Patents

Literature

43results about How to "Reduce the probability of accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

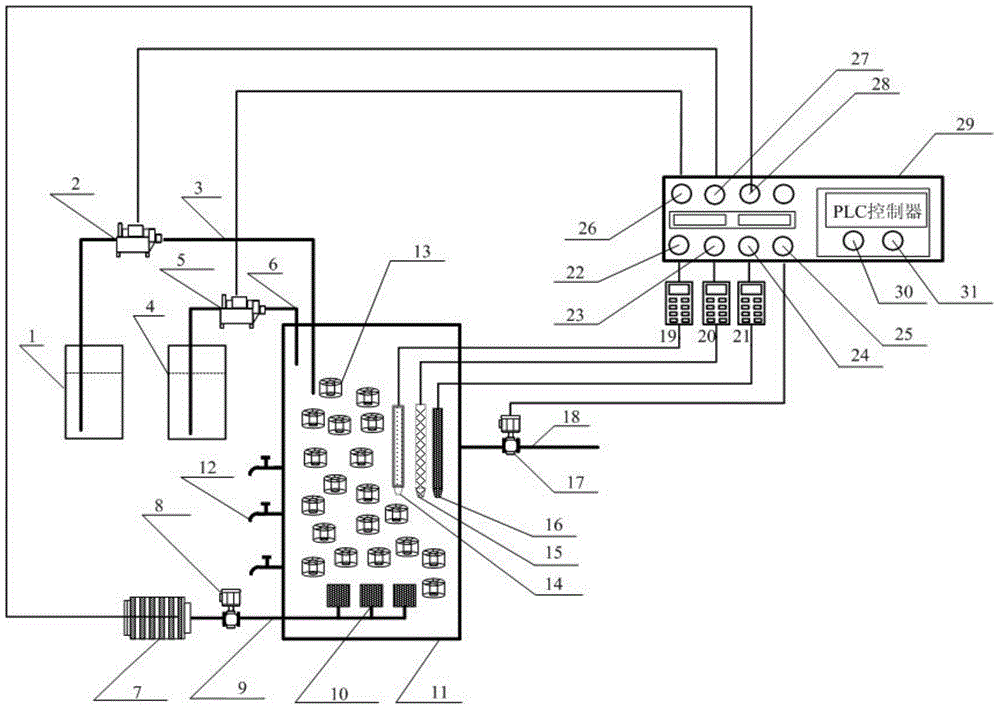

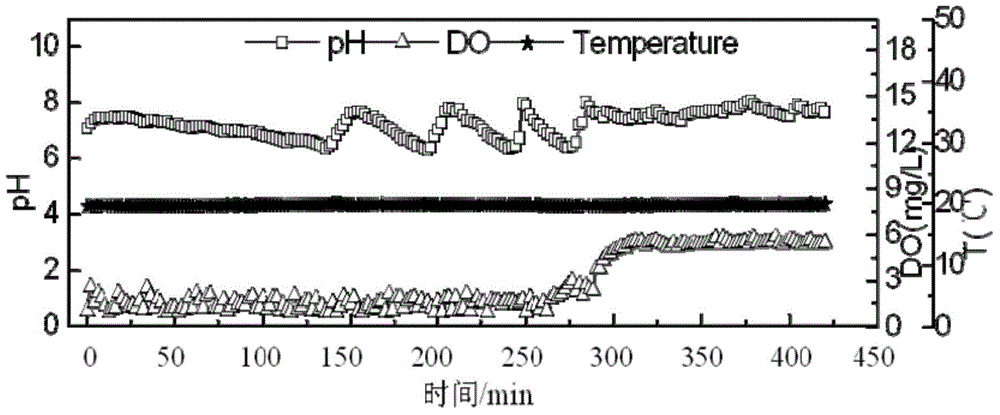

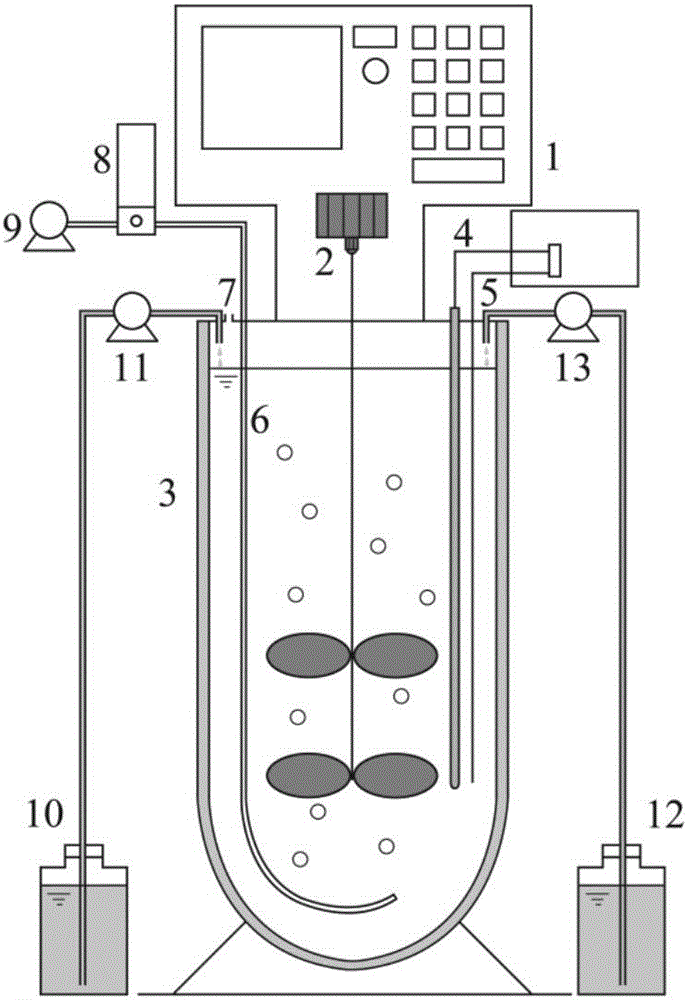

Immobilized nitrobacteria enrichment culture method and device in sewage treatment process

ActiveCN104962505AReduce the probability of accumulationPromote enrichmentBioreactor/fermenter combinationsBiological substance pretreatmentsActivated sludgeBiofilm

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

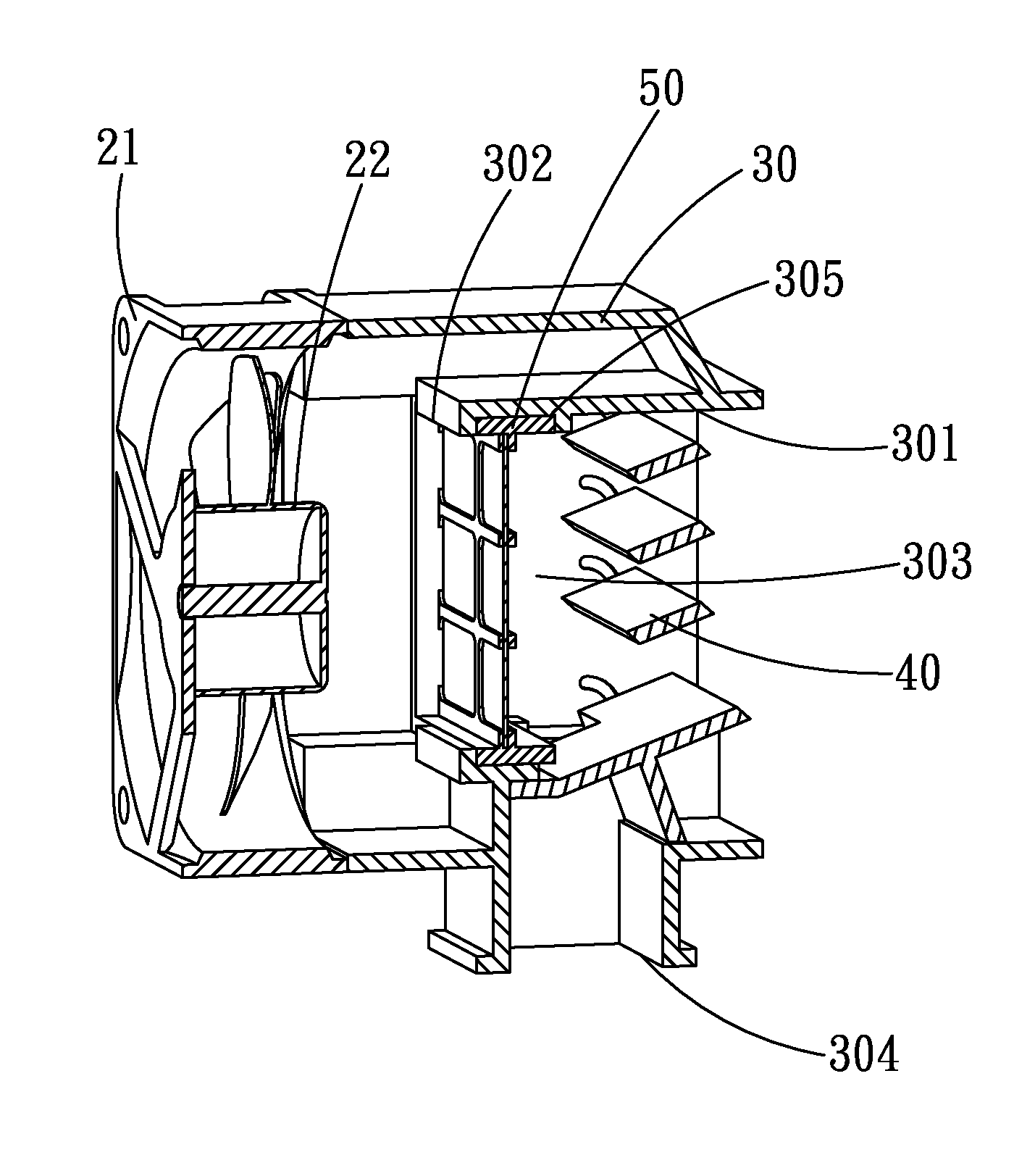

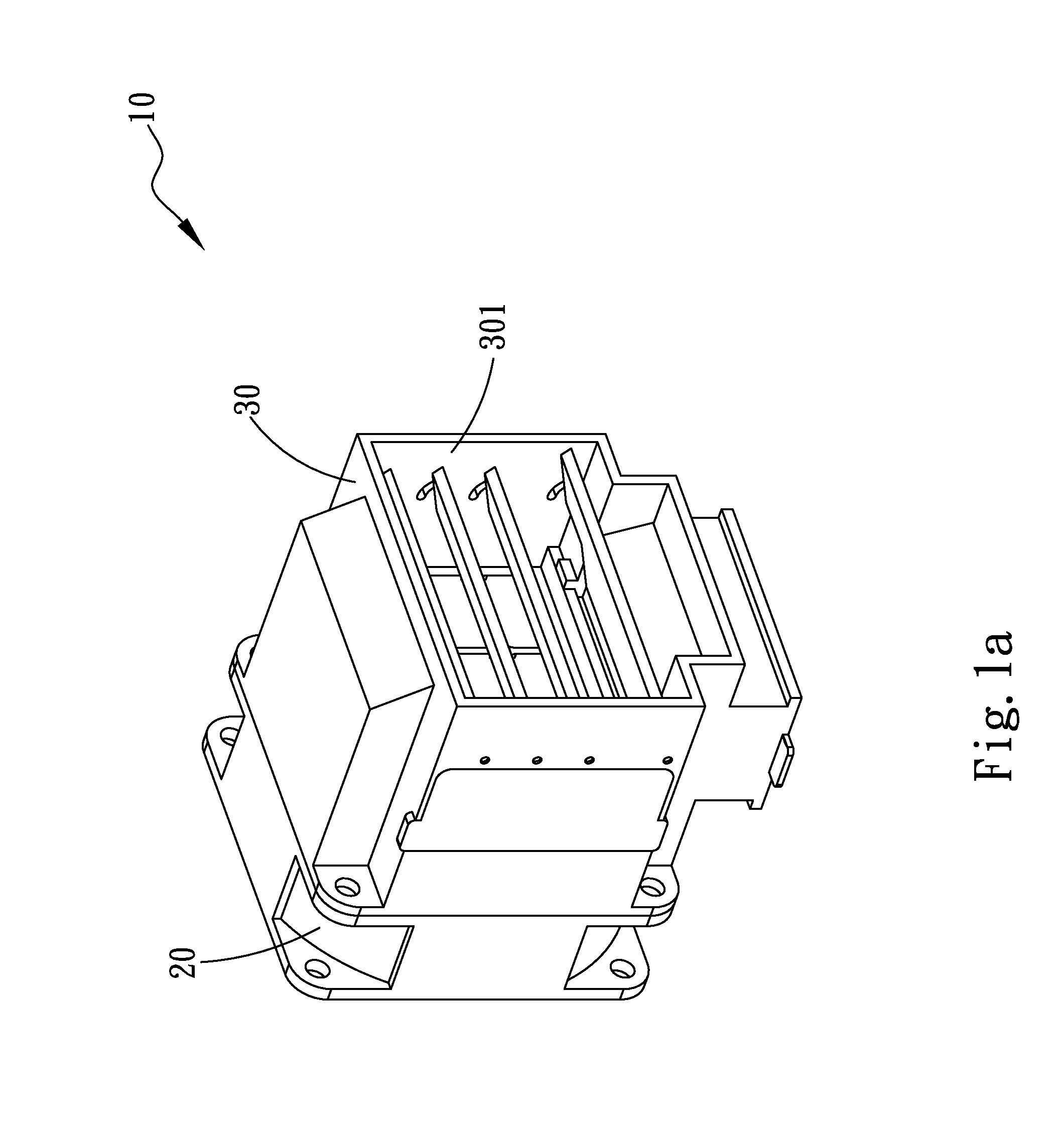

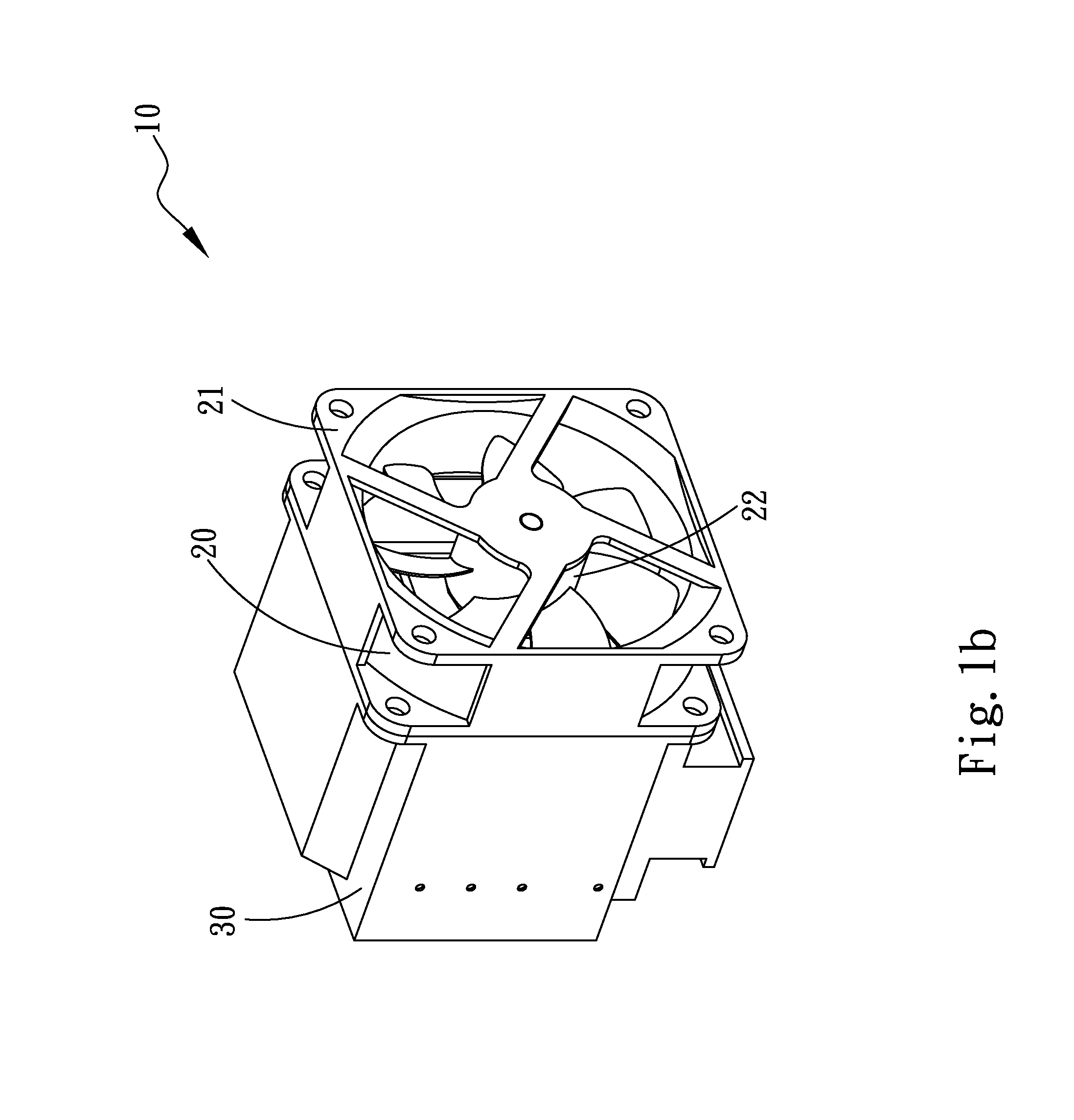

Dustproof axial-flow fan device

A dustproof axial-flow fan device includes an axial-flow fan and a mount body. The axial-flow fan has a frame body and a fan propeller rotatably mounted in the frame body. The mount body has an inlet and an outlet. At least one shutter slat is disposed at the inlet. A filter mesh is disposed at the outlet. An opening is formed at a bottom of the mount body. When the fan propeller forward rotates, air flows from the inlet into the mount body and filters through the filter mesh to flow out of the outlet. When the fan propeller reversely rotates, the shutter slat is closed to block the inlet. In this case, the air flows from the outlet into the mount body to blow off the dust from the filter mesh. The shutter slat will stop and make the dust drop out from the opening to remove the dust.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

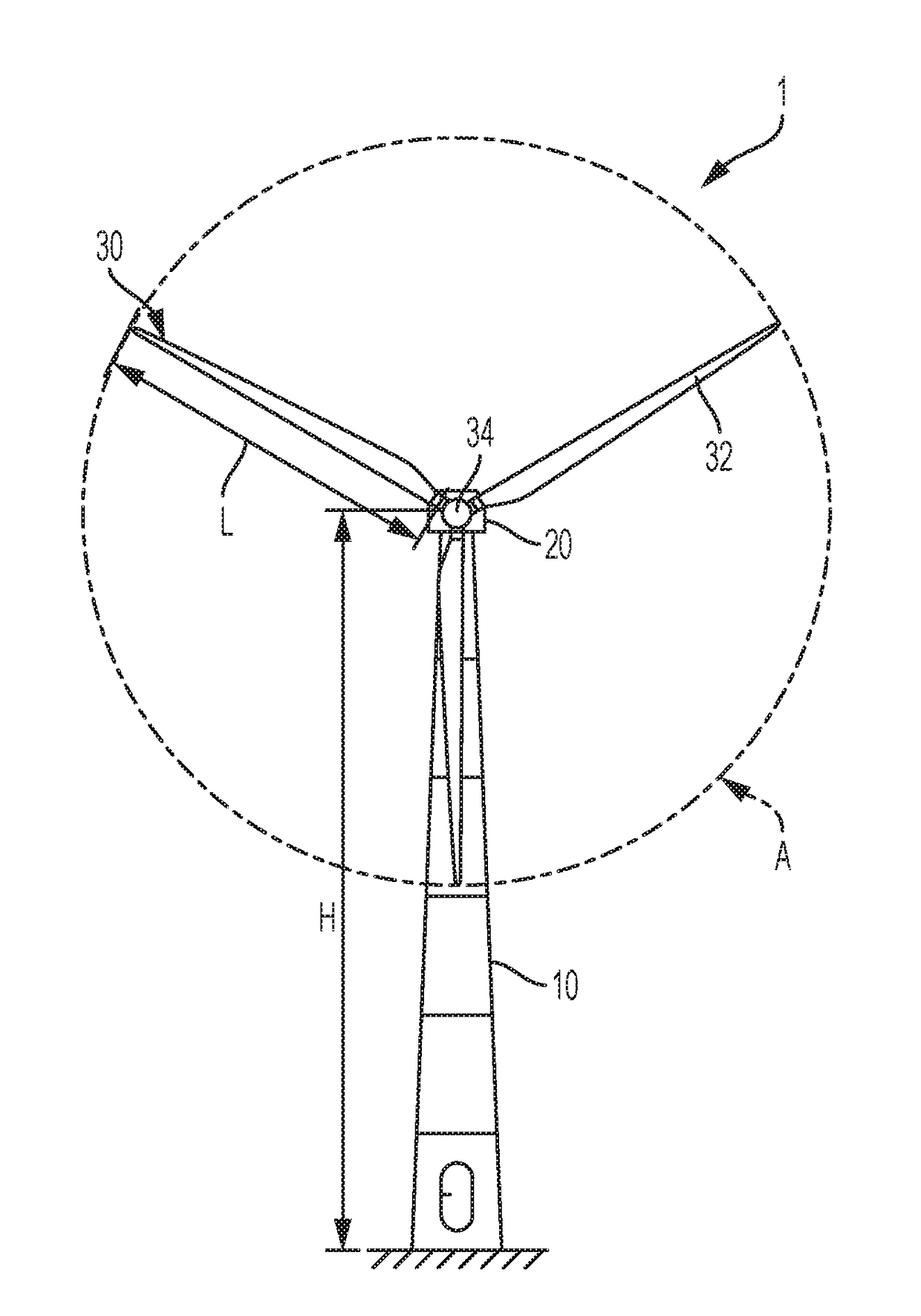

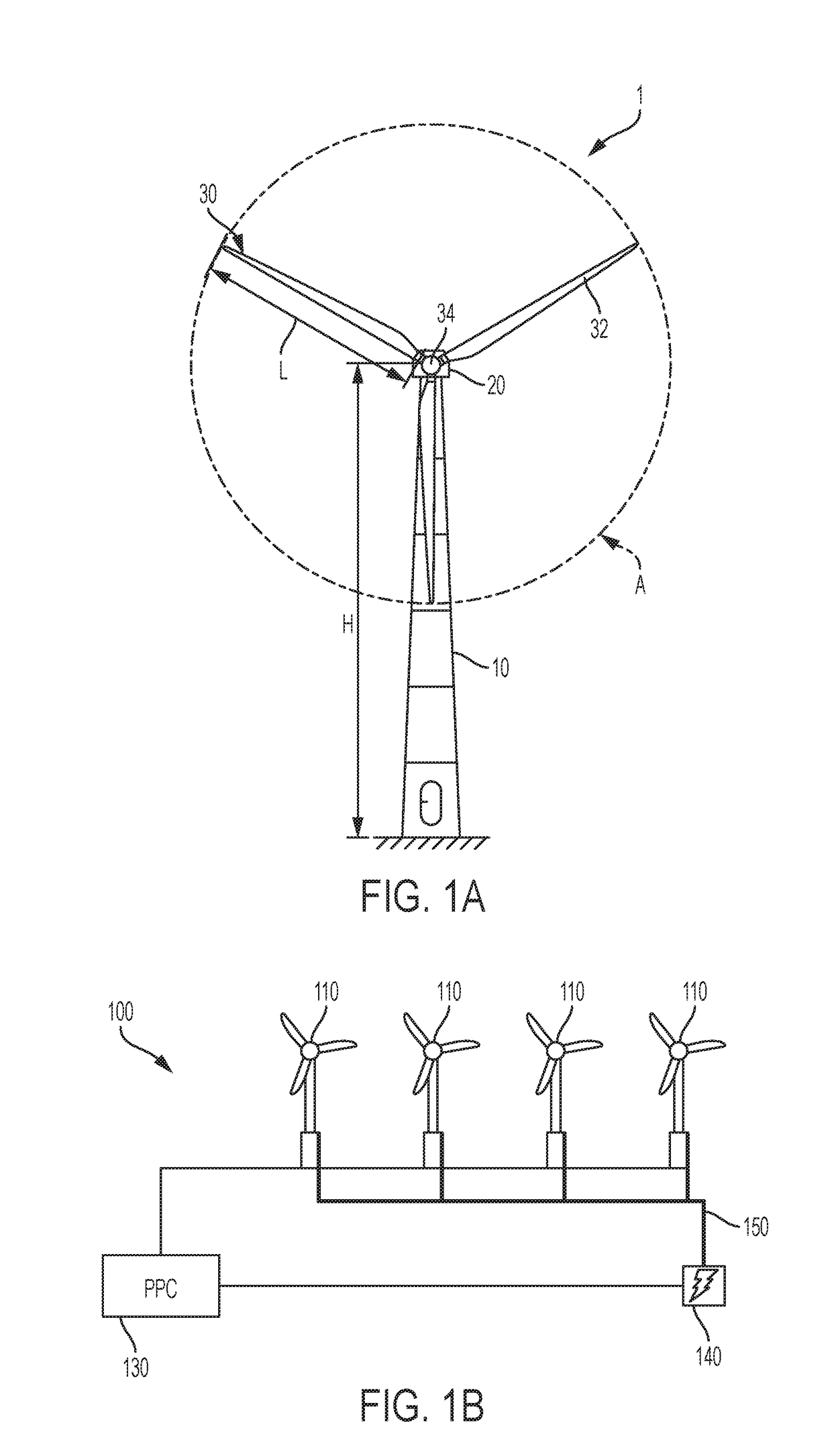

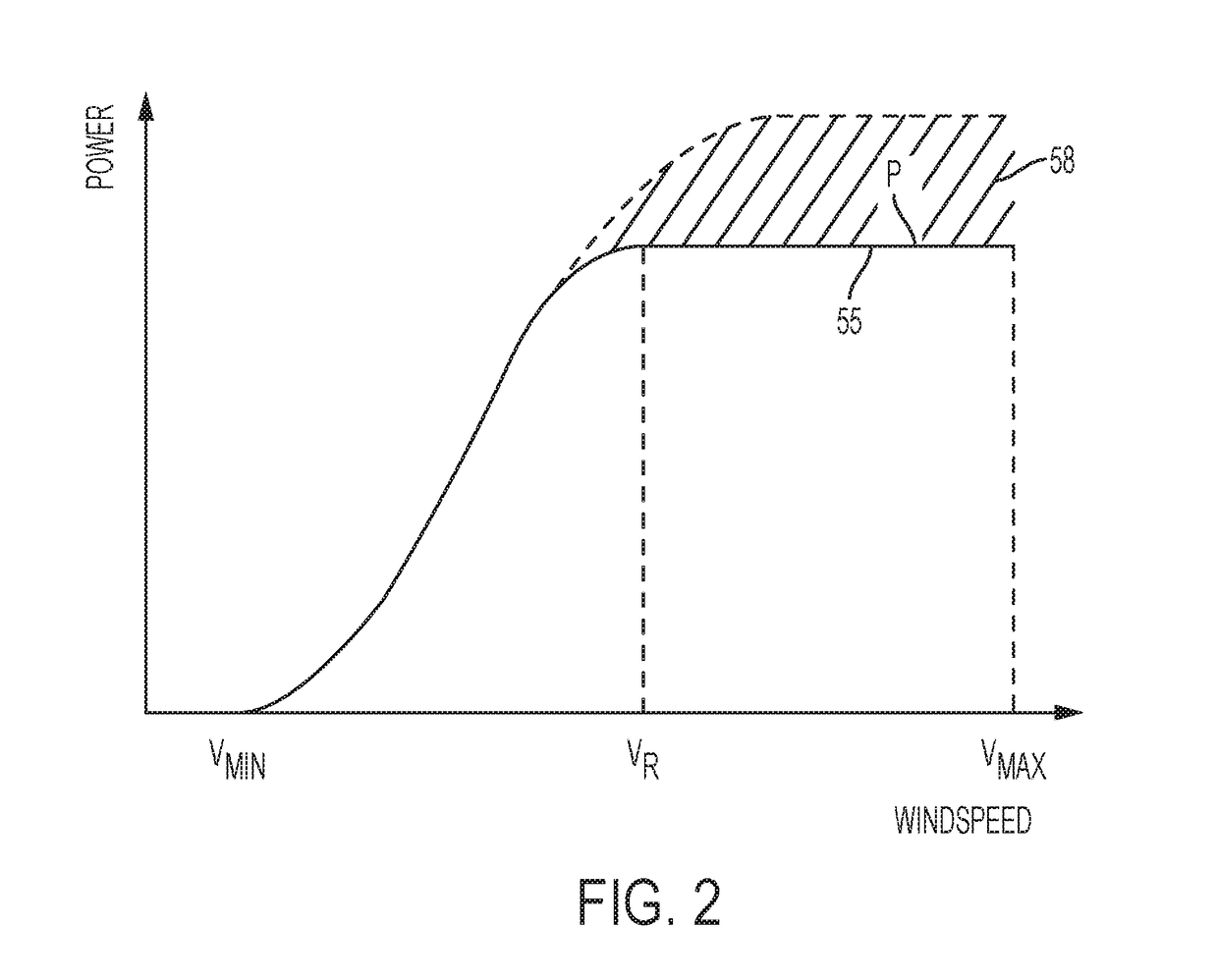

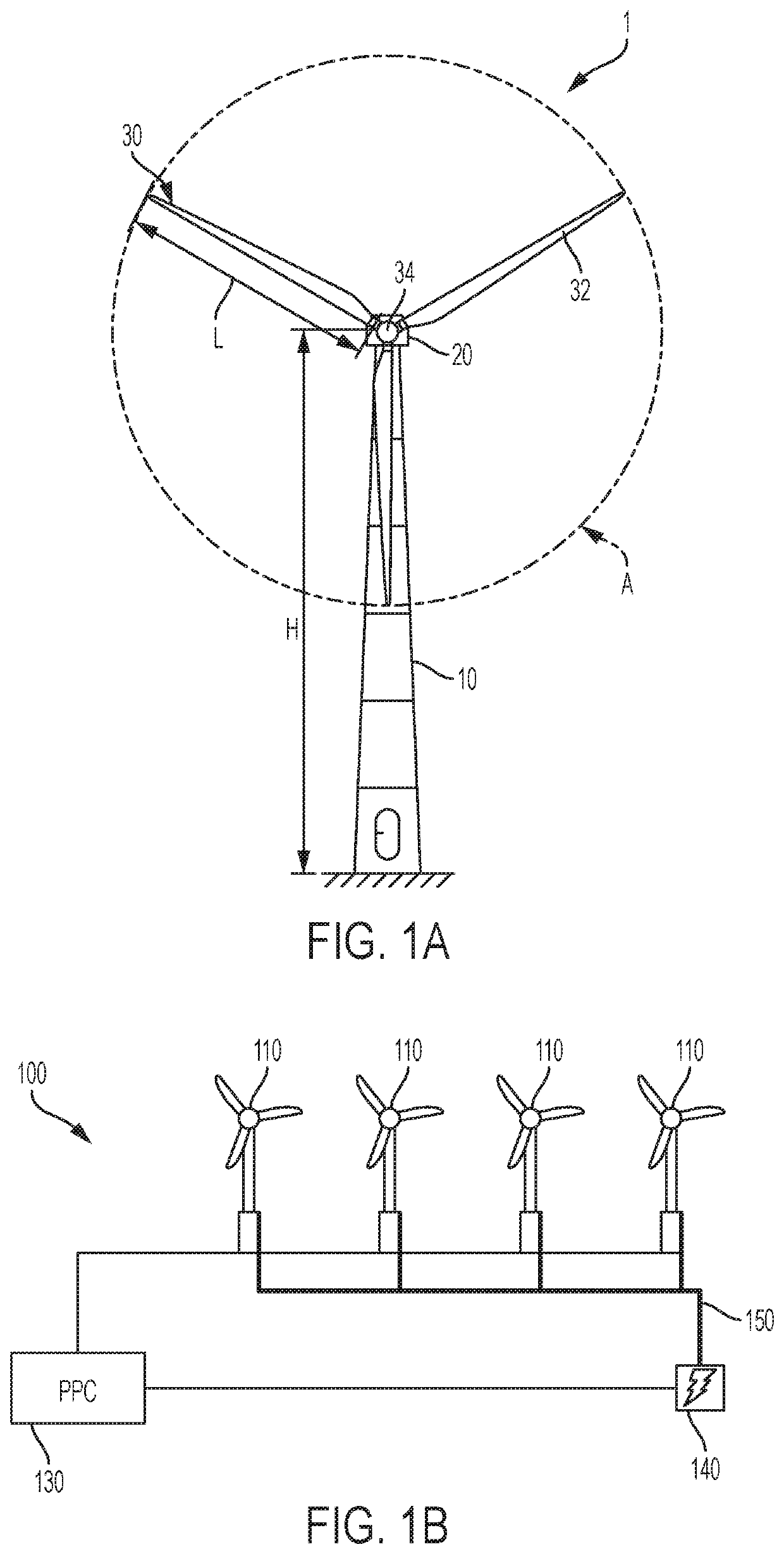

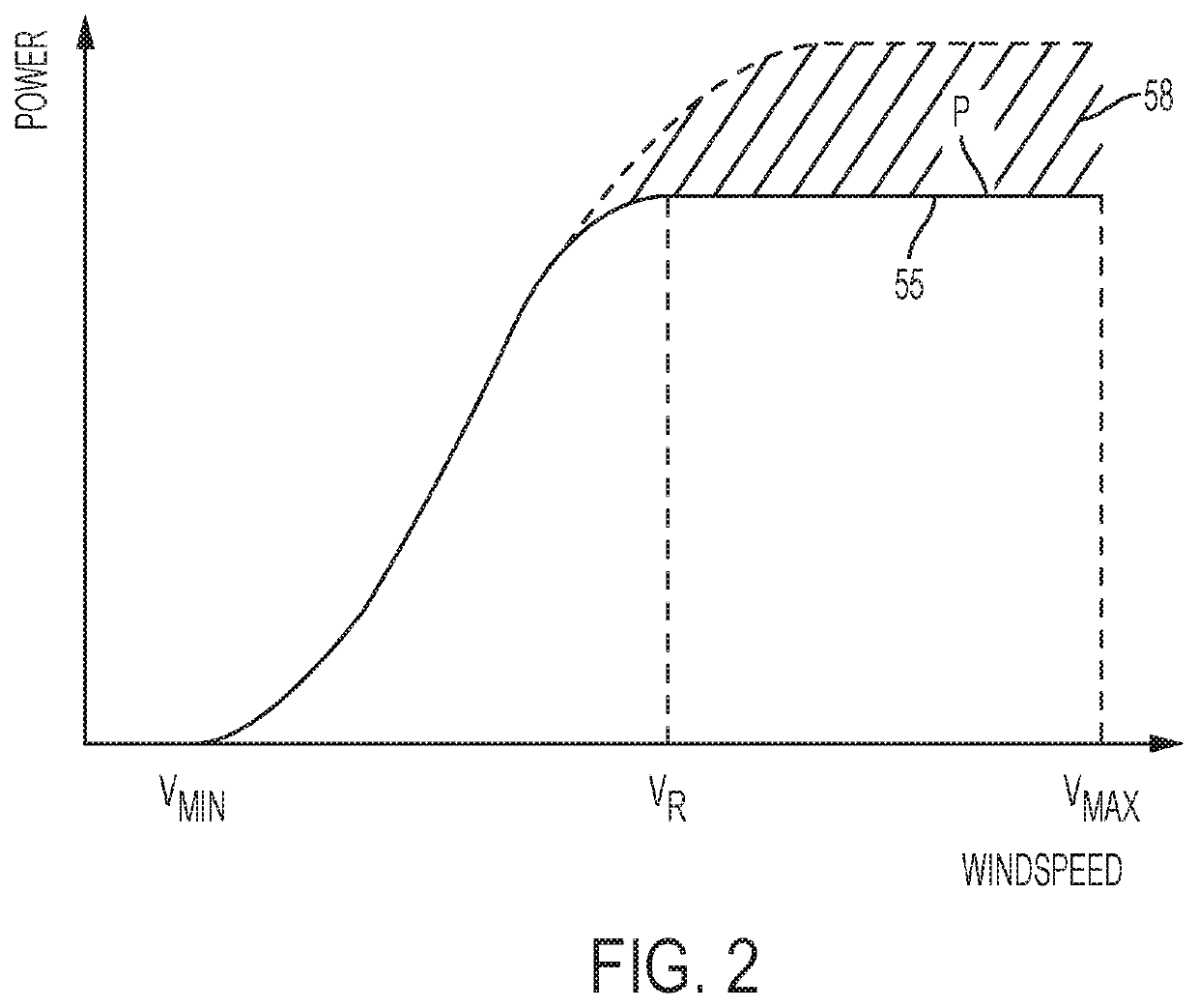

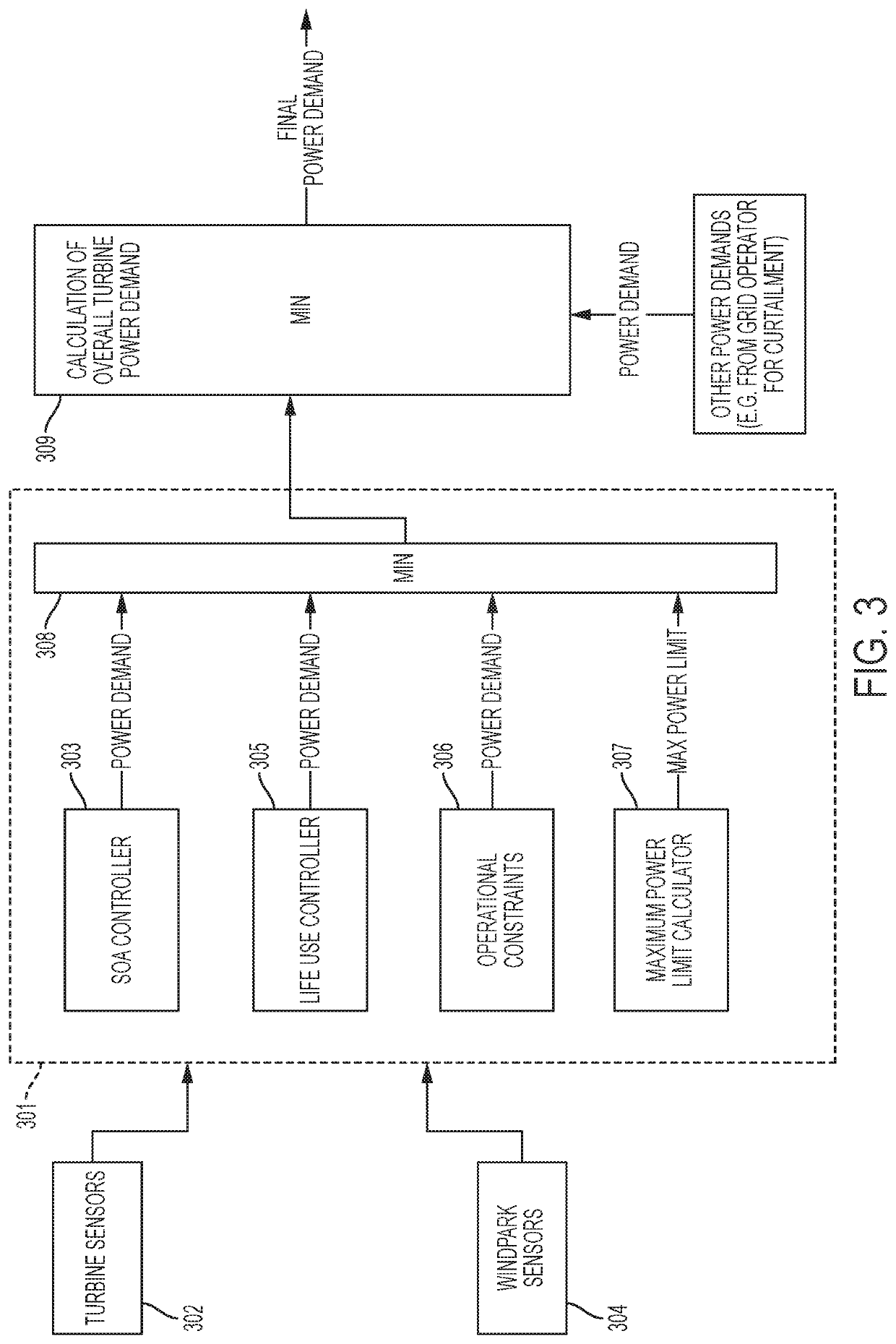

Control method and system for protection of wind turbines

ActiveUS20180156197A1Reduce the probability of accumulationOver-rating to be reducedWind motor controlMachines/enginesControl signalTurbine

A method is provided of controlling a wind turbine that is operating according to a control signal causing the wind turbine to be over-rated above the wind turbine's rated power. The method comprises: obtaining one or more signals, or values of variables, that indicate the fatigue lifetime of one or more of the wind turbine's components from turbine sensors; applying a lifetime usage estimator algorithm to the signals or values to determine measures of the fatigue life consumed by each of the turbine components; calculating, for each of the turbine components, a rate of consumption of fatigue life based on the measures of the fatigue life consumed by each of the turbine components; and controlling the turbine to reduce the amount of power by which the wind turbine is over-rated based on the rate of consumption of fatigue life for at least one of the turbine components.

Owner:VESTAS WIND SYST AS

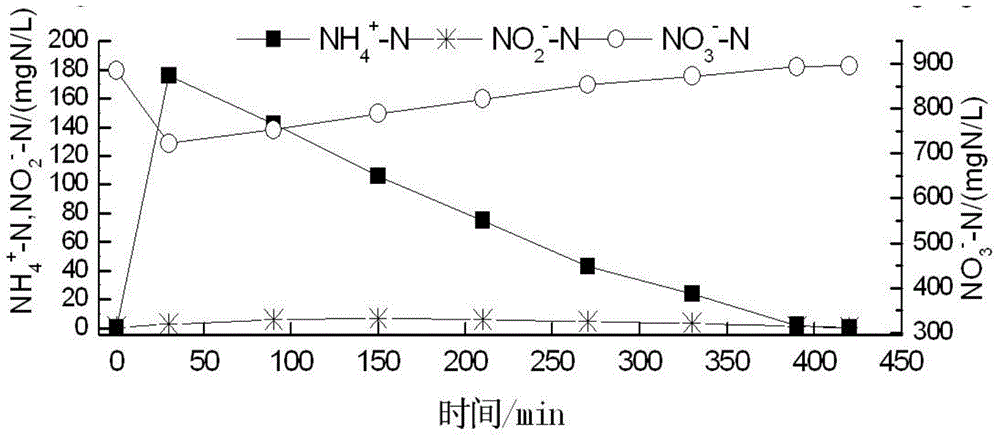

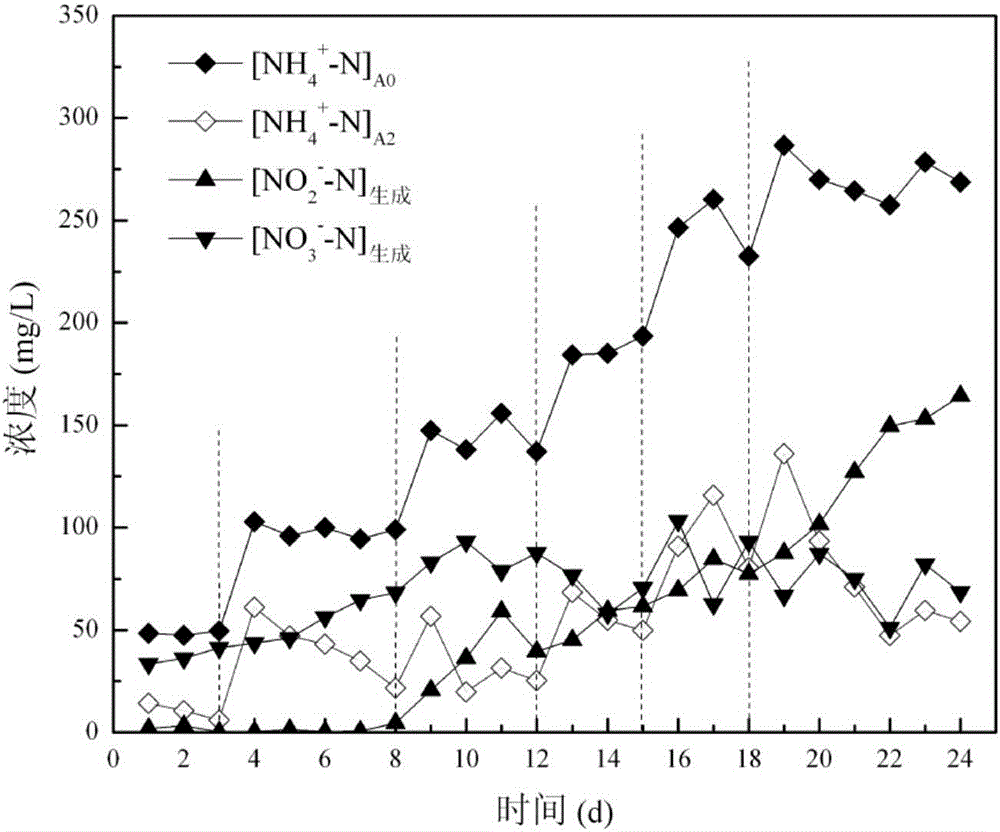

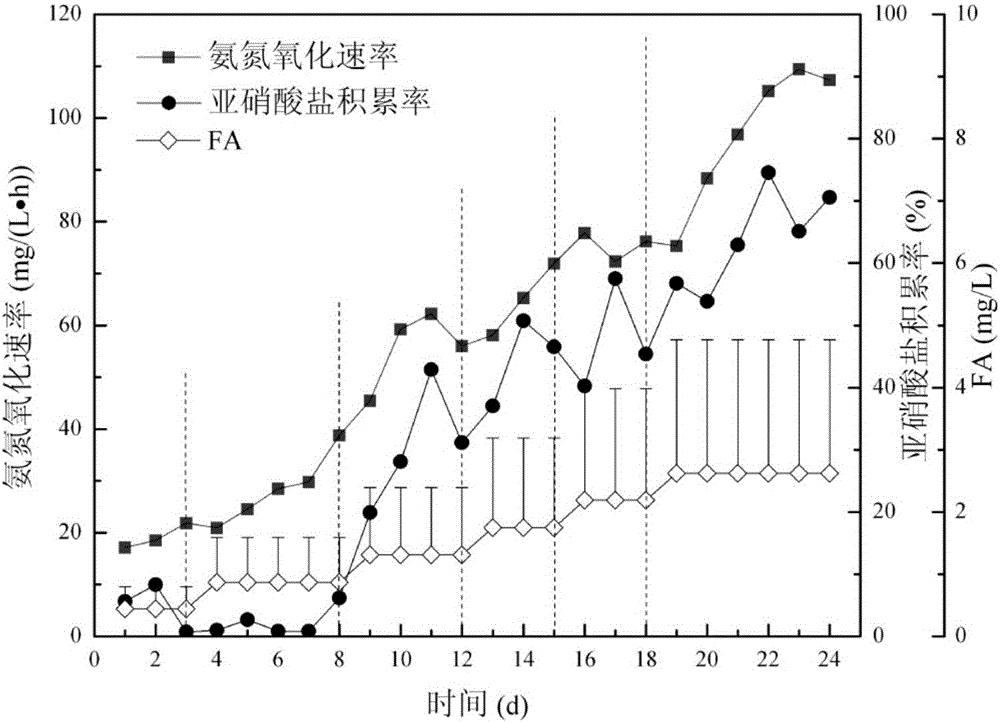

Method for screening and enrichment culture of nitrifying bacterium floras with alternation of intermittent ammonia nitrogen flow and intermittent operation

ActiveCN106396132AIncrease oxidation rateControl levelWater treatment parameter controlBacteriaActivated sludgeNitrifying bacteria

The invention discloses a method for screening and enrichment culture of nitrifying bacterium floras with alternation of intermittent ammonia nitrogen flow and intermittent operation, and belongs to the technical field of water treatment. According to the method, activated sludge containing nitrifying bacteria is used as inoculation sludge, and the screening and enrichment culture of the nitrifying bacterium floras are achieved by using a bacterial fermentation tank by virtue of a method for alternation of intermittent ammonia nitrogen flow and intermittent operation. The initial ammonia nitrogen load is gradually increased by using intermittent operation so as to improve the ammonia-nitrogen oxidation rate, and the ammonia nitrogen flow and intermittent operation maintain the ammonia-nitrogen oxidation rate and achieve a low nitrite accumulation rate. By adopting the method, the screening and enrichment culture of the nitrifying bacterium floras can be achieved in a short time. The nitrifying bacterium floras obtained by the method disclosed by the invention have an advantage in numbers in total bacterial count, and a high ammonia-nitrogen oxidation rate and a high nitrite oxidation rate can be achieved.

Owner:BEIJING UNIV OF TECH

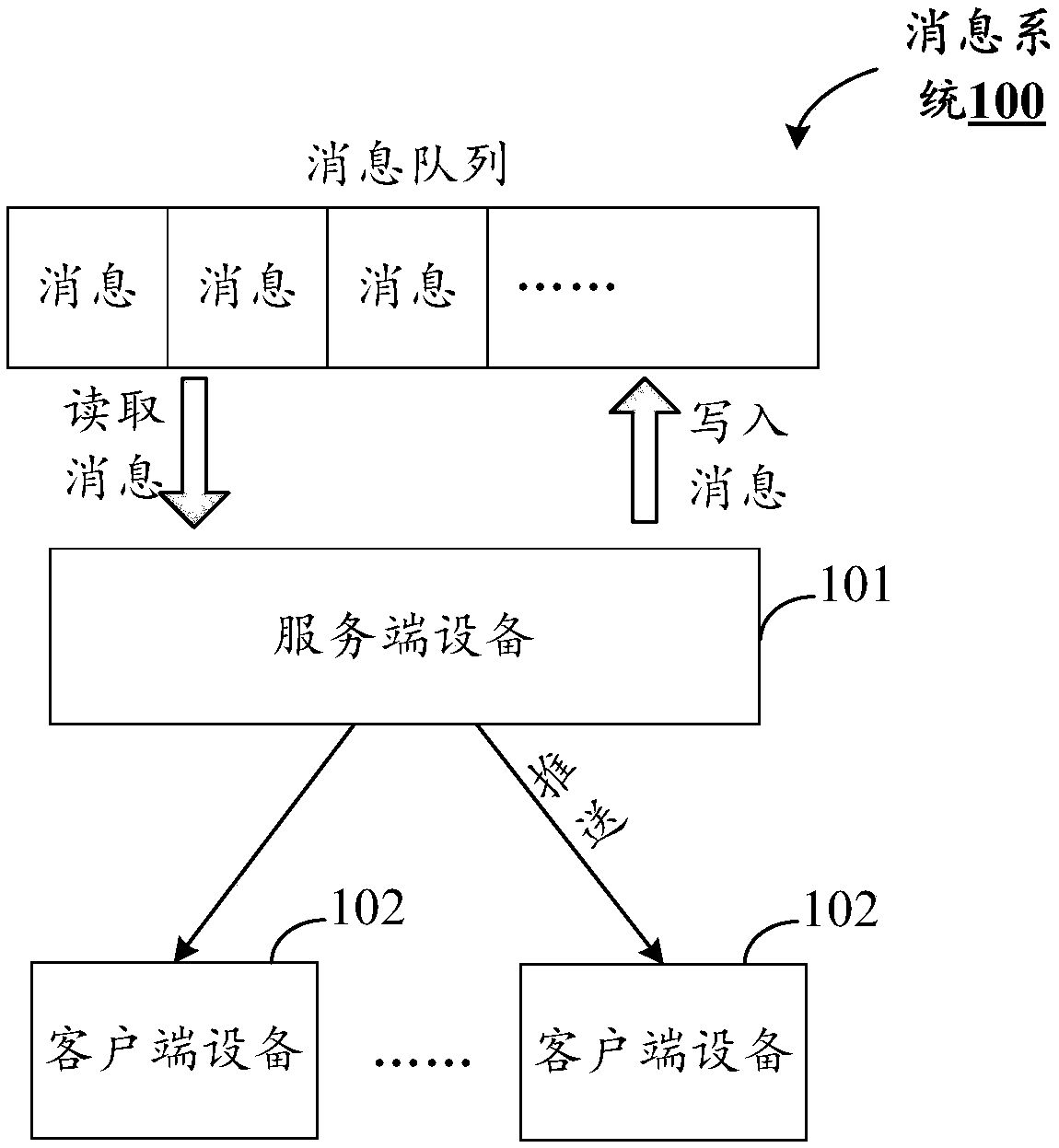

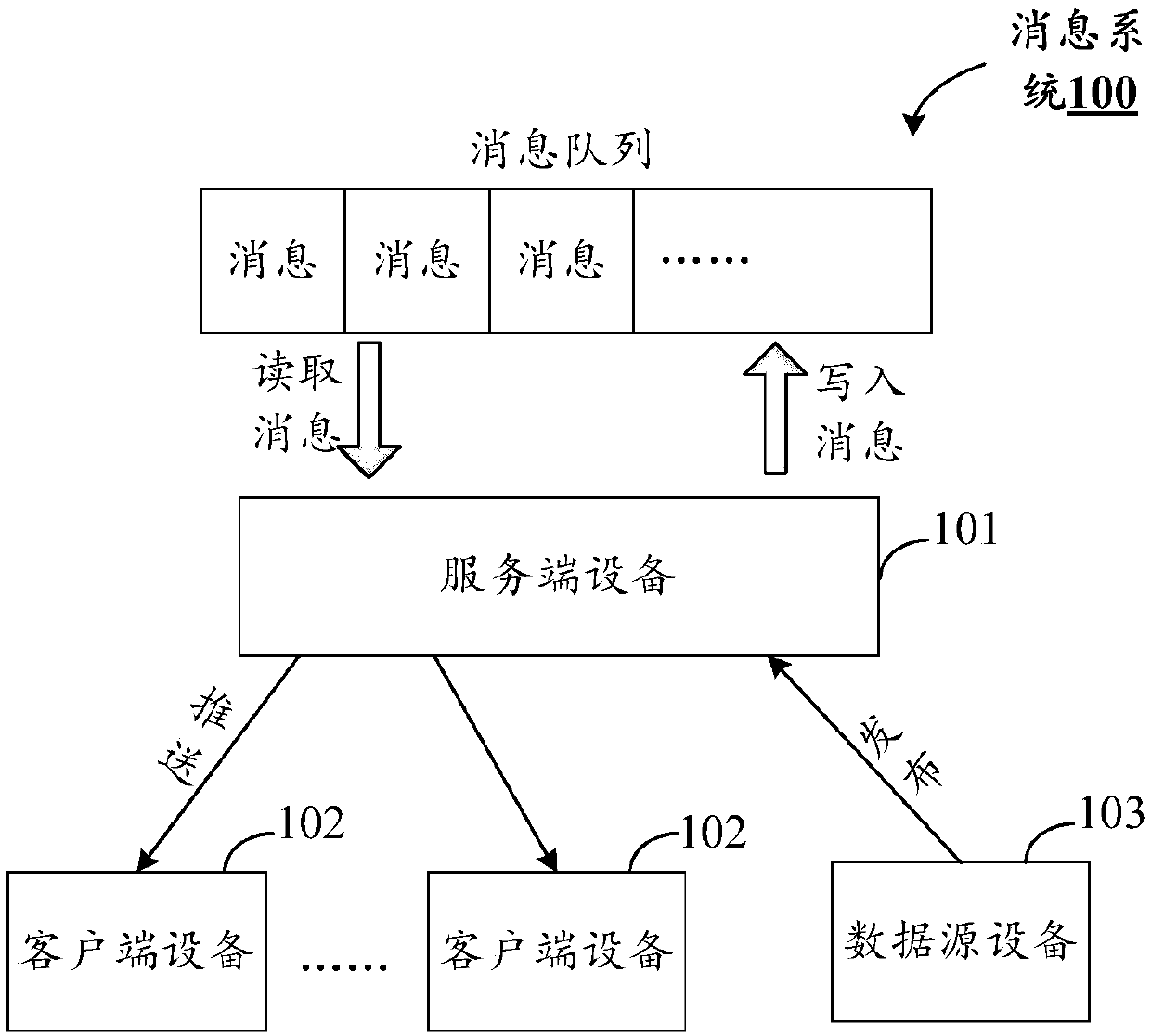

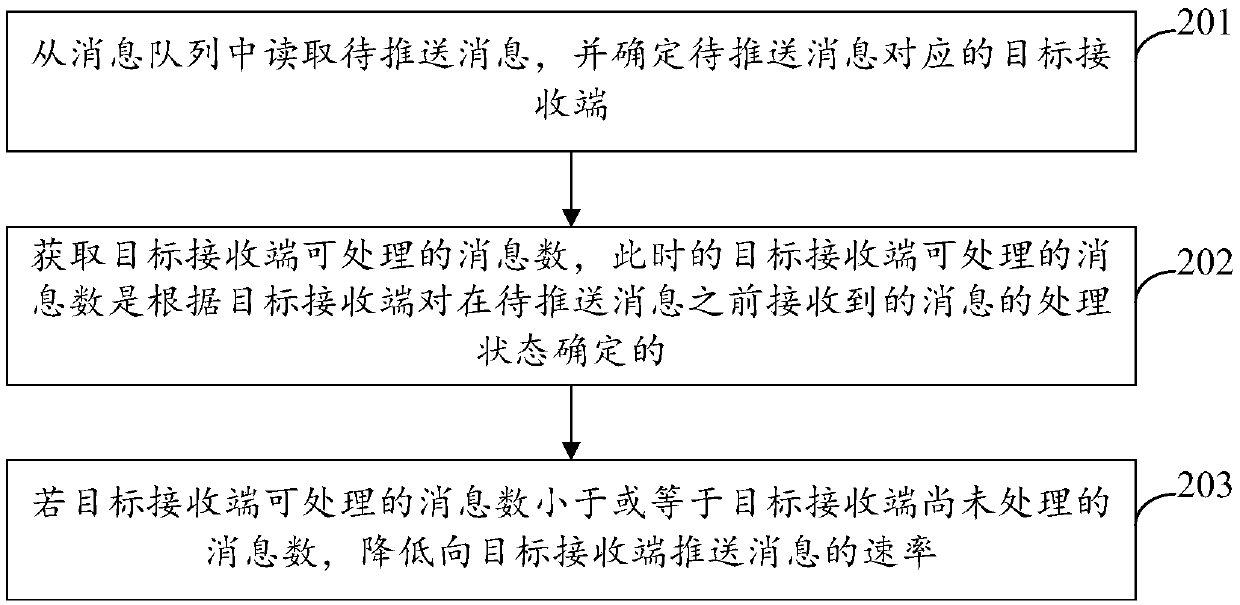

Message pushing method, device and system

PendingCN110324250AReduce the probability of accumulationImprove service qualityData switching networksComputer hardwareQuality of service

The embodiment of the invention provides a message pushing method, device and system. In the embodiment of the invention, when a new message needing to be pushed is read from the message queue; firstly, a receiving end corresponding to a new message is determined; the number of messages which can be processed by the receiving end is determined in combination with the processing state of the receiving end for the previously received messages; whether the receiving end has the capability of continuously processing the new message or not is judged according to the number of messages which can beprocessed by the receiving end and the number of messages which are not processed by the receiving end; and when the receiving end has no capability to continue to process the new message, the probability of message accumulation on one side of the receiving end can be reduced to a certain extent by reducing the rate of pushing the message to the receiving end, so that the service quality of the message system is improved on the whole.

Owner:ALIBABA GRP HLDG LTD

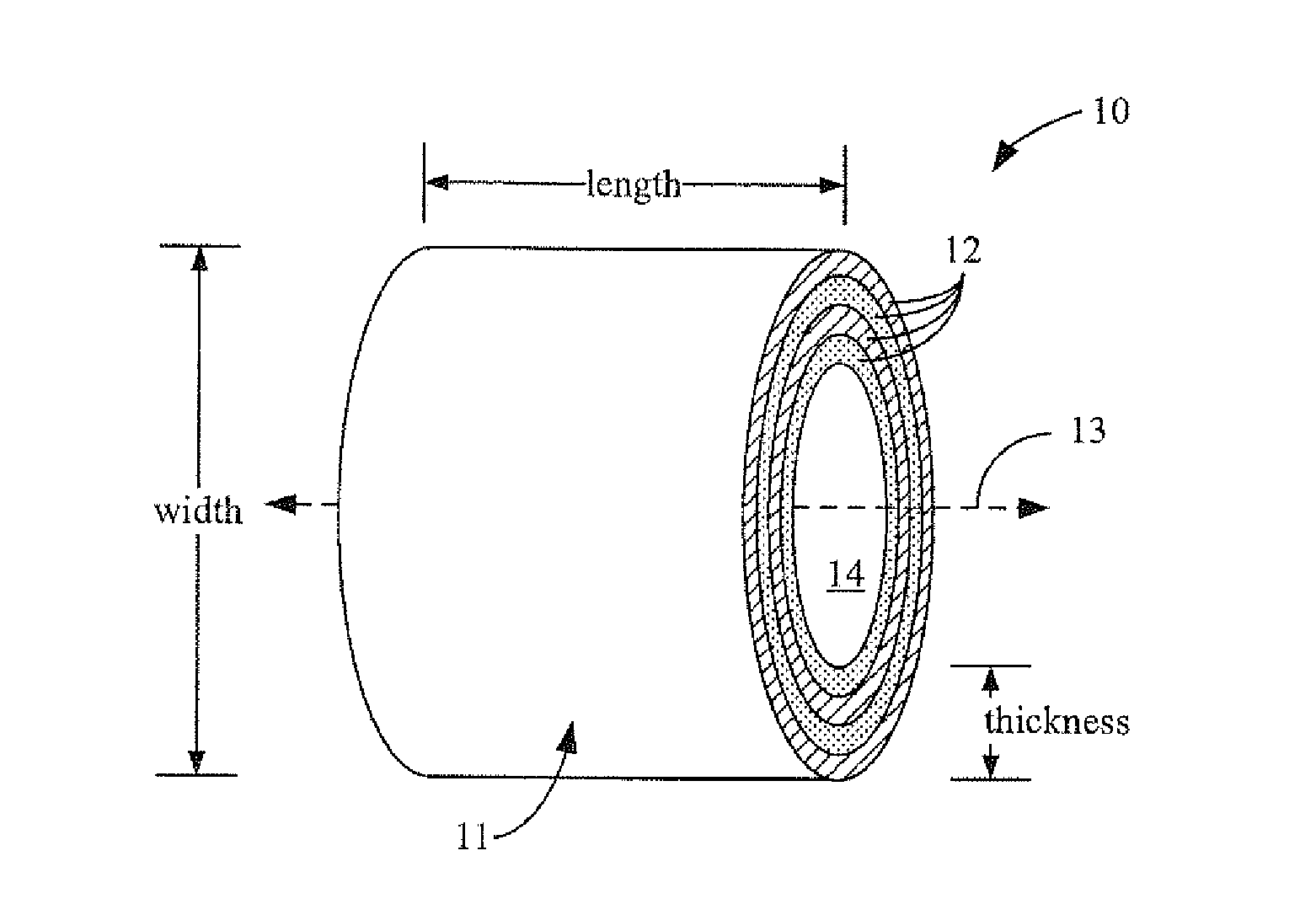

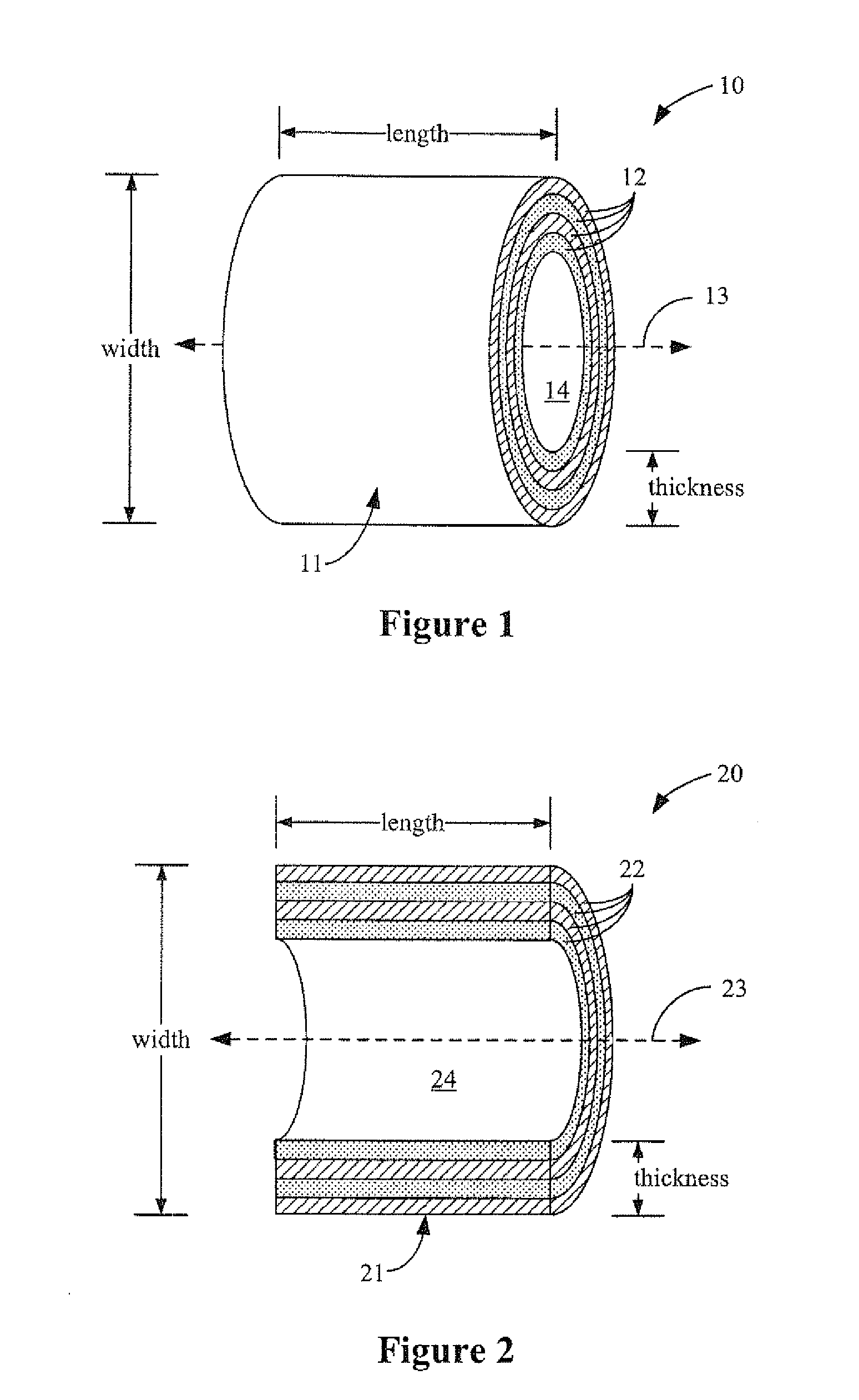

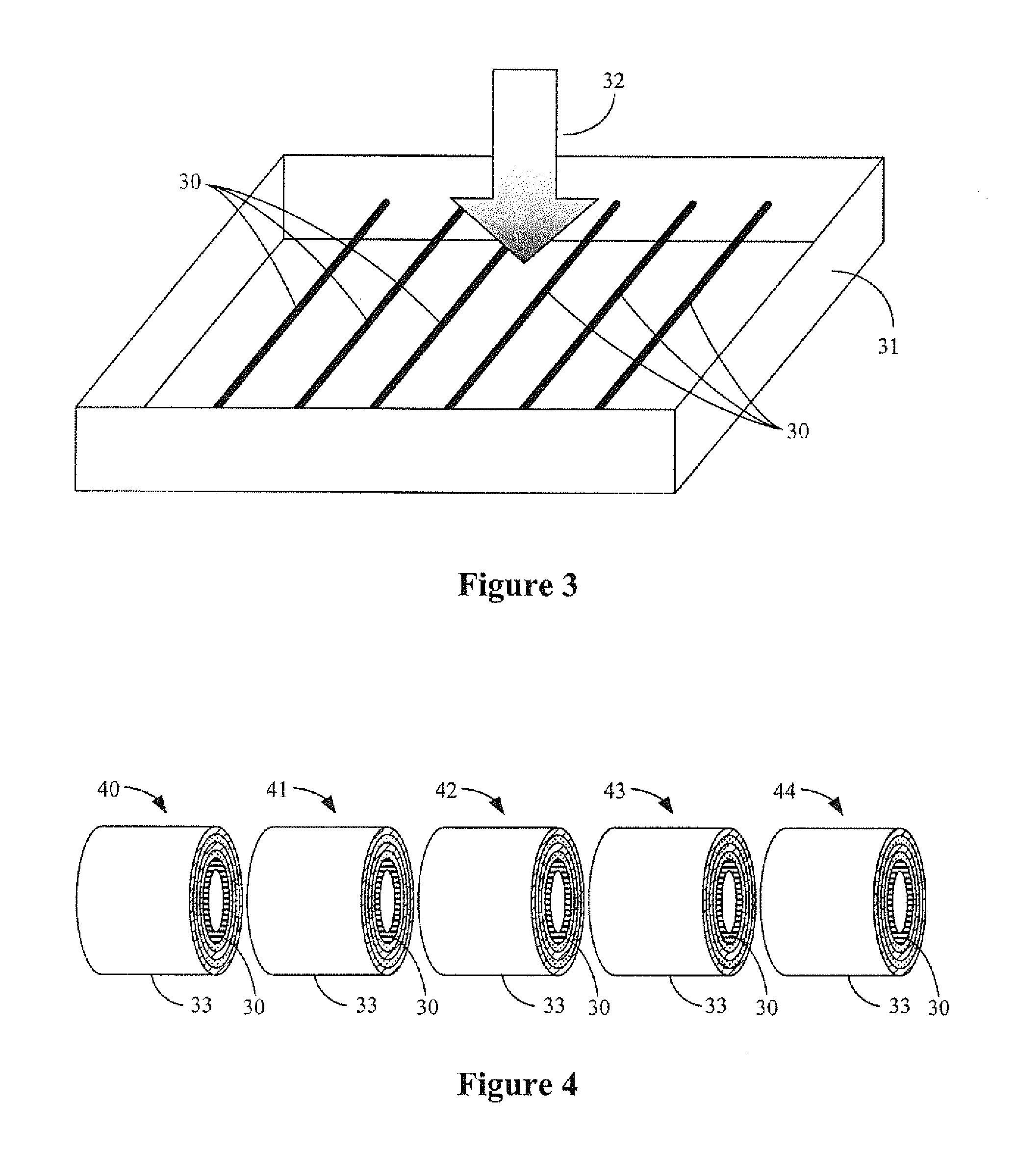

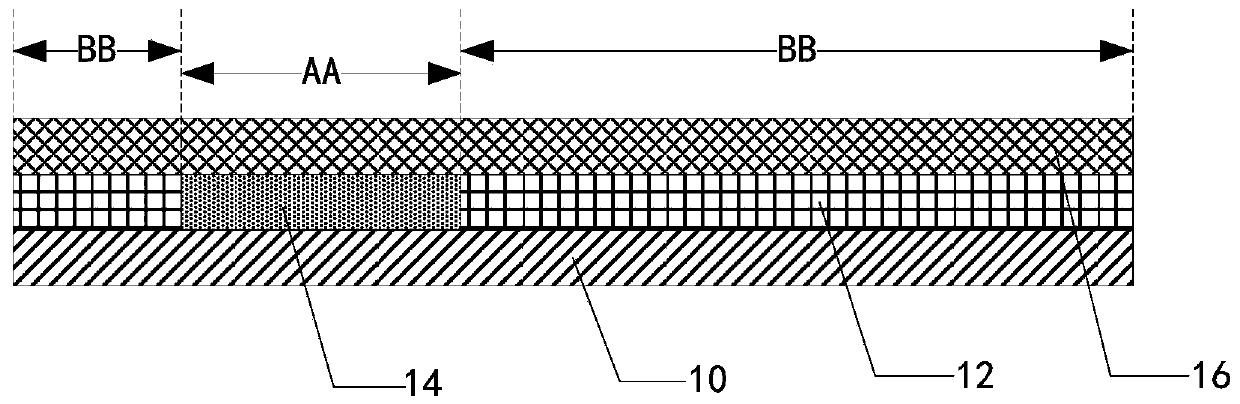

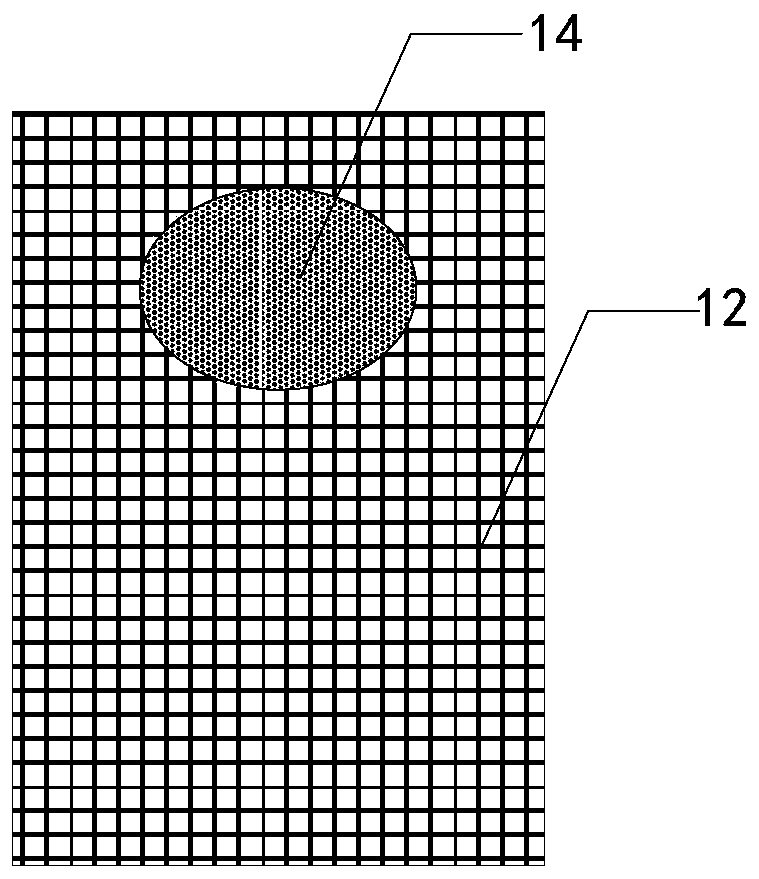

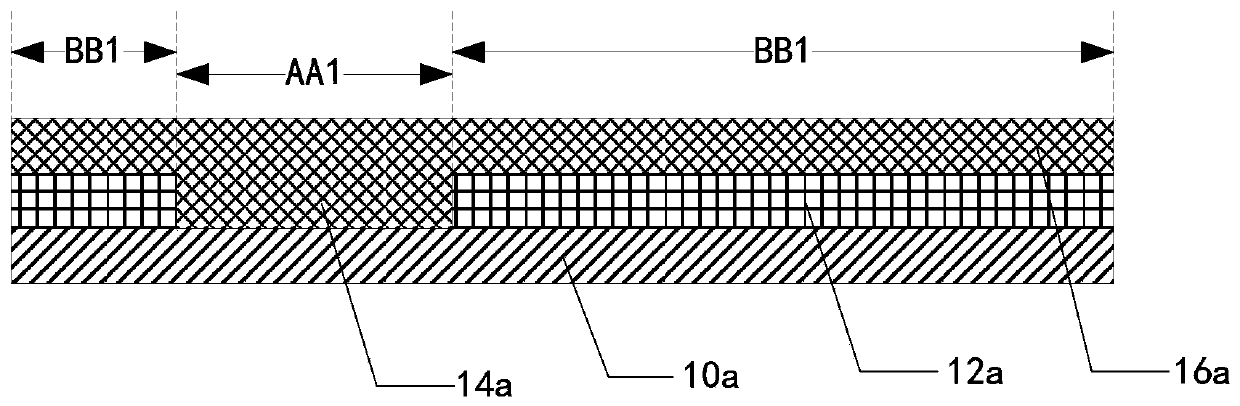

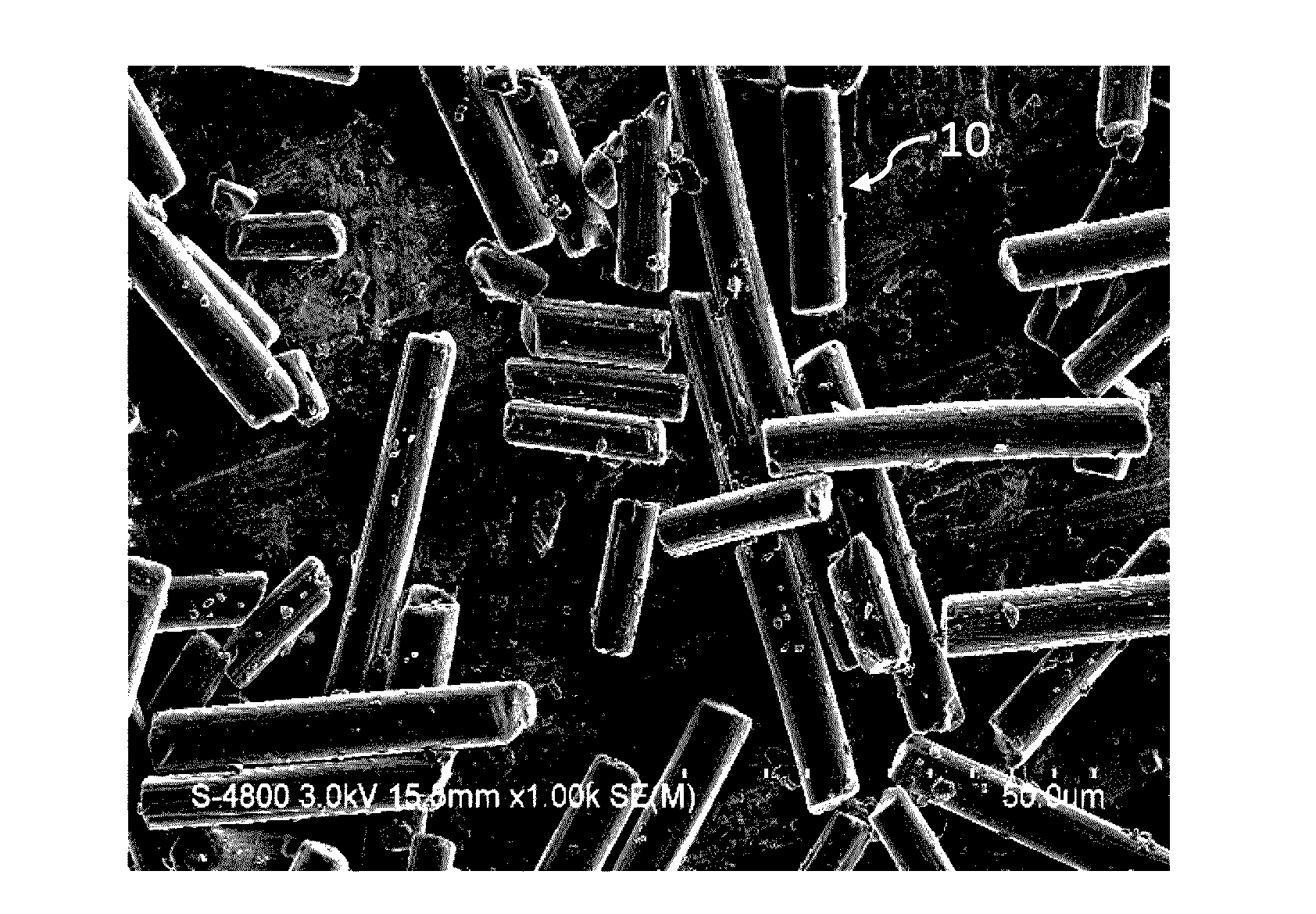

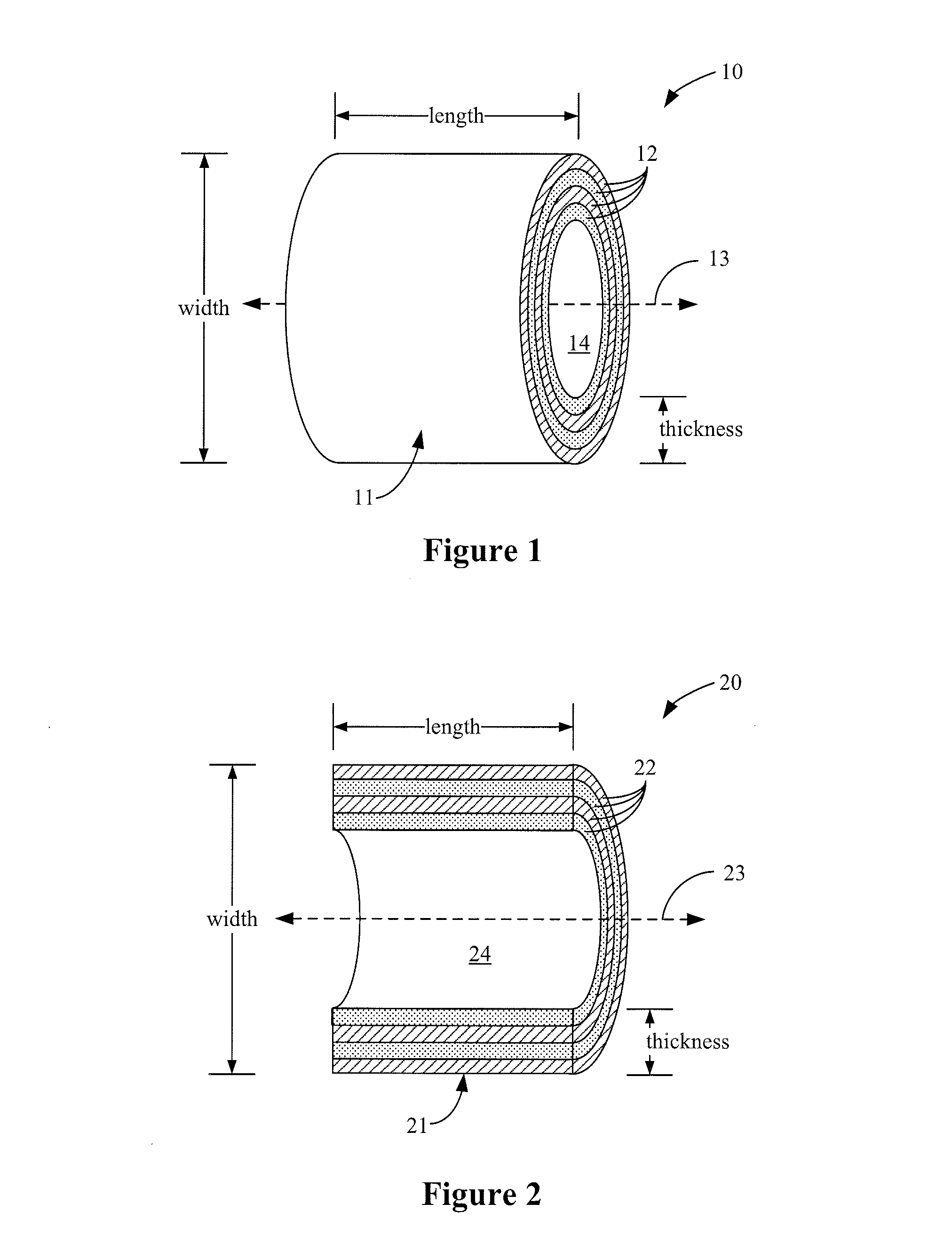

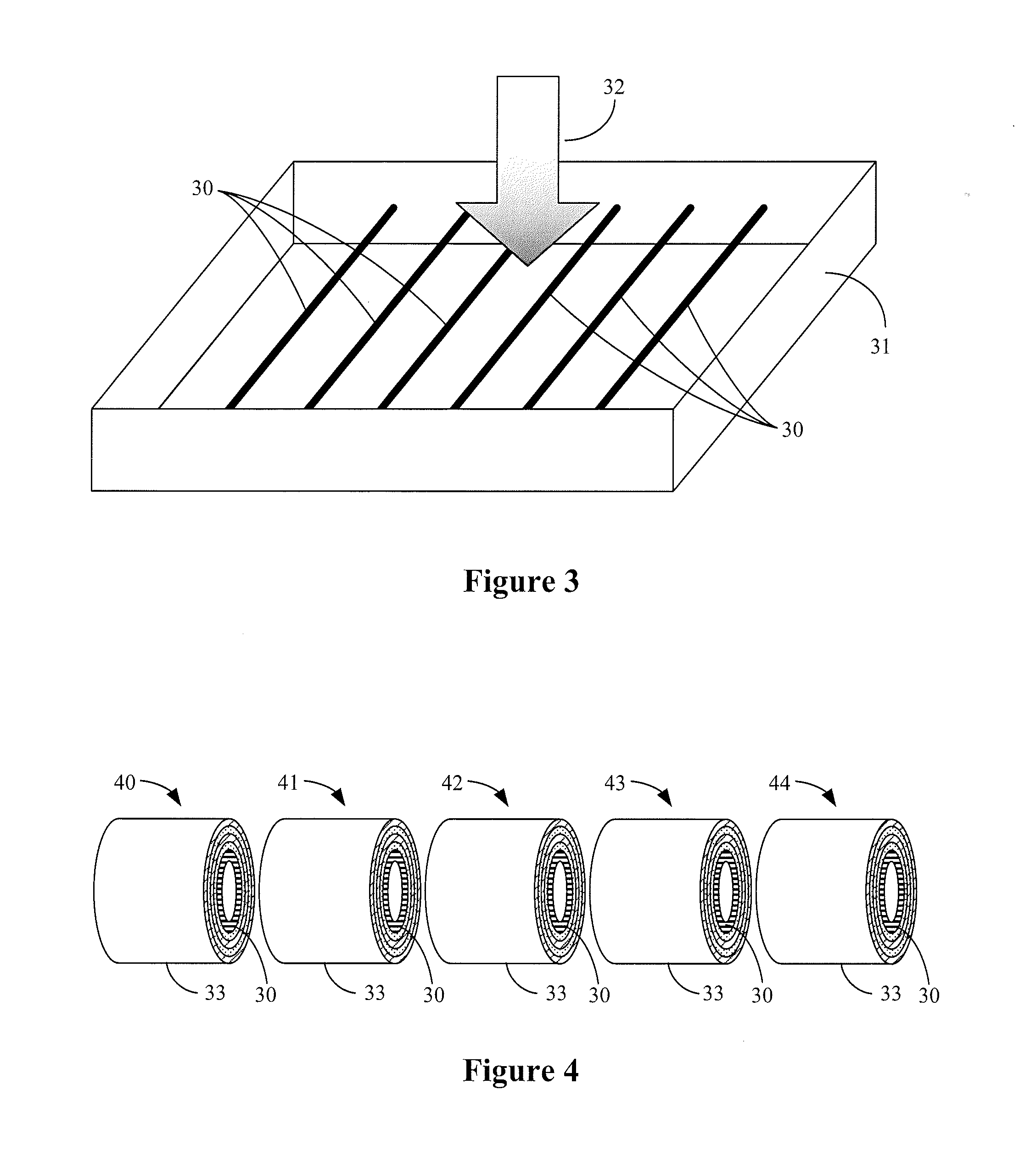

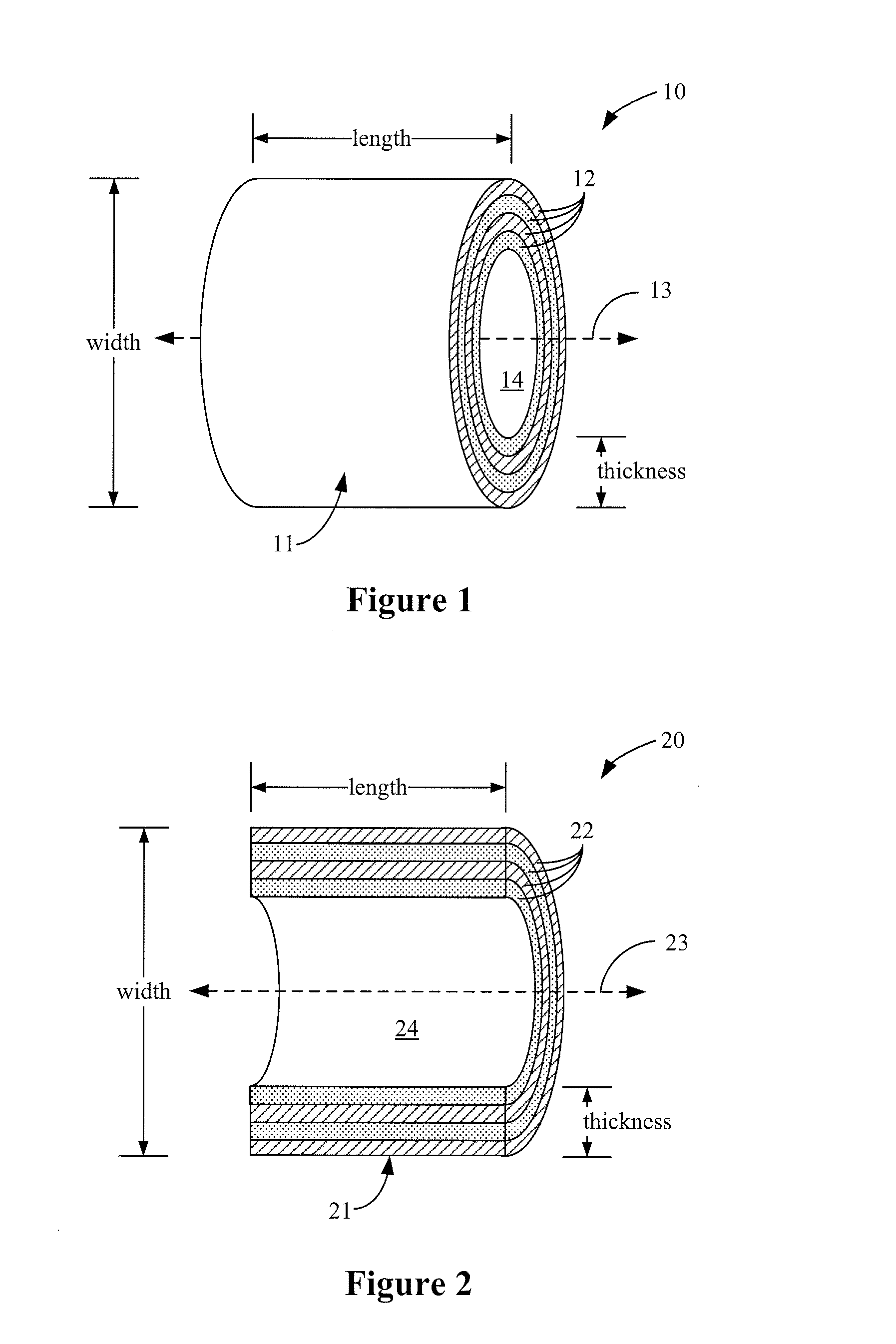

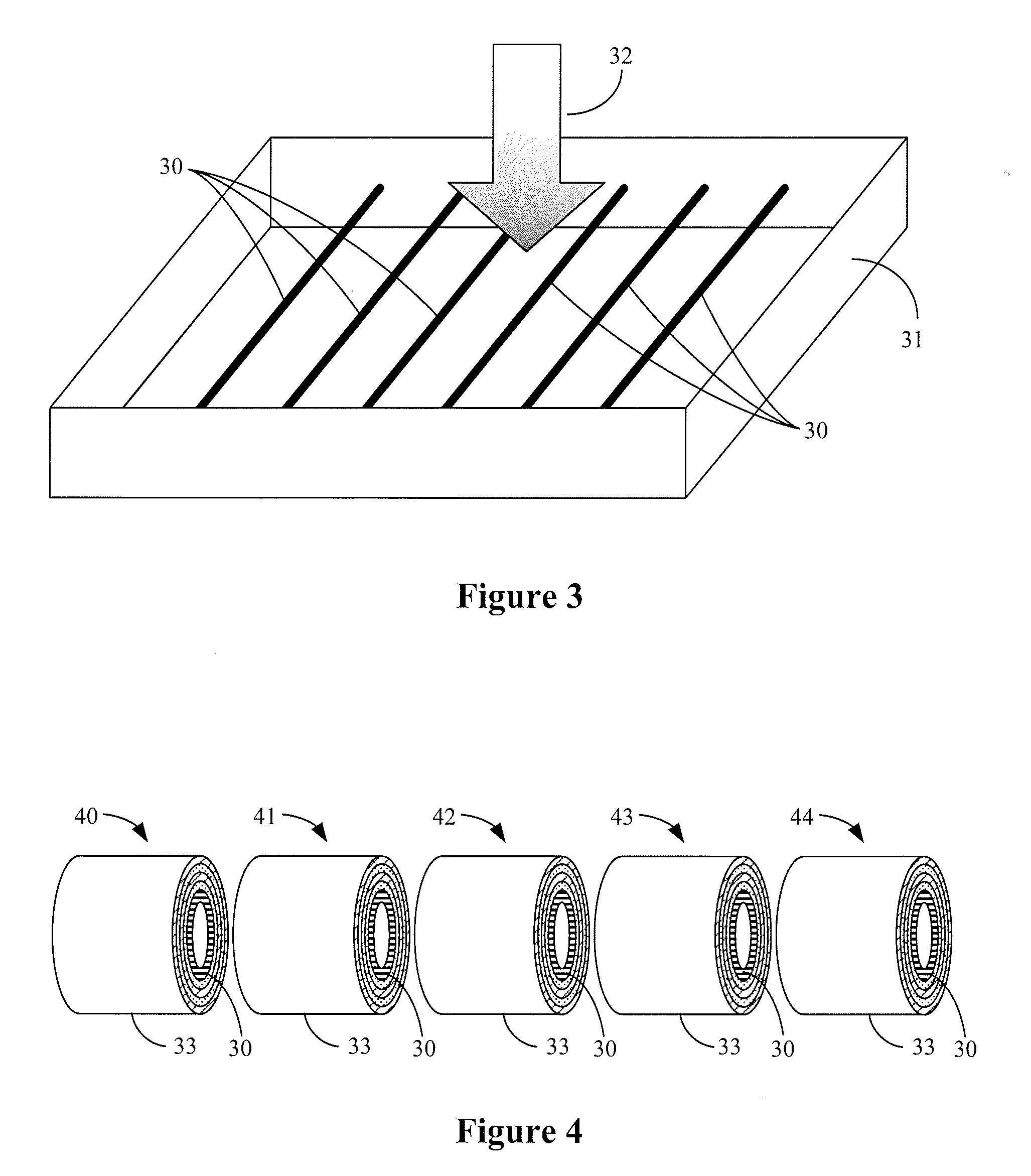

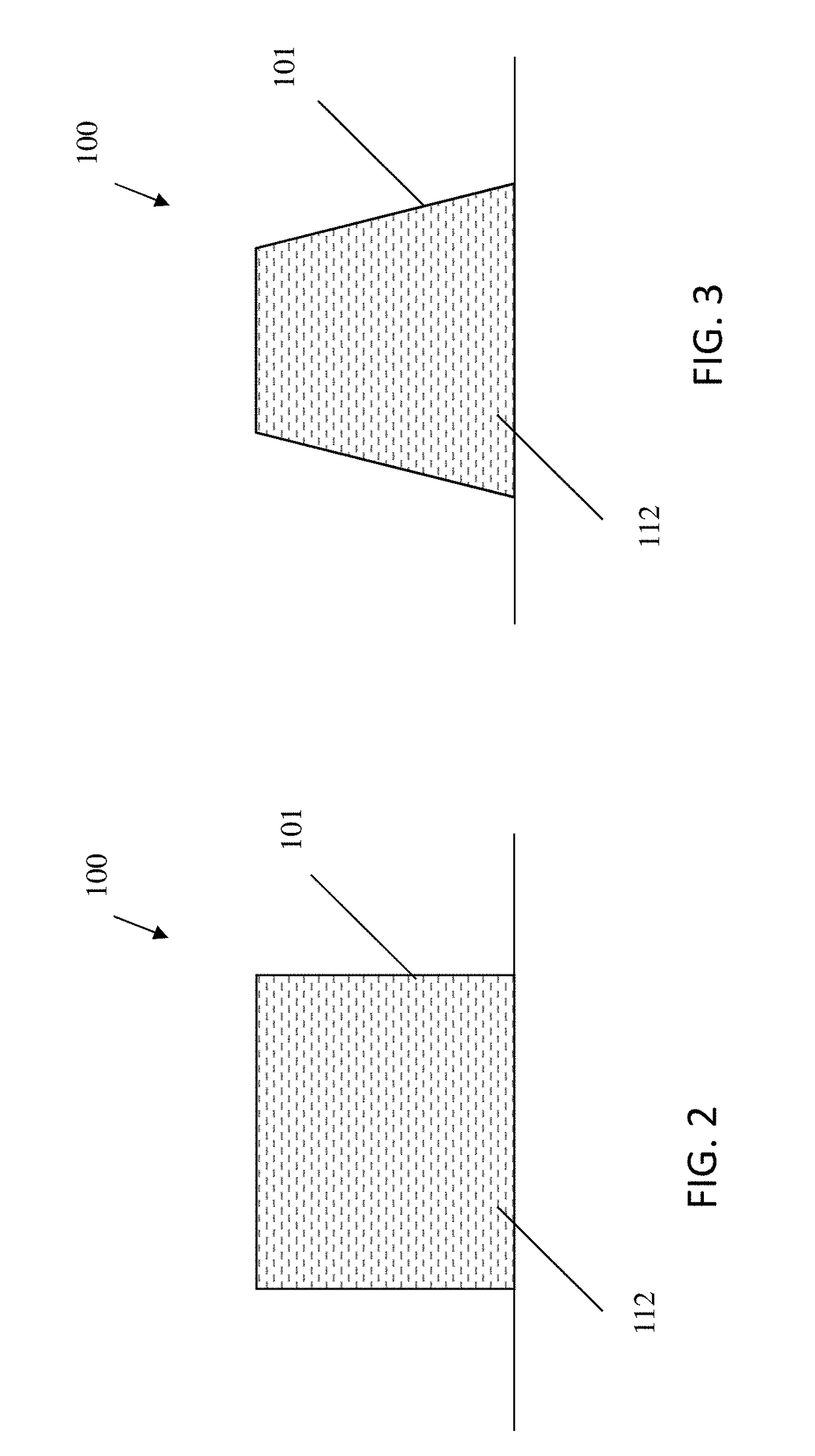

Layered reactive particles with controlled geometries, energies, and reactivities, and methods for making the same

ActiveUS20140102605A1Easily tailored/controlledEasy to handleLayered productsVacuum evaporation coatingEngineeringEnergy density

An energetic composite having a plurality of reactive particles each having a reactive multilayer construction formed by successively depositing reactive layers on a rod-shaped substrate having a longitudinal axis, dividing the reactive-layer-deposited rod-shaped substrate into a plurality of substantially uniform longitudinal segments, and removing the rod-shaped substrate from the longitudinal segments, so that the reactive particles have a controlled, substantially uniform, cylindrically curved or otherwise rod-contoured geometry which facilitates handling and improves its packing fraction, while the reactant multilayer construction controls the stability, reactivity and energy density of the energetic composite.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

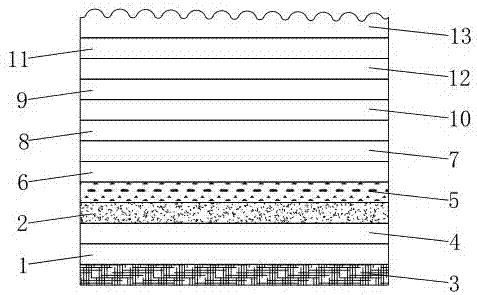

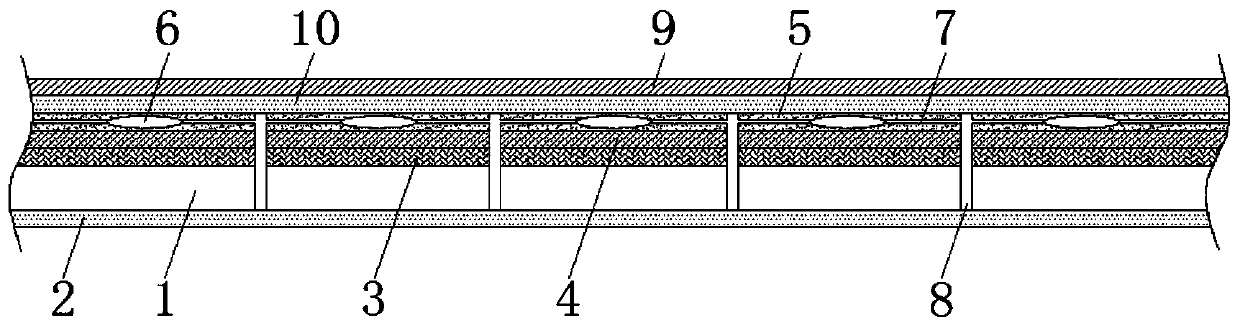

Polarizer, electronic equipment and preparation method of polarizer

ActiveCN110187427AAvoid gap filling problemsReduce accumulationPolarising elementsPhase differencePolarizer

The invention discloses a polarizer, electronic equipment and a preparation method of the polarizer. The polarizer comprises a basement membrane, a linearly polarizing film, a transparent filling bodyand a phase difference film, wherein a first region and a second region surrounding around the first region are defined on the surface of one side of the basement membrane; the linearly polarizing film is located on the surface of the side of the basement membrane and covers the second region; the transparent filling body is arranged at the same layer with the linearly polarizing film and coversthe first region; and the phase difference film covers the linearly polarizing film and one side, far away from the basement membrane, of the transparent filling body. By virtue of the way, the polarizer disclosed by the invention can relatively simply form a depolarized region.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

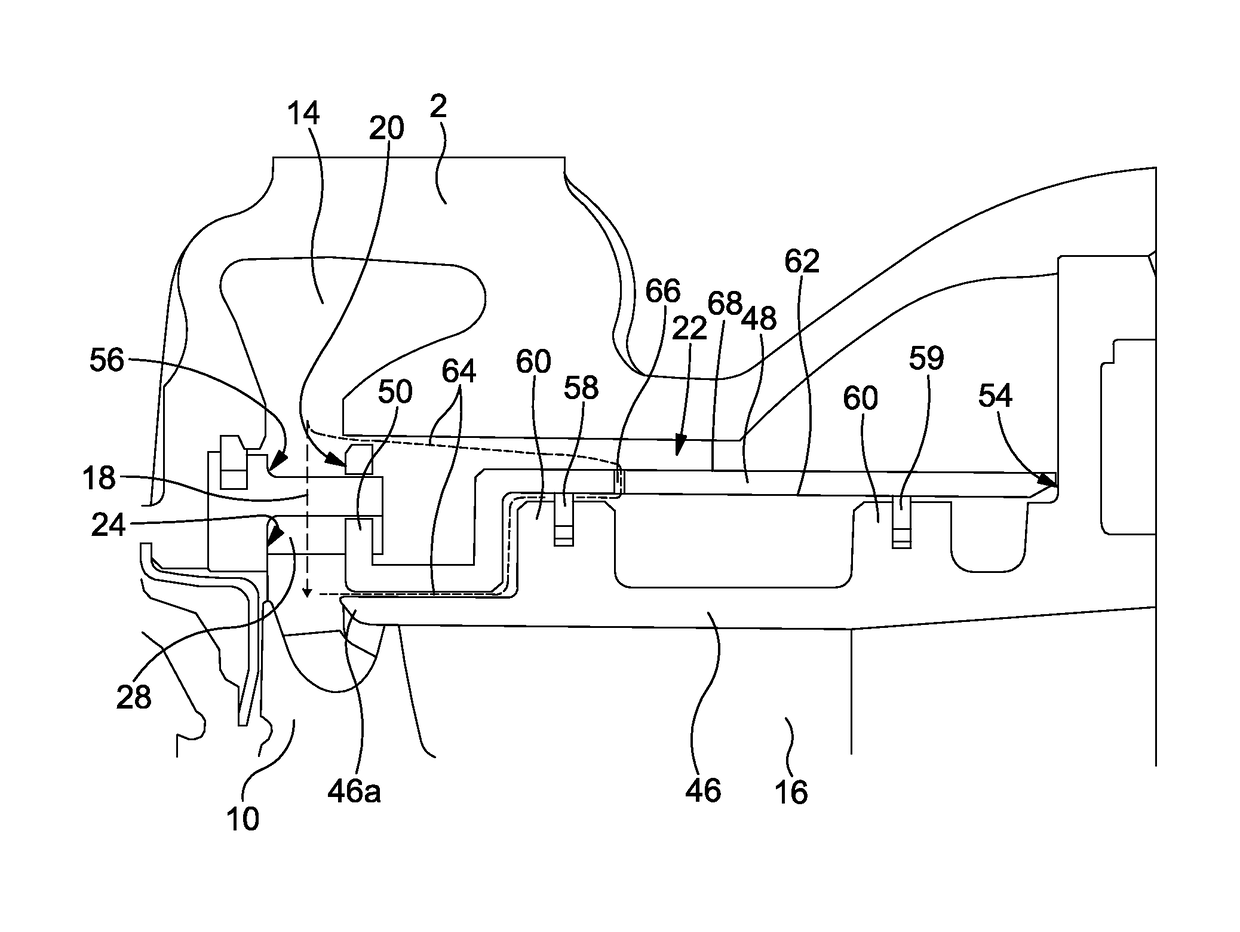

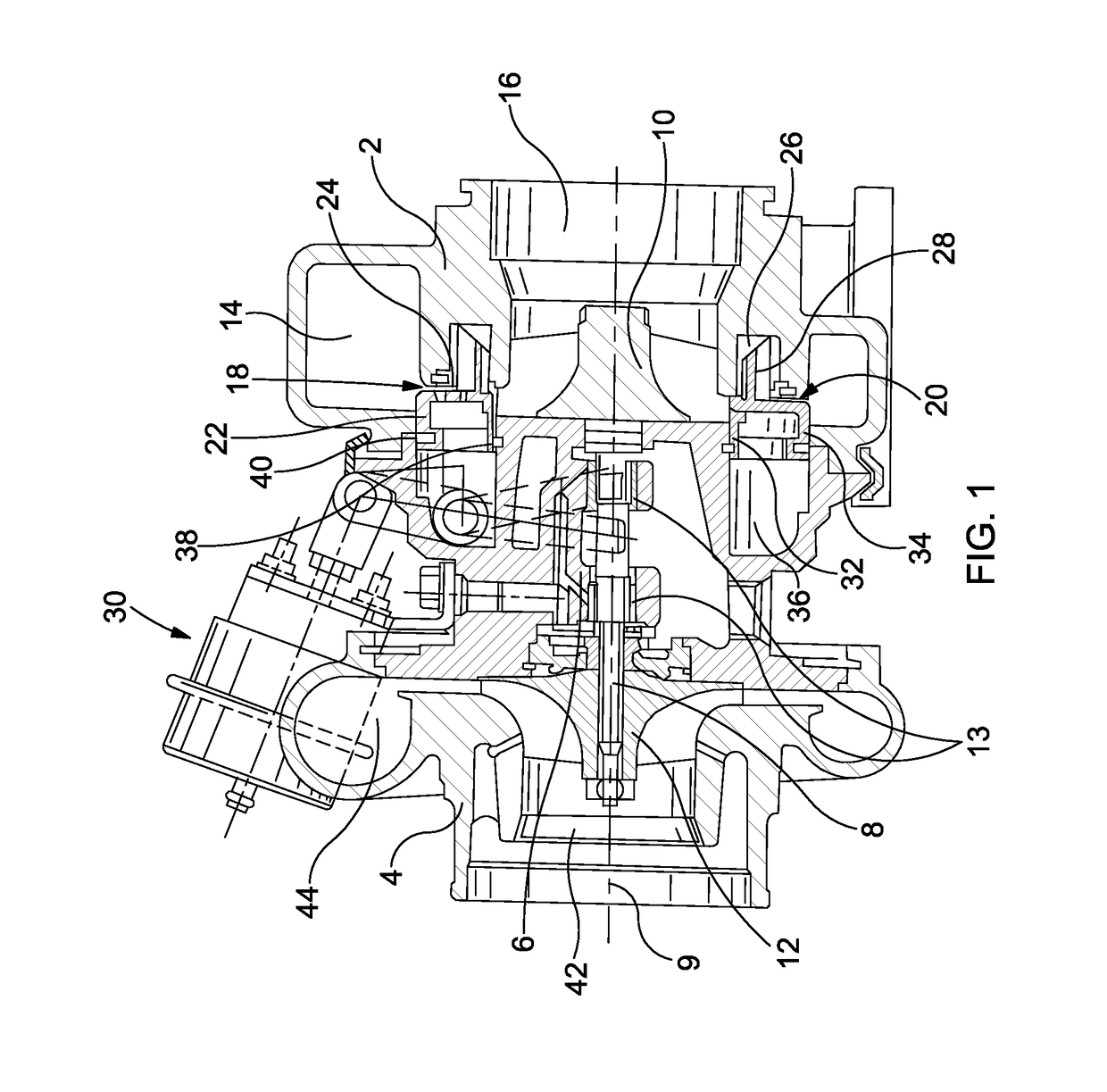

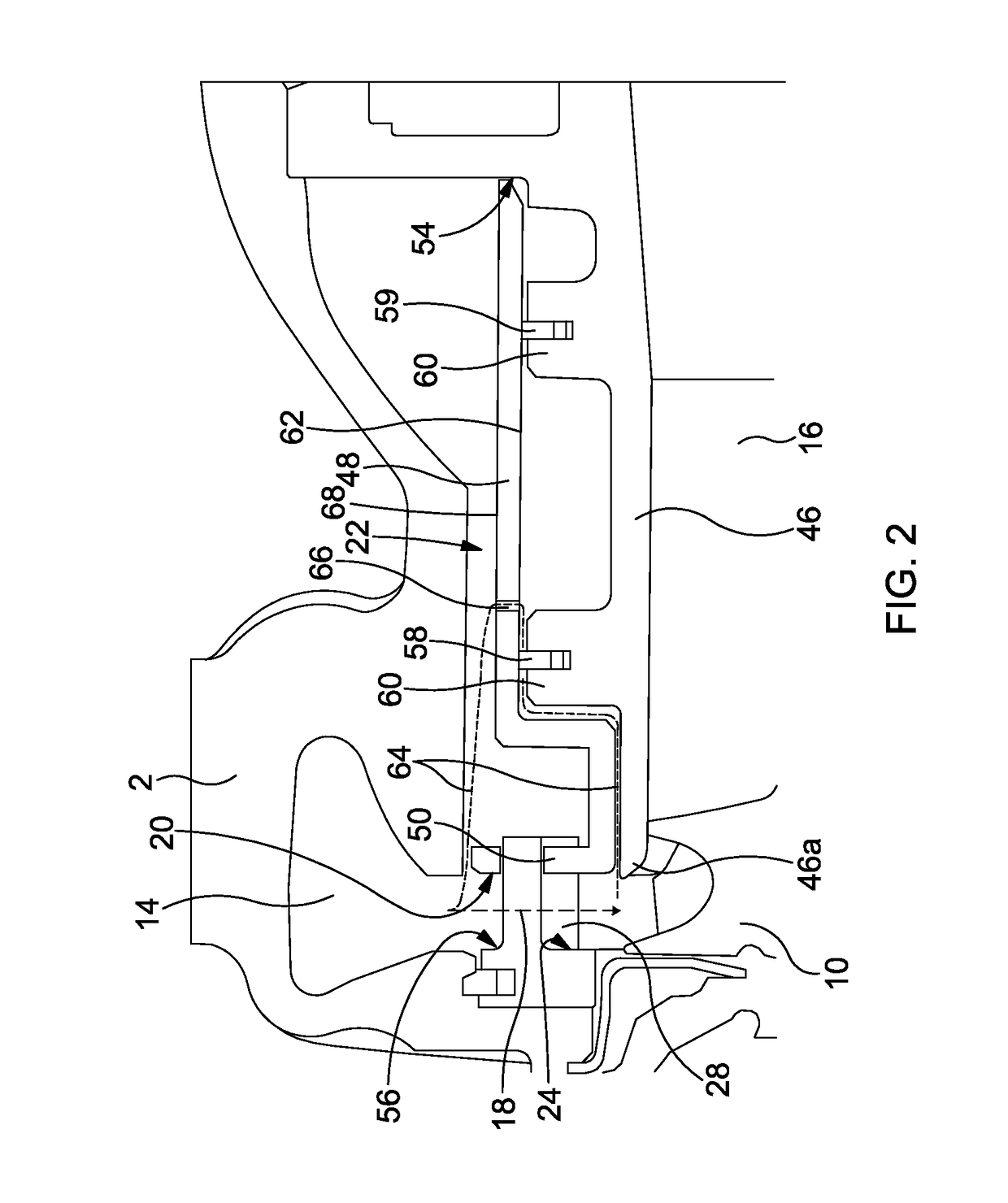

Variable geometry turbine

ActiveUS9816434B1Improve performanceOptimal comparative sizeInternal combustion piston enginesEngine componentsImpellerTurbine wheel

A variable geometry turbine comprises a turbine wheel and a primary inlet passage of variable axial width. The turbine has a secondary inlet passage provides a flow path for a working fluid which circumnavigates at least part of the primary inlet passage. A seal element and one or more apertures are cooperable to selectively allow or prevent fluid flow through the secondary inlet passage. The ratio of the minimum cross-sectional area of the flow path through the primary inlet passage to that of the secondary inlet passage is between 1.3 and 1.7.

Owner:CUMMINS LTD WEST YORKSHIRE

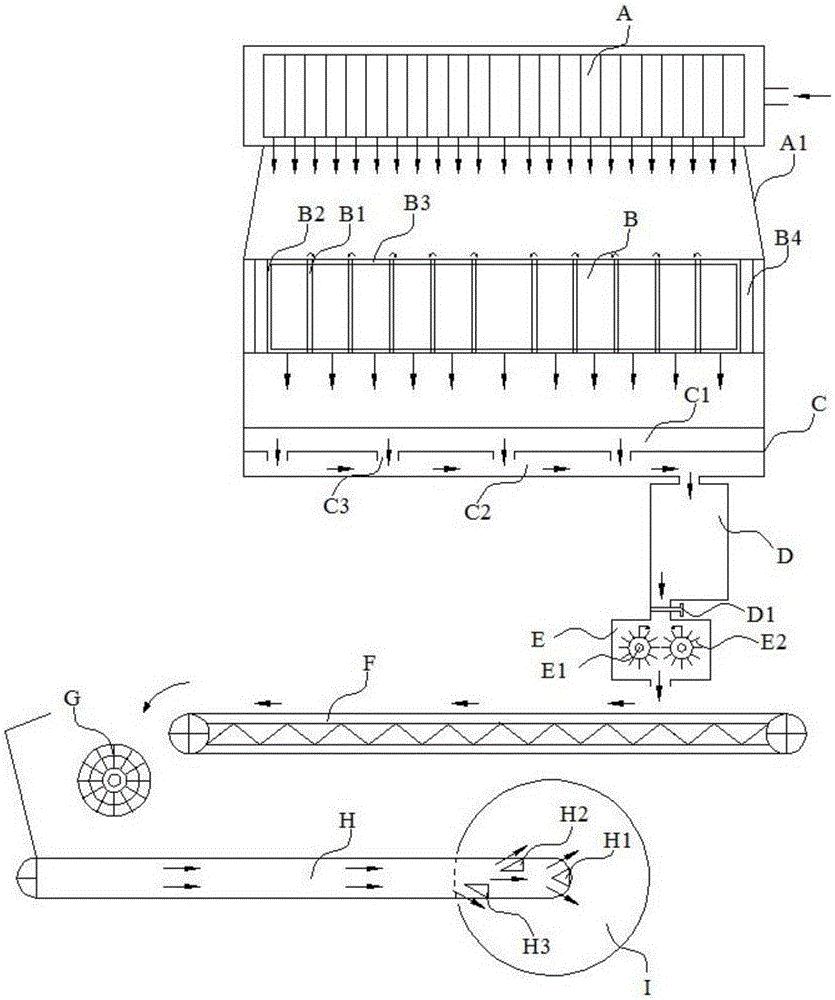

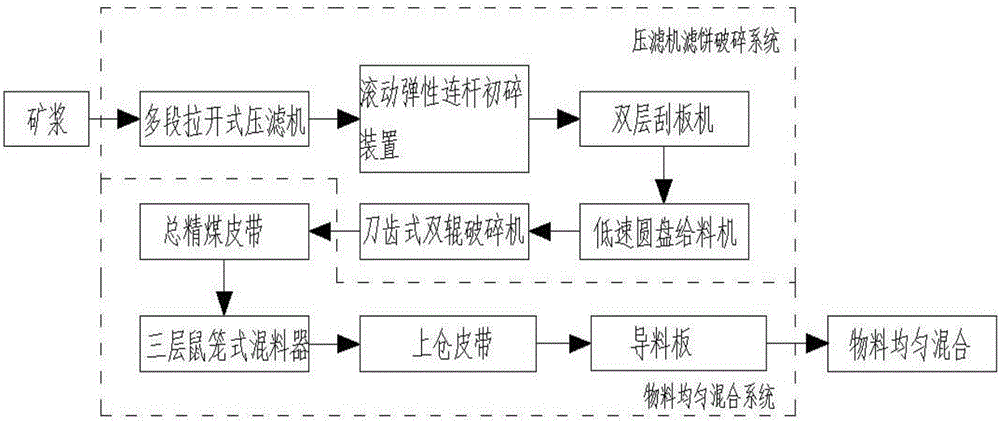

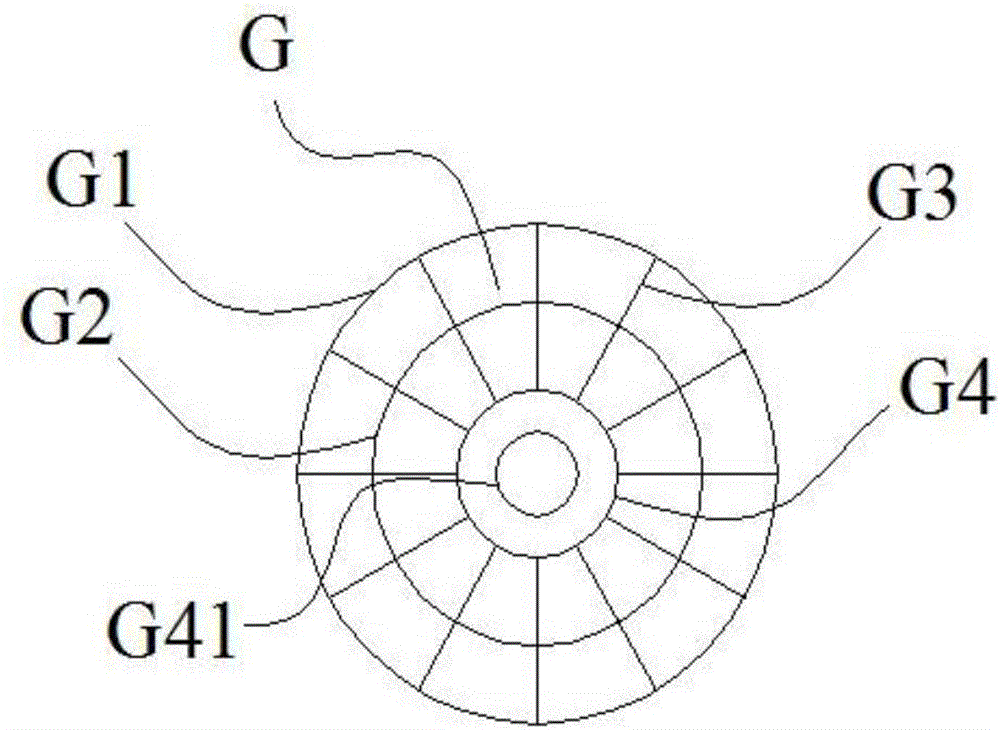

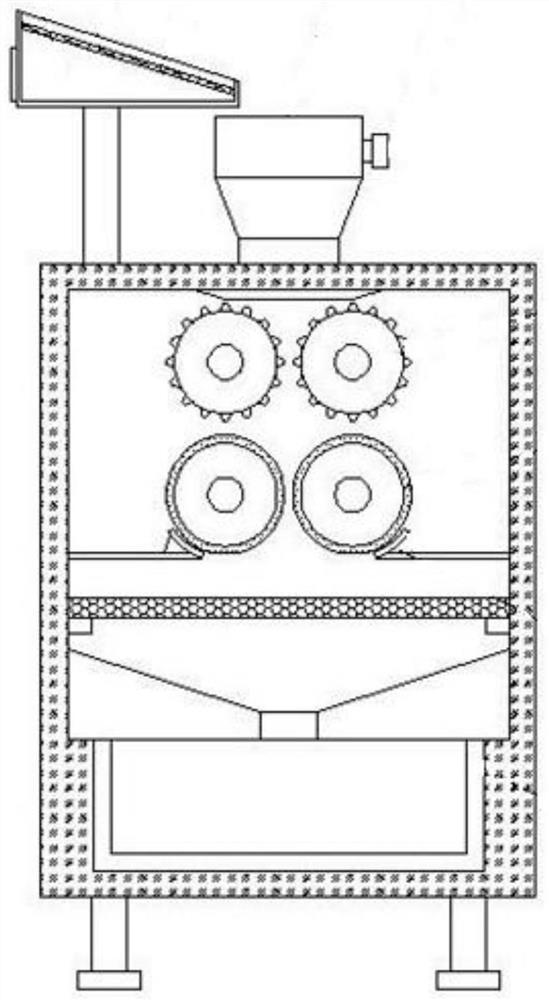

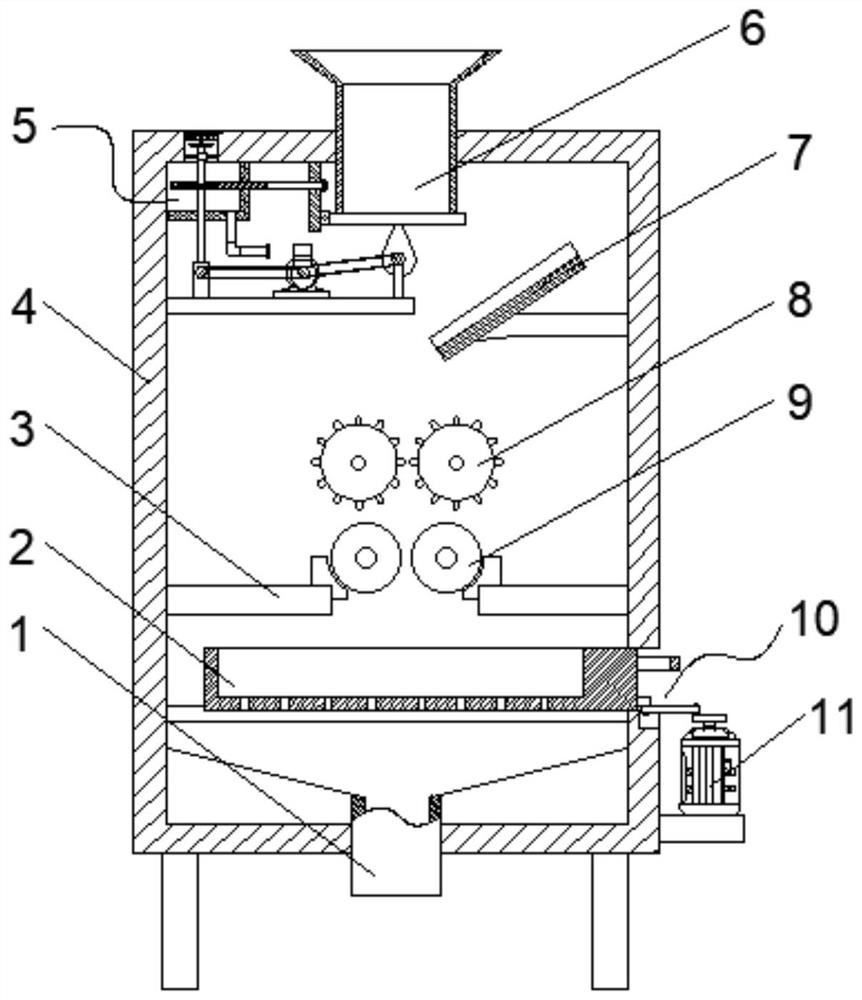

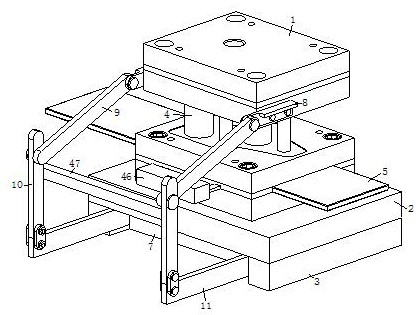

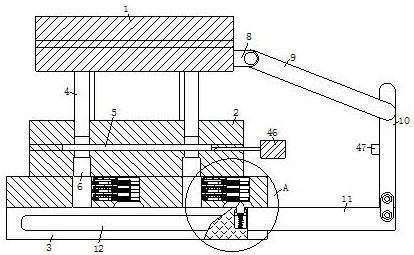

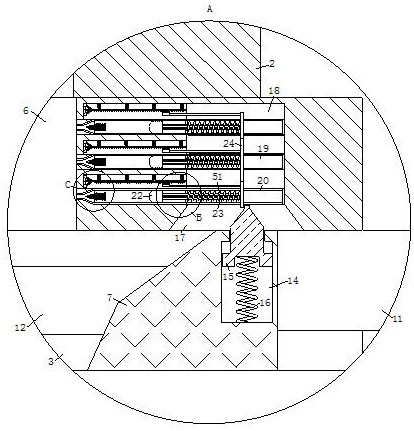

Filter press filter cake crushing system and method

ActiveCN106733081AReduce the probability of accumulationEliminate accumulationGrain treatmentsLow speedEngineering

The invention relates to the technical field of coal preparation plant filter press filter cake crushing, in particular to a filter press filter cake crushing system and method. Following work systems are included, filter cakes of a multi-section pull-open type press filter impact on a rolling elastic connecting rod primary crushing device arranged in a press filter discharging chute through the dead load of the filter cakes, and primary crushing is finished; a coal leveler capable of doing the transverse movement back and forth is further arranged in the press filter discharging chute, and material stocking is prevented; the primarily-crushed materials enter a double-layer scraper conveyor, an upper layer of the double-layer scraper conveyor is used for storing materials, and a lower layer of the double-layer scraper conveyor is used for continuously conveying the materials through scraper blades; discharged materials of the double-layer scraper conveyor enter a low-speed disc feeder, and the discharging amount is controlled by adjusting the rotation speed and the discharging port opening degree; and the discharged materials enter a cutter tooth type double-roller crusher, cutter teeth used for cutting are arranged on rollers moving in the opposite directions, and blocky coal slime is crushed into fine-grain-level coal slime. According to the filter press filter cake crushing system and method, the technology layout, equipment selection and structural design are reasonable, material crushing is uniform, and the effect is reliable and stable.

Owner:ANHUI UNIV OF SCI & TECH

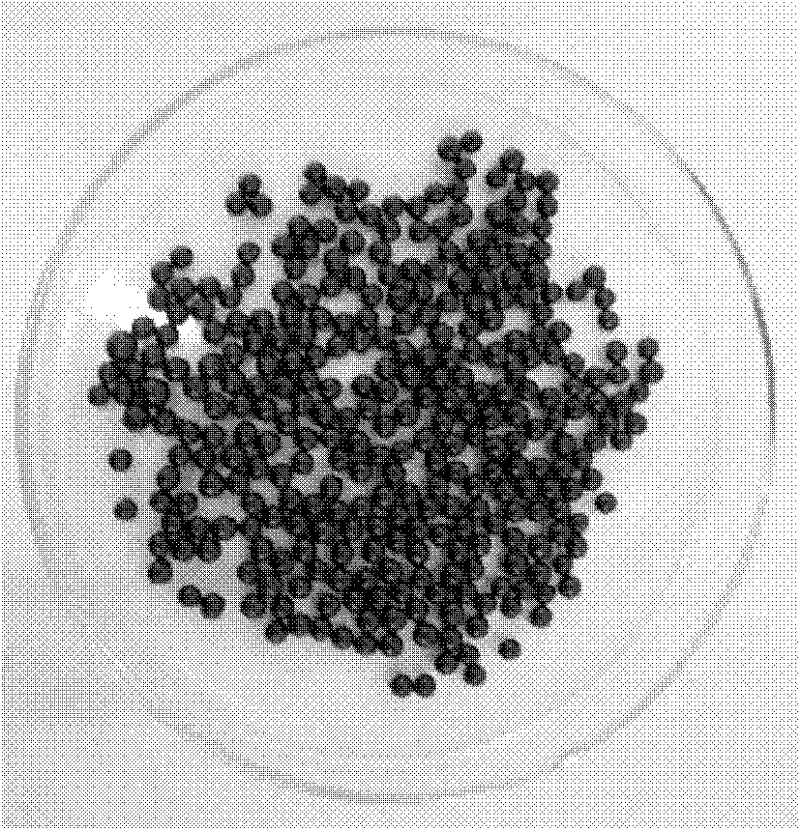

A wastewater denitrification method for rapidly realizing simultaneous short-range nitrification and denitrification

InactiveCN102285717AGood removal effectReduce the probability of accumulationTreatment with aerobic and anaerobic processesChemistryShort cycle

A sewage denitrification method for rapidly realizing synchronous short-range nitrification-denitrification relates to a rapid sewage denitrification method. Methods: 1. Expanded culture of aerobic denitrifying bacteria; 2. Centrifuge the expanded cultured bacteria liquid to collect the bacteria and make a bacterial suspension; 3. Mix the bacterial suspension with the embedding solution, and then drop it on Cross-link in the agent overnight to get the bacterium ball; 4. Add the bacterium ball to the SBR reactor that has realized the short-cut nitrification to complete. In the present invention, adding the fungus balls to the SBR reactor does not affect the operation of the short-range process, and at the same time, it can effectively denitrify NO2--N into nitrogen to realize synchronous removal, and the removal effect of ammonia nitrogen is stable, which can be maintained at more than 90%. Ammonia nitrogen can basically be maintained below 5mg / L; the COD removal rate reaches over 90%, and the average COD of the effluent is 25.5mg / L; effectively improves the processing capacity of the process for pollutants, with short cycles and low energy consumption.

Owner:HARBIN INST OF TECH

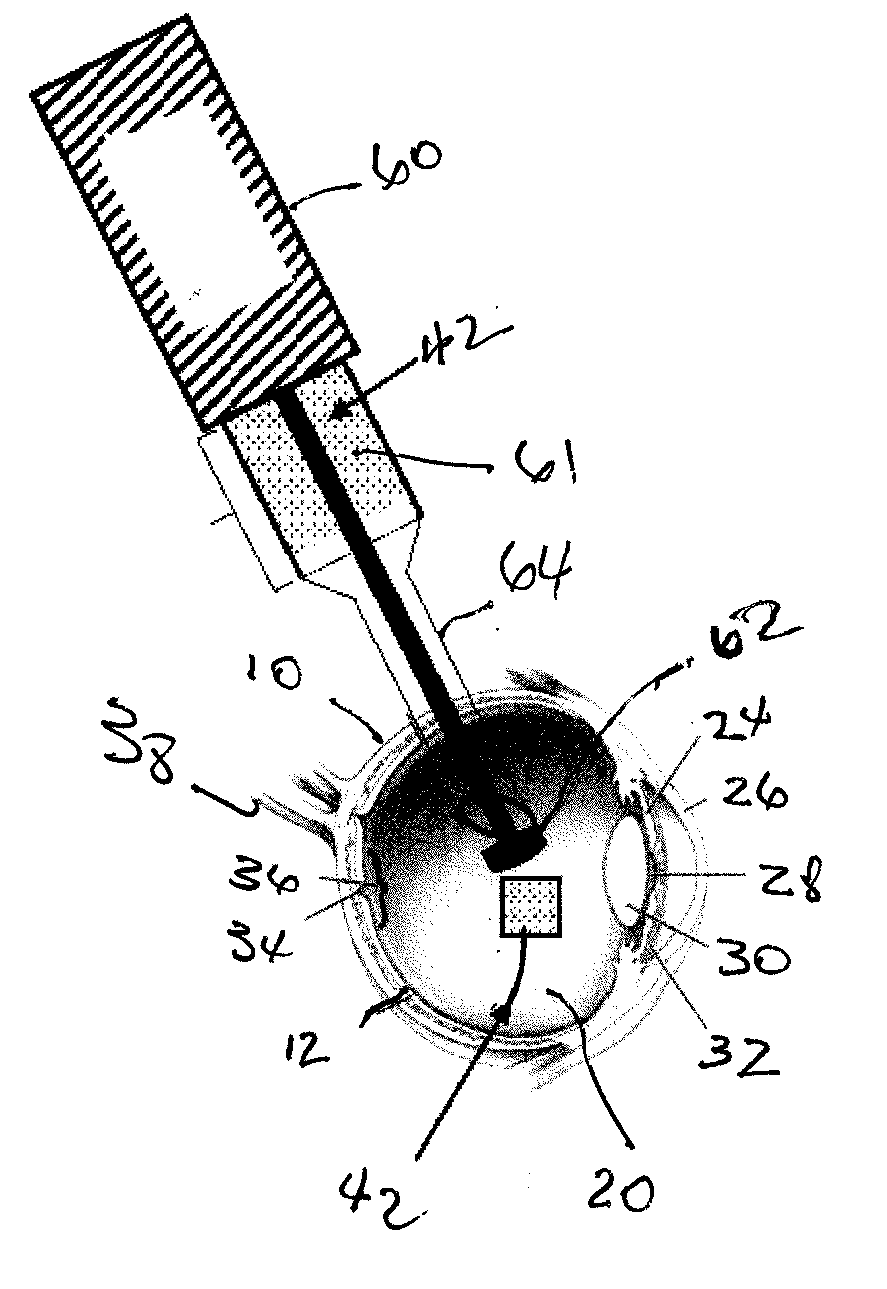

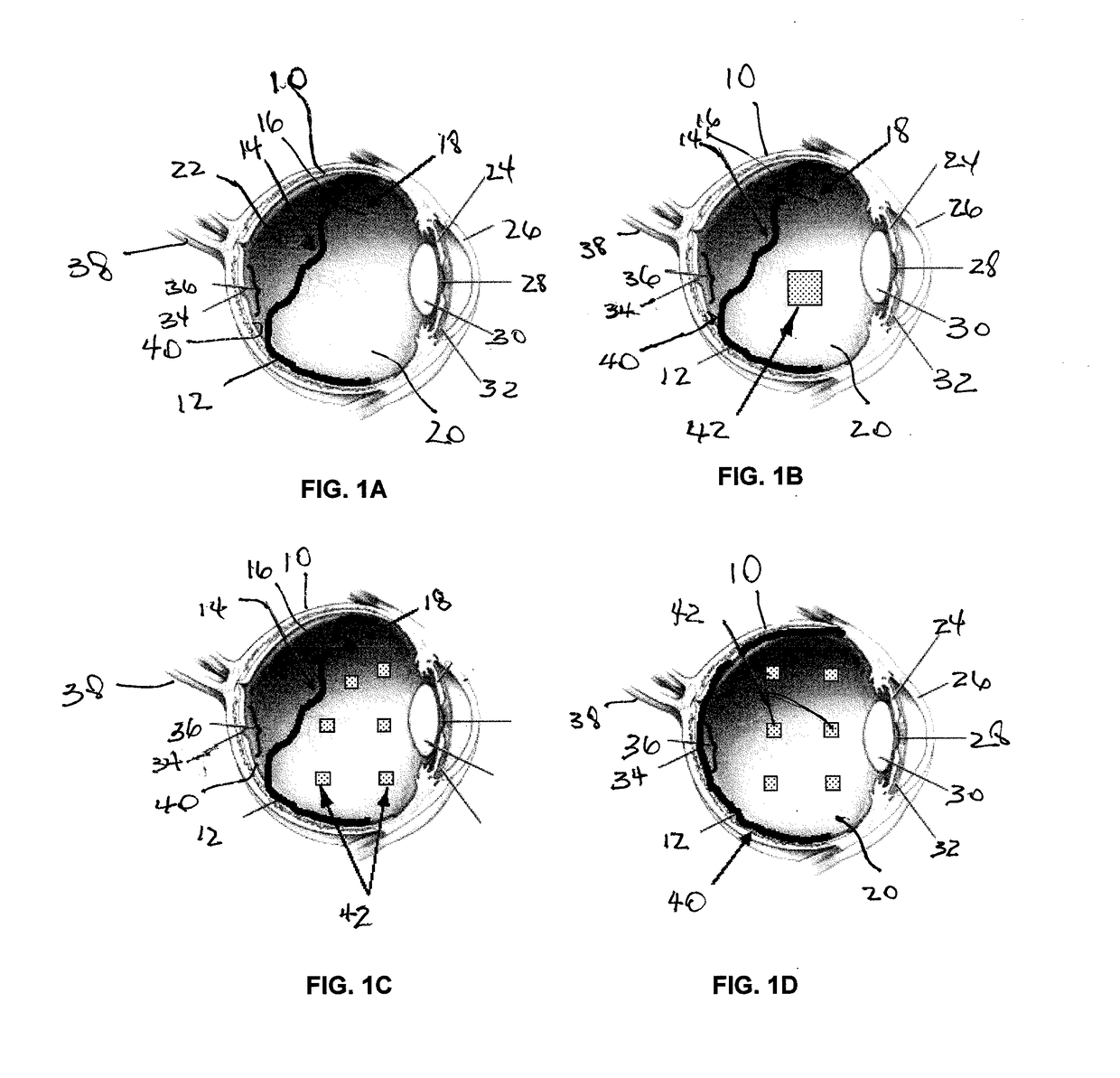

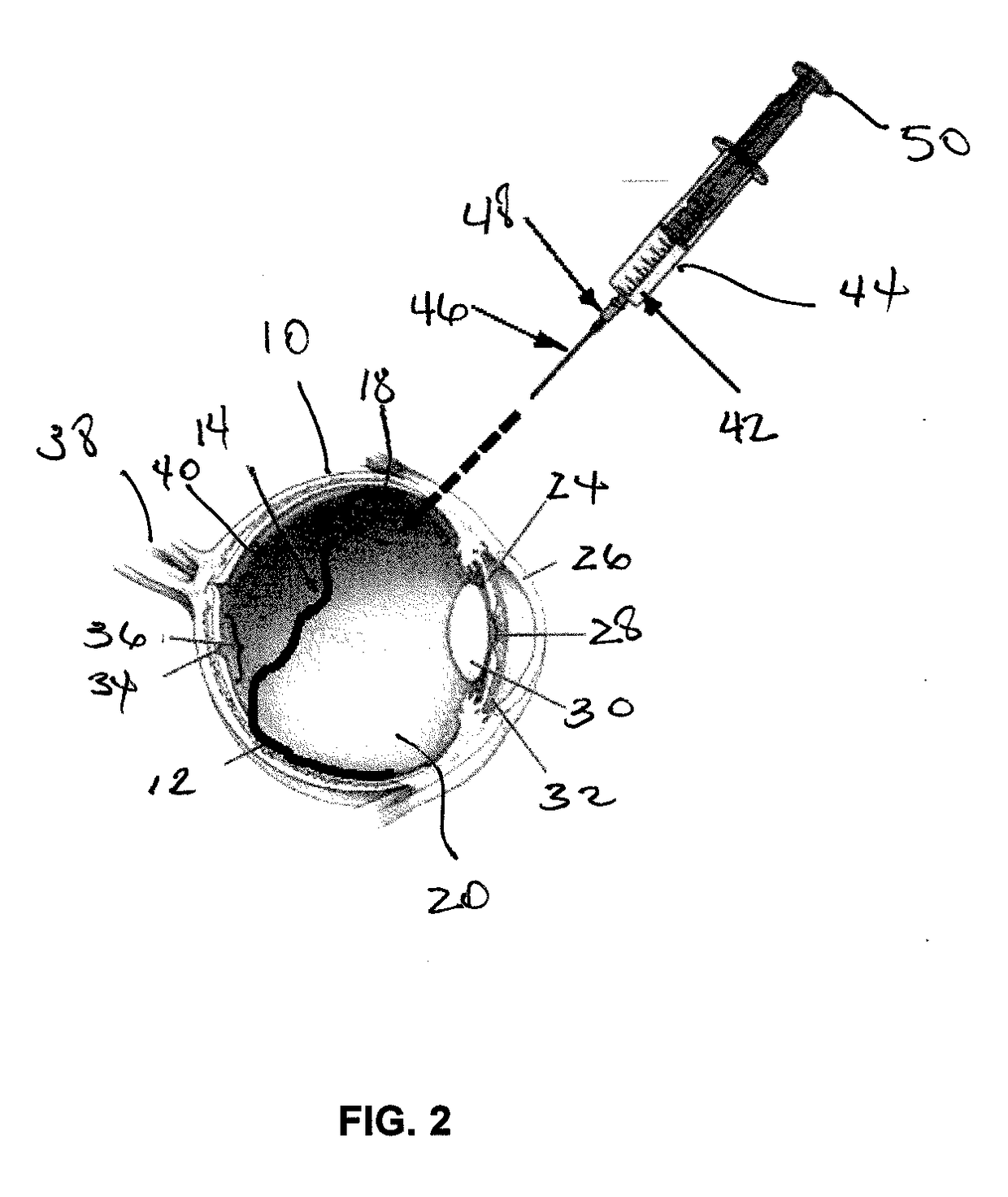

Methods and devices for treating a retinal detachment

ActiveUS20180185288A1Reduce probabilityDiffusion slowPowder deliverySenses disorderOphthalmologySubretinal fluid

A method of treating a detachment of a retina of an eye, the method including the steps of injecting a substance into a vitreous cavity of the eye, the substance slowing flow of fluid through the vitreous cavity into a subretinal space to reduce a rate of accumulation of a subretinal fluid in the subretinal space to below a rate of removal of the subretinal fluid from the subretinal space by retinal pigment epithelium; and permitting the retinal pigment epithelium to reattach the retina. The invention also includes devices for practicing the method.

Owner:VITREAN INC

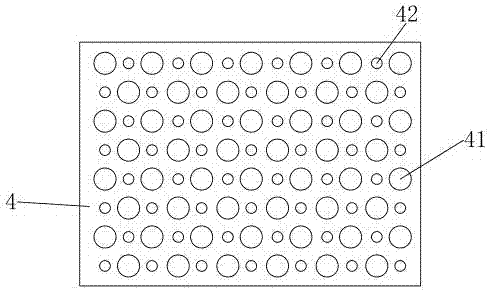

Indoor decoration wallpaper

InactiveCN106917477APromote blood circulationGood for healthCovering/liningsLayered productsBiochemical engineeringMoisture absorption

The invention discloses indoor decoration wallpaper, which comprises a wallpaper base material layer and a coating layer, wherein the coating layer is arranged on the wallpaper base material layer; a waterproof coating is arranged at the back side of the wallpaper base material layer; an air hole layer is arranged under the coating layer; first ventilation holes are uniformly distributed in the air hole layer; second ventilation holes are formed between the adjacent first ventilation holes; the diameter of the second ventilation holes is smaller than the radius of the first ventilation holes; a bamboo charcoal layer is arranged on the coating layer; a waterproof layer is arranged on the bamboo charcoal layer; a reinforcing layer is arranged on the waterproof layer; an antibacterial layer is arranged on the reinforcing layer; an air purification layer is arranged on the antibacterial layer; an adsorption layer is arranged on the air purification layer; an appearance layer is arranged on the adsorption layer; decoration bulges are arranged on the appearance layer. The indoor decoration wallpaper has the advantages of moisture absorption, ventilation, antibacterial effect, anti-corrosion effect, strong ventilation performance and the like; harmful substances in the air can be absorbed; faint scent can be released; the indoor air can be purified; green and environment-friendly effects are achieved; the living life of people is facilitated; in addition, the service life is long; the appearance is attractive.

Owner:全南县韬寻机械设备开发有限公司

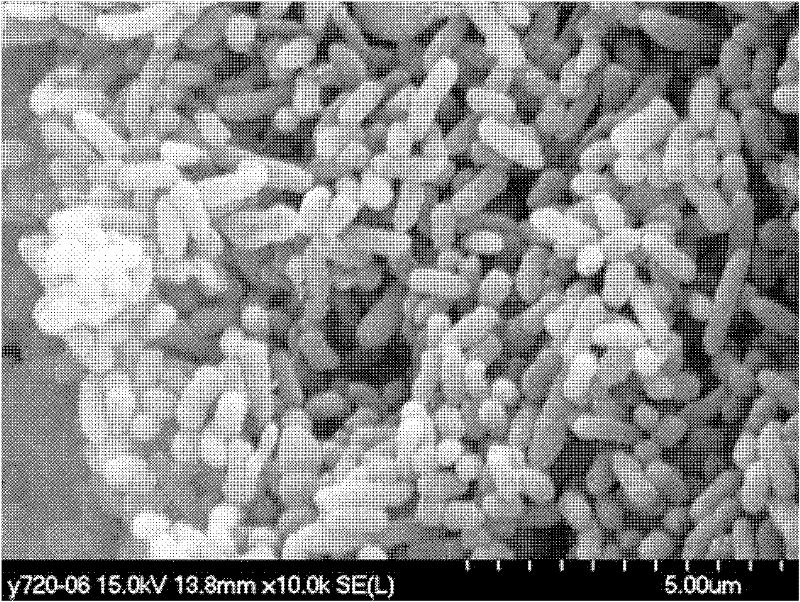

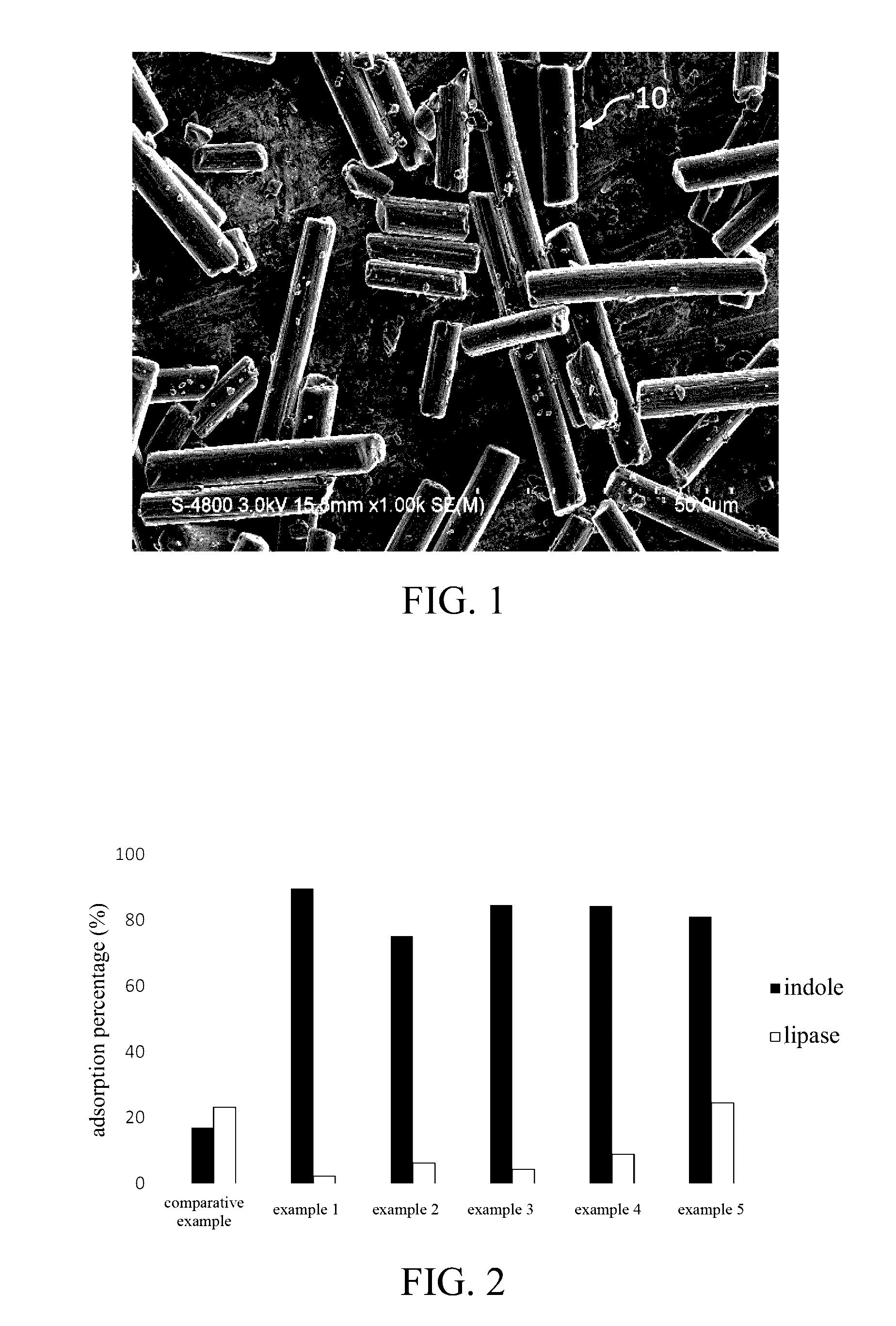

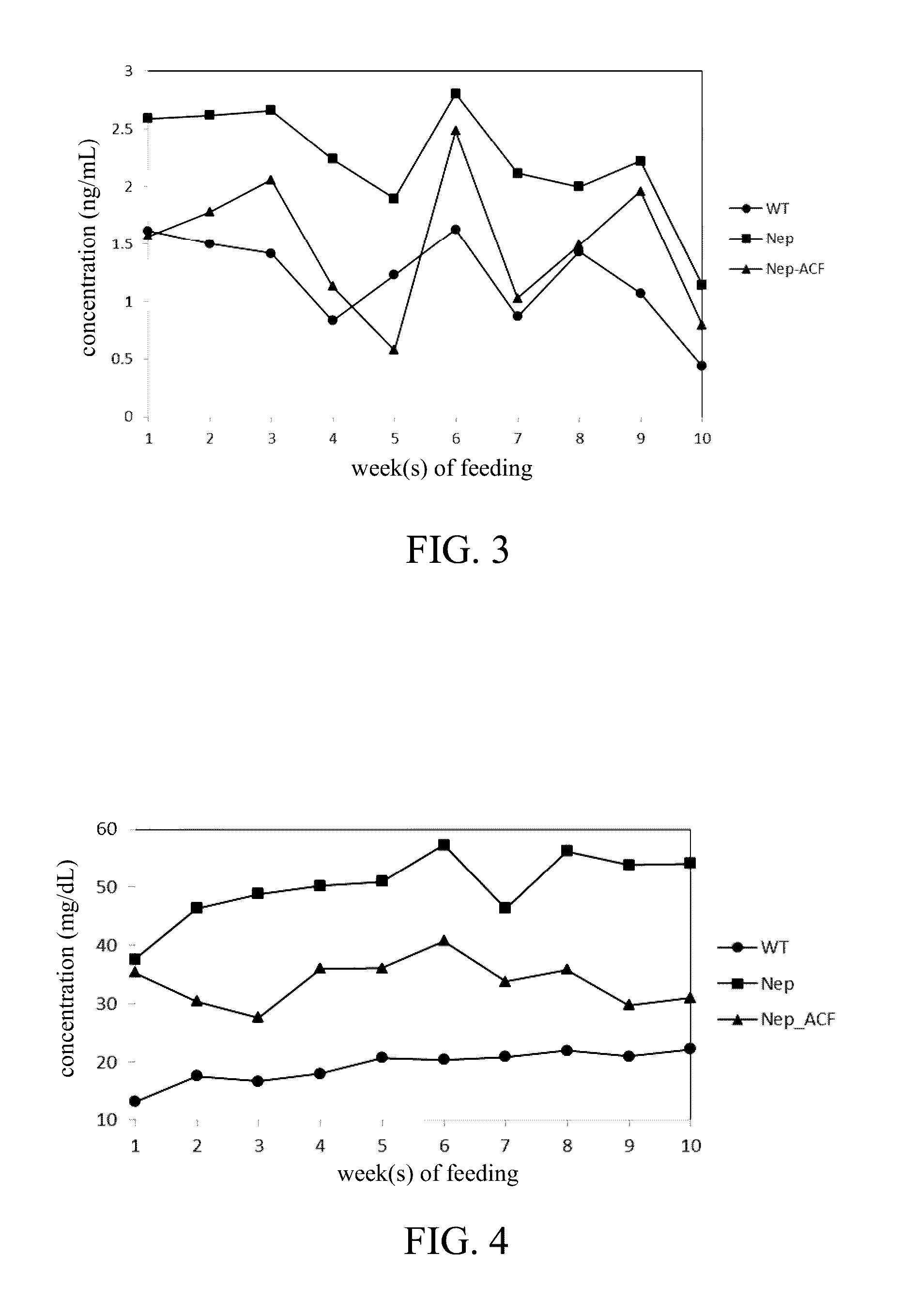

Adsorbent for reducing uremic toxins in vivo

InactiveUS20160296558A1Improve adsorption capacityReduce the amount requiredOther chemical processesInorganic non-active ingredientsActivated carbonNephropathy

An adsorbent for reducing uremic toxins in vivo includes polyacrylonitrile-based activated carbon fibers having the following properties: a) an average diameter of 5 μm to 30 μm; b) a BET specific surface area of more than 390 m2 / g; c) a total acidic group content of larger than 1.2 meq / g or a total basic group content of larger than 1 meq / g. Because the adsorbent of the present disclosure has a higher adsorption capacity for precursors of uremic toxins than for the normal enzyme protein in intestinal tract, the adsorbent of the present disclosure can effectively prevent the deterioration of renal function, and thus can be used as a therapeutic agent and a preventive for kidney disease.

Owner:BIO MEDICAL CARBON TECH

Composite moisture-proof wall cloth and production process thereof

InactiveCN110722841AReduce concentrationImprove comfortLayered productsPhysical chemistryEngineering

The invention relates to the technical field of wall cloth decoration material production, and discloses a composite moisture-proof wall cloth and a production process thereof. The composite moisture-proof wall cloth comprises a fabric layer, wherein a first nanometer waterproof coating is arranged at the bottom of the fabric layer, a noise reduction layer is arranged at the top of the fabric layer, a flame-retardant non-woven fabric is arranged at the top of the noise reduction layer, and an elastic weaved cloth is arranged at the top of the flame-retardant non-woven fabric. According to theinvention, through the composite photocatalyst coating coated on the front surface of the composite moisture-proof wall cloth, after the wall cloth and the wall surface are installed, the composite photocatalyst coating coated on the outer surface of the wall surface can be catalyzed by matching with indoor light or external light, so that the composite photocatalyst coating can react with indoortoxic and harmful gas such as formaldehyde and the like so as to reduce the concentration of the indoor toxic and harmful gas, remove the odor, purify the air, improve the comfort of the indoor personnel and benefit the health of the indoor personnel.

Owner:绍兴市新丝路布业有限公司

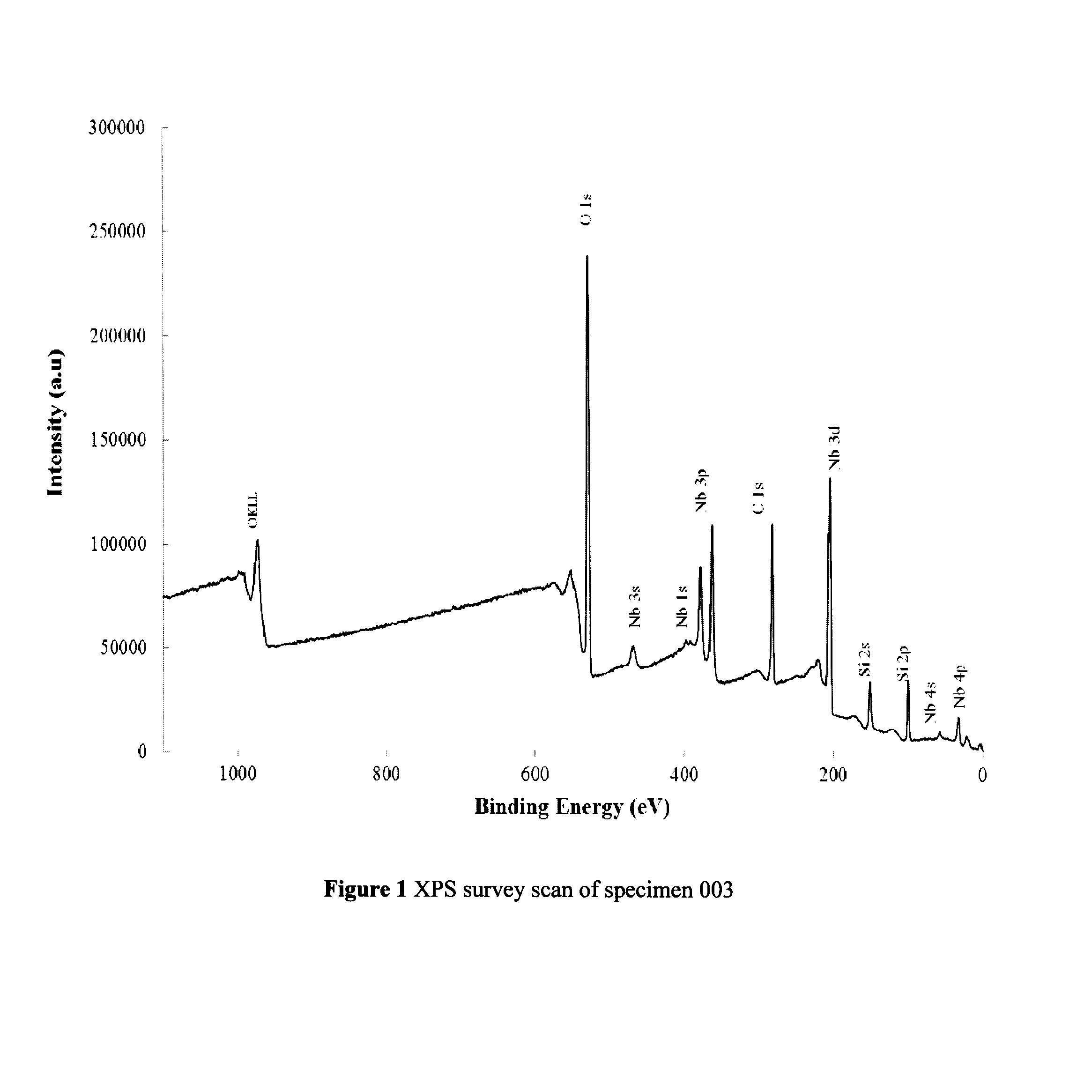

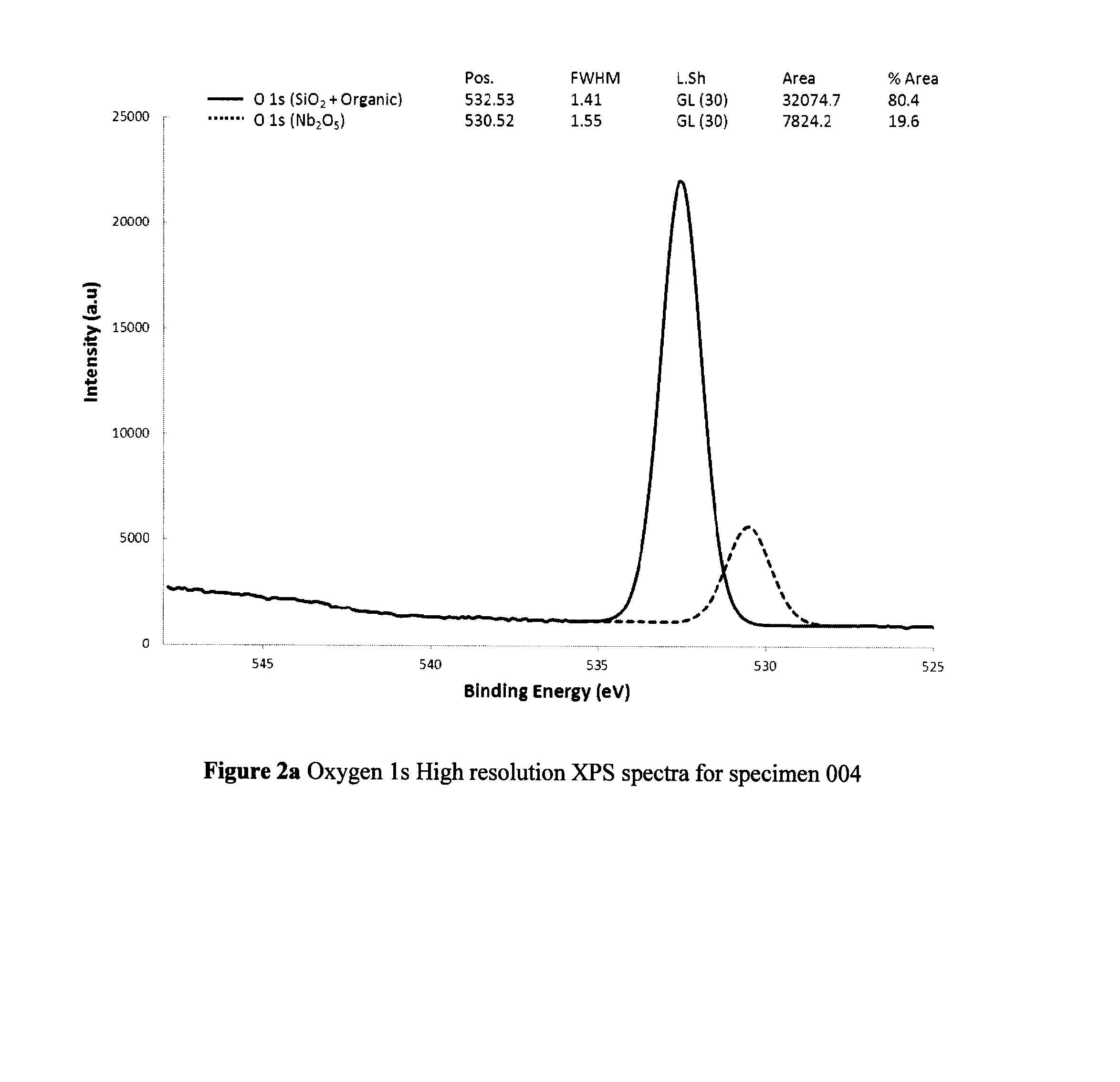

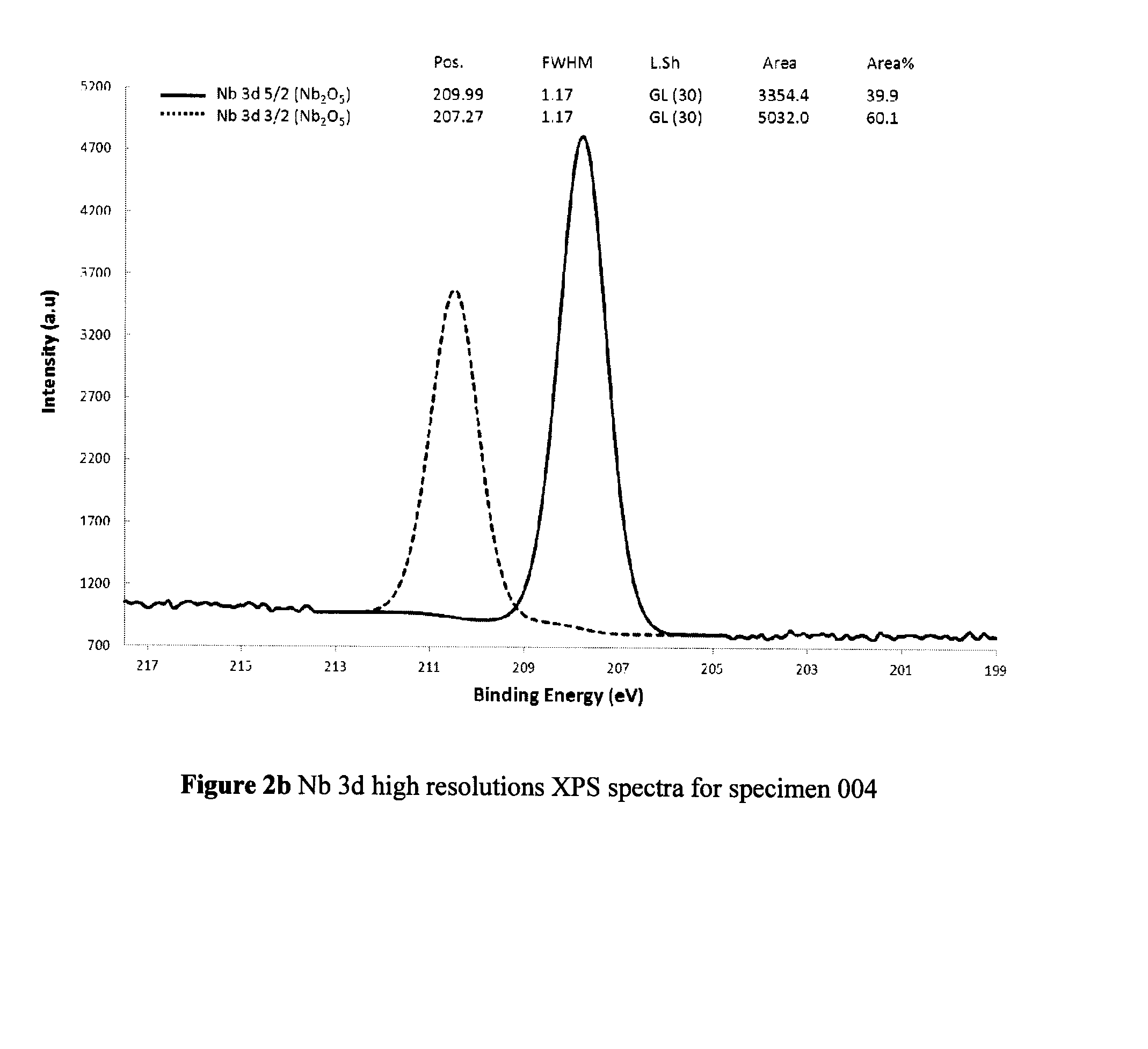

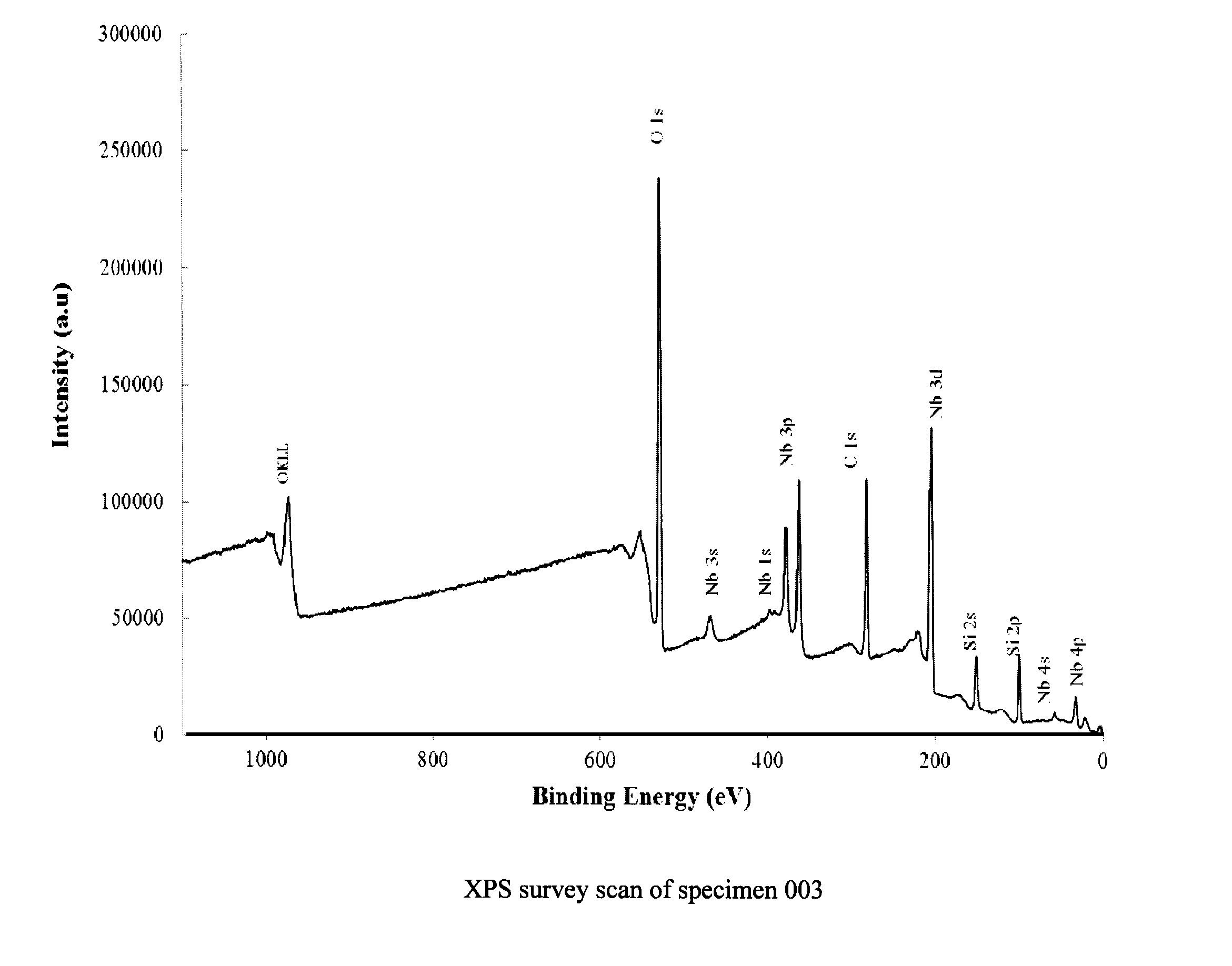

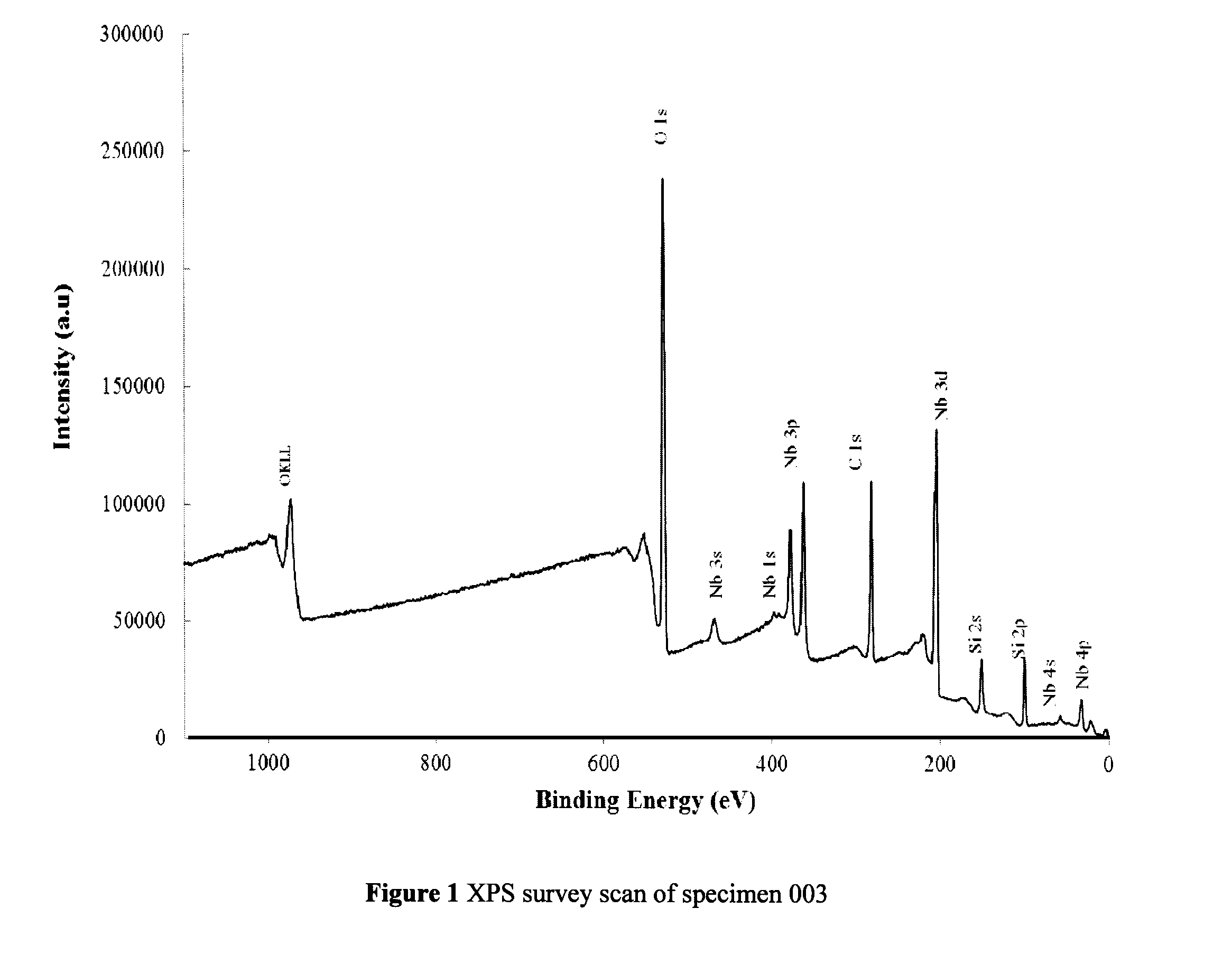

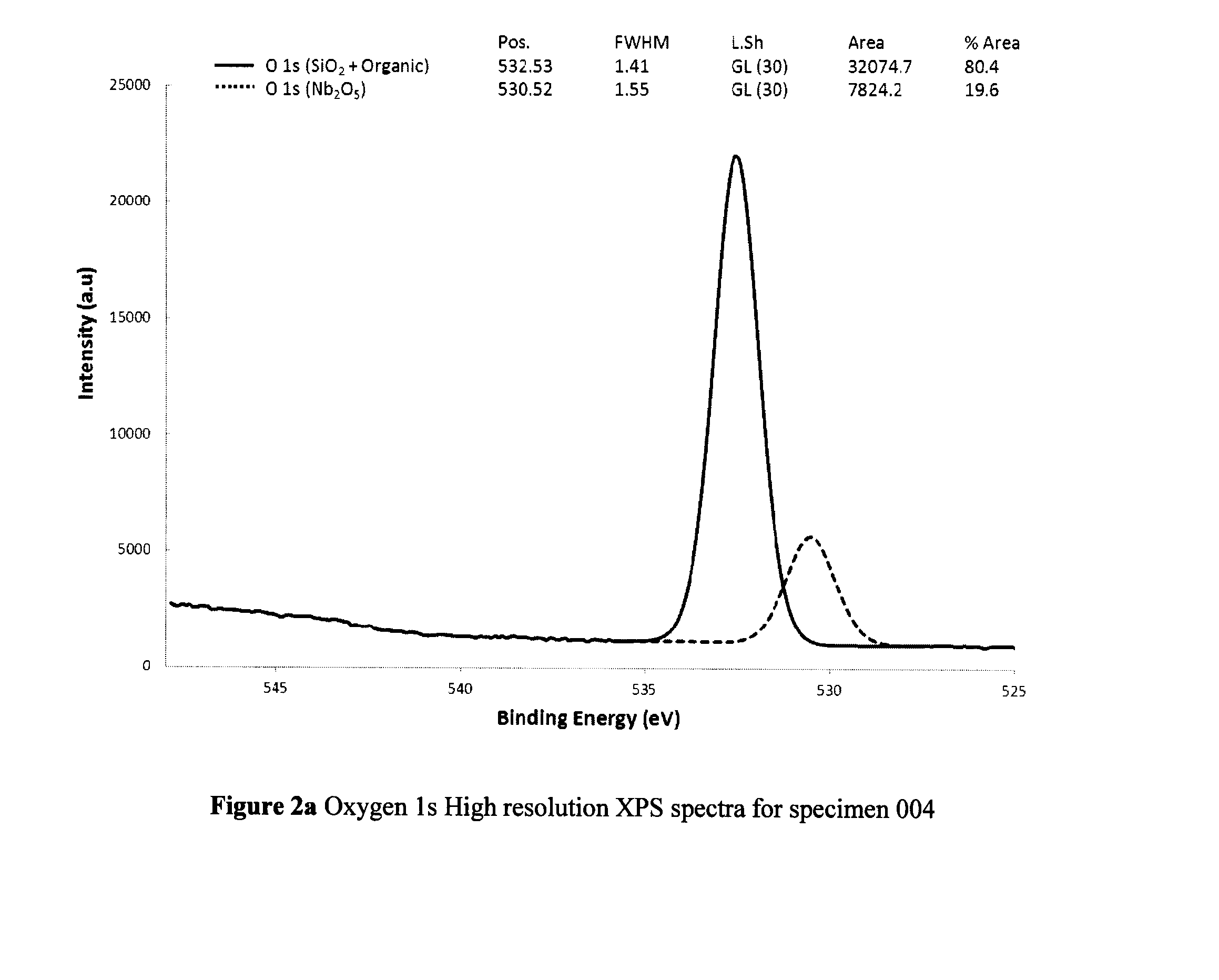

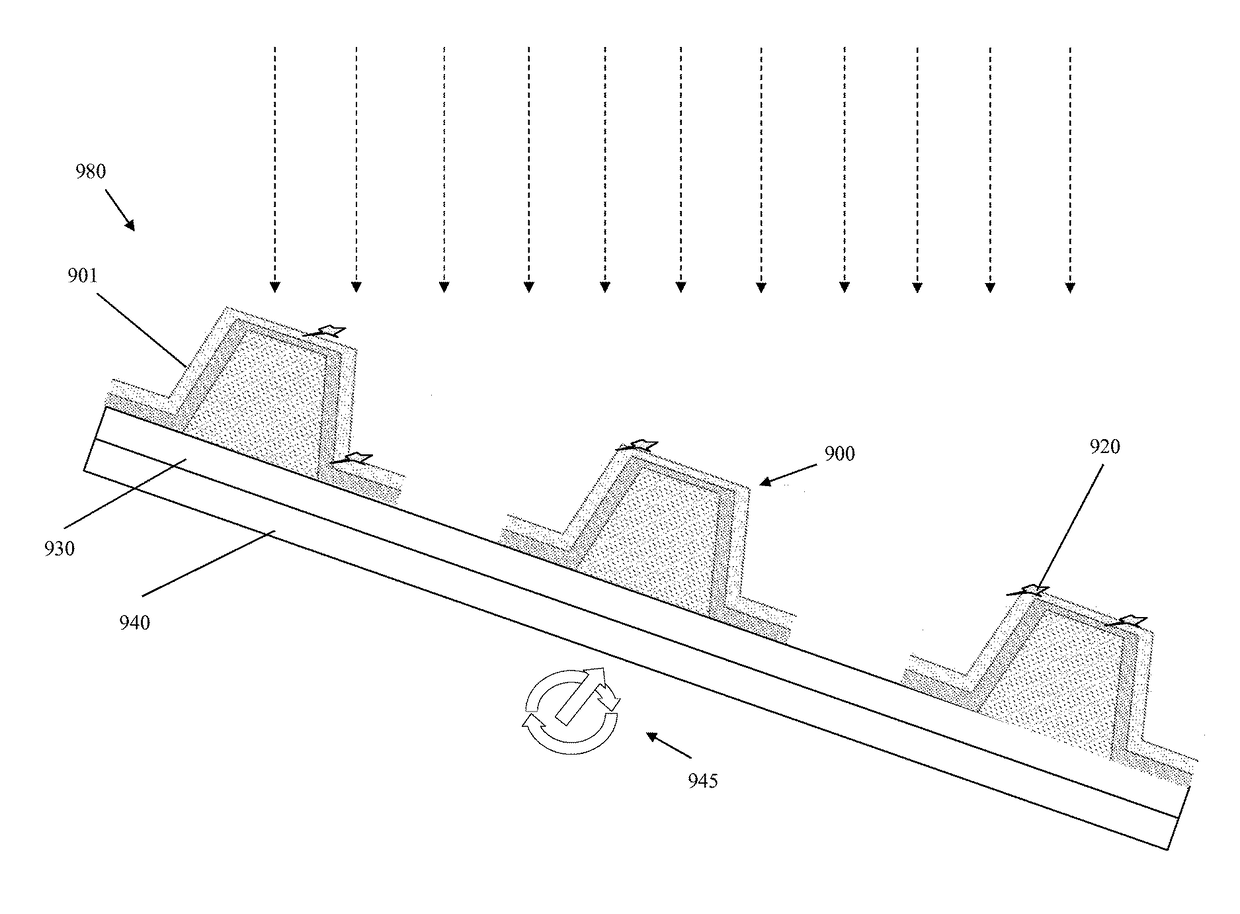

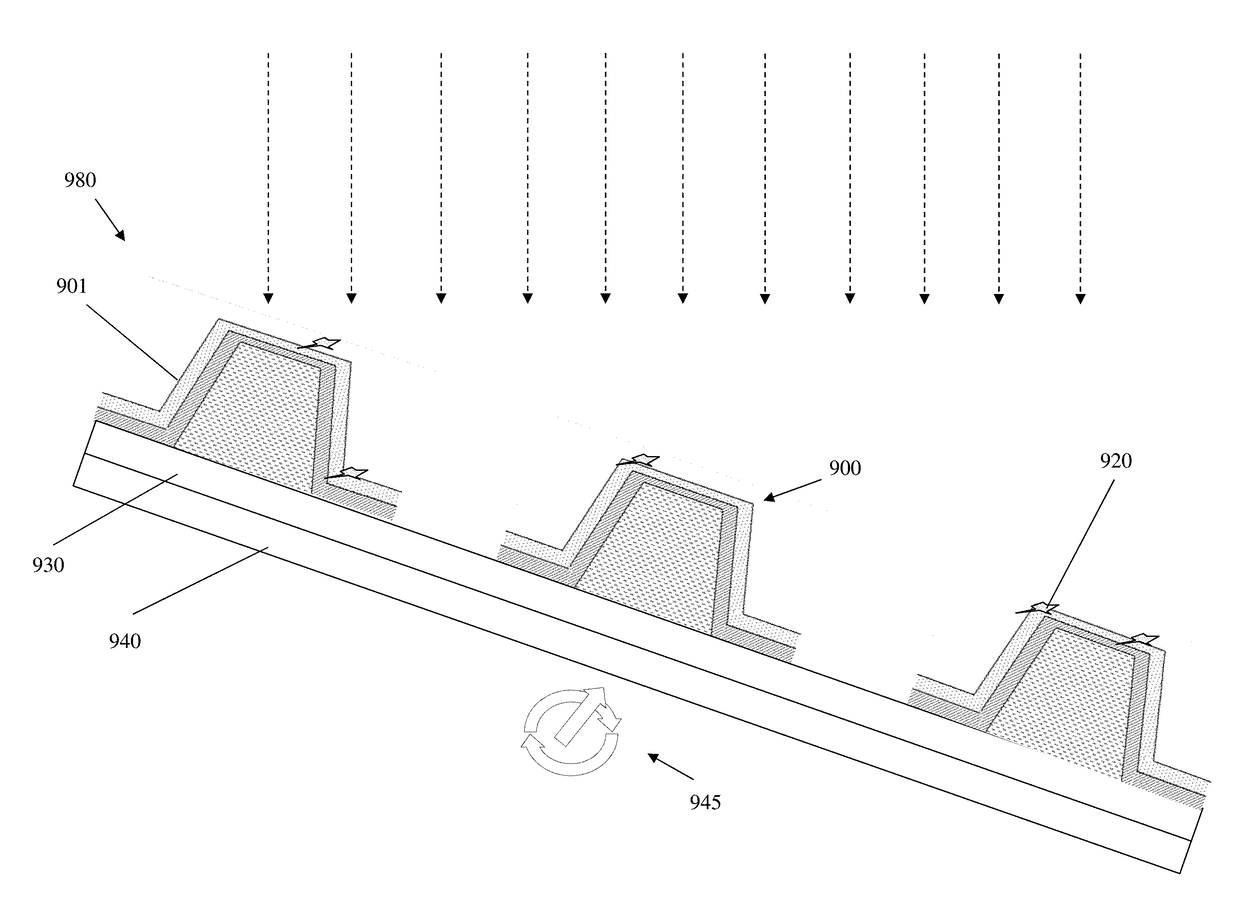

Anti-Fouling Surface, and Radiation Source Assembly and Fluid Treatment System Comprising Same

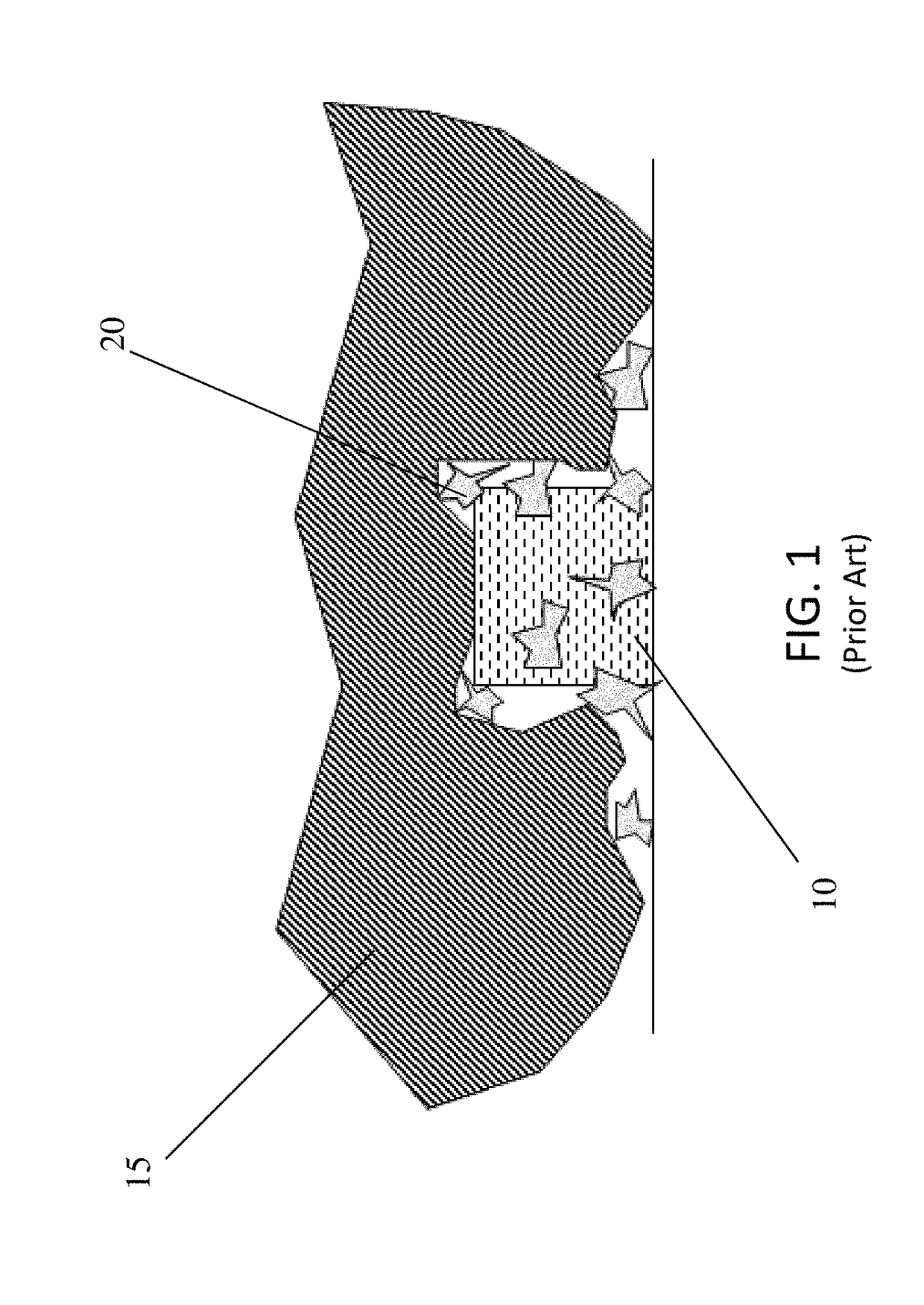

InactiveUS20140191137A1Reduce frequencyReduce the probability of accumulationOptical radiation measurementTantalum compoundsChemistryAqueous solution

An element having an immersible portion for contact with an aqueous liquid, the immersible portion having a contact surface for contact with the aqueous liquid, the contact surface configured to have strong acidity, a radiation (e.g., ultraviolet radiation) source assembly, a radiation (e.g., ultraviolet radiation) source module and a fluid (e.g., water) treatment system incorporating this element applicable to any surface in contact with fluid that is susceptible to build-up of fouling materials. The embodiments obviates or mitigates the rate of accumulation of fouling on surfaces in contact with aqueous solution, such as the protective (e.g., quartz) sleeves in an ultraviolet radiation fluid treatment system, by modifying at least a portion of the surface of those sleeves in contact with fluid (e.g., water) to have an inherent strong surface acidity.

Owner:TROJAN TECH

Control method and system for protection of wind turbines

ActiveUS10927814B2Reduce the probability of accumulationOver-rating to be reducedWind motor controlMachines/enginesControl signalControl theory

A method is provided of controlling a wind turbine that is operating according to a control signal causing the wind turbine to be over-rated above the wind turbine's rated power. The method comprises: obtaining one or more signals, or values of variables, that indicate the fatigue lifetime of one or more of the wind turbine's components from turbine sensors; applying a lifetime usage estimator algorithm to the signals or values to determine measures of the fatigue life consumed by each of the turbine components; calculating, for each of the turbine components, a rate of consumption of fatigue life based on the measures of the fatigue life consumed by each of the turbine components; and controlling the turbine to reduce the amount of power by which the wind turbine is over-rated based on the rate of consumption of fatigue life for at least one of the turbine components.

Owner:VESTAS WIND SYST AS

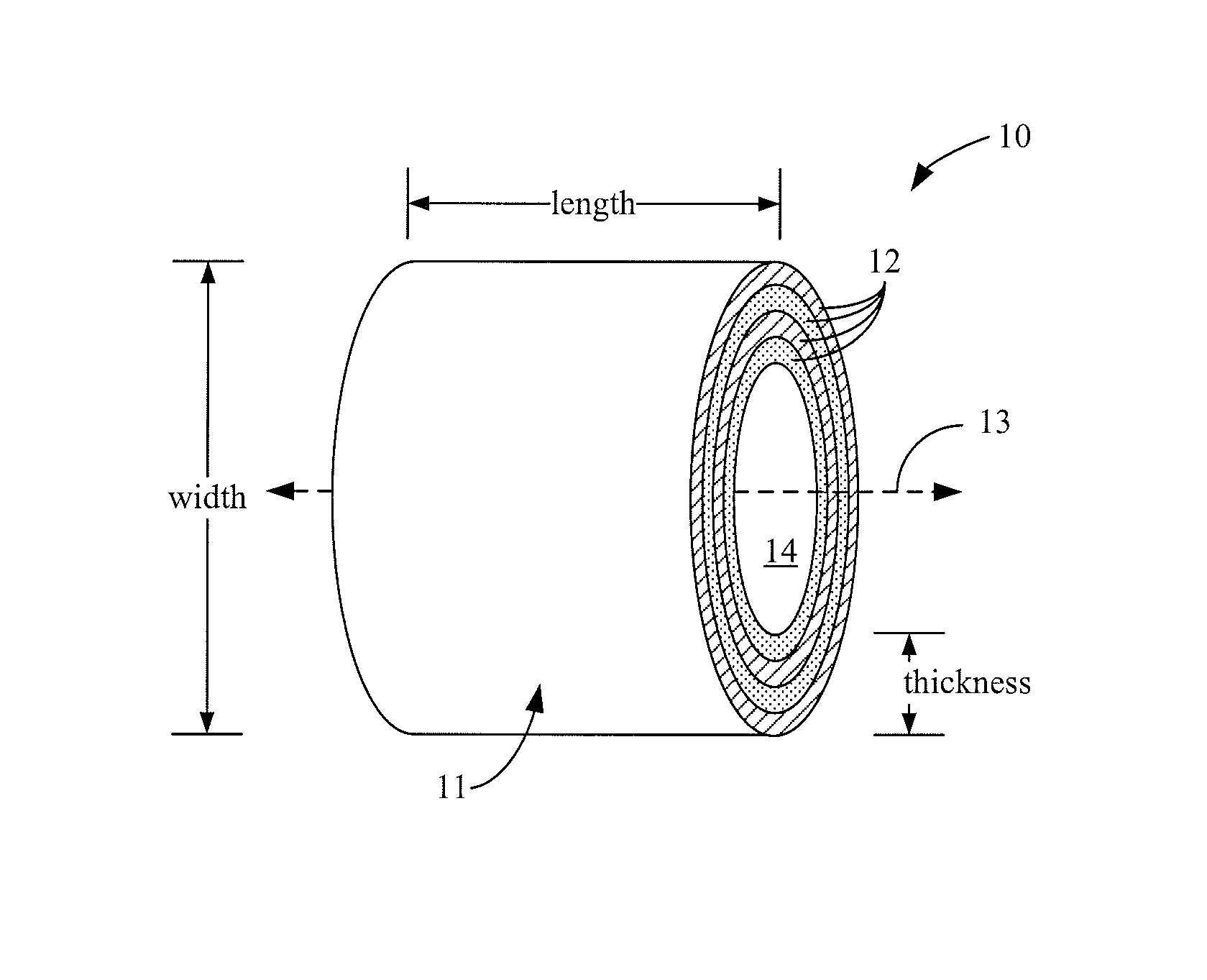

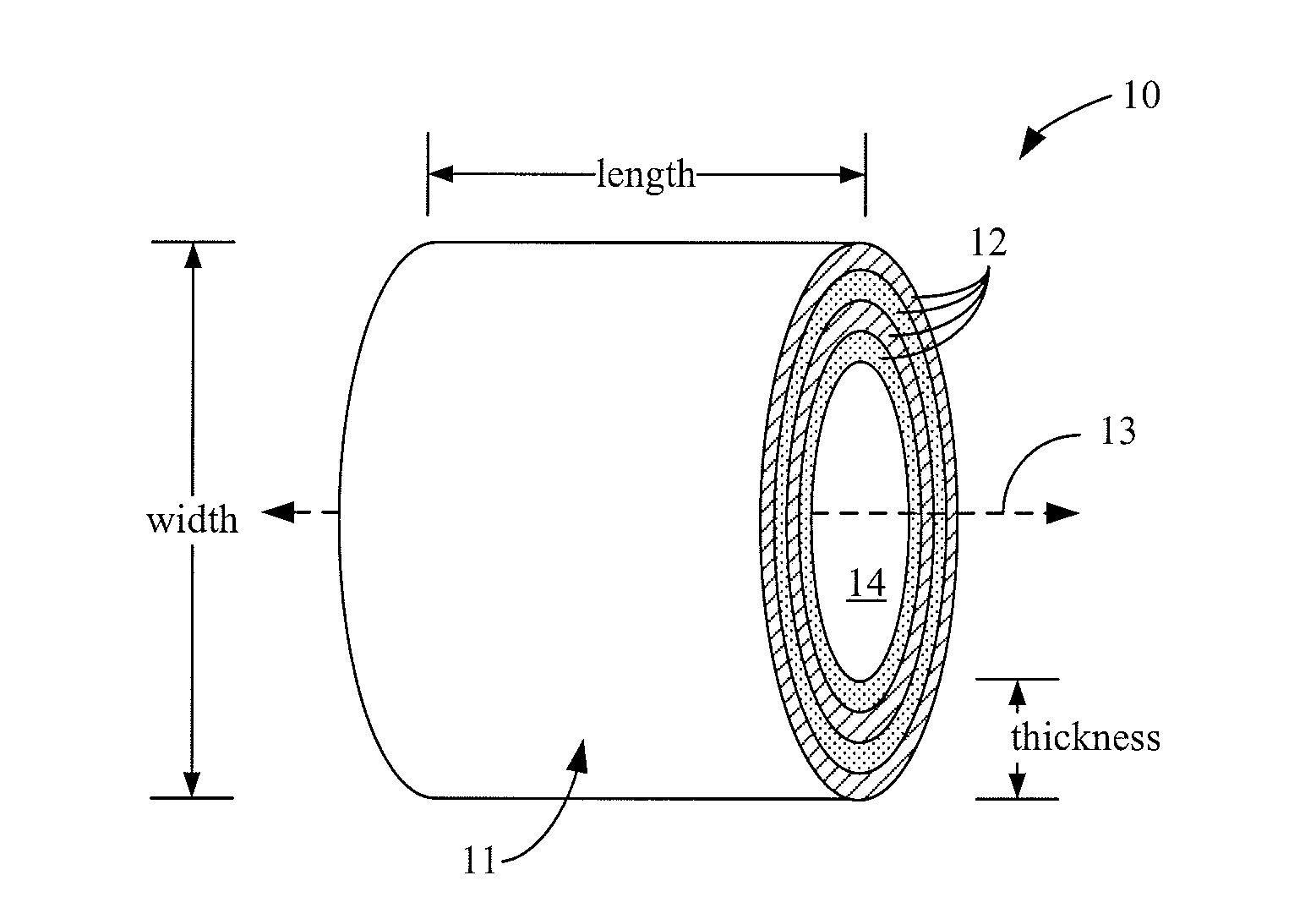

Layered reactive particles with controlled geometries, energies, and reactivities, and methods for making the same

ActiveUS8431197B2Easily tailored/controlledEasy to handleLayered productsVacuum evaporation coatingEngineeringEnergy density

An energetic composite having a plurality of reactive particles each having a reactive multilayer construction formed by successively depositing reactive layers on a rod-shaped substrate having a longitudinal axis, dividing the reactive-layer-deposited rod-shaped substrate into a plurality of substantially uniform longitudinal segments, and removing the rod-shaped substrate from the longitudinal segments, so that the reactive particles have a controlled, substantially uniform, cylindrically curved or otherwise rod-contoured geometry which facilitates handling and improves its packing fraction, while the reactant multilayer construction controls the stability, reactivity and energy density of the energetic composite.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

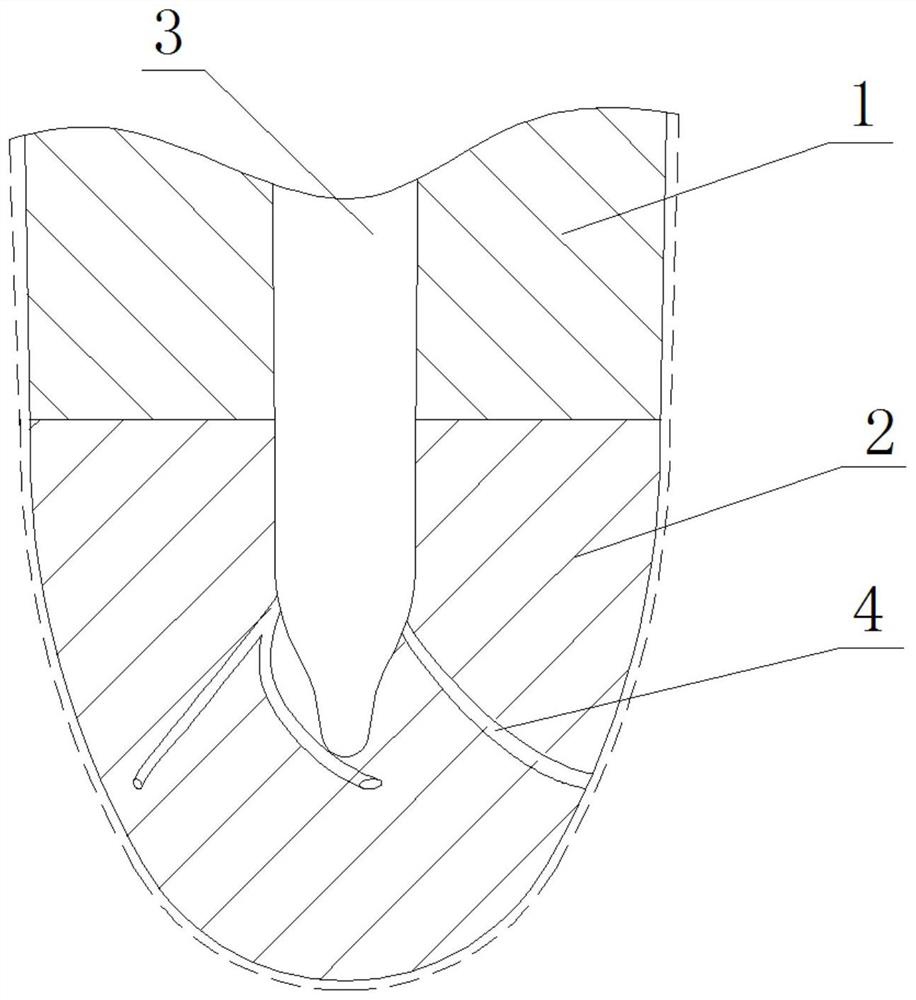

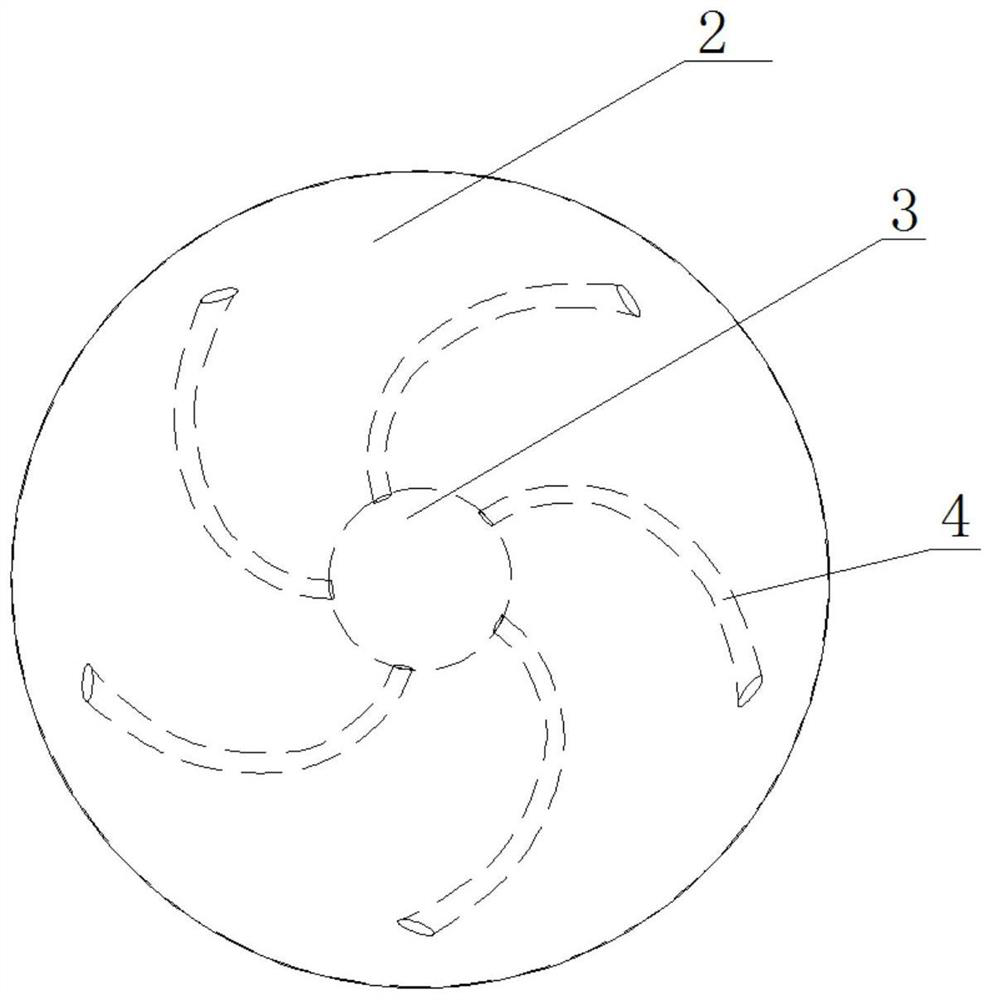

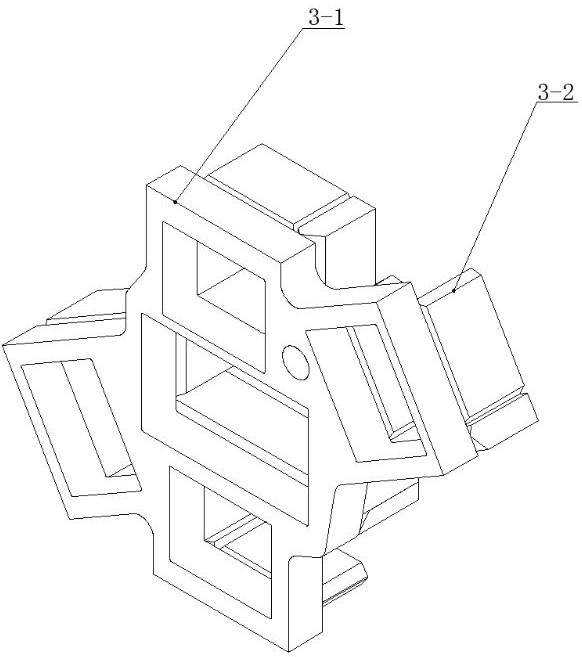

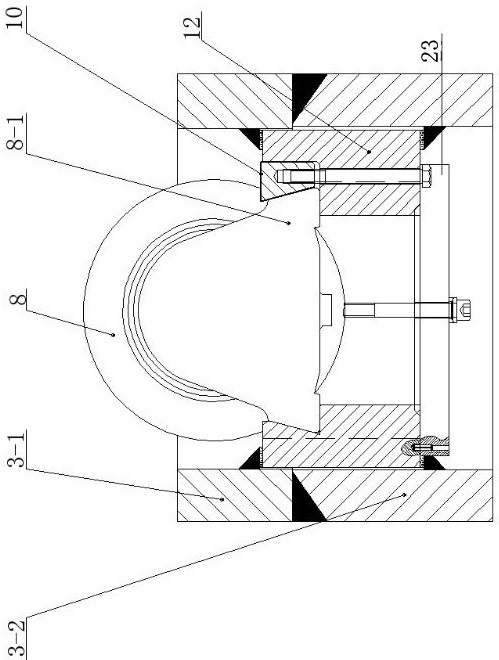

Continuous casting porous stopper rod and continuous casting system

ActiveCN113547112AImprove cleanlinessLarge specific surface areaMelt-holding vesselsShielding gasEngineering

The invention relates to a continuous casting porous stopper rod which comprises a rod body and a rod head connected with the rod body, and further comprises a blowing channel arranged in the rod body, blowing branches used for conveying shielding gas, arranged on the rod head, connected with the blowing channel and used for distributing the shielding gas conveyed by the blowing channel to all directions; the number of the air blowing branches is at least two, and the air outlet direction of the at least two air blowing branches has components in the circumferential direction of the stopper rod. Due to the fact that the air outlet directions of the multiple air blowing branches have components in the circumferential direction of the stopper rod, the multiple air blowing branches face the same circumferential direction, bubbles rotating around the rod head are formed around the rod head, surrounding molten steel is driven to rotate, and attachments in a water gap can be better cleaned.

Owner:칭다오정왕철강수통제주식유한회사

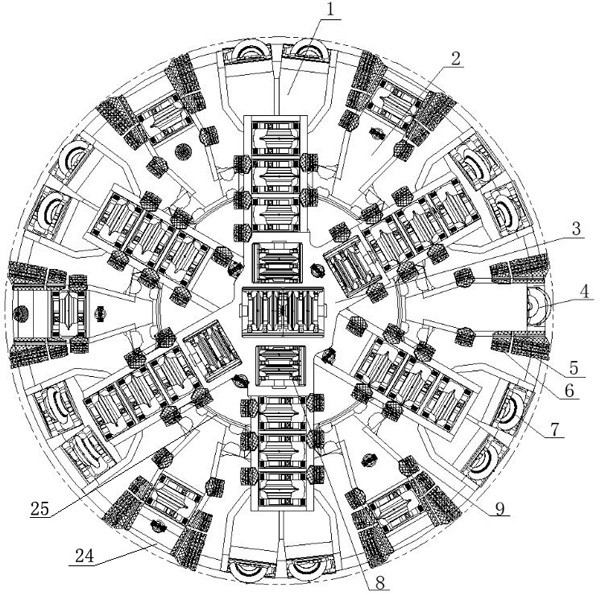

A multi-mode shield machine cutterhead and its shield machine

ActiveCN110985027BEvenly distributedThe structure is evenly stressedTunnelsMechanical engineeringPhysics

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

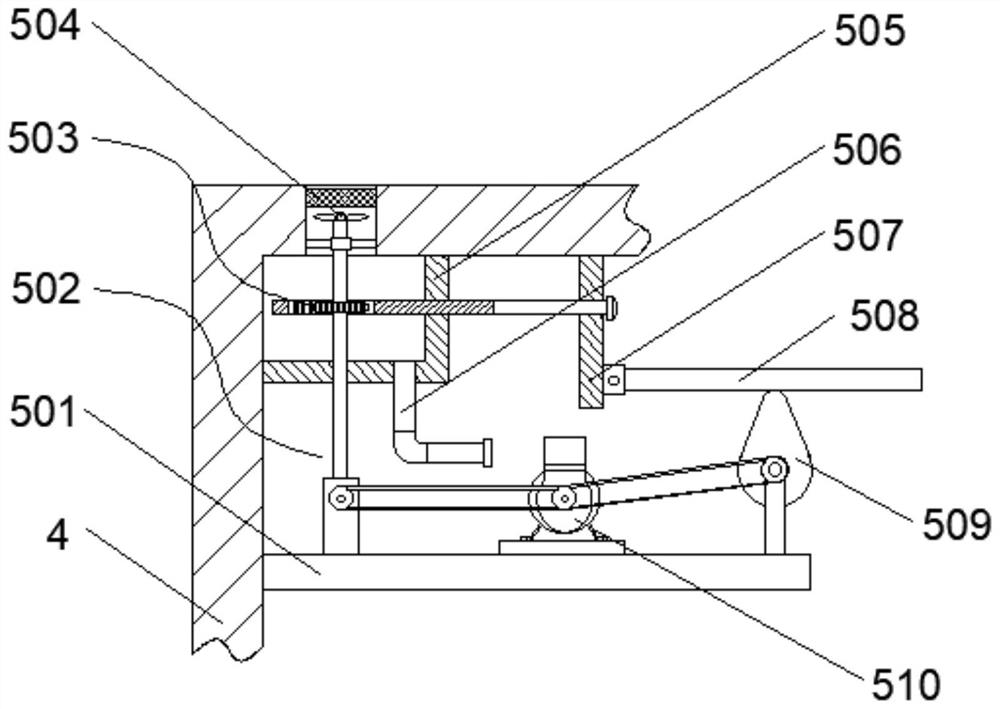

Flour mill for wheat processing

ActiveCN114260057AReduced compaction efficiencyConvenient speed adjustmentSaving energy measuresGrain treatmentsGear wheelElectric machine

The flour mill for wheat processing comprises a mounting box, a speed regulating mechanism is arranged in a cavity of the mounting box, the speed regulating mechanism comprises a first limiting plate and a second limiting plate which are fixedly connected with the mounting box, and a second driving motor is arranged at the top of the first limiting plate; a cam is arranged on one side of the second driving motor, the output end of the second driving motor is in transmission connection with the cam through a belt and a belt wheel, a shielding plate is hinged to the bottom of the second limiting plate, and the cam is in sliding connection with the shielding plate. A baffle plate is in clearance rotation through rotation of a cam, so that wheat output in a feeding pipe is conveniently subjected to speed regulation, the wheat is prevented from reaching a guide plate too fast, a moving plate is driven to move through rotation of a second rotating shaft in cooperation with an incomplete gear, an impact head impacts the bottom of the feeding pipe in a reciprocating mode, and the wheat output speed is increased. And wheat accumulated at the bottom of the feeding pipe can be conveniently shaken down.

Owner:安徽谷丰源食品有限公司

Anti-fouling surface, and radiation source assembly and fluid treatment system comprising same

InactiveUS9029798B2Strong acidReduce frequencyScattering properties measurementsPretreated surfacesUltravioletUltraviolet radiation

An element having an immersible portion for contact with an aqueous liquid, the immersible portion having a contact surface for contact with the aqueous liquid, the contact surface configured to have strong acidity, a radiation (e.g., ultraviolet radiation) source assembly, a radiation (e.g., ultraviolet radiation) source module and a fluid (e.g., water) treatment system incorporating this element applicable to any surface in contact with fluid that is susceptible to build-up of fouling materials. The embodiments obviate or mitigates the rate of accumulation of fouling on surfaces in contact with aqueous solution, such as the protective (e.g., quartz) sleeves in an ultraviolet radiation fluid treatment system, by modifying at least a portion of the surface of those sleeves in contact with fluid (e.g., water) to have an inherent strong surface acidity.

Owner:TROJAN TECH

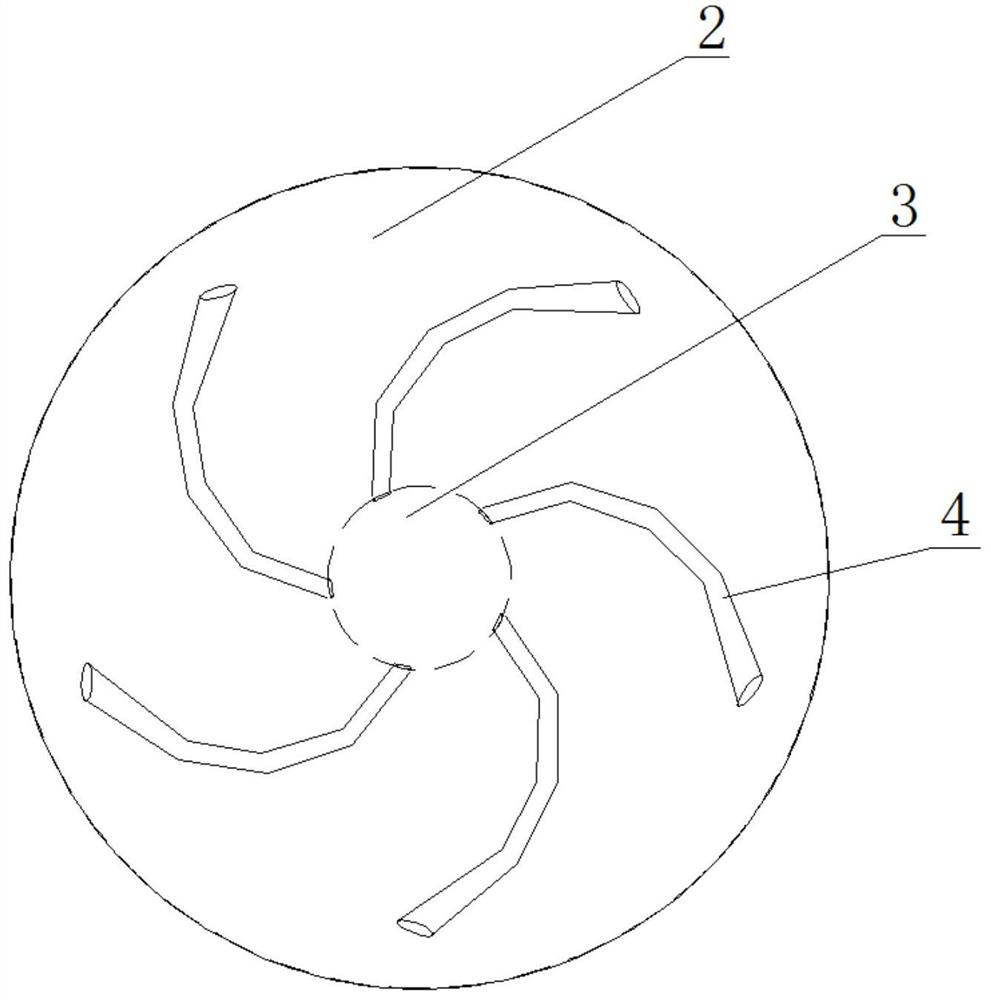

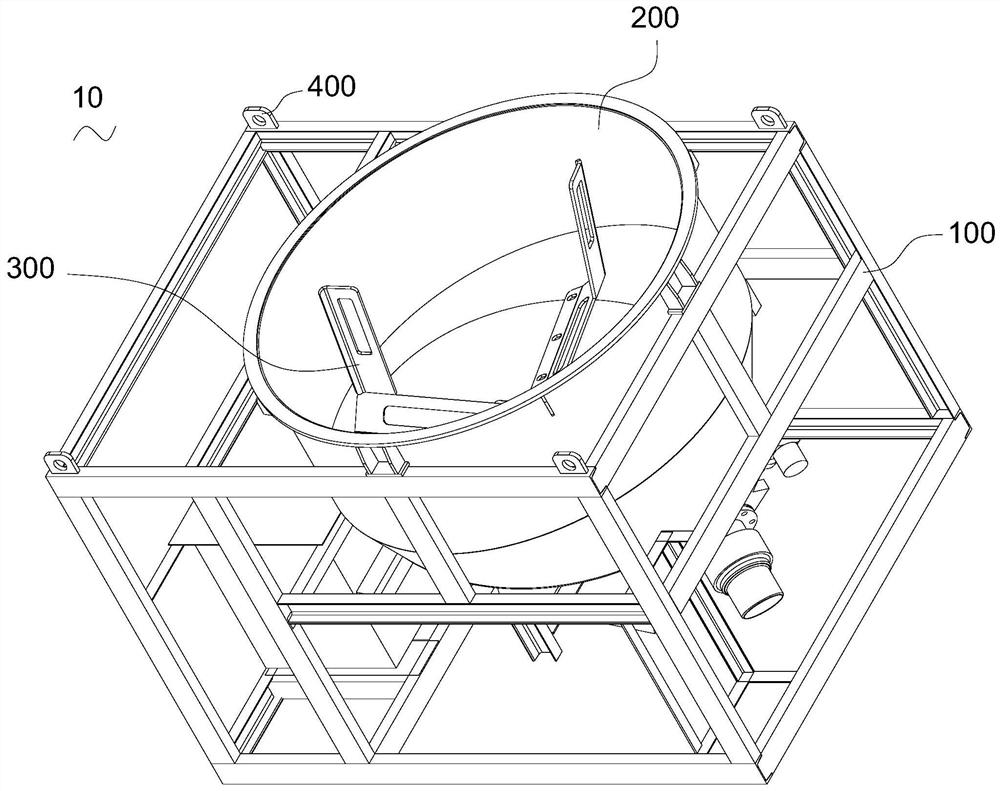

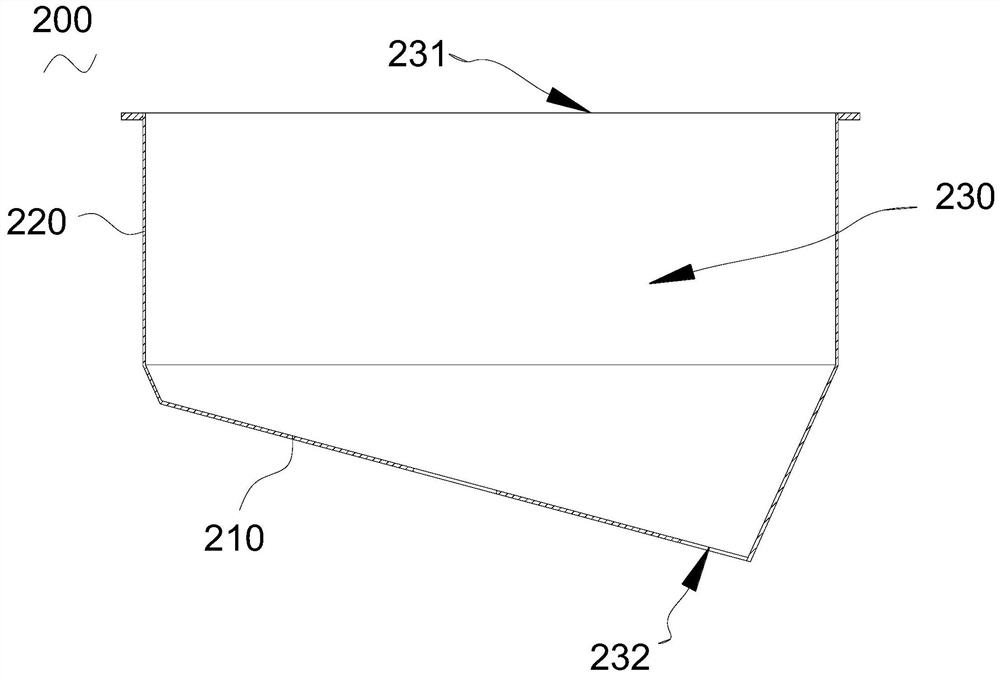

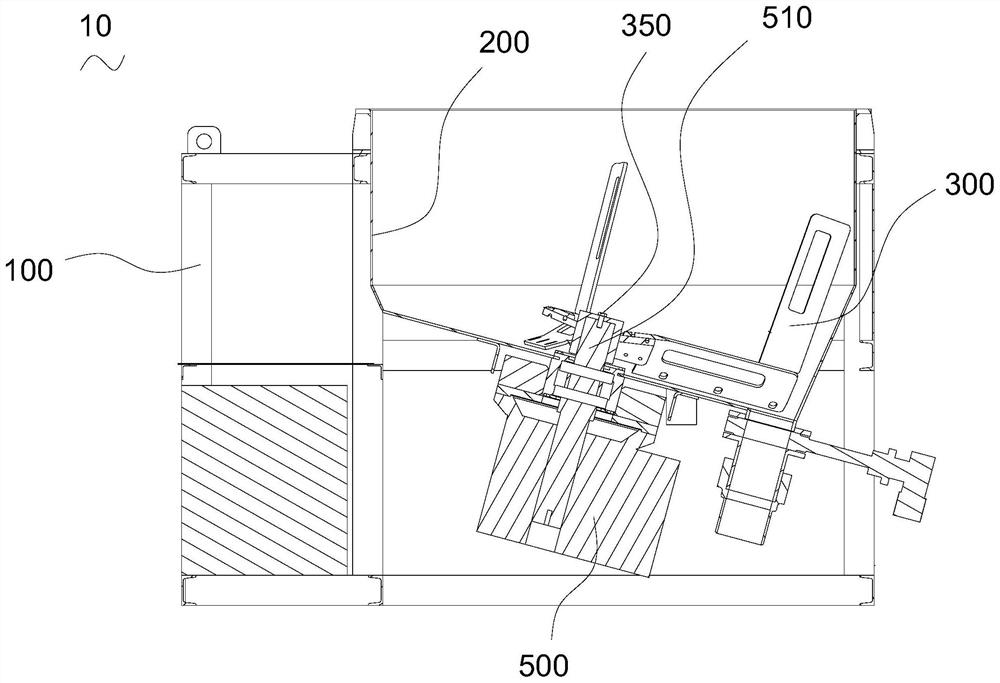

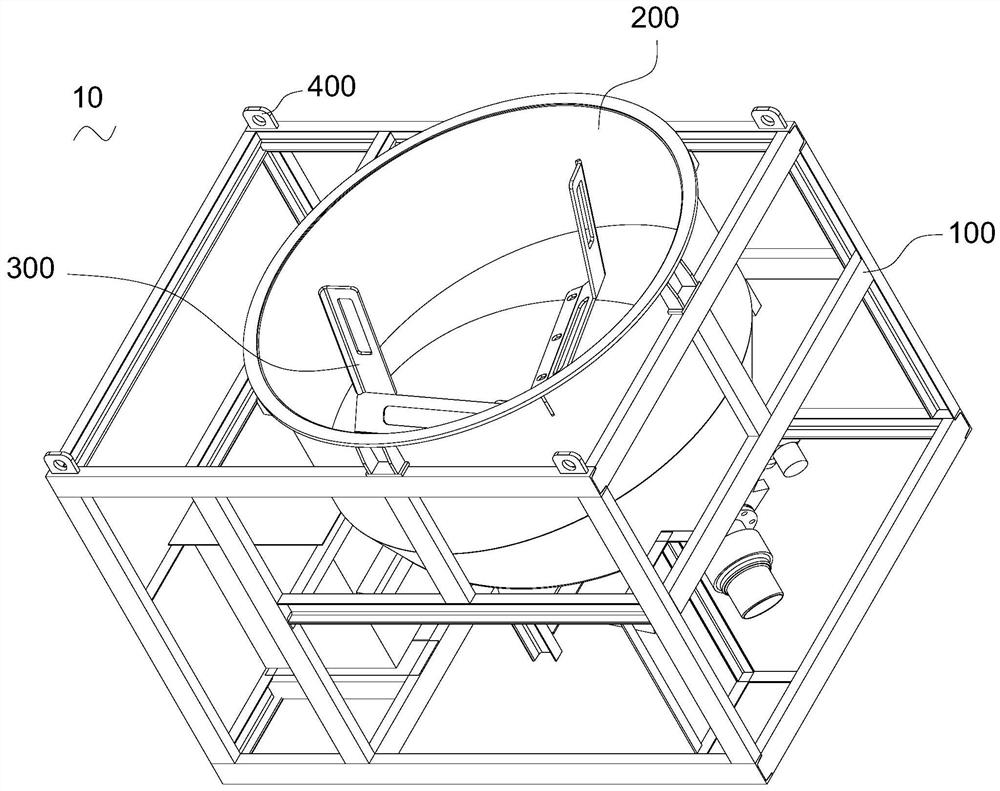

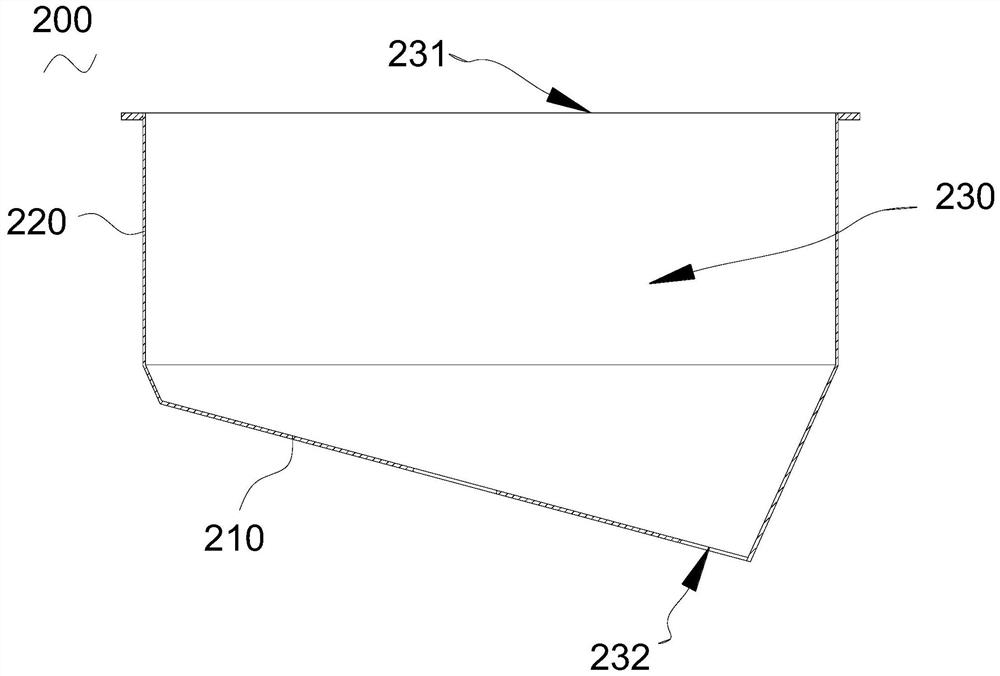

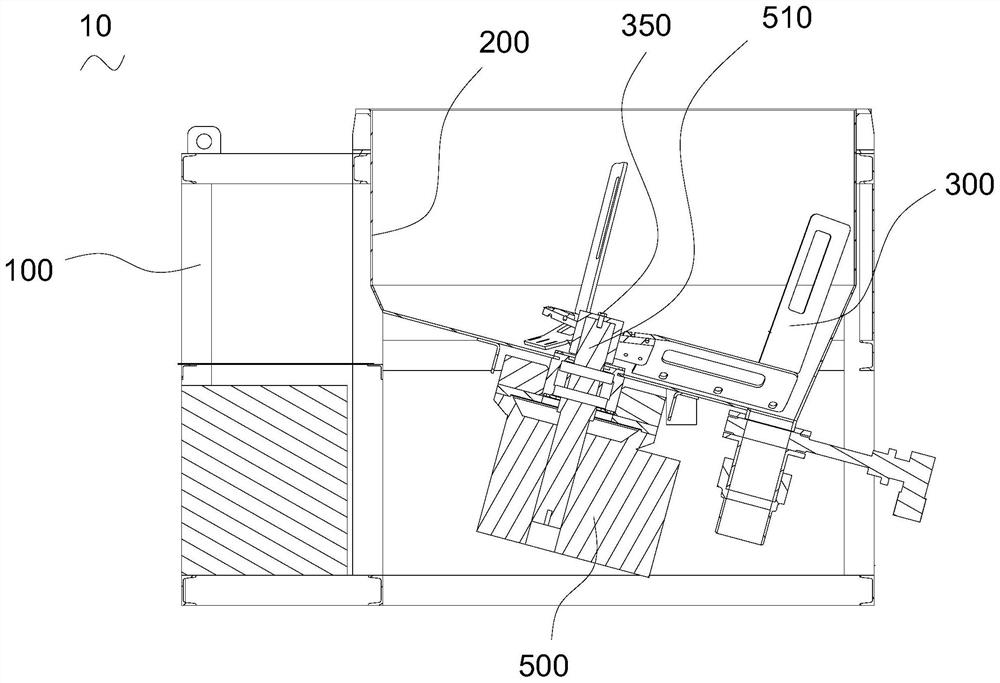

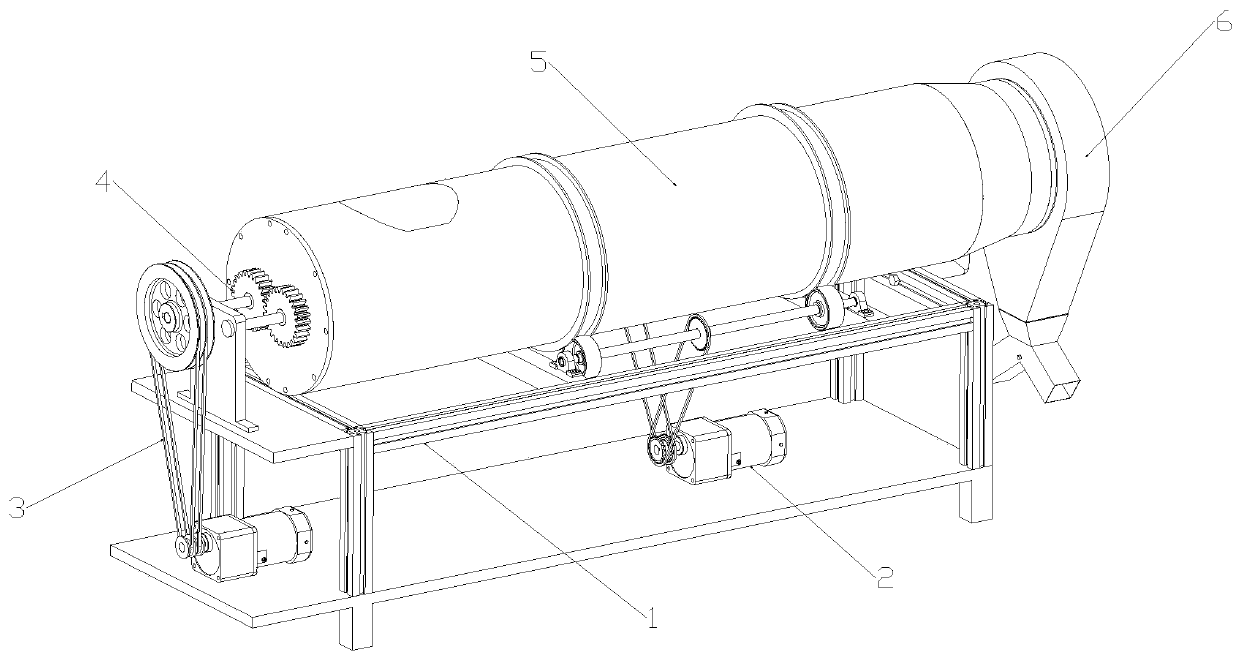

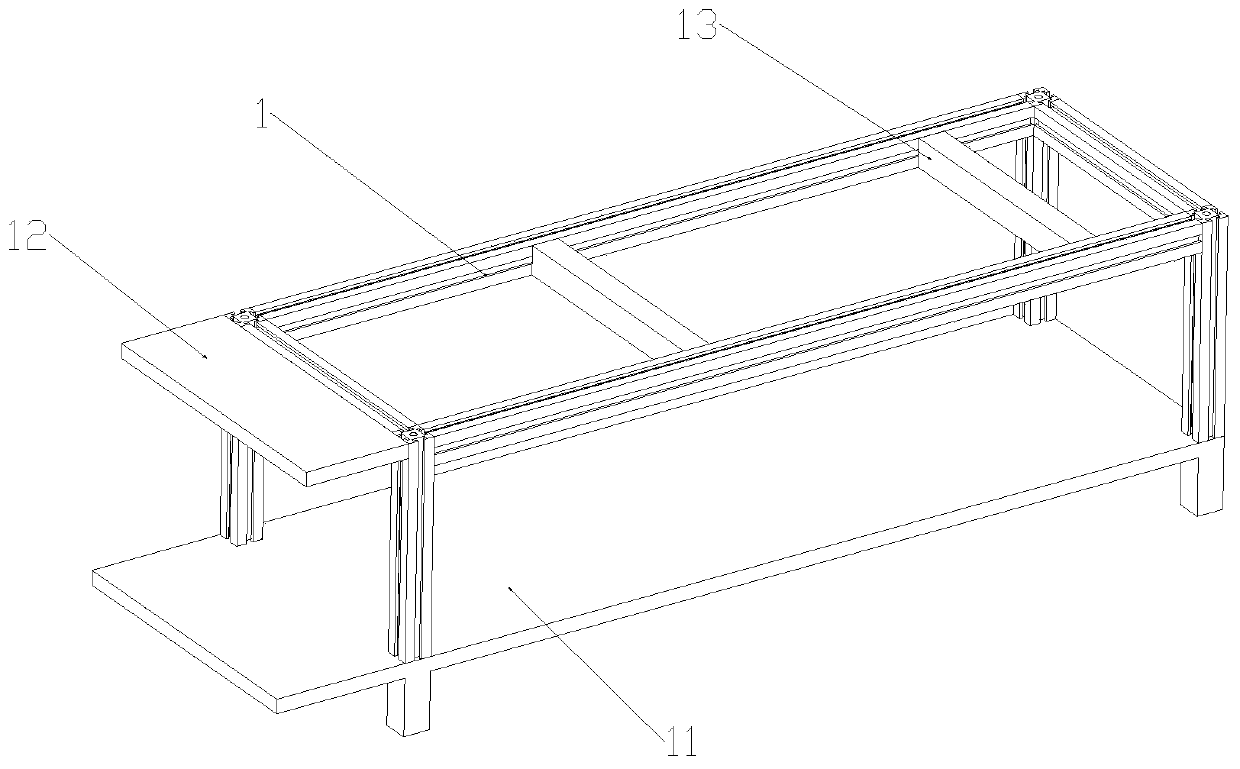

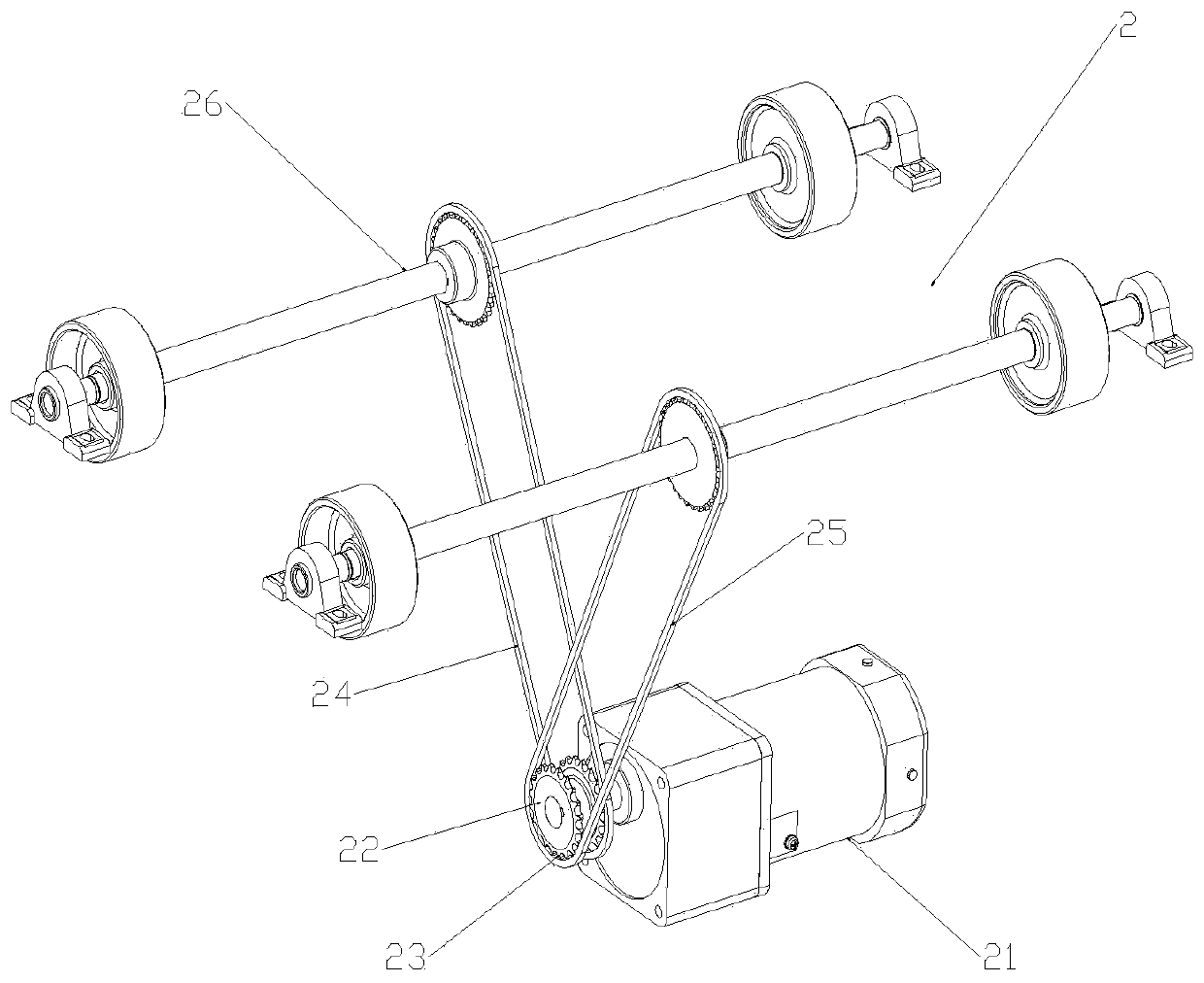

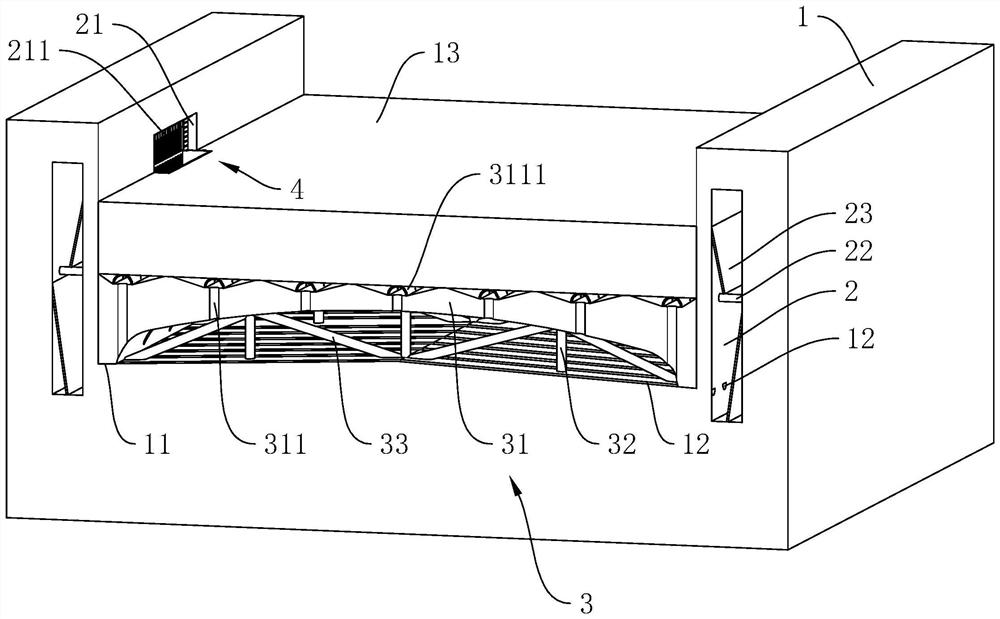

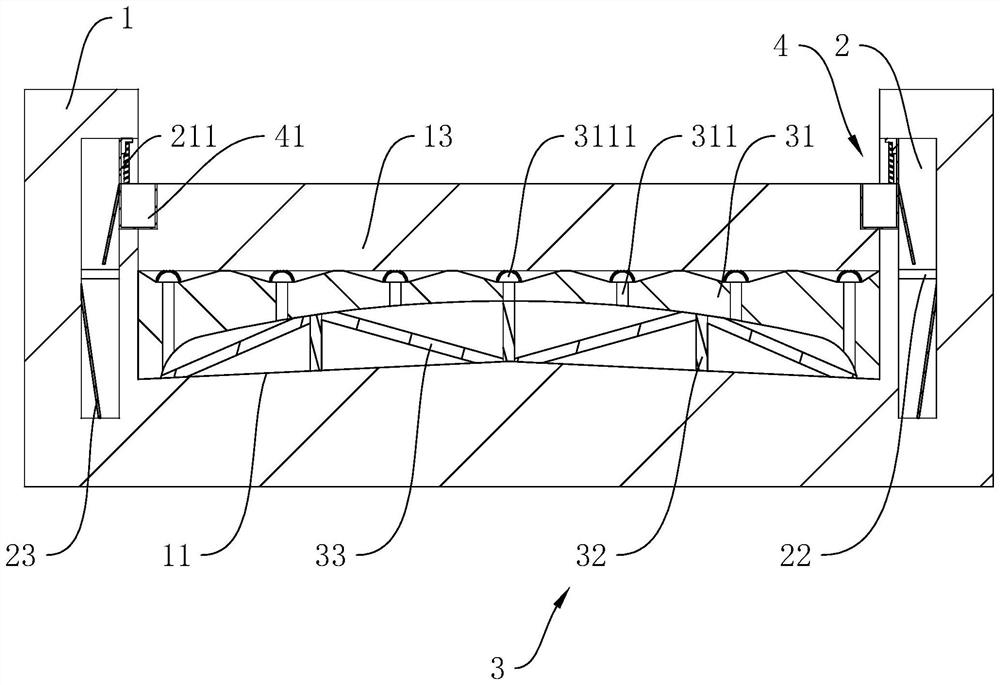

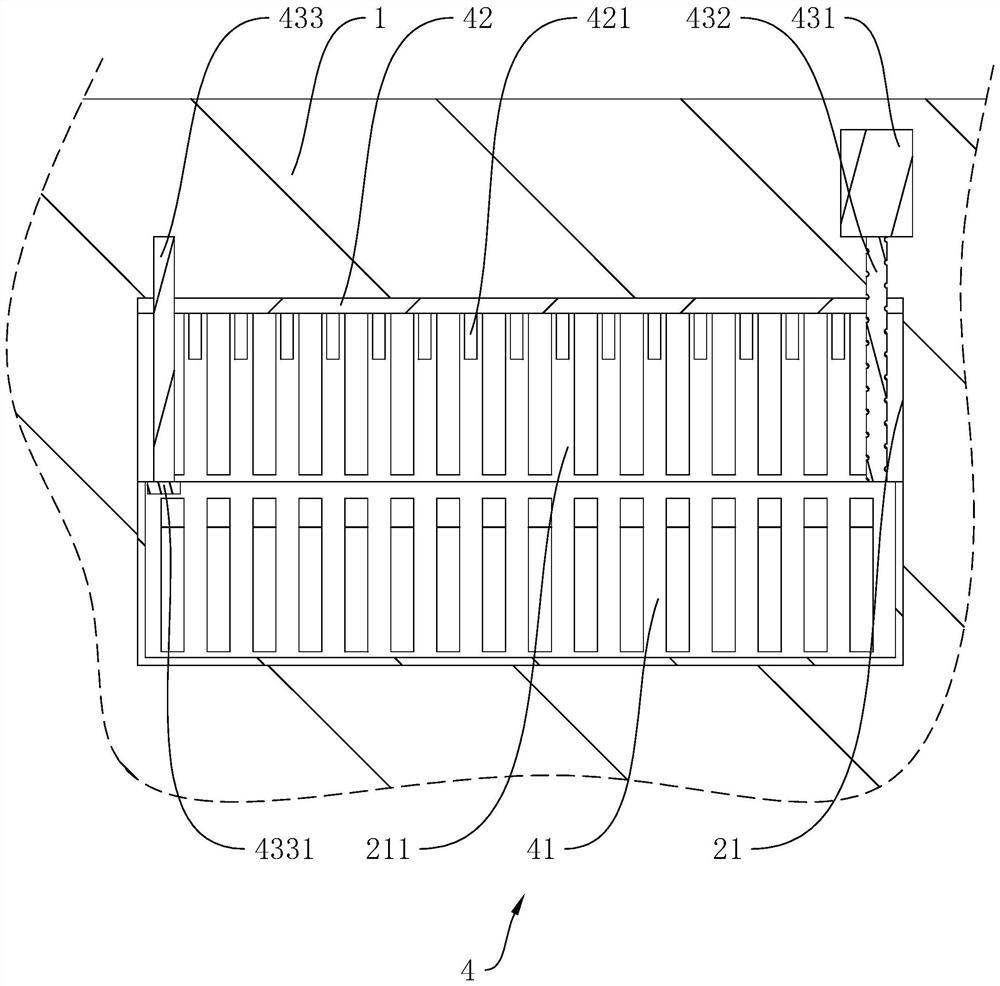

Mixing mechanism and self-compacting concrete mixer for rail transit precast slab rail structure

ActiveCN112405844AReduce the probability of accumulationImprove the mixing effectCement mixing apparatusArchitectural engineeringStructural engineering

The invention relates to a mixing mechanism and a self-compacting concrete mixer for a rail transit precast slab rail structure. The mixing mechanism is used for being arranged in a hopper in a rotating mode so as to mix self-compacting concrete in the hopper. The mixing mechanism comprises a shaft sleeve and multiple blade assemblies, the shaft sleeve is used for sleeving a driving rotating shaftand is in transmission connection with the driving rotating shaft, the multiple blade assemblies are arranged in the circumferential direction of the shaft sleeve at intervals, each blade assembly comprises a transverse mixing part and a vertical mixing part, one ends of the transverse mixing parts are arranged on the shaft sleeve, the other ends of the transverse mixing parts are connected to one ends of the vertical mixing parts, an included angle is formed between the lengthwise direction of each vertical mixing part and the lengthwise direction of the corresponding transverse mixing part,and the sides, deviating from the vertical mixing parts, of the transverse mixing parts are used for making contact with the bottom wall of the hopper in a sliding mode. According to the mixing mechanism and the self-compacting concrete mixer for the rail transit precast slab rail structure, due to the arrangement of the mixing mechanism, the mixing effect of the self-compacting concrete mixer for the rail transit precast slab rail structure is better.

Owner:CENT SOUTH UNIV +2

Mixing mechanism and self-compacting concrete mixer for rail transit prefabricated slabs

ActiveCN112405844BReduce the probability of accumulationImprove the mixing effectCement mixing apparatusDrive shaftArchitectural engineering

The invention relates to a mixing mechanism and a self-compacting concrete mixer used for rail transit prefabricated slabs. The stirring mechanism is used to be rotatably installed in the hopper to stir the self-compacting concrete in the hopper. The stirring mechanism includes a shaft sleeve and multiple blade assemblies. The shaft sleeve is used to be sleeved on the driving shaft and connected with the driving shaft through transmission. A plurality of vane assemblies are arranged at intervals along the circumference of the shaft sleeve. Each blade assembly includes a horizontal stirring piece and a vertical stirring piece. One end of the horizontal stirring piece is installed on the shaft sleeve, and the other end is connected with one end of the vertical stirring piece. The longitudinal direction of the vertical stirring member and the longitudinal direction of the horizontal stirring member are arranged at an included angle. The side of the horizontal stirring member facing away from the vertical stirring member is for slidably contacting with the bottom wall of the hopper. Therefore, the arrangement of the above-mentioned mixing mechanism makes the mixing effect of the self-compacting concrete mixer used for rail transit prefabricated slabs better.

Owner:CENT SOUTH UNIV +2

Stamping die for metal plate stamping

PendingCN114733958AReduce the probability of accumulationReduce workloadMetal-working feeding devicesPositioning devicesStructural engineeringWaste material

The invention belongs to the field of stamping dies, and particularly relates to a stamping die for sheet metal stamping, which comprises an upper die, a lower die, a support table and a pushing component. A plurality of punches are installed on the bottom face of the upper die, a metal sheet is slidably installed in a groove in the top face of the lower die, a plurality of waste holes are formed in the bottom face of the groove in the top face of the lower die, supporting tables are fixedly connected to the bottom faces of the two sides of the lower die, a push plate is slidably installed between the supporting tables on the two sides, and a transmission unit is installed on one side of the push plate. The top end of the transmission unit is fixedly connected with the side surface of the upper die; the upper die and the lower die are pushed by a punching machine to be closed, the punch is driven to punch a metal sheet, waste falls down from the waste hole, the upper die descends to conduct power transmission through the transmission unit, the push plate is pushed to slide between the supporting tables on the two sides, the falling waste is pushed out, the waste accumulation probability is reduced, the workload of workers is reduced, and the production efficiency is improved. And the safety of workers during working is improved.

Owner:南通旭志精工科技有限公司

Layered reactive particles with controlled geometries, energies, and reactivities, and methods for making the same

ActiveUS20130078466A1Easily tailored/controlledEasy to handleLayered productsVacuum evaporation coatingEngineeringEnergy density

An energetic composite having a plurality of reactive particles each having a reactive multilayer construction formed by successively depositing reactive layers on a rod-shaped substrate having a longitudinal axis, dividing the reactive-layer-deposited rod-shaped substrate into a plurality of substantially uniform longitudinal segments, and removing the rod-shaped substrate from the longitudinal segments, so that the reactive particles have a controlled, substantially uniform, cylindrically curved or otherwise rod-contoured geometry which facilitates handling and improves its packing fraction, while the reactant multilayer construction controls the stability, reactivity and energy density of the energetic composite.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

Solder bump array probe tip structure for laser cleaning

ActiveUS9835653B2Reduce the probability of accumulationEasy to cleanElectronic circuit testingElectrical measurement instrument detailsBall grid arrayLaser

Owner:INT BUSINESS MASCH CORP

Twin-screw puffing equipment and using method thereof

The invention discloses twin-screw puffing equipment and a using method thereof. The twin-screw puffing equipment comprises a workbench, wherein a first driving device is arranged below the workbench,the first driving device comprises a first servo motor fixed on one side of the upper end of a support bottom plate, a second driving device is arranged at one side below the workbench, the second driving device comprises a second servo motor fixed at the upper end of the support bottom plate, a rotating device comprises a first screw fixedly connected with the central position of a belt pulley,and the side edge of the first screw is provided with a second screw. According to the twin-screw structure, the equipment can be changed into meshing type, non-meshing type and partial meshing type by disassembling and assembling according to the existing part structure, so that multiple functions are realized, and the production cost is reduced; meanwhile, the position of a connecting sleeve canbe adjusted, fastening bolts and the two end walls of the connecting sleeve are tightly connected, clamping and fixing of the connecting sleeve are realized, the rotation direction of a propeller canbe reversed, and free adjustment of co-rotation and counter-rotation is achieved.

Owner:安徽珠峰生物科技有限公司

Urban road comprehensive drainage system and urban road

ActiveCN114250665ARealize multi-path drainageImprove drainage efficiencySewerage structuresPaving gutters/kerbsRoad engineeringArchitectural engineering

The invention relates to an urban road comprehensive drainage system and an urban road, and belongs to the technical field of road engineering, the urban road comprehensive drainage system comprises a roadbed and drainage channels, a foundation pit is formed in the roadbed, the drainage channels are arranged on the two sides of the foundation pit, drainage openings are formed in the drainage channels, and a plurality of water guide channels are formed in the bottom wall of the foundation pit; the two ends of the water guide channel communicate with the two drainage channels correspondingly, a water seepage layer is arranged in the foundation pit, and a supporting assembly used for supporting the water seepage layer is arranged in the foundation pit. The method has the effect of reducing accumulated water possibly existing on the urban road surface so as to improve the drainage efficiency of the urban road.

Owner:中泰建工(北京)建筑工程有限公司

Solder bump array probe tip structure for laser cleaning

InactiveUS20180059141A1Reduce the probability of accumulationEasy to cleanElectronic circuit testingElectrical measurement instrument detailsBall grid arrayLaser

A probe tip structure that decreases the accumulation rate of Sn particles to the probe tip and enables considerably more efficient and complete laser cleaning is disclosed. In an embodiment, the probe structure includes an array of probe tips, each probe tip having an inner core; an interfacial layer bonded to the inner core; and an outer layer bonded to the interfacial layer, wherein the outer layer is resistant to adherence of the solder of the ball grid array package.

Owner:INT BUSINESS MASCH CORP

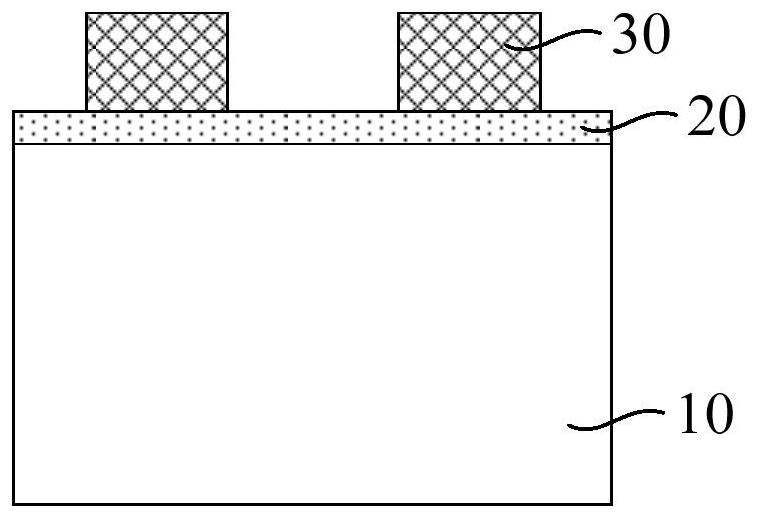

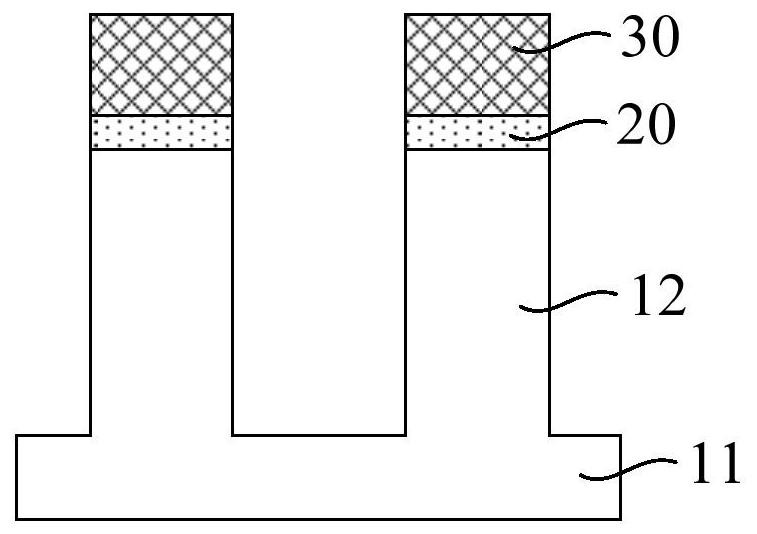

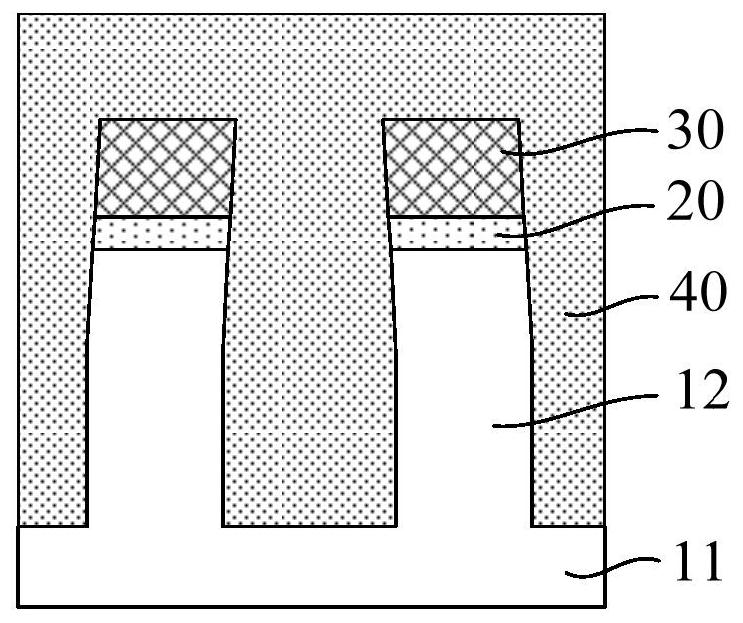

Semiconductor structure and forming method thereof

PendingCN113972169AReduce the probability of accumulationReduce extrusion pressureTransistorSolid-state devicesComposite materialStructural engineering

The invention discloses a semiconductor structure and a forming method thereof. The forming method comprises the steps of providing a substrate; forming a mask layer on the substrate; forming a compensation side wall on the side wall of the mask layer; etching the base by taking the mask layer and the compensation side wall as masks to form a substrate and fin parts protruding out of the substrate; removing the compensation side wall; and after the compensation side wall is removed, forming an isolation layer covering part of the side wall of the fin part on the substrate exposed out of the fin part. After the fin parts are formed, the compensation side walls are removed, then the isolation layer is formed, the process of forming the isolation layer comprises the step of filling the space between the fin parts with the isolation material layer, the size of the top opening of the opening defined by the mask layer, the fin parts and the substrate is large by removing the compensation side walls, and therefore in the process of depositing the isolation material layer, the bottom of the opening is easily filled with the isolation material layer, so the probability of accumulation of the isolation material layer at the top of the fin part is reduced, the extrusion force of the isolation material layer on the fin part is reduced, the problem of fin part bending is improved, and the performance of the semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com