Patents

Literature

2040results about "Semiconductor electrostatic transducers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

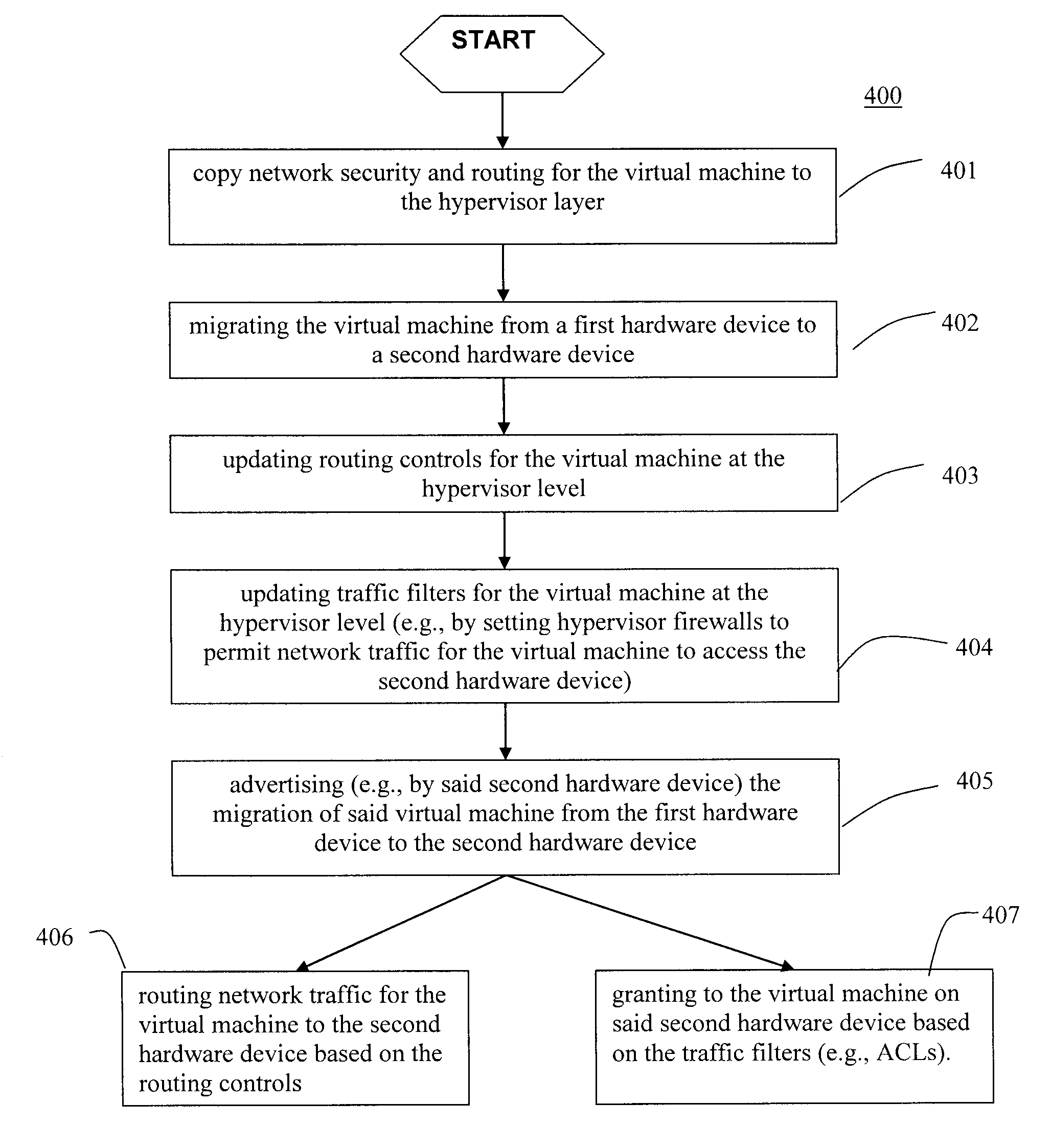

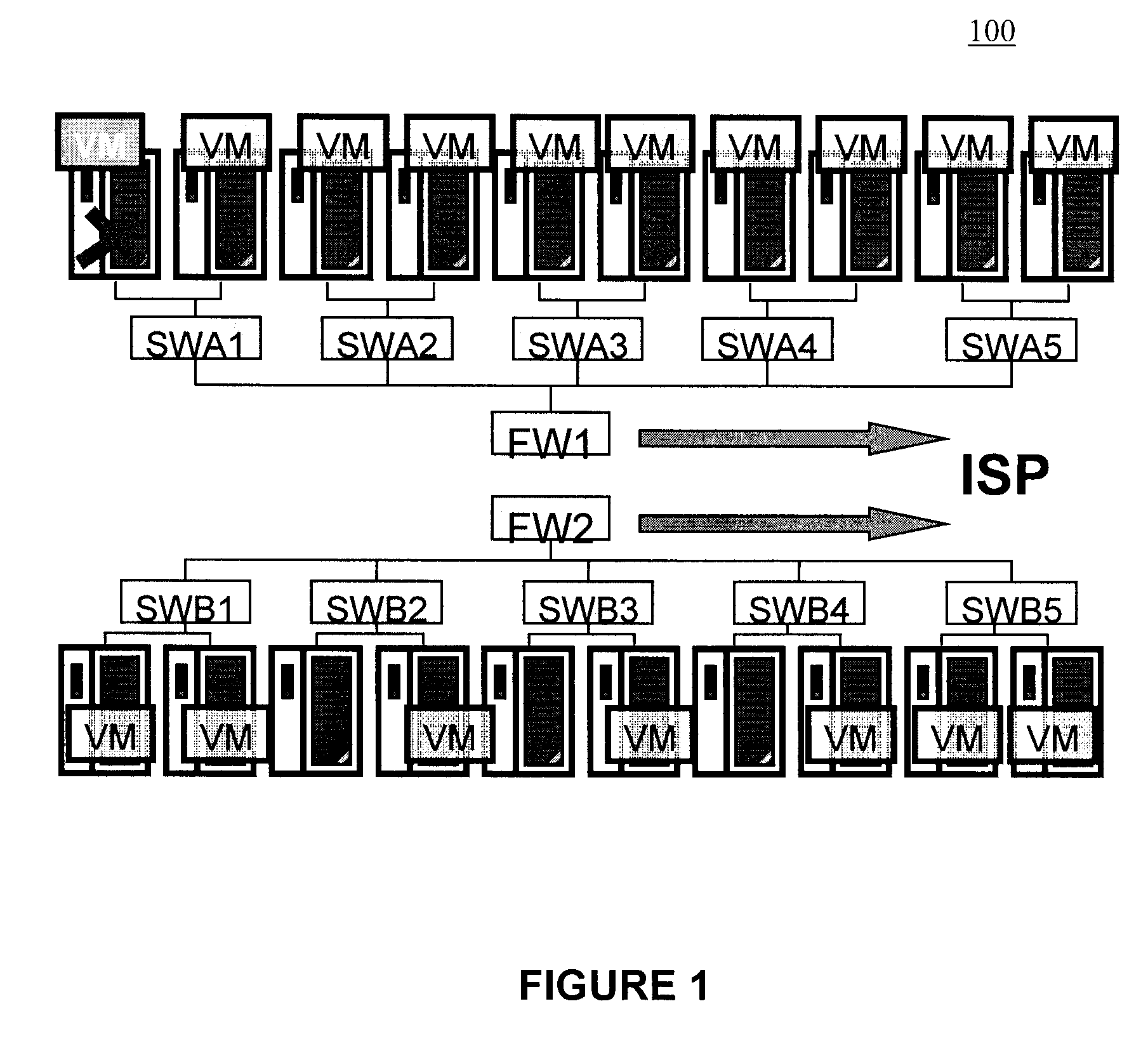

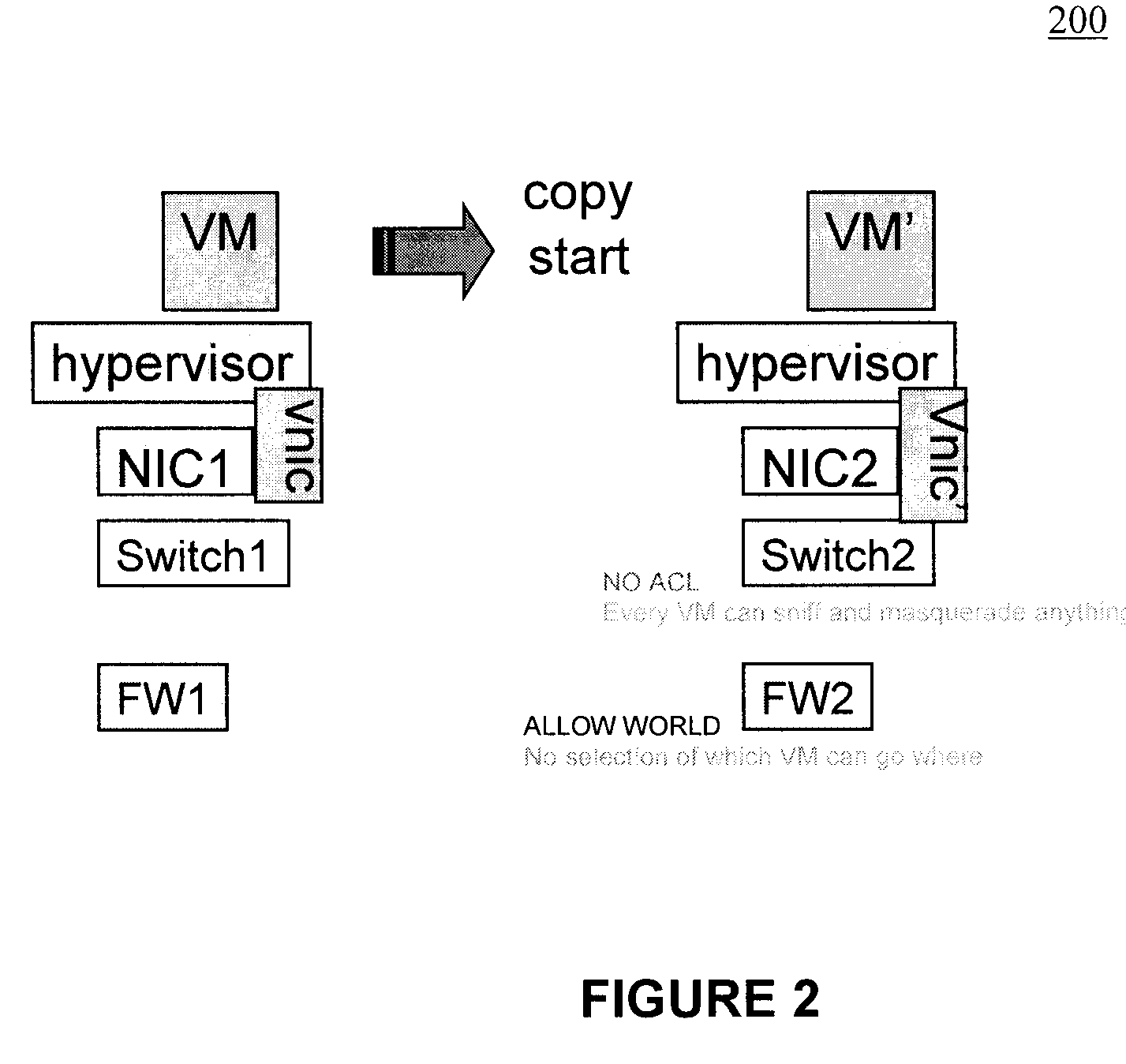

Moveable access control list (ACL) mechanisms for hypervisors and virtual machines and virtual port firewalls

ActiveUS20080163207A1Efficient responseRapid deploymentSemiconductor electrostatic transducersMicrophone structural associationVLAN access control listAccess control list

A method (and system) which provides virtual machine migration with filtered network connectivity and control of network security of a virtual machine by enforcing network security and routing at a hypervisor layer at which the virtual machine partition is executed, and which is independent of guest operating systems.

Owner:DAEDALUS BLUE LLC

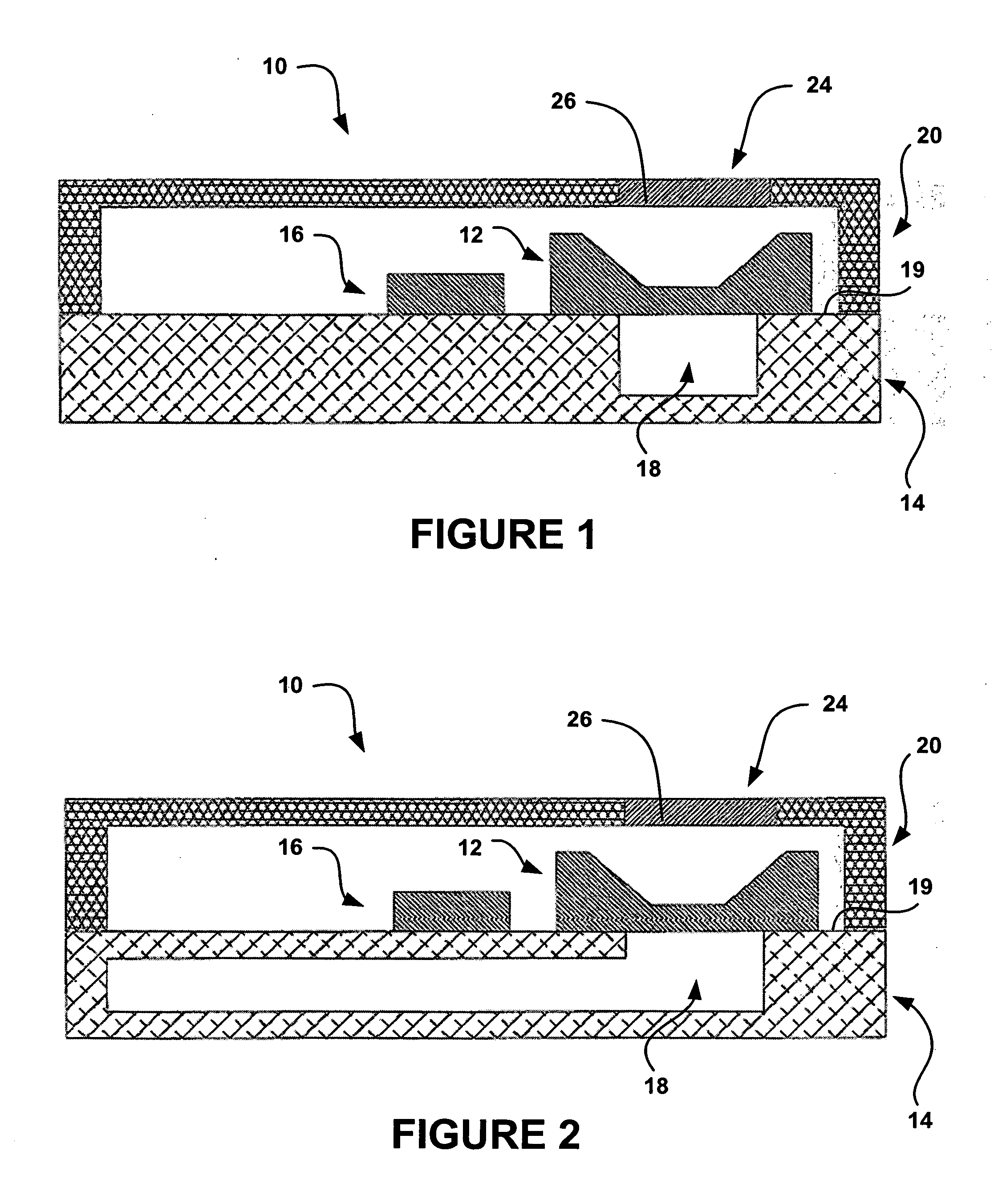

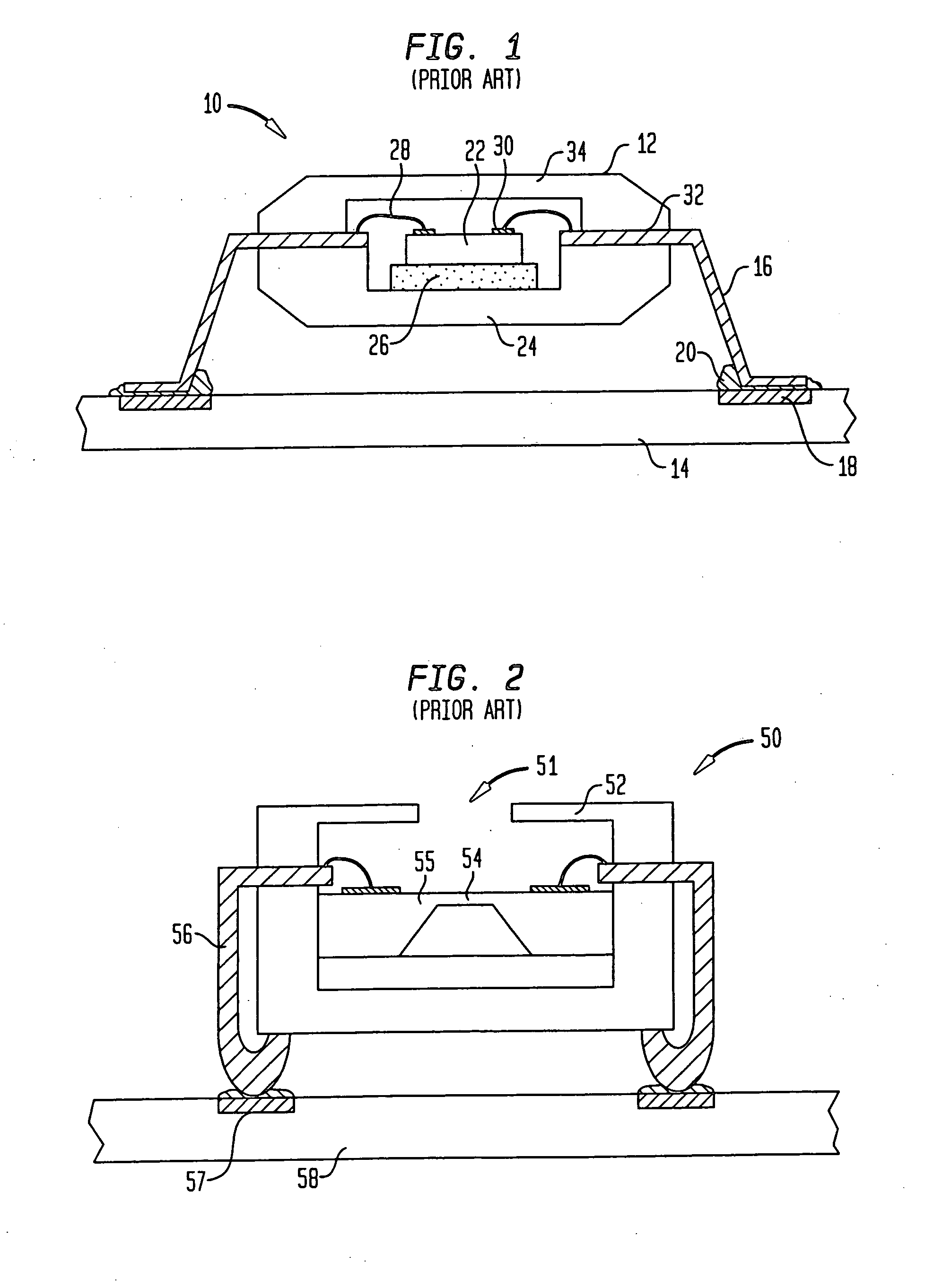

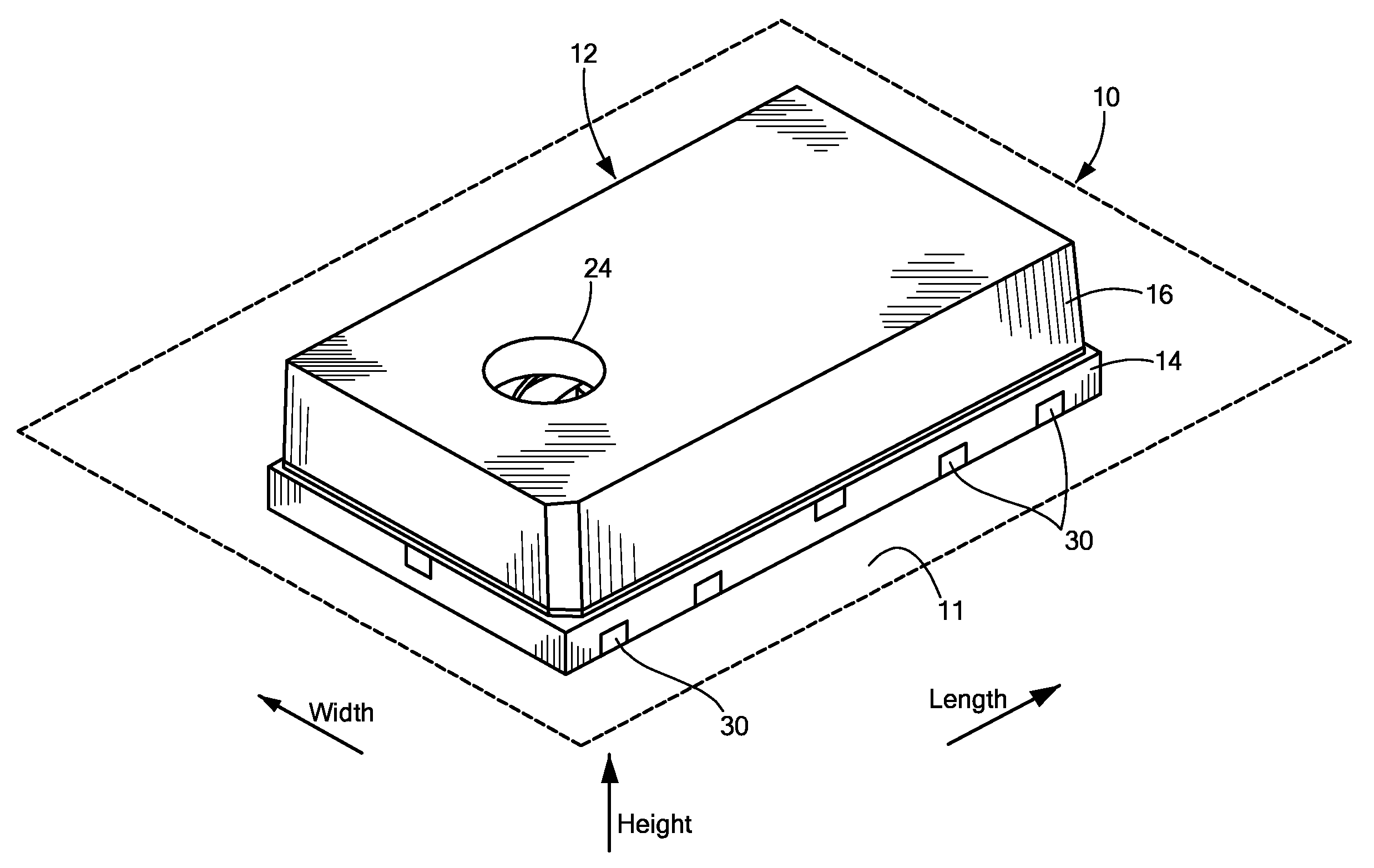

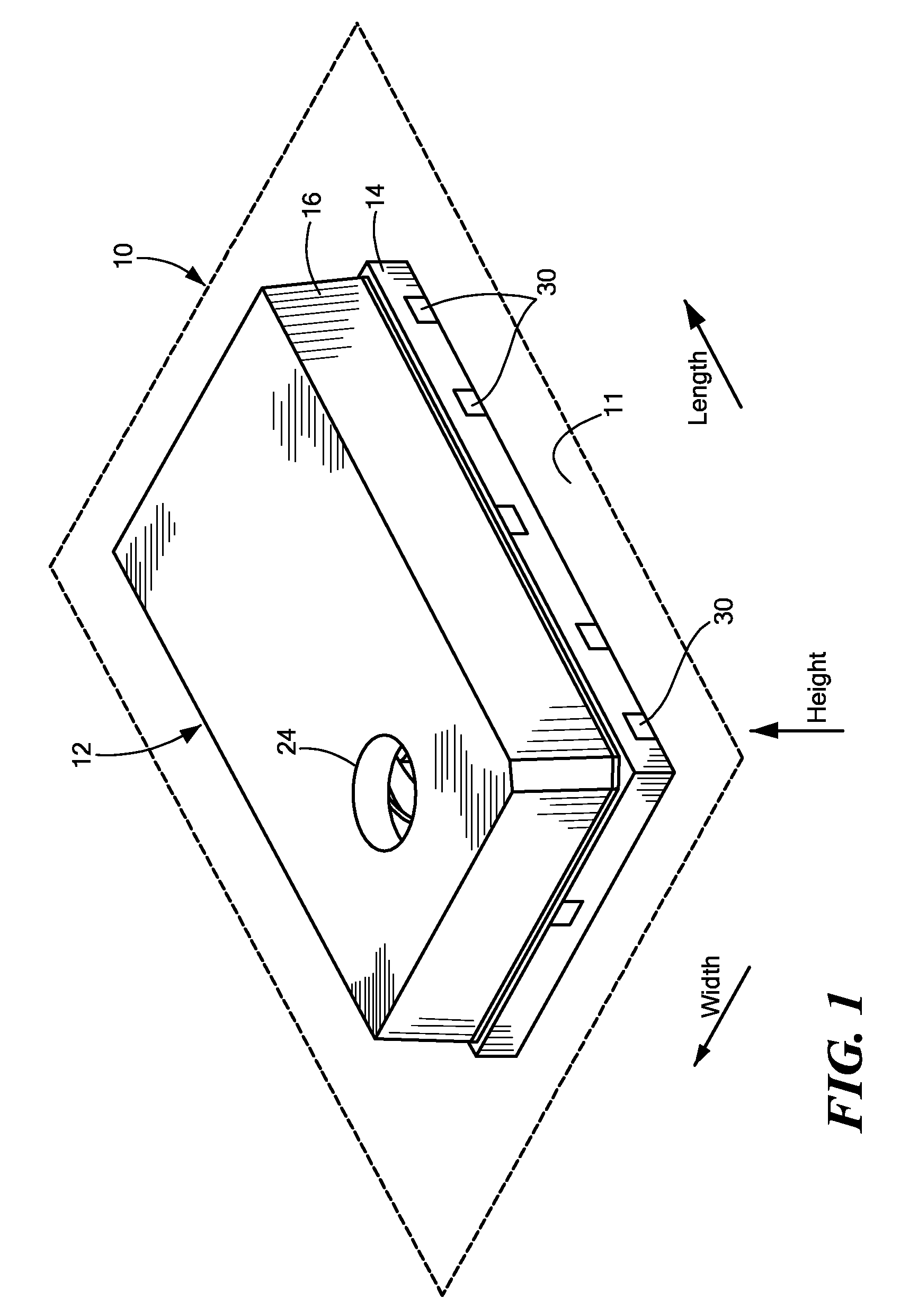

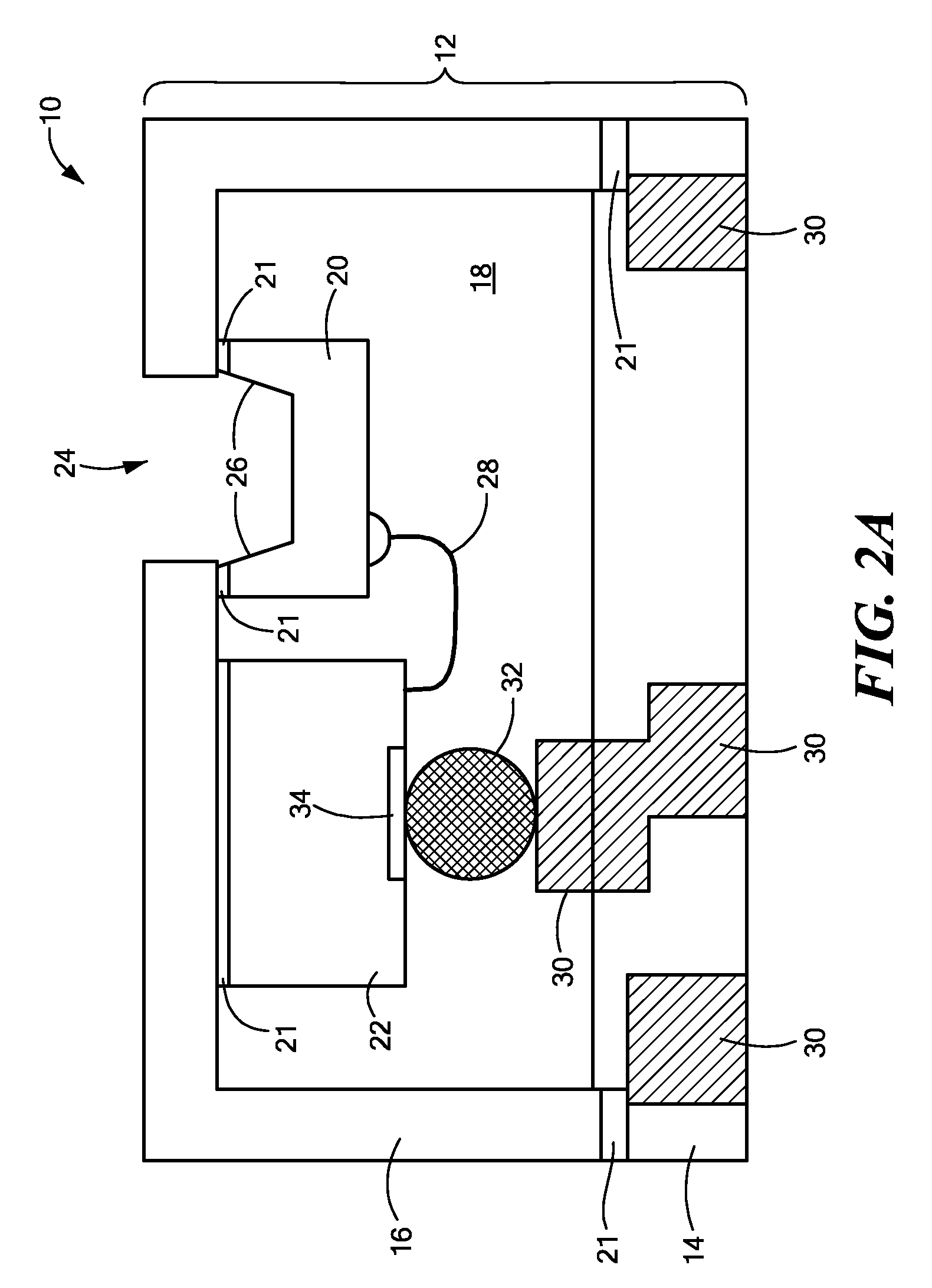

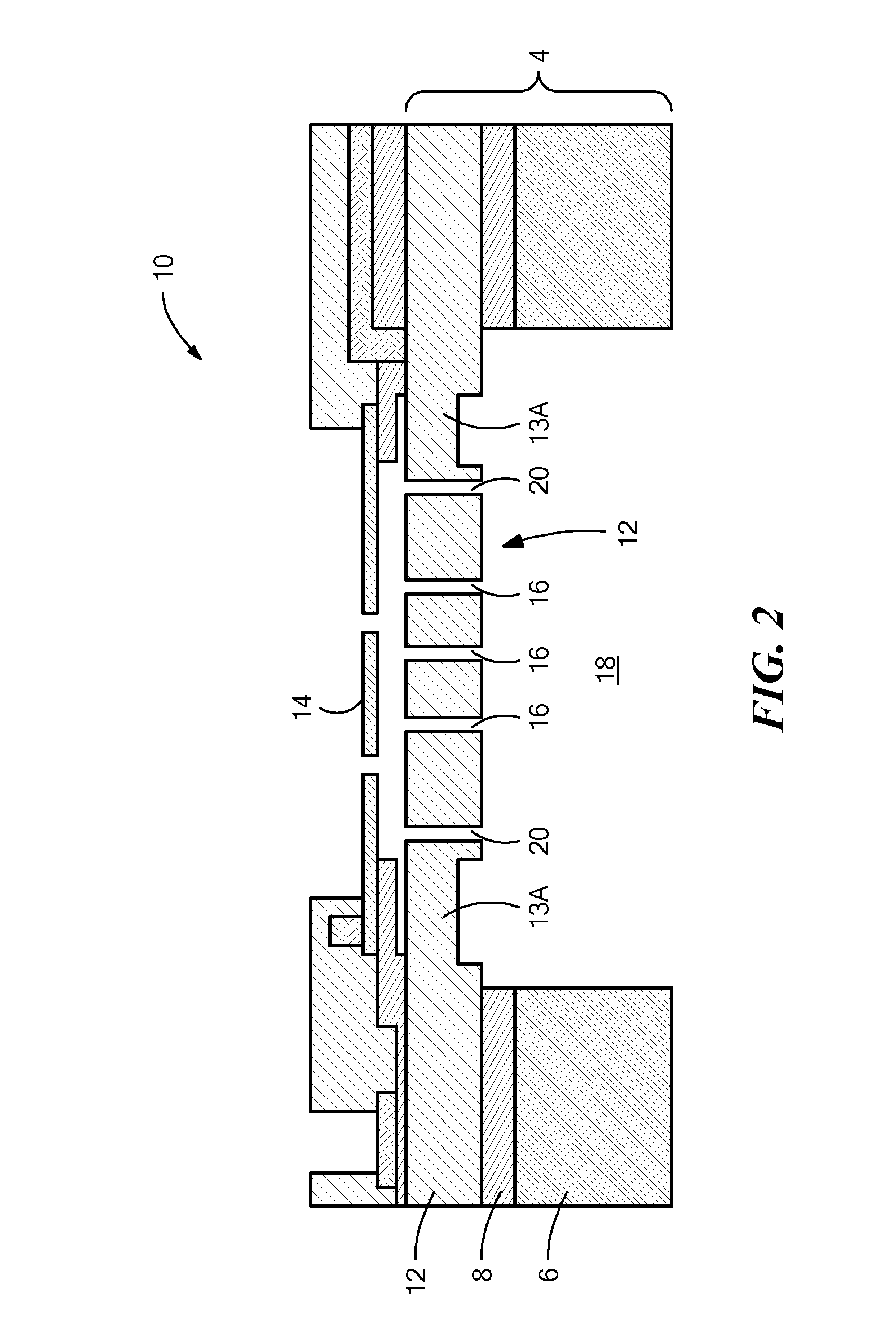

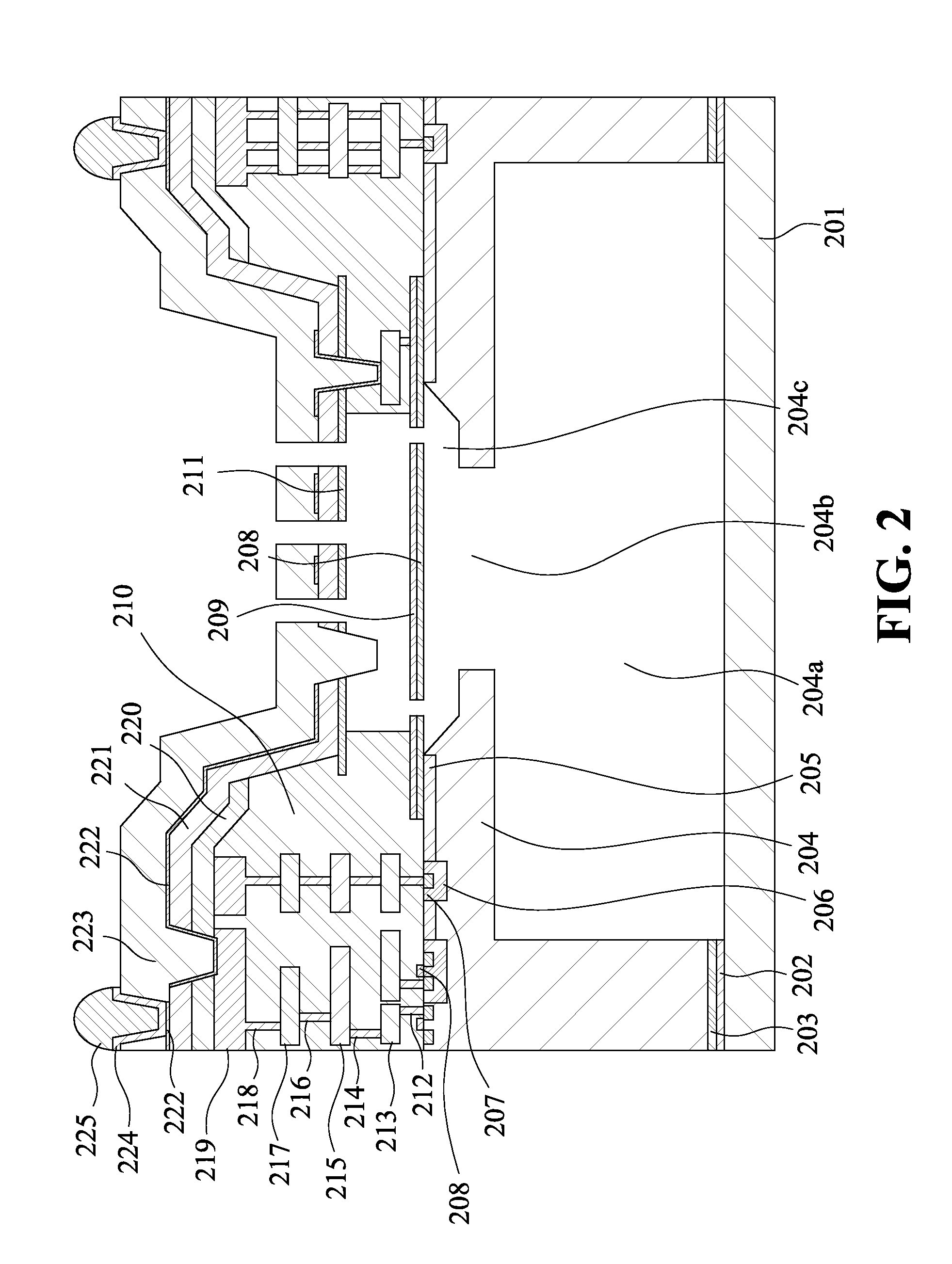

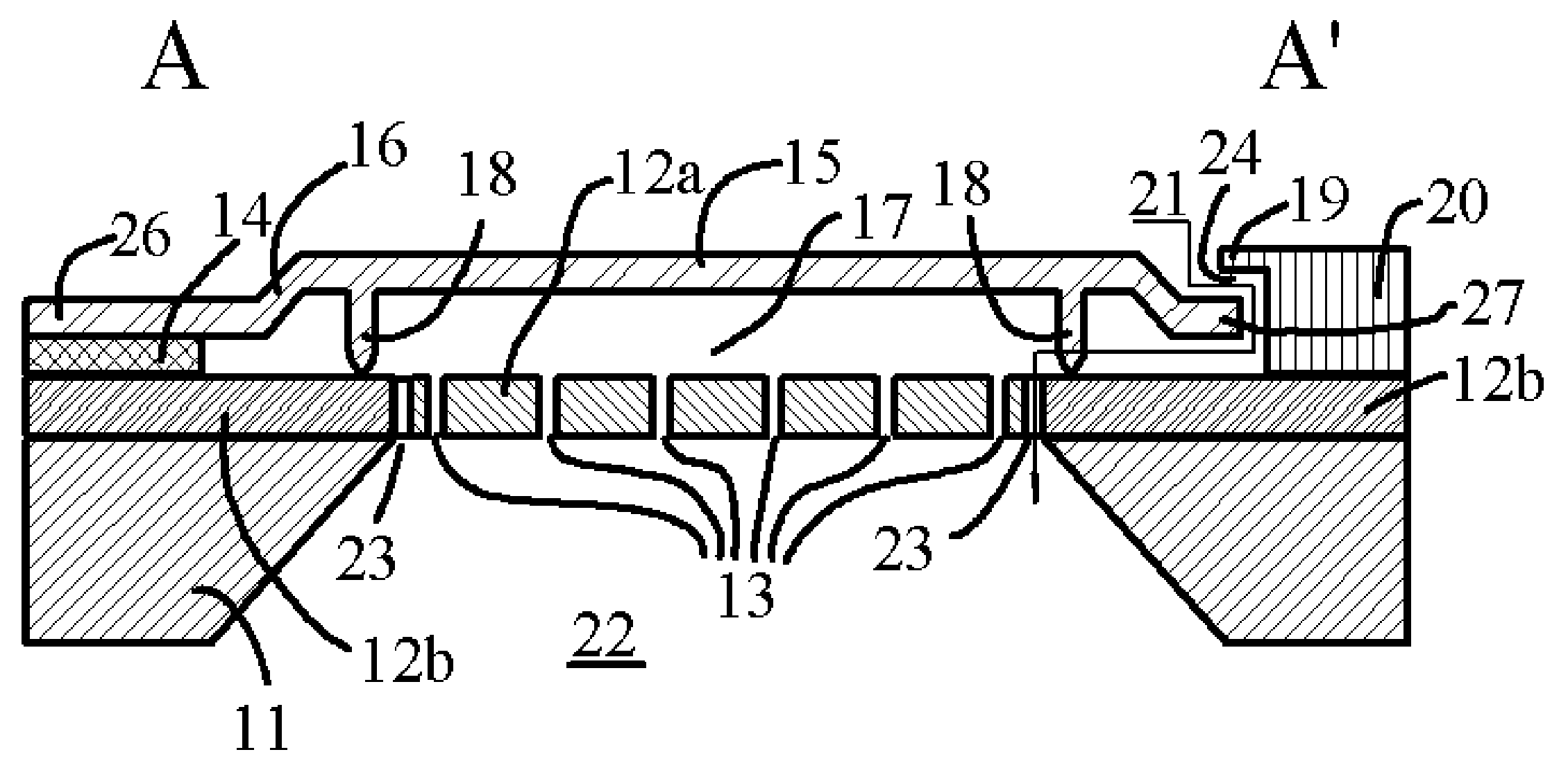

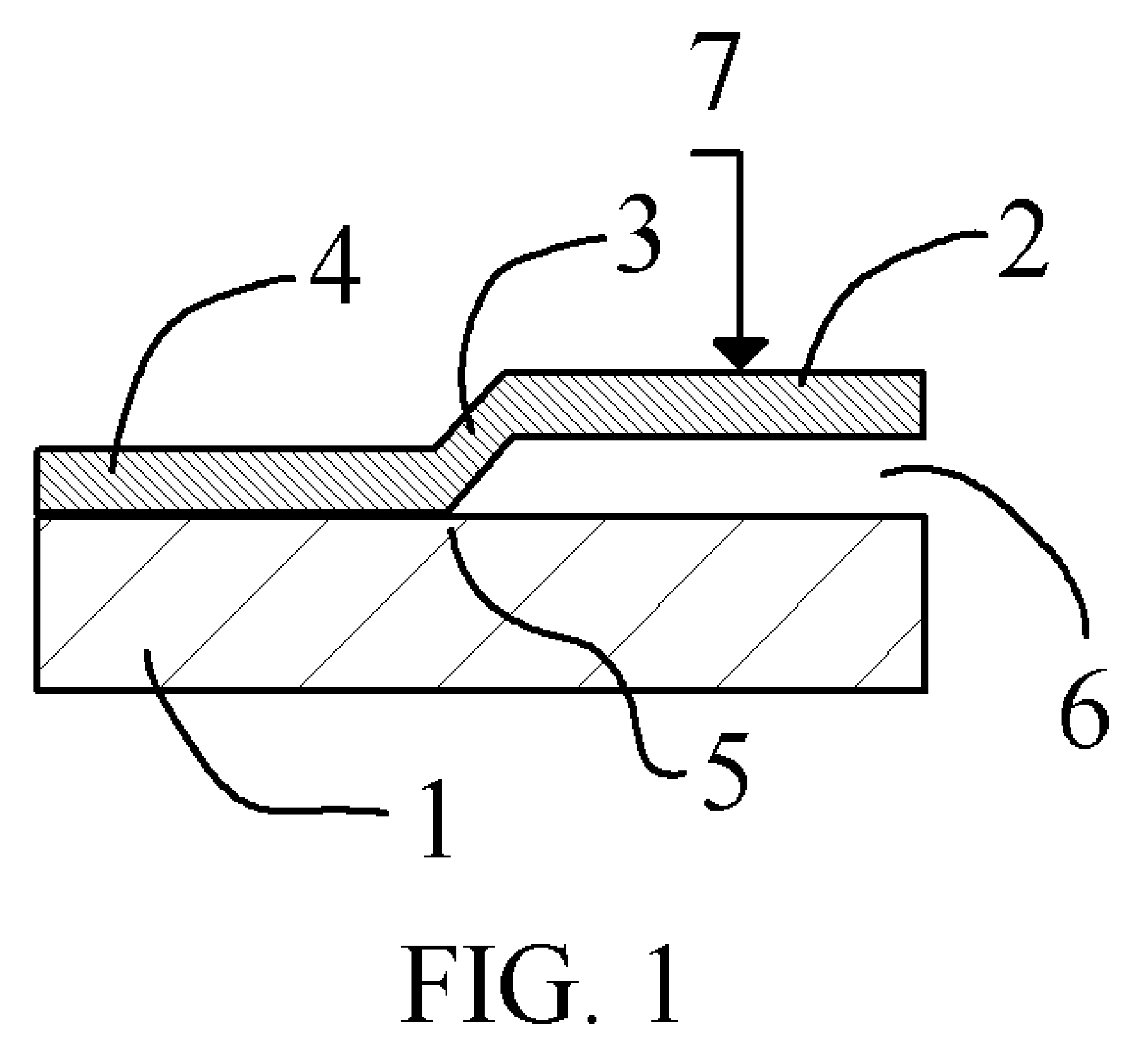

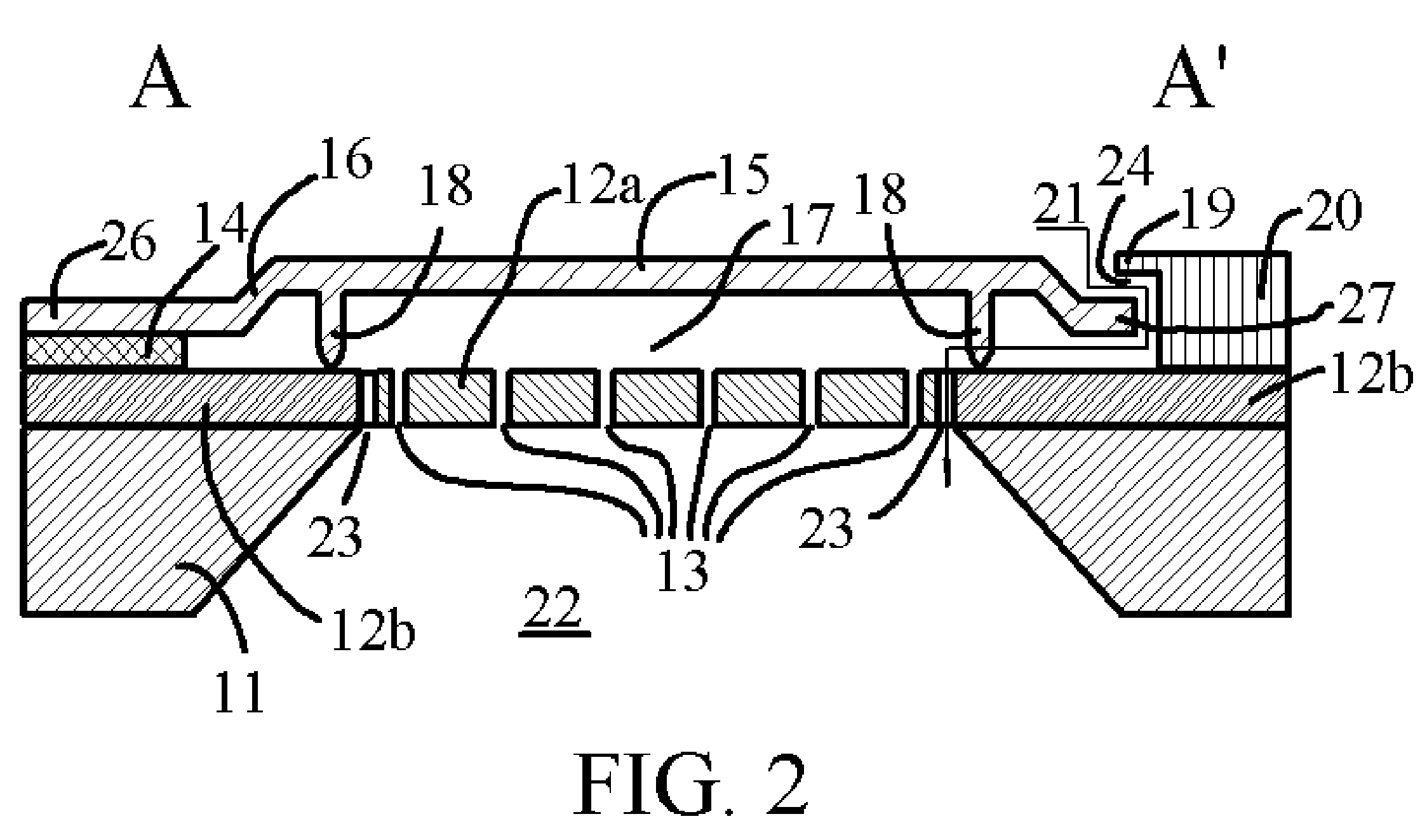

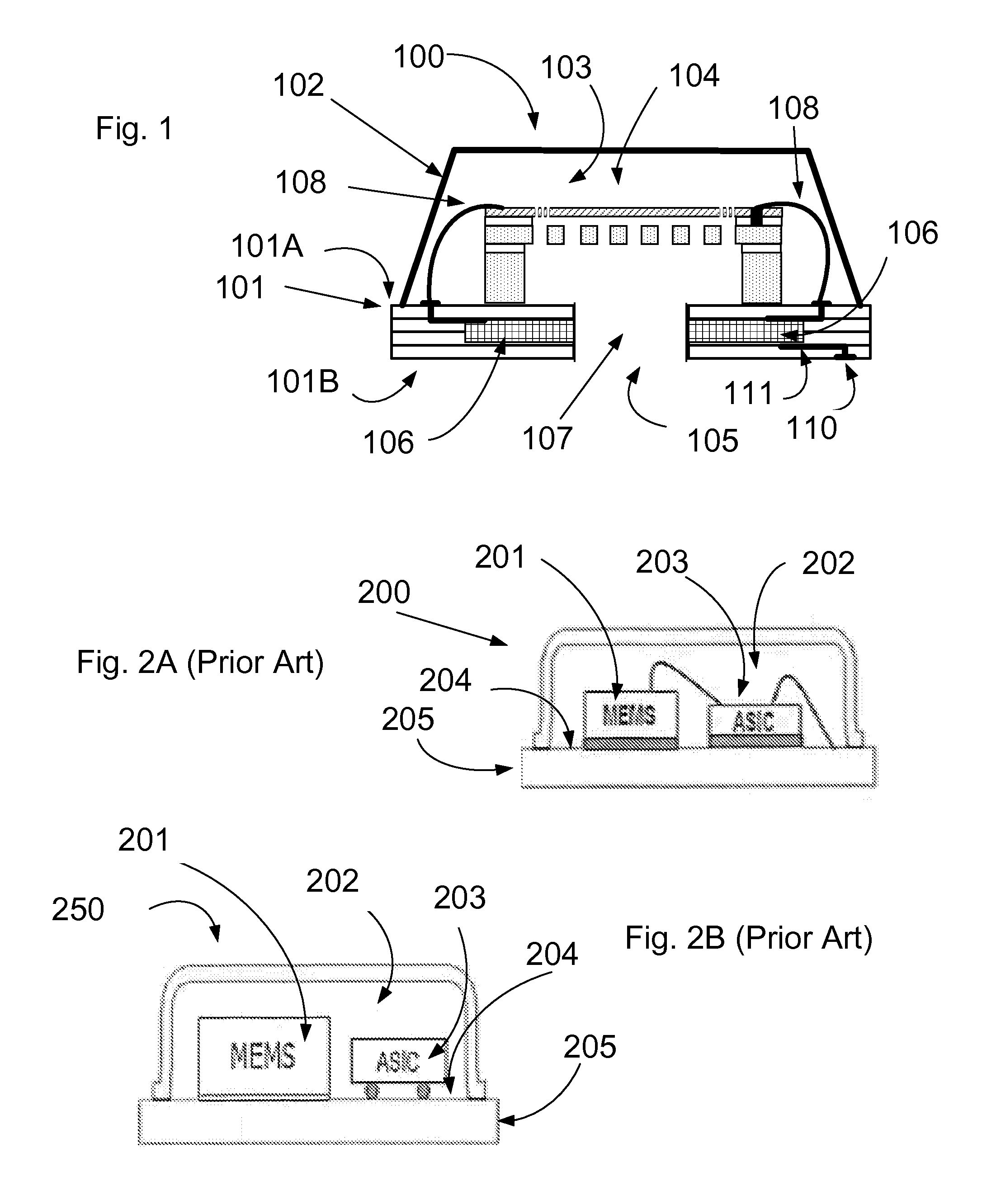

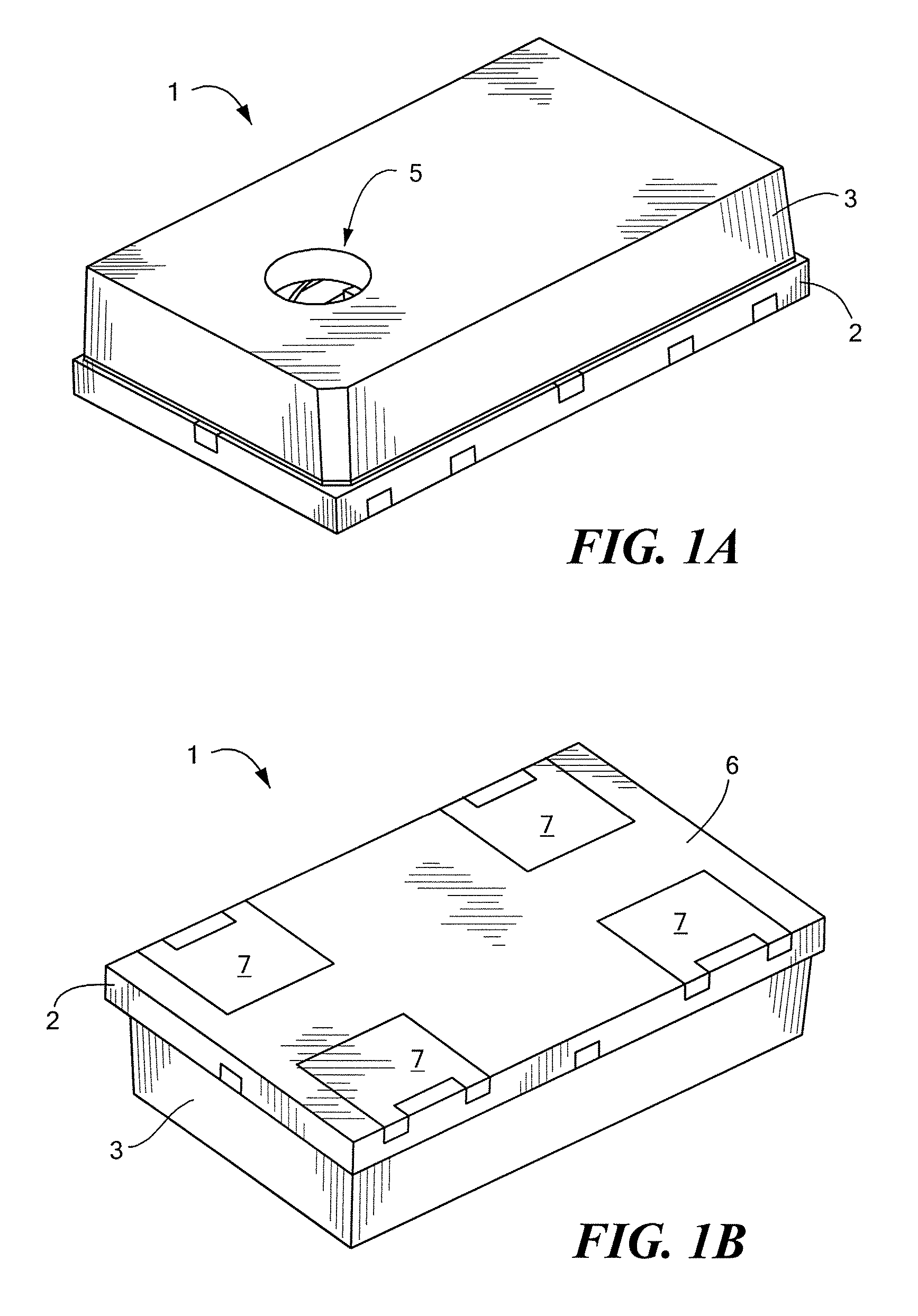

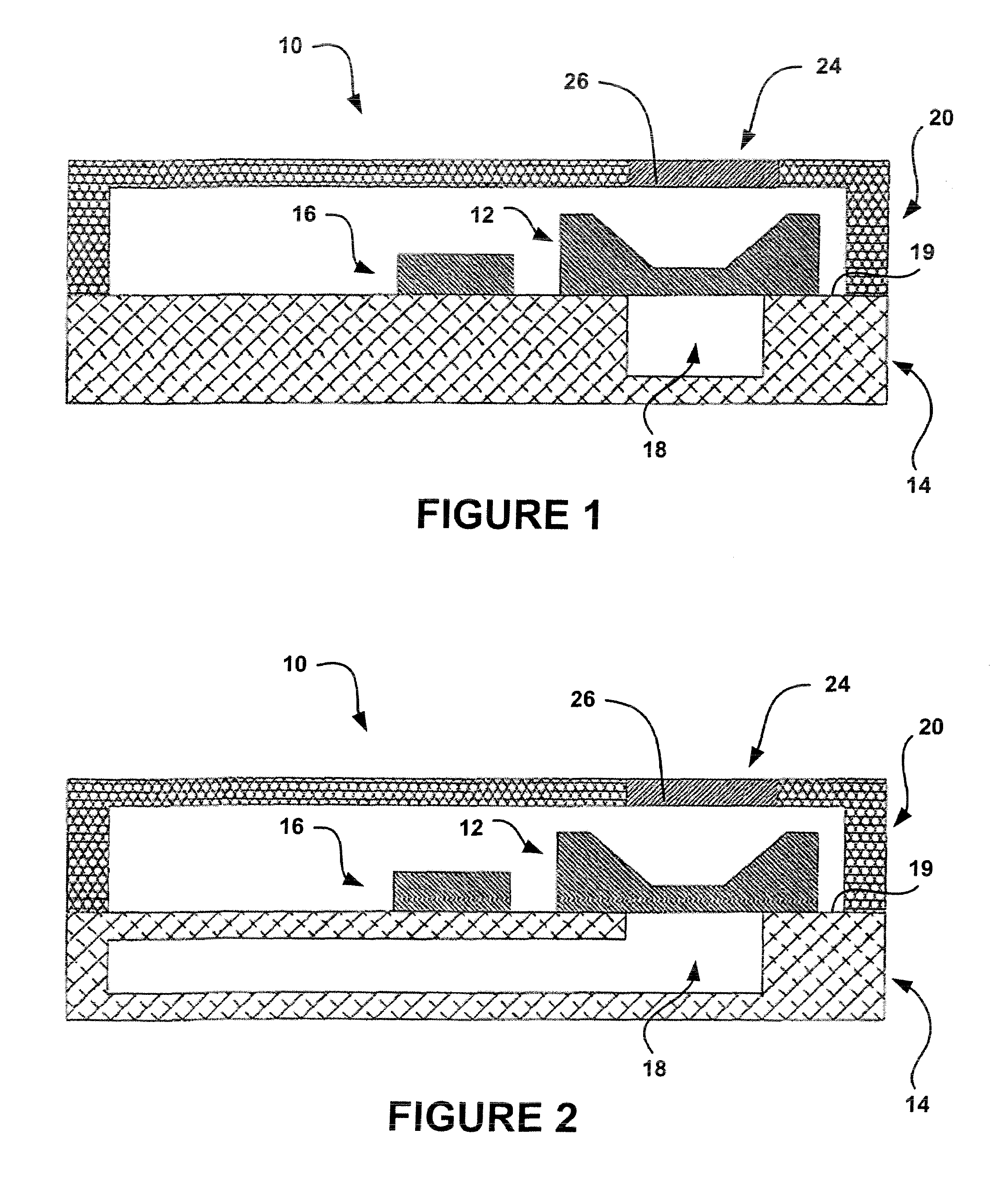

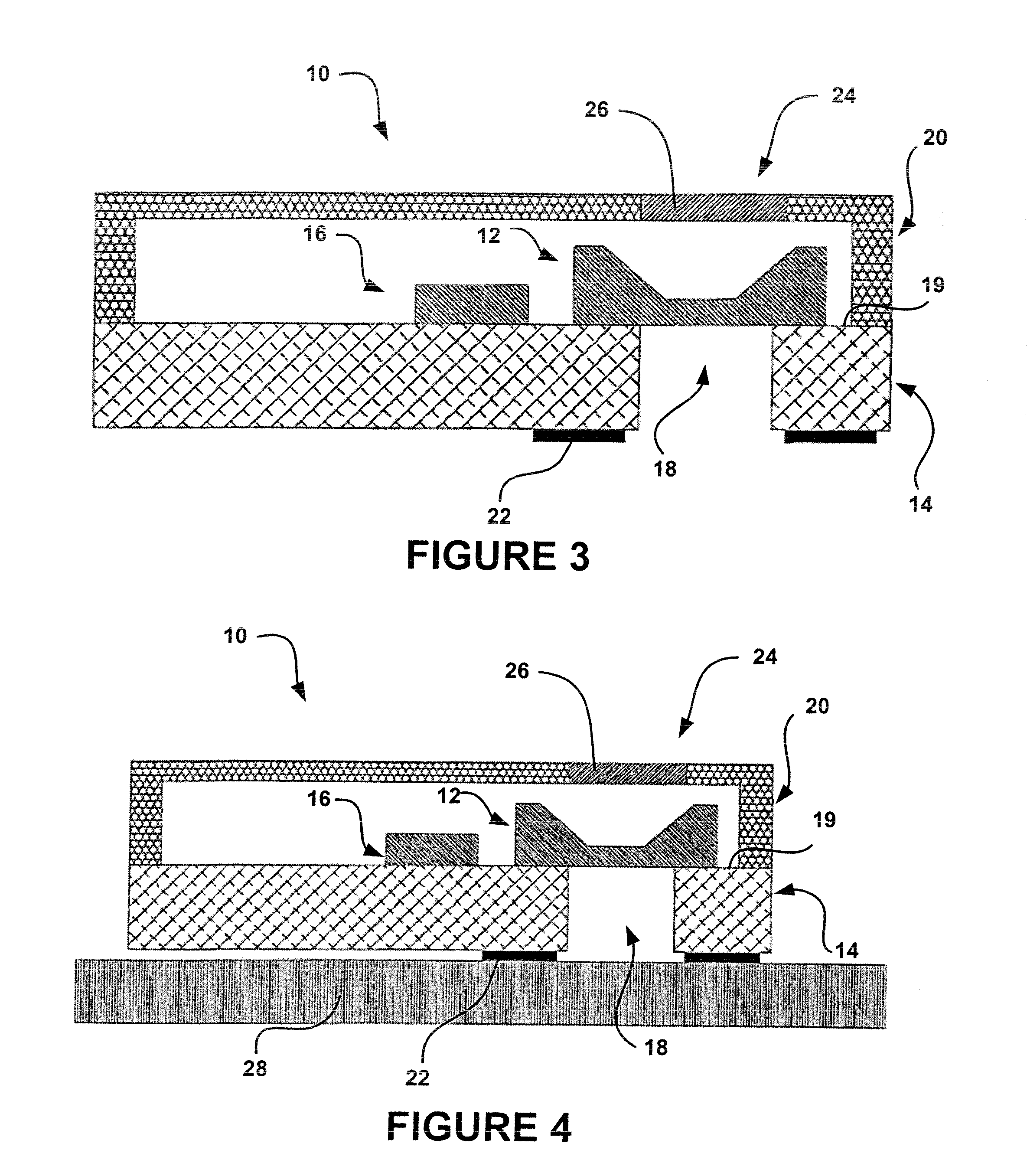

Silicon condenser microphone and manufacturing method

InactiveUS20050018864A1Piezoelectric/electrostrictive microphonesDecorative surface effectsCapacitanceTransducer

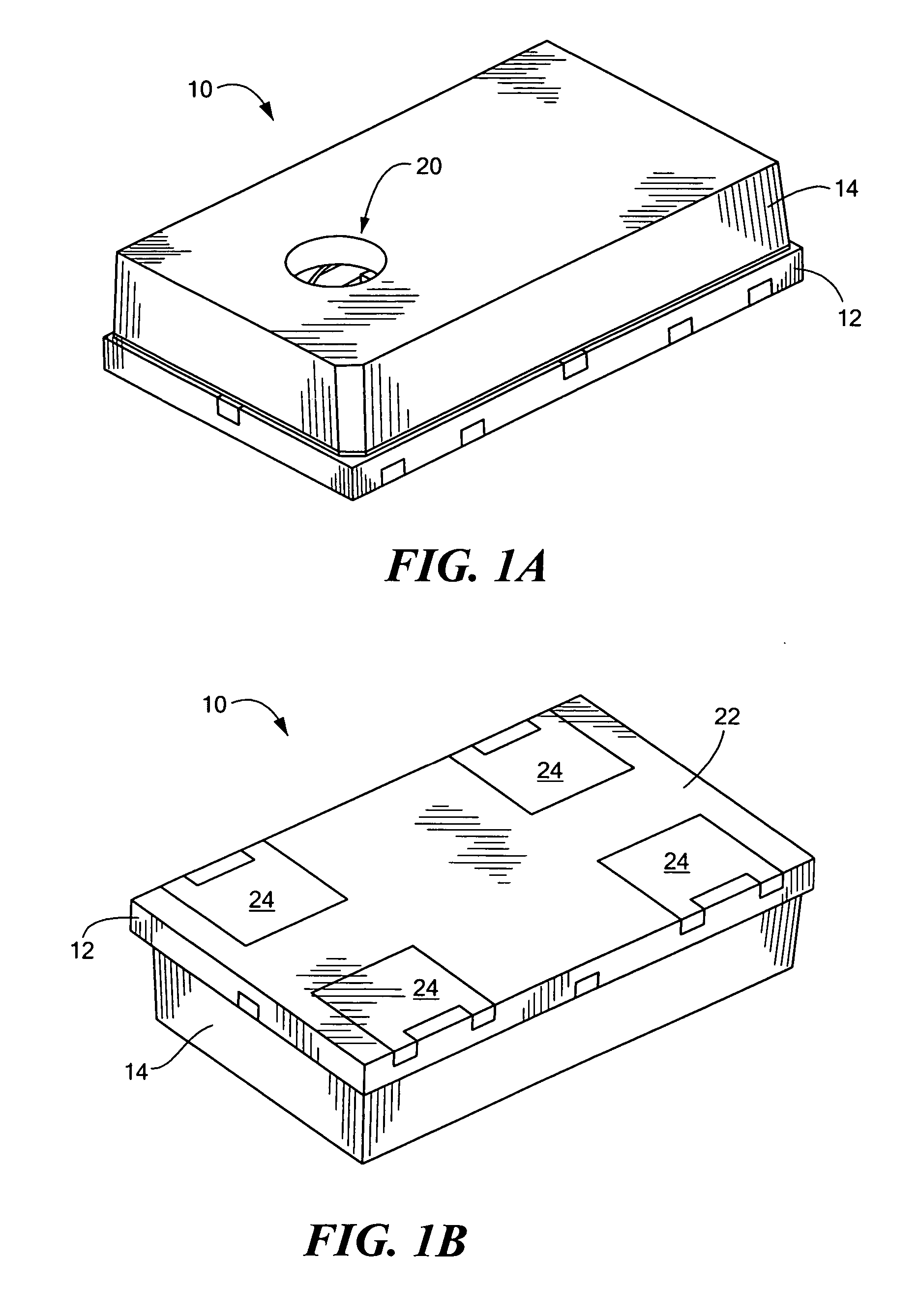

A silicon condenser microphone package is disclosed. The silicon condenser microphone package comprises a transducer unit, substrate, and a cover. The substrate includes an upper surface having a recess formed therein. The transducer unit is attached to the upper surface of the substrate and overlaps at least a portion of the recess wherein a back volume of the transducer unit is formed between the transducer unit and the substrate. The cover is placed over the transducer unit and includes an aperture.

Owner:KNOWLES ELECTRONICS INC

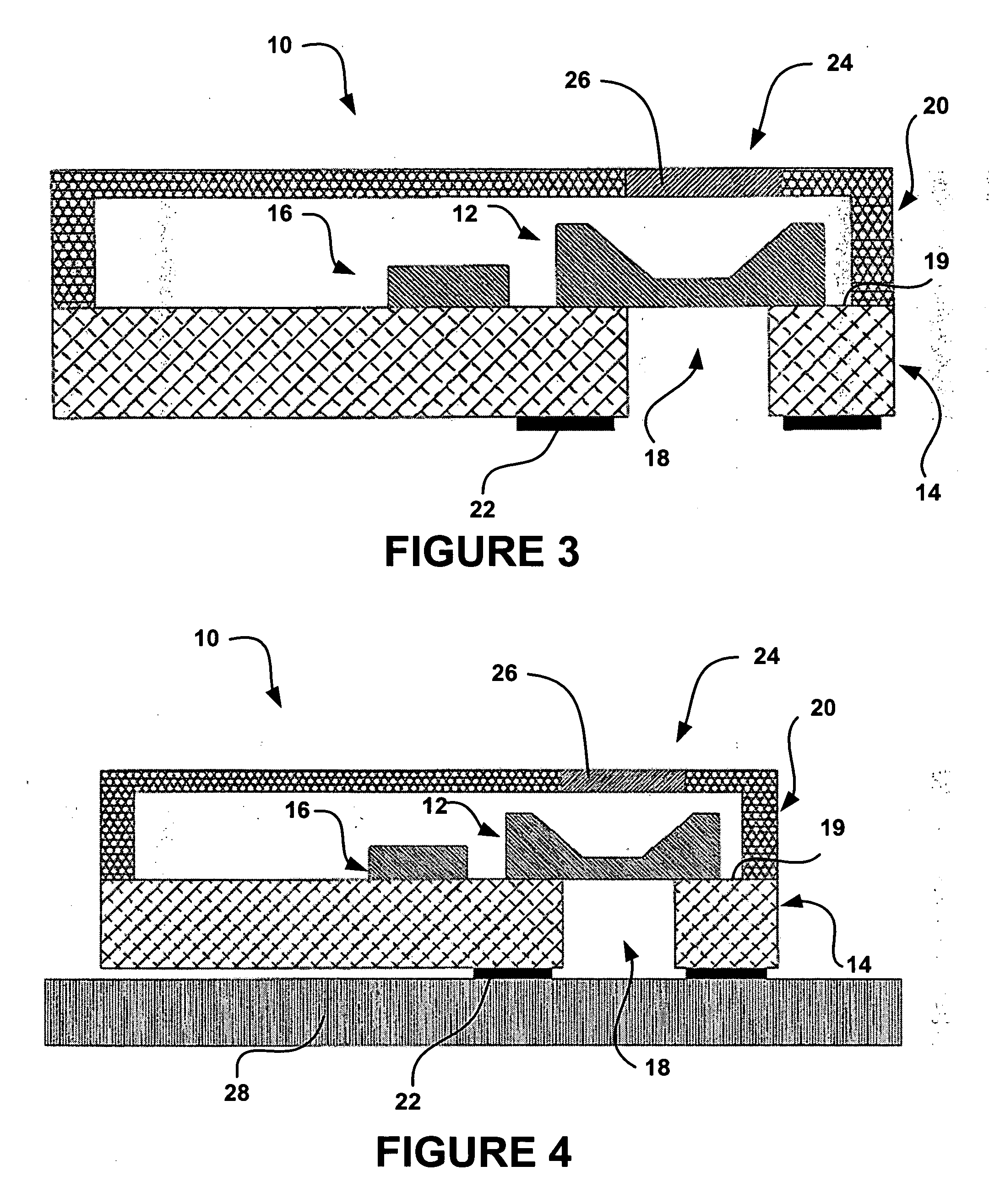

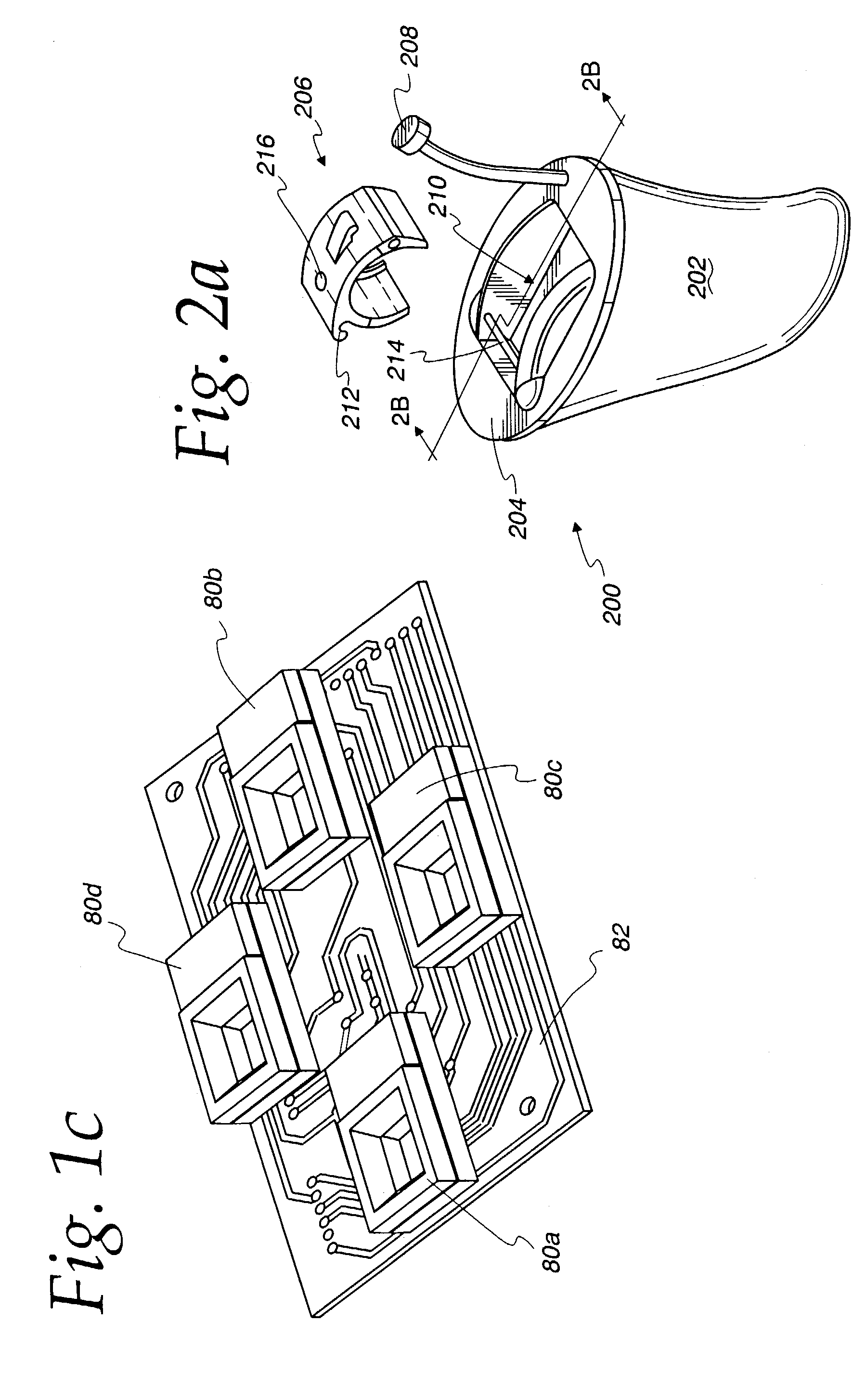

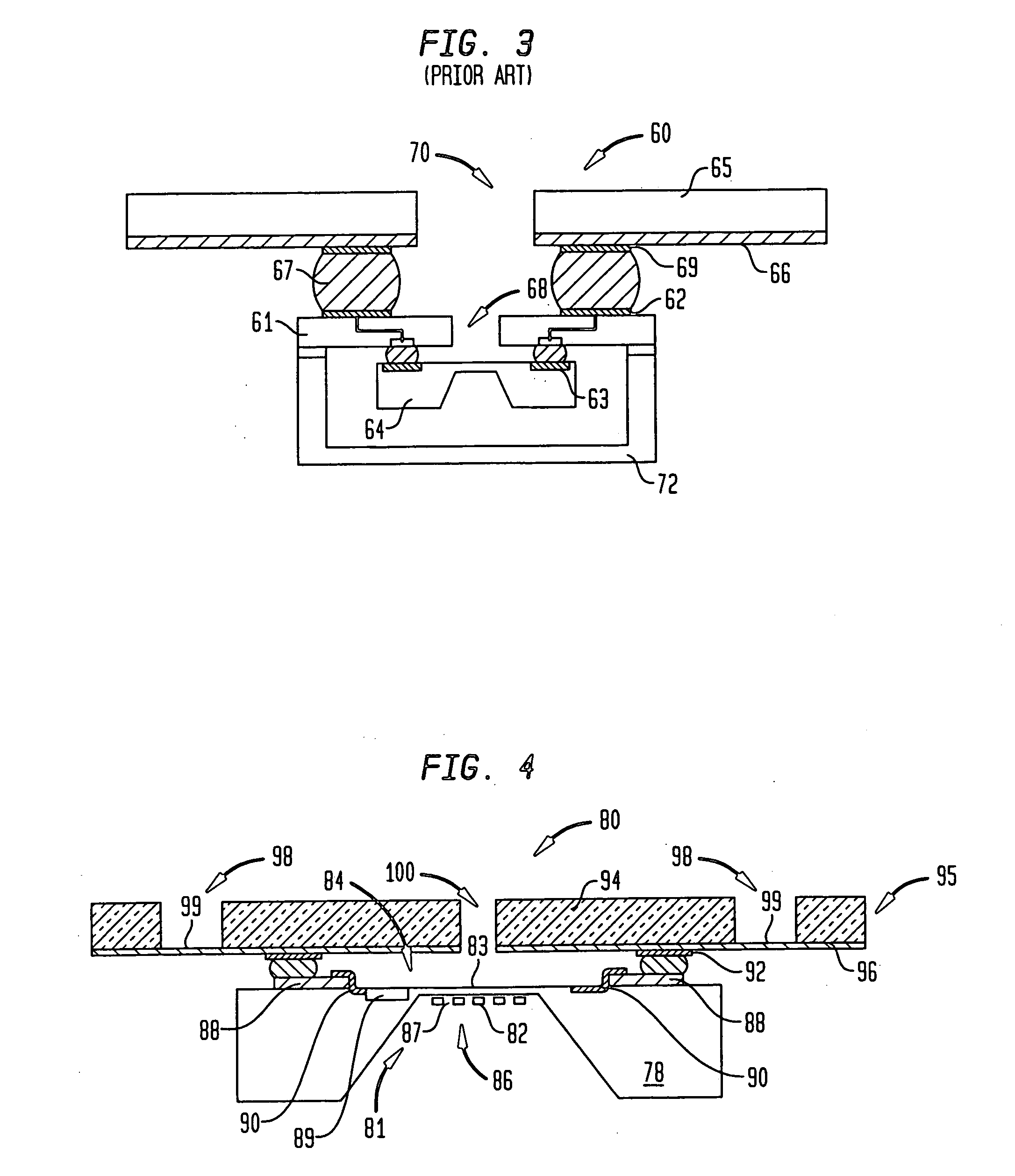

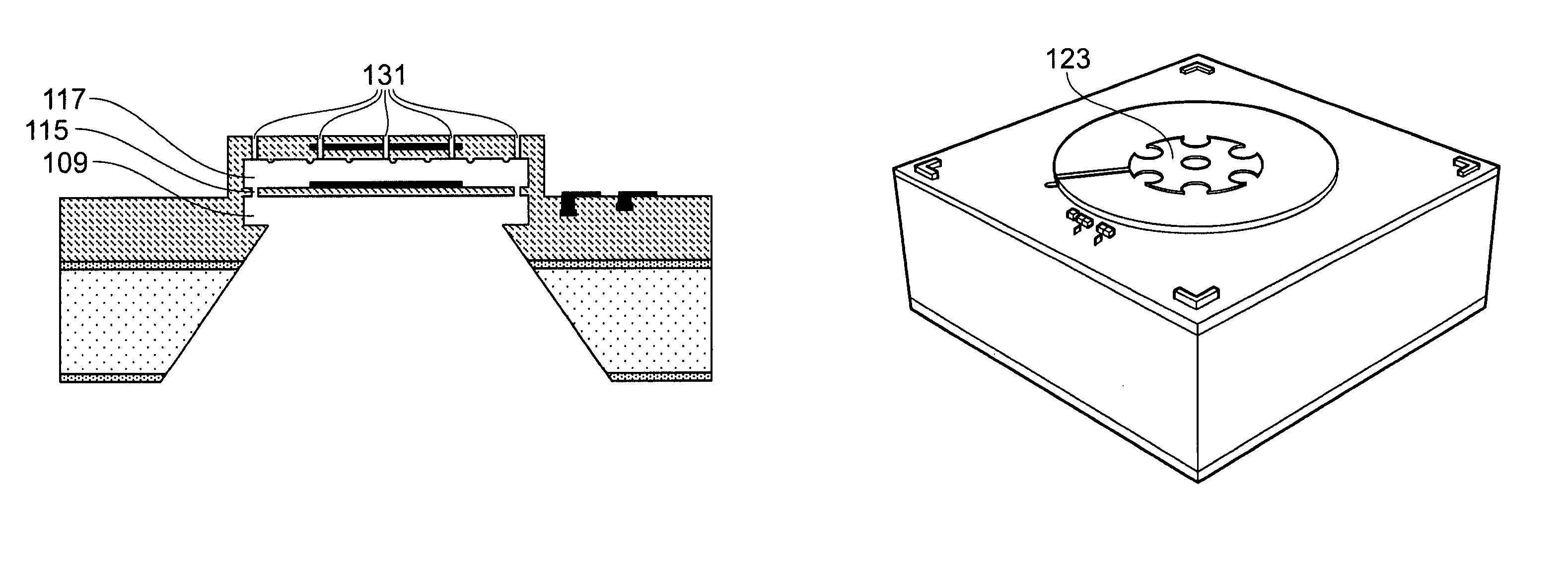

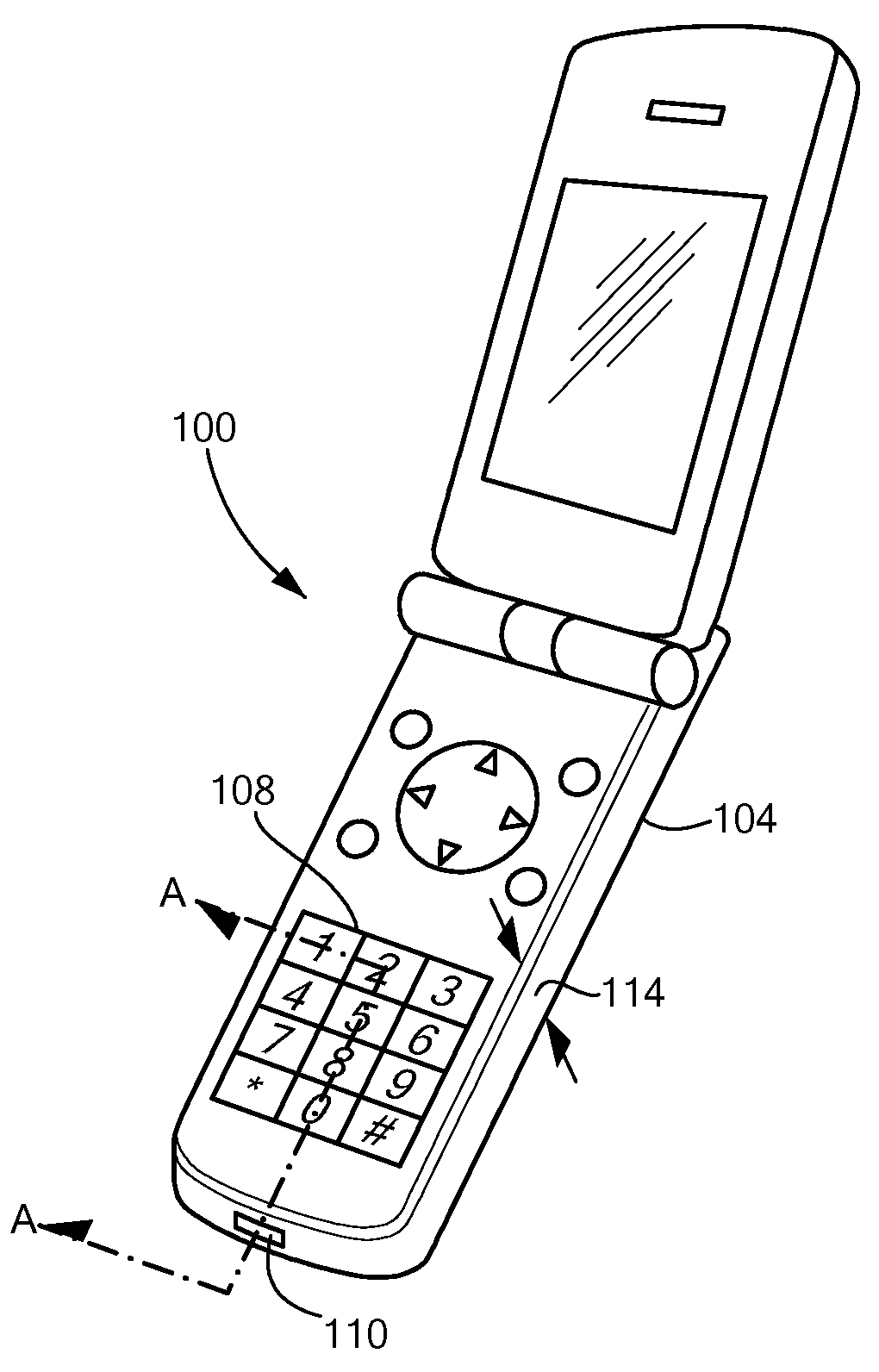

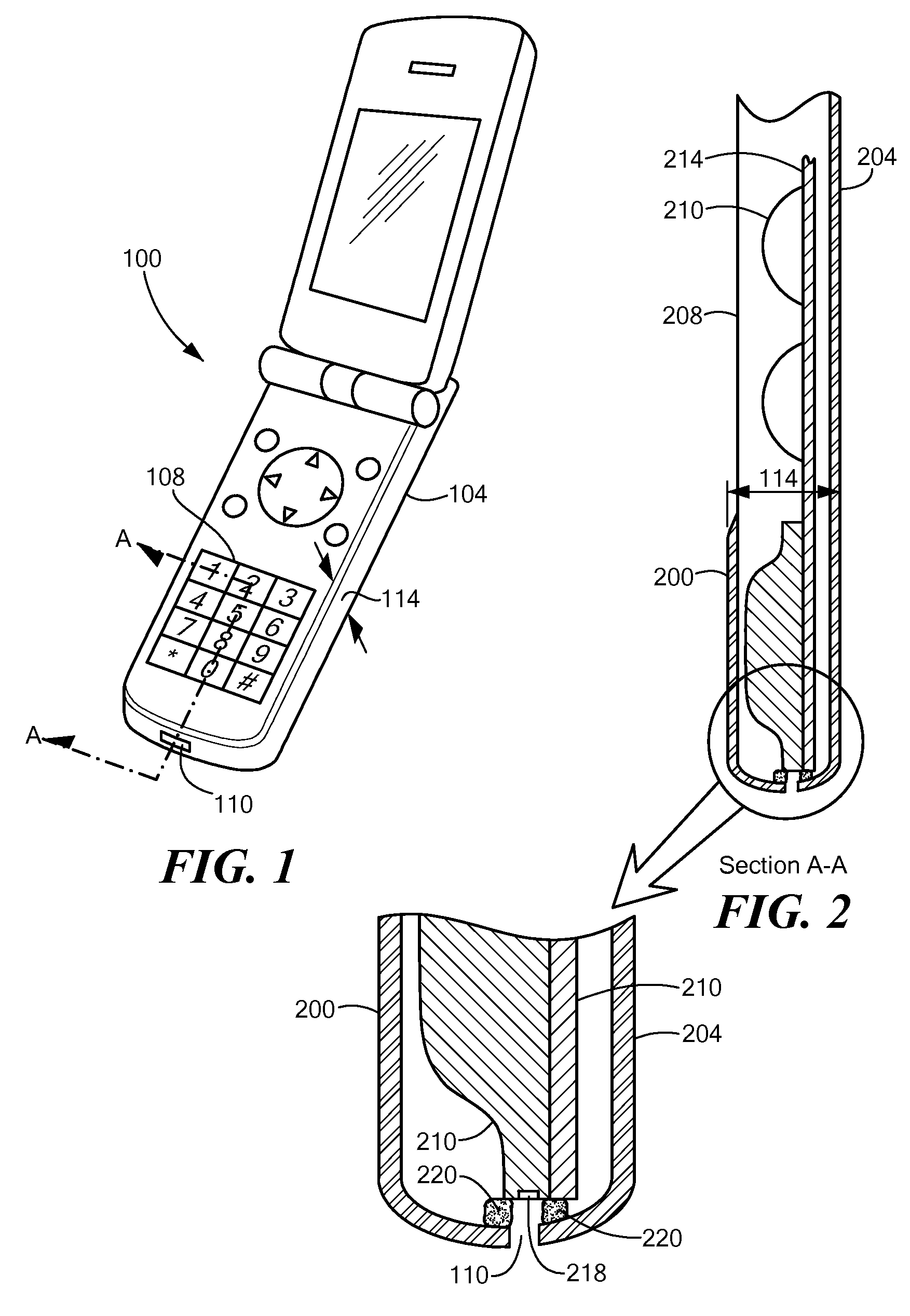

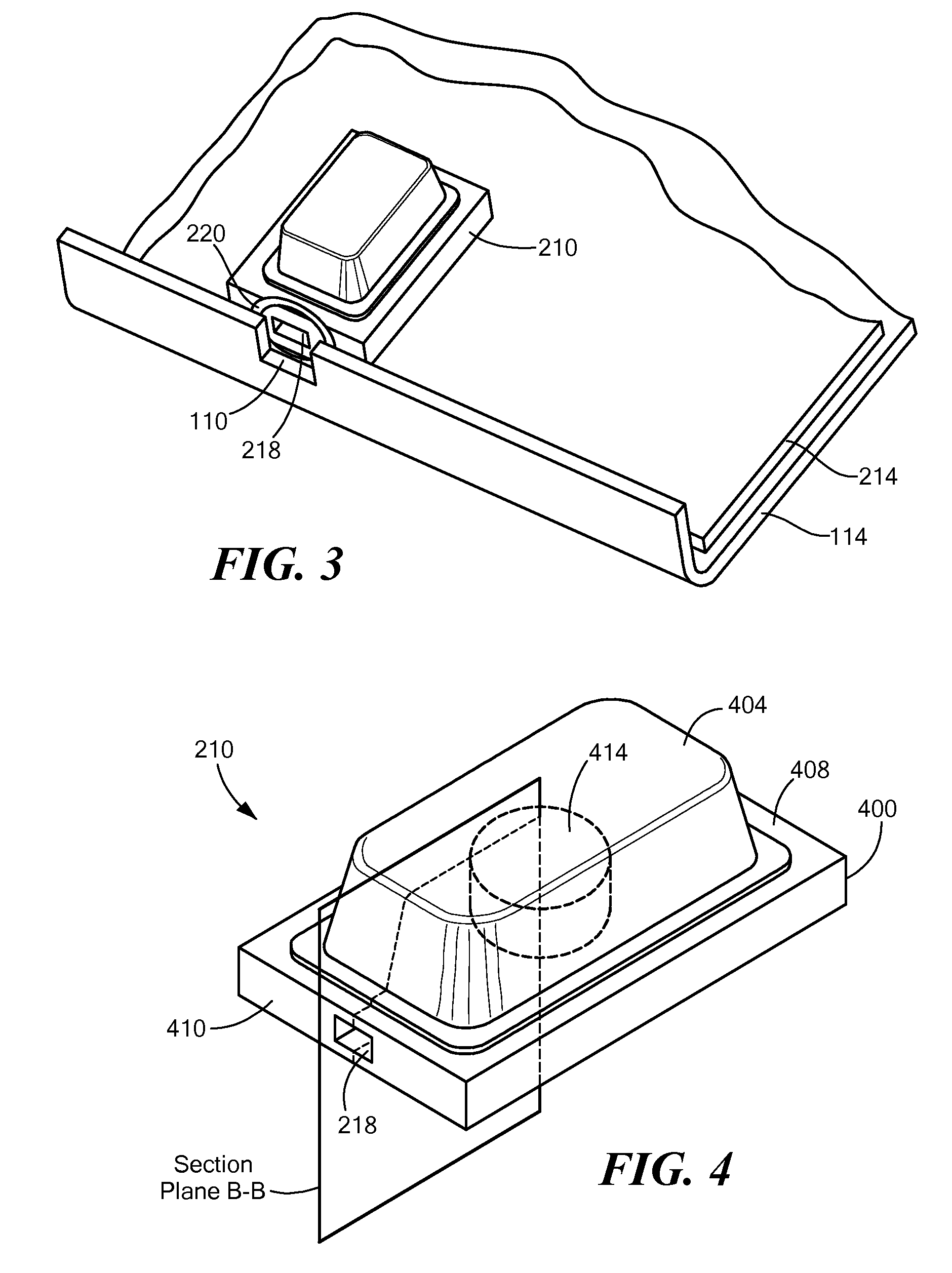

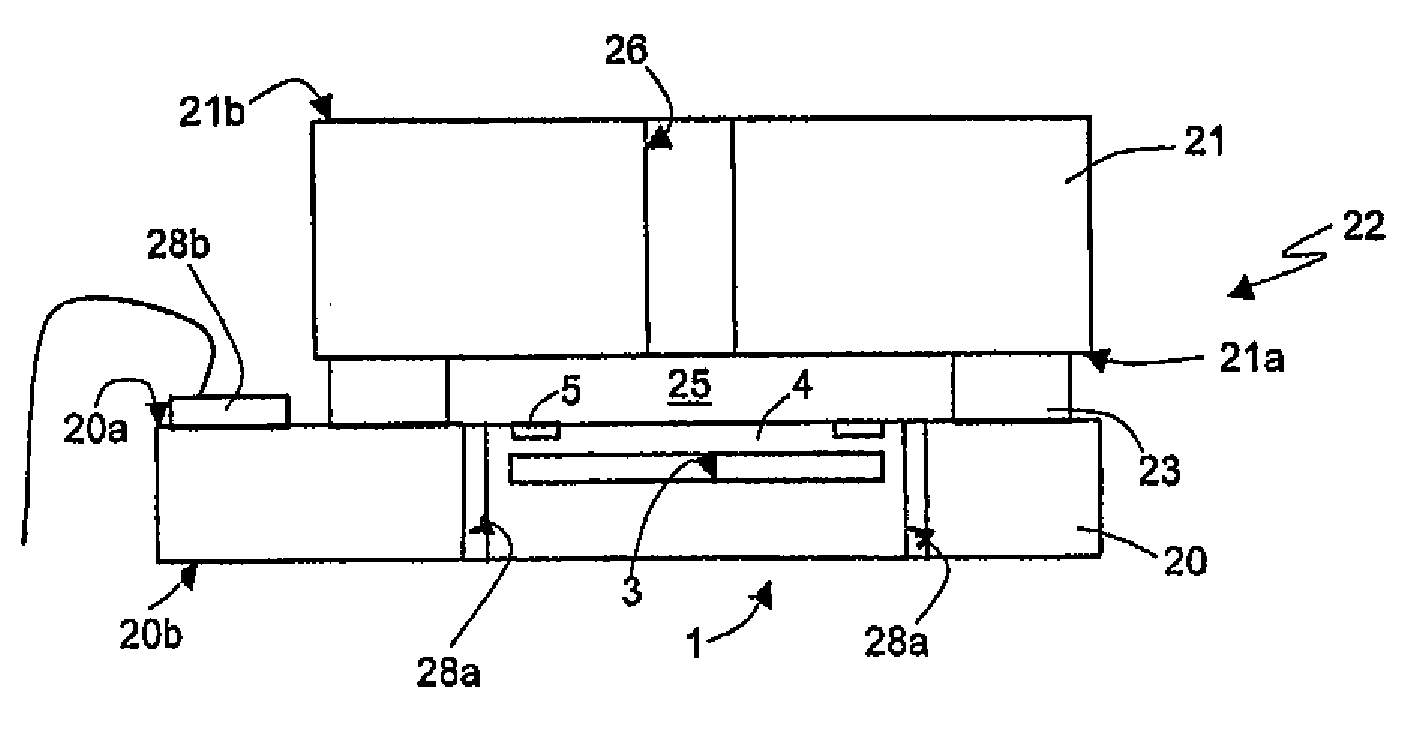

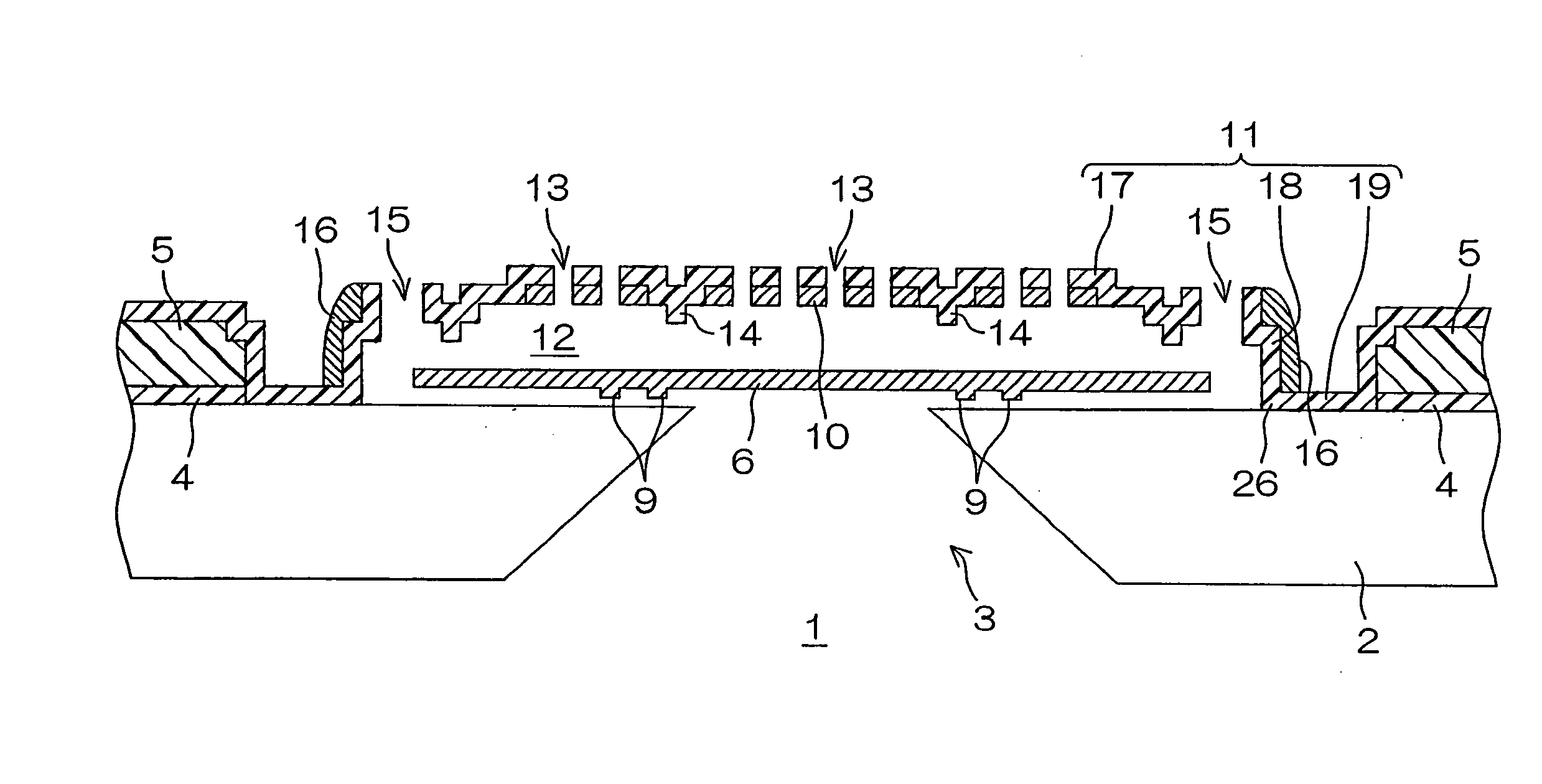

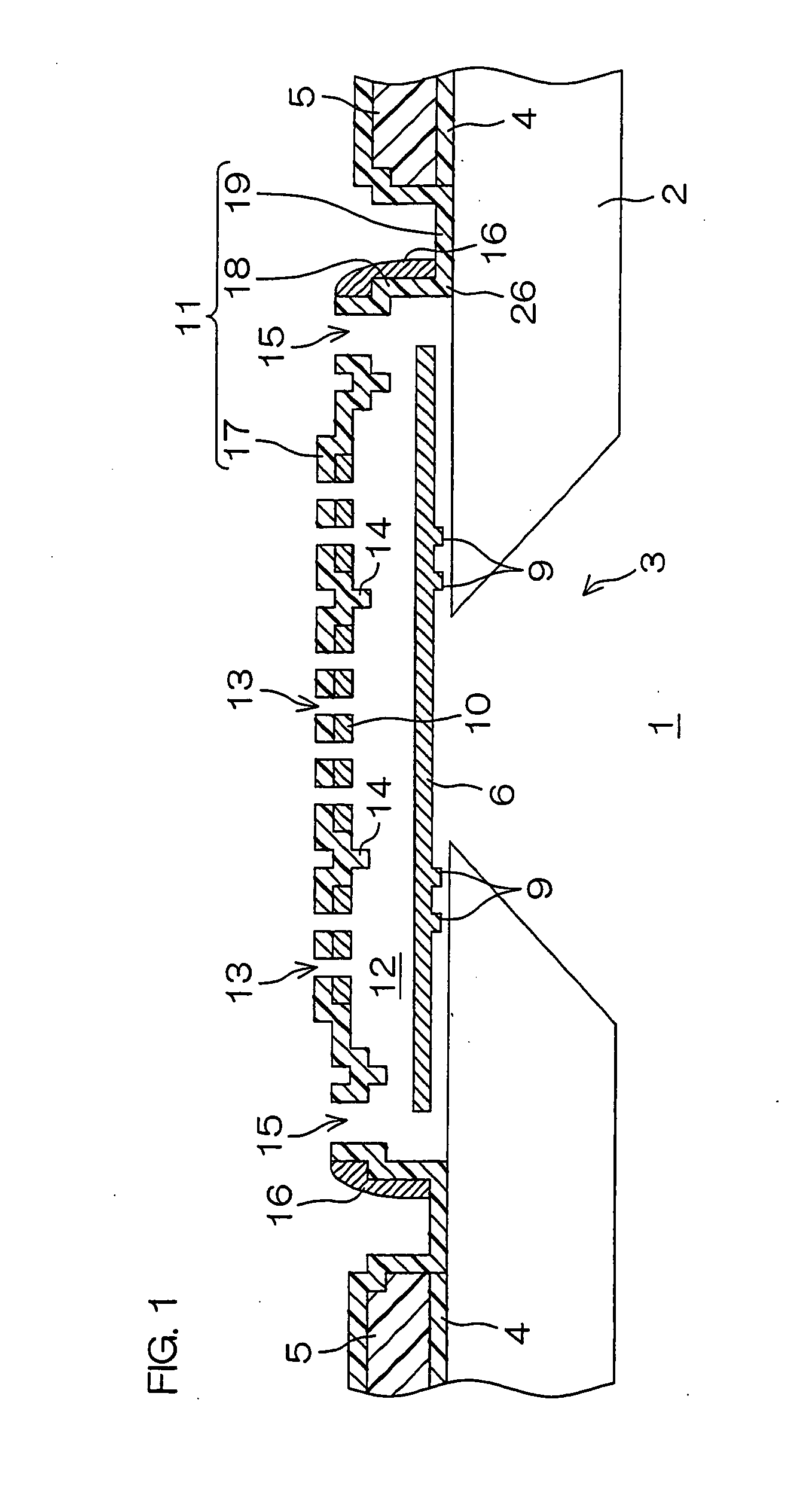

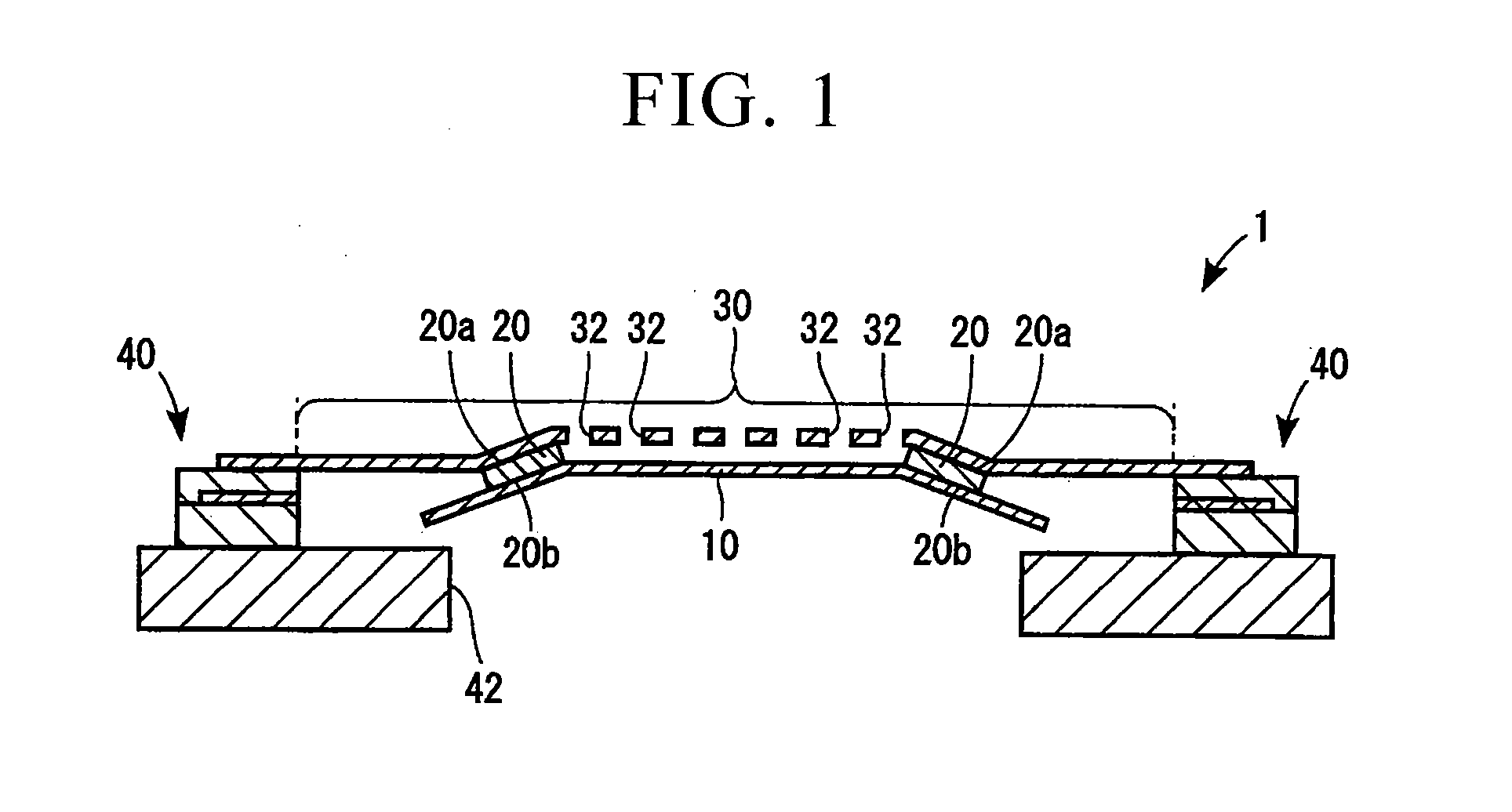

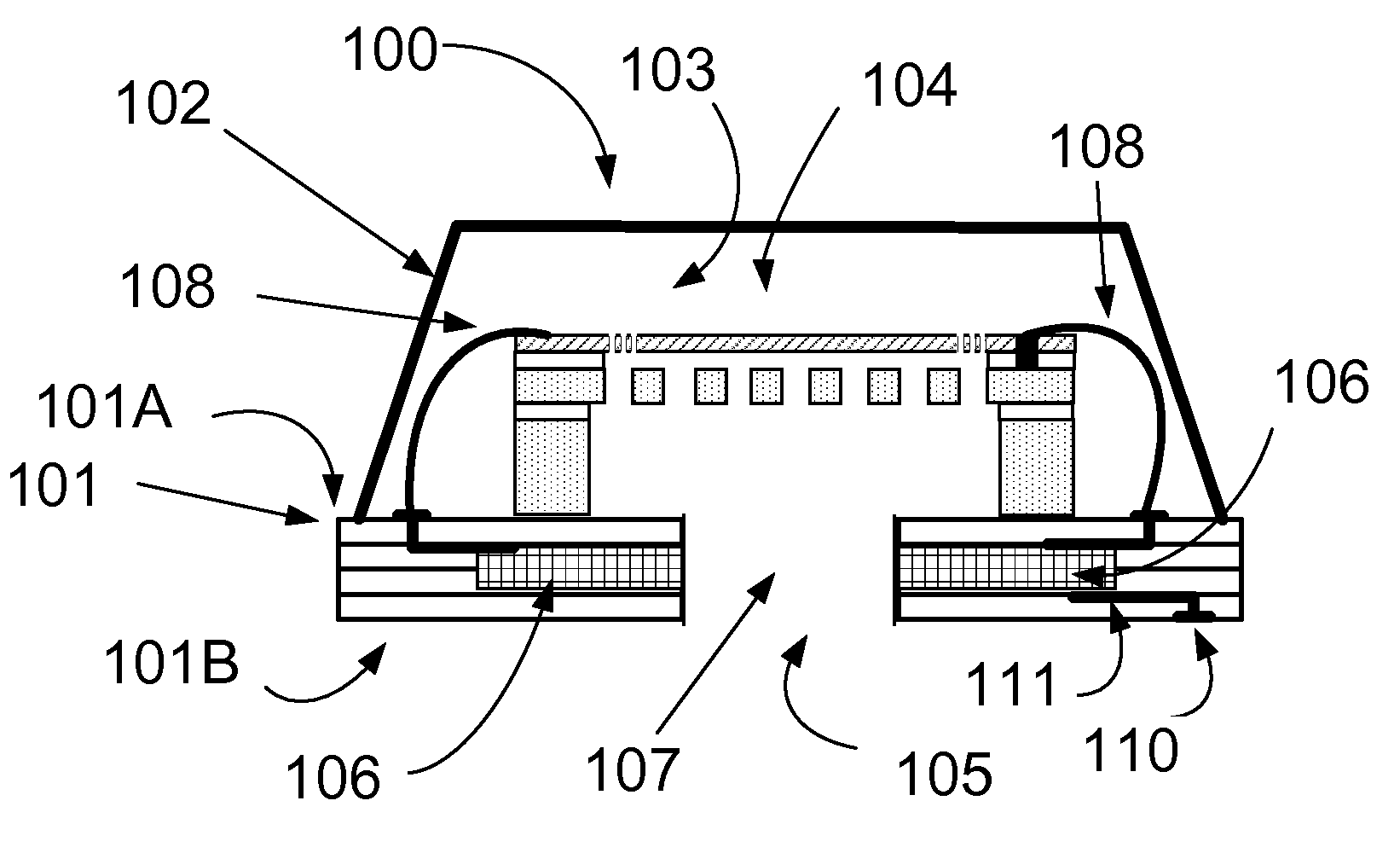

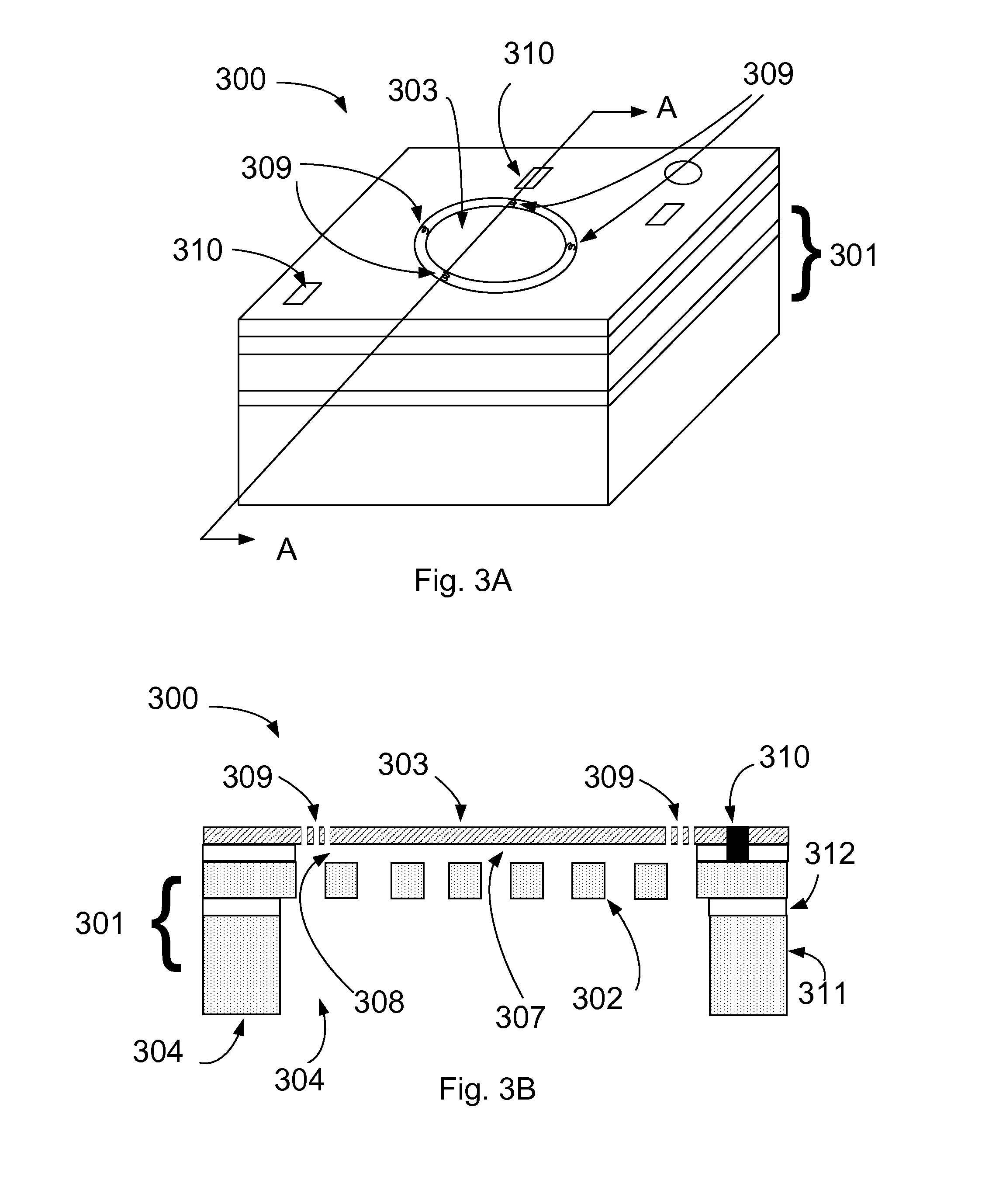

Silicon-based transducer for use in hearing instruments and listening devices

InactiveUS7142682B2Improve signal-to-noise ratioAdditive manufacturing apparatusSemiconductor electrostatic transducersConvertersAudio power amplifier

A silicon-based transducer assembly coupled to a movable structure in a hearing instrument. The transducer assembly includes at least one microphone chip and an ASIC having multiple integrated components such as any combination of a DSP, an A / D converter, an amplifier, a filter, or a wireless interface. The movable structure may be a battery access door, a volume dial, a switch, or a touch pad. A protection strip can be disposed across the battery access door to prevent debris from clogging the silicon-based transducer assembly. The transducer assembly may also include an array of microphone chips to achieve adaptive beam steering or directionality. When equipped with a wireless interface, the hearing instrument wirelessly communicates with another hearing instrument or with a network.

Owner:TDK CORPARATION

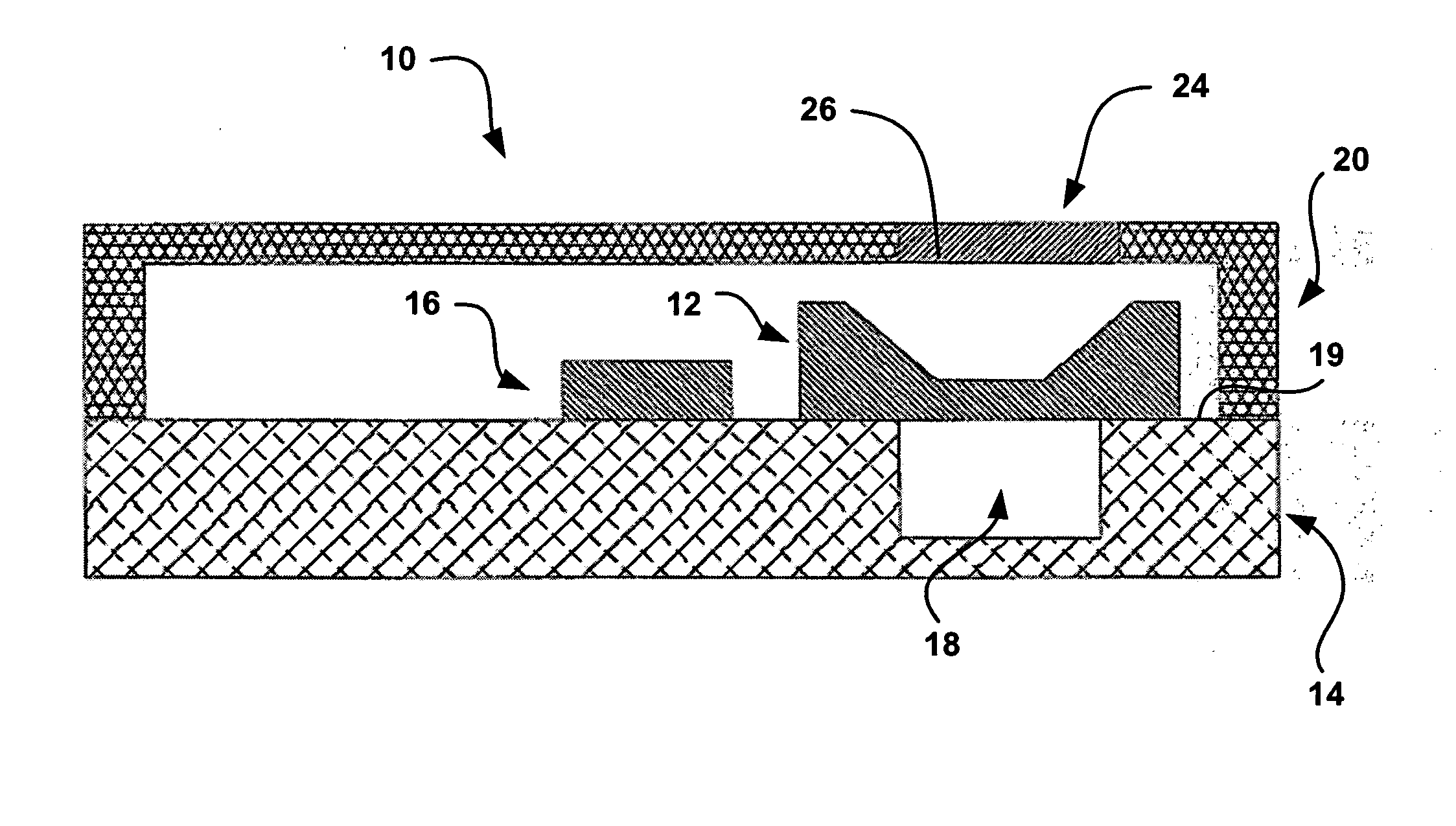

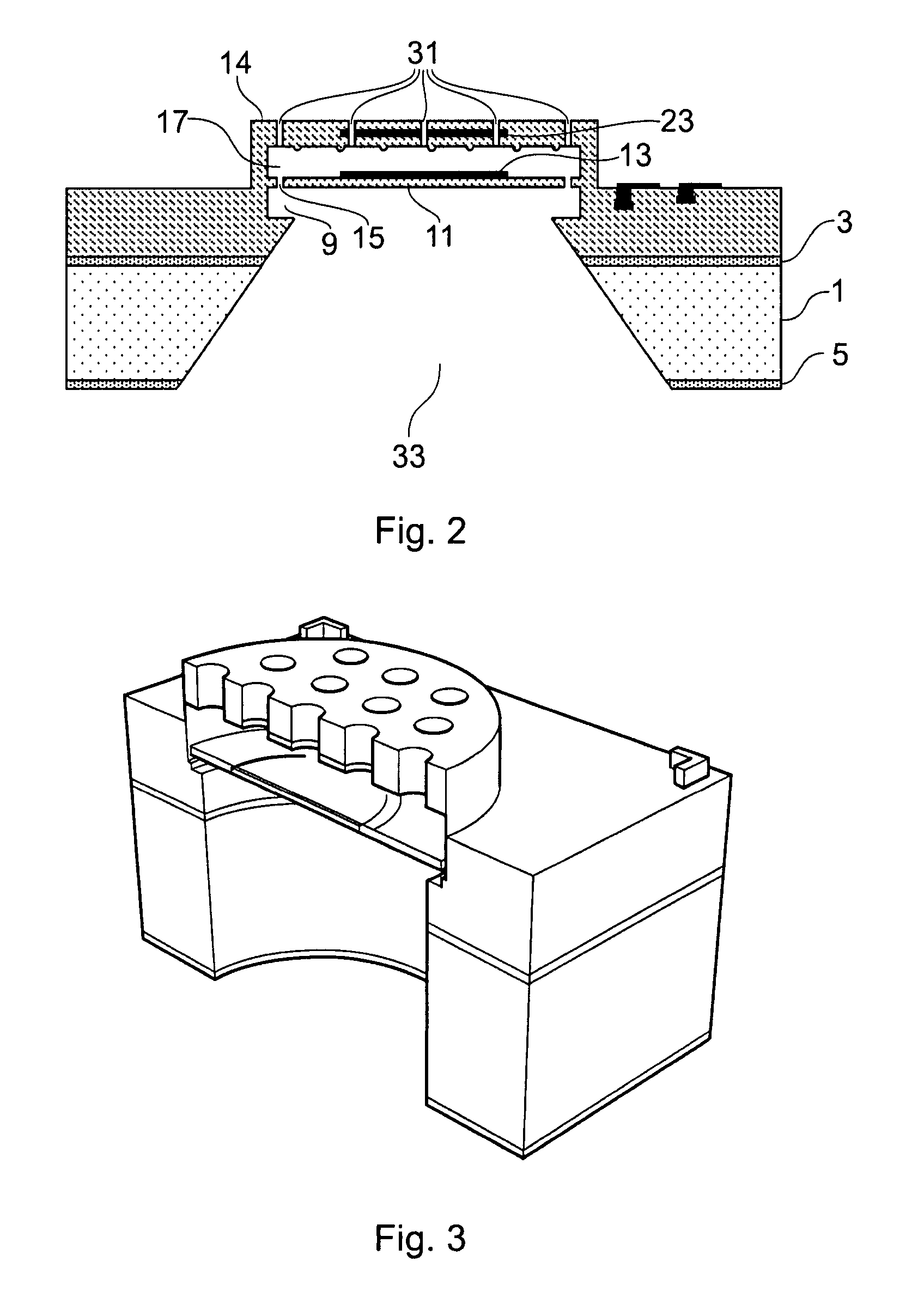

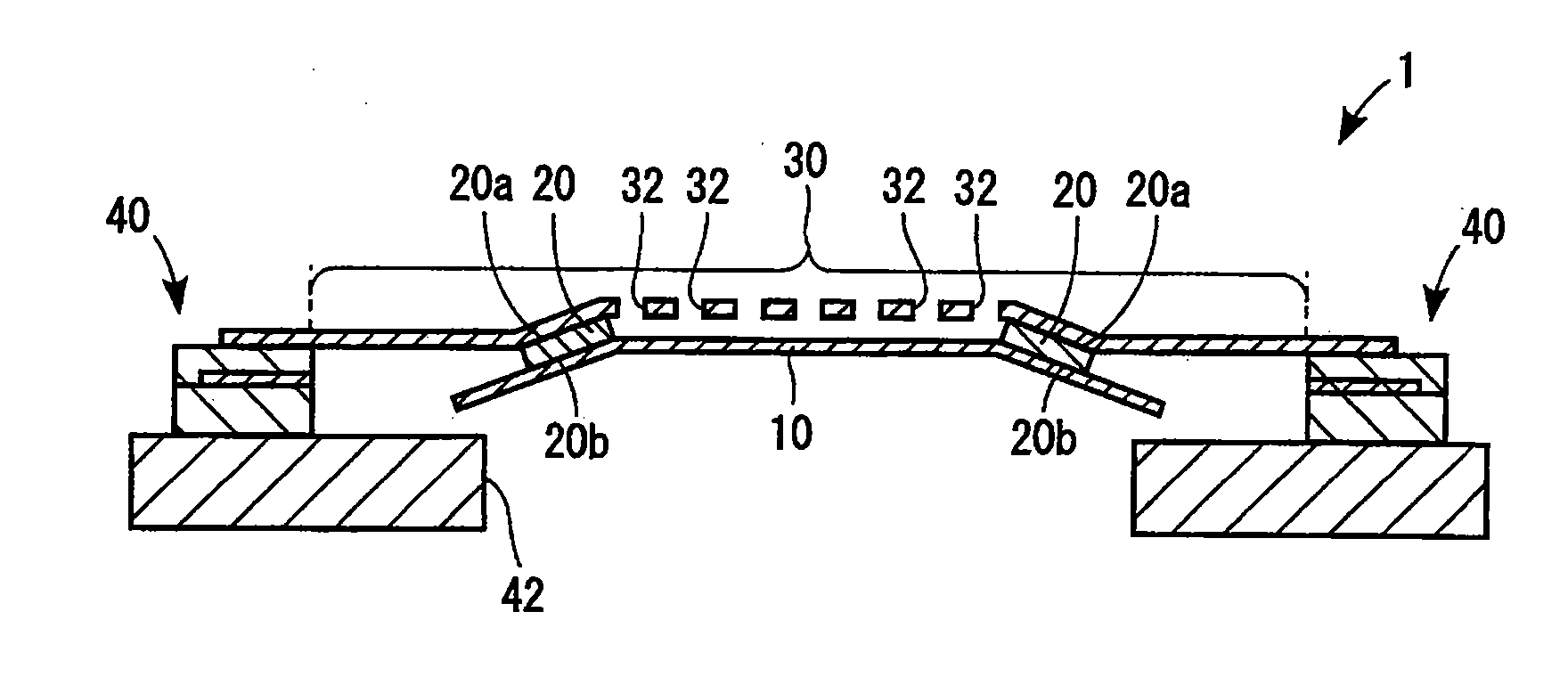

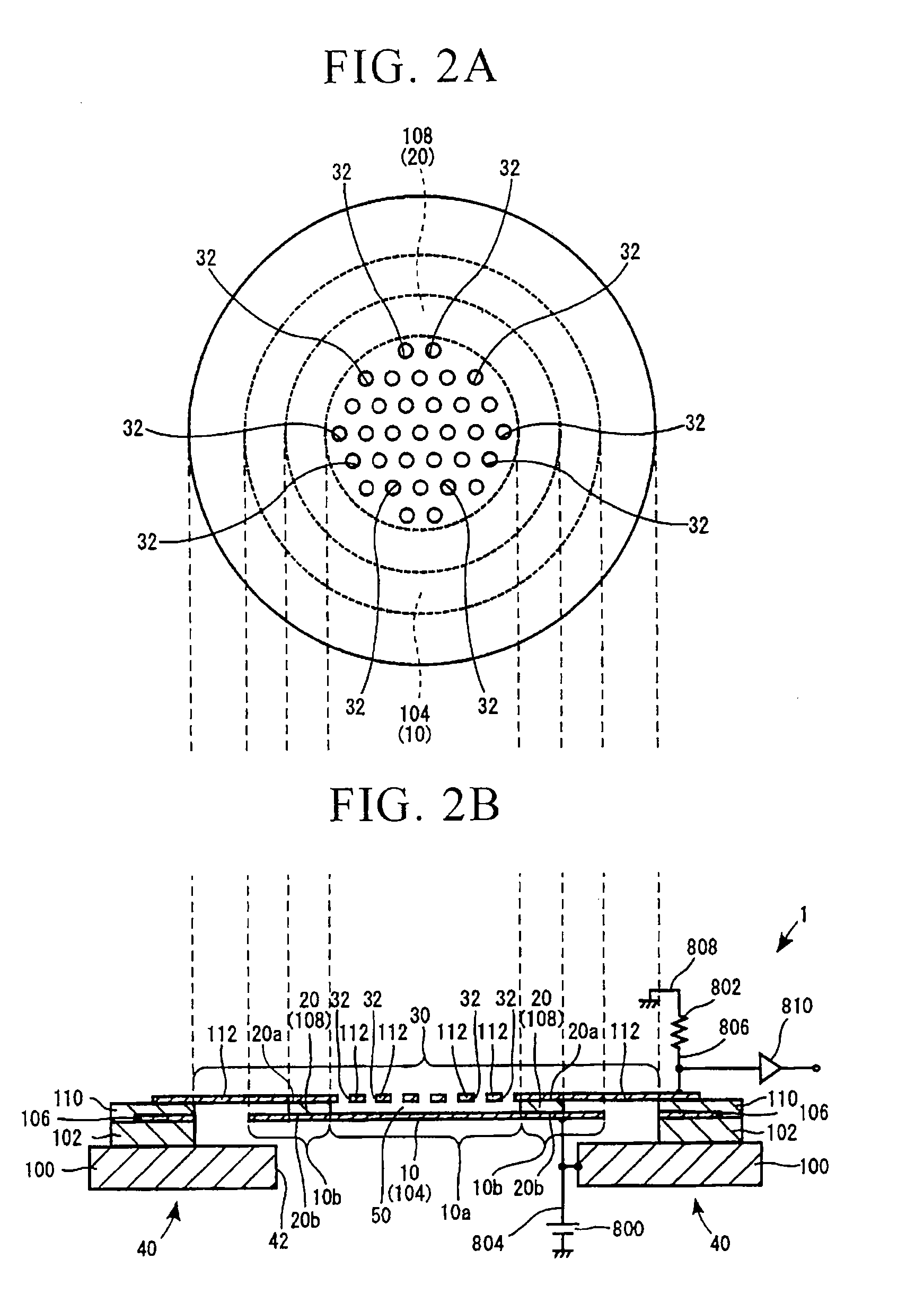

Assembly of a capacitive acoustic transducer of the microelectromechanical type and package thereof

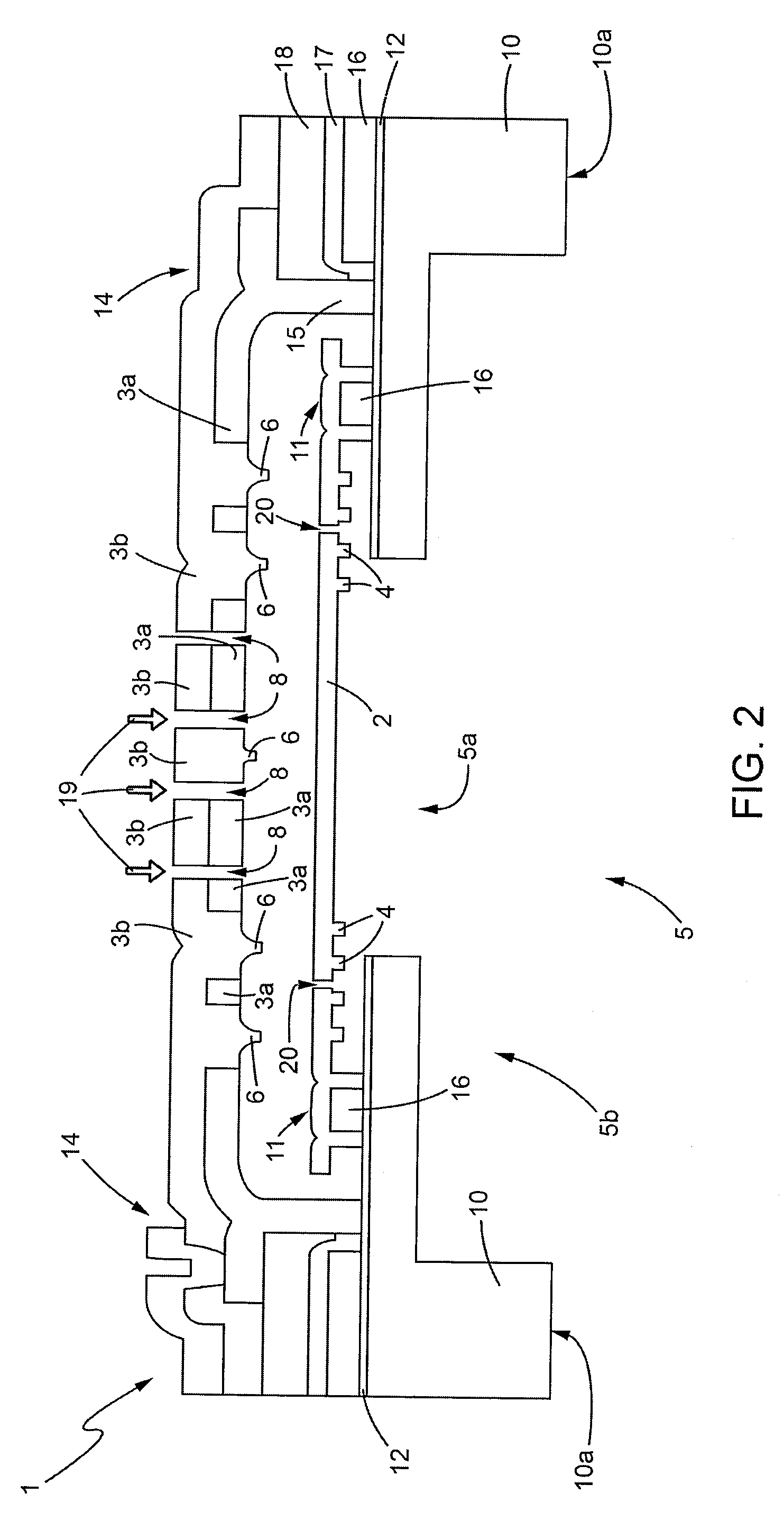

A microelectromechanical-acoustic-transducer assembly has: a first die integrating a MEMS sensing structure having a membrane, which has a first surface in fluid communication with a front chamber and a second surface, opposite to the first surface, in fluid communication with a back chamber of the microelectromechanical acoustic transducer, is able to undergo deformation as a function of incident acoustic-pressure waves, and faces a rigid electrode so as to form a variable-capacitance capacitor; a second die, integrating an electronic reading circuit operatively coupled to the MEMS sensing structure and supplying an electrical output signal as a function of the capacitive variation; and a package, housing the first die and the second die and having a base substrate with external electrical contacts. The first and second dice are stacked in the package and directly connected together mechanically and electrically; the package delimits at least one of the front and back chambers.

Owner:STMICROELECTRONICS SRL

Packaged acoustic and electromagnetic transducer chips

InactiveUS20050189635A1Semiconductor/solid-state device detailsSemiconductor electrostatic transducersDielectricAcoustic energy

Various embodiments of packaged chips and ways of fabricating them are disclosed herein. One such packaged chip disclosed herein includes a chip having a front face, a rear face opposite the front face, and a device at one of the front and rear faces, the device being operable as a transducer of at least one of acoustic energy and electromagnetic energy, and the chip including a plurality of bond pads exposed at one of the front and rear faces. The packaged chip includes a package element having a dielectric element and a metal layer disposed on the dielectric element, the package element having an inner surface facing the chip and an outer surface facing away from the chip. The metal layer includes a plurality of contacts exposed at at least one of the inner and outer surfaces, the contacts conductively connected to the bond pads. The metal layer further includes a first opening for passage of the at least one of acoustic energy and electromagnetic energy in a direction of at least one of to said device and from said device.

Owner:TESSERA INC

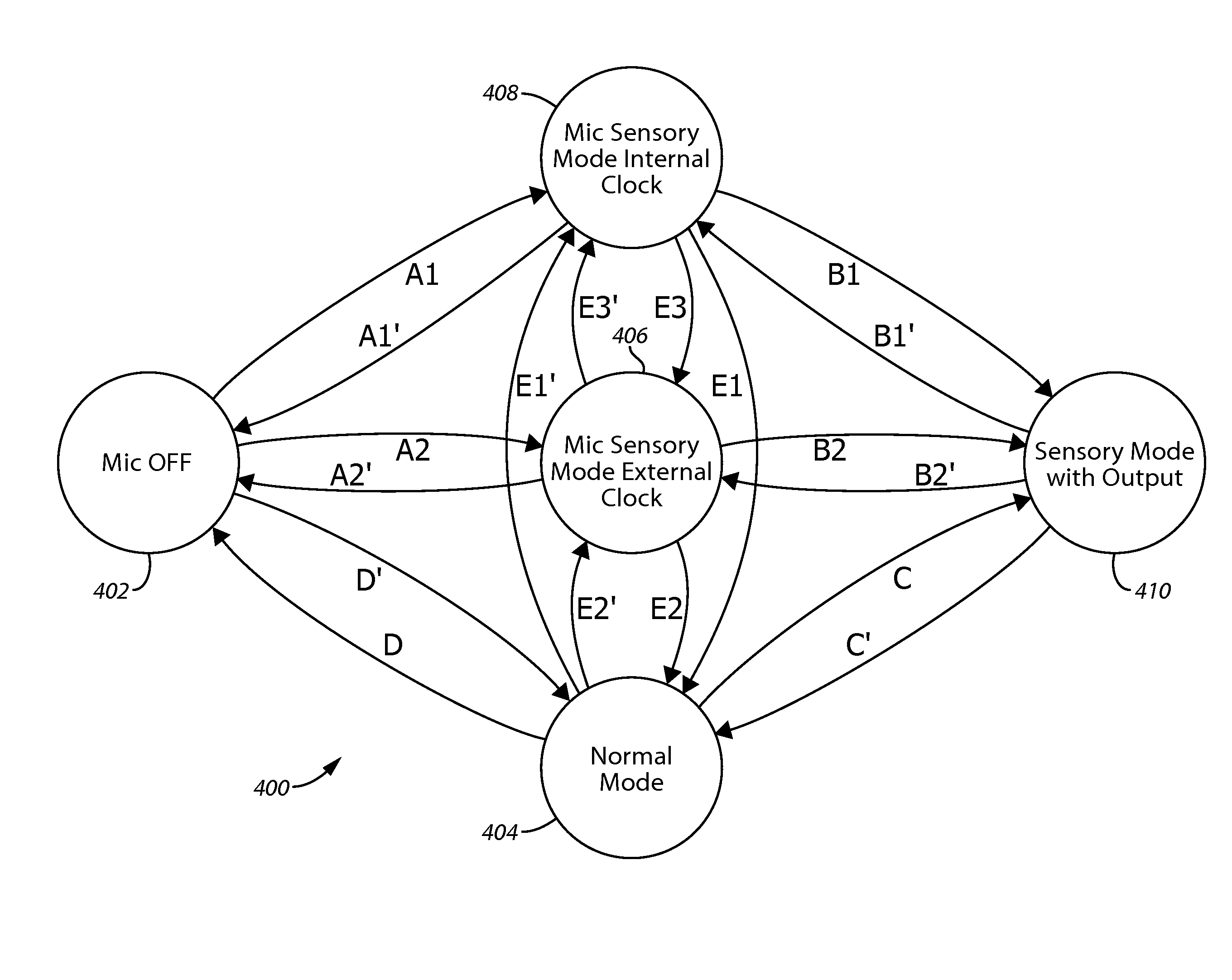

Synchronization of buffered data in multiple microphones

InactiveUS9111548B2Semiconductor electrostatic transducersElectrostatic transducer microphonesDigital dataAnalog signal

Owner:KNOWLES ELECTRONICS INC

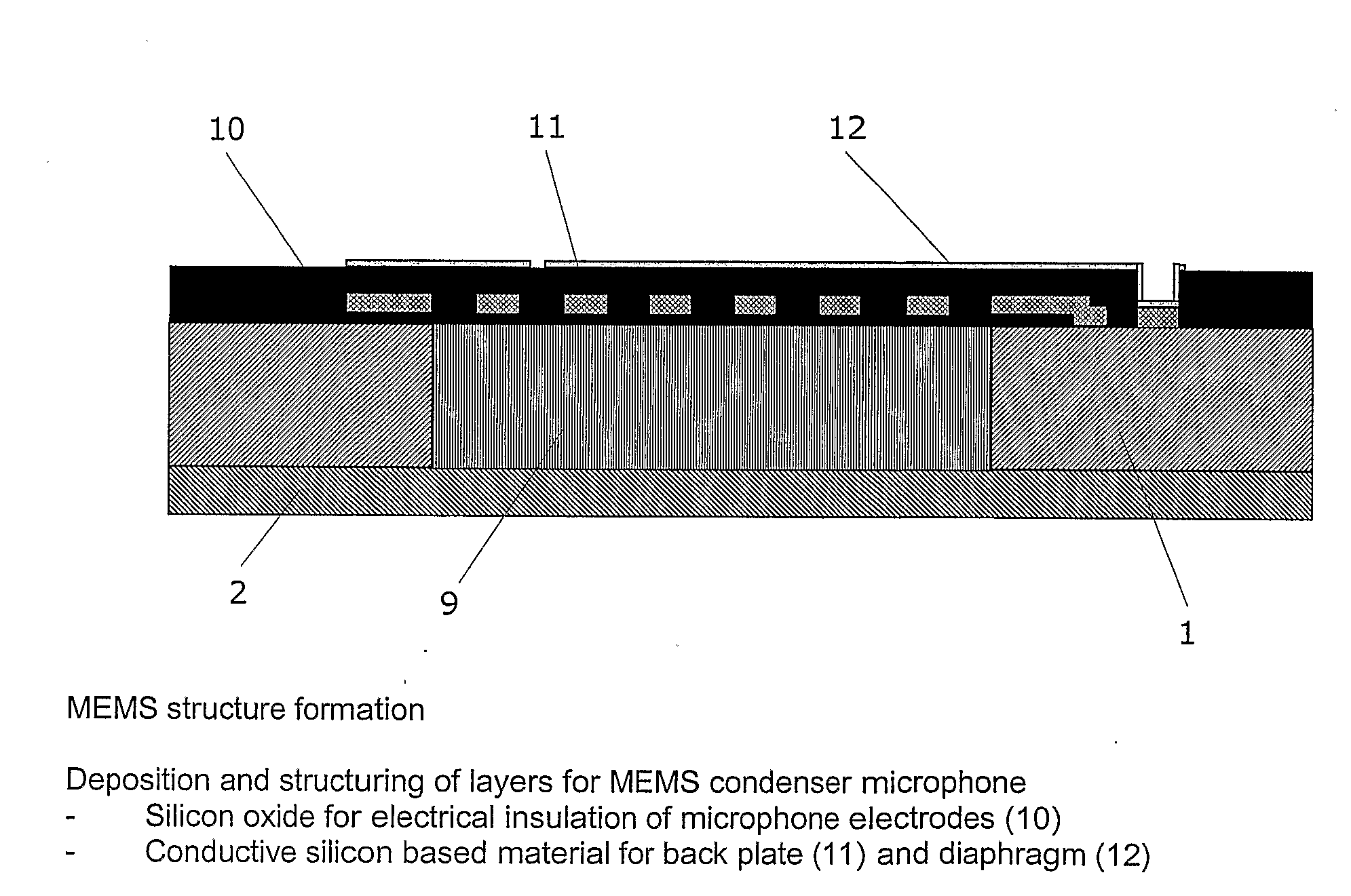

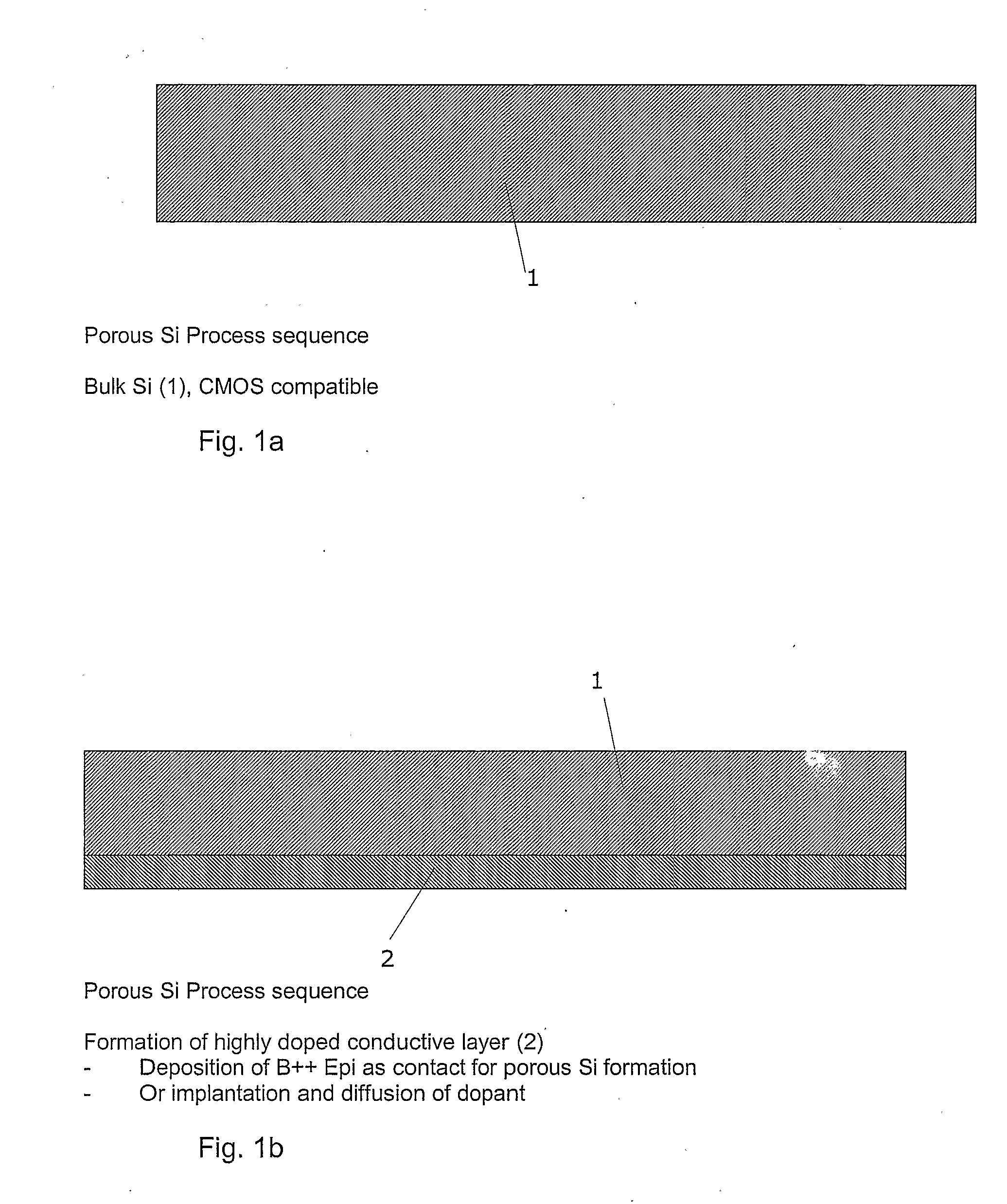

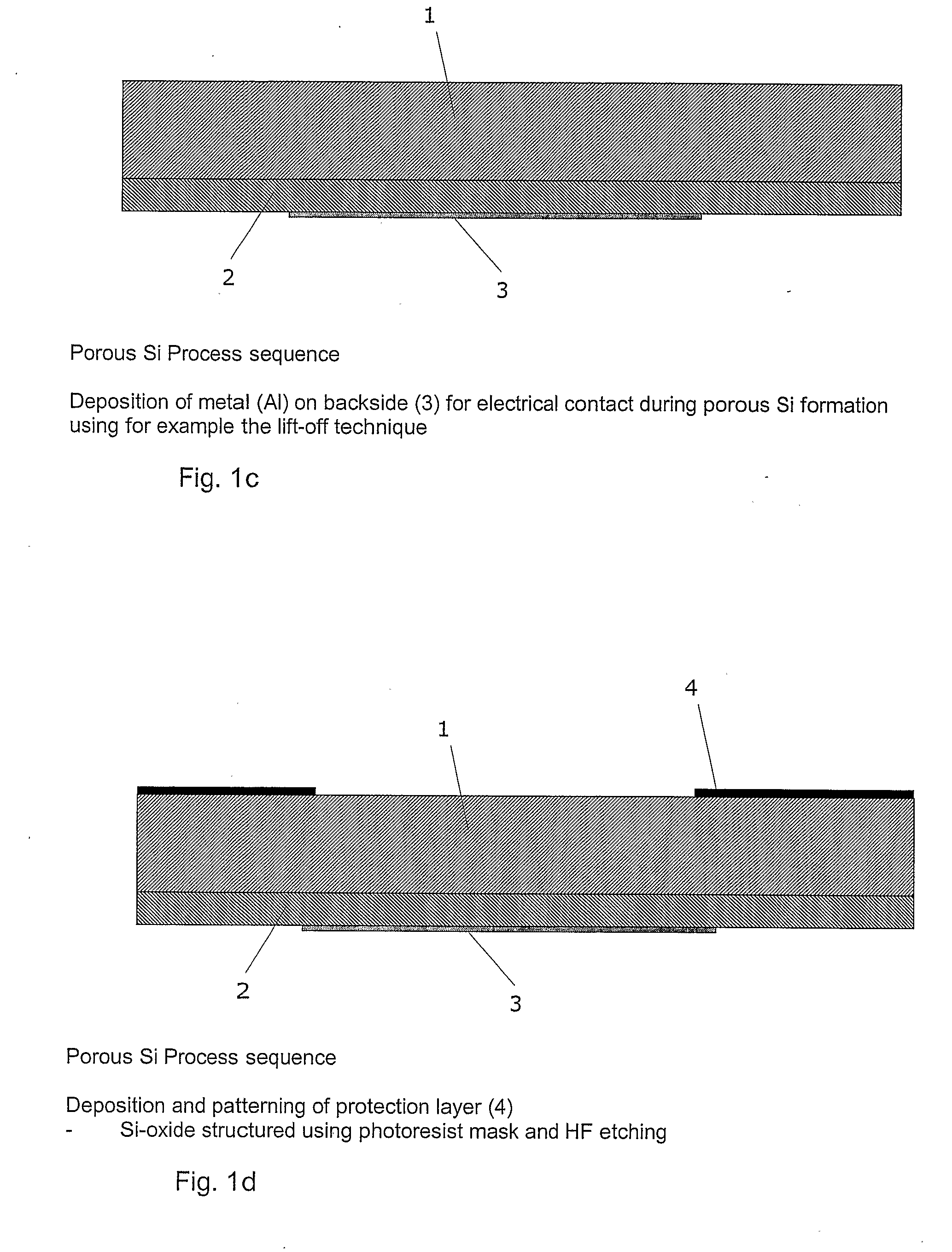

MEMS process and device

InactiveUS7781249B2NanotechSemiconductor/solid-state device testing/measurementEngineeringAcoustic wave

Owner:CIRRUS LOGIC INC

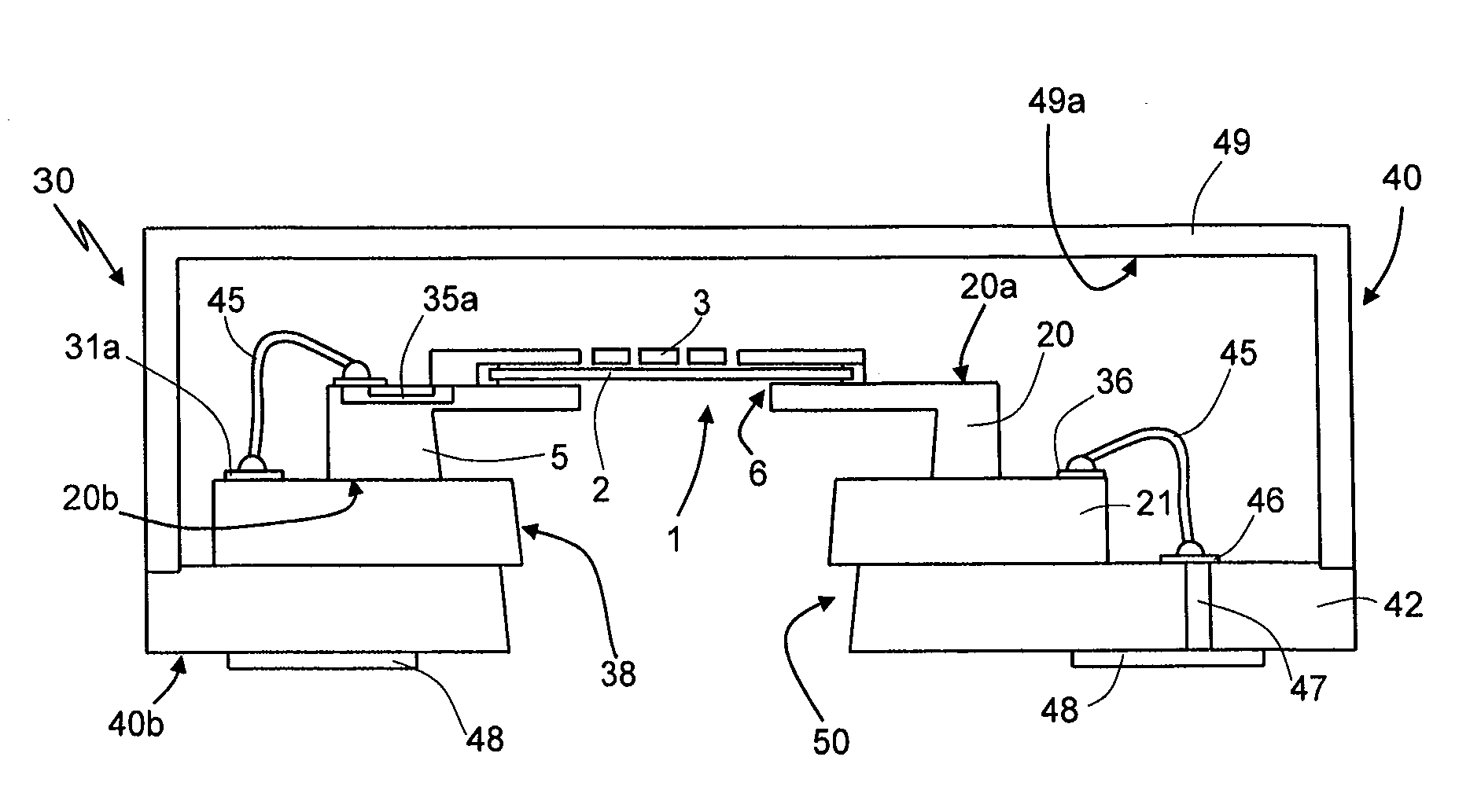

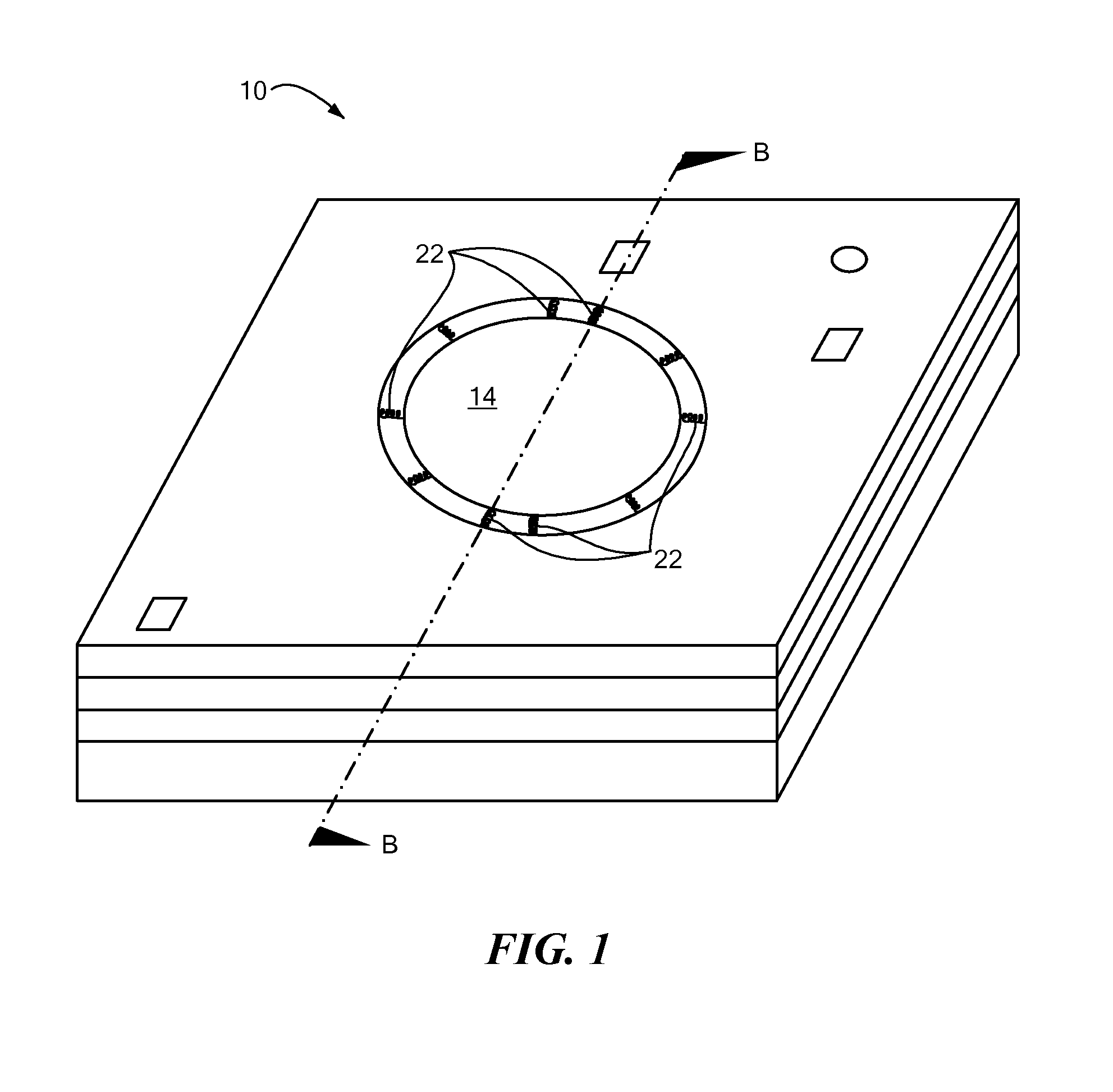

Surface mountable transducer system

InactiveUS7221767B2Established economically and reliablySuitable for mass productionSemiconductor electrostatic transducersElectrostatic transducer microphonesSurface mountingElectrical connection

The present invention relates to a surface mountable acoustic transducer system, comprising one or more transducers, a processing circuit electrically connected to the one or more transducers, and contact points arranged on an exterior surface part of the transducer system. The contact points are adapted to establish electrical connections between the transducer system and an external substrate, the contact points further being adapted to facilitate mounting of the transducer system on the external substrate by conventional surface mounting techniques.

Owner:BALLY TECHNOLOGIES +1

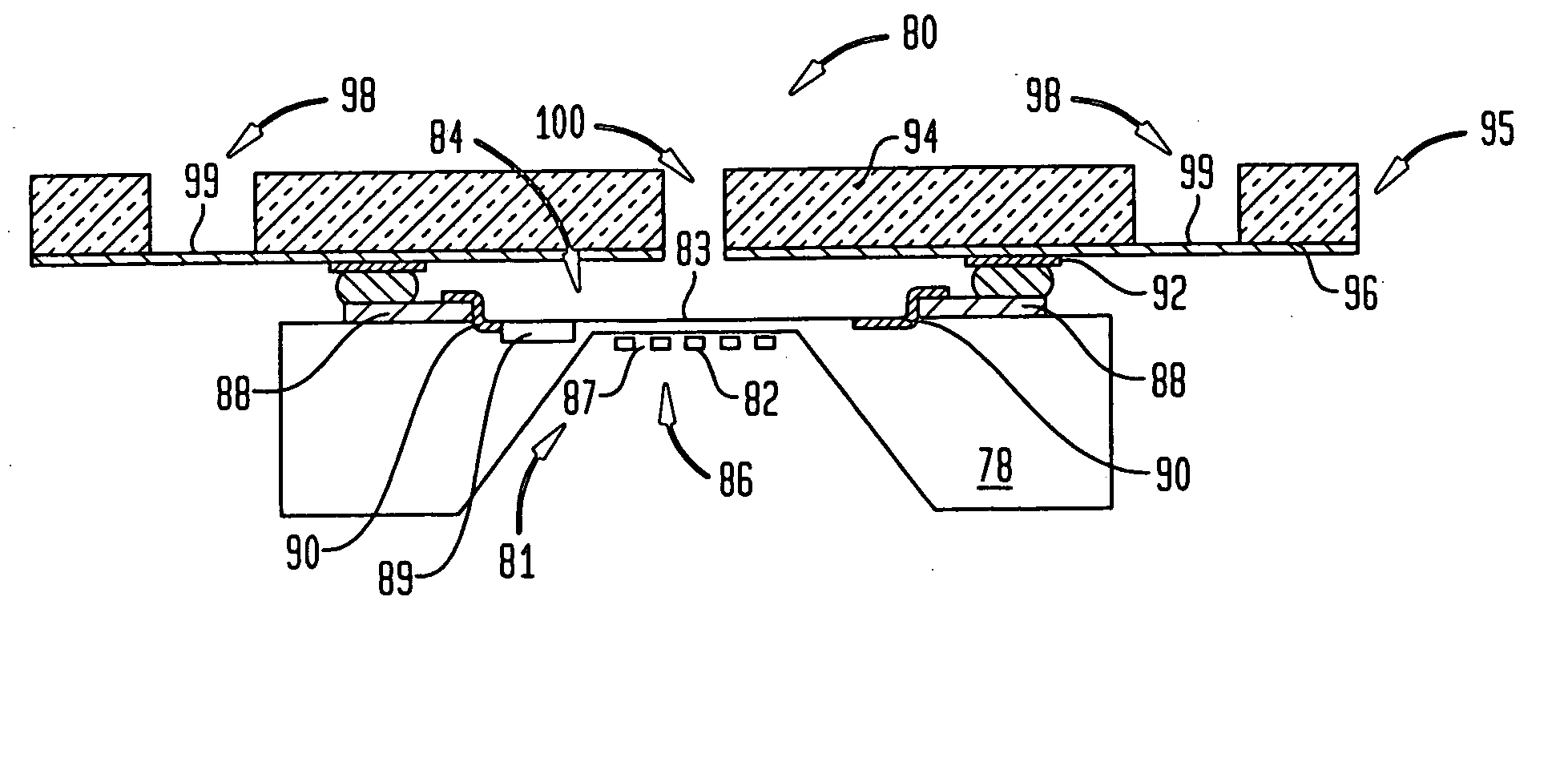

Microphone System with Silicon Microphone Secured to Package Lid

InactiveUS20080175425A1Piezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersEngineeringSilicon

A microphone system has a base with at least one electrical port for electrically communicating with an external device. The system also has a solid metal lid coupled to the base to form an internal chamber, and a silicon microphone secured to the lid within the chamber. The lid has an aperture for receiving an audible signal, while the microphone is electrically connected to the electrical port of the base.

Owner:ANALOG DEVICES INC

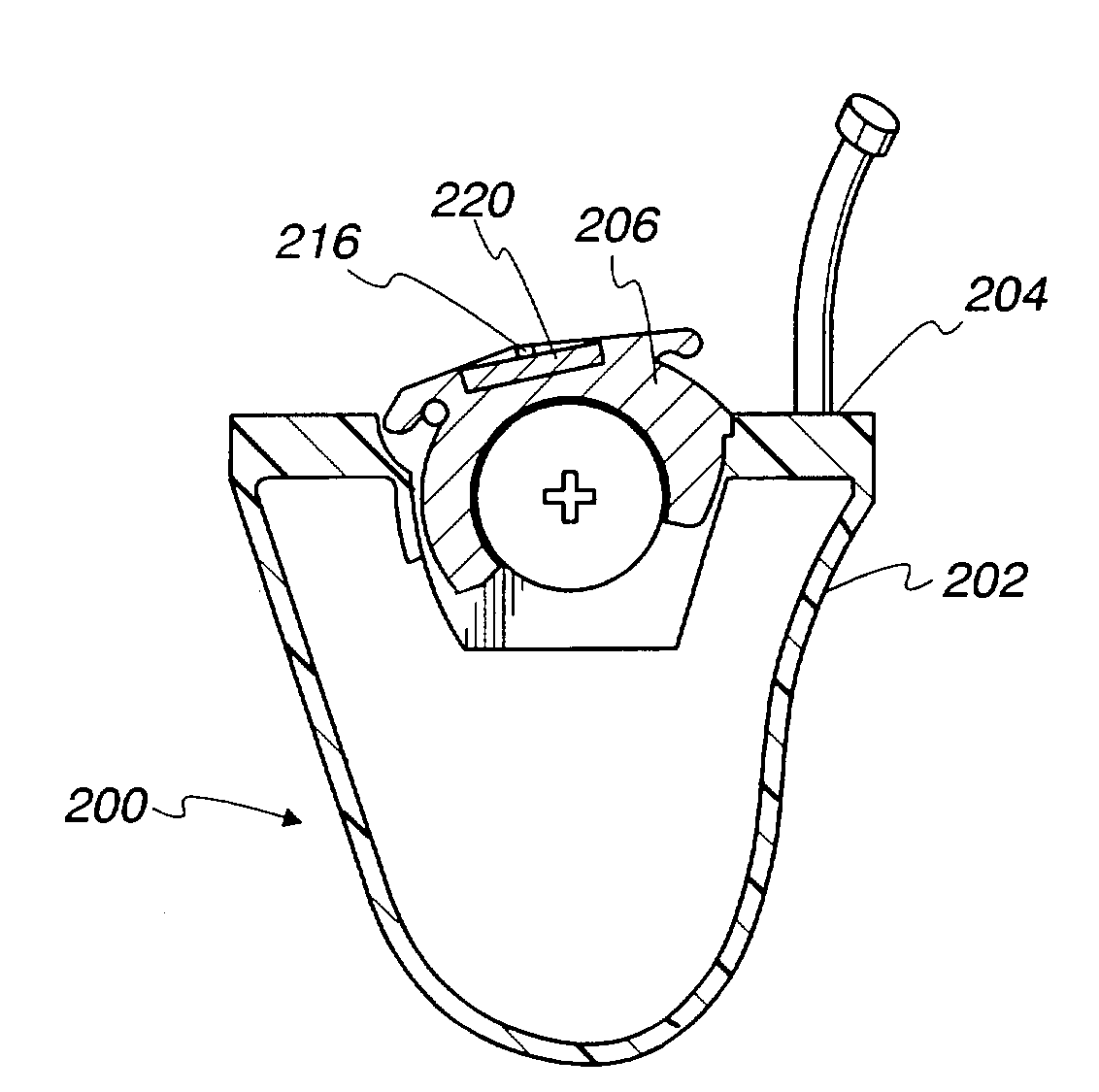

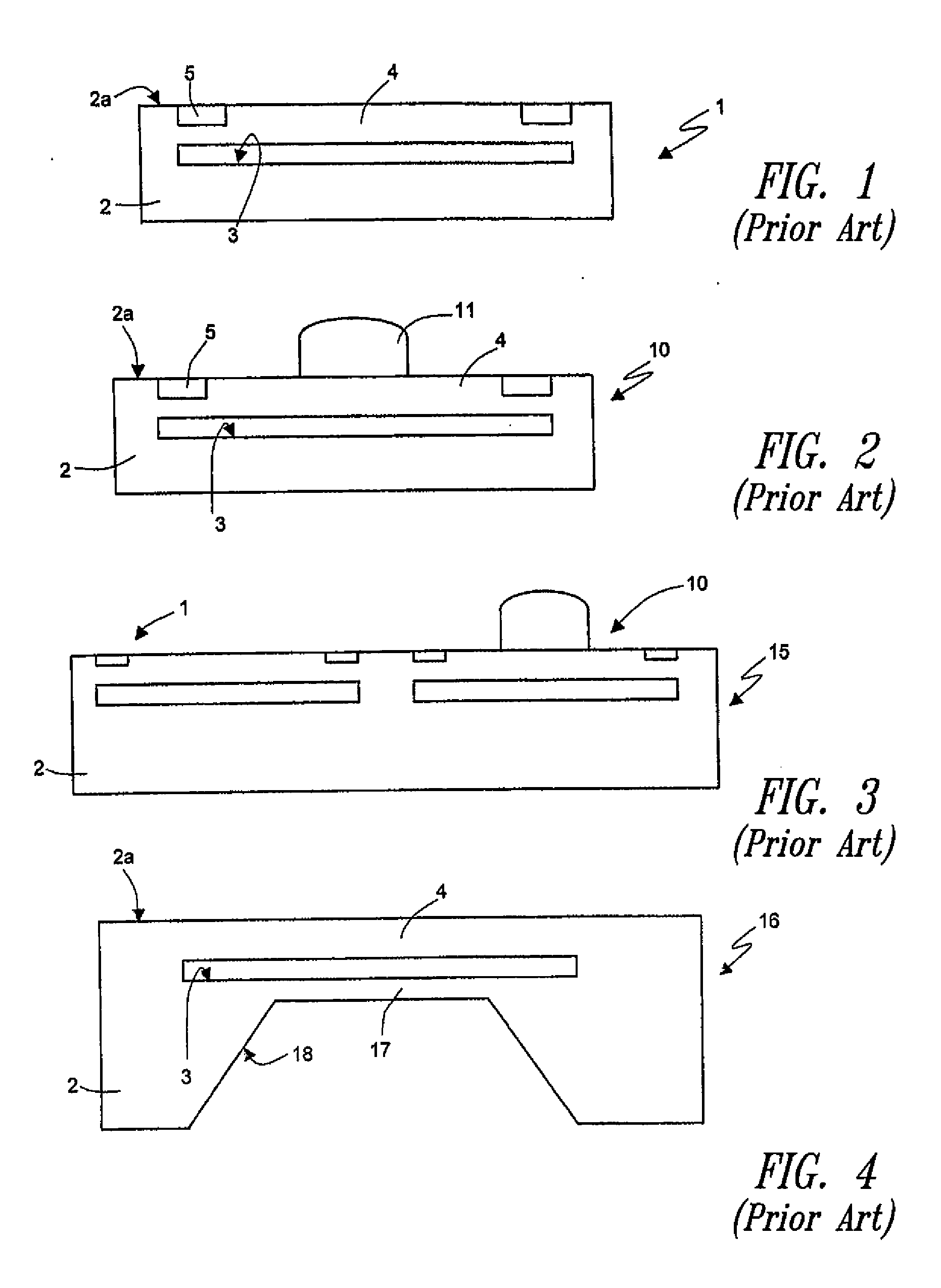

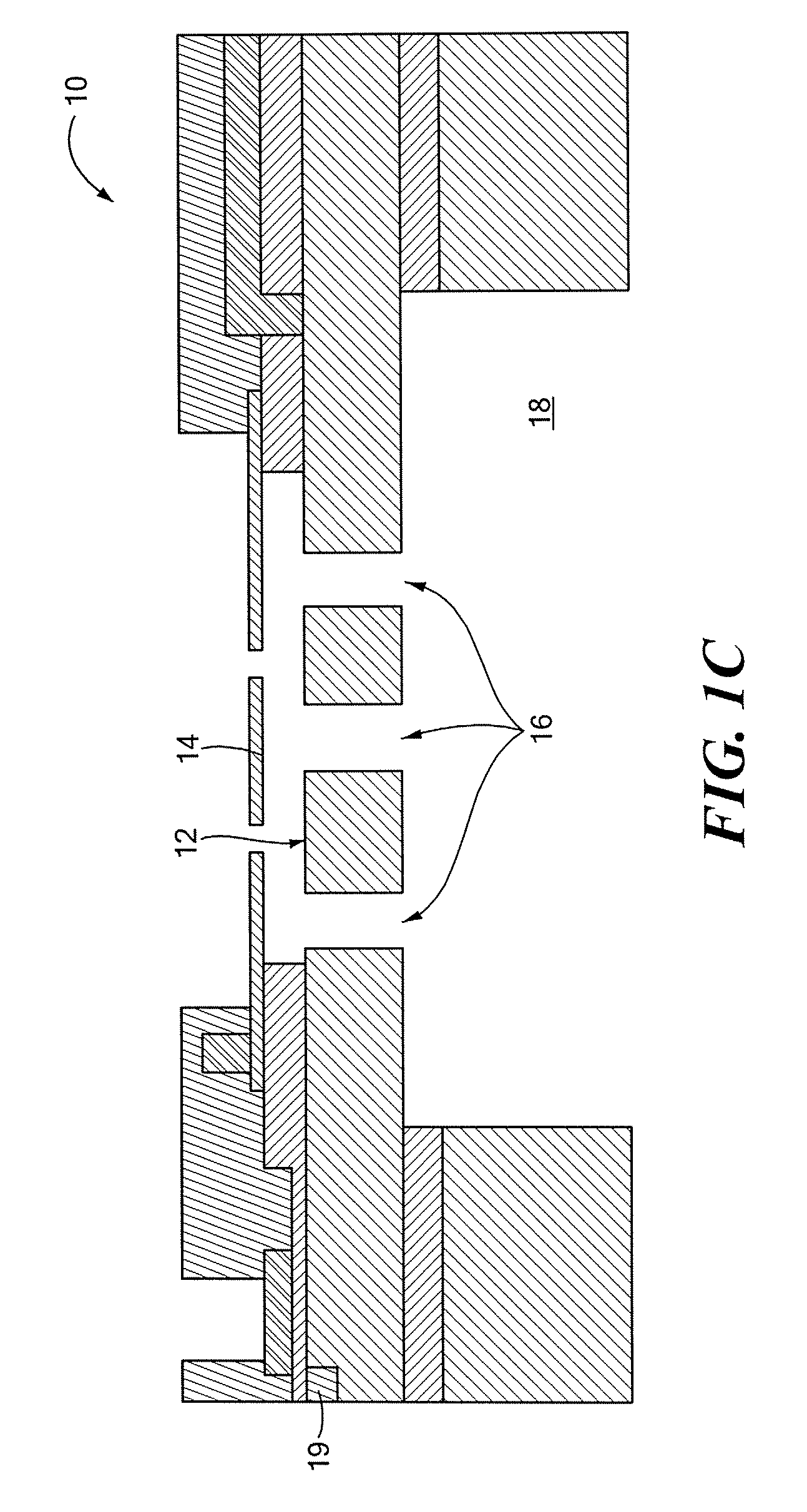

Side-ported MEMS microphone assembly

ActiveUS20100128914A1Piezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersMems microphone

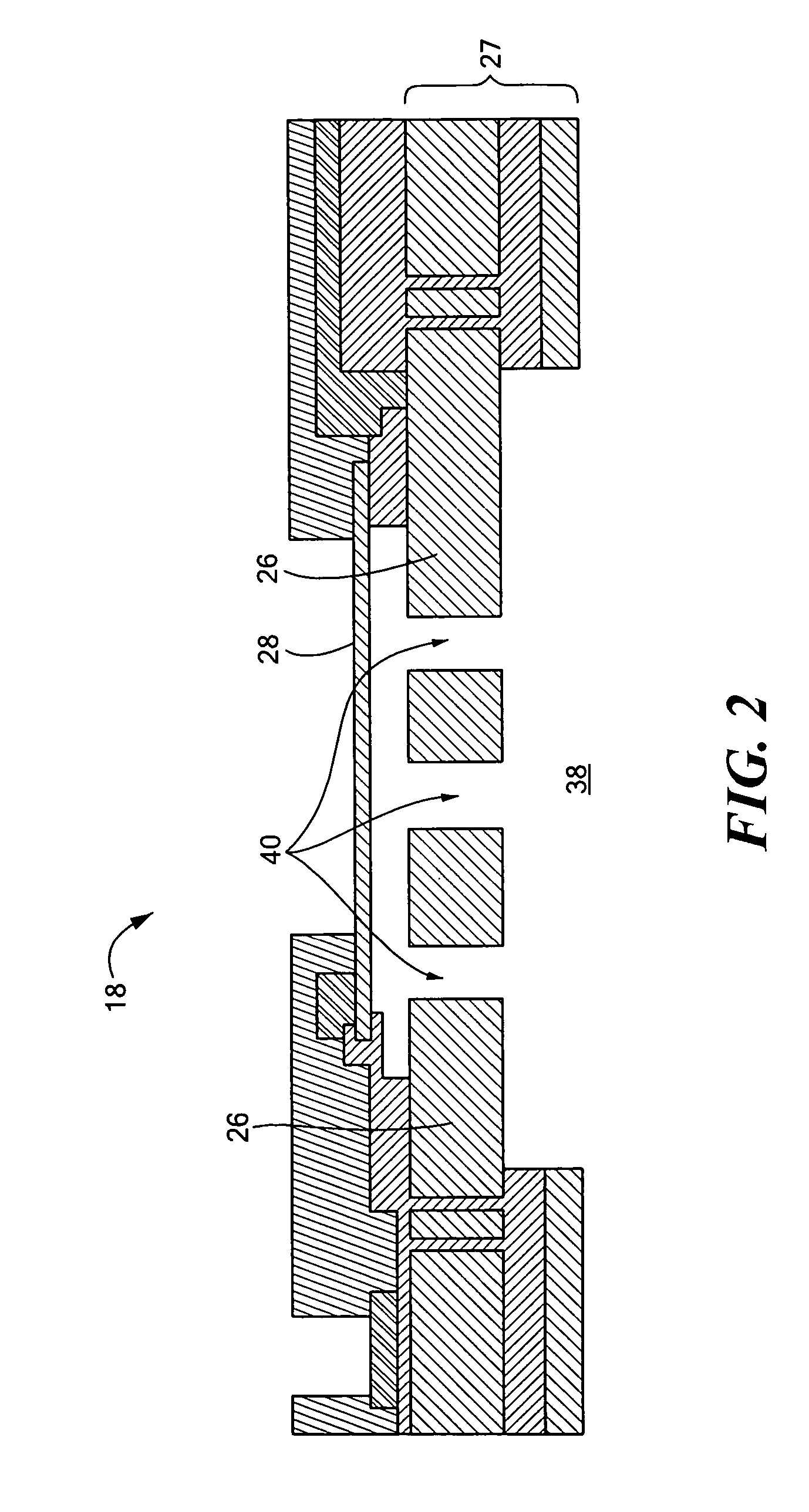

A side-ported MEMS microphone package defines an acoustic path from a side of the package substrate to a microphone die disposed within a chamber defined by the substrate and a lid attached to the substrate. Optionally or alternatively, a circuit board, to which the microphone package is mounted, may define an acoustic path from an edge of the circuit board to a location under the microphone package, adjacent a bottom port on the microphone package. In either case, the acoustic path may be a hollow passage through at least a portion of the substrate or the circuit board. The passage may be defined by holes, channels, notches, etc. defined in each of several layers of a laminated substrate or circuit board, or the passage may be defined by holes drilled, molded or otherwise formed in a solid or laminated substrate or circuit board.

Owner:INVENSENSE

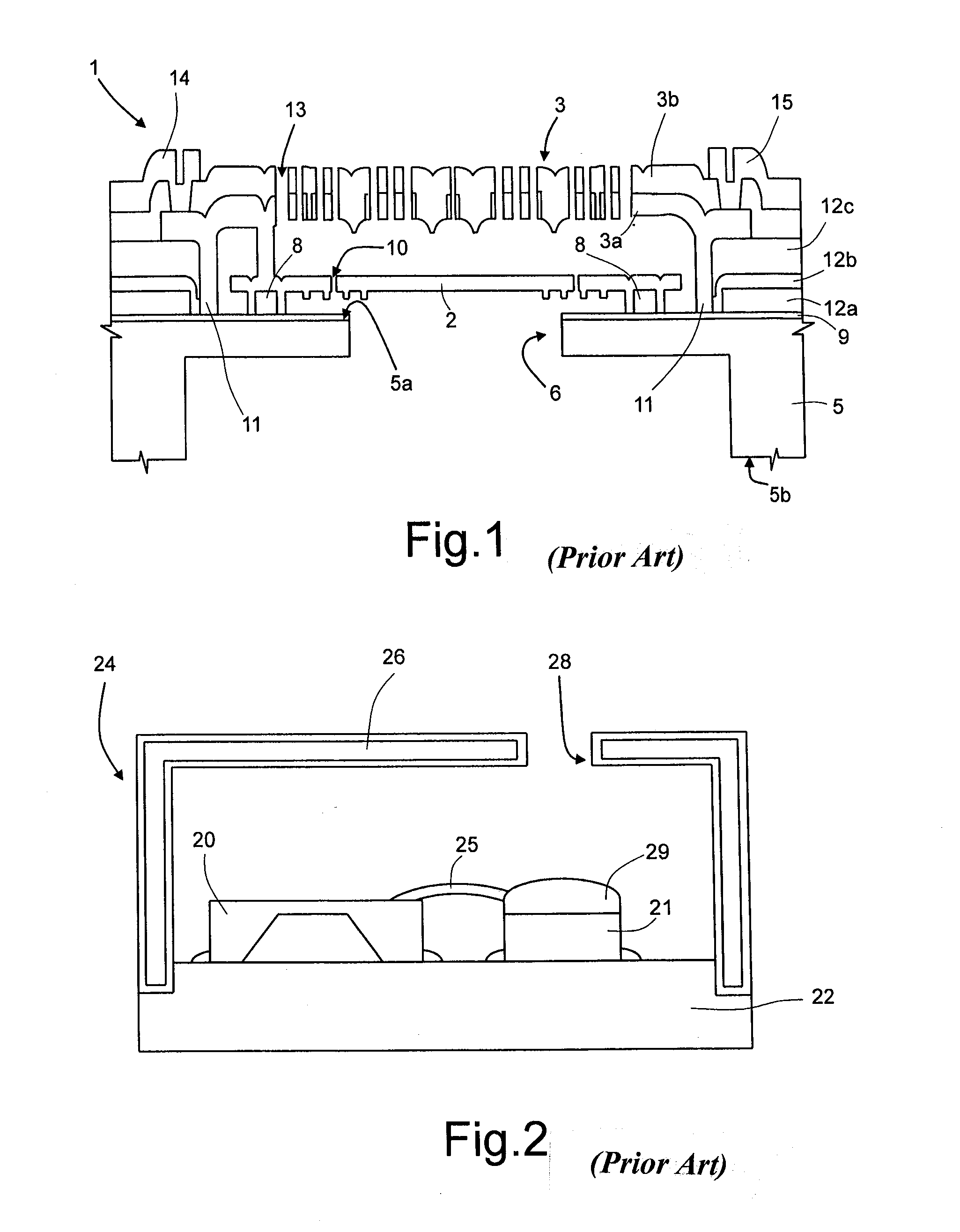

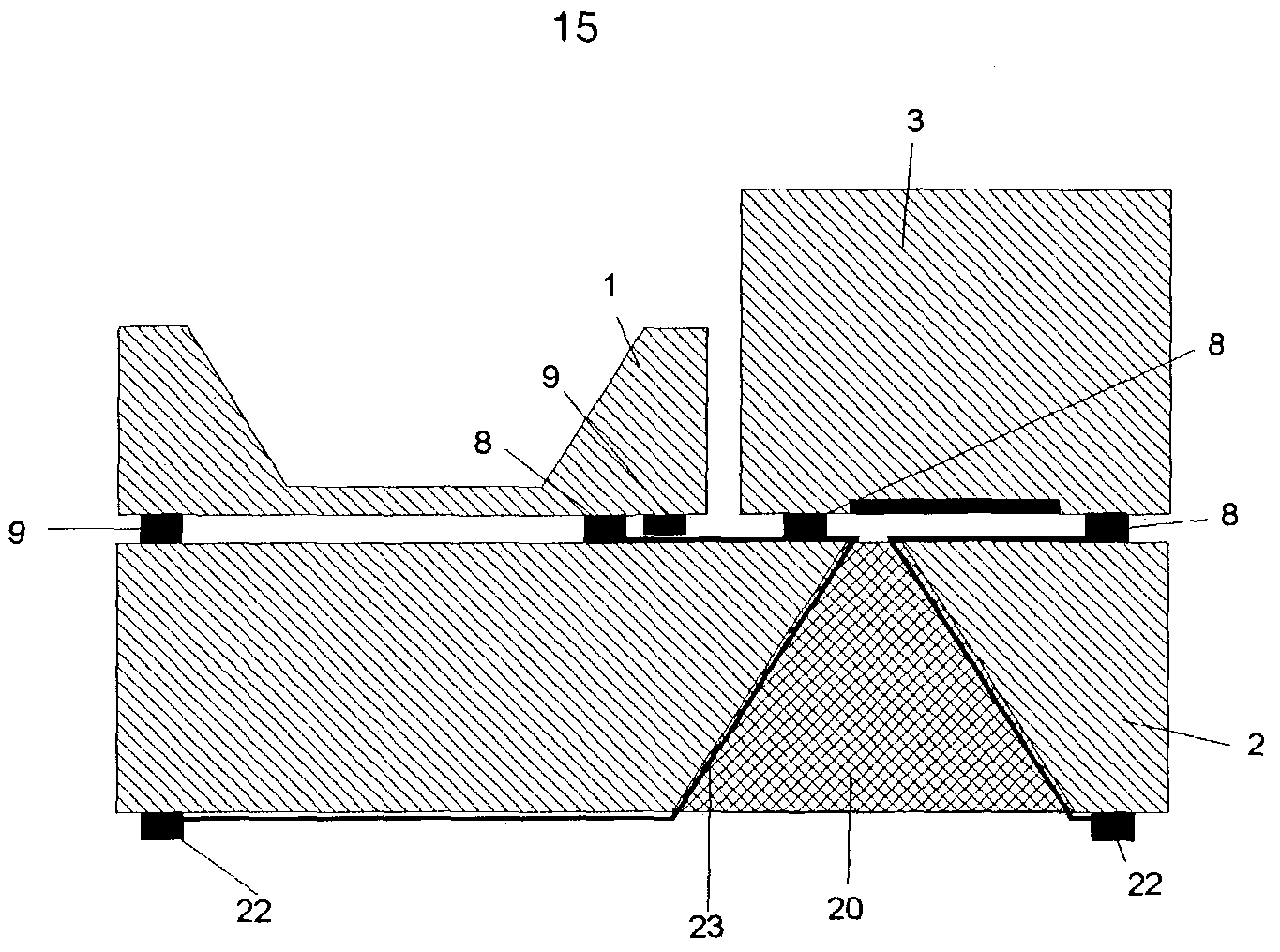

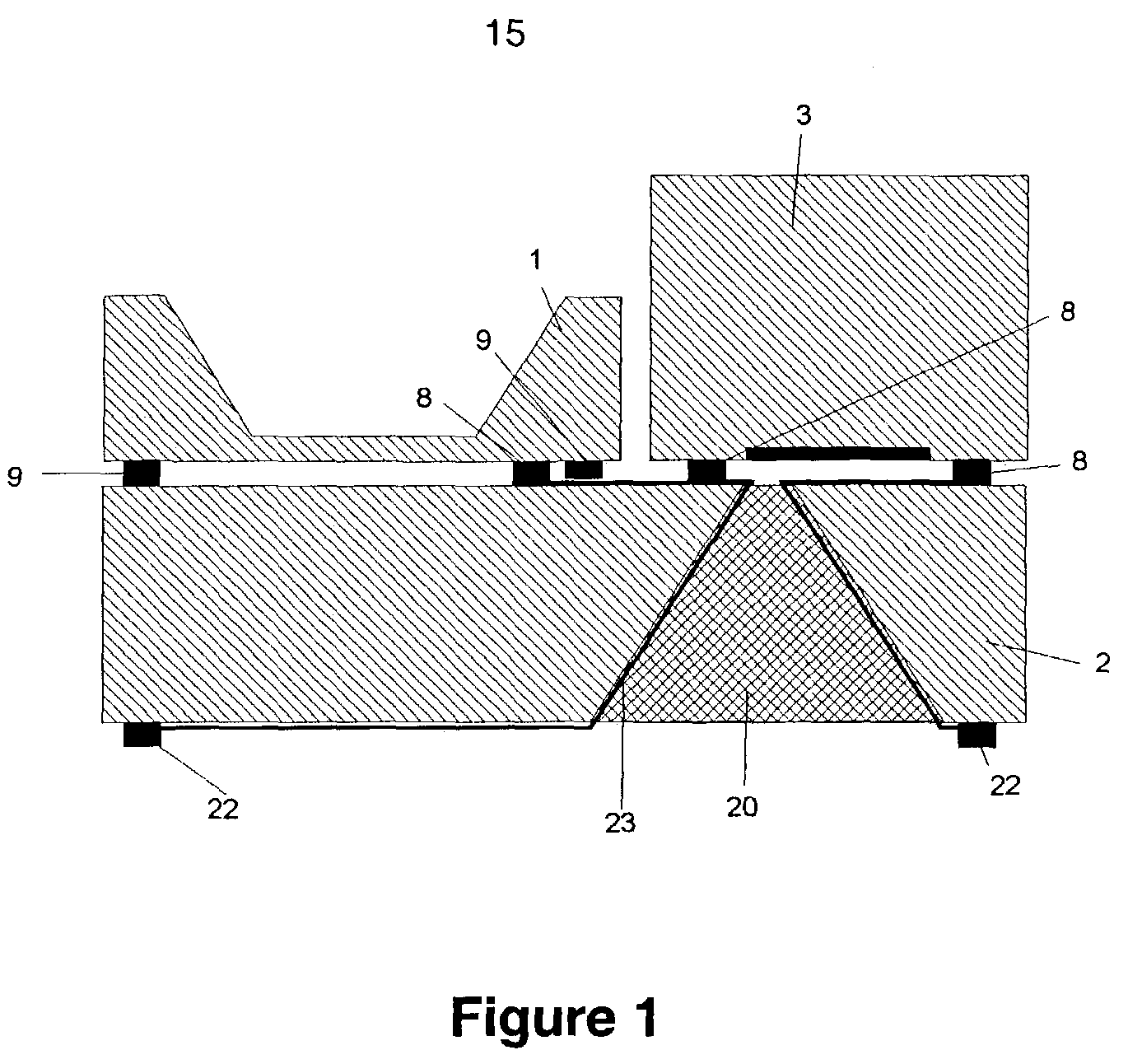

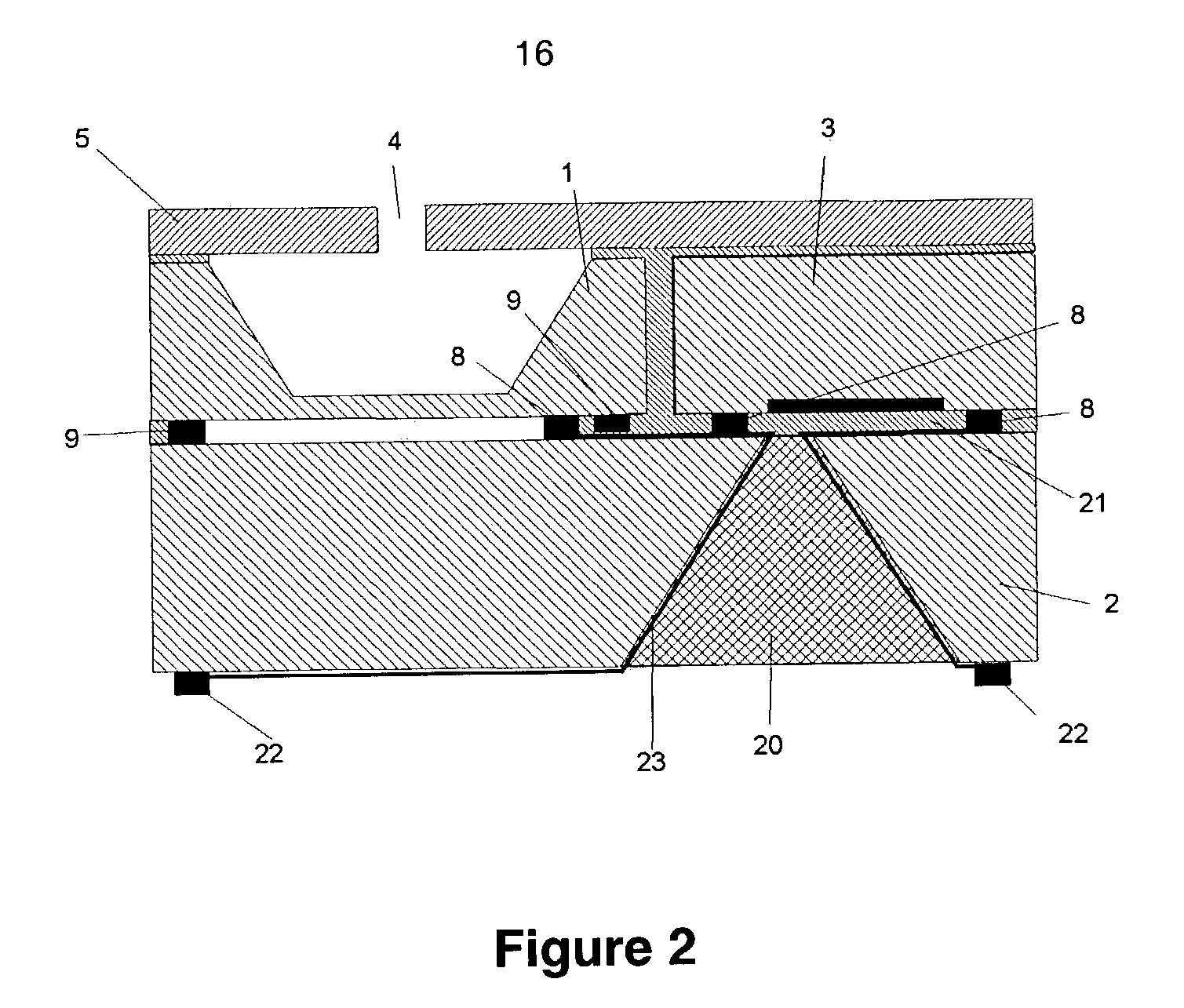

Silicon capacitive microphone

InactiveUS6847090B2Transducer detailsSemiconductor electrostatic transducersSemiconductor materialsEngineering

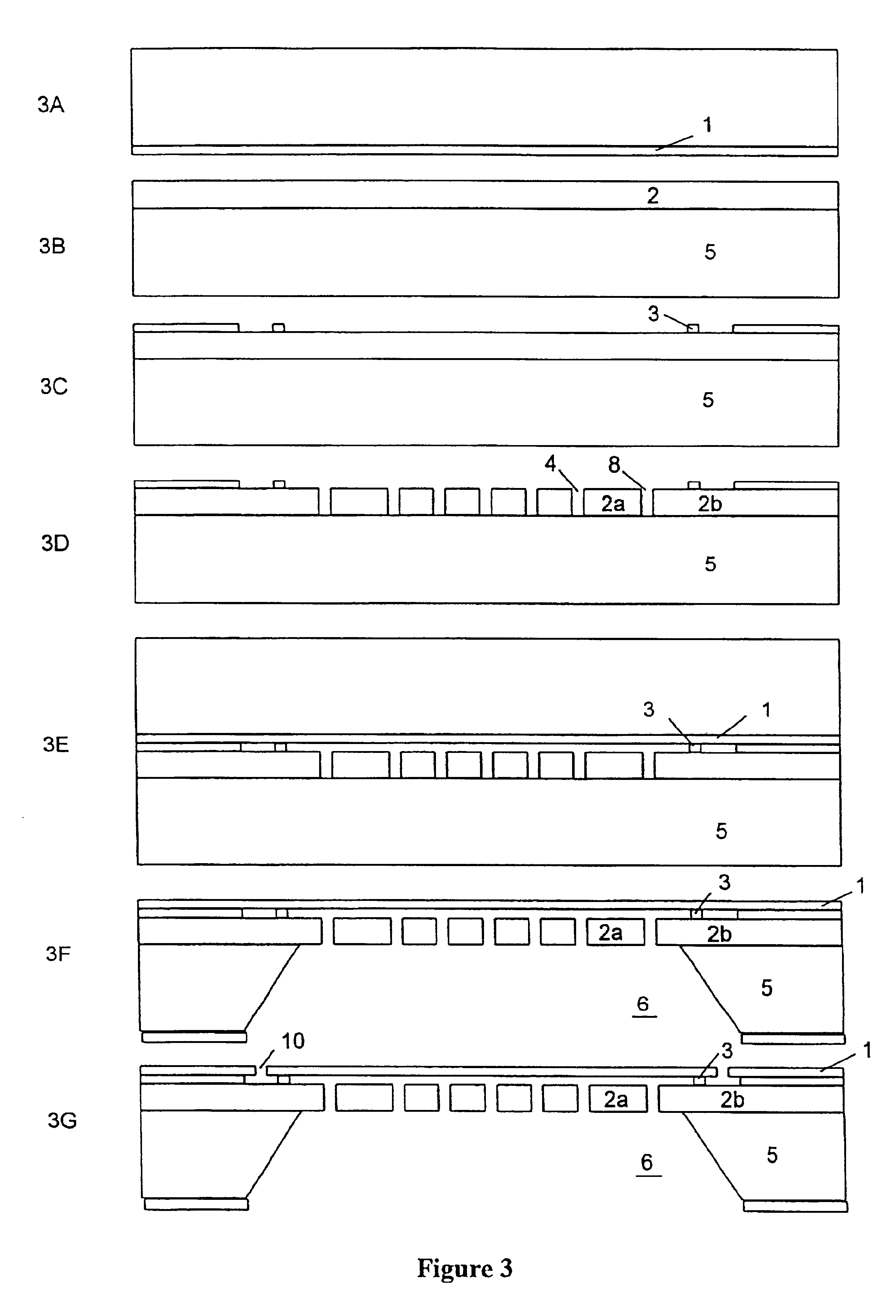

The present invention is directed to a process for the manufacture of a plurality of integrated capacitive transducers. The process comprises the steps of supplying a first substrate of a semiconductor material having first and second faces, supplying a second substrate of a semiconductor material having first and second faces, forming a diaphragm layer on the first face of the first substrate, forming a backplate layer on the first face of the other of the second substrate, forming a support layer on the backplate layer, etching a plurality of supports from the support layer, for each of the capacitive transducers, etching a plurality of vents from the backplate layer, for each of the capacitive transducers, positioning the diaphragm layer of the first substrate adjacent with the support layer of the second substrate, and welding the diaphragm layer and the support layer together, removing at least a portion of the first substrate to expose the diaphragm layer, for each of the capacitive transducers, removing a portion of the second substrate to expose the vents, for each of the capacitive transducers, and, etching a portion of the diaphragm layer, for each of the capacitive transducers.

Owner:KNOWLES ELECTRONICS INC

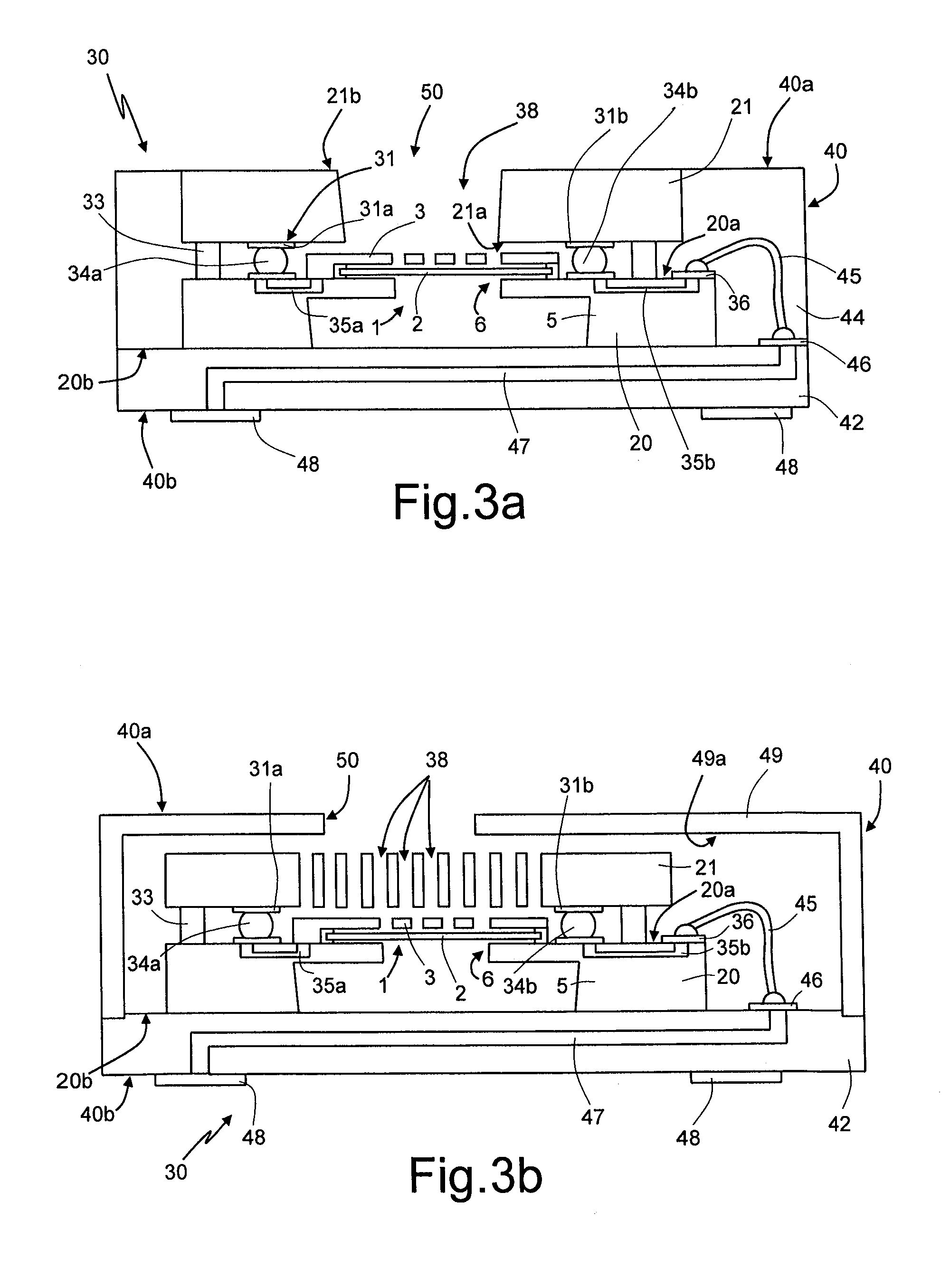

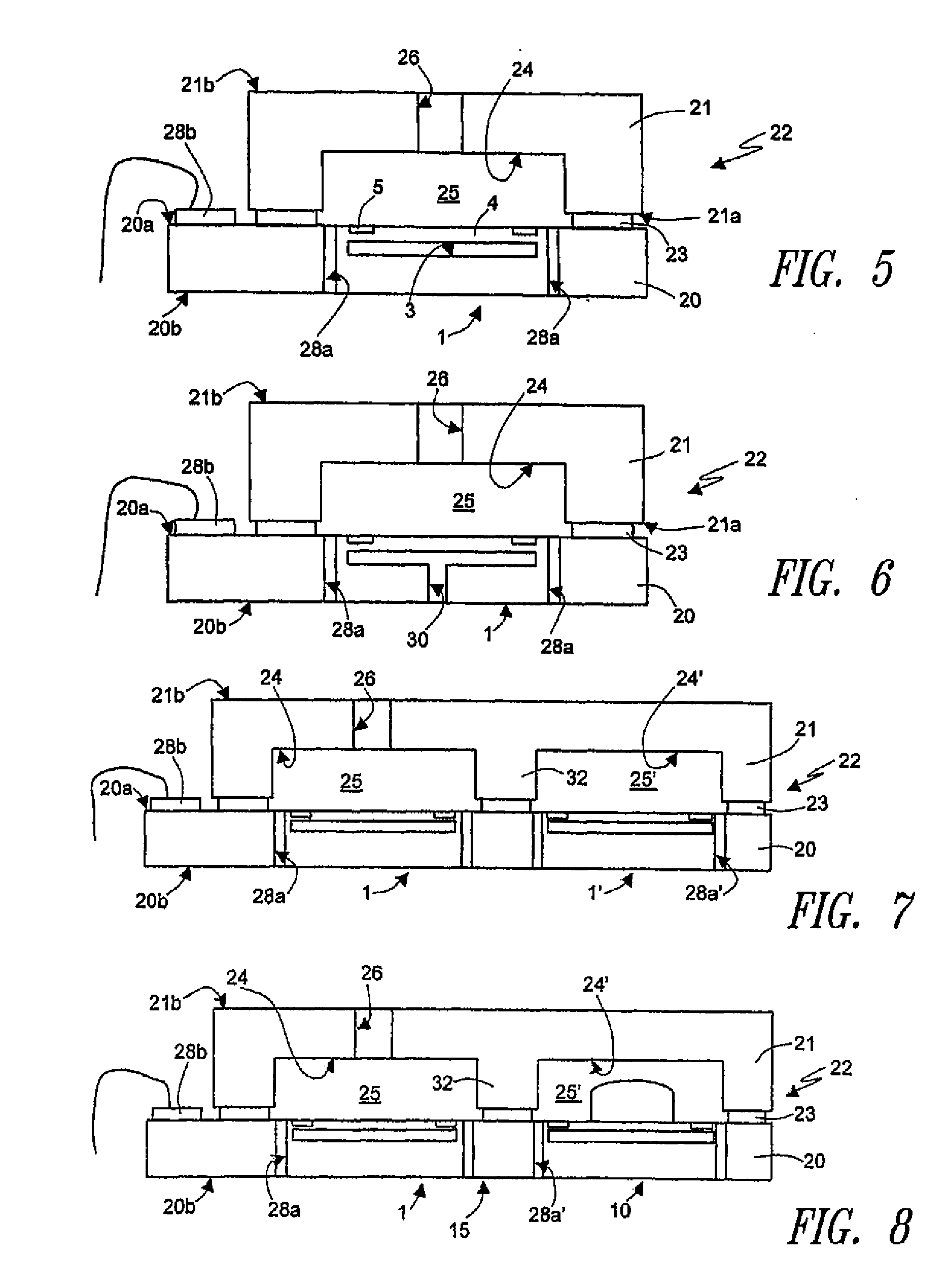

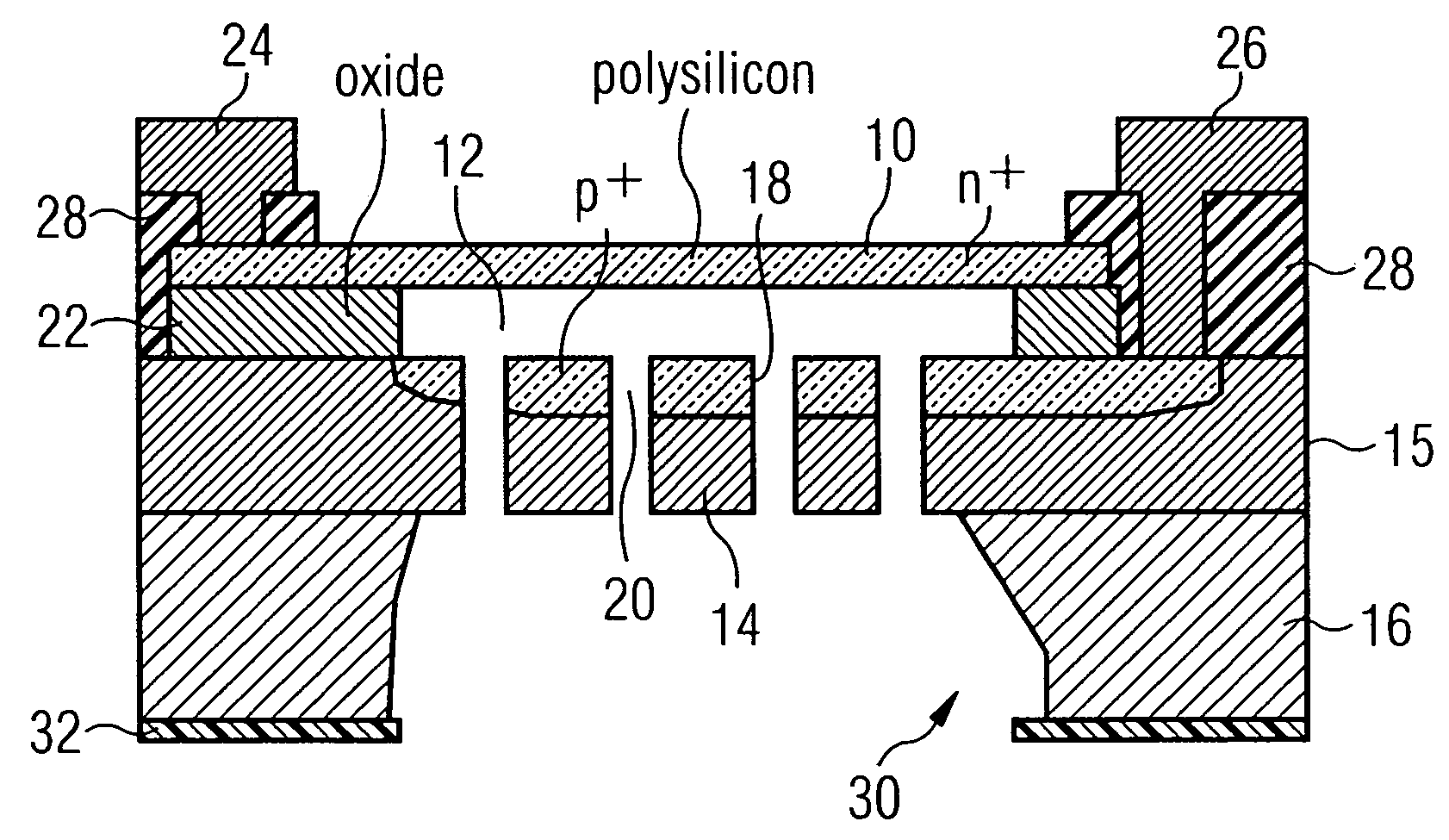

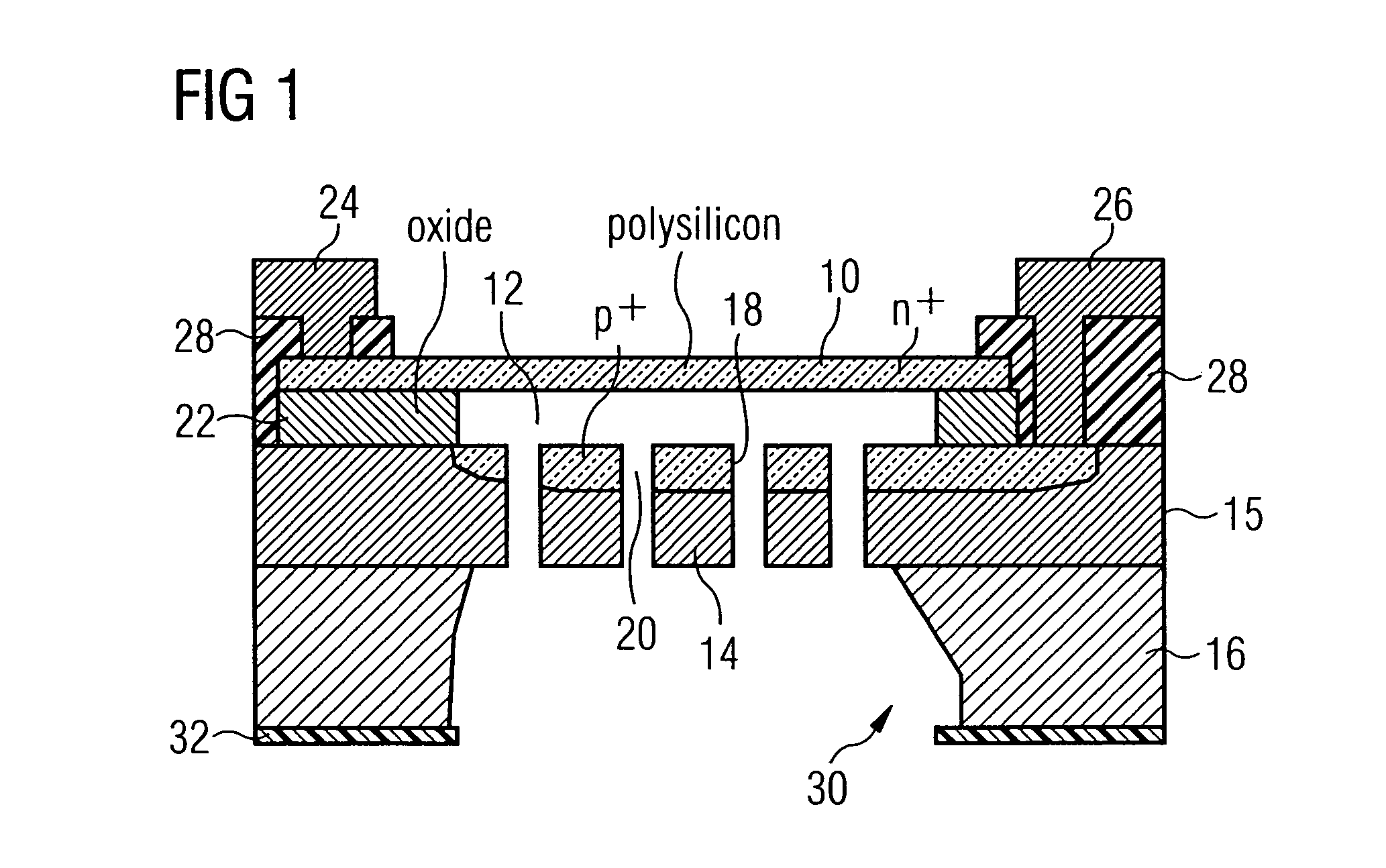

Multi-Microphone System

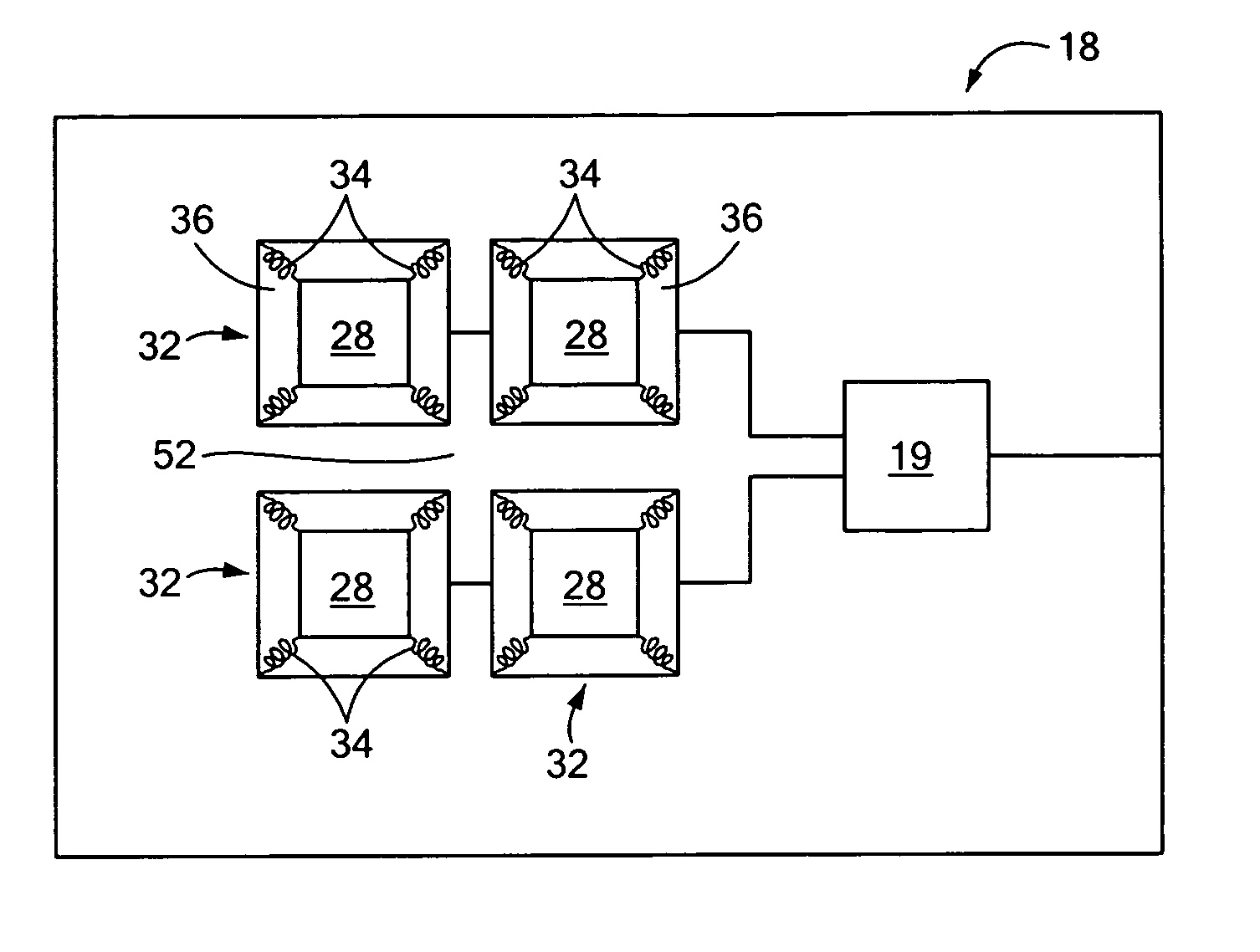

ActiveUS20070047746A1Piezoelectric/electrostrictive microphonesTransducer detailsCapacitanceEngineering

A microphone system implements multiple microphones on a single base. To that end, the microphone system has a base, and a plurality of substantially independently movable diaphragms secured to the base. Each of the plurality of diaphragms forms a variable capacitance with the base and thus, each diaphragm effectively forms a generally independent, separate microphone with the base.

Owner:INVENSENSE

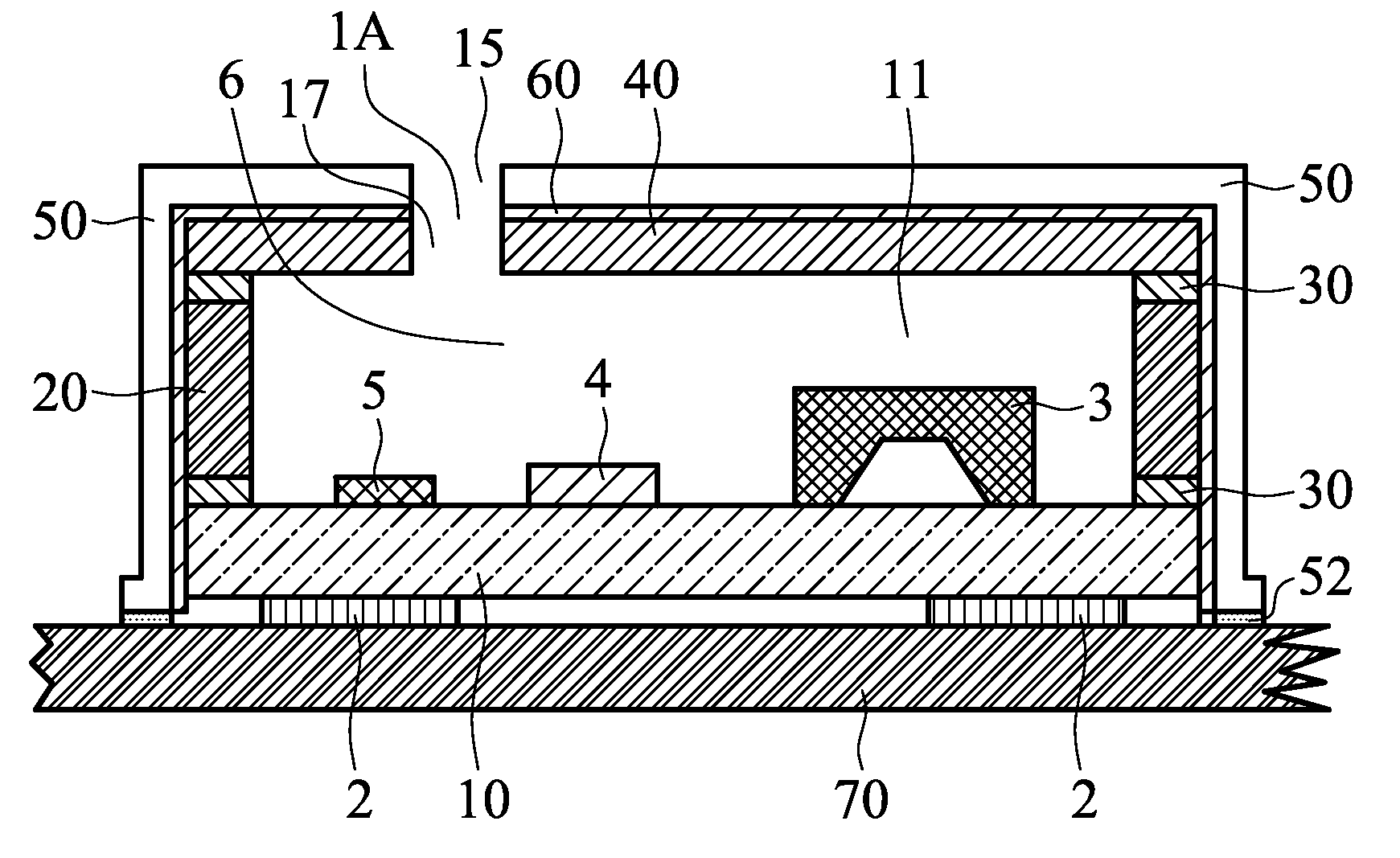

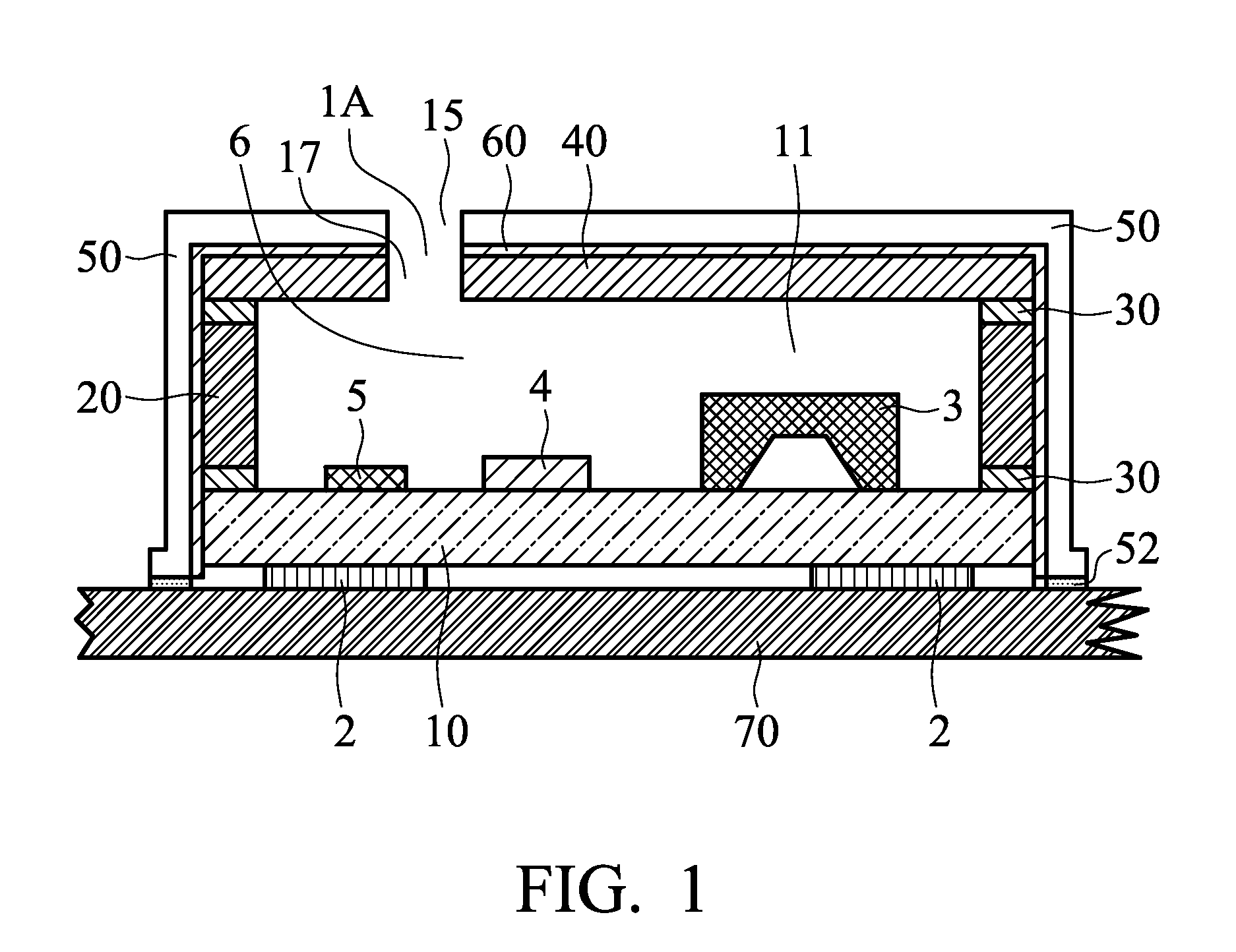

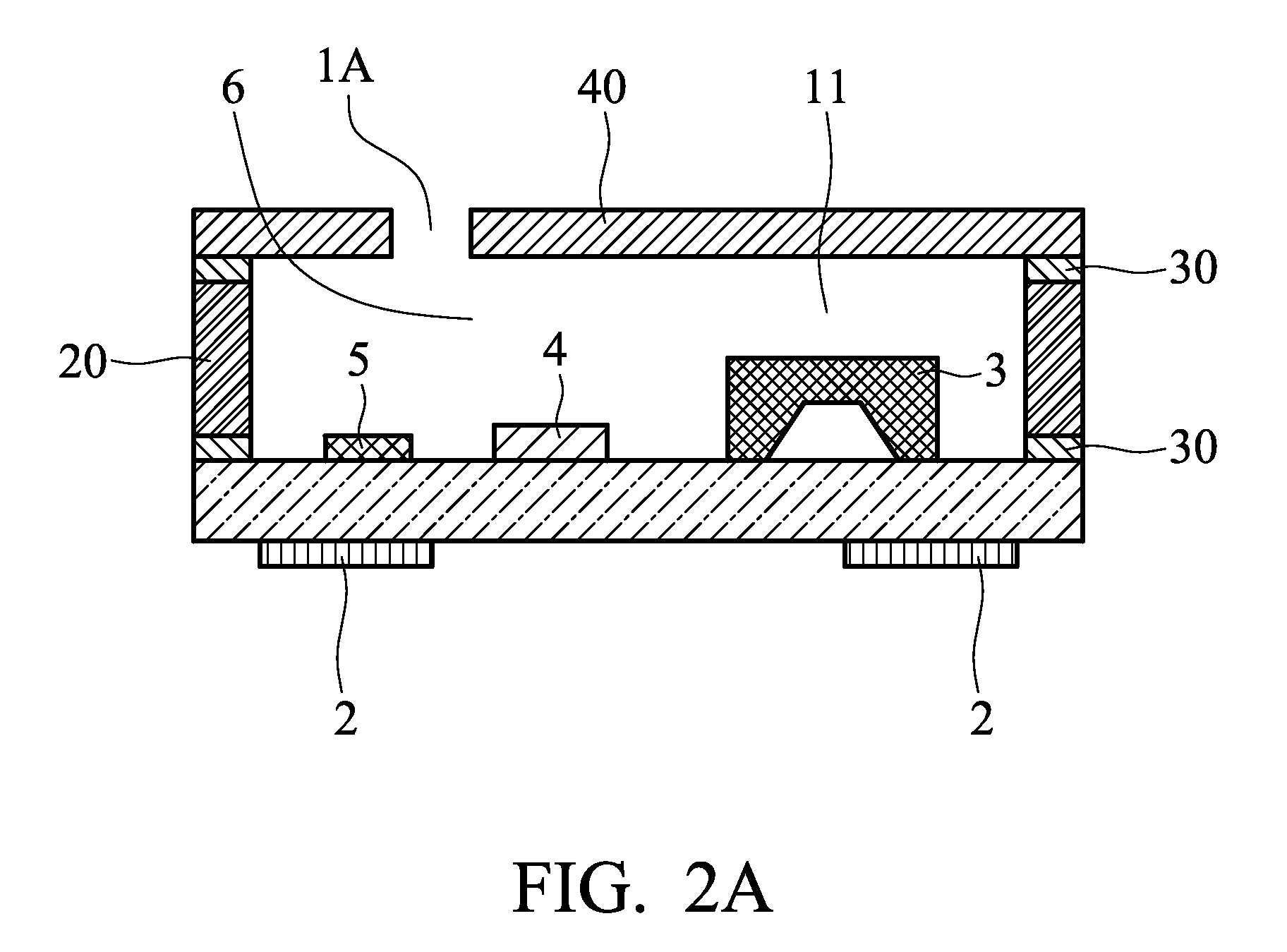

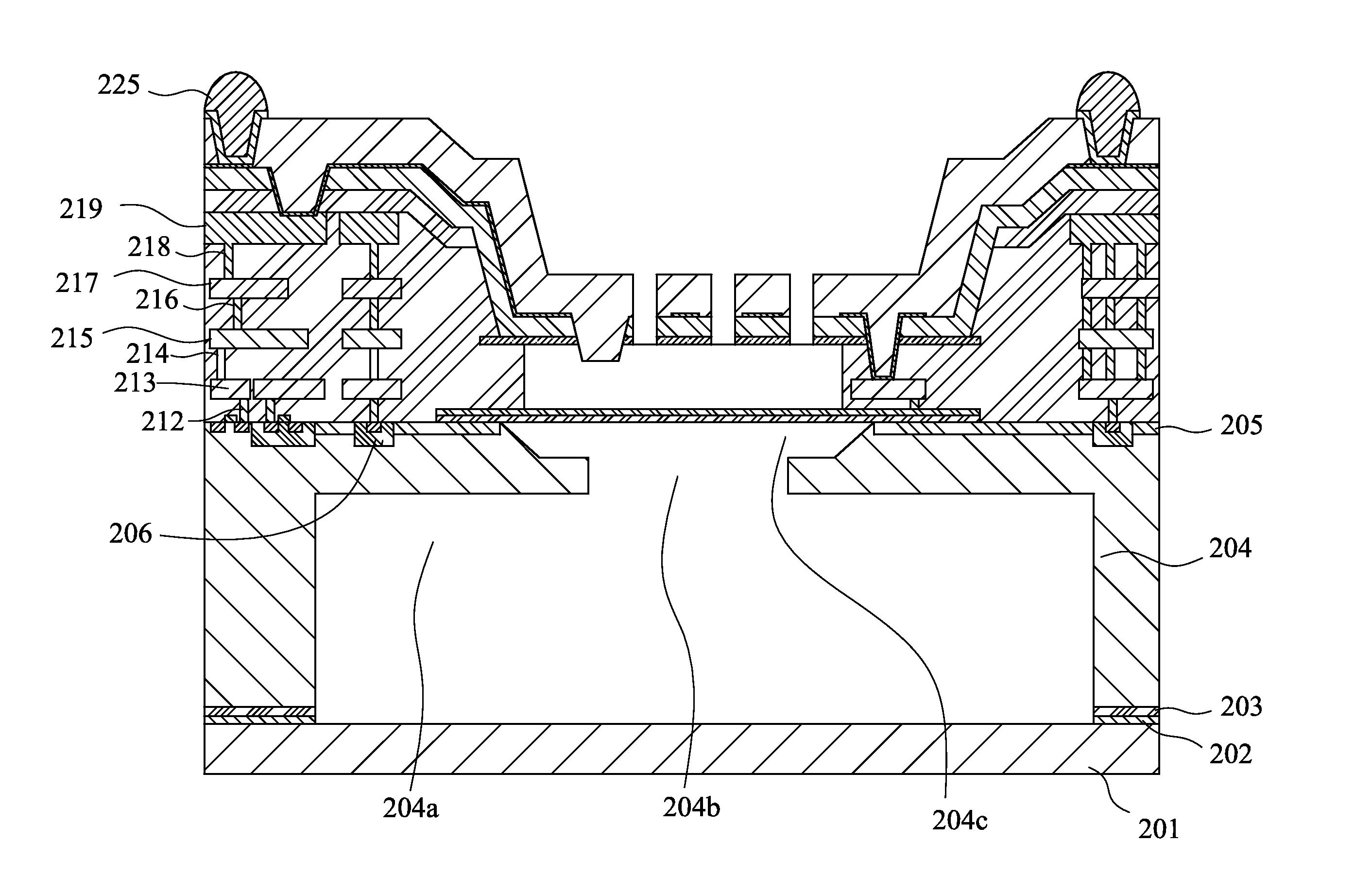

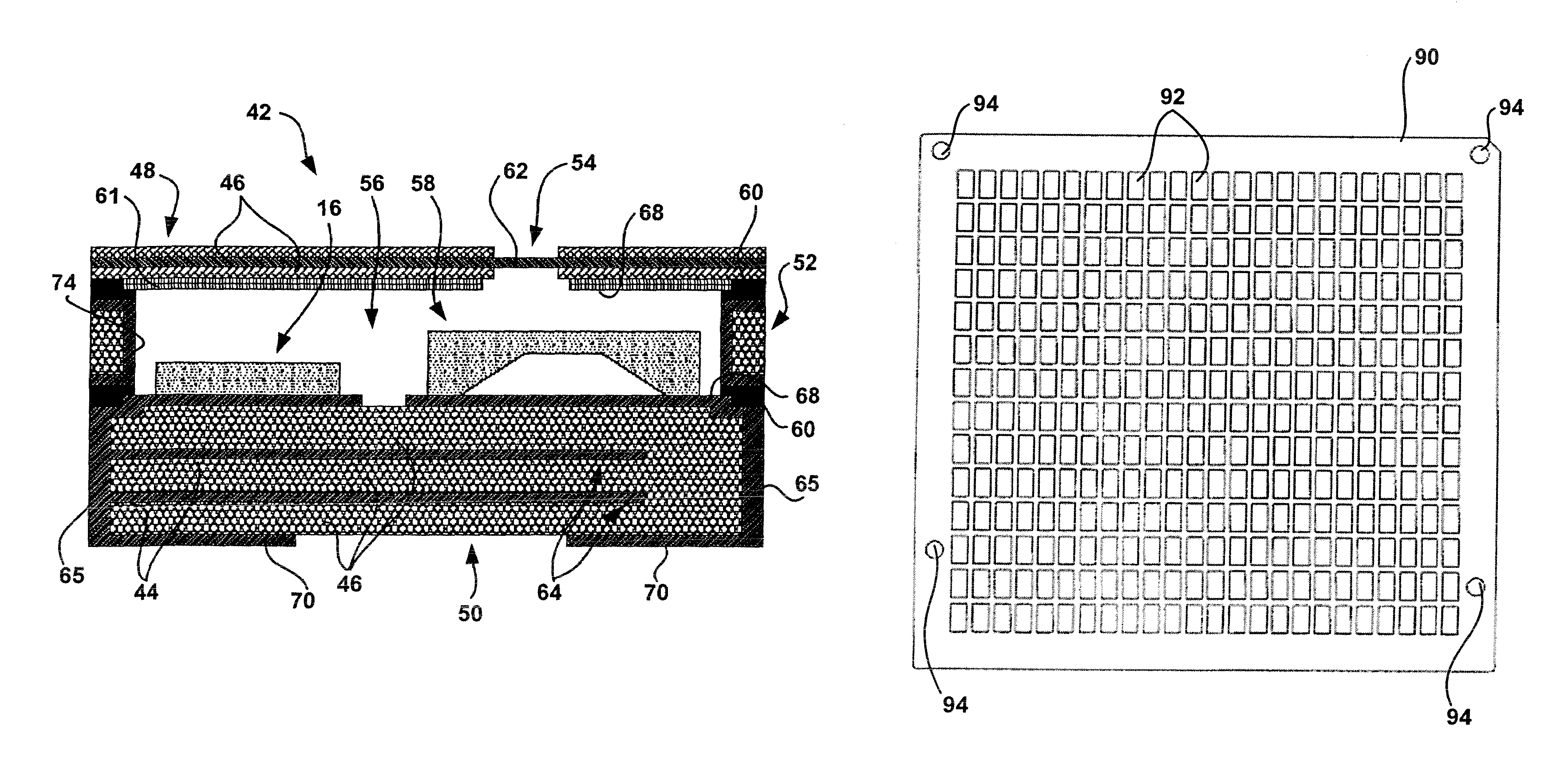

Miniature MEMS condenser microphone packages and fabrication method thereof

ActiveUS20100183181A1Piezoelectric/electrostrictive microphonesLine/current collector detailsAcoustic absorptionMems microphone

MEMS microphone packages and fabrication methods thereof are disclosed. A MEMS microphone package includes a cavity that houses a MEMS sensing element, an IC chip and other passive elements supported by a common substrate. The cavity is formed by a top cover member, a housing wall surrounds and supports the top cover member and the common substrate supports the housing wall. A conductive casing encloses and surrounds the cavity, and is electrically connected to a common analog ground lead on a PCB board. The top cover member and the housing wall are non-conductive. And the conductive casing is not connected directly to the ground leads of the package. An acoustic absorption layer is sandwiched between the conductive casing and the cavity which is formed by the top cover member, the housing wall and the substrate.

Owner:NEOMEMS TECH INC WUXI CHINA

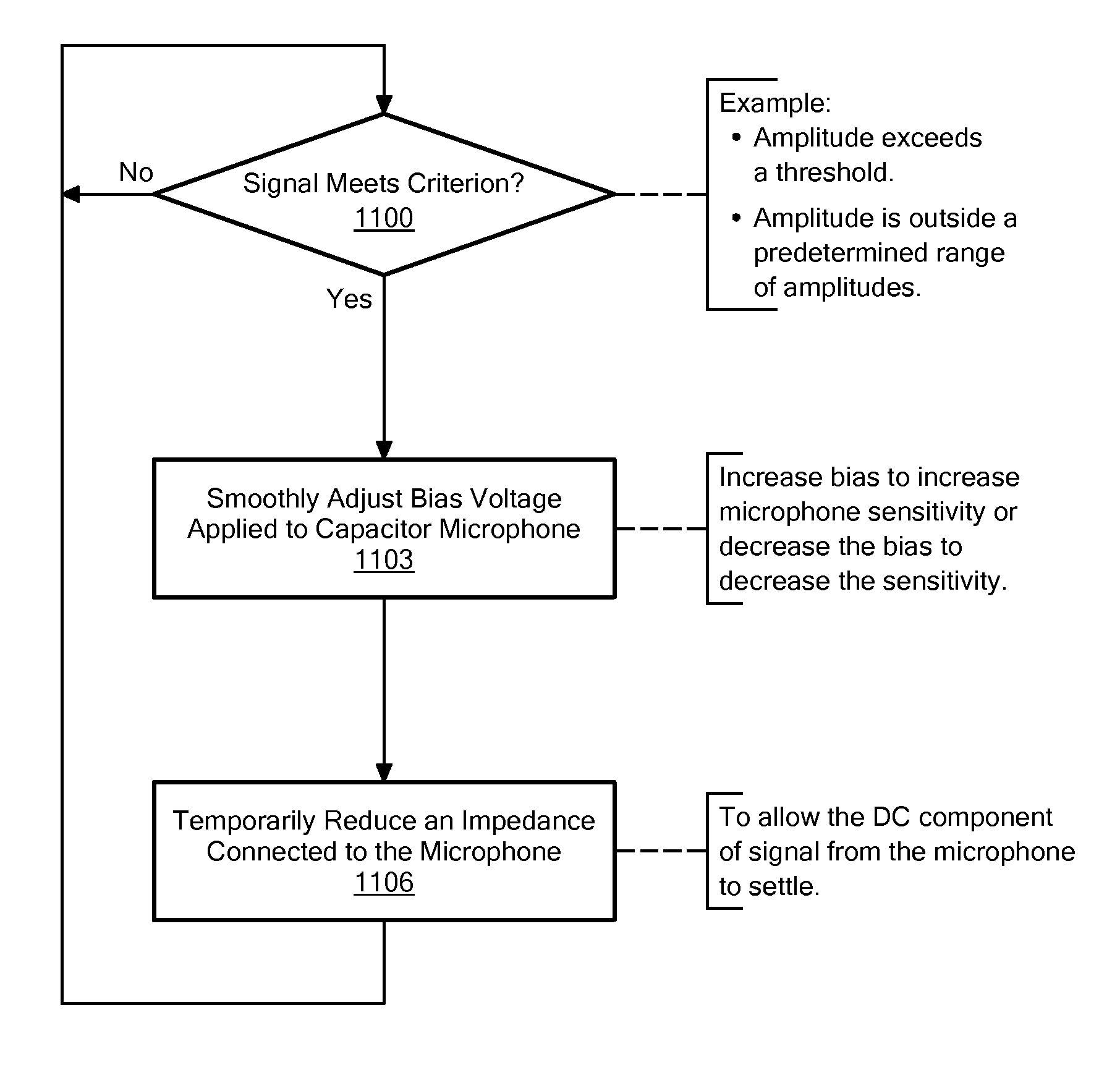

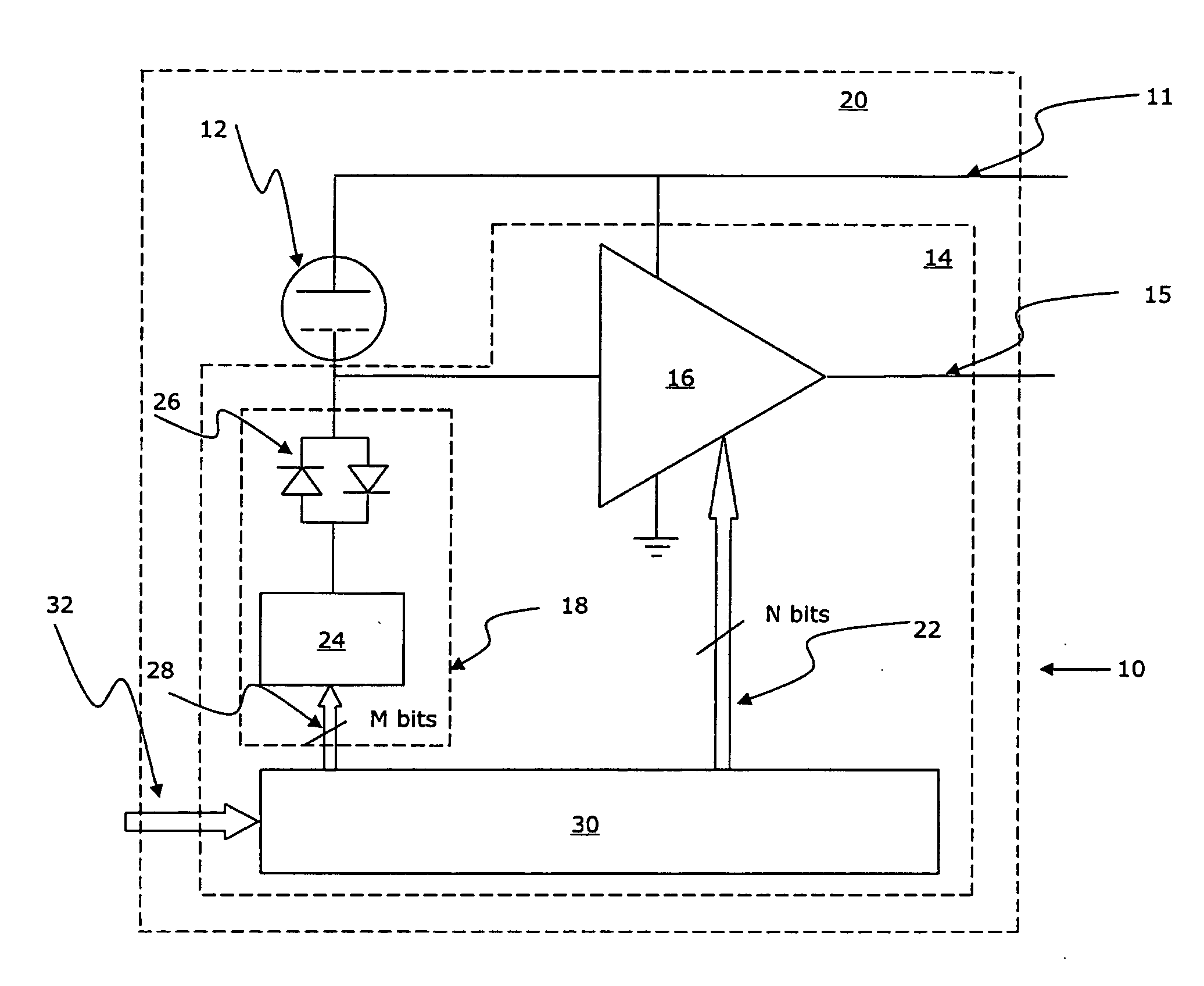

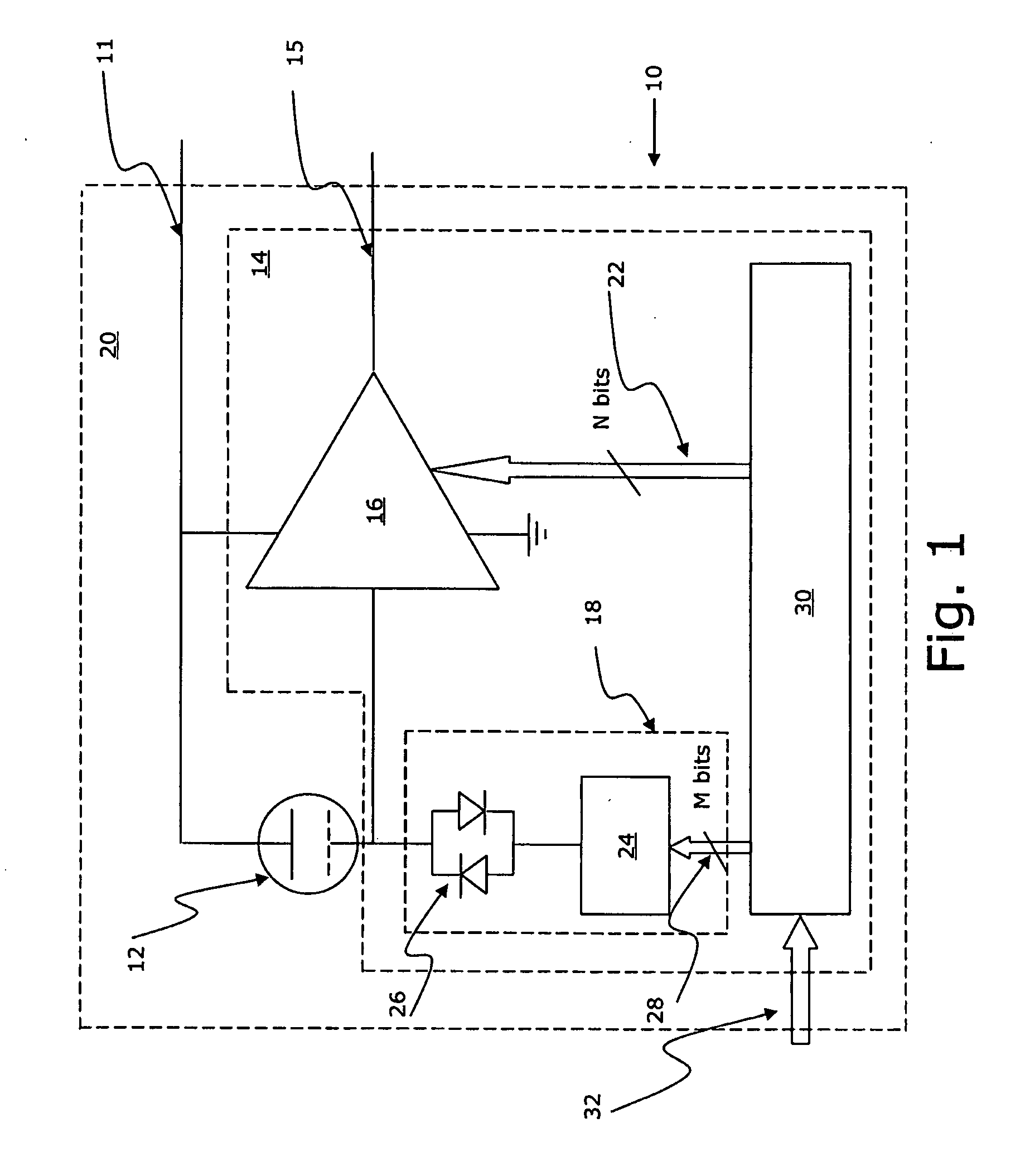

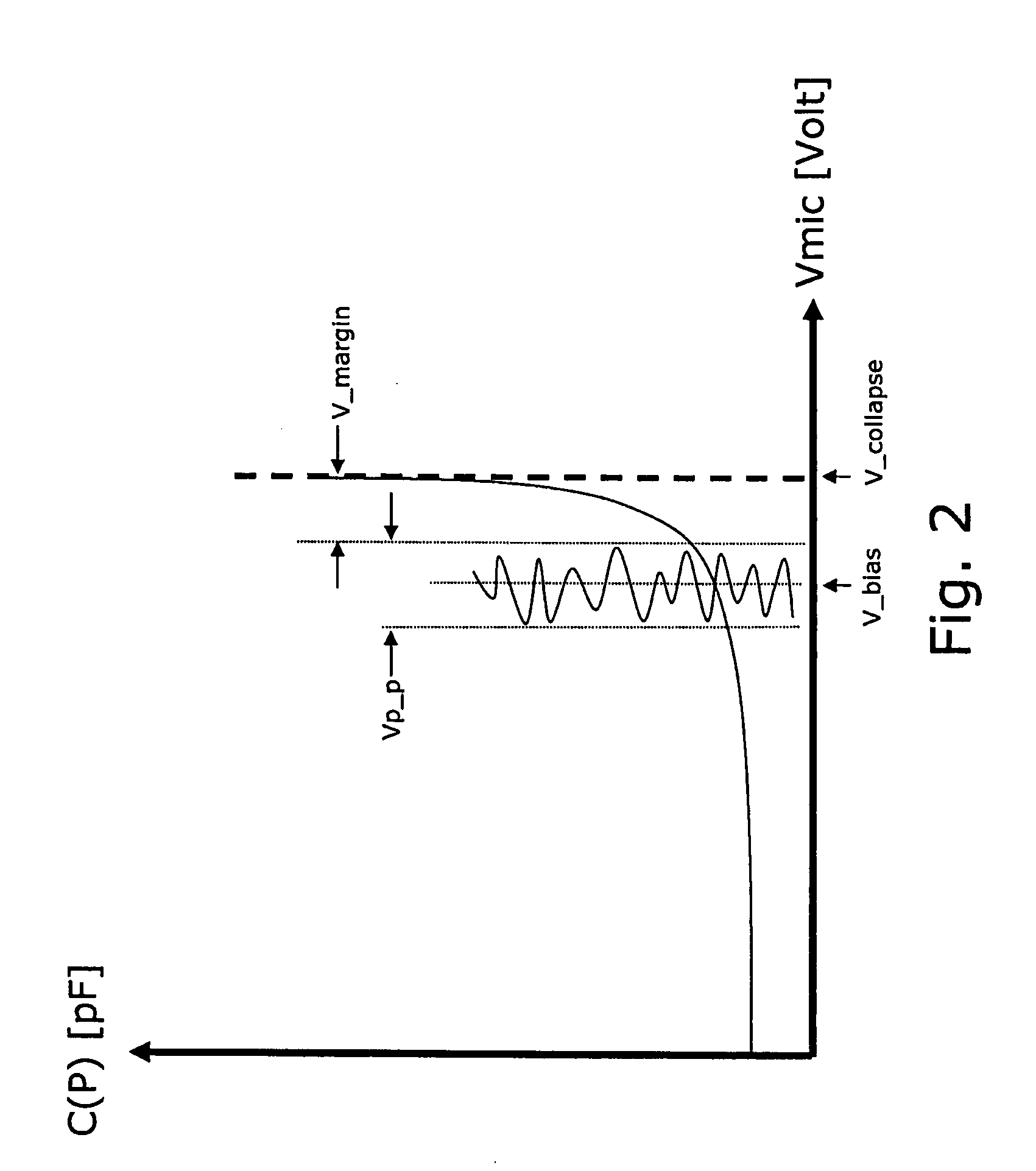

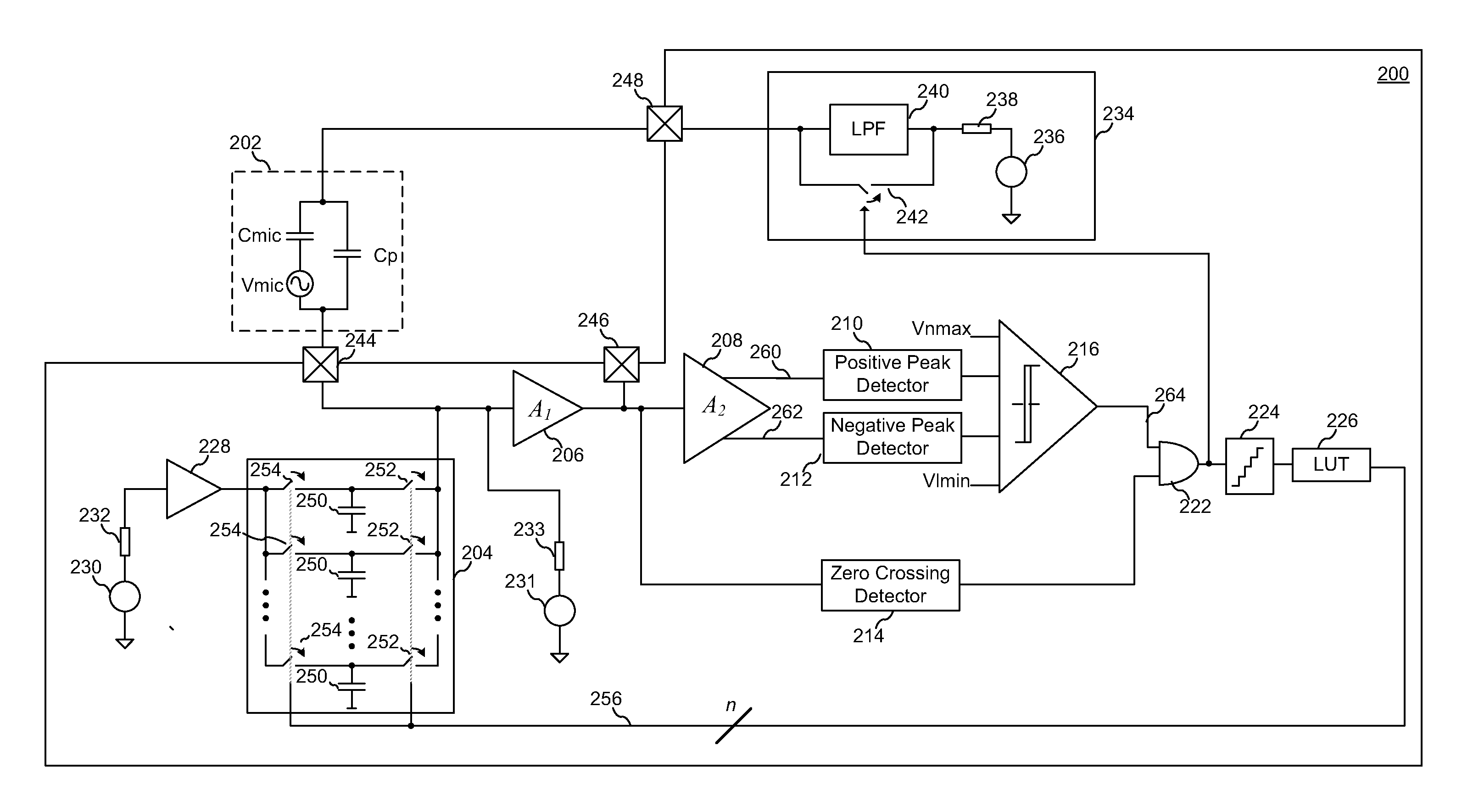

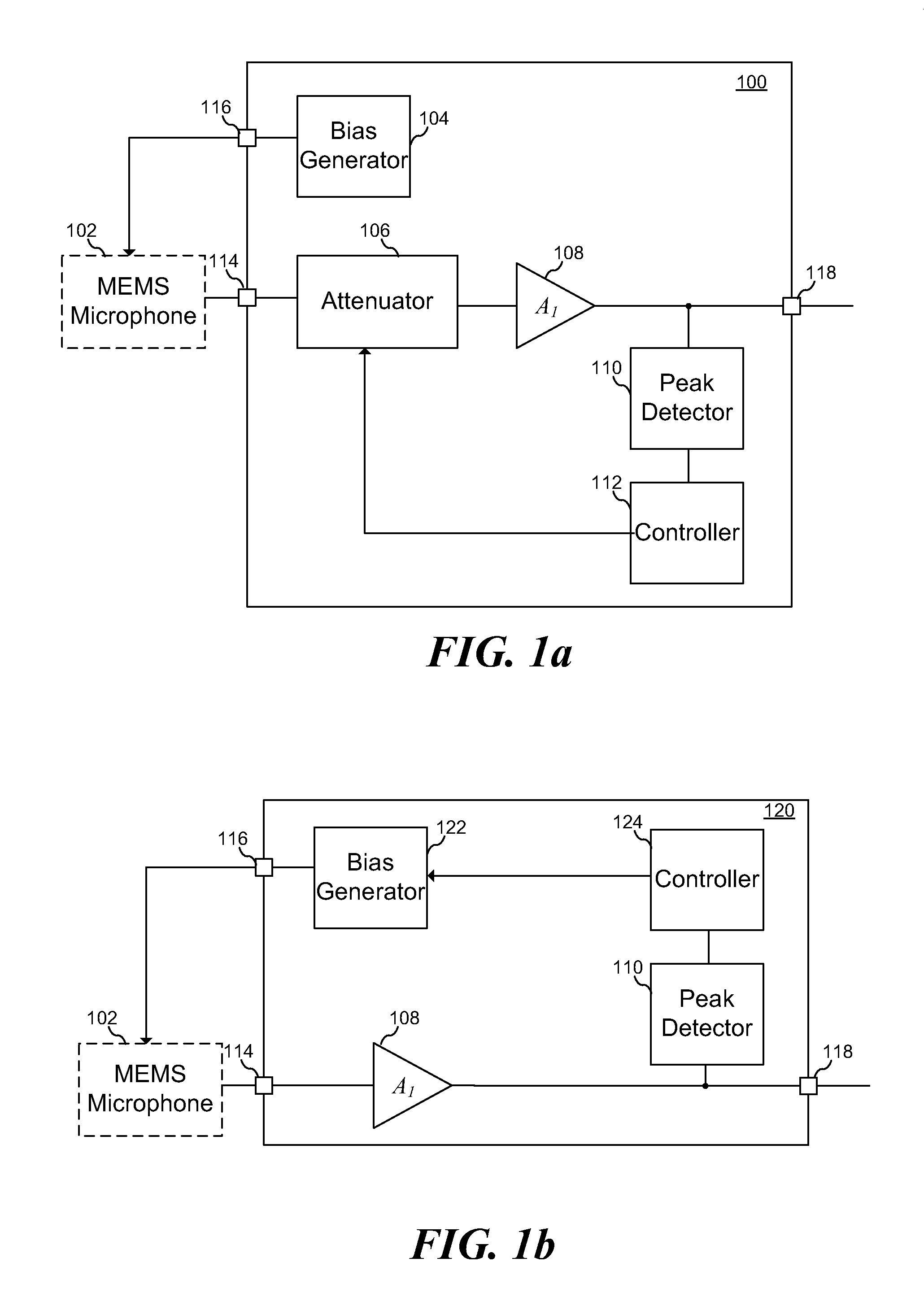

MEMS Microphone with Programmable Sensitivity

A control circuit monitors a signal produced by a MEMS or other capacitor microphone. When a criterion is met, for example when the amplitude of the monitored signal exceeds a threshold or the monitored signal has been clipped or analysis of the monitored signal indicates clipping is imminent or likely, the control circuit automatically adjusts a bias voltage applied to the capacitor microphone, thereby adjusting sensitivity of the capacitor microphone.

Owner:INVENSENSE

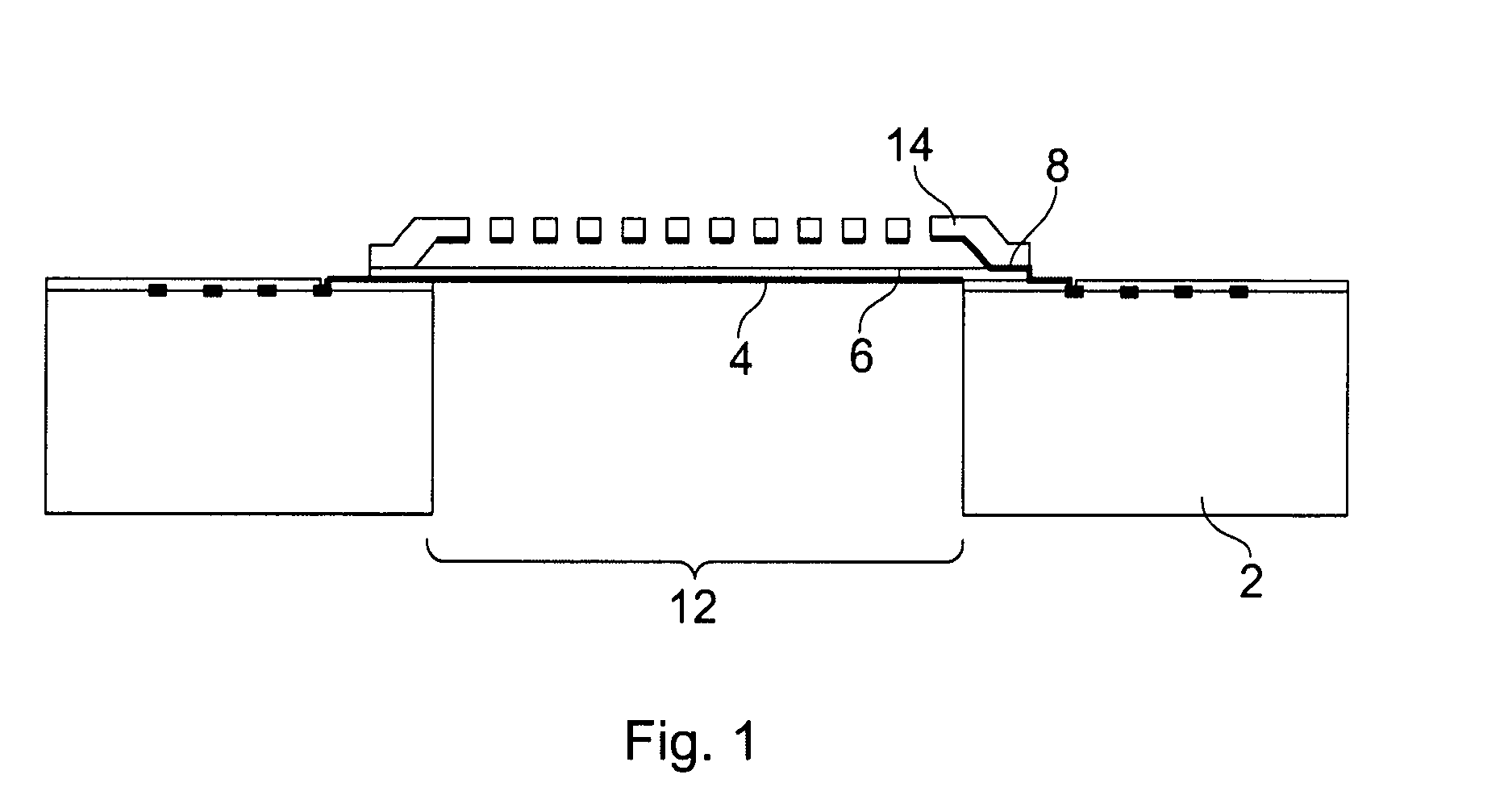

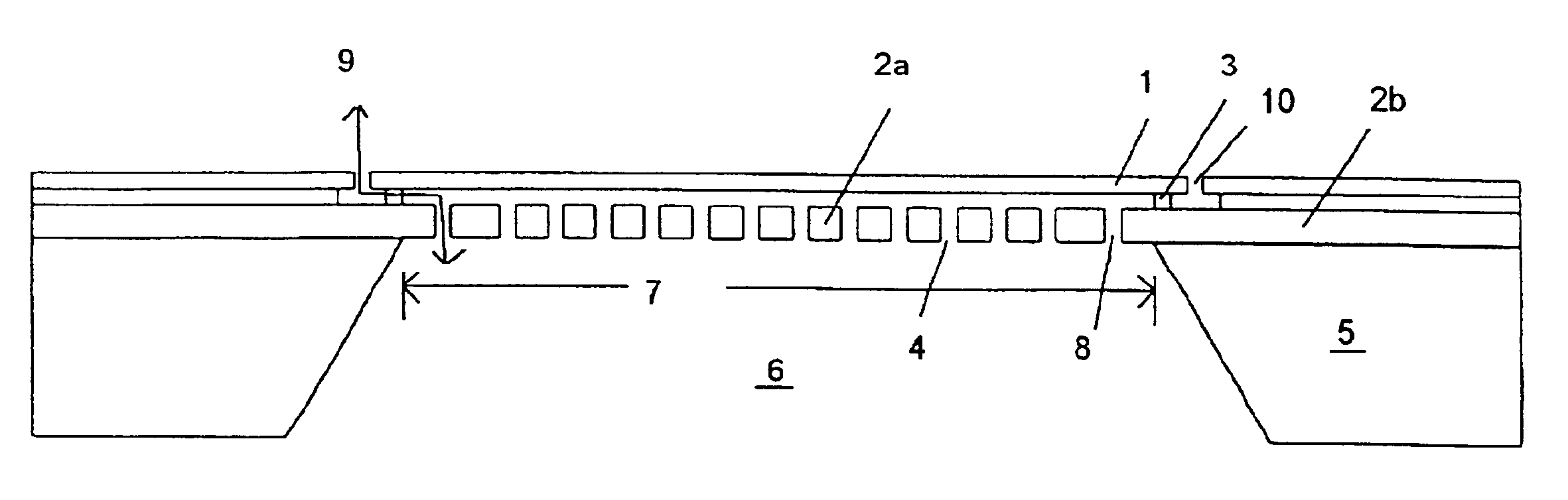

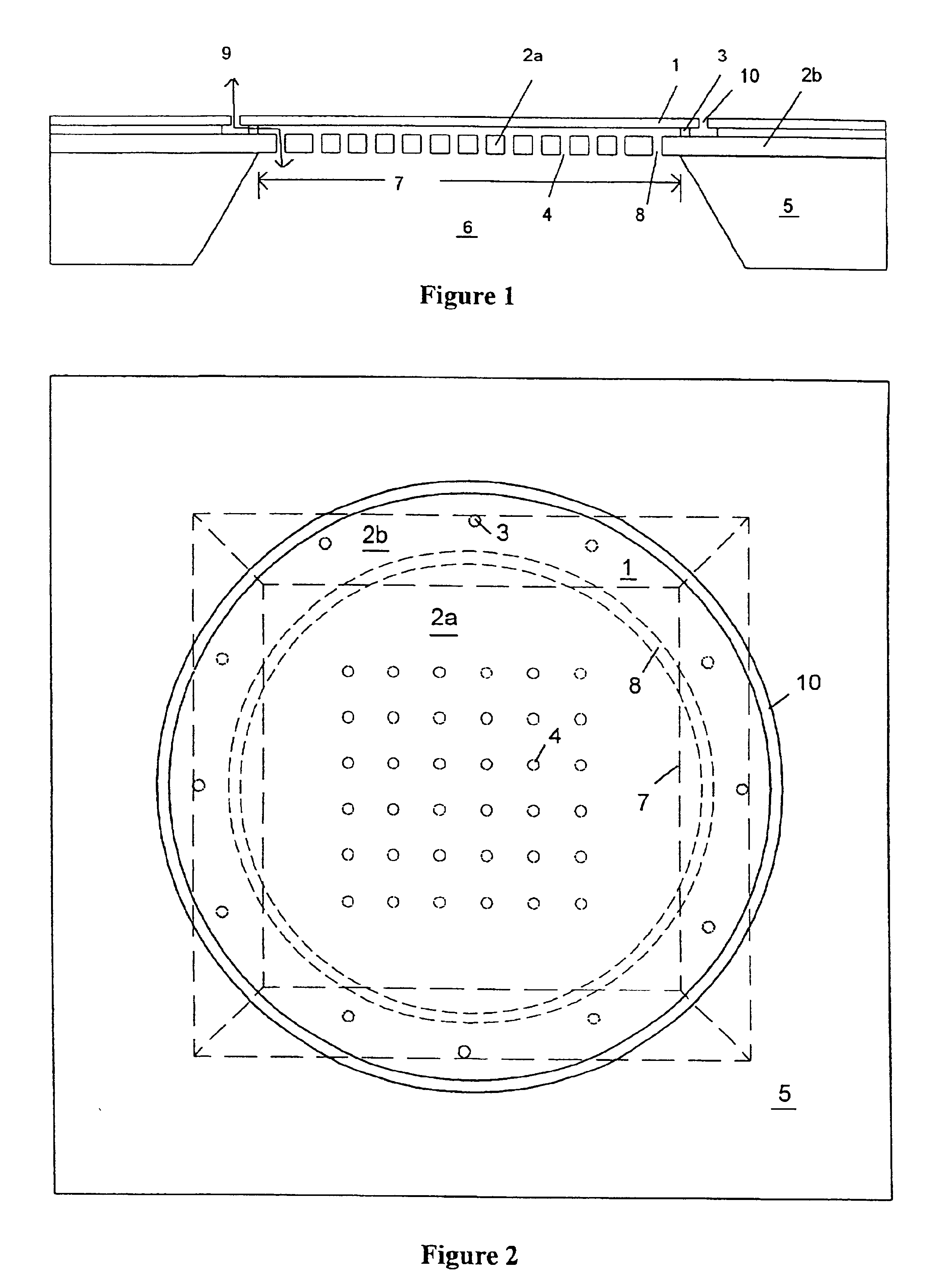

Substrate-level assembly for an integrated device, manufacturing process thereof and related integrated device

ActiveUS20080315333A1Low costSemiconductor electrostatic transducersSemiconductor/solid-state device detailsSemiconductor materialsEngineering

A substrate-level assembly having a device substrate of semiconductor material with a top face and housing a first integrated device, including a buried cavity formed within the device substrate, and with a membrane suspended over the buried cavity in the proximity of the top face. A capping substrate is coupled to the device substrate above the top face so as to cover the first integrated device in such a manner that a first empty space is provided above the membrane. Electrical-contact elements electrically connect the integrated device with the outside of the substrate-level assembly. In one embodiment, the device substrate integrates at least a further integrated device provided with a respective membrane, and a further empty space, fluidically isolated from the first empty space, is provided over the respective membrane of the further integrated device.

Owner:STMICROELECTRONICS SRL

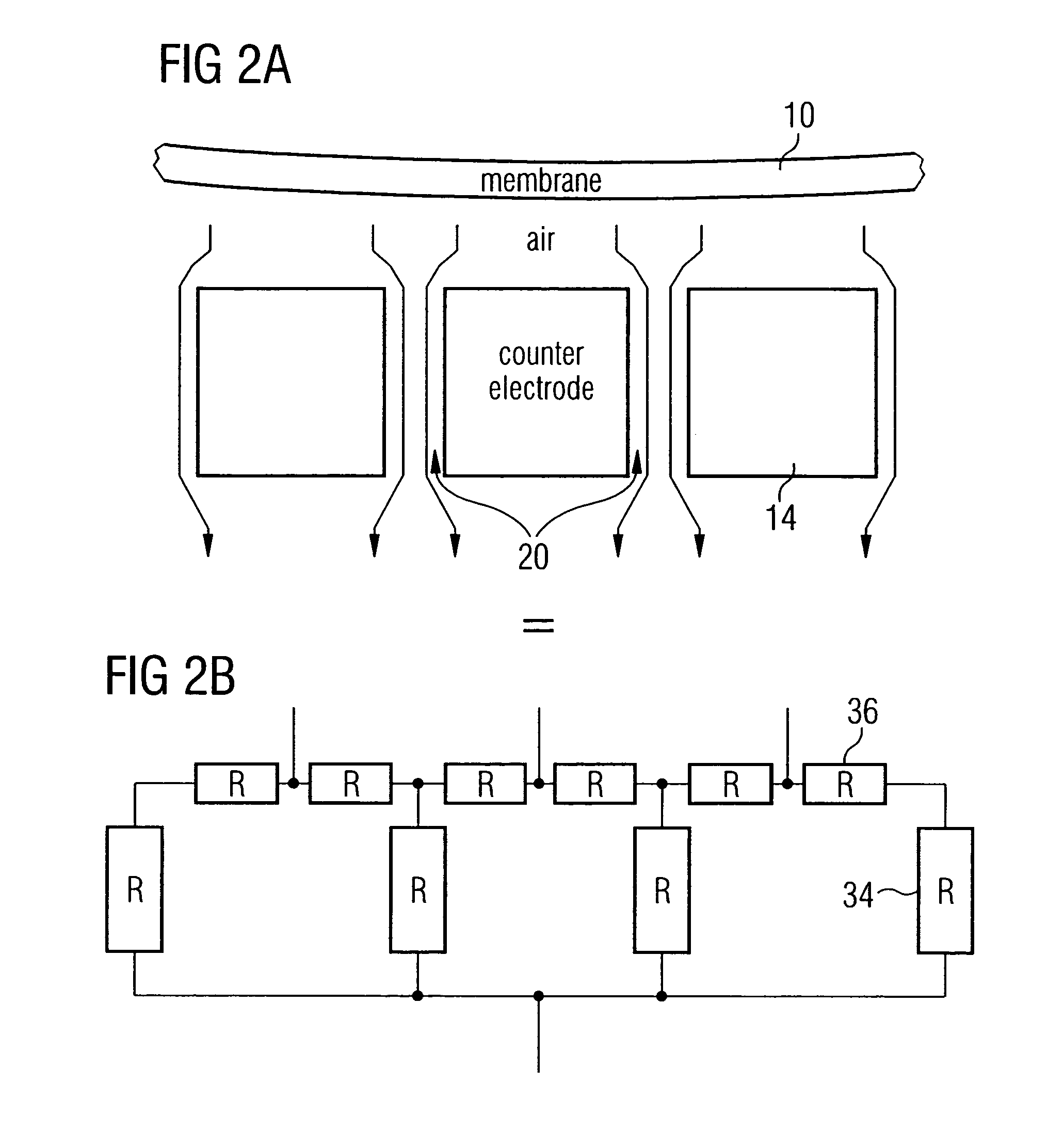

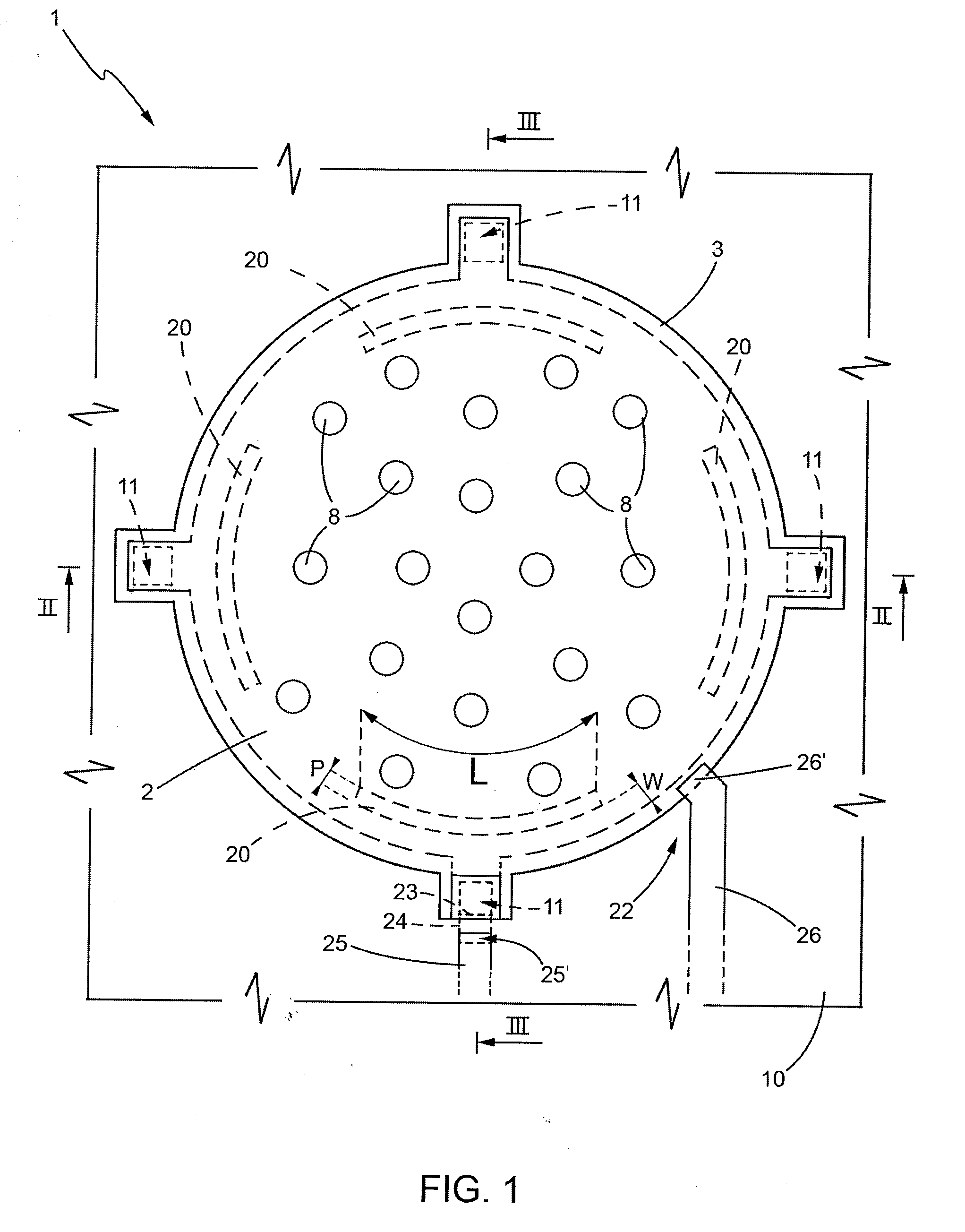

Micromechanical sensors and methods of manufacturing same

InactiveUS7190038B2Easy to closeProcess integrationSemiconductor electrostatic transducersFluid pressure measurement by electric/magnetic elementsEngineeringMaterial Perforation

A micromechanical sensor and, in particular, a silicon microphone, includes a movable membrane and a counter element in which perforation openings are formed, opposite to the movable membrane via a cavity. The perforation openings are formed by slots, the width of which maximally corresponds to double the spacing defined by the cavity between the membrane and the counter element.

Owner:INFINEON TECH AG

Method of etching sacrificial layer, method of manufacturing MEMS device, MEMS device and MEMS sensor

InactiveUS20100065930A1Damage suppressionSimple structureSemiconductor electrostatic transducersSemiconductor/solid-state device detailsEngineeringMems sensors

The method of etching a sacrificial layer according to the present invention includes the steps of forming a sacrificial layer having a protrusive shape on a base layer, forming a covering film covering the sacrificial layer, forming a protective film made of a material whose etching selection ratio to the sacrificial layer is greater than the etching selection ratio of the covering film to the sacrificial layer on a portion of the covering film opposed to the side surface of the sacrificial layer, and etching the sacrificial layer after the formation of the protective film.

Owner:ROHM CO LTD

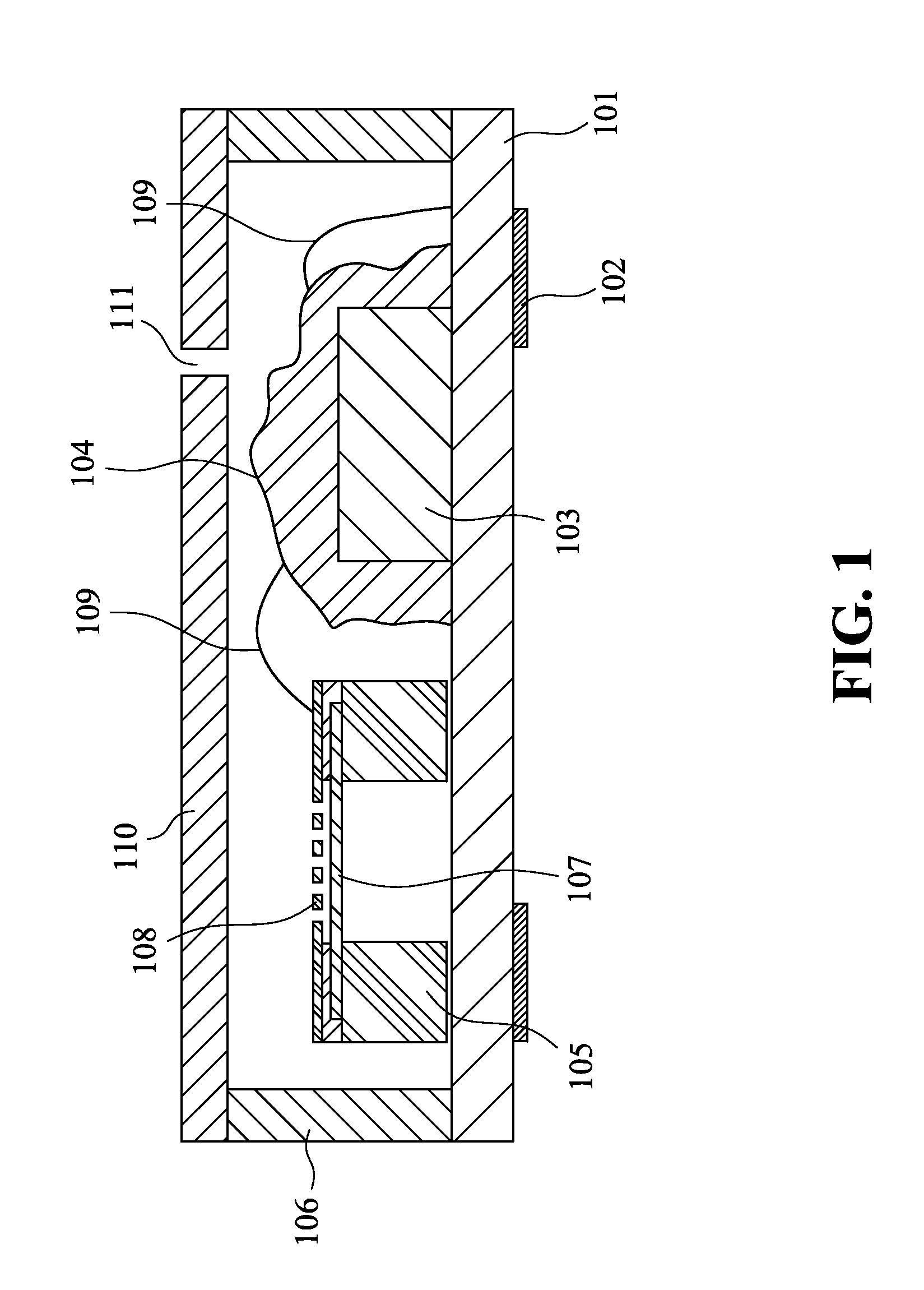

Condenser microphone

InactiveUS20070201710A1High sensitivityReduce tensile stressMicrophonesLoudspeakersCapacitanceEngineering

A condenser microphone includes a support, a plate having a fixed electrode bridged across the supports, a diaphragm, which has a moving electrode at a center portion thereof and which vibrates due to sound waves applied thereto, and a spacer, in which a first end is fixed to the plate, and a second end is fixed to the near-end portion of the diaphragm so as to surround the center portion of the diaphragm, wherein an air gap is formed between the plate and the diaphragm. This reduces the tensile stress of the diaphragm so as to increase the amplitude of vibration of the diaphragm. Hence, it is possible to increase the sensitivity of the condenser microphone. A structure constituted of the plate, the diaphragm, and the spacer is bridged across the support by means of the bridges, which absorb the residual stress of the diaphragm due to the deformation thereof.

Owner:YAMAHA CORP

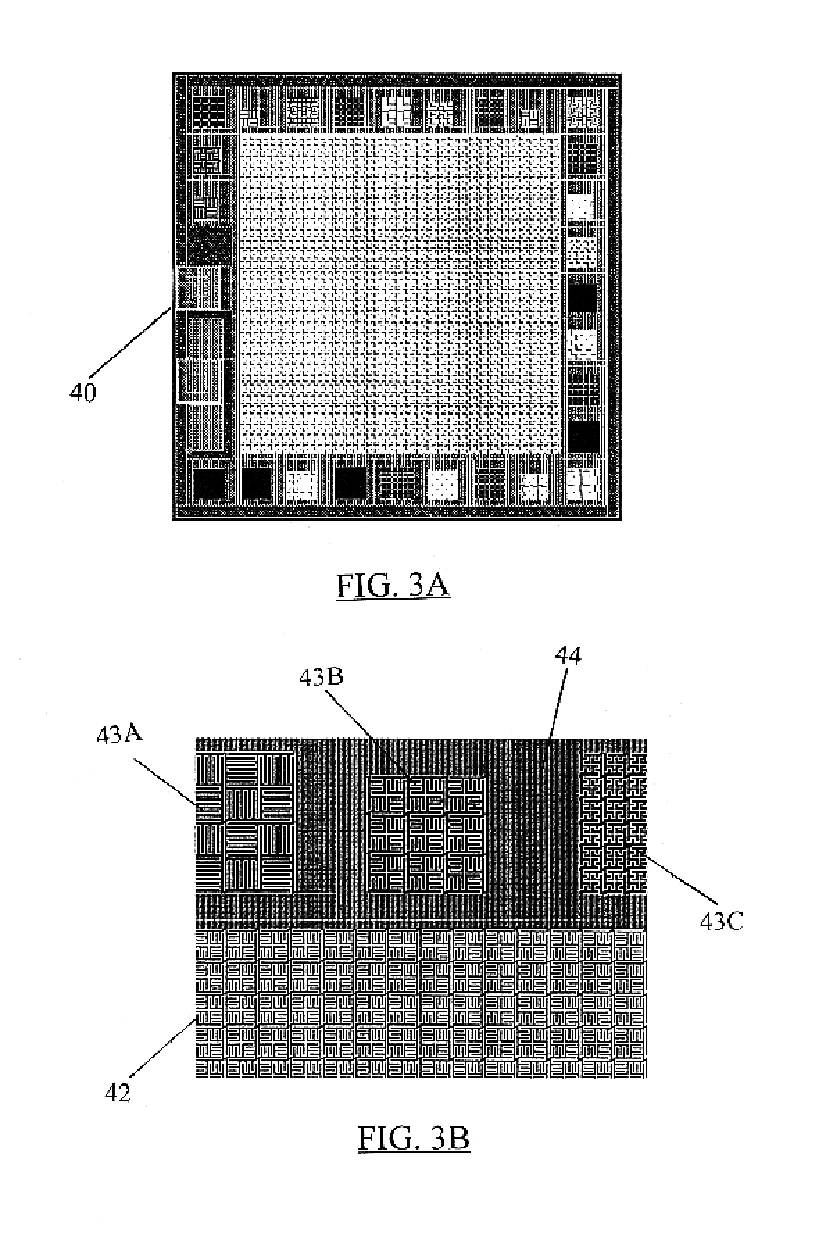

Integrated MEMS device

InactiveUS20130161702A1Improve reliabilityReduce manufacturing costMicrophonesLoudspeakersCMOSControl layer

An integrated MEMS device is provided, including, from bottom up, a bonding wafer layer, a bonding layer, an aluminum layer, a CMOS substrate layer defining a large back chamber area (LBCA), a small back chamber area (SBCA) and a sound damping path (SDP), a set of CMOS wells, a field oxide (FOX) layer, a set of CMOS transistor sources / drains, a first polysilicon layer forming CMOS transistor gates, a second polysilicon layer, said CMOS wells, said CMOS transistor sources / drains and said CMOS gates forming CMOS transistors, an oxide layer embedded with a plurality of metal layers interleaved with a plurality of via hole layers, and a gap control layer, an oxide layer, a first Nitride deposition layer, a metal deposition layer, a second Nitride deposition layer, an under bump metal (UBM) layer made of preferably Al / NiV / Cu and a plurality of solder spheres.

Owner:WINDTOP TECH CORP

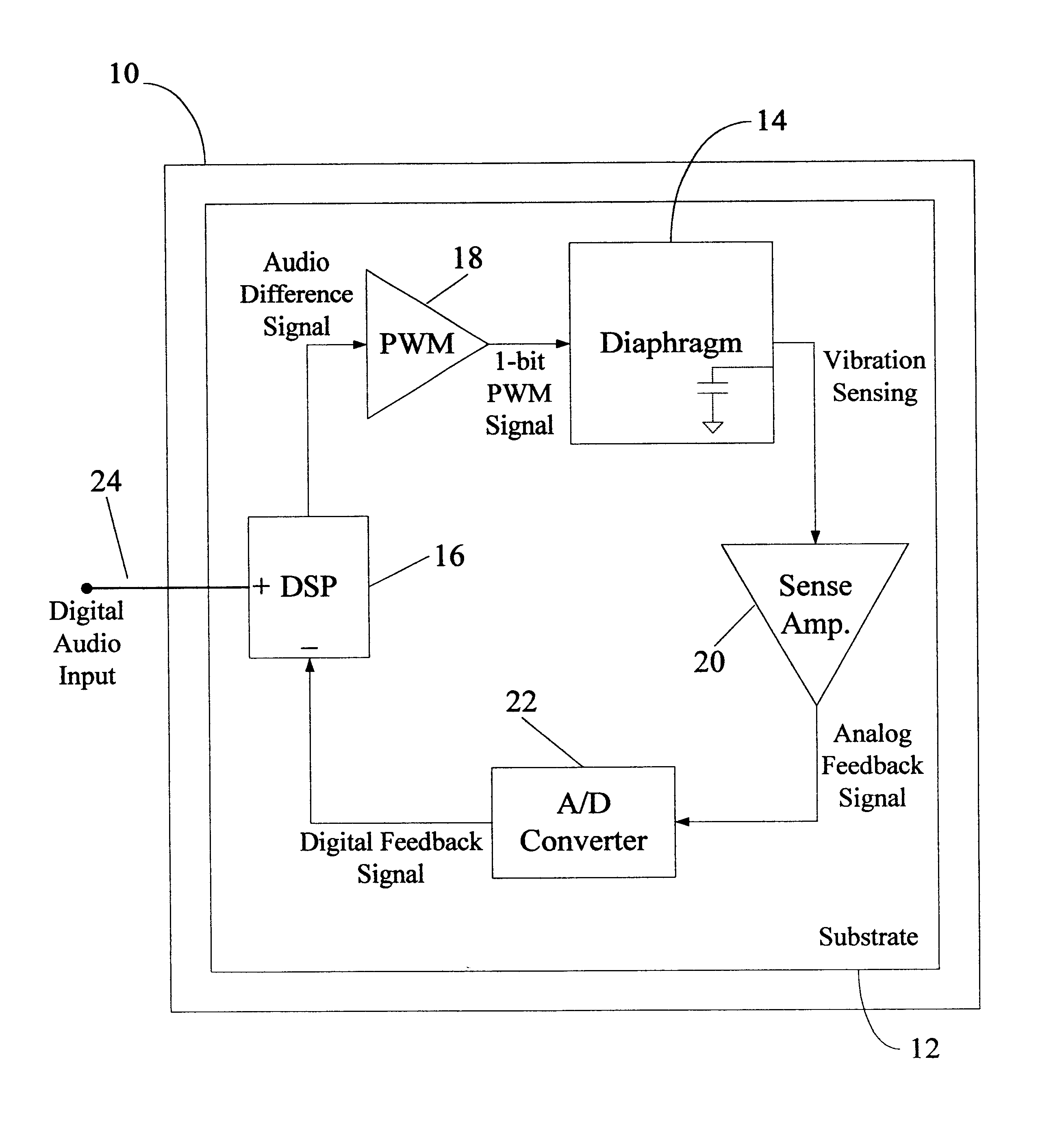

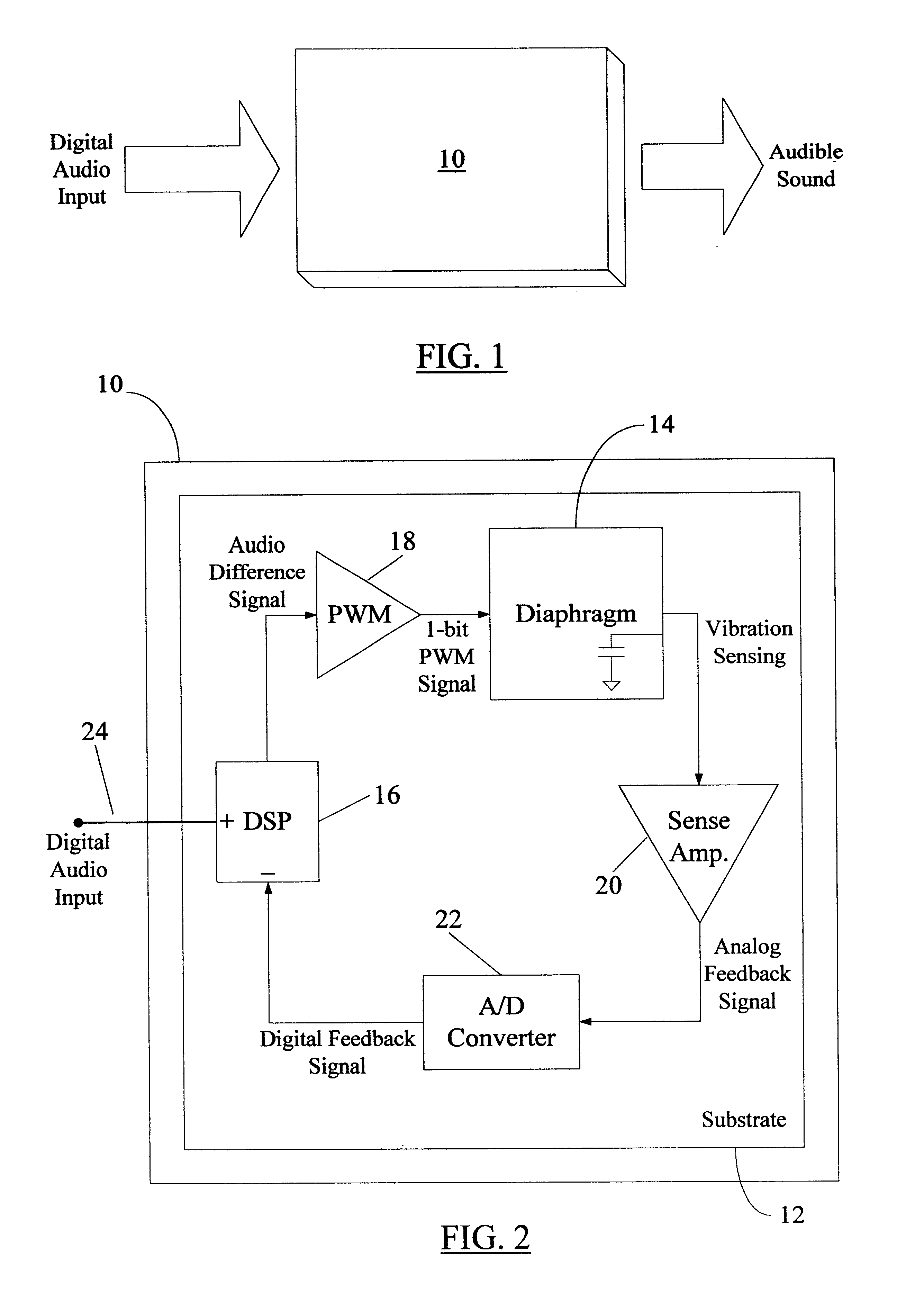

MEMS digital-to-acoustic transducer with error cancellation

InactiveUS6829131B1Low production costHigh quality audio reproductionCircuit-breaking switches for excess currentsTelevision system detailsTransducerEngineering

An acoustic transducer comprising a substrate; and a diaphragm formed by depositing a micromachined membrane onto the substrate. The diaphragm is formed as a single silicon chip using a CMOS MEMS (microelectromechanical systems) semiconductor fabrication process. The curling of the diaphragm during fabrication is reduced by depositing the micromachined membrane for the diaphragm in a serpentine-spring configuration with alternating longer and shorter arms. As a microspeaker, the acoustic transducer of the present invention converts a digital audio input signal directly into a sound wave, resulting in a very high quality sound reproduction at a lower cost of production in comparison to conventional acoustic transducers. The micromachined diaphragm may also be used in microphone applications.

Owner:CARNEGIE MELLON UNIV

Micromachined Capacitive Microphone

InactiveUS20060280319A1Wide and flat frequency responseHigh sensitivitySemiconductor electrostatic transducersDeaf-aid setsElectrical conductorEngineering

This invention relates to a micromachined capacitive microphone having a shallowly corrugated diaphragm that is anchored at one or more locations on the support has a plurality of dimples to support itself and rest freely on the perforated backplate. The diaphragm whose ends are not anchored is bounded by the taps of edge rail. Also disclosed includes: a fixed perforated backplate having one or more regions; an adjustable cantilever formed by the diaphragm, the support and the backplate; a plurality of dimples maintaining vertical separation between diaphragm and backplate; and the patterning of conductor electrodes carried by diaphragm and backplate.

Owner:GENERAL MEMS CORP

Microphone Package with Embedded ASIC

ActiveUS20120087521A1Transducer detailsSemiconductor electrostatic transducersEngineeringMems microphone

A packaged microphone has a base, a lid coupled to the base forming an interior, a MEMS microphone secured to the base within the interior, and an integrated circuit embedded in the base. Apertures in the base and integrated circuit are aligned to form an aperture from the exterior of the package to the interior.

Owner:INVENSENSE

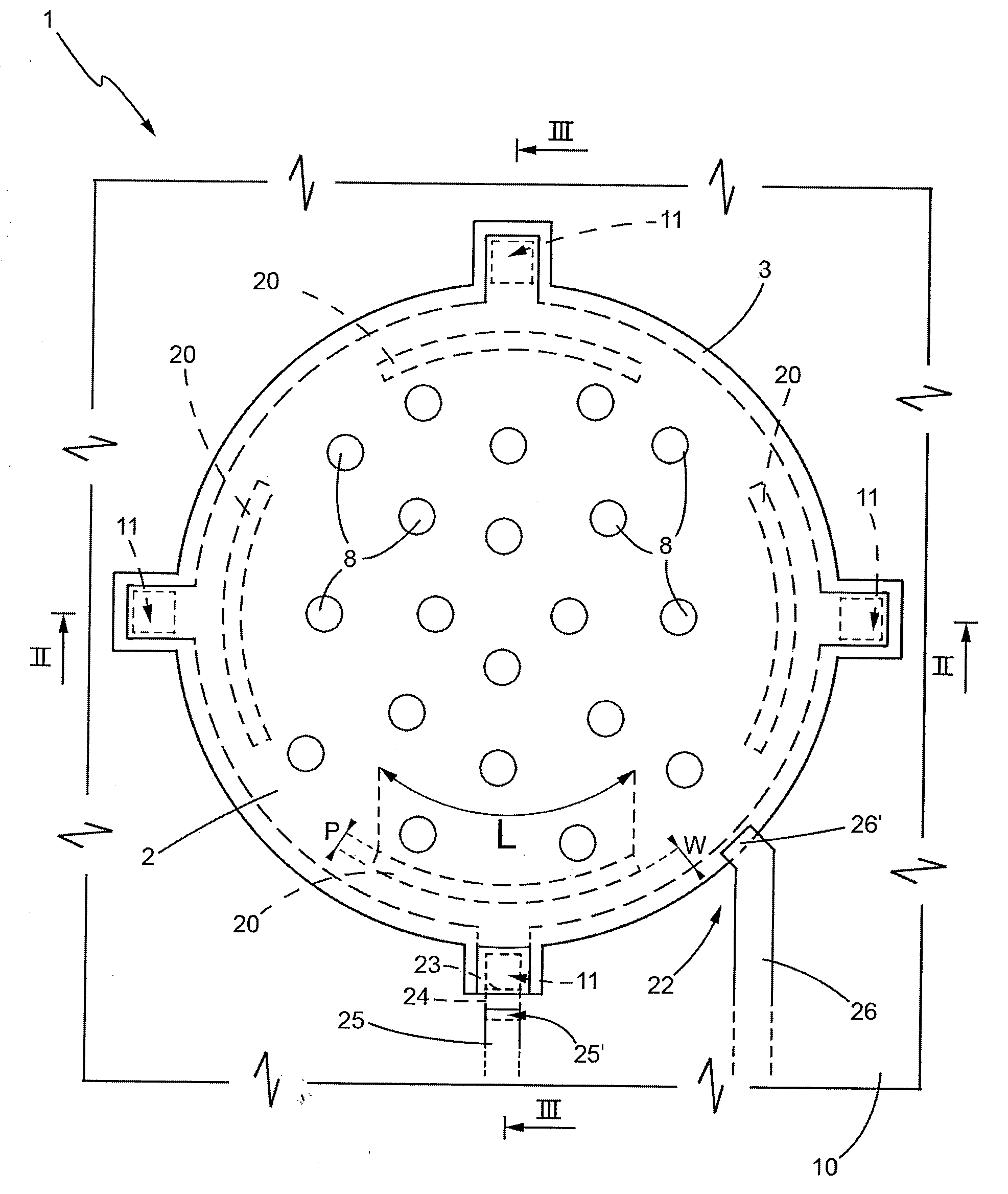

Integrated acoustic transducer obtained using MEMS technology, and corresponding manufacturing process

ActiveUS20100158279A1Semiconductor electrostatic transducersElectrostatic transducer microphonesTransducerEngineering

A MEMS acoustic transducer provided with a substrate having cavity, and a membrane suspended above the cavity and fixed peripherally to the substrate, with the possibility of oscillation, through at least one membrane anchorage. The membrane comprises at least one spring arranged in the proximity of the anchorage and facing it, and is designed to act in tension or compression in a direction lying in the same plane as said membrane.

Owner:STMICROELECTRONICS SRL

Calibrated microelectromechanical microphone

ActiveUS20080075306A1Improve production yieldMaximize sensitivitySemiconductor electrostatic transducersElectrostatic transducer microphonesVoltage generatorAudio power amplifier

A MEMS microphone comprising a MEMS transducer having a back plate and a diaphragm as well as controllable bias voltage generator providing a DC bias voltage between the back plate and the diaphragm. The microphone also has an amplifier with a controllable gain, and a memory for storing information for determining a bias voltage to be provided by the bias voltage generator and the gain of the amplifier.

Owner:TDK CORPARATION

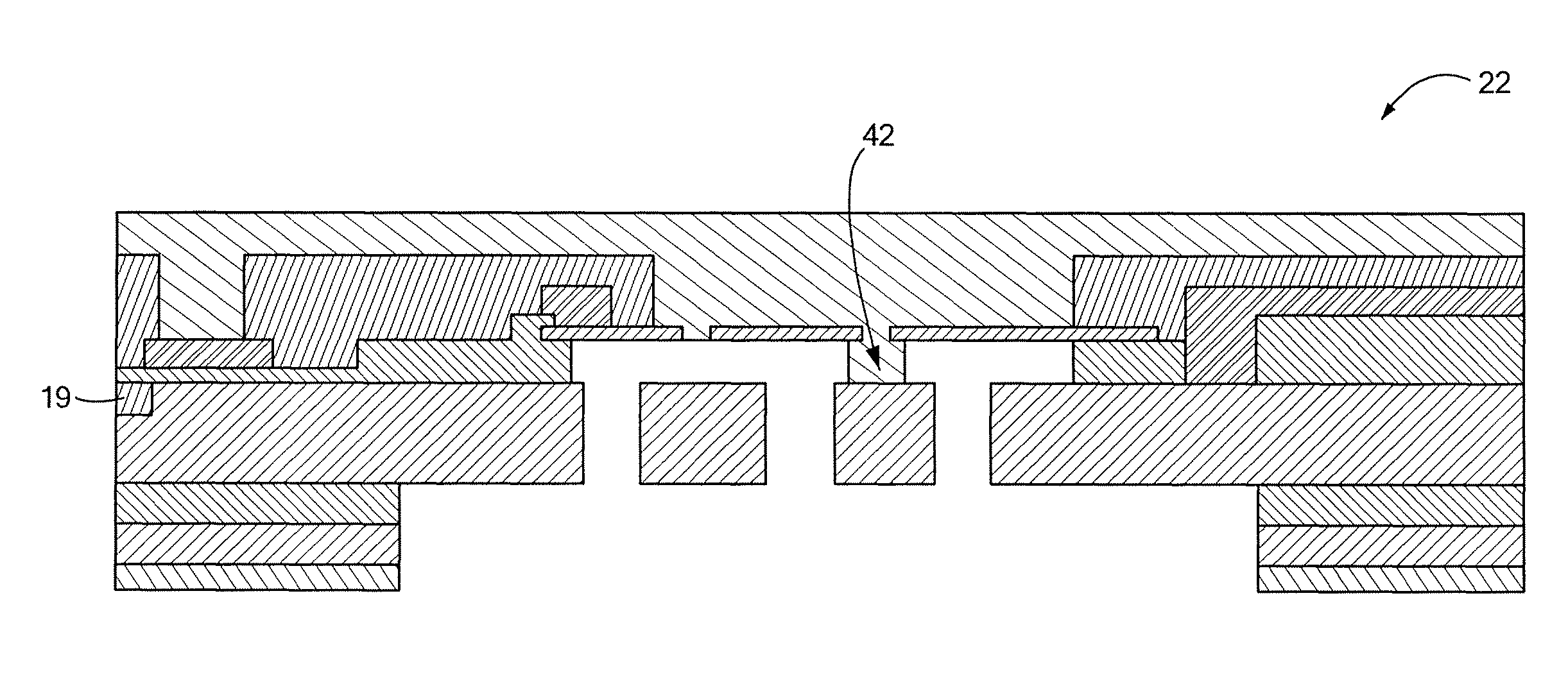

Single Die MEMS Acoustic Transducer and Manufacturing Method

ActiveUS20090169035A1Semiconductor electrostatic transducersSemiconductor/solid-state device manufacturingSemiconductor materialsTransducer

The invention relates to an acoustic micro-electrical-mechanical-system (MEMS) transducer formed on a single die based on a semiconductor material and having front and back surface parts opposed to each other. The invention further relates to a method of manufacturing such an acoustic MEMS transducer. The acoustic MEMS transducer comprises a cavity formed in the die to thereby provide a back volume with an upper portion facing an opening of the cavity and a lower portion facing a bottom of the cavity. A back plate and a diaphragm are arranged substantially parallel with an air gap there between and extending at least partly across the opening of the cavity, with the back plate and diaphragm being integrally formed with the front surface part of the die. The bottom of the cavity is bounded by the die. The diaphragm may be arranged above the back plate and at least partly extending across the back plate. It is preferred that the backside openings are formed in the die with the openings extending from the back surface part of the die to the cavity bottom. Part of or all of the backside openings may be acoustically sealed by a sealing material.

Owner:TDK CORPARATION

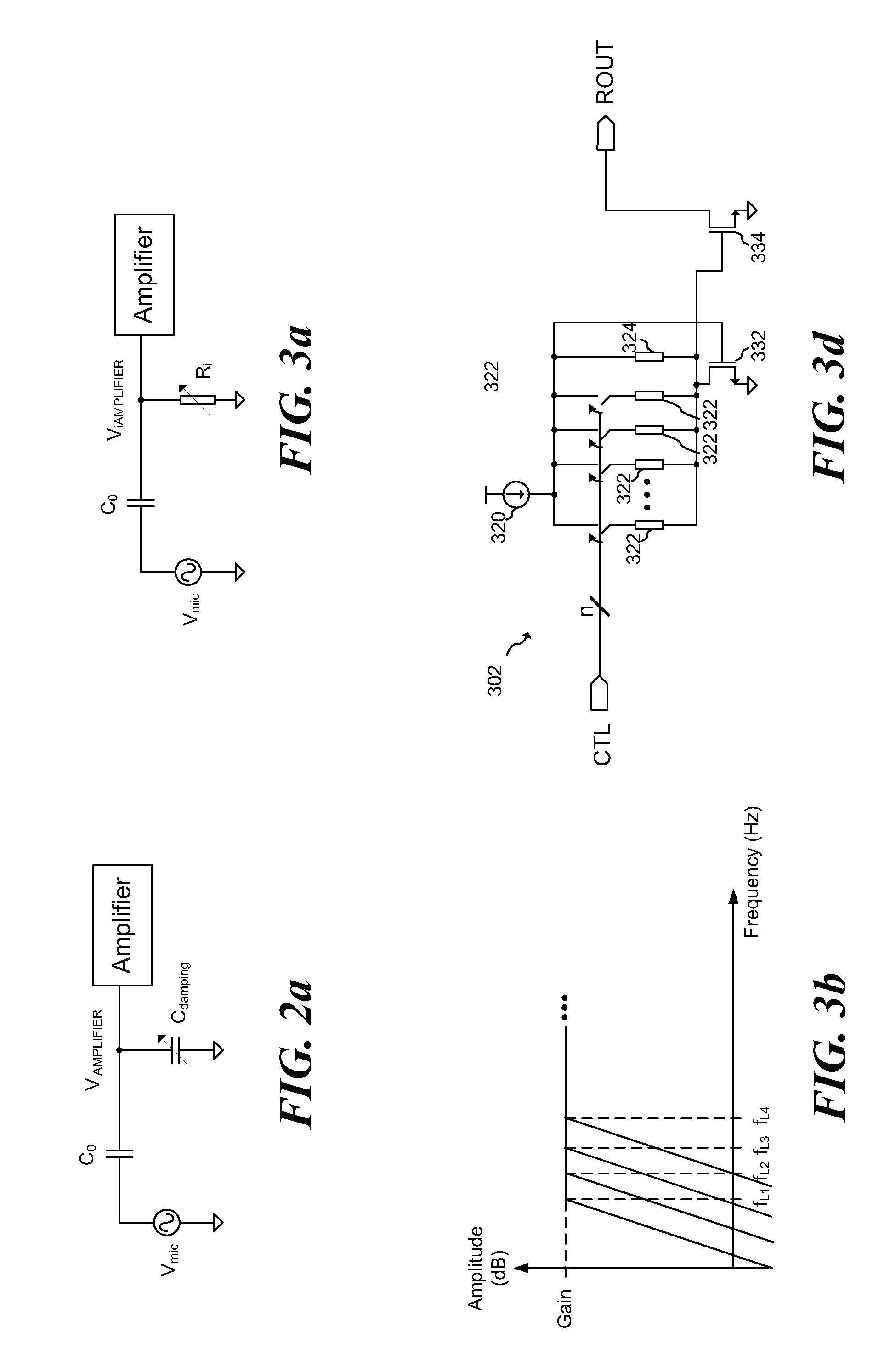

System and Method for Low Distortion Capacitive Signal Source Amplifier

ActiveUS20130051582A1Amplifier modifications to reduce non-linear distortionAmplifier modifications to reduce temperature/voltage variationCapacitanceLow distortion

According to an embodiment, a method includes amplifying a signal provided by a capacitive signal source to form an amplified signal, detecting a peak voltage of the amplified signal, and adjusting a controllable impedance coupled to an output of the capacitive signal source in response to detecting the peak voltage. The controllable impedance is adjusted to a value inversely proportional to the detected peak voltage.

Owner:INFINEON TECH AG

Integrated microphone

ActiveUS7795695B2Semiconductor electrostatic transducersMicrophone structural associationCapacitanceEngineering

A method of forming a microphone having a variable capacitance first deposits high temperature deposition material on a die. The high temperature material ultimately forms structure that contributes to the variable capacitance. The method then forms circuitry on the die after depositing the deposition material. The circuitry is configured to detect the variable capacitance.

Owner:INVENSENSE

Silicon condenser microphone and manufacturing method

InactiveUS7381589B2Interconnection arrangementsSemiconductor/solid-state device detailsTransducerCondenser microphone

A silicon condenser microphone package is disclosed. The silicon condenser microphone package comprises a transducer unit substrate, and a cover. The substrate includes an upper surface having a recess formed therein. The transducer unit is attached to the upper surface of the substrate and overlaps at least a portion of the recess wherein a back volume of the transducer unit is formed between the transducer unit and the substrate. The cover is placed over the transducer unit and includes an aperture.

Owner:KNOWLES ELECTRONICS INC

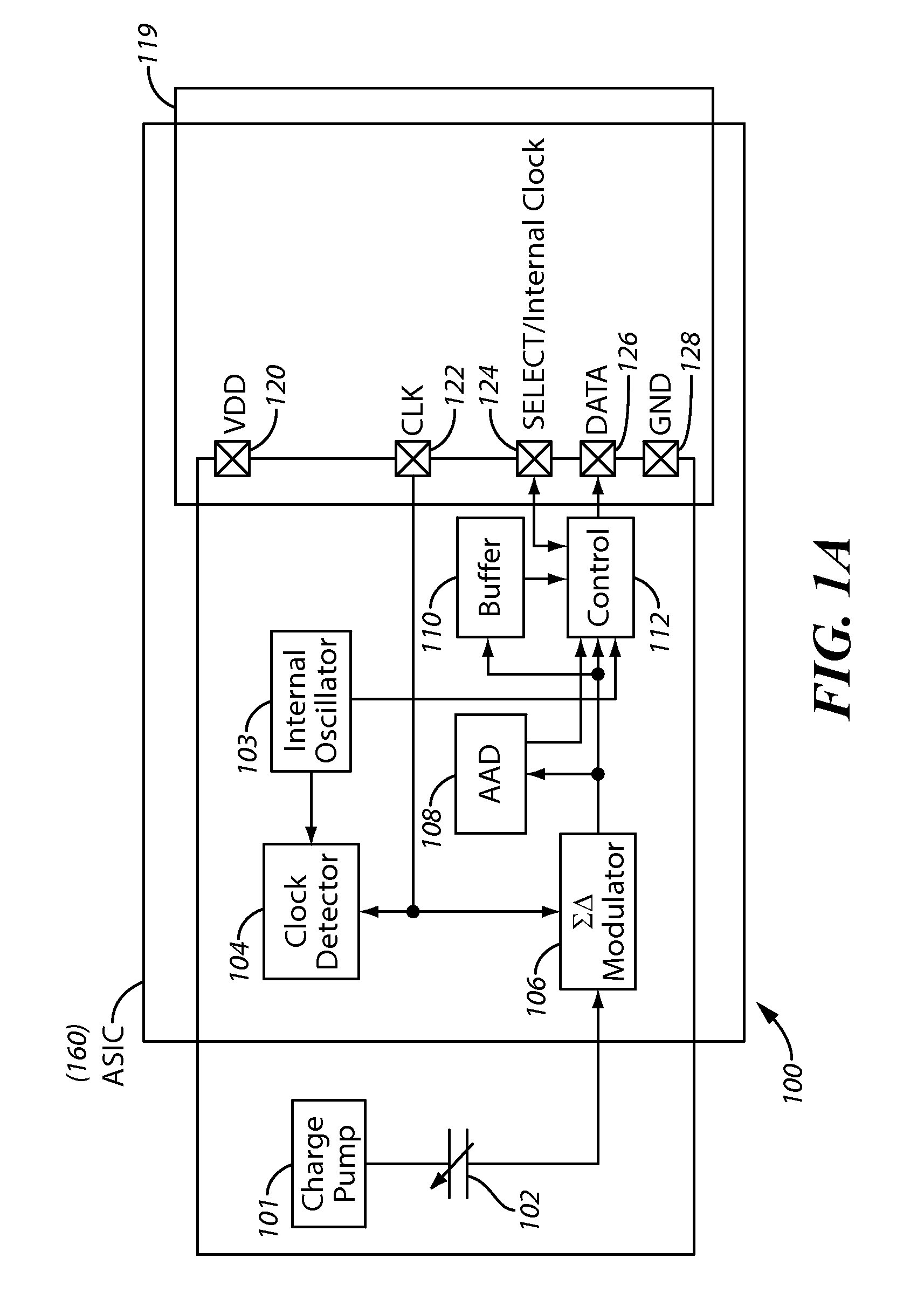

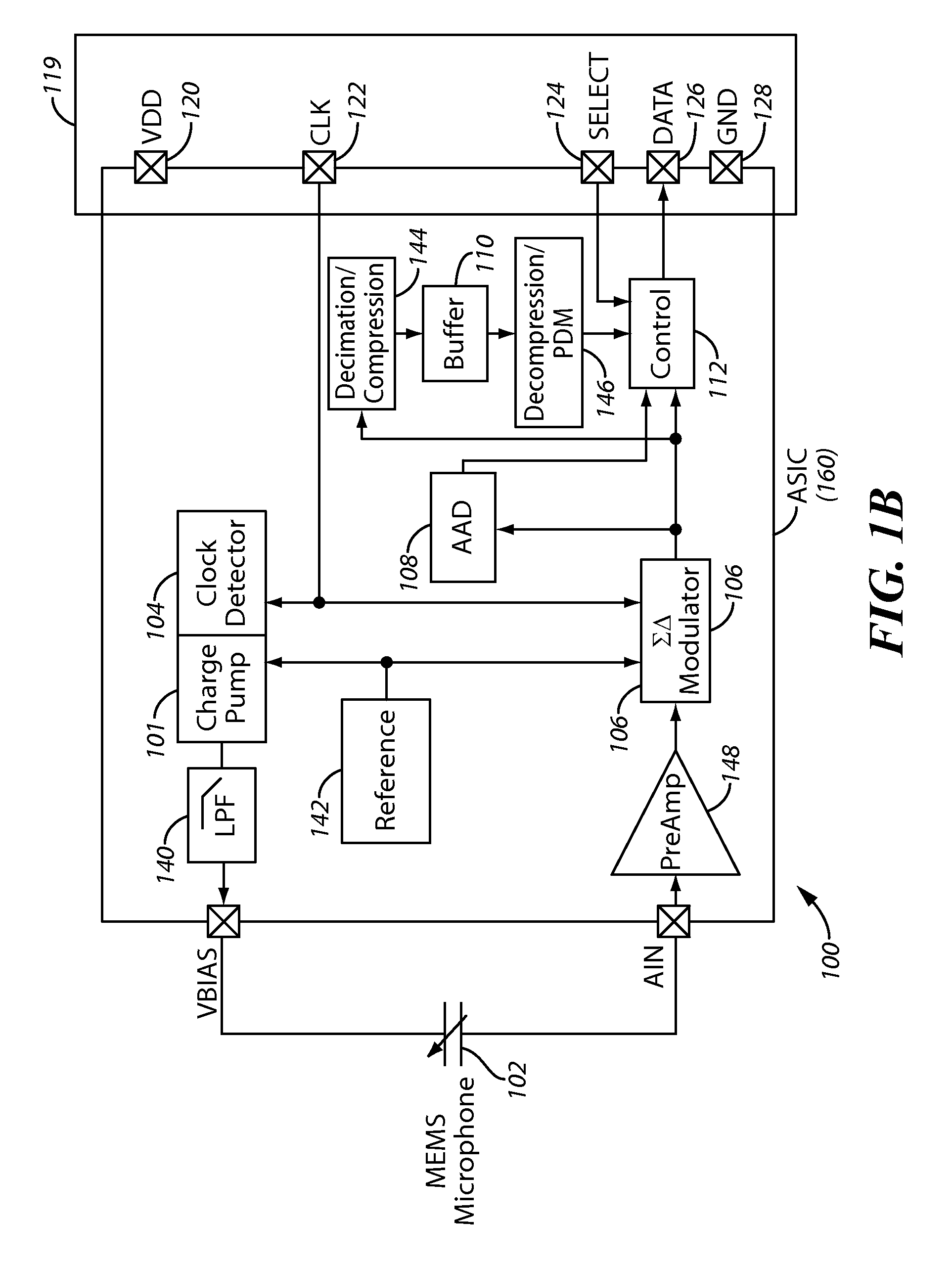

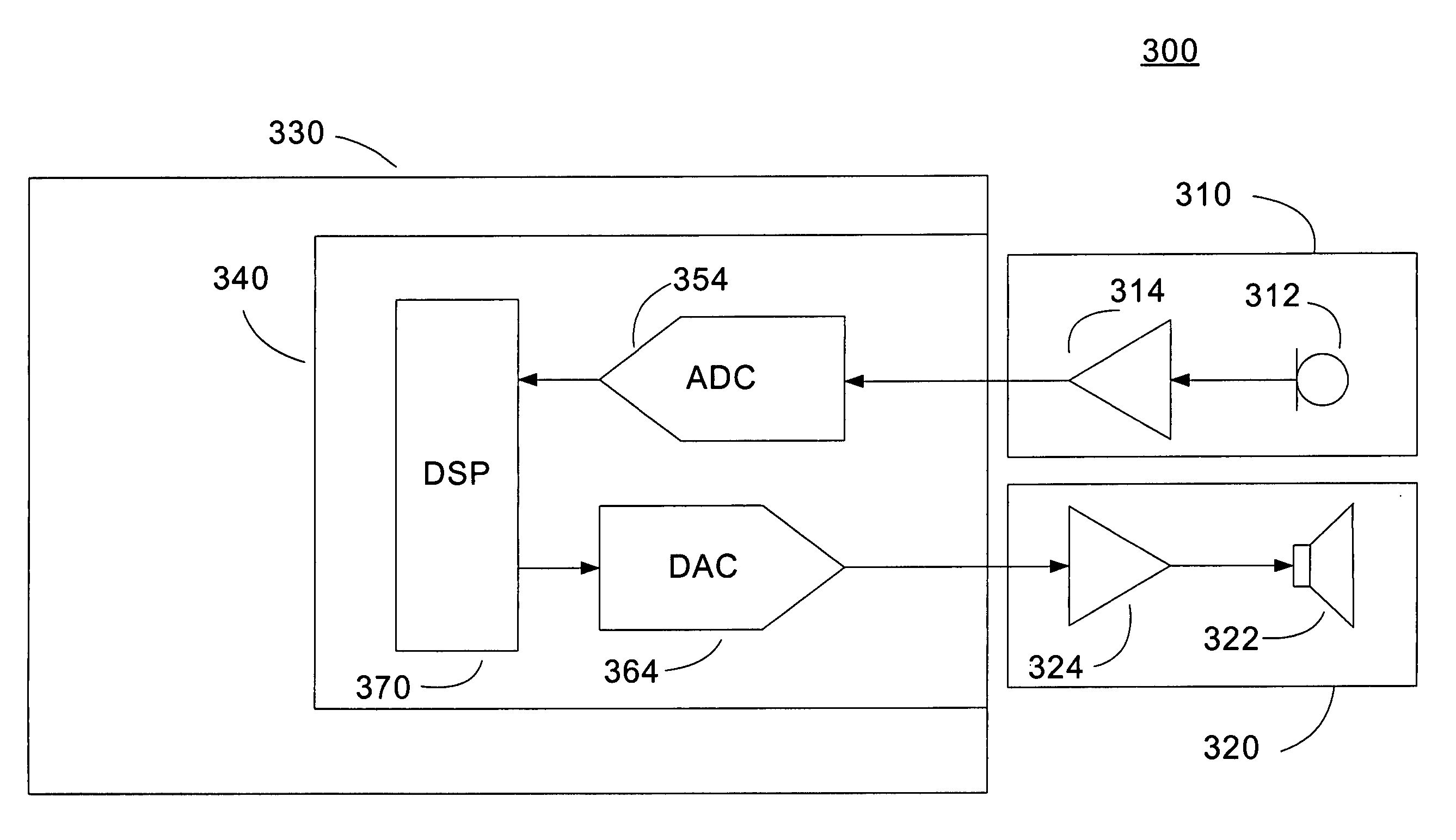

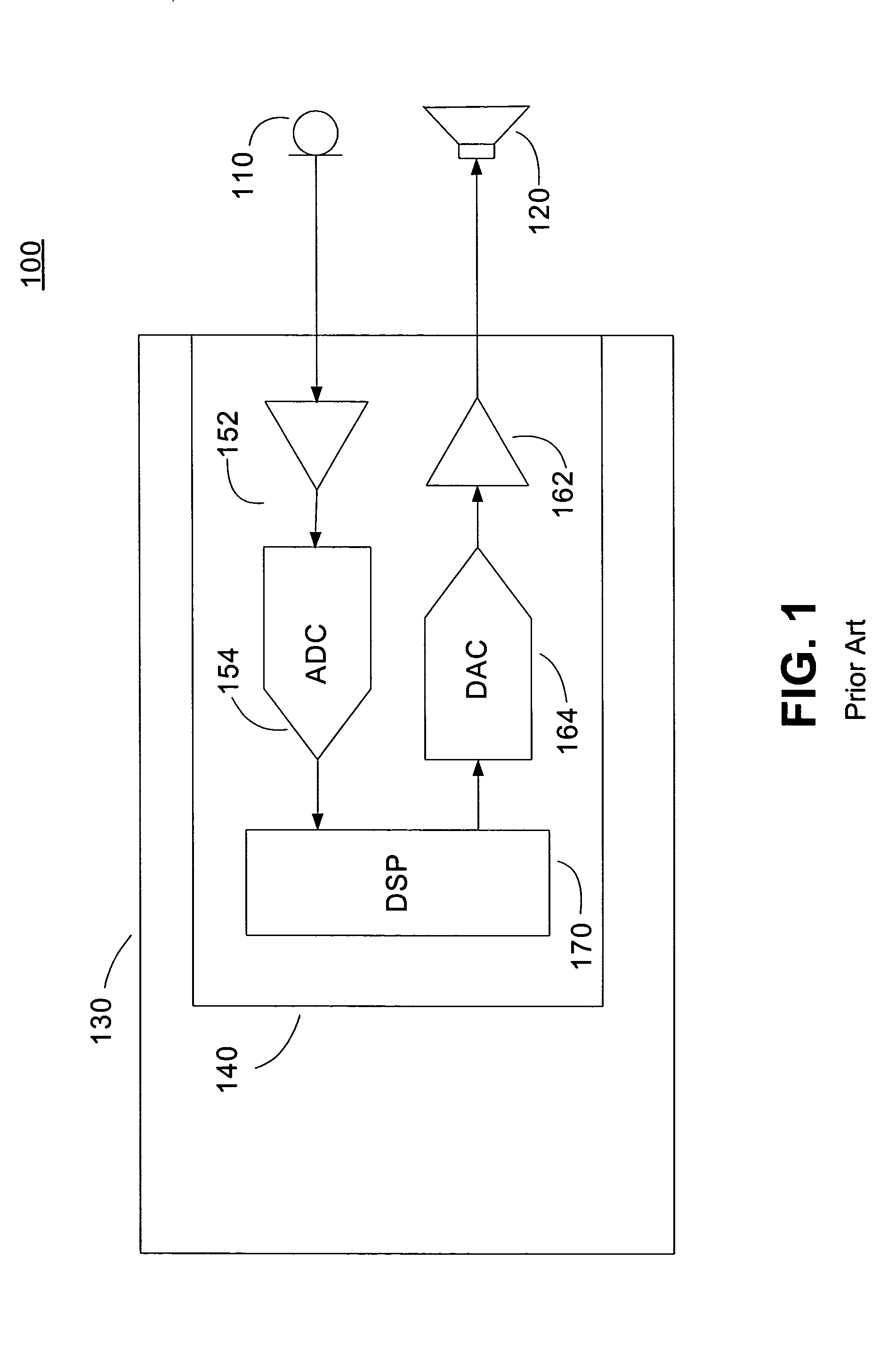

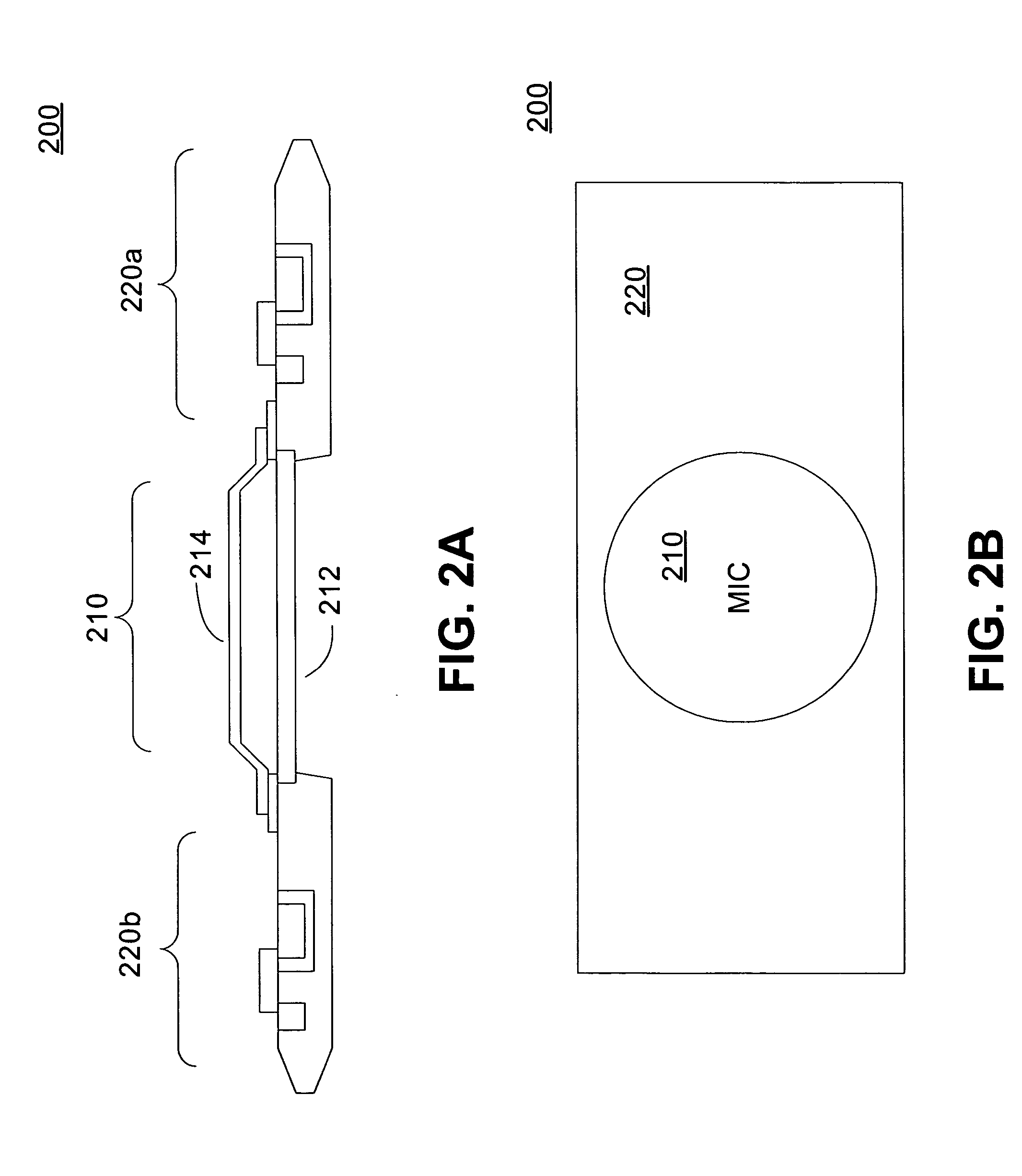

Integrated audio codec with silicon audio transducer

ActiveUS20060034472A1Gain controlSemiconductor electrostatic transducersControl signalMems microphone

An integrated audio transducer with associated signal processing electronics is disclosed. A silicon audio transducer, such as a MEMS microphone or speaker, can be integrated with audio processing electronics in a single package. The audio processing electronics can be configured using control signals. The audio processing electronics can provide a single line serial data interface and a single line control interface. The audio transducers can be integrated with associated processing electronics. A silicon microphone can be integrated with an Analog to Digital Converter (ADC). The ADC output can be a single line serial interface. The ADC can be configured using a single line serial control interface. A speaker may be integrated with a Digital to Analog Converter (DAC). Audio transducers can also be integrated with more complex processing electronics. Audio processing parameters such as gain, dynamic range, and filter characteristics may be configured using the serial interface.

Owner:QUALCOMM INC

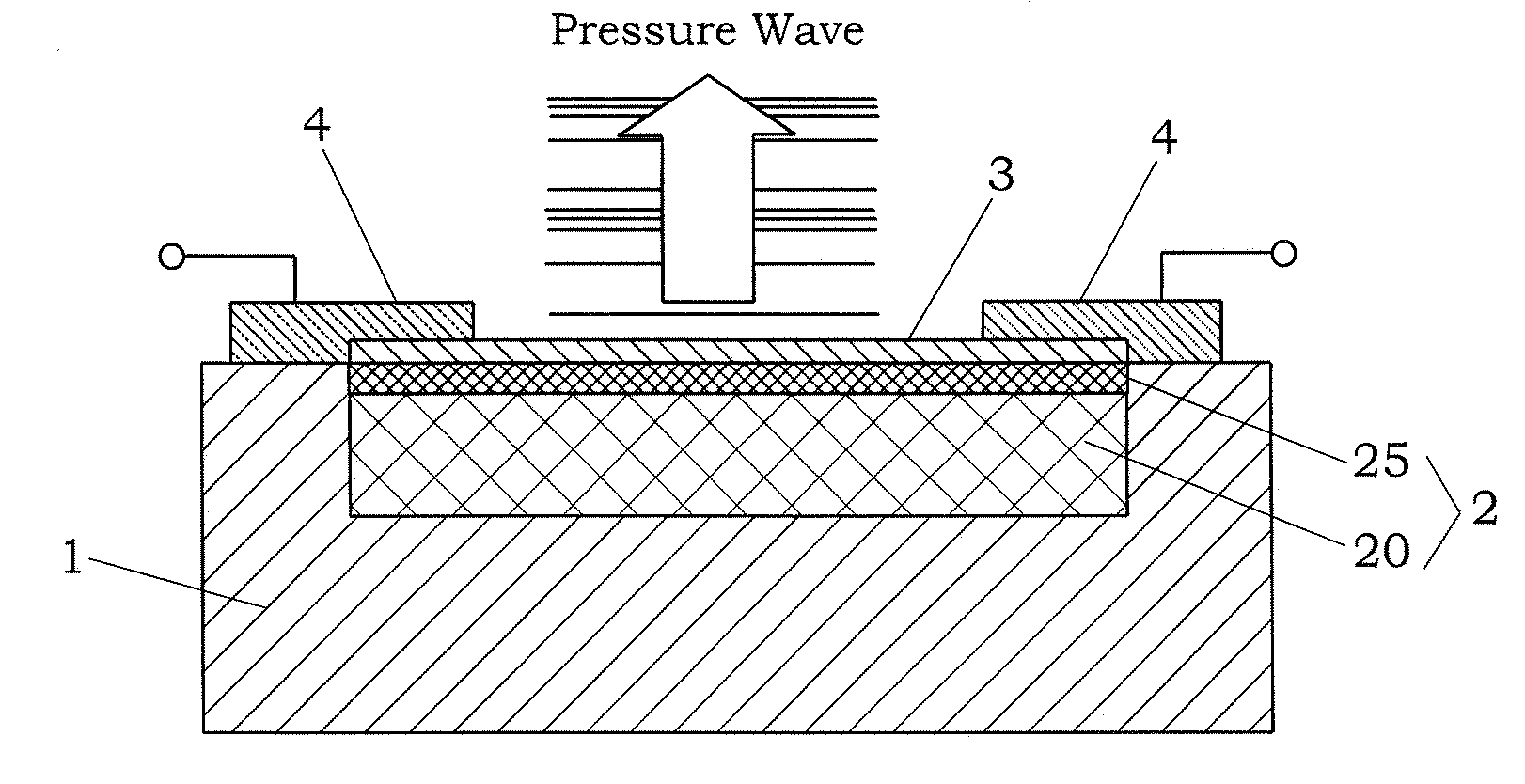

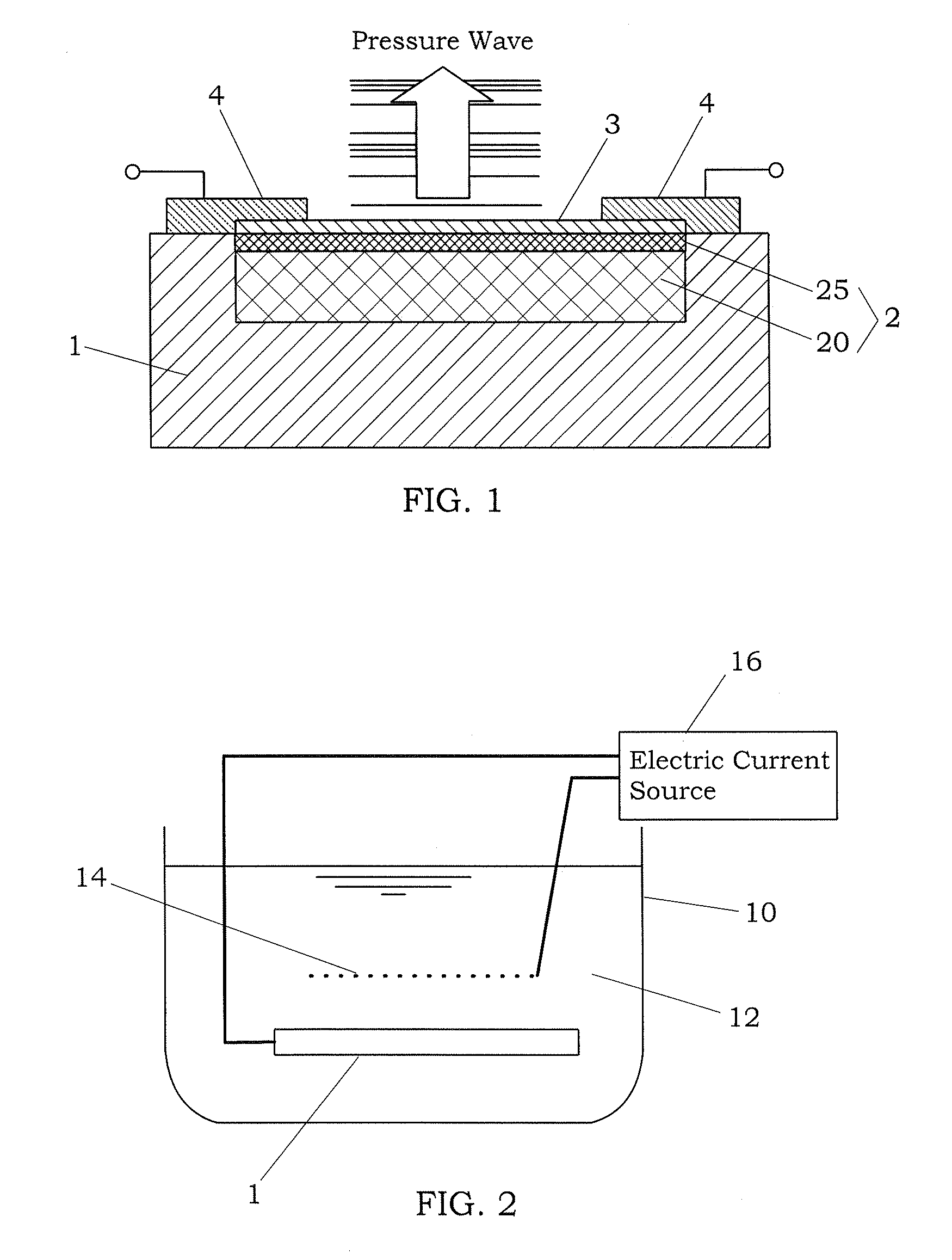

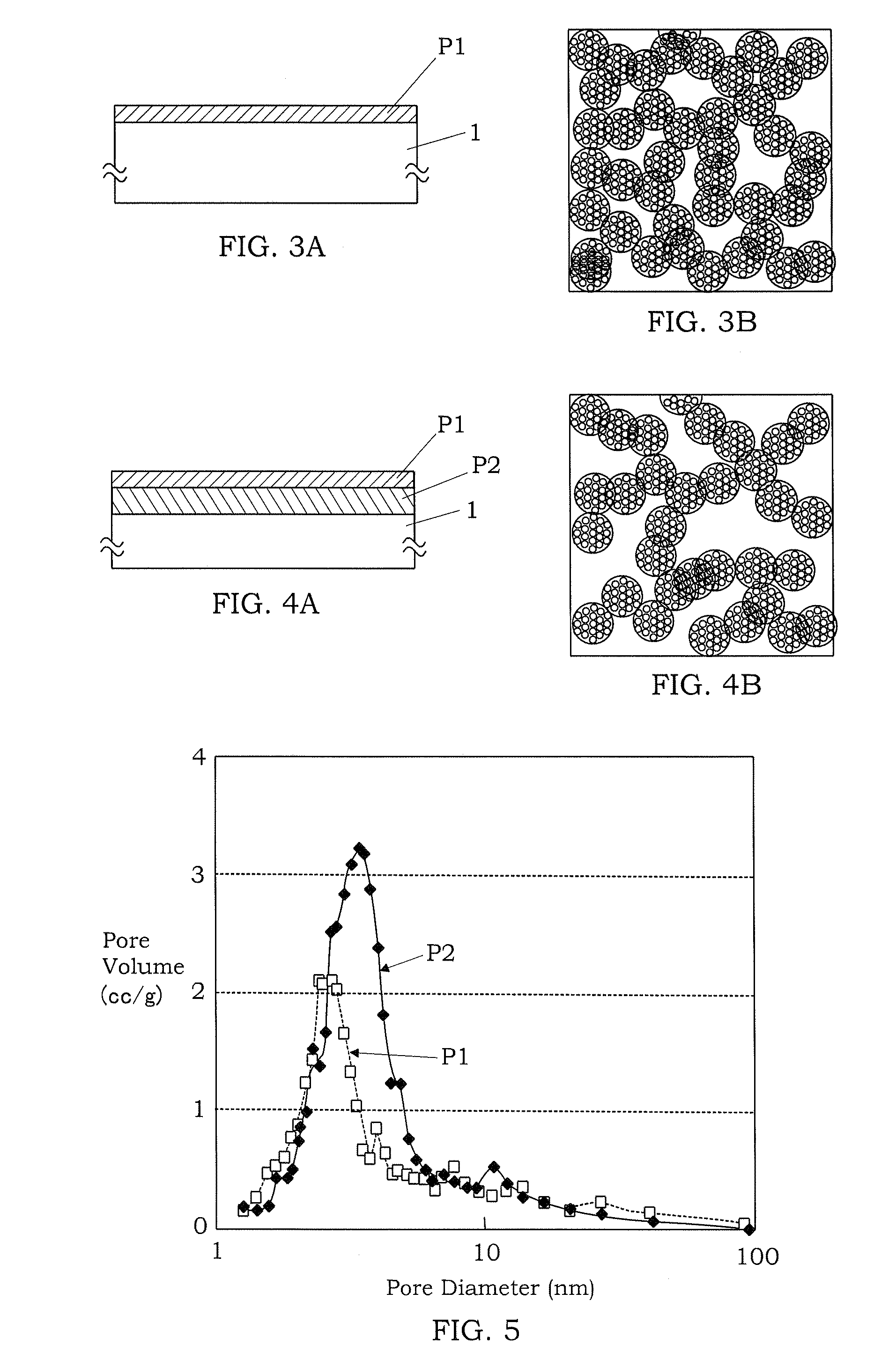

Pressure wave generator and production method therefor

InactiveUS20090145686A1Avoid production cutsInhibited DiffusionElectrothermic-effect transistorSemiconductor electrostatic transducersPorous layerEngineering

A pressure wave generator is provided, which has excellent output stability over time. This pressure wave generator comprises a substrate, a heat generating layer, and a heat insulating layer formed between the substrate and the heat generating layer. A pressure wave is generated in a surrounding medium (air) by a change in temperature of the heat generating layer, which is caused upon energization of the heat generating layer. The heat insulating layer comprises a porous layer and a barrier layer formed between the porous layer and the heat generating layer to prevent diffusion of reactive substances such as oxygen and moisture in the air and impurities into the porous layer. By the formation of the barrier layer, it is possible to prevent a reduction in output of the pressure wave generator caused by a change over time of the porous layer.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com