Patents

Literature

913 results about "Dewatered sludge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making hydrophobically associative polymers, methods of use and compositions

InactiveUS6417268B1Cosmetic preparationsSludge treatment by de-watering/drying/thickeningHydrophilic monomerSludge

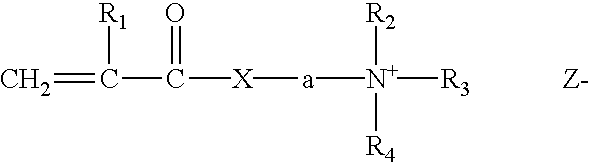

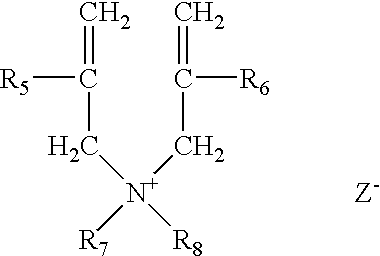

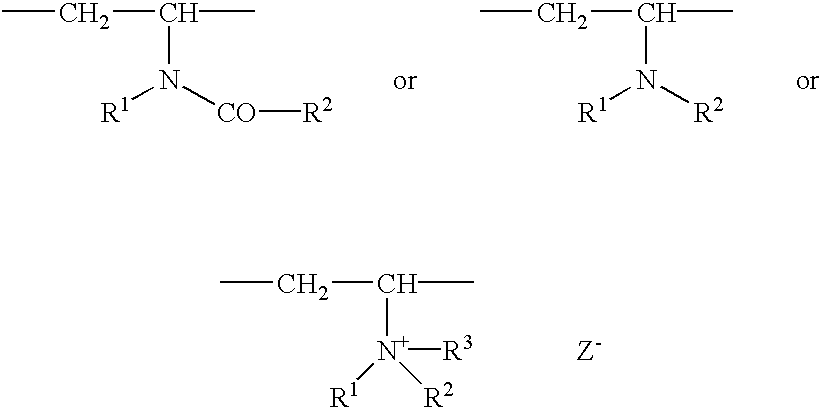

Method for producing an hydrophobically associative polymer is provided which is characterized by forming a monomer solution comprising a surfactant, at least one hydrophobic ethylenically unsaturated monomer, at least one hydrophilic monomer selected from nonionic ethylenically monomers, cationic ethylenically unsaturated monomers, anionic ethylenically unsaturated monomers or mixtures thereof, and water; forming a salt solution comprising a multivalent salt and water; mixing the monomer solution and salt solution to form a mixed solution; and charging the mixed solution with an initiator, thereby polymerizing the monomers to form the hydrophobically associative polymer in a dispersion. Aqueous dispersion containing the hydrophobically associative polymer formed by the method. The aqueous dispersion containing the hydrophobically associative polymer may be used in a paint formulation, in a mobility control fluid useful in enhanced oil recovery, in a secondary or tertiary oil recovery system, in an enhanced oil recovery method, in a cementious composition, in an oil well drilling mud formulation, in a fracturing fluid formulation, in a wastewater treatment system, or in a dewatering sludge system.

Owner:SOLENIS TECH CAYMAN

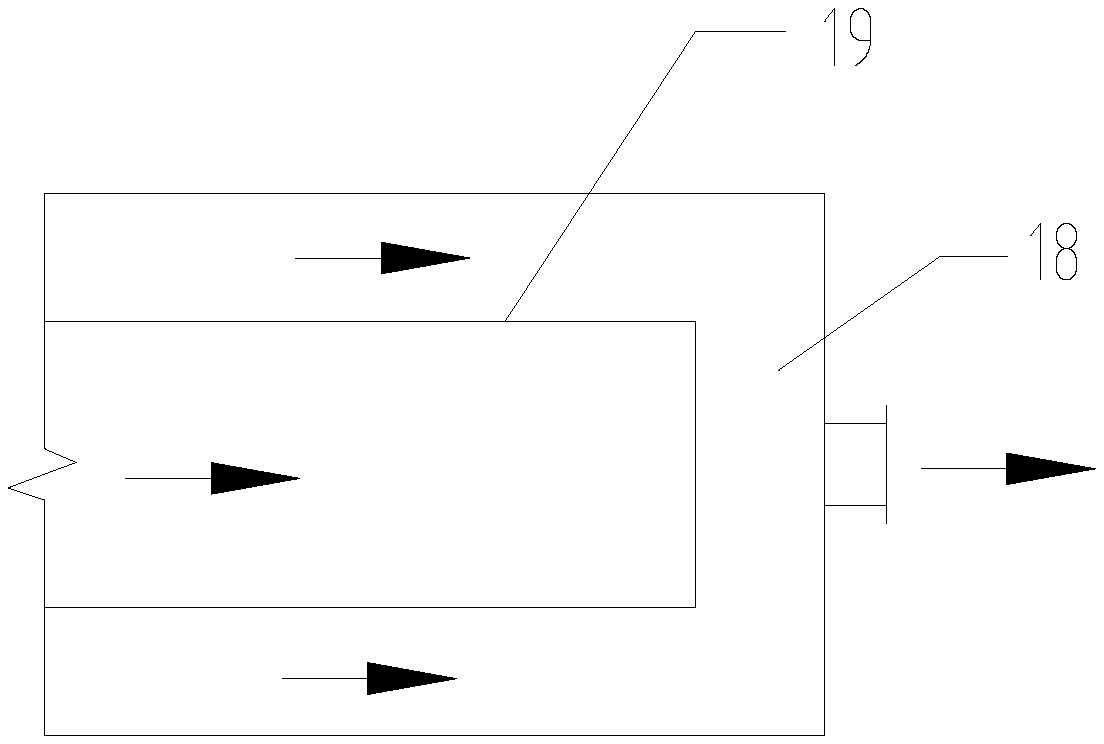

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

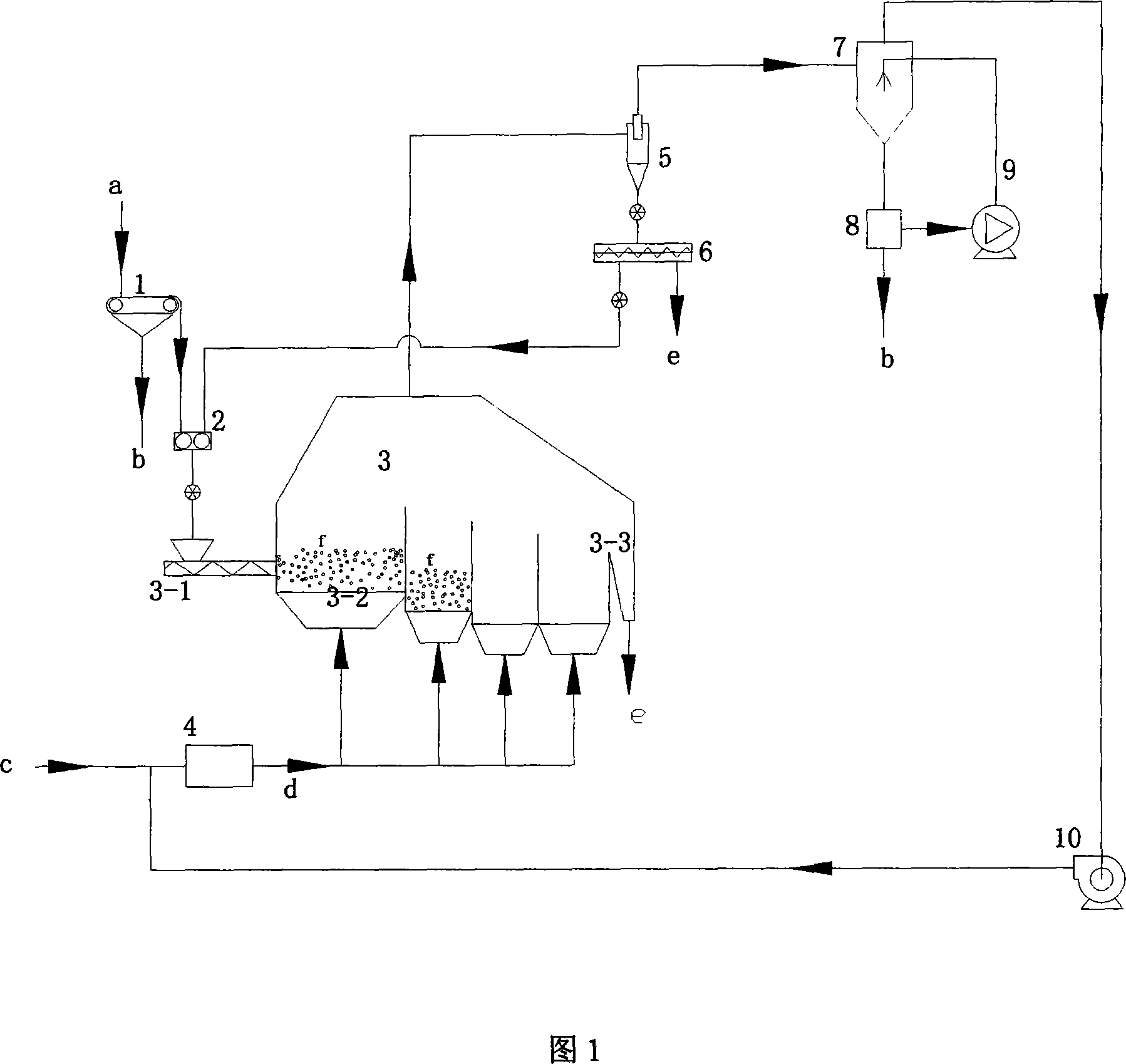

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

Method for preparing haydite from urban sewage plant sludge

InactiveCN101148346AHas a lightweightLight weightCeramic materials productionClaywaresChemical industryExpanded clay aggregate

The present invention discloses one kind of haydite produced with dewatered sludge, fly ash and clay as material and its production process, and belongs to the field of environment technology. The haydite is produced dewatered sludge, fly ash and clay as material, and through mixing and sintering at gradually raised temperature. It is yellow or brown spherical solid in the bulk specific weight of 650-750 kg / cu m, granular specific weight of 1050-1150 kg / cu m, water absorption of 5.80-10.8 %, and specific surface area of 2.29-5.56 sq m / g. The production process is simple and low in cost, and the haydite has light weight, high strength, small water absorption, great specific surface area and other features. The haydite has wide use in building, environment protection, metallurgy, chemical industry, and other industry.

Owner:SHANDONG UNIV

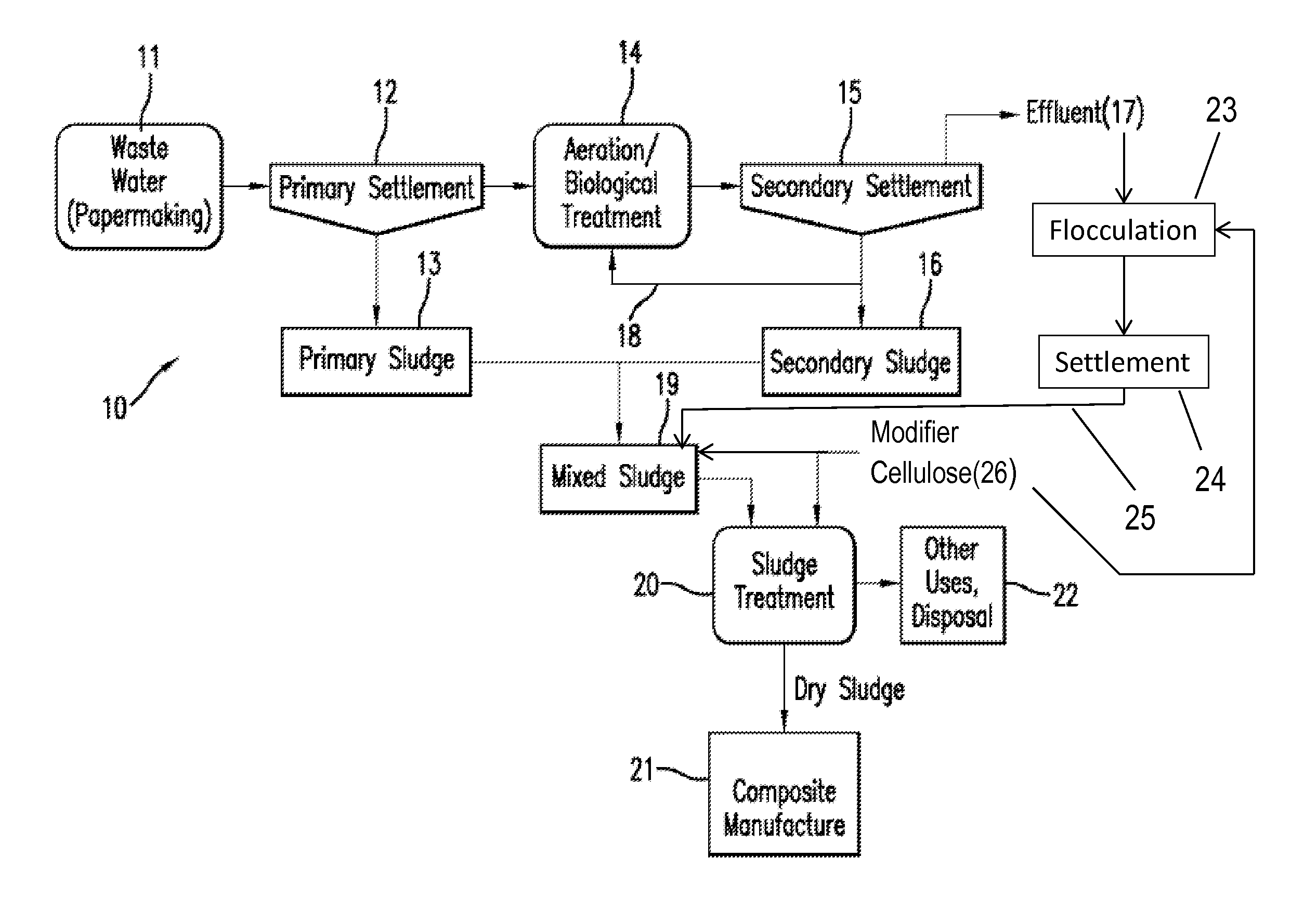

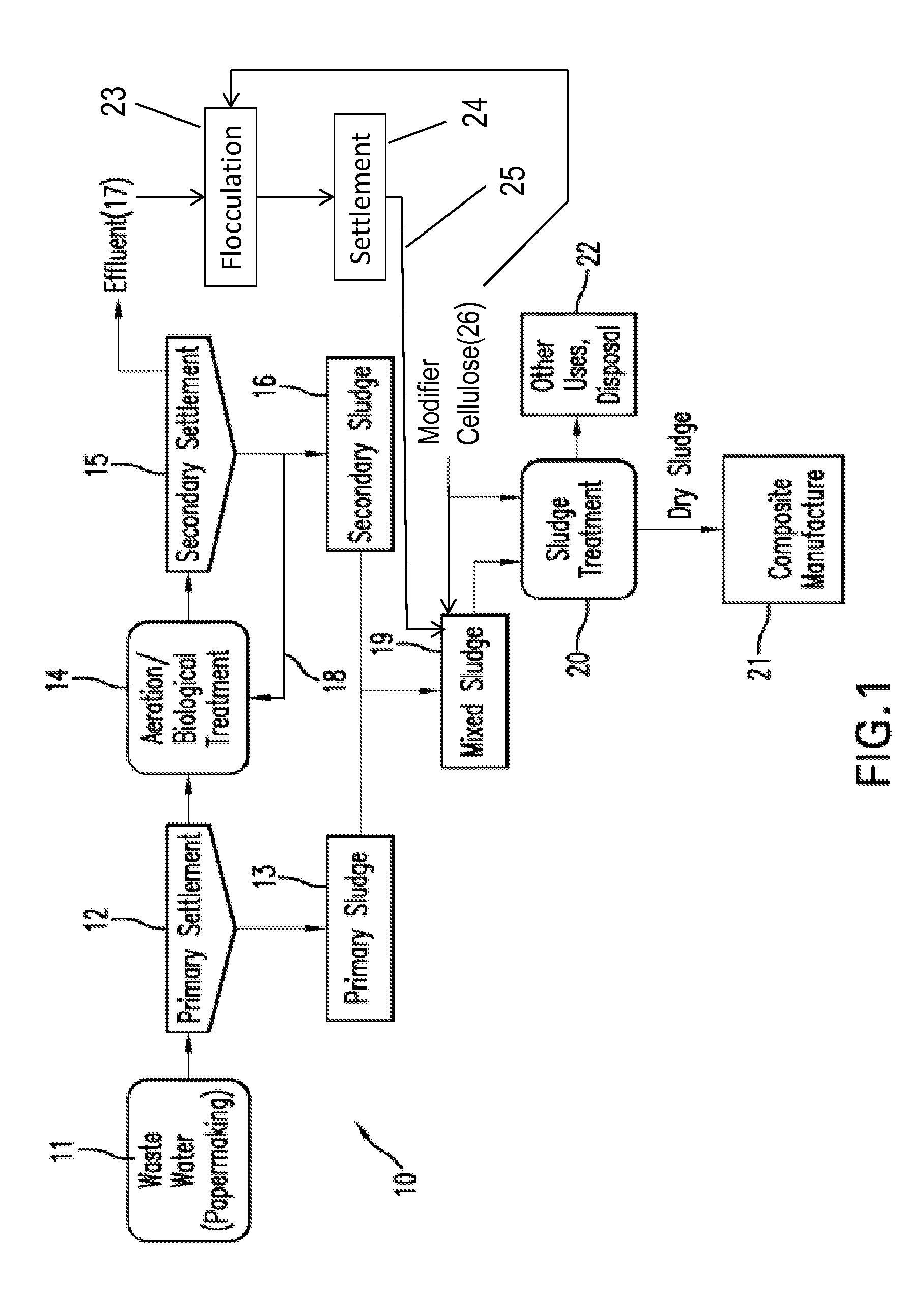

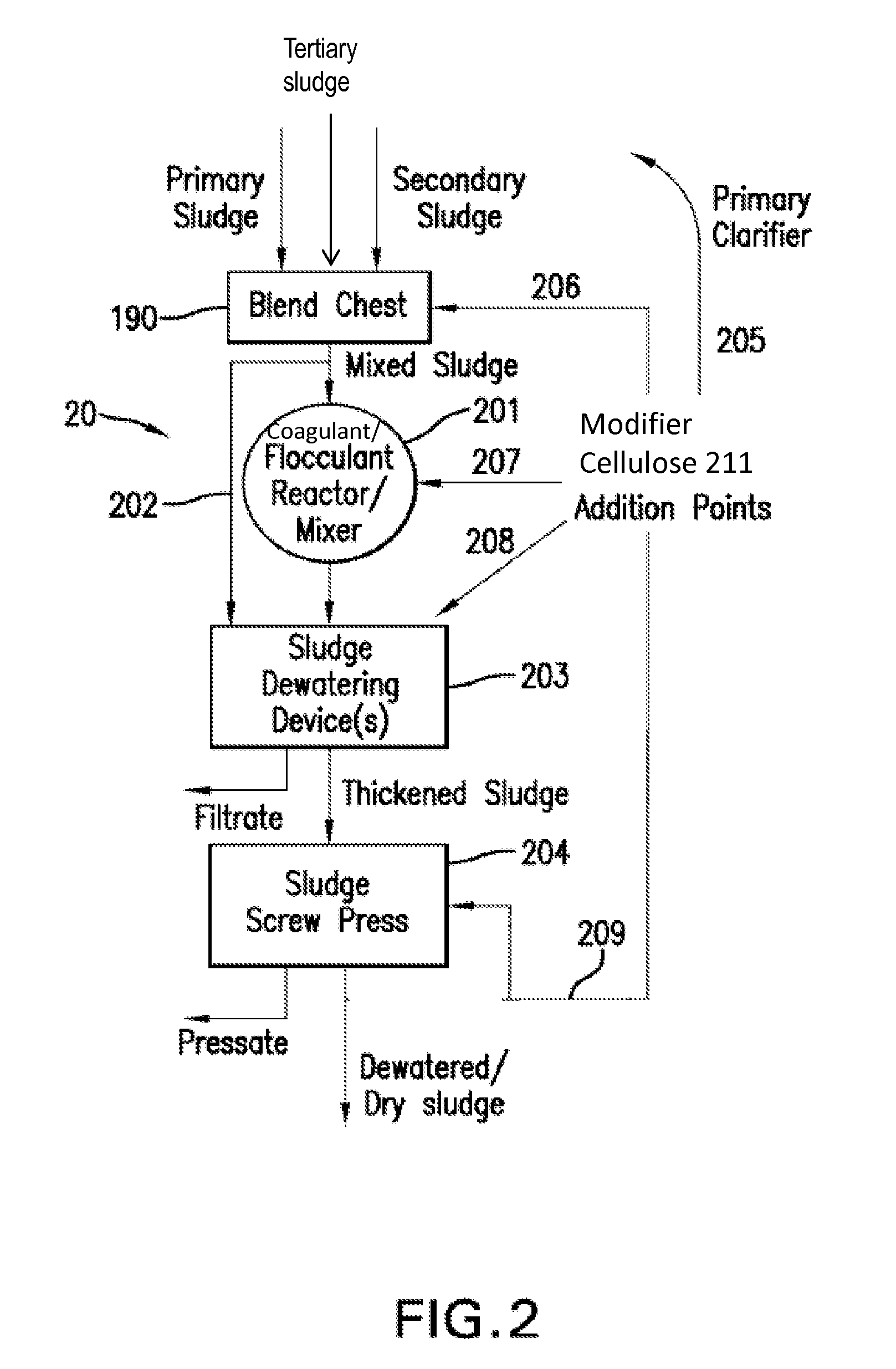

Use Of Celluloses In Sludge Dewatering, And Sludge Products Thereof

InactiveUS20150197439A1Accelerates the dehydration processNon-macromolecular adhesive additivesInksParticulatesPrill

Methods to improve dewatering in industrial and municipal sludges are described. One method involves admixing sludge from a papermaking process and modified cellulose to provide modified sludge with the modified cellulose present in an effective amount to improve dewatering in the treated sludge, such as in allowing use of reduced amounts of coagulant and / or reducing dewatering times, increased dewatered volumes, and reduced sludge product moisture contents, and the like. The dewatered sludge may be formed into a dried particulate, and may be used as filler or other component of concrete, rubber, asphalt, plastics, resin-wood composite products, and other composite products.

Owner:BUCKMAN LAB INT INC

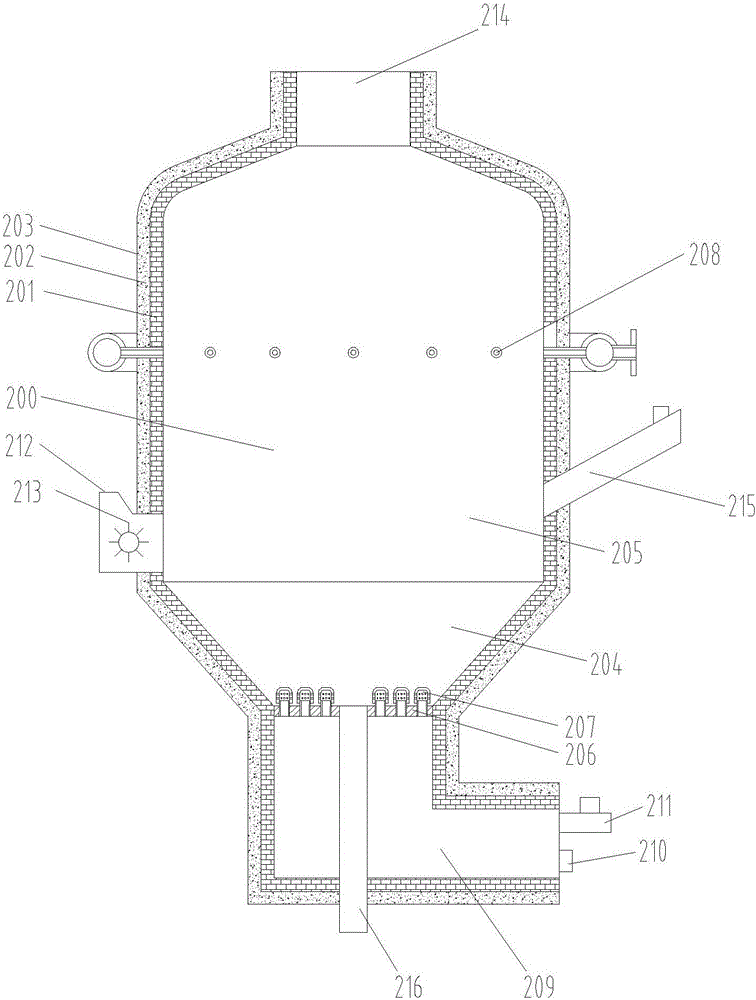

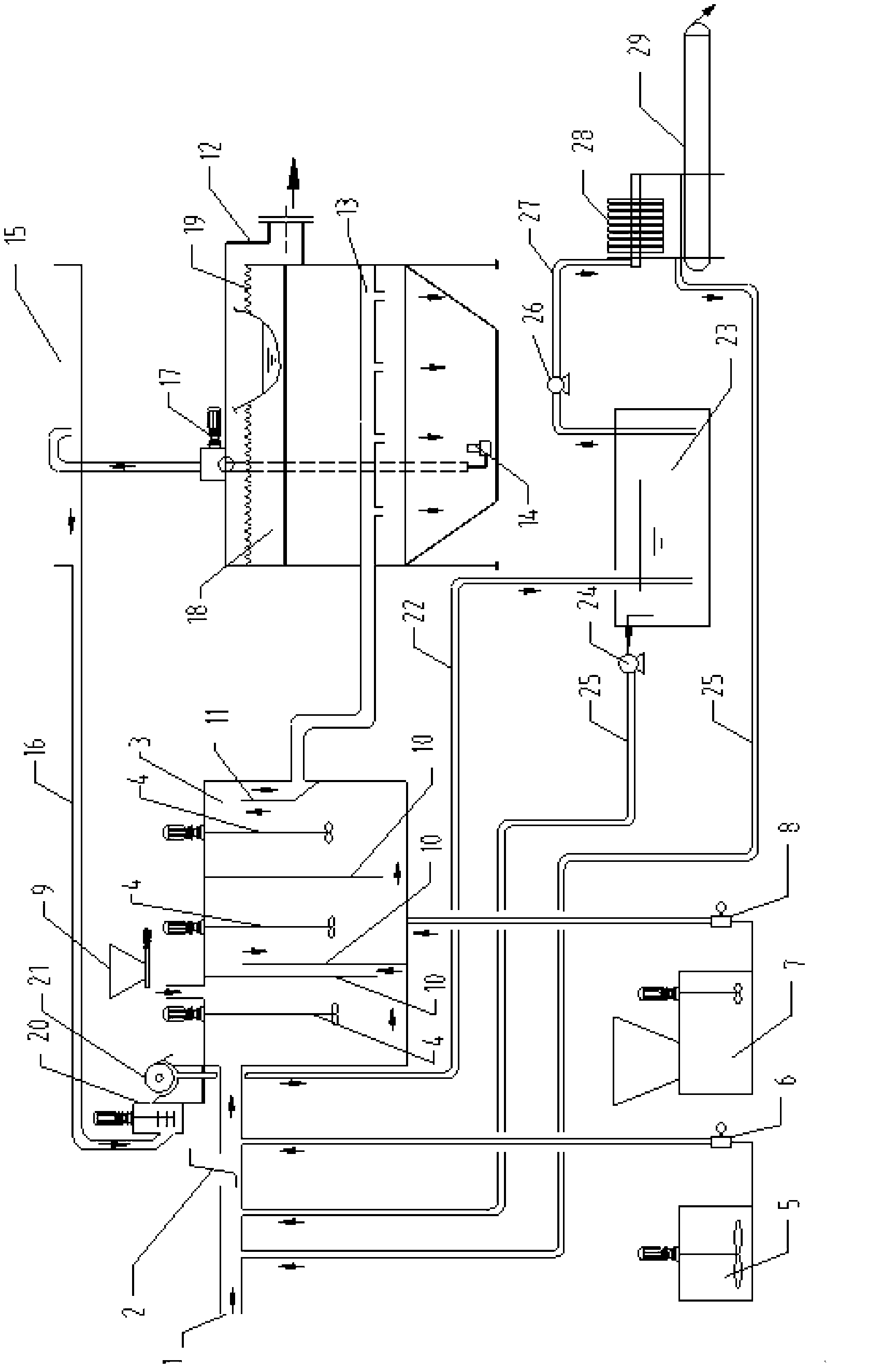

Sludge biological carbonizing technology based on hydrothermal reaction

ActiveCN102875005ALow running costImprove energy efficiencySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningPhysical chemistryCombustible gas

The invention discloses a sludge biological carbonizing technology based on hydrothermal reaction. The sludge biological carbonizing technology comprises the steps as follows: 1) dewatering the sludge, and transferring the sludge into a sludge pre-storage bin to be stored; 2) preheating the dewatered sludge; 3) transferring the preheated dewatered sludge into a hydrothermal reactor, thus obtaining hydrothermal lysis solution; 4) returning the hydrothermal lysis solution into a preheating system to preheat the dewatered sludge, and cooling the hydrothermal lysis solution so as to obtain a gaseous product; 5) transferring the cooled hydrothermal lysis solution into a filter press for filter pressing, thus obtaining a reacting filtrate and a solid product; 6) drying the solid product produced in previous step, and then transferring the solid product into a dry type carbonizing furnace to be carbonized, so as to obtain the solid biological carbon and other products, and transferring the other products into a gas-liquid separating device to be separated so as to obtain combustible gas and tar; and 7) transferring the gaseous product obtained in step 4) and the combustible gas and tar obtained in step 6) into a firebox to be burnt so as to generate heat; and supplying the generated heat to a hydrothermal reactor and the dry type carbonizing furnace. With the adoption of the sludge biological carbonizing technology disclosed by the invention, the product with high additional value can be obtained; and meanwhile, the energy can be saved.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

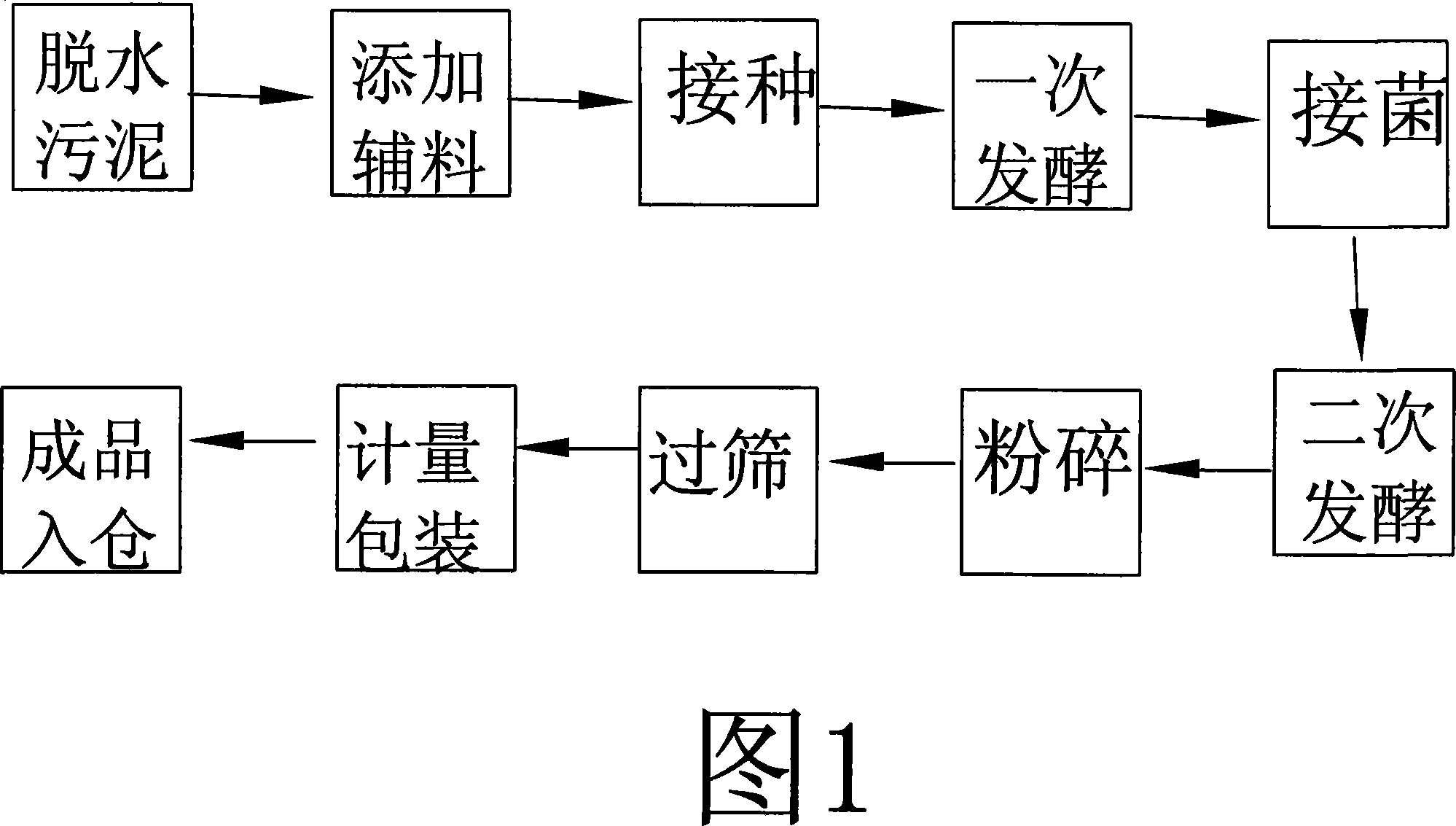

Organic soil conditioner prepared with city sludge and its usage

InactiveCN101066898AIncrease available nutrientsMeet nutrient needsClimate change adaptationBioloigcal waste fertilisersChemical structureSewage

The present invention relates to one kind of organic soil conditioner prepared with city sludge and its production process. The material for the organic soil conditioner consists of dewatered sludge from city domestic sewage 53-72 wt%, organic agricultural waste 4-18 wt%, inorganic supplementary material 2-15 wt%, fertilizer balancing agent 1-5 wt%, and composite microbes 0.5-2 wt%. The production process of the organic soil conditioner includes the following steps: 1. fermenting the dewatered sludge from city domestic sewage, the organic agricultural waste and the inorganic supplementary material with saccharomycetes; 2. inoculating the composite microbes to the first fermented product for secondary decaying; and 3. sieving and packing to produce the organic soil conditioner. The organic soil conditioner has high nutritious component content, and can improve physical and chemical structure of soil, improve agricultural product quality and raise soil fertility.

Owner:刘奋安

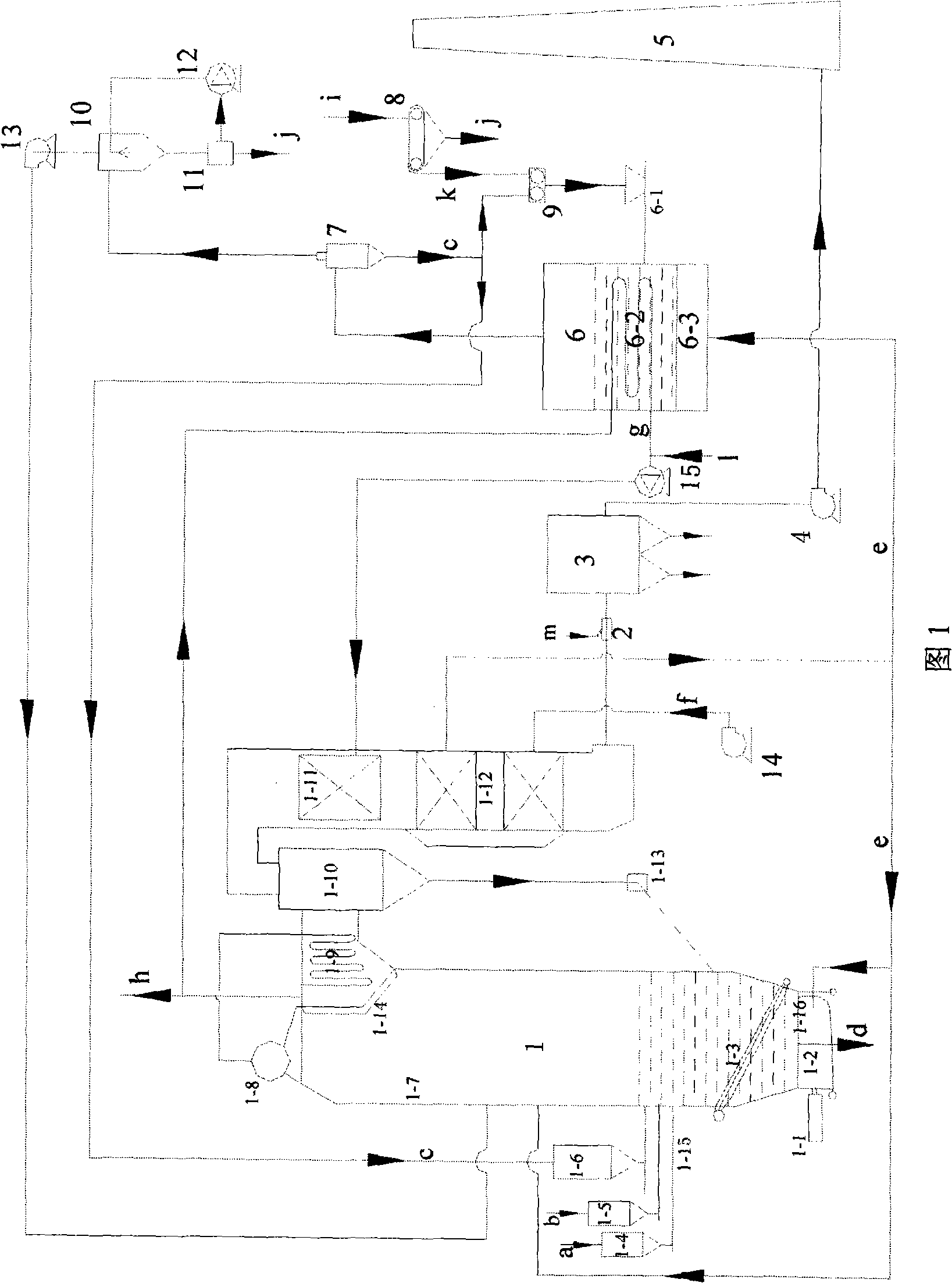

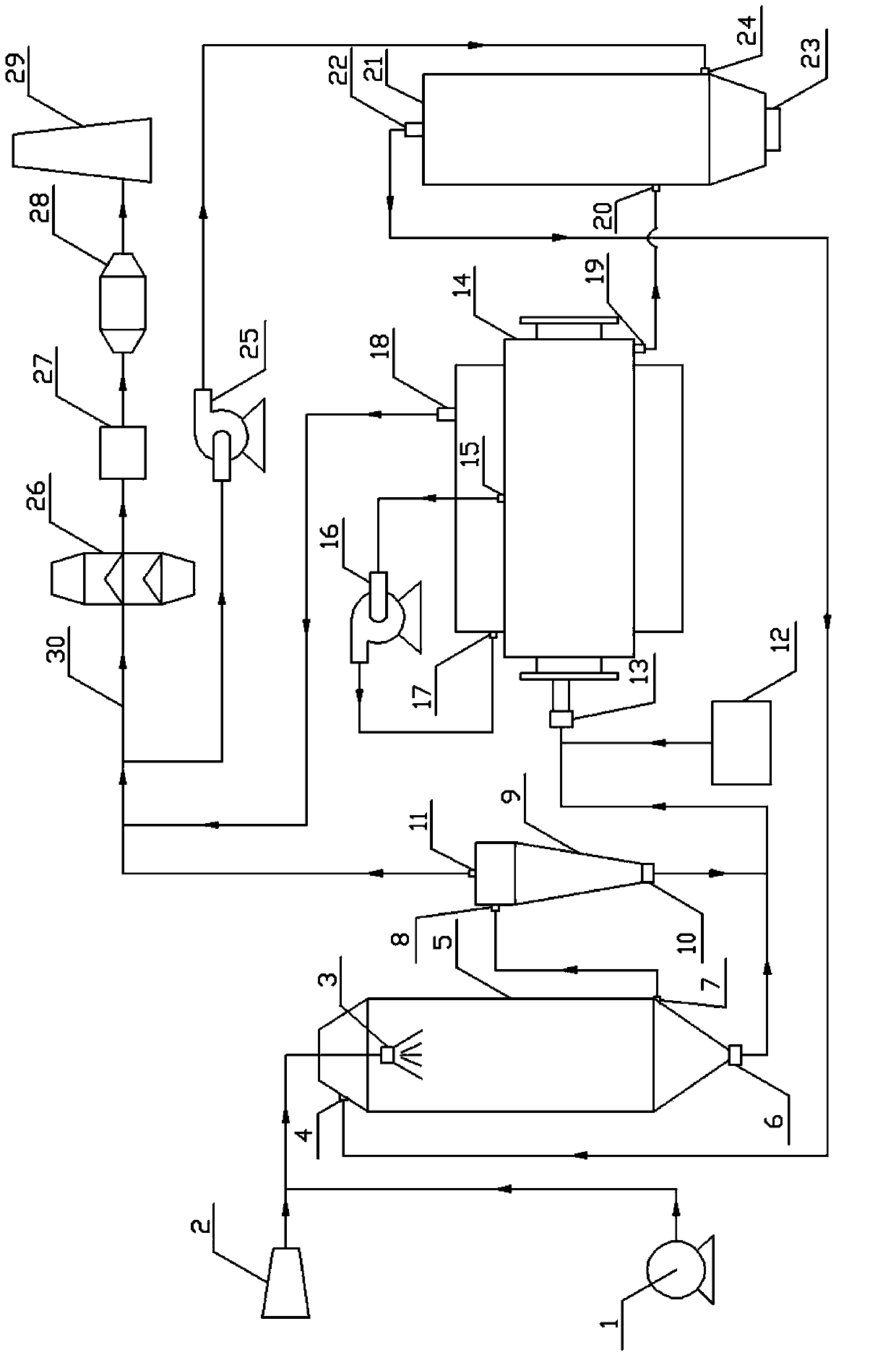

Sludge drying burning combination treatment method

ActiveCN101265008ASimple processLower the altitudeSludge treatment by de-watering/drying/thickeningIncinerator apparatusFluidized bed dryingTreatment effect

The invention relates to a sludge drying and incineration combined treatment method with good treatment effect, wide sludge adaptability, and safe and stability system. To avoid agglomeration of mechanically dewatered sludge (k) in a fluidized bed dryer (6), a part of dried sludge (c) is premixed with the mechanically dewatered sludge (k) and then fed into the fluidized bed dryer (6). The dried sludge (c) is incinerated into a circulating fluidized bed incinerator (1) to generate superheated vapor. The superheated vapor is condensed to hot water in a heat exchange tube (6-2) of the fluidized bed dryer (6) and then recycled to the circulating fluidized bed incinerator (1). The arrangement of buried pipes (1-3) and fractional air supply inside the circulating fluidized bed incinerator (1) can effectively control the lower temperature of the circulating fluidized bed incinerator (1) to prevent deflagration of dried sludge. The entire system has no emission of pollutants such as unpleasant odor, acidic gases, heavy metals and dioxin; is safe and reliable; and can operate for a long time.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

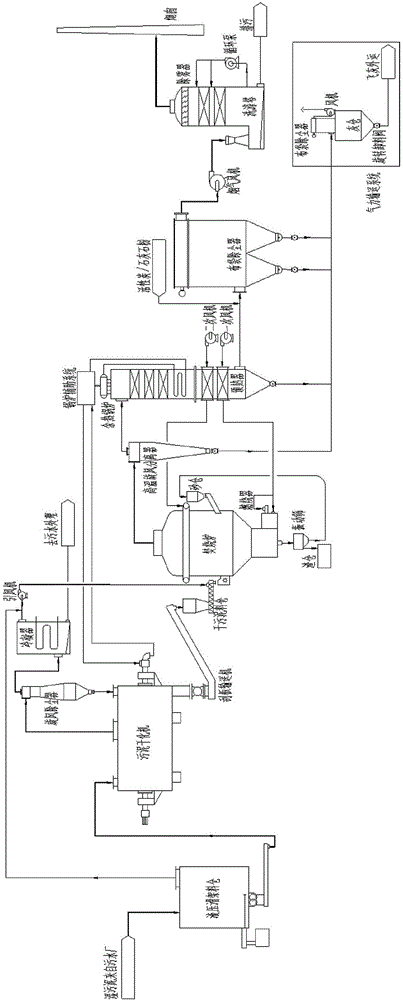

Method using drying and incineration to treat sludge

InactiveCN105948459AEfficient removalImprove thermal efficiencySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesThermal energyMoisture recycling

The invention discloses a method using drying and incineration to treat sludge. The method includes: the pre-dewatered sludge of a sewage treatment plant is conveyed into a sludge bin, with an arch breaking function, of a system, then the sludge is conveyed to a horizontal stirring sludge drying machine through a sludge pump, and the sludge is subjected to stirring and indirect heat exchange to remove moisture and increase heat value and conveyed into a fluidized bed incinerator for incineration; smoke generated by the incineration is subjected to pre-dust-removing by a high-temperature separator and conveyed into a waste heat boiler system so as to recycle heat serving as the heat source of the drying machine, the processed smoke is conveyed into a preheater to preheat air entering the fluidized bed incinerator, and then the smoke enters a cloth-bag dust remover and is processed by a washing tower and discharged in a standard-reaching manner through a chimney; the tail gas generated by the drying machine is subjected to moisture recycling by a condenser and dust removing and then conveyed into the fluidized bed incinerator; fly ash is collected by a pneumatic conveying system to serve as a construction raw material. The method has the advantages that stable, harmless and recycling type sludge treatment can be achieved by the incineration of the dried sludge, the system effectively utilizes the incineration heat to serve as the heat source of the drying machine, and the smoke generated by the incineration is effectively treated and discharged in a standard-reaching manner.

Owner:SHANDONG QISHENG ELECTRICAL & MECHANICAL ENG

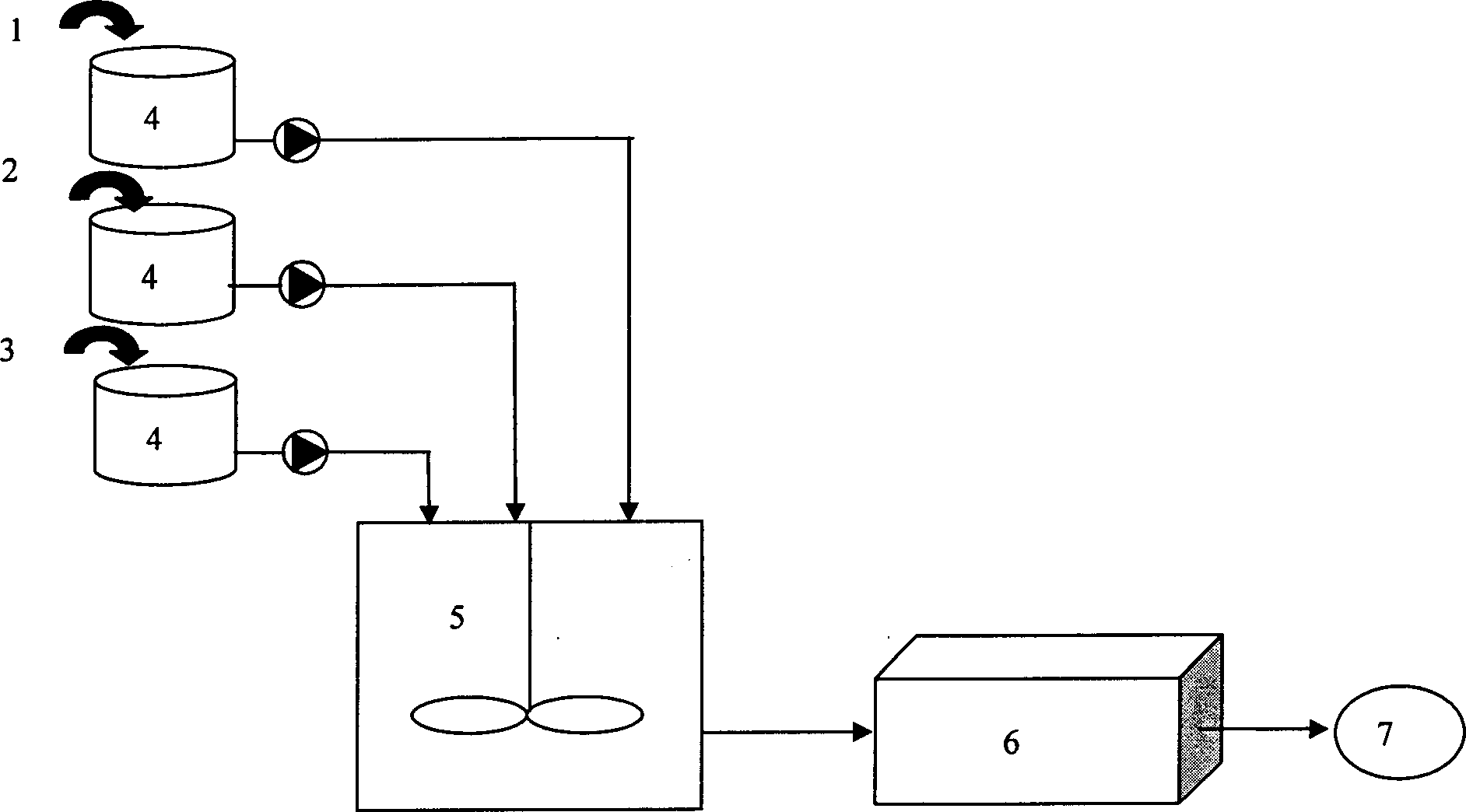

Sludge aerobic composting method by utilizing composting compound microbial inoculum

InactiveCN101973795AImprove reproductive abilityAdapt quicklyBio-organic fraction processingOrganic fertiliser preparationNitrogenSewage

The invention discloses a sludge aerobic composting method by utilizing composting compound microbial inoculum, which relates to a sludge aerobic composting method. The invention solves the problems of poor competitive power, long composting period and great nitrogen loss of the microbial inoculum in the prior sludge aerobic composting method. The method comprises the following steps: 1. carryingout amplification culture on microbial liquid A; 2. carrying out acclimation culture on the compound microbial inoculum A; 3. carrying out amplification culture on microbial liquid B; 4. carrying outacclimation culture on the compound microbial inoculum B; 5. taking dewatered sludge from a sewage plant, and mixing with conditioner; 6. inoculating the compound microbial inoculum, and composting; 7. and covering a layer of compound microbial inoculum B on the surface of the compost, and composting until the compost temperature reaches the ambient temperature, thereby finishing the sludge aerobic composting. The method shortens the time for the compost to reach the high temperature period by 2-3 days, shortens the composting period to 10-15 days, lowers the ammonia volatile amount of the compost by 30-50%, reduces the environmental pollution and enhances the fertilizer efficiency. The invention is applicable to sludge aerobic composting.

Owner:HARBIN INST OF TECH

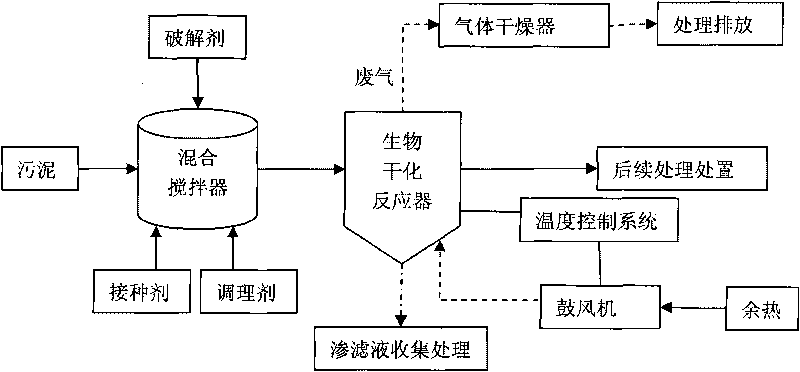

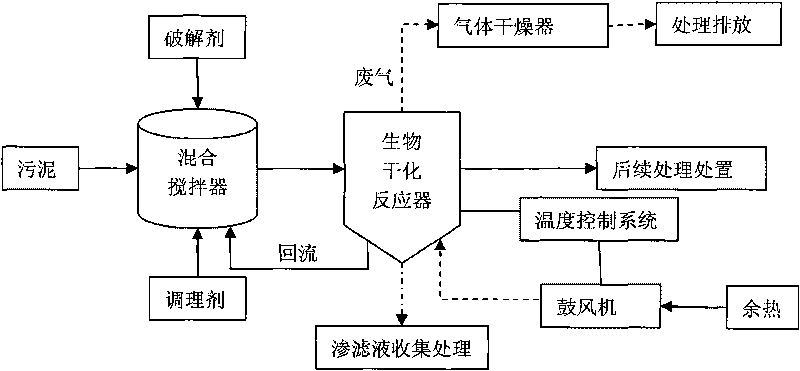

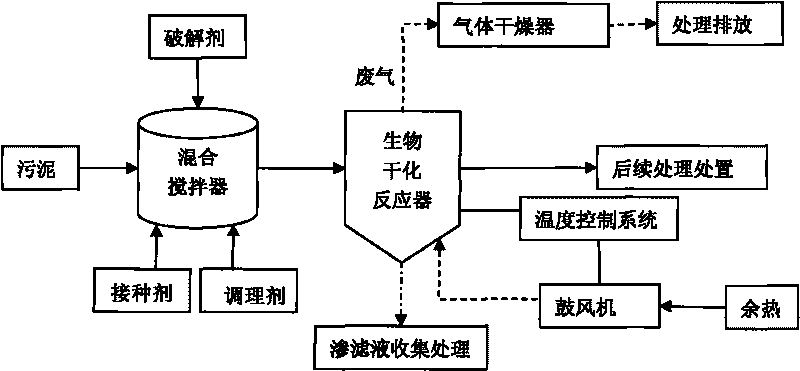

Biological drying method for treating dewatered sludge of urban sewage plant

InactiveCN101746941AEasy to losePromote biological responseSludge treatment by de-watering/drying/thickeningBiological sludge treatmentPulp and paper industryMunicipal sewage

The invention discloses a biological drying method for treating dewatered sludge of an urban sewage plant, and belongs to the technical field of solid waste treatment. The method comprises the following steps: adding an alkaline cracking agent into the dewatered sludge, uniformly mixing, adding a conditioning agent, and adding an inoculating agent for inoculation or utilizing a biological drying finished product for reflux inoculation; after uniformly stirring the mixture, placing the mixture in a biological drying reactor, and introducing residual heat, wherein the temperature of hot wind is between 80 and 120 DEG C, the ventilation amount of each 1kg of mixture is between 15 and 150 L / h, and the temperature of the reactor is between 50 and 60 DEG C; connecting a hot wind outlet to a gas drier, removing moisture, and treating and discharging residual gas; and performing once mechanical stirring for 3 to 5 minutes per hour, and treating 3 to 5 days to obtain the treated sludge. The residual heat adopted by the method has wide source; a drying product can be used for fueling, fertilizing, preparing a soil modifying agent or directly dumped; the drying time is remarkably reduced; and the biological drying method has the advantages of simple technology, low cost, economy and high efficiency.

Owner:TSINGHUA UNIV

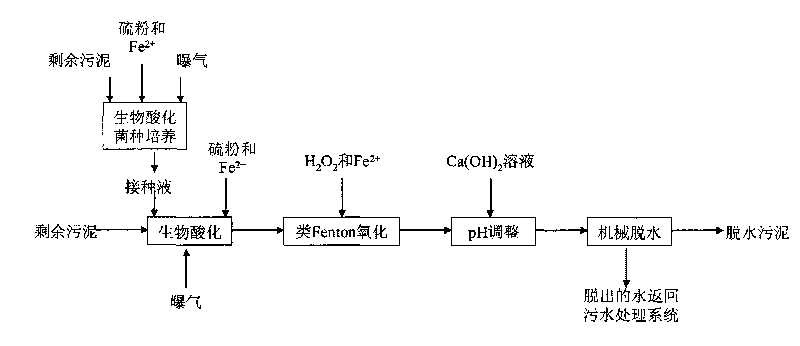

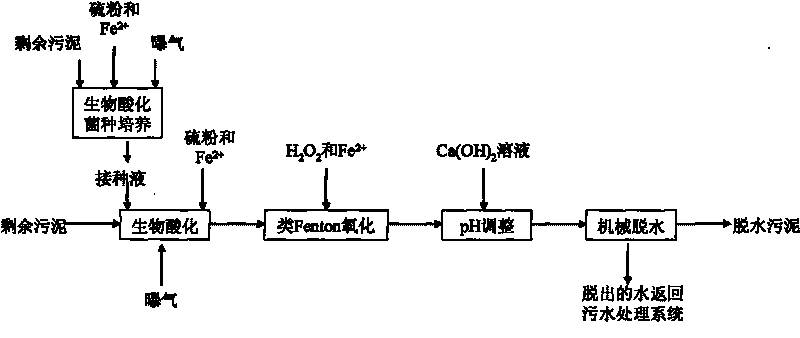

Method for improving dewatering performance of excess sludge by combining biological acidification and Fenton-like oxidation

InactiveCN101759337AImprove dehydration effectReduce volumeSludge treatment by oxidationBiological sludge treatmentFiltrationDewatered sludge

The invention relates to a method for improving dewatering performance of excess sludge by combining biological acidification and Fenton-like oxidation, which belongs to the technical field of sludge treatment. The method comprises that: under the condition of adding a sufficient quantity of substrates, indigenous acidification bacteria serving as inoculation liquid are cultured and acclimatized from sludge; the inoculation liquid is added to excess sludge in order to perform biological acidification on the sludge under an aerobic stirring condition in the presence of a sufficient quantity of substrates till the pH of the sludge is 2 to 3; under the catalytic action of Fe2+ and Fe3+, H2O2 produces strong oxidative free radicals and other Fenton-like oxidized sludge; Ca(OH)2 solution is added to the treated sludge to regulate the pH of the sludge to be between 6 and 7; and the treated sludge is dewatered by a plate-frame pressure filtration method or a centrifugal dewatering method in order to obtain dewatered sludge with water content between 65 and 75 percent. The combination of biological acidification and Fenton-like oxidation for improving the dewatering performance of excess sludge can improve reaction efficiency, shorten reaction time, increase treatment capacity and reduce cost for sludge treatment.

Owner:BEIJING FORESTRY UNIVERSITY

Solidifying agent for solidifying and stabilizing treatment of generated dewatered sludge in sewage plant

InactiveCN101172749AIncrease skeleton compositionHarm reductionSludge treatment by de-watering/drying/thickeningSolid waste managementSodium BentoniteSewage

The invention relates to curing agent used for curing and stabilizing dewatered sludge produced by a sewage plant. The invention is characterized in that curing material and assistant curing material bentonite are added by weight in the dewatered sludge, and each component is mixed evenly, and the weight percentage of each component is 30 to 80 percent of sludge, 15 to 30 percent of curing material, and 5 to 40 percent of bentonite. The curing material is formed by concrete, lime, fly ash and gypsum by weight. The invention has the advantages that the disposed sludge can be disposed by burying to be as fillings for the using of renewable recources. The curing agent can improve the high water content and the low intensity of the sewage, and has the advantages of increasing curing effect, reducing curing material use amount and reducing disposal cost. The compositions of the curing agent of concrete, fly ash, lime, gypsum and bentonite have wide distribution and low price with finished produces selling, thereby realizing the industrialization of sludge curing and stabilizing techniques.

Owner:HOHAI UNIV

Method for preparing ceramsite by utilizing dried sludge and burnt fly ash

InactiveCN102060426AAchieving simultaneous reductionAchieving processing powerSludge treatment by de-watering/drying/thickeningSodium BentoniteExpanded clay aggregate

The invention discloses a method for preparing ceramsite by utilizing dried sludge and burnt fly ash, belonging to the technology of reduction, harmless treatment and disposal and recycling of dangerous solid waste. The method comprises the following steps of: drying dewatered sludge with moisture content of 75-85% to obtain dry sludge; crushing the dry sludge, and then screening; mixing the screened dry sludge, burnt fly ash and bentonite uniformly according to a certain proportion to obtain a mixture; injecting the mixture into a powder pressing machine for extruding and forming to obtain a blank; preheating the blank at certain time; roasting the blank at high temperature at certain time; and naturally cooling to room temperature to obtain a ceramsite product. Simultaneous reduction, harmless treatment and disposal and recycling of two dangerous wastes of the burnt fly ash and municipal sludge are realized with the method, and the produced ceramsite product conforms to the standard of toxic leaching and meets the requirement of lightweight aggregate of buildings. The method has the advantages of simplicity in process, less investment, low operating cost, large required quantity of the produced ceramsite products and the like.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION +1

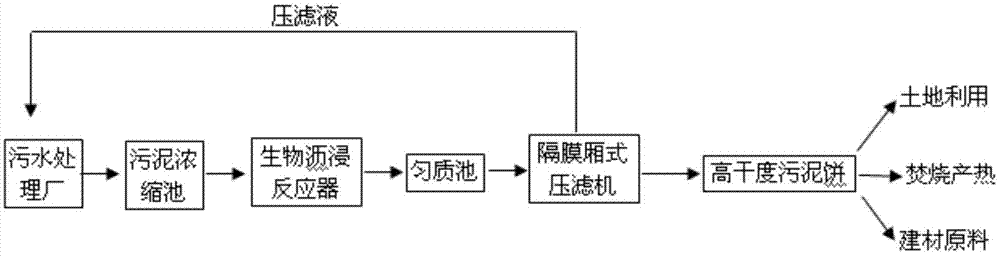

New method for deeply dewatering sludge through bio-leaching process rapid conditioning

ActiveCN103936246ASimple processLow running costSludge treatment by de-watering/drying/thickeningSludge processingSludge cakeResource utilization

The invention discloses a new method for deeply dewatering sludge through bio-leaching process rapid conditioning. The method comprises the steps of firstly performing bio-leaching conditioning on sludge, namely, directly pumping concentrated liquid sludge of a sewage treatment plant into a bio-leaching reactor which contains special composite microbial community, performing treatment for 1.5-2 days, changing bound water in the sludge into free water which can be removed relatively easily by virtue of the microbial substitution effect, biological oxidation effect and biological acidification effect, dissolving out heavy metals from the sludge at the same time, entering an aqueous phase, killing pathogens in the sludge, then collecting the sludge subjected to bio-leaching in a homogeneous pool, directly transporting to a common-pressure diaphragm chamber type filter press by virtue of a pump, and dewatering, wherein the moisture content of dewatered sludge cake is less than 60%, and no flocculant like PAM (polyacrylamide) is added during the preparation process. The method disclosed by the invention is performed under normal temperature and pressure, and has low cost; the dewatered sludge cake is low in moisture content, odorless, and yellowish-brown in color; and the organic matters, calorific values and nutrients of the dewatered sludge can not be reduced, thus facilitating the subsequent resource utilization.

Owner:NANJING AGRICULTURAL UNIVERSITY

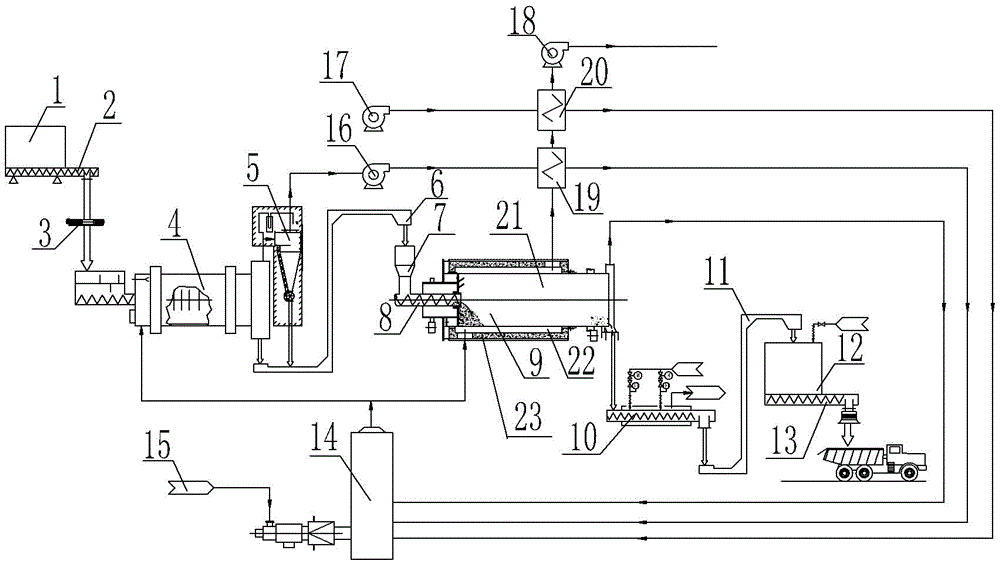

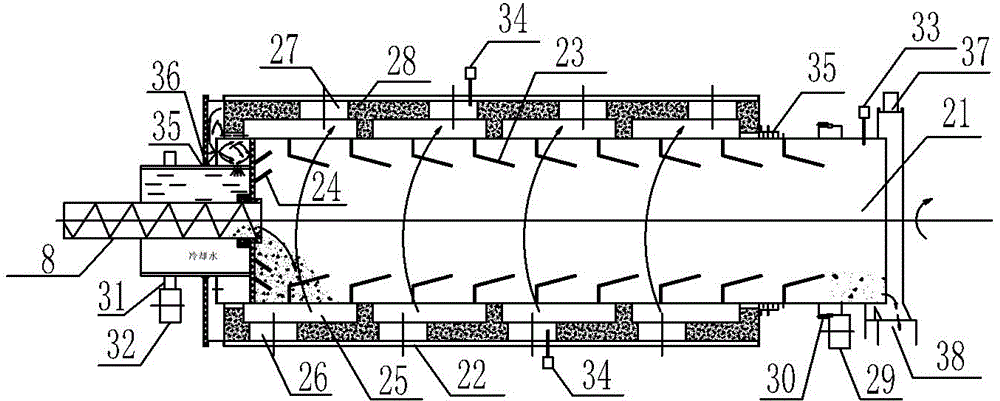

High temperature carbonization system of sludge and carbonization process

InactiveCN103145307ATo achieve the purpose of energy savingReduce volumeSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCarbonizationExhaust fumes

Owner:CECEP BOTH HUBEI ENVIRONMENT ENG & TECH

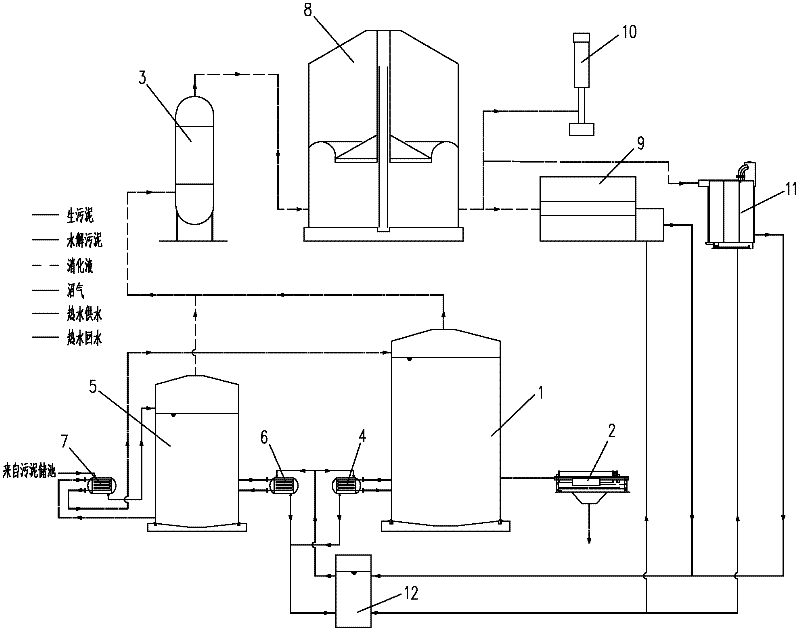

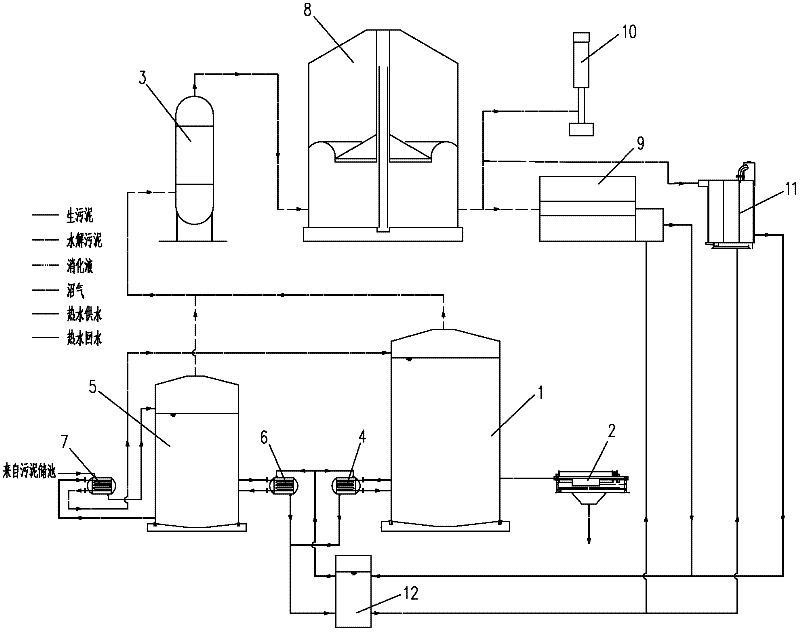

Urban sludge treating method and equipment

ActiveCN102241464AImprove energy recoveryRelease fullySludge treatment by de-watering/drying/thickeningGaseous fuelsTowerDigestion

The invention provides an urban sludge treating method, which comprises the following steps of: heating concentrated sludge to 45-55 DEG C, feeding into a high-temperature hydrolytic acidification reactor, and undergoing a high-temperature hydrolysis anaerobic digestion reaction at the pH 6.5-7.5 and at the temperature 40-55 DEG C for 2-5 days to obtain a hydrolytic acidification product; lowering the temperature of the hydrolytic acidification product to 35-40 DEG C, feeding into a medium-temperature methane producing digestion reactor, and undergoing a medium-temperature hydrolysis anaerobic digestion reaction at the temperature 35-38 DEG C for 10-17 days to obtain marsh gas and digested sludge; desulfurizing the marsh gas; and dehydrating the digested sludge to produce dehydrated sludge and digestive fluid. According to the method, resource, minimization and harmlessness of urban sludge treatment are fully realized. The invention further discloses urban sludge treating equipment, which comprises the medium-temperature methane producing digestion reactor, a dehydrator, a desulfurizing tower, a high-temperature hydrolytic acidification reactor and a heat exchanger, wherein a heater is arranged on the high-temperature hydrolytic acidification reactor. The equipment has a simple overall structure, and is easy to realize.

Owner:CSD BEIJING E P DEV CO LTD

Preparation and method for drying sludge through deep dehydrating

InactiveCN102229464AImplement processing reduction requirementsNo noiseSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentMechanical pressDewatered sludge

The invention relates to a preparation and a treatment method, and especially relates to a preparation and a method for drying sludge through deep dehydrating. The preparation comprises: 0.000002 to 0.00001 parts of an organic polymeric flocculants, 0.00025 to 0.0025 parts of a coagulating modifier, 0.0005 to 0.00375 parts of a sterilizing deodorant, and 0.00025 to 0.0025 parts of a nucleating converting agent. The method comprises the following steps: a sludge gravity thickening initial dehydrating step, a sludge regulating step, a mechanical press-filtrating step, and a filtrate refluxing step. With the preparation and the method provided by the present invention, sludge deep dehydrating processes can be carried out in series, processing efficiency can be improved, and energy consumption can be reduced. The controllability of the method is high. With the method, recycling is realized.

Owner:ZHEJIANG JIEFENG ENVIRONMENTAL PROTECTION TECH ENG COMPANY

Magnetic separation method and apparatus for mine water underground treatment

ActiveCN103232132AProportionally largeAccelerated precipitationWaste water treatment from quariesMultistage water/sewage treatmentFlocculationTherapeutic effect

The invention discloses a magnetic separation method for a mine water underground treatment. The method comprises: removing large particle impurities and floating substances in mine water; adding a magnetic seed and a coagulant; stirring for 1-2 min at a rotation speed of 200-250 rotation / min; adding an auxiliary coagulant; stirring for 1-2 min at a rotation speed of 20-50 rotation / min; stirring for 3-5 min at a rotation speed of 10-20 rotation / min; conveying the water with the magnetic flocculation treatment to a precipitation tank; and carrying out nature precipitation through the floc weight, wherein the upper layer clear water can be subjected to standard discharge or be reused, the precipitated magnetic sludge is dispersed, the magnetic seed is separated to be recycled, and the remaining non-magnetic sludge is dewatered and then is conveyed to the on-well, wherein a water content of the dewatered sludge is less than 60%. The invention further discloses a magnetic separation apparatus for the mine water underground treatment, wherein the apparatus is designed according to the method. According to the present invention, the method and the apparatus are matched appropriately, an integration degree is high, an occupation area is small, energy consumption is low, operation cost is low, a treatment effect is good, and the method and the apparatus are especially suitable for construction under the mine.

Owner:SCIMEE TECH & SCI CO LTD

Sludge fuel stick and its prepn

InactiveCN1810940ALow costSolve the way outSludge treatment by de-watering/drying/thickeningBiofuelsCombustionPlant stalk

The present invention is one kind of sludge fuel stick and its preparation process, and belongs to the field of solid waste treating technology. The sludge fuel stick is prepared with dewatered sludge 50-70 wt%, combustion improver 20-50 wt%, adhesive 3-5 wt% and desulfurizing agent 5-10 wt%. The preparation process includes mixing the said materials in a stirrer, pelletizing in a pelletizer, forming and stoving. The present invention can treating sludge as well as plant stalk, furnace slag, coal slag, flyash and other solid waste and utilize heat in sludge.

Owner:TSINGHUA UNIV

Sludge reduction and recycling treatment device and sludge treatment method

InactiveCN104211274AAchieve recyclingHarmlessSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisOxygenCoal pyrolysis

Provided are a sludge reduction and recycling treatment device and a sludge treatment method. The method includes the steps of performing spray drying on dewatered sludge, mixing coal pyrolysis, using pyrolytic carbon incineration ash as a raw building material, recycling pyrolysis oil and pyrolysis gas as supplement energy, performing up-to-standard discharging on flue gas emitted by a pyrolysis furnace after subjecting the flue gas to treatment in a spray tower, a mist removal device and an activated carbon adsorption bed, and supplying an incinerator with low heat of the pyrolysis furnace. The sludge reduction and recycling treatment device and the sludge treatment method have the advantages of being capable of achieving a sludge recycling recovery rate of 95%, a sludge reduction rate of over 96%, a heavy metal solidification rate of 95% and zero emission of pollutants; the generation of harmful gas such as dioxin is inhibited due to fully-enclosed oxygen-free environment pyrolysis and sulfur in coal; residual dioxin can be decomposed by being burnt at the temperature above 950 DEG C so as to ensure no generation and emission of dioxin in an entire reaction process of a system; a mixture of flue gas, low heat, pyrolysis gas and pyrolysis oil can be recycled, so that energy consumption and treatment costs are reduced.

Owner:天津德人生态环境科技集团有限公司

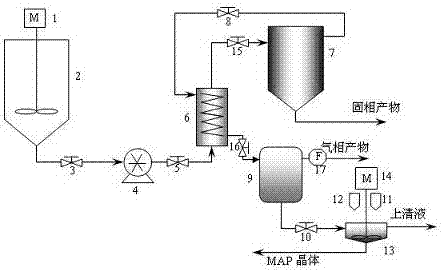

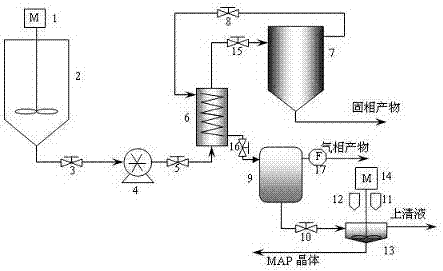

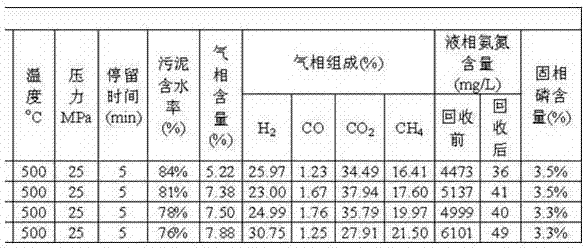

Method and equipment for resource utilization of dewatered sludge in sewage plant by supercritical treatment

InactiveCN102267789AImprove liquidityImprove processing efficiencyOther chemical processesSolid waste disposalSorbentResource utilization

The invention discloses a method and equipment for supercritical treatment and resource utilization of dewatered sludge of a sewage plant. The method is characterized in that: the dewatered sludge (the water content is 77 to 85 percent) is directly treated in a supercritical water vaporization mode, the flowability of the sludge is improved through a high-speed stirring device, blockage of a tubular reactor is prevented by adopting a high-pressure fluidized bed device, high heat of a gas-liquid separation process is fully utilized, and the low-temperature sludge is heated by using a heat exchanger; and the liquid phase product with high ammonia nitrogen content is directly recycled by a magnesium ammonium phosphate (MAP) method. The method has the advantages that: any moisture is not added in the vaporization process, and the sludge treatment efficiency is high; the heat can be utilized in the process; ammonia nitrogen in the liquid phase product is timely reclaimed so as to reduce secondary pollution; the reclaimed supernate can be recycled, the periodically discharged solid phase product with low heavy metal content can be directly used as a phosphate fertilizer, and the solid phase product with high heavy metal content can be used as an adsorbent; and the treatment expense of the whole system is reduced by resource utilization of the liquid phase product and the solid phaseproduct.

Owner:HOHAI UNIV

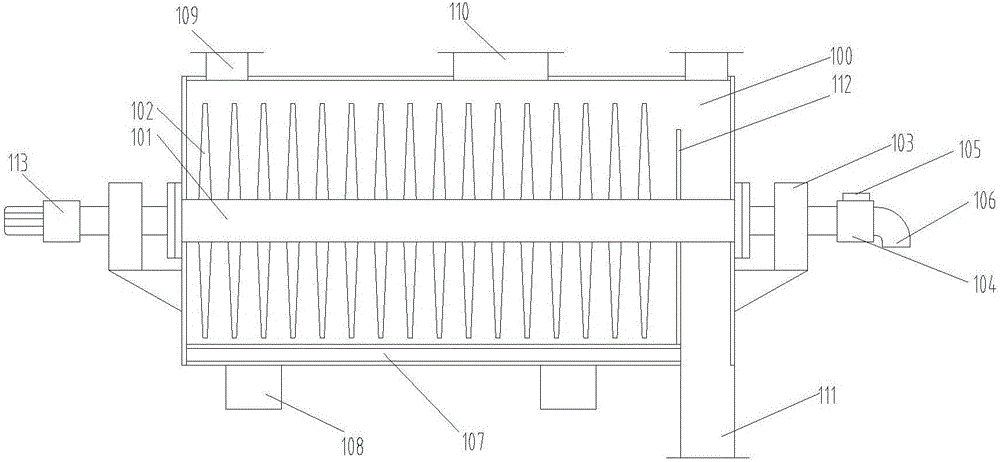

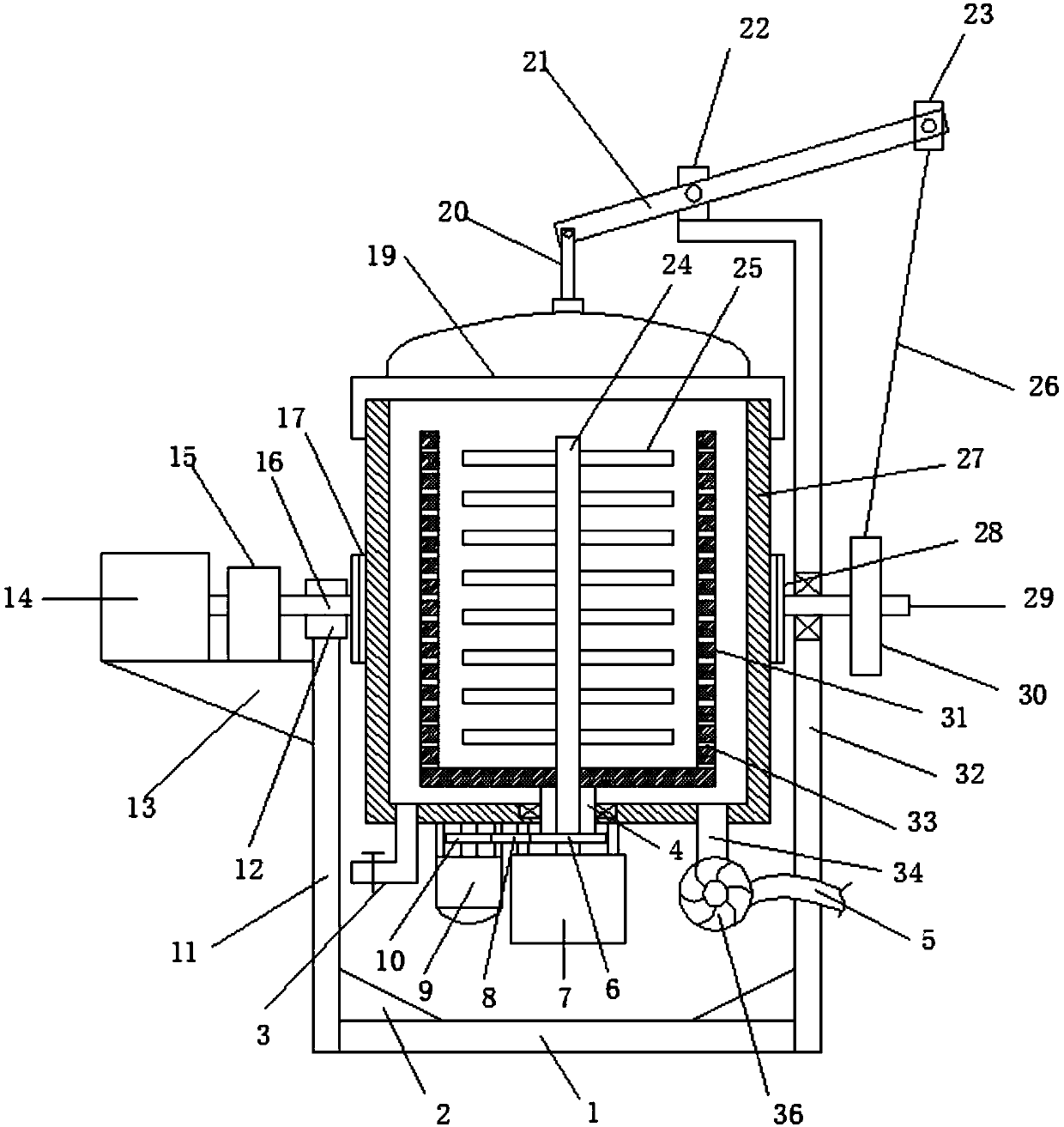

Roller centrifugal type environment-friendly treatment device for sludge dewatering

InactiveCN108033664AReasonable structureInnovative designSludge treatment by de-watering/drying/thickeningRotary centrifugesDrive shaftEngineering

The invention discloses a roller centrifugal type environment-friendly treatment device for sludge dewatering. The device comprises a fixing base plate; a first supporting frame is arranged on the left side of the upper end of the fixing base plate; a guide base is arranged at the upper end of the first supporting frame; a driving shaft is arranged in the middle of the guide base; a first rotatingdisc is arranged at the right end of the driving shaft; a second supporting frame is arranged on the right side of the upper end of the fixing base plate; a driven shaft is arranged in the middle ofthe second supporting frame through a bearing; a second rotating disc is arranged at the left end of the driven shaft; an outer cylinder is arranged between the first rotating disc and the second rotating disc; a first motor is arranged on the left side of the lower end of the outer cylinder; a driving belt wheel is arranged at the upper end of the first motor; a driven belt wheel is connected tothe right end of the driving belt wheel through a belt; a main shaft is arranged at the upper end of the driven belt wheel; an inner cylinder is arranged at the upper end of the main shaft; and a counter shaft is arranged in the main shaft. According to the device, sludge can be efficiently dewatered by utilizing the centrifugal force, the dewatering efficiency of the sludge can be improved, and meanwhile, the dewatered sludge can be quickly poured out.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

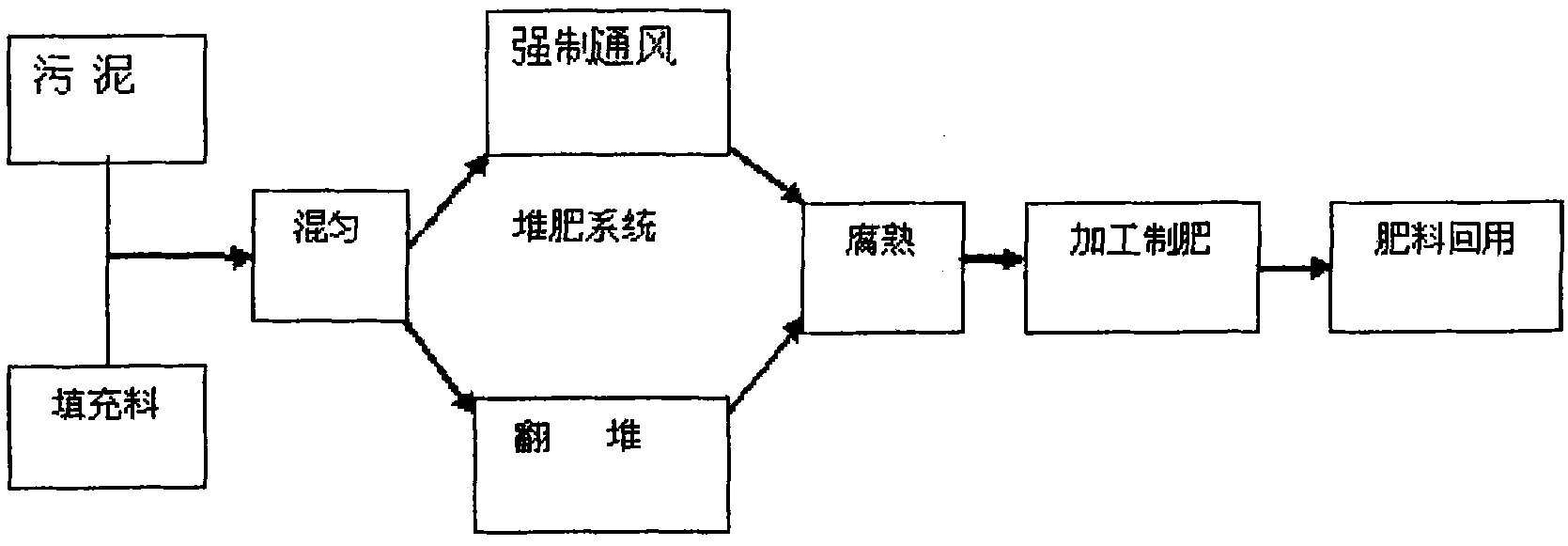

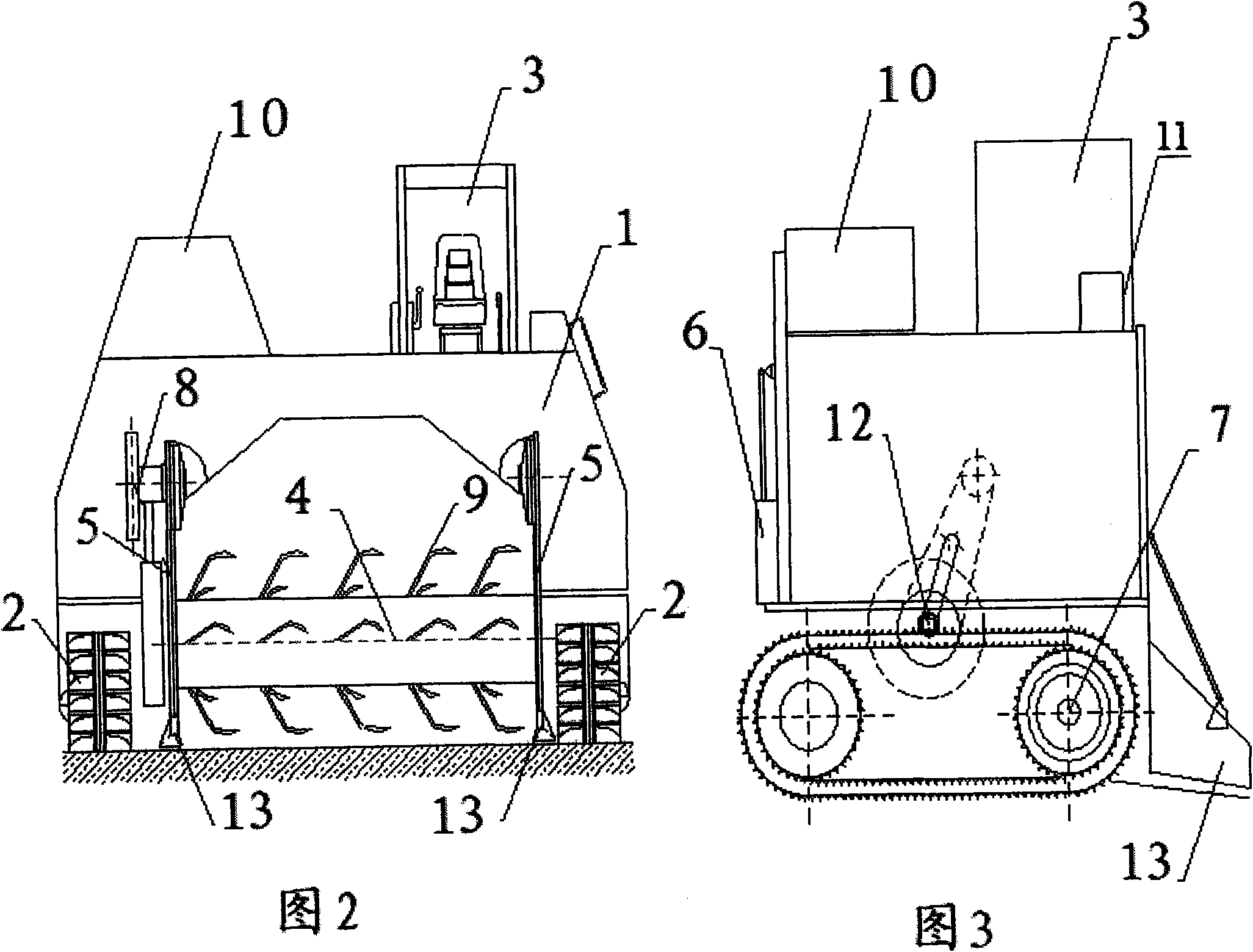

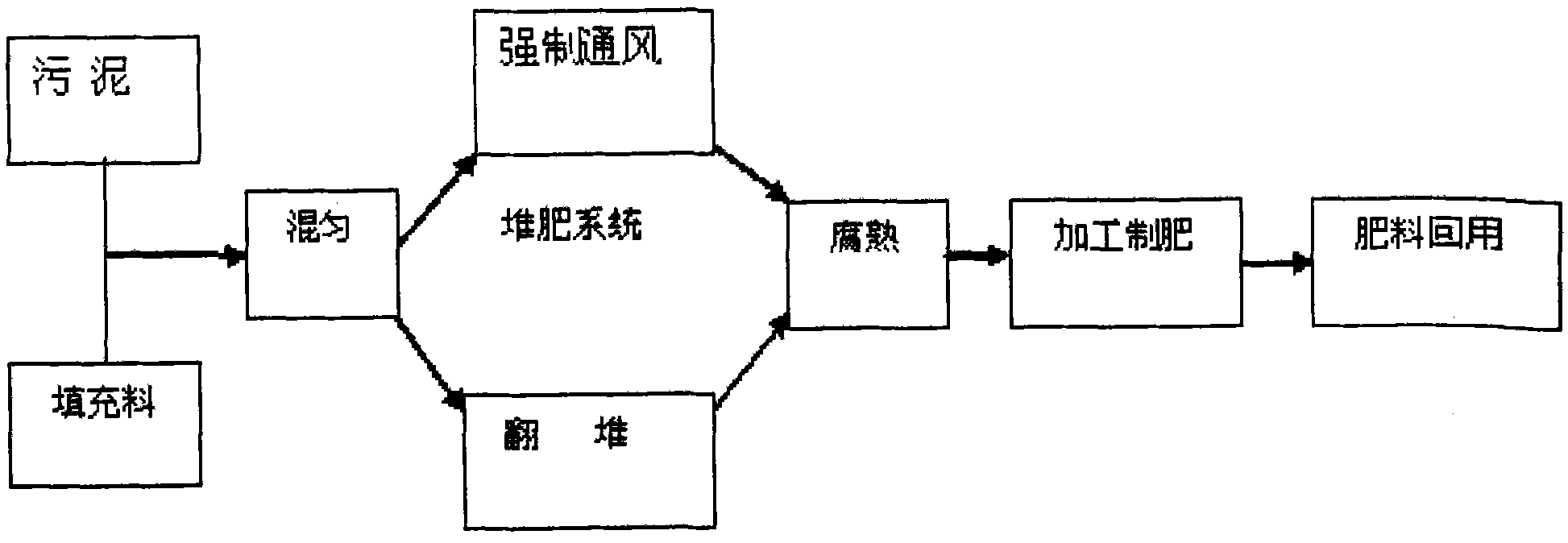

Self-propelled turning device for sludge compost and treatment method

ActiveCN102030570AEasy to walkSmall footprintSludge processingOrganic fertiliser preparationSludge compostOxygen

The invention relates to a self-propelled turning device for sludge compost and a treatment method and belongs to environmentally-friendly solid waste treatment. The method comprises that: a mixing step, an aerobic compost period, a thoroughly decomposing step, a processing and compost production step and an odor treatment step, wherein the mixing step aims to adjust the moisture and the carbon nitrogen rate of dewatered sludge, improve the loosening degree, increase a contact area with air and contributes to aerobic fermentation; in the aerobic compost period, the oxygen is supplied through forced ventilation, and organic matters in materials begin to ferment under the action of aerobes; the thoroughly composting step comprises that: the sludge subjected to compost fermentation is not thoroughly decomposed, and is required to continuously undergo a thoroughly decomposing and ageing stage, namely secondary fermentation; the processing and compost production step comprises that: the sludge compost is processed according to fertilizer use and market demand to serve as a product for sales so as to improve overall economic efficiency; and the odor treatment step comprises that: odor is generated in the process of aerobic compost and can be discharged after deodorization treatment. In recent years, solid wastes have become important environmental problems limiting urban development. The composting treatment is a way to utilize solid waste resources and is gradually taken into account at home and abroad.

Owner:BMEI

Sludge Dewatering and Drying

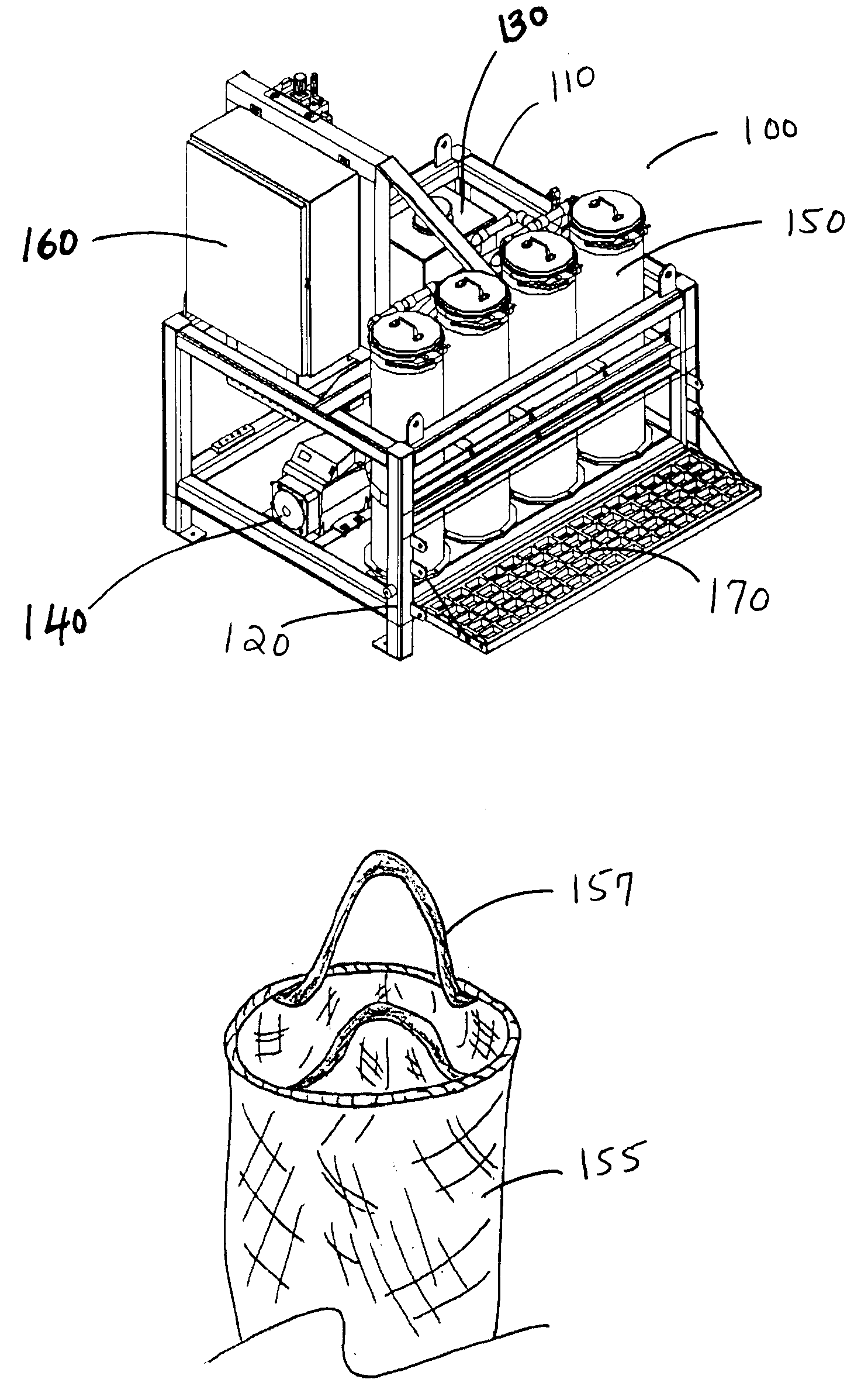

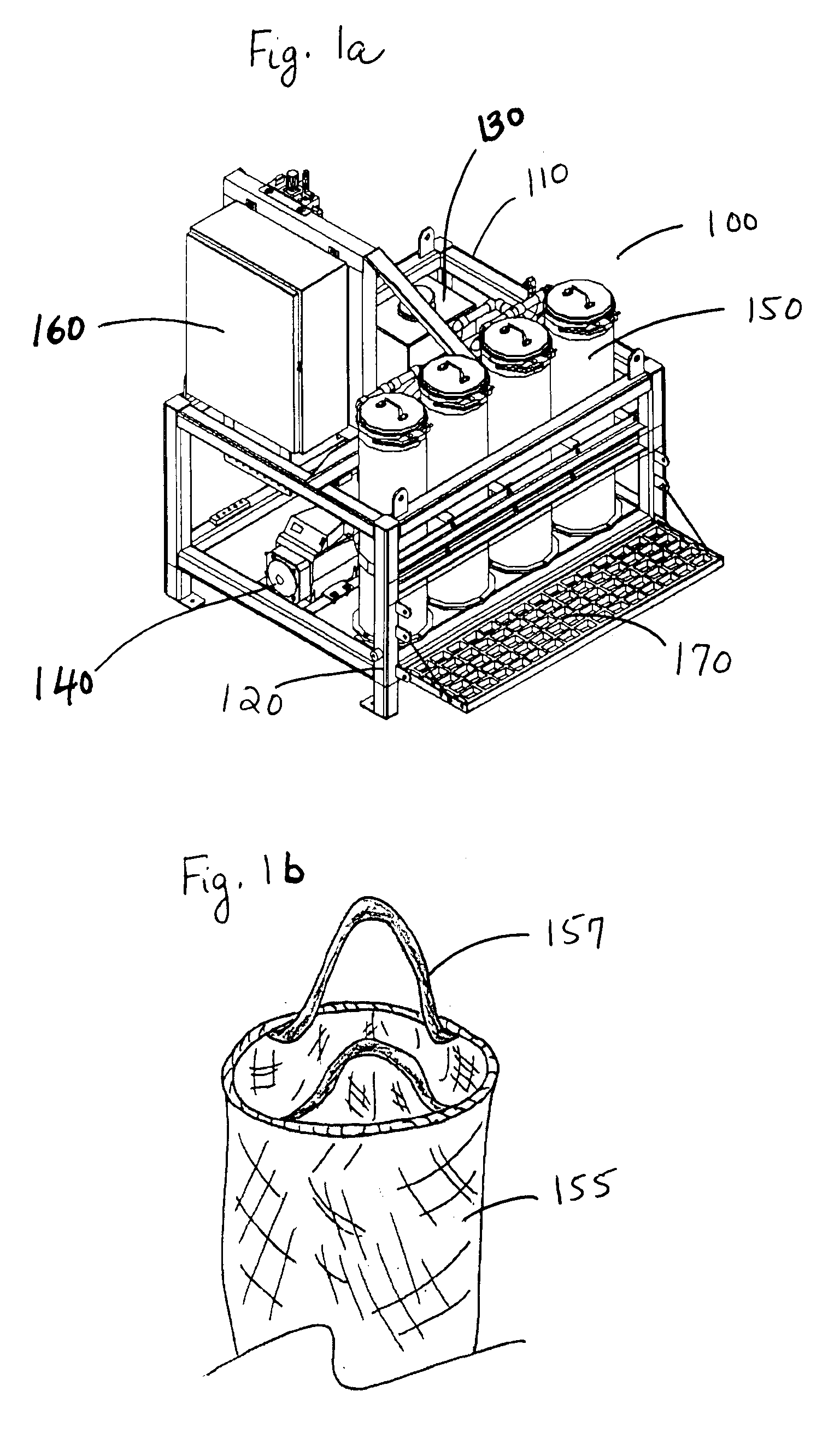

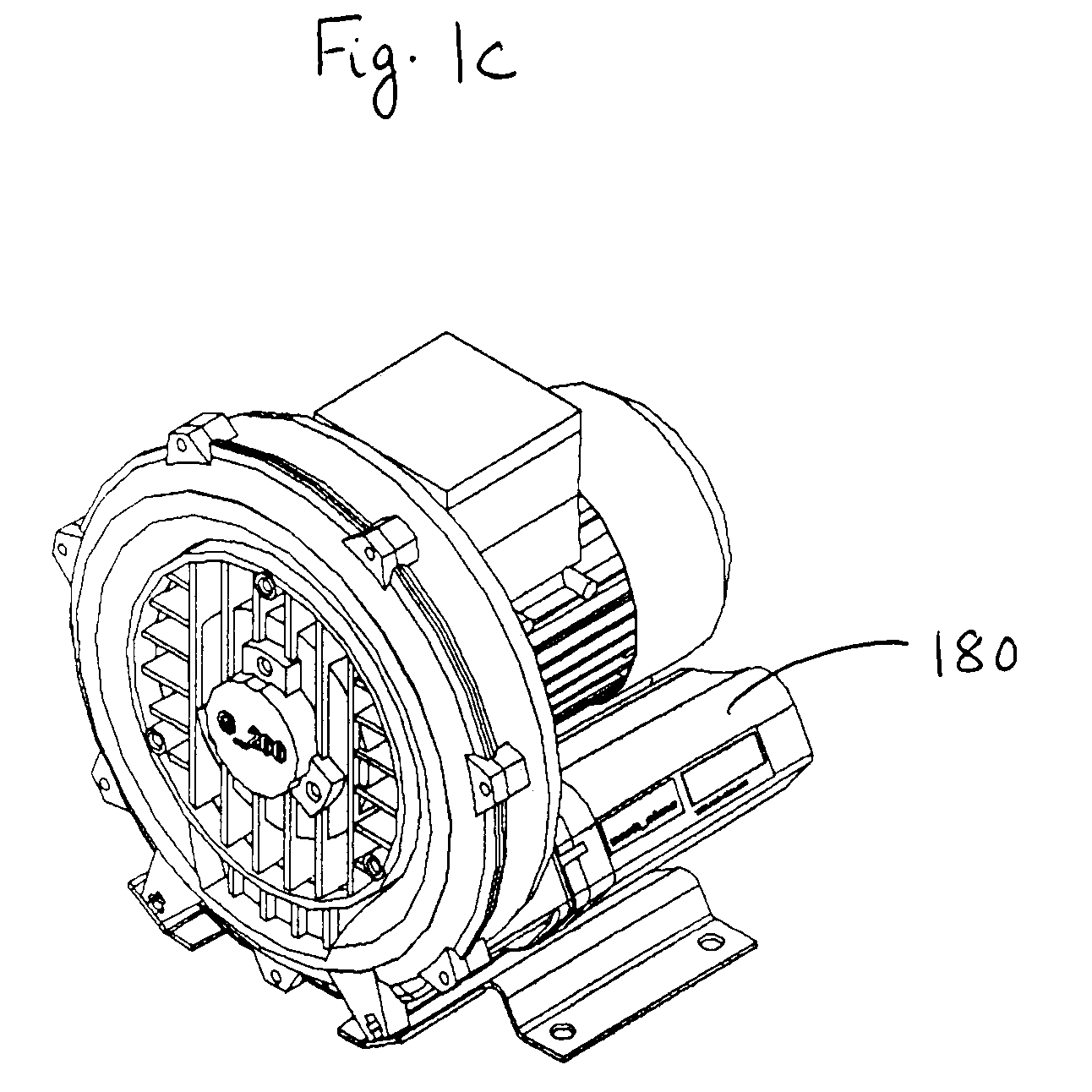

InactiveUS20100170854A1Reduce disposal costsFacilitates environmental complianceAuxillariesDrying solid materials without heatFiltrationDewatered sludge

Methods, apparatus and systems for dewatering and drying the dewatered sludge. Sludge pumped into the sludge dewatering apparatus is mixed in-line with a pre-measured quantity of polymers to agglomerate solids entrained in the sludge. The agglomerated sludge is routed to a filtration station comprising filtration chambers. The filtration chambers are fitted with industry standard filter bag. The agglomerated sludge is subjected to dewatering in the filter bags and the dewatered sludge is subsequently compacted, dried and discarded.

Owner:SEVERN TRENT DE NORA LLC

Method for efficiently dewatering of sludge

InactiveCN102826733AEfficient dehydrationShorten the concentration timeSludge treatment by de-watering/drying/thickeningDiaphragm pumpDry weight

The invention relates to a method for efficiently dewatering of sludge. The method comprises the following steps of: adding an organic flocculant and a physical conditioner to a gravity thickening tank, wherein the amount of the added organic flocculant is 0.2 per mill to 5.0 per mill of the dry weight of the thickened sludge, and the amount of added physical conditioner is 1% to 10% of the dry weight of the thickened sludge; tempering: adding a calcium coagulant aid to the sludge slurry based on the amount of 1% to 5% of the dry weight of the thickened sludge; and then adding a ferrum flocculant after 1 to 10 minutes based on the amount of 0.5% to 5% of the dry weight of thickened sludge; reacting for 1 to 20 minutes; dewatering: introducing the tempered sludge into a plate-and-frame filter press through a pneumatic diaphragm pump, and charging for 20 to 30 minutes, and dewatering at 0.5 to 2.5Mpa; and discharging: discharging the dewatered sludge from the plate-and-frame filter press. According to the method, the chemical and physical combination mode is adopted to condition for boosting coagulation in the sludge thickening stage; the inorganic flocculant and the coagulant aid are added for further preprocessing in the sludge tempering stage; mechanical equipment with relatively high pressure is adopted to dewater, so that the effect of dewatering can be further improved, and efficient dewatering of the sludge in the urban wastewater treatment plant can be achieved.

Owner:NANJING FORESTRY UNIV

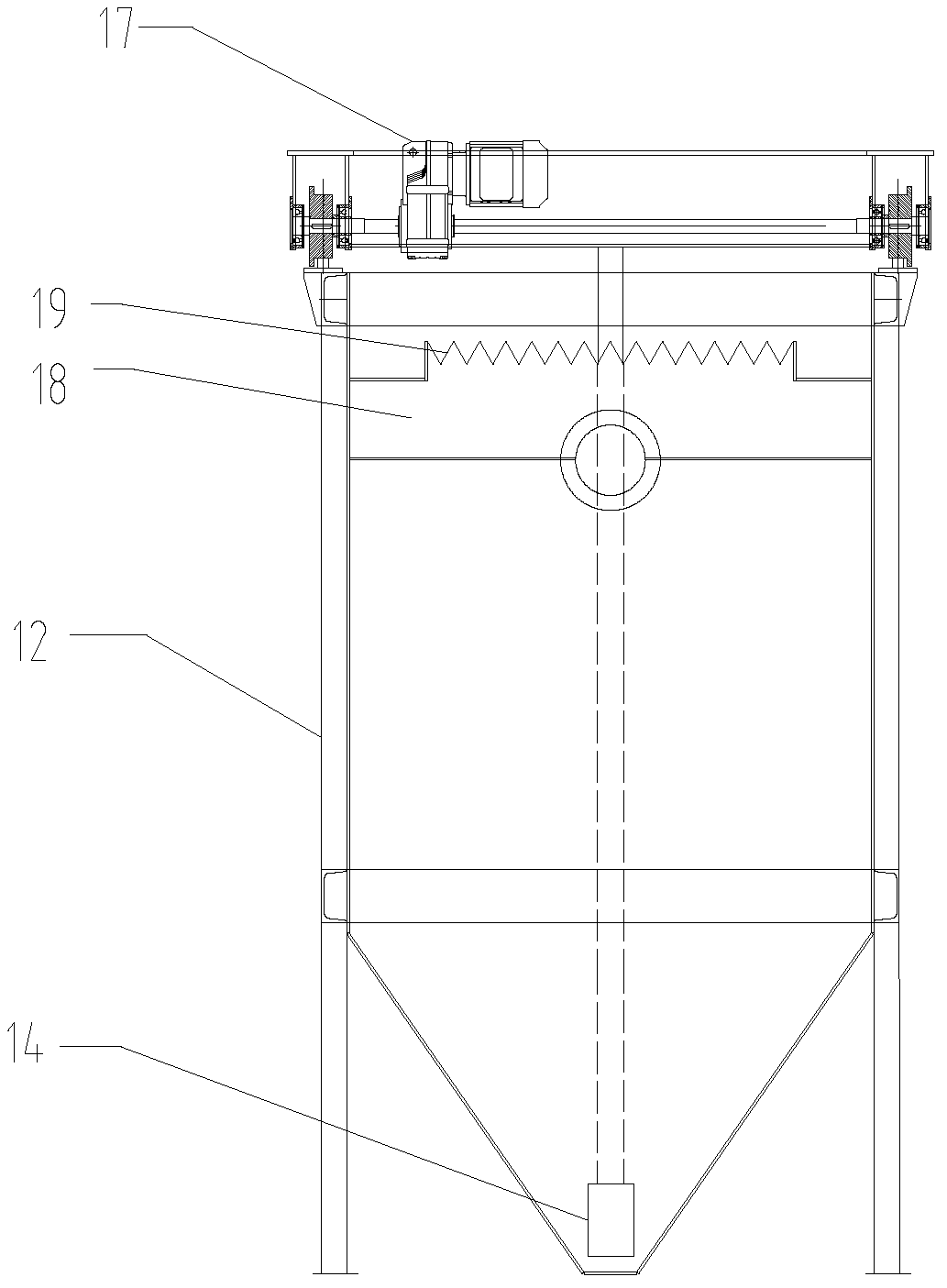

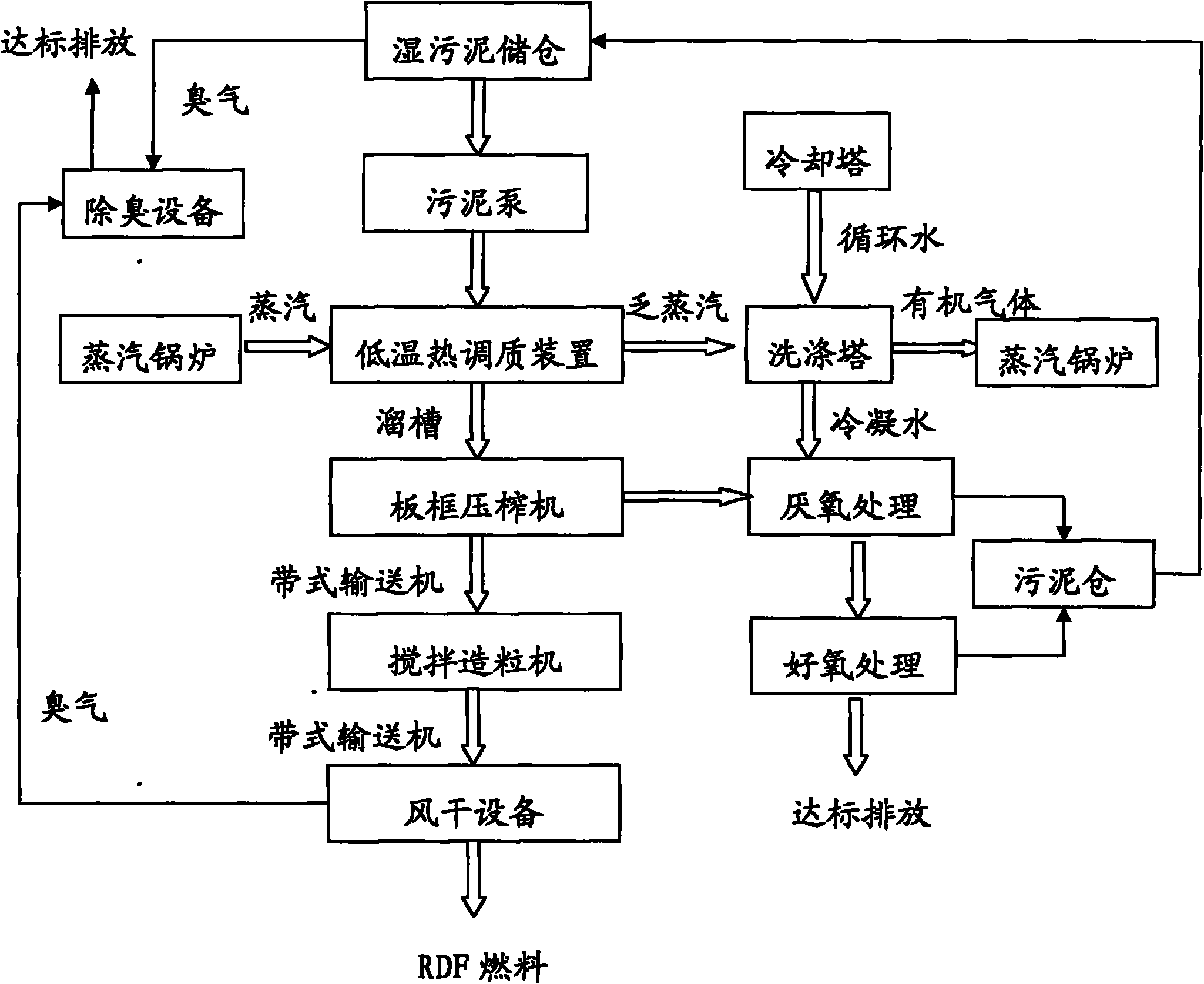

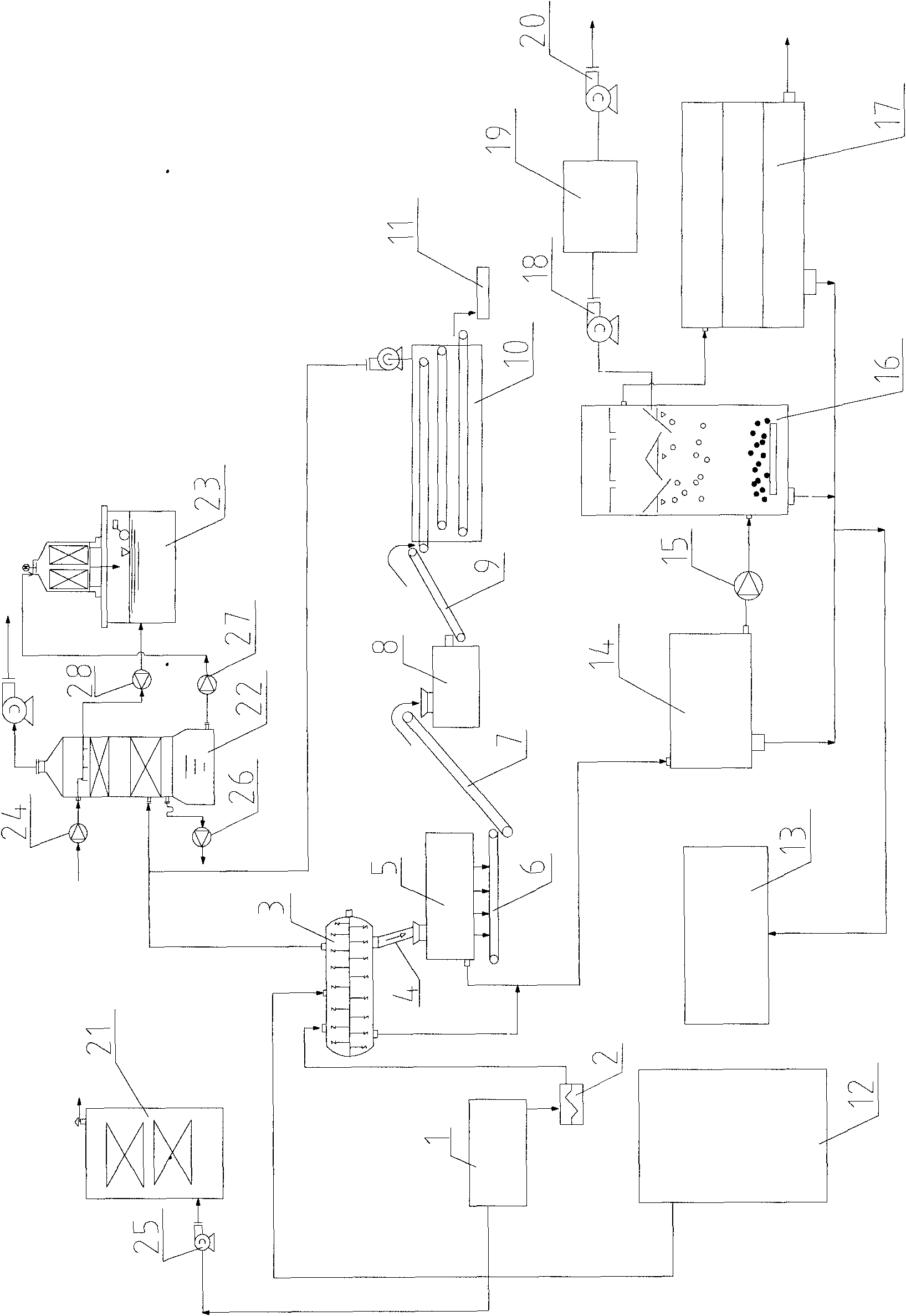

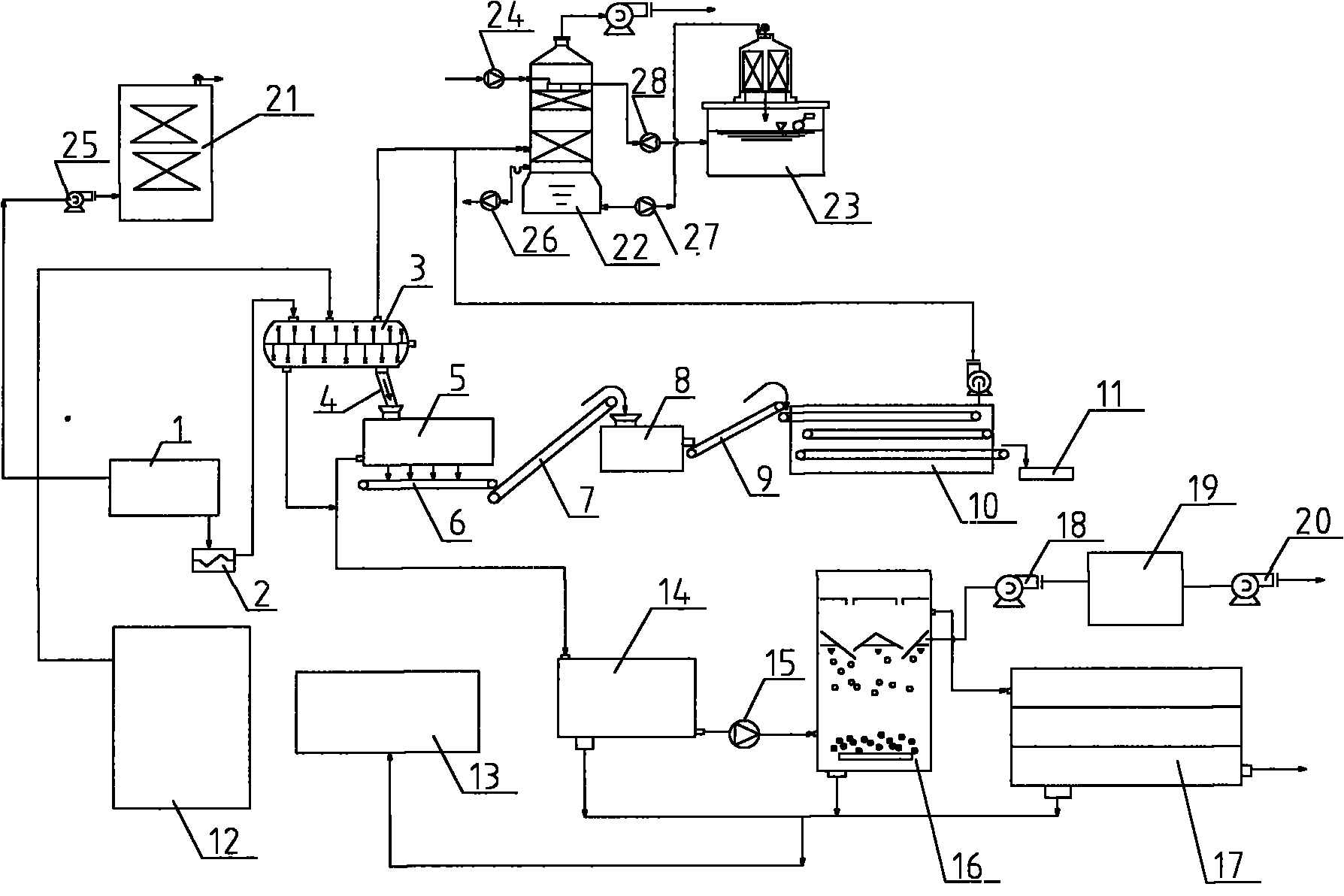

Complete steam low-temperature thermally hardening, tempering and drying device and method for sludge

ActiveCN101844859AImprove securityNo electrostatic explosionSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesHandling systemFilter press

The invention discloses a complete steam low-temperature thermally hardening, tempering and drying device for sludge and a method for treating sludge and belongs to the field of solid wastes. The system comprises a sludge storing and conveying system, a low-temperature thermally hardening and tempering device, a plate frame filter-pressing and dewatering system, a pelletizing and air-drying system, a waste gas treating system, a deodorizing system, a waste water treating system and a steam supply system, wherein the sludge storing and conveying system is used for ensuring the temperature safety, environment-friendly storage and transportation of the sludge; the low-temperature thermally hardening and tempering device is used for damaging the outer wall structures of solid-phase substances such as cells and the like in the sludge and improving the dewatering performance of the sludge; the plate frame filter-pressing and dewatering system is used for dewatering the thermally hardened and tempered sludge; the pelletizing and air-drying system is used for pelletizing and naturally drying dewatered sludge; the waste gas treating system is used for collecting waste steam produced by the low-temperature thermally hardening and tempering device; the deodorizing system is used for treating odor produced by the system; the waste water treating system is used for treating drained liquid produced by plate frame filter-pressing treatment; and the steam supply system is used for supplying saturated steam to the low-temperature thermally hardening and tempering device. Therefore, the aims of drying the sludge, reducing energy consumption, lowering cost and providing favorable conditions for subsequent resource recycling of the sludge are fulfilled.

Owner:BMEI

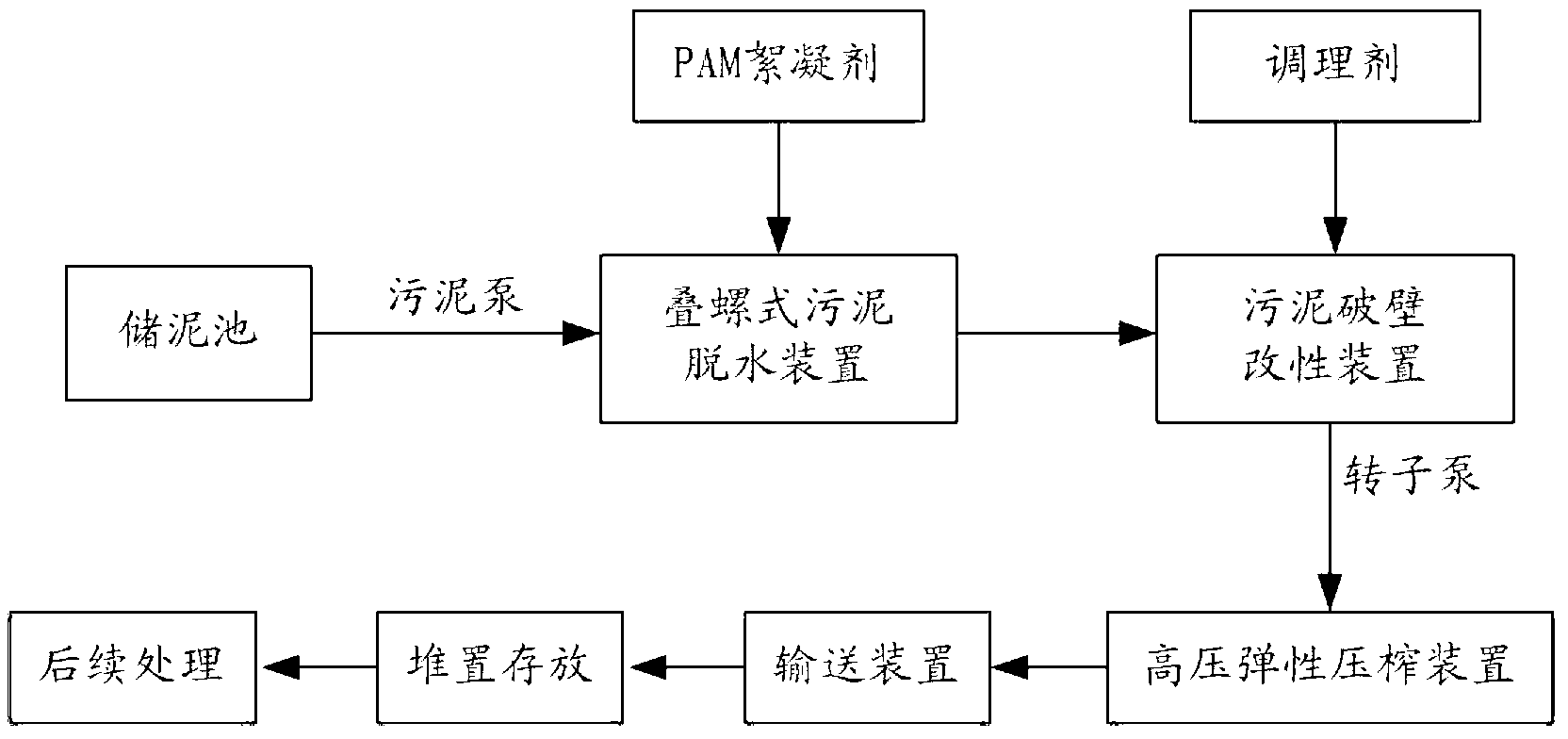

Sludge deep dewatering treatment system and process

InactiveCN103253842AHigh calorific valueSolve problems that are difficult to deal with effectivelySludge treatment by de-watering/drying/thickeningSludge cakeNational standard

Relating to the technical field of sludge treatment, the invention discloses a sludge deep dewatering treatment system and a process specific to the problems that the water content of dewatered sludge cannot reach the national standard and the heat energy loss is great in existing sludge dewatering technologies. The treatment system comprises a volute sludge dewatering device, a sludge wall breaking modification device, a high pressure elastic squeezing device, a sludge transportation device and a wastewater treatment discharge device that are connected in order. The treatment process includes the steps of: a. concentration: subjecting primary sludge to concentration by means of mechanical extrusion; b. modification: mixing the concentrated sludge with curing conditioners in the sludge wall breaking modification device uniformly to make the discharged sludge reach modification requirements; and c. filter pressing: carrying out filter pressing on the modified sludge so as to obtain a sludge cake with a water content of less than 60%-50%. The treatment system and process provided in the invention are especially suitable for deep dewatering on sludge.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

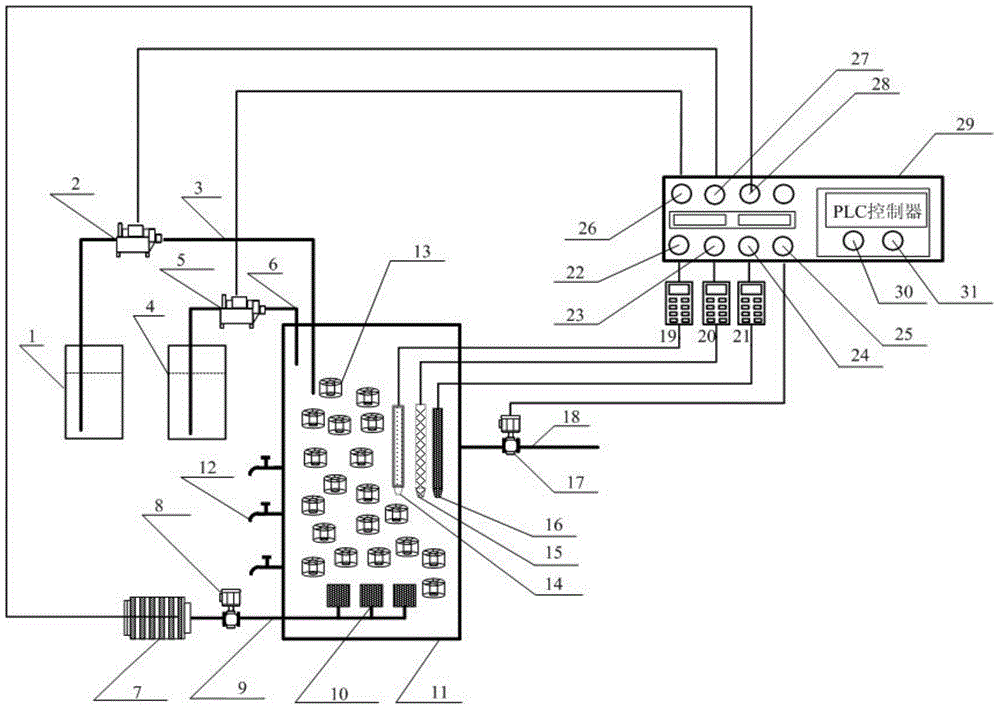

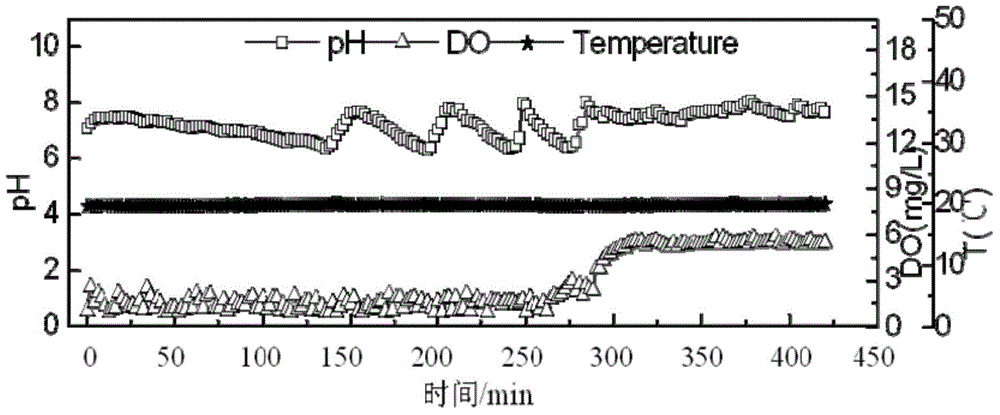

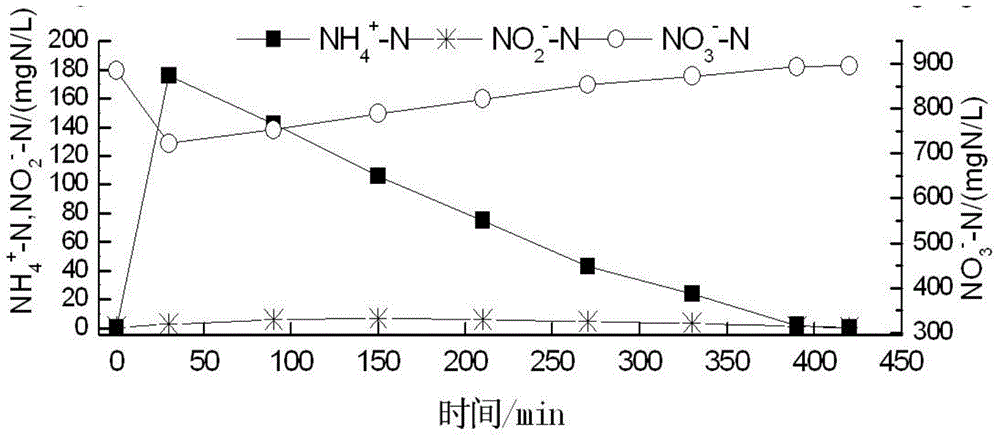

Immobilized nitrobacteria enrichment culture method and device in sewage treatment process

ActiveCN104962505AReduce the probability of accumulationPromote enrichmentBioreactor/fermenter combinationsBiological substance pretreatmentsActivated sludgeBiofilm

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

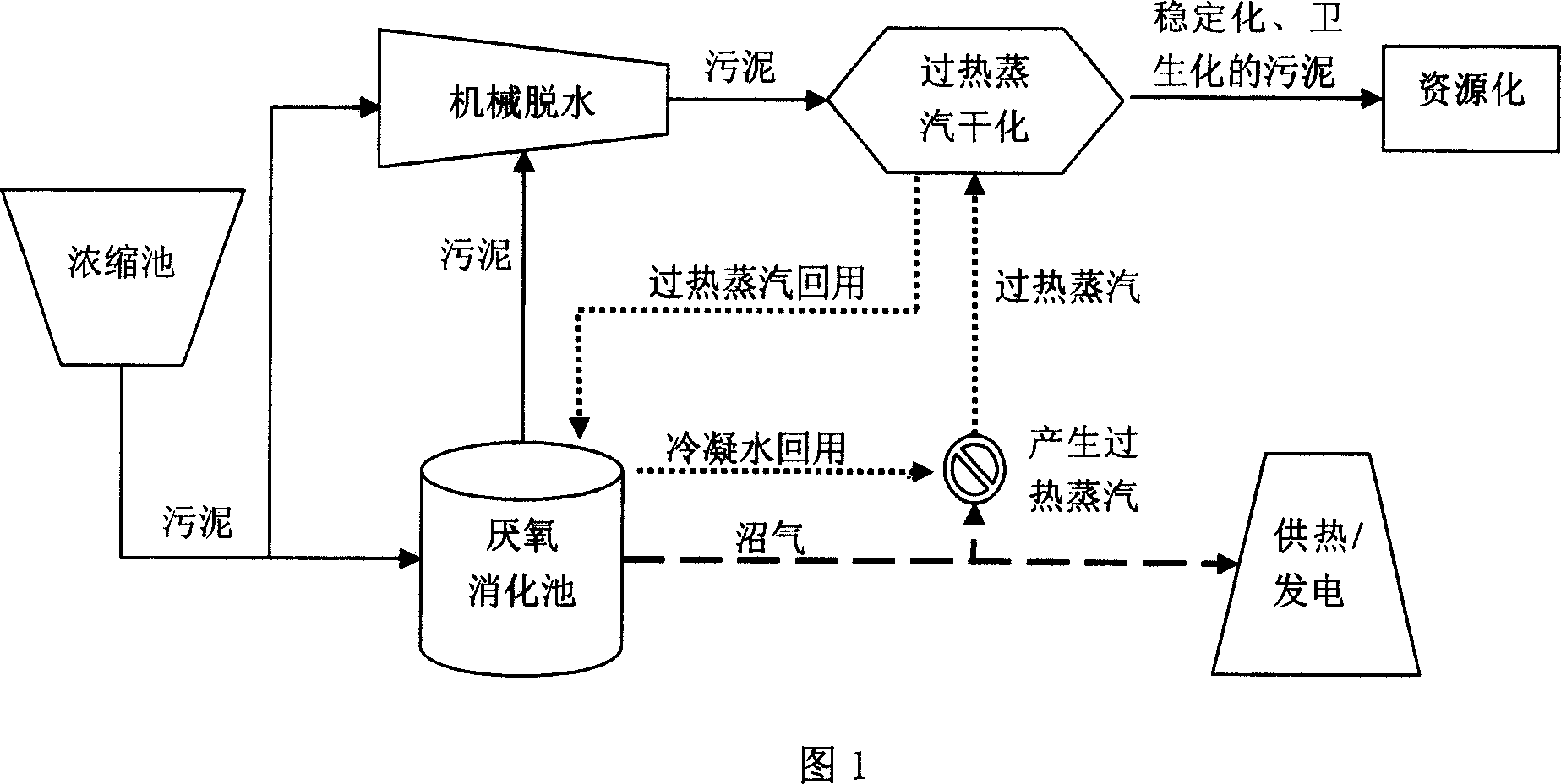

Low consumption highly effective sludge drying method

InactiveCN101012095AAchieve reductionHigh drying heat efficiencySludge treatment by de-watering/drying/thickeningWaste based fuelPulp and paper industryFood consumption

The invention discloses a low-consumption high-effective sludge drying method in the solid waste disposing technical domain, which is characterized by the following: introducing condensed sludge at certain proportion into anaerobic digestion tank; adopting partial methane from digestion tank to generate overheat steam and other methane to burn or generate power; making digestive sludge into mechanic hydrolytic chamber; introducing hydrolytic sludge into overheat steam drying device; evaporating water in the sludge; dehydrating; sterilizing; refluxing overheat steam into anaerobic digestion tank; circulating overheat steam after condensing and deodorizing.

Owner:TSINGHUA UNIV

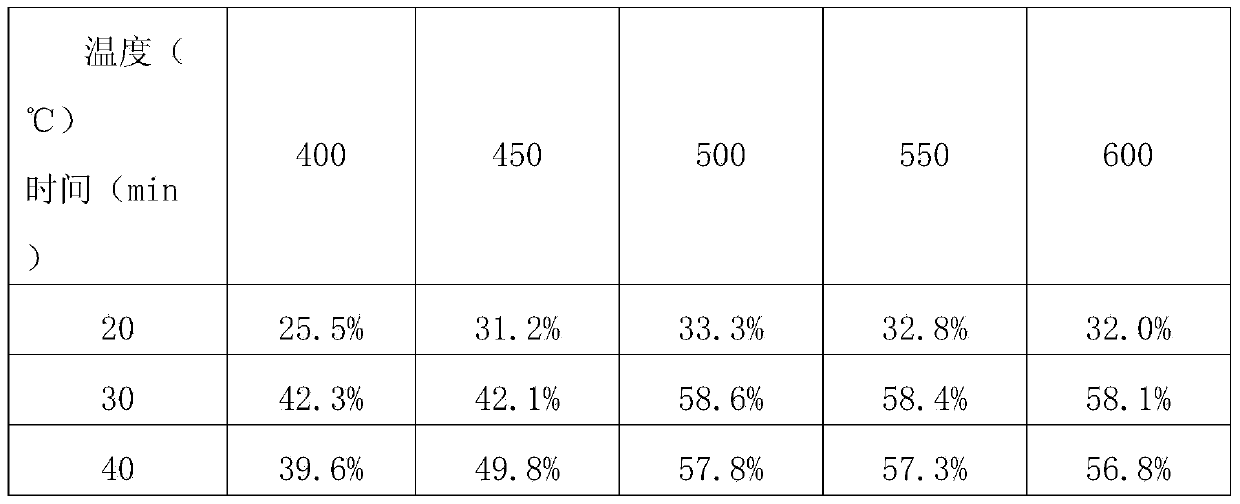

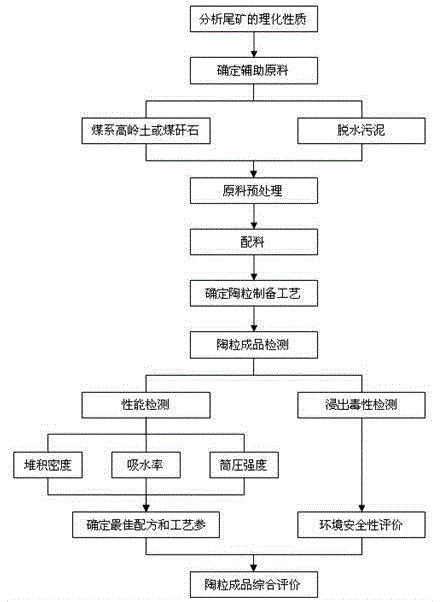

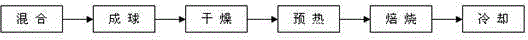

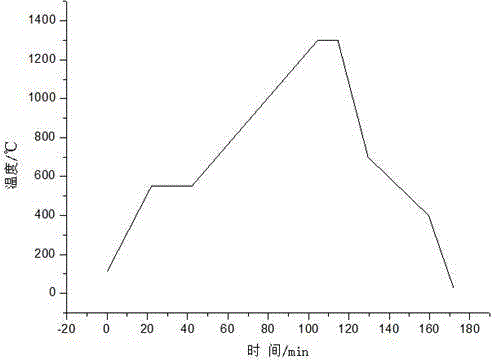

Method for preparing ultralight ceramsites from clay iron-containing tailings

ActiveCN104876625AImprove performanceSimple production processCeramicwareCoal measuresExpanded clay aggregate

The invention discloses a method for preparing ultralight ceramsites from clay iron-containing tailings. The ultralight ceramsites are prepared from the following raw materials in percentage by weight according to dry basis weight: 40-48 percent of clay iron-containing tailings, 40-48 percent of coal series kaolinite or coal gangue and 8-15 percent of dewatered sludge; the method comprises the following preparation processes: mixing materials, pelletizing, drying, preheating, calcining and cooling; under an optimum formula and process conditions that the preheating temperature is 500-600 DEG C, calcination temperature is 1250-1350 DEG C, and the heating rate is 10-15 DEG C / min, the all-solid waste ultralight ceramsites with the bulk density of 390 kg / m<3>, cylinder compressive strength of 1.2 MPa and the water absorption of 3.8% can be prepared through firing, and meet requirements of GB / T17431.1-2010, a novel approach is developed for abundant utilization of tailings, coal gangue and dewatered sludge and obvious economic benefits, environmental benefits and social benefits are realized.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com