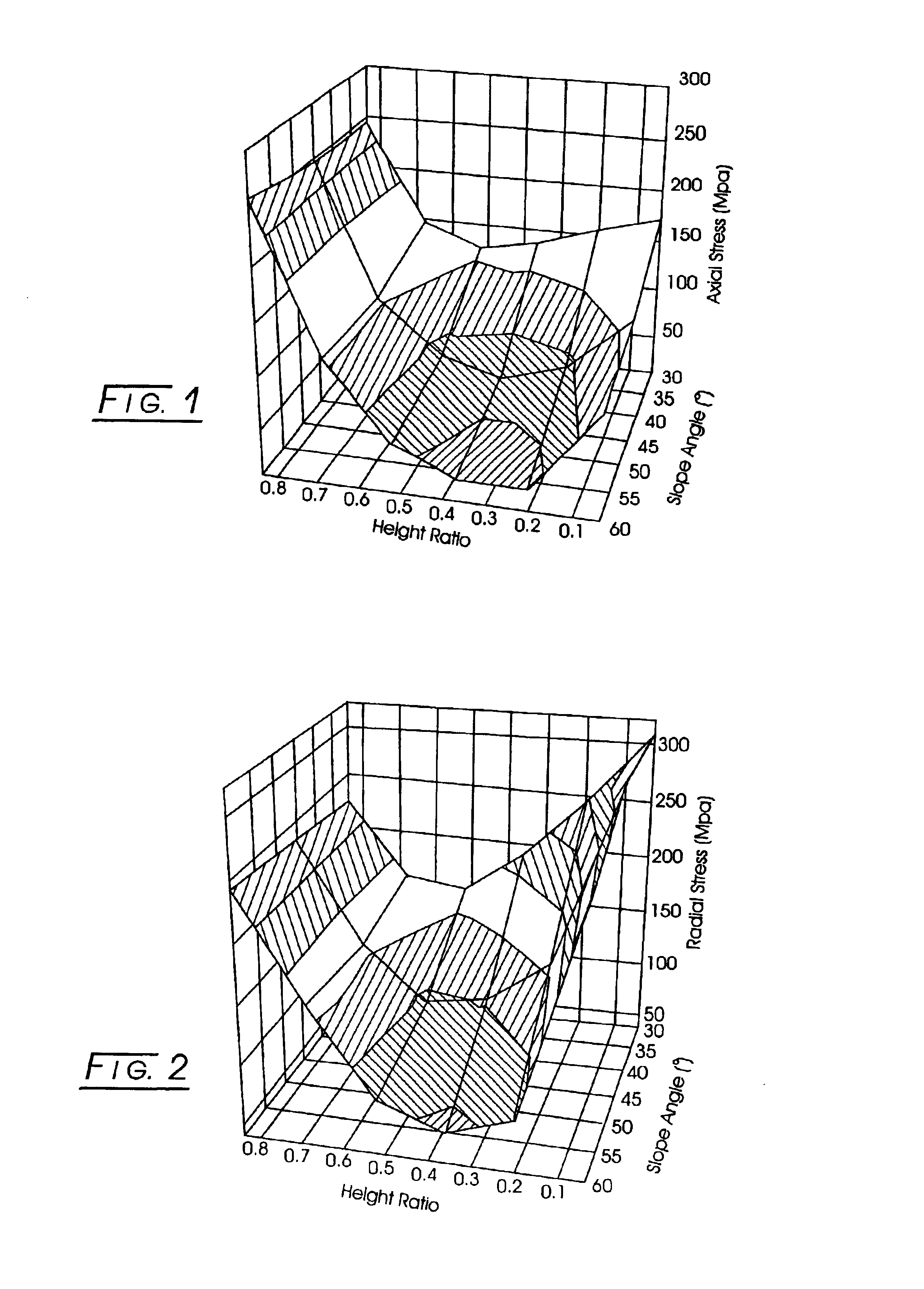

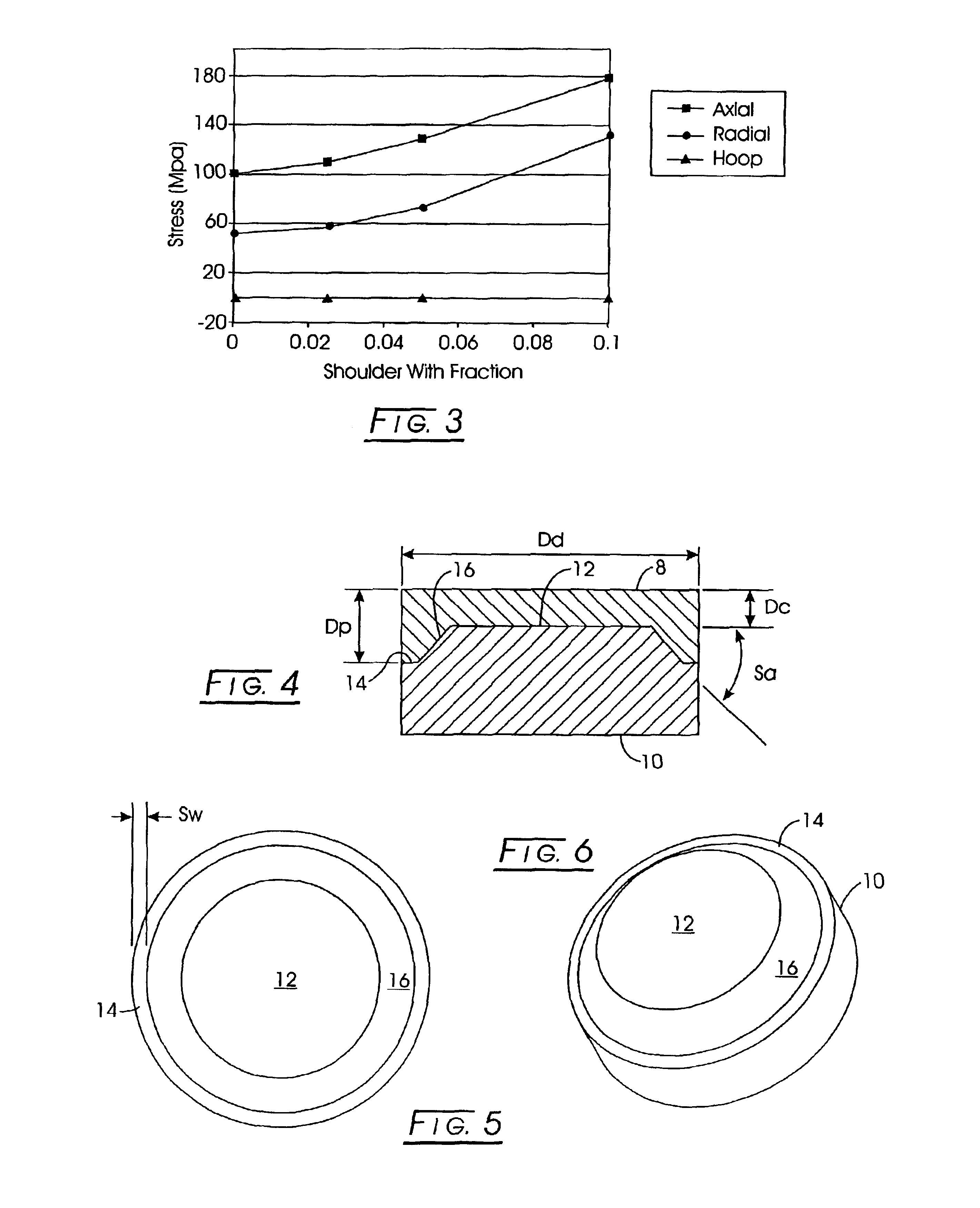

InactiveUS6933049B2Reduce residual stressPigmenting treatmentDrill bitsSlope angleMechanical engineering

An abrasive tool insert includes (a) a substrate having a support face that includes (1) an inner support table, (2) an outer shoulder having a width, Sw, and (3) a downwardly sloping interface from the support table to the shoulder, which interface has a slope angle, Sa. A continuous abrasive layer, integrally formed on the substrate support face, includes (1) a center having a height, Dc, (2) a diameter, Dd, (3) a periphery having a height, Dp, in contact with the shoulder and which periphery forms a cutting edge. Sw:Dd ranges from between 0 and about 0.5. For each Sa and Sw:Dd, Dc:Dp is selected so as to diminish residual stress in the abrasive layer.

Owner:GE SUPERABRASIVES

Anti-bending multimode fiber and manufacturing method thereof

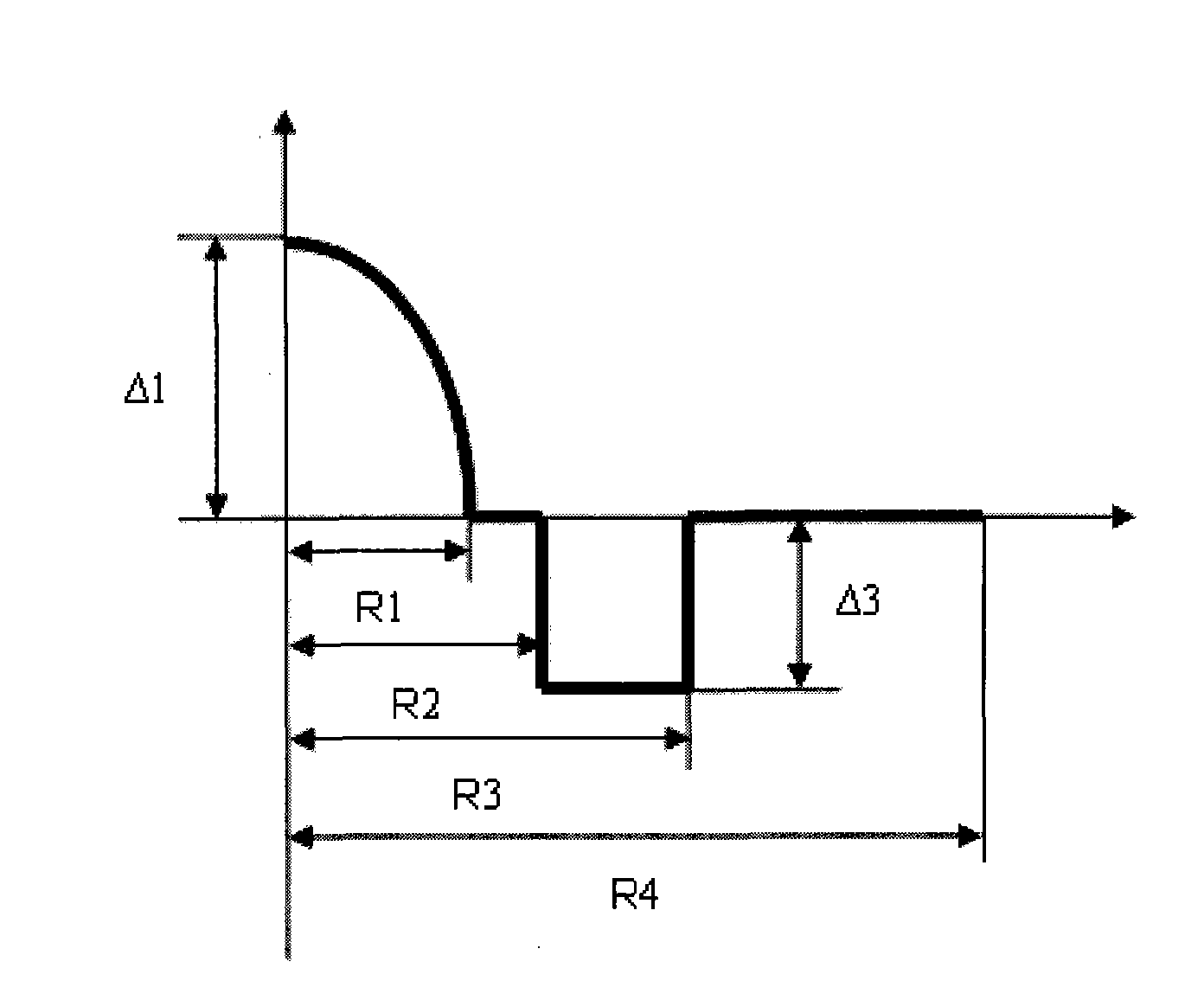

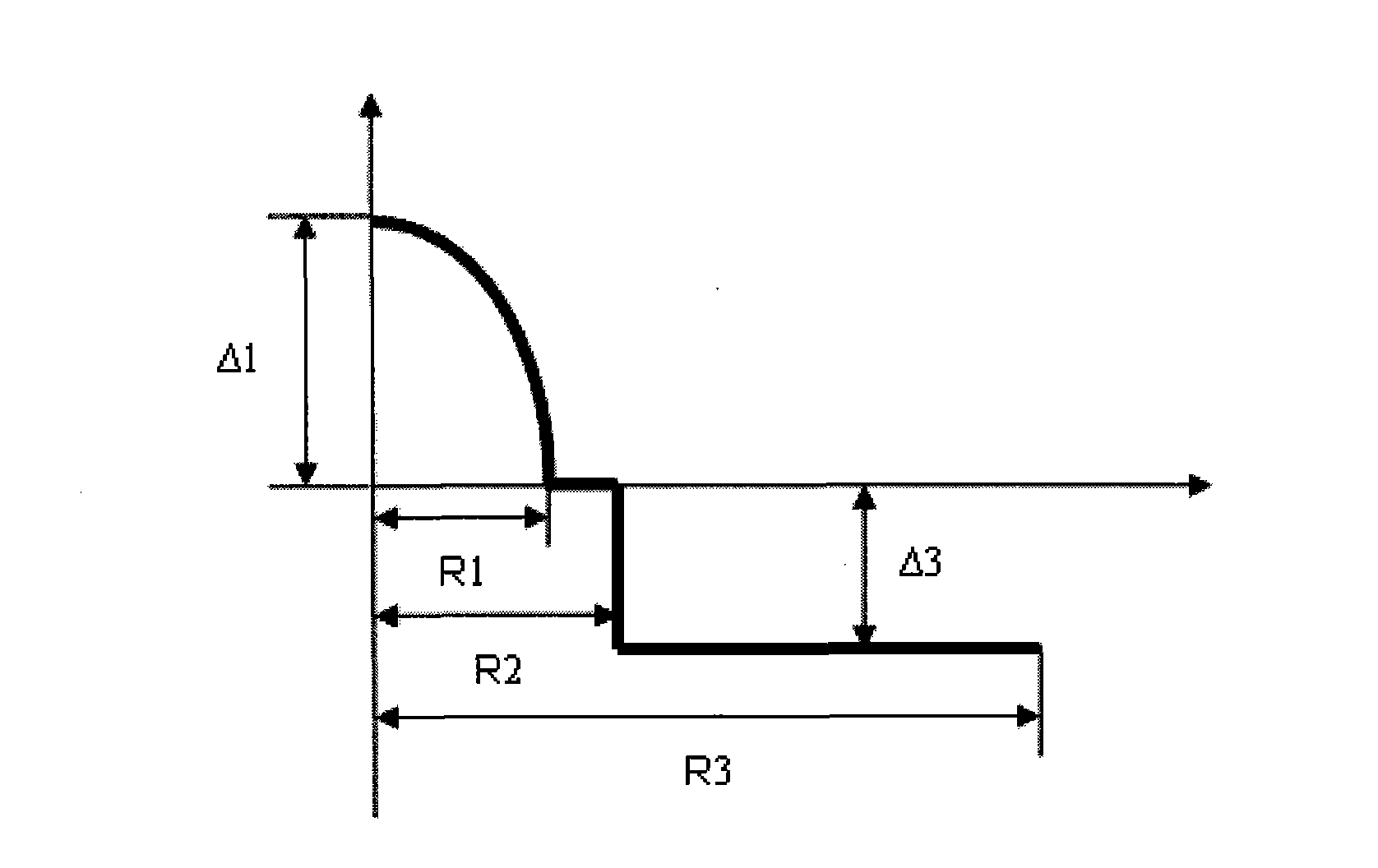

ActiveCN101634728AReduce bend add-on attenuationImprove bending resistanceGlass making apparatusOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

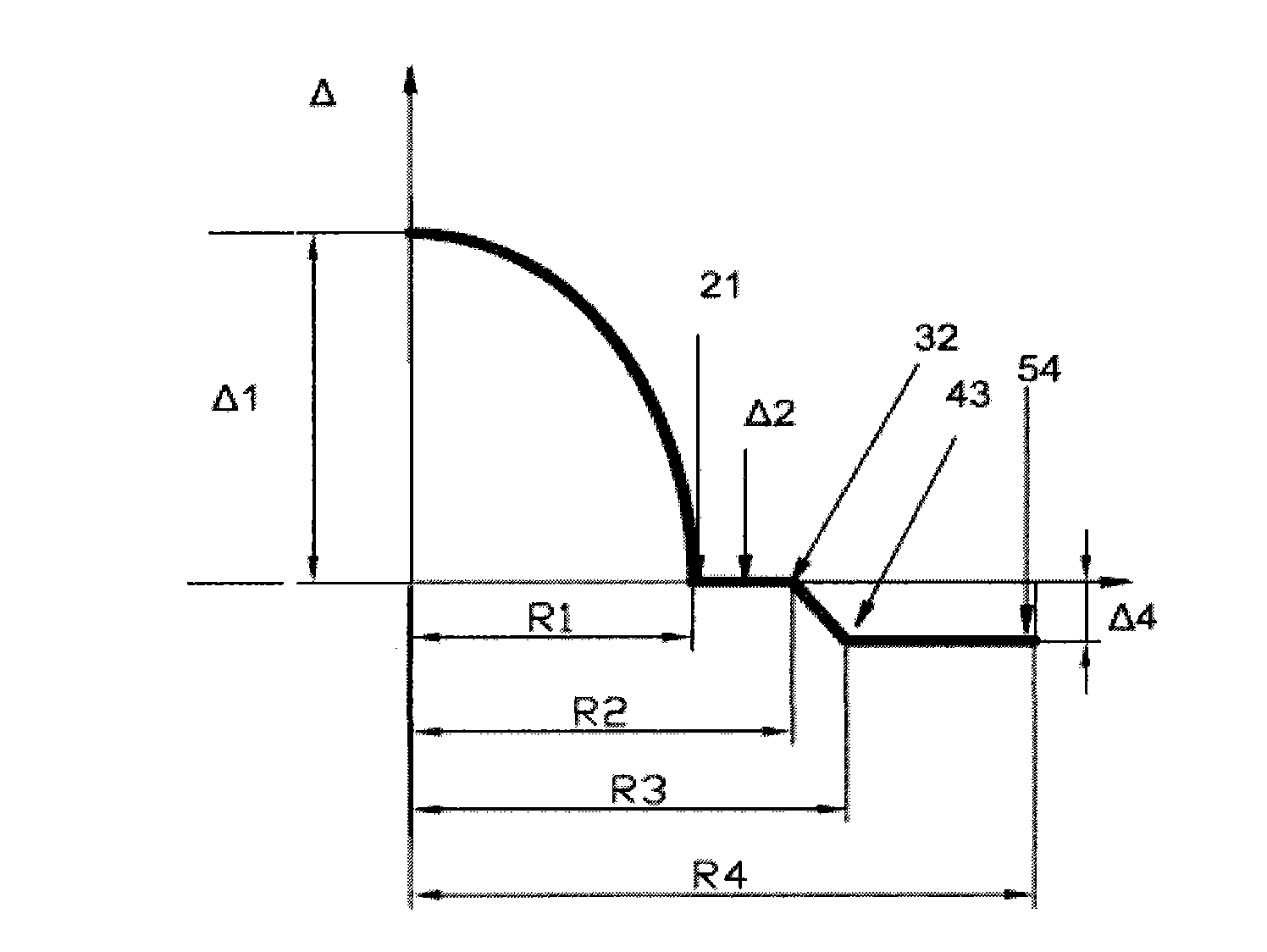

The invention relates to an anti-bending multimode fiber and manufacturing method thereof. The fiber comprises a core and a cladding and is characterized in that the radius of core R1 is 24-26 microns, refractive index section of the core is like a parabola, refractivity maximum delta1 is 0.9-1.1%, the cladding outside the core is composed of three parts, the radius of inner cladding R2 is 1.04-1.6 times of the radius of core R1, delta2 is minus 0.01-0.01%, intermediate cladding is gradually changed in refractive index, the radius of intermediate cladding R3 is 1.06-1.8 times of R1, refractivity is gradually changed into delta4 from delta2, the radius of outer cladding R4 is 2.38-2.63 times of R1, and delta4 is minus 0.20% to minus 0.40%. The invention reduces fiber bending additional attenuation and improves anti-bending performance of fiber but also basically eliminates inner stress of fiber, greatly improves mechanical properties of fiber, and service life of fiber operating in minor radius for a long time also can be guaranteed. The manufacturing method of the invention is simple, convenient and effective and is applicable to mass production.

Owner:EVERPRO TECH COMPANY

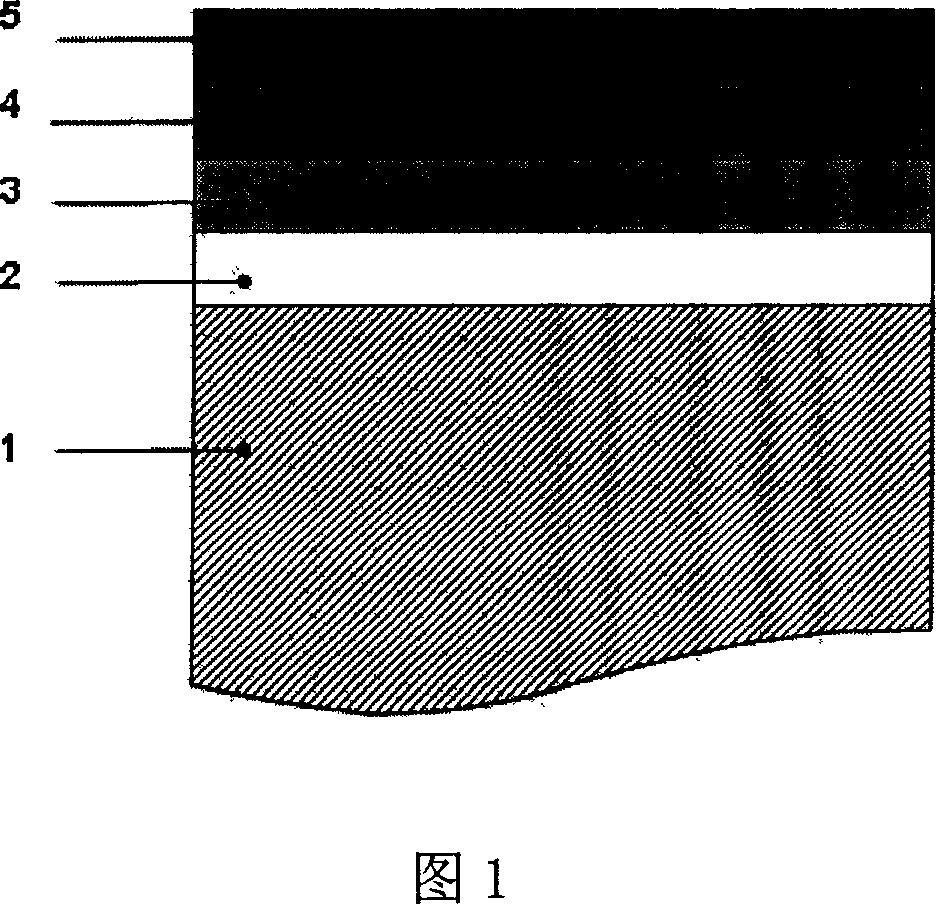

Prepreg applied for multi-layer board of printed electronic circuit

ActiveCN101220160ALow dielectricReduce residual stressSynthetic resin layered productsCircuit susbtrate materialsSolventFilling materials

The invention pertains to the technical field of the copper clad laminate, which more particularly relates to a prepreg applied to a printing circuit multilayer board. The prepreg comprises reinforced materials and resin composite, wherein, the reinforced materials is glass fiber paper, and according to part by weight, the formulation of the resin composite is as follows: 20 to 84 portions of resin, 0 to 35 portions of filling materials, 0.01 to 0.3 portions of curing accelerator and 10 to 45 portions of solvent; the resin composite solvent is soaked in the glass fiber paper for 1 to 5 minutes, and is put in a 140 to 200 DEG C oven for baking for 2 to 10 minutes; after the solvent is removed, the prepreg applied to multilayer PCB processing materials is obtained; white flake and spot problems of base materials during the manufacturing procedures of the multilayer PCB are prevented, problems of de-lamination, shrink resin, holes and crack of the resin and white flake, etc. that come up after the multilayer PCB goes through cold and hot impact are improved, and the prepreg has good reliability and low cost.

Owner:GUANGDONG SHENGYI SCI TECH

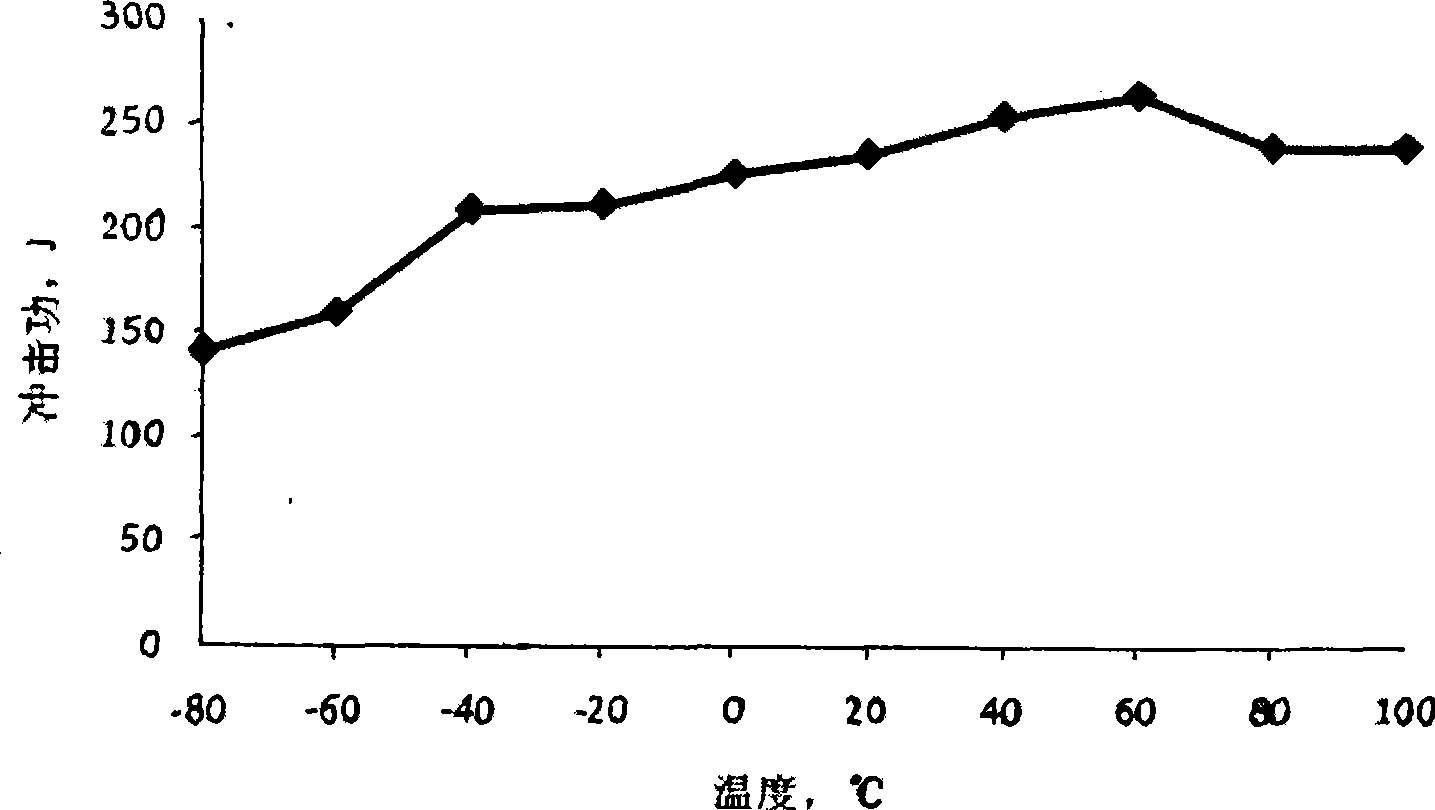

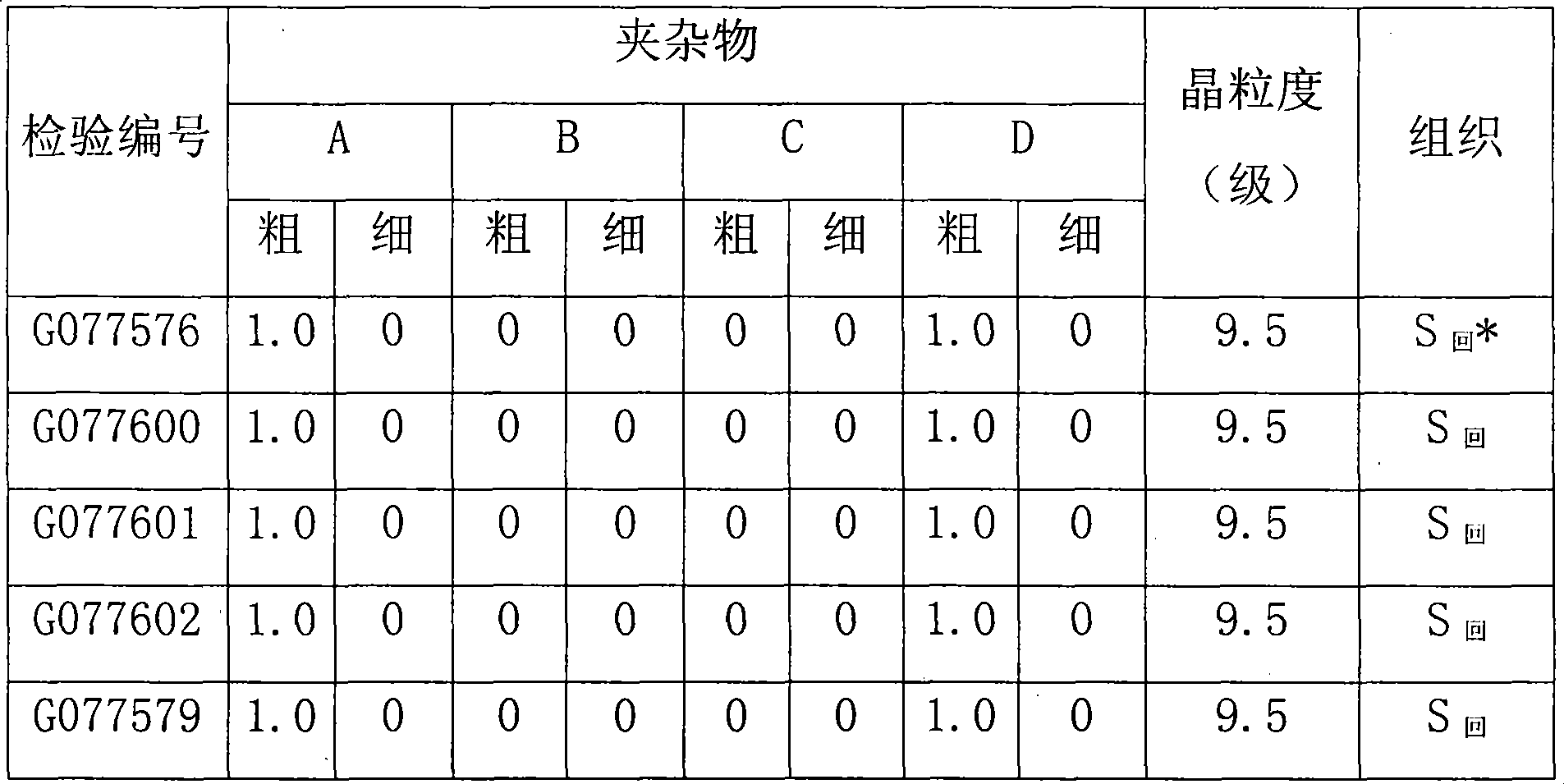

Rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and production method thereof

InactiveCN102251180ALow elemental contentReduce residual stressDrilling rodsProcess efficiency improvementRare earthFlame cutting

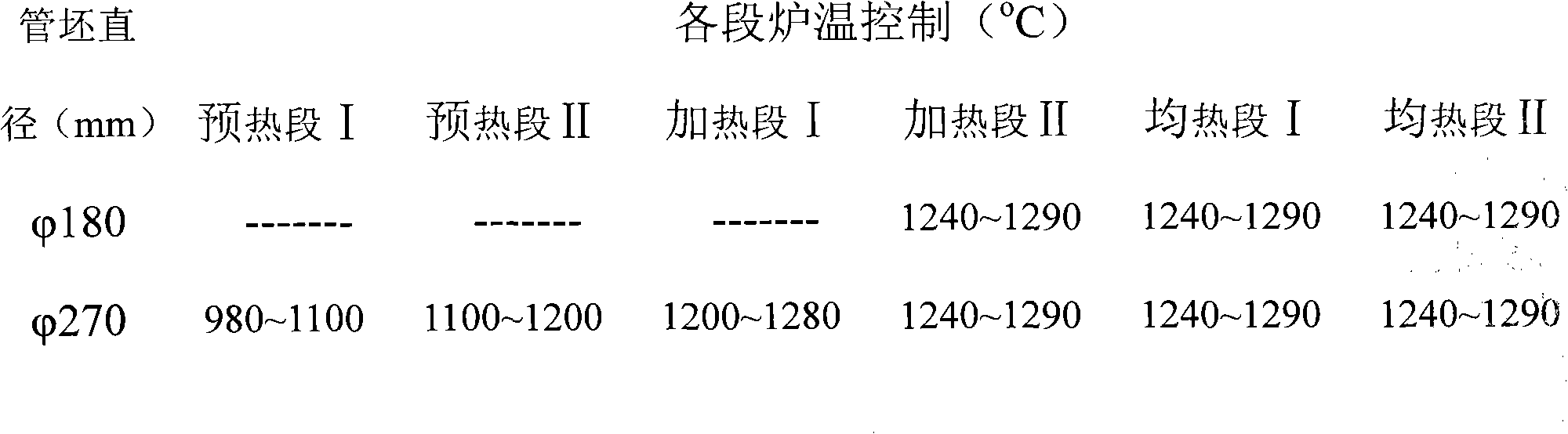

A rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and a production method thereof belong to the technical fields of ferrous metal smelting and metal press working. The petroleum casing comprises the following raw materials by weight percent: 90% of blast furnace molten iron and 10% of high quality steel scrap. The casing blank comprises the following chemical components by weight percent: 0.18-0.35% of C, 0.10-0.35% of Si, 0.55-1.10% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.60-1.10% of Cr, 0.15-0.50% of Mo, 0.01-0.03% of Al, 0.0005-0.0100% of RE ( RE is the mixed rare earth metals of Ce and La and the weight percents of Ce and La are 67% and 33% respectively), less than 0.10% of Cu, less than 0.10% of Ni and the balance of Fe and trace elements. The process flow of the production method is as follows: pretreating molten iron, smelting in a top-bottom blowing converter, refining in a ladle furnace (LF), performing VD vacuum treatment, performing continuous casting of round billets, performing flame cutting, heating the casing blanks, boring, performing continuous rolling, performing sizing and diameter reducing, cooling, performing saw cutting, performing heat treatment, straightening, performing flaw inspection and lathing screw threads. The mechanical properties of the petroleum casing are as follows: the strength is no less than 140000PSI, the residual stress is no more than 80MPa, the impact power is no less than 80J and the grain size is no less than the grade 8. The product is characterized in that the residual stress is low, the content of harmful elements is low, the impact toughness is high, the grains are small, and the product resists extrusion and is difficult to damage.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

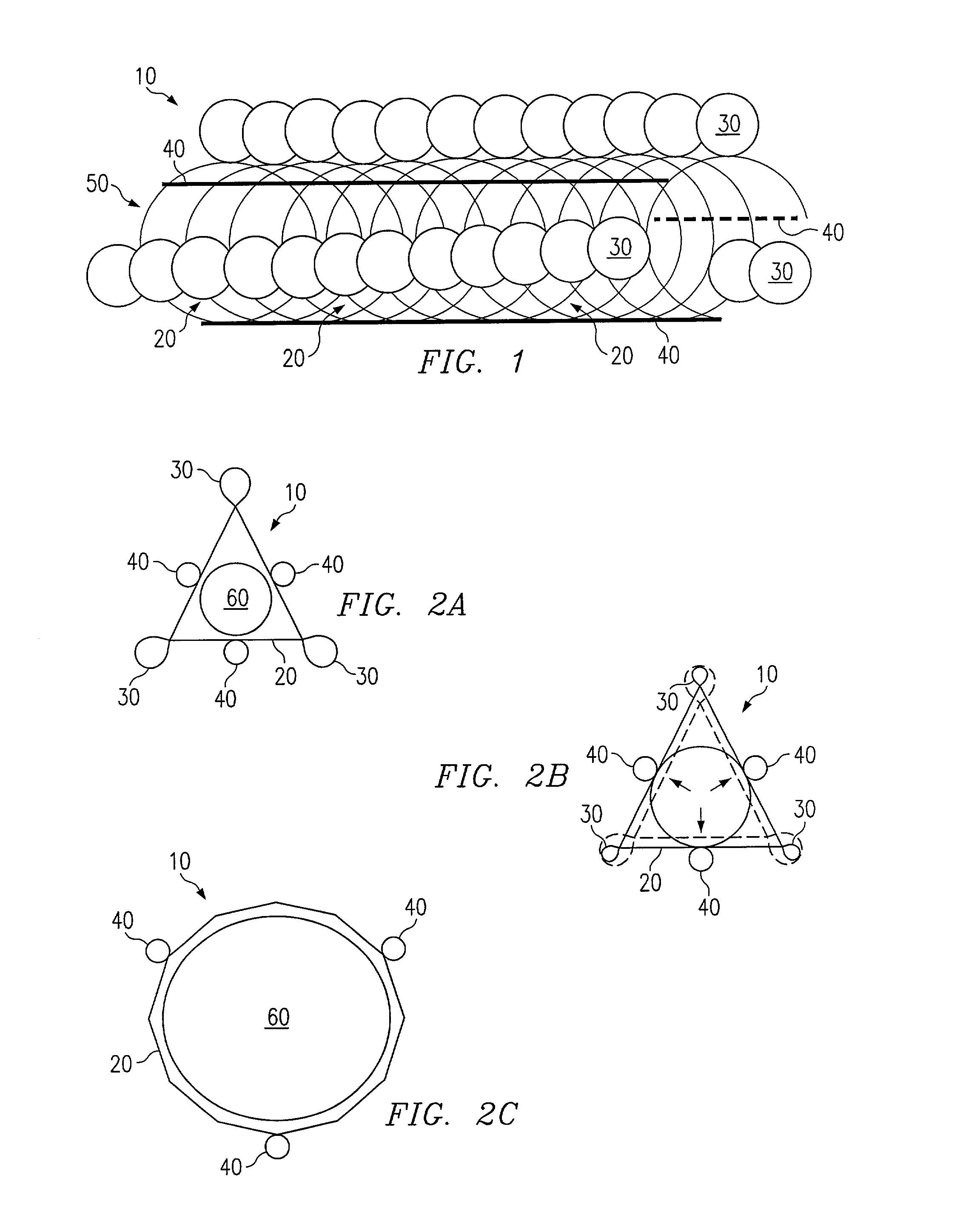

Expandable biodegradable polymeric stents for combined mechanical support and pharmacological or radiation therapy

InactiveUS7128755B2Avoid residual stressAbsorb in timeStentsBlood vesselsAngioplasty balloonRadiation therapy

An expandable biodegradable polymeric stent is fabricated with biodegradable polymer fibers (Poly-L-lactic acid, PLLA) in a coil shape that is constructed with both central and external or internal peripheral lobes. It is delivered and expanded using a conventional angioplasty balloon system. The disclosed stent can serve as a temporary scaffold for coronary vessels after PTCA or for peripheral endovascular stenting, or it can provide mechanical palliation for strictures of ductile organs (trachea, esophagus, bile and pancreatic ducts, ureter etc.). The disclosed stent also serves as a unique device for specific local drug delivery. Therapeutic agents (chemical compounds, protein enzyme and DNA sequences) and cells can be loaded into the stent and gradually released to target tissues. Local radiation therapy can also be delivered by a specially adapted stent.

Owner:DUNING

Self-lubricating composite soft coating cutter and manufacture method thereof

ActiveCN1927579ARealize self-lubricating functionSelf-lubricating function preventsLayered productsVacuum evaporation coatingManufacturing technologyMiddle frequency

The invention relates to a self-lubricant composite soft coat blade, and relative production. Wherein, said blade uses the MoS2 / Zr / Ti composite coat blade made from middle-frequency magnetic-control multi-arc plating method; the surface of blade is MoS2 layer, between which can base there are Ti, MoS2 / Zr / Ti, and MoS2 / Zr transition layer; when using said blade to cut, the surface of blade can form continuous lubricant layer, to realize self-lubricant function; since the solid lubricant has low shearing strength, the solid lubricant layer will be transferred to the surface of work piece, to form transfer film and the friction in the cutting process will generate inside the solid lubricant layer, to reduce friction, reduce shearing force and reduce shearing temperature.

Owner:ZHEJIANG DEWEI CEMENTED CARBIDE MFG CO LTD

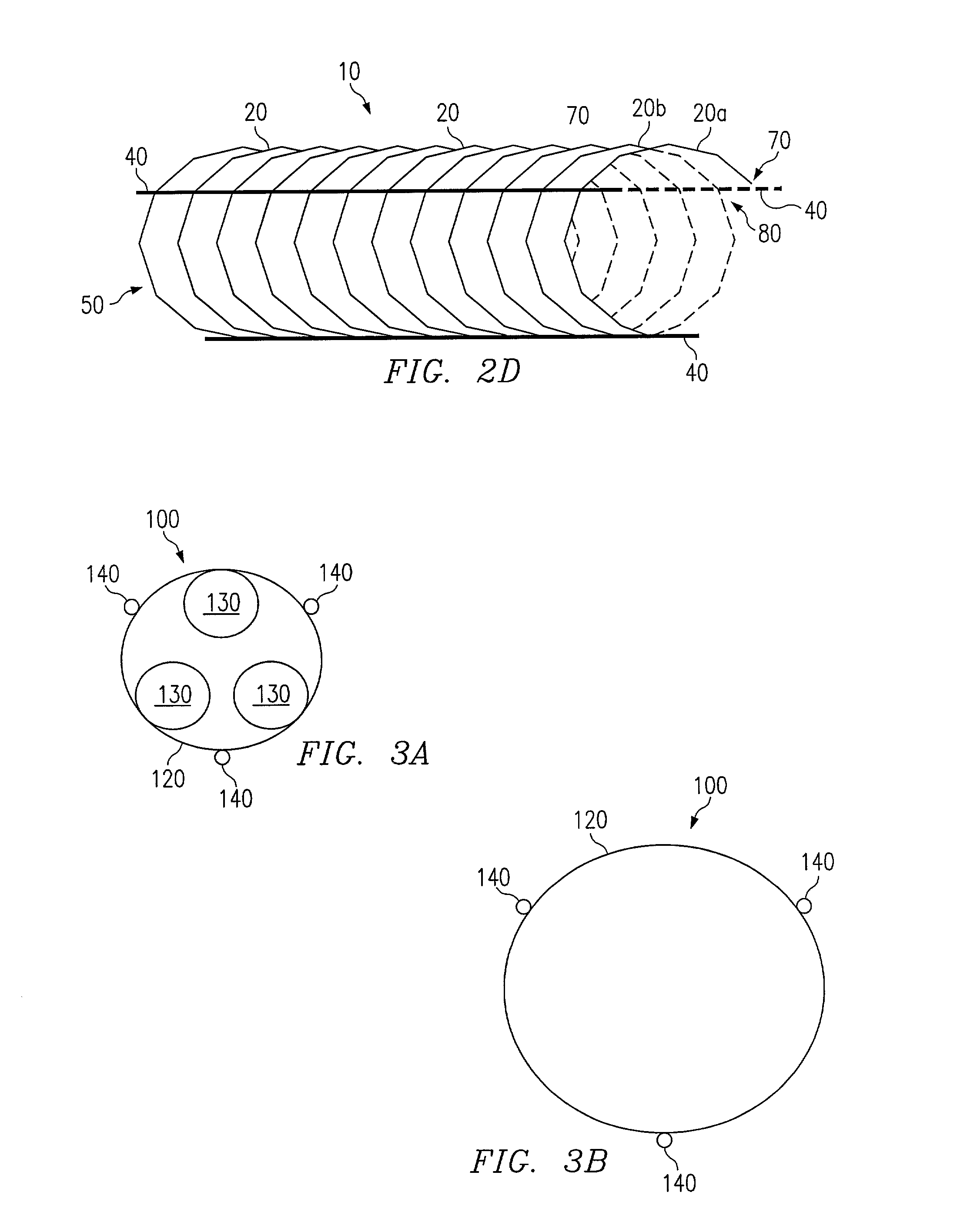

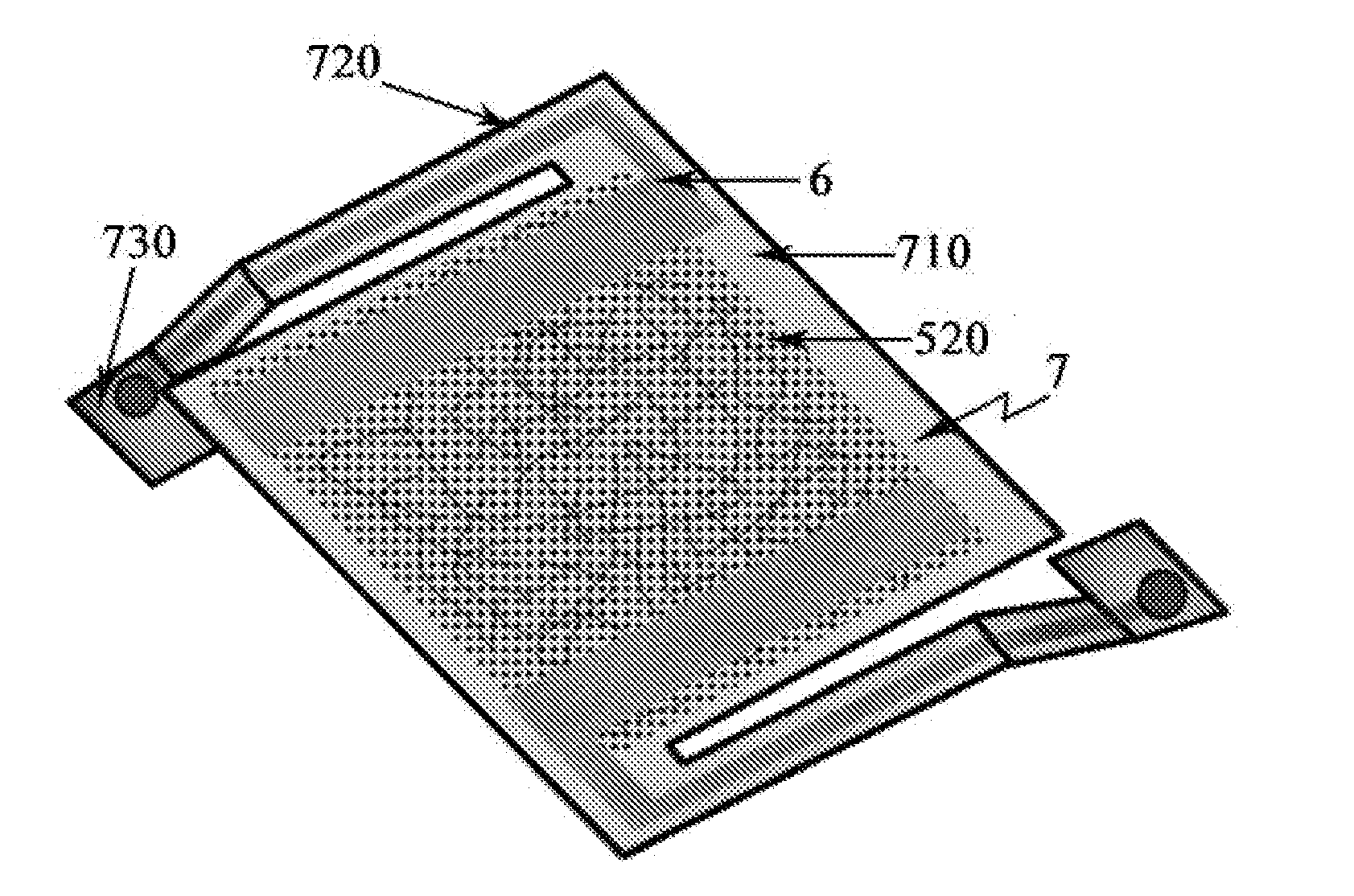

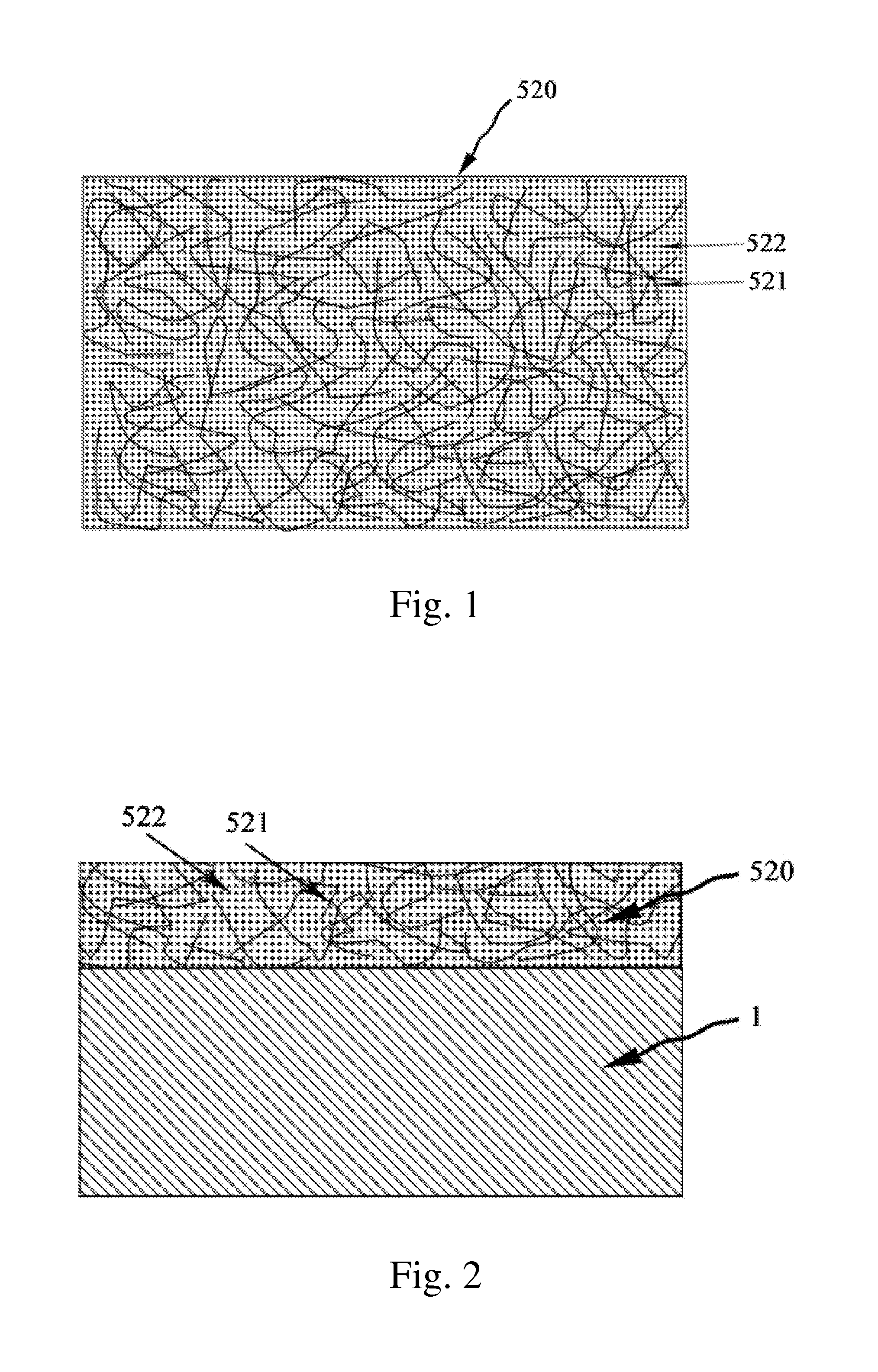

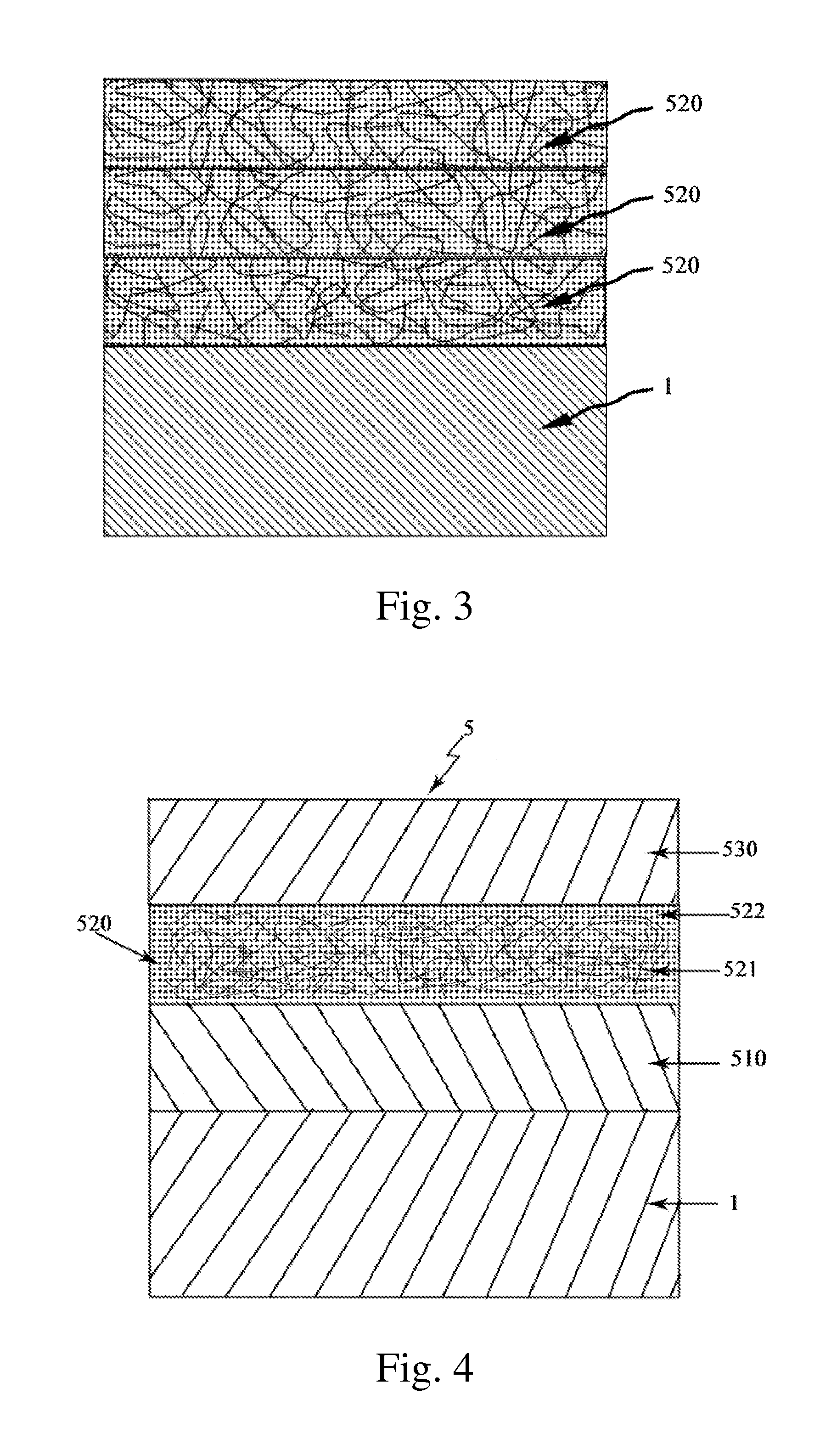

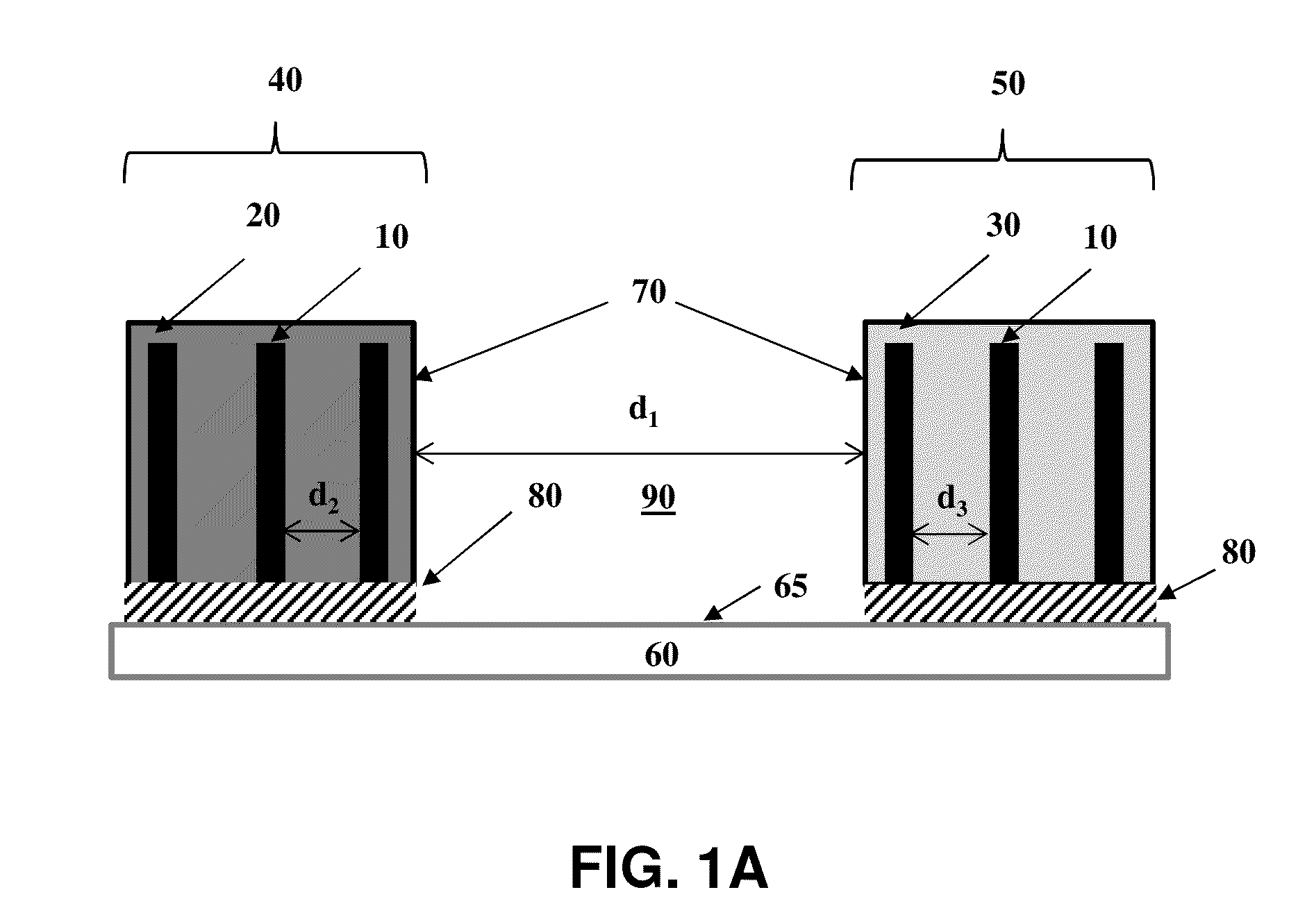

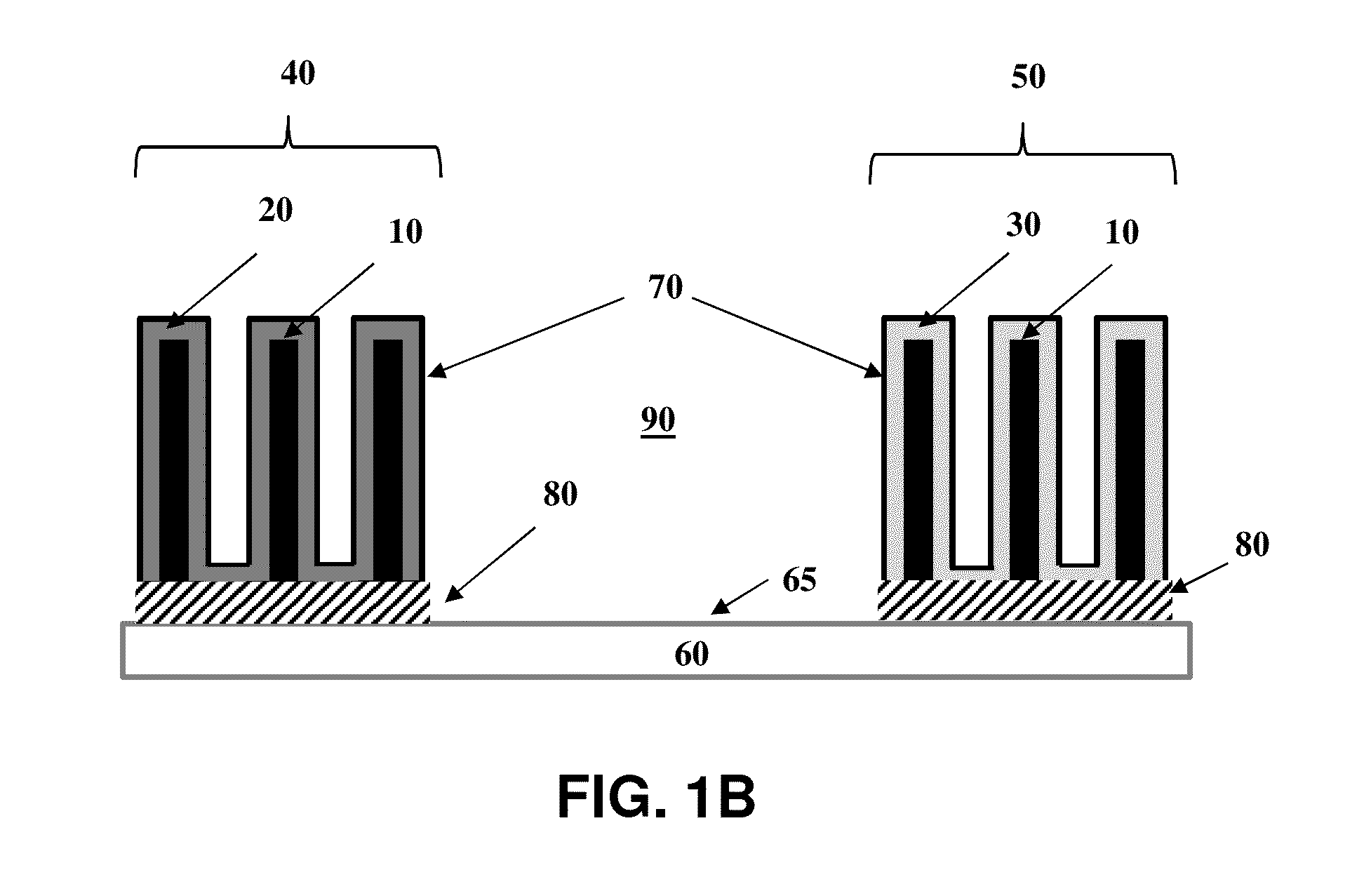

Freestanding, heat resistant microporous film for use in energy storage devices

ActiveUS20120145468A1Low thermal shrinkageHigh level of loadingPrimary cell to battery groupingAuxillary drivesCross-linked polyethyleneMelting Point Temperature

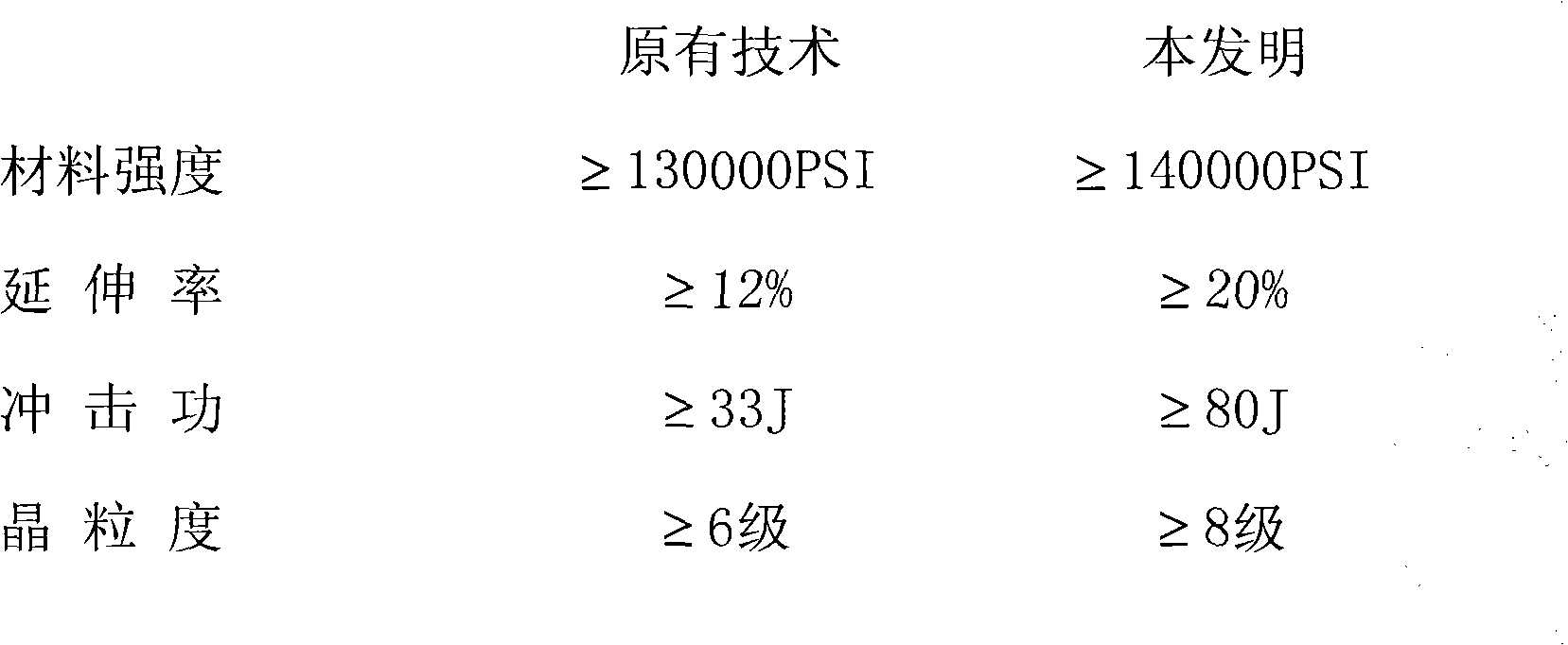

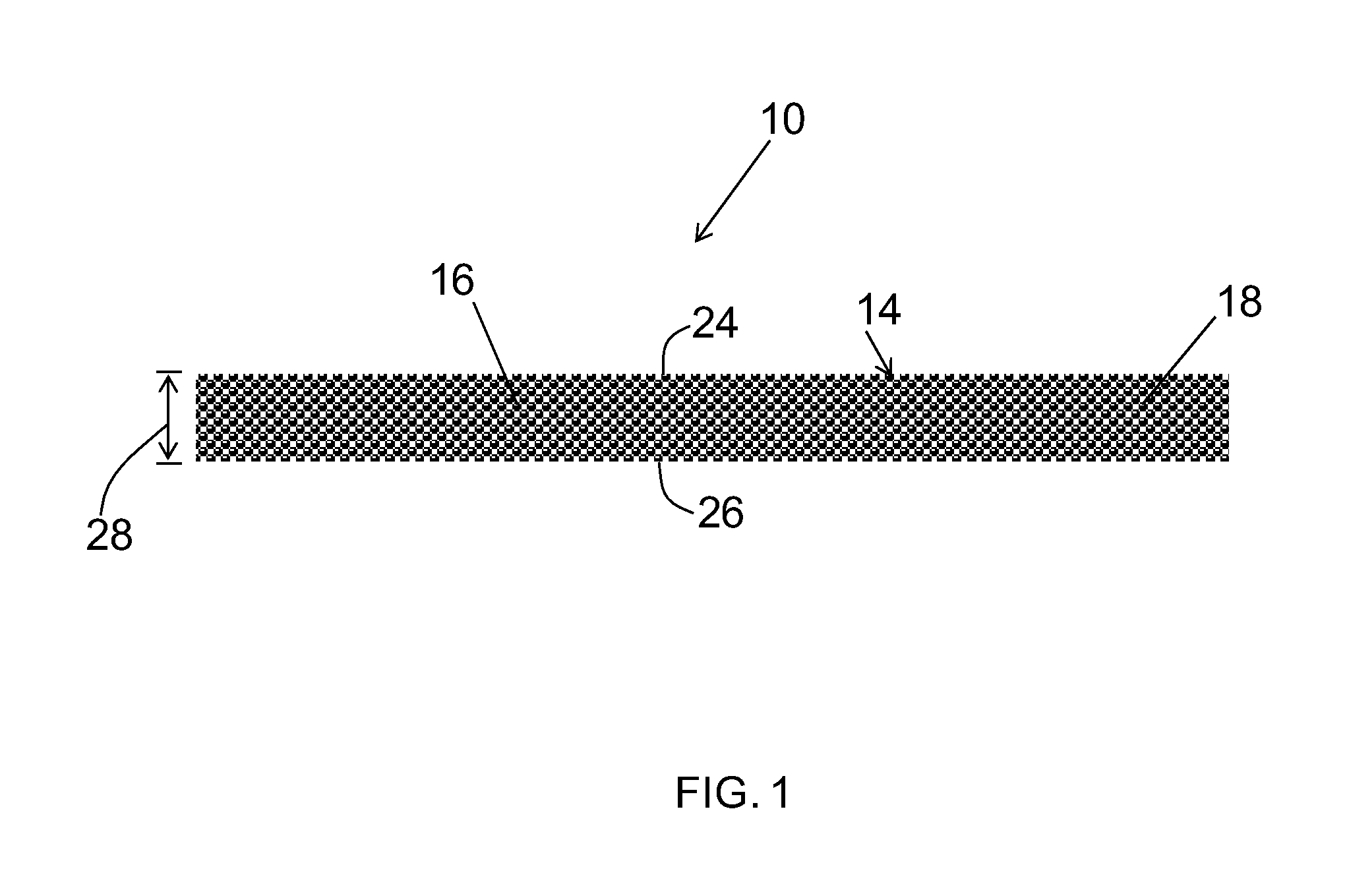

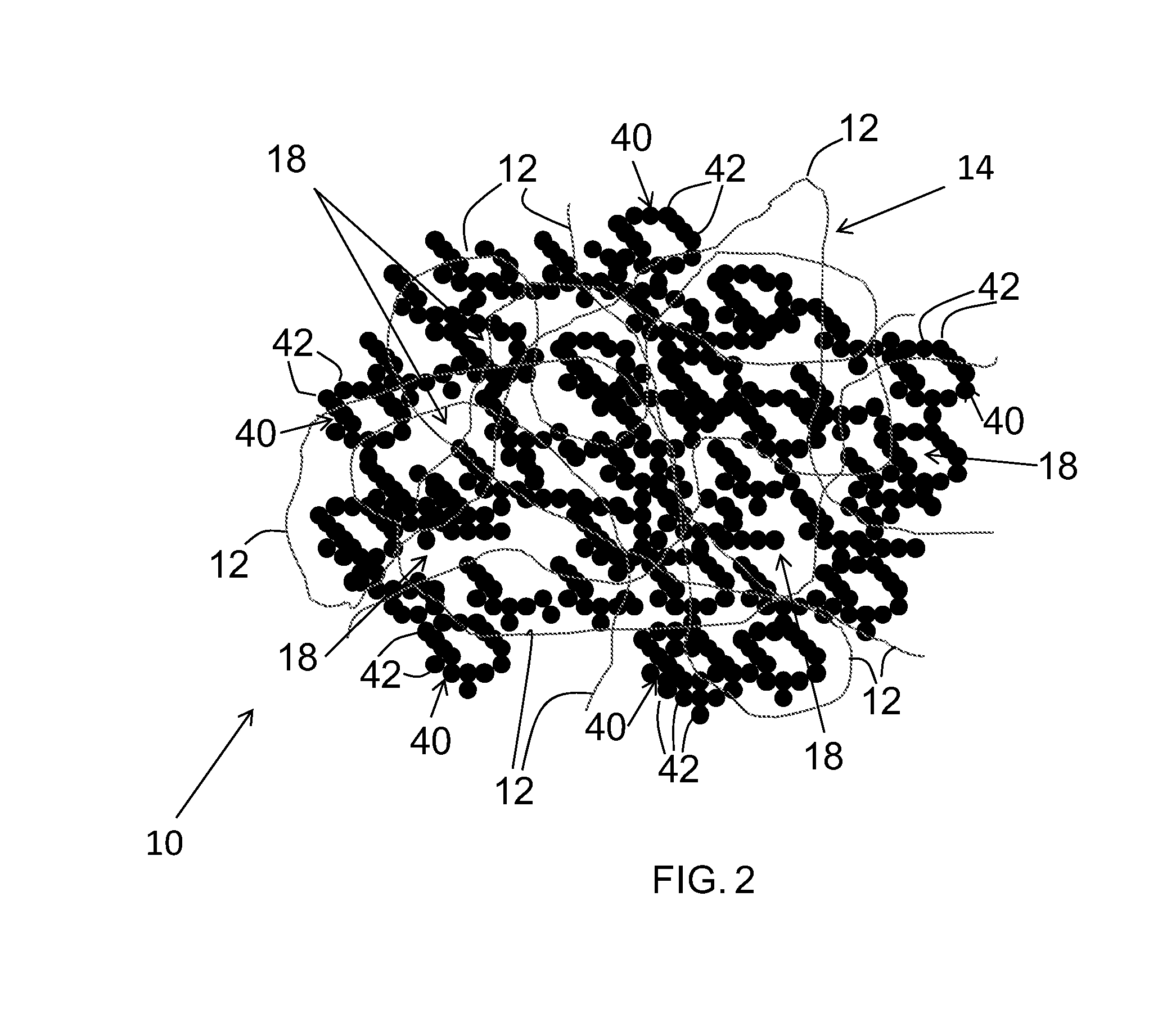

Preferred embodiments of a freestanding, heat resistant microporous polymer film (10) constructed for use in an energy storage device (70, 100) implements one or more of the following approaches to exhibit excellent high temperature mechanical and dimensional stability: incorporation into a porous polyolefin film of sufficiently high loading levels of inorganic or ceramic filler material (16) to maintain porosity (18) and achieve low thermal shrinkage; use of crosslinkable polyethylene to contribute to crosslinking the polymer matrix (14) in a highly inorganic material-filled polyolefin film; and heat treating or annealing of biaxially oriented, highly inorganic material-filled polyolefin film above the melting point temperature of the polymer matrix to reduce residual stress while maintaining high porosity. The freestanding, heat resistant microporous polymer film embodiments exhibit extremely low resistance, as evidenced by MacMullin numbers of less than 4.5.

Owner:AMTEK RES INT

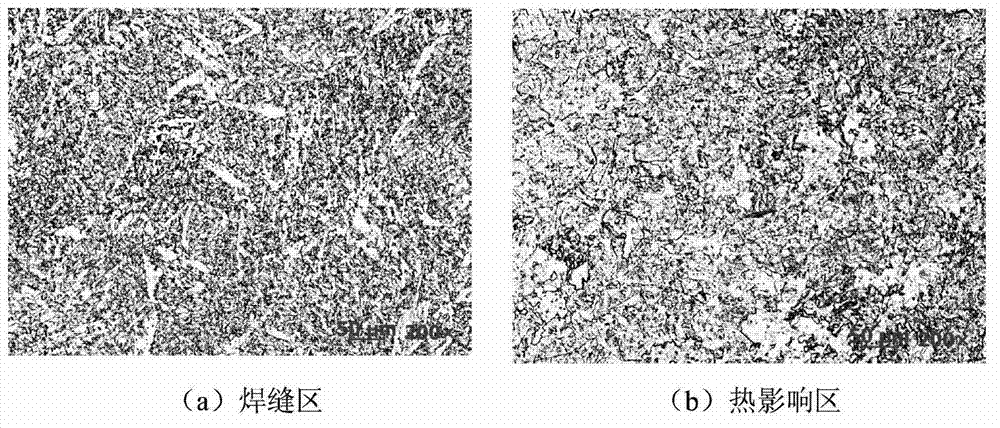

Field welding repair method especially for larger and penetrating defects in steel casting with heavy wall thickness

The invention relates to a field welding repair method especially for larger and penetrating defects in a steel casting with heavy wall thickness. The method comprises a pre-welding preparation process, a welding repair process and a post-welding quality inspection process, wherein the welding repair process comprises the steps of (1) preheating; (2) carrying out 1 to 2 layers of backing weld for all positions of a groove by adopting TIG weld, and filling the whole bottom of the groove with solid wire materials; (3) warming up to 220 to 330 DEG C, carrying out constant thermal insulation for 3 to 8 hours, adopting manual arc welding to implement the filler welding for the groove, hammering the welded bead immediately with an air hammer, and ensuring the dense and uniform traces of the hammer; (4) carrying out dehydrogenation heat treatment; (5) carrying out post-welding treatment: carrying out stress annealing at the temperature of 500 to 550 DEG C, then carrying out high tempering at the temperature of 700 to 750 DEG C, and finally, cooling at the speed of 65 to 150 DEG C / h to the room temperature. After welding repair, a welding seam is tested to be good in quality, and have low possibility of cracking again.

Owner:SUZHOU NUCLEAR POWER RES INST +4

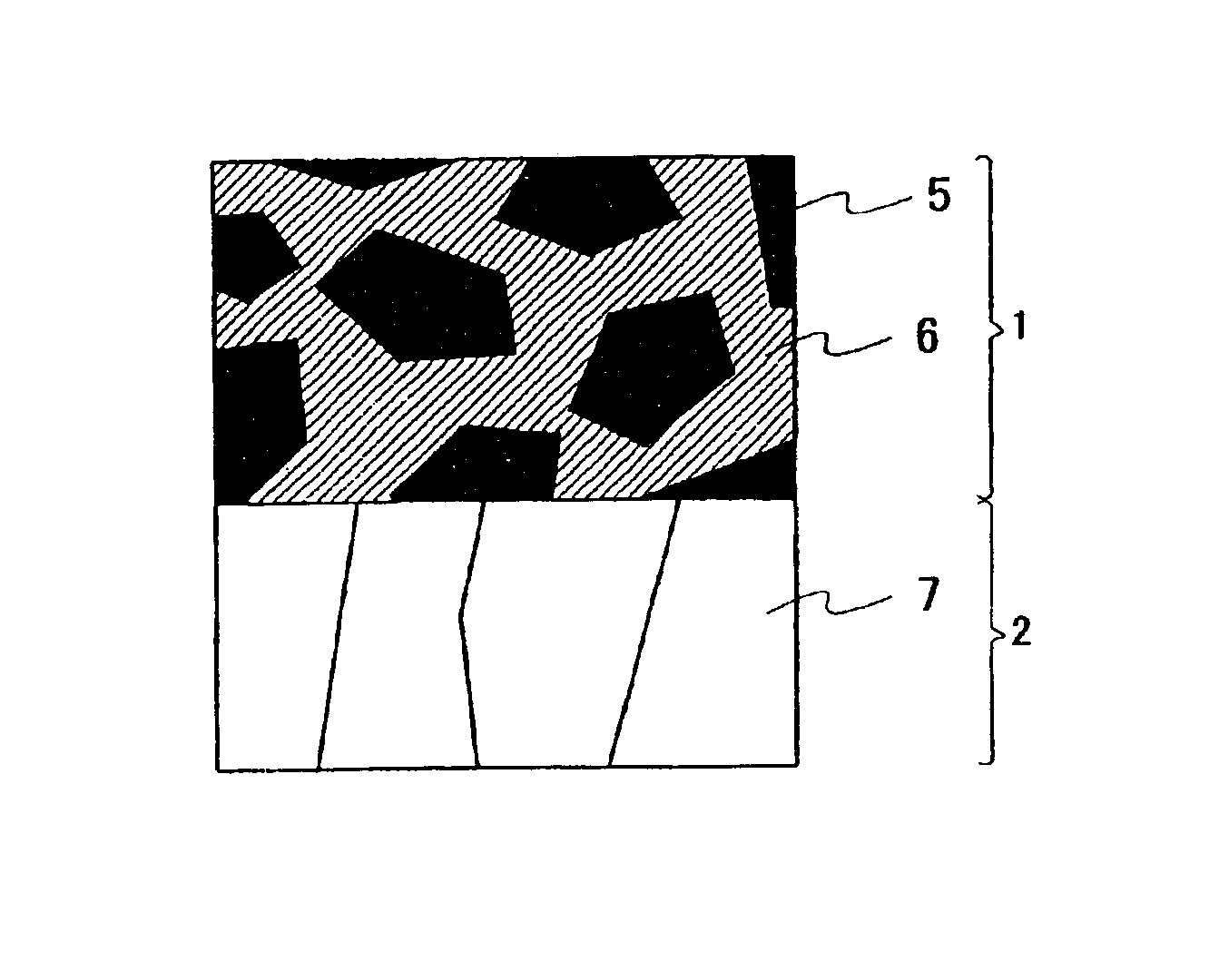

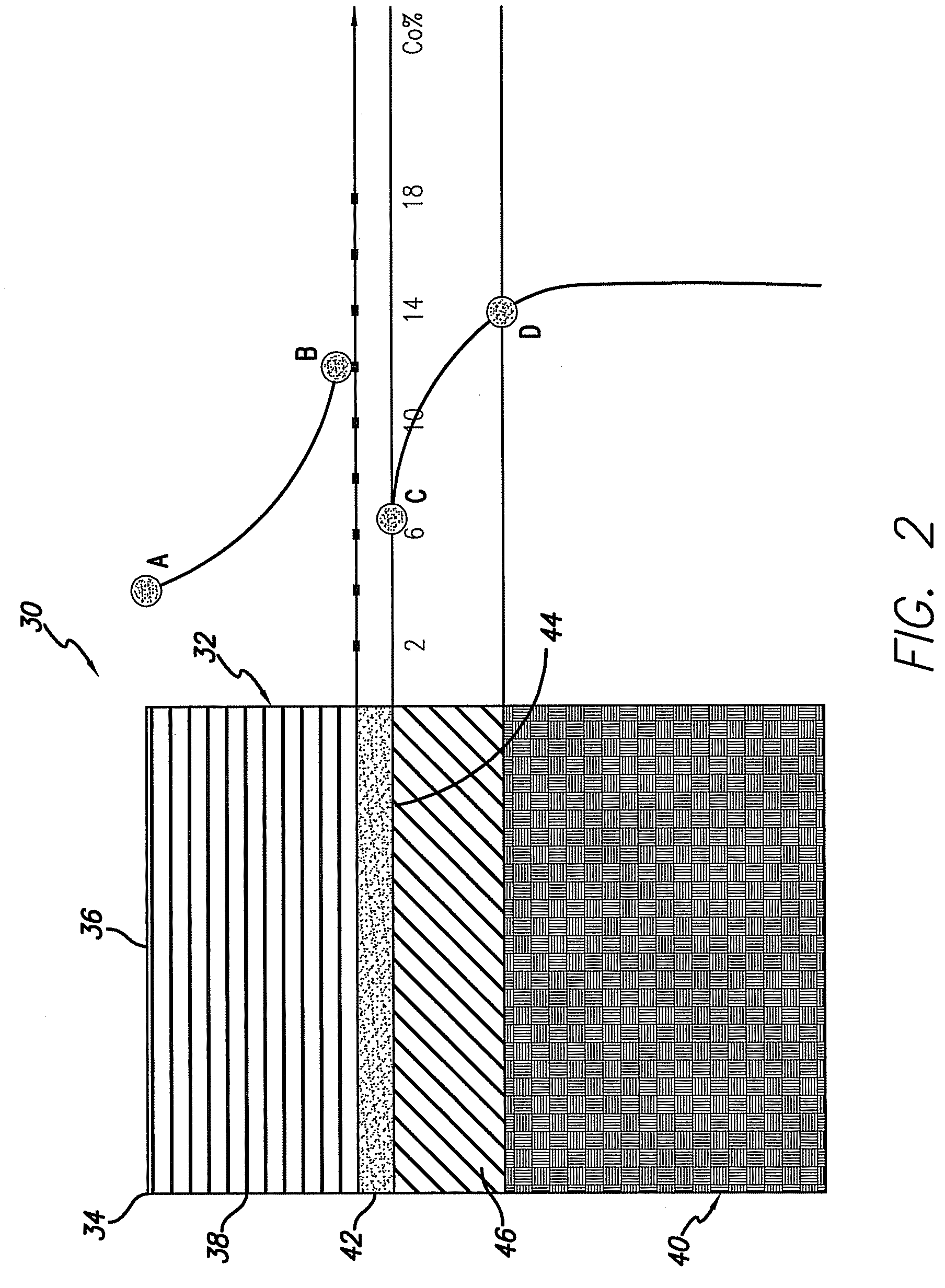

Polycrystalline diamond construction with controlled gradient metal content

ActiveUS20090152017A1Hardness resistanceResistance to stabilityDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Polycrystalline diamond constructions comprises a diamond body attached to a metallic substrate, and having an engineered metal content. The body comprises bonded together diamond crystals with a metal material disposed interstitially between the crystals. A body working surface has metal content of 2 to 8 percent that increases moving away therefrom. A transition region between the body and substrate includes metal rich and metal depleted regions having controlled metal content that provides improved thermal expansion matching / reduced residual stress. A point in the body adjacent the metal rich zone has a metal content that is at least about 3 percent by weight greater than that at a body / substrate interface. The metal depleted zone metal content increases gradually moving from the body, and has a thickness greater than 1.25 mm. Metal depleted zone metal content changes less about 4 percent per millimeter moving along the substrate.

Owner:SMITH INT INC

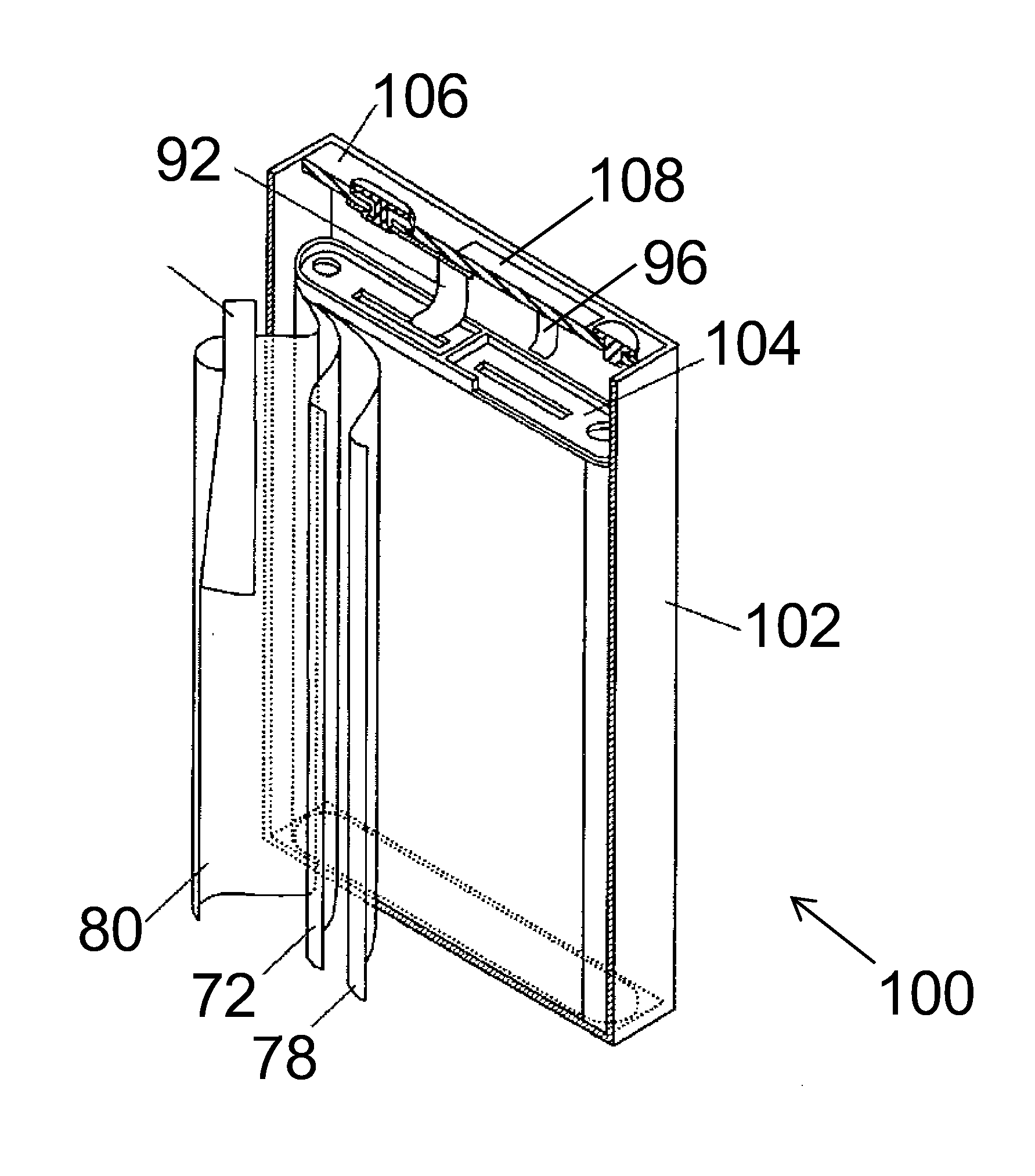

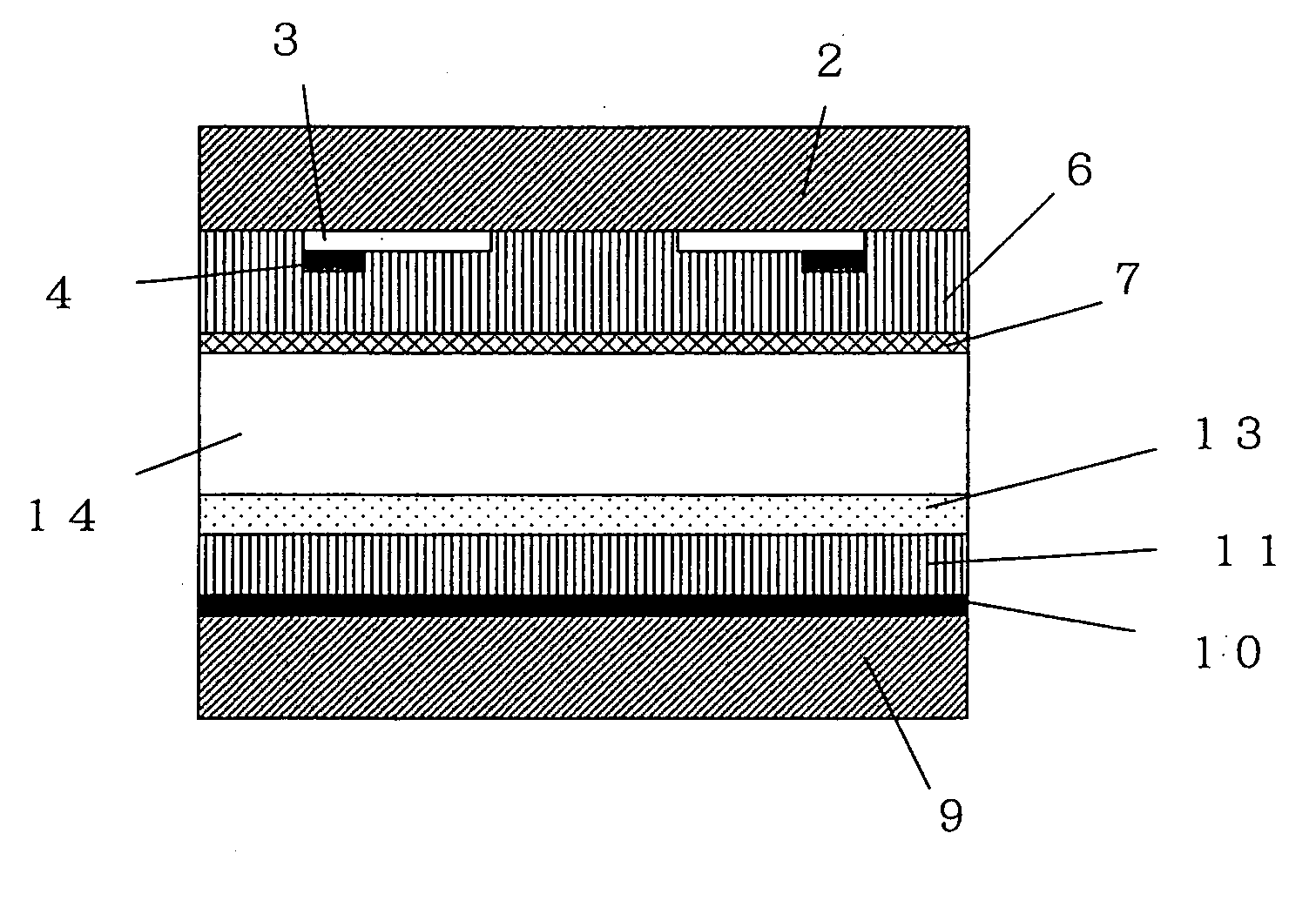

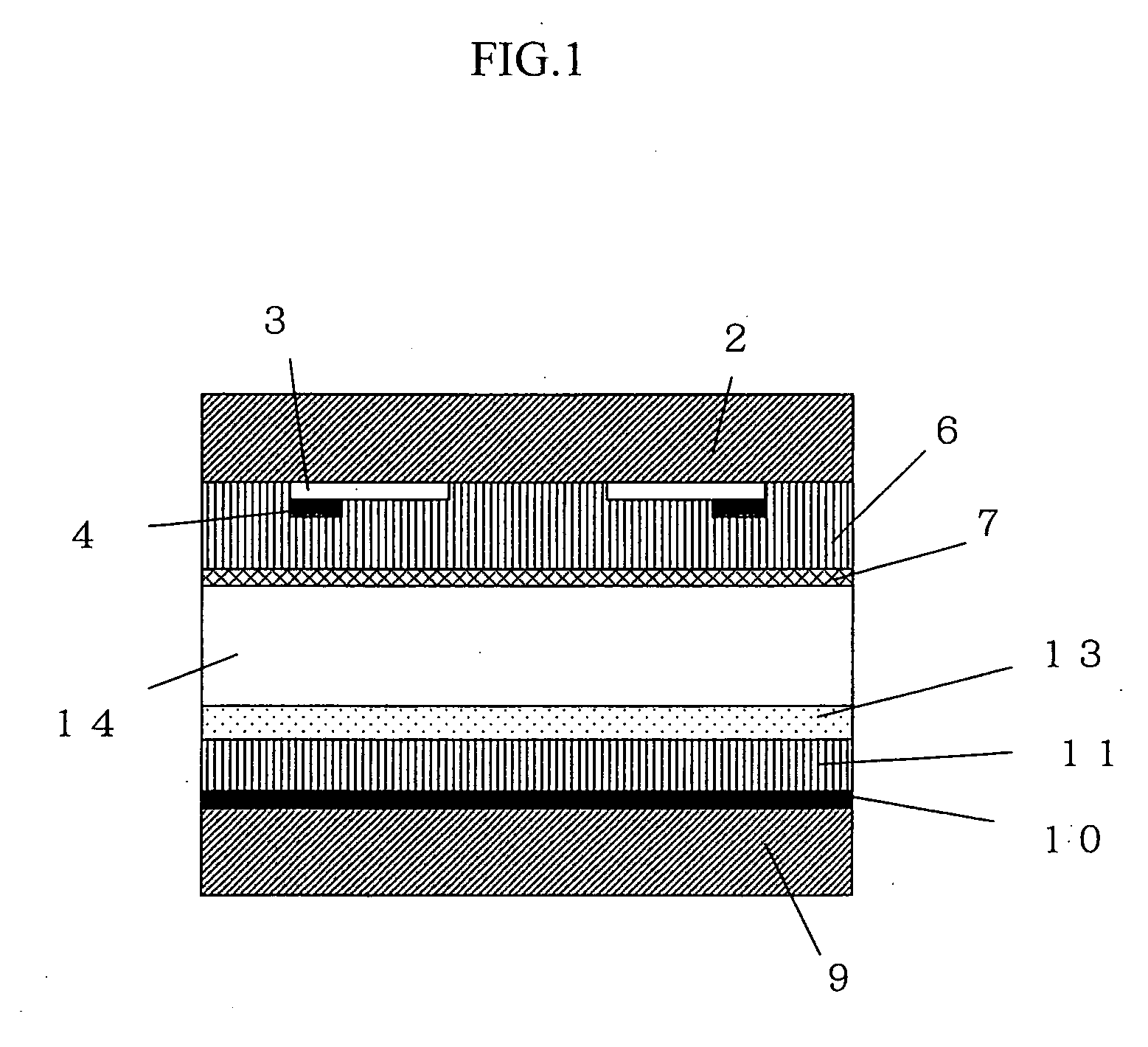

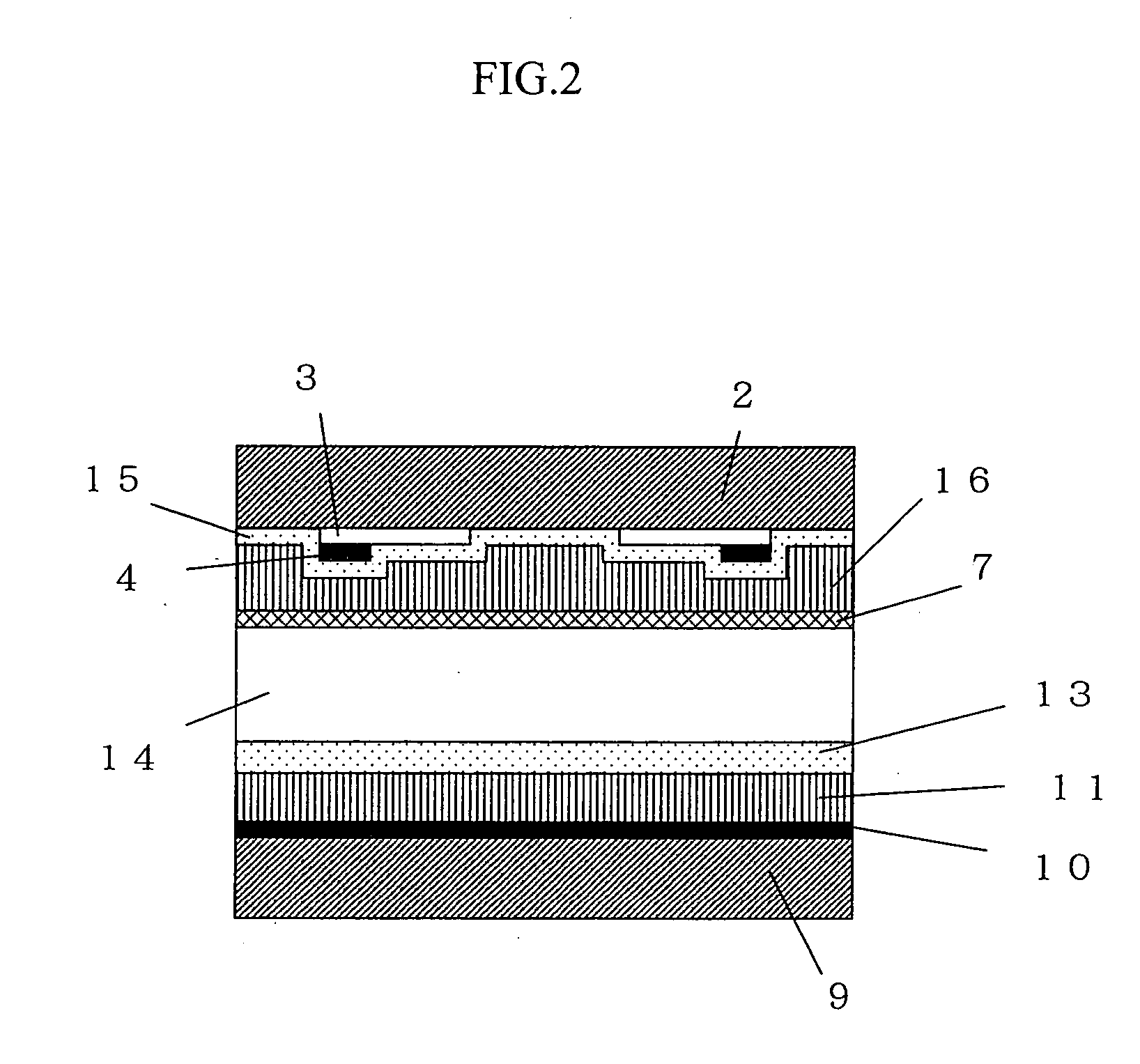

Microbolometer for infrared detector or Terahertz detector and method for manufacturing the same

InactiveUS20110315981A1Improve business performanceLow costSemiconductor/solid-state device manufacturingPyrometry using electric radation detectorsComposite filmMicrobolometer

A microbolometer includes a micro-bridge structure for uncooling infrared or terahertz detectors. The thermistor and light absorbing materials of the micro-bridge structure are the vanadium oxide-carbon nanotube composite film formed by one-dimensional carbon nanotubes and two-dimensional vanadium oxide film. The micro-bridge is a three-layer sandwich structure consisting of a layer of amorphous silicon nitride base film as the supporting and insulating layer of the micro-bridge, a layer or multi-layer of vanadium oxide-carbon nanotube composite film in the middle of the micro-bridge as the heat sensitive and light absorbing layer of the microbolometer, and a layer of amorphous silicon nitride top film as the stress control layer and passivation of the heat sensitive film. The microbolometer and method for manufacturing the same can overcome the shortcomings of the prior art, improve the performance of the device, reduce the cost of raw materials and is suitable for large-scale industrial production.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

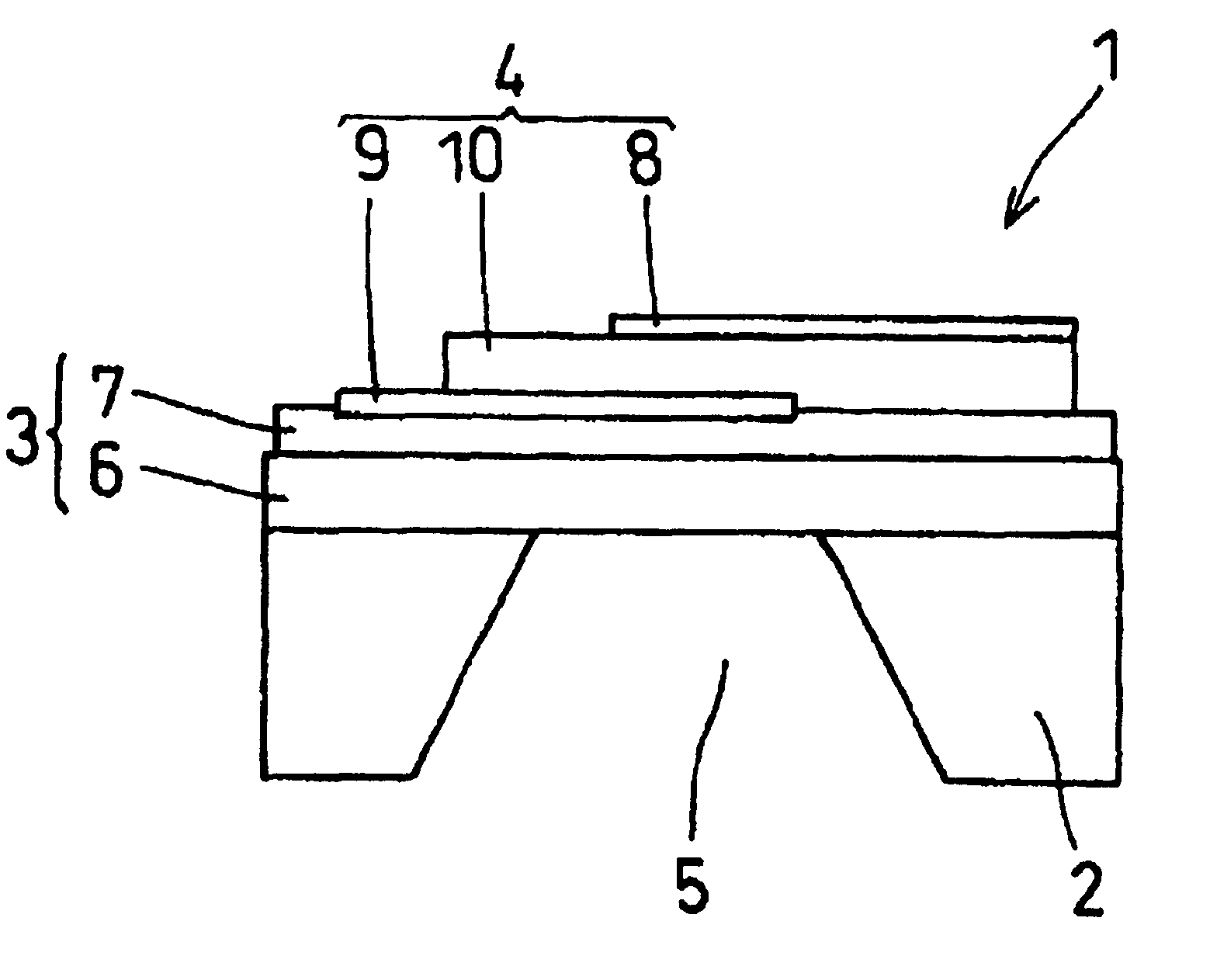

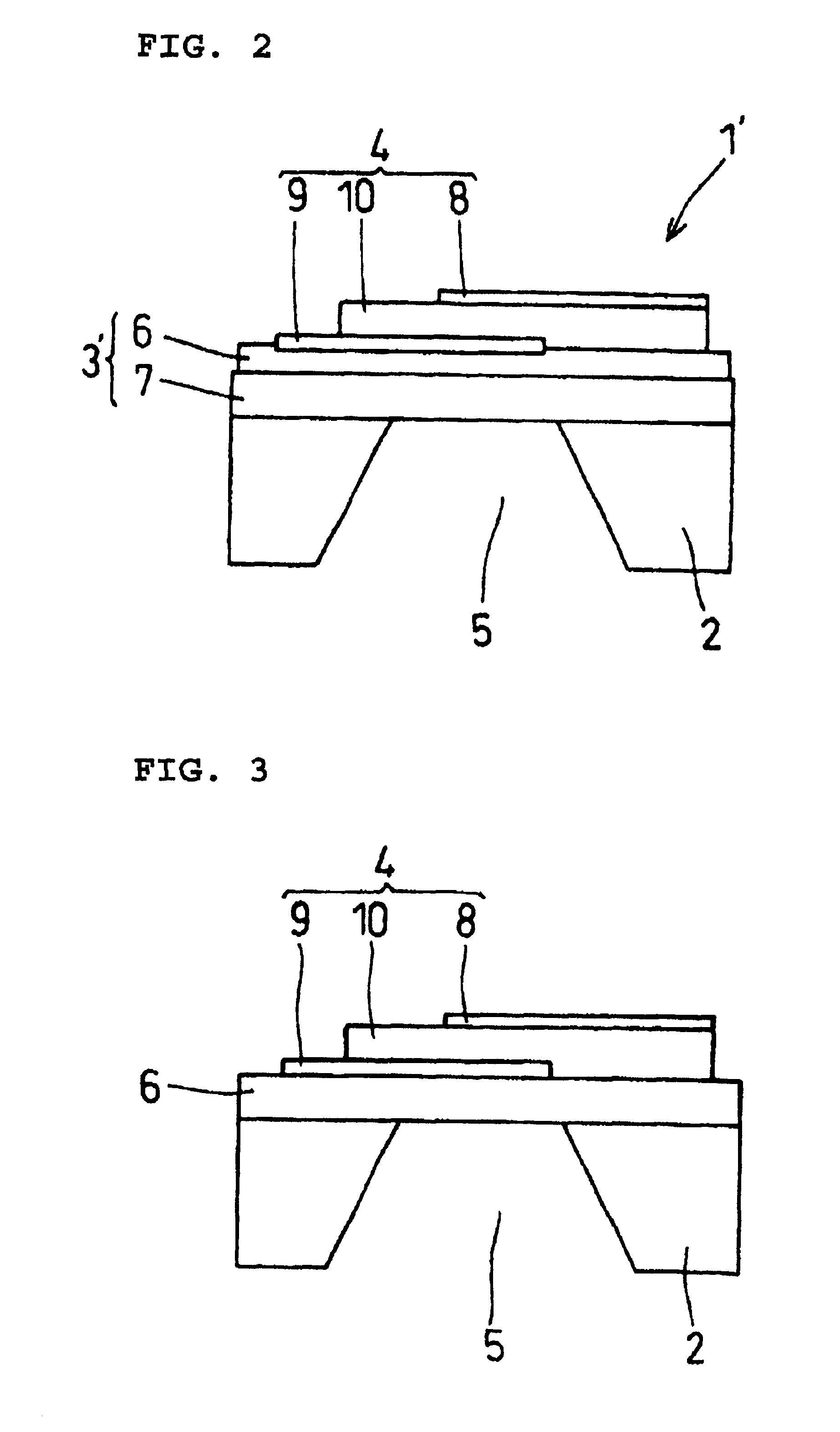

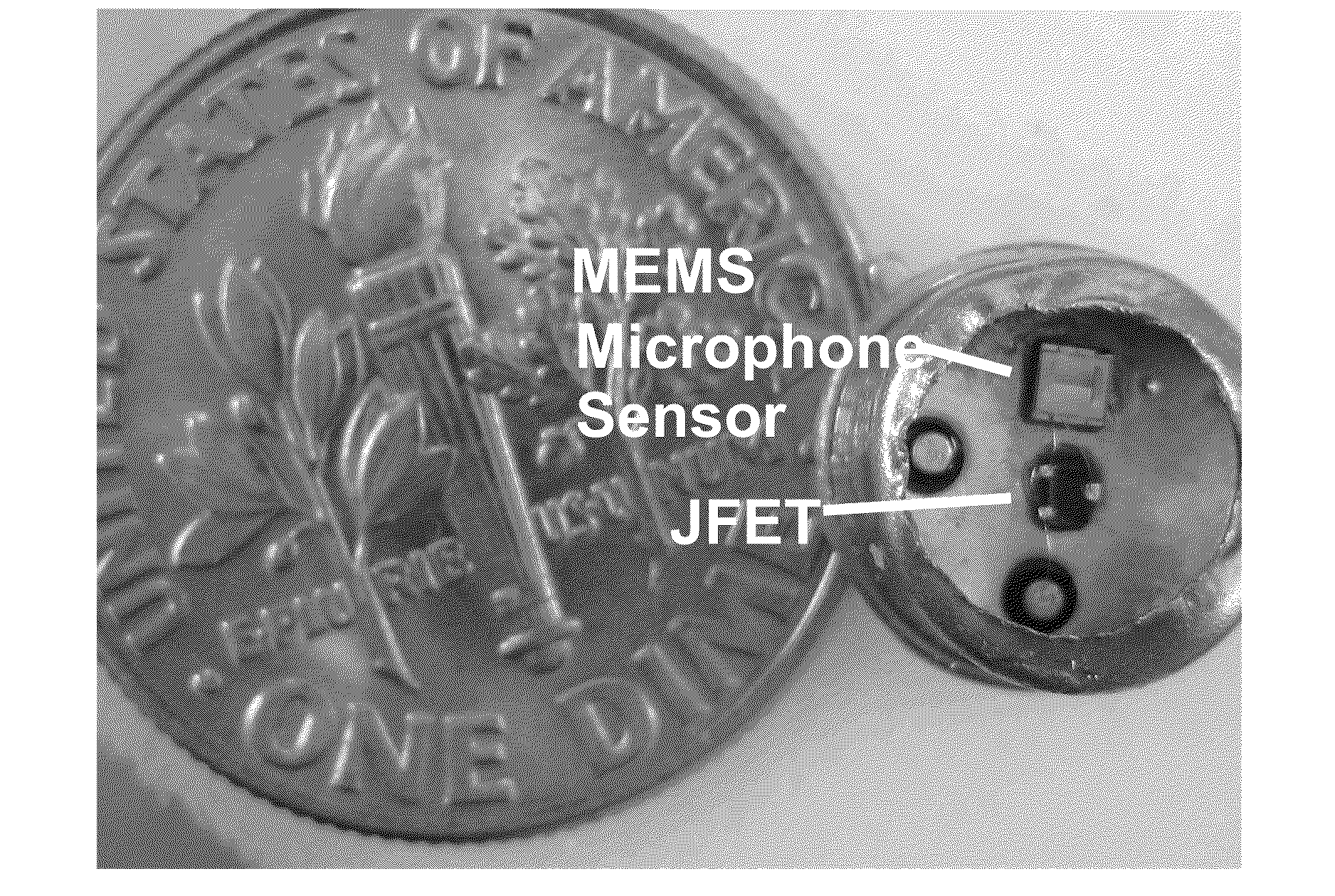

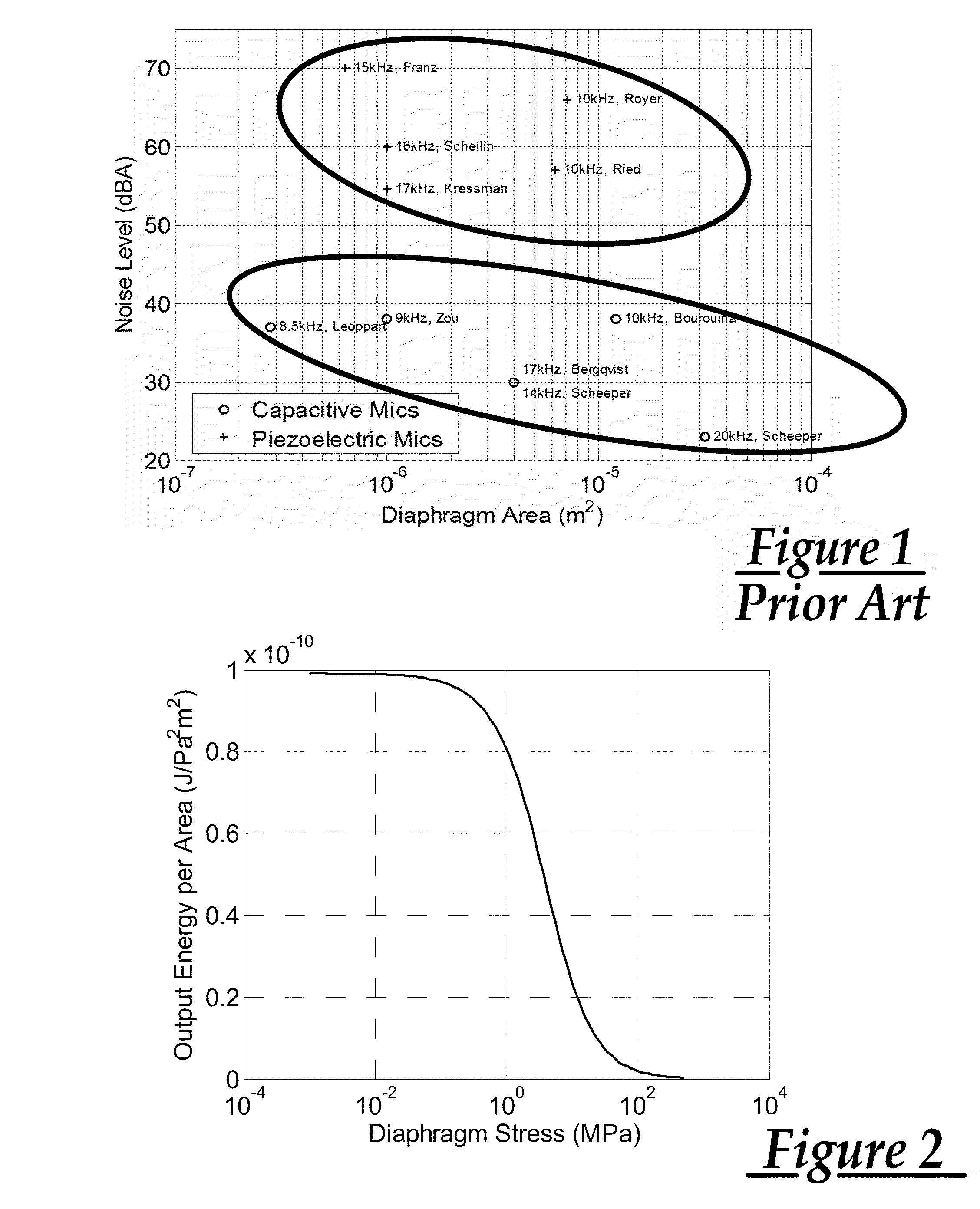

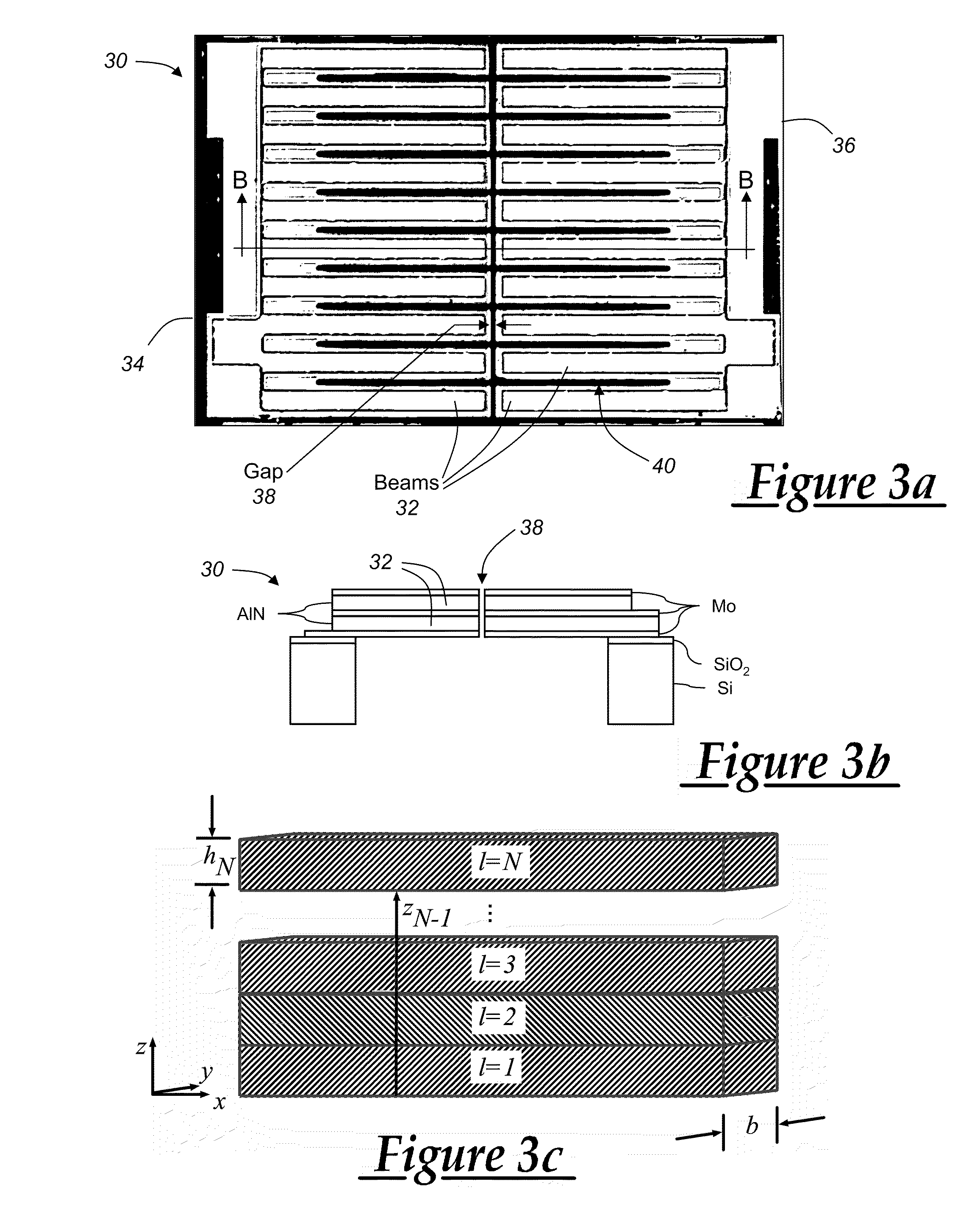

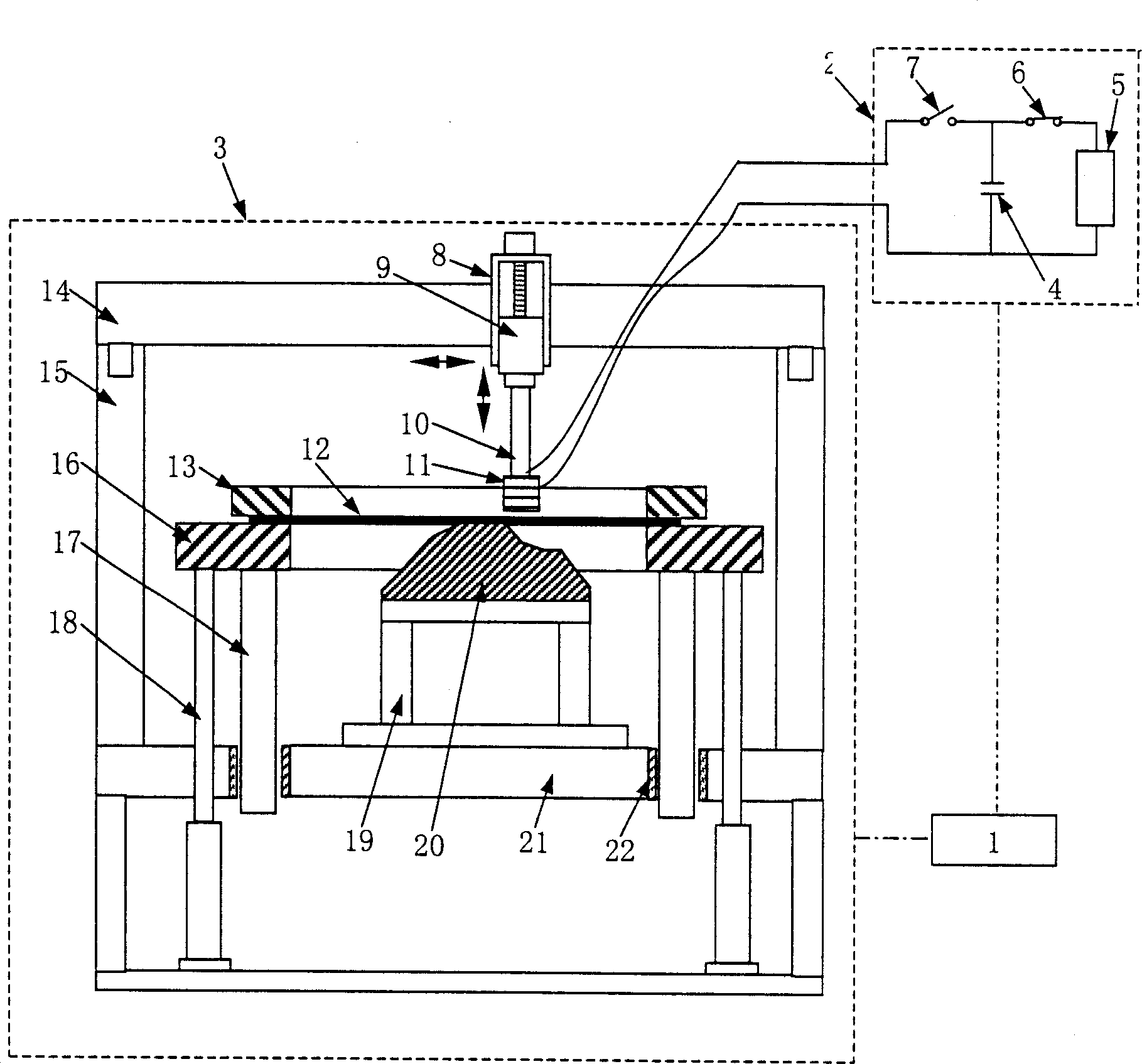

Piezoelectric MEMS microphone

ActiveUS20100254547A1Reduce residual stressPiezoelectric/electrostrictive microphonesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric memsMicrophone

A piezoelectric MEMS microphone comprising a multi-layer sensor that includes at least one piezoelectric layer between two electrode layers, with the sensor being dimensioned such that it provides a near maximized ratio of output energy to sensor area, as determined by an optimization parameter that accounts for input pressure, bandwidth, and characteristics of the piezoelectric and electrode materials. The sensor can be formed from single or stacked cantilevered beams separated from each other by a small gap, or can be a stress-relieved diaphragm that is formed by deposition onto a silicon substrate, with the diaphragm then being stress relieved by substantial detachment of the diaphragm from the substrate, and then followed by reattachment of the now stress relieved diaphragm.

Owner:THE RGT OF THE UNIV OF MICHIGAN

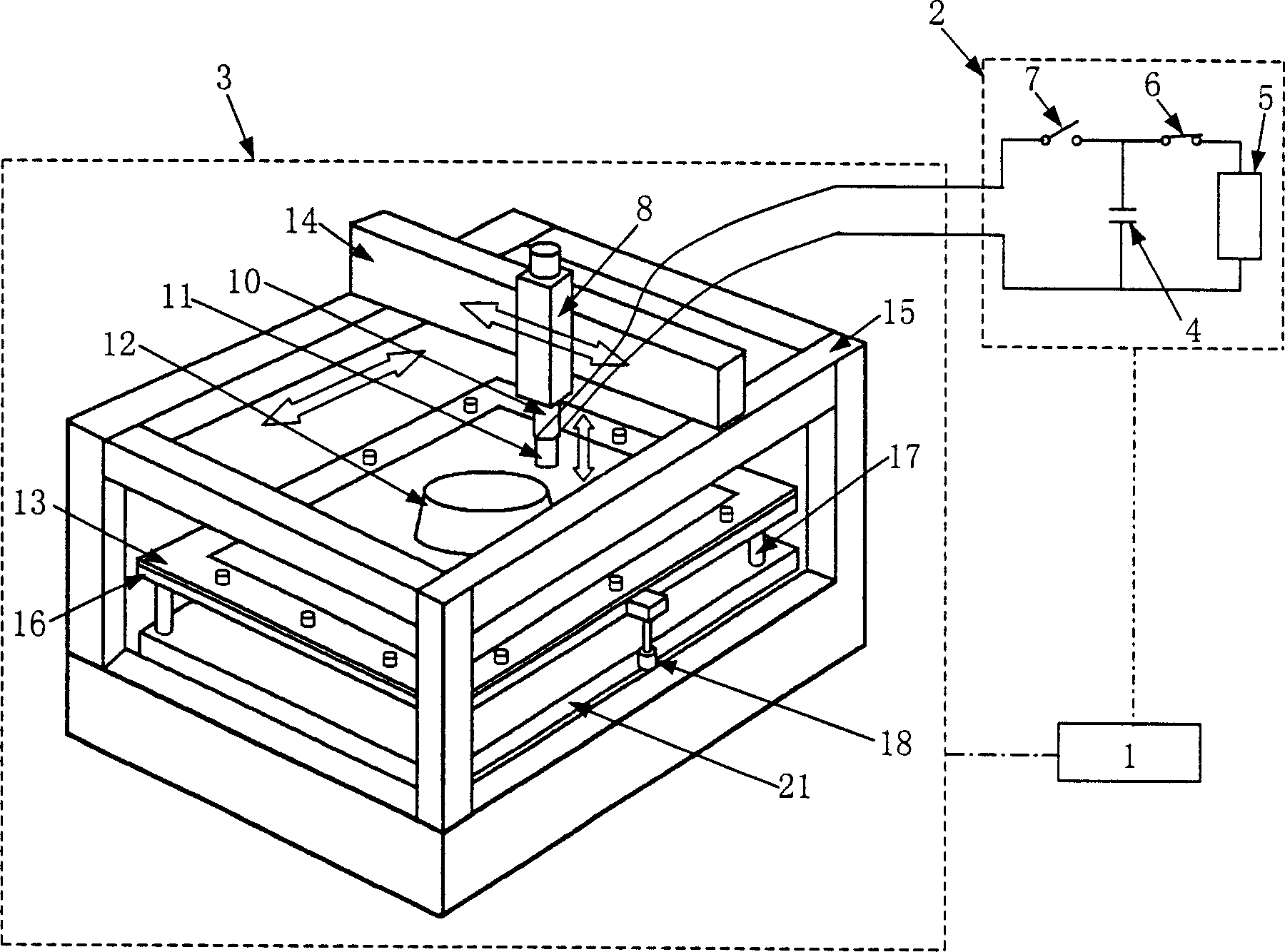

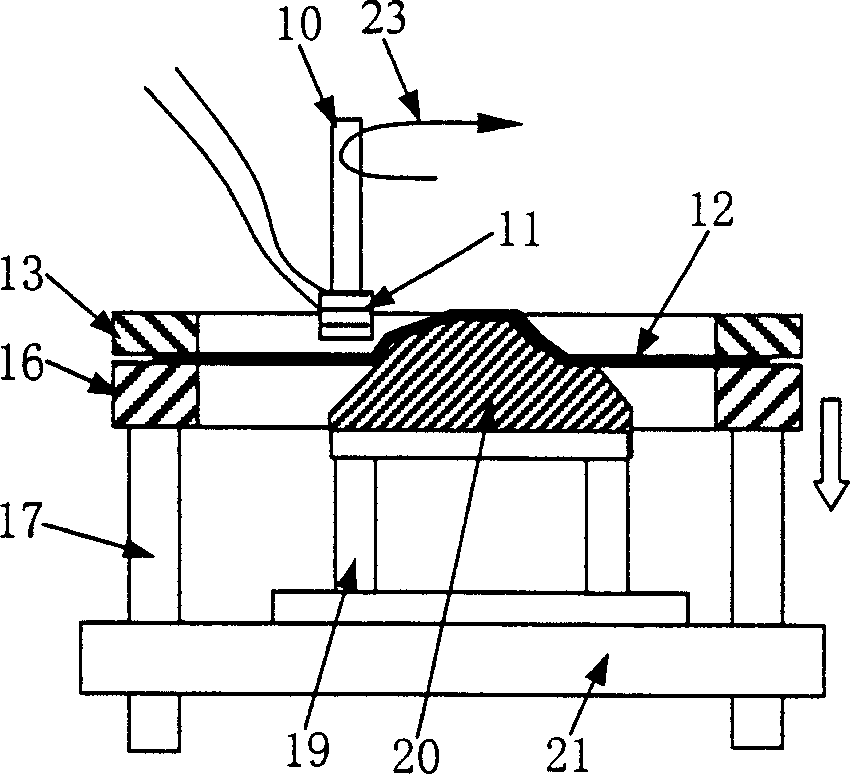

Electromagnetic inching forming method and its device for plate moving coil

InactiveCN1821910AGood repeatabilityEasy energy control and automated productionProgramme controlComputer controlEngineeringElectromagnetic pulse

This invention relates to an electromagnetic progressive shaping method for plate moving coils and a device, in which, said device includes a computer control system, an electromagnetic force generation system and a three-shaft digital control shaping system including a plate clamping elevating device, a supporting model frame and an electromagnetic shaping clamping rod, in which, the computer controls the coil to move downward along the contour of a model profile from the top according to the contour data of the model profile and the plate is formed partly relying on the magnetic force of coil till to the bottom of the model and finish the entire process.

Owner:HUAZHONG UNIV OF SCI & TECH

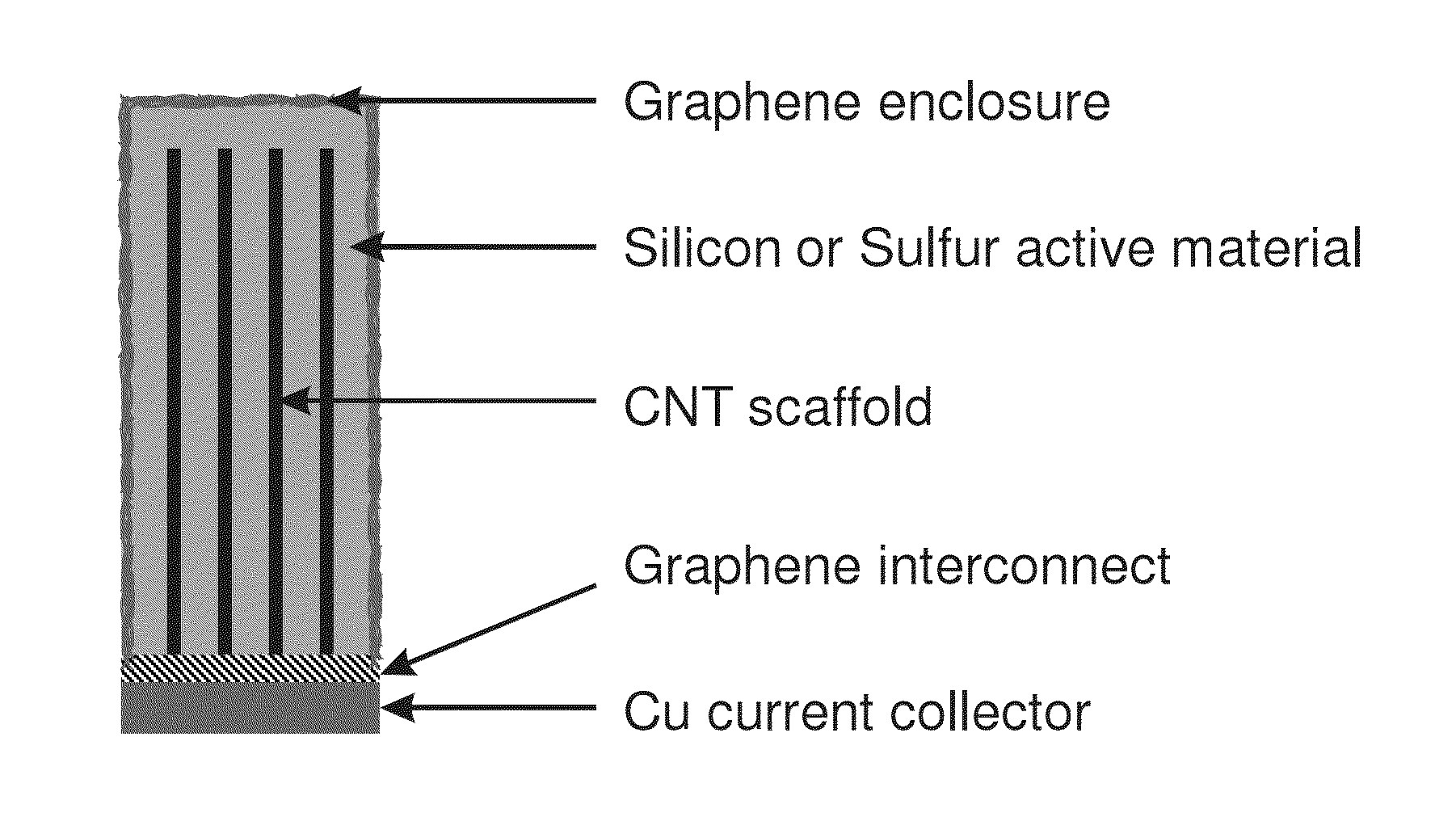

Carbon Nanotubes - Graphene Hybrid Structures for Separator Free Silicon - Sulfur Batteries

ActiveUS20150010788A1Improve power performanceImprove cycle lifeMaterial nanotechnologyFinal product manufactureMetallic lithiumDischarge rate

Provided herein are electrochemical systems and related methods of making and using electrochemical systems. Electrochemical systems of the invention implement novel cell geometries and composite carbon nanomaterials based design strategies useful for achieving enhanced electrical power source performance, particularly high specific energies, useful discharge rate capabilities and good cycle life. Electrochemical systems of the invention are versatile and include secondary lithium ion cells, such as silicon-sulfur lithium ion batteries, useful for a range of important applications including use in portable electronic devices. Electrochemical cells of the present invention also exhibit enhanced safety and stability relative to conventional state of the art lithium ion secondary batteries by using prelithiated active materials to eliminate the use of metallic lithium and incorporating carbon nanotube and / or graphene, composite electrode structures to manage residual stress and mechanical strain arising from expansion and contraction of active materials during charge and discharge.

Owner:CALIFORNIA INST OF TECH

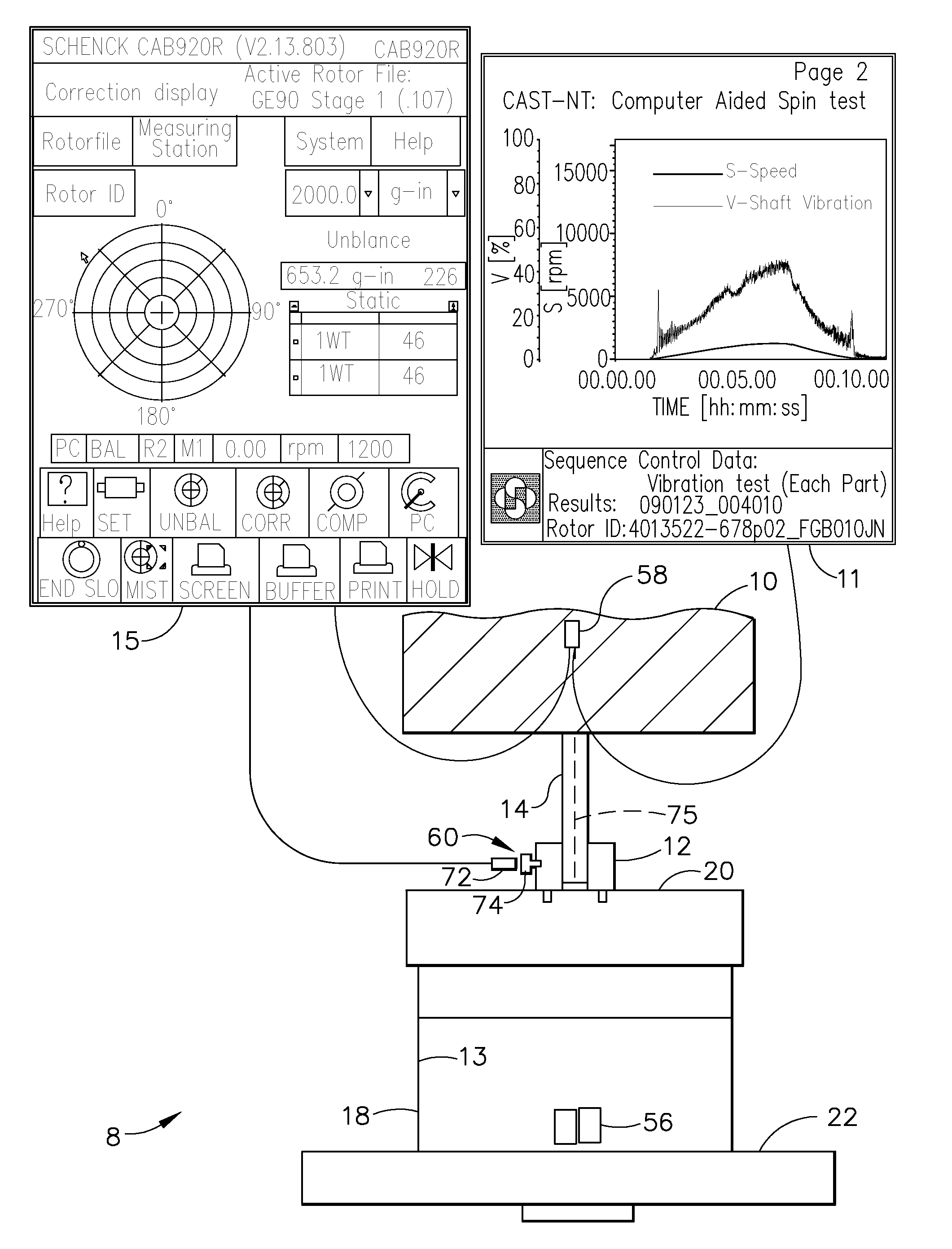

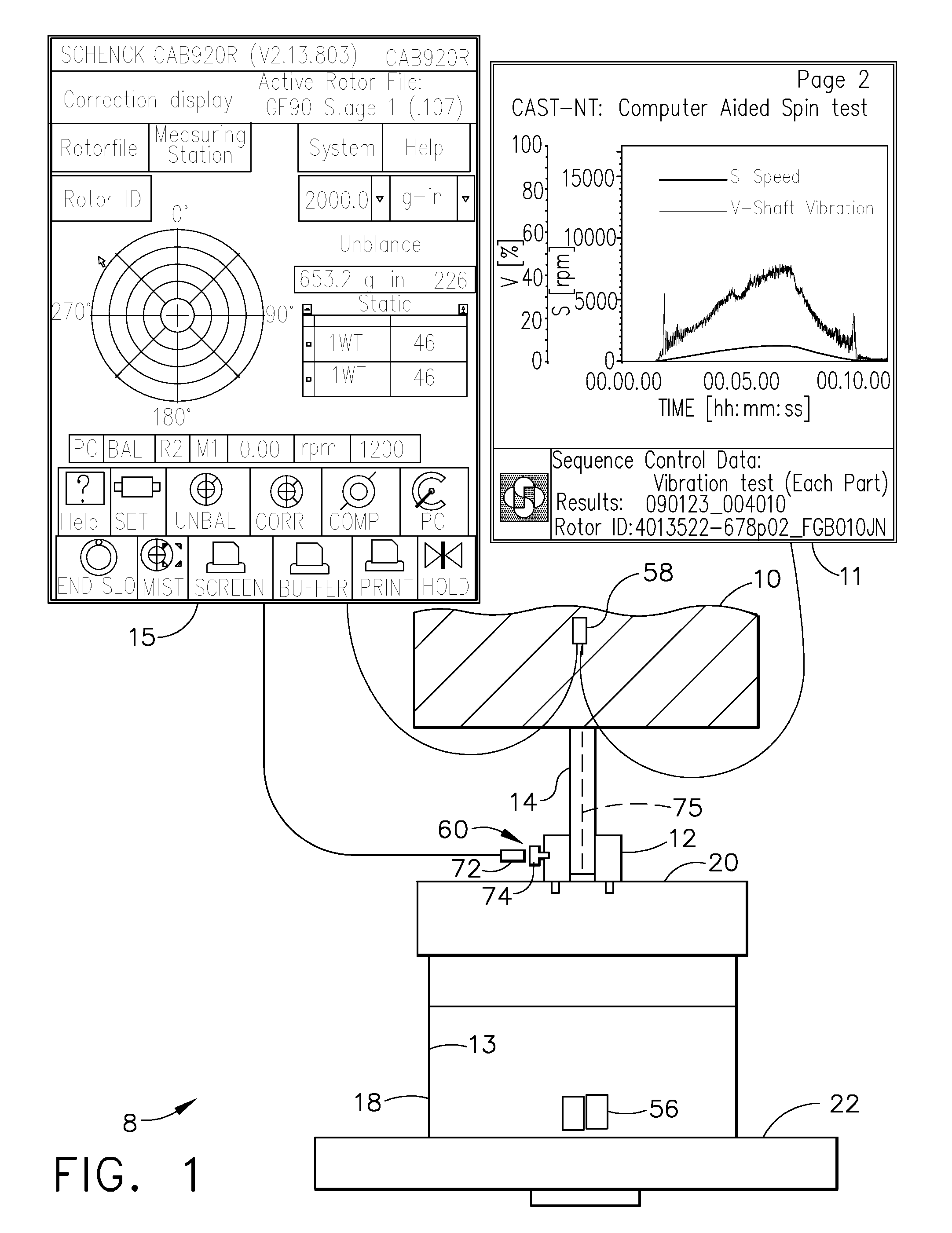

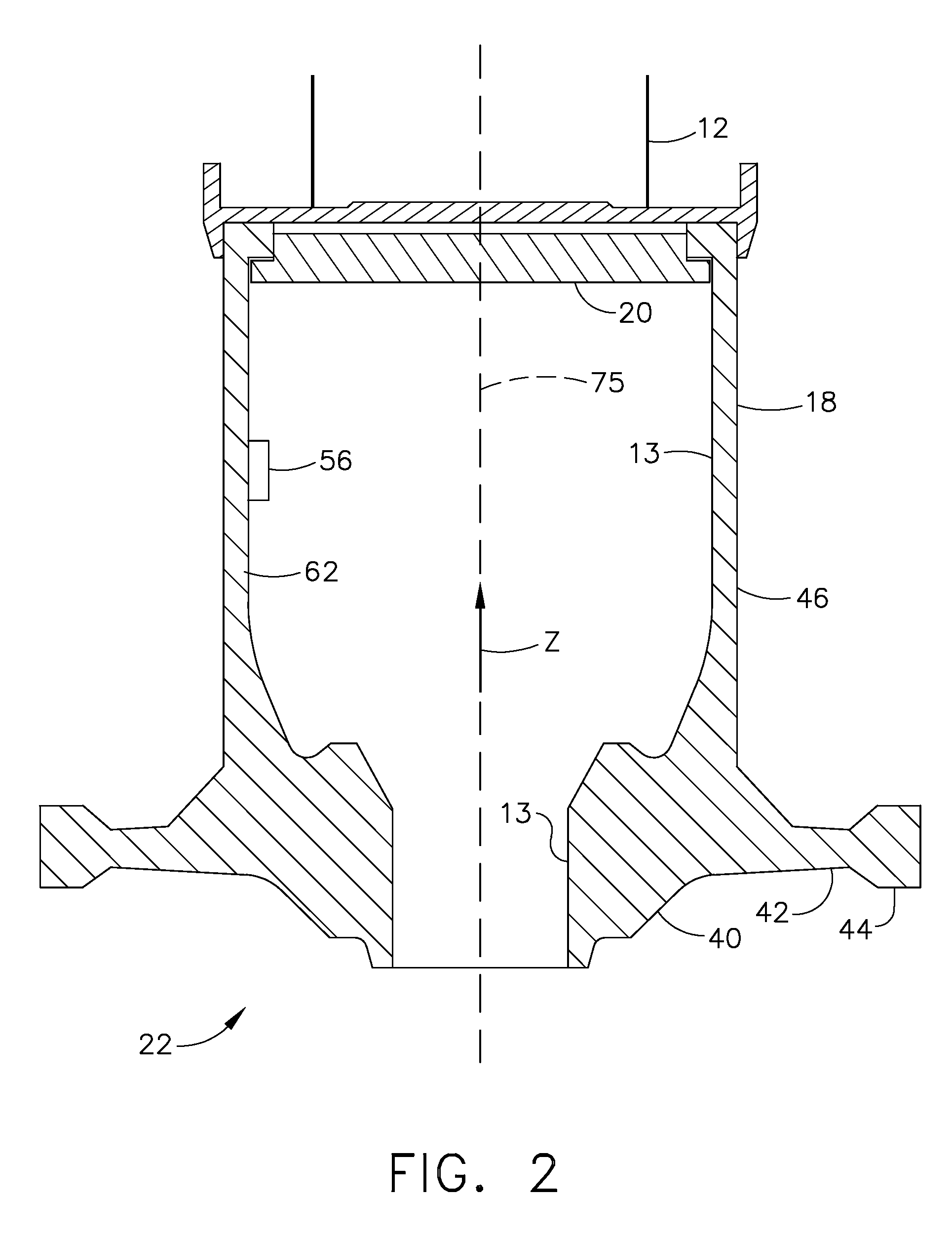

Method and apparatus for pre-spinning rotor forgings

ActiveUS20100212422A1Relieve forging induced residual stressAvoid excessive rotationForce measurementStatic/dynamic balance measurementHigh densityRotation velocity

A method and system for relieving forging induced residual stresses in a rotor forging balances a pre-spin machine with the forging mounted thereon at a first rotational speed and then pre-spins the forging with it mounted on the machine at a substantially greater second rotational speed. A one per rev sensor is used for determining a weight placement angle and a vibration sensor is used for determining an amount of weight to add to a spinning assembly including the forging during the balancing. High-density non-metallic balance weights adhesively attached on an inside surface of the forging or spinning assembly may be used. The rotational inertia of the spinning assembly may be checked during a spin up period by determining a rate of rotational acceleration vs. torque applied to the spinning assembly and used to stop the pre-spinning if it is to great.

Owner:GENERAL ELECTRIC CO

Manufacture method of large caliber high steel grade corrosion proof seamless steel tube in diameter phi 219.0-460.0mm

ActiveCN101417296AReduce adverse effectsImprove mechanical propertiesTemperature control deviceFurnace typesSuperficial massPetroleum

The invention provides a production method of a large caliber high steel-grade corrosion-resistant seamless steel tube with the diameter of phi 219.0-phi460.0mm, which comprises the steps of the techniques of: steel making, tube rolling, thermal treatment and processing of the steel tube, and the like, and produces the large caliber high steel-grade corrosion-resistant seamless steel tube with the diameter of phi 219.0-phi460.0mm. The method has the effects of solving the problem of extremely unfavorable influence of the harmful elements such as P, S, and the like on the corrosion resistance of a petroleum-special tube and obtaining a high-quality round billet, adopts the combination of phi 460 three-roller retained mandrel POF rolling mill with high-end thermal rolling control technique to obtain fine quality tube bodies with different sizes, and obtains pipeline tubes with eligible surface quality and combination property by reasonable thermal treatment technique and the control technique of the residual stress of the steel tube, which not only has high strength and excellent corrosion-resistant property but also has good toughness. The invention has the beneficial effects that the steel tube has good physical-chemical properties, high tube body size precision, and convenience for use as well as being beneficial for the safety of long-distance delivery ducts, and can be widely used for the acid oil-gas fields containing hydrogen sulfide.

Owner:TIANJIN STEEL PIPE MFG CO LTD

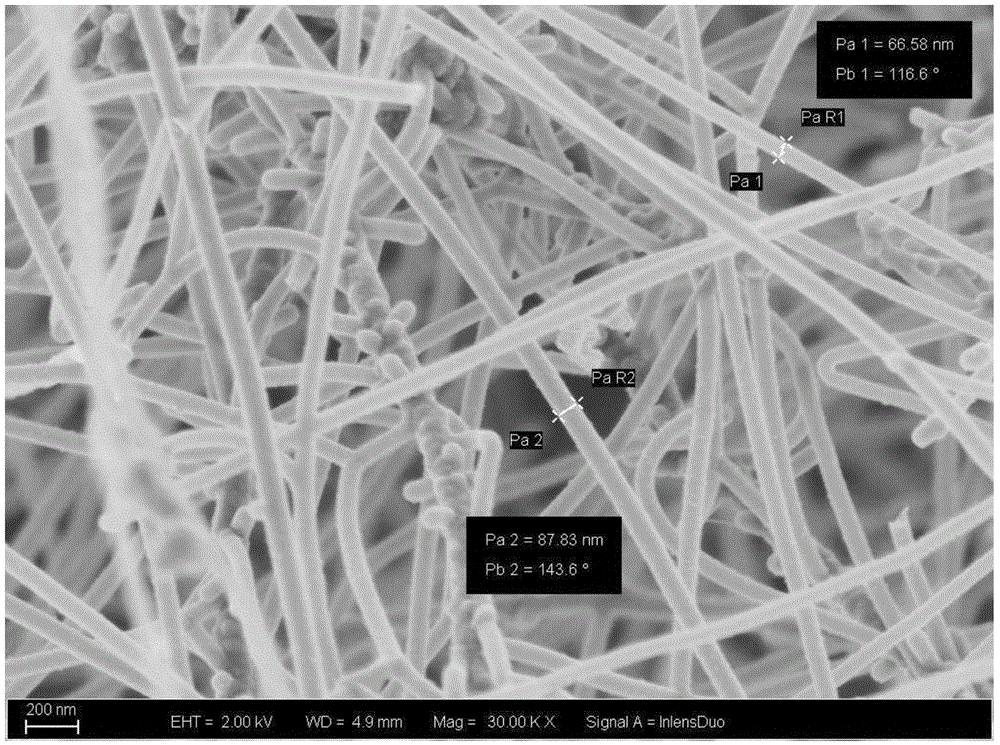

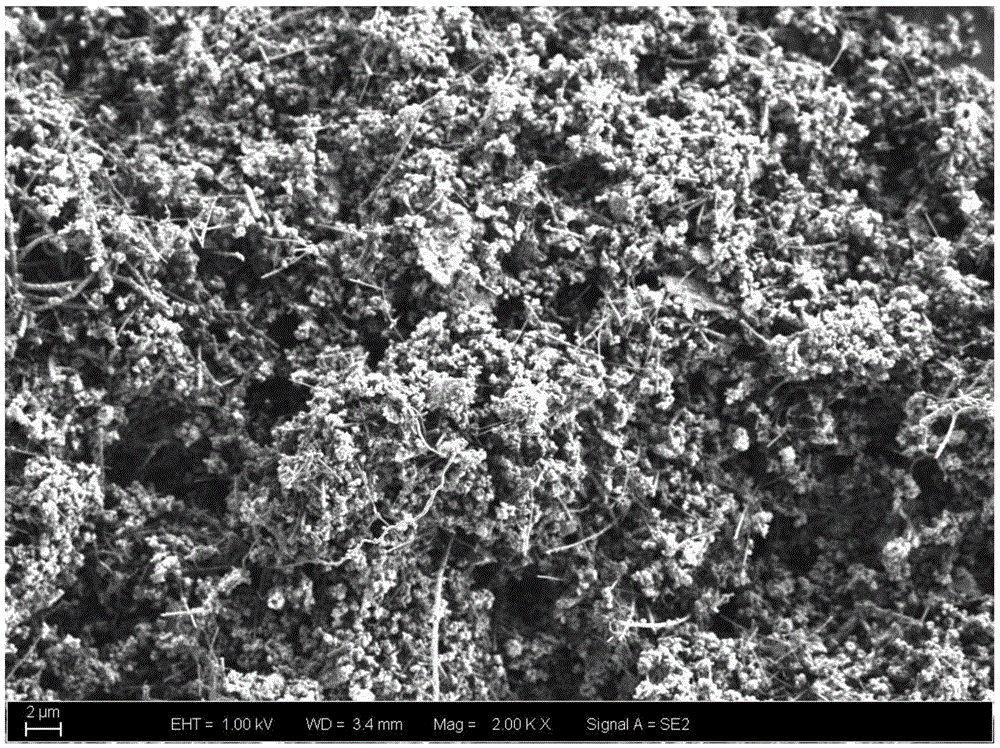

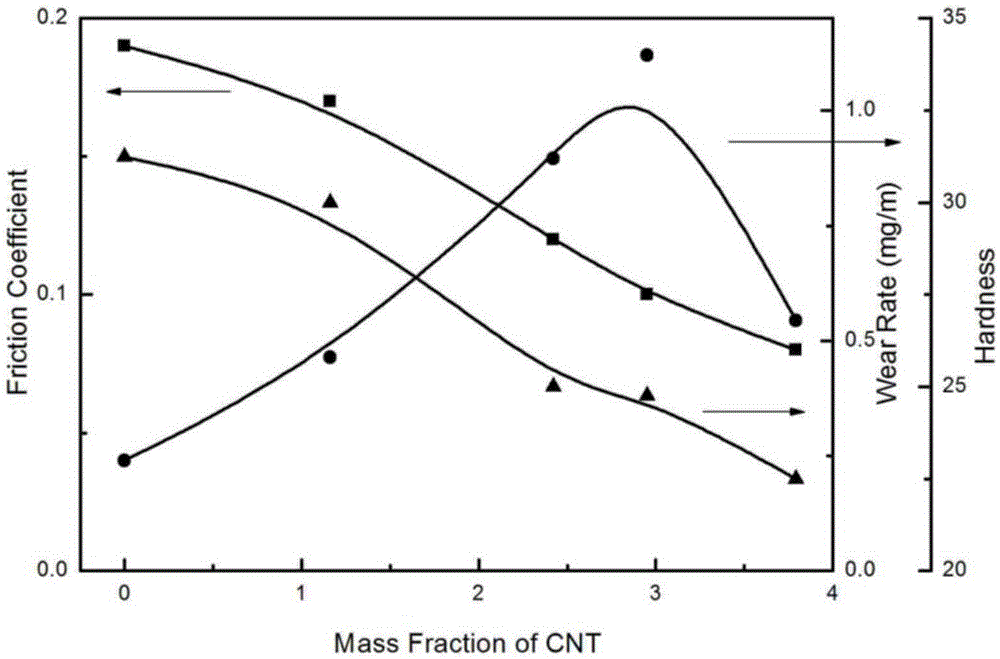

Nano-carbon-reinforced wear-resistant composite material

The invention belongs to the technical field of materials, and specifically relates to a nano-carbon-reinforced wear-resistant composite material. The nano-carbon-reinforced wear-resistant composite material comprises the following components in percentage by mass: 55-99% of metal powder, 0.1-35% of ceramic powder, and 0.01-15% of nano-carbon, wherein the metal powder is used as a composite material matrix; the ceramic powder is used as a wear-resistant filling material; and the nano-carbon comprises single-wall carbon nano-tubes, multi-wall carbon nano-tubes and other materials, and is mainly used for improving the heat-conducting performance, strength, toughness, wear resistance and other performances of the composite material. The wear-resistant composite material disclosed by the invention can keep a stable friction coefficient and a low wear rate under the conditions of a heavy load, a high speed, and long-time braking.

Owner:SUZHOU FIRST ELEMENT NANO TECH

Glass composition and paste composition suitable for a plasma display panel, and plasma display panel

InactiveUS20050242725A1Reduce residual stressAlternating current plasma display panelsCoatingsTransmittanceTransparent conducting film

A glass composition that is lead-free, and that, when used in a PDP, suppresses coloration of a dielectric layer, a transparent conductive film and a glass substrate, and suppresses reduction in transmittance of the dielectric layer. The glass composition is includes GeO2 0.1-20 wt %, B2O3 3-35 wt %, ZnO 4-45 wt %, Bi2O3 10-80 wt %, is free of PbO, and SiO2 content is not more than 0.5 wt %. It is preferable to further include in the glass composition Al2O3 up to 8 wt % and at least one selected from the group consisting of MgO, CaO, SrO, and BaO, up to 20 wt %.

Owner:PANASONIC CORP

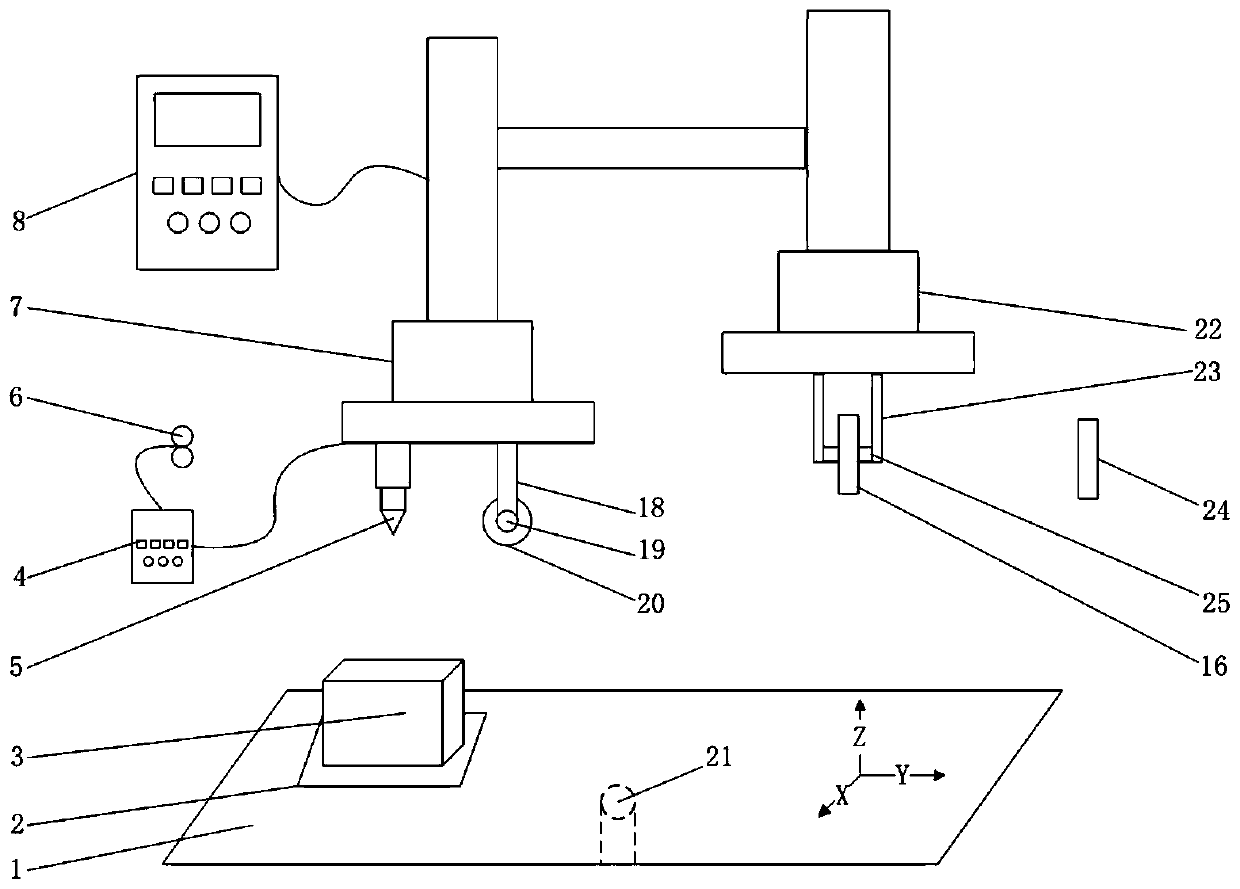

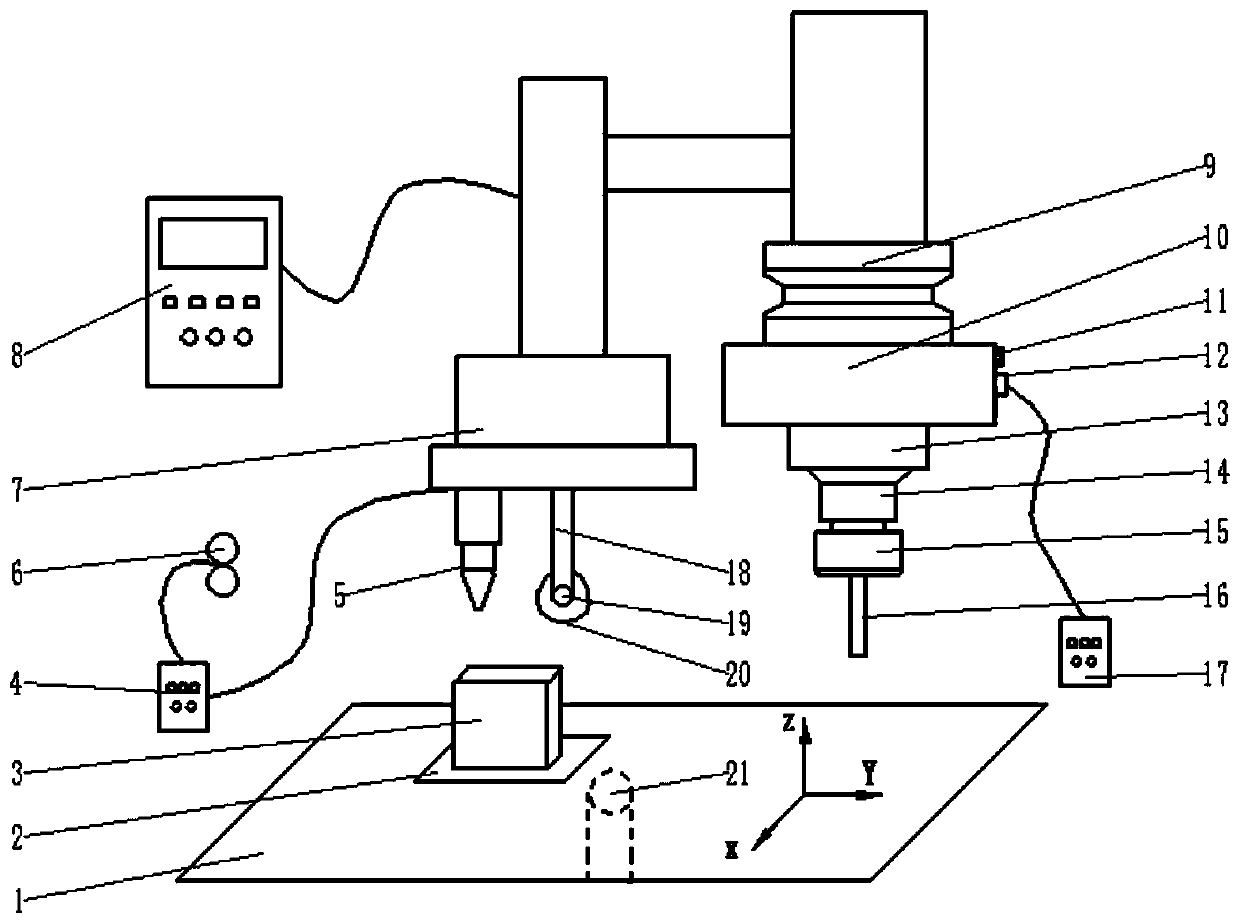

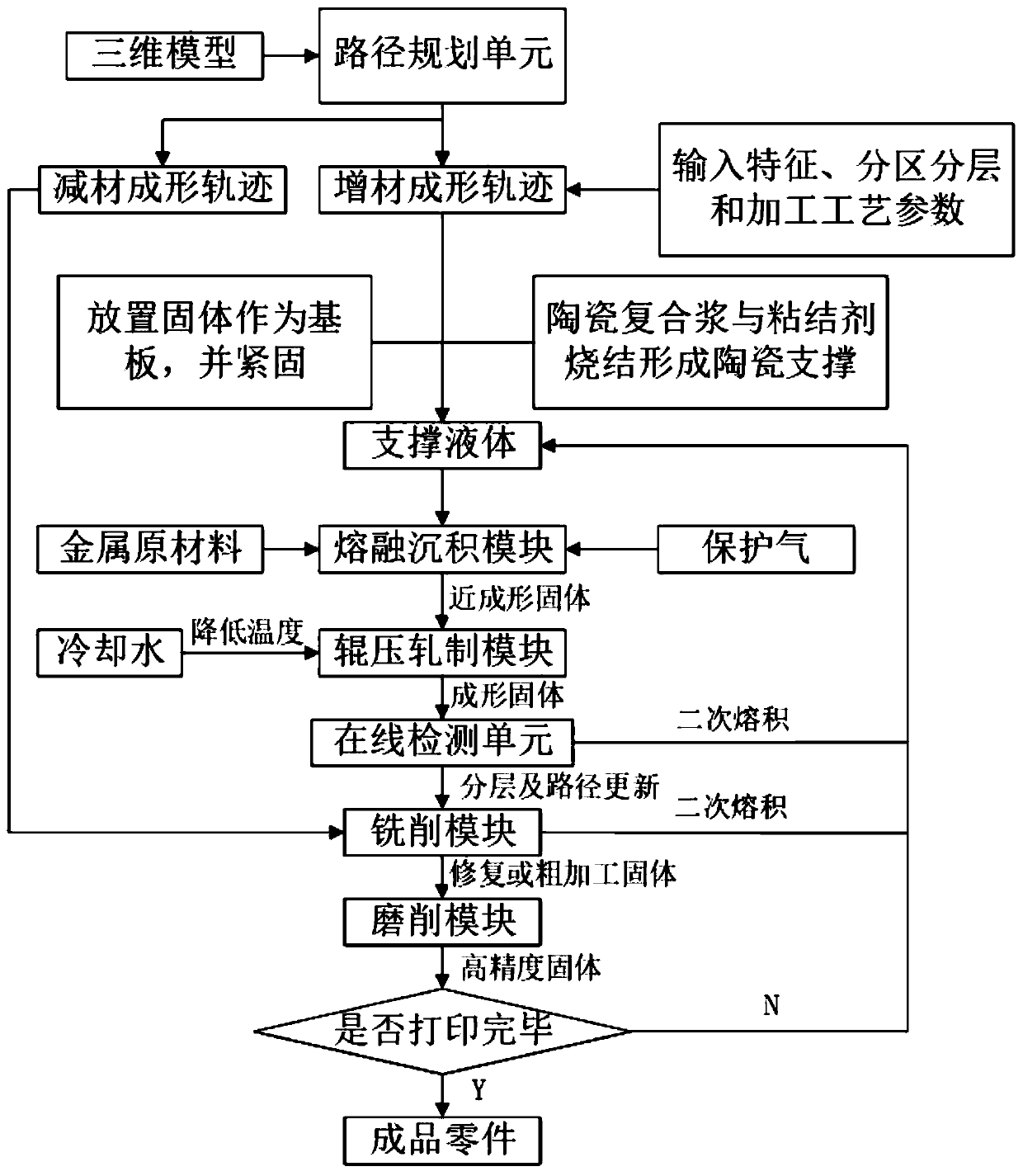

Metal part manufacturing system and method adopting micro-casting-forging and milling-grinding in-situ composite

InactiveCN110076566AImprove tissue mechanical propertiesImprove processing efficiencyAdditive manufacturing apparatusOther manufacturing equipments/toolsEngineeringManufacturing systems

The invention belongs to the field of metal part manufacturing, and particularly discloses a metal part manufacturing system and method adopting the micro-casting-forging and milling-grinding in-situcomposite. The system involves a micro-casting-forging module, a milling module, a five-axis linkage workbench and a control device, wherein the micro-casting-forging module is connected with the milling module and comprises a fusion deposition sub-module and a roller-pressing rolling sub-module, the five-axis linkage workbench is positioned below the micro-casting-forging module and the milling module, and is used for containing metal parts to be formed, and the control device is connected with the fusion deposition sub-module, the roller-pressing rolling sub-module, the milling module and the five-axis linkage workbench. According to the system and method, micro-casting-forging and a milling process are composited to process and manufacture the metal parts, so that the problems that whenthe metal parts are made through the additive manufacturing, the structure is not uniform, the deformation is serious, the residual stress is large, the structure performance is poor, and the surfacequality is poor are solved, and the system and method is especially suitable for processing a high-performance complicated special-shaped element.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com