Patents

Literature

115 results about "Piezoelectric mems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piezoelectric MEMS microphone

ActiveUS20150350792A1Piezoelectric/electrostrictive microphonesMicrophonesTransducerPiezoelectric mems

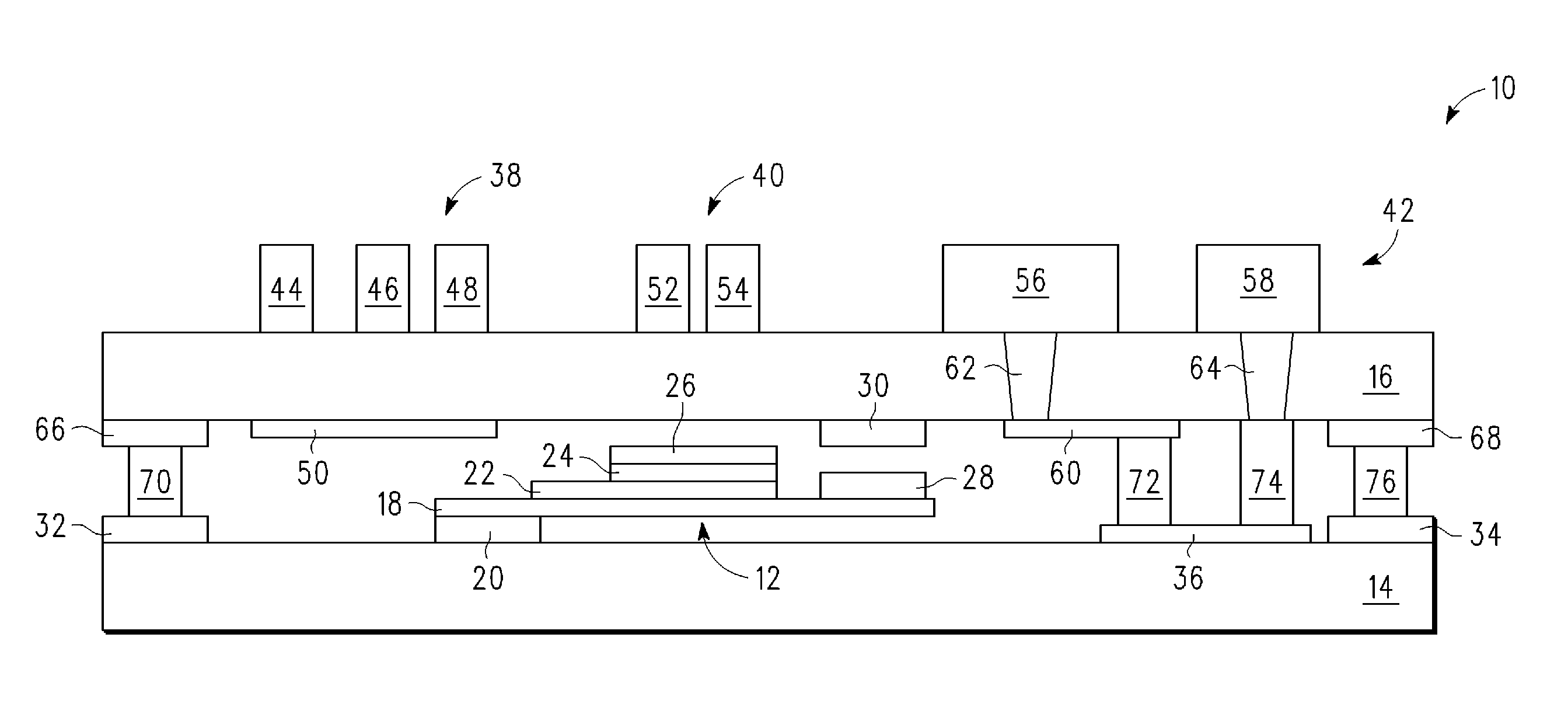

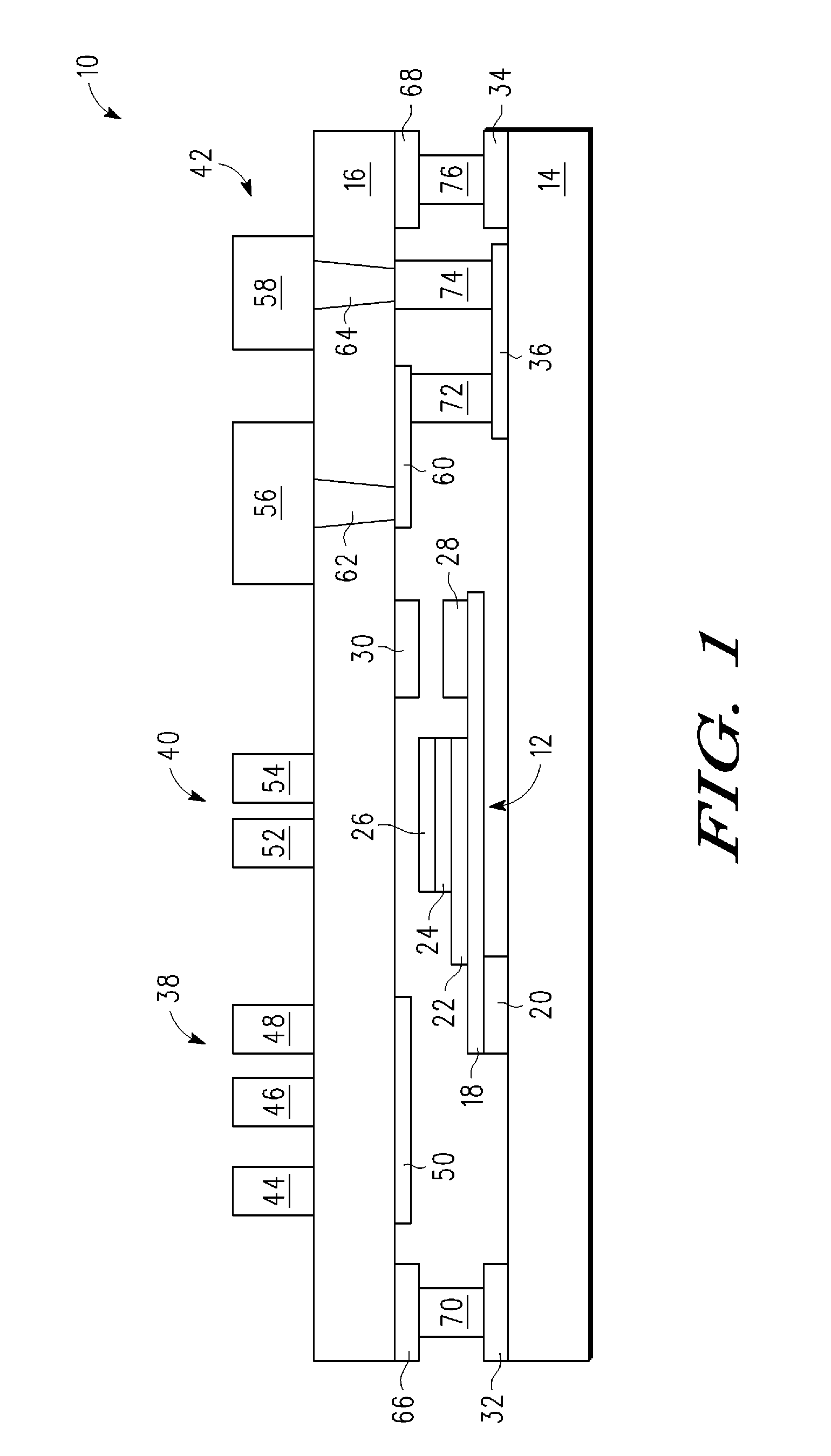

A microphone including a casing having a front wall, a back wall, and a side wall joining the front wall to the back wall, a transducer mounted to the front wall, the transducer including a substrate and a transducing element, the transducing element having a transducer acoustic compliance dependent on the transducing element dimensions, a back cavity cooperatively defined between the back wall, the side wall, and the transducer, the back cavity having a back cavity acoustic compliance. The transducing element is dimensioned such that the transducing element length matches a predetermined resonant frequency and the transducing element width, thickness, and elasticity produces a transducer acoustic compliance within a given range of the back cavity acoustic compliance.

Owner:RGT UNIV OF MICHIGAN +1

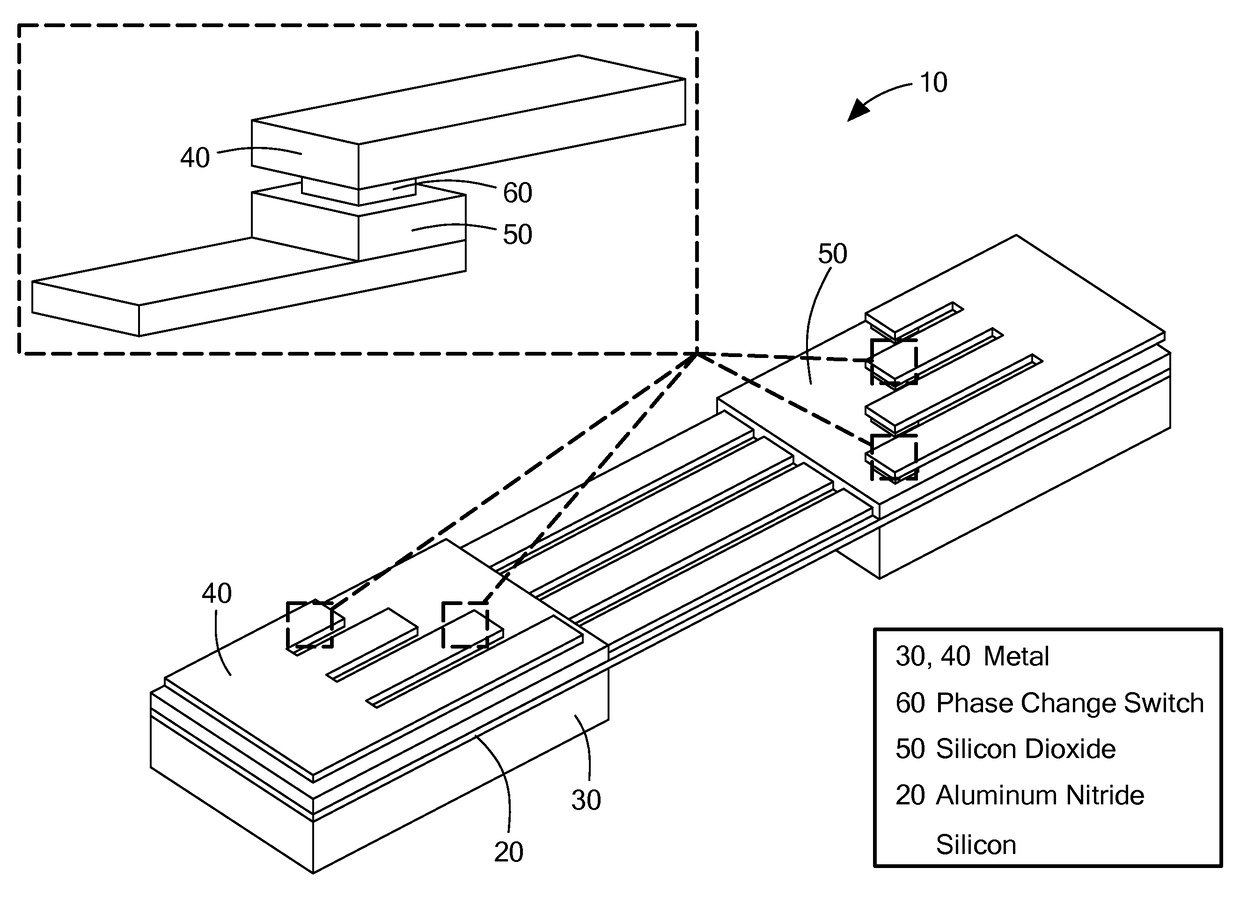

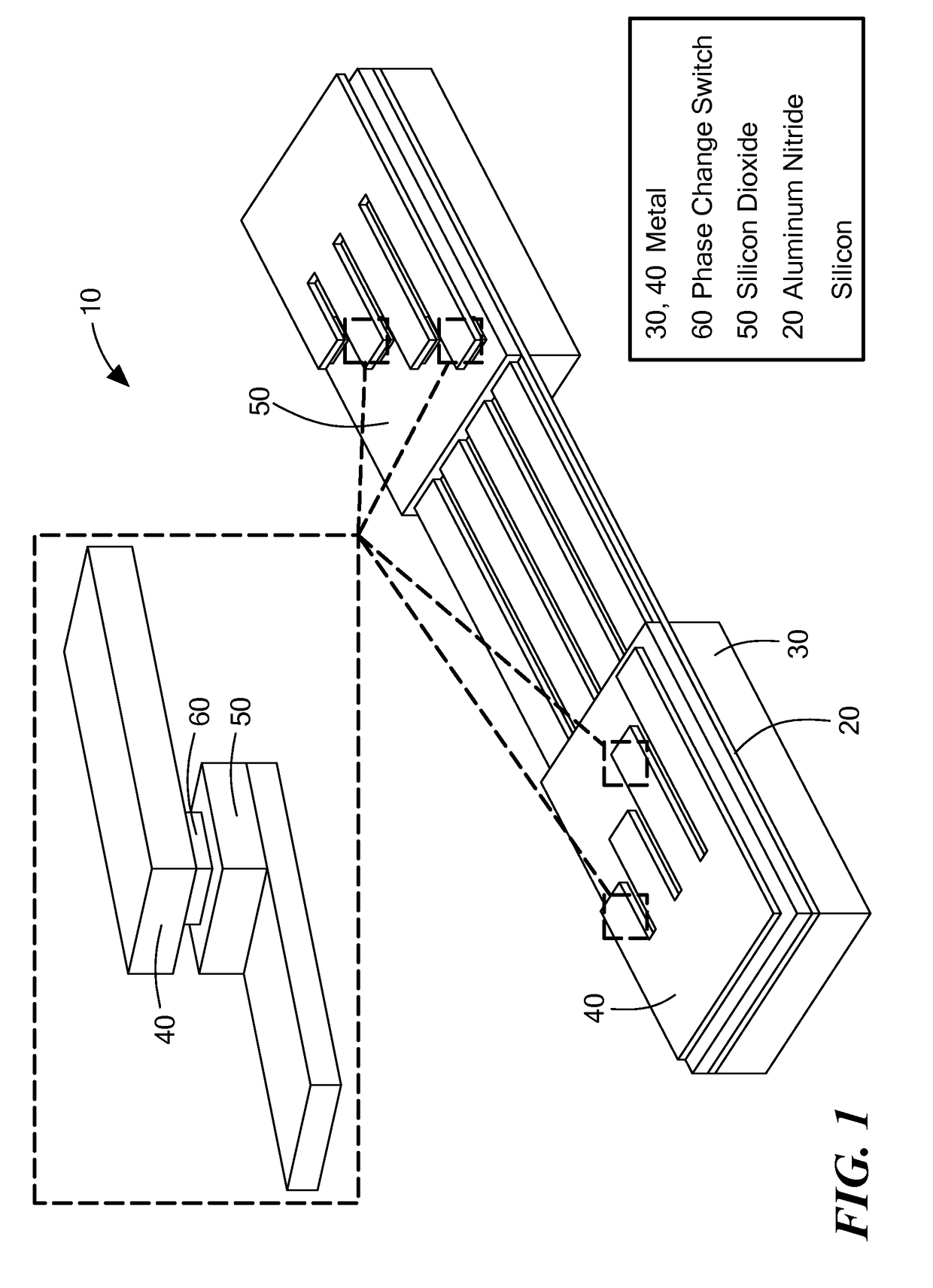

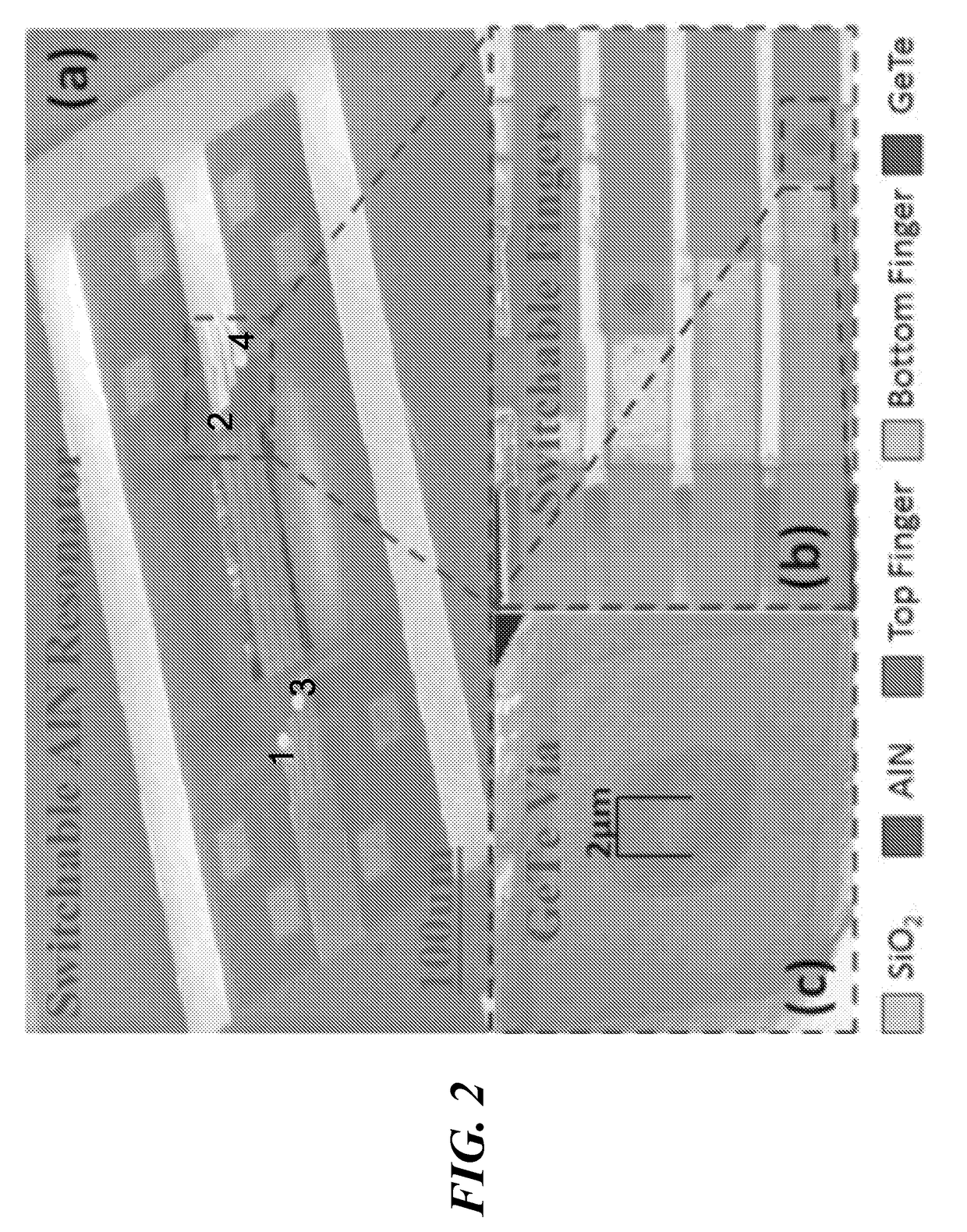

Piezoelectric MEMS Resonator with Integrated Phase Change Material Switches

ActiveUS20170187347A1Shorten the counting processReduce development costsImpedence networksPiezoelectric/electrostrictive device material selectionPiezoelectric memsFilter system

A monolithic integration of phase change material (PCM) switches with a MEMS resonator is provided to implement switching and reconfiguration functionalities. MEMS resonator includes a piezoelectric material to control terminal connections to the electrodes. The PCM is operable between an ON state and an OFF state by application of heat, which causes the phase change material to change from an amorphous state to a crystalline state or from a crystalline state to an amorphous state, the amorphous state and the crystalline state each associated with one of the ON state and the OFF state. A method of fabricating the MEMS resonator with phase change material is provided. A reconfigurable filter system using the MEMS resonators is also provided.

Owner:NORTHEASTERN UNIV

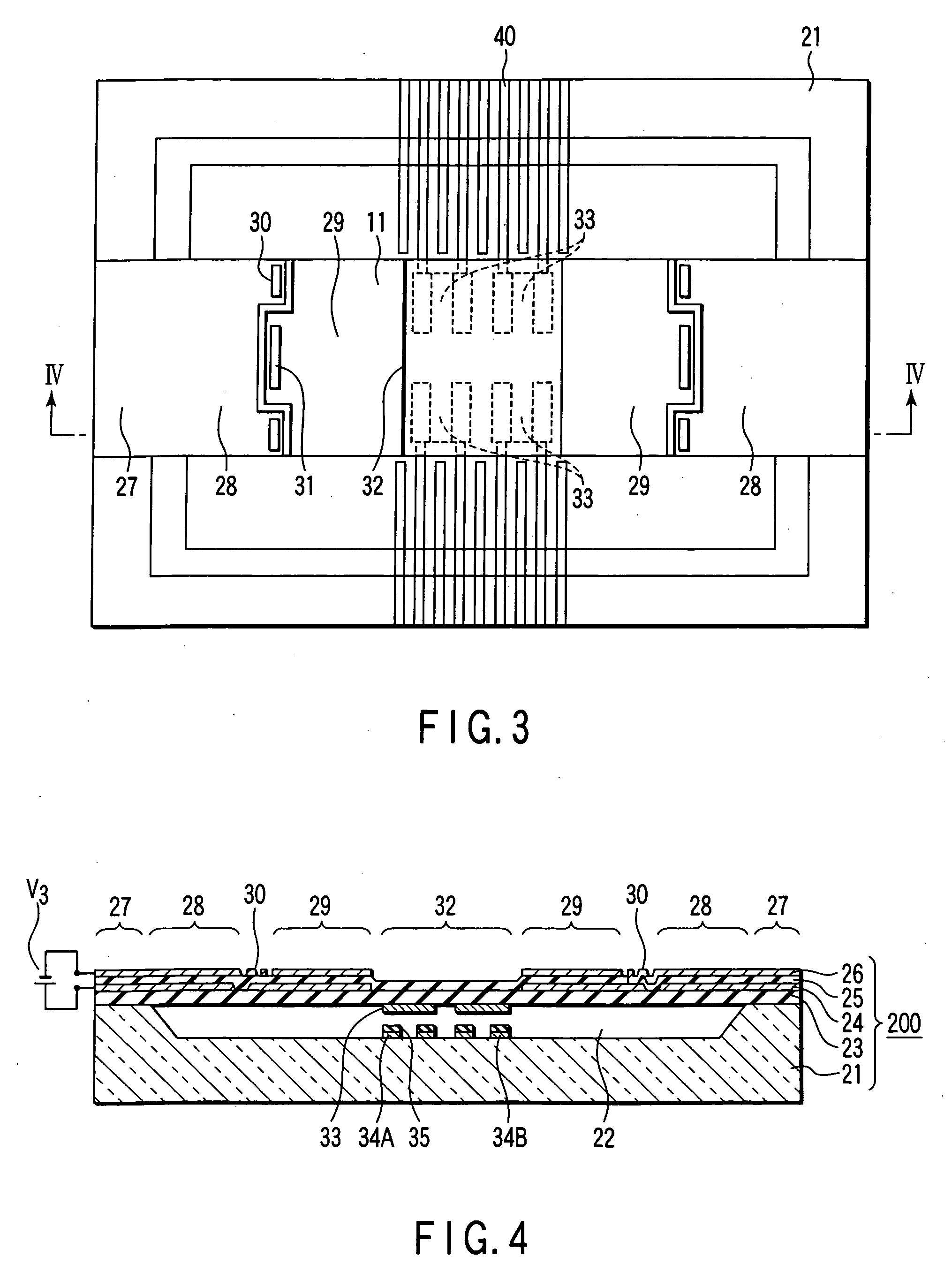

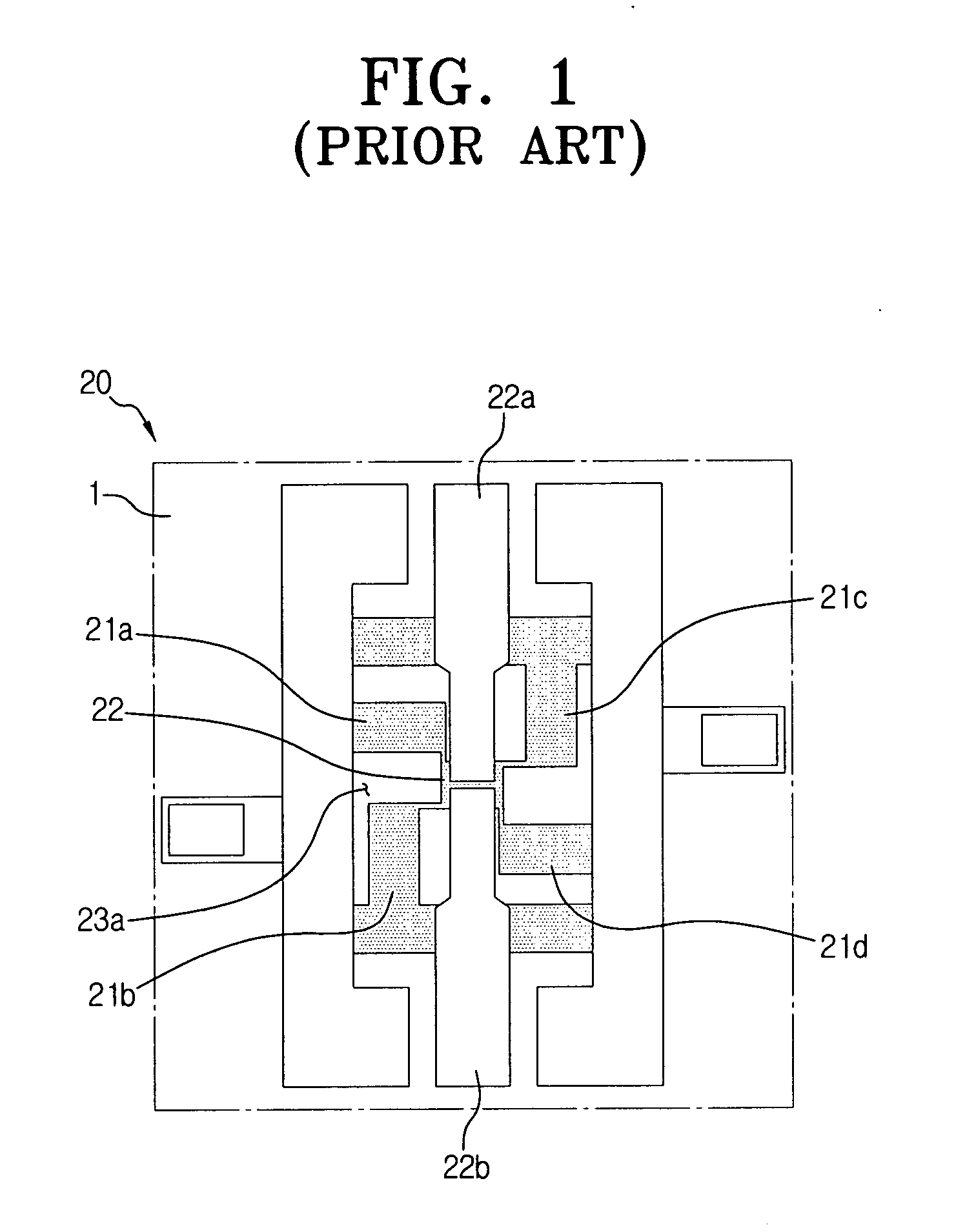

Piezoelectric MEMS element and tunable filter equipped with the piezoelectric MEMS element

InactiveUS20060067840A1Multiple-port networksPiezoelectric/electrostriction/magnetostriction machinesElectricityCapacitance

In a MEMS type variable capacity having a piezoelectric driving mechanism, a movable head having movable electrodes are arranged thereon, stationary electrodes is positioned to face the movable electrodes, and a piezoelectric driving beam structure is joined to the movable head and have one end fixed to the substrate. The movable electrode and the stationary electrode form a variable capacity. In the variable capacity, the distance and capacitance between the movable electrode and the stationary electrode of the variable capacity can be maintained constant so as to realize a reproducibility and a reliable controllability.

Owner:KK TOSHIBA

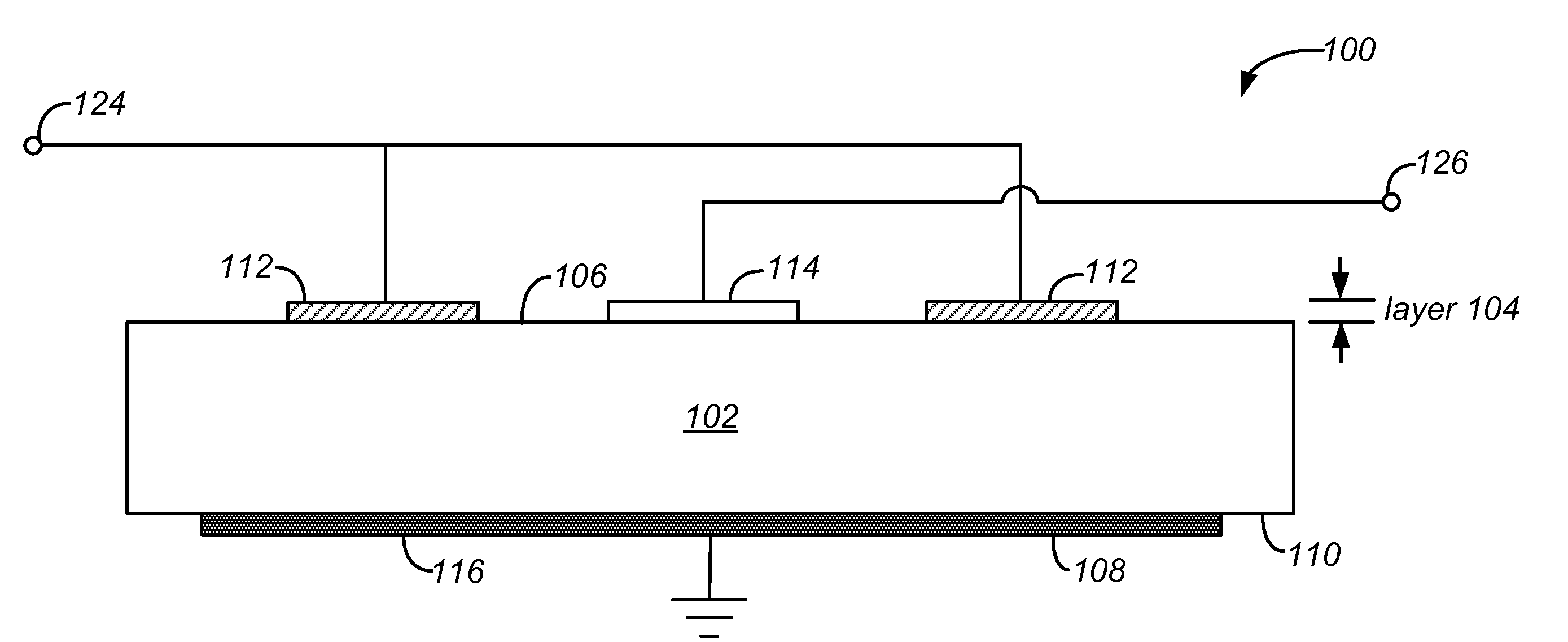

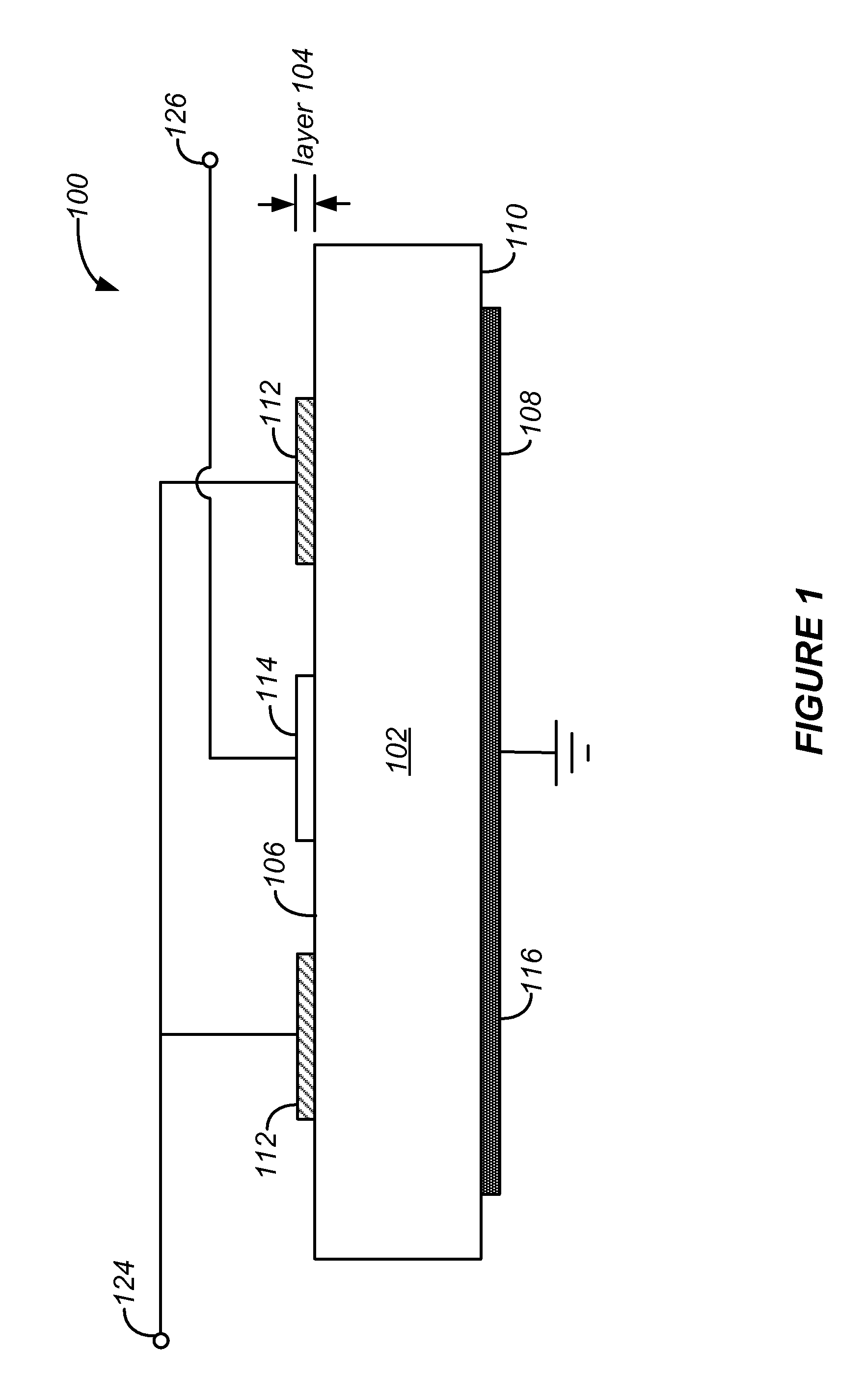

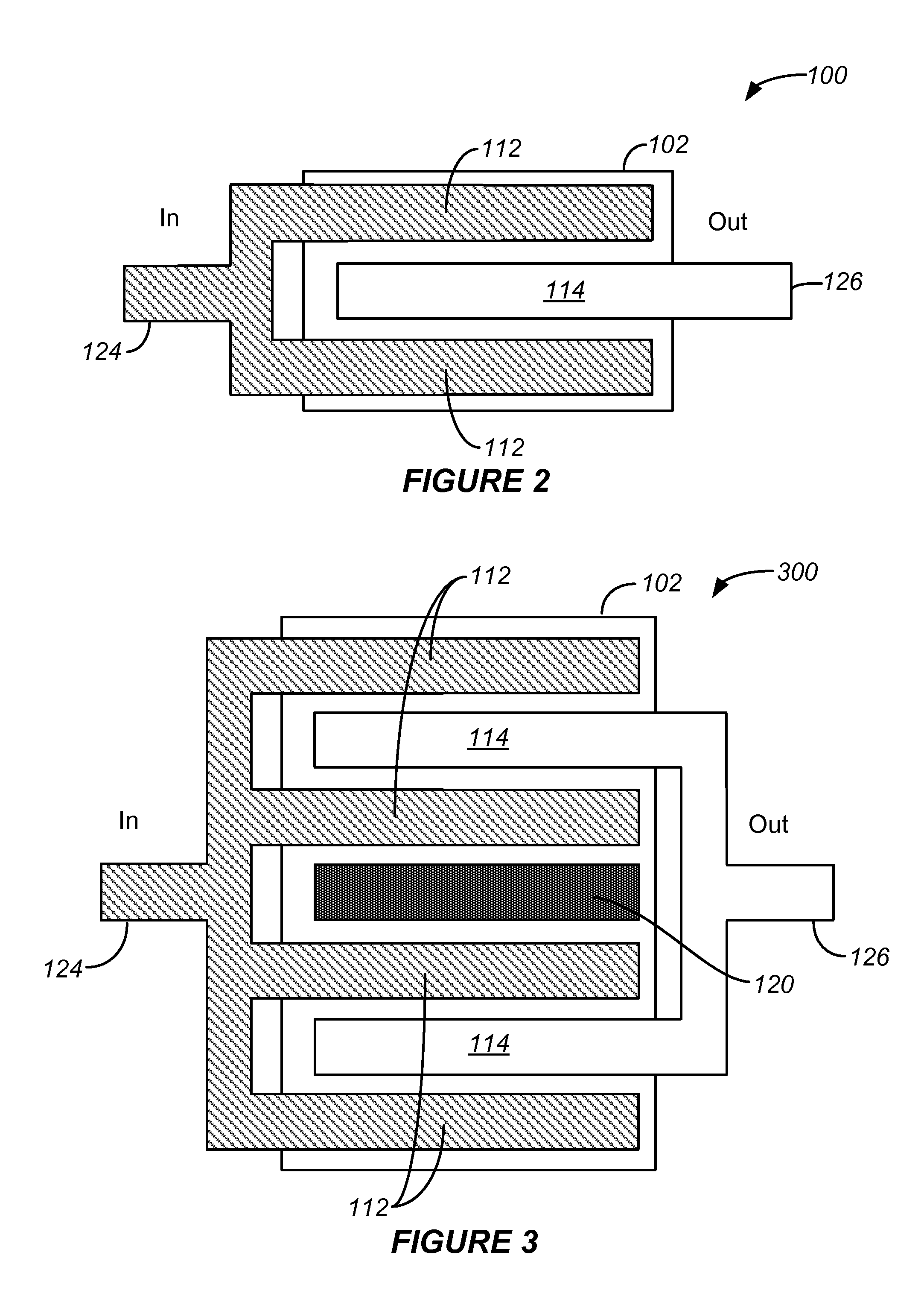

Piezoelectric MEMS transformer

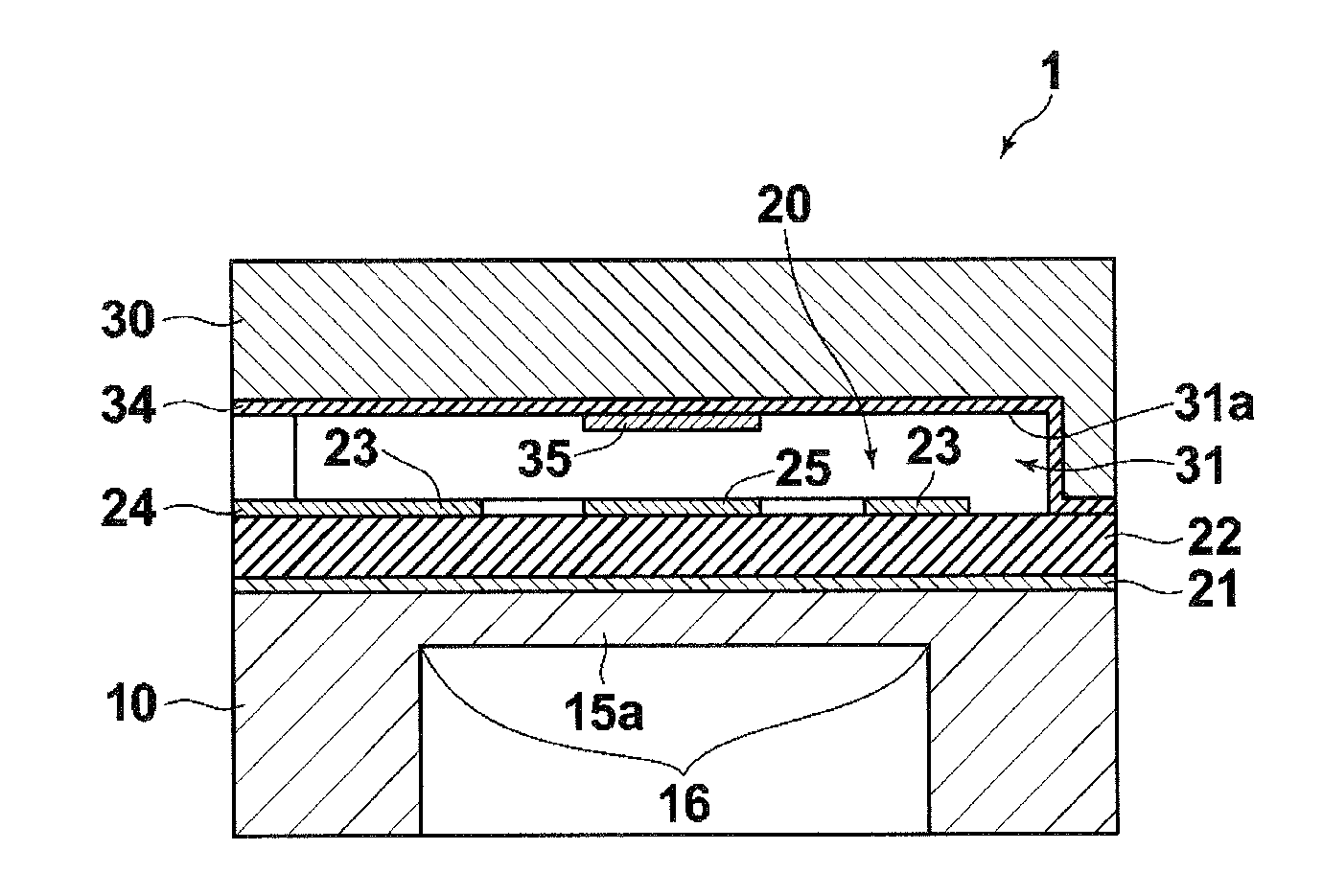

InactiveUS20130134838A1Improved coupling efficiencyImprove energy conversionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric memsEngineering

This disclosure provides implementations of electromechanical systems piezoelectric resonator transformers, devices, apparatus, systems, and related processes. In one aspect, a transformer includes a piezoelectric layer; a first conductive layer arranged over a first surface of the piezoelectric layer including a first set of electrodes and a second set of electrodes interdigitated with the first set. The transformer includes a second conductive layer arranged over a second surface including at least a third set of electrodes. In some implementations, the transformer includes a first port capable of receiving an input signal and to which the first set of electrodes are coupled, and a second port capable of being coupled to a load and of outputting an output signal, the second set of electrodes being coupled to the second port. Generally, a ratio of the number of electrodes of the second set to the first set characterizes a transformation ratio.

Owner:SNAPTRACK

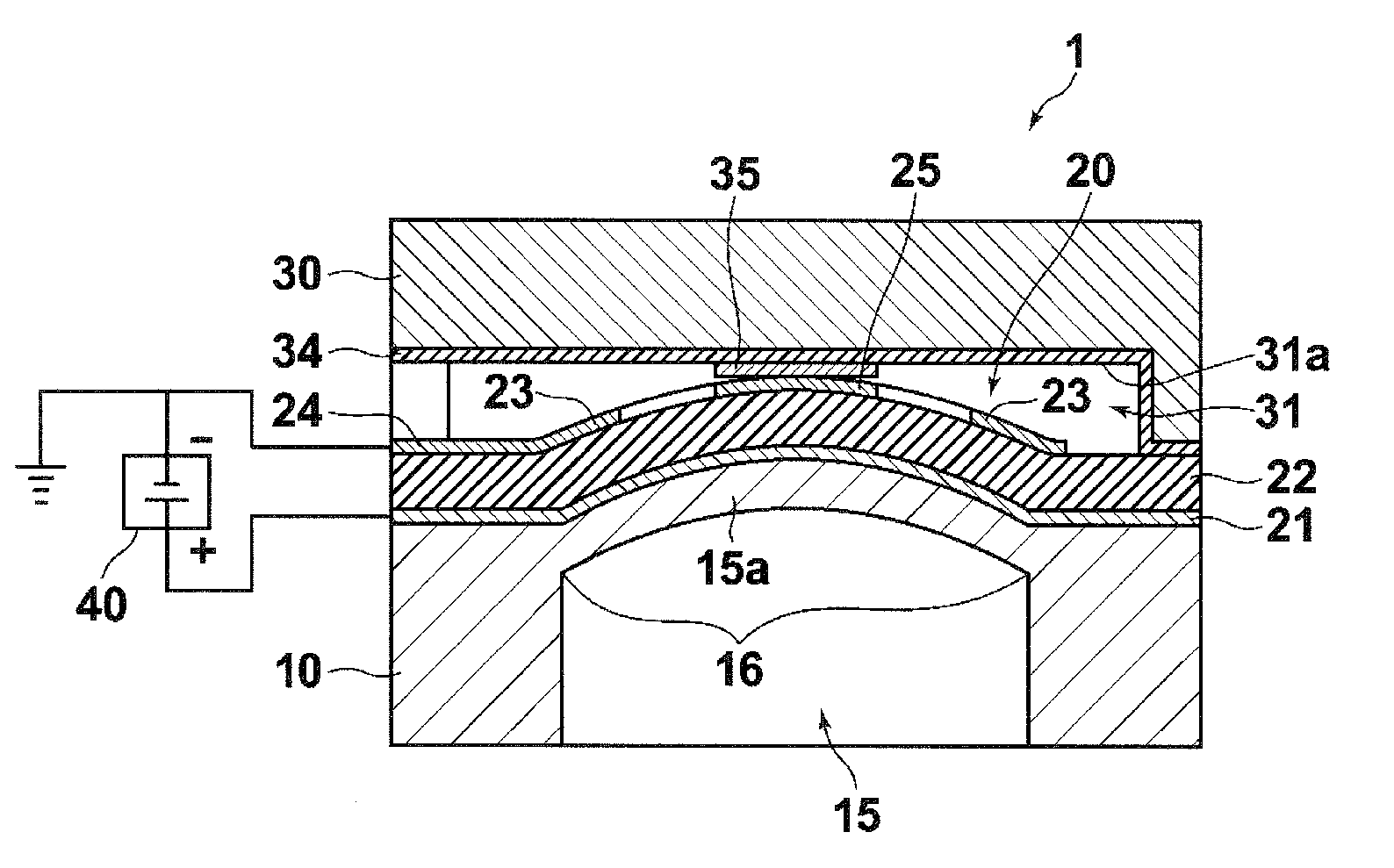

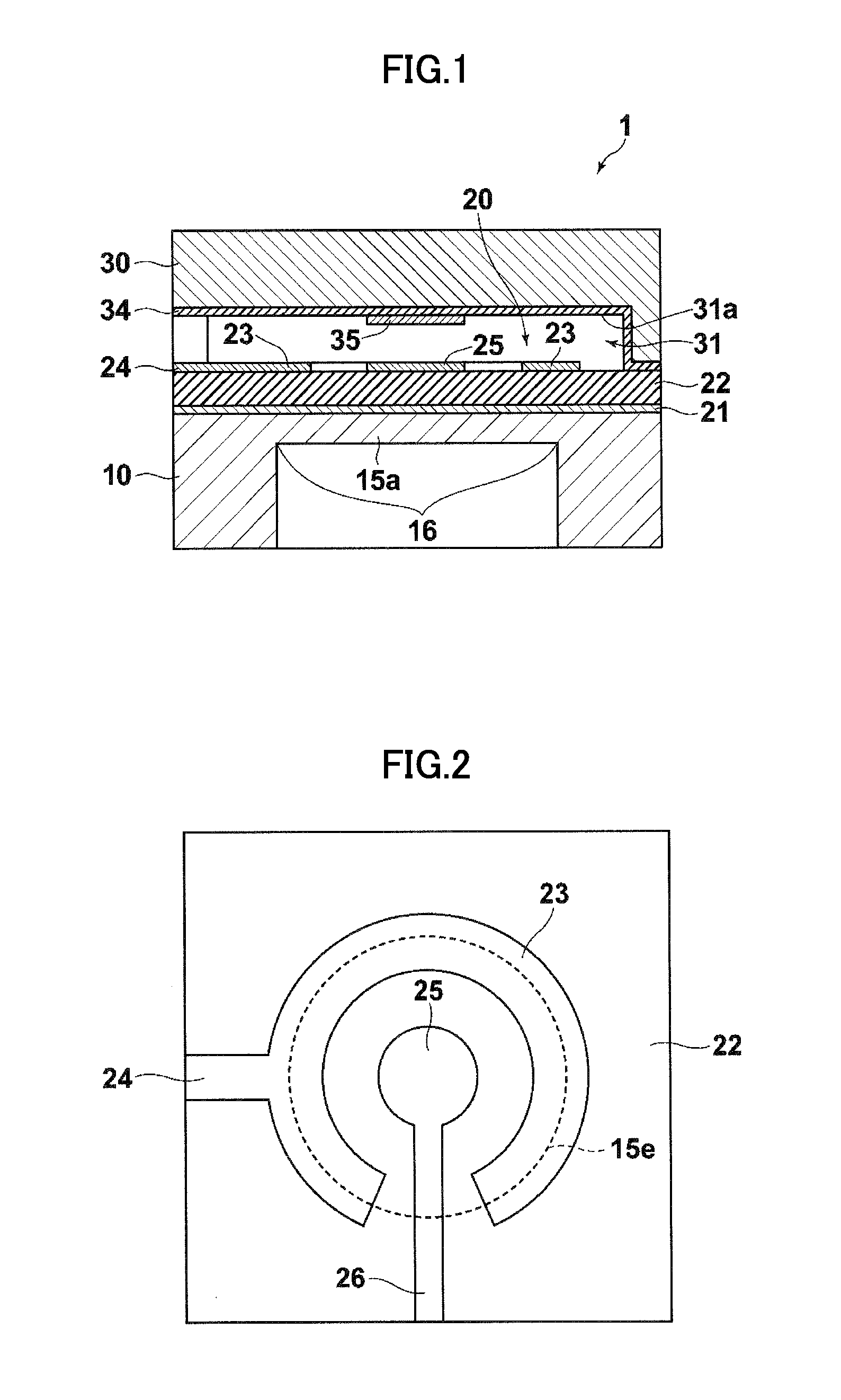

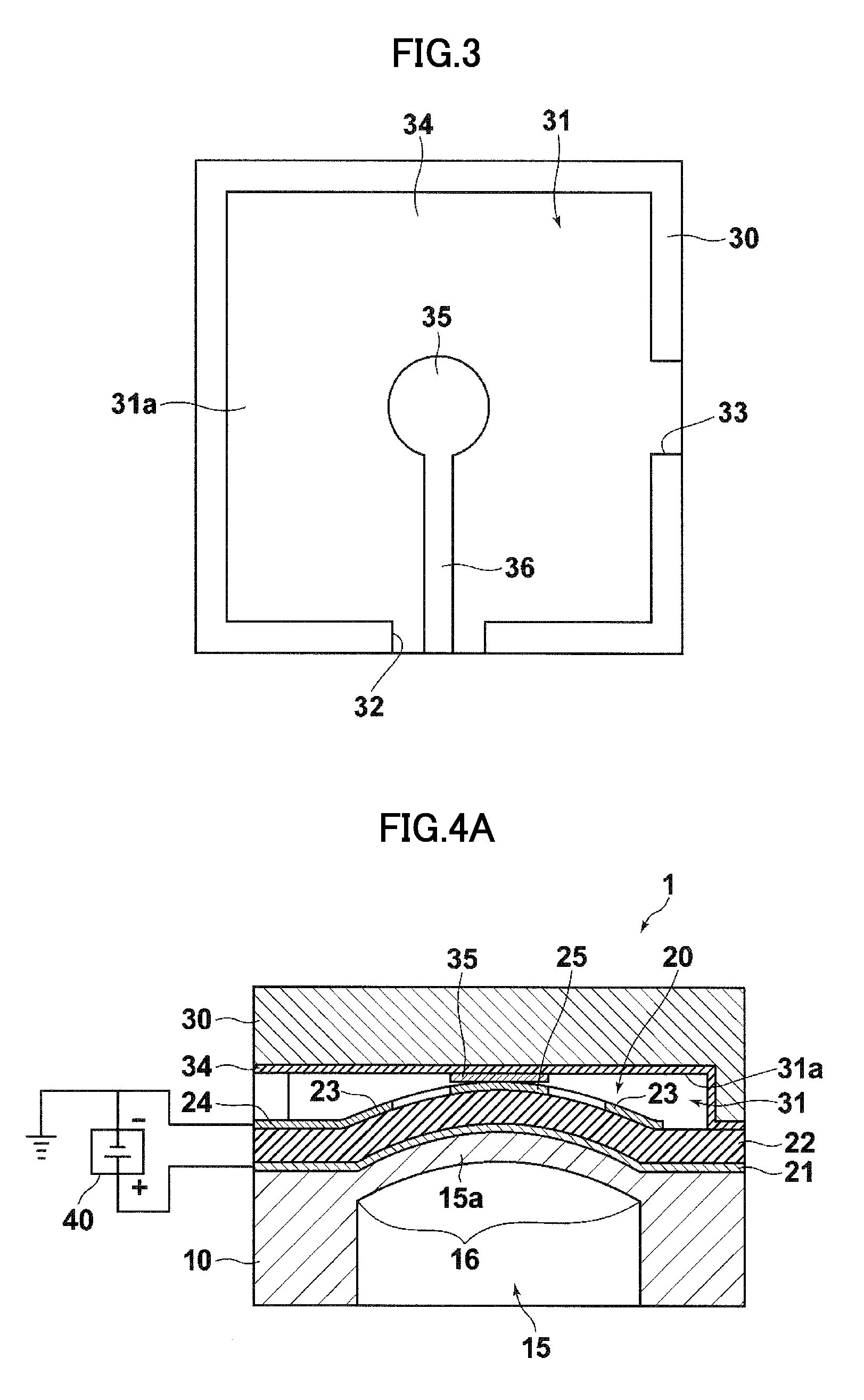

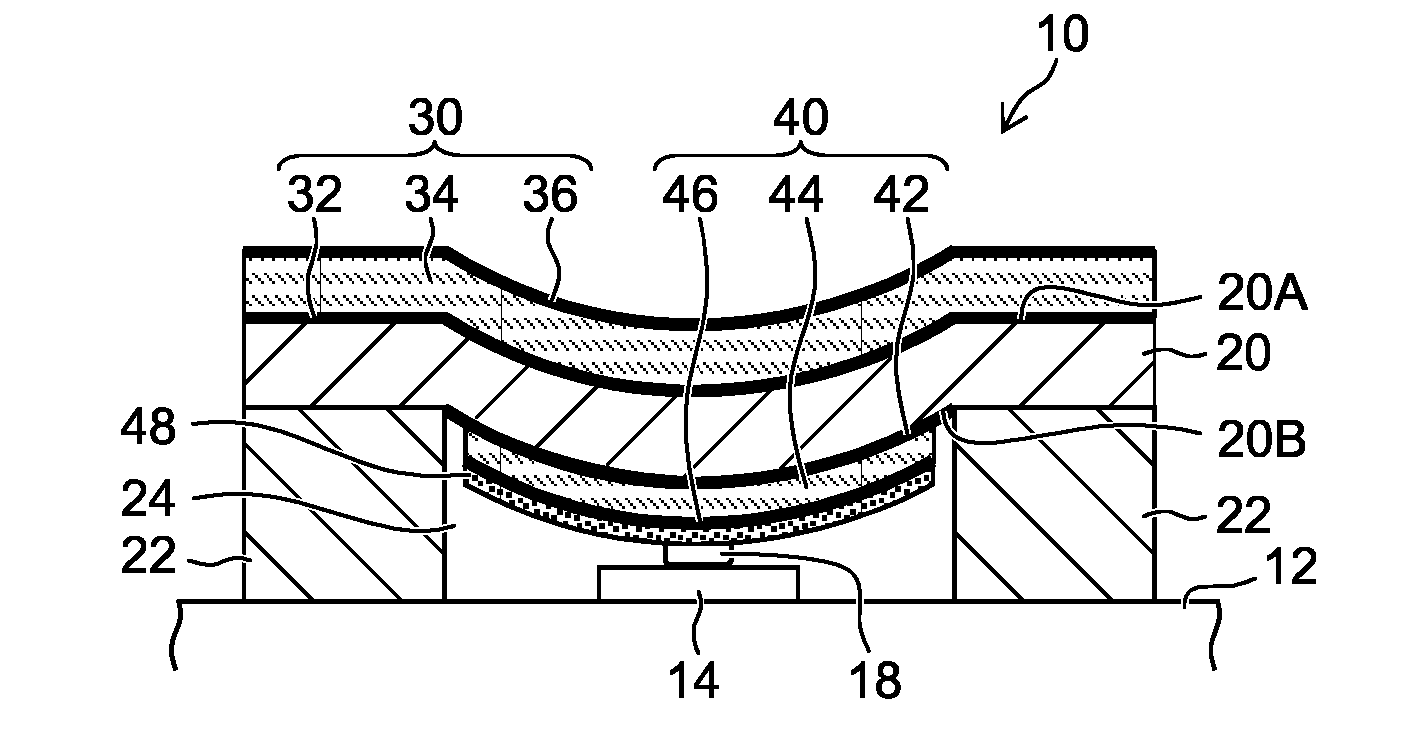

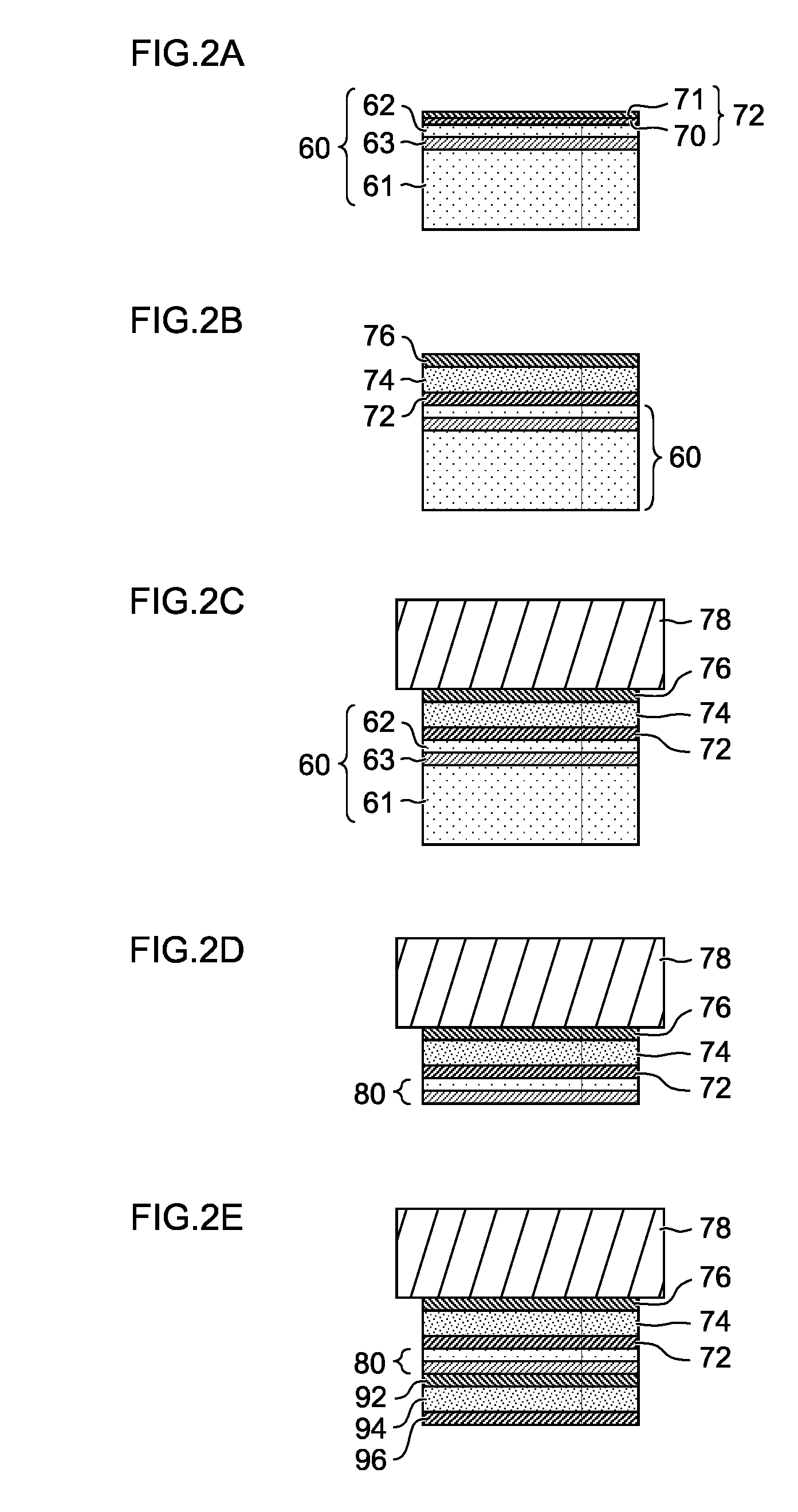

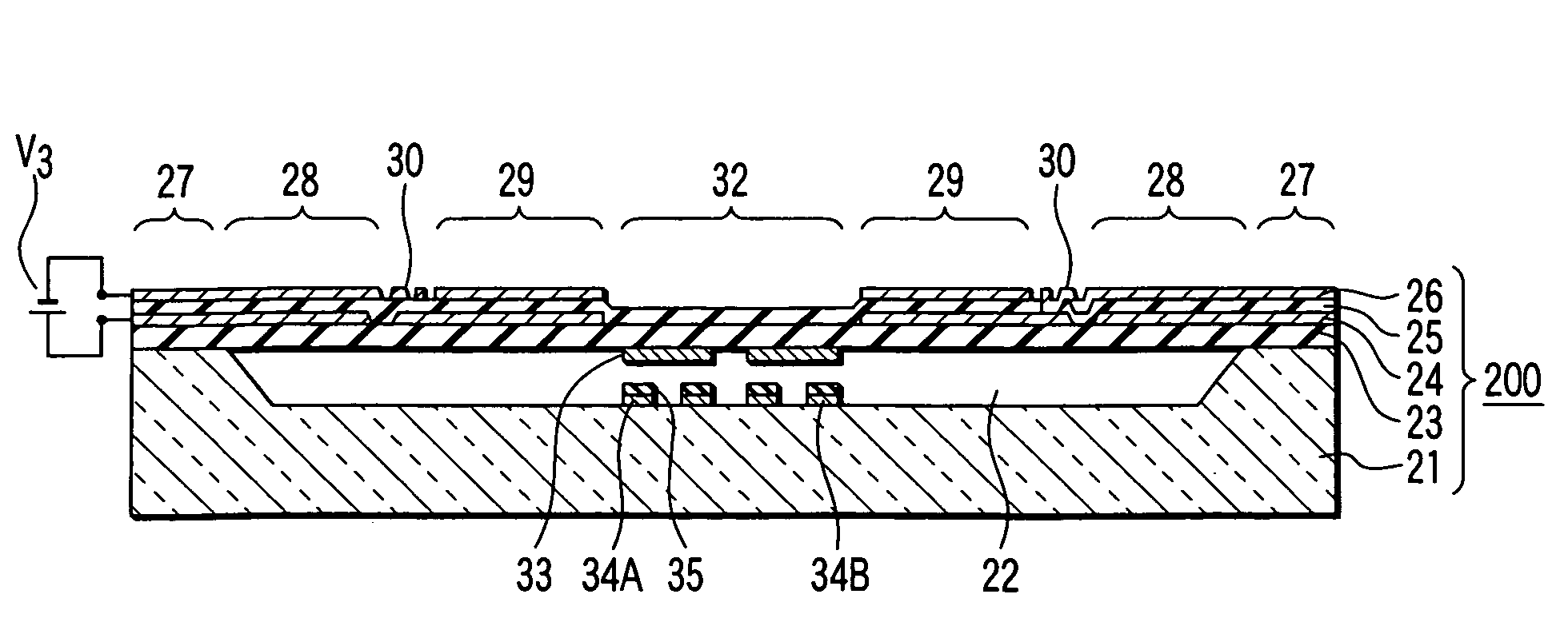

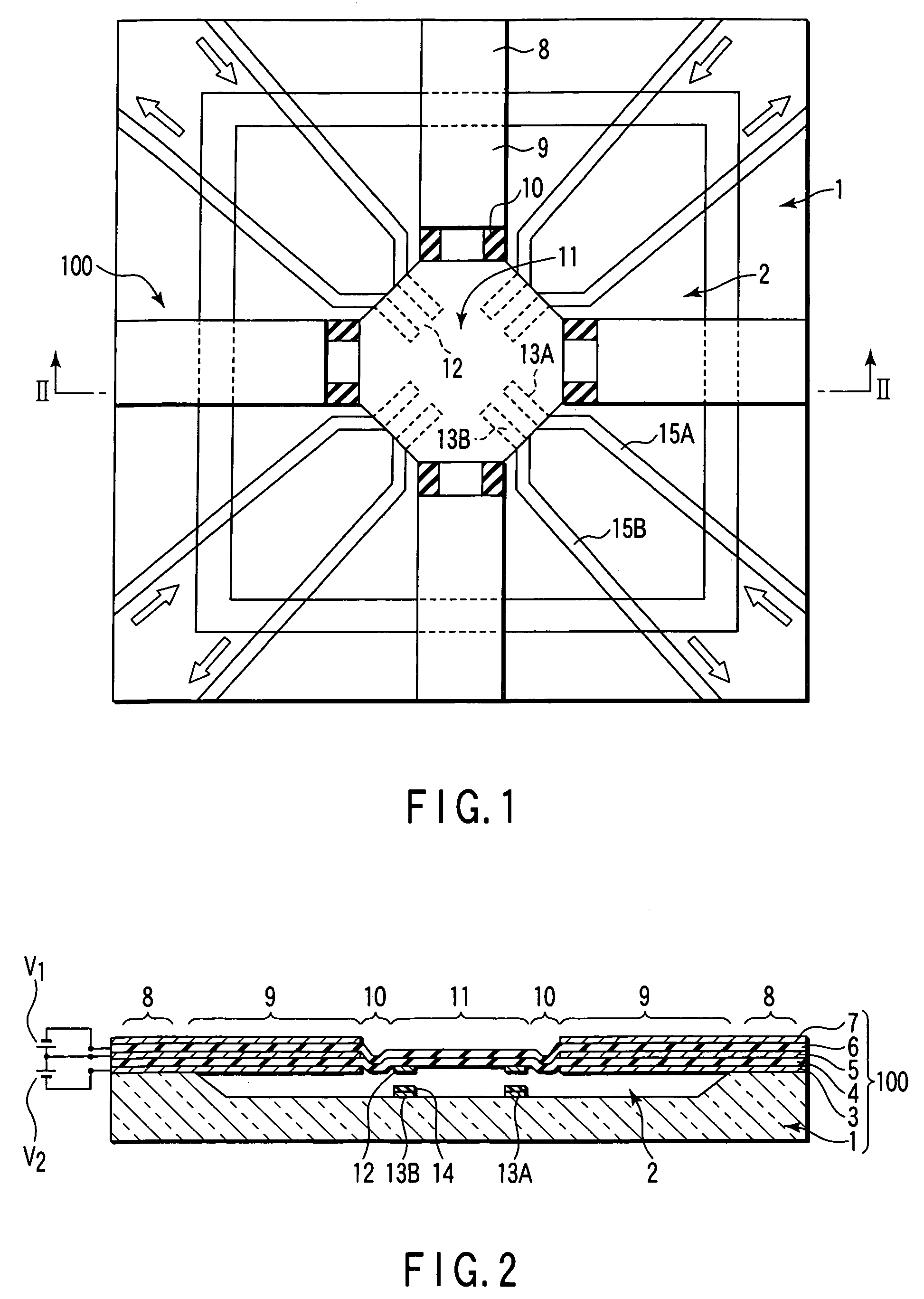

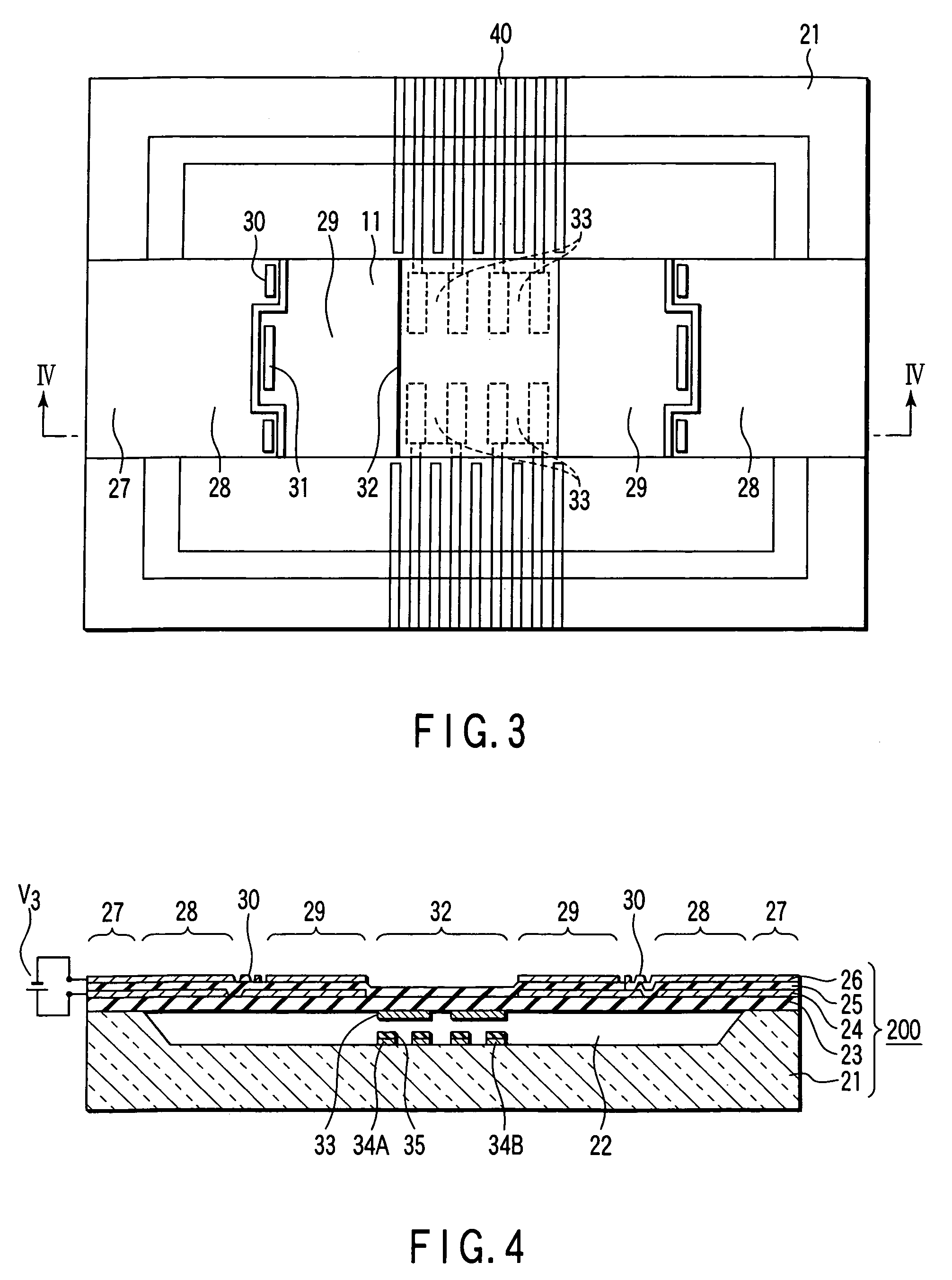

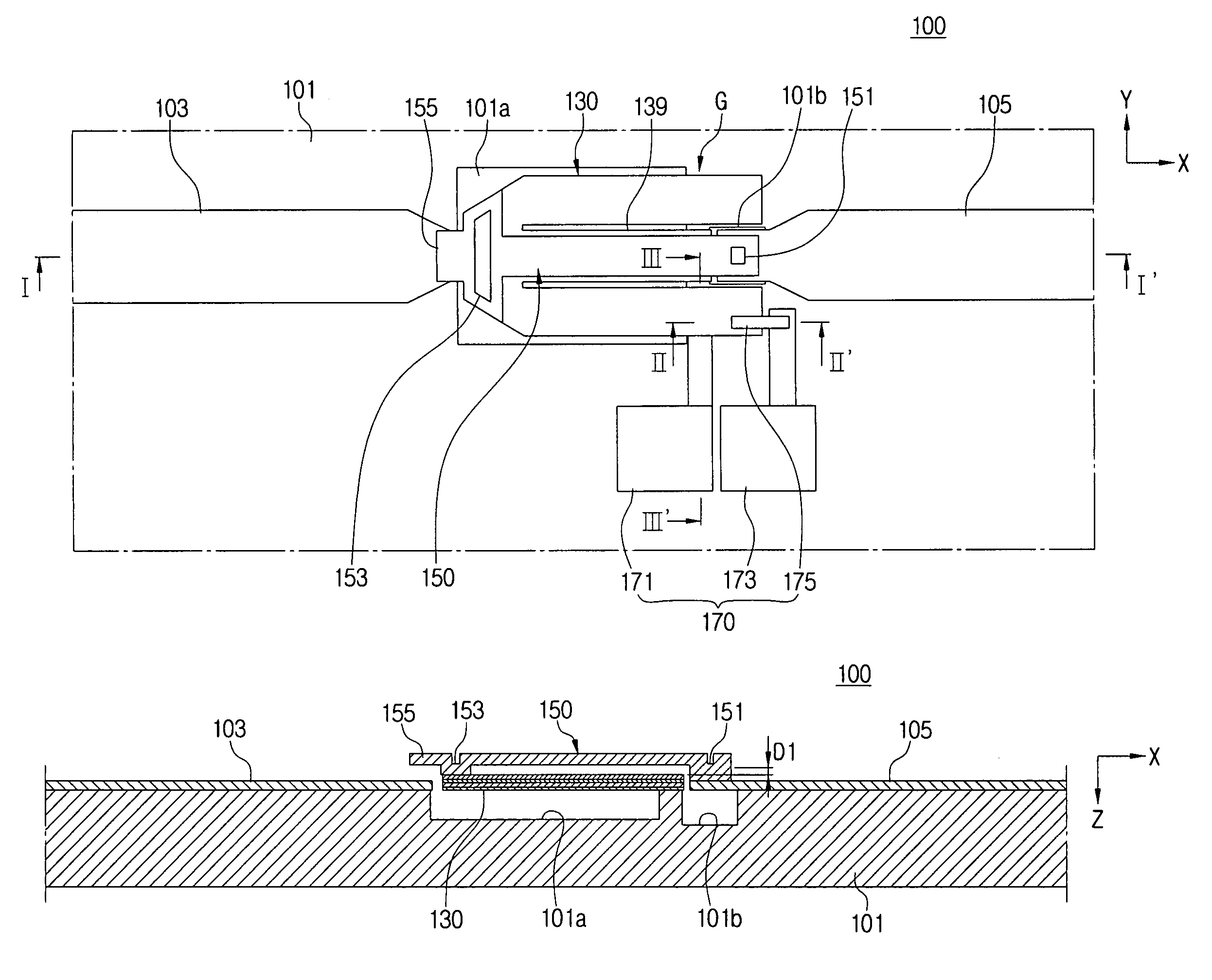

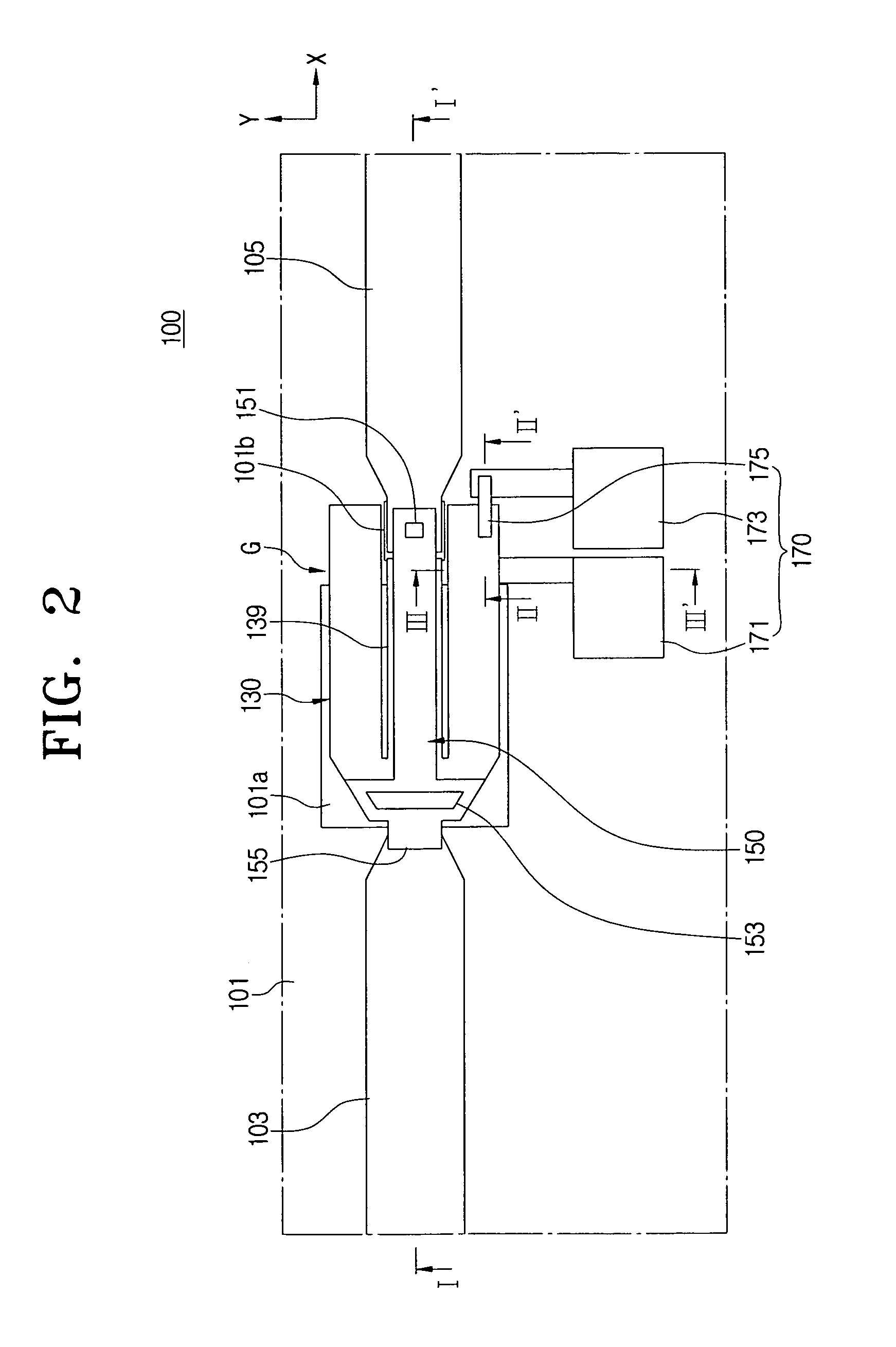

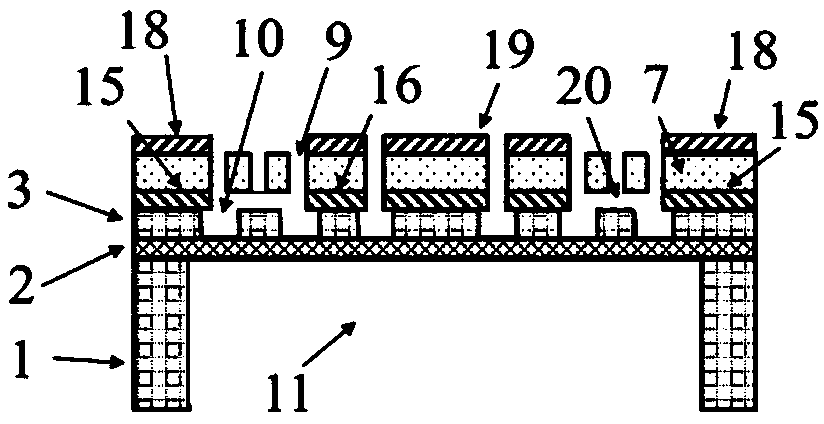

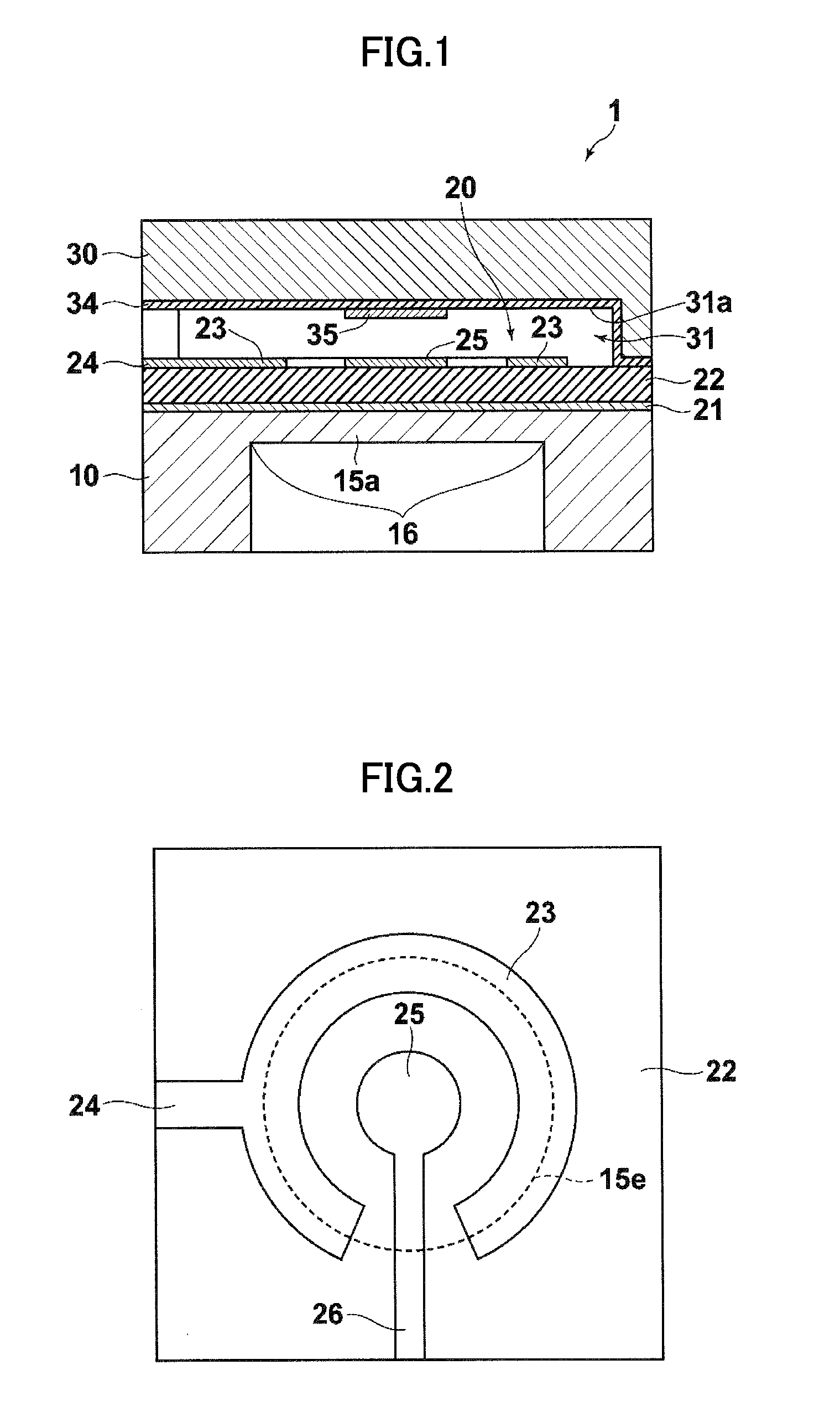

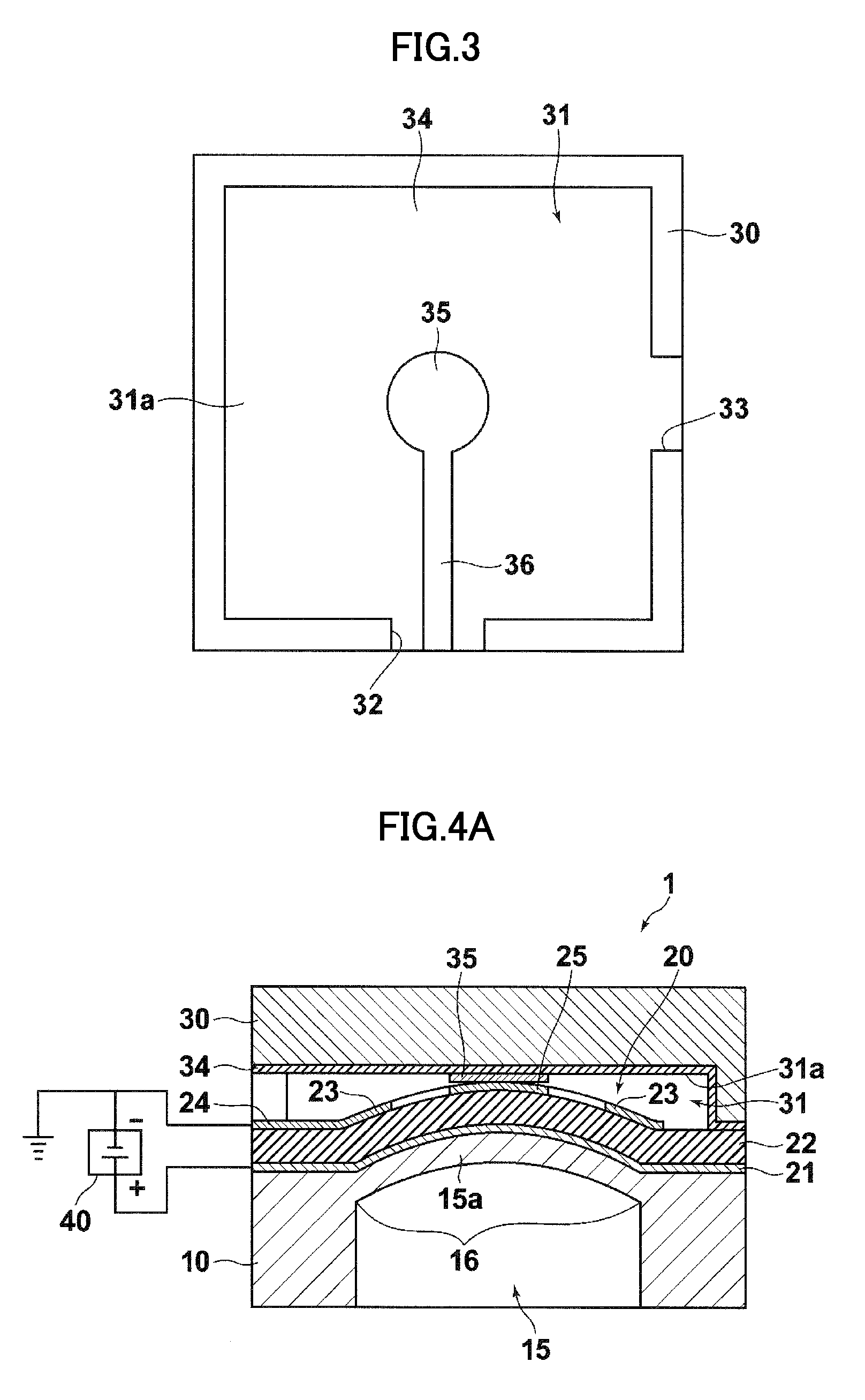

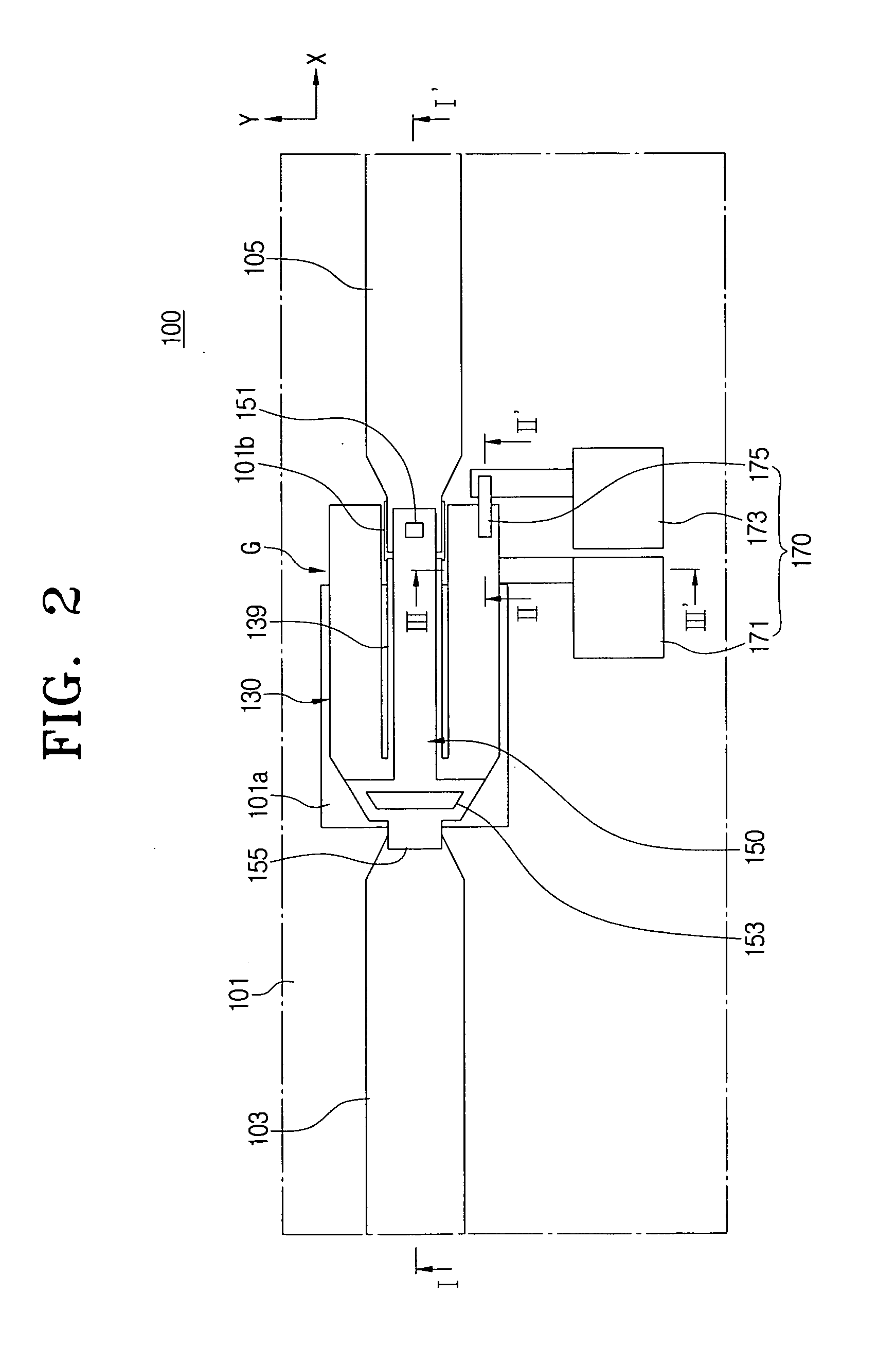

Piezoelectric MEMS element, voltage control oscillator, communication apparatus, and method of manufacturing piezoelectric drive type MEMS element

ActiveUS20110074248A1Simple structureSimple manufacturing methodPiezoelectric/electrostriction/magnetostriction machinesCapacitor with electrode distance variationPiezoelectric memsEngineering

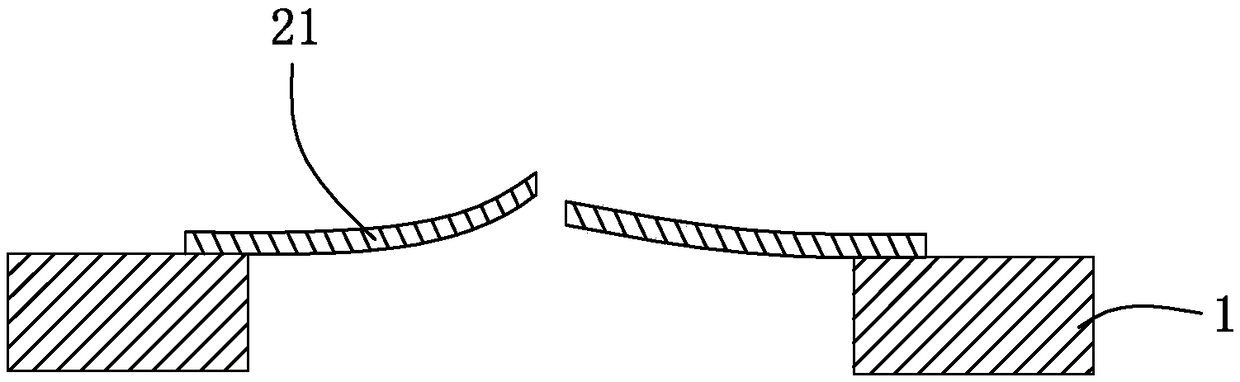

A piezoelectric drive type MEMS element includes: a first substrate including, in a portion thereof, a movable part which is driven by a piezoelectric drive section to be displaced in a convex shape, a movable electrode being provided on a surface of the movable part; and a second substrate which is bonded to the first substrate and supports a fixed electrode facing the movable electrode via a prescribed gap, wherein the piezoelectric drive section includes a piezoelectric film provided on a region of the first substrate which forms the movable part as a portion of the movable part, and a pair of electrodes disposed so as to sandwich the piezoelectric film.

Owner:FUJIFILM CORP

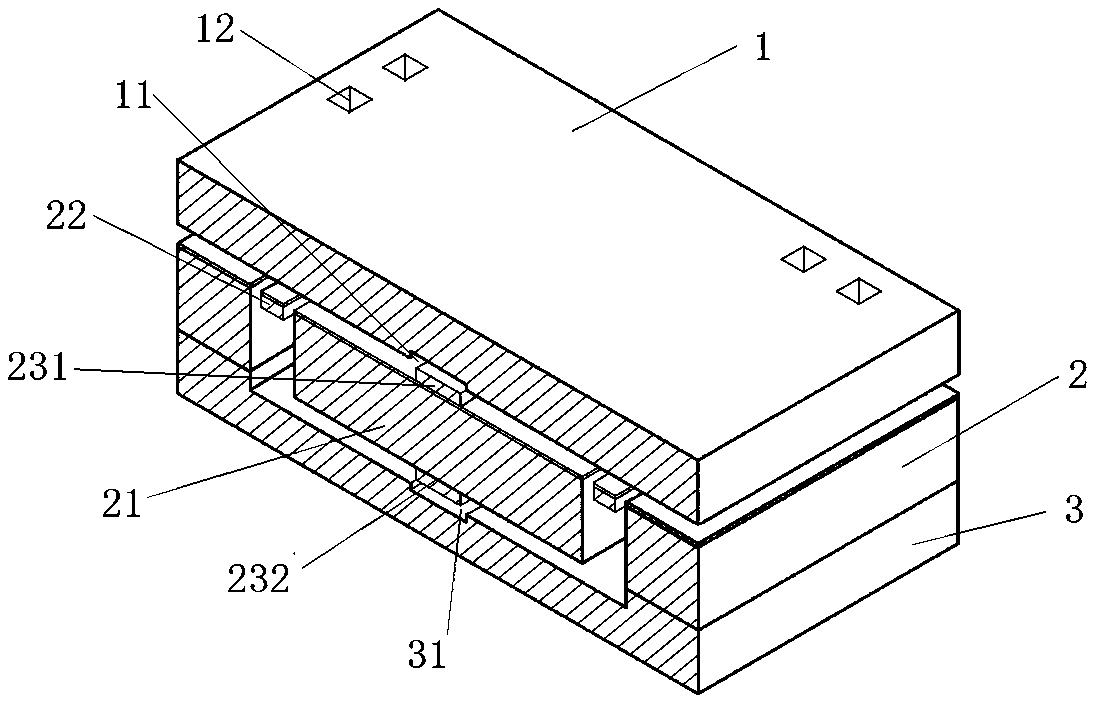

Piezoelectric MEMS microphone

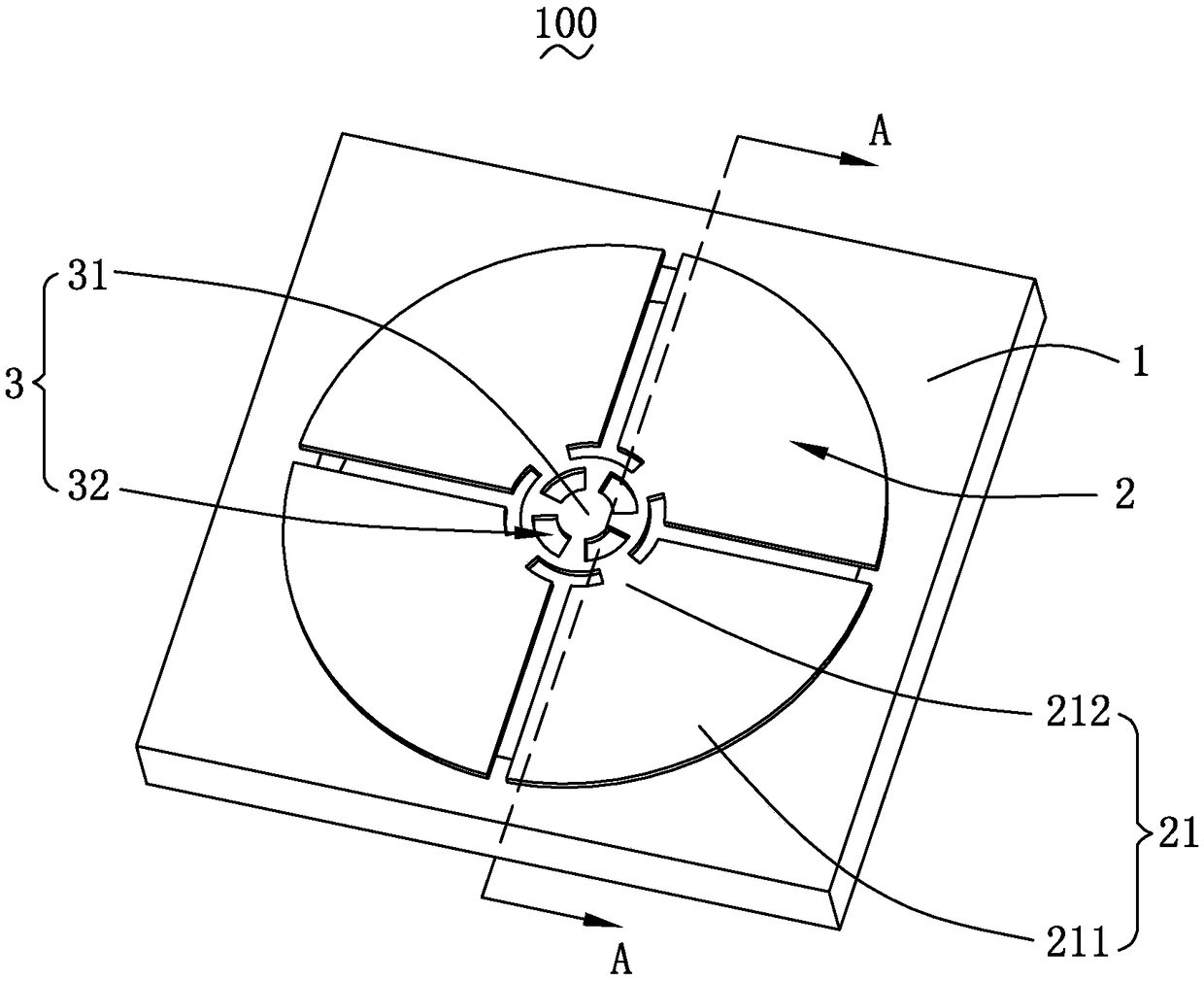

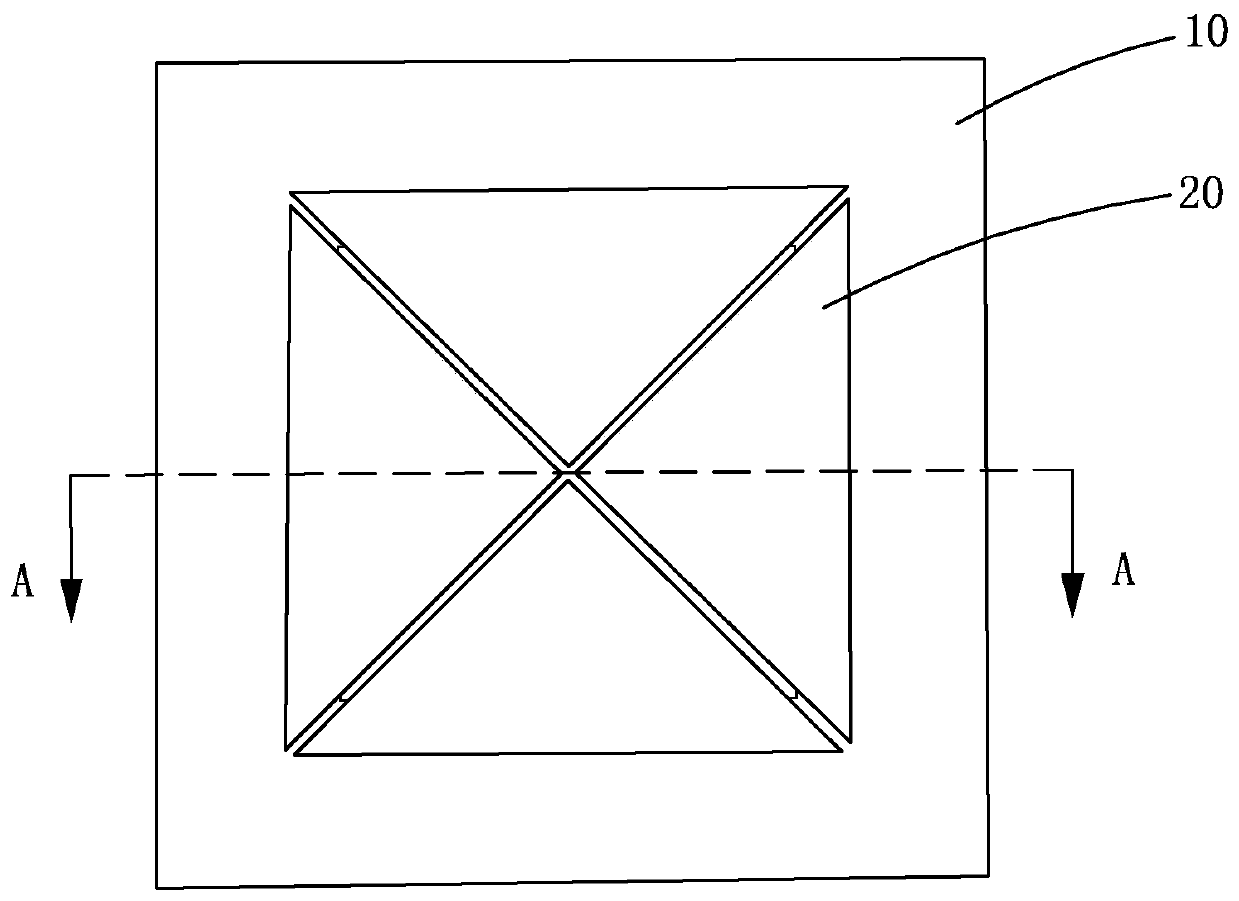

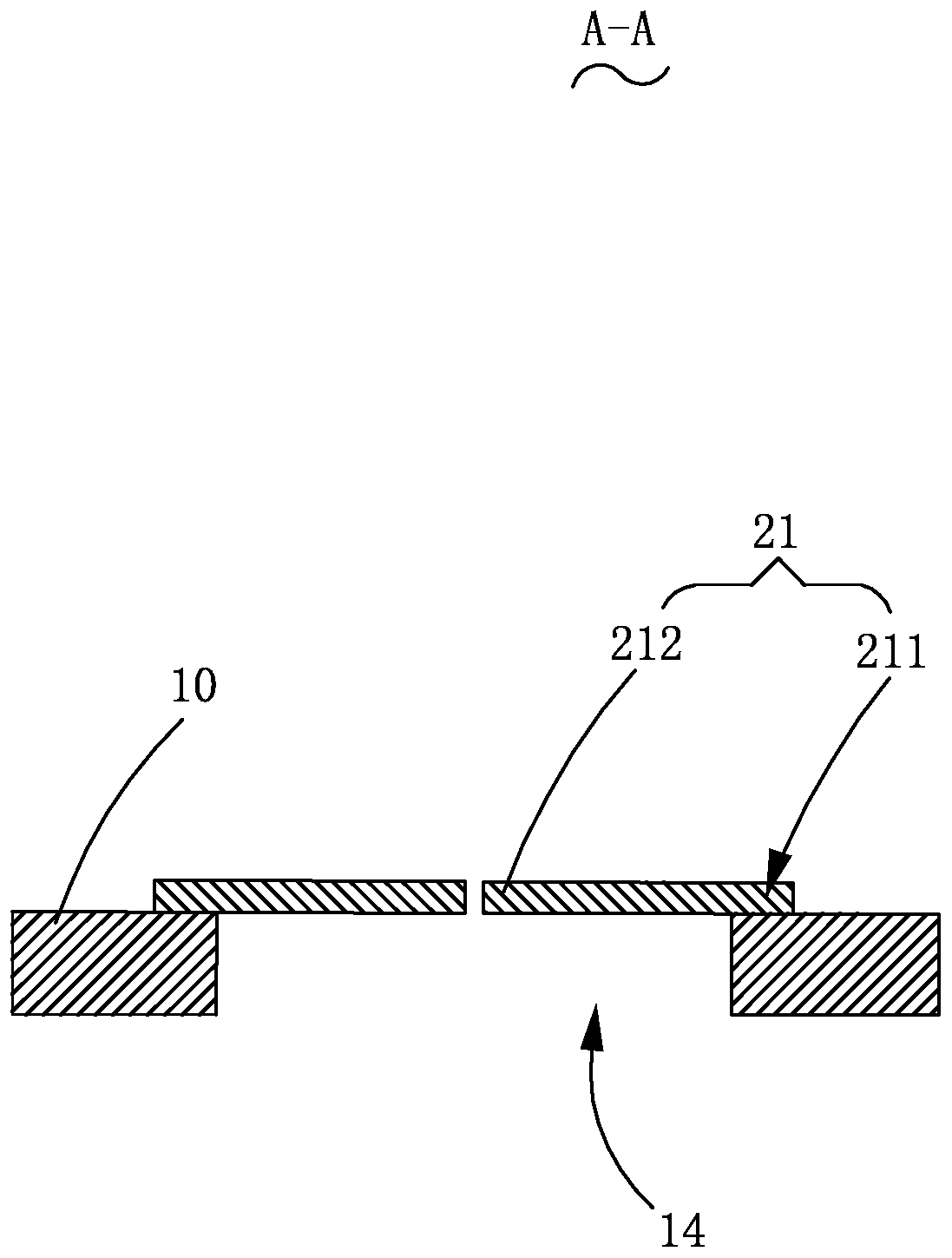

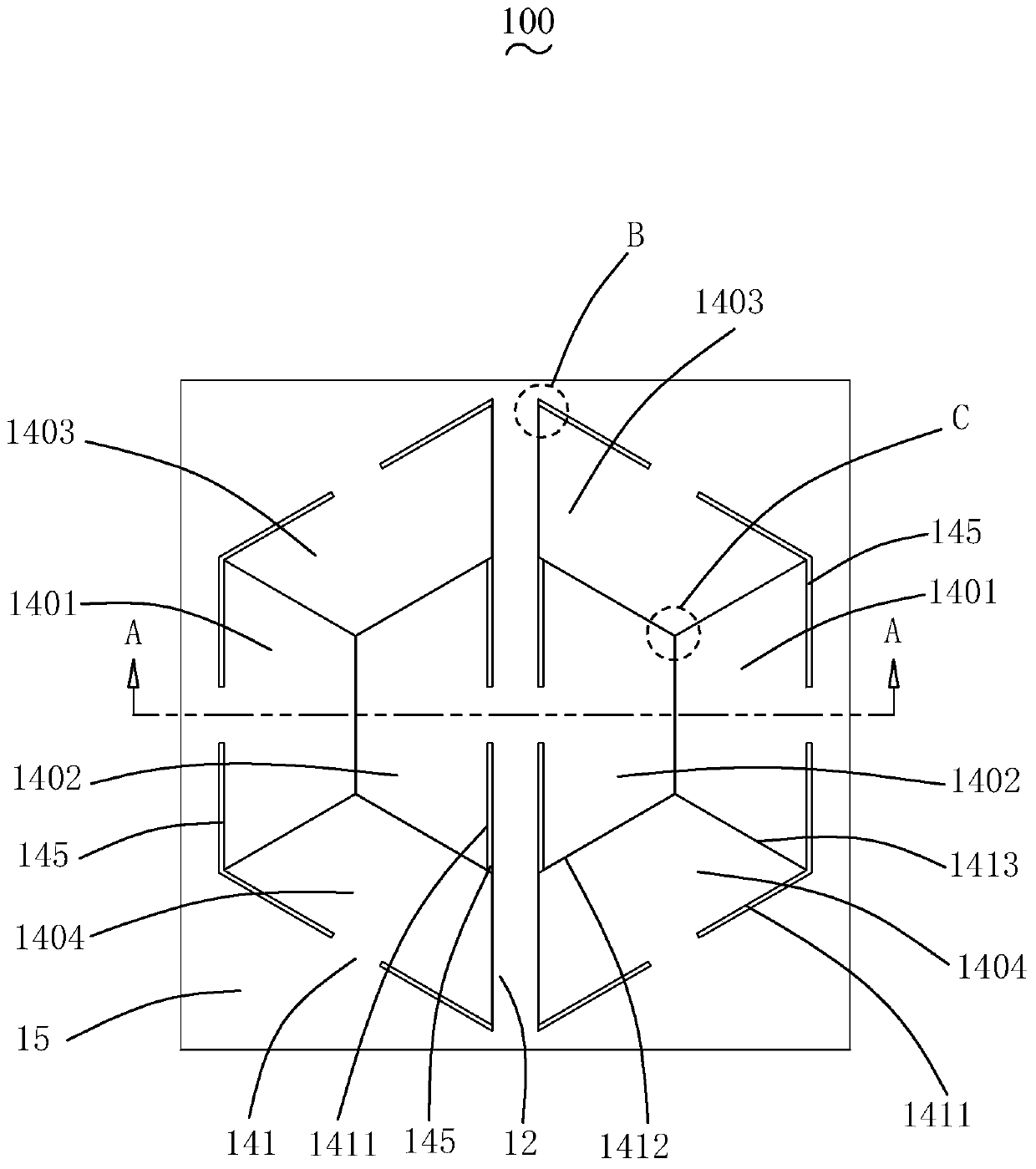

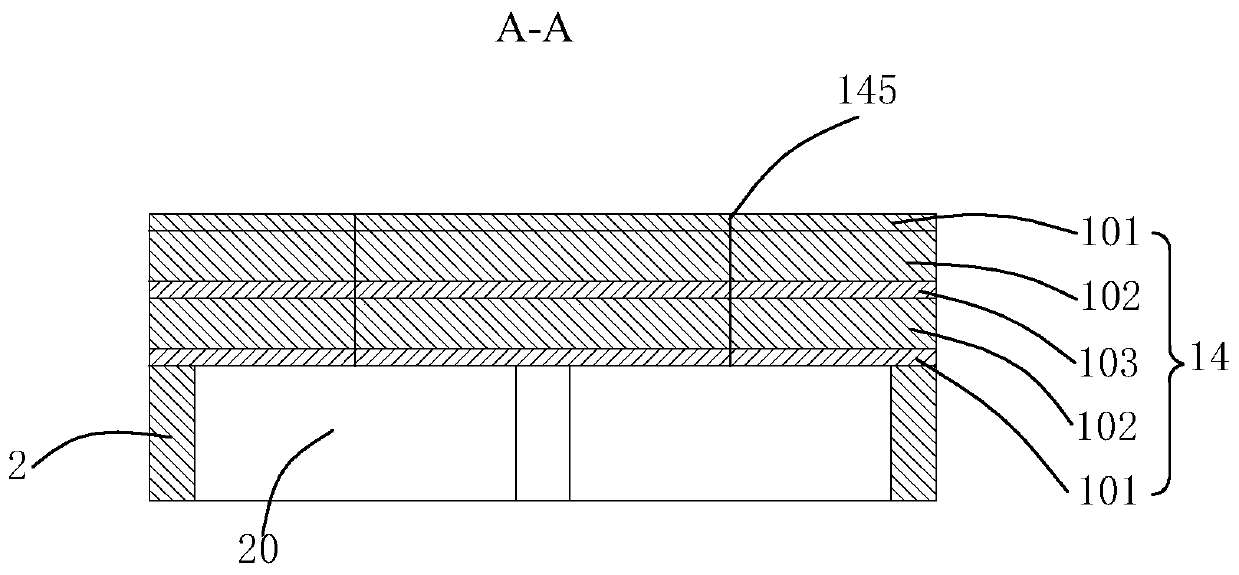

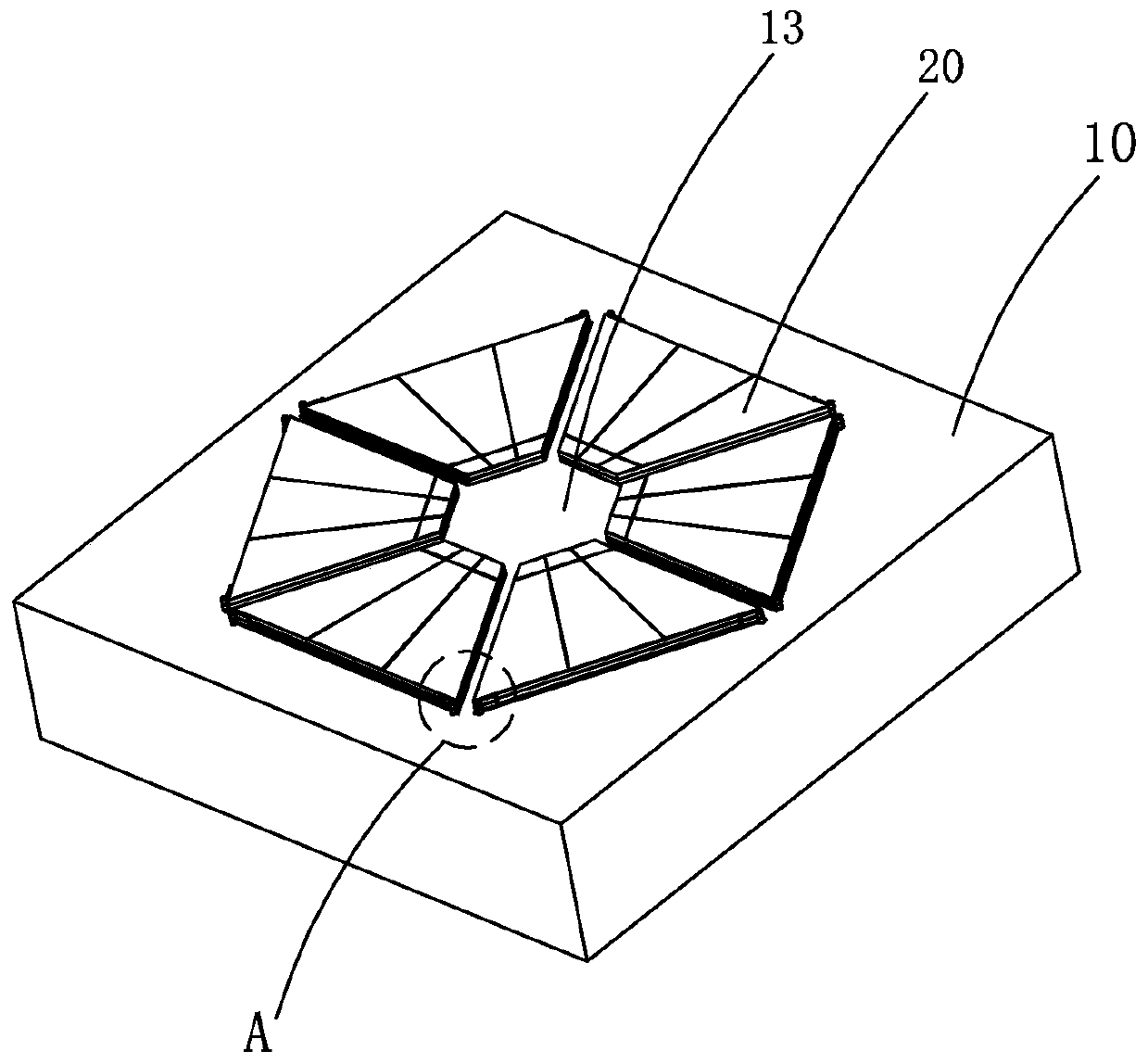

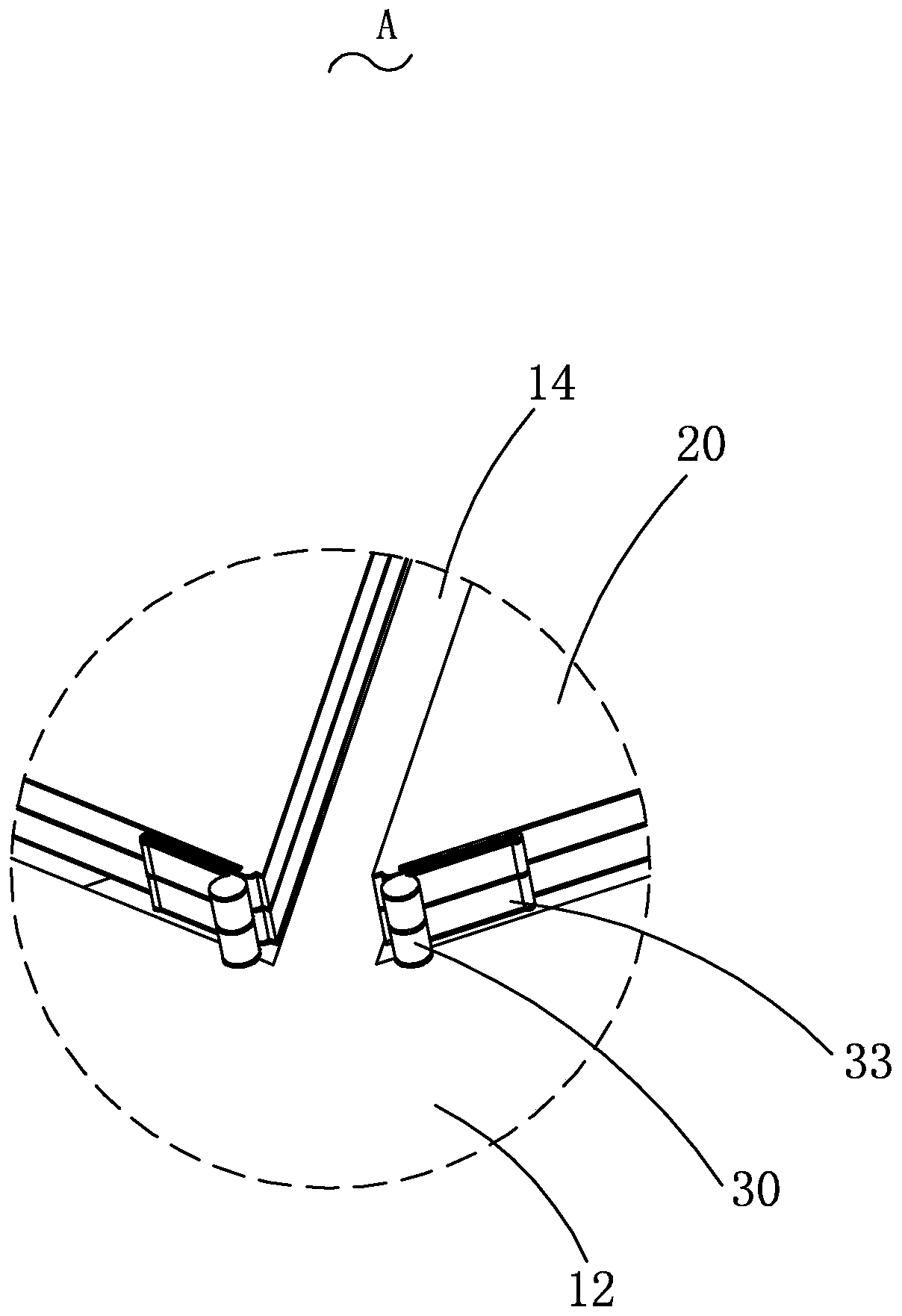

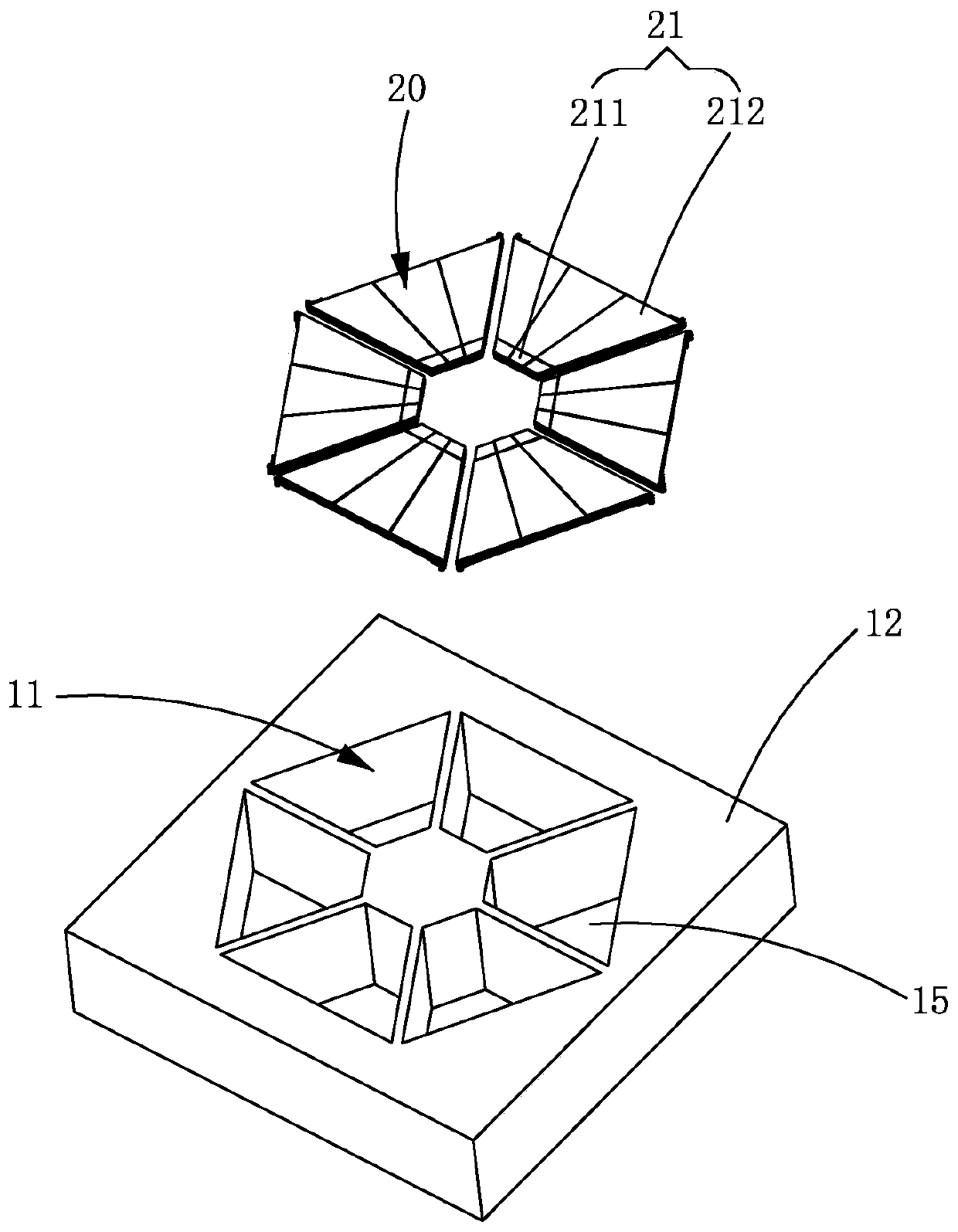

ActiveCN109495829AImprove drop resistanceStructural difference is smallPiezoelectric/electrostrictive microphonesMicrophonesPiezoelectric memsEngineering

The invention provides a piezoelectric MEMS microphone, comprising a substrate having a rear cavity, and a piezoelectric diaphragm disposed on the substrate. The piezoelectric diaphragm comprises a plurality of diaphragms, each of the diaphragms comprises a fixed end connected to the substrate and a free end connected to the fixed end and suspended above the rear cavity, and adjacent two of the diaphragms are spaced or in contact with each other. The piezoelectric EMES microphone further comprises a constraining structure at a central region of the piezoelectric diaphragm, and free ends of atleast two of the diaphragms are connected to the constraining structure. Compared with the related art, the piezoelectric MEMS microphone limits the free ends of the diaphragms in the same plane by the constraining structure, thereby improving the uniformity of product performance and the anti-drop performance.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

Piezoelectric MEMS microphone

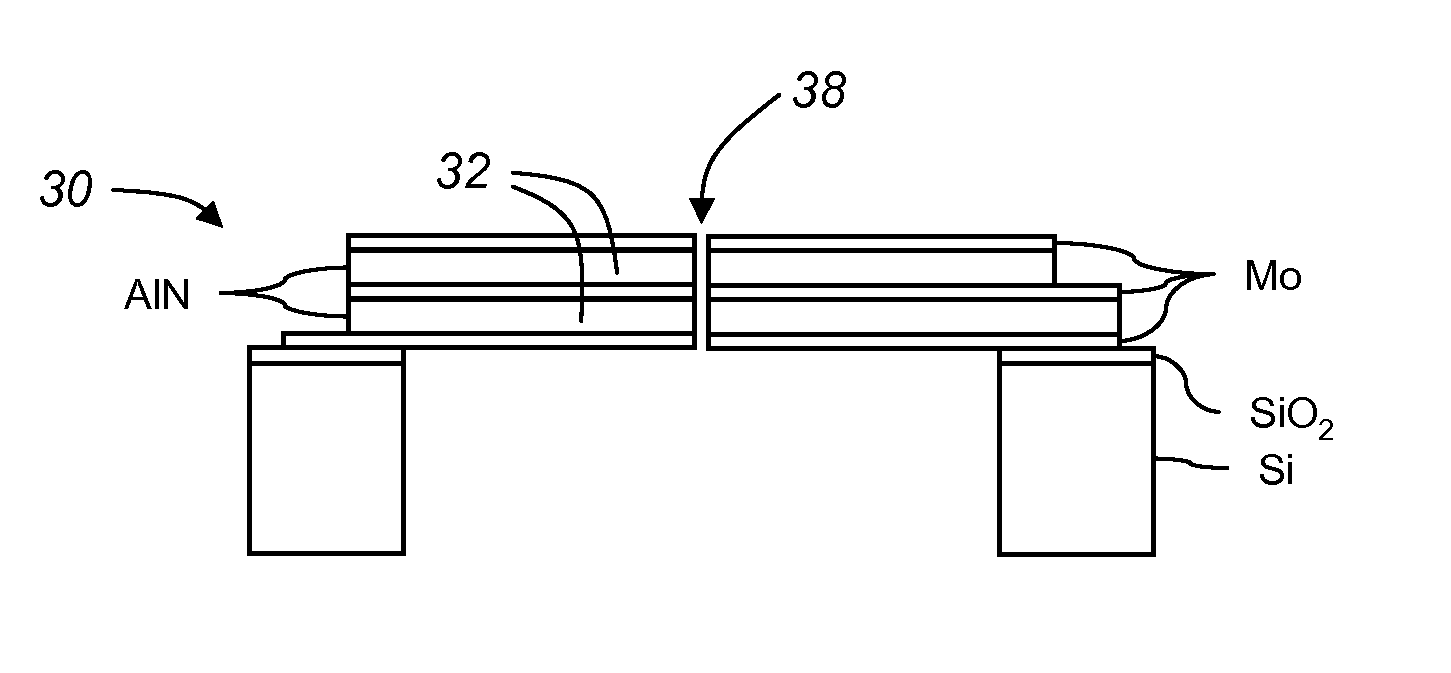

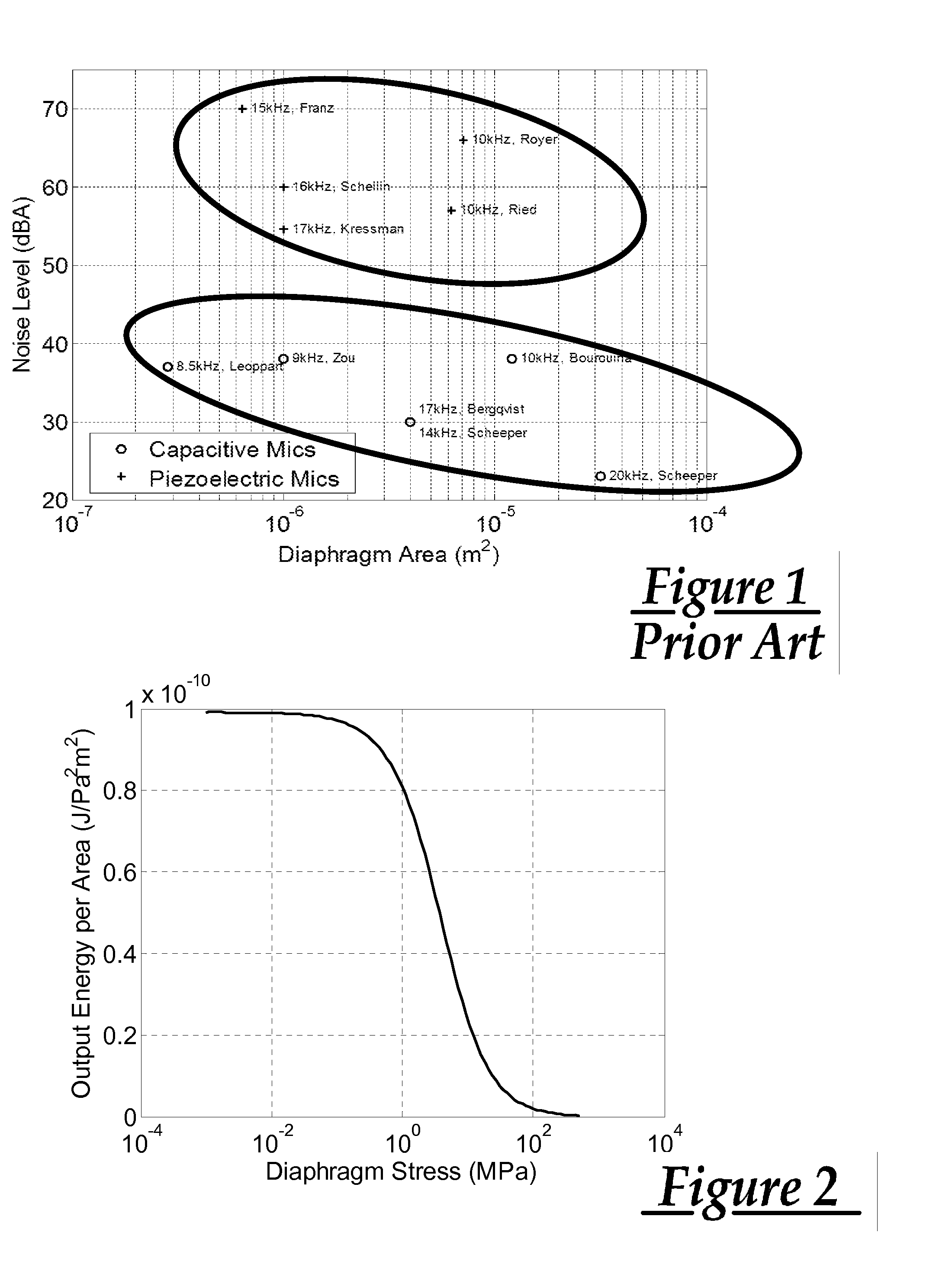

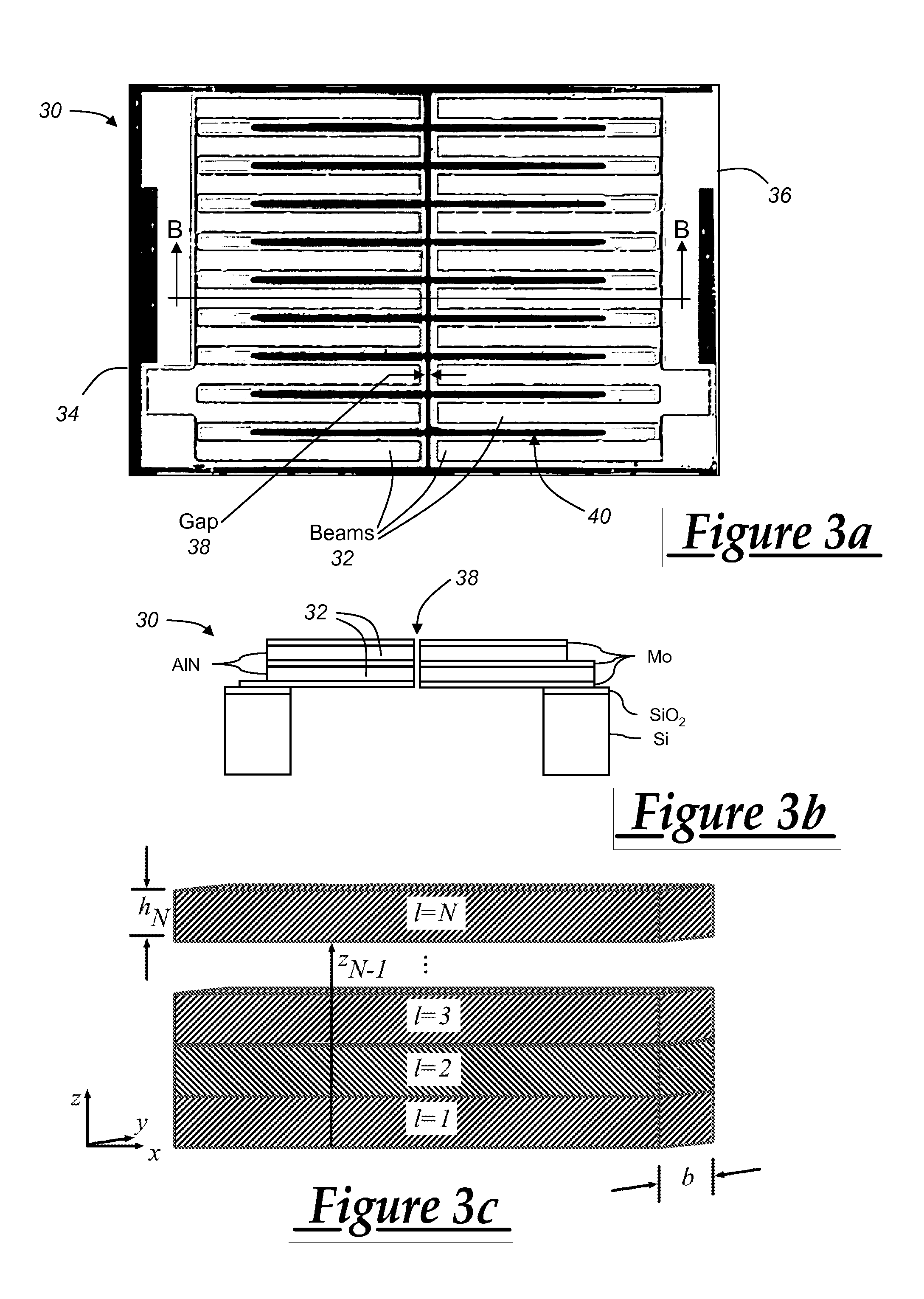

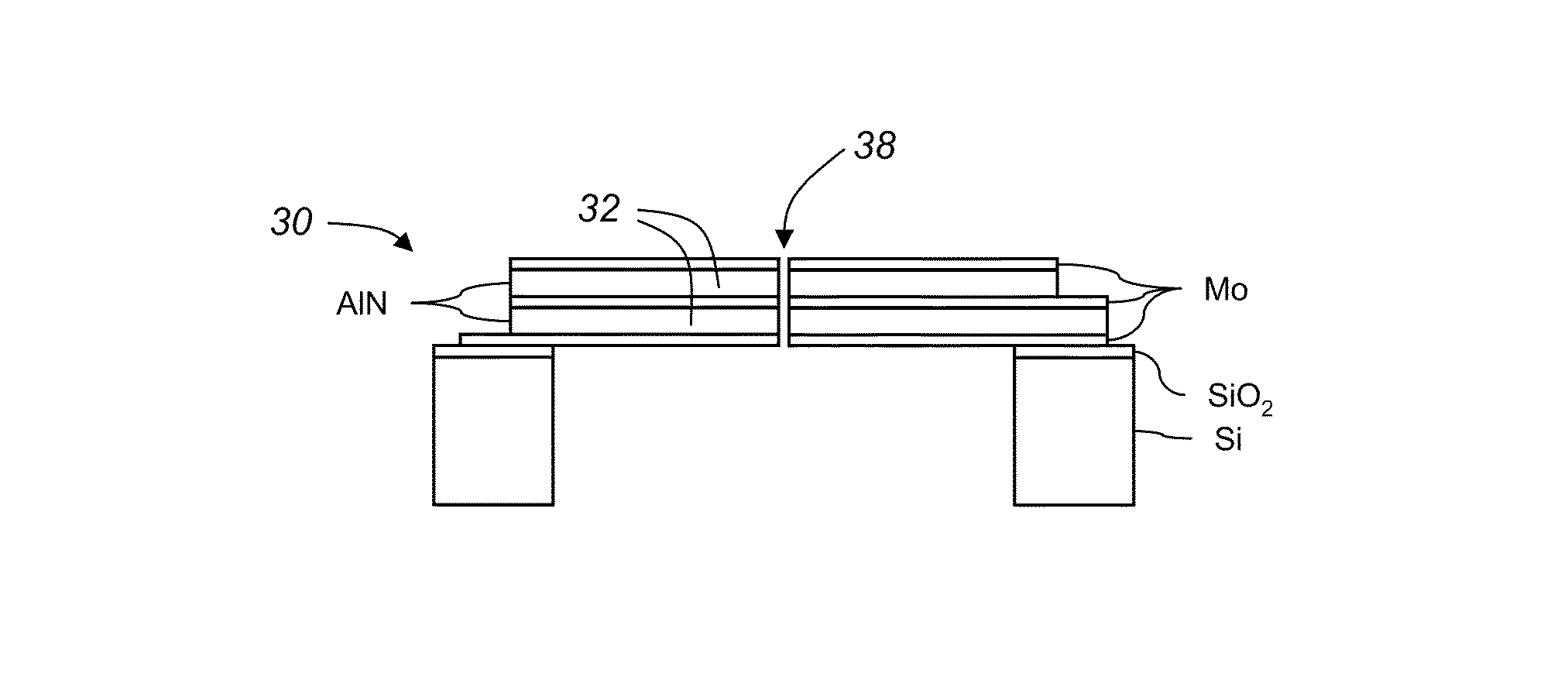

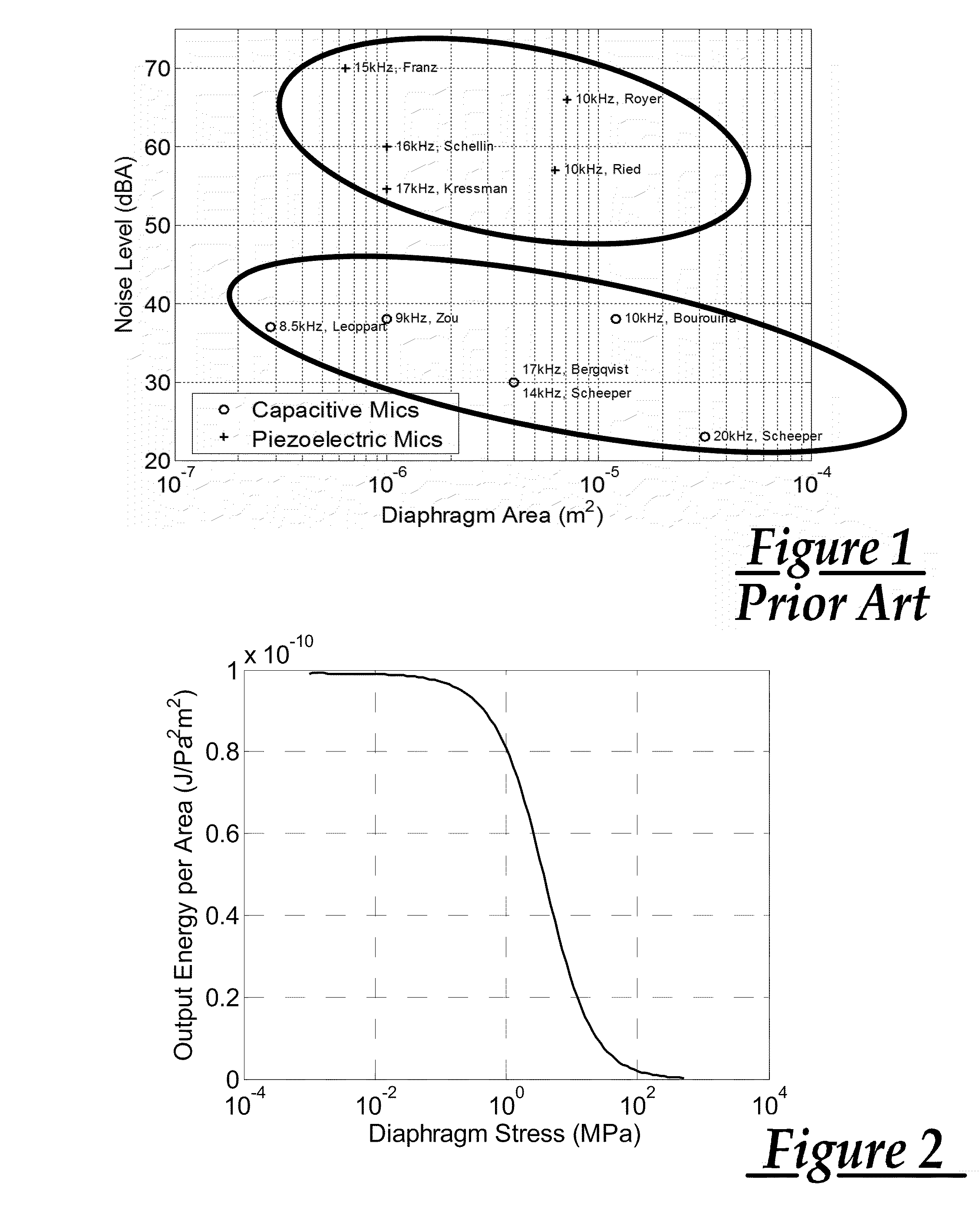

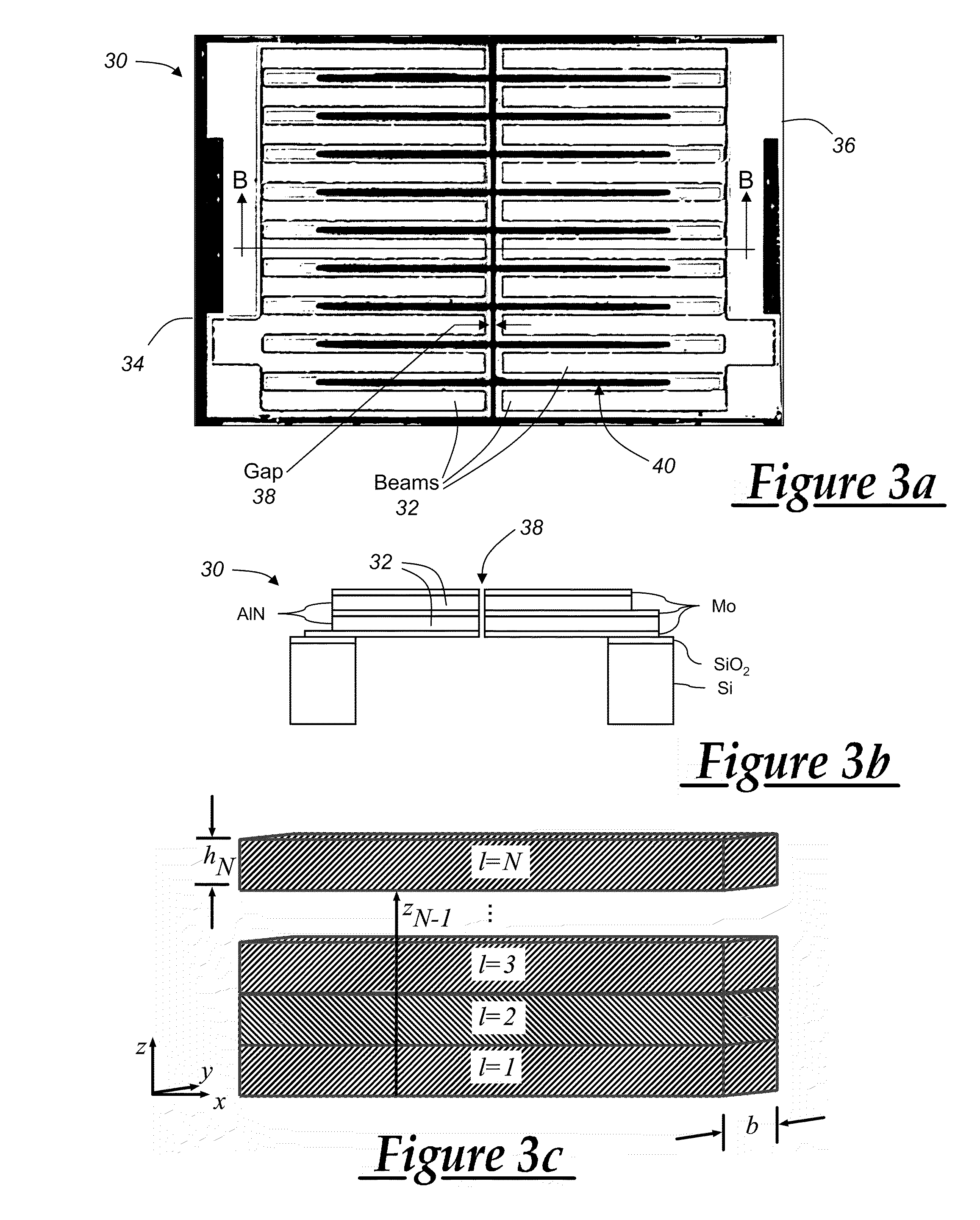

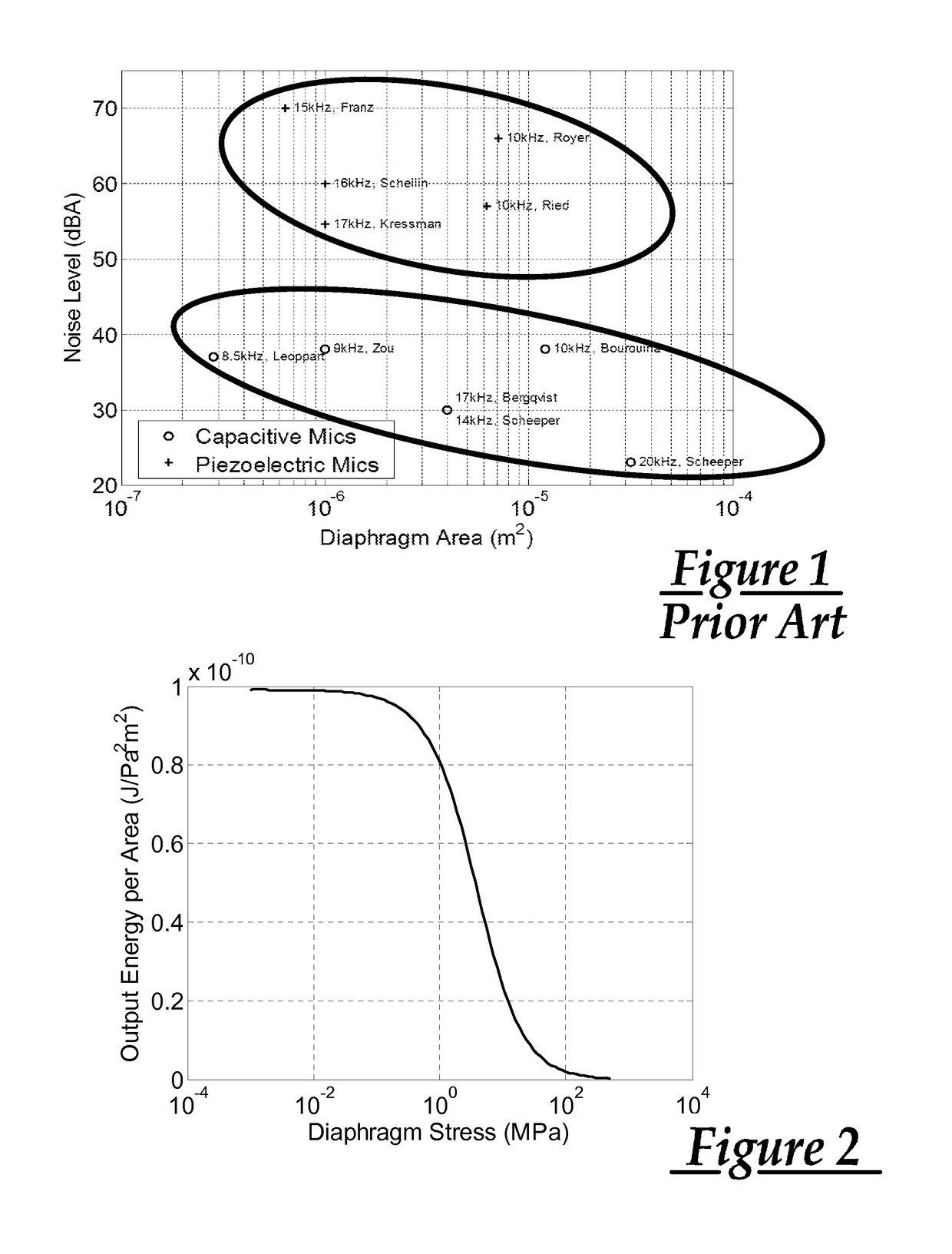

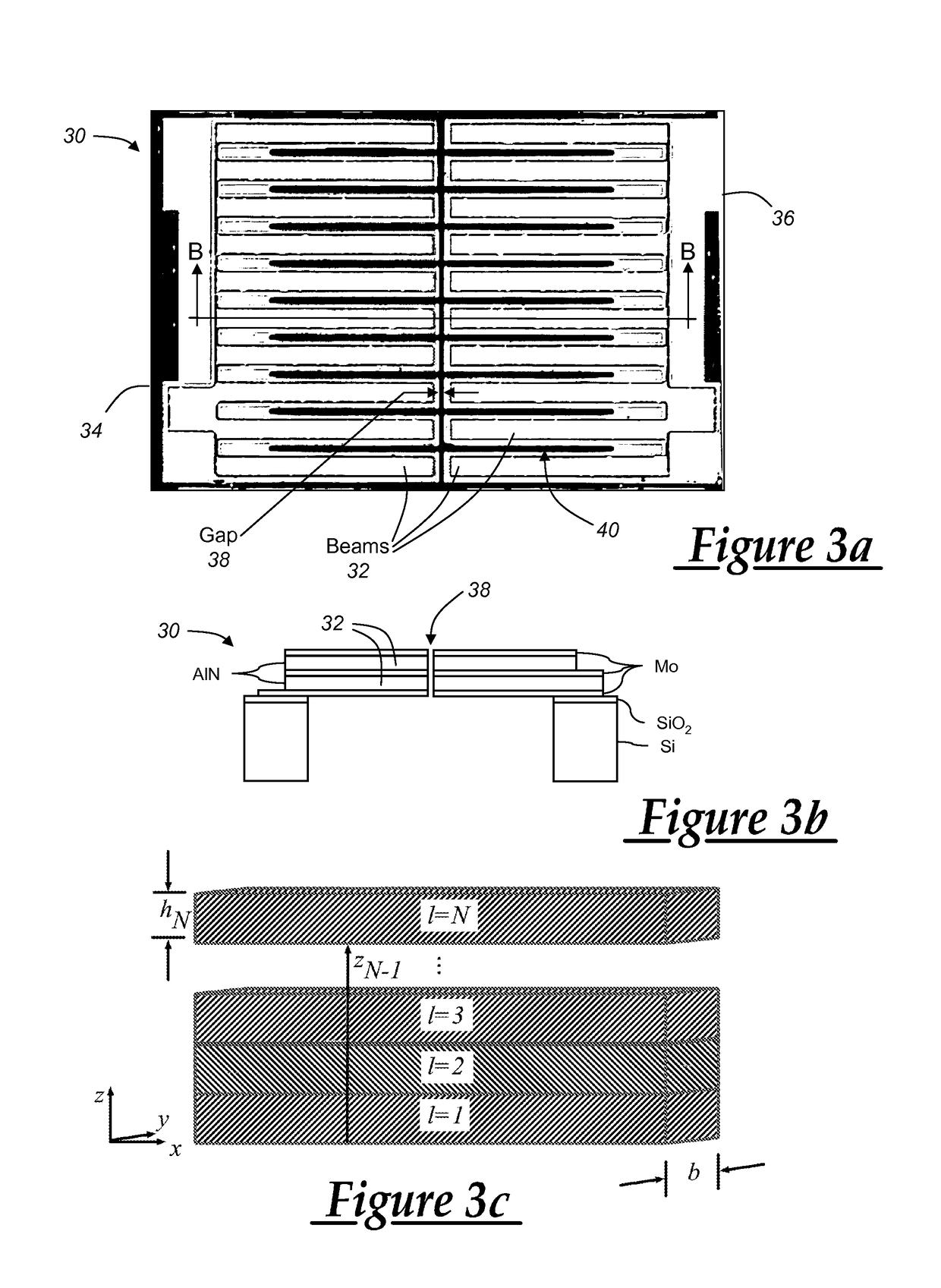

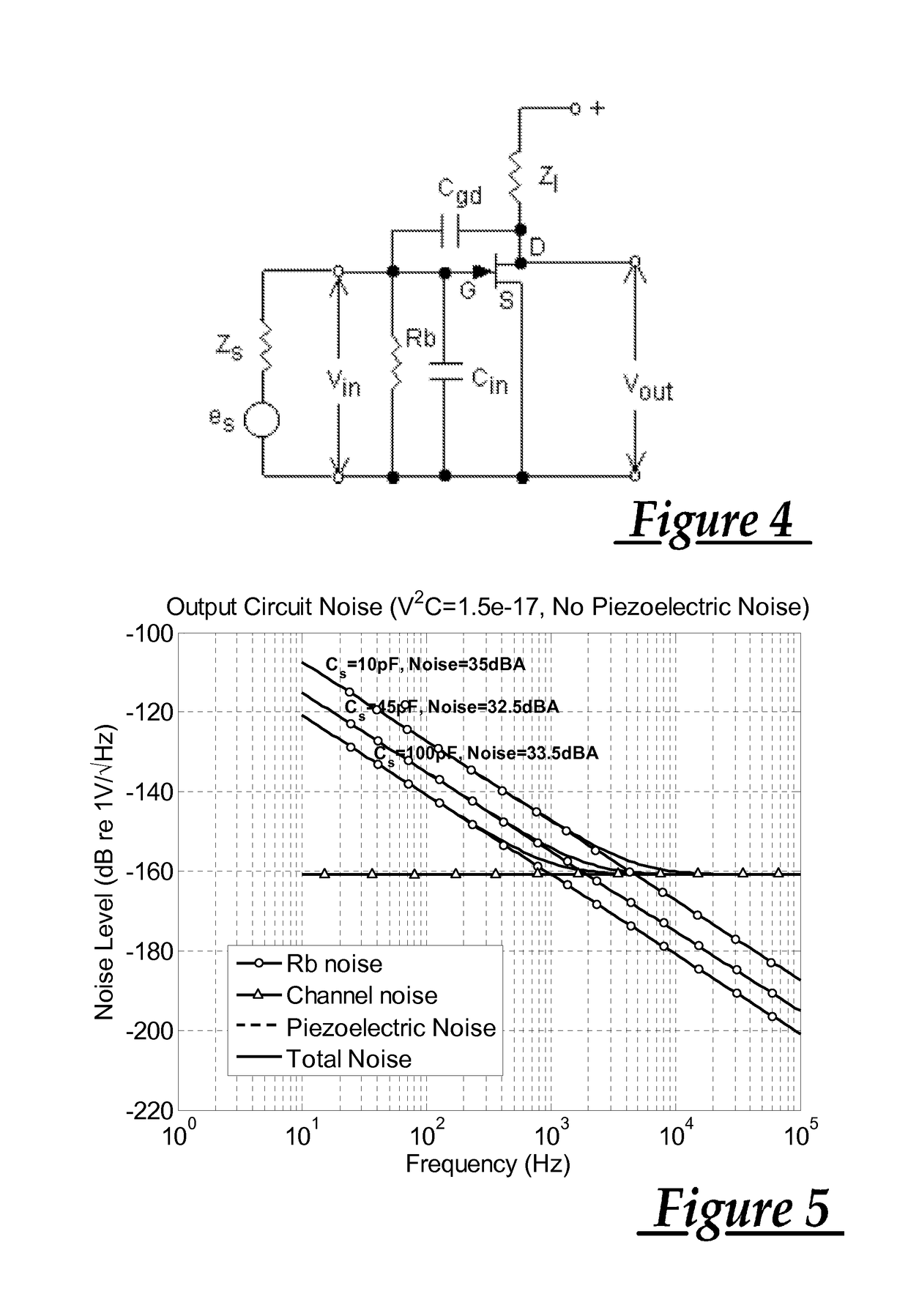

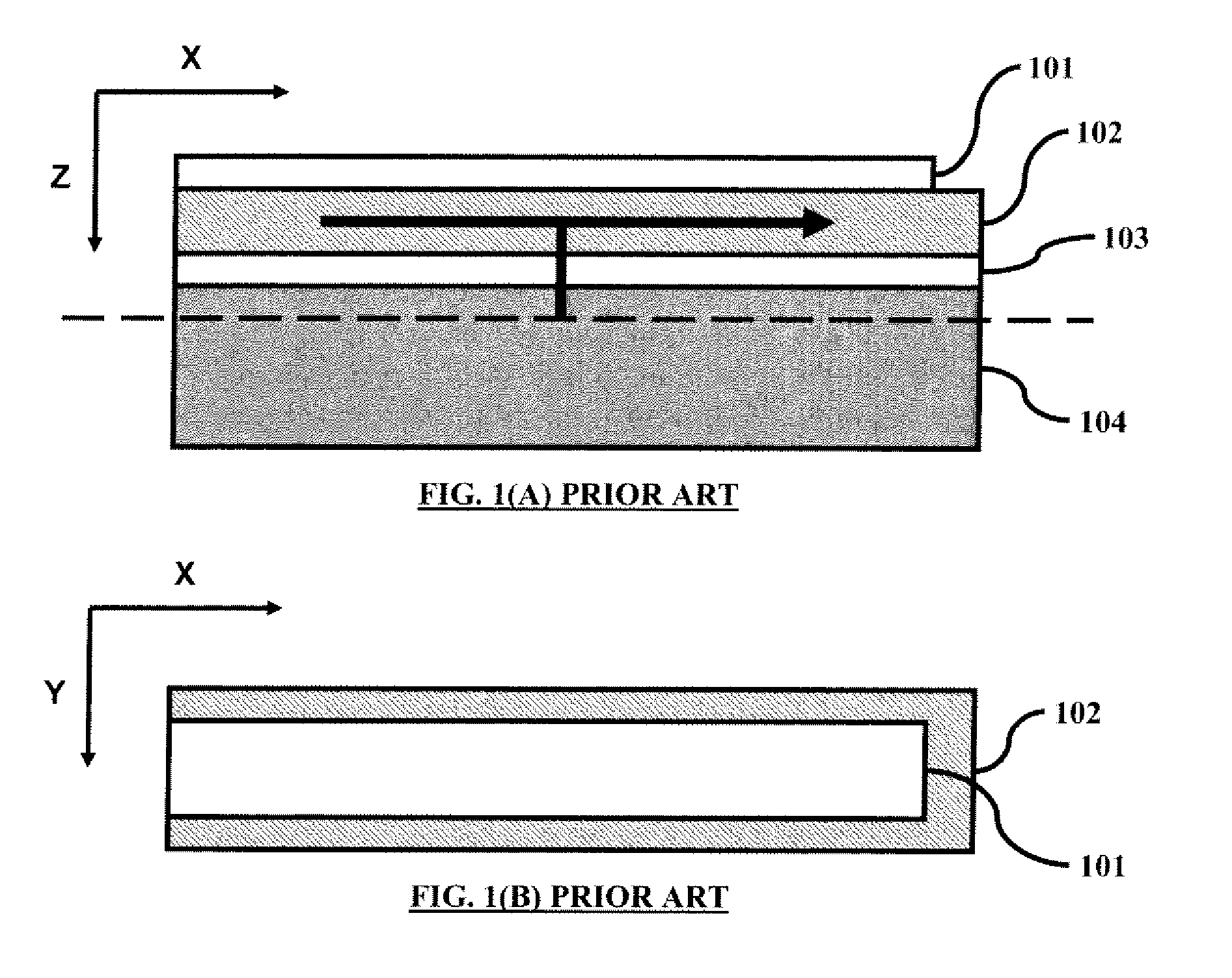

ActiveUS8531088B2Reduce residual stressPiezoelectric/electrostrictive microphonesMicrophonesCantilevered beamPiezoelectric mems

A piezoelectric MEMS microphone comprising a multi-layer sensor that includes at least one piezoelectric layer between two electrode layers, with the sensor being dimensioned such that it provides a near maximized ratio of output energy to sensor area, as determined by an optimization parameter that accounts for input pressure, bandwidth, and characteristics of the piezoelectric and electrode materials. The sensor can be formed from single or stacked cantilevered beams separated from each other by a small gap, or can be a stress-relieved diaphragm that is formed by deposition onto a silicon substrate, with the diaphragm then being stress relieved by substantial detachment of the diaphragm from the substrate, and then followed by reattachment of the now stress relieved diaphragm.

Owner:RGT UNIV OF MICHIGAN

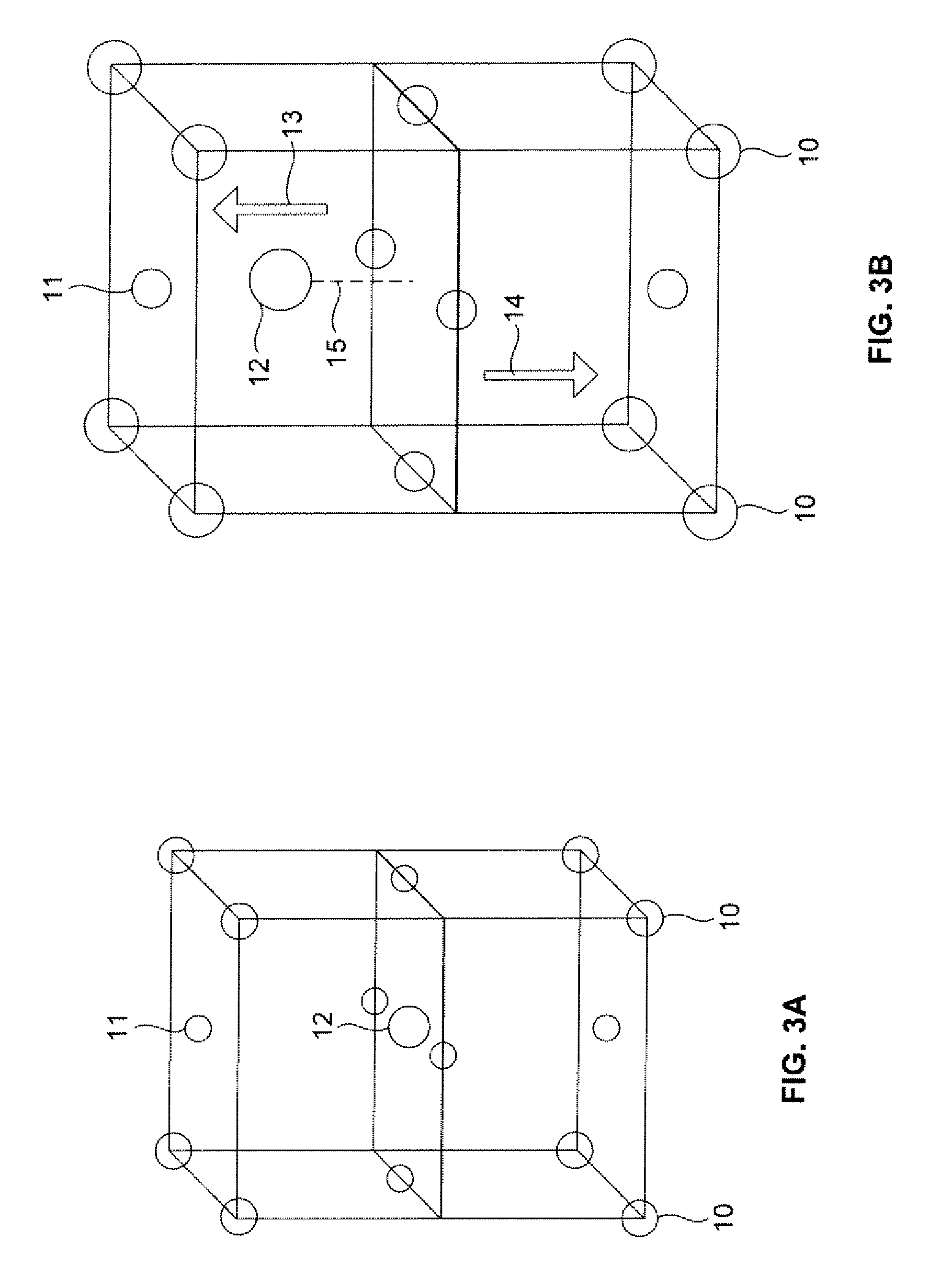

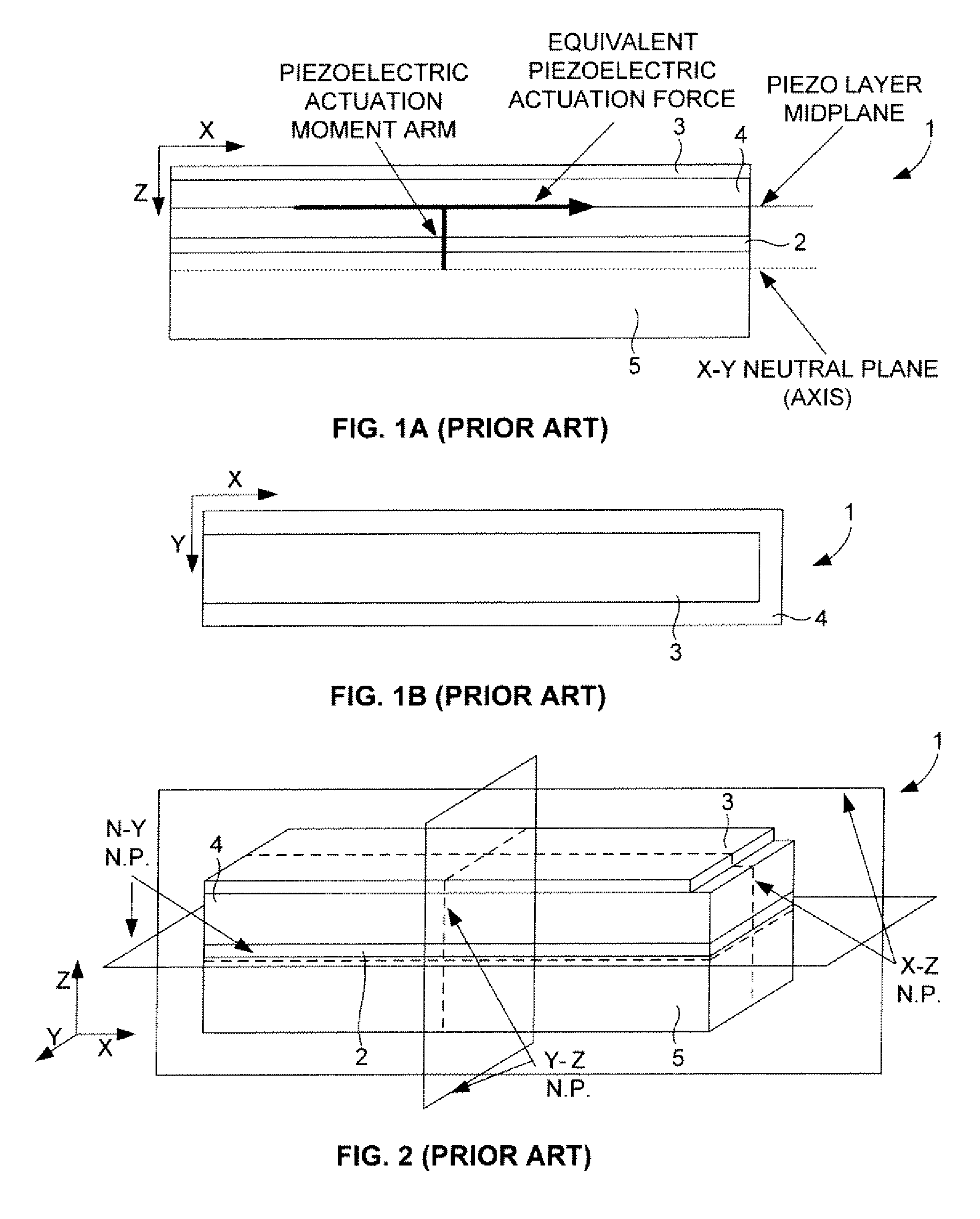

Large force and displacement piezoelectric MEMS lateral actuation

InactiveUS20100045141A1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesPiezoelectric memsEngineering

A piezoelectric microelectromechanical systems (MEMS) actuator includes a silicon substrate; an actuator beam comprising a first end region connected to the silicon substrate and a second end region connected to a mechanically compliant spring assembly; a first electrode over the silicon substrate; a piezoelectric layer above the first electrode; a second electrode over the piezoelectric layer; a conductive top structural layer above the second electrode, wherein a center half of the actuator beam is configured as a positive deflection region, and wherein both the first electrode and the second electrode supply voltage to both positive and negative deflection regions of the actuator beam.

Owner:ARMY UNITED STATES OF AMERICA AS REPRESENTED BY

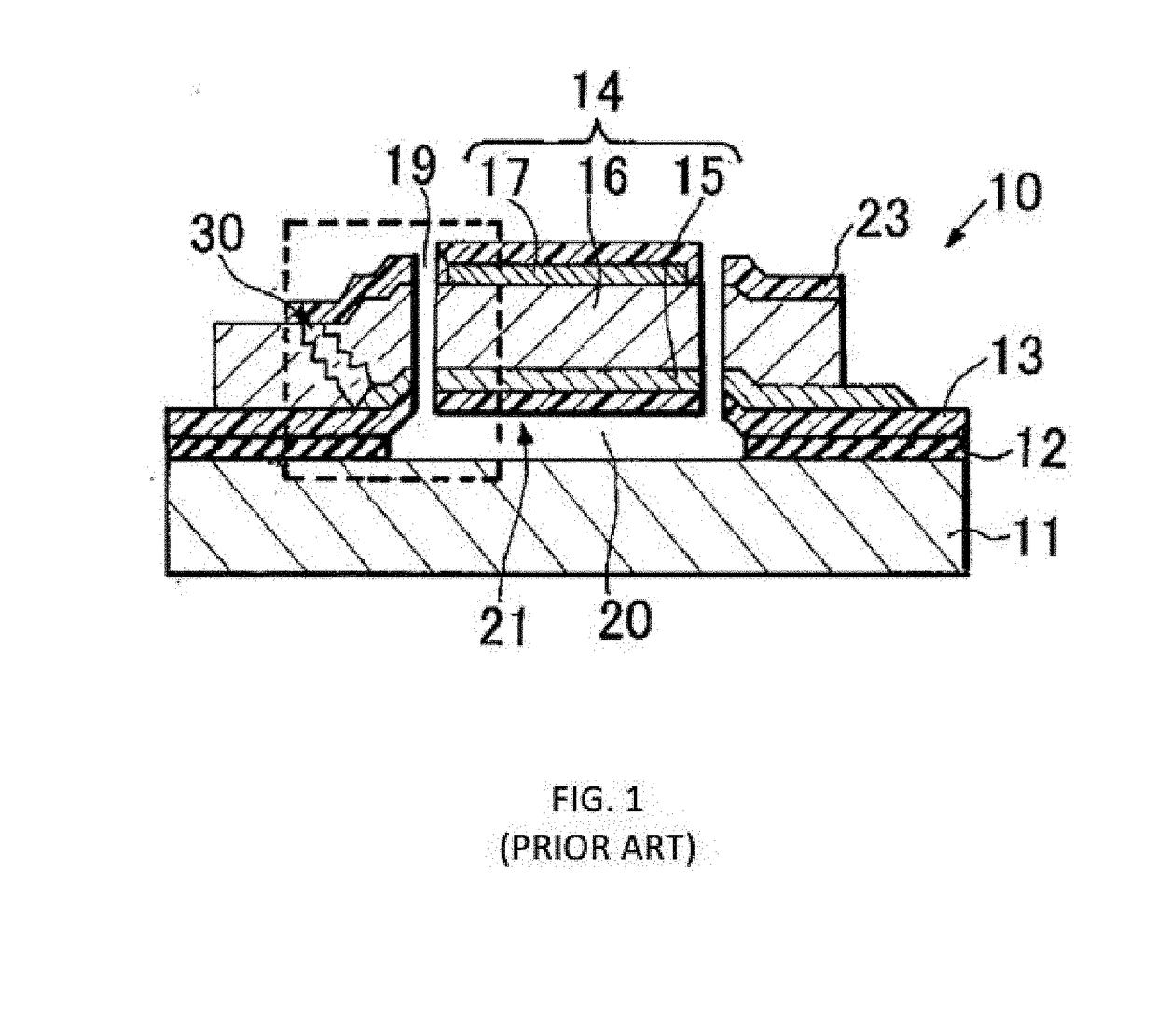

Piezoelectric MEMS switch and method of manufacturing piezoelectric MEMS switch

InactiveUS20110148255A1Reduce warpageImprove operationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric memsEngineering

A piezoelectric MEMS switch includes: a base substrate; a diaphragm arranged to oppose the base substrate via a gap; a first piezoelectric drive section constituted by layering a first lower electrode, a first piezoelectric body and a first upper electrode on a first surface of the diaphragm, the first surface being across the diaphragm from the gap; a second piezoelectric drive section constituted by layering a second lower electrode, a second piezoelectric body and a second upper electrode on a second surface of the diaphragm, the second surface facing the gap; a fixed electrode provided on a gap side of the base substrate; and a movable electrode which is fixed to a second piezoelectric drive section side of the diaphragm and opposes the fixed electrode in such a manner that the movable electrode makes contact with and separates from the fixed electrode according to displacement of the diaphragm.

Owner:FUJIFILM CORP

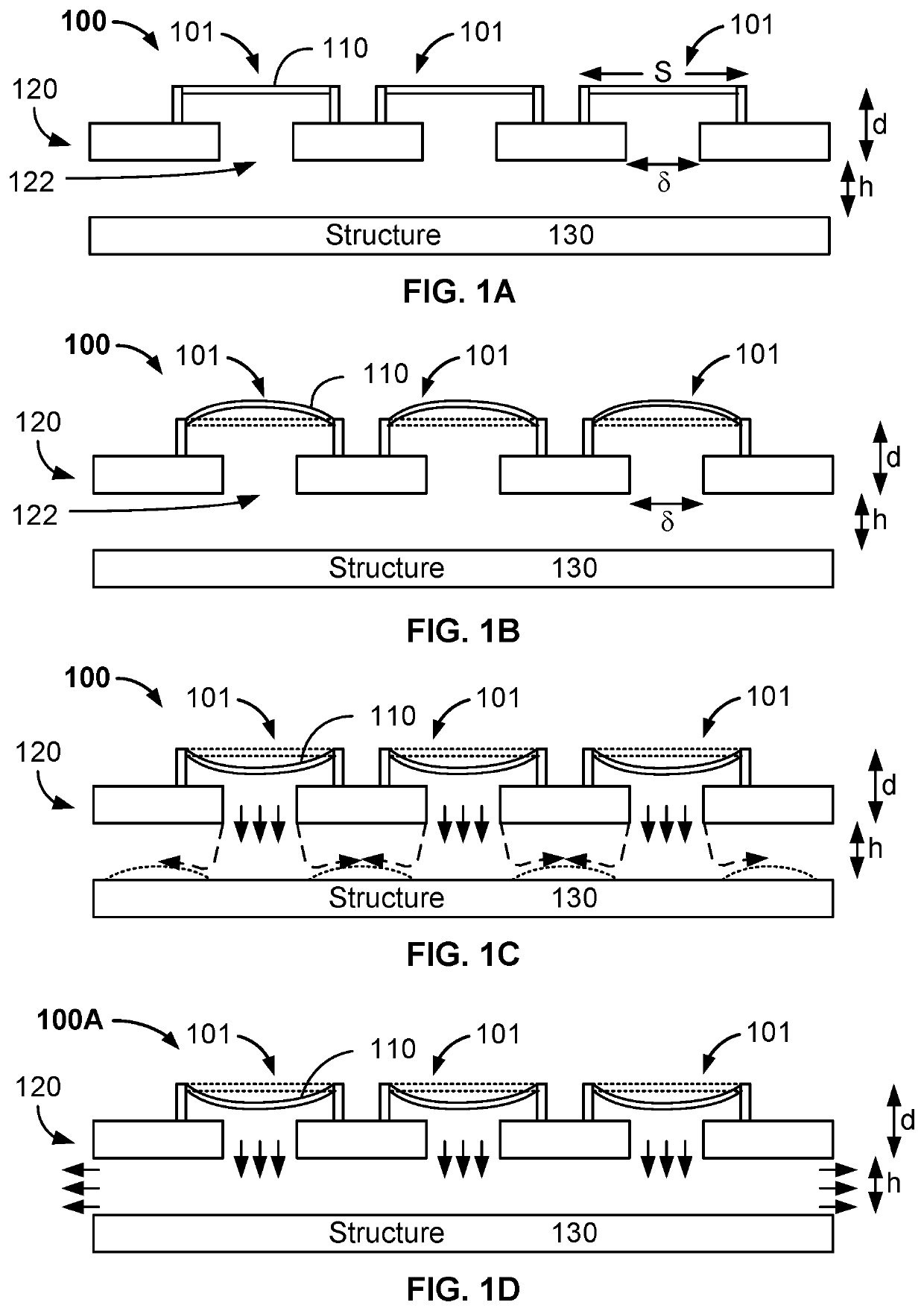

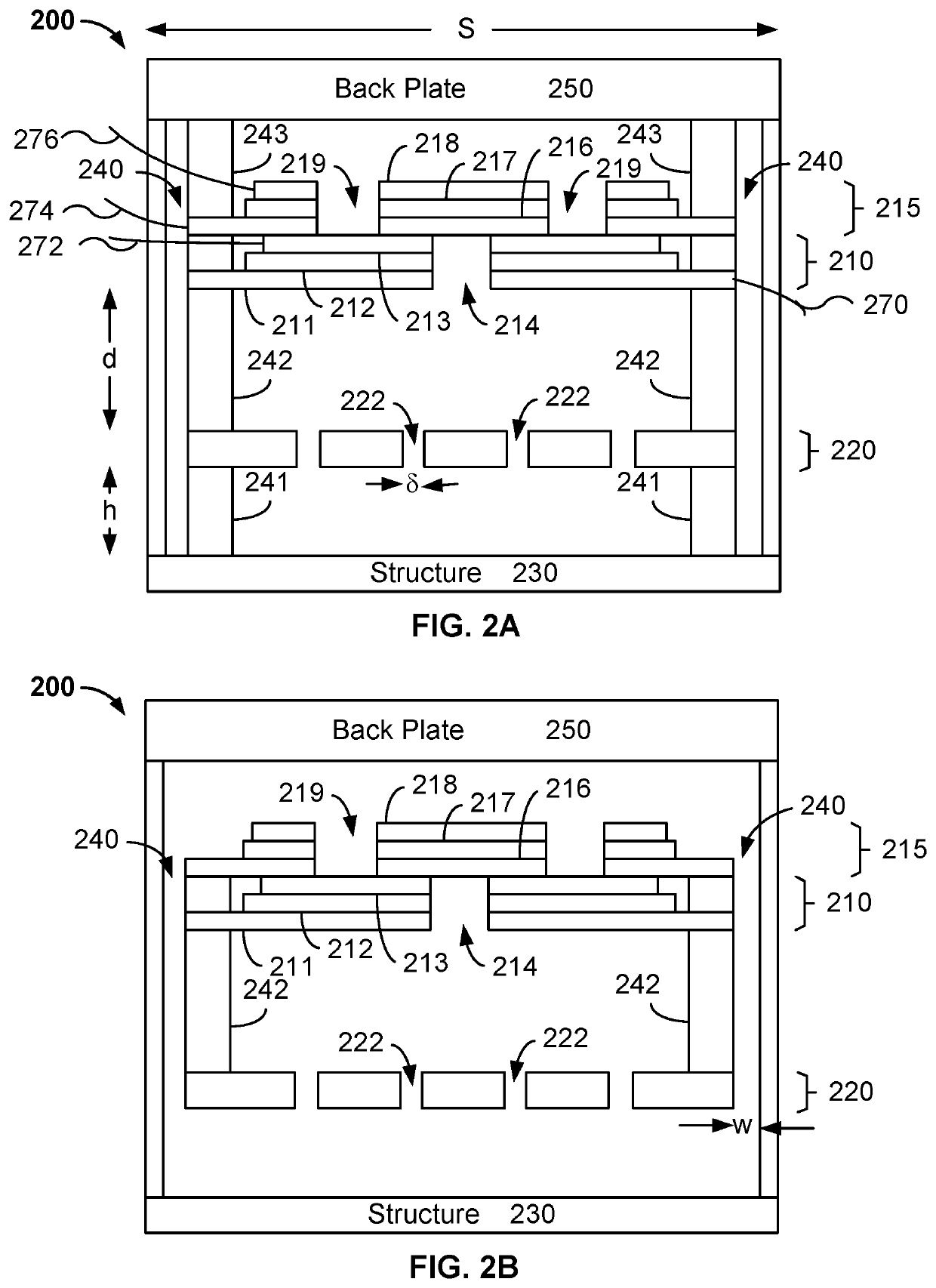

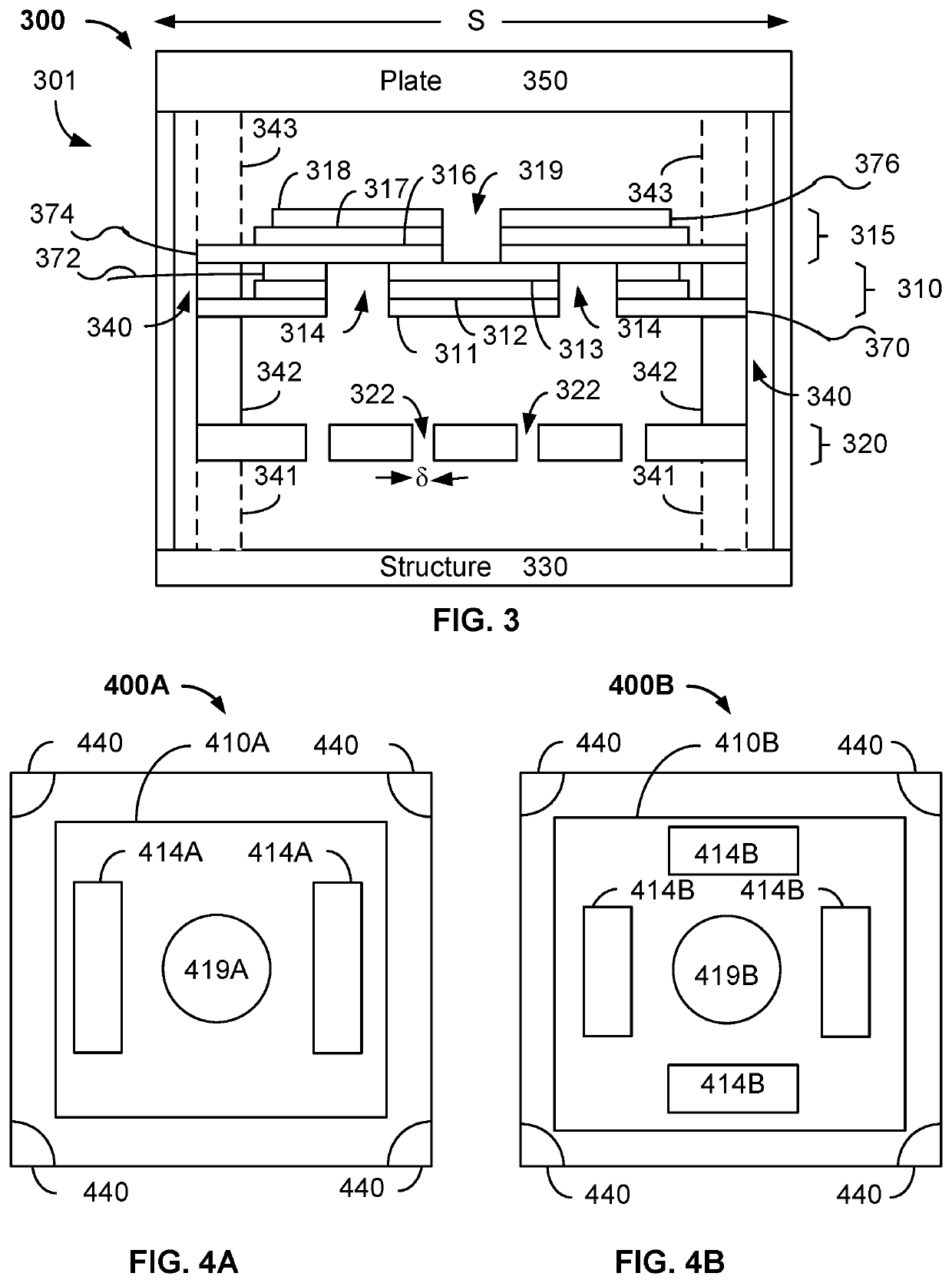

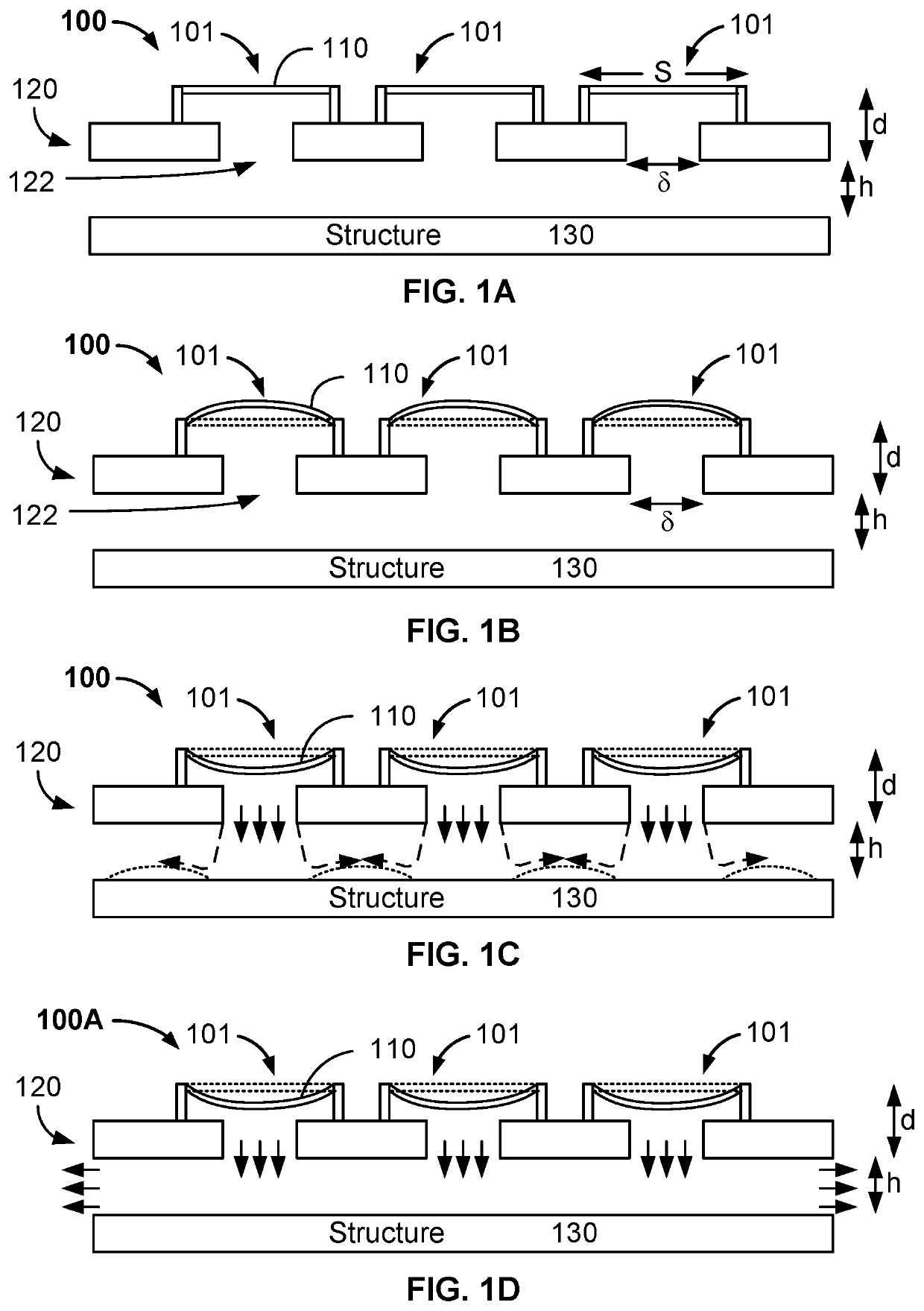

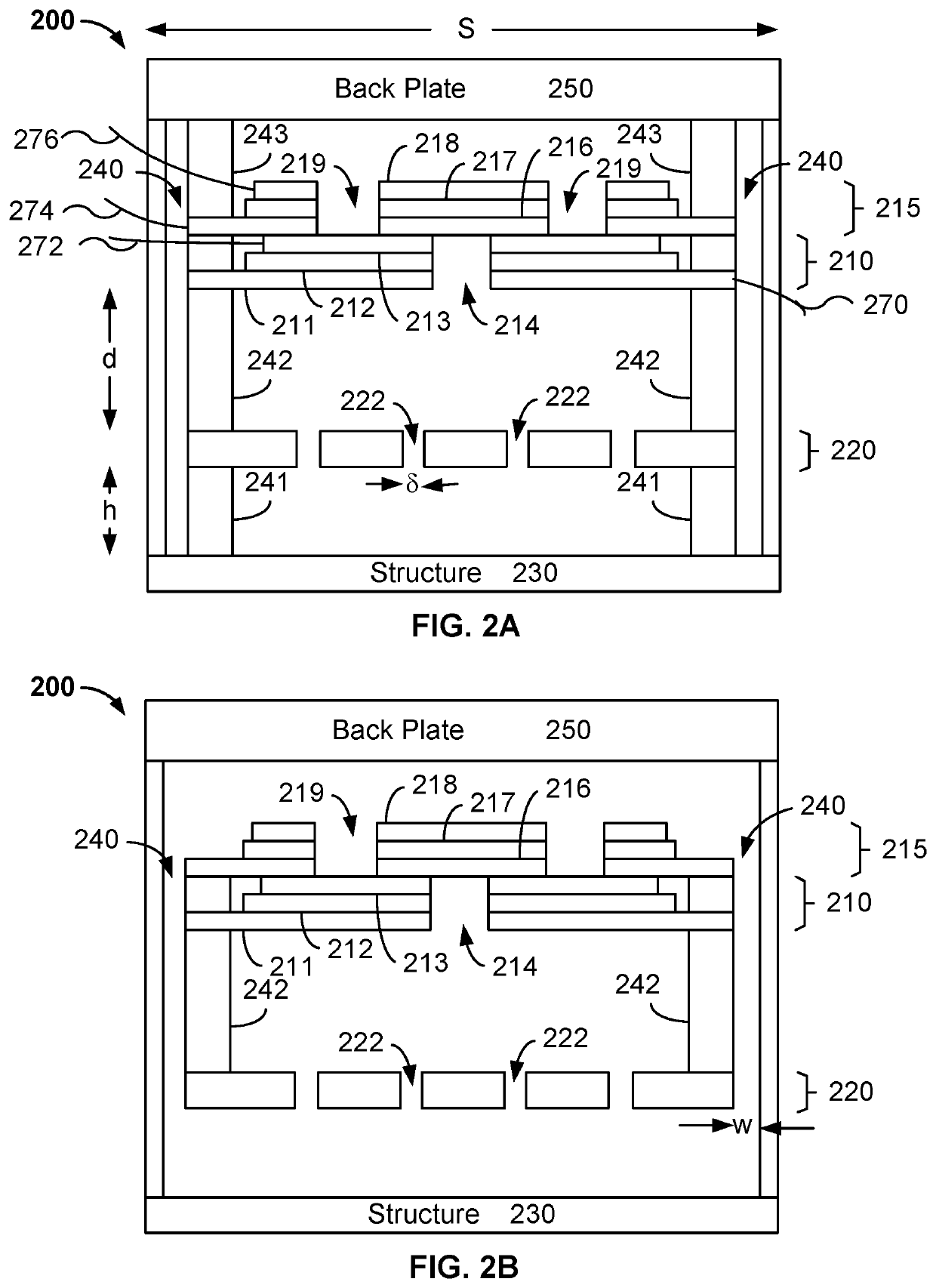

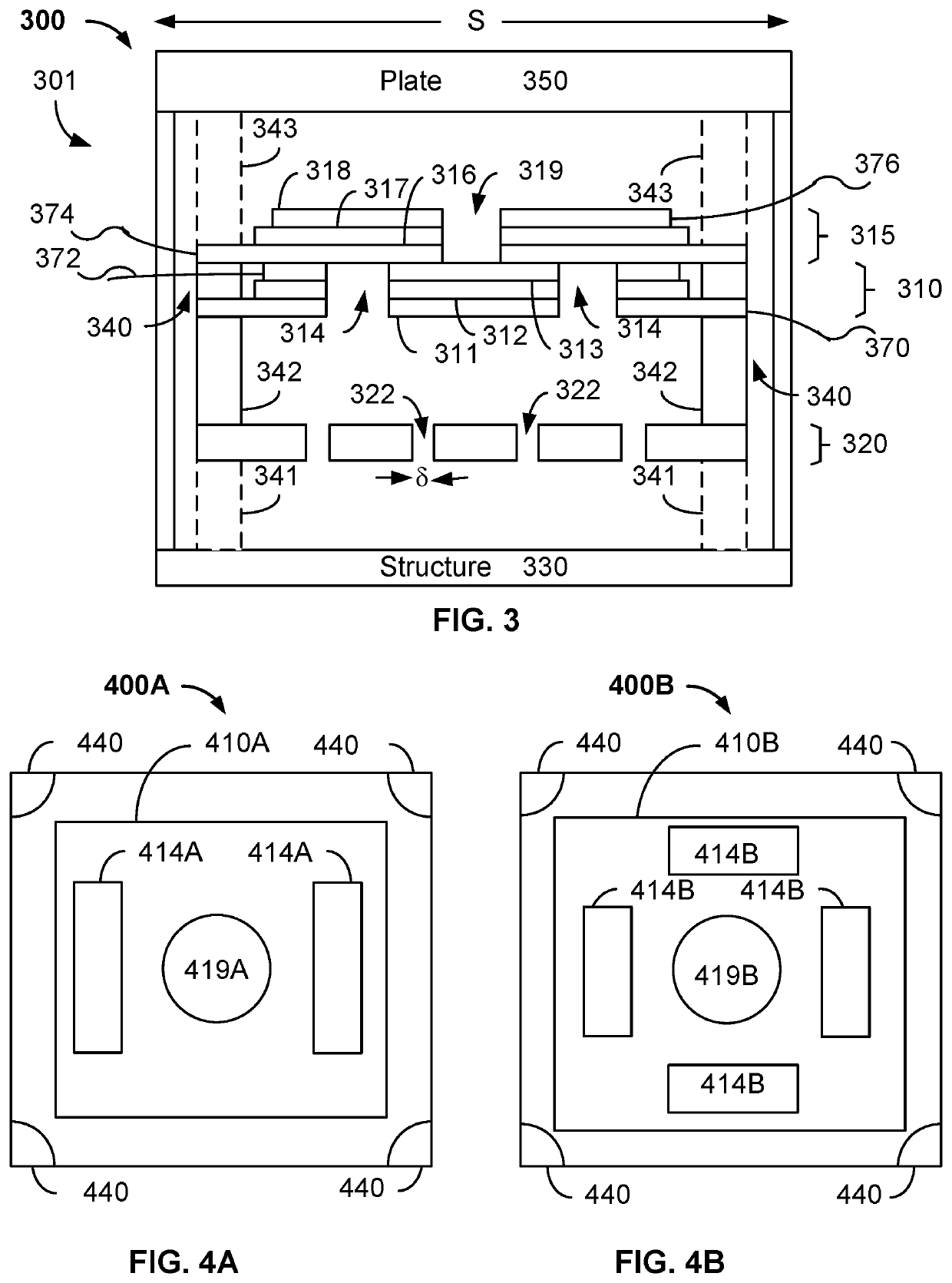

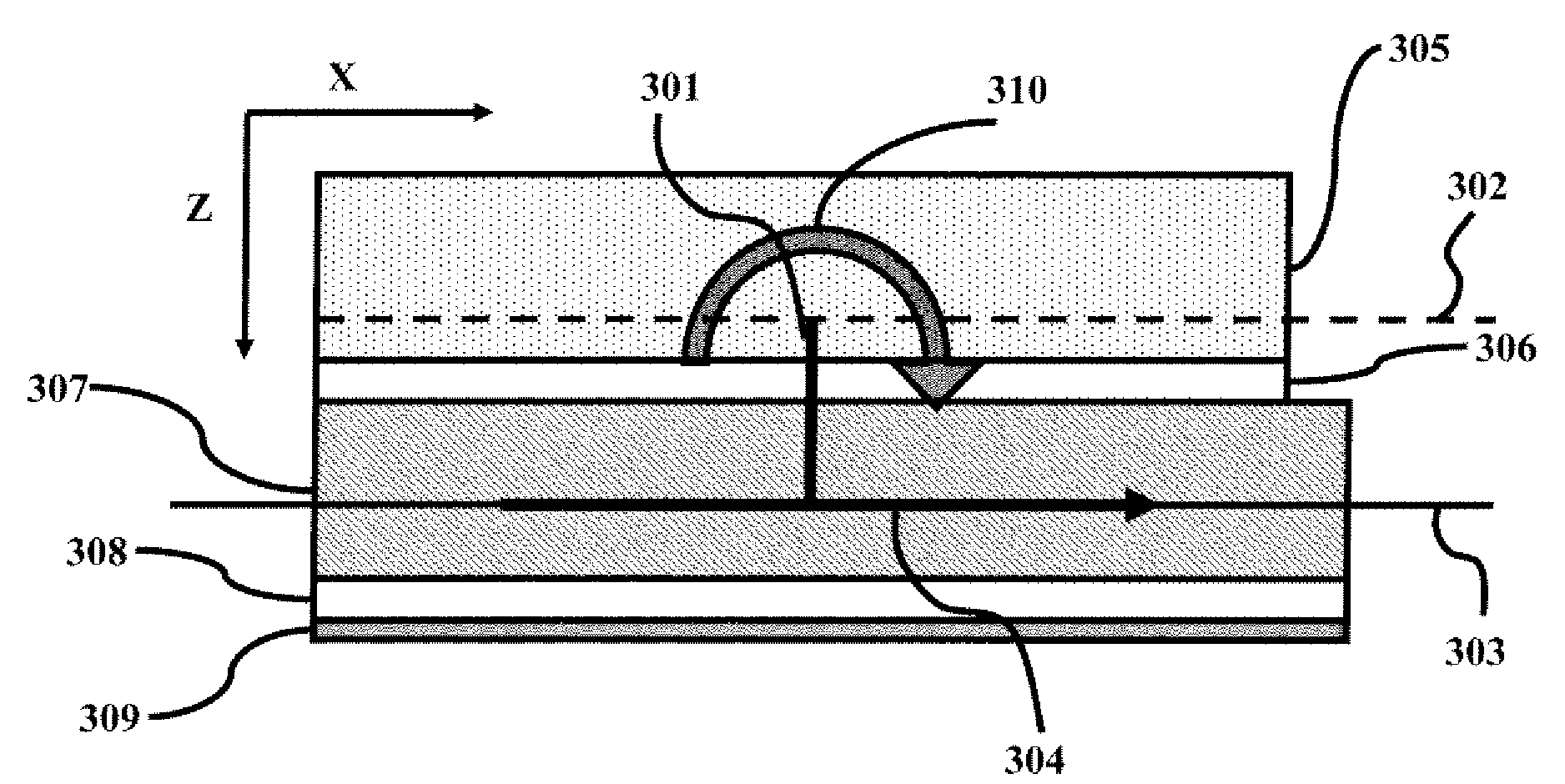

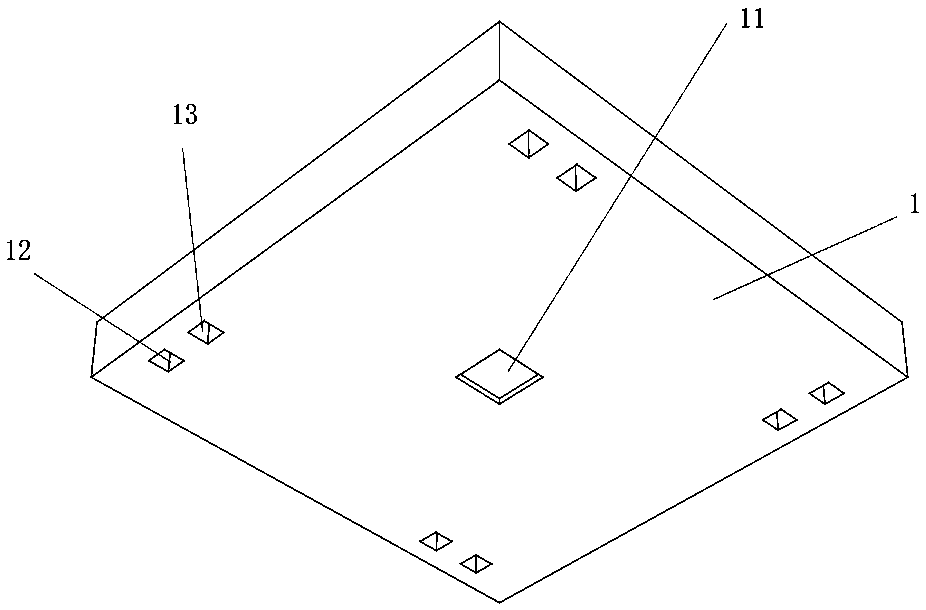

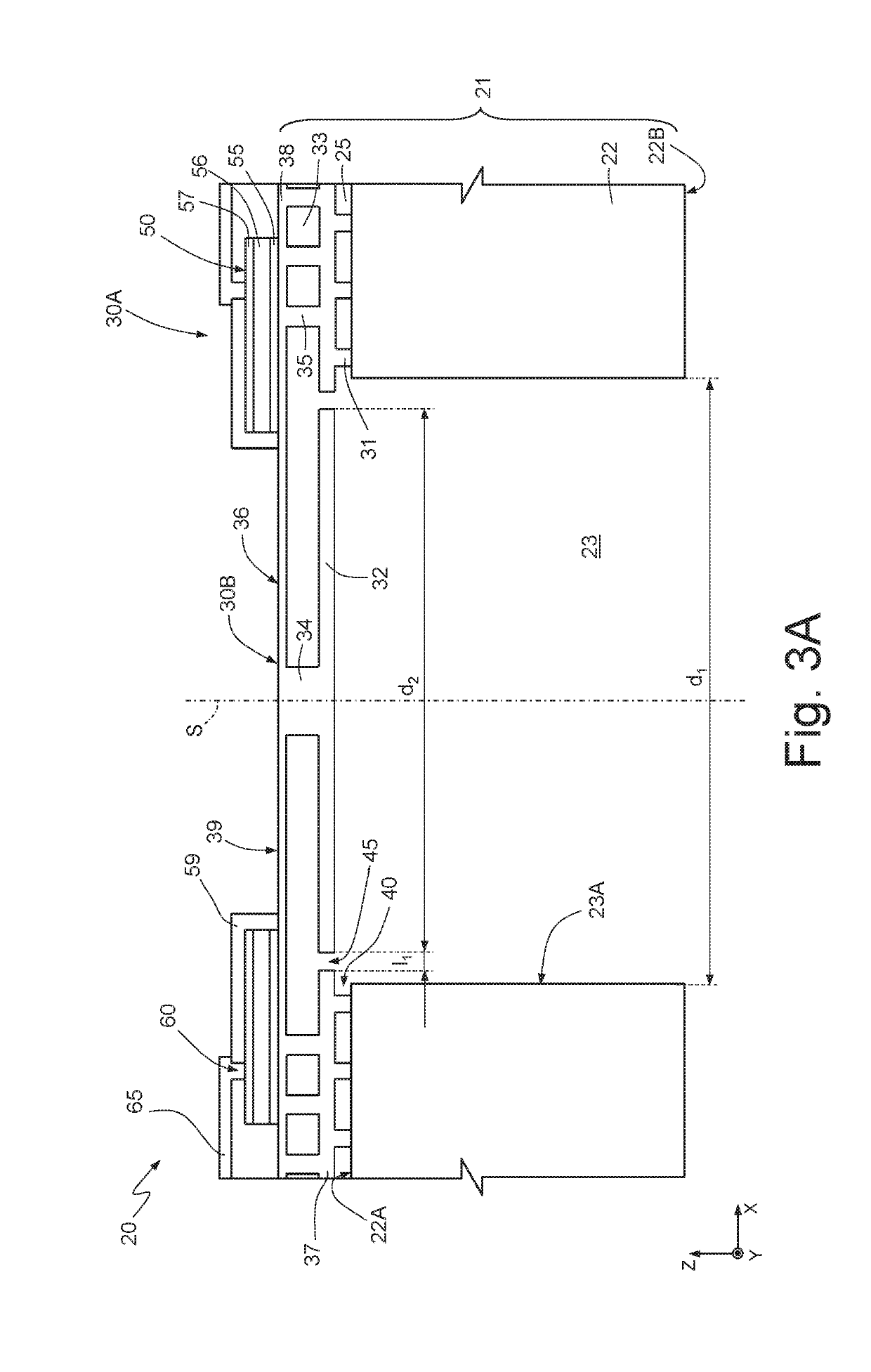

Piezoelectric MEMS-based active cooling for heat dissipation in compute devices

ActiveUS10943850B2Semiconductor/solid-state device detailsFlexible member pumpsThermodynamicsActive cooling

Owner:FRORE SYST INC

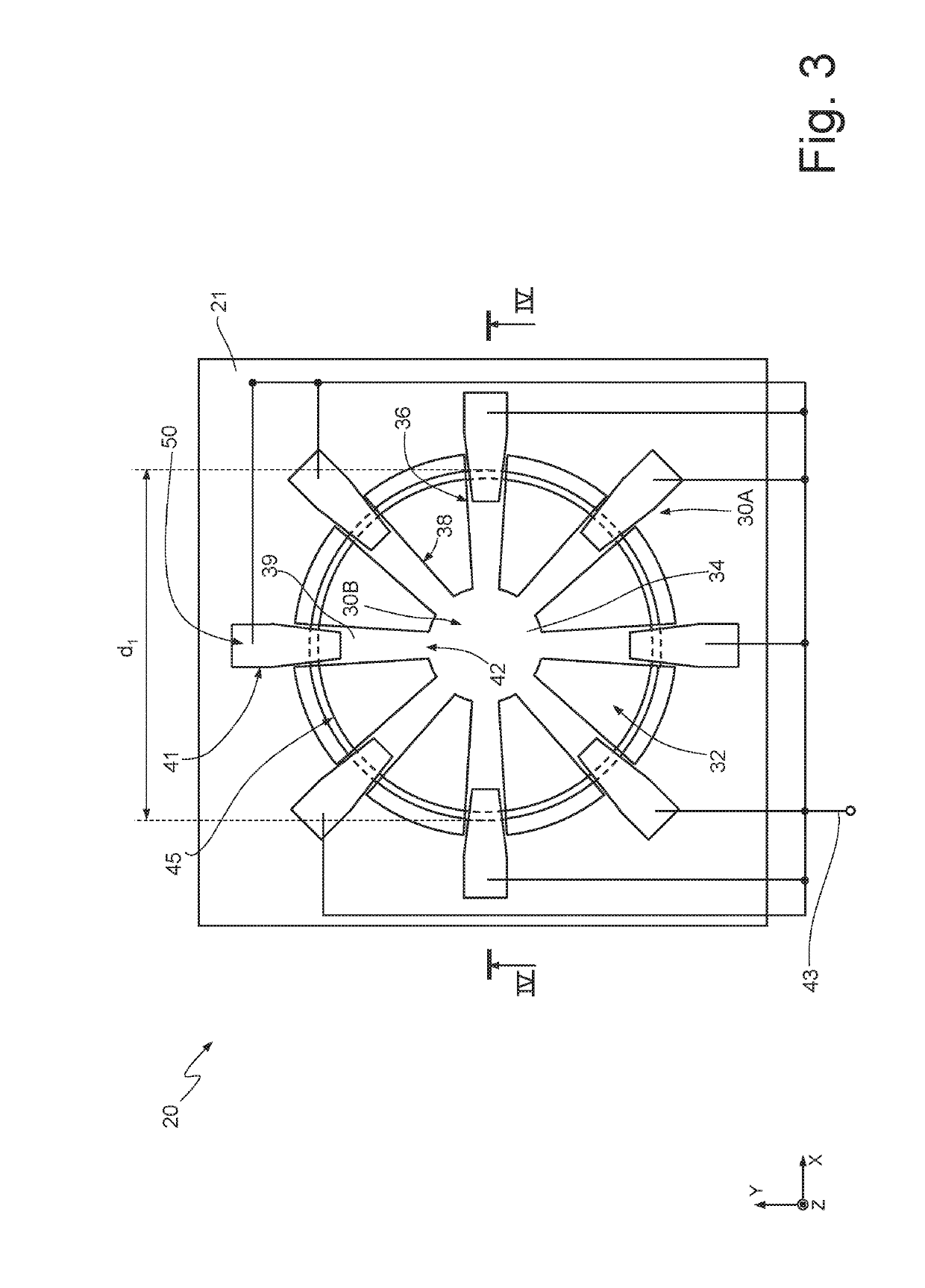

Piezoelectric MEMS microphone

ActiveCN110545511AHigh sensitivityPiezoelectric/electrostrictive microphonesMicrophonesPiezoelectric memsEngineering

The invention provides a piezoelectric MEMS (Micro Electro Mechanical System) microphone. The piezoelectric MEMS microphone comprises a substrate with a cavity and a piezoelectric vibrating diaphragmarranged on the substrate, wherein the substrate comprises an annular base and a supporting column arranged on the inner side of the annular base at intervals, the piezoelectric vibrating diaphragm comprises a plurality of diaphragms arranged in the circumferential direction of the supporting column at intervals, each diaphragm comprises a fixed end connected with the supporting column and a freeend suspended above the cavity, and the width of each diaphragm is gradually increased from the fixed end to the free end. According to the piezoelectric MEMS microphone, under the action of sound pressure, the free end vibrates, the short fixed end is driven by the wide free end, and the diaphragm close to the fixed end deforms greatly to generate more charges, so that the sensitivity can be further improved.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

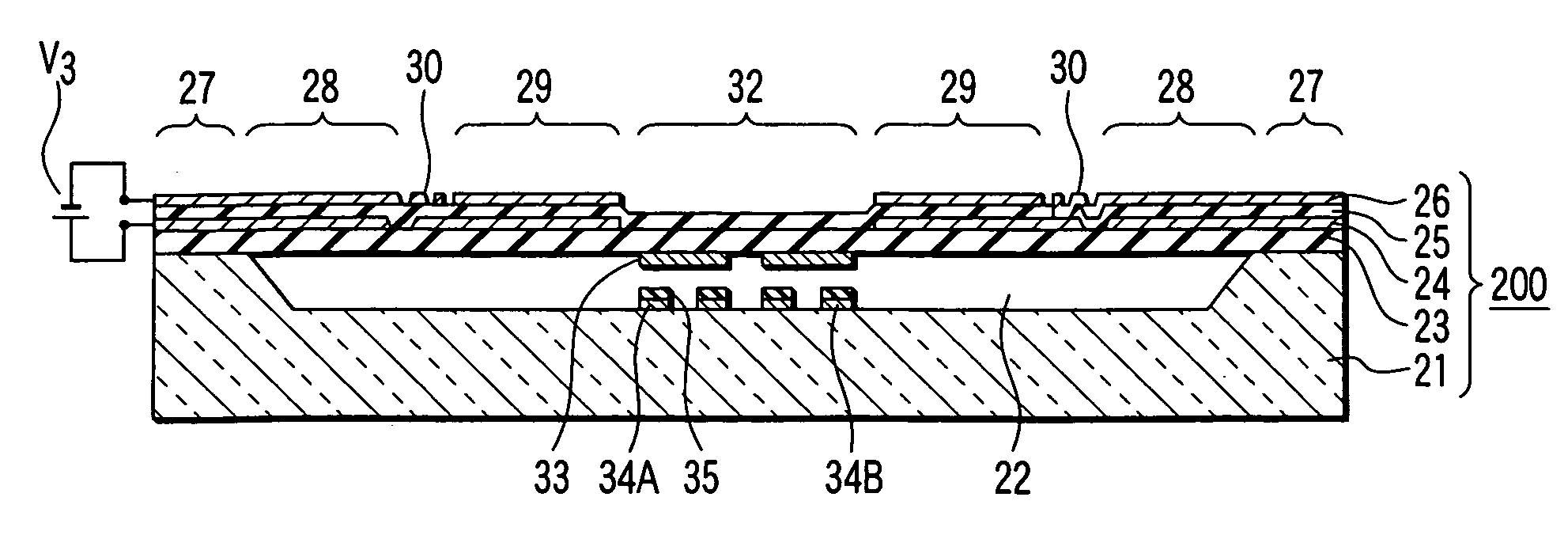

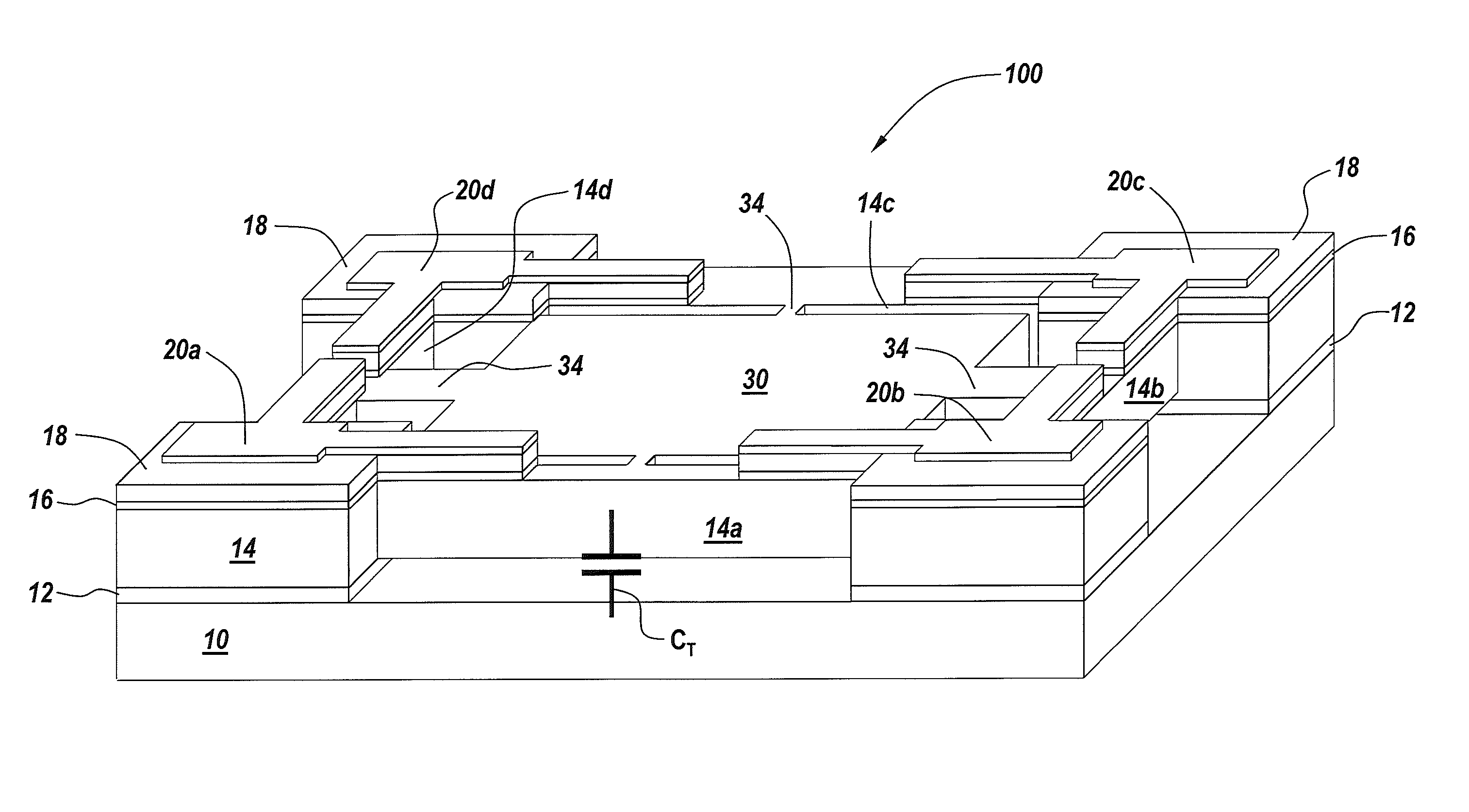

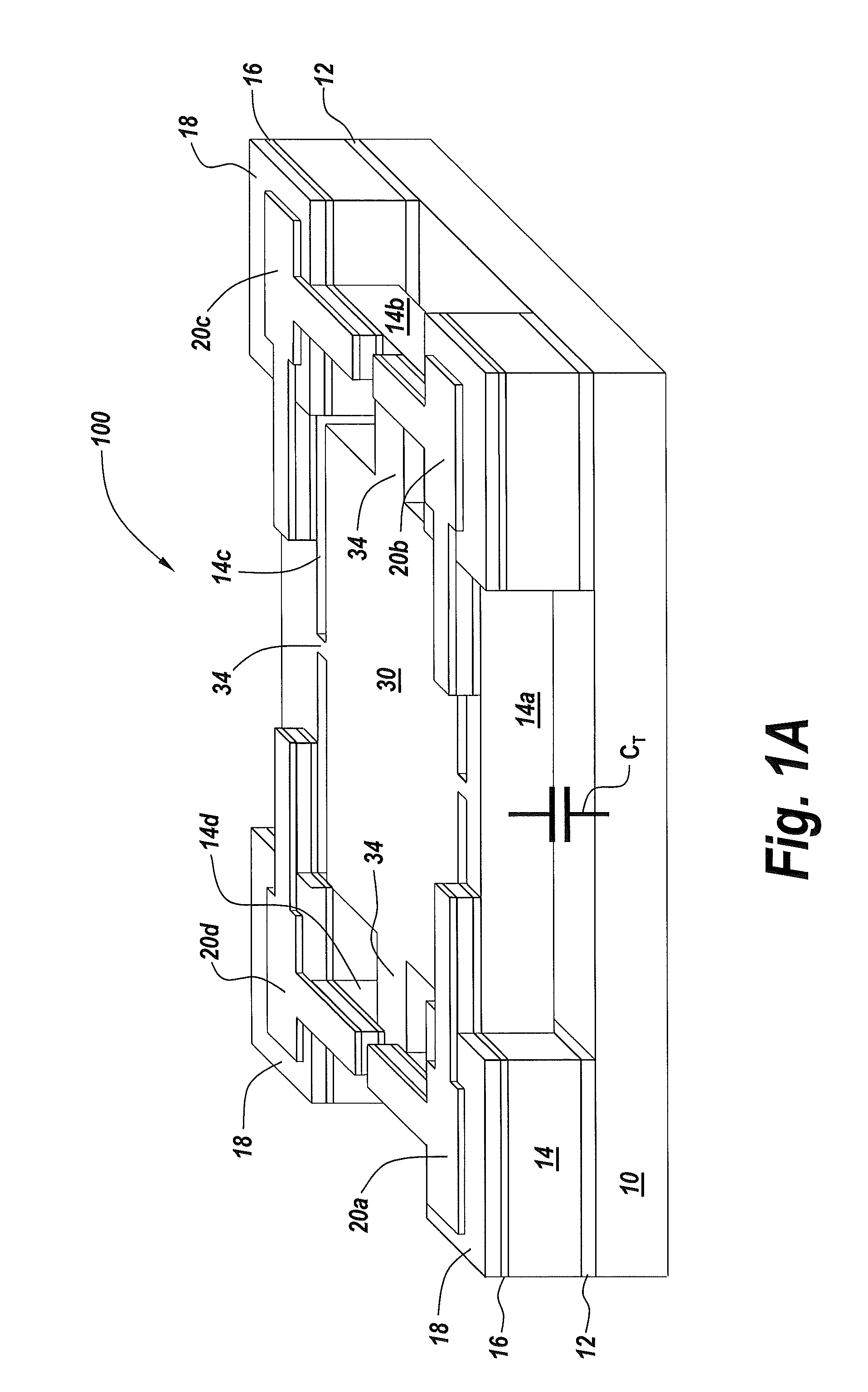

Piezoelectric MEMS element and tunable filter equipped with the piezoelectric MEMS element

InactiveUS7471031B2Multiple-port networksPiezoelectric/electrostriction/magnetostriction machinesCapacitancePiezoelectric mems

In a MEMS type variable capacity having a piezoelectric driving mechanism, a movable head having movable electrodes are arranged thereon, stationary electrodes is positioned to face the movable electrodes, and a piezoelectric driving beam structure is joined to the movable head and have one end fixed to the substrate. The movable electrode and the stationary electrode form a variable capacity. In the variable capacity, the distance and capacitance between the movable electrode and the stationary electrode of the variable capacity can be maintained constant so as to realize a reproducibility and a reliable controllability.

Owner:KK TOSHIBA

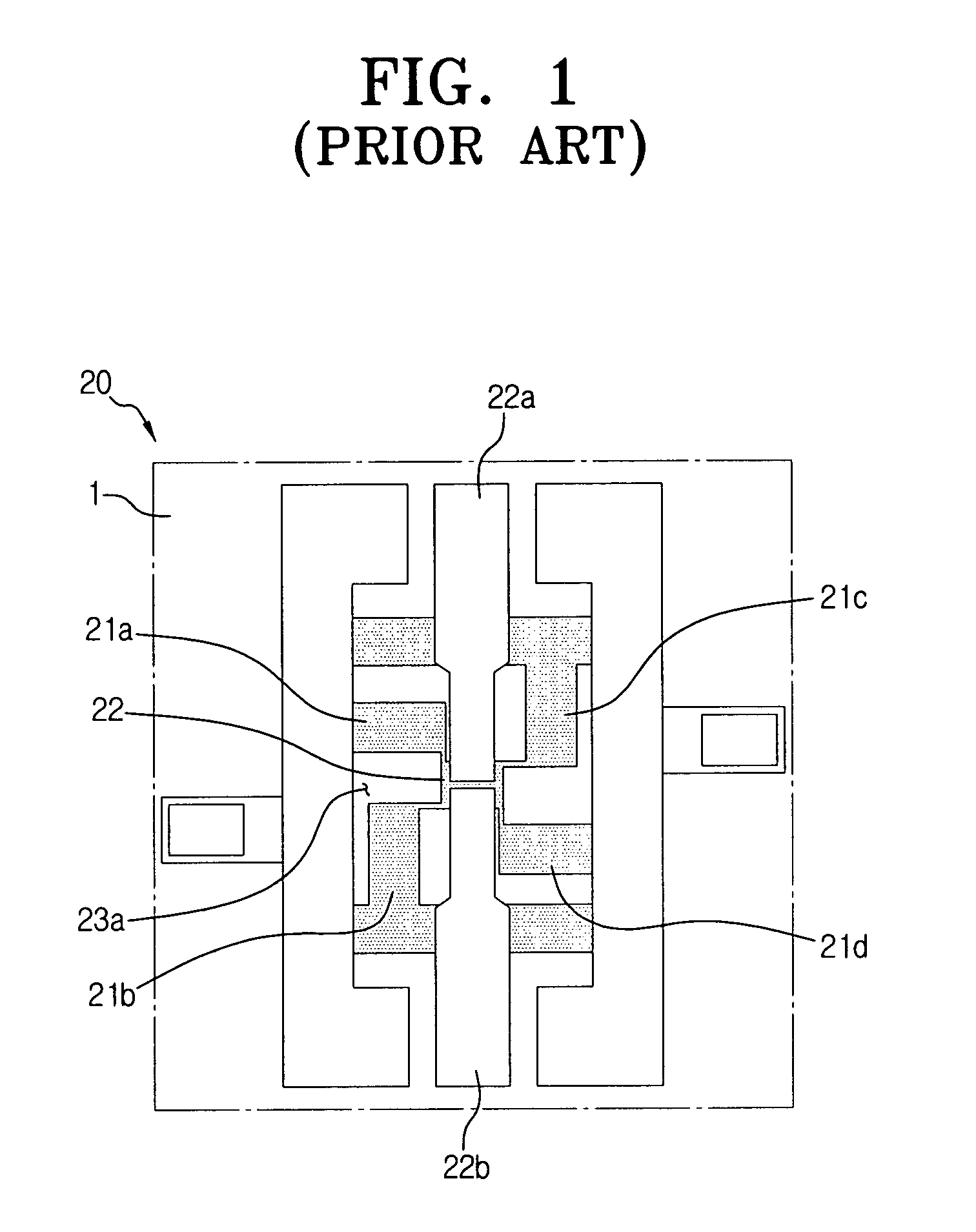

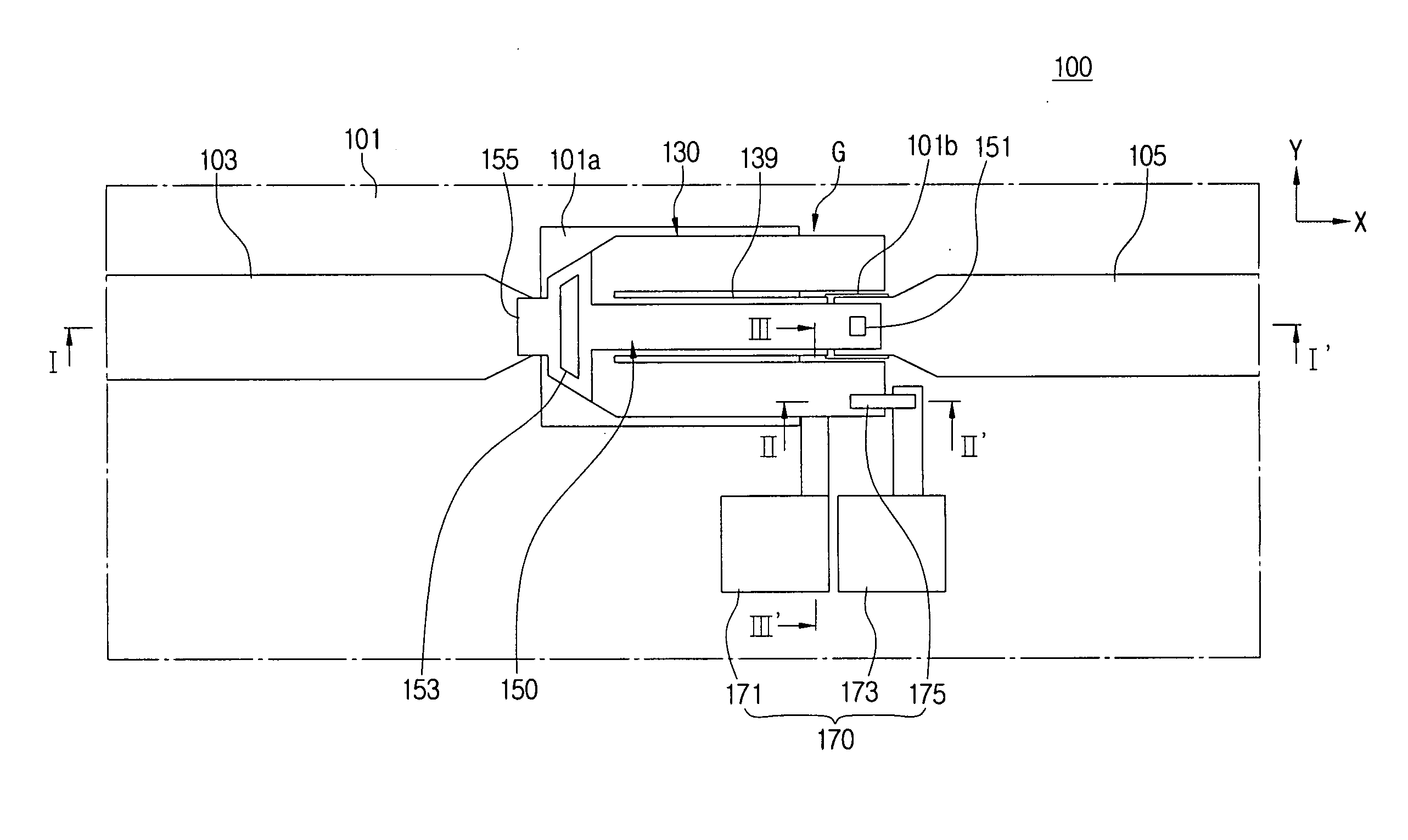

Piezoelectric MEMS switch and method of fabricating the same

InactiveUS7545246B2Increase freedomImprove drivabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsPiezoelectric mems

A piezoelectric Micro Electro Mechanical System (MEMS) switch includes a substrate, first and second fixed signal lines symmetrically formed in a spaced-apart relation to each other on the substrate to have a predetermined gap therebetween, a piezoelectric actuator disposed in alignment with the first and the second fixed signal lines in the predetermined gap, and having a first end supported on the substrate to allow the piezoelectric actuator to be movable up and down, and a movable signal line having a first end connected to one of the first and the second fixed signal lines, and a second end configured to be in contact with, or separate from the other of the first and second fixed signal lines, the movable signal line at least one side thereof being connected to an upper surface of the piezoelectric actuator.

Owner:SAMSUNG ELECTRONICS CO LTD

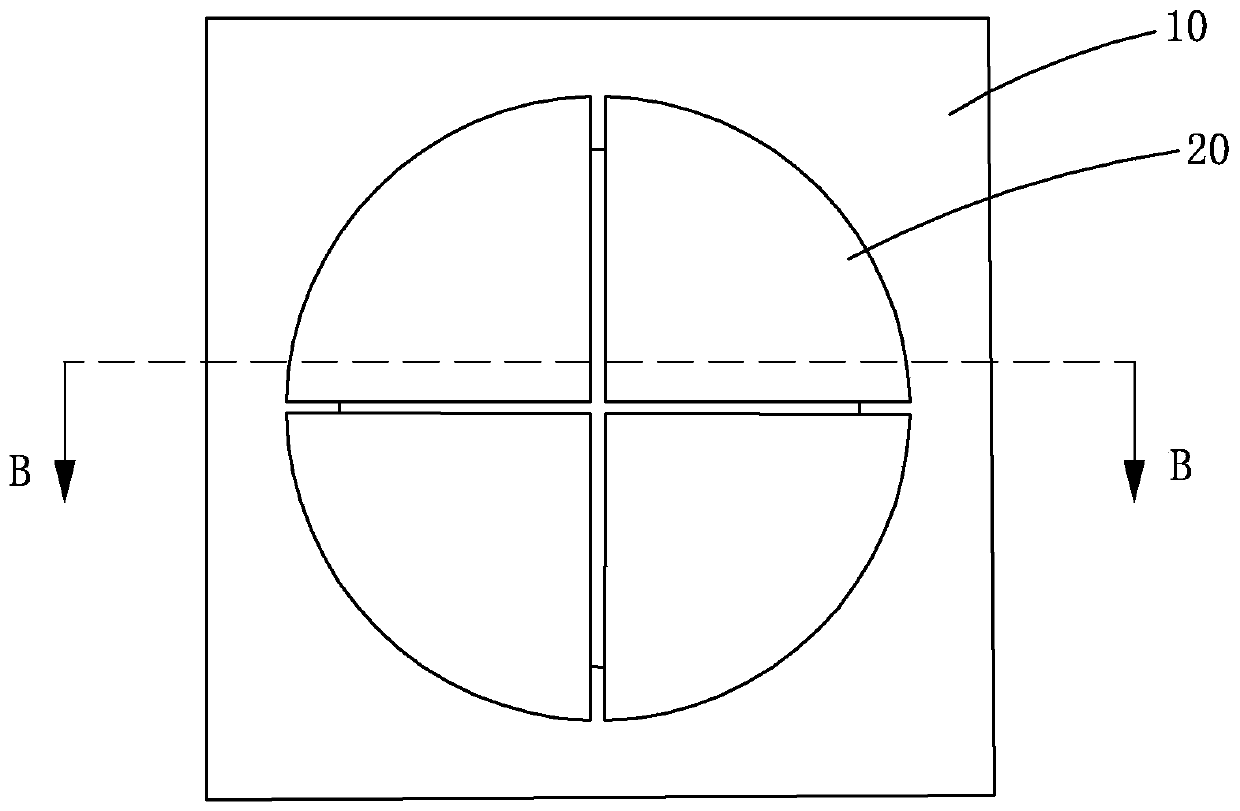

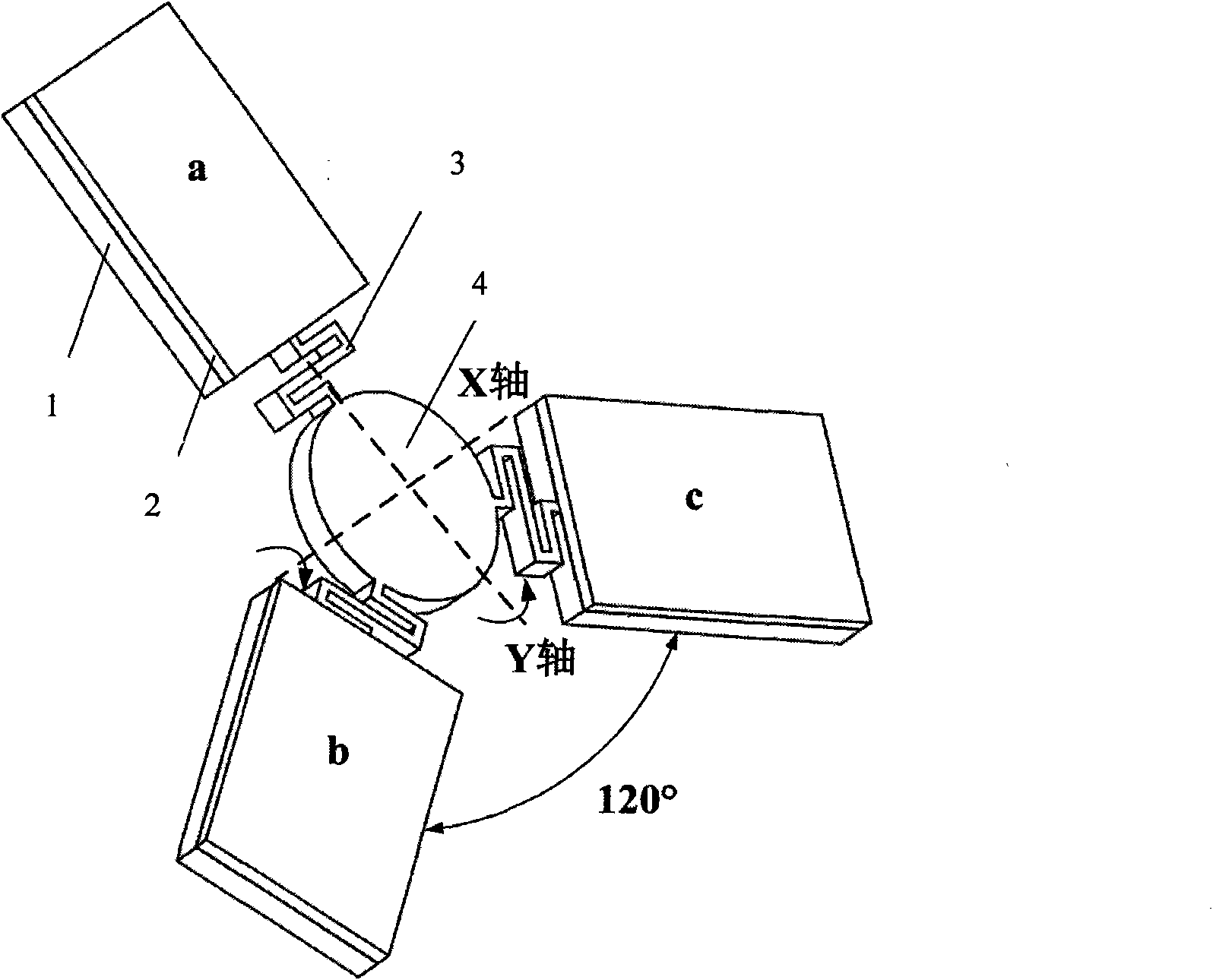

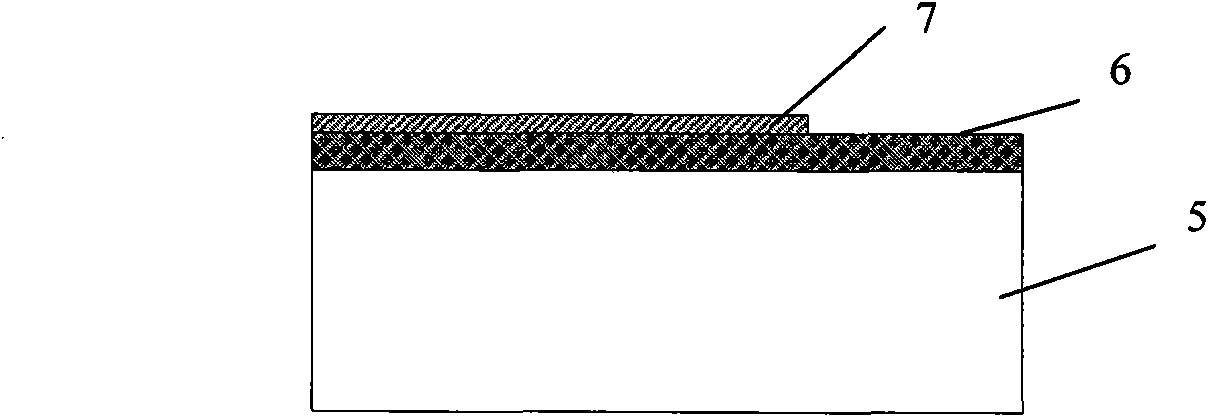

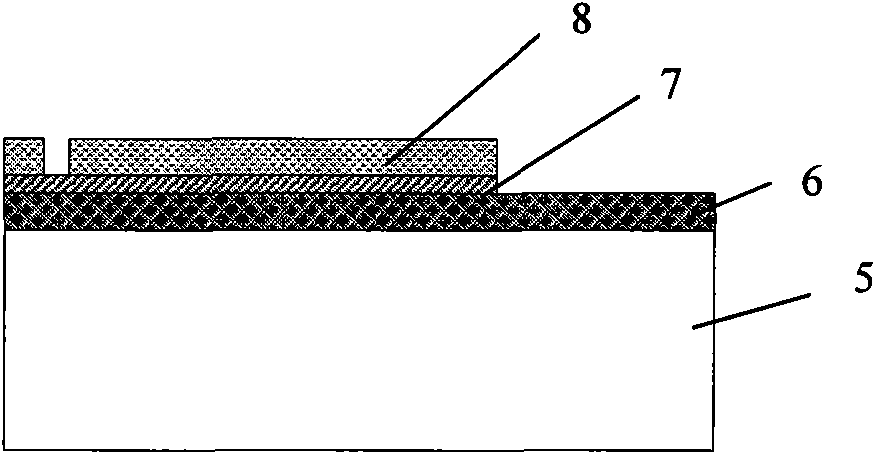

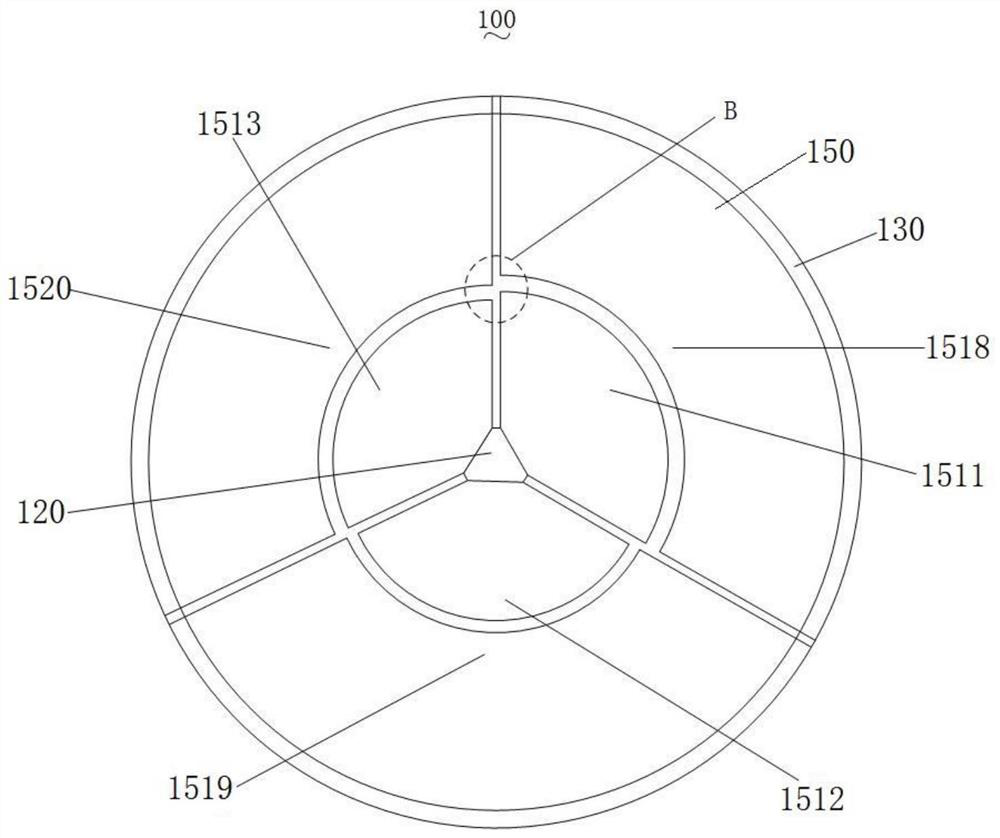

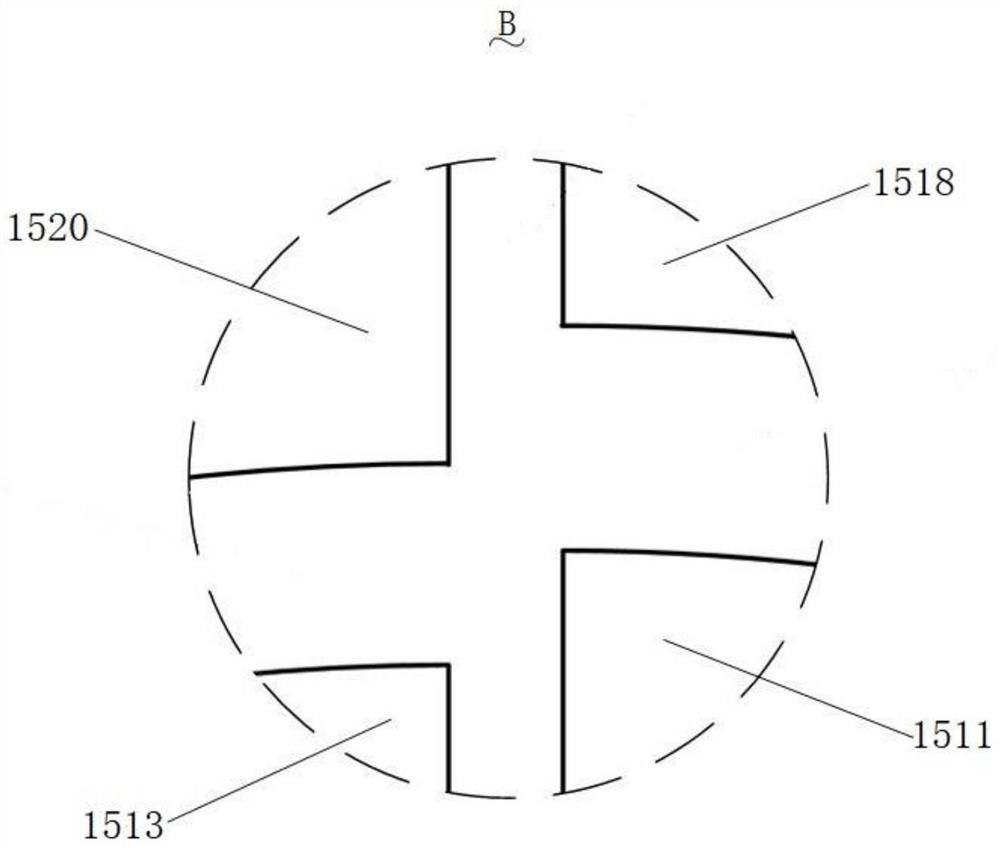

MEMS micro-lens driven by three piezoelectric cantilever beams and manufacturing method thereof

InactiveCN101937128ALow working voltageSmall sizeDecorative surface effectsChemical vapor deposition coatingSurface patternPiezoelectric mems

The invention relates to an MEMS micro-lens driven by three piezoelectric cantilever beams and a manufacturing method thereof and belongs to the technical field of piezoelectric MEMS appliance designs and integrated manufacturing. The MEMS micro-lens comprises a micro-reflecting mirror surface, the piezoelectric cantilever beams and arched bent elastic narrow beams, wherein each of the piezoelectric cantilever beams is formed by fixing a PZT driving membrane with more than 2 mu m thickness on the surface of a silicon cantilever beam; the three piezoelectric cantilever beams are connected with the micro-lens micro-reflecting mirror surface through three arched bent elastic narrow beams respectively; and the piezoelectric cantilever beams are distributed in a way that an included angle of 120 degrees is formed between every two piezoelectric cantilever beams. The manufacturing method comprises the following steps of: firstly, preparing a piezoelectric thick membrane on a substrate and etching piezoelectric cantilever beam patterns on the piezoelectric thick membrane; secondly, preparing a Au / Cr two-layer metal top electrode and a micro micro-reflecting mirror surface pattern on the PZT piezoelectric thick membrane; and finally, etching a Si substrate on the front and back faces so as to form the MEMS micro-lens driven by the three piezoelectric cantilever beams. The MEMS micro-lens has the advantages of many deflecting directions, strong driving force of the PZT thick membrane and low optical loss. The manufacturing process is compatible with the MEMS process, so that the MEMS micro-lens has the potential of mass production and can be widely applied in the field of optical communication.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

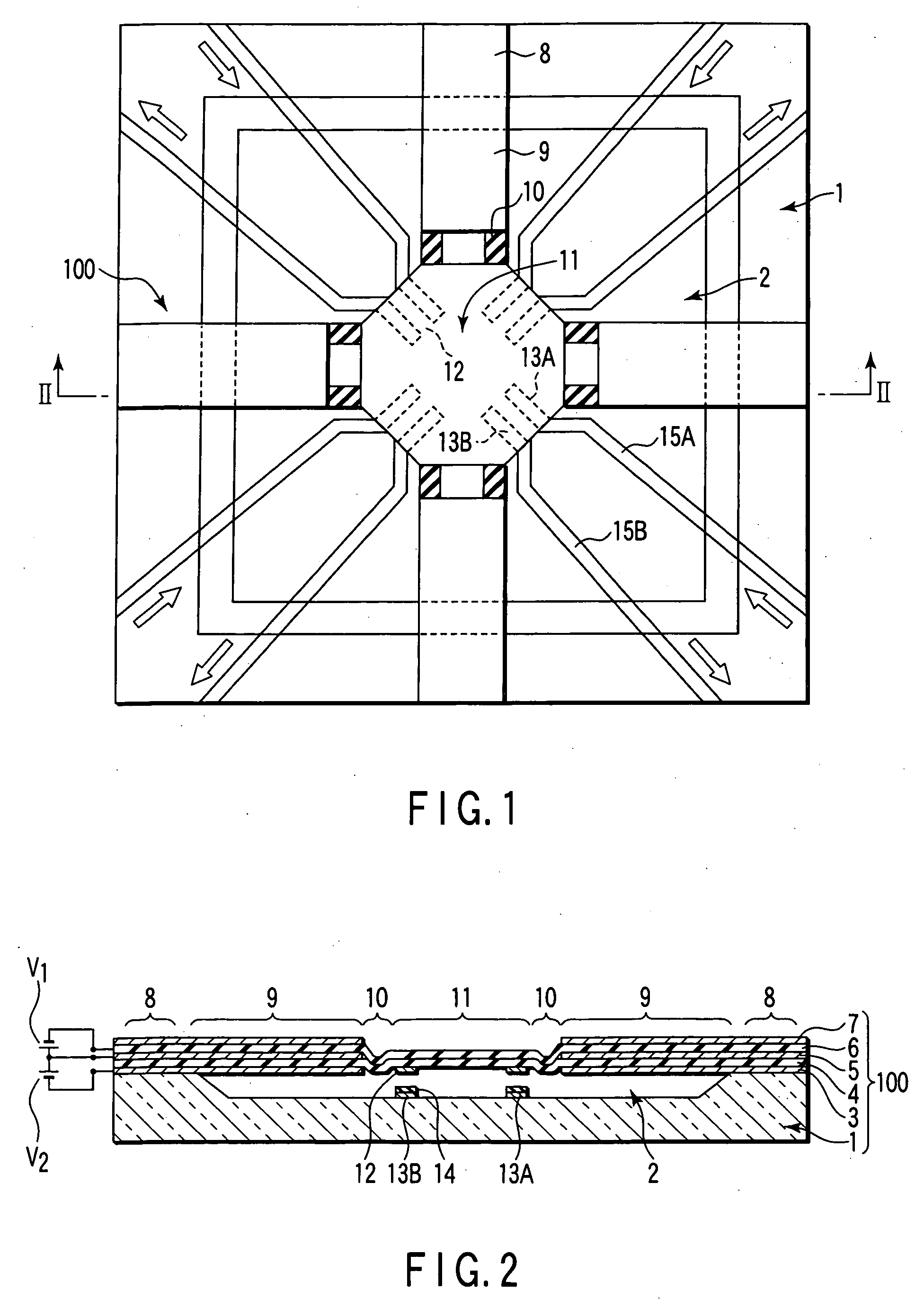

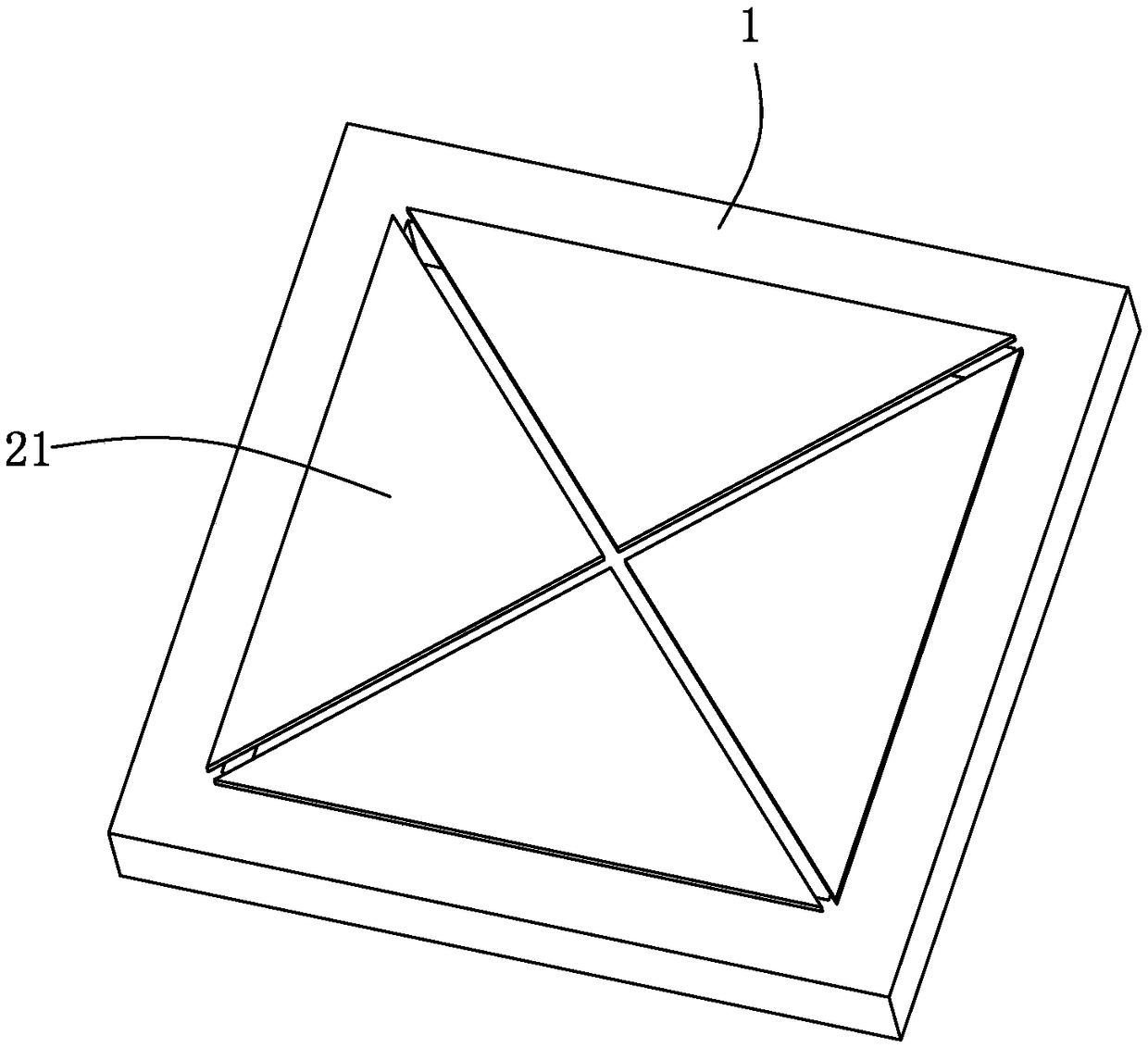

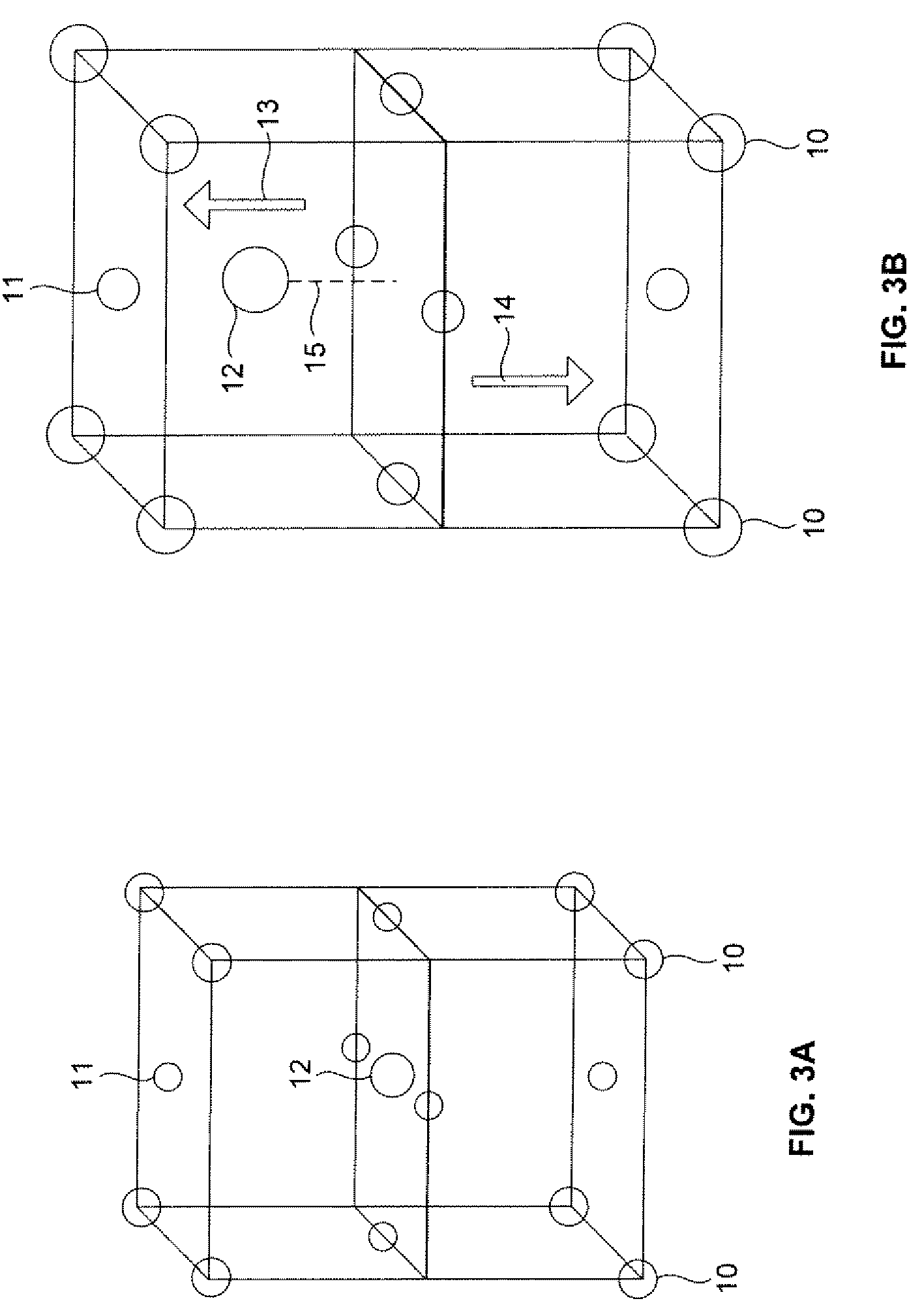

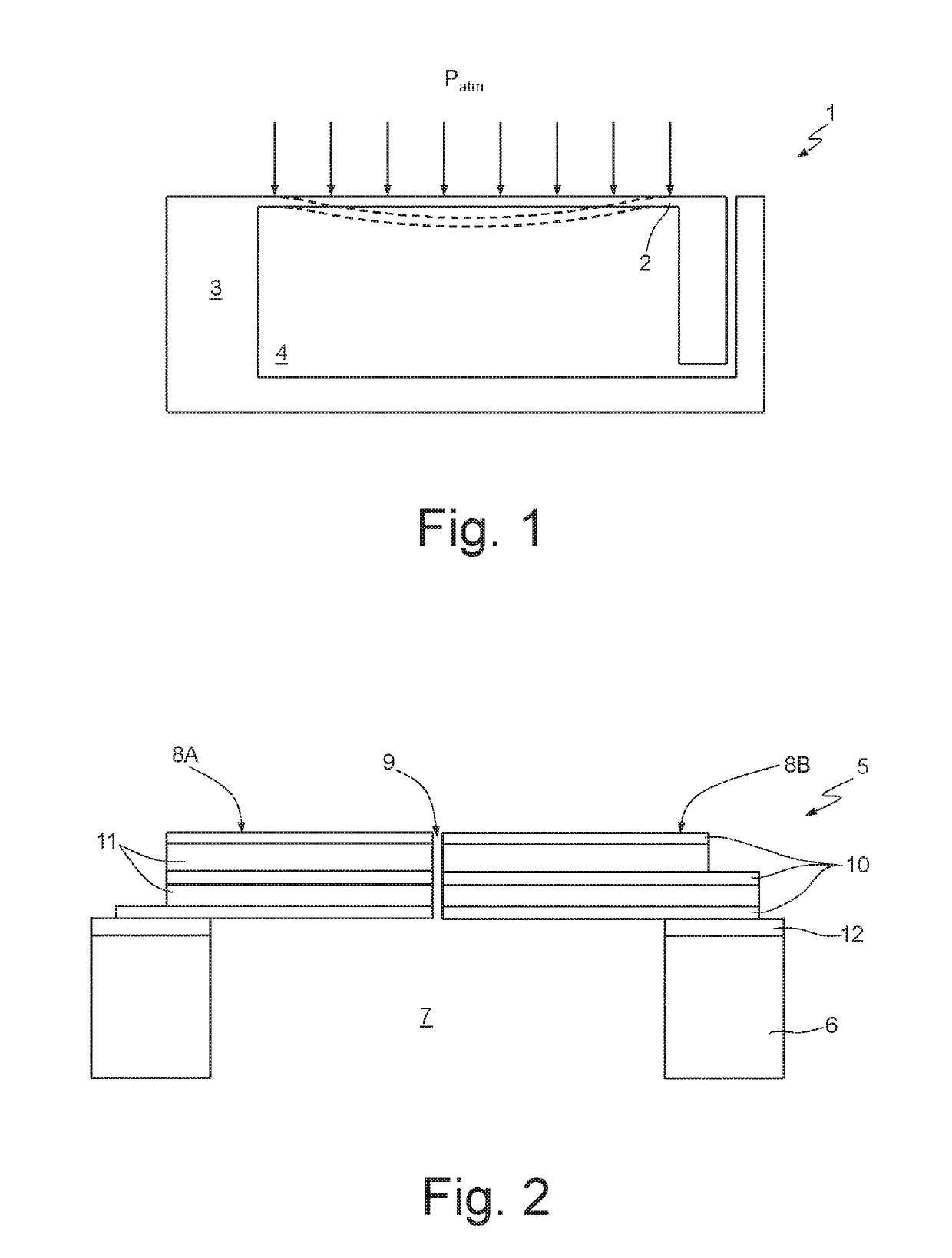

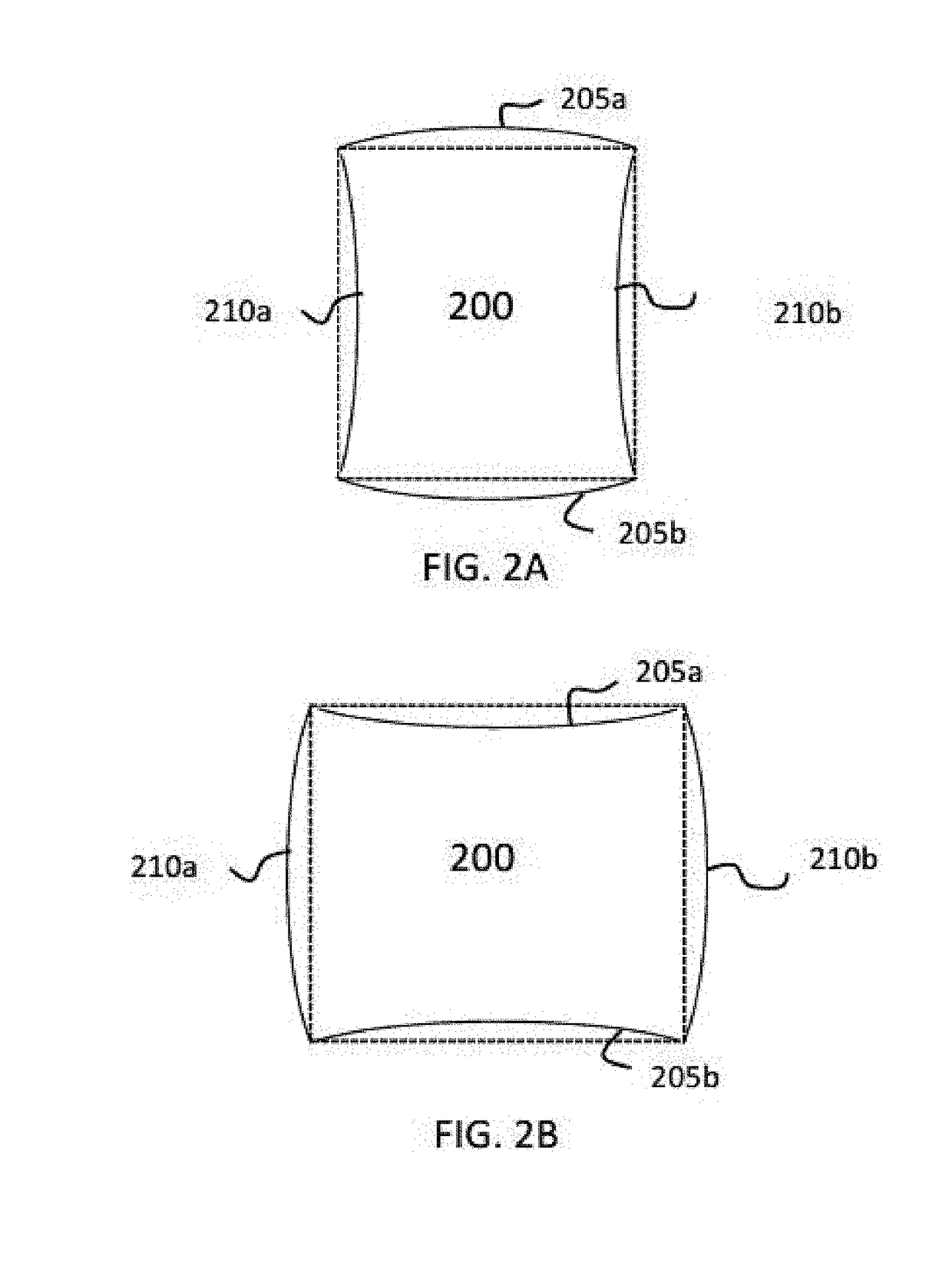

Tunable Piezoelectric MEMS Resonators suitable for real-time clock applications

InactiveUS8450913B1Low resonance frequency of operationSmall sizeImpedence networksPiezoelectric/electrostriction/magnetostriction machinesReal-time clockShaped beam

A microelectromechanical resonator can include a suspended frame-shaped beam anchored at four corners thereof to a surrounding substrate along with a suspended resonator plate tethered on four sides thereof to corresponding sides of the frame-shaped beam. A pair of drive electrodes are provided on first and third diametrically opposite corners of the frame-shaped beam and a pair of sense electrodes are provided on second and fourth diametrically opposite corners of the frame-shaped beam. The resonator may also include a ground electrode on the frame-shaped beam and a piezoelectric layer sandwiched between each of the drive and sense electrodes and the ground electrode.

Owner:GEORGIA TECH RES CORP

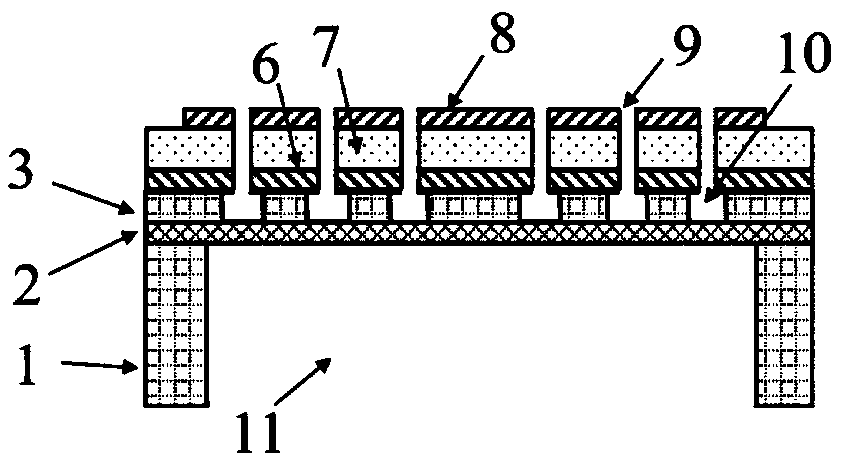

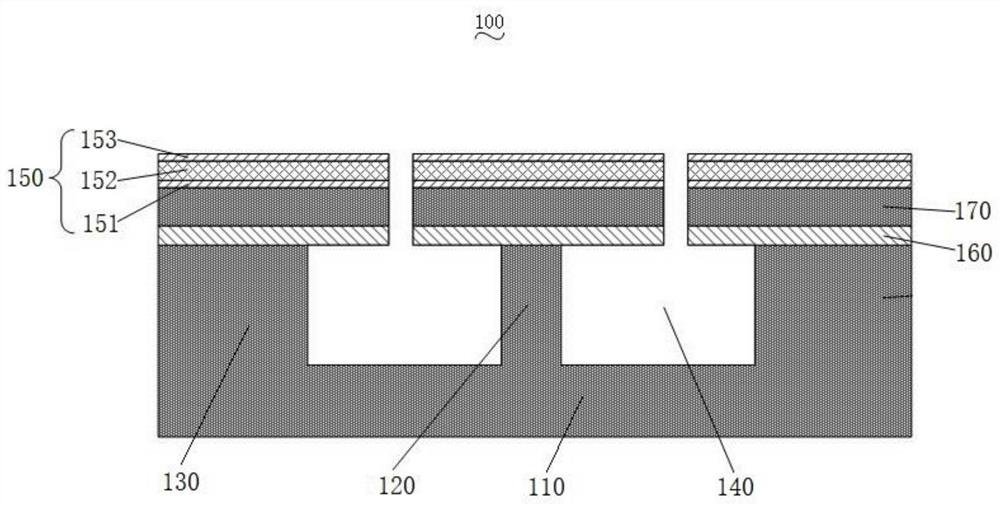

High-sensitivity piezoelectric MEMS sensor and preparation method thereof

ActiveCN108917991AImprove performanceIncrease deflectionTelevision system detailsImpedence networksInter layerPiezoelectric mems

The invention discloses a high-sensitivity piezoelectric MEMS sensor and a preparation method thereof. The piezoelectric MEMS sensor comprises a substrate and a piezoelectric stacking structure; the substrate is composed of a substrate bottom layer, a substrate intermediate layer and a substrate top layer from bottom to top; the substrate bottom layer is provided with a back cavity, and the substrate top layer is provided with regularly distributed hollow grooves; and the piezoelectric stacking structure is provided with a plurality of release holes penetrating through the piezoelectric stacking structure and communicating with the hollow grooves. According to the piezoelectric MEMS sensor of the invention, when the piezoelectric stacking structure, the substrate top layer and the substrate intermediate layer generate deformation, the flexural deflection of a piezoelectric film is increased due to the existence of the hollow grooves, the deformation degree of the piezoelectric film isenhanced, and a stronger electrical signal is output, so that the sensitivity of the piezoelectric sensor is improved.

Owner:武汉敏声新技术有限公司

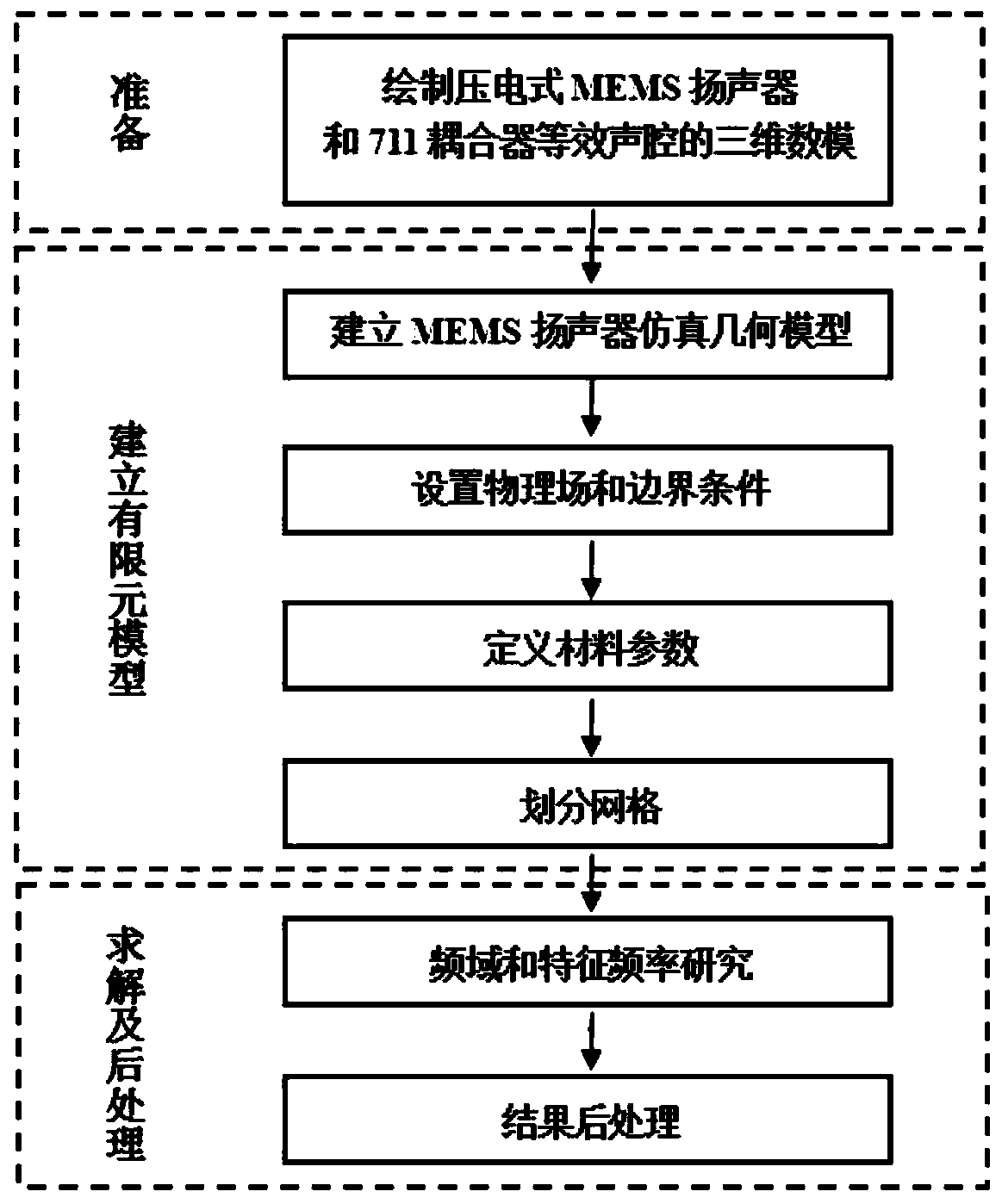

Numerical simulation analysis method for basic characteristics of piezoelectric MEMS loudspeaker

ActiveCN110442907ASimple structural designGood for guiding design structureSustainable transportationSemiconductor electrostatic transducersCapacitanceElement model

The invention discloses a numerical simulation analysis method for basic characteristics of a piezoelectric MEMS loudspeaker. The method comprises the following steps: 1) establishing a simulation geometric model of the MEMS loudspeaker; 2) setting physical fields and boundary conditions, including respectively setting material models, piezoelectric constitutive relations, dampers, constraint conditions, impedance boundaries, voltage loads and the like in 'solid mechanics', 'electric fields', 'pressure acoustics, frequency domains' and 'thermo-viscous acoustics, frequency domains' physical fields; 3) defining material parameters; and 4) setting the type and the size of the grid, and dividing the grid; 5) solving and calculating: respectively solving the finite element model by adopting frequency domain and characteristic frequency researches; and (6) result post-processing: obtaining a sound pressure level frequency response curve, a sound pressure and sound pressure level distributiondiagram, a change relation of capacitance values along with frequency, the magnitude and distribution diagram of stress / strain / displacement / speed / acceleration on a vibration part, and the resonance frequency and vibration mode of the MEMS loudspeaker through post-processing.

Owner:ZHEJIANG ELECTRO ACOUSTIC R&D CENT CAS

Piezoelectric MEMS microphone

A microphone including a casing having a front wall, a back wall, and a side wall joining the front wall to the back wall, a transducer mounted to the front wall, the transducer including a substrate and a transducing element, the transducing element having a transducer acoustic compliance dependent on the transducing element dimensions, a back cavity cooperatively defined between the back wall, the side wall, and the transducer, the back cavity having a back cavity acoustic compliance. The transducing element is dimensioned such that the transducing element length matches a predetermined resonant frequency and the transducing element width, thickness, and elasticity produces a transducer acoustic compliance within a given range of the back cavity acoustic compliance.

Owner:RGT UNIV OF MICHIGAN +1

Self-poling piezoelectric MEMS device

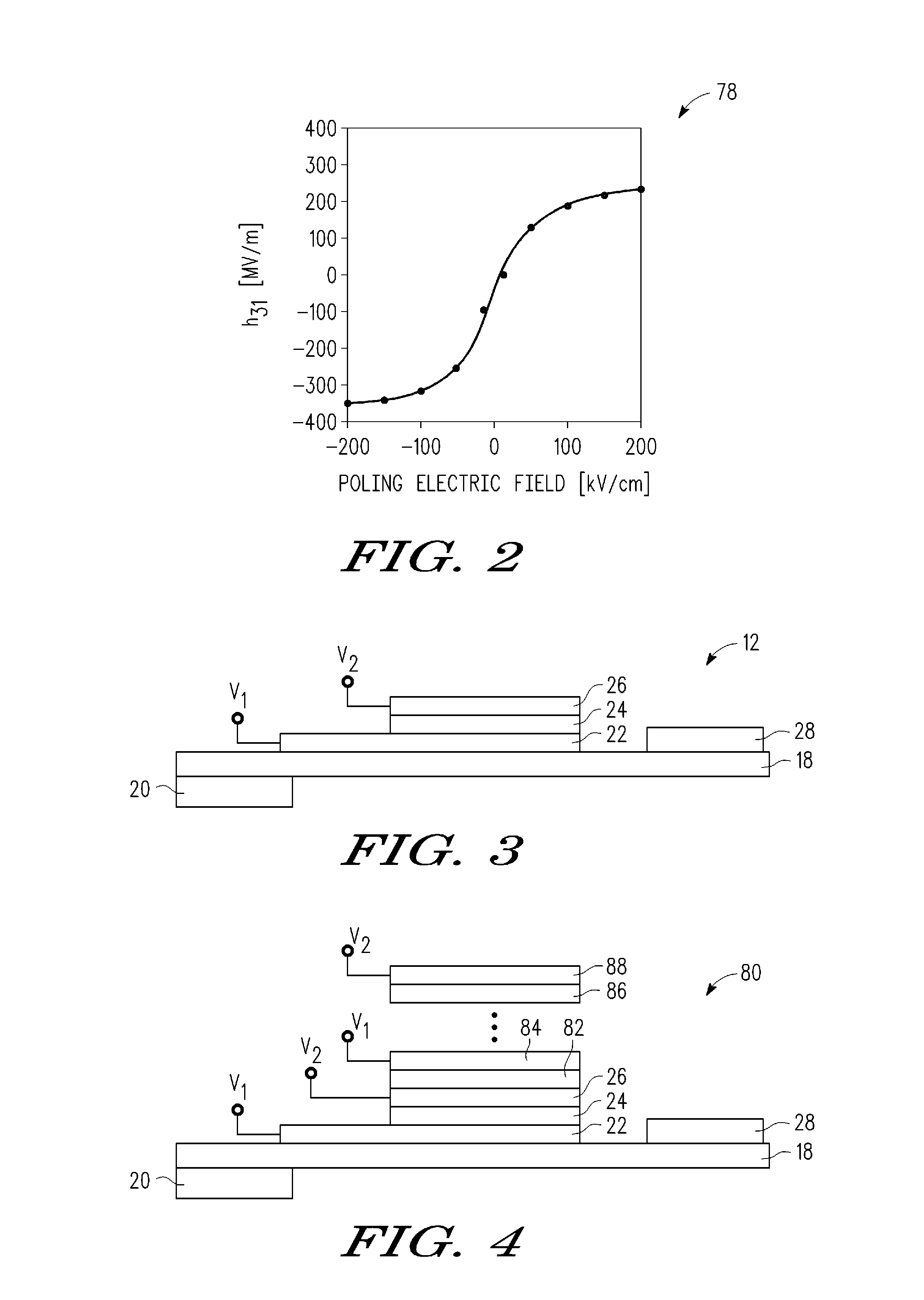

InactiveUS20090085432A1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesPiezoelectric memsOperating voltage

A self-poling piezoelectric based MEMS device is configured for piezoelectric actuation in response to application of a device operating voltage. The MEMS device comprises a beam, a first electrode disposed on the beam, a layer of piezoelectric material having a self-poling thickness disposed overlying a portion of the first electrode, and a second electrode overlying the layer of piezoelectric material. The layer of piezoelectric material is self-poled in response to application of the device operating voltage across the first and second electrodes. In addition, the self-poled piezoelectric material has a poling direction established according to a polarity orientation of the device operating voltage as applied across the first and second electrodes.

Owner:FREESCALE SEMICON INC

Piezoelectric MEMS element, voltage control oscillator, communication apparatus, and method of manufacturing piezoelectric drive type MEMS element

ActiveUS8476804B2Simplify manufacturing stepsIncrease productionPrecision positioning equipmentPiezoelectric/electrostriction/magnetostriction machinesElectricityPiezoelectric mems

A piezoelectric drive type MEMS element includes: a first substrate including, in a portion thereof, a movable part which is driven by a piezoelectric drive section to be displaced in a convex shape, a movable electrode being provided on a surface of the movable part; and a second substrate which is bonded to the first substrate and supports a fixed electrode facing the movable electrode via a prescribed gap, wherein the piezoelectric drive section includes a piezoelectric film provided on a region of the first substrate which forms the movable part as a portion of the movable part, and a pair of electrodes disposed so as to sandwich the piezoelectric film.

Owner:FUJIFILM CORP

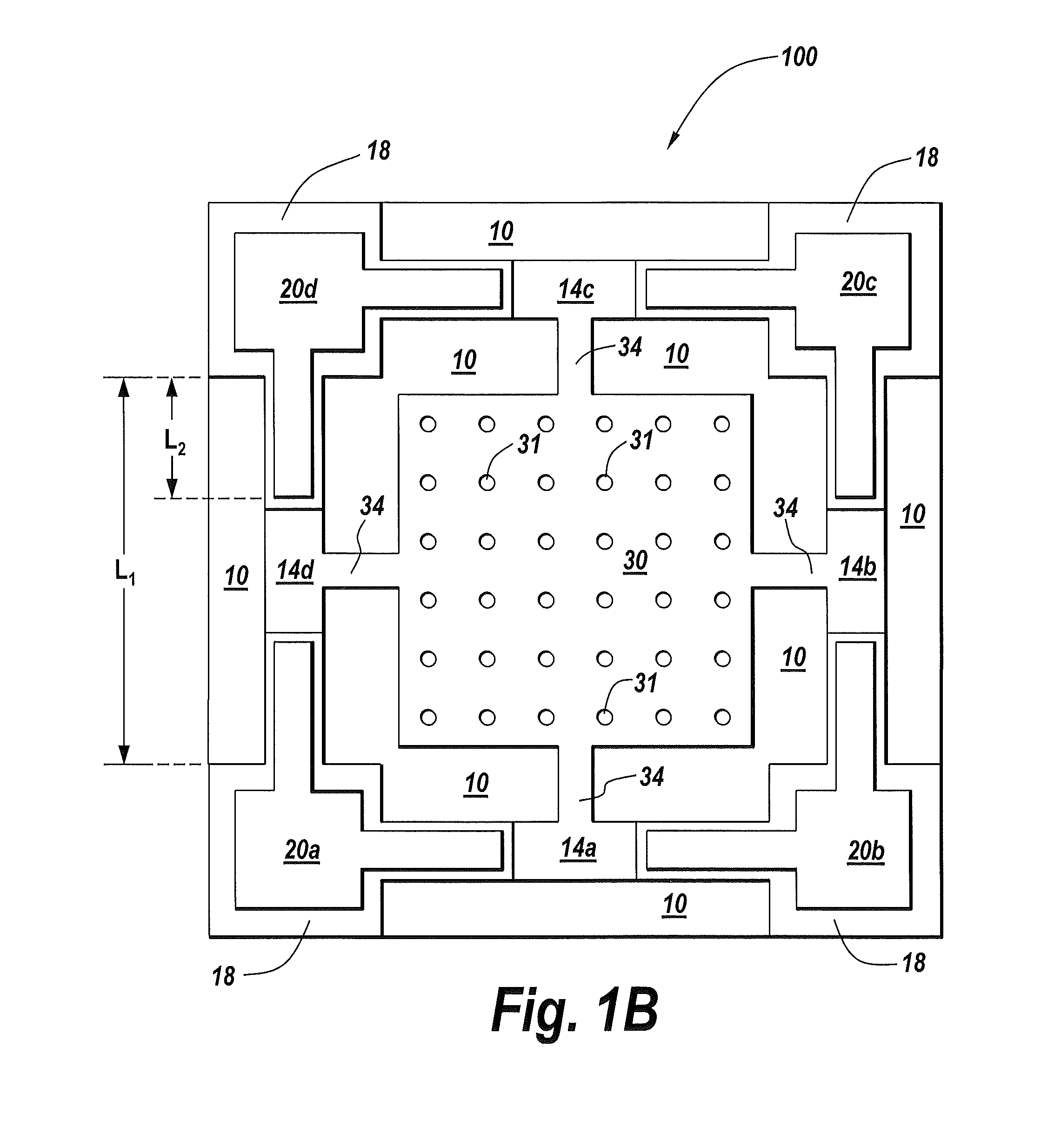

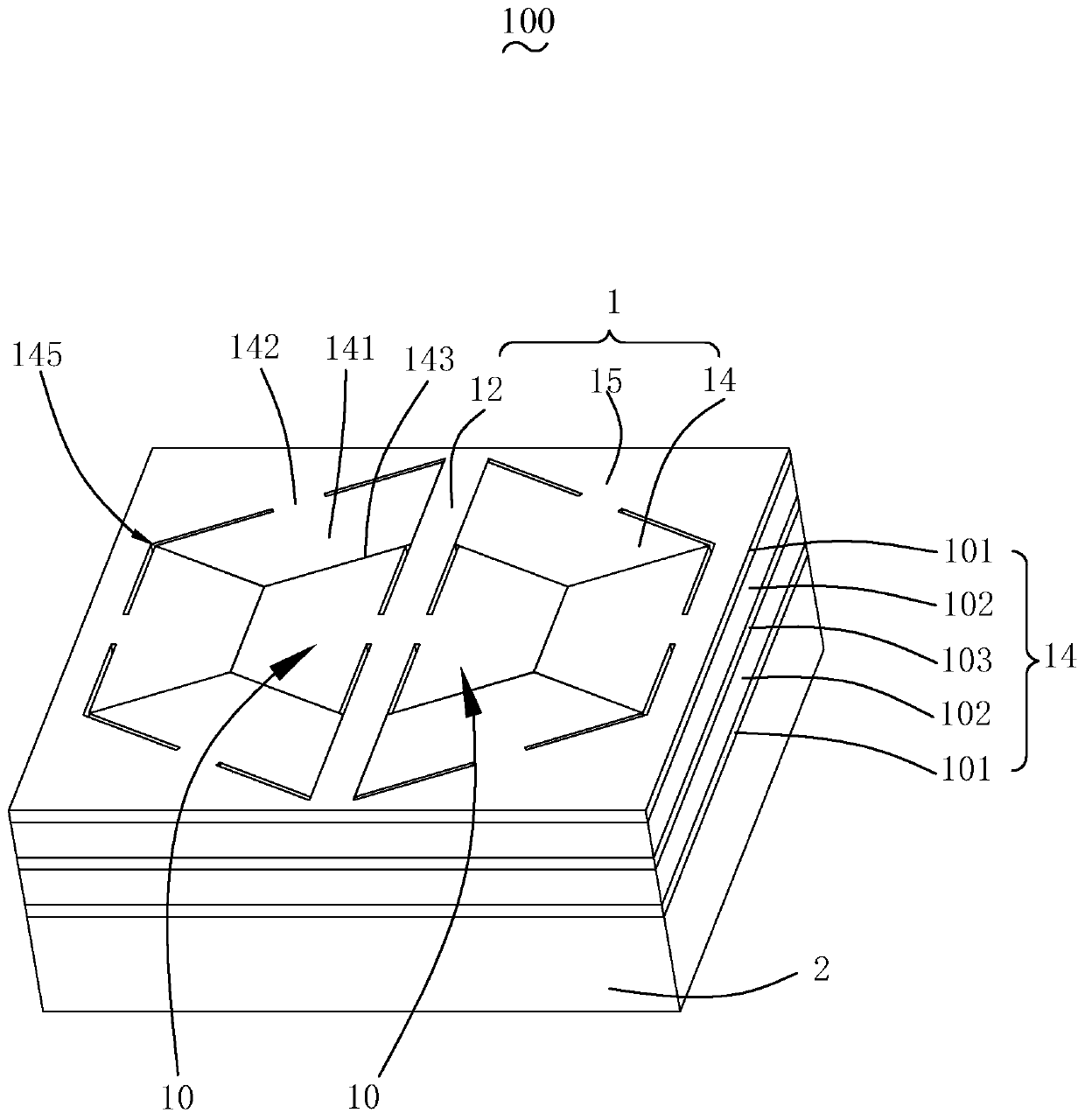

Two-dimensional addessable array of piezoelectric mems-based active cooling devices

ActiveUS20200049386A1Semiconductor/solid-state device detailsFlexible member pumpsCommunication interfaceActive cooling

A cooling system and method for using the cooling system are described. The cooling system includes a plurality of individual piezoelectric cooling elements spatially arranged in an array extending in at least two dimensions, a communications interface and driving circuitry. The communications interface is associated with the individual piezoelectric cooling elements such that selected individual piezoelectric cooling elements within the array can be activated based at least in part on heat energy generated in the vicinity of the selected individual piezoelectric cooling elements. The driving circuitry is associated with the individual piezoelectric cooling elements and is configured to drive the selected individual piezoelectric cooling elements.

Owner:FRORE SYST INC

Piezoelectric MEMS microphone

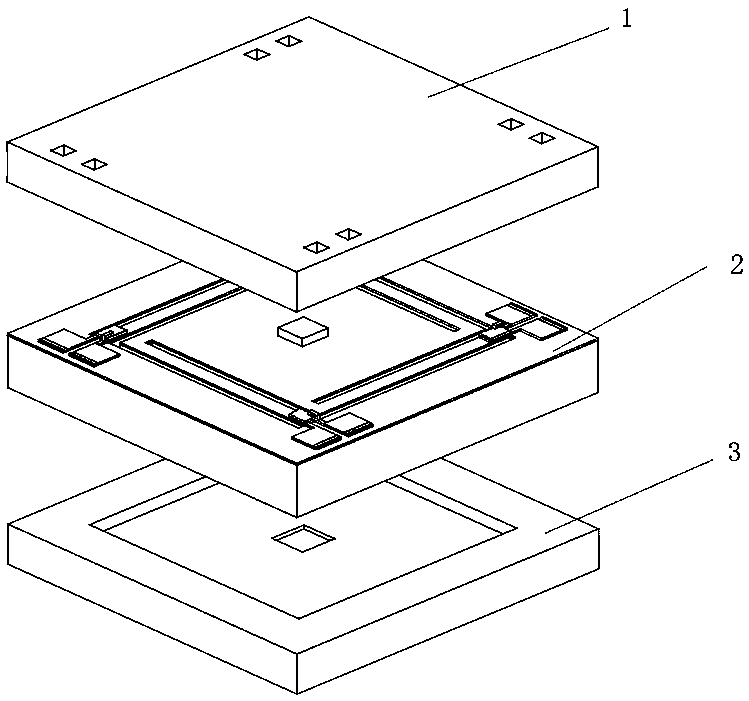

ActiveCN111294715ARaise the resonant frequencyHigh sensitivitySemiconductor electrostatic transducersElectrostatic transducer microphonesPiezoelectric memsEngineering

The invention provides a piezoelectric MEMS microphone. The piezoelectric MEMS microphone comprises: a substrate with a back cavity; and a piezoelectric vibrating diaphragm which is arranged right opposite to the back cavity and comprises a supporting part arranged above the back cavity, wherein the piezoelectric vibrating diaphragm is divided into at least two vibrating areas by the supporting part, the piezoelectric vibrating diaphragm further comprises at least one diaphragm arranged in each vibrating area, each diaphragm comprises a fixed end connected with the substrate or the supportingpart, a free end parallel to the fixed end and arranged oppositely, and a main body part connected with the fixed end and the free end, and the free end and the main body part are both suspended abovethe back cavity, and the width of the main body part is gradually reduced from the fixed end to the free end. Compared with the prior art, the piezoelectric MEMS microphone has the advantages that the resonant frequency is high, the sound pressure utilization area is large, and the sensitivity of the microphone is further improved.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

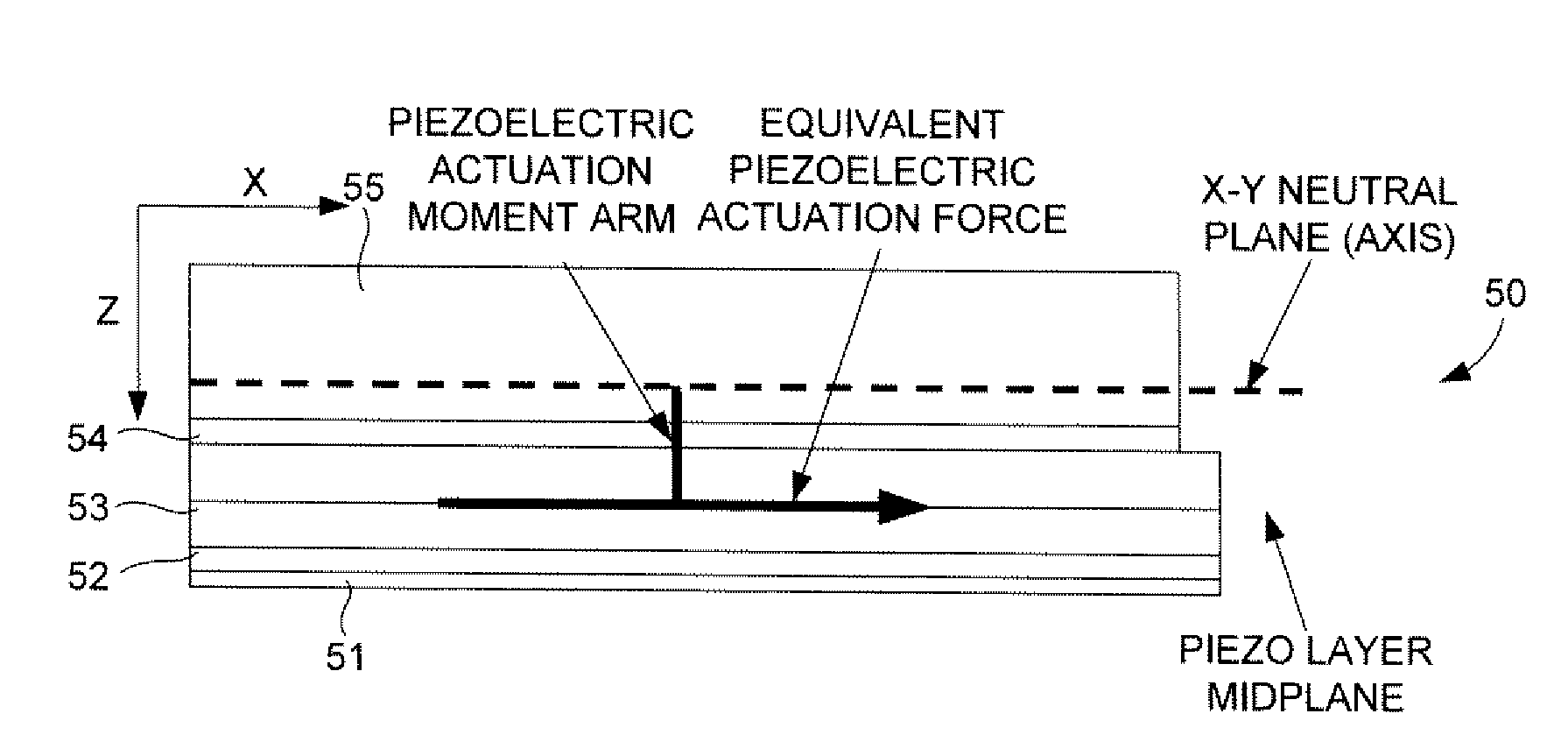

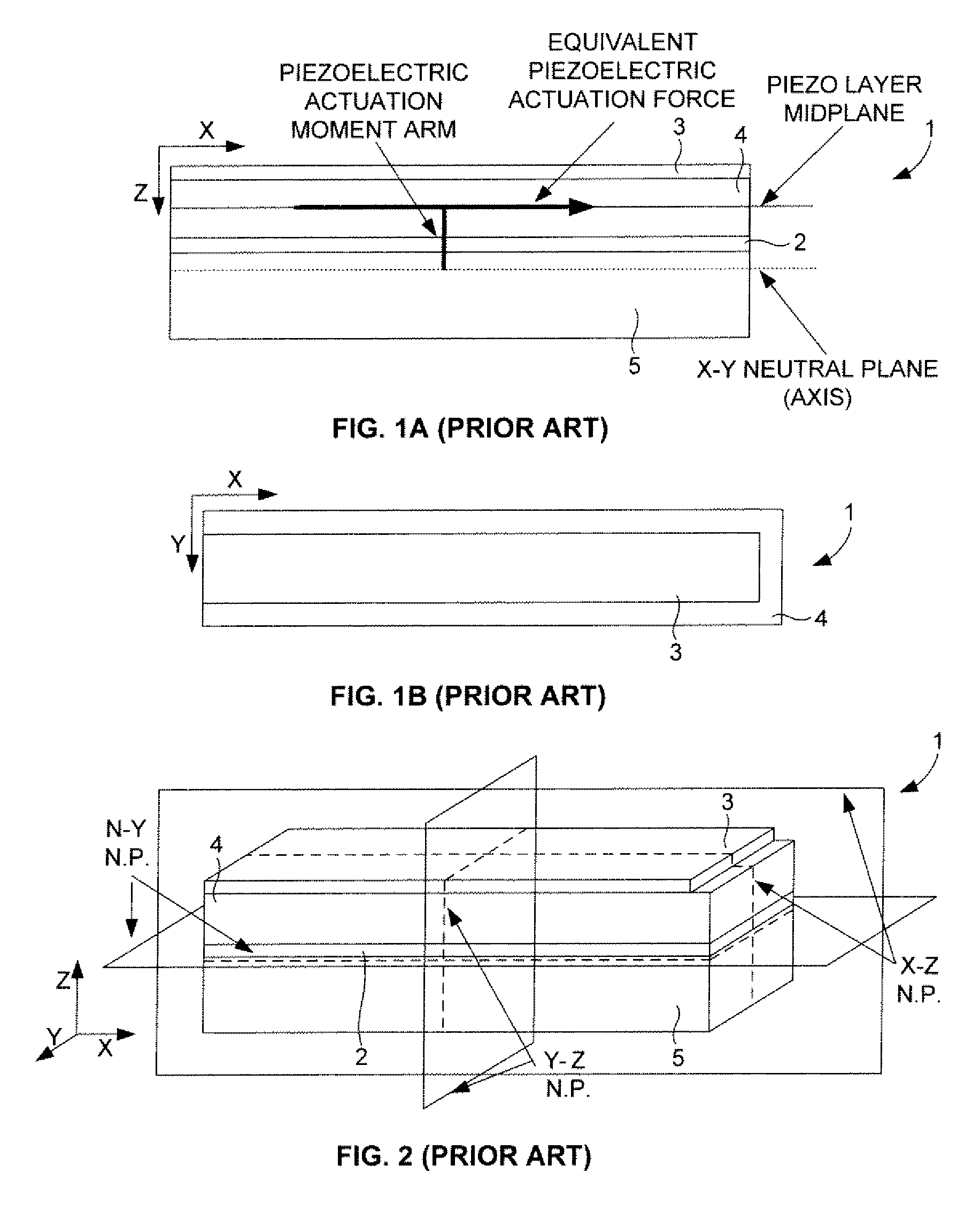

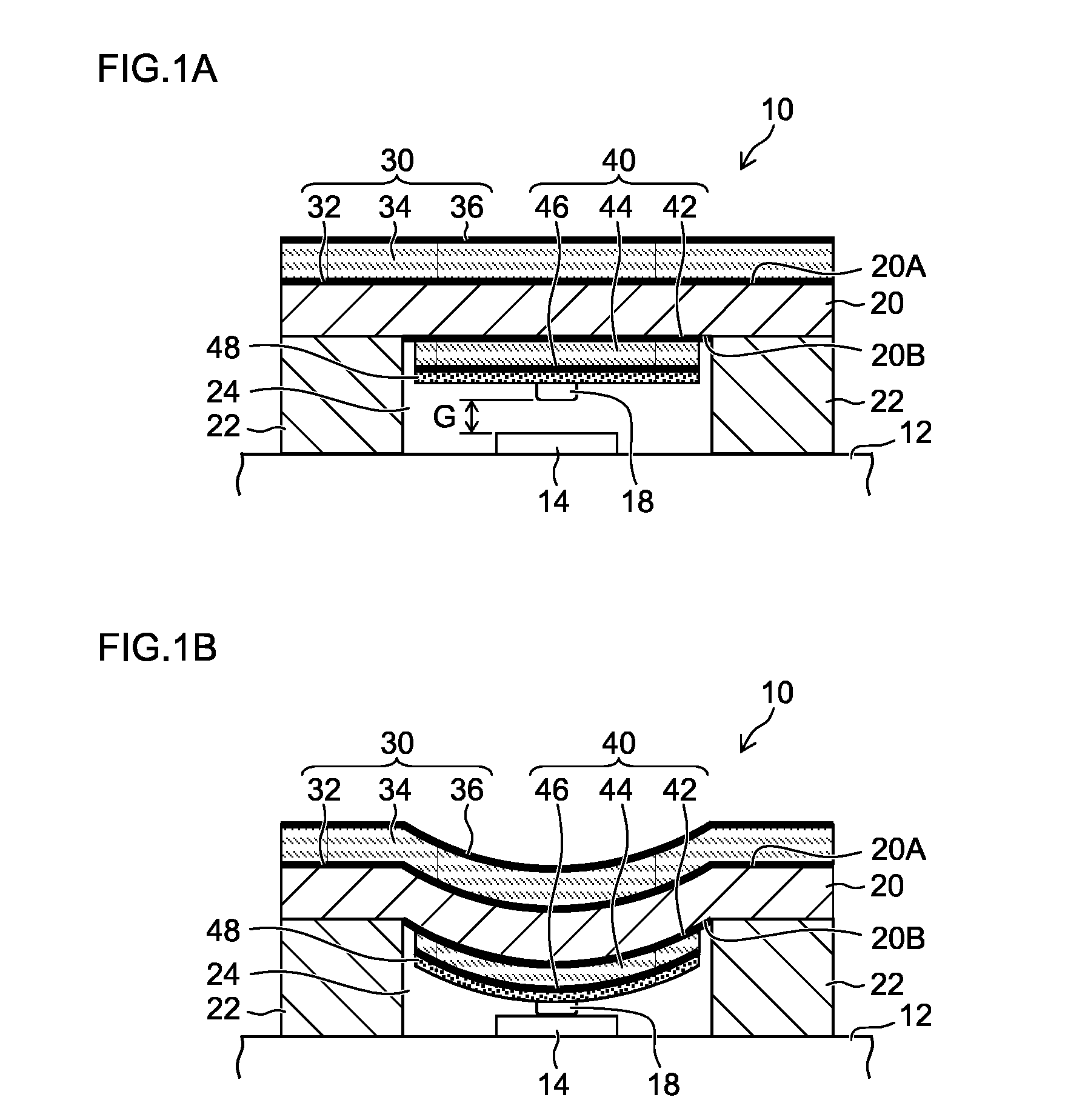

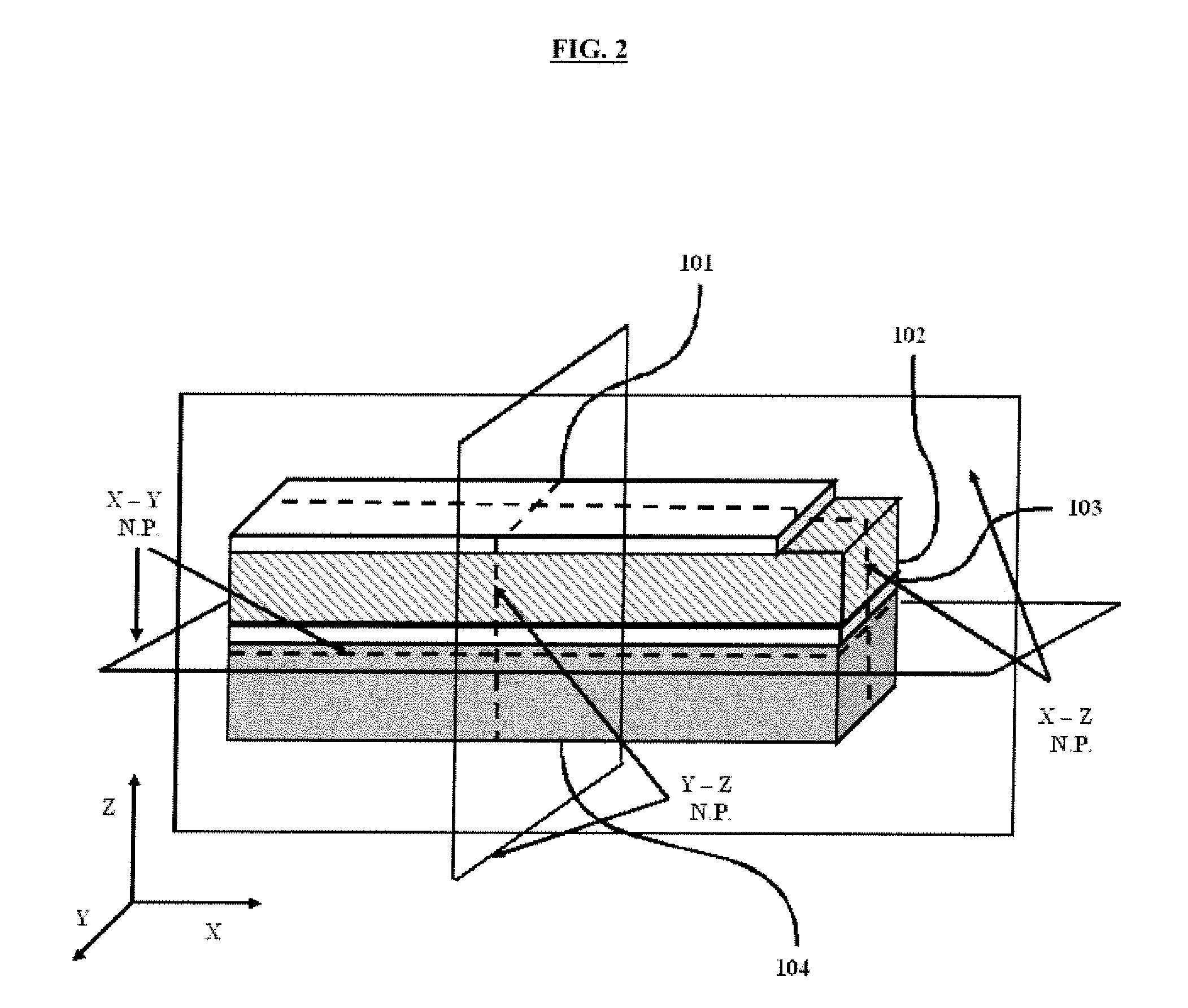

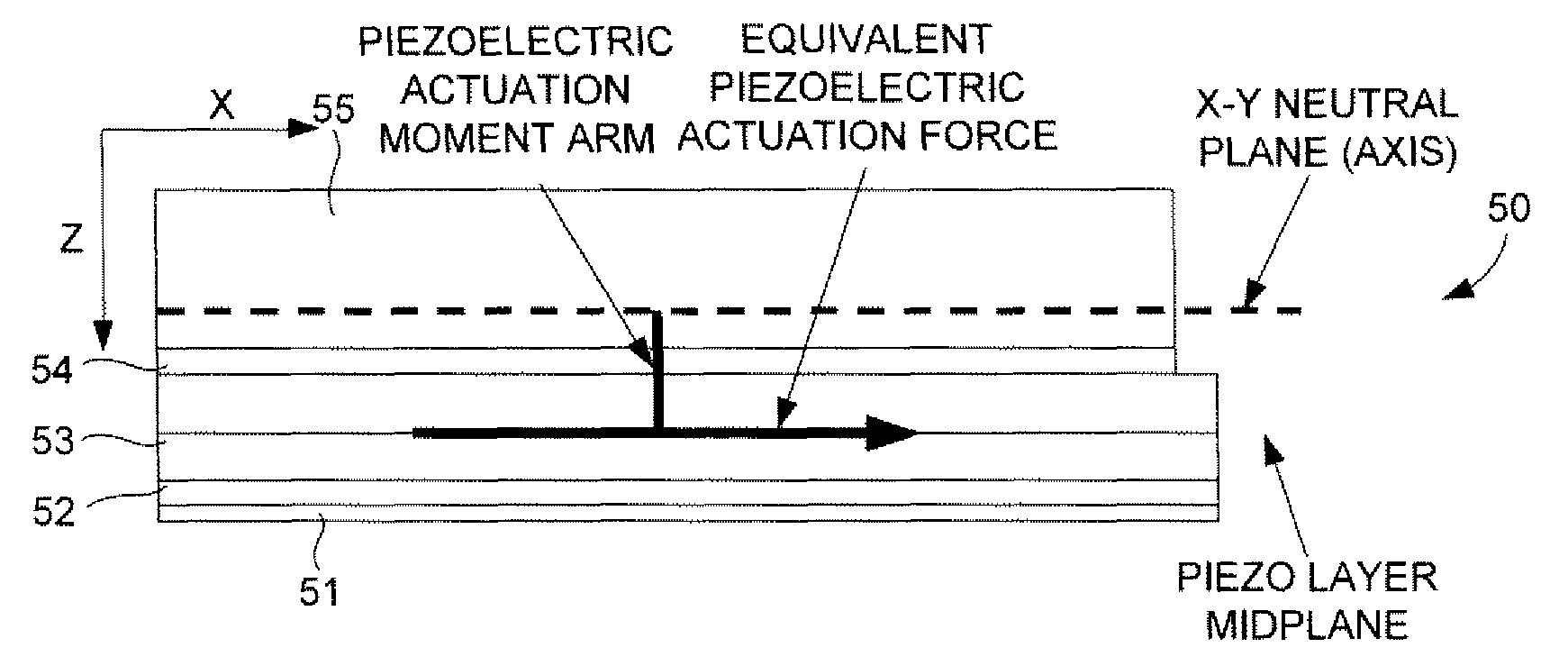

Negative vertical deflection piezoelectric MEMS actuators and method of fabrication

InactiveUS20100045142A1Optimal actuator performanceImprove performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesVertical deflectionPiezoelectric mems

Co-fabricating of vertical piezoelectric MEMS actuators that achieve large positive and negative displacements through operating electric fields in excess of the coercive field includes forming a large negative displacement vertical piezoelectric MEMS actuator, forming a bottom structural dielectric layer above a substrate layer; forming a bottom electrode layer above the structural dielectric layer; forming an active piezoelectric layer above the bottom electrode layer; forming a top electrode layer above the active piezoelectric layer; forming a top structural layer above the top electrode layer, wherein the x-y neutral plane of the negative displacement vertical piezoelectric MEMS actuator is above the mid-plane of the active piezoelectric layer, wherein the negative displacement vertical piezoelectric MEMS actuator is partially released from the substrate to allow free motion of the actuator; and combining the large negative displacement vertical piezoelectric MEMS actuator and a large positive displacement vertical piezoelectric MEMS actuator on the same the substrate.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Large force and displacement piezoelectric MEMS lateral actuation

InactiveUS7876026B2Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsPiezoelectric memsEngineering

A piezoelectric microelectromechanical systems (MEMS) actuator includes a silicon substrate; an actuator beam comprising a first end region connected to the silicon substrate and a second end region connected to a mechanically compliant spring assembly; a first electrode over the silicon substrate; a piezoelectric layer above the first electrode; a second electrode over the piezoelectric layer; a conductive top structural layer above the second electrode, wherein a center half of the actuator beam is configured as a positive deflection region, and wherein both the first electrode and the second electrode supply voltage to both positive and negative deflection regions of the actuator beam.

Owner:ARMY UNITED STATES OF AMERICA AS REPRESENTED BY

Piezoelectric MEMS microphone

ActiveCN110650420AReduce noiseRaise the resonant frequencyPiezoelectric/electrostrictive microphonesMicrophonesPiezoelectric memsNoise

The invention provides a piezoelectric MEMS microphone, comprising a substrate with a cavity, a piezoelectric vibrating diaphragm arranged on the substrate, and a constraint piece connected with the substrate and the piezoelectric vibrating diaphragm, wherein the substrate comprises an annular base defining a cavity, and a supporting column arranged in the cavity and spaced from the annular base;the piezoelectric vibrating diaphragm comprises a plurality of diaphragms; each diaphragm comprises a fixed end connected with the supporting column and a free end suspended above the cavity; and oneend of the constraint piece is fixedly connected with the free end, and the other end of the constraint piece is connected with the part, not connected with the fixed end, of the substrate. For the piezoelectric MEMS microphone, under the action of sound pressure, the free end vibrates, and the piezoelectric vibrating diaphragm close to the fixed end can generate a voltage signal, and a restraining piece is arranged between the substrate and the piezoelectric vibrating diaphragm and can restrain the deformation of the diaphragm, so that the resonant frequency of the piezoelectric vibrating diaphragm is improved, and the noise of the whole piezoelectric MEMS microphone is reduced.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

Piezoelectric MEMS acceleration sensor and a preparation method thereof

ActiveCN109160484AImprove all-round anti-overload abilityHigh sensitivitySubsonic/sonic/ultrasonic wave measurementDecorative surface effectsElectricityLower limit

The invention provides a piezoelectric MEMS acceleration sensor and a preparation method thereof. The piezoelectric MEMS acceleration sensor comprises a cover plate, a detecting structure layer and abottom substrate which are successively connected. The middle part of the detecting structure layer is provided with a sensitive mass block and an L-shaped fixed supporting beam. An upper limit position column and a low limit position column are respectively arranged at that center of the upper and lower sides of the detection structure layer, and are respectively match with a cover plate and a base substrate. Furthermore a two-time silicon-silicon binding method is utilized, thereby forming the piezoelectric MEMS acceleration sensor with a closed inner part. When the whole device is subjectedto non-overload acceleration, the piezoelectric ceramic thin film is deformed and a voltage signal is generated on the surface of the device. When subjected to overload acceleration, limited by the limit structure of the outer frame, the sensitive mass only damps the gap distance of the displacement sensor system, thus playing the role of omni-directional overload protection.

Owner:HEFEI UNIV OF TECH

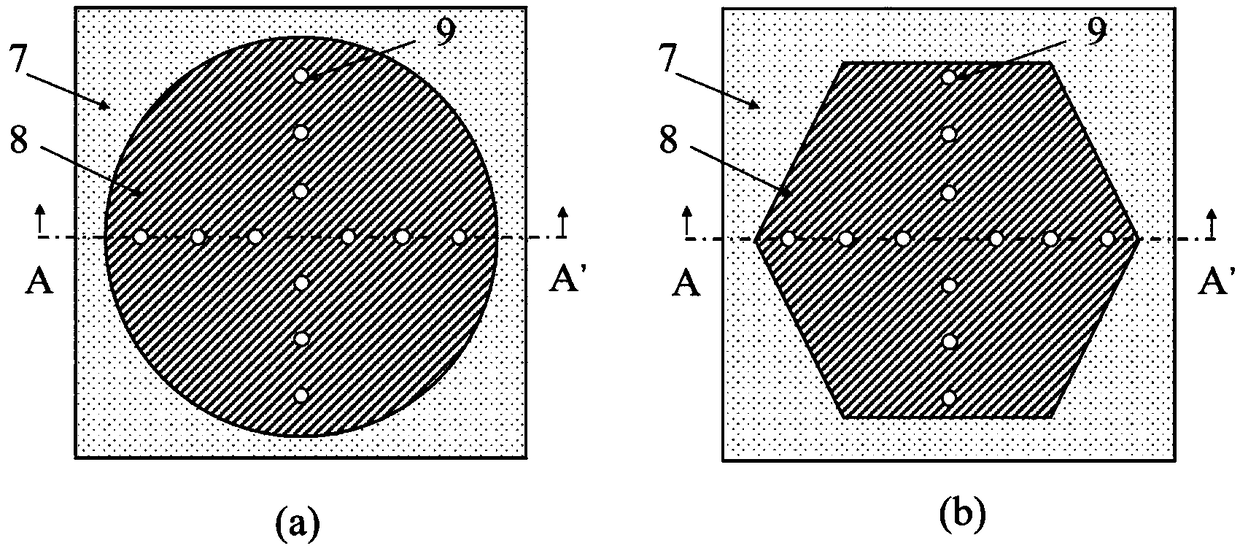

Piezoelectric acoustic MEMS transducer and fabrication method thereof

ActiveUS20190327562A1Piezoelectric/electrostrictive microphonesMicrophonesSemiconductor materialsTransducer

A piezoelectric MEMS transducer formed in a body of semiconductor material, which has a central axis and a peripheral area and comprises a plurality of beams, transverse to the central axis and having a first end, coupled to the peripheral area of the body, and a second end, facing the central axis; a membrane, transverse to the central axis and arranged underneath the plurality of beams; and a pillar, parallel to the central axis and rigid with the second end of the beams and to the membrane. The MEMS transducer further comprises a plurality of piezoelectric sensing elements arranged on the plurality of beams.

Owner:STMICROELECTRONICS SRL

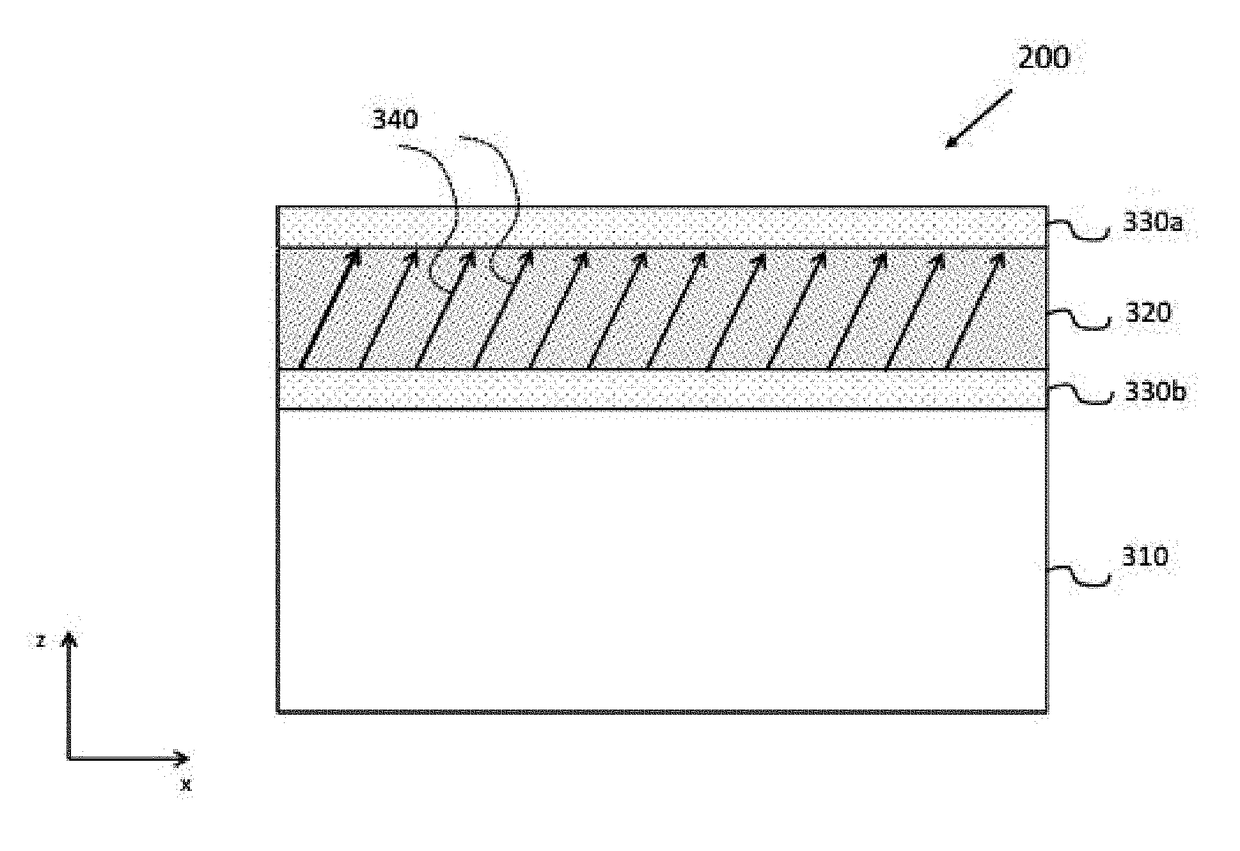

Piezoelectric MEMS resonator with a high quality factor

ActiveUS20180019728A1Motional impedance is decreasedHigh quality factorImpedence networksPiezoelectric/electrostrictive/magnetostrictive devicesPiezoelectric memsVertical axis

A MEMS resonator is provided with a high quality factor and lower motional impedance. The MEMS resonator includes a silicon layer having opposing surfaces, a piezoelectric layer above one of the surfaces of the silicon layer, and a pair of electrodes disposed on opposing surfaces of the piezoelectric layer, respectively. Moreover, the piezoelectric layer has a crystallographic axis that extends at an angle relative to the vertical axis of the MEMS resonator.

Owner:MURATA MFG CO LTD

Piezoelectric MEMS switch and method of fabricating the same

InactiveUS20070231065A1Increase freedomImprove drivabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsPiezoelectric mems

A piezoelectric Micro Electro Mechanical System (MEMS) switch includes a substrate, first and second fixed signal lines symmetrically formed in a spaced-apart relation to each other on the substrate to have a predetermined gap therebetween, a piezoelectric actuator disposed in alignment with the first and the second fixed signal lines in the predetermined gap, and having a first end supported on the substrate to allow the piezoelectric actuator to be movable up and down, and a movable signal line having a first end connected to one of the first and the second fixed signal lines, and a second end configured to be in contact with, or separate from the other of the first and second fixed signal lines, the movable signal line at least one side thereof being connected to an upper surface of the piezoelectric actuator.

Owner:SAMSUNG ELECTRONICS CO LTD

Broadband high-sensitivity resonant piezoelectric MEMS microphone

ActiveCN112601169AHigh sensitivityPiezoelectric/electrostrictive microphonesMicrophonesPiezoelectric memsEngineering

The invention discloses a broadband high-sensitivity resonant piezoelectric MEMS microphone, and the microphone comprises a substrate and a piezoelectric diaphragm; the top of the substrate is provided with a central support part and a peripheral support part, and a back cavity is arranged between the central support part and the peripheral support part, so that a central vibration area and a peripheral vibration area are formed between the central support part and the peripheral support part; the piezoelectric vibrating diaphragm is suspended on the back cavity, the piezoelectric vibrating diaphragm comprises a plurality of diaphragms, the central vibrating area is provided with at least one diaphragm mounted on the central supporting part, the peripheral vibrating area is provided with at least one diaphragm mounted on the peripheral supporting part, the plurality of diaphragms are different in one or more of shape, size or thickness, and a gap is formed between every two adjacent diaphragms; the resonant frequencies of the diaphragms are different, so the sensitivity curve of the microphone can generate a section of flat broadband between the minimum resonant frequency and the maximum resonant frequency of the piezoelectric diaphragm, and the sensitivity curve of the microphone has higher sensitivity in the frequency band range.

Owner:武汉敏声新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com