Patents

Literature

593 results about "Disc cutter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A disc cutter is a specialised, often hand-held, power tool used for cutting hard materials, ceramic tile, metal, concrete, and stone for example. This tool is very similar to an angle grinder, chop saw, or even a die grinder, with main difference being cutting disc itself, (circular diamond blade, or resin-bonded abraisive cutting wheel for disc cutter vs. abrasive grinding wheel for angle grinder). This tool is highly effecient at cutting very hard materals especialy when compared to hand tools.

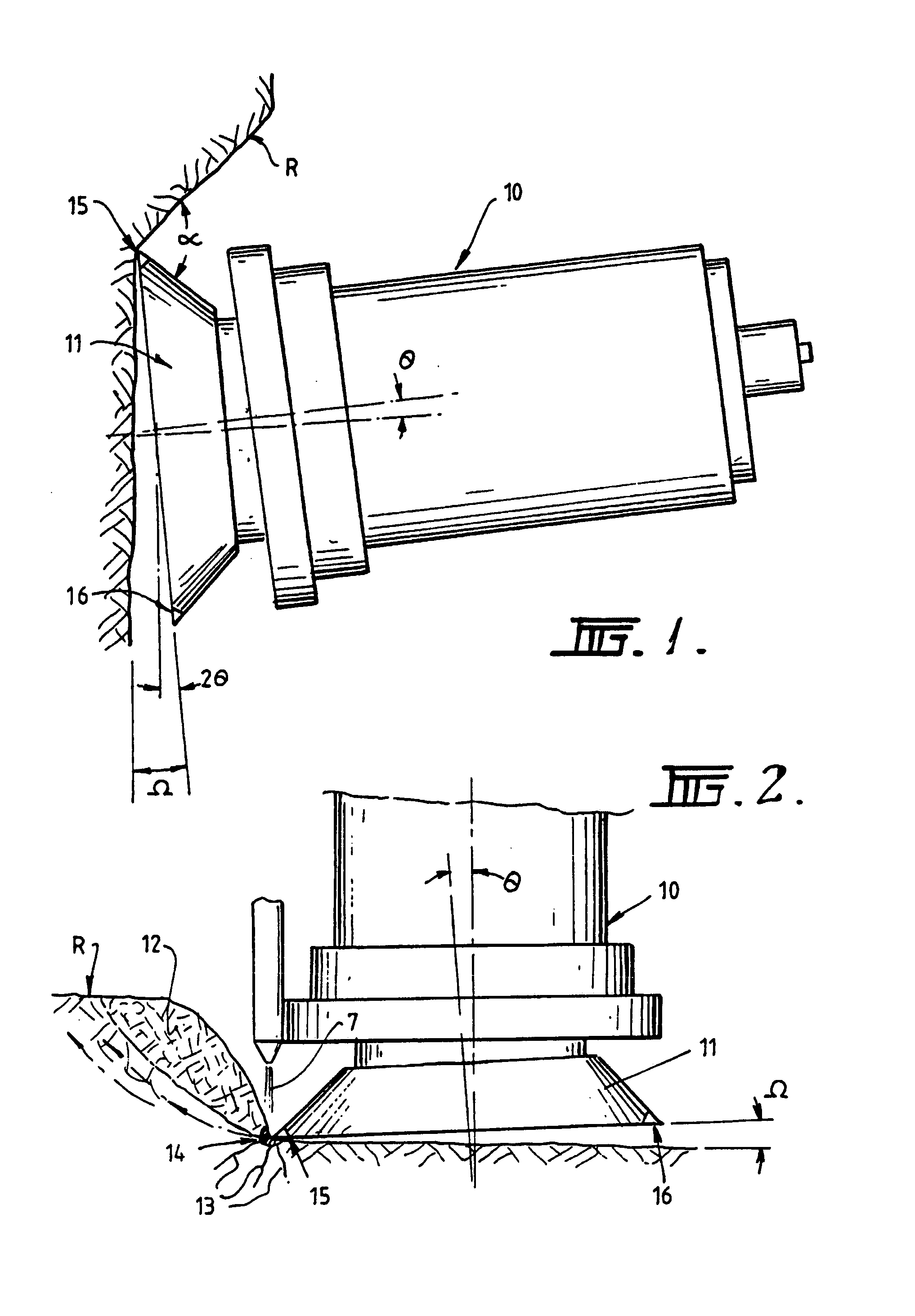

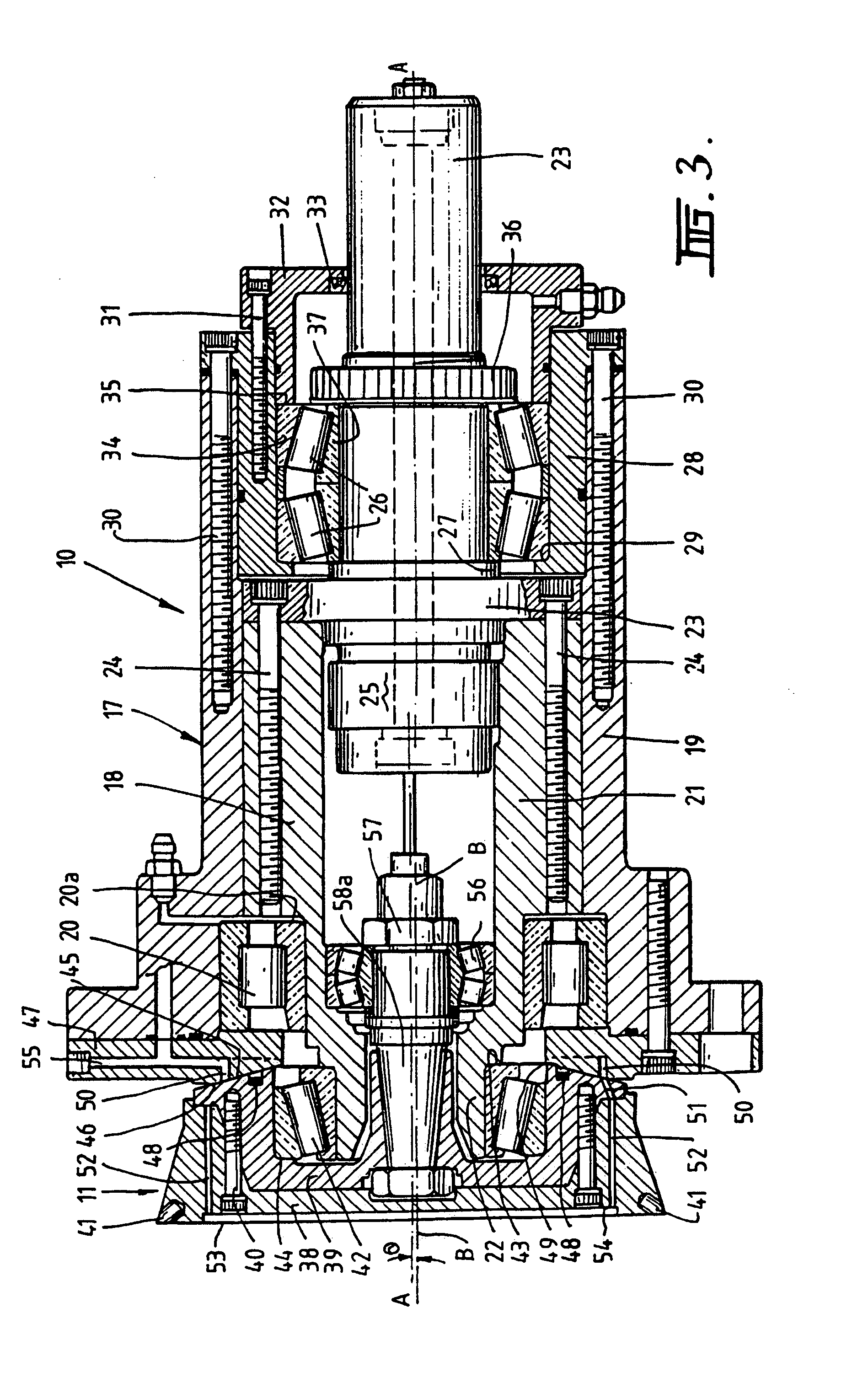

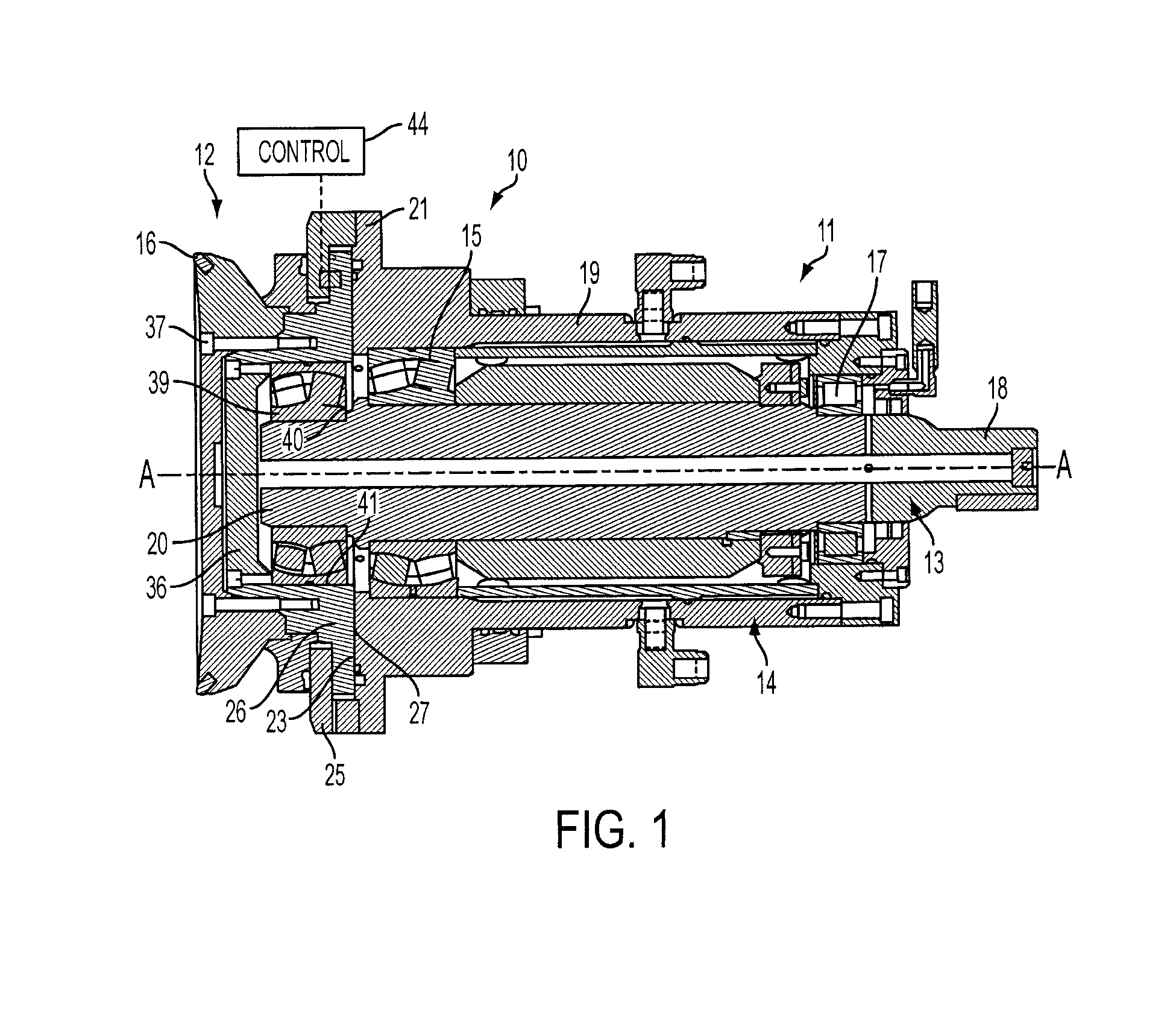

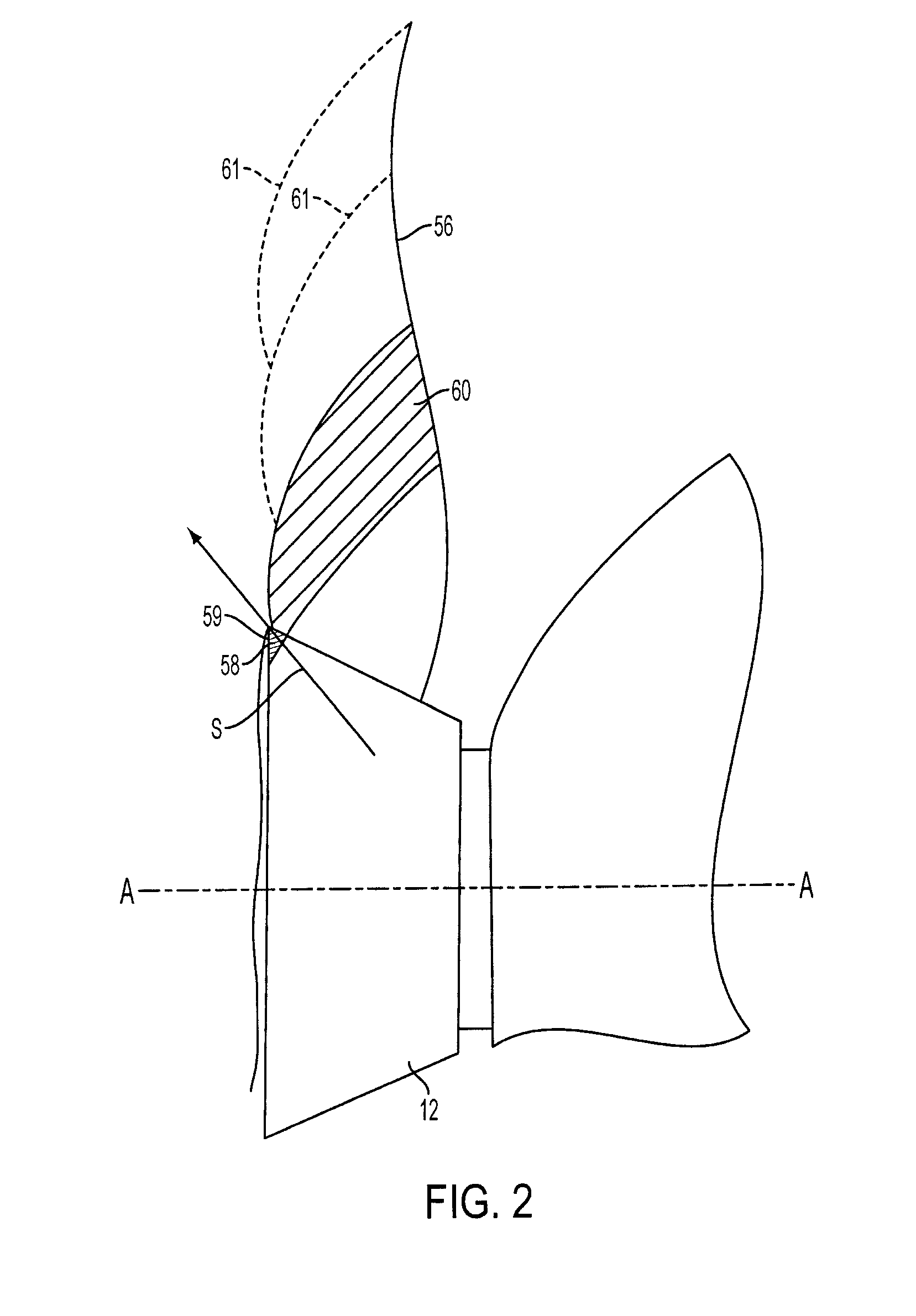

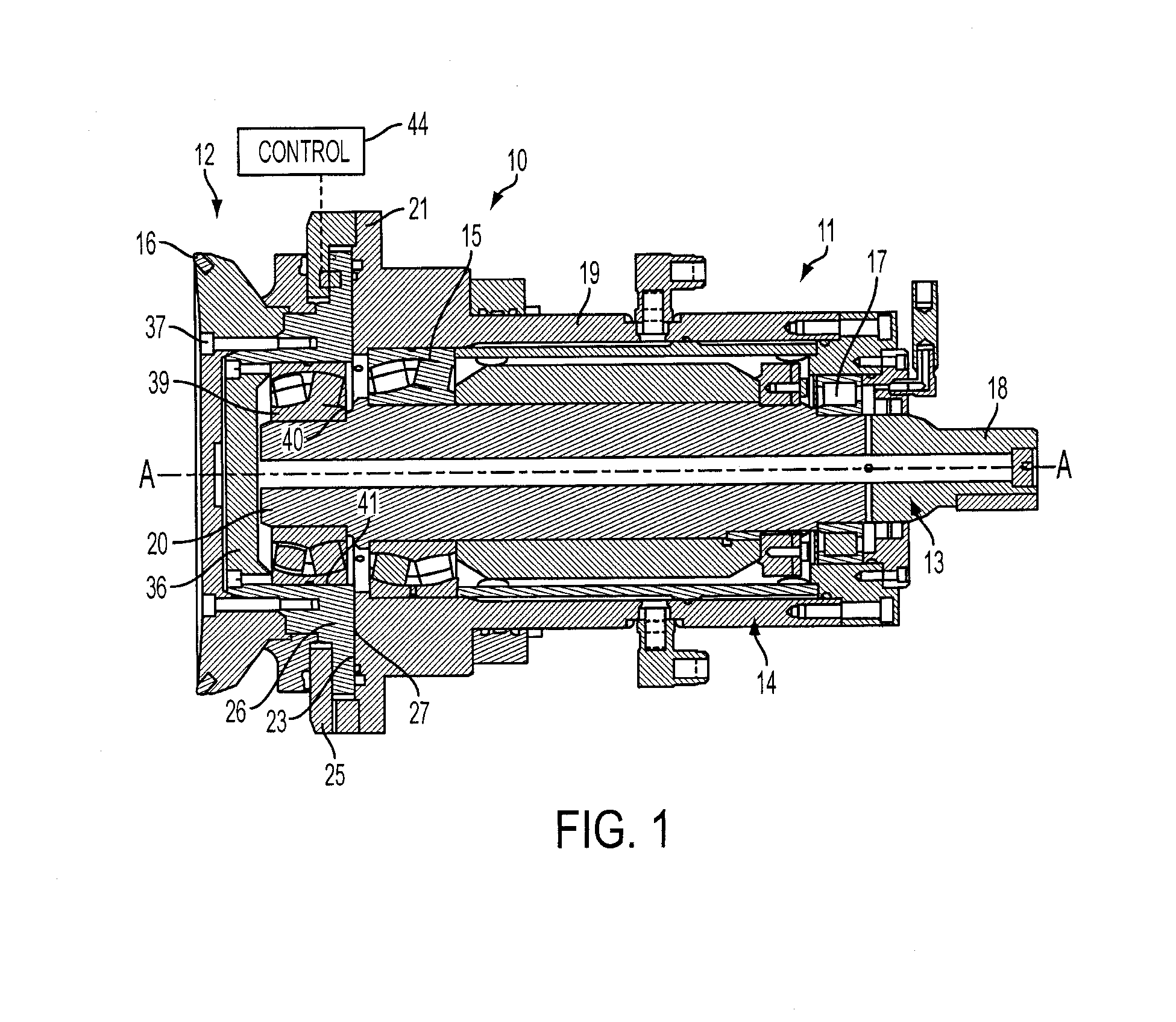

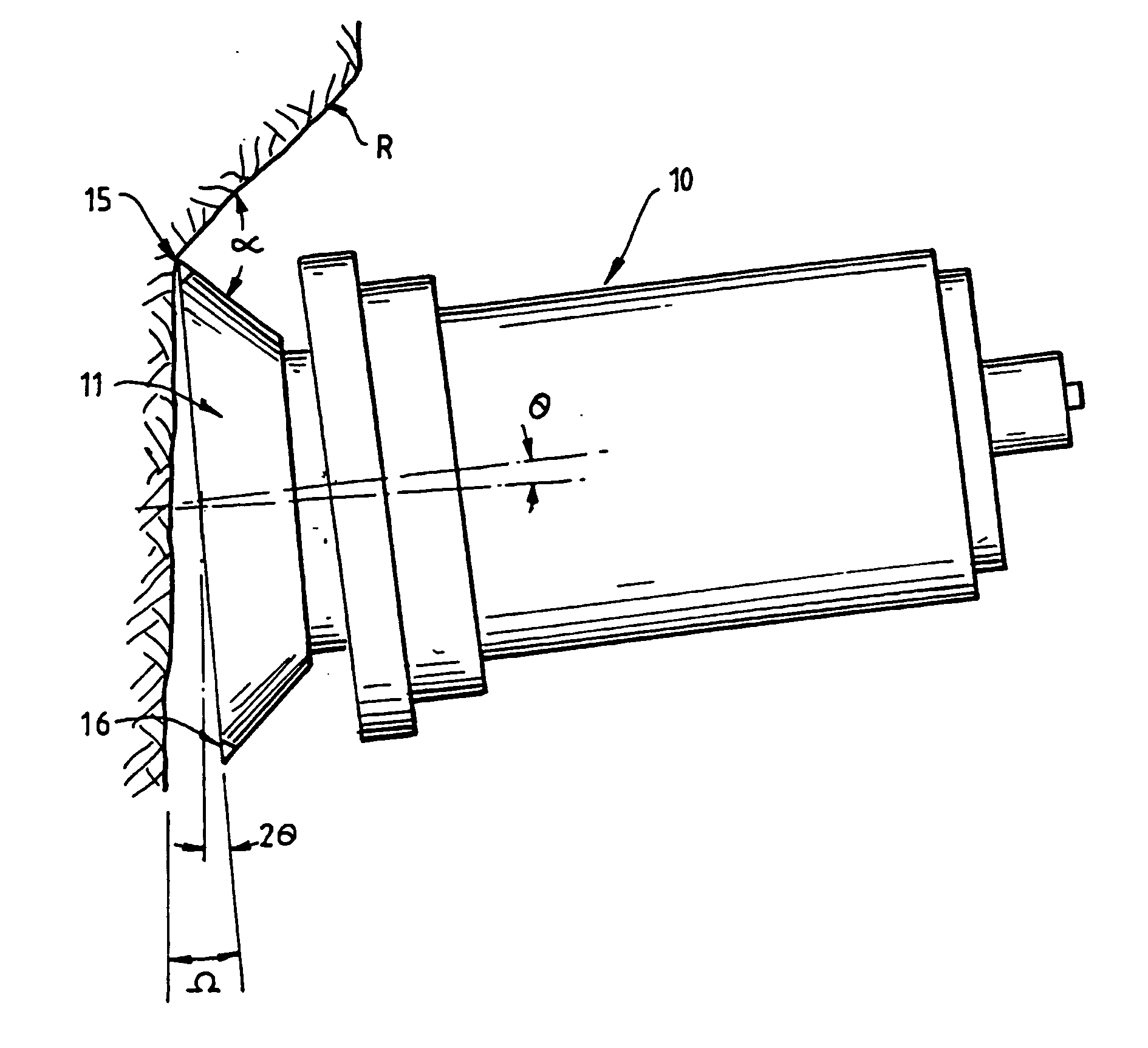

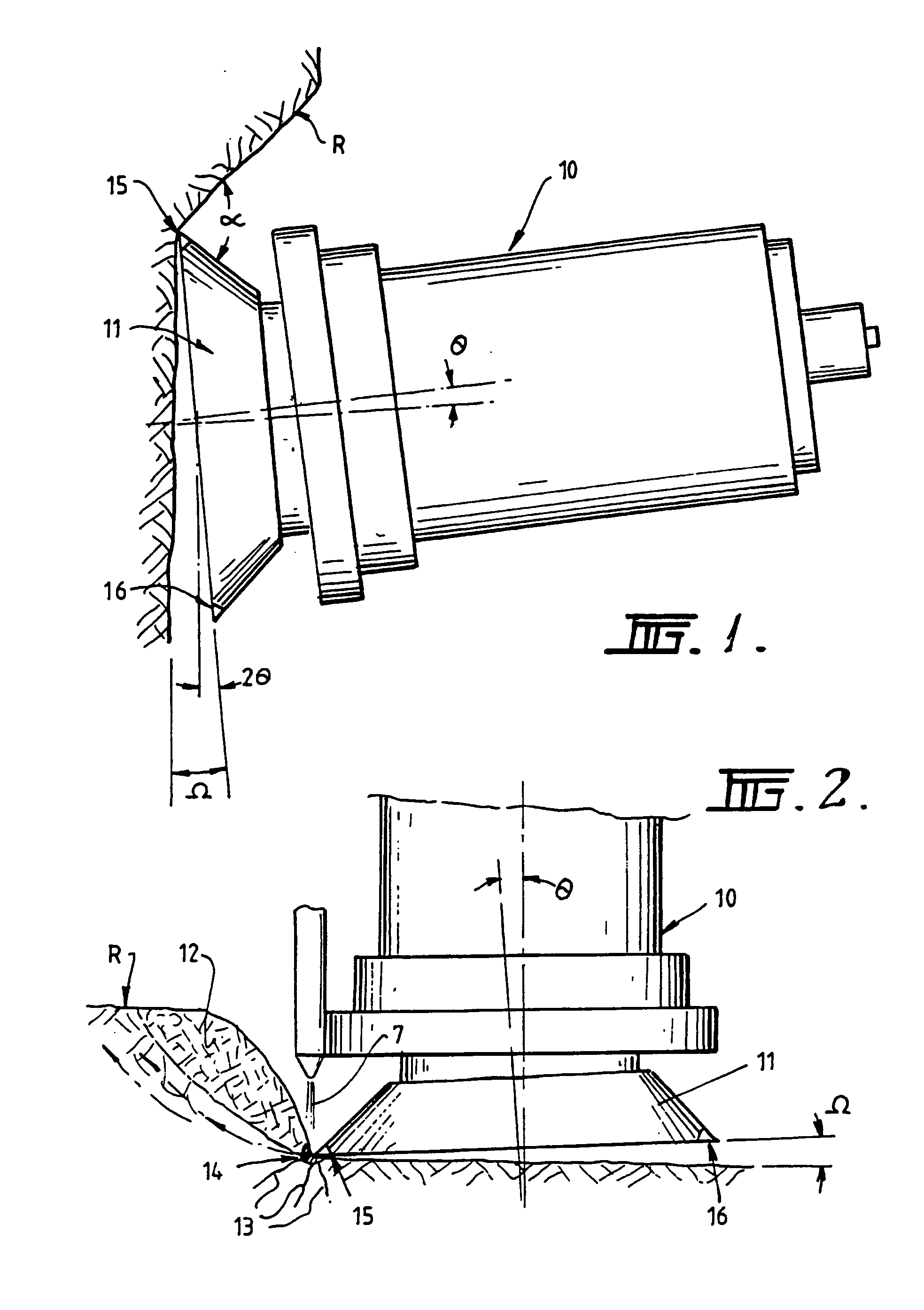

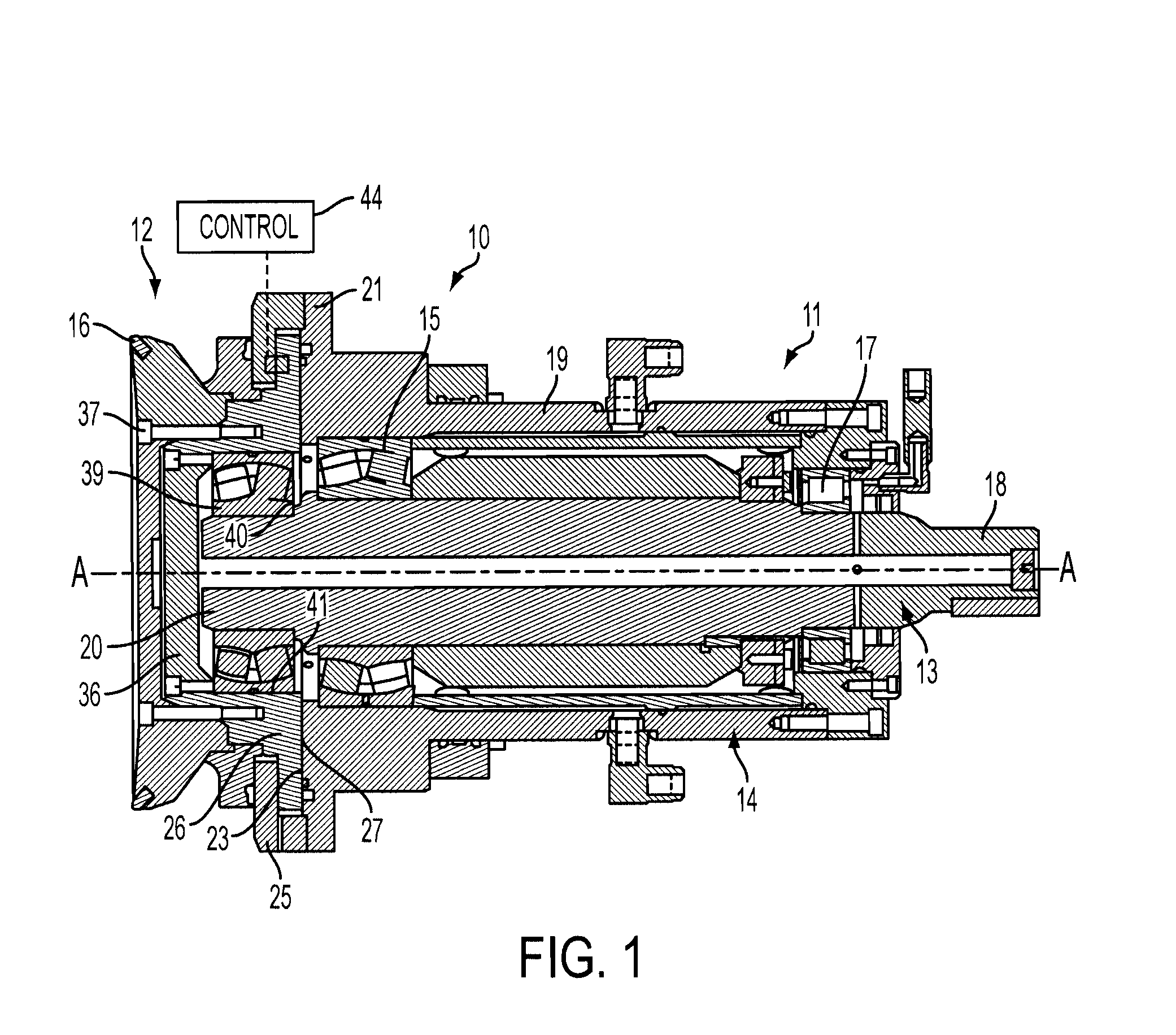

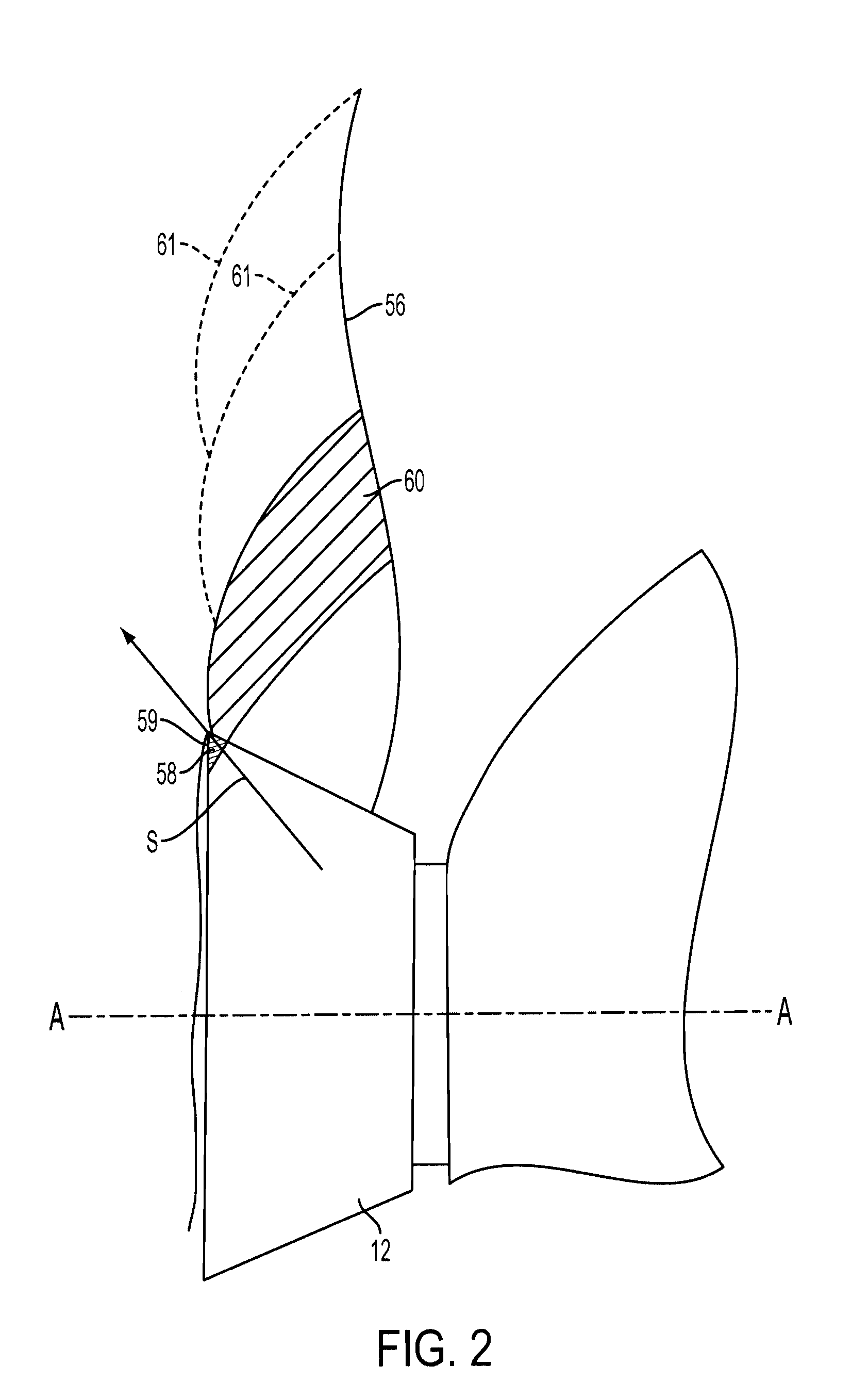

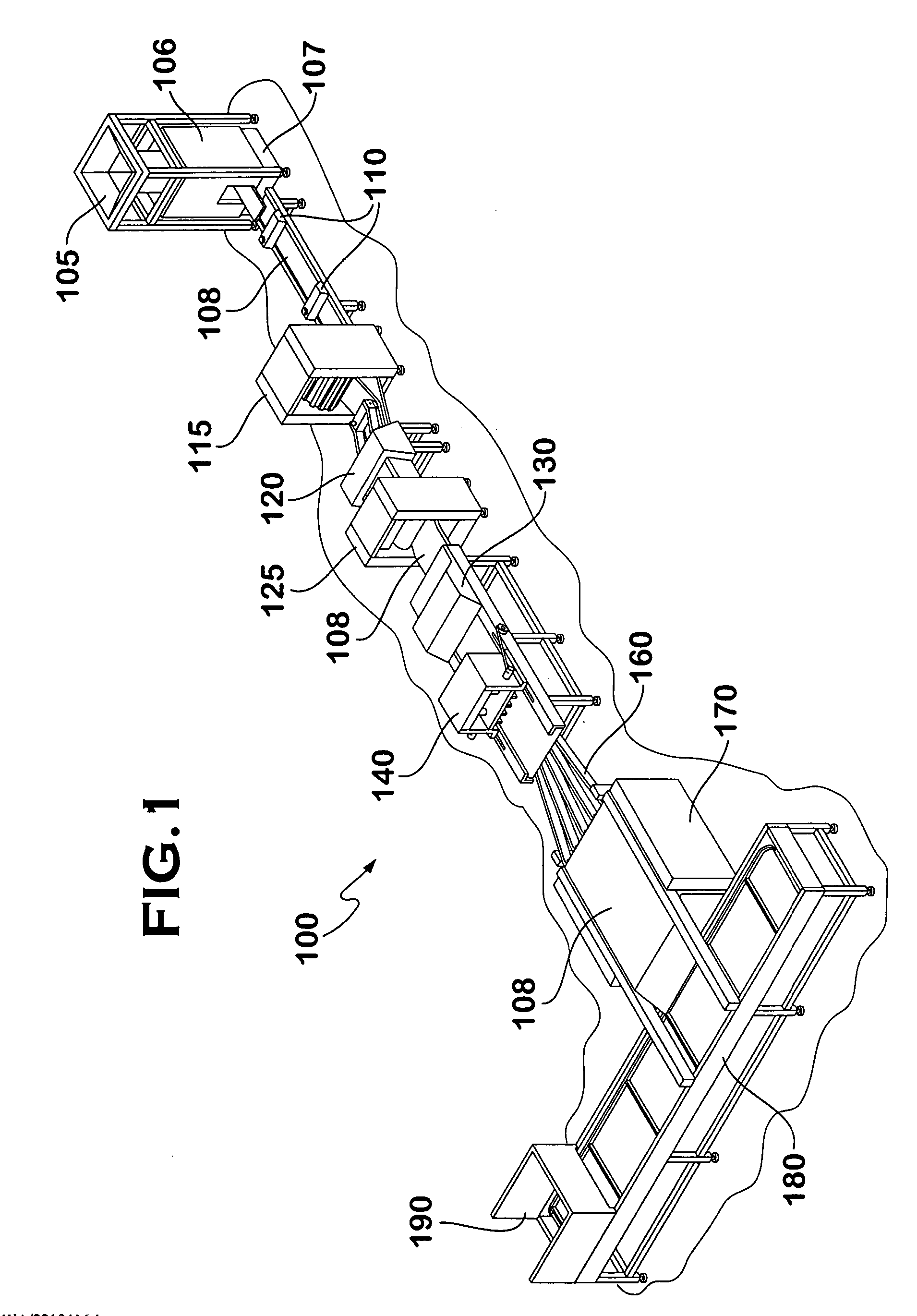

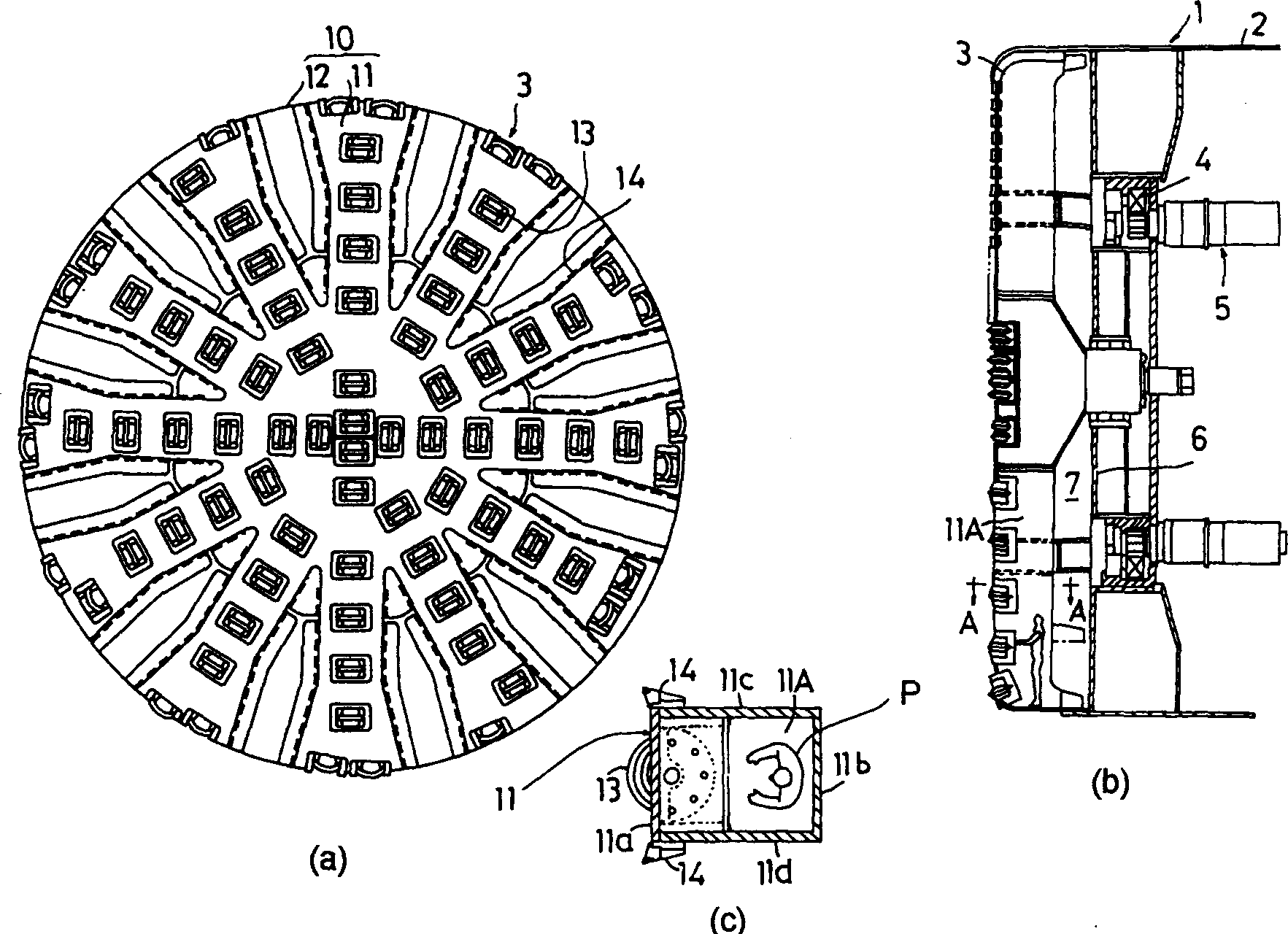

Rock boring device with an oscillating and nutating rotary disc cutter

InactiveUS7182407B1Cheap manufacturingGuaranteed economical operationTunnelsCutting machinesEngineeringDisc cutter

A rock boring device (10) including a rotary disc cutter (11). The disc cutter (11) is driven in an oscillating manner and also driven or free to nutate, and the device includes a mounting section (22) for the rotary disc cutter and a driven section (21), and wherein the mounting section (22) is angularly offset from the axis of the driven section whereby the rotary disc cutter will both oscillate and nutate.

Owner:ODYSSEY TECH

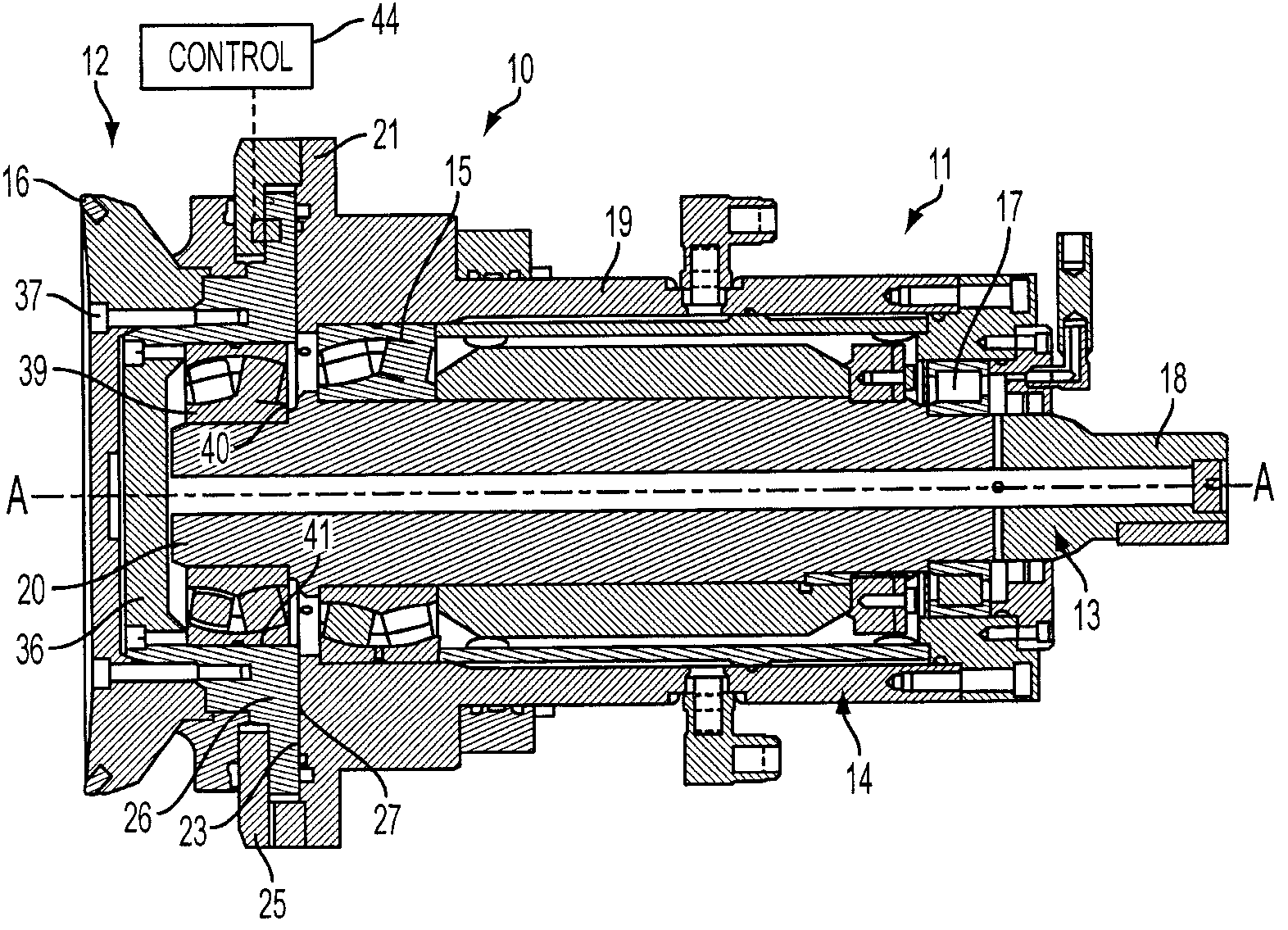

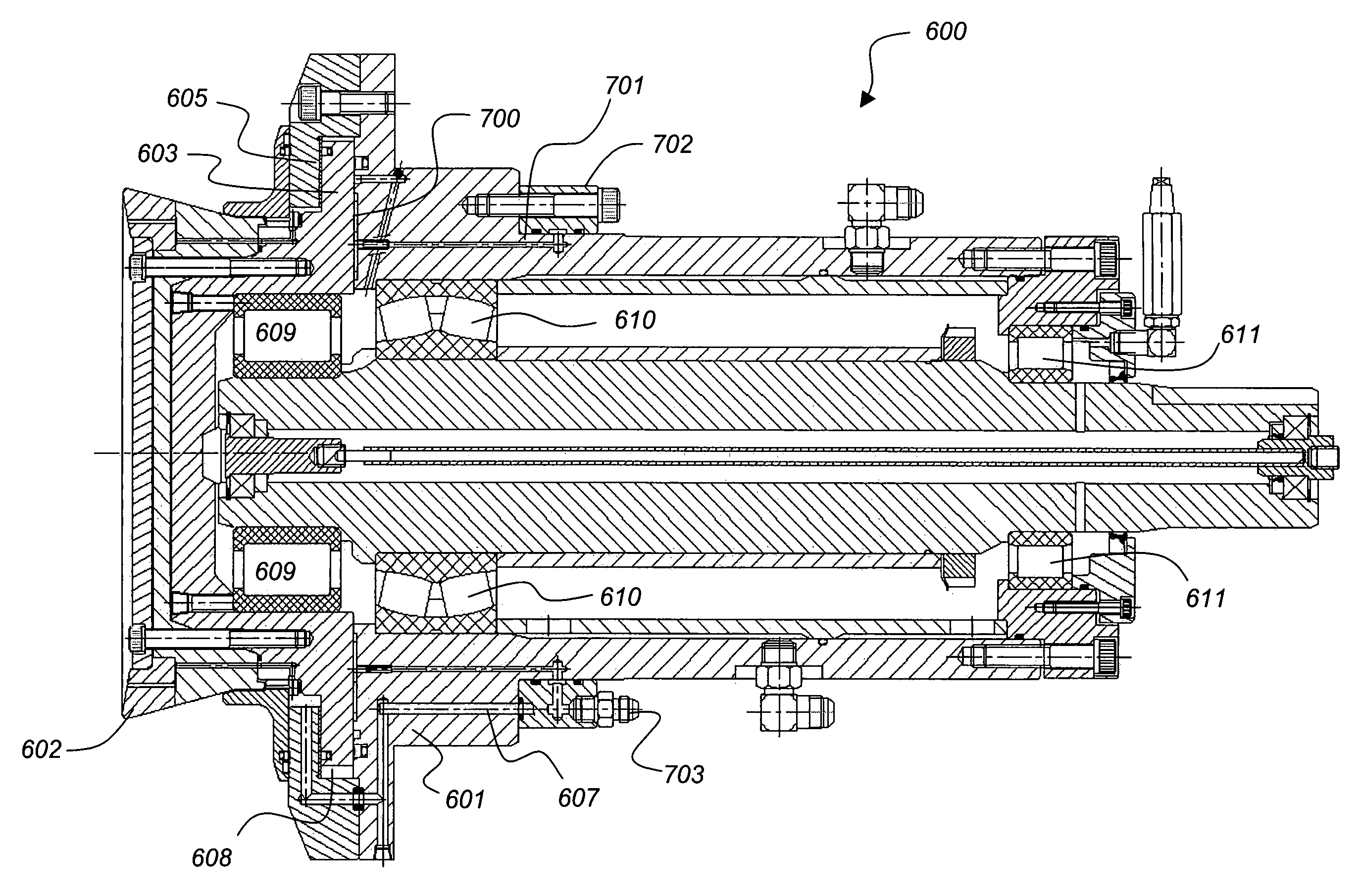

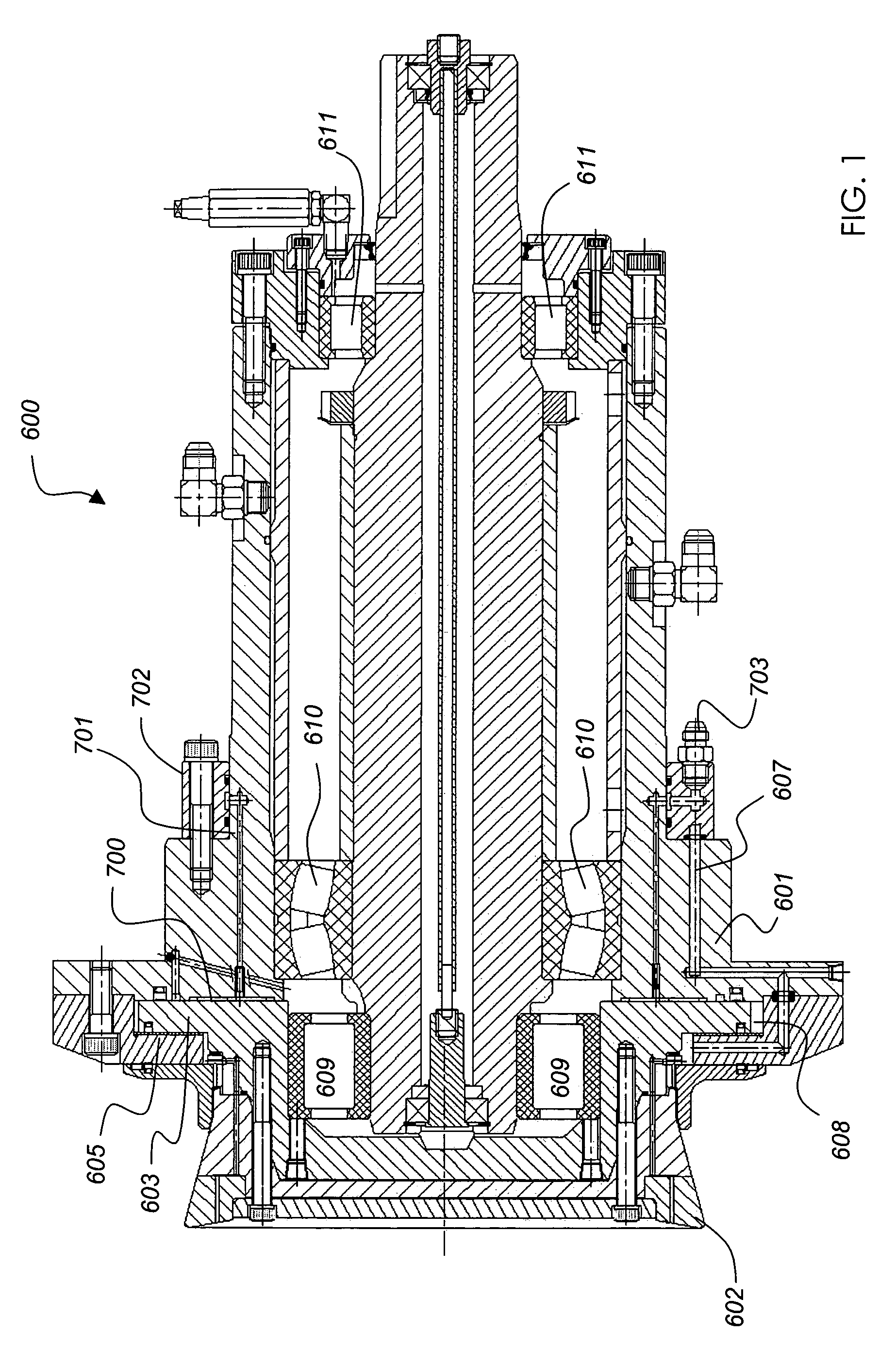

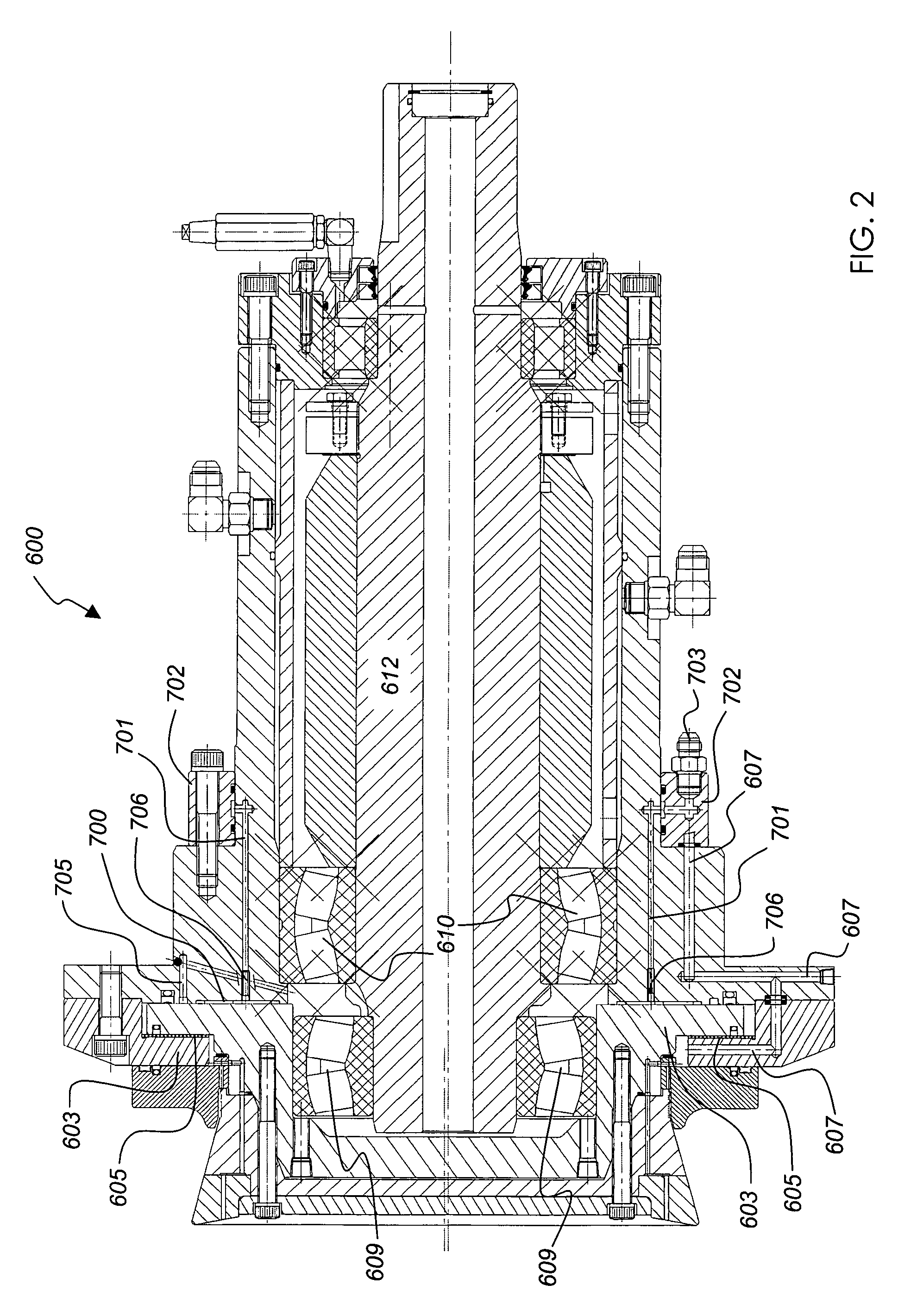

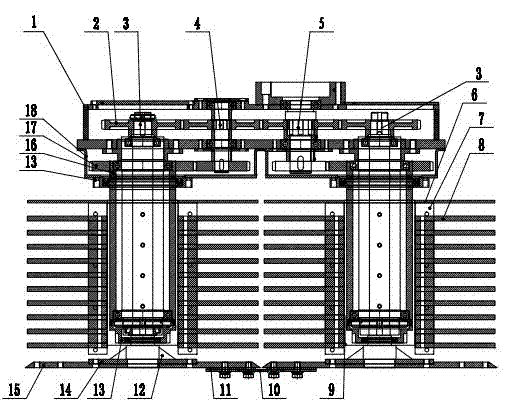

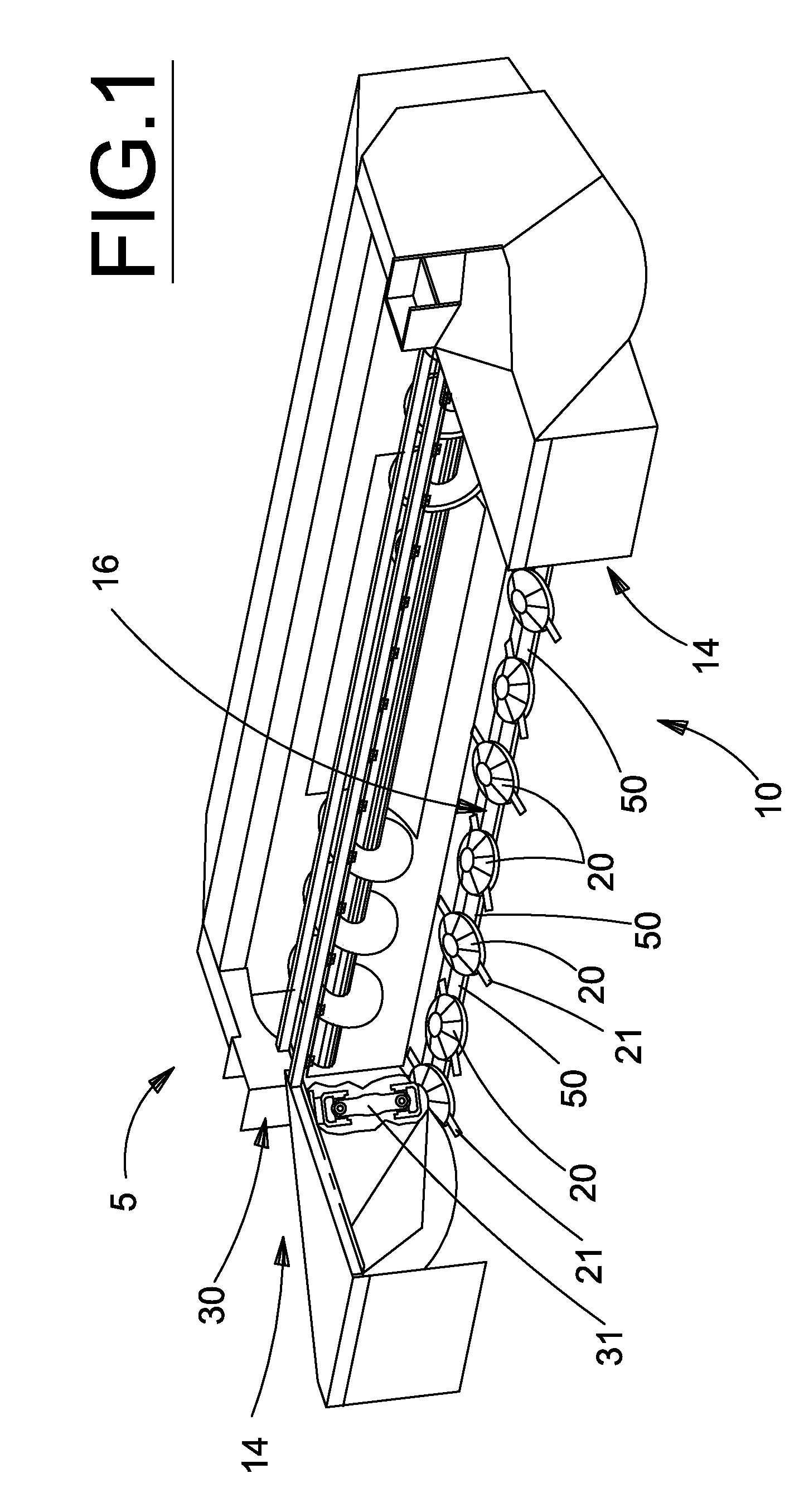

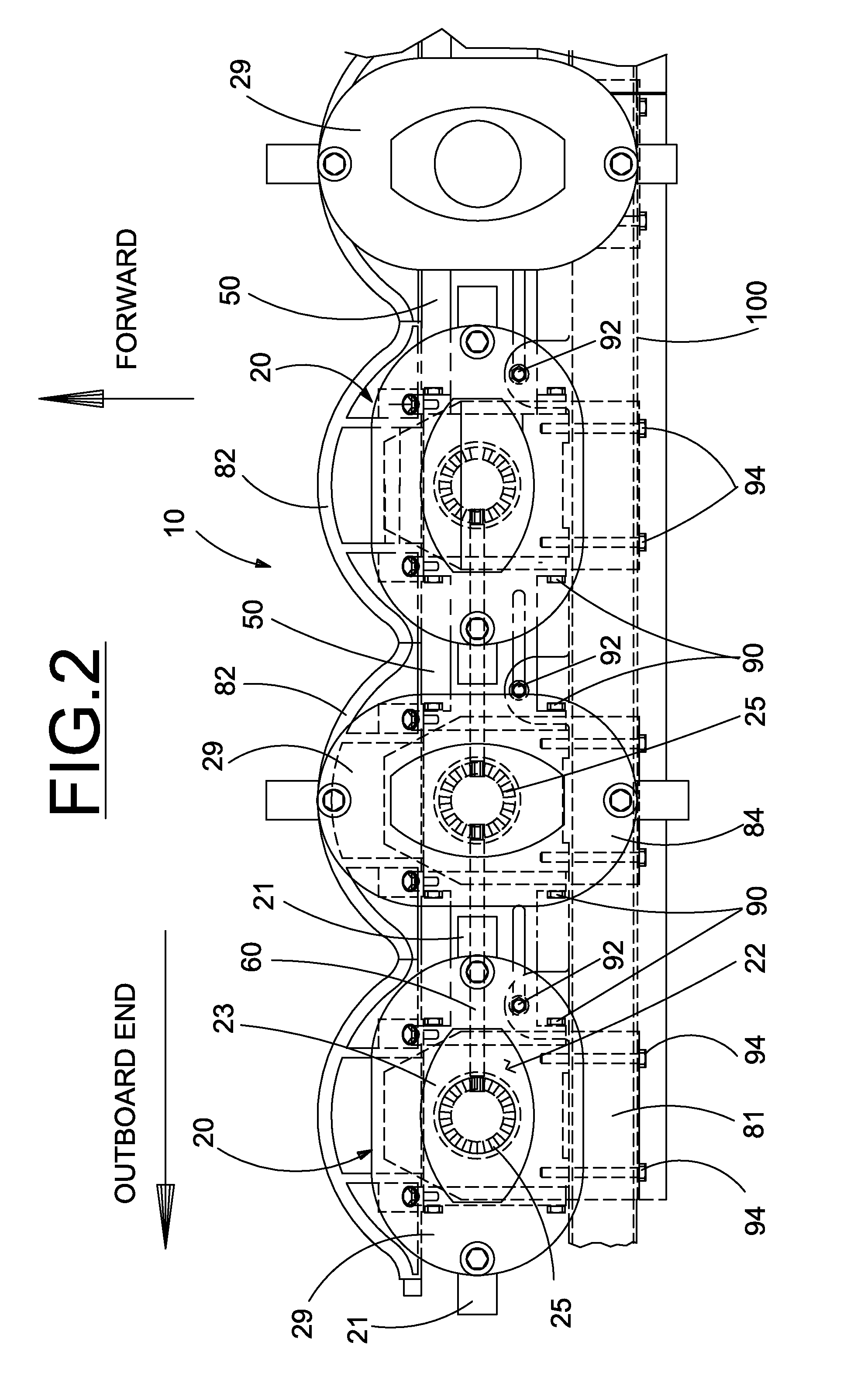

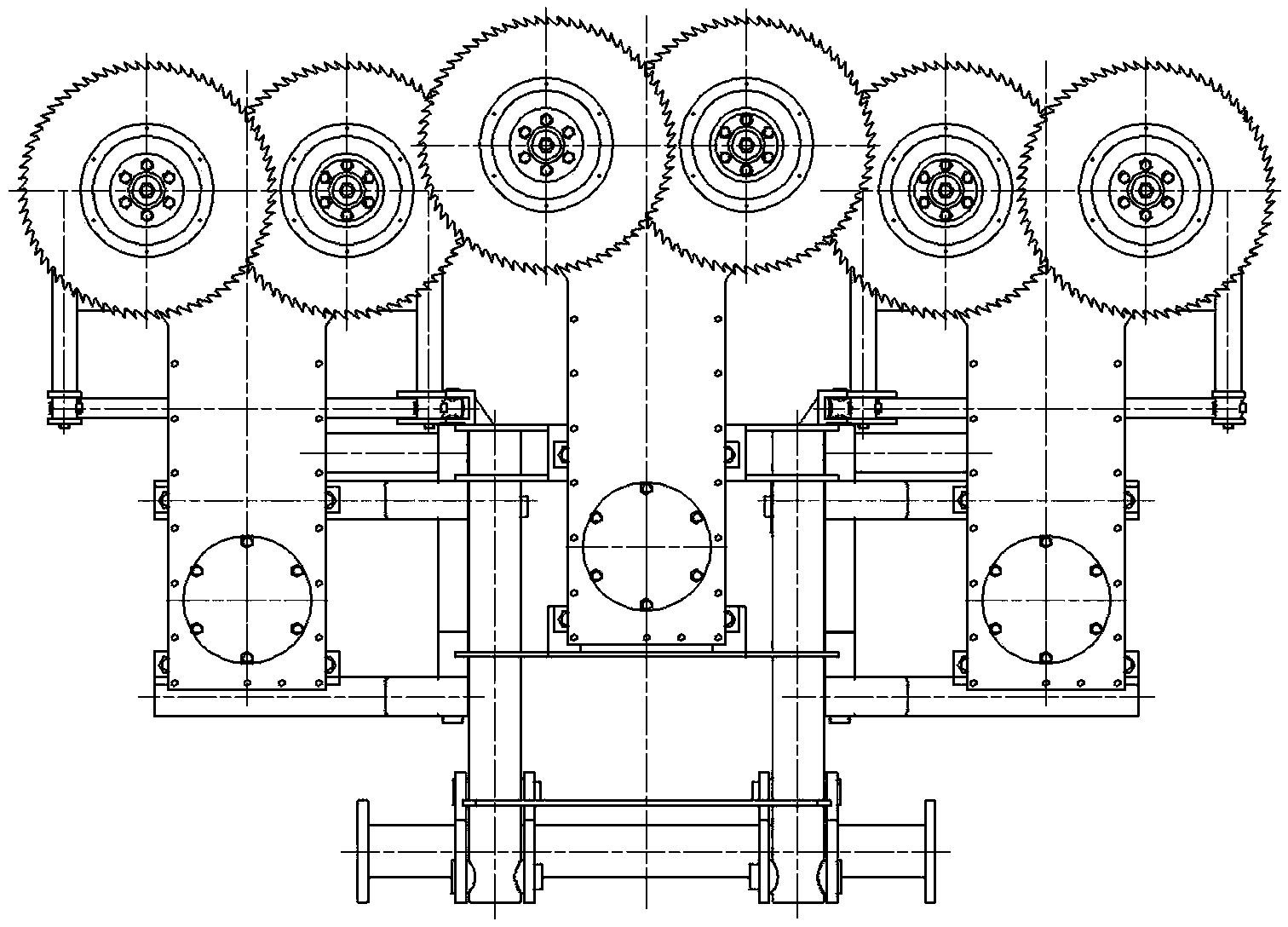

Mining machine with driven disc cutters

A mining machine includes a cutting mechanism with an arm, and a substantial weight of more than a thousand pounds attached to the arm. The mining machine also includes a first disc cutter adapted to engage the material to be mined and mounted on a first disc cutter assembly for eccentrically driving the first disc cutter, the first disc cutter assembly being mounted within the substantial weight. The mining machine also includes at least a second disc cutter spaced apart from the first disc cutter assembly and adapted to engage the material to be mined, and mounted on a second disc cutter assembly for eccentrically driving the second disc cutter, the second disc cutter assembly being mounted within the substantial weight.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

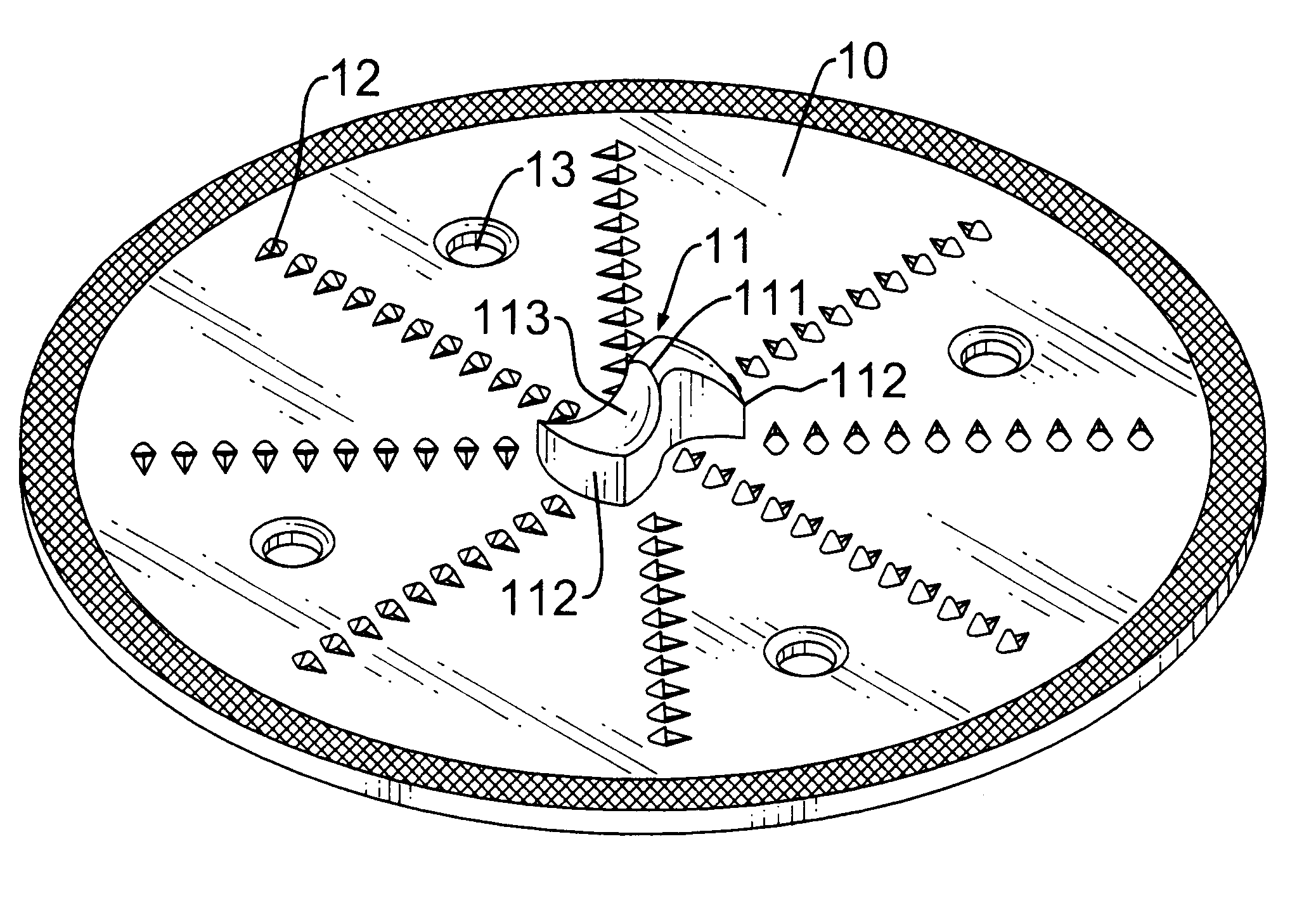

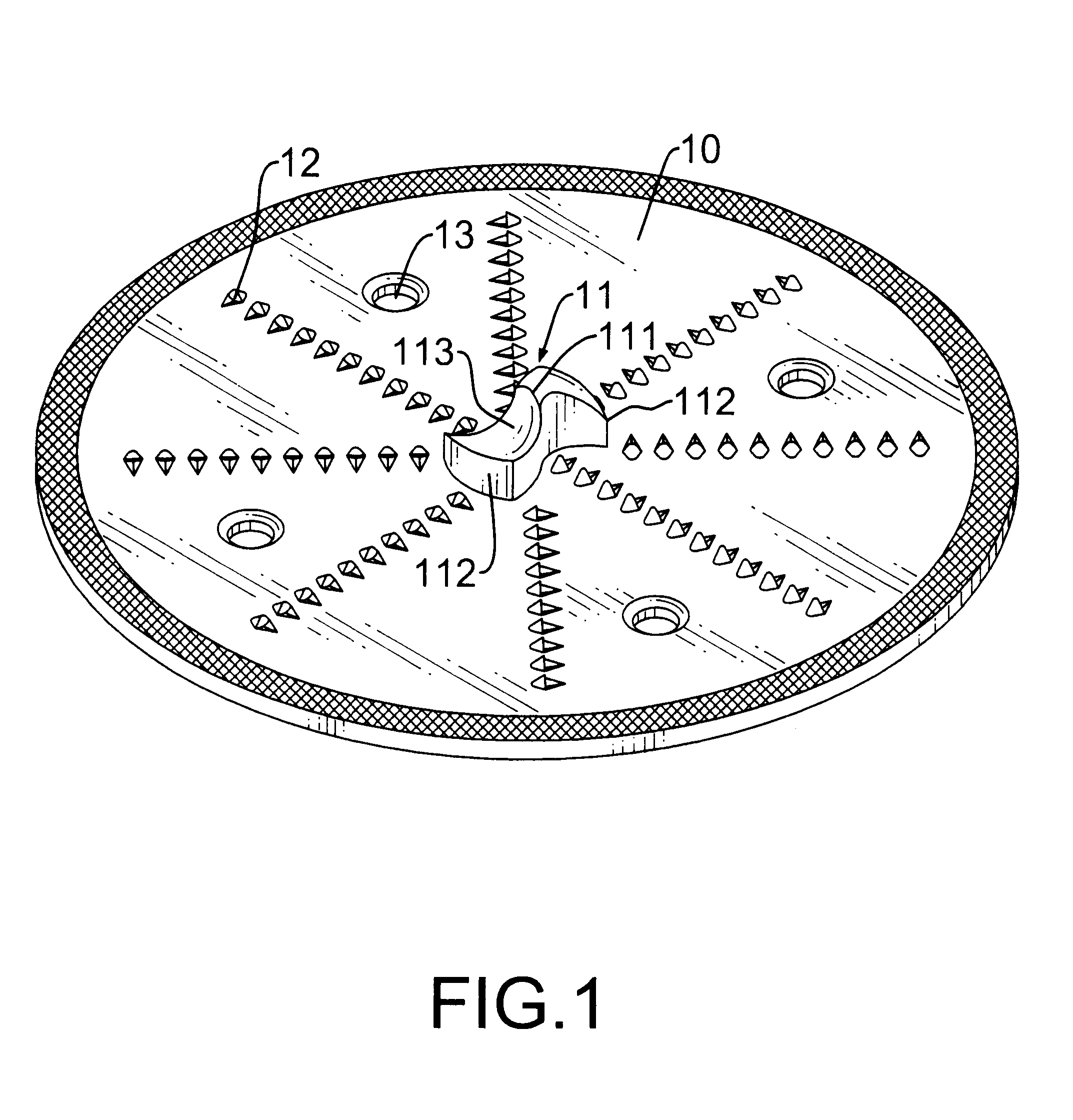

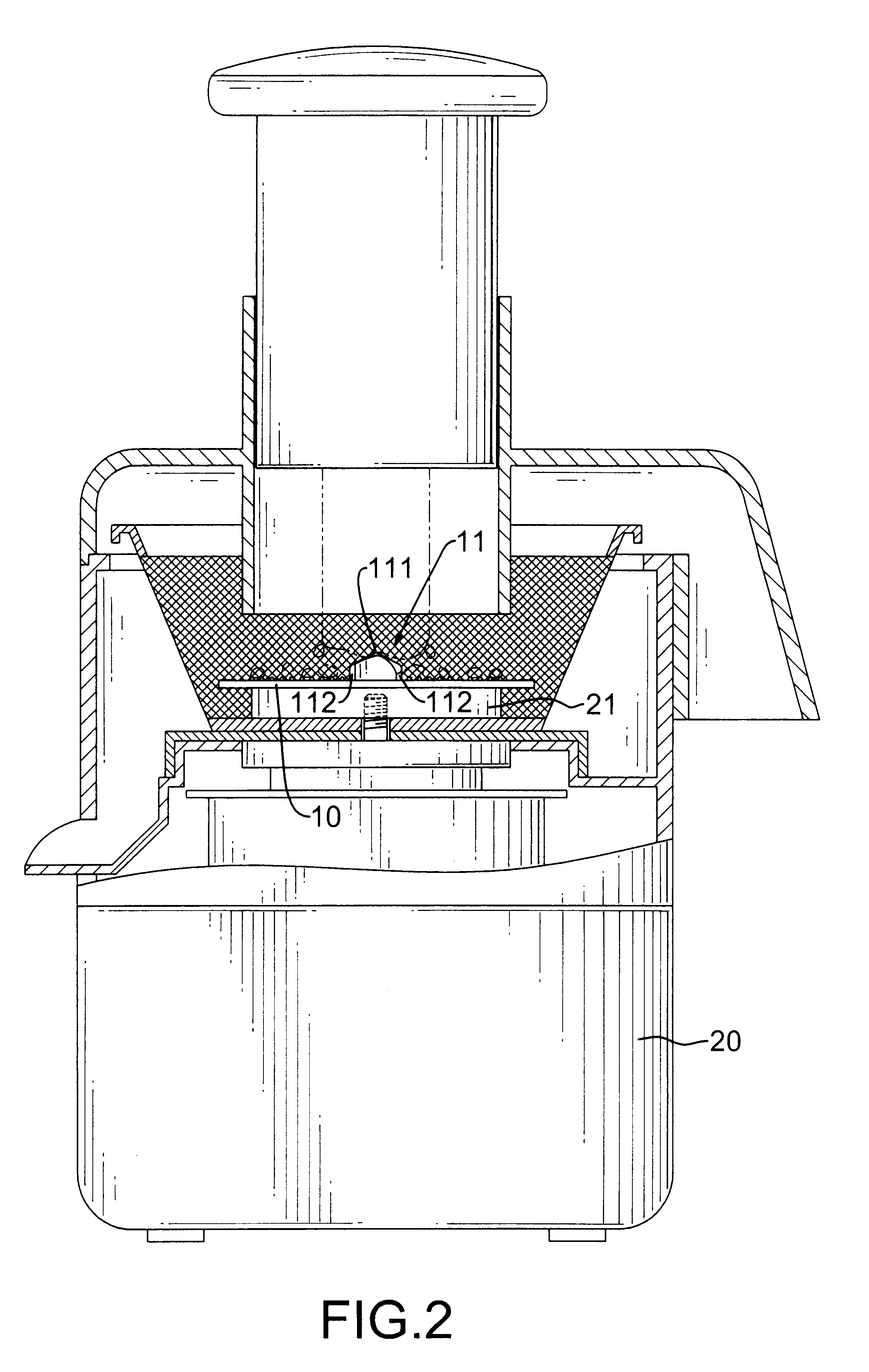

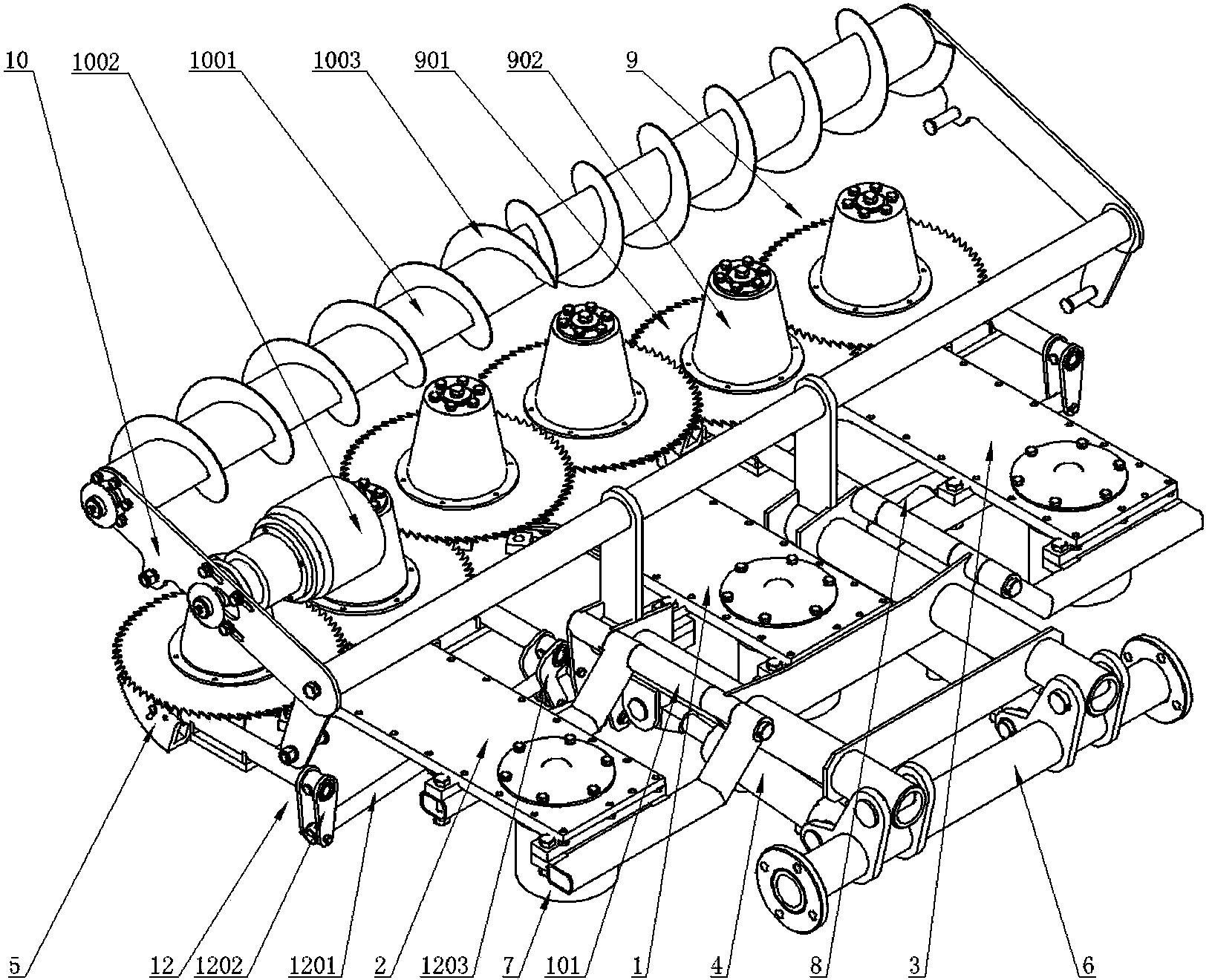

Disc cutter for fruit and vegetable juice extractor

A disc cutter for a fruit and vegetable juice extractor includes a disc body and a food disintegrating device. The disc body is rotatably mounted in the juice extractor has a top, a center and grinding blades. The grinding blades are radially formed in the top of the disc body for grinding food into juice. The food disintegrating device is attached to the top at the center of the disc body and includes a pointed body having a tapered top and two opposite edges. The tapered top has a central tip and a fluted land defined in the tapered top adjacent one of the edges. Therefore, the rotating pointed body will disintegrate efficiently the inserted food into several large pieces for the grinding blades to grind completely into juice without any food remaining on the pointed body.

Owner:CHEN MING SUNG

Mining machine with driven disc cutters

A mining machine includes a cutting mechanism with an arm, and a substantial weight of more than a thousand pounds attached to the arm. The mining machine also includes a first disc cutter adapted to engage the material to be mined and mounted on a first disc cutter assembly for eccentrically driving the first disc cutter, the first disc cutter assembly being mounted within the substantial weight. The mining machine also includes at least a second disc cutter spaced apart from the first disc cutter assembly and adapted to engage the material to be mined, and mounted on a second disc cutter assembly for eccentrically driving the second disc cutter, the second disc cutter assembly being mounted within the substantial weight.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

Rock boring device

InactiveUS20070090678A1Cheap manufacturingGuaranteed economical operationTunnelsCutting machinesEngineeringDisc cutter

Owner:ODYSSEY TECH

Calculation method for predicting wear amount of disc hob of roadheader

InactiveCN102278961ASimple data calculation and processingLife expectancyMeasurement devicesSpecial data processing applicationsEngineeringProlongation

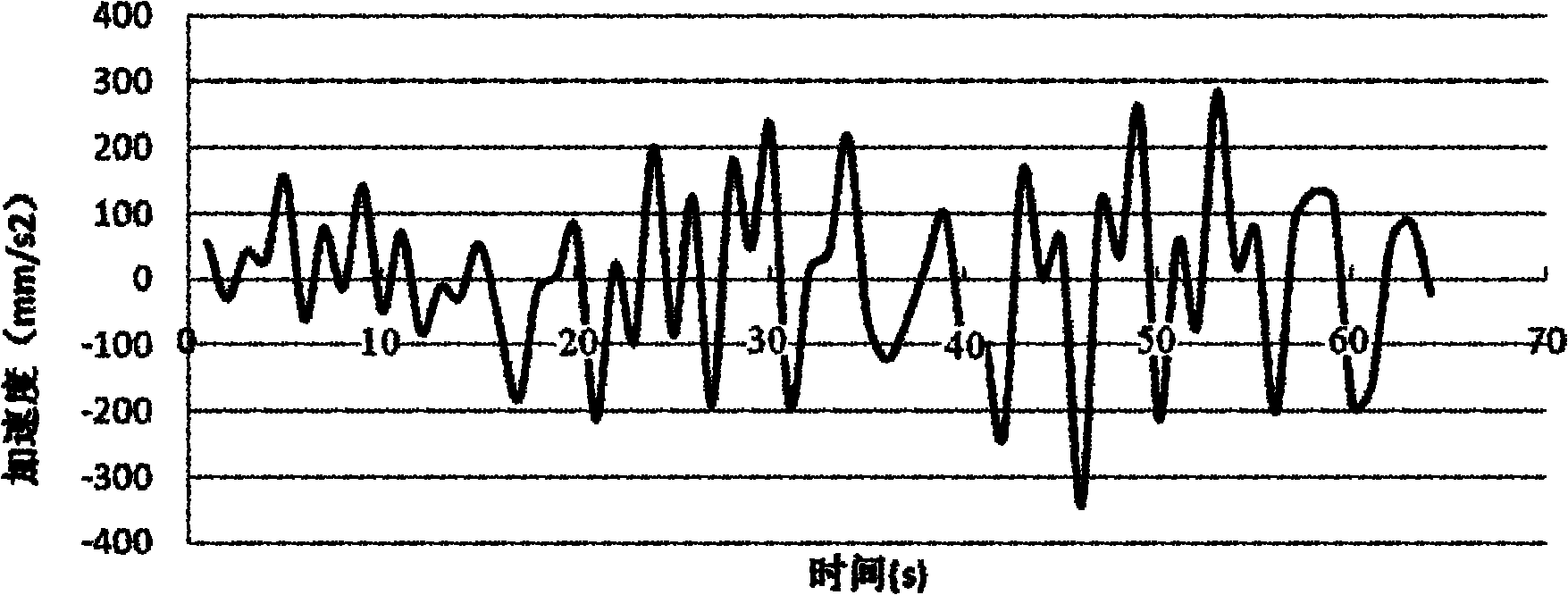

The invention discloses a heading machine disc cutter wear extent pre-estimate calculating method. According to the method, a known heading machine structure parameter and a known technique parameter in a construction process are referred, and a corresponding relation between disc cutter rotation frequency and wear extent is directly established. The calculating method comprises the following steps: (1) measuring the disc cutter acceleration change in a rock breaking process, and obtaining disc cutter rotation frequency; (2) establishing a corresponding relation between the disc cutter rotation frequency and friction work; (3) establishing a corresponding relation between the disc cutter rotation frequency and the wear extent. The disc cutter wear extent at different times and different positions are obtained finally. According to the invention, an accurate disc cutter wear extent pre-estimate calculating formula is established, operation and data processing are simple, and a problem that determining the disc cutter wearing degree and predicting disc cutter life are needed in construction is solved. The invention provides a theory for optimization design of a cutterhead and cutterarrangement scheme and prolongation of disc cutter service life.

Owner:TIANJIN UNIV

Rotating speed variable driving shield cutterhead energy-saving hydraulic control system

InactiveCN101216052AAvoid lostSimple structureServomotor componentsServomotorsHydraulic motorMotor drive

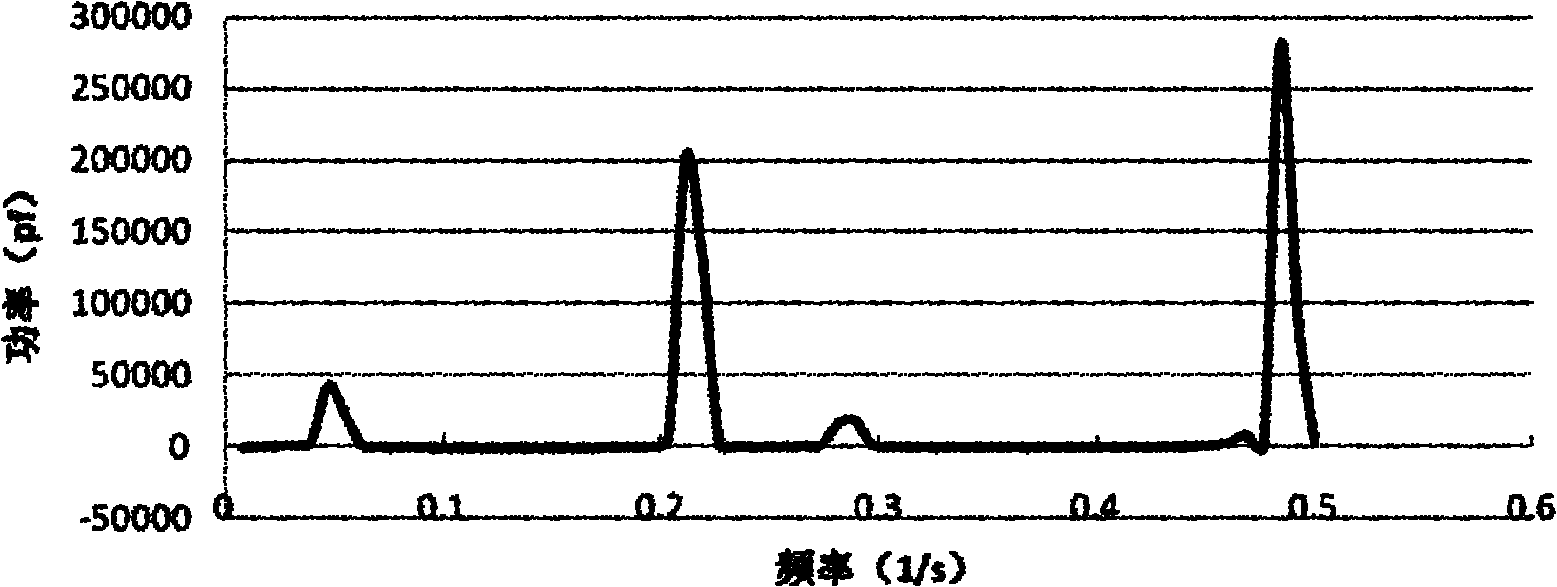

The invention discloses a variable speed drive shield disc cutter energy saving hydraulic control system, which comprises a main hydraulic circuit consisting of a variable speed motor, a two-way hydraulic pump, a one-way valve, a hydraulic motor, a hydraulic lock and a change valve; and a feed circuit. The output rotation speed of an asynchronous motor driving the two-way hydraulic pump is variable speed controlled. The output signal of a rotary speed controller is adjusted in real time according to the rotation speed required to cut earth by a disc cutter to change the rotation speed of the asynchronous motor, thus controlling the output flow of the two-way hydraulic pump and driving the hydraulic motor to output the moment and the rotation speed that the disc cutter requires to overcome the load. The main hydraulic circuit adopts a closed type hydraulic circuit, and directly feeds the oil of the oil discharge outlet of the hydraulic motor into the inlet port of the motor through the two-way hydraulic pump, thus reducing the volume of a hydraulic system pumping station. Two stages of high and low working pressure are provided so that the shield disc cutter can work on two different geological conditions of soft ground and hard rock. By adopting variable speed control, the output flow of the hydraulic pump is matched with the load power of the disc cutter, thus significantly saving the energy.

Owner:ZHEJIANG UNIV

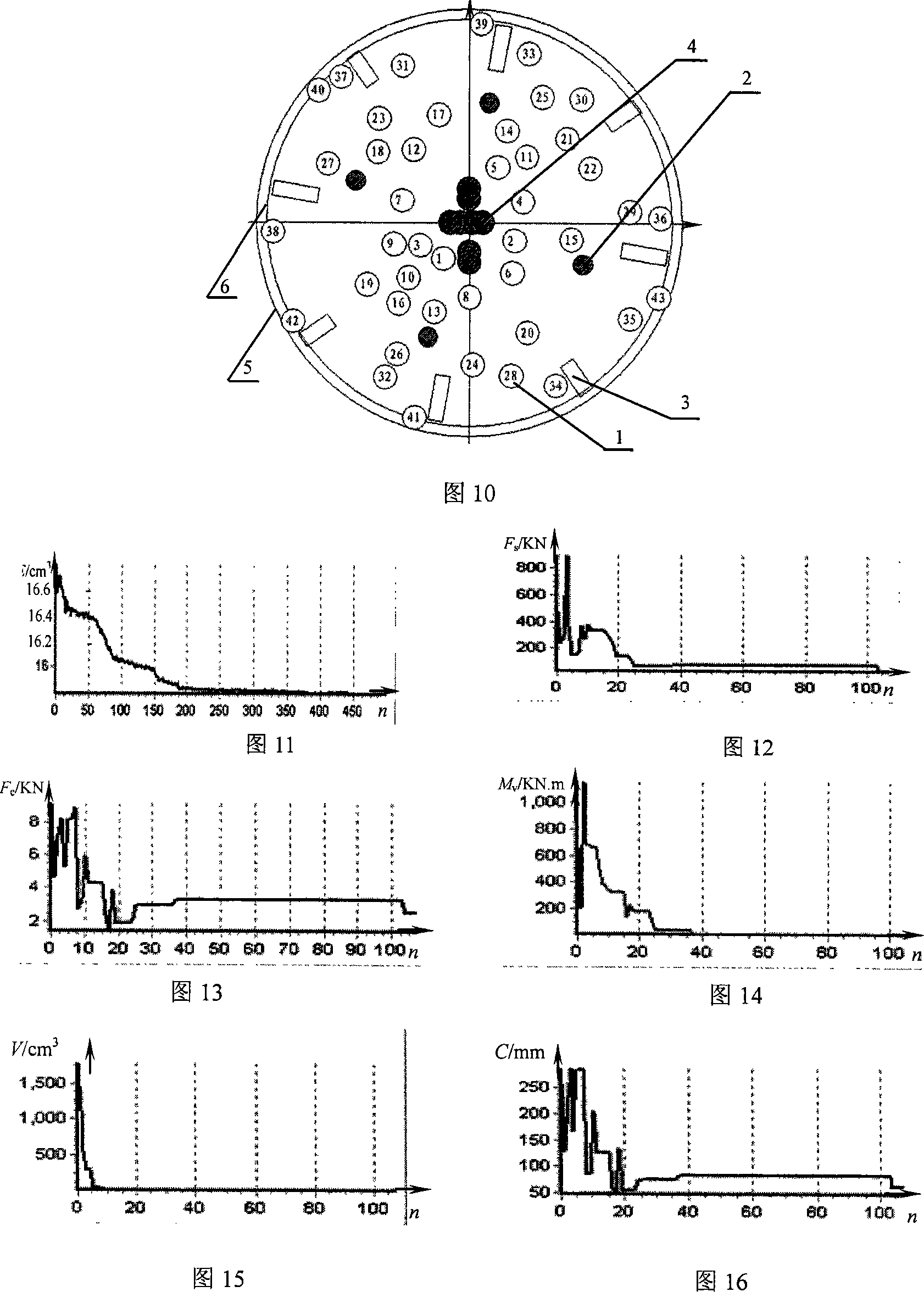

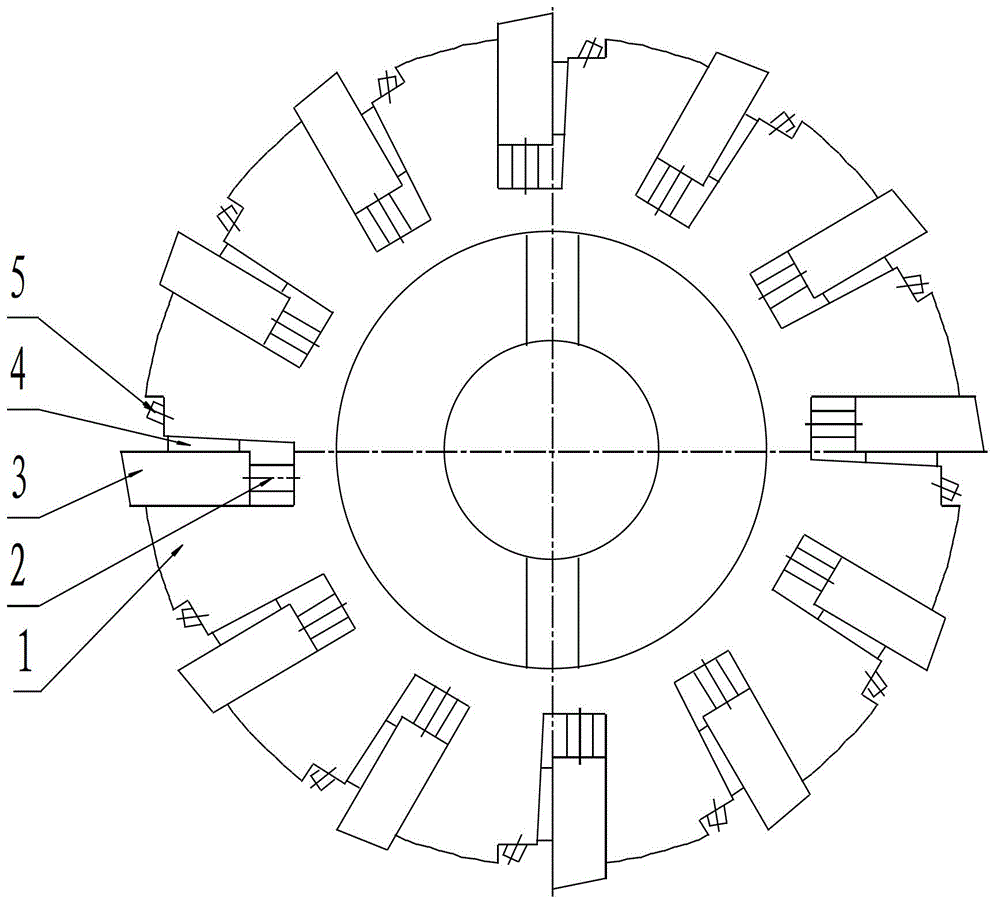

All-section rock tunneling machine cutter layout design optimization method

InactiveCN101086208AShorten the development cycleReduce vibrationTunnelsDesign cycleGenetic algorithm

The invention relates to a disk cutter layout design optimization method of development machine, concerning not micro and multi-modal disk cutter layout design optimization problems, especially applicable to full-face rock tunnel boring machine tool optimized layout design. A full-face rock tunnel boring machine knife tool layout design method, first determine disc hob position on the knife set and knife set overall technical performance parameters, in accordance with the actual knife tool layout technical requirements of the full-face rock tunnel boring machine, establishment of the binding properties of complex nonlinear multi-objective optimization model for knife tool layout; layout tool to establish grading optimization design model of knife tool layout polar pathway and angle calculation; putting the knife tool polar pathway and disc cutter knife polar angle as a design variable, adoption the genetic algorithm. The invention fast and effective in the determination of the knife tool optimized layout on the knife disc, made the knife disc having a small outside force and outside torque, thereby prolonging knife disc, knife tool and knife disc axletree life of the development machine, shorten the design cycle and improve design efficiency .

Owner:XCMG KAIGONG HEAVY IND NANJING

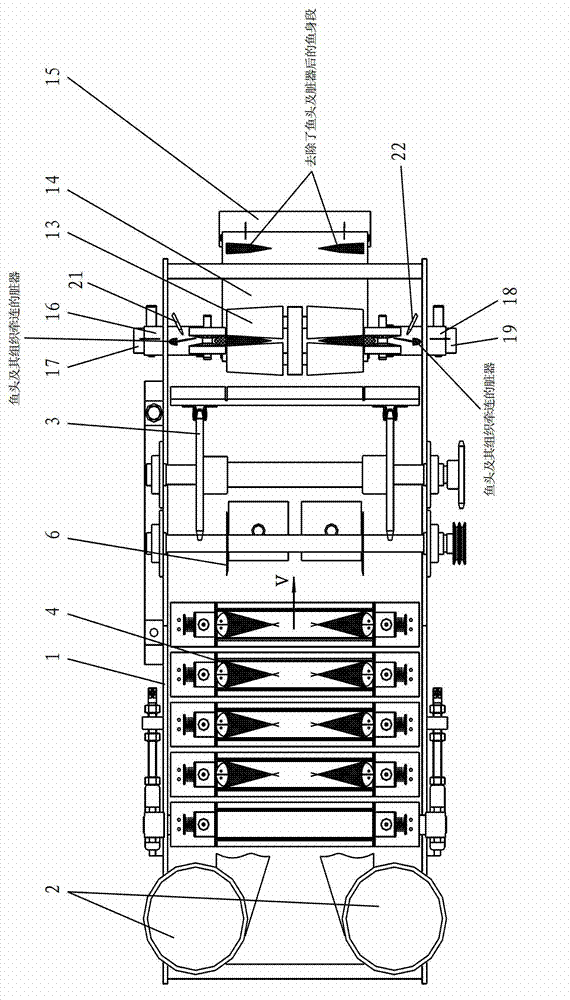

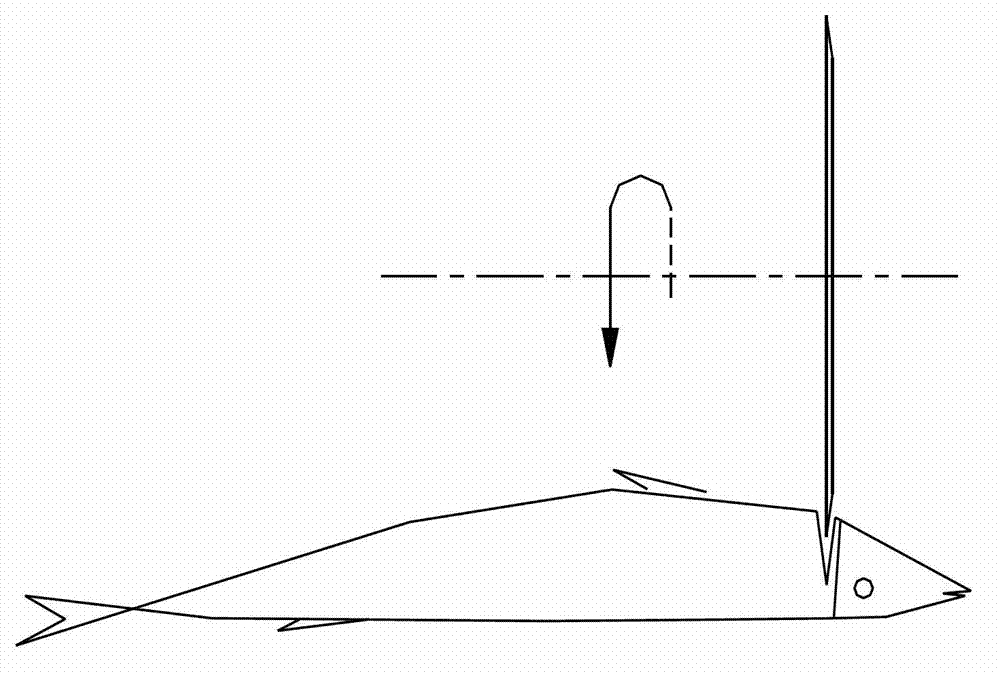

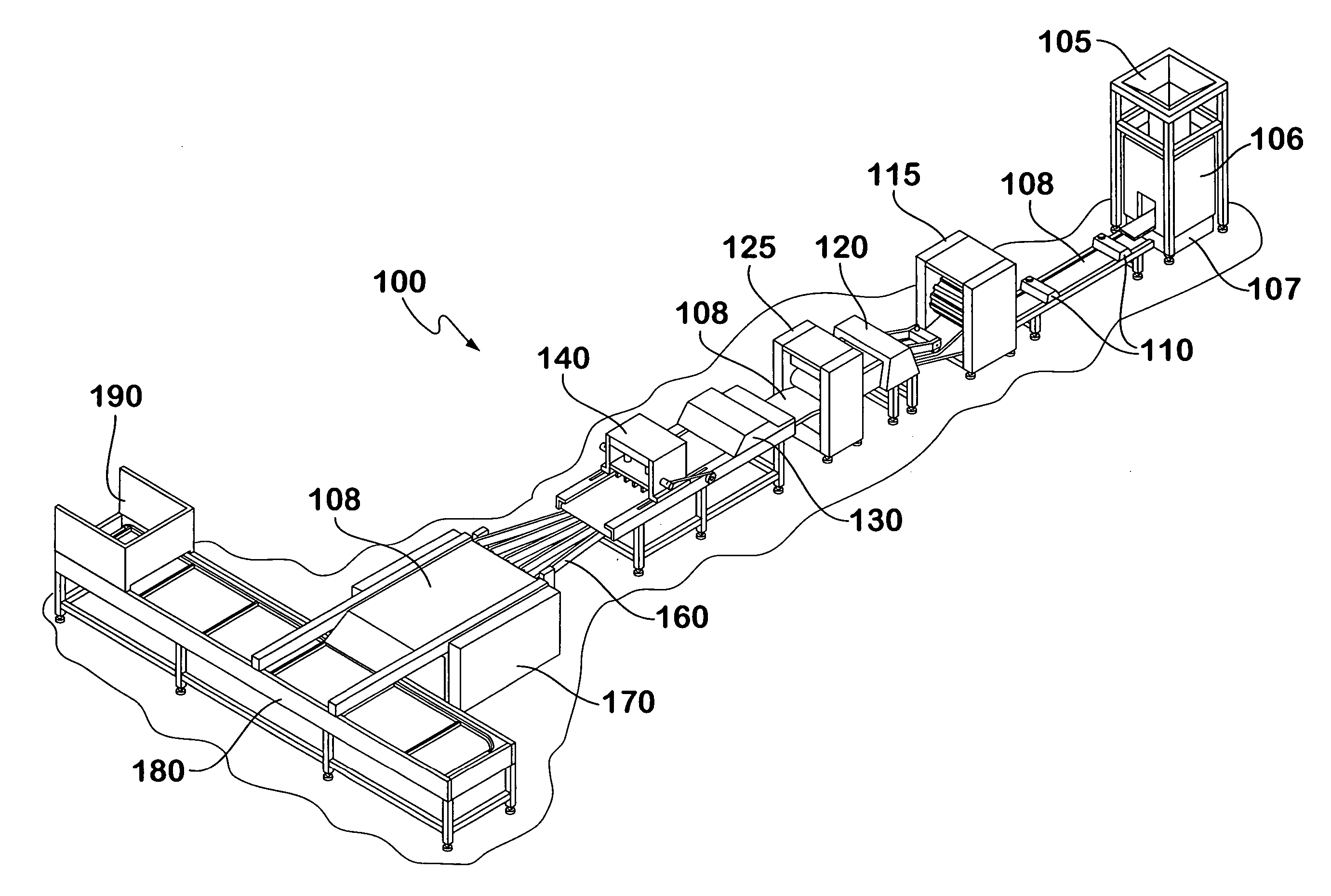

Machining method and machining equipment for removing heads and viscera of small fishes

InactiveCN102860346AReduce labor intensityImprove labor productivityFish processingThroatFish processing

The invention relates to a machining method and machining equipment for removing heads and viscera of small fishes and belongs to the field of fish processing. The machining method includes the followings steps of firstly, placing small fishes on a fish body conveying belt via a directional fish body feeder unit; secondly, placing the small fishes in distance-adjustable positioning grooves of the fish body conveying belt in a manner that the backs of the fish bodies face upwards and the bellies of the fish bodies face downwards, cutting off spines and peripherally connected muscular tissues via a disc cutter of a head cutting device while guaranteeing that the heads and the bodies of the backs of the fish bodies are cut off without cutting off flesh tissue of the bellies of the fish bodies and throat tissues connected with the viscera and the heads; thirdly, conveying the fish bodies not completely cut off and separated to a viscera remover device via a synchronous feeder, clamping and conveying the fish bodies, pulling and removing the heads, the viscera and connected throat tissues; and fourthly, conveying the fish bodies to a fish container, and feeding the heads and the viscera into other containers.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

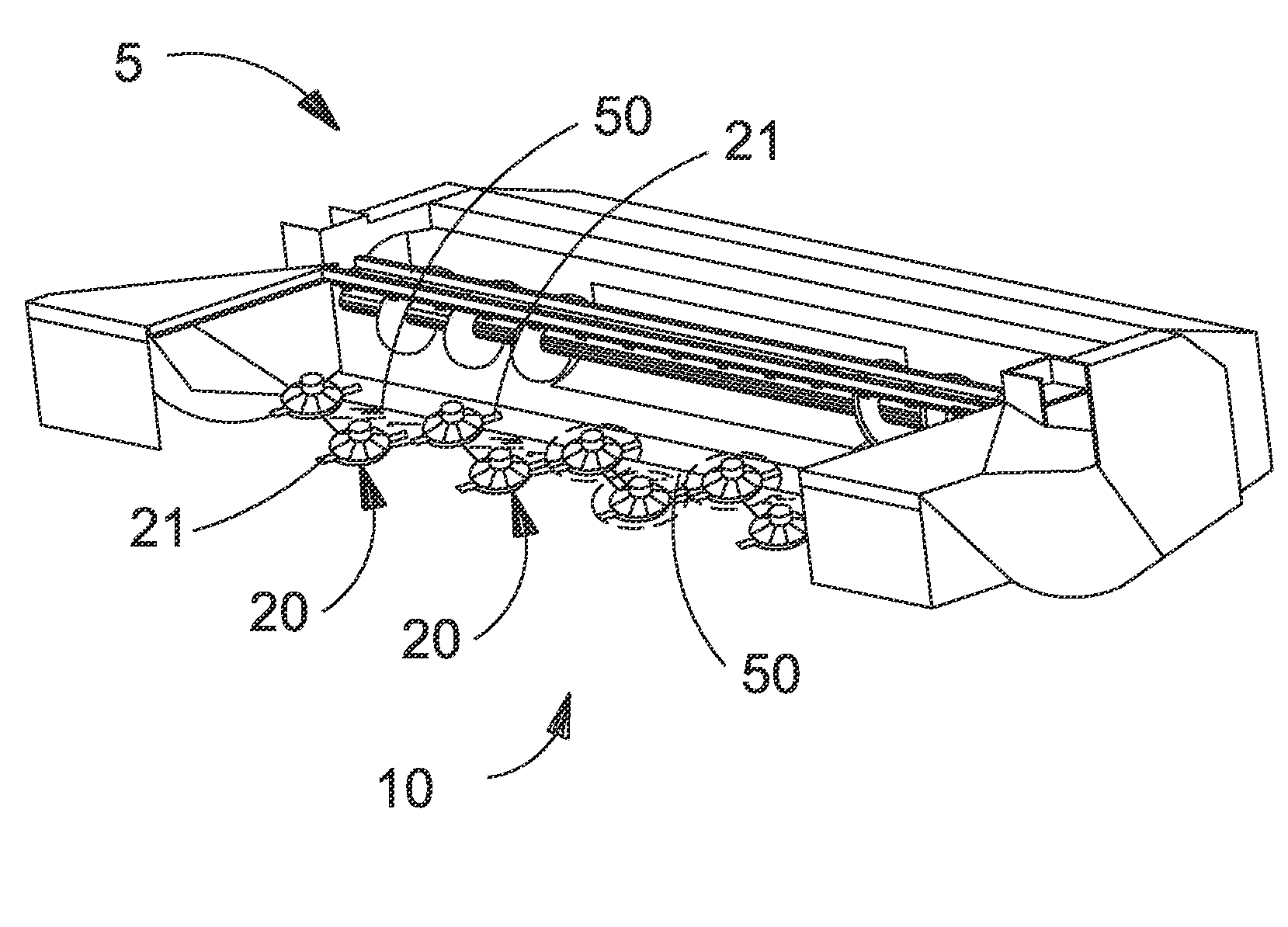

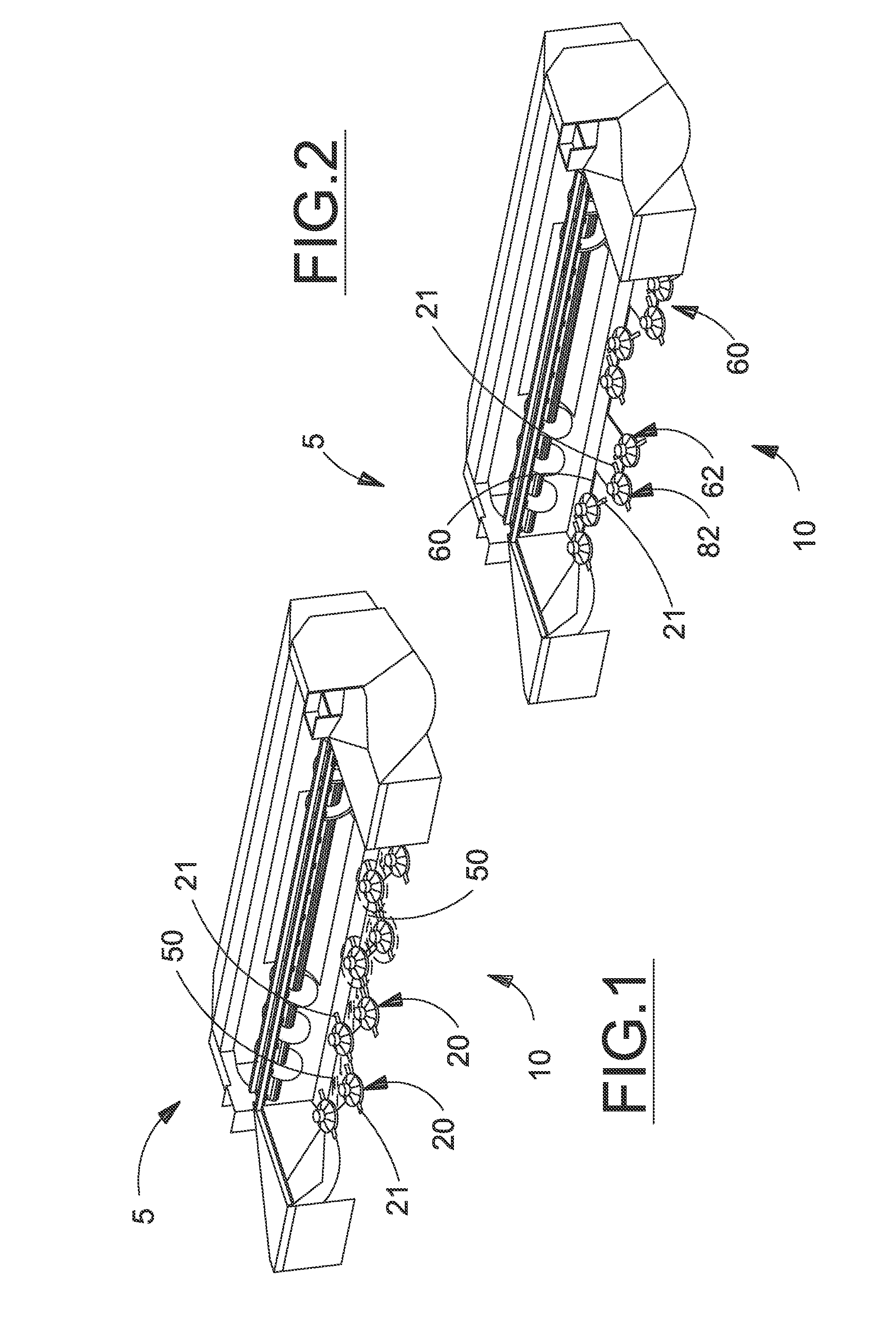

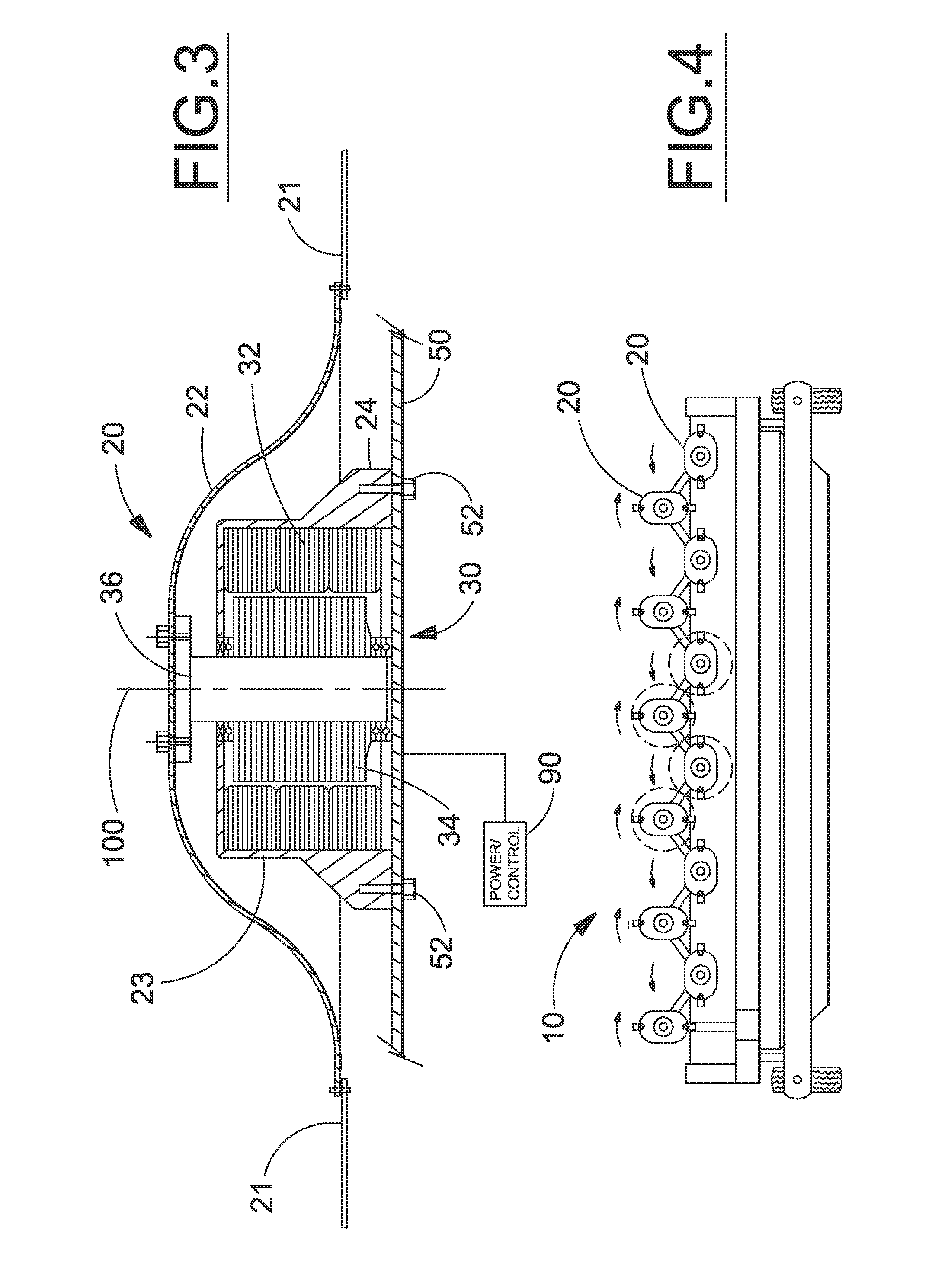

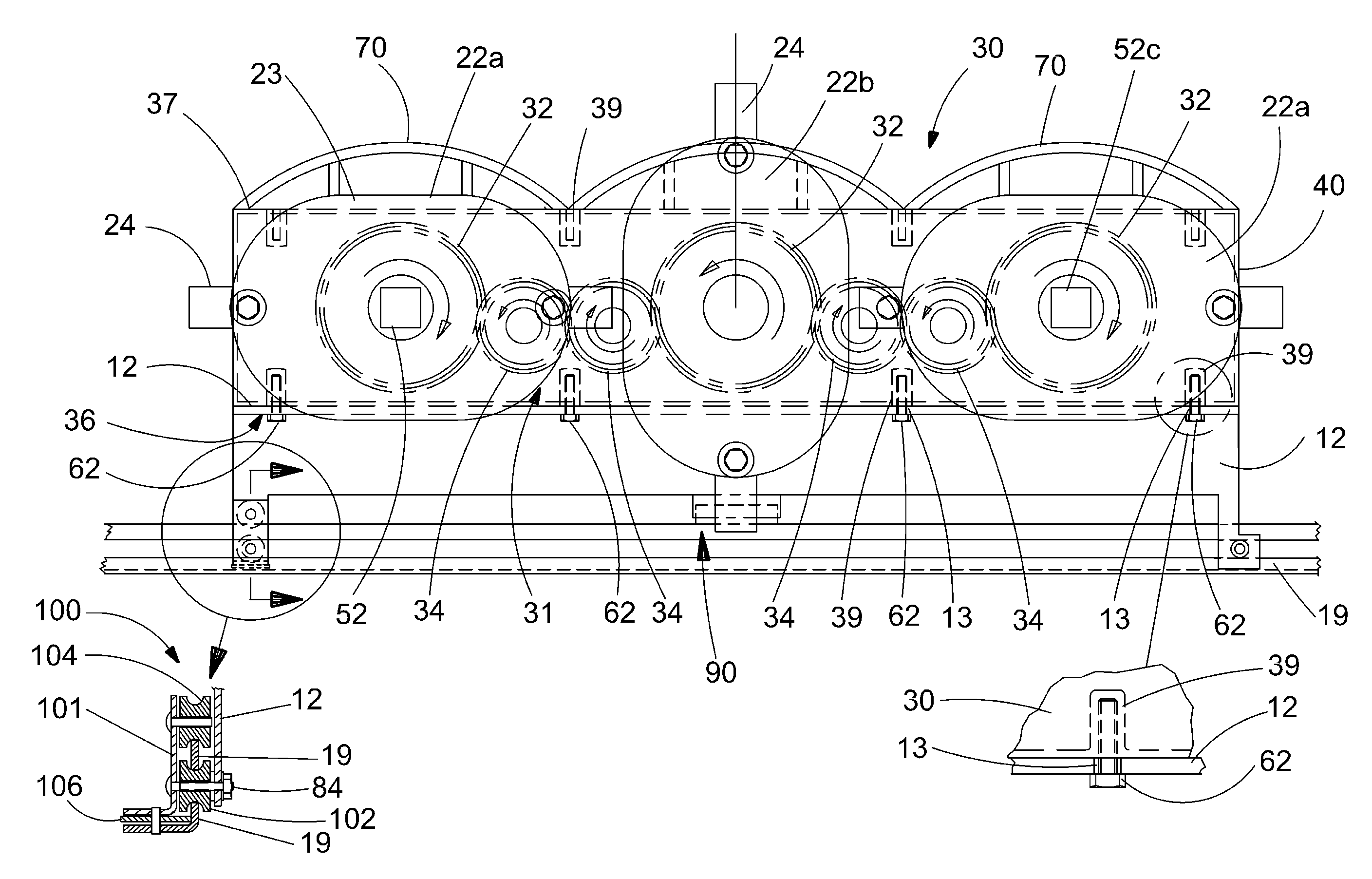

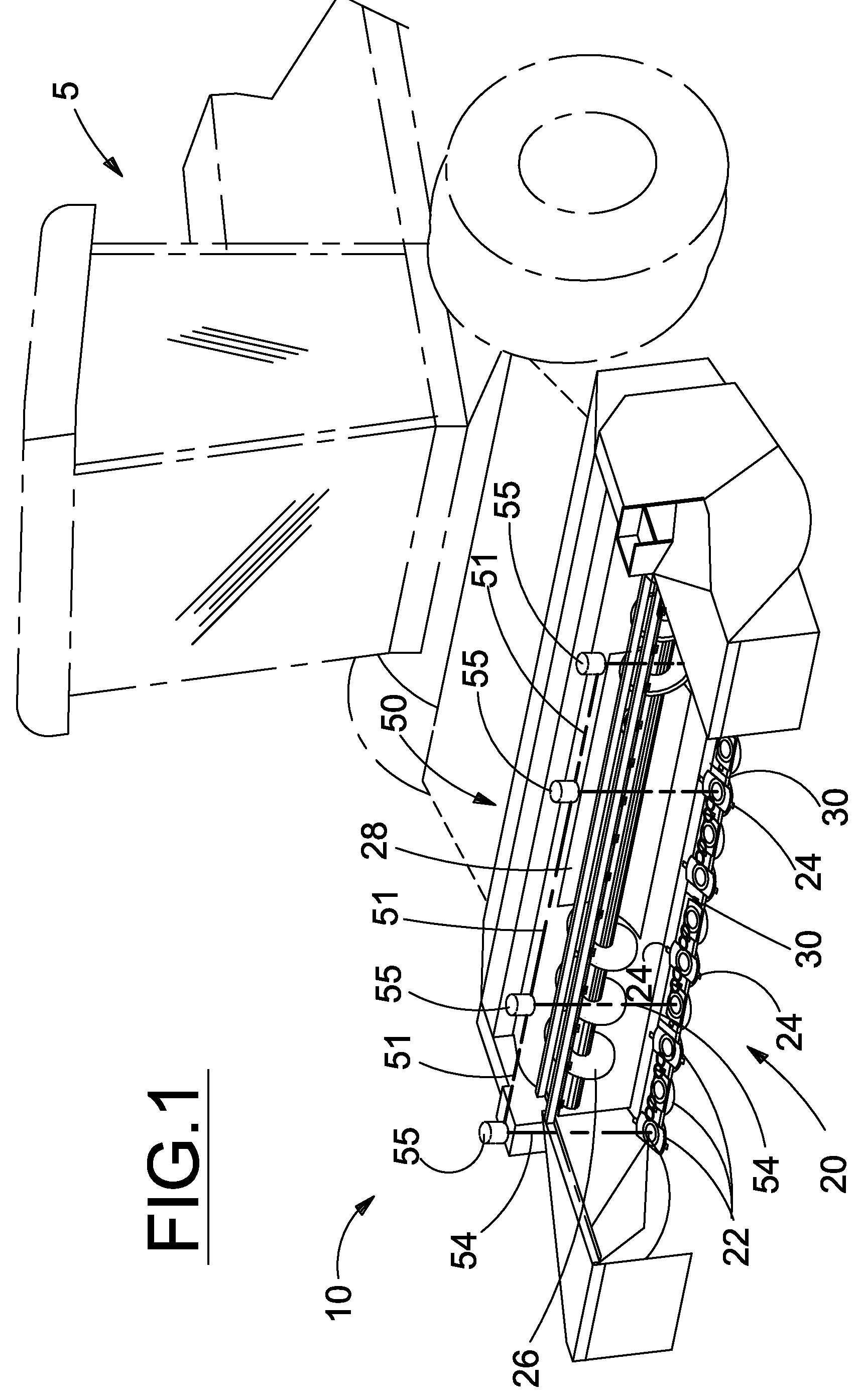

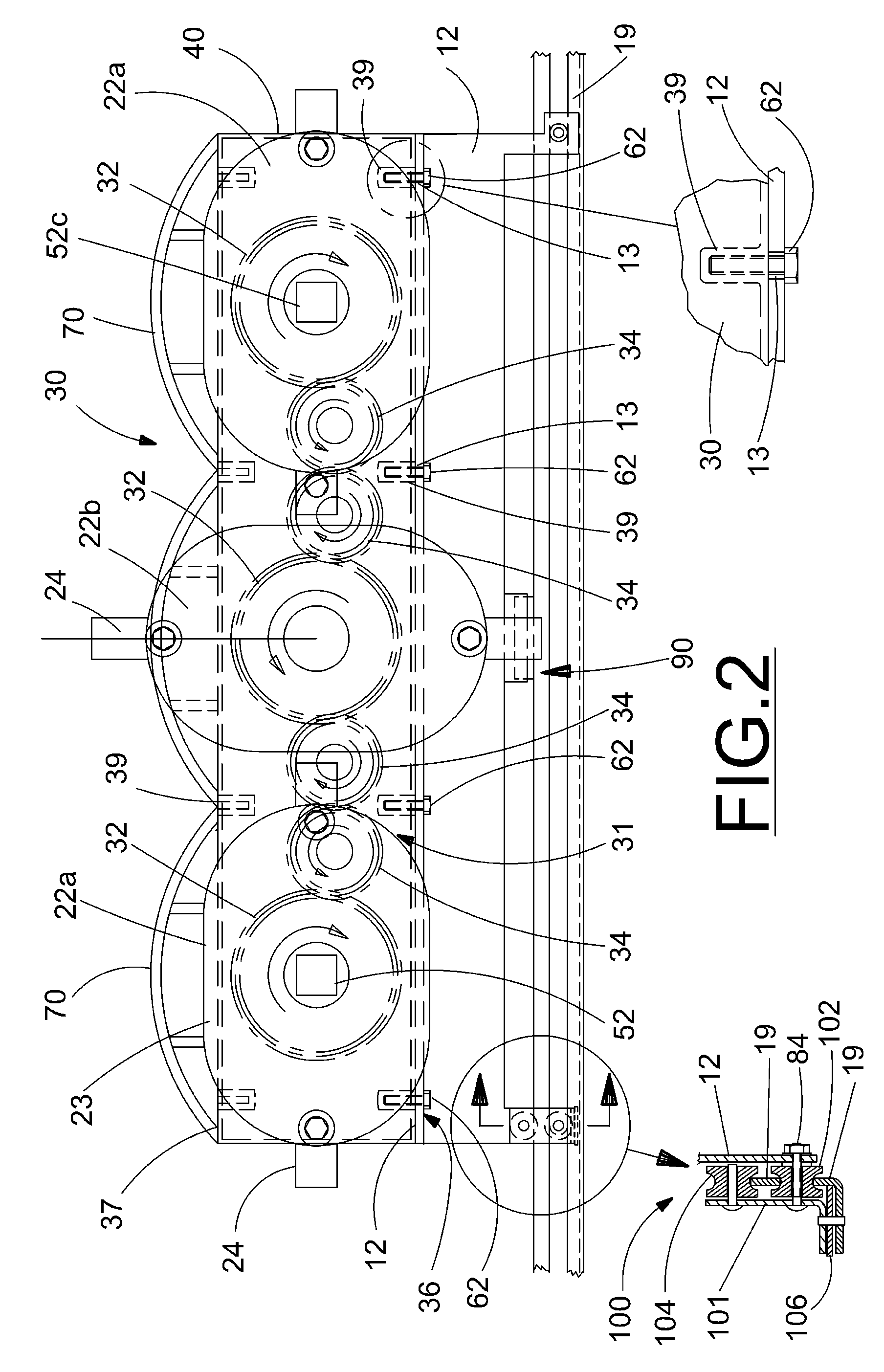

Modular electric disc cutterbar and controller

ActiveUS20130152535A1Eliminate needReduce weightAgricultural machinesAnalogue computers for trafficMotor driveControl system

An electric motor-driven rotary disc cutter module for a cutterbar in an agricultural harvester. In one embodiment, each rotary disc module includes an electric motor driver. Individual cutterhead modules are staggered fore and aft along the cutterbar to provide continuous cutting across the lateral width of the cutterbar without requiring synchronized rotation of the cutterheads. Individual speed and / or rotational direction adjustment of each cutterhead enables optimized crop cutting performance and / or crop movement within the header. A control system may be included to monitor performance and manage individual operation of the cutterhead modules. In a second embodiment, a pair of cutterheads are powered by a single electric motor wherein rotational input for the second cutterhead is transferred by a simple geartrain. The pair of cutterheads is combined into a modular arrangement with the modules being staggered fore and aft on the cutterbar to provide a continuous lateral cutting swath.

Owner:CNH IND CANADA

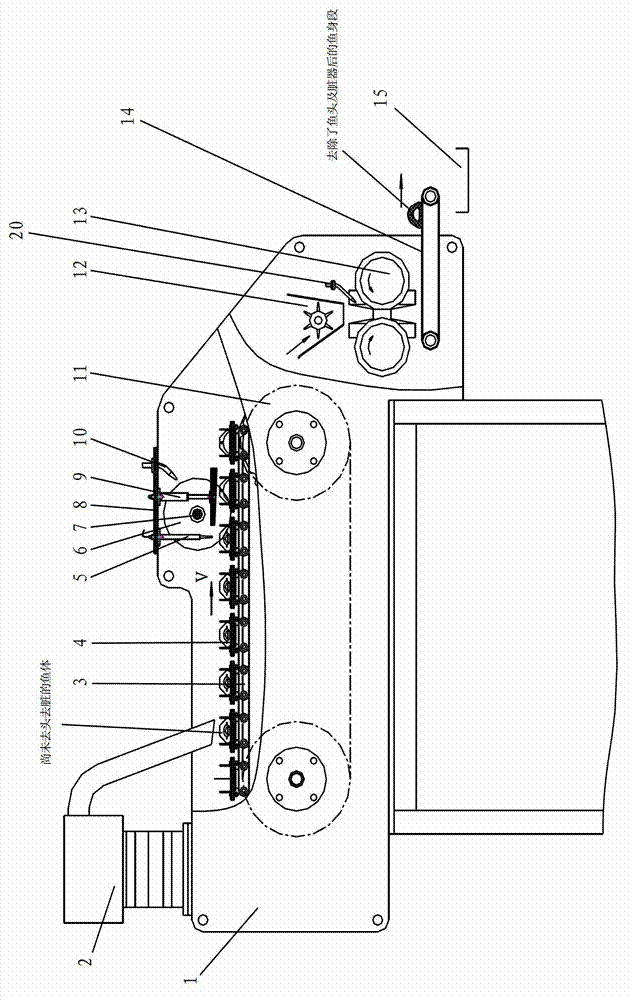

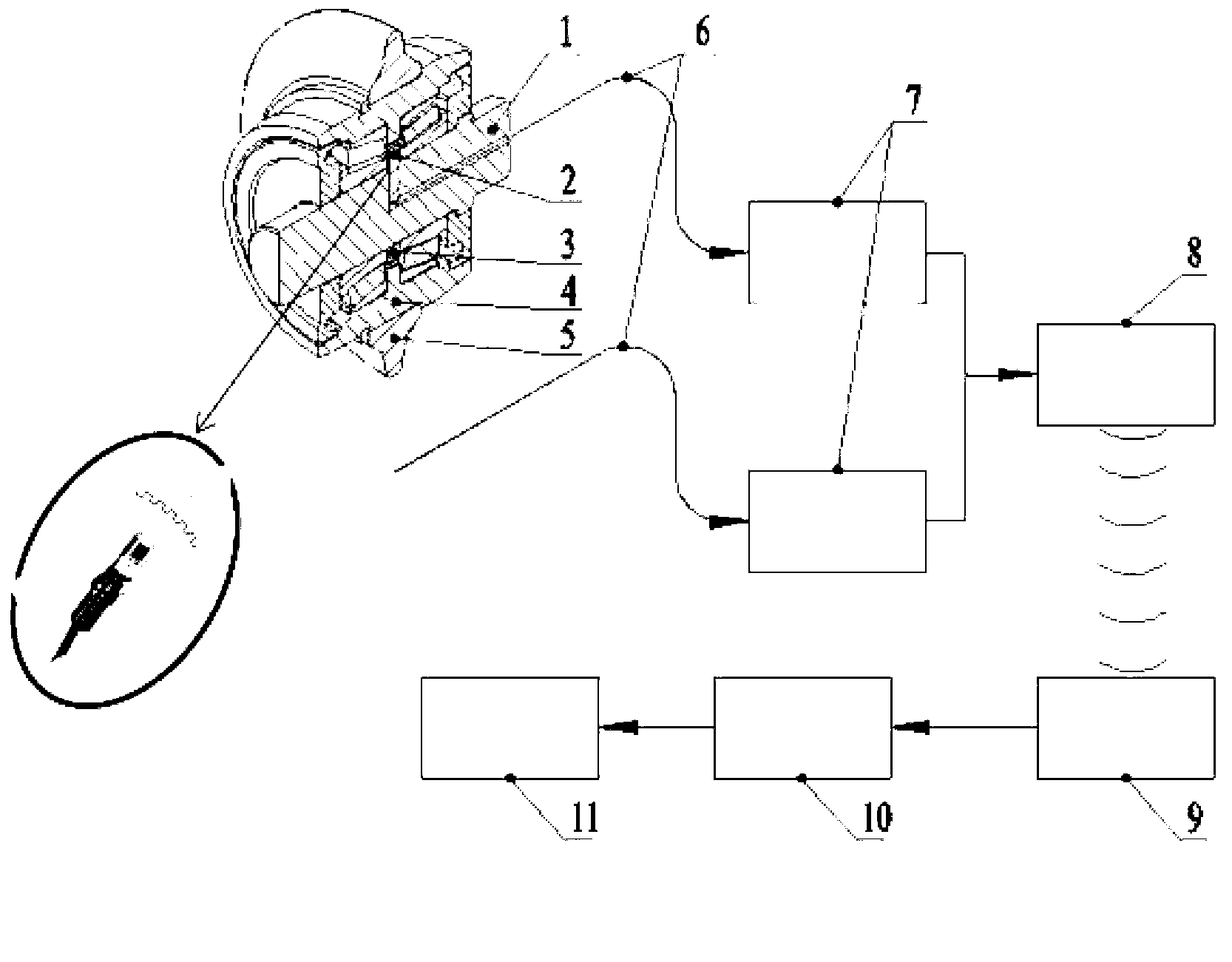

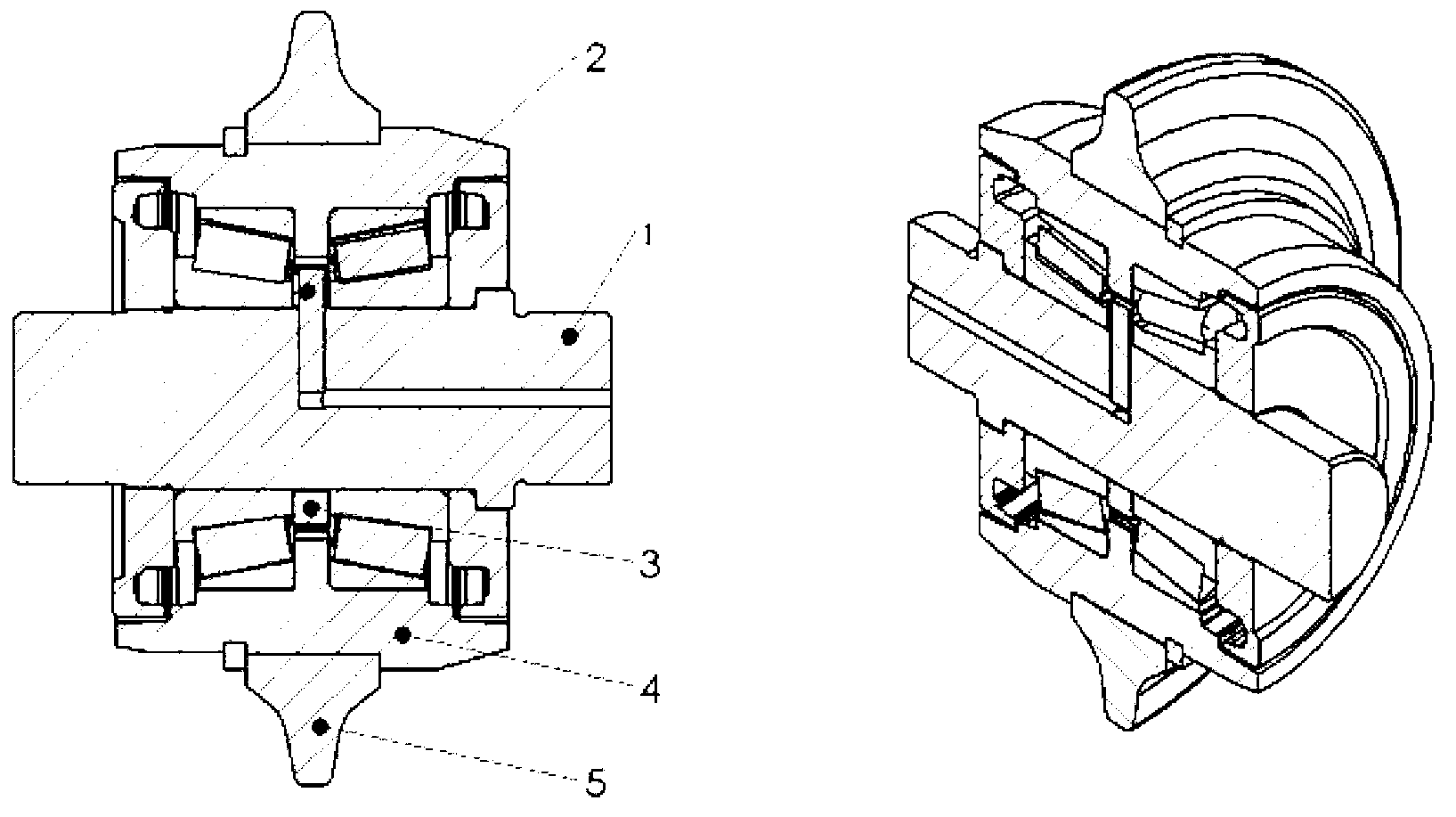

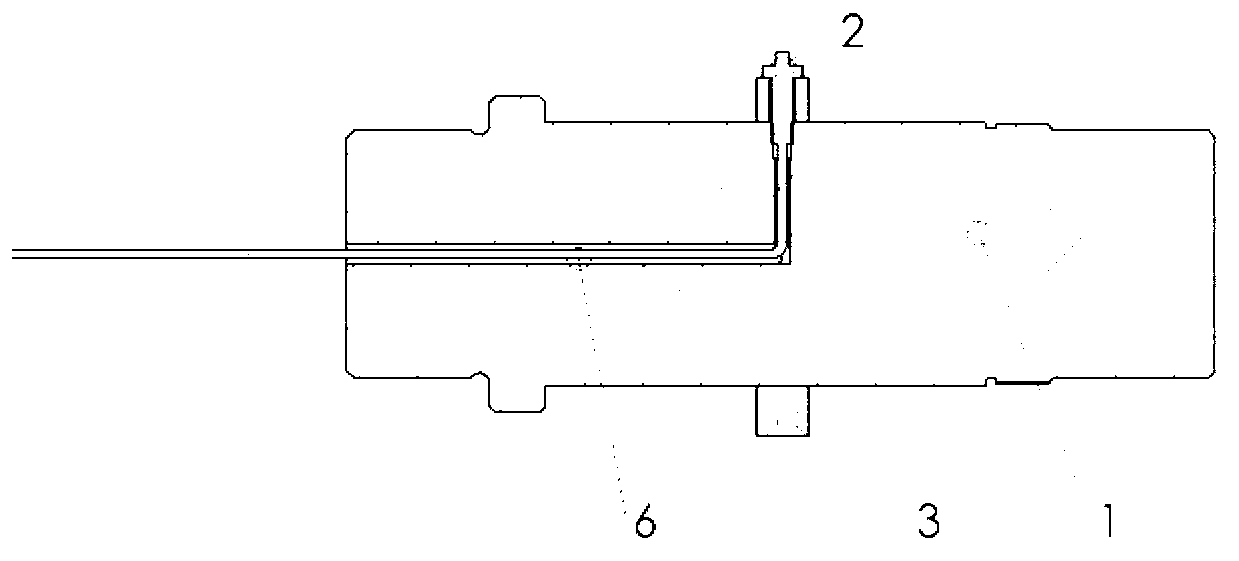

System and method for monitoring operation state of disc cutter group of cutterhead of tunneling machine

ActiveCN103226151AGroup performance is goodGuaranteed uptimeMachine part testingAnalysing solids using sonic/ultrasonic/infrasonic wavesMonitoring systemControl room

The invention discloses a system and a method for monitoring the operation state of a disc cutter group of a cutterhead of a tunneling machine. The method comprises the following steps: detecting the autorotation speed of each disc cutter by using a sensor; and transmitting a rotating speed signal to a computer in a control room of the tunneling machine by using a wireless data transmission device so as to judge the operation state of the disc cutters according to the rotating speed signal and the preset reference value relationship. The system and the method have the technical effect that the individual reference value of each individual of the disc cutter group is subjected to data processing and visual display, so that the operation state and the wear state of the disc cutter group of the tunneling machine can be displayed in real time. The monitoring system can provide selection help for an operator of the tunneling machine so as to determine whether to replace and maintain cutters or not, or change a tunneling control parameter to reach higher cutter group operation performance. By the method, manpower consumption can be reduced obviously, construction risk can be reduced, and work efficiency can be improved.

Owner:湖南奥通智能研究院有限公司

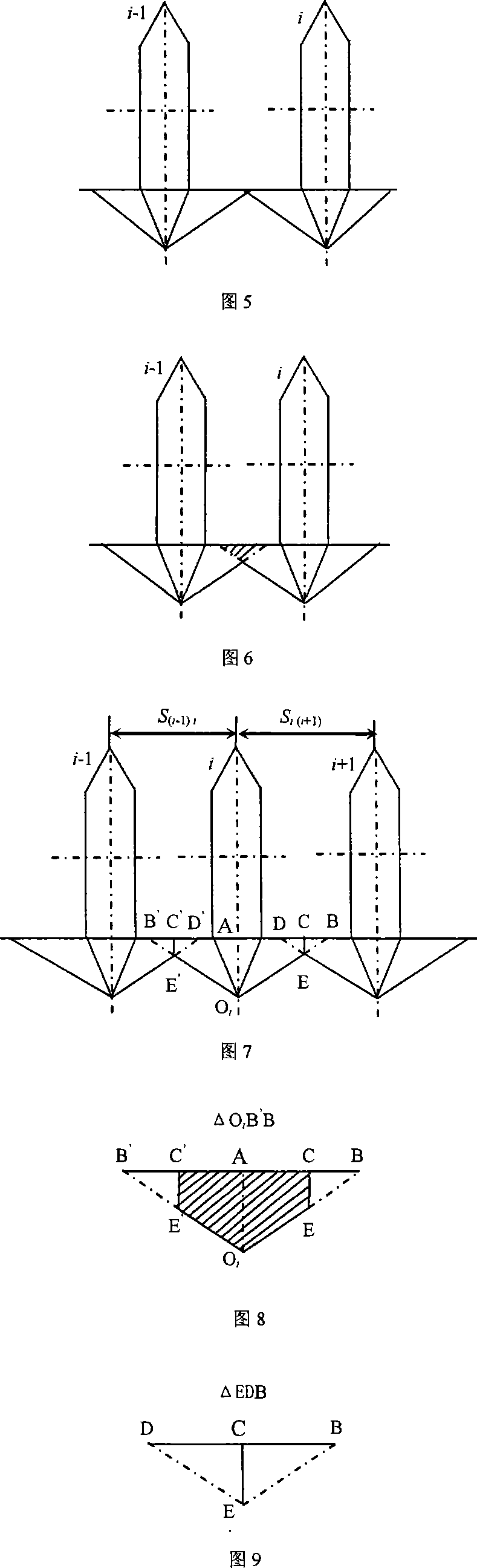

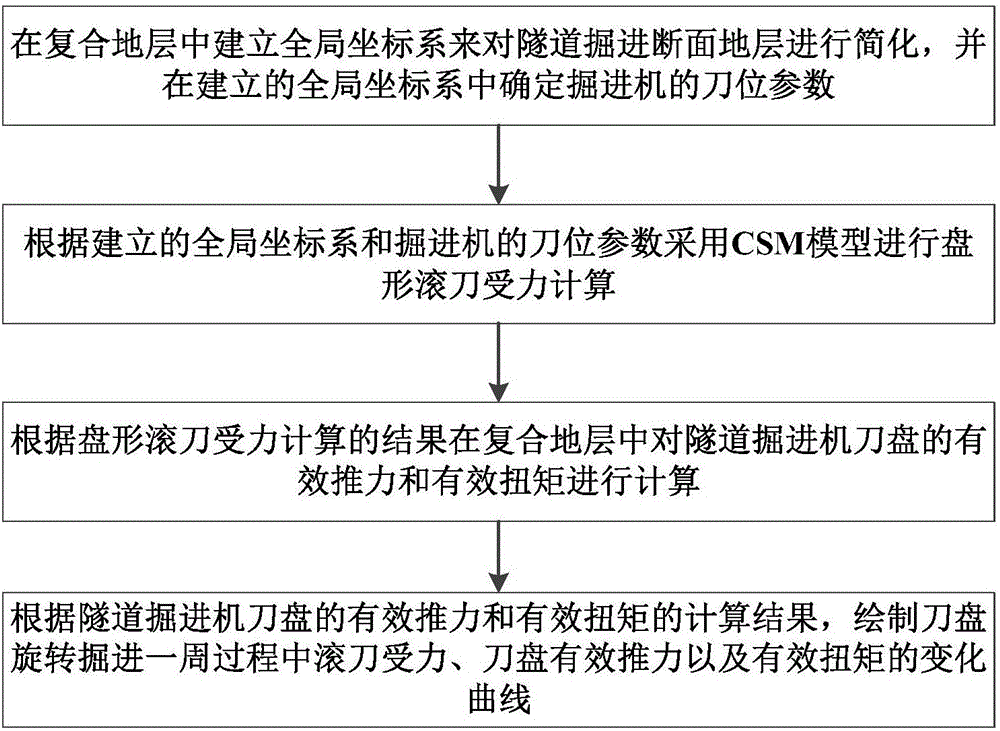

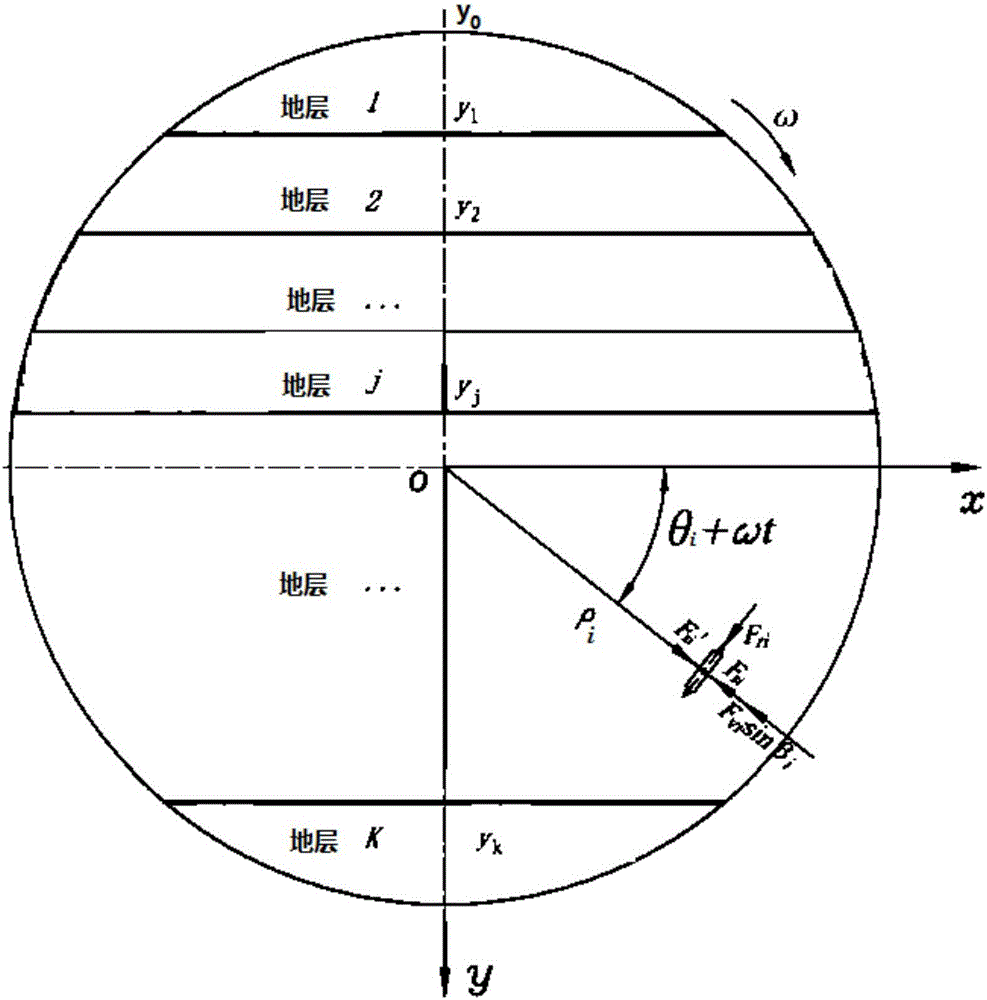

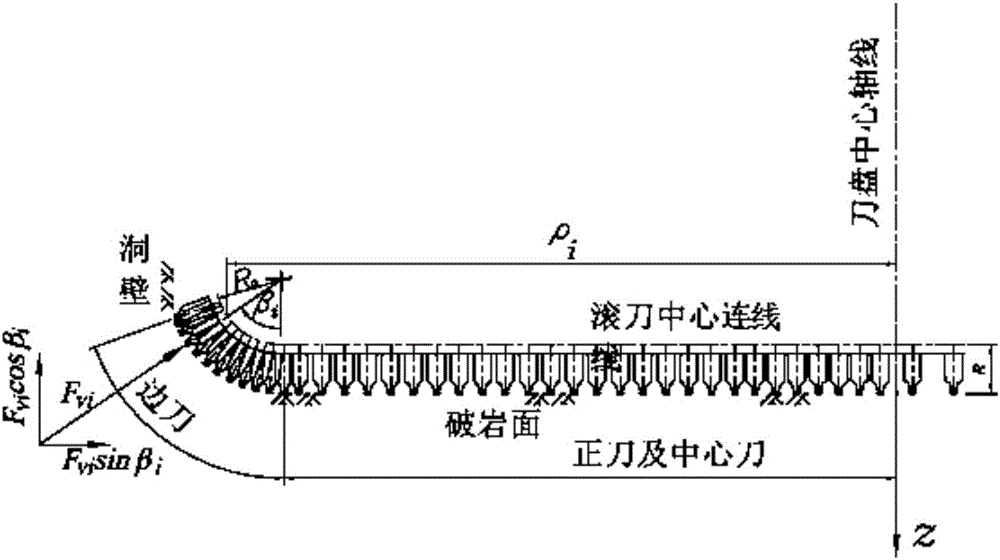

Effective thrust and torque calculation method of tunnel boring machine cutterhead on the basis of CSM (Colorado School of Mines) model

InactiveCN106383931AReal-time grasp of force changesConvenient guidanceGeometric CADSpecial data processing applicationsEngineeringTunnel boring machine

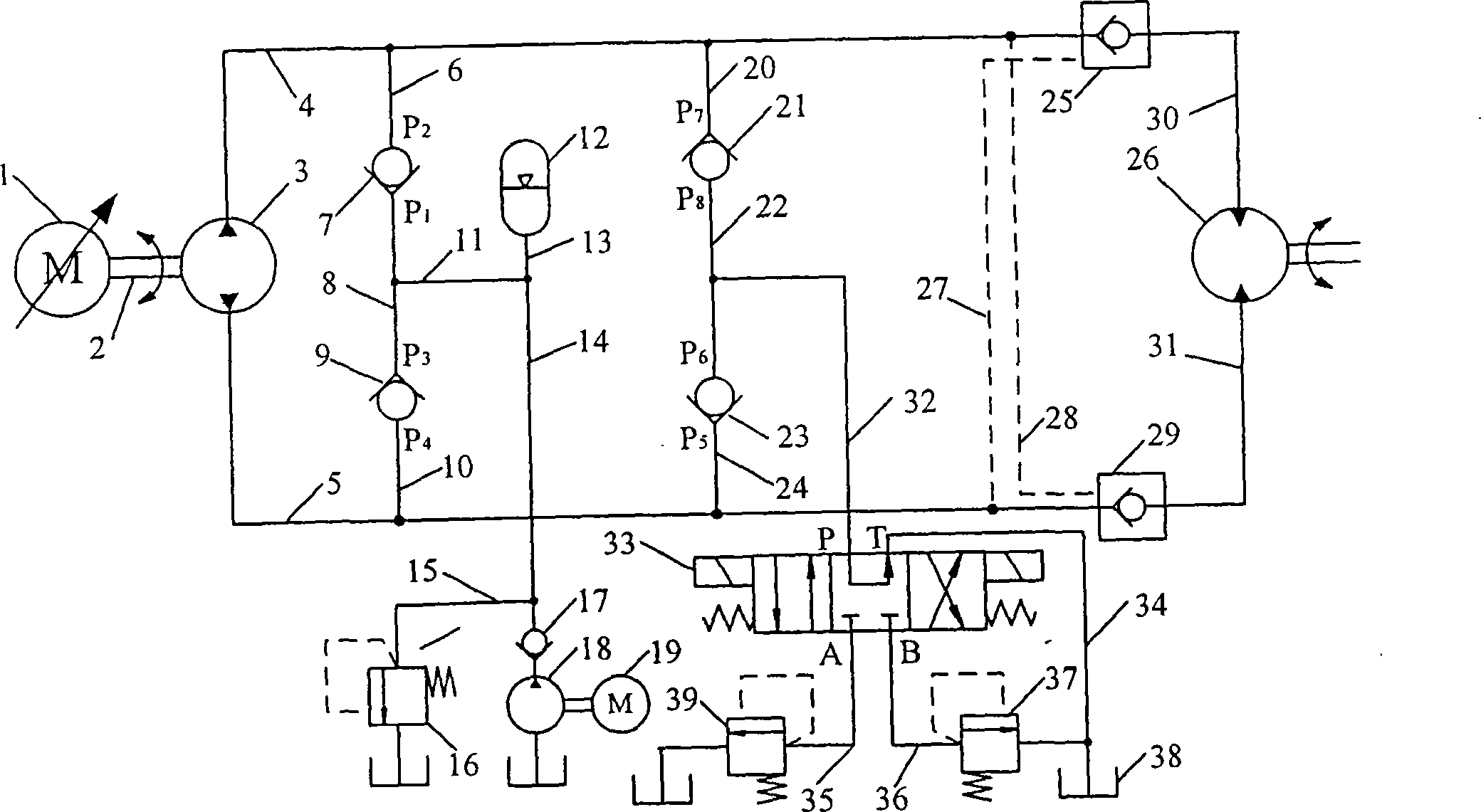

The invention discloses an effective thrust and torque calculation method of a tunnel boring machine cutterhead on the basis of a CSM (Colorado School of Mines) model. The method comprises the following steps of: establishing a global coordinate system in a compound stratum to simplify a tunnel boring section, and determining the cutter spacing parameter of the tunnel boring machine in the established global coordinate system; according to the established global coordinate system and the cutter spacing parameter of the tunnel boring machine, adopting the CSM model to carry out disc cutter stress calculation; according to the result of the disc cutter stress calculation, calculating the effective thrust and the effective torque of the tunnel boring machine cutterhead in the compound stratum; and according to the calculation result of the effective thrust and the effective torque of the tunnel boring machine cutterhead, drawing a change curve of cutter stress and the effective thrust and the effective torque of the cutterhead when the cutterhead rotates and bores for one circle. The method provides a theoretical basis for the reasonable selection and monitoring of the thrust and the torque of the cutterhead in an excavation construction process of the tunnel boring machine, and is more scientific, objective and reliable. The method can be widely applied to the field of tunnel construction.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

Mining machine with driven disc cutters

A mining machine including a cutting mechanism comprising an arm having an arm end, a disc cutter adapted to engage the material to be mined and mounted on the arm end. The disc cutter is driven by the arm into the material to be mined, and the arm further includes a main portion, and a wrist portion pivotally attached to the main portion.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

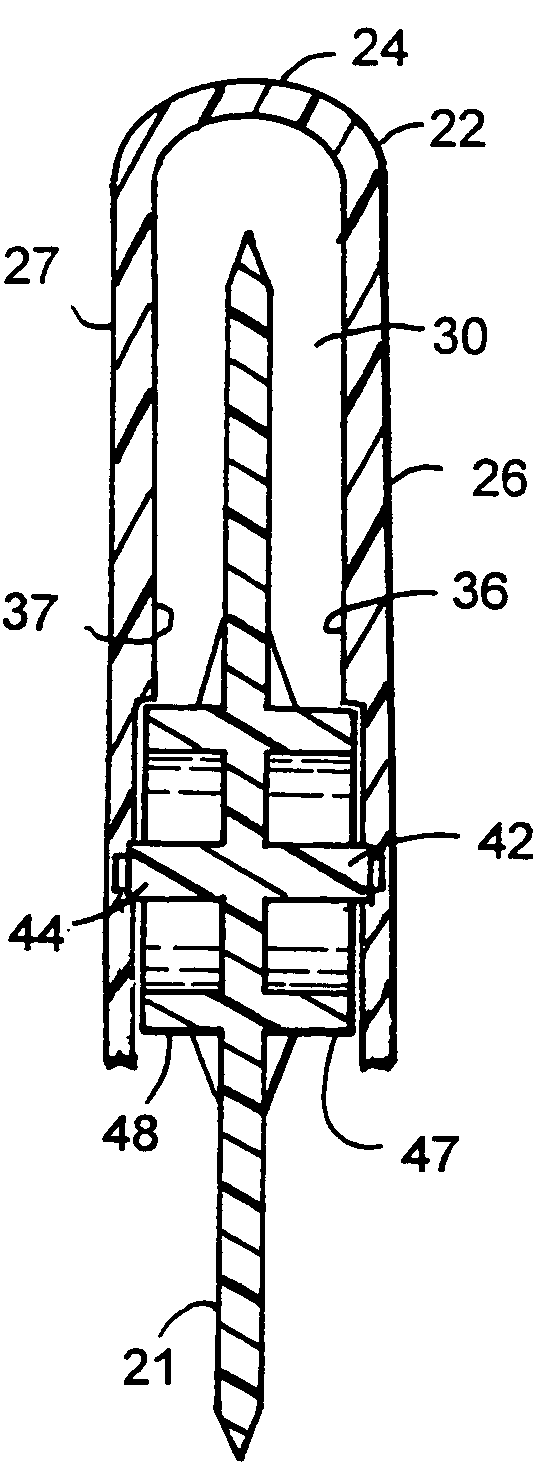

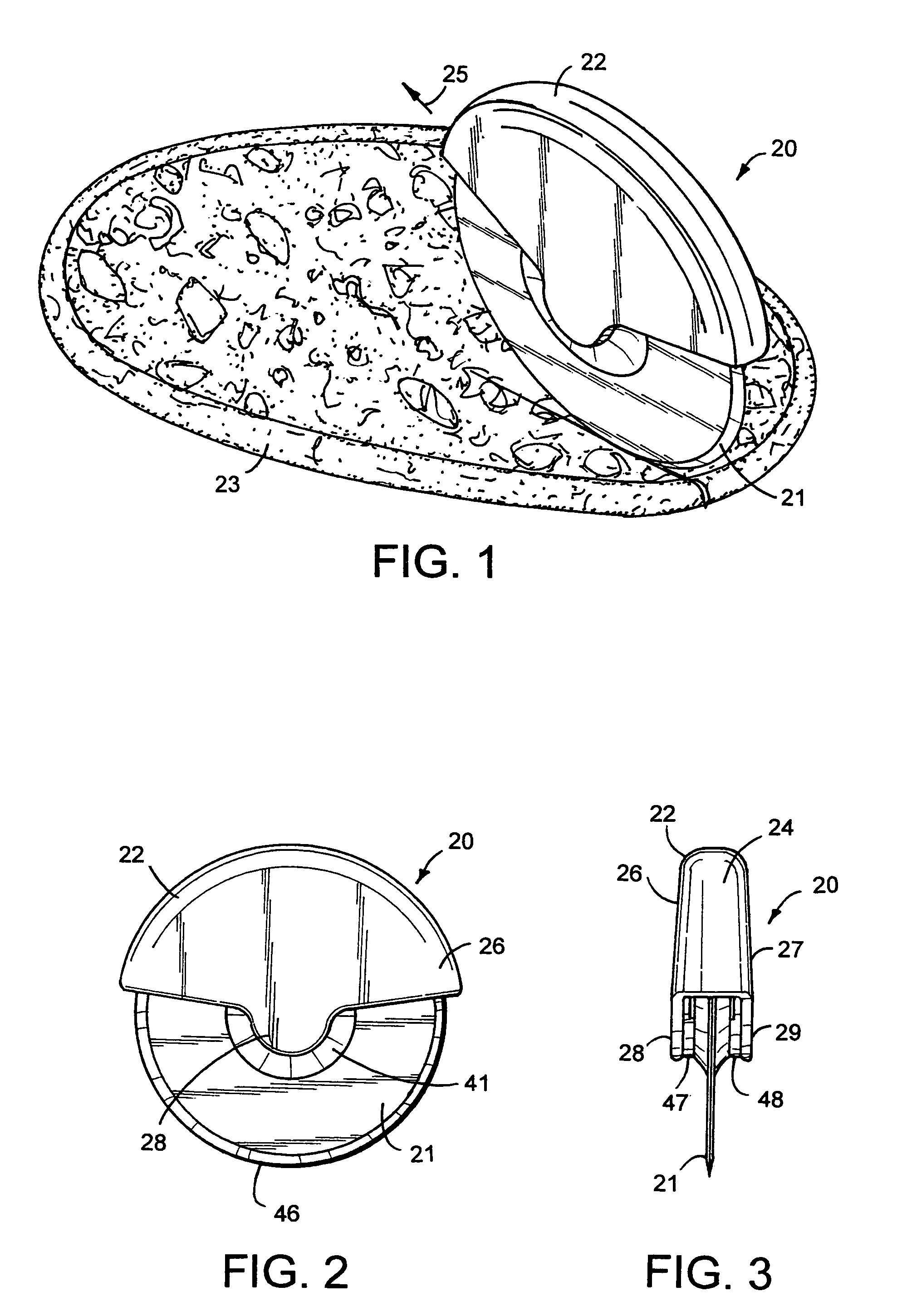

Disc cutter

A pizza cutter has a hollow semi-circular shaped handle having a convex curved radiused top edge to facilitate use and reduce hand stress. A removable cutter wheel has outwardly extending axles having protrusions on the outer ends thereof that have a snap fit relationship with recesses on the inner surfaces of the handle whereby the cutter wheel can easily be snapped into and out of the handle for cleaning. The cutter wheel has a dual inner and outer axle assembly engaging complementary shaped bearing surfaces on the handle to distribute pressure exerted on the wheel and keep the cutter wheel aligned with the handle when cutting movement is applied to the cutter.

Owner:FEY INDS

Disk cutter

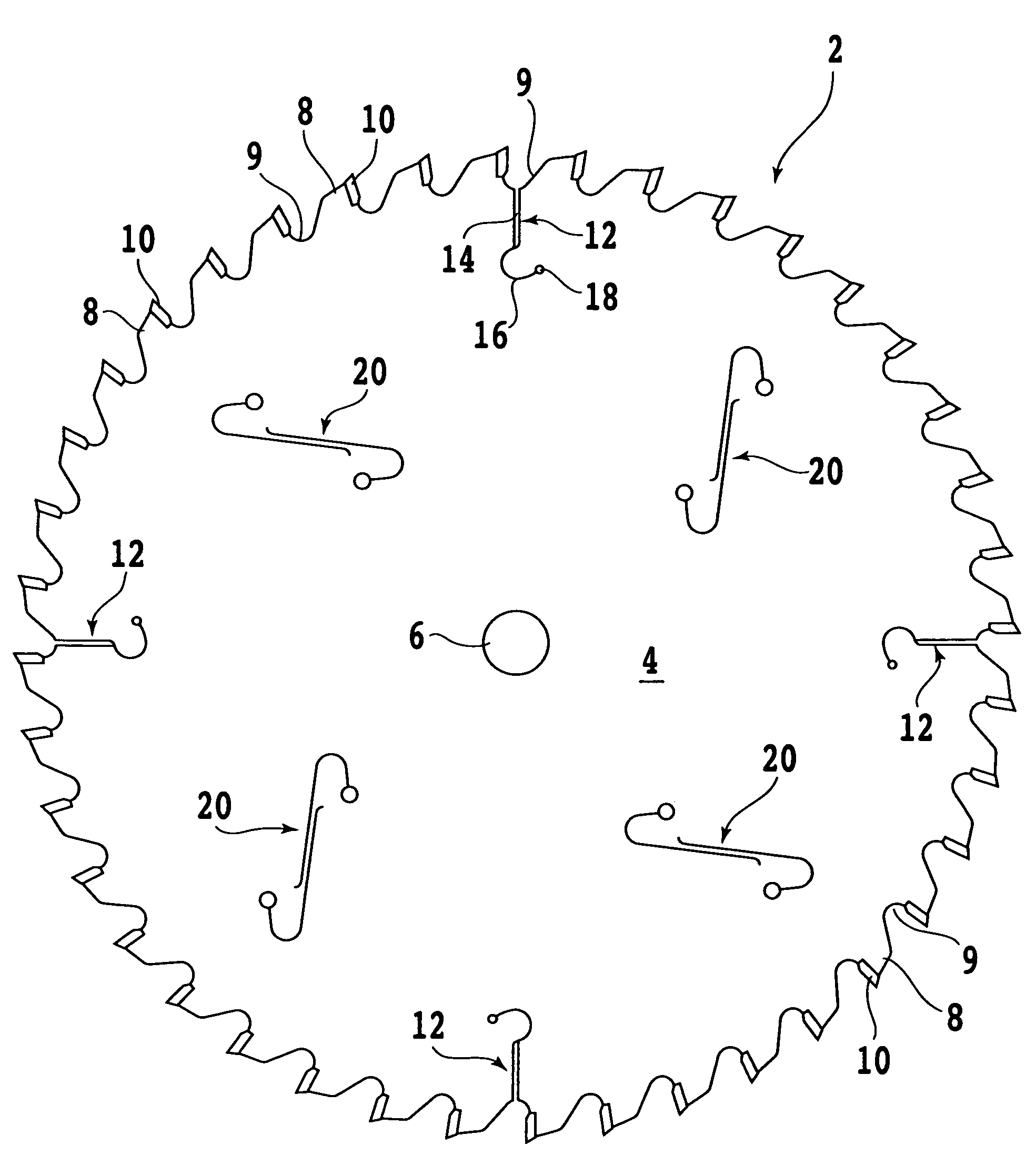

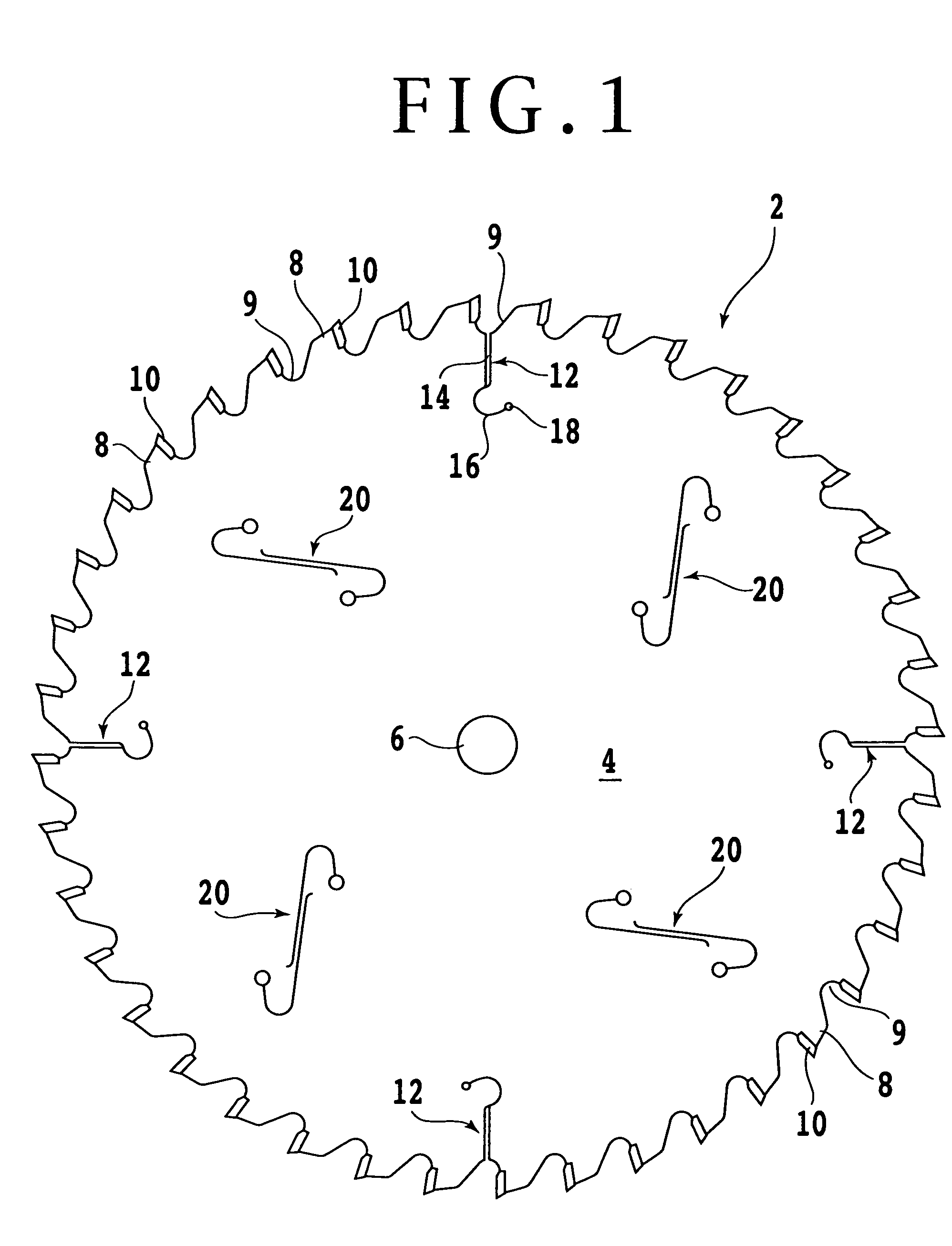

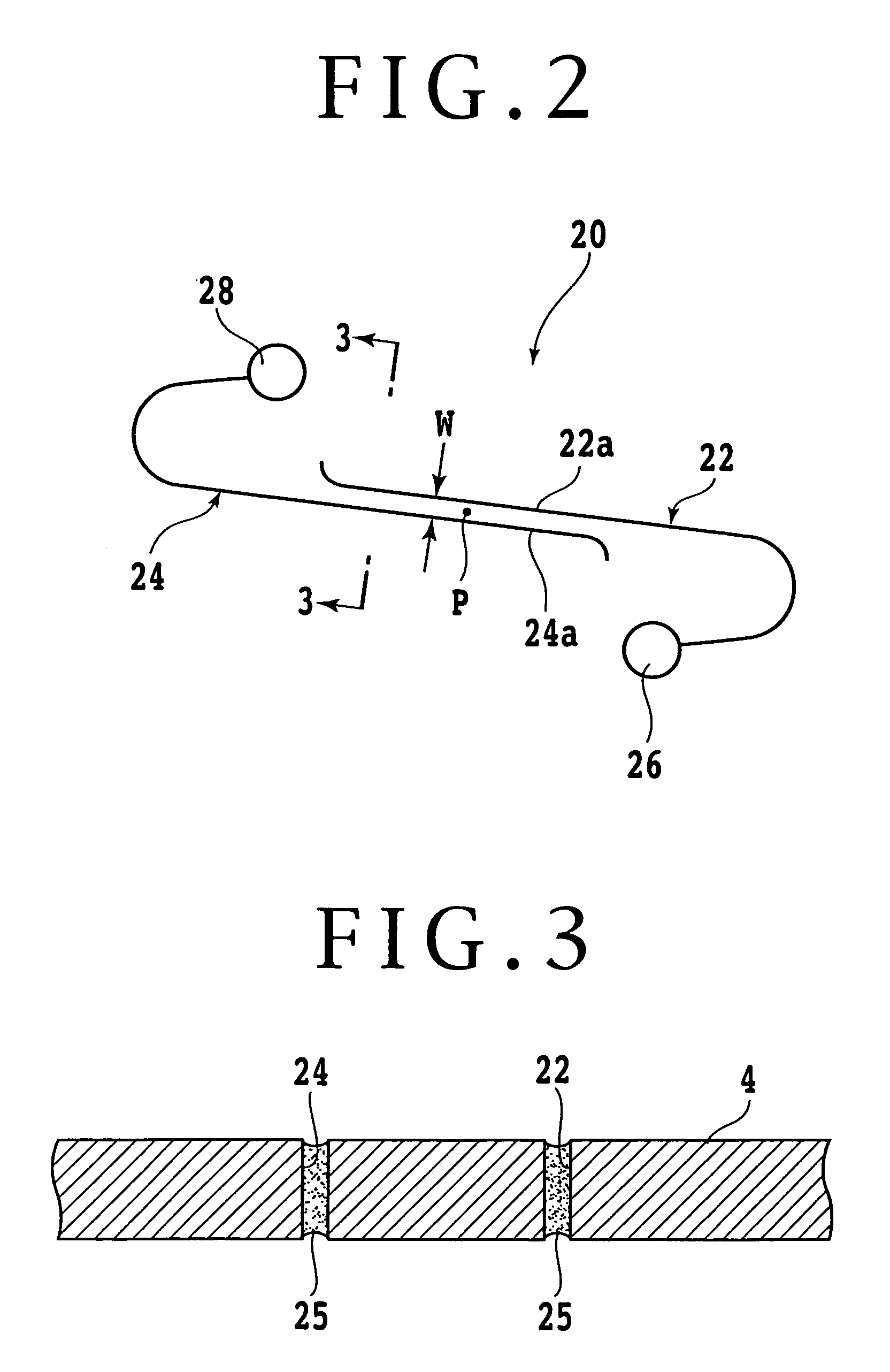

ActiveUS7156010B2Reduce stepsEfficientlyMetal sawing devicesMetal sawing toolsCircular discDisc cutter

A disk cutter including an annular disk-shaped base, a plurality of tip supports formed integrally along an outer circumference of the base, a gullet is defined between adjacent ones of the tip supports, a plurality of tip inserts respectively fixed to the tip supports, a plurality of outer slits formed at an outer circumferential portion of the base at given intervals, each of the outer slits having an outer end opening to the gullet, a plurality of intermediate slit pairs formed at a radially intermediate portion of the base at the given intervals, each of the intermediate slit pairs is located between adjacent ones of the outer slits. Each intermediate slit pair includes a substantially J-shaped first slit and a substantially inverted J-shaped second slit arranged in point symmetrical relationship with the first slit. Each of the first and second slits is filled with a viscous material.

Owner:TENRYU SAW MFG

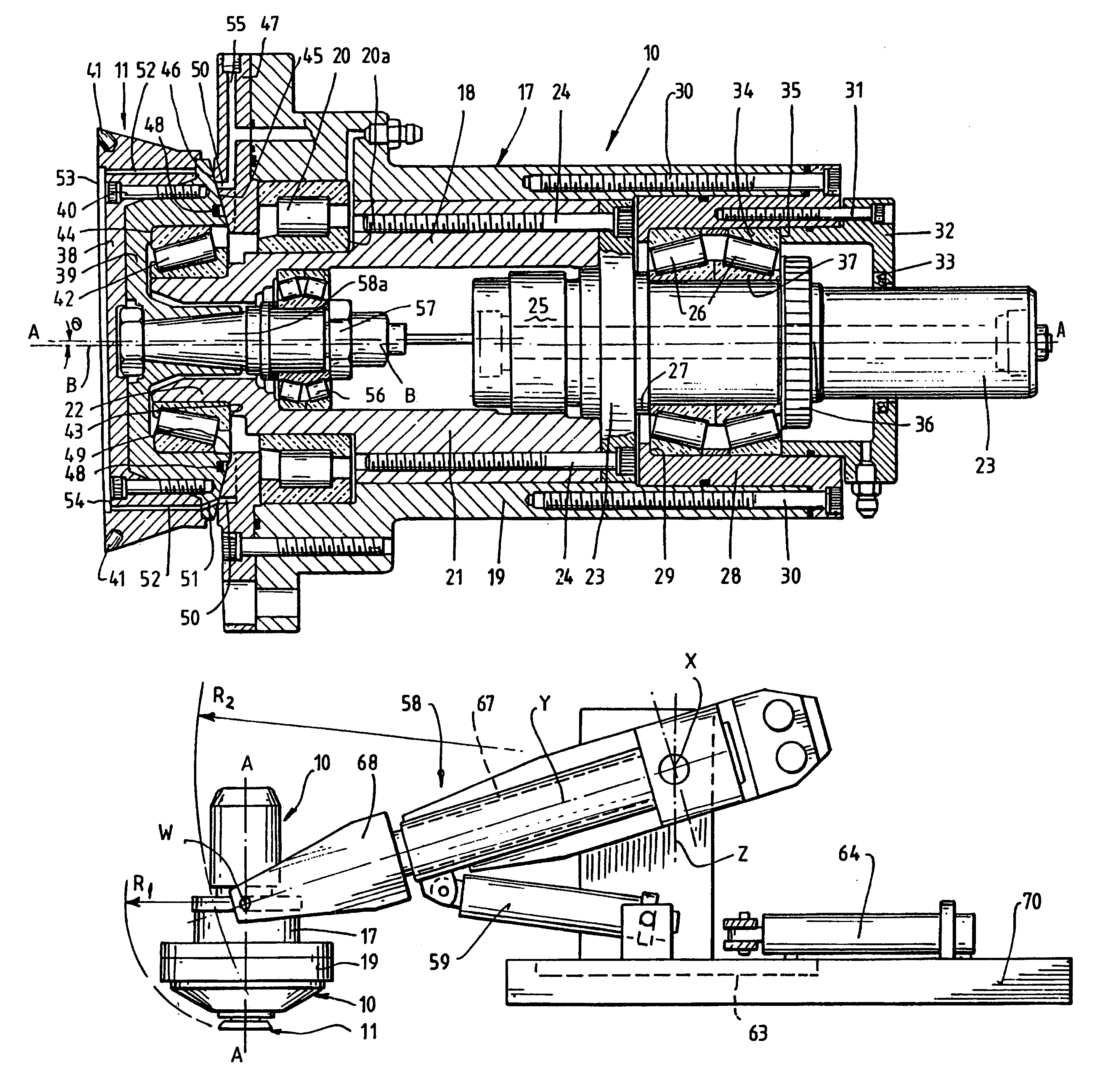

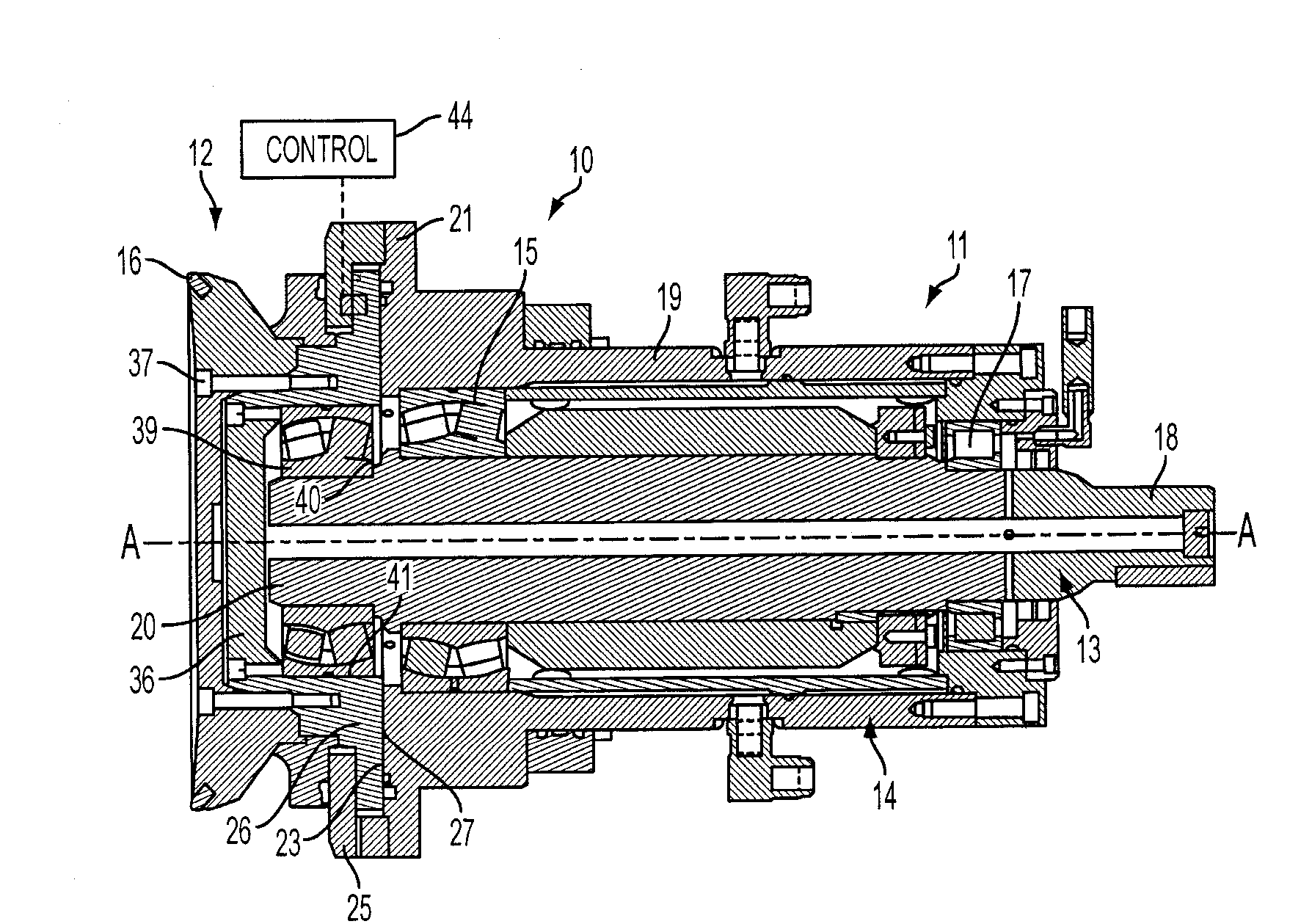

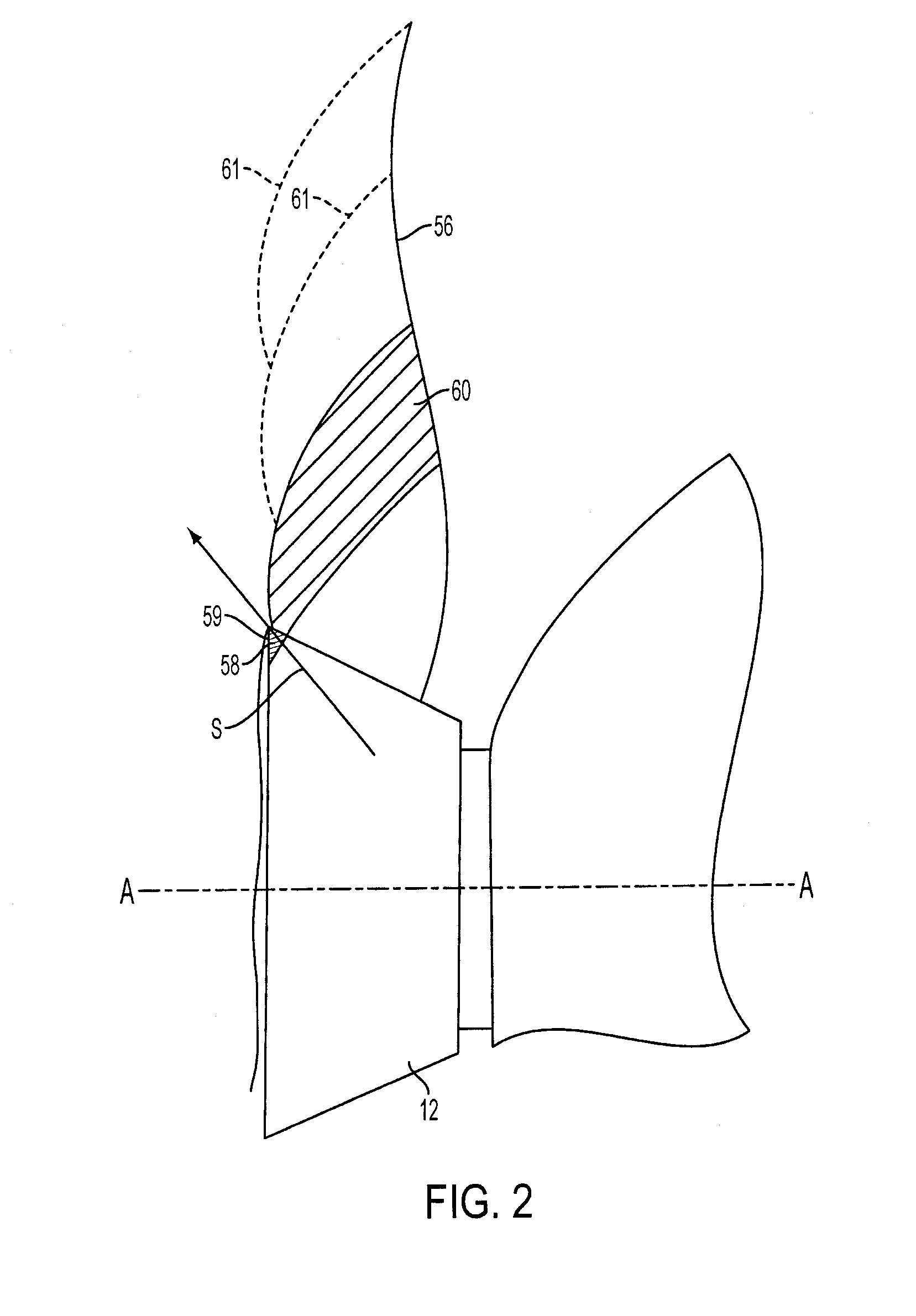

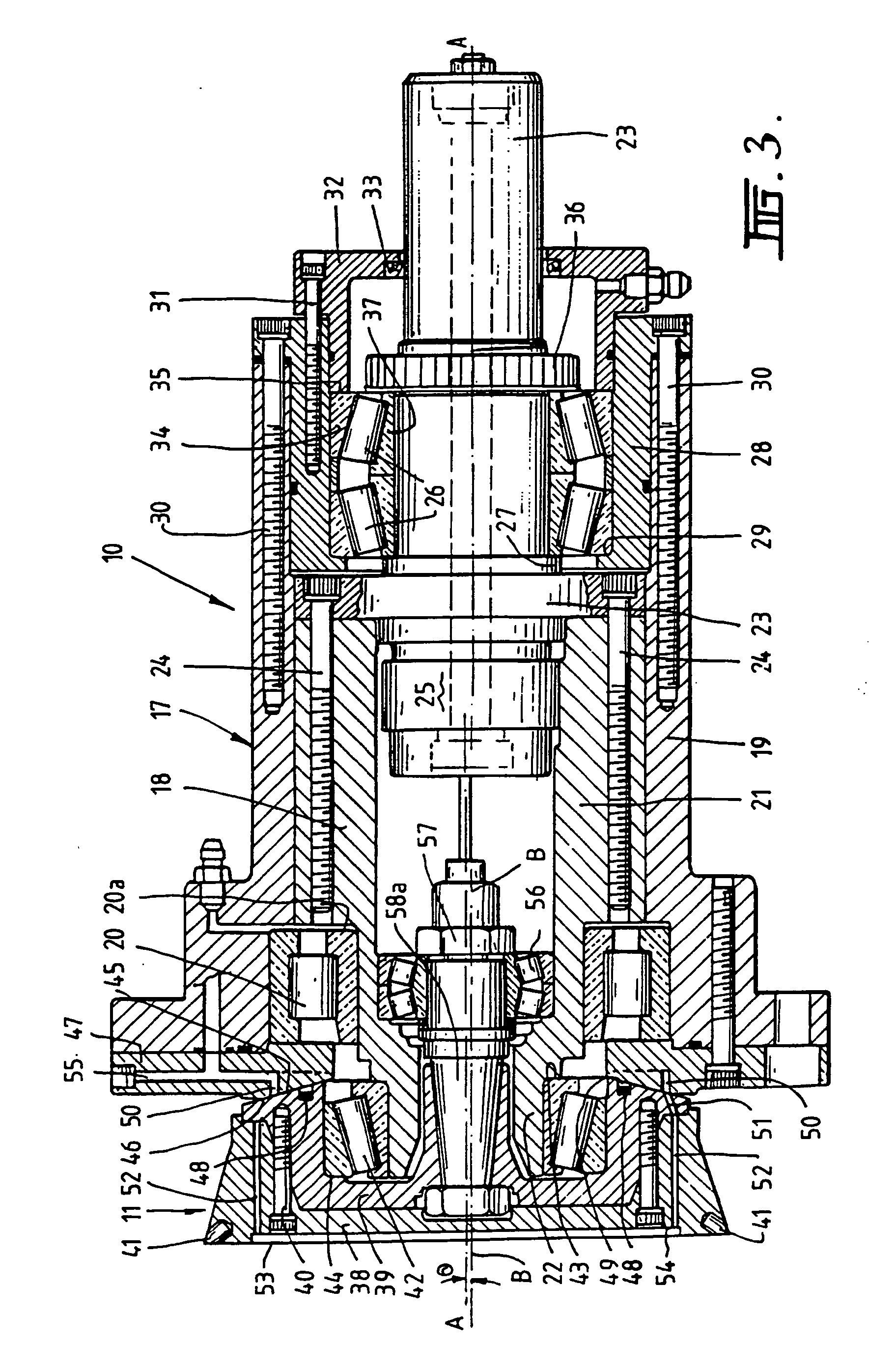

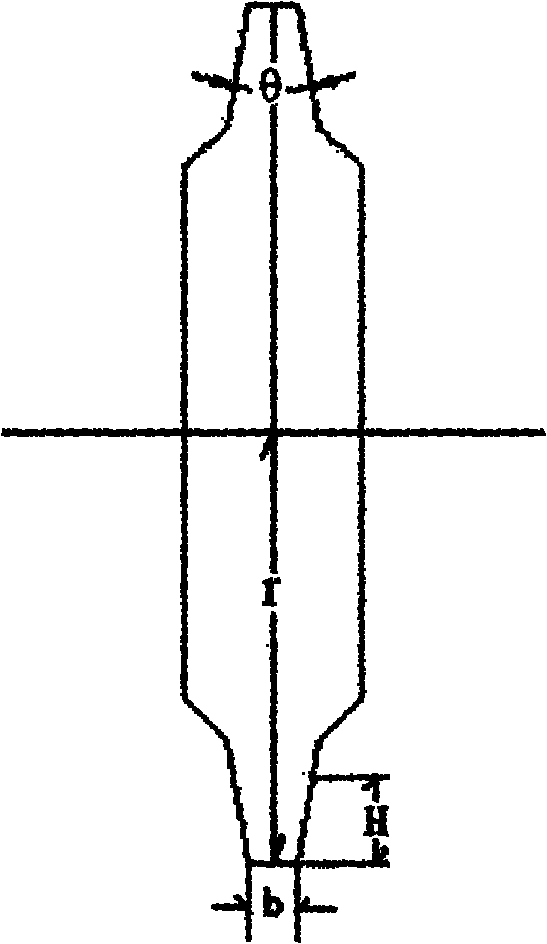

Oscillating disc cutter with speed controlling bearings

InactiveUS7384104B2Rotation speed is limitedInduce a rotational dragRotary combination bearingsLiquid resistance brakesDrive shaftRotation velocity

An oscillating disc cutter including a cutting disc and a drive mechanism. The drive mechanism includes a drive shaft to effect eccentric oscillation of the cutting disc and a radial bearing disposed to permit relative rotation between the drive shaft and the cutting disc. The cutter further including a hydrostatic axial bearing disposed to react axial forces while accommodating induced rotation of the cutting disc when operatively engaged and to induce a rotational drag thereby limiting rotational peed of the cutting disc when free running. A water pressurized fluid bearing induces a predetermined axial load in the hydrostatic bearing such that a predetermined maximum running clearance in the hydrostatic bearing is maintained.

Owner:ODYSSEY TECH

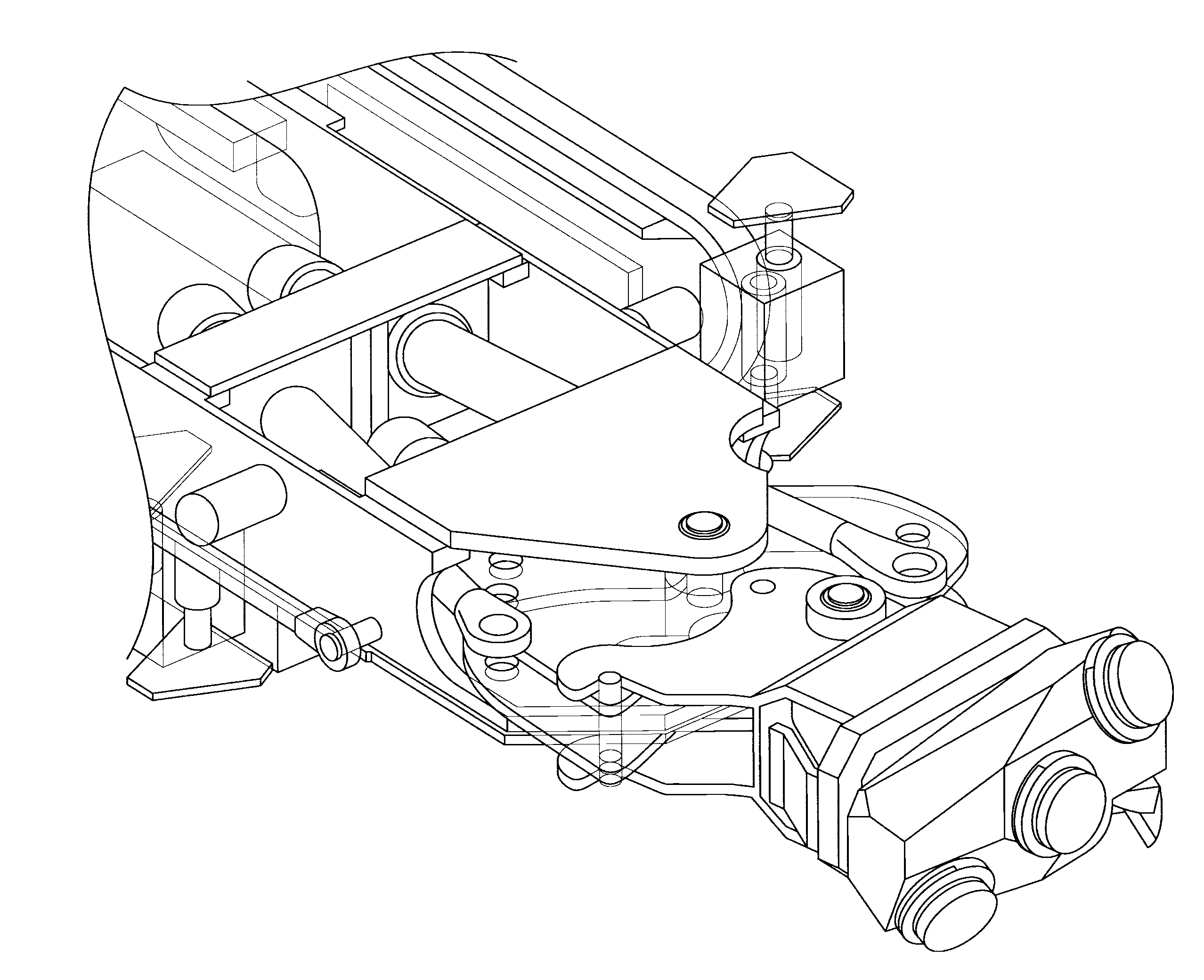

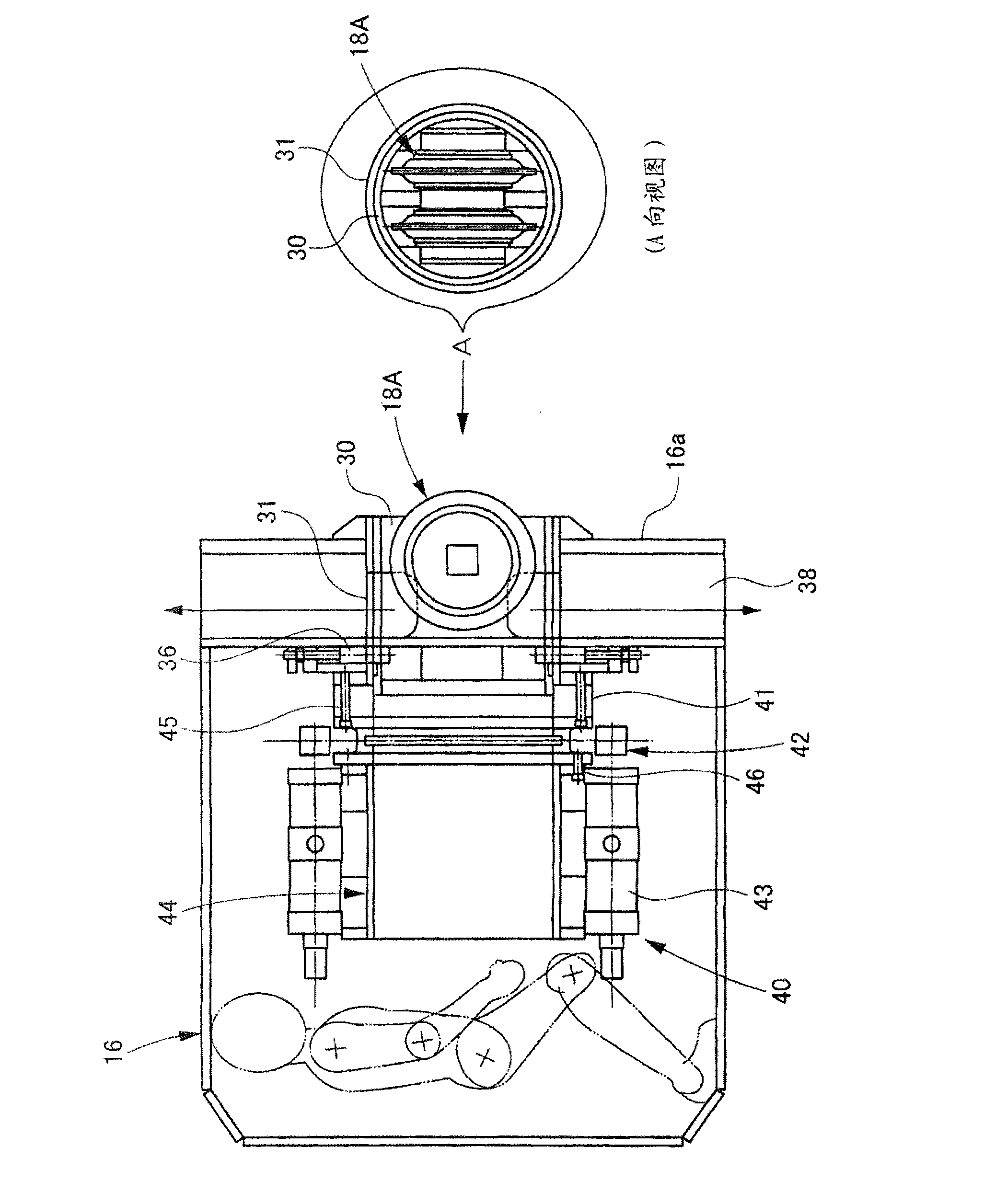

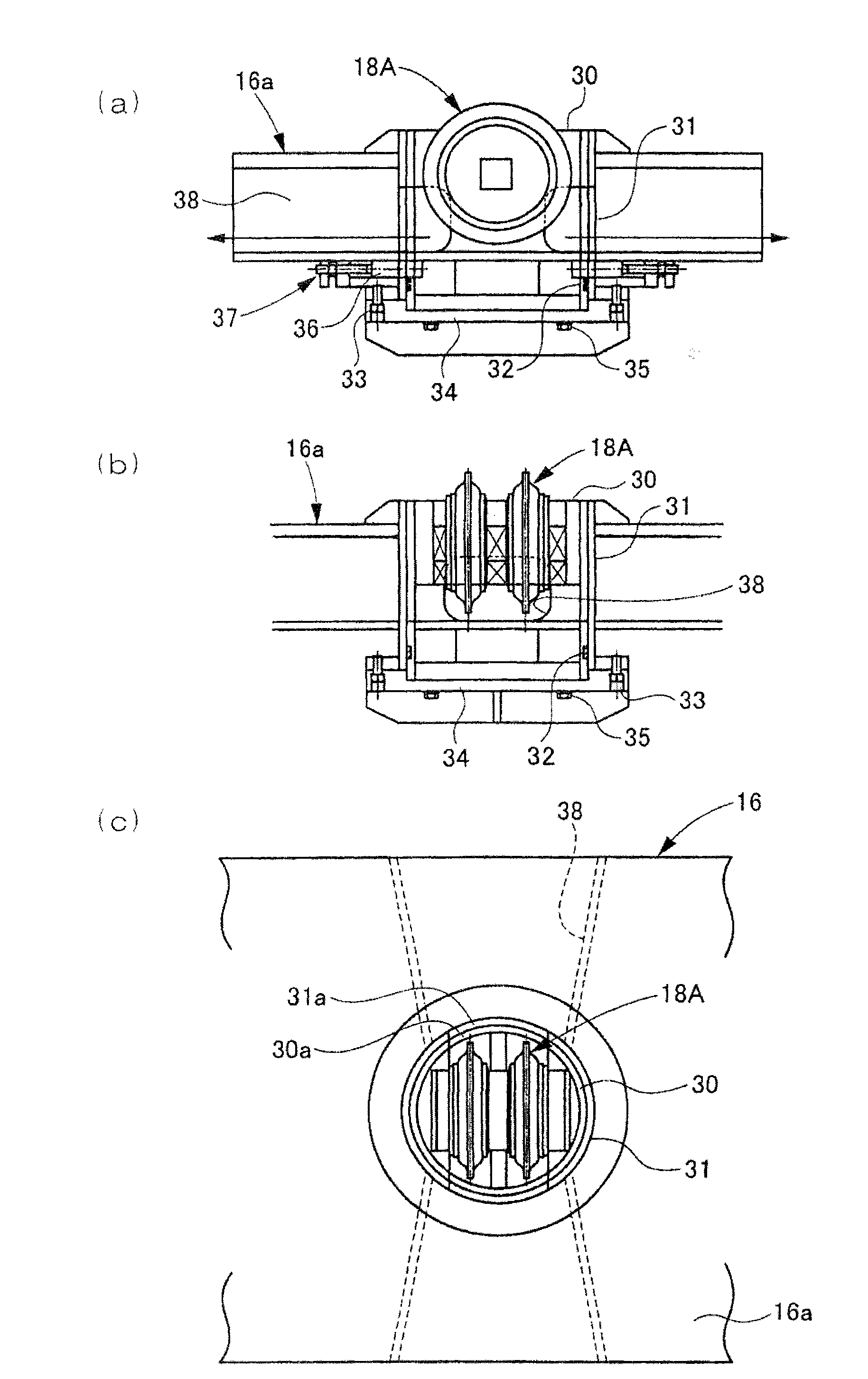

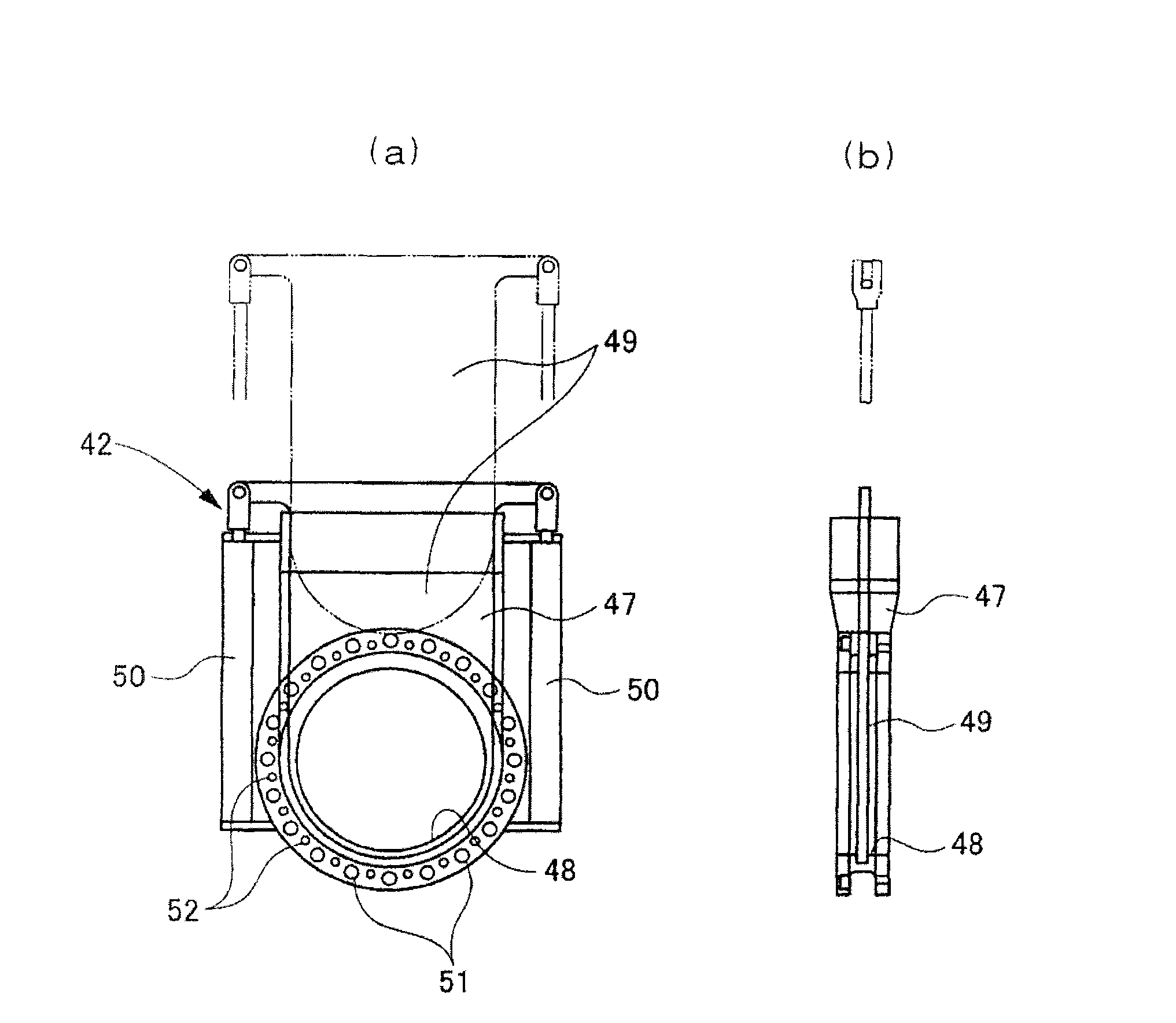

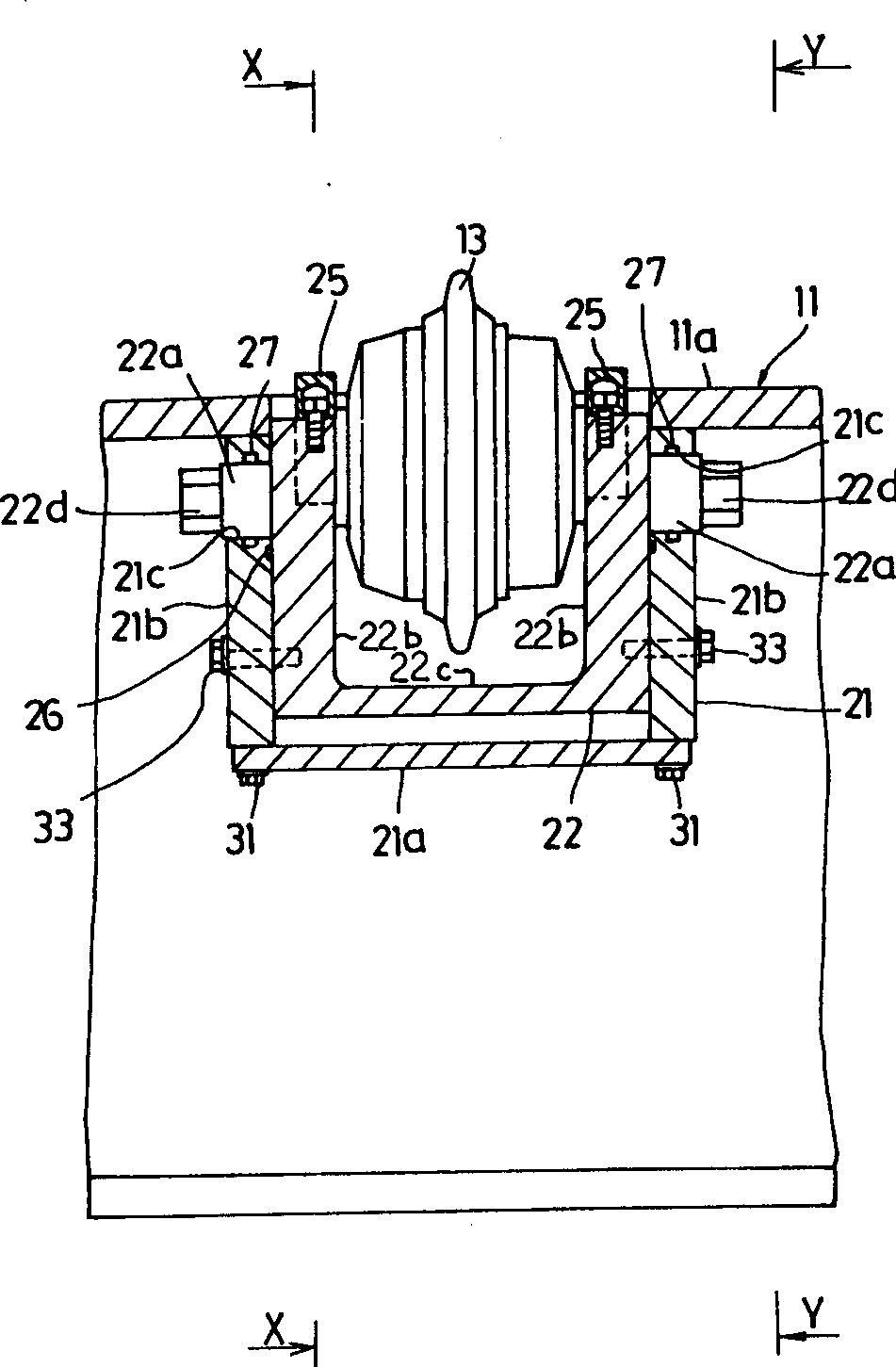

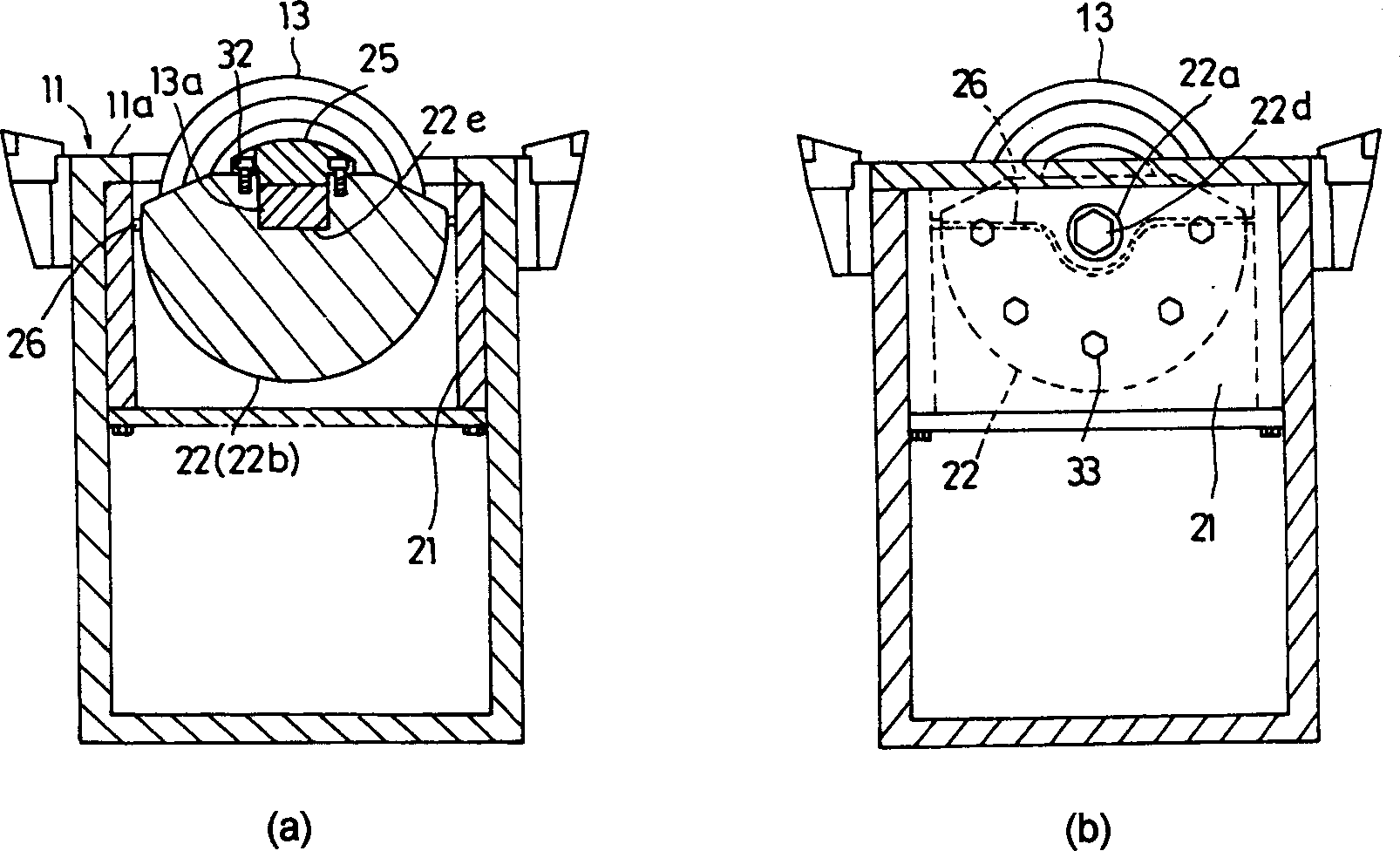

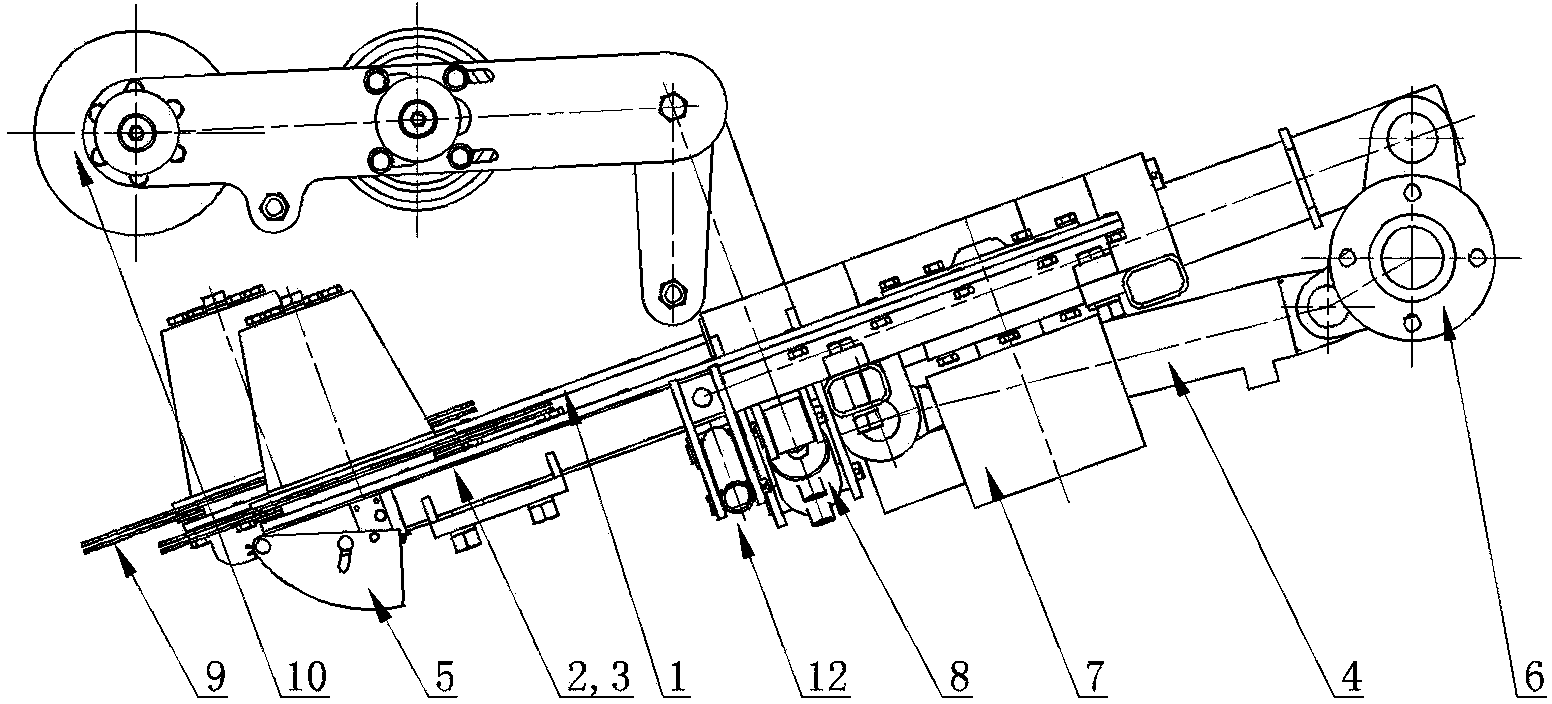

Replacing device and method for disc cutters of tool head

The invention provides a replacing device and method for disc cutters of a tool head, which allow operators to replace the disc cutters safely and to arrange the disc cutters at required intervals, with low cost. The replacing device (40) is arranged in the tool head (12) formed by installing a seat frame (30) supporting the replaceable double disc cutter (18A) in a freely rotatable manner through a fixing plate (34) to an installing bed (31). The replacing device can replace the double disc cutter for each seat frame in a cutter disc spoke (16) under atmospheric pressure behind the tool head. The replacing device comprises a sluice valve (42) which can be connected with a rear-end opening of the installing bed in a freely detachable manner and thus takes the place of the fixing plate, a replacing guide member (44) which can be connected with the rear portion of the sluice valve and thus guides the seat frame to move back and forth relative to the installing bed, and a loading and unloading jack (43) which is installed on the replacing guide member for enabling the seat frame to move back and forth.

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

Three-disc module for a mower cutterbar

A gear-driven modular disc cutter assembly that may be used singly or in combination on a header of an agricultural harvester to form a modular disc cutterbar. The modules feature a low profile to minimize disruption of incoming crop flow and are coordinated such that any two adjacent cutters are either converging or diverging the crop flow (e.g. any two adjacent cutters rotate in opposite directions). Additionally, the modules are suitable for mounting on a movable frame which allows the cutterbar to be folded in a horizontal plane to reduce the transverse width of the cutterbar to facilitate transport of the harvester between fields.

Owner:CNH CANADA +1

Square dough products and method of making the same

InactiveUS20070184161A1Easy to separateDough treatmentDough-sheeters/rolling-machines/rolling-pinsDisc cutterSheet material

A dough sheeting system for sheeting highly viscous bagel dough is presented. A continuous sheet of bagel dough is sheeted on a sheeting table including a satellite roller device, a cross roller device, and a gauging roller device arranged in series. The sheeting table reduces the dough sheet to a final thickness and width before a slitting device incorporating a plurality of rotary disc cutters, cuts the dough sheet into a plurality of dough sheets. Then a docker device cuts and virtually simultaneously presses the plurality of dough sheets to create a depressed center portion. A second cycle of the docker device cuts and presses again the depressed center portions of each newly created bagel dough piece. A spreading belt conveyor, a reciprocating conveyor, and a board indexing conveyor transport the bagel dough pieces to a proofing board for proofing and processing.

Owner:ENTENMANNS PRODS

Disc cutter trimming mechanism of sheet extrusion machine

ActiveCN104890208APrevent non-rotationAvoid the situationMetal working apparatusDisc cutterExtrusion

The invention discloses a disc cutter trimming mechanism of a sheet extrusion machine. The mechanism comprises a lower disc cutter, a first rotating shaft, an upper cutter base, an upper cutter base positioning mechanism, an upper disc cutter, a second rotating shaft, a lower cutter base and a lower cutter base positioning mechanism, and is characterized in that an upper cutter acceleration mechanism is mounted on the upper cutter base, wherein a sheet following ring drives the upper disc cutter to rotate through a gear acceleration mechanism; and the gear acceleration mechanism enables the rotating linear velocity of the upper disc cutter to be quicker than the rotating linear velocity of the lower disc cutter. Compared with the prior art, the mechanism has the following beneficial effects: as the upper cutter acceleration mechanism is arranged, sheets are pulled to effectively drive the lower cutter and the upper cutter to rotate, the rotating linear velocity of the upper cutter is quicker than the passing linear velocity of the sheets, and the cutting of the cutter is facilitated; and the mechanism is simple in structure and excellent in use effect, effectively eliminates the slip phenomenon, and prevents the condition of incapability of cutting off the sheets due to no rotation of the upper cutter.

Owner:GUANGDONG DESIGNER MASCH CO LTD

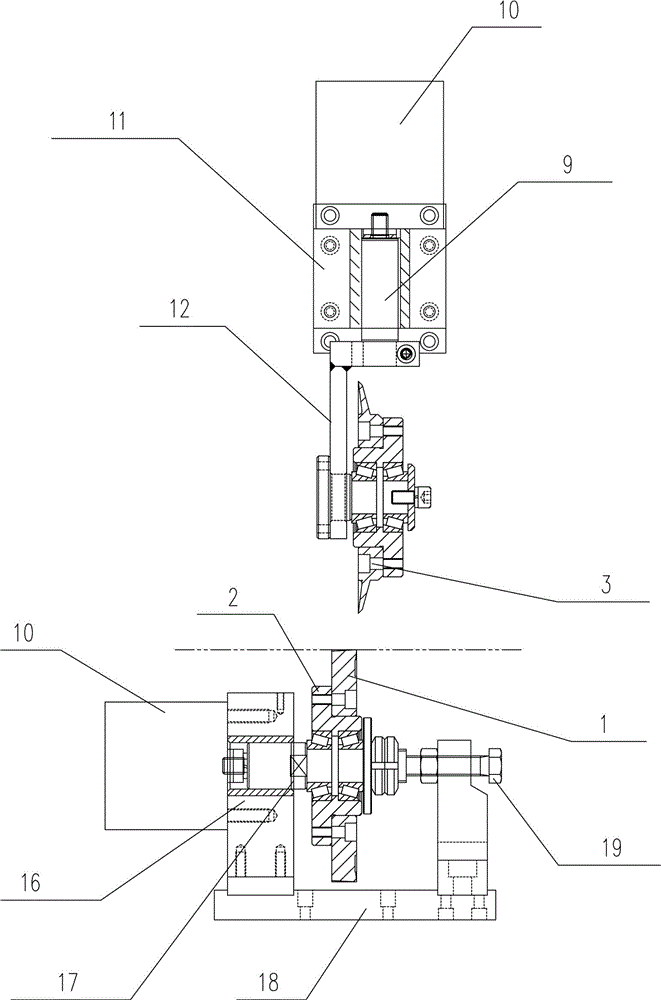

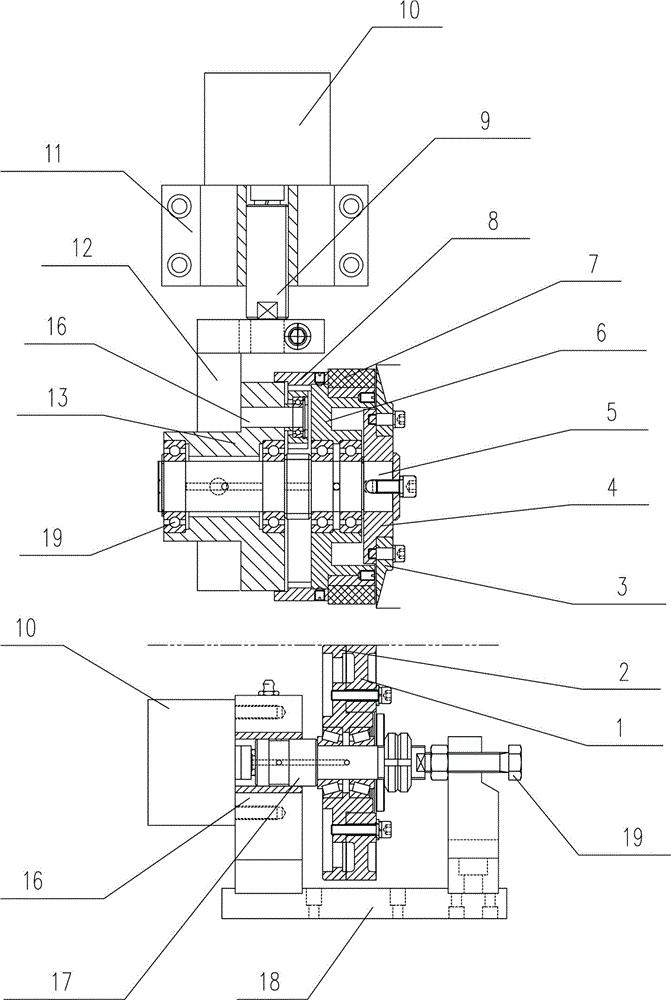

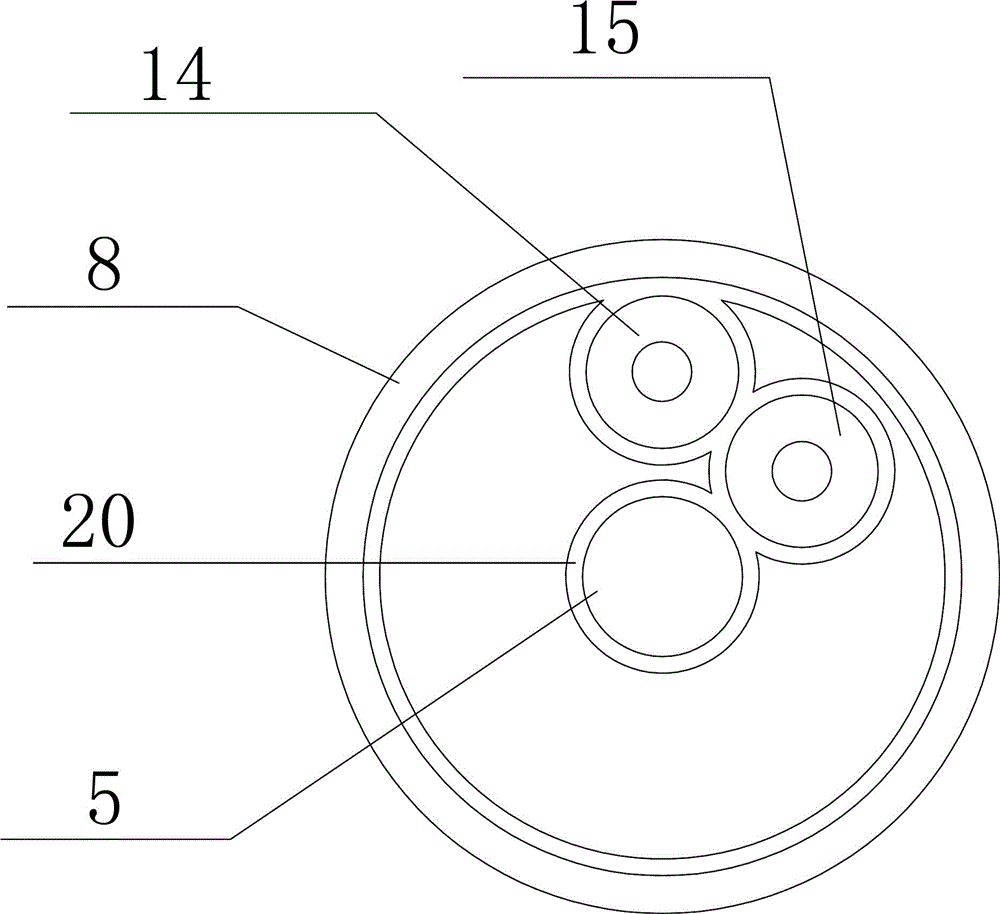

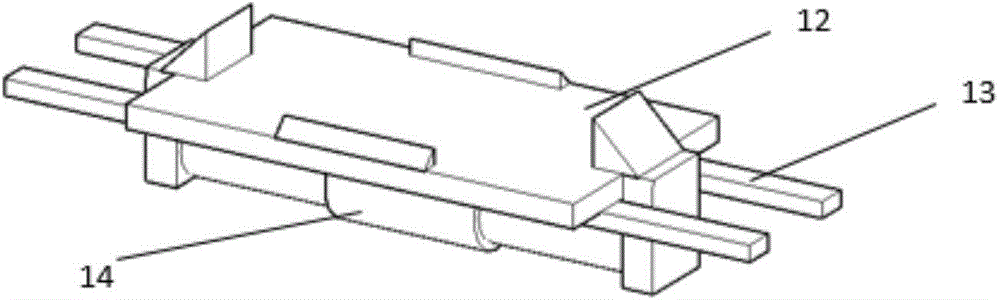

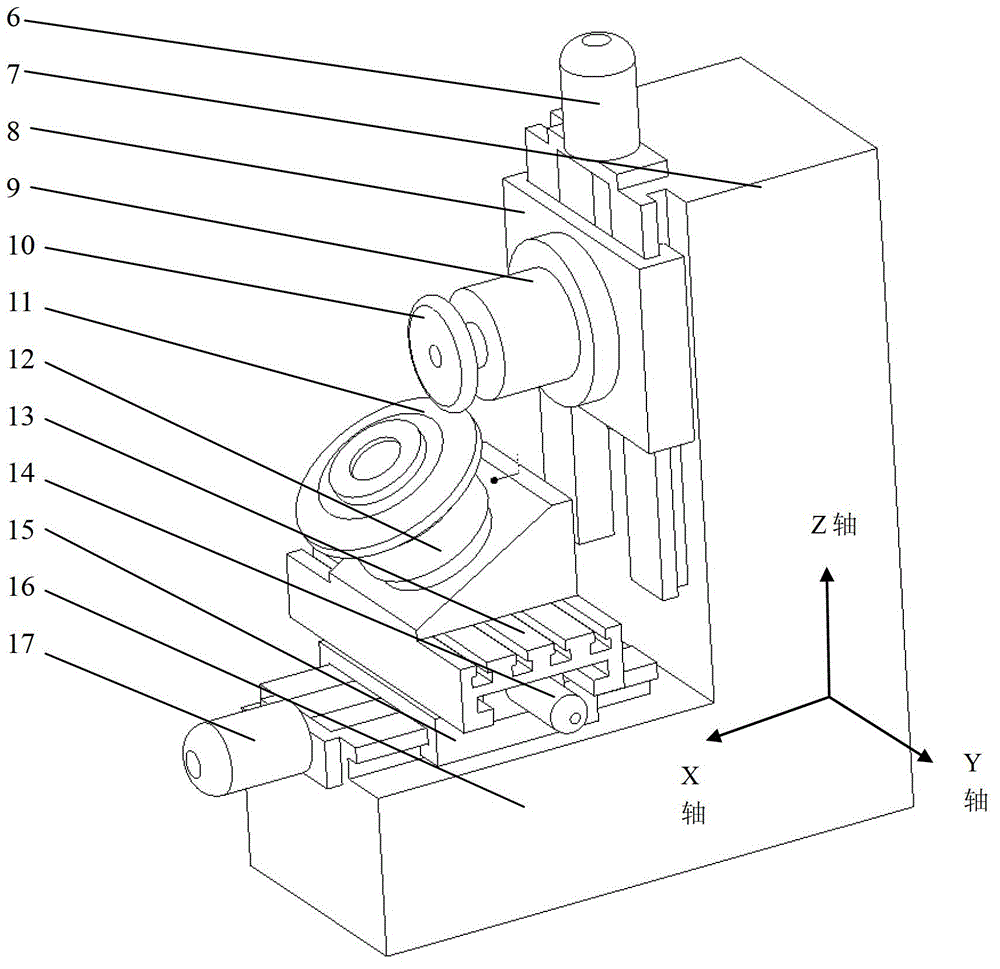

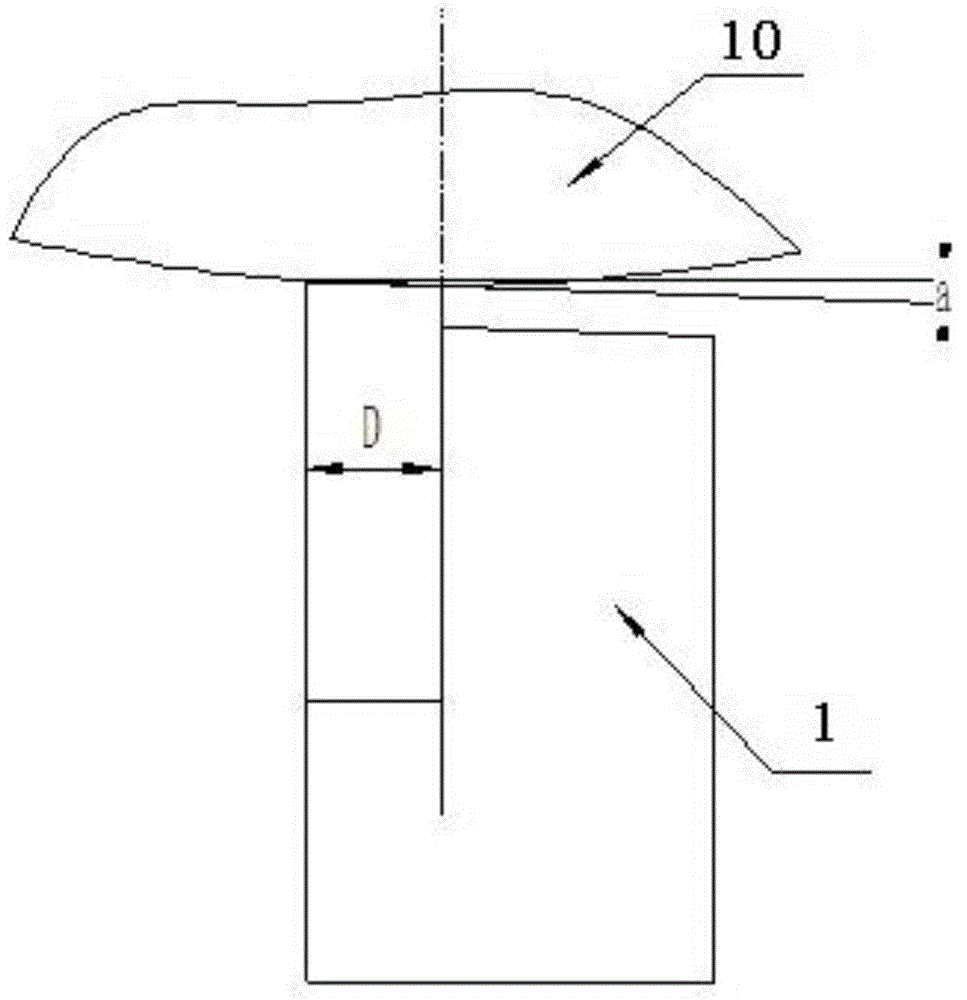

Device for testing wear resistance of disc cutter of TBM (tunnel boring machine) and application

The invention relates to a device for testing wear resistance of a disc cutter of a TBM (tunnel boring machine). The device comprises a base (1), a reaction frame (2), a vertical hydraulic cylinder (3), vertical guide rods (4), a vertical stress cushion block (5), a bearing (6), a cutter-like body (7), a cutter ring fixture (8), a cutter ring sample (9), a model case (10), a rock sample (11), a model case fixing block (12), transverse slides (13), a transverse hydraulic cylinder (14) and a test system, wherein the transverse hydraulic cylinder (14) drives the rock sample (11) to reciprocate in a horizontal plane, the vertical hydraulic cylinder (3) drives the cutter ring sample (9) to move up and down in a vertical plant, the cutter ring sample (9) reciprocates along with the rock sample (11) to realize reciprocating rolling, and the wear resistance of the cutter ring sample is tested through the test system. Compared with the prior art, the device can test the wear resistance of different cutter rings and can test effects caused by different factors on wear to the cutter rings.

Owner:TONGJI UNIV

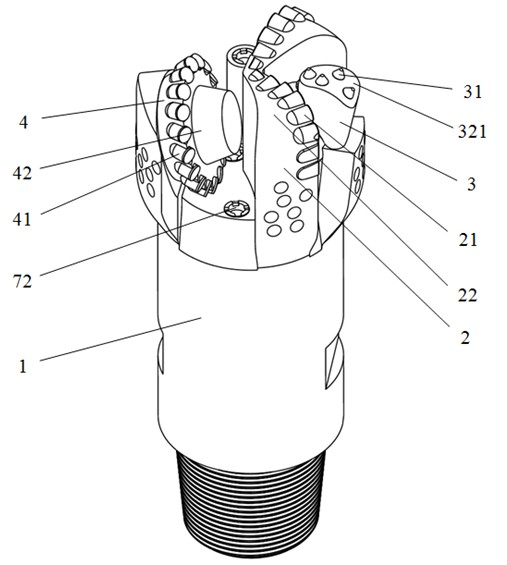

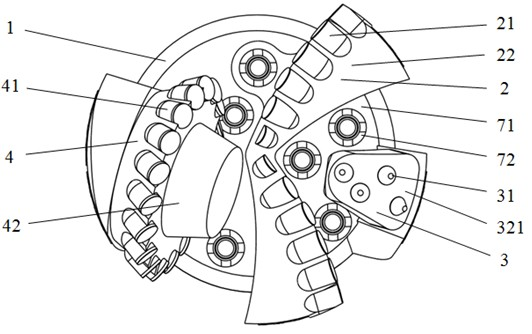

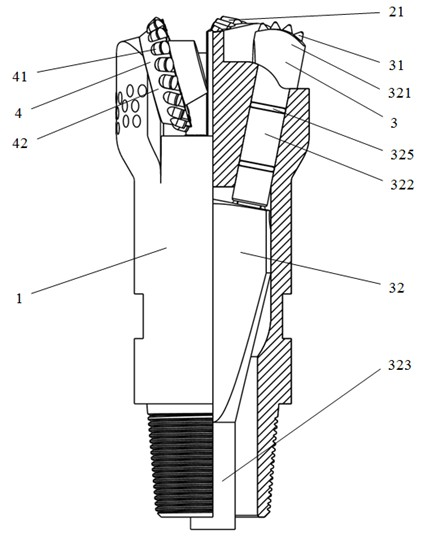

Crossed scraping-impacting composite drill bit

ActiveCN102678053AReduce difficultyReduce rock breaking energy consumptionDrill bitsConstructionsMining engineeringHydraulic structure

The invention discloses a crossed scraping-impacting composite drill bit belonging to the field of rock blasting tools for drilling equipment for oil and gas, mine engineering and building foundation engineering construction, geology, hydrology and the like. The crossed scraping-impacting composite drill bit comprises a drill bit body, a fixed cutting structure, a disc cutter cutting structure and a hydraulic structure, wherein the fixed cutting structure, the disc cutter cutting structure and the hydraulic structure are arranged on the drill bit body; the drill bit body is also provided with an impact cutting structure; and the impact cutting structure comprises a force transferring mechanism for transferring impact forces and impact cutting teeth, wherein the impact cutting teeth are solidified on a punch arranged at the tail end of the force transferring mechanism, and the punch can slide or slidingly impact relative to the drill bit body in the impact force transferring direction. Compared with a drill bit for blasting a rock in a cutting way, the crossed scraping-impacting composite drill bit is not only beneficial to the drilling of the cutting teeth of the drill bit to stratums and the increment of the rock blasting efficiency, but also beneficial to the retardance of the wear rate of the cutting teeth and particularly has remarkable technical advantages for higher-strength and stronger-abrasiveness stratums which are difficult to drill.

Owner:SOUTHWEST PETROLEUM UNIV

Shield digger bit

PURPOSE: To provide a cuter head for a shield machine capable of switching a disc cutter between a cutting position and a water cut-off position by means of a compact structure and safely and easily replacing the disc cutter from a cutter head spoke inside without performing any soil improvement for reducing a cost and a construction period. CONSTITUTION: This cutter head is provided with a disc cutter mounting box 21 and a disc cutter cover 22 pivoted to the disc cutter mounting box 21 for supporting the disc cutter rotationally. The bottom part of the disc cutter mounting box 21 is constructed so that it can be freely opened / closed by detaching / attaching a bolt 31 and can be switched between the cutting position for performing cutting and the water cut-off position for sealing water by means of the disc cutter cover 22 when a pivot shaft 22a is turned. In selection of the water cut-off position, the disc cutter 13 can be replaced from the inside of the cutter head spoke 11.

Owner:KOMATSU LTD

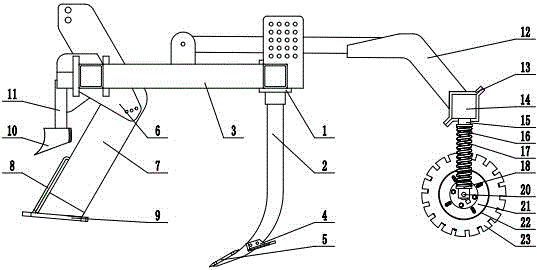

Integrated cutting and conveying device of sugarcane harvester

The invention discloses an integrated cutting and conveying device of a sugarcane harvester. The integrated cutting and conveying device comprises a cutting mechanism and a conveying mechanism fixed to each other. The conveying mechanism comprises a feeding fixed plate and a rubber plate. The feeding fixed plate is fixed on a roller. The rubber plate penetrates through the feeding fixed plate and is then fixedly connected to the outside of the roller. Cut canes are effectively conveyed back by the feeding fixed plate and the rubber plate disposed on the roller. Gears in a gear bank have different tooth numbers, so that rotation speed of the rubber plate is smaller than that of a disc cutter, the cut canes can be timely, stably and orderly conveyed to subsequent procedures through the feeding fixed plate and the rubber plate, multi-breakage of the canes is avoided, cane harvesting quality is improved, and damage of sugar content of the canes is avoided.

Owner:LINHAI HENGFENG MACHINERY

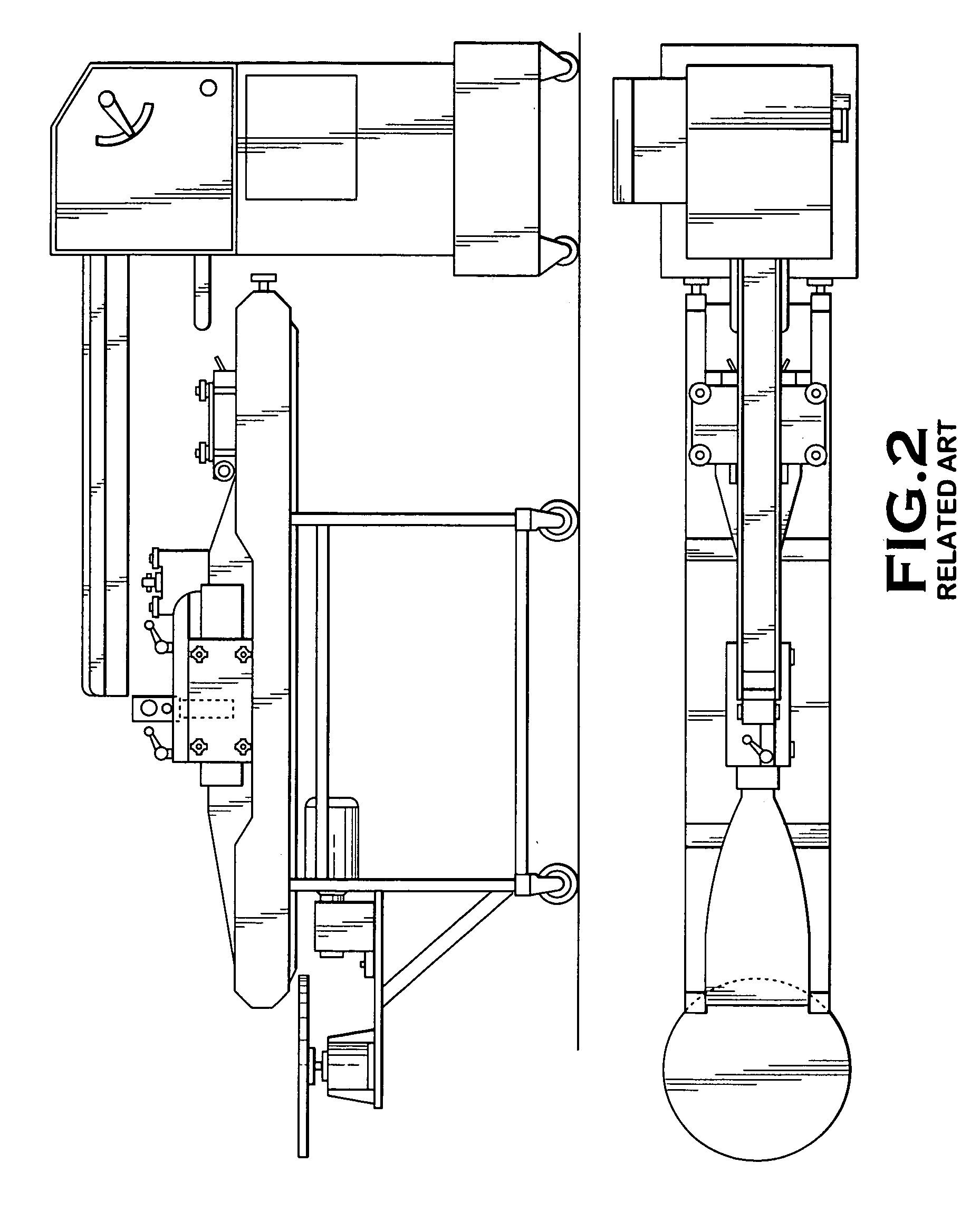

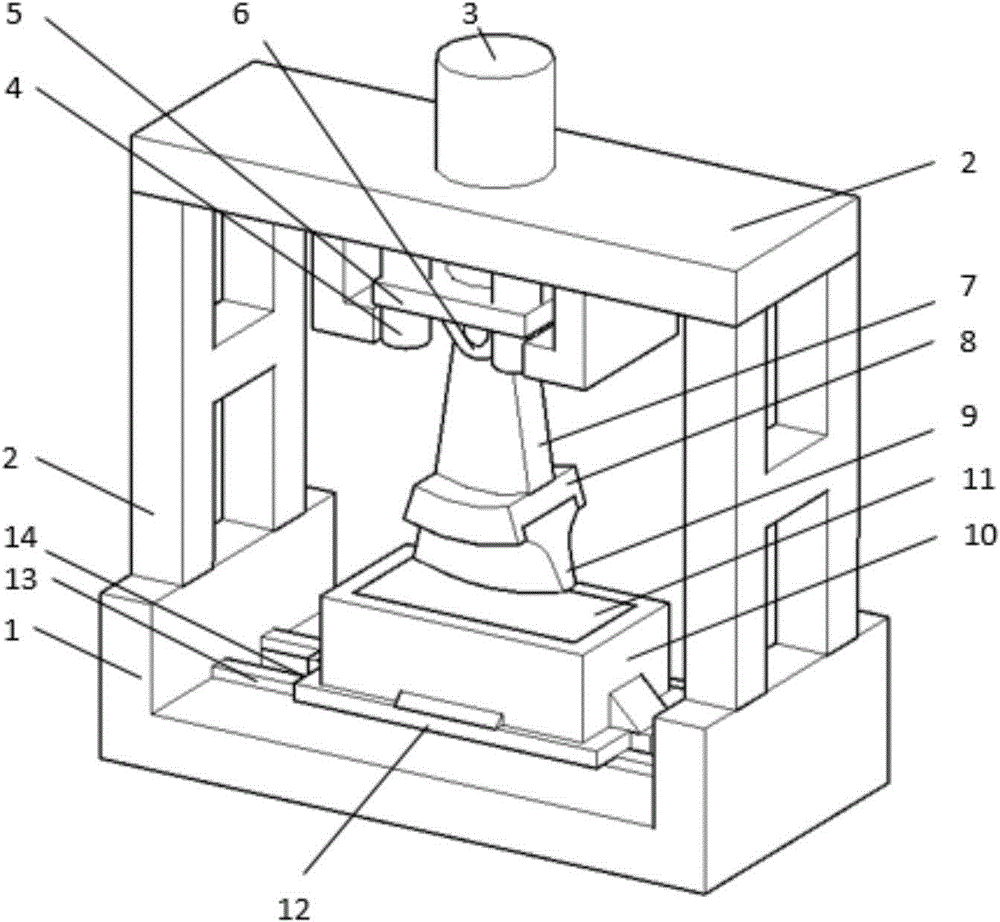

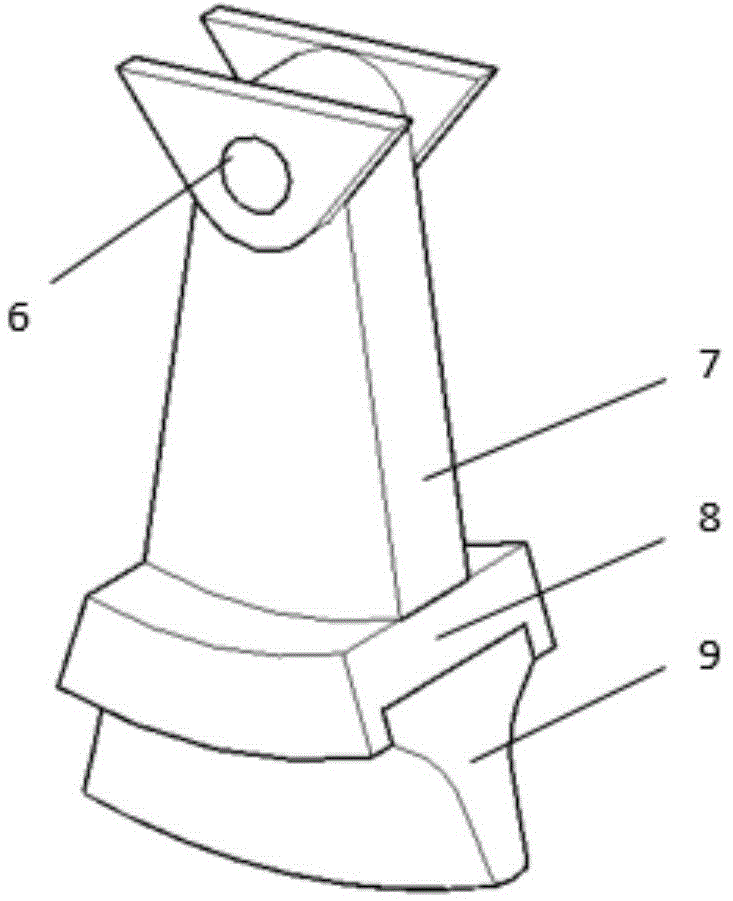

Numerical control tool grinder used for grinding of disc milling cutter blade

InactiveCN102717308AHigh movement precisionAchieve grindingGrinding drivesMilling cuttersNumerical controlMilling cutter

The invention relates to a numerical control tool grinder used for grinding of a disc milling cutter blade. The numerical control tool grinder is characterized by comprising a lathe bed (16), an upright post (7), a transverse worktable, a longitudinal worktable, a numerical control rotating worktable (12), a vertical feeding carriage (8) and a grinding electric main shaft (9), wherein the transverse worktable and the longitudinal worktable forms a cross sliding table structure so as to be assembled on the lathe bed (16); and the numerical control rotating worktable (12) is assembled on the transverse worktable in an inclination manner, and a disc cutter to be grinded is installed on a positioning core shaft which is fixedly connected with the numerical control rotating worktable (12). The numerical control tool grinder provided by the invention adopts a multi-shaft numerical control linkage lathe, the kinematic accuracy of the lathe is high, the grinding of complex cambered surface is realized, the grinding of a disc cutter blade shape is met, and the formation problem of cutters such as large-scale and small-batch gears, screw rods and worms is solved.

Owner:NANJING GONGDA CNC TECH

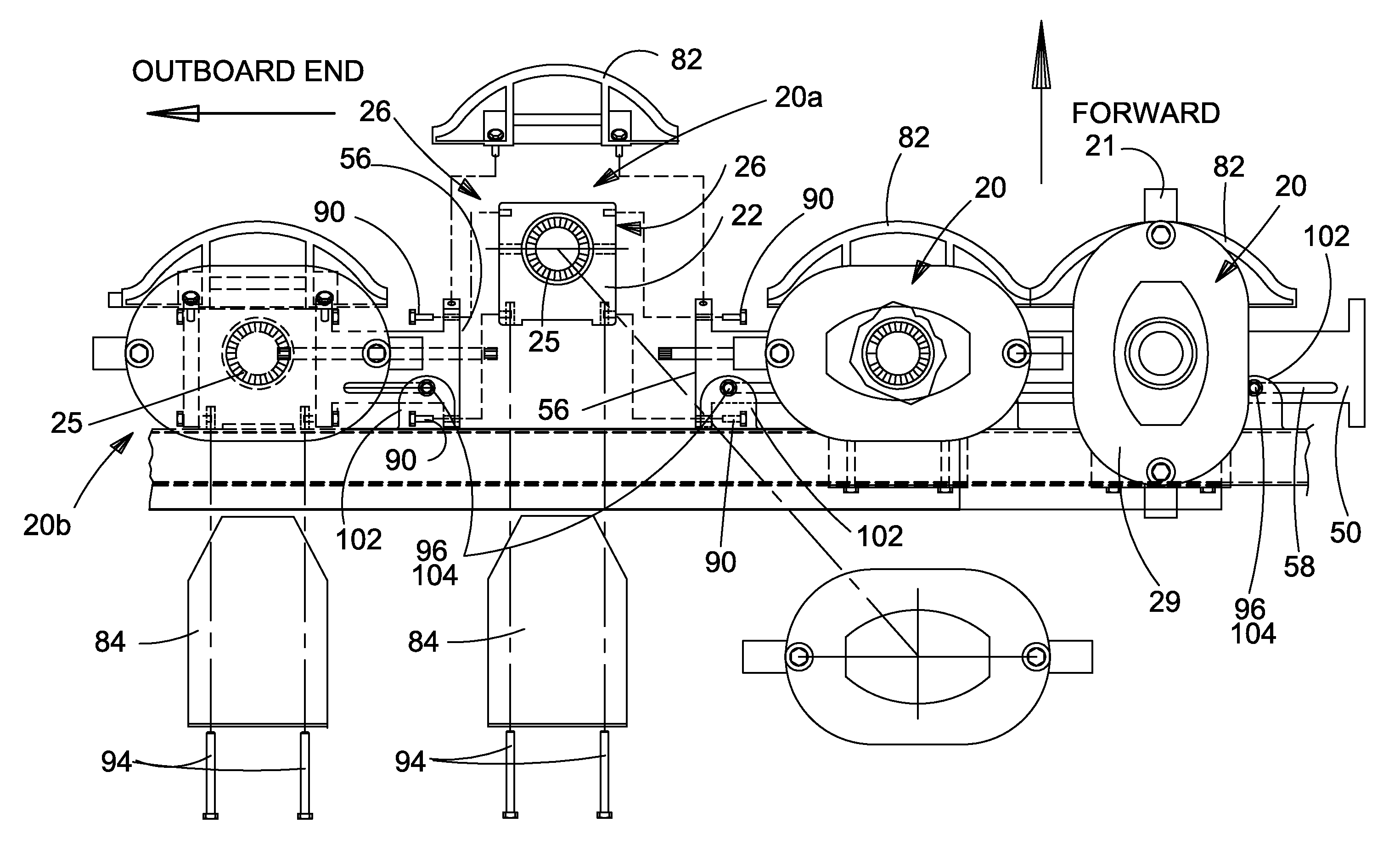

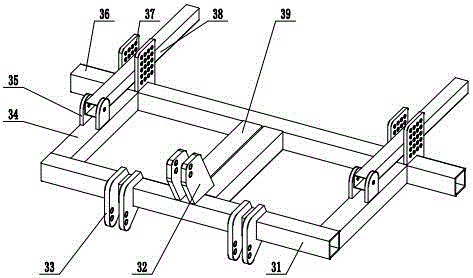

Modular disc cutterbar

A disc cutter module mounting structure for an agricultural header that enables one or more disc cutter modules and interconnection spacers to be temporarily laterally displaced a distance sufficient to disengage the transverse drive apparatus from a failed module thereby allowing the failed module to be removed from the header for repair or replacement. The laterally displaced modules and spacers need only be disconnected from the outboard drive shaft; lateral displacement is accomplished by the incorporation of slotted mounting guides on the spacers and a plurality of spaced-apart support tabs on the header frame. The mounting structure also supports the modules and spacers during the removal / replacement process reducing the need for jacks to support modules as they are being repositioned on the header.

Owner:BLUE LEAF I P INC

Omnidirectional profiling cutting table

ActiveCN104255175ARealize the pitching actionMeet the agricultural technical requirements for flat stubble harvestingMowersHeadersEarth surfaceDisc cutter

The invention discloses an omnidirectional profiling cutting table. A middle profiling assembly is hinged to a connecting frame, and the pitching action of the middle profiling assembly relative to the connecting frame and the longitudinal profiling action of the middle profiling assembly are controlled by use of a longitudinal profiling oil cylinder; a left profiling assembly and a right profiling assembly are hinged to the middle profiling assembly from the two sides, respectively, and the transverse profiling action of the left profiling assembly and the right profiling assembly controlled by use of a transverse profiling oil cylinder. A disc cutter is arranged on the front end of each profiling assembly; a profiling sensor is arranged under each profiling assembly to receive a surface height variation signal, and according to the surface height variation signals, the profiling oil cylinders are controlled to drive the profiling assemblies to act, and therefore, consistent cutting height, flat cutting and no ripping are guaranteed, and the agricultural technical requirements of stubble rejuvenation are met.

Owner:SHANXI AGRI UNIV

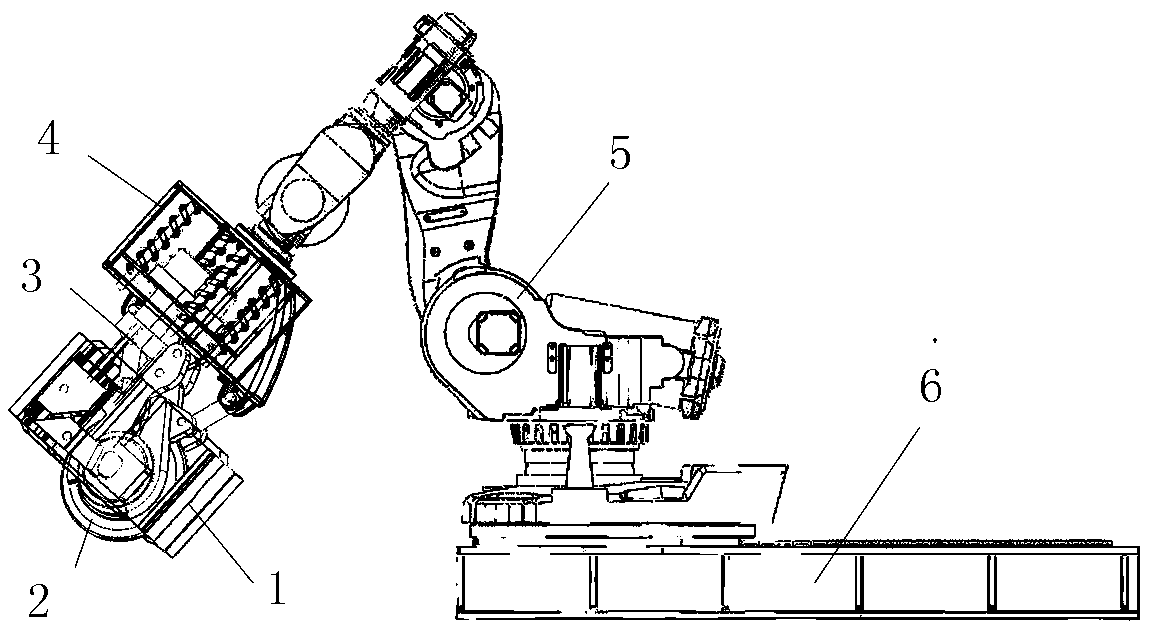

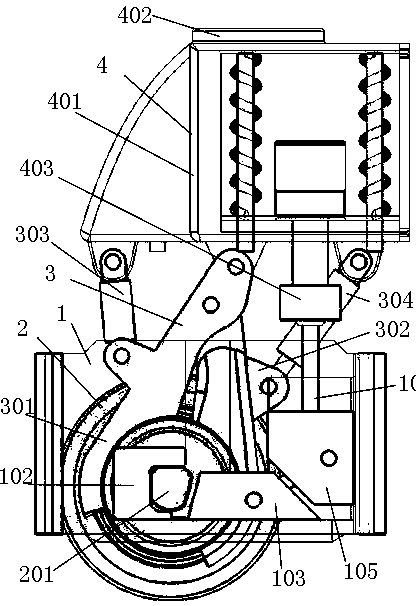

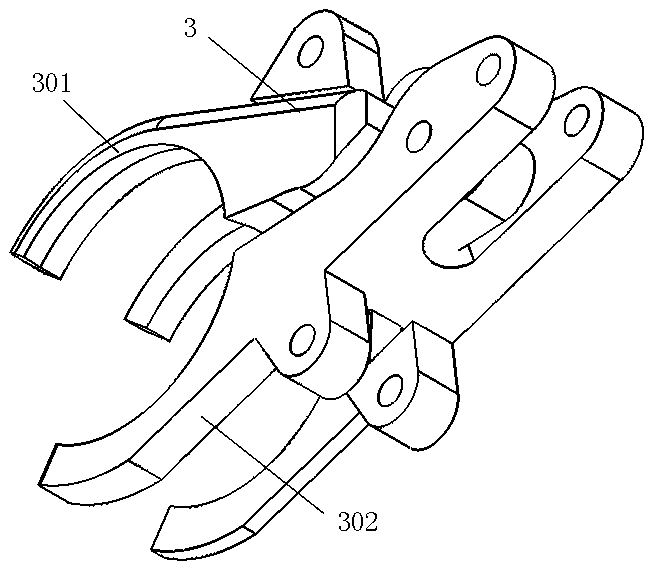

Robot suitable for automatic replacement of disc cutter and using method of robot

ActiveCN109434849ALow tool change rateConstruction riskClimate change adaptationMetal working apparatusMaterial resourcesEngineering

The invention discloses a robot suitable for automatic replacement of a disc cutter and a using method of the robot. The robot and the using method solve the technical problems of low tool change rateand high construction risk of workers in shield and TBM construction. The robot comprises a cutter holder and a mechanical arm. A cutter is arranged on the cutter holder. The cutter holder is connected with the mechanical arm through a mechanical hand. According to the robot suitable for automatic replacement of the disc cutter and the using method of the robot, a cutter replacing dexterous handand a bolt dexterous hand are designed in cooperation with the cutter holder, the cutter replacing dexterous hand clamps the cutter, and the bolt dexterous hand controls the left and right movement ofan abutting sliding block, so that the tightness of the cutter is further realized; the cutter replacing dexterous hand and the bolt dexterous hand simultaneously act without manual participation incutter replacing; and the mechanization degree is high, the operation is quick and convenient, and manpower and material resources are saved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Prediction method for TBM disc cutter wear

InactiveCN108710722AAvoid complex internal mechanism research processOvercome the defect of only accurately predicting the hob on the cutter headDesign optimisation/simulationSpecial data processing applicationsPredictive methodsEngineering

The invention belongs to the technical field of TBM disc cutter wear, and particularly relates to a prediction method for TBM disc cutter wear. The prediction method comprises the following steps thattunneling parameters, cutter ring wear losses and cutter ring characteristics in the TBM tunneling process are determined; a cutter ring comprehensive wear coefficient computing model is built; and aTBM effective tunneling distance prediction model based on cutter ring comprehensive wear coefficients is built; and an influence mechanism that the disc cutter ring wear is influenced by various factors on the condition that the geological conditions are the same as the cutter ring properties is analyzed. According to the prediction method, the concept of the cutter ring comprehensive wear coefficients is proposed, a disc cutter wear prediction model is built, and the technical problem that in TBM construction, the disc cutter consumption is difficult to predict is solved.

Owner:ZHENGZHOU UNIV

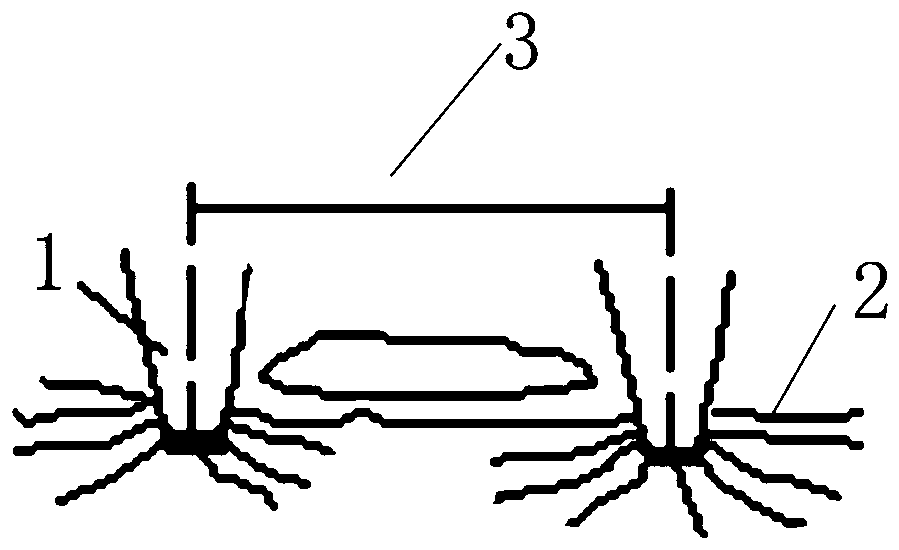

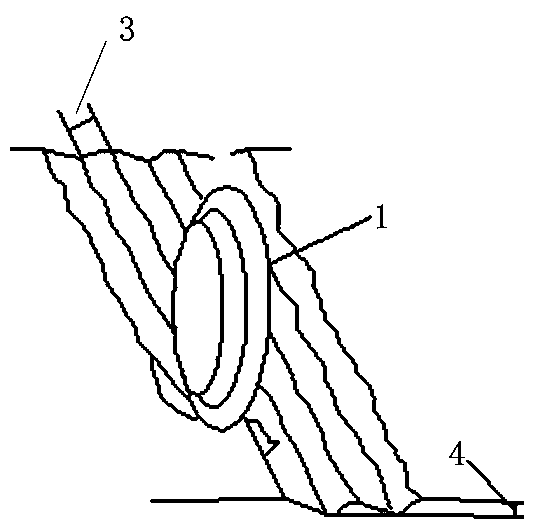

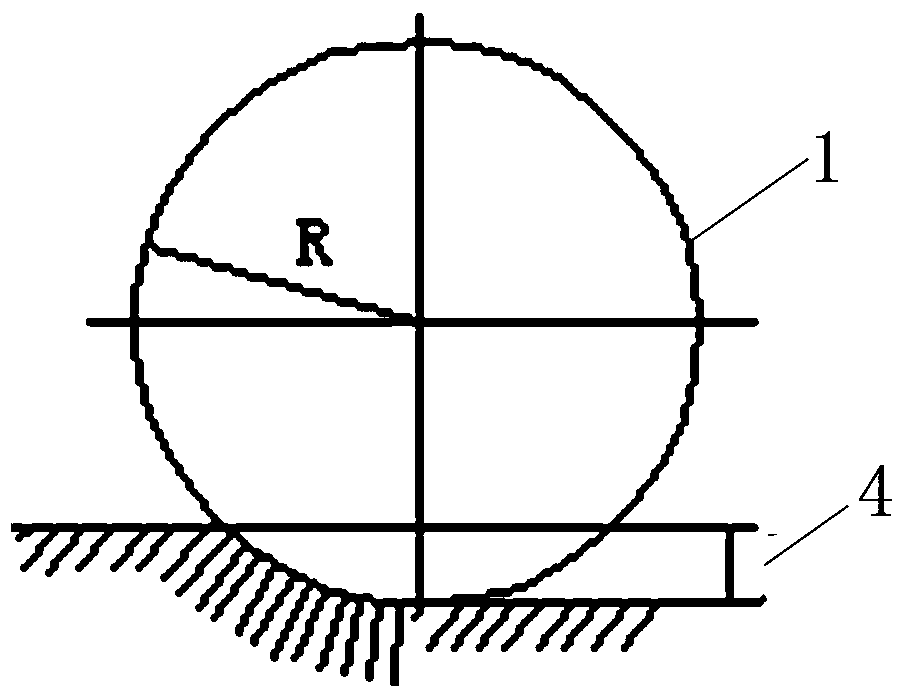

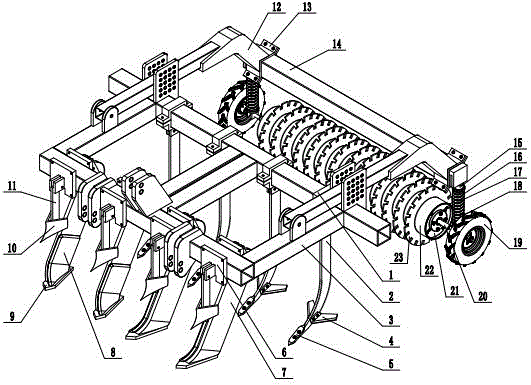

Combined deep scarification and land preparation machine

InactiveCN105981496ALow traction resistanceGuaranteed profilingSpadesSaving energy measuresConventional tillageScarification

The invention relates to a combined deep scarification and land preparation machine which is characterized by comprising a rack, a full-direction deep scarification device and a turnover device, wherein the turnover device is arranged in front of the full-direction deep scarification device; the rack consists of a front beam, an upper suspended plate, lower suspended plates, transverse beams, fixed transverse beams, fixing plates, limiting plates, a rear beam and support beams; a partial deep scarification device is arranged on the rear beam; a soil crushing depth limiting device is arranged behind the support beams. According to the combined deep scarification and land preparation machine, a shallow layer and a conventional tillage mellow soil layer are loosened by using the turnover device, subsequently deep soil is cut by using the full-direction deep scarification device and is crushed by using the partial deep scarification device, furthermore the ploughed soil is crushed and flattened by using disc cutters in the soil crushing depth limiting device. In a word, by adopting the combined deep scarification and land preparation machine, combined soil preparation, shallow layer turnover operation, single full-direction deep scarification operation and partial deep scarification operation can be achieved according to agricultural requirements of different crops, the effect of one-machine multi-functions is achieved, the resistance can be reduced, the energy can be saved, and a good operation effect can be achieved.

Owner:SHIHEZI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com