Patents

Literature

10970results about "Tunnels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

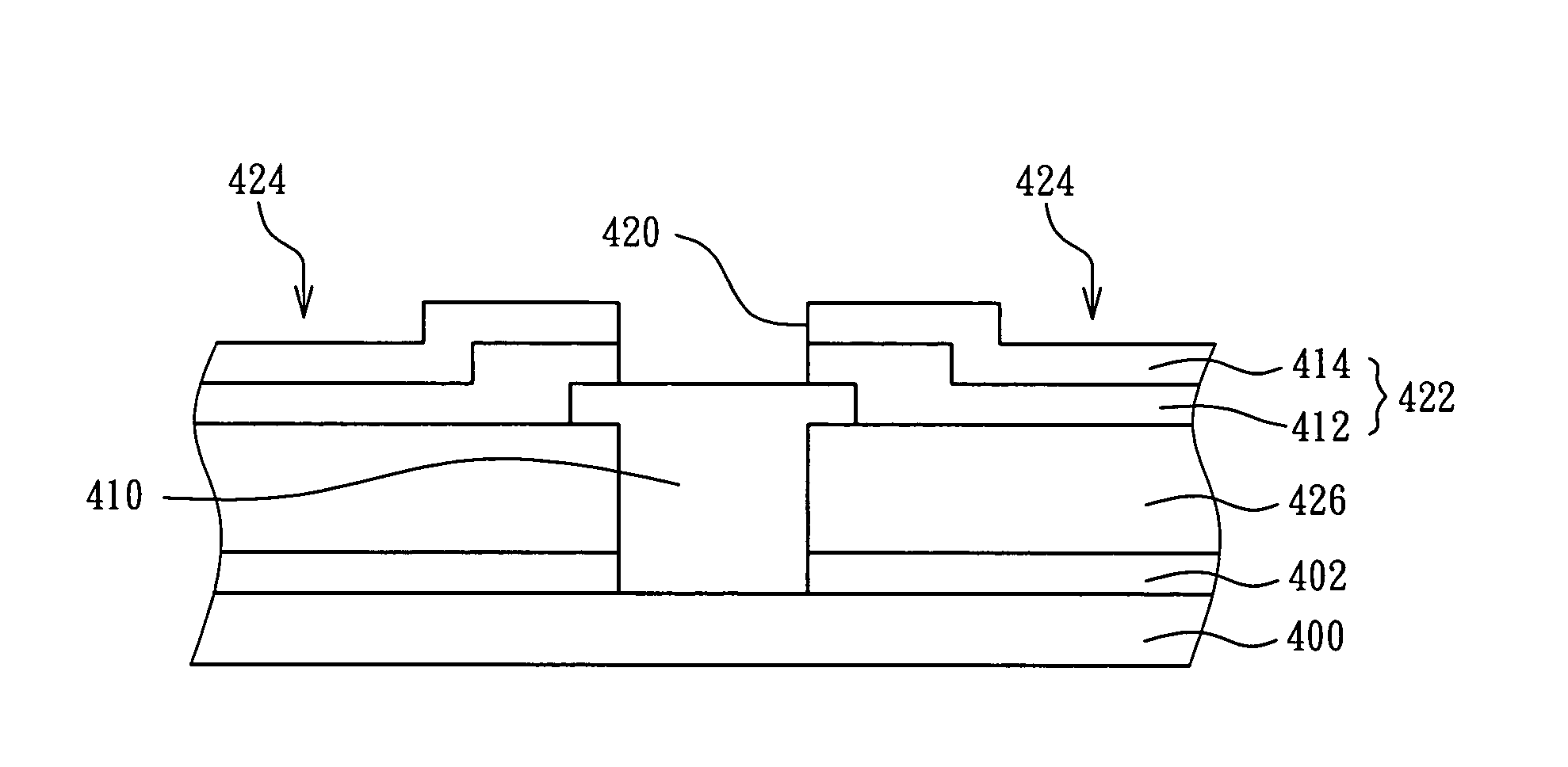

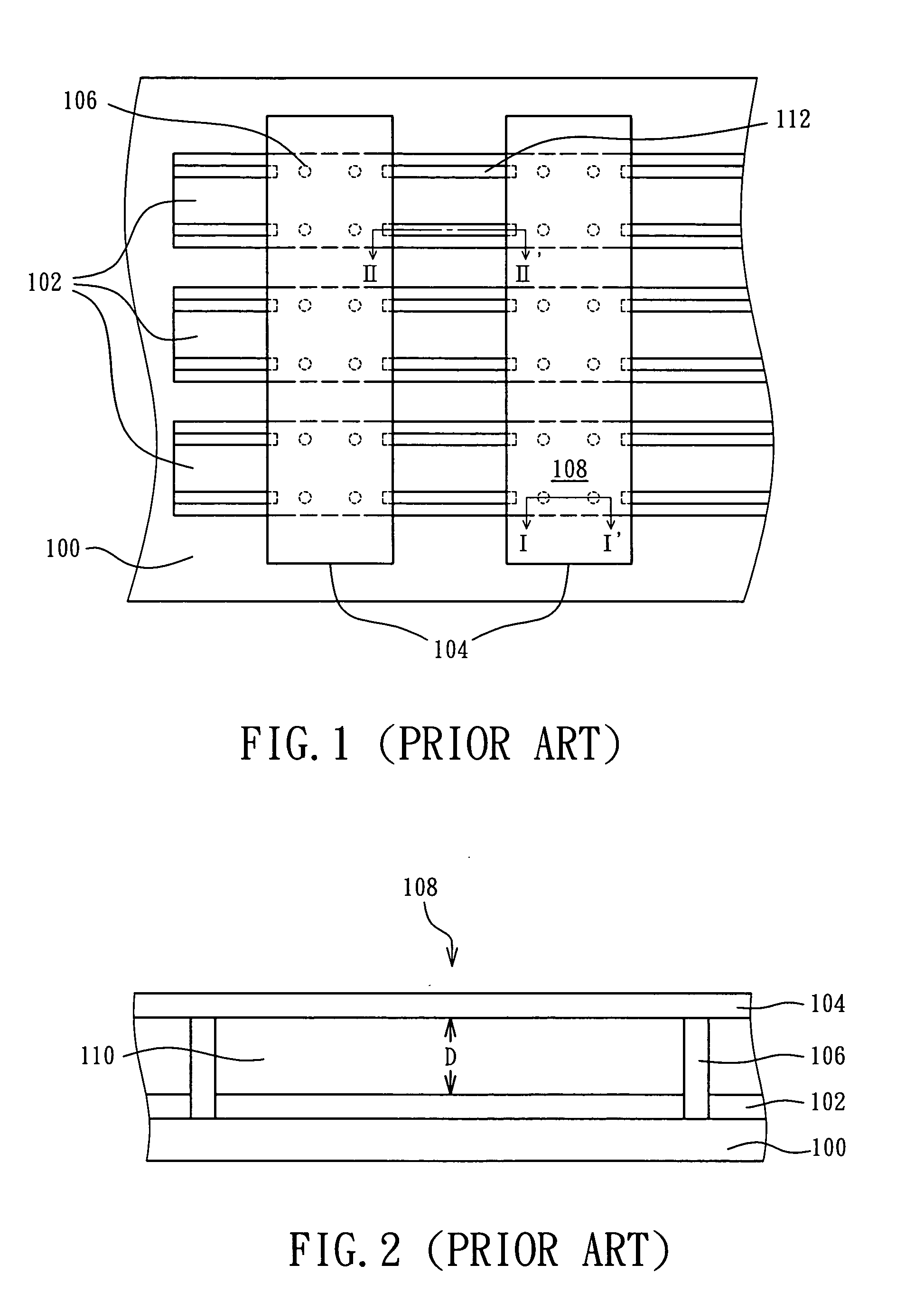

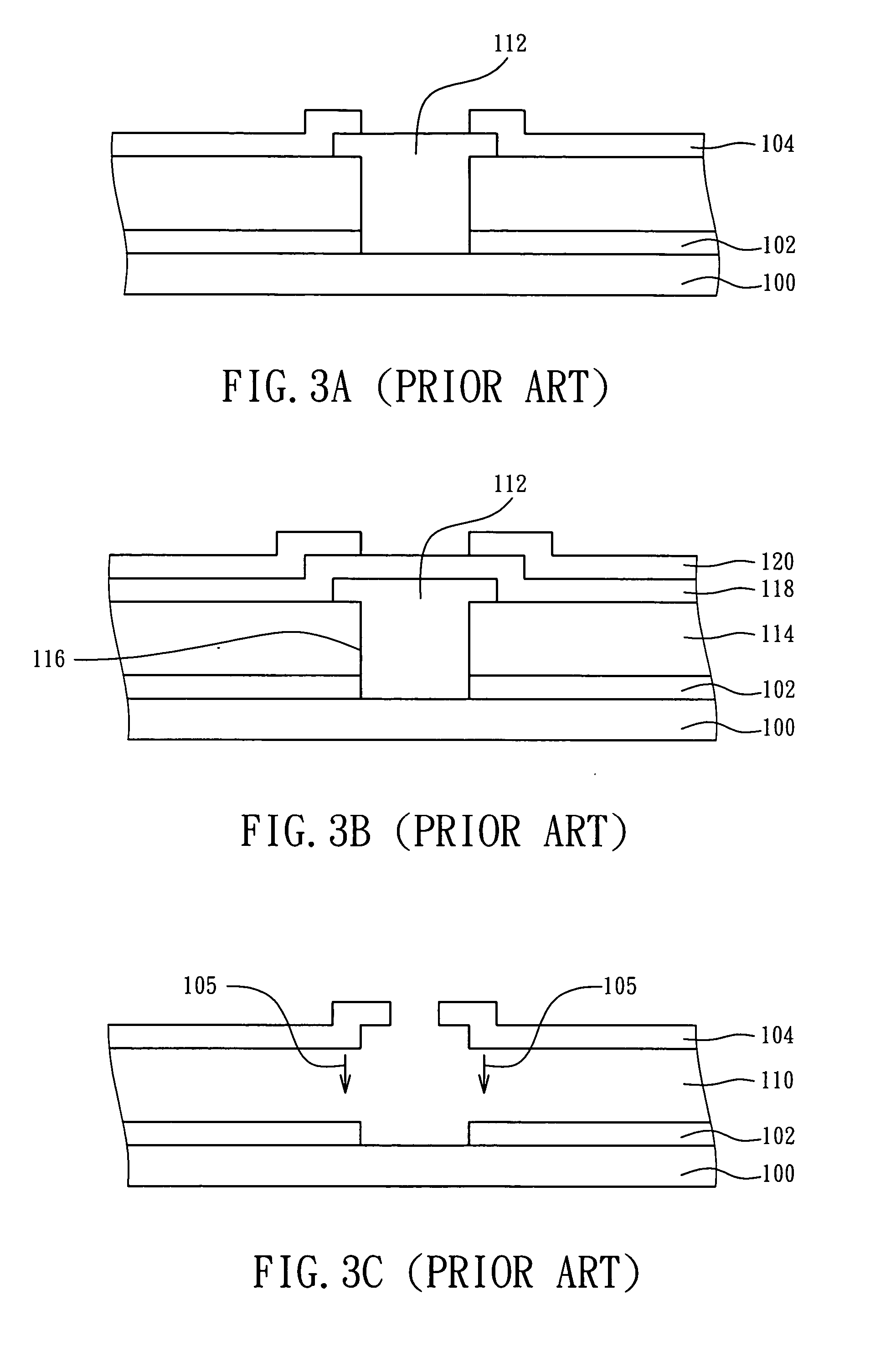

Interference display cell and fabrication method thereof

InactiveUS20050046948A1High resolutionSimple and easy manufacturing processVehicle fittings for liftingItem transportation vehiclesConductive materialsEngineering

An optical interference display unit with a first electrode, a second electrode and support structures located between the two electrodes is provided. The second electrode has at least a first material layer and a second material layer. At least one material layer of the two is made from conductive material and the second conductive layer is used as a mask while an etching process is performed to etch the first material layer to define the second electrode.

Owner:SNAPTRACK

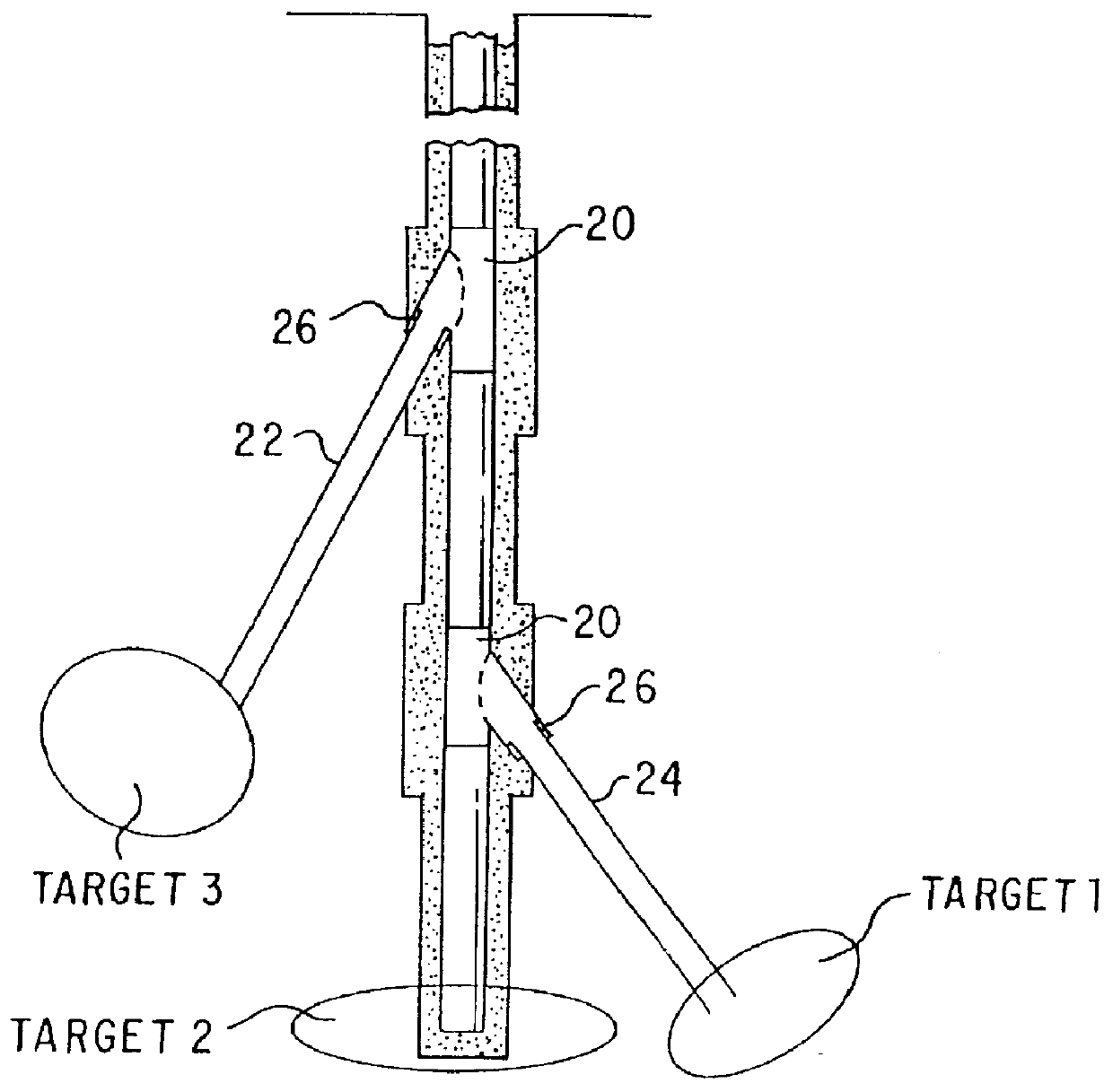

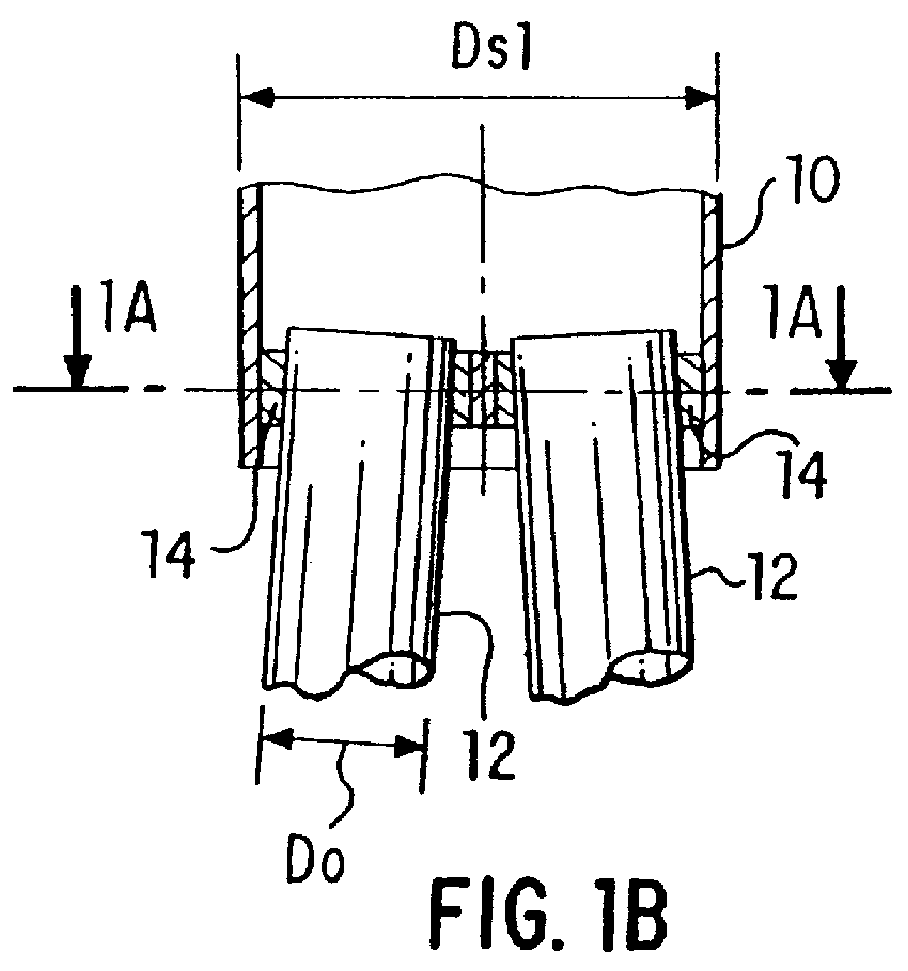

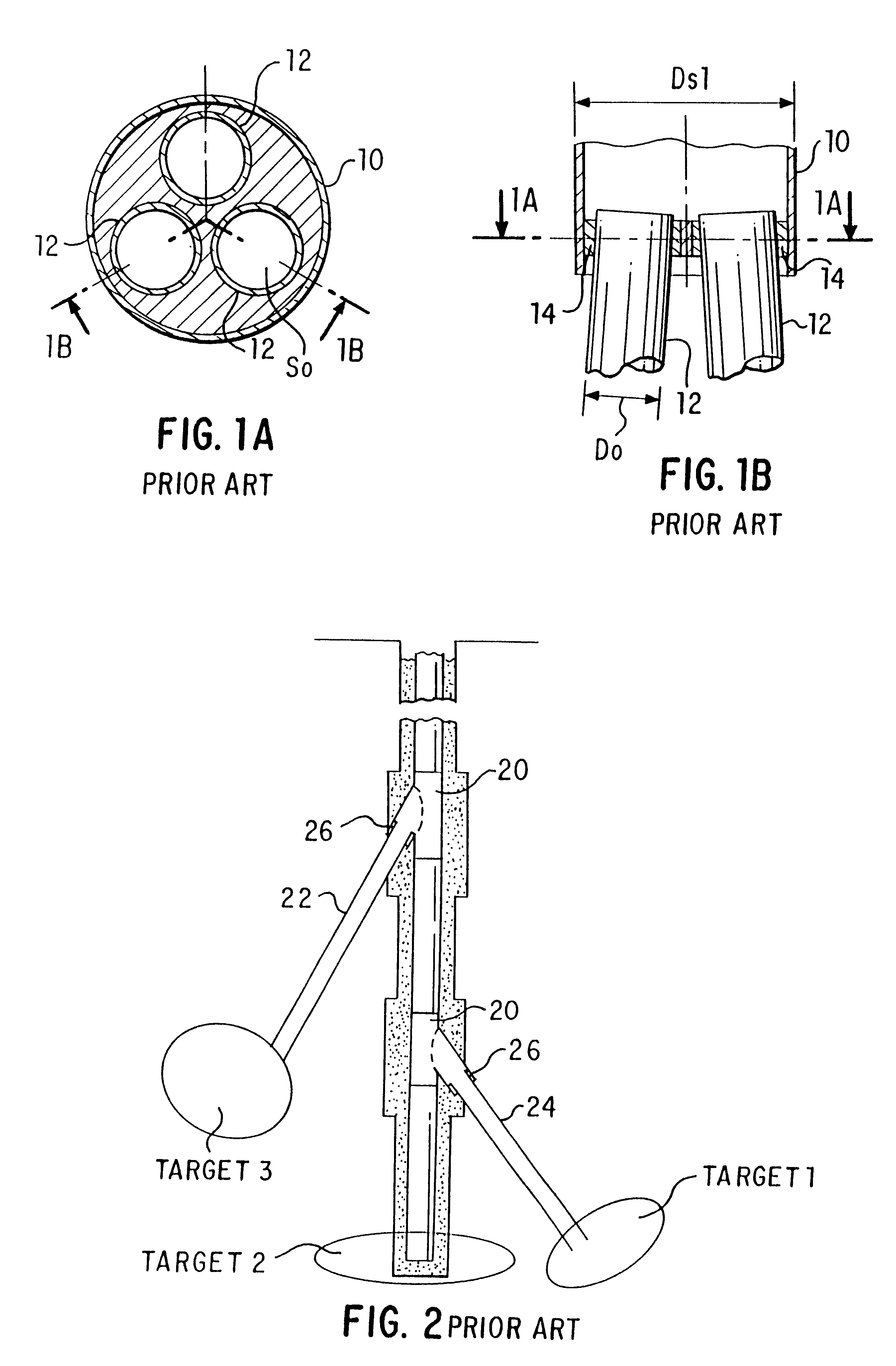

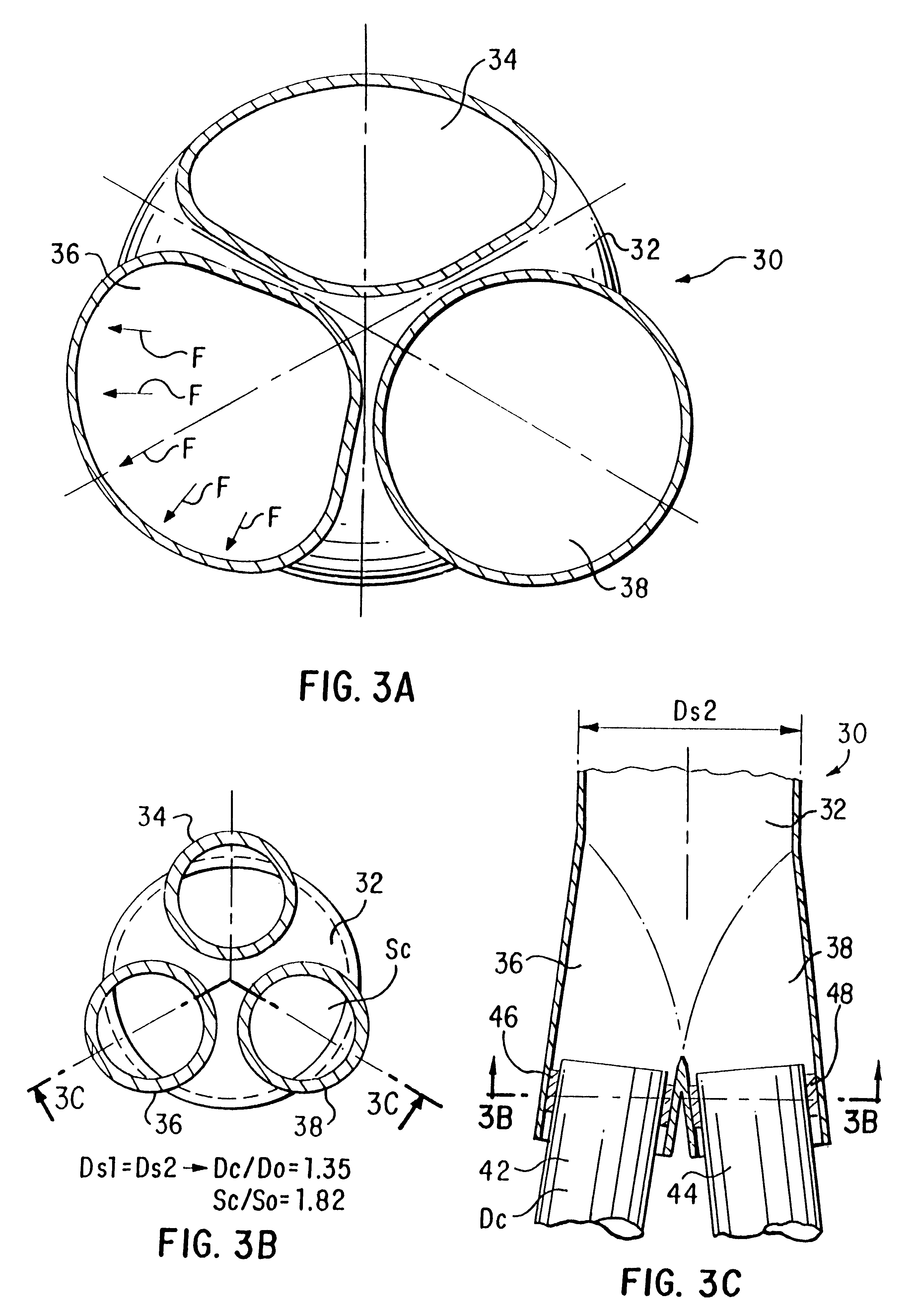

Method for establishing branch wells at a node of a parent well

InactiveUS6079495AOptimized areaFluid communicationDrilling rodsConstructionsEngineeringMechanical engineering

A method for creating multiple branch wells from a parent well is disclosed. A multiple branching sub is provided for placement at a branching node of a well. Such sub includes a branching chamber and a plurality of branching outlet members. The outlet members during construction of the branching sub, have previously been distorted into oblong shapes so that all of the branching outlet members fit within an imaginary cylinder which is coaxial with and substantially the same radius as the branching chamber. After deployment of the branching sub via a parent casing in the well, a forming tool is lowered to the interior of the sub. The outlet members are extended outwardly by the forming tool and simultaneously formed into substantially round tubes. Next, each outlet member is plugged with cement, after which each branch well is drilled through a respective outlet member. If desired, each branch may be lined with casing and sealed to a branching outlet by means of a casing hanger. A manifold placed in the branching chamber controls the production of each branch well to the parent well.

Owner:SCHLUMBERGER TECH CORP

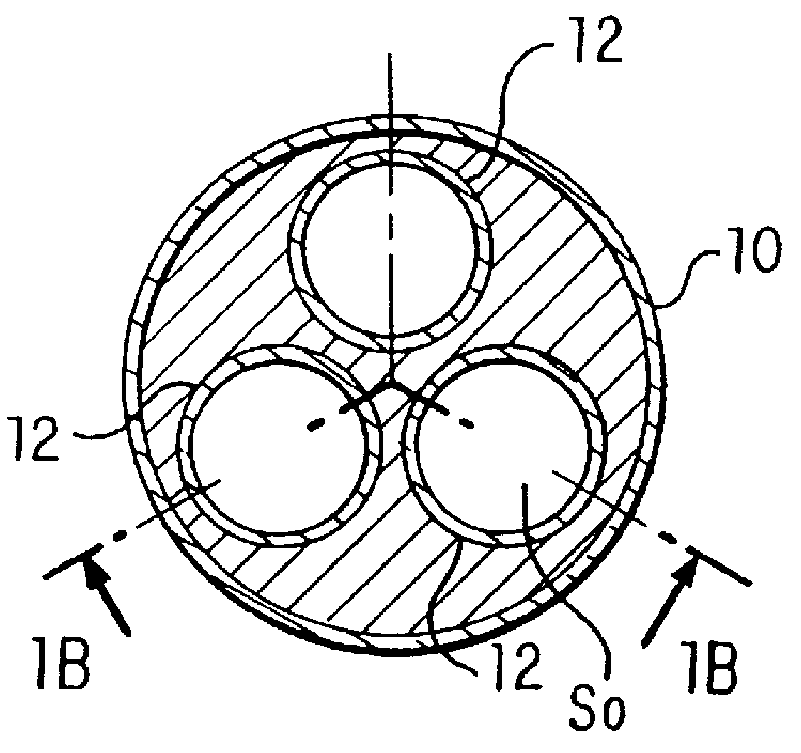

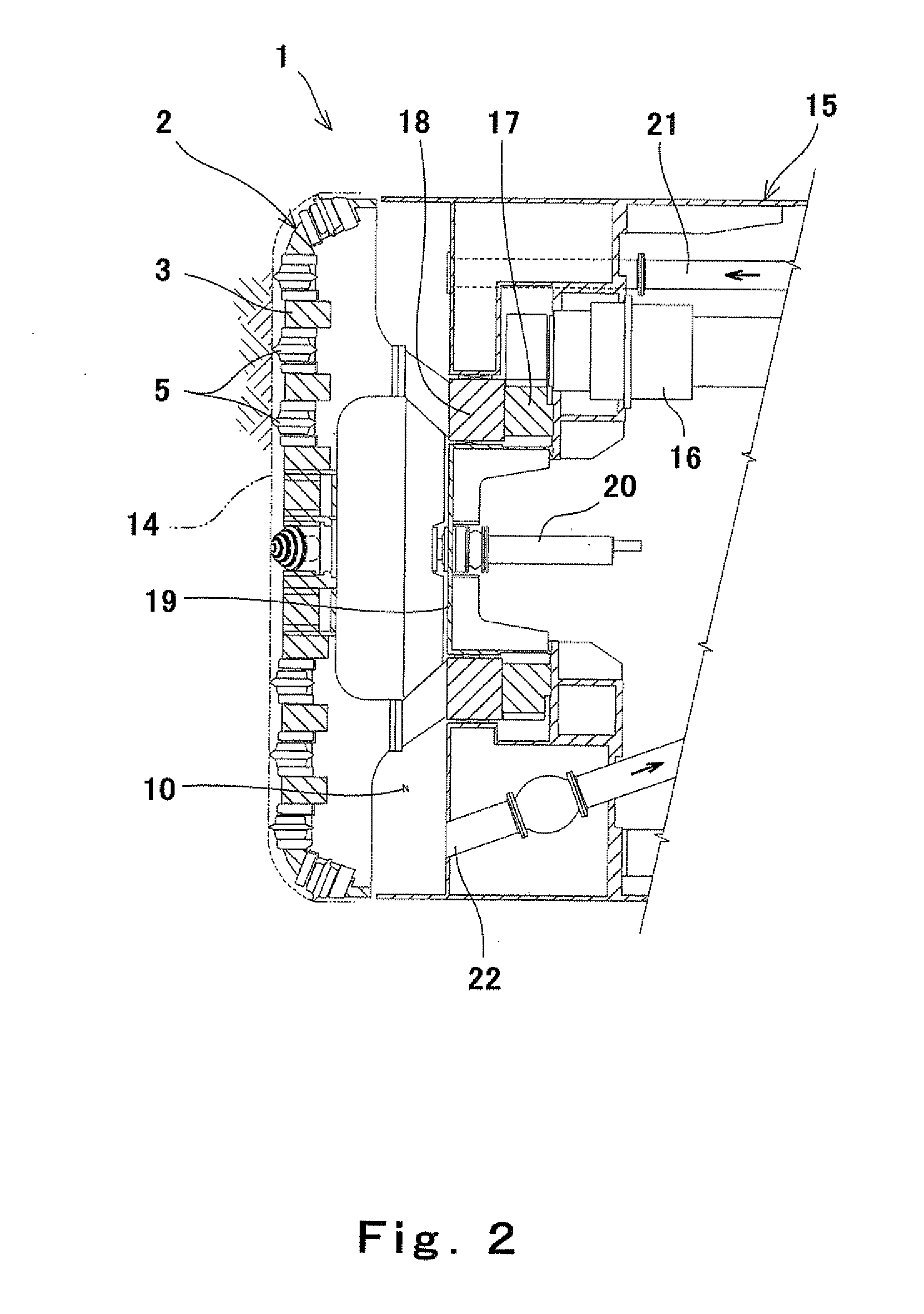

Abrasion detecting apparatus detecting abrasion of component of cutter head and tunnel boring machine including abrasion detecting apparatus

ActiveUS20110031017A1Efficient executionLabor savingEarth drilling toolsSurveyTunnel boring machineEngineering

An abrasion detecting apparatus is configured to detect an abrasion of a component of a cutter head of a tunnel boring machine configured to excavate a ground using a cutter to bore a tunnel, the abrasion detecting apparatus including: an abrasion detection probe located rearward of a front end of the cutter by a certain distance and located forward or rearward of a front end of a component, whose abrasion needs to be detected, of the cutter head by a certain distance, the abrasion detection probe including an abrasion detecting portion at a front end portion thereof, the abrasion detecting portion abrading away by contact with the ground to be excavated; and a detecting device configured to detect an abrasion of the abrasion detecting portion.

Owner:UNDERGROUND INFRASTRUCTURE TECH CORP

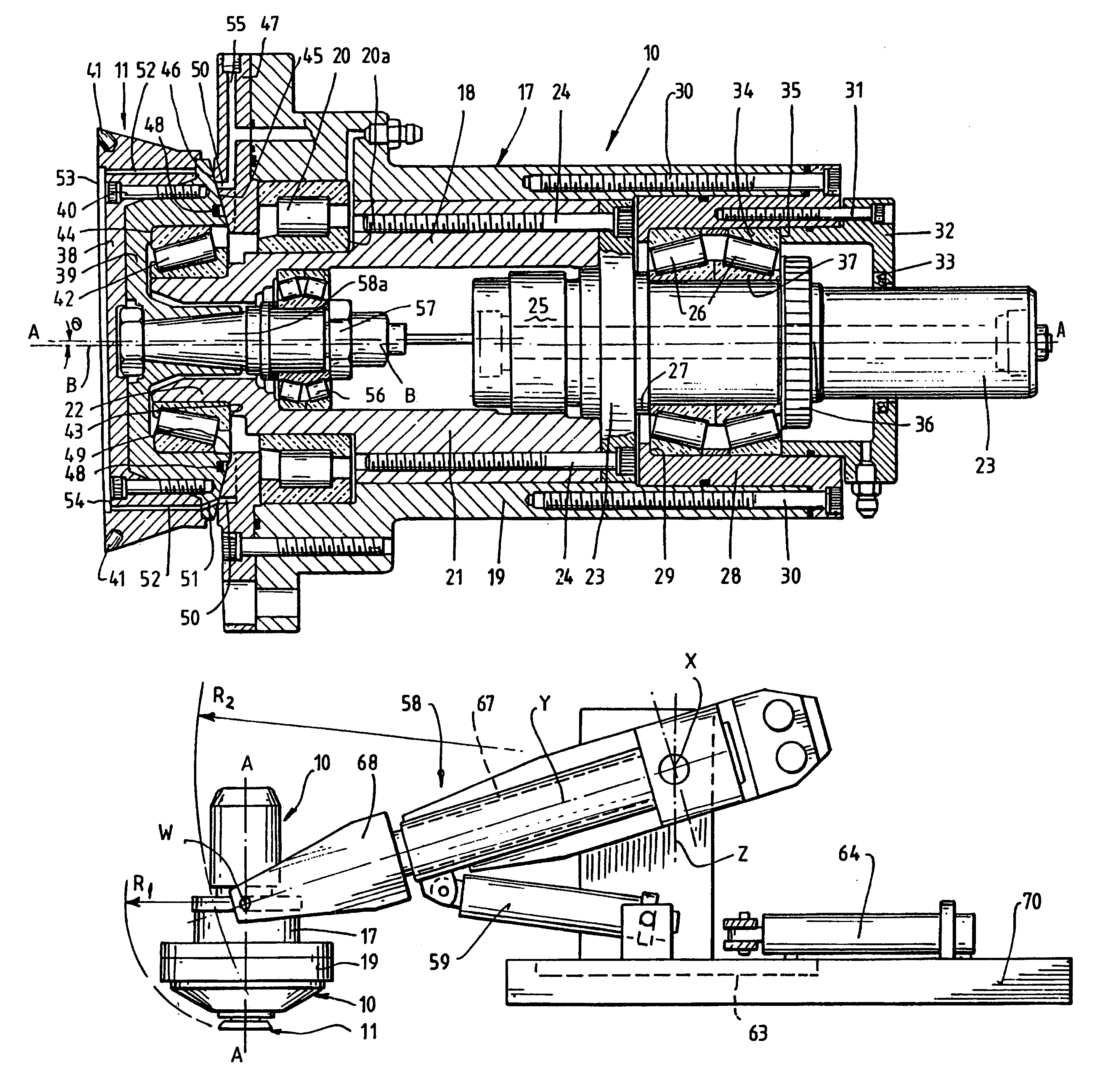

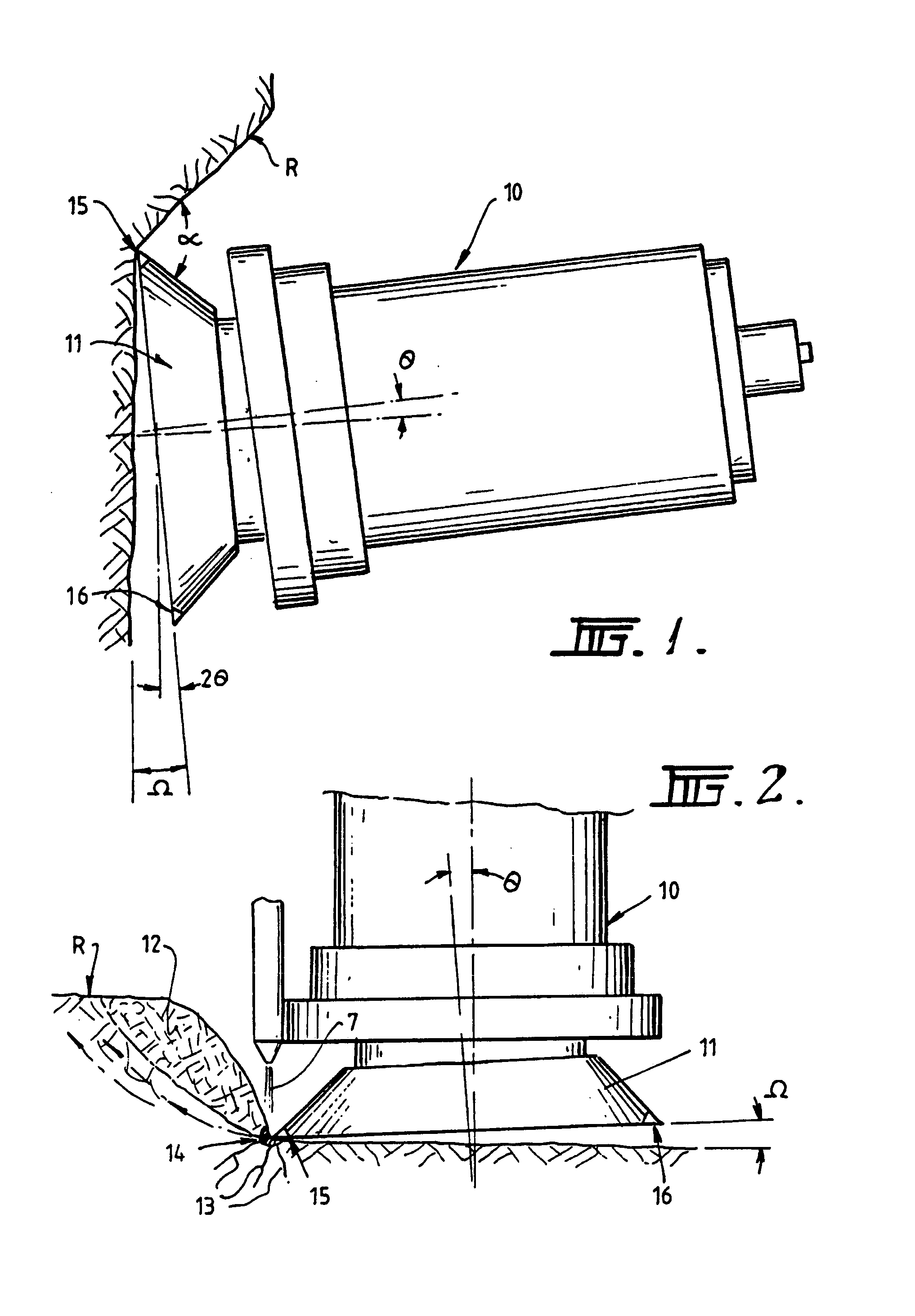

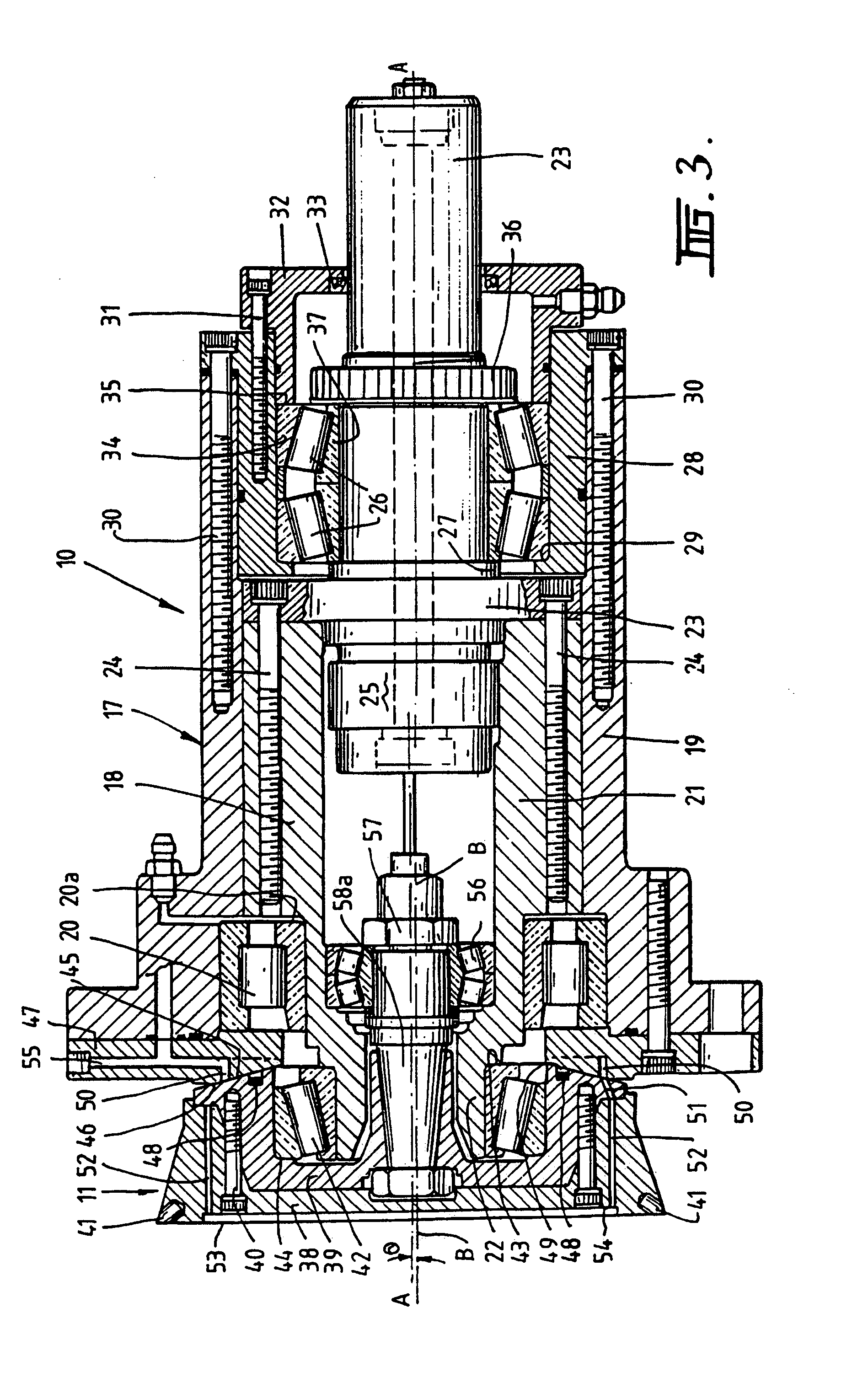

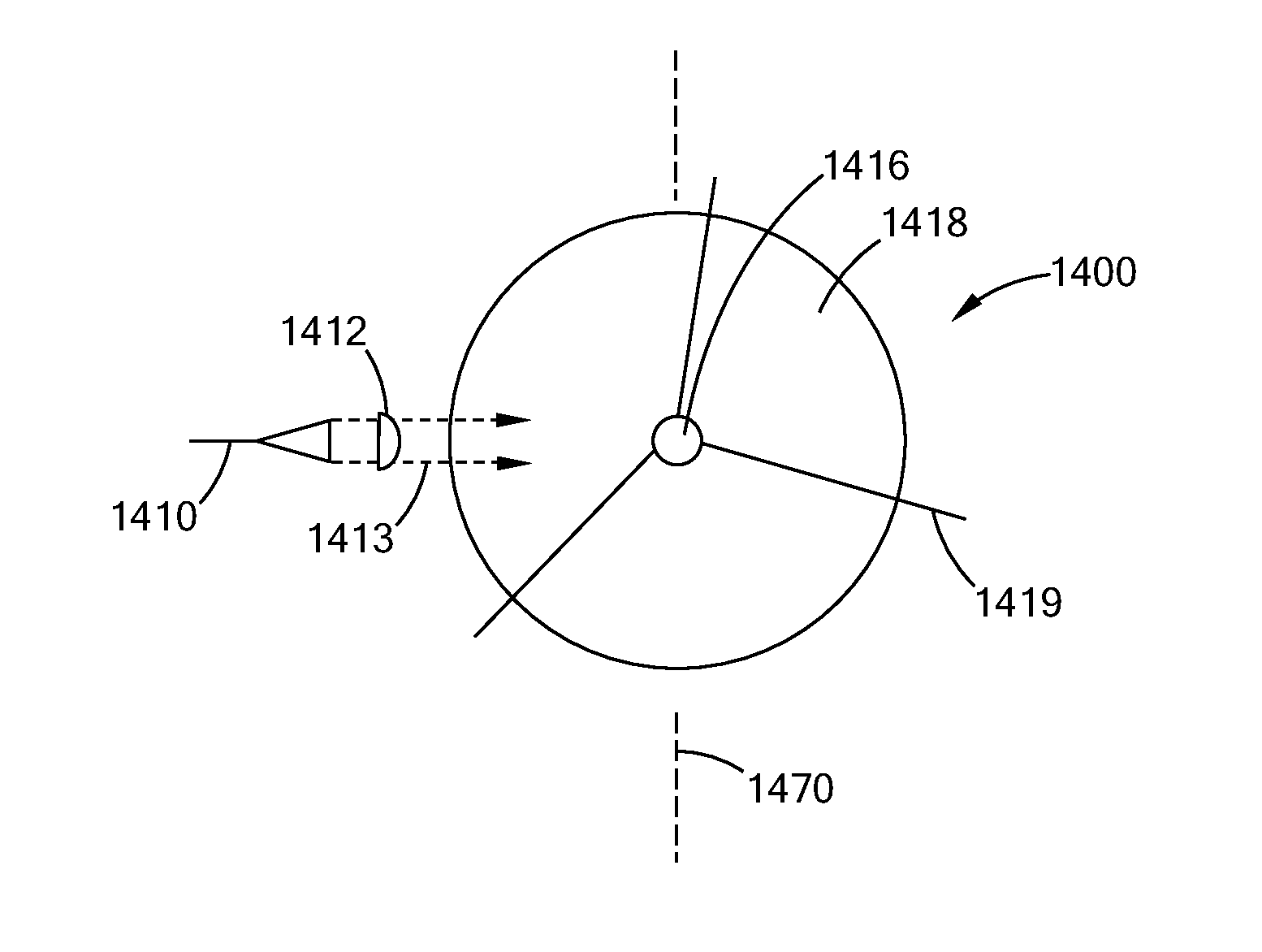

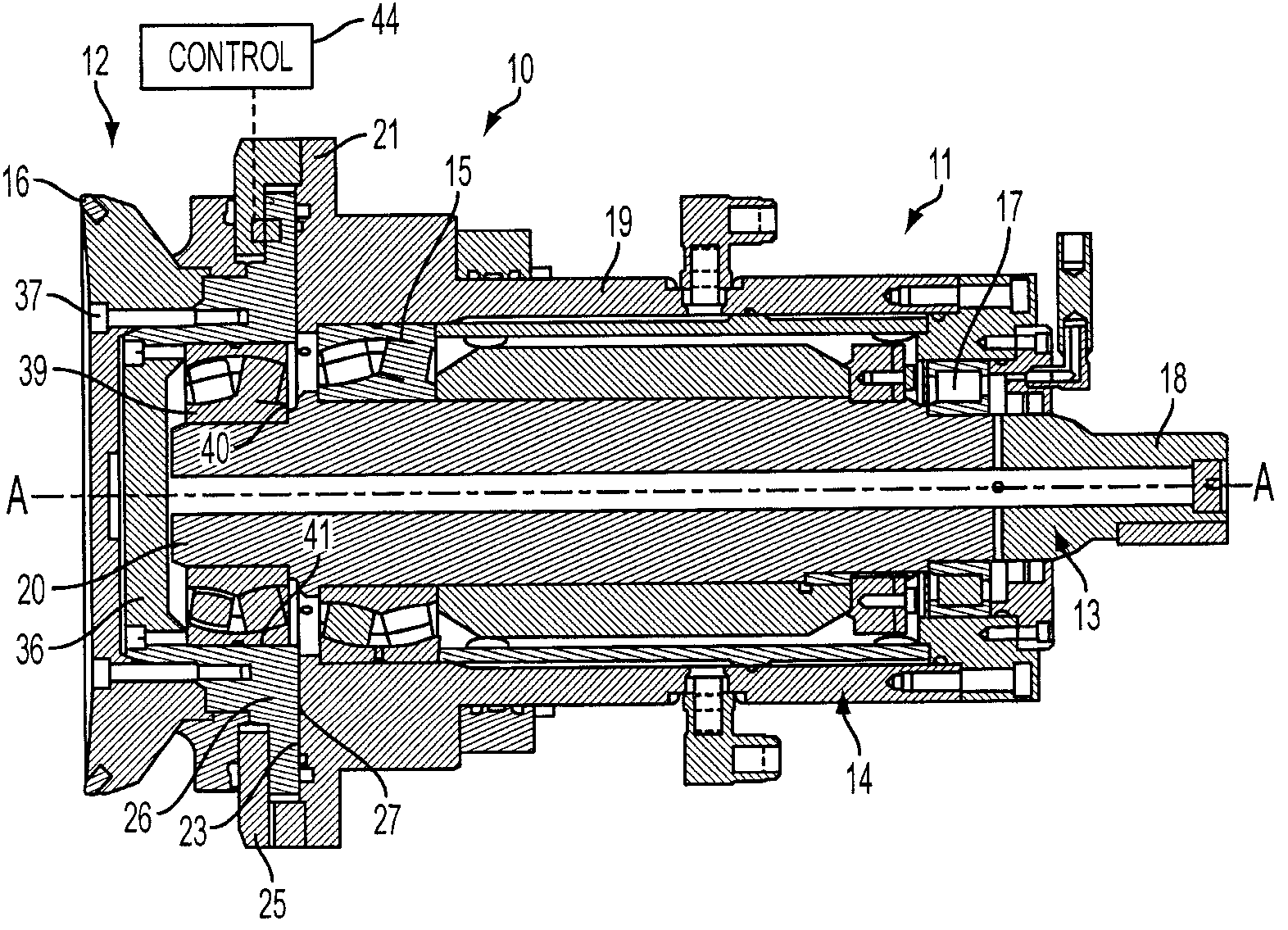

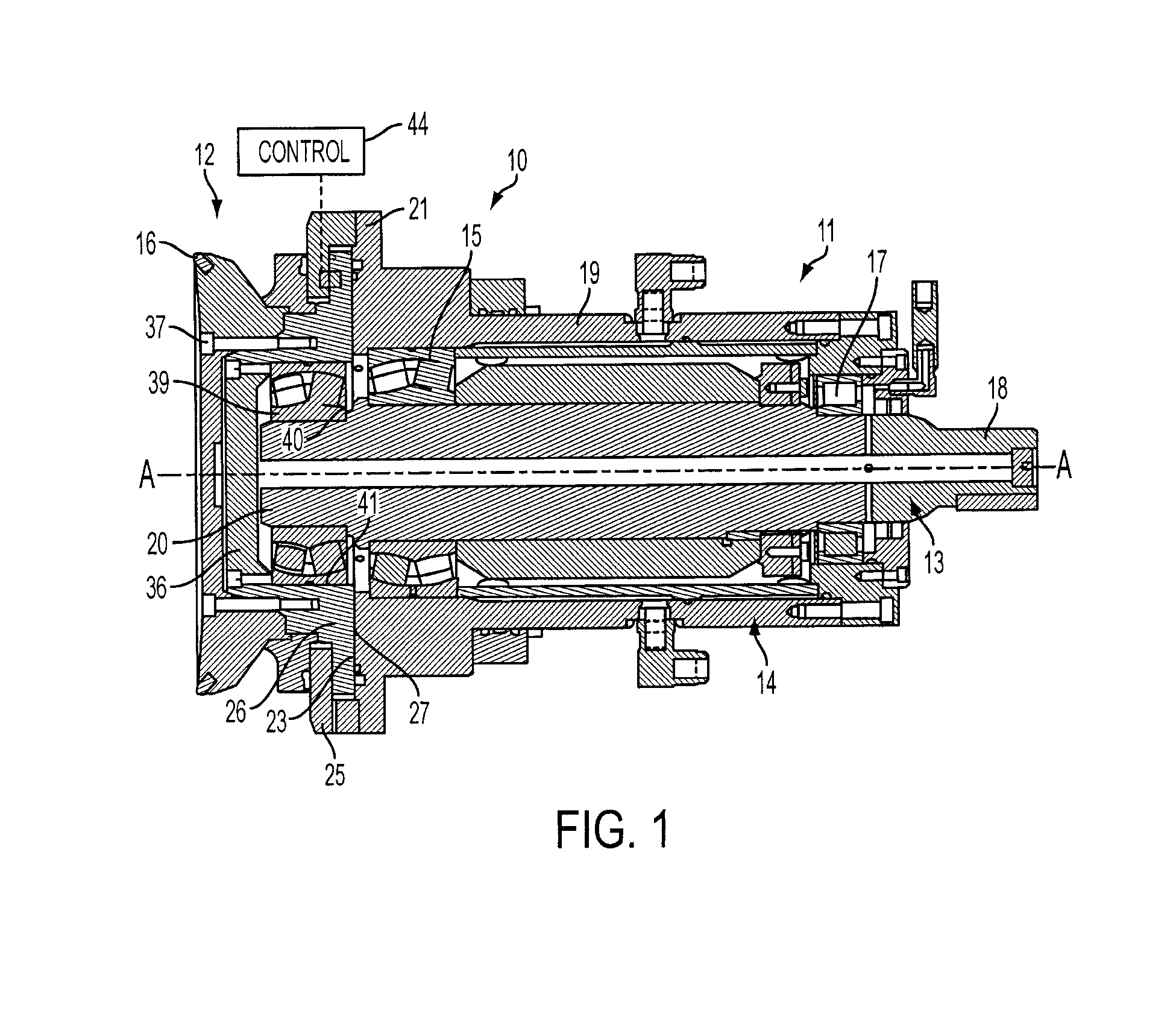

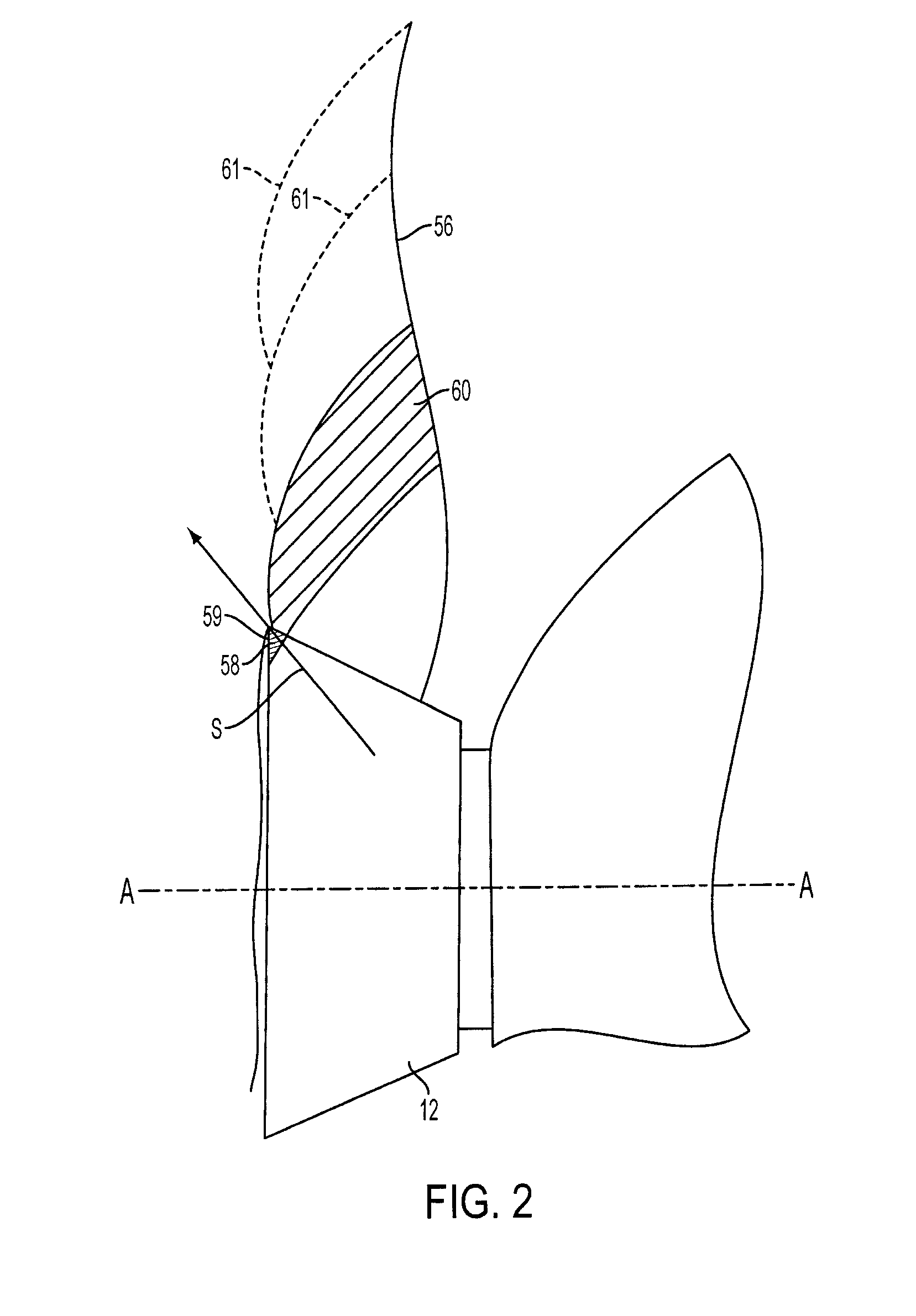

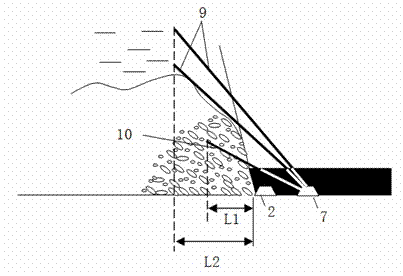

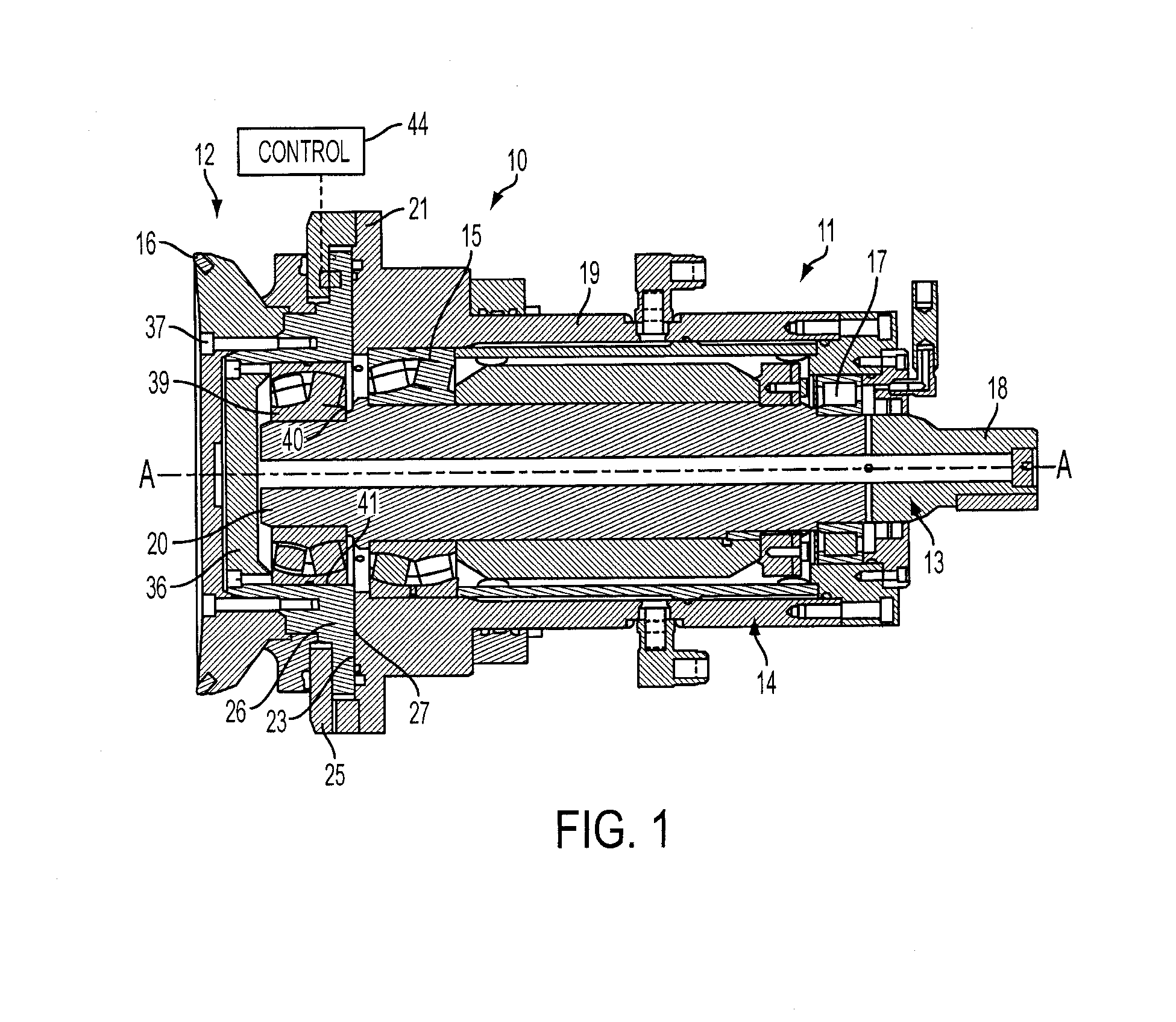

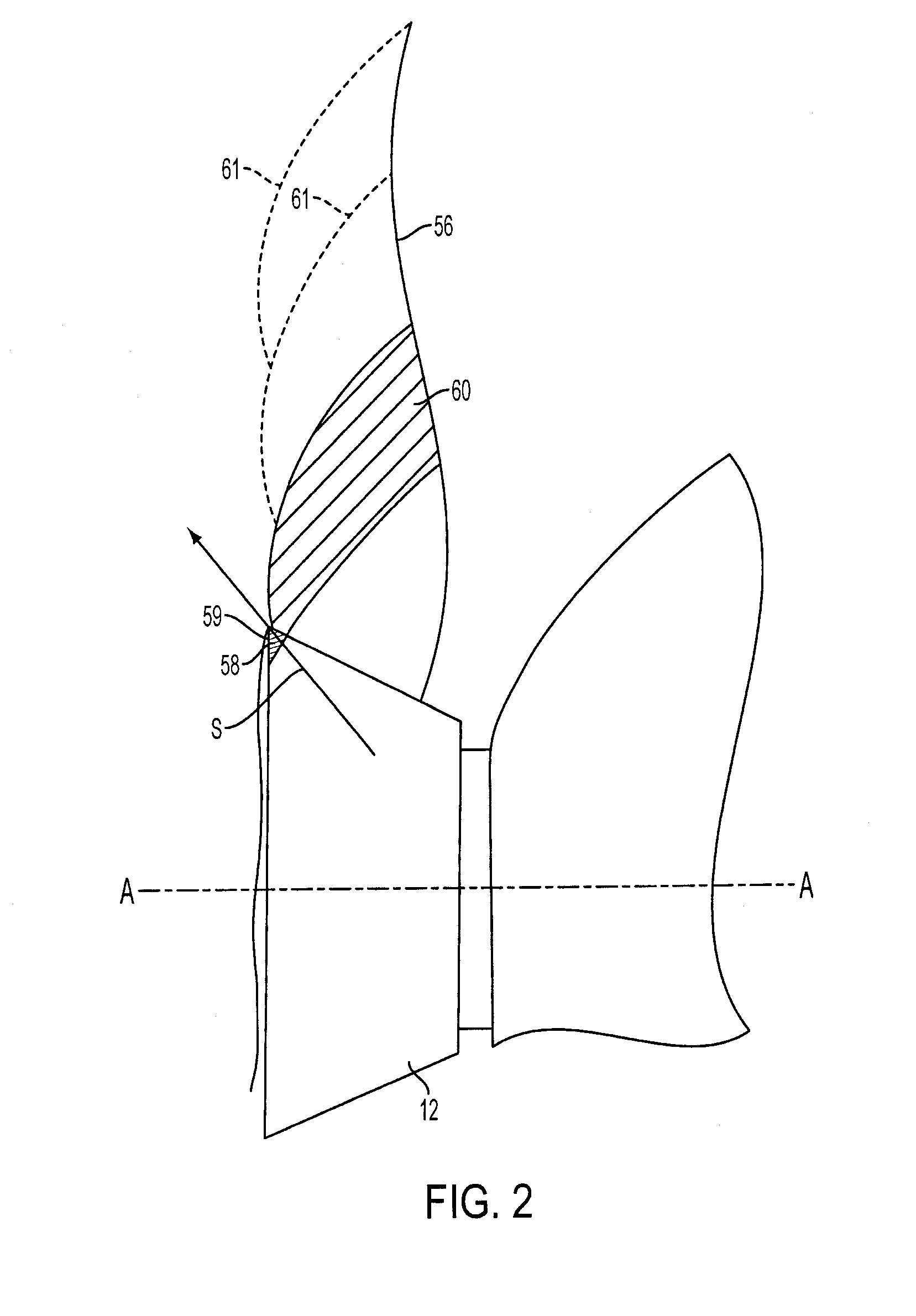

Rock boring device with an oscillating and nutating rotary disc cutter

InactiveUS7182407B1Cheap manufacturingGuaranteed economical operationTunnelsCutting machinesEngineeringDisc cutter

A rock boring device (10) including a rotary disc cutter (11). The disc cutter (11) is driven in an oscillating manner and also driven or free to nutate, and the device includes a mounting section (22) for the rotary disc cutter and a driven section (21), and wherein the mounting section (22) is angularly offset from the axis of the driven section whereby the rotary disc cutter will both oscillate and nutate.

Owner:ODYSSEY TECH

High power laser tunneling mining and construction equipment and methods of use

ActiveUS20140231398A1Underground miningWelding/cutting auxillary devicesHigh power lasersEngineering

There are provided high power laser and laser mechanical earth removing equipment, and operations using laser cutting tools having stand off distances. These equipment provide high power laser beams, greater than 1 kW to cut and volumetrically remove targeted materials and to remove laser affected material with gravity assistance, mechanical cutters, fluid jets, scrapers and wheels. There is also provided a method of using this equipment in mining, road resurfacing and other earth removing or working activities.

Owner:FORO ENERGY

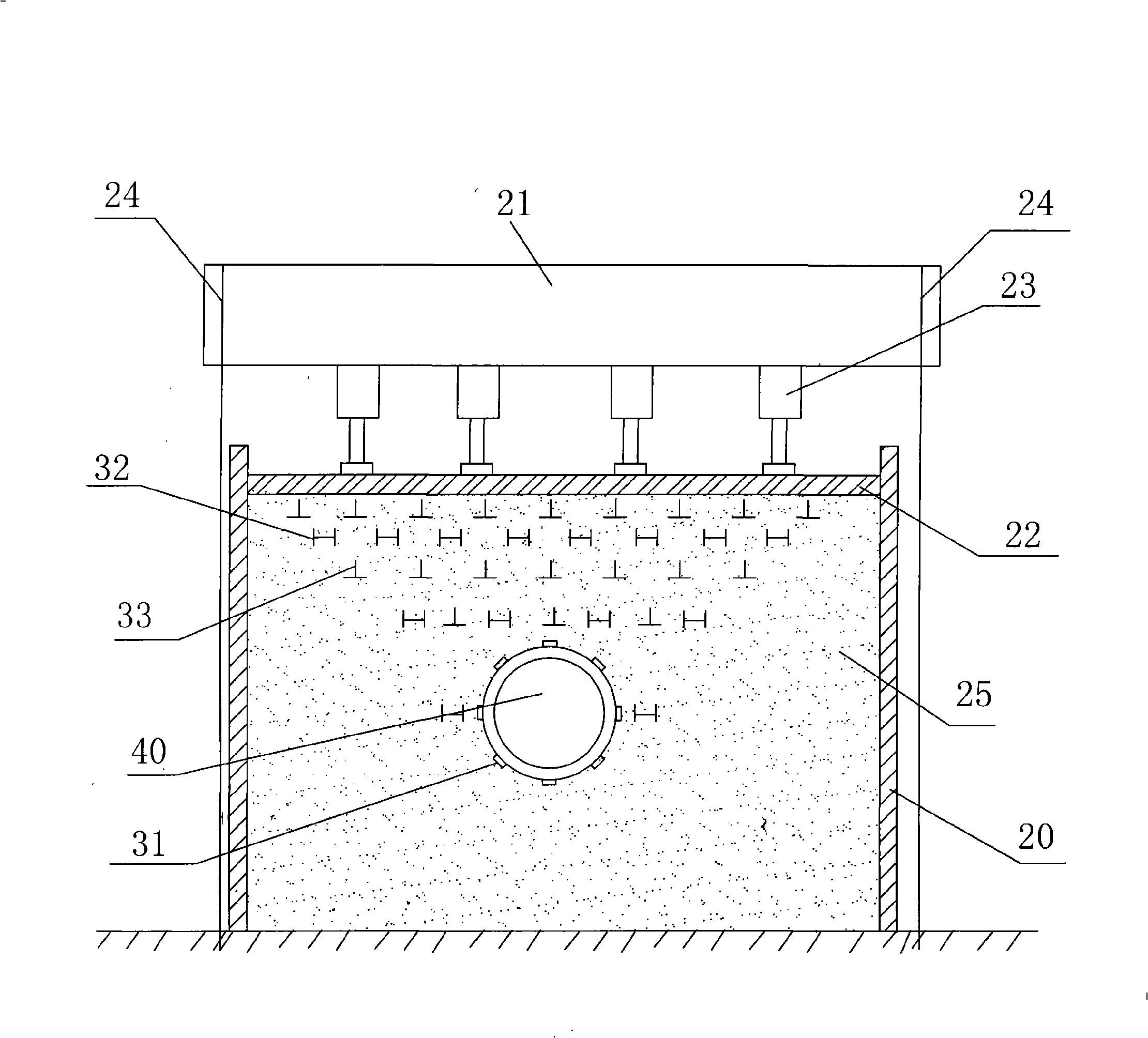

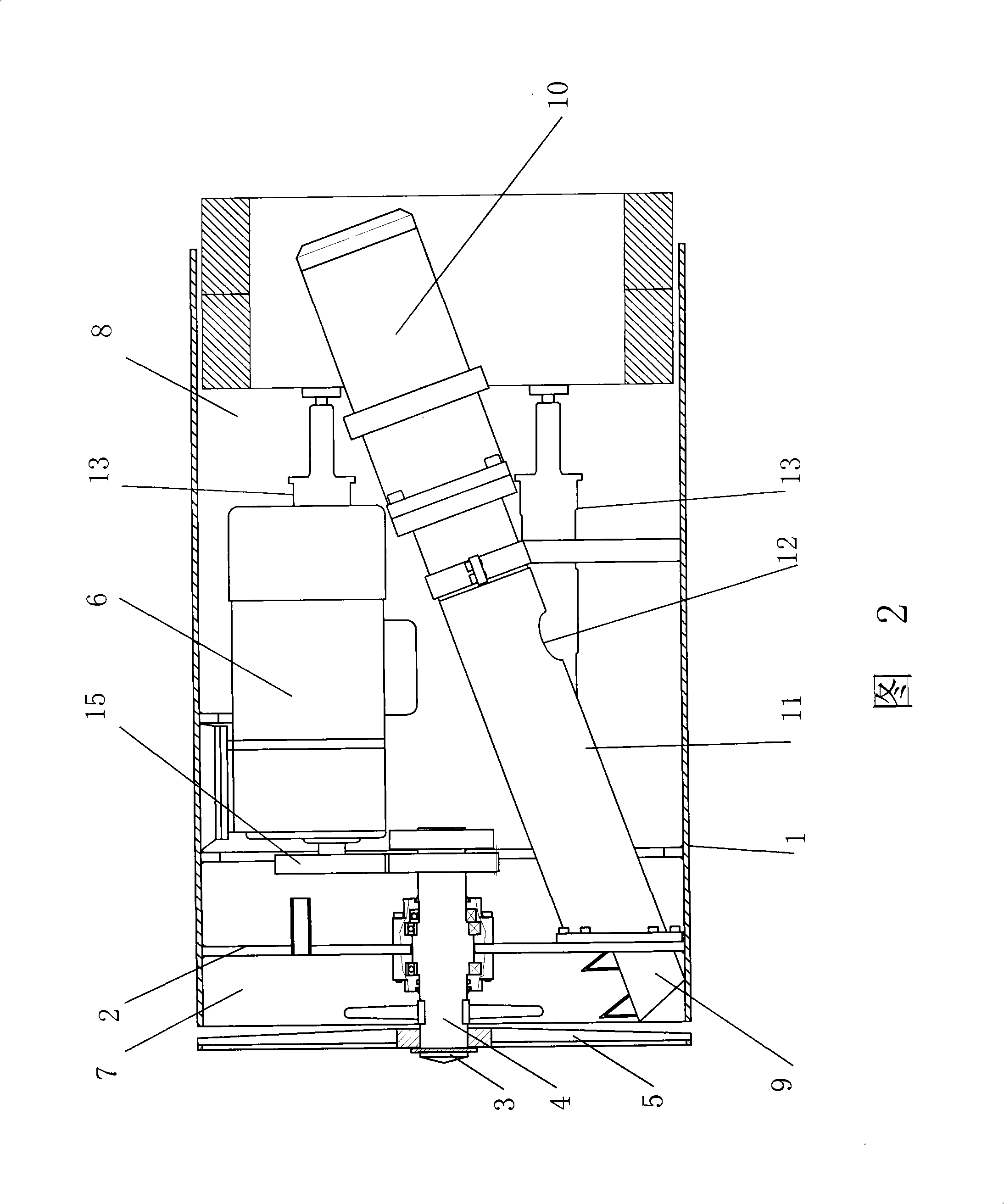

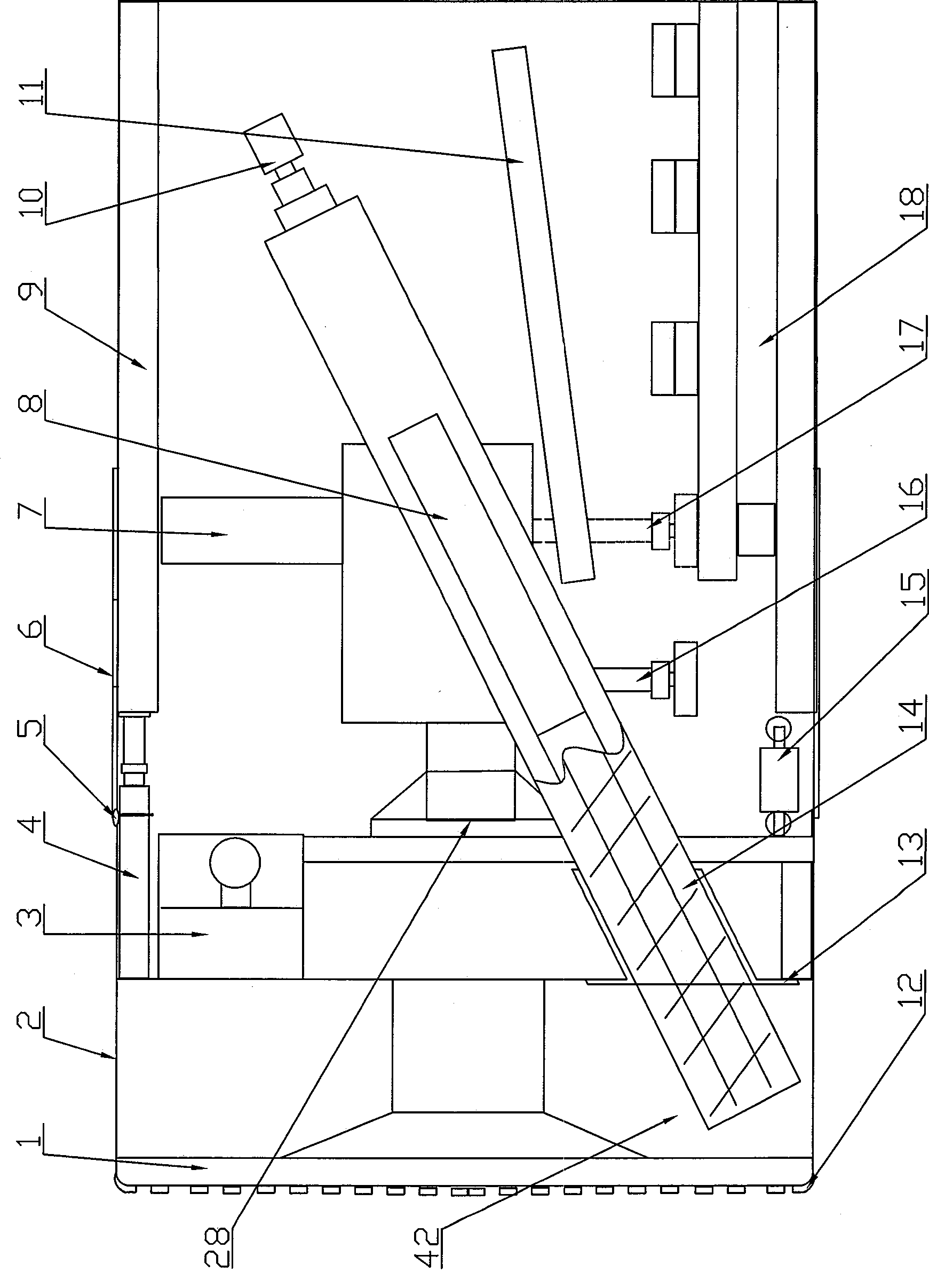

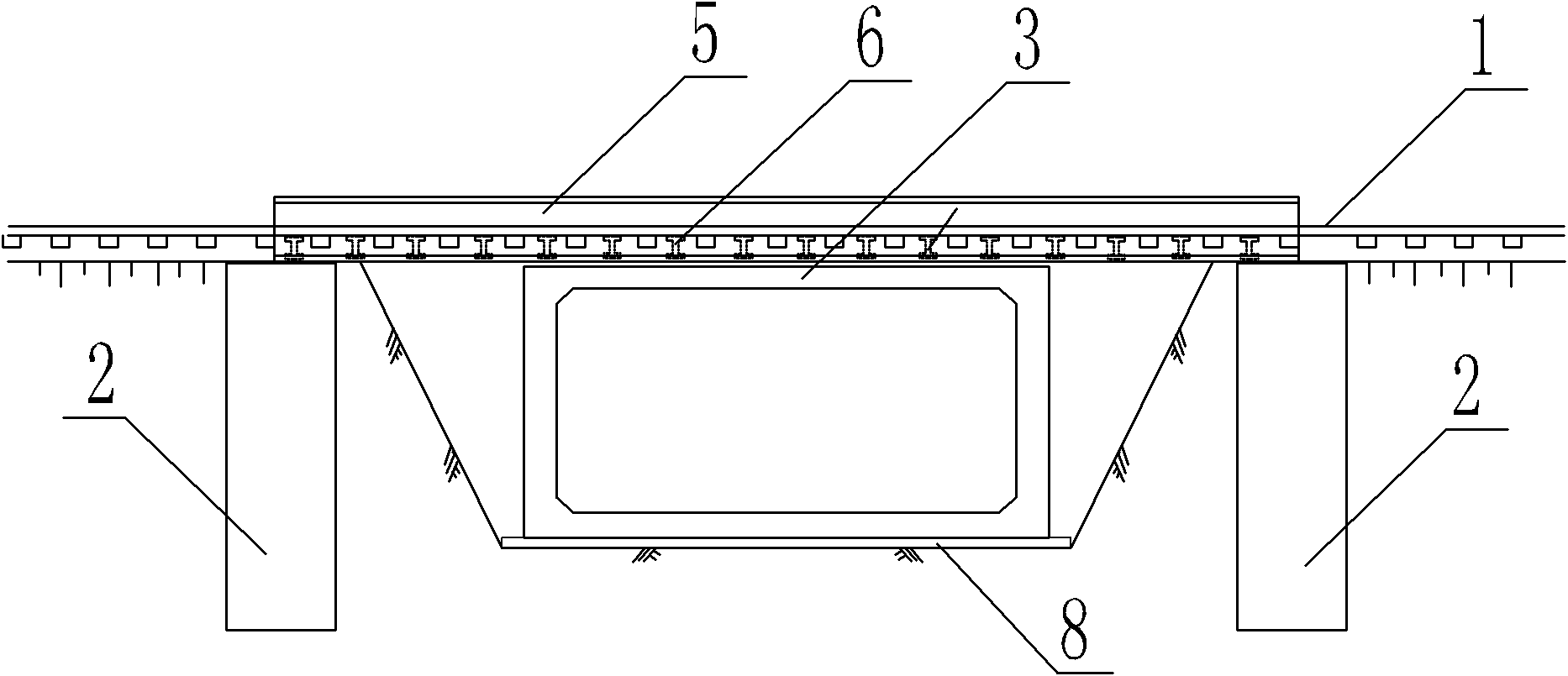

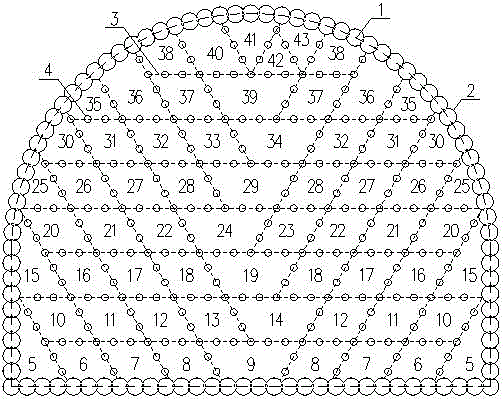

Soil pressure balancing type tunnel shielding simulation experiment system

ActiveCN101403306AEfficient constructionConstruction safetyEducational modelsTunnelsElectricityGrating

The invention relates to a soil pressure balance type tunnel shield analog experiment system, a rectangular soil coelom with the upper part provided with an opening is internally provided with a shield machine model and filled with a simulated soil body, the axle wire of the shield machine model is overlapped with that of the soil coelom; the upper surface of the simulated soil body is covered with a layer of concrete cushion the upper surface of which is connected with a horizontal loading beam by more than two soil pressure jacks, the horizontal loading beam is connected with the bottom of the soil coelom by an anchor rope; and the simulated soil body is also internally embedded with a soil pressure box, a grating fiber optical sensor and a displacement meter, wherein, the soil pressure box, the grating fiber optical sensor and the displacement meter are all electrically connected with a data acquisition and processing device. The system can simulate the influence of shield tunnel construction between subways of cities on the stratum and surrounding environment more conveniently, actually and effectively, and provide more actual and accurate experimental data for tunnel construction and design so as to guarantee the high-efficiency and safety of the shield tunnel construction of cities.

Owner:SOUTHWEST JIAOTONG UNIV

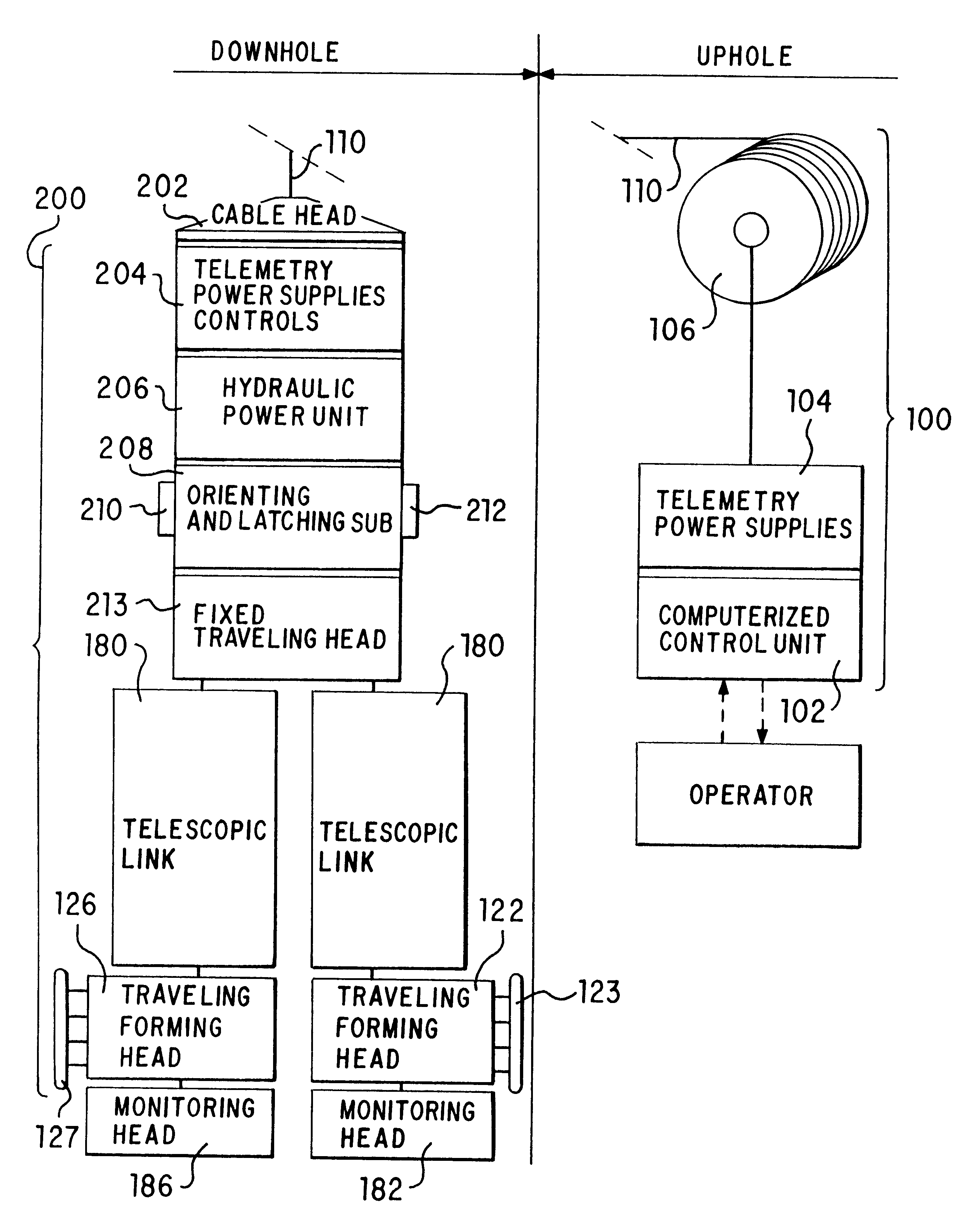

Apparatus for establishing branch wells at a node of a parent well

InactiveUS6170571B1Optimized areaFluid communicationDrilling rodsConstructionsEngineeringMechanical engineering

A method and apparatus for creating multiple branch wells from a parent well is disclosed. A multiple branching sub is provided for placement at a branching node of a well. Such sub includes a branching chamber and a plurality of branching outlet members. The outlet members during construction of the branching sub, have previously been distorted into oblong shapes so that all of the branching outlet members fit within an imaginary cylinder which is coaxial with and substantially the same radius as the branching chamber. After deployment of the branching sub via a parent casing in the well, a forming tool is lowered to the interior of the sub. The outlet members are extended outwardly by the forming tool and simultaneously formed into substantially round tubes. Next, each outlet member is plugged with cement, after which each branch well is drilled through a respective outlet member. If desired, each branch may be lined with casing and sealed to a branching outlet by means of a casing hanger. A manifold placed in the branching chamber controls the production of each branch well to the parent well.

Owner:SCHLUMBERGER TECH CORP

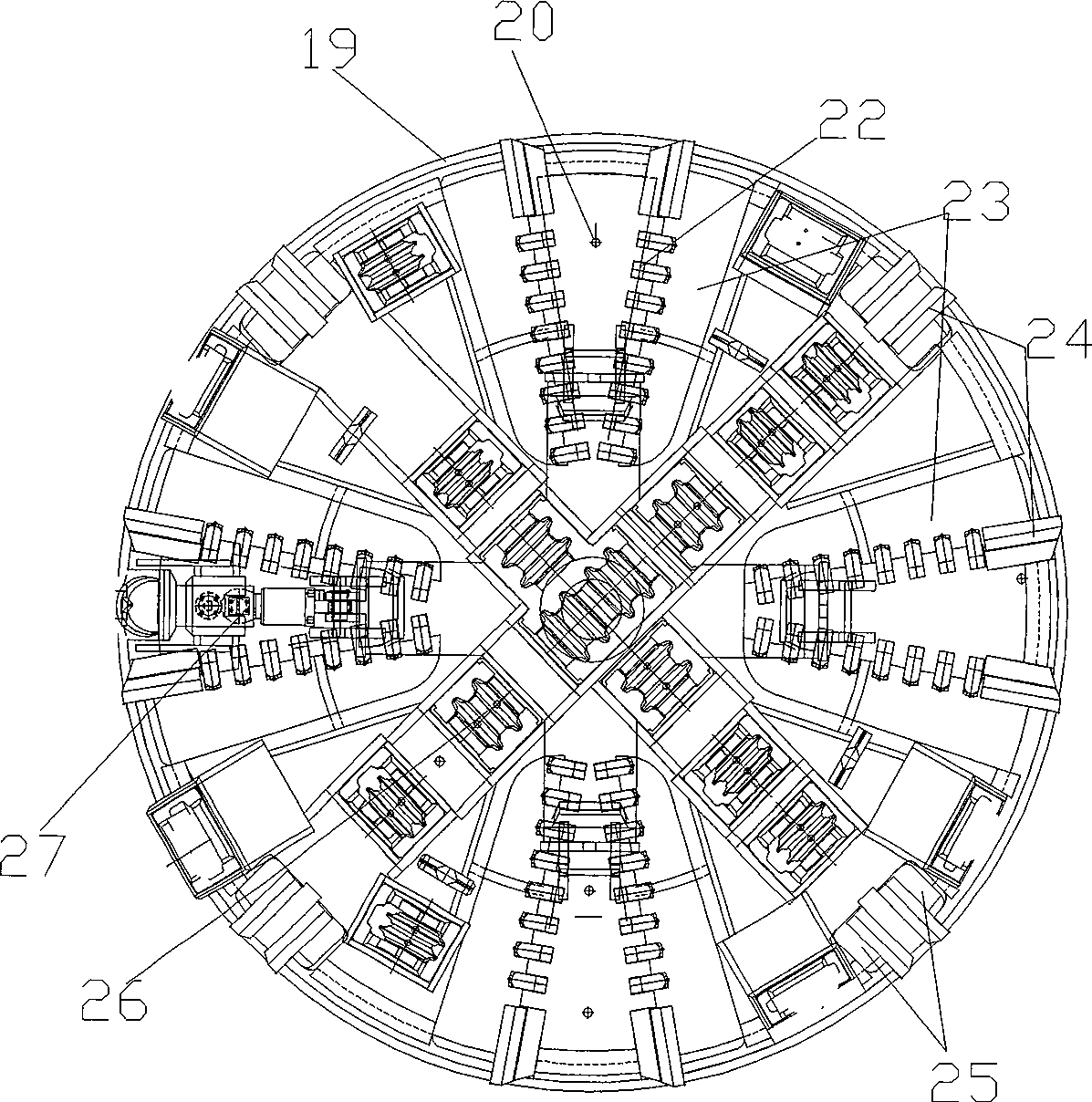

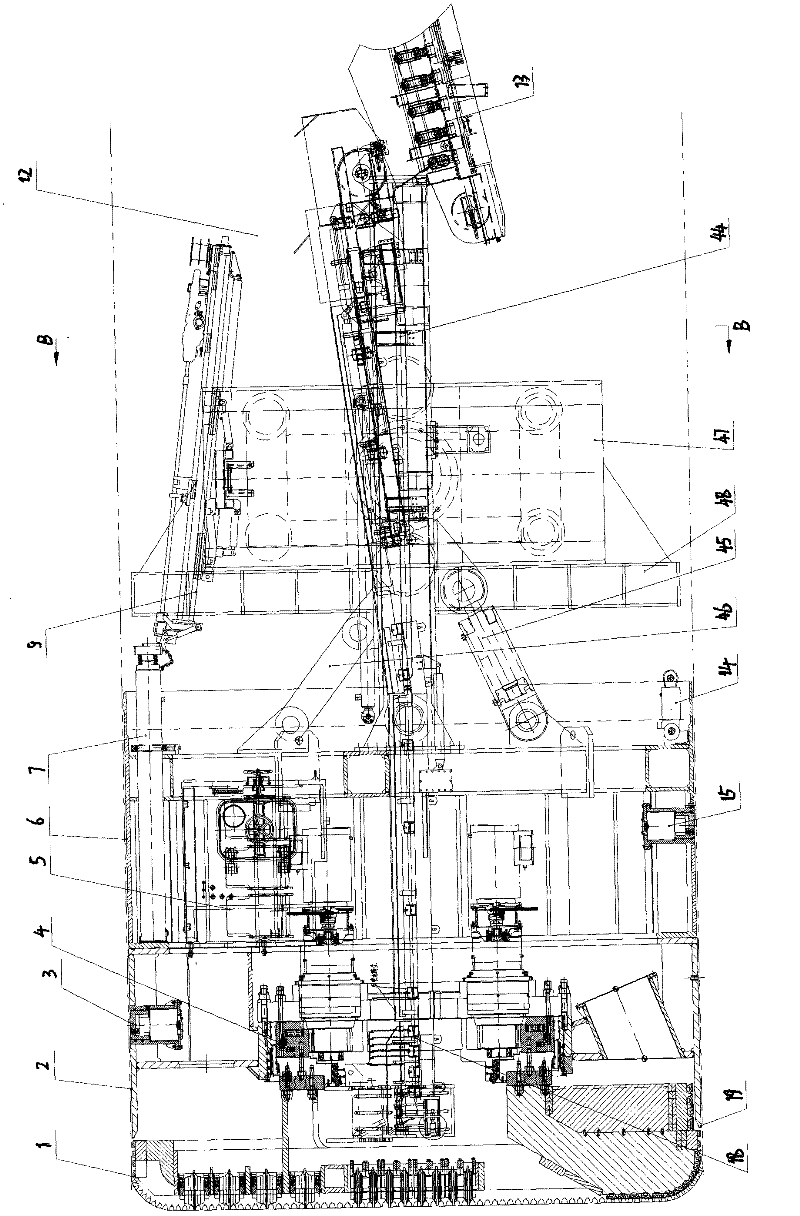

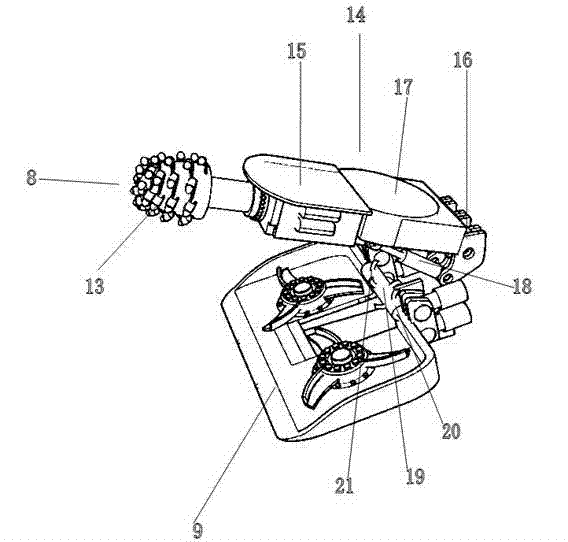

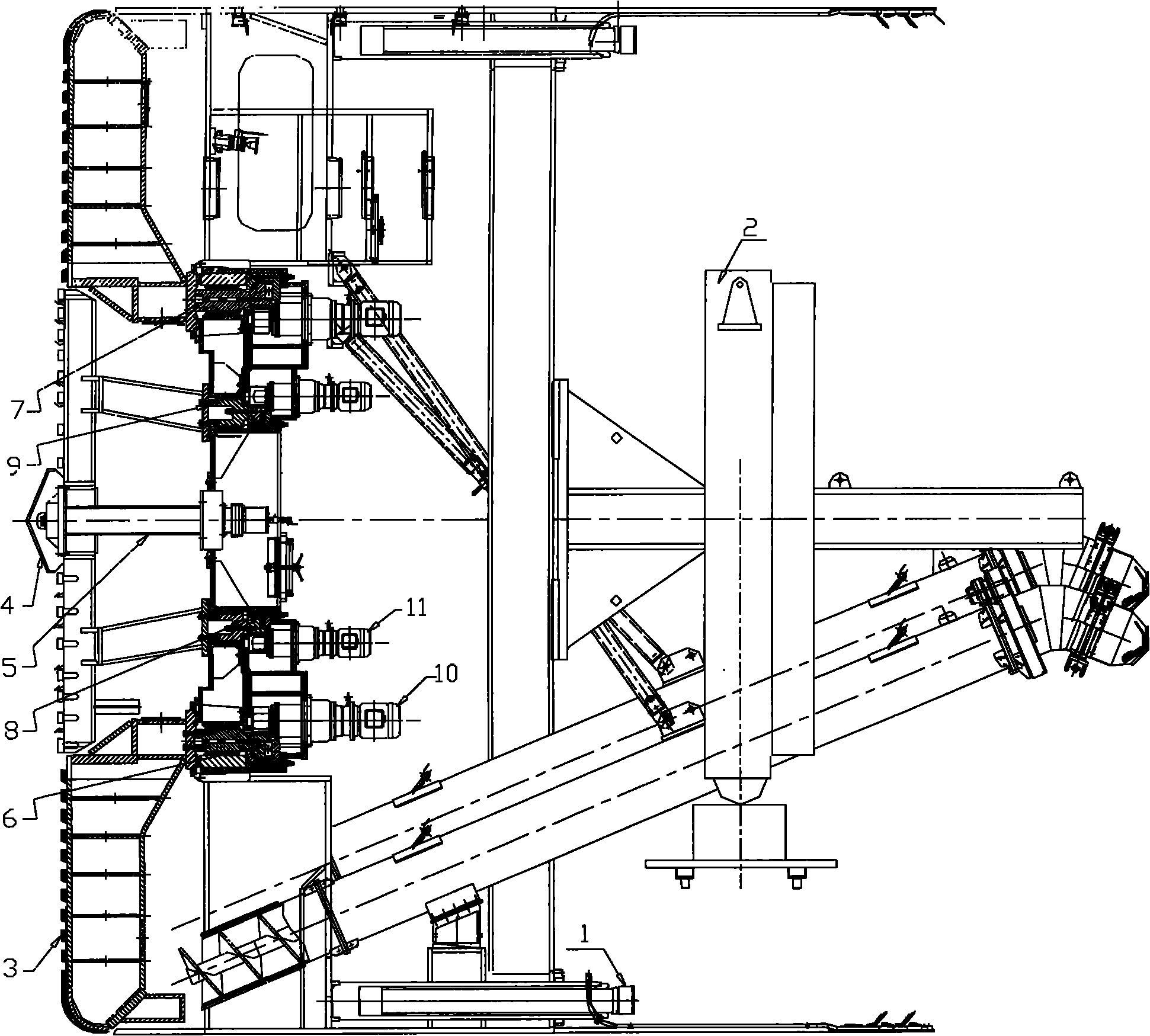

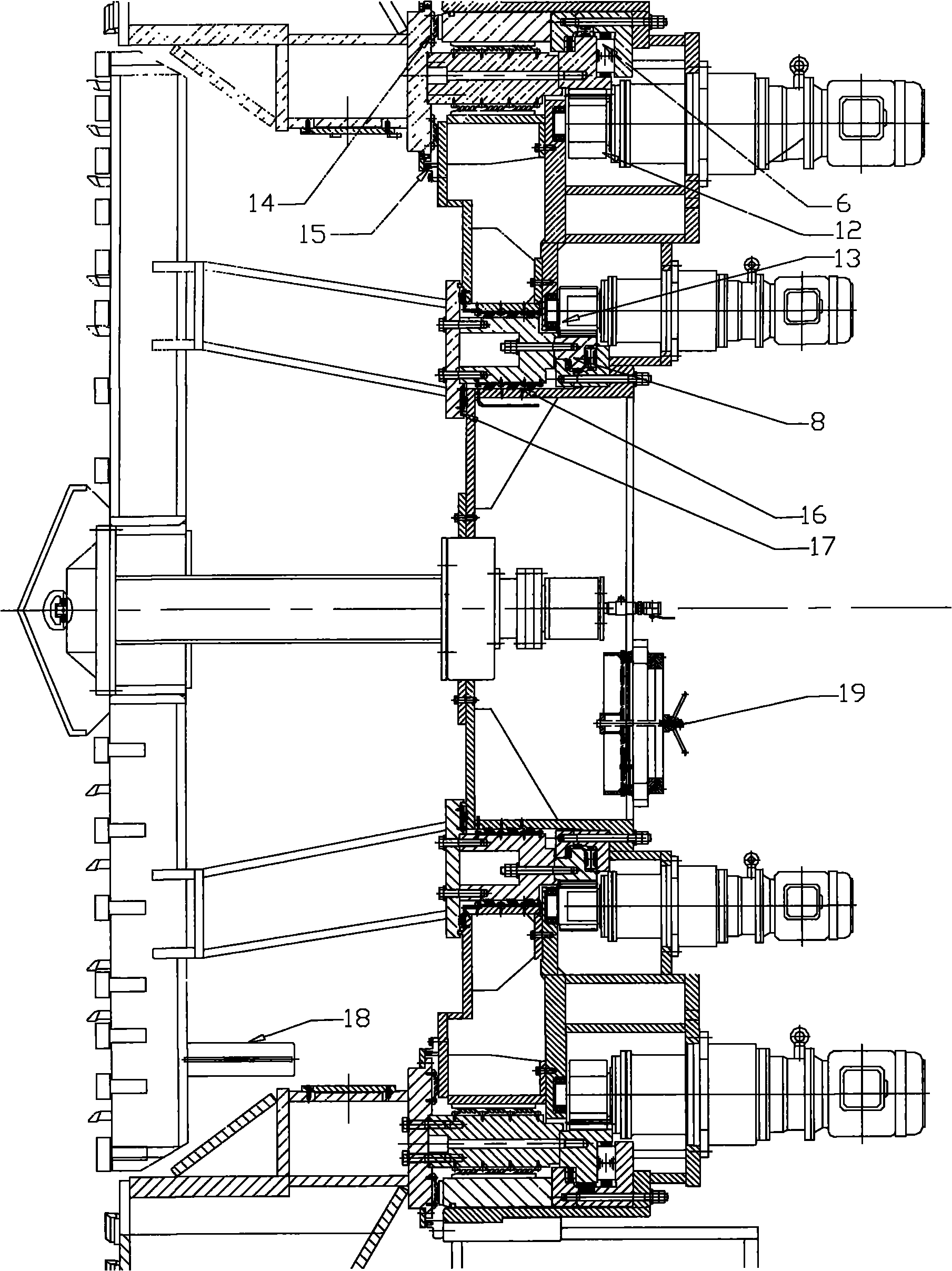

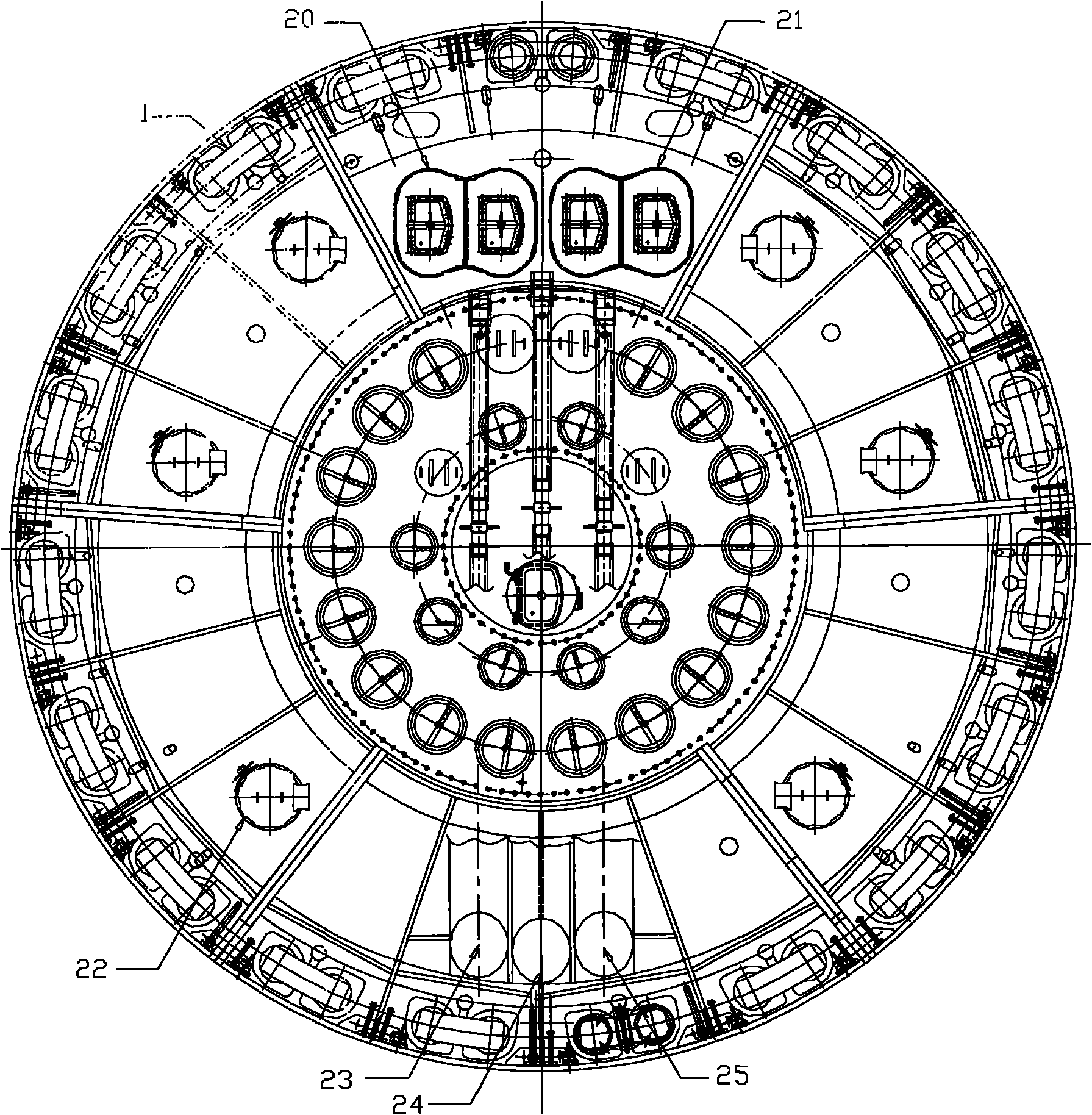

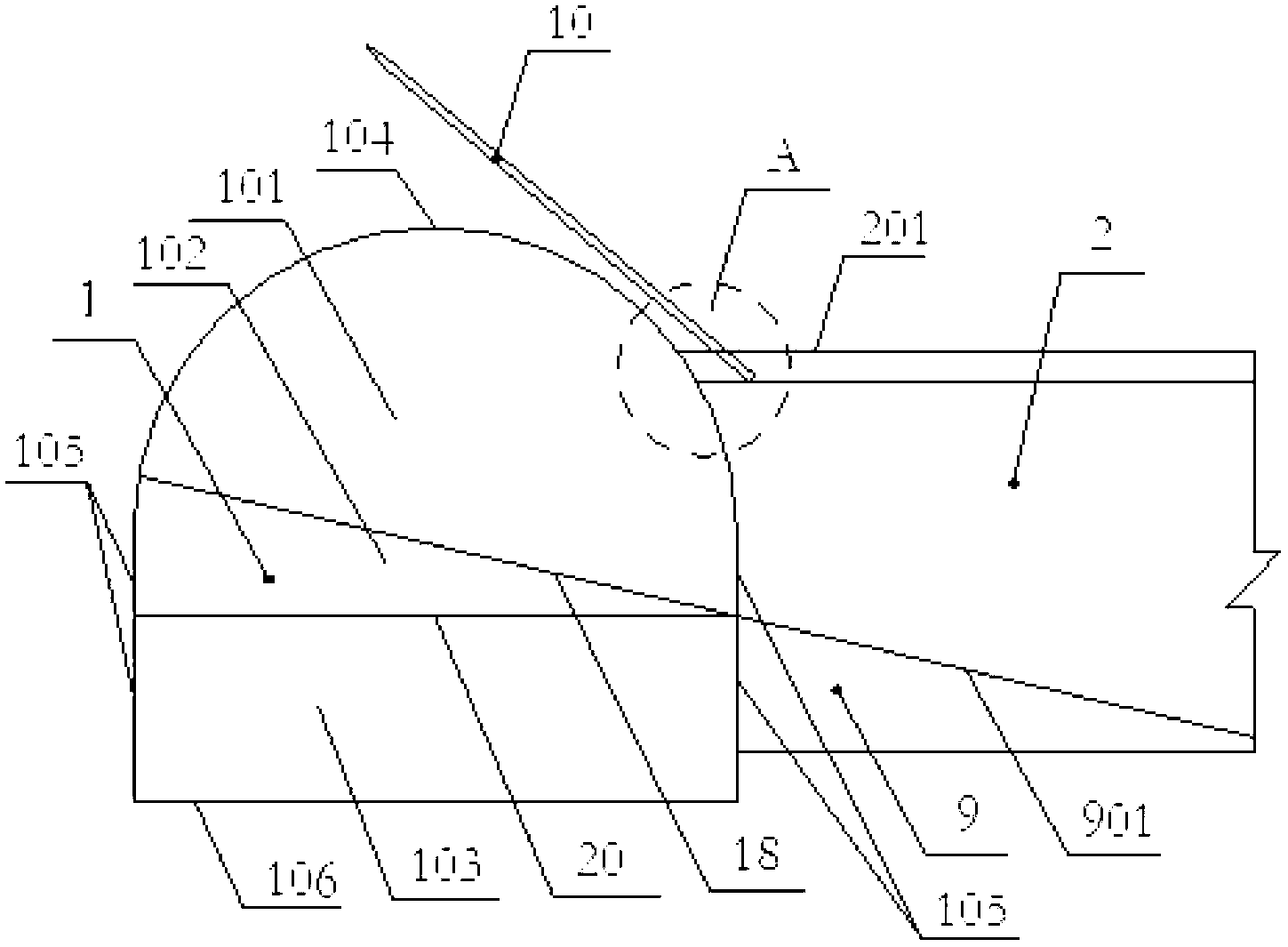

Composite shield structure suitable for bad ground construction

The invention provides a compound tunnel shield suitable for construction of complex formation, relating to an architectural construction machinery. The compound tunnel shield comprises a compound cutter head suitable for construction of soft soil formation, hard rock formation, formation with uneven hardness and compound formation with both soft soil and hard rock; 3 excavation modes adopting an open mode, a local atmospheric pressure mode or an excavated surface stabilization mode of an earth pressure balance mode according to different geological characteristics of the geology, and a ground conditioning system; the cutter head is respectively provided with a soft soil layer construction tool and a hard rock layer construction tool, cutters are changed to adapt to different formations in the process of the construction thereof; addition agent is injected into the cutter head surface, a soil chamber or a screw conveyer and the addition agent and muck are mixed by rotary stirring of the cutter head, the soil chamber or the screw conveyer to adapt to different formations through ground conditioning. The invention solves the problem of safe construction of the tunnel shield in soft soil, decomposed rock, formations with uneven hardness, sand layer and sand gravel formation, etc.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

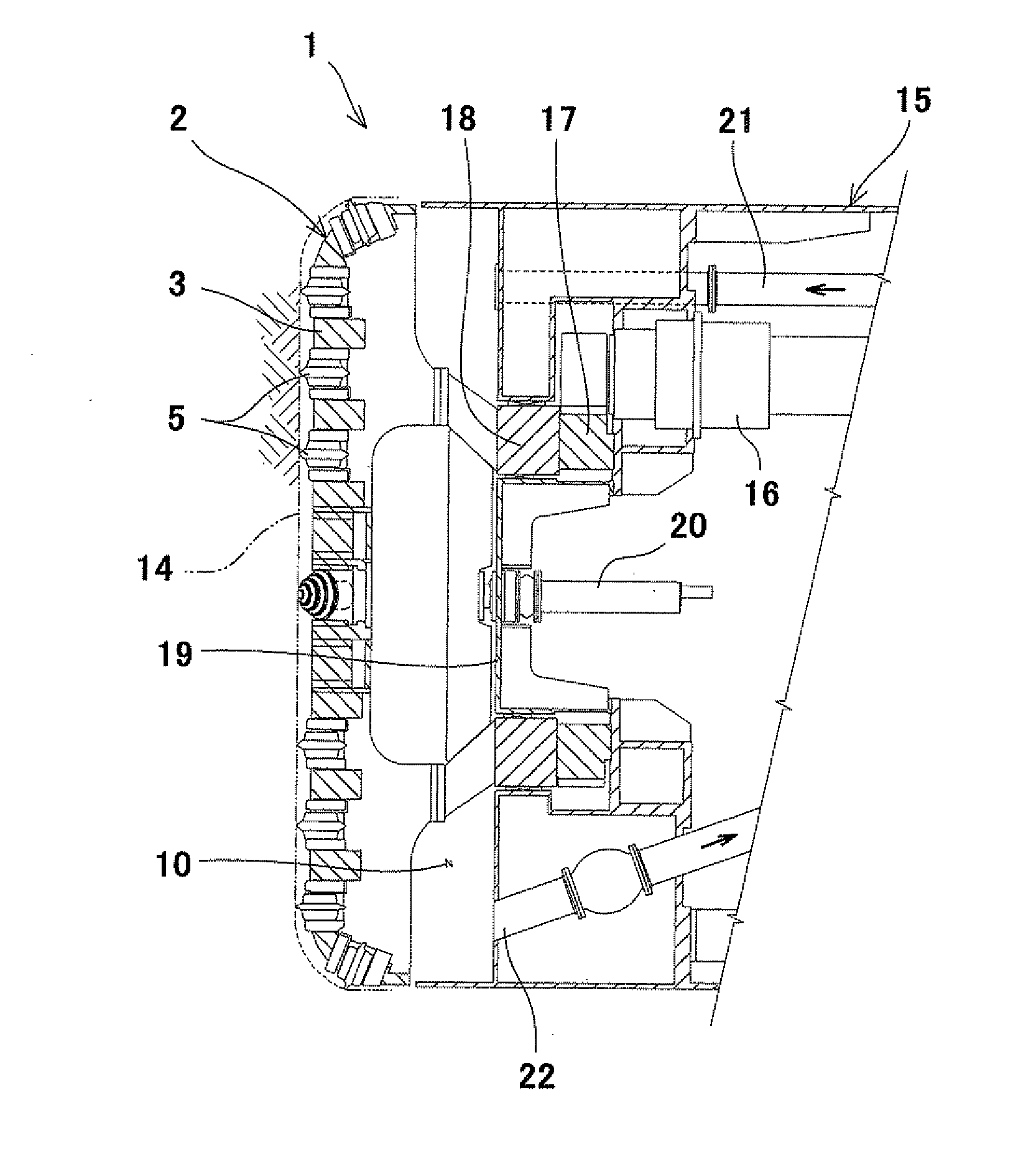

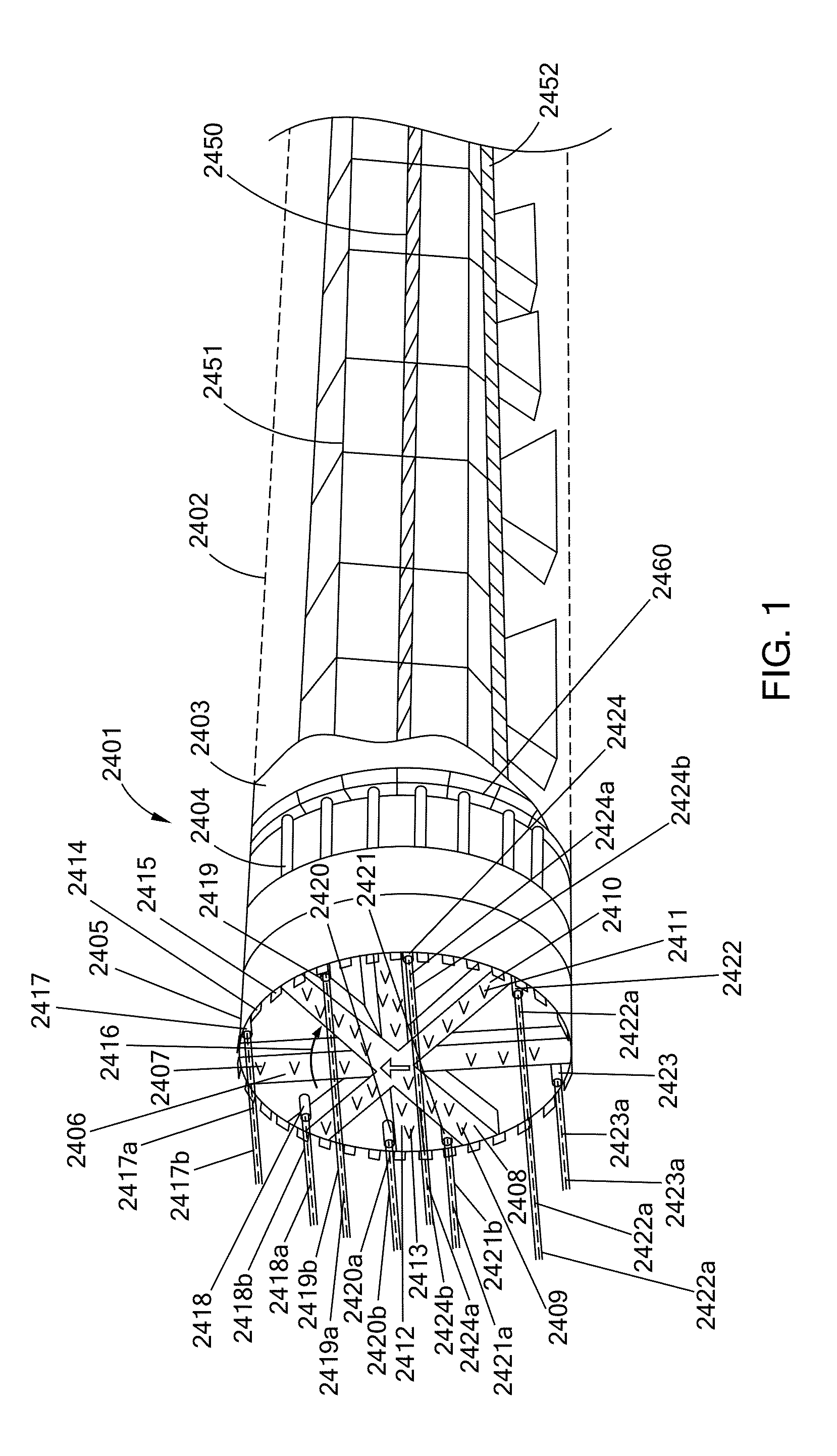

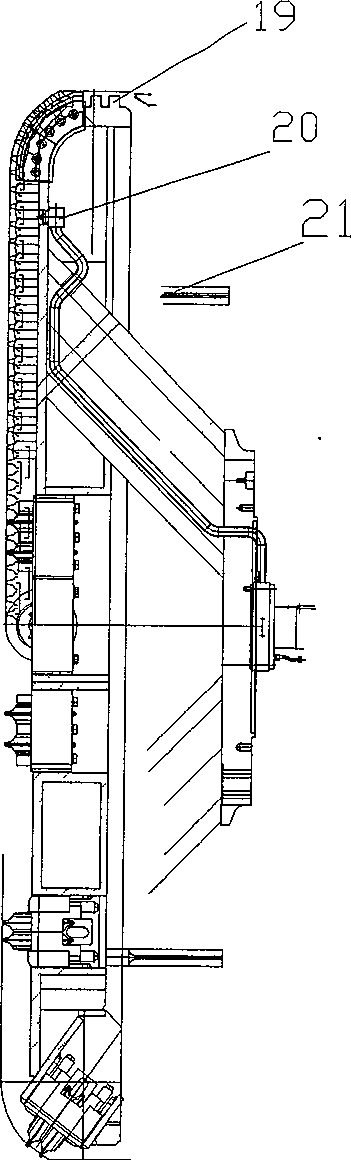

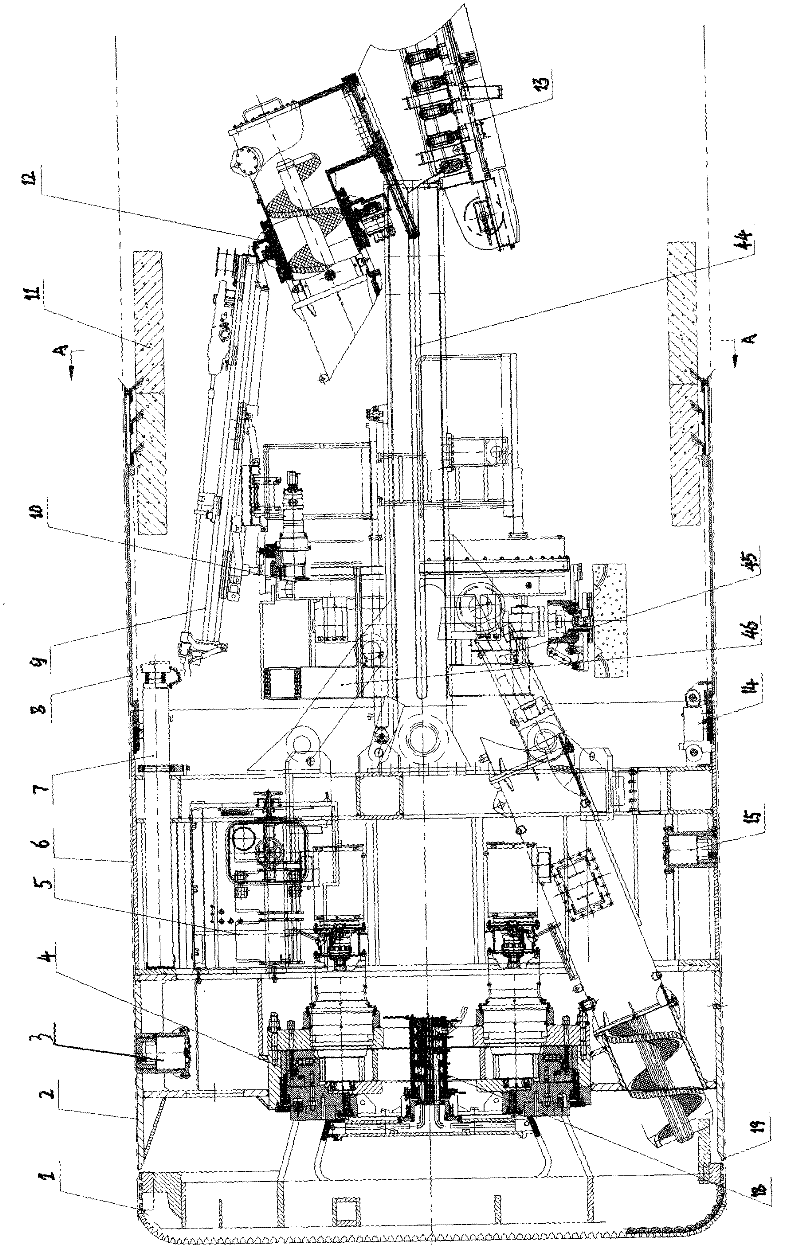

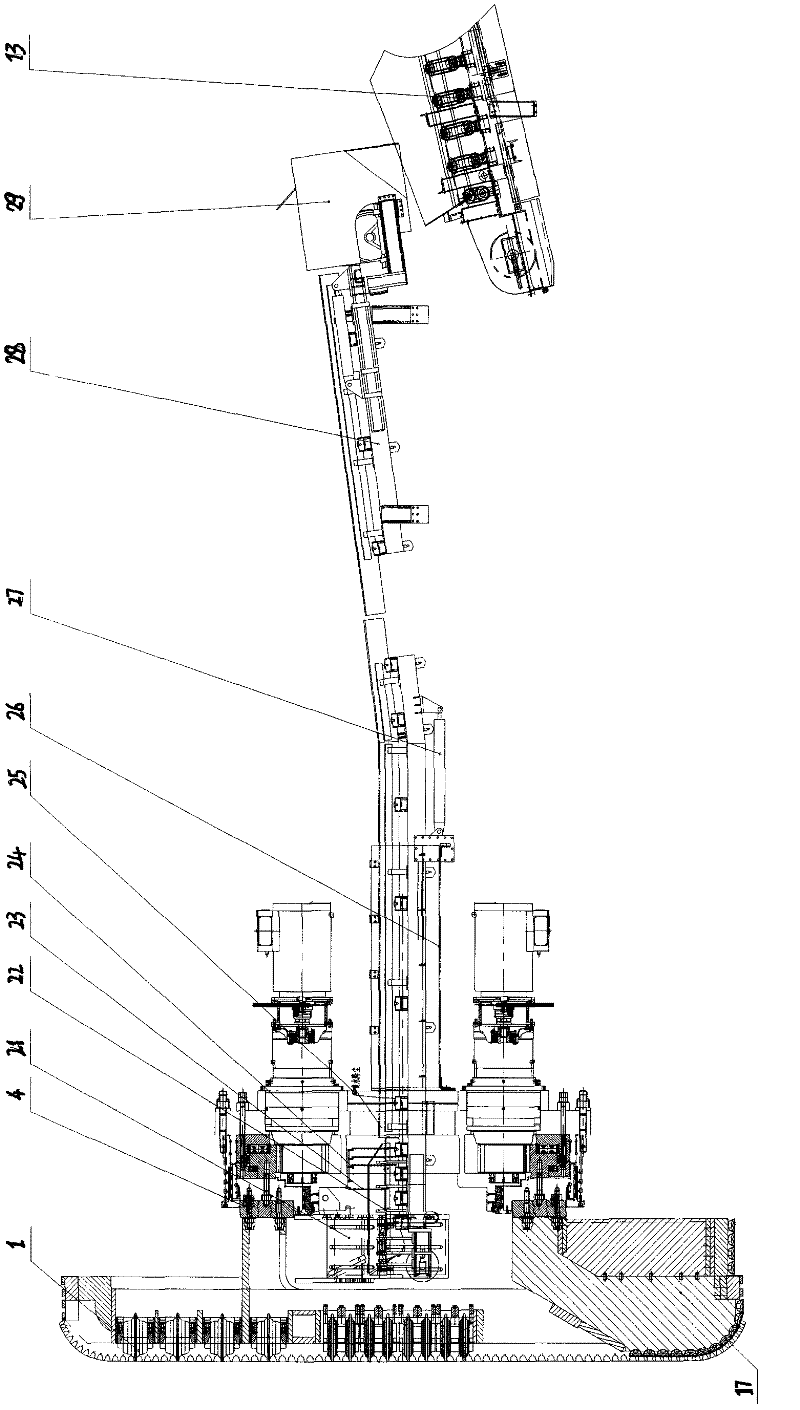

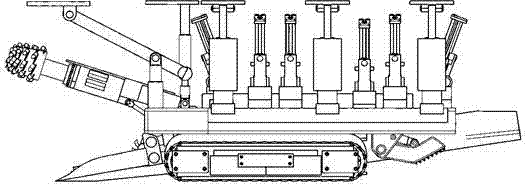

Mixed TBM (Tunnel Boring Machine) with multiple-boring mode and tunnel supporting mode

ActiveCN102383805AControl face stabilityEnsure construction safetyTunnelsSludgeTunnel boring machine

The invention discloses tunnel construction equipment, in particular a mixed TBM (Tunnel Boring Machine) with a multiple-boring mode, which is suitable for sludge, clay, sand, grit, decomposed rock, hard rock and composite transition stratum. According to the invention, three modes of an earth pressure balance mode, a shield open mode and a TBM mode are adopted for construction according to different stratum geological conditions and construction tunnel supporting requirements; a deslagging mode is that a spiral conveyer or a TBM belt conveyor is adopted for deslagging; and simultaneously, a supporting mode can adopt a finned-tube lining or flexible post-supporting mode. The mixed TBM disclosed by the invention has very strong geological adaptability, is especially suitable for soft, hard and complex stratal construction of a mains underground engineering, and simultaneously, has the advantages that the whole machine has low manufacture cost, the mode conversion is relatively simple, the interference to mating construction is small, the control is convenient, the equipment manufacture cost is low, the economic property and practicability are achieved, and the use requirements of the flexible supporting mode of the construction can be met.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Mining machine with driven disc cutters

A mining machine includes a cutting mechanism with an arm, and a substantial weight of more than a thousand pounds attached to the arm. The mining machine also includes a first disc cutter adapted to engage the material to be mined and mounted on a first disc cutter assembly for eccentrically driving the first disc cutter, the first disc cutter assembly being mounted within the substantial weight. The mining machine also includes at least a second disc cutter spaced apart from the first disc cutter assembly and adapted to engage the material to be mined, and mounted on a second disc cutter assembly for eccentrically driving the second disc cutter, the second disc cutter assembly being mounted within the substantial weight.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

Construction method of three parallel metro tunnels with ultra-small clear distance

InactiveCN104196537AAdvanced and reasonable construction methodsEfficient construction methodsTunnelsSocial benefitsEconomic benefits

The invention discloses a construction method of three parallel metro tunnels with an ultra-small clear distance. The method includes a tunnel portal and open-cut tunnel construction method, a barrel digging method, an explosion method, an advanced small pipe construction method, a steel mesh hanging method, a vertical steel frame erecting method, a combined anchor rod construction method, a primary lining supporting construction method, a tunnel waterproof construction method, a secondary tunnel lining construction method, a pouring method, a geological advanced forecast method and a monitoring and measuring method. Compared with the prior art, the construction method is advanced, reasonable, efficient and concise; on the basis that stability of surrounding rocks, constructed tunnels and surrounding buildings and safety of construction personnel in a construction area are guaranteed, engineering quality is guaranteed, construction cost is effectively lowered, the constriction time is shortened, and social benefits and economic benefits of enterprises are remarkable.

Owner:GUANGDONG PROVINCIAL ARCHITECTURAL ENG MACHINERY CONSTR

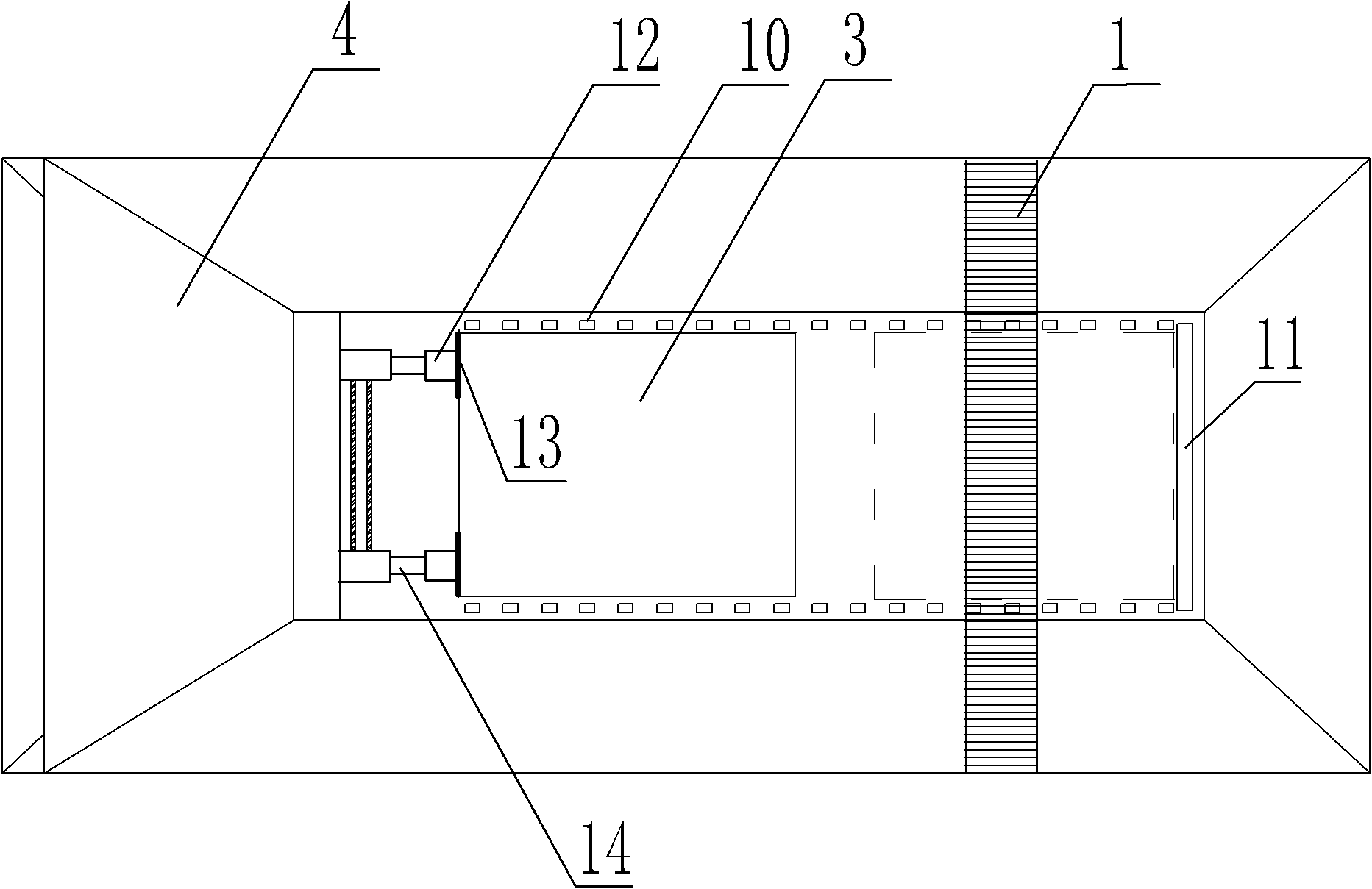

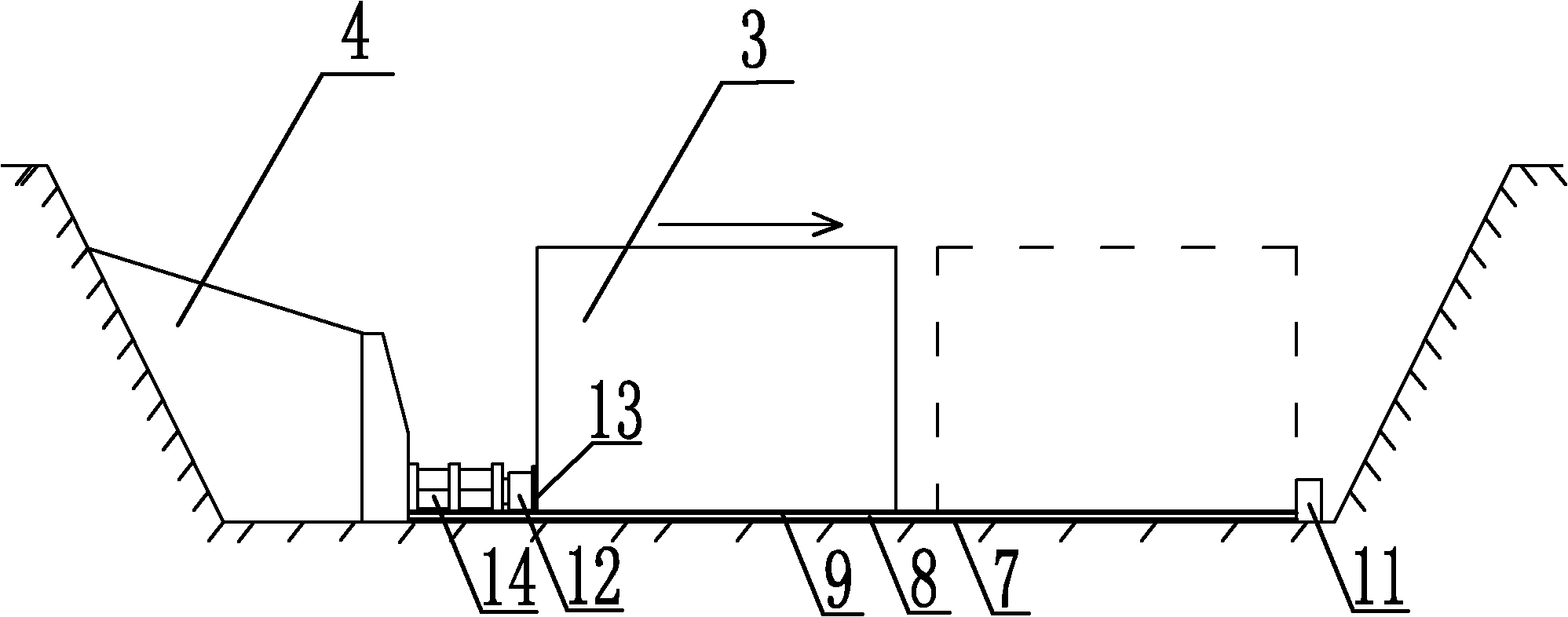

Construction method for underground box culvert of existing railway line

The invention relates to a construction method for an underground box culvert of an existing railway line which is characterized in that a first-dig last-push construction method is adopted; a temporary beam foundation is firstly constructed and a working pit is dug; a D-shaped temporary beam and a cross beam are erected to reinforce the existing railway line; a foundation pit on the jacking section is dug; the box culvert prefabricated in the working pit is integrally jacked by utilizing a hydraulic jack for the back constructed in advance; and the displacement of the box culvert is controlled by a positioning beam. The invention solves the construction difficulties in the prior art, overcomes the phenomena of head raise, head stab, over head and the like of the box culvert during jacking construction, has the advantages of great technical superiority, line safety guarantee and construction speed acceleration, and is suitable for the box culvert construction of underpasses, bridges and culverts of the existing railway underpass line on railway.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

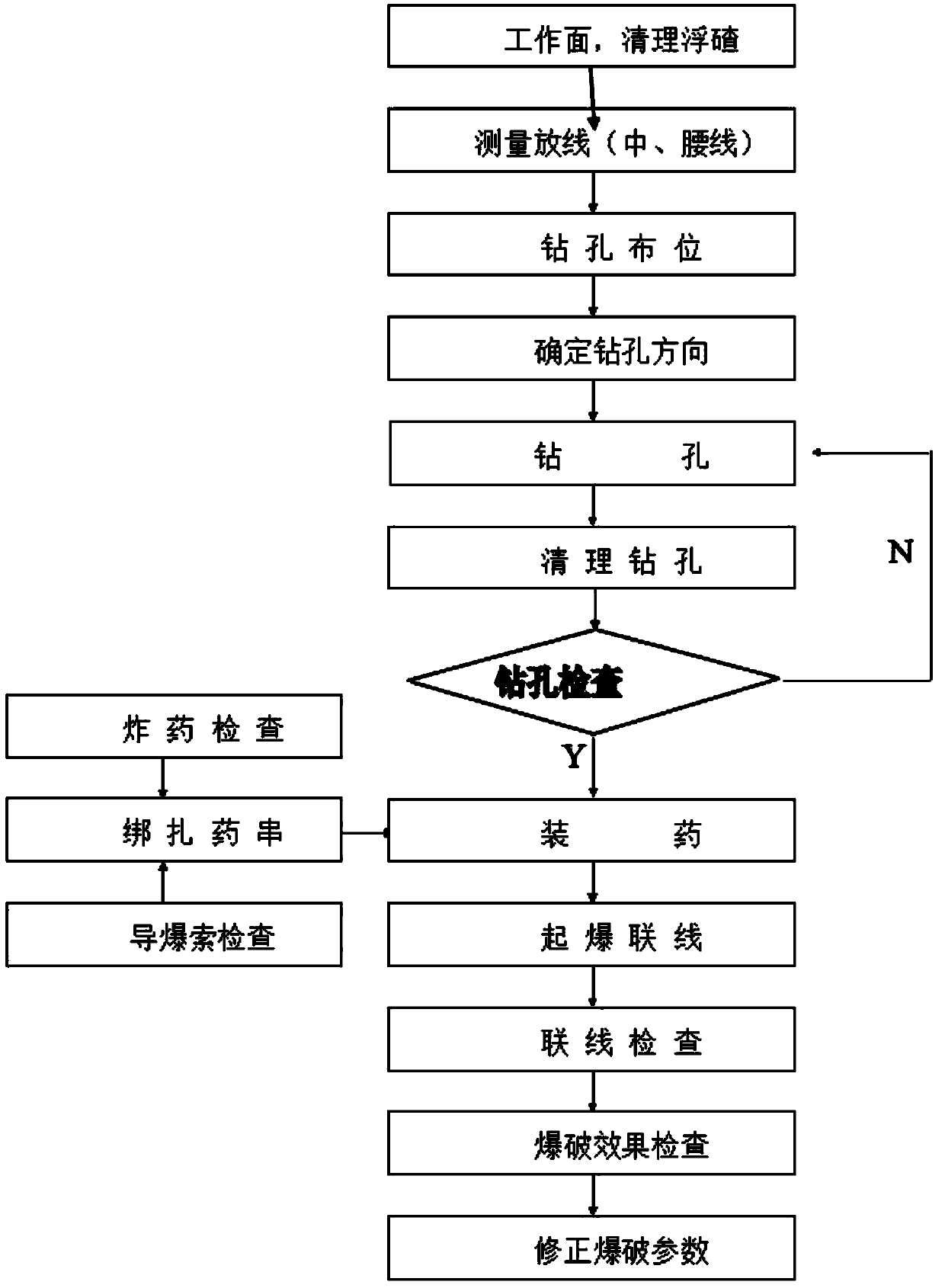

Hard rock tunnel non-blasting digging blocking method and construction method

The invention relates to a hard rock tunnel non-blasting digging blocking method and a construction method. According to the method, a hole drilling core taking technology is utilized, mutually engaged cutting peripheral holes are formed along a tunnel digging contour line, so that a hole wall-shaped digging free face is formed on the periphery of a tunnel face; a hydraulic splitting machine splitting technology is used, in addition, the characteristic that the tensile intensity and the shearing-resistant intensity of rock are much smaller than the pressure-resistant intensity is utilized, the tunnel face digging blocking is firstly carried out, in each digging block, the synchronous splitting digging splitting surfaces do not exceed two, in addition, the two splitting surfaces are in large-angle obtuse angle intersection, in addition, at least one digging free face vertical to the tunnel face is included, then, the digging construction sequence from the lower side to the upper side and from the periphery to the middle is adopted, and the smaller splitting force is used for carrying out rock pulling cracking and shearing cutting splitting digging on the tunnel face along the splitting surface. The hard rock tunnel non-blasting digging blocking method has the advantages that the adverse influence of vibration, noise and dust in the hard rock digging construction can be eliminated, and the utilization rate of tunnel hole slag as building stone materials can be improved.

Owner:FUZHOU PLANNING DESIGN & RES INST

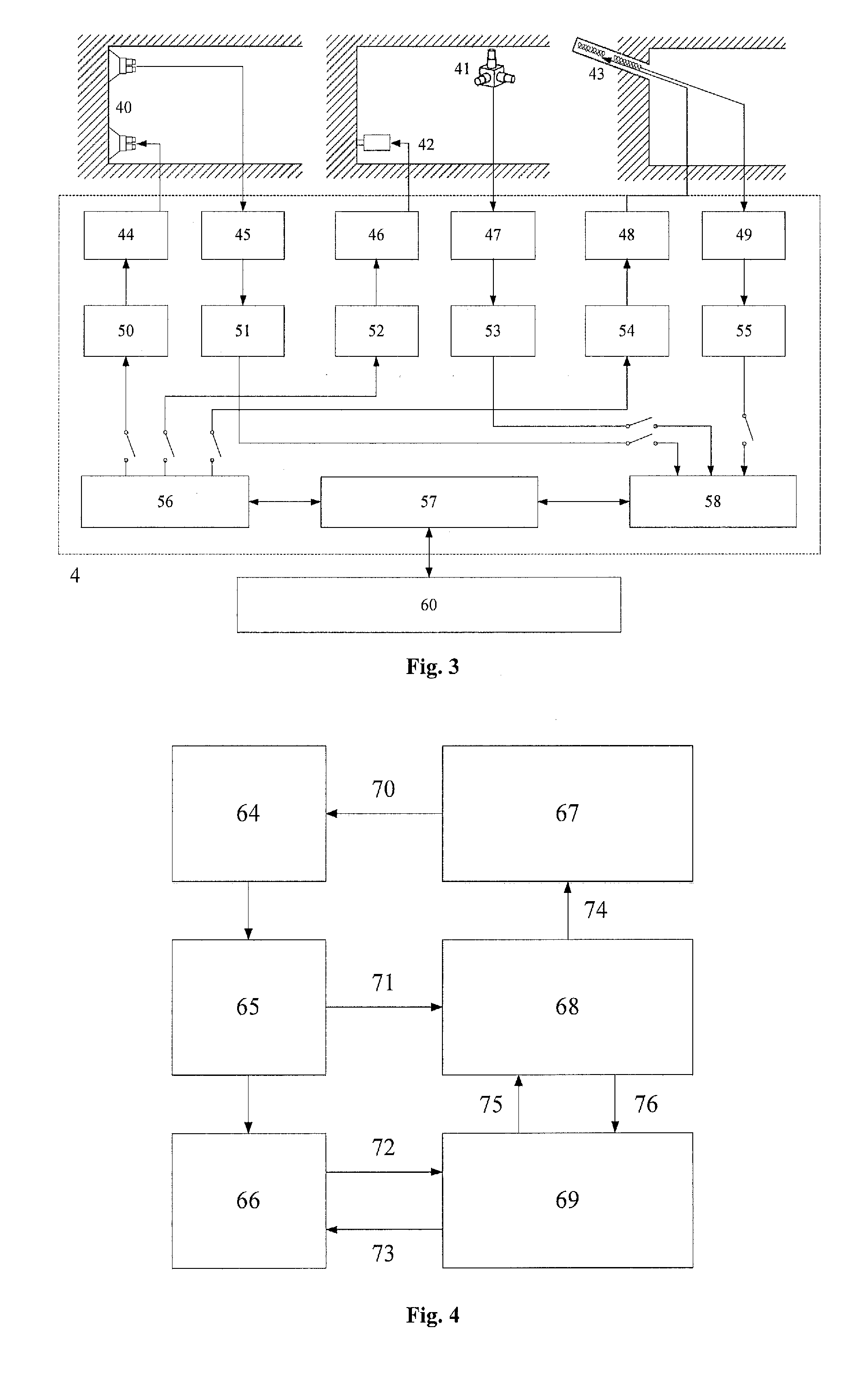

Comprehensive advanced geological detection system carried on tunnel boring machine

ActiveUS20150233242A1Improve accuracyImprove efficiencySeismic signal processingTunnelsDecision systemComputer module

The present invention presents a comprehensive advanced geological detection system carried on a tunnel boring machine. The comprehensive advanced geological detection system includes a multifunctional combination main frame, an induced polarization detection device, a seismic wave detection device, an integrated junction device, a borehole ground penetrating radar detection device and a comprehensive interpretation and decision system; the multifunctional combination main frame includes a time division multiplexing control module, an excitation source control module and a parallel data acquisition module; the excitation source control module outputs trigger signals to the three detection devices respectively, and the three detection devices respectively output measurement data and feedback signals to the time division multiplexing control module through the parallel data acquisition module; and the comprehensive interpretation and decision system supports geological interpretations and decisions through the inversion / migration imaging joint inversion of three detection methods.

Owner:SHANDONG UNIV

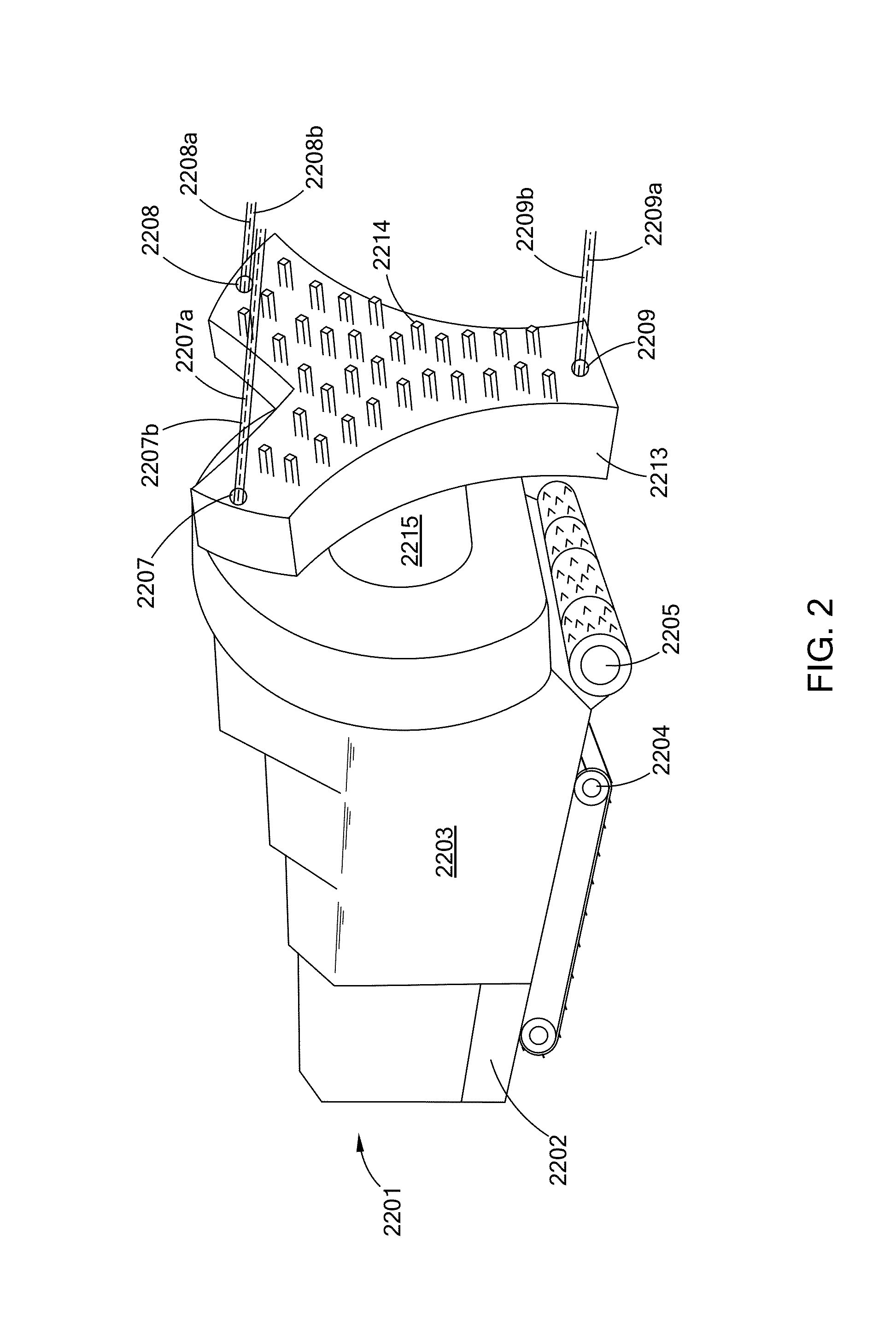

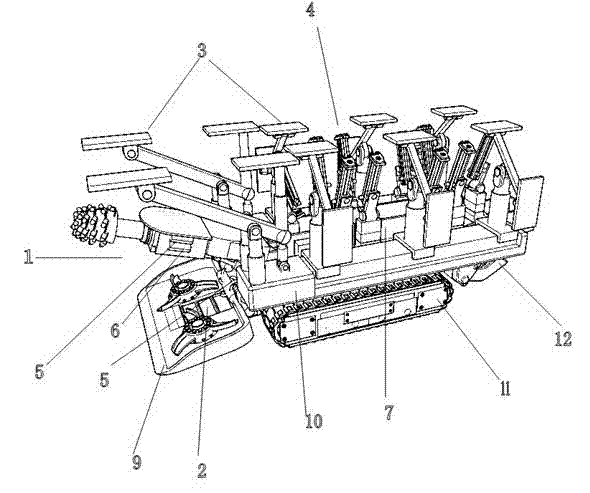

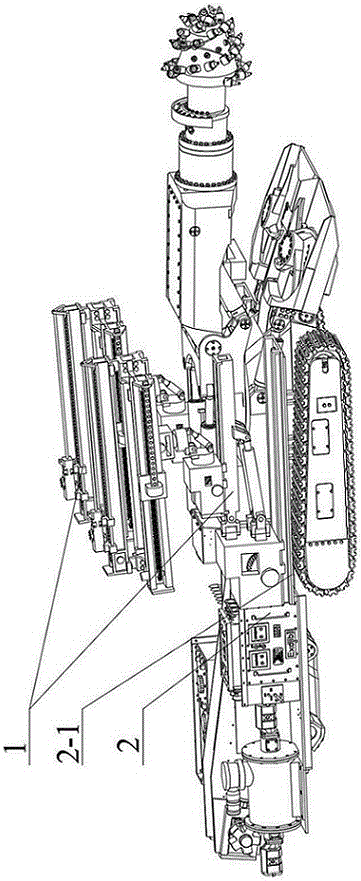

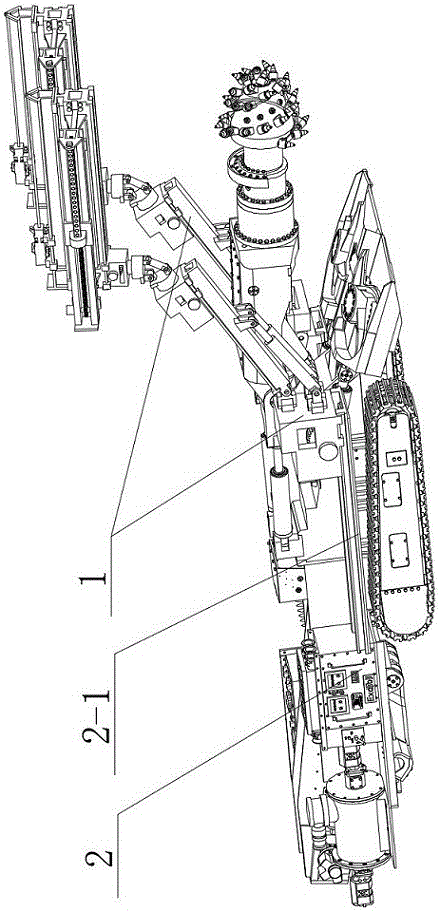

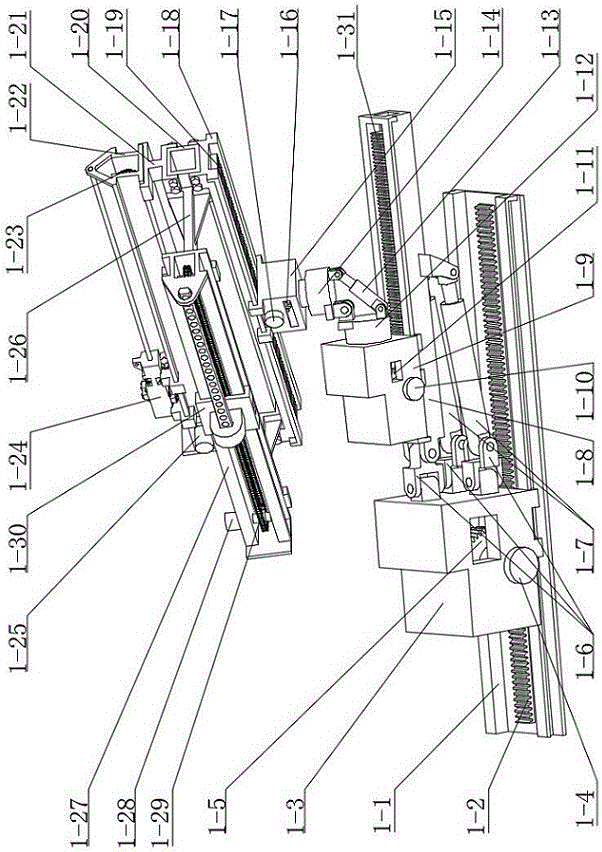

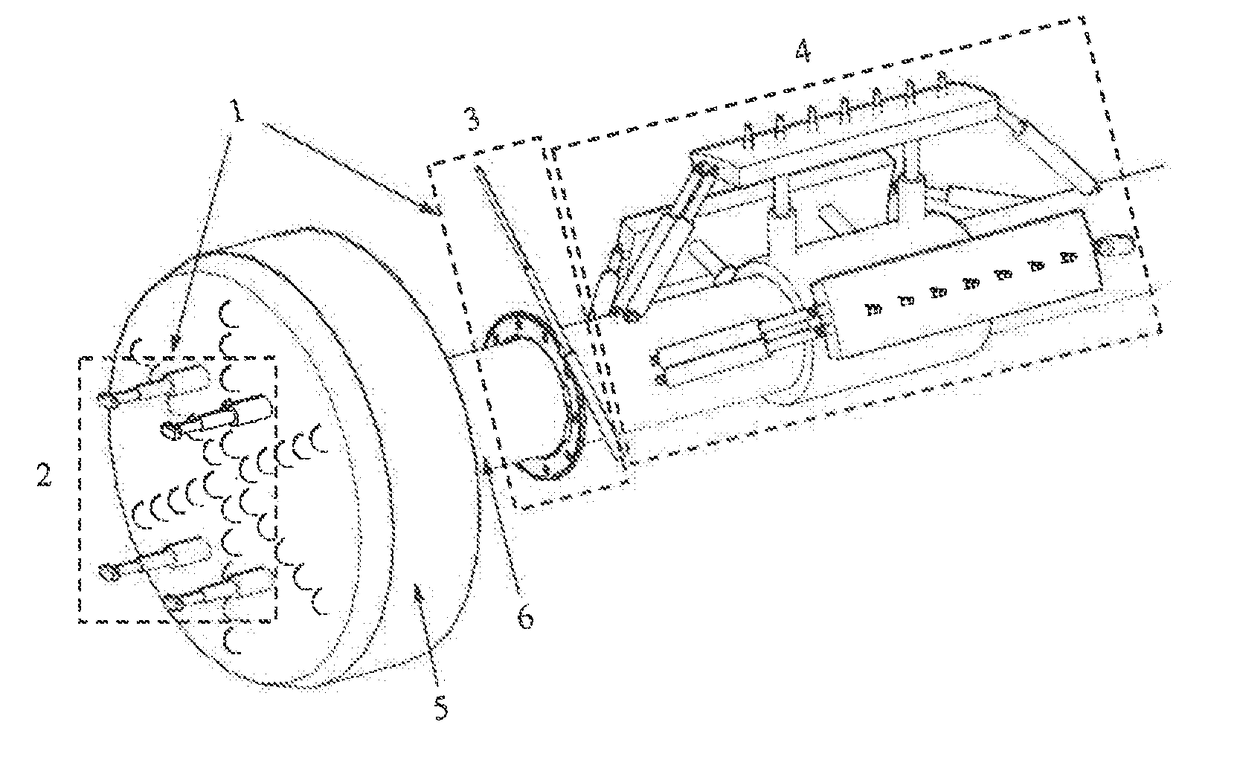

Unmanned roadway driving and anchoring all-in-one machine

InactiveCN104500086AImprove adjustabilityFlexible cuttingMine roof supportsTunnelsSupporting systemControl system

The invention discloses an unmanned roadway driving and anchoring all-in-one machine. The unmanned roadway driving and anchoring all-in-one machine comprises a driving system, a conveying system, a temporary support system, an anchoring system, a driving all-in-one machine water system, a sensing system and an electrical control system. A feed moving roller at the connection portion between a shovel of the driving system and the front end of the conveying system can prevent feed clogging at the shovel and the front end of a scraper conveyor. The temporary support system is uniform in supporting, can move relative to the driving and anchoring all-in-one machine to achieve no-deferring synchronization of driving, supporting and anchoring and can be adapted to the round, uprightly oval, approximately oval or rectangular cross section of a roadway to be applicable to driving and supporting operations of roadways of a variety of ground pressure and directions. The sensing system and the electrical control system of the driving and anchoring all-in-one machine can effectively collect and process information such as, light, distance, humidity and gas and the electrical control system performs automatic or remote manual analysis so as to achieve unattended operations in the working process and greatly improve the safety factor of the operations.

Owner:SHANXI DATONG UNIV

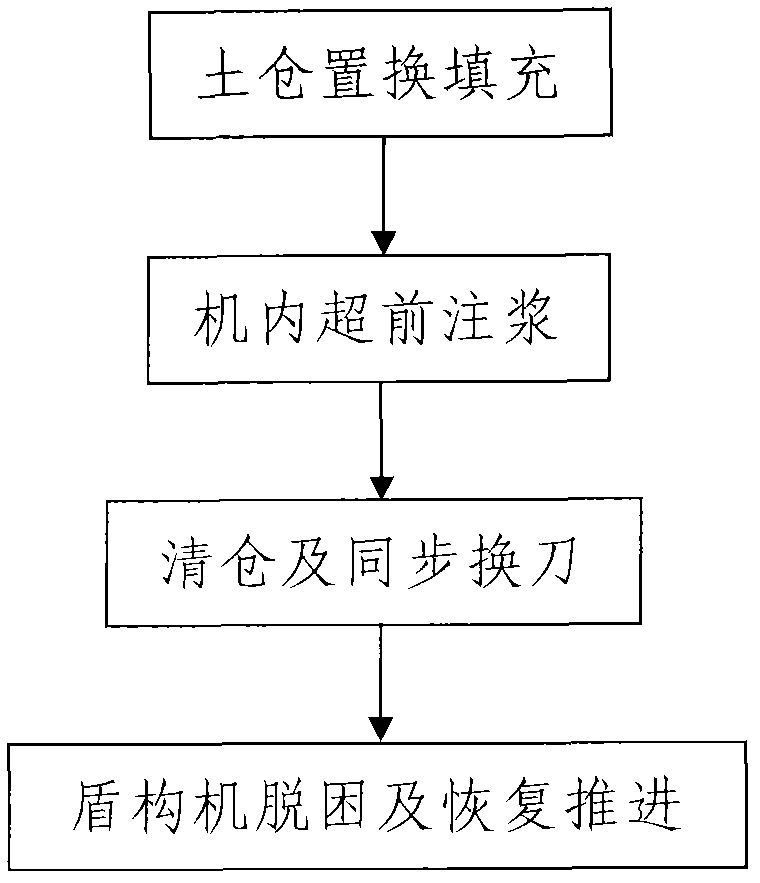

Method for exchanging tool of shield machine for tunnel construction

The invention discloses a method for exchanging a tool of a shield machine for tunnel construction, which comprises the steps of: (1) soil cabin replacement filling: performing the process of soil cabin replacement filling by using a spiral excavating machine and a slip casting system synchronously working with the spiral excavating machine; (2) advanced slip casting inside the machine: beating a plurality of slip casting pipes into the soil on the upper part of the shield machine from inner to outer inside the shield machine by respectively passing through a plurality of advanced geologic holes and then synchronously injecting cement paste into the soil on the upper part of the shield machine through the slip casting pipes by using a slip casting device till the cement paste cannot be injected any more; (3) cleaning cabin and exchanging tool synchronously: manually cleaning the cement plaster solidified inside the soil cabin and synchronously exchanging the tool mounted on the shield machine; and (4) getting rid of the difficult position of the shield machine and recovering the process. The method provided by the invention has the advantages of reasonable design, convenience for operation, low cost, high safety factor, good use effect and capable of solving the problem that the tool cannot be exchanged in the traditional tool exchanging mode under severe tool exchanging conditions.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

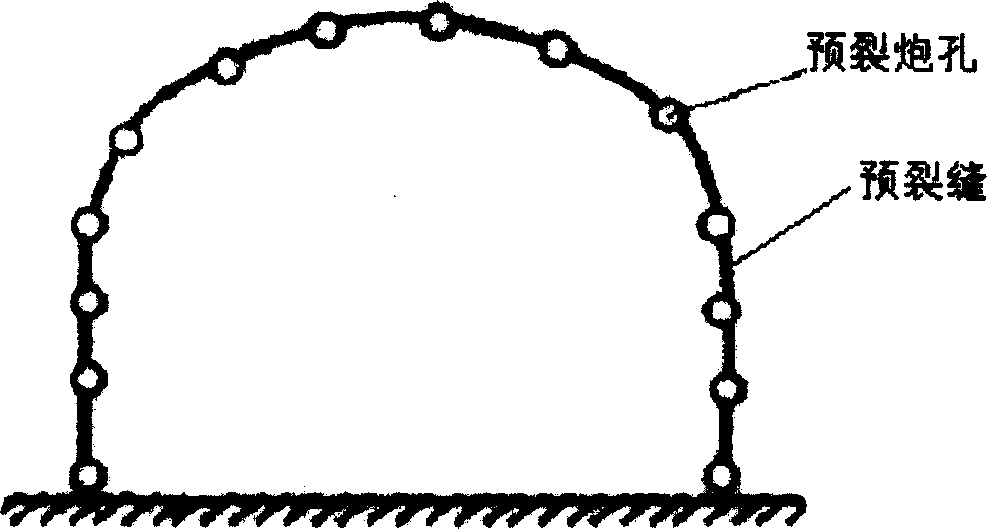

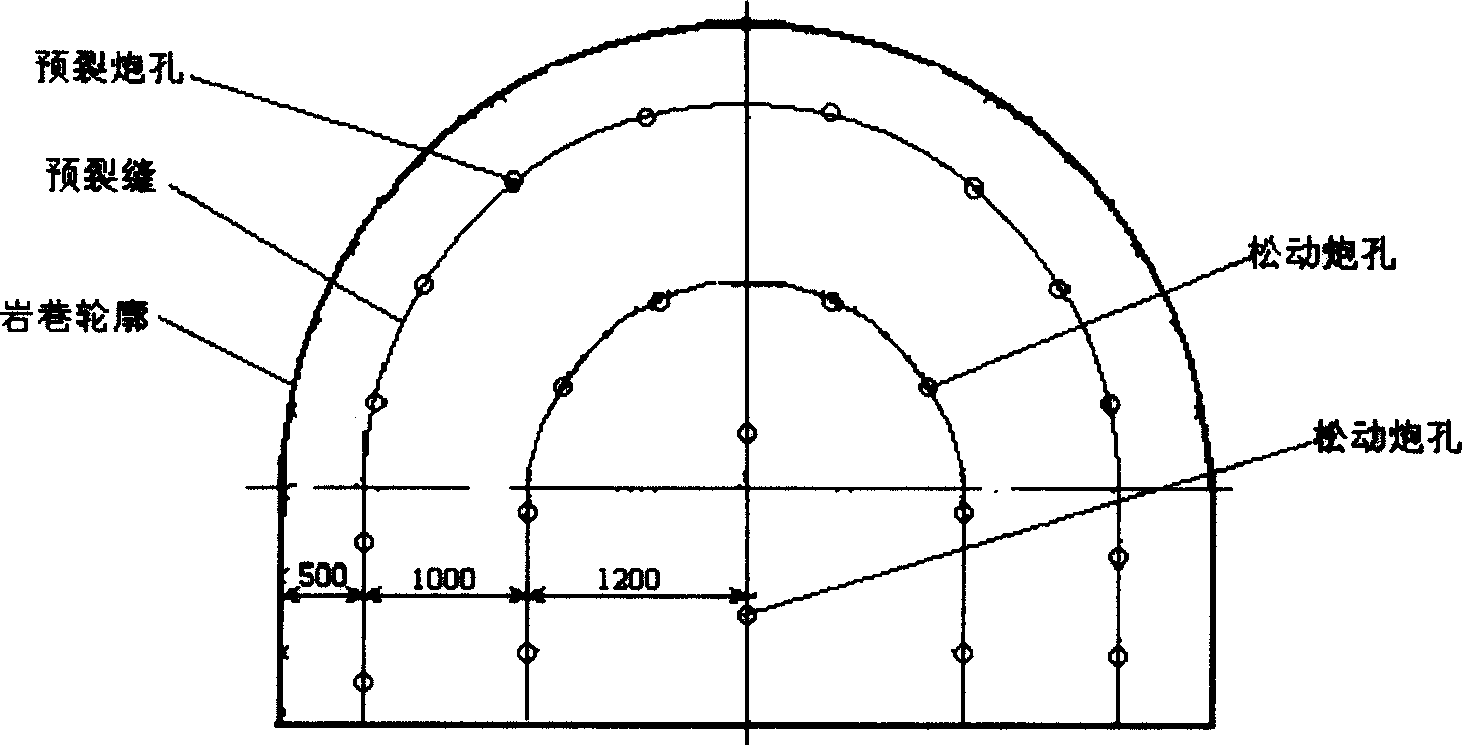

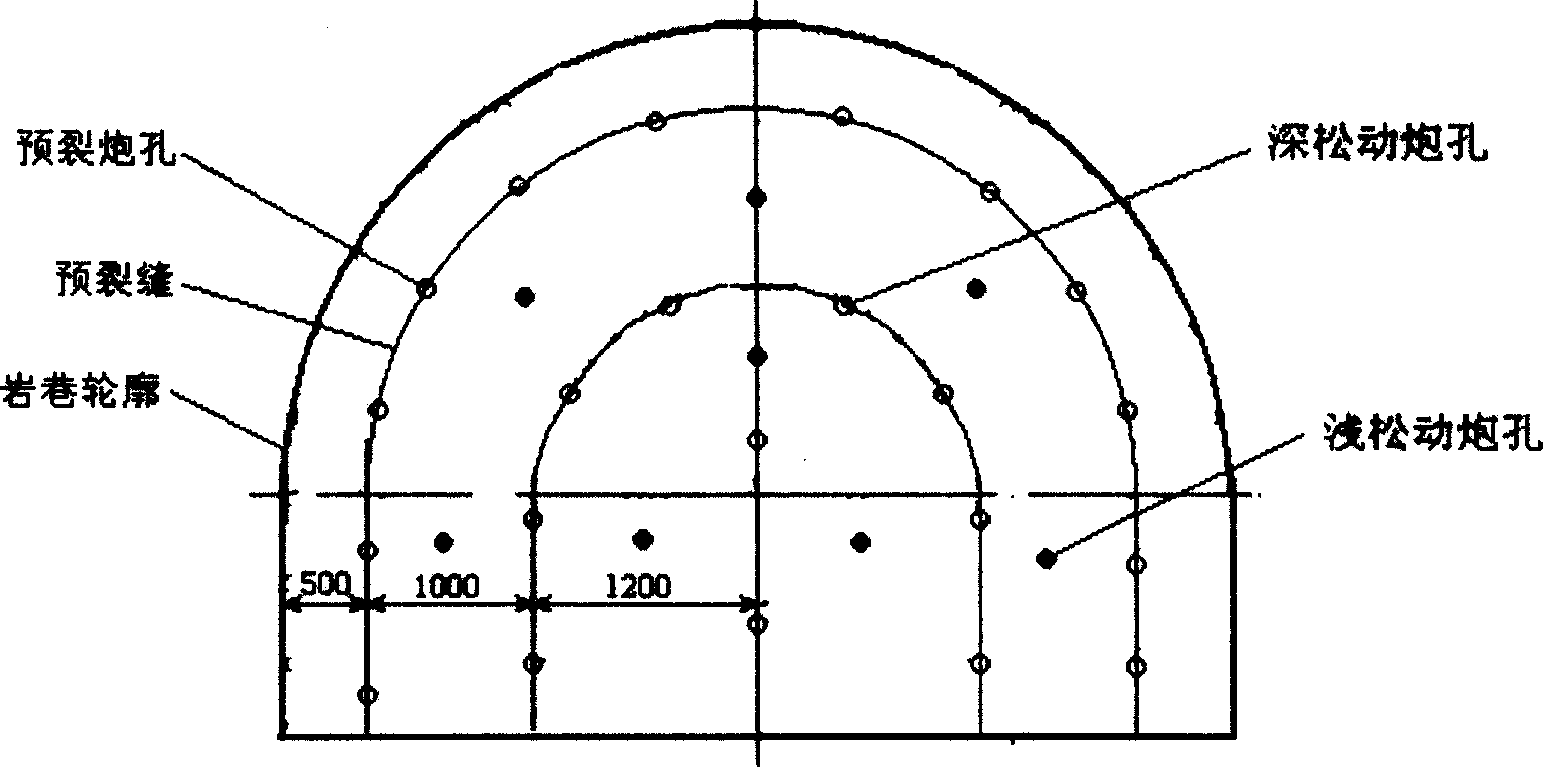

Rock lane digging method

The invention discloses a rock gangway drifting method. Firstly, directional blasting technology is adopted, and presplitting cracks are arranged close to the periphery of a rock gangway through blasting. Secondly, loosening blasting technology is adopted to break rocks in the presplitting cracks; directional blasting and loosening blasting can be performed separately and also can be performed synchronously and initiated in sequence; the directional blasting is initiated before the loosening blasting. Finally, a rock gangway drifting machine is adopted to drill broken rocks. By adoption of combination of drifting of the drifting machine and controlled blastings, the invention has the advantages of great reduction of damage on surrounding rocks, increase of safety, improvement of drifting speed and reduction of cost, and is a rock gangway drifting method having the advantages of high efficiency, safety, low cost, good operating environment and low labor intensity. The invention is suitable for drifting various rock gangways and particularly suitable for drifting rock drifts with high hardness.

Owner:杨仁树

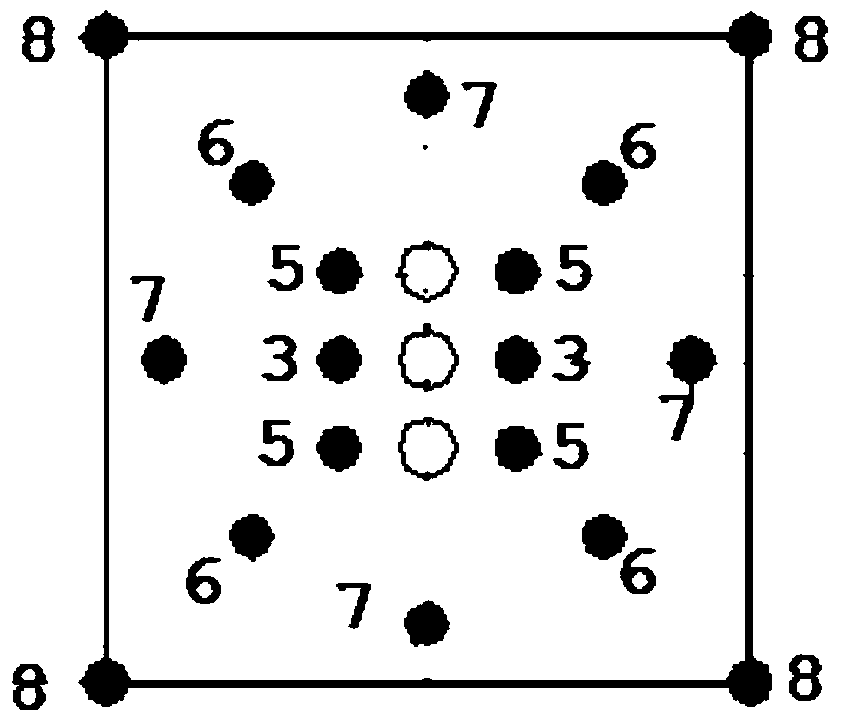

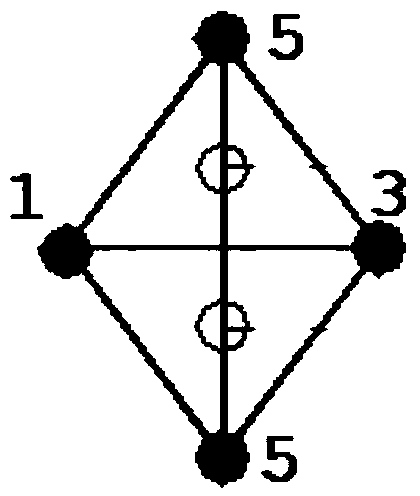

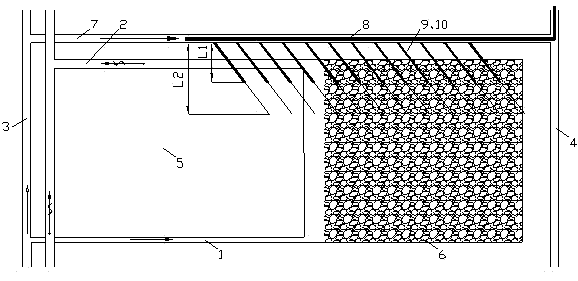

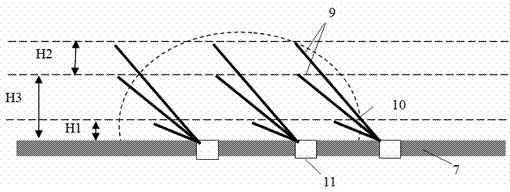

Gas extraction method of cross hole drilling area of gas discharge laneway

ActiveCN102226413AEffective interceptionEffective gush controlDirectional drillingGas removalDrill siteOblique angle

The invention discloses a gas extraction method of a cross hole drilling area of a gas discharge laneway, comprising the following steps: tunnelling an mining area return airway parallel to a mining area track roadway at the tail part of the gas discharge laneway; arranging drill sites on the gas discharge laneway along the roof of a coal seam at intervals; respectively constructing multiple high-level drilling holes with different oblique angles and different lengths and a low-level hole in a worked out area direction in the middle and upper part of each drill site; arranging an extraction pipe after hole drilling construction in each drill site is finished; sealing the holes; and connecting the drilling holes in each drill site into the extraction pipe of the gas discharge laneway through an upper confluence pipe and a lower confluence pipe for extraction, thus realizing the safe production of a gas coal seam group. The method is safe and reliable, can effectively intercept pressure relief gas at an upper neighbor layer, effectively controls the gas from flowing out from a stope face, lowers the gas concentration of an upper corner, and ensures the safe production of the stope face.

Owner:CHINA UNIV OF MINING & TECH

Mining machine with driven disc cutters

A mining machine includes a cutting mechanism with an arm, and a substantial weight of more than a thousand pounds attached to the arm. The mining machine also includes a first disc cutter adapted to engage the material to be mined and mounted on a first disc cutter assembly for eccentrically driving the first disc cutter, the first disc cutter assembly being mounted within the substantial weight. The mining machine also includes at least a second disc cutter spaced apart from the first disc cutter assembly and adapted to engage the material to be mined, and mounted on a second disc cutter assembly for eccentrically driving the second disc cutter, the second disc cutter assembly being mounted within the substantial weight.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

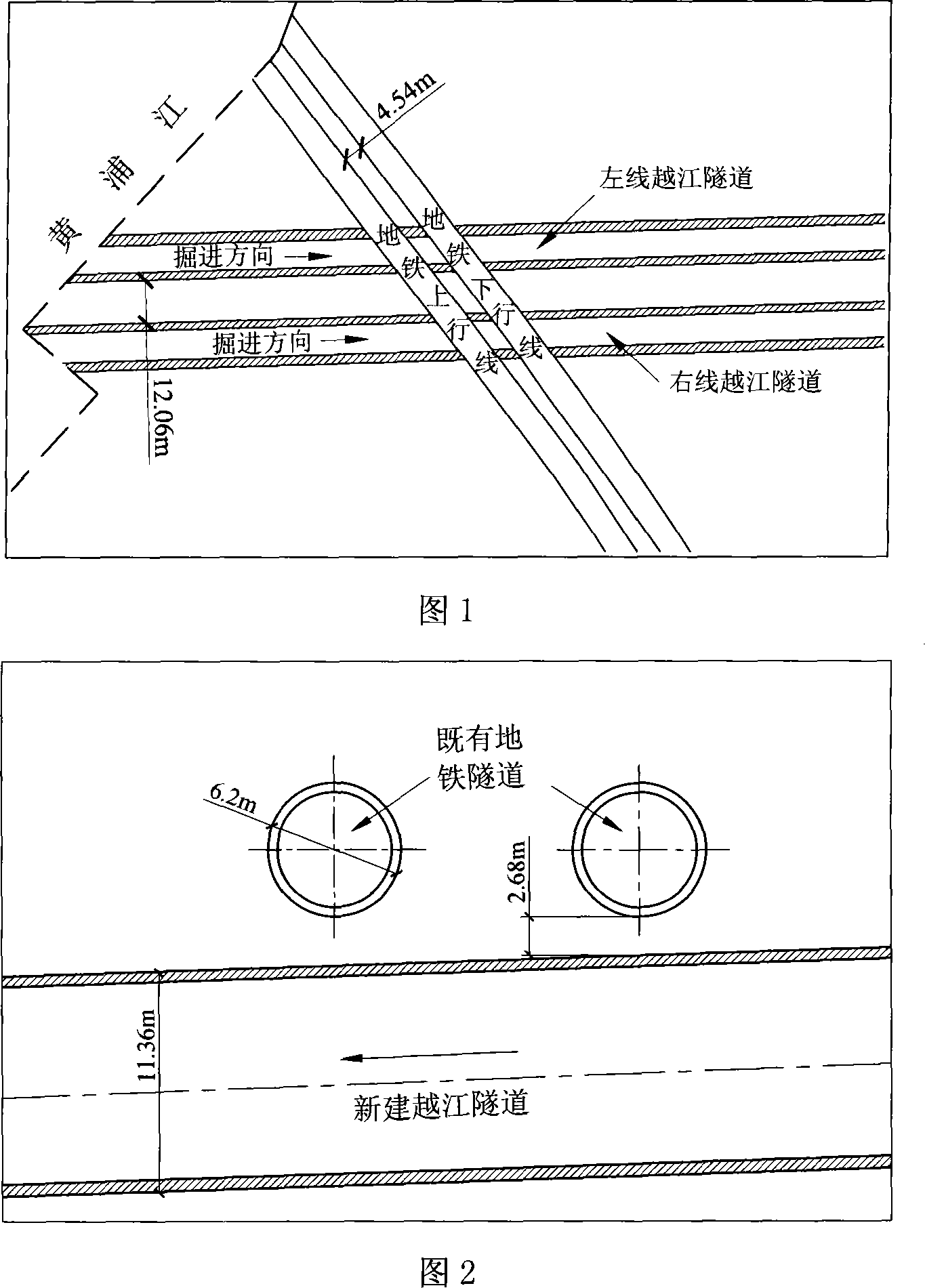

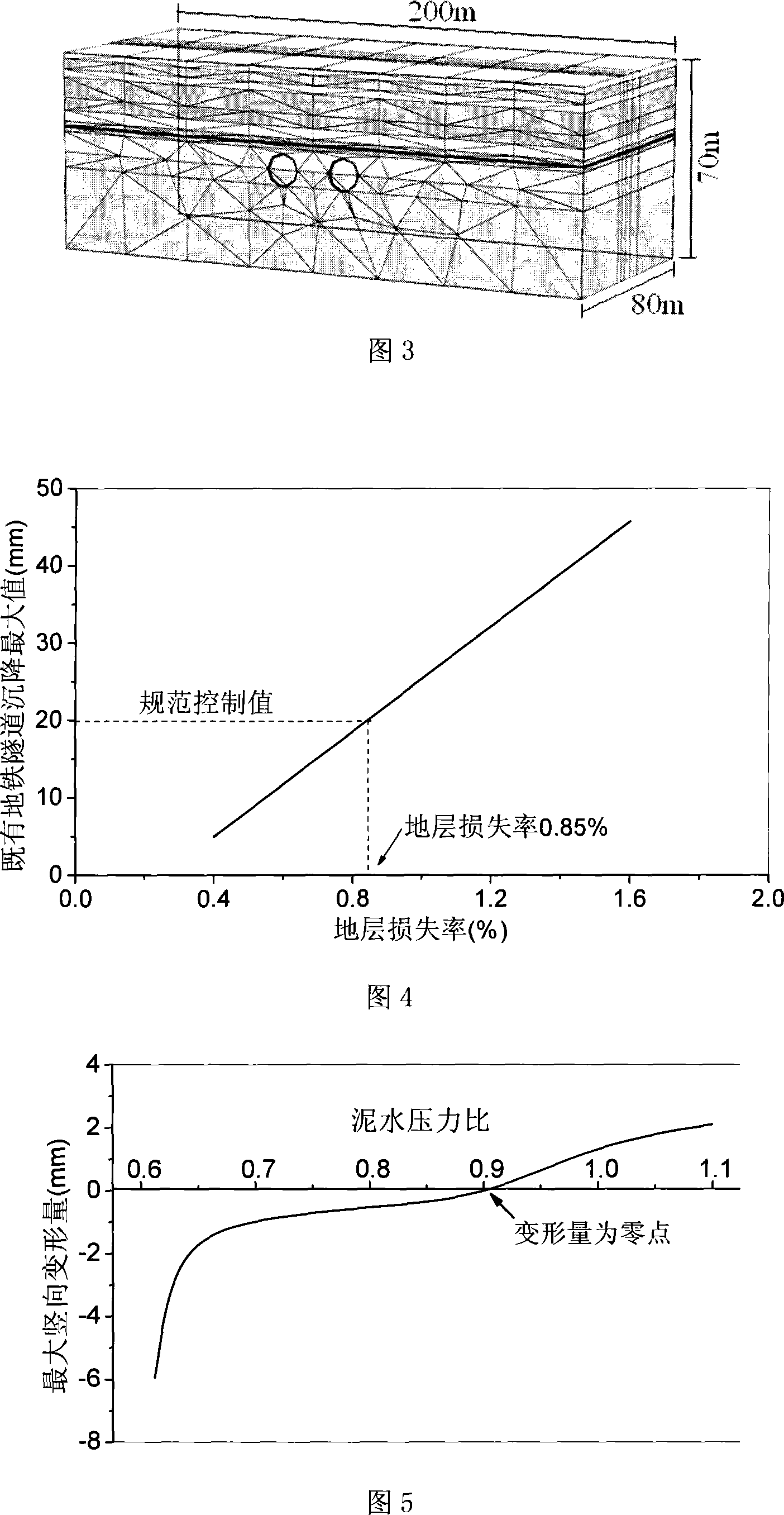

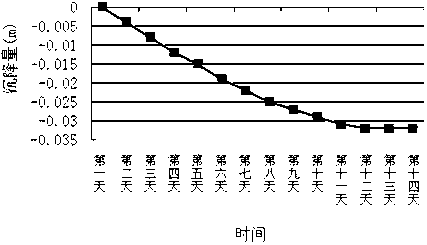

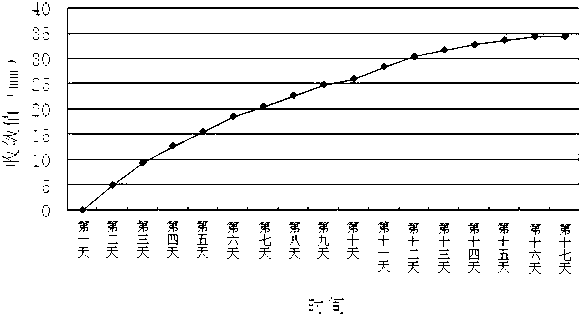

Large diameter tunneling close range down-traversing small diameter subway tunnel distortion control method

InactiveCN101215969AGuarantee smooth constructionEnsure safetyTunnelsUnderground tunnelFinite element method

The invention discloses a method for controlling distortion for deep large diameter shield tunnels to under-pass small diameter tunnels, which pertains to the technical field of tunnel engineering. According to the method, the control range of the stratum loss ratio of newly established tunnels and the optimum value of the support pressure of the shield cut surface are acquired by using the finite-element method; soil pressure in front of the shield cut surface is kept relatively balanced by setting the optimal value of the support pressure, and the support pressure fluctuation range of the cut surface is controlled to range from minus 10kPa to plus 10kPa; the stratum loss ratio of the newly established tunnels is controlled within the allowed range. According to the construction technique measures, a test propelling area is arranged before the shield reaches a cross position. In the area, construction is carried out according to the situation of the existing underground tunnels above; and construction parameters are controlled and regulated to adjust the support pressure, the propulsive velocity and the amount of the grout to be injected in time; the shield passes through the cross position in combination with the optimal values of the construction parameters of the test propelling area. The invention can not only ensure the construction of tunnels to be carried out safely and smoothly, but also minimize the influence of construction on ambient environment.

Owner:SHANGHAI JIAO TONG UNIV

Shield tunneling machine split starting construction method

InactiveCN103711499AImprove construction efficiencyLow construction costTunnelsArchitectural engineeringShield tunneling

The invention discloses a shield tunneling machine split starting construction method and belongs to the technical field of building construction. The method comprises the following steps: (1) cleaning an underground site, (2) starting base seat underground assembling and laying rails, (3) moving a first trolley and a second trolley underground and moving the first trolley and the second trolley backward, (4) moving a duct piece cart underground, (5) moving a connecting bridge and a spiral conveyor underground in a hoisting mode, and moving the connecting bridge and the spiral conveyor backward, (6) moving a starting table underground, smear ing lubricating grease, moving a cutter disk and a shield body underground and locating and assembling the cutter disk and the shield body, (7) assembling, (8) starting trying tunneling, (9) restoring to normal shield tunneling. The method has the advantages of effectively solving the problem that a shield tunneling machine cannot be operated and run normally for being restricted by the actual environment of a shield tunneling staring operation shaft on a construction site, greatly improving construction efficiency, saving construction cost, and reducing construction difficulty.

Owner:CHINA RAILWAY 13TH BUREAU GRP 6TH ENG COMPANY

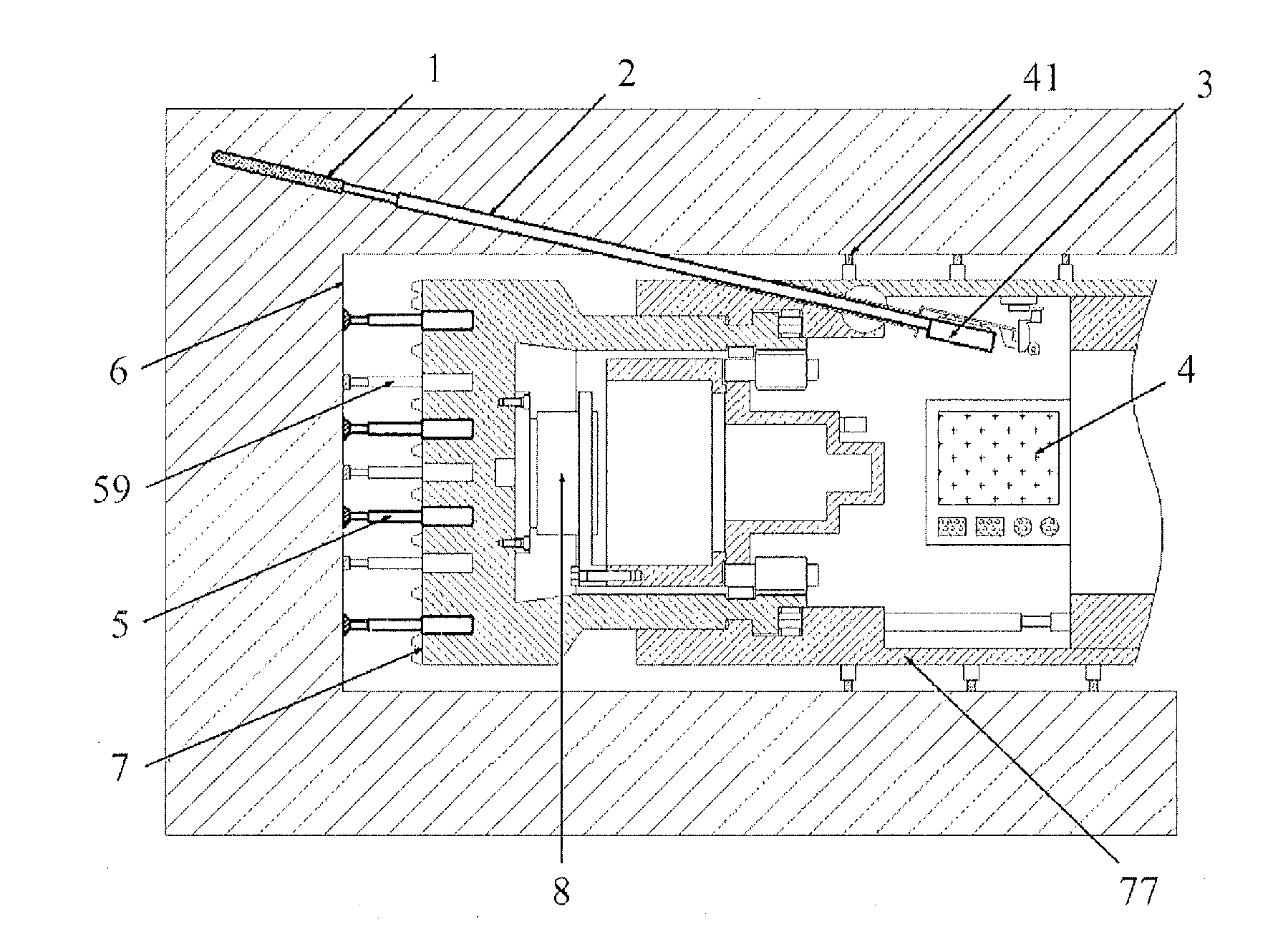

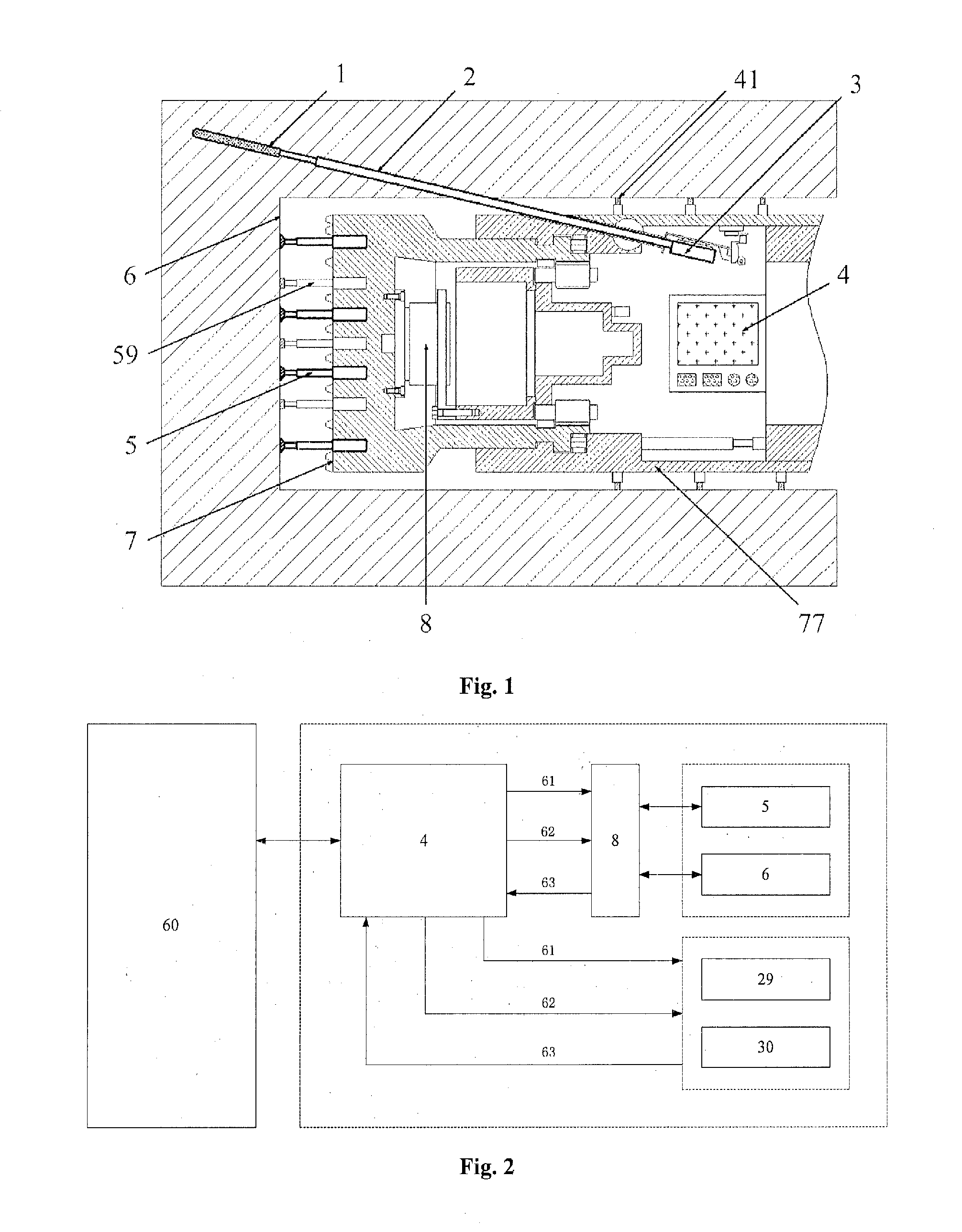

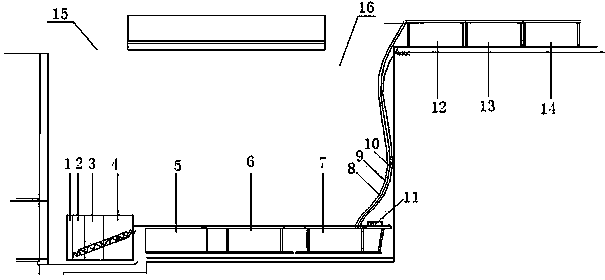

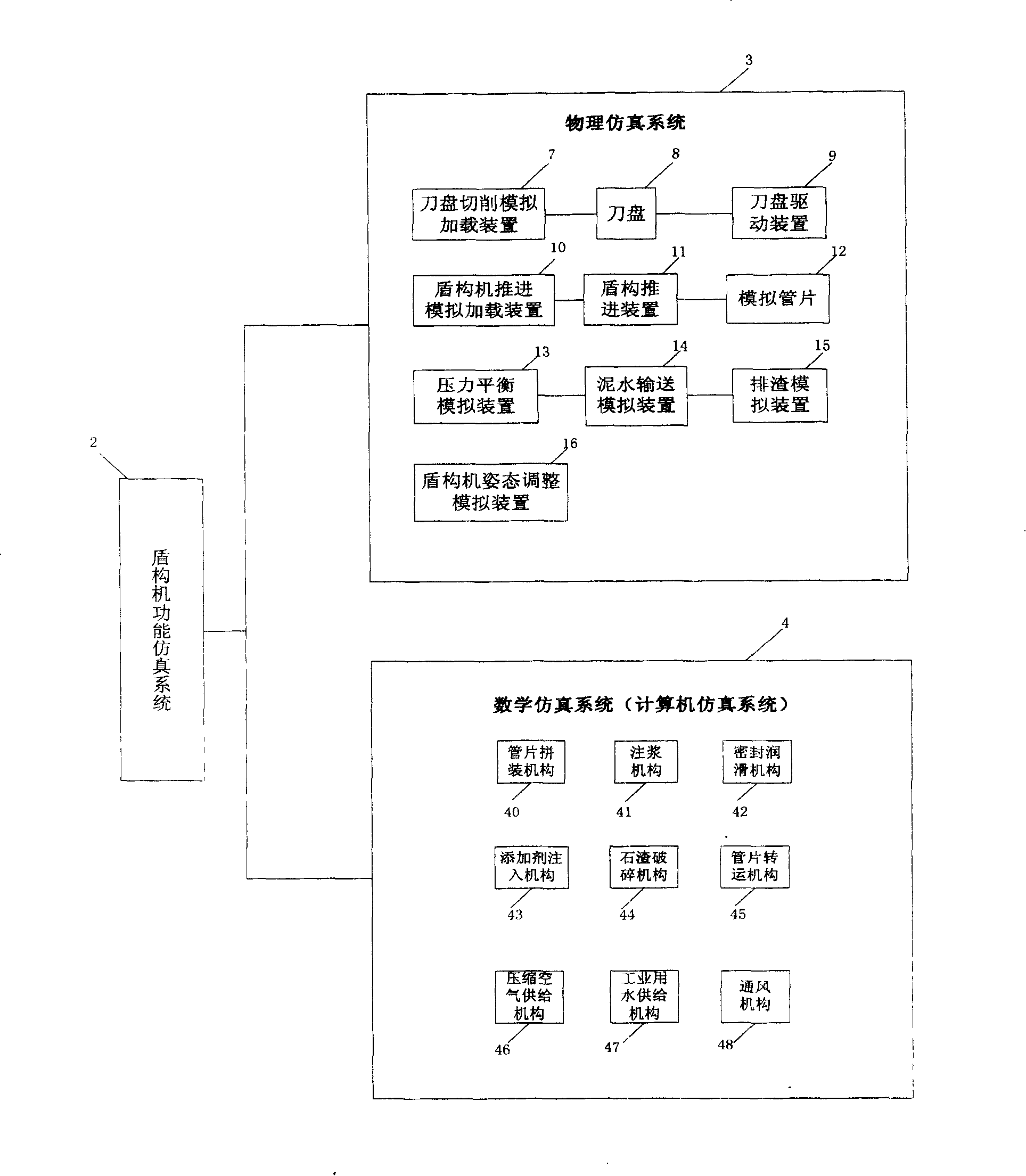

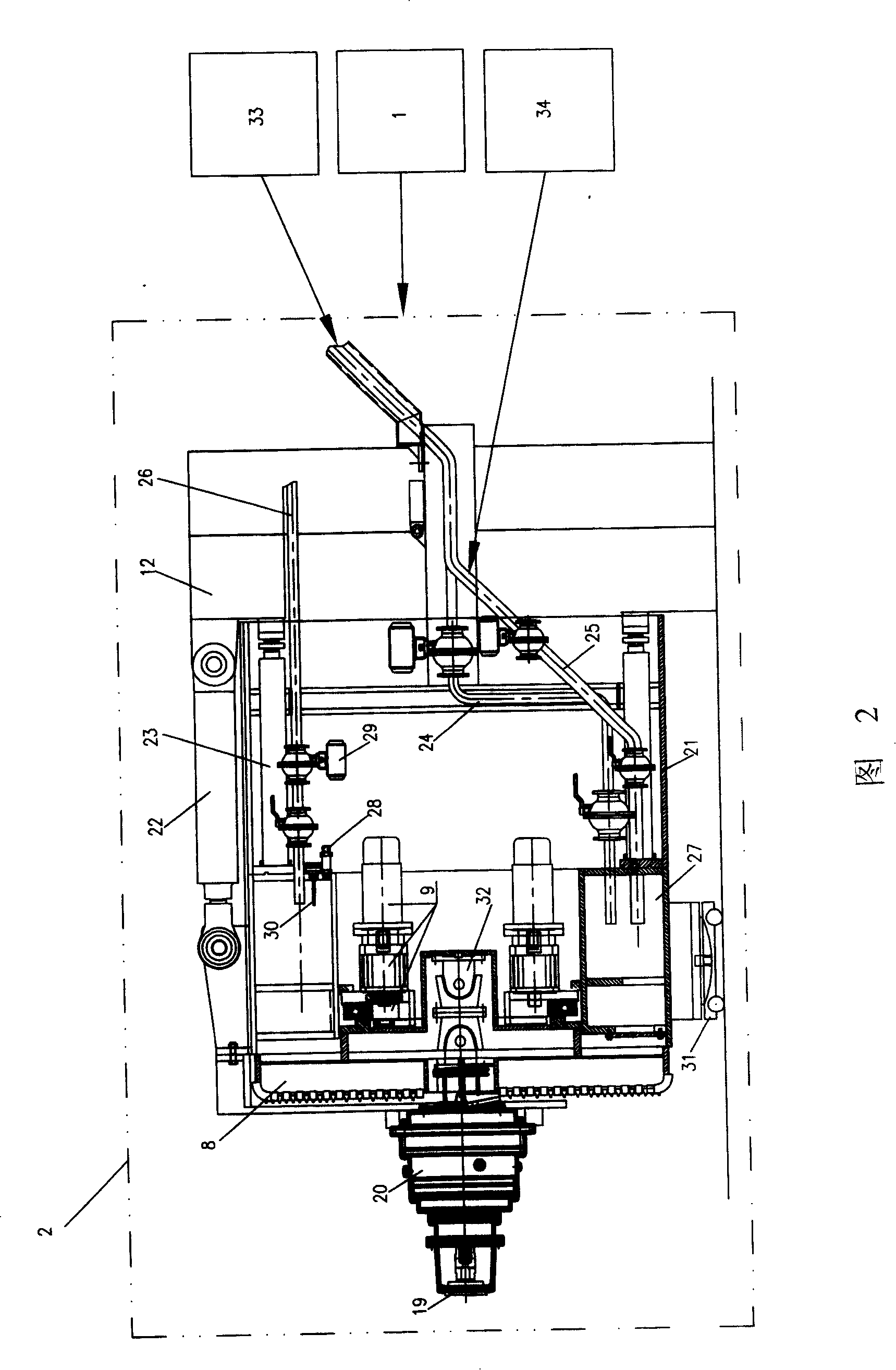

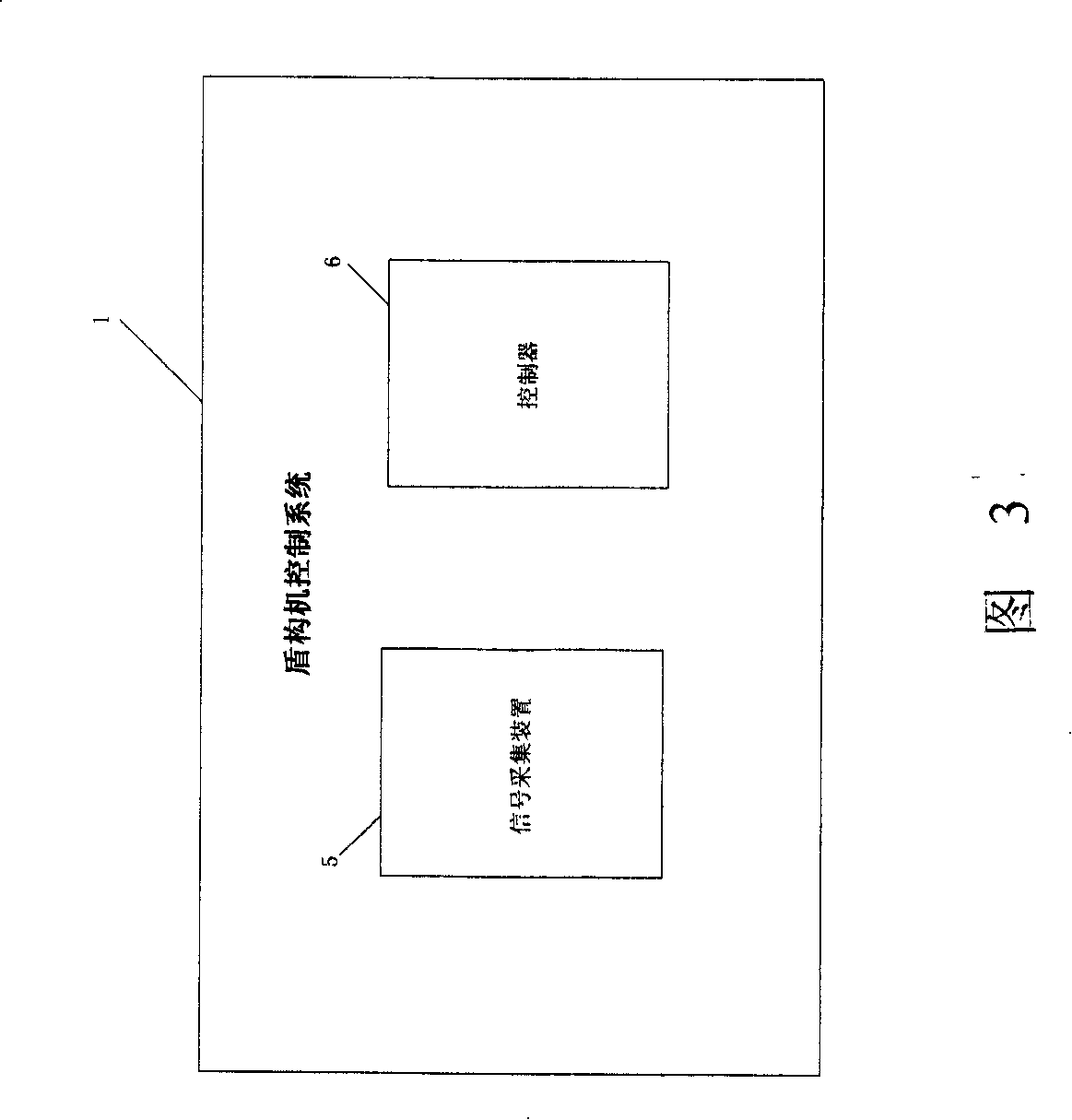

Tunnelling machine control system detection test platform

InactiveCN101211185AVersatileHigh degree of simulationSimulator controlElectric testing/monitoringMachine controlMathematical simulation

A test bench for testing a shield machine control system comprises a shield machine function simulation system and a sensing device arranged in the function simulation system, wherein the sensing device is communicated with the shield machine control system to be tested, and the function simulation system can be a physical simulation system, a mathematical simulation system or a combination of the physical simulation system and the mathematical simulation system. The test bench for testing the shield machine control system can completely simulate various functions of various types of shield machines, so as to test the correctness of the shield machine control system in design, assembly and debugging, avoid the risk arising from direct communication with the shield machine when the design of the control system is faulty, and shorten the circle of developing a new machine. Meanwhile, the invention is helpful for optimization and modification of the shield machine control system and remote fault diagnosis on the shield machine operated in a tunnel.

Owner:CHINA RAILWAY TUNNEL

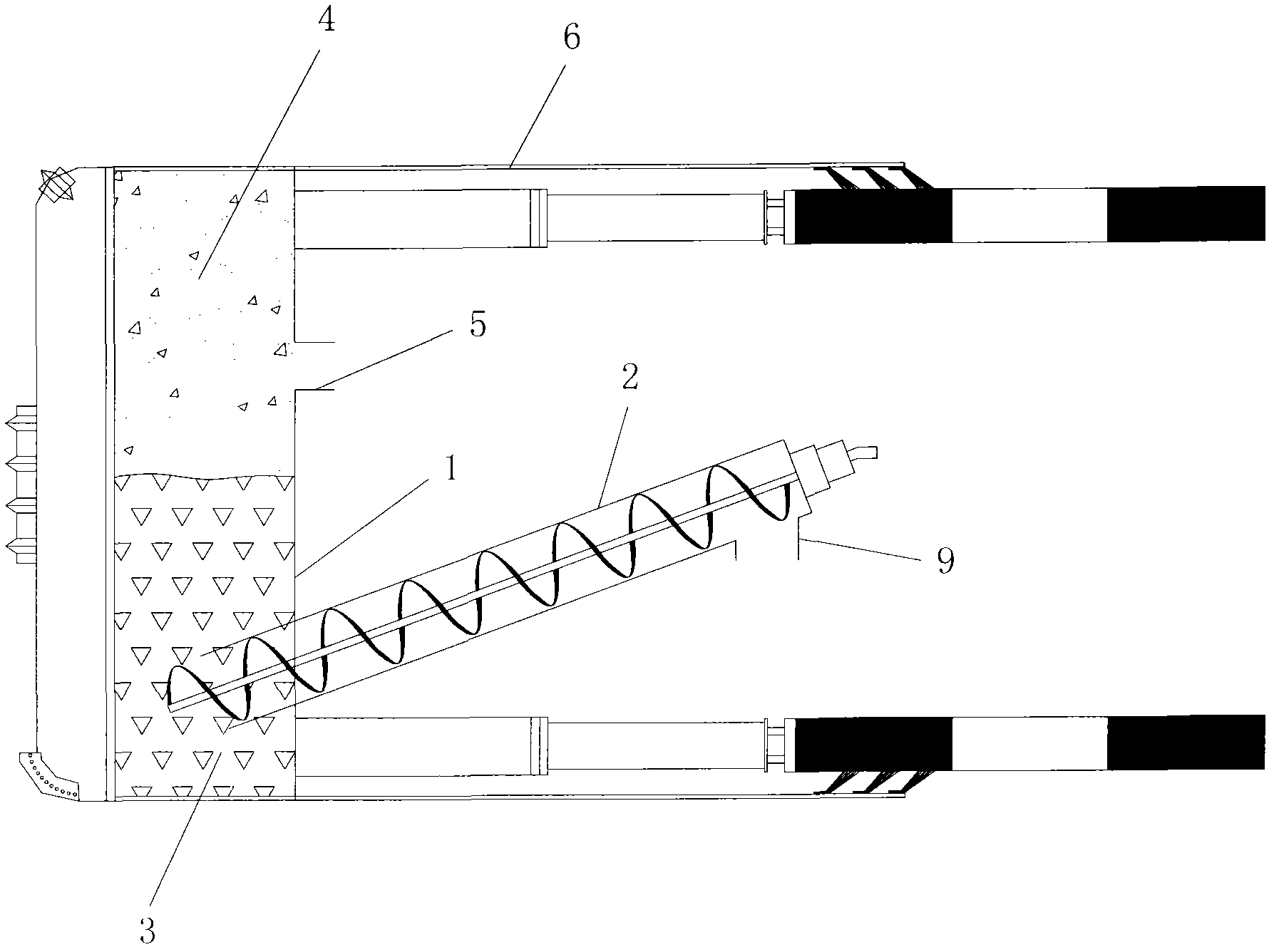

Large-diameter earth pressure balance shield machine

InactiveCN101798928AReduce wear rateChange the situation of uneven damageTunnelsControl theoryEarth pressure balance

The invention relates to a large-diameter earth pressure balance shield machine. The machine comprises a cutterhead, a cutterhead drive part, a propulsion oil cylinder, an erector, spiral conveyors and a frame; the cutterhead is a double-cutterhead which comprises a peripheral large cutterhead and an independent central cutterhead; the cutterhead drive part comprises two driving mechanisms which drive the peripheral large cutterhead and the independent central cutterhead respectively; and the peripheral large cutterhead and the independent central cutterhead rotate independently and bidirectionally. Compared with the prior art, the shield machine adopts the double-cutterhead design, greatly optimizes a cutting speed of the cutterhead on a soil body, further improves a propulsion speed of the shield, optimizes the disturbance effect of the cutterhead on the soil body, and prevents the rolling of a shield machine body; different opening rates are designed on the cutterhead and are suitable for different situations of a central part and a peripheral part when a tunnel is advanced; and three spiral conveyors discharge soil, effectively control the posture of the shield, and prevent the deviation of a tunnel axis.

Owner:SHANGHAI LIXING ENG TECH DEV

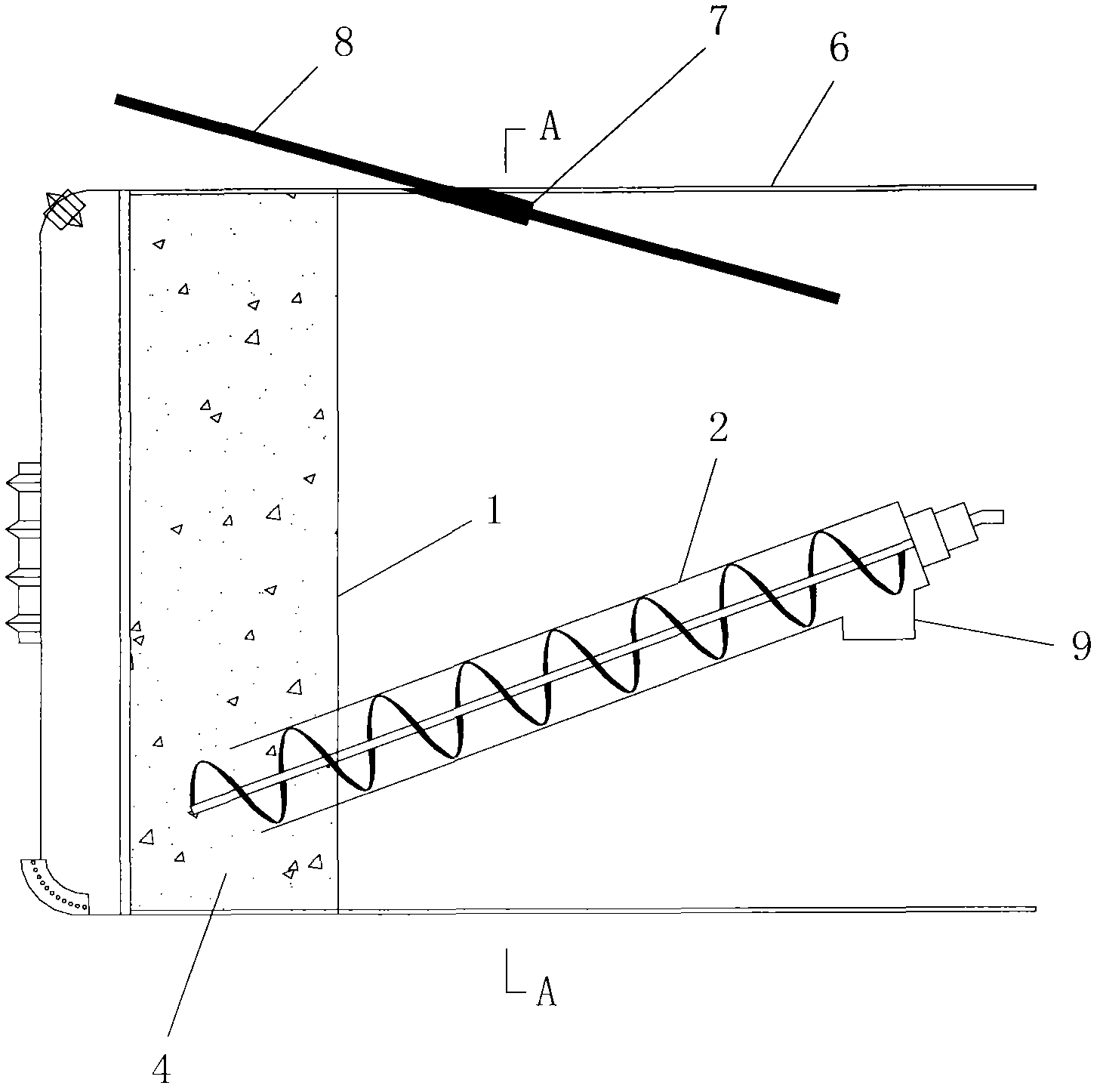

Drilling and bursting type heading machine

ActiveCN105804764AImprove drilling efficiencyLow drilling efficiencyDisloding machinesSlitting machinesHydraulic motorHydraulic cylinder

The invention discloses a drilling and bursting type heading machine which comprises a drilling and bursting device, an angle control device, a front-back telescopic device and a cantilever type heading machine body. The drilling and bursting device is installed on a front-back moving component of the front-back telescopic device. The front-back telescopic device is installed on the cantilever type heading machine body. The drilling and bursting device comprises a fixing frame, a rock drill component and a bursting device component, wherein the rock drill component and the bursting device component are fixed to and installed on the fixing frame. The angle control device comprises an installation base, an auxiliary rotary hydraulic motor, an adjusting hydraulic cylinder and a main rotary hydraulic motor. When the front-back moving component of the front-back telescopic device completely stretches out, the distance between the front end of the drilling and bursting device and a working surface is smaller than the distance between the front end of a cutting head of the cantilever type heading machine body and the working surface. The drilling and bursting type heading machine is compact in structure, a hard rock stratum with the rock stratum hardness being larger than 10 can be rapidly drilled and burst on the premise that the energy consumption is not increased, and accordingly the purposes of improving the heading efficiency and reducing potential safety hazards are achieved.

Owner:CHINA UNIV OF MINING & TECH

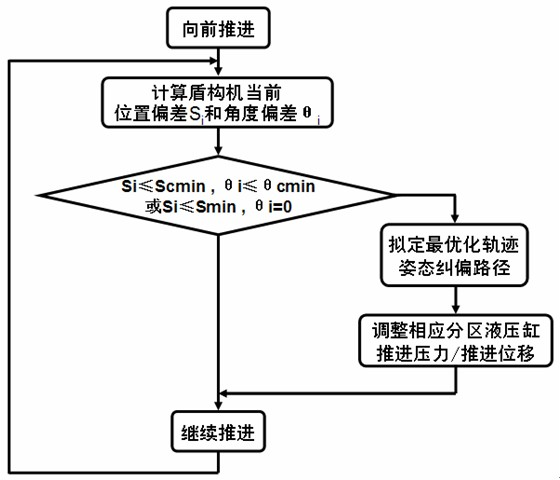

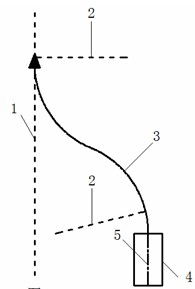

Track and posture composite control method in shield tunneling process

ActiveCN102102522AEliminate positional deviationEliminate Angle DeviationTunnelsHydraulic cylinderAngular deviation

The invention discloses a track and posture composite control method in a shield tunneling process. The method comprises the following steps of: performing control by setting threshold values for a posture and a track; immediately adjusting the posture as long as the posture deviates to exceed the limit even though the track does not reach a deviation correction threshold; solving current positional deviation Si and angular deviation theta I of a shield machine through measurement and calculation when a shield works; continuously propelling the shield machine when the Si is less than or equal to a positional deviation threshold value Scmin of a track and posture composite controller and theta i is less than or equal to an angular deviation threshold value theta cmin of the track and posture composite controller or when the Si is less than or equal to positional allowable deviation Smin of actual tunnel construction and theta i is equal to 0; contrarily, automatically adjusting propelling pressure of a hydraulic cylinder of each sub-region and propelling displacement to simultaneously eliminate the positional deviation and the angular deviation generated in a tunneling process. Thus, an actual tunneling route of the shield machine is controlled within a design axial range of a tunnel, unnecessary overbreak and underbreak are avoided, and the forming quality of the tunnel is improved.

Owner:ZHEJIANG UNIV

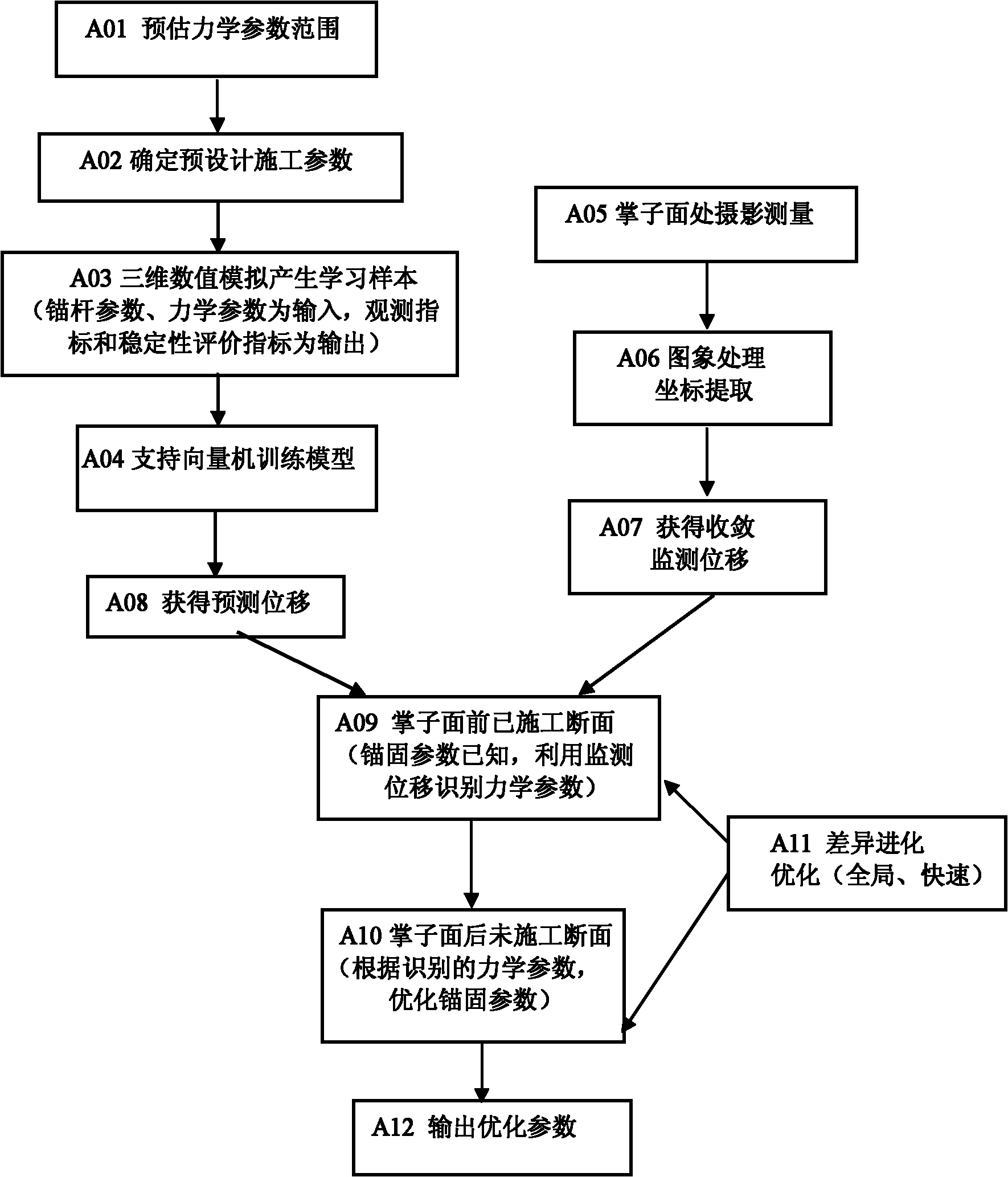

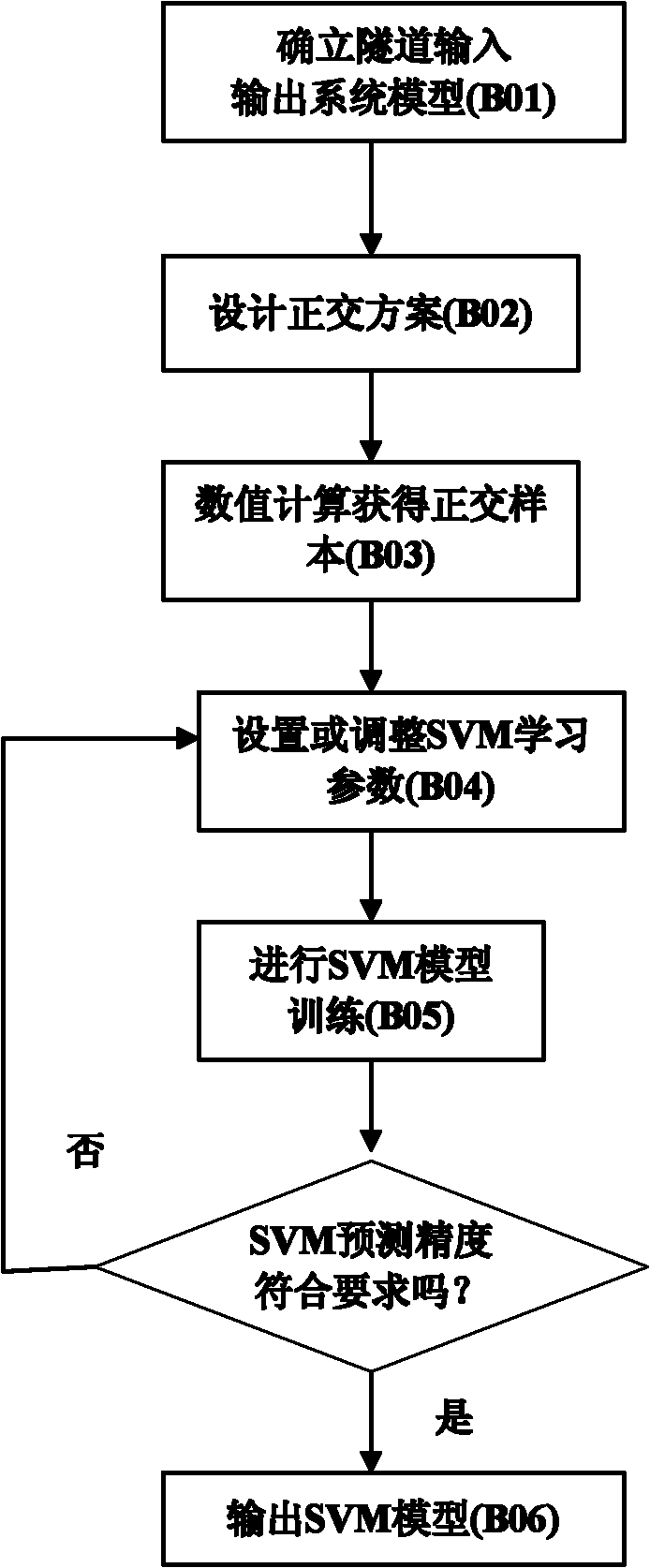

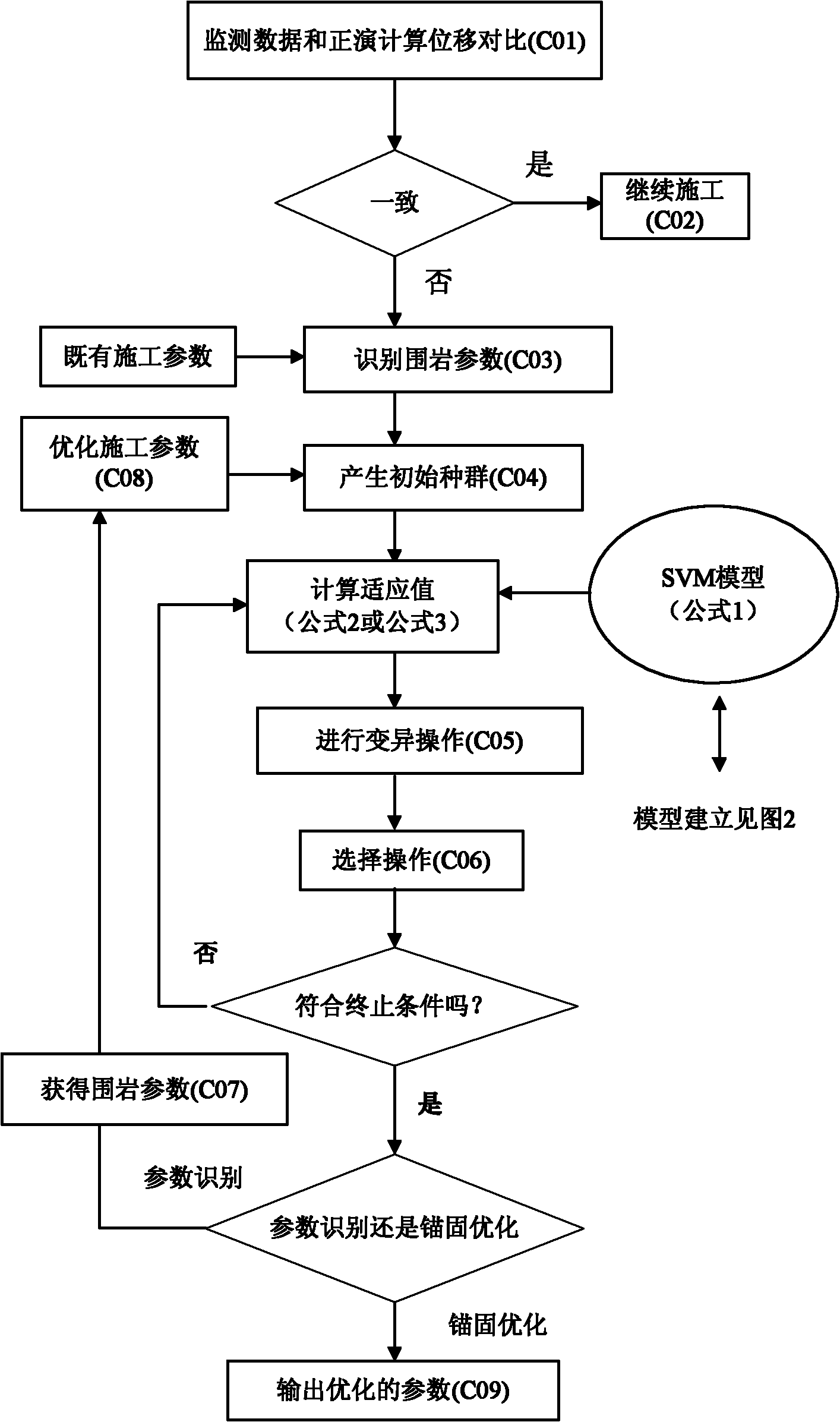

Quick feedback analyzing system in tunnel constructing process

InactiveCN102155231AOvercoming the blindness of pre-designDynamic information construction improvementMining devicesTunnelsEngineeringAlgorithm optimization

The invention discloses a quick feedback analyzing system in a tunnel constructing process. The system adopts a scheme: understanding currently adopted designing construction parameters; establishing a tunnel excavation three-dimensional finite element numerical grid calculation model; acquiring surrounding rock layering and convergent displacement monitoring information after a tunnel is excavated; establishing a non-linear support vector machine model; fixing an anchoring parameter according to the actual construction parameter, and optimally identifying rock mechanic parameters by adoptinga differential optimization algorithm; optimizing the construction parameter of an anchoring scheme by adopting a differential evolution algorithm; and optimizing the rock mechanic parameters by calling the differential evolution and optimization algorithms to further solve the construction parameter of the anchoring scheme, and outputting the construction parameter of the optimized anchoring scheme as a construction scheme through a computer display screen to guide the constructors to construct. The quick feedback analyzing system ensures that the monitoring information is used for optimizing the anchoring parameter while being used for identifying the surrounding rock parameters, so that the dynamic information construction is improved to a level of quantitative analysis.

Owner:DALIAN MARITIME UNIVERSITY

Construction method applicable to intersection between inclined shaft and slant hole of weak surrounding rock tunnel

The invention discloses a construction method applicable to an intersection between an inclined shaft and a slant hole of a weak surrounding rock tunnel, and the method comprises the following steps that (1) the inclined shaft is dug; (2) the arch part of an inclined shaft section is supported; (3) the vertical central line of a face at the intersection between the inclined shaft and the slant hole serves as a boundary, first a slant hole section on one side of the boundary is dug, and sectional digging is adopted on every side; an area which is enclosed by the arch top of the slant hole, the side walls of the slant hole on both sides and the extended surface of the ramp slope surface of the inclined shaft is a I part; an area which is enclosed by the plane of the intersection line of the ramp slope surface on an inclined shaft digging surface, the side walls of the slant hole on both sides and the extended surface of the ramp slope surface of the inclined shaft is a II part; and an area which is enclosed by the plane of the intersection line of the ramp slope surface on the inclined shaft digging surface, the side walls of the slant hole on both sides and the bottom of the slant hole is a III part; the slant hole section on the other side is dug in a sectional way; (4) supporting and reinforcement are carried out; and (5) inverted arch and lining construction are carried out. According to the method, the deformation of surrounding rock is reduced, some temporary supporting steps are saved on the premise of good safety, so that the procedures are simple, the construction cost is reduced, and the construction progress is improved.

Owner:中铁二十三局集团第四工程有限公司 +1

Rock breaking seismic source and active source three-dimensional seismic combined advanced detection system using tunnel boring machine

A rock breaking seismic source and active source three-dimensional seismic combined detection system uses a tunnel boring machine for three-dimensional seismic combined detection by active seismic source and rock breaking seismic source methods. Long-distance advanced prediction and position recognition of a geological anomalous body are realized using the active source seismic method. Machine construction is adjusted and optimized according to the detection result; real-time short-distance accurate prediction of the body is realized using the cutter head rock breaking vibration having weak energy but containing a high proportion of transverse wave components as seismic sources and adopting an unconventional rock breaking seismic source seism recording and handling method. An area surrounding rock quality to be excavated is represented and assessed. A comprehensive judgment is made to the geological condition in front of the working face with the results of active source and rock breaking seismic source three-dimensional seismic advanced detection.

Owner:SHANDONG UNIV

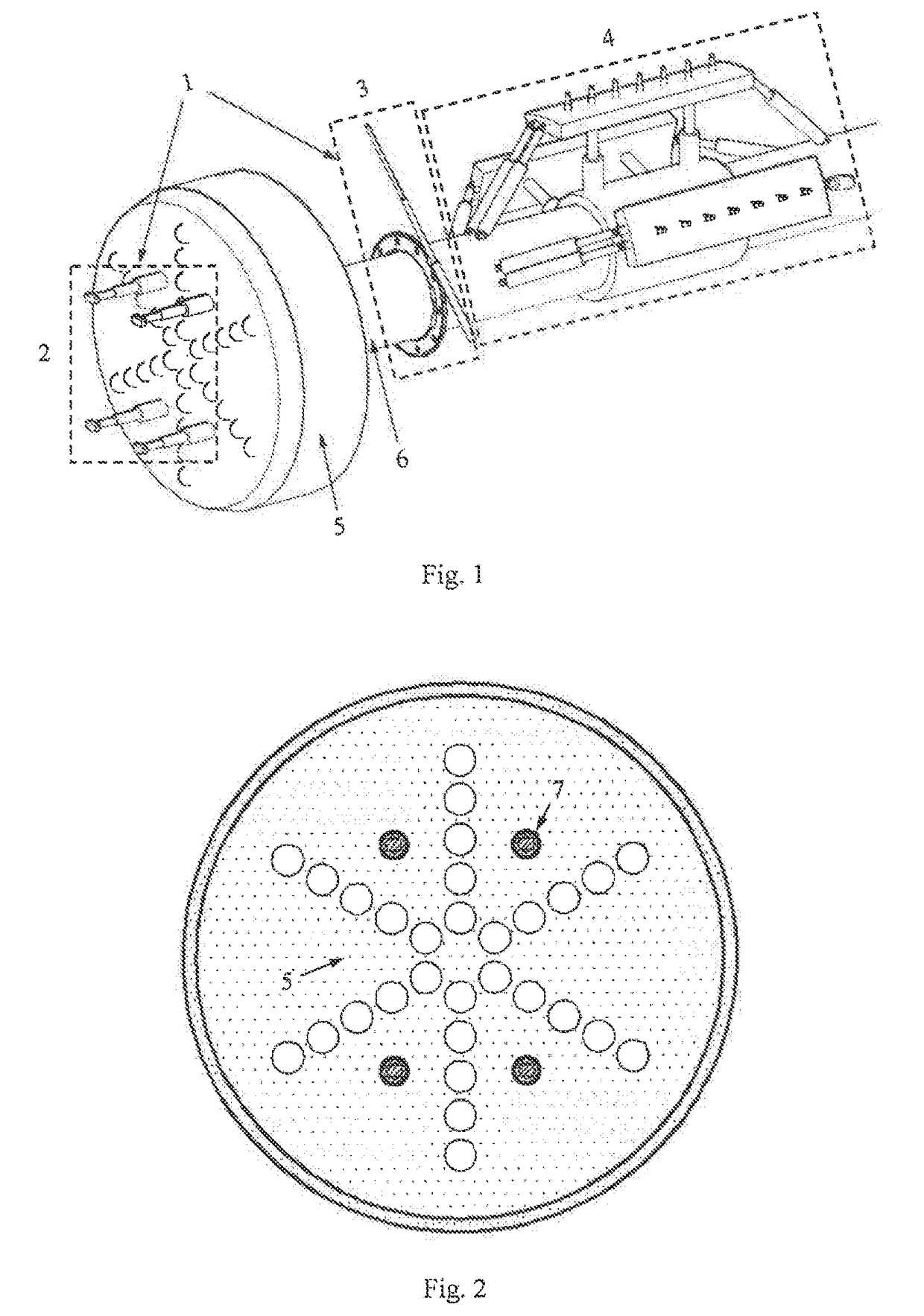

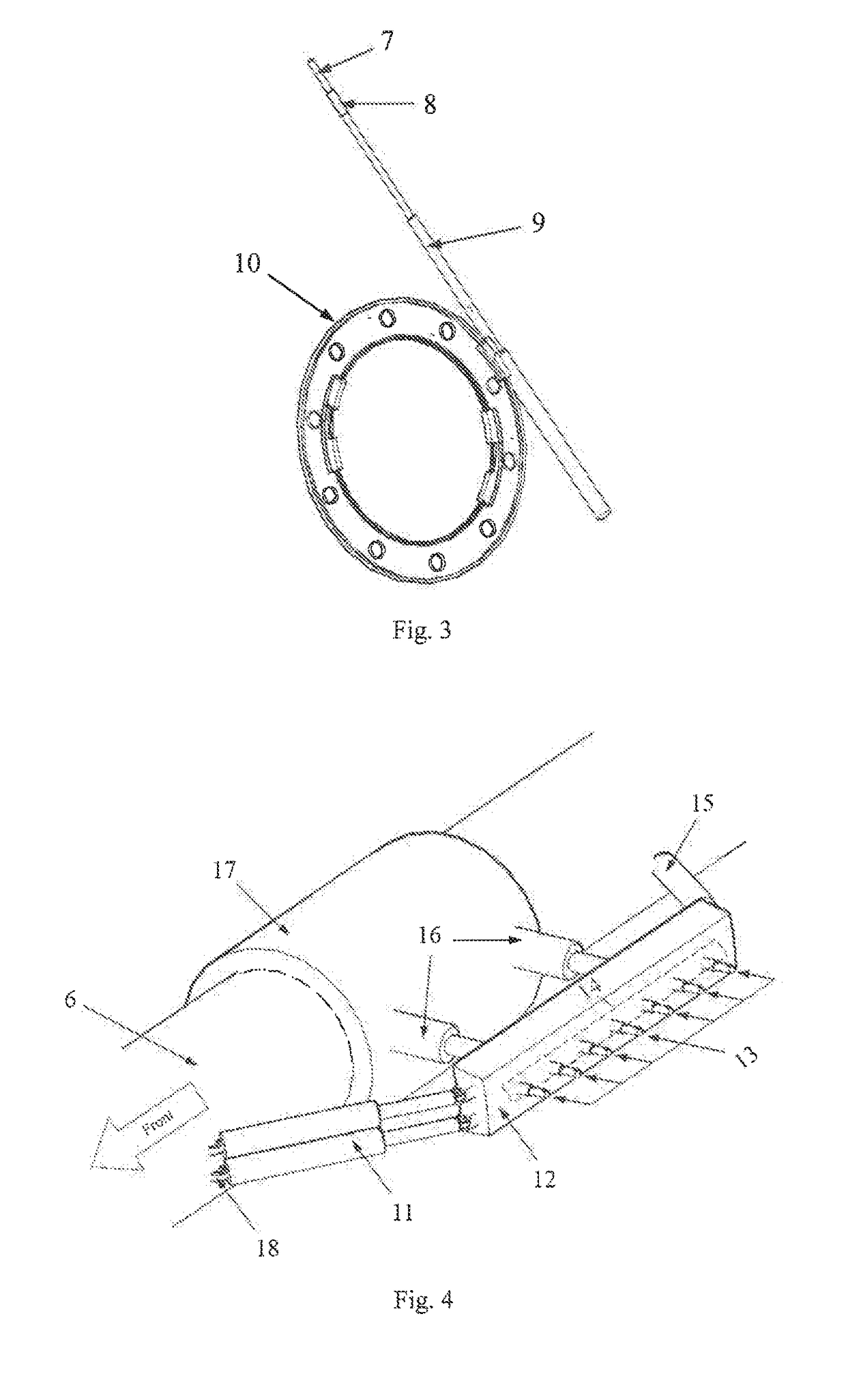

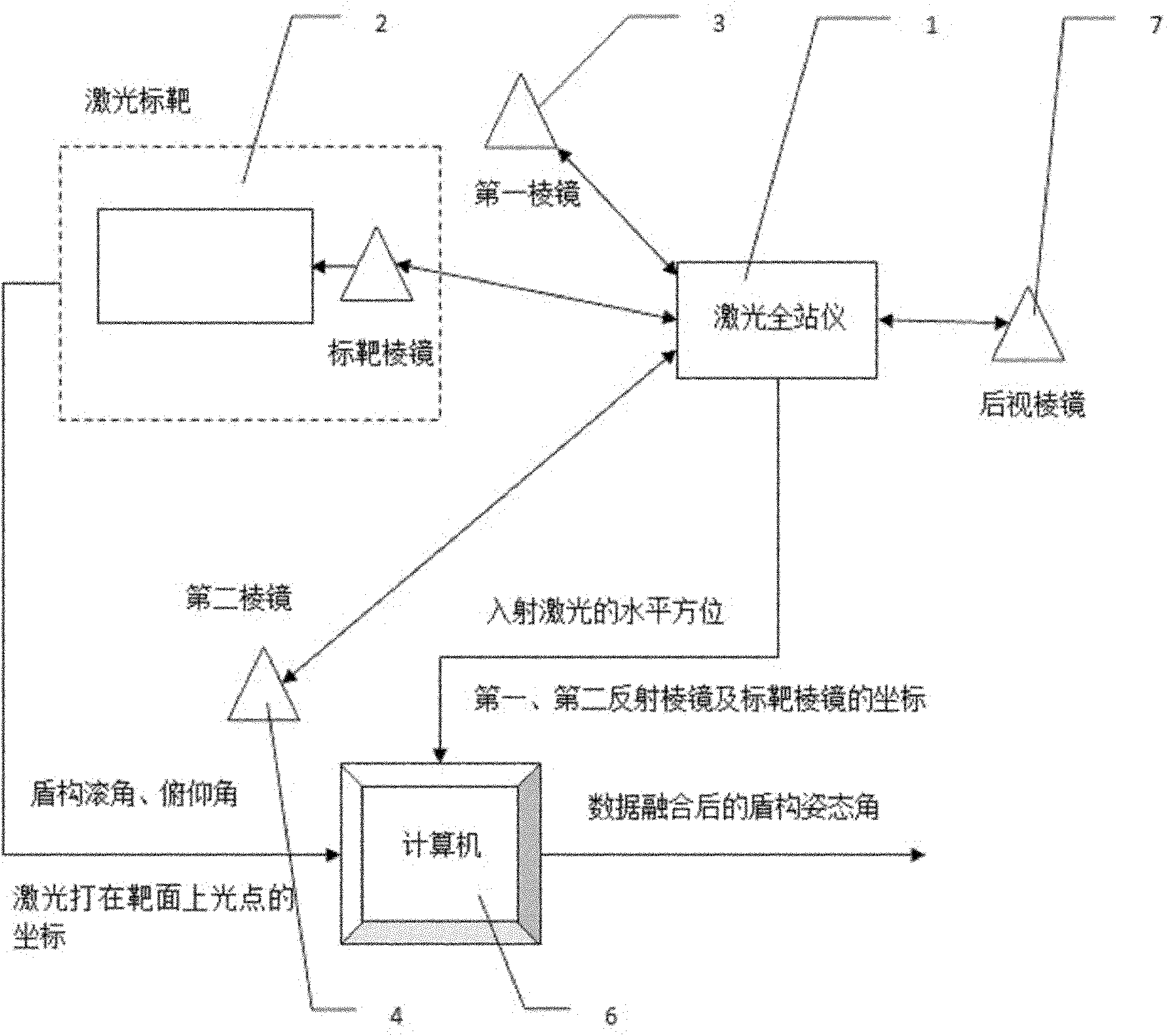

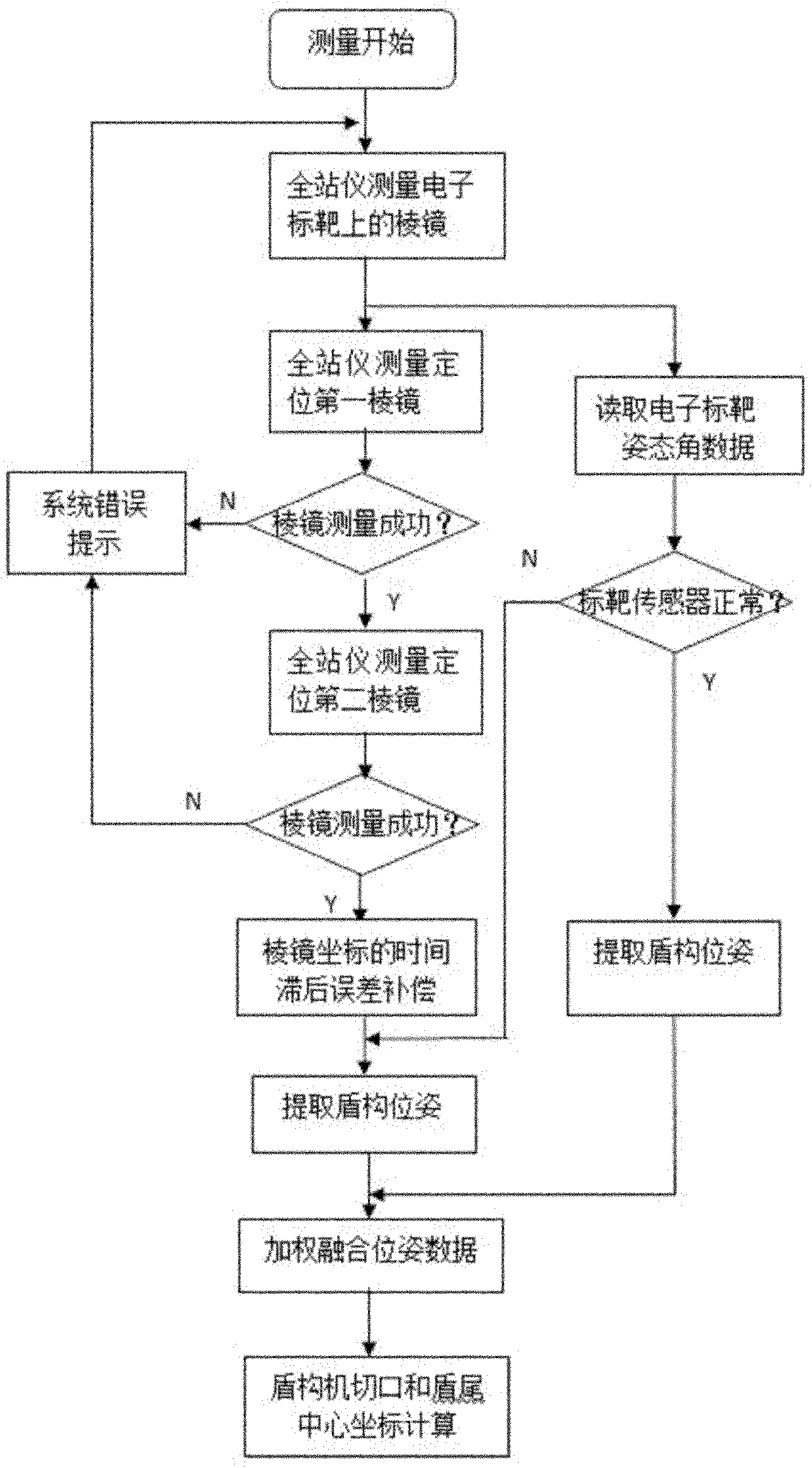

Real-time guide system of multi-sensor data fusion shield machine

ActiveCN102052078AImproving pose measurement accuracyImprove reliabilityAngle measurementTunnelsContinuous measurementLaser target

The invention relates to a real-time guide system of a multi-sensor data fusion shield machine, comprising a laser overall meter, a laser target, a first prism, a second prism, a rear-view prism and a computer, wherein the rear-view prism is used for detecting whether the position of the laser overall meter is changed or not in the measuring process; the laser target is used for measuring an attitude angle of the shield machine in real time; the first prism and the second prism are respectively arranged at both ends of the shield machine; the laser overall meter measures coordinates of the first prism, the second prism and a laser target prism under a geodetic coordinate system by emitting lasers; and the computer computes to obtain multigroup attitude angles by combining with attitude angle data measured by the laser target and carries out fusion processing so as to obtain optimized shield machine attitude angles for implementing the real-time guide of the shield machine. The invention can still obtain the shield machine attitude angles when sensors inside the laser target are faulty or positioning prisms are shielded, ensures the continuous measurement and has high measurement accuracy, strong work stability, and the like.

Owner:WUHAN INTELLIGENT EQUIP IND INST CO LTD

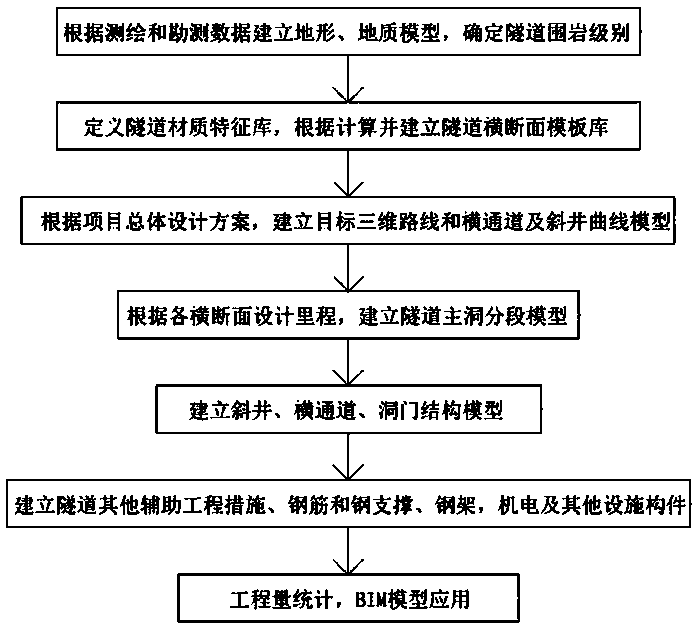

Highway tunnel designing method based on BIM

The invention discloses a highway tunnel designing method based on BIM. The highway tunnel designing method based on the BIM includes the steps that 1, according to mapping and reconnaissance data, aterrain model and a geologic model are built, and tunnel surrounding rock grades are determined; 2, a tunnel texture feature library is defined, and a tunnel cross section model library is establishedthrough calculation; 3, according to a project overall design scheme, a tunnel three-dimensional path and cross aisle and inclined shaft space curve model is built; 4, according to design kilometersof all tunnel cross sections, a tunnel main cave subsection model is built; 5, an inclined shaft model, a cross-aisle model and a tunnel portal structure model are built; 6, other tunnel auxiliary engineering measure components including reinforcing steel bars, steel shotcrete, steel frames and electromechanical parts are built; 7, tunneling work amount accounting is conducted, and a BIM model isapplied. According to the highway tunnel designing method based on the BIM, the terrain model and the geologic model are fused with a tunnel main body, three-dimensional paths can be modified in realtime, related drawings are automatically modified, therefore, the purpose is achieved that engineering design information is completely reflected in the BIM model, and model information transfer and application in the later period are facilitated.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com