Patents

Literature

24607results about How to "Suitable for mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

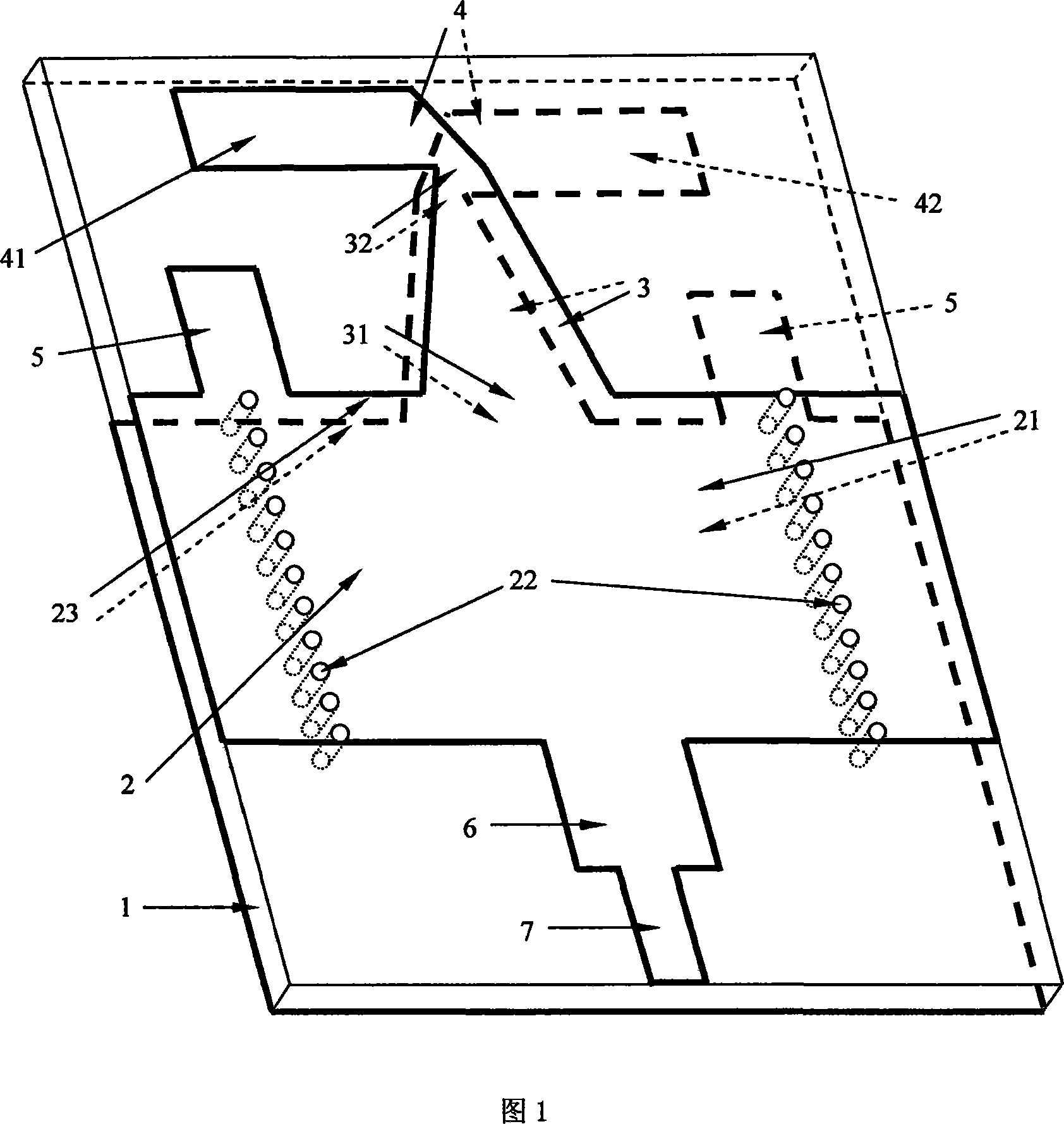

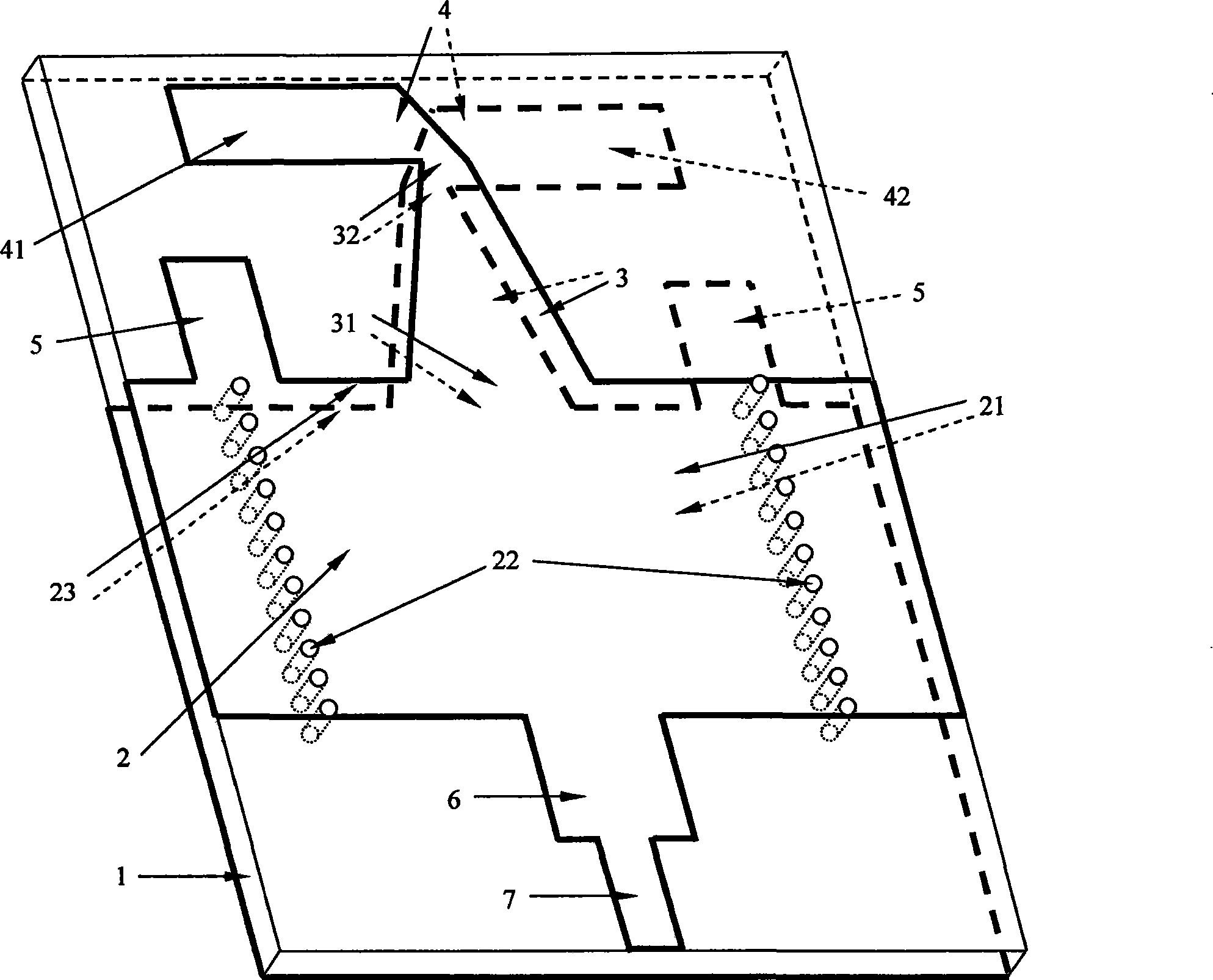

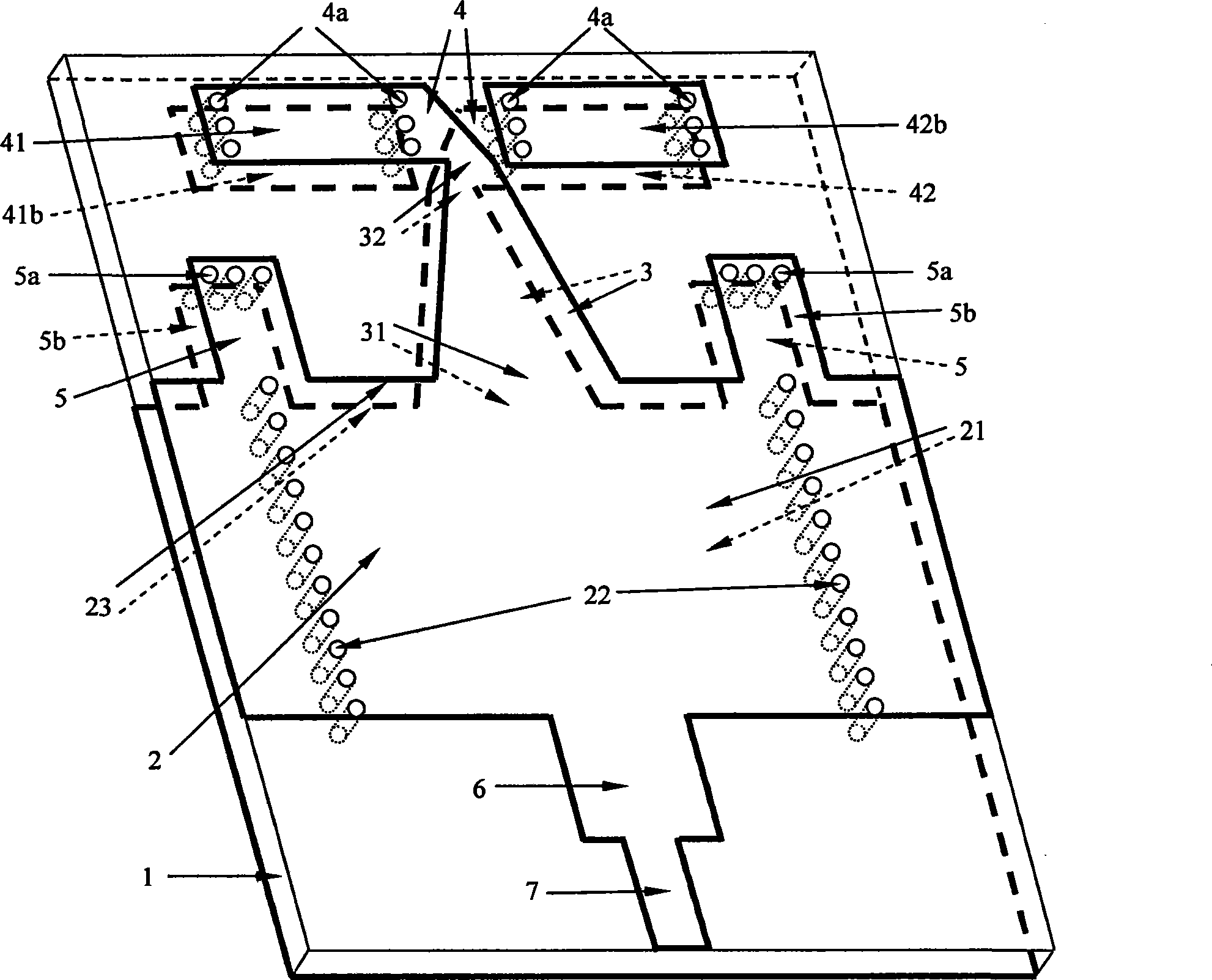

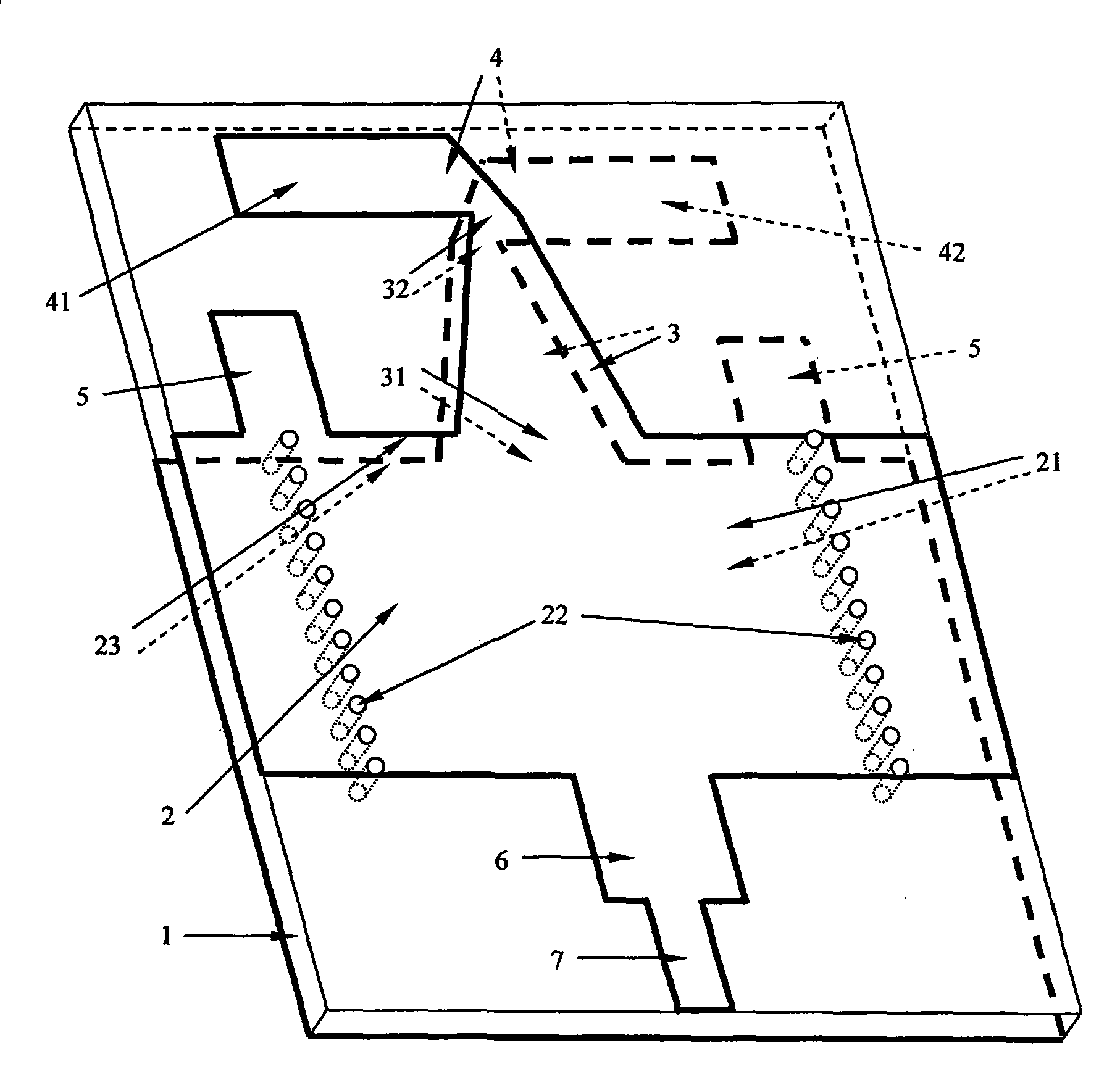

Printing antenna with baseplate integrated waveguide feeder

ActiveCN101075702ASealing is simple, convenient and economicalTo achieve the purpose of sealingRadiating elements structural formsRadarEngineering

A chip integrated waveguide feeding print antenna is composed by a chip with its two metal sides being transfixed with metal through holes in array. The two metal sides are in axial symmetry. There is an intergrading section to one side of the waveguide centerline on two surface of the chip linking with transmission line. To the outer end of the intergrading section links a vibrator antenna. To the opposite side of the intergrading section on the waveguide links a micro-strip intergrading commutator linking with micro-strip transmission line.

Owner:南京易太可通信技术有限公司

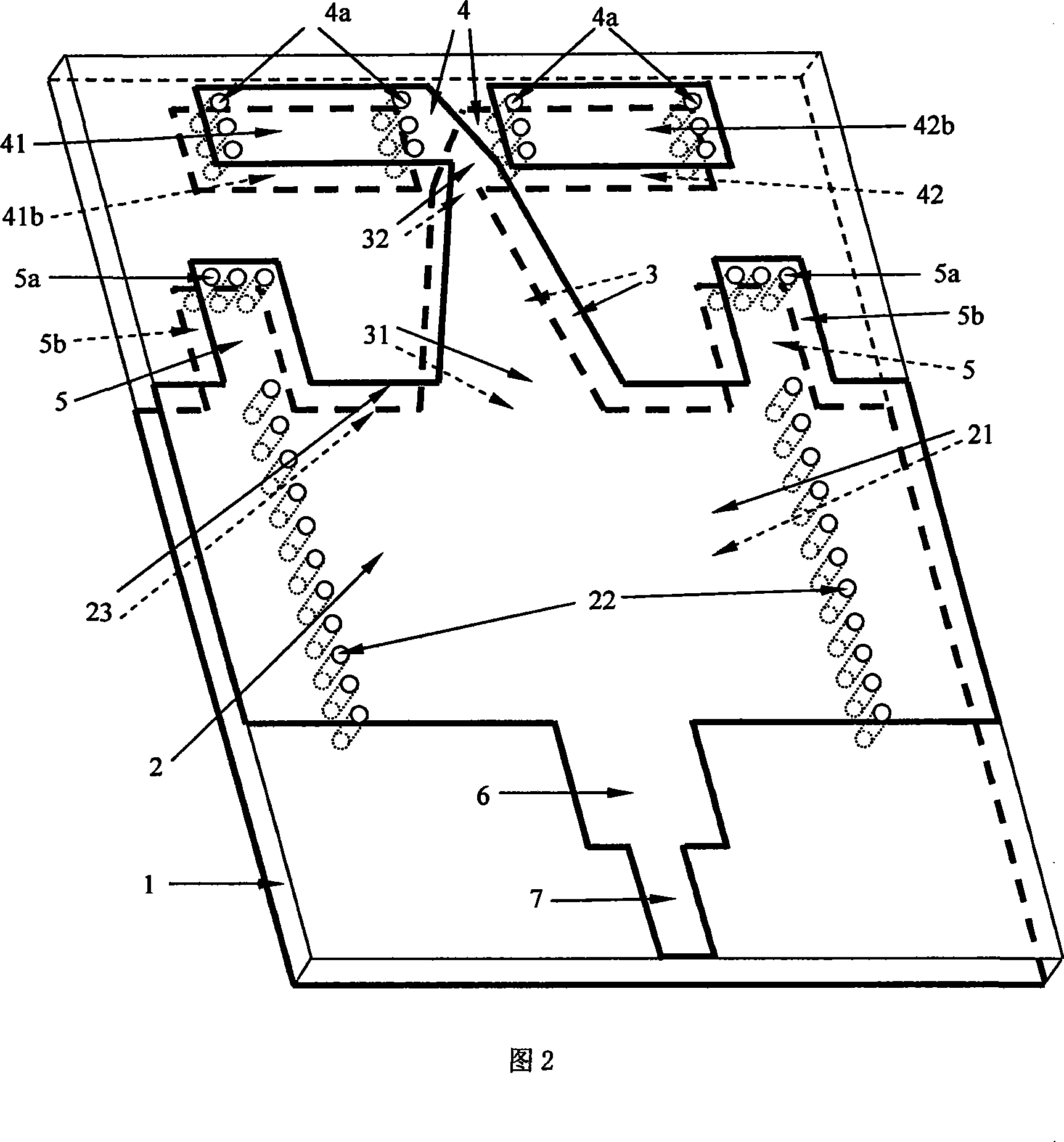

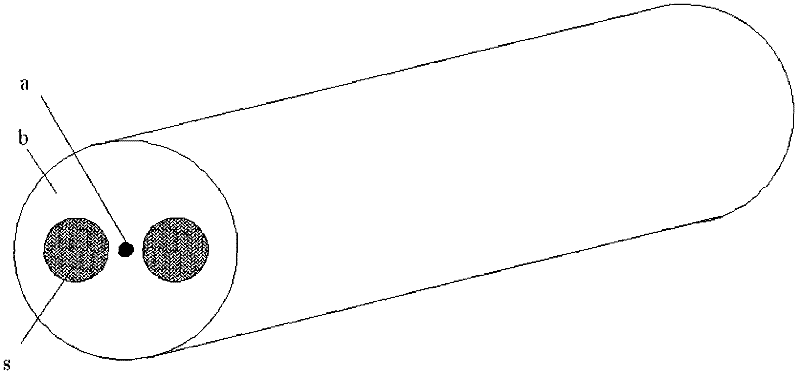

Manufacture method for polarization maintaining fiber and polarization maintaining fiber

InactiveCN102351415AImprove the finishImprove processing efficiencyGlass making apparatusOptical fibre with polarisationSurface finishPolarization-maintaining optical fiber

The invention provides a manufacture method for polarization maintaining fiber and a polarization maintaining fiber, and relates to optical waveguide fibers in the field of fiber-optical communication and fiber optical sensors. The method comprises the following steps that: (1) two oppositely arranged open slots with a same shape are inwardly provided at a side surface of a glass mother rod, stress rods are machined to obtain a shape matching the open slots, and the centers of the cross sections of the two open slots and the center of circle in the cross section of the glass mother rod are in a same line; (2) the stress rods are respectively inserted into each open slot on the glass mother rod, and the assembled glass mother rod and stress rods are put in a cannula to form a preformed rod of the polarization maintaining fiber; (3) the preformed rod of the polarization maintaining fiber is drew to form the polarization maintaining fiber. According to the invention, the glass mother rod is provided with the open slots, and the stress rods are embedded in the open slots, thereby obtaining high process repeatability; inner surfaces of the open slots have high fineness, and the open slots have good symmetry, thereby improving processing efficiency; therefore, the optical performance and reliability of the polarization maintaining fiber are substantially improved.

Owner:RUIGUANG TELECOMM TECH CO LTD

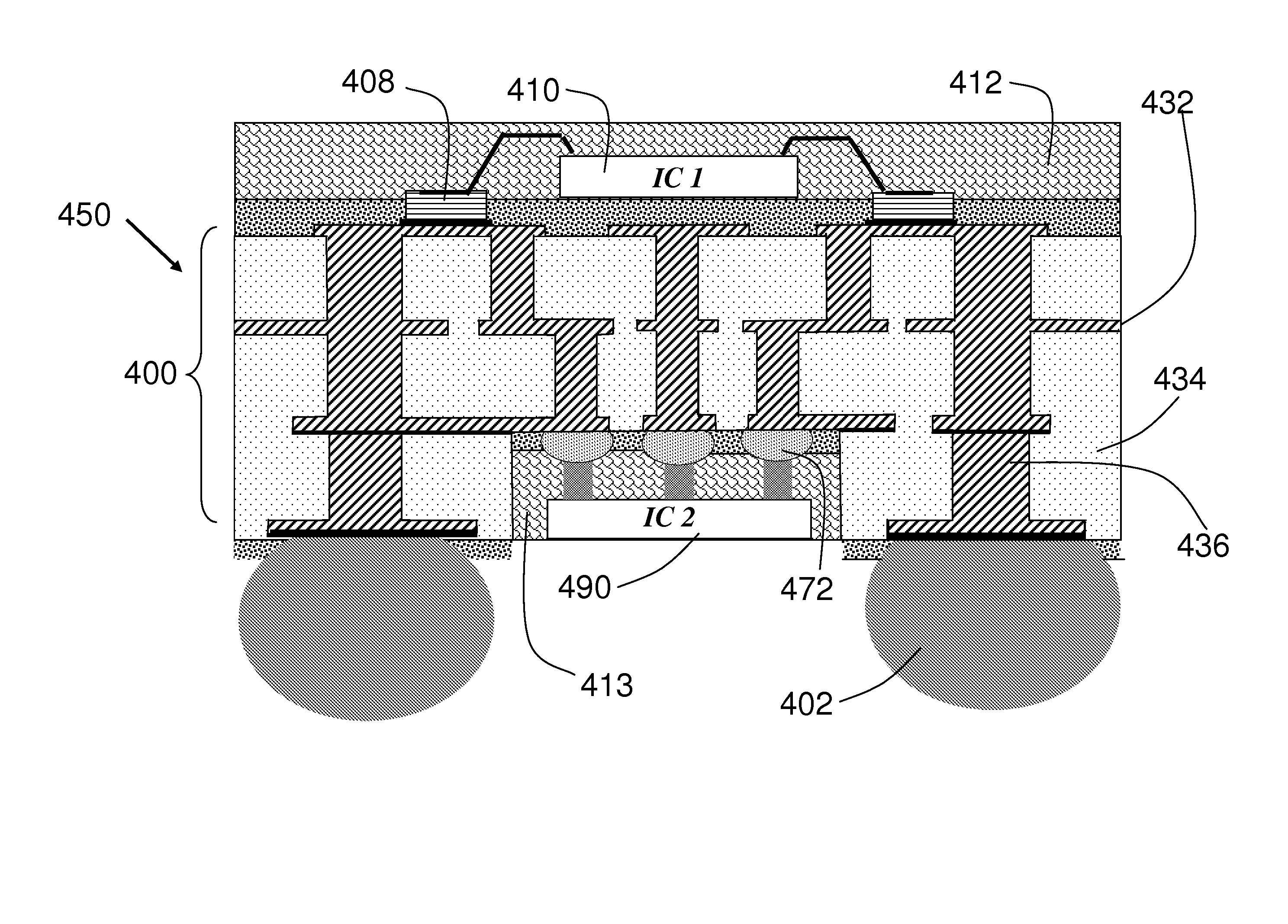

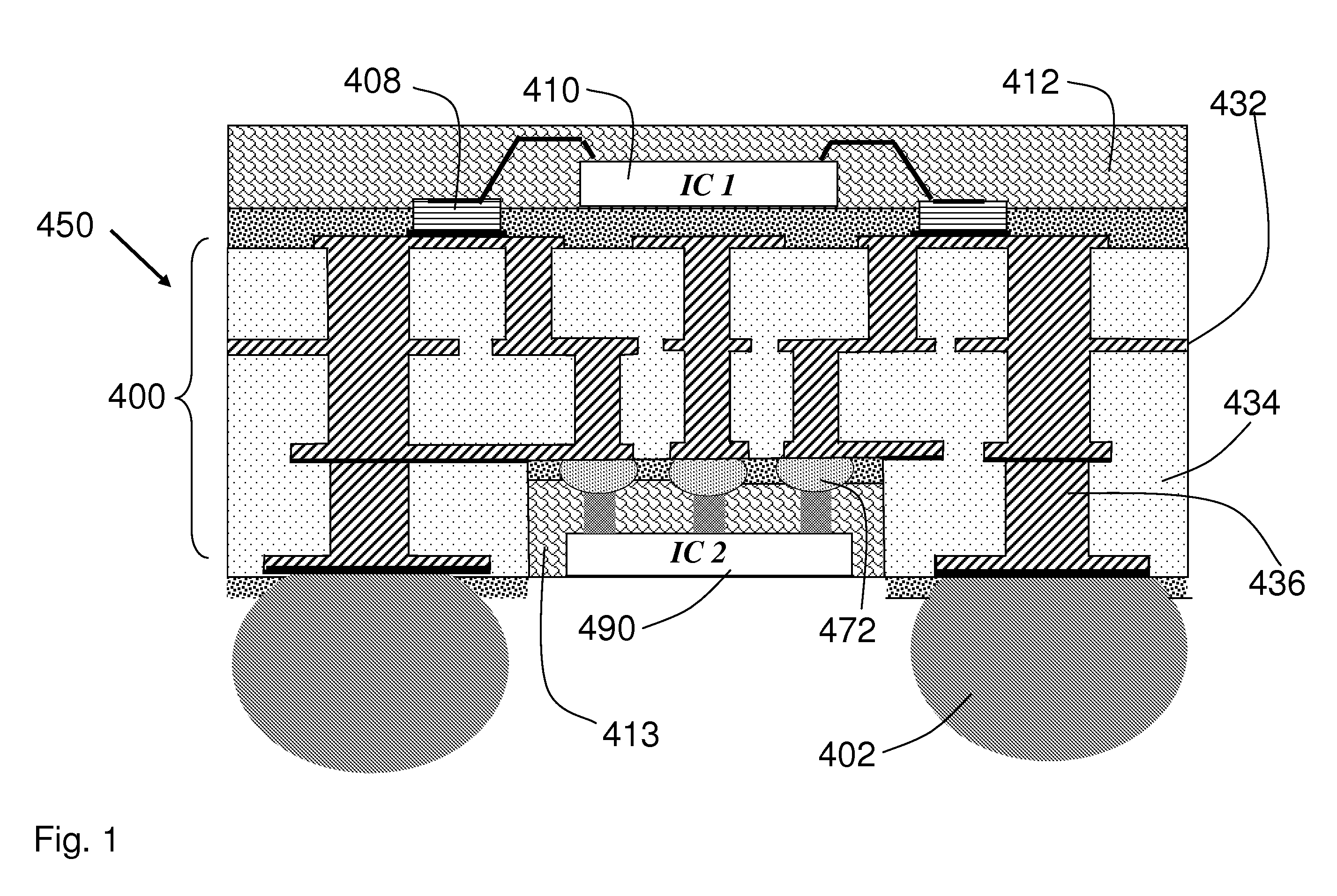

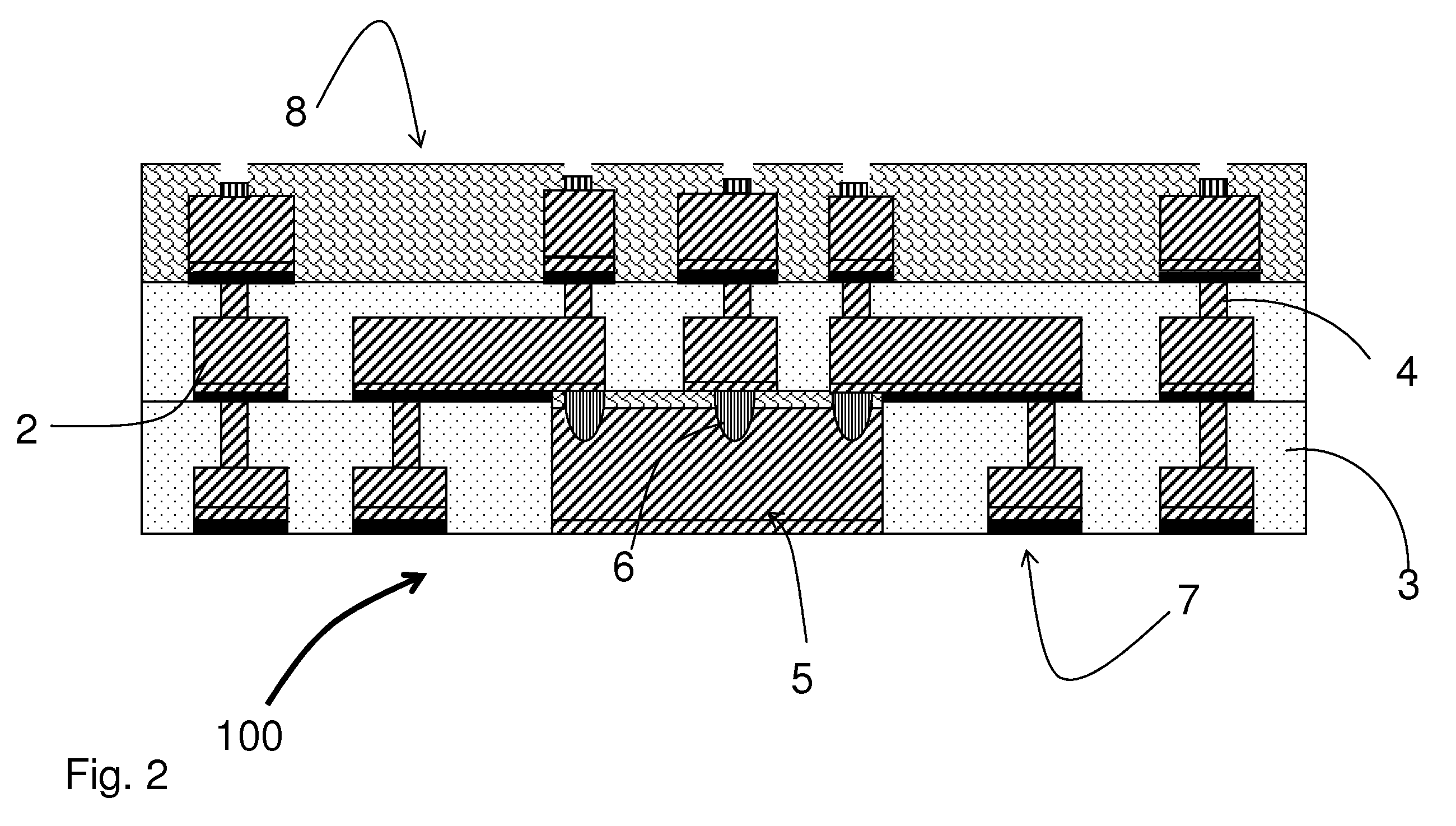

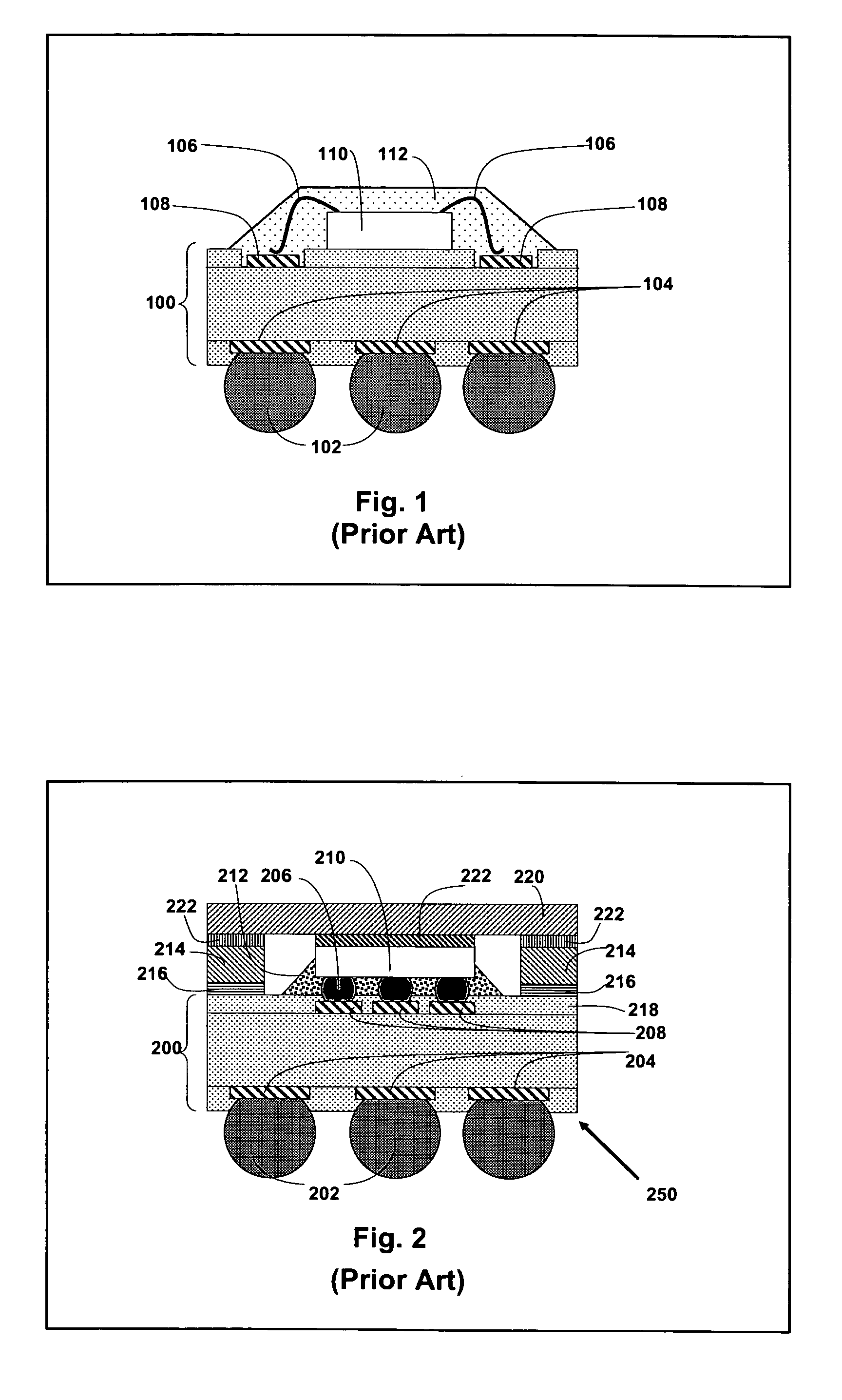

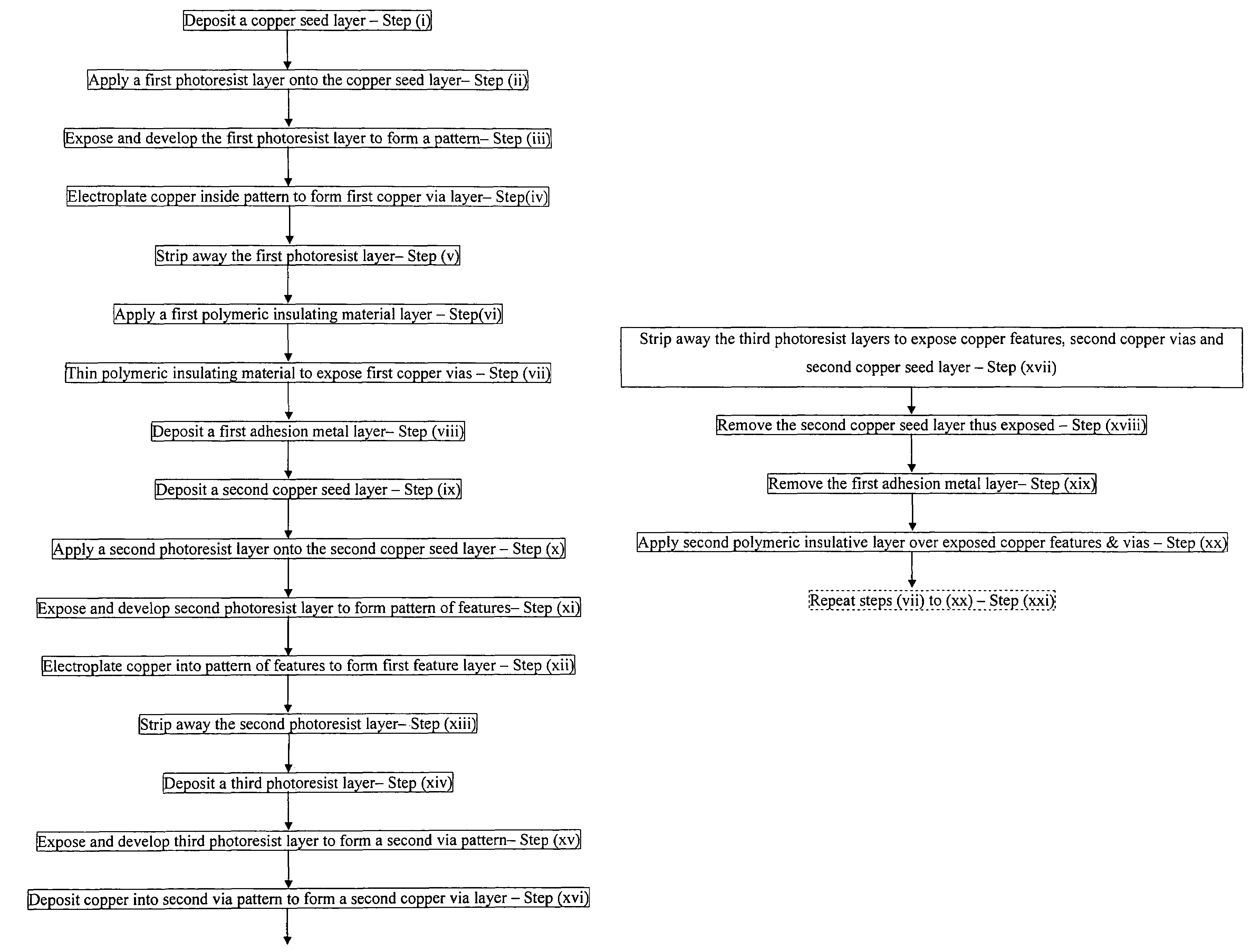

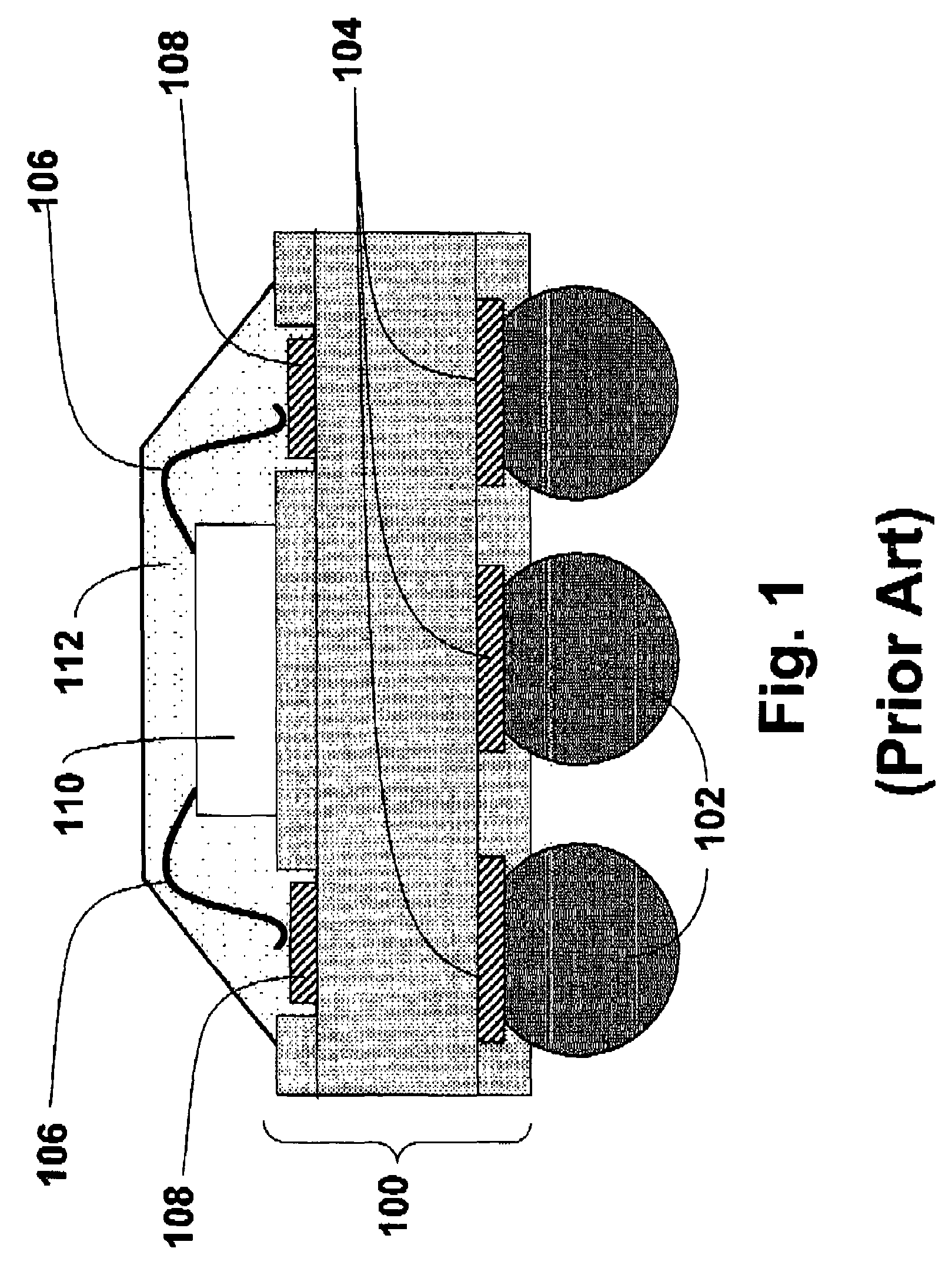

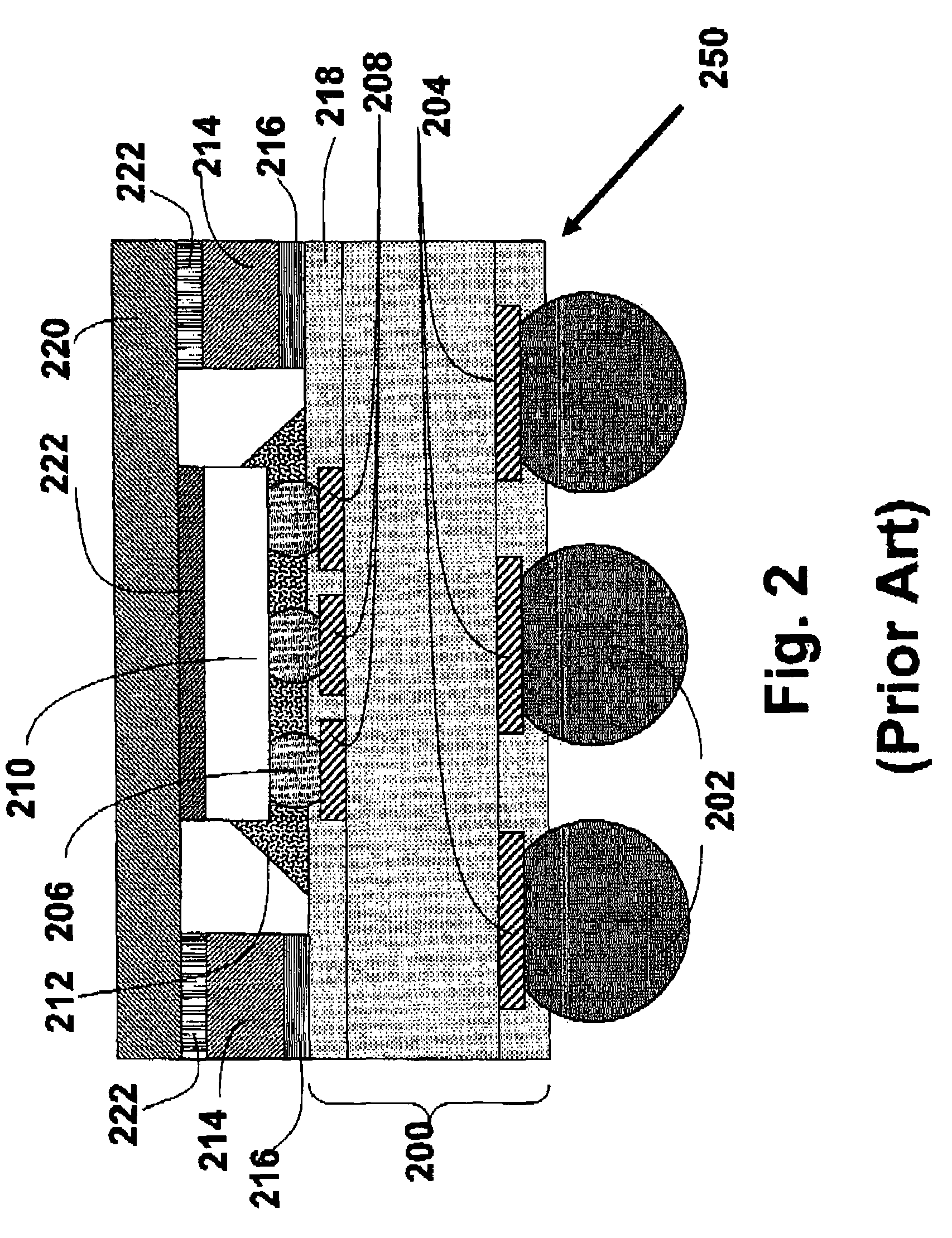

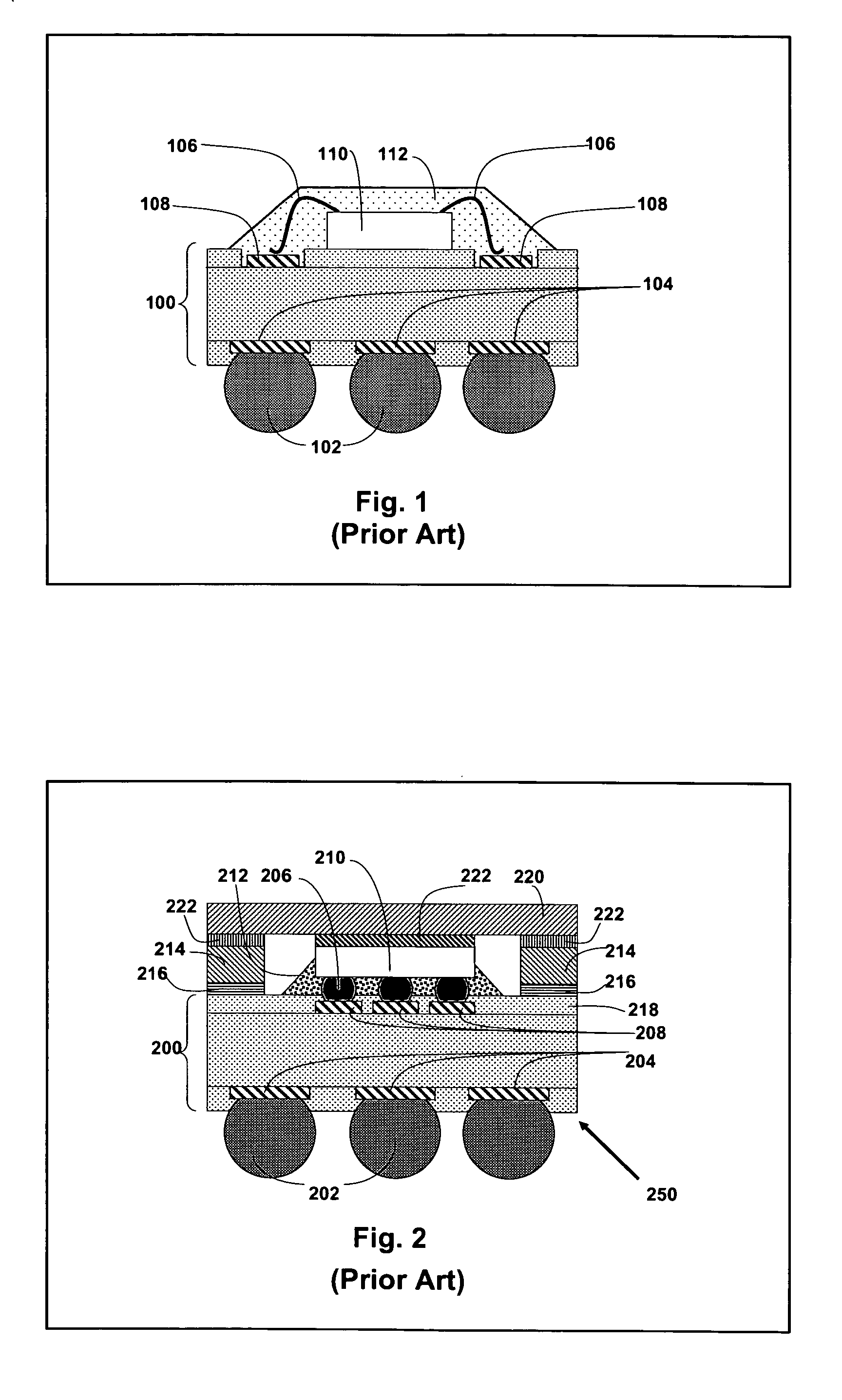

Coreless cavity substrates for chip packaging and their fabrication

ActiveUS20070289127A1High yieldSuitable for mass productionDecorative surface effectsSemiconductor/solid-state device detailsElectrical and Electronics engineeringCopper

A method for fabricating an IC support for supporting a first IC die connected in series with a second IC die; the IC support comprising a stack of alternating layers of copper features and vias in insulating surround, the first IC die being bondable onto the IC support, and the second IC die being bondable within a cavity inside the IC support, wherein the cavity is formed by etching away a copper base and selectively etching away built up copper.

Owner:ZHUHAI ADVANCED CHIP CARRIERS & ELECTRONICS SUBSTRATE SOLUTIONS TECH

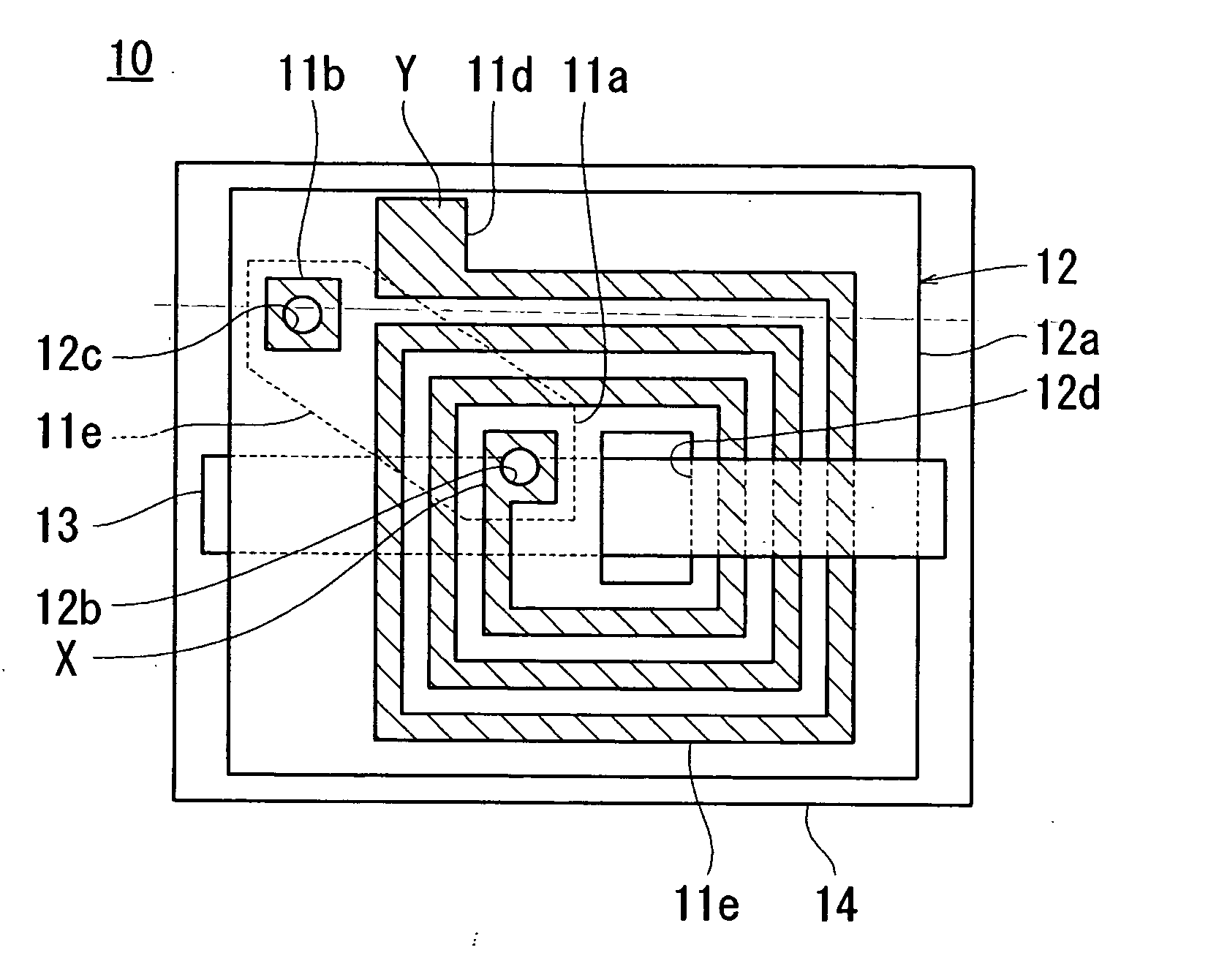

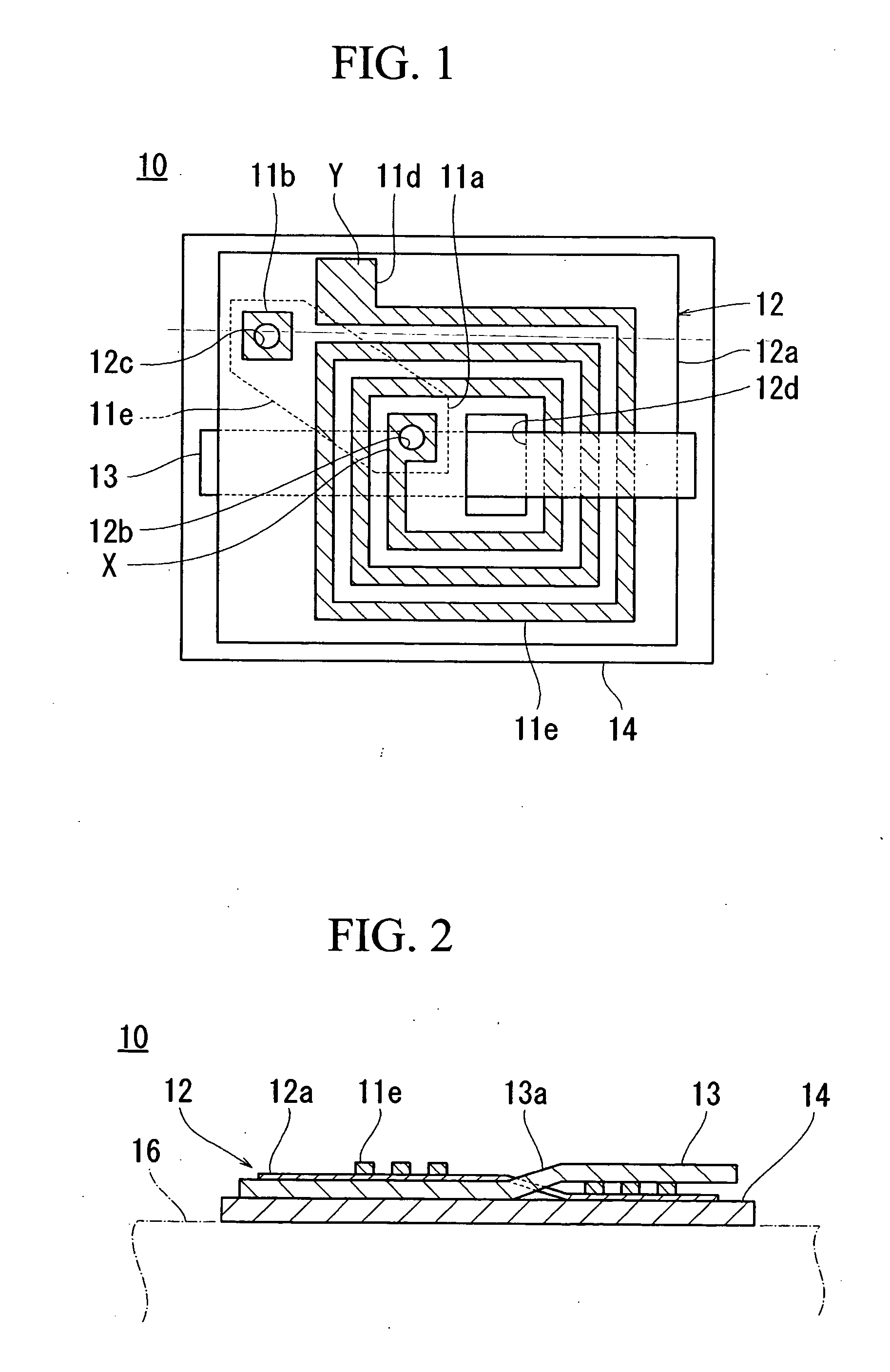

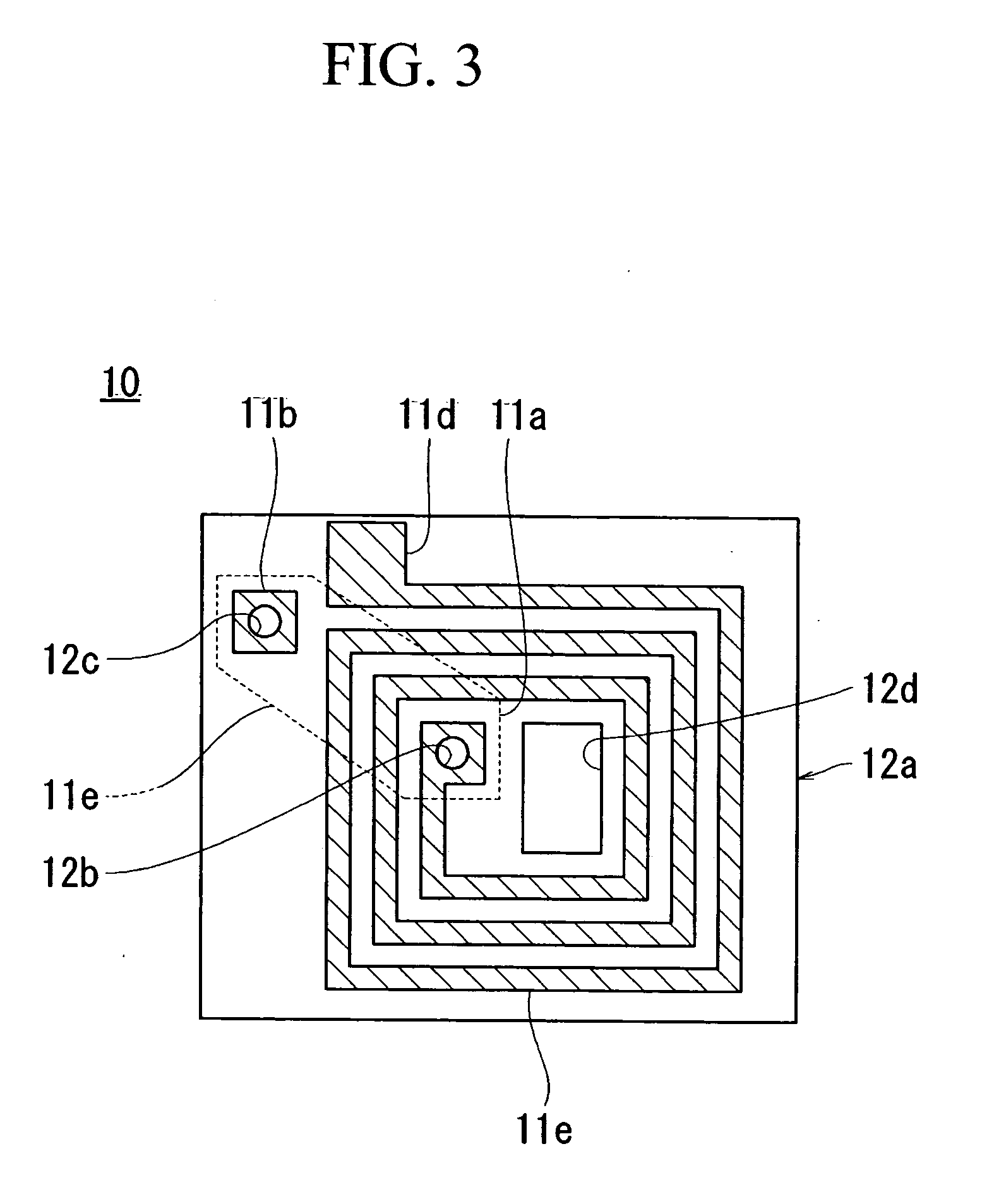

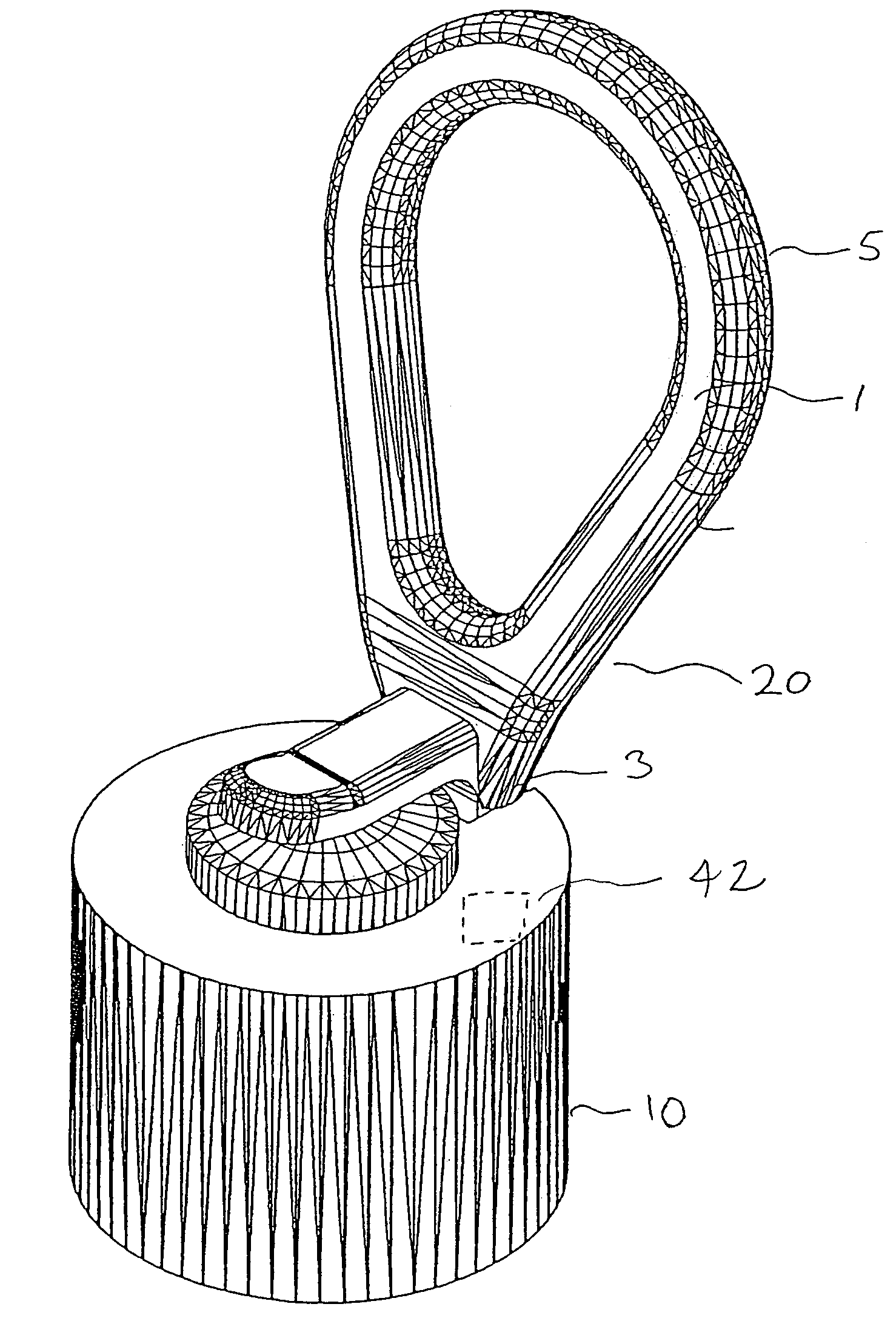

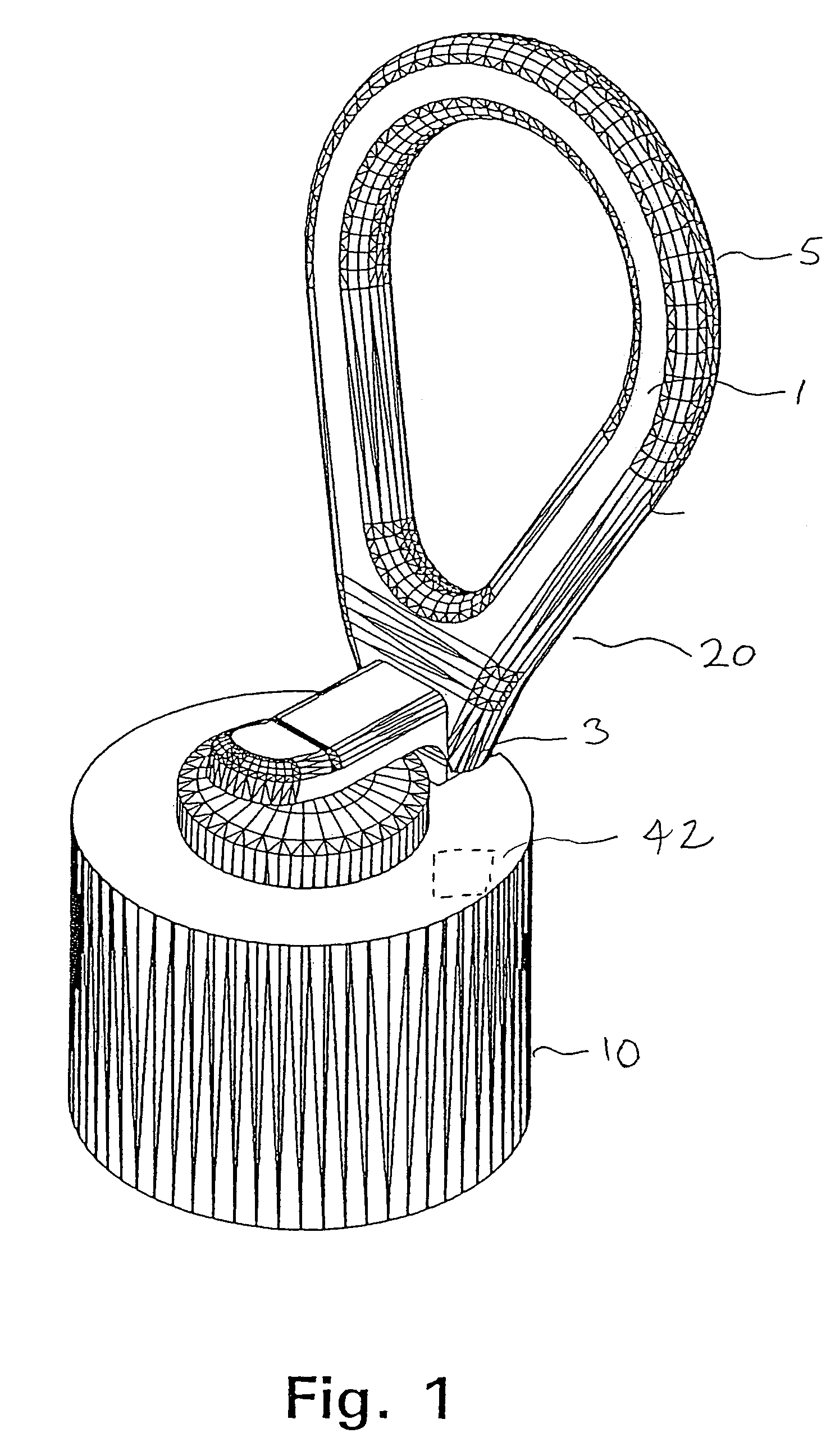

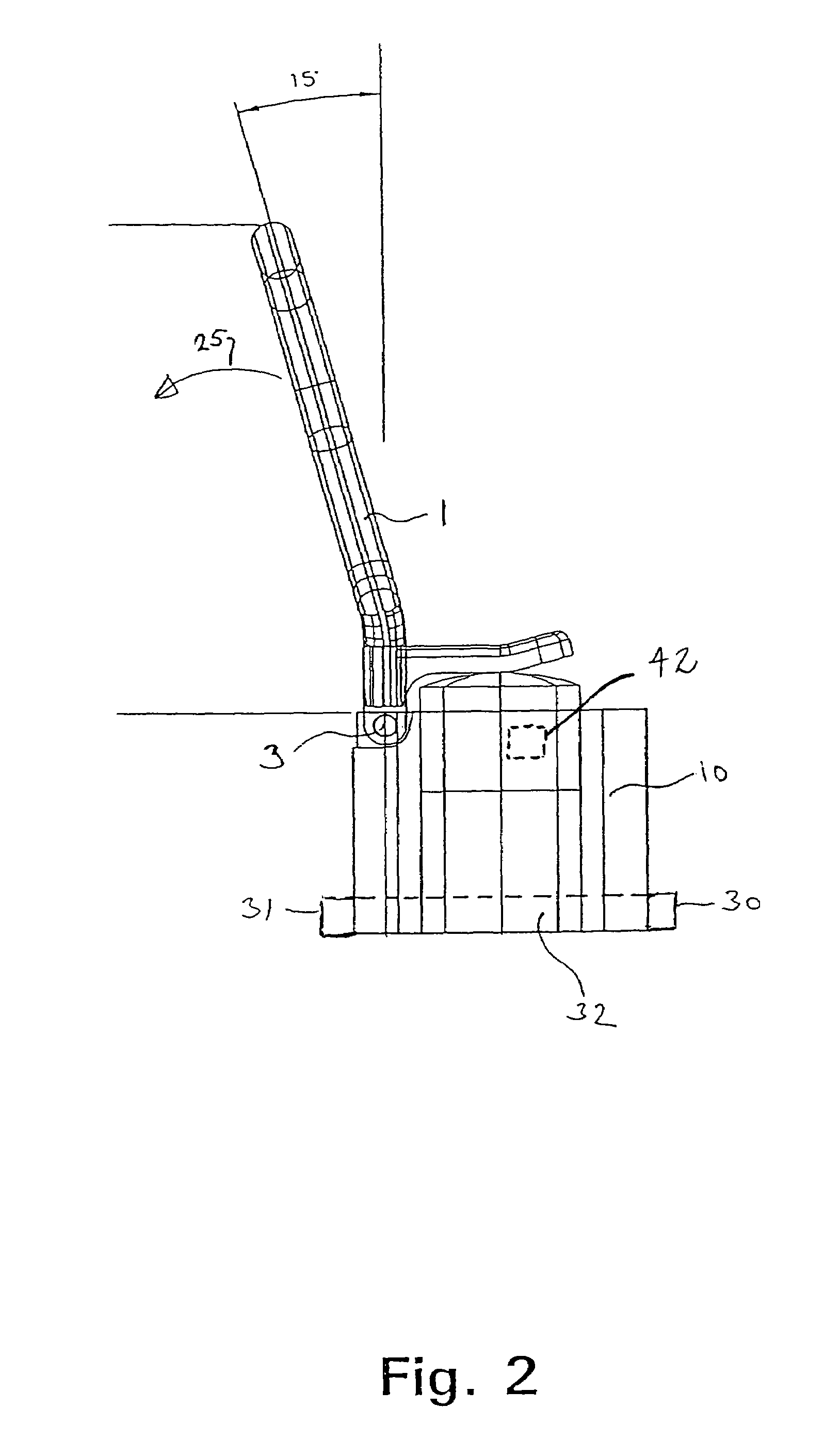

Antenna coil and rfid-use tag using it, transponder-use antenna

InactiveUS20050007296A1Improve rigidityHigh frequencyLoop antennas with ferromagnetic coreOther printing matterAir coreNon magnetic

An antenna coil includes an air-core coil wound helically in a plane and a plate magnetic core member inserted in the air-core coil to be approximately parallel with a plane of the air-core coil. The magnetic core member is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member is a magnetic coating formed by applying and drying the composite member. A non-magnetic conductive plate that has a conductivity is layered on a surface of the air-core coil through which the magnetic core member is inserted. The conductive plate is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. The antenna coil is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

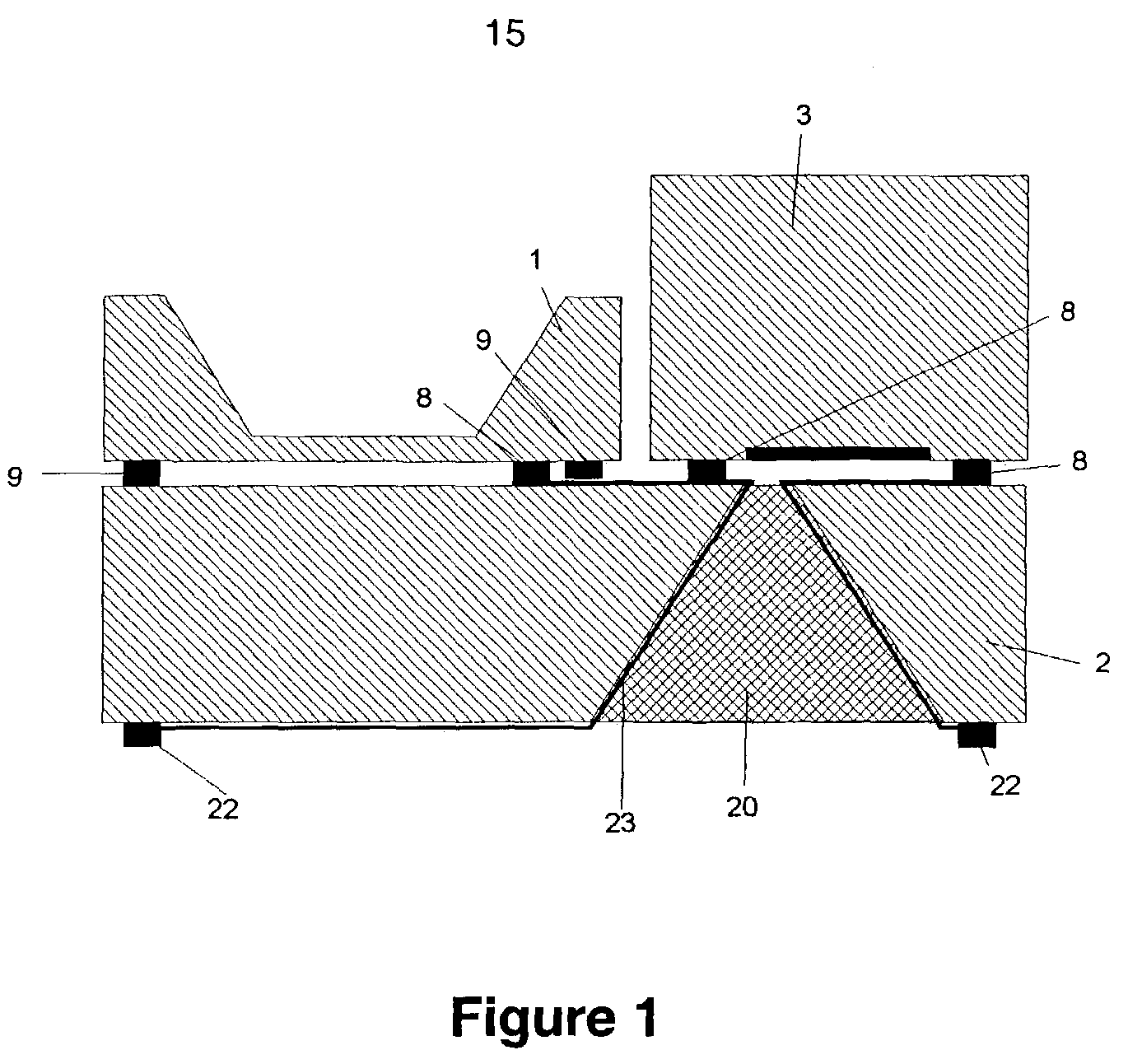

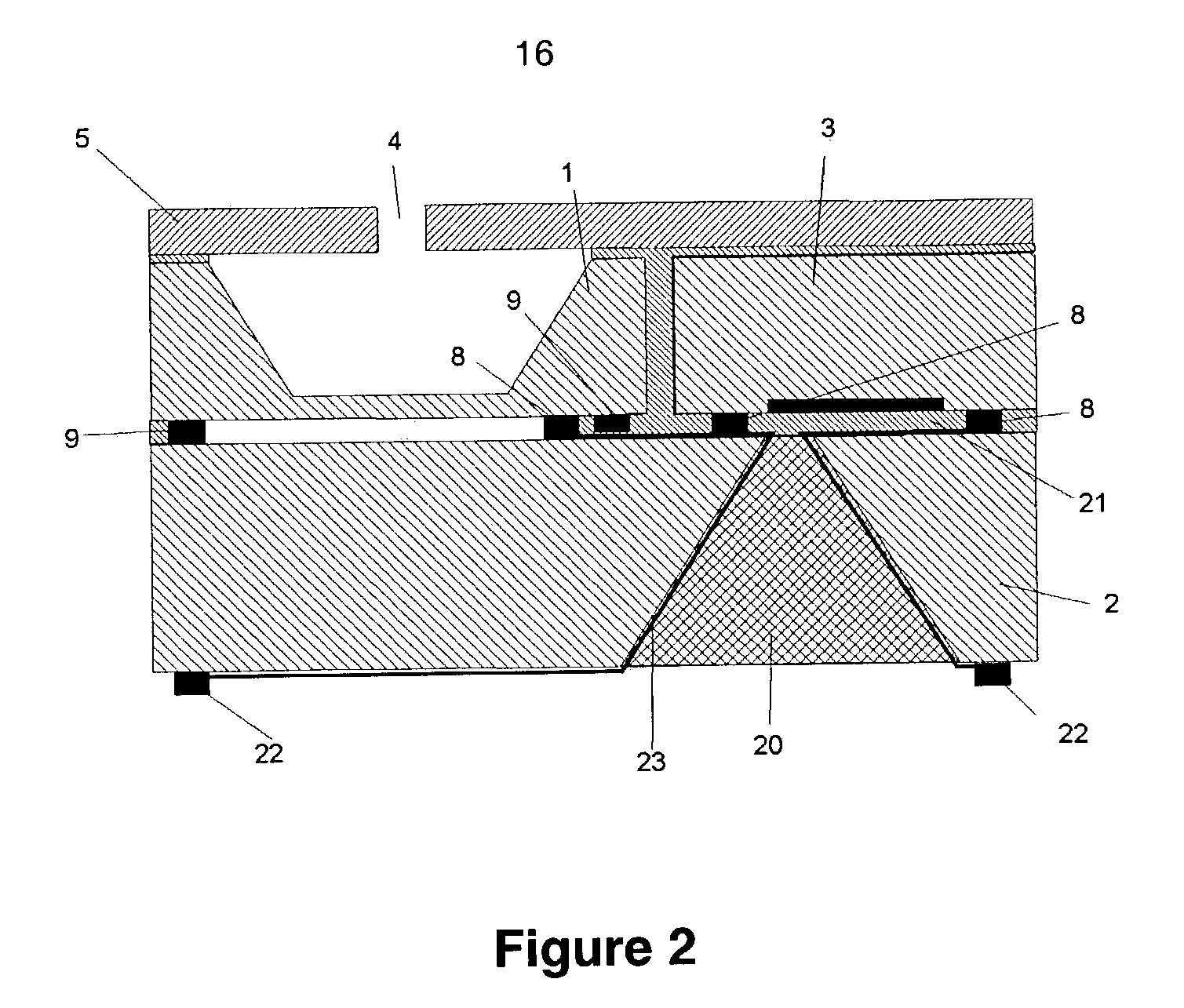

Surface mountable transducer system

InactiveUS7221767B2Established economically and reliablySuitable for mass productionSemiconductor electrostatic transducersElectrostatic transducer microphonesSurface mountingElectrical connection

The present invention relates to a surface mountable acoustic transducer system, comprising one or more transducers, a processing circuit electrically connected to the one or more transducers, and contact points arranged on an exterior surface part of the transducer system. The contact points are adapted to establish electrical connections between the transducer system and an external substrate, the contact points further being adapted to facilitate mounting of the transducer system on the external substrate by conventional surface mounting techniques.

Owner:BALLY TECHNOLOGIES +1

Coreless cavity substrates for chip packaging and their fabrication

ActiveUS7669320B2High yieldSuitable for mass productionDecorative surface effectsSemiconductor/solid-state device detailsCopperElectrical and Electronics engineering

A method for fabricating an IC support for supporting a first IC die connected in series with a second IC die; the IC support comprising a stack of alternating layers of copper features and vias in insulating surround, the first IC die being bondable onto the IC support, and the second IC die being bondable within a cavity inside the IC support, wherein the cavity is formed by etching away a copper base and selectively etching away built up copper.

Owner:ZHUHAI ADVANCED CHIP CARRIERS & ELECTRONICS SUBSTRATE SOLUTIONS TECH

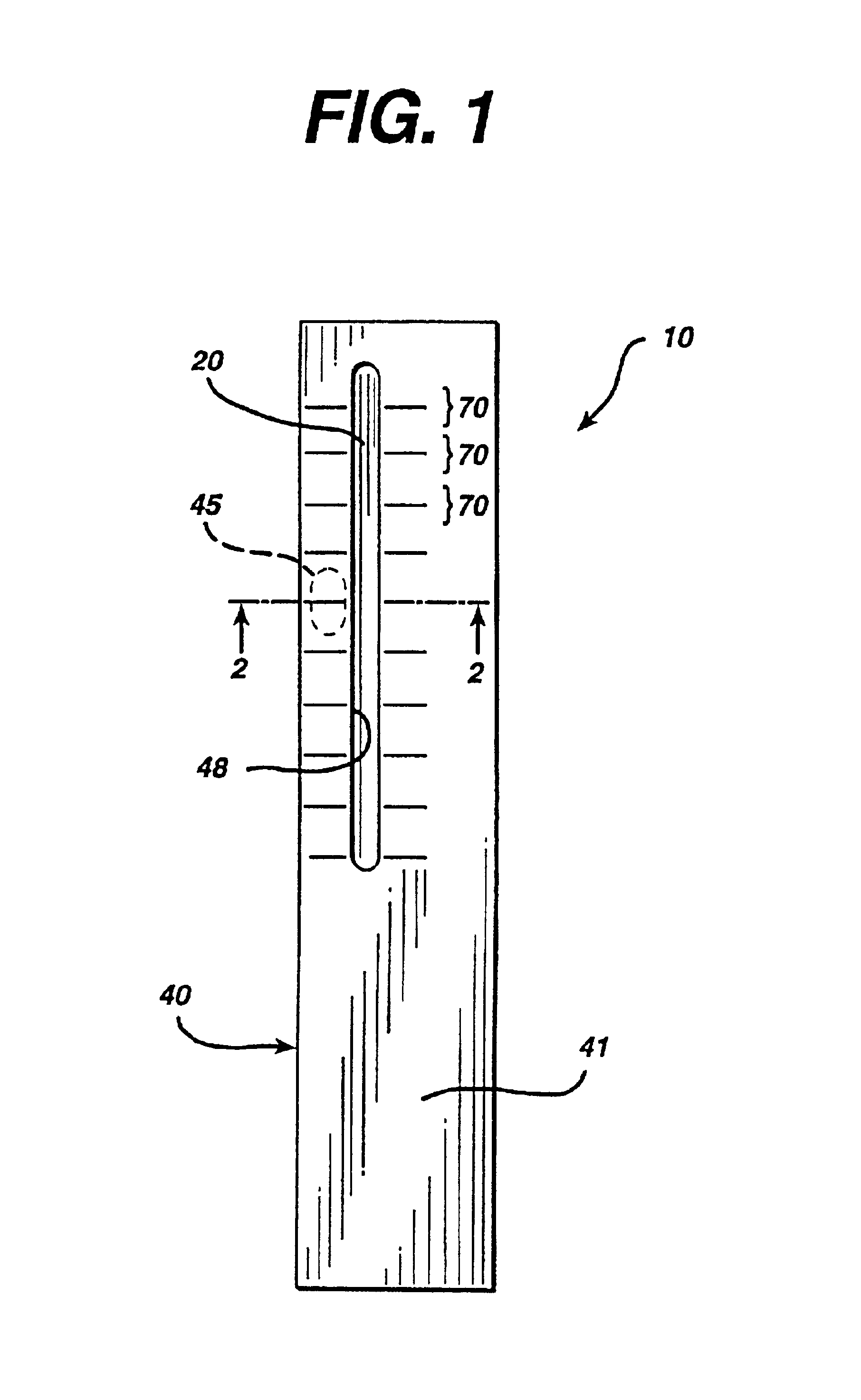

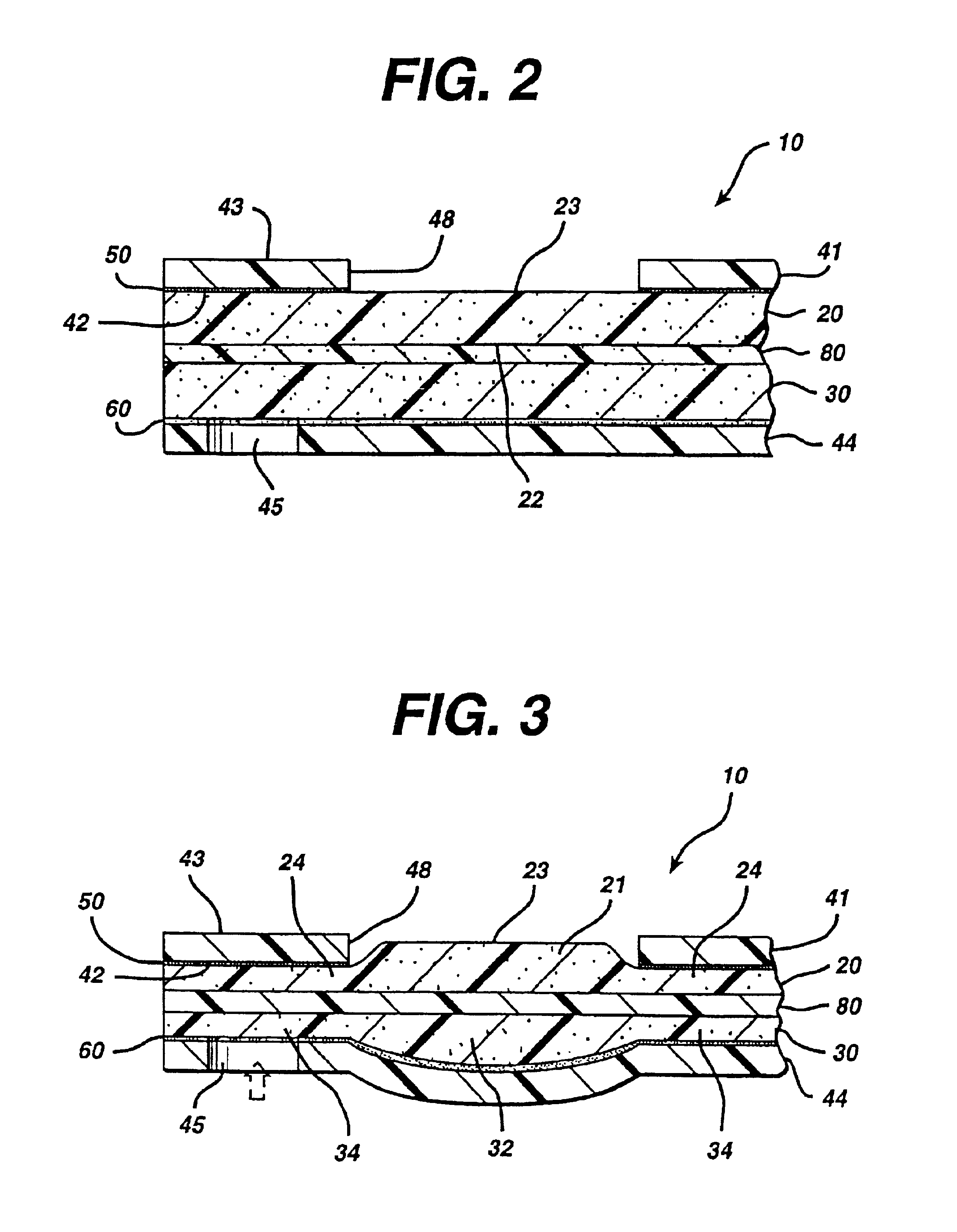

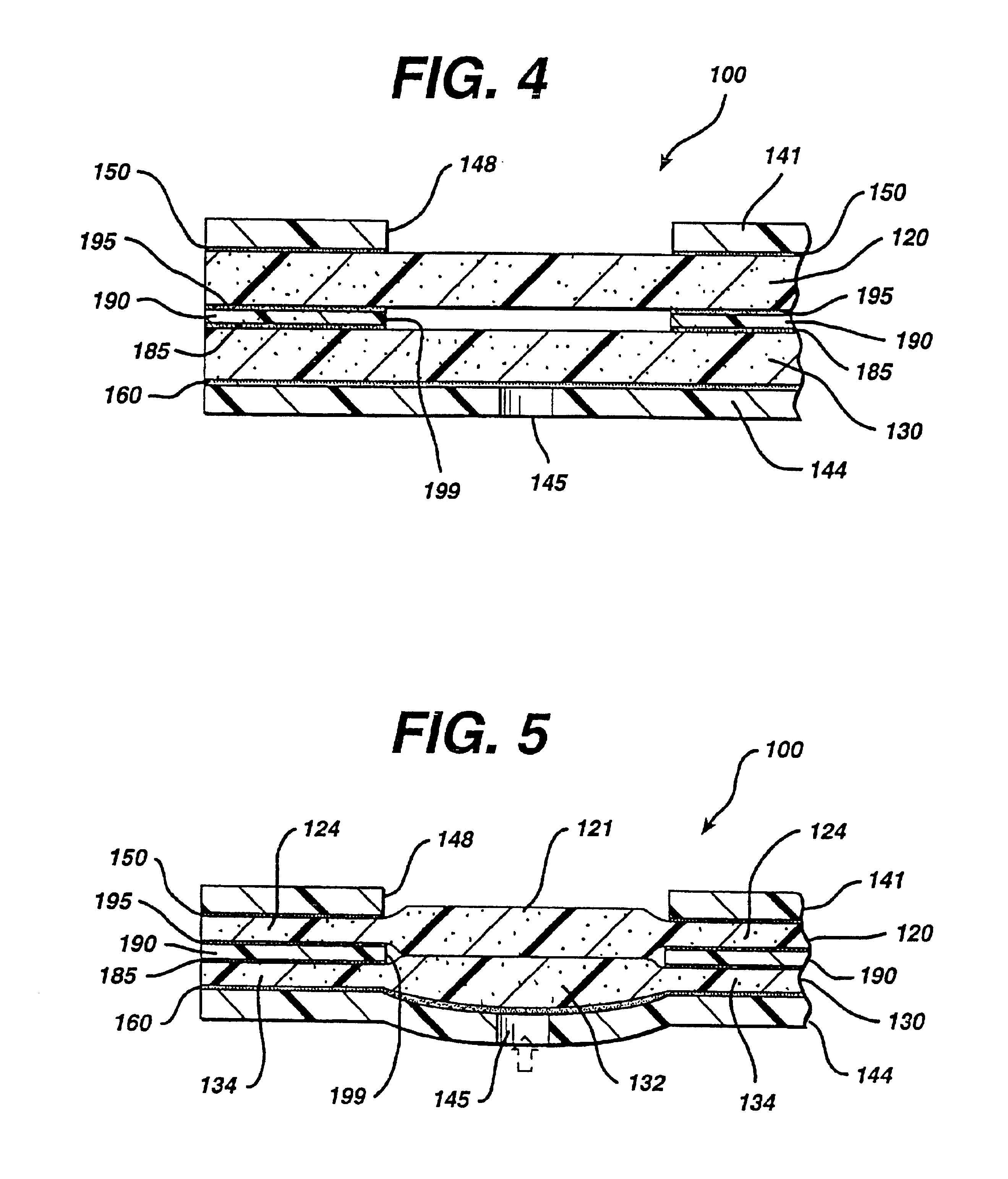

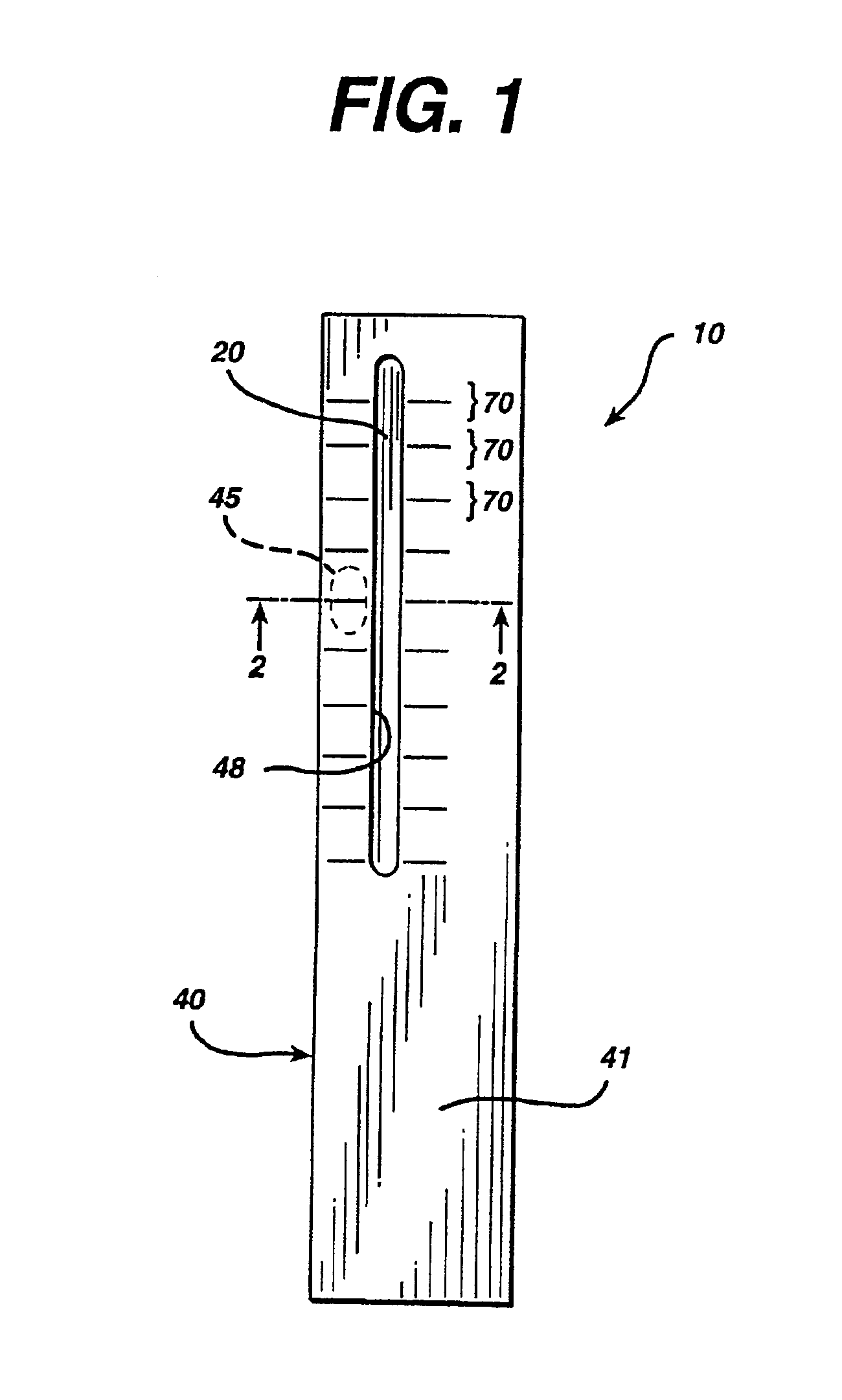

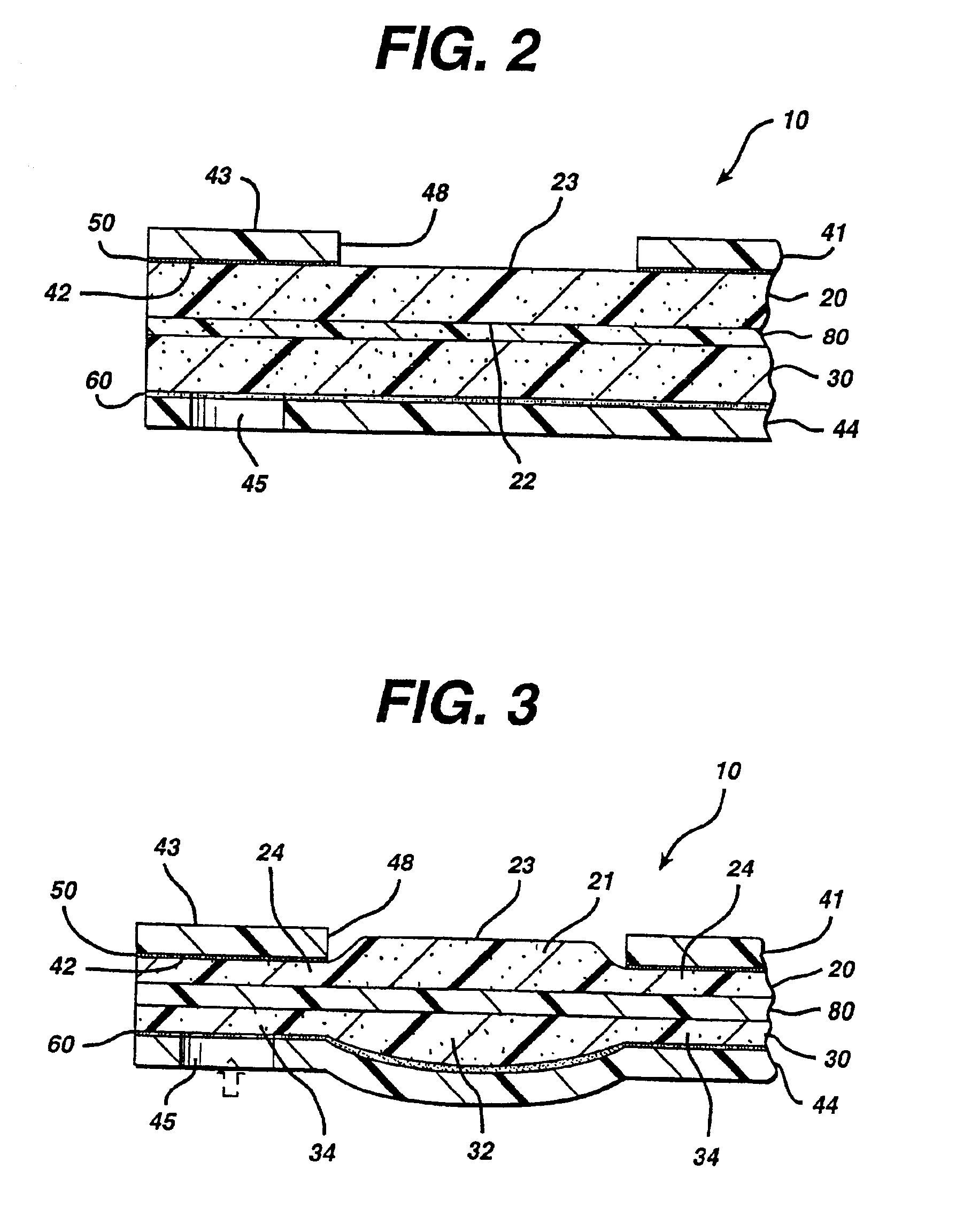

Test strip for measuring analyte concentration over a broad range of sample volume

InactiveUS6986869B2Minimizing any tendencySuitable for mass productionAnalysis using chemical indicatorsMicrobiological testing/measurementAnalytePorous layer

Owner:LIFESCAN IP HLDG LLC

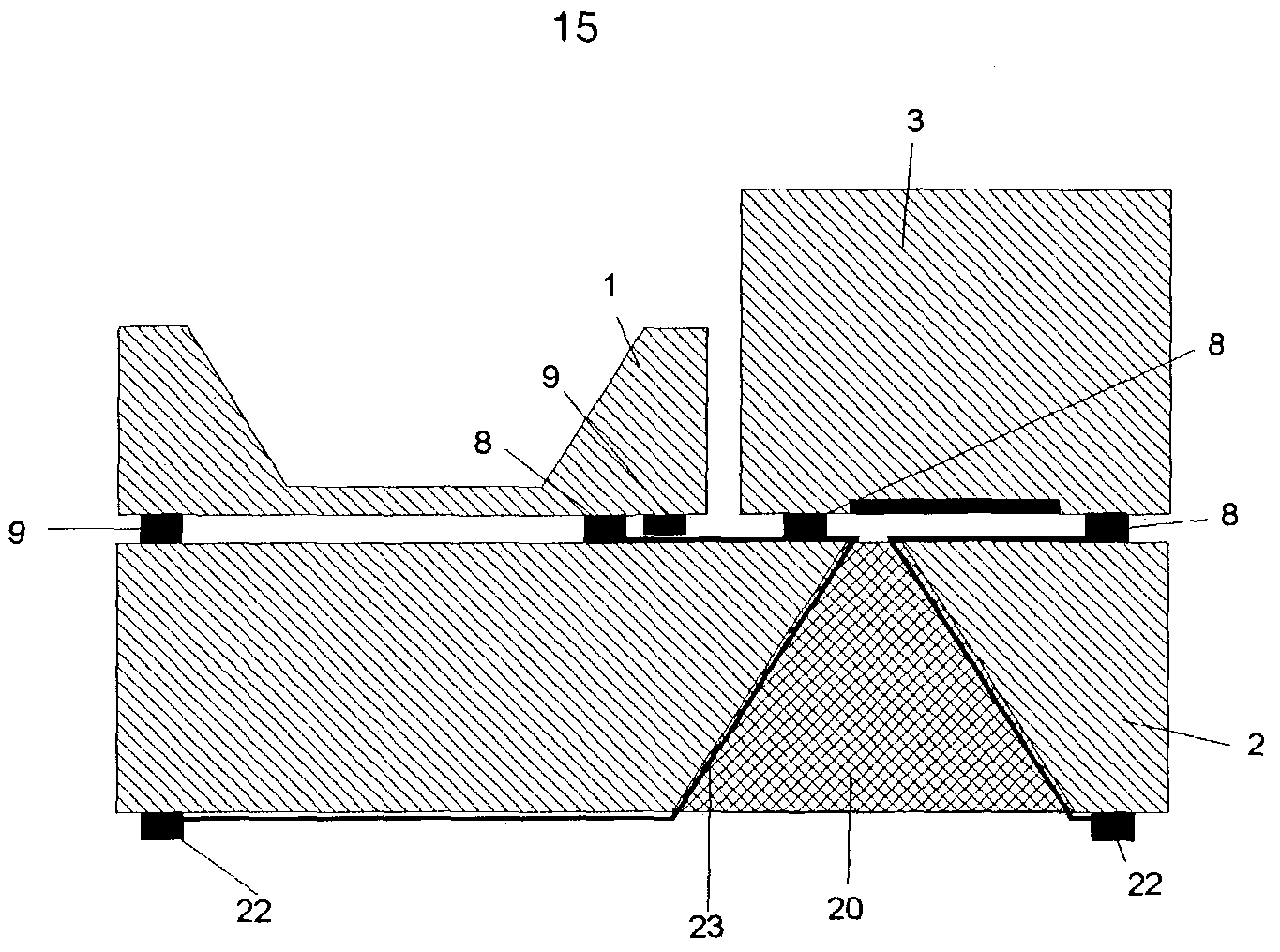

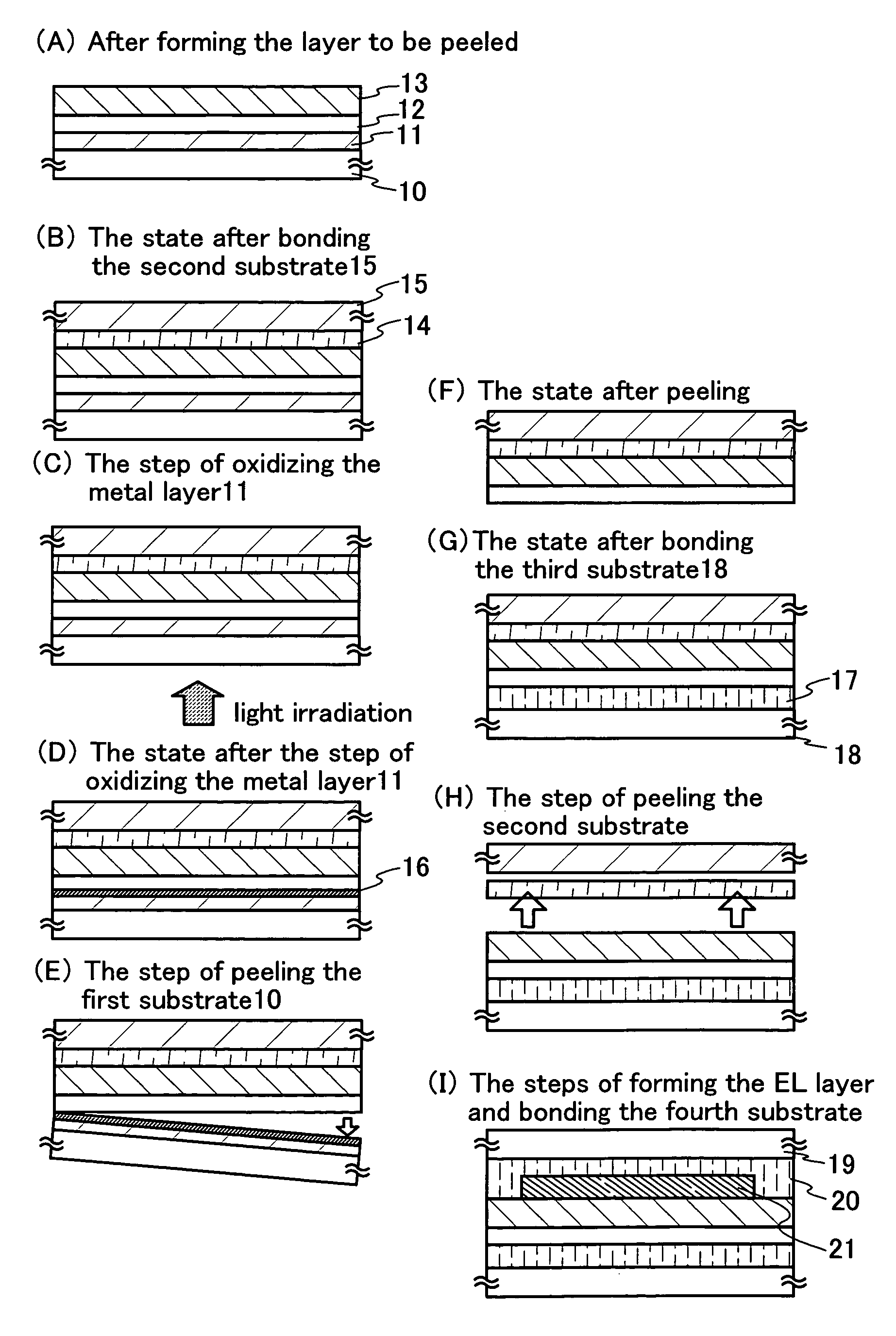

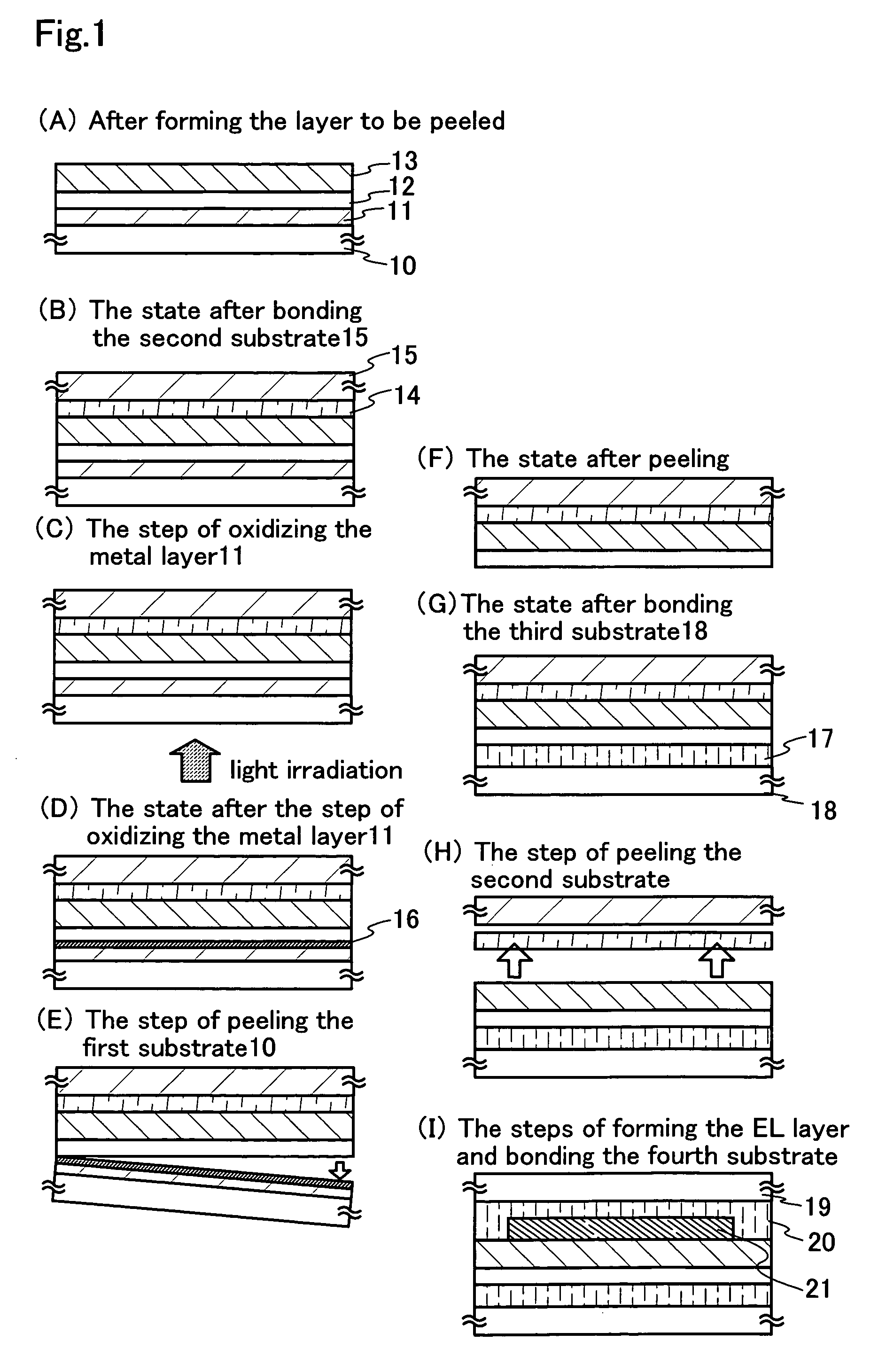

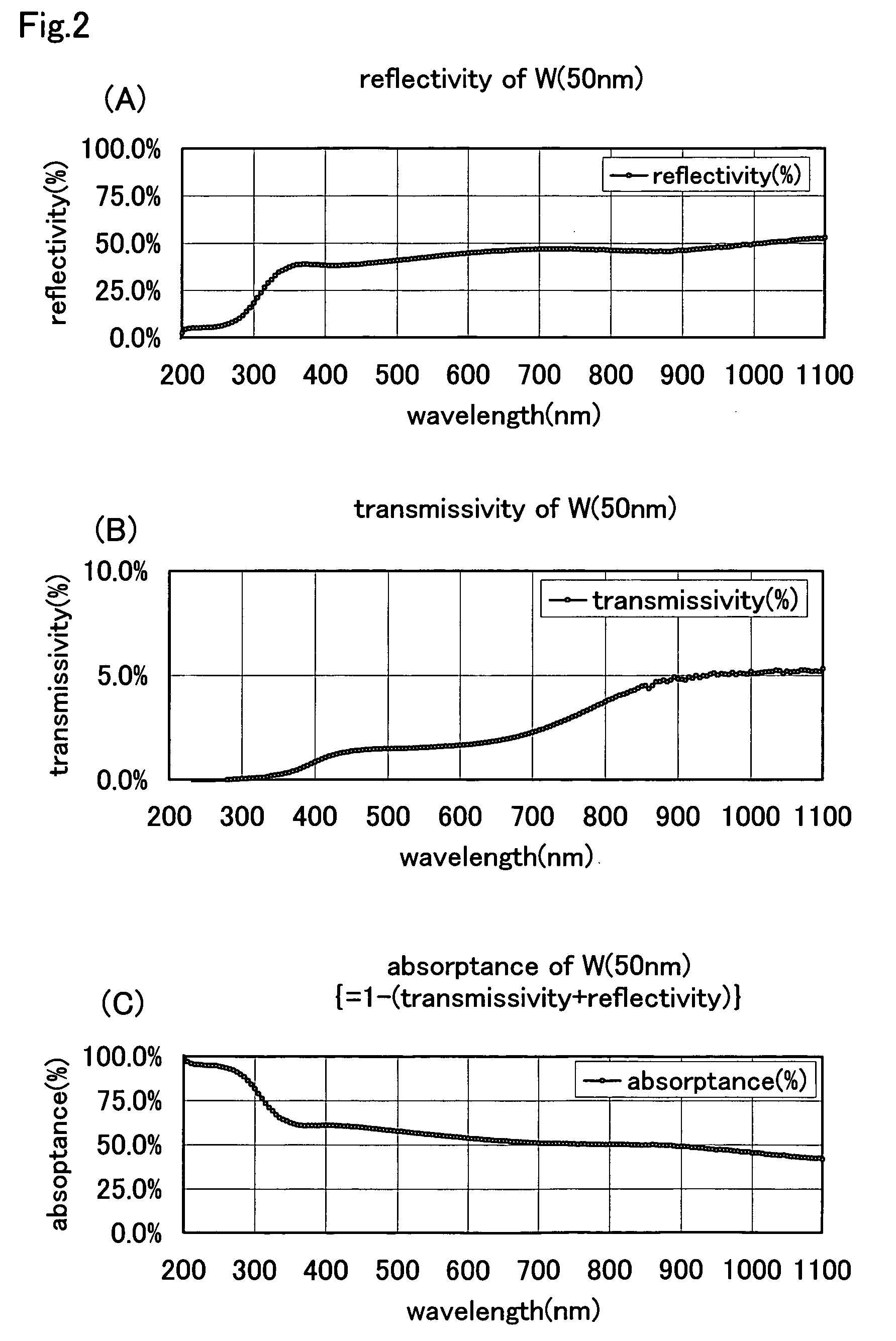

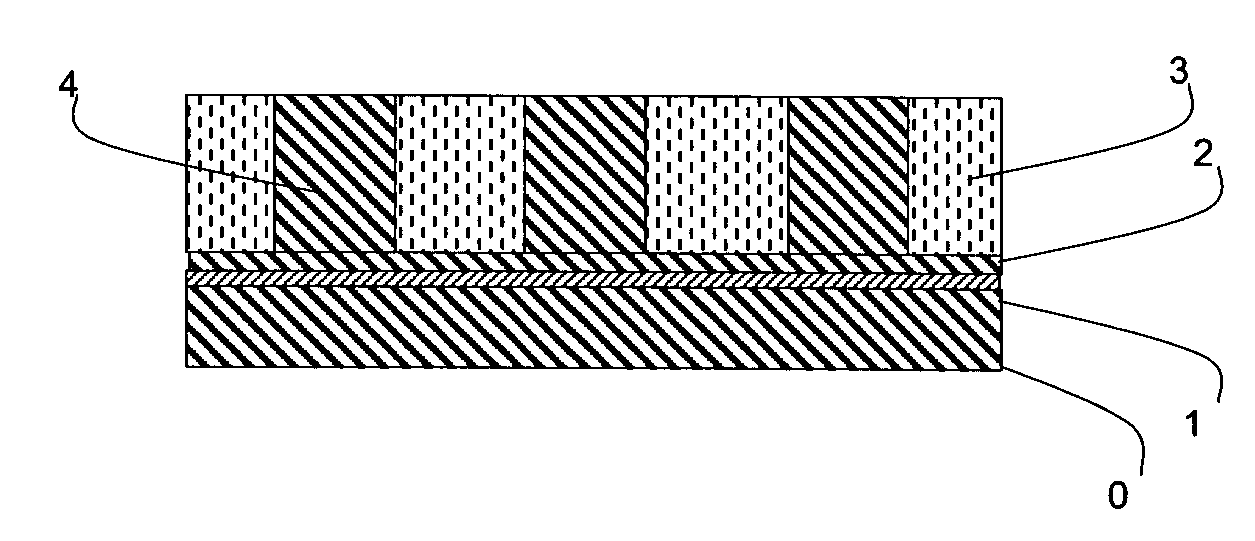

Semiconductor device and manufacturing method thereof

InactiveUS7189631B2High yieldSmall areaTransistorSemiconductor/solid-state device detailsOxideLaser beams

It is an object of the present invention to provide a peeling method that causes no damage to a layer to be peeled and to allow not only a layer to be peeled with a small surface area but also a layer to be peeled with a large surface area to be peeled entirely. Further, it is also an object of the present invention to bond a layer to be peeled to various base materials to provide a lighter semiconductor device and a manufacturing method thereof. Particularly, it is an object to bond various elements typified by a TFT, (a thin film diode, a photoelectric conversion element comprising a PIN junction of silicon, or a silicon resistance element) to a flexible film to provide a lighter semiconductor device and a manufacturing method thereof.When a metal layer 11 is provided over a substrate, an oxide layer 12 is provided in contact with the metal layer 11, a layer to be peeled 13 is formed, and the metal layer 11 is irradiated with a laser beam to perform oxidization and form a metal oxide layer 16, a clear separation is possible with a physical means within the metal oxide layer 12 or at an interface between the metal oxide layer 16 and the oxide layer 12.

Owner:SEMICON ENERGY LAB CO LTD

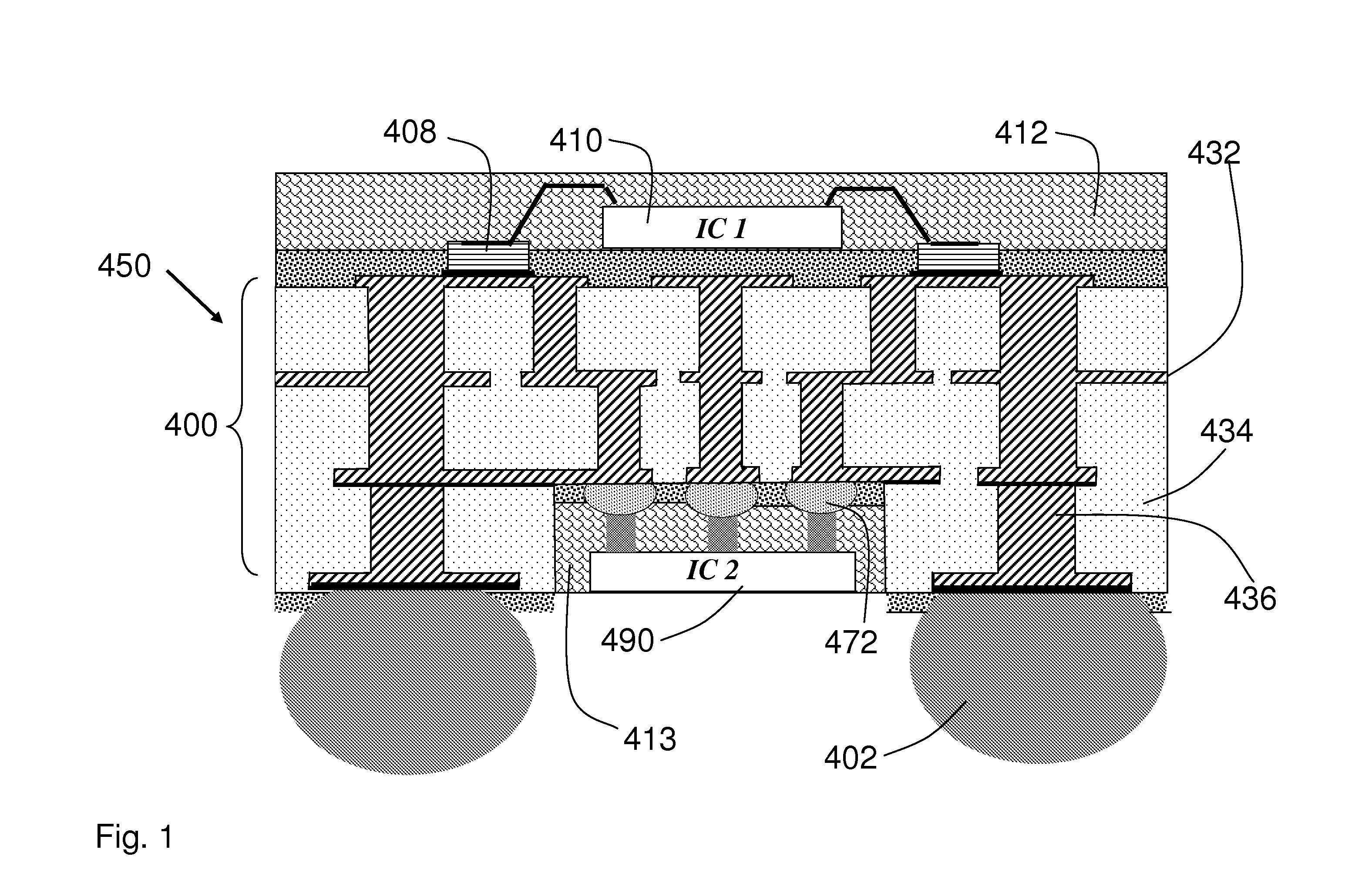

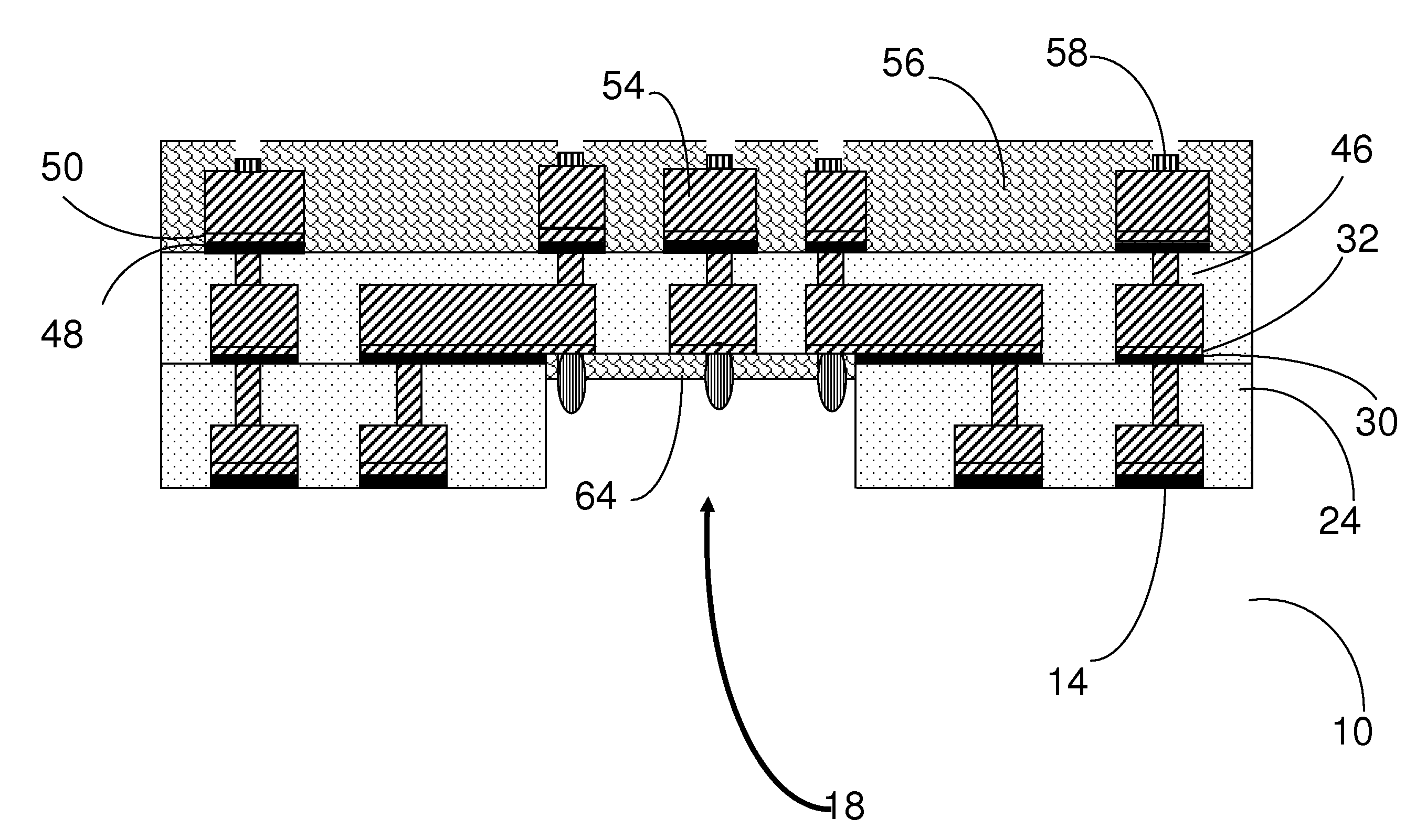

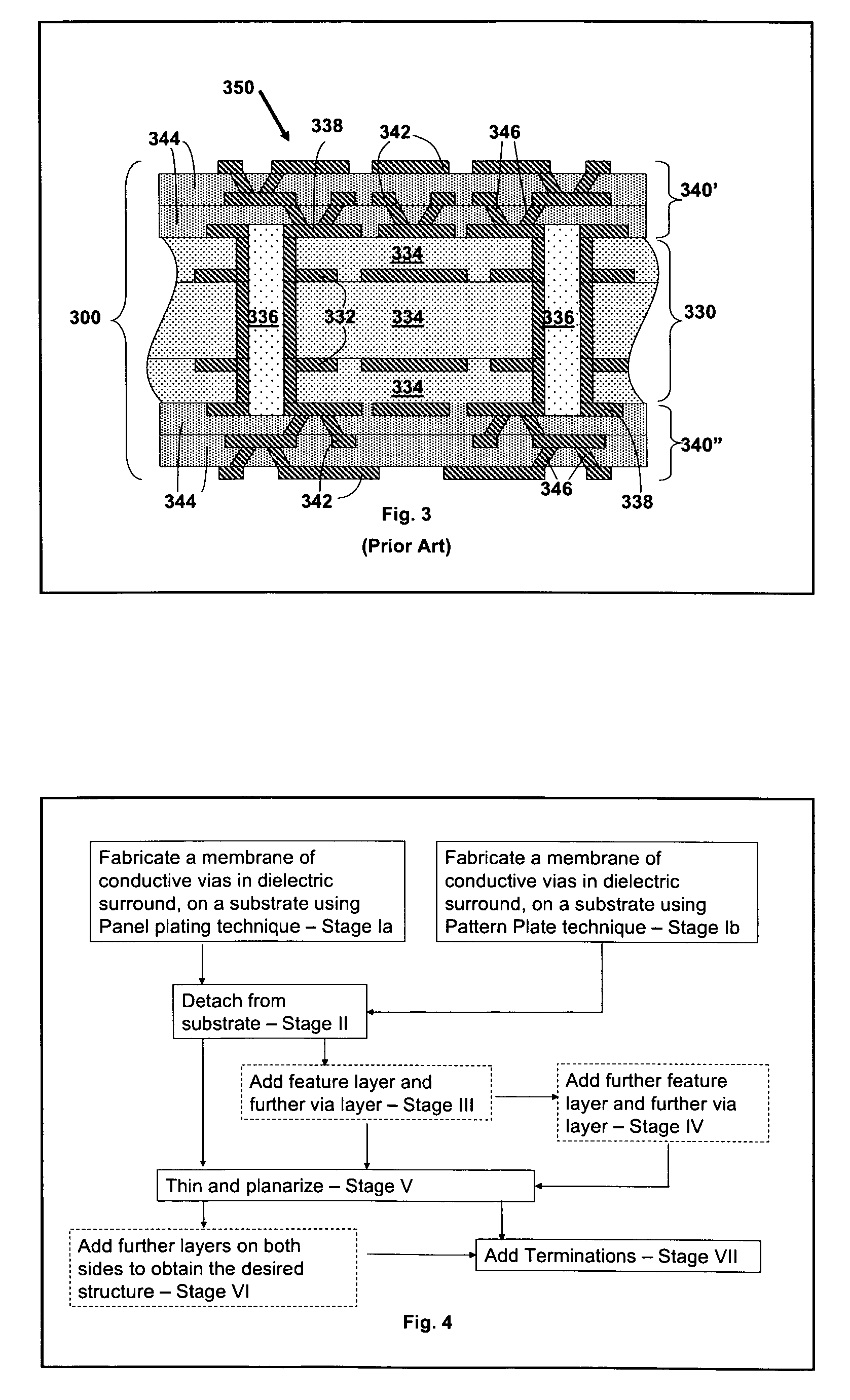

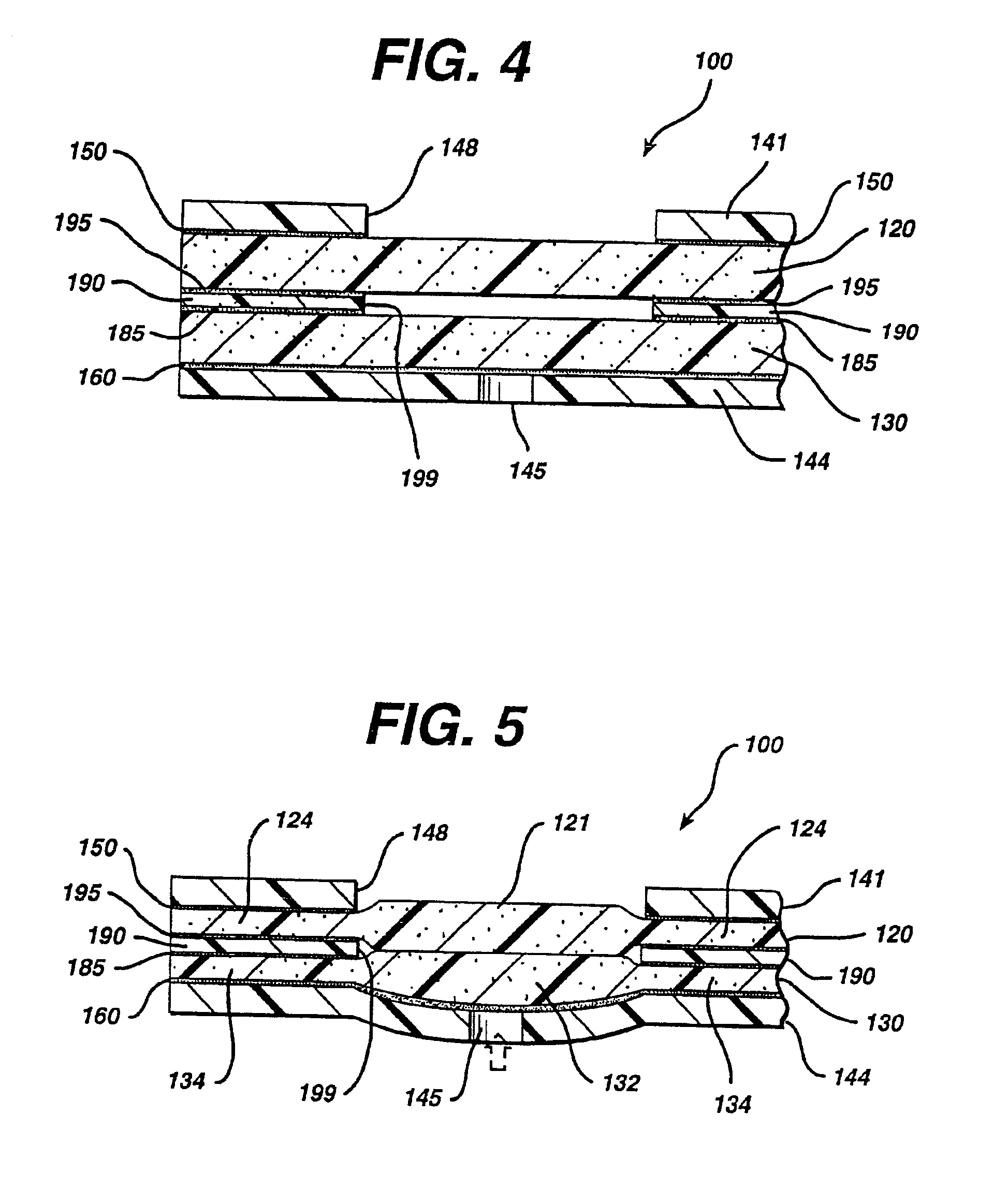

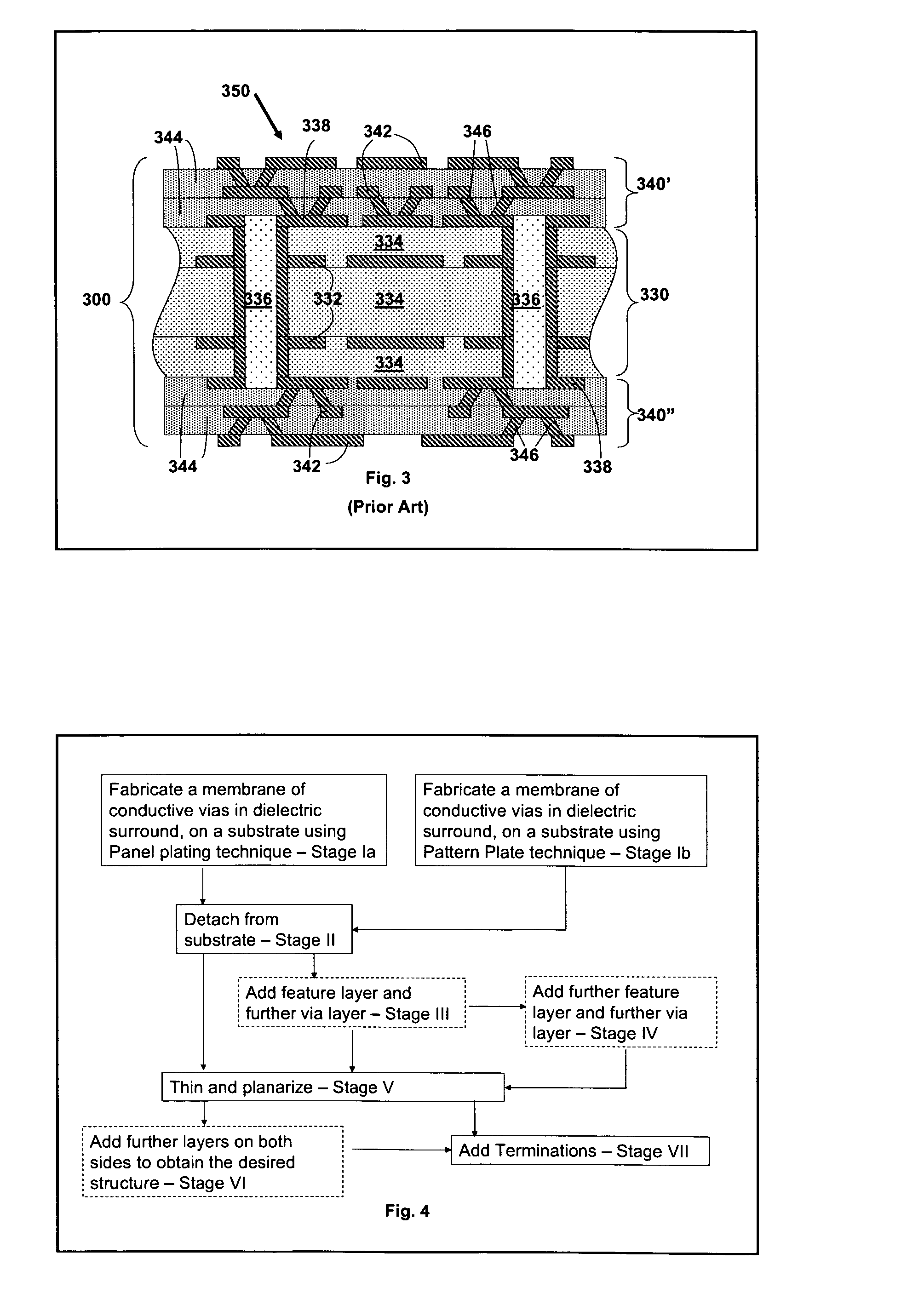

Advanced multilayer coreless support structures and method for their fabrication

ActiveUS7682972B2Suitable for mass productionHigh yieldSemiconductor/solid-state device detailsPrinted circuit aspectsDielectricEngineering

A method of fabricating a free standing membrane including via array in a dielectric for use as a precursor in the construction of superior electronic support structures, includes the steps of fabricating a membrane of conductive vias in a dielectric surround on a sacrificial carrier, and detaching the membrane from the sacrificial carrier to form a free standing laminated array. An electronic substrate based on such a free standing membrane may be formed by thinning and planarizing laminated array, followed by terminating.

Owner:ZHUHAI ADVANCED CHIP CARRIERS & ELECTRONICS SUBSTRATE SOLUTIONS TECH

Printing antenna with baseplate integrated waveguide feeder

ActiveCN101075702BSealing is simple, convenient and economicalTo achieve the purpose of sealingRadiating elements structural formsRadarEngineering

A chip integrated waveguide feeding print antenna is composed by a chip with its two metal sides being transfixed with metal through holes in array. The two metal sides are in axial symmetry. There is an intergrading section to one side of the waveguide centerline on two surface of the chip linking with transmission line. To the outer end of the intergrading section links a vibrator antenna. To the opposite side of the intergrading section on the waveguide links a micro-strip intergrading commutator linking with micro-strip transmission line.

Owner:南京易太可通信技术有限公司

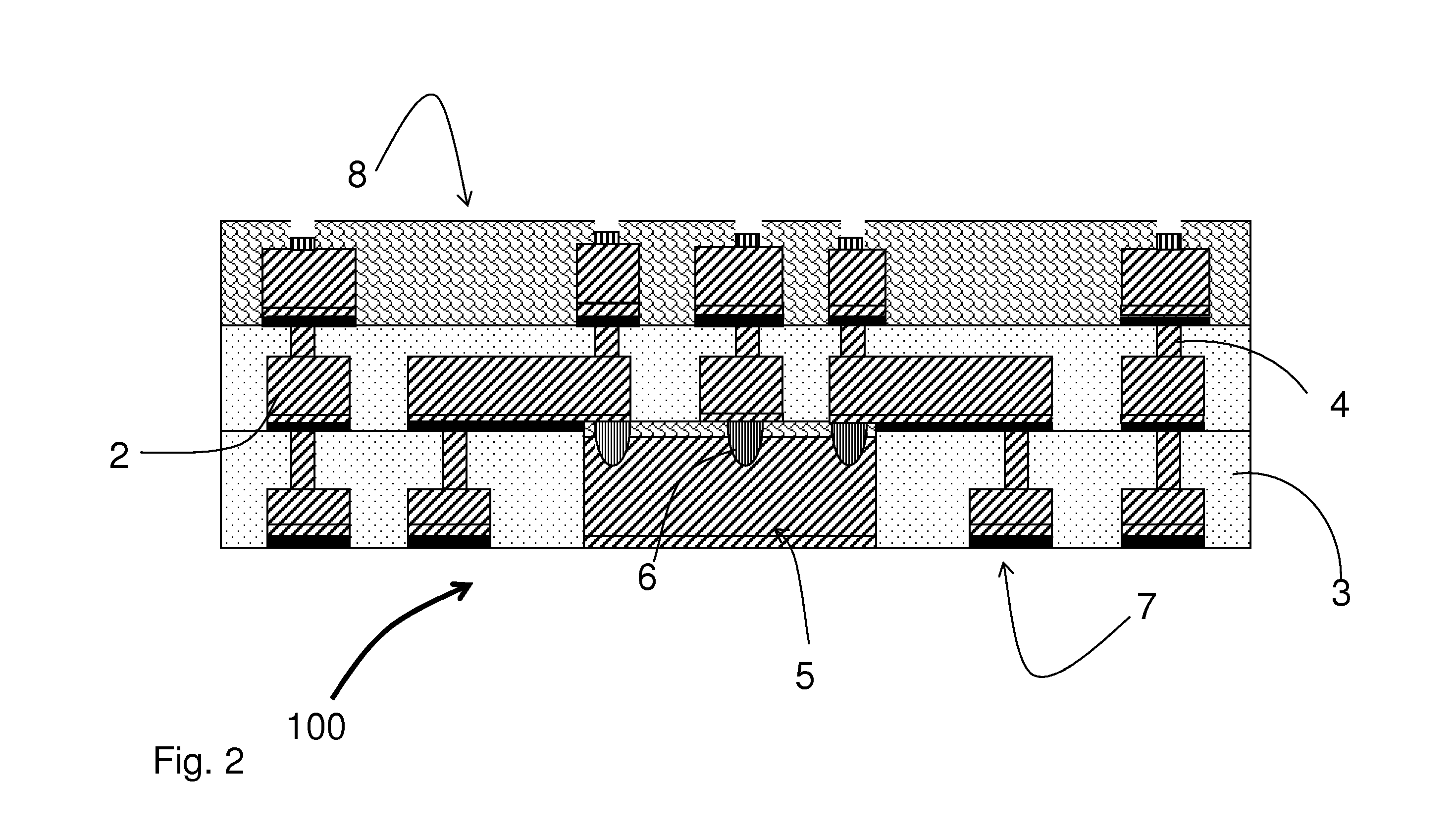

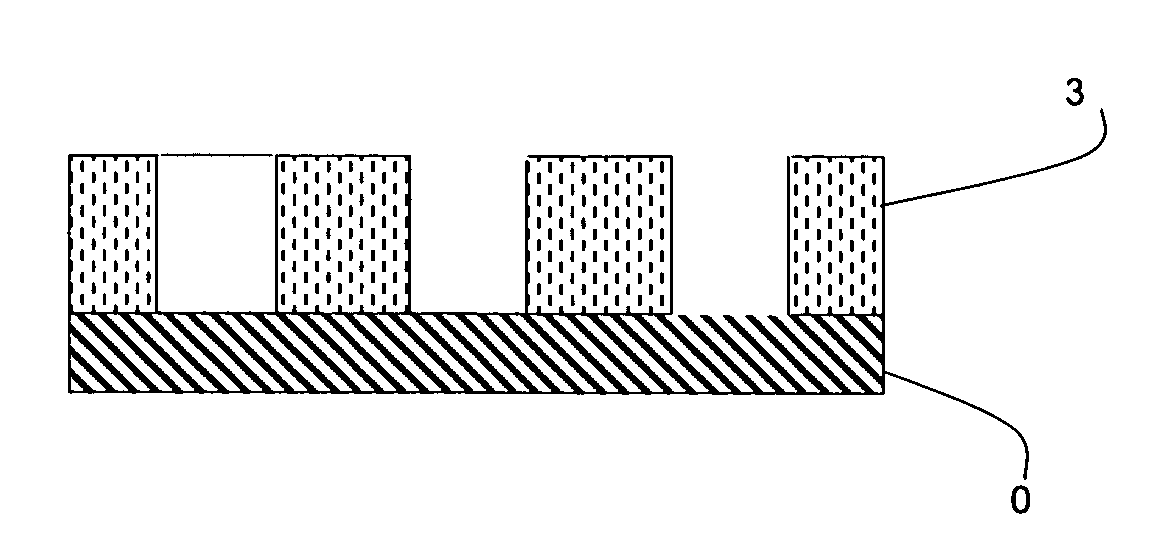

Integrated circuit support structures and their fabrication

ActiveUS7635641B2Suitable for mass productionHigh yieldSemiconductor/solid-state device detailsPrinted circuit aspectsEngineering physicsProtection layer

A method of fabricating an electronic substrate comprising the steps of; (A) selecting a first base layer; (B) depositing a first etchant resistant barrier layer onto the first base layer; (C) building up a first half stack of alternating conductive layers and insulating layers, the conductive layers being interconnected by vias through the insulating layers; (D) applying a second base layer onto the first half stack; (F) applying a protective coating of photoresist to the second base layer; (F) etching away the first base layer; (G) removing the protective coating of photoresist; (H) removing the first etchant resistant barrier layer; (I) building up a second half stack of alternating conductive layers and insulating layers, the conductive layers being interconnected by vias through the insulating layers, wherein the second half stack has a substantially symmetrical lay up to the first half stack; (J) applying an insulating layer onto the second hall stack of alternating conductive layers and insulating layers, (K) removing the second base layer, and (L) terminating the substrate by exposing ends of vias on outer surfaces of the stack and applying terminations thereto.

Owner:ZHUHAI ADVANCED CHIP CARRIERS & ELECTRONICS SUBSTRATE SOLUTIONS TECH

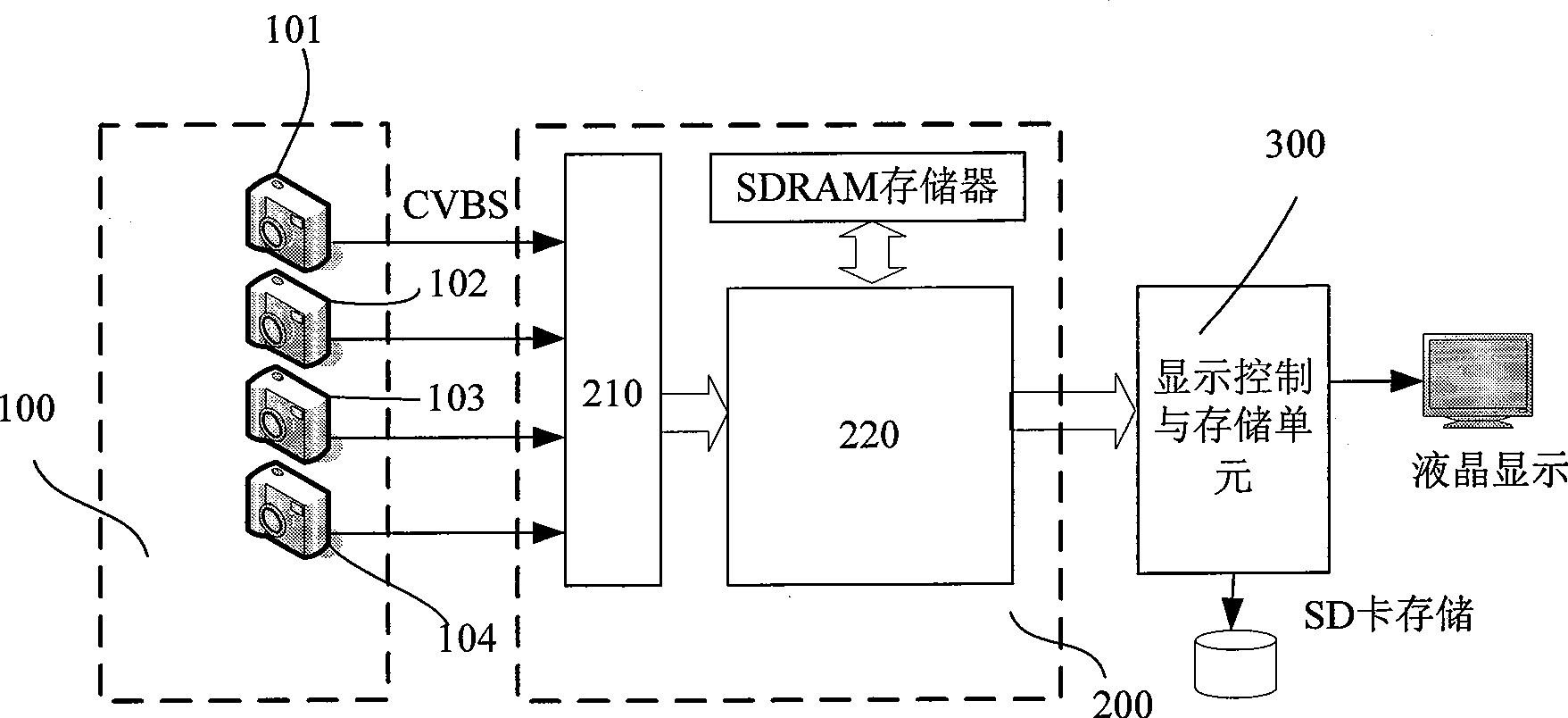

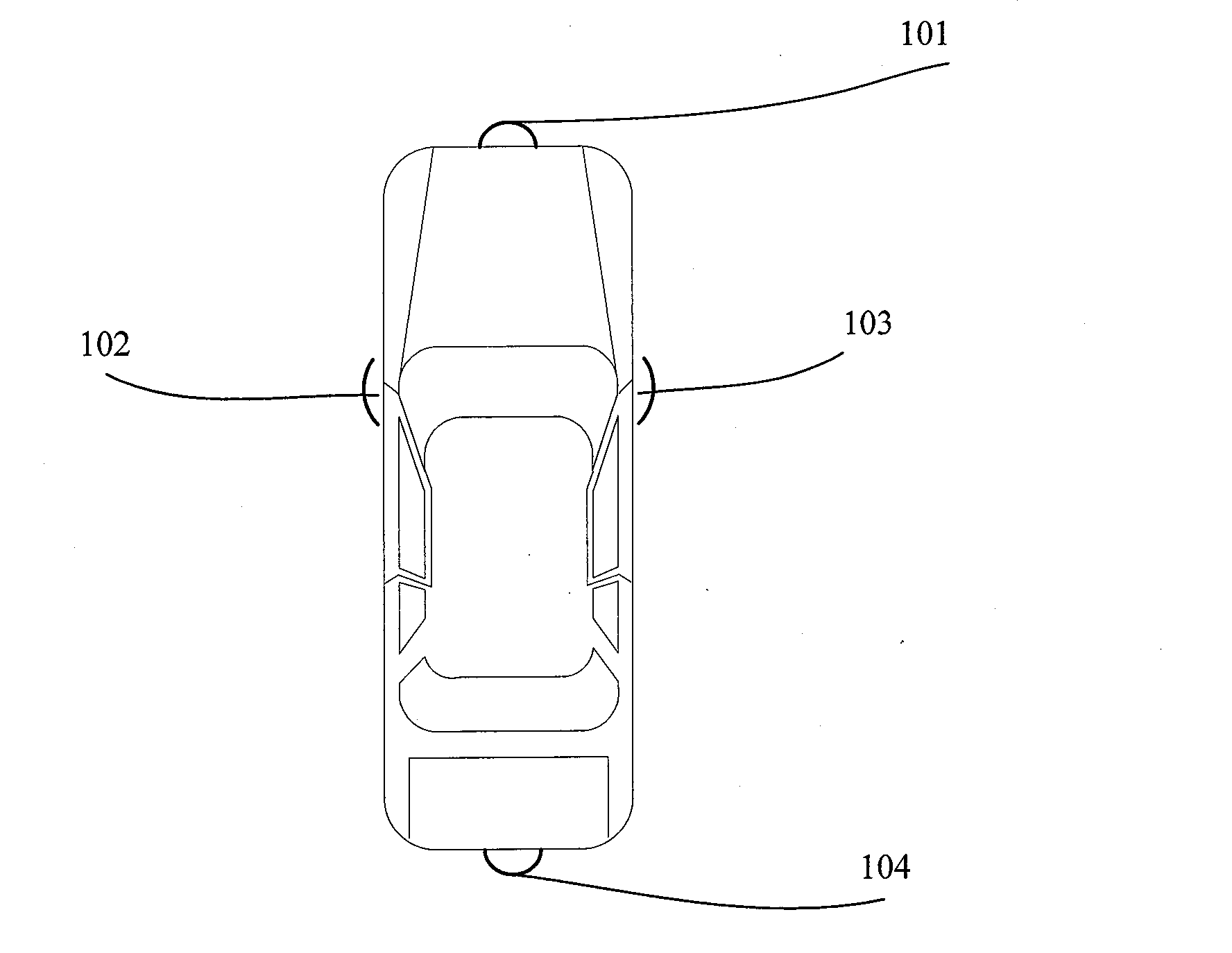

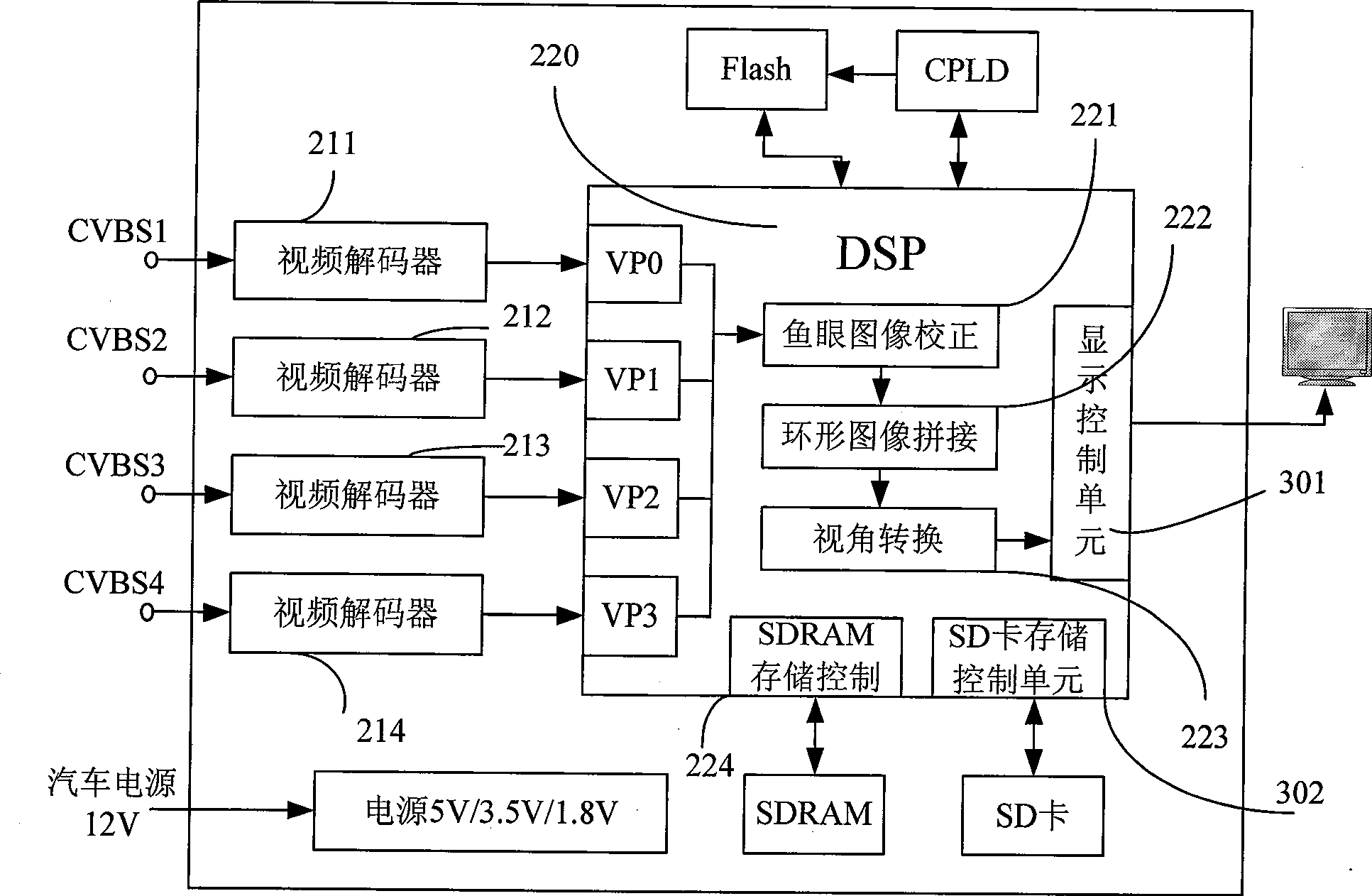

Method for synthesizing 360 DEG ring-shaped video of vehicle assistant drive

InactiveCN101442618ALow costSuitable for mass productionTelevision system detailsColor television detailsBlind zoneDriver/operator

The invention discloses a method for synthesizing annular video of 360 degrees for assistant drive of a vehicle. The method adopts a video acquisition unit, an annular video synthesis unit and a display control and storage unit, and has the characteristics of reliable stability, low cost and suitable batch production. The method can acquire video signals in real time for four super-wide-angle fish-eye cameras arranged at front, back, left and right of the vehicle, carries out treatment of fish-eye image correction, annular image mosaic and vision angle conversion on four channels of the video signals through a video decoding unit and a video synthesizing control unit to generate a panoramic displayed plan view of 360 degrees, achieves multiple display modes through the display control and storage unit, and can selectively store correlated video information. The method can provide surrounding scenes for a driver, and eliminate vision blind area thereof, and is favorable for the driver to achieve safe and accurate vehicle driving operations. The method is used for assistant drive for sedans, business vehicles and heavy trucks of various grades, and passenger coaches of different types.

Owner:葛晨阳

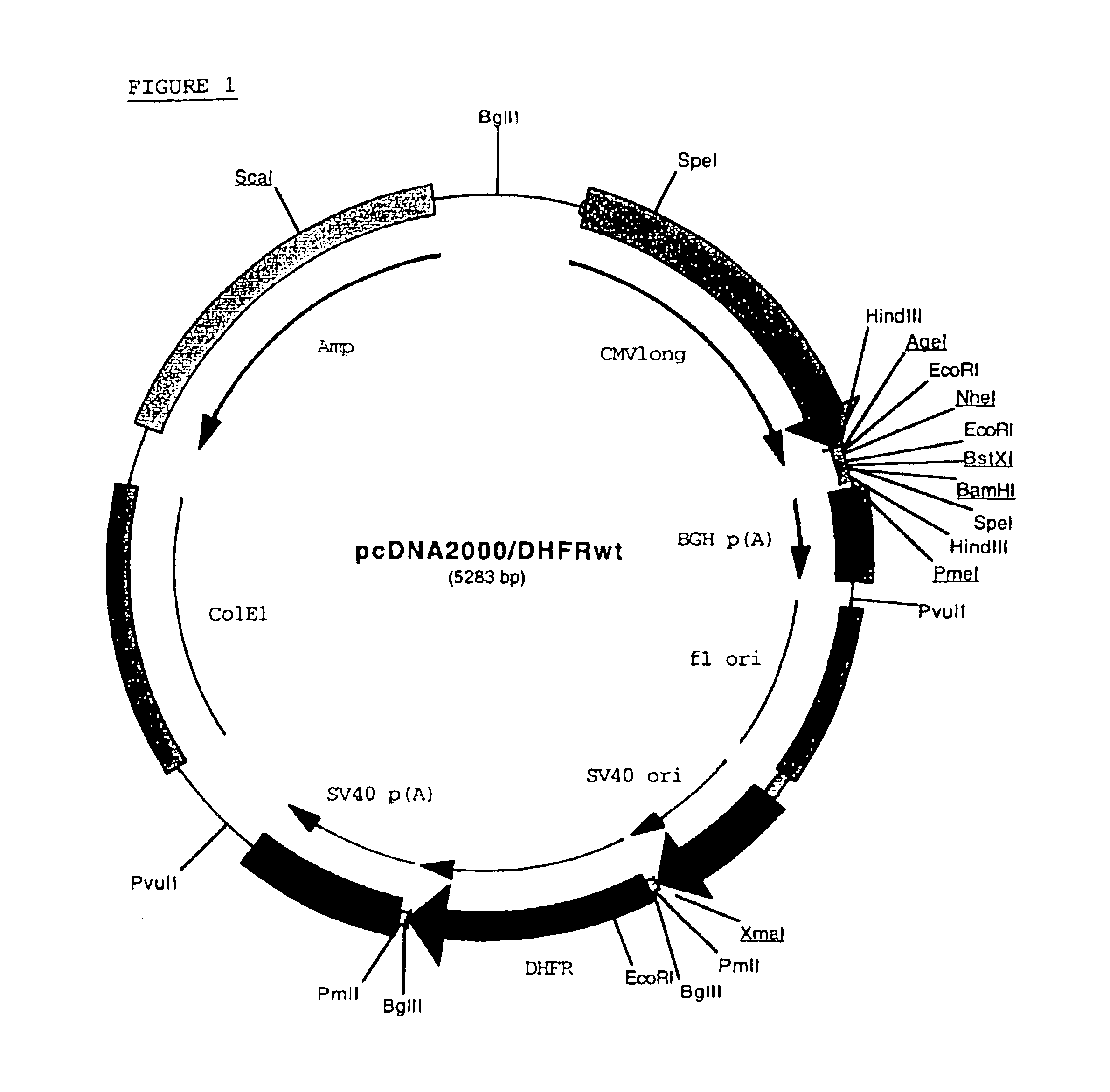

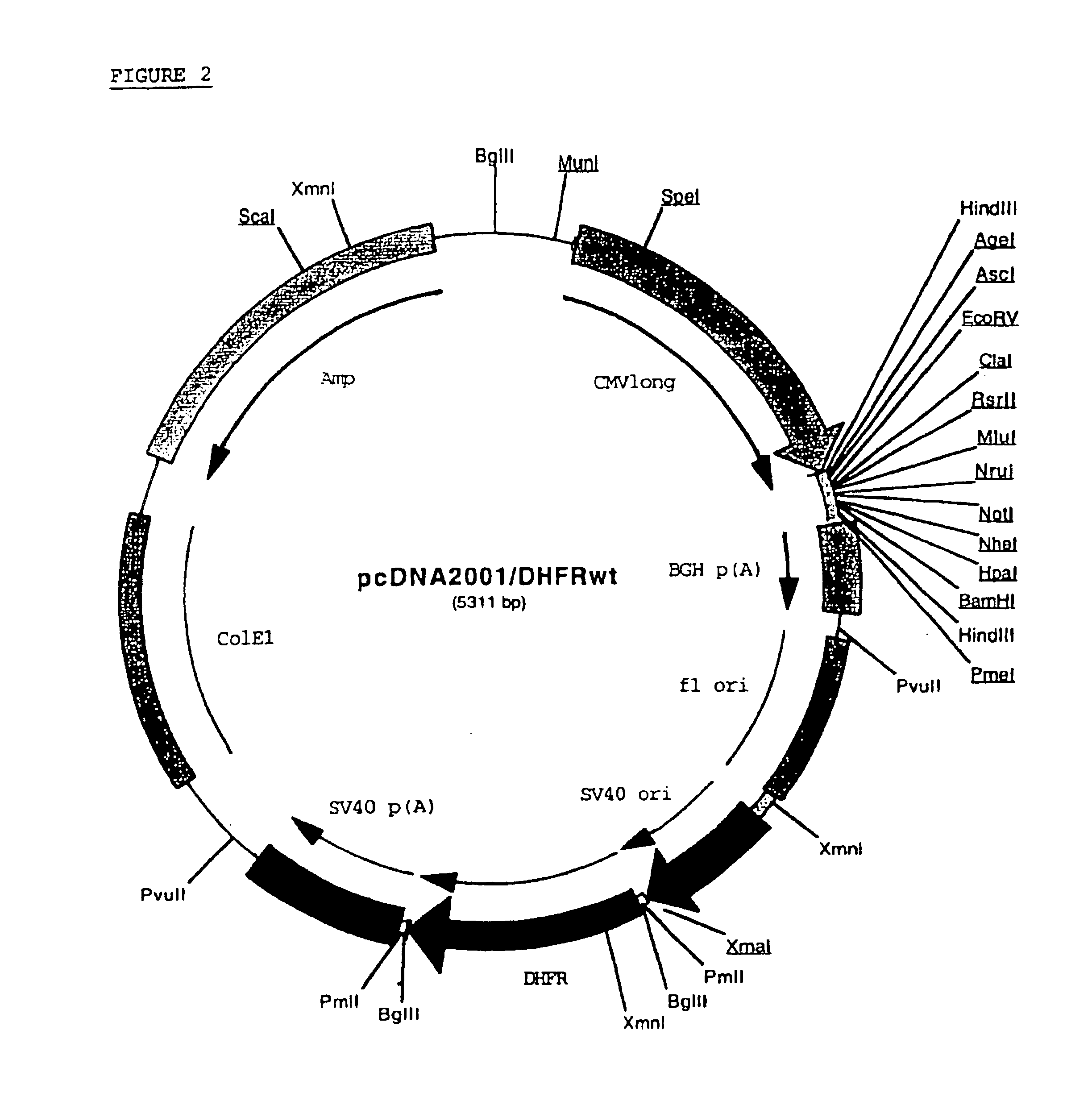

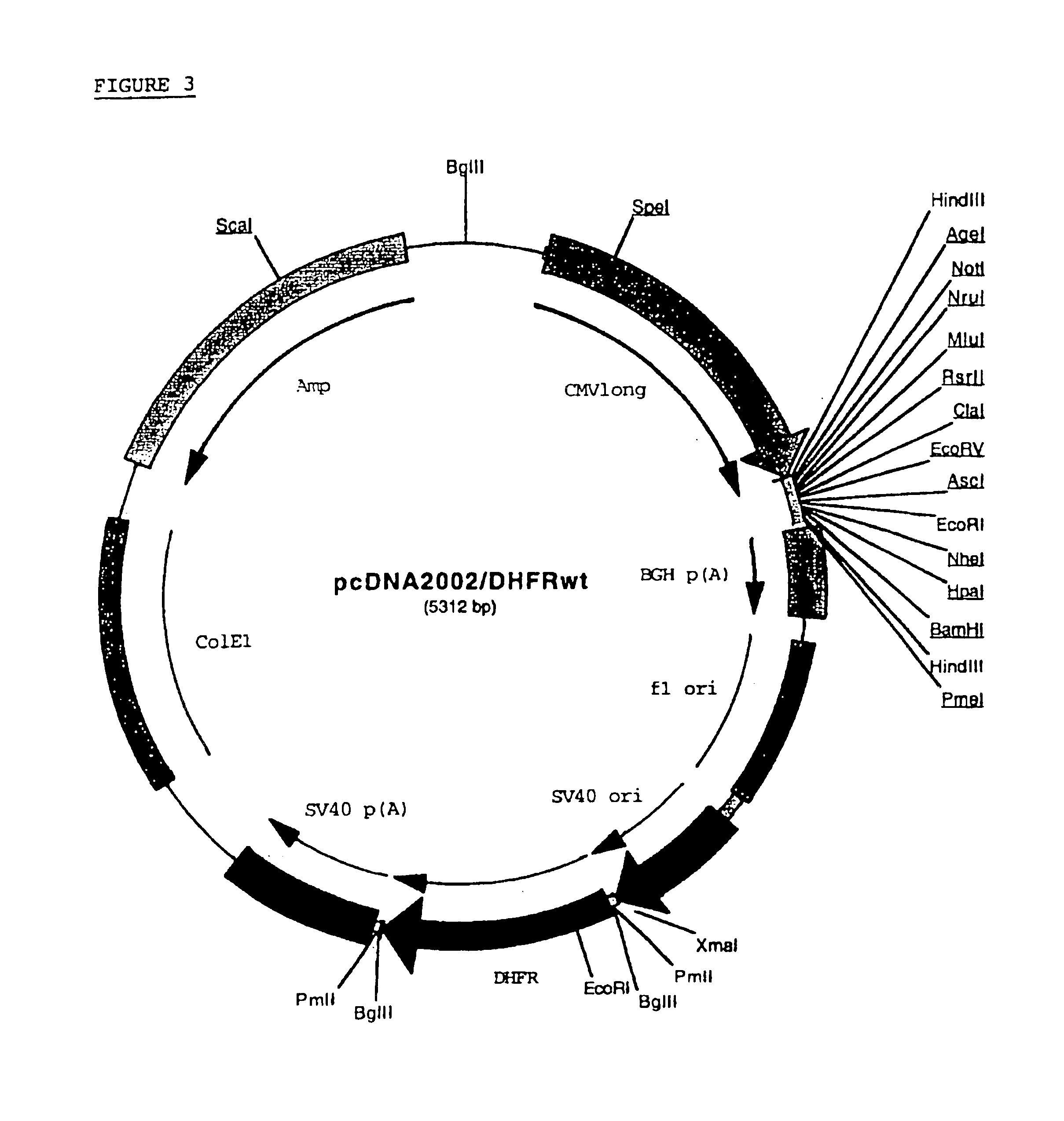

Recombinant protein production in a human cell

InactiveUS6855544B1Easy to handleLarge-scale (continuous) productionSsRNA viruses negative-senseSugar derivativesHamsterHuman cell

Methods and compositions for the production of recombinant proteins in a human cell line. The methods and positions are particularly useful for generating stable expression of human recombinant proteins of interest that are modified post-translationally, for example, by glycosylation. Such proteins may have advantageous properties in comparison with their counterparts produced in non-human systems such as Chinese Hamster Ovary cells.

Owner:JANSSEN VACCINES & PREVENTION BV

Method of making a test strip for determining analyte concentration over a broad range of sample volumes

InactiveUS6949221B2Minimizing any tendencySuitable for mass productionMicrobiological testing/measurementMaterial analysis by optical meansAnalytePorous layer

A test strip for determining the concentration of an analyte in a body fluid includes a membrane in fluid communication with a porous layer. The membrane and the porous layer are divided into compressed portions, which restrict the capillary flow of the body fluid, and uncompressed portions. The uncompressed portions are adapted to absorb and retain body fluids in excess of the amount required for operation of the test strip. The test strip may be constructed with an internal relief chamber to accommodate the uncompressed portions. A method of making the test strip by pressure and / or heat sealing individual components on a shaping die is also provided.

Owner:LIFESCAN IP HLDG LLC

Advanced Multilayered Coreless Support Structures and their Fabrication

ActiveUS20070281471A1Suitable for mass productionHigh yieldSemiconductor/solid-state device detailsPrinted circuit aspectsDielectricEngineering

A method of fabricating a free standing membrane comprising a via array in a dielectric for use as a precursor in the construction of superior electronic support structures, comprising the stages:I—Fabricating a membrane comprising conductive vias in a dielectric surround on a sacrificial carrier, andII—Detaching the membrane from the sacrificial carrier to form a free standing laminated array, and a method of fabricating an electronic substrate based on such a membrane comprising at least the stages of:(I) Fabricating a membrane comprising conductive vias in a dielectric surround on a sacrificial carrier;(II) Detaching the membrane from the sacrificial carrier to form a free standing laminated array;(V) Thinning and planarizing, and(VII) Terminating.

Owner:ZHUHAI ADVANCED CHIP CARRIERS & ELECTRONICS SUBSTRATE SOLUTIONS TECH

Hearing aid adapted for discrete operation

InactiveUS7221769B1Accidental activation of be prevent and minimisePrecise positioningEar supported setsHearing device specific toolsPotentiometerUser assistance

The present invention relates to a hearing aid, which allows a hearing aid user to discretely operate his / her hearing aid by applying a force to a portion of the ear carrying the hearing aid. A number of different functions of the hearing aid, such as turning a battery supply on / off, adjusting a volume control, selecting a particular pre-programmed listening program, etc., may be provided in a hearing aid according to the present invention—all without directly engaging the hearing aid or switches or potentiometers thereof. Furthermore, if the hearing aid is adapted for use within the ear canal, the present invention may provide user assistance so to allow simple and convenient removal of the aid from the ear canal.

Owner:SONION ROSKILDE

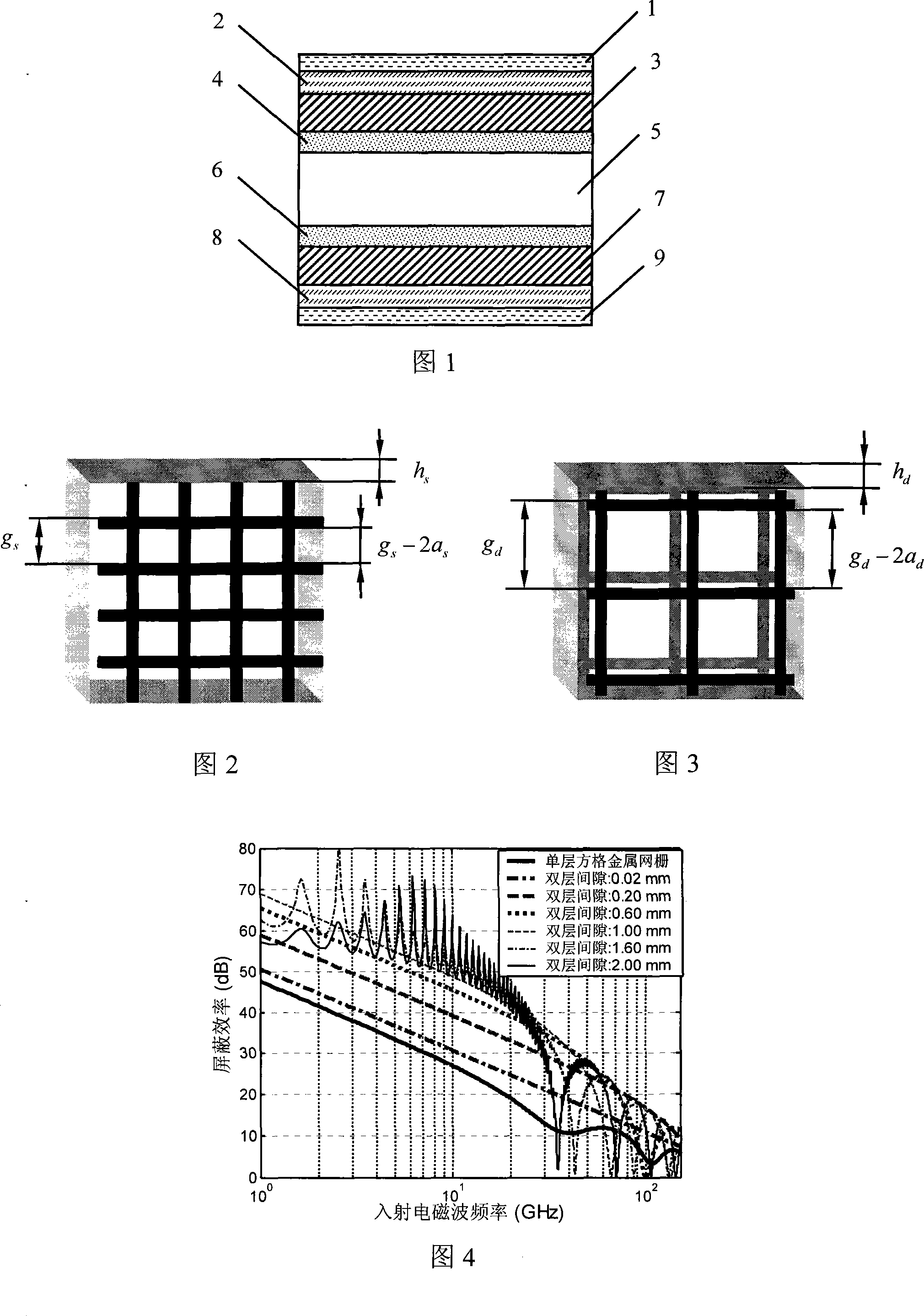

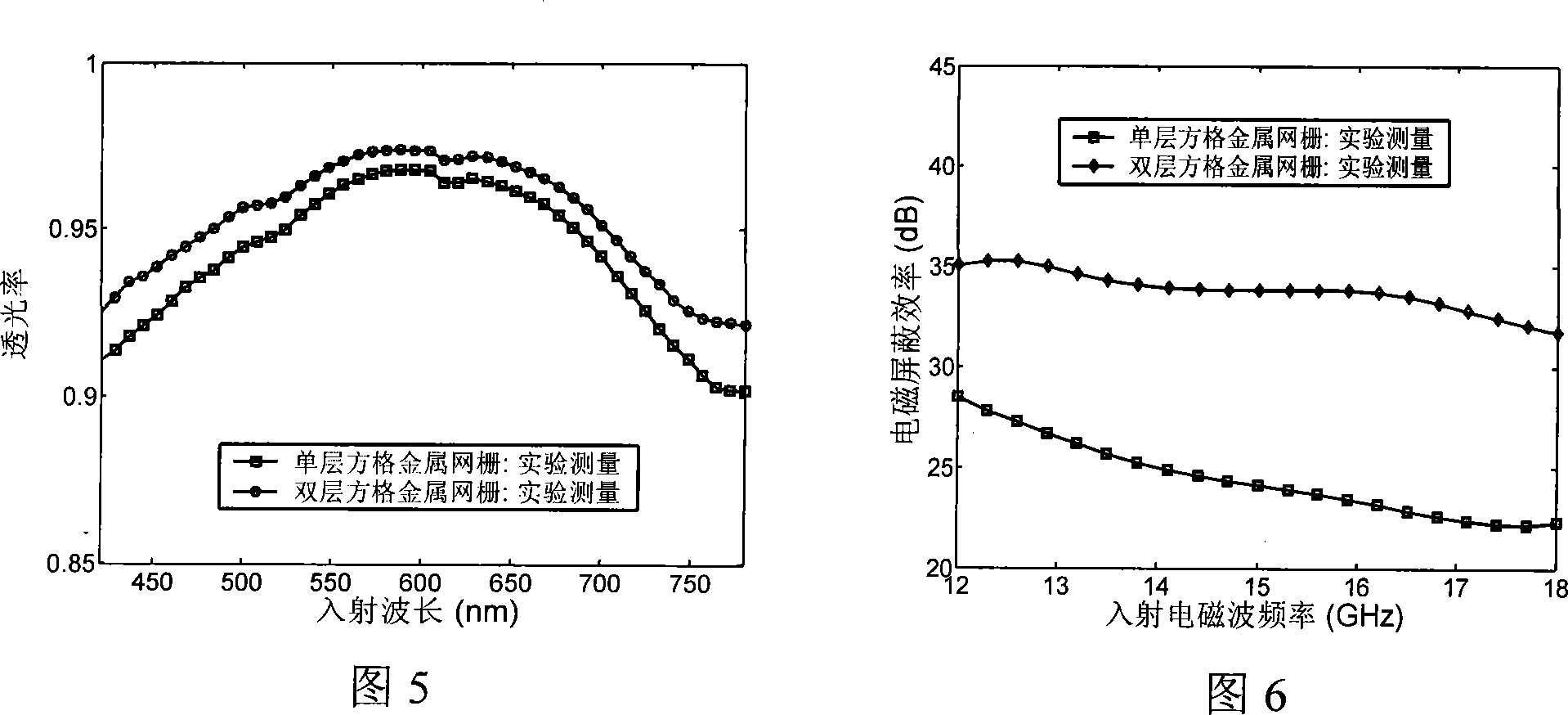

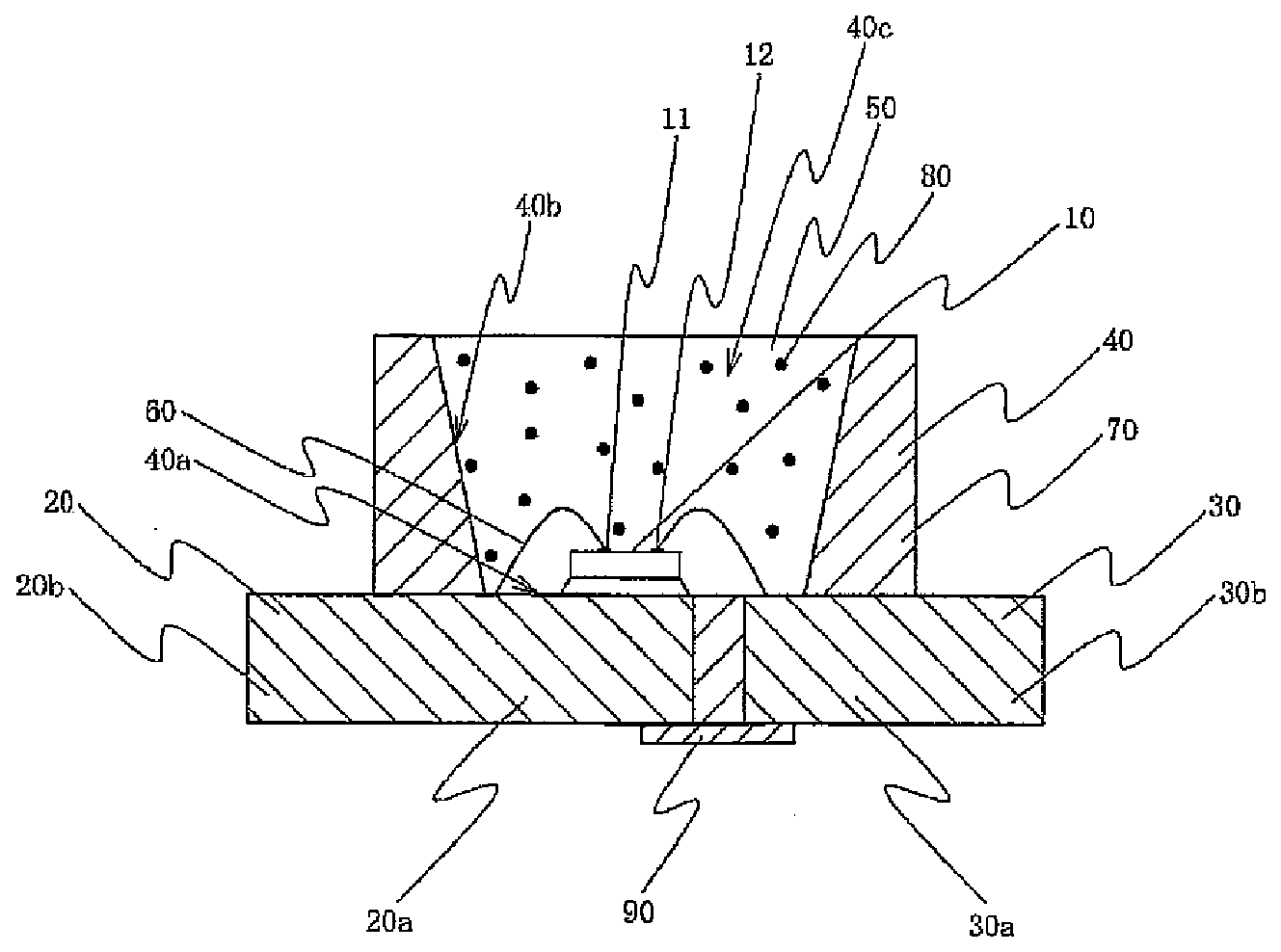

Electromagnetic shielding optical window with double-layer pane metal gridding structure

ActiveCN101222840AHigh shielding efficiencyWide shielding bandMagnetic/electric field screeningUnderlayOptical transmittance

The invention relates to an electromagnetic shielding optical window with a two-double pane metal grating structure and belongs to the optical transparent piece electromagnetic shielding technical field; the electromagnetic shielding optical window is formed by placing two layers of pane metal gratings or metal silk screens with the same structure parameters on two sides of the optical window or a transparent underlay in parallel; a side length of a pane of the two-double pane metal grating is greater than two times of a side length of a pane of the prior monolayer pane metal grating; the space between two layers of pane metal gratings is two to four times of the side length of the pane; compared with the prior monolayer pane metal grating, the optical window adopting the two-double pane metal grating structure does not reduce light transmittance, substantially improves the shielding efficiency of microwaves and millimeter waves, solves the problems that the high light transmittance and strong electromagnetic shielding efficiency can not simultaneously considered in the prior optical window electromagnetic shielding technology and is suitable for electromagnetic shielding in aerospace equipment, security facilities, medical diagnostic instruments and other military and civil optical transparent pieces.

Owner:HARBIN INST OF TECH

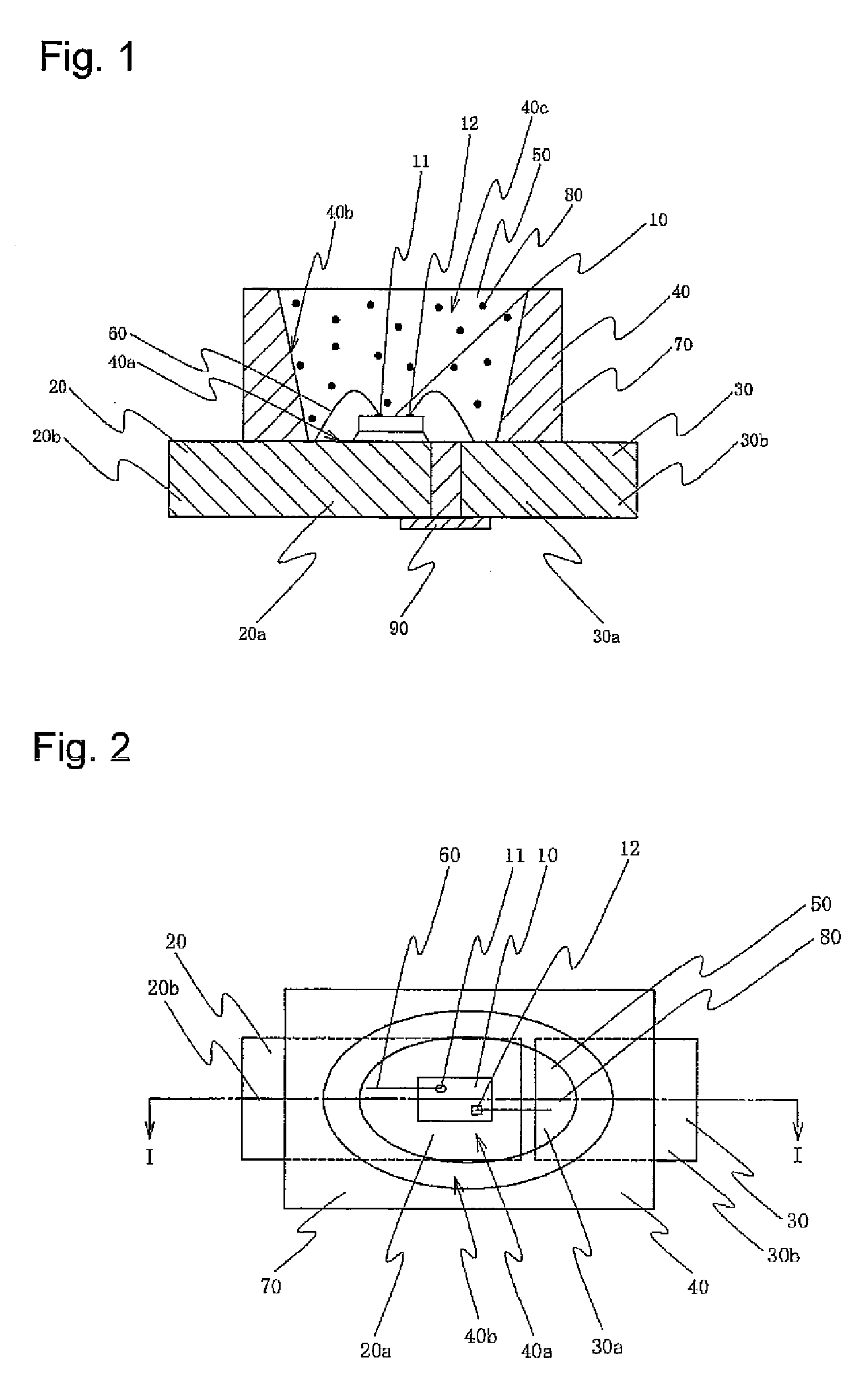

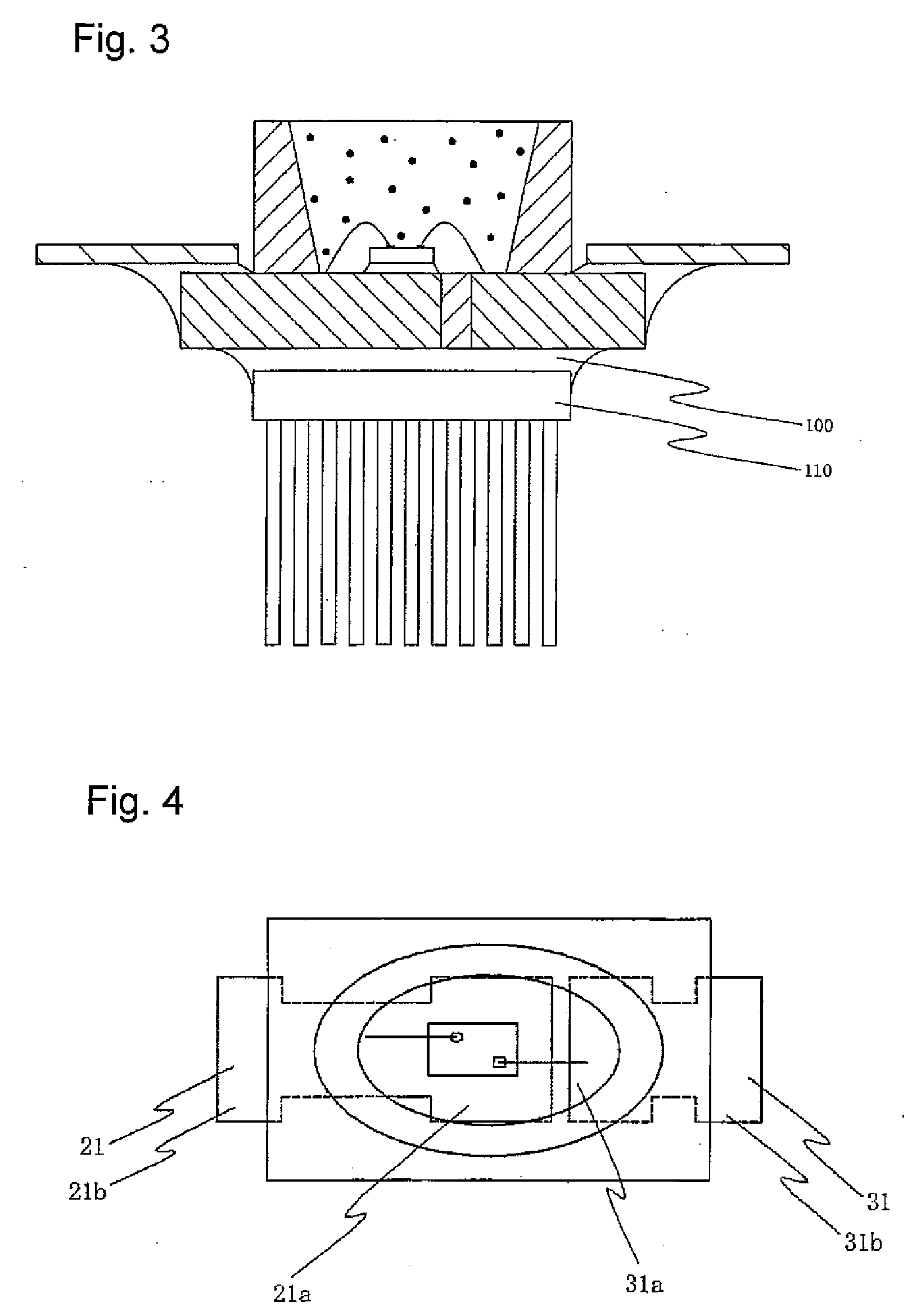

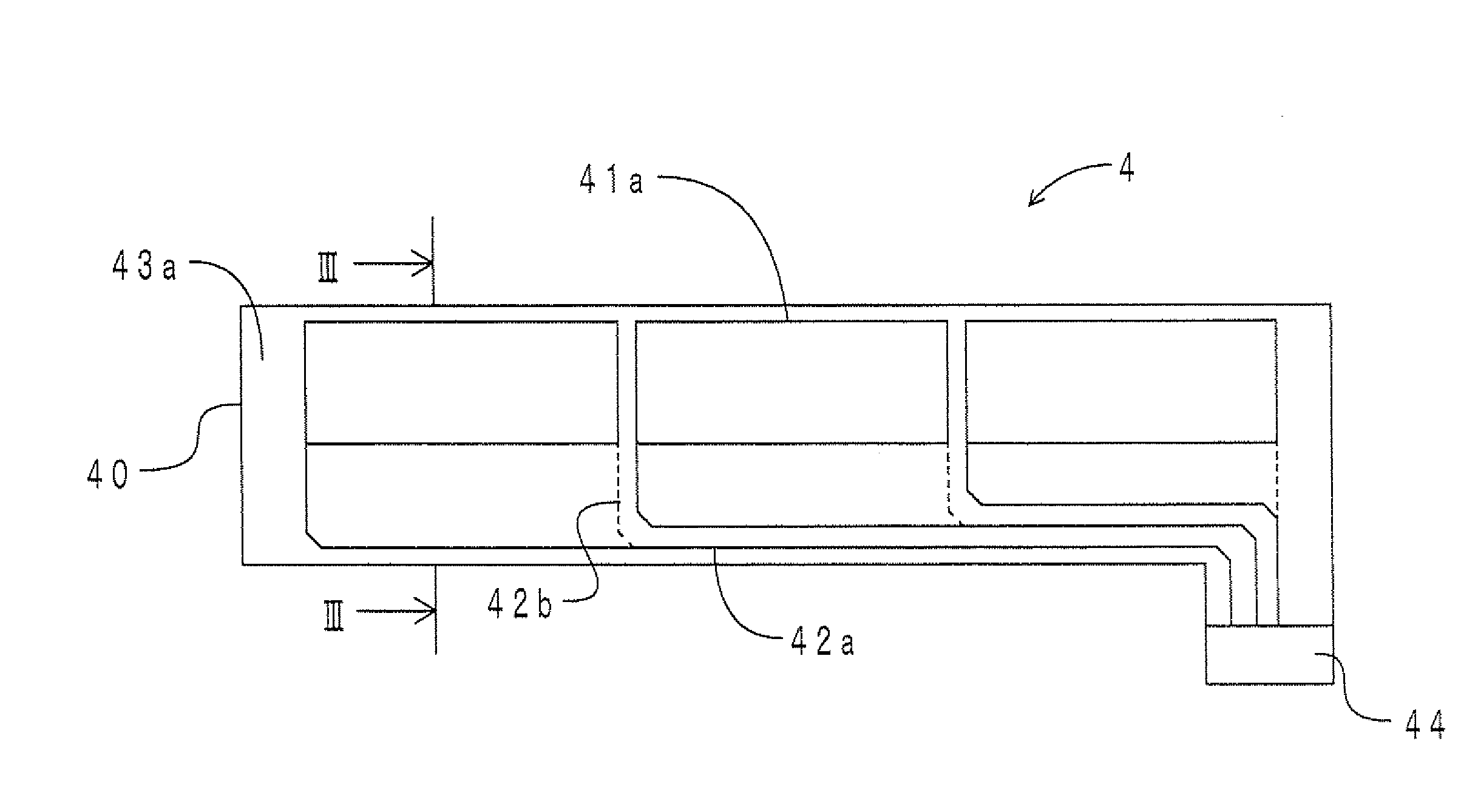

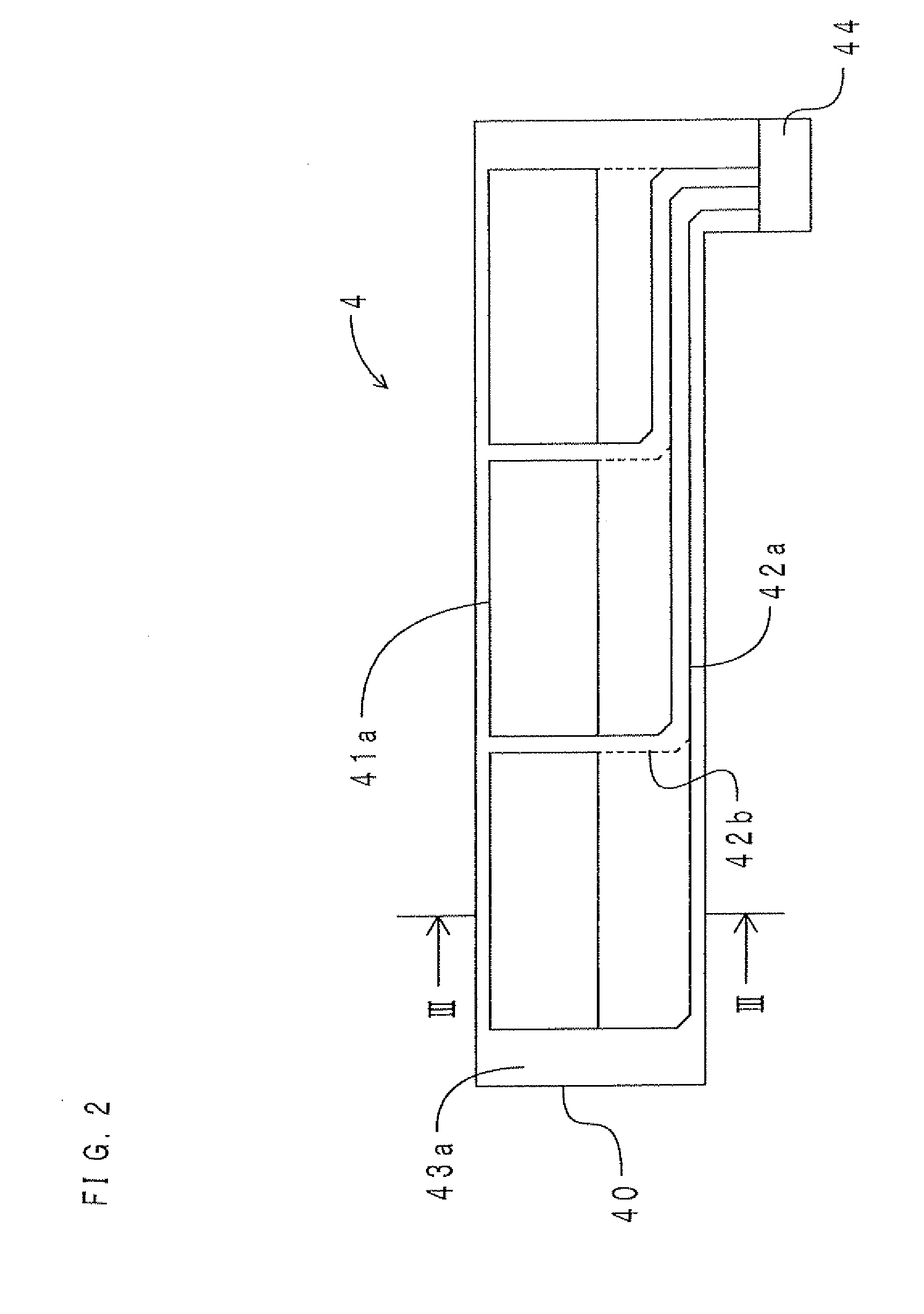

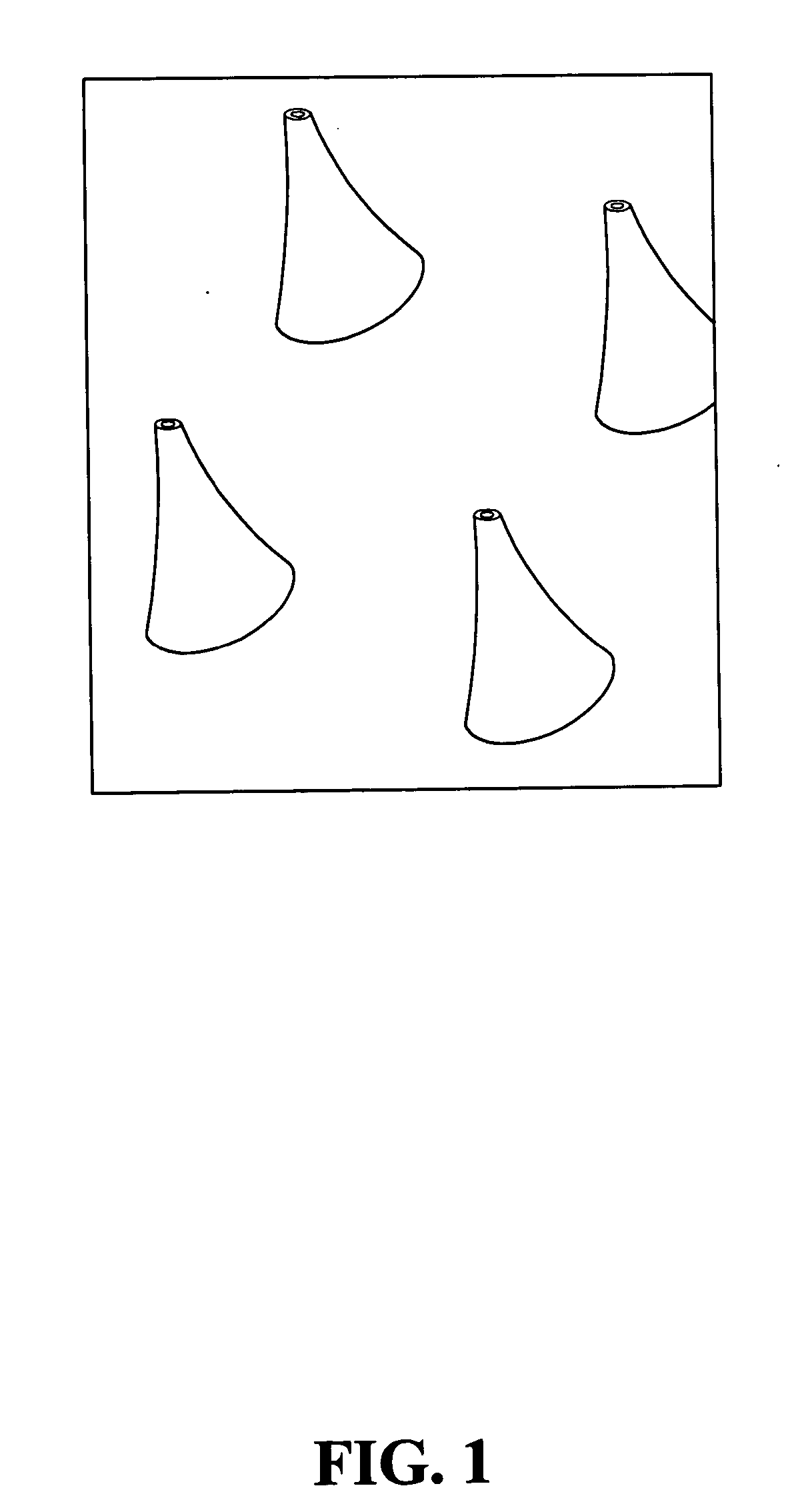

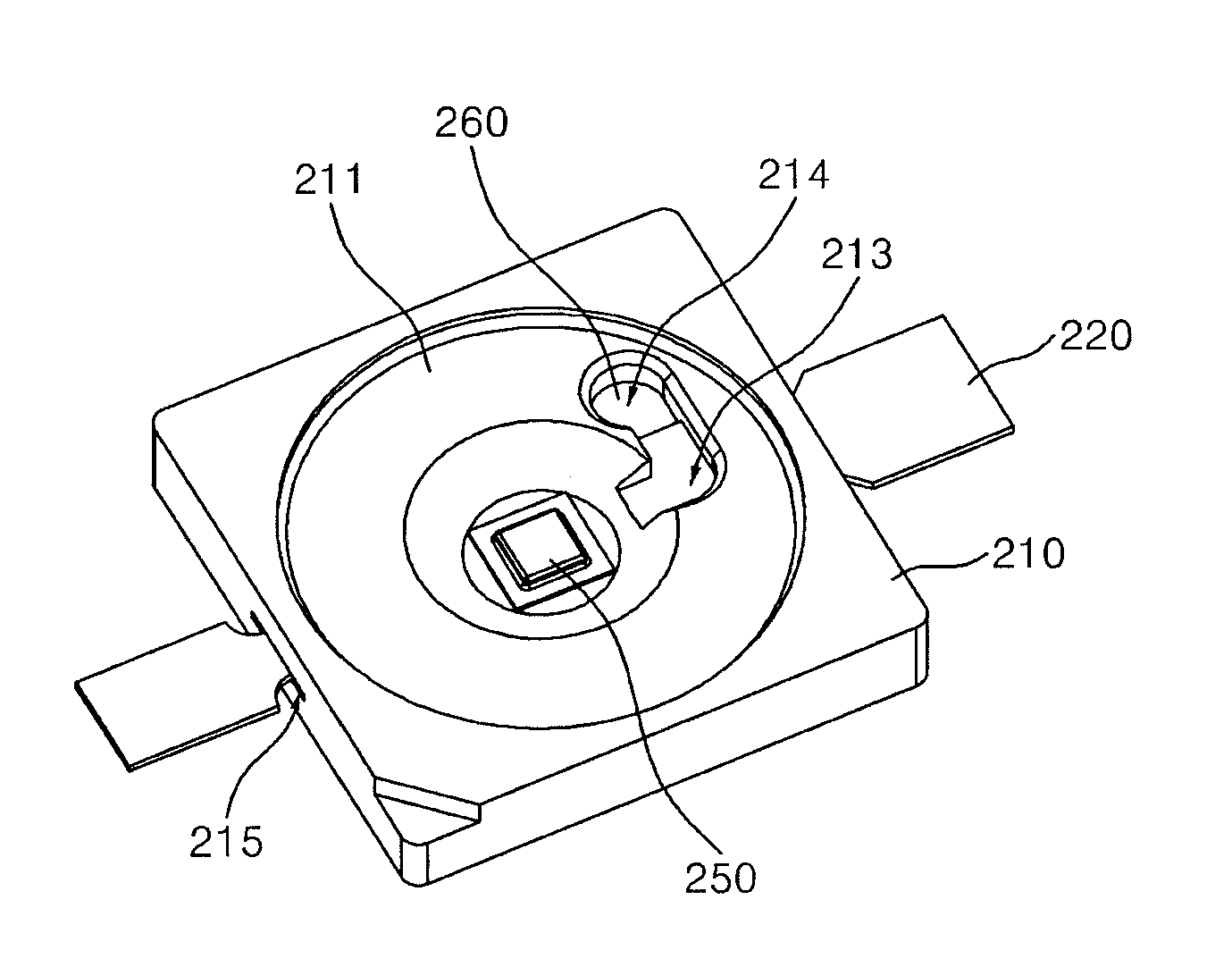

Resin molding, surface mounted light emitting apparatus and methods for manufacturing the same

ActiveUS20090050925A1Easy to useSuitable for mass productionSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyShell molding

The present invention provides a surface mounted light emitting apparatus which has long service life and favorable property for mass production, and a molding used in the surface mounted light emitting apparatus.The surface mounted light emitting apparatus comprises the light emitting device 10 based on GaN which emits blue light, the first resin molding 40 which integrally molds the first lead 20 whereon the light emitting device 10 is mounted and the second lead 30 which is electrically connected to the light emitting device 10, and the second resin molding 50 which contains YAG fluorescent material and covers the light emitting device 10. The first resin molding 40 has the recess 40c comprising the bottom surface 40a and the side surface 40b formed therein, and the second resin molding 50 is placed in the recess 40c. The first resin molding 40 is formed from a thermosetting resin such as epoxy resin by the transfer molding process, and the second resin molding 50 is formed from a thermosetting resin such as silicone resin.

Owner:NICHIA CORP

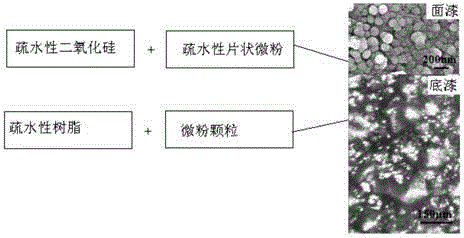

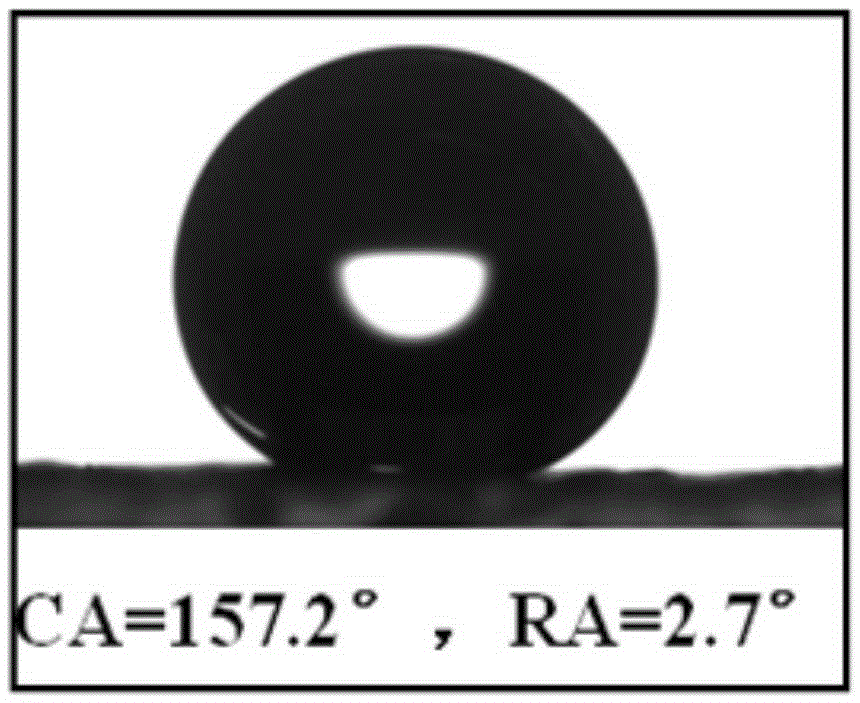

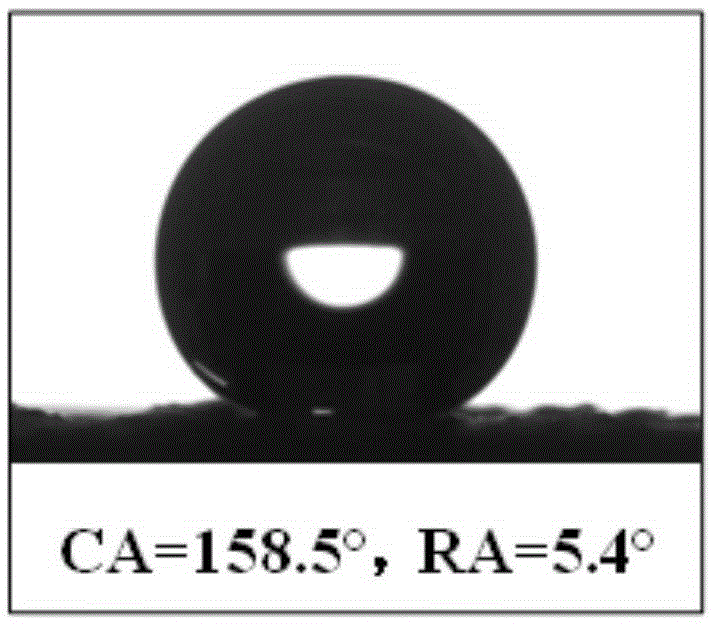

Highly-wear-resistant super-hydrophobic composite coating and preparation method thereof

The invention discloses a highly-wear-resistant super-hydrophobic composite coating and a preparation method thereof. The preparation method includes the steps that the surface of a base is coated with hydrophobic resin primer containing compound micropowder through a brush coating or spray coating method, the surface of the resin primer is sprayed with hydrophobic organic / inorganic hybrid nano-paint after semi-curing, and the highly-wear-resistant super-hydrophobic composite coating is obtained after complete curing. The highly-wear-resistant super-hydrophobic composite coating and the preparation method thereof have the advantages that equipment and the process are simple, operation is easy and cost is low, and have the industrial mass production prospect. The prepared super-hydrophobic composite coating can be applied to various hard / soft bases such as glass, copper, aluminum, stainless steel, exterior wall tiles, wood, paper and cloth and can bear damage of external force such as sanding.

Owner:SOUTHEAST UNIV

Capacitive sensor

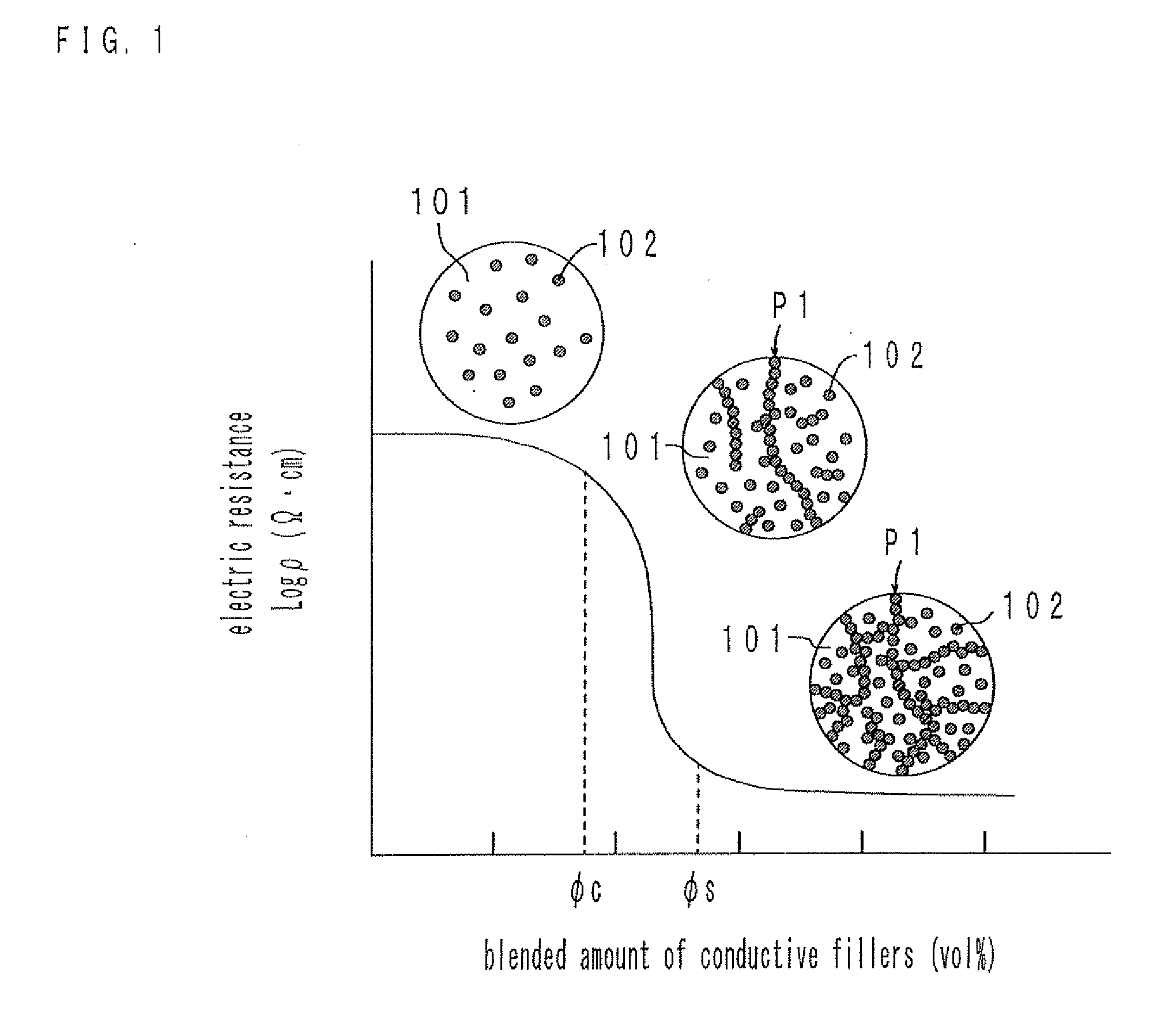

ActiveUS20100033196A1Improve conductivityWell formedResistance/reactance/impedenceForce measurementElastomerCapacitive sensing

A capacitive sensor includes a dielectric layer made of an elastomer and a pair of electrodes arranged via the dielectric layer, and detects deformation on the basis of electrostatic capacity variation between the pair of electrodes. The pair of electrodes contain an elastomer and conductive fillers filled into the elastomer, are expandable and contractible in accordance with deformation of the dielectric layer, and exhibit little conductivity variation even when the pair of electrodes expand and contract. At least one of the dielectric layer and the electrodes is formed by a printing method using a dielectric layer coating containing a formation component of the dielectric layer or an electrode coating containing a formation component of the electrode.

Owner:TOKAI RUBBER IND LTD

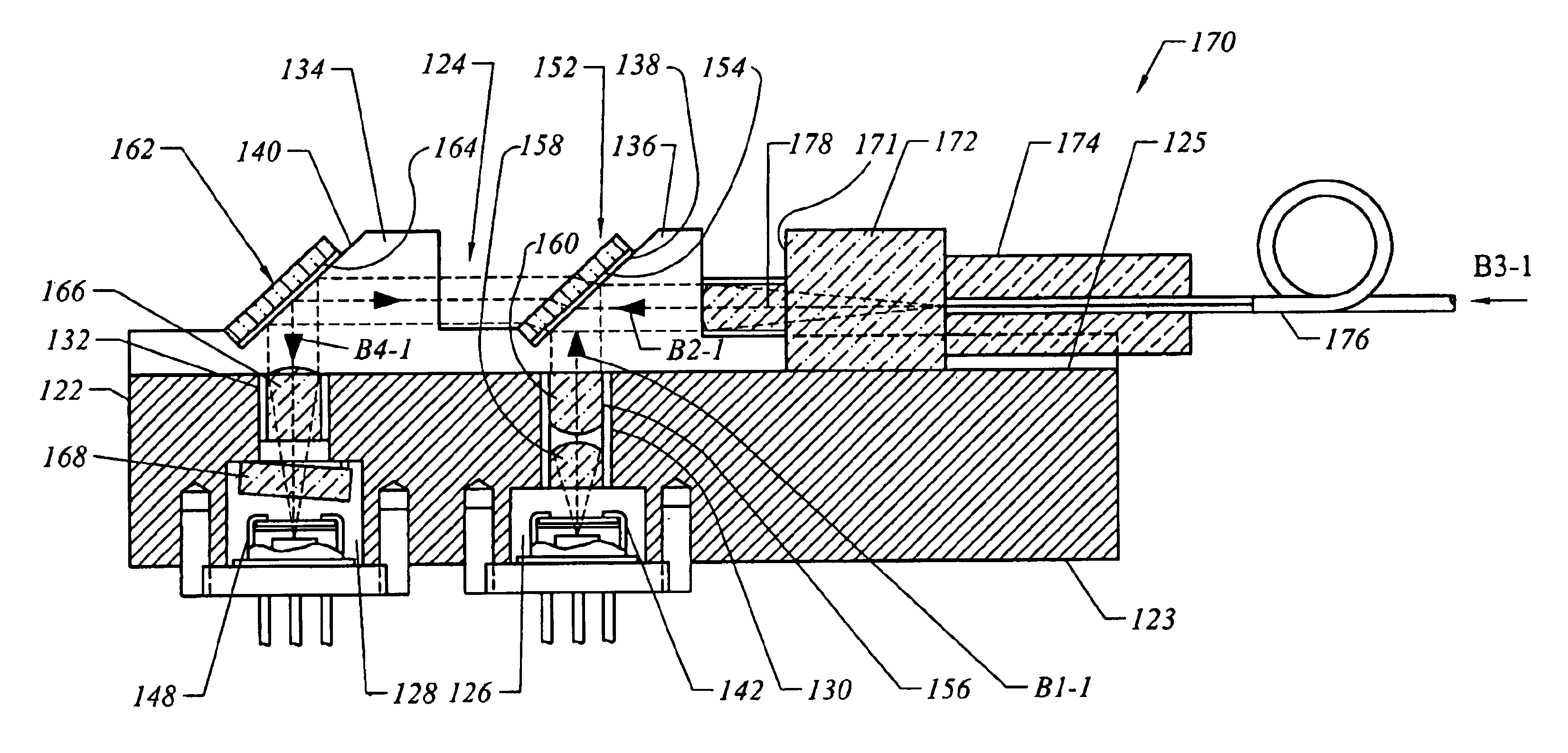

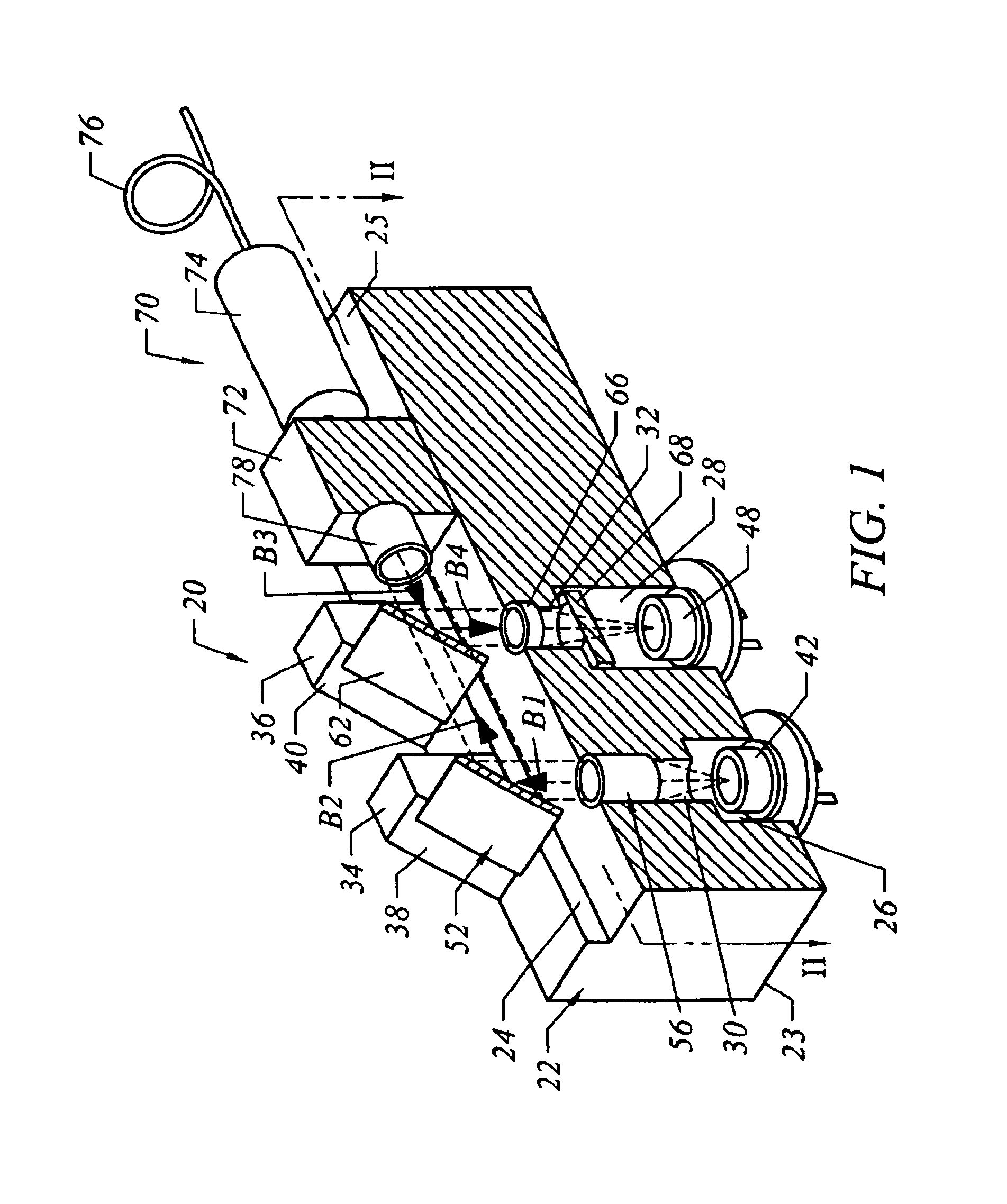

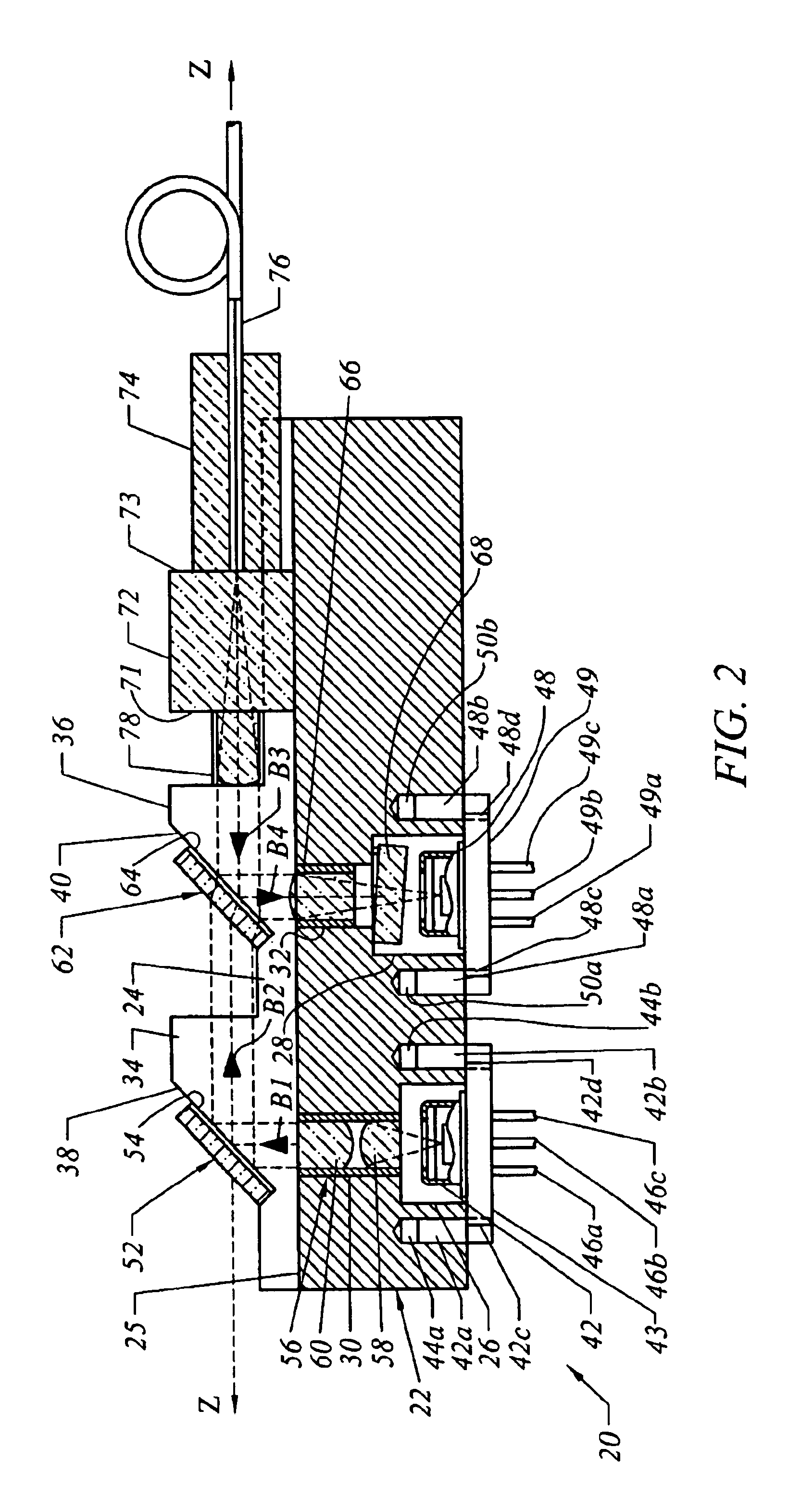

Optical module for high-speed bidirectional transceiver

InactiveUS6939058B2Simplified adjustment procedureEasy constructionCoupling light guidesTransceiverOptical Module

The optical module of the invention for high-speed bidirectional transceiver consists of a signal receiving unit, a signal transmitting unit, a common receiving-transmitting optical fiber, and a fiber coupling unit. The laser diode and the photodiode are arranged parallel to each other in closely located recesses of the module housing. Such an arrangement makes it possible to shorten distances for guiding lead wires from the terminals of the PC board to the respective terminals of the transmitting and receiving diodes. The laser diode emits a first transmitting laser beam that passes through a microobjective that collimates the beam and directs into onto a full-reflection mirror located inside the module housing. The full-reflection mirror reflects the first transmitting beam at an angle of 90° and transmits it to the end face of an optical fiber through an optical fiber collimator that centers the beam with the fiber core. The module is provided with a second mirror, which is fully transparent to the aforementioned first transmitting beam, but is fully reflective to a second transmitting beam that may propagate in a direction opposite to the first transmitting beam on a different wavelength. Alignment of the optical components is facilitated due to the fact that it is carried out with diffractionally limited and collimated beams.

Owner:MICROALIGN TECH +1

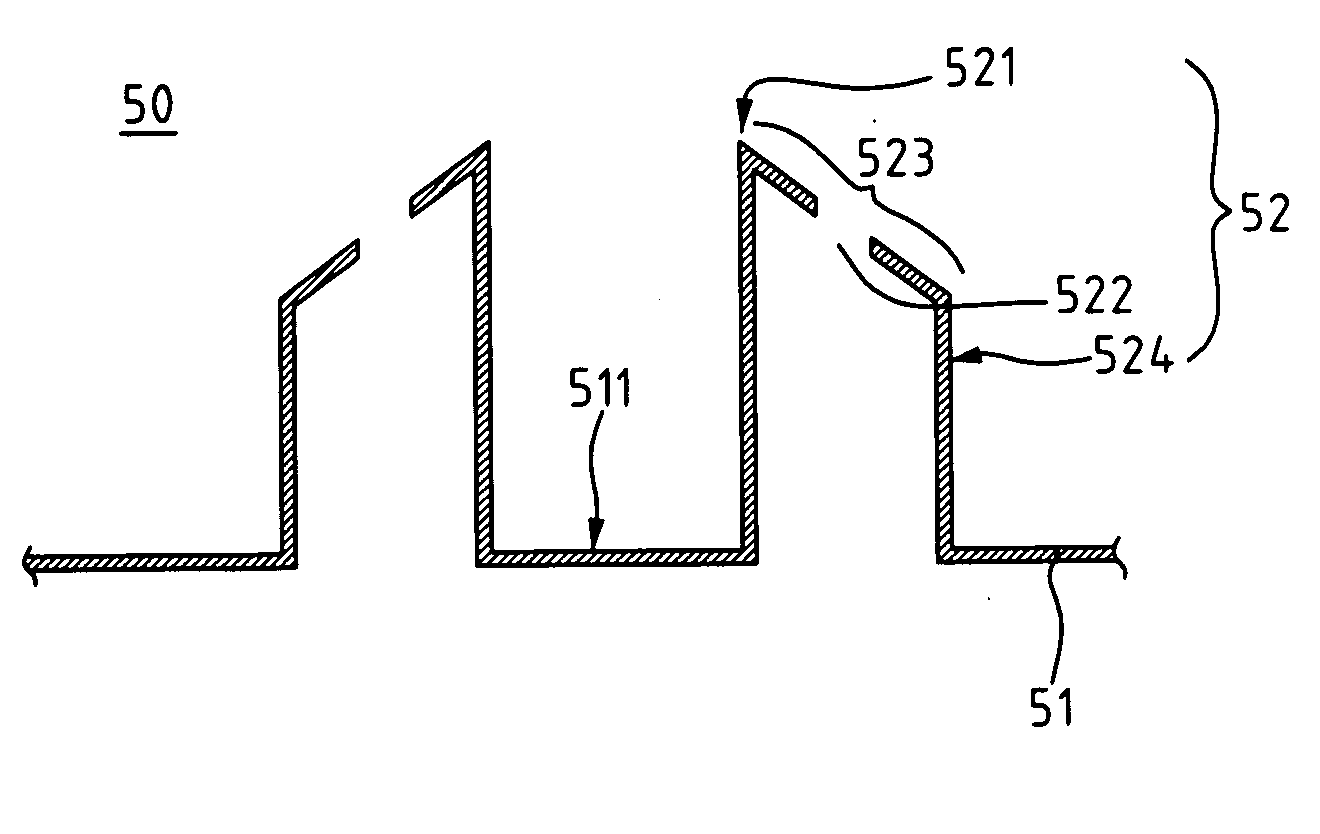

Microneedle array device and its fabrication method

InactiveUS20060015061A1Simple processLow costSurgeryMicroneedlesElectroplatingBiomedical engineering

A microneedle array device and its fabrication method are provided. The microneedle array device comprises a supporting pad and plural of microneedles. Each microneedle has a top portion with a via thereon, thereby the microfluid may flow in or out. The intersection between the top portion and the inner tube of a microneedle forms a convex needle structure, and is almost perpendicular to the upper surface. For each microneedle, a hollow closed tube is formed between the top portion and the supporting pad. The fabrication method uses the substrates with high transmittance and plural of convex area thereon as the upper and lower caps, and applies a photolithography process to fabricate a microneedle array mold. It then sputters or electroplates metal material on the mold. The microneedle array is formed after having taken off the mold. It is a simple fabrication process.

Owner:IND TECH RES INST

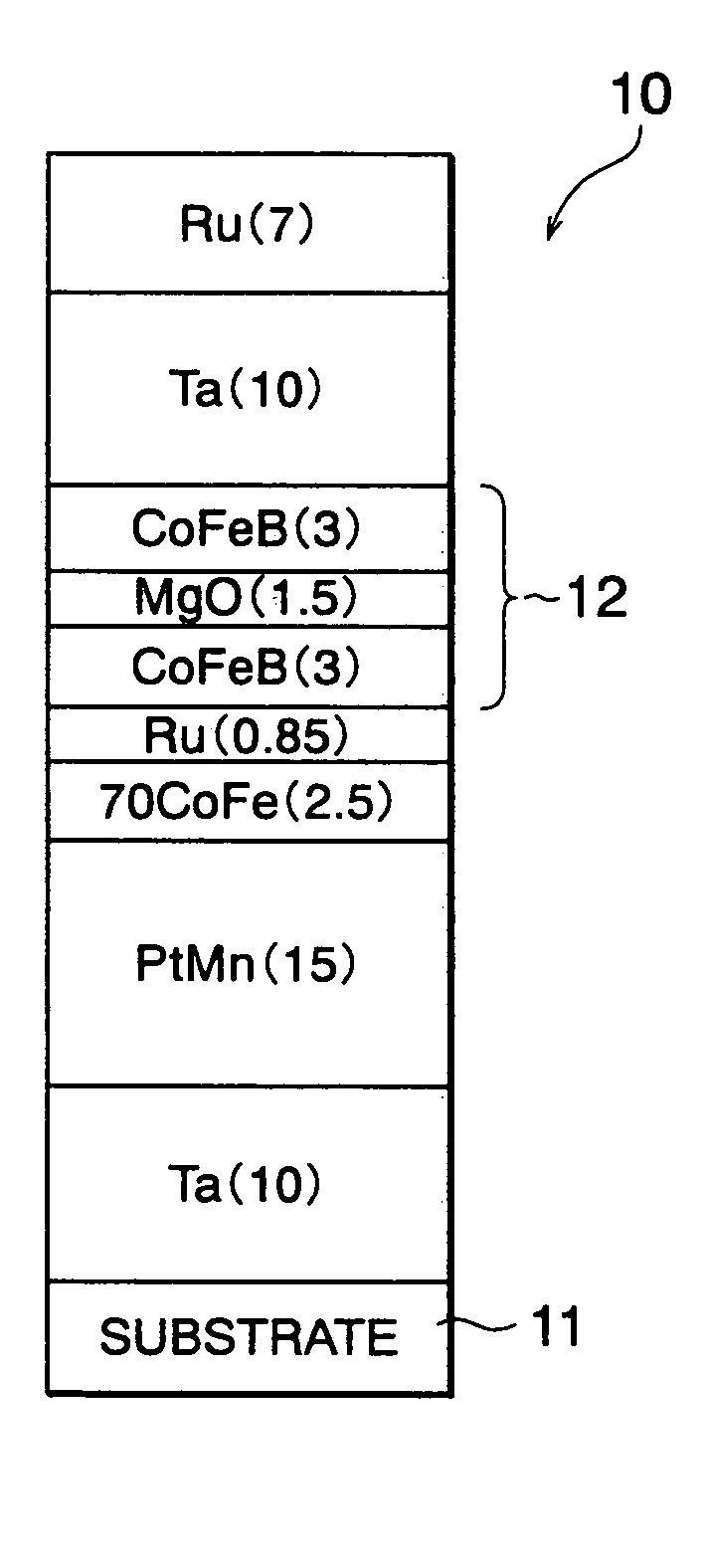

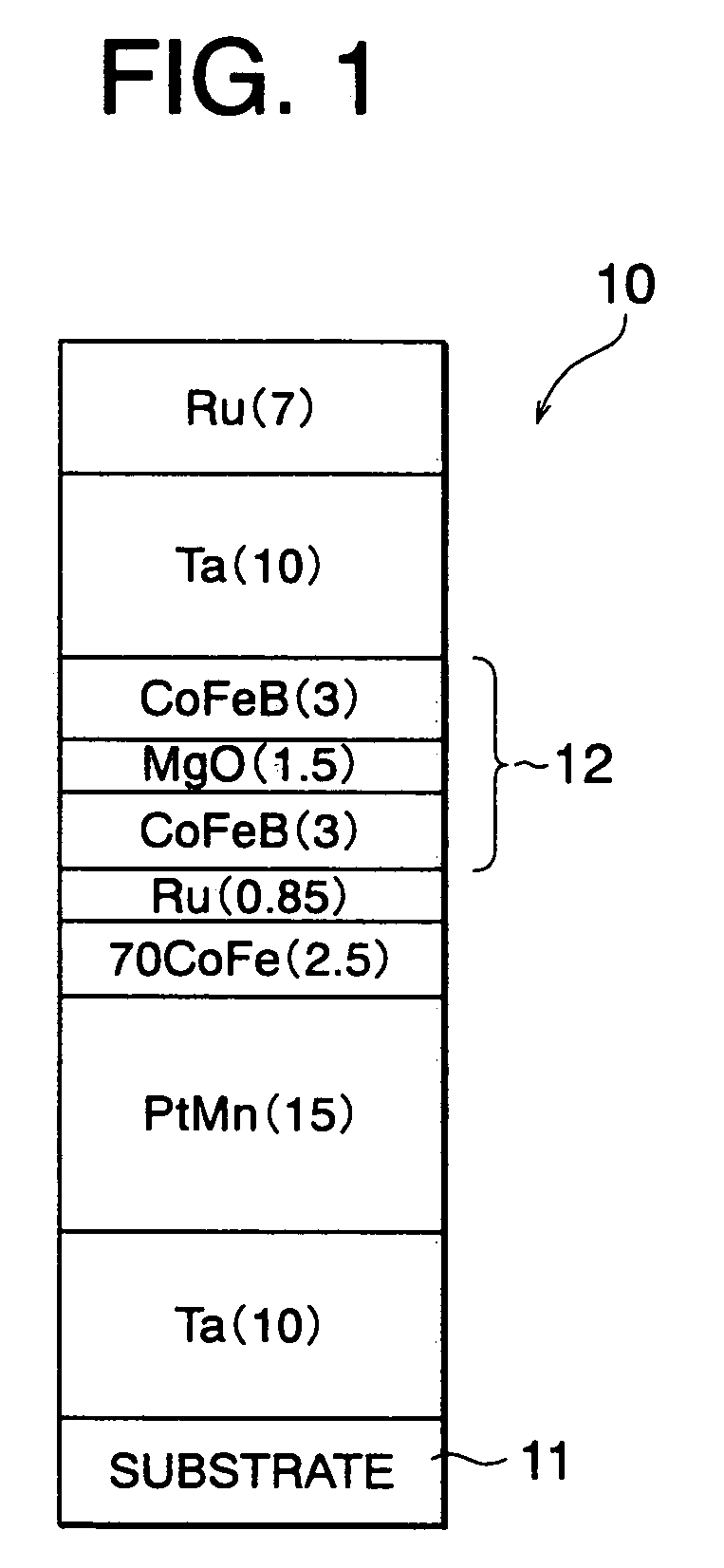

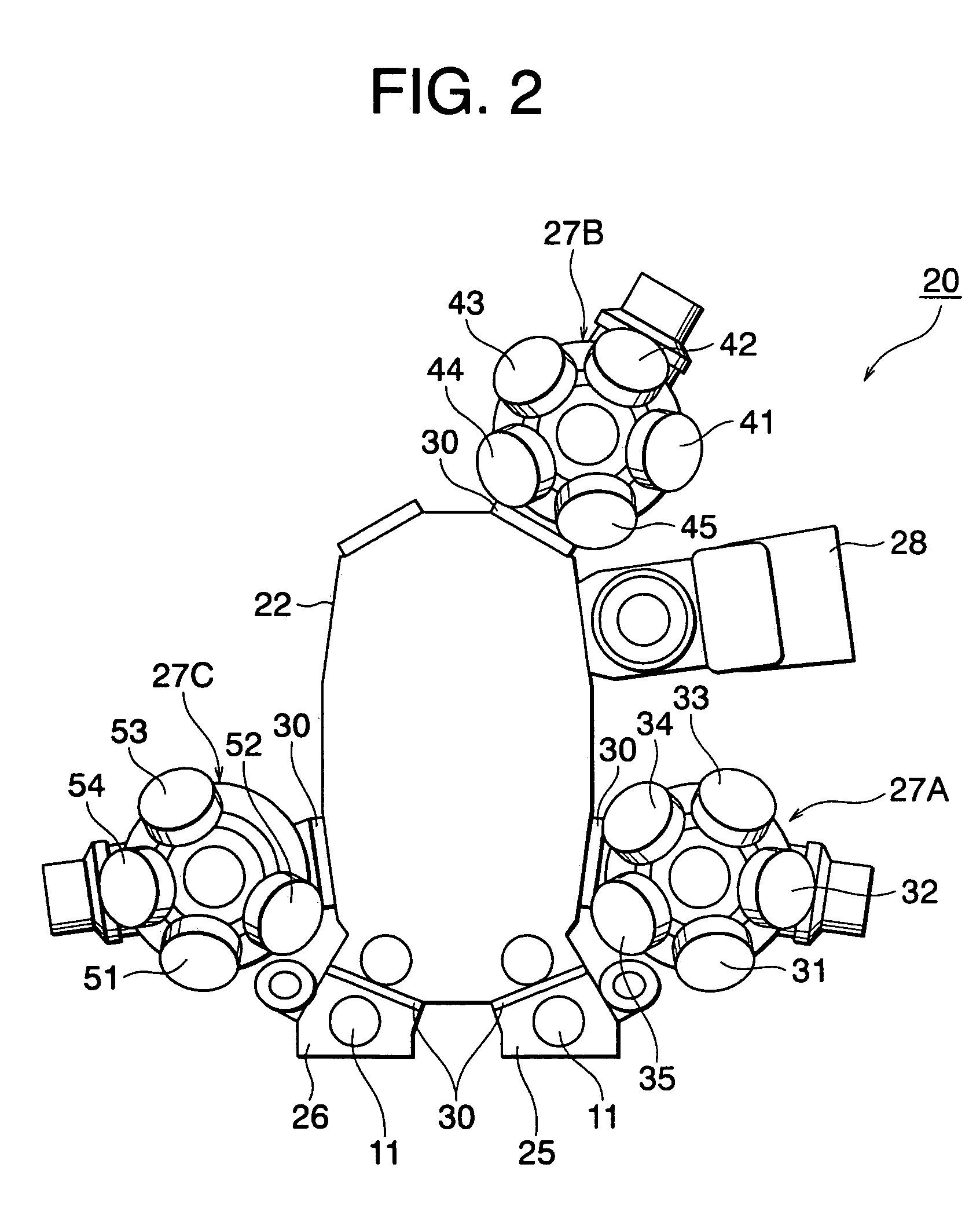

Magnetoresistance effect device and method of production of the same

InactiveUS20060056115A1Increase valueMaintain good propertiesNanomagnetismMagnetic-field-controlled resistorsMethods of productionMolecular physics

A magnetoresistance effect device including a multilayer structure having a pair of ferromagnetic layers and a barrier layer positioned between them, wherein at least one ferromagnetic layer has at least the part contacting the barrier layer made amorphous and the barrier layer is an MgO layer having a highly oriented texture structure.

Owner:CANON ANELVA CORP +1

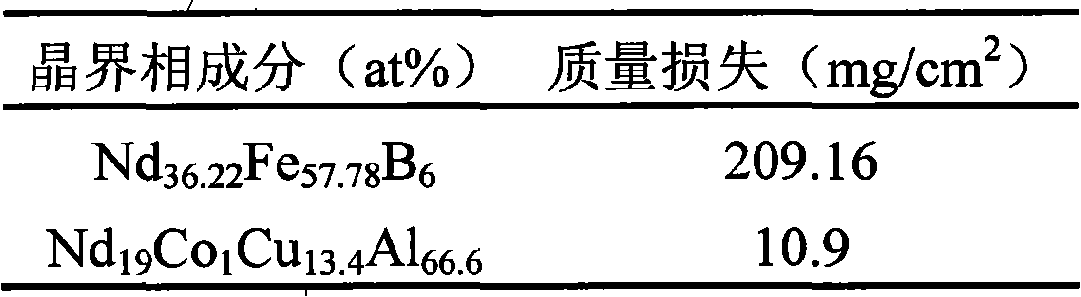

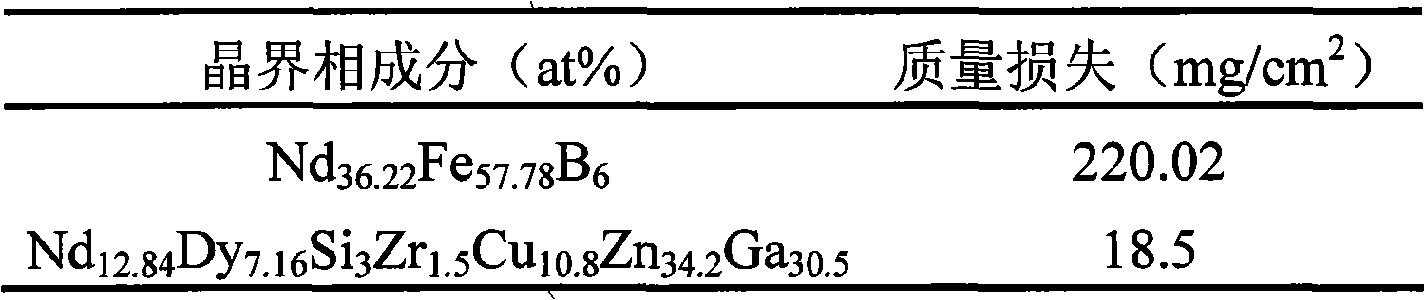

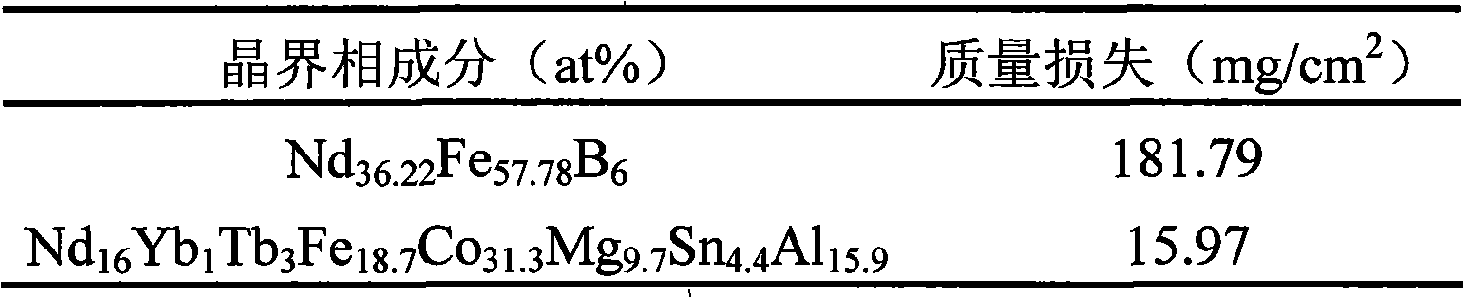

Grain boundary phase-reconstructed high-corrosion resistance Sintered NdFeB magnet and preparation method thereof

ActiveCN101320609ALow melting pointGuaranteed MagneticInorganic material magnetismInductances/transformers/magnets manufactureElectrode potentialPowder mixture

The invention discloses a sintered Nd-Fe-B magnet with high corrosion resistance and the grain boundary reconstruction and a preparation method thereof. The composition of the invention is that: NdeFe100-e-f-gBfMg, wherein, e is greater than or equal to 6 and equal to or less than 24, f is greater than or equal to 5. 6 and equal to or less than 7, g is greater than or equal to 0.03 and equal to or less than 8, M is one or some of elements Dy, Tb, Pr, Sm, Yb, La, Co, Ni, Cr, Nb, Ta, Zr, Si, Ti, Mo, W, V, Ca, Mg, Cu, Al, Zn, Ga, Bi, Sn and In; The method is that: main phrase alloy and reconstructed grain boundary phase alloy are respectively pulverized and mixed uniformly; the powder mixture is pressed to a mould in the magnetic field, and fabricated into a sintering magnet in a high vacuum sintering furnace. By the reconstruction of the grain boundary phase composition, the invention can obtain the grain boundary phase alloy with low melting point and high electrode potential, decrease the potential difference between the main phase and the grain boundary phase on the basis of ensuring the magnetic properties, promote the intrinsic corrosion resistance of magnet, and has the advantages of simple process, low cost and being suitable for the batch production. Therefore, by combining the grain boundary reconstruction and double alloy method, the sintered Nd-Fe-B magnet with high intrinsic corrosion resistance can be prepared.

Owner:ZHEJIANG UNIV

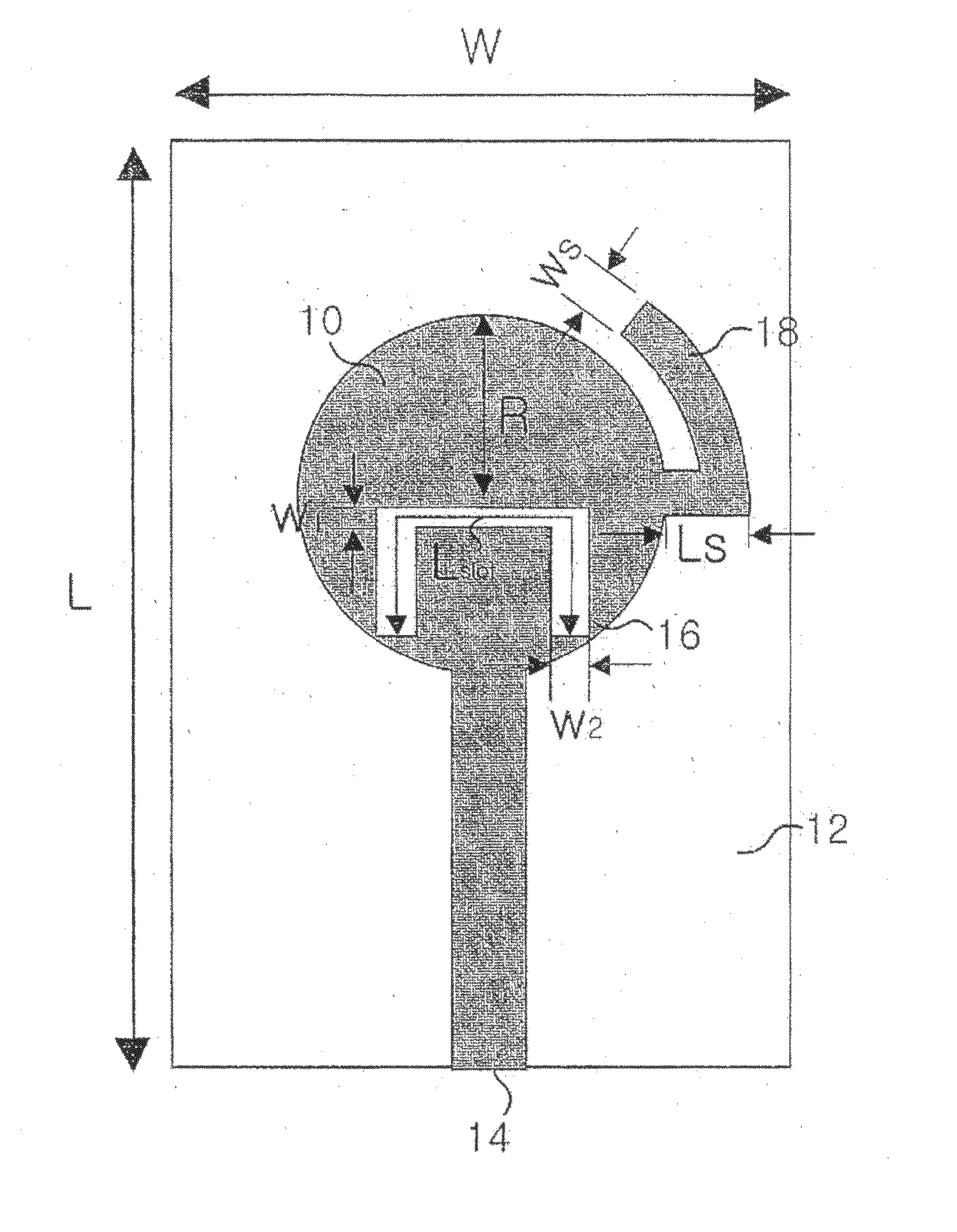

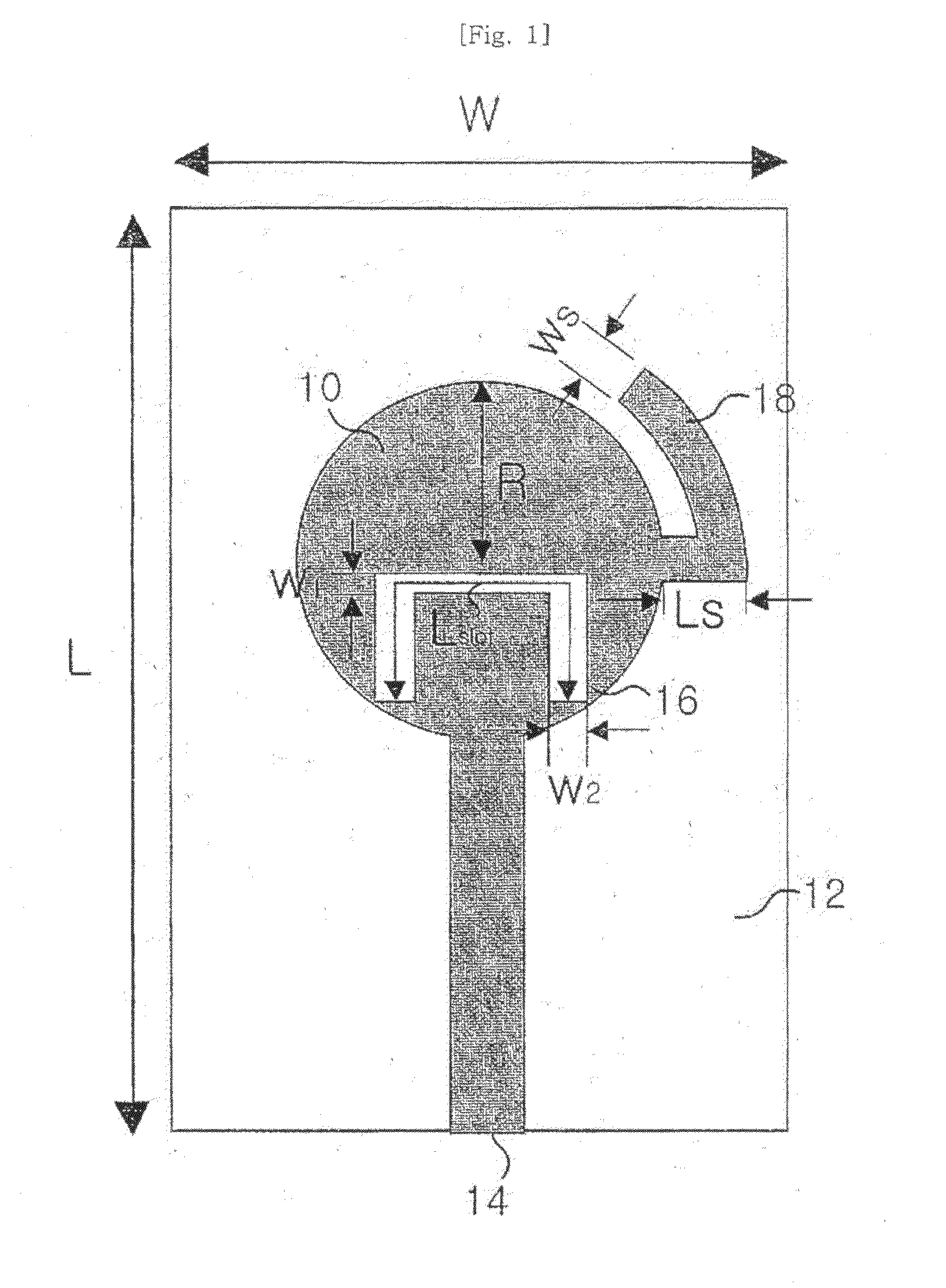

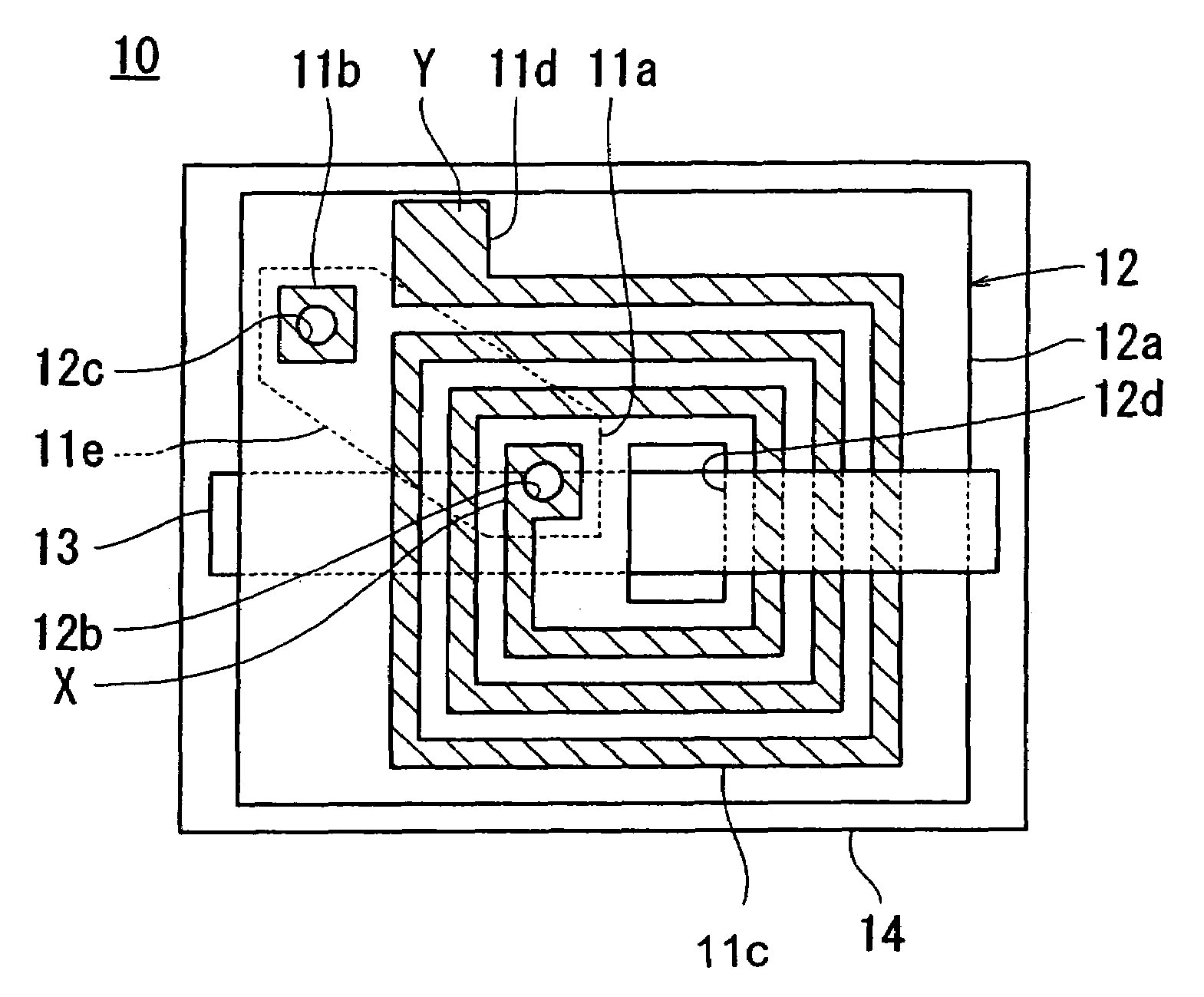

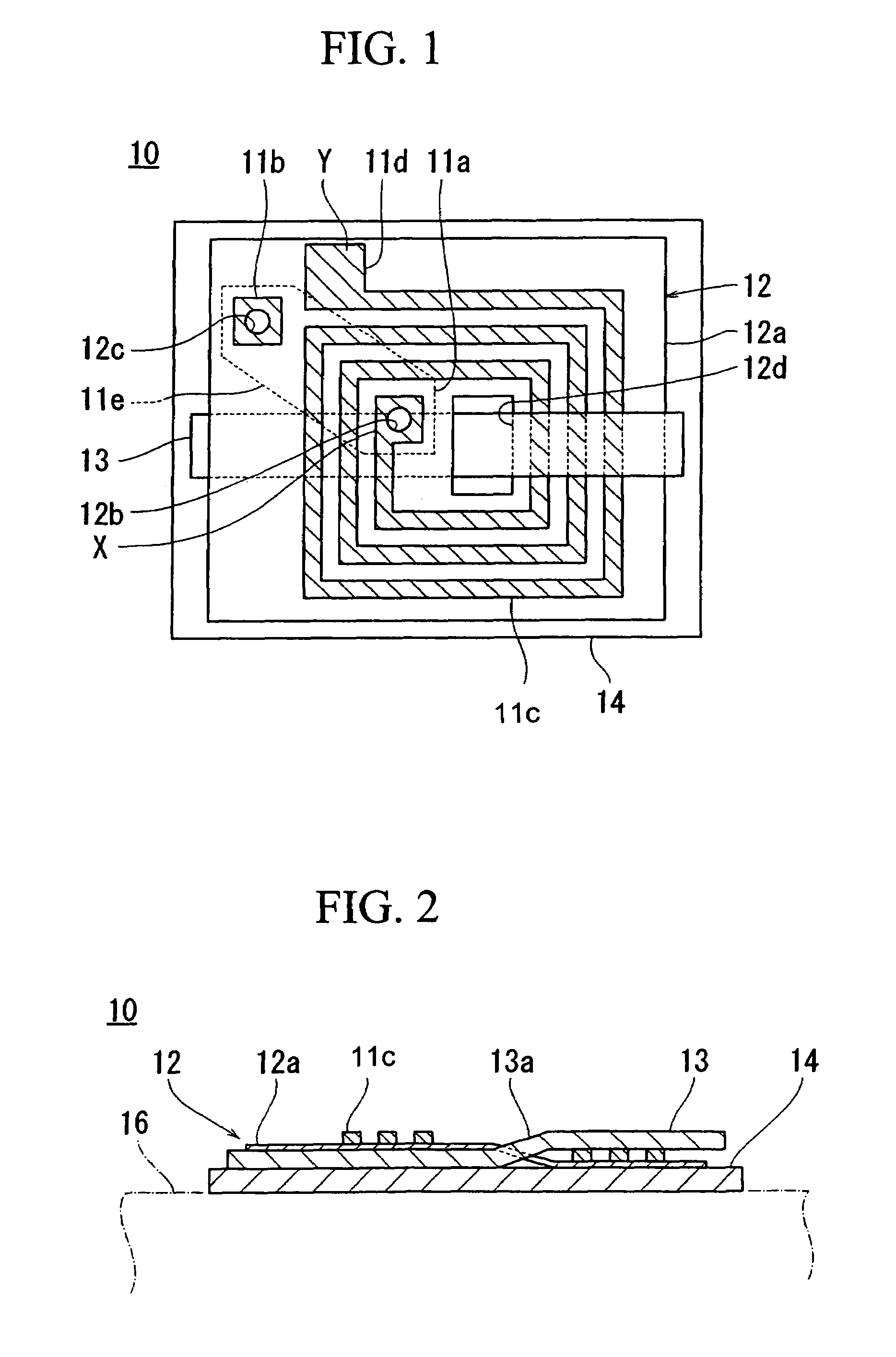

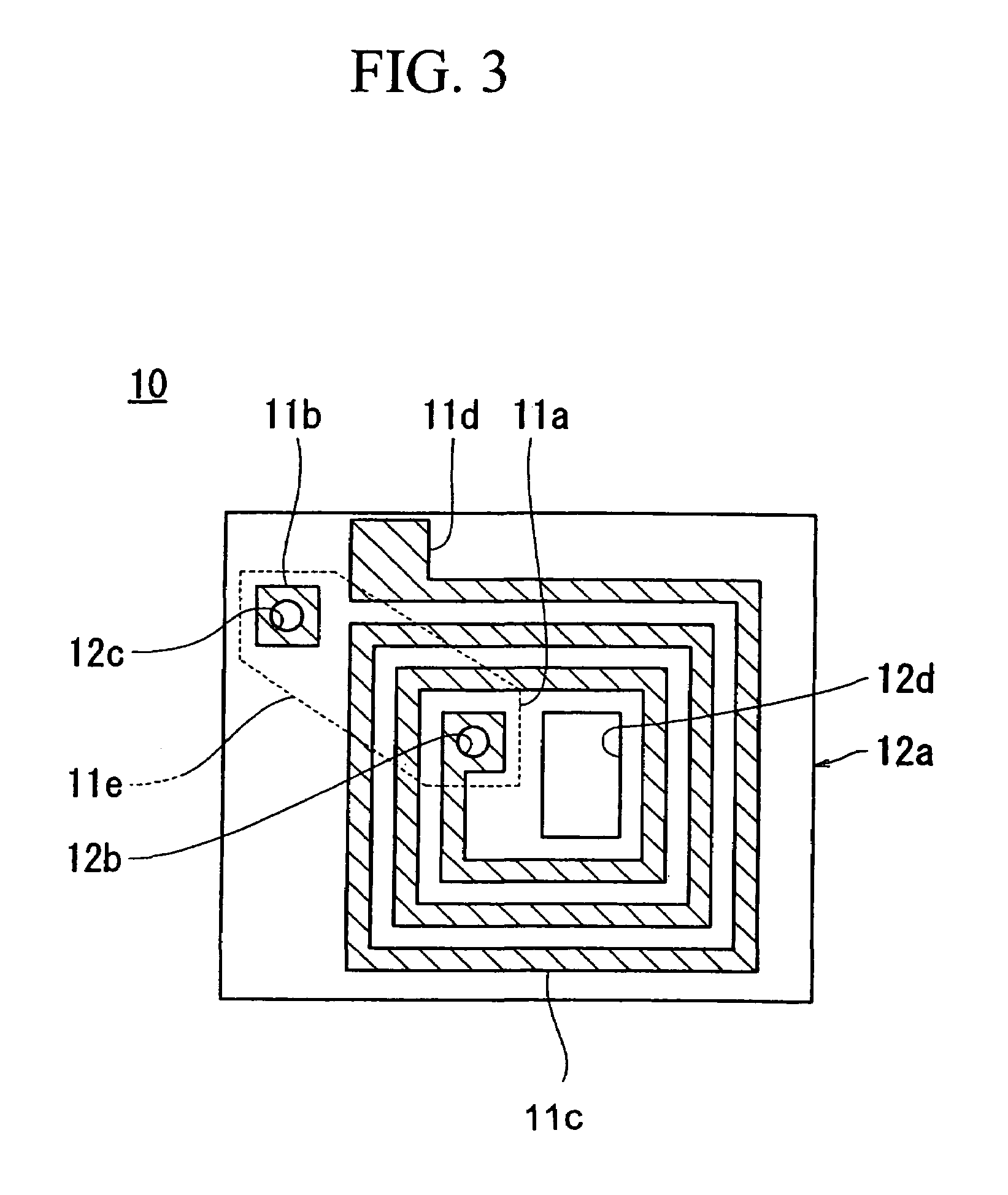

Ultra-wideband antenna having a band notch characteristic

InactiveUS20100182210A1High bandwidthImprove featuresSimultaneous aerial operationsAntenna supports/mountingsUltra-widebandIntermediate frequency

The present invention discloses an antenna for ultra-wideband (UWB) communication having a band-stop characteristic. According to an embodiment of the present invention, the UWB antenna is a patch antenna employing microstrip feeding. In order to expand a bandwidth at a low frequency band, a stub is formed in a radiating element. Furthermore, since steps are formed in a ground plane, an antenna characteristic at an intermediate frequency band can be improved and a UWB characteristic can be obtained. According to another embodiment of the present invention, the UWB antenna is a patch antenna employing microstrip feeding and has a recess formed in the ground plane, thereby implementing the UWB characteristic. The antenna of the present invention has an inverse U-shaped slot formed in the radiating element, thus implementing the band-stop characteristic at the UNII band. In addition, the antenna of the present invention has includes a ground plane having a small area and has omnidirectional radiating patterns accordingly.

Owner:EMW CO LTD

Antenna coil, and RFID-use tag using it, transponder-use antenna

InactiveUS7088304B2Improve rigidityHigh frequencyLoop antennas with ferromagnetic coreOther printing matterEngineeringNon magnetic

An antenna coil includes an air-core coil wound helically in a plane and a plate magnetic core member inserted in the air-core coil to be approximately parallel with a plane of the air-core coil. The magnetic core member is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member is a magnetic coating formed by applying and drying the composite member. A non-magnetic conductive plate that has a conductivity is layered on a surface of the air-core coil through which the magnetic core member is inserted. The conductive plate is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. The antenna coil is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

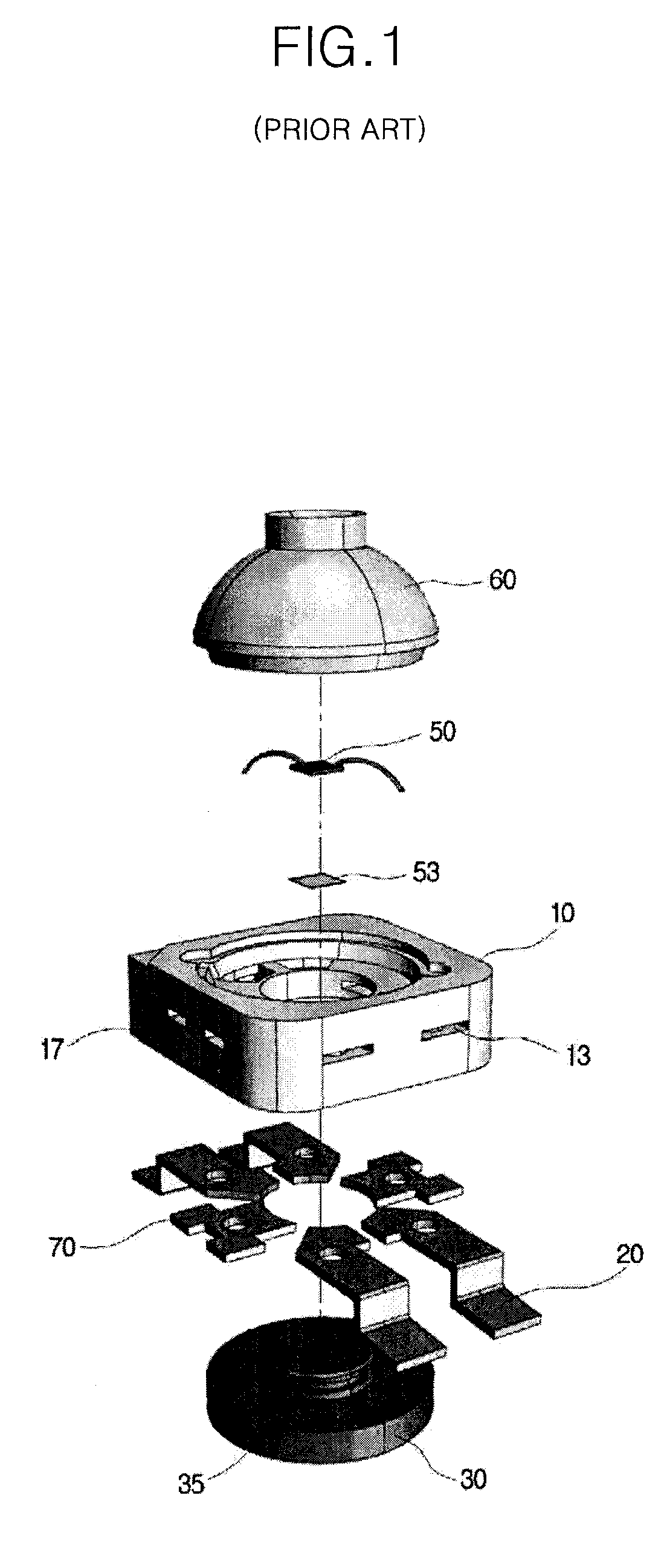

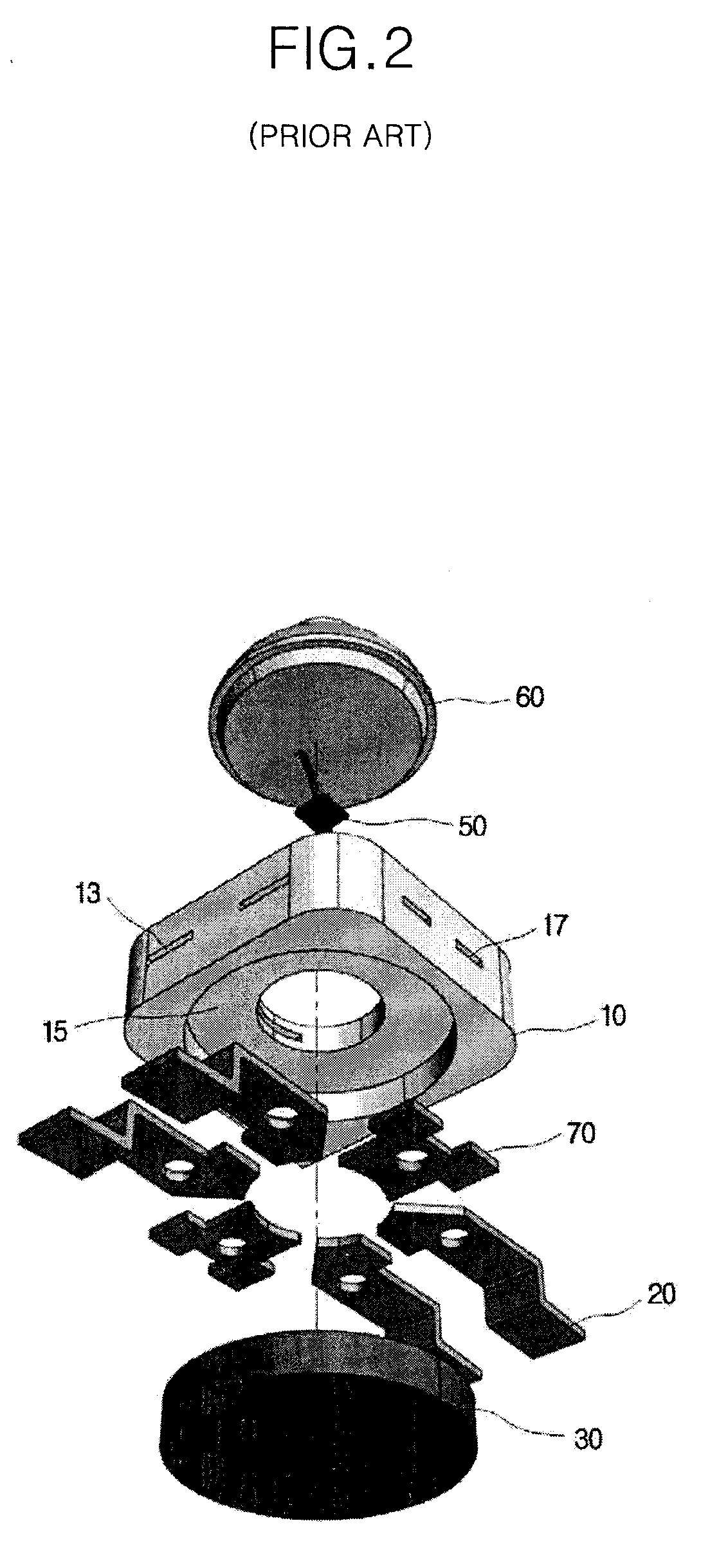

High Power Light Emitting Diode Package

InactiveUS20080089072A1Efficient couplingIncrease powerLighting heating/cooling arrangementsSolid-state devicesEngineeringConductive materials

A high power light emitting diode (“LED”) package is disclosed. The high power LED package includes a housing made of an insulating material and having a cavity in its central portion; a lead frame made of a conductive material, including an inner lead exposed by the cavity of the housing and an outer lead extending outside the housing; a heat sink above which the inner lead is placed and having a portion exposed by the cavity of the housing; an LED chip mounted on the exposed portion of the heat sink and electrically connected to the inner lead; a lens portion coupled to the housing to cover the cavity of the housing; and an insulating adhesive sheet interposed between the inner lead and the heat sink for electrically insulating and thermally coupling the inner lead and the heat sink.

Owner:ALTI ELECTRONICS

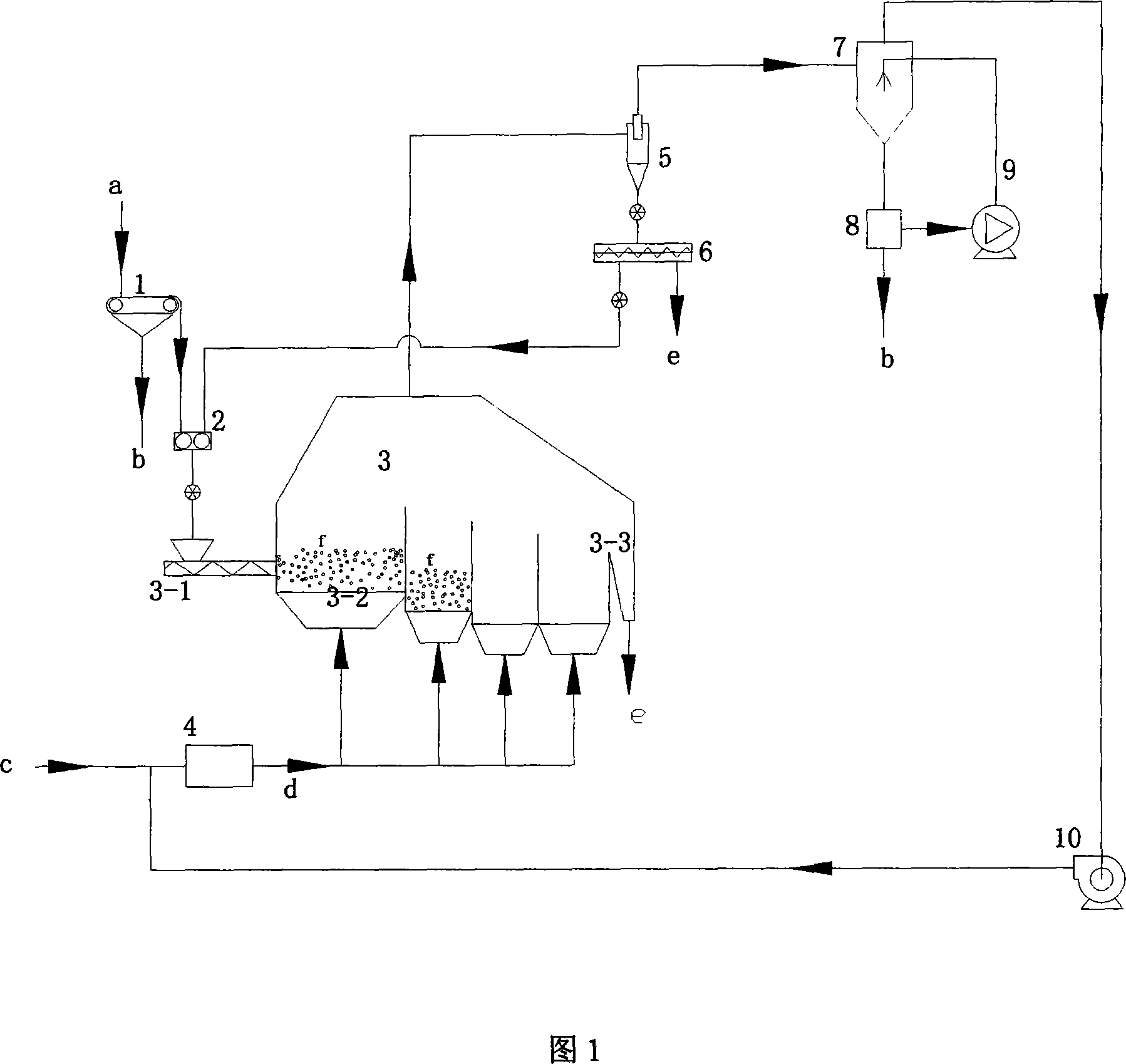

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

Preparation method of hydrophilic antimicrobial film of which surface is coated with dopamine and polyethyleneimine cations

InactiveCN104524986ALong-term hydrophilicLong-lasting antibacterialSemi-permeable membranesPolymer chemistryAntibacterial property

The invention discloses a preparation method of a hydrophilic antimicrobial film of which the surface is coated with dopamine and polyethyleneimine cations. The preparation method comprises the following steps that a base film is prepared, the base film is immersed in a dopamine solution, a polydopamine layer is formed on the surface of the base film by dopamine auto-agglutination, and the polydopamine layer and a polyethyleneimine aqueous solution undergo a reaction so that the hydrophilic antimicrobial film is prepared by the cationization reaction. The preparation method is simple and easy and has mild reaction conditions. The prepared hydrophilic antimicrobial film has excellent hydrophilicity and antibacterial properties, reduces adherence of microbes such as organic matters and bacteria, has a bacterium killing capability and prolongs a film service life.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Mobile phone shell and preparation method thereof

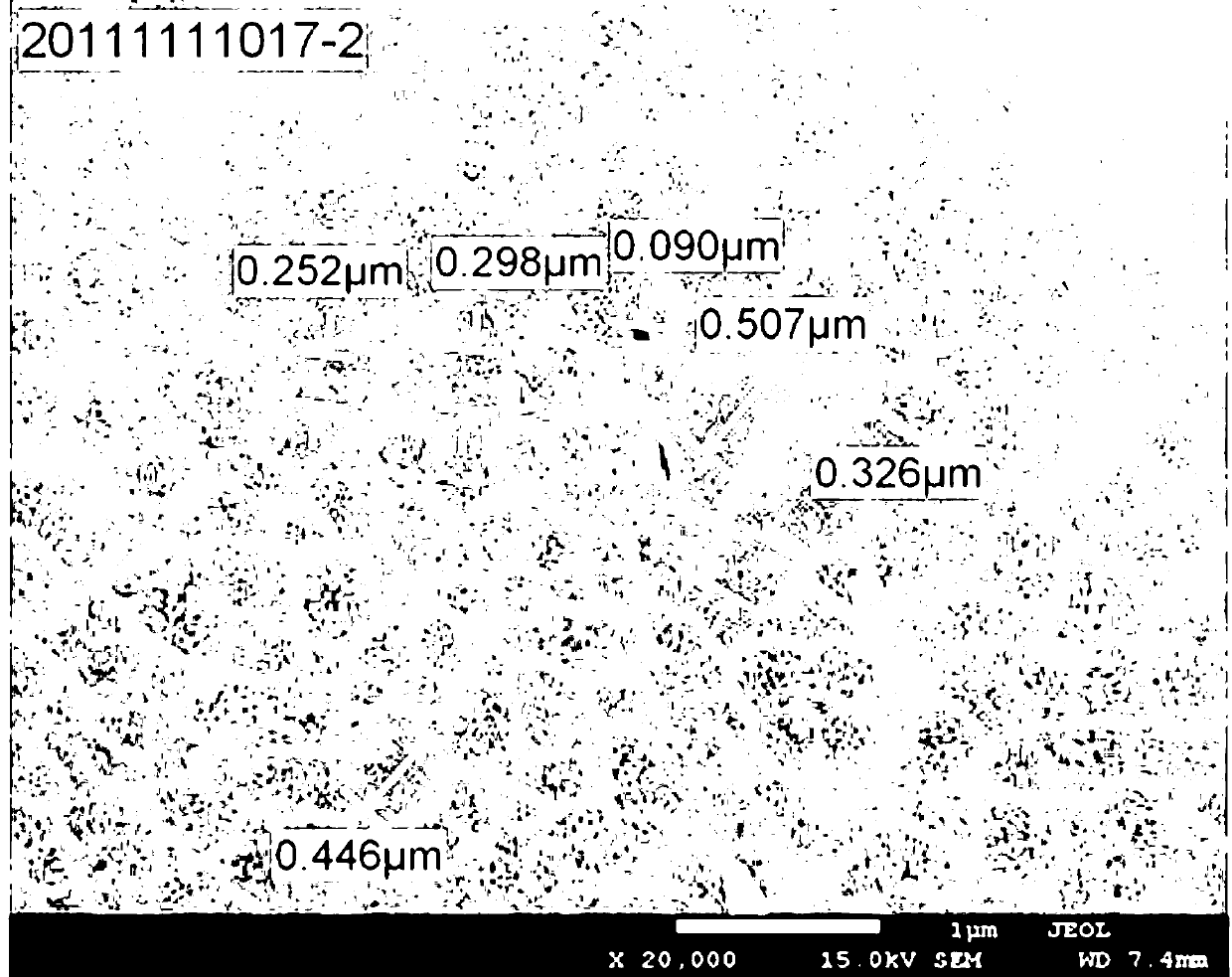

ActiveCN103297565AImprove corrosion resistanceAppearance has no effectAnodisationSmall component housingsMobile phoneNanotechnology

The invention provides a mobile phone shell and a preparation method of the mobile phone shell. The mobile phone shell comprises a plastic piece and a metal shell body which is combined with the plastic piece, wherein the surface of a face, combined with the plastic piece, of the metal shell body is provided with an oxidation film layer, corrosion holes are formed in the surface layer of a face, opposite to the plastic piece, of the oxidation film layer, the hole diameter of each corrosion hole is 200 nanometers to 2000 nanometers, nanometer micro holes are formed in the inner layer of the oxidation film layer, the hole diameter of each nanometer micro hole is 10 nanometers to 100 nanometers, and resin compositions of the plastic piece are filled in the nanometer micro holes and the corrosion holes. The prepared mobile phone shell is resistant to abrasion, falling and corrosion.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com